Explosion-proof laser radar

A technology of laser radar and cover plate, which is applied in the direction of re-radiation of electromagnetic waves, utilization of re-radiation, measuring devices, etc., can solve the problem of affecting the effective amount of laser beam emission and reception, blocking laser beam emission and reception, and affecting the working effect of laser radar And other problems, to achieve the effect of improving the effective range, enhancing the light transmittance, and improving the explosion-proof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

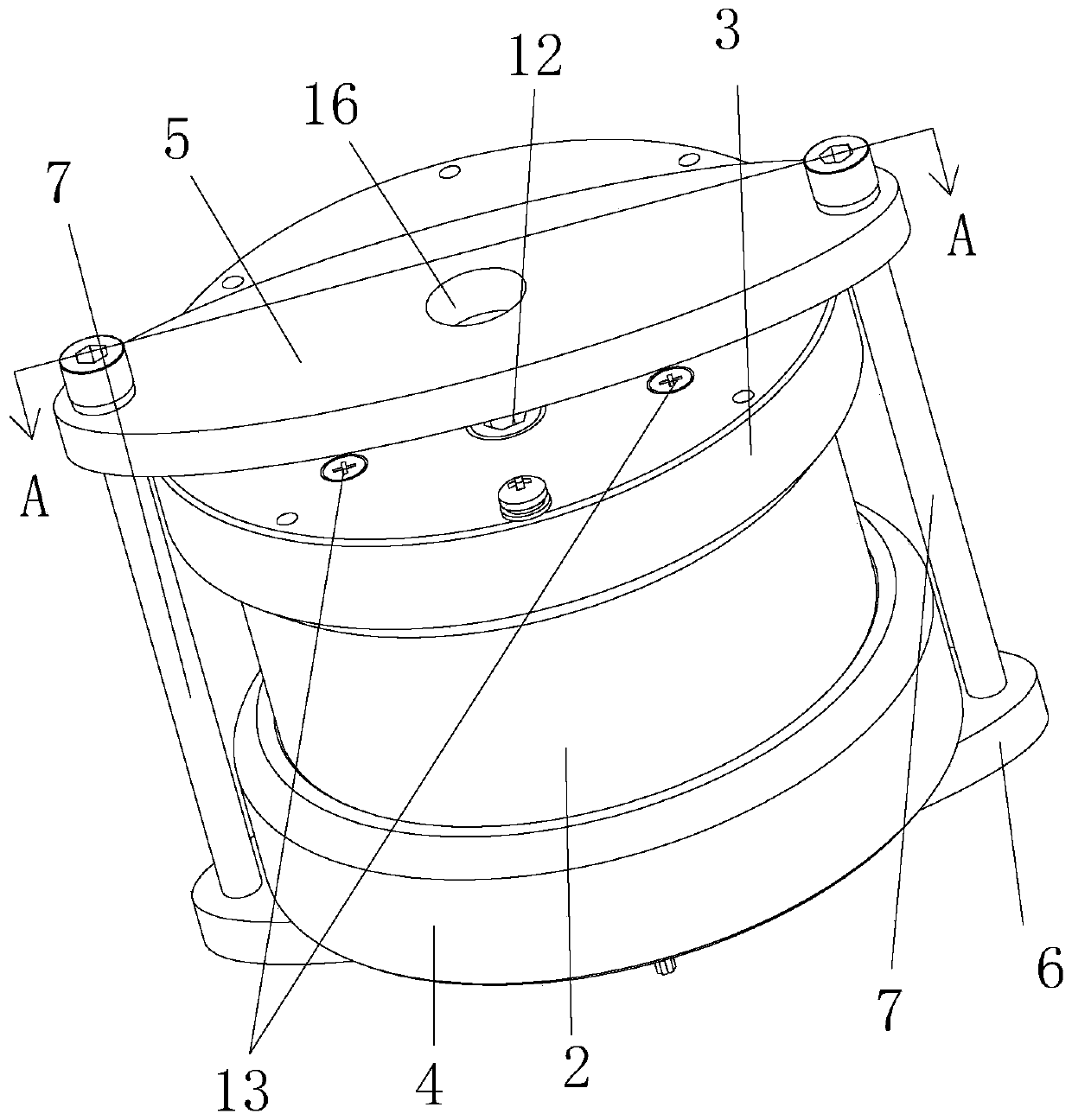

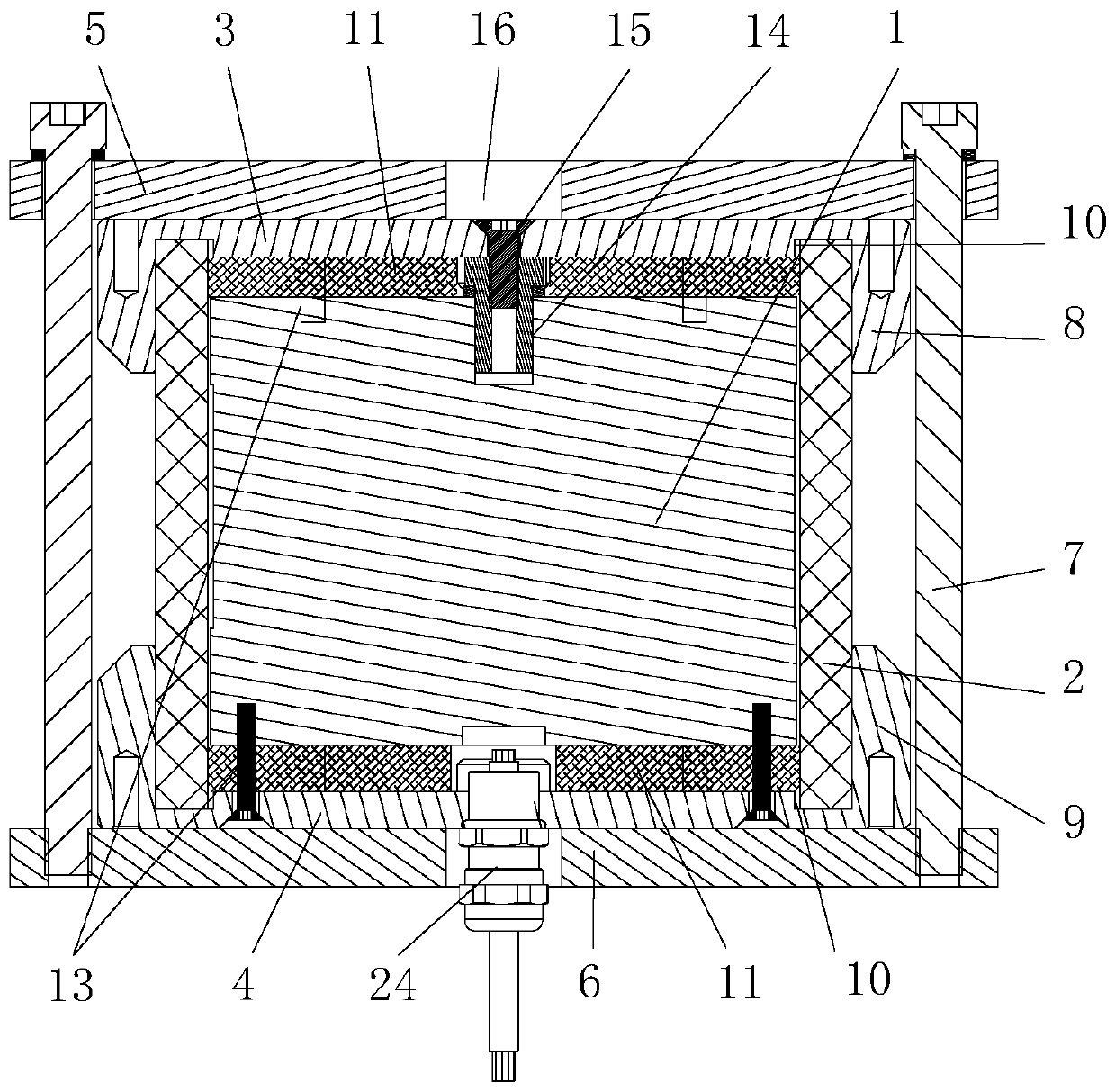

[0053] Such as Figure 1-2 As shown, an explosion-proof laser radar includes a laser radar body 1, a glass cover 2 covering the outside of the laser radar body 1, and an upper cover 3 and a lower cover 4 respectively fixed at both ends of the glass cover 2. The glass cover 2 is fixedly connected with the upper cover plate 3 and the lower cover plate 4 to form the first explosion-proof structure of the laser body 1 .

