Patents

Literature

613results about How to "Improve scraping effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

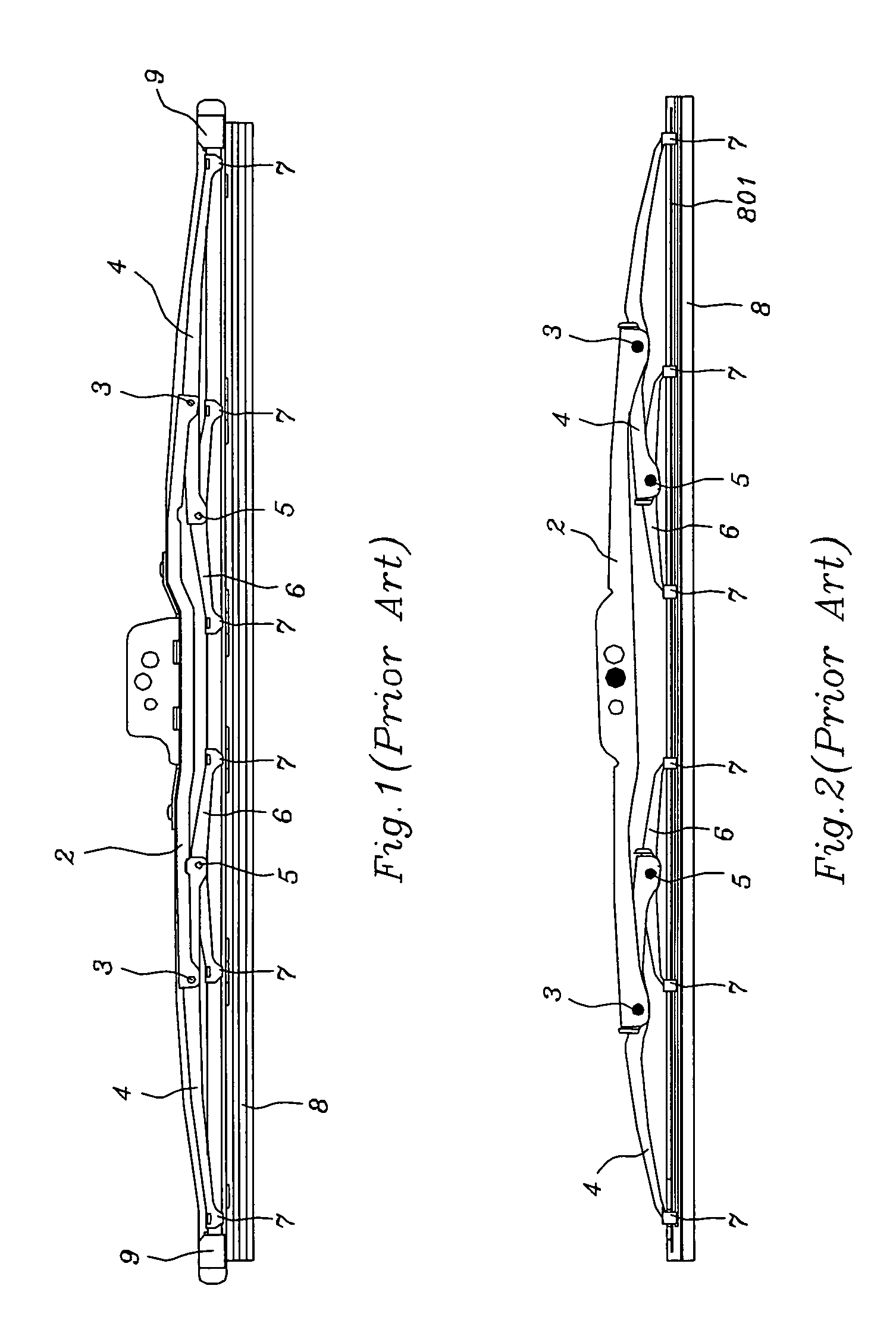

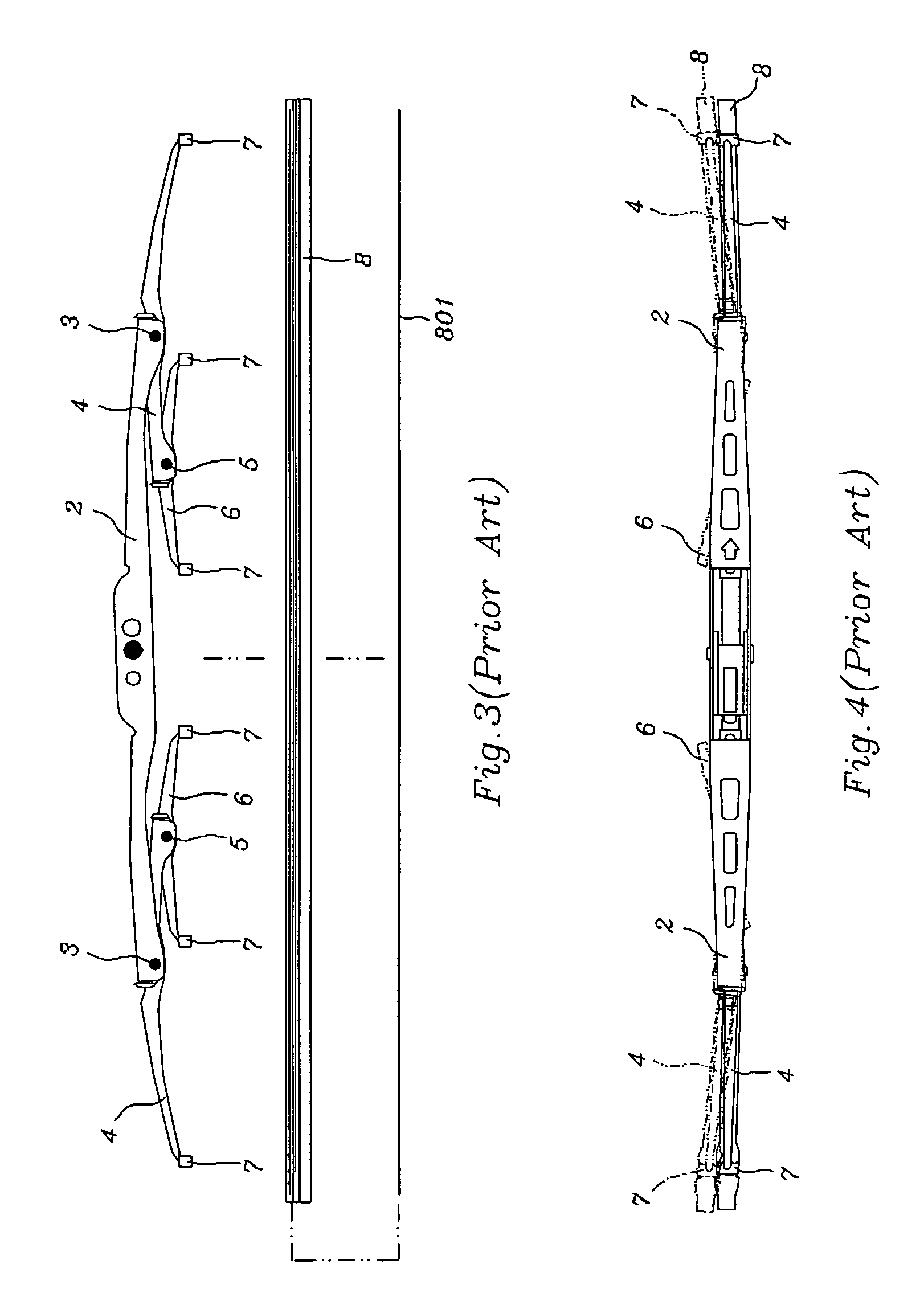

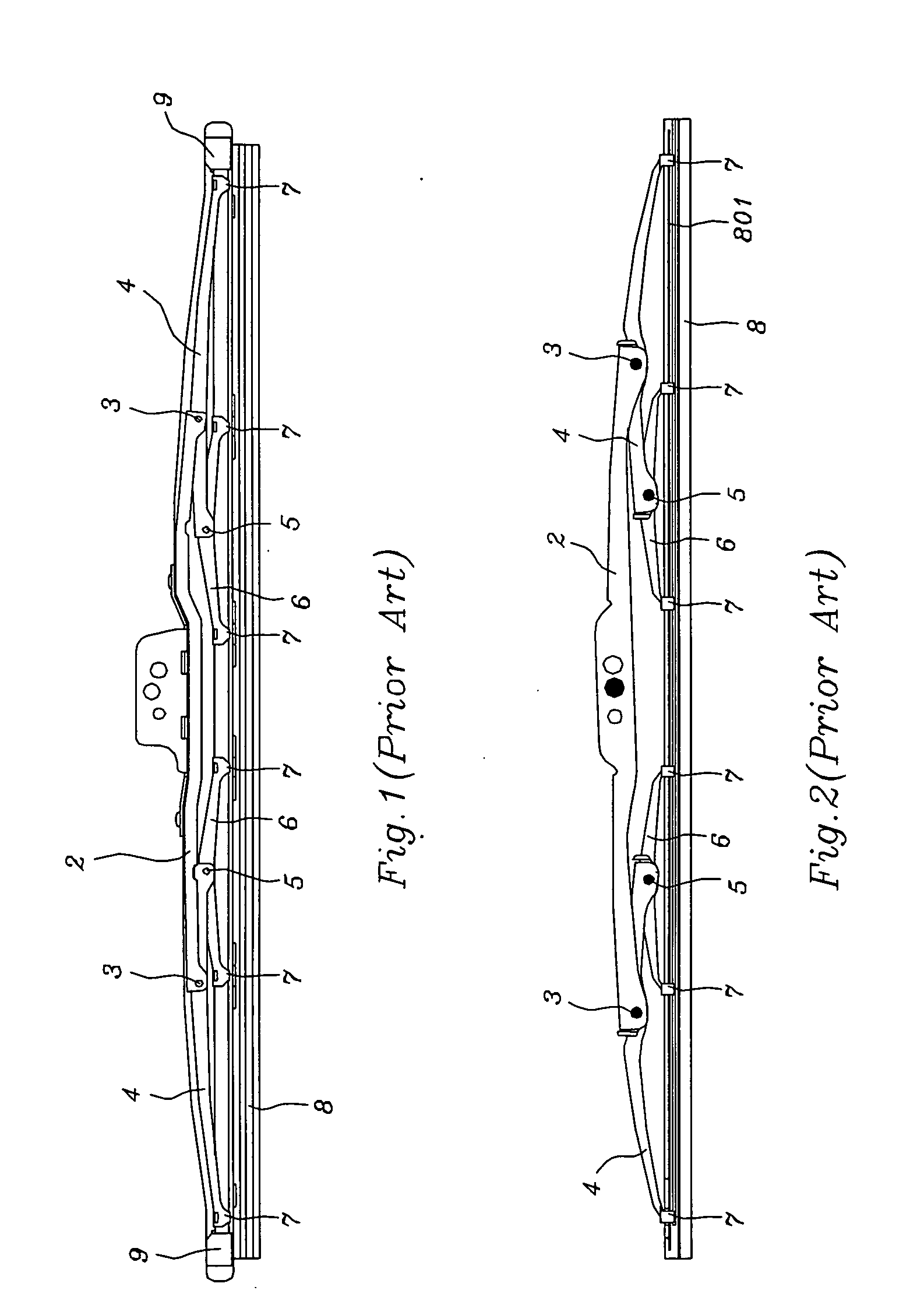

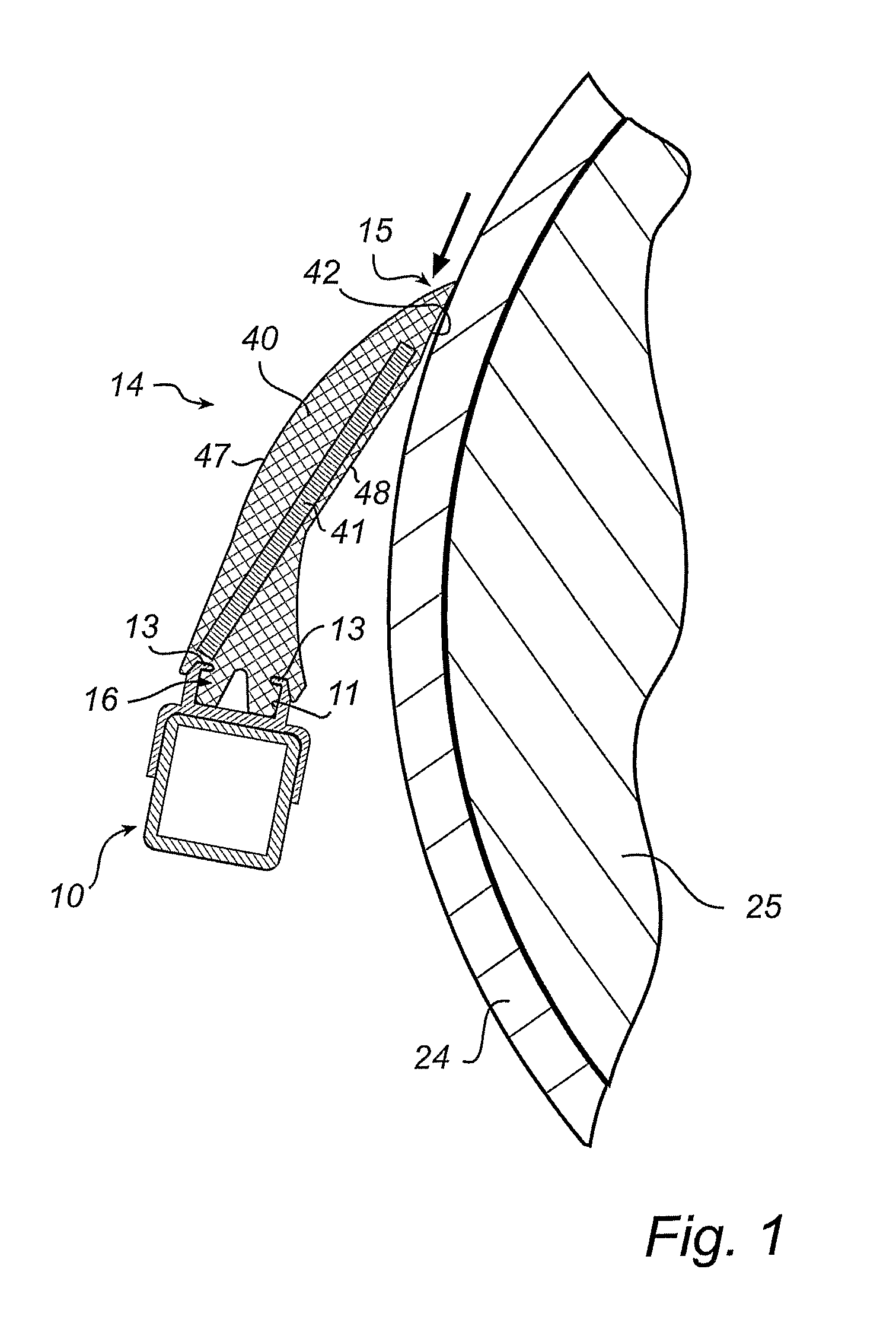

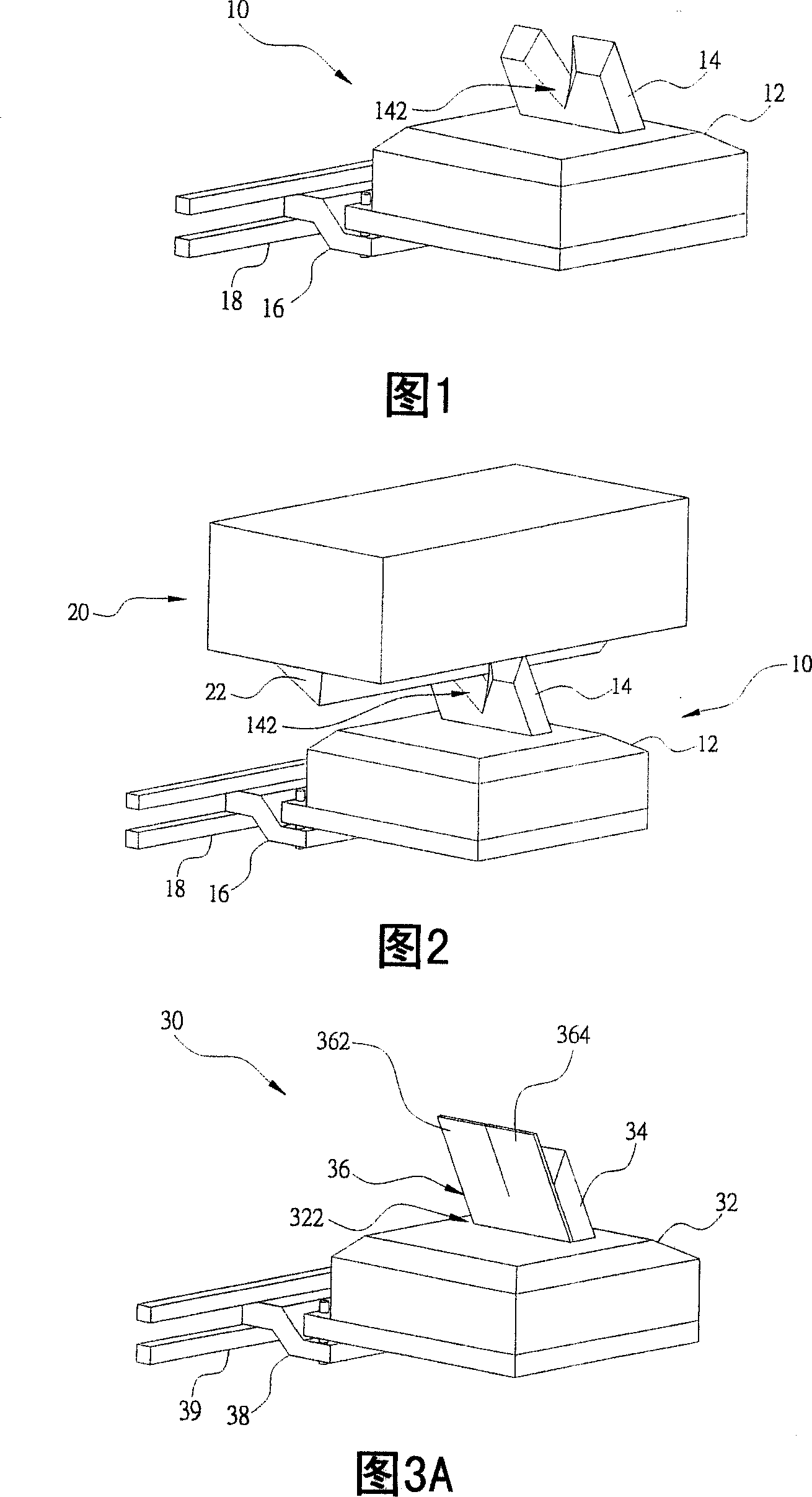

Windshield wiper structure for vehicles

InactiveUS7150066B1Improve scraping effectExtended service lifeWindow cleanersVehicle cleaningEngineeringCircular segment

A windshield wiper structure for vehicles includes a truss saddle, a bow elastic stripe, a cover body, some detachable clamping devices, a strip scraper and a frame cover. Hollow pressure adjusting vents are created on said bow elastic stripe in order to keep nearly the same elasticity at every section of said bow elastic stripe. Hence, force can be equalized in every portion of the whole wiper thereby achieving even pressure distribution. As a result, the contact between the strip scraper and the windshield glass is uniformly tight and hermetic to enhance the scraping effect of the windshield wiper as the effect of prolonging service-lifetime while reducing expenses associated with wiper replacement, thereby providing enhanced economy and environmental protection.

Owner:HUANG SHIH HSIEN

Windshield wiper structure for vehicles

InactiveUS20060282972A1Improve scraping effectExtended service lifeWindow cleanersVehicle cleaningBand shapeEngineering

A windshield wiper structure for vehicles, comprises a truss saddle, a bow elastic stripe, a cover body, some detachable clamping devices, a strip scraper and a frame cover; wherein, some hollow pressure adjusting vents are created on said bow elastic stripe in order to keep nearly same elasticity at every sections of said bow elastic stripe. Hence, it can equilibrate force in every portions of whole wiper such that achieving in adjust-effect of even pressure distribution. Then, the contact between said strip scraper and the windshield glass is holistically even tight uniformly and hermetic closely to enhance the scraping effect of windshield wiper as well as the effect of prolonging service-lifetime with reducing expense in association with decreasing of replacing new product frequency in consequence of such even pressure distribution. Thus, it has more effect in economy and environmental protection.

Owner:HUANG SHIH HSIEN

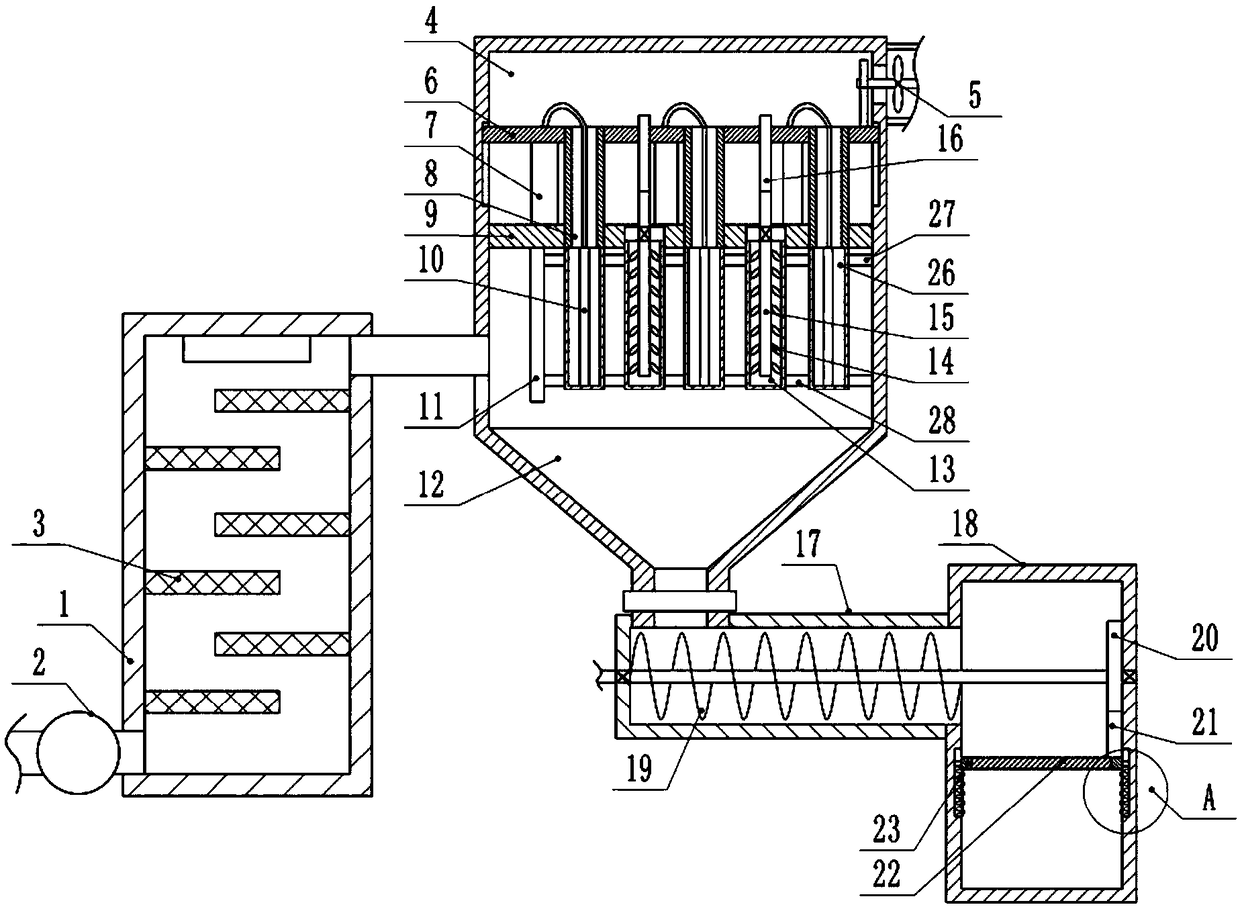

Phosphogypsum based plastering gypsum

The invention discloses a phosphogypsum based plastering gypsum, and relates to a plastering material for a building wall. The phosphogypsum based plastering gypsum mainly comprises 75 to 95 percent of phosphogypsum based building gypsum, 1 to 3 percent of sierozem powder, 0.1 to 0.5 percent of retarder, 1.1 to 5.5 percent of composite water retention agent, 0.3 to 1 percent of ethylene-vinyl acetate copolymerized latex powder, and 0 to 20 percent of stuffing. The phosphogypsum based plastering gypsum effectively improves water retention property and lowers cost by adopting the combination of cellulose ether water retention agent and bentonite, effectively adjusts settling time and prolongs operable time by adopting the retarder, improves construction property, cohesive property and cracking resistance by doping the stuffing and the latex powder, and reduces adverse effects of impurities on the strength of plastering gypsum by adding the sierozem powder. The phosphogypsum based plastering gypsum has the advantages of good workability and construction property, long operable time, high breaking resistance, compression resistance and adhesion strength, good volume stability, good cracking resistance and lower cost, and can be used for a plastering layer of the building wall.

Owner:CHONGQING UNIV

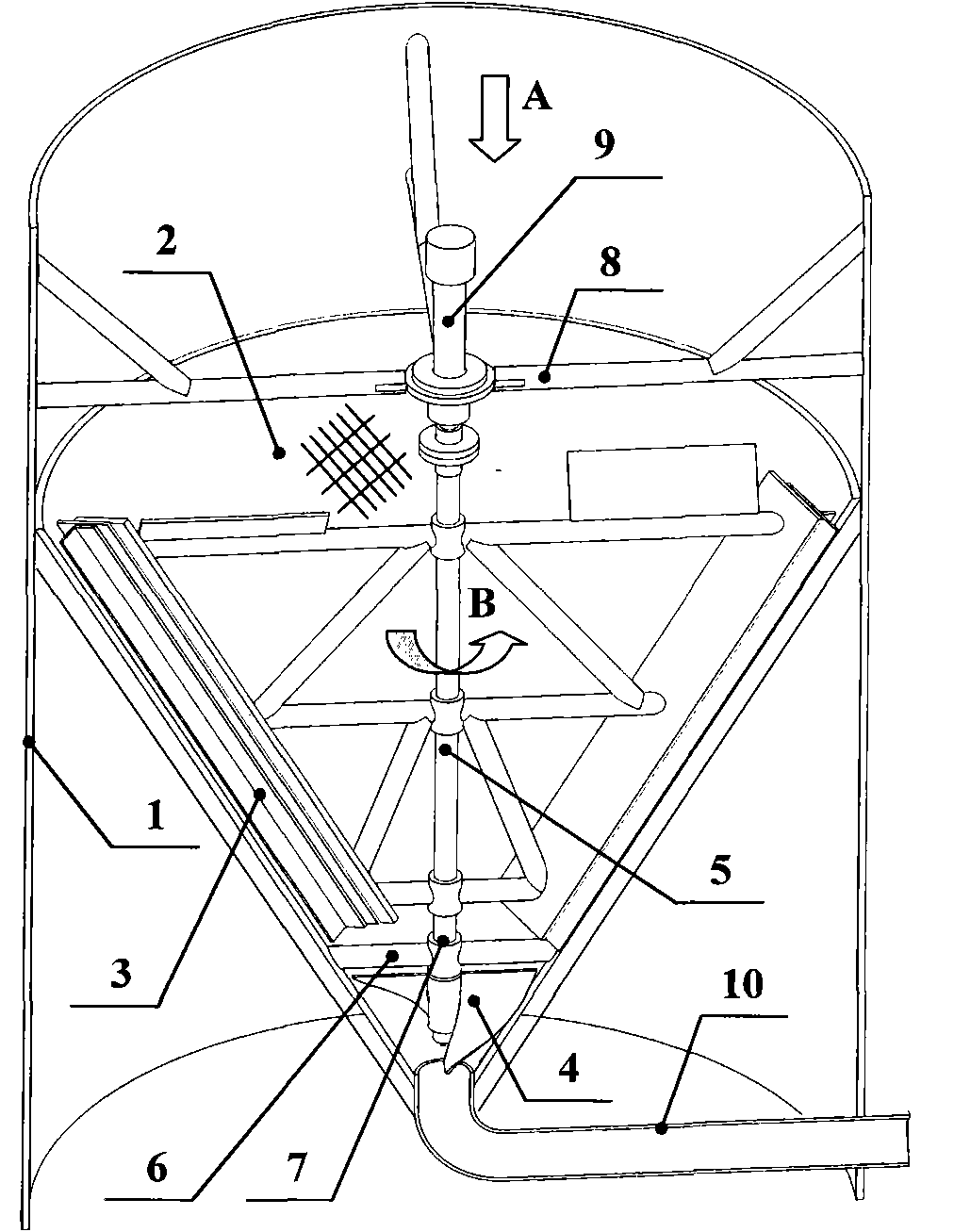

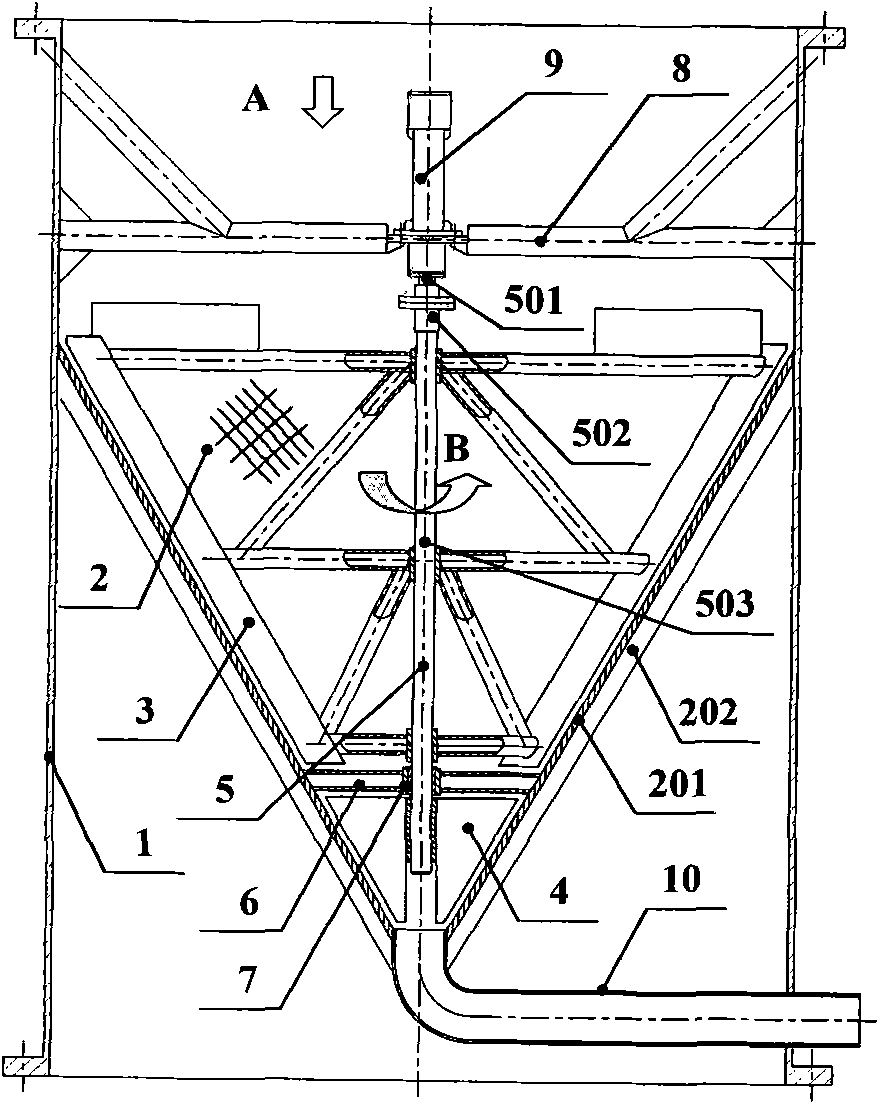

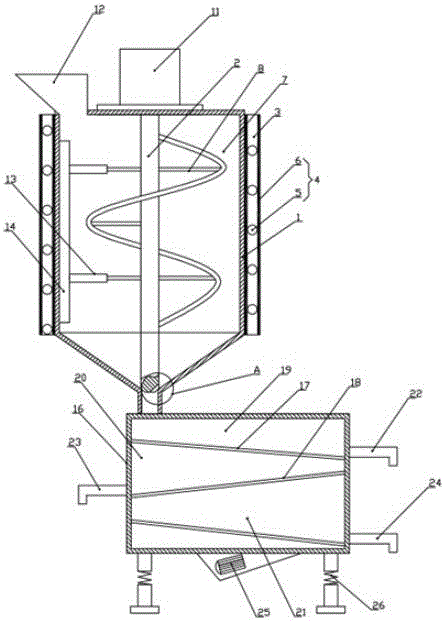

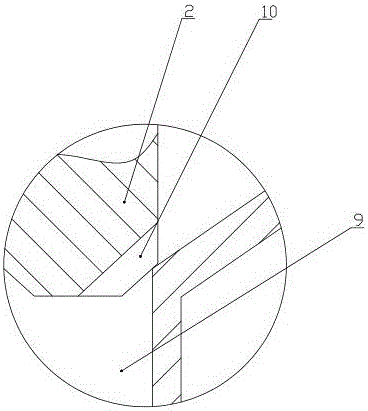

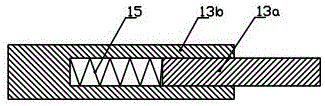

Self-rotating clean collecting device

ActiveCN101979121AReduce stressImprove abilitiesStationary filtering element filtersImpellerFiltration

