Patents

Literature

932results about How to "Improve explosion-proof performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

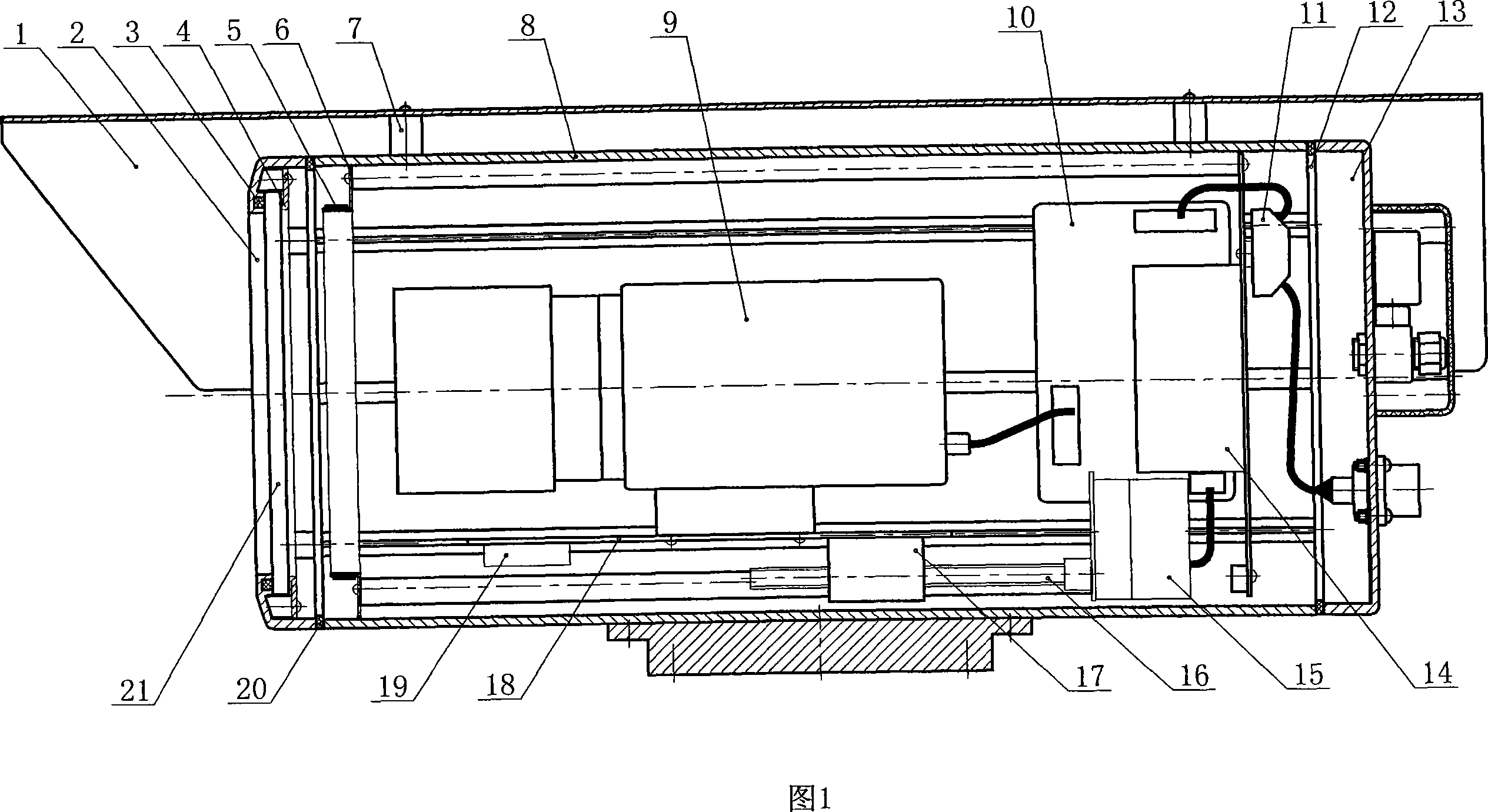

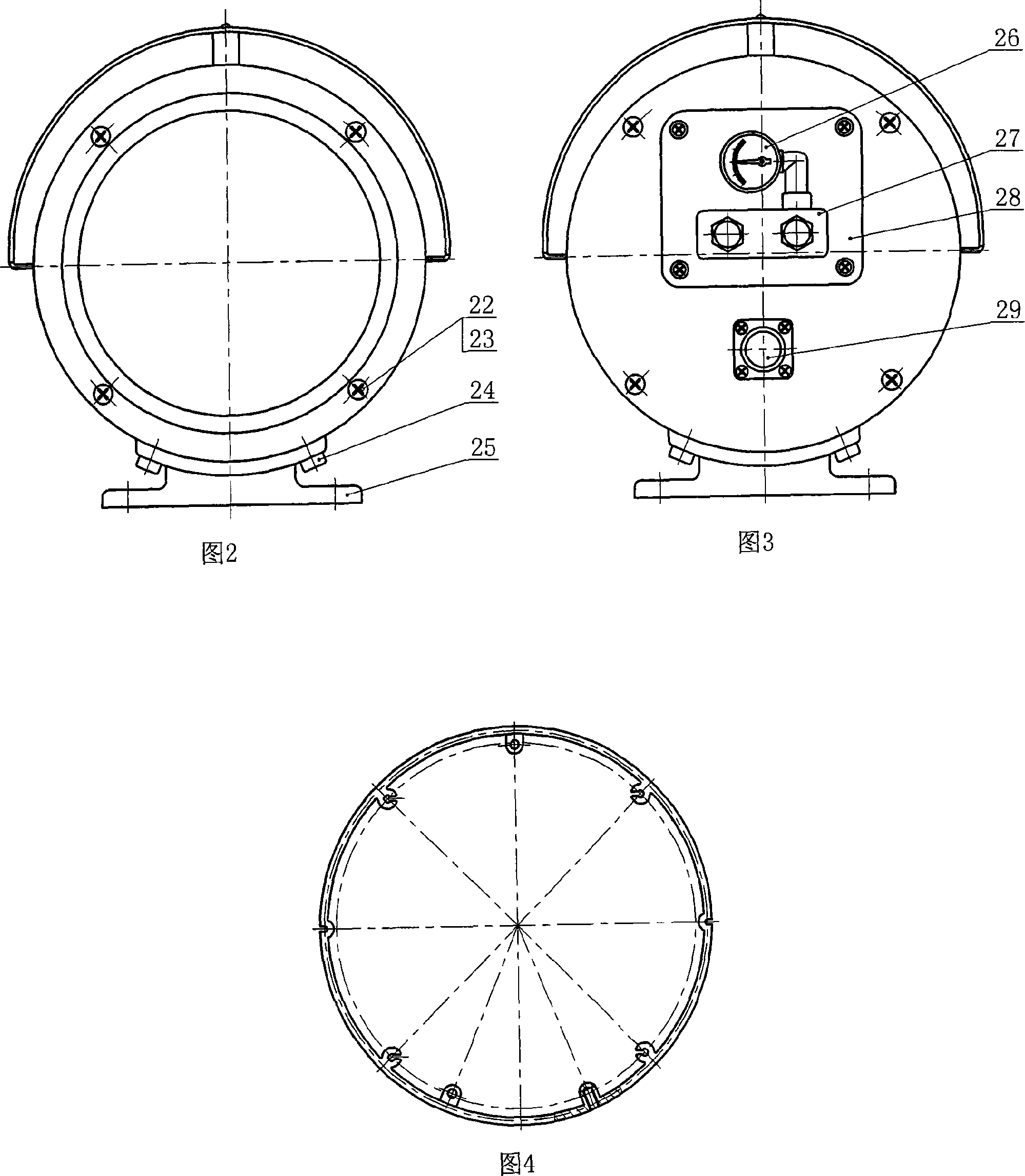

High resolution infrared gas sensor

InactiveCN101825566AHigh test sensitivityImprove test accuracyColor/spectral properties measurementsOptical cavityGas detector

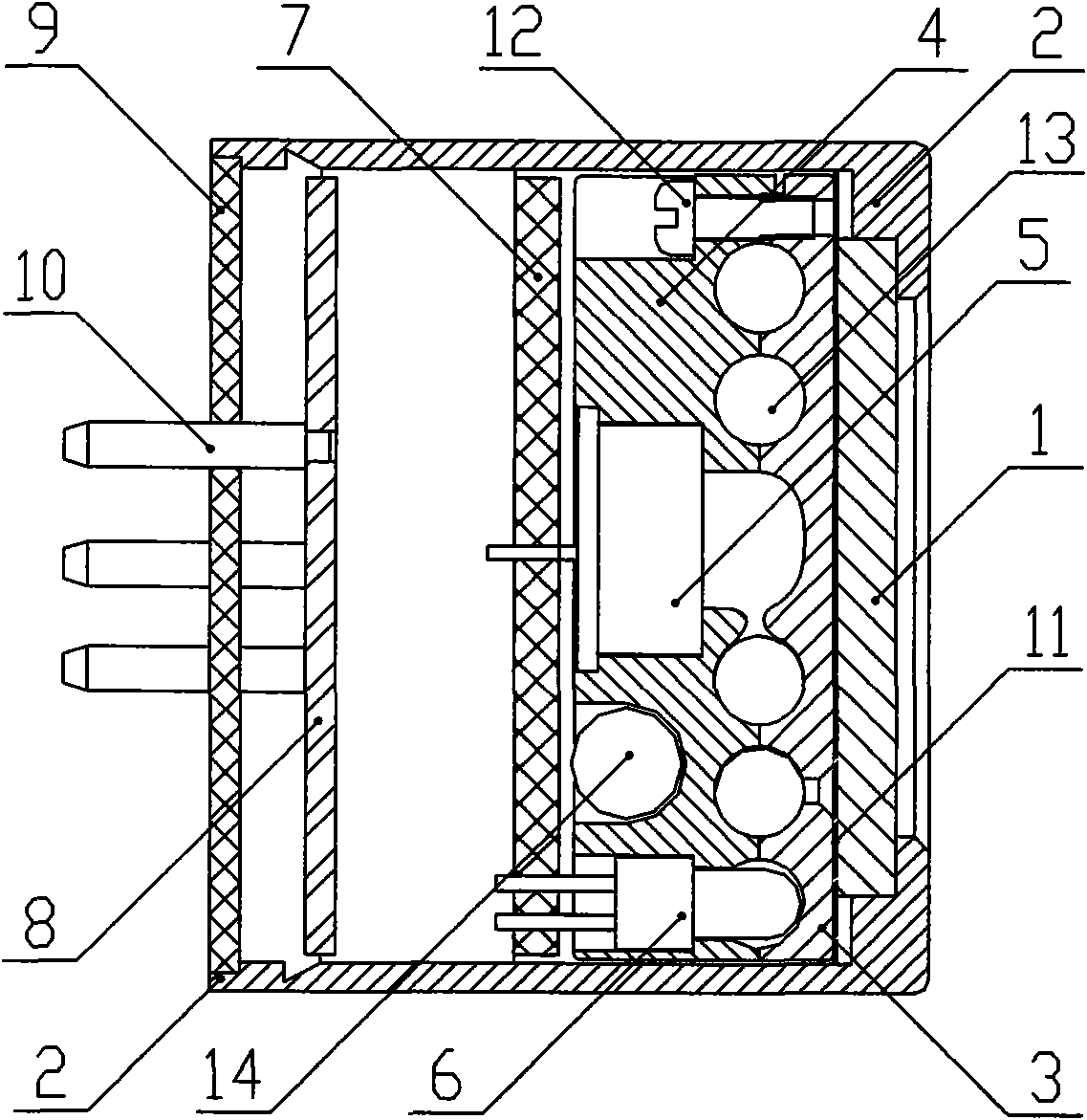

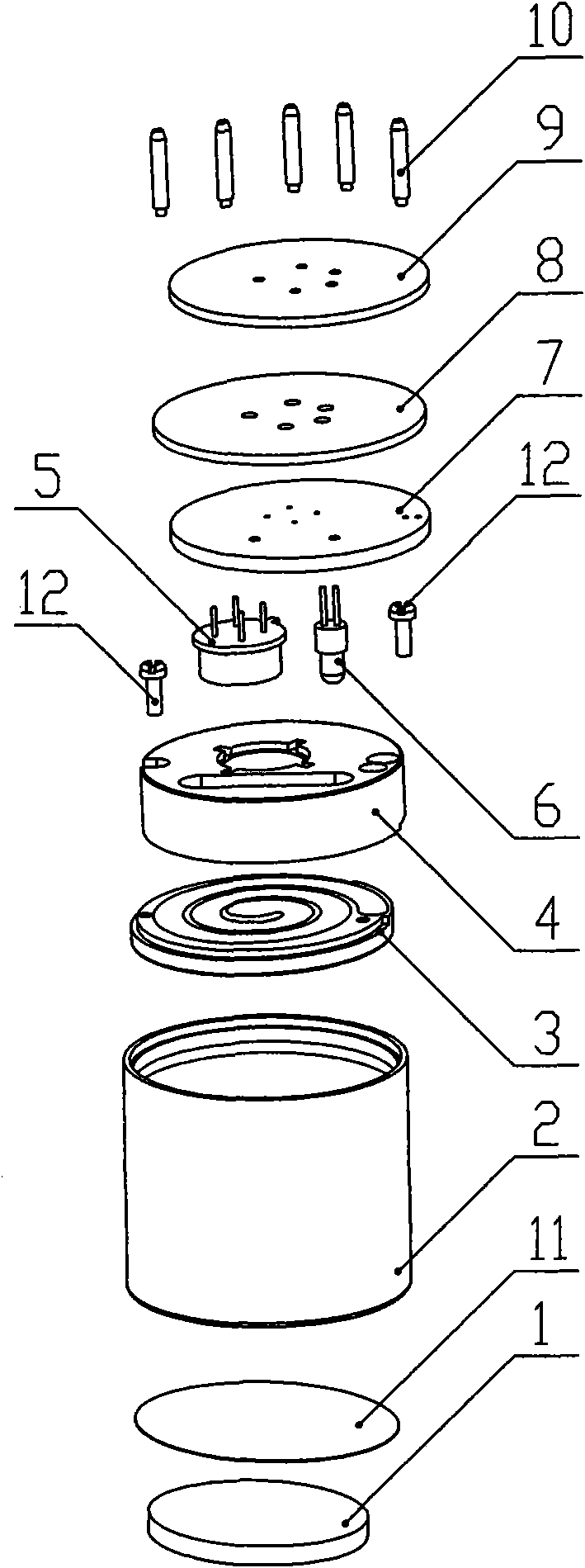

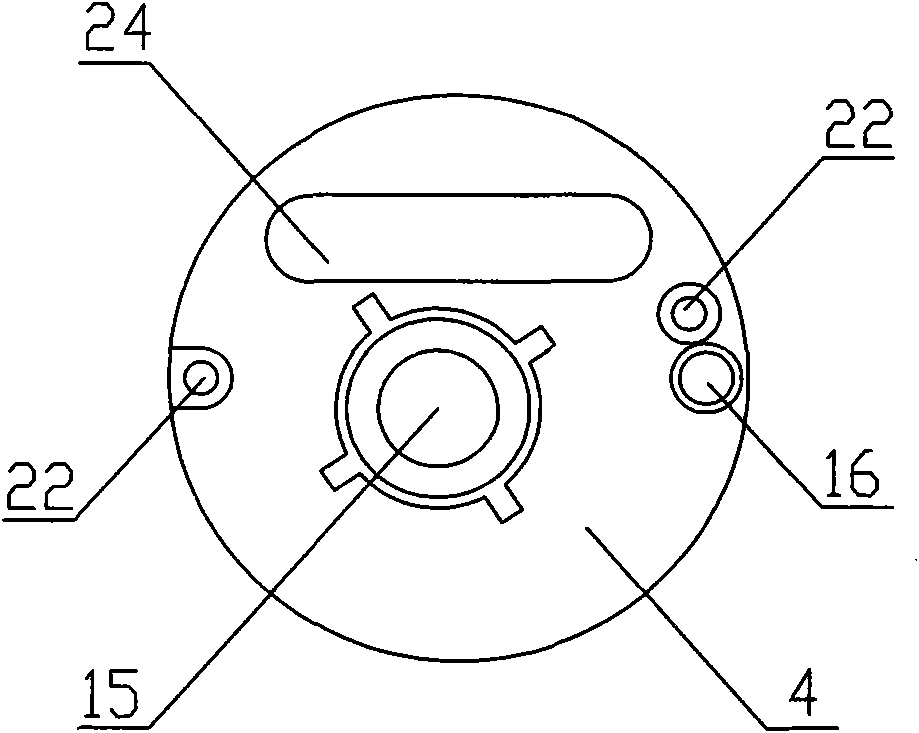

The invention provides a high resolution infrared gas sensor which comprises a shell, a metallurgical powder net, a shell cover, an output pin, an infrared gas detector and an infrared light source, wherein the shell is internally and sequentially provided with an optical cavity, a signal control and collection circuit board and a main circuit board, the optical cavity is internally provided with an optical channel and is provided with a vent hole, the probe end of the infrared gas detector is arranged at one end in the optical channel, and the light emitting end of the infrared light source is arranged at the other end in the optical channel; a pin of the infrared gas detector and a pin of the infrared light source are respectively connected with a signal control and collection circuit, the signal control and collection circuit is connected with a main control circuit, and one end of the output pin is connected with the main control circuit; the optical channel is in an Archimedes spiral shape, and the inner wall of the optical channel is coated by gold. The sensor adopts the Archimedes spiral shape optical channel in a limited space to enable an optical path to be dramatically enhanced, thereby enhancing the test sensitivity and the test accuracy of the sensor.

