Patents

Literature

2884results about How to "High degree of mechanization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Upward and downward staged rock drilling, sublevel bottom cutting and ore removal subsequent backfilling mining method

ActiveCN106677780AImprove securityEnsure safetyUnderground miningTunnel/mines ventillationDetonationEngineering

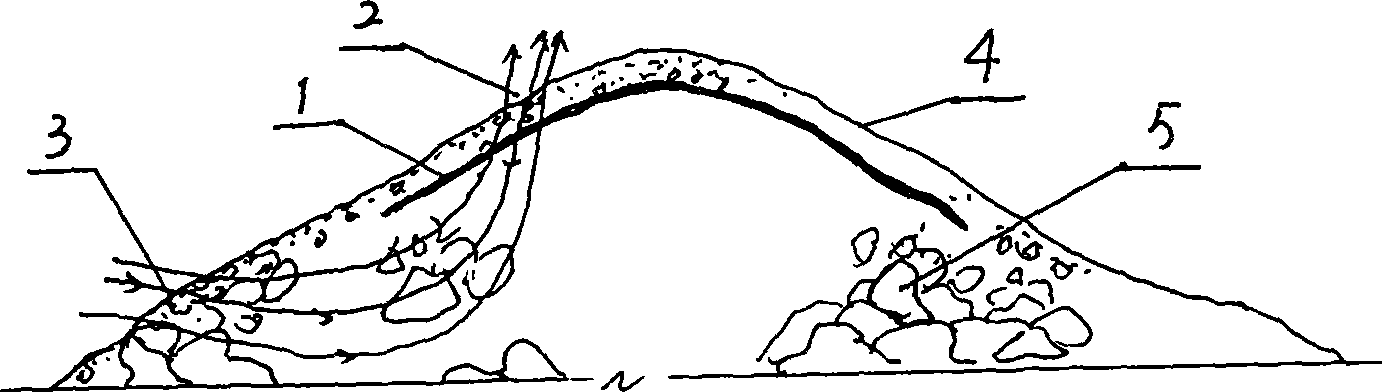

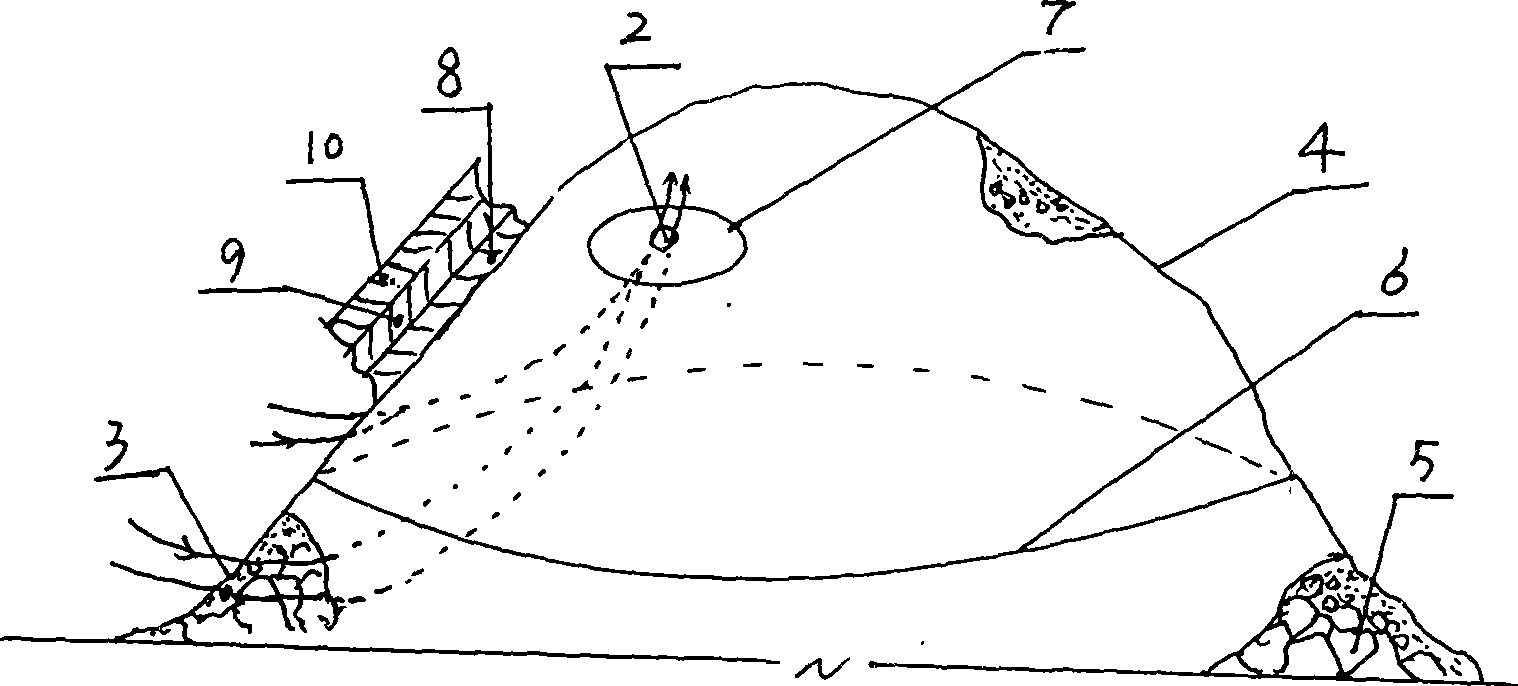

The invention provides an upward and downward staged rock drilling, sublevel bottom cutting and ore removal subsequent backfilling mining method. The method includes the following steps that panels are divided in the ore direction, a stope preparation system is arranged, upward fan-shaped medium-depth blast holes are drilled from one side to the other side of a chamber, the blast holes are filled with explosives for detonation, and an undercut space is formed after detonation; cut grooves are formed through a VCR method, and as for ore above the undercut space, downward vertical deep holes are drilled in a drilling chamber at the top of the chamber, and the holes are filled with explosives for detonation with the cut grooves as a compensation space; the chamber in each panel is subjected to two-step backstoping, after ore removal of a first-step chamber is finished, the first-step chamber is filled with cementing materials, after the first-step chamber is filled and cured, a second-step chamber is subjected to backstoping, the backstoping steps of the second-step chamber are the same as those of the first-step chamber, and the second-step chamber is filled with cemented filling bodies and non-cemented filling bodies; and the steps are repeated in this way till backstoping of all chambers are completed. The upward and downward staged rock drilling, sublevel bottom cutting and ore removal subsequent backfilling mining method has the advantages that the rock drilling efficiency of the upward fan-shaped medium-depth blast holes is improved, the waste hole rate is lowered, efficient and safe bottom ore removal is achieved, and the mechanization level is high.

Owner:MCC NORTH (DALIAN) ENG TECH CO LTD

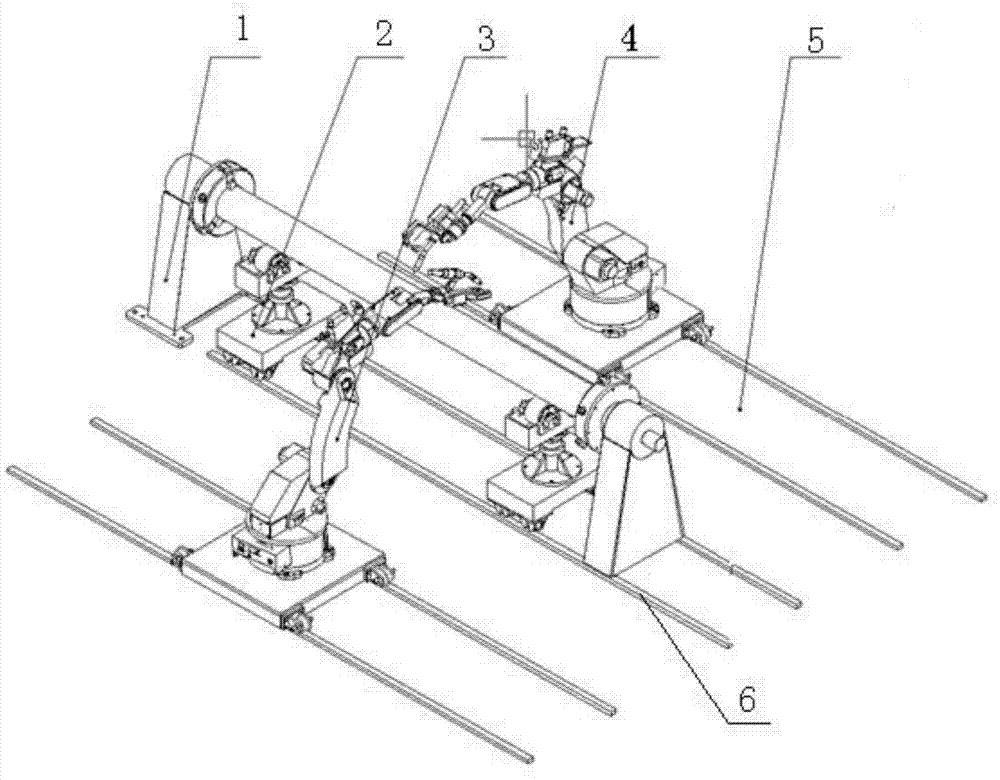

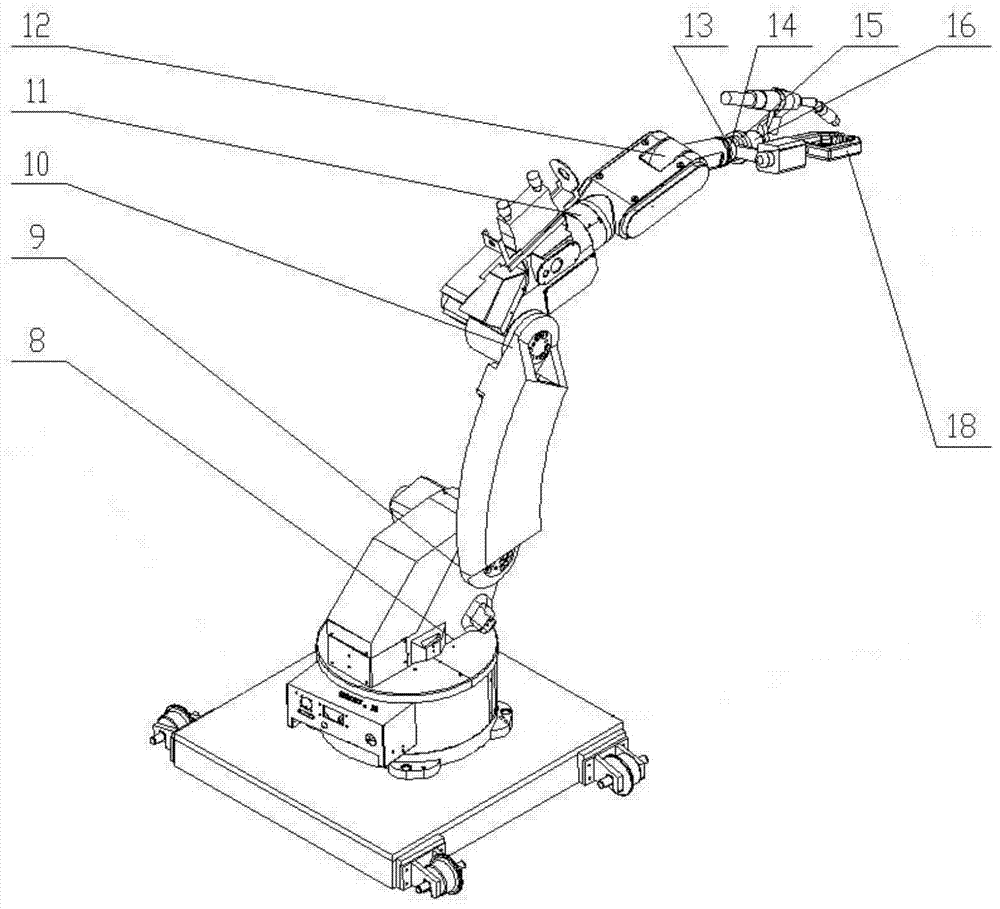

Integrated workstation based on robot cutting, welding and carrying in pipe processing

ActiveCN103567677AImprove processing qualityImprove machining accuracyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSmall footprint

The invention discloses an integrated workstation based on robot cutting, welding and carrying in pipe processing. The integrated workstation comprises a headstock and tailstock position changer, a movable support, a welding robot, a cutting robot, a middle sliding rail and two side sliding rails, wherein the headstock and tailstock position changer comprises a headstock base and a tailstock base; a pipe workpiece is clamped between clamping and fixing devices on the headstock base and the tailstock base; a lifting driving device is installed on a sliding base of the movable support; a roller is installed on the lifting driving device and is tangent with the pipe workpiece; the welding robot and the cutting robot are slidably installed on the two side sliding rails on the two sides of the pipe workpiec respectively to finish carrying, cutting and welding operation and the like. The integrated workstation based on the robot cutting, welding and carrying in pipe processing is an integrated working system, can ensure good consistency in pipe processing, improves the processing quality and the processing precision of the whole pipe workpiece, and is simple in structure, less in equipment and small in occupied area.

