Patents

Literature

359results about How to "Improve scraping efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

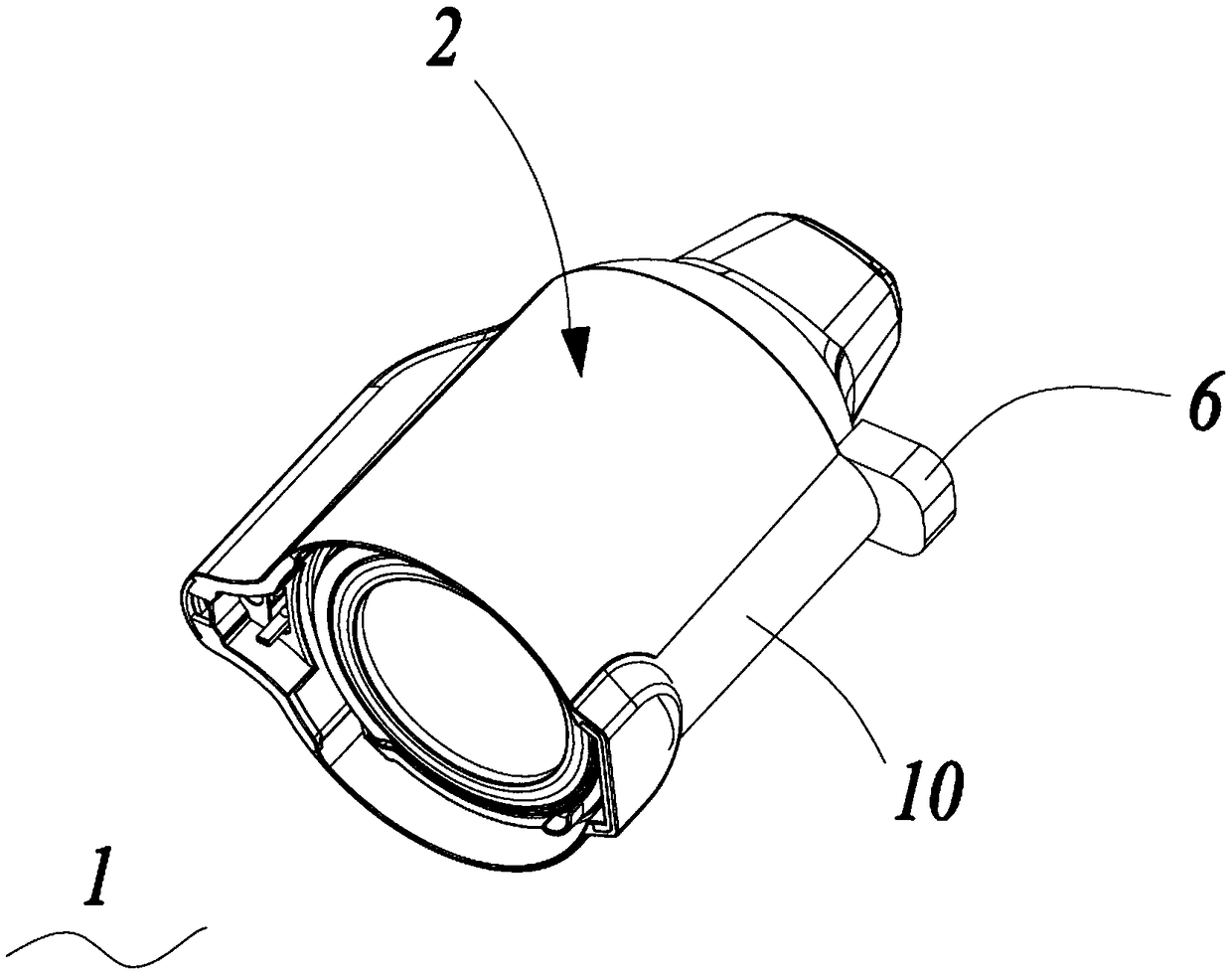

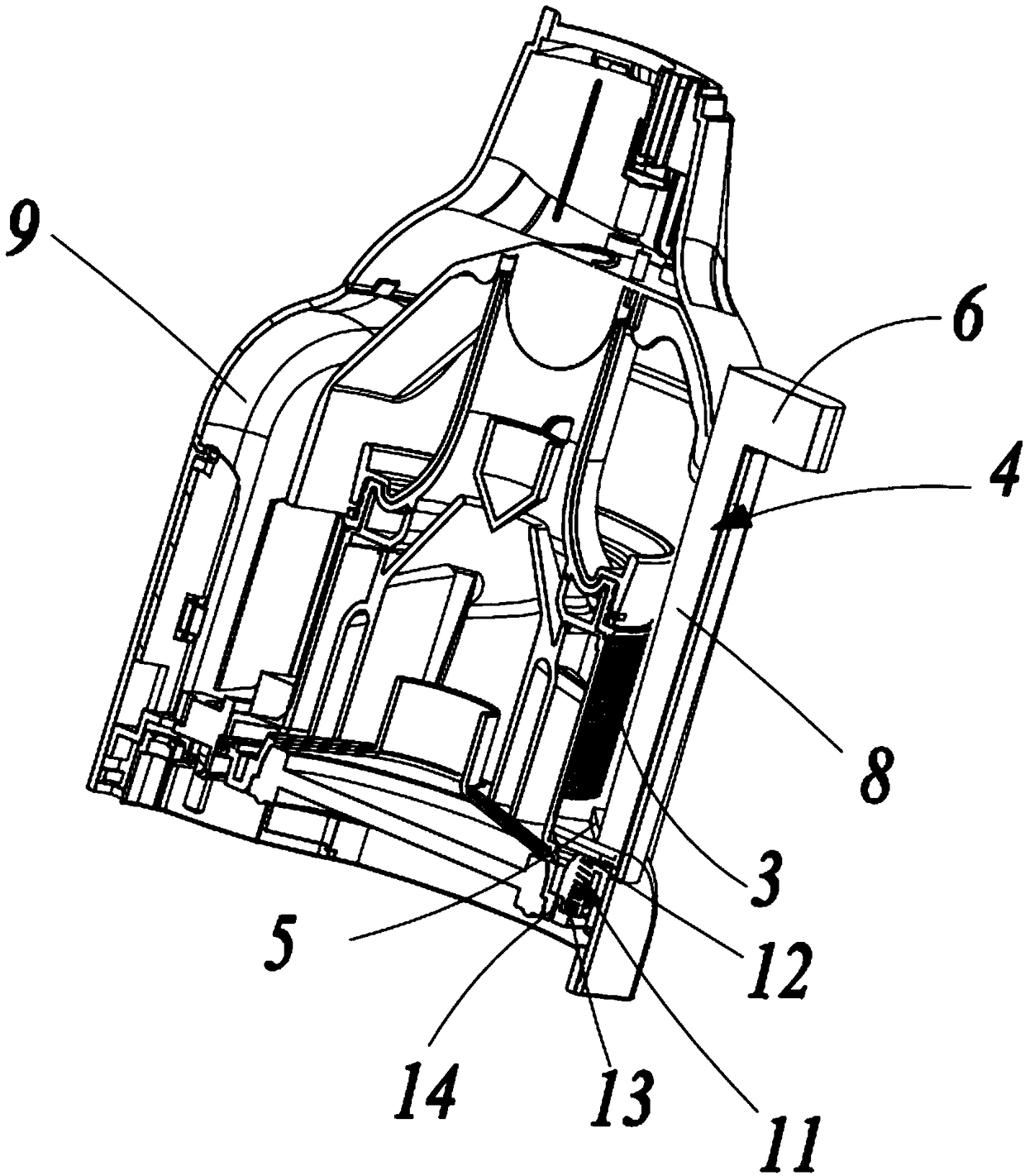

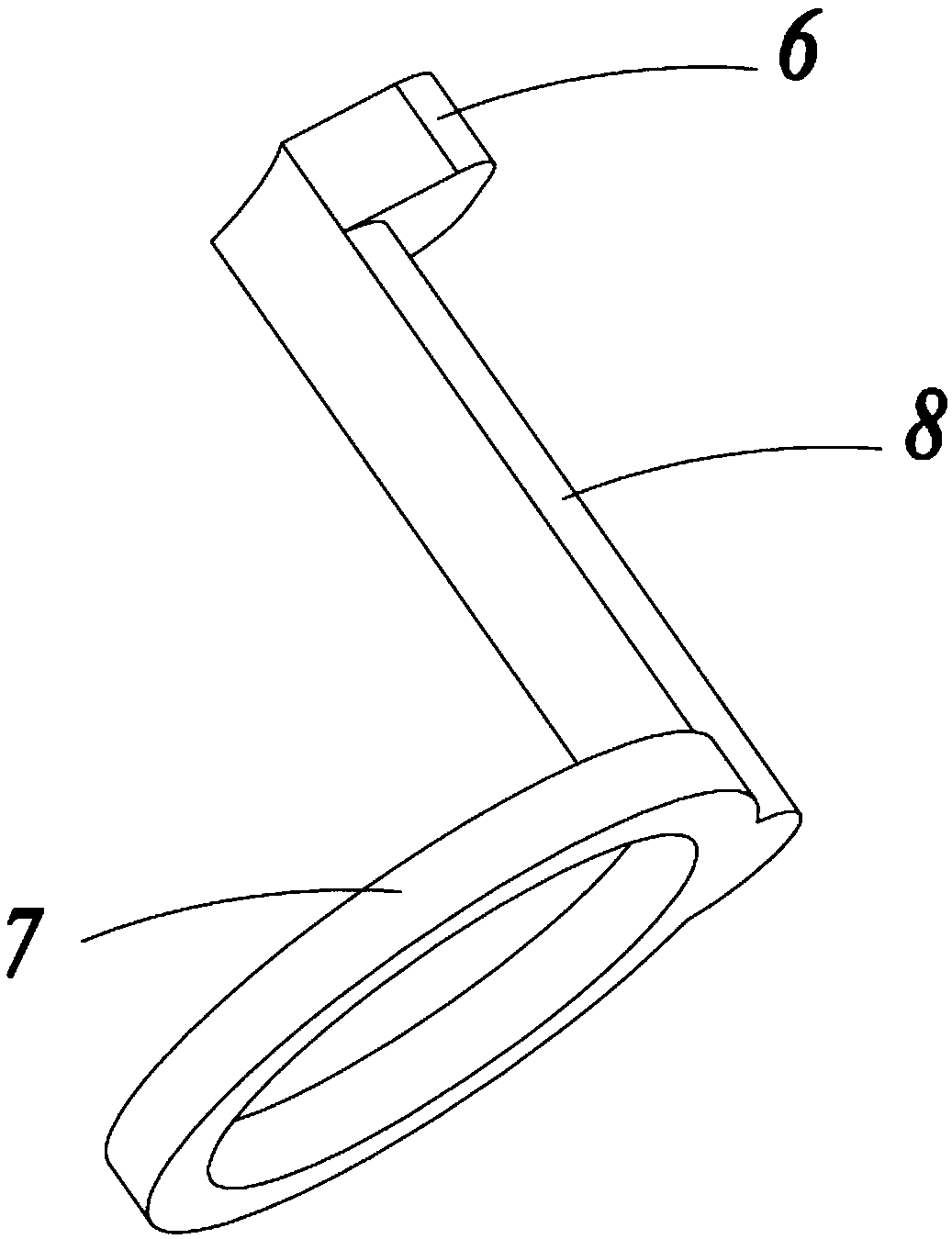

Dust collecting device and dust collector provided with same

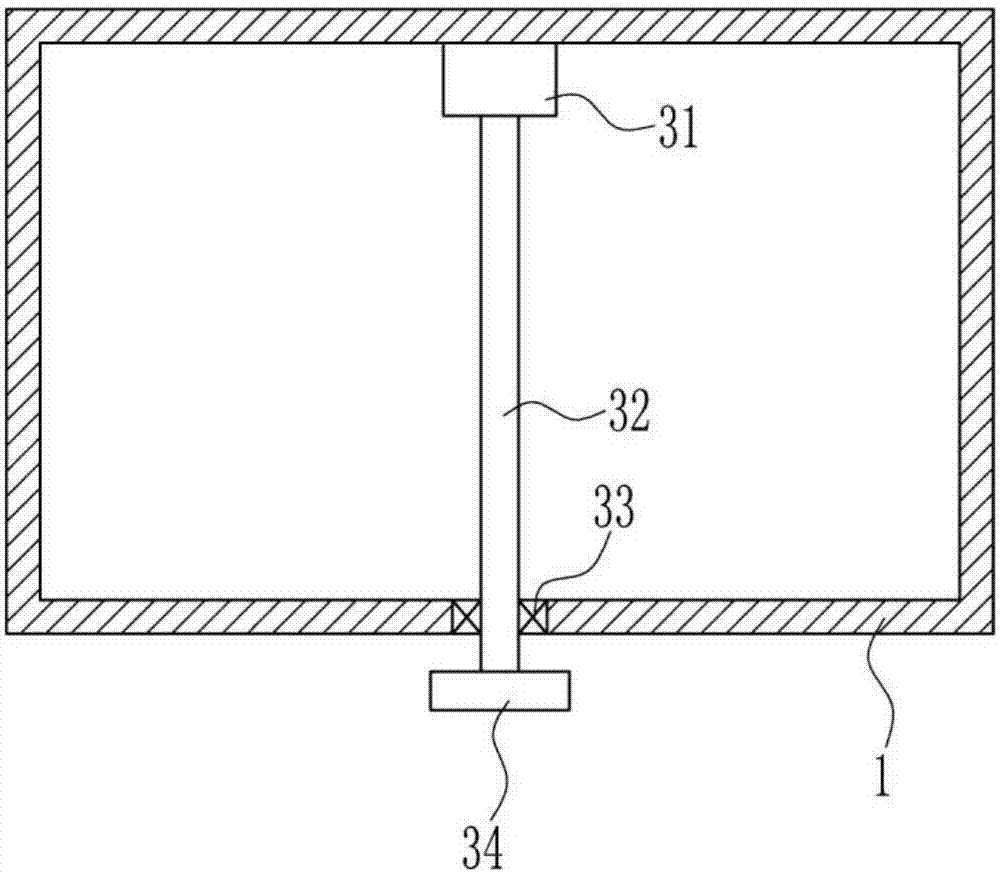

The invention provides a dust collecting device. The dust collecting device comprises a dust collecting cup and a filtering screen cover arranged in the dust collecting cup. The dust collecting devicefurther comprises a scraper blade bracket at least arranged in the dust collecting cup and a scraper blade connected to the scraper blade bracket. The scraper blade bracket is provided with a handlearranged outside the dust collecting cup. The handle operably drives the scraper blade to move between two ends of the outer wall surface of the filtering screen cover to scrape away dust on the filtering screen cover. The invention further provides a dust collector provided with the dust collecting device. The dust collecting device adopts manual dust scraping, and has the advantages that the structure is simple and compact, application is easy and convenient, the cost is low, dust scraping efficiency is high, and user experience is excellent.

Owner:SUZHOU HAILY ELECTRIC

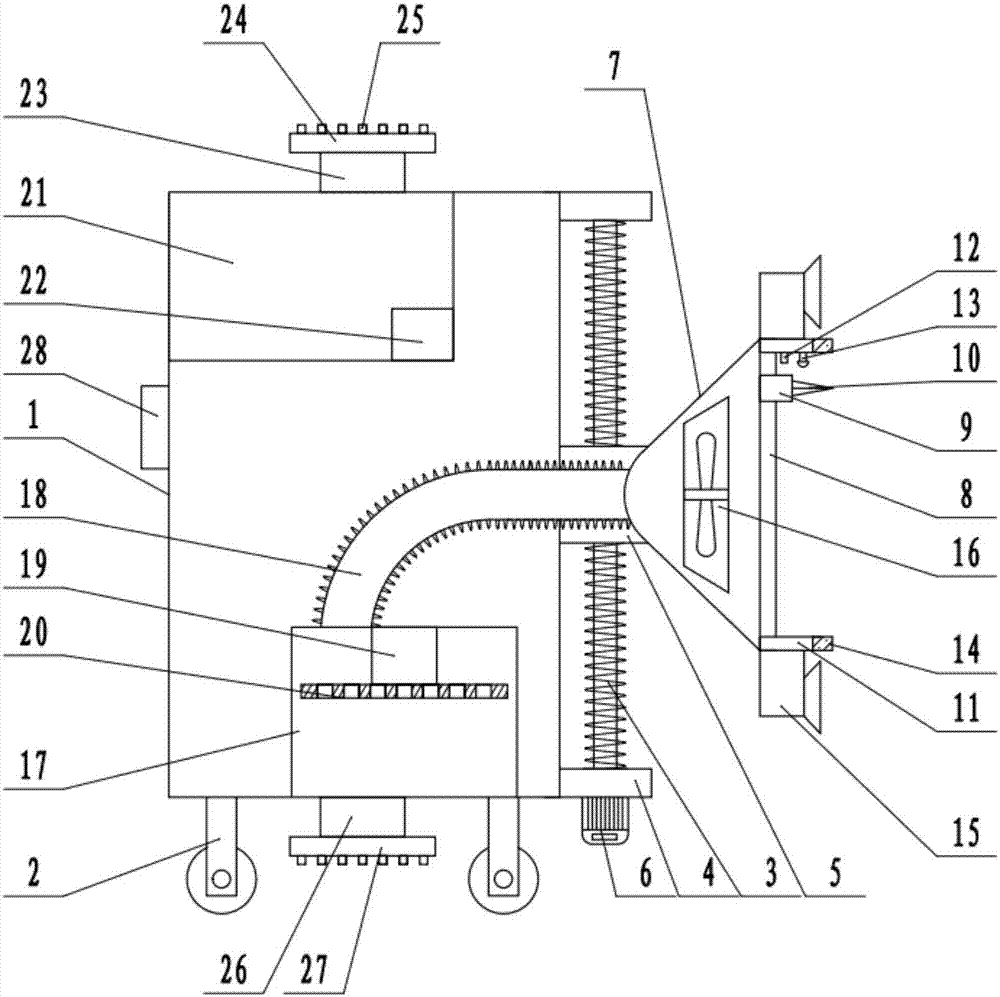

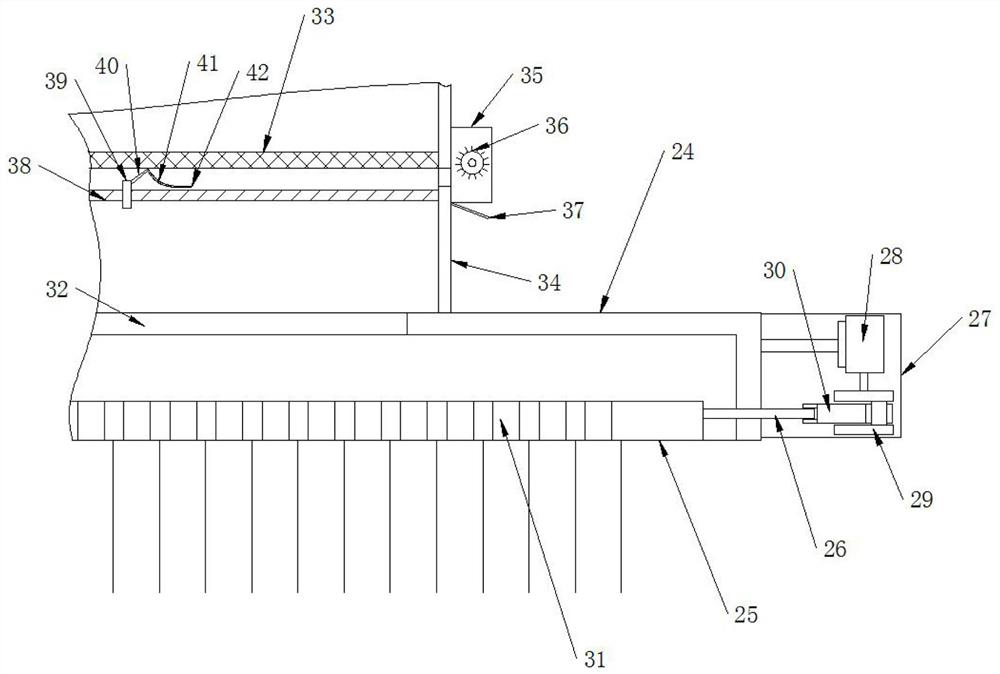

Scraping machine for wall paints

The invention discloses a scraping machine for wall paints. The scraping machine comprises a shell, universal wheels, a scraping hopper, a scraping knife, a collecting tank and a water tank, wherein a screw rod is arranged at the right side of the shell; a sliding block is sheathed on the screw rod; the scraping hopper is fixedly connected at the right side of the sliding block; the upper end and the lower end of the scraping hopper are respectively and fixedly connected with the scraping plate; a linear module is arranged between the scraping plates; a knife rest is arranged at the side wall of the linear module; the scraping knife is fixedly connected at the right side wall of the knife rest; the water tank is arranged in the shell; and drying machines are fixedly connected on the scraping plates. The scraping machine disclosed by the invention has the advantages that the paints on walls are scraped by utilizing up-down movement of the scraping knife, so that the working efficiency is improved and the labor is saved; dust generated in the wall scraping process is sucked into the collecting tank by utilizing an exhausting fan to prevent the dust from splashing around, and simultaneously the dust in the collecting tank is compressed, so that the space is saved; when the wall scraping operation is carried out, water is sprayed on the scraping knife and the wall paints are softened, so that the scraping efficiency is improved; and in the process of wall scraping operation, the scraping hopper slides up and down, so that the wall scraping area is expanded.

Owner:广西东创智能科技有限公司

Wall scraping device with slag collecting function

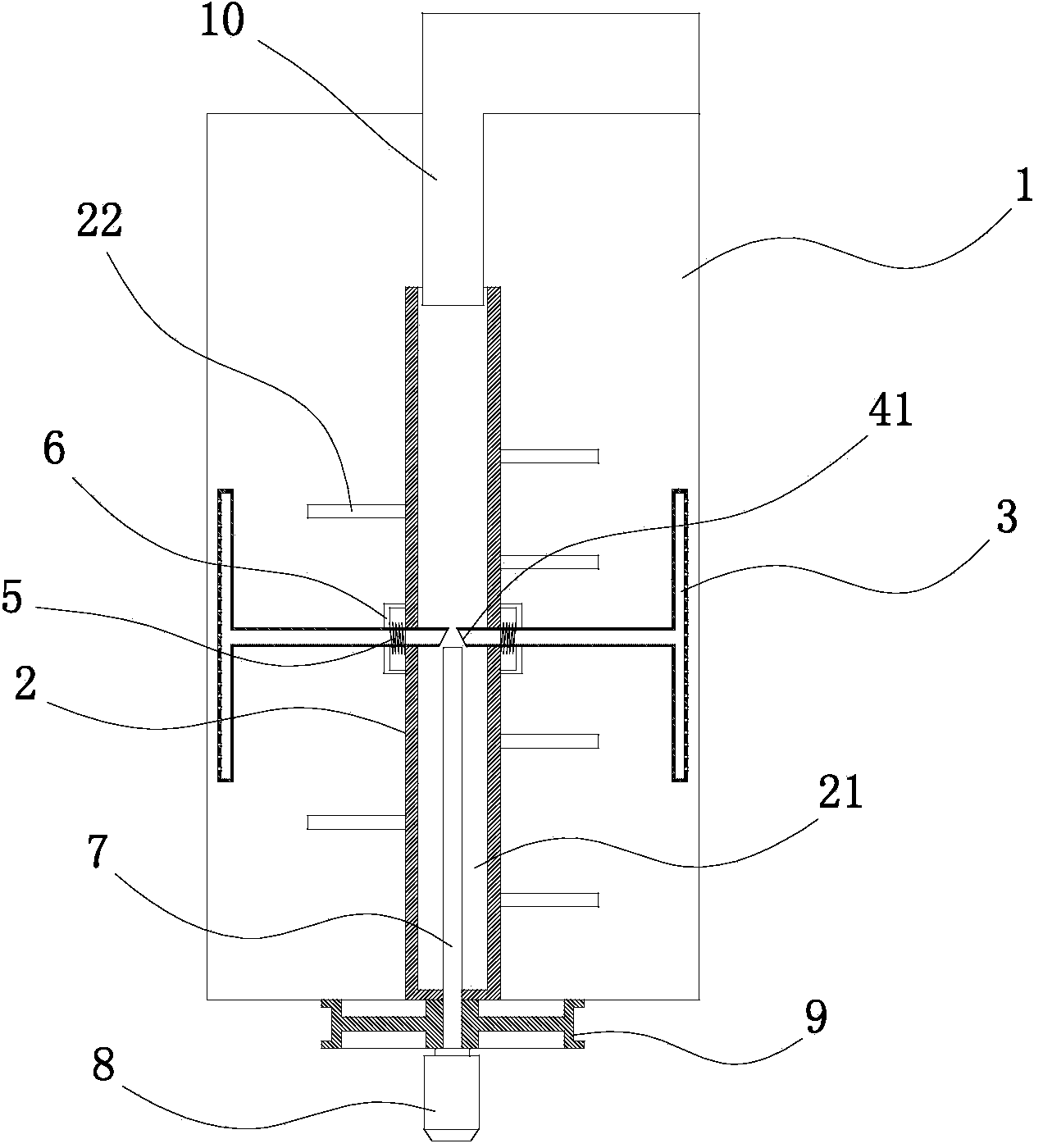

InactiveCN107344309AAvoid random driftProtect healthBuilding repairsPlane surface grinding machinesDrive shaftSlag

The invention discloses a wall skin scraping device with the function of collecting debris, which comprises a moving plate, a first driving motor and a second driving motor; the moving plate is rotatably connected with a turret, and the turret is nested with a first drive Motor, the first driving motor is fixedly connected with the turret; the first driving motor is connected to a scraping wheel through a drive shaft; a grinding wheel is arranged on the rear side of the scraping wheel. The present invention is provided with a scraping wheel and a grinding wheel to scrape the wall and the ceiling, the scraping is thorough, and has a good scraping effect; the invention is provided with a turret, so that the device can scrape the ceiling operation, scraping efficiency is high, and manpower is saved; the present invention is equipped with a dust and slag collection device, which collects dust and slag efficiently and intensively during the operation process, avoids random dust floating, keeps the working environment clean and protects operators health.