Owner:郑州炜盛电子科技有限公司

Composite armor structure preventing blast waves

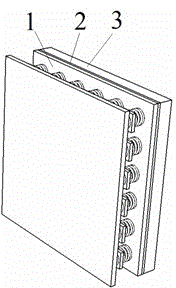

InactiveCN104792224AImprove explosion-proof performanceExplosion shock wave barrierSynthetic resin layered productsArmour platesMetal sphereEngineering

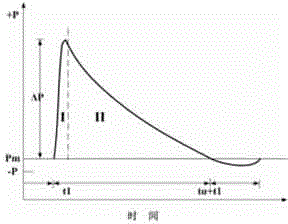

The invention relates to a composite armor structure preventing blast waves. The composite armor structure comprises a metamaterial layer, a combining layer and an energy-absorption buffering layer in sequence from outside to inside. The metamaterial layer and the energy-absorption buffering layer are combined in an optimized mode through the combining layer. The metamaterial layer is of a microstructure composed of a metal-nonmetal sphere system and can block shock waves in the area near the peak overpressure value in blast waves. The microstructure composed of the metal-nonmetal sphere system comprises metal balls, elastic materials and base body materials, and the metal balls wrapped by the metal materials are embedded into the base body materials. The blast resistant structure can effectively block explosion shock waves and more easily absorb explosion pressure waves, and therefore the explosion proofing ability of the structure is improved.

Owner:ACADEMY OF ARMORED FORCES ENG PLA +1

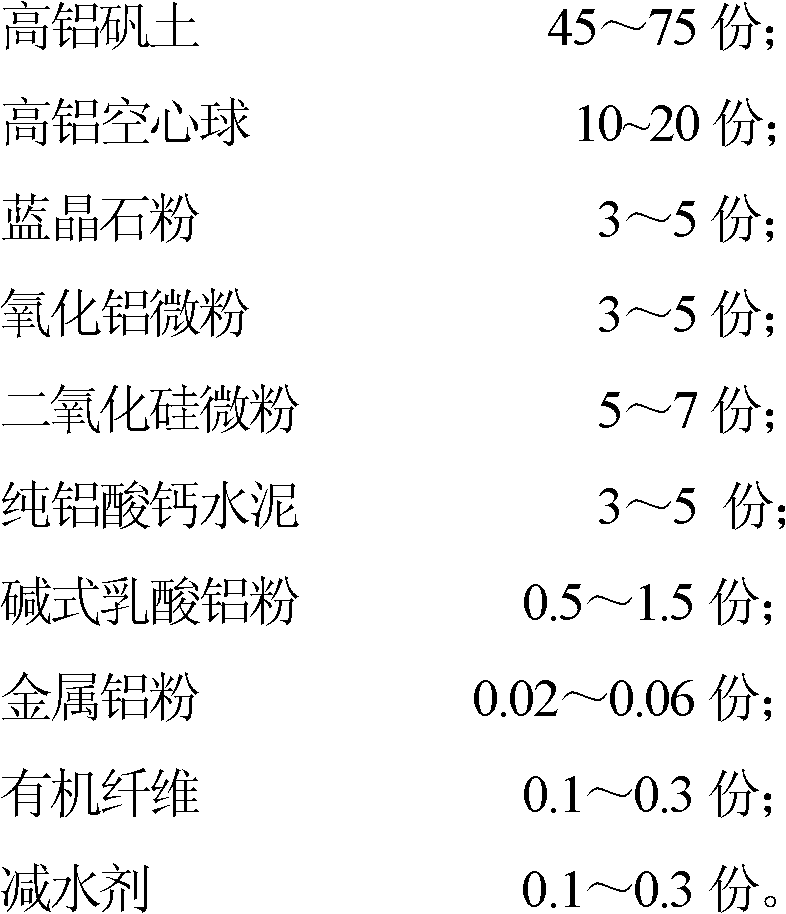

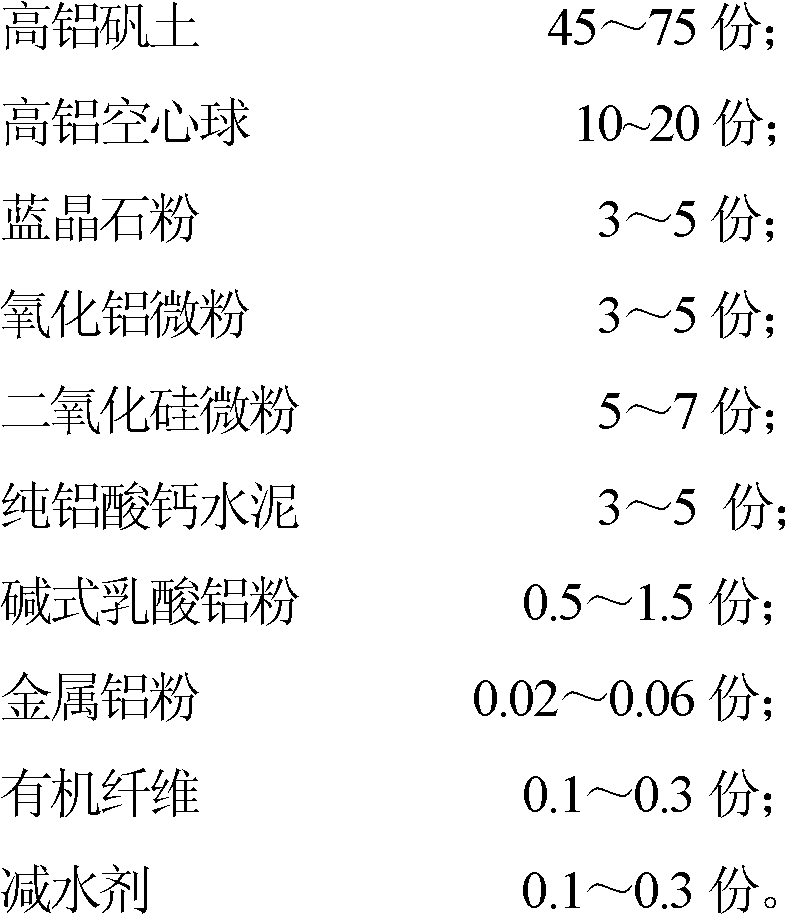

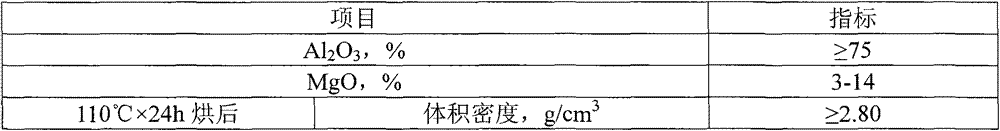

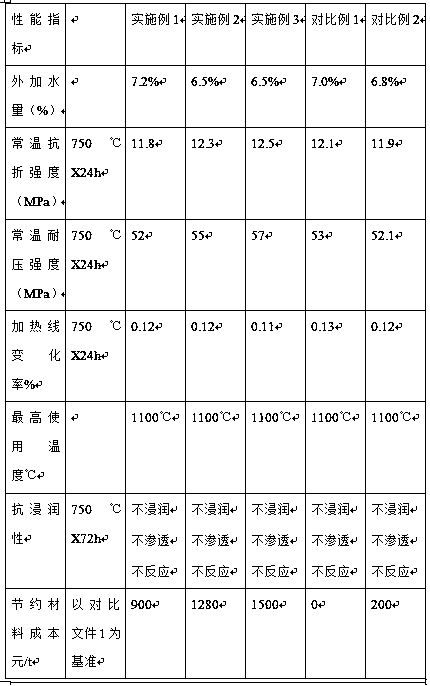

Ladle permanent lining pouring material capable of rapid roasting

The invention provides a ladle permanent lining pouring material capable of rapid roasting. The pouring material mainly comprises 45-75 parts of high bauxite, 10-20 parts of high-alumina hollow spheres, 3-5 parts of cyanite powder, 3-5 parts of alumina micro powder, 5-7 parts of silica micro powder, 3-5 parts of pure calcium aluminate cement, 0.5-1.5 parts of basic aluminium lactate powder, 0.02-0.06 part of metal aluminium powder, 0.1-0.3 part of organic fibres, and 0.1-0.3 part of water reducer. The pouring material capable of rapid roasting, provided by the invention, has the characteristics of being high in strength and refractoriness, good in thermal shock resistance, low in volume density and thermal conductivity, and considerable long in service life.

Owner:BAOSHAN IRON & STEEL CO LTD

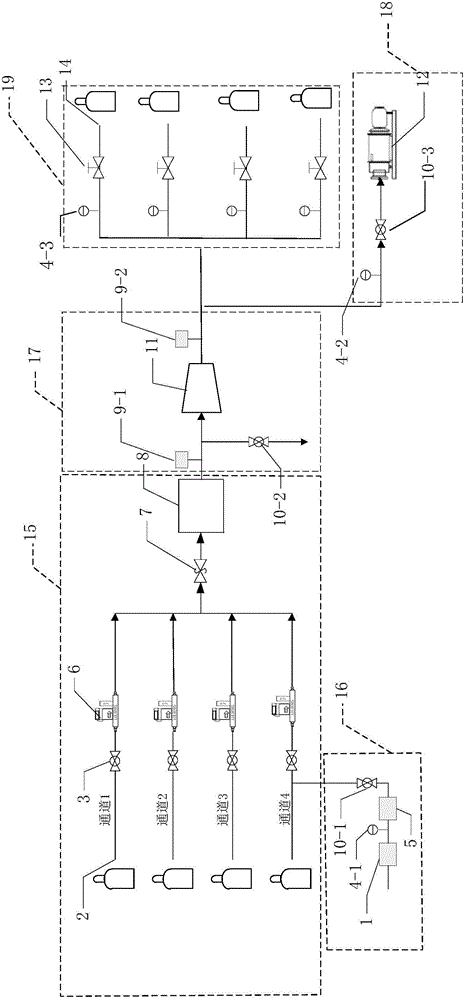

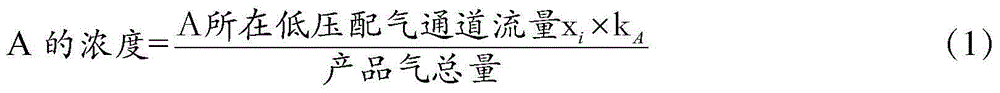

Anti-explosion multi-component dynamic air distribution device and method

ActiveCN104147948AStable pressureAnti-explosion effectMixer accessoriesMixing gases with gases/vapoursEngineeringAir compressor

The invention discloses an anti-explosion multi-component dynamic air distribution device and method. The device comprises a low-pressure air distribution system 15, an air compression generation device 16, a pressurization system 17, a vacuumization system 18 and a filling system 19. Through the adoption of a back pressure valve, the pressure of gas at the gas outlet end of the back pressure valve is stable before the gas enters a gas mixer, so that an anti-explosion effect is achieved; due to the adoption of a variable frequency diaphragm compressor, product gas is high in purity and free of impurity gas pollution; moreover, the pressure in the low-pressure air distribution channel is stabilized in a safe pressure range by adjusting the working frequency of the variable frequency diaphragm compressor to achieve the anti-explosion effect; flow control ranges of n mass flow controllers are distributed in a trapezoidal shape for real-time control on gas flow, so that the air distribution precision is improved; air generated by the air compressor is utilized as a diluent gas channel, so that the cost is saved; an alarm function can be performed in an air distribution process.

