Patents

Literature

53results about How to "Improve stope production capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

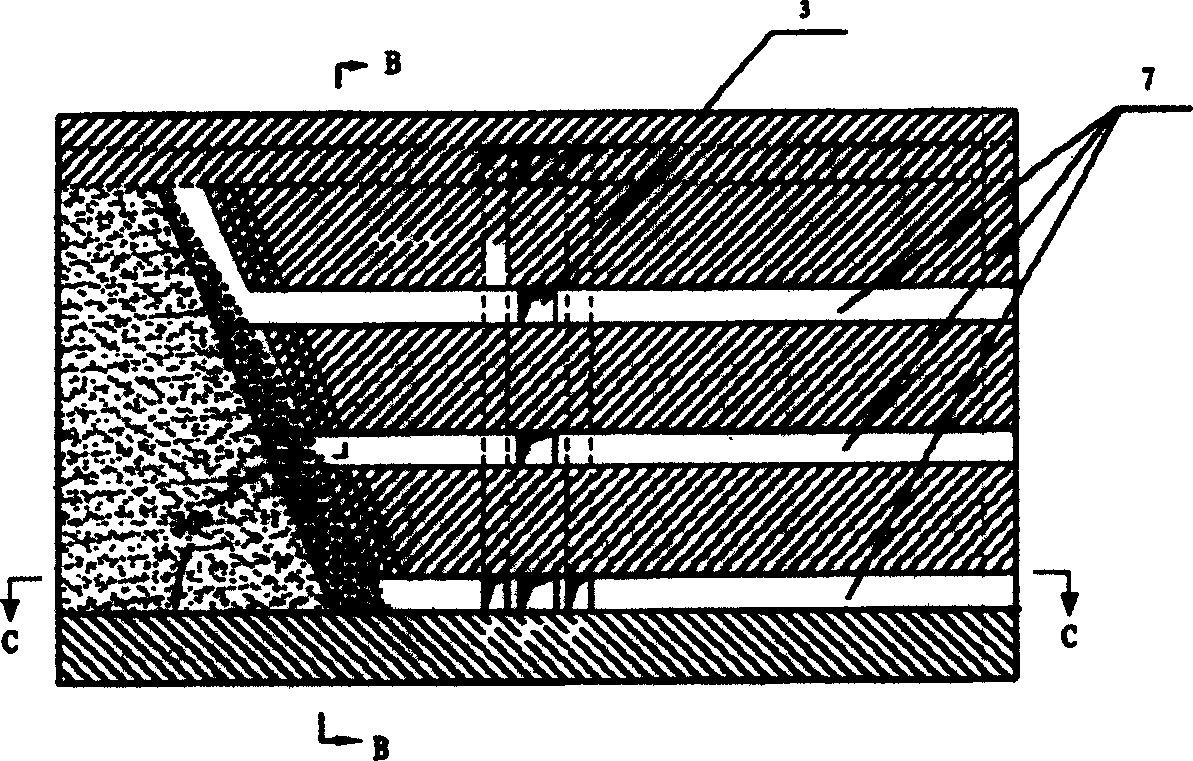

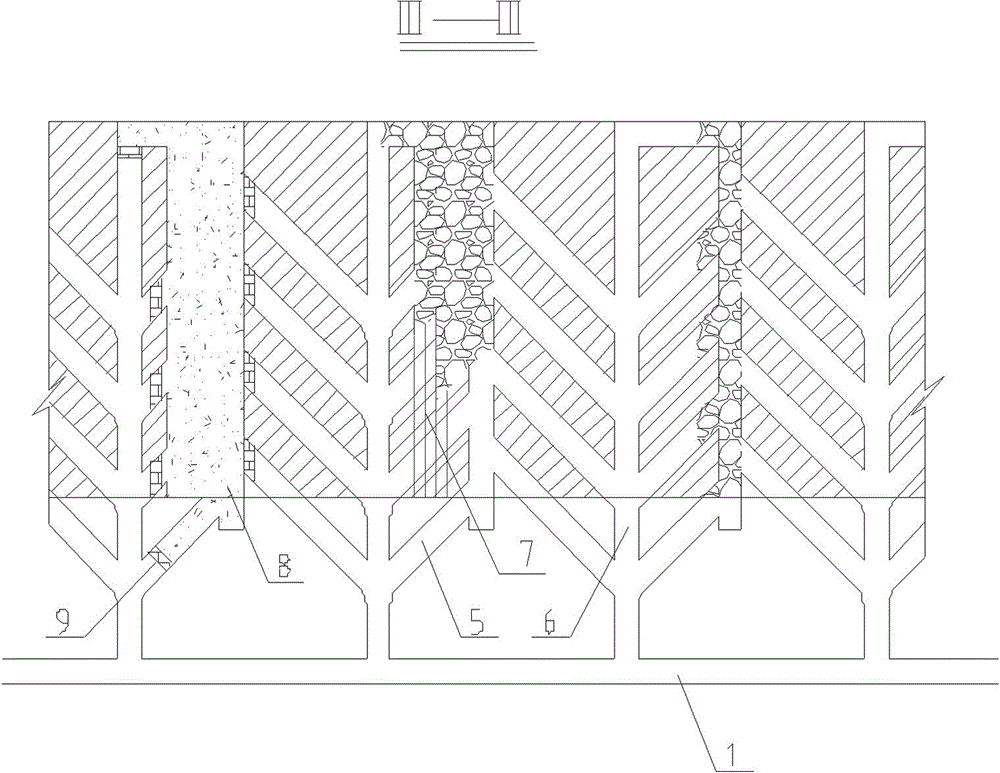

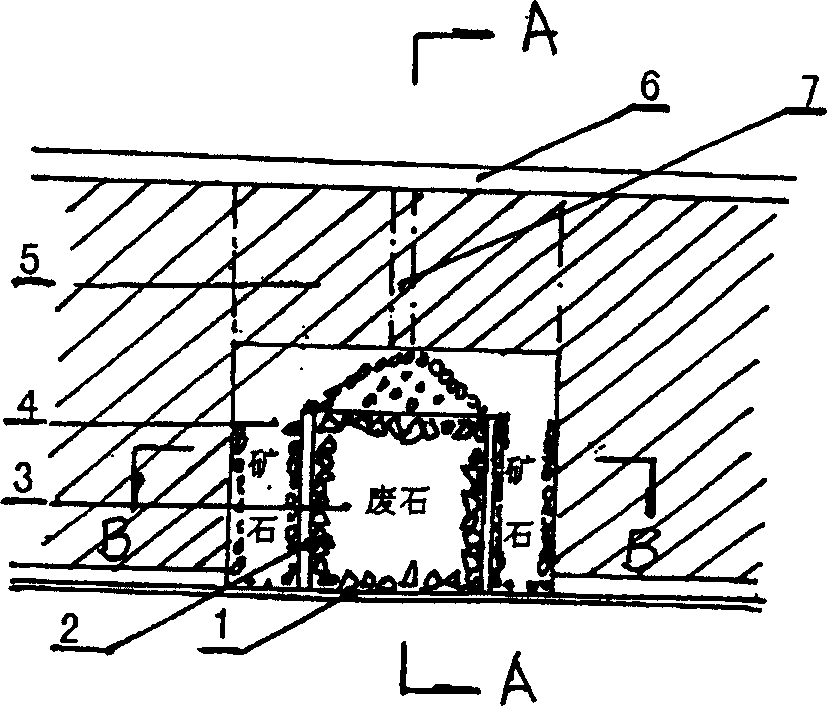

Continuous mining method of stepped sectional extruding and ore caving followed by filling

In the continuous mining method, ore body are divided into sections, subsections and mini-sections stepwisely along the ore vein; arranging mini-section drilling mine tunnels along the ore vein in the ore body bottom wall and connecting the mini-section tunnels with the main ramp way via linking tunnel; arranging support and filling tunnel along ore vein in the upper wall in the ore section; stoping from two ends to the central part of the bordroom via stepped continuous advance; drilling fanned holes with rock drill machine, breaking ore with rock explosive, charging with charging machine and combined elementary error detonation; filling finished stope via filling tunnel and filling dewatering device; and supporting crushed upper wall roof with deep anchor rod and steel fiber concrete. The present invention has high production capacity, high safety, less ore loss and low mining cost.

Owner:CENT SOUTH UNIV

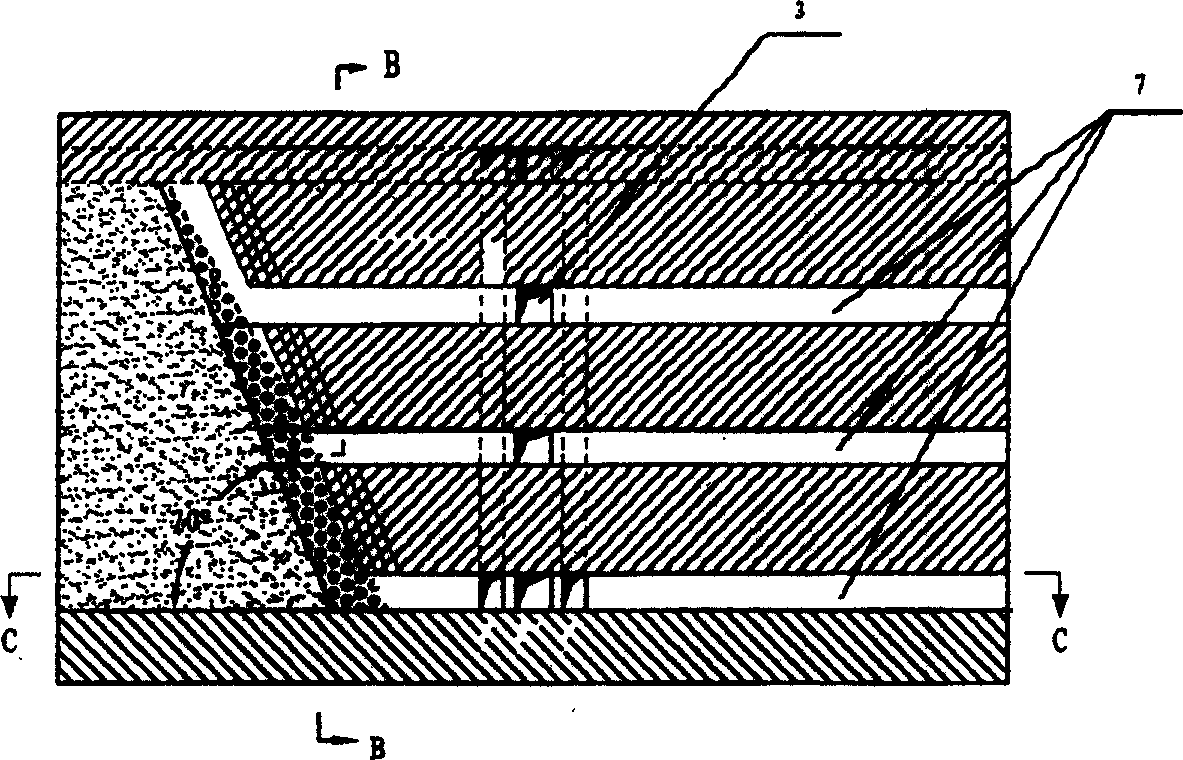

Fully-segmented presplitting squeezing primary-blasting mining method

InactiveCN102155228AHigh mining intensityImprove efficiencyUnderground miningBlastingMineralogyUltimate tensile strength

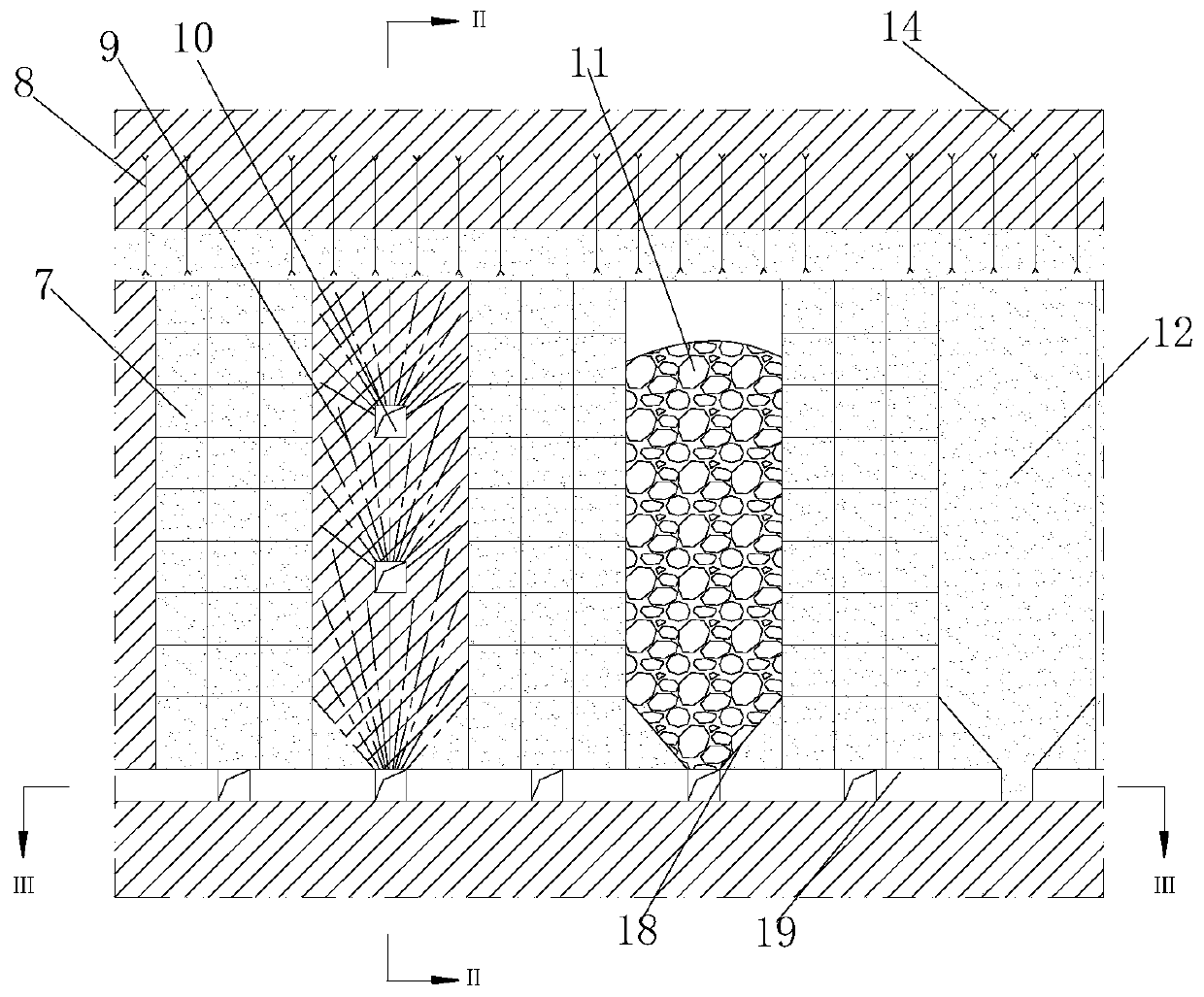

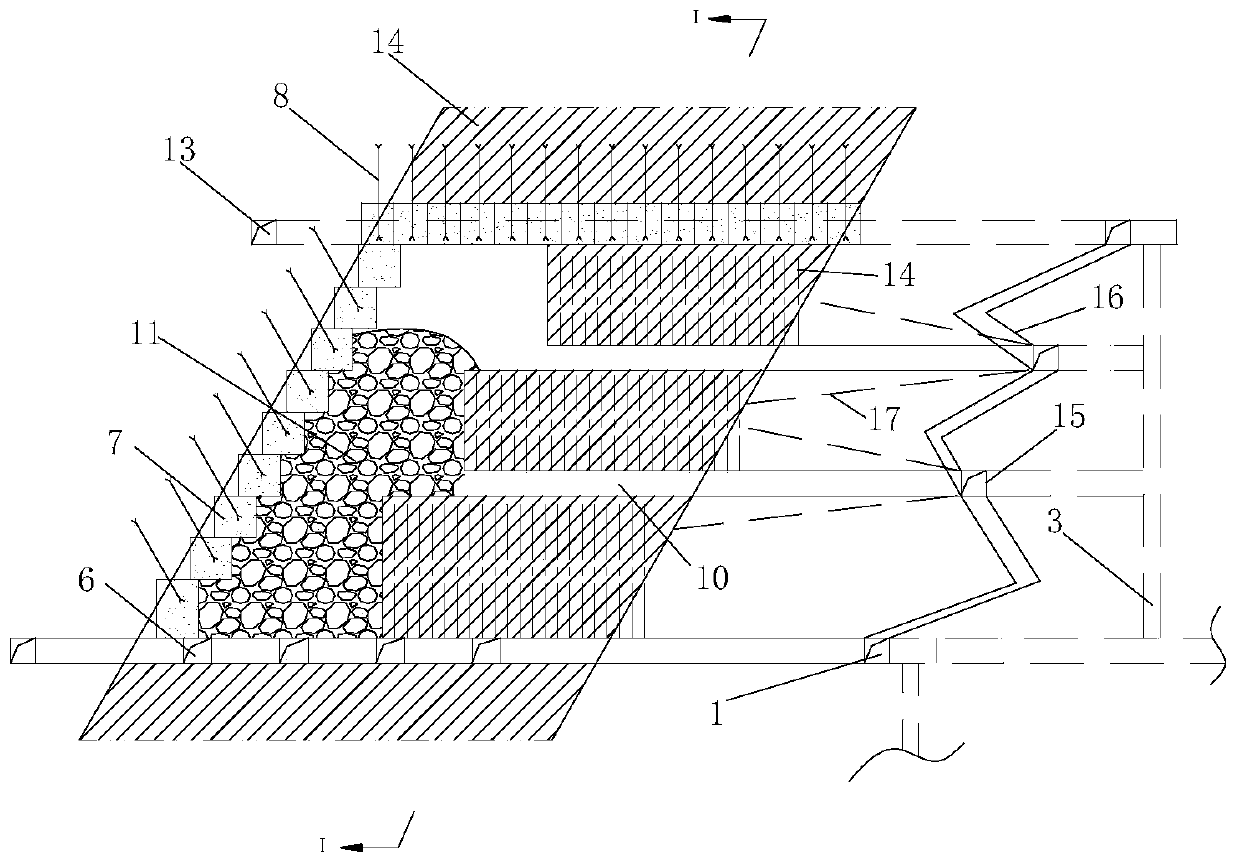

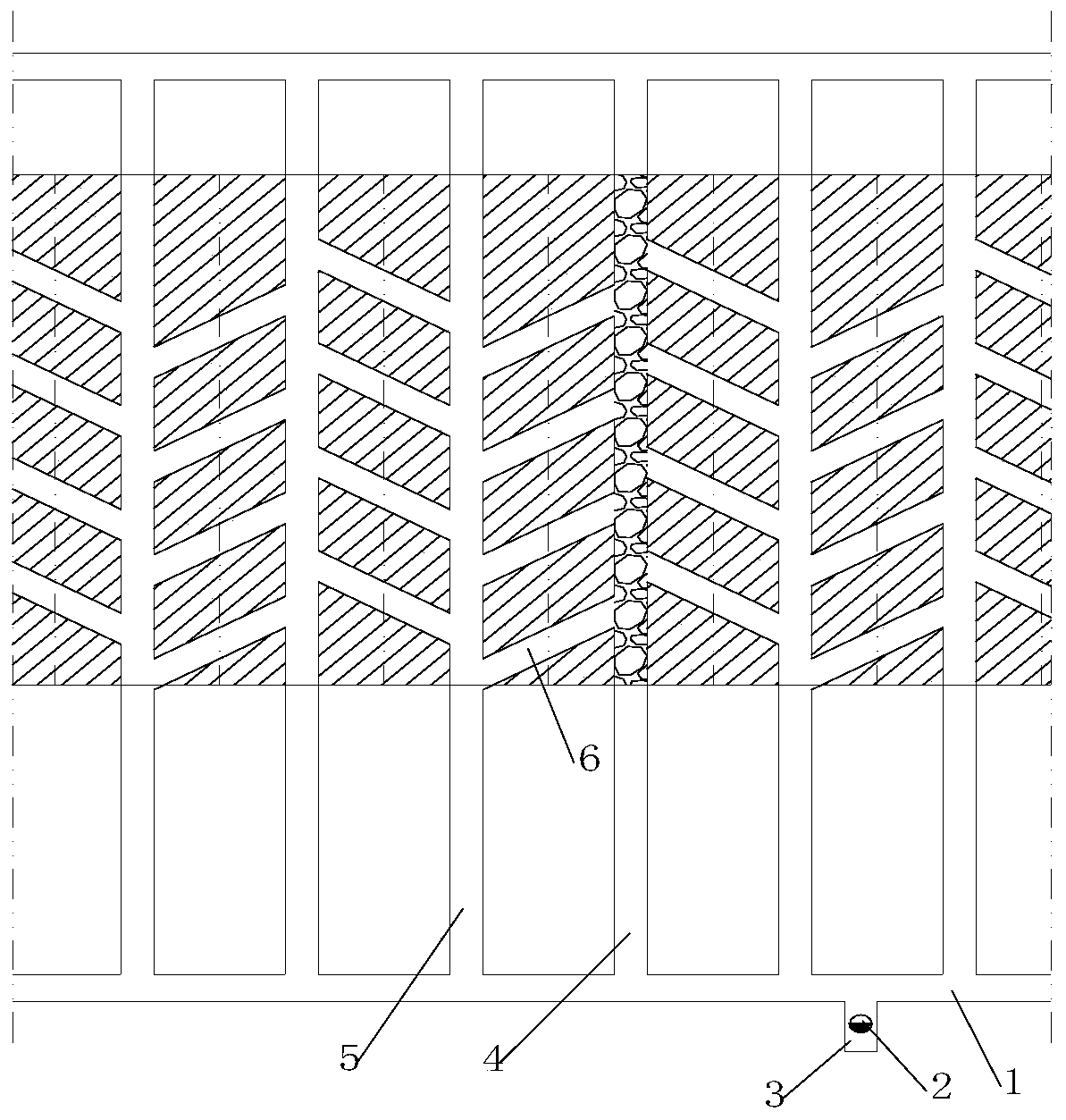

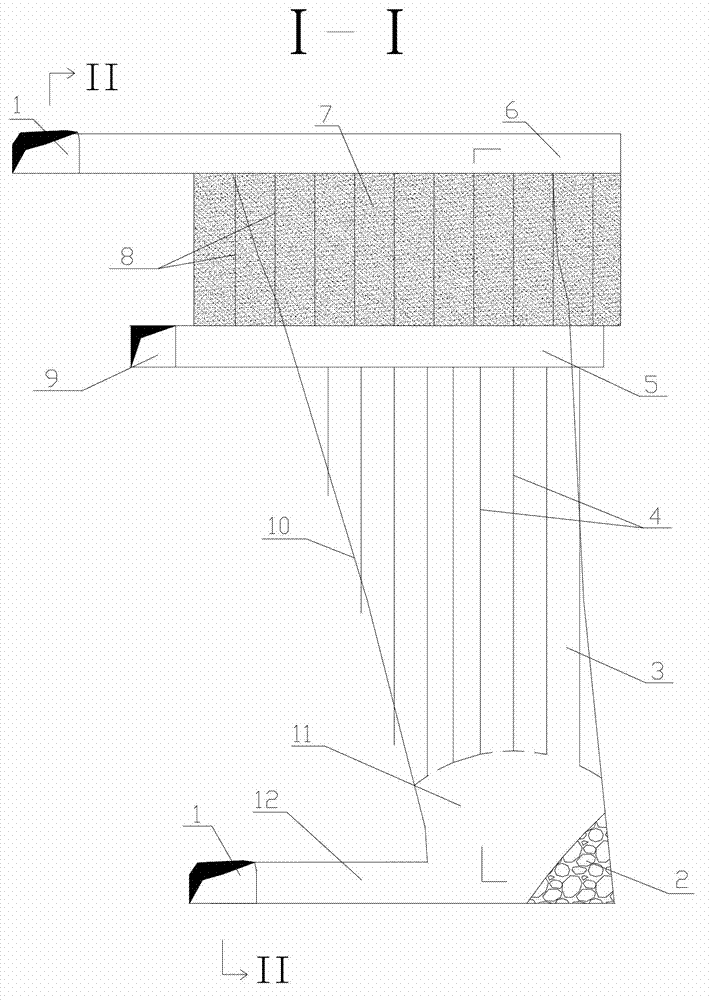

The invention discloses a fully-segmented presplitting squeezing primary-blasting mining method. The method comprises the following steps of: 1, performing sublevel mining on slowly inclined thick and large crushed ore bodies; 2, arranging a stope free with a bottom structure along a direction vertical to the direction of the ore bodies; 3, using a trackless development mode of a lower plate outside-vein sublevel tunnel and an outside-vein concentrated winze; 4, constructing a full-section pre-control top tunnel serving as a shoring tunnel and a drilling tunnel; 5, performing presplit blasting so as to form the outline of the stope, squeezing and blasting so as to form a mine, and performing presplitting, squeezing and primary-blasting on the fully-segmented ore bodies to form the mine; 6, concentratively removing the ore by trackless equipment under a fully-segmented open stope; and 7, concentratively filling in a large scale after full segmentation. The method has the remarkable characteristics of high mining safety, simple process, low loss and depletion, high mechanical degree and mining strength, high production capability of the stope, high efficiency, low cost, low labor intensity and the like.

Owner:CENT SOUTH UNIV

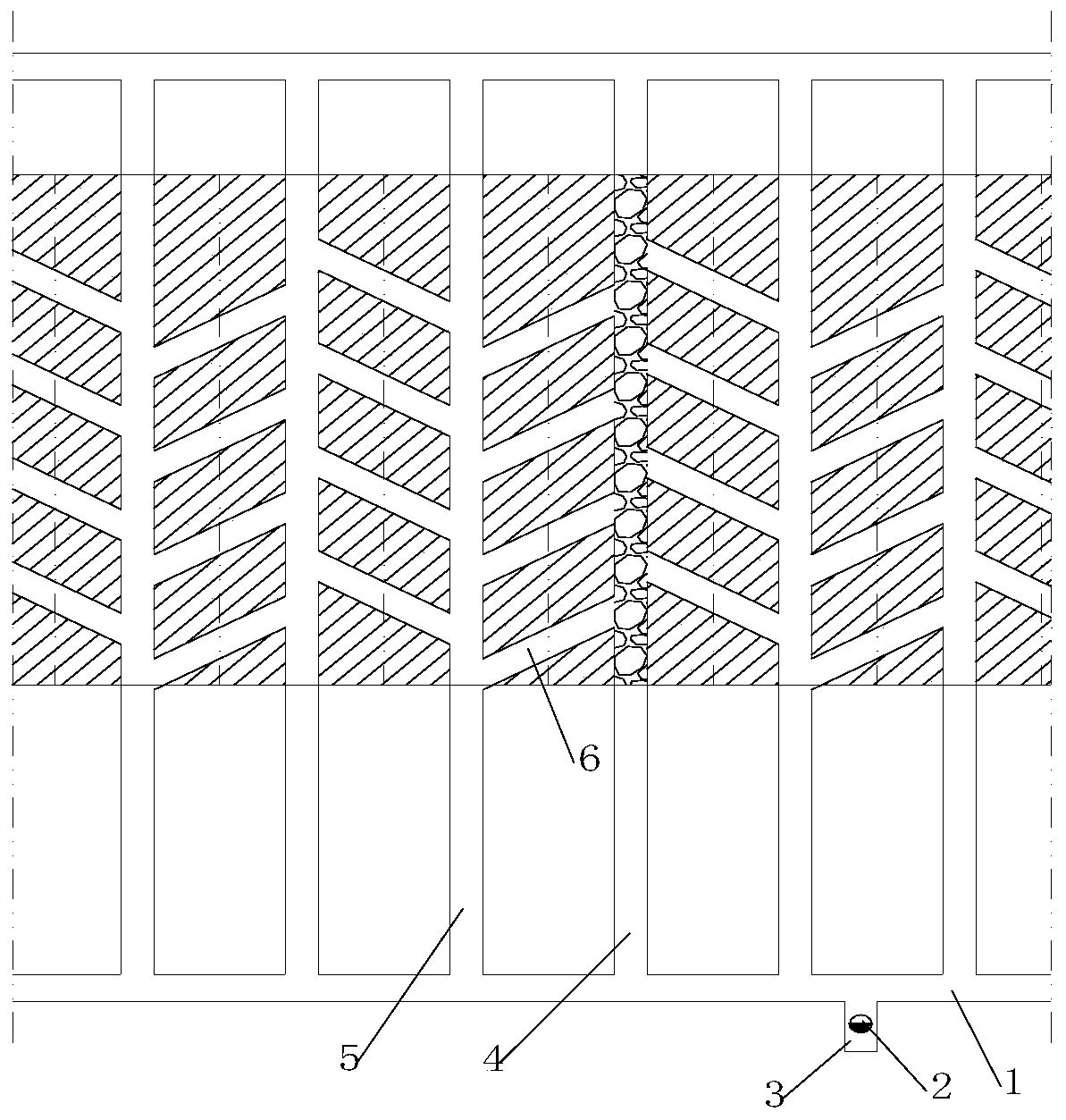

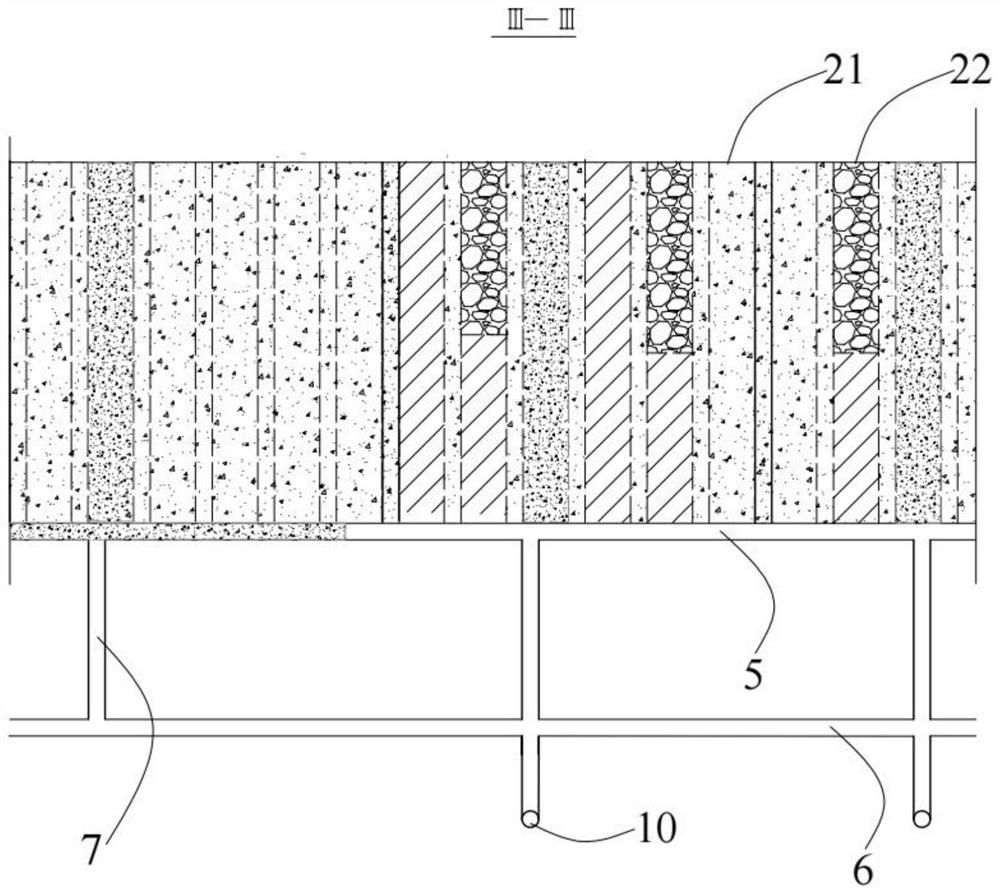

Point pillar type full-ore-deposit middle-section-free upward high-layering continuous propelling fill mining method

ActiveCN102392641AImprove stope production capacityRaw ore cost reductionUnderground miningSurface miningMechanical engineeringMineralogy

The invention relates to an underground mining technology, in particular to a point pillar type full-ore-deposit middle-section-free upward high-layering continuous propelling fill mining method. In the technical scheme, large panel mining is adopted; point pillars are reserved in a stope; an accurate mining project is arranged on rock; the height of a slice drift is 20 meters; light exposure roof control is adopted; the layering height is increased to 7.5-8 meters; a headspace of 2 meters is reserved after every filling for serving as the operating space of a next layer; no middle section lane or roof and bottom pillars are reserved; and continuous propelling and mining of a full ore deposit from bottom to top layer after layer is adopted. The method has the beneficial effects that: the middle section exploration and transportation work amount is reduced, the slice drift work amount is reduced, the layering height is increased, and the mining efficiency is increased; a full-ore-deposit upward continuous propelling fill mining process is adopted, so that the continuity of a milling, filling and discharging process is enhanced, the using amount of cement is reduced greatly, and thefilling cost is reduced; and the problems of large quantity of layering filling times, low mining efficiency and high cost are solved.