Owner:吴佳慧

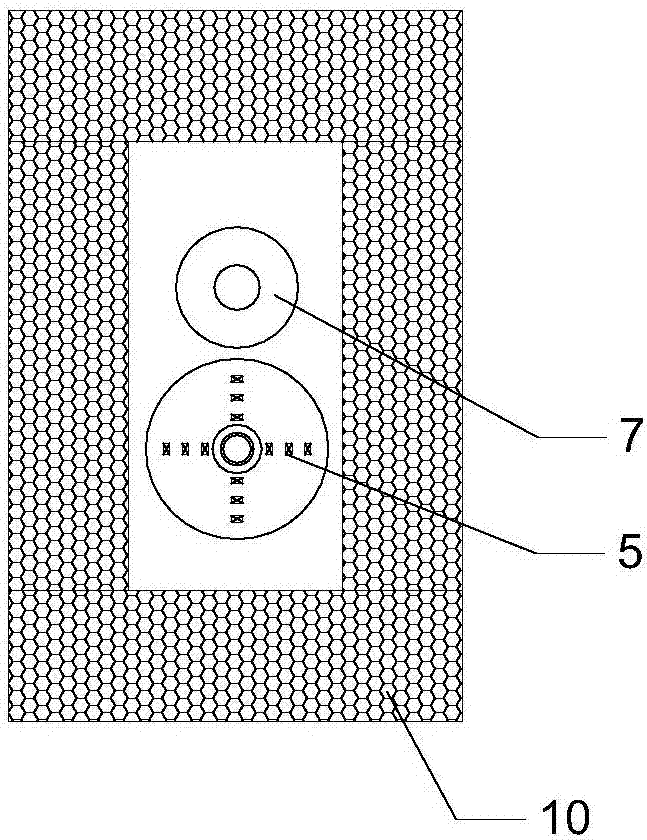

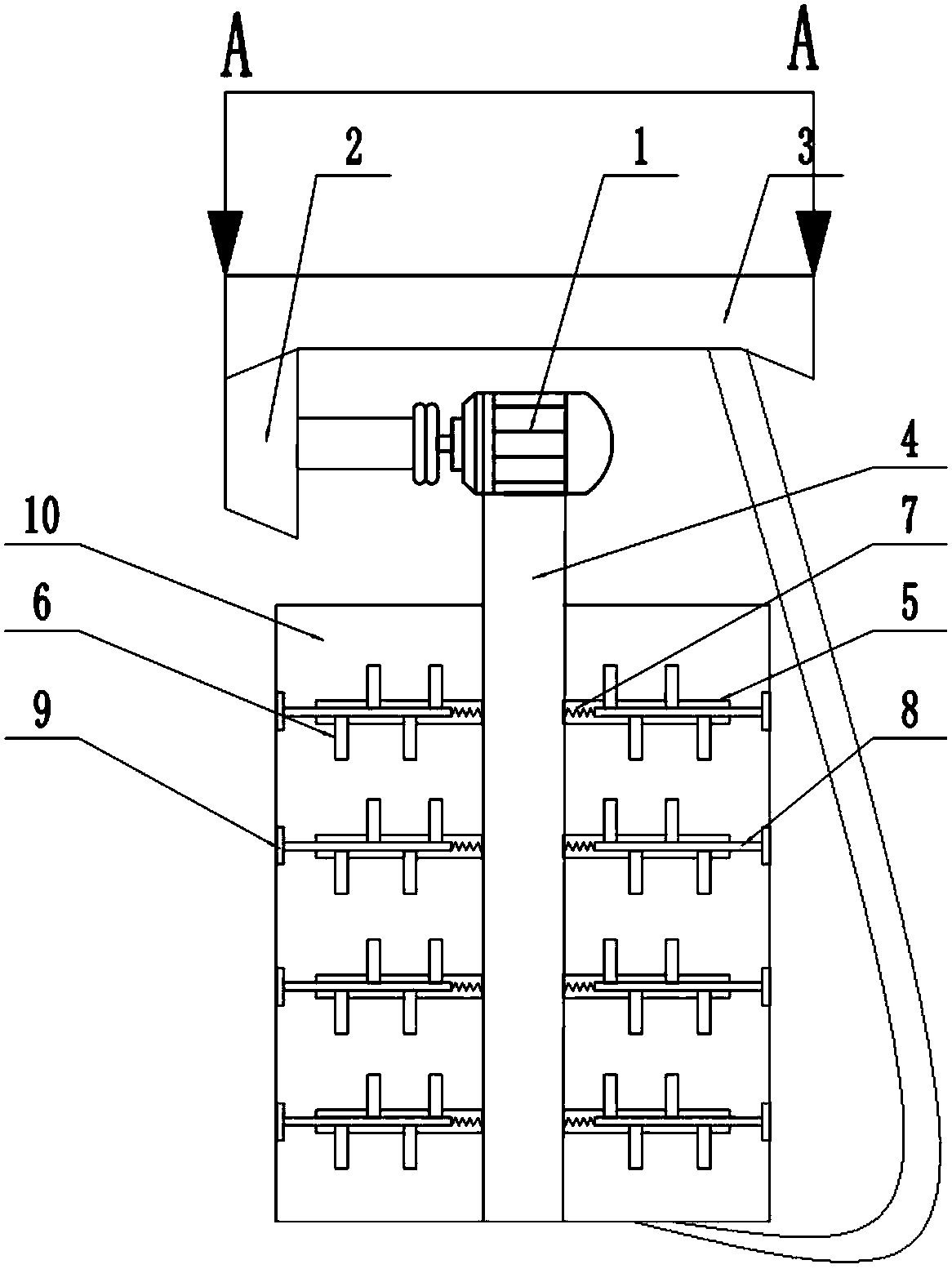

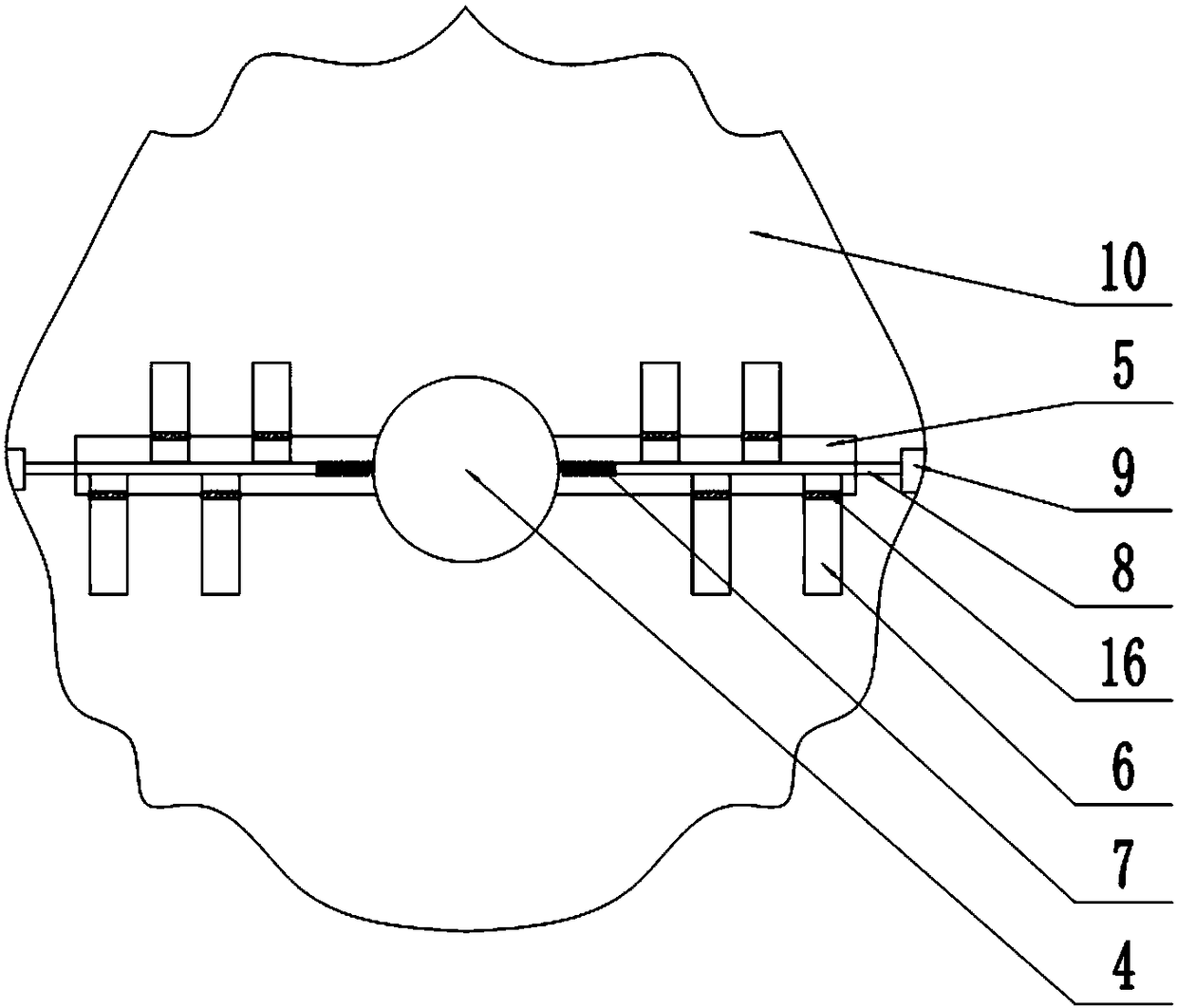

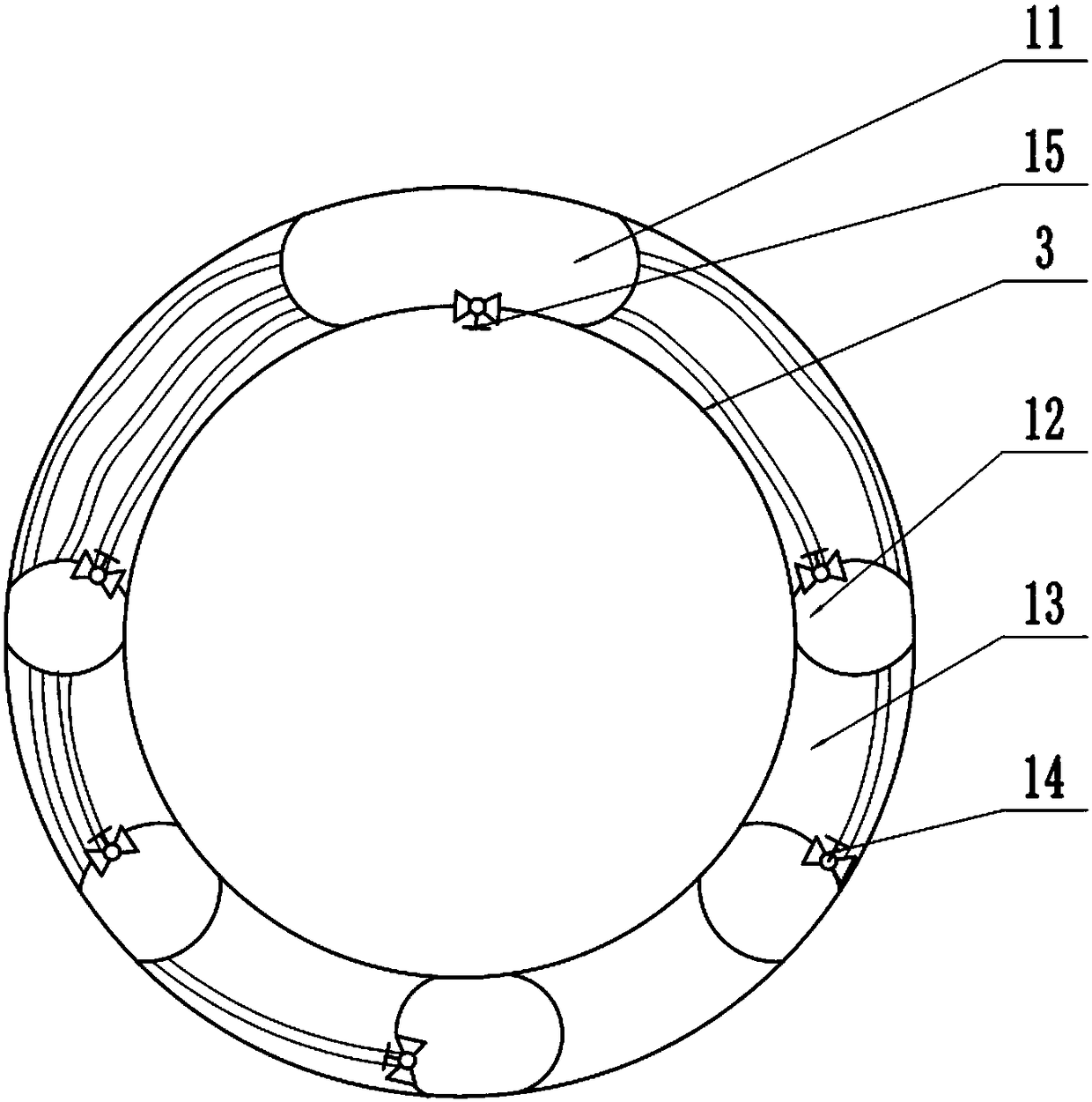

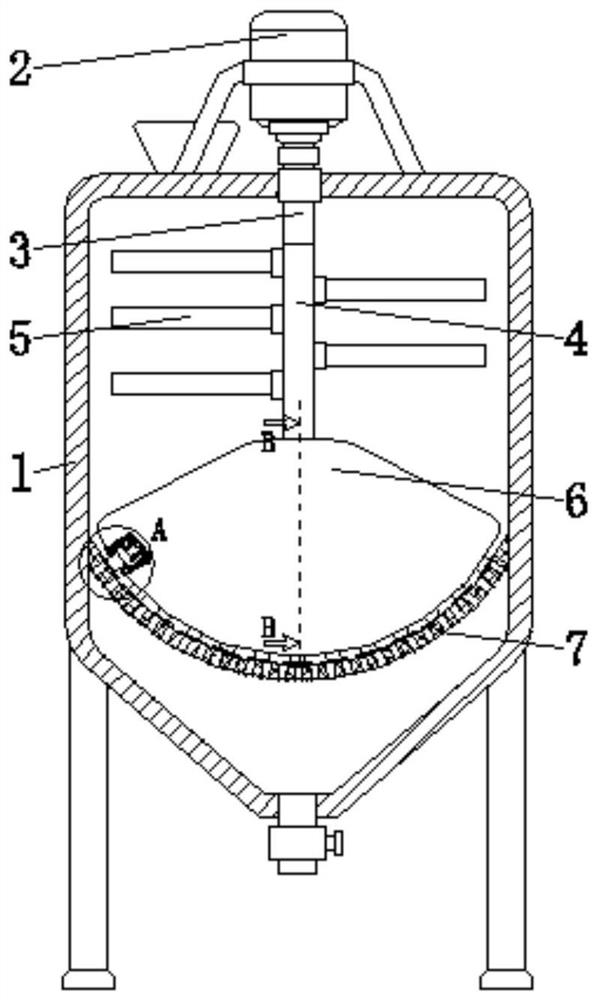

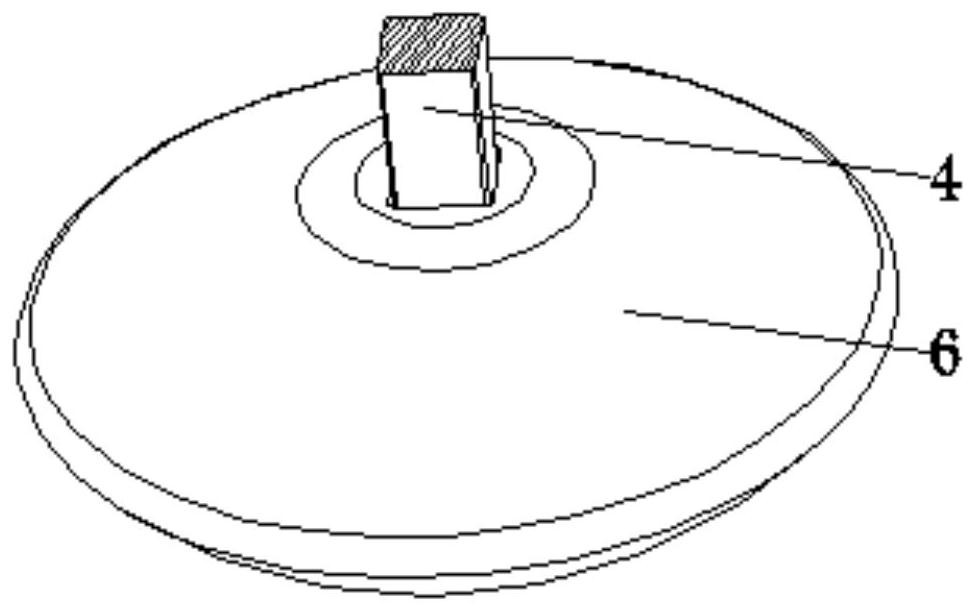

Electroplate liquid stirring device

InactiveCN108355530AImprove stirring efficiencyImprove the mixing effectShaking/oscillating/vibrating mixersTransportation and packagingEngineeringCheck valve

The invention belongs to the technical field of stirring devices, and particularly discloses an electroplate liquid stirring device. The electroplate liquid stirring device comprises an outer bucket and a spindle, wherein the spindle is rotatably connected with a plurality of stirring shafts, the stirring shafts are provided with a plurality of stirring rods; the inner wall of the outer bucket isof an irregular concave-convex shape; each stirring shaft is of a hollow structure, is provided with a plurality of through holes and is connected with an elastic element; the elastic element is connected with a push rod; the stirring rod and the push rod are hinged to each other; a sealing ring is arranged between the through holes and the stirring rods; the stirring rod and the sealing ring aretightly fit; the upper end of the spindle is connected with a motor; the motor is laterally arranged; the output shaft of the motor is connected with a bevel gear, the upper side of the bevel gear isprovided with a ring gear; the inner part of the ring gear is hollow; the bottom of the ring gear is provided with helical teeth; an air collection bag and an air discharging bag are arranged in the ring gear; the outer wall of the ring gear is provided with an air inlet check valve; one side of the air collection bag is provided with an air outlet check valve; the other end of a hose is in sealing connection with the air discharge bag; one side of the air discharge bag is provided with an air discharge check valve. When the technical scheme of the invention is adopted, the stirring effect andthe stirring efficiency of the electroplate can be improved.

Owner:关怡

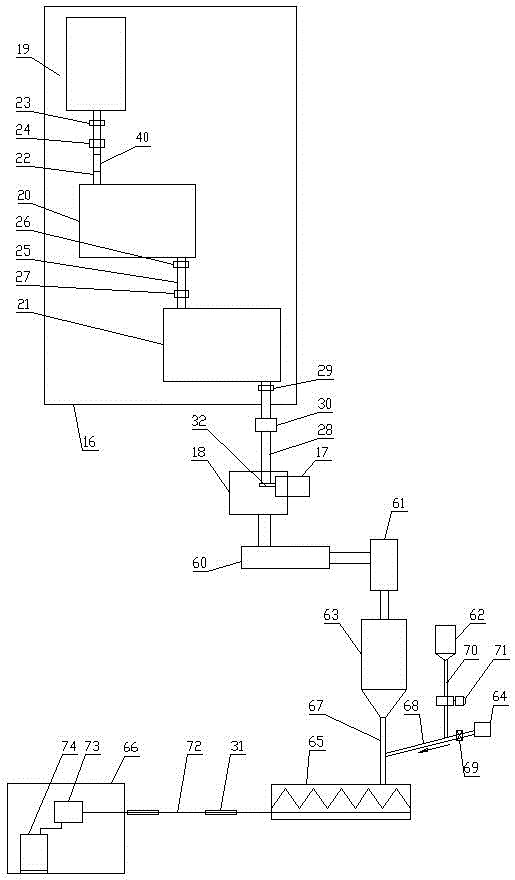

Bamboo charcoal polylactic acid melt direct spinning technology

ActiveCN105463588AReduce installationEvenly mixedSpinning head liquid feederMelt spinning methodsPowder mixtureLactide

A bamboo charcoal polylactic acid melt direct spinning technology comprises the steps that 1, lactide and bamboo charcoal micro powder are added into a stirring tank to be stirred; 2, the lactide and bamboo charcoal micro powder mixture falls into a preliminary polymerization tank through a first pipeline for preliminary polymerization; 3, a polylactic acid bamboo charcoal melt falls into a final polymerization tank through a second pipeline for final polymerization; 4, a third valve on the bottom of the final polymerization tank is switched on, and the polylactic acid bamboo charcoal melt is pumped out and conveyed into a spinning manifold through a third metering pump; 5, a spinning metering pump and a spinning component are arranged in the spinning manifold, and the polylactic acid bamboo charcoal melt is metered and pressurized by the spinning metering pump and then enters the spinning component to be spun into bamboo charcoal polylactic acid fiber. According to the spinning technology, polylactic acid is modified through nanoscale bamboo charcoal micro powder, so that the prepared fiber has lower initial modulus, higher moisture regain, higher wear resistance, higher air permeability and better hand feeling.

Owner:HENAN LONGDU BIOLOGY TECH

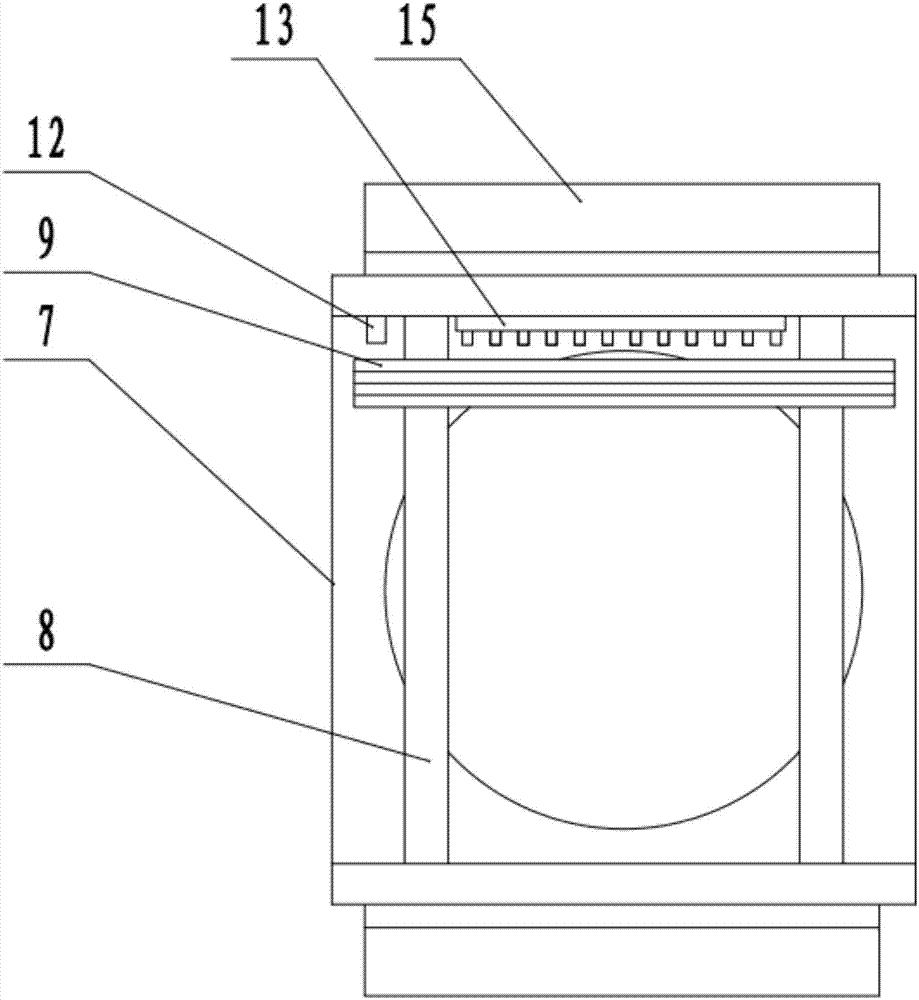

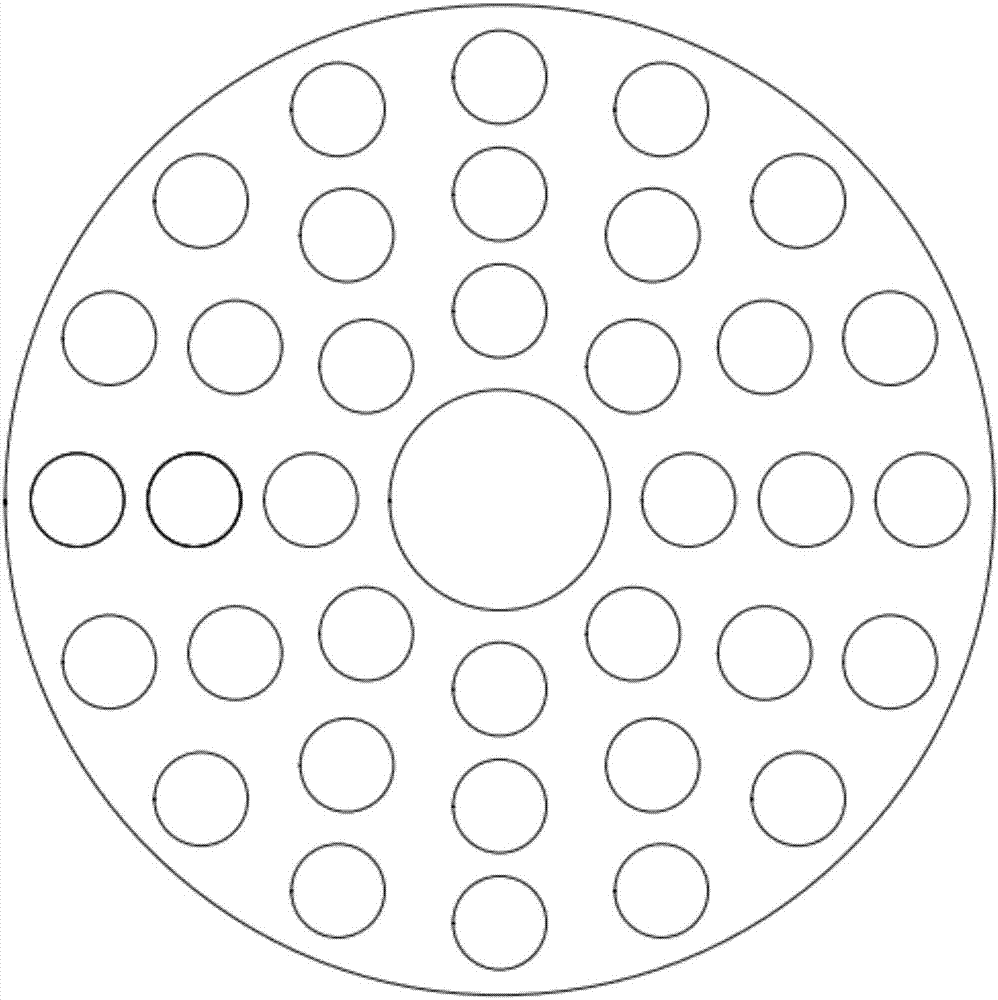

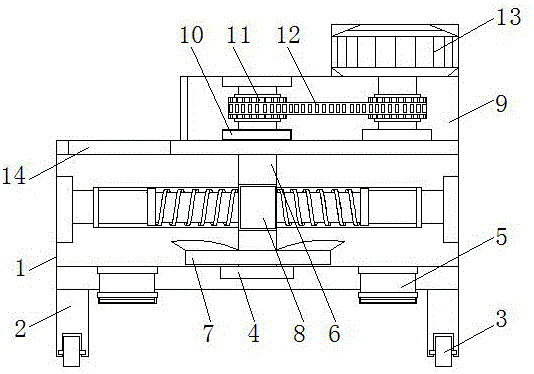

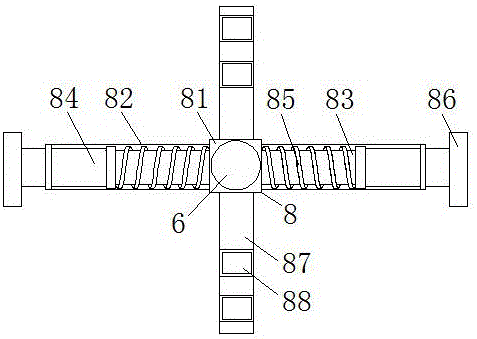

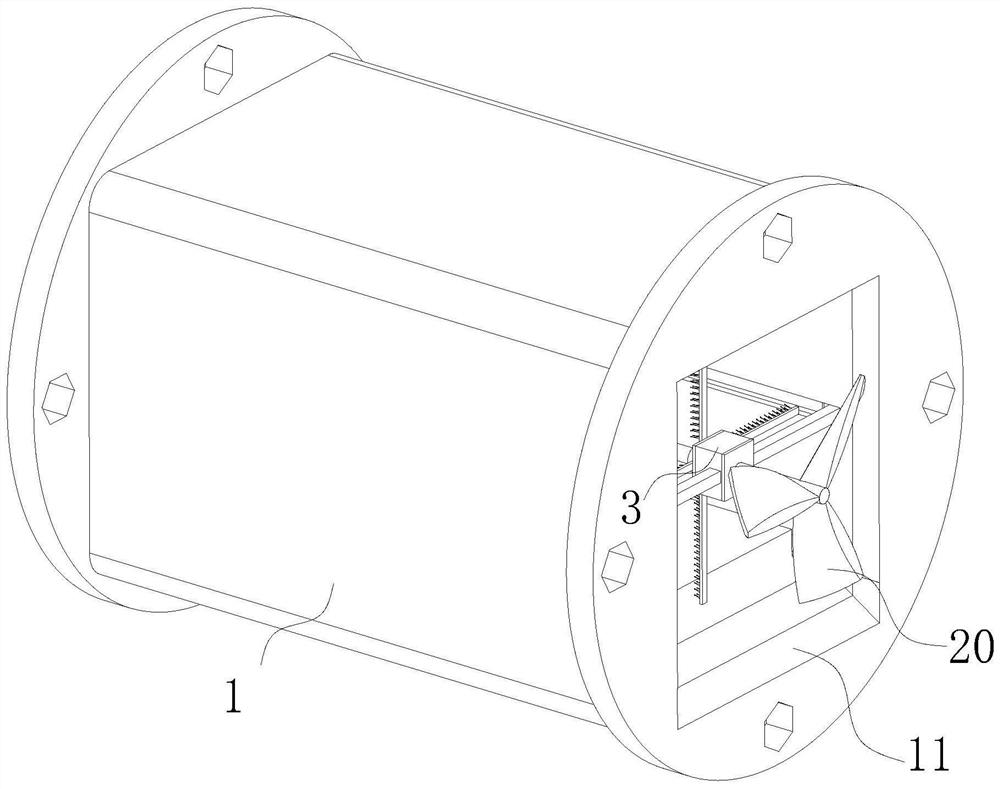

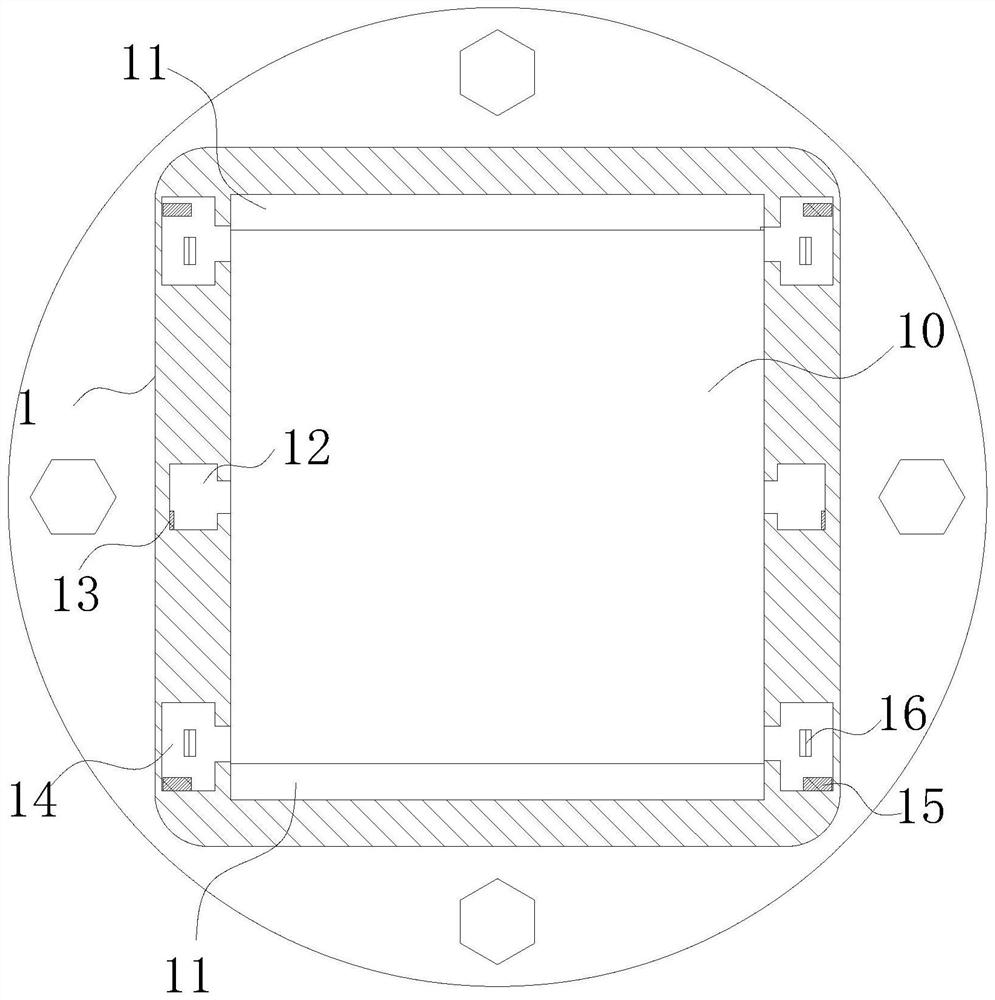

Feed processing equipment

The invention discloses feed processing equipment. The feed processing equipment comprises a grinding tank and a driving motor, wherein a rotating shaft is rotatably connected to the center of the topof the grinding tank; the top end of the rotating shaft is fixedly connected with an output shaft of the driving motor through a coupling; a square connecting rod is fixed to the bottom end of the rotating shaft and located in the center of the interior of the rotating shaft; deflector rods are fixed to the surface of the square connecting rod; a grinding device is arranged at the bottom end of the square connecting rod, the grinding device is in sliding connection with the square connecting rod; and a sieve plate is fixed to the position, close to the bottom of the grinding device, in the grinding tank. The invention relates to the technical field of feed processing. According to the feed processing equipment, the effects of uniform grinding and adhesion prevention are achieved; elasticpressing can be carried out, and the grinding space is automatically and moderately increased, so that large and small granular materials uniformly leak, and grinding is rapid and uniform; and meanwhile, sticky materials on the inner wall can be automatically scraped off, so that the working efficiency and the use performance are improved.