The invention discloses a self-rotating clean collecting device, and belongs to the technical field of filtration. The device is characterized by consisting of a main pipeline or an outer shell, a filter screen assembly, a self-rotating scouring scraper assembly, a conical impeller, a rotating shaft, a rear bearing supporting assembly, a rear bearing assembly, a front bearing supporting assembly, a front bearing assembly and an extraction pipe; the self-rotating scouring scraper assembly and the conical impeller are arranged on the rotating shaft positioned at the rotation axis of the conical filter screen assembly, and the rotating shaft is supported and positioned through the front and rear bearing assemblies and generates self rotation under the action of fluid in the main pipeline or the outer shell; the solid substances in the fluid are filtered in a filter screen, collected at the tail part of the filter screen assembly under the combined action of the self-rotating scouring scraper assembly, the conical impeller and the fluid and then extracted from the extraction pipe; and meanwhile, the filter screen assembly keeps clean all the time under the combined action of the self-rotating scouring scraper assembly, the conical impeller and the fluid. The device has good collecting effect, low flow resistance and long service life.

Owner:TSINGHUA UNIV

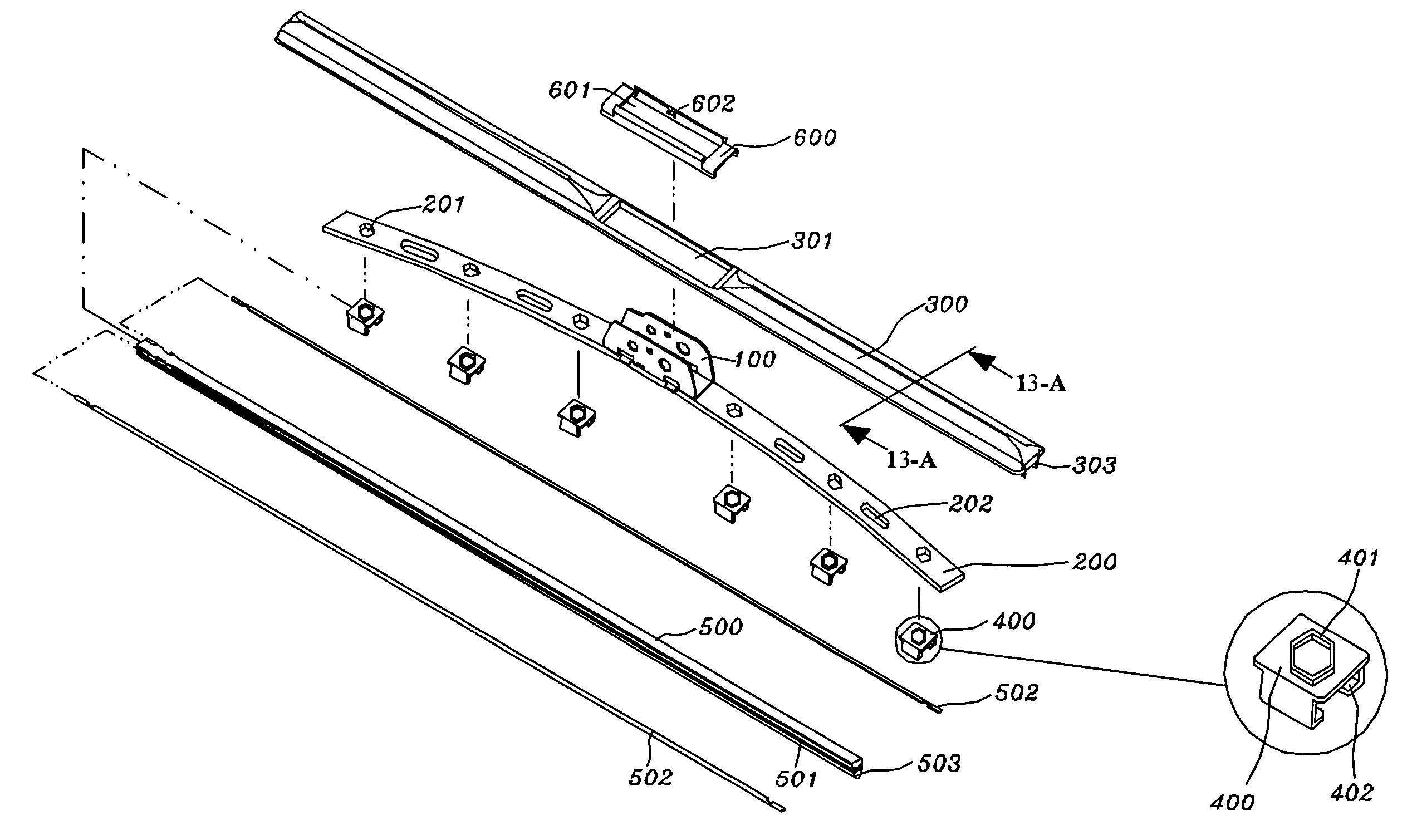

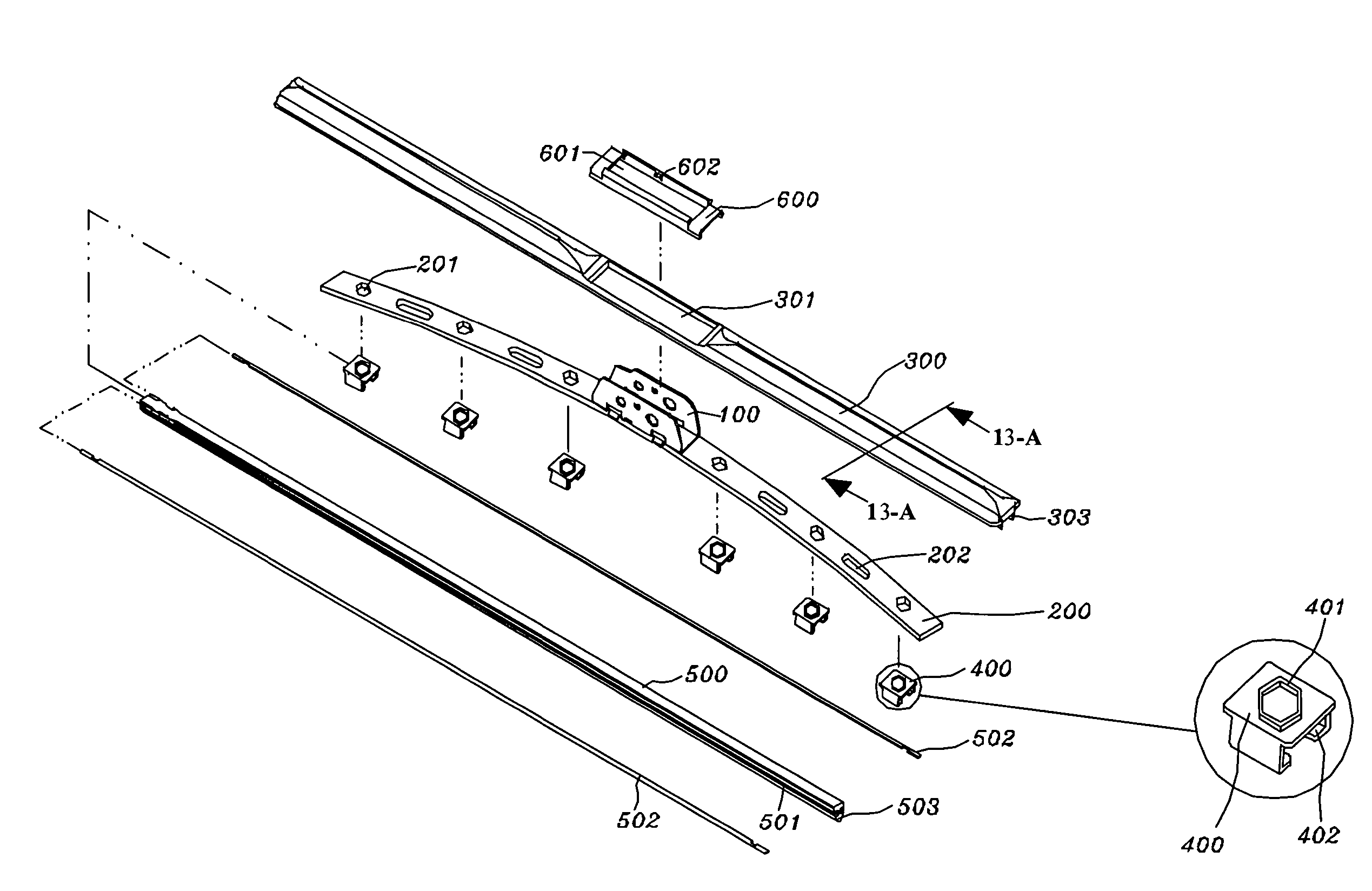

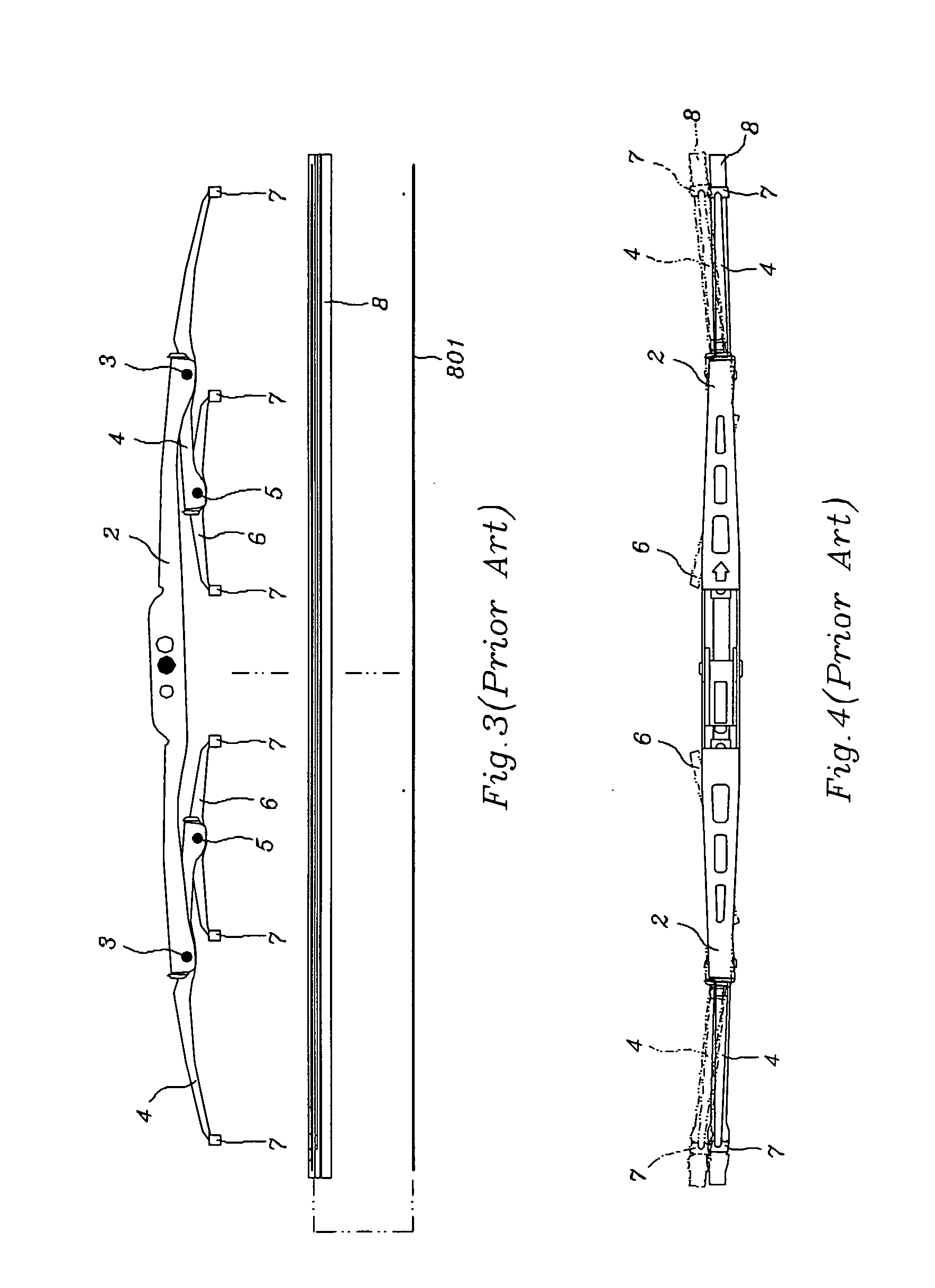

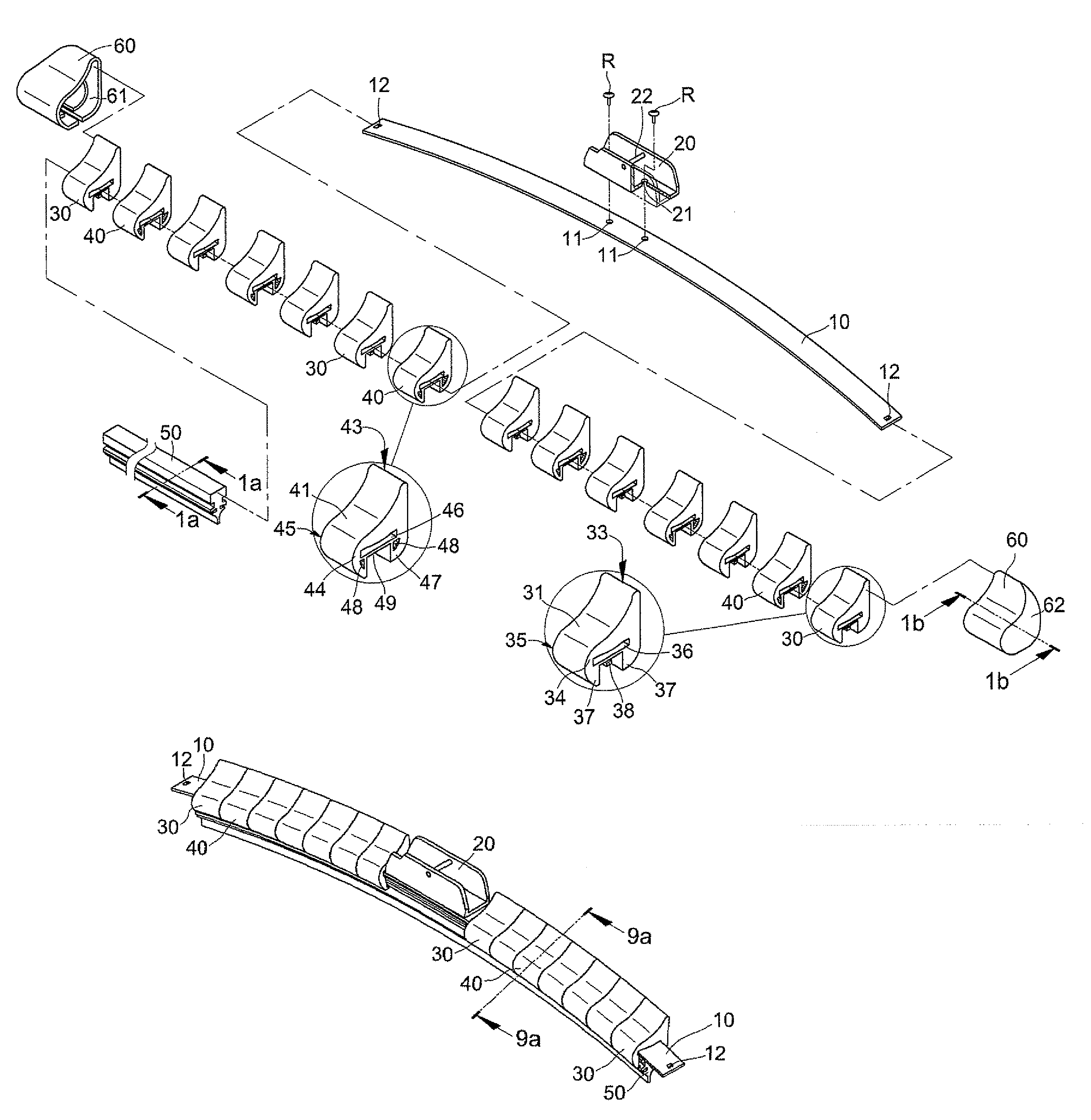

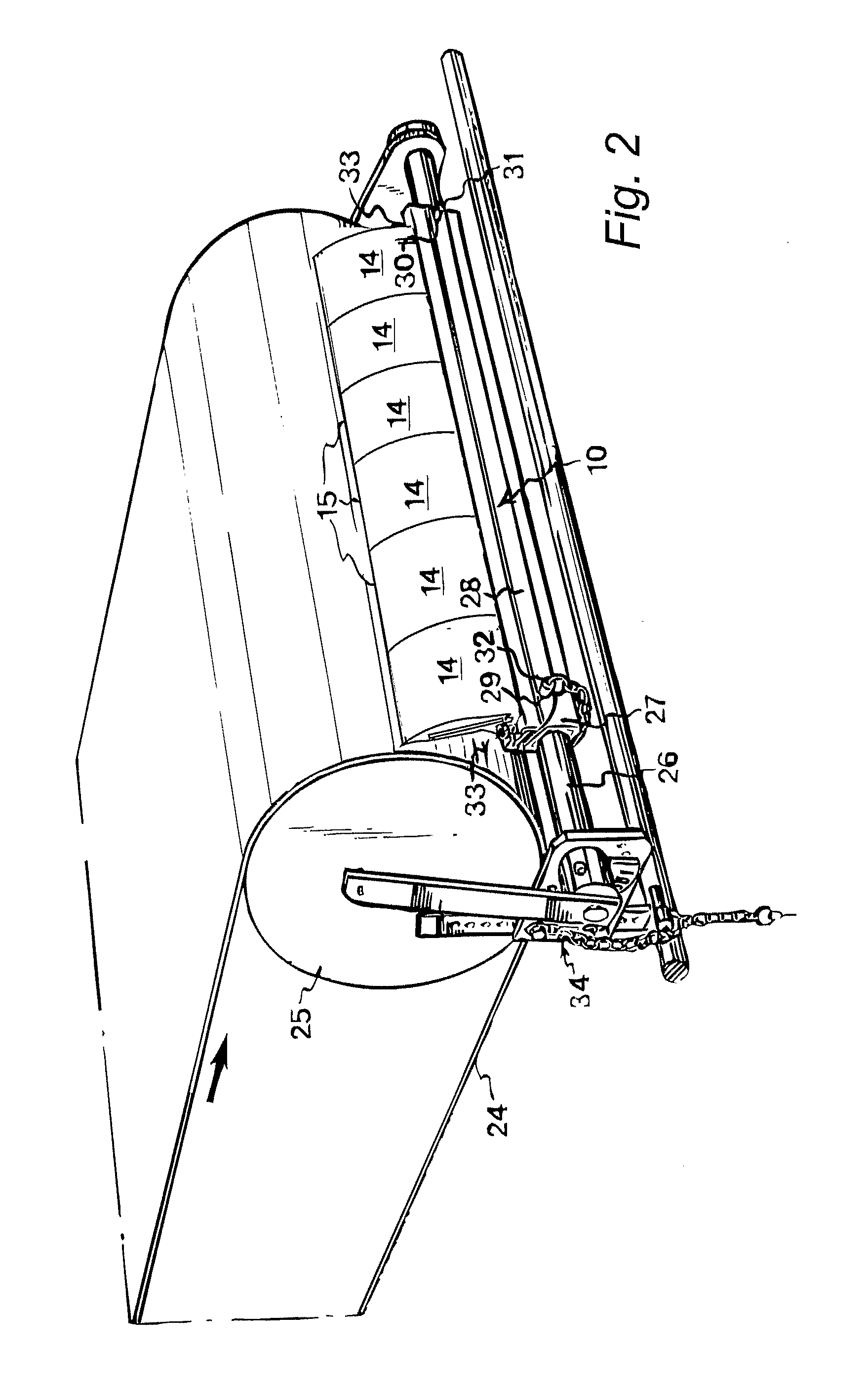

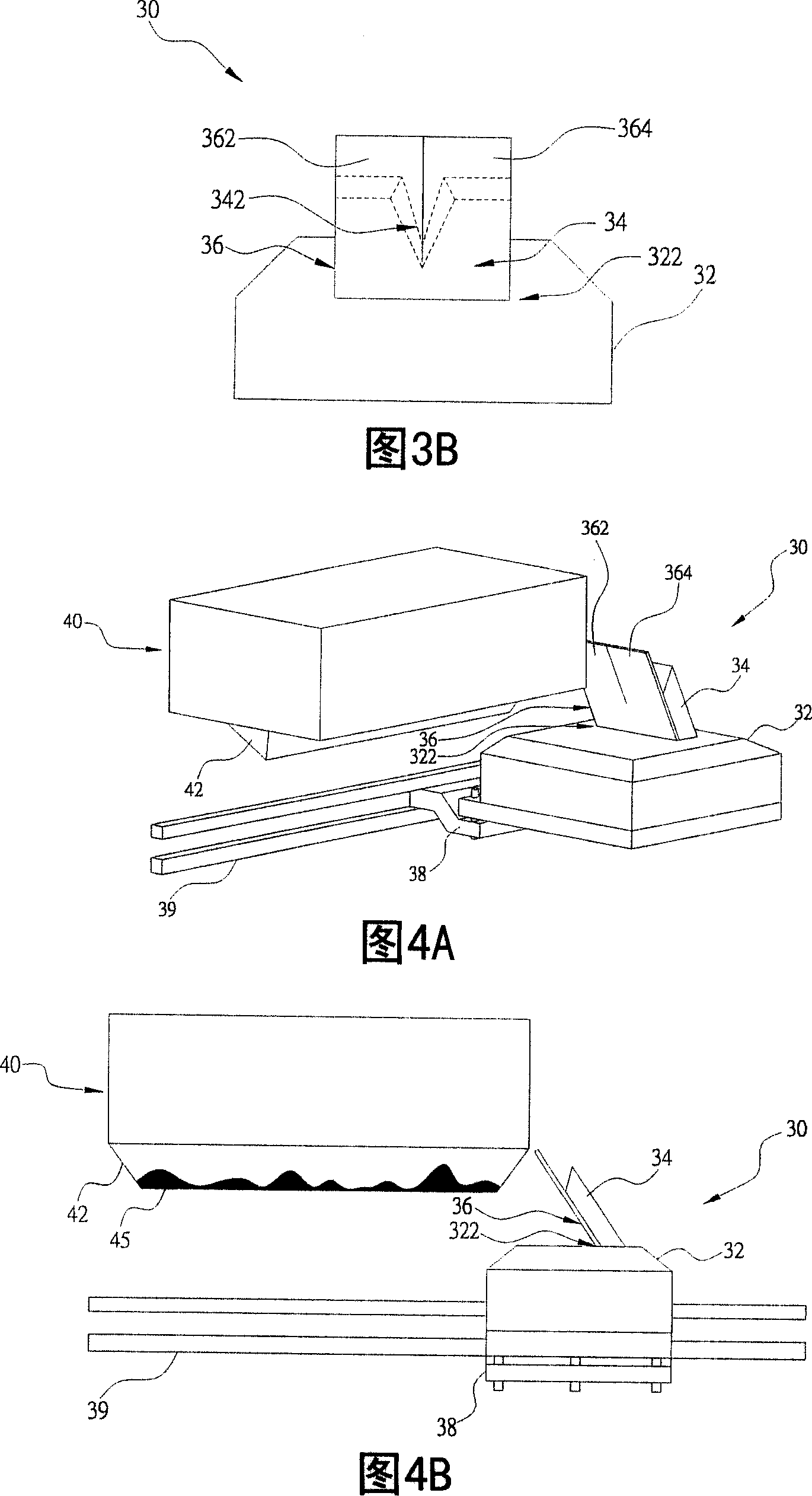

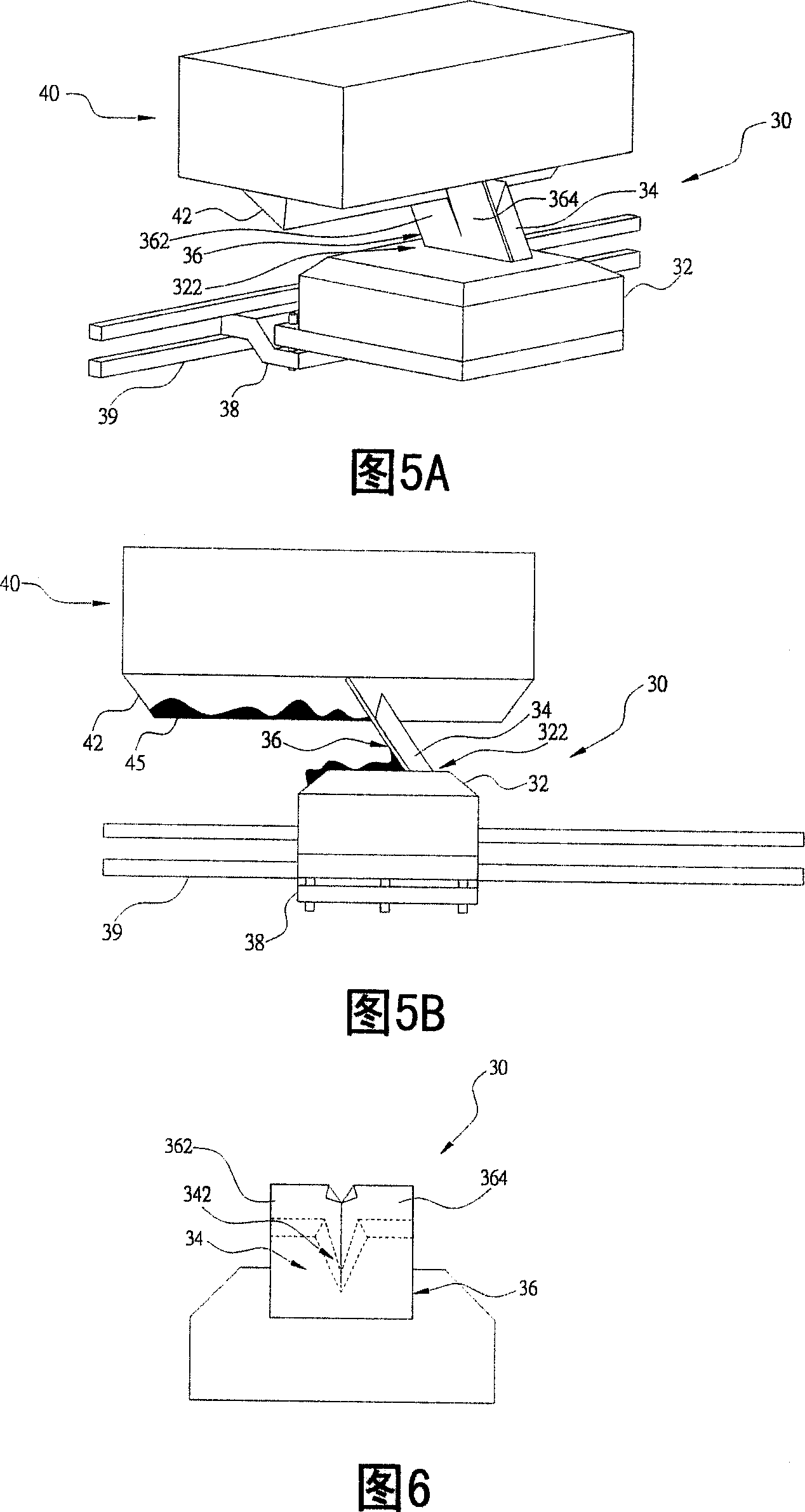

Structure for array combinational type of windshield wiper

InactiveUS7540062B1Easily and smoothly producedReduce manufacturing costWindow cleanersVehicle cleaningEngineeringWindshield

A structure for an array combinational type of windshield wiper comprises an elastic curved strip, a supporting mount, and a plurality of lodging blocks and a plurality of counterweight blocks which are disposed on the elastic strip in an array. This arrangement provides flexibility in matching the length of the array of lodging blocks and counterweight blocks with the length of the elastic curved stripe such that various windshield wipers of different lengths and specifications can be easily produced.