Owner:PERIC SPECIAL GASES CO LTD

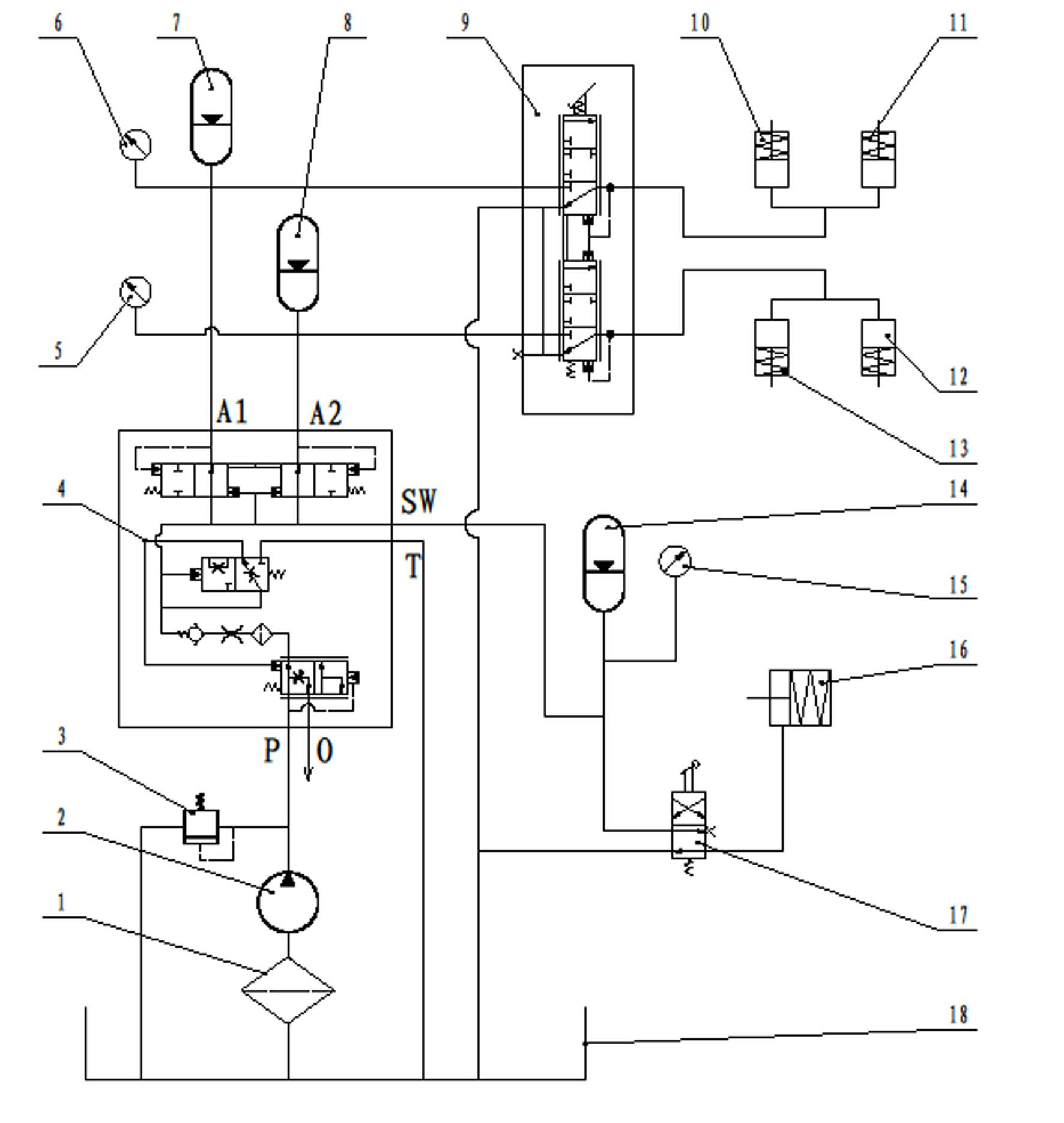

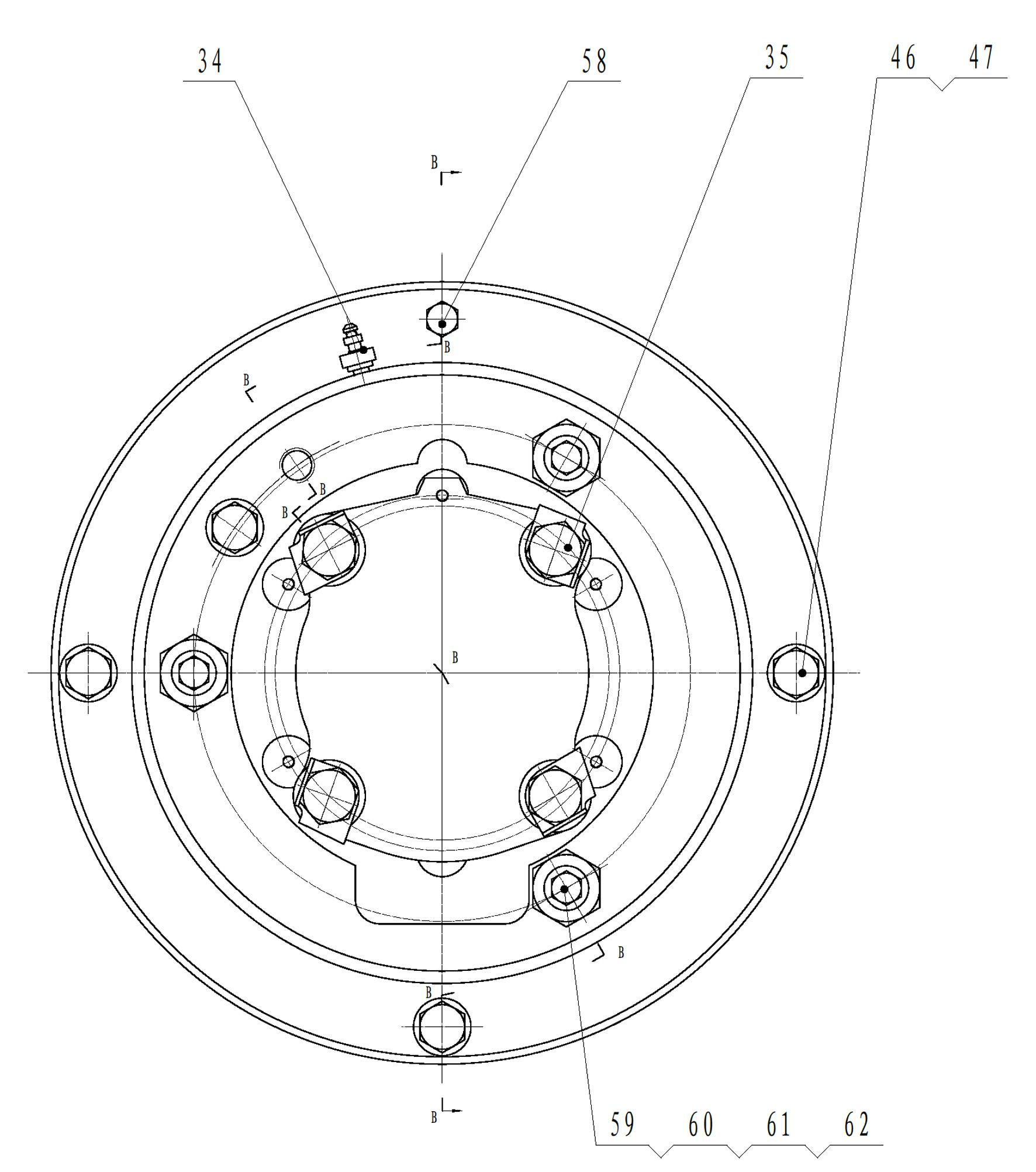

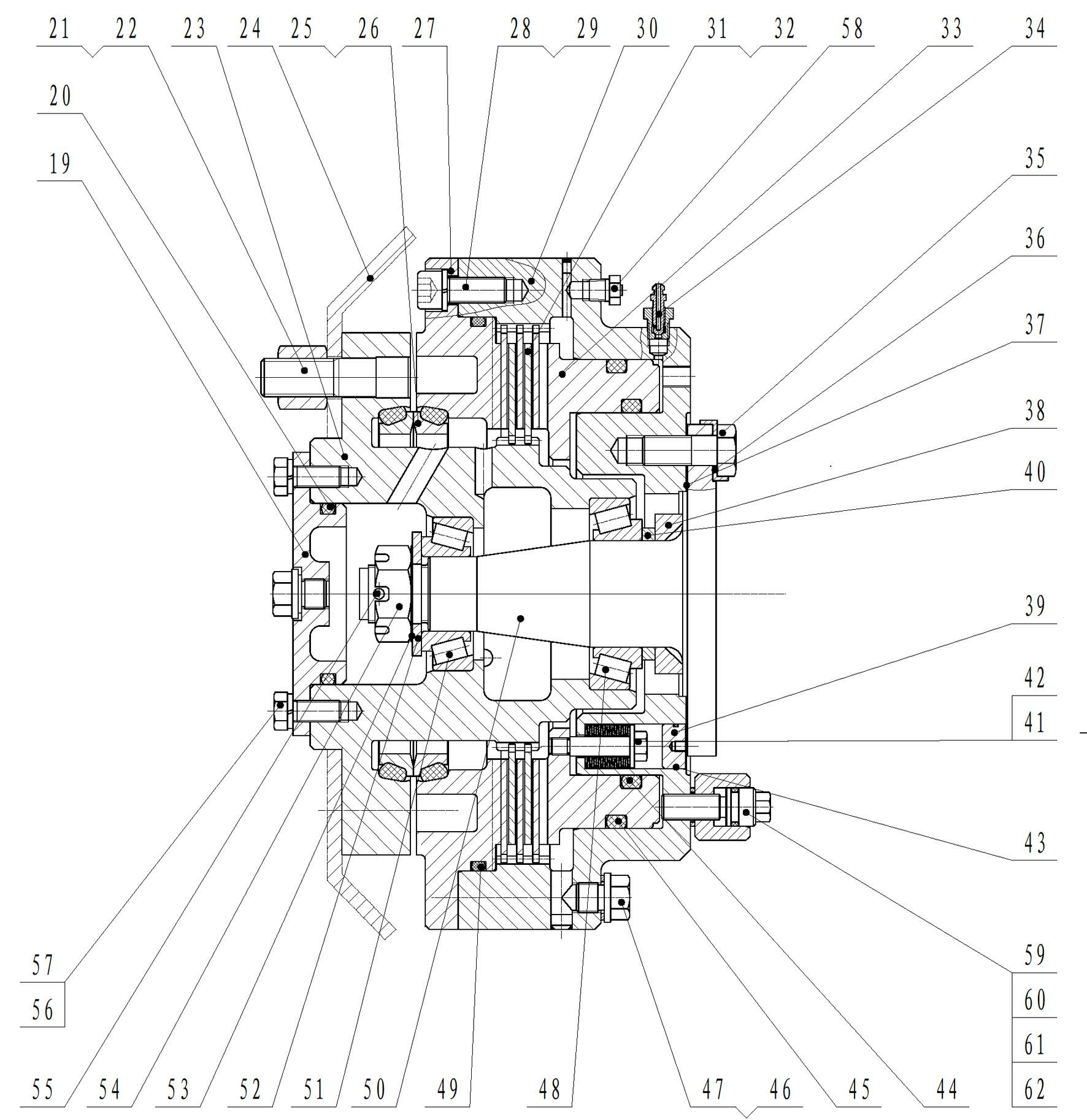

Double-tube fully-hydraulic braking device with closed wet-type multi-disc brakes for coal mine explosion-proof vehicle

ActiveCN102514562AImprove braking effectReduce labor intensityFluid braking transmissionDouble tubeHydraulic pump

The invention belongs to the technical field of braking devices of coal mine auxiliary conveying machinery, in particular to a double-tube fully-hydraulic braking device with closed wet-type multi-disc brakes for a coal mine explosion-proof vehicle. The invention aims to provide an explosion-proof, antipollution, stable, reliable and sensitive brand-new braking system. The braking device comprises a charging valve, wherein an oil feeding opening P of the charging valve is connected with a hydraulic pump, the oil opening A1 and opening A2 of the charging valve are connected with a front brake energy accumulator and a rear brake energy accumulator, and the oil opening SW is communicated with a parking braking oil pipe; the front and rear braking energy accumulators are connected with serial pedal braking valves respectively; the serial pedal braking valves are connected with a front service brake and a rear service brake respectively; parking braking energy accumulators are connected with parking braking valves; and parking braking valves are connected with parking brakes. The braking device meets the conditions for use in a special underground environment, can improve the braking efficiency and working efficiency and safety of the underground explosion-proof vehicle, reduce labor intensity, reduce casualty and accident rates and make underground conveying safer.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

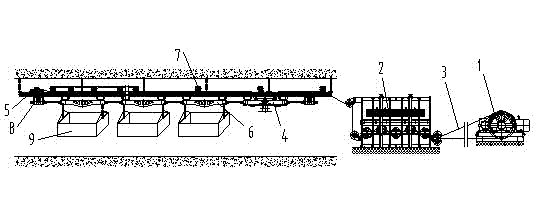

Coal mine transportation system

The invention provides a coal mine transportation system comprising a power system, a tensioning device, a guy cable, a shuttle car, a hanging rail, at least one lifting device, a plurality of groups of guy cable spacing components and a rope return wheel, wherein the shuttle car and the lifting device are hung on the hanging rail and are in sliding connection with the hanging rail; the lifting device is mounted and connected with the shuttle car; the groups of guy cable spacing components are fixedly connected with the hanging rail; the rope return wheel is mounted and connected to the tail end of the hanging rail; the guy cable penetrates the power system and the tensioning device, and further penetrates the guy cable spacing components and the rope return wheel; and the head and the tail of the guy cable are both fixedly connected with the shuttle car. The coal mine transportation system is low in cost and noise, reliable in performance and high in anti-explosion effect.

Owner:常州御发工矿设备有限公司

Positive-pressure type video camera lens protective cover

InactiveCN101135829AImprove sealingAvoid water seepageInstrument housingHermetically-sealed casingsCamera lensPositive pressure

Owner:杜永辉

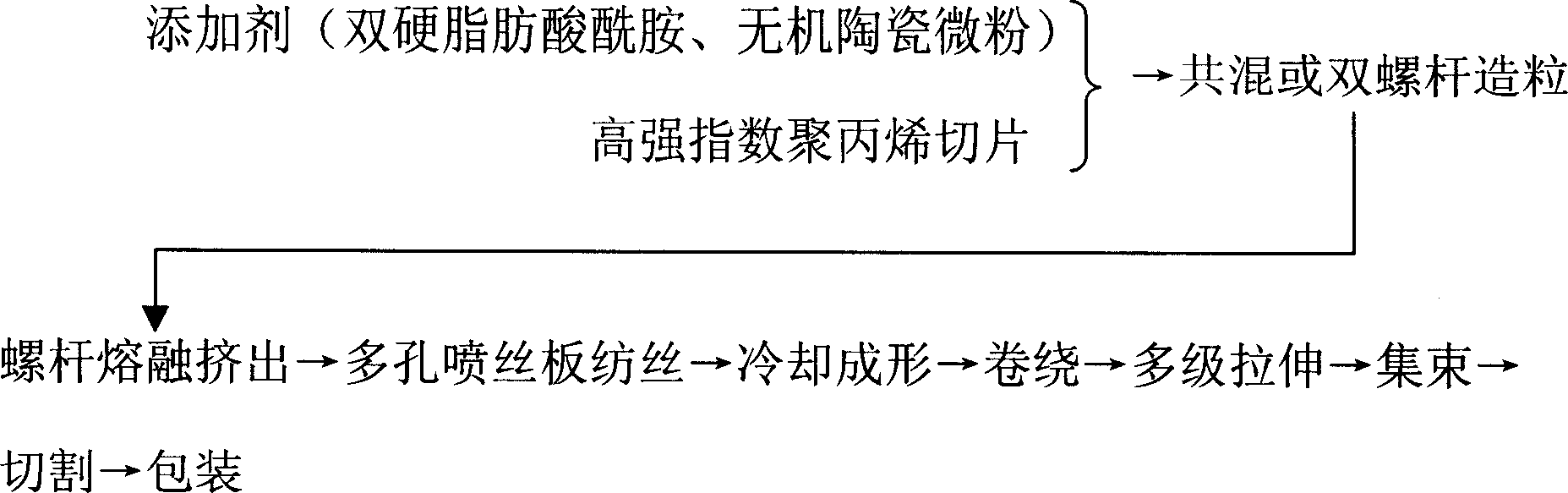

Porous polypropylene modified fiber for antiexplosive concrete

InactiveCN1888161AImprove explosion-proof performanceEasy to cleanFilament/thread formingMonocomponent polypropylene artificial filamentFiberHigh pressure

The present invention discloses a porous polypropylene modified fibre for explosion-proof concrete. It is characterized by that said fibre is made up by using polypropylene chip whose melting index is 16-60 as main body raw material, adding 0.1-1% of distearic amide surfactant and 0.1-6% of inorganic ceramic micro-powder and making all the above-mentioned materials undergo the processes of mixing, granulating, high-pressure spinning and multistage drawing.

Owner:SHENZHEN OCEAN POWER INDUSTRIAL CO LTD

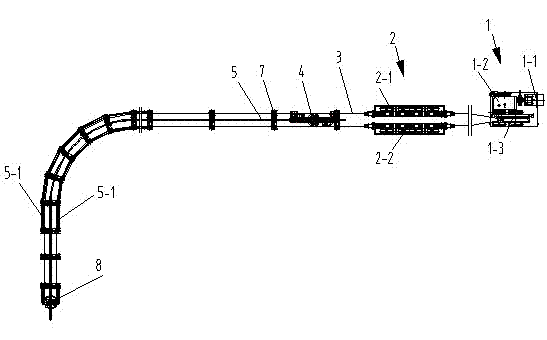

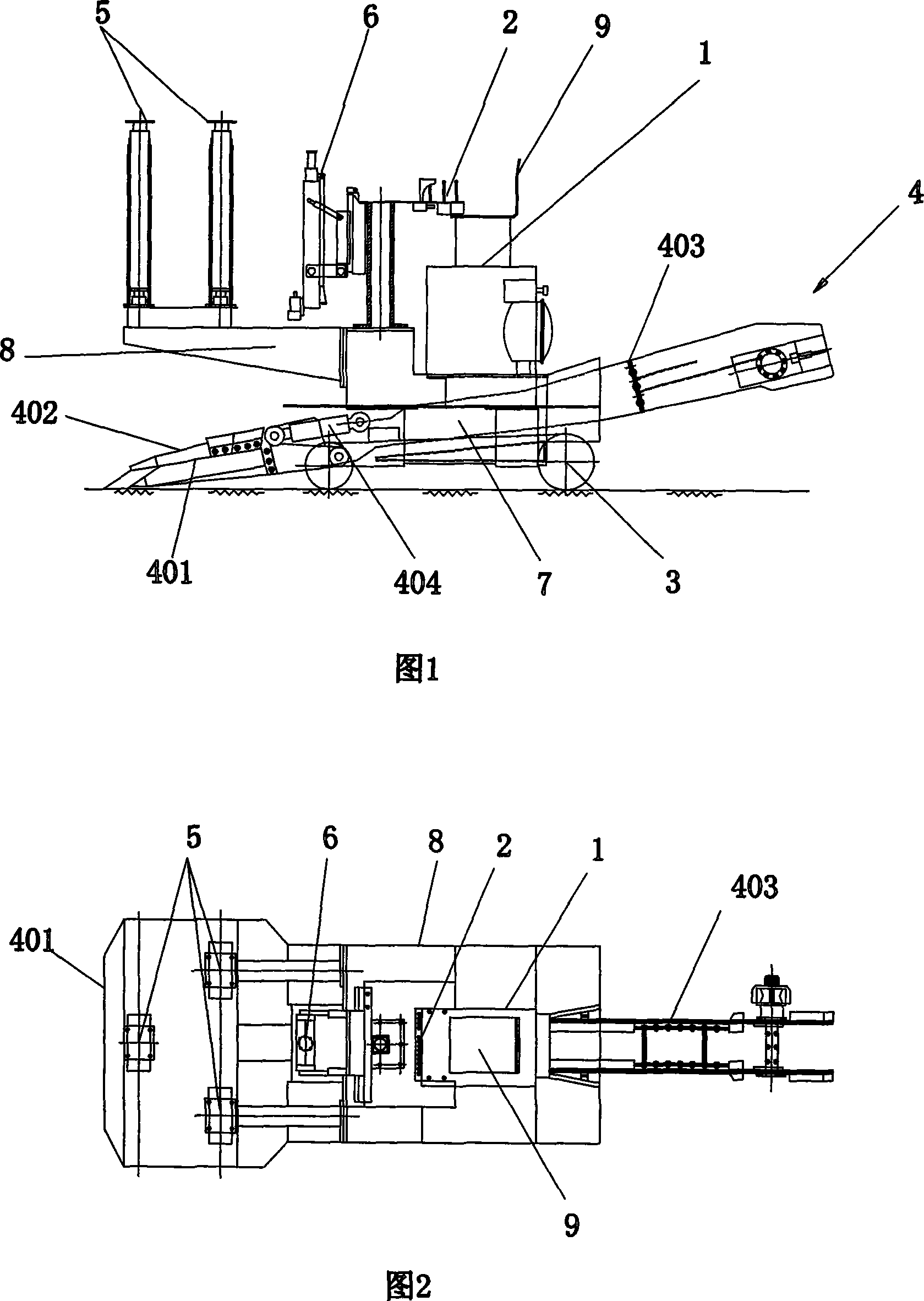

Explosion coal-falling, coal-loading, coal-conveying and anchor-rod supporting mechanism integration operation method and apparatus

InactiveCN101025086AIncrease the speed of excavationExcavation section is largeUnderground miningSurface miningResource recoveryEngineering

The invention provides a blast-winning, coal loading, coal conveying and anchor rod-timbering mechanical integrated operating method and device. And the device mainly comprises: hydraulic system, hydraulic control table, track walking part, coal loading and conveying part, timbering part, and hydraulic anchor rod machine, and the method uses integrated device, scraper conveyor and gate coal conveyor; and its drivage circulating speed is 1m to 1.5 m, blast-winning and after the fumes have settled, making the integrated device enter into the operating site, and after completing coal loading and conveying, making anchor rod timbering; after completing the anchor rod timbering operation, making the integrated device exit the operating site and over 20 meters distant from the operating site, and then making drilling and blasting operation. And it improves explosion level of blast winning and resources recovery, and reduces operators.

Owner:闫振东

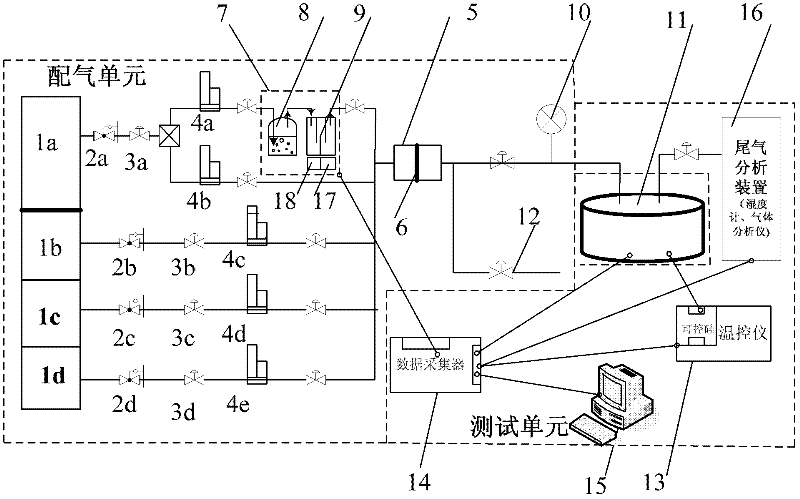

Gas sensor test system

InactiveCN102495110AMeet the needs of performance testingAvoid volatilityMaterial resistanceGas analysisTemperature control

The invention discloses a gas sensor test system. The system comprises a gas distribution unit, a gas sensitivity measuring device and a test unit. The gas distribution unit comprises an air supply unit, more than one tested gas supply units, and a gas mixing chamber for uniformly mixing air and the tested gas. The gas mixing chamber is communicated with the gas sensitivity measuring device, and is provide for inputting the mixed gas to the gas sensitivity measuring device through a pipeline. The test unit comprises a data acquisition device, a temperature control instrument connected with the data acquisition device, a tail gas analysis device and a computer, wherein the data acquisition device respectively forms electrical connections with the air supply unit and the gas sensitivity measuring device, and the tail gas analysis device is communicated with the gas sensitivity measuring device through a pipeline.