Owner:莱阳和美华饲料有限公司

Clearing device of stirring machine

InactiveCN106378870APrevent solidificationImprove stirring efficiencyCement mixing apparatusEngineeringMechanical engineering

The invention discloses a clearing device of a stirring machine. The clearing device comprises a housing; a base is fixedly mounted at the bottom end of the housing; wheels are movably arranged at the bottom end of the base in a sleeving mode; a bearing is fixedly mounted in the middle of the bottom end of the inner cavity of the housing; a discharge valve, which is positioned on the side surface of the bearing, is fixedly mounted at the bottom end of the housing; the shaft center of the bearing is in movable sleeve connection with the bottom end of the rotary shaft; stirring paddles, which are positioned above the bearing, are fixedly arranged at the bottom end of the rotary shaft in the sleeving mode; a stirring device which is positioned above the stirring paddles is arranged on the rotary shaft in the sleeving mode; and the top end of the rotary shaft penetrates through the top end of the housing, extends to an inner cavity of a machine case, and is in movable sleeve connection with the top end of the inner cavity of the machine case. According to the clearing device disclosed by the invention, the stirring paddles are arranged for uniformly stirring a cement material, so that cement is uniformly distributed at the bottom end of the housing while stirred, cement adhered on the inner wall of the housing is scraped off by a scraping plate, and the cement is prevented from being solidified on the inner wall of the housing, and therefore, stirring efficiency is improved, and cost is saved.

Owner:WUXI RISHENG CHEM CO LTD

Automatic flow division device for gutter oil and water

InactiveCN107032446AEasy to separateGuaranteed timeFatty/oily/floating substances removal devicesLiquid separationFiltrationCrop cultivation

The invention discloses an automatic flow division device for gutter oil and water. The automatic flow division device comprises a separation box. A vertical first retaining plate, a vertical second retaining plate and a vertical third retaining plate are fixedly connected to the inner side wall of the separation box. Openings are formed in the bottoms of the first retaining plate and the third retaining plate. A filtration plate is arranged between the first retaining plate and the inner side wall of the separation box. A filtration barrel is arranged at the top of the filtration plate. The bottom of the second retaining plate is abutted against the inner bottom of the separation box. A first rotating shaft and a second rotating shaft are arranged above the second retaining plate. The first rotating shaft is positioned above the second rotating shaft. Belt wheels fixedly sleeve the first rotating shaft and the second rotating shaft respectively. The automatic flow division device has the advantages that the structure is simple, and the design is novel; the oil and the water in gutter oil can be separated by the device, the waste oil can be used for fuel extraction or serve as industrial oil, the waste water can be used for fish culture or fertilizer for crop cultivation, environmental pollution caused by direct discharge to river channels is avoided, and waste materials can be changed into things of value.

Owner:南通秋祥信息科技有限公司

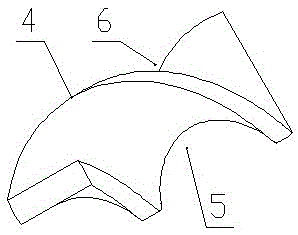

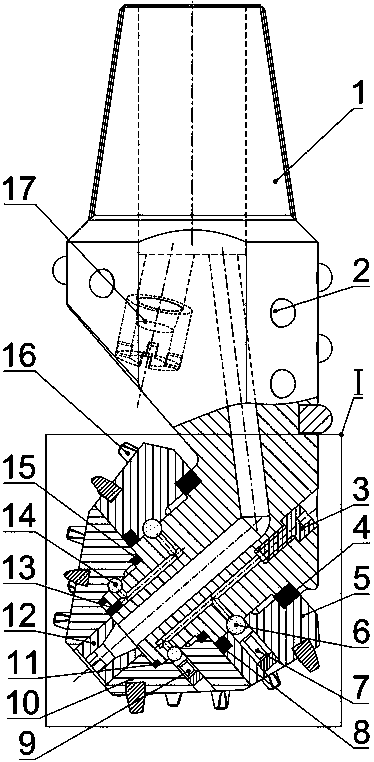

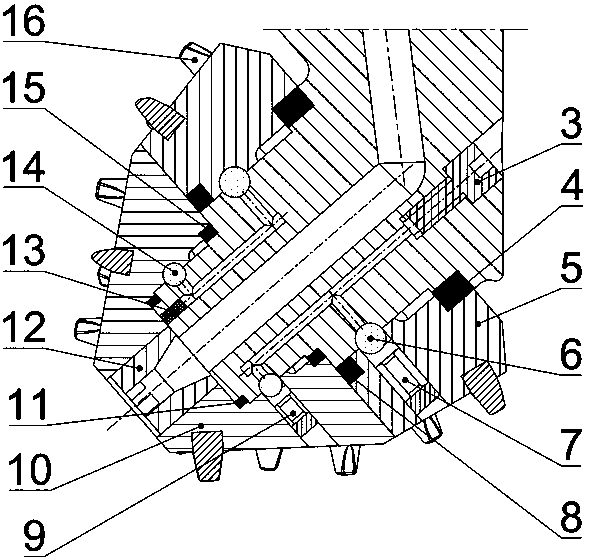

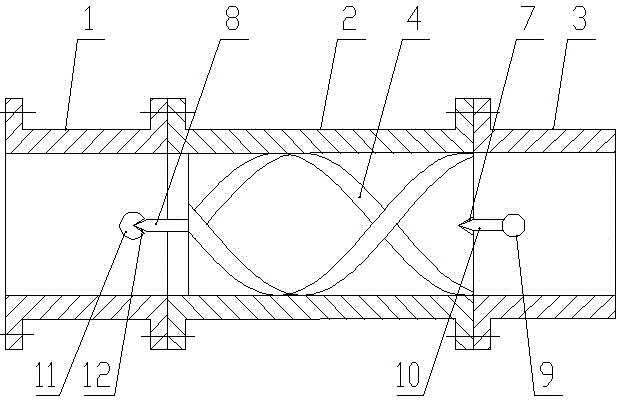

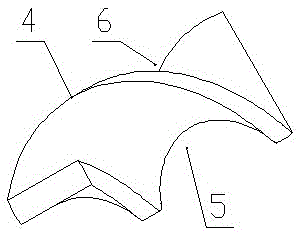

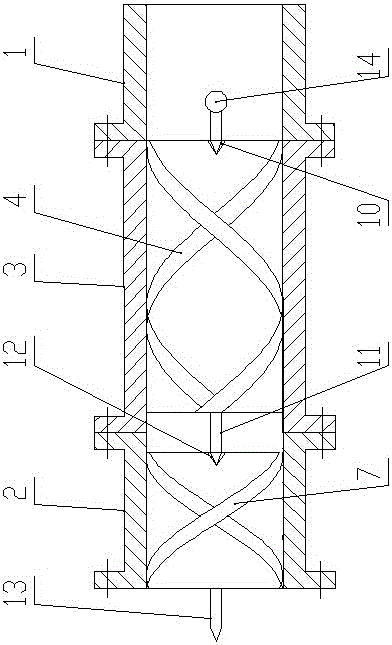

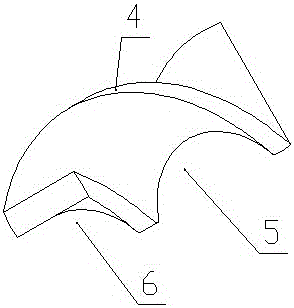

Split single roller bit

The invention relates to a split single roller bit. The split single roller bit is mainly composed of a drilling bit jaw, a cone lower body, a cone upper body, teeth, diameter keeping teeth, a steel ball, a retaining plug, an oil mouth, an oil blocking plug and a rectangular sealing ring. The drilling bit jaw is connected with the cone lower body and the cone upper body through a drilling bit palmaxial neck aslant arranged at the lower end of the drilling bit jaw, and in the drilling process, the cone lower body and the cone upper body rotate along with a bit body and also spin around the drilling bit palm axial neck respectively to achieve the task of scraping and smashing rocks of the cone lower body and the cone upper body. A split structure is adopted by the split single roller bit, the teeth scraping efficiency of a roller small end tooth ring and teeth of a middle tooth ring can be improved, the rock smashing efficiency of the bit is improved, conical structures are adopted by the cone lower body and the cone upper body, the split single roller bit is applicable to smashing a hard stratum, and the effective service life of the split single roller bit is prolonged.

Owner:SOUTHWEST PETROLEUM UNIV +2

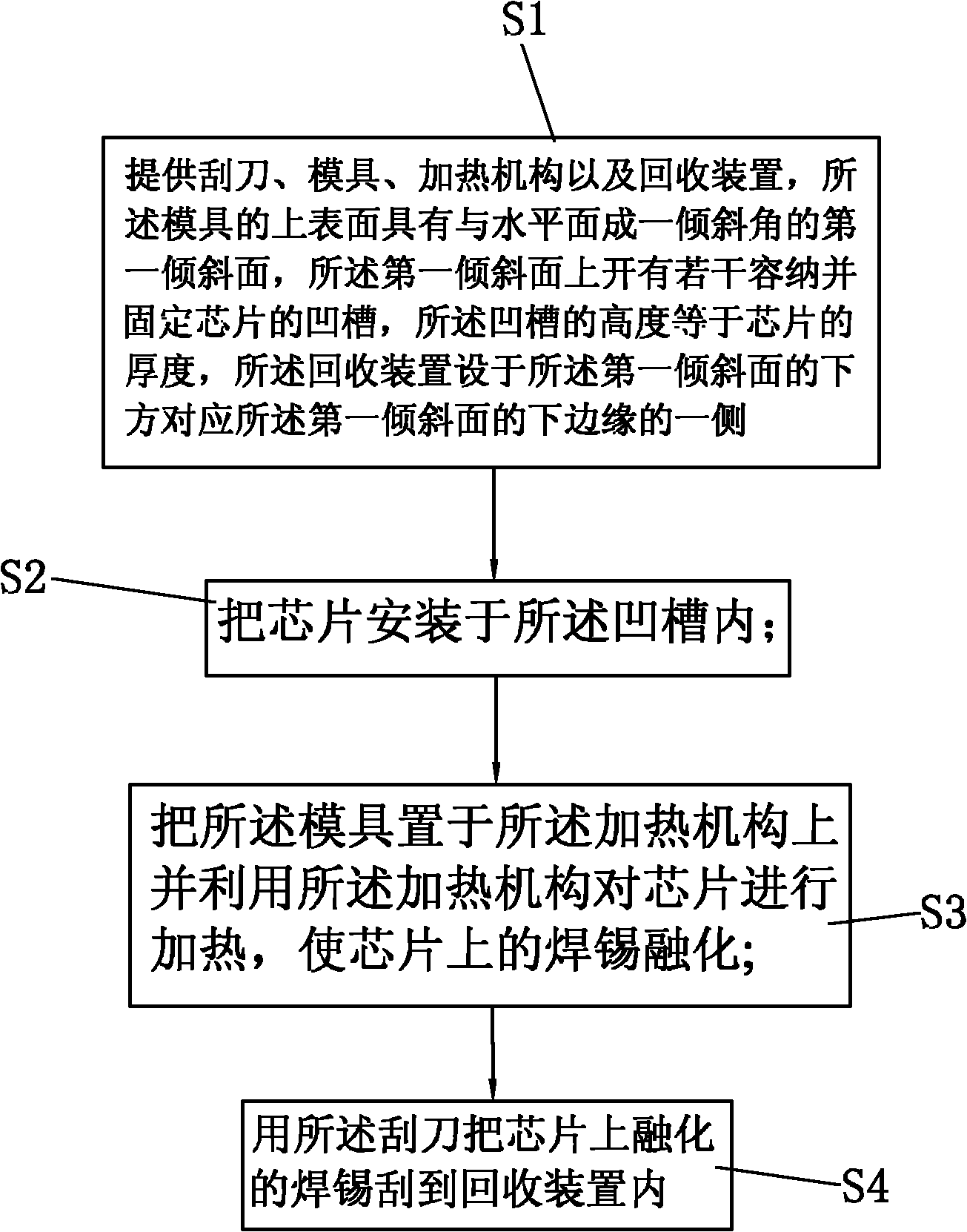

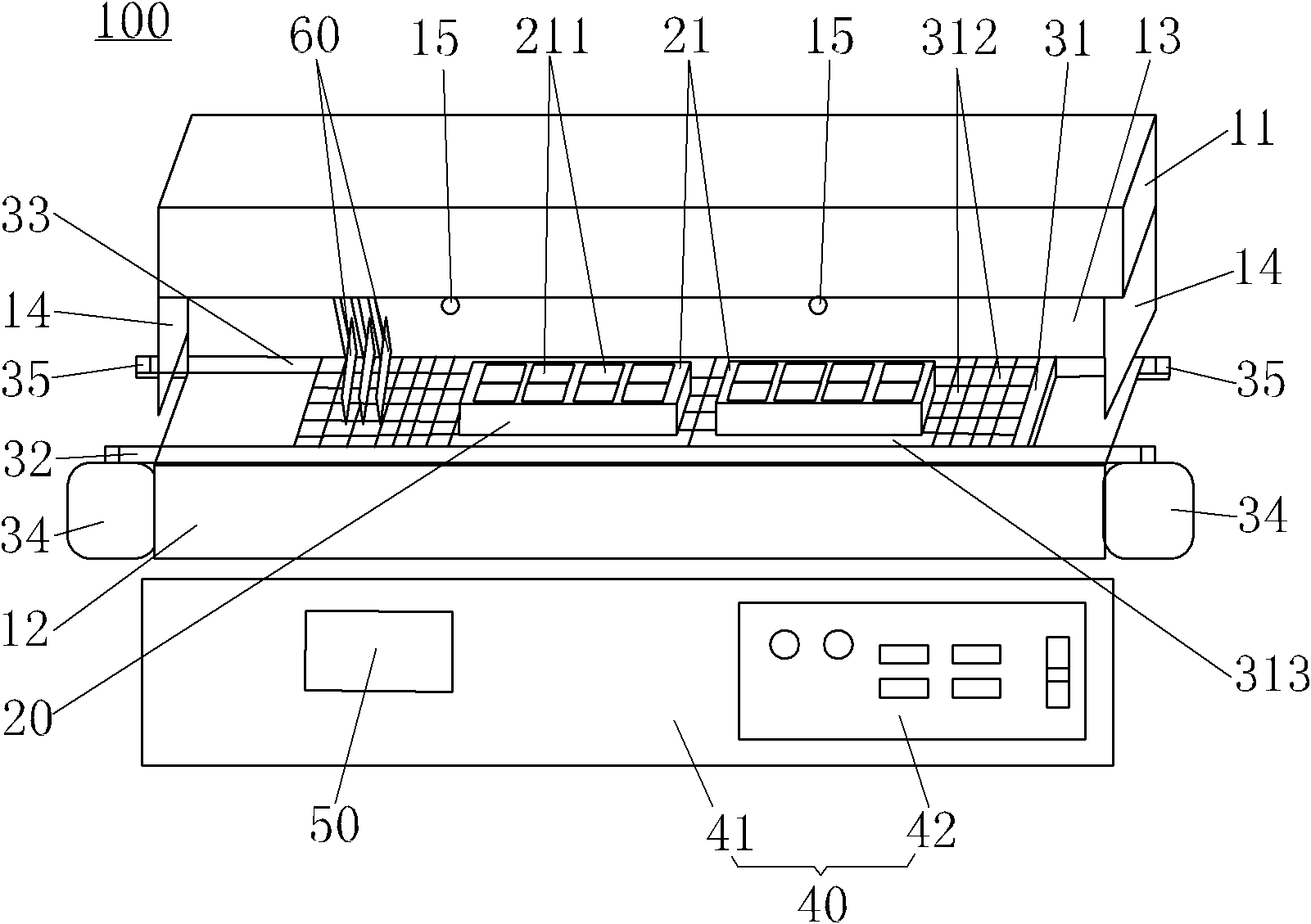

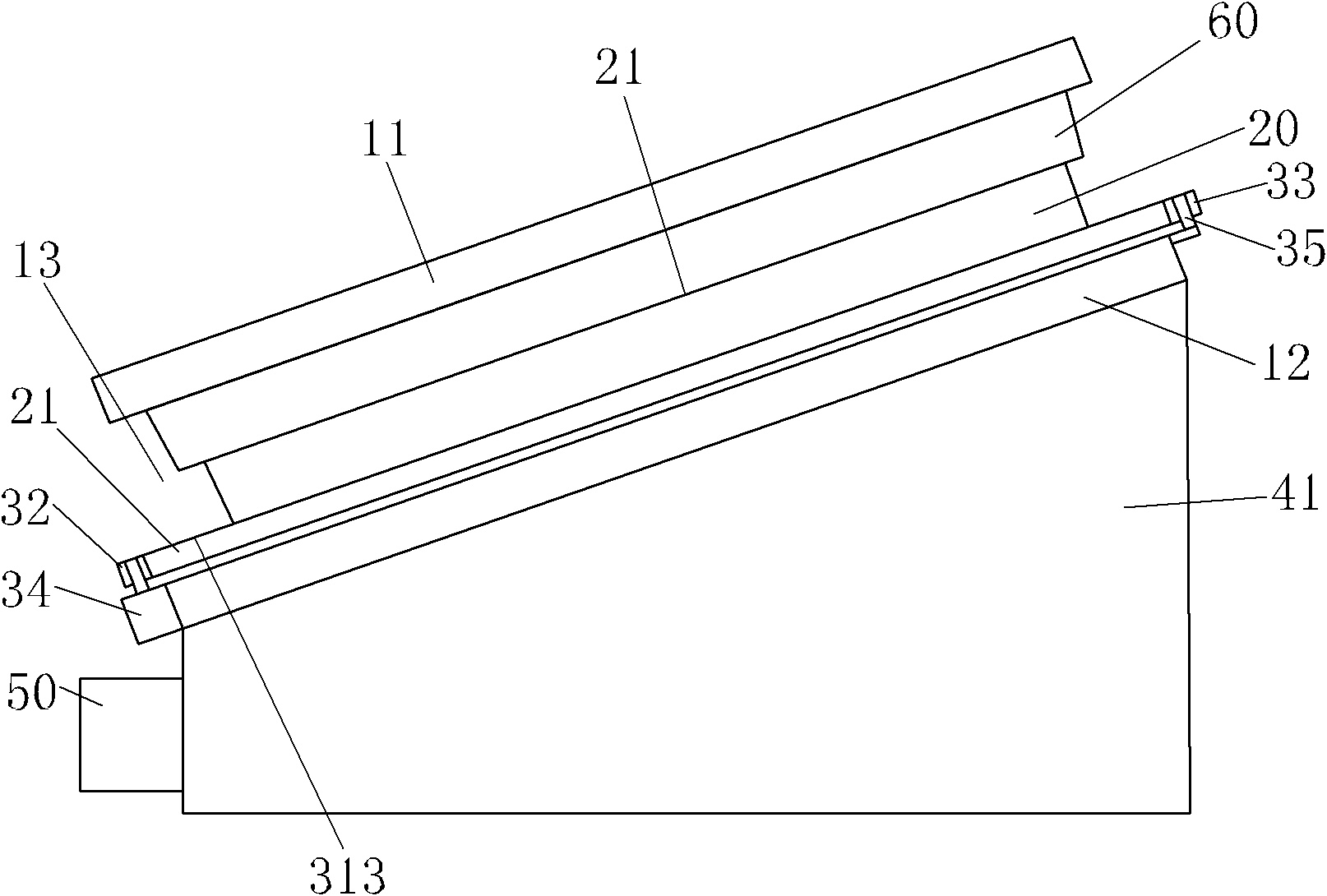

Detinning processing method of chip and chip detinning machine applying method

The invention discloses a detinning processing method of a chip, and the method comprises the following steps: providing a scraper, a die, a heating mechanism and a recovery device, wherein a first inclined plane which forms an inclination angle with the horizontal plane is arranged on the upper surface of the die, a plurality of grooves for accommodating and fixing chips are formed on the first inclined plane, the height of each groove is equivalent to the thickness of each chip, and the recovery device is arranged on one side corresponding to the lower edge of the first inclined plane belowa conveying mechanism; arranging the chips in the grooves; placing the die on the heating mechanism, and utilizing the heating mechanism to heat the chips so as to melt soldering tin on the chips; and utilizing the scraper to scrape the soldering tin on the chips into the recovery device. In the method, the scraper is utilized for scraping off the molten soldering tin form the chips, the soldering tin can stably slide into the recovery device along the wall of the scraper, the loss of the soldering tin is low, and the recovery rate is high; and furthermore, the plurality of the grooves are arranged on the die, the plurality of the chips can be scraped according to needs, and the tin scraping efficiency is high. In addition, the invention further provides a chip detinning machine applying the detinning processing method of the chip.

Owner:何光宁

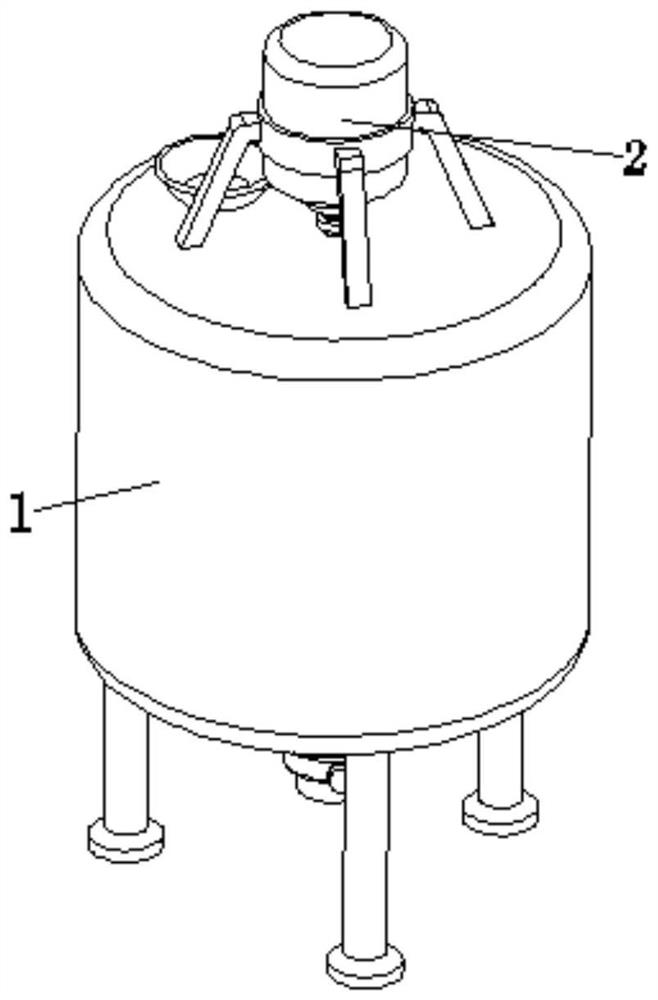

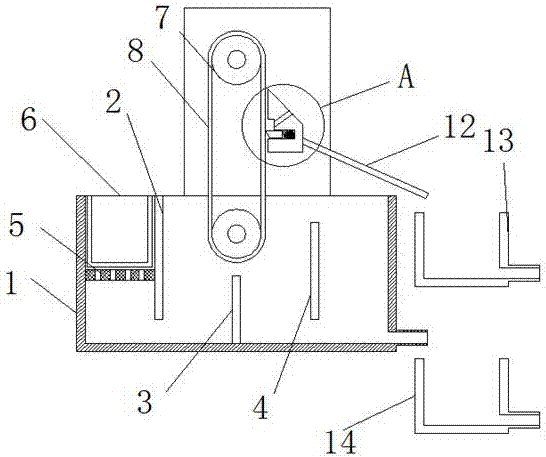

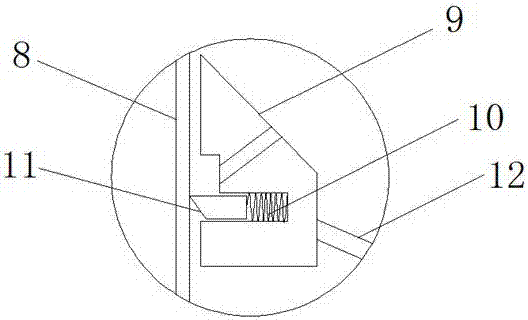

Mixing barrel with water flushing scraper blade for chemical use

InactiveCN104307400AReduce resistanceImprove scraping efficiencyRotary stirring mixersMixer accessoriesWater sourcePiston rod

The invention relates to a mixing barrel with a water flushing scraper blade for chemical use. The mixing barrel comprises a mixing barrel, and a stirring shaft arranged inside the mixing barrel, wherein the mixing shaft is of a barrel-shaped structure with a central through hole, the upper end of the stirring shaft is provided with an opening, the lower end of the stirring shaft is fixedly connected with a belt pulley, the upper end surface of the mixing barrel is fixedly connected with a water inlet pipe, the water inlet pipe extends into the central through hole of the stirring shaft and is connected with an external water supply, a cylinder is arranged on the lower surface of the belt pulley, a piston rod of the cylinder is fixedly connected with a mandril, the mandril penetrates through the belt pulley and the mixing barrel to extend into the mixing shaft, two sides of the mixing shaft are provided with scraper blades by virtue of connecting rods, gaps are reserved between the scraper blades and the inner wall of the mixing barrel, the connecting rods and the scraper blades are of shell structures with inner cavities, the side walls of the scraper blades are provided with a plurality of through holes, the connecting rods are connected with the stirring shaft in a manner of sliding in the axial direction, the end parts of the connecting rods are provided with inclined openings and extend into the central through hole of the stirring shaft, the inclined openings are respectively positioned above the mandril, the outer side of the stirring shaft is fixedly connected with mounting sleeves, and the mounting sleeves are internally provided with springs fixedly connected with the outer walls of the connecting rods.