Owner:中钢矿业开发有限公司 +1

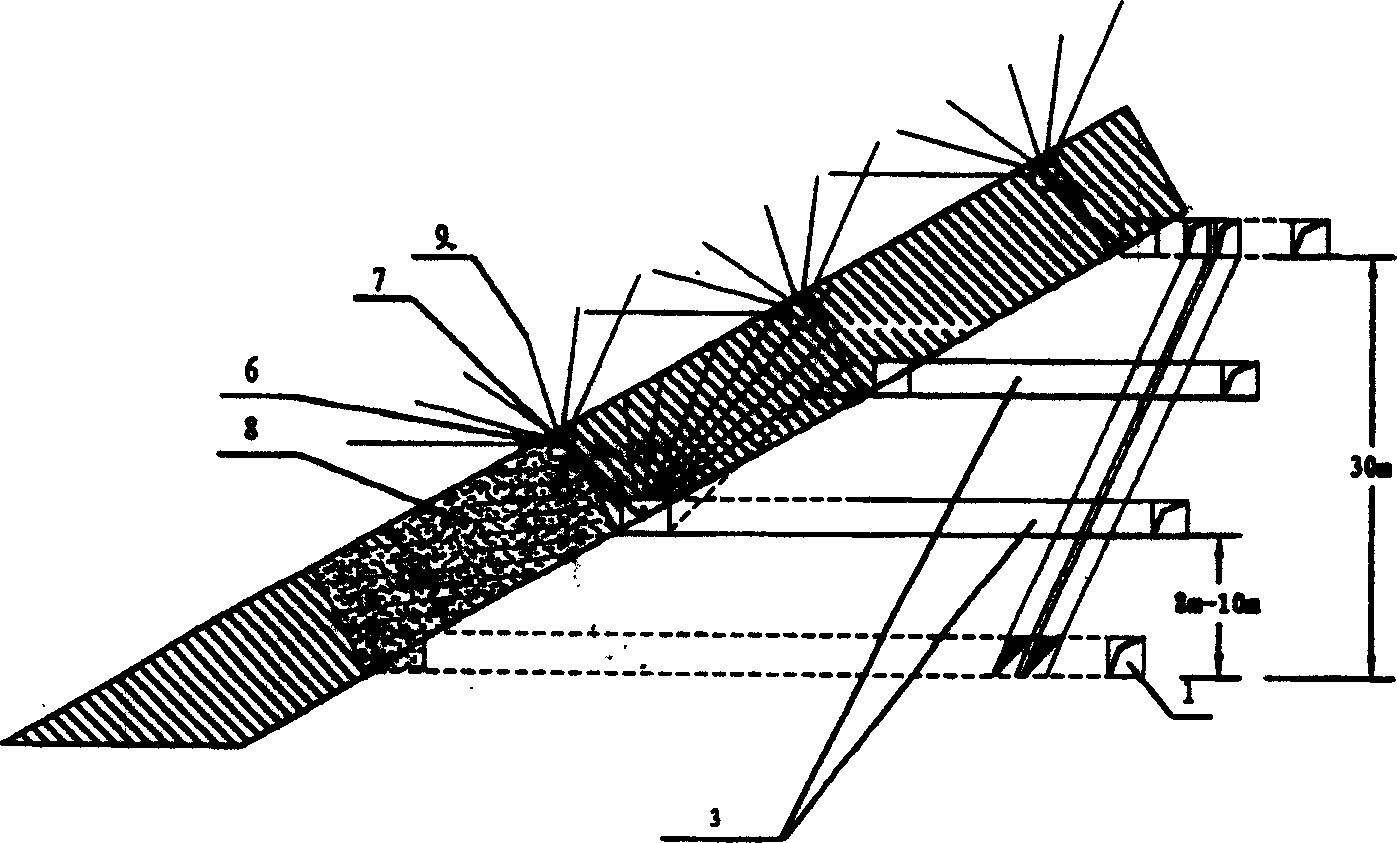

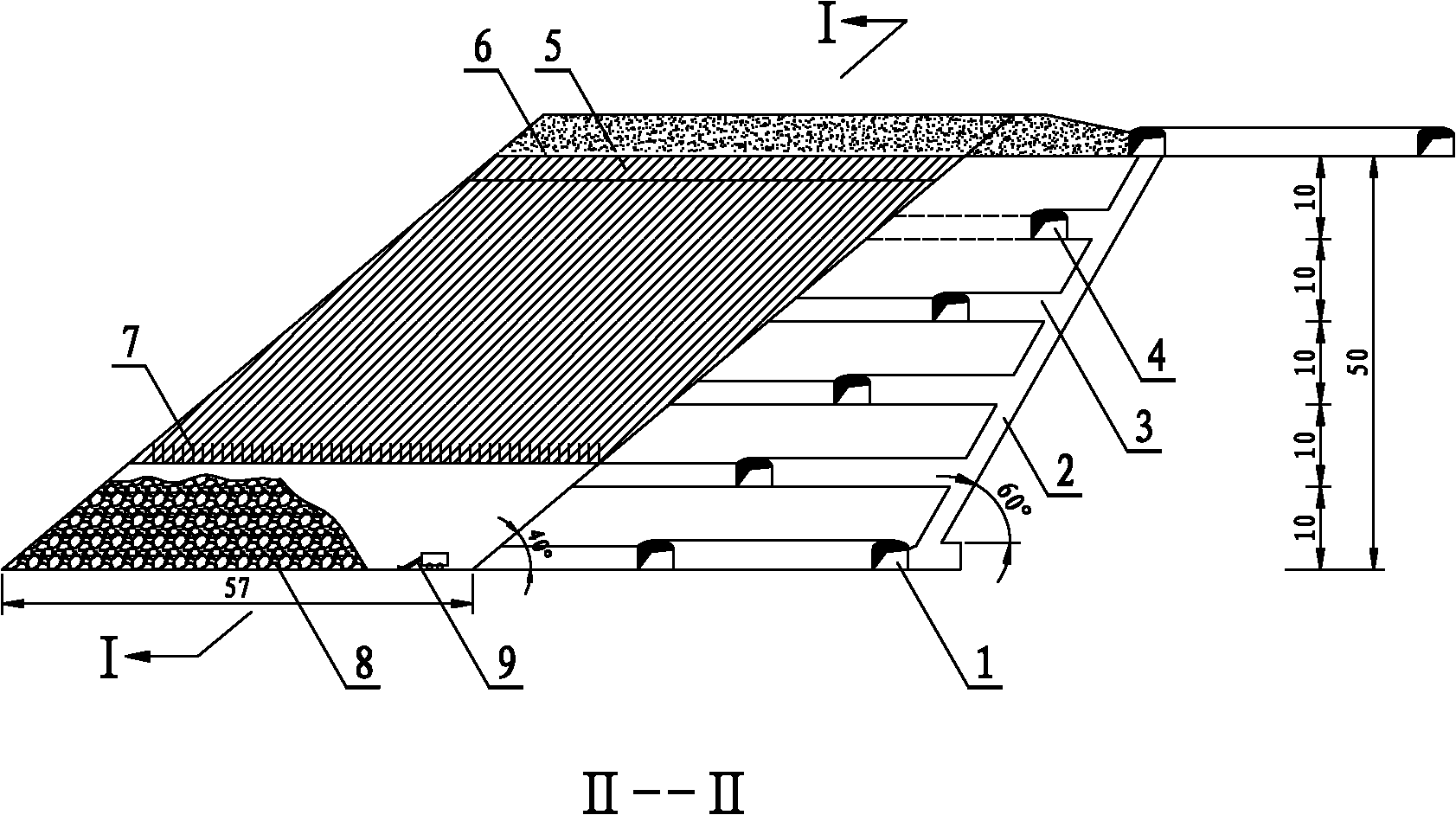

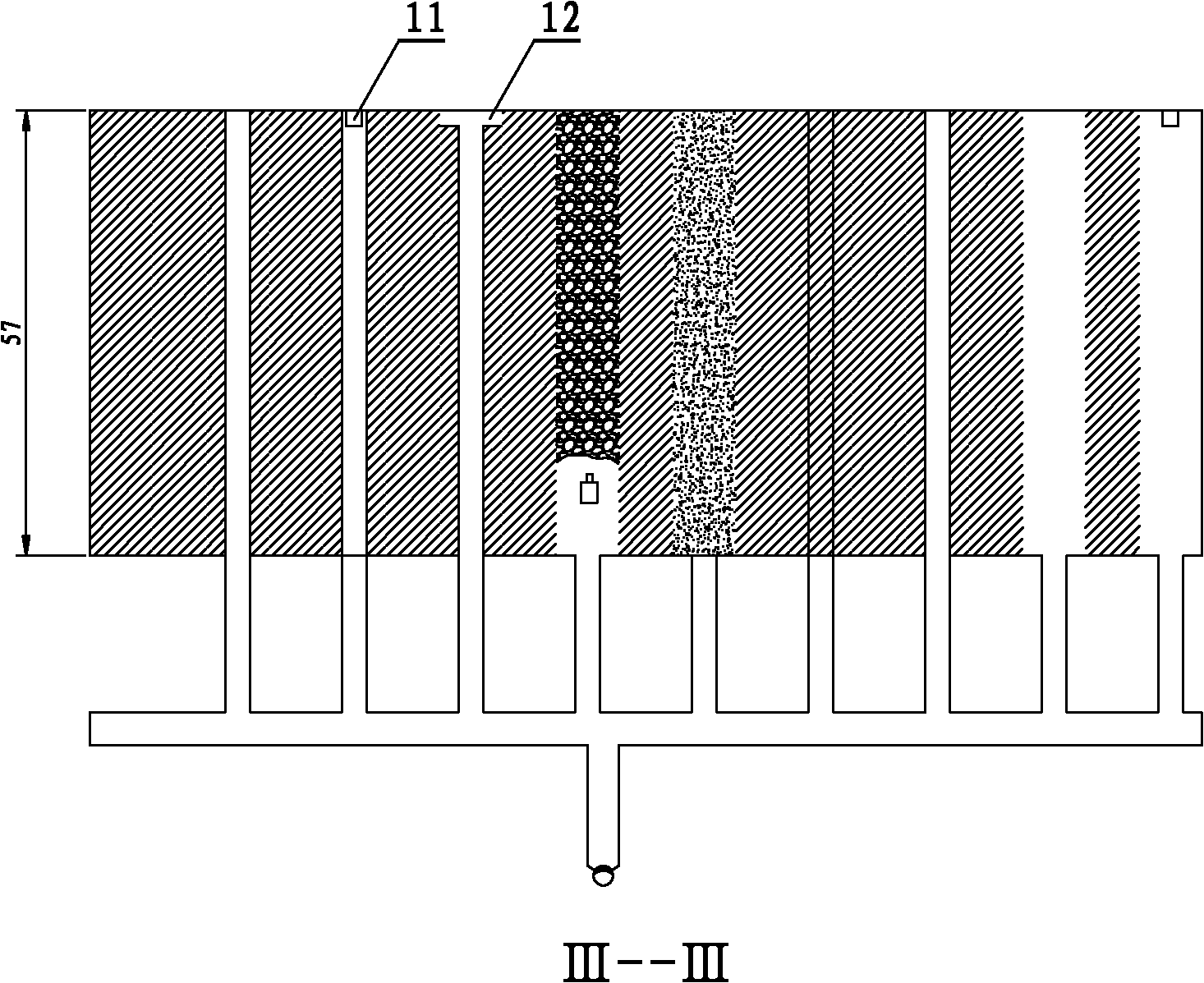

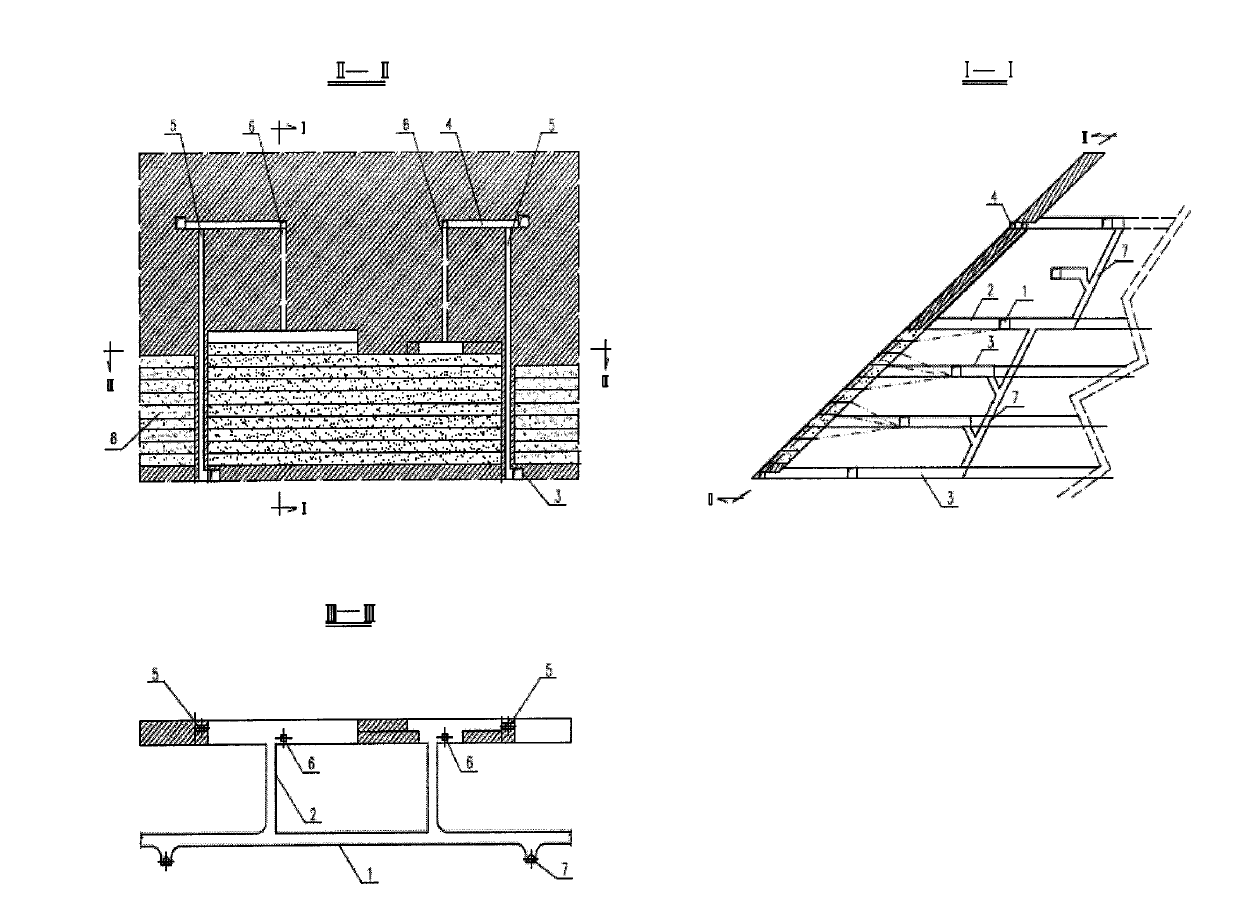

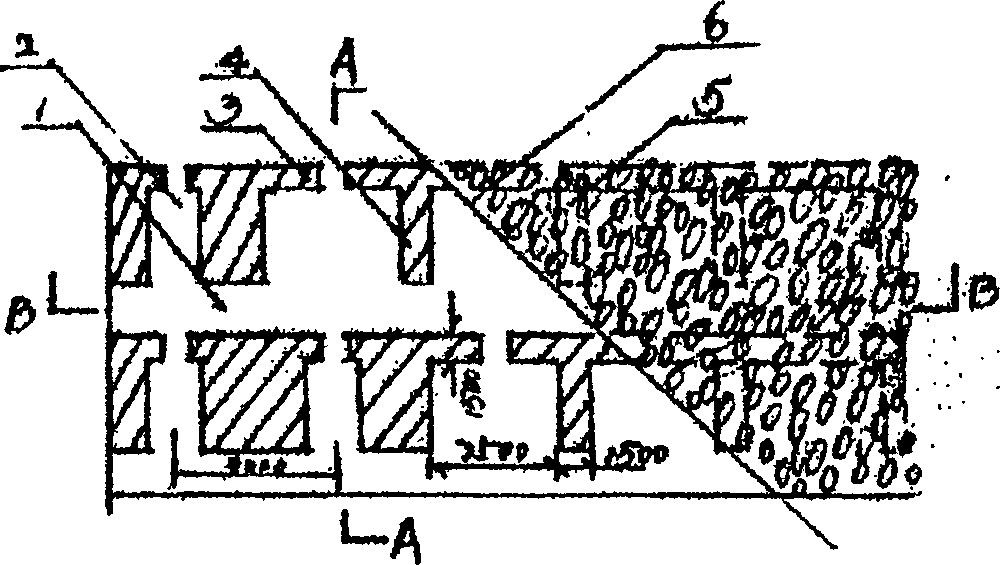

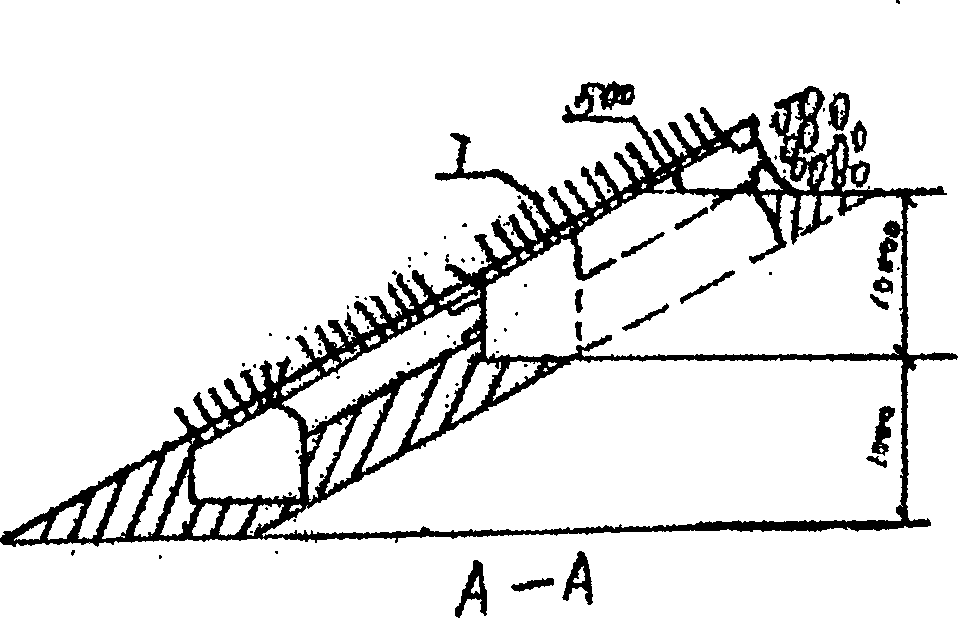

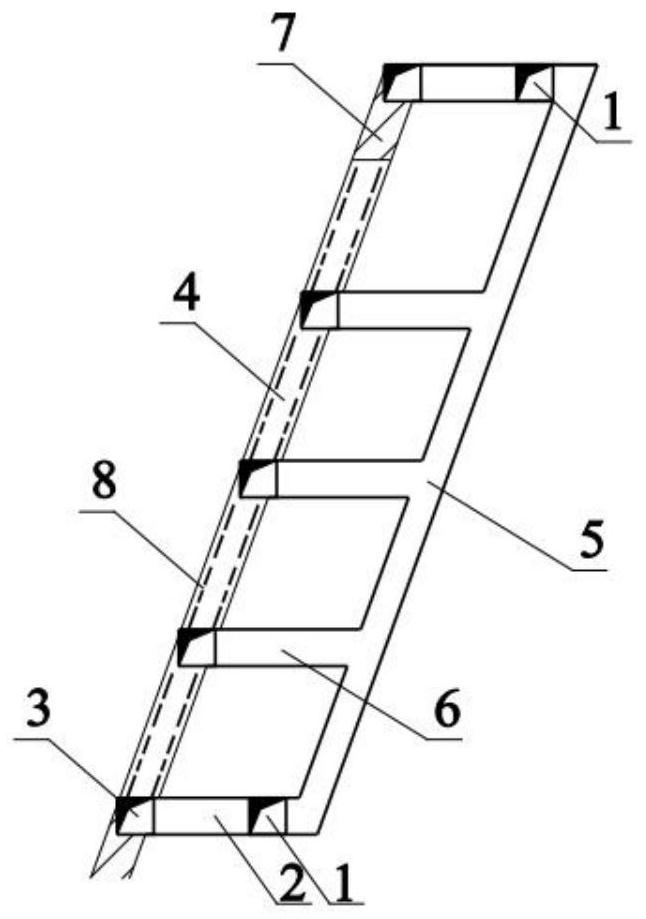

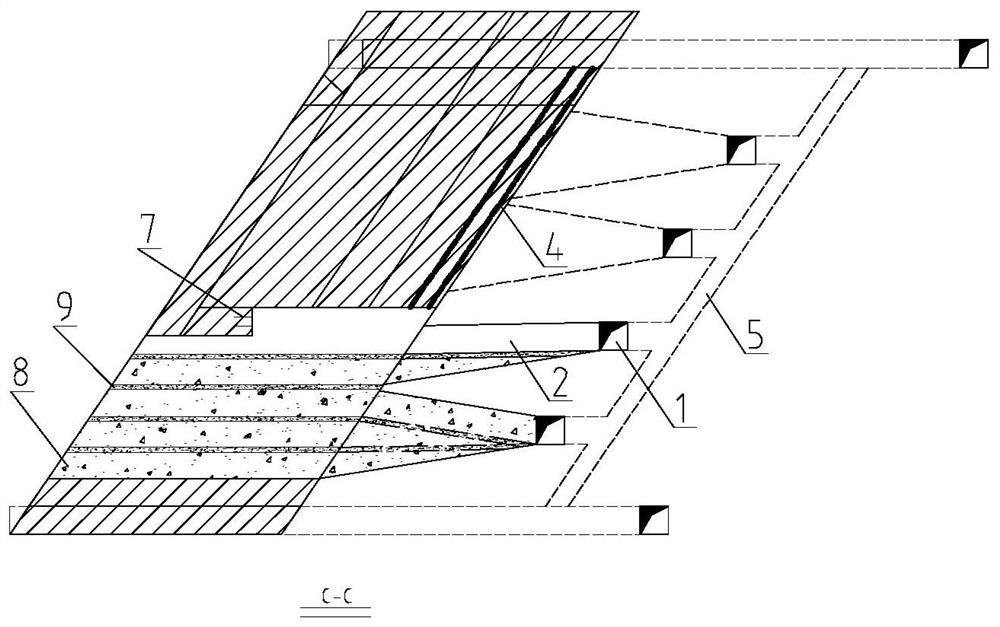

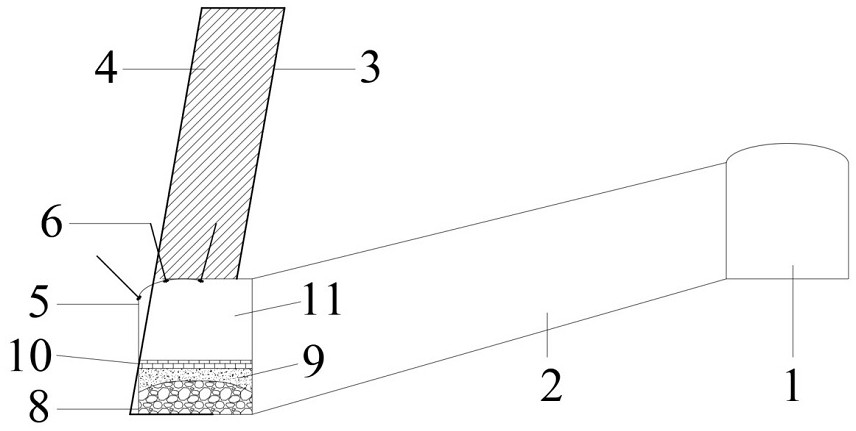

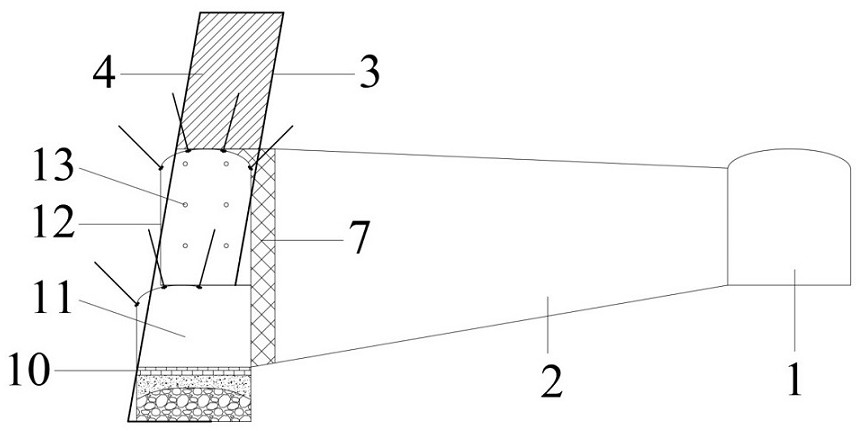

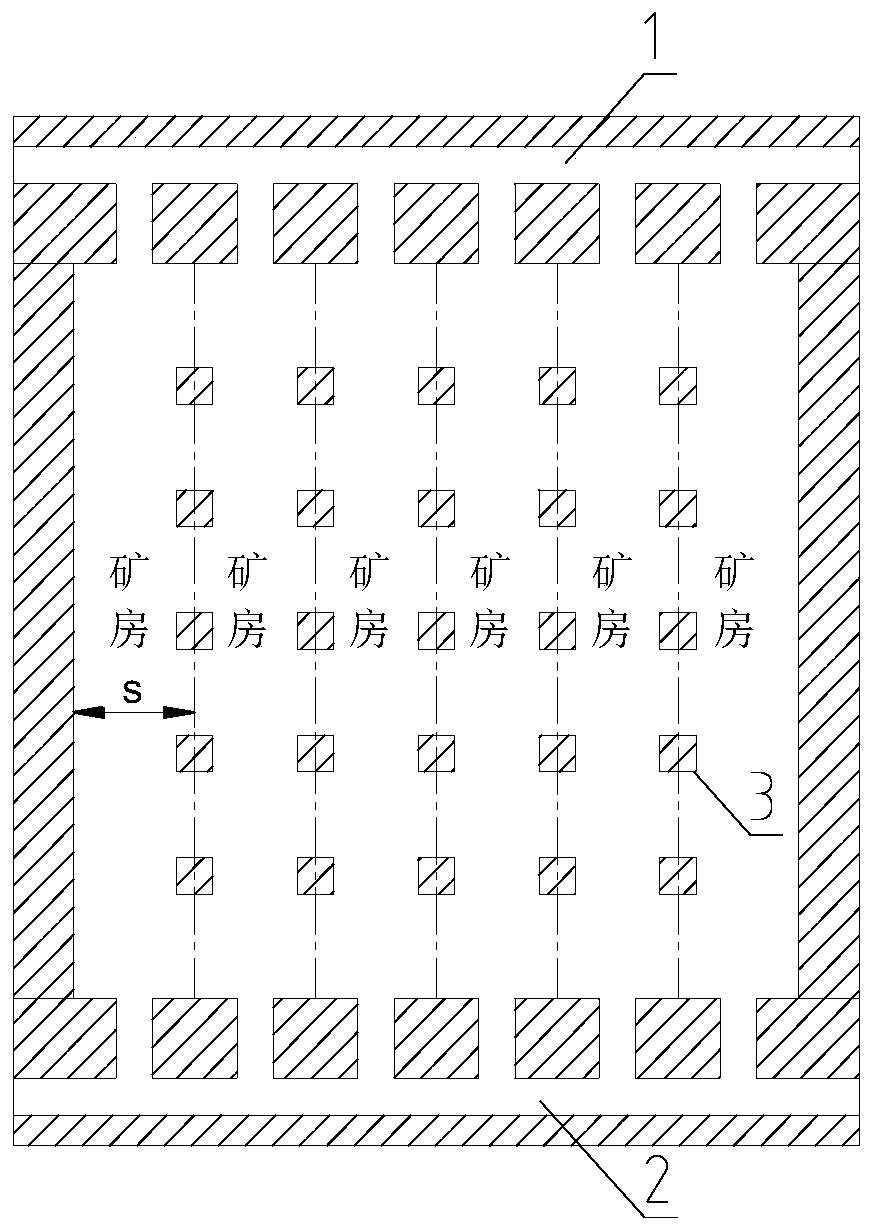

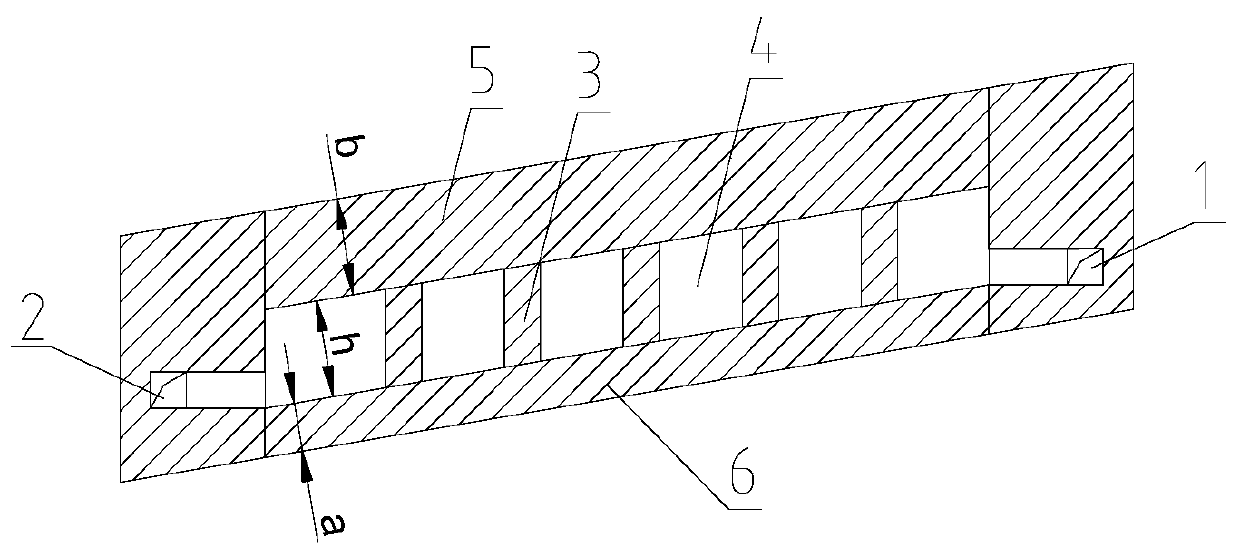

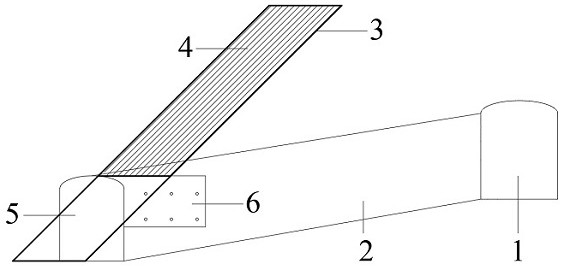

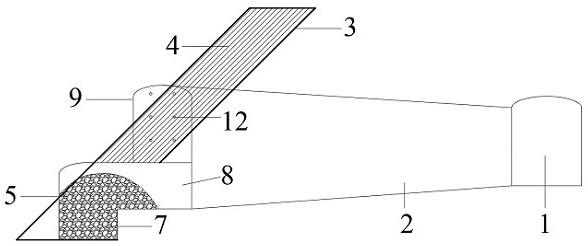

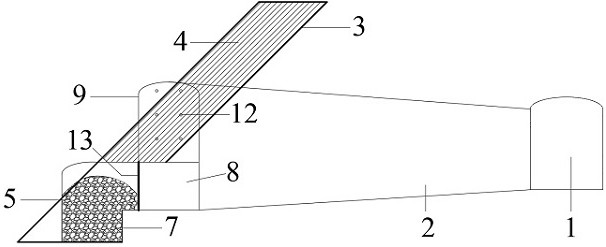

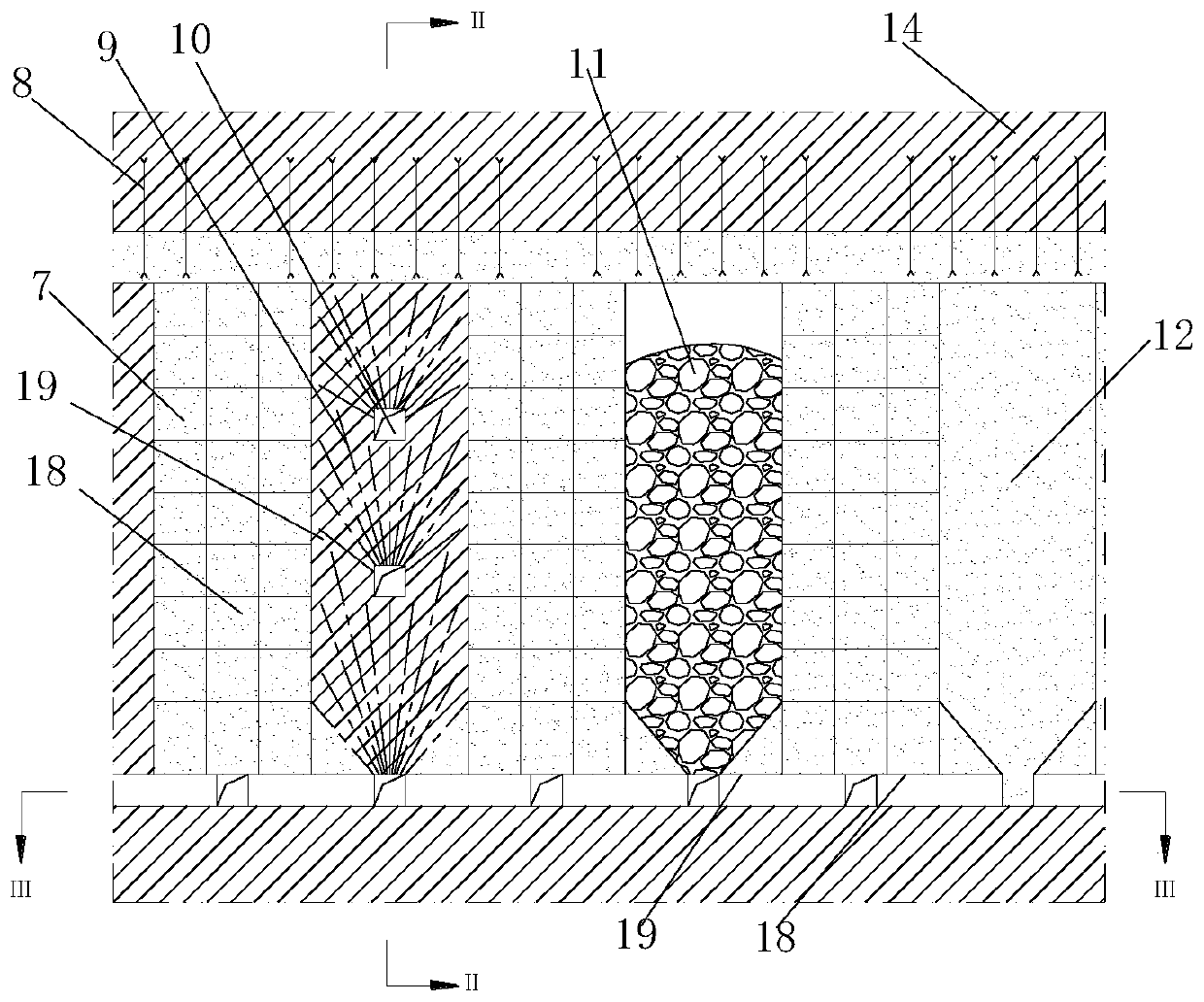

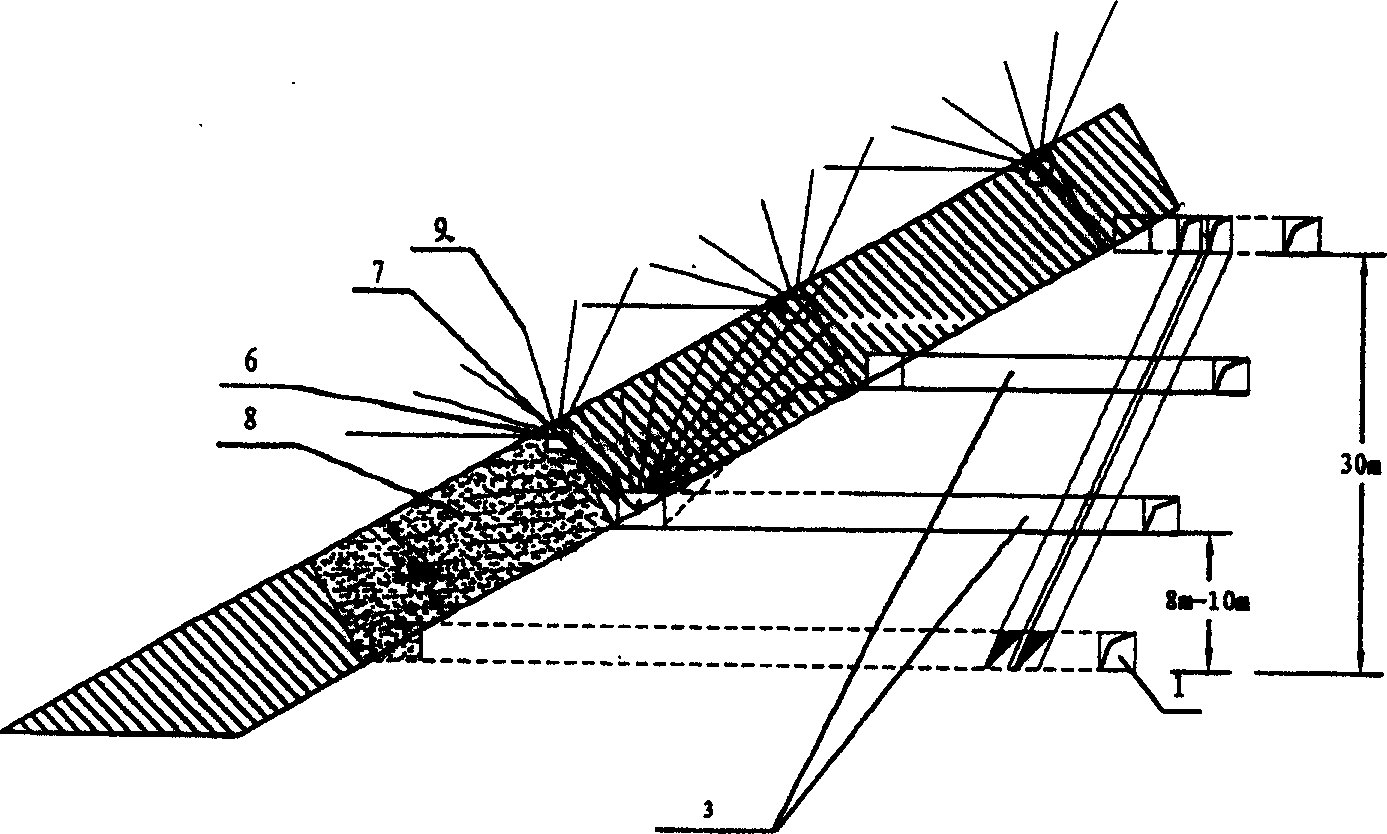

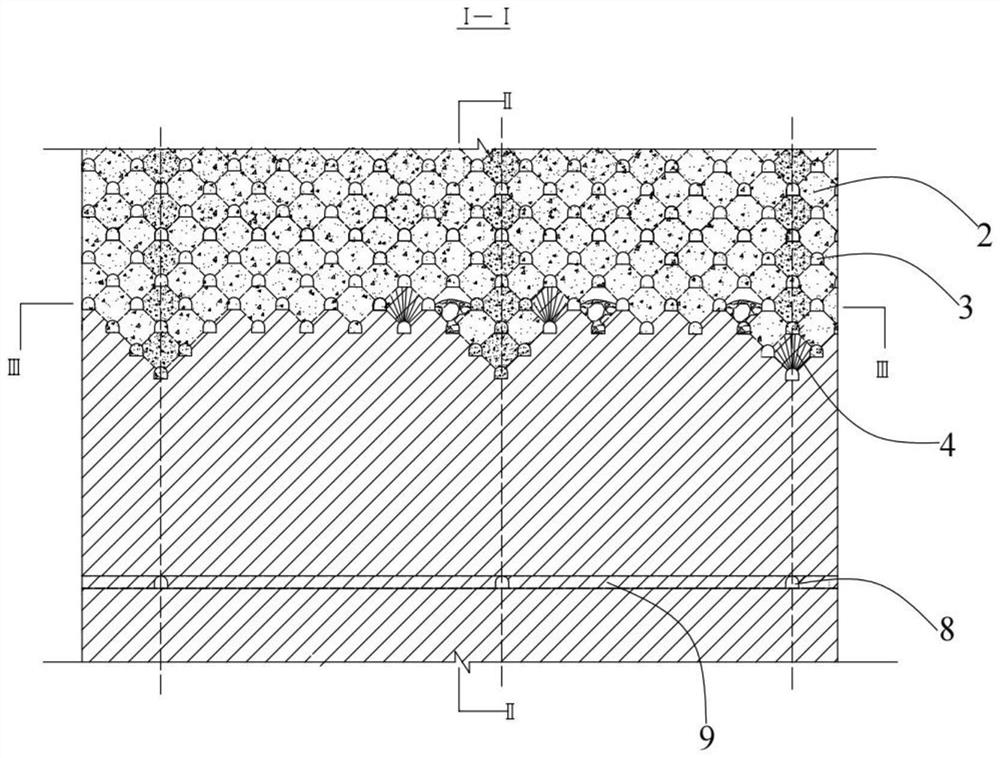

Diagonal ore-break-down medium-length hole mining method for steeply-inclined thin vein ore body

ActiveCN104989404AReduce depletionReduce lossesUnderground miningSurface miningRoom and pillar miningStart stop

The invention discloses a diagonal ore-break-down medium-length hole mining method for a steeply-inclined thin vein ore body. The method comprises the following steps: arranging a stope according to the strike of the ore body, dividing rooms, pillars and sections according to the inclination direction of the ore body and arranging a level haulage roadway along the vein of the ore body from the footwall of the ore body; driving ore-drawing crosscuts into the ore body from where the level haulage roadway is located; horizontally arranging an undercutting roadway along the vein and parallely driving rock-drilling prospecting rises along slant height; arranging ore drop shafts to abut against the haulage roadway; starting stoping from one side of the stope, stopping stoping when the undercutting roadway is driven to the position of the first rock-drilling prospecting rise and then driving the rock-drilling prospecting rise; allowing a medium-length hole drilling machine to gradually travels from undercutting roadway to rock-drilling prospecting rise, drilling medium-length upward blast hole, carrying out denotation and drawing ore out from the bottom ore-drawing crosscuts; and after the first rock-drilling prospecting rise reaches a certain position, continuing driving the undercutting roadway until the position of the second rock-drilling prospecting rise is arrived at, carrying out medium-length hole mining, and repeating the above-mentioned operations until stoping of the stope is completed. The diagonal ore-break-down medium-length hole mining method has the advantages of high production efficiency, great production capacity and good operation security.

