Patents

Literature

208 results about "Stoping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Stoping is the process of extracting the desired ore or other mineral from an underground mine, leaving behind an open space known as a stope. Stoping is used when the country rock is sufficiently strong not to collapse into the stope, although in most cases artificial support is also provided.

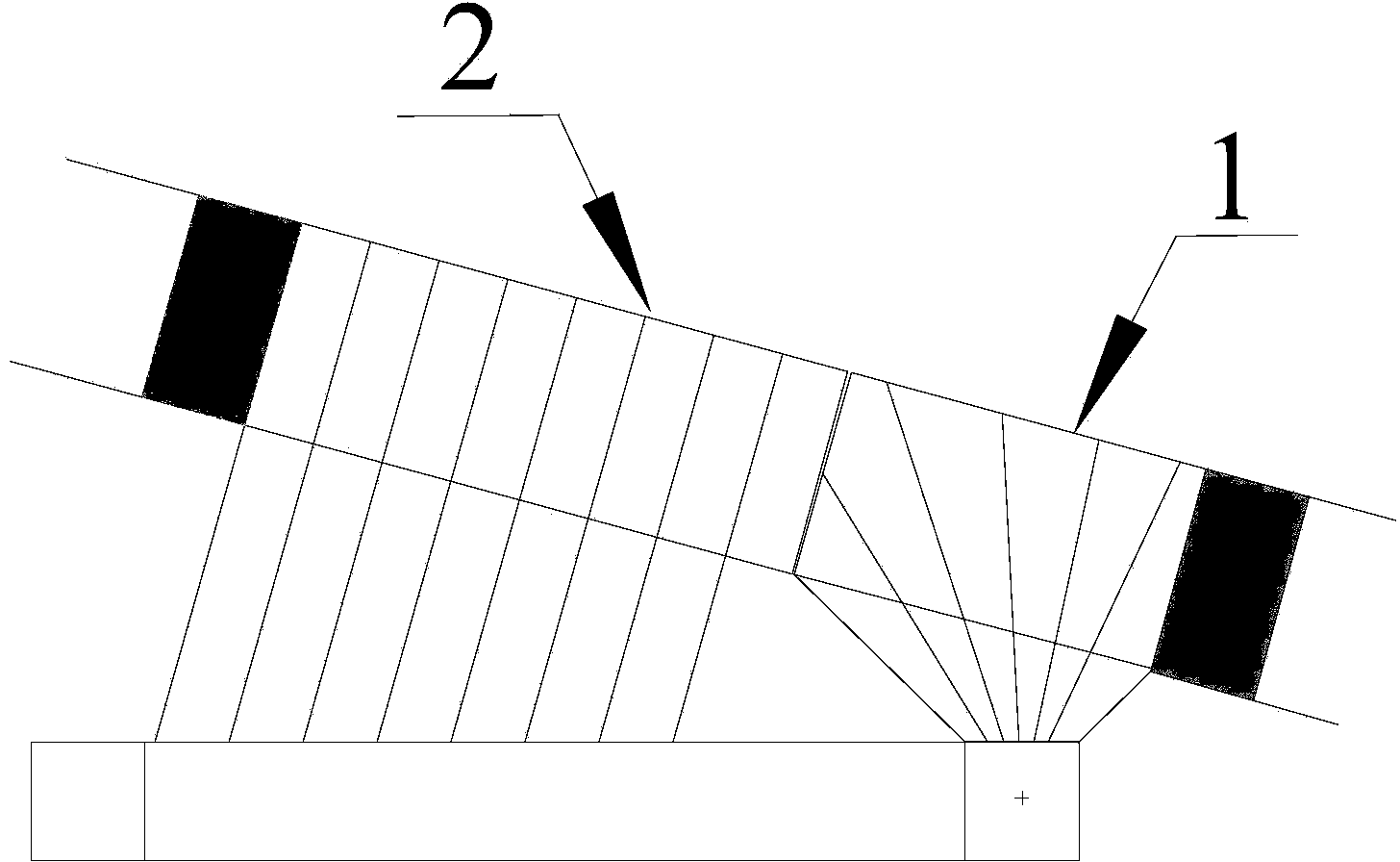

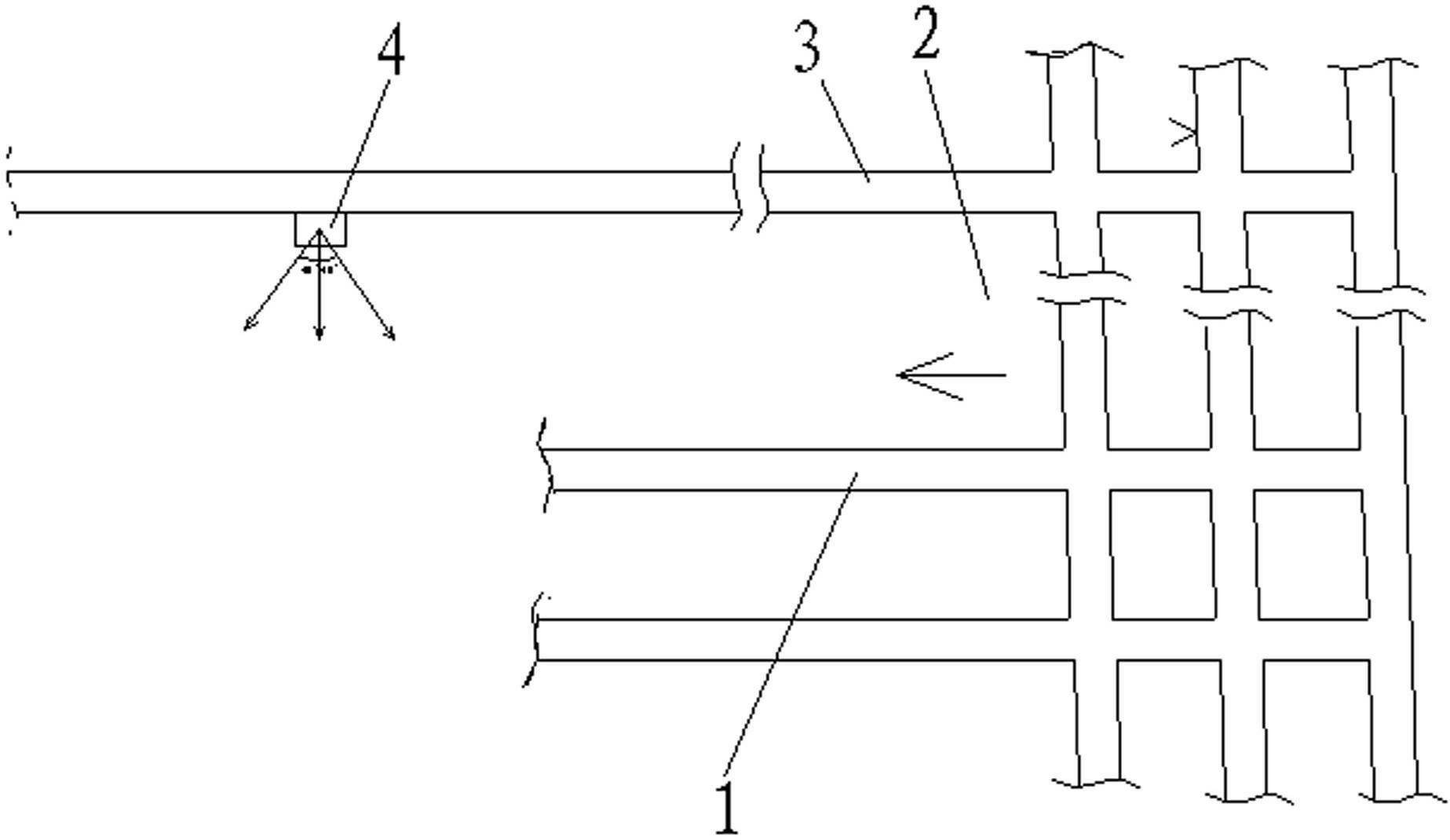

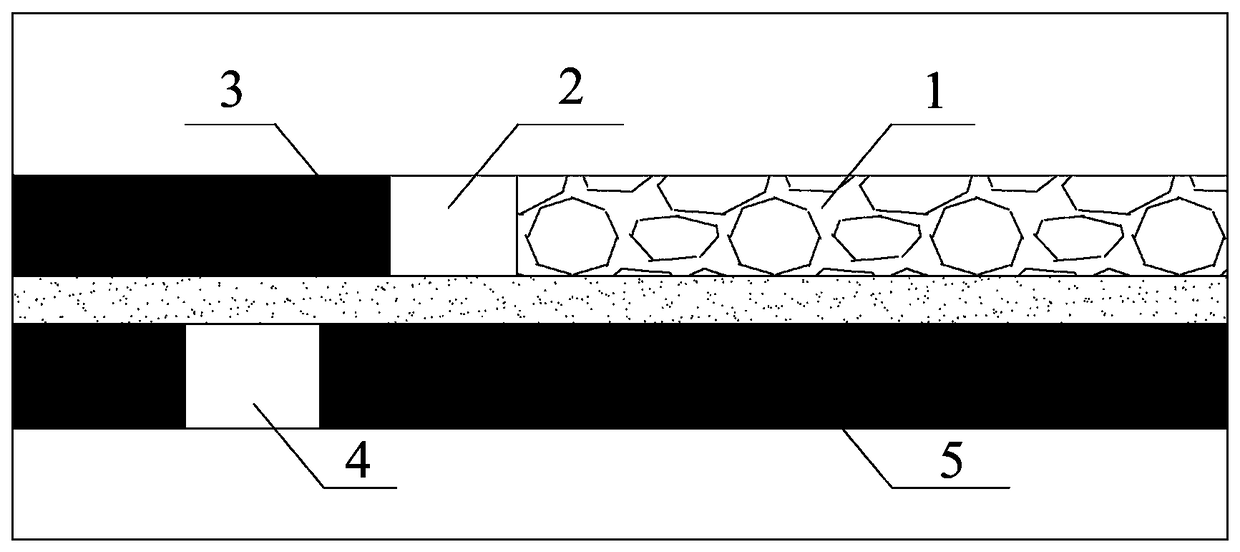

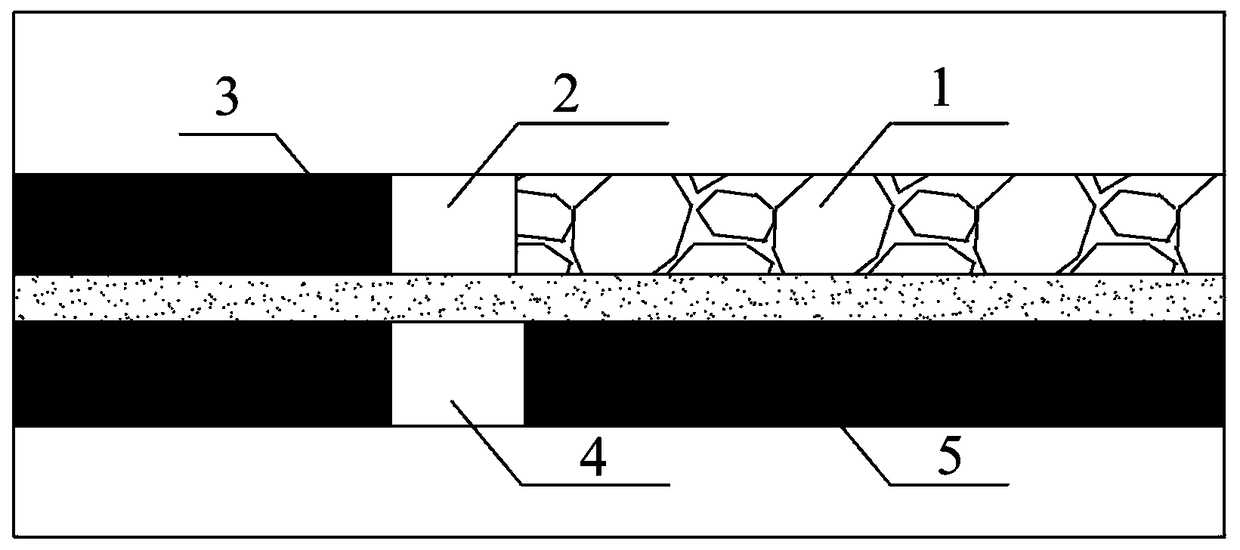

Novel mining method of gently-inclined thin and medium thickness ore bodies

InactiveCN103590831ARealize complementary advantagesJob safetyUnderground miningSurface miningWorkloadStoping