Owner:南通洋口资产经营管理有限公司

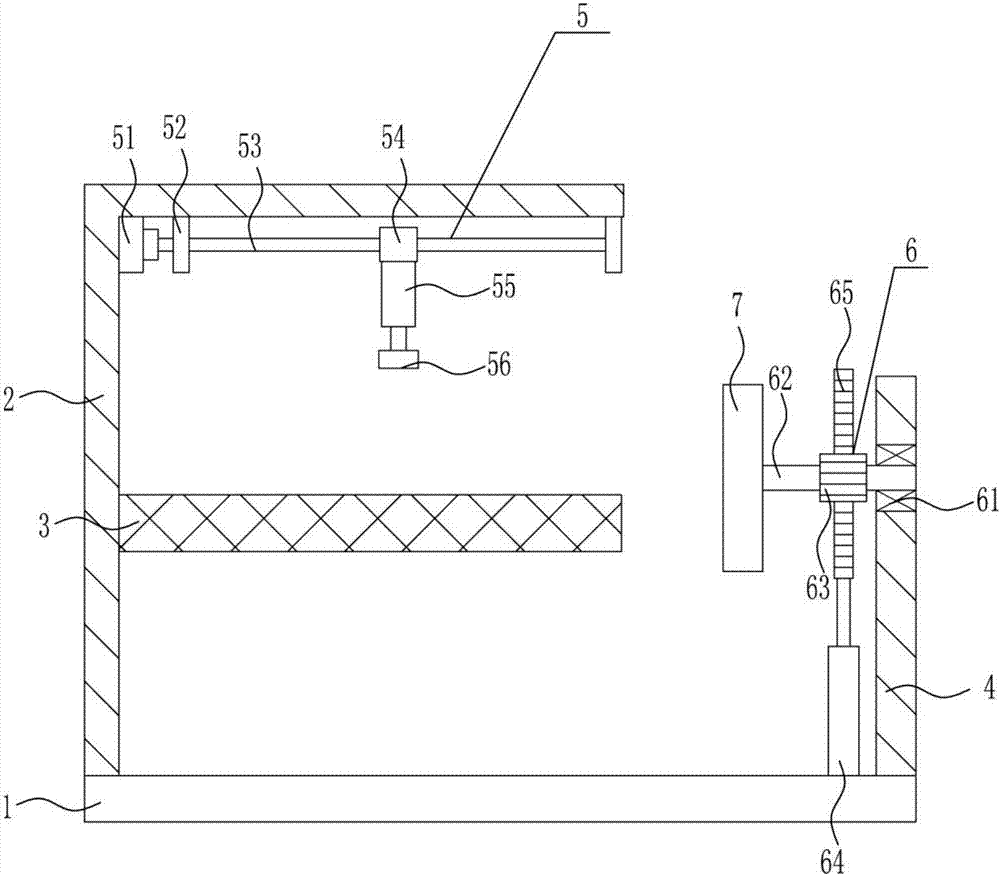

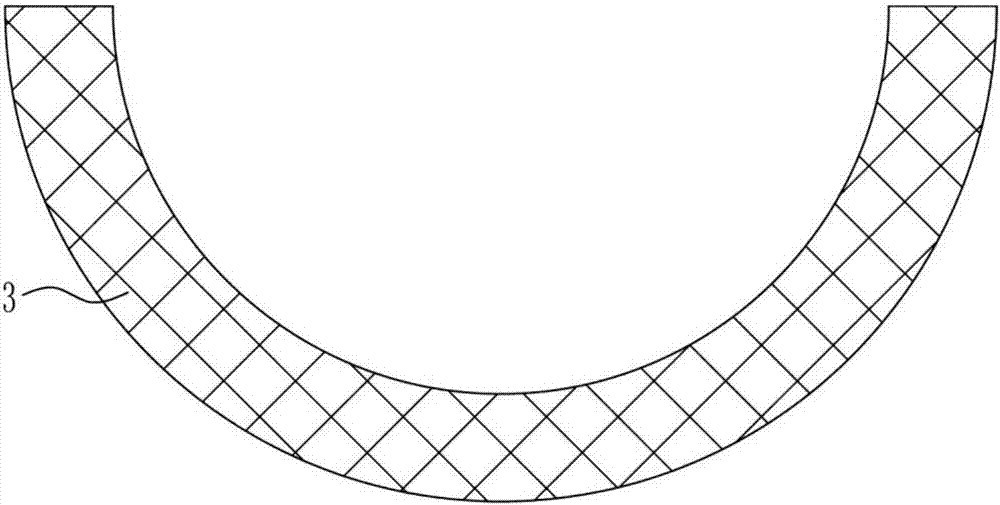

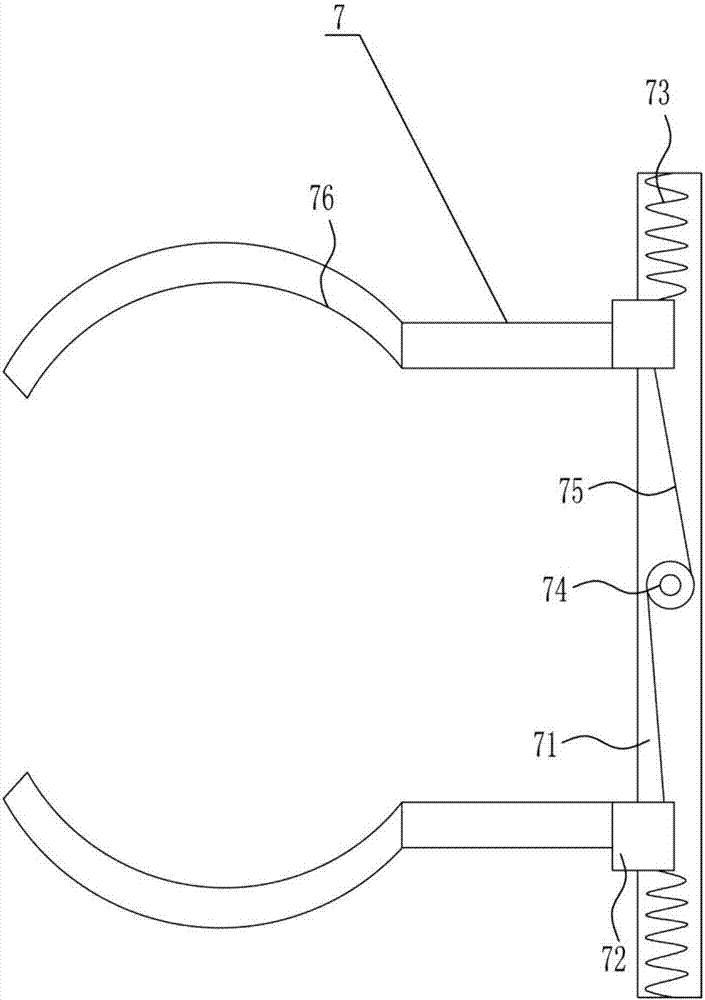

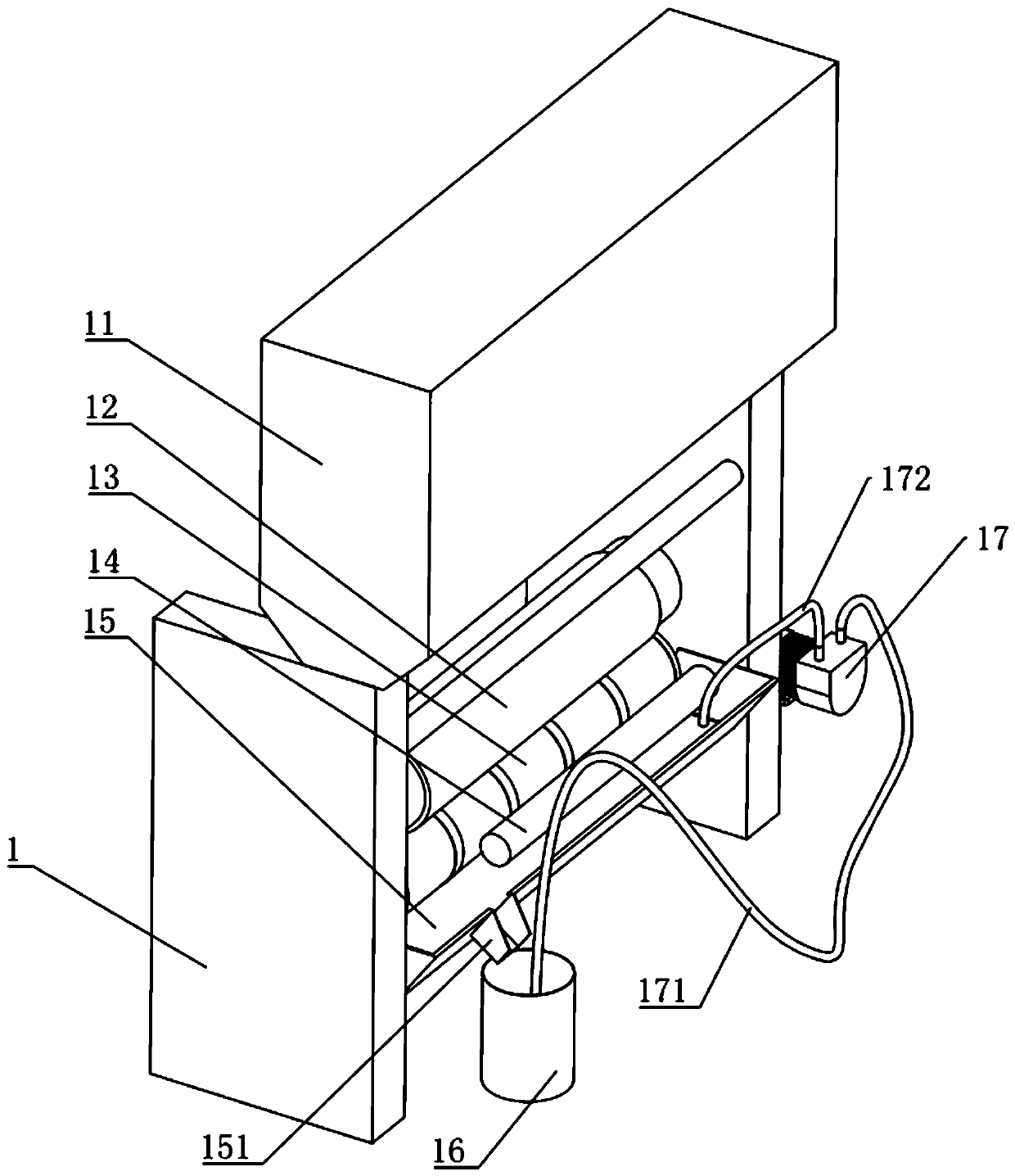

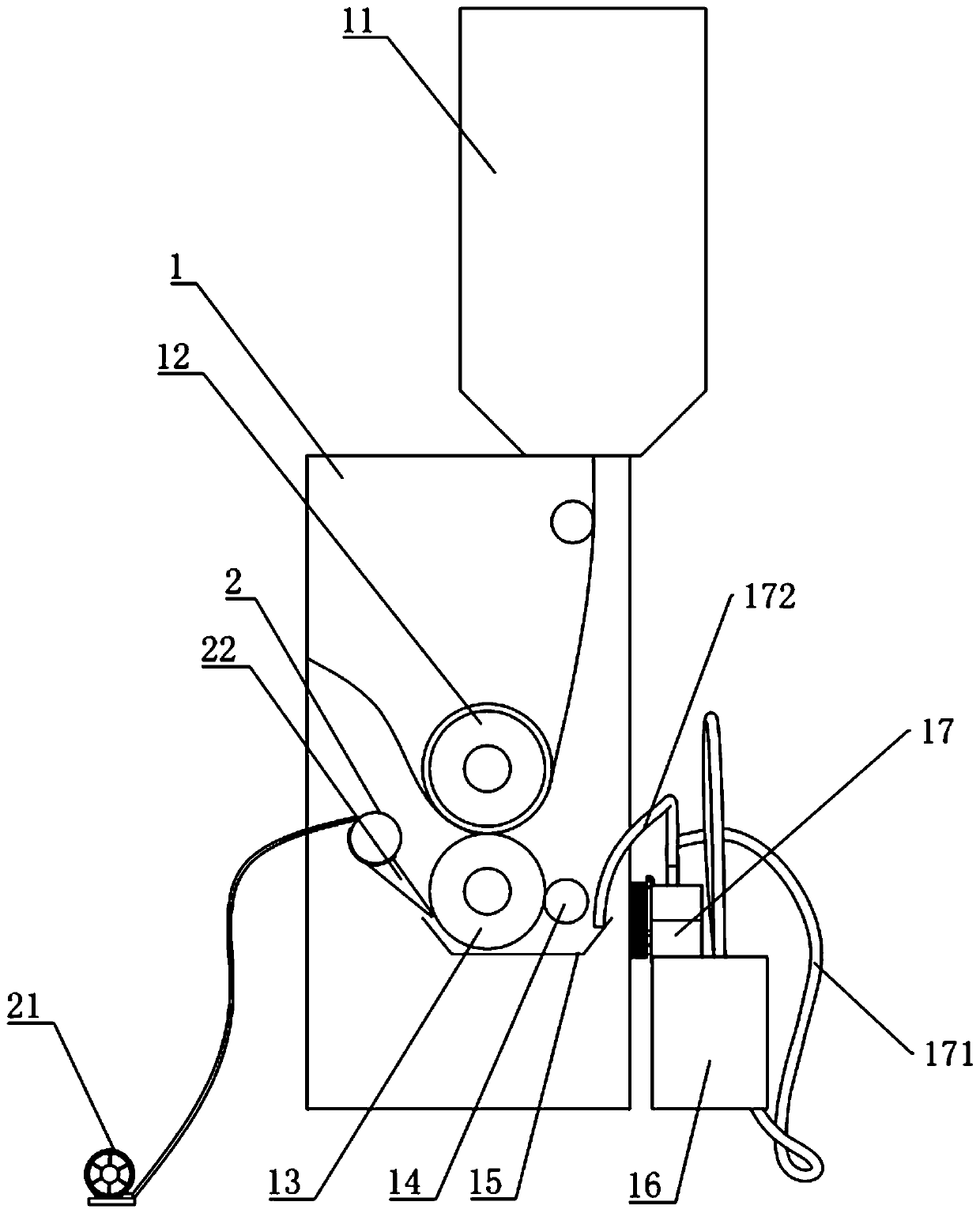

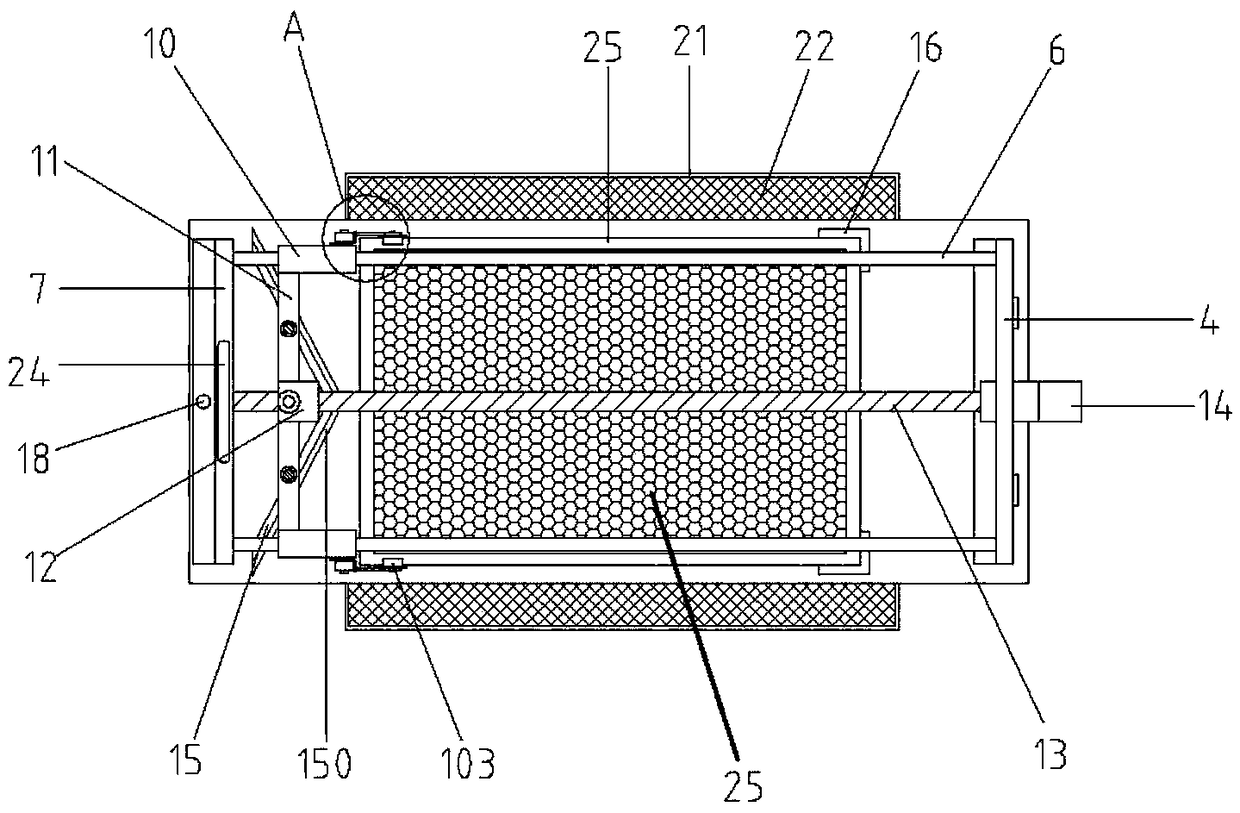

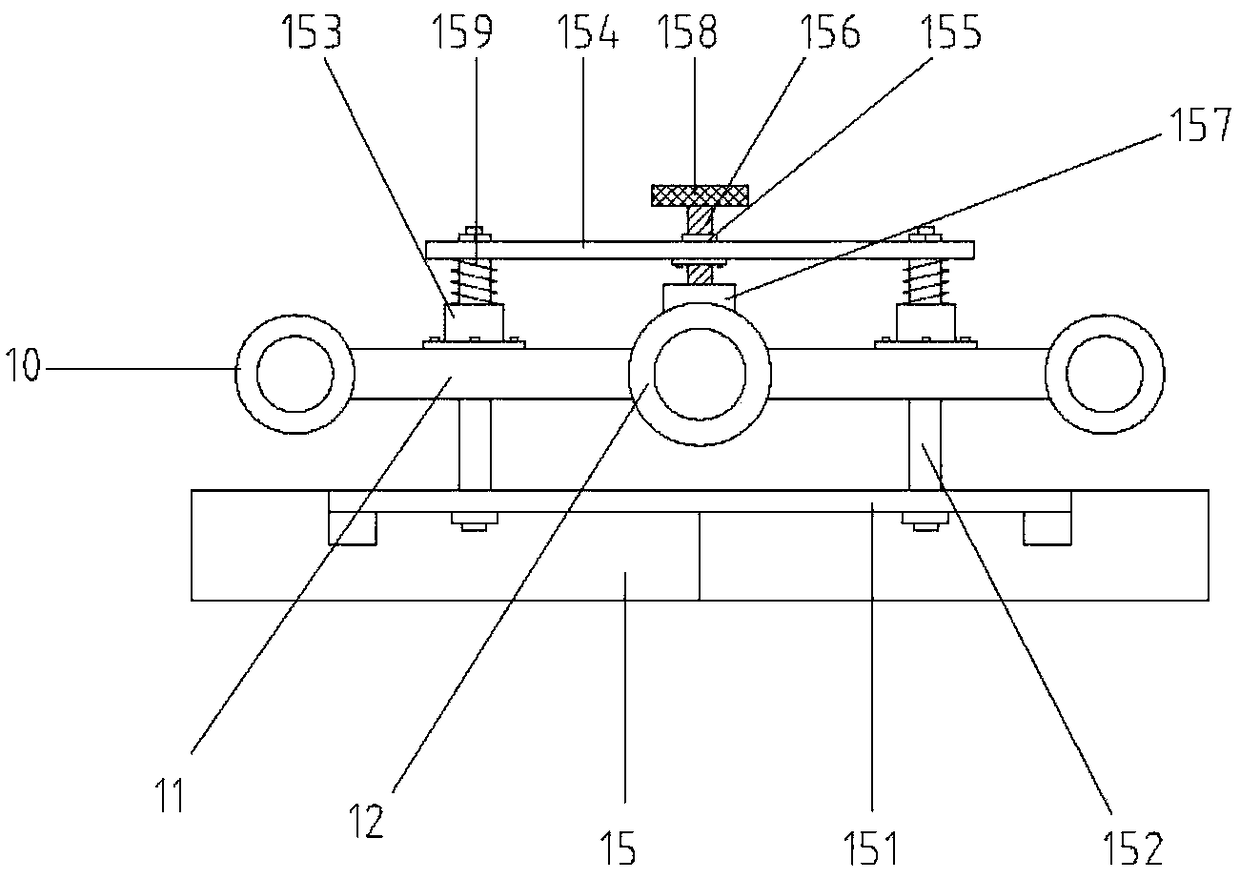

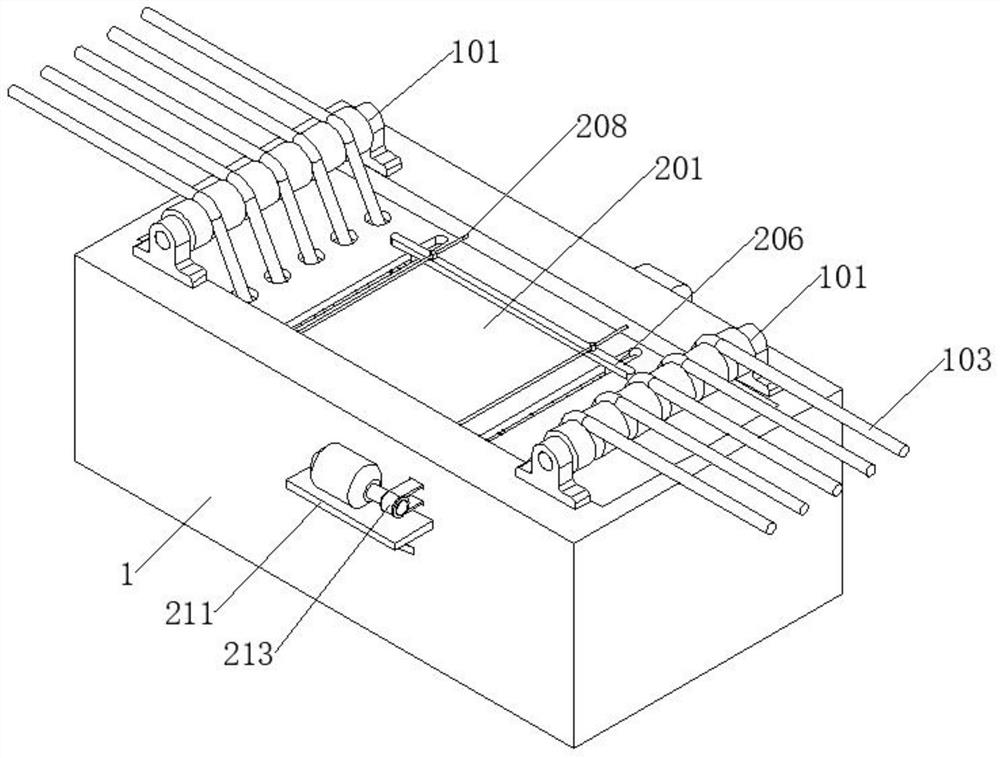

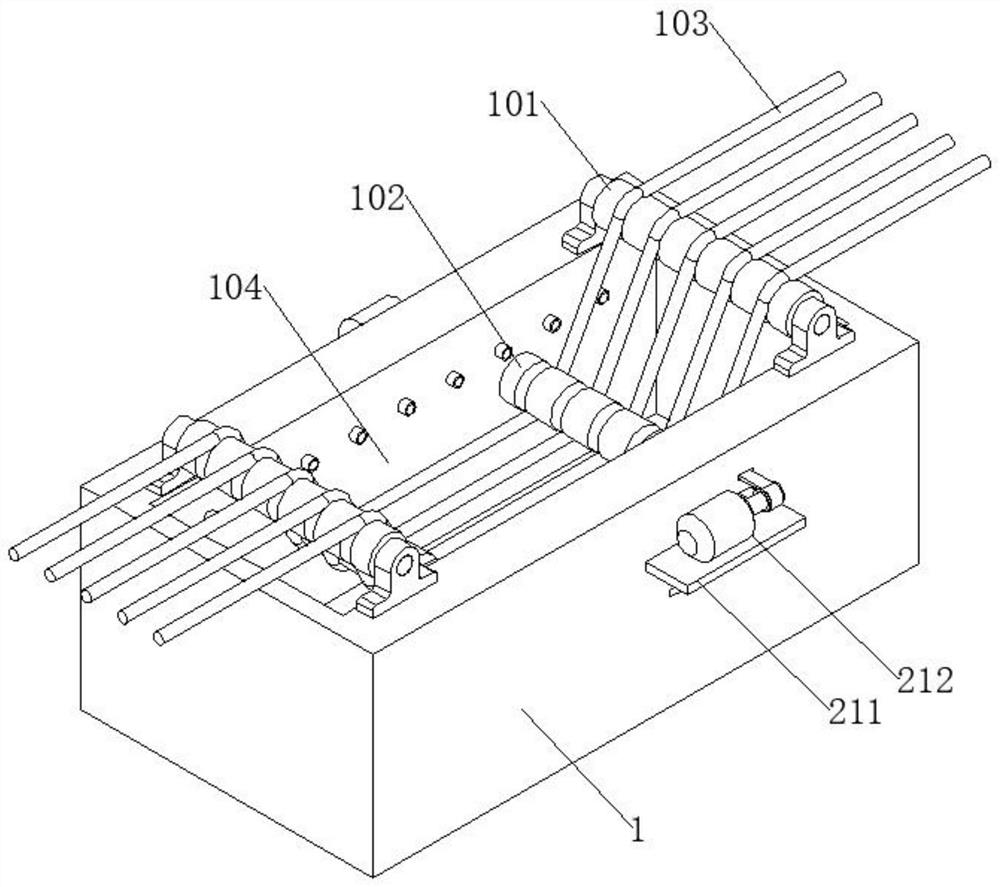

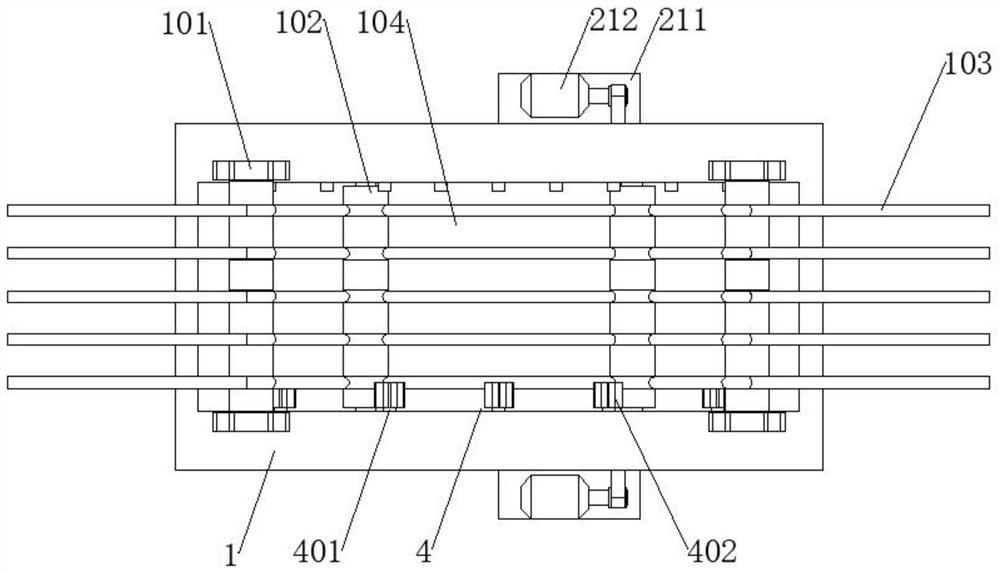

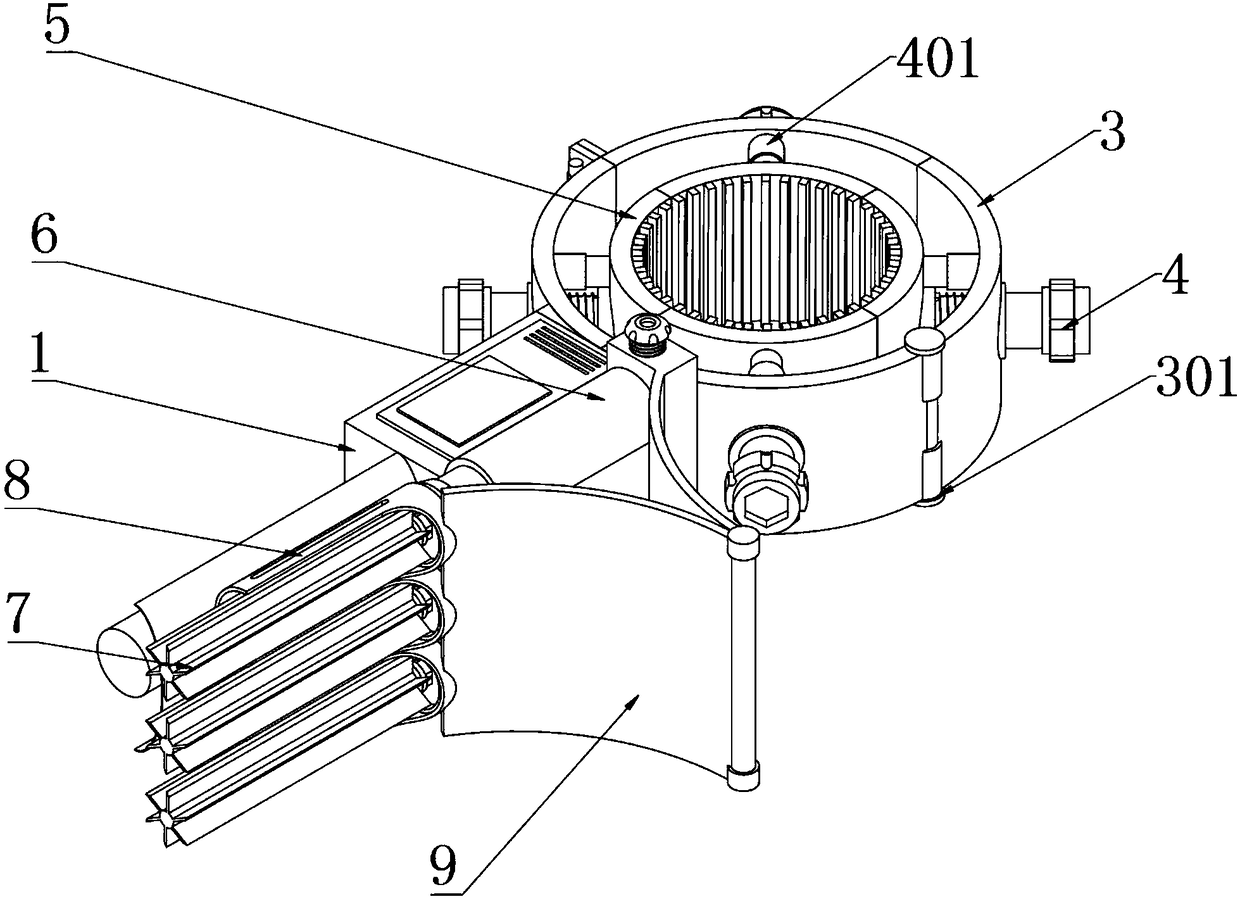

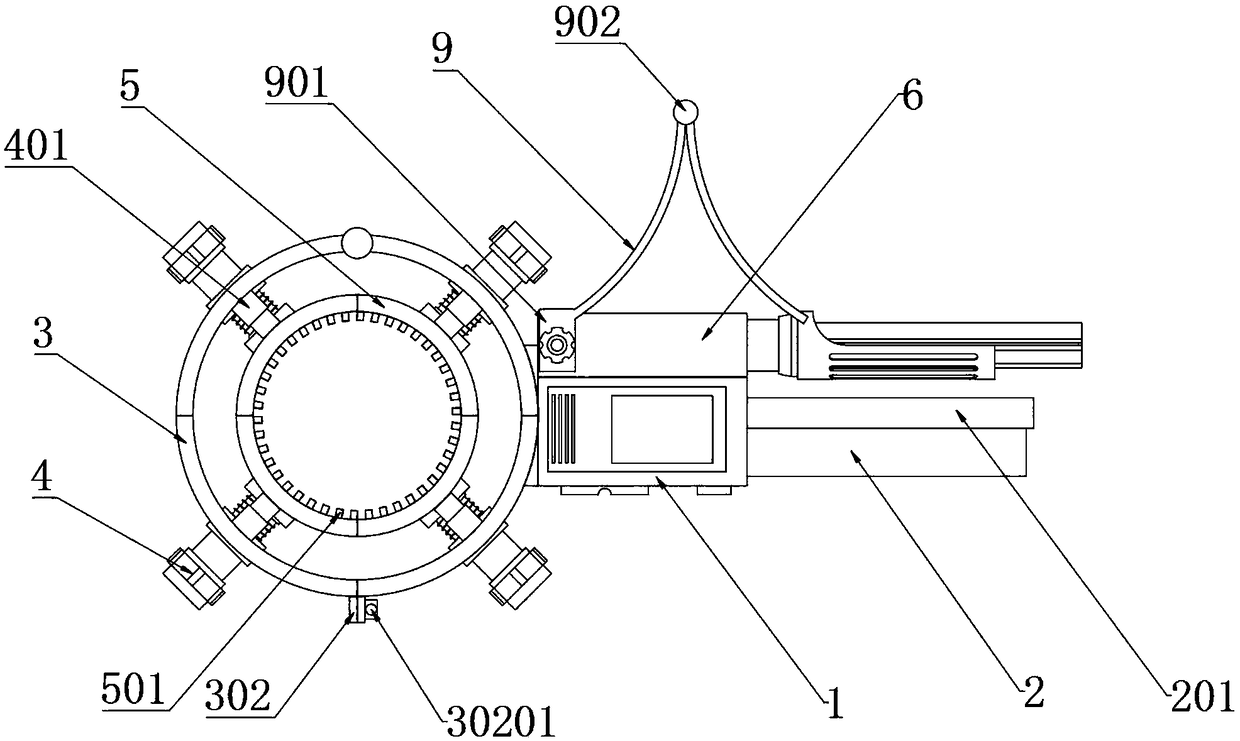

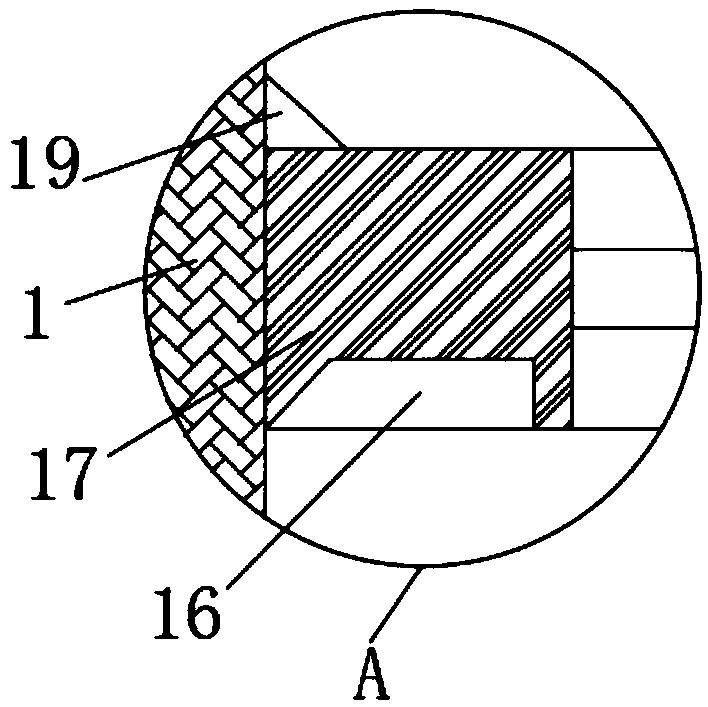

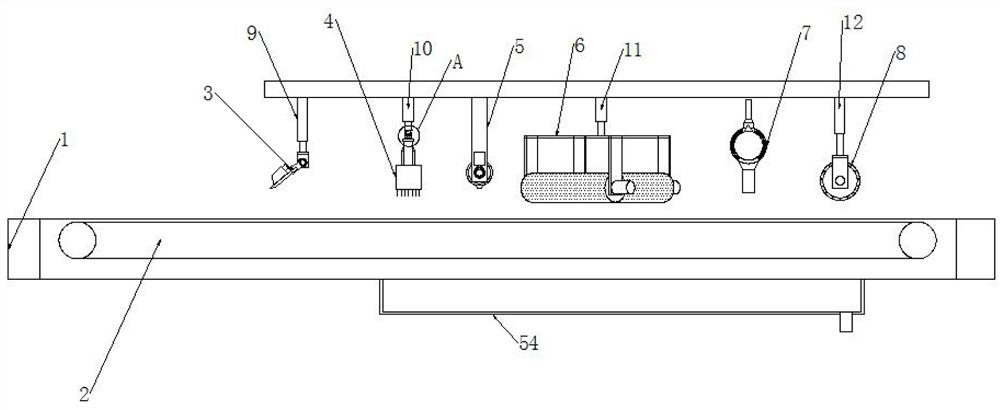

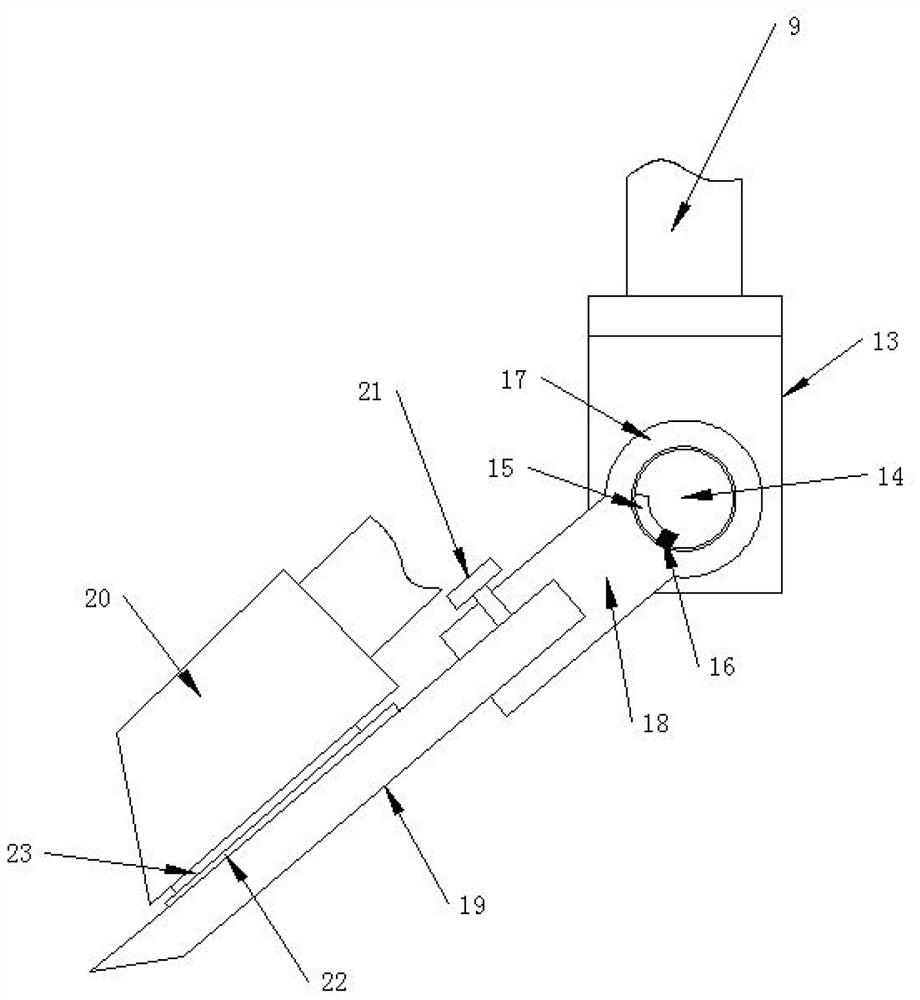

Cedar peeling equipment applied to wood production

InactiveCN108000658AImprove scraping efficiencyEasy to operateTree debarkingDrying gas arrangementsWood productionEngineering

The invention relates to cedar peeling equipment, in particular to the cedar peeling equipment applied to wood production. The technical problem to be solved by the invention is to provide the cedar peeling equipment applied to the wood production, wherein the cedar peeling equipment is high in peeling efficiency, capable of saving time and efforts and simple to operate. The cedar peeling equipment applied to the wood production comprises a base plate, a left bracket, an arc-shaped placing plate, a right bracket and the like; the left bracket is arranged at the left side of the top of the baseplate; the right bracket is arranged at the right side of the top of the base plate; the arc-shaped placing plate is arranged at the middle part of the right side of the left bracket; a peeling mechanism is arranged at the internal top of the left bracket; a rotating mechanism is arranged at the left side of the right bracket; a clamping mechanism is arranged at the left side of the rotating mechanism and is positioned just at the right of the arc-shaped placing plate. The cedar peeling equipment provided by the invention is used for peeling a cedar by utilizing the peeling mechanism, can realize peeling by rotating the cedar by mutual cooperation of the rotating mechanism and the clamping mechanism, realizes complete peeling and realizes the effects of being high in peeling efficiency, saving time and efforts and being simple to operate.

Owner:钟清

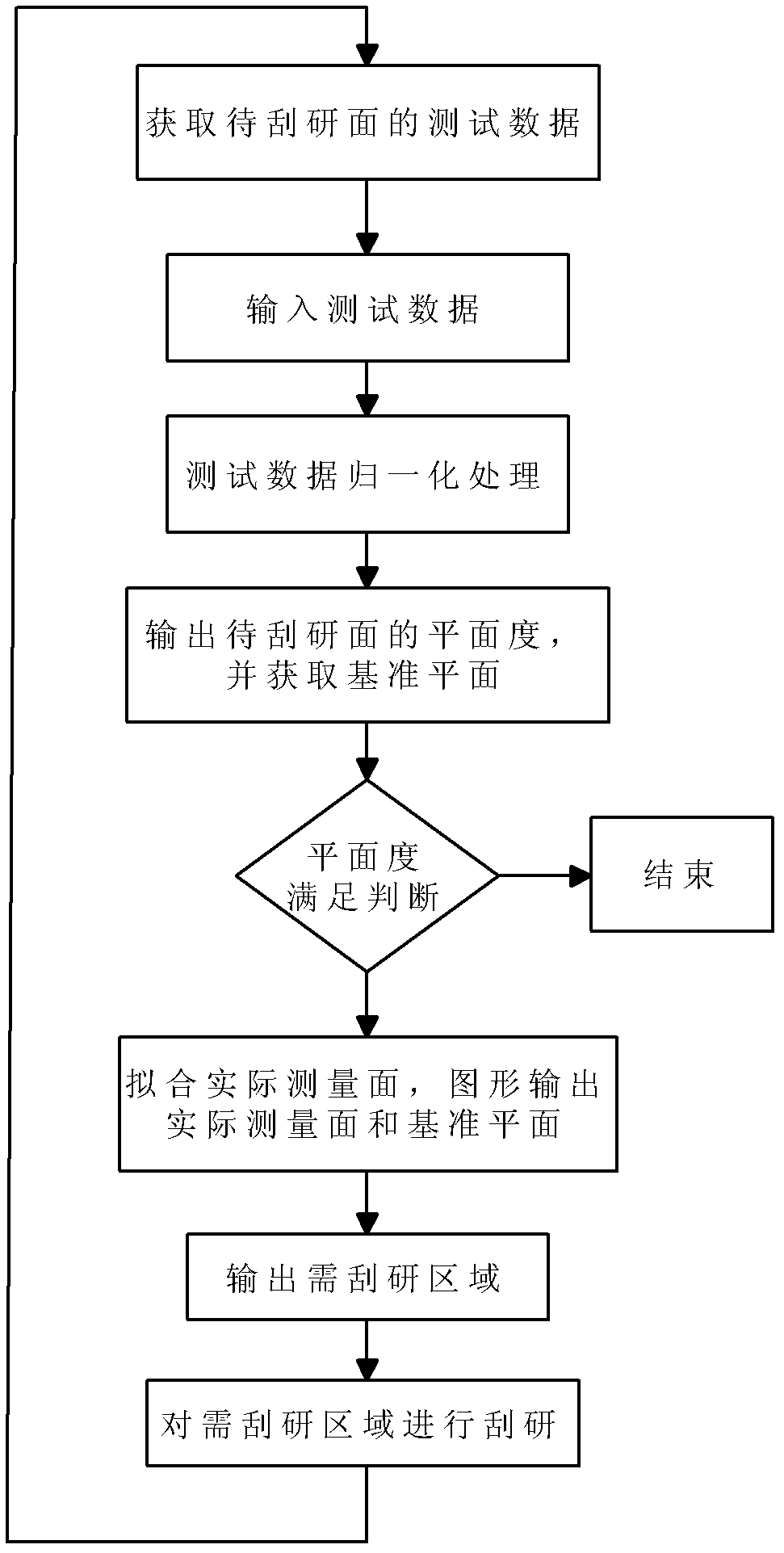

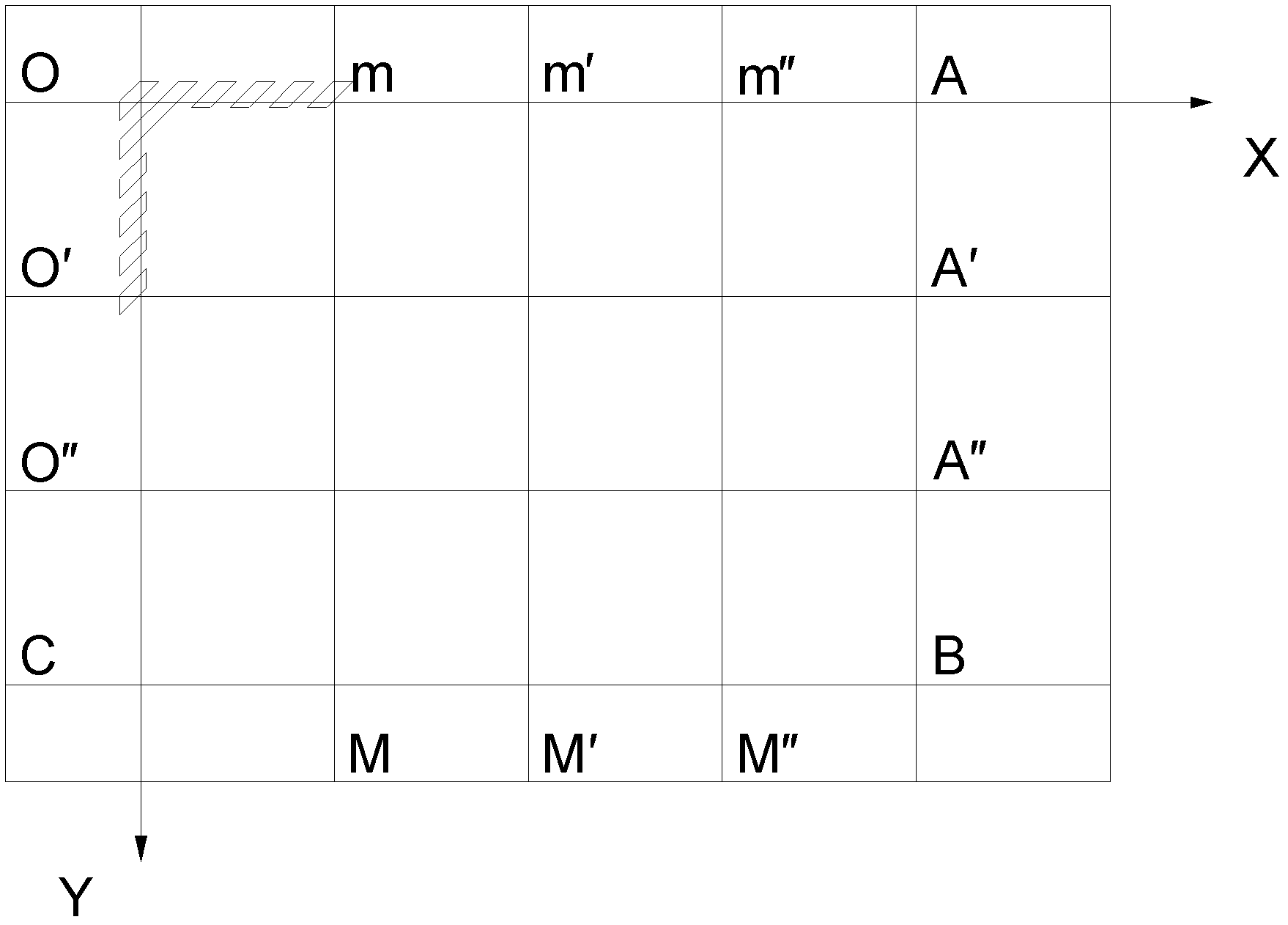

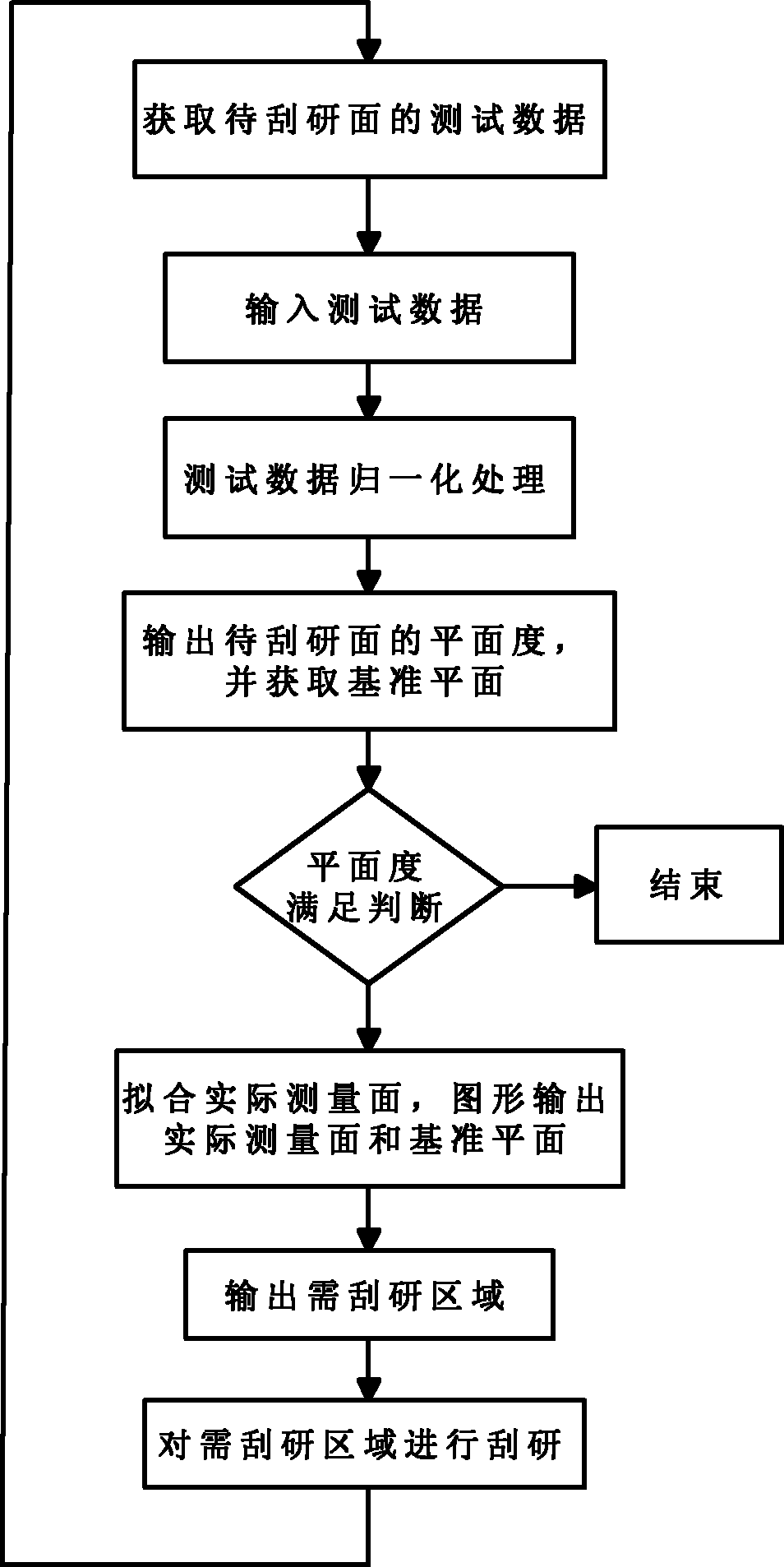

Plane scraping method based on flatness measurement

InactiveCN102632456ALow proficiency requirementShorten the timeGrinding feed controlGrinding machinesGraphicsMechanical engineering