Owner:HUANG SHIH HSIEN

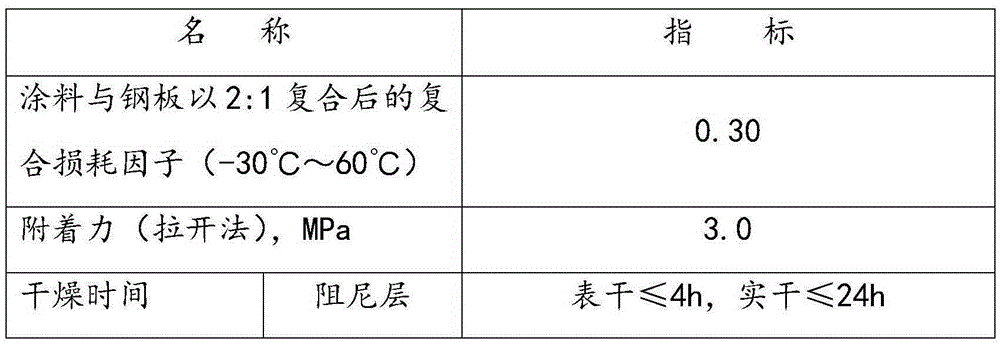

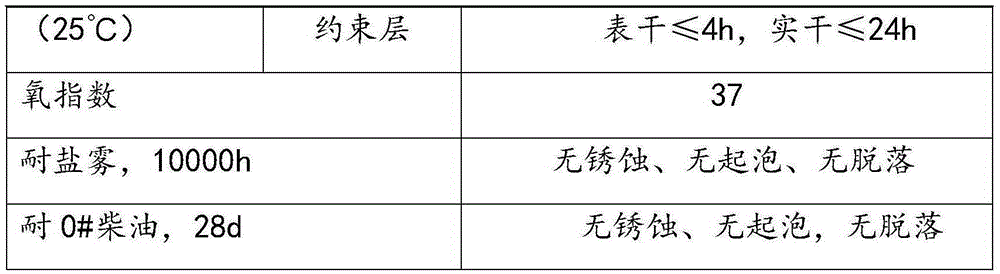

Special composite damping coating for ships and warships and preparation method thereof

ActiveCN105273599ANo pollution in the processEasy constructionAnti-corrosive paintsPolyurea/polyurethane coatingsPolyolSolvent free

The invention discloses a special composite damping coating for ships and warships and a preparation method thereof. The special composite damping coating comprises a damping layer and a constraint layer, wherein the damping layer refers to a two-component solvent-free polyurethane coating and comprises a first component and a second component; the first component refers to an isocyanate prepolymer synthesized by polyisocyanates and polyol; the second component comprises a chain extender, a dispersing agent, an antifoaming agent, a catalyst, a damping filler and pigments; the constraint layer refers to a two-component solvent-free epoxy resin coating and comprises a component A and a component B; the component A comprises a liquid epoxy resin, a reactive diluent, a dispersing agent, an antifoaming agent, a flame retardant, a thixotropic agent, talcum powder, wollastonite in powder and coarse whiting; and the component B comprises a modified curing agent, an antifoaming agent and a thixotropic agent. The coating adopts a constrained damping structure and is mainly used for reducing structural vibration and noise of naval vessels, the stealth capability, tactical qualities and comfortable capability can be improved, and the material has excellent sound insulation, antiseptic properties and medium resistance.

Owner:QINGDAO AIR NEW MATERIALS

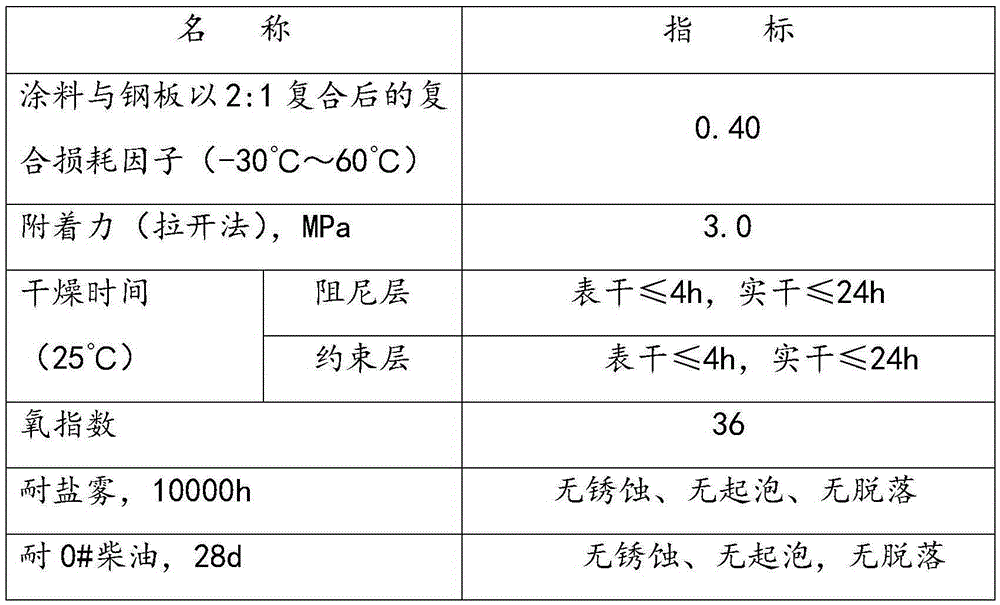

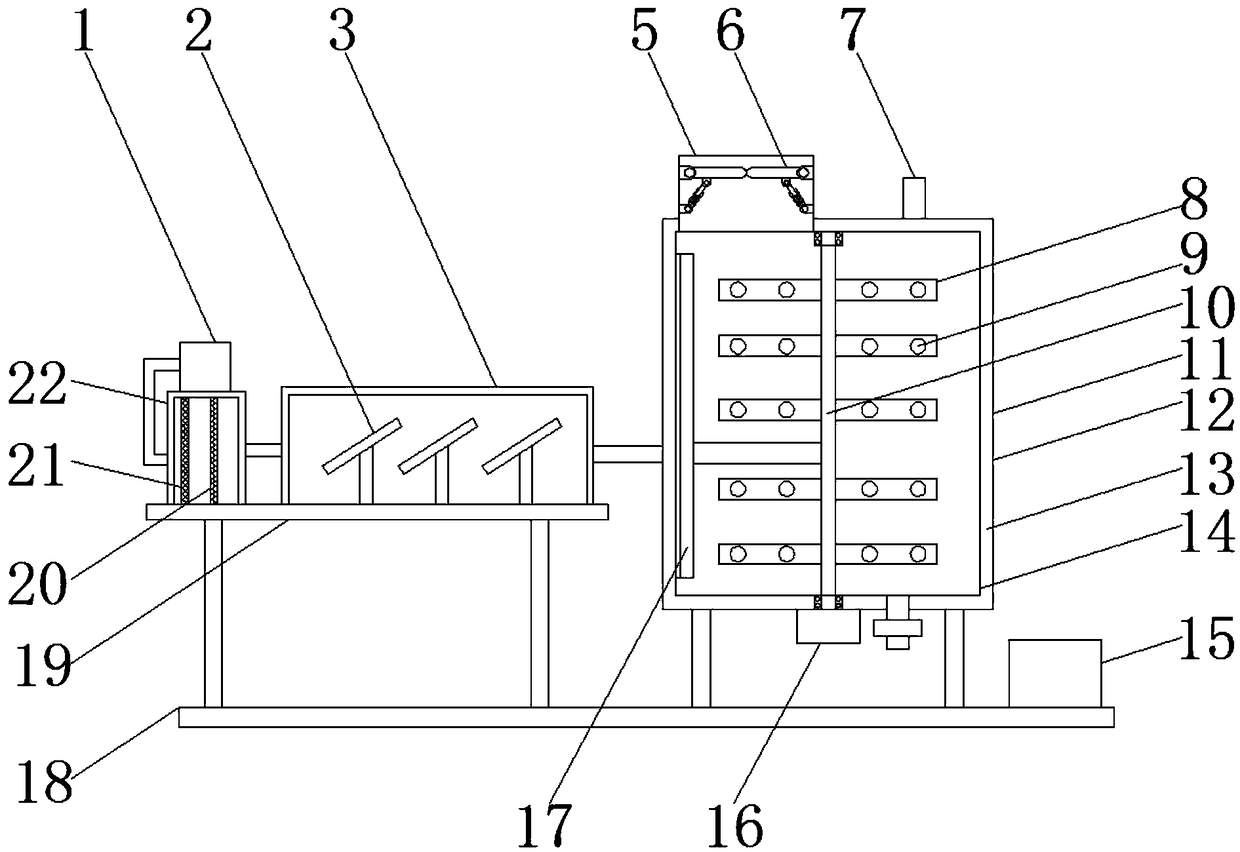

Dust recycling system

ActiveCN108619840AExtension of timeEasy to reuseSievingCombination devicesProtection systemAir purification

The invention belongs to the technical field of environmental protection systems, and particularly discloses a dust recycling system. The dust recycling system comprises a cooling unit, a dust removalunit and a recycling unit, wherein the dust removal unit comprises a dust removal box; a partition plate divides the dust removal box into an upper part, namely an air purification chamber and a lower part, namely a filter chamber; a plurality of fixed filter bags and movable filter bags are alternately arranged in the filter chamber; an air exhaust mechanism is arranged in the air purification chamber; the upper ends of the movable filter bags are connected with a lifting mechanism; the lifting mechanism is connected with the air exhaust mechanism; the air exhaust mechanism works to drive the movable filter bags to rise up and fall off through the lifting mechanism; upper scraper blades are arranged at the upper parts of the movable filter bags; lower scraper blades are arranged at the lower parts of the fixed filter bags; the insides of the fixed filter bags are connected with rotating shafts, driven by the lifting mechanism, in a rotatable manner; flexible blades are arranged on the rotating shafts; the recycling unit comprises a material feeding mechanism and a screening mechanism; the material feeding mechanism is communicated with an ash bucket; and the screening mechanism is communicated with the material feeding mechanism and is located at the end, far away from the ash bucket, of the material feeding mechanism. The dust recycling system realizes ash cleaning of the filter bags in a dust filtering process, and is high in dust removal efficiency and high in dust recycling efficiency.

Owner:GUIZHOU HUANKE ENVIRONMENT ECOLOGICAL RES & DEV CO LTD

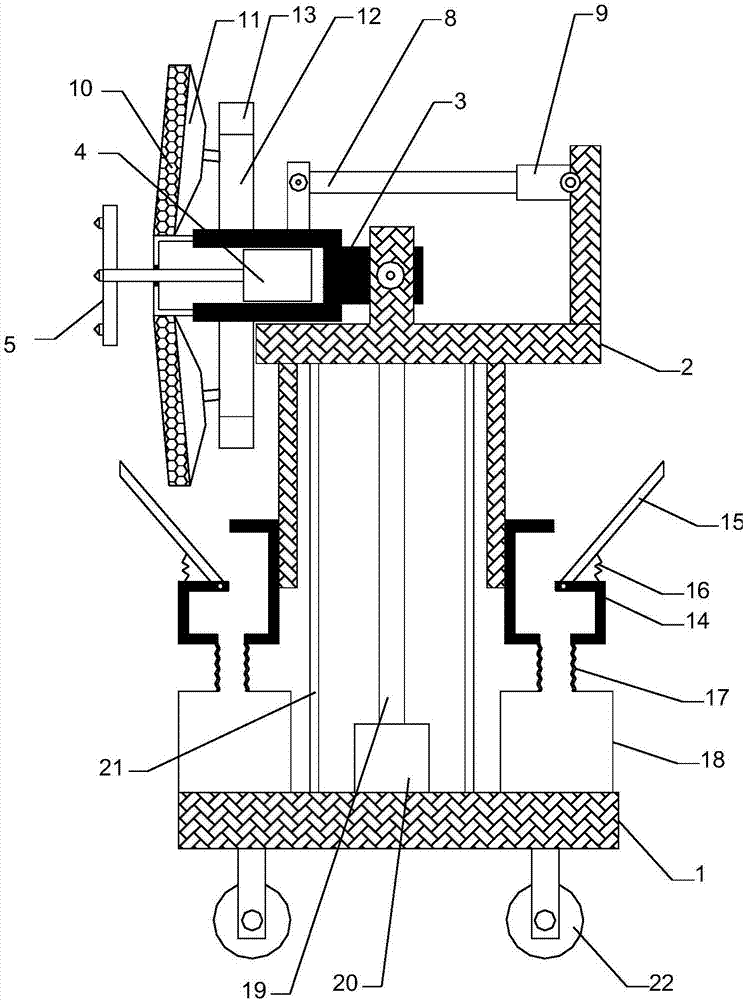

Wall scraping device with slag collecting function

InactiveCN107344309AAvoid random driftProtect healthBuilding repairsPlane surface grinding machinesDrive shaftSlag

The invention discloses a wall skin scraping device with the function of collecting debris, which comprises a moving plate, a first driving motor and a second driving motor; the moving plate is rotatably connected with a turret, and the turret is nested with a first drive Motor, the first driving motor is fixedly connected with the turret; the first driving motor is connected to a scraping wheel through a drive shaft; a grinding wheel is arranged on the rear side of the scraping wheel. The present invention is provided with a scraping wheel and a grinding wheel to scrape the wall and the ceiling, the scraping is thorough, and has a good scraping effect; the invention is provided with a turret, so that the device can scrape the ceiling operation, scraping efficiency is high, and manpower is saved; the present invention is equipped with a dust and slag collection device, which collects dust and slag efficiently and intensively during the operation process, avoids random dust floating, keeps the working environment clean and protects operators health.

Owner:吴佳慧

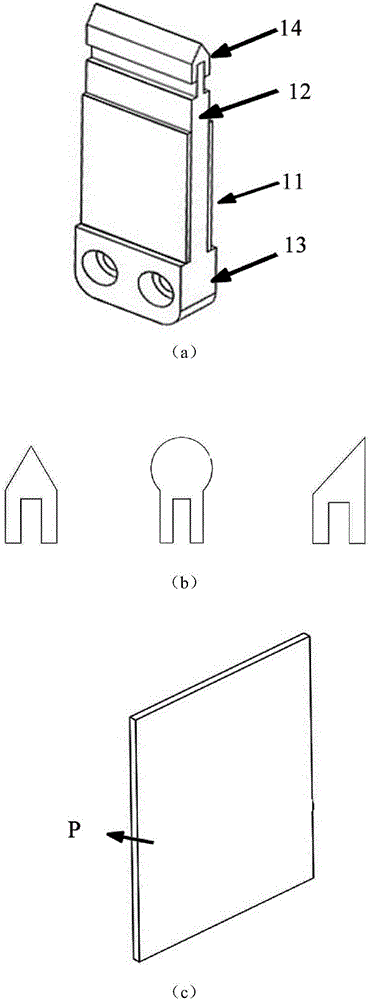

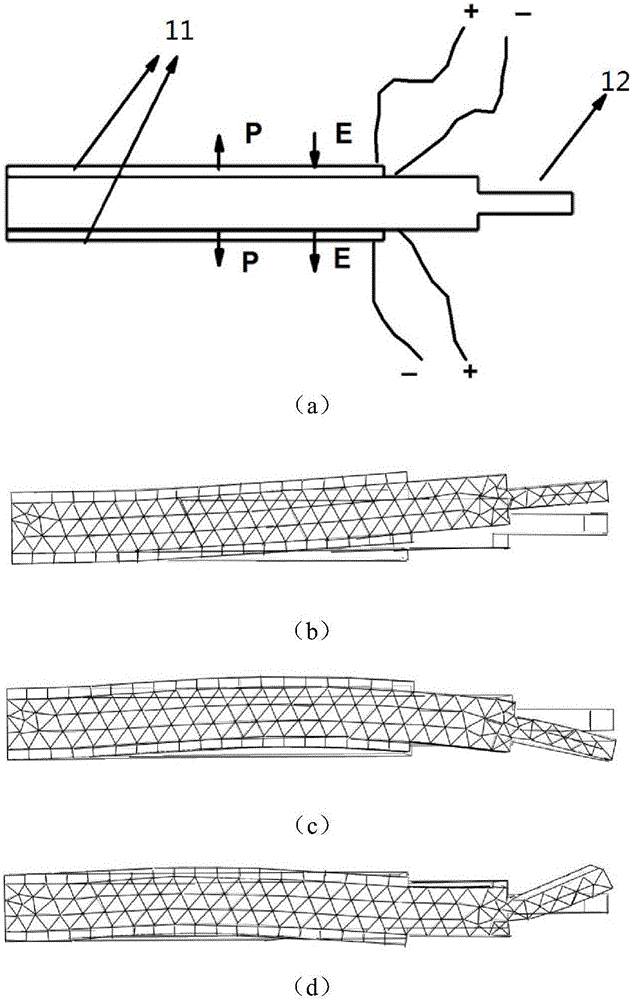

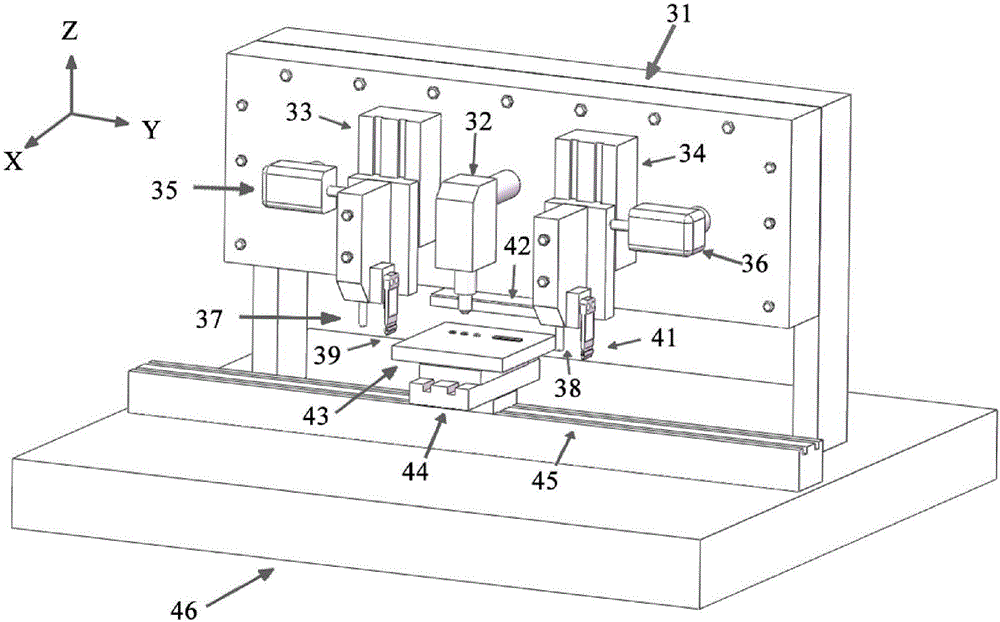

Broadband piezoelectric vibrating scraper, spraying type 3D printing of broadband piezoelectric vibrating scraper, and printing method

ActiveCN106738867AEfficient exclusionReduce friction3D object support structuresApplying layer meansVibration amplitudeEngineering

The invention discloses a broadband piezoelectric vibrating scraper, spraying type 3D printing of the broadband piezoelectric vibrating scraper, and a printing method. According to the piezoelectric vibrating scraper disclosed by the invention, a tool bit in high-frequency vibration scraps the surface of size, and an ultrasonic shock effect is generated, so that bubbles in the size are effectively removed; besides, through the high-frequency vibration of the tool bit, the friction between the tool bit and the surface of the size is effectively reduced, so that the effect of flatting the surface of the size is achieved, and high smooth finish is obtained; the vibration amplitude and the working frequency of the piezoelectric vibrating scraper can be comprehensively adjusted according to materials, viscosity or granularity and the like of the spray size to obtain the best scraping and coating effect; and through the precise control of the vertical distance between the tool bit and a 3D printer moving platform, the layer thickness of a printed layer is precisely controlled, and the control of the thickness of the printed layer in micrometer scale is realized. The piezoelectric vibrating scraper provided by the invention well makes up for deficiencies of a conventional piezoelectric sprayer in the aspects of the control of the thickness of the printed layer, size shaping quality, the smooth finish of the surface of the printing size, and the like.