Owner:NANJING UNIV OF TECH

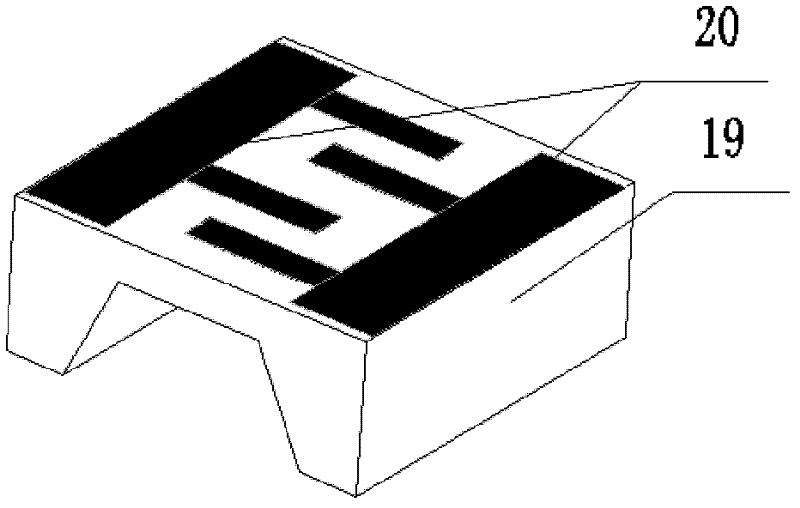

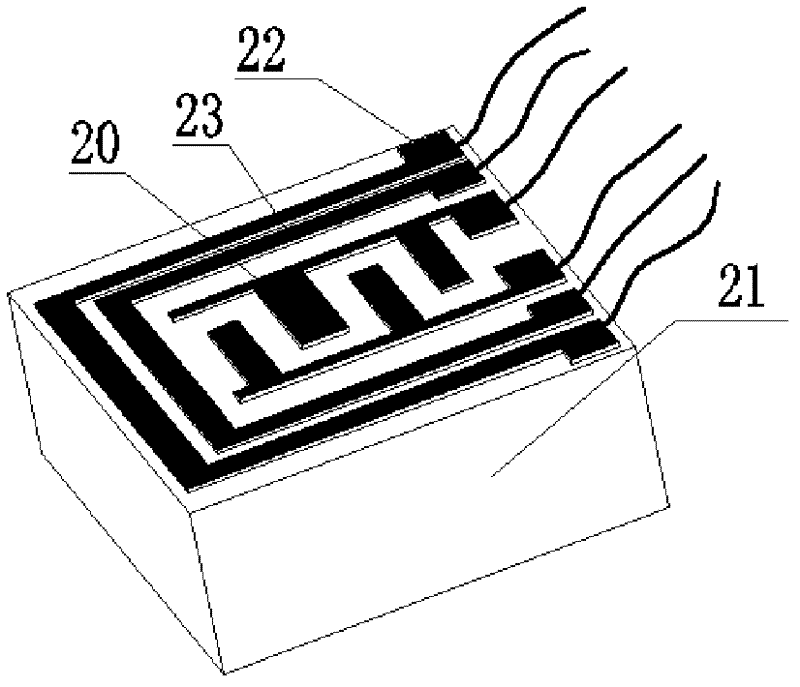

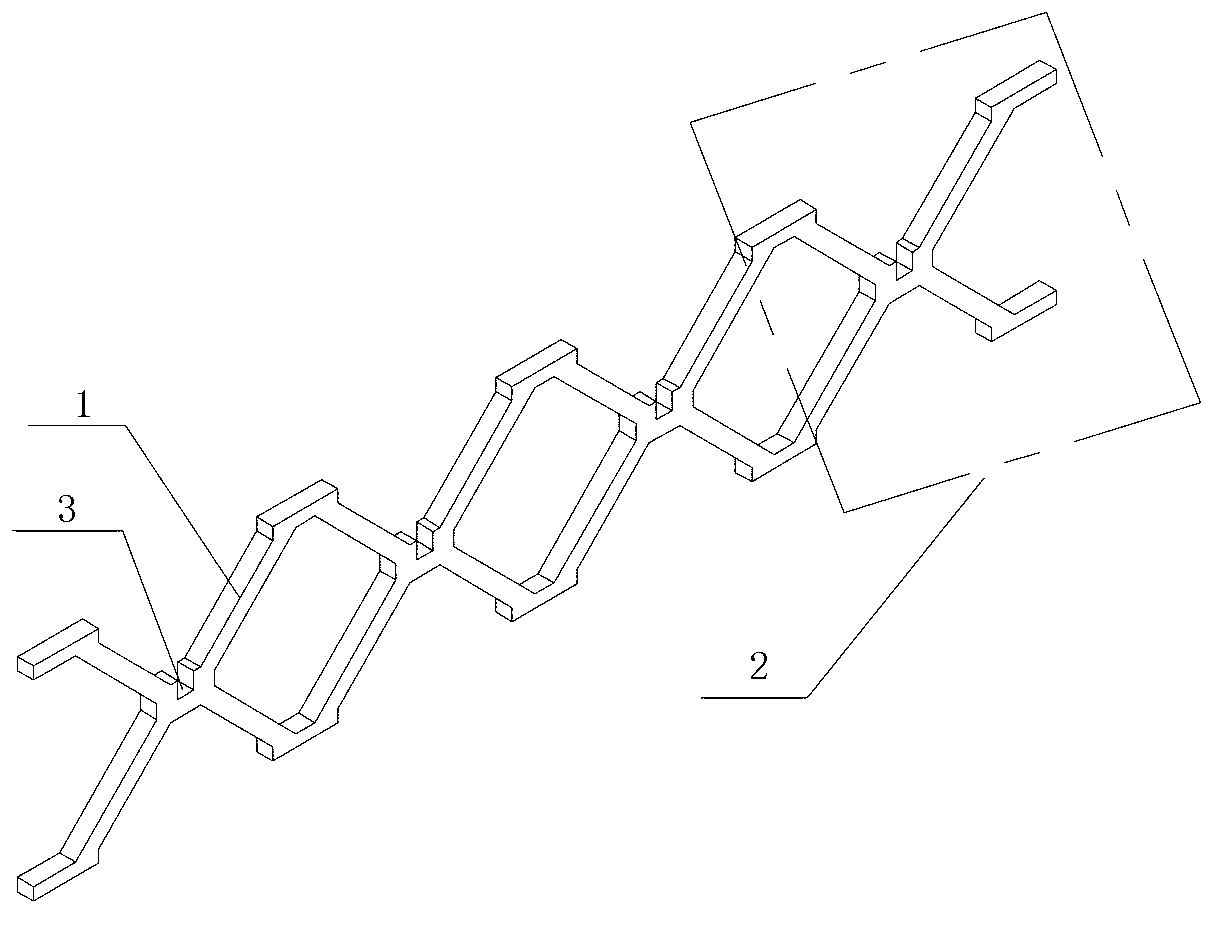

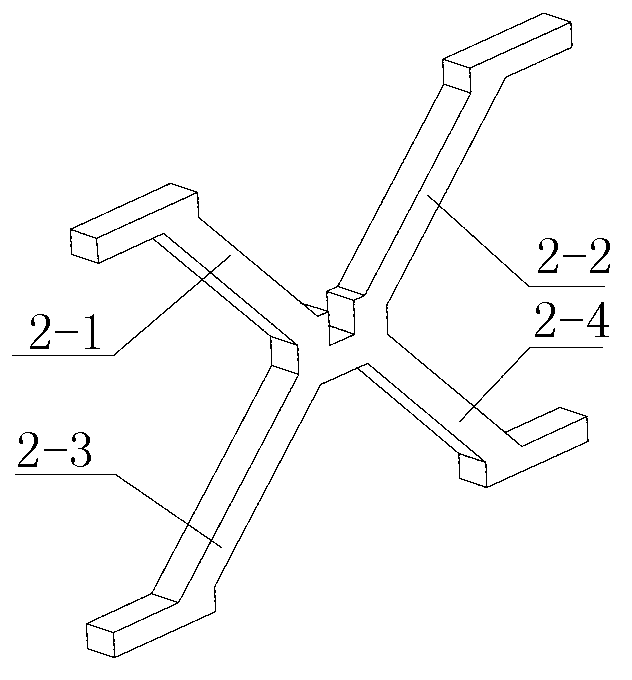

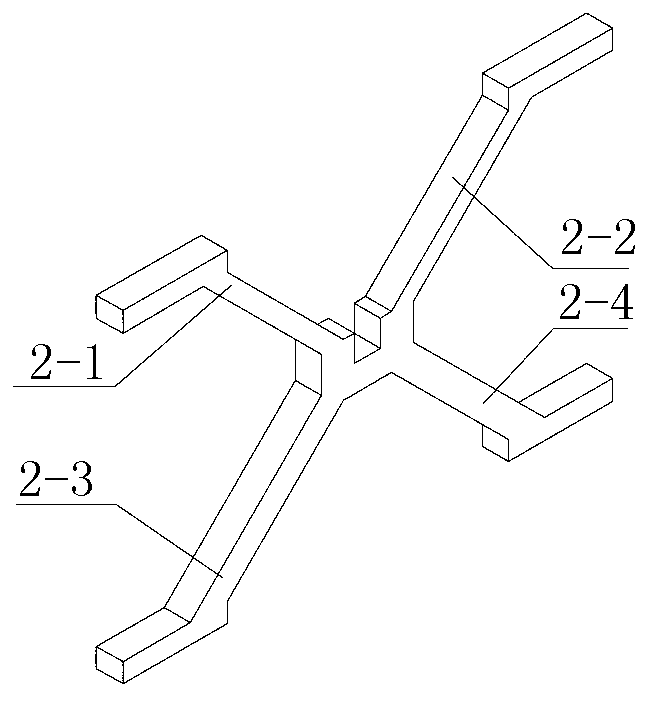

Core material of dot matrix laminboard and manufacturing method of core material by using extruding and interlocking

InactiveCN103302908AEasy snap-in assemblySimple processLaminationLamination apparatusDot matrixMaterials science

The invention discloses a core material of a dot matrix laminboard and a core material manufacturing method by using extruding and interlocking, and relates to a core material of the laminboard and a manufacturing method for the core material. The invention aims to solve the problems that the preparation technology of the conventional core material of the dot matrix laminboard is complicated, the cost is high, and the core material is difficultly produced in batches. According to a scheme I, each connection strip is integrated by a plurality of X-shaped units which are sequentially connected with one another; notches are formed above the intersections of the X-shaped units; two groups of connection strips are perpendicular to each other and are clamped with each other through the notches. According to a scheme II, each connection strip comprises a plurality of V-shaped units and a plurality of connectors; the connection strips in two groups are clamped with each other through first notches and notches in the connectors. According to a scheme III, connection plates are extruded; the connection plates in the step 1 are cut into connection strips with the equal thicknesses; the two groups of connection strips are perpendicular to one another and are clamped with one another through the notches. According to a scheme IV, the difference from the scheme III is that the connection strips in the two groups are clamped with one another through the first notches and the notches in the connectors. The core material is used for preparing the dot matrix laminboard.

Owner:HARBIN INST OF TECH

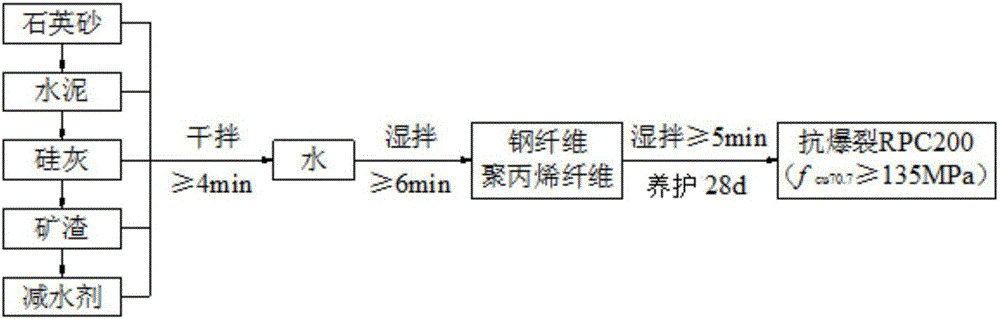

200MPa grade anti-bursting reactive powder concrete under construction site curing conditions and preparation method thereof

The invention discloses a 200MPa grade anti-bursting reactive powder concrete under construction site curing conditions and a preparation method thereof. The concrete is prepared from the following components by weight: 1 part of cement, 0.25-0.35 part of modified silica fume, 0.15-0.35 part of ground slag, 1.0-1.5 parts of quartz sand, 0.030-0.040 part of a polycarboxylate superplasticizer, 0.15-0.25 part of steel fiber, 0.00175-0.003 part of polypropylene fiber, and 0.20-0.25 part of water. The 200MPa grade anti-bursting reactive powder concrete provided by the invention has the advantages of simple process and strong operability, is suitable for extensive site construction and curing, and is in favor of popularization and application of reactive powder concrete. The use of slag and the non-high temperature steam curing conditions have important significance for protecting the environment and saving energy.