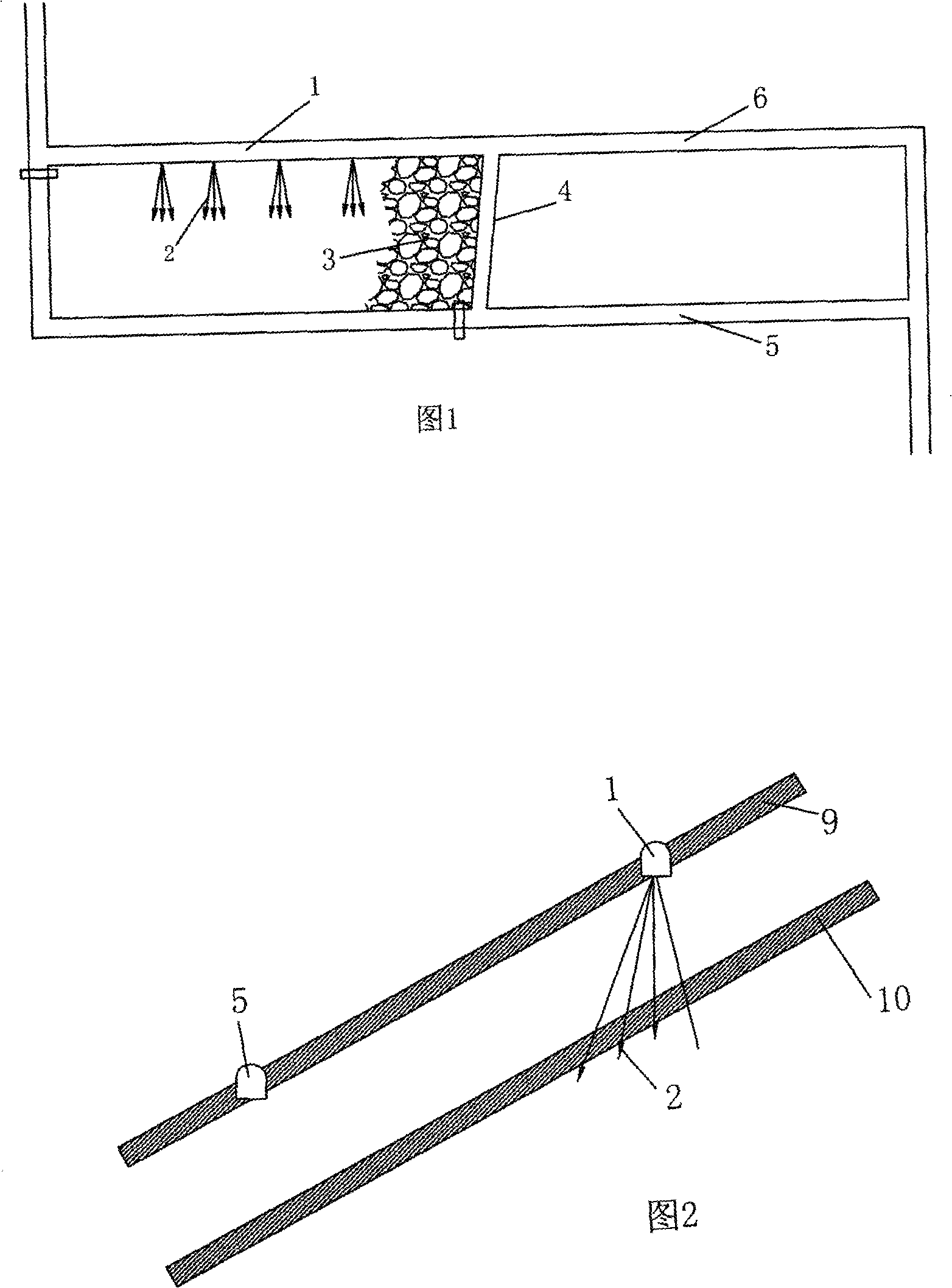

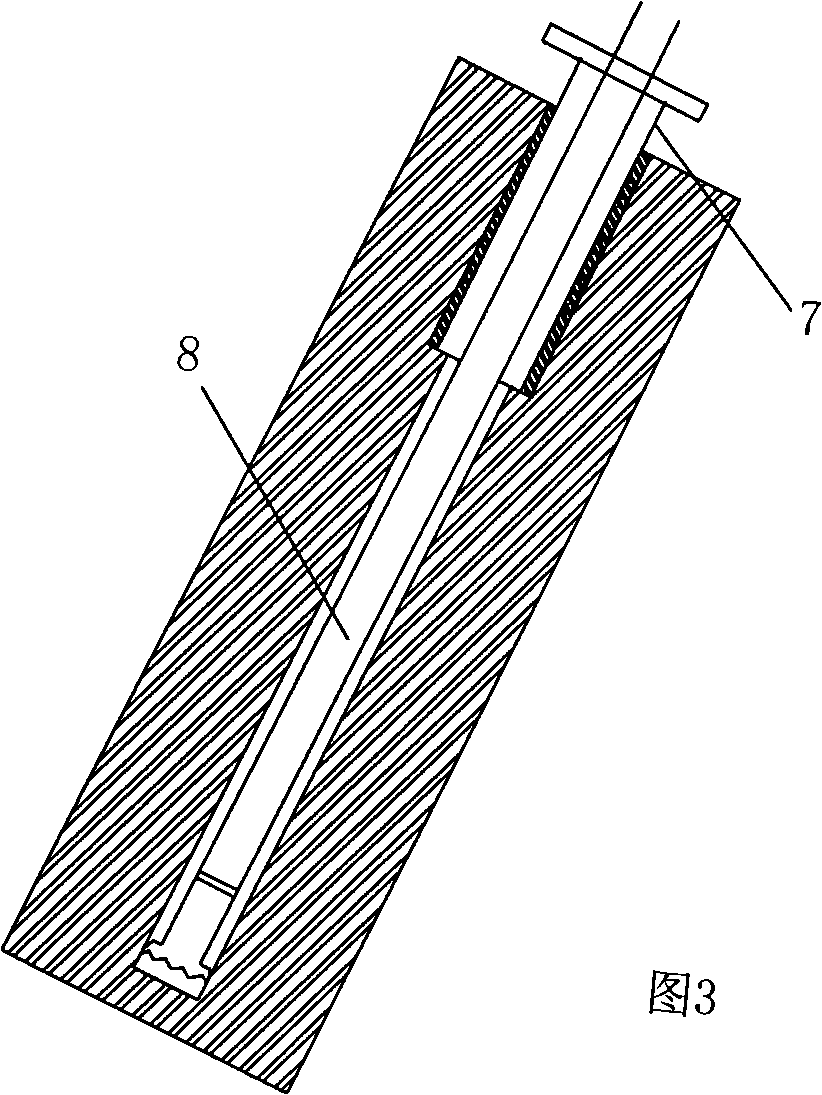

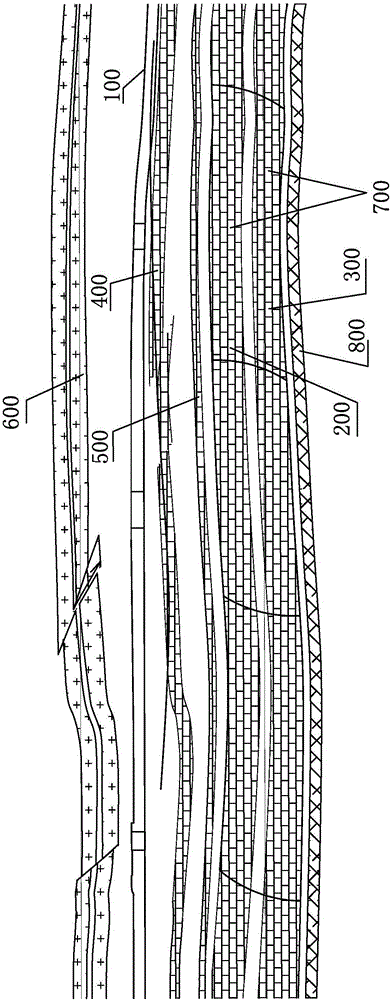

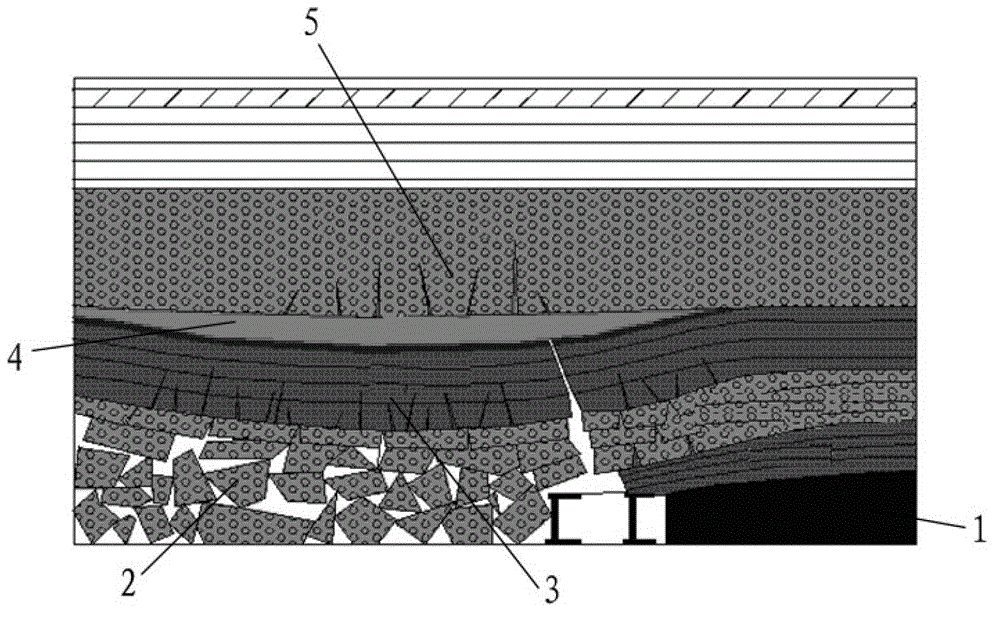

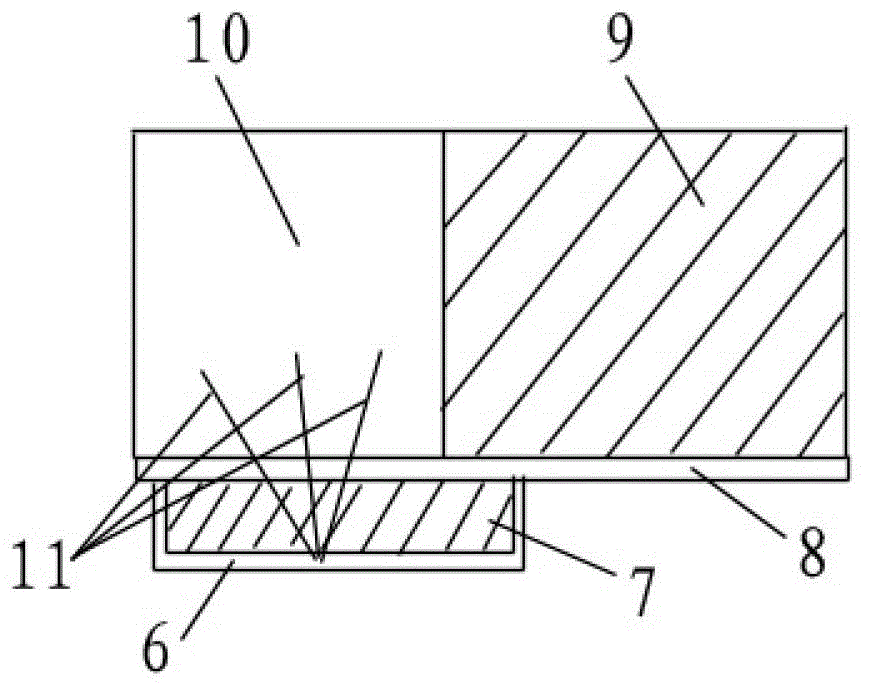

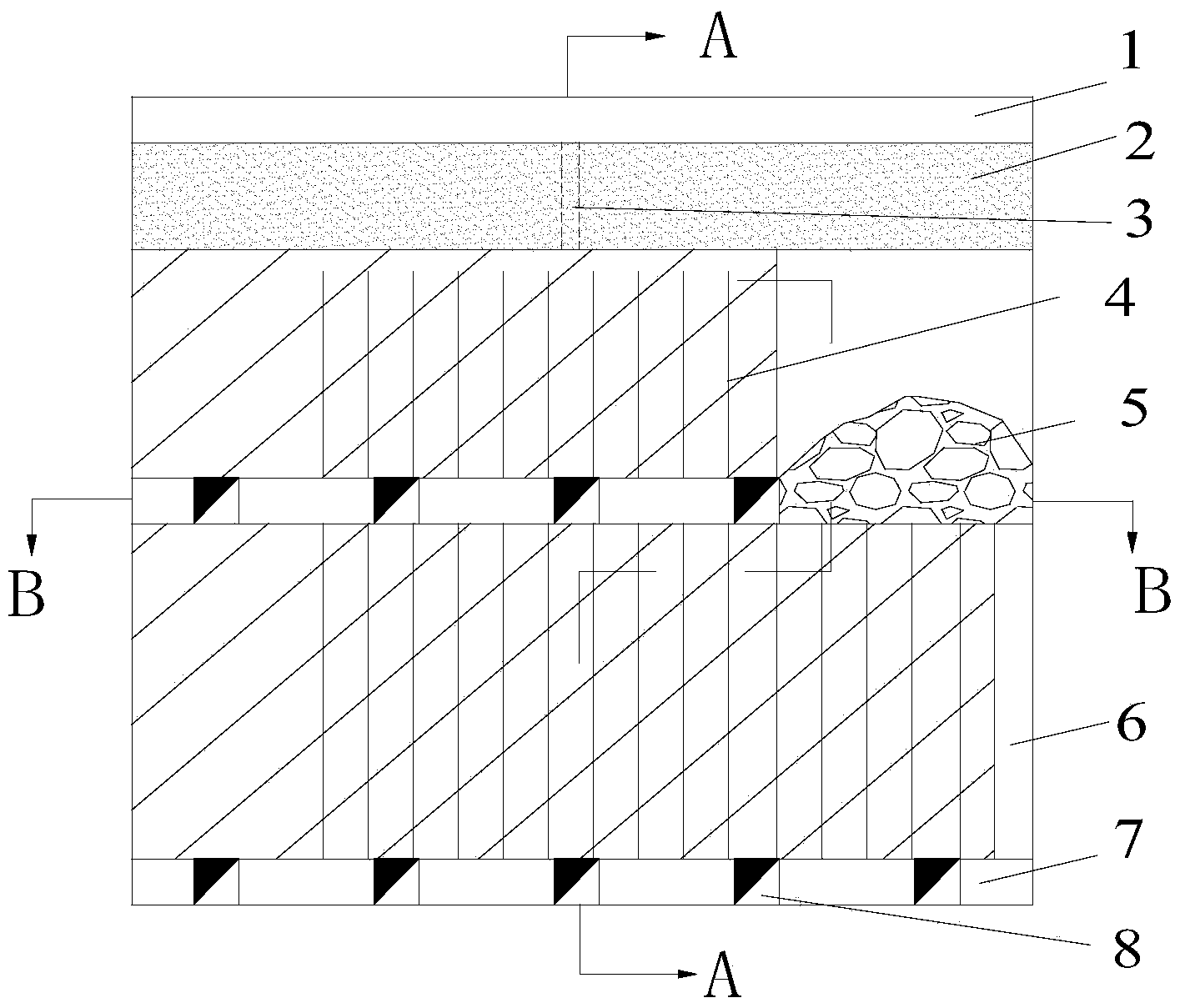

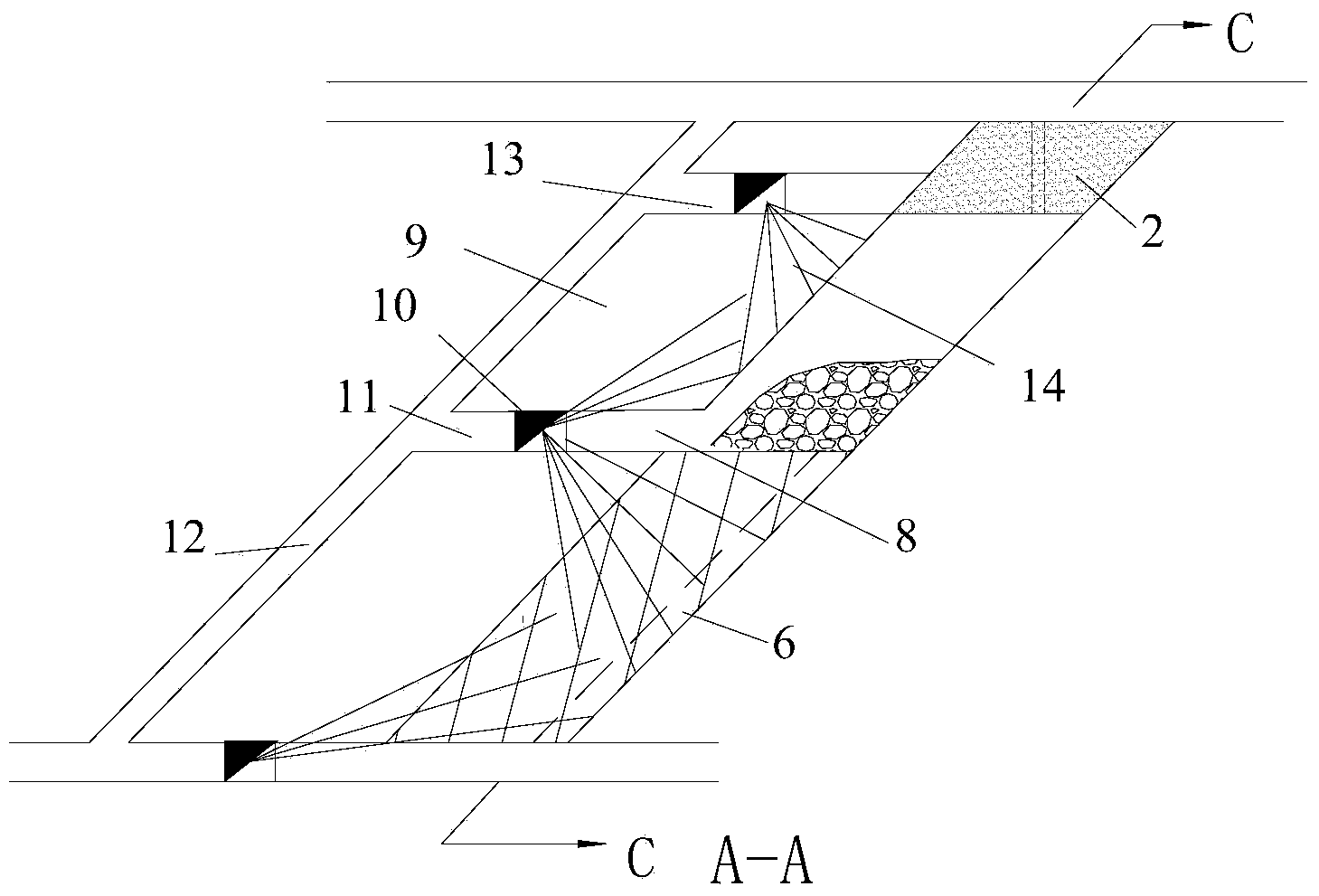

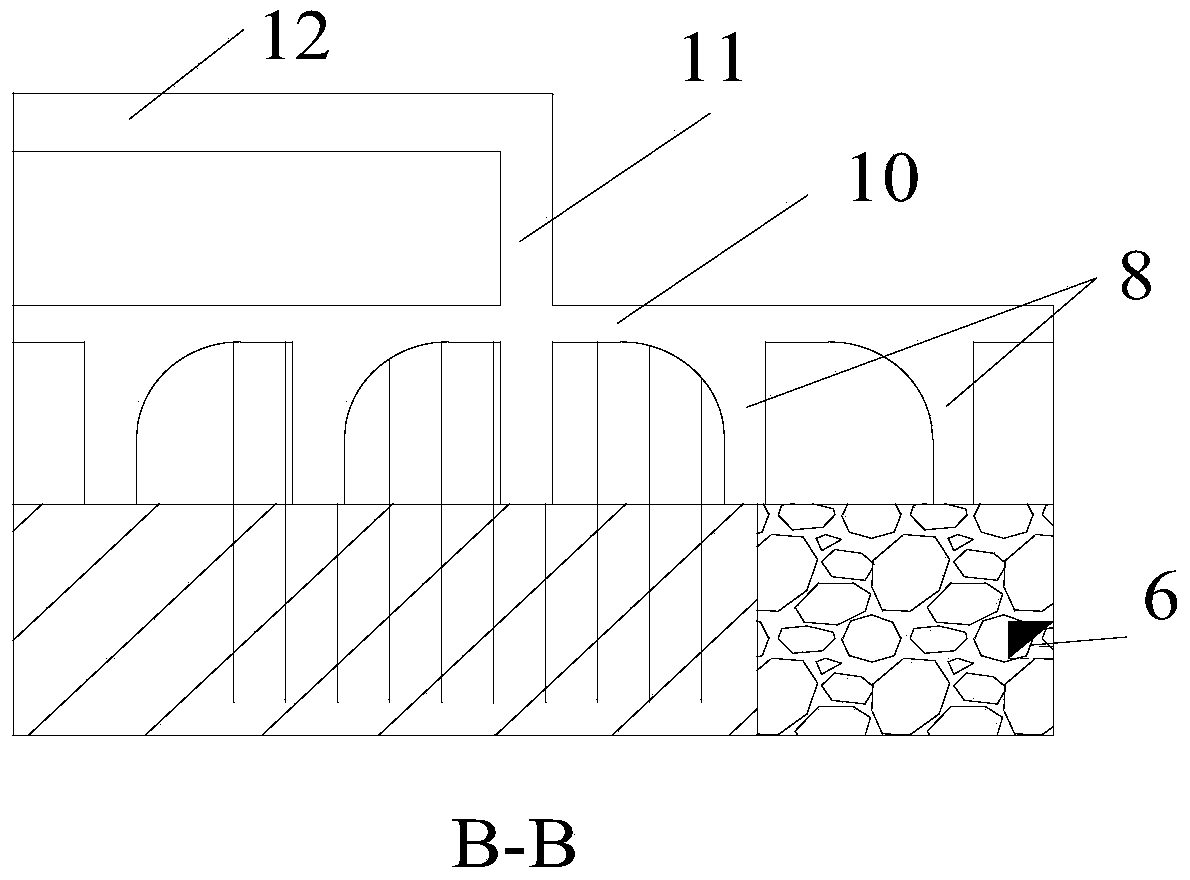

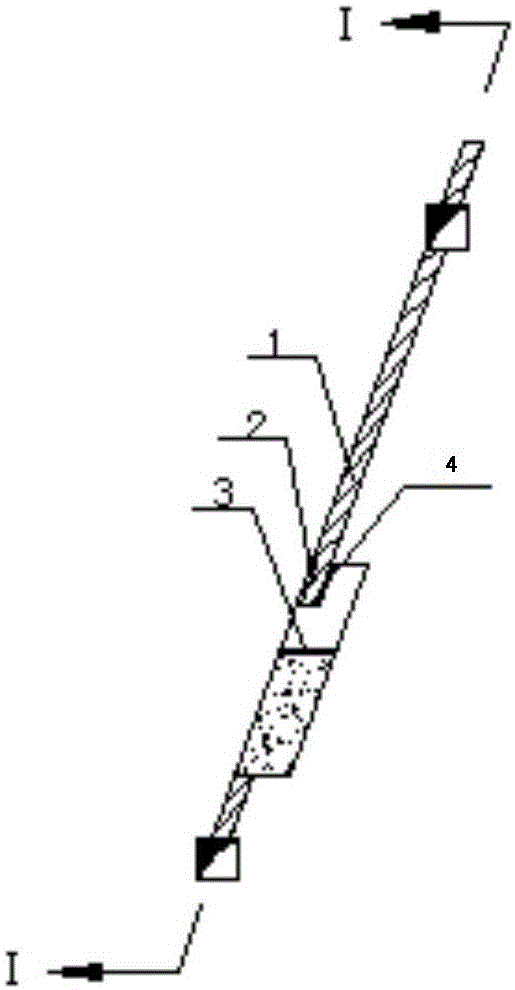

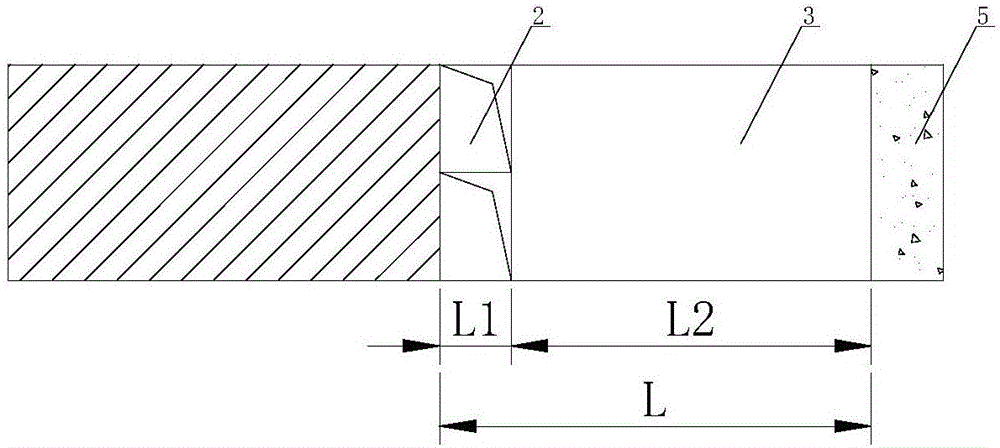

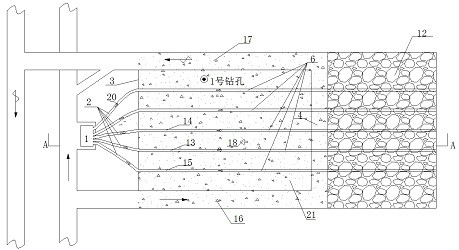

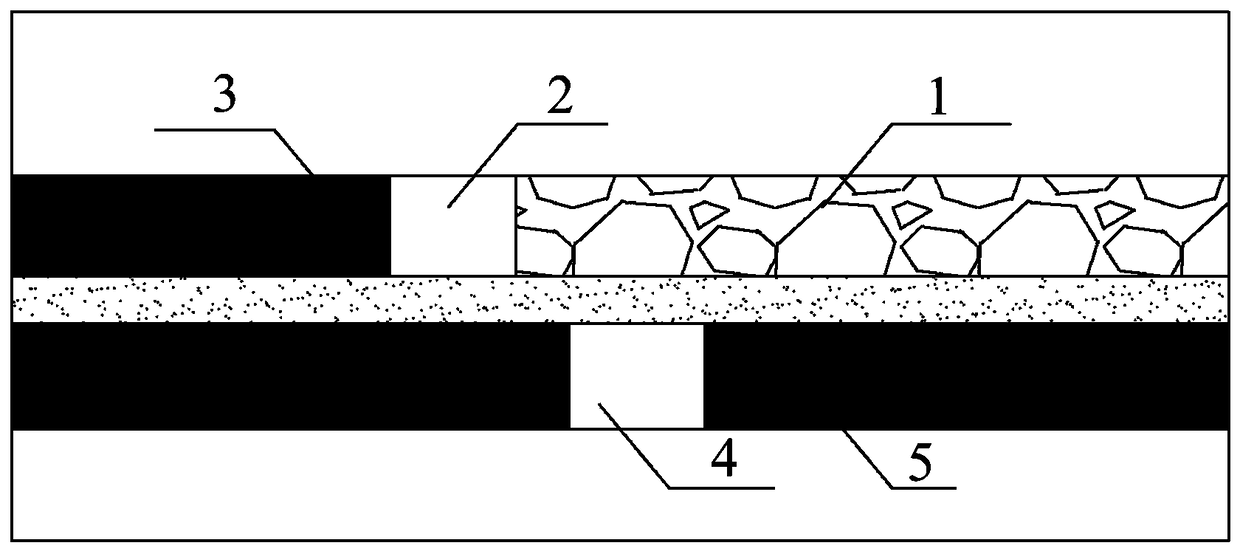

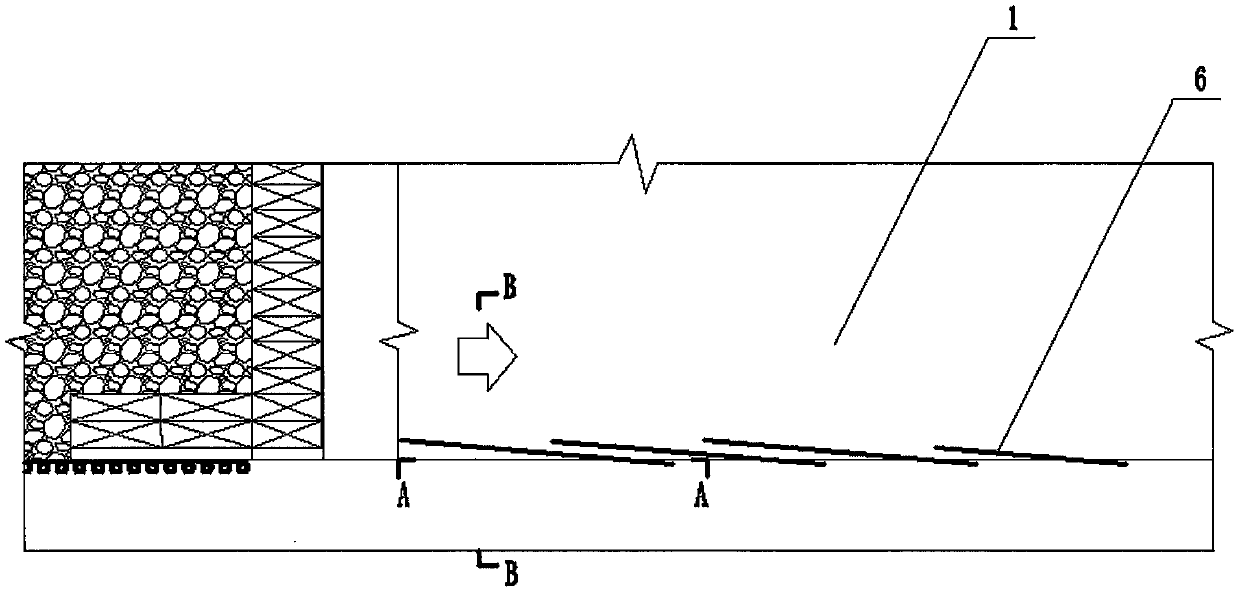

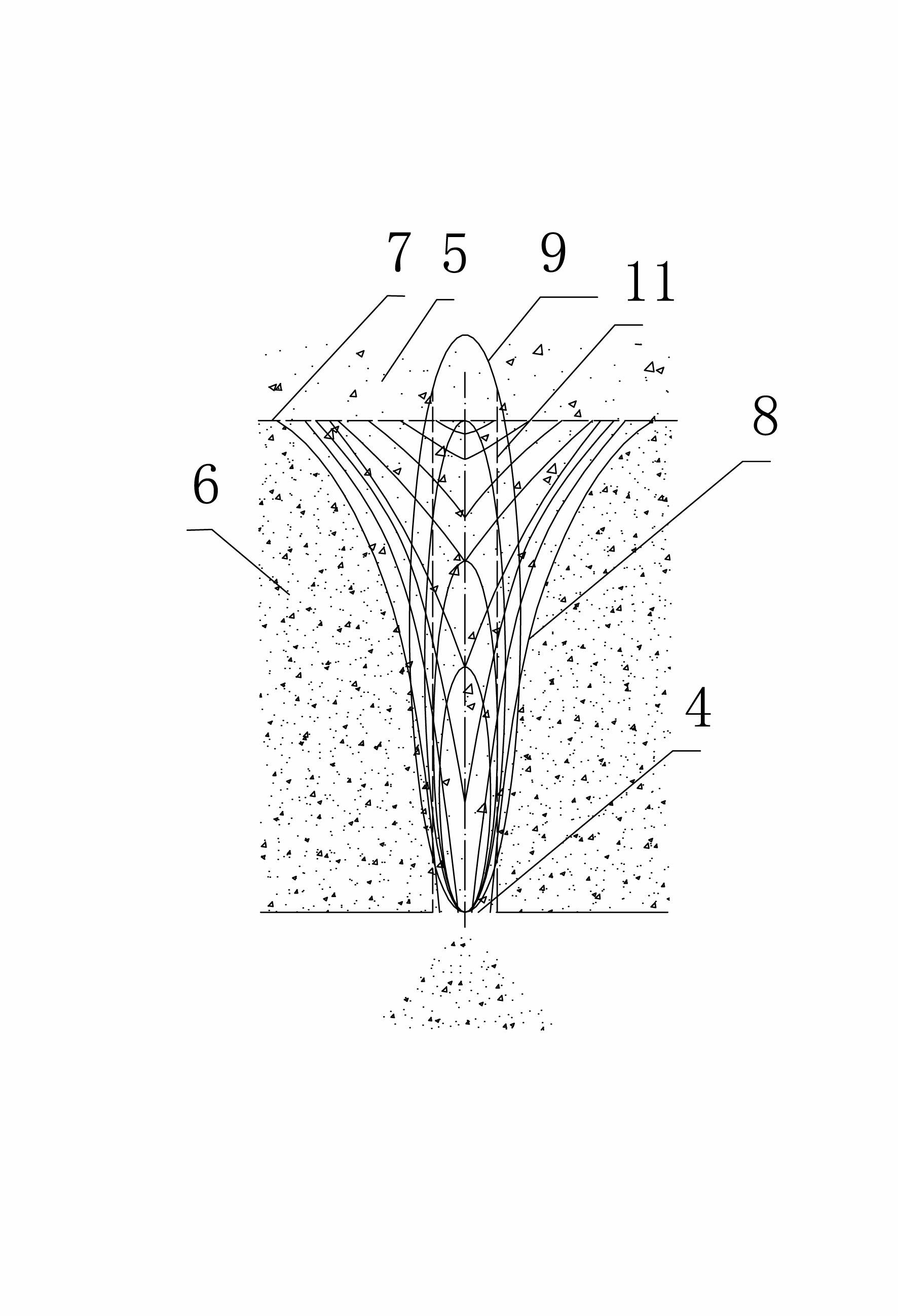

The invention discloses a novel mining method of gently-inclined thin and medium thickness ore bodies. According to the method, ore bodies in one stope are stoped by dividing the stope into two stope areas through steps: firstly, stoping is performed at the stope area (1) by using a pillarless sublevel caving method: the ore bodies are directly caved in single sublevel by using medium-length blastholes; a certain empty area formed after ore removal is used as a free surface for stoping of the stope area (2); then, the stoping is performed at the stope area (2) by using a blasting force carrying mining method; fan-shaped medium-length blastholes are arranged in a manner perpendicular to the ore body tendency, and are filled with powder according to sections, the decking parts are the parts from the lower disc boundaries of the ore bodies to the hole bottoms; the empty area formed during the stoping of the stope area (1) is used as a free surface for blasting row by row; ores in the stope area (2) are thrown in the empty area by using the blasting force. The method integrates the pillarless sublevel caving method and the blast force carrying mining method, so that the supporting difficulty and the workload are reduced, the operation is safer, the mining cost is low, and the labor productivity is high.