Owner:PEKING UNIV

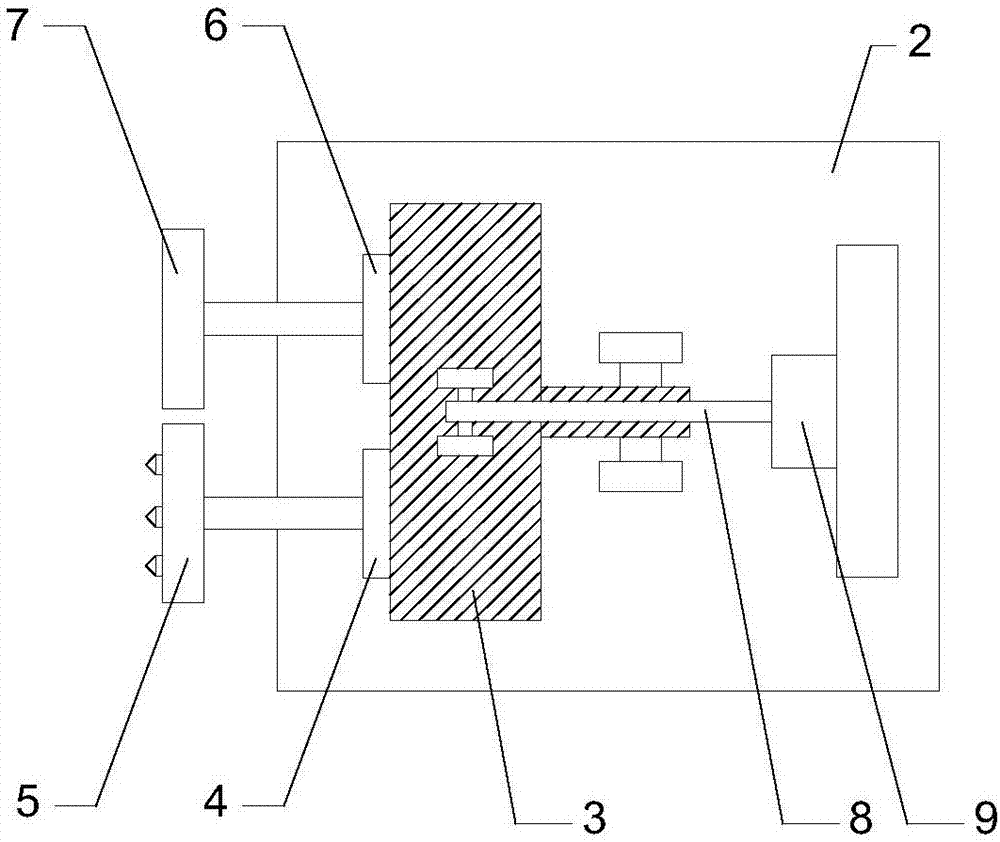

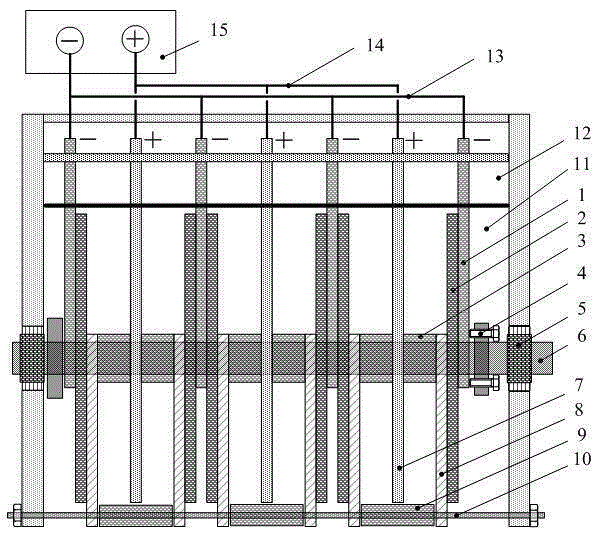

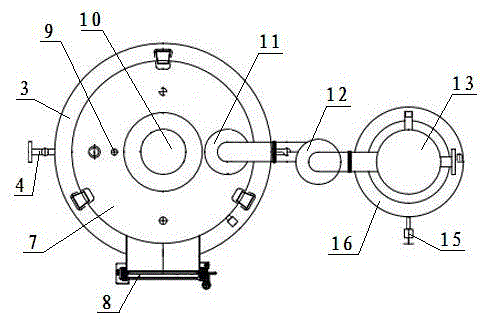

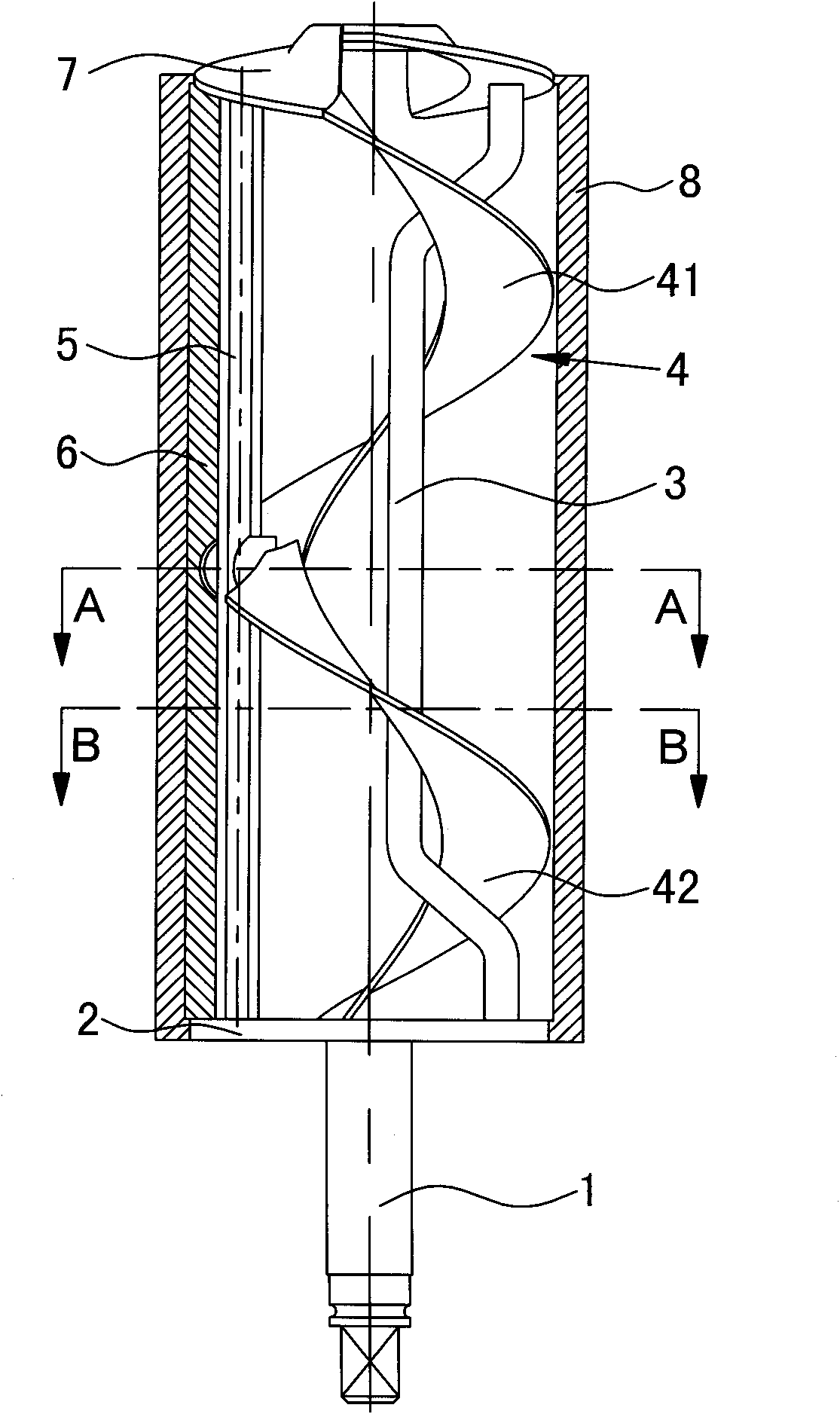

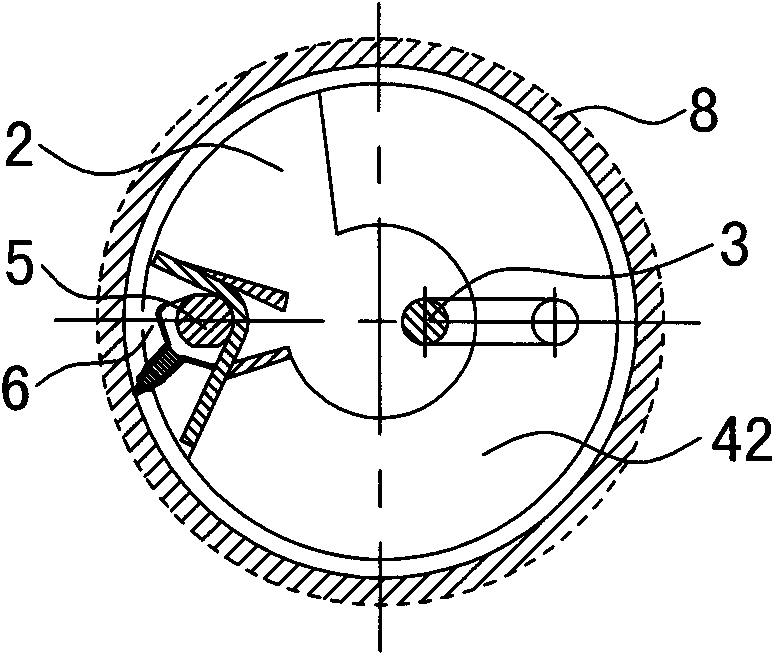

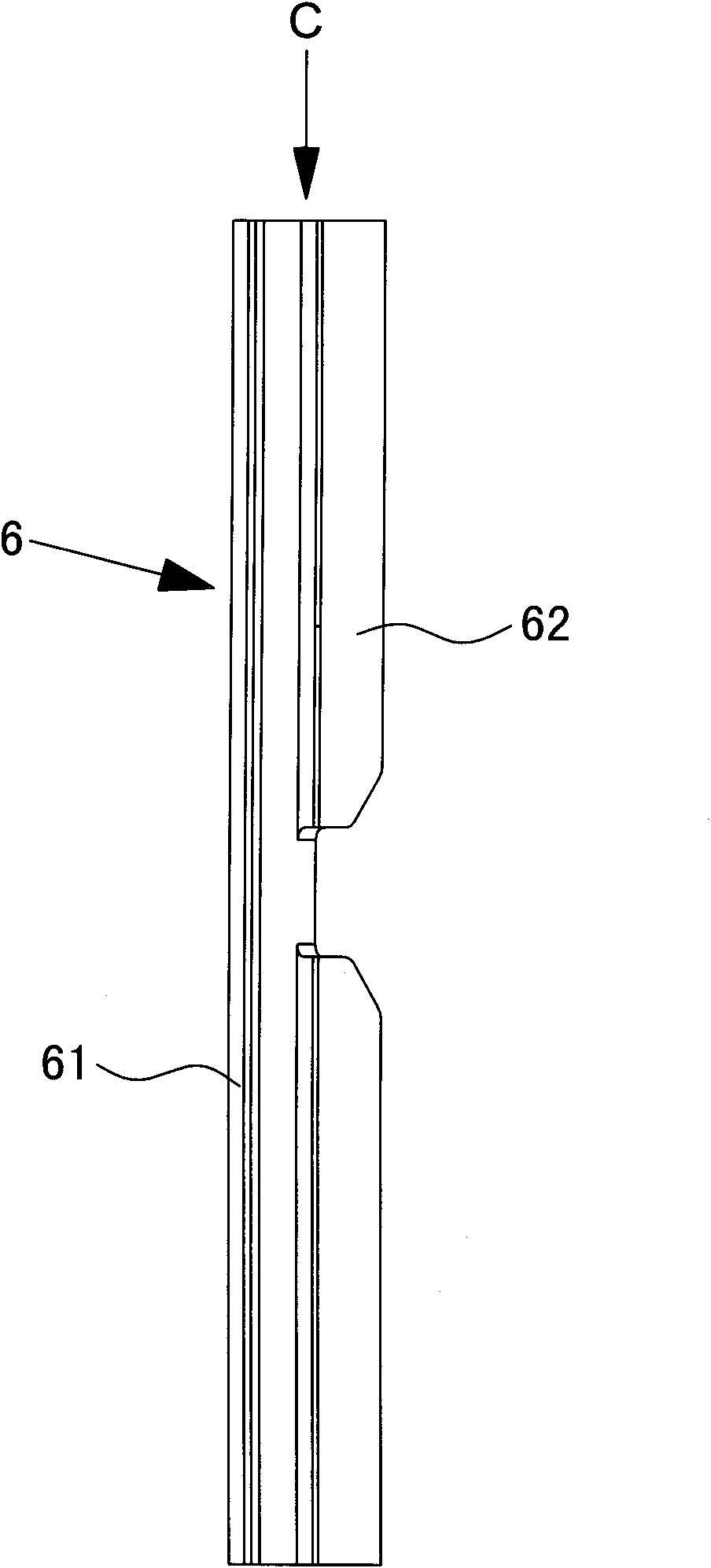

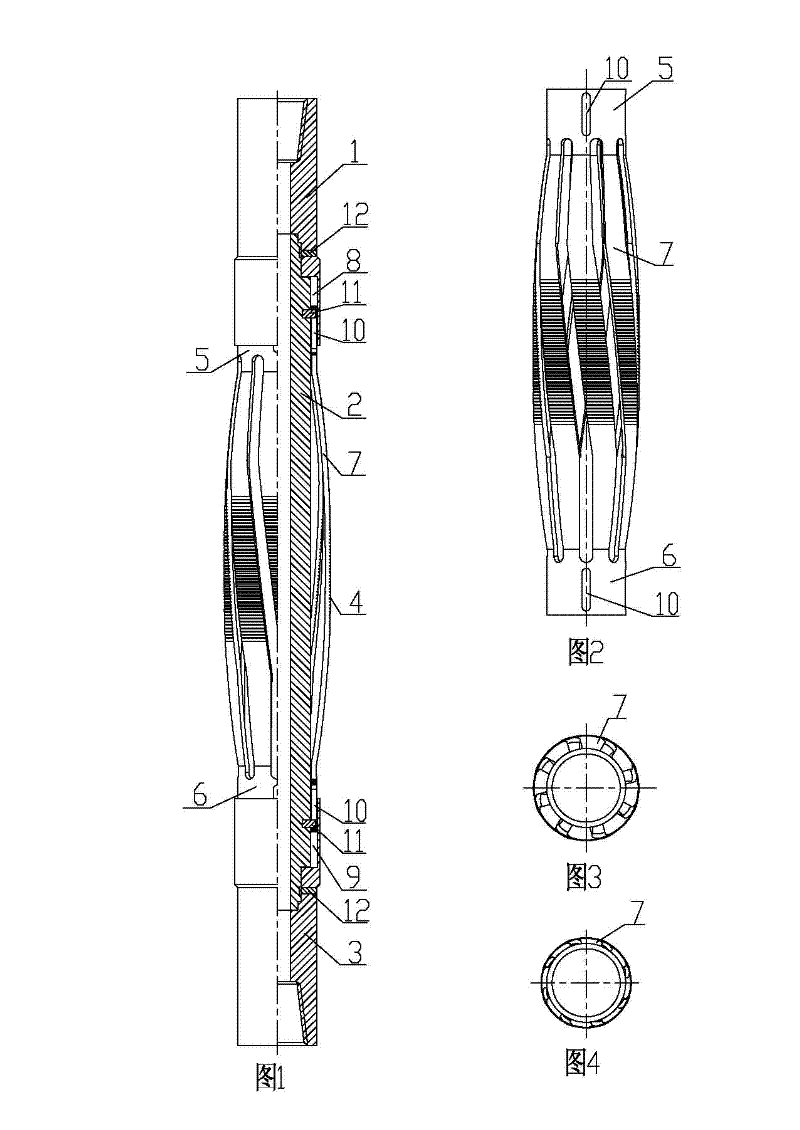

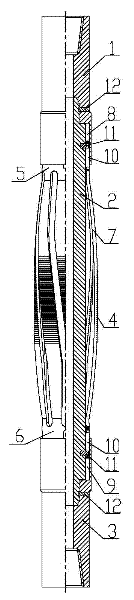

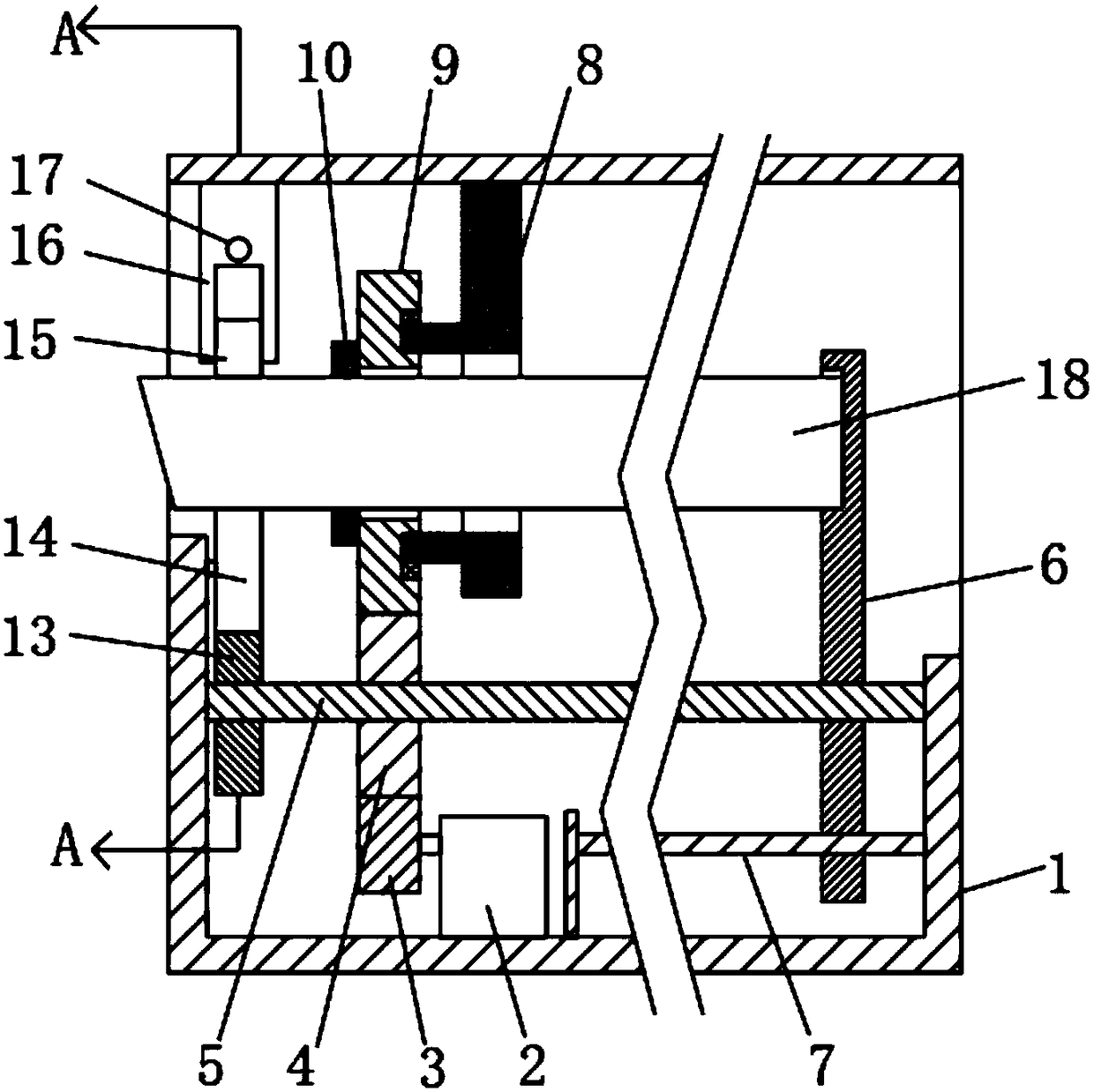

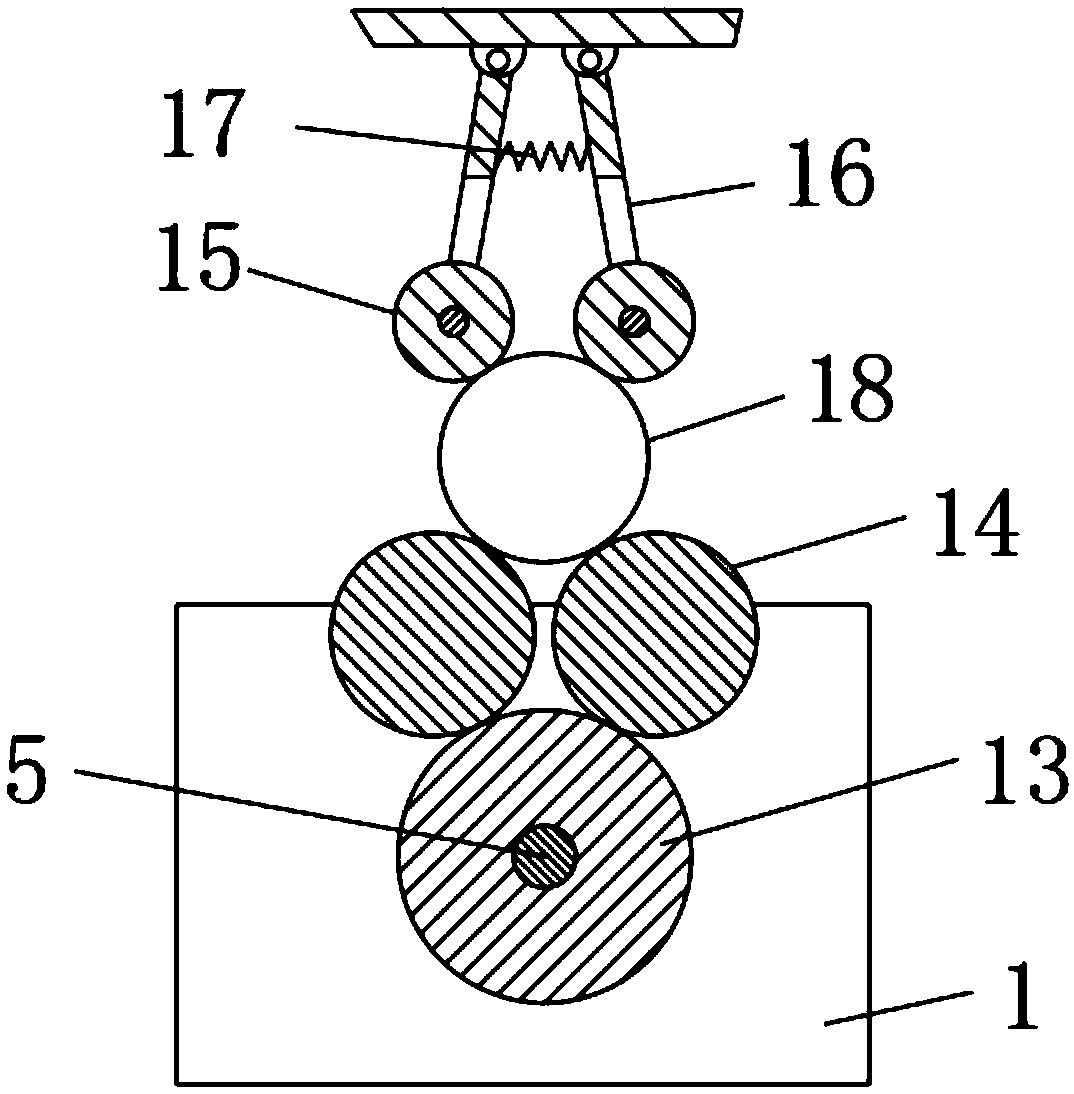

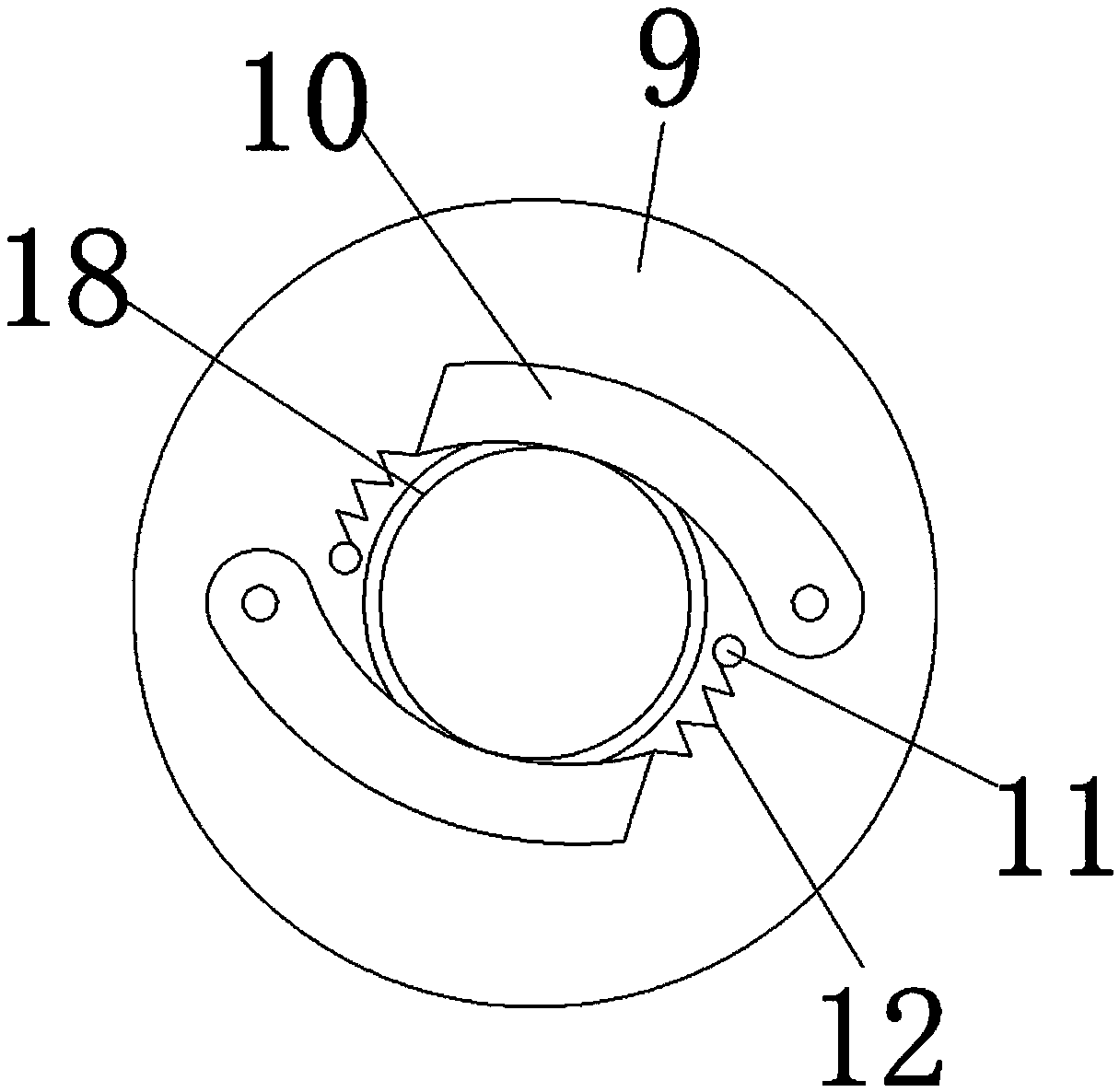

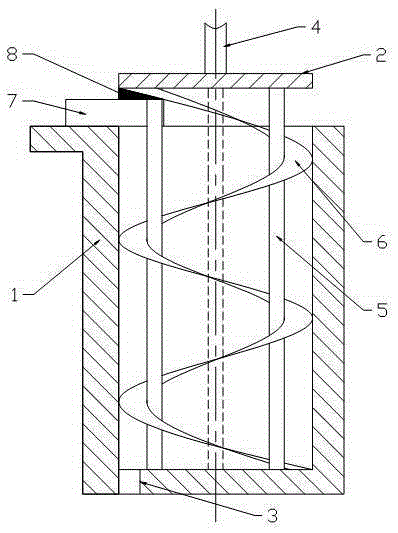

Rotating negative electrode scale scraping and removing device

InactiveCN105329985AImprove scrapingGood descaling effectSpecific water treatment objectivesWater/sewage treatment by electrochemical methodsPower flowPhysics

The invention relates to a rotating negative electrode scale scraping and removing device which comprises negative electrode conductive columns 1, negative electrode plates 2, a rotating shaft 6, positive electrode plates 7 and scrapers 8. The negative electrode conductive columns 1 are closely attached to the negative electrode plates 2. The negative electrode conductive columns 1, the negative electrode plates 2, the scrapers 8 and the positive electrode plates 7 are sequentially connected to the rotating shaft 6 in series. A central limiting and correcting block 3 is arranged between the scrapers 8 and the positive electrode plates 7. The negative electrode plates 2 rotate around the rotating shaft 6. A jackscrew 4 is arranged on one side of each negative electrode conductive column 1. Currents are guided into the negative electrode plates 2 by the negative electrode conductive columns 1. In the rotating process of the negative electrode plates 2, the scrapers 8 are closely attached to and scrap the surfaces of the negative electrode plates 2. The purpose of inputting currents to the rotating negative electrode plates without electric brushes is achieved, electrode intervals are easily decreased to the maximum degree, and the scale scraping and removing effects of the negative electrode plates are improved.

Owner:卫士循环水处理(北京)有限公司

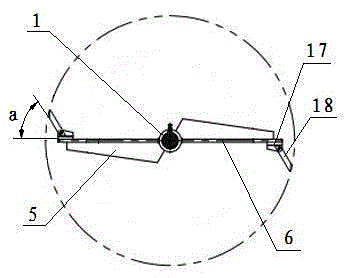

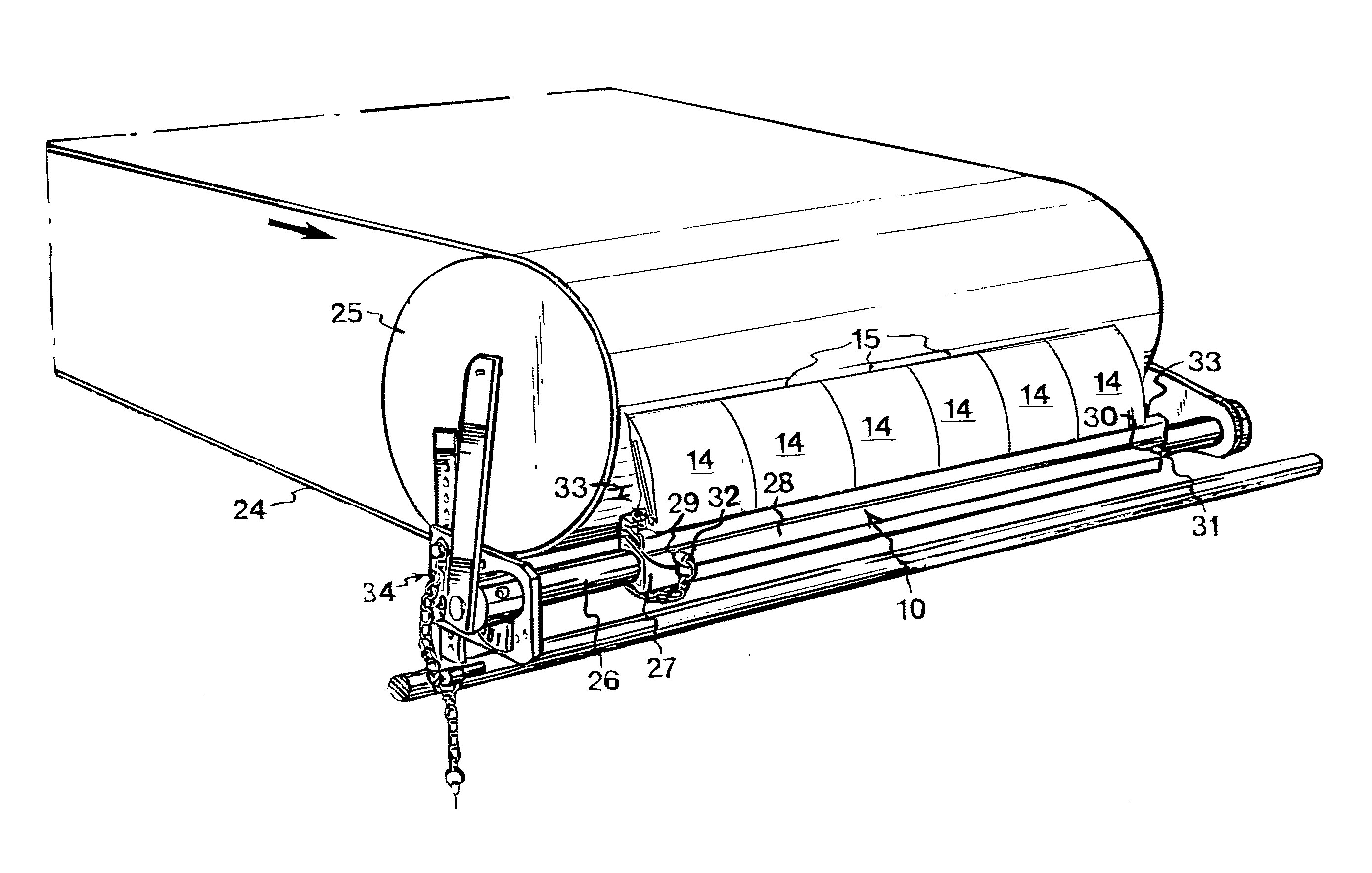

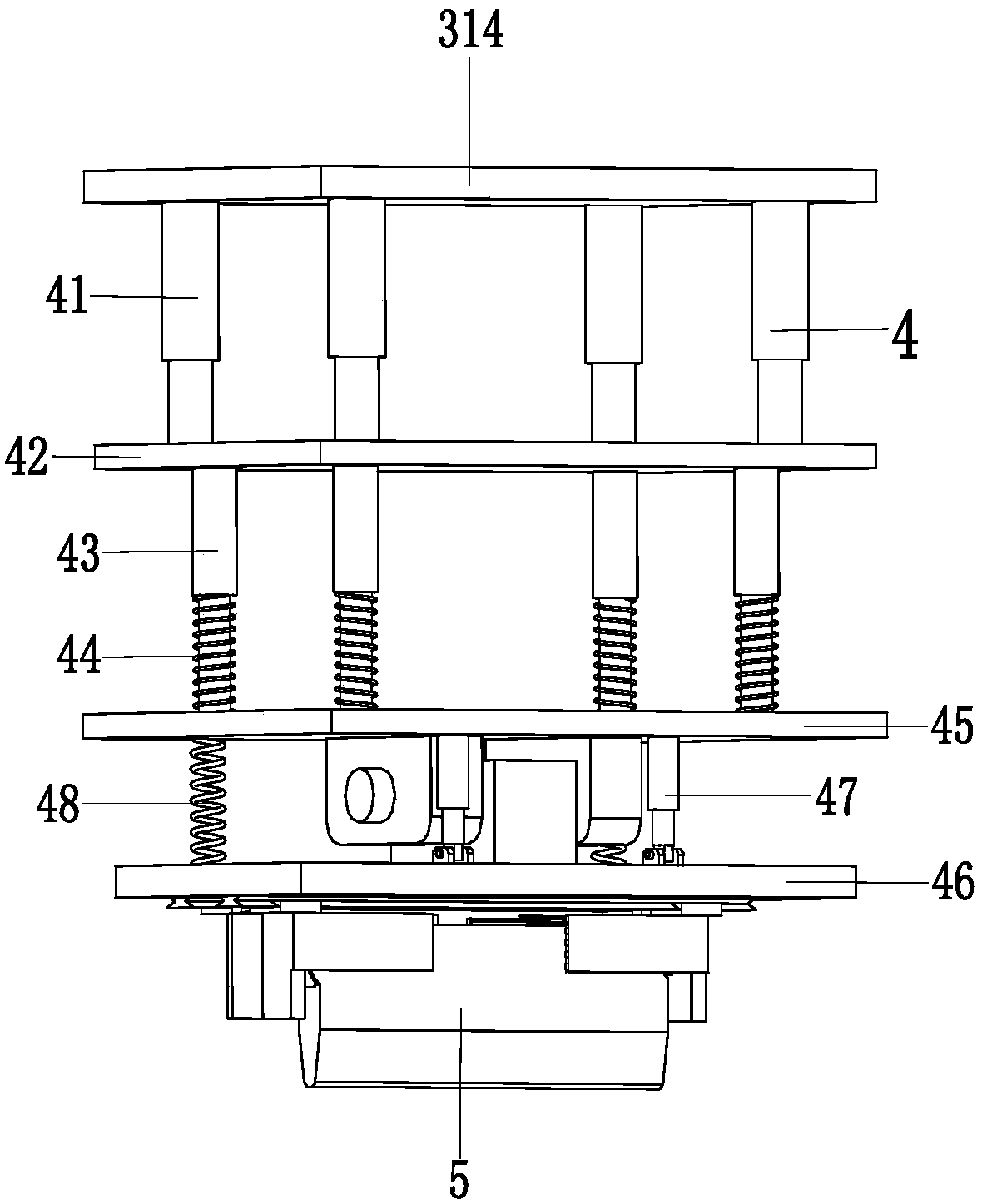

Pine bark treatment machine for acquiring rosin which mainly comprises natural resin and is raw material for preparing latex paint

The invention relates to a pine tree skin treatment machine for the collection of natural resin rosin, which is a raw material for latex paint preparation There are a rotating device and a lifting support device, the scraping device and the recovery device are installed on the rotating device, and the two slotting devices are symmetrically installed on the lifting support device. The invention can solve the problem that the existing manual scraping and grooving of pine trees have poor skin scraping effect and easily scratch the tree, the scraped pine bark cannot be recycled, two kinds of tools are required for scraping and straight grooving, and the inclined It is impossible to control the groove depth and other problems when grooving; it can automatically scrape the bark of pine trees, and automatically open straight grooves and oblique grooves for pine trees. Recycling, skin scraping and straight grooving require advantages such as a tool.