Owner:SHANDONG JIANZHU UNIV

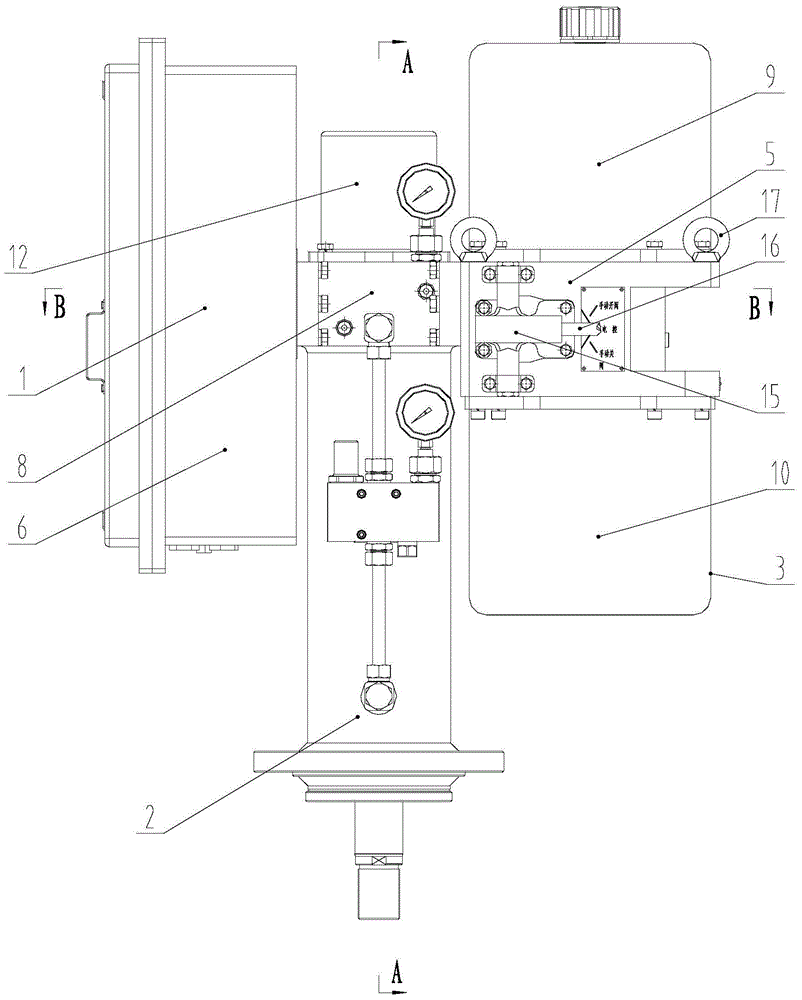

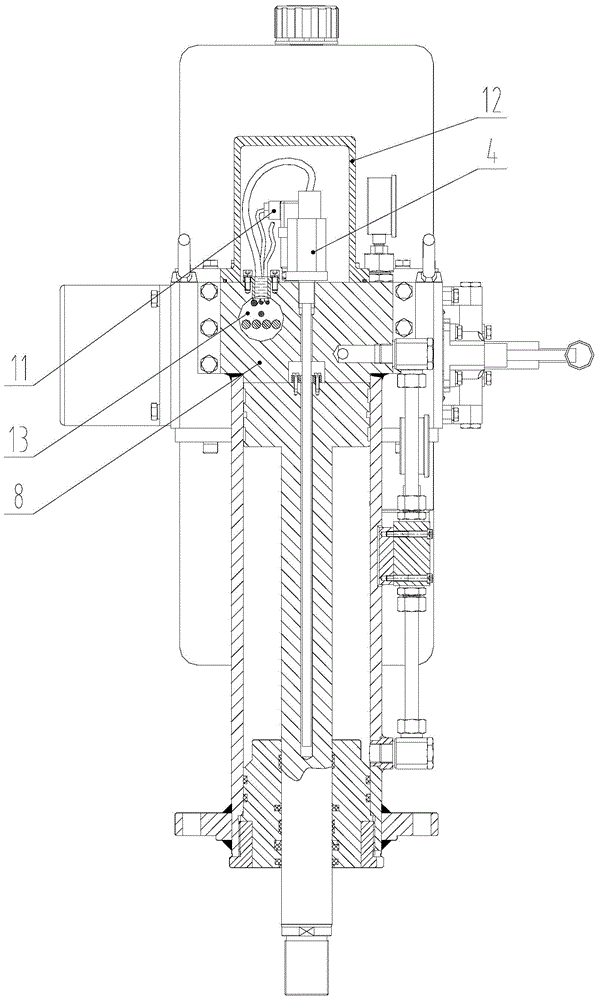

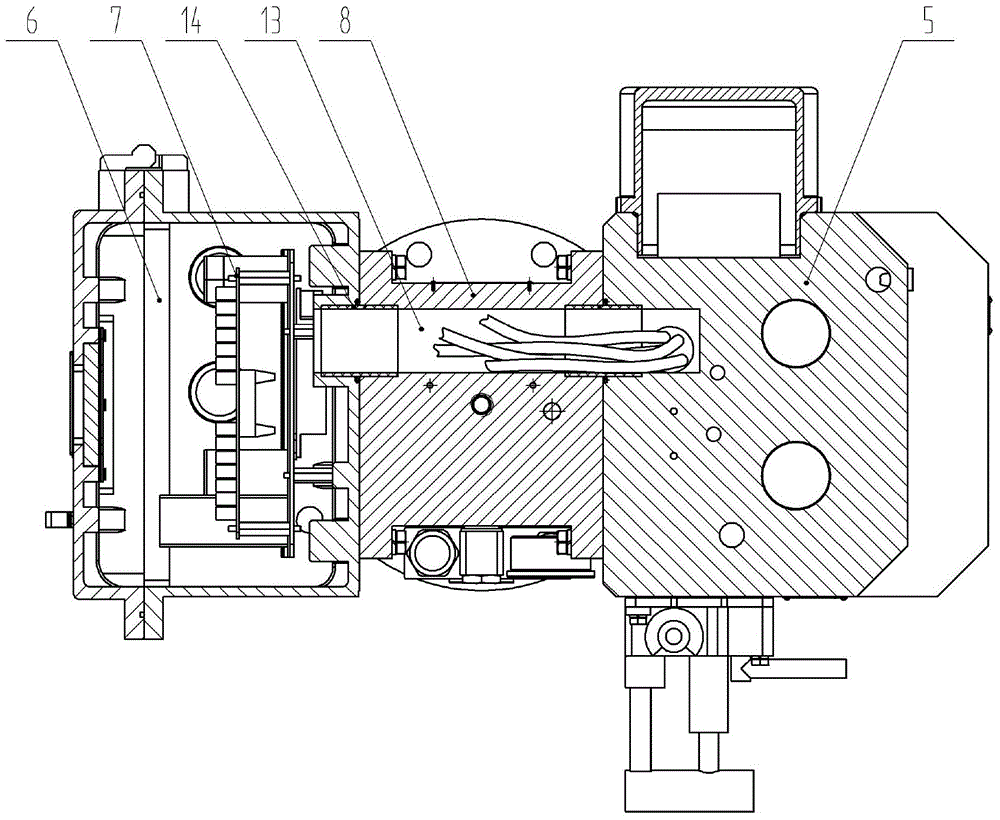

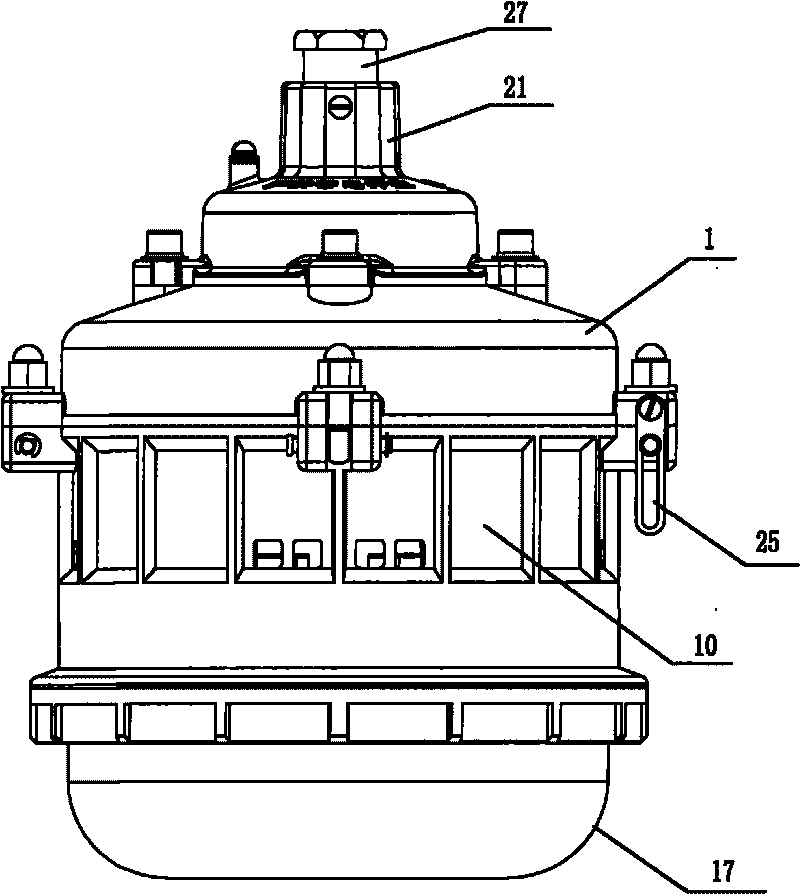

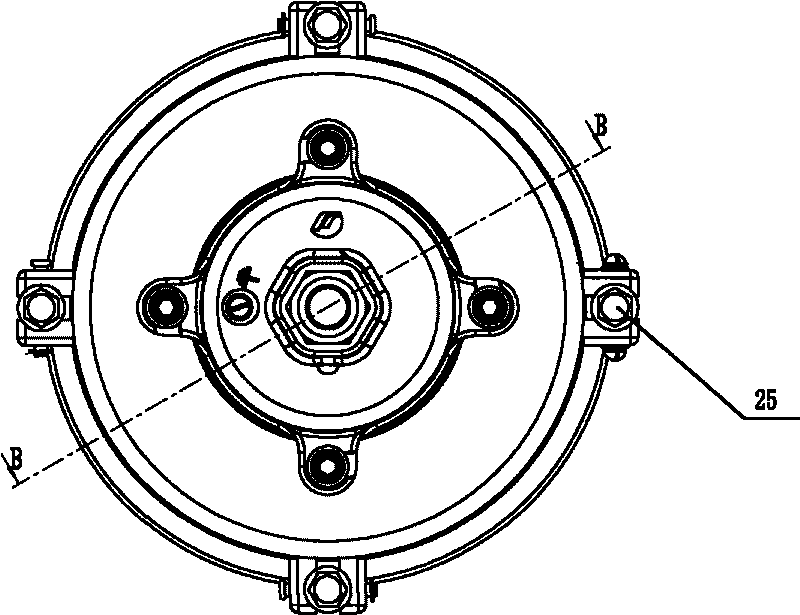

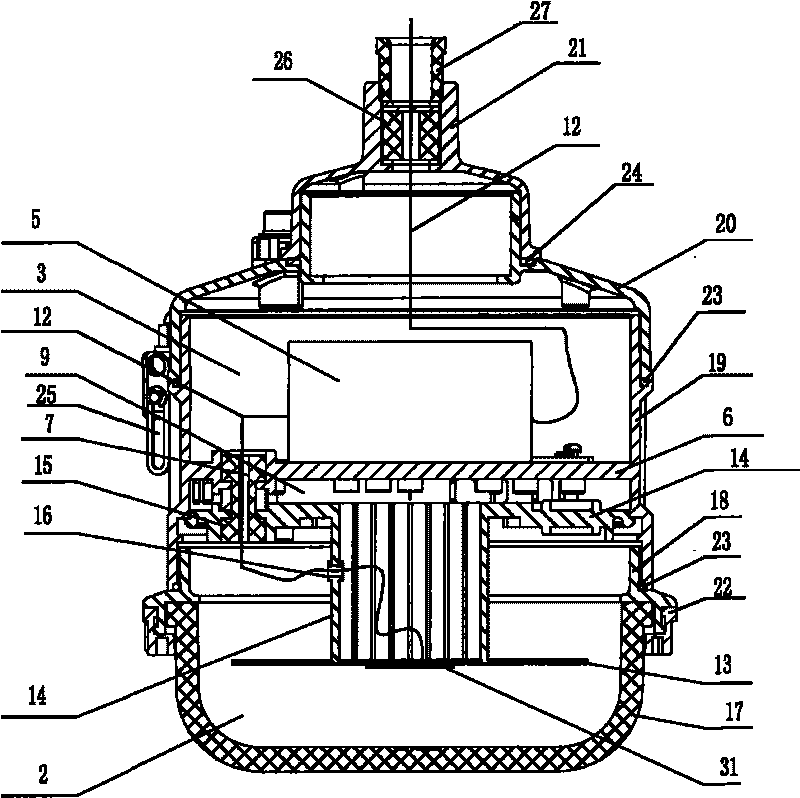

Explosion-proof hybrid electro-hydraulic integrated actuator for valve

ActiveCN104565506AReasonable function layoutImprove completenessOperating means/releasing devices for valvesEngineeringActuator

The invention discloses an explosion-proof hybrid electro-hydraulic integrated actuator for a valve. The actuator comprises electrical control box, double-acting cylinders and hydraulic power unit; with a piston displacement of the displacement sensors and detectors for detecting the pressure of the pressure on the double-acting cylinder sensor, double-acting cylinders driven by a hydraulic power unit telescopic movement; hydraulic power unit according to the motor, pump, manifold, valve blocks flow matching, piping and other integration body, the valve of the invention hybrid integrated electro-hydraulic explosion actuators, cylinders comes with displacement and pressure testing, to create conditions for the realization of high-precision positioning of double-loop control, modular design, functional and reasonable layout, and enhance the degree of integration and explosion-proof performance.