Owner:CENT SOUTH UNIV

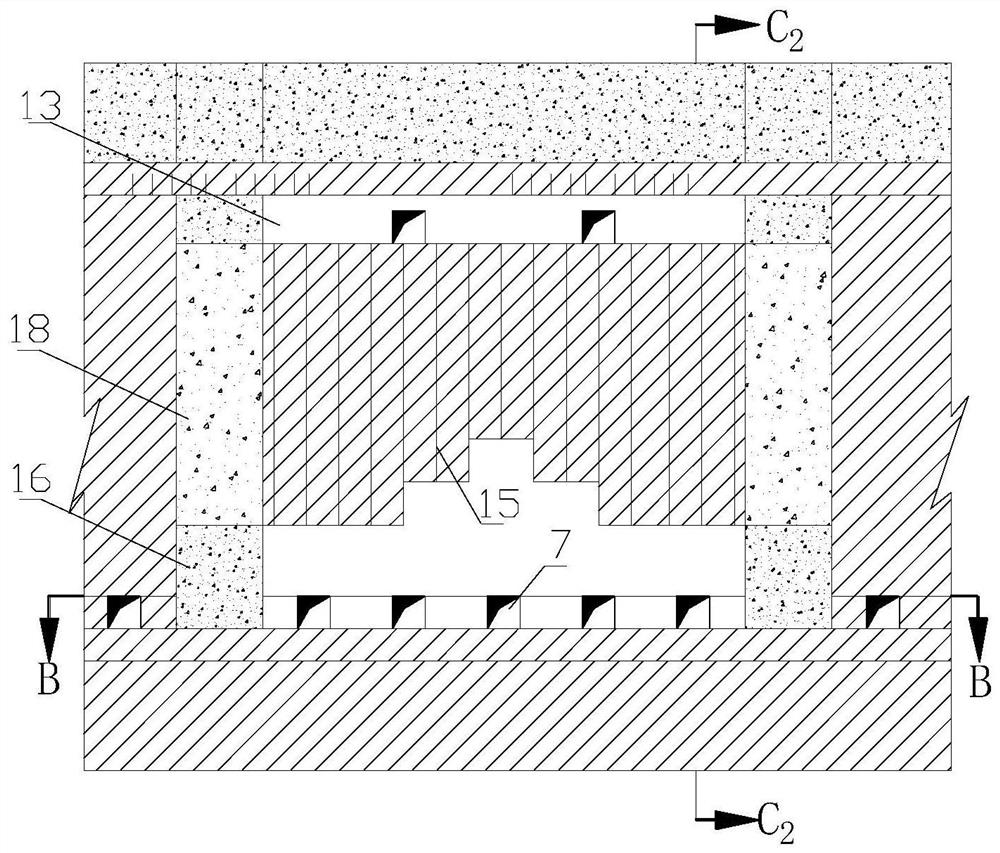

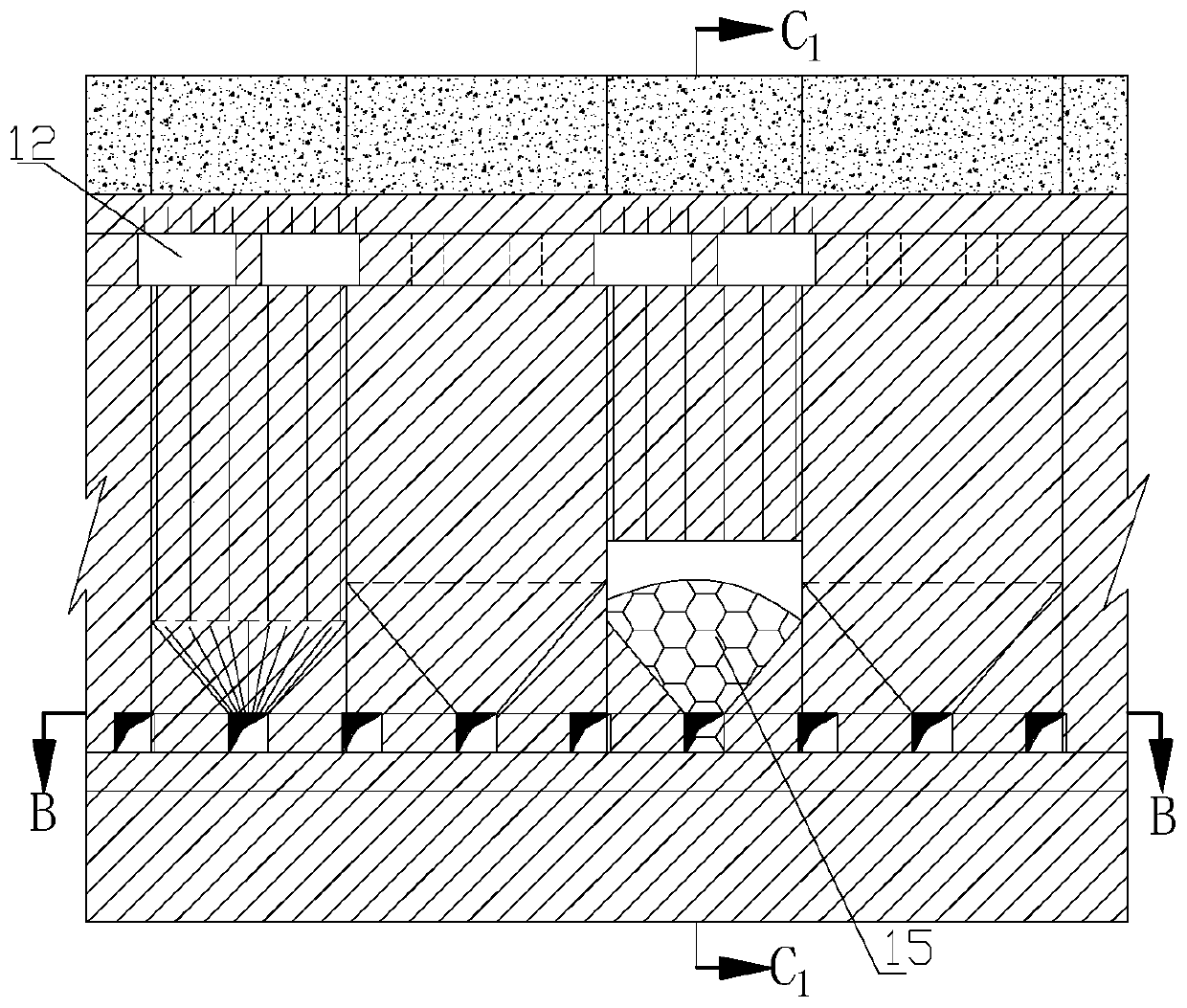

Chamber and overhand cut combined cut-and-filling stoping method in pre-roof-protecting stage

InactiveCN104847352AImprove mining safetyImprove stope production capacityUnderground miningSurface miningEngineeringCut and fill

The invention relates to a chamber and overhand cut combined cut-and-filling stoping method in a pre-roof-protecting stage. The method comprises the following steps: dividing a middle ore body into panels along the trend of the ore body, further dividing the middle section into a plurality of sections in the vertical direction, and mainly adopting a footwall out-out-pulse traceless accurate mining mode; arranging chambers and pillars in the panels at intervals; recovering the chambers first, and adopting a sublevel open stoping method with subsequent backfilling; after recovering the chambers, recovering the pillars and adopting an overhand horizontal cut-and fill method for the pillars, and before recovering the chamber in stages, pre-supporting a long cable in advance for an upper panel in a sublevel upper panel supporting lane; pre-supporting the fore-set by using an anchor rod and a metal net in an air return cross gateway below the fore-set; when the pillars are recovered in layers, stopping mining when the pillar is 3m close to the main crack of the upper panel F1 in horizontal distance and reserving the panel as an upper panel roof-protecting ore of the sub layer, and when the lower layer is recovered, fully recovering the upper panel roof-protecting ore reserved in the previous layer, and meanwhile, reserving the upper panel roof-protecting ore in the lower sub layer; and sequentially circularly recovering and reserving the upper panel roof-protecting ore. By virtue of the method provided by the invention, safe, efficient and low-cost mining can be implemented for thick and large ores which are relatively broken.

