Coal-to-olefin industrial exhaust gas comprehensive treatment device and method

A technology for industrial waste gas and coal-to-olefins, applied in gas treatment, separation methods, chemical instruments and methods, etc., can solve problems such as high concentration of organic matter, difficulty in recycling, unstable concentration and gas volume, difficulty in reaching the tail gas index, etc., and achieve the tail gas index Excellent, efficient treatment and resource utilization, high explosion-proof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

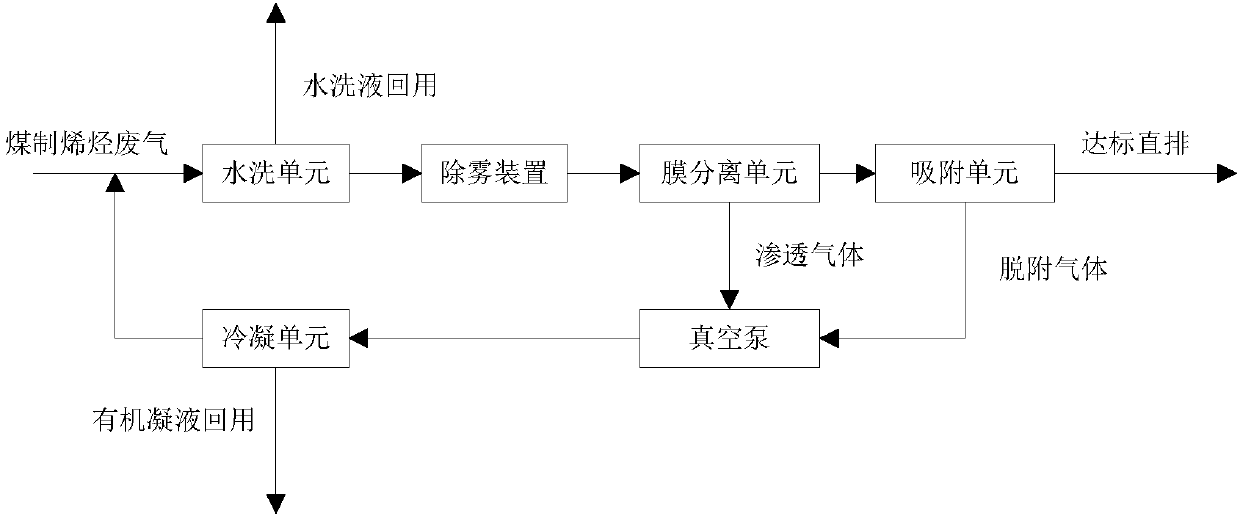

[0040] In the tank area of the coal-to-olefins plant, the exhaust gas is treated by the breathing valve on the top of the tank. After the exhaust gas from the tank roof breathing valve is discharged, it enters the exhaust gas collection pipeline, and enters the treatment device through the blower at the front of the device, with a concentration of 20000-400000mg / m 3 , the main pollutants are methanol, ethanol, ethylene glycol, methyl formate, dimethyl oxalate, and may also contain a small amount of other organic pollutants, including various alkanes, alkenes, cycloalkanes, halogenated hydrocarbons, aromatic compounds, etc. . After the exhaust gas passes through the blower, it first enters the water washing unit. The water washing unit uses softened tap water as the washing liquid. The water washing unit adopts a multi-stage spray washing tower. The gas-liquid contact time exceeds 2 minutes. After washing, the pollutants in the exhaust gas are transformed into methanol, The ...

