Chamber and overhand cut combined cut-and-filling stoping method in pre-roof-protecting stage

A backfill mining method and pre-roofing technology, which is applied in the fields of backfill, ground mining, mining equipment, etc., can solve the problems of layered backfill and mining-connected roofing, restricting the comprehensive production capacity of mining, and small layered mining height. , to achieve the effect of reducing the amount of mining engineering, high filling operation efficiency, and large drilling volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0030] Embodiments of the present invention include the following steps:

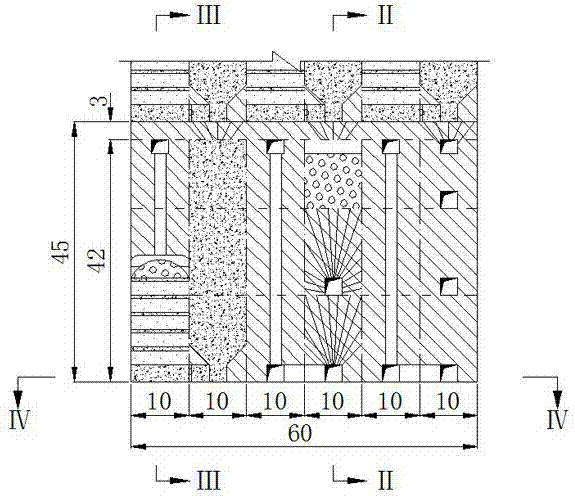

[0031] 1. The panel area is arranged along the strike, with a length of 60m. Generally, it is a horizontally thick ore body of more than 40m. The height of the middle section is 45m, the height of the section is 15m, and the thickness of the top column is 3m. No bottom column and inter-pillar are left. Mine rooms and ore pillars are arranged at intervals in the panel, and the width of the mine rooms and ore pillars are both 10m.

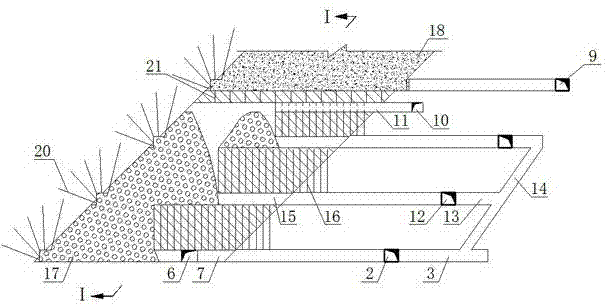

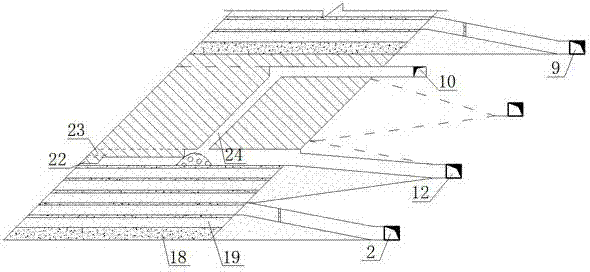

[0032] 2. Arrange the trackless mining system in the footwall of the ore body, see figure 1 , figure 2 , image 3 and Figure 4 ,

[0033] Firstly, the middle transportation lane 2 is constructed through the middle connecting lane 1, and then the loading lane 3 and the central mine shaft 14 are constructed at the bottom wall of the middle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com