Owner:CHONGQING CHUANYI AUTOMATION

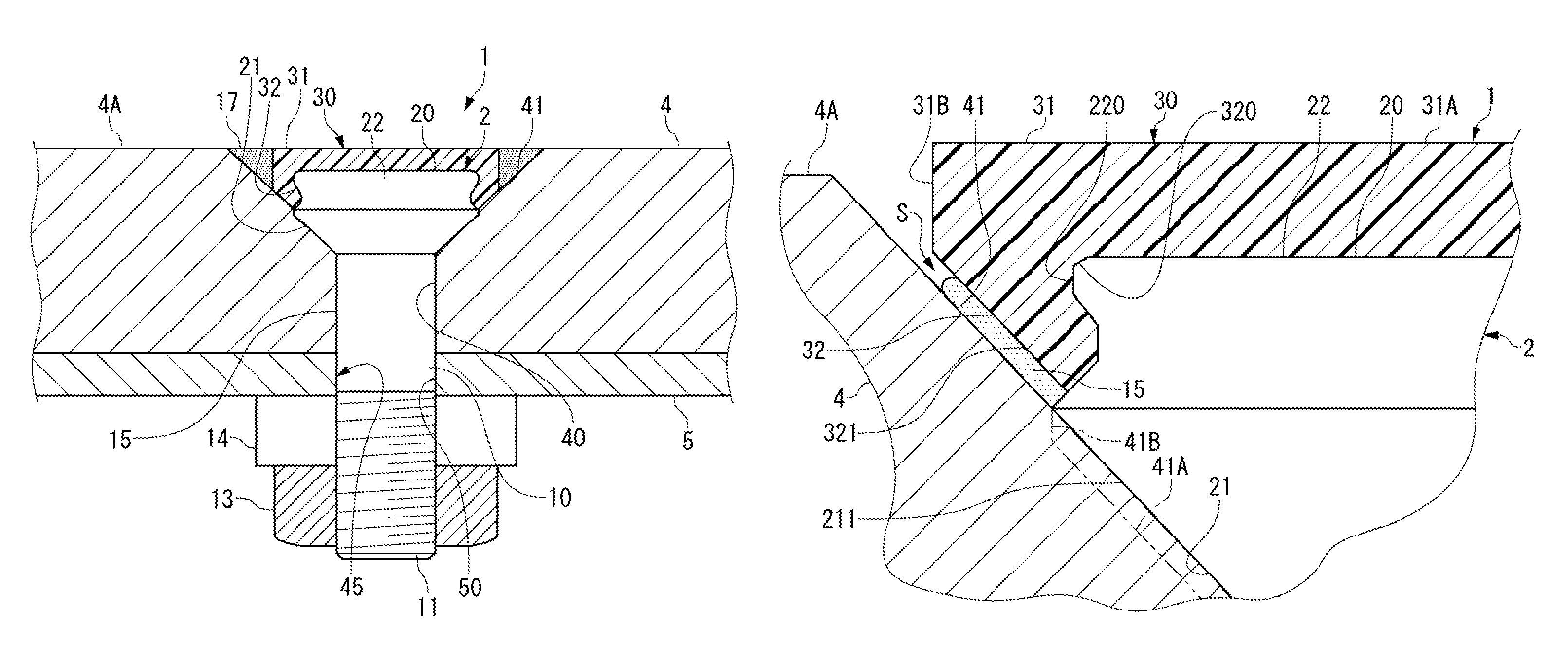

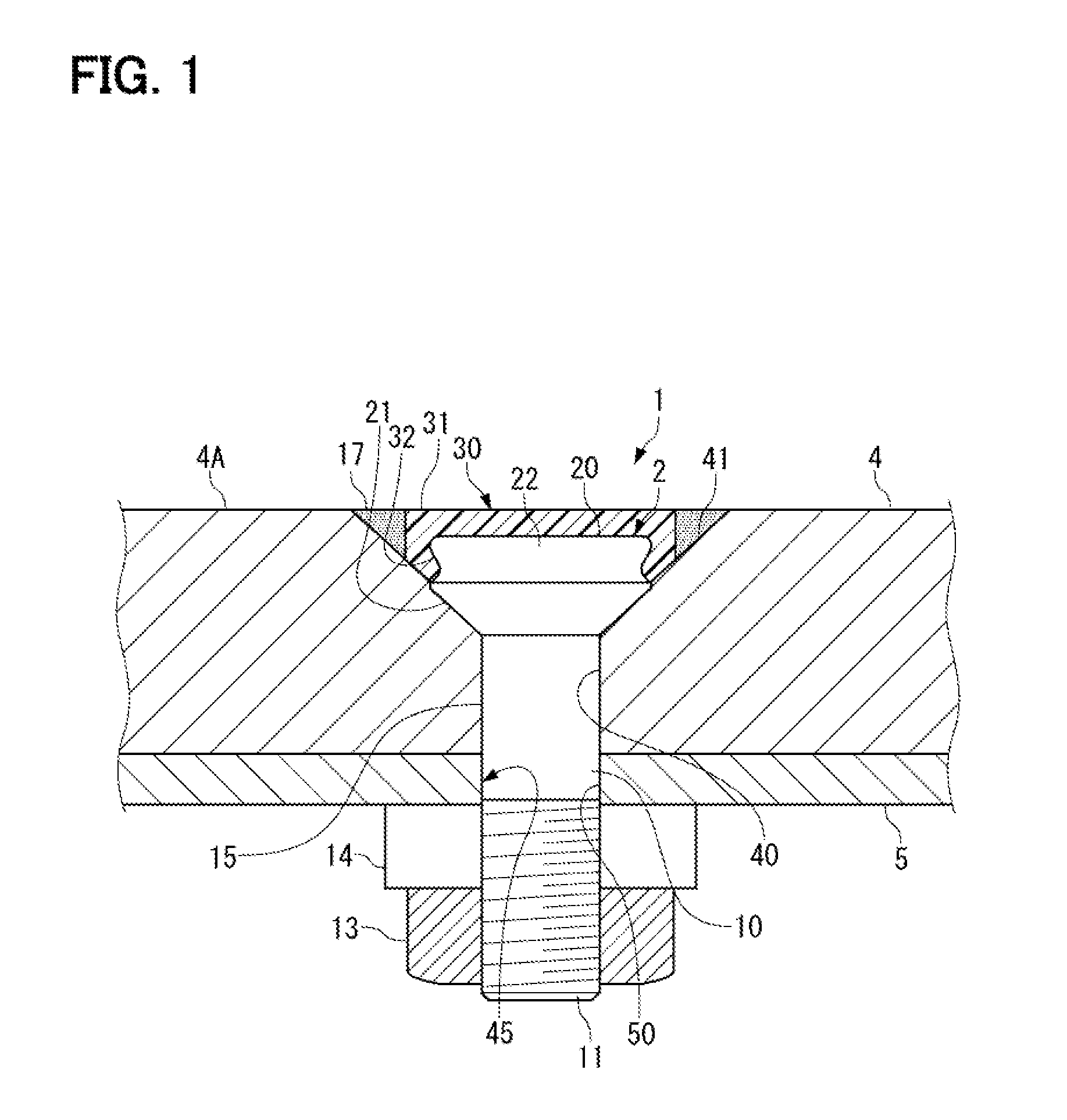

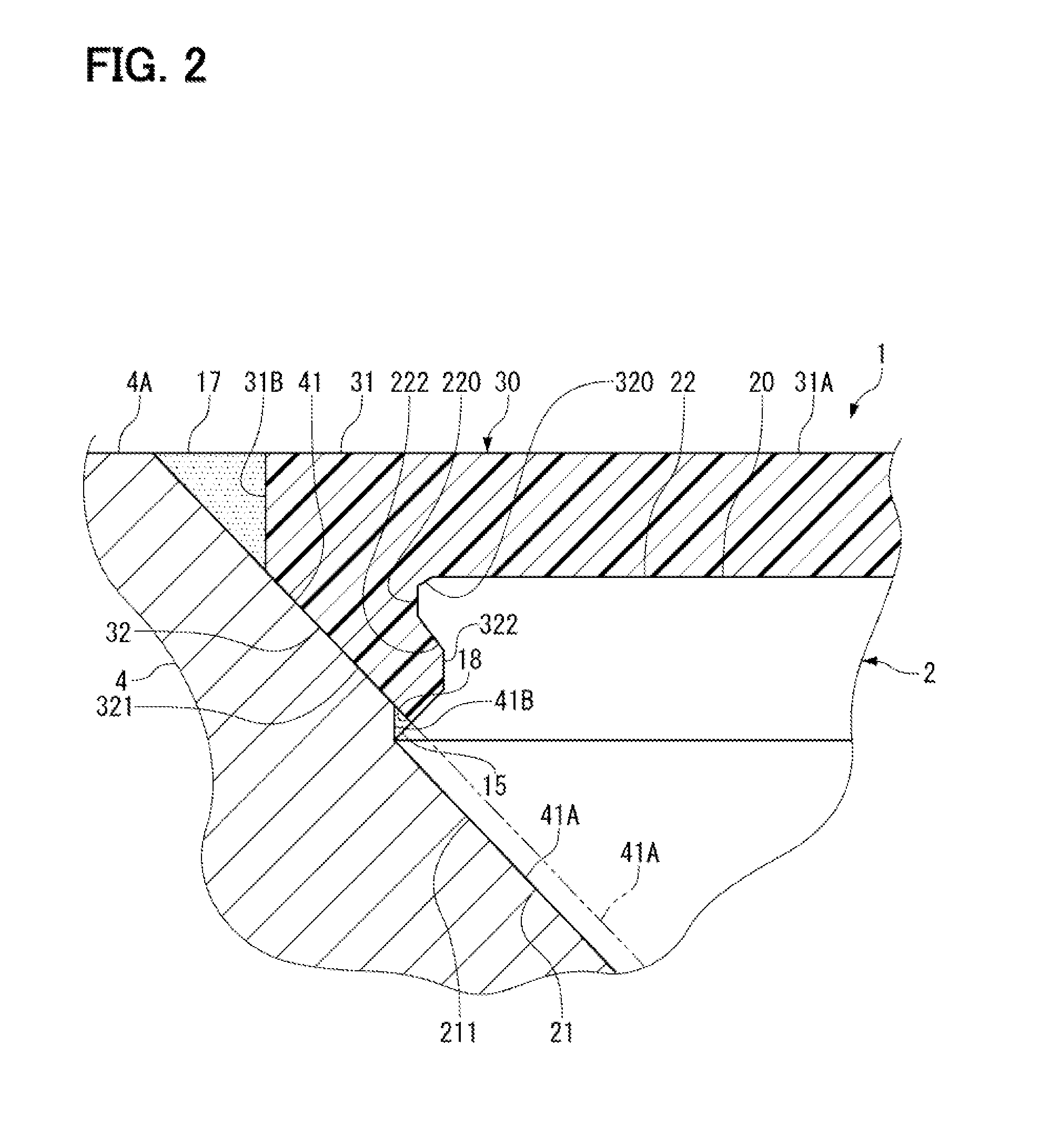

Lightning protection fastener and aircraft

ActiveUS9290276B2Guaranteed smoothHigh dielectric strengthAircraft lighting protectorsNutsPlastic materialsBiomedical engineering

An aircraft of the present invention includes an outer panel 4 made of a fiber reinforced plastic material, a support member 5, and a lightning protection fastener 1. The fastener 1 includes a metal fastener body 2 having a shaft portion 10 and a head portion 20, and an insulating member 30 made of an insulating plastic material and mounted to the head portion 20. The portion 20 has a frustoconical-shaped fastener seat surface 211. The panel 4 includes a receiving surface 41 conforming to the fastener seat surface 211. The member 30 includes an insulating seat surface 321 retracted from a plane of the fastener seat surface 211 such that, when a portion 41A of the receiving surface 41 which is opposed to the fastener seat surface 211 is depressed, an insulating seat surface 321 comes into contact with the receiving surface 41.

Owner:MITSUBISHI AIRCRAFT

Storage iron runner castable produced by adopting waste iron runner material

The invention discloses a storage iron runner castbale produced by adopting a waste iron runner material. The storage iron runner castable comprises the following components in parts by mass: 15-20 parts of waste iron runner material, 20-30 parts of brown fused alumina particles, 3-5 parts of brown fused alumina fine powder, 5-10 parts of electric smelting compact corundum particles, 2-5 parts of electric smelting compact corundum fine powder, 3-5 parts of magnesia-alumina spinel, 10-20 parts of silicon carbide, 2-5 parts of silicon powder, 1-2 parts of activated aluminum oxide micro powder, 4-6 parts of crystalline flake graphite, 0.5-1 part of a silane coupling agent, 3-8 parts of aluminate cement, 1-4 parts of a compound water reducer, 1-2 parts of a compound antidetonant, and 1-2 parts of an antioxidant. The storage iron runner castable makes full use of the waste material, thus greatly lowering comprehensive cost; due to the materials of the different particle sizes, the construction efficiency is improved; for the addition of the crystalline flake graphite and magnesia-alumina spinel powder, the molding density of the castable is improved, the castable is promoted in sintering, and the density, strength, volume stability and residue resistance of the castable are improved.

Owner:长兴煤山新型炉料有限公司

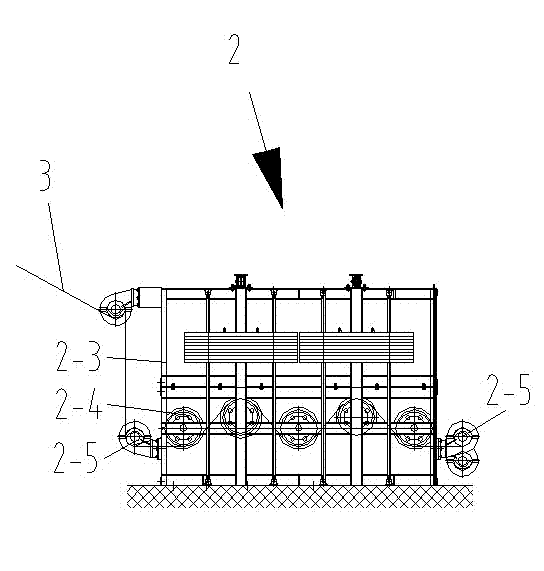

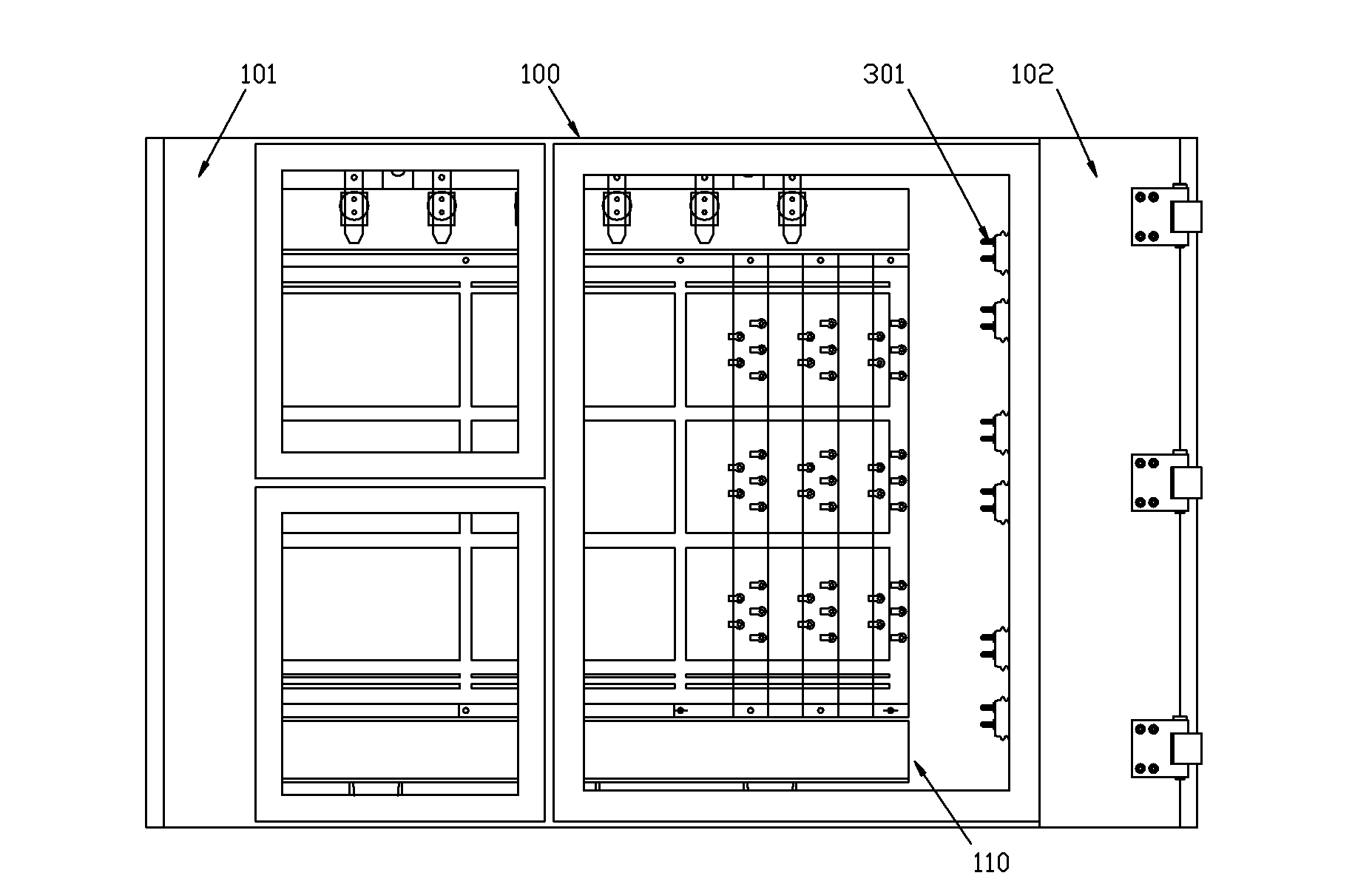

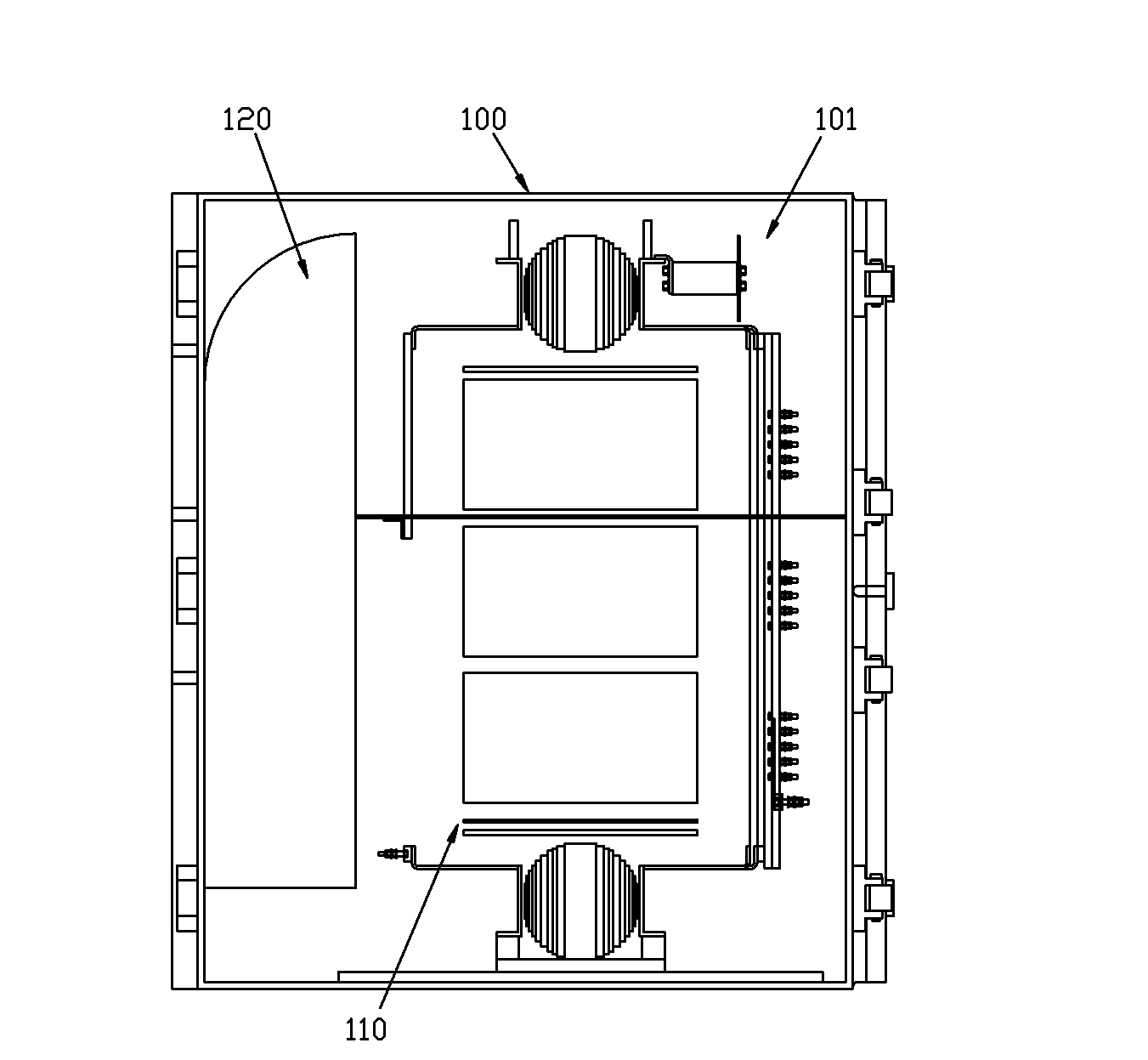

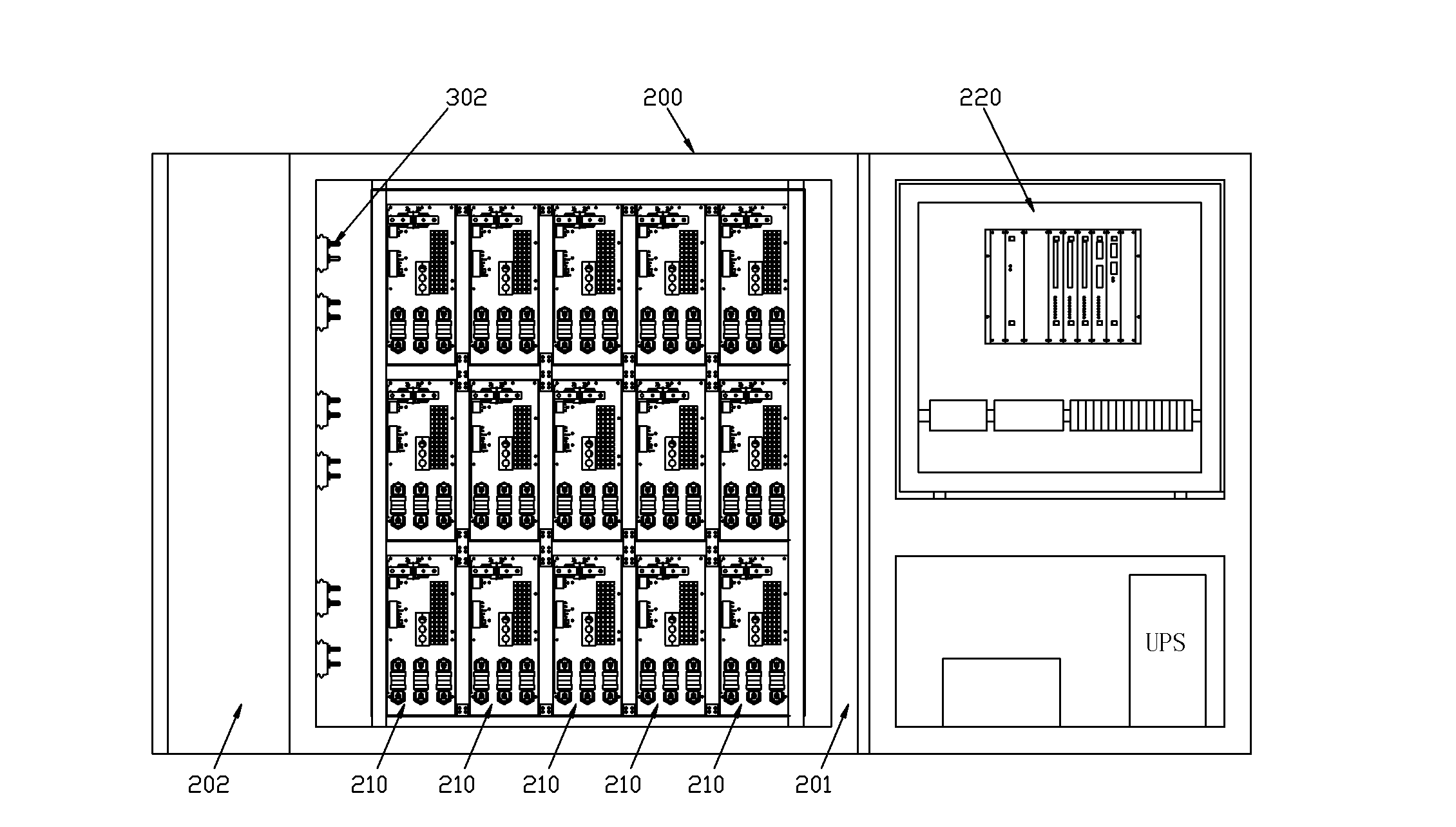

Mining high-voltage frequency converter with explosion-proof type

InactiveCN102307000APrevent Chain ExplosionsImprove explosion-proof performanceCooling/ventilation/heating modificationsPower conversion systemsControl signalEngineering

The invention discloses a mining high-voltage frequency converter with an explosion-proof type. The frequency converter comprises a phase-shifting transformer unit explosion-proof box and a power unit explosion-proof box; a phase-shifting isolation transformer and a heat radiation system are arranged in the phase-shifting transformer unit explosion-proof box; and a plurality of sets of power units, a control unit and a heat radiation system are arranged in the power unit explosion-proof box, wherein the plurality of sets of power units are in series connection. A high-tension side of the phase-shifting isolation transformer is in series connection with a three phase high voltage power network; the plurality of sets of power units are respectively connected with a low tension side of the phase-shifting isolation transformer; and the power units and the control unit are connected by a fiber. According to the invention, all assembling combination surfaces of the phase-shifting transformer unit explosion-proof box and the power unit explosion-proof box are constructed into sealing structures, so that an external environment is isolated from the phase-shifting transformer unit explosion-proof box and the power unit explosion-proof box; therefore, it can be avoided that corresponding chain explosions happen at high-risk occasions including a coal mine and the like and an explosion-proof effect is good. Besides, a control signal is transmitted by a fiber, so that an electrical isolation capability and an anti-electromagnetic interference performance are good.