Owner:SANSHANDAO GOLD MINE SHANDONG GOLD MINING LAIZHOU

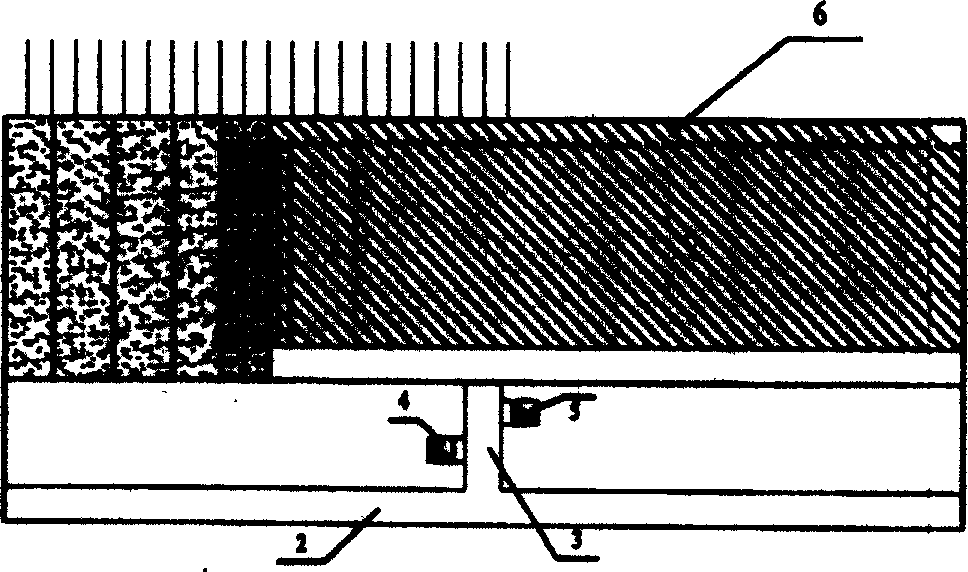

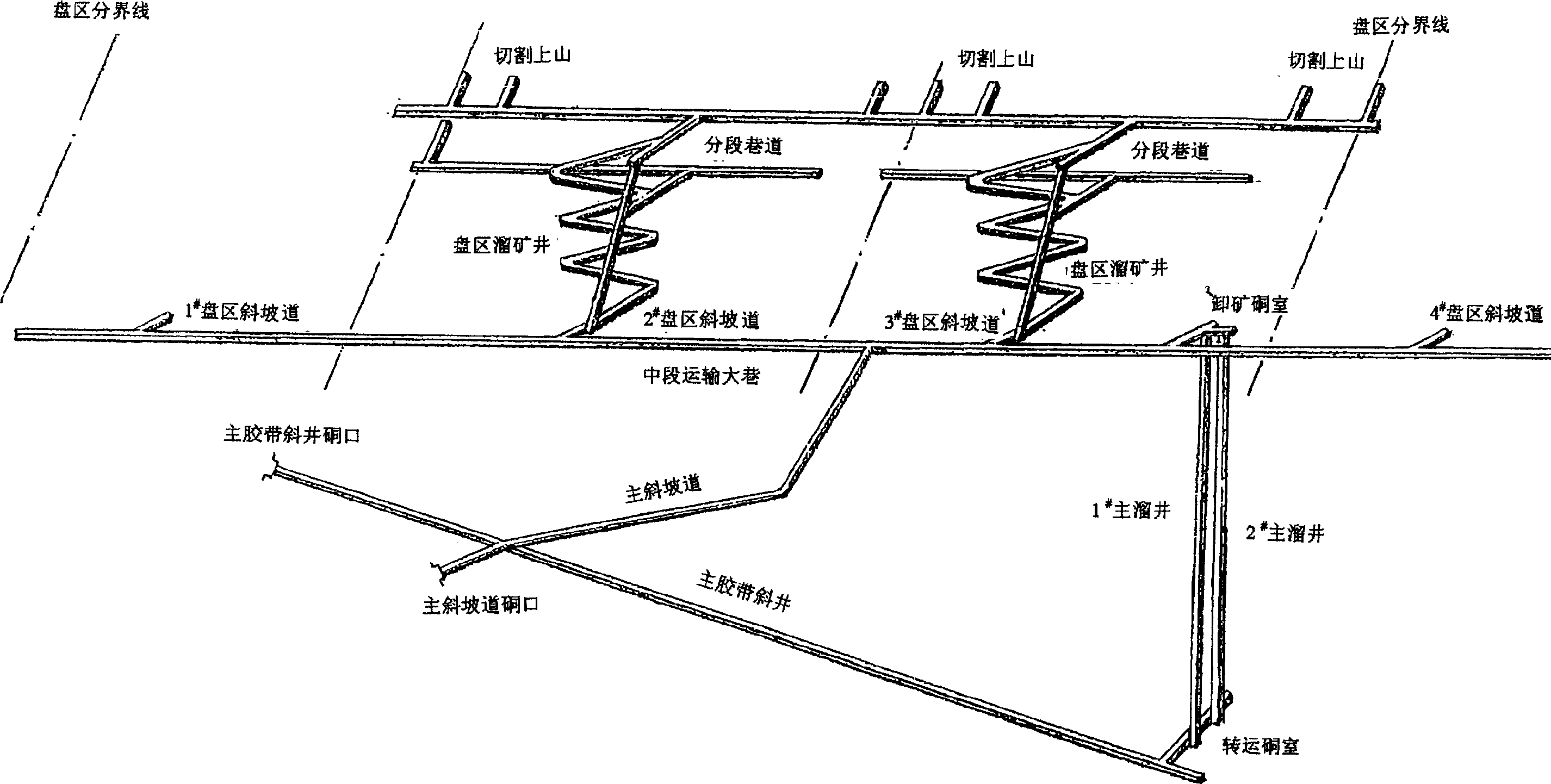

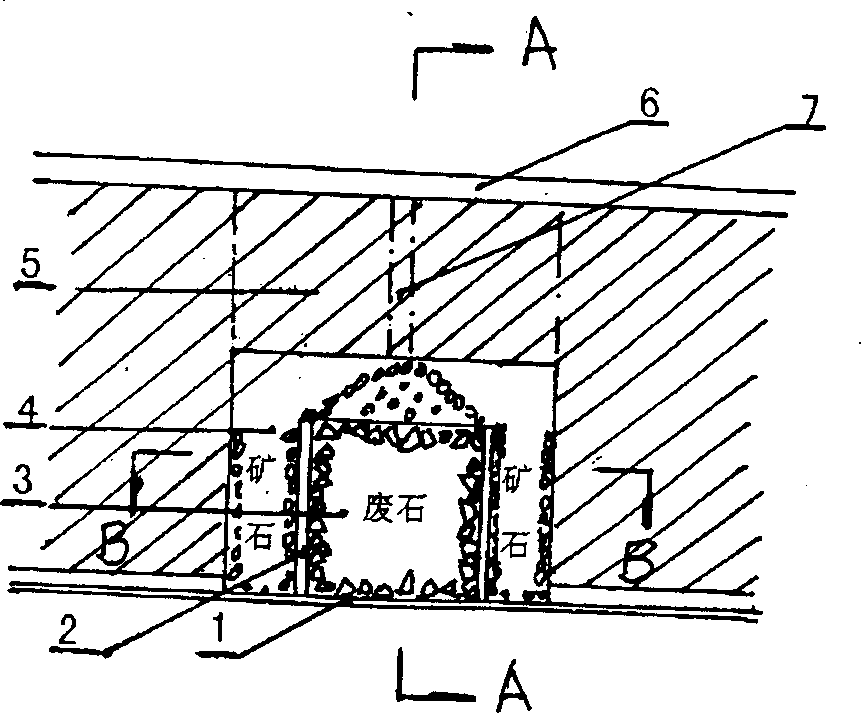

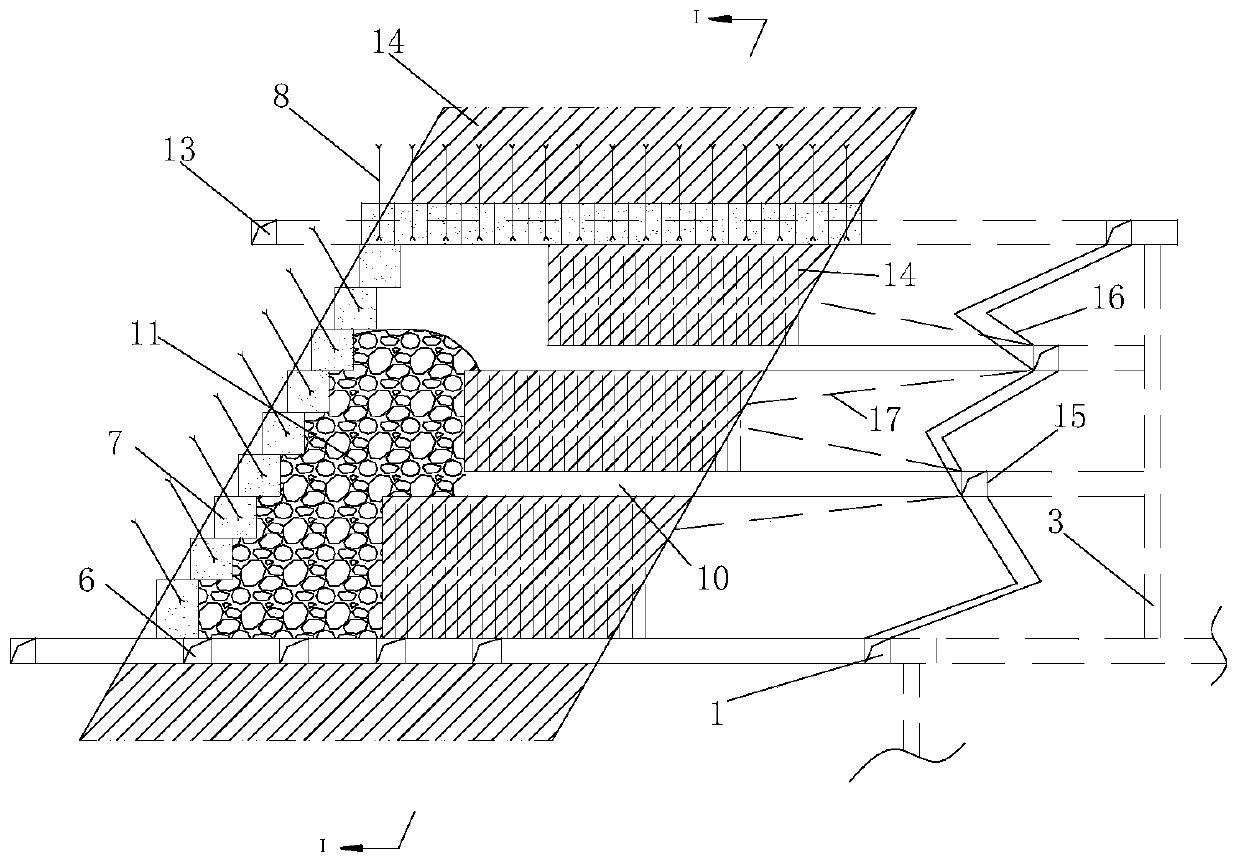

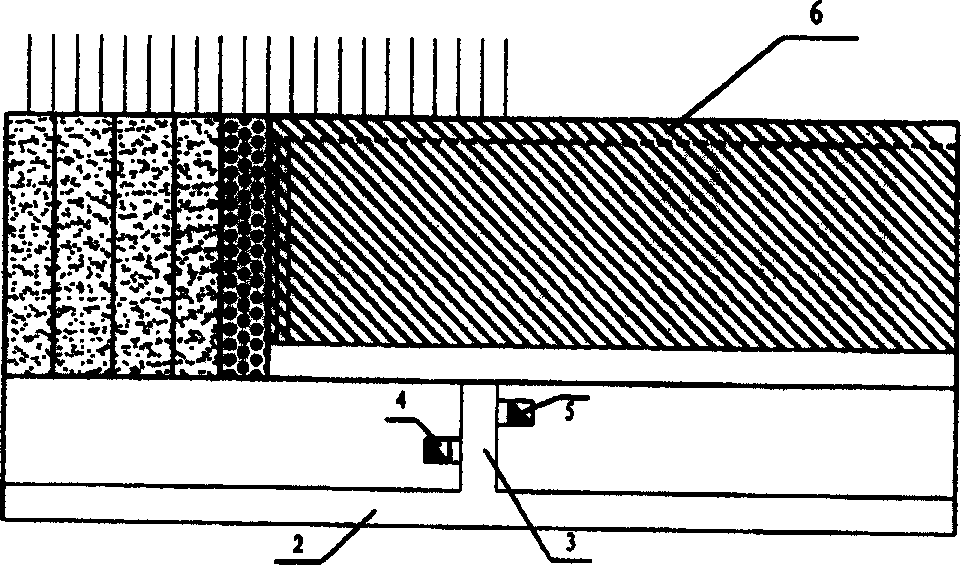

Roof bolt protection and sectioned empty field method for phosphorate rock mining

InactiveCN1458390AImprove stope production capacityReduce depletion rateUnderground miningSurface miningTruckMineralogy

The present invention relates to underground exploitation of phosphorate rock mineral and aims at providing slow inclined middle thick ore body exploiting method. The said exploitation process includes tunneling adit and main inclined tunnel, tunneling middle section main entry, dividing ore body into several panels, tunneling inclined panel slope, dividing the middle section into subsections, dividing subsection ore body into small room via subsection horizontal gallery and cutting raise, supporting roof with anchorage bar and metal net; drilling to bring down with rock drilling machine with cutting raise as free plane; stoping along strike direction; exploding residual ore column to empty area; conveying ore with carry scraper to ore chute and transporting ore with truck. The present invention is suitable for phosphate ore of ore body inclination 0-90 deg and ore body thickness 2-20 m.

Owner:贵州开磷设计研究院有限责任公司

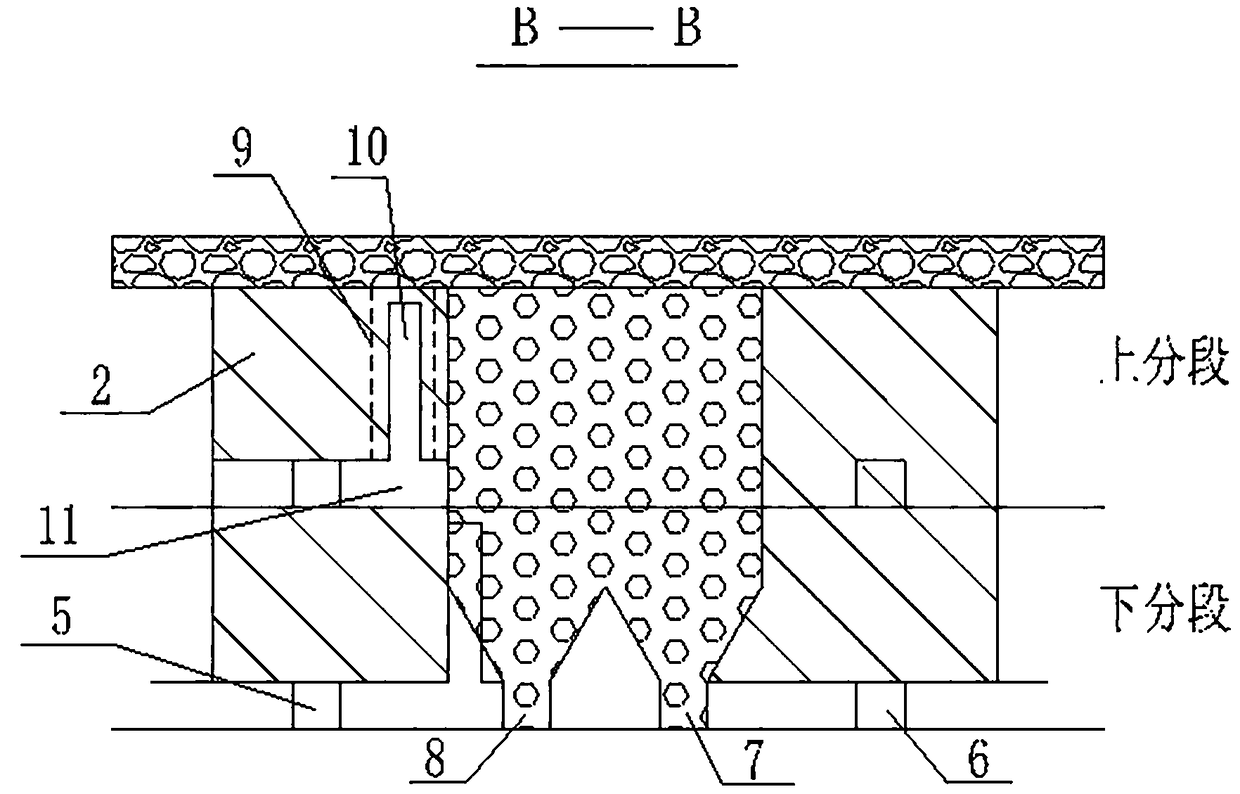

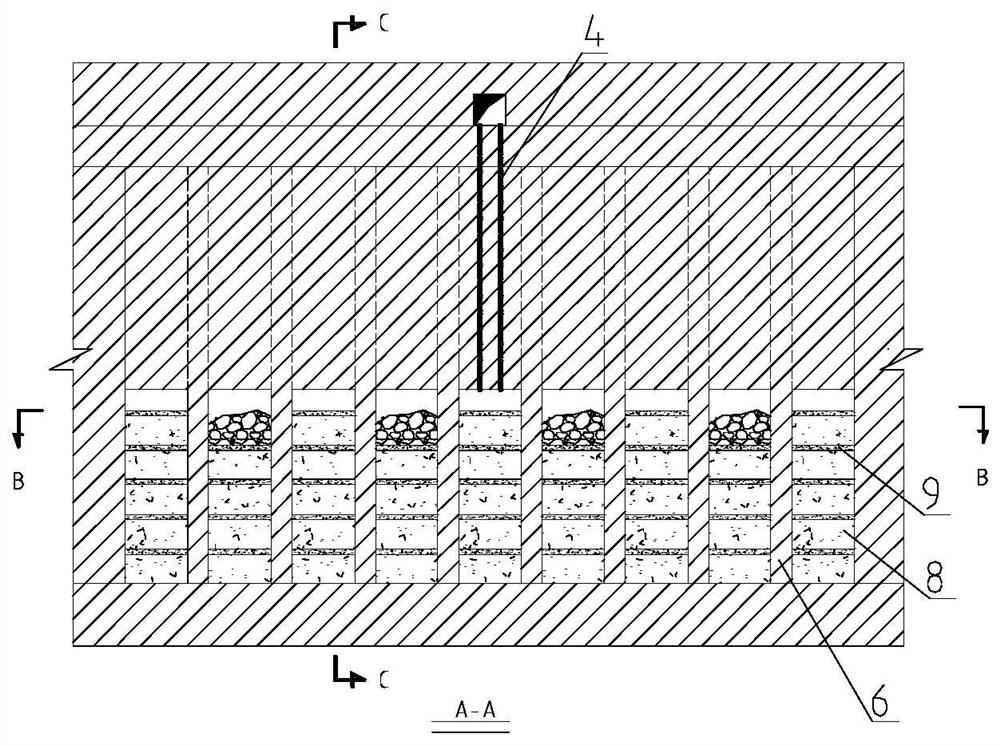

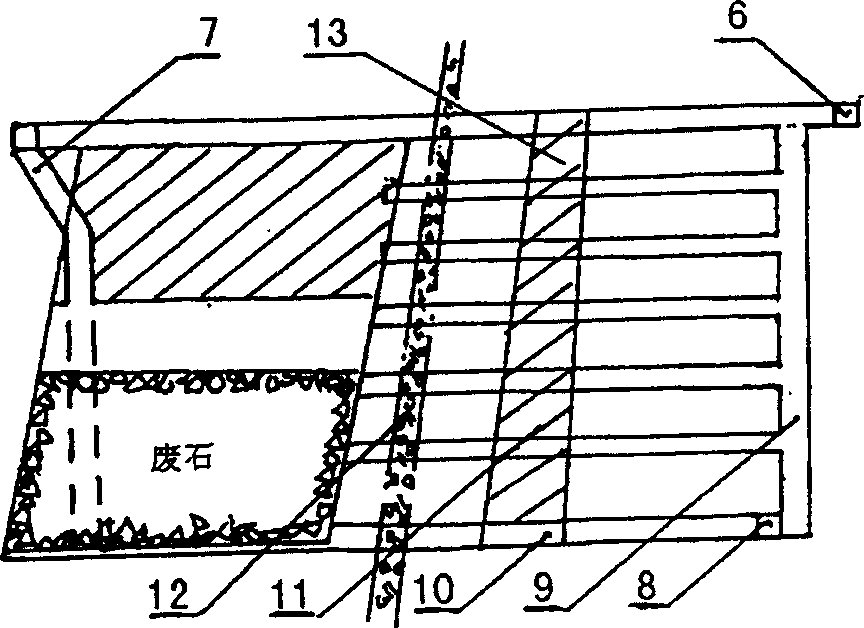

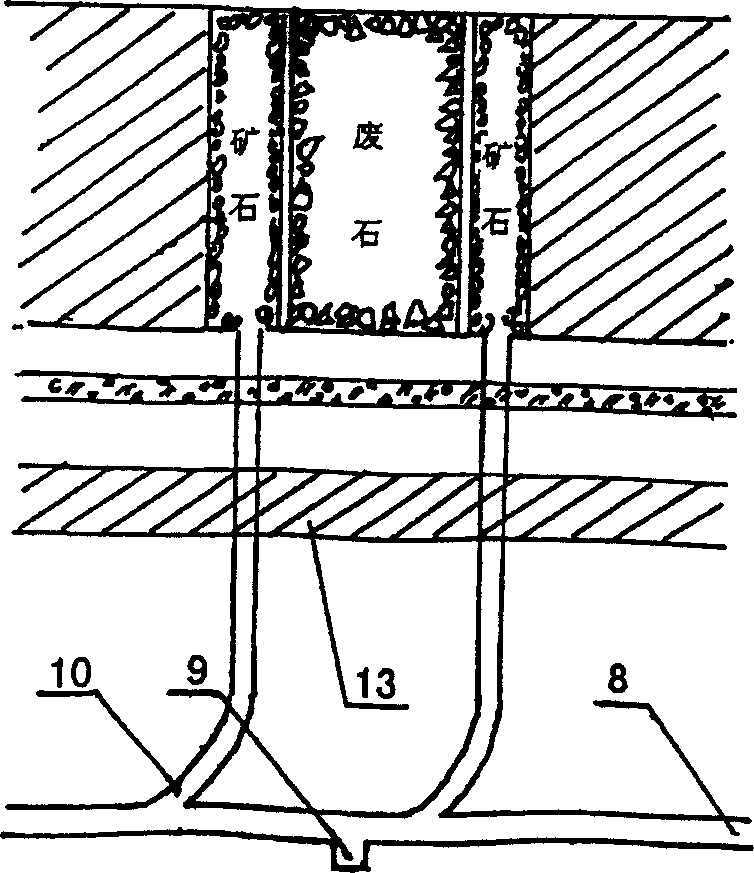

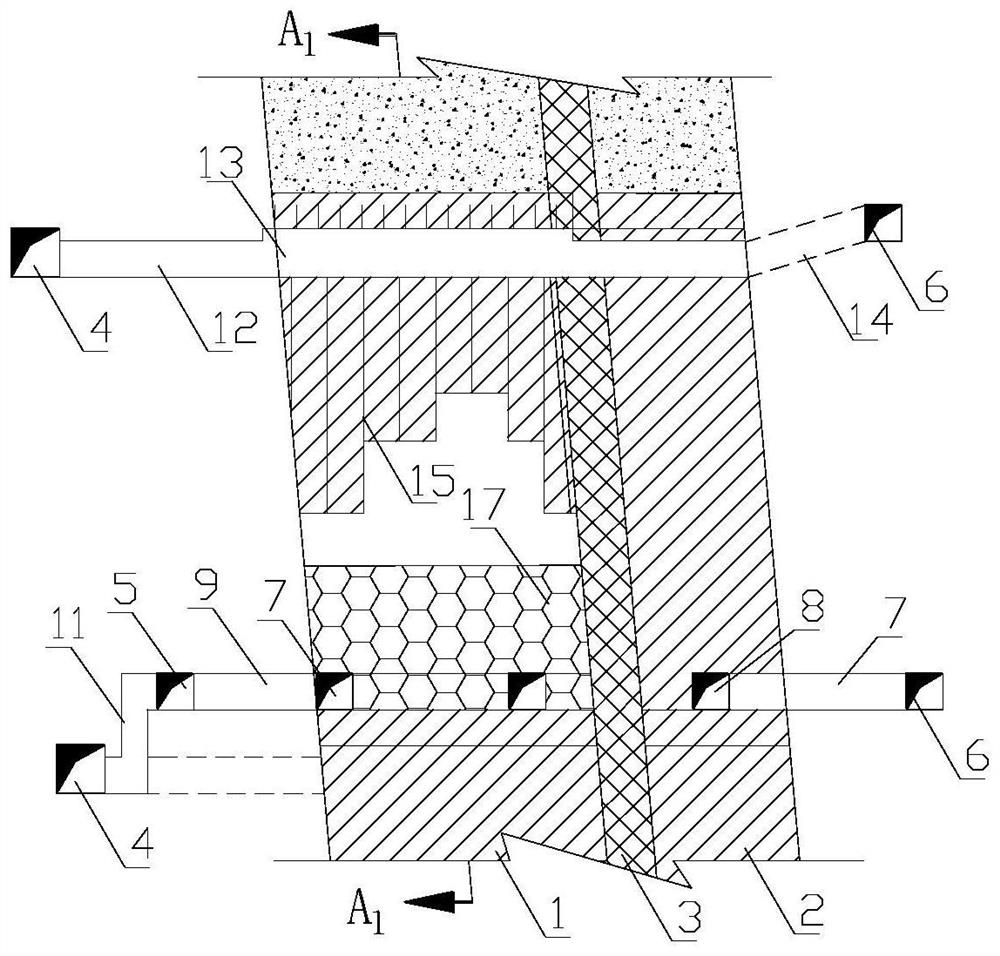

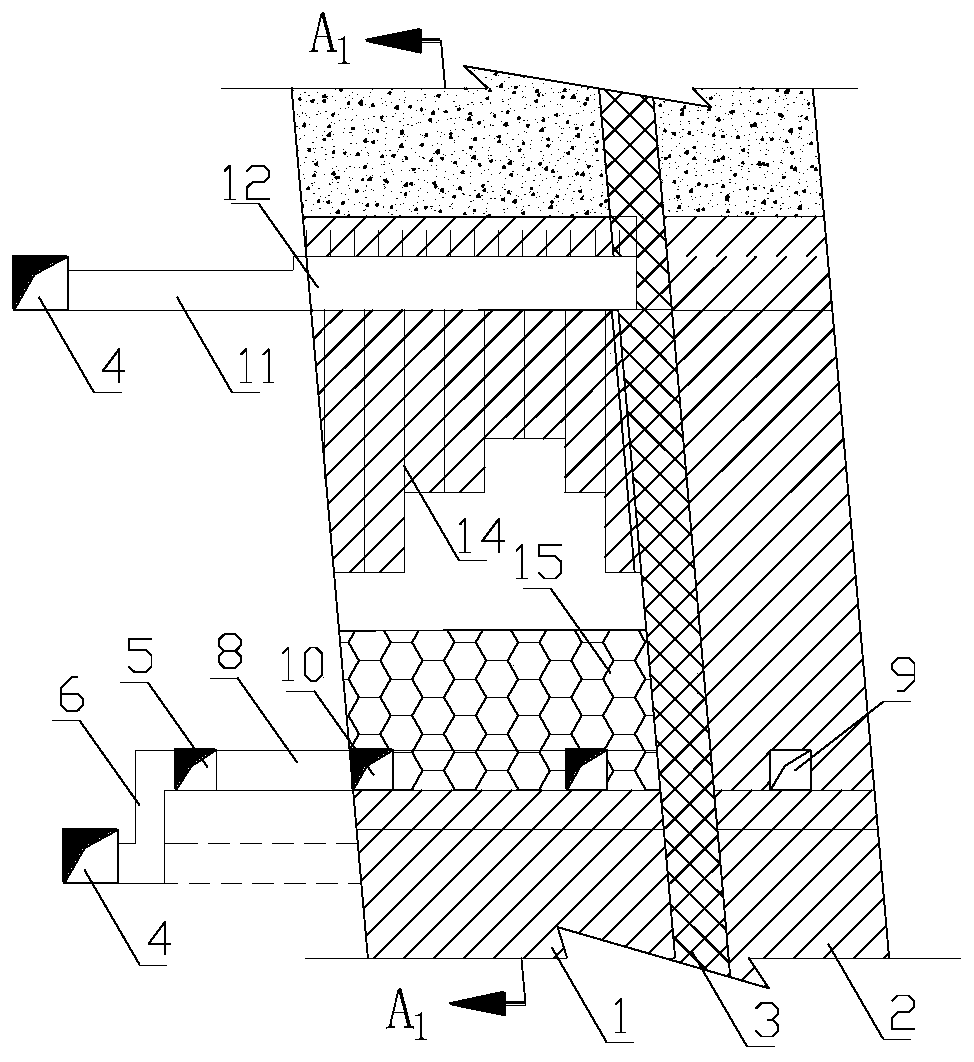

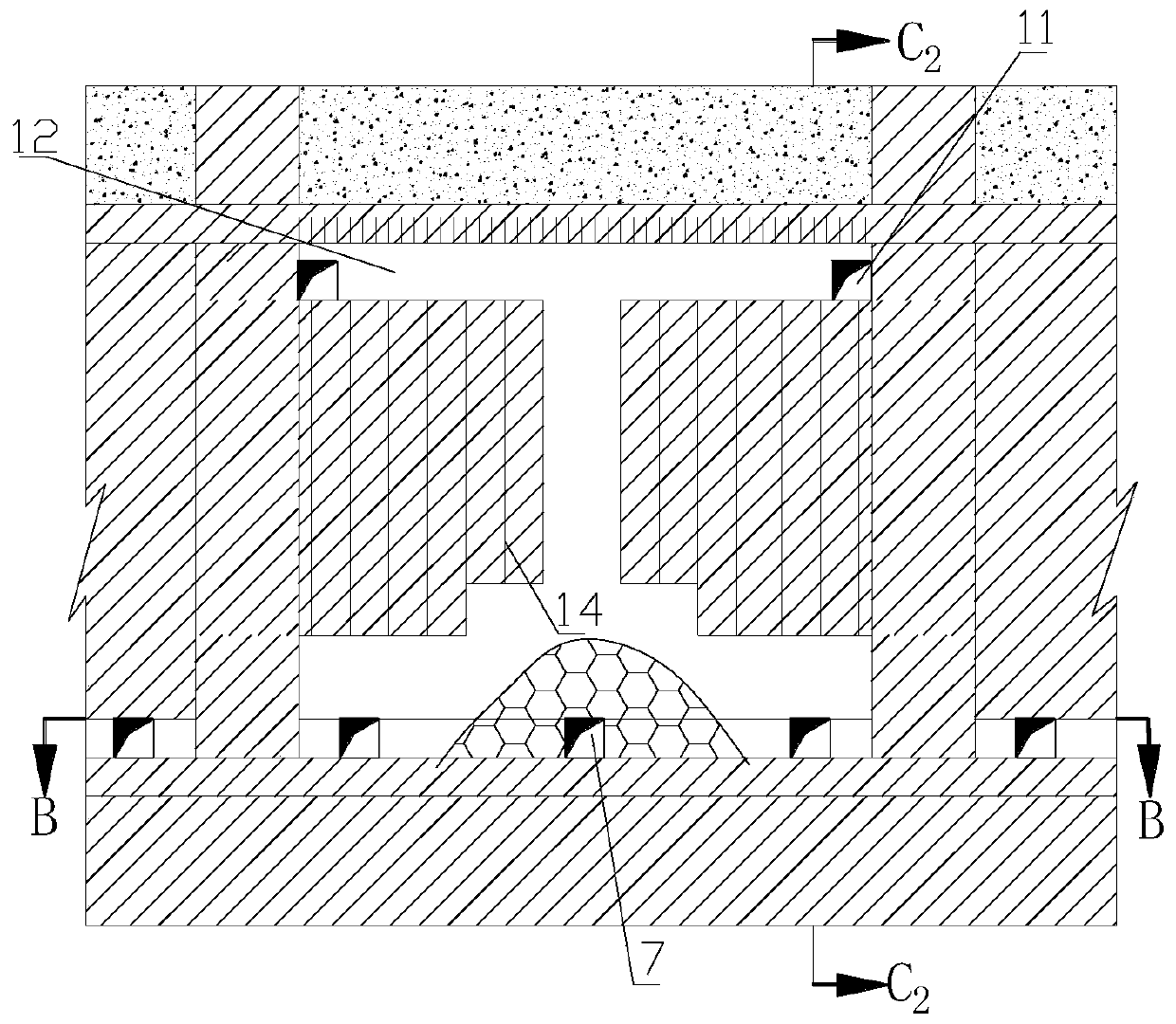

Large-structure sublevel drilling stage ore removal mining method with delayed filling

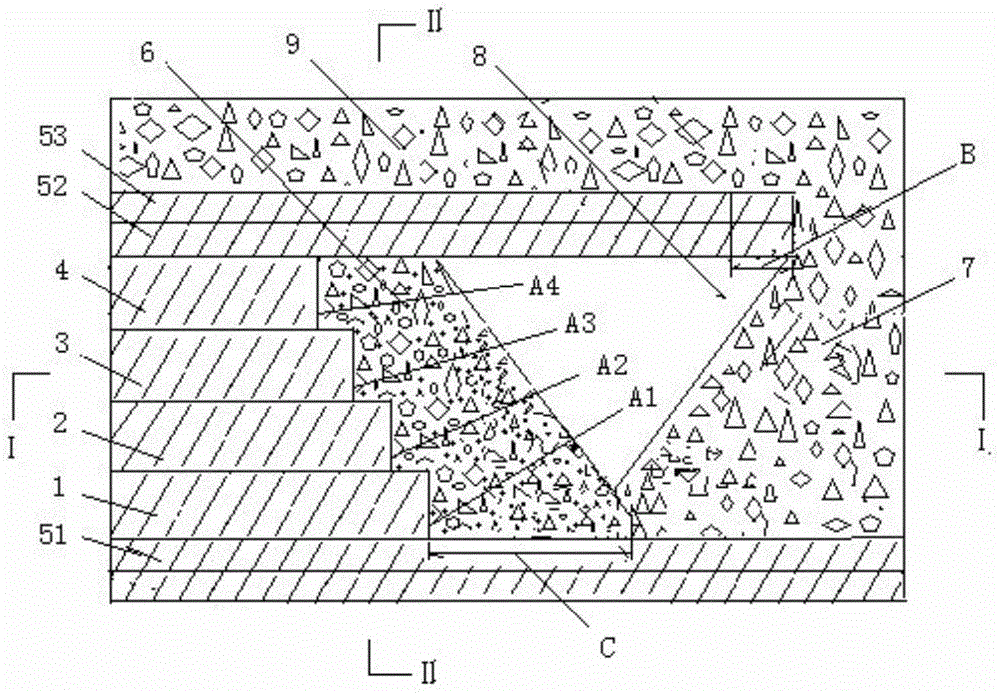

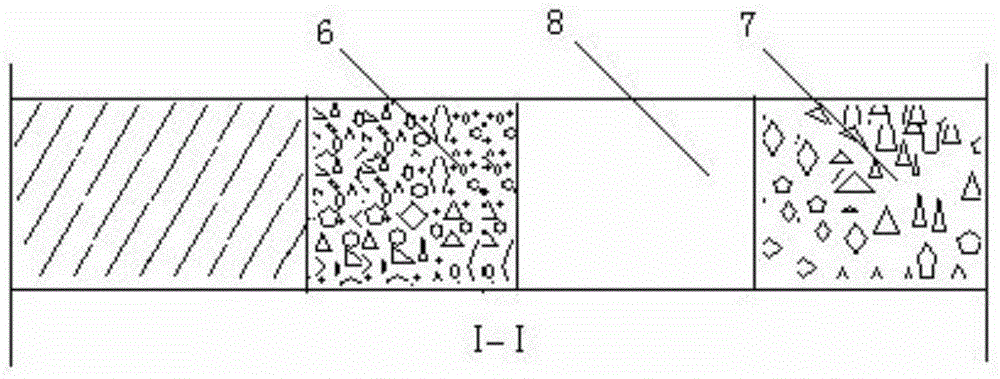

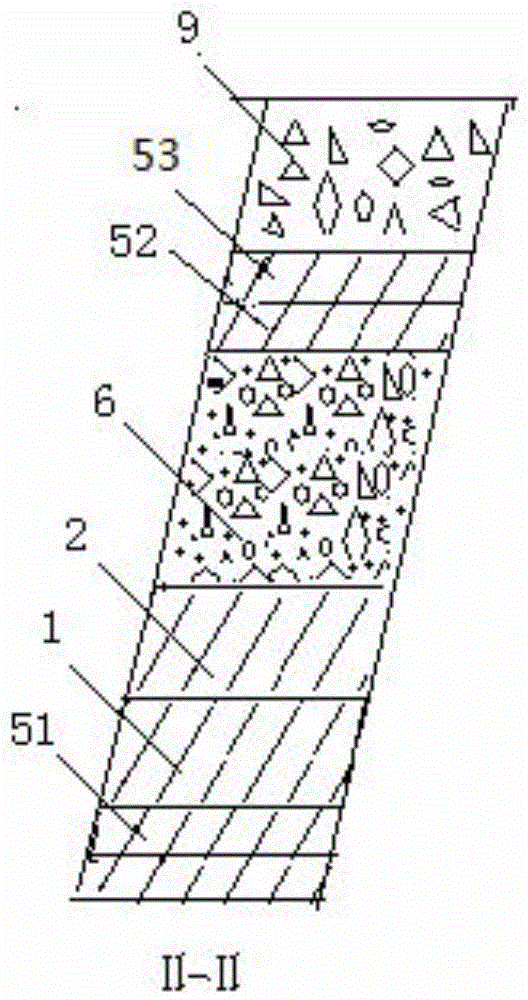

ActiveCN104863592AReduce labor intensityImprove stope production capacityUnderground miningSurface miningResource recoveryStructure of the Earth

The invention relates to a large-structure sublevel drilling stage ore removal mining method with delayed filling. The mining method comprises stoping in stopes and bottom structure recovery which are carried out synchronously in a crossed manner, and comprises the following steps: step 1, stoping in odd-numbered stopes, wherein the stoping manner is sublevel drilling stage ore removal, and mined out space I is not filled immediately; step 2, stoping in 1 / 2 bottom structures I corresponding to the odd-numbered stopes, and filling ore rooms and the mined out space I, corresponding to the 1 / 2 bottom structures I, of the ore rooms after stoping is finished; step 3, stoping in even-numbered stopes, wherein mined out space II is not filled immediately; step 4, stoping in 1 / 2 bottom structures II corresponding to ore pillars, and filling the ore pillars and the mined out space II, corresponding to the 1 / 2 bottom structures II, of the ore pillars after stoping is finished. The mining method has the advantages that the mining-cutting work amount is reduced greatly; the production capacity of a single stope is high; the efficiency is high; workers' labor intensity is low; production, dispatching and management are simple. Moreover, stoping of the main ore in a stope and recovery of ore in the bottom structure of the stope are realized synchronously in a crossed manner, and the stoping operation is safe, so that the resource recovery rate is high.