Owner:宋当建

Composite printing paste and application thereof

InactiveCN101768878ACompatibility is reasonableImprove performanceDyeing processAlkalinityPreservative

The invention relates to a composite printing paste and application thereof. The composite printing paste is prepared from the following raw materials in parts by weight: 60-90 parts of modified starch, 2-30 parts of plant gum powder and 0.1-0.6 part of water solube preservative. The composite printing paste has the following application: taking 3-10 parts of composite printing paste and 90-97 parts of water in parts by weight, and uniformly mixing, wherein the optimized parts in part of the raw materials are 4-6 parts of composite printing paste and 94-96 parts of water. The composite printing paste has the advantages that the compounding is reasonable, stable property, the acidity or alkalinity is especially suitable for printing, the paste has good compatibility with other chemicals, and the cost is low; the anti-corrosion property is high, the paste is difficult to nourish bacteria and deteriorate and is suitable for storing for a long term, and the raw paste and printing ink have long preservation time and no toxicity; the anionic paste has good rheological property and ensures good printing property.

Owner:金军

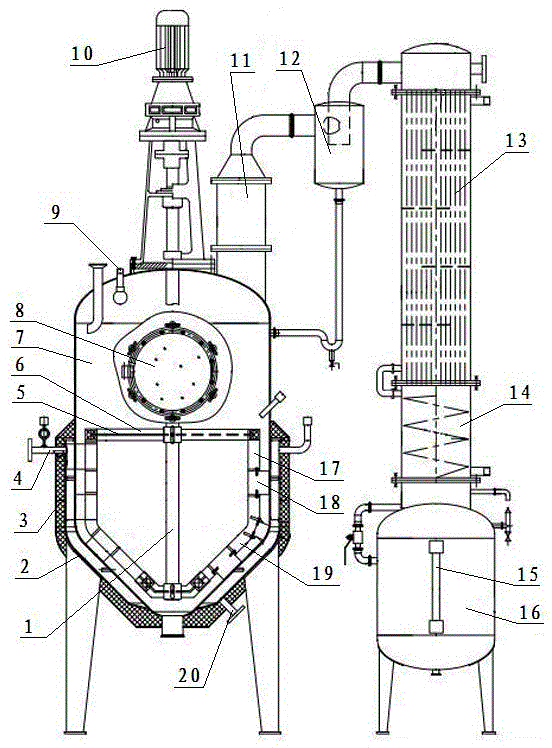

Vacuum concentrator

InactiveCN105126364AReduce heat transfer efficiencyPrevent scalingEvaporator accessoriesVapor–liquid separatorHeat transfer efficiency

The invention discloses a vacuum concentrator, which relates to the technical field of pharmaceutical equipment manufacturing. The vacuum concentrator comprises a concentrating tank, wherein a jacket is arranged outside the concentrating tank, a vapor-liquid separator, a condenser, a cooler and a liquid collecting device are connected to a vapor outlet of the concentrating tank in sequence, a mixing device which is connected with a motor is installed in the concentrating tank, the mixing device comprises a rotating shaft and at least two mixing paddles which are installed on the rotating shaft, a rotating frame is installed on the rotating shaft, the rotating frame is composed of a V-shaped rod and vertical rods which are connected to both ends of the V-shaped rod, a cross rod is connected between the two vertical rods, and a plurality of scrapers of which the outer sides are abutted with the inner wall of the concentrating tank are installed on the V-shaped rod and the vertical rods. Compared with the prior art, the scrapers of the vacuum concentrator rotate along with the rotating shaft, so as to scrape extract bonded to the inner wall of the concentrating tank, prevent the wall surface from being scaled and prevent the heat transfer efficiency of the concentrating tank from being reduced.

Owner:GUANGXI XINLONG PHARMA

Corn threshing device

The invention discloses a corn threshing device. The corn threshing device comprises a chassis. Two sliding rods perpendicular to the chassis are vertically fixed on the central line of the chassis. A handle is sleeved on each sliding rod and can move on each sliding rod up and down. A cylindrical knife tackle is fixed between the two handles and comprises two rectangular knife blades. The two knife blades form the cylindrical knife tackle, all core kernels can be scraped at one time after the cylindrical knife tackle is sleeved on a corn cob, and working efficiency is greatly improved; the scraped corn kernels can be collected due to the arrangement of the chassis; a locating ring is arranged at the center of the chassis, the corn cob can be vertically arranged in the locating ring without being additionally held by hands, and the corn threshing device is convenient to use and hygienic; by the adoption of the structure, the probability that arms of operators are hurt accidentally is reduced to the maximum; the cylindrical knife tackle is formed by the two thin stainless steel knife blades, so that the corn threshing device is safe, hygienic and low in cost.

Owner:长兴大洋生物饲料有限公司

Stainless steel auger of ice cream machine

The invention provides a stainless steel auger of an ice cream machine, which comprises a stainless steel mixing barrel, wherein an auger shaft and an auger blade are installed in the stainless steel barrel; the auger shaft comprises a positioning shaft and an auger fixing shaft; a bottom plate is connected between the positioning shaft and one end of the auger fixing shaft; a material pushing impeller is connected at the other end of the auger fixing shaft; the auger blade is a spiral blade made of stainless steel; a fixing shaft of the material pushing impeller is installed at a side of an edge between the bottom plate and the material pushing impeller; a plastic scrapper which can swing freely is arranged at the outer part of the fixing shaft of the material pushing impeller; and the plastic scrapper is matched with the inner wall of the stainless steel mixing barrel. In operation, the positioning shaft is driven to rotate through a driving force, and drives the bottom plate, and the fixing shaft of the stainless steel auger connected on the bottom plate; the spiral blade made of stainless steel is installed on the fixing shaft of the auger; particularly the plastic scrapper which can swing freely is arranged at the outer part of the fixing shaft of the material pushing impeller, therefore, the plastic scrapper always adheres to the inner wall of the mixing barrel, and materials on the inner wall of the mixing barrel can be scraped cleanly in time.

Owner:王日君

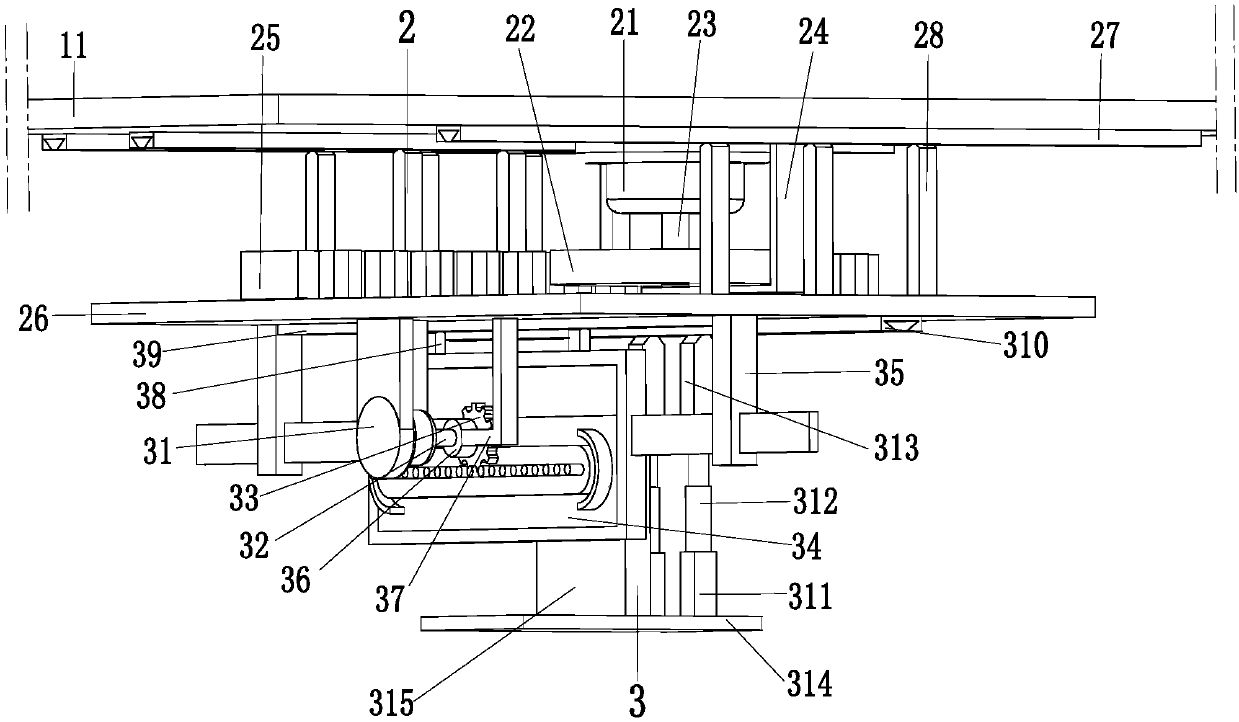

Concrete floor leveling device for municipal construction

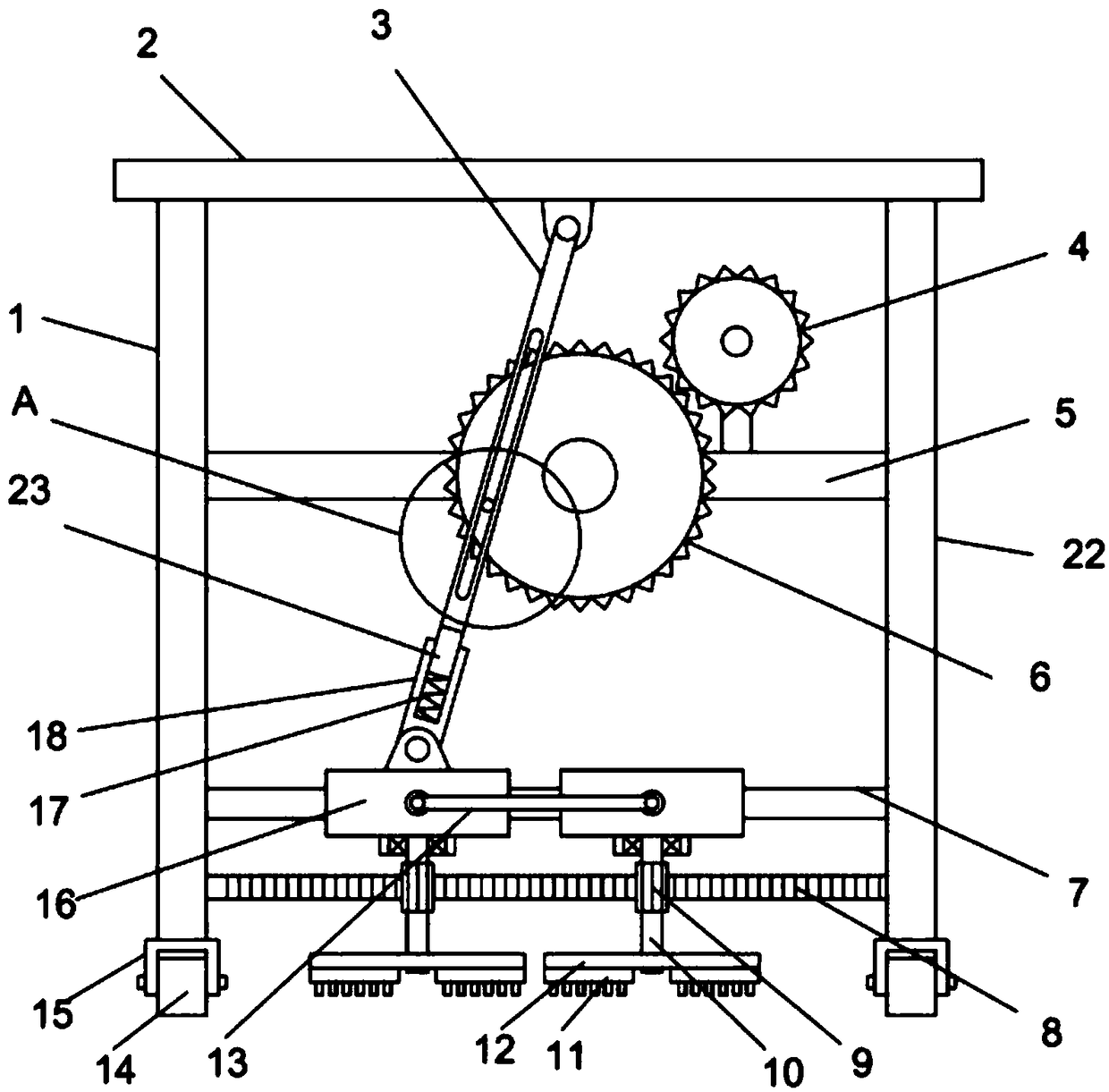

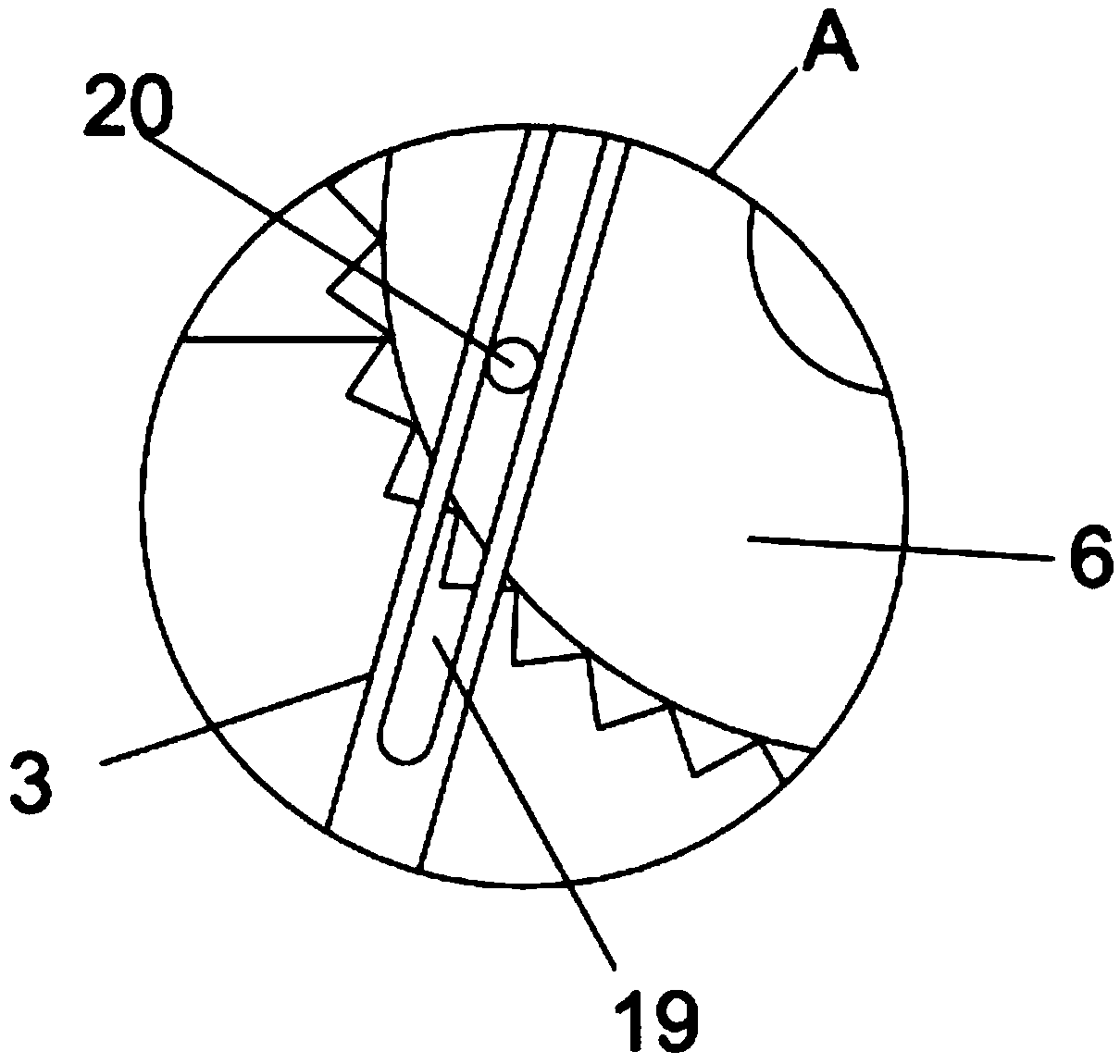

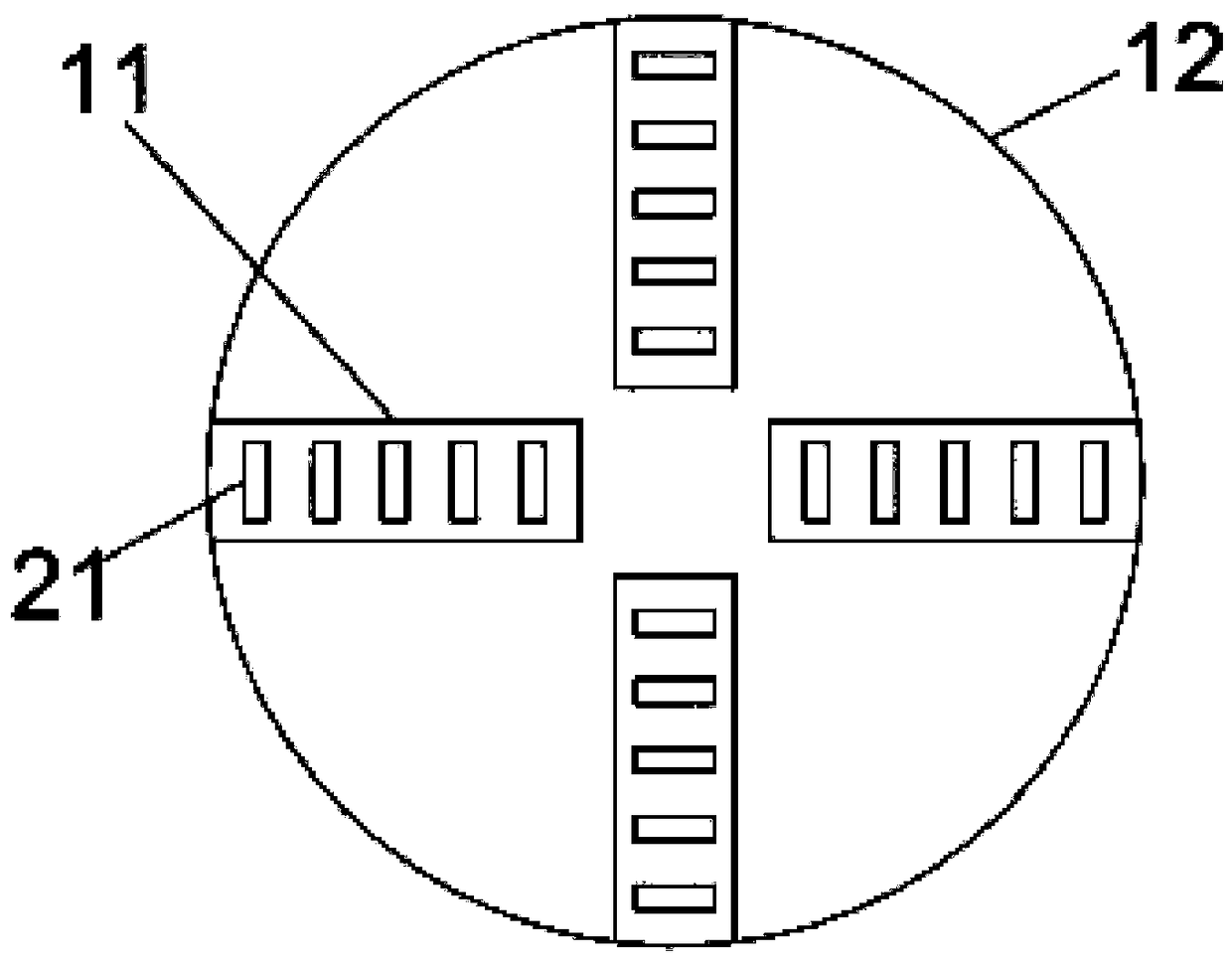

ActiveCN108625260ARealize left and right reciprocating motionImplement rotary scrapingRoads maintainenceGear driveGear wheel

The invention discloses a concrete floor leveling device for municipal construction. A top plate is horizontally fixedly mounted at the tops of a left stand plate and a right stand plate; a horizontalsupporting plate is horizontally fixedly mounted between the left stand plate and the right stand plate; a transmission hinge pin penetrates through a swinging plate and is connected with a strip-shaped hole in sliding and matched modes; a straight rack is horizontally fixedly mounted between the left stand plate and the right stand plate; and the bottoms of sliding casing pipes are connected with vertically arranged rotating shafts by bearings in a pivot mode. A driven gear rotates and drives the transmission hinge pin to drive the swing plate to swing clockwise, and therefore the sliding casing pipes can reciprocate in a left-and-right mode, and rotating discs can drive scraper plates to level uneven places of the concrete floor; when the rotating shafts horizontally move, a cylindricalstraight gears drive the straight rack in a meshing mode, and therefore the cylindrical straight gears can drive the rotating discs to rotate by the rotating shafts, further, the scraper plates can scrap the floor in a rotary mode; and the scraping effect is excellent, the leveling range is wide and working efficiency is effectively improved.

Owner:JIANGXI LONGZHENG SCI & TECH DEV

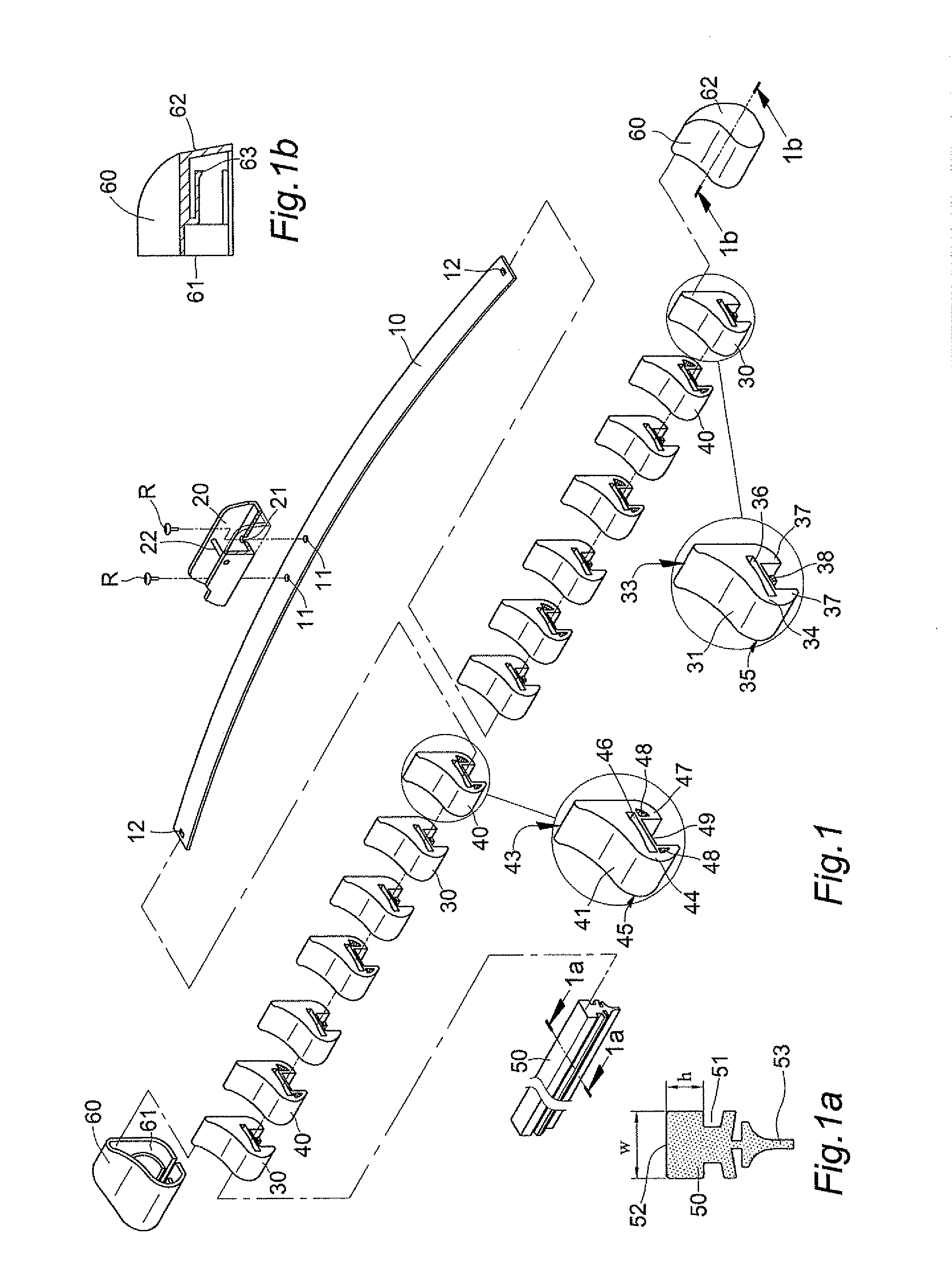

Scraper Blade and Method of Manufacturing the Same

InactiveUS20090218196A1Long useful lifeImprove scraping effectCleaningPolycarbonate plasticEngineering

A scraper blade adapted to scrape off material from a surface has a scraper tip at one end and a mounting base at its other end and is tapered towards the tip at least in the outer end of the scraper blade, its scraper blade portion which extends from the tip and to a point adjacent to or in the mounting base being made with at least two layers, which extend longitudinally along said scraper blade portion, and is characterised in that at least one first layer is made of polyurethane with a lower hardness and a higher abrasion resistance than at least one second layer which is mainly made of polycarbonate plastic, said at least one second polycarbonate plastic layer being adapted to reinforce and stiffen said at least one first layer, which constitutes a main contact surface against said surface.

Owner:METABO MINERALS SWEDEN

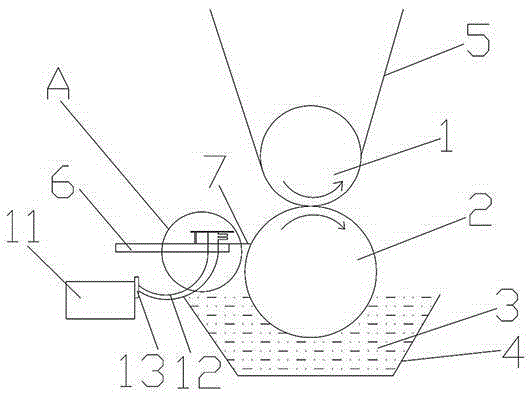

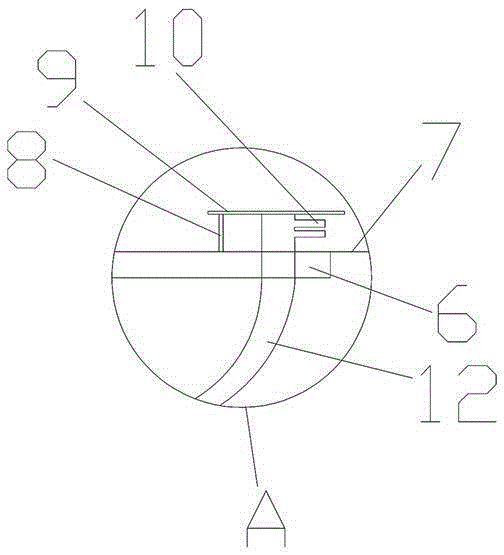

Spiral casing scraper

InactiveCN102330544AReasonable structureEasy to useCleaning apparatusStructural engineeringMechanical engineering

The invention relates to the technical field of casing scrapers, and discloses to a spiral casing scraper. The spiral casing scraper comprises an upper joint, a scraper body, a scraping pipe and a lower joint, wherein the middle part of the inner side of the upper joint is fixedly connected with the upper end of the outer side of the scraper body; the middle part of the inner side of the lower joint is fixedly connected with the lower end of the outer side of the scraper body; and the scraping pipe which can be constricted radially is sleeved on the scraper body between the upper joint and the lower joint, and a scraping gear is arranged on the scraping pipe. The spiral casing scraper disclosed by the invention is reasonable and compact in structure, and easy to use; through the axial elongation of an elastic scraping sheet, the outer diameter of the middle part of the elastic scraping sheet is reduced, therefore, the spiral casing scraper is suitable to be used for scraping casings with different inside diameters, so that the spiral casing scraper is strong in commonality; meanwhile, an annular and downward scraping gear is arranged on the outer side of the middle part of the elastic scraping sheet, therefore, the spiral casing scraper can carry out annular scraping on the inner walls of casings, so that the scraping effect is better.