Owner:UNIV OF SCI & TECH BEIJING

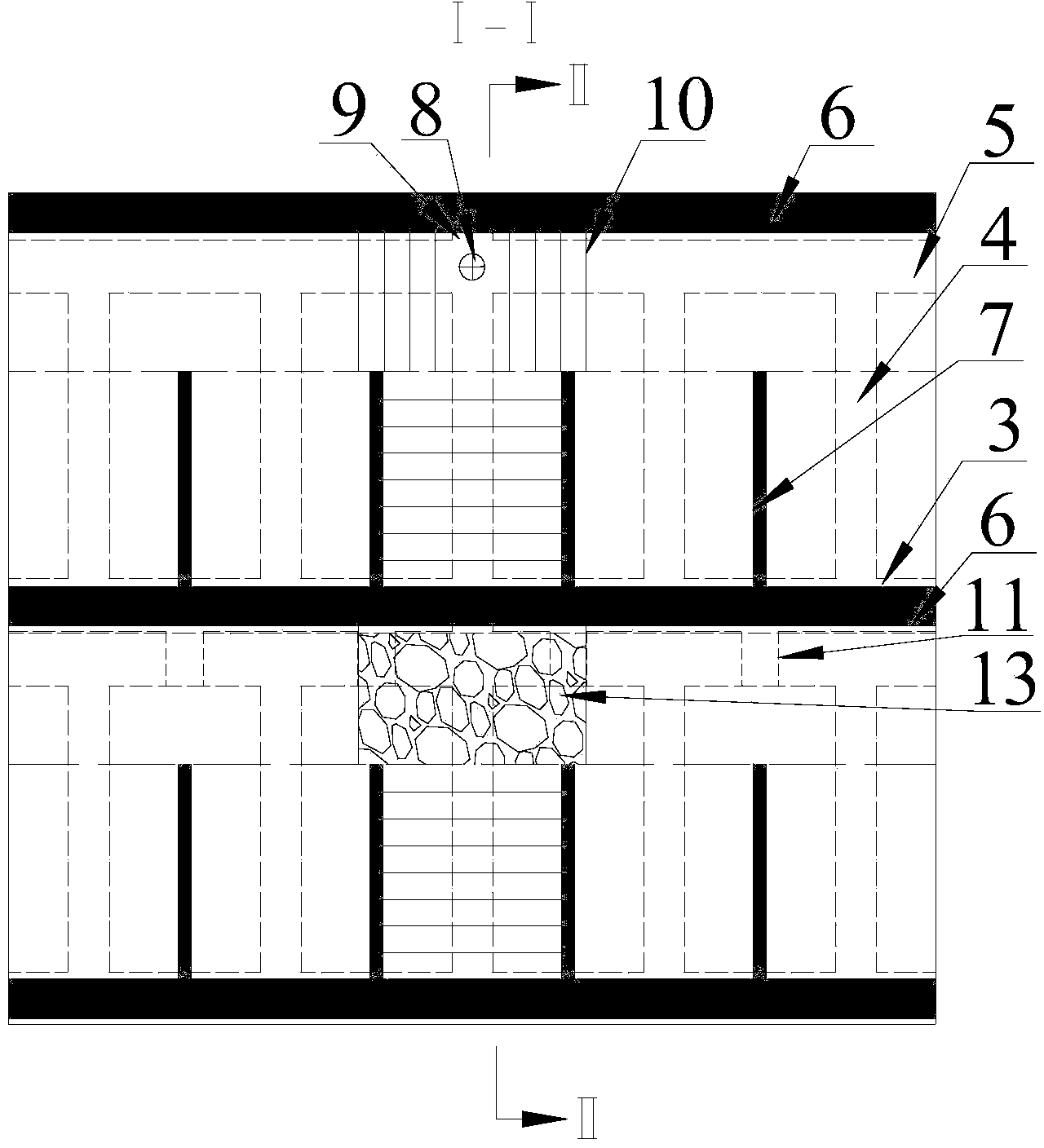

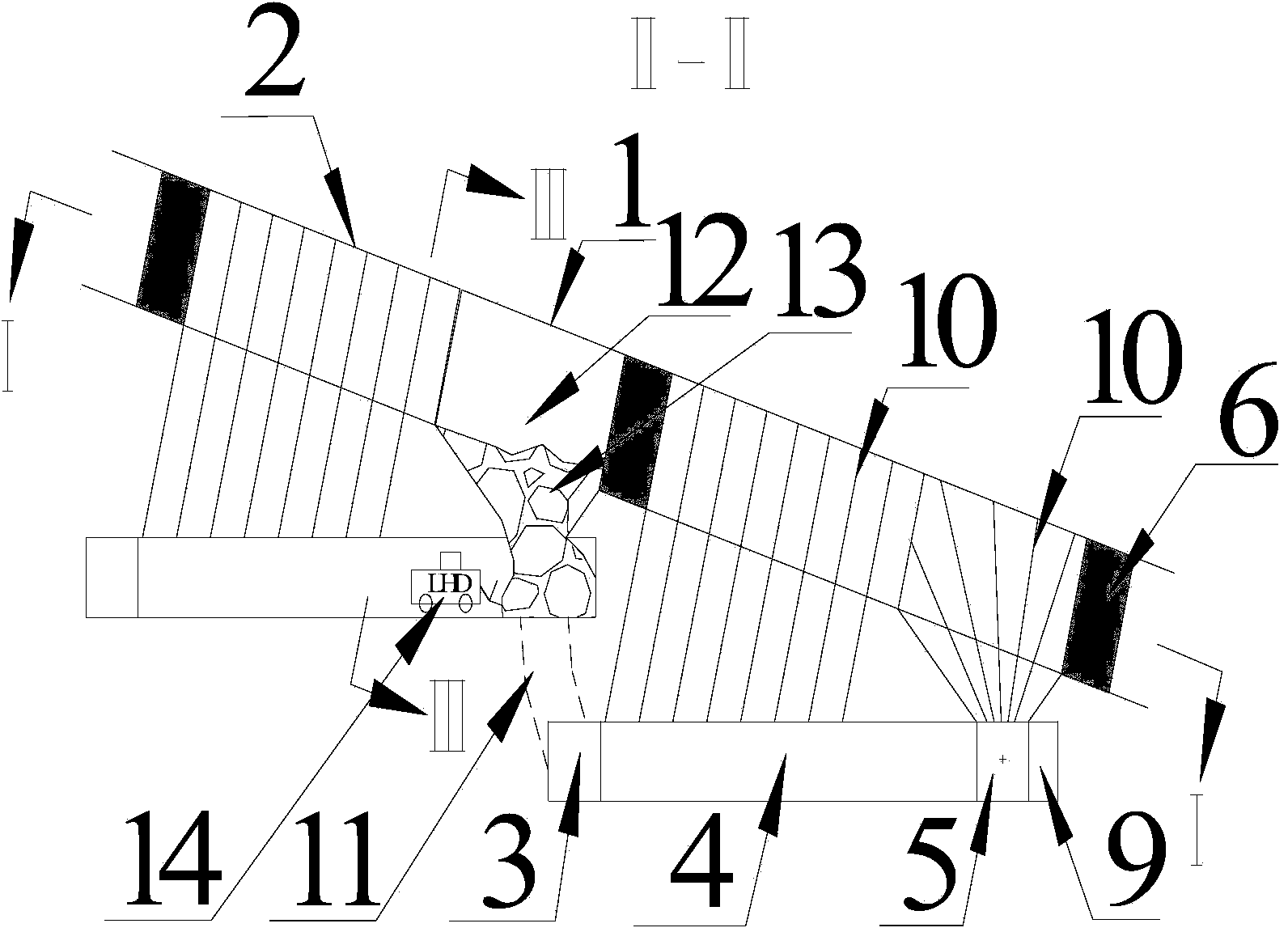

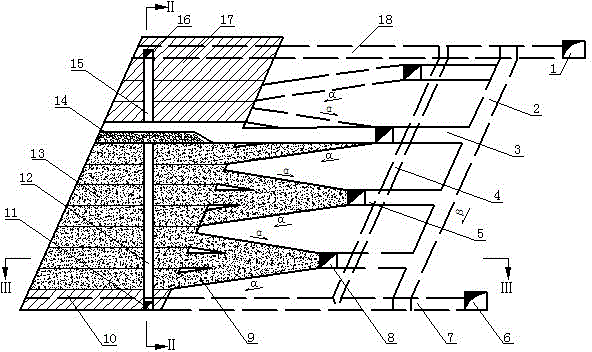

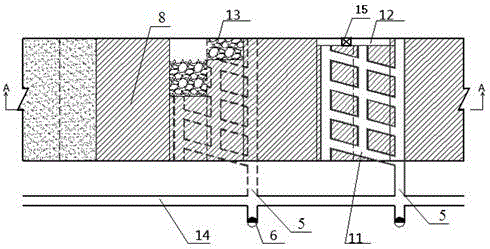

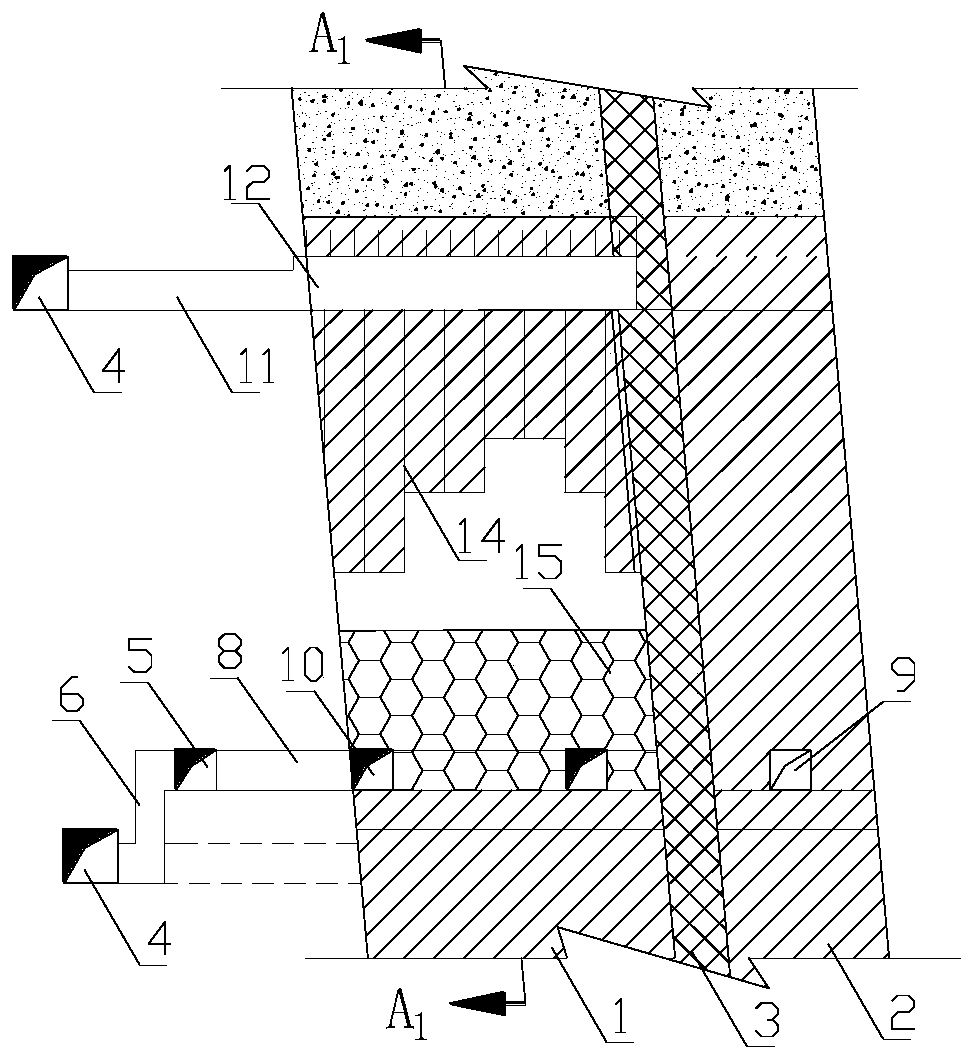

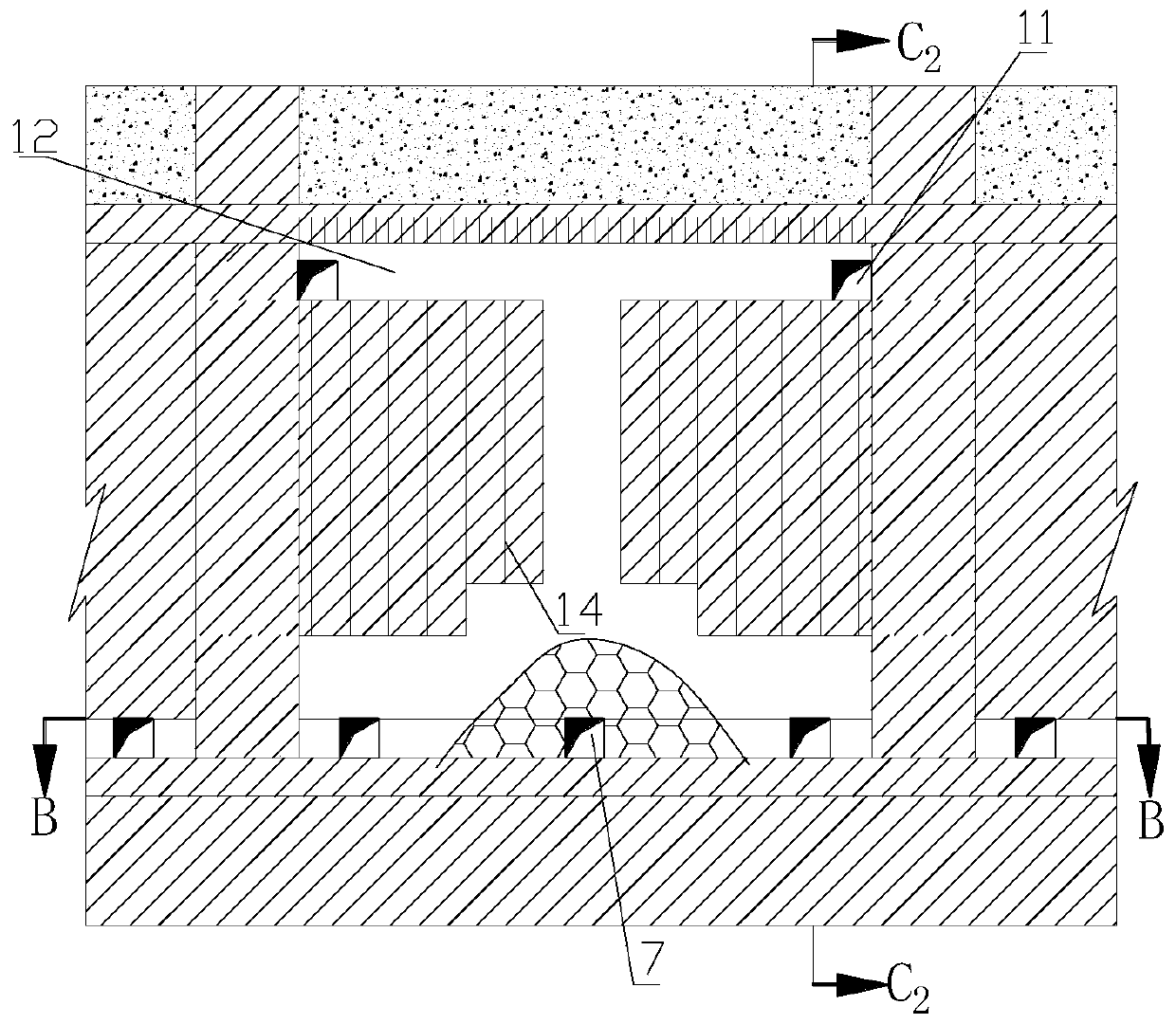

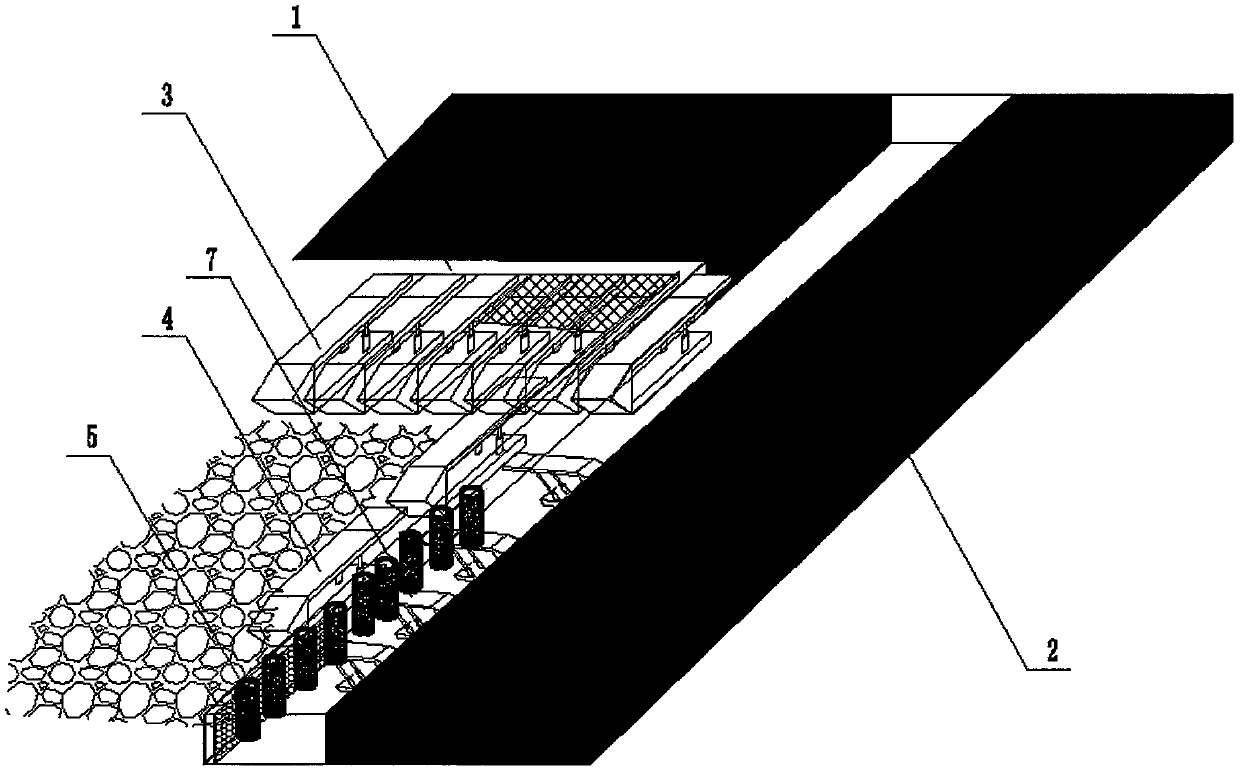

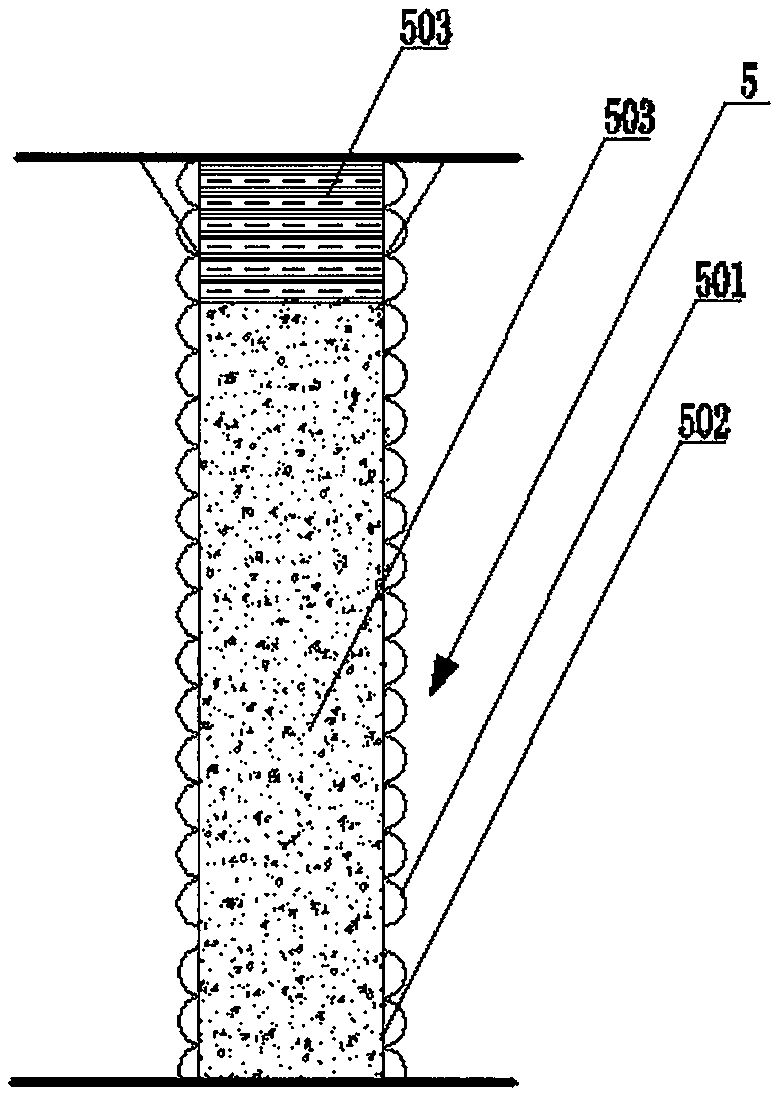

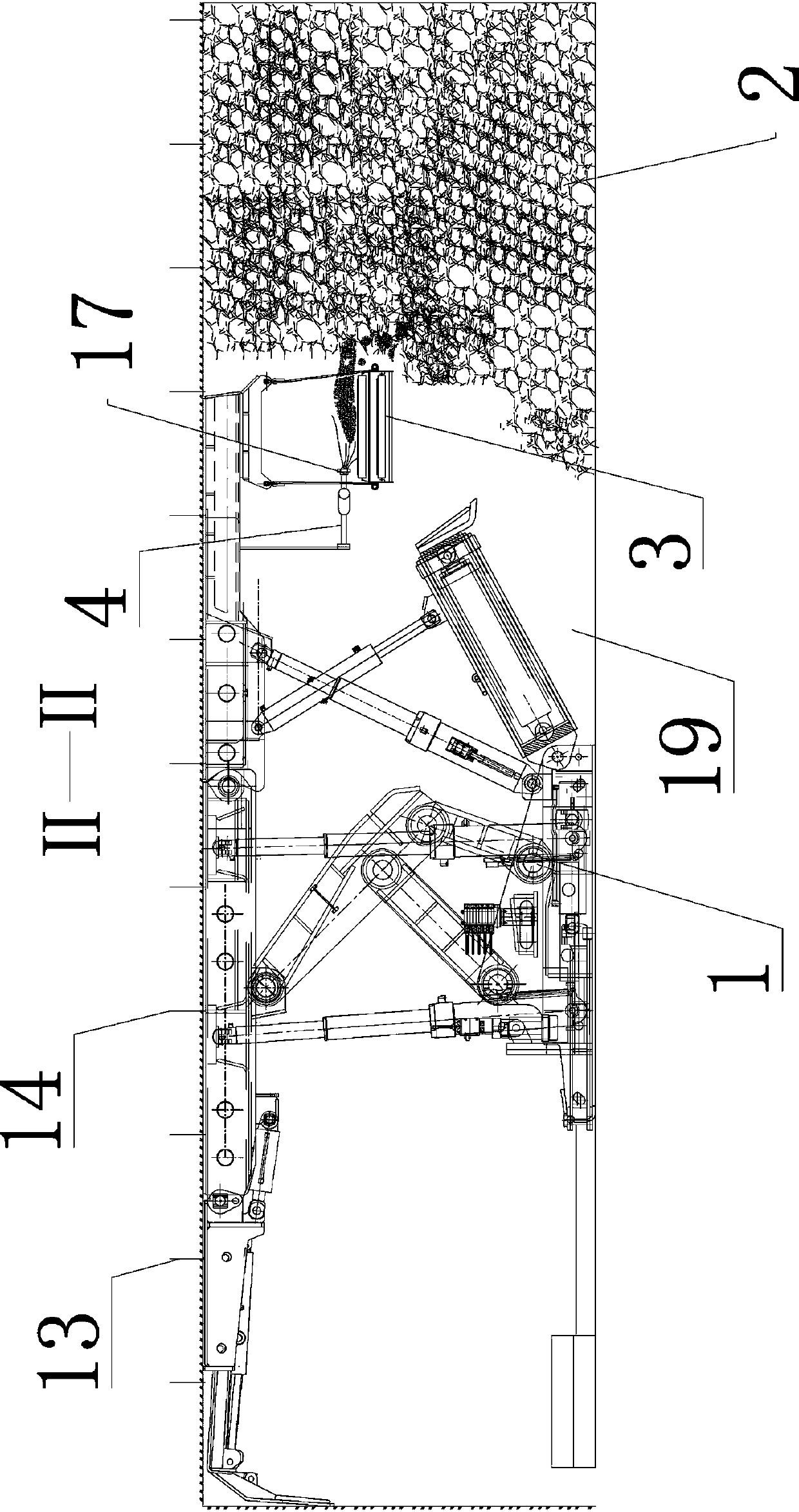

Panel mechanized centralized ore-pass upward horizontal cut-and-filling stoping method

InactiveCN103557002AIncrease production capacityHigh degree of mechanizationUnderground miningSurface miningFiltrationStructural engineering