Embodiment 2

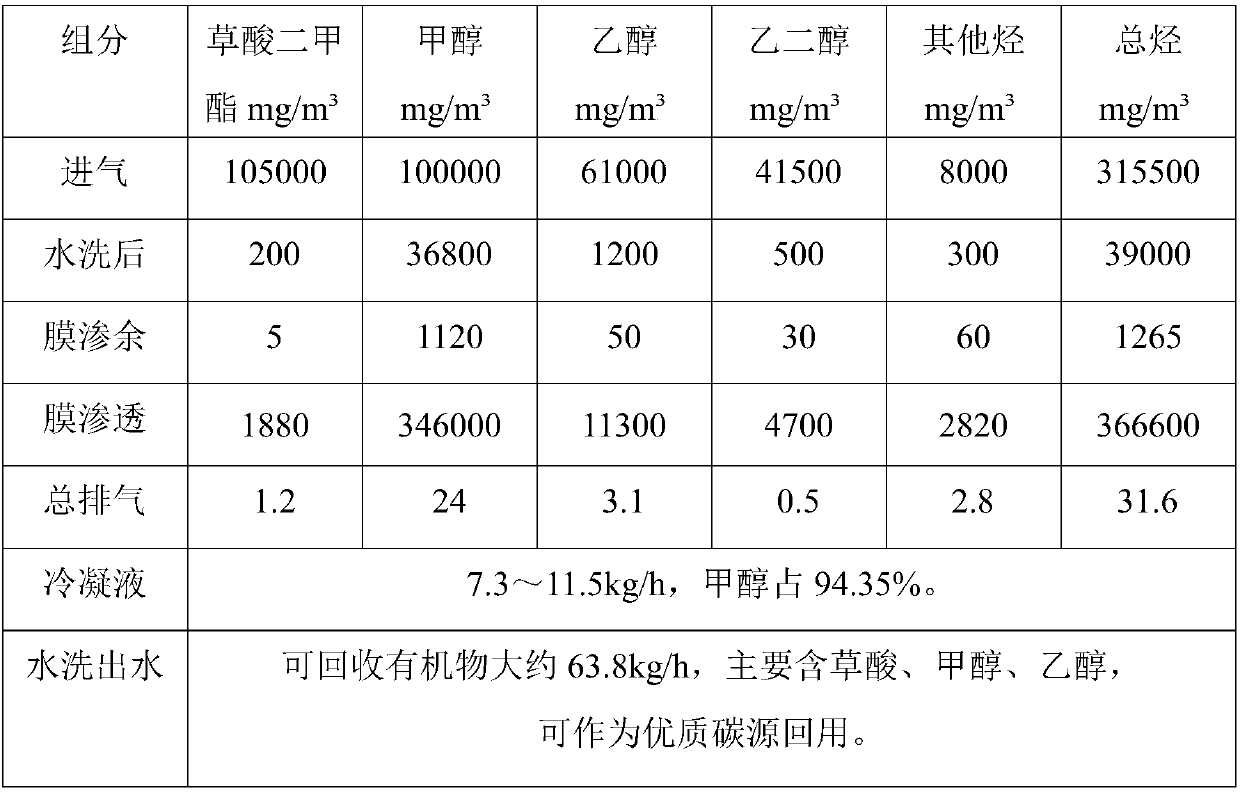

[0042] Treatment of high-concentration coal-to-olefin waste gas discharged from the reaction kettle of the coal-to-olefin plant, the waste gas composition of nitrogen (volume fraction) is 86%, and dimethyl oxalate is 105,000 mg / m 3 , Methanol 100000mg / m 3 , ethanol 61000mg / m 3 , ethylene glycol 41500mg / m 3 , other hydrocarbons 8000mg / m3. Other hydrocarbons mainly include alkanes, olefins and a small amount of aromatics and halogenated hydrocarbons. The total gas flow rate is 100~300m 3 / h, the temperature is lower than 120°C, the washing unit adopts a spray tower, the superficial speed of the tower is 2.0m / s, the overall size is Φ3600×8500mm, the quantity is 2, the amount of softened water is 105t / h, and the material of the washing unit is 304 stainless steel; the membrane Component parameters, material POMS, filling volume 40㎡, methanol / nitrogen separation coefficient 38.5, methanol / oxygen separation coefficient 20.4, permeation flux 1.25-1.48m 3 / ㎡h; adsorption tank par...