Owner:CNPC XIBU DRILLING ENG

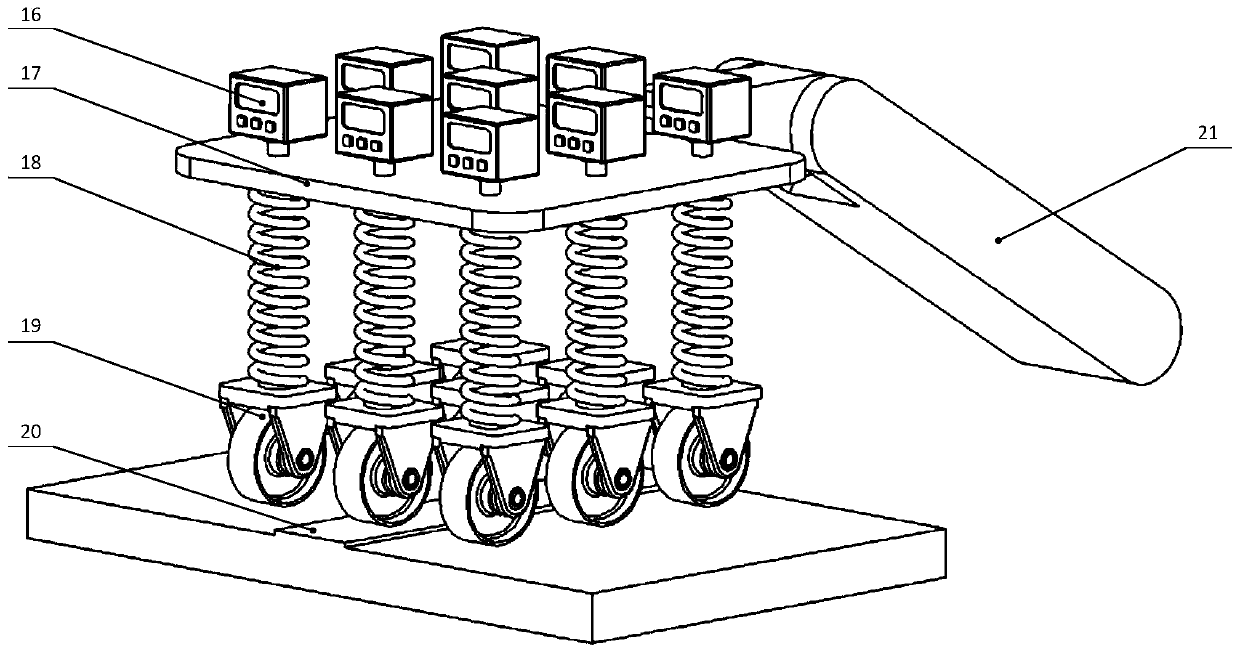

Mixer with screening function

InactiveCN106563374AWell mixedAvoid mixingSievingTransportation and packagingPulp and paper industryFood processing

Relating to food processing machinery, the invention discloses a mixer with screening function. The mixer includes a stirring tank and a stirring shaft installed in the stirring tank. The outer surface of the stirring tank is coated with an installation layer, and the installation layer is internally equipped with a heating device. The lower end of the stirring tank is inverted cone shaped, and the bottom of the stirring tank is provided with a material outlet. The stirring shaft is equipped with a flake stirring blade, and the flake stirring blade is fixed on the stirring shaft spirally. The stirring shaft is also provided with a connecting rod, and the connecting rod is provided with a scraping plate. The lower end of the stirring shaft abuts against a discharge port, and the lower end is provided with a material guide chute. A screening box is disposed below the stirring tank, and the discharge port is communicated with the screening box. A vibrating motor and elastic stand columns are mounted on the bottom surface of the screening box. The mixer provided by the invention can complete chicken essence stirring, drying and screening by one time, is more convenient to use, and is also convenient for scraping off the chicken essence adhered to the stirring tank inner wall.

Owner:成都市红鑫科技有限公司

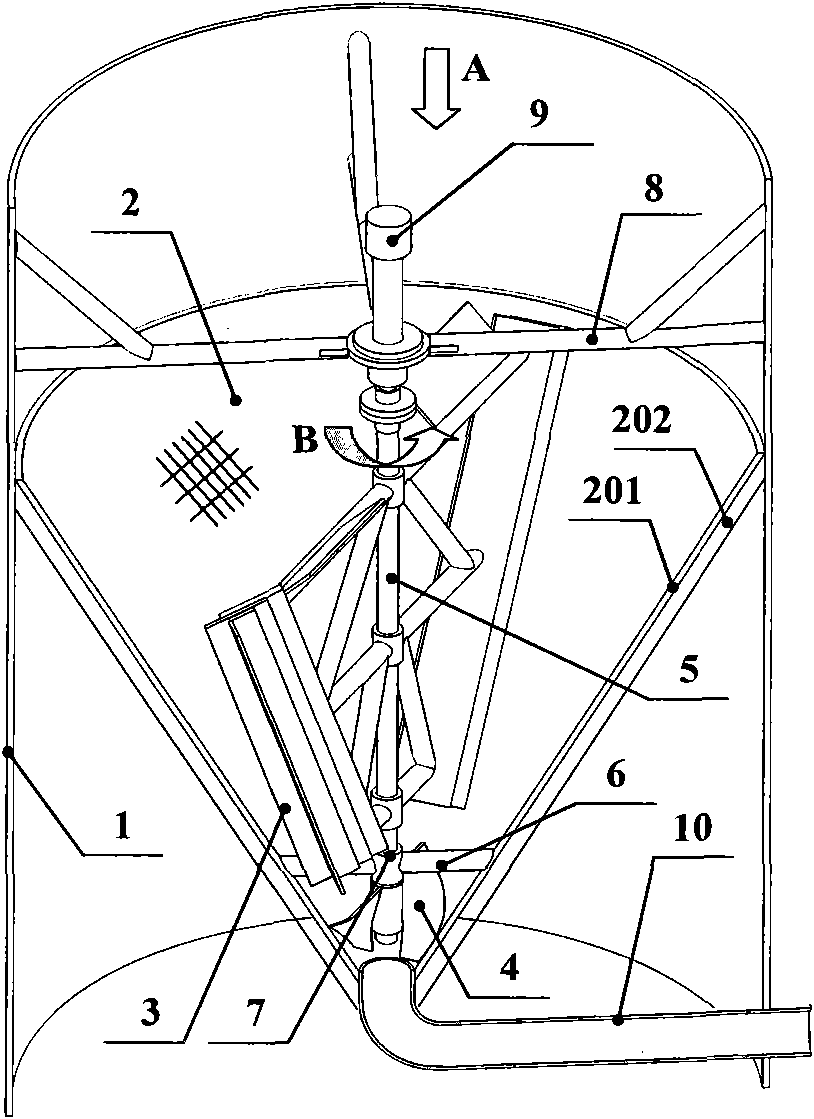

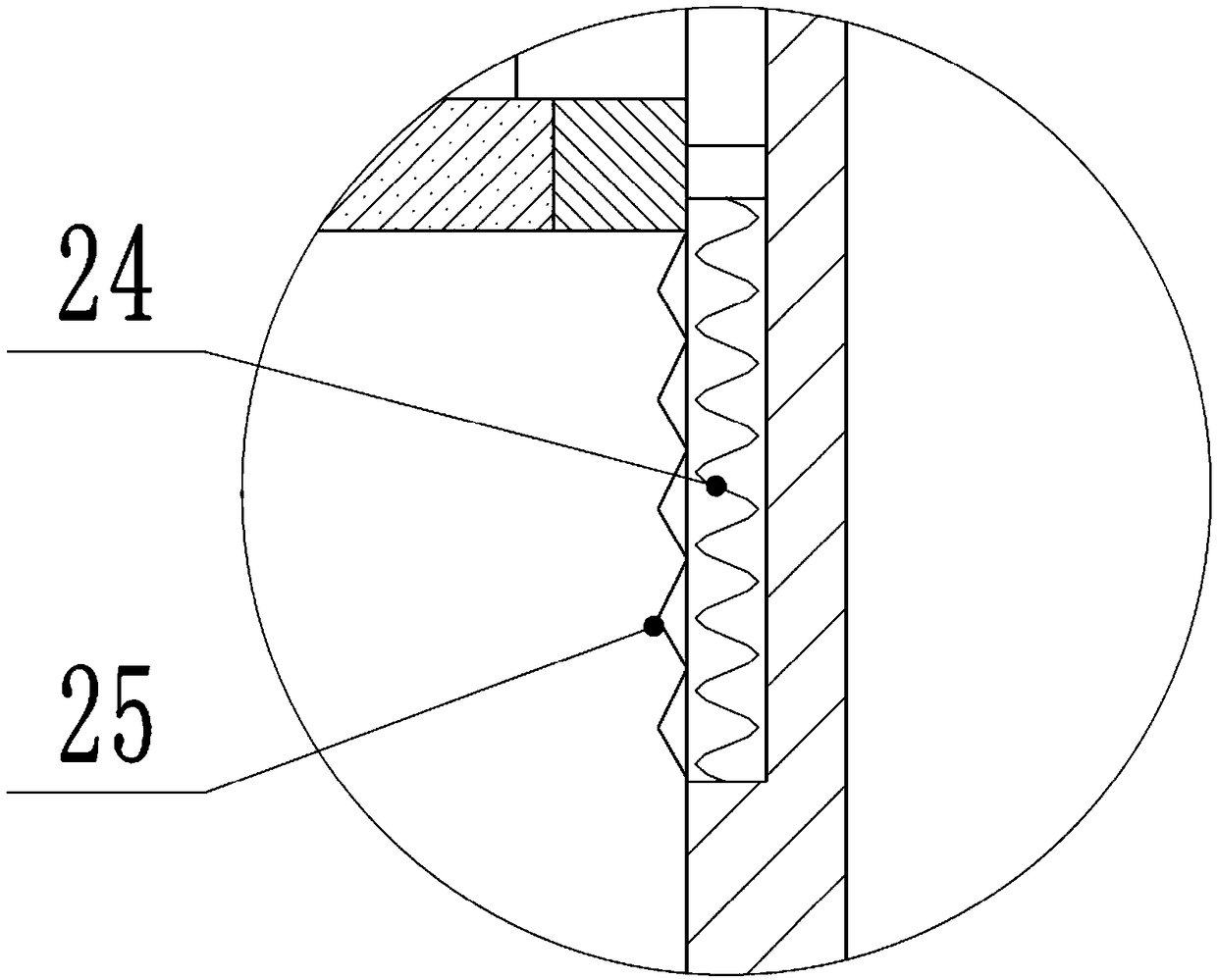

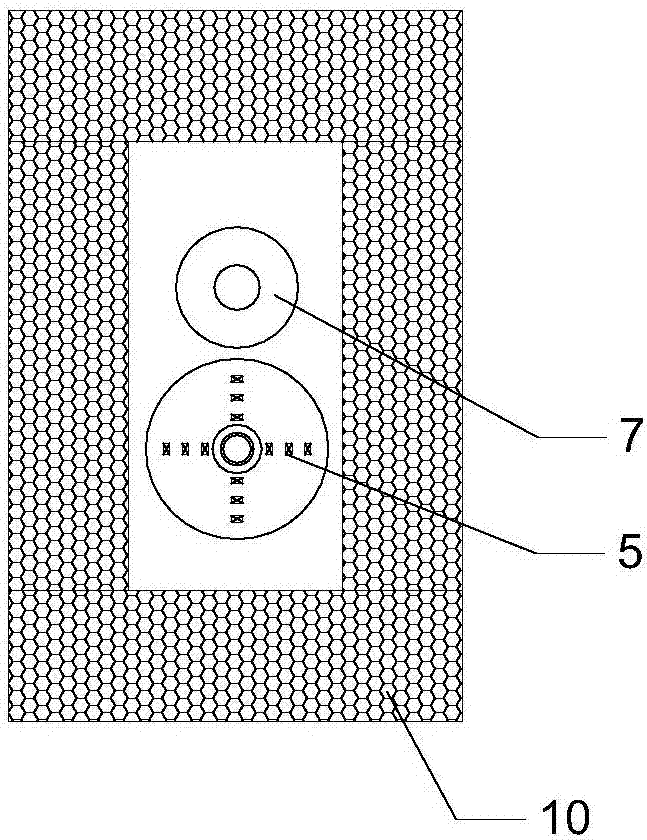

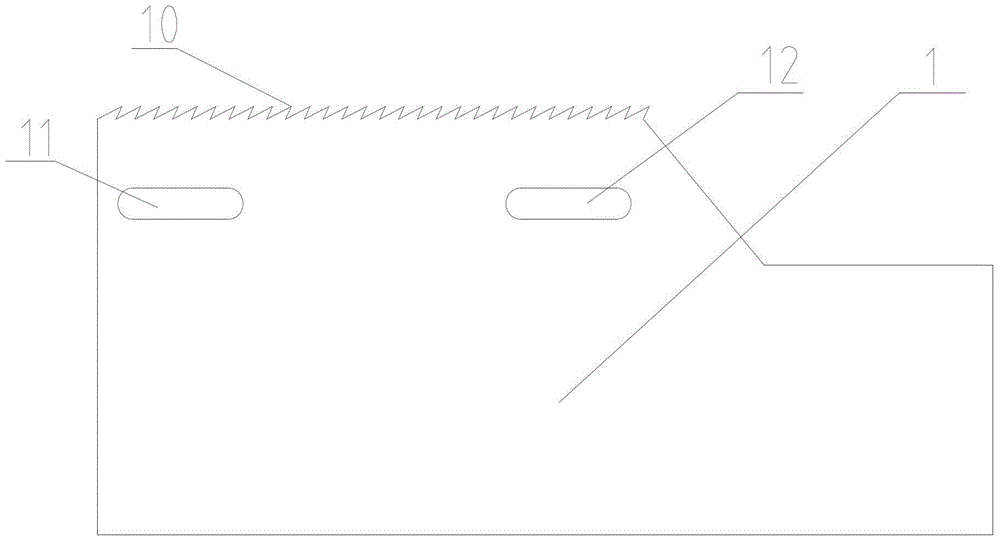

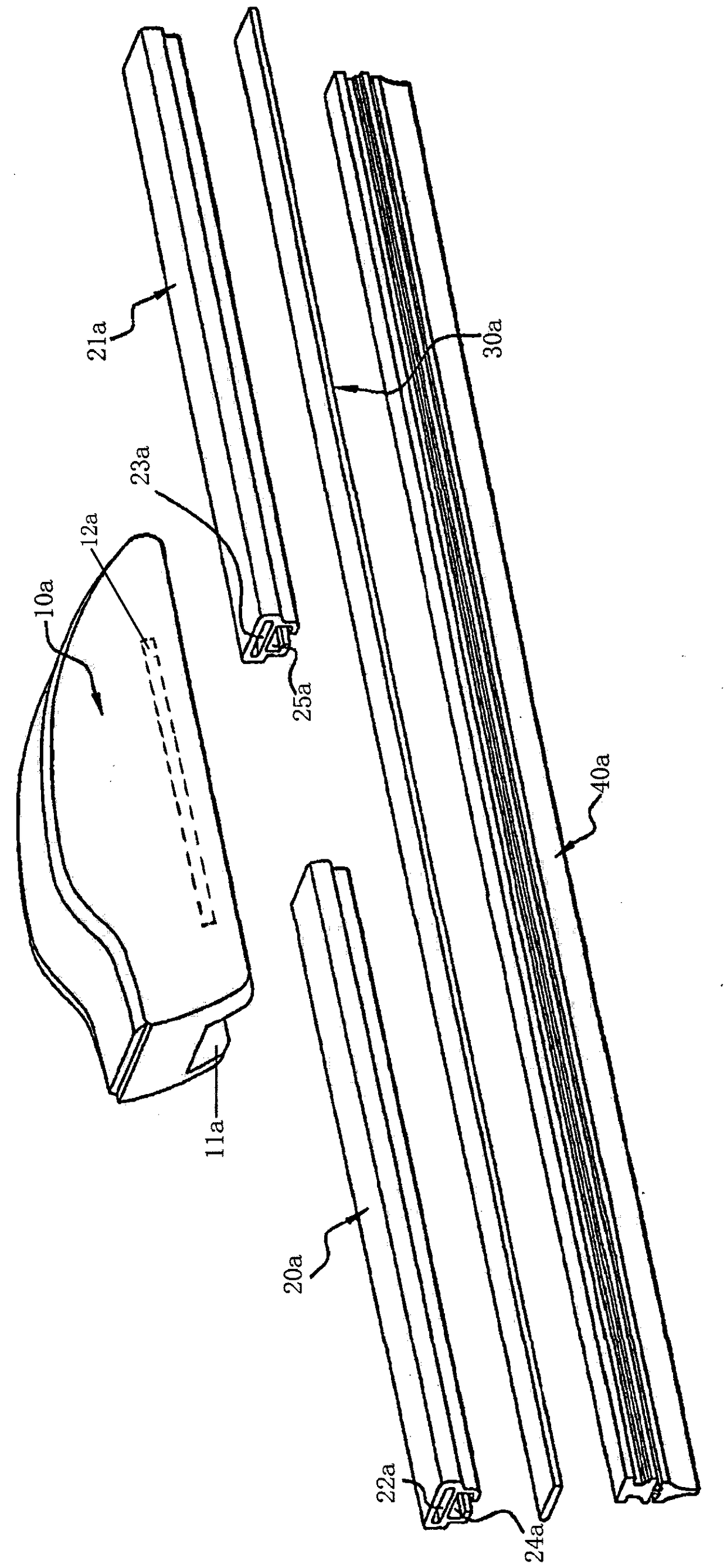

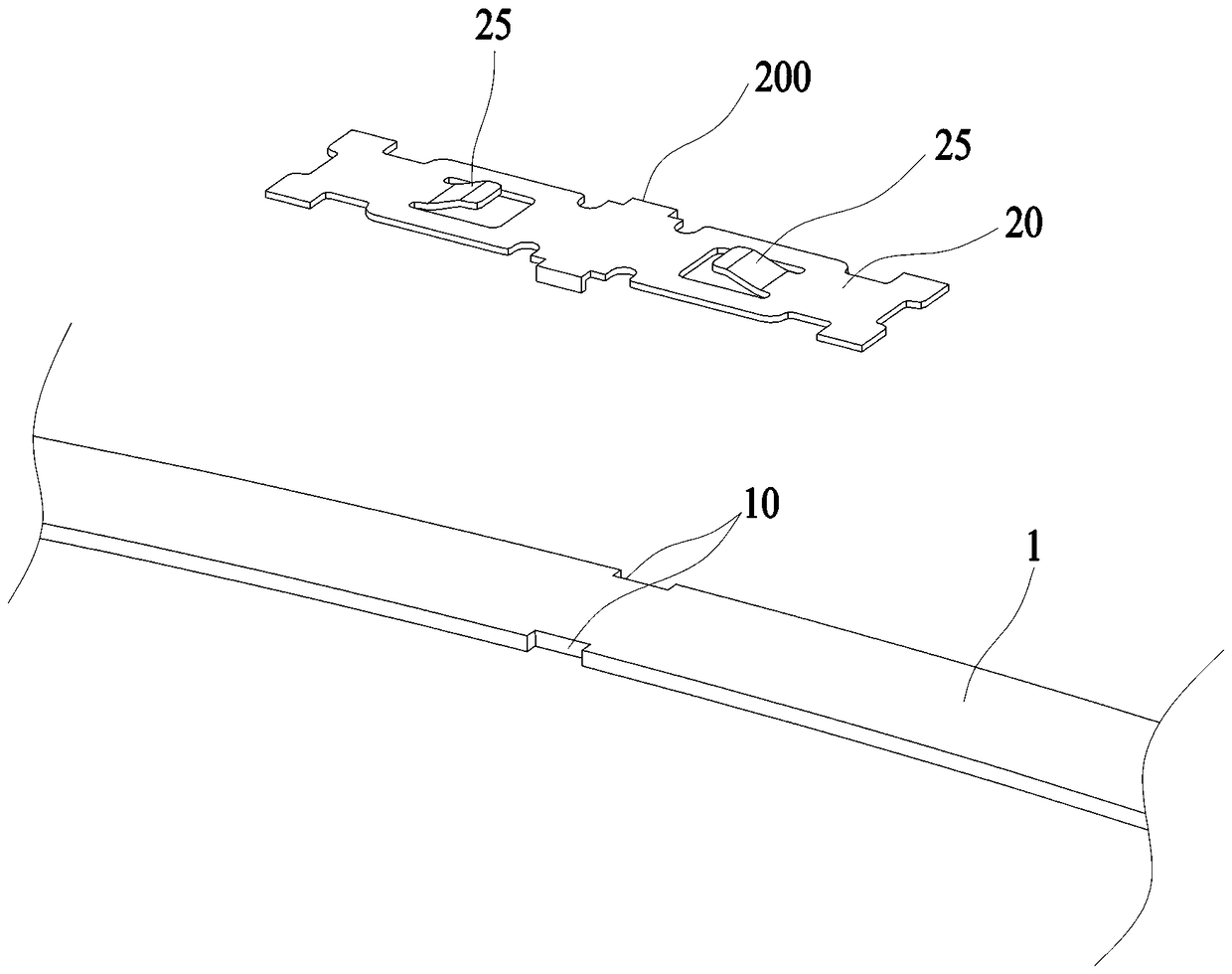

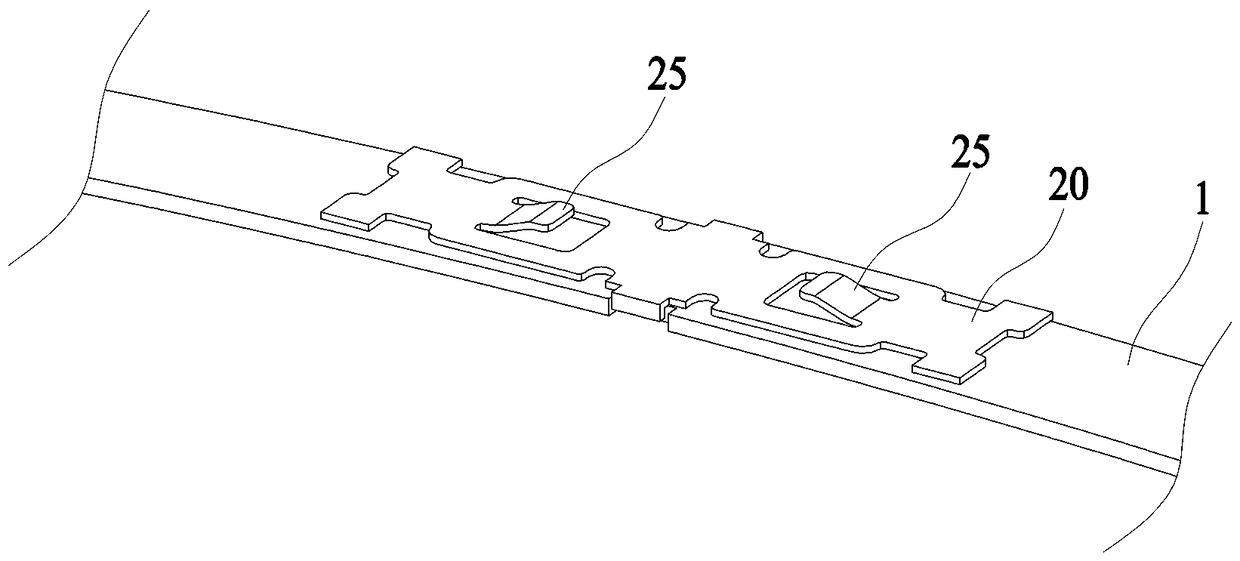

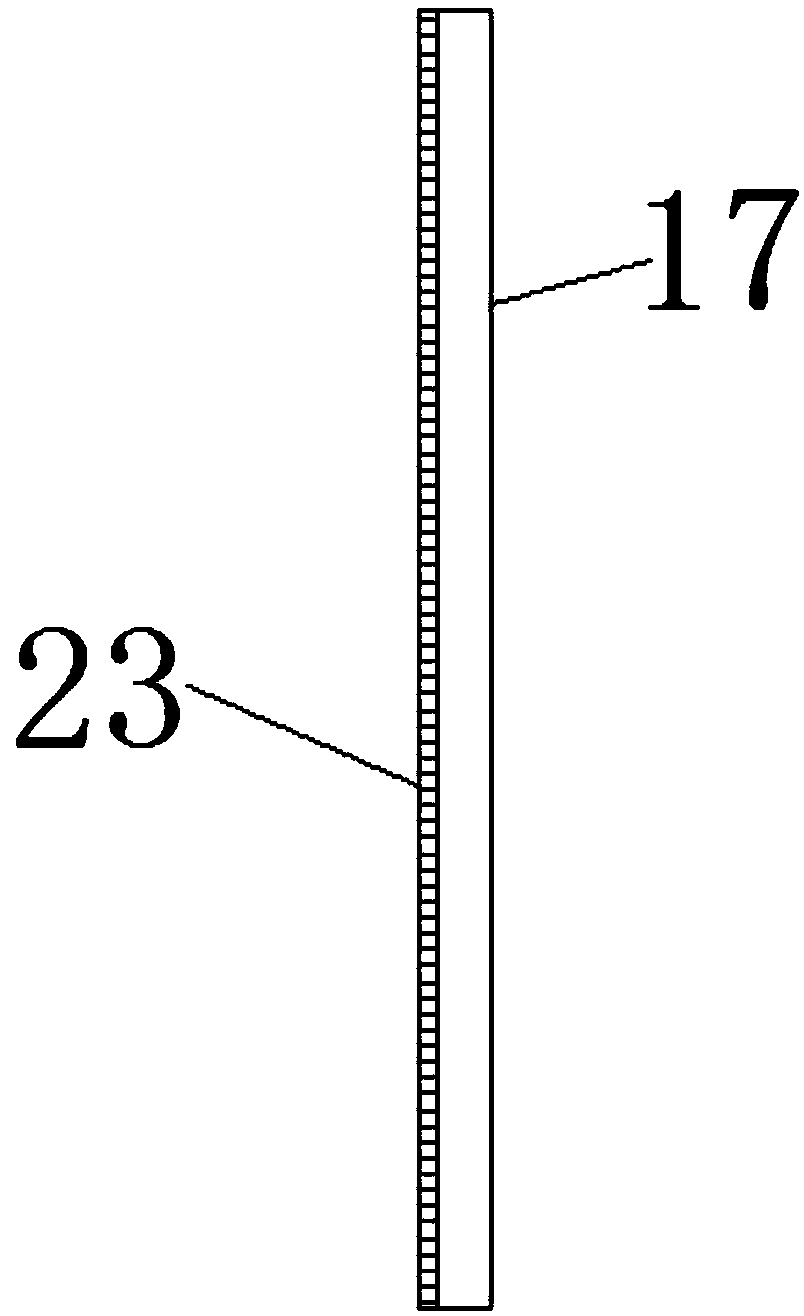

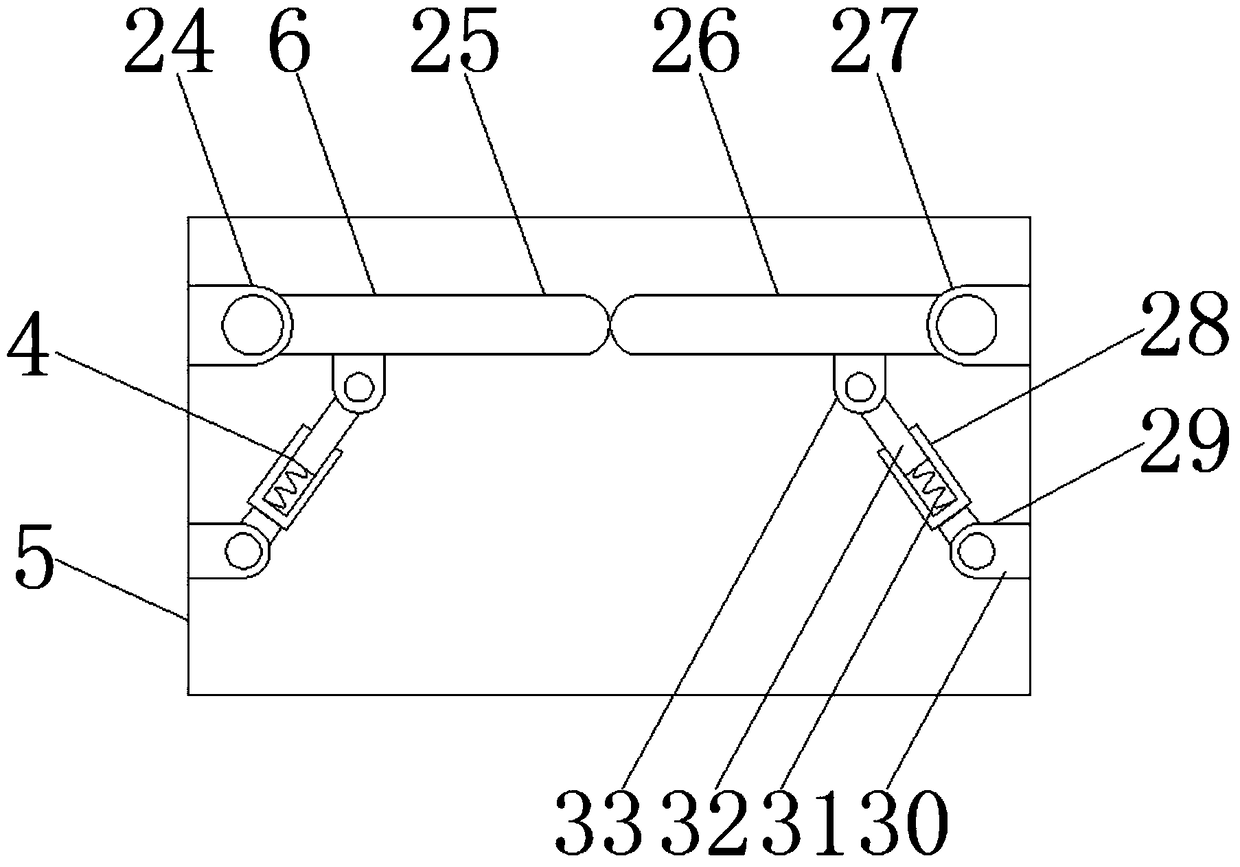

Novel wiper elastic support part, wiper joint base and wiper

ActiveCN108583517ARealize limit fitImprove scraping effectVehicle cleaningEngineeringMechanical engineering

The invention discloses a novel wiper elastic support part (1). The wiper elastic supporting part (1) is a piece-shaped body, positioning shrapnel (20, 21, 22, 23, 24) is additionally arranged on theupper surface of the wiper elastic supporting part (1), the positioning shrapnel (20, 21, 22, 23, 24) is in the shape of a thin sheet, and at least one limiting block (25, 26, 27) extending upwards isarranged on the upper surface of the positioning shrapnel (20, 21, 22, 23, 24). By adopting the wiper elastic supporting part (1), a load-bearing clamping piece (2) which is provided with the wiper elastic supporting part (1) in a penetrating mode is conveniently arranged in a wiper joint base (3) matched with the load-bearing clamping piece (2) in a penetrating mode, the limiting blocks (25, 26,27) on the positioning shrapnel (20, 21, 22, 23, 24) are used for being positioned and matched mutually with positioning parts (32,33) of the wiper joint base (3), at the point, the load-bearing clamping piece (2) does not need to be treated in sections, it is ensured that a scraping strip (5) can be fully arranged in the load-bearing clamping piece (2) a penetrating mode, and the scraping effectof a wiper is improved.