Owner:NANJING PANDA ELECTRONICS +1

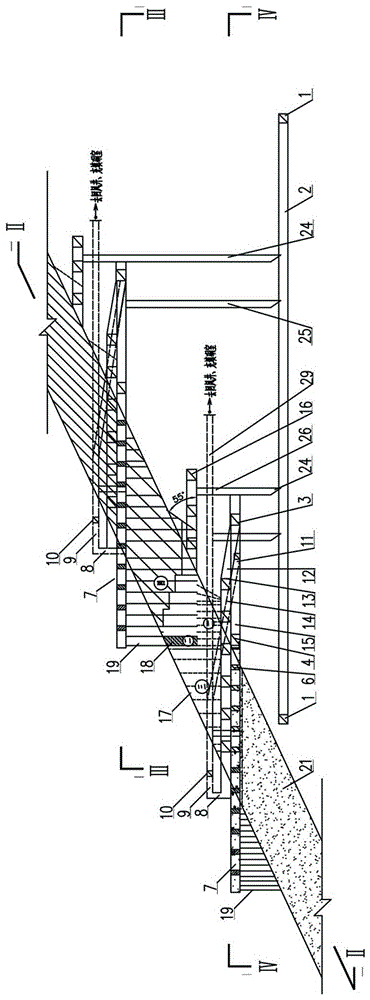

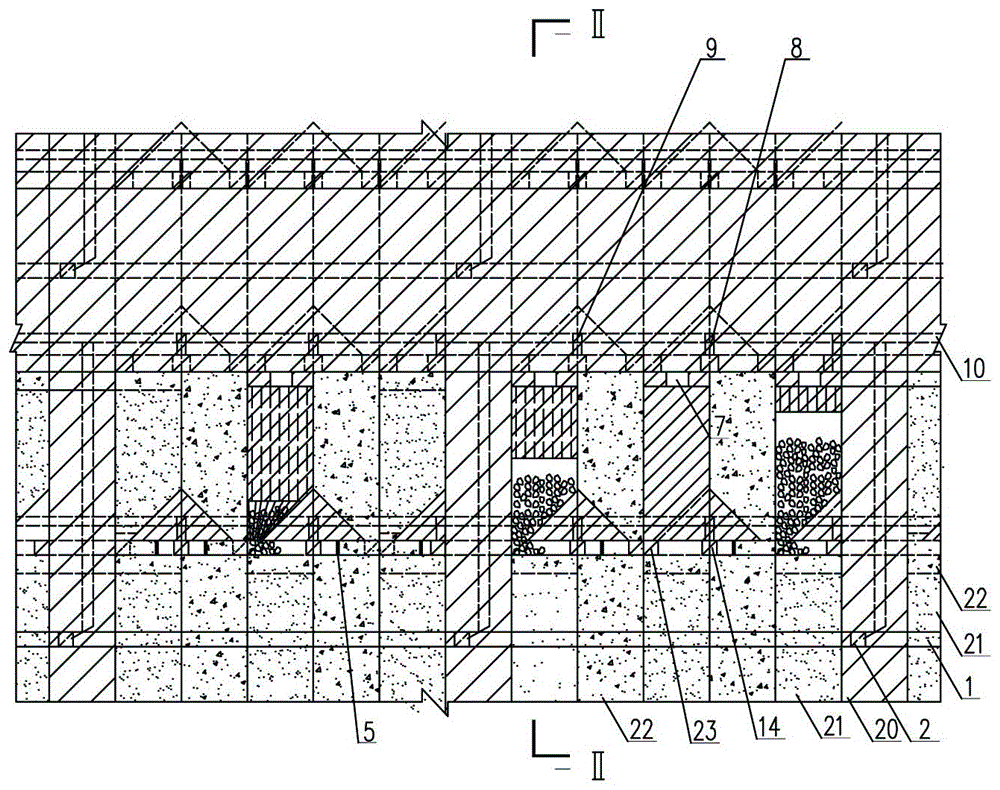

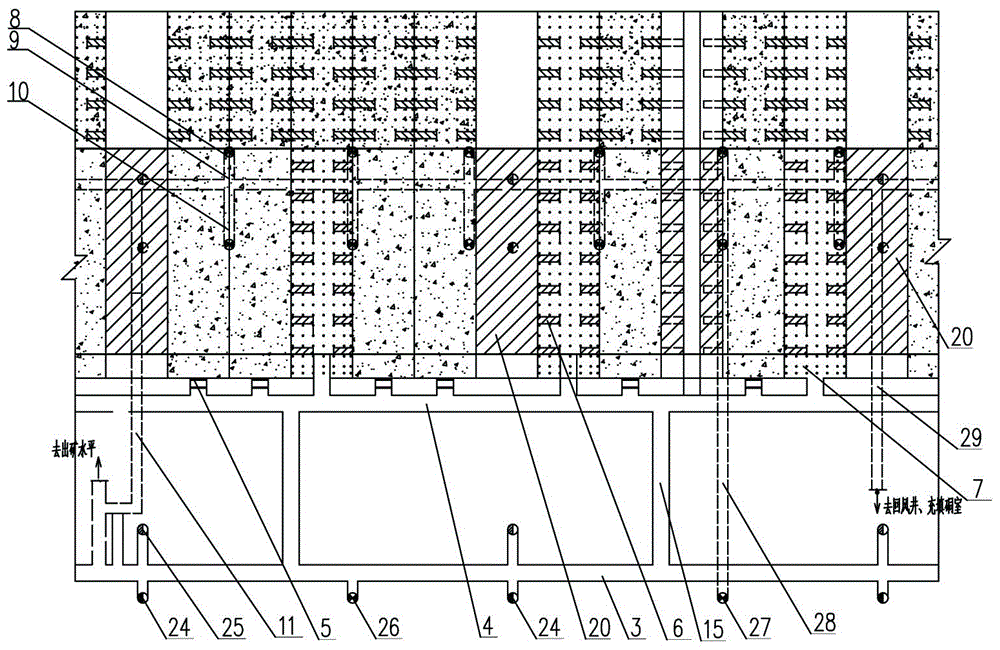

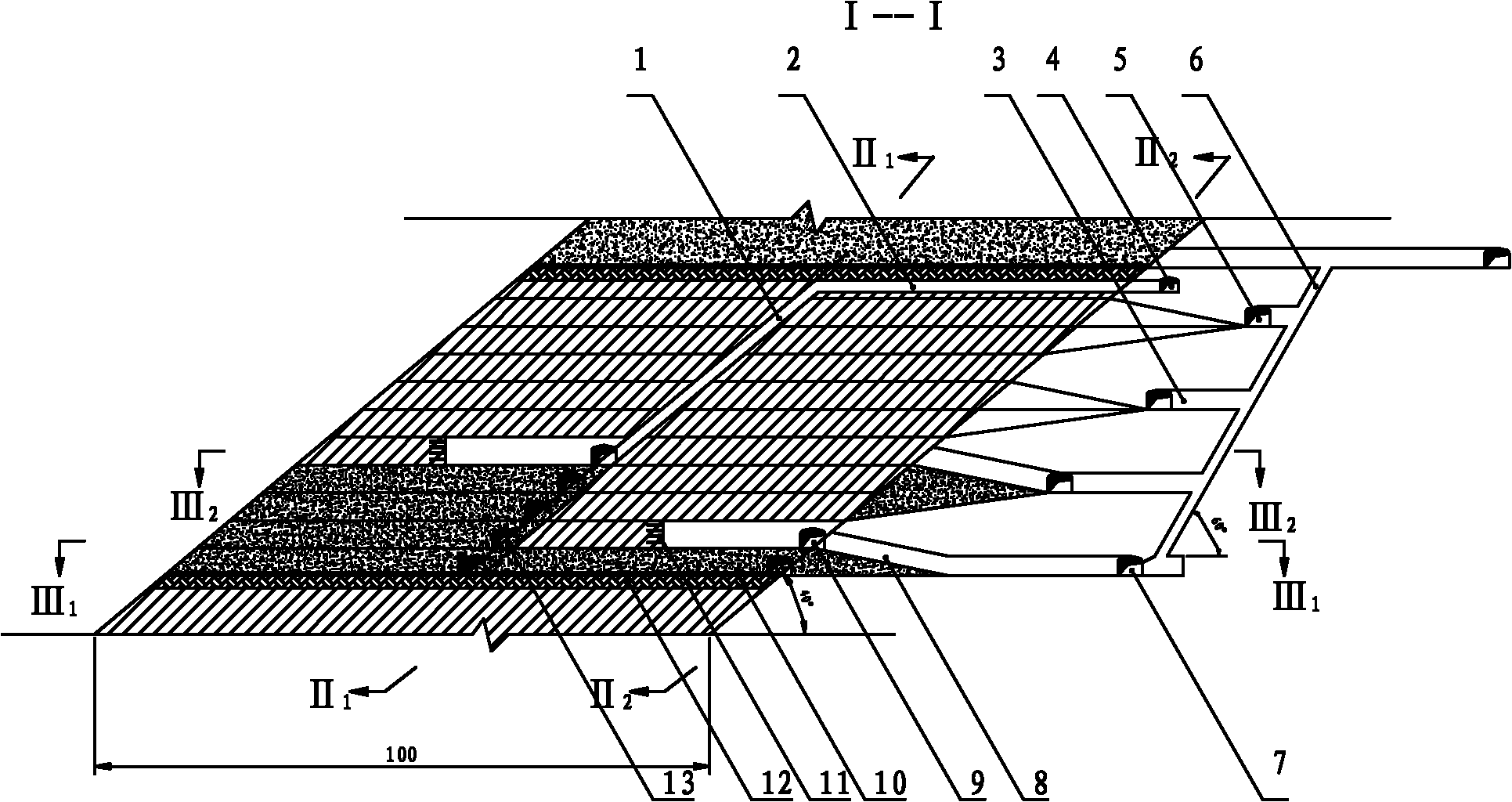

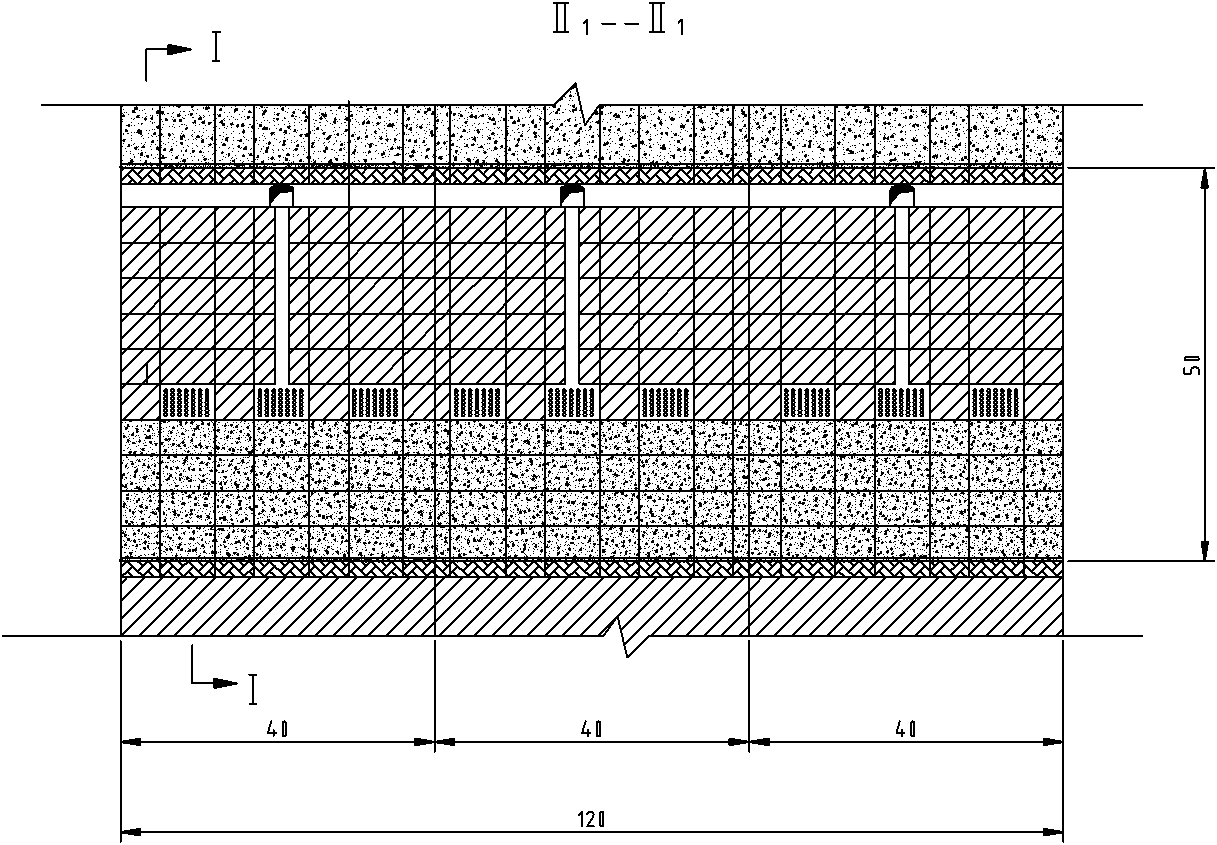

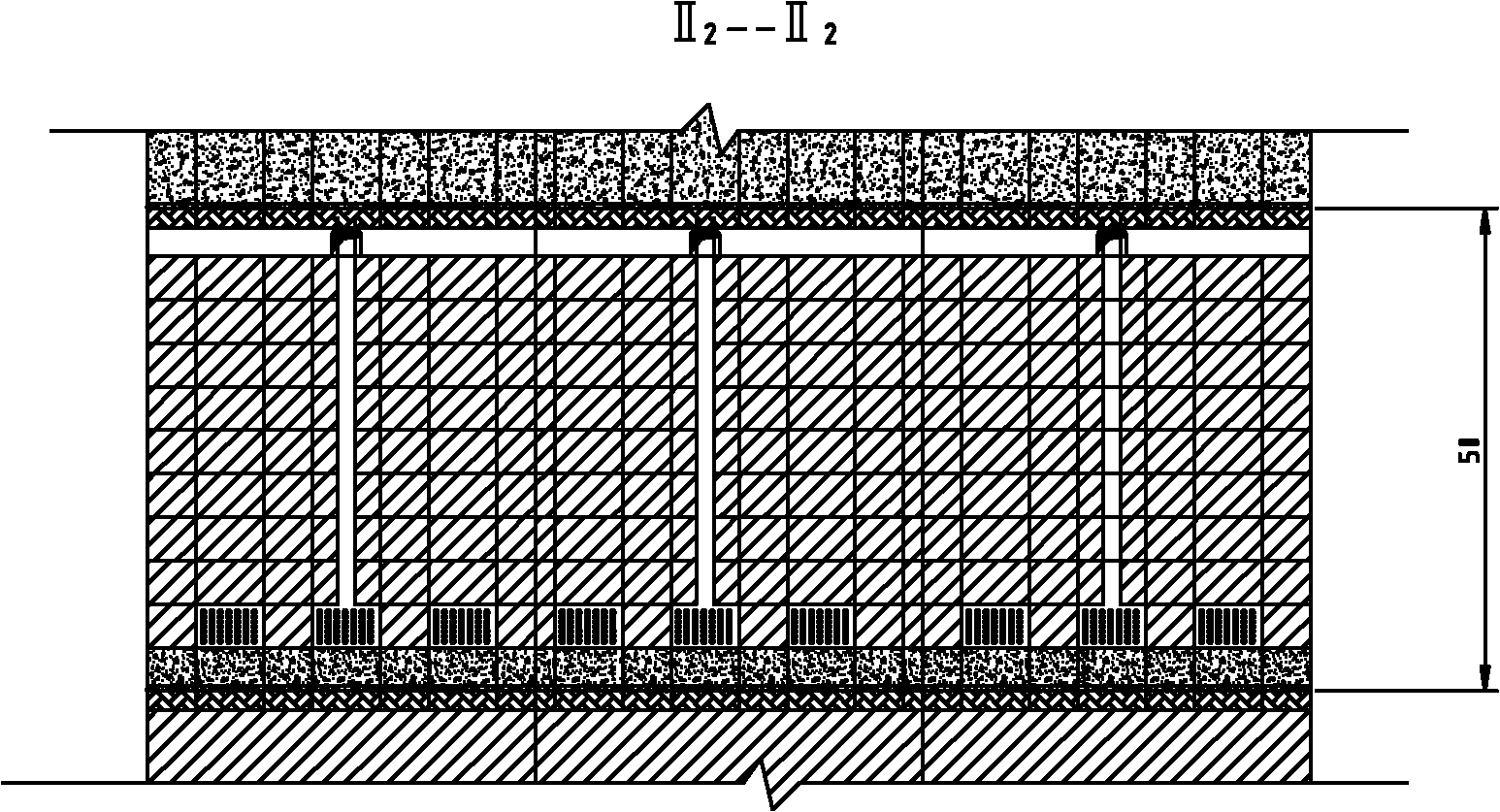

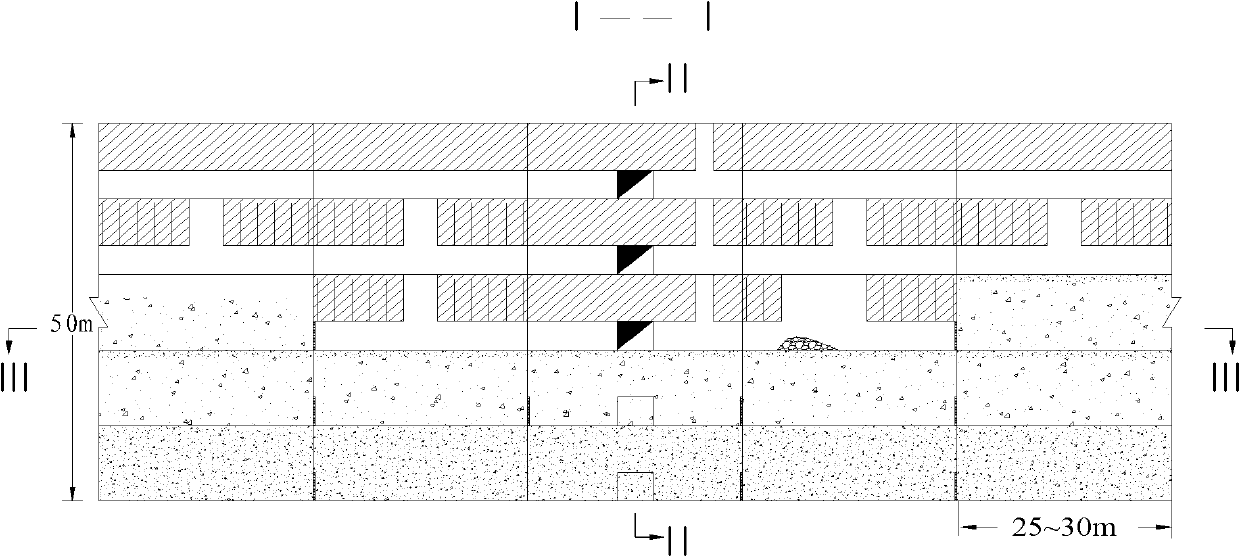

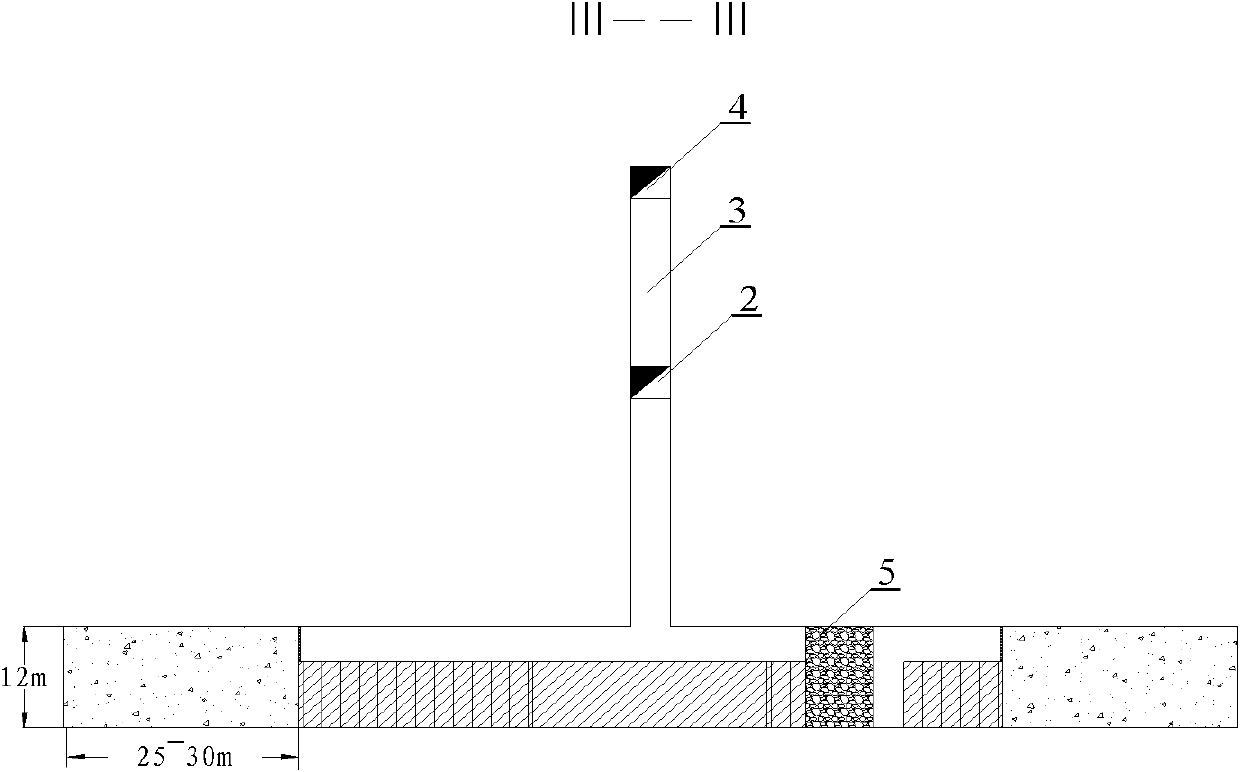

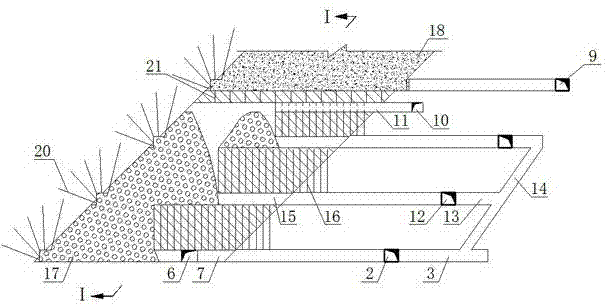

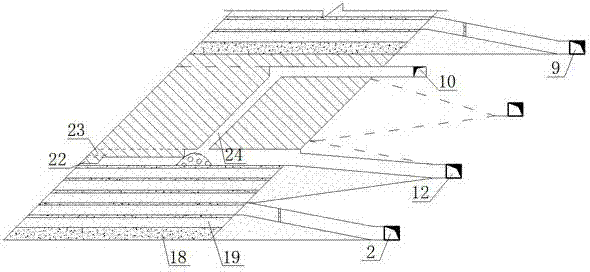

Stepped non-pillar continuous filling mining method for deep well super high large breaking ore body panel

InactiveCN101818643ASafe miningMining guaranteeUnderground miningSurface miningEngineeringCompressive strength

The invention discloses a stepped on-pillar continuous filling mining method for deep well super high large breaking ore body panel. An ore body is divided into a front part and a rear part in a super high large breaking ore body center by an transportation roadway, then the front part and the rear part are respectively divided into a plurality of panels, no pillar exists between pillars, each panel is partitioned into a primary extracting drift and a second extracting drift, the panels in the front part are extracted at first and then the panels in the rear part are extracted, the front and rear panels are extracted in a stepped manner, each production technology is carried out in the same level, and procedures can not influence each other; after the stop back production is finished, the primary extracting drift is filled with cement and the secondary extracting drift is filled by classifying tailings while roof-contacted filling is ensured; and the primary extraction drift and the secondary extraction drift adopt high strength filling topping, and binding materials are added in the filling tailings so as to improve the compression strength of a topping layer. The invention has the characteristics of high extraction safety, small loss and dilution, high mechanical degree, large stope amount, large back production strength, high production capability, short back production time and the like.

Owner:CENT SOUTH UNIV

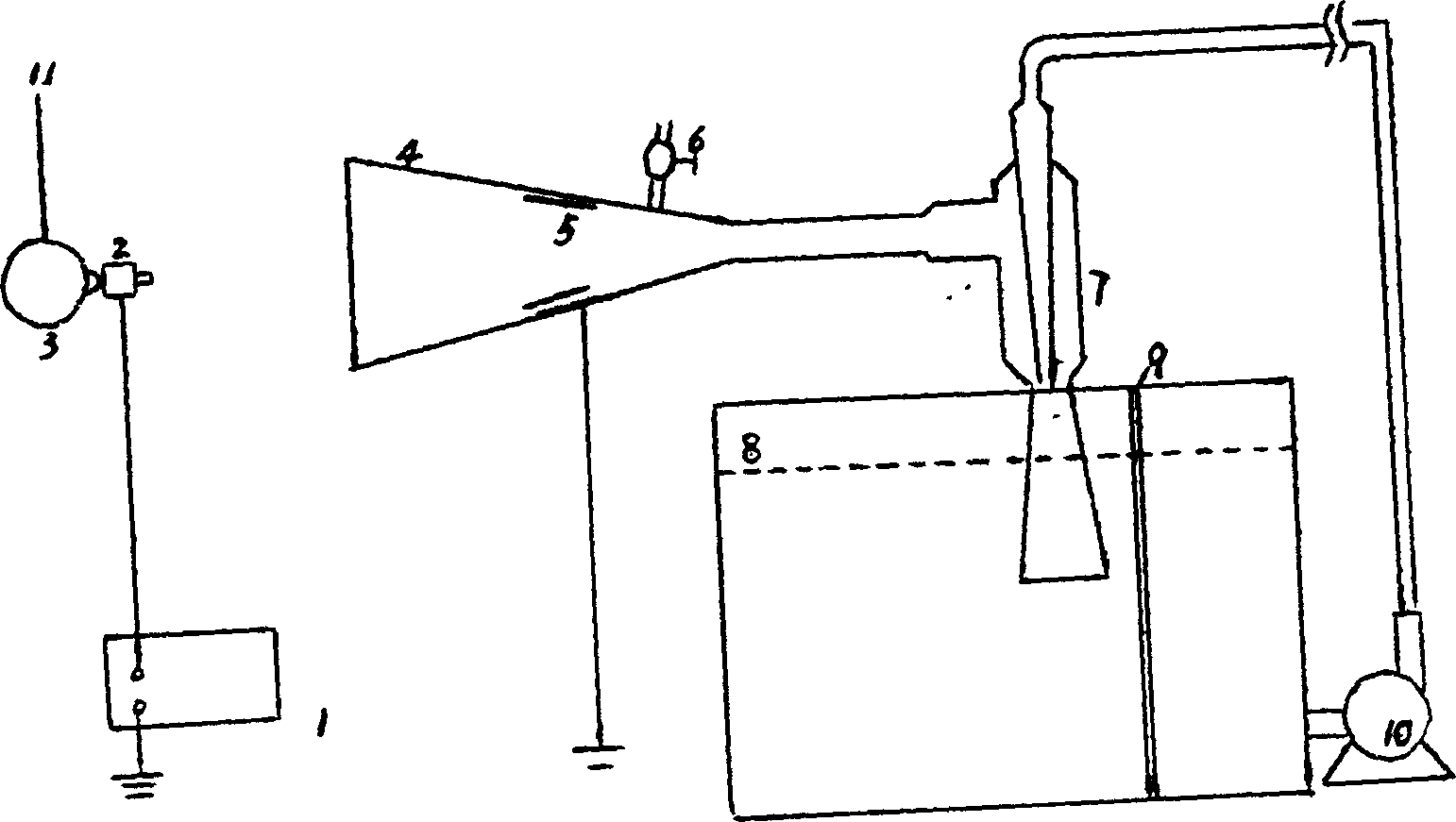

Method and equipment of preparing high performance zirconium oxide continuous fiber

InactiveCN1459418AGood effectHigh molecular weightInorganic material artificial filamentsZirconium oxidesFiberStructure and function

A process for preparing high-performance continuous fibre of zirconium oxide includes such steps as synthesizing acetylacetone-zirconium polymer as precursor from acetylacetone and zirconium oxychloride as main materials, dissolving in methanol to obtain the spinning solution, drying spinning to obtain continuous fibre of precursor, heat treating in a multifunctional sintering furnace by special atmosphere and high-temp. airflow spraying for stretching. Its advantages are high tensile strength (over 2.6 GPa) and long length up to several kilometers.

Owner:绍兴市圣诺超高温晶体纤维材料有限公司

Medium-length hole mining method in multiple blasting free faces of high dipping thin veins

InactiveCN102635356AIncrease job securityStrong mining continuityUnderground miningSurface miningPunchingMineralogy

The invention discloses a medium-length hole mining method in multiple blasting free faces of high dipping thin veins. The medium-length hole mining method is characterized by comprising the steps of: arranging ore blocks along the trend of a core body, dividing the ore body into a medium section and a segment in the altitude; drilling a gate way in the segment and arranging in veins along the ore body; arranging a flat ore removal structure on the bottom along the veins; arranging a cutting raise from one ends of the ore blocks, arranging a manway at the other ends of the ore blocks; and upwards and downwards punching forwards leaning medium-length holes, with the cutting raise as free faces, and blasting caved ores in the segment by multiple free faces, and withdrawing the ore centrally at the bottom. The medium-length hole mining method has the remarkable characteristics of high mining safety, little resource dilution rate, good production continuity, high level of mechanization, low cost, high efficiency, low labor intensity and the like.

Owner:CENT SOUTH UNIV

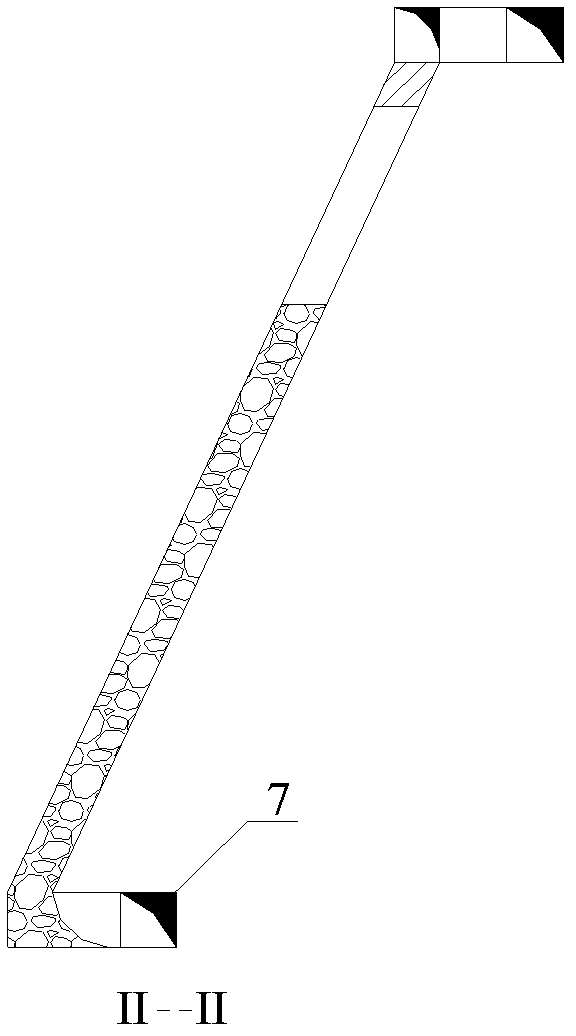

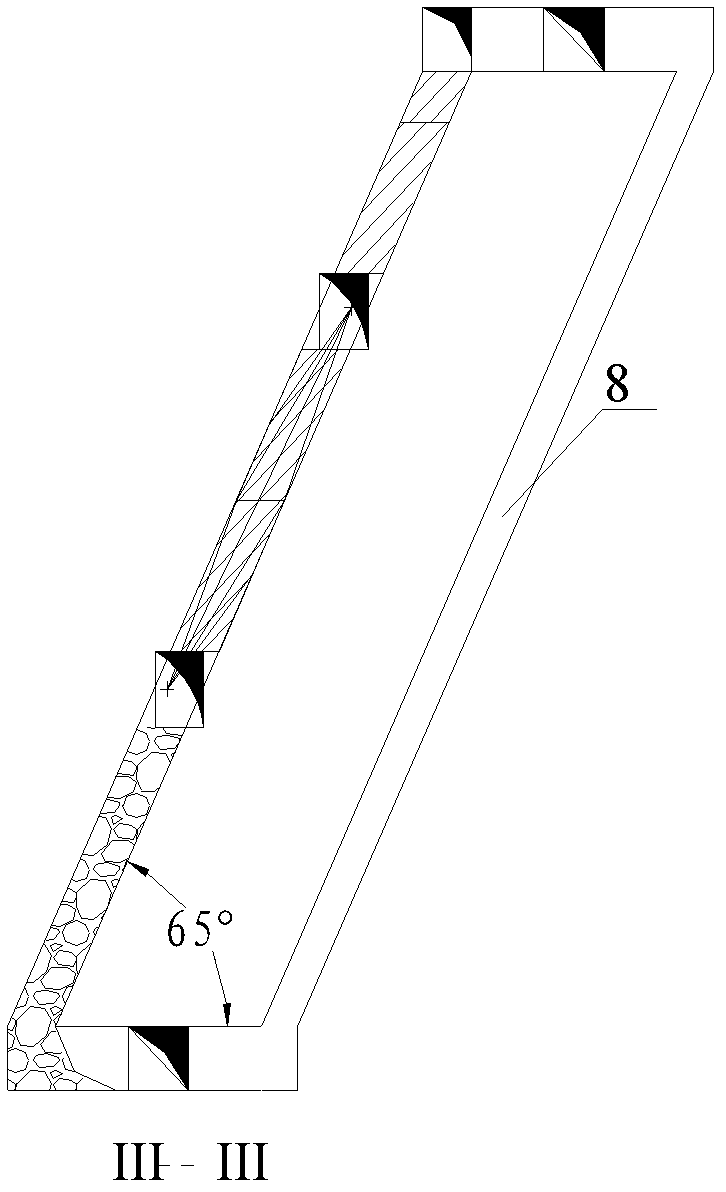

Rib-pillar-free continuous sublevel filling method for mining preparation in medium-thickness slope crushed ore body vein

The invention discloses a rib-pillar-free continuous sublevel filling method for mining preparation in a medium-thickness slope crushed ore body vein. The method comprises the following steps of: dividing a mine block into panel structures with a plurality of sections and bunches, namely dividing sections in a panel, not leaving a rib pillar in the sections, and dividing continuous extraction units; arranging a slope ramp of the panel on an ore body hanging wall, and arranging sectional roadways namely rock drilling ore removal gate ways in the vein; making all the sectional roadways in the panel mutually communicated, and the allocation and transportation of trackless equipment flexible and convenient; performing quarry central up cutting before the extraction, and ensuring the deep hole construction in a quarry upward sector in good conditions; performing operation such as multiple-section quarry rock drilling, blasting, supporting, ore removing, filling and paralleling; using a rib-pillar-free continuous extraction way backing from two wings of the panel to the center in the same sectional quarry, wherein an extraction process is performed sequentially; and filling a gob with tailings or waste stones. The invention relates to the rib-pillar-free continuous sublevel filling method suitable for medium-thickness slope crushed ore bodies, which has a low mining preparation ratio, low loss and high efficiency and the extraction is safe.