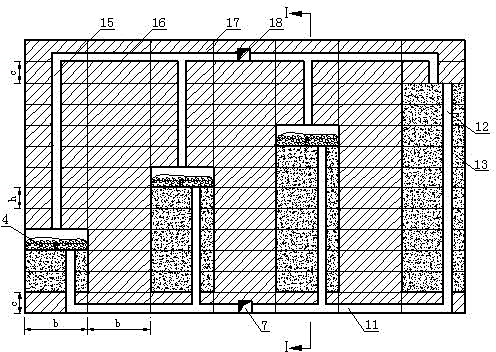

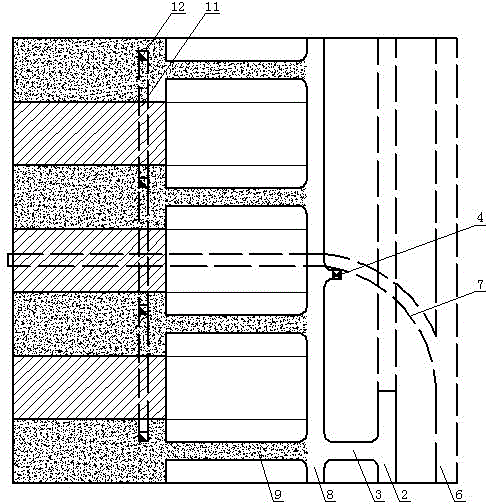

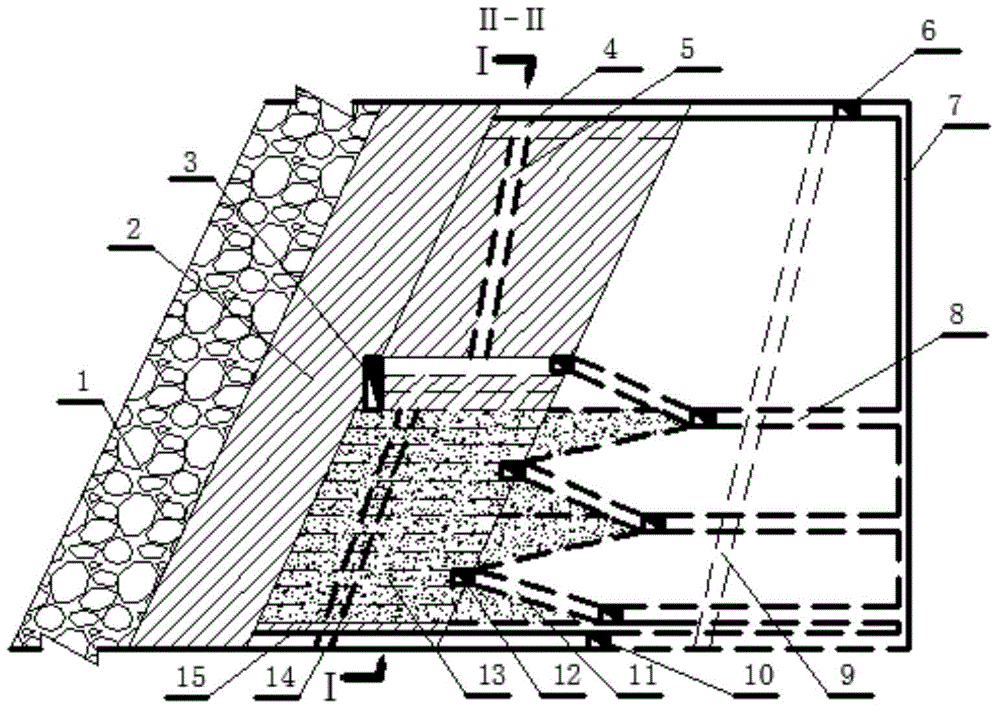

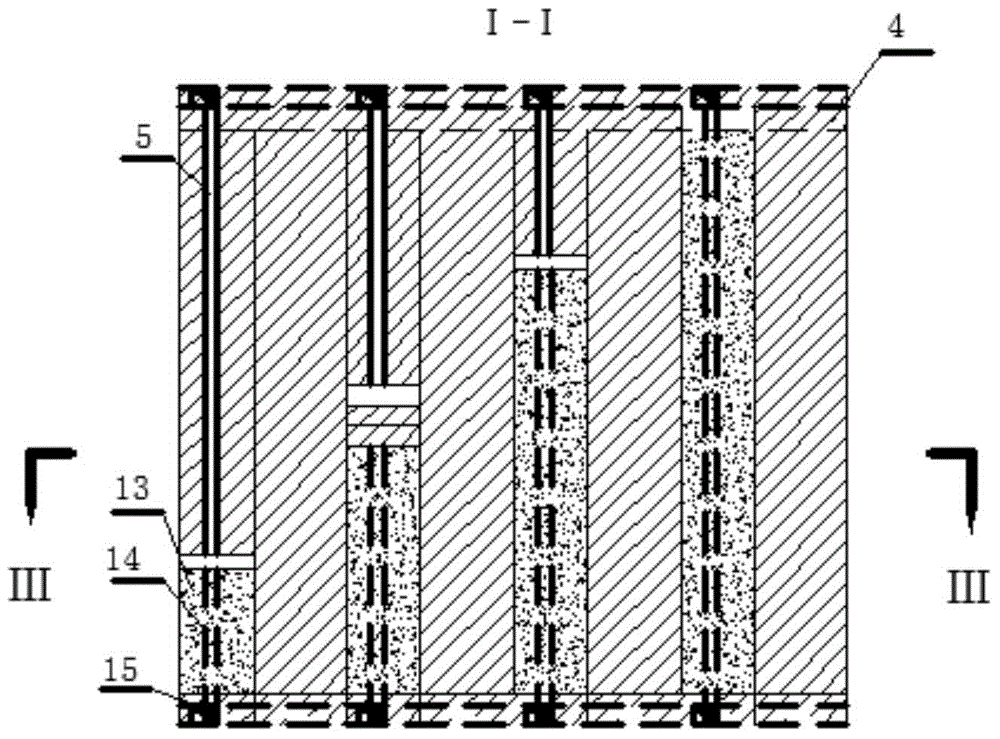

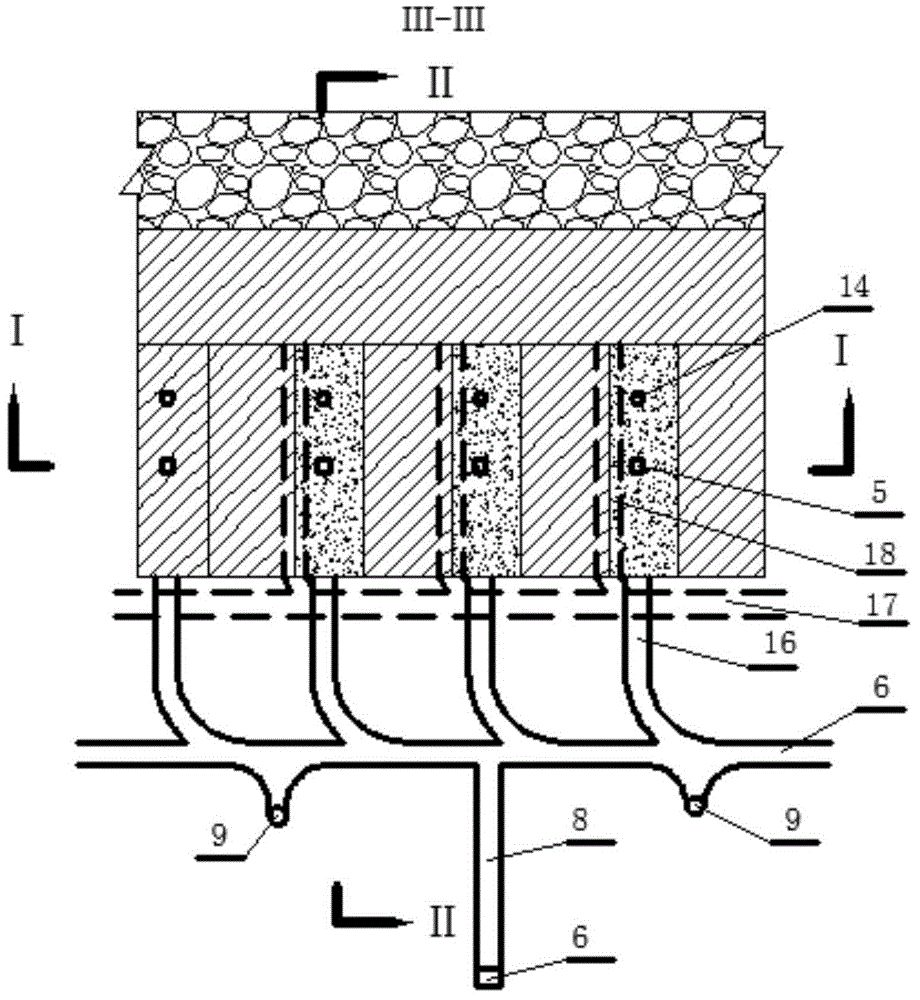

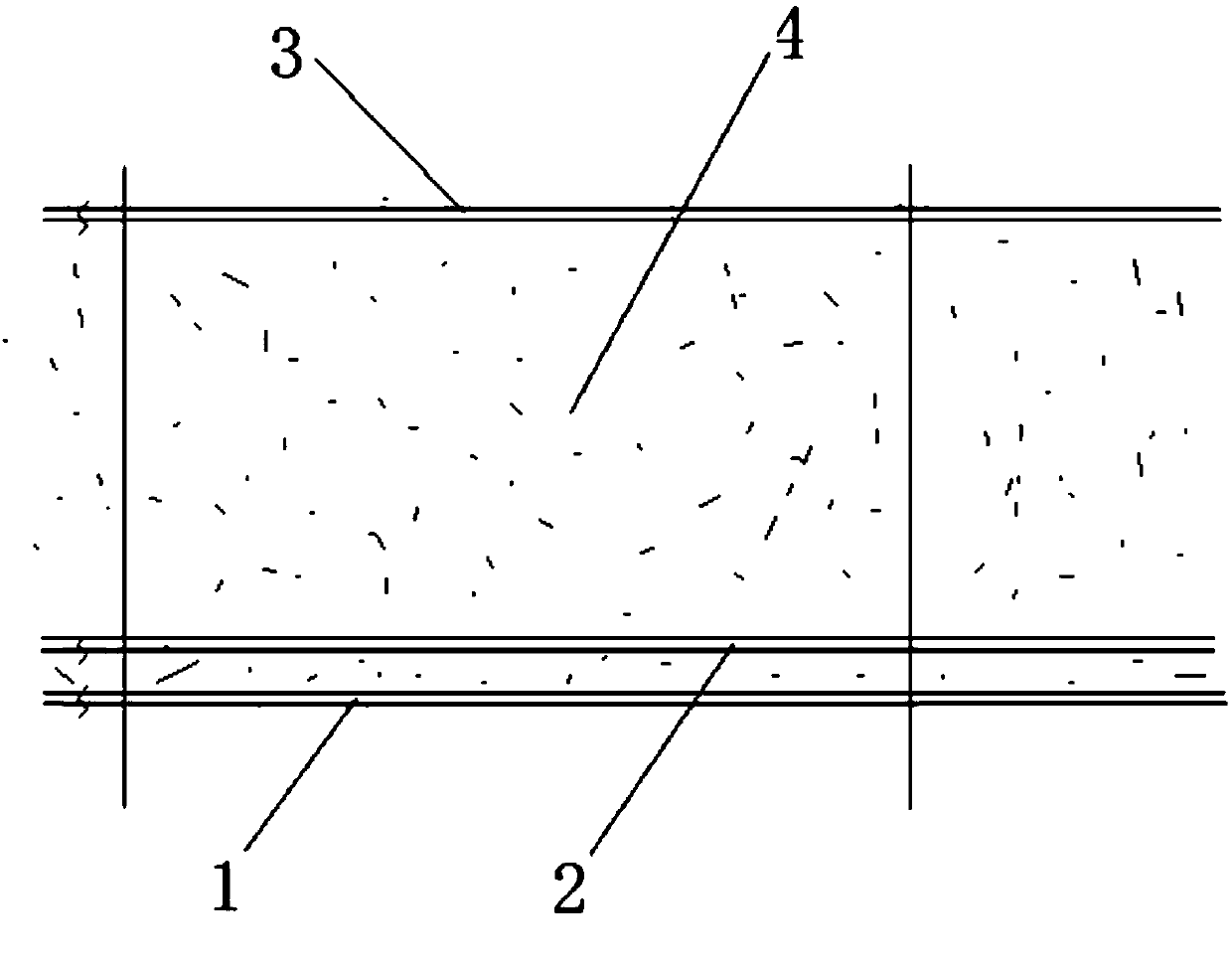

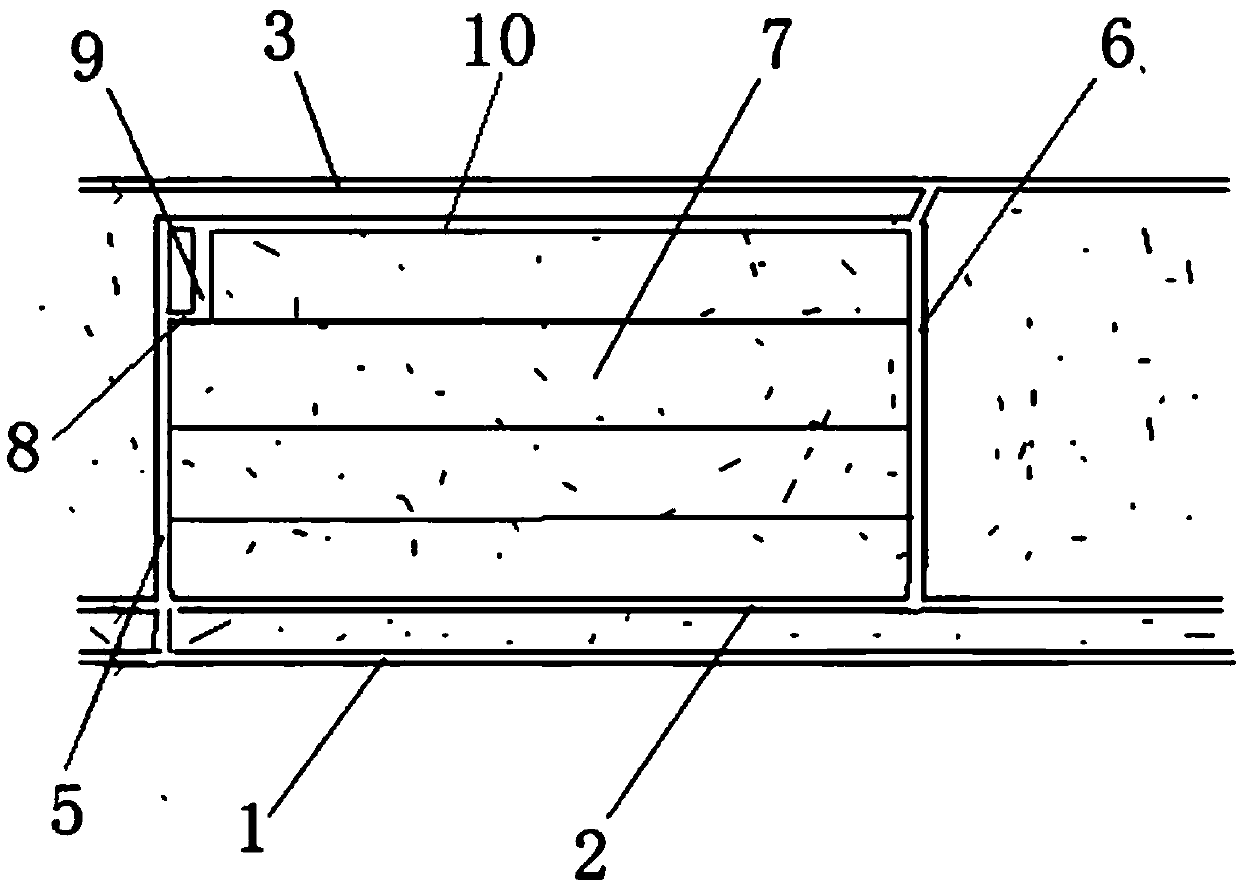

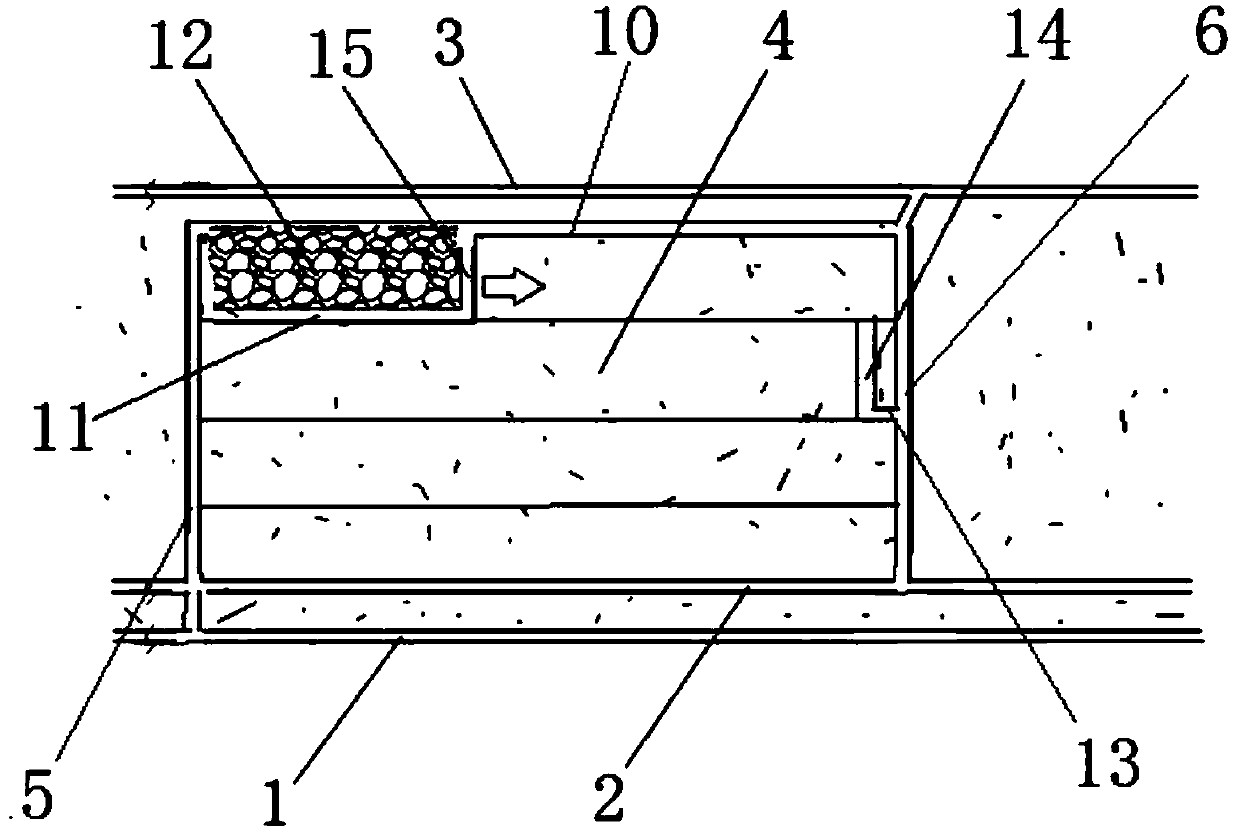

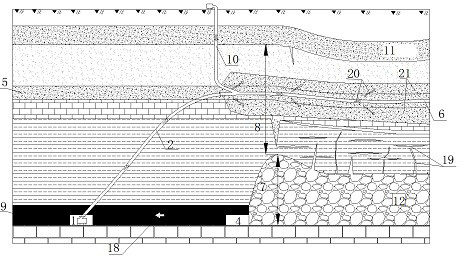

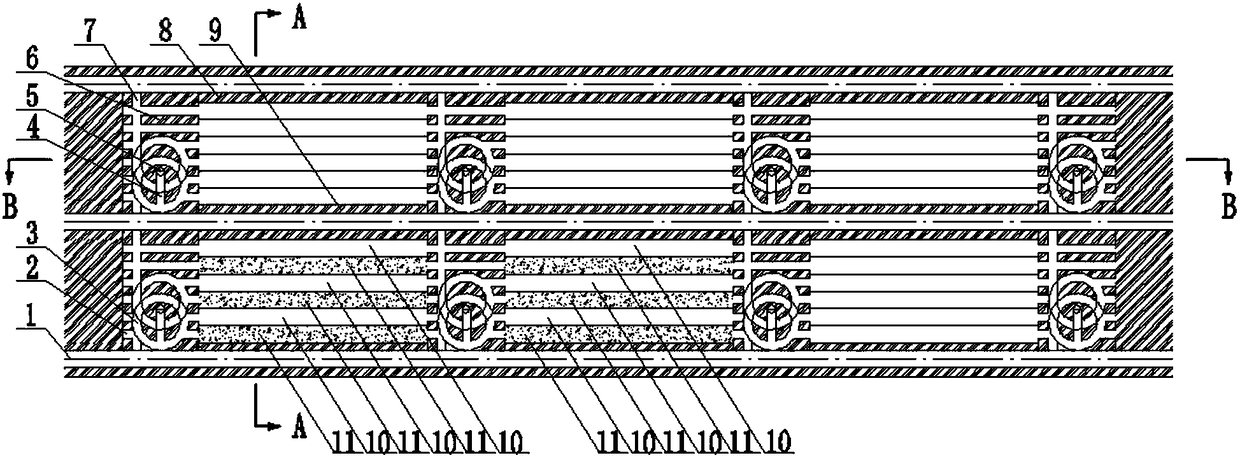

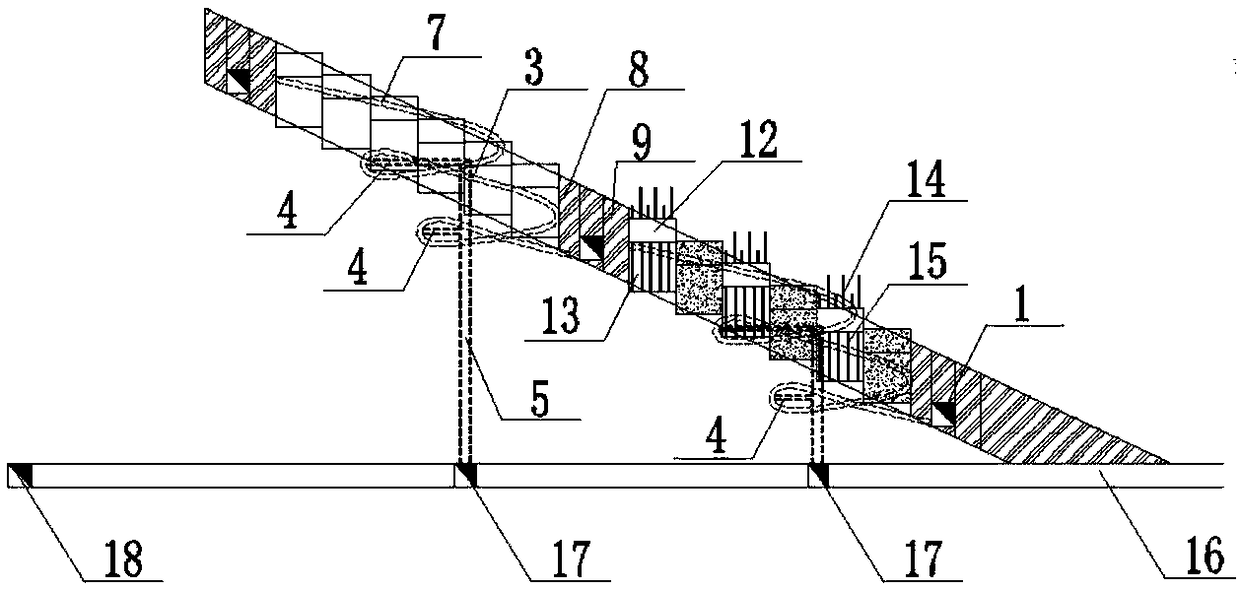

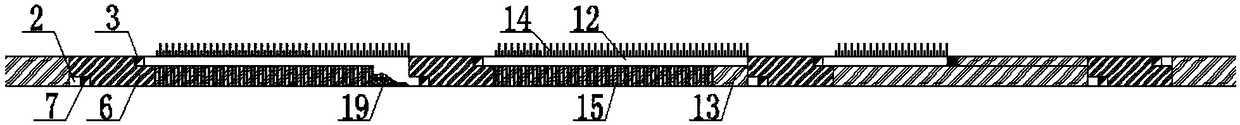

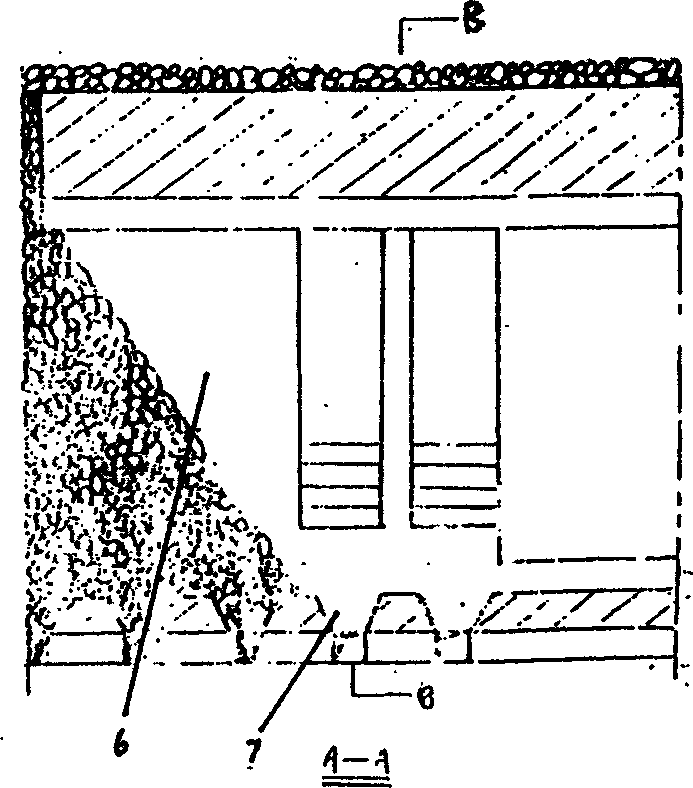

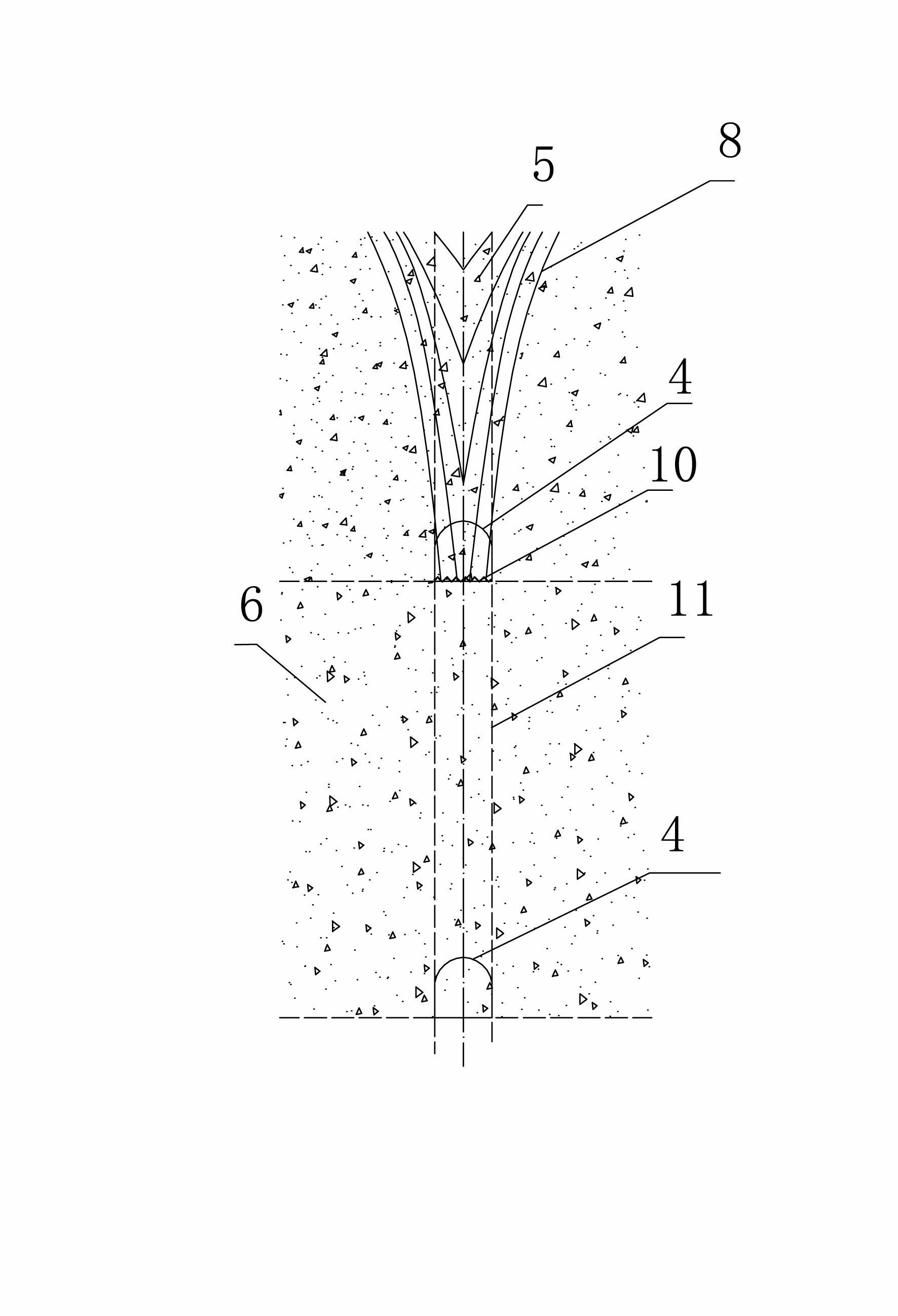

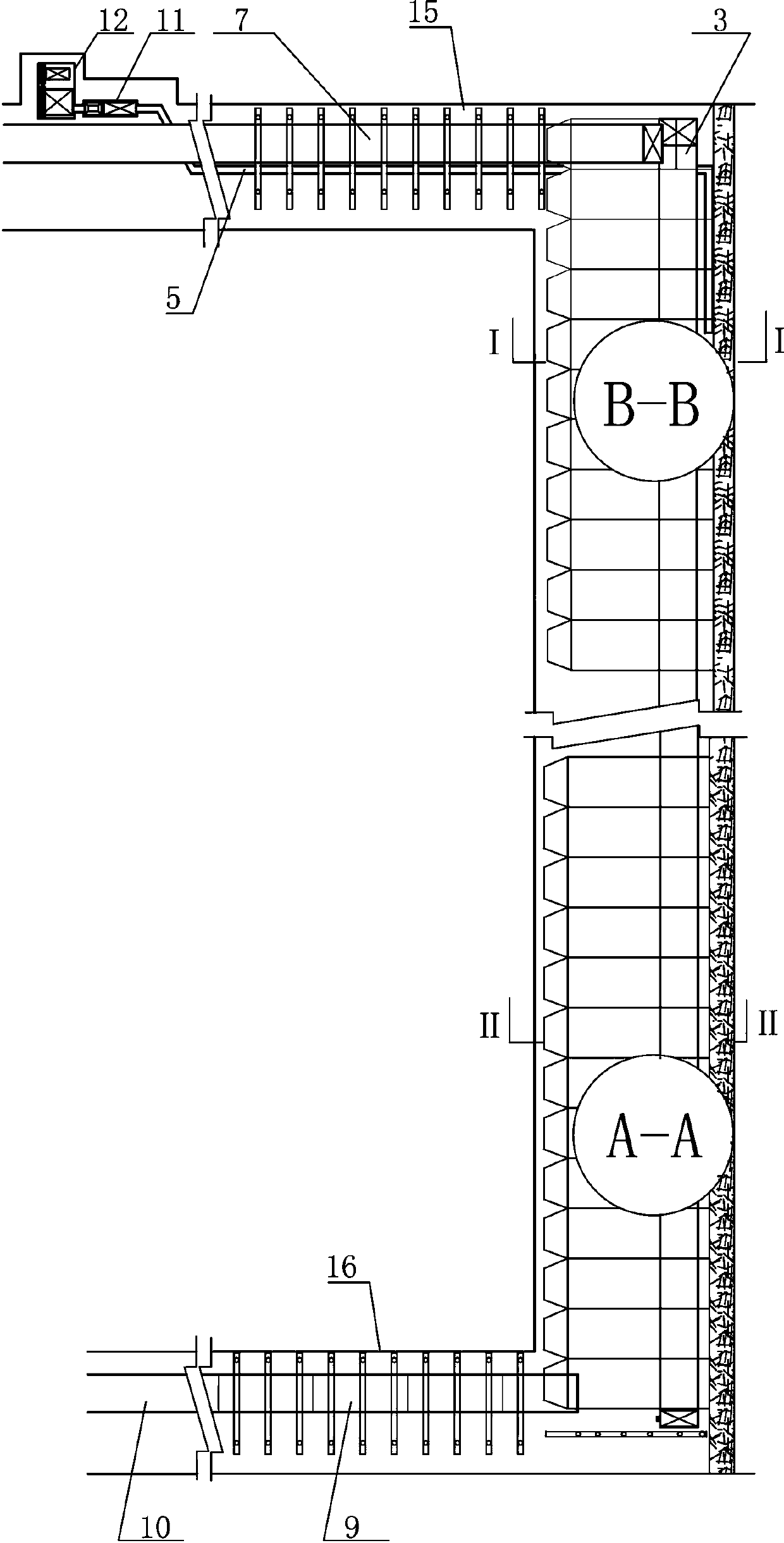

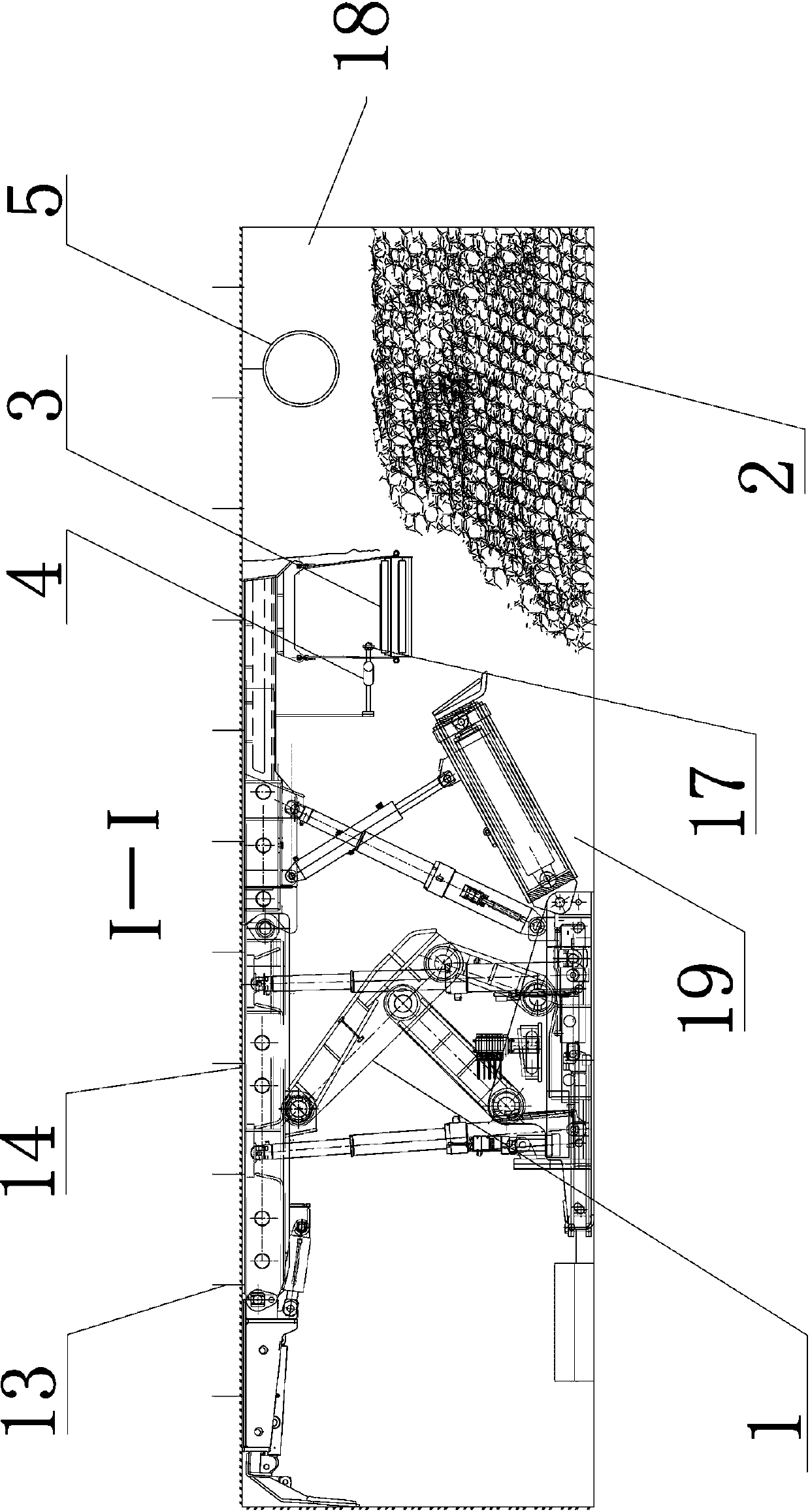

The invention relates to a panel mechanized centralized ore-pass upward horizontal cut-and-filling stoping method. According to the technical scheme, an ore body is divided into panels in stages along the trend, and the panels are divided into chambers and studs at equal intervals according to the trend; a top pillar (17) and a bottom pillar (10) are left; the chambers and the studs are horizontally layered; a sublevel roadway (8), a pulse external slope ramp (2), a stope cross gateway (9) and a panel centralized ore-pass (4) are distributed on the panel lower plate to form a trackless stope preparation system; an upper-stage transverse drift (18) and a lower-stage transverse drift (7) pass through corresponding ventilation filling shaft cross gateway (16) and pedestrian water-filtration patio cross gateway (11) to be communicated with a ventilation filling shaft (15) and a pedestrian water-filtration patio (12) in each chamber or ore pillar. Mechanical mining is adopted, so that all chambers are stoped at the same time, and a mined-out area and the stope cross gateway (9) are filled when every layer is stoped; after the chamber mining is completed, the studs are stoped by using the same method, and the top pillar (17) and the bottom pillar (10) are finally stoped. The panel mechanization-centralized ore-pass upward horizontal cut-and-filling stoping method disclosed by the invention has the advantages of being high in production capability, high in stoping efficiency, simple in stoping process and good in operation safety.

Owner:WUHAN UNIV OF SCI & TECH

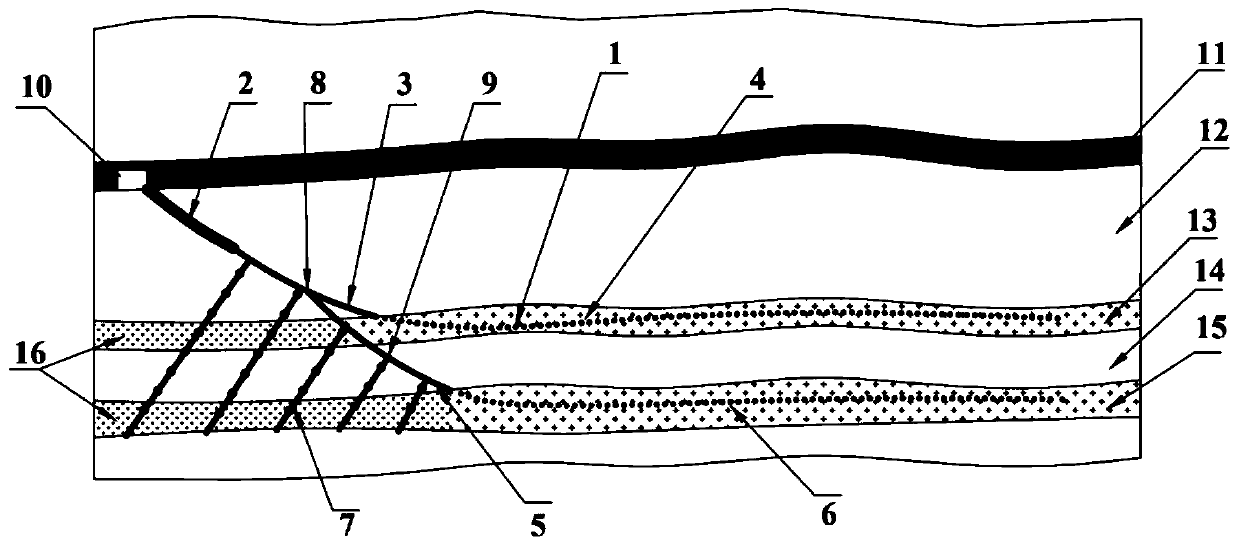

Yolk coal rock formation downward hole pumping and mining pressure relief mash gas construction method

The invention relates to a method for drainaging pressure relief gas construction by a downward borehole in soft coal seam and strata, characterized in that a downward cross-seam borehole is arranged on the roadway segment retained for next sublevel on the mining face of a protecting layer, and the lower covered protecting coal seam is gas pre-drainaged through the downward cross-seam borehole. The construction of the downward cross-seam borehole comprises the following steps: a borehole enlarging segment is formed downwards from the bottom plate of the coal seam of the roadway segment retained for next sublevel, the borehole protection is finished in the inner sleeve in the middle lower part of the borehole enlarging segment, slurry is injected between the outer wall of the inner sleeve and a rock to from a borehole sealing segment, and the further construction of the downward cross-seam borehole is carried out in the inner sleeve. According to the invention, the pressure relief gas of the protecting layer namely the lower covered coal seam is maximally drainaged when the protecting layer is mined, the mining effect of the protecting layer is improved, and the safe stoping of the mining face is ensured.

Owner:HUAINAN MINING IND GRP

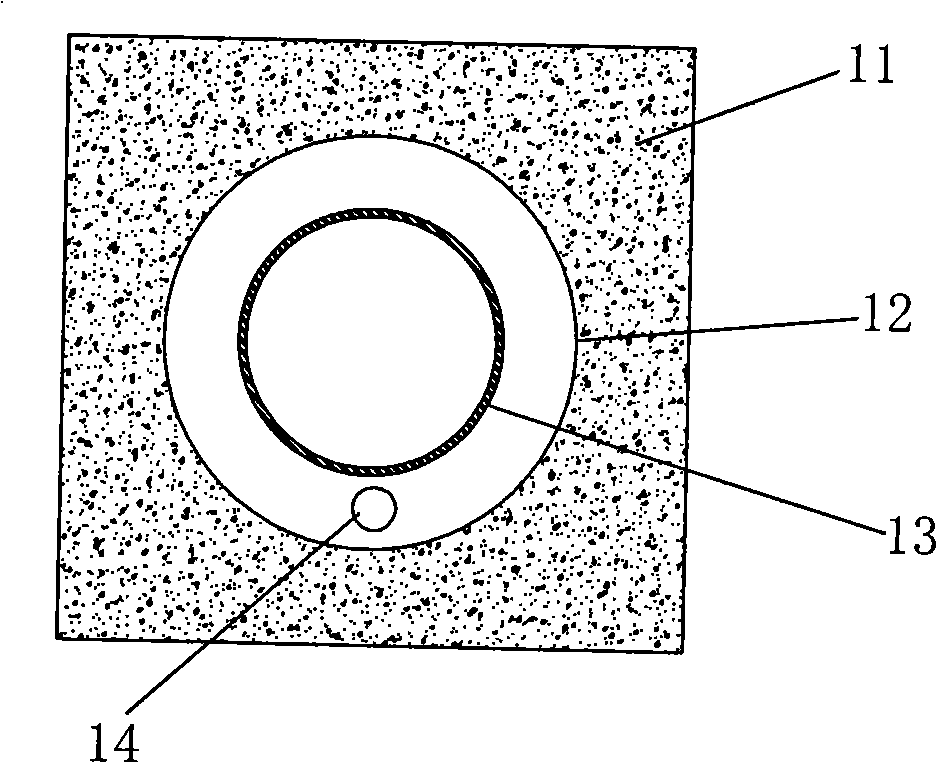

Comprehensive underground test method for deformation and damage of terranes of mining top plate and mining bottom plate of coal bed

ActiveCN101581234AGood for fine graspAccurate determination of damage depth valuesMining devicesSeismology for water-loggingSeismic velocityEngineering

The invention discloses a comprehensive underground test method for deformation and damage of terranes of mining top plate and mining bottom plate of a coal bed, comprising the following steps of: (1) constructing a comprehensive test system; (2) utilizing a network parallel electrical method to synchronously collect test electrode supply current and potential signal in boreholes of the top plate and the bottom plate, thus obtaining the electric field distribution situation between the top plate and the bottom plate of the working face in a control area; (3) respectively extracting the electric field parameter distribution situation of rock masses, the seismic velocity distribution situation and the displacement variation of terranes at different places in the borehole in the control area according to the collected data characteristics of various geophysical fields; (4) dynamically obtaining the parameter change of the geophysical fields in a detected area at different time along with the advancing state of the working face; and (5) completing the installation and sealing of facilities in the tested borehole before the stoping of the coal face. The method precisely masters the damage situation of the rock masses, thus not only delimitating the deformation and damage distribution situation of rock masses in the control area, but also precisely determining the water-guiding fissure zone height of the covered rock masses of the top plate and the damage depth value of the bottom plate.