Owner:CHINA MINMETALS CHANGSHA MINING RES INST +1

Filled mining method

InactiveCN1424487AShort filling lengthHigh speedUnderground miningSurface miningUltimate tensile strengthMineralogy

Owner:广东金鼎黄金有限公司

Environmental reconstruction subsection medium-length hole subsequent filling mining method

ActiveCN110331978AImprove securityEnsure safetyUnderground miningSurface miningTwo stepOperation safety

The invention discloses an environmental reconstruction subsection medium-length hole subsequent filling mining method which is mainly suitable for ore rock crushing and thick or extremely thick inclined ore body stopping. An ore body is divided into disc areas and ore blocks, the ore blocks are divided into first-step stopes and second-step stopes, and stopping is conducted through two steps. Themethod comprises the steps that firstly, the first-step stopes, ore bodies in the range of top columns arranged on the upper portions of the second-step stopes and ore bodies at the bottoms of the second-step stopes are stoped by adopting a drift-and-fill method, and filling is conducted by adopting high-strength cemented filling bodies; secondly, disc ore bodies on the first-step stopes and thesecond-step stopes are stoped by adopting the drift-and-fill method; and lastly, the second-step stopes are stoped by adopting a staged deep-hole empty-field subsequent filling method. The environmental reconstruction subsection medium-length hole subsequent filling mining method has the advantages that the stopping operation safety is good, the production capacity of the stopes is high, the production cost is low, and the ore body production condition change and horse stone adaptability is good.

Owner:CHINA MINMETALS CHANGSHA MINING RES INST

Deep hole caving backfilling stoping method for artificially freezing stope roof

ActiveCN102926753AIncrease production capacityEfficient mining processUnderground miningSurface miningWater flowMineralogy

The invention discloses a deep hole caving backfilling stoping method for artificially freezing the stope roof. The method comprises the following steps that: by the artificial freezing method, the stope roof which is extremely unstable is frozen into a stable freezing body, which creates conditions for personnel and equipment entering the stope; and by the big-diameter deep hole caving backfilling stoping process, the medium and deep hole caving is applied, the goaf is filled once after stoping is finished, and the freezing body is unfrozen, so that the aim of safely and highly efficiently mining ore mass with extremely unstable roof is achieved. The method is specially applied to stoping of underground metal mines which are highly difficult to mine and of which the roof has rock gaps and a developed water flowing structure and is loose, soft, fragile and extremely unstable, and has the characteristics of safety in operation, high production efficiency, high capacity of producing ore blocks and low mining cost.

Owner:CENT SOUTH UNIV

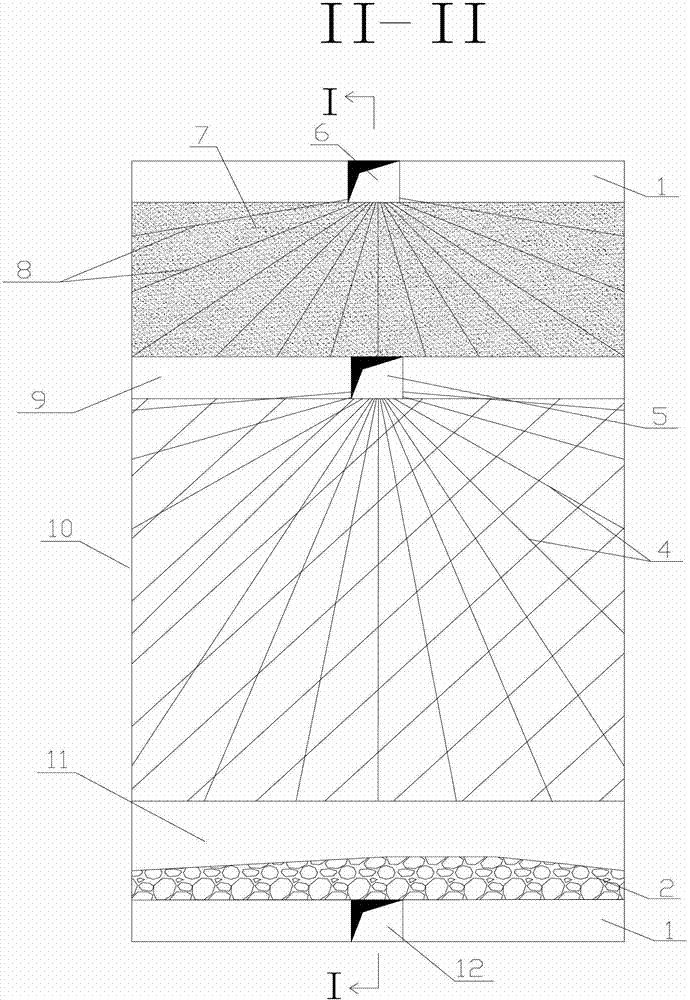

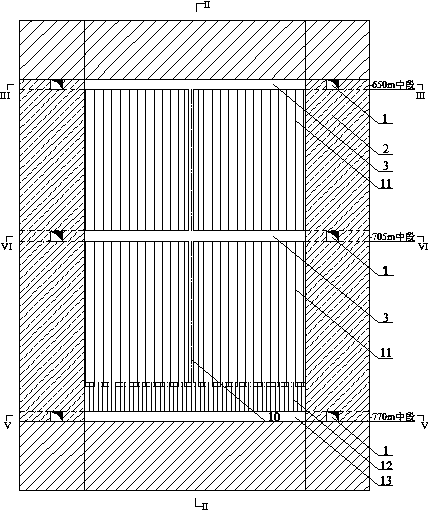

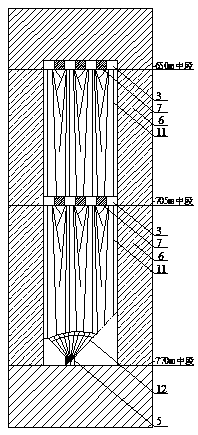

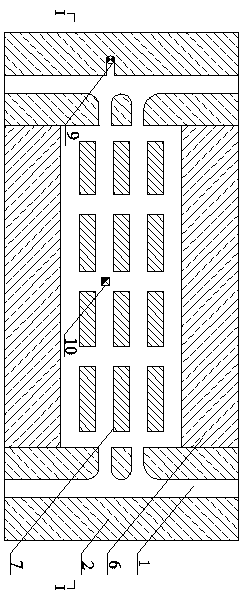

Super-large-scale stope large-diameter deep-hole high-stage open stope subsequent filling mining method and application

InactiveCN109989754AImprove rock drilling efficiencyLarge amount of mining and cuttingUnderground miningSurface miningStopingMaterials science

The invention discloses a super-large-scale stope large-diameter deep-hole high-stage open stope subsequent filling mining method and application. The method comprises the following steps: (1) a stoping scheme: ore blocks are arranged perpendicular to the trend of an ore body, the ore blocks are divided into ore chambers and ore columns, the ore chambers and the ore columns are arranged at intervals, a stope is divided into two middle sections by adopting double-middle-section continuous stoping, and a stoping method of middle-section rock drilling, double-middle-section continuous ore breaking ground, bottom ore removal structure sharing and subsequent first filling is adopted; (2) stope preparations; (3) courtyard cutting; (4) rock drilling and blasting; (5) ore removal; and (6) filling.The method has the beneficial effects that the super-large-scale stope has the advantages of being small in stope cutting work amount, large in stope ore quantity and the like; the stope is divided into two middle sections for rock drilling, the technical difficulty of deep-hole rock drilling of the stope is reduced, and the rock drilling efficiency of the stope is improved; the double-middle-section continuous ore breaking ground is adopted, and the bottom ore removal structure is shared, and the method has the advantages that the production capacity of a single stope is improved, the miningand cutting cost is reduced, the stoping efficiency is improved, and the like.

Owner:ANHUI TONGGUAN (LUJIANG) MINING CO LTD

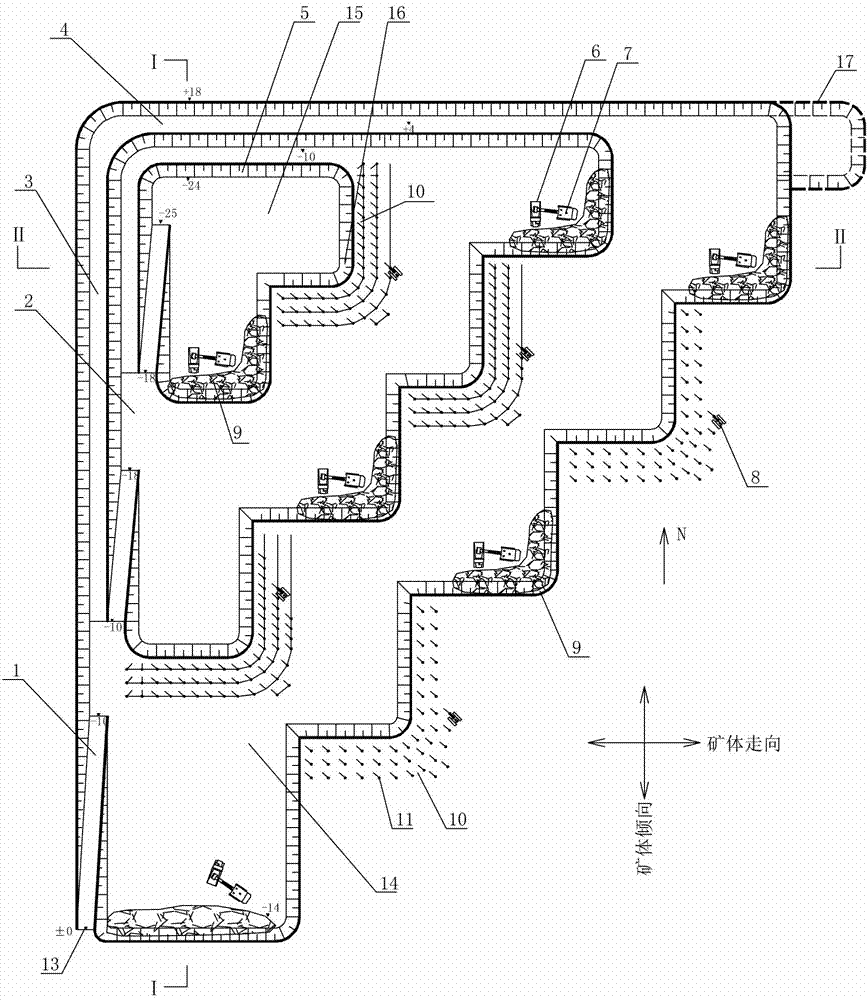

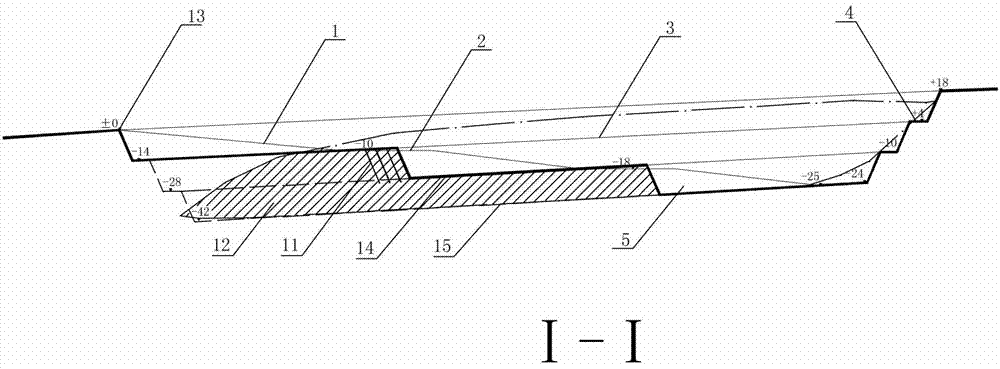

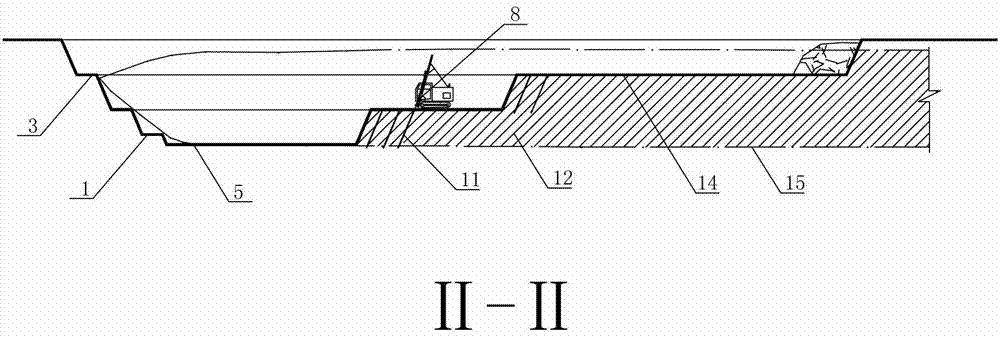

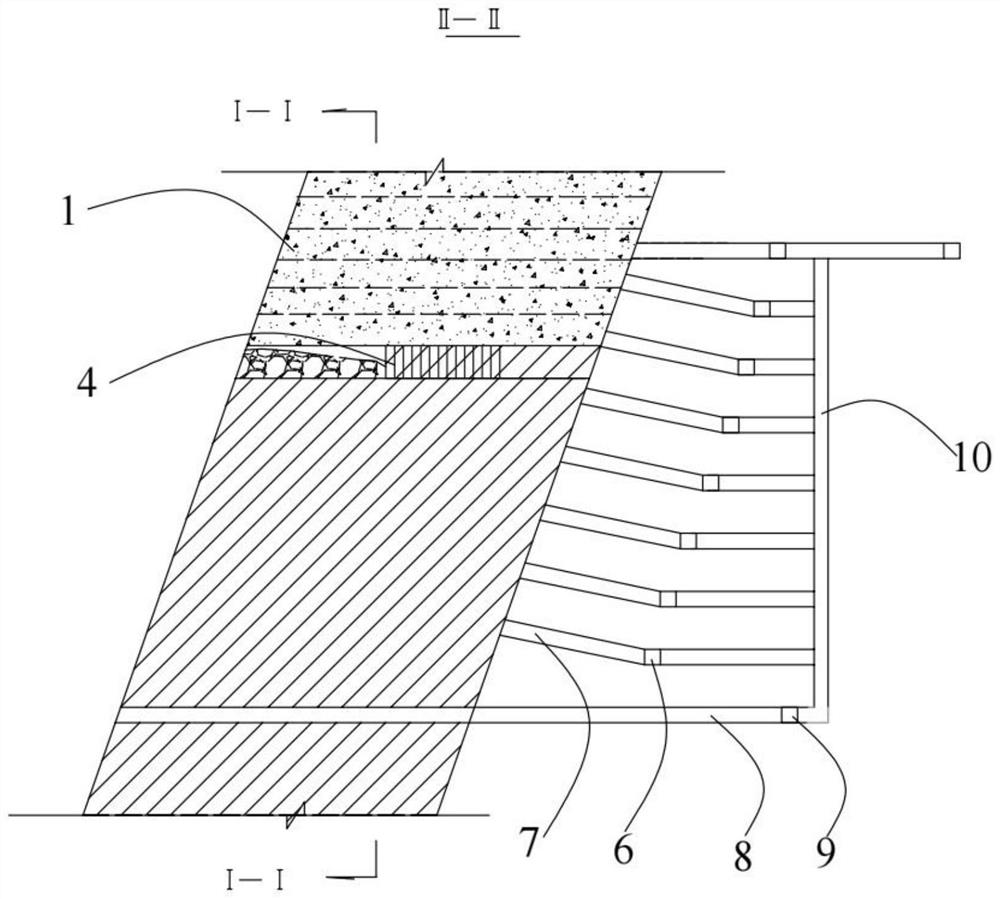

Open pit mining method for gentle tip ore body

ActiveCN107989617AShorten the transportation distanceReduce transport lifting workOpen-pit miningOpen-pit miningEngineering

The invention discloses an open pit mining method for a gentle tip ore body. The gentle tip ore body is divides into inclined layers with the equal thickness and parallel to a bottom plate of the orebody for mining; a main inlet and outlet is arranged at lower corner of the ore body, and the inclining direction of an inclined transporting channel is opposite to that of ore body; and section opening is conducted in the inclining direction and the striking direction of the ore body, a inverted-L type section opening ditch is formed, and a work line is arranged to be as a step composed of multiple reversed-L working surfaces. According to the open pit mining method, by optimizing the position of the inlet and outlet and arrangement of the transporting channel and adjusting arrangement and propelling direction of the work line and the working surface of an open pit, the fact that a triangle ore belt appears the slope surface of the step is avoided, the resource recovery rate is improved advantageously, dilution is reduced, mining construction organization is simplified, the mining cost is reduced, the blasting effect is improved advantageously, the production capacity of the pit is improved, and the initial development engineering amount and the transporting cost are reduced.

Owner:KUNMING METALLURGY COLLEGE

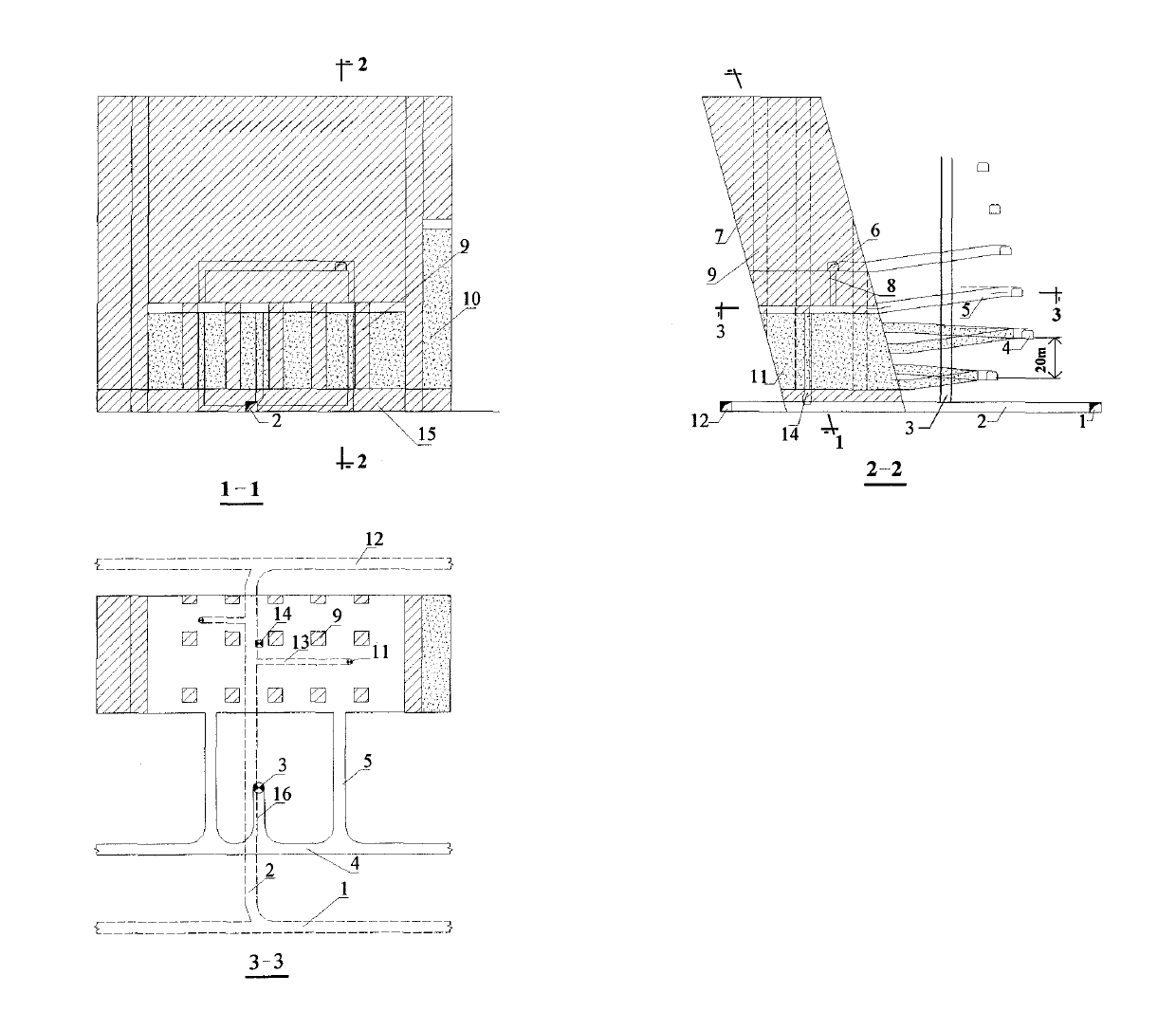

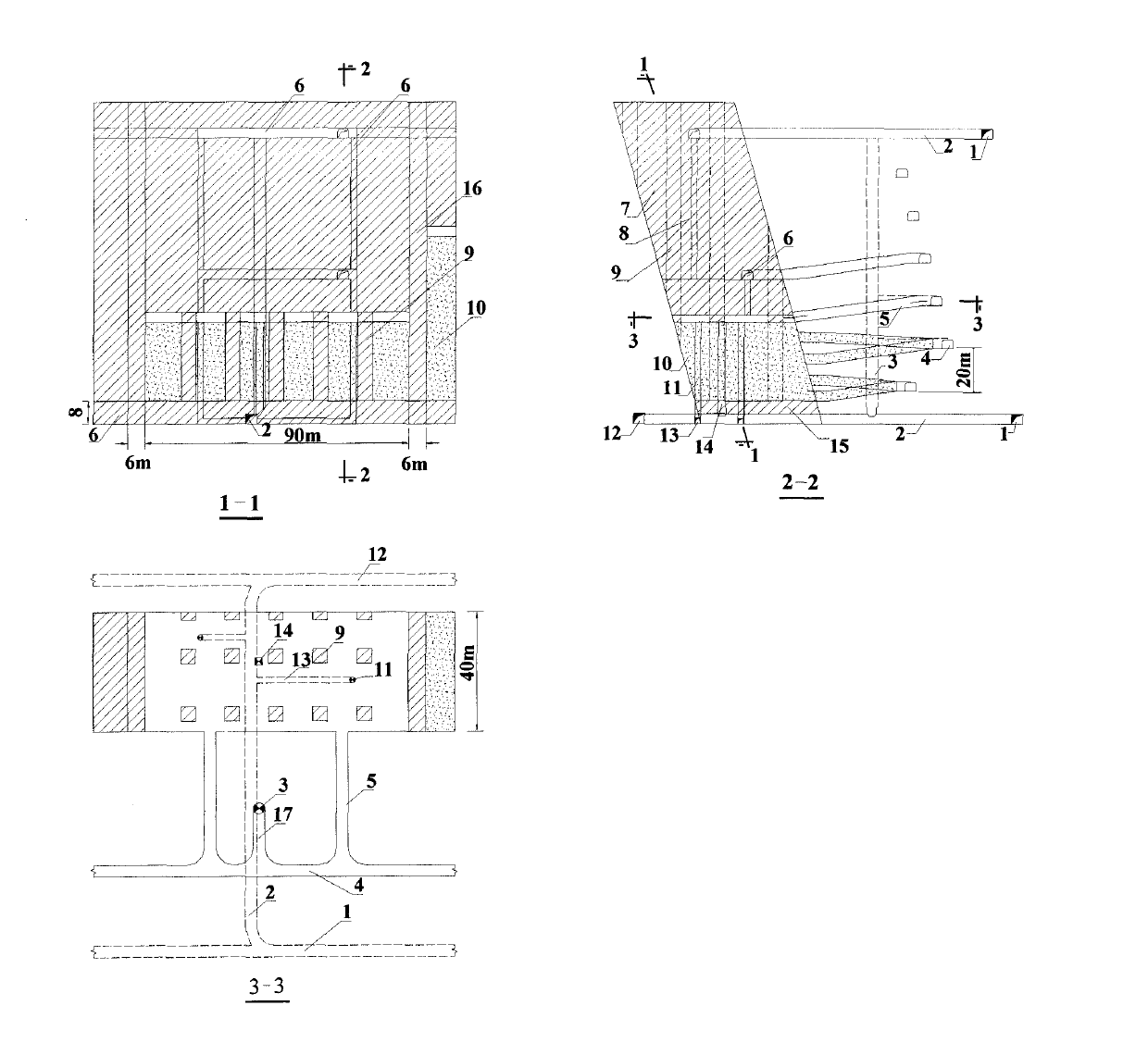

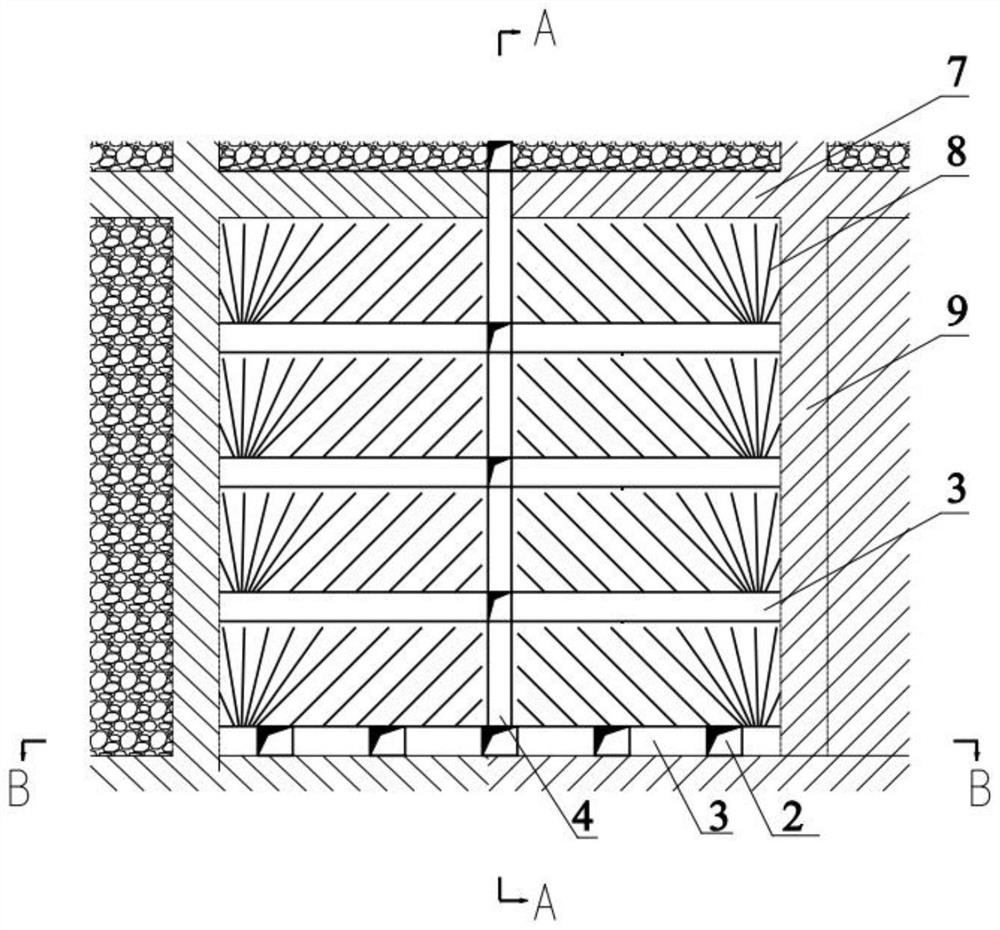

Open stope mining method for steeply inclined vein ore body

ActiveCN113446006AImprove stabilityAvoid falling accidentsUnderground miningClimate change adaptationMining engineeringRock cutting

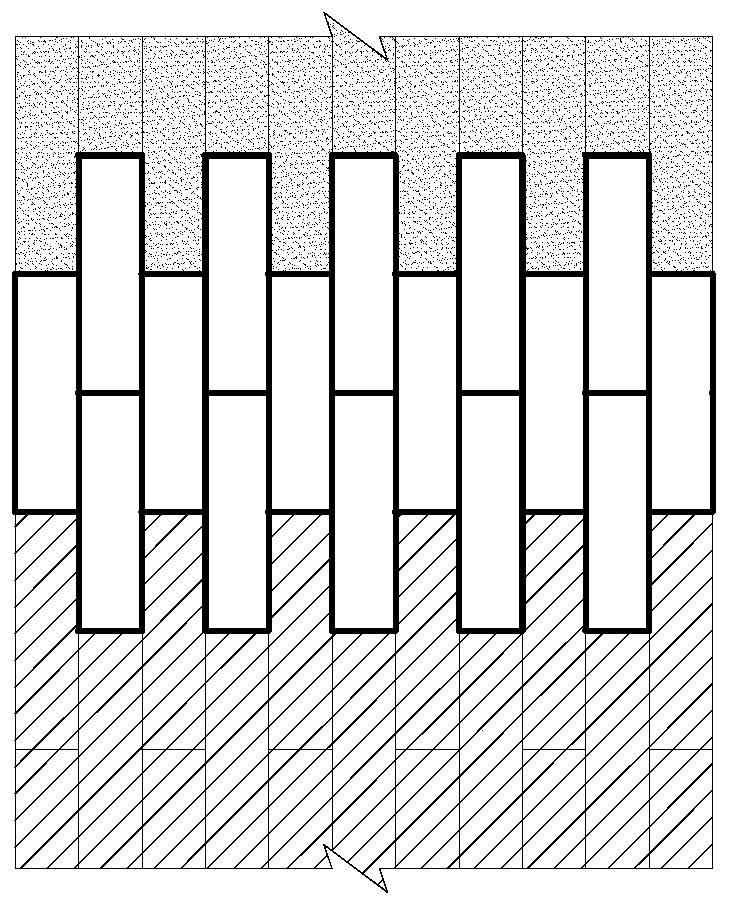

The invention discloses an open stope mining method for a steeply inclined vein ore body. The open stope mining method comprises the steps that a stope is arranged in the moving direction of the ore body, a plurality of rock drilling roadways are formed, the rock drilling roadways are arranged in parallel along a vein at equal intervals in the vertical height direction of the stope, a stope preparation well is formed in the middle of the stope, the widths of the rock drilling roadways and the stope preparation well are consistent with the mining width of the stope, and top columns and studs are reserved in the stope; and the rock drilling roadways and the stope preparation well are used as blasting free faces, and multi-free-face blasting and overall area caving of the ore body in a chamber are achieved. By the adoption of the mining method, mining operation is conducted in the rock drilling roadways, the rock drilling roadways are good in stability, safe and reliable, surrounding rock caving hazards of the stope can be avoided, the operation environment is improved, and the operation safety coefficient is increased; and according to the mining method, the rock drilling roadways and the stope preparation well are used as the blasting free surfaces, the multi-free-surface blasting area is integrally caved, the whole stope is completed through one-time blasting, and the production capacity of the stope is greatly improved.