Owner:CENT SOUTH UNIV +1

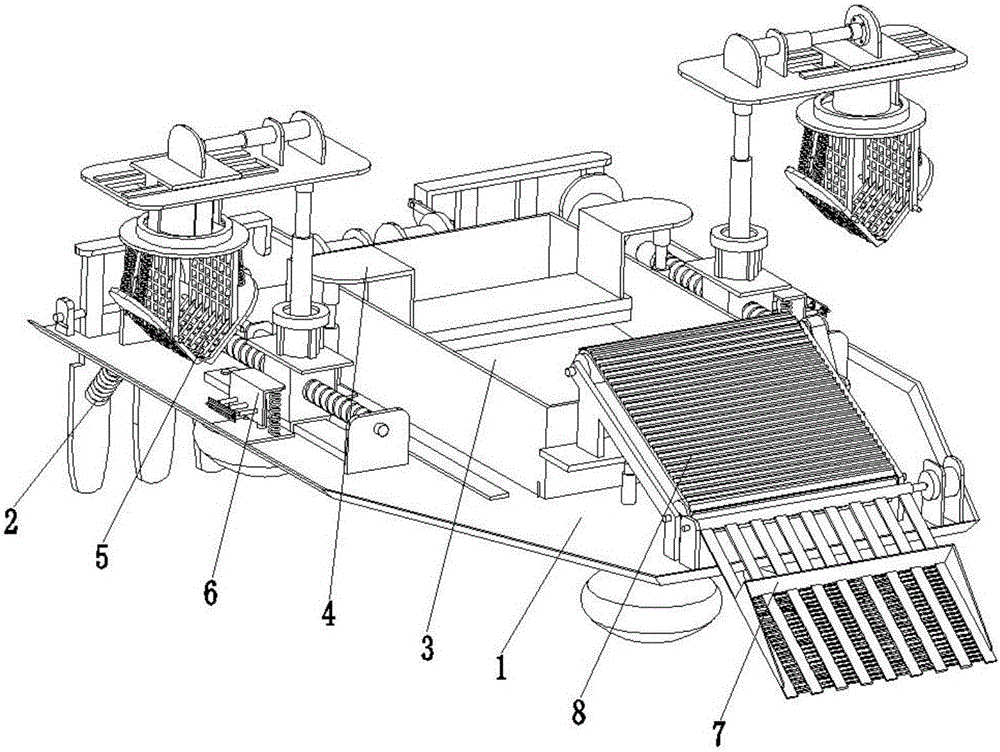

Environment-friendly type river and lake controlling and cleaning equipment

ActiveCN106759196APlay a dredging roleKeep water cleanWater cleaningWaterborne vesselsCompression deviceWater quality

The invention relates to environment-friendly type river and lake controlling and cleaning equipment. The environment-friendly type river and lake controlling and cleaning equipment comprises a boat body, power devices, a storage slot, a compression device, movable gripping devices, cut-off devices, a salvaging device and a conveying device, wherein the power devices are symmetrically mounted at the left side and the right side behind the boat body separately along the longitudinal central axis of the boat body; the compression device is positioned above the storage slot; the movable gripping devices are separately positioned at the left side and the right side of the compression device; the cut-off devices are positioned at the outer sides of the movable gripping devices; the salvaging device is positioned in front of the boat body; and the conveying device is positioned between the salvaging device and the storage slot. The environment-friendly type river and lake controlling and cleaning equipment integrates the functions of floating force adjusting, water-surface travelling, waste compacting, aquatic plant gripping, garbage salvaging, garbage conveying and the like, realizes the functions of eliminating aquatic plants in rivers and lakes as well as floating waste on the water surface, achieves the effect of dredging the rivers and the lakes, keeps water in the rivers and the lakes clean, is high in integral mechanical degree, is complete in function and is high in operating efficiency.

Owner:广东祥实建设有限公司

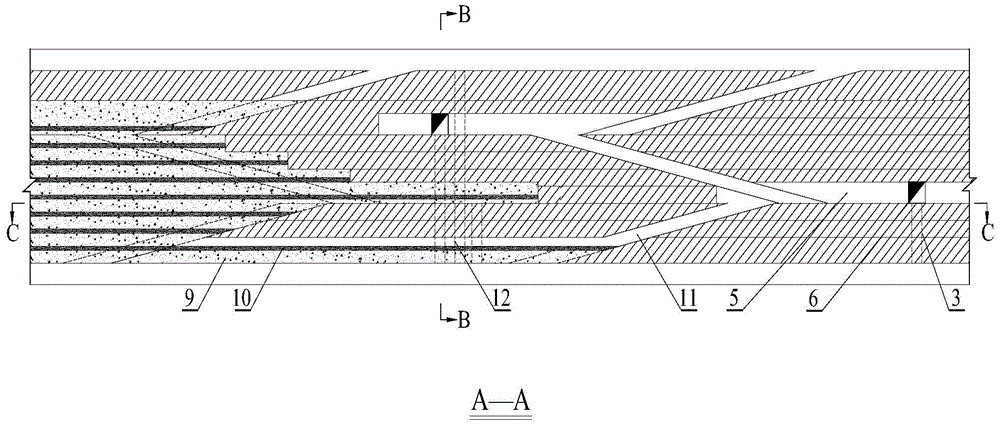

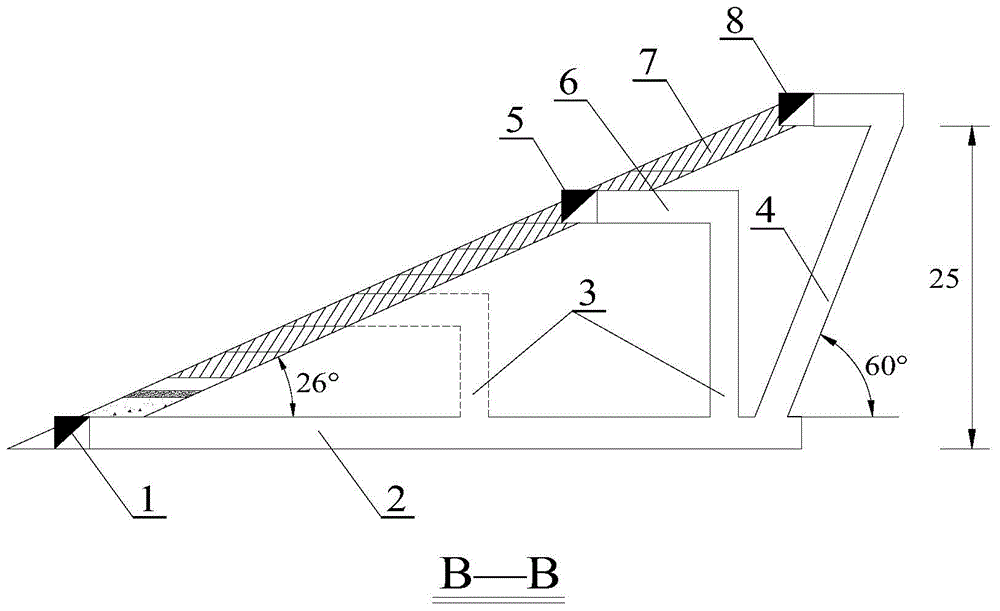

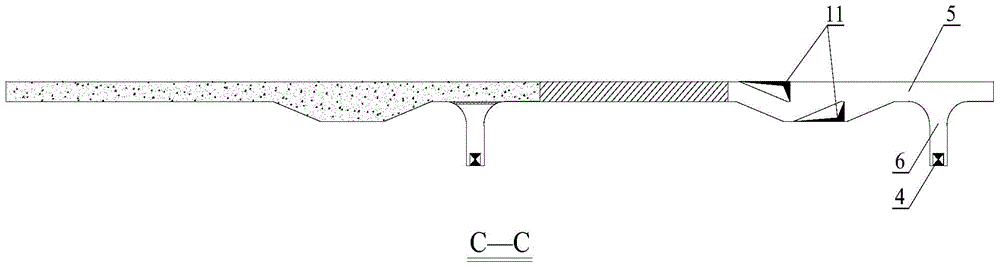

Upward cut-and-fill mining method for in-vein slope ramp of gentle dip thin vein

ActiveCN104060991AEnsure safetyImprove recovery efficiencyUnderground miningSurface miningVeinCut and fill

The invention discloses an upward cut-and-fill mining method for an in-vein slope ramp of a gentle dip thin vein. The method comprises the following steps: stoping layers of an ore body, tunneling a cross gateway from a bottom middle haulage drift to the ore body, tunneling a diagonal slope ramp along the vein to rise for certain height, and tunneling a slice drift, a reversing chamber and a sectional ore removal draw shaft forwards along the vein, wherein the reversing chamber and the sectional ore removal draw shaft are perpendicular to the slice drift; reversely tunneling the diagonal slope ramp along the vein from one side of the slice drift to rise for the certain height, and tunneling the slice drift, the reversing chamber and the sectional ore removal draw shaft along the vein; dividing a stope by using the diagonal slope ramp as the boundary, continuously propelling from one end of the vein to the other end of the vein, reaching all the layers of the ore body by virtue of the diagonal slope ramp which is tunneled in the vein, and sequentially stoping and filling from bottom to top by virtue of each layer stoping unit in the stope. The upward cut-and-fill mining method for the in-vein slope ramp of the gentle dip thin vein is high in mechanization degree, small in out-vein stope preparation engineering amount, low in labor intensity, low in ore dilution loss, safe to operate and high in efficiency.

Owner:河南发恩德矿业有限公司

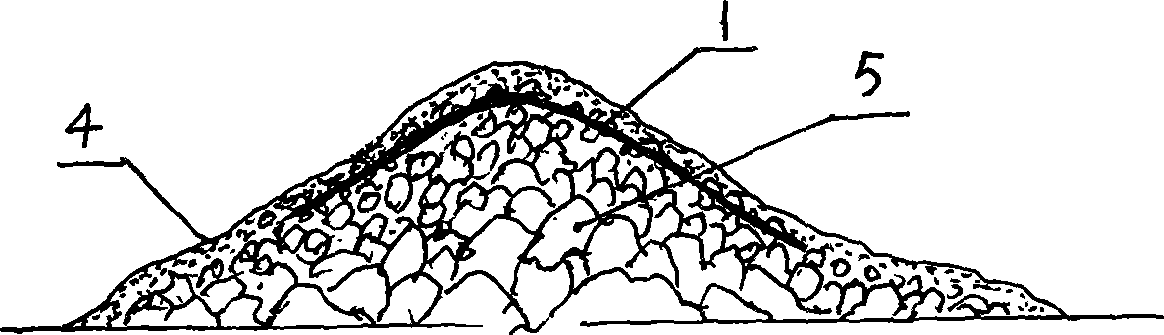

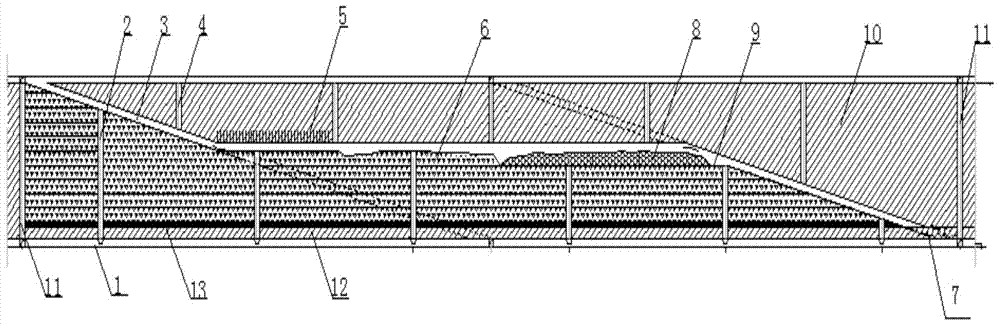

Method for comprehensively treating ecological environment of coal gangue hill

InactiveCN101519966AReduce flowAvoid formingUnderground miningSurface miningRevegetationEcological environment

The invention relates to a method for comprehensively treating the ecological environment of a coal gangue hill, which belongs to the field of mineral waste treatment and ecological environment restoration. The method mainly solves the problems of fire extinction, fire prevention and vegetation construction of the coal gangue hill. The method comprises the steps: the on-site reconnaissance of the coal gangue hill is carried out, and a construction operation plan is established; with fire prevention as principal and the combination of fire prevention and fire extinction, the fire prevention is crucial and is combined with the fire extinction, a thin layer of slurry is firstly sprayed on the coal gangue hill by a mechanical method to completely seal to form a sealing layer (8), transition slurry is sprayed on the sealing layer (8) to completely cover the sealing layer (8) to form a transition layer (9), slurry containing grass-shrub vegetation is spayed on the transition layer (9) to completely cover the transition layer (9) to form a planting layer (10); the contour line girdle band type operation in the spraying process is carried out from bottom to top to gradually and completely cover the hill, and different operating modes are selected according to practical conditions. The invention can not disturb the structure of the coal gangue hill, takes the fire prevention as the principal, combines the fire prevention with the fire extinction, has good and durable fire prevention effect, uses reliable and effective fire prevention and fire extinction measures as guarantee conditions to construct the planting layer, adopts grass-shrub plants, carries out hill sealing management and ensures vegetation restoration; in addition, the method uses the prior specialized mechanical devices to carry out construction operation, is easy to implement, has little difficulty, high efficiency and low investment and can ensure treatment effect.