Owner:张平松 +1

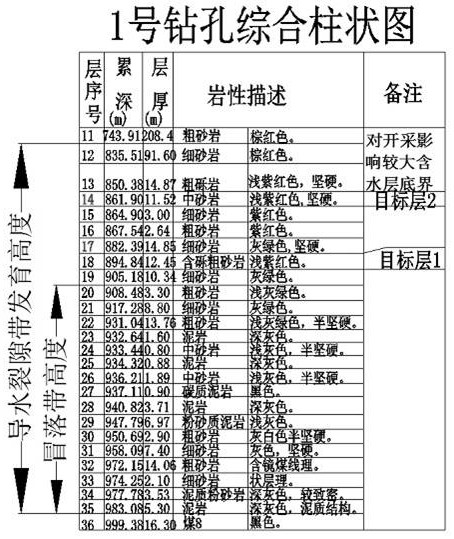

Method for reconstructing floor limestone aquifer into natural-artificial composite integrated aquiclude

ActiveCN104989403AHigh compressive strengthIncrease the critical value of water inrush coefficientUnderground miningSurface miningLimestone aquiferEngineering

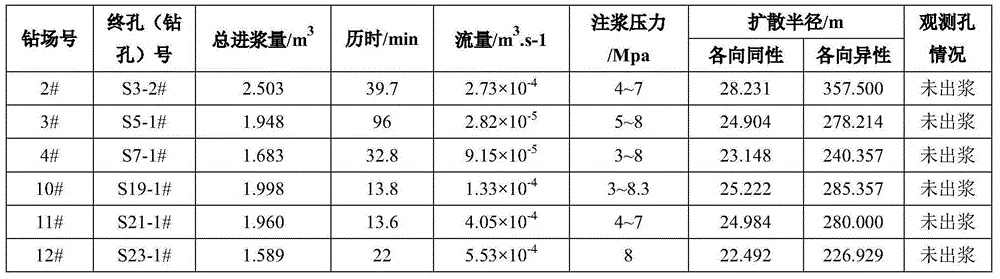

The invention provides a method for reconstructing a floor limestone aquifer into a natural-artificial composite integrated aquiclude. The method comprises the following steps: carrying out research on prevention and treatment of harm of limestone water in a coal seam floor on a working face and determining a target layer for grouting reinforcement; constructing an end hole along the inclination direction of limestone in the target layer; carrying out advanced detection on the target layer via the position of the constructed end hole and subjecting the target layer to grouting reinforcement and reconstruction; and carrying out comparative study on the water-resisting properties of the layer before and after grouting. According to the invention, since the floor limestone aquifer is reconstructed into a natural-artificial composite integrated key water-resisting layer through grouting reinforcement, the integral strength of floor rock and the critical value of a water bursting coefficient are improved, prevention and treatment of hazards of deep high-confined limestone water are realized, and important guarantee is provided for safe stoping of the working surface.

Owner:CHINA COAL XINJI ENERGY CO LTD

Stope face roof water pre-drainage construction method

The invention relates to coal mine underwater treatment technology, in particular to a stope face roof water pre-drainage construction method, which solves the technical problem of treatment of a water-bearing bed on a coal seam of a stope face. As the process of stoping on the stope face includes down stoping firstly and up stoping secondly, stope face roof water is drained in advance through roadways beside the stope face before stoping, a drill site chamber and a water bin are constructed at the lowest position of each of the roadways, two drainage pipelines are paved on each of the roadways, an independent drainage system is utilized, drainage holes are drilled in the drill site chamber towards the stope face roof, and water for drilling is led into the water bin through hoses directly and is drained by the drainage system of the roadways. Since roof water is drained in advance, water inflow during the stoping process is reduced effectively, troubles to production of coal mines due to the roof water are eliminated, affection of flood disaster to production is avoided, a safe and comfortable working environment is provided for the stoping operation, and conditions for stability and high yield of the stope face are created.

Owner:SHANXI JINCHENG ANTHRACITE COAL MINING GRP CO LTD

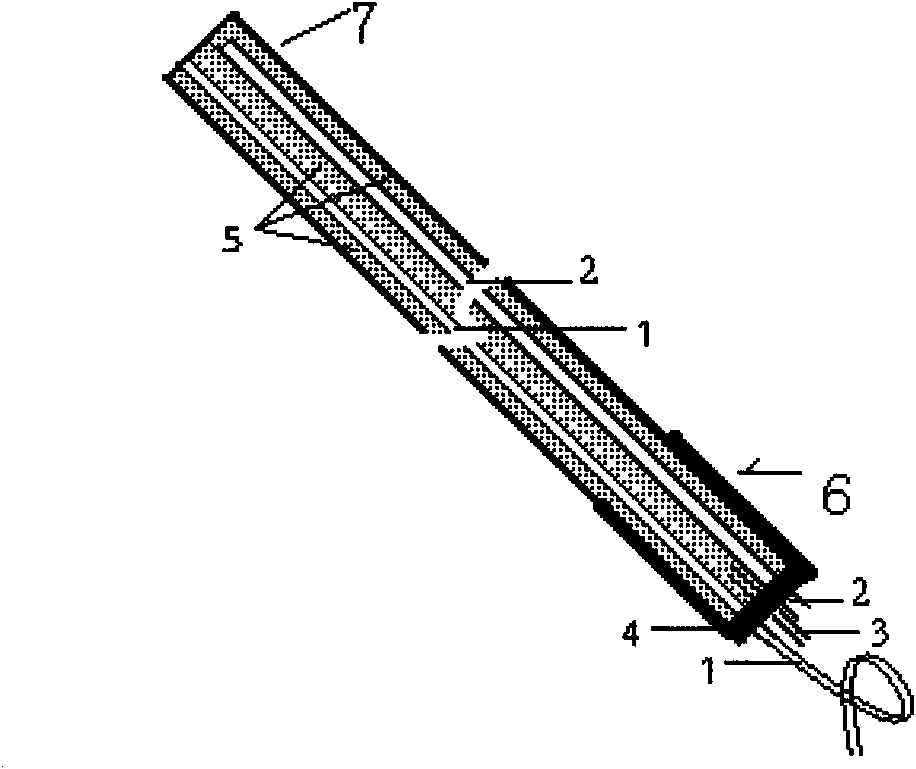

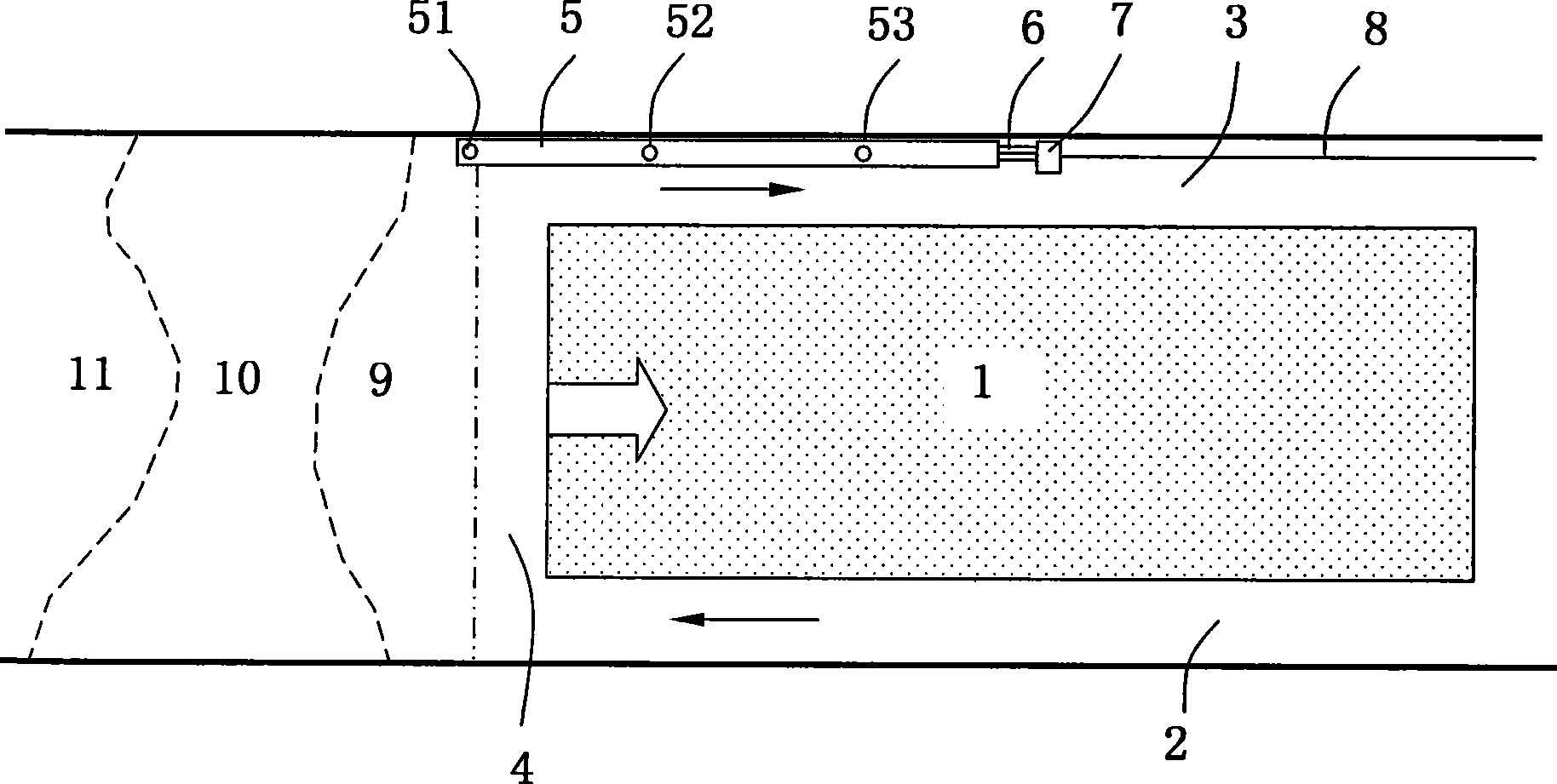

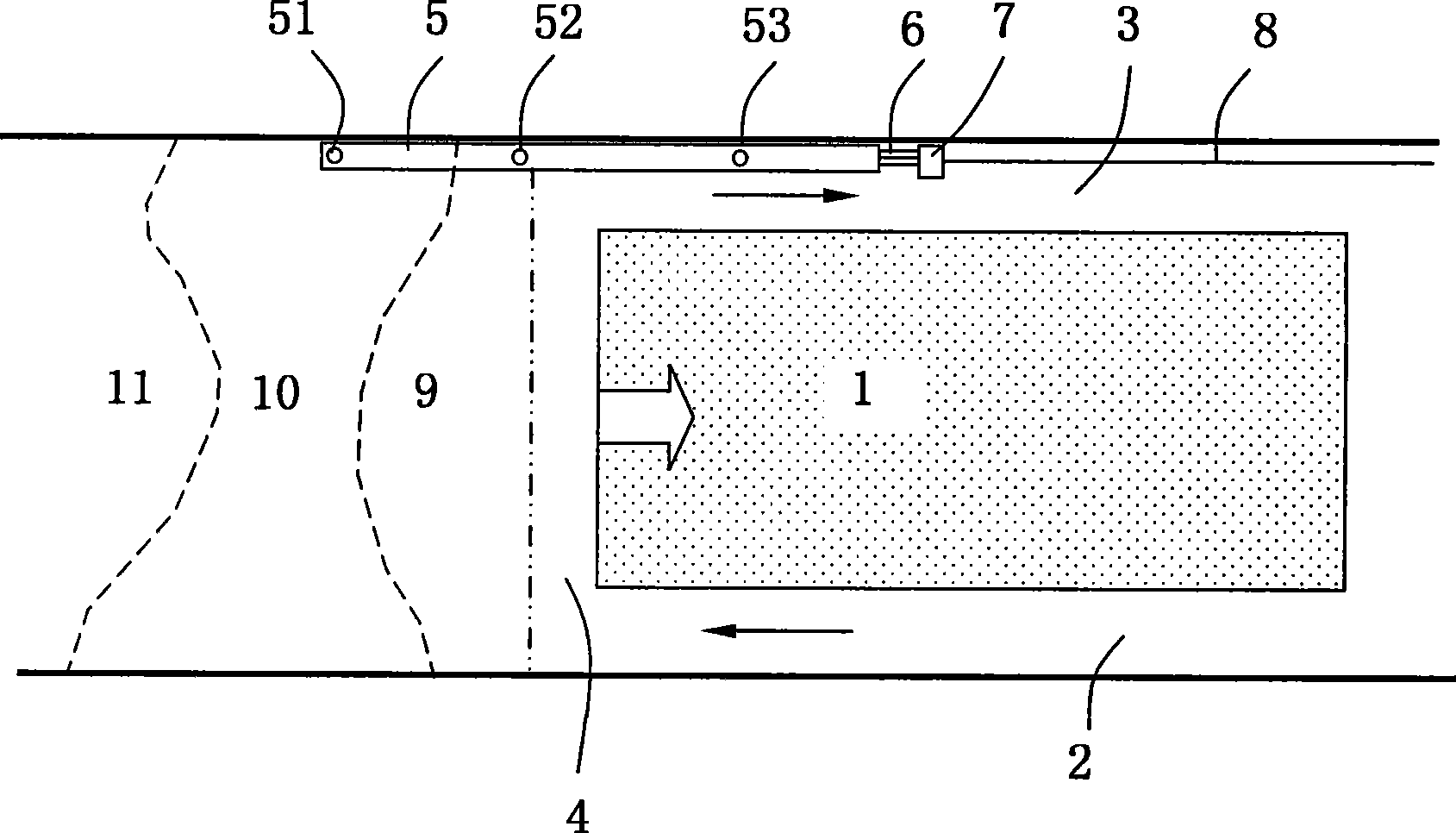

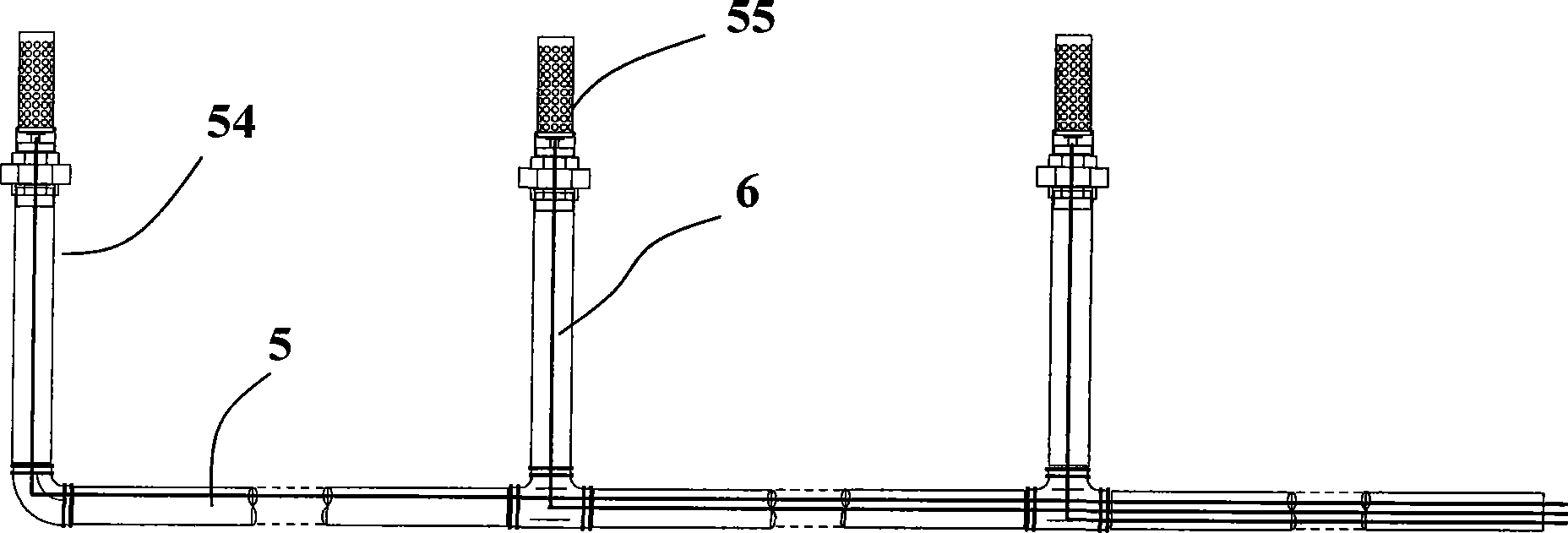

Gas testing method and device for worked-out section of stope of coal mines

The invention relates to a gas detection method and a device thereof in a goaf of stope of coal mines, which can carry out dynamic detection to the gas in the goaf of stope of coal mine. The invention lays a hard protective pipe with a plurality of detection through holes in an air-return gate road of the area of stope of coal mines, and leads the first detection through hole of the hard protective pipe to be positioned at the joint of the goaf and a working face, and gas collecting pipes are positioned in the hard protective pipe and penetrate out respectively from the detection through holes. During detection, the gas collecting pipe corresponding to the first detection through hole is communicated with a gas collecting main pipe so as to collect the gas in the goaf in real time and send the gas to a detection center for analysis. When the stope working face advances for a certain distance, the gas collecting pipe corresponding to the second detection through hole is communicated with the gas collecting main pipe, and a next hard protective pipe is laid after the last gas collecting pipe in the current hard protective pipe finishes the collecting mission, therefore, dynamic detection to the gas in the goaf can be realized.

Owner:XIAN UNIV OF SCI & TECH +1

Method for preventing and treating separation layer water of top plate of coal face

ActiveCN102943690AEffective releaseAvoid delamination water damage accidentsDrainageEngineeringStoping

The invention relates to a method for preventing and treating separation layer water of a top plate of a coal face. The method is characterized in that a drainage lane is constructed on a lower side of the coal face in the stoping direction and is at a position a preset distance away from the outer side of a lane; when the distance that a working face advances equals to a preset value of a caving step pitch, a plurality of separation layer water drainage holes are constructed from the drainage lane to a mined out space; orifice pipes are arranged on all the drainage holes, and the outlet water pressure of the pipe openings are detected; when separation layer water is drained through the drainage holes, the working face continues to advance forwards; and according to the indication of outlet water pressure of the pipe openings, the higher the pressure is, the more the drainage holes are, so as to ensure that before the working face advances to the caving step pitch, the outlet water pressure of the pipe openings is not more than 0.2 MPa. After the method provided by the invention is adopted, separation layer water can be drained effectively, so that accidents of damage of separation layer water can be avoided; and meanwhile, stoping of the working face and drainage of the separation layer water do not conflict, so that continuous and safe stoping of the working face can be realized.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

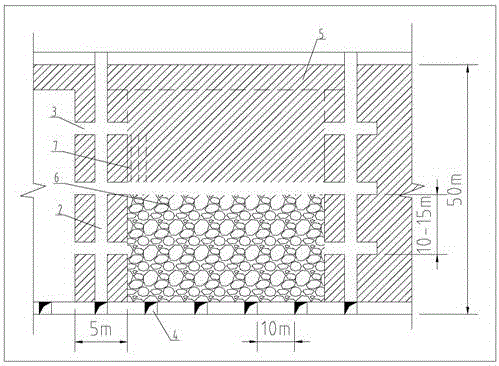

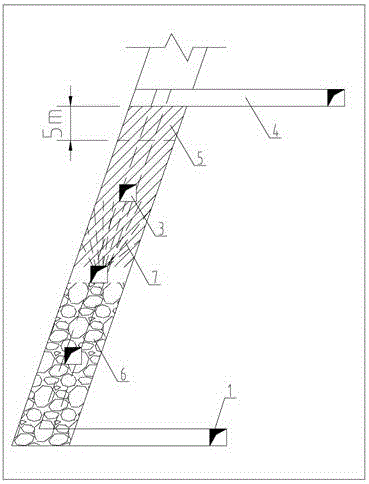

Mining method with residual ore recovery function

InactiveCN104895566AImprove operational safetyImprove mining efficiencyUnderground miningSurface miningShotcreteStoping

The invention belongs to the technical field of mining, and further discloses a mining method with a residual ore recovery function. The mining method comprises the following steps: reserving a safety pillar which is in the thickness range of 5-15 m on the hanging side of the residual ore; dividing the ore body into continuous stoping units, completing stoping and filling, and then stoping the next stoping unit, wherein the stoping units comprise three continuous ore beds, namely the higher slice, the middle slice and the lower slice; preferably stoping the higher slice, and then sequentially stoping the middle slice and the lower slice; under the situation that complete stoping is finished, performing filling; after stoping the ore body of the higher slice, adopting concrete spraying support, anchor-plate retaining or anchor-plate retaining and bolt-connected chain support for supporting the pit, and utilizing the feed path as a compensation space, stoping the ore bodies of the two lower slices from the other side cross heading, after the ore bodies of the higher slice, the middle slice and the lower slice are mined, performing filling. The mining method with the residual ore recovery function is a safe and efficient filling mining method, can realize efficient recovery of residual ore, and can ensure both the mining efficiency and the safety.

Owner:WUHAN UNIV OF SCI & TECH

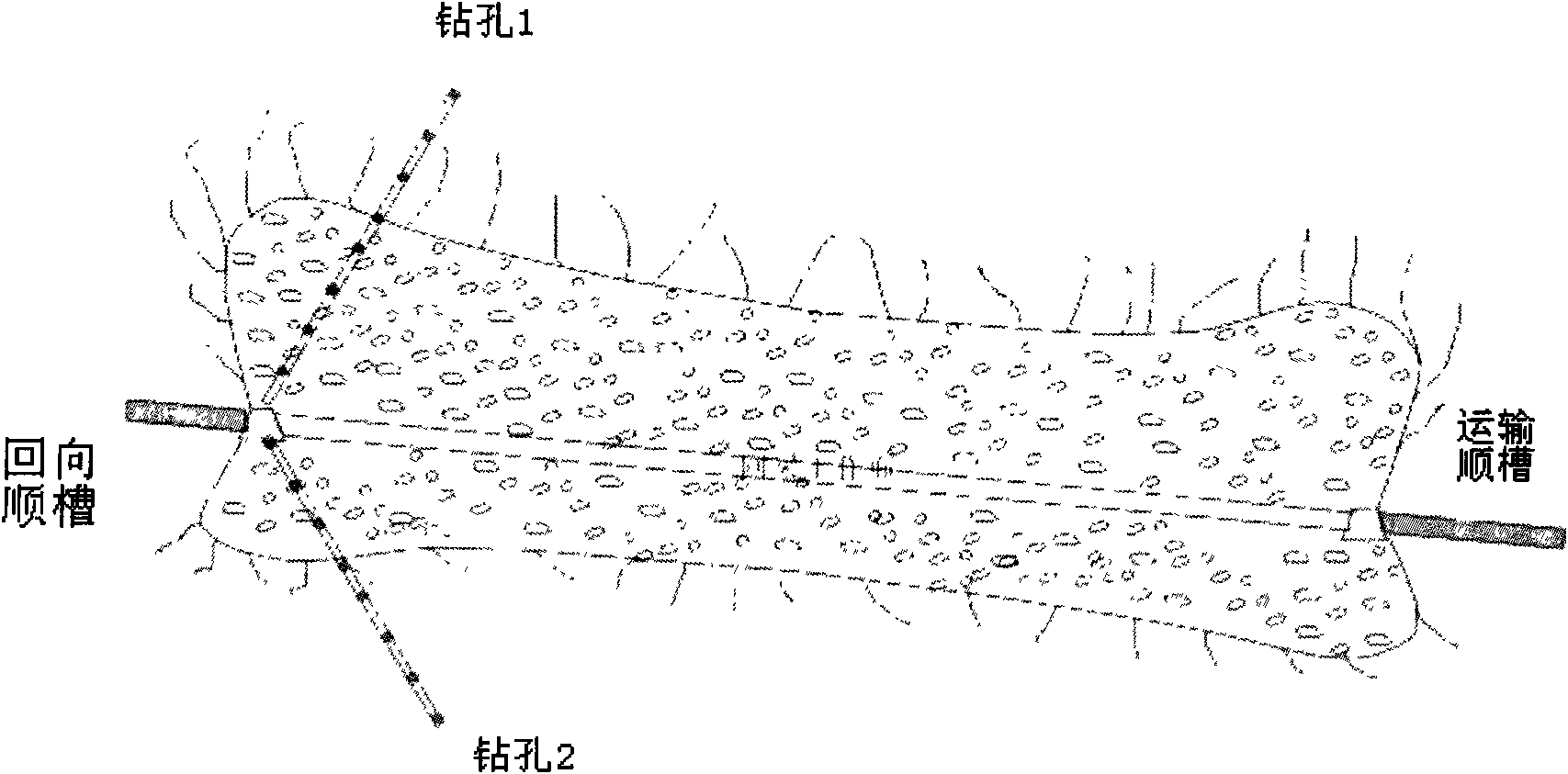

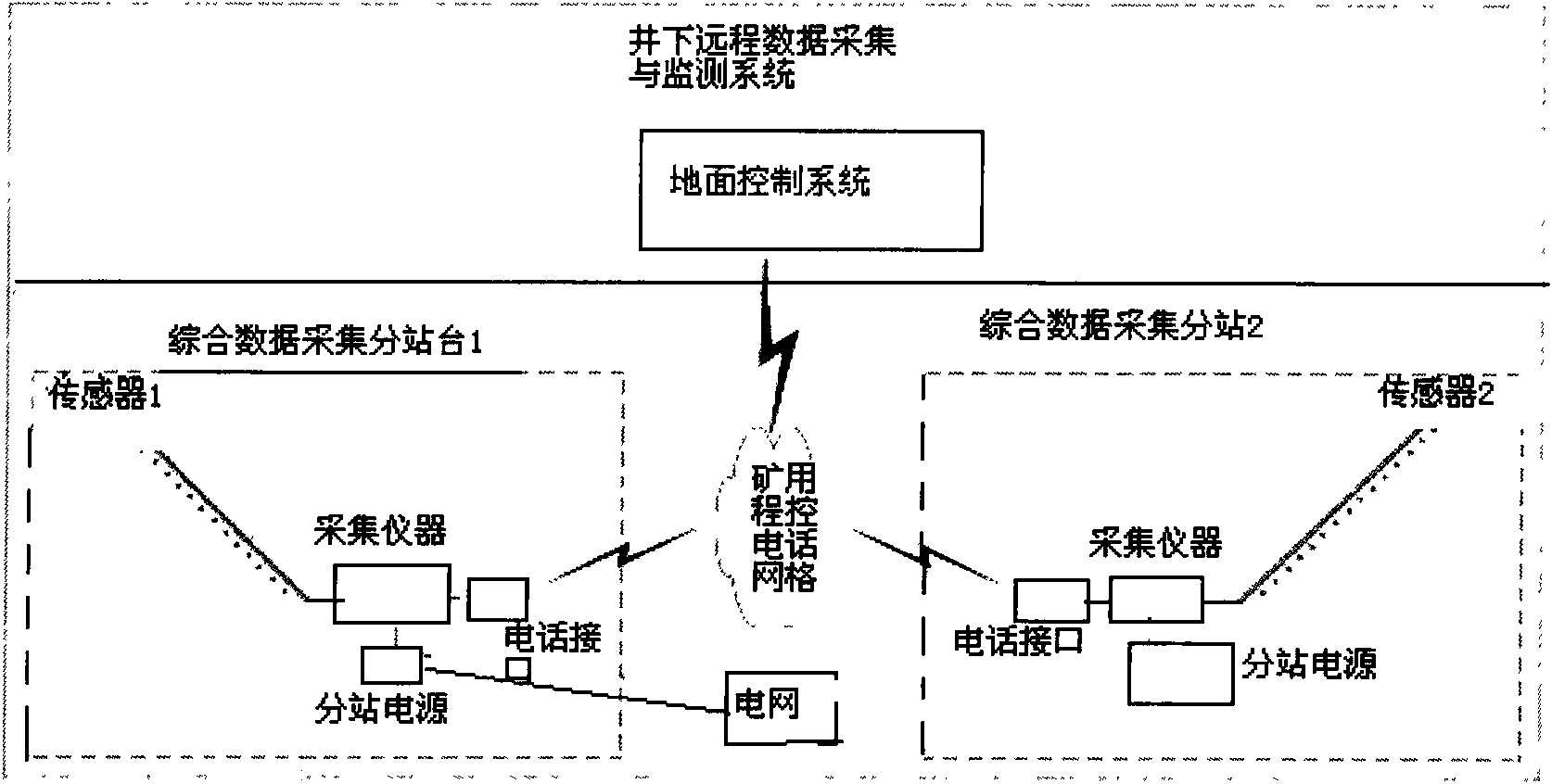

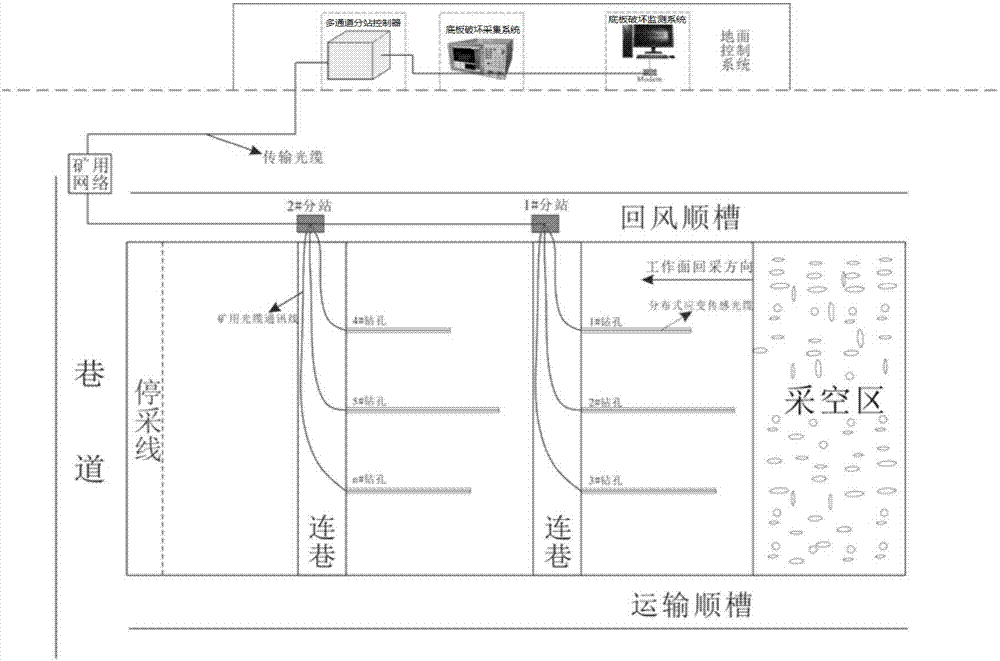

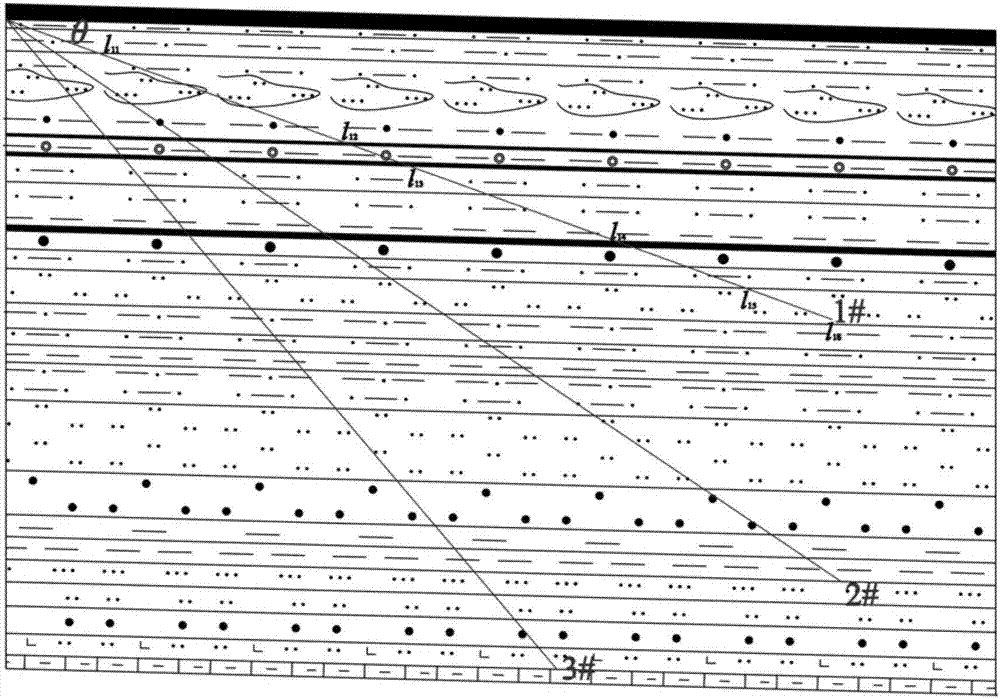

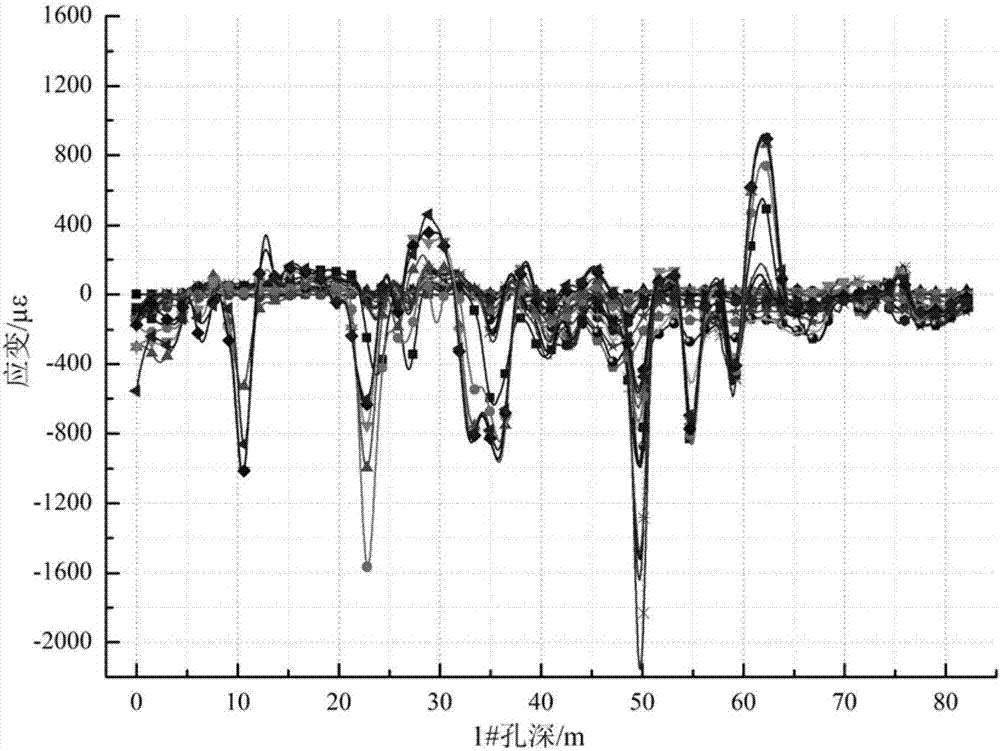

Real-time monitoring and prewarning system and method for damage depth of coal seam floor of stope face

