Full-automatic rotary multi-station grinding wheel forming machine

A rotary, multi-station technology, used in manufacturing tools, metal processing equipment, grinding devices, etc., can solve the problems of unsatisfactory production efficiency and product quality, inability to adjust the mold cavity flexibly, and low degree of automation. To achieve the effect of convenient and quick adjustment, simple structure, and improved purity and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

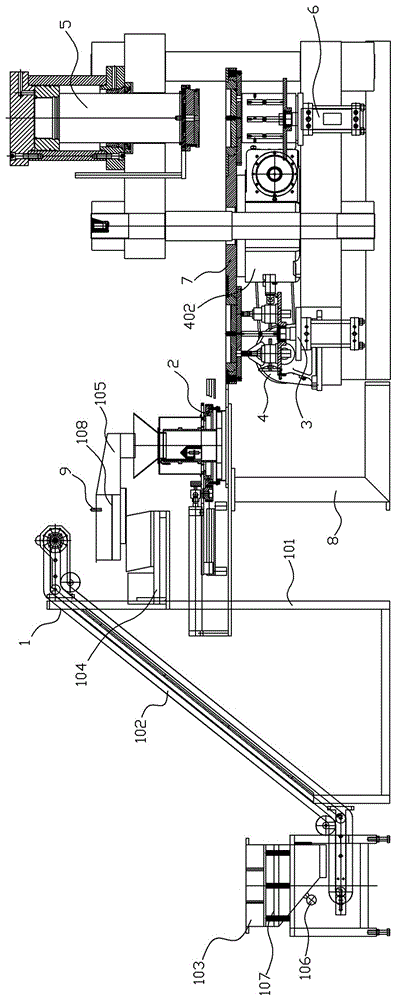

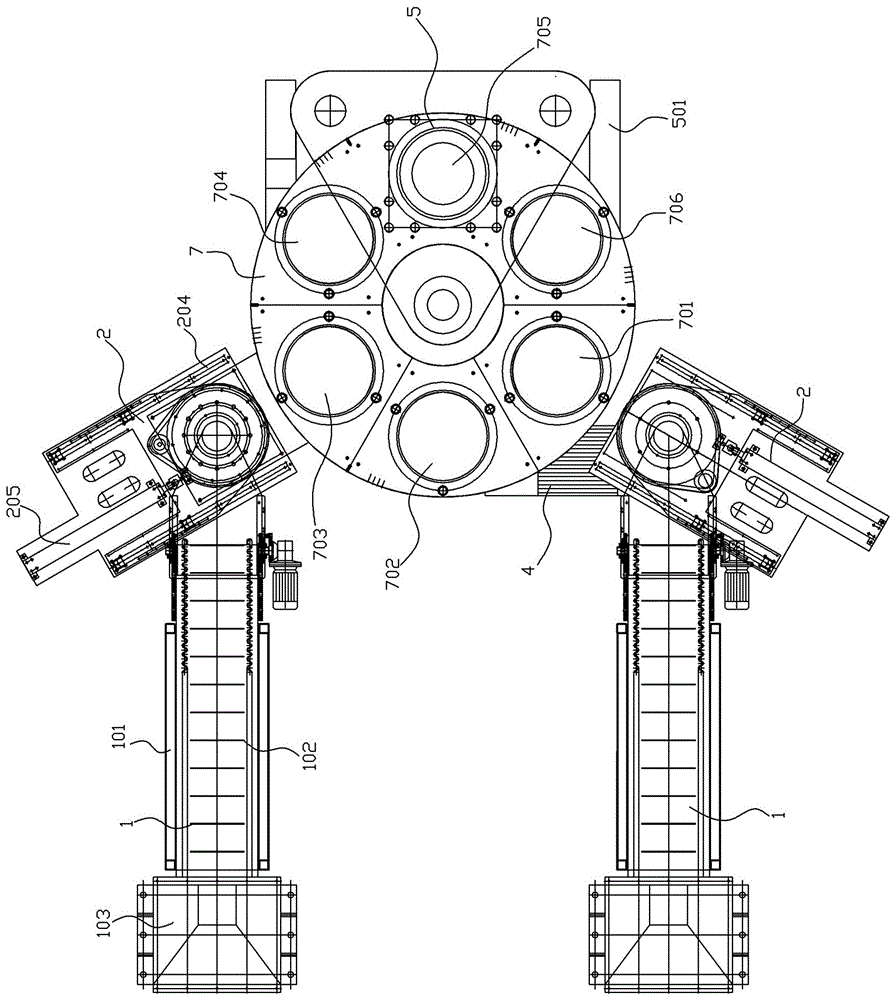

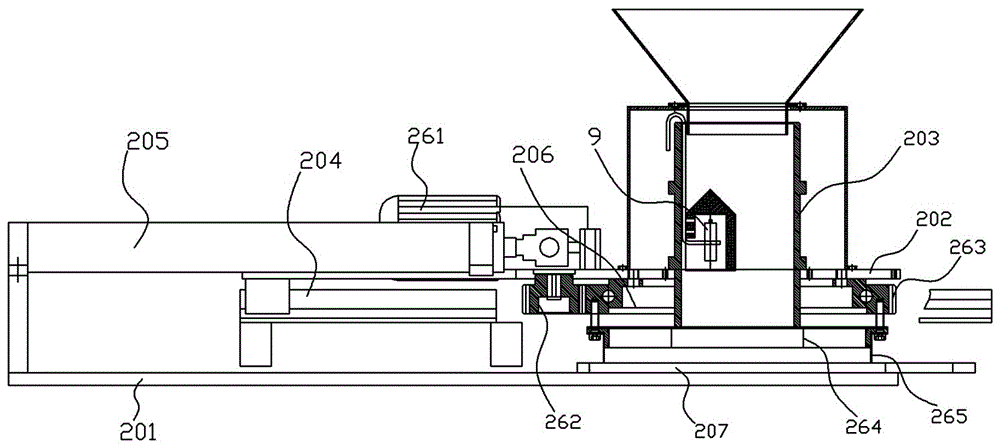

[0038] The fully automatic rotary multi-station grinding wheel forming machine of the present invention comprises a lifting conveying mechanism 1, a material pushing and scraping mechanism 2, a constant volume adjusting mechanism 3, a workbench transmission power mechanism 4, a pressure forming mechanism 5, and a mold unloading and ejecting mechanism 6. The mold mounting frame 7 and the numerical control unit, the lifting and conveying mechanism 1 is provided with a pushing and scraping installation platform 8 on the blanking side, and the pushing and scraping mechanism 2 is fixedly arranged on the pushing and scraping installation platform 8; The pushing and scraping mechanism 2 is located at the lower part of the lifting and conveying mechanism 1 on the blanking side, and the pressure forming mechanism 5 is located at the side of the pushing and scraping installation platform 8. The frame 7 is installed on the workbench transmission power mechanism 4; the scraping plane of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com