Owner:赵平 +1

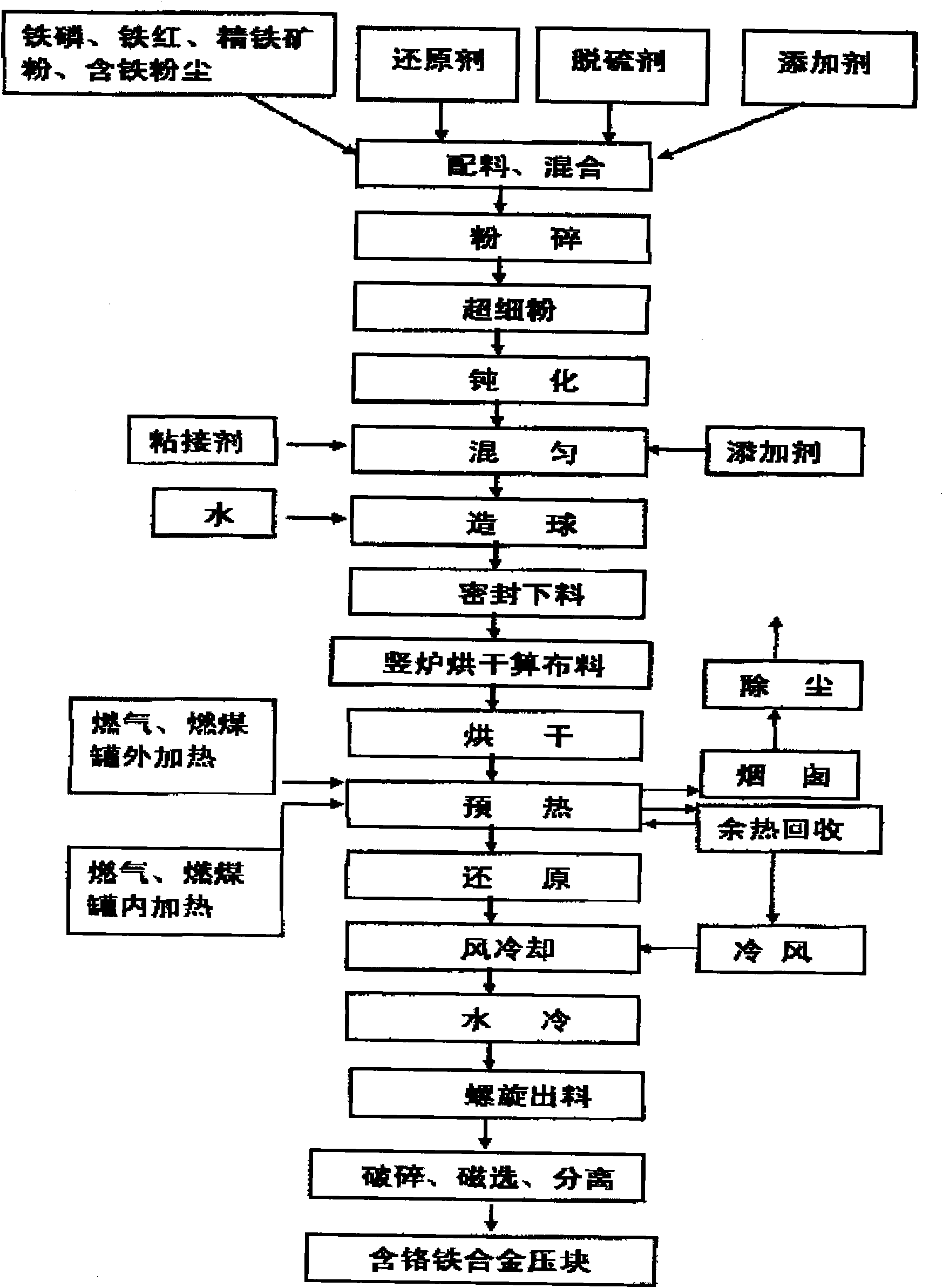

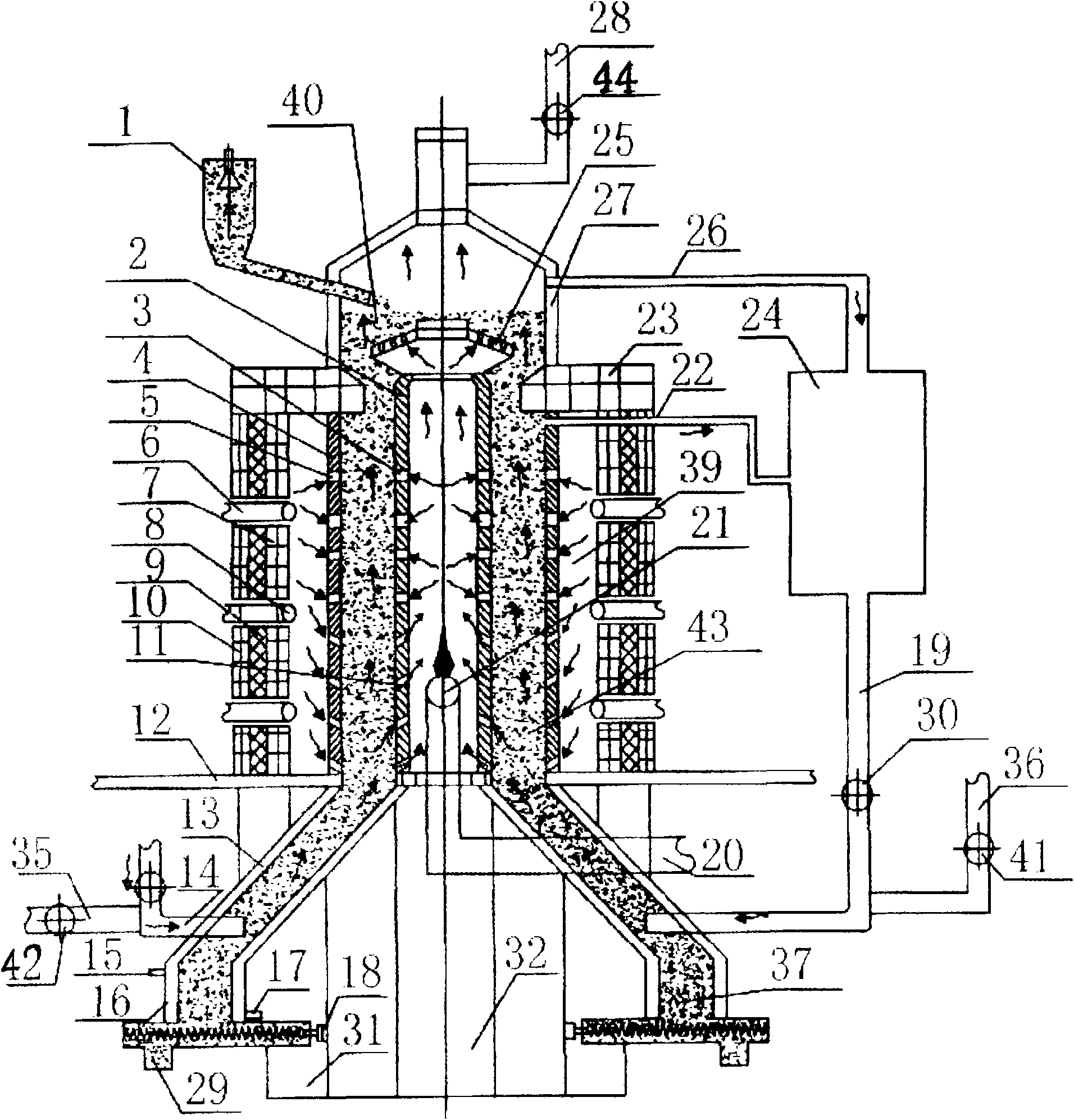

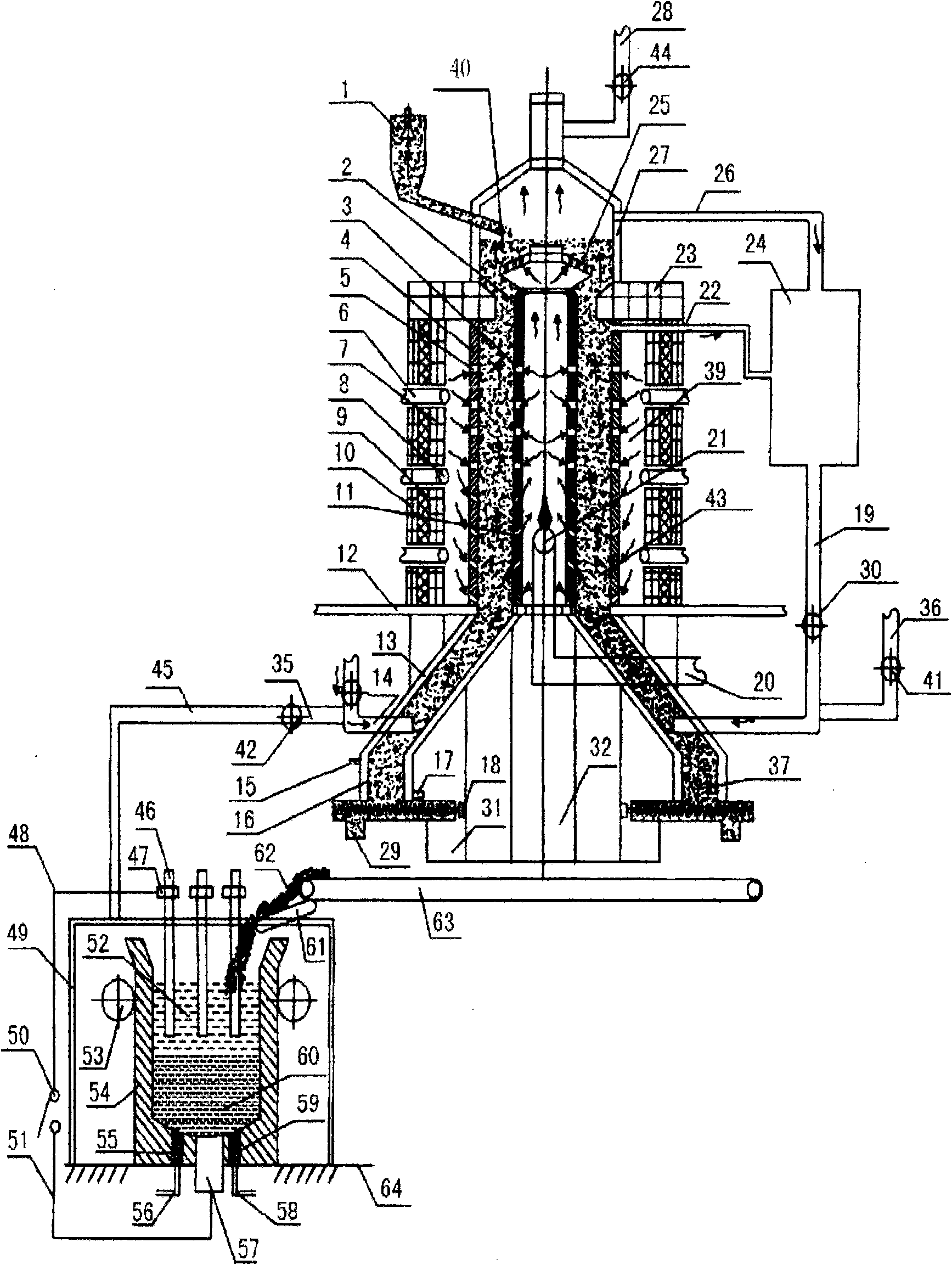

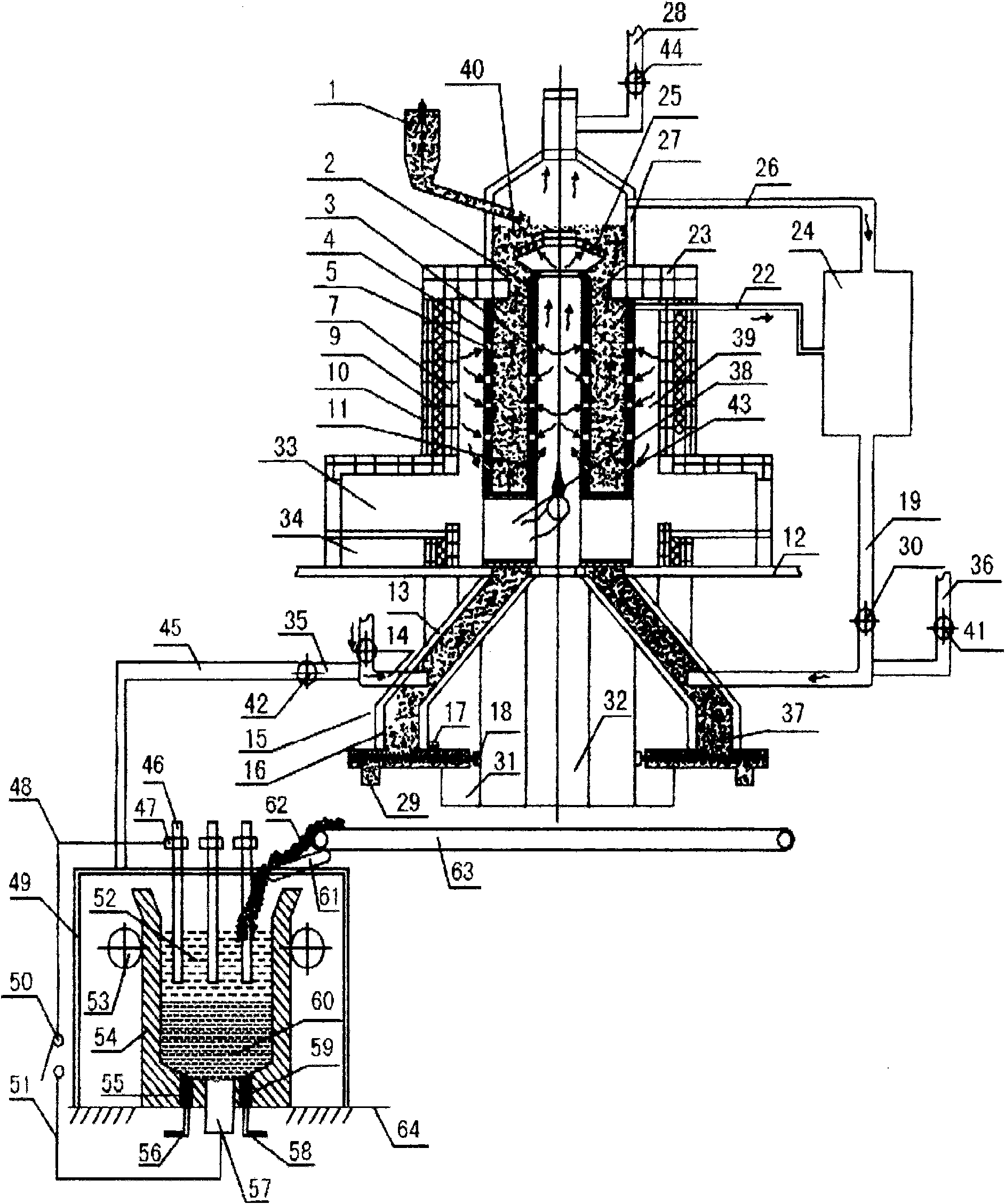

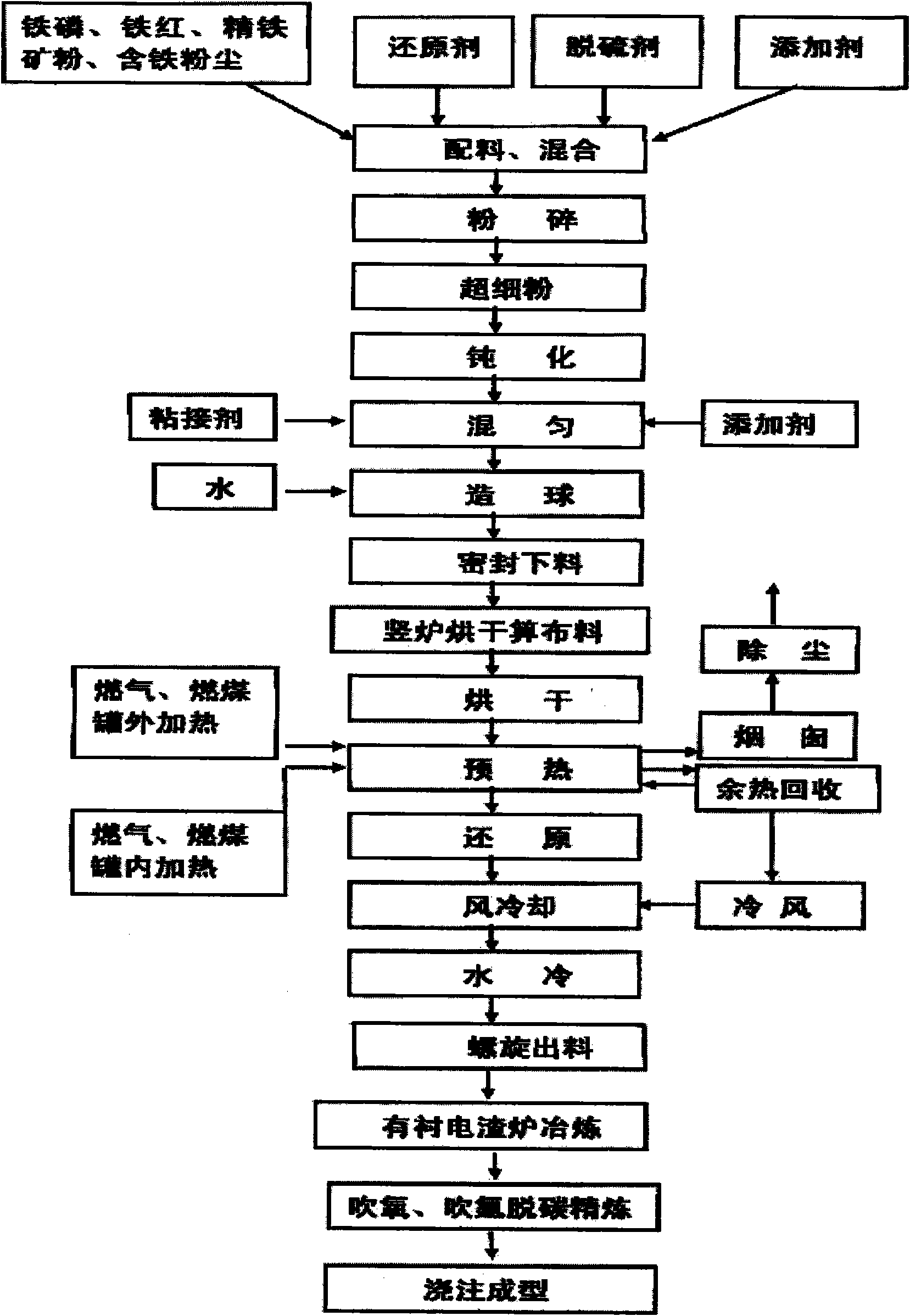

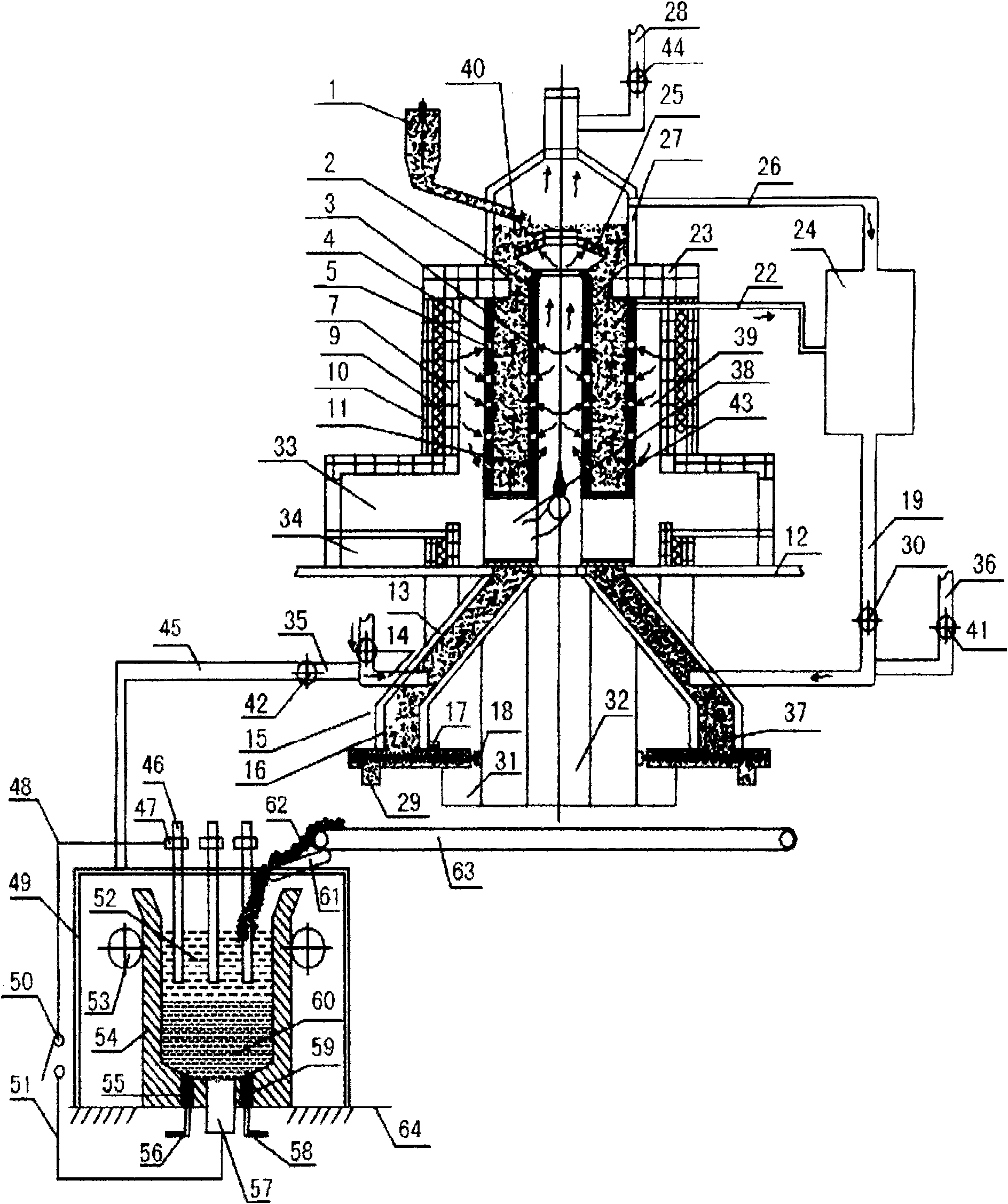

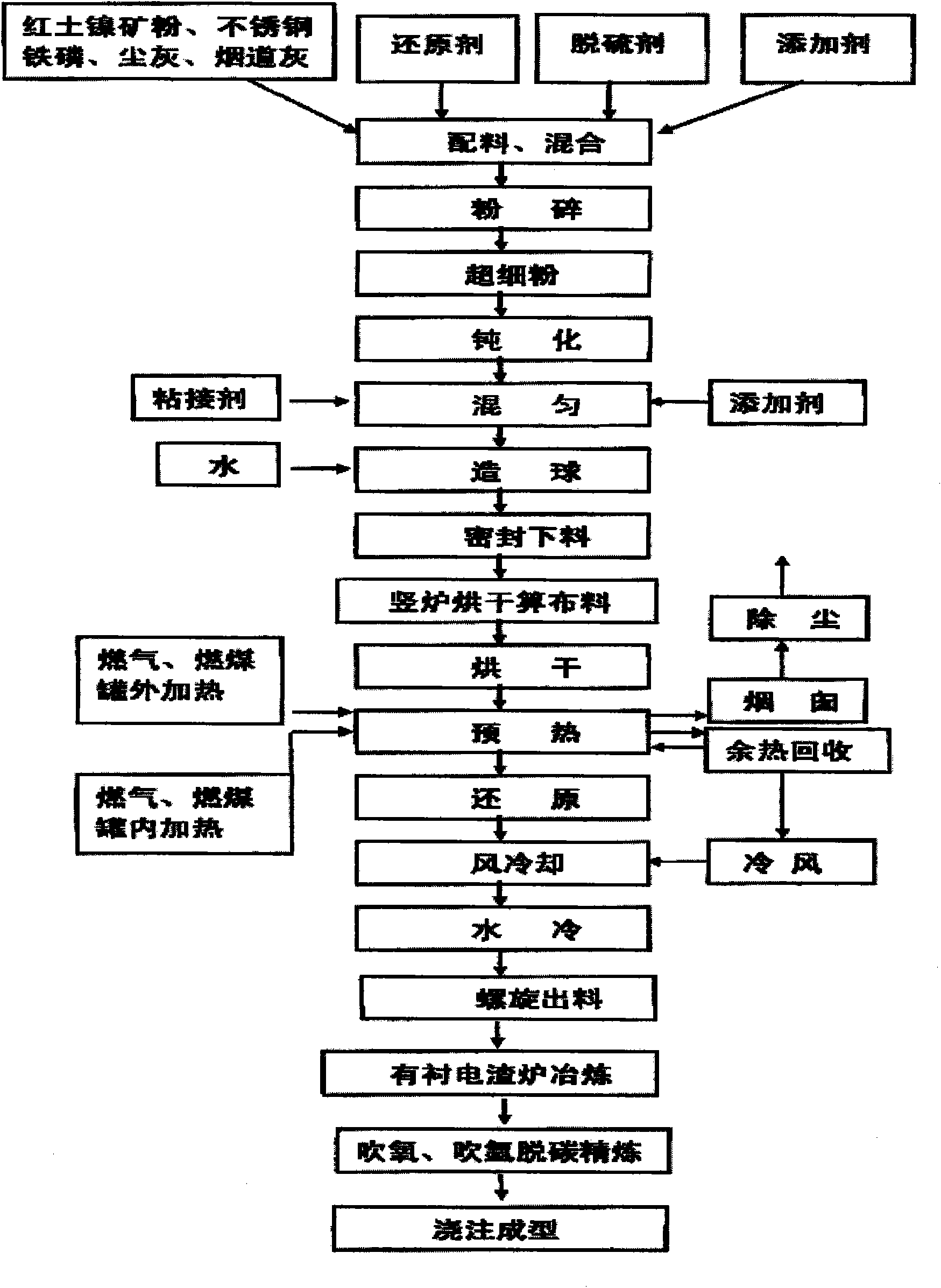

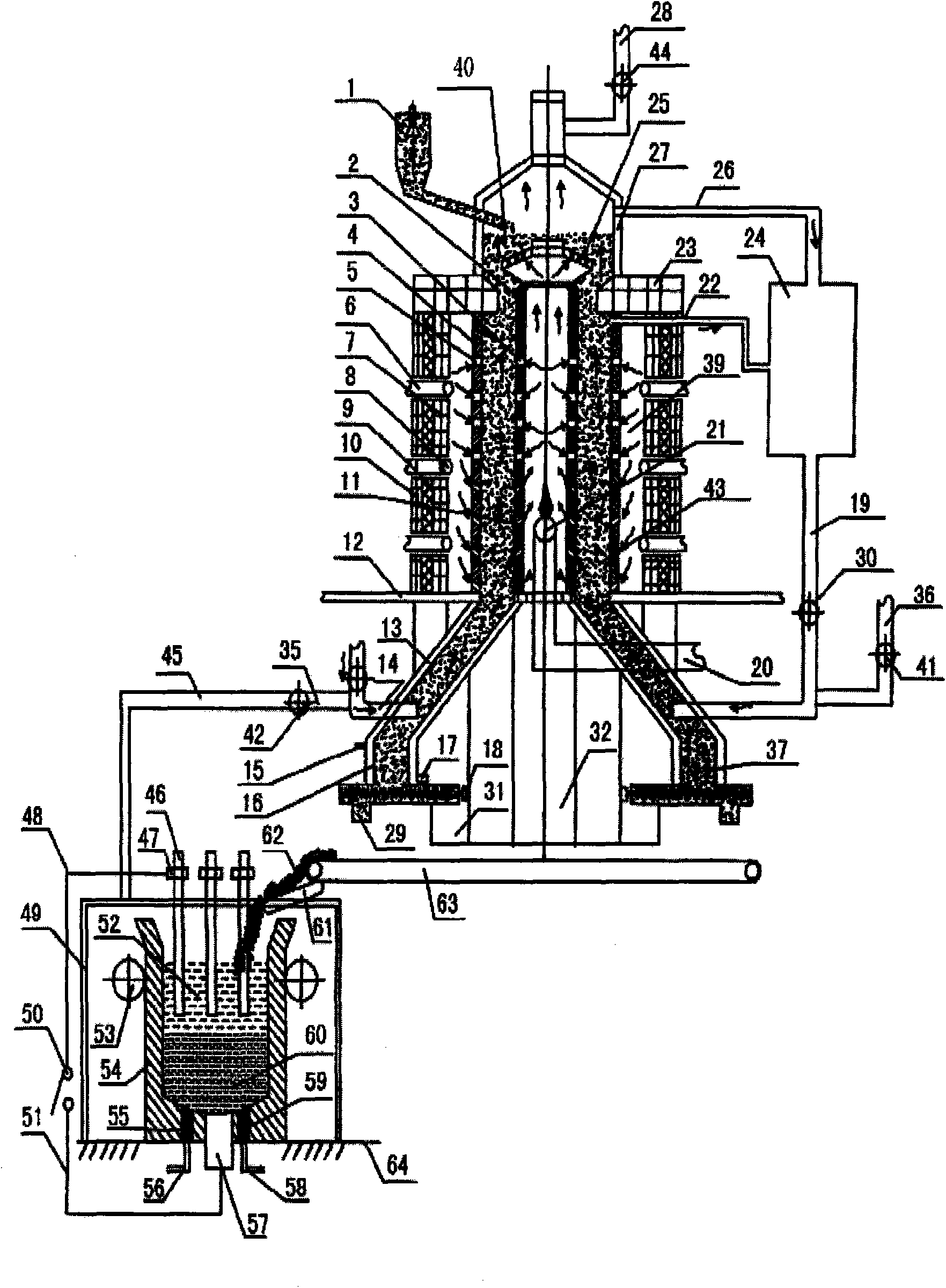

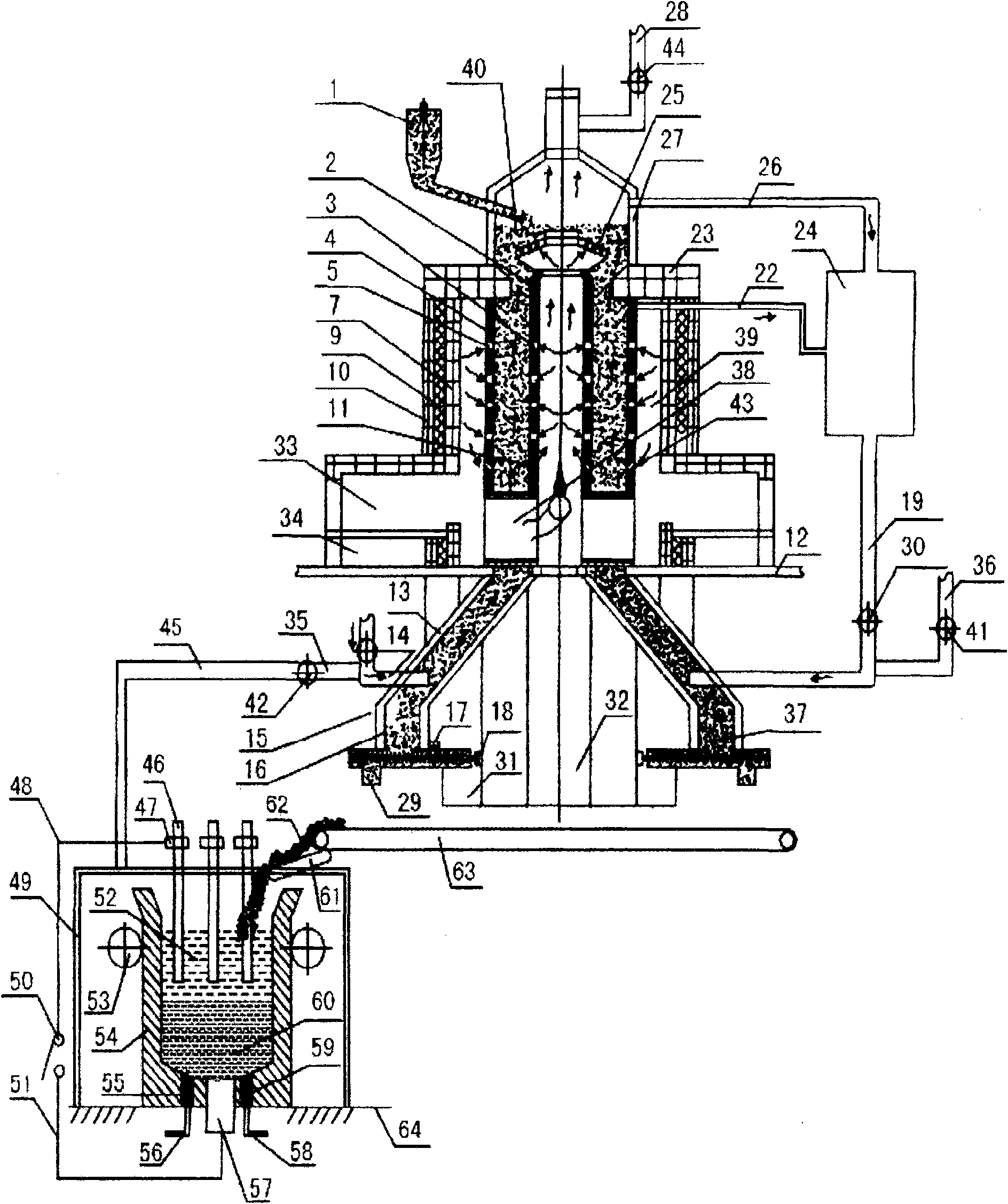

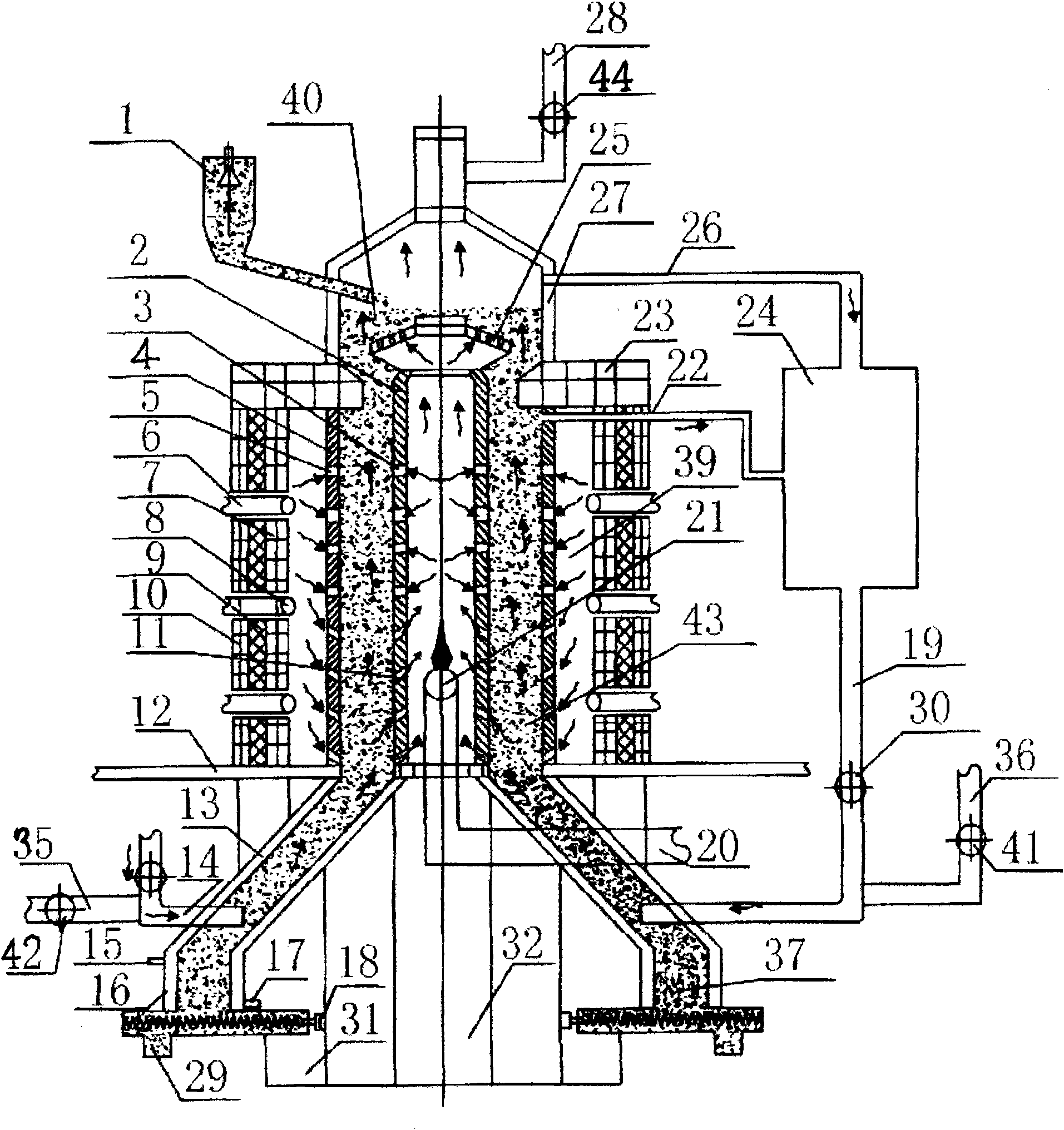

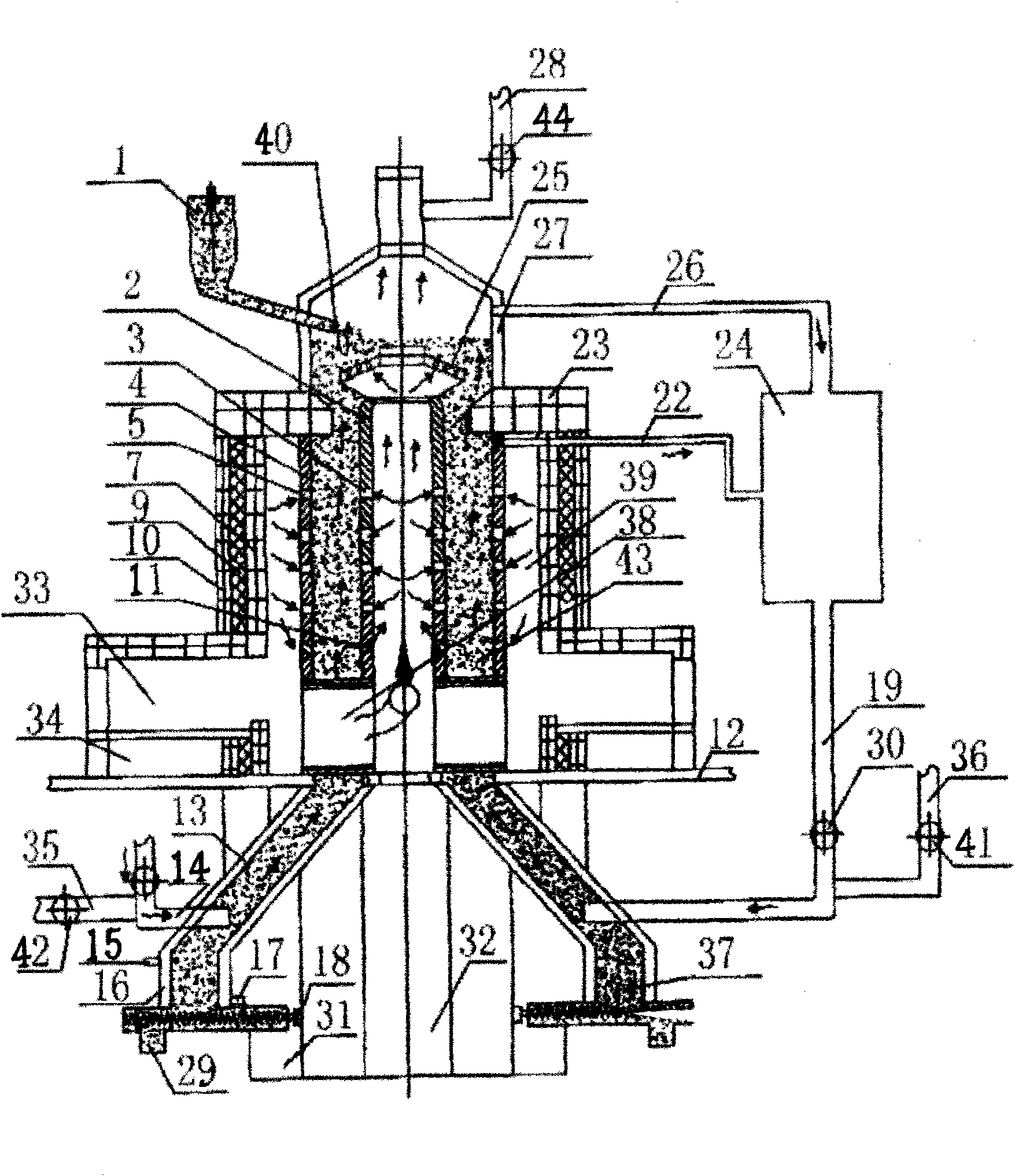

Preparation process and device of sponge iron

InactiveCN101538632AGuaranteed uniformityReduce wasteProcess efficiency improvementShaft furnaceResource consumptionUltra fine