Owner:XIAMEN FUKE CAR ACCESSORIES

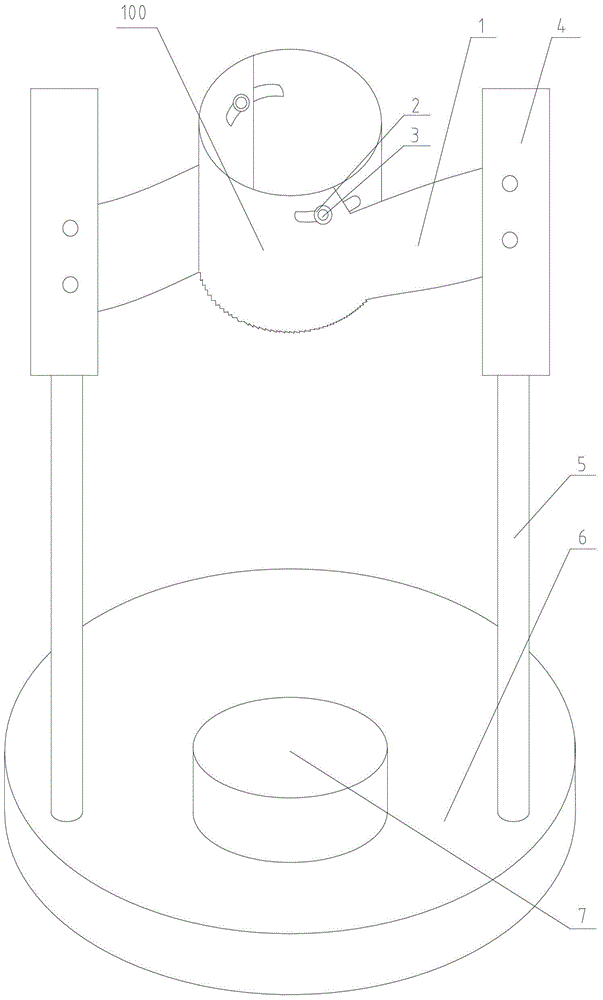

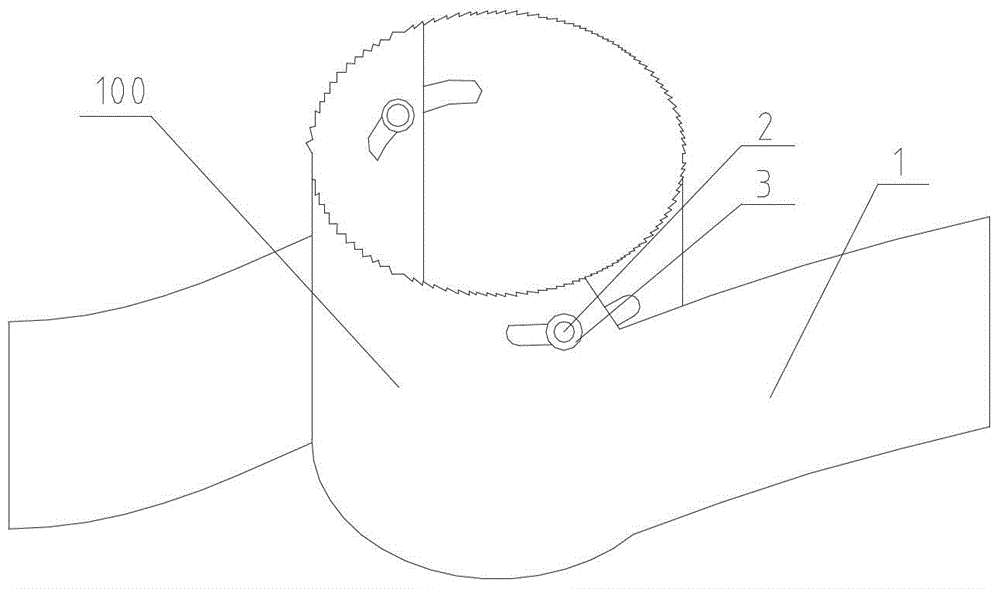

Bamboo tube green-skin-scraping device and green-skin-scraping method thereof

The invention provides a bamboo tube green-skin-scraping device and a green-skin-scraping method thereof. The bamboo tube green-skin-scraping device comprises a rack, a first green-skin-scraping assembly, a second green-skin-scraping assembly and a motor, wherein a pushing plate driven by a screw rod is arranged in the rack; the first green-skin-scraping assembly is arranged on the left side of the pushing plate and comprises a third gear; the third gear is fixed on the screw rod and driven by a second gear; blades used for scraping green skin on the surface of a bamboo tube is arranged on oneend surface of the third gear; the second green-skin-scraping assembly is mounted on the left side of the first green-skin-scraping assembly, and comprises second friction wheels and a compressing assembly; the second friction wheels are fixed on the screw rod and driven by a first friction wheel; the compression assembly is used for compressing the bamboo tube on the second friction wheels in the green-skin-scraping process all the time; the motor is fixed on a base of the rack; and through a first gear, the second gear is driven by the motor to rotate. The bamboo tube green-skin-scraping device provided by the invention integrates the bamboo tube feeding function and the function of scraping the green skin on the surface of the bamboo tube; the scraping of the green skin on the surfaceof the bamboo tube is automated; the operation is simple; the labor quantity is greatly reduced; the green skin on the excircle surface of the bamboo tune is scraped through the blades and the friction wheels; the green-skin-scraping speed is improved; and the green-skin-scraping effect is improved.

Owner:瑞安市维品商贸有限公司

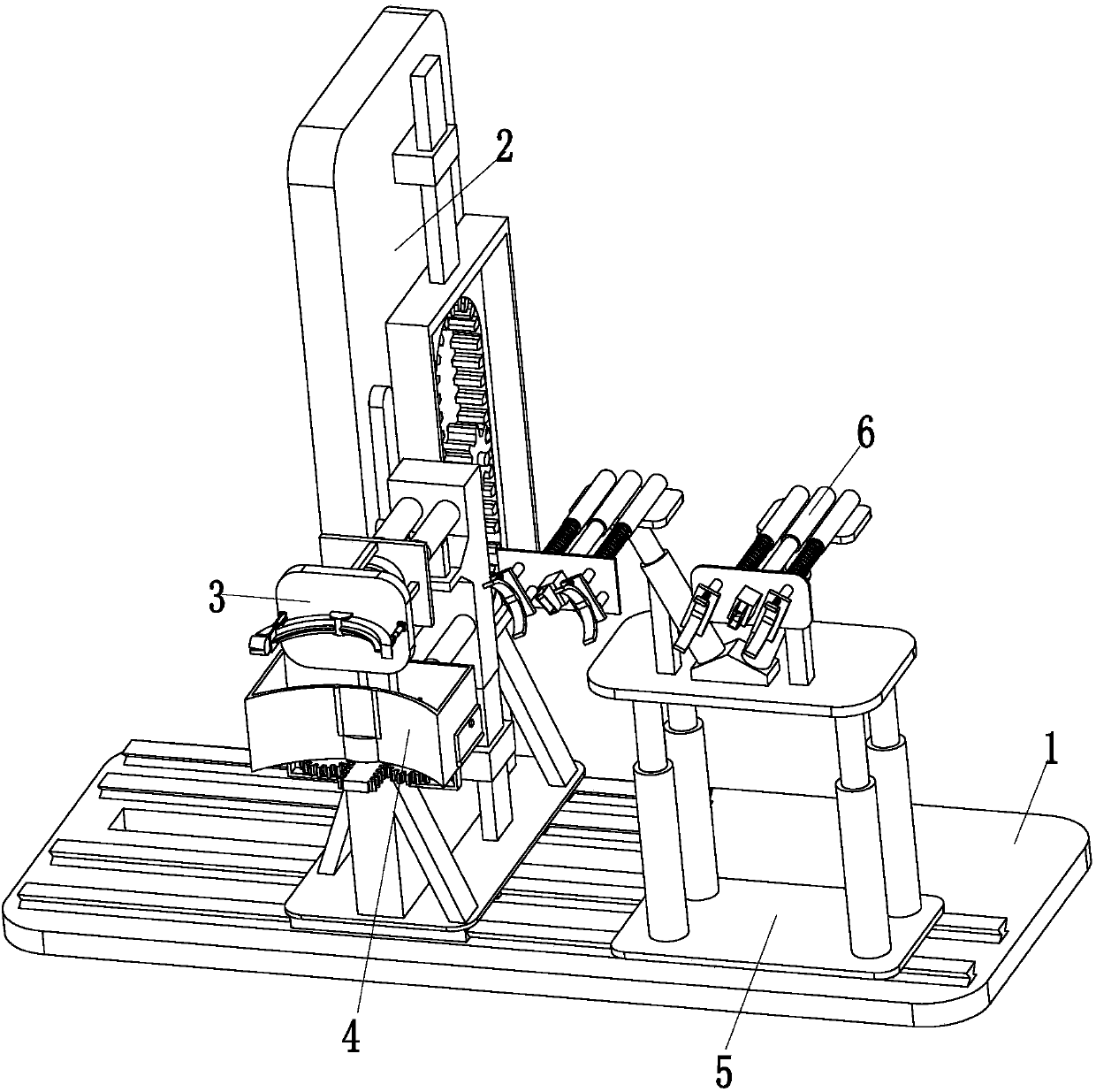

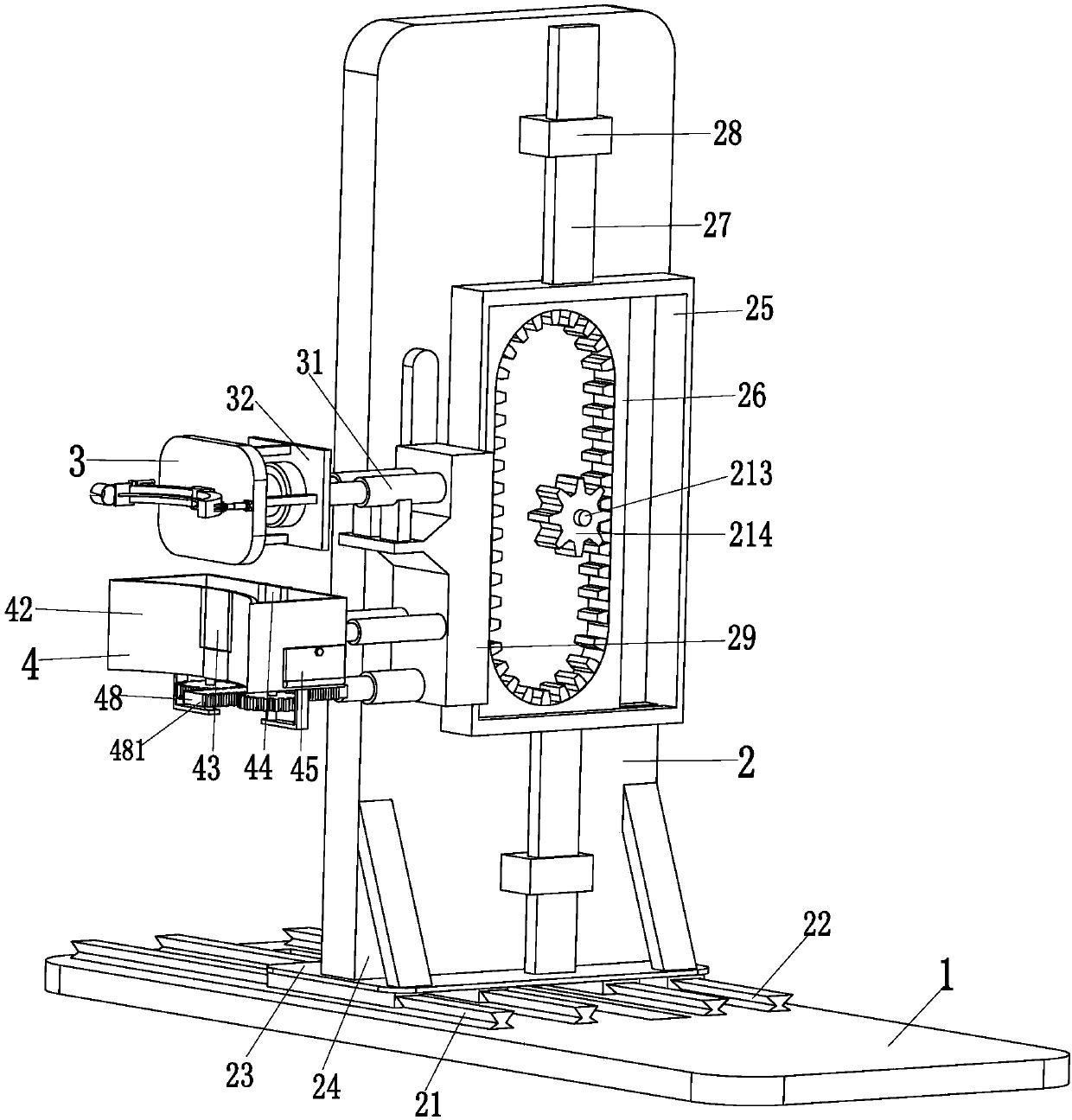

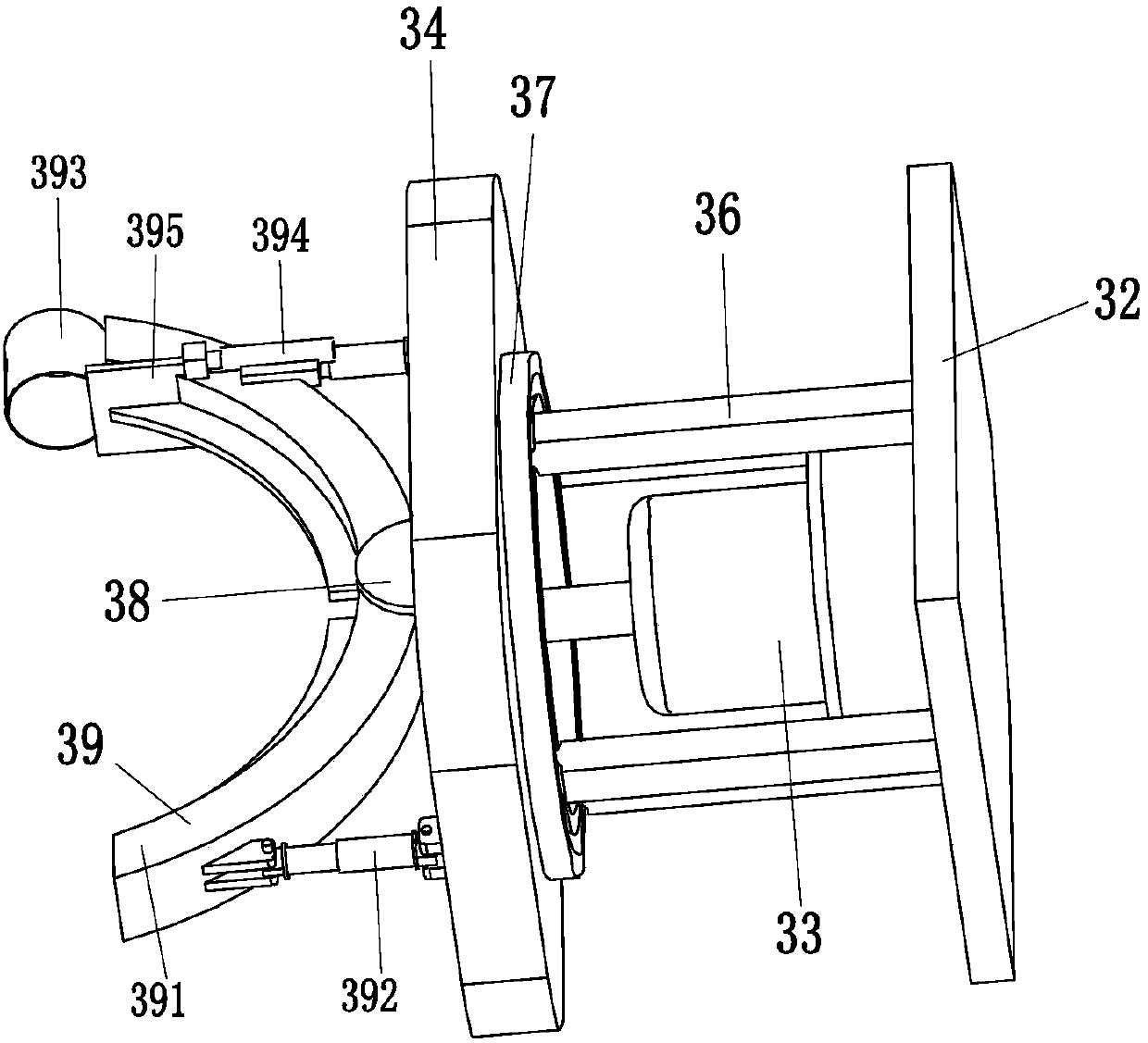

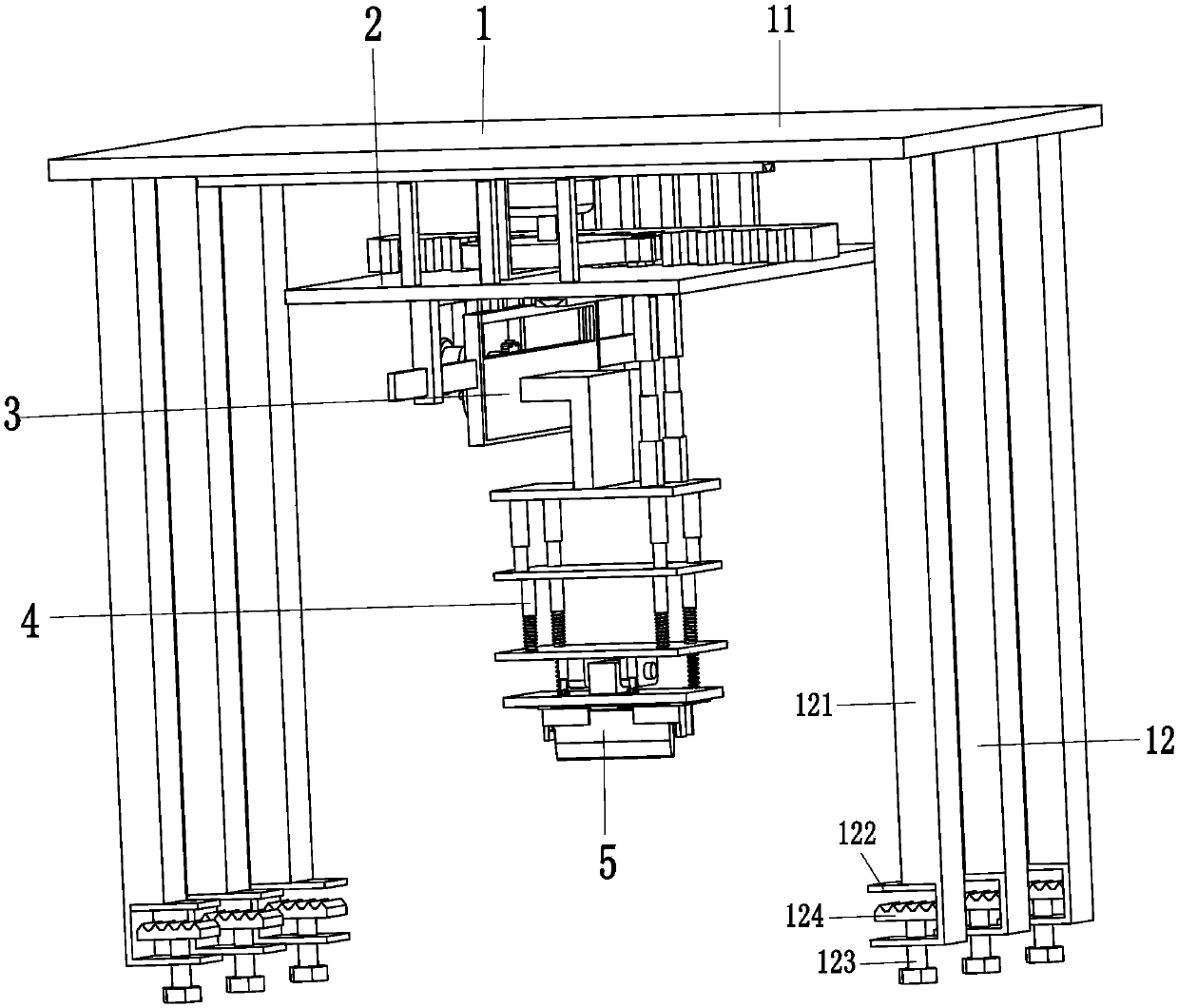

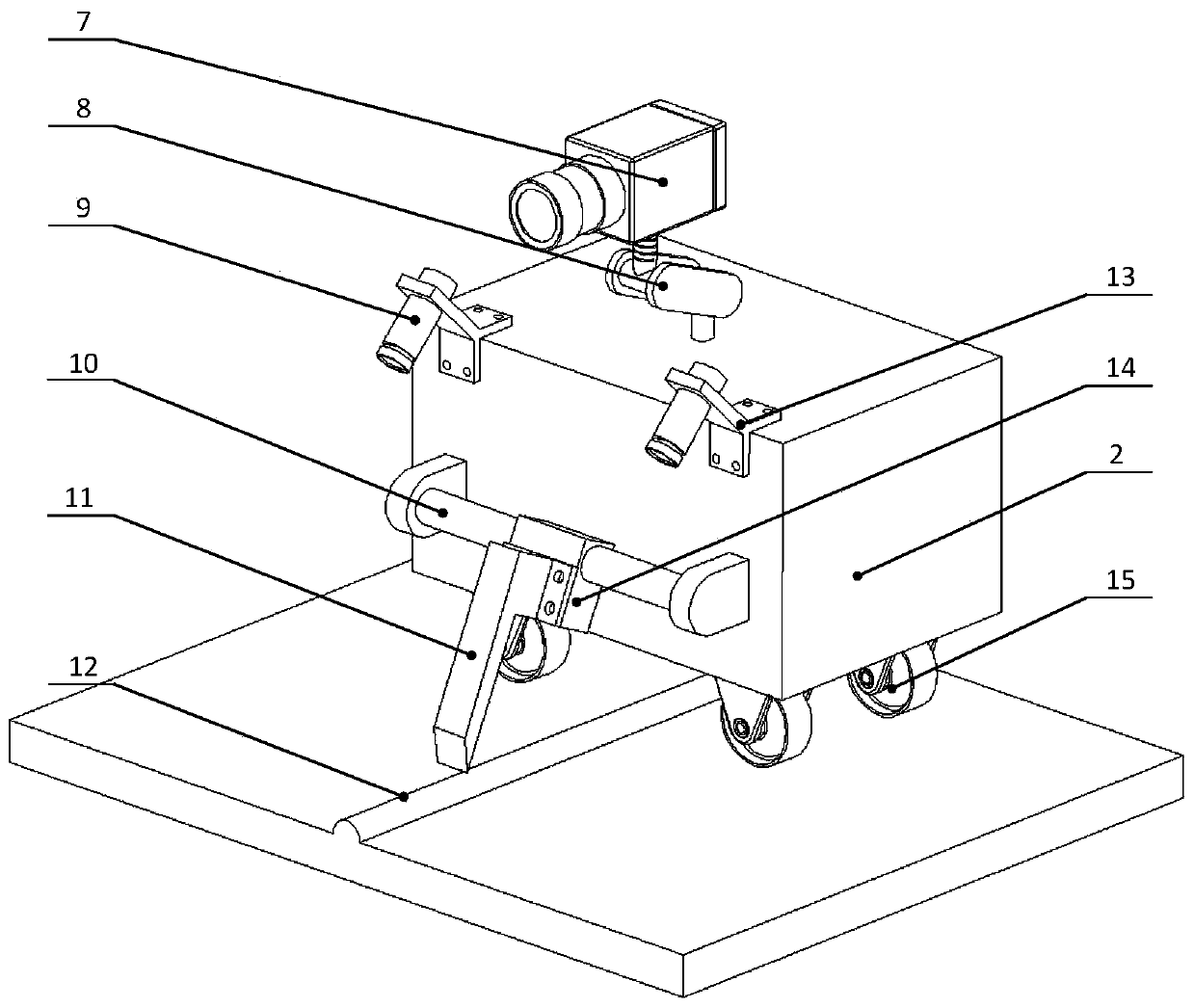

Back-scraping device with adjustable intensity against medical neuropathic pain diseases

InactiveCN107714411AHigh degree of mechanizationRealize the work of automatic scrapingSuction-kneading massageEngineeringPain disorder

The invention relates to a back-scraping device with adjustable intensity against medical neuropathic pain diseases. The back-scraping device includes a supporting device, a transverse movement device, a longitudinal movement device, an adjusting device and a fixing device. The transverse movement device is mounted on the supporting device, the longitudinal movement device is mounted at the bottomof the transverse movement device, the bottom of the longitudinal movement device is connected with the top of the adjusting device, and the fixing device is mounted on the adjusting device. According to the back-scraping device, the problems that an existing scraping therapy machine is used for scraping therapy, the mechanical degree is low, the position needs to be adjusted manually, the scraping therapy dynamics is not adjustable, and the angle of a scraping therapy plate cannot be adjusted are solved. A function of scraping therapy with the adjustable intensity can be achieved, and the back-scraping device has the advantages that the mechanical degree is high, the position adjustment is performed automatically, the scraping therapy dynamics can be adjusted, and the angle of the scraping therapy plate can be adjusted.

Owner:倪菊莲

Printing knife rest system based on intaglio printing and working method thereof

ActiveCN105291554ALarge airflow areaDry fastCylinder pressesPlaten pressesPrinting inkElectrical and Electronics engineering

The invention discloses a printing knife rest system based on intaglio printing. The printing knife rest system comprise a knife rest, an ink scraping blade, a support, a slide rail, air taps, an air pump, an air tube and an adjusting valve. Printing ink is contained in an ink fountain, the bottom of an intaglio printing roller is immersed into the printing ink, and an impression roller conveys printing paper to the connecting position of the impression roller and the intaglio printing roller. The knife rest is arranged on the left side of the intaglio printing roller, and the ink scraping blade is arranged at the front end of the knife rest. The slide rail is arranged on the knife rest and is fixed through the support, and the air tube penetrates through the knife rest to be connected with the slide rail. The air taps are arranged on the upper portion of the air tube, and the lower portion of the air tube is connected with the air pump. The adjusting valve is arranged at the connecting position of the air tube and the air pump. According to the printing knife rest system, the printing ink in the non-image-text position of a forme is quickly blow-dried through exhausted air flow, and unnecessary stains are prevented from being formed on the printing paper, so that the purpose of improving the surface printing effect is achieved. The invention further discloses a working method of the printing knife rest system based on intaglio printing.