ActiveCN107387166AGuaranteed safe miningImprove accuracyMining devicesData acquisitionStructural engineering

The invention discloses a real-time monitoring and prewarning system and method for the damage depth of a coal seam floor of a stope face. The system comprises a plurality of drill holes formed in the working face of each connected lane. Distributed strain sensing cables are separately buried in all the drill holes. A plurality of data acquisition substations are arranged in an air return way in a mine. The strain sensing cables in all the connected lanes are connected with the corresponding data acquisition substations separately. The data acquisition substations are connected with one another through cables and then are connected with a multi-channel substation controller through a mining network. A monitoring station is connected with the multi-channel substation controller through a strain acquisition instrument. Strain data of all the drill holes are acquired by the multi-channel substation controller, dynamic acquisition, processing and early warning explaining operation of the strain data volume of the floor rock stratum of the whole region of the working face are conducted in real time, the destructive growth depth of a floor in the working face is monitored in real time through the strain change of a rock stratum, and the water inrush prediction of the floor of the working face is improved.

Owner:ANHUI UNIV OF SCI & TECH

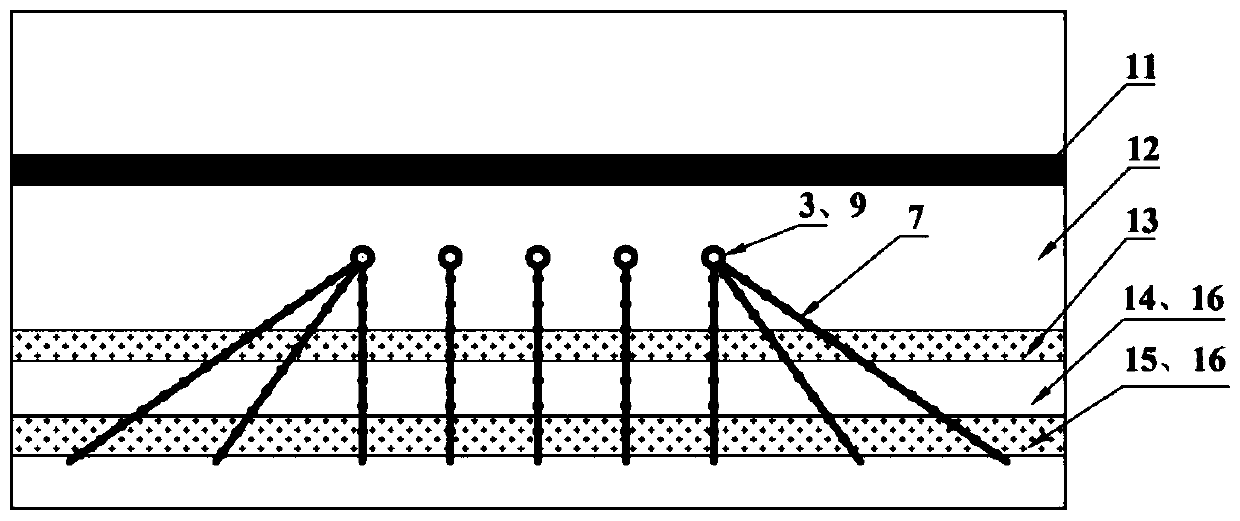

Medium-length hole ore breaking synergistic anchor cable support subsequent filling mining method of combined reconstructed structural body

ActiveCN103437769AGuarantee of technical problems in safe and efficient miningSafe and efficient miningUnderground miningSurface miningEngineeringStoping

The invention discloses a medium-length hole ore breaking synergistic anchor cable support subsequent filling mining method of a combined reconstructed structural body. The method adopts downward type sublevel stoping, and comprises the following steps: firstly, excavating a top cut heading way in a hanging wall surrounding rock; building an artificial roof (reserved with a fill raise) along the ore body striking direction by adopting smooth blasting after top cut is completed; excavating a multifunctional roadway integrating the functions of rock drilling, supporting and ore removal along the ore body striking direction in the hanging wall surrounding rock; and arranging fan-shaped blast holes by medium-length holes, and arranging a surrounding rock grouting reinforcement and anchor cable support hanging wall project by utilizing the medium-length holes at the same time to integrate surrounding rock grouting reinforcement, ore breaking by blasting and anchor cable support. By adopting retreat type stoping and ore removal by a scraper, the method realizes safe, efficient and large-scale stoping of ore bodies. The mining method is suitable for mining the inclined ore bodies with surrounding rocks which are evenly and stably distributed, and has the characteristics of being small in stope preparation work amount, safe and reliable to operate, high in stoping efficiency, etc.

Owner:CENT SOUTH UNIV

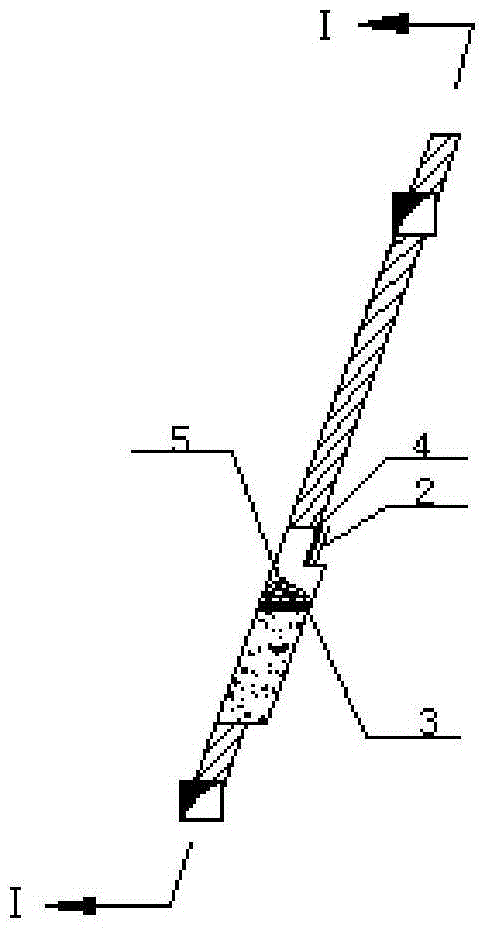

Presplitting type wall cutting and filling stoping method for thin ore vein

InactiveCN105735996AReduce mining dilution rateReduce stacking pressureUnderground miningBlastingSocial benefitsEconomic benefits

The invention discloses a presplitting type wall cutting and filling stoping method for a thin ore vein. The presplitting type wall cutting and filling stoping method for the thin ore vein comprises the steps that a presplitting hole is drilled in the interface of the thin ore vein and surrounding rock on the hanging side or heading side of the wall to be cut, presplitting blasting is conducted, the ore vein and the surrounding rock of the cut wall are blasted at different times, and ore drawing or filling is conducted independently; and all the steps are circulated till a whole ore block is extracted. Simultaneous millisecond blasting is conducted on the presplitting hole and an ore body blasted in the early stage or the surrounding rock of the cut wall, namely the presplitting hole is blasted firstly and then the ore body or the surrounding rock of the cut wall is blasted. After ore drawing (under the condition that mining is conducted firstly) or filling (under the condition that wall cutting is conducted firstly), secondary blasting of the surrounding rock is conducted for on-site filling or the ore body is blasted for ore drawing. All the steps are circulated till the whole ore block is extracted. According to the presplitting type wall cutting and filling stoping method for the thin ore vein, by introducing the presplitting blasting technique into the wall cutting and filling method, separate stoping of ore and wall rock of the thin ore vein is achieved in the true sense, the dilution rate of extraction of the thin ore vein is greatly decreased, and the probability of breakage and cost increase which are caused by excessive dilution of ore is lowered; in addition, the mineral separation technological index can be improved easily, the tailing stacking pressure is relieved, and high economic benefits and social benefits are achieved.

Owner:CENT SOUTH UNIV +1

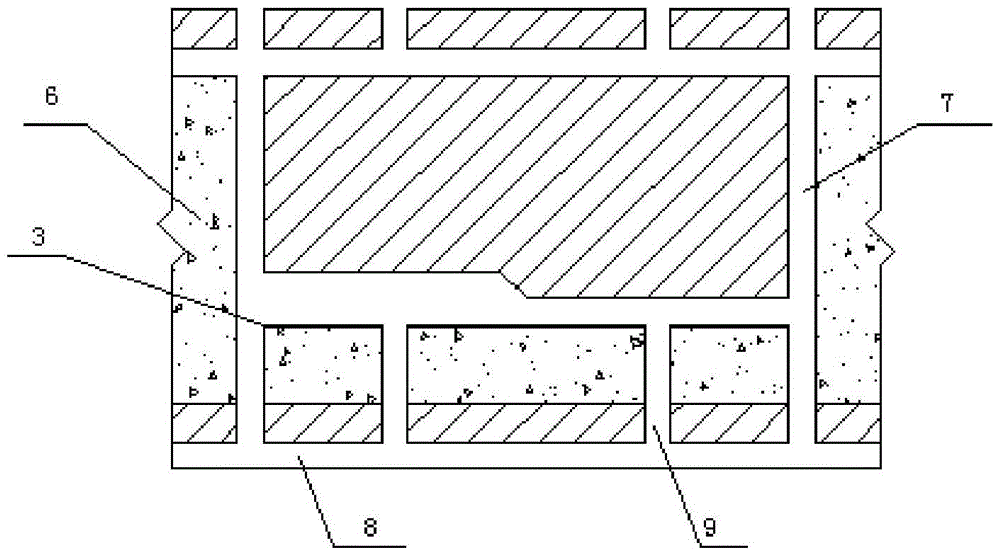

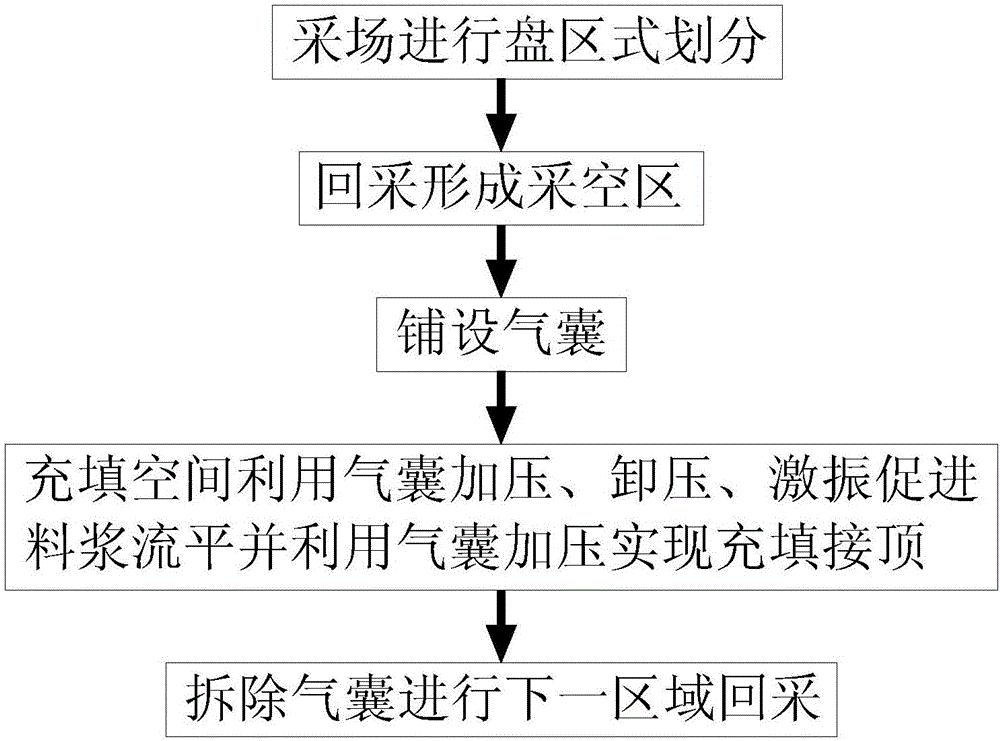

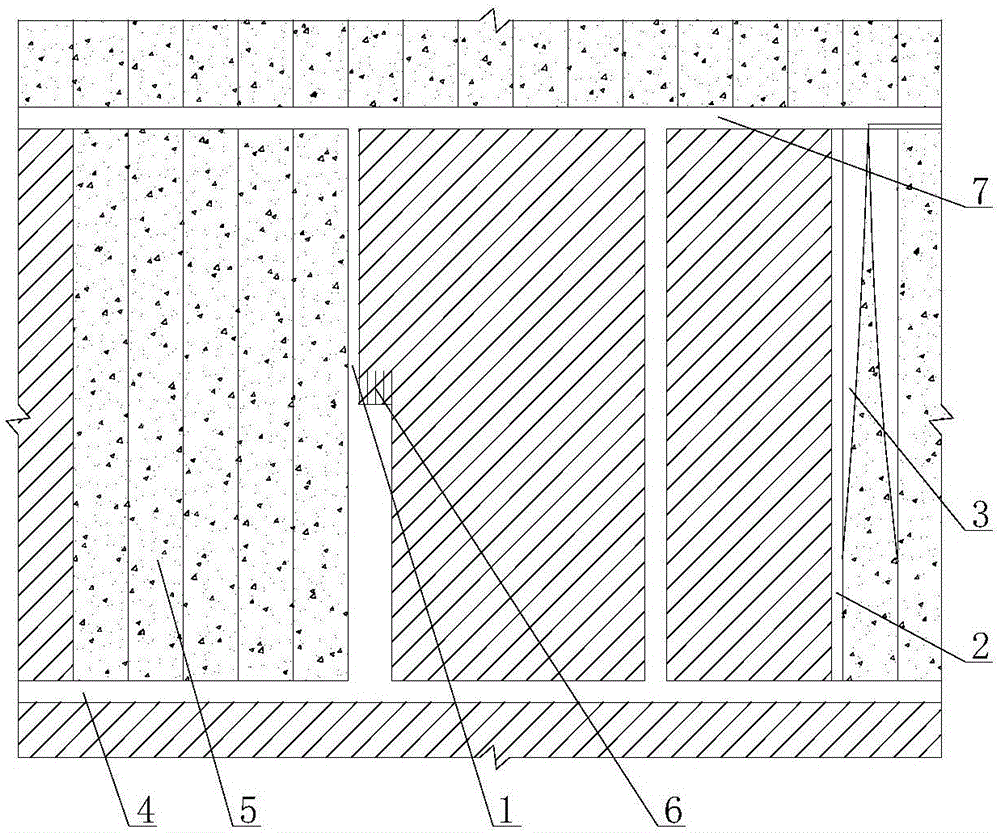

Separation-wall-free initiative top filling wall type filling mining method

ActiveCN106382118AImprove early strengthHigh strengthUnderground miningSurface miningSlurryEngineering

The invention discloses a separation-wall-free initiative top filling wall type filling mining method. Panel type division is adopted; in a panel, a cutting roadway is used as a mining starting line to carry out lateral back-stoping; after the back-stoping, a goaf is formed; in a process of filling the goaf, the goaf is divided into a reserved cutting roadway and a filling space by adopting an airbag; a filling bag is laid in the filling space and filling slurry is conveyed by a pipeline and is used for filling; in a filling process, the leveling of the slurry is accelerated through manners of pressurizing, releasing pressure or exciting oscillation by the airbag; after the filling space is fully filled with slurry, the inner part of the airbag is pressurized before the filling slurry is finally set, so that the airbag is expanded and the filling slurry is squeezed, and furthermore, the filling slurry is compacted and initiative complete top filling is realized; in the next cycle of back-stoping, the reserved cutting roadway of the airbag is used as the mining starting line to mine. The initiative top filling of a filling body is realized and the consumption of the materials is less; the used airbag can be repeatedly used and cyclic utilization of resources can be realized. The separation-wall-free initiative top filling wall type filling mining method is applicable to mining of slowly inclined and inclined thin veins or safe, continuous and efficient mining of large and thick ore bodies.

Owner:CHINA MINMETALS CHANGSHA MINING RES INST

Mining area self-reserved roadway non-pillar mining method suitable for gently inclined coal seam

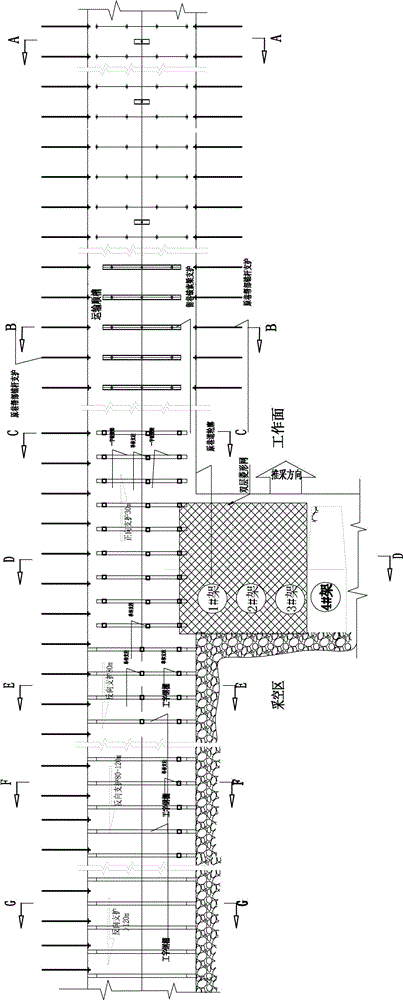

ActiveCN107725053AReduce excavation costsSave resourcesUnderground miningSurface miningCoal pillarStoping

The invention discloses a mining area self-reserved roadway non-pillar mining method suitable for a gently inclined coal seam. The method comprises the following steps of determining the exploitationrange for gob-side entry retaining without coal pillars in a coal mine, forming openings at main roadways, tunneling two mining area roadways and an air return roadway of a first-mining working face,and widening a crosscut to connect with a main air return roadway; connecting the three roadways and the crosscut, so as to form a preparation roadway and an air ventilation system of the mining area, which is the main feature of the method. The method is characterized in that the open-off cut is performed on a first working face, and various production systems are arranged; the stoping is performed on the first working face, and a gob-side entry retaining technique is used for remaining the roadway with a certain width as a transportation roadway of a second working face; the stoping is performed on the second working face, and the roadway with a certain width is remained as an air return roadway of a third working face; the steps are repeated for the subsequent working faces. The methodis used for realizing the stoping without roadway tunneling and coal pillars in the mining area.

Owner:SHANDONG UNIV OF SCI & TECH

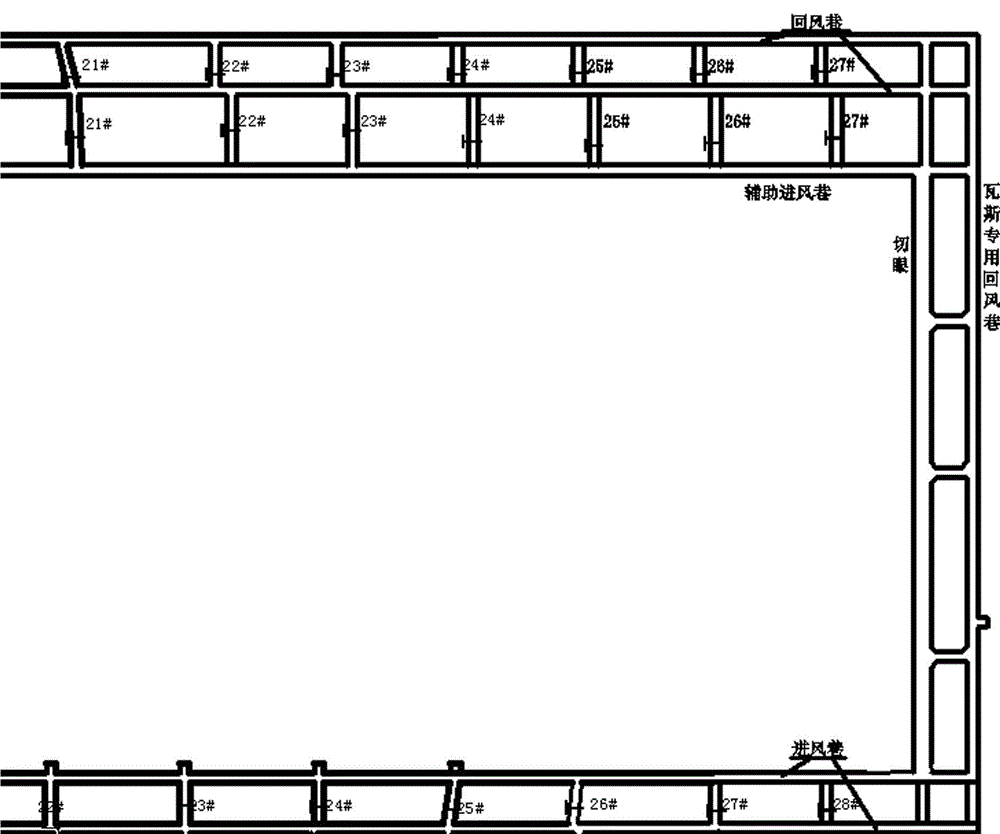

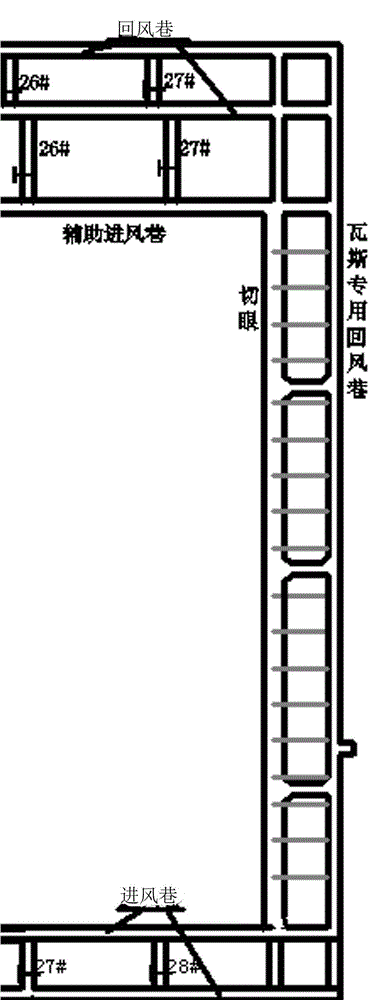

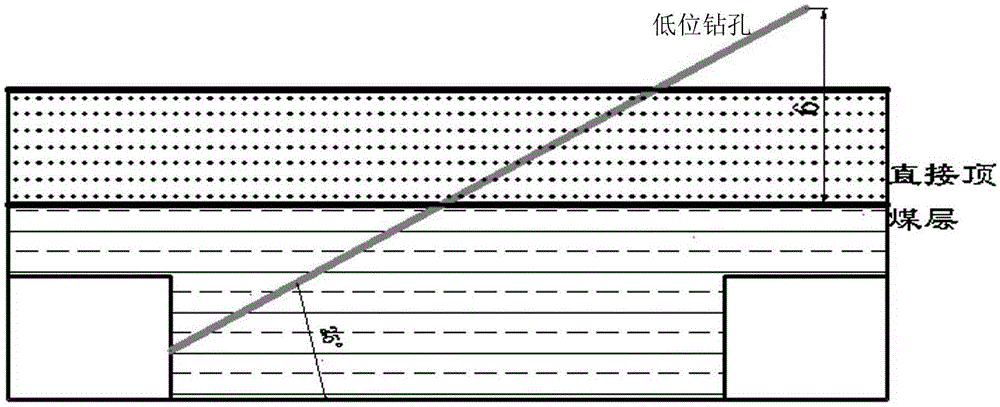

Drill hole layout method for gas extraction during primary mining and stoping of large mining height fully-mechanized face

The invention relates to a drill hole layout method for gas extraction during primary mining and stoping of a large mining height fully-mechanized face and mainly aims at solving the problem of transfinite gas during primary mining and stoping of the large mining height fully-mechanized face. A technical scheme of the drill hole layout method is as follows: low-position drill holes are formed in a gas special return airway of the fully-mechanized face mainly for extracting residual coal gas of a primary mining section; aiming at a problem that high-position drill holes do not function during primary mining, medium-position drill holes are formed for extracting goaf gas; aiming at a problem that the gas of adjacent coal seams rushes into the working face during primary mining and stoping of the working face, low adjacent layer gas stopping drill holes are formed and high-position drill holes are formed for extracting the goaf gas during normal stoping of the working face; the goaf gas is extracted orderly and continuously through the low-position holes, the medium-position holes and the high-position holes and the lower adjacent layer decompression gas is extracted through bottom-plate stopping holes; as a result, the gas extraction amount and the utilization rate of the gas are increased; moreover, a gas emission rate of the goaf is reduced; a windblown gas pressure is reduced; an advancing speed of the working face is increased and a coal yield is increased.

Owner:SHANXI JINMEI GRP TECH RESEACH INST +1

Technology for preventing and treating coal seam roof water damage through dynamic pressure maintaining grouting blocking fissures of horizontal long drill holes in mining fractured zone

InactiveCN112392431AReduce water lossMitigate the threat of water damageSealing/packingSlurryStoping

The invention discloses a technology for preventing and treating coal seam roof water damage through dynamic pressure maintaining grouting blocking fissures of horizontal long drill holes in a miningfractured zone, and relates to the technical field of stope face safety of coal mines with roof water damage. At present, domestic roof water damage prevention and control technologies mainly comprisegoaf filling, strip mining, thickness-limited mining, drainage, static grouting and the like, and great limitations exist in deep water-rich extra-thick coal seam mining, such as waste of a large number of resources, high cost and unsatisfactory water control effect. According to hydrogeology of a mining area and development characteristics of the height of a mining overlying strata water diversion fractured zone under specific mining conditions, a reasonable target layer is selected, the horizontal long drill holes are formed, slurry meeting the requirements of the technology is selected, and along with mining of a working face, the horizontal long drill holes in the mining fractured zone dynamically block fissures in a pressure maintaining mode to prevent and treat coal seam roof waterdamage.