The invention relates to a preparation process and a device of sponge iron, belonging to metallurgical industry steel-making raw material. The process comprises the following steps: mixing iron-containing raw materials with reducing agent, solvent and catalyst to prepare ultra fine powder, passivating and mixing to make pelletizing materials, sending the prepared pelletizing materials into a reducing furnace, drying and roasting, and obtaining sponge iron after the reduction reaction. The reducing device is connected with an upper furnace above a furnace base, a lower furnace body is connected to the downside of the furnace base, the upper end of the upper furnace body is connected with an upper furnace mantle, a drying bed grate is positioned at the upper end in the upper furnace body, a purifying device is connected with the upper furnace body and the lower furnace body through pipelines, and a residual heat circulating device is connected with the lower furnace body. The invention has the advantages that: firstly, the reduction temperature is reduced, the reduction speed is increased, the energy consumption is reduced, the production cost is lowered, the production efficiency is improved, and the uniformity of the quality is ensured; secondly, the degree of mechanization is high, the procedure is simple, the yield is large, the mass production can be performed; thirdly, the waste of raw materials is lowered, the environment pollution is reduced; and fourthly, the waste resource can be recycled so as to save the resource consumption.

Owner:丁家伟 +1

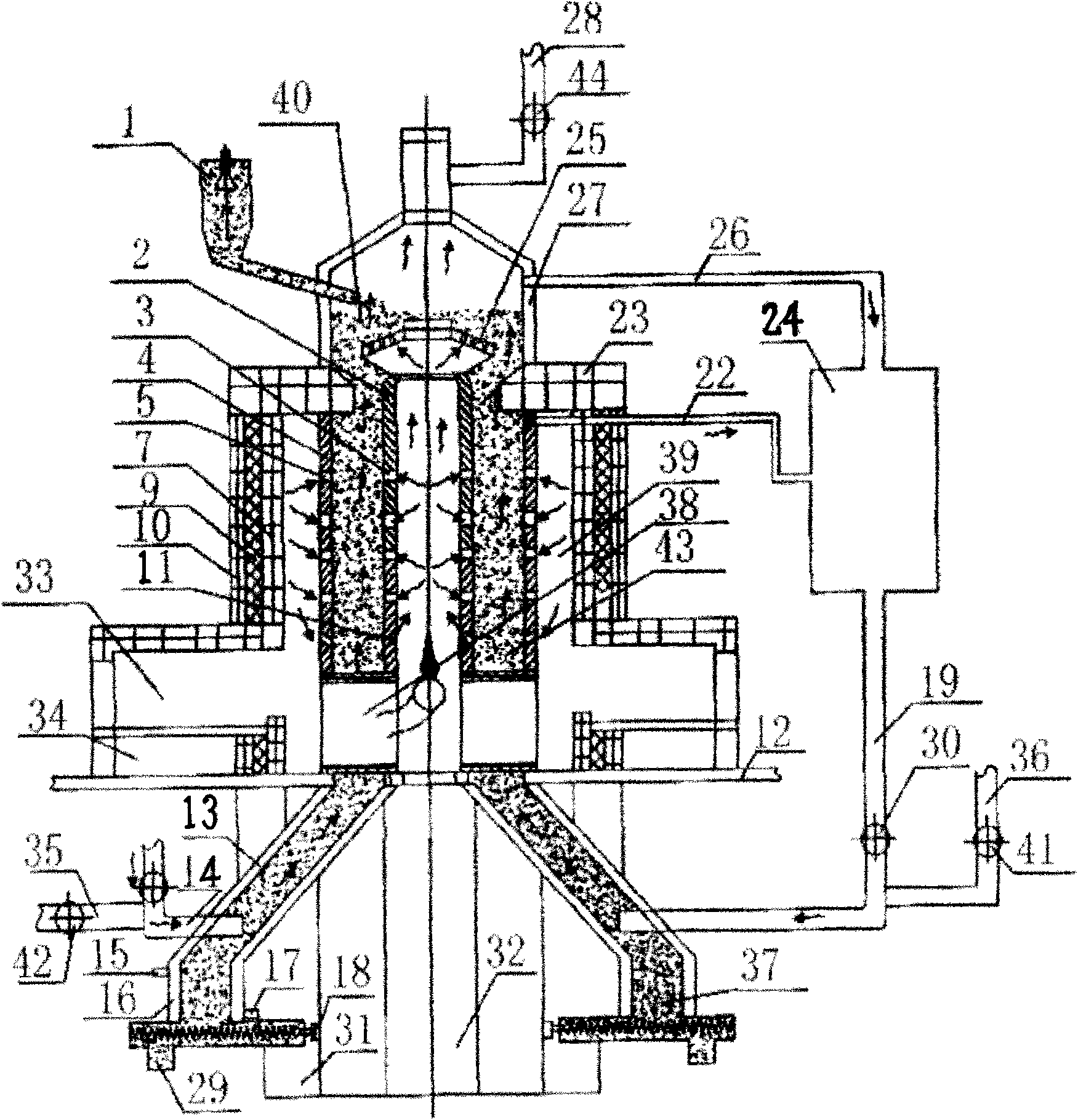

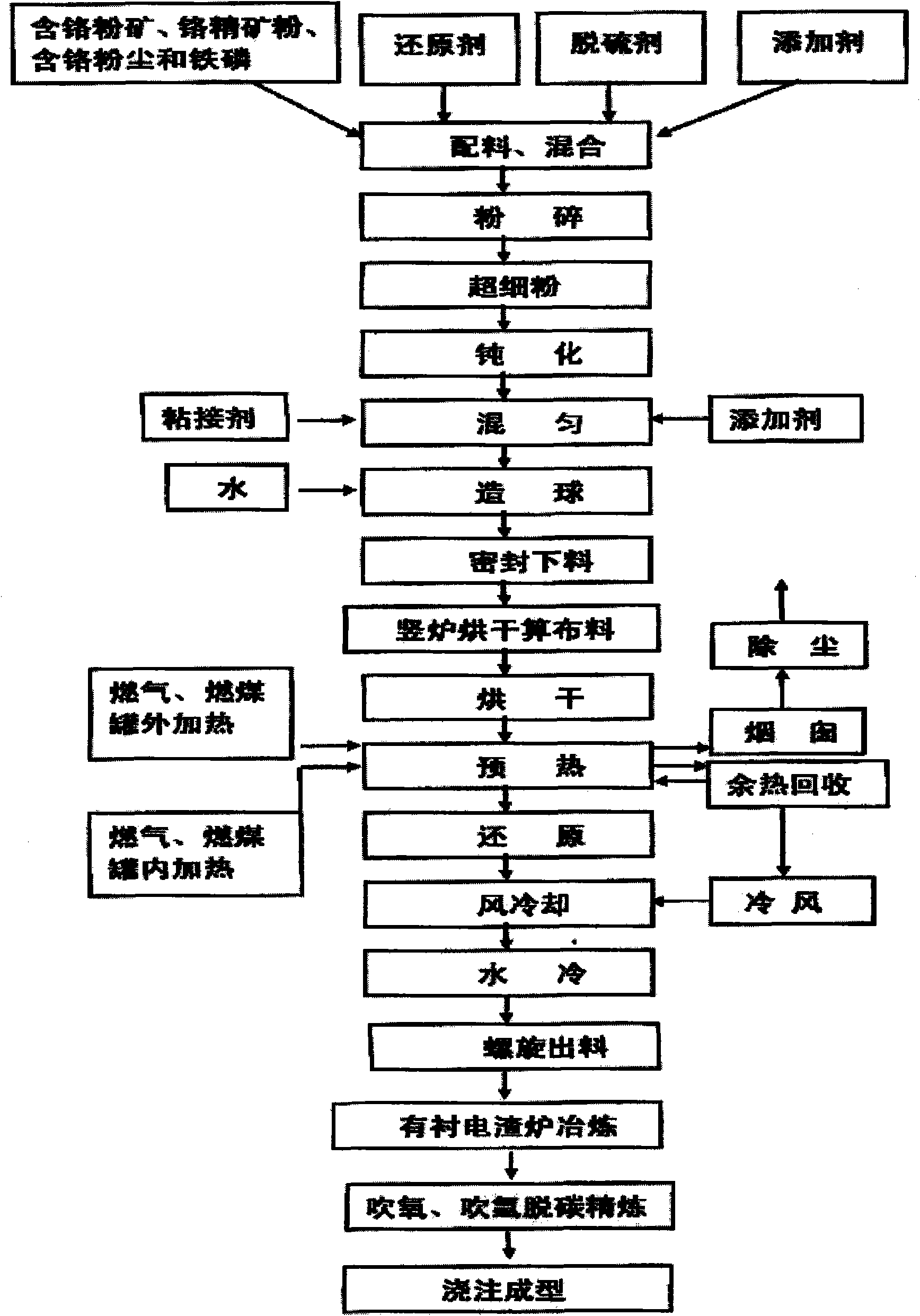

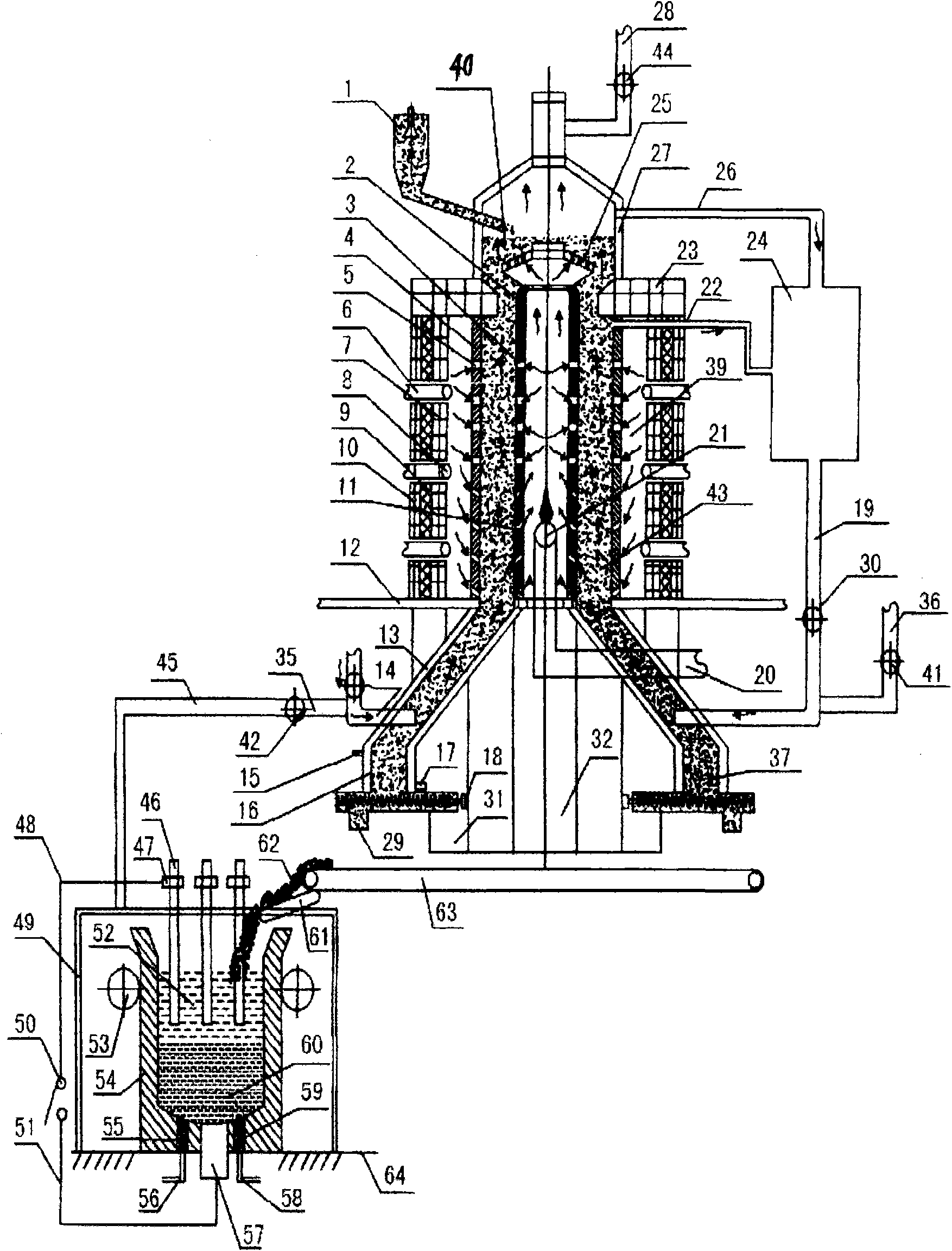

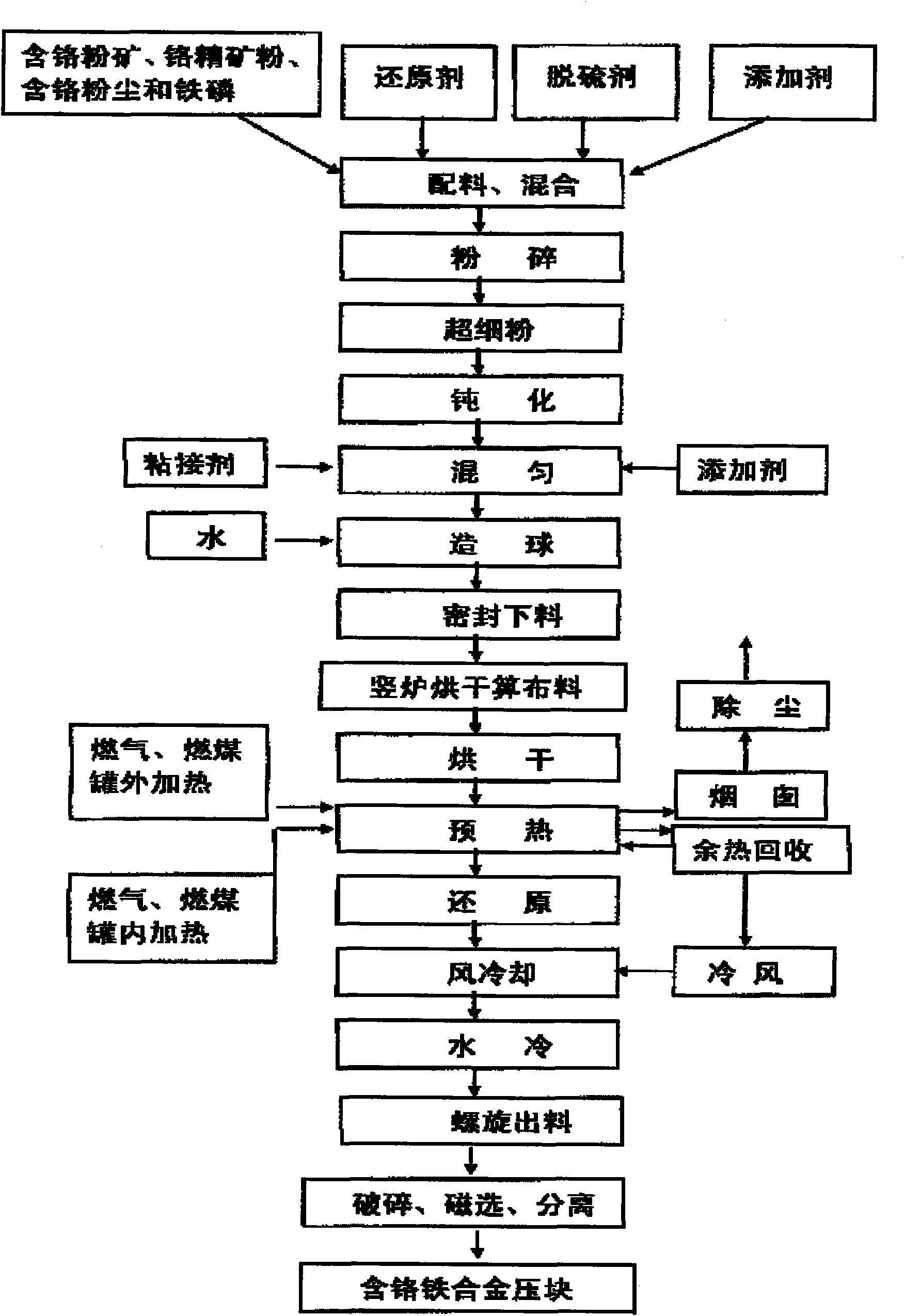

Process and device for smelting chromium irons and chromium-containing molten iron by using chromium ore powder

InactiveCN101538629AImprove applicabilityHigh recovery rateProcess efficiency improvementShaft furnaceUltra fineSolvent

The invention relates to a process and a device for smelting chromium irons and chromium-containing molten iron by using chromium ore powder, which belongs to metallurgical industry steel-making raw material. The process comprises the following steps: mixing chromium iron containing raw materials with reducing agent, solvent and catalyst to prepare ultra fine powder, mixing to make pelletizing materials, sending the pelletizing materials into a reducing furnace, obtaining chromium irons pellets after the reduction reaction, and directly adding reduced pellets into a lining electroslag furnace for being smelted into the chromium-iron alloy or the chromium-containing molten iron. The device comprises an internal-external heating vertical reducing furnace, a lining electroslag furnace and a residual heat recovery system. The invention has the advantages that: firstly, the reduction temperature is low, the speed is high, the energy consumption is reduced, the production cost is lowered, the production efficiency is high, and the uniformity of the quality is good; secondly, the degree of mechanization is high, the procedure is simple, the yield is large, the mass production can be performed; thirdly, the waste of raw materials is reduced, the environment pollution is lowered; fourthly, the source of raw materials adopting the chromium ore powder and chromium-containing waste, the cost is low; fifthly, the waste resource can be recycled so as to save the resource consumption; and sixthly, the high-temperature pellets are directly smelted by adopting the lining electroslag furnace, the heat efficiency is high, the energy consumption is low, the material purity is high and the quality is good, and the device is simple with less investment.

Owner:丁家伟

Mechanical continuous mining method for gently inclined thin ore body

ActiveCN101975064ASolve the mining disasterResolutionUnderground miningSurface miningEngineeringDrill

The invention discloses a mechanical continuous mining method for a gently inclined thin ore body. Based on the principle of lengthening the slope distance to reduce the angle, ore blocks are arranged in an inclined way, so that an angle smaller than the original inclination angle can be formed between a working plane and the horizontal plane, thus creating an operating space for a drill jumbo and a scraper; a return air shaft is arranged at the corner of one ore room so as to be communicated with an upper horizontal return airway; each ore room is provided with an orepass used for the transmission of ores in the ore room; and a tunnel is respectively excavated along the strike direction above and below each ore room, the upper tunnel is used for ventilation connection, and the lower tunnel is used for ore removal connection. The invention is especially applicable to the mining of the gently inclined thin ore body of an underground mine, mining preparation has no requirements for undercutting projects, and the drill jumbos and scrapers are used for the operation, thereby achieving the characteristics of high degree of mechanization, high production efficiency, full-thickness continuous mining and low ore loss rate.