Owner:GANZHOU NONFERROUS METALLURGICAL RES INST

Descending open stope subsequent filling mining method

ActiveCN111101946AImprove stope production capacityImprove recovery efficiencyUnderground miningSurface miningMining engineeringRock cutting

The invention discloses a descending open stope subsequent filling mining method. The method comprises the following steps of dividing a body to be mined into stopes, and stoping by adopting a medium-length hole or deep hole rock drilling blasting mode; vertically arranging adjacent stopes in a staggered manner in the horizontal direction; and stoping any stope after stoping of the vertically adjacent upper stope and the horizontally adjacent upper stope and filling maintenance. The method is suitable for mining of hard inclined to steep medium-thick ore bodies or horizontal to gently inclinedthick and large ore bodies under the condition that the rock mass of underground metal / nonmetal mines is generally extremely poor or the deep high stress condition, and has the characteristics of high stope production capacity, high stoping efficiency, high mechanical operation degree and the like.

Owner:BEIJING MINING & METALLURGICAL TECH GRP CO LTD

Progressive caving mining method

InactiveCN104153782AAvoid the disadvantages of massive miningMining loss rate is lowUnderground miningSurface miningEngineering

The invention discloses a progressive caving mining method. An ore body is divided into a middle section in a vertical direction, the middle section is divided into subsections, a roof pillar is divided at the upper part of the middle section, a floor pillar is divided at the lower part of the middle section, an inverted trapezoidal mining area is distributed in the middle section, a first wing of the inverted trapezoidal mining area is a substoping area, a substoping working face is distributed from bottom to top in a step shape, and caving ores are left; a second wing of the inverted trapezoidal mining area is a rock stratum caving area and is covered by caving rocks; the top part of the inverted trapezoidal mining area is a roof and floor pillar, a part of the roof and floor pillar, close to the second wing, is a caving area, and a concentrated mined-out area is formed at the bottom of the inverted trapezoidal mining area; a barren rock goaf is formed between an ore pile of the first wing and a rock pile of the second wing under the roof and floor pillar of the inverted trapezoidal mining area, and the majority of caving ores are mined out under a rock-free overlying condition. Mining can be continuously carried out along an ore trend, and the method has the characteristics of high production capacity, low mining loss dilution rate, and low mining cost.

Owner:CHINA MINMETALS CHANGSHA MINING RES INST

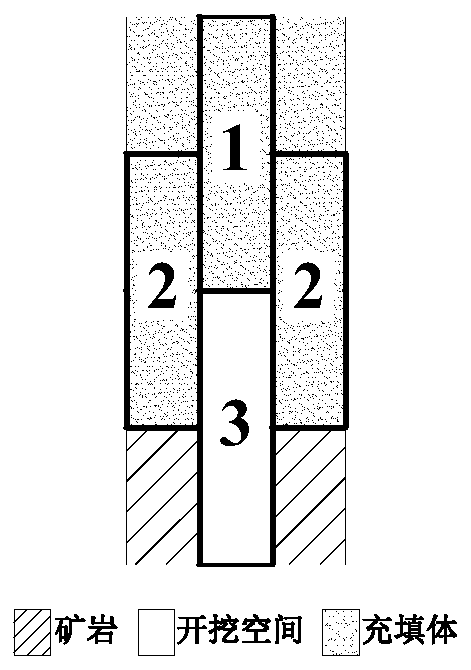

Deep-hole subsequent filling mining method at stage of environmental reconstruction

The invention discloses a deep-hole subsequent filling mining method at a stage of environmental reconstruction, and is mainly applicable to stoping of ore-rock fragmentation and thick to extremely thick inclined ore bodies. The ore body is divided into a panel area and an ore block, wherein the ore block is internally divided into two steps of a first step stope and a second step stope for stoping; firstly, a drift-and-drill method is used for stoping the ore bodies in a range of top pillar of the upper part of the first step stope and the second step stope, and the ore body at the bottom ofthe second step stope, and the first step stope and the second step stope are filled with high strength paste cement filling, then the drift-and-drill method is used for stoping the upper panel ore bodies of the first step stope and the second step stope, and finally, a stage deep-hole subsequent filling method is used for stoping the second step stope. According to the application deep-hole subsequent filling mining method, the safe working conditions of the stoping of the type of ore body can be significantly improved, the production capacity of the stope is ensured, the dilution and loss rate is reduced, and the amount of accurate mining cutting work is reduced.

Owner:CHINA MINMETALS CHANGSHA MINING RES INST

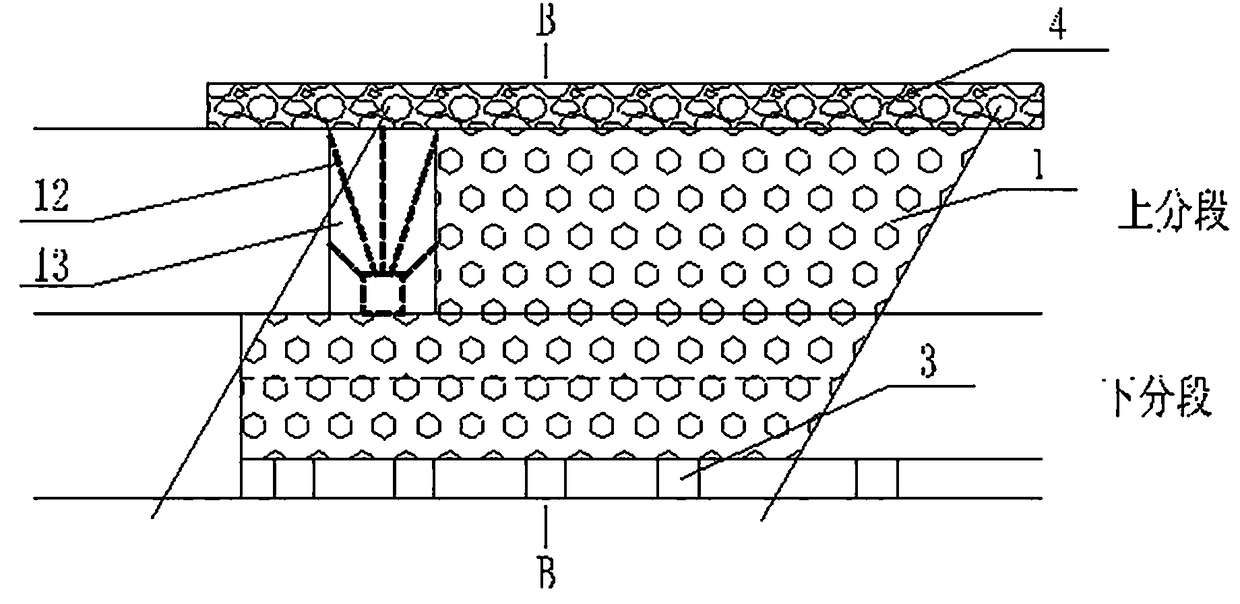

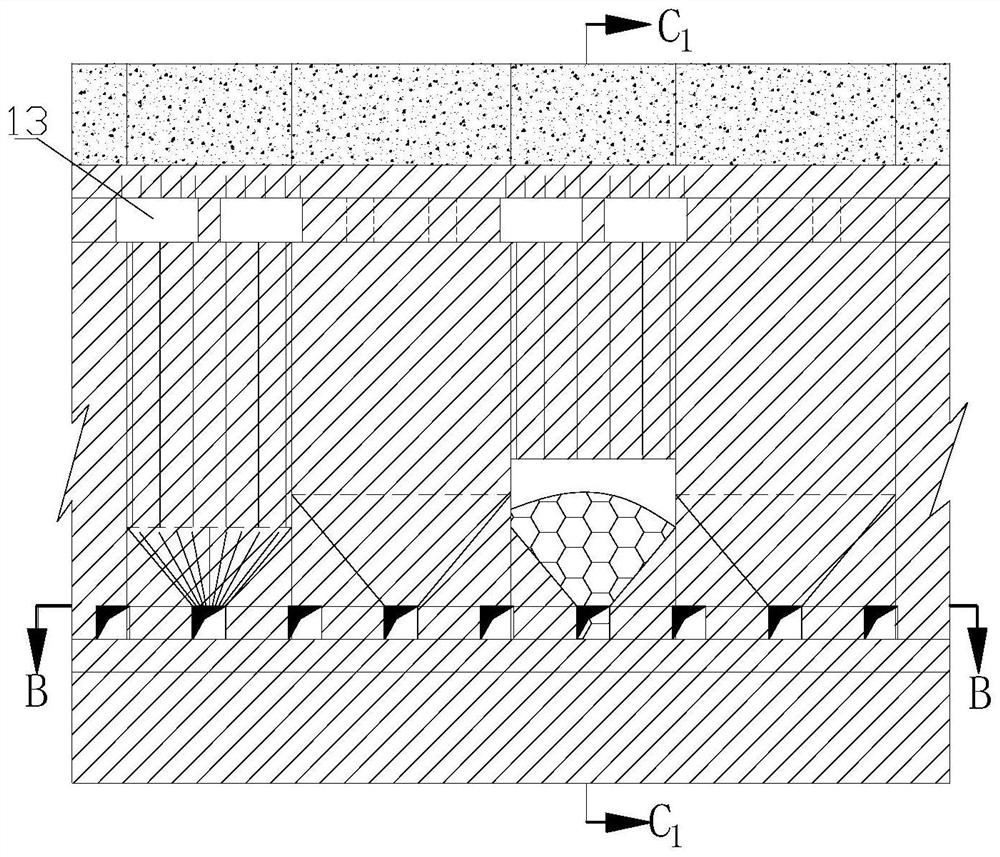

High sublevel double-hexagon caving mining method

InactiveCN109356581AHigh recovery rateReduce depletionDisloding machinesUnderground miningMineralogy

The invention belongs to the technical field of mining, and particularly relates to a high sublevel double-hexagon caving mining method. The method comprises the following steps of 1, preliminary mining cutting; 2, rock drilling; 3, exploding and ore breaking; and 4, ore removing. The method integrates the advantages of the sublevel caving without sill pillar method, the block stoping method, thehigh-end wall drawing method and other methods, and therefore the recovery rate of pure ore is improved, and the problem of excessive loss and dilution is solved.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

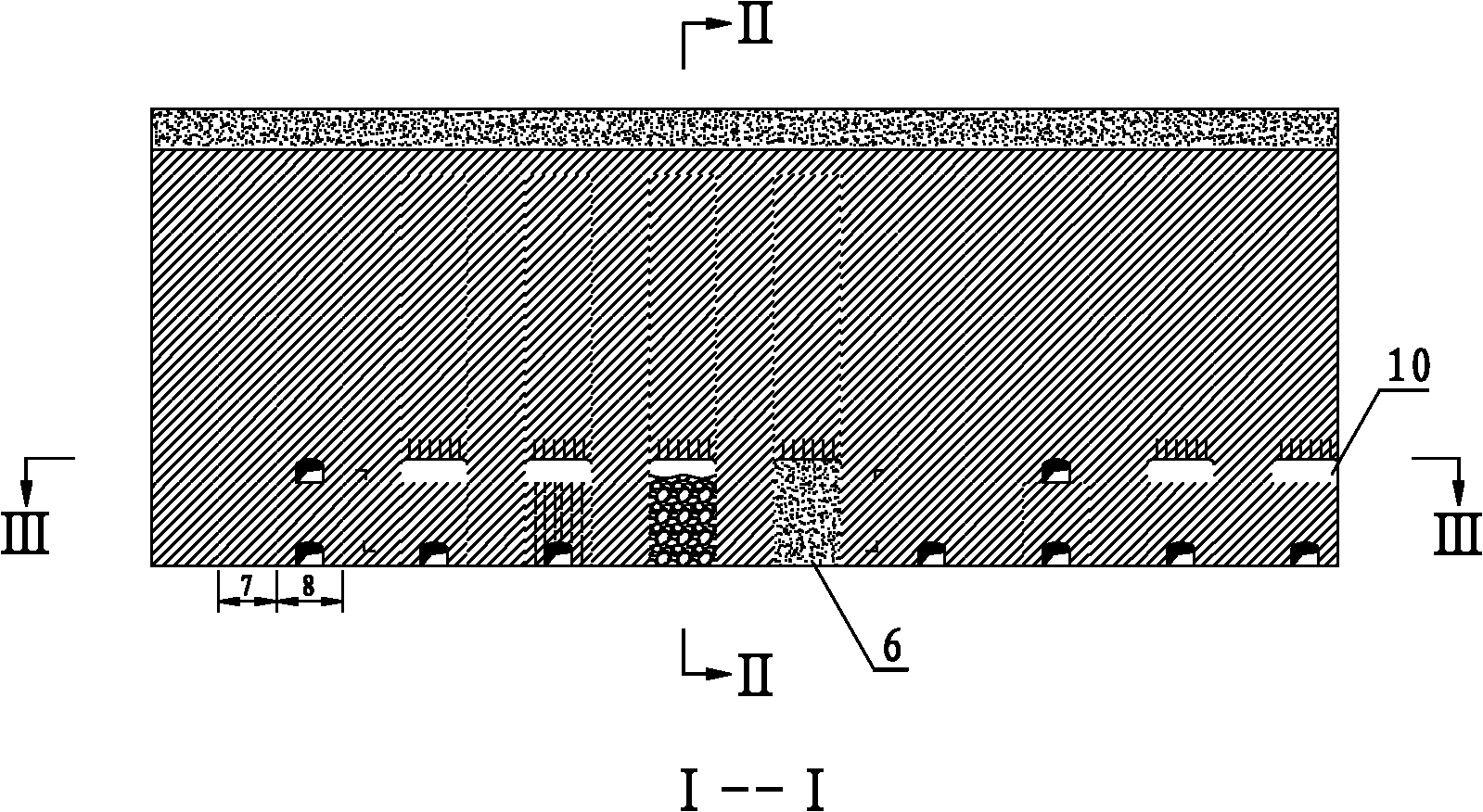

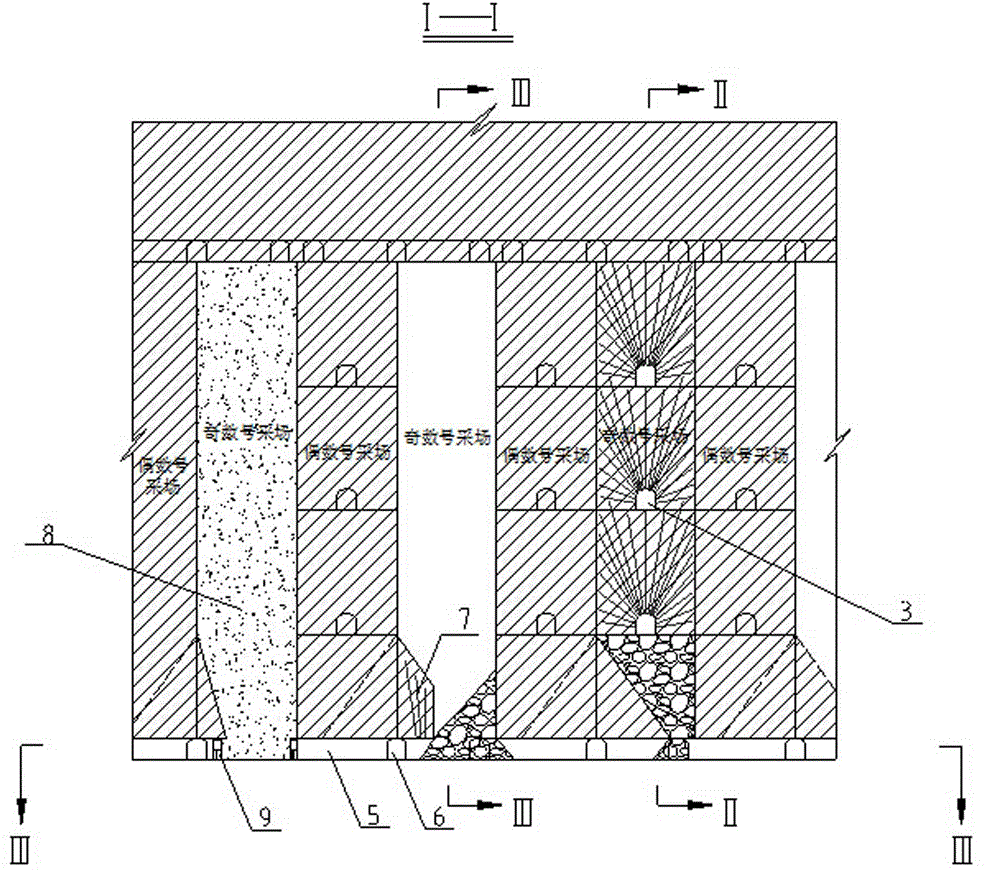

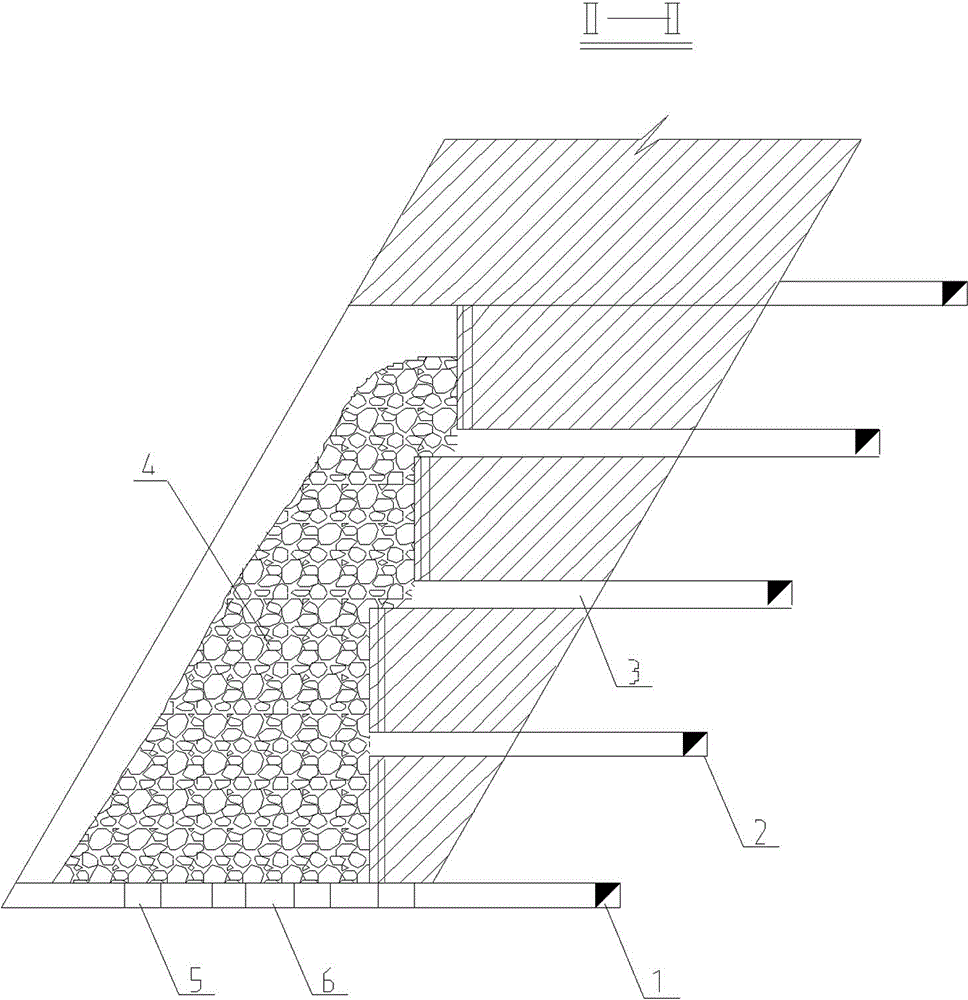

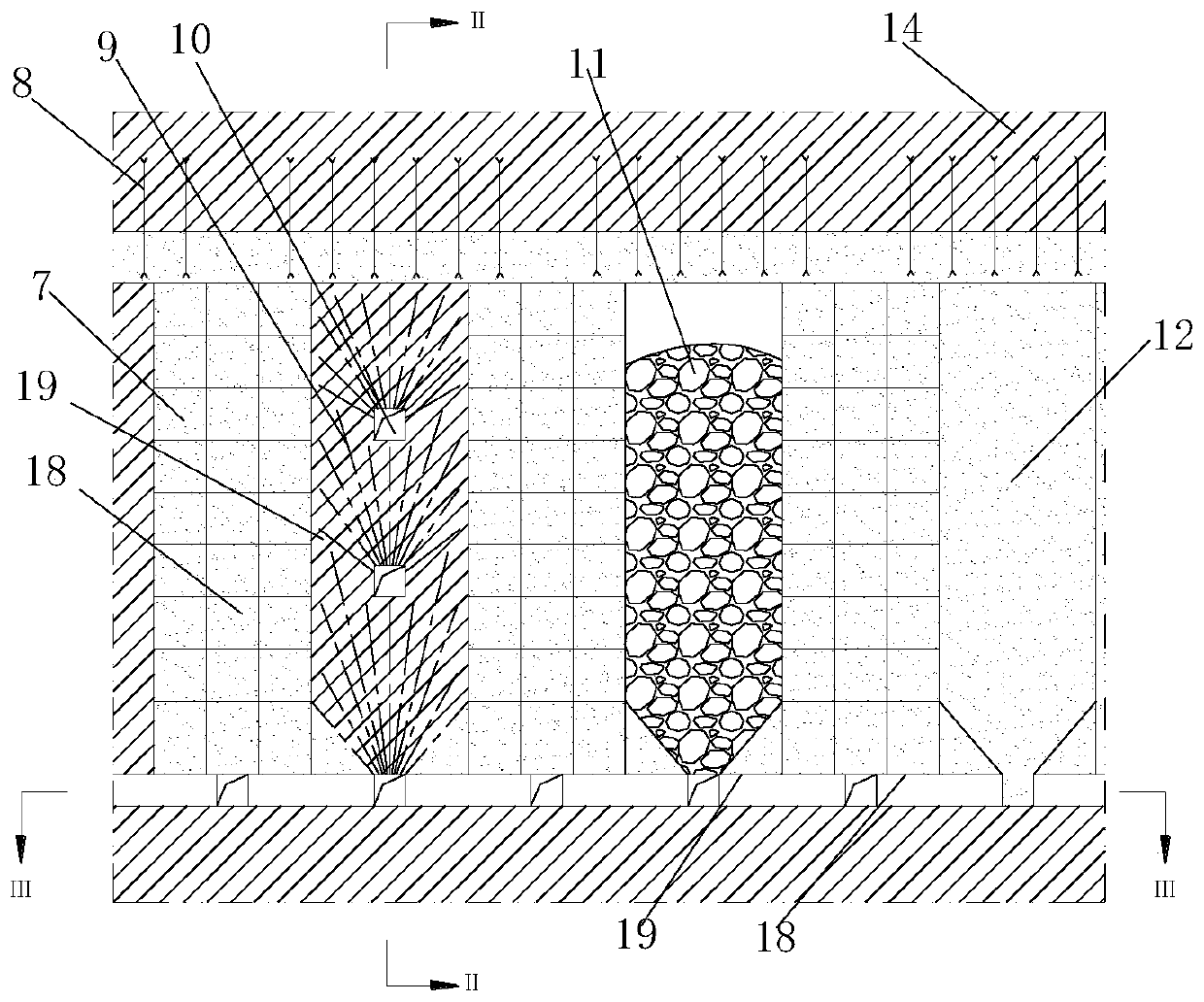

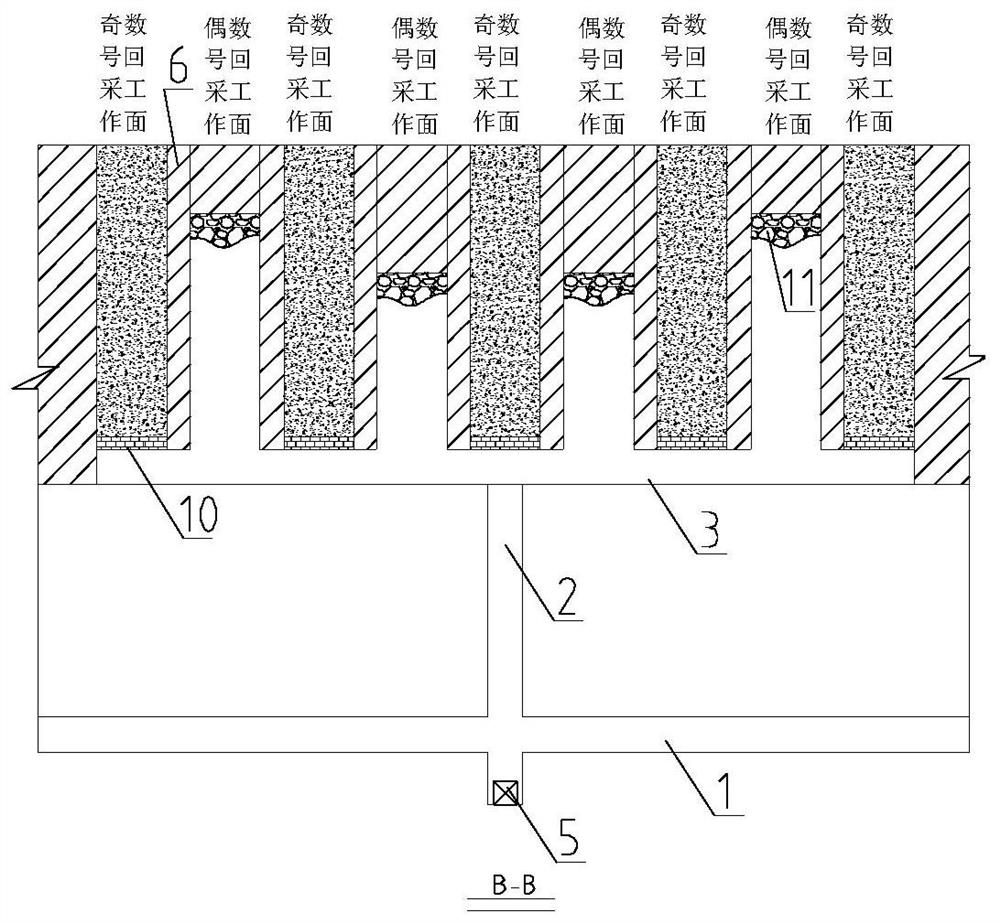

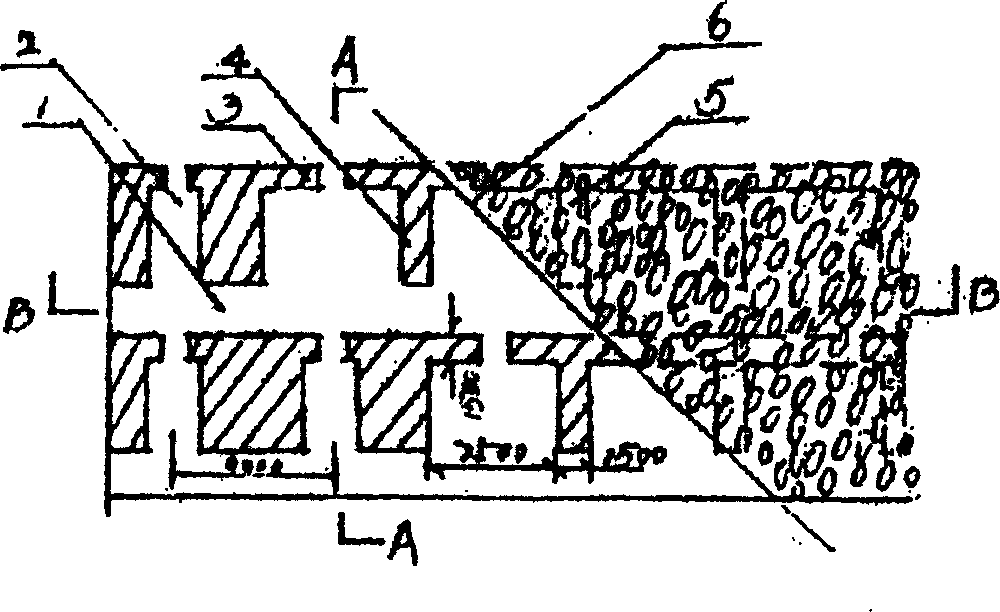

Wall column type upward horizontal layered filling mining method

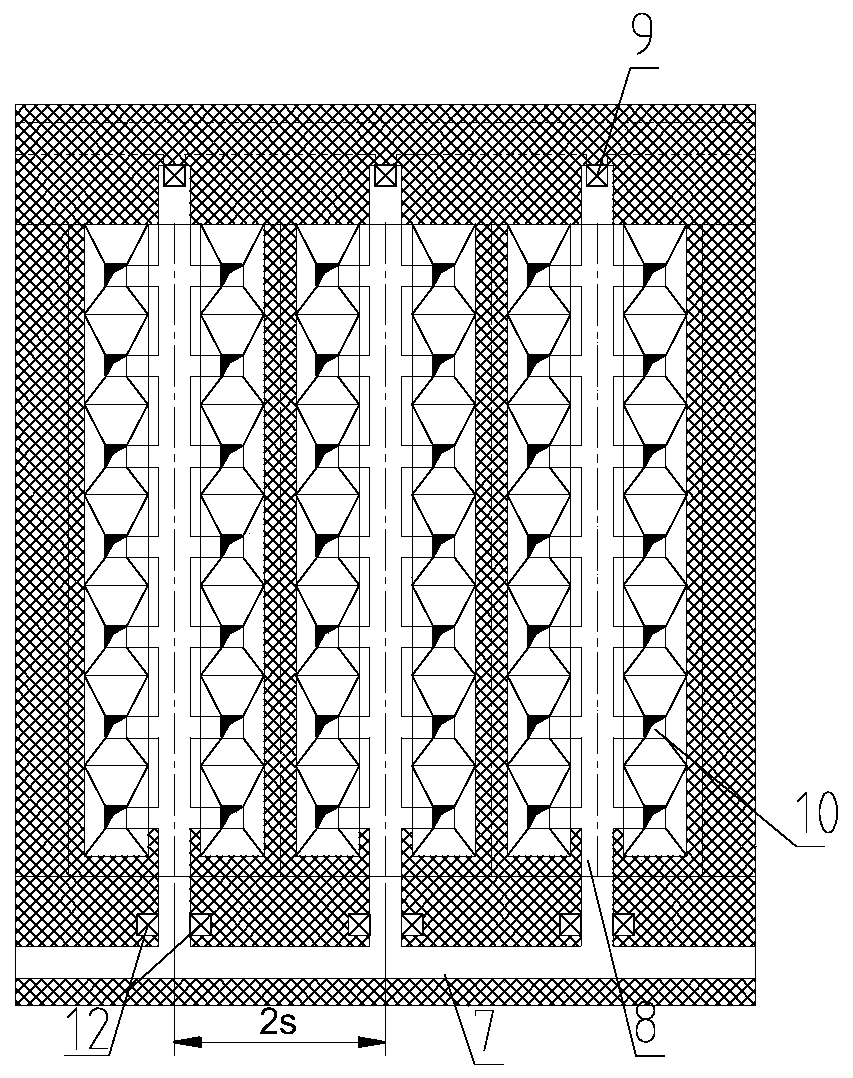

InactiveCN111894592AImprove stope production capacityImprove efficiencyUnderground miningBlastingDetonatorRock cutting