Owner:江苏聚友电气有限公司

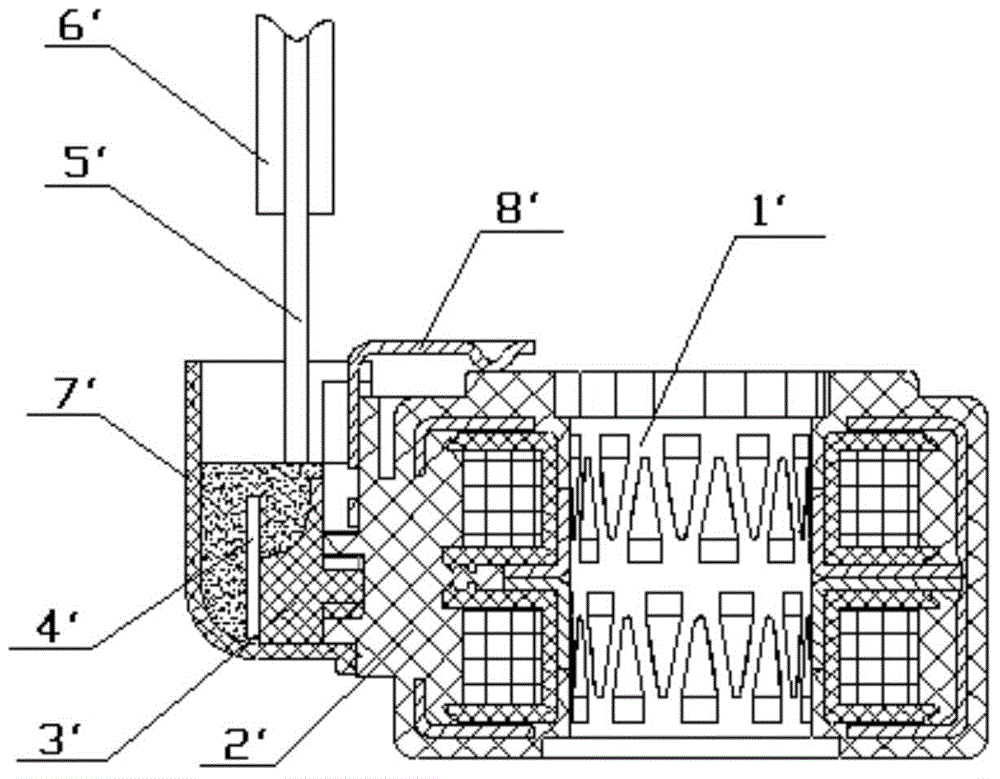

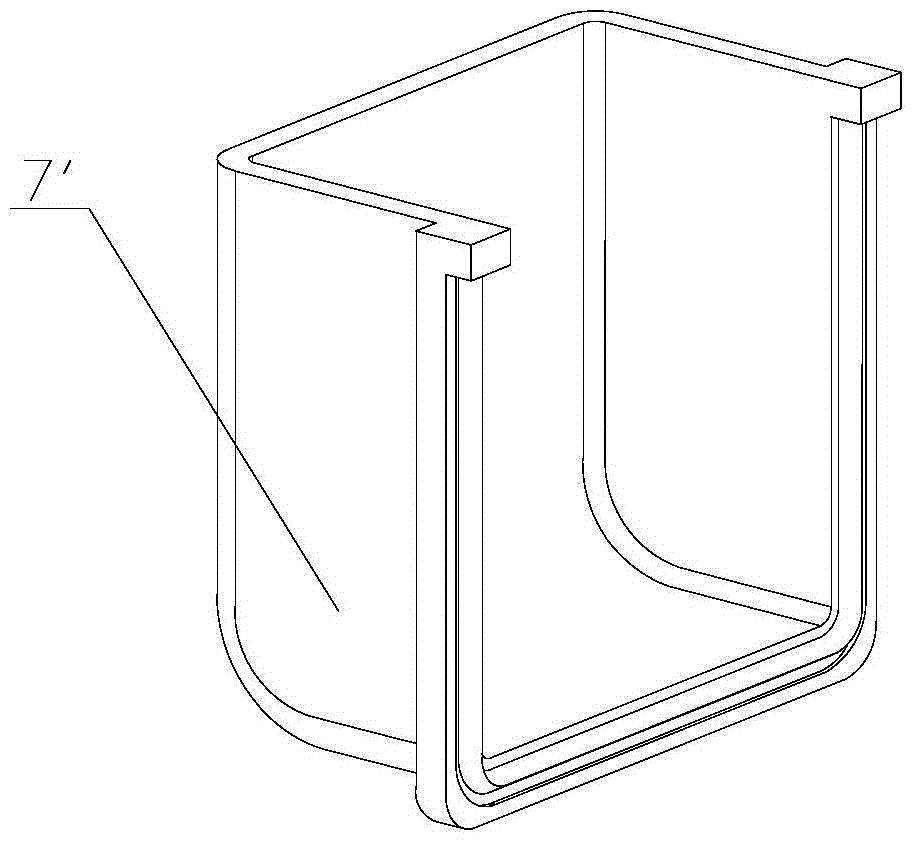

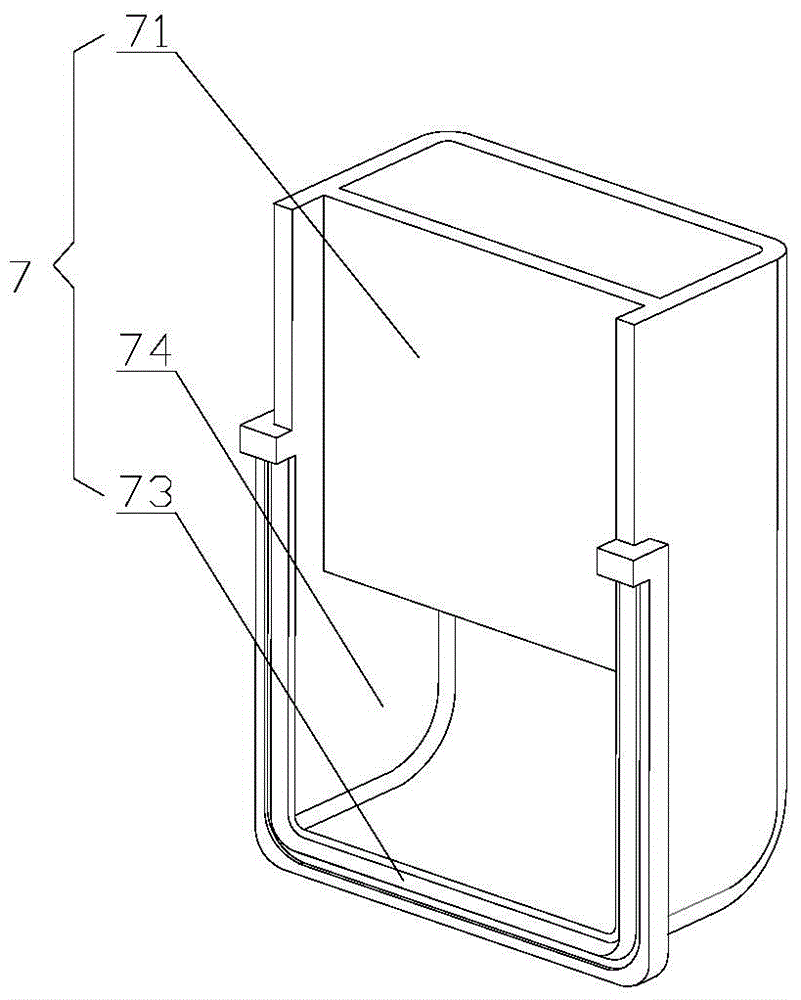

Explosion-proof coil, electronic expansion valve and machining method of explosion-proof coil

ActiveCN106151646AImprove explosion-proof performanceMeet certification requirementsOperating means/releasing devices for valvesEfficient regulation technologiesElectronic expansion valveMachining

The invention discloses an explosion-proof coil which comprises a winding (1) and a winding shell (2). A cable mounting part (3) and a circuit board (4) are arranged on the winding shell (2). A leading wire (5) is installed on the circuit board (4). A protection sleeve (6) is arranged outside the leading wire (5). A housing (7) is further fixedly connected outside the winding shell (2). The top end of the housing (7) is higher than the bottom end of the protection sleeve (6). The housing (7), the cable mounting part (3), the circuit board (4), the leading wire (5) and part of the protection sleeve (6) are formed into a whole through encapsulation. Compared with the prior art, encapsulation of the bottom end of the protection sleeve (6) is achieved through the explosion-proof coil, the electric insulation performance of the joint of the circuit board (4) is guaranteed, the explosion-proof performance of the explosion-proof coil is improved, the explosion-proof coil is made to meet the national certification requirements for explosion-proof coils, and meanwhile, market requirements for the explosion-proof coil of an electronic expansion valve can also be met. The invention further provides the electronic expansion valve with the explosion-proof coil applied and a machining method of the explosion-proof coil.

Owner:ZHEJIANG SANHUA INTELLIGENT CONTROLS CO LTD

Explosion proofing castable for steel ladle working layer

The invention belongs to the technical field of a refractory material technology for steel ladles in the ferrous metallurgy industry, and discloses an explosion proofing castable for a steel ladle working layer. The explosion proofing castable is characterized in that a composite explosion-proof agent and a composite water reducing agent are introduced in the castable, and the composition and the mixing ratio of the castable are adjusted, so that the inner structure of a material is improved, the air permeability and the strength at an intermediate temperature of the material are improved, the problem that the castable is peeled, separated and then cracked during being baked can be effectively avoided, the resulting loss of a user can be avoided, and simultaneously, the baking time is reduced, the energy is saved, and the pollution is reduced.

Owner:北京利尔高温材料股份有限公司

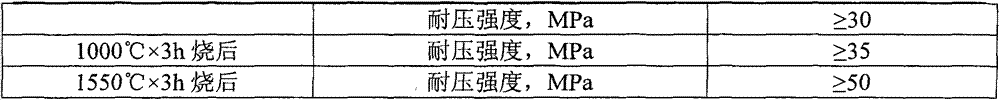

Adjustable explosion relief valve of storage battery

InactiveCN102709505AControl internal pressureAvoid explosionCell component detailsEngineeringPhysics

An adjustable explosion relief valve of a storage battery comprises a valve body, an adjusting nut, a pressure spring, a piston, a seal ring, a plug pin and a plug pin spring, wherein the adjusting nut is arranged at the back end of the valve body and connected with one end of the pressure spring arranged inside the valve body, the other end of the pressure spring is connected with one end of the piston, the other end of the piston is connected with the seal ring, the plug pin spring is arranged in the valve body and fixedly connected with the plug pin, a pit corresponding to the plug pin is arranged on the upper portion of the piston, a first channel is arranged on the inner side of the front end of the valve body and communicated with a cavity where the plug pin is arranged through a second channel, a through hole is arranged on the seal ring, and a decompression hole corresponding to the through hole is arranged on the valve body. The adjustable explosion relief valve has the advantages of being convenient to use, high in practicability, and capable of effectively controlling the inside pressure of the storage battery and preventing the storage battery from exploding due to the overhigh pressure inside.

Owner:刘立文

Blowback fast explosion suppression device for coal mining working face

ActiveCN102061929AFast closing actionStrong explosion-proof performanceMining devicesDust removalShock waveControl system

The invention provides a blowback fast explosion suppression device for a coal mining working face, and relates to a blowback fast explosion suppression device, which is used for solving the problem that shock wave and flame caused by explosion can not be effectively prevented in the existing coal mining working face. The blowback fast explosion suppression device is equipped with an explosion suppression door and two explosion suppression windows; and in case of explosion, a control system controls the explosion suppression door and the two explosion suppression windows to be closed so as to play the role of suppressing explosion. The blowback fast explosion suppression device is applicable to a roadway of a coal mine.