The invention discloses a plane scraping method based on flatness measurement. The plane scraping method includes acquiring a plurality of points on a surface to be scraped at first; computing the flatness of the surface to be scraped by a visualized software capable of processing and fitting data; then judging whether the surface needs to be scraped or not according to the flatness of the surface to be scraped; fitting a graph of the surface to be scraped and a graph of a reference surface of the surface to be scraped according to the multiple points on the surface to be scraped if the surface needs to be scraped; outputting regions which are higher than the reference surface and are required to be scraped on the surface to be scraped; and scraping the outputted regions required to be scraped by an operator by the aid of a scraping plate. Accordingly, only the portions, higher than the reference surface, on the surface to be scraped need to be scraped, most of areas of the surface to be scraped do not need to be scraped, scraping time is saved, scraping pertinence is improved, scraping efficiency is also enhanced, and requirements on proficiency of the scraping operator are lowered.

Owner:SUZHOU JIANG YUAN PRECISION MACHINERY +1

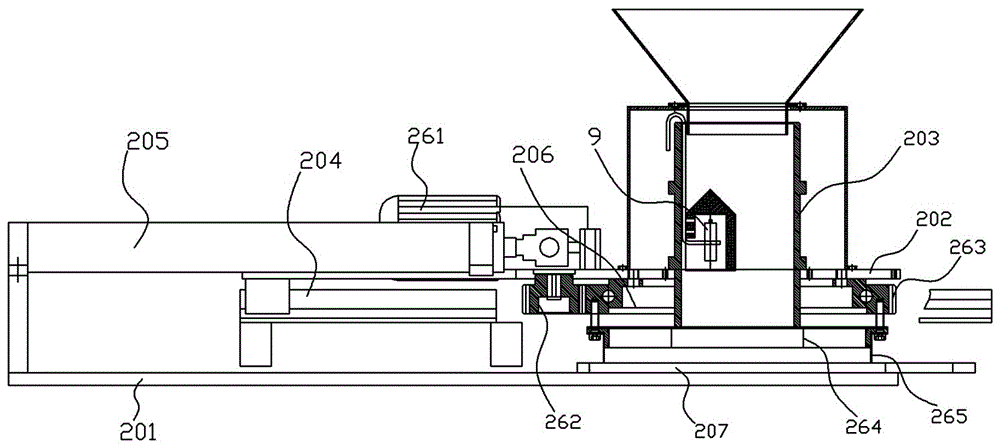

Bamboo charcoal polylactic acid particle spinning technology

ActiveCN105463589AImprove scraping efficiencyEasy to manufactureSpinning head liquid feederMelt spinning methodsHigh wear resistanceMoisture regain

A bamboo charcoal polylactic acid particle spinning technology comprises the steps that bamboo charcoal micro powder and polylactic acid particles are mixed and then sent to a granulation screw extruder to be produced into a bamboo charcoal polylactic acid master batch; the bamboo charcoal polylactic acid master batch is dried; the bamboo charcoal polylactic acid master batch is subjected to quantitative metering of a micro-meter and then sent into a spinning screw extruder together with polylactic acid dry chips to be processed into a bamboo charcoal polylactic acid melt; the bamboo charcoal polylactic acid melt is filtered through a melt filter; the filtered bamboo charcoal polylactic acid melt is sent into a spinning manifold through a melt pipeline; the bamboo charcoal polylactic acid melt is spun into bamboo charcoal polylactic acid fiber through a spinning component in the spinning manifold. According to the spinning technology, polylactic acid is modified through nanoscale bamboo charcoal micro powder, so that the prepared fiber has lower initial modulus, higher moisture regain, higher wear resistance, higher air permeability and better hand feeling.