Embodiment 3

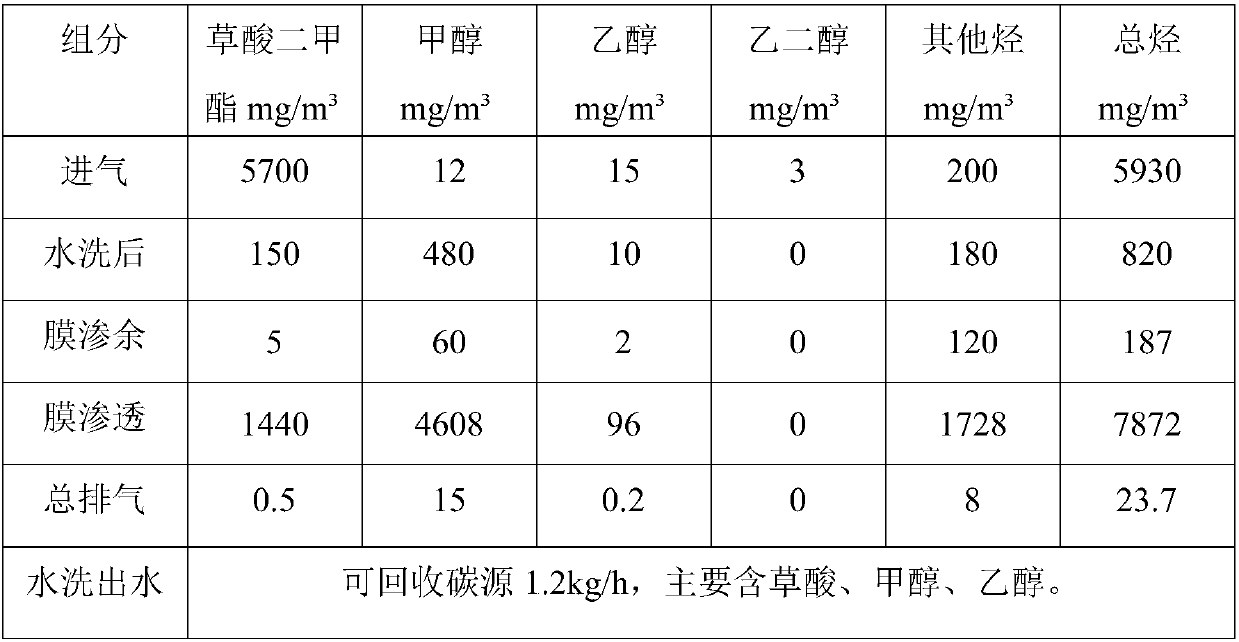

[0049] Treat the waste gas discharged from the breathing valve of the dimethyl oxalate storage tank, the waste gas composition is: air (volume fraction) is 98%, dimethyl oxalate 5700mg / m 3 , Methanol 12mg / m 3 , ethanol 15mg / m 3 , ethylene glycol 3mg / m 3 , other hydrocarbons 200mg / m 3 . Other hydrocarbons mainly include alkanes and alkenes. The total flow of gas flow is 200m 3 / h, temperature 70°C (±5°C), washing unit adopts packed tower, superficial velocity 2.0m / s, external dimension, Φ2200×5000mm, quantity 2, demineralized water consumption 40t / h, washing unit material stainless steel; Membrane module parameters, material PDMS, filling volume 20㎡, methanol / nitrogen separation coefficient 33.5, methanol / oxygen separation coefficient 18.6, permeation flux 1.85-2.10m 3 / ㎡h; adsorption tank parameters, molecular sieve adsorbent, iodine adsorption value of the adsorbent 600-900mg / g, filling capacity 3.6t, adsorption tank size Φ3200×6000mm, quantity 2 sets.

[0050] The mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com