Owner:陈存强 +1

Continuous stoping and filling mining method for gently inclined medium-thick ore body

ActiveCN108104869AHigh degree of mechanizationIncrease production capacityMaterial fill-upMineralogyStoping

The invention provides a continuous stoping and filling mining method for a gently inclined medium-thick ore body and belongs to the technical field of mining. According to the continuous stoping andfilling mining method, the gently inclined medium-thick ore body is divided into sections in the vertical direction, the ore body is divided into stoping units, the stoping units are divided into strips in the moving direction of the ore body, separation pillars are reserved between the adjacent strips in the moving direction of the ore body, inclined ramps are excavated in the separation pillars,and stope connection roadways are excavated along the inclined ramps; the strips in the same stoping unit are divided into six first-step stopes and six second-step stopes, interval stoping is conducted on the stopes in the same stoping units, stoping is conducted on the first-step stopes firstly, then the first-step stopes are filled, and after filling body curing reaches the specified time, stoping is conducted on the second-step stopes; and after several adjacent stoping unit ore main bodies are completely mined and the stopes are filled, the stoping is conducted on the separation pillars,top safety pillars and bottom safety pillars between the stoping units. According to the continuous stoping and filling mining method, the mechanical degree is high, the production capacity is high,the ore stoping rate is high, the ore dilution rate is low, and safety is good.

Owner:UNIV OF SCI & TECH BEIJING +1

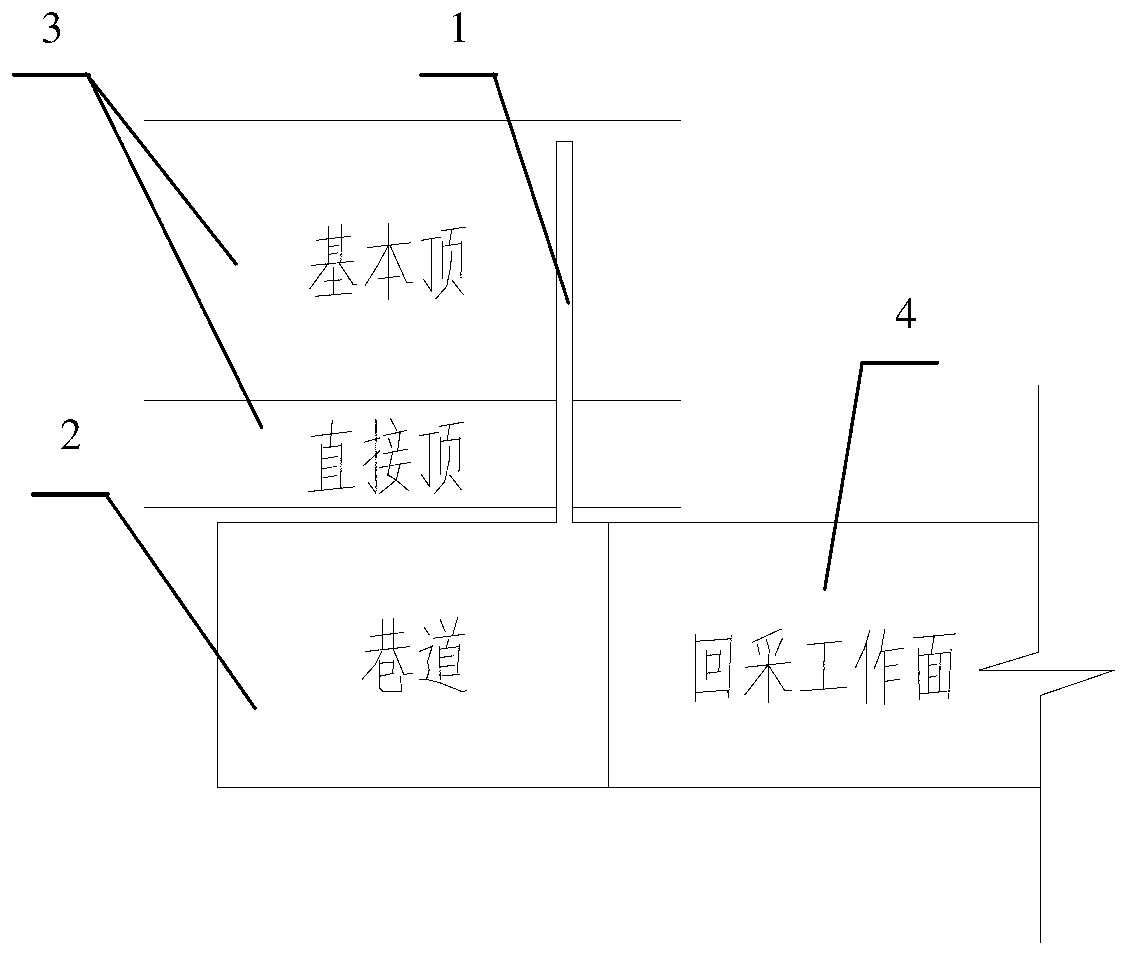

Gob-side entry retaining mining support process method

ActiveCN104061001AImproving the safety environment of lane keeping operationImprove resource recoveryUnderground chambersTunnel liningStopped workEngineering

The invention discloses a gob-side entry retaining mining support process method. The method comprises the following steps: I, performing mining entry retaining reinforcement or roadway driving entry retaining reinforcement primary support; II, performing advance support on the end of the entry retaining side of a stoping work face, and adopting beeline-shaped beams and single hydraulic pillars in advance segment support like an advance support method adopted in ordinary stoping, wherein the differences lie in that 1, the advance support length in entry retaining is 5 meters greater than a length required in a specification, namely, the normal mining length is 25 meters while the entry retaining mining length is 30 meters; 2, longitudinal beeline-shaped beams are changed into transverse beeline-shaped beams, namely, the beeline-shaped beams are arranged along the work face instead of a roadway; III, performing double-net support on No. 1 to No. 3 frames on the stoping work face; IV, preserving roadway support; V, forming a natural false edge on the side of an entry retaining stoping side, wherein along with the continuous forward movement of the work face, the direct top in a stoping region collapses, dropping gangues naturally roll onto a diamond mesh behind the No. 1 to No. 3 frames at the end, and rocks covering the mesh drop naturally under the action of deadweights.

Owner:BINHU COAL MINE ZAOZHUANG MINING GRP

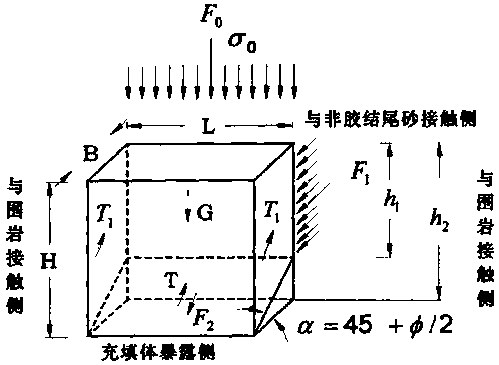

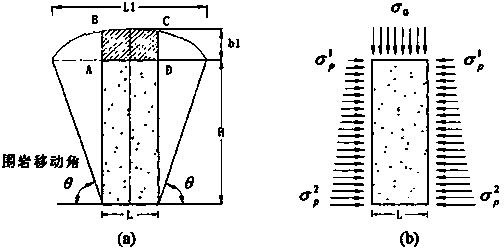

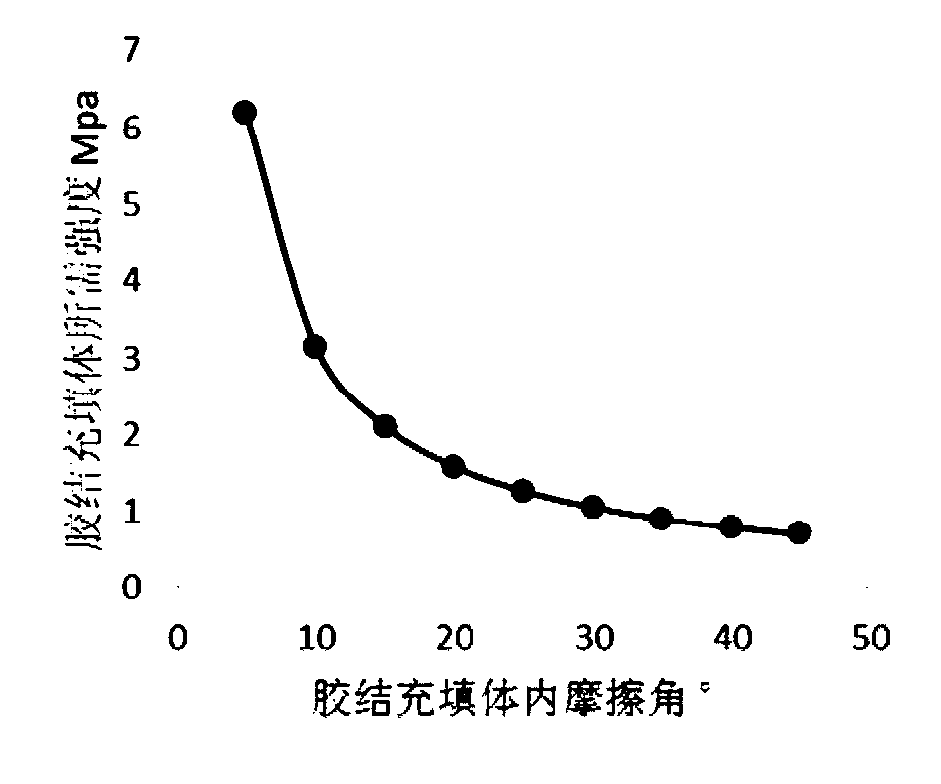

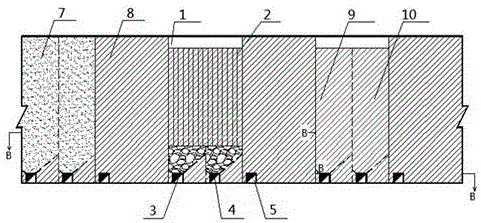

Construction method of large-volume-filling-body strength model of two-step open-stope subsequent-filling

ActiveCN107918712AHigh strengthSolve the disadvantages of solving the required strength of cemented filling bodyDesign optimisation/simulationSpecial data processing applicationsMineral SourcesVolume filling

Owner:YUXI MINING +1

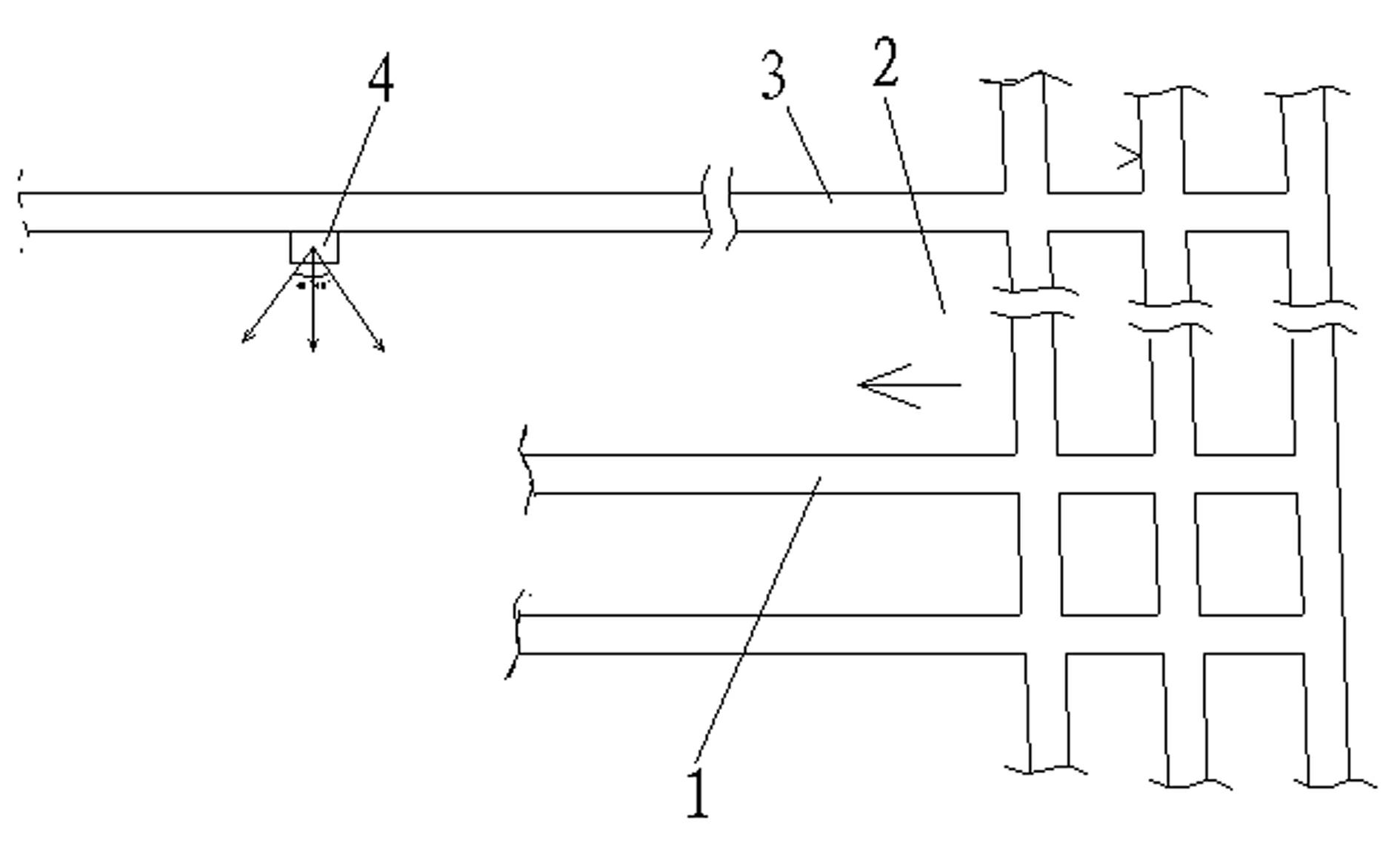

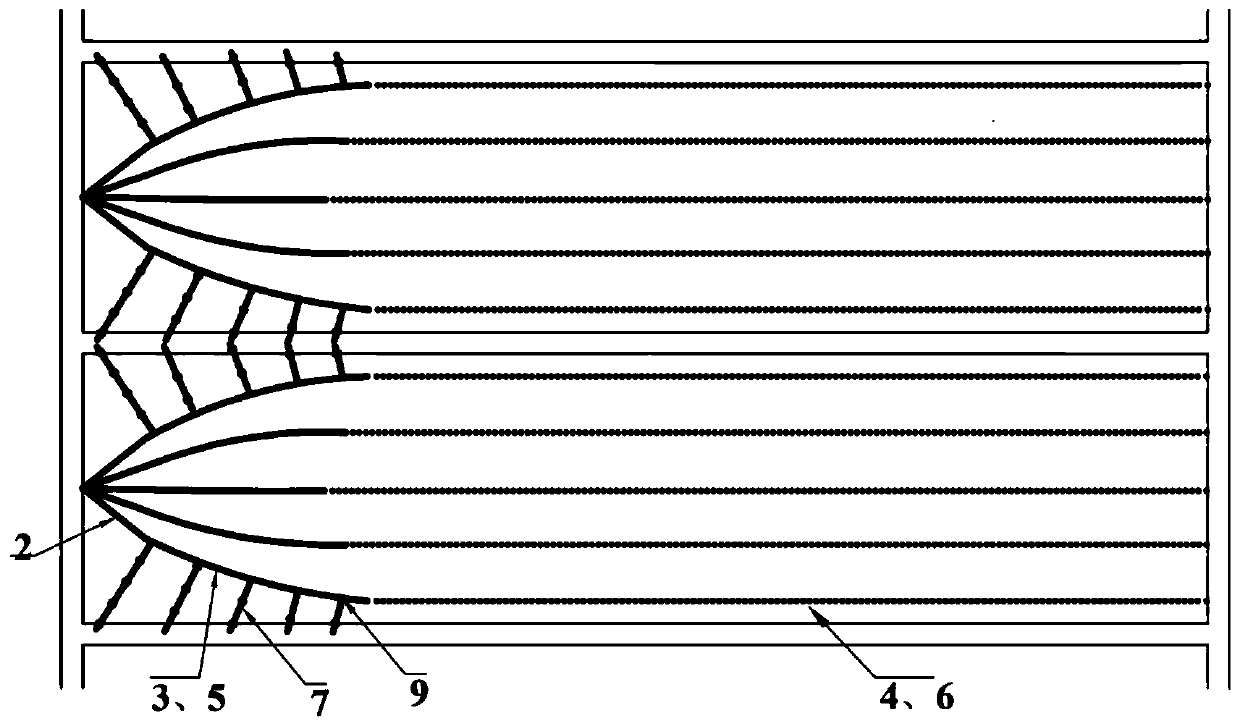

Novel method for collaboratively exploiting underground double stopes of underground mine

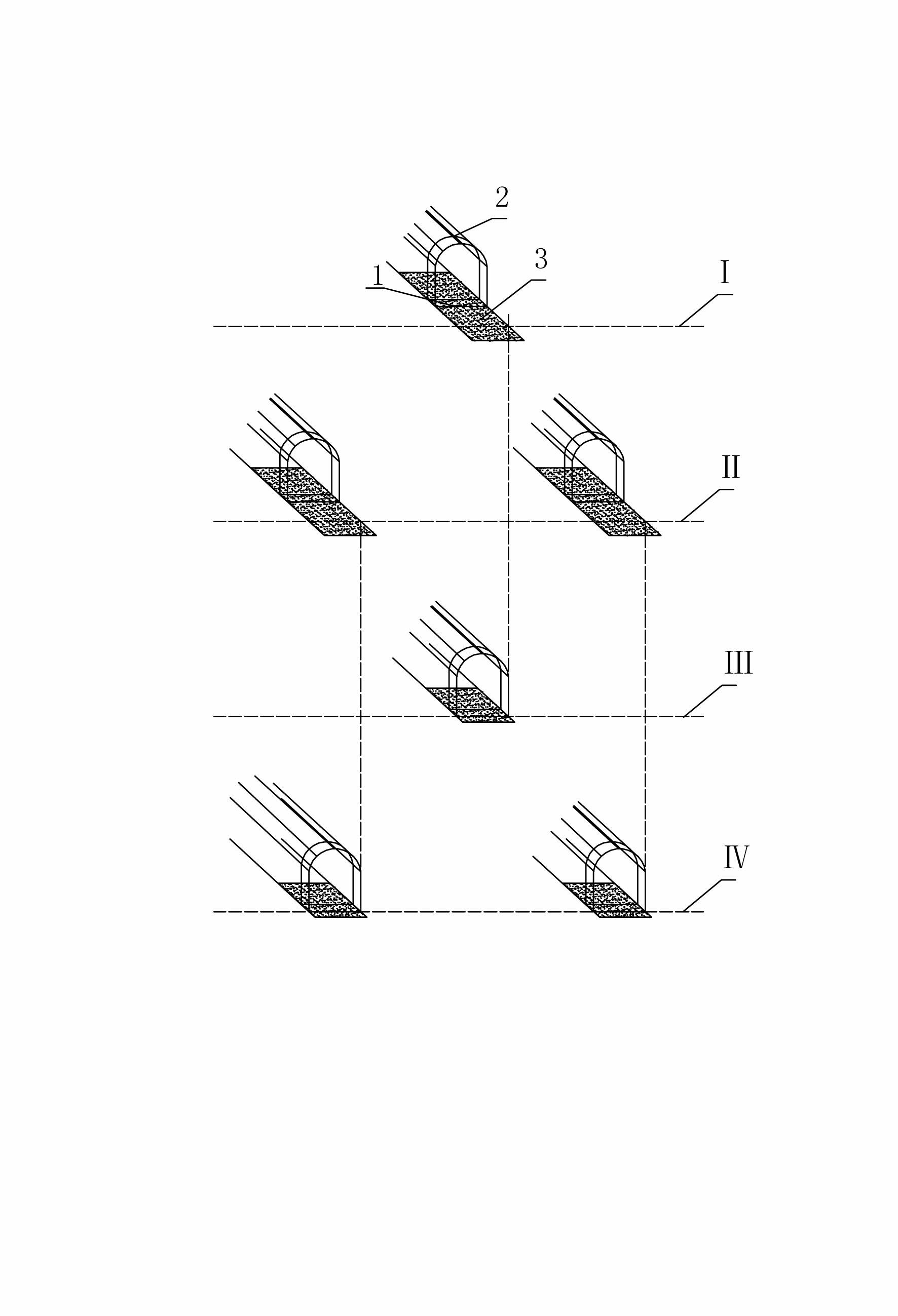

ActiveCN105952450AIncrease production capacityImprove mining efficiencyUnderground miningSurface miningEngineeringStoping

The invention discloses a novel method for collaboratively exploiting underground double stopes of an underground mine. Each ore block is internally divided into two stopes including a left stope room (9) and a right stope room (10), and a jamb (8) is reserved between every two ore blocks. A drilling chamber (1) is formed in the top end of each ore block, a downward blast hole (2) is formed in each drilling chamber (1) through deep hole rock drilling equipment, a controlled blasting technology is adopted, initiation of explosion is conducted segment by segment to achieve one-time explosion, the working face of the left stope room (9) is ahead of the working face of the right stope room (10), advancing is conducted in a ladder form, and caved ores are transported to a winze through an ore removal linked lane; an ore removal lane (5) is arranged on a single side of each ore block, the left stope room (9) and the right stope room (10) share the same ore removal lane (5), after stoping of a whole ore block is stopped, a goaf is subjected to backfill, a filing body (7) is formed, and the filing body (7) supports the jambs (8). By means of the novel method, double-stope synchronous stoping can be achieved for inclined and large and thick ore bodies which are good in rock-ore stability, and production capacity is high; synchronous ore removal of the two stope rooms can be achieved through only one ore removal lane of an ore removal structure at the bottom, and therefore the stope preparation work amount is reduced.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

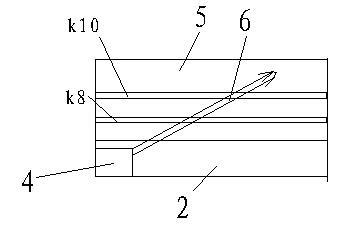

Medium-length hole shrinkage stoping method

InactiveCN105041317AReduce the amount of mining and cuttingImprove rock drilling efficiencyUnderground miningSurface miningRock cuttingStoping

The invention provides a medium-length hole shrinkage stoping method. Stope preparation engineering comprises a ventilation way shaft, a segmented contact way, an ore drawing contact way, an extracted ore drift and a stope drift; personnel and equipment enter a working site through the ventilation way shaft and the segmented contact way; during recovery, a YGZ90 drilling machine is used for drilling upward fan-shaped blast holes along the height direction of a stope room; blasting recovery is performed from bottom to top one by one in a segmented manner; 'local ore drawing' is carried out after blasting is finished; and after flat fielding, a recovery work face has space with the size of 3m so as to meet requirements of rock drilling, then next blasting recovery operation cycle is performed until blasting recovery of the stope room is finished, and a large number of ores are discharged. The medium-length hole shrinkage stoping method has the advantage of small mining and development engineering amount of a shallow-hole shrinkage mining method and the advantage of high production efficiency of a sublevel open stop mining method, and has quite high reference and popularization significance on recovery of medium thick ore bodies in domestic mines.

Owner:CHINA NERIN ENG

Advance grouting transformation method of bottom plate combination directional holes of deeply-buried aquifers underground coal mine

ActiveCN110566118ASolving Governance ChallengesImprove governance efficiencyUnderground chambersDirectional drillingBlind zoneTherapeutic effect

The invention relates to an advance grouting transformation method of bottom plate combination directional holes of deeply-buried aquifers underground a coal mine. The advance grouting transformationmethod includes the steps that the bottom plate combination directional holes are constructed, and comprise deflecting hole sections entering the aquifers from aquicludes and horizontal hole sectionsstarting from the deflecting hole sections and extending inside the aquifers; jet hole sections penetrating through one or more of the aquifers in an extending mode are constructed on the side walls of the deflecting hole sections at the preset interval, and the jet hole sections do not intersect with the horizontal hole sections in the aquifers and cover blind areas of the horizontal hole sections; and grouting is conducted on the horizontal hole sections and the jet hole sections to transform aquifer bottom plates into aquiclude bottom plates. According to the advance grouting transformationmethod, the problems that the distance from a coal seam is large, the number of the aquifers is large, the treatment effect of the coal seam bottom plates with the high water pressure is poor, the blind areas are prone to existing are solved, the advantages that the grouting covering area is wide, no blind area exists in treatment, and efficiency is high are achieved, advance area grouting transformation of the bottom plates of the multiple deeply-buried aquifers is achieved, and the technical guarantee is provided for safe stoping of a working face.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

Method of arranging ultra-close seam mining surrounding-rock roadway

InactiveCN109139013AImprove securityEfficiencyUnderground miningSurface miningAssistive technologyEconomic benefits

The invention discloses a method of arranging an ultra-close seam mining surrounding-rock roadway. Three roadway arrangement modes are used according to the relative position of a lower seam roadway and a gob of an upper mining zone and include an exterior-alternate roadway arrangement mode, an overlapping roadway arrangement mode and an interior-alternate roadway arrangement mode; in two case oftwo ultra-close lower seams and ultra-close seam group lower seams in upper, middle and lower levels, the above three different roadway arrangement modes are used respectively according to different upper pillar widths. The method provided herein helps provide a complete assistant technique of mining ultra-close lower seams; reliable technical guarantee is provided for the safe stoping of the ultra-close lower seams; normal production linking of shafts is guaranteed; significant economic benefit is created; safety, efficiency and economy of ultra-close seam mining are also improved.

Owner:DATONG COAL MINE GRP

Flat-bottomed pillar sublevel caving method of reinforced concrete structure artificial roof

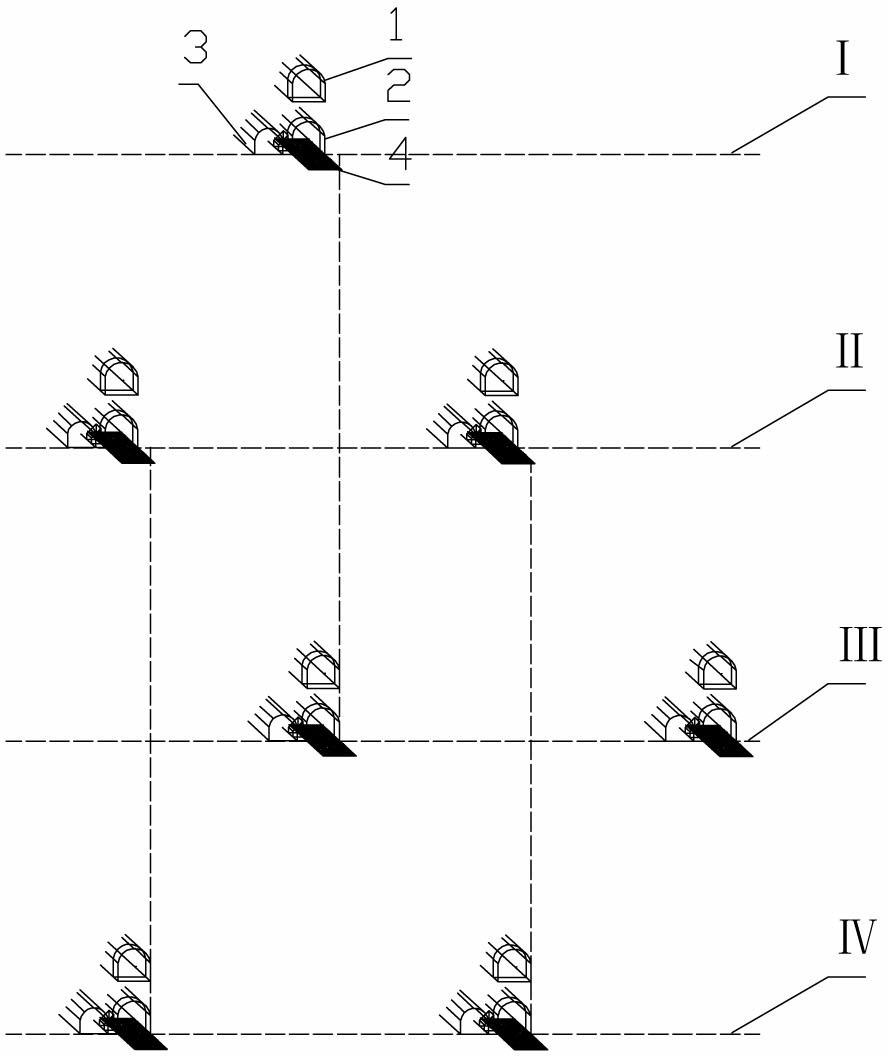

ActiveCN102305074AReduce depletionImprove recovery rateUnderground miningSurface miningElectricityReinforced concrete

The invention relates to a flat-bottomed pillar sublevel caving method of a reinforced concrete structure artificial roof. The method comprises the following steps of: performing sublevel stoping under a covering rock formation, wherein upper and lower sublevel stoping inlet passages are arranged in a diamond-shaped staggered mode in space, and provided with mining tunnels and bottom structures; and adopting scraper ore removal. The method is characterized in that: a scraper ore removal bottom structure adopts a flat-bottomed scraper bottom structure; before ore-bearing tunnels in all inlet passages under which the stoping inlet passages are formed are blasted to form bottom structures, along with the stoping of a stoping working surface, the reinforced concrete structure artificial roof with the same width as that of the ore-bearing tunnels is continuously paved at waste rock funnel control points of the ore-bearing tunnels; and all the inlet passages just above which the artificial roofs are arranged perform the ore removal under the covering of the reinforced concrete structure artificial roofs. The method has the advantages that: during ore removal, the artificial roofs can effectively prevent the formation of waste rock funnels, the ore stoping rate is improved, and the problem of loss and dilution is effectively solved.

