Advance grouting transformation method of bottom plate combination directional holes of deeply-buried aquifers underground coal mine

A technology of floor combination and advanced grouting, which is applied in drilling equipment and methods, directional drilling, wellbore lining, etc., can solve the problems of high drilling cost, difficulty in depressurizing water drainage, and unsatisfactory mining conditions under pressure. The effect of safe and efficient hole forming and high governance efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

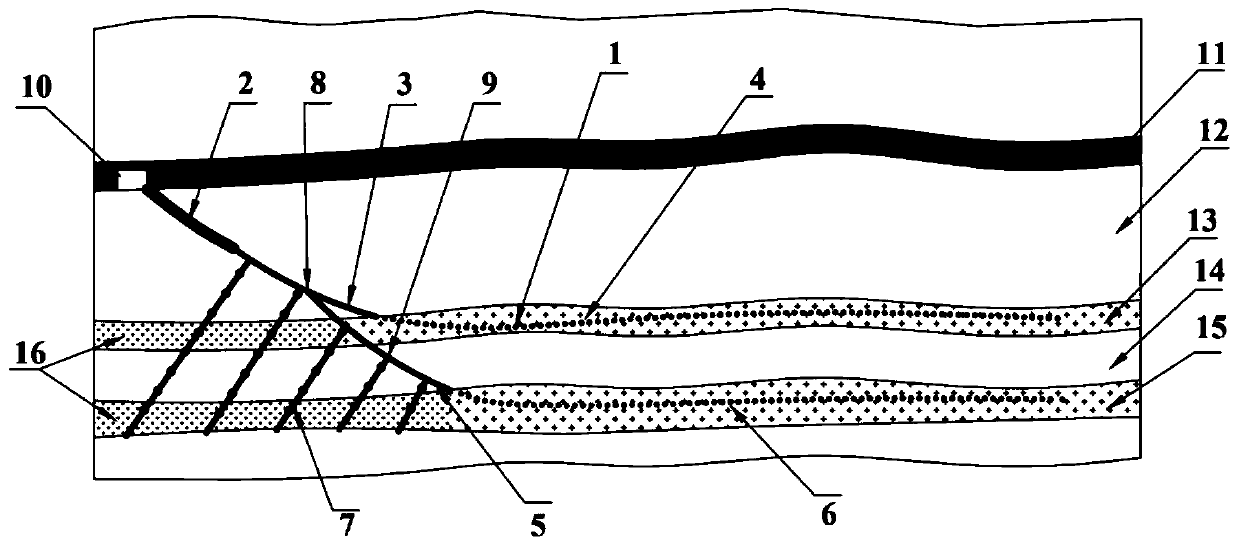

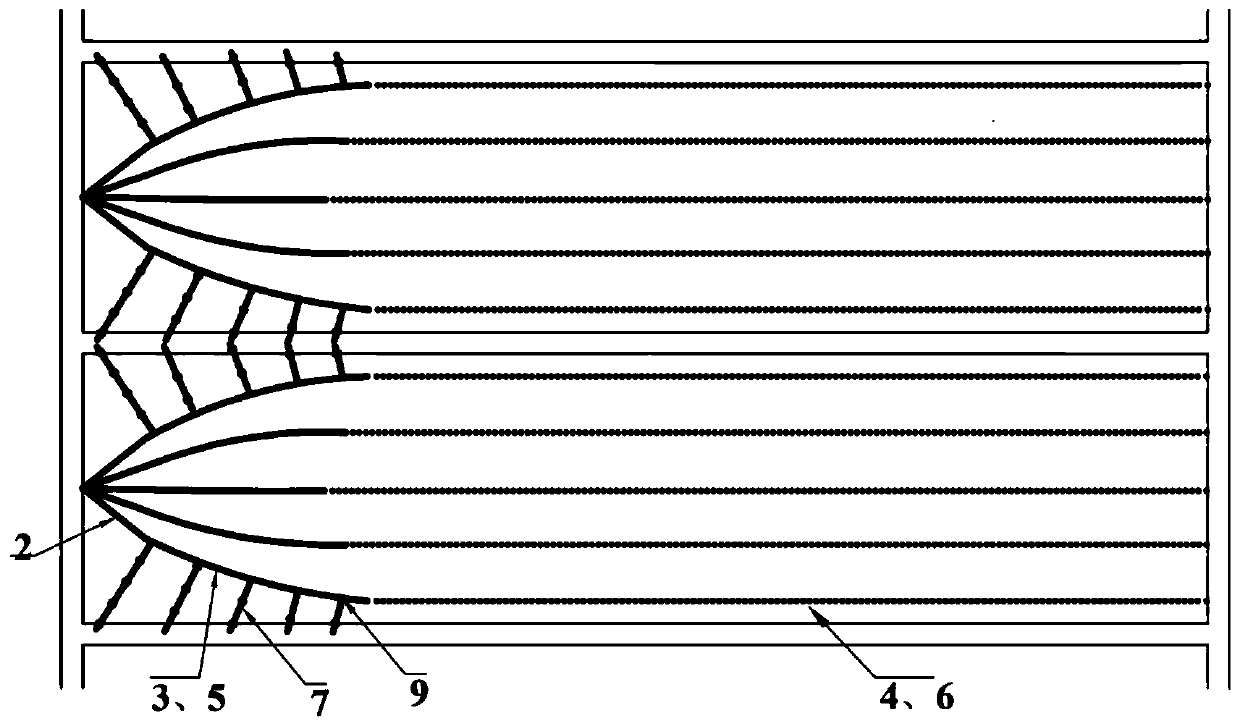

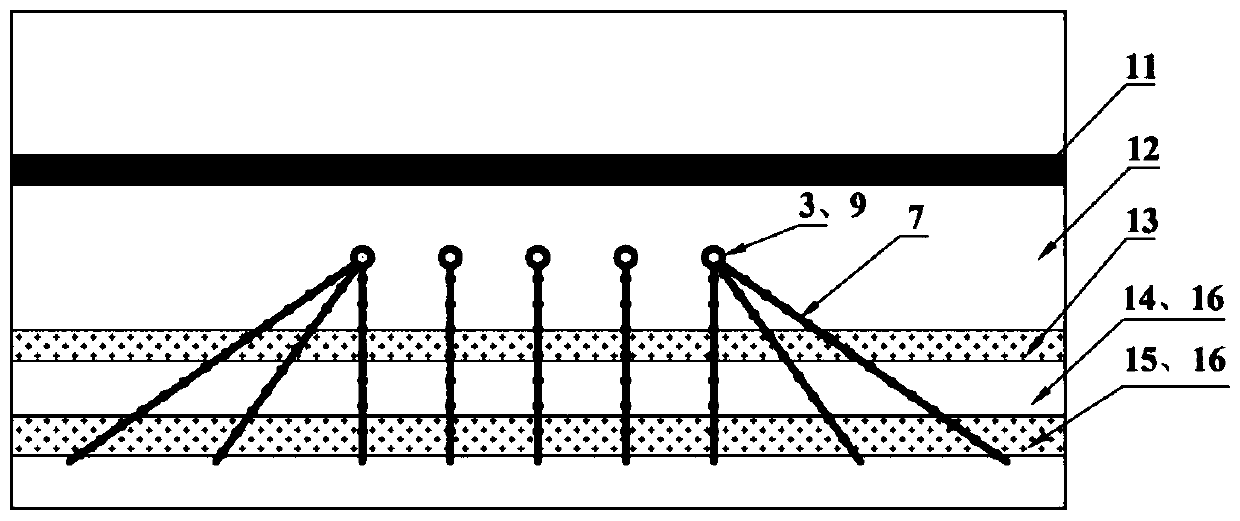

[0035] see figure 1 Combination directional hole 1 in the advanced grouting reconstruction method of deep buried aquifer bottom plate combined directional hole in coal mine is composed of casing hole section 2, upper deflection hole section 3, upper horizontal hole section 4, lower deflection hole section 5, lower The horizontal hole section 6 and the jet hole section 7 are composed. The above whipped hole section 3 is reserved with a directional branch point 8 and a jet flow branch point 9 .

[0036] The method for advanced grouting reconstruction of deep-buried aquifer bottom plate combined directional holes in underground coal mines comprises the following steps:

[0037] Step 1: Construction of the casing hole section. In the set drilling site 10, holes are drilled from the coal seam 11 to the lower side, and after the construction is carried out to the designed position with the full-eye rotary straight drilling tool, the casing is lowered, and then cement slurry is inj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com