Divided unloading and sublevel filling mining method based on rhombic stoping structure

A filling mining method and diamond-shaped technology, which can be applied in the direction of filling, ground mining, mining equipment, etc., can solve the problems of high mining cost, large mining loss and dilution, and low production efficiency, and achieve the goal of ensuring safe, low-cost and economical mining Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

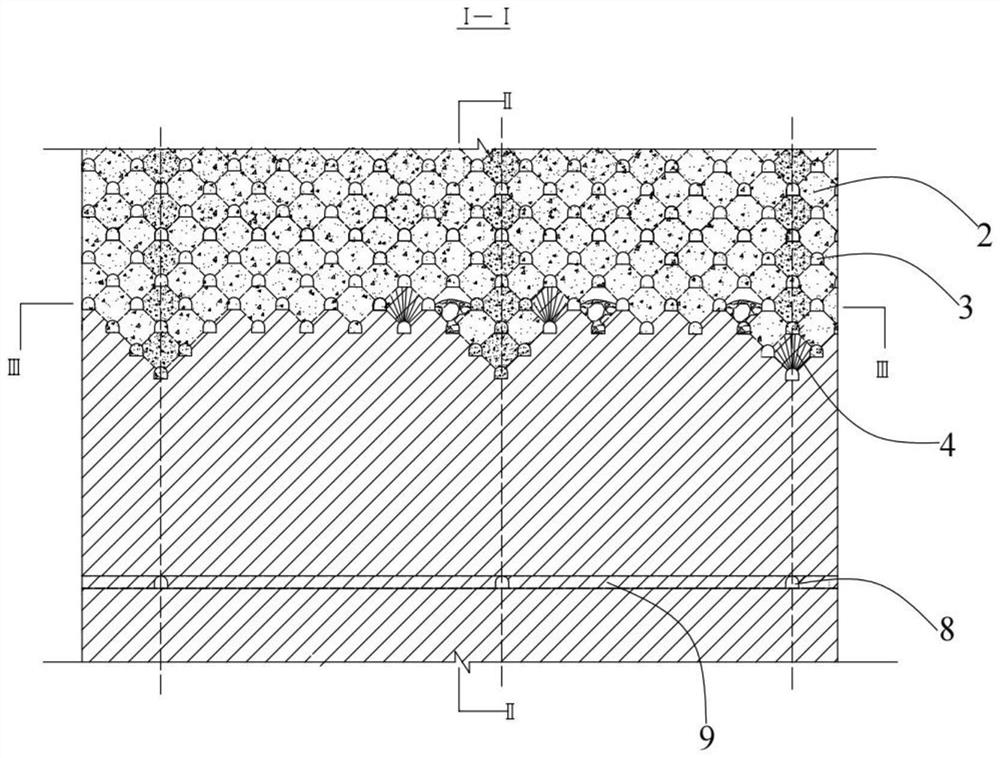

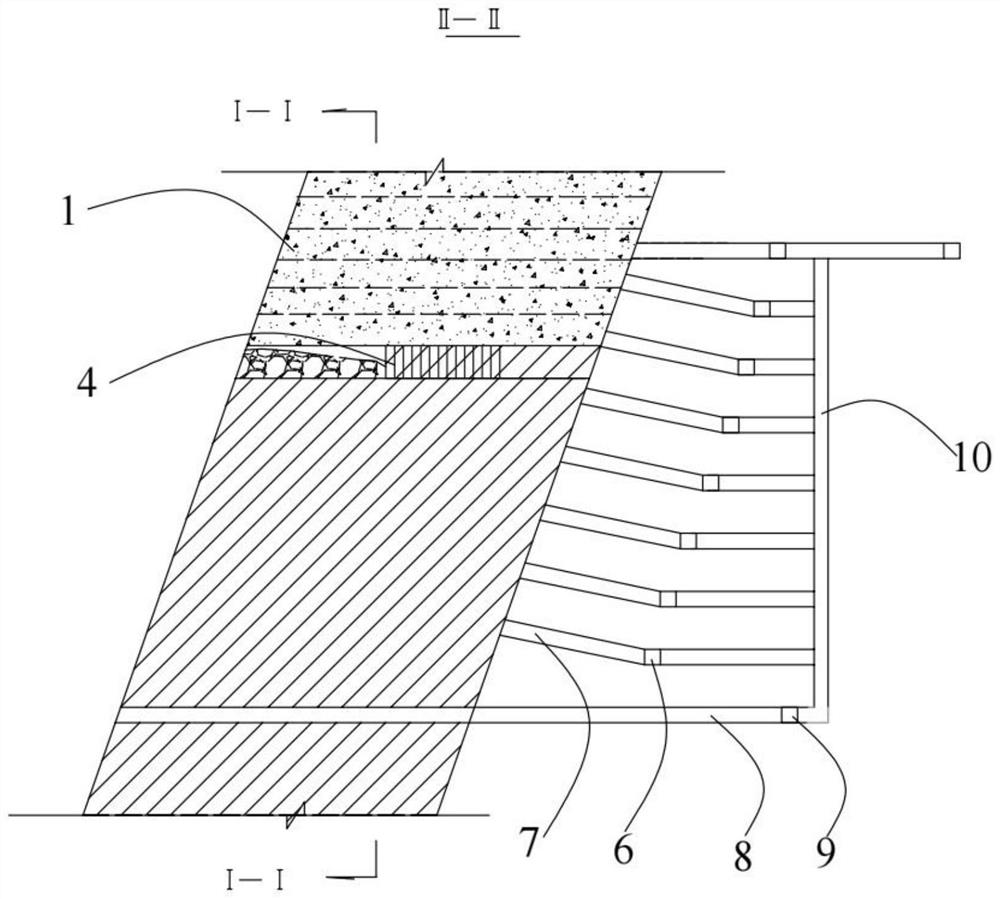

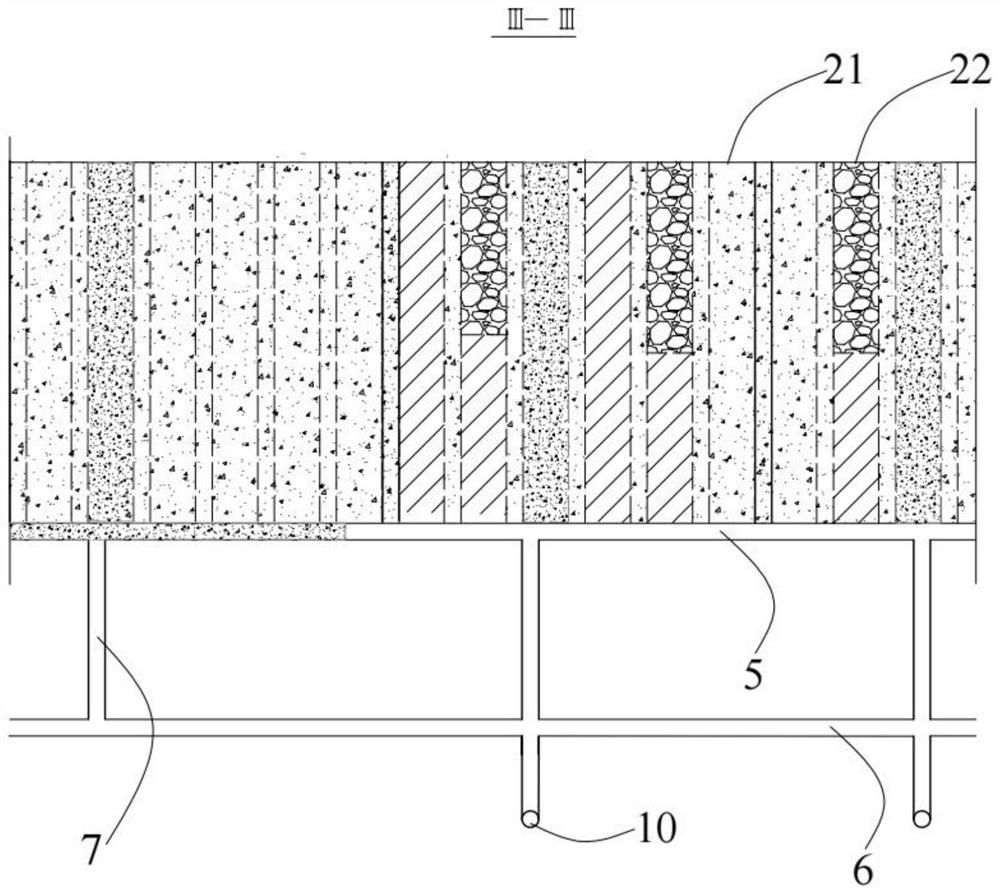

[0042] This embodiment provides a subarea unloading subsection filling mining method based on a rhombus mining structure, including the following steps:

[0043] S1. Set the middle section stope with a mining height of 100m in the panel area to be mined, and divide the width along the ore bed into partitions with a width of 120m, and divide the middle section stope into 20 subsection stopes 1 with a height of 5m in the height direction; Every 2 subsection stopes 1 height horizontal excavation of subsection entryways 6, and the subsection entryways 6 are connected by ramps. Excavate 1 upper segmental contact roadway from segmental level entry 6 to the ore deposit boundary of upper segmental stope 1 and 1 horizontal contact road to the horizontal ore bed boundary of this segmental stope 1, and then along the segmental stope 1 Excavate along vein transportation level entry 5 on the floor of the ore deposit, start from along vein transportation level entry 5, and excavate a rock d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com