Owner:JIANGSU SHUNTAI PACKAGING & PRINTING SCI TECH

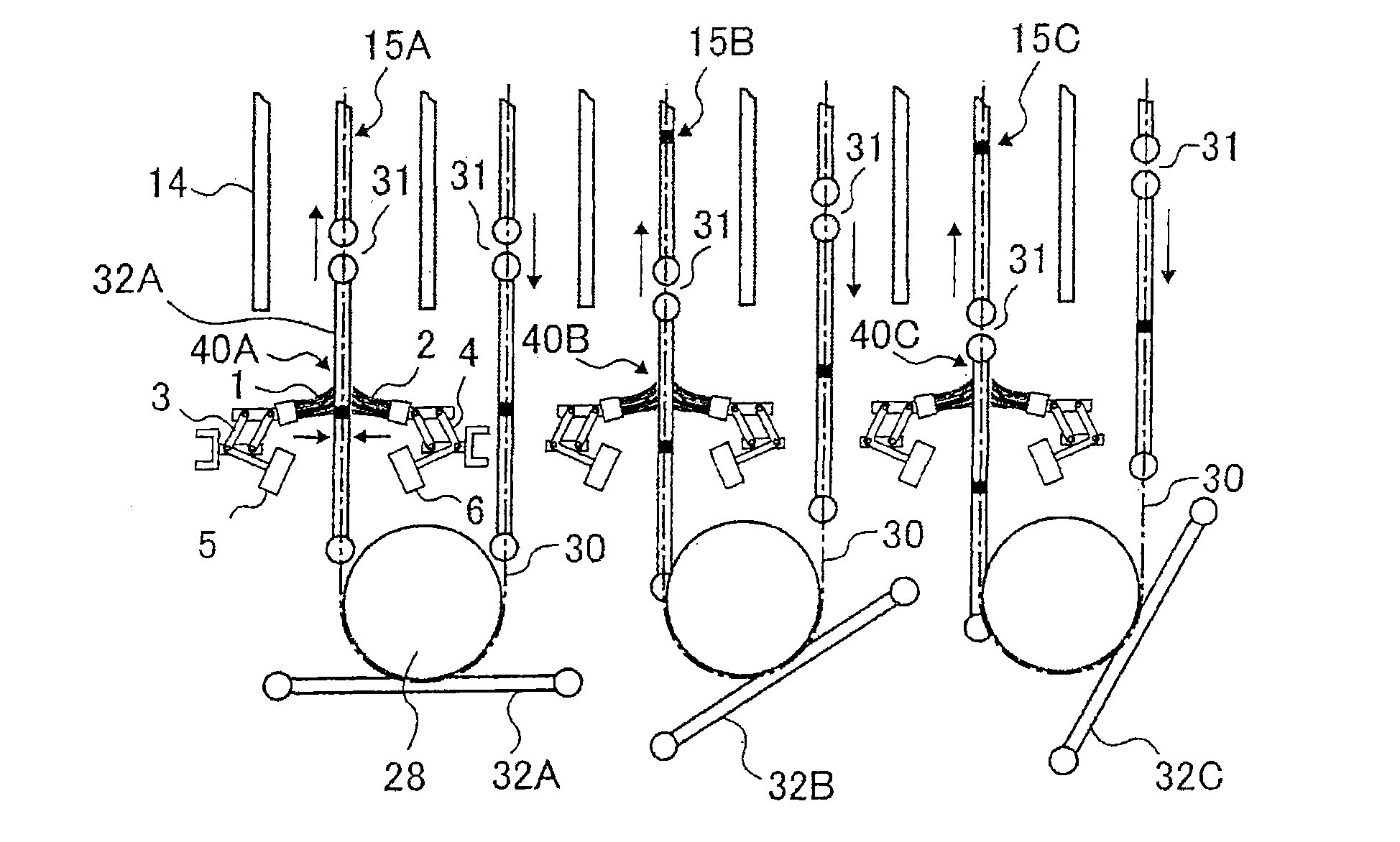

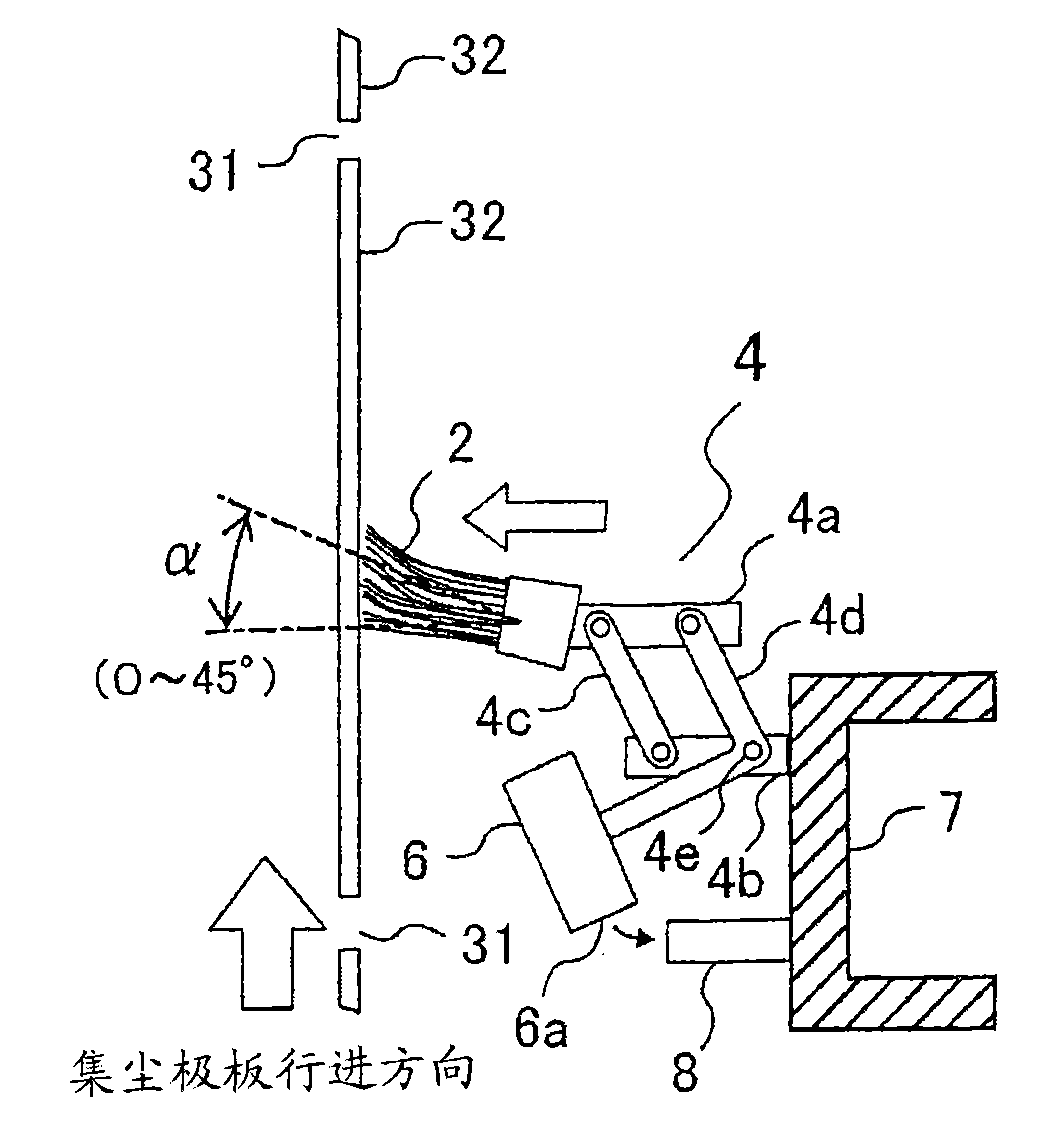

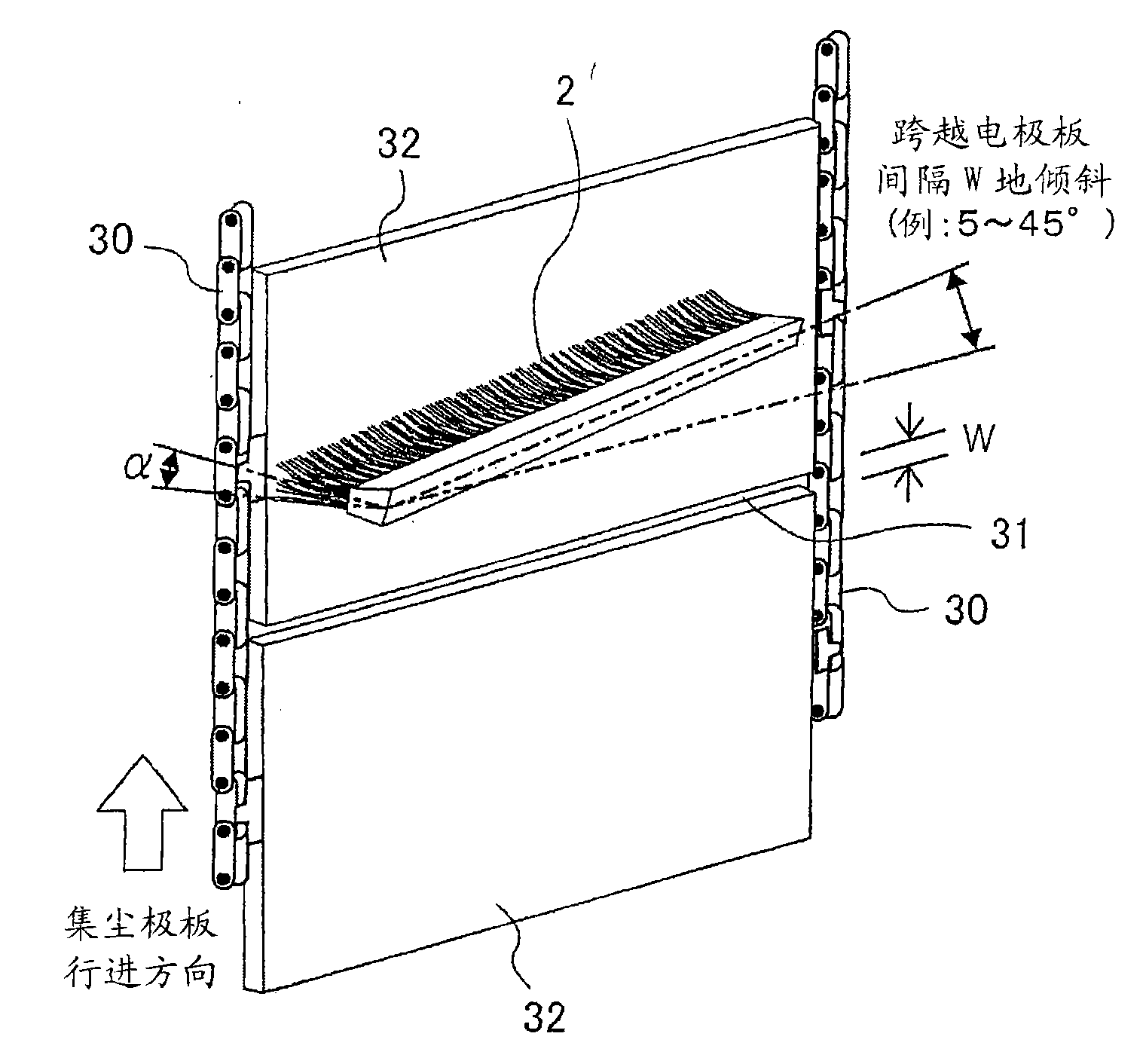

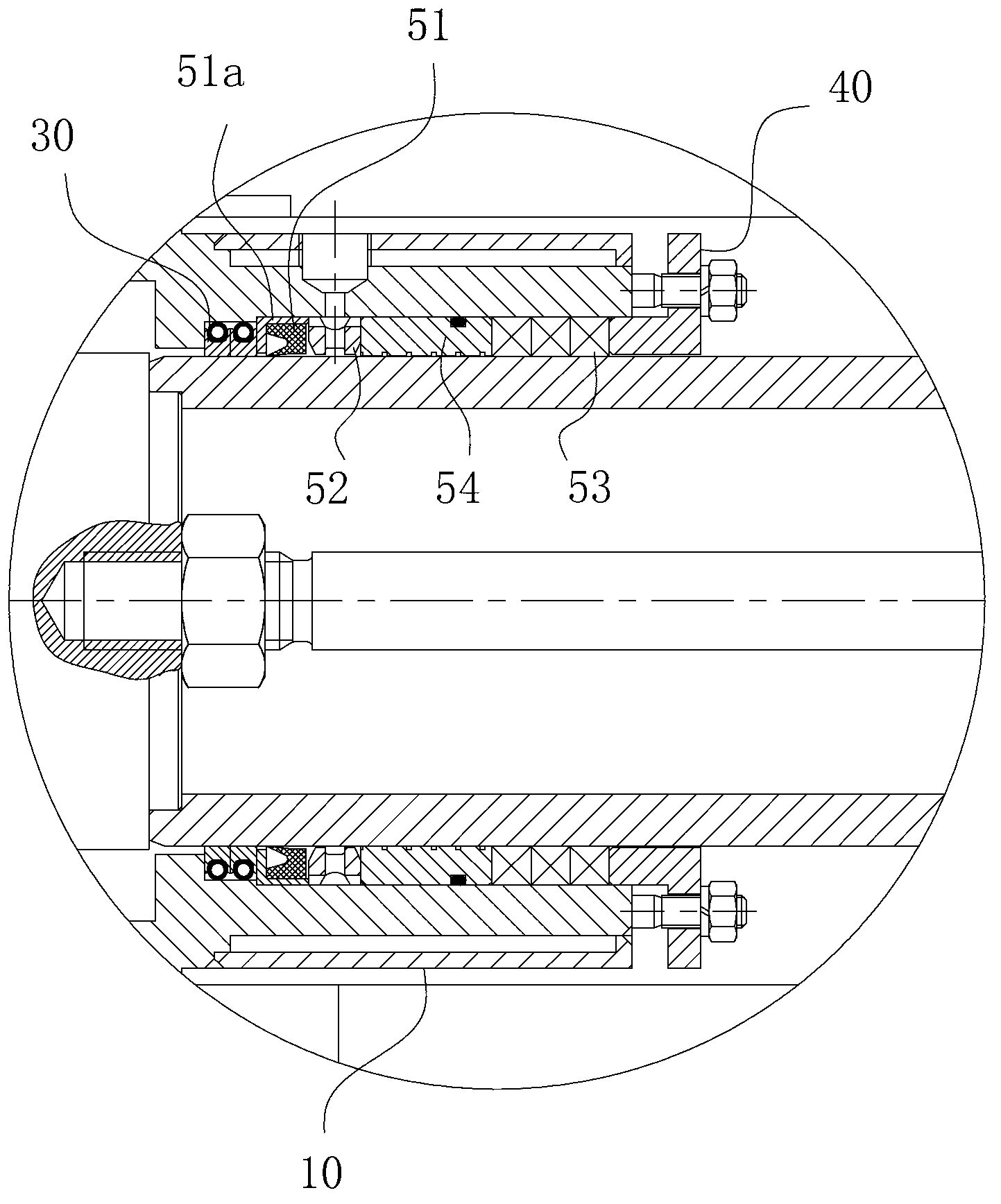

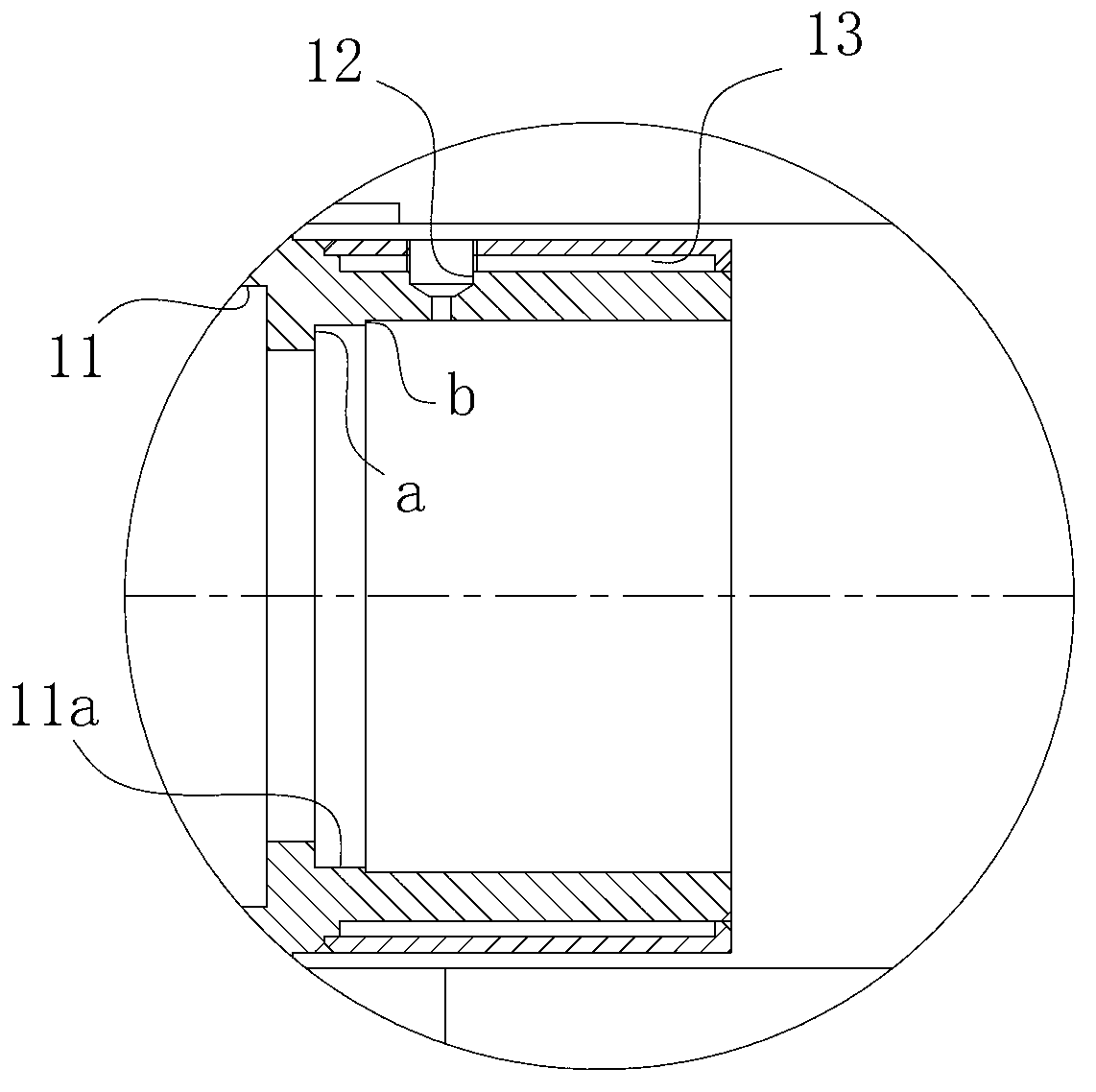

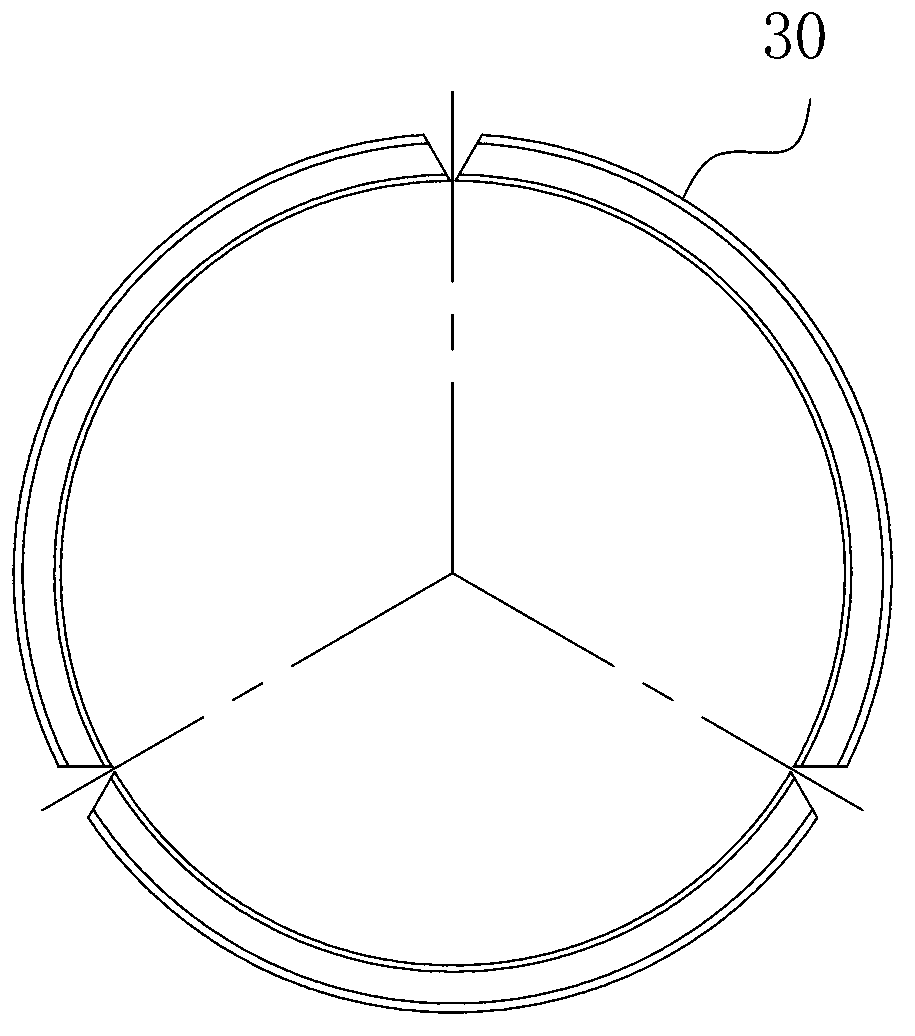

Electric precipitation device and scraping device

InactiveCN101786045ALow costImprove scraping effectExternal electric electrostatic seperatorElectrodes cleaningElectricityEngineering

The invention provides an electric precipitation device and scraping device capable of reducing cost for scraping the dust and keeping the scraping performance for a long time. The movable electrode type electric precipitation device comprises a box for making the dirty gas flowing from a gas inlet to an outlet; a plurality of discharge electrodes suspended in a gas passage as the precipitation area in the box; a plurality of movable electrodes, wherein a plurality of precipitation electrode plates suspended on paired circular chains to form a loop and a rotary ring and a scraping mechanism scrapes the surface of the dust precipitation electrode plate of the rotary ring at the preset position. The scraping mechanism comprises: a long brush extending along the width direction and contacting with the surface of the precipitation electrode plate; a link mechanism with one end mounted on the brush and another end fixed by a fixing component; a force application mechanism for pushing the brush towards the precipitation electrode plate by the link mechanism and a limit mechanism for limit the movement of the brush to prevent the pushed brush embedded into the clearance between the adjacent two precipitation electrode plates.

Owner:HITACHI PLANT TECH LTD

Combined sealing device for plunger pump

ActiveCN103306969ARealize the purpose of pre-protectionAvoid erosion and fragmentationPositive displacement pump componentsPumpsEngineeringCylinder block

The invention belongs to the field of solid pumps, and particularly relates to a combined sealing device for a plunger pump for pumping high-viscosity media such as tar residue. The combined sealing device at least comprises a pump cylinder block with a plunger hole, and a plunger part matched with the plunger hole in a splicing manner, wherein the plunger part can reciprocate linearly along the plunger hole; a cavity defined by the front end of the plunger part and a hole wall of the plunger hole forms a pumping cavity for accommodating and squeezing materials; a sealing unit for filling a fit clearance between the plunger part and the plunger hole is sandwiched between a peripheral wall of the plunger part and the hole wall of the plunger hole; the combined sealing device for the plunger pump further comprises a scrape ring for scraping off the viscous materials from the peripheral wall of the plunger part and / or the hole wall of the plunger hole; the scrape ring is embedded into the hole wall of the plunger hole and / or the peripheral wall of the plunger part is sleeved with the scrape ring in a surrounding manner; the scrape ring isolates the sealing unit from the pumping cavity; and the combined sealing device can realize an effect of high-seal conveying of the solid materials in the combined sealing device, and effectively ensure long service lives of sealing parts in the plunger pump simultaneously.

Owner:合肥华升泵阀股份有限公司

Spiral scraper structure

The invention discloses a spiral scraper structure. The spiral scraper structure comprises a cutter holder, wherein a rotation shaft is fixed to the circle center of the upper end surface of the cutter holder; a plurality of support rods parallel to an axis of a feed cylinder are uniformly distributed at the periphery of the circle center of the end surface on the lower end surface of the cutter holder; a support rod fixing end is fixed on the lower end surface of the cutter holder; a scraper is fixed to all the support rods; the scraper is spiral; the axial length of the scraper is equal to the length of the support rod; the upper end of the scraper is fixed to the lower end surface of the cutter holder; the outer edge of the scraper presses against the inner wall of the feed cylinder; the top of the feed cylinder is connected with a material collection box in a sliding manner in a direction vertical to the axis; the material collection box is detachably matched with the feed cylinder; a scraping plate is mounted on the material collection box and presses against the scraper. The invention aims to provide a spiral type scraper structure; linear scrapers are changed into spiral scrapers; the material collection box is additionally mounted on the scraper, so that the material can be scraped thoroughly even the scraper has defects; meanwhile, the dispersoid adhered to the scraper can be effectively collected; the waste is avoided.

Owner:徐州天骋智能科技有限公司

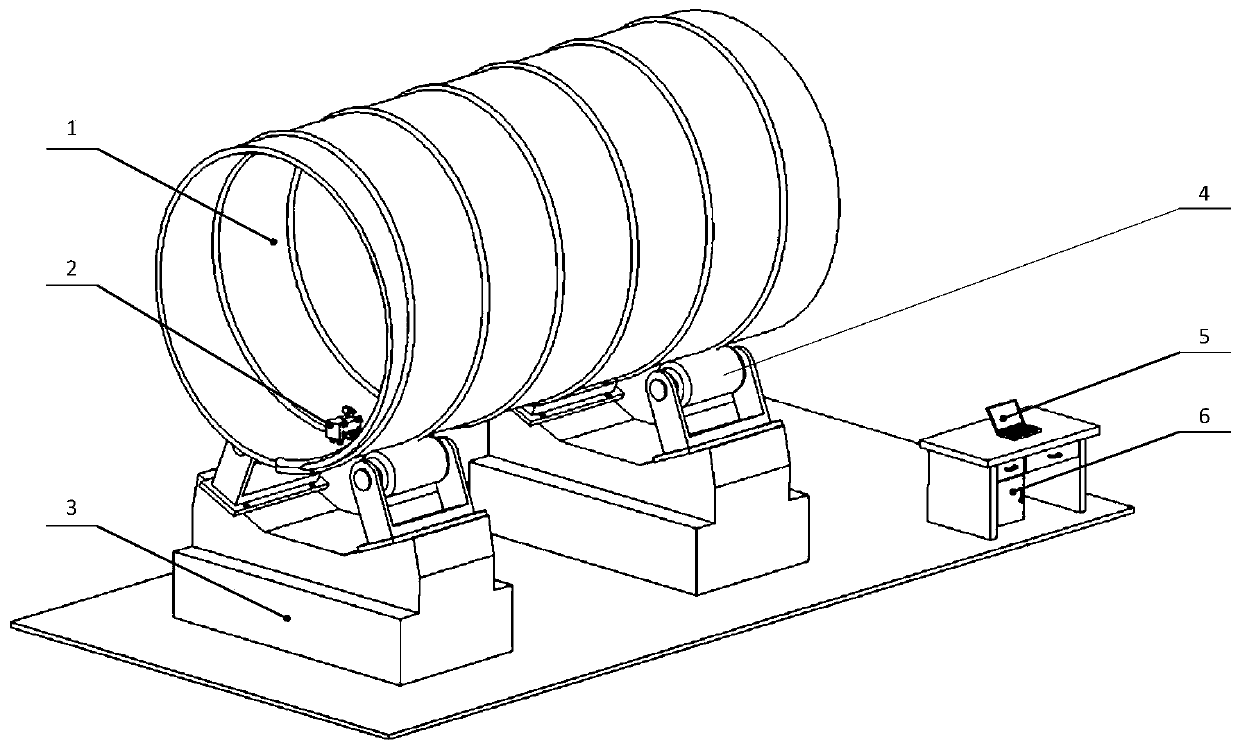

Submerged-arc welding pipe internal burr removal device and method

ActiveCN110102826ARealize closed-loop controlImprove scraping effectAutomatic controlSubmerged arc welding

The invention relates to a submerged-arc welding pipe internal burr removal device and method, and belongs to the field of submerged-arc welding pipe production. The internal burr removal device comprises a computer, a machine fame, a left pair and a right pair of supporting rollers arranged on the machine frame and used for placing a pipe blank, a trolley which is placed in the pipe blank when internal burrs are removed and a burr excess weld metal detection device; and wheels are arranged at the bottom of the trolley, an image recognition device used for photographing morphology images of the internal burrs to be scraped is mounted at the top of the trolley, a scraping device used for scraping the internal burrs is mounted on the lower part of a vehicle body of the side surface of the trolley, and a temperature measuring device used for measuring temperature data of the internal burrs at a weld bead is mounted on the upper part of the vehicle body of the side surface. According to the submerged-arc welding pipe internal burr removal device and method, the scraping process of the internal burrs is automatically controlled based on a machine vision technology, through the linkage of the computer with the image recognition device, the temperature measuring device, the scraping device and the excess weld metal detection device, closed-loop control over the whole process of morphology detection of the internal burrs, tool positioning, temperature detection, scraping and internal burr excess weld metal detection is realized.

Owner:YANSHAN UNIV

Scraping structure of spray scraping machine

ActiveCN101011685AIncrease scraping areaImprove scraping effectSpray nozzlesAgricultural engineeringNozzle

The scraping structure of a nozzle scraper comprises a substrate, a scraping block and a scraping blade, with the scraping block inside the substrate and having a scraping slot, the scraping blade at the front of the scraping block to increase the scraping area of the gel left on the nozzle. It can effectively improve the scraping effect, avoiding the impact to processing quality due to left gel on the nozzle, to improve the production qualification rate, reduce consumption to the scraping block and extend the durability of the scraping block.

Owner:AU OPTRONICS CORP

Environment-friendly material stirring device with dustproof function

InactiveCN108745102AQuick sealAvoid pollutionRotary stirring mixersTransportation and packagingEngineeringSolar heat

The invention discloses an environment-friendly material stirring device with a dustproof function. The environment-friendly material stirring device comprises a scraping plate, a brush, solar heat collection plates, a stirring tank and a base. The environment-friendly material stirring device has the advantages that the scraping plate is used for scraping materials adhered on the inner wall of the stirring tank, accordingly, effects of stirring materials can be guaranteed, and wastage of the materials can be prevented; effects of scraping the materials adhered on the inner wall of the stirring tank further can be improved by the brush, and accordingly the practicality of the environment-friendly material stirring device can be improved; the solar heat collection plates are used for absorbing solar energy, and accordingly air in a heat-insulation cover can be heated; external air can flow into a filter tank by the aid of an exhaust fan and can be heated by the aid of the solar heat collection plates, accordingly, energy can be saved, and environments can be protected; air in a cavity further can be exhausted via a gas outlet pipe, accordingly, hot air in the cavity can be continuously circulated, the purposes of continuously heating and drying the materials in the stirring tank further can be achieved, and the practicality of the environment-friendly material stirring device further can be improved.

Owner:张梅梅

Environment-friendly type normal-temperature curing sealant and preparation method thereof

InactiveCN104327763AUniform thicknessImprove scraping effectMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesElastomerThermoplastic elastomer

The invention relates to an automobile sealant which comprises rubber, a thermal plastic elastomer, a plasticizing agent, tackifying resin, an anti-aging agent, a thickening agent, packing and a solvent. A preparation method comprises the following steps: thinning rubber in a two-roller machine 10 times for later use; soaking the thinned rubber, SBS, the plasticizing agent and the tackifying resin in the solvent for 1-2 days till being completely dissolved, and subsequently uniformly stirring; adding the packing, the anti-aging agent and the thickening agent into the soaked mixed solvent, and grinding for 3-5 times by using a three-roller machine till the materials are uniform; putting the uniformly grinded rubber into a defoaming machine, and defoaming for 20 minutes till the surface is fine in gloss; and packaging a finished product. The automobile sealant has the effects of environment-friendliness and no toxicity, and the solvent used in the sealant is an environment-friendly non-toxic solvent. The sealant is good in blade coating property, the surface is smooth and fine after blade coating, and the coating is uniform in thickness. The sealant is outstanding in thermal resistance and is free of crack or blister after being baked at 100 DEG C.

Owner:三友(天津)高分子技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com