Owner:HENAN LONGDU BIOLOGY TECH

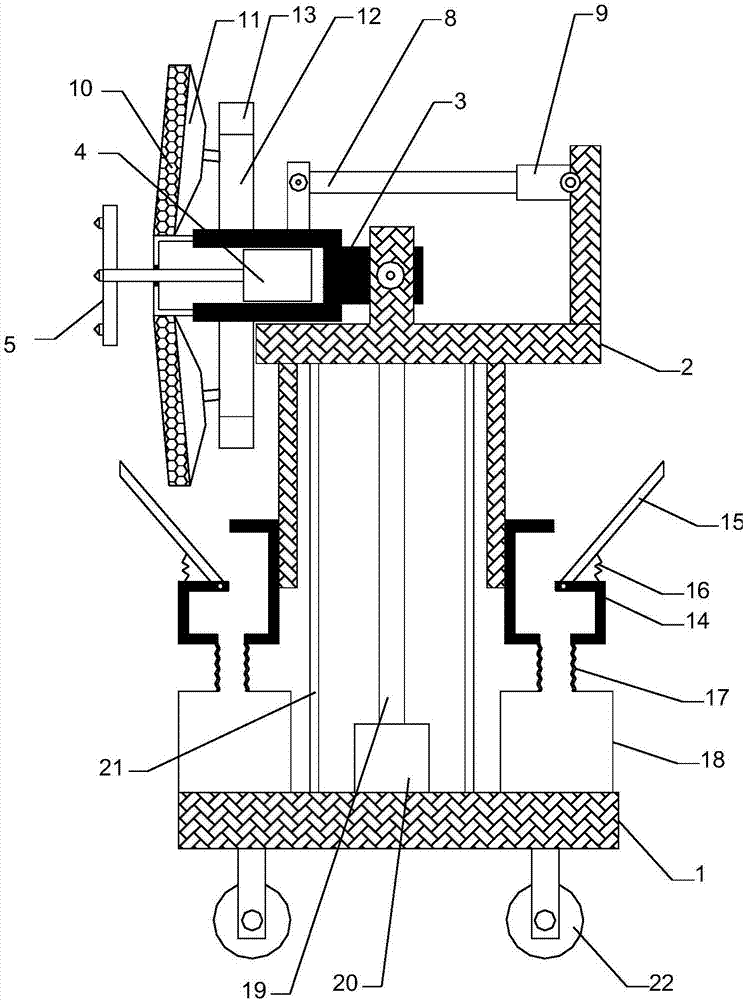

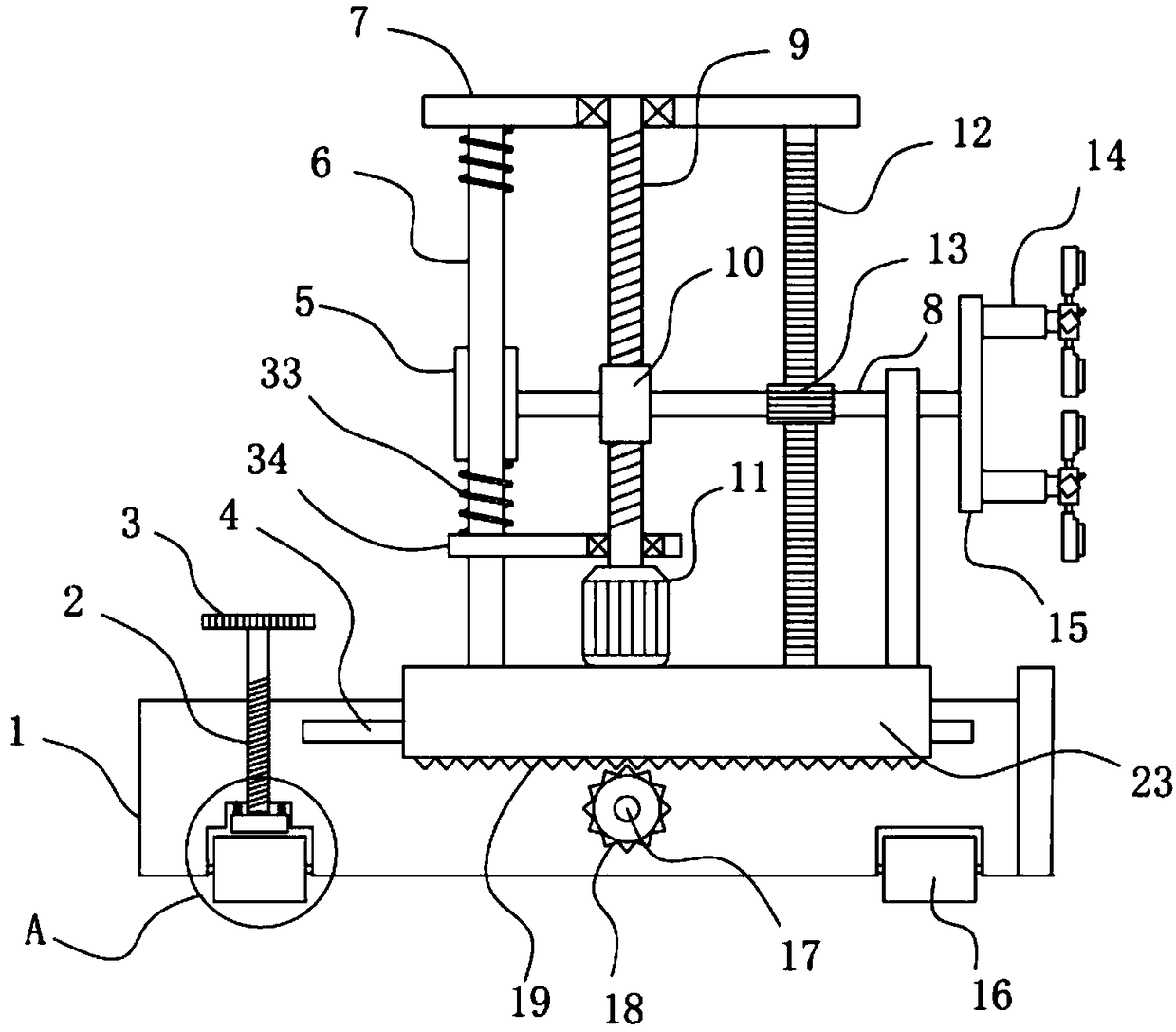

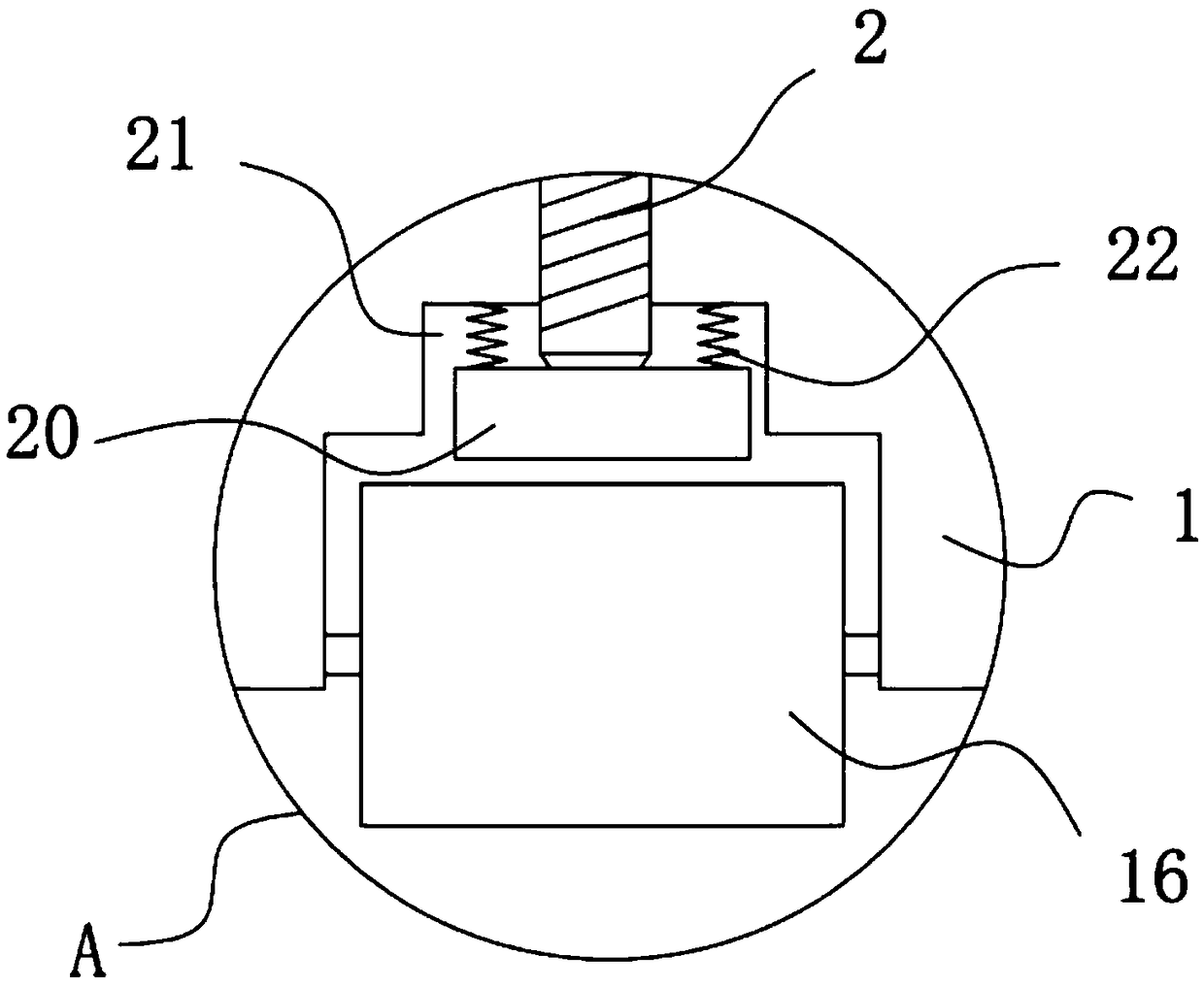

Wall scraping device for building construction

InactiveCN108915285AImprove scraping efficiencyIncreased scraping rangeBuilding repairsEngineeringBuilding construction

The invention discloses a wall scraping device for building construction, which comprises a vehicle body, a sliding support frame is slidably mounted on the vehicle body, an upright post is verticallyfixed on the sliding support frame, a roof is fixedly arranged on the top of the upright post, a positive and reverse motor I is fixedly arranged on the sliding support frame, the side wall of the vehicle body is transversely provided with a guide groove, the inner side wall of the sliding support frame is fixedly provided with a slide block which is slidably embedded in the guide groove, and theside wall of the screw sleeve rod is connected with a rotating shaft through a bearing; the scraping device disclosed by the invention is ingenious in structure, reasonable in design and convenient to adjust, wall skin scraping by blades is achieved by rotating the scraping mechanism. The scraping mechanism can reciprocate up and down, so that the scraping range of the wall surface is greatly increased, the arrangement of the rotating seat and the sliding post within and the limiting spring plays an effective buffering role in the wall scraping process, thereby improving the scraping qualityof the wall skin, simultaneously playing a buffer protection role on the blade, prolonging the service life and improving the stability.

Owner:湖北省清江路桥建筑有限公司

Photogravure press and squeegee device thereof

The invention discloses a photogravure press and a squeegee device thereof, belongs to the field of photogravure presses, and aims to provide a photogravure press squeegee device which can overcome the defect that ink stored in sunken image-text areas is blown away when ink on the surfaces of printing rollers is removed through an air blowing method. According to the technical scheme, the photogravure press squeegee device is characterized in that the squeegee device comprises an imprinting roller and a printing roller; an ink plate is arranged under the printing roller; an air blowing barrelconnected with an air blower is arranged on one side of the printing roller; an air flowing channel is formed in the side wall, facing the printing roller, of the air blowing barrel; the air flowing channel is formed in the tangential direction of the printing roller; the air outlet direction of the air flowing channel is opposite to the line speed direction of the position, close to the air flowing channel, of the printing roller; a plurality of partition plates are evenly distributed in the air flowing channel in the axial direction of the printing roller; the air flowing channel is dividedinto a plurality of air chambers through the partition plates; insertion grooves are formed in the positions which are located on the sides, away from the printing roller, of all the air chambers, ofthe joint of the air flowing channel and the air blowing barrel; and arc-shaped insertion plates are arranged in the insertion grooves.

Owner:东莞市信彩包装有限公司

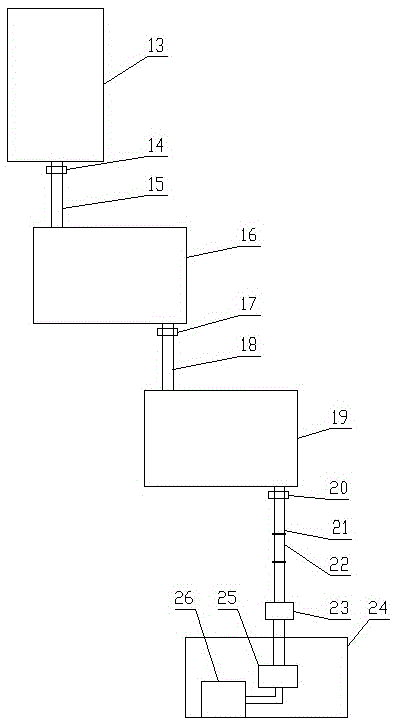

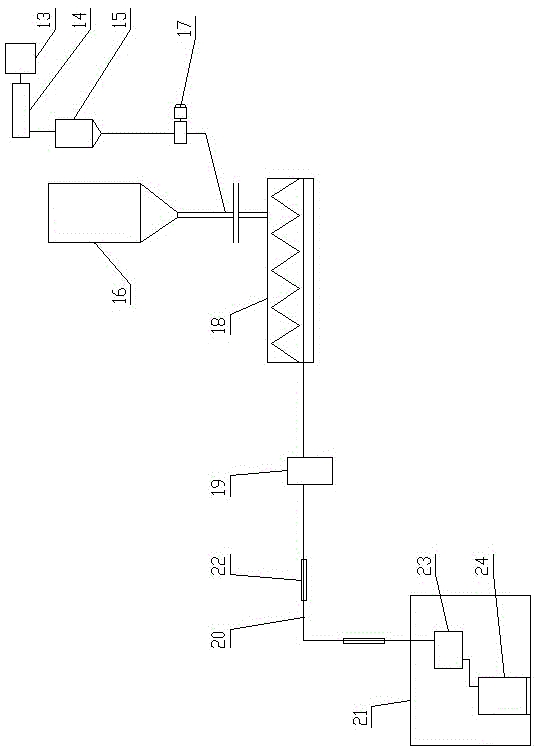

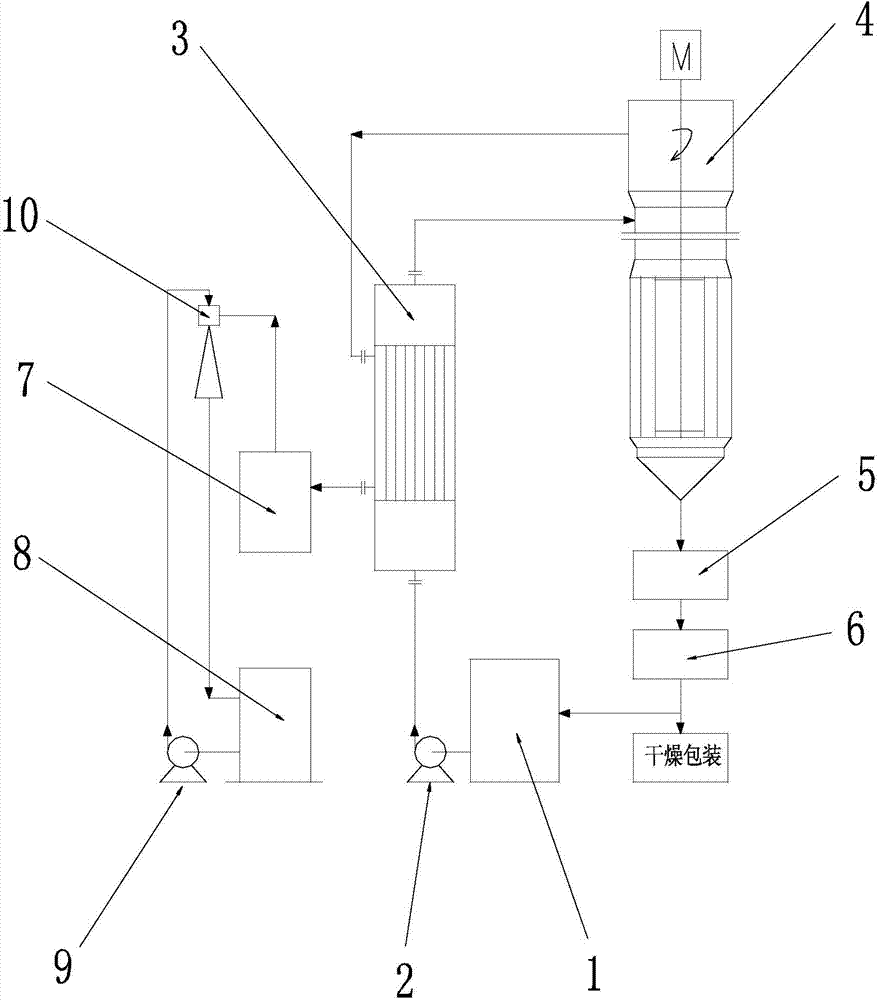

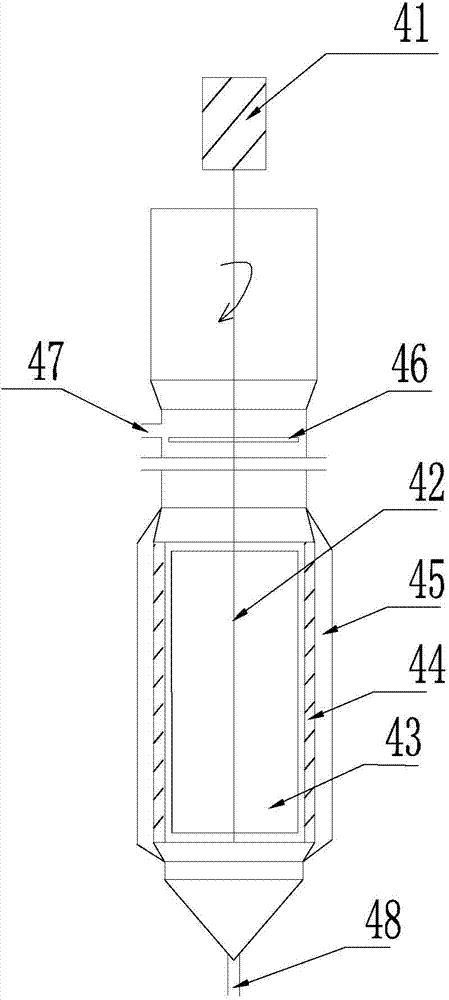

Evaporation and concentration system and method

InactiveCN103785185AReasonable designSimple structureEvaporator accessoriesVapor–liquid separatorEvaporation

The invention relates to an evaporation and concentration system. The evaporation and concentration system comprises a raw material tank, a feeding pump, a heater, a wiped-film evaporator, a crystal grower and a liquid-solid separator, which are sequentially connected with one another, wherein a liquid outlet of the liquid-solid separator is connected with the raw material tank; a jacket is arranged on the outer surface of the heater; an inlet is formed in the upper part of the jacket; an outlet is formed in the lower part of the jacket; the inlet of the jacket is communicated with an air outlet formed in the top of the wiped-film evaporator; the outlet of the jacket is connected with a gas-liquid separator and a jet pump sequentially. The evaporation and concentration system provided by the invention has the advantages of energy conservation and high efficiency, zero discharge in a concentration process is realized, and good evaporation conditions are created.

Owner:莱州市新力复合材料有限公司

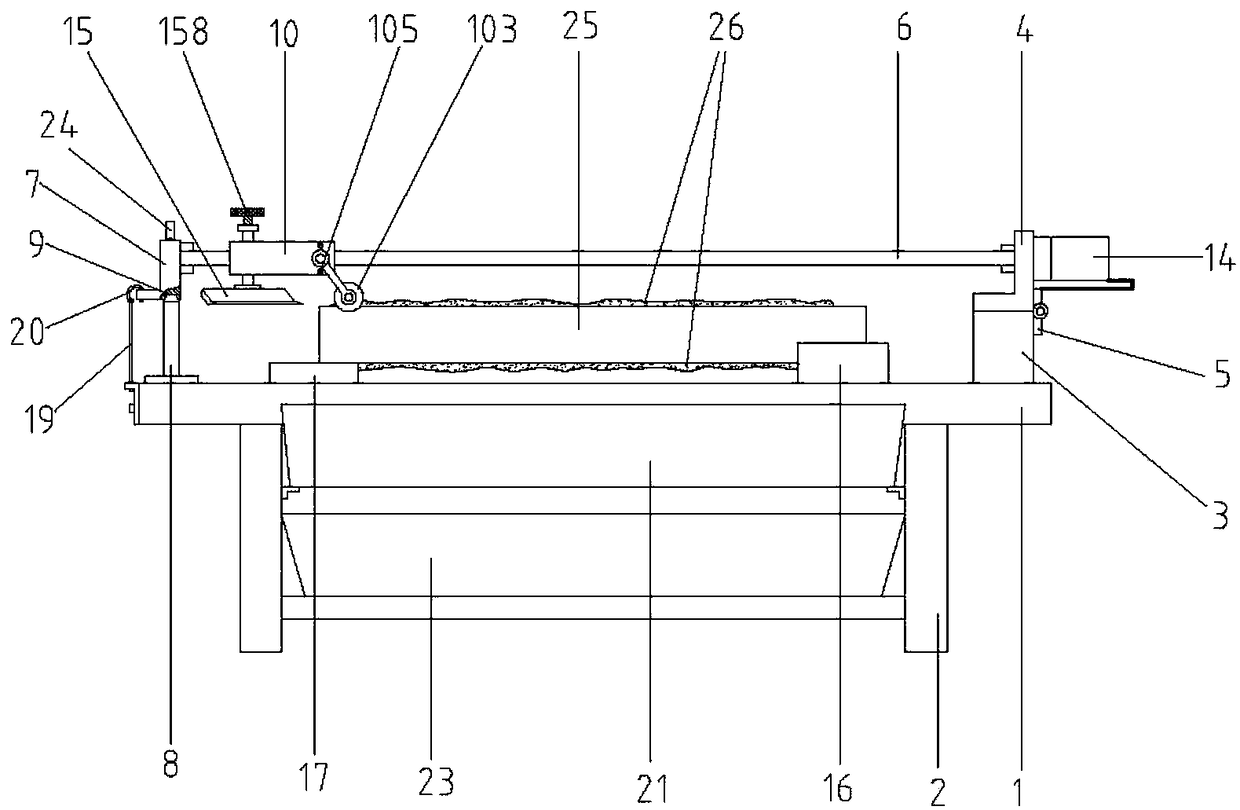

Automatic beeswax scraping device

PendingCN109315321AImprove scraping efficiencyImprove the efficiency of honey extractionHoney collectionFatty substance recoveryHoneycombBeeswax

The invention relates to the technical field of honey production, and discloses an automatic beeswax scraping device. The device includes a worktable and support legs, the right end of the worktable is provided with a connection block, the top surface of the connection block is provided with a right connection bar, the two ends of the right connection bar are provided with two slide rods which areparallel, a left connection bar is arranged between the left ends of the two slide rods, the left end of the worktable is provided with a positioning column, the bottom surface of the left connectionbar is provided with a positioning hole corresponding to the positioning column, the two slide rods are provided with sliding sleeves, a connection plate is arranged between the sliding sleeves, andthe center of the connection plate is provided with a screw sleeve, a screw rod passing through the screw sleeve is arranged between the left connection bar and the right connection bar, the right endof the screw rod is provided with a motor which can rotate in two directions, the lower side of the connection plate is provided with a scraper, the left end of the worktable is provided with an elastic cable, and the outer end of the elastic cable is provided with a drag hook. The device can quickly scrape beeswax on the surface of a honeycomb without damaging the honeycomb.

Owner:浙江机电职业技术学院

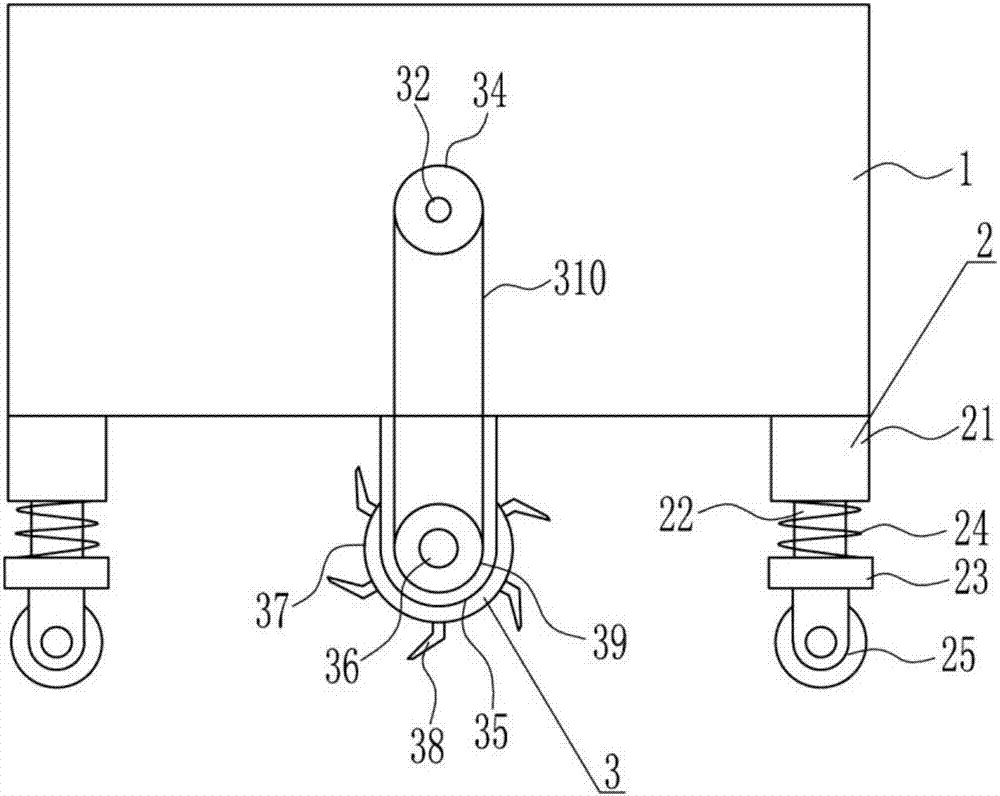

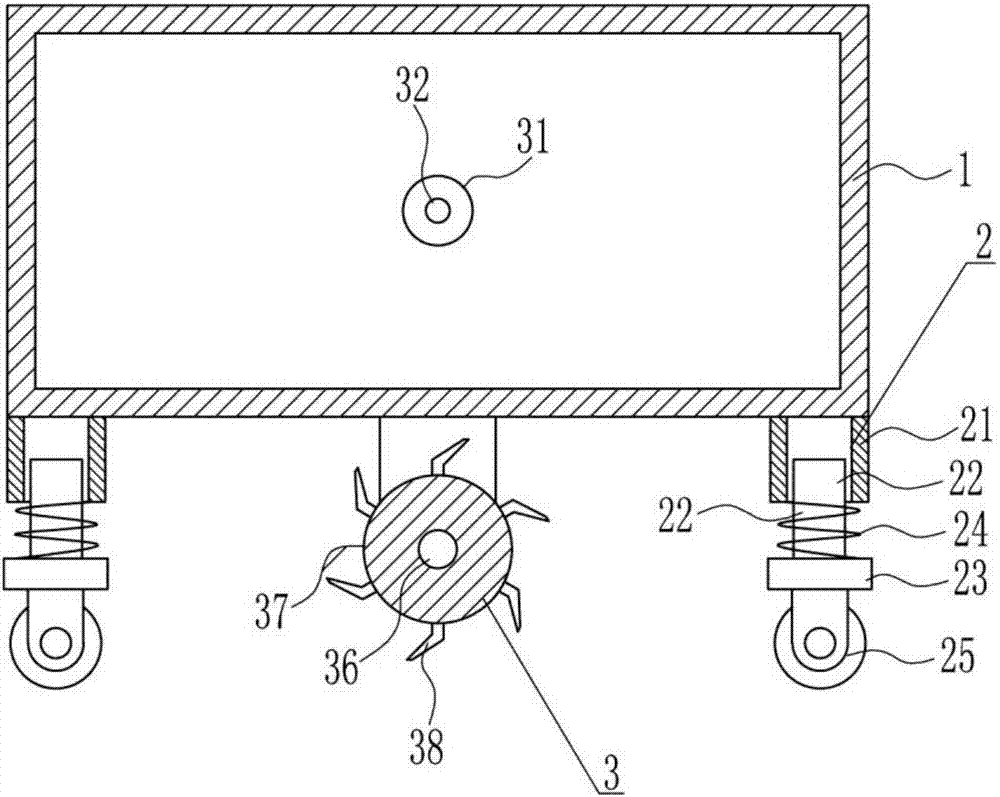

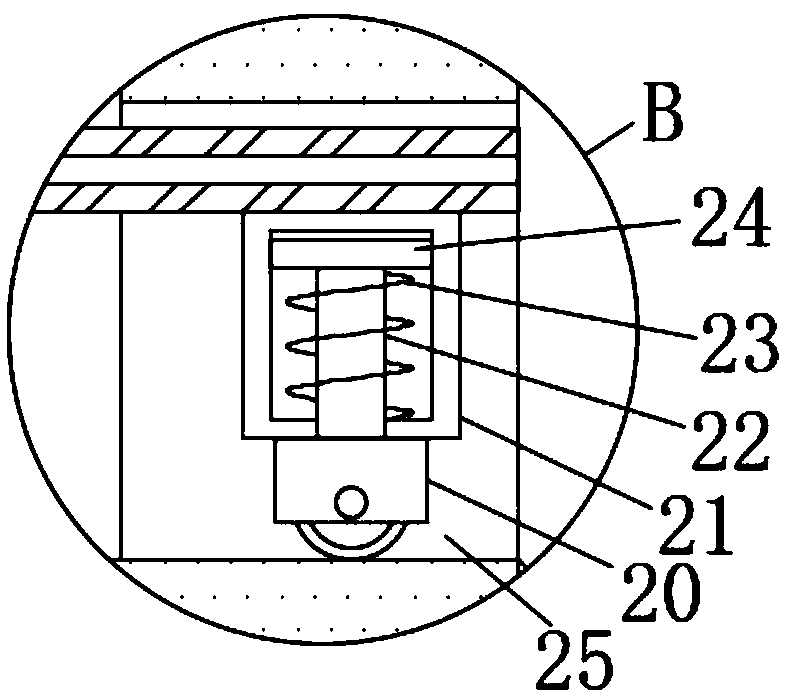

Windshield deicing device used for vehicle

InactiveCN108001420AFull deicingEasy to scratch offCleaning apparatus for vehicle exteriorsEngineeringWindshield

The invention relates to a deicing device, and especially relates to a windshield deicing device used for a vehicle. A technical problem to be solved is to provide the windshield deicing device used for a vehicle, and the device is high in deicing efficiency and has no damage on a windshield. In order to solve the above technical problem, the invention provides the windshield deicing device used for a vehicle. The device comprises a cabinet, four corners on the bottom of the cabinet are provided with buffer devices, and the middle part of the bottom of the cabinet is provided with a scraping device. The device scrapes ice blocks on a windshield through the scraping device, a blowing device improves ice scraping efficiency, and the buffer devices make the scraping device safe when the scraping device deices. The device achieves effects of high deicing efficiency and no damage on the windshield.