The invention discloses a wall column type upward horizontal layered filling mining method which is suitable for stoping low-grade thick and large ore bodies with medium ore stability and above and unstable surrounding rocks. The method comprises the following steps that an ore body is divided into stopes in the strike direction; the stopes are divided into stoping working faces perpendicular to the strike direction of the ore body and numbered in sequence, wall columns are reserved between the stoping working faces, stoping is carried out in a layered mode from bottom to top, and in order toguarantee stability of the wall columns, the stoping working faces on the two sides of the wall columns are not stoped simultaneously; stoping is carried out on the layered inner stoping working facesin two steps, odd stoping working faces are stoped and filled in the first step, and even stoping working faces are stoped and filled in the second step; and during working face stoping, a drill jumbo is adopted for constructing horizontal shallow holes, a nonelectric millisecond nonel detonator is adopted for detonation, caved ore is shoveled out through a carry-scraper and unloaded into an outside-vein draw shaft, and after working face stoping is completed, a filling retaining wall is constructed and filled. The method has the advantages of being large in stope production capacity, high inefficiency, small in supporting amount, low in filling cost and the like.

Owner:CHINA MINMETALS CHANGSHA MINING RES INST

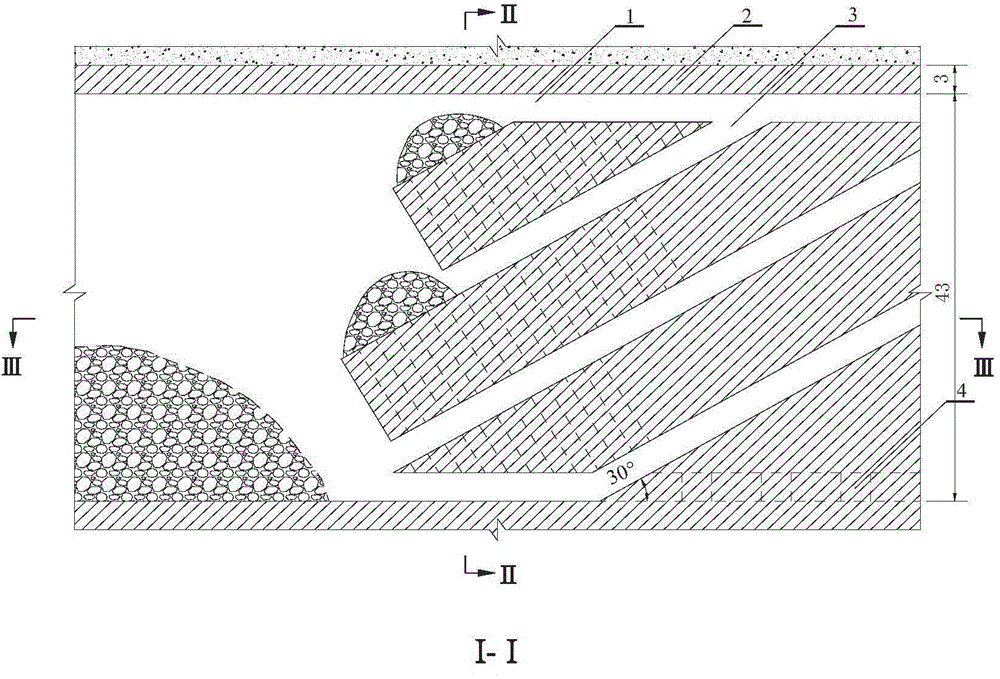

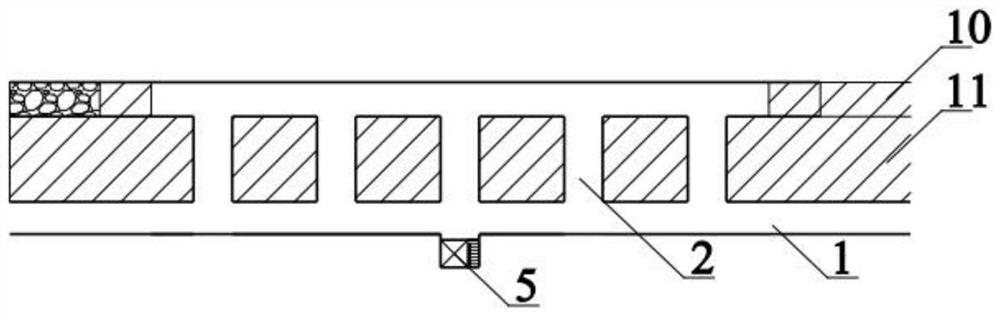

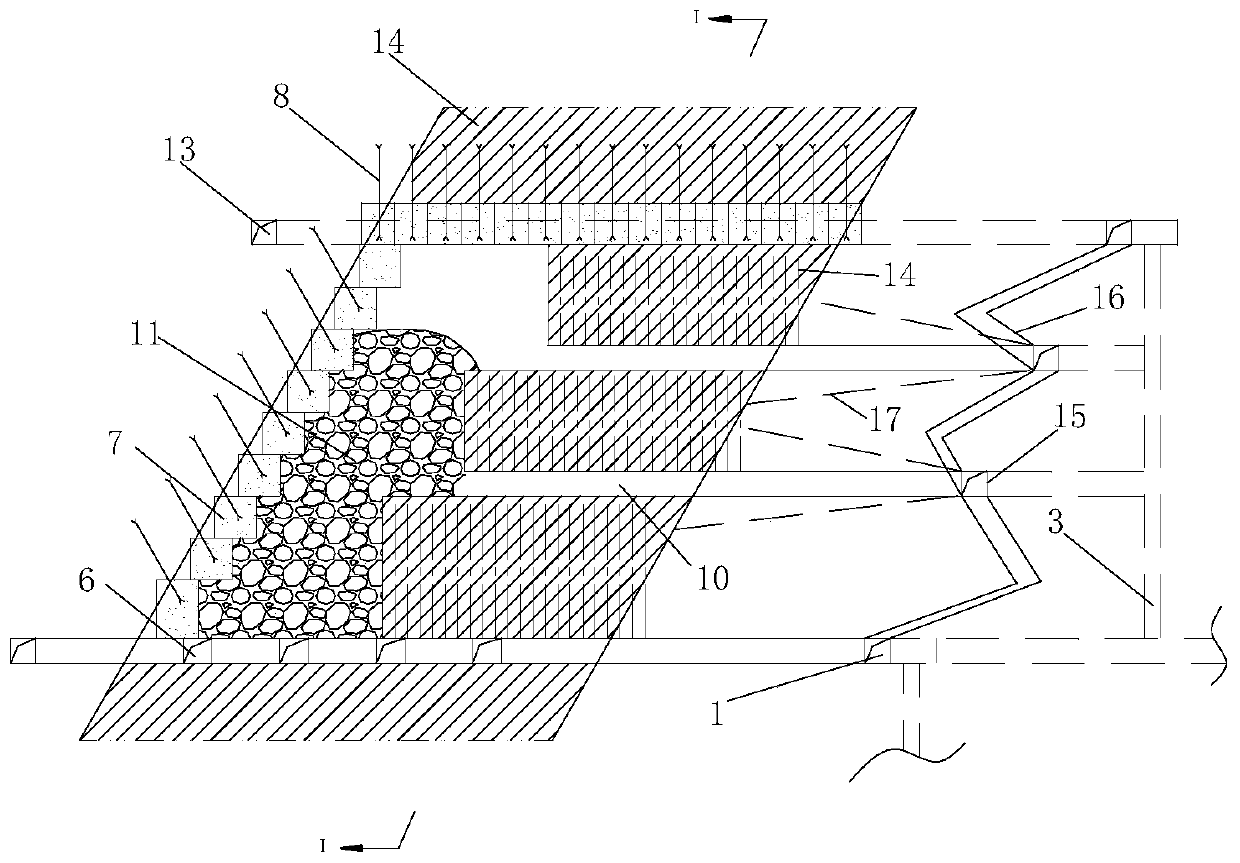

Empty-support cutting roadway type upward wide drift filling mining method

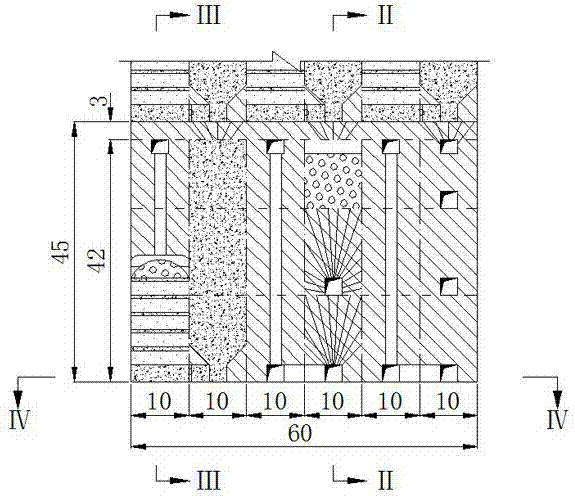

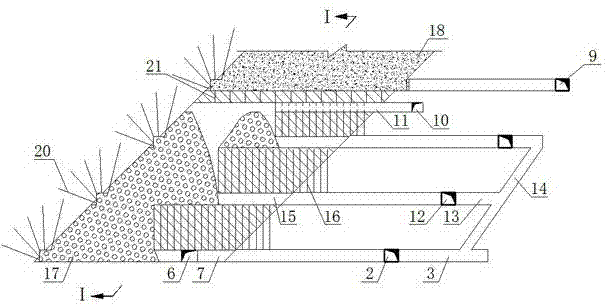

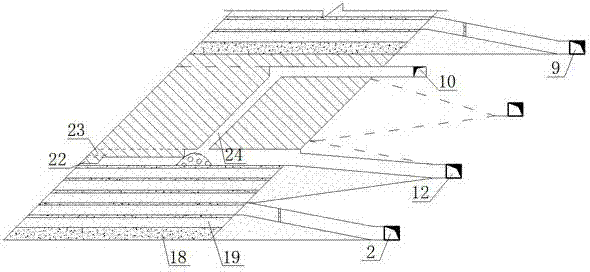

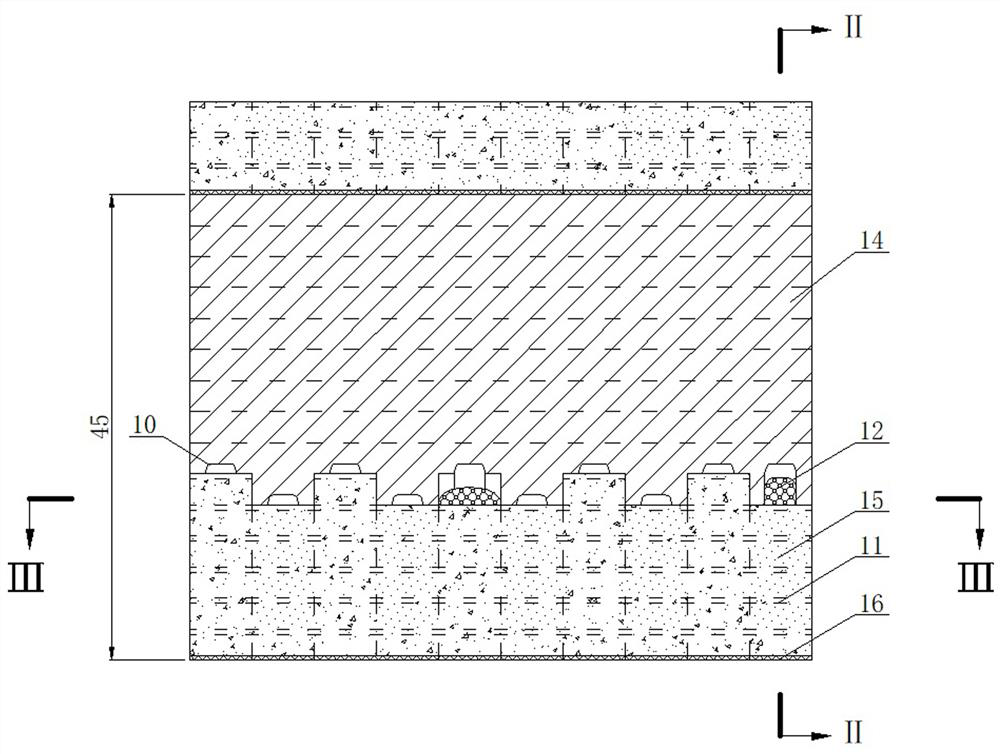

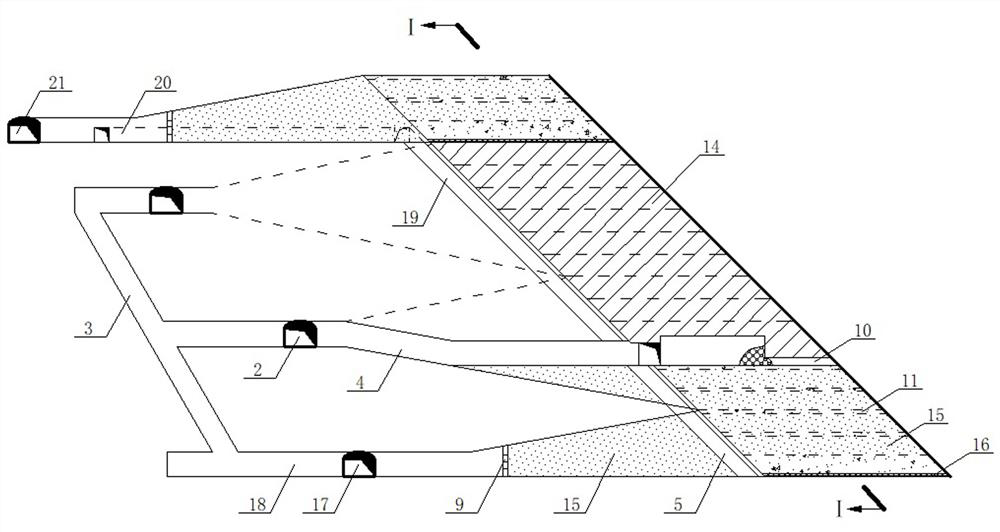

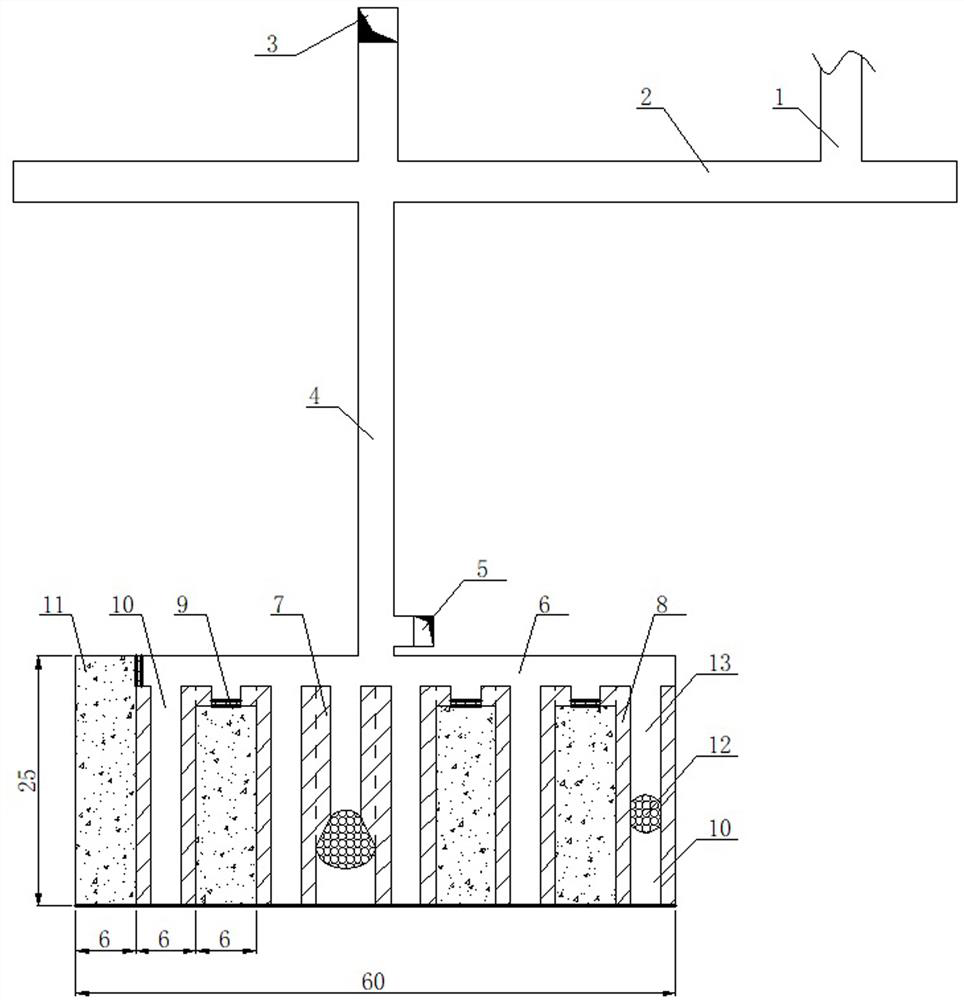

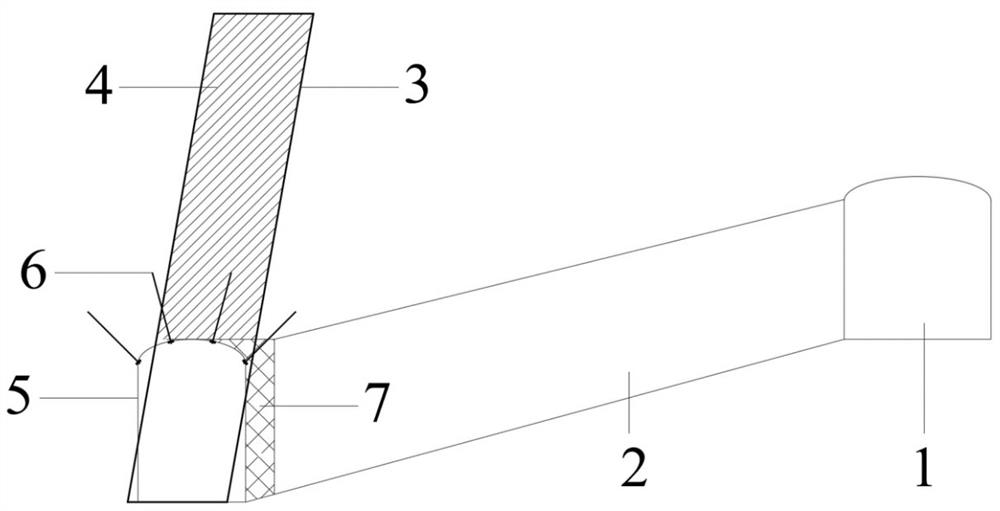

InactiveCN111663945AImprove stope production capacityIncrease production capacityUnderground chambersUnderground miningMining engineeringStructural engineering

The invention relates to an empty-support cutting roadway type upward wide drift filling mining method. A stope is arranged in the strike direction, the length is 60 m, the width of an orebody is thehorizontal thickness of the orebody, the height of the middle section is 45 m, the subsection height is 15 m, and no basal or middle pillars exist. The middle-section orebody is divided into the stopes in the strike direction of the orebody, the middle section is divided into a plurality of subsections in the vertical direction, and a footwall trackless extravein sampling mode is adopted; a stopeconnection roadway is constructed towards footwall of the orebody perpendicular to a middle section roadway or subsection roadways, and layered connection roadways are constructed along the footwall of the orebody after reaching the orebody; strip-shaped roads are arranged vertically in the stope; and the strip-shaped roads are subjected to two-step interval stoping. After filling is finished, empty-support cutting roadways with the width of 3 m and the height of 1 m are reserved along the full length regardless of the one-step mining or two-step mining of the strip-shaped roads. By adopting the mining method, the production capacity of one single stope is greatly improved, the mining operation cost is reduced, and the method has the outstanding advantages of simple process, safety and high efficiency.

Owner:SANSHANDAO GOLD MINE SHANDONG GOLD MINING LAIZHOU

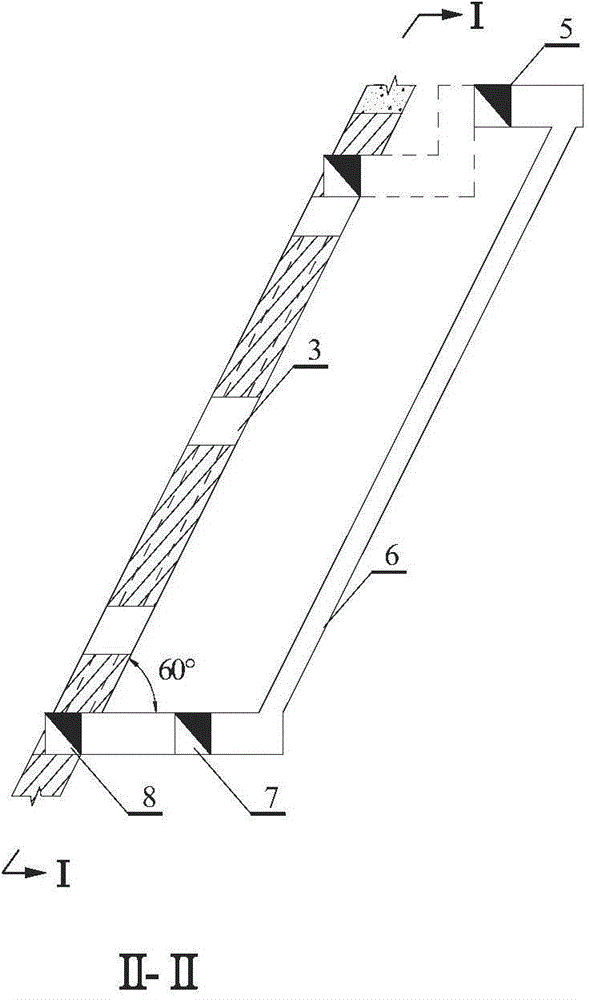

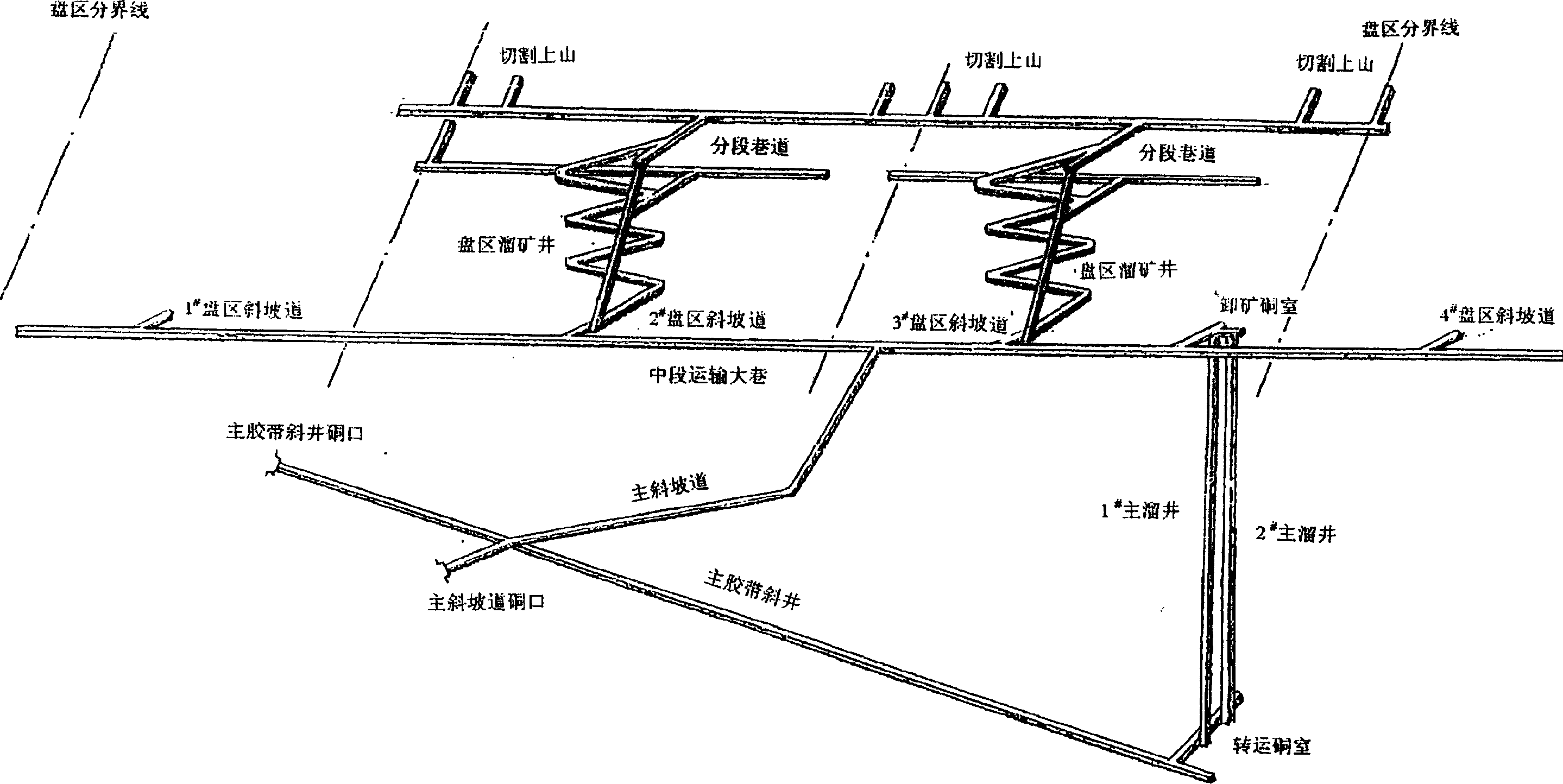

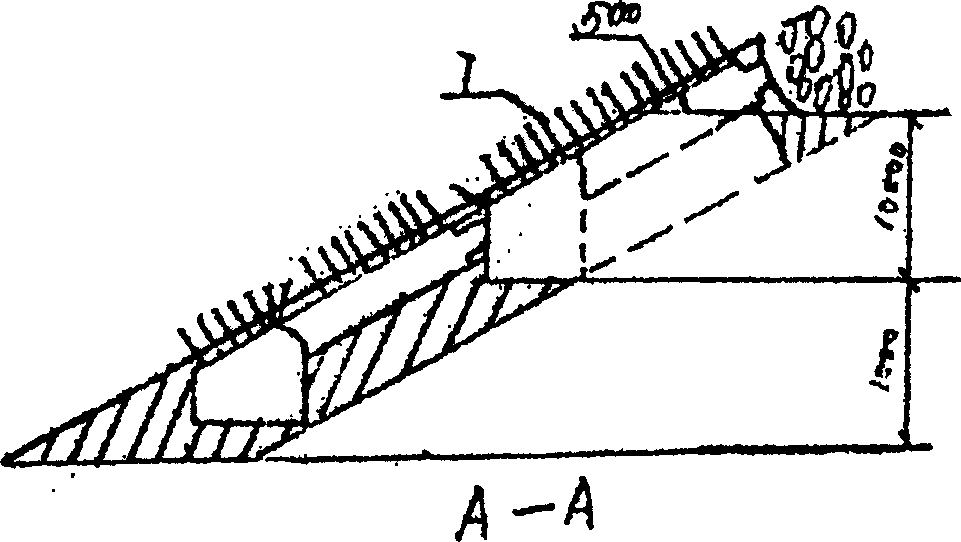

Mechanized filling mining method for steeply inclined thin vein under soft rock stratum condition

InactiveCN112727463AReduce unit consumptionReduce labor intensityUnderground miningSurface miningMining engineeringRock cutting

The invention discloses a mechanized filling mining method for a steeply inclined thin vein under a soft rock stratum condition. An accurate mining mode of slope ramp exploitation, segmented transport roadway connection and draw shaft ore removal is adopted to recover the ore body layer by layer from bottom to top; undercut approach road stoping is completed in a single-head tunneling mode, and a goaf formed by an undercut approach road is used as a free face to press down the ore body, so that the stoping efficiency is improved, and the ventilation condition is improved; lower disc waste rock and a non-cemented filling body are brushed and expanded to form a priming coat, and a high-strength cemented filling body is poured to form a glue face layer, so that unit consumption of steel and cement is reduced, and the filling cost is reduced; and drill jumbo efficient drilling, shotcrete jumbo rapid supporting and scraper centralized ore removal are assisted, so that the stope production capacity is greatly improved, the labor intensity of workers is reduced, the number of underground operating personnel is reduced, and stoping operation safety is guaranteed. The steps are repeated until the whole ore block is completely stoped. The method has the remarkable advantages of being high in mechanization degree, low in comprehensive cost, large in stope production capacity, good in safety and the like.