[0054] The upper cover plate 3 is provided with an upper pull plate 5 , and the lower cover plate 4 is provided with a pull plate 6 . Two pull rods 7 are connected between the upper pull plate 5 and the lower pull plate 6; The two tie rods 7 are arranged symmetrically, and the distance between the two tie rods 7 is large, so as to reduce the loss influence on the laser radar beam transmission.

[0055] The pull rod 7 cooperates with the upper pull plate 5 and the lower pull plate 6 to strengthen the connection strength between the glass cover 2, the upper cover...

Embodiment 2

[0071] Such as Figure 4-5 As shown, an explosion-proof laser radar includes a laser radar body 1, a glass cover 2 covering the outside of the laser radar body 1, and an upper cover 3 and a lower cover 4 respectively fixed at both ends of the glass cover 2. The glass cover 2 is fixedly connected with the upper cover plate 3 and the lower cover plate 4 to form the first explosion-proof structure of the laser body 1 .

[0072] The upper cover plate 3 is provided with an upper pull plate 5 , and the lower cover plate 4 is provided with a pull plate 6 .

[0073] An annular cover body 19 is connected between the upper pull plate 5 and the pull down plate 6; the cover body 19 is provided with a window 20 adapted to the lidar body 1; the cover body 19 is connected with the upper pull plate 5, the pull down plate Plate 6 is fixedly connected.

[0074] Between the upper pull plate 5 and the upper cover plate 3 are respectively provided ring grooves and ring strips that match each oth...

Embodiment 3

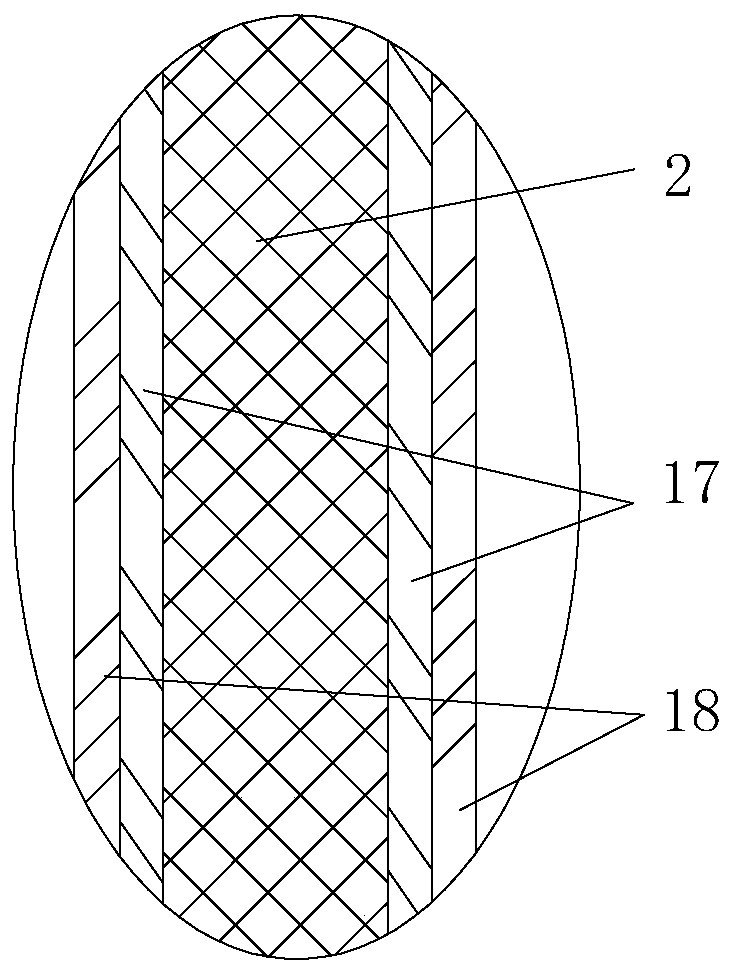

[0093] Based on embodiment 1 or embodiment 2, such as Figure 7 As shown, the glass cover 2 of the present invention is double-layer glass; there is a gap between the double-layer glass, and the gap is in a vacuum state. The double-layer glass structure can further improve the explosion-proof performance of the glass cover 2, and a vacuum is set between the double-layer glass to reduce laser transmission loss.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com