Owner:泉州憨鼠教育咨询有限公司

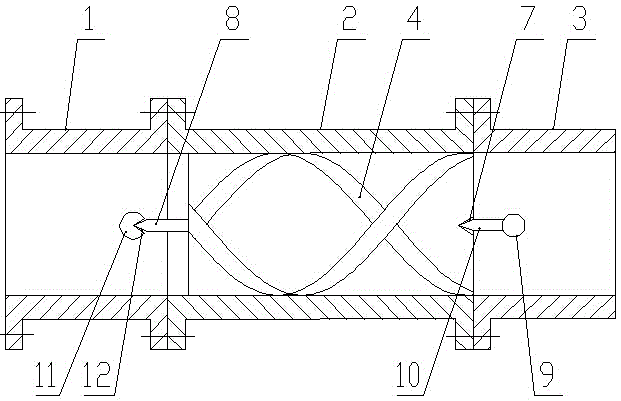

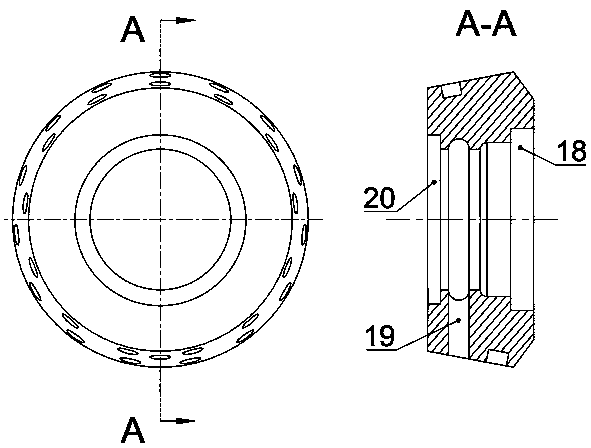

Oil ring for an internal combustion engine

InactiveUS7252292B2Reduce moment of inertiaReduce frictionPiston ringsBraking action transmissionReciprocating motionMoment of inertia

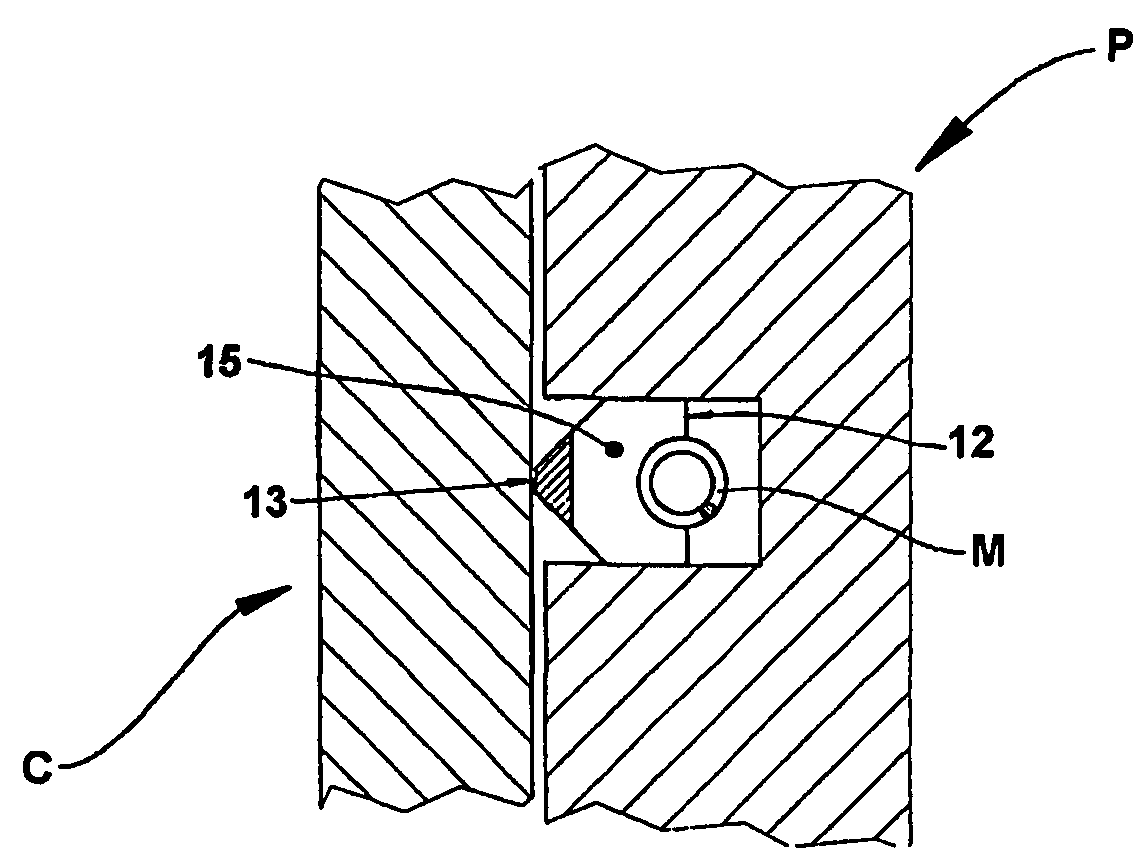

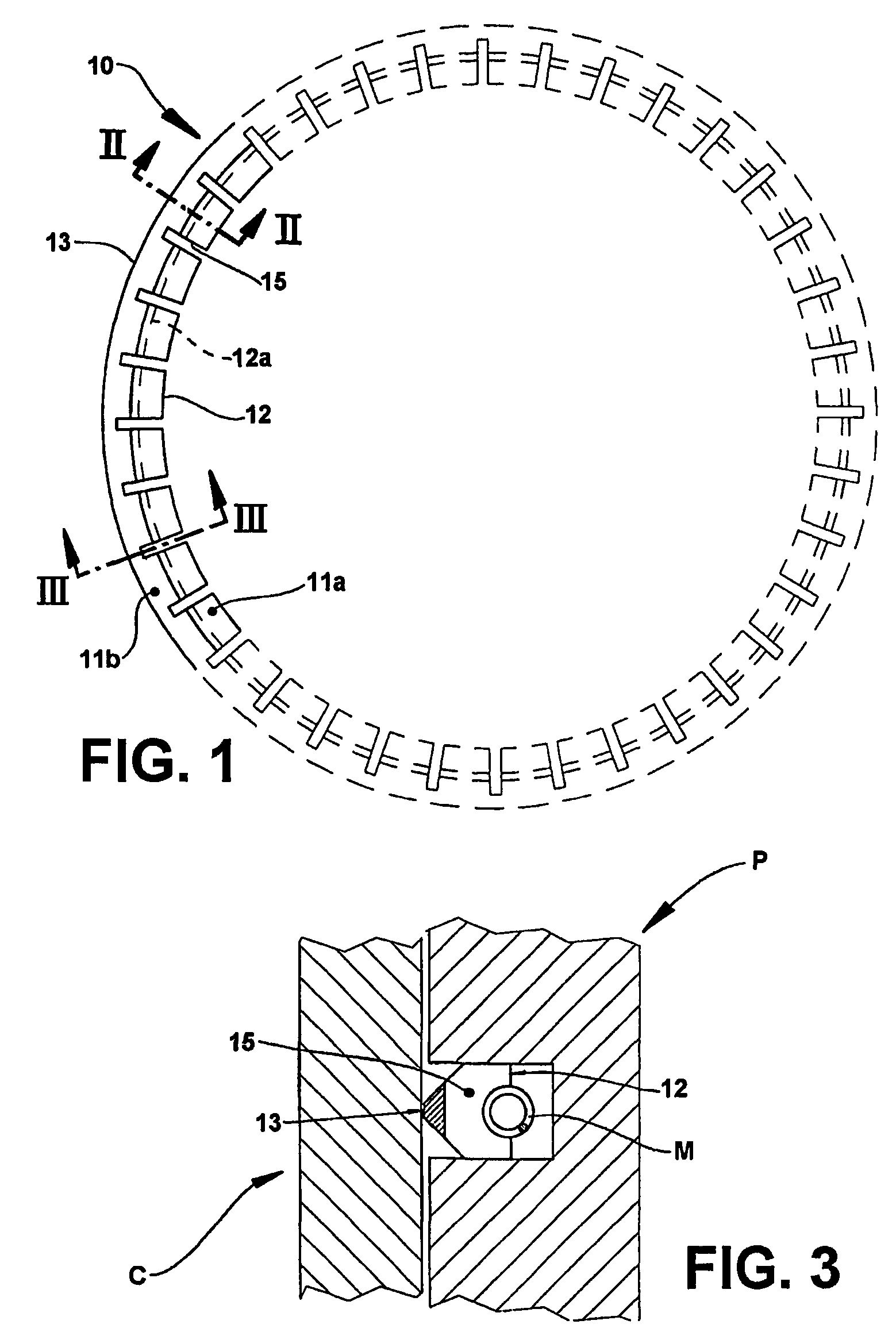

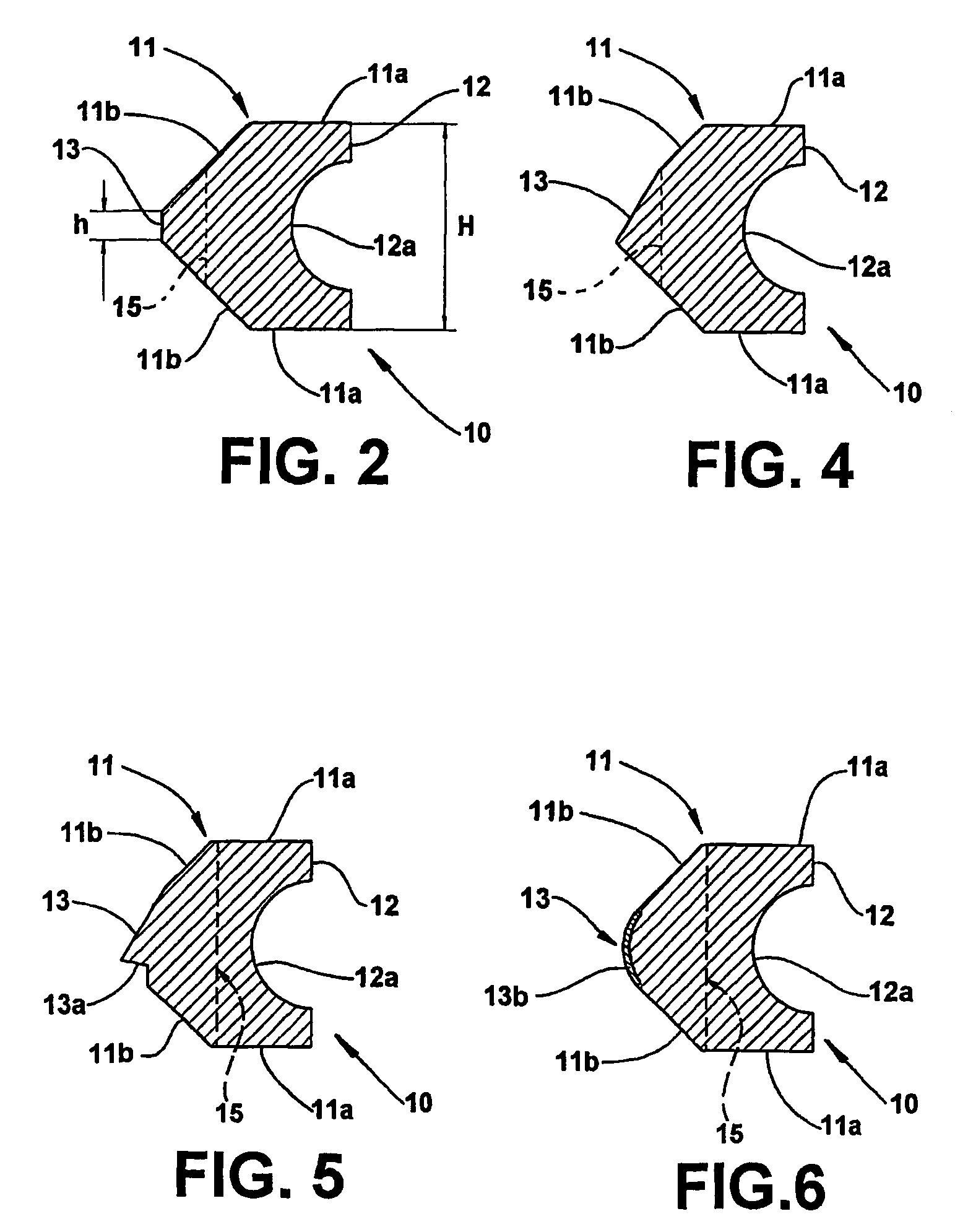

An oil ring for an internal combustion engine, comprising a metallic annular body (10) to be mounted around a piston (P) reciprocating inside a cylinder (C) of the engine, said annular body (10) having opposite lateral faces (11), an internal face (12) onto which will be seated a resilient expander (M), and an external contact face (13) to be seated against the internal face of the cylinder (C) and having a height (h) that is substantially smaller than the height (H) of the internal face (12). Each lateral face (11) is defined by one or more lateral face portions (11a, 11b), which are designed to reduce the moment of inertia of the annular body (10), giving higher conformability to the latter. Preferentially, but not exclusively, the annular body (10) can be further provided with channels (15, 16), extended along at least part of the ring hight and which are radially spaced back in relation to the external contact face (13).

Owner:MAHLE COMPONENTS DE MOTORES DO BRASIL

Galvanized steel wire galvanizing device

InactiveCN112251700AAvoid manual operationReduced chance of poisoningHot-dipping/immersion processesEngineeringGalvanization

The invention relates to the field of galvanizing, and particularly relates to a galvanized steel wire galvanizing device. The galvanized steel wire galvanizing device comprises a galvanizing tank, wherein a pair of guide rollers is mounted on the galvanizing tank, a galvanizing solution tank is dug in the galvanizing tank, a pair of limiting rollers are rotatably connected in the galvanizing solution tank, and steel wires are connected between the guide rollers and the limiting rollers; and an automatic heat preservation scraping mechanism is arranged in the galvanizing solution tank, arranged on the upper sides of the limiting rollers and comprises a cover plate. According to the galvanized steel wire galvanizing device, by arranging the corresponding mechanisms on the galvanizing tank,the solidification speed of a surface layer galvanizing solution is greatly decreased, an operator does not need to frequently conduct scraping work, meanwhile, the hands of the operator are liberated, the operator does not need to manually scrape the galvanizing solution solidified on the inner surface layer of the galvanizing tank, the whole device can be automatically removed, the safety of theoperator is greatly improved, meanwhile, the scraping efficiency is improved, the steel wire galvanizing effect is greatly improved, and the situation that the steel wires are affected by the solidified galvanizing solution is avoided.

Owner:ANHUI HUITENG INTELLIGENT TRANSPORTATION TECH CO LTD

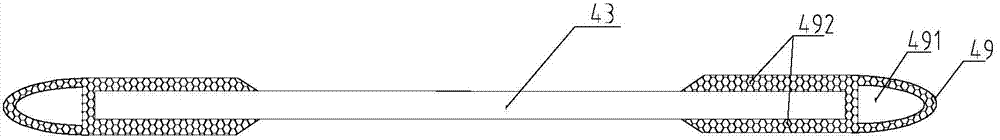

Extinction spinning production process for polylactic acid slice with titanium dioxide

ActiveCN105734701AImprove scraping efficiencyEasy to manufactureSpinning head liquid feederArtificial thread manufacturing machinesFiberLactide

The invention discloses an extinction spinning production process for polylactic acid slices with titanium dioxide. The extinction spinning production process comprises the following steps: (1) adding a catalyst, a stabilizing agent and lactide into a stirring tank; (2) preheating a lactide mixture by using a polylactic acid pre-polymerization mixing device, and performing primary mixing in a pre-polymerization tank; (3) performing final polymerization in a final polymerization tank; (4) producing polylactic acid slices (5), mixing dry titanium dioxide powder with the polylactic acid slices, dropping into a spinning screw extruder, and mixing by using a moving-static integrated pipeline mixing device; (6) spinning molten polylactic acid into extinction or semi-extinction extinction fiber by using a spinning component. Only a plurality groups of mixing units are arranged on a third conveying tube directly, a mixing system mounted on the conveying tube is canceled, the cost is reduced, the purpose of uniformly mixing materials can be achieved, and the conveying and mixing efficiency is greatly improved.

Owner:HENAN LONGDU BIOLOGY TECH

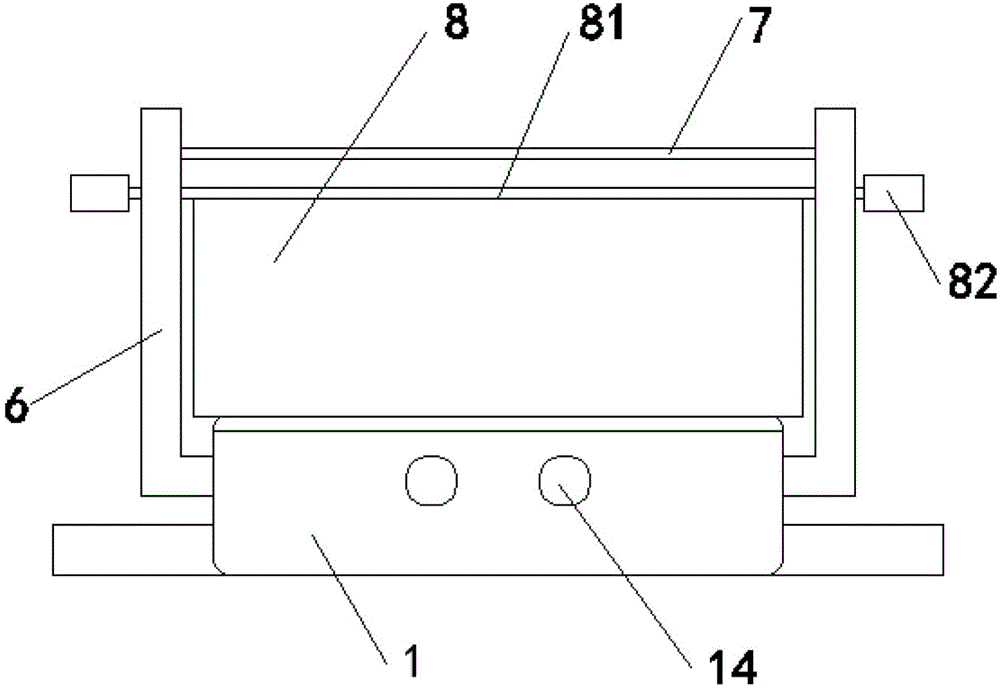

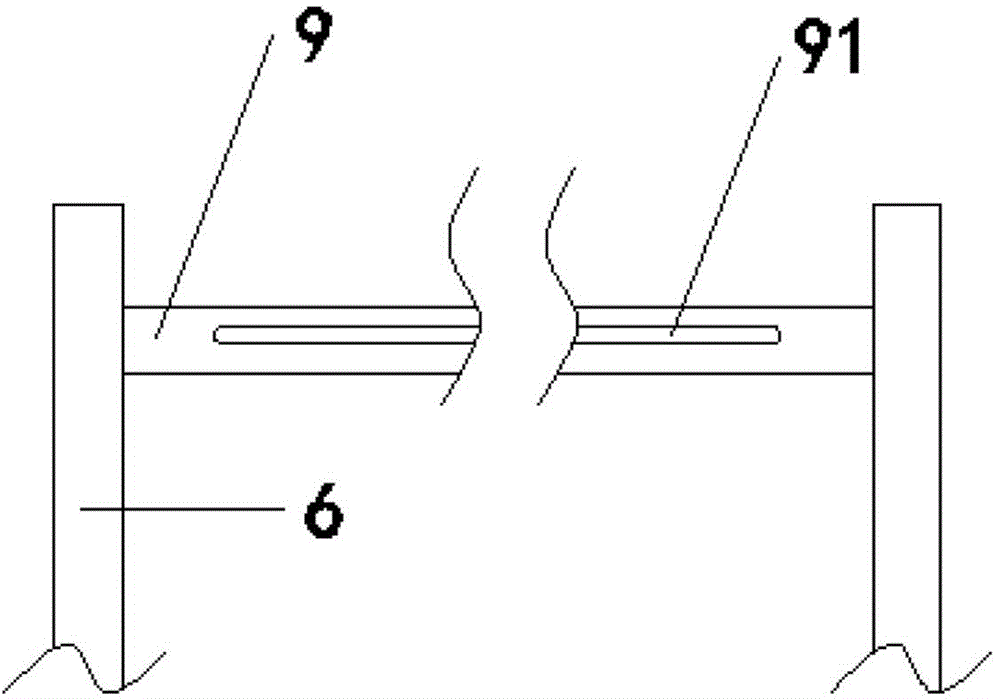

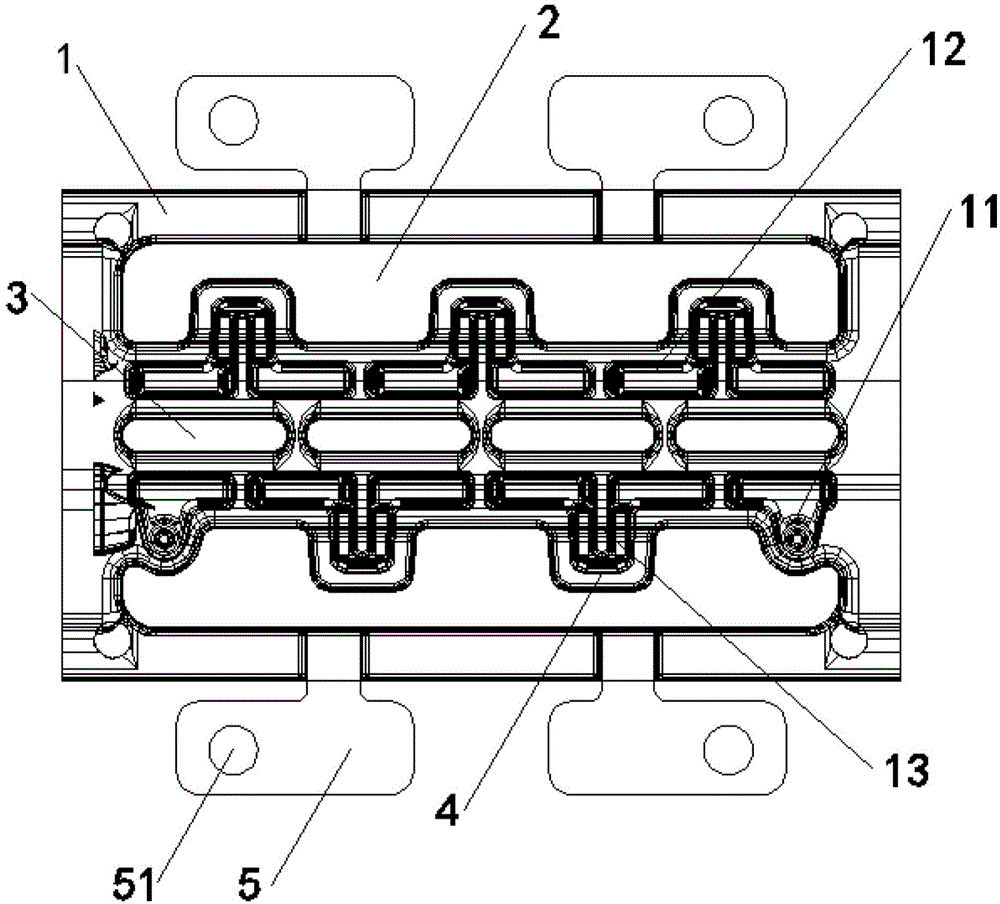

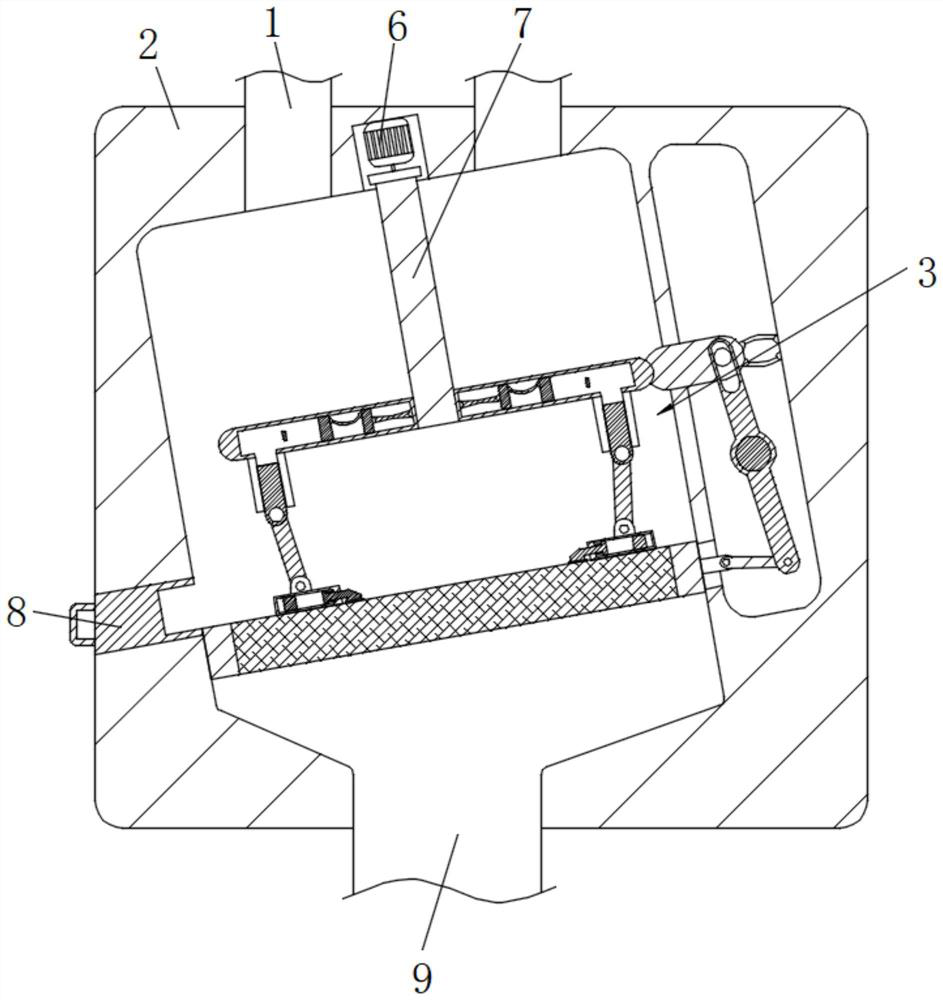

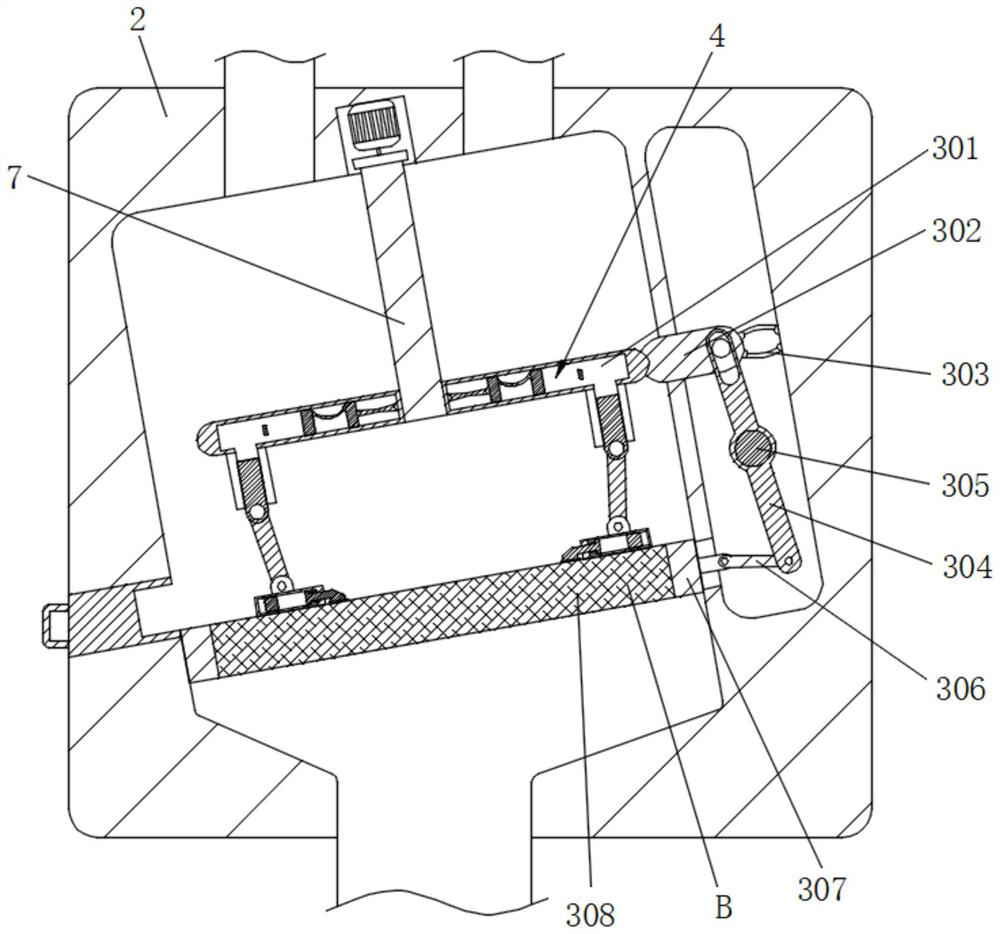

Cast welding die for busbar of storage battery

The invention provides a cast welding die for a busbar of a storage battery, and relates to the technical field of production of storage batteries. The cast welding die comprises a die body; a plurality of groups of forming units for casting the busbar of the storage battery are arranged on the upper surface of the die body; each forming unit comprises a concave anode channel, a concave anode channel, brackets symmetrically arranged at the side corner of the die body, two propping rods which are fixedly arranged in parallel on the top part of the bracket, and scraper plates which are movably arranged on the propping rods, wherein the concave anode channel and the concave cathode channel are arranged in parallel; the scraper plates are wider than the die body. According to the cast welding die for the busbar of the storage battery, the whole structure is simple; after the die body is carried out from a lead liquid pool, excessive lead liquid residual on the upper surface of the die body can be scraped by the scraper plates; the scraping can be done at a time, so that the scraping efficiency is high; after scraping, the scraper plates are upwards rotated to be positioned above a propping plate; therefore, that the scraper plates and the die body are dipped into the lead liquid pool together can be avoided.

Owner:长兴杰盛机械制造厂

Environment-friendly wastewater filtering device

InactiveCN113813681AGuaranteed water filtration efficiencySpeed up the slideMoving filtering element filtersFiltrationWastewater

The invention relates to the technical field of environmental protection, and discloses an environment-friendly wastewater filtering device. The device comprises a box body, an inlet is formed in the top of the box body, an outlet is formed in the bottom of the box body, a drawing block is slidably connected to the interior of the box body, a motor is fixedly connected to the top of the inner wall of the box body, and a rotating rod A is fixedly connected to one end of the motor. And a filter screen vibration sliding mechanism is arranged in the box body. By arranging the filter screen vibration sliding mechanism, a filter screen fixing frame drives an internal filter screen to continuously lift and vibrate in the box body, so that residues blocked on the surface of the filter screen during long-term filtration of wastewater are vibrated to slide into the drawing block through vibration, the sliding speed of the residues into the drawing block is further increased, and the long-term water passing filtering efficiency of the filter screen is ensured; and by arranging a scraping mechanism, stains which are attached to the working surface and cannot be cleaned due to vibration are effectively filtered for a long time.