Owner:CENT SOUTH UNIV

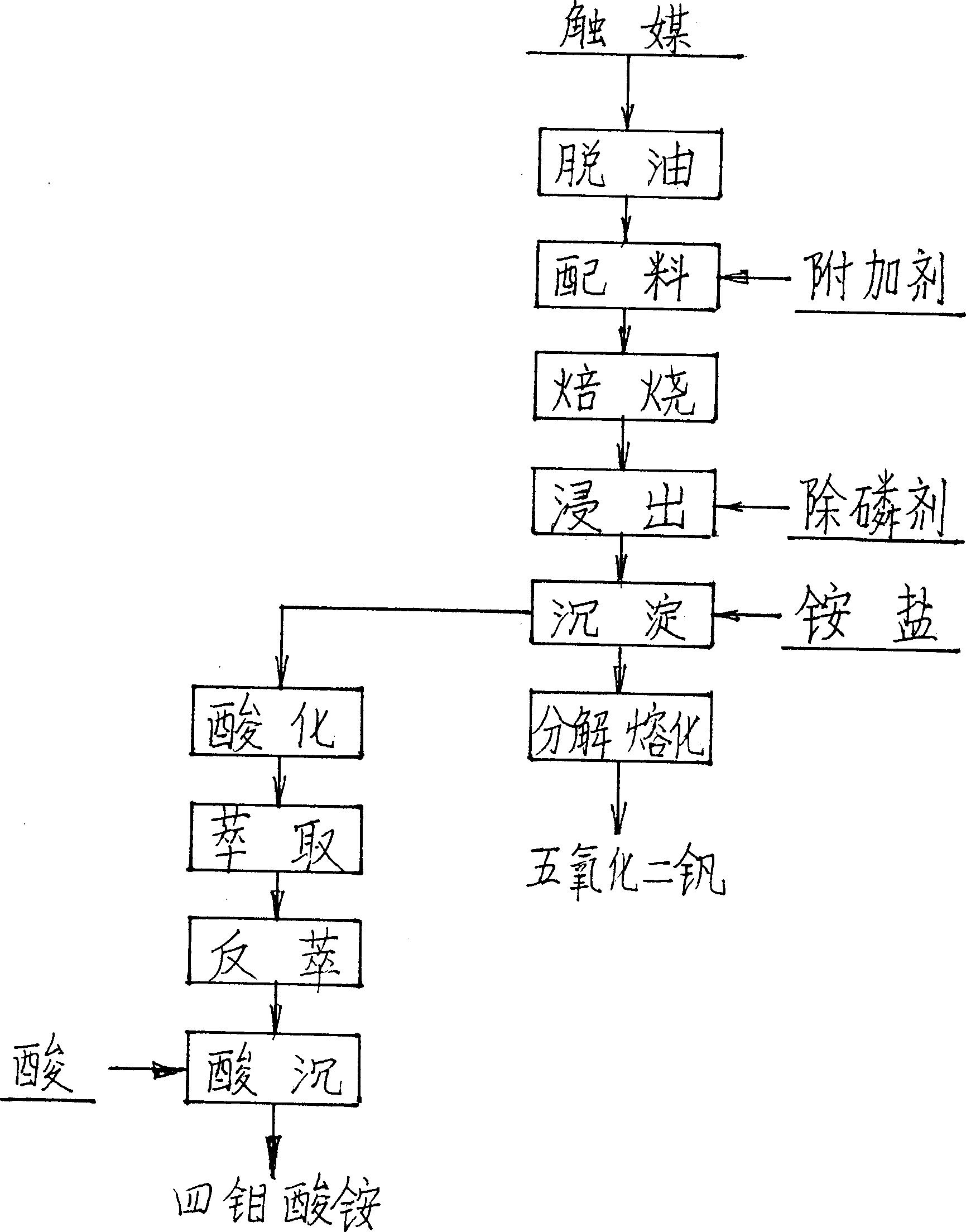

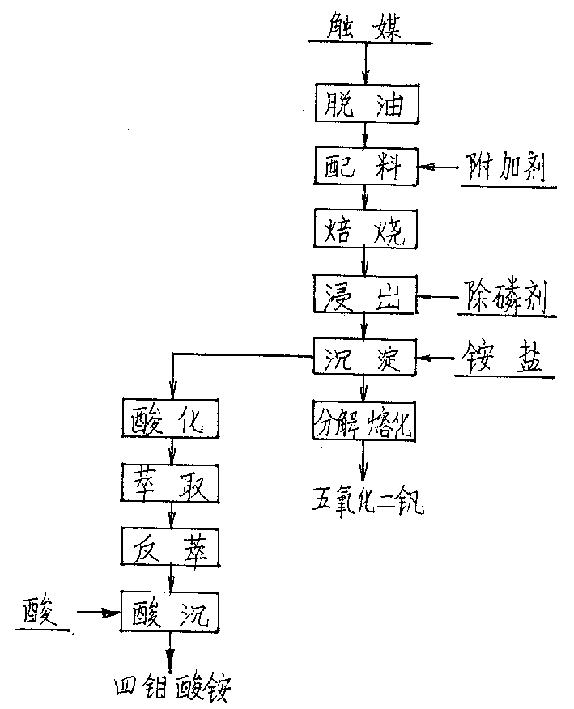

Wet process of extracting vanadium and/or molybdenum from waste catalyst

InactiveCN1453379ALess investmentReduce consumptionProcess efficiency improvementMagnesium saltAmmonium metavanadate

The present invention is wet process of extracting vanadium and / or molybdenum form waste petrochemical catalyst alumina carrier containing V, Mo and other elements. The wet process includes high-temperature deoiling the catalyst in natural granularity, mixing with sodium carbonate, high-temperature oxidation and roasting in a kiln or furnace to obtain water soluble sodium vanadate and sodium molybdate; countercurrent water soaking of the chamotte to obtain solution containing V and Mo in certain concentration, adding calcium salt and magnesium salt to eliminate P and other impurities, addingammonium salt solution into the clear solution to obtain ammonium metavanadate, decomposing and melting ammonium metavanadate to obtain V2O5 product; adding acid to the supernatant and organic phase extraction of Mo, ammonia water reverse extraction to obtain ammonium molybdate, and adding acid to precipitate ammonium tetramolybdate or molybdate product.

Owner:CITIC JINZHOU METAL

High-intensity wood plastic composite board and fabrication method thereof

InactiveCN101708614AEasy to produceHigh strengthWood veneer joiningFlat articlesMechanical propertyWhite oil

The invention relates to a wood plastic composite, in particular to a high-intensity wood plastic composite board and a fabrication method thereof. The method for fabricating the high-intensity wood plastic composite board comprises the following steps: treating nano titanium dioxide with silane coupling agent to obtain modified nano titanium dioxide; mechanically stirring the modified nano titanium dioxide, plastic particles, maleic anhydride grafted plastic particles, calcium stearate and the like, and extruding and pelleting all the materials to obtain modified plastic particles; mechanically stirring the modified plastic particles, wood flour, terpene resin, chopped glass fiber, white oil, antioxidant and the like, and extruding, melt-blending and pelleting all the materials to obtain high-intensity wood plastic composite particles; and finally extruding the high-intensity wood plastic composite particles with a machine to mold the high-intensity wood plastic composite board. The high-intensity wood plastic composite board has extremely wide application range, and is applied to the fields such as transportation, construction, decoration, ornament, municipal works, garden and park, packaging and the like. The high-intensity wood plastic composite board has the advantages of reproducibility, low cost and higher mechanical properties such as static bending strength and the like, thereby being an ideal material for replacing wood. Compared with traditional wood plastic composites, the high-intensity wood plastic composite board has longer service life, and is a novel upgrade product of the present wood plastic composites.

Owner:江苏森诺塑胶科技有限公司

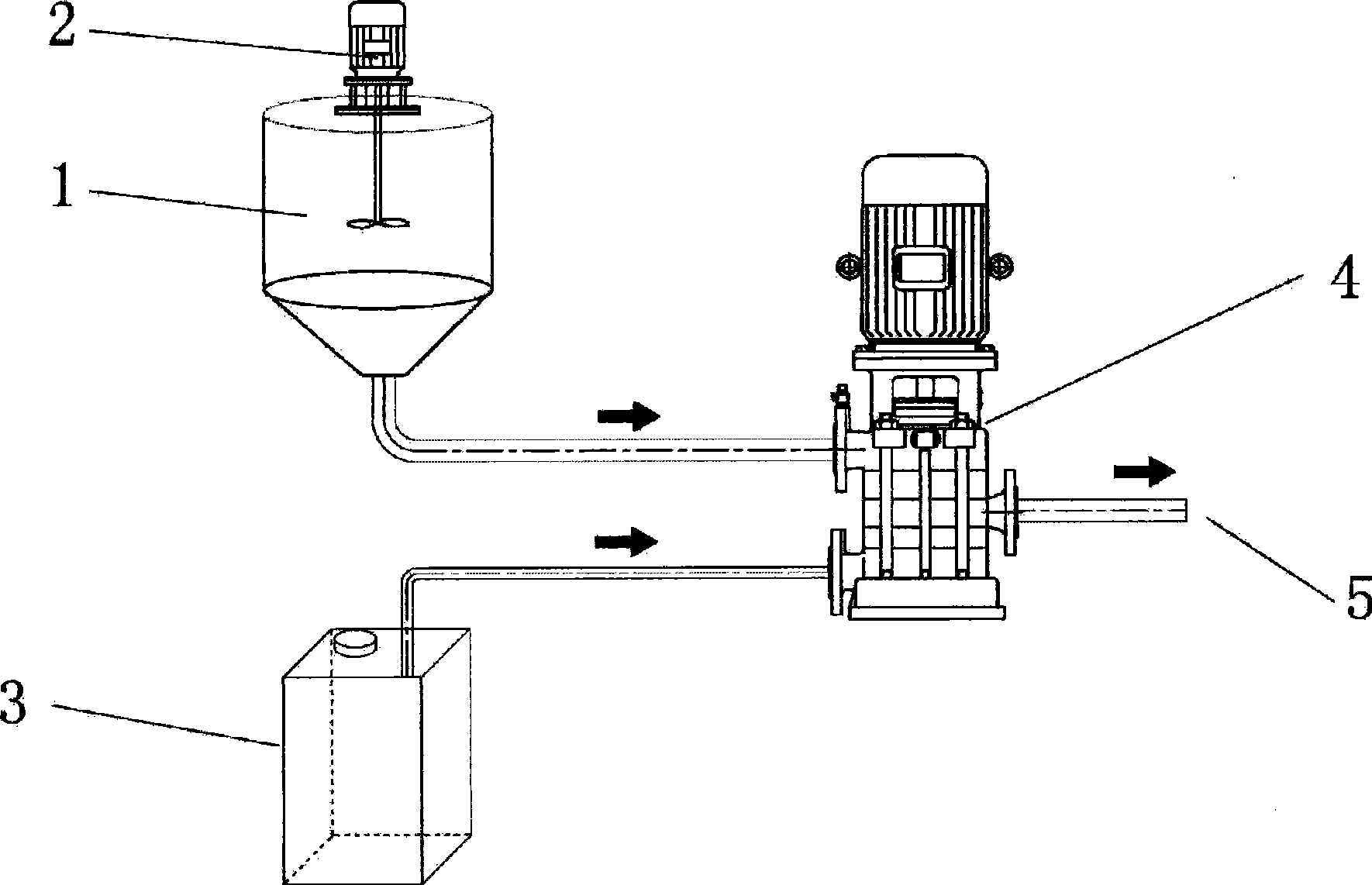

Sludge treatment method and sludge foaming lightweight concrete produced therefrom and use

InactiveCN101381191ASolve processing problemsNo pollutionSludge treatmentSolid waste managementFoaming agentFilling materials

The invention discloses a sludge treatment method, as well as sludge foamed lightweight concrete produced through the method and application thereof. In the method, sludge produced by sewage treatment first reacts with quicklime so as to form sludge hydrated lime; then the sludge hydrated lime is mixed with cement and water so as to form sludge concrete; foaming agent produces foam by utilizing a foaming system of a foaming machine; and the foam is mixed with the sludge concrete. The sludge treatment method can directly obtain the sludge foamed lightweight concrete. The sludge foamed lightweight concrete has a plurality of functions, which can be used as a filling material, a heat insulating material, a walling material, a sound insulation material, a mine tunnel filling material, an artificial landscape manufacturing material, a road recovery material, a pipe base filling material and the like. The sludge treatment method is low in cost and friendly to environment, can directly produce the sludge foamed lightweight concrete with a plurality of functions, and not only solves the sludge treatment problems in the sewage treatment industry, but also ensures the full utilization of the sludge.

Owner:BEIJING SIFANGRUGANG CONCRETE PROD

Ginkgoleaf oral cavity disintegrating tablet and its preparation method

ActiveCN1555843AImprove Medication AdherenceSolve the difficulty of taking medicineUnknown materialsPharmaceutical non-active ingredientsCoronary heart diseaseAngina

A oral disintegating tablet of gingko leaf for treating coronary heart disease, angina pectoris, acute cerebral infaction and cerebral arte riosclerosis is prepared from the extract of gingko leaf, filler, disintegrant, flavouring, flowing aid, lubricant, etc.

Owner:GUIZHOU YIBAI PHARMA CO LTD

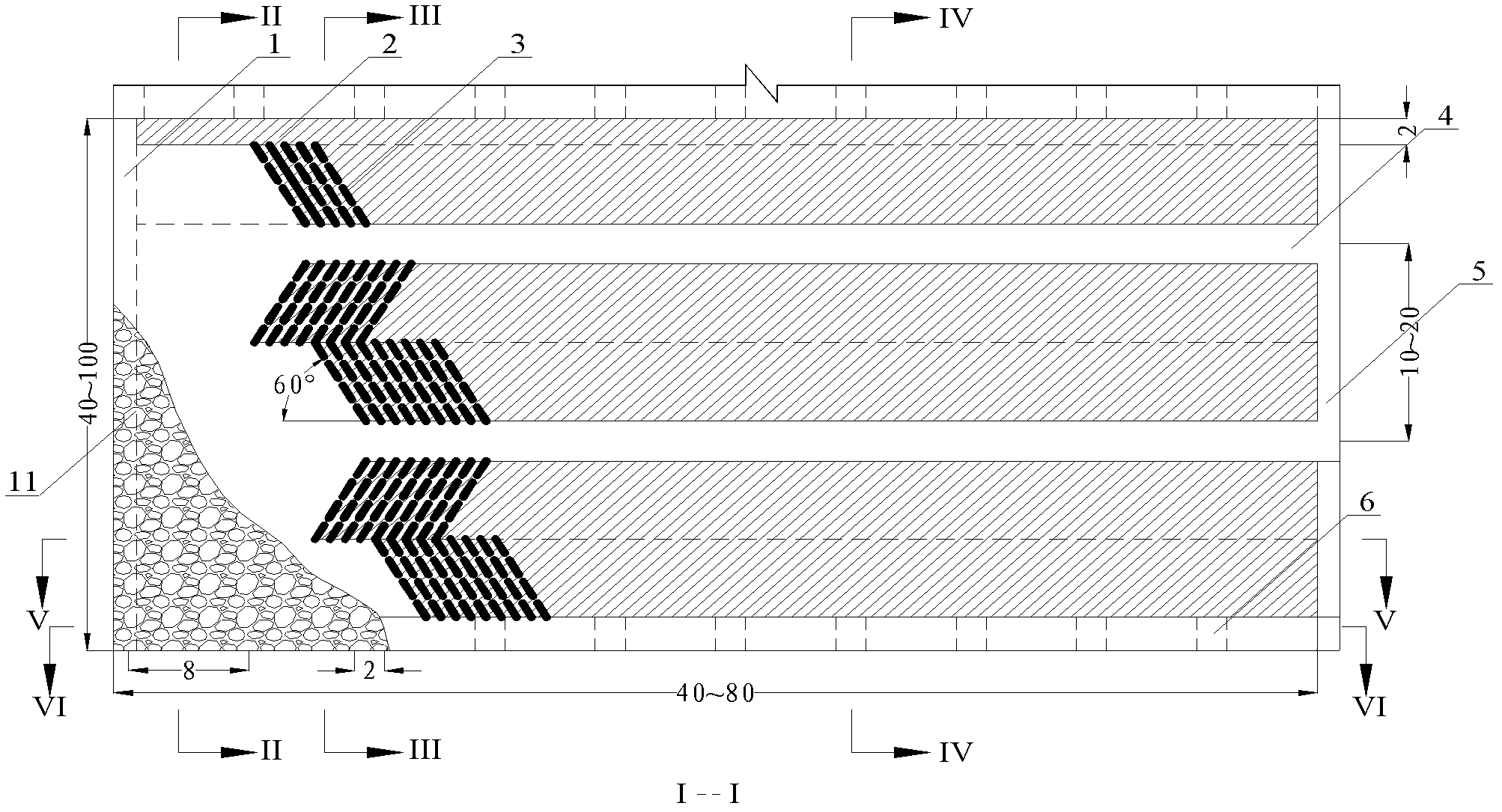

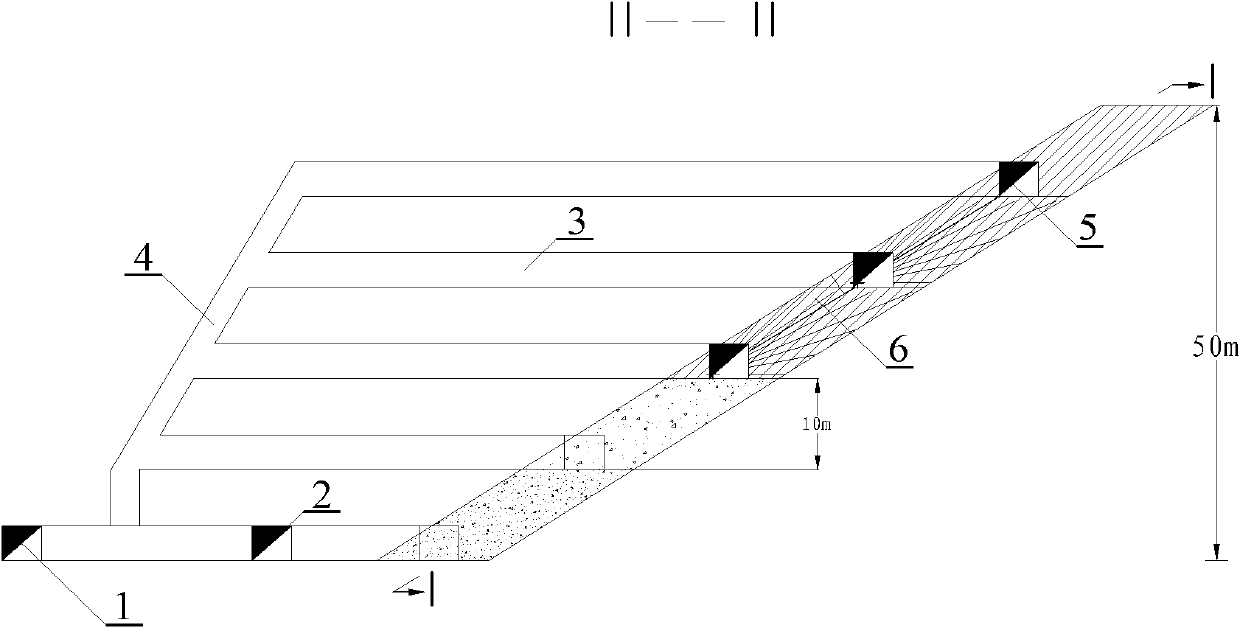

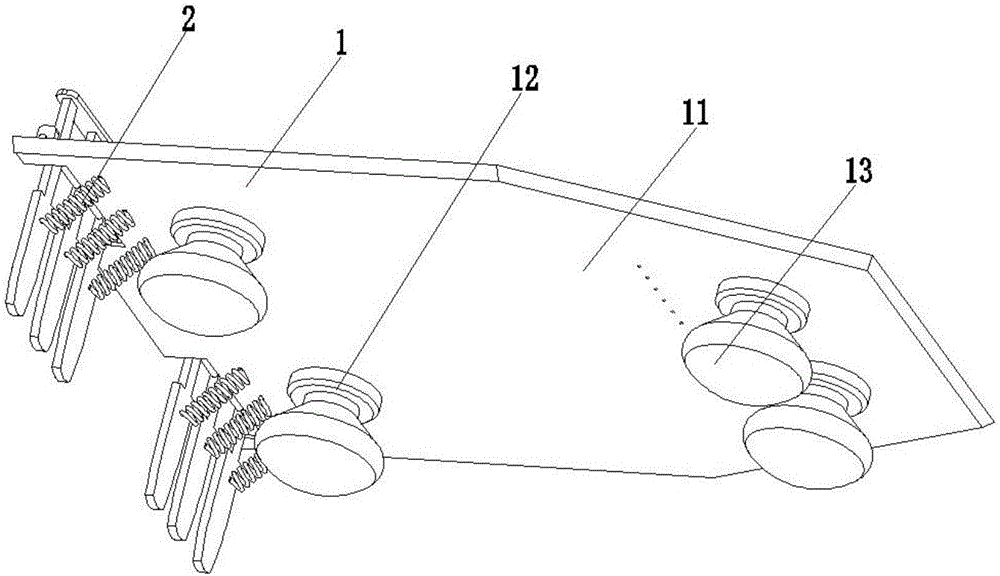

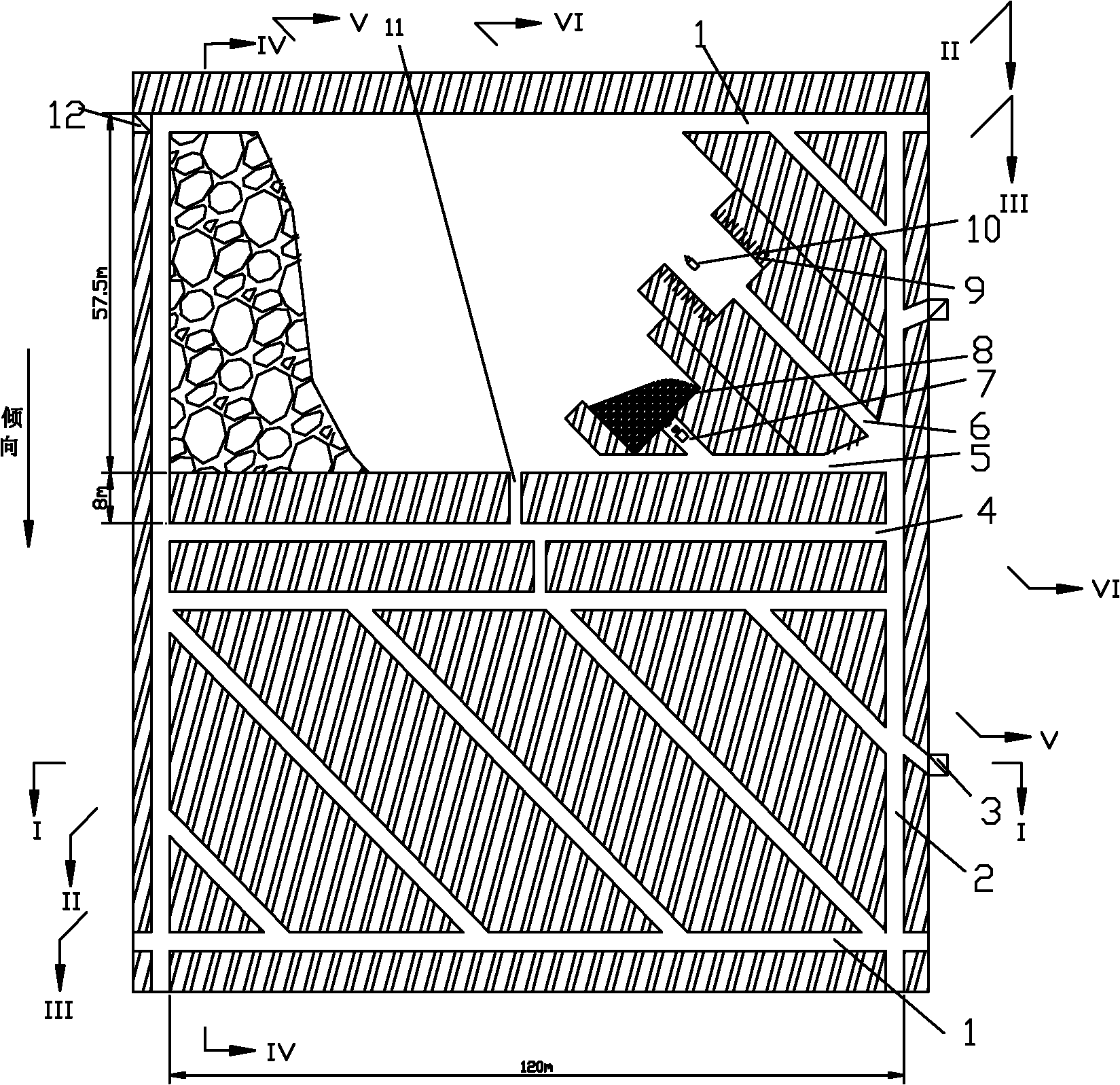

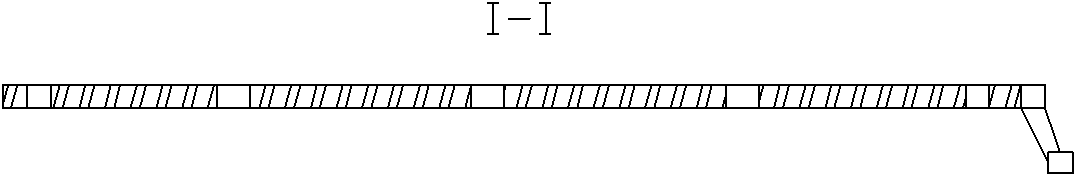

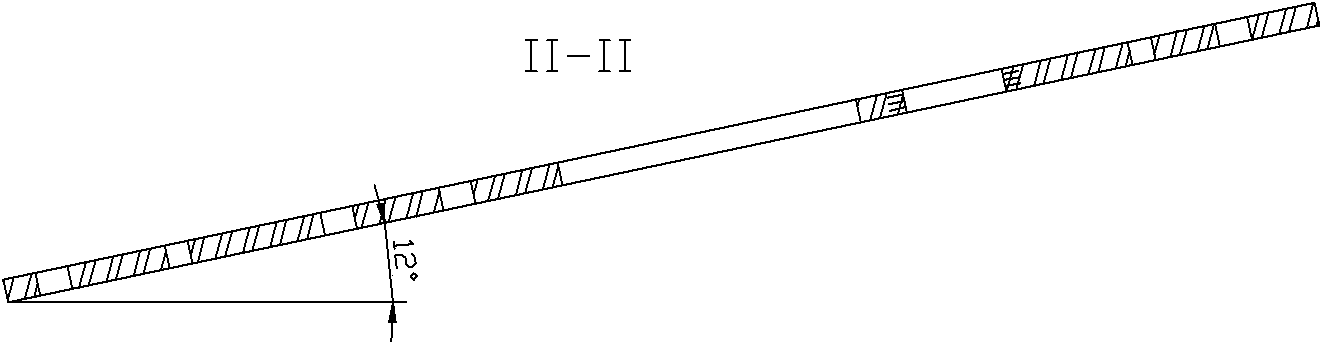

Thin ore-body mechanized highly-layering continuous mining method

ActiveCN104747190AIncrease production capacityHigh degree of mechanizationUnderground miningSurface miningMineralogyPedestrian

The invention discloses a thin ore-body mechanized highly-layering continuous mining method. The method comprises the following steps: (a) a vein division stage: dividing a vein into a plurality of parallelogram ore blocks by utilizing 15 to 20 percent gradient slope ramps along the direction of an ore body; (b) arranging a pedestrian ventilation raise and a filling raise, and pouring an artificial fake bottom; (c) carrying out layering extraction from an undercutting layer of a stope room, and forming a complete in-vein slope ramp; (d) dividing the stope room into a rock drilling working face, an ore production working face and a filling working face, wherein the three working faces are alternately operated in parallel; (e) carrying out layering operation on a stope, wherein the layering operation includes rock drilling, explosive loading, detonation, ventilation, prying, ore discharging, ore powder clearing, arranging of an on-the-way ore chute, filling, stope support and laying of a concrete soleplate; (f) recovering a bottom column after the stope room is extracted. By adopting the method, the slope ramp stope preparation in the vein, fully mechanized operation and highly-layering filling can be realized. The method has the advantages of high mining safety, small mining-cutting ratio, small ore loss and depletion and high production efficiency.