Owner:ANSTEEL GRP MINING CO LTD

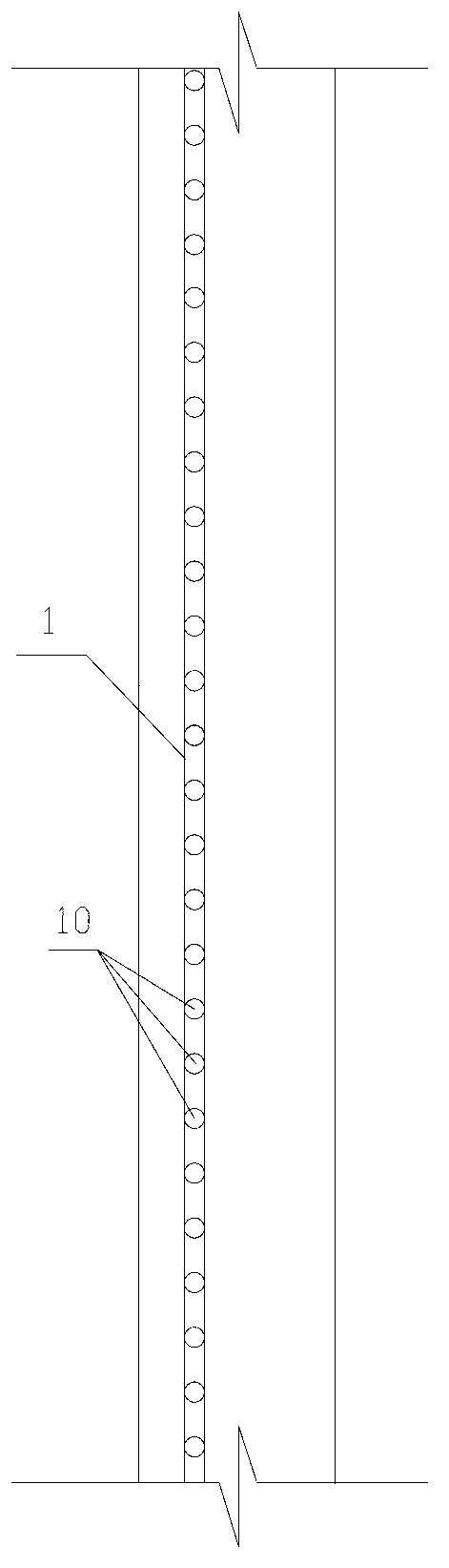

Method for controlling deformation of surrounding rock of basic rimrock layer on presplitting blasting mining roadway

InactiveCN103216264AReduce mining impactReduce labor intensityMining devicesDeformation monitoringGeophysics

The invention belongs to the field of underground construction, and provides a method of deformation of surrounding rock on a mining roadway influenced by mining and controlled through presplitting blasting. A drill hole is formed in the surrounding rock of a top plate in the mining roadway, a loading structure of continuous loading and spaced loading is used in the hole, blasting is used for acting between an upper overlaying rock layer of a mining working face and a main roof of the mining roadway to form a presplitting cutting seam, the influence of the mining working face on the mining roadway is lowered, and meanwhile a surrounding deformation monitoring section is arranged to test the effect of presplitting cutting. According to the method of the deformation of the surrounding rock on the mining roadway influenced by minding and controlled through presplittig blasting, the problem that the deformation of the surrounding rock of the mining roadway is difficult to control due to being influenced by mining can be effectively solved, and the mining roadway influenced by mining can be guaranteed to be normally used in the production process.

Owner:WUPING ZIJIN MINING CO LTD

Safe and efficient mining method for steeply-inclined and two-layer ore body

ActiveCN110374601AHigh engineering reuse rateIncrease productivityUnderground miningSurface miningStopingSafe operation

The invention discloses a safe and efficient mining method for a steeply-inclined and two-layer ore body. The mining method is particularly suitable for the stoping of the steeply-inclined and two-layer ore body of which ore rock is stable, of which a lower ore body >= 15 m in thickness, and of which an upper ore body >= 8 m in thickness. The mining method comprises the steps of firstly mining thelower ore body of which an ore block is arranged perpendicular to the run of the ore body, dividing the ore block into an ore chamber and an ore pillar to preform stoping in two steps, then mining the upper ore body of which an ore block is arranged along the run of the ore body, dividing the interior of the ore block into an ore chamber and a rib pillar, only mining the ore chamber, and leavingthe rib pillar for roof management and ground pressure control. The stoping of the upper ore body and the lower ore body are all adopt a level large-diameter deep hole for blasting mining; the caved ore is removed by a scraper in a bottom structure; and a goaf is filled afterwards. The safe and efficient mining method for the steeply-inclined and two-layer ore body has the advantages of safe operation, low ratio of preparation to cut, high production capacity of a stope, high efficiency, good ground pressure control effect and the like.

Owner:CHINA MINMETALS CHANGSHA MINING RES INST

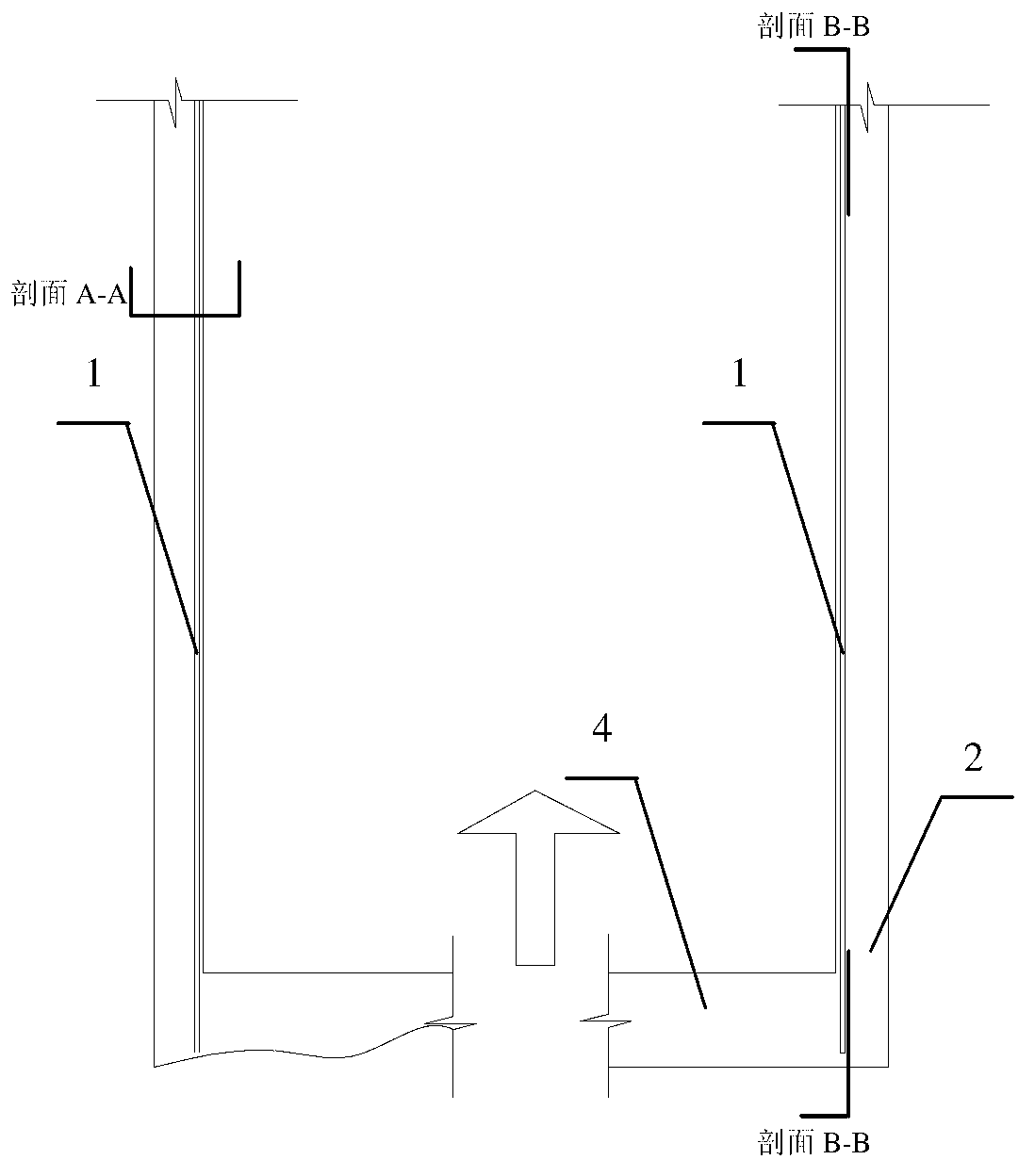

Stoping working face supporting-relief combined gob-side entry retaining roadway and construction method

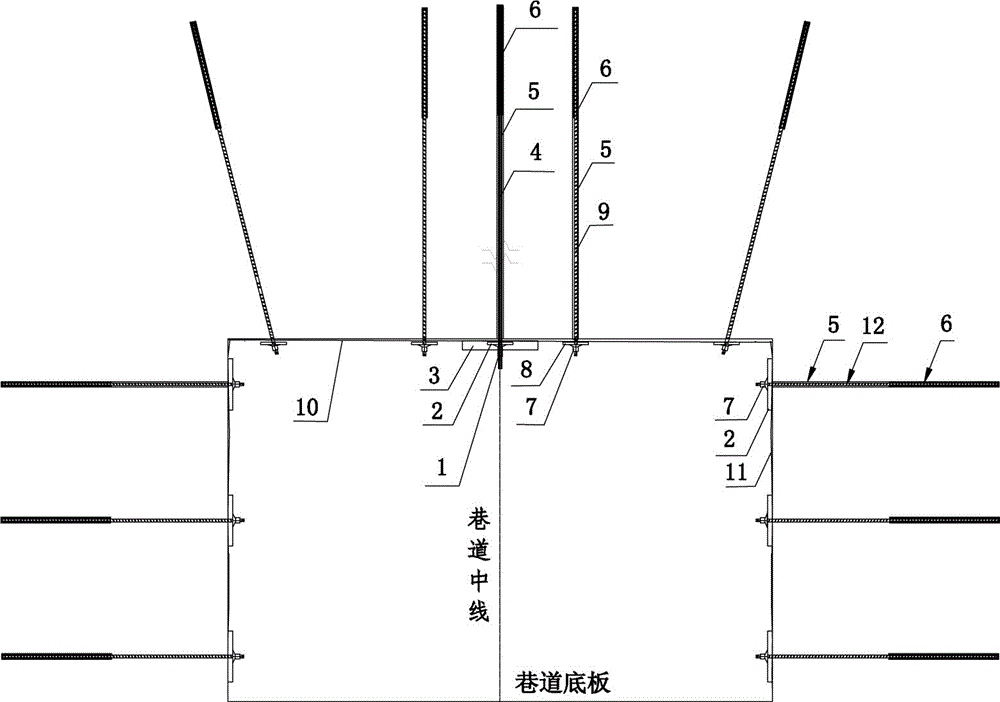

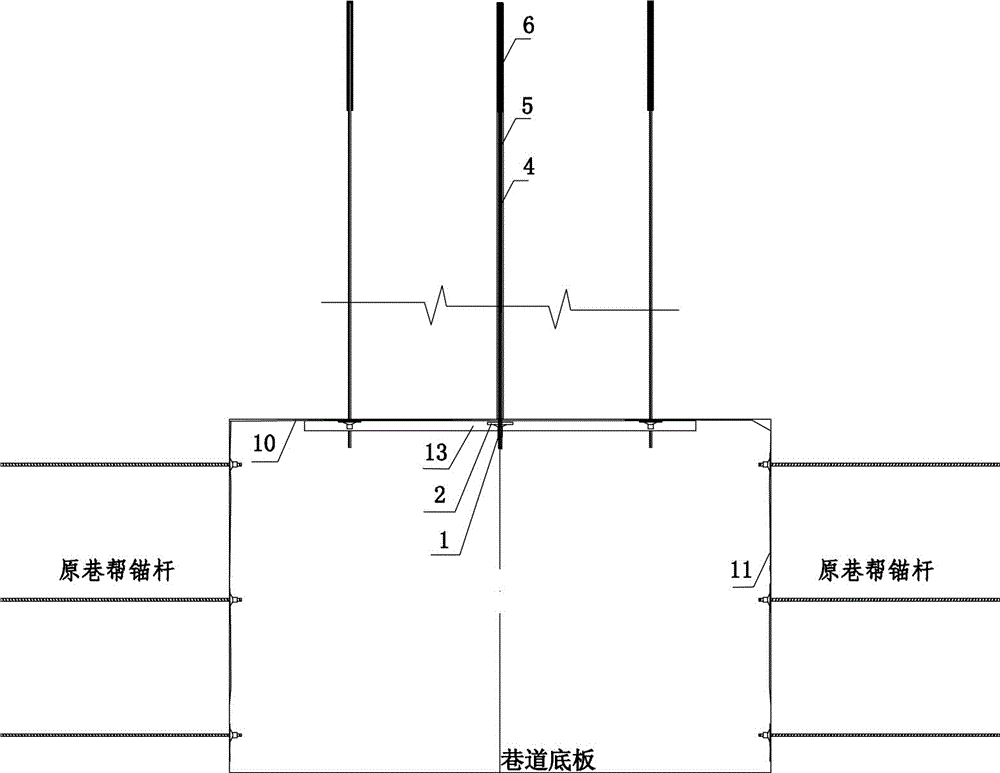

PendingCN110847912AEnsure safetyFast and efficient supportUnderground chambersMaterial fill-upStopped workArchitectural engineering

The invention discloses a stoping working face supporting-relief combined gob-side entry retaining roadway. The stoping working face supporting-relief combined gob-side entry retaining roadway is arranged between a gob of a stoping working face and an adjacent working face, gangue-blocking hydraulic supports are arranged on the side adjacent to the gob and the side, close to the gob, behind an endsupport of the stoping working face along the trend of the roadway in the mode of closely following the end support, the gangue-blocking length is not less than the maximum daily pushing progress ofthe stoping working face, pier columns are arranged on the inner side, close to the gob, of the roadway, the pier columns are filled with concrete to a certain height, and then the pier columns are filled with high-water materials to ensure under-pressure roof contact; and in a mining-affected area of the advanced stoping working face or a lagging gob-side entry retaining roadway area, hydraulic pressure-relief drilled holes are formed from the roadway to a roof. The stoping working face supporting-relief combined gob-side entry retaining roadway is high in safety and reliability, high in construction speed, high in mechanization degree, low in cost and good in airtightness and has high adaptability to various geological conditions.

Owner:TIANDI SCI & TECH CO LTD

Mining method for inclined medium-thick bedded or thick-bedded orebody continuous stoping

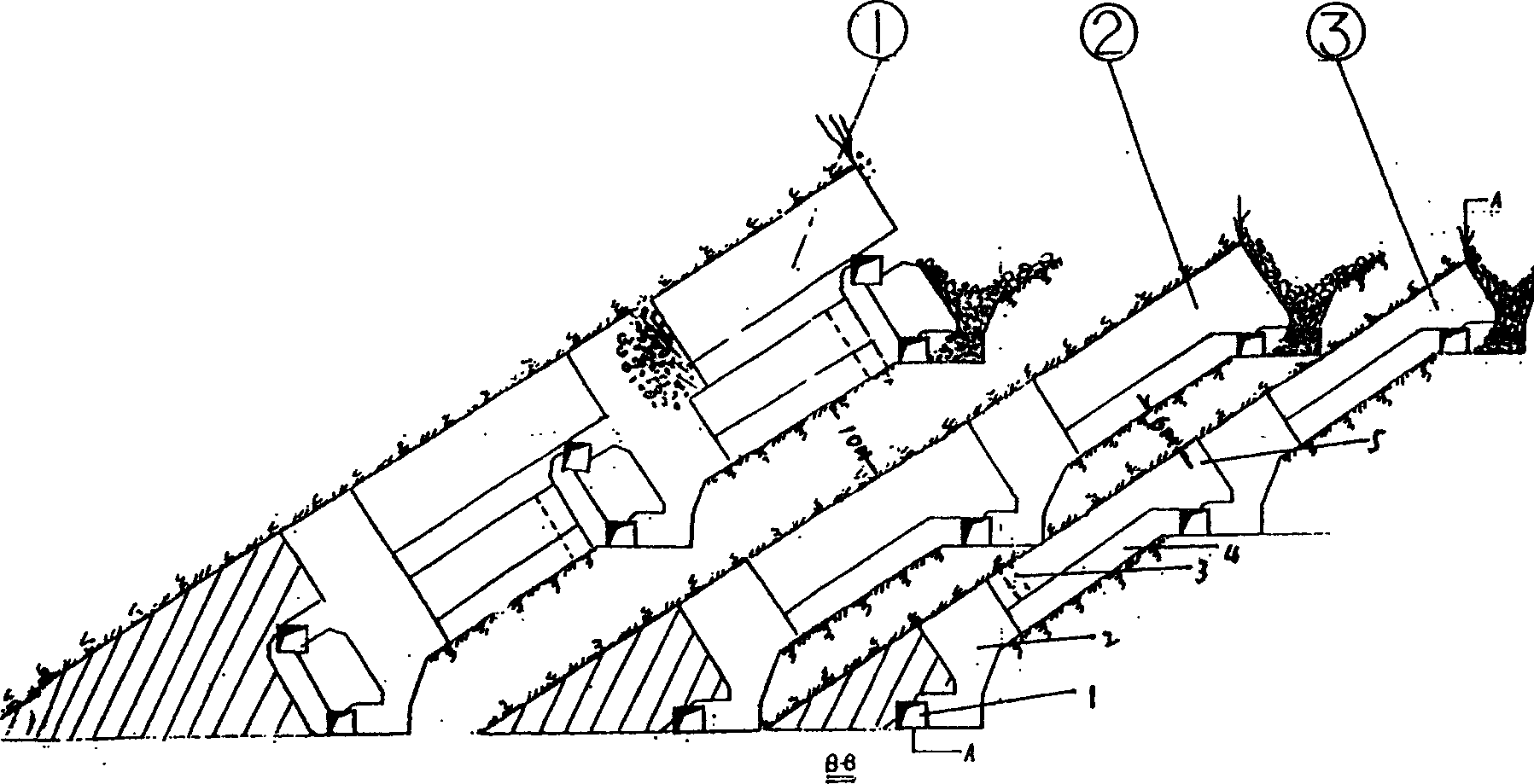

InactiveCN1548702AReduce mining costsIncrease labor productivity andUnderground miningSurface miningStopingMineralogy

The present invention belongs to the field of underground mining method of various useful mineral, and is especially the mining of inclined layers of mediate thickness and thick mineral layer. The present invention features that by means of one increased rise heading and the explosion of columnar explosive, ore is thrown from the stope to preset chute opening. The said mining method has high safety, high efficiency, capacity of mining rock gangue layer, lowered lean ore loss and lowered mining cost. The present invention solves the difficult problem of mining inclined mine body.

Owner:CENT SOUTH UNIV

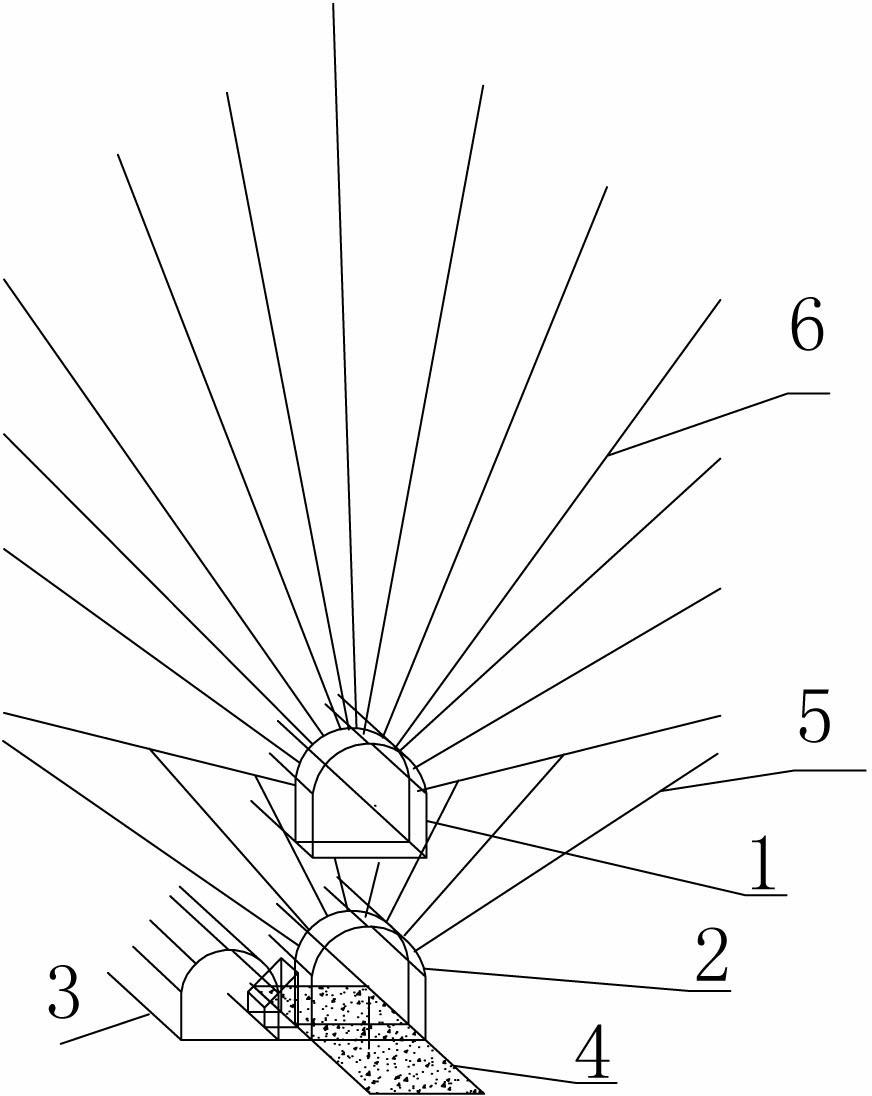

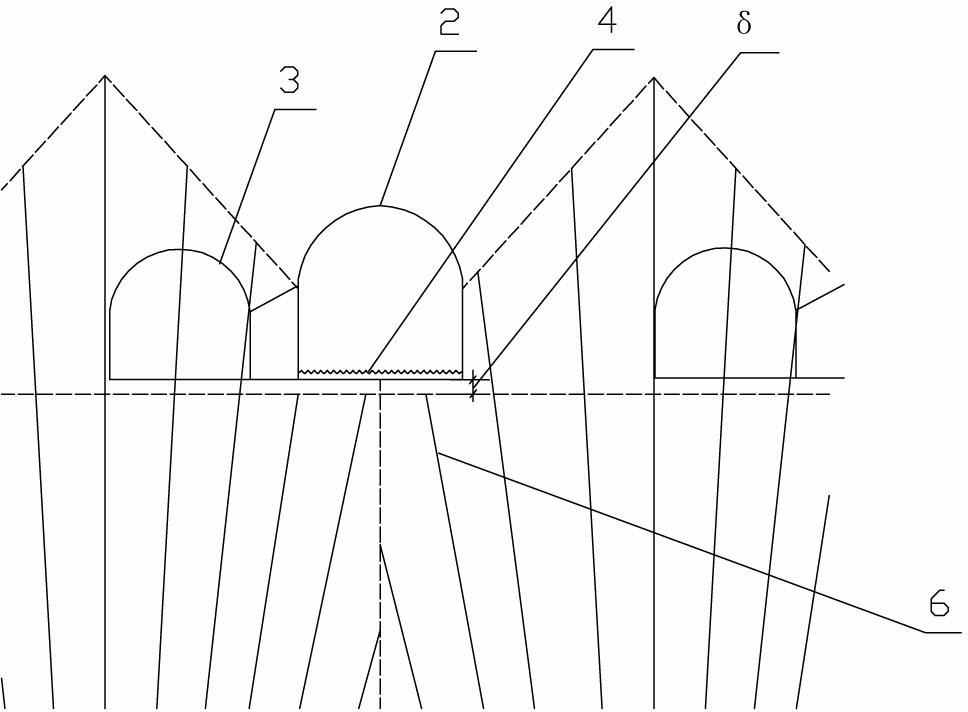

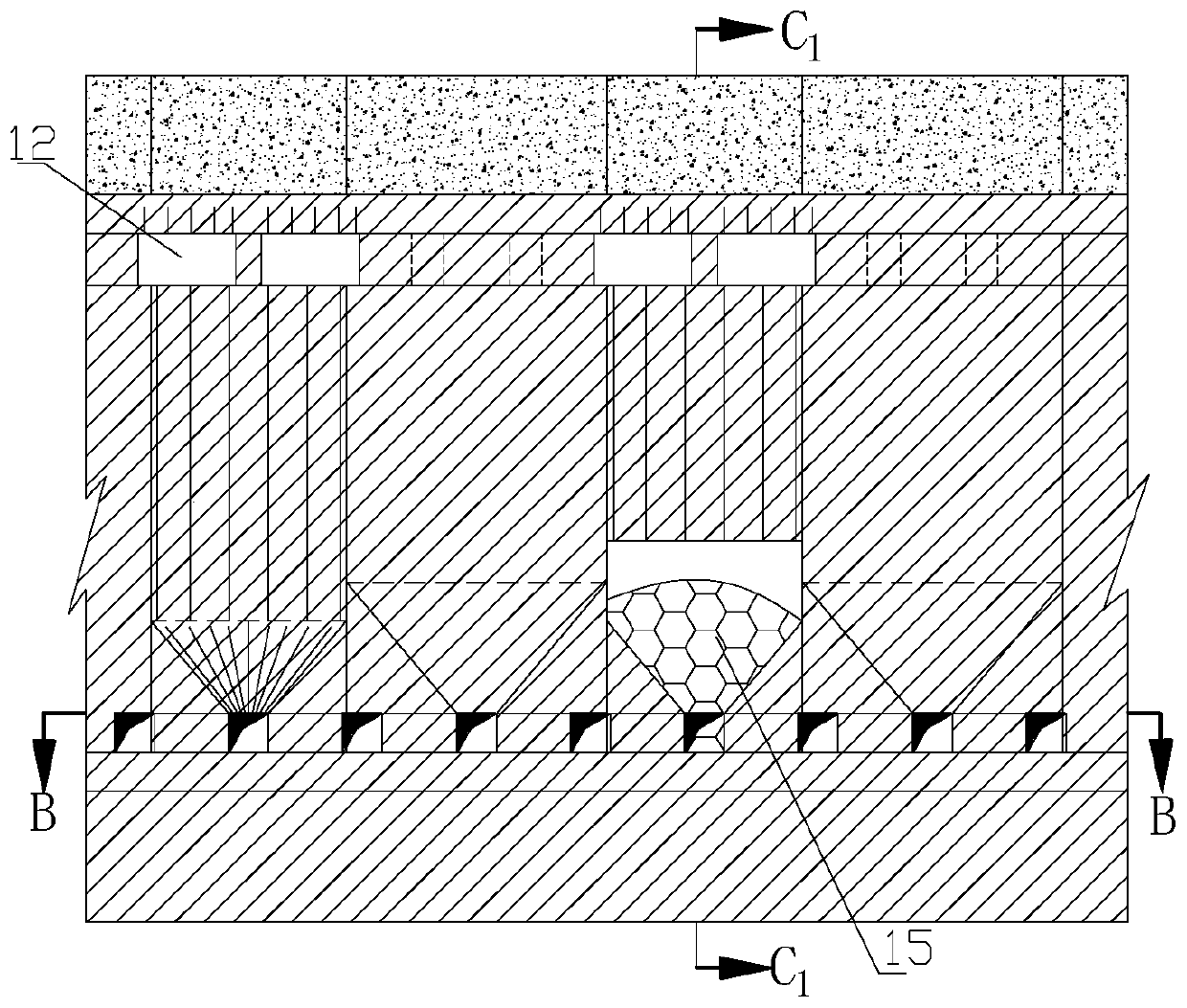

End ore-drawing caving mining technology with high efficient using steel concrete composite man-made false roofs

ActiveCN102418528ASmall laying areaEasy constructionUnderground miningSurface miningRock cuttingRebar

The invention relates to an end ore-drawing caving mining technology with high using steel concrete composite man-made false roofs, characterized in that: in the stoping process of the end ore-drawing caving mining technology, with the stoping of the working face, waste-ore hopper control points at the ends of all stoping drifts continuously pave the man-made false roofs, the waste-ore hopper control points are arranged right above the stoping drifts, all stoping drifts which are provided with steel concrete composite man-made false roofs directly above the stoping drifts are subject to drilling, blasting and drawing under the shadow of man-made false roofs; the waste-ore hopper control point is an area which is located at the boundary between overlaying rock right above the draw holes and the caved ore and has the same width with the draw holes, and a man-made false roof comprises a structural steel support of the bottom layer of the bottom, a rhombic reinforcement mat of the top layer, and a concrete casting layer. According to the invention, caved ores can be separated from the overlaying rocks which are arranged in the top central area, the formation of the waste ore hopper is effectively prevented when ore drawing, thus the impoverishment and loss of ores obtained by the end ore-drawing caving mining technology is reduced, and the highly efficient end ore-drawing caving mining is realized.

Owner:ANSTEEL GRP MINING CO LTD

Pneumatic gangue combined filling device and coal mining method

PendingCN110130979AReduce sinkingReduced footprintUnderground miningSurface miningStopped workEngineering

The invention relates to coal mining equipment and method which use a gangue filling method to manage a roof, in particular to a pneumatic gangue combined filling device and coal mining method. The pneumatic gangue combined filling device comprises a track gate road (a material conveying roadway of a stoping working face), a belt gate road (a coal conveying roadway of the stoping working face) andthe stoping working face; and the pneumatic gangue combined filling device is characterized in that a support roof is fixedly installed at the top of the stoping working face through anchor rods, a hanging belt is arranged below the support roof, wherein the head end and the tail end of the hanging belt are connected with the track gate road and the belt gate road, a plurality of hydraulic supports for a coal mine are installed on the front side of the hanging belt in a spaced mode, the hanging belt is fixed behind all the hydraulic supports for the coal mine, and high-pressure wind power devices for blowing gangue conveyed by the hanging belt into a goaf, of the working face, behind tail beams of the supports are each installed on the lower parts of the tail beams of all the hydraulic supports for the coal mine. The problem of full filling of the goaf is solved, the ground depression is reduced, and the lifting transportation pressure is relieved.

Owner:SHANDONG DONGSHAN GUCHENG COAL MINE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com