Owner:CENT SOUTH UNIV

Gently inclined minded-out area roof and floor residual ore stoping method

ActiveCN111005724AEliminate hidden dangers in empty areasReduce mining and filling costsUnderground miningSurface miningMining engineeringMineralogy

The invention provides a gently inclined minded-out area roof and floor residual ore stoping method. The method is suitable for the stoping operation of gently inclined minded-out area roof and floorresidual ore with high ore grade and good value. A carry-scraper ore output hopper bottom structure is arranged in foot wall rock, a lower-layer ore body is firstly stoped, then an upper-layer ore body is stoped, and finally a minded-out area is filled. When the lower-layer ore body is stoped, an upper old mined-out area is regarded as a free surface and a compensation space, a fan-shaped middle-deep hole is adopted to collapse ore, a part of the ore is output from the inside of the carry-scraper ore output bottom structure, then the fan-shaped middle-deep hole is adopted, a lower mined-out area is regarded as a free surface and a compensation space, the upper-layer ore body is collapsed, collapsed ore is completely output in the carry-scraper bottom structure, and then the mined-out areais filled with a low-strength cemented filling body or a non-cemented filling body. Compared with the prior art, the method has the advantages of safe stoping operation, high stope production capacity, low cost and the like.

Owner:NANHUA UNIV

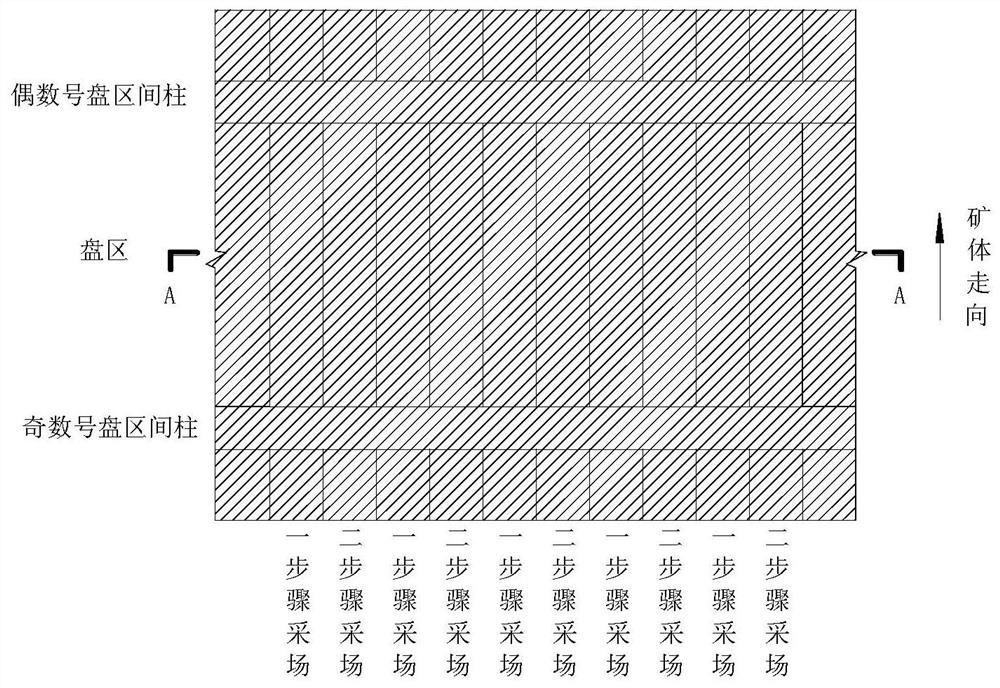

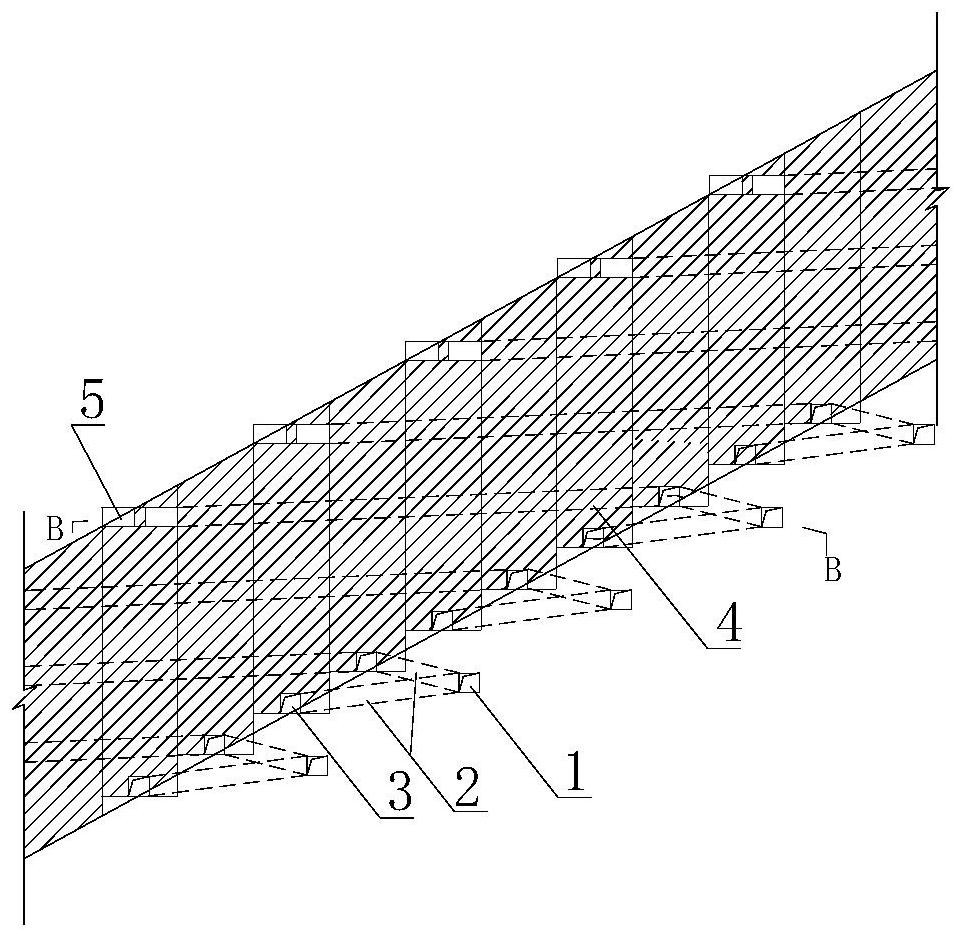

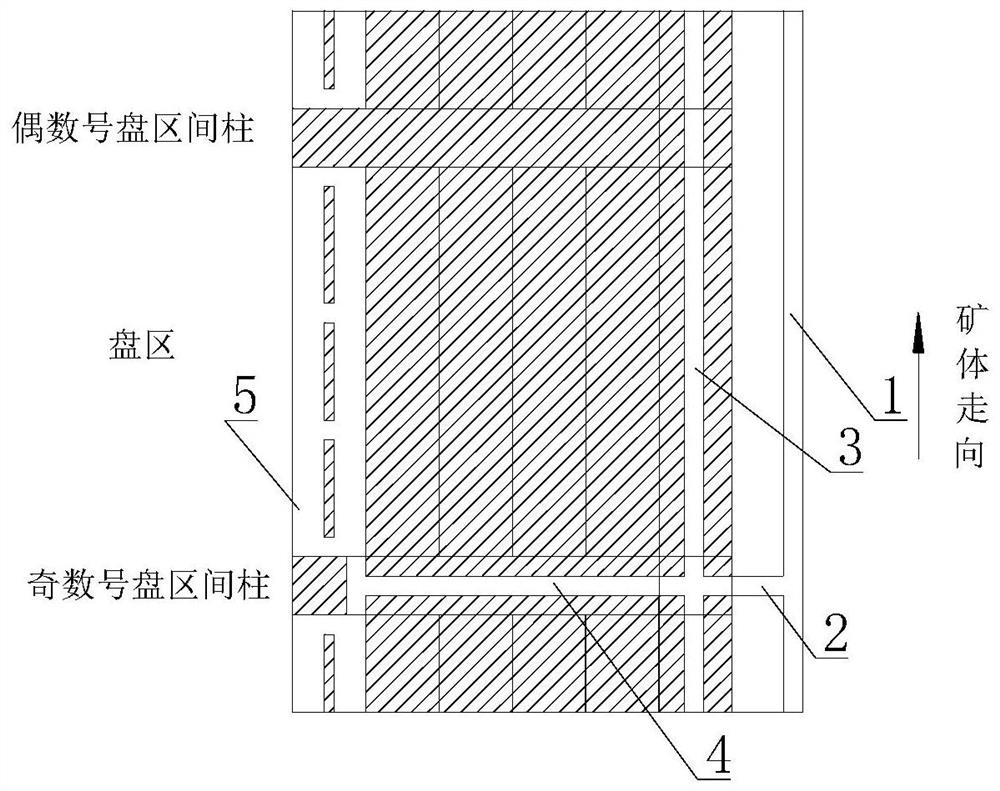

Inclined large and thick ore body cooperative mining method

ActiveCN111677509AImprove stope production capacityIncrease productivityUnderground chambersDisloding machinesMining engineeringMineralogy

The invention discloses an inclined large and thick ore body cooperative mining method. The inclined large and thick ore body cooperative mining method comprises the following steps of dividing an orebody into panels in a trend direction, wherein panel studdings are reserved among panels, and mining the panels first and then mining the panel studdings; dividing the panels into first step stopes and second step stopes arranged in the trend direction for recovery in two steps, adopting large diameter deep hole blasting ore caving in the first step stopes and the second step stopes, shoveling caved ores by a carry-scraper through a sectional transportation roadway, a transportation cross gateway and an ore removal roadway, and carrying out subsequent filling in a goaf; dividing the panel studdings into odd number panel studdings and even number panel studdings, mining the even number panel studdings first, then mining the odd number panel studdings, recovering all the even number panel studdings, recovering the odd number panel studdings by taking one every the other one, and carrying out substoping from top to bottom in the panel studdings by using medium-length holes. The inclinedlarge and thick ore body cooperative mining method has the advantages of being high in production capacity of stope, high in efficiency, high in ore recovery rate, small in accurate mining cutting work amount, high in synergic utilization ratio and the like.

Owner:NANHUA UNIV +2

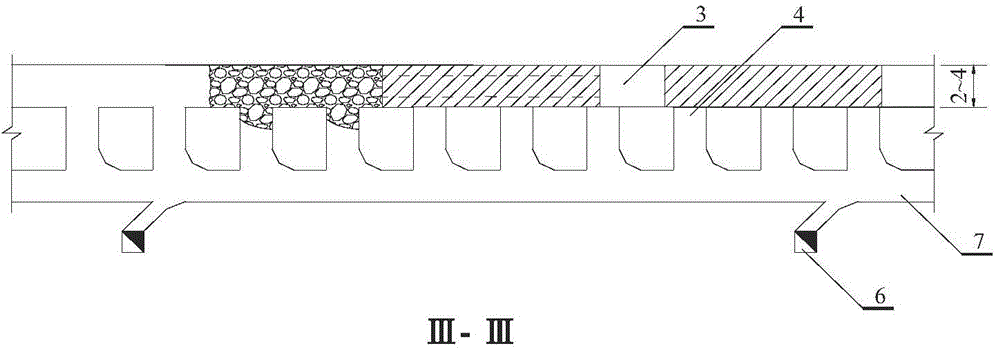

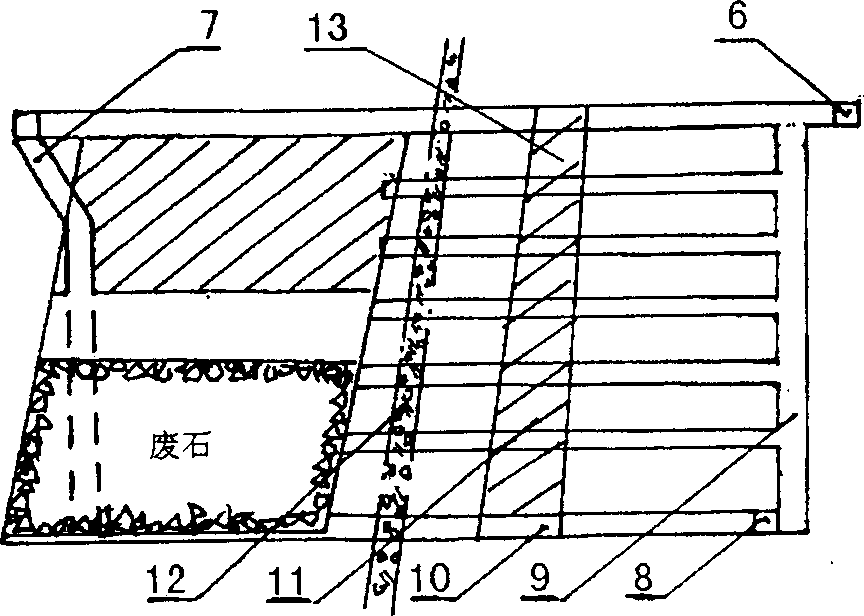

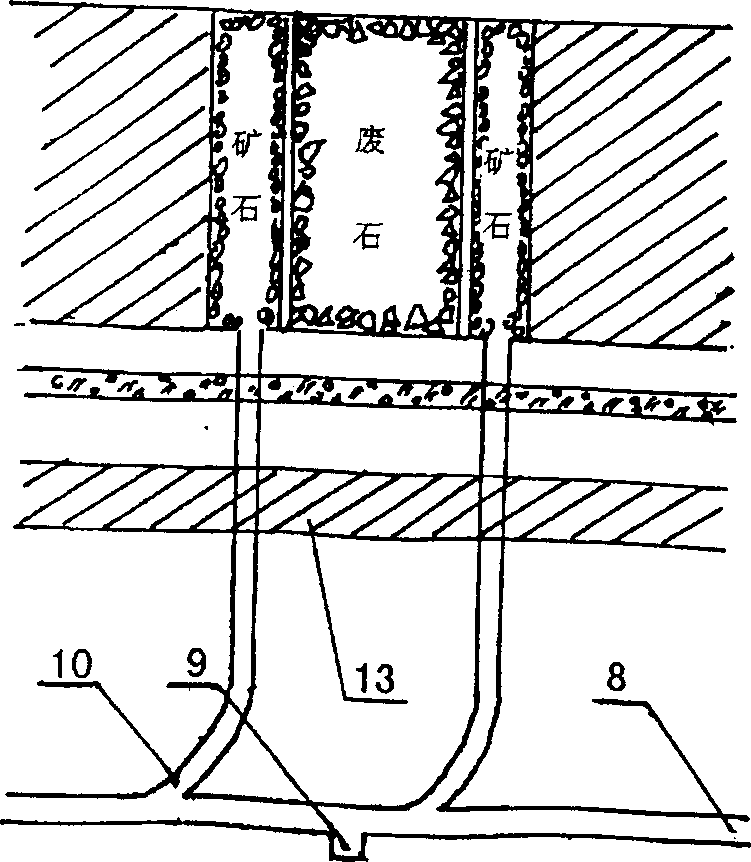

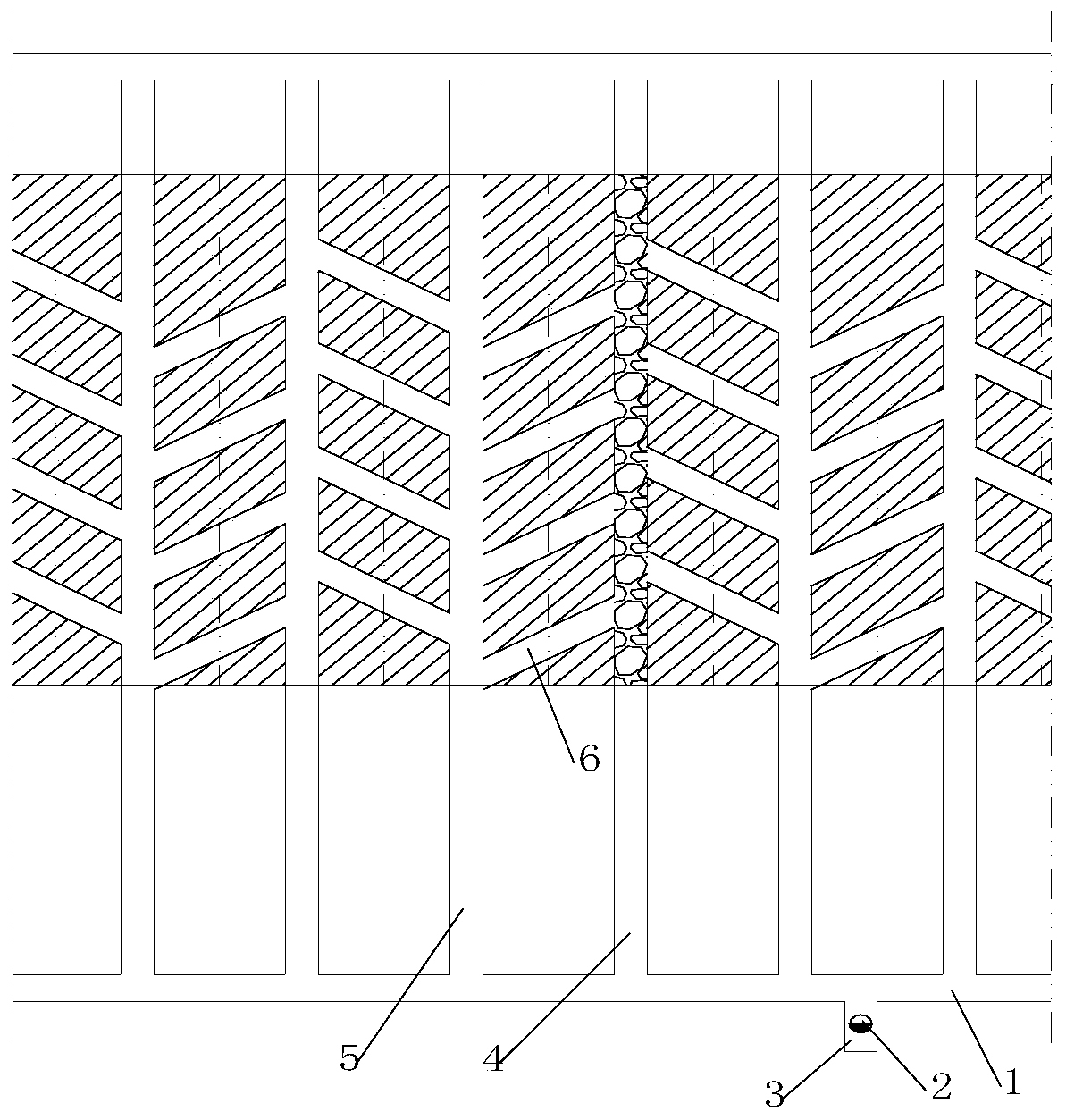

Mechanized mining and waste rock filling method for inclined thin vein

ActiveCN112796759AReduce labor intensityReduce in quantityUnderground miningSurface miningMining engineeringSlag

The invention discloses a mechanized mining and waste rock filling method for an inclined thin vein. The method comprises the following steps of: stoping an ore body layer by layer from bottom to top by adopting a stope preparation mode of slope ramp development outside the vein, sectional haulage roadway connection and ore removal of a panel draw shaft; finishing undercutting drift stoping by adopting a single-head tunneling mode; performing goaf waste rock filling by brushing and expanding footwall surrounding rock and throwing blasting; removing slag by utilizing a carry-scraper, and erecting an isolation baffle between a brushing and expanding area and a goaf; pressing the mined ore body downwards by adopting a drill jumbo and utilizing the goaf formed by the brushing and expanding area as a free surface, so that the stoping efficiency is improved; and removing the isolation baffle, performing footwall brushing and expanding again, and repeating the steps until the whole sectional stoping operation is finished. The method disclosed by the invention has the advantages of high mechanization degree, simple filling process, low comprehensive cost, high stope production capacity, high safety and the like.

Owner:CENT SOUTH UNIV

A deep hole and subsequent filling mining method in the stage of environmental reconstruction

The invention discloses a deep-hole subsequent filling mining method at a stage of environmental reconstruction, and is mainly applicable to stoping of ore-rock fragmentation and thick to extremely thick inclined ore bodies. The ore body is divided into a panel area and an ore block, wherein the ore block is internally divided into two steps of a first step stope and a second step stope for stoping; firstly, a drift-and-drill method is used for stoping the ore bodies in a range of top pillar of the upper part of the first step stope and the second step stope, and the ore body at the bottom ofthe second step stope, and the first step stope and the second step stope are filled with high strength paste cement filling, then the drift-and-drill method is used for stoping the upper panel ore bodies of the first step stope and the second step stope, and finally, a stage deep-hole subsequent filling method is used for stoping the second step stope. According to the application deep-hole subsequent filling mining method, the safe working conditions of the stoping of the type of ore body can be significantly improved, the production capacity of the stope is ensured, the dilution and loss rate is reduced, and the amount of accurate mining cutting work is reduced.

Owner:CHINA MINMETALS CHANGSHA MINING RES INST

Continuous mining method of stepped sectional extruding and ore caving followed by filling

In the continuous mining method, ore body are divided into sections, subsections and mini-sections stepwisely along the ore vein; arranging mini-section drilling mine tunnels along the ore vein in the ore body bottom wall and connecting the mini-section tunnels with the main ramp way via linking tunnel; arranging support and filling tunnel along ore vein in the upper wall in the ore section; stoping from two ends to the central part of the bordroom via stepped continuous advance; drilling fanned holes with rock drill machine, breaking ore with rock explosive, charging with charging machine and combined elementary error detonation; filling finished stope via filling tunnel and filling dewatering device; and supporting crushed upper wall roof with deep anchor rod and steel fiber concrete. The present invention has high production capacity, high safety, less ore loss and low mining cost.

Owner:CENT SOUTH UNIV

Roof bolt protection and sectioned empty field method for phosphorate rock mining

InactiveCN1195149CImprove working conditionsImprove stope production capacityUnderground miningSurface miningAditField methods

The present invention relates to underground exploitation of phosphorate rock mineral and aims at providing slow inclined middle thick ore body exploiting method. The said exploitation process includes tunneling adit and main inclined tunnel, tunneling middle section main entry, dividing ore body into several panels, tunneling inclined panel slope, dividing the middle section into subsections, dividing subsection ore body into small room via subsection horizontal gallery and cutting raise, supporting roof with anchorage bar and metal net; drilling to bring down with rock drilling machine with cutting raise as free plane; stoping along strike direction; exploding residual ore column to empty area; conveying ore with carry scraper to ore chute and transporting ore with truck. The present invention is suitable for phosphate ore of ore body inclination 0-90 deg and ore body thickness 2-20 m.

Owner:贵州开磷设计研究院有限责任公司

Filled mining method

InactiveCN1186519CShort filling lengthHigh speedUnderground miningSurface miningUltimate tensile strengthMineralogy

Owner:广东金鼎黄金有限公司

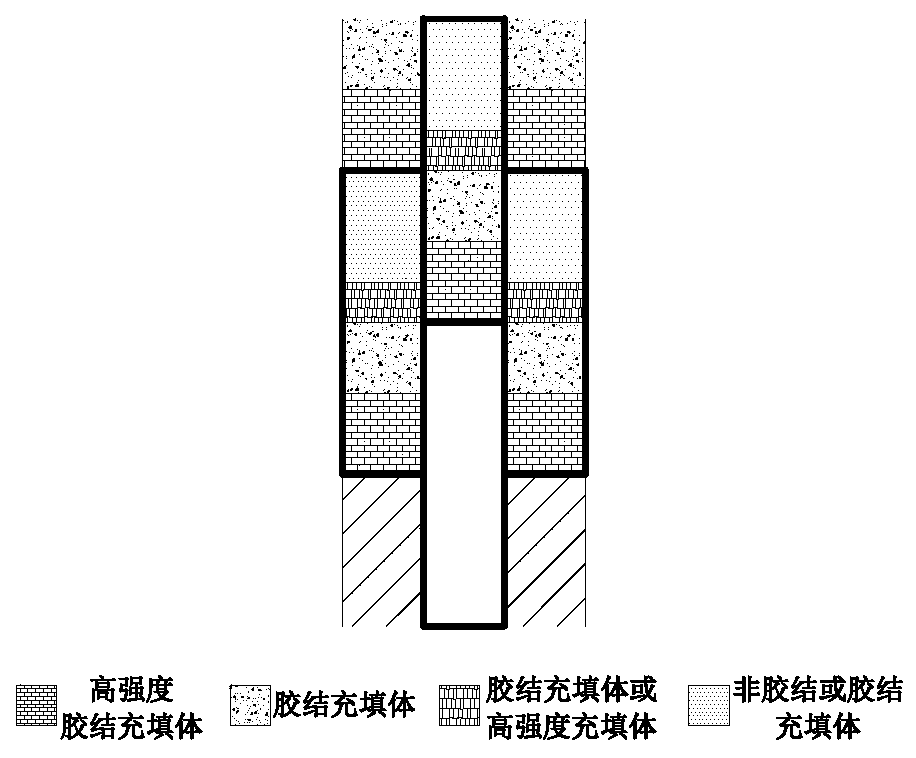

A Deep Hole Mining Method in Stages of Steeply Inclined Double Layer Ore Body

ActiveCN110388209BOperational safety is guaranteedImprove working environmentUnderground miningSurface miningMining engineeringMechanical engineering

The invention discloses a high-dipping double-layer ore body stage deep-hole mining method, which is especially suitable for recovery of a high-dipping double-layer ore body, wherein the ore rock is stable, the thickness of the lower layer of ore body is more than or equal to 15 m and the thickness of the upper layer of ore body is more than or equal to 8 m. The lower layer of ore body is mined and then the upper layer of ore body is mined, a lower layer of ore body stope is arranged vertical to the direction of the ore body, an ore room and an ore column are recovered in two steps, an upper layer of ore body stope is arranged vertical to the direction of the ore body, and an ore room and an or column are recovered in two steps. Recovery of the upper layer of ore body and the lower layer of ore body is as follows: stage large-diameter deep-hole blasting ore break down is adopted, the ore room is mined, then the ore column is mined, the bottom of 6 to 10 m and the top of 4 to 6 m of a dead zone are filled with high-strength cemented filling bodies after recovery of the ore room and the ore column, the other dead zones of the ore room are filled with the cemented filling bodies, andthe other dead zones of the ore column are filled with low-strength cemented filling bodies or non-cemented filling bodies. The high-dipping double-layer ore body stage deep-hole mining method has theadvantages of high operation safety, small stope preparation cutting engineering quantity, short stope preparation time, high stope production capacity, high efficiency and the like.

Owner:CHINA MINMETALS CHANGSHA MINING RES INST

Divided unloading and sublevel filling mining method based on rhombic stoping structure

ActiveCN114562268AIncrease costSolve the costUnderground miningBlastingMechanical engineeringMineralogy

The invention provides a zoning unloading and sublevel filling mining method based on a rhombic stoping structure. A to-be-mined panel is provided with a middle section stope and divided into sublevel stopes, and zoning is carried out along the trend of an ore deposit; in the middle-section stope, the rhombic stoping structures are adopted for stoping from top to bottom in sequence, mining is conducted in a step-by-step and filling-while-mining mode, and the rhombic stoping structures between the subareas are firstly mined. According to the method, the rhombic stoping structures of the lower mining units between the subareas are mined in advance, so that unloading is achieved to relieve damage of horizontal tectonic stress to the lateral wall of the stope; the large-size rhombic stoping structure is large in structural parameter, the bearing capacity is remarkably improved, the problem that the lateral walls of the adjacent stopes of the soft and broken ore deposit are extremely prone to collapse is solved, and the safety production capacity of the stopes is improved. In addition, the rhombic stoping structures are distributed in an up-and-down staggered mode, ore loss can be reduced, and mining efficiency is improved. According to the method, the aim of safely, efficiently and economically exploiting the low-grade soft broken thick and large ore deposit at low cost under the condition of high-level tectonic stress is achieved.

Owner:CHINA MINMETALS CHANGSHA MINING RES INST

A safe and efficient mining method for steeply inclined double-layer ore bodies

ActiveCN110374601BHigh engineering reuse rateIncrease productivityUnderground miningSurface miningStopingSafe operation

Owner:CHINA MINMETALS CHANGSHA MINING RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com