Owner:GUANGXI UNIV

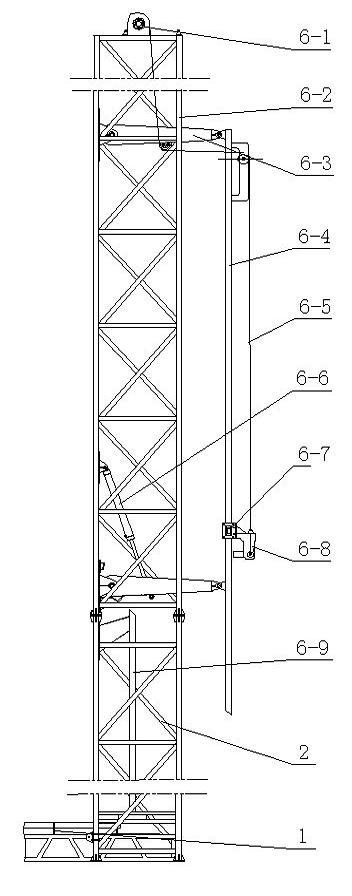

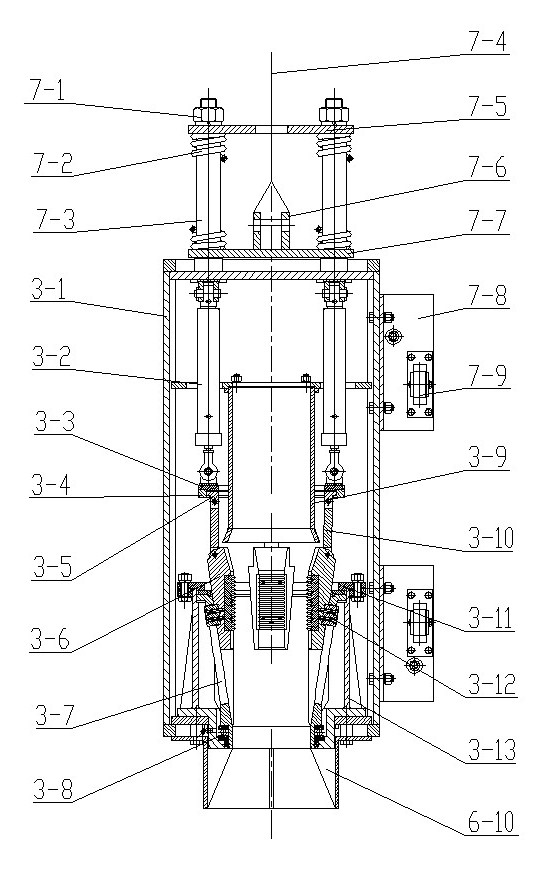

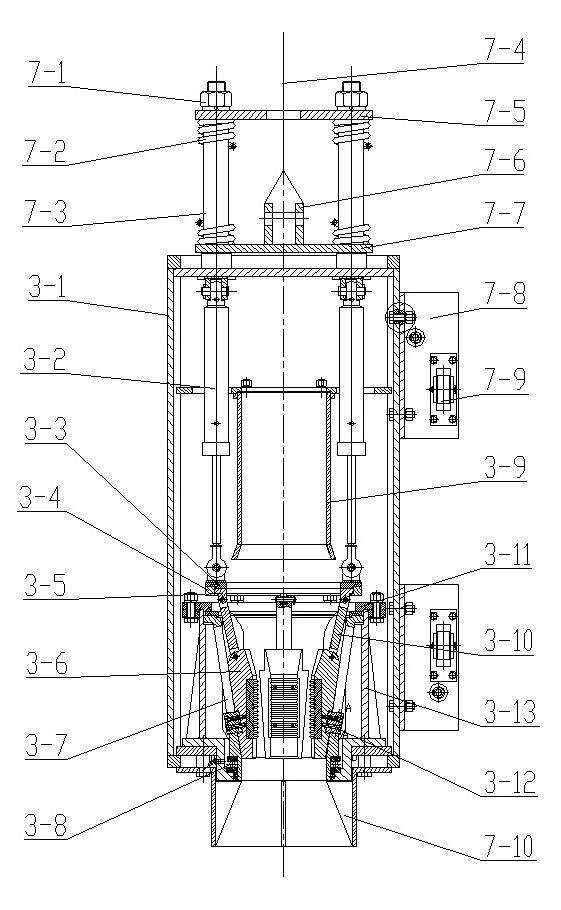

Automatic racking device for drill rod

ActiveCN102140897AThe overall structure design is simpleHigh degree of mechanizationDrilling rodsDrilling casingsTransfer mechanismPipe fitting

The invention provides an automatic racking device for a drill rod. A drill rod horizontal-conveying mechanism is adopted to convey one end of a first drill rod to be below a support frame, a drill rod transfer mechanism is used for inserting the lower end of the first drill rod into a mousehole clamp hand, and then a stand-rod lifting mechanism is used for lifting the first drill rod; meanwhile,the drill rod transfer mechanism is used for lifting a second drill rod, and the second drill rod is clamped by the mousehole clamp hand; the first drill rod descends, the lower end of the first drill rod contacts with the upper end of the second drill rod, a hydraulic tong fixedly arranged on a well platform connects the first drill rod with the second drill rod to form a double joint; thus three drill rods are connected into a three-joint unit; and a three-joint unit racking mechanism is used for transferring the three-joint unit into a driving or three-jointing box. The invention has a simple and reasonable design, realizes the automated operation of drill rod movement, three-jointing connection and three-jointing racking, is high in mechanization degree, reduces the labor intensity of workers, enhances the work efficiency, prevents people from being in direct contact with pipe fittings and enhances the safety and the reliability.

Owner:建湖县鸿达阀门管件有限公司

Smelting process and device of pure iron

InactiveCN101538634AImprove applicabilityHigh recovery rateShaft furnaceProcess efficiency improvementUltra fineSolvent

The invention relates to a smelting process and a device of pure iron, belonging to metallurgical industry steel-making raw material. The process comprises the following steps: mixing iron-containing raw materials with reducing agent, solvent and catalyst to prepare ultra fine powder, mixing to make pelletizing materials, sending the prepared pelletizing materials into a reducing furnace, obtaining metallic pellets after the reduction reaction, and directly adding the reduced pellets into a lining electroslag furnace for being smelted into pure iron. The device comprises an internal-external heating vertical reducing furnace, a lining electroslag furnace and a residual heat recovery system. The invention has the advantages that: firstly, the reduction temperature is low, the speed is high, the energy consumption is reduced, the production cost is lowered, the production efficiency is high, and the uniformity of the quality is good; secondly, the degree of mechanization is high, the procedure is simple, the yield is large, the mass production can be performed; thirdly, the waste of raw materials is reduced, the environment pollution is lowered; fourthly, the source of raw materials adopting iron ore concentrate powder and iron-containing metallurgical waste, the cost is low; fifthly, the waste resource can be recycled so as to save the resource consumption; and sixthly, the high-temperature pellets are directly smelted by adopting the lining electroslag furnace, the heat efficiency is high, the energy consumption is low, the material purity is high and the quality is good, and the device is simple with less investment.

Owner:丁家伟 +1

A construction method for the communication channel of the broken stratum in the shield tunnel crossing the river

ActiveCN102287198AEnsure normal excavationMake sure the excavation is completeUnderground chambersBlastingEnvironmental resistanceGround contact

The invention relates to a construction method for an underground tunnel, in particular to a construction method for a river-crossing shield tunnel crushed stratum communication channel, which is used for solving the problems of failure of stratum reinforcement, long working period, high cost, poor quality and the like existing in the construction process of the conventional river-crossing shieldtunnel crushed stratum communication channel. The method comprises the following steps of: determining the position of the communication channel; before opening, performing pre-grouting to integrallyconsolidate broken rock outside the excavation outline of the communication channel; forming a high-strength waterproof curtain; before excavation, performing stress conversion; drilling and partitioning to remove a left line pipe sheet, brushing the top, performing tunnel excavation with a combined damping burst technology, and timbering; and drilling and partitioning to remove a right line pipesheet, brushing the top, and performing second lining construction by adopting a combination template. Due to the adoption of the construction method, water seepage is avoided after excavation, the technology is advanced, the blank of a communication channel pre-grouting technology is fulfilled, the working period is short, the mechanical degree is high, the process is simple, construction is environmentally-friendly, collapse is avoided, and over-excavation is greatly lowered; and the method has a wide application range.

Owner:CHINA RAILWAY 12TH BUREAU GRP +1

Process and device for smelting ferronickel and nickel-containing molten iron by using lower-nickel materials

InactiveCN101538631AImprove applicabilityHigh recovery rateShaft furnaceSolventMetallurgical industry

The invention relates to a process and a device for smelting ferronickel and nickel-containing molten iron by using lower-nickel materials, which belongs to metallurgical industry steel-making raw material. The process comprises the following steps: mixing ferro nickel containing raw materials with reducing agent, solvent and catalyst to prepare ultra fine powder, mixing to make pelletizing materials, sending the pelletizing materials into a reducing furnace, obtaining chromium irons pellets after the reduction reaction, and directly adding reduced pellets into an lining electroslag furnace for being smelted into ferro nickel alloy or the nickel-containing molten iron. The device comprises an internal-external heating vertical reducing furnace, a lining electroslag furnace and a residual heat recovery system. The invention has the advantages that: firstly, the reduction temperature is low, the speed is high, the energy consumption is reduced, the production cost is lowered, the production efficiency is high, and the uniformity of the quality is good; secondly, the degree of mechanization is high, the procedure is simple, the yield is large, the mass production can be performed; thirdly, the waste of raw materials is reduced, the environment pollution is lowered; fourthly, the source of raw materials adopting nickel oxide ore or nickel-containing waste, the cost is low; fifthly, the waste resource can be recycled so as to save the resource consumption; and sixthly, the high-temperature pellets are directly smelted by adopting the lining electroslag furnace, the heat efficiency is high, the energy consumption is low, the material purity is high and the quality is good, and the device is simple with less investment.

Owner:丁家伟

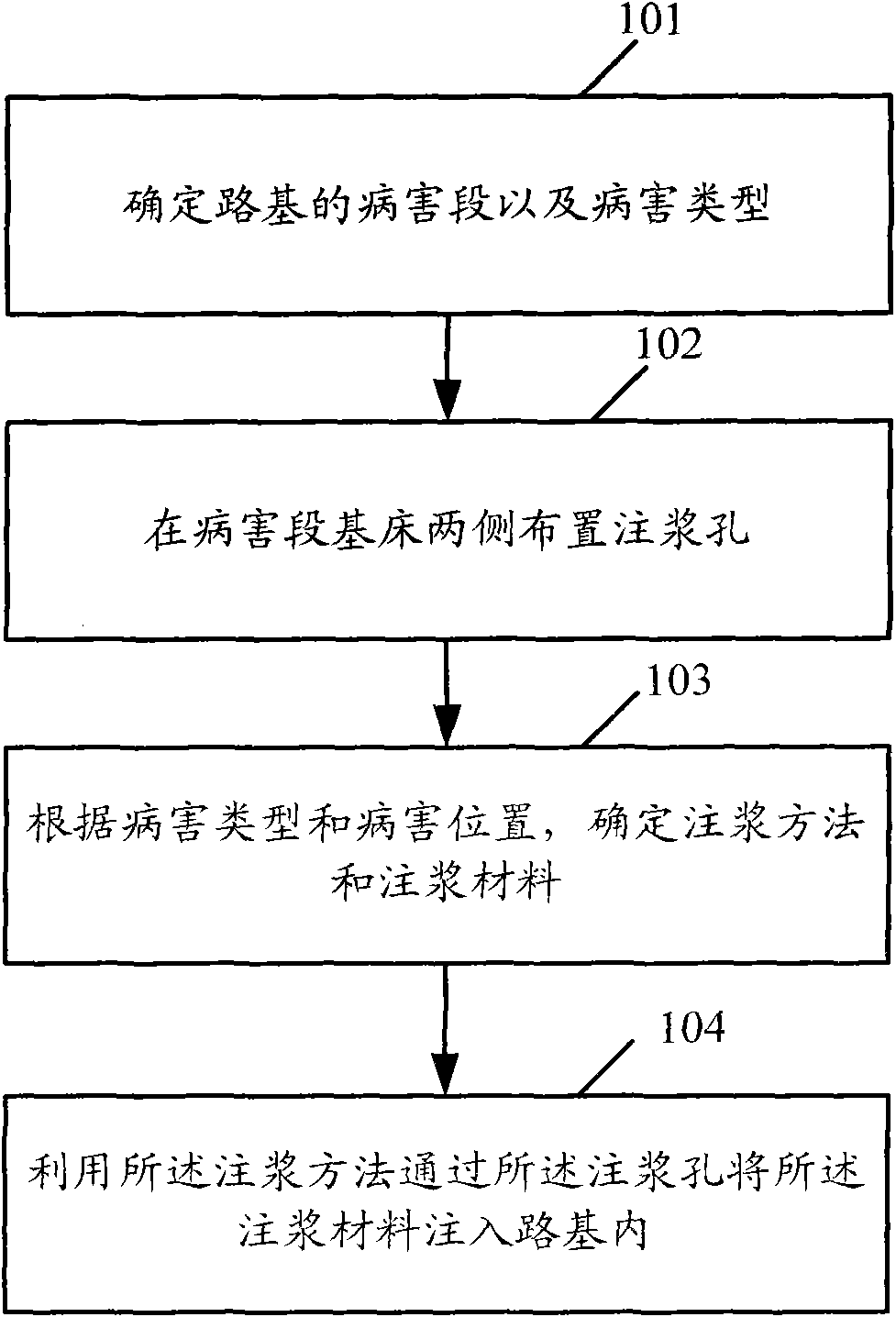

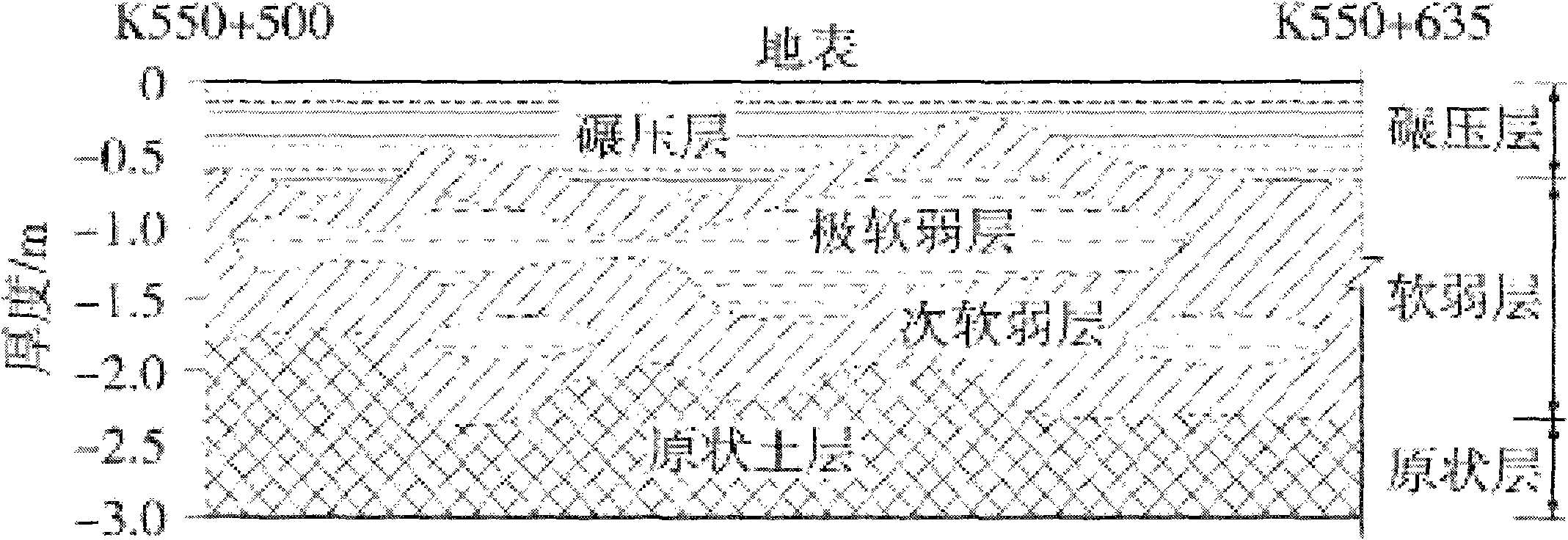

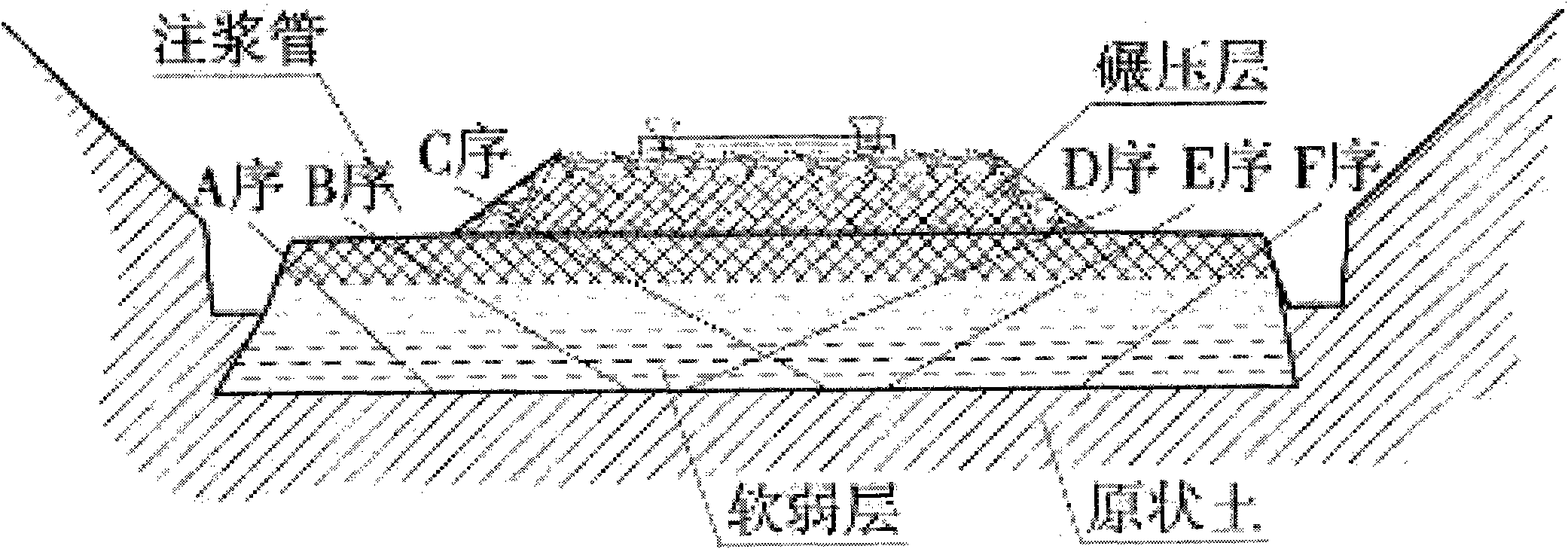

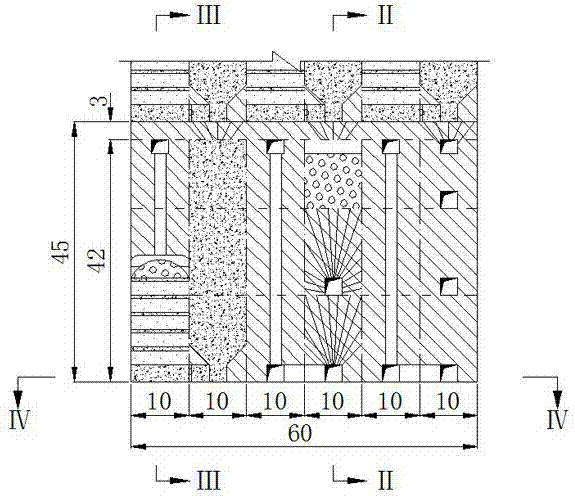

Railroad bed repair method without affecting existing running conditions

InactiveCN102071607AImprove waterproof and drainage performanceImprove bearing capacityTrack maintainenceSoil preservationFrostFreeze injury

The invention discloses a railroad bed repair method without affecting existing running conditions. The method comprises the following steps of: determining the destroy section position and the destroy type of a bed; drilling grouting holes on two sides of the destroy section bed; determining a grouting method and a grouting material according to the destroy type and the destroy section position; and grouting the grouting material into the bed by using the grouting method through the grouting holes. The construction of the scheme does not occupy the railway running space, does not affect normal running of the railway, and can perform reinforcement from the surface of the bed to the deep place of dozens of meters below the bed. The foundation and the ground surface do not need to be dug during construction, so the method has low labor intensity, high mechanization degree and short construction period, effectively treats frost boiling, sinking, extrusion, freezing injury and the like, improves the bearing capacity of the bed and improves the drainage resistance of the bed.

Owner:北京中铁瑞威基础工程有限公司

Anti-ageing wood-plastic composite board and preparation method thereof

InactiveCN101708617AEasy to produceHigh degree of mechanizationDomestic articlesFlat articlesUltravioletStearate

The invention relates to a wood-plastic composite, in particular to an anti-ageing wood-plastic composite board and a preparation method thereof. The anti-ageing wood-plastic composite board of the invention is manufactured by mechanically mixing and melt-mixing wood meal, calcium carbonate powder, plastic particles, maleic anhydride, stearate, pigment, antibacterial agent, antioxidant and ultraviolet absorber in sequence, and extruding and molding the mixture. The anti-ageing wood-plastic composite board has extremely wide application, is suitable for the industries of architectural decoration, transportation, furniture, municipal administration, gardens and the like, is renewable, has low cost, ageing resistance and ultraviolet resistance, is an ideal material for replacing wood, and is a novel upgraded product of the wood-plastic composite.

Owner:江苏森诺塑胶科技有限公司

Chamber and overhand cut combined cut-and-filling stoping method in pre-roof-protecting stage

InactiveCN104847352AImprove mining safetyImprove stope production capacityUnderground miningSurface miningEngineeringCut and fill

The invention relates to a chamber and overhand cut combined cut-and-filling stoping method in a pre-roof-protecting stage. The method comprises the following steps: dividing a middle ore body into panels along the trend of the ore body, further dividing the middle section into a plurality of sections in the vertical direction, and mainly adopting a footwall out-out-pulse traceless accurate mining mode; arranging chambers and pillars in the panels at intervals; recovering the chambers first, and adopting a sublevel open stoping method with subsequent backfilling; after recovering the chambers, recovering the pillars and adopting an overhand horizontal cut-and fill method for the pillars, and before recovering the chamber in stages, pre-supporting a long cable in advance for an upper panel in a sublevel upper panel supporting lane; pre-supporting the fore-set by using an anchor rod and a metal net in an air return cross gateway below the fore-set; when the pillars are recovered in layers, stopping mining when the pillar is 3m close to the main crack of the upper panel F1 in horizontal distance and reserving the panel as an upper panel roof-protecting ore of the sub layer, and when the lower layer is recovered, fully recovering the upper panel roof-protecting ore reserved in the previous layer, and meanwhile, reserving the upper panel roof-protecting ore in the lower sub layer; and sequentially circularly recovering and reserving the upper panel roof-protecting ore. By virtue of the method provided by the invention, safe, efficient and low-cost mining can be implemented for thick and large ores which are relatively broken.