Owner:季晓辉

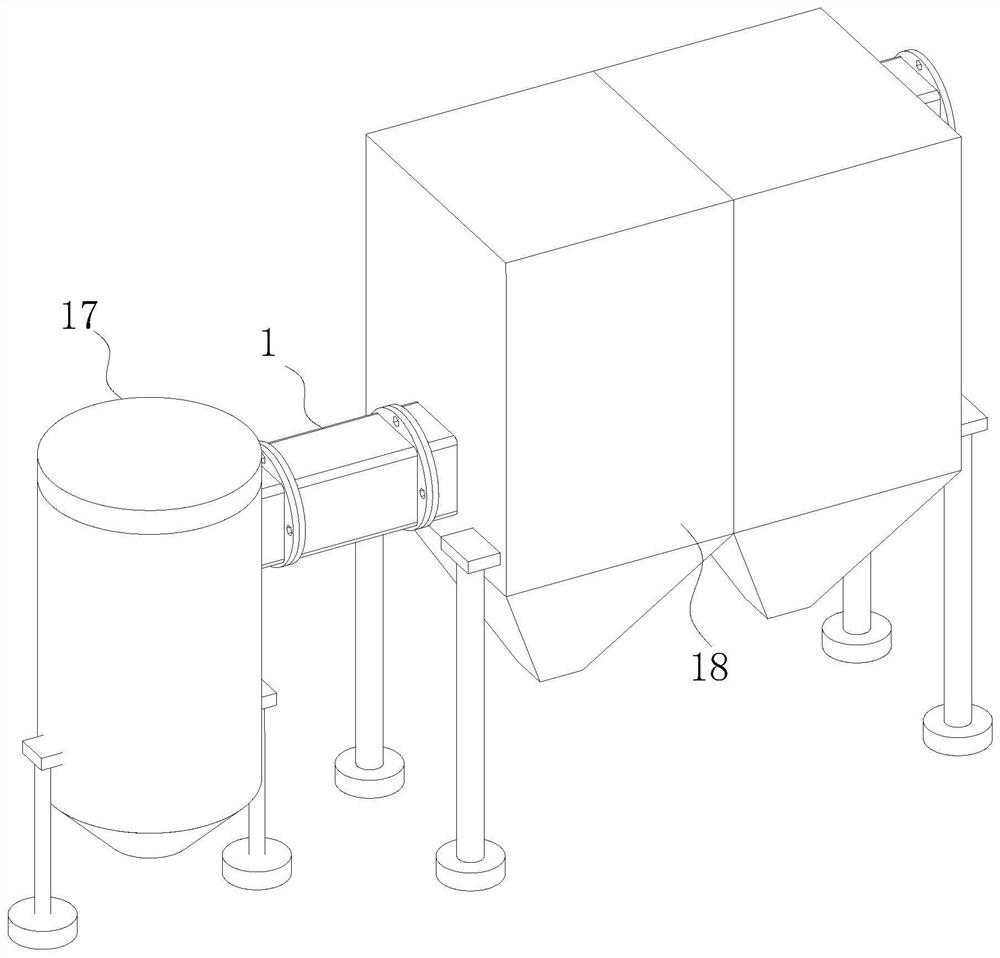

Energy-saving and environment-friendly flue gas desulfurization equipment

PendingCN114247284AReduce damageImprove desulfurization efficiencyGas treatmentDispersed particle filtrationFlue gasFlue-gas desulfurization

The invention discloses energy-saving and environment-friendly flue gas desulfurization equipment in the technical field of flue gas desulfurization, which comprises a self-scraping communicating pipe communicated between an exhaust port of an absorption tower and an air inlet of a bag-type dust collector, and a scraper part driven by hot air pressure and a flow stirring part driven by the scraper part are arranged in the self-scraping communicating pipe. The scraper part comprises two wall scraping plates which are symmetrically arranged and can be turned and closed, the outer side walls of the wall scraping plates are in sliding connection with the inner wall of the ventilation channel of the self-scraping communicating pipe, and the two wall scraping plates are arranged on one side of the exhaust port of the absorption tower and cover the ventilation channel in the self-scraping communicating pipe; the flow stirring part comprises a suction fan blade and a reverse blowing fan blade which are rotationally mounted at the axial lead position of the ventilation channel; flue gas in the ventilation channel integrally passes in a pulse airflow mode, self-cleaning of the interior of the ventilation channel is achieved in the airflow passing process, the desulfurization efficiency in the absorption tower and the dust removal efficiency in the bag-type dust remover are reversely improved, heat energy of the flue gas is utilized, and more energy conservation and environmental protection are achieved.

Owner:新疆金禾山能源科技有限公司

Landscaping maintenance equipment

InactiveCN108377778AImprove operational safetyImprove scraping efficiencyCuttersCutting implementsEngineeringLandscape maintenance

The invention provides landscaping maintenance equipment. The landscaping maintenance equipment comprises a control device, a fixing bolt and a chute, wherein a cylindrical handle is vertically arranged on the side wall of the right end of a shell of the control device, and an arc-shaped shield is fixedly arranged on the control device on the inner side of the handle; the control device is internally provided with a storage battery, three motors are sequentially arranged on the side wall of the rear end of the control device from top to bottom, and the motors are fixedly embedded on the control device and electrically connected with the control device; and the right end of each motor is rotationally connected with a scraper through a rotating shaft, and a blocking body is arranged on the motor between the scraper and the handle. The cylindrical handle is vertically arranged on the side wall of the right end of the shell of the control device, and the arc-shaped shield is fixedly arranged on the control device on the inner side of the handle; and the control device is internally provided with the storage battery, the three motors are sequentially arranged on the side wall of the rear end of the control device from top to bottom, and the motors are fixedly embedded on the control device and electrically connected with the control device.

Owner:蒋驰叶

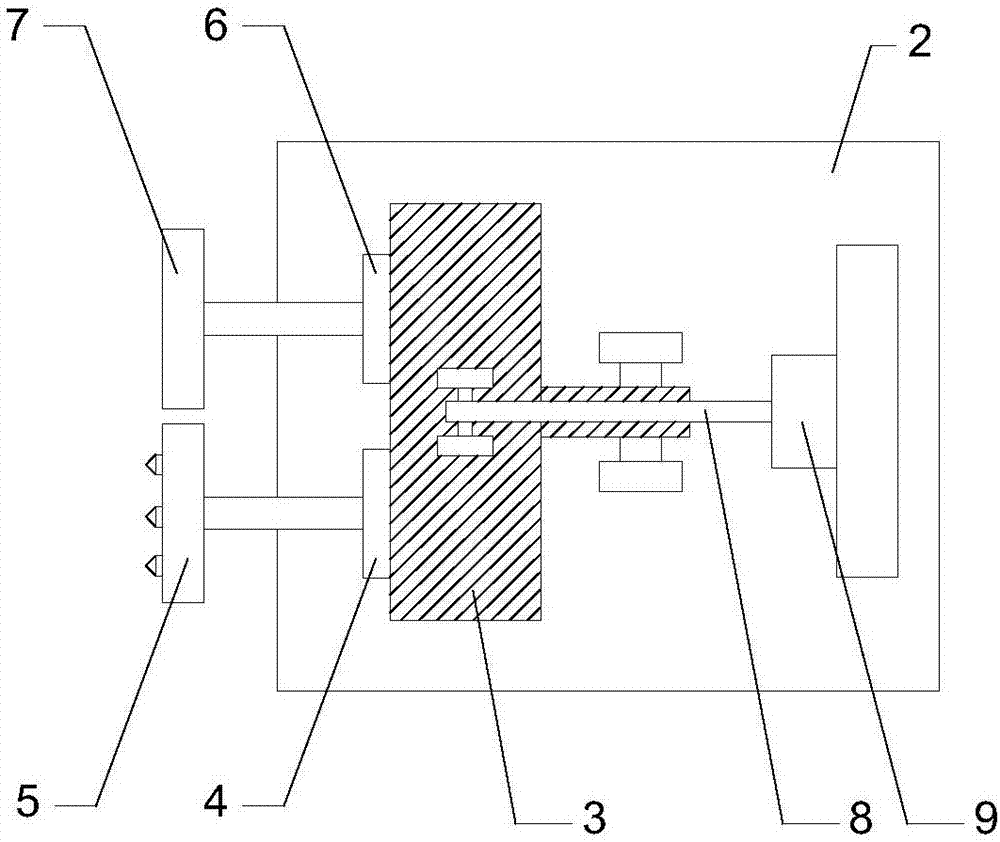

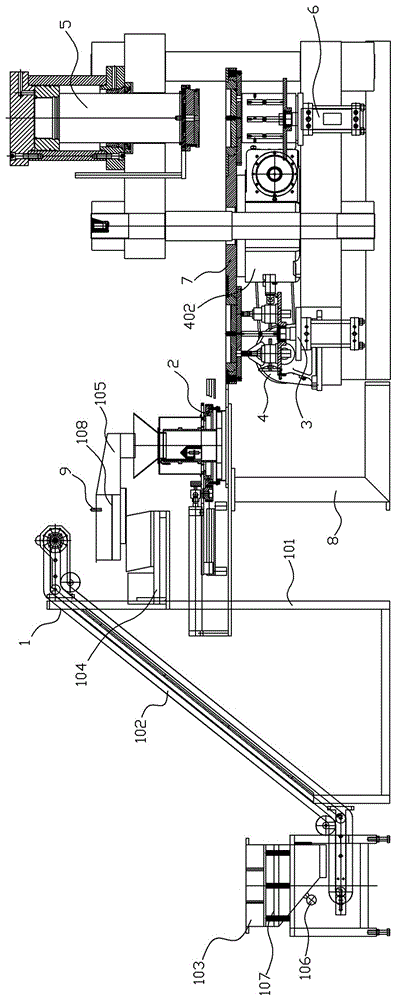

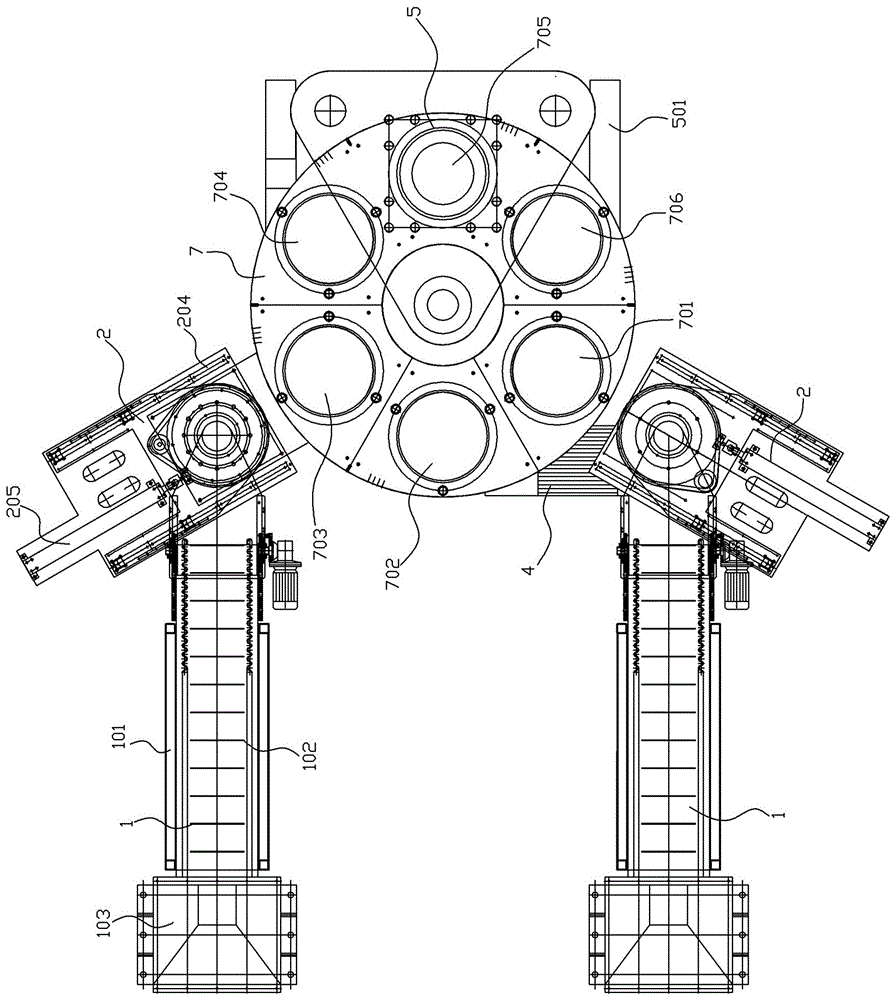

Full-automatic rotary multi-station grinding wheel forming machine

ActiveCN106041770AHigh purityQuality improvementGrinding devicesNumerical controlUltimate tensile strength

The invention relates to the technical field of grinding materials, grinding tools and grinding wheels, particularly to a full-automatic rotary multi-station grinding wheel forming machine which comprises lifting conveying mechanisms, pushing and scraping mechanisms, a constant-volume adjusting mechanism, a worktable transmission power mechanism, a compression forming mechanism, a demoulding ejection mechanism, a mould mounting frame and a numerical control unit, wherein a plurality of mould cavities are uniformly distributed on the mould mounting frame in a circumferential direction; each mould cavity correspond to one station, and the mould cavities correspond to a primary scraping station, a screen piece placing station, a secondary scraping station, a core ring placing station, a compression station and a demoulding station in sequence; and any one of the six stations is controlled to open or close according to needs. According to the full-automatic rotary multi-station grinding wheel forming machine, feeding, pushing and scraping, adjusting, compression and finished product ejection are all completed automatically, so that the equipment reliability and the degree of automation are greatly improved, and meanwhile the labor intensity of workers is lowered; and owing to automatic production the production efficiency, the product quality and the product conformity are all improved remarkably.

Owner:ZHENGZHOU HONGYI MACHINERY

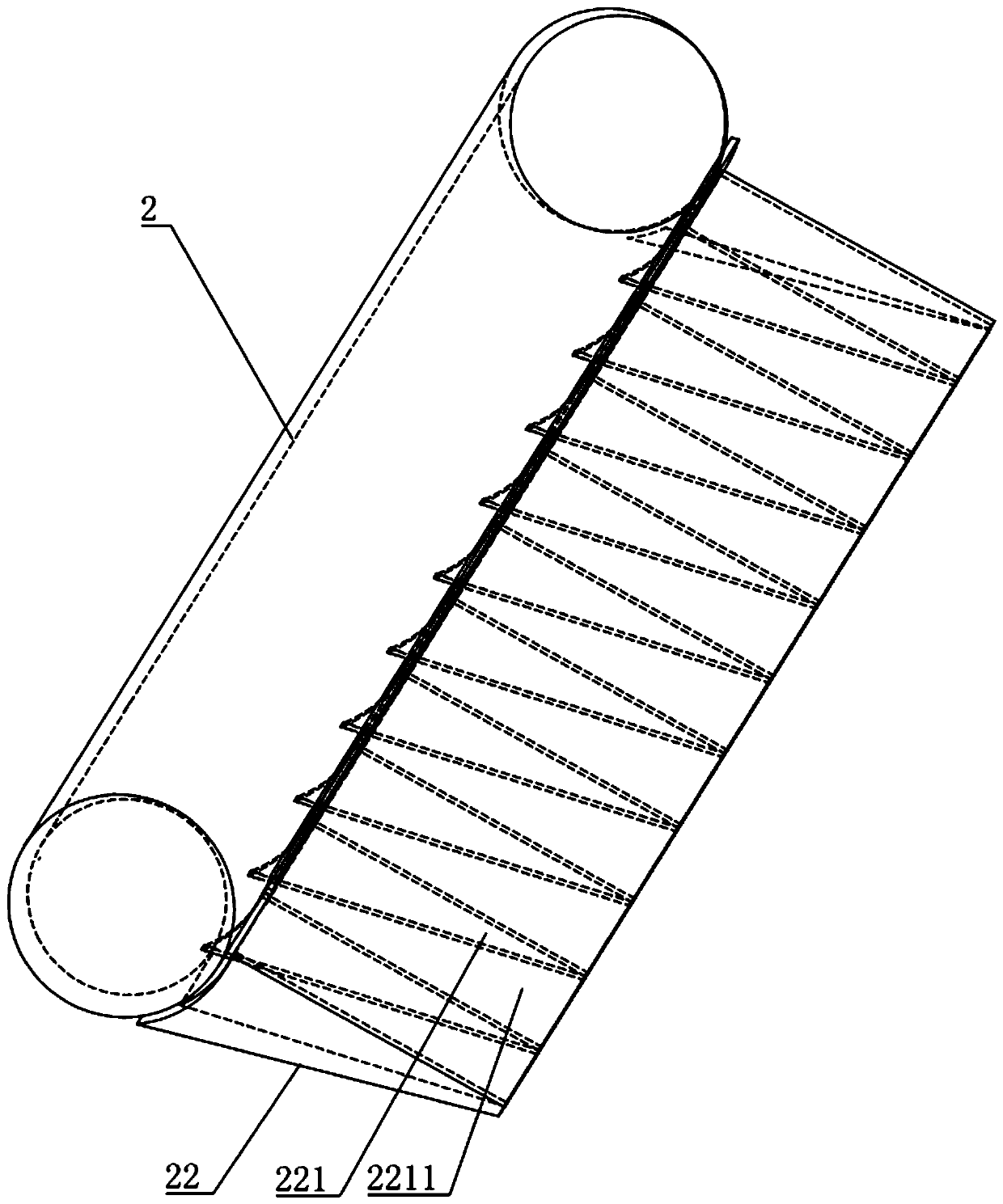

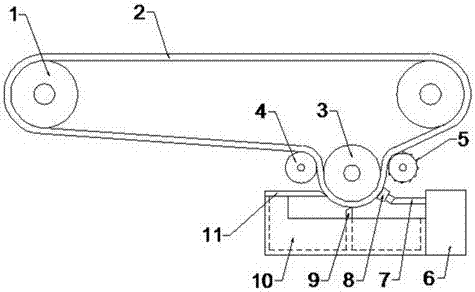

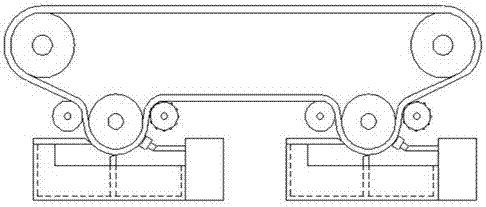

Self-cleaning device suitable for conveying belt for small metal part hardening and tempering

The invention discloses a self-cleaning device suitable for a conveying belt for small metal part hardening and tempering. The self-cleaning device comprises a conveying device and cleaning device bodies arranged at the lower end of the conveying device; the conveying device comprises a pair of transmission shafts, a reversing shaft and the conveying belt, wherein the reversing shaft is arranged below the transmission shafts, and the conveying belt surrounds the transmission shafts and the reversing shaft; a pair of limiting shafts which are symmetrically arranged and located on the outer sideof the conveying belt are arranged on the two sides of the reversing shaft; each cleaning device body comprises a water spraying assembly, a water scraping plate and a material scraping assembly which are sequentially arranged in the conveying direction of a lower layer of the conveying belt; each water spraying assembly comprises a water tank, a liquid guide pipe and a spray head, wherein the spray head extends to the end surface of the conveying belt; and each material scraping assembly comprises a waste material box and a material scraping plate fixed to the upper end of the waste materialbox. The self-cleaning device has the advantages that the cleaning device bodies comprise the water spraying assemblies and are used for wetting impurities on the surface of the conveying belt, and therefore subsequent material scraping can be facilitated; the reversing shaft and the limiting shafts are arranged and are used for increasing the contact area between the conveying belt and the reversing shaft, and therefore the set range of the cleaning device bodies can be widened, and the cleaning effect can be improved.

Owner:无锡琨圣智能装备股份有限公司

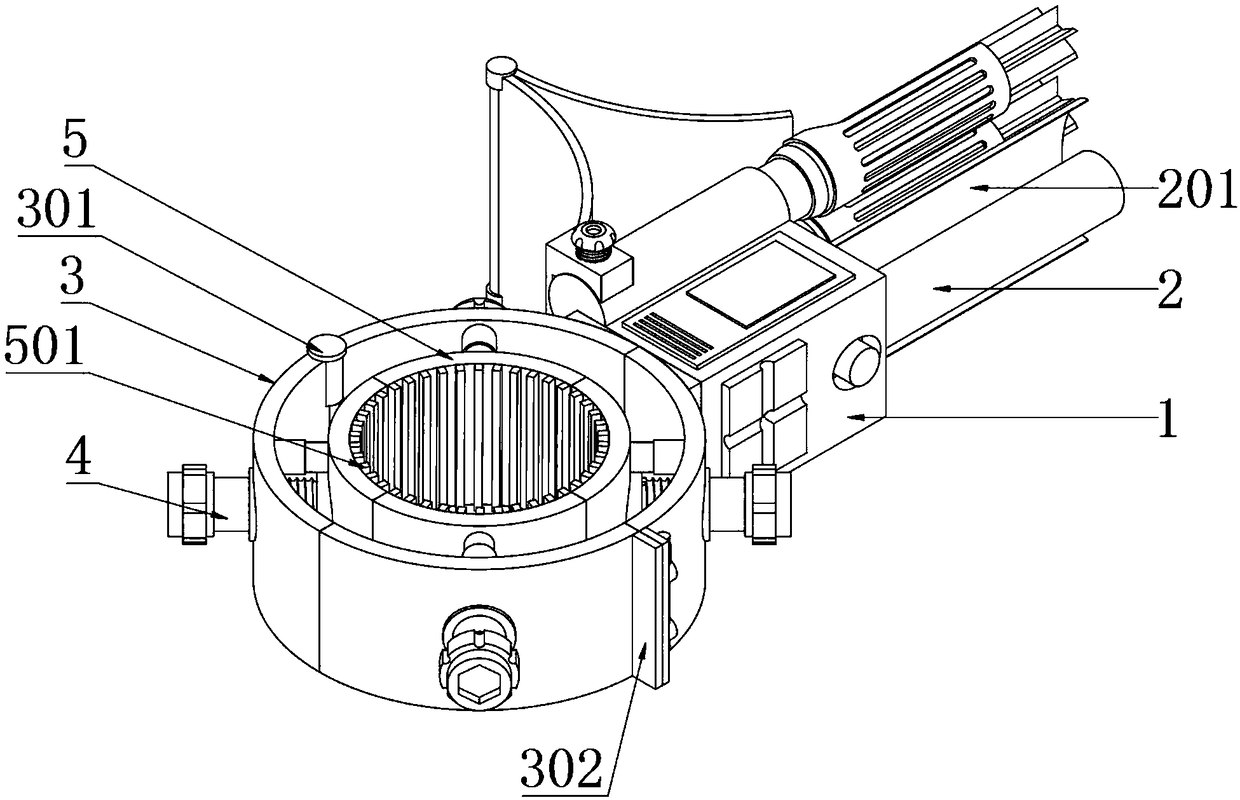

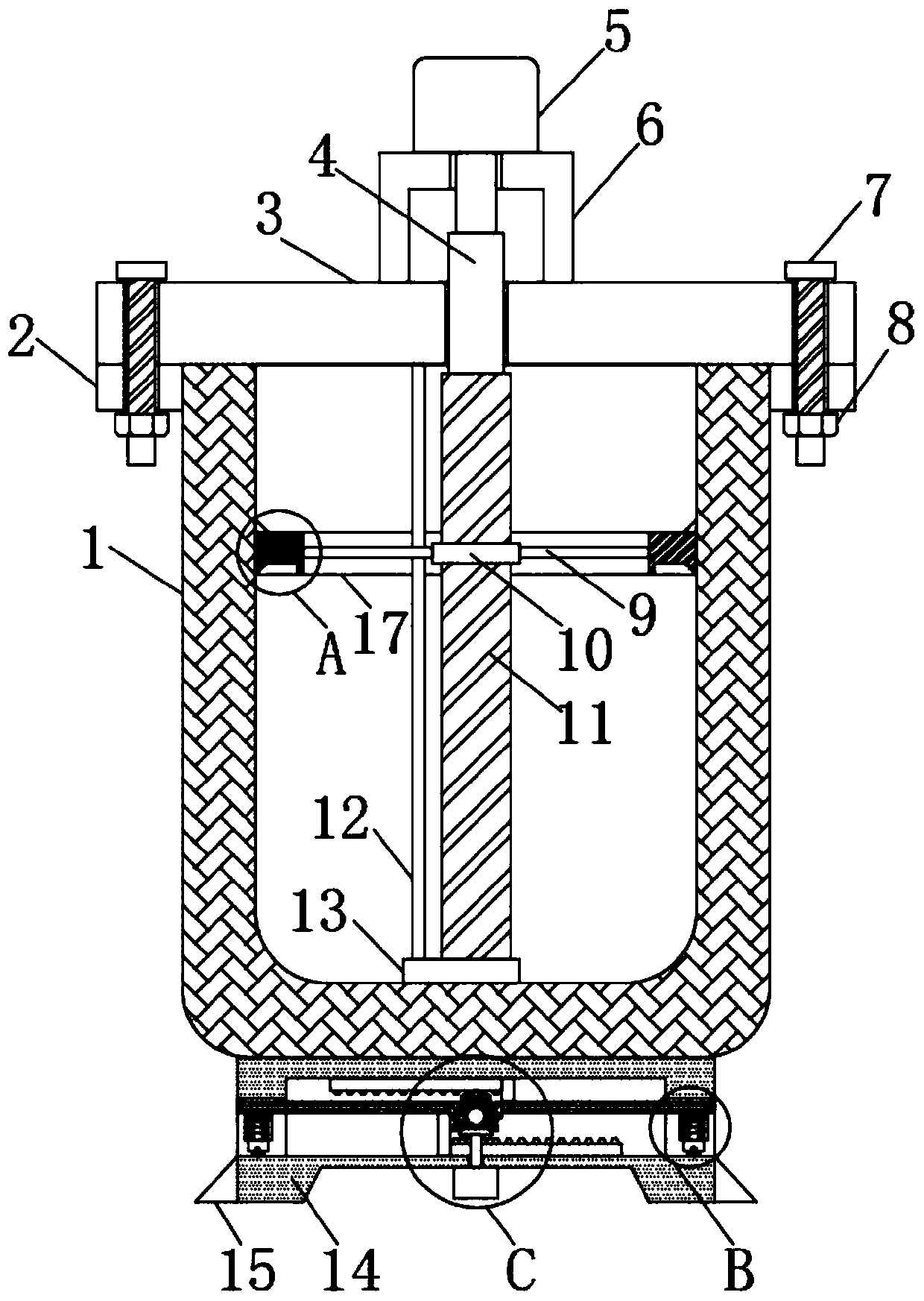

Optical fiber filling paste technology tank with lifting paste scraping plate

InactiveCN109592238AEasy to take backImprove stabilityLarge containersFibre mechanical structuresLocking mechanismEngineering

The invention discloses an optical fiber filling paste technology tank with a lifting paste scraping plate. A tank body is included and fixedly connected with a tank cover through a locking mechanism.An installing frame is fixedly connected to the upper end of the tank cover. A first motor is fixedly connected to the upper end of the installing frame. An output shaft of the first motor penetratesthrough the upper end of the installing frame and extends inwards. The output shaft of the first motor and the installing frame are rotationally connected. The tank cover is provided with a lifting mechanism connected with the first motor. A material scraping mechanism is arranged in the tank body and connected with the lifting mechanism. The optical fiber filling paste technology tank is reasonable in structure design, oil paste on the inner wall of the technology tank is scrapped to the inner bottom, accordingly, the oil paste in the tank can be sufficiently sucked out and utilized, the utilization rate can be increased, and oil paste waste is reduced; and through increasing of supporting points of a base, the stability of the technology tank is improved, and accordingly stable placement can be achieved.

Owner:ZHANGPU PI IND DESIGN CO LTD

Photovoltaic panel cleaning tool assembly

ActiveCN112691959AImprove scraping efficiencyGuaranteed cleanlinessDispersed particle filtrationDrying solid materials without heatPhysicsEngineering

The invention discloses a photovoltaic panel cleaning tool assembly, and relates to the technical field of surface cleaning. The photovoltaic panel cleaning tool assembly comprises a working platform, a conveying belt is rotatably arranged on the working platform, and the working platform is sequentially provided with a glue scraping device, an ash cleaning device, a water spraying device, a water guide device, a drying device and a wiping device in the feeding direction of the conveying belt. The problems that the surface of a photovoltaic panel is prone to cracking due to rigid contact between a glue cleaning part and the surface of the photovoltaic panel in the prior art; a film is adhered to other surfaces of the photovoltaic panel or adhered to the glue cleaning part, so that operators need to clean the film and the glue cleaning part subsequently; the number of times of contact with the surface of the photovoltaic panel is low, so that the wiping effect is common, and a filtering assembly needs to be frequently disassembled and cleaned; cleaning liquid is prone to flowing into all parts of a cleaning tool, and the cleanliness of the working environment is affected; and due to the fact that a drying assembly is low in efficiency, the drying time is prolonged are solved.

Owner:山东瑞智投新能源科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com