Owner:SANSHANDAO GOLD MINE SHANDONG GOLD MINING LAIZHOU

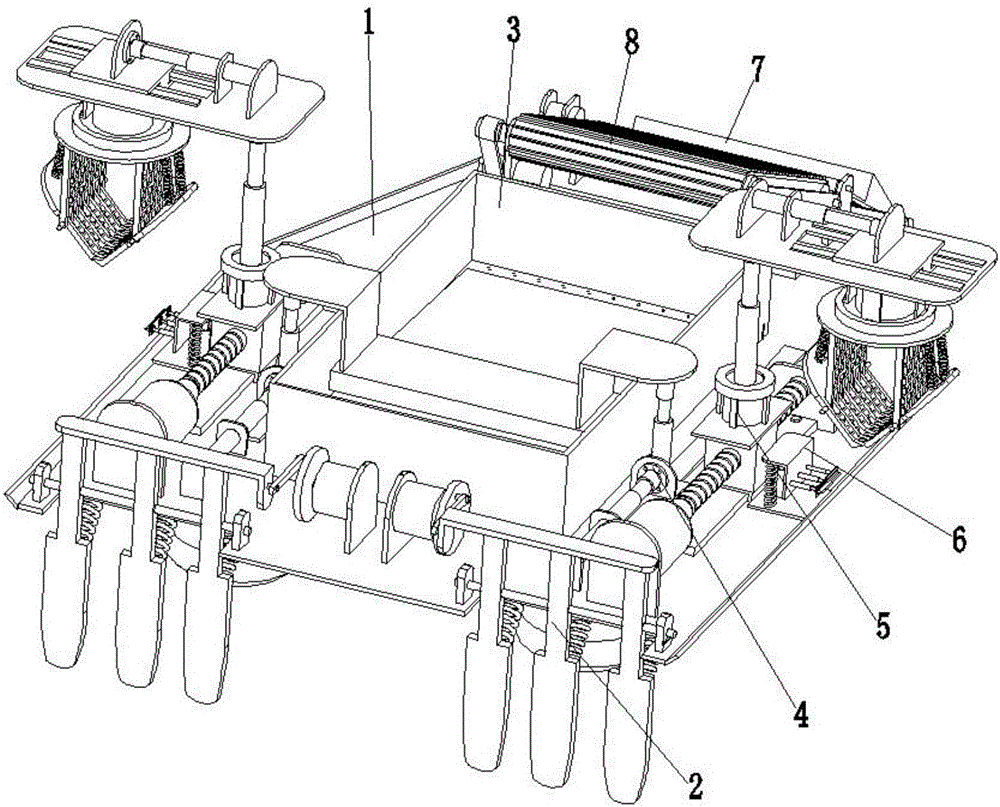

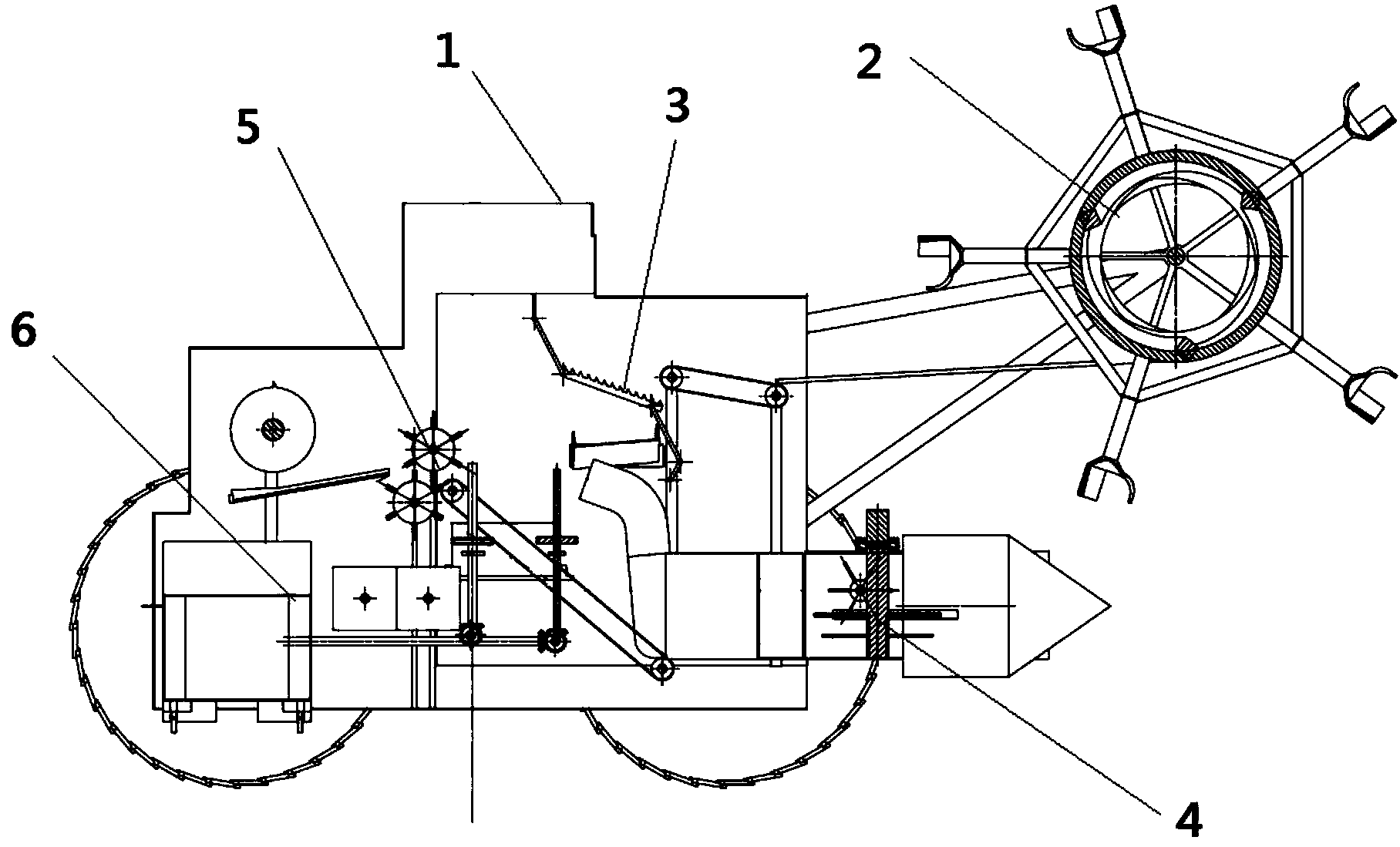

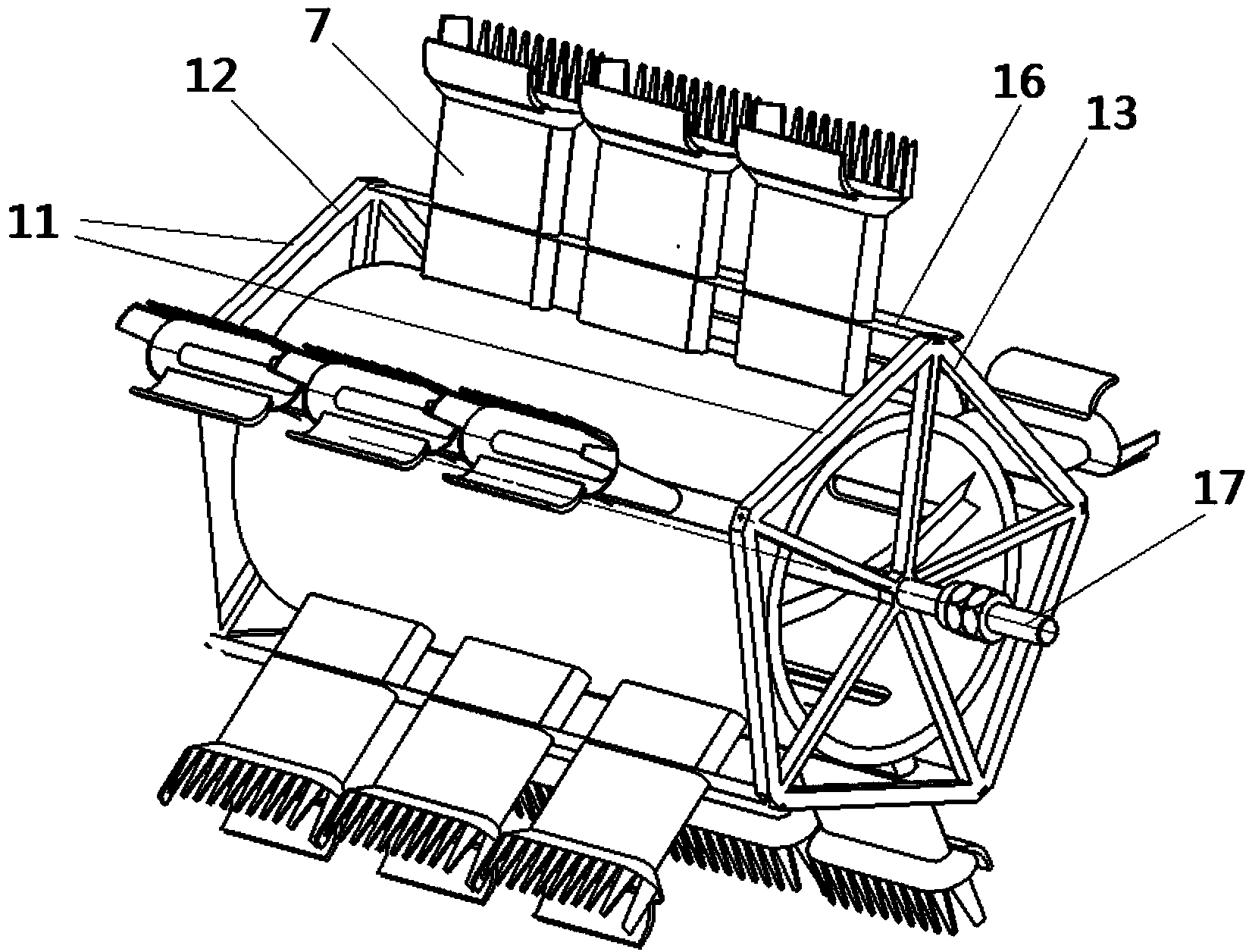

Comb tooth type ricinus communis combine harvester with fruit picking and straw fixed length fixed quantity and bundling functions

The invention relates to a comb tooth type ricinus communis combine harvester with fruit picking and straw fixed length fixed quantity and bundling functions. The combine harvester is reasonable in structure and integrates picking, separating and cleaning of castor seeds with fixed length segmentation, fixed quantity compaction and automatic bundling of straw. A comb tooth picking system and a feed-in disc type header system are located at the front end of a harvester body, a separating and cleaning system and a hob type fixed length segmentation system are located at the middle end of the harvester body, and fixed quantity compaction and bundling systems are located at the rear end of the harvester body; a comb tooth picking device which rotates anticlockwise is adopted for the comb tooth picking system to pick off the castor seeds and send the castor seeds to the separating and cleaning system, the castor seeds after being collected and separated through a grain collection bin are arranged below an outlet of the separating and cleaning system, a divider is arranged in the front of the harvester body, ricinus communis straw is fed into the disc type header system, the cutoff straw is fed into the hob type fixed length segmentation system through a stalk lifting conveyer belt, and an outlet of the hob type fixed length segmentation system is connected with the fixed quantity compaction and bundling systems; all the systems are driven by a power device through corresponding transmission devices.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY +1

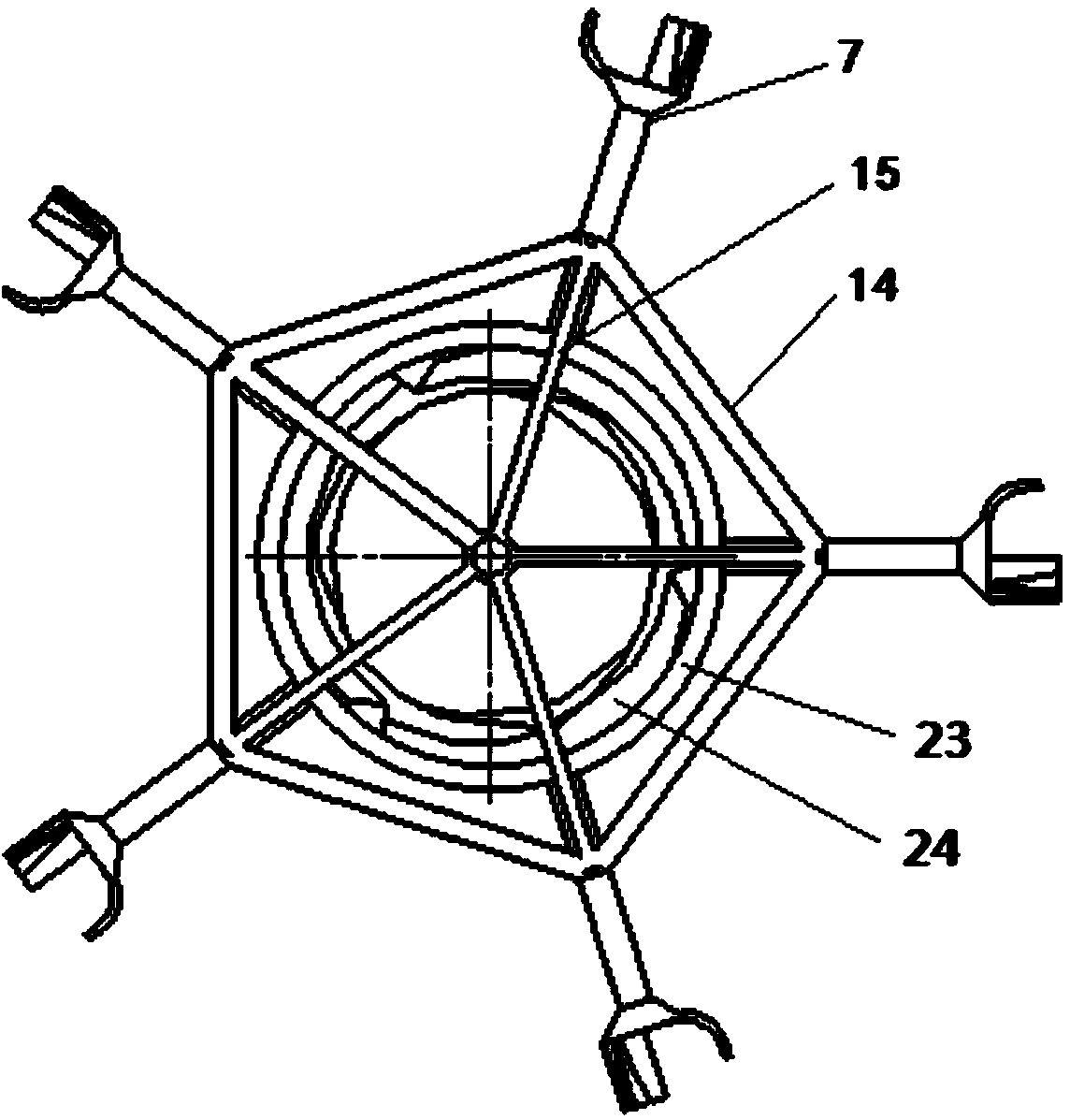

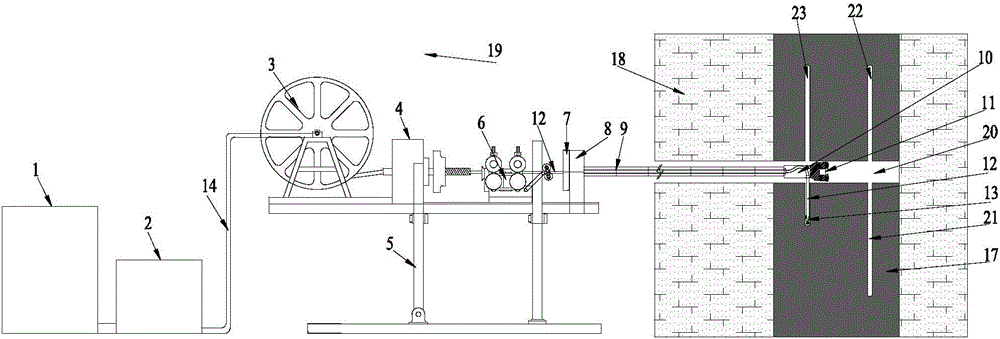

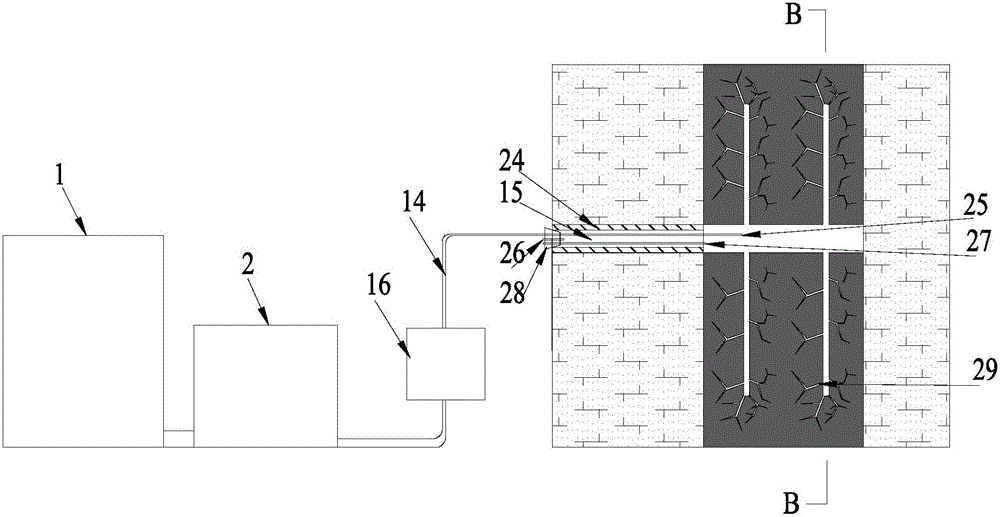

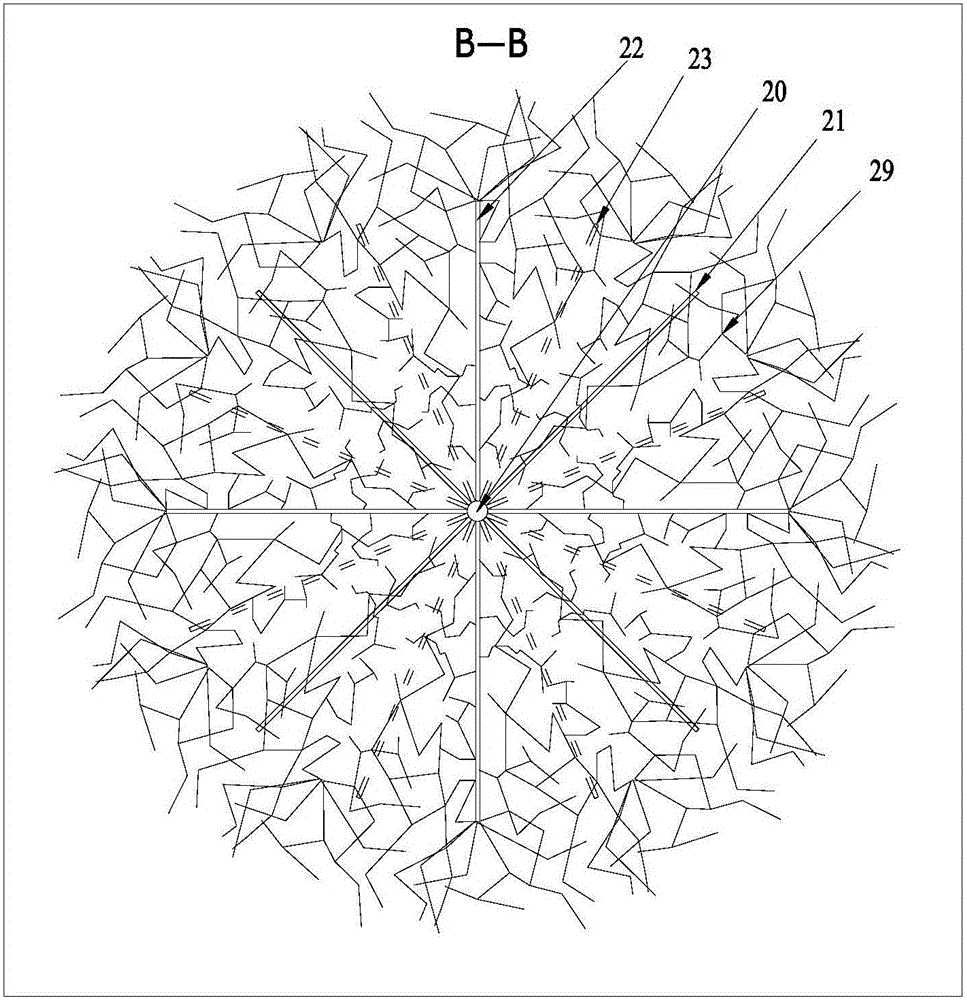

Composite fracturing and uniform permeability-improving method for tree-like boreholes in coal seams of underground coal mine

ActiveCN105156085AReduce workloadCompact and reasonable structure designFluid removalSealing/packingDrill holeCoal

The invention discloses a composite fracturing and uniform permeability-improving method for tree-like boreholes in coal seams of an underground coal mine. The composite fracturing and uniform permeability-improving method is suitable for permeability improvement of soft low-permeability coal seams, and is characterized in that a gas exhausting and mining hole serve as a mother hole, uniformly distributed self-advancing boreholes serve as tree-like son boreholes, and a tree-like borehole net is subjected to hole-sealing fracturing. Compared with a conventional hydraulic fracturing method, the composite fracturing and uniform permeability-improving method can realize uniform fracturing of the low-permeability coal seams to enlarge the fracturing range of single crossing boreholes, so that uniform permeability improvement is achieved, and the shortcomings that the crossing boreholes subjected to conventional hydraulic fracturing are low in utilization ratio, and a single major fracture can damage top and bottom beds are overcome. The composite fracturing and uniform permeability-improving method is simple to operate, large in permeability improvement range and good in permeability improvement effect and provides a guarantee for safety production of the underground coal mine.

Owner:CHONGQING UNIV

Preparation of functional nanometer short fiber and its application in cigarette filter tip

InactiveCN1603036AImprove filtration efficiencyReduce contentArtifical filament manufactureFiberCellulose acetate

The invention relates to a preparation of the function nanometer short fiber. It is mainly utilized the electrostatic spinning technique to quickly draw and transform the polymer solution to solid superfine fiber in high voltage electric field, produce nanometer fiber whose diameter is form fifty nanometers to one thousand nanometers. The fiber is directly collected in the water, and accelerated to collect by using the circulating water vacuum pump. It is utilized the shearing effect caused by the high velocity flow while the forming of the vacuum to quickly shear the collected nanometer long fiber into short one whose length is several millimeters. The catalyst is added in to the spinning liquid while the nanometer is preparing. The cellulose acetate nanometer short fiber and the filter tip fiber filament tow that is prepared by the above method are compounded to manufacture cigar filter. Not only can the compounded filter body effectively increase the filter efficiency of the inhalator grain with the submicron grade and nanometer grade, but also greatly increase the filter area at the same time to effectively reduce the content of the tar and other chemical composition in the smog.

Owner:林童 +2

Process and device for preparing chromium iron by using chromium ore powder

InactiveCN101538630AHigh recovery rateGuaranteed uniformityProcess efficiency improvementShaft furnaceResource consumptionSolvent

The invention relates to a process and a device for preparing chromium iron by using chromium ore powder, which belongs to metallurgical industry steel-making raw material. The process comprises the following steps: mixing chromium iron containing raw materials with reducing agent, solvent and catalyst to prepare ultra fine powder, mixing to make pelletizing materials, sending the pelletizing materials into a reducing furnace, drying and roasting, and obtaining chromium irons after the reduction reaction. The reducing device is connected with an upper furnace above a furnace base, a lower furnace body is connected to the downside of the furnace base, the upper end of the upper furnace body is connected with an upper furnace mantle, a drying bed grate is positioned at the upper end in the upper furnace body, a purifying device is connected with the upper furnace body and the lower furnace body through pipelines, and a residual heat circulating device is connected with the lower furnace body. The invention has the advantages that: firstly, the reduction temperature is low, the reduction speed is high, the energy consumption is reduced, the production cost is lowered, the production efficiency is high, and the uniformity of the quality is ensured; secondly, the device is simple with less investment, the degree of mechanization is high, the procedure is simple, the yield is large, the mass production can be performed; thirdly, the waste of raw materials is reduced, the environment pollution is lowered; fourthly, the cost is low because the chromium ore powder and chromium-containing waste are adopted as raw materials; and fifthly, the waste resource can be recycled so as to save the resource consumption.

Owner:丁家伟

Mechanical underground excavation construction method for large underground parking lot

ActiveCN105370287ASolve construction problemsReduce construction riskUnderground chambersTunnel liningEnvironment effectReinforced concrete

The invention discloses a mechanical underground excavation construction method for a large underground parking lot, comprising the following steps: constructing two parallel construction tunnels at two ends of the position of the proposed space of the parking lot according to the design condition of the parking lot, marking the rectangular section of the space of the parking lot on the side wall of the construction tunnel, and dividing the rectangular section of the whole space of the parking lot into a plurality of small rectangular sections with same size; and then carrying out segmental jacking construction sequentially on the small rectangular sections, namely the linear distance between the two construction tunnels, by adopting a rectangular tube push bench, and synchronously arranging the rectangular tube push bench inside, then removing profile steel parts between two adjacent rectangular pipe jacking rooms, and constructing reinforced concrete stand columns, beams and bottom plates, thus completing construction of the underground parking lot. The method can be used for solving the difficulty of constructing an underground parking lot without disturbing the ground environment conditions of urban areas; is high in construction speed, small in environmental influence and high in economic benefits; and is high in mechanization degree and small in construction risks.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

Industrialized cultivation method for hericium

The invention discloses an industrialized cultivation method for hericium. The cultivation method for the hericium has the advantages of simple process, short production period, non-polluted products, high biological efficiency and no seasonal and regional limitation.

Owner:SHANGHAI ACAD OF AGRI SCI +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com