Owner:HARBIN INST OF TECH

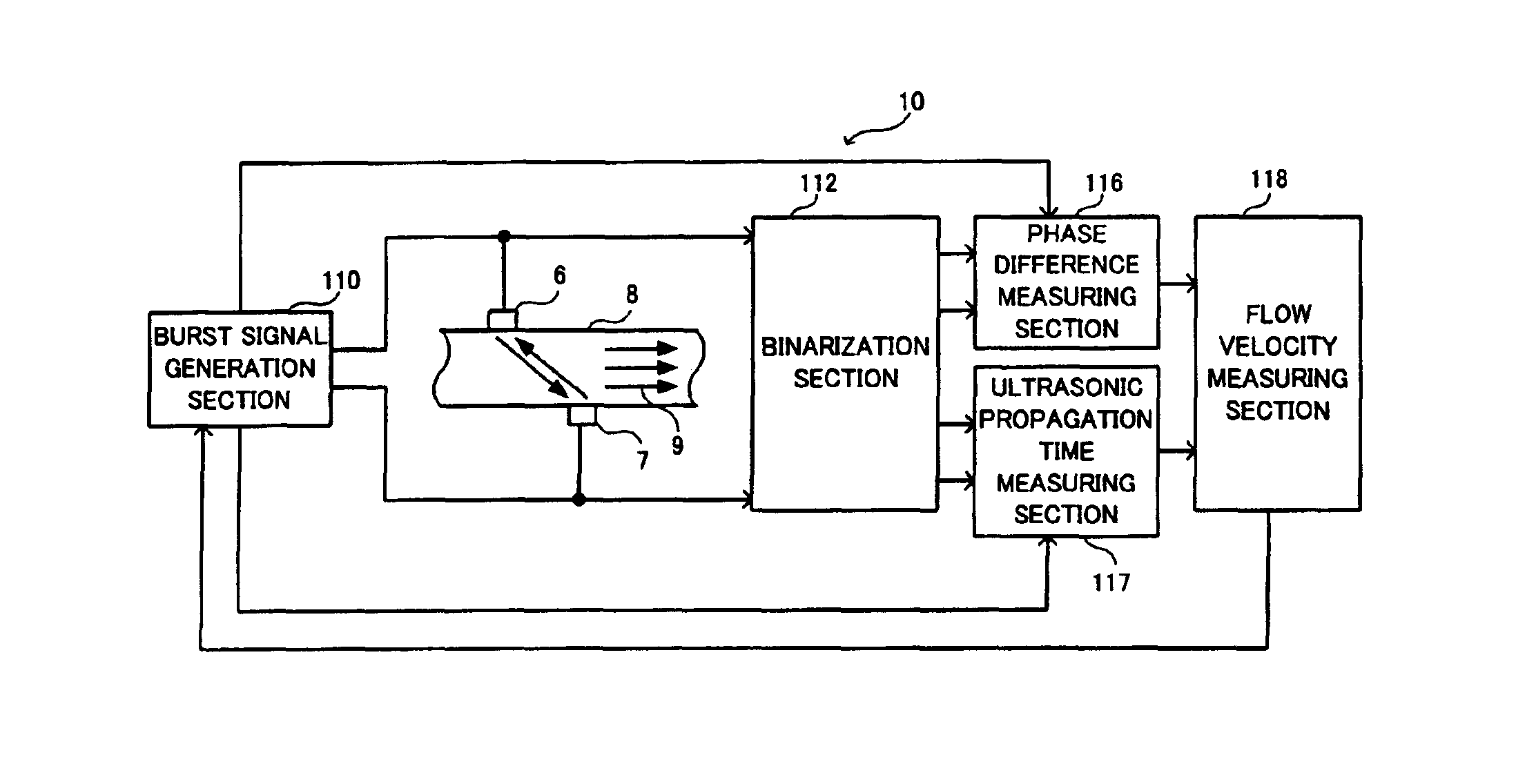

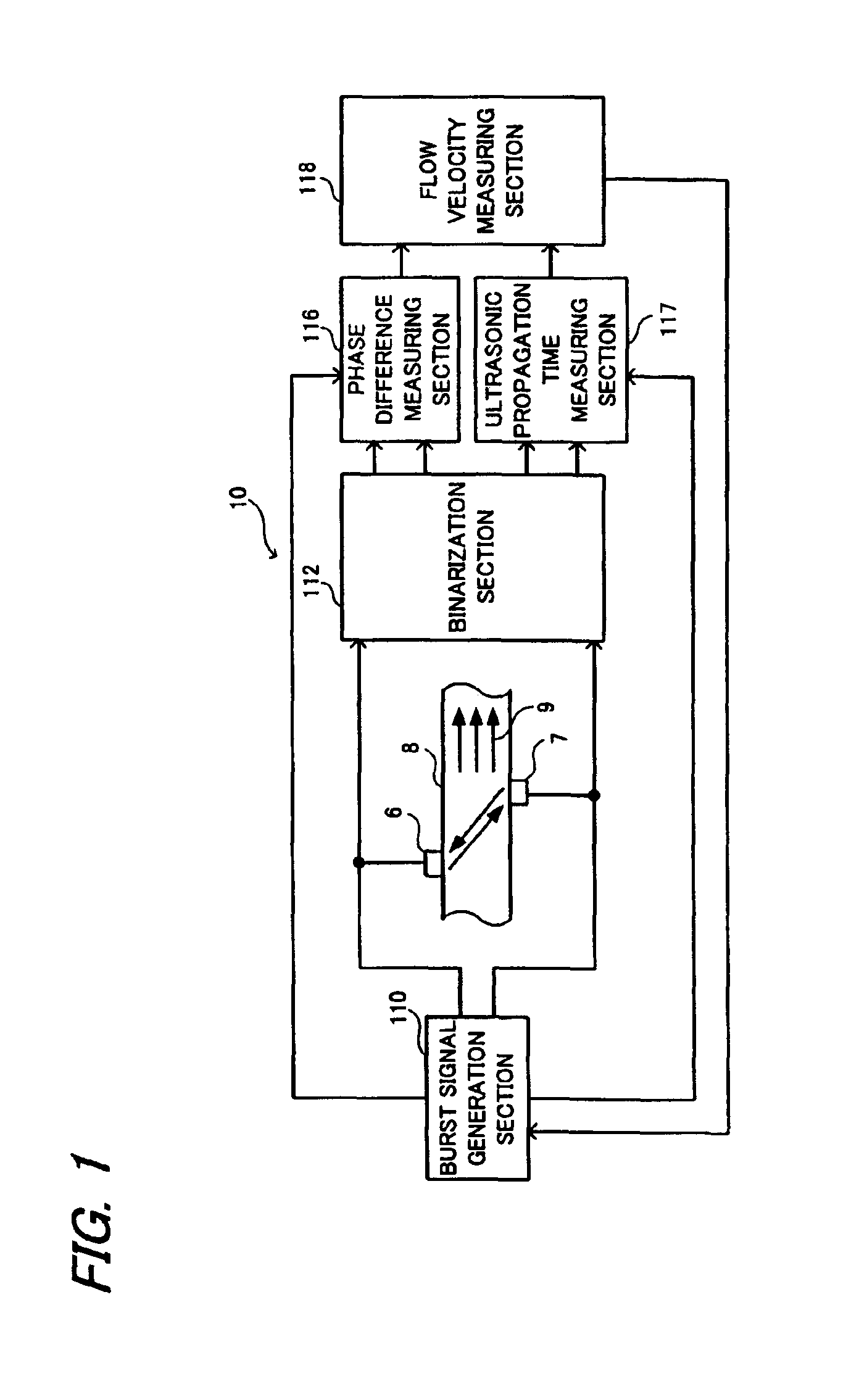

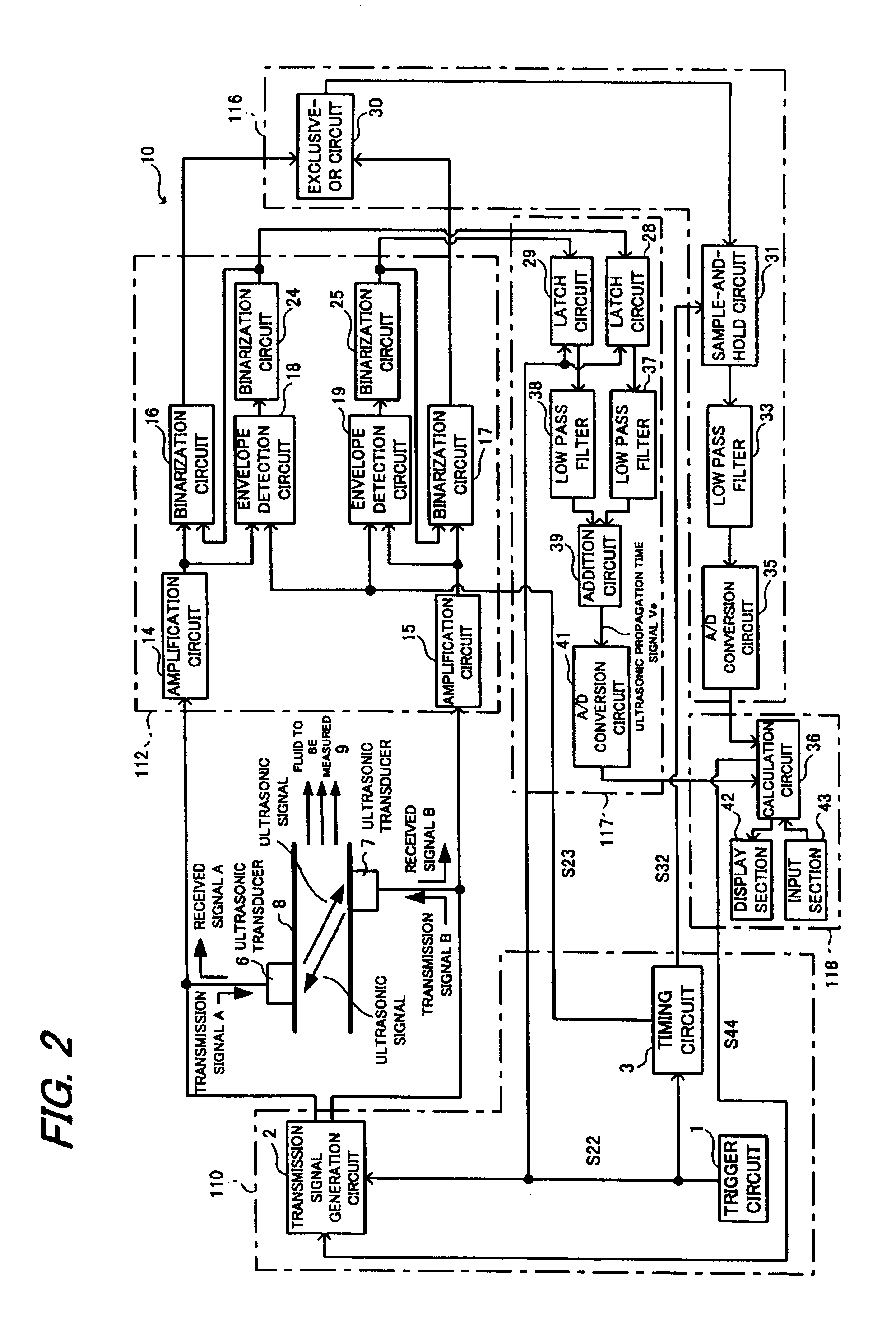

Ultrasonic current meter

InactiveUS6928369B2Accurate measurementReduce processing speedFlow propertiesVolume/mass flow measurementEngineeringUltrasound

The present invention provides a small, low power consumption ultrasonic flow velocity meter. The burst signal generation section 110 generates two kinds of burst signals with a phase difference and sends these burst signals to a pair of transmission / reception ultrasonic transducers 6 and 7 located on the upstream side and downstream side of the conduit to be measured 9. Upon reception of the corresponding burst signals, the pair of the transmission / reception ultrasonic transducers 6 and 7 convert the burst signals, send ultrasonic waves with a phase difference to the conduit to be measured 9, receive the ultrasonic wave sent by the other transmission / reception ultrasonic transducer and propagated through the conduit to be measured and convert the ultrasonic waves to received signals. These received signals are binarized through the binarization circuits 16 and 17, exclusive-ORed by the exclusive-OR circuit 30 and converted to a phase difference signal indicating a phase difference and the flow velocity of the conduit to be measured 9 is measured based on this phase difference signal.

Owner:TOKIMEC INC

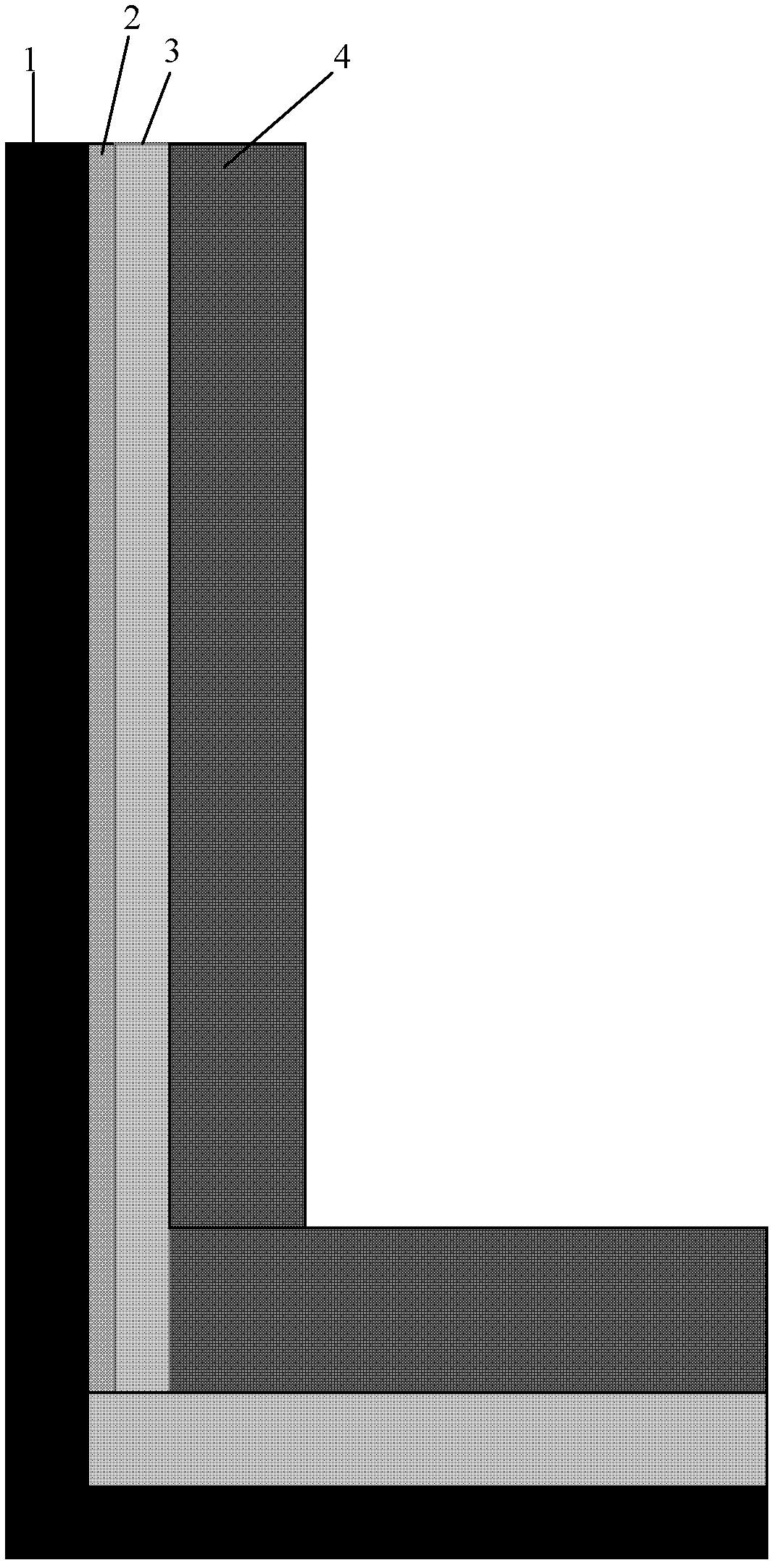

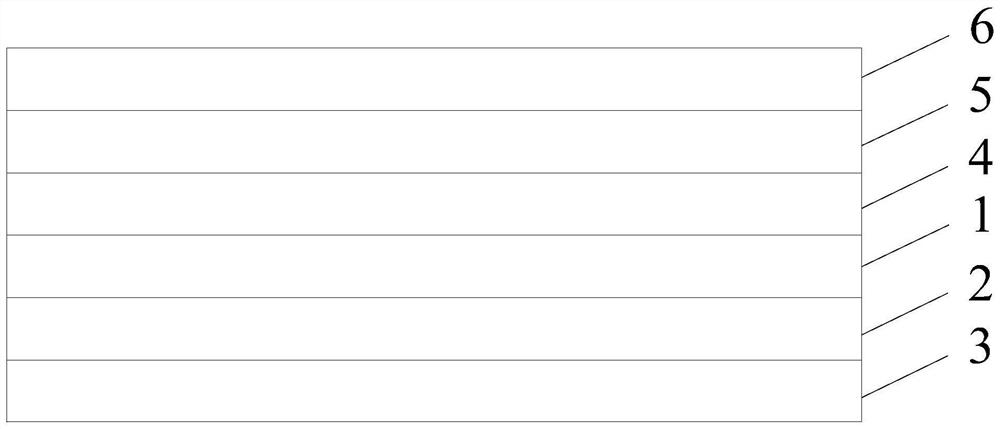

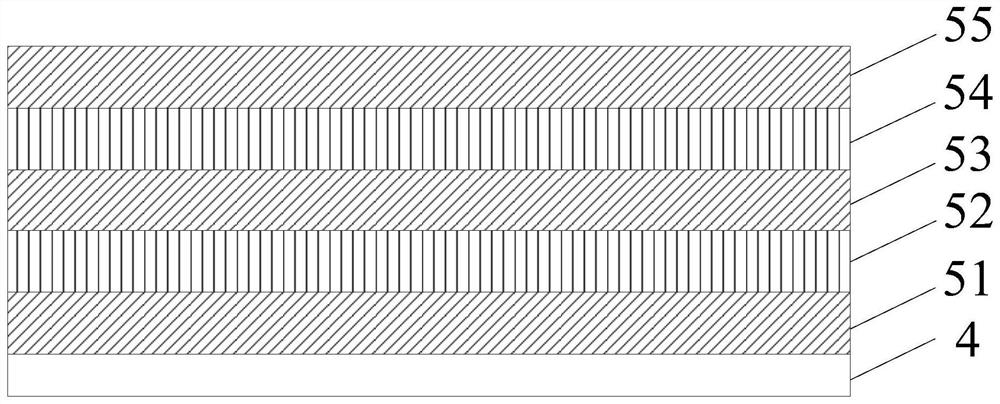

Anti-dazzle, anti-reflection and anti-fingerprint film

InactiveCN112694847AImprove anti-reflection effectImprove explosion-proof performanceFilm/foil adhesivesFilm baseThin membrane

The invention discloses an anti-dazzle, anti-reflection and anti-fingerprint film. The anti-dazzle, anti-reflection and anti-fingerprint film comprises a film base layer, an adhesive layer, a release film, an anti-dazzle layer, an anti-reflection layer and an anti-fingerprint layer, wherein the adhesive layer and the release film are sequentially arranged on one side of the film base layer from inside to outside; the anti-dazzle layer, the anti-reflection layer and the anti-fingerprint layer are sequentially arranged on the other side of the substrate from inside to outside; the anti-dazzle layer is prepared on the film base layer through combination of cured resin and UV transfer printing; the anti-reflection layer is formed by sequentially and alternately laminating a first preset number of high-refractive-index film layers and a second preset number of low-refractive-index film layers on the anti-dazzle layer; and the anti-fingerprint layer is coated on the anti-reflection layer. The anti-dazzle layer formed in a UV transfer printing mode is stable, the anti-reflection layer obtained by alternately stacking the high-refractive-index film layers and the low-refractive-index film layers is good in anti-reflection effect, the fingerprint prevention effect is good, the hardness is high, the abrasion resistance is good, the anti-dazzle layer is attached to the base material through an attaching process, the explosion resistance of the glass can be enhanced, and the film is environmentally friendly, low in cost and high in production yield.

Owner:ANHUI SHENGLI PRECISION MFG TECH CO LTD

Non-stick aluminum castable

The invention discloses non-stick aluminum castable. The non-stick aluminum castable contains a pouring main ingredient and an admixture, wherein the pouring main ingredient is prepared from fused quartz particles, aluminum silicate fiber residue balls, fused quartz powder, aluminate cement, sodium tripolyphosphate, alundum powder and a compound additive; the admixture is prepared from polypropylene explosion-proof fibers and citric acid. Compared with the prior art, the invention has the beneficial effects of low cost, high performance, large wetting angle, low coefficient of thermal expansion, high scouring resistance and capability of prolonging service life.

Owner:艾文斯(焦作)冶金材料有限责任公司

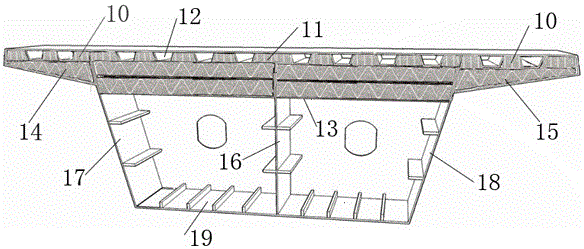

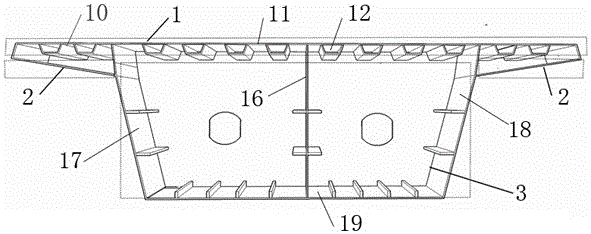

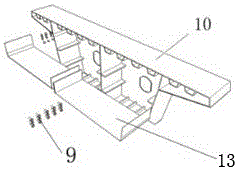

Steel box girder section design with anti-explosion and anti-impact effects

InactiveCN106087709AReduces the possibility of losing bearing capacityTo redistributeBridge structural detailsBridge materialsBridge engineeringBridge type

The invention relates to steel box girder section design with anti-explosion and anti-impact effects, belongs to the technical field of bridge engineering steel box girder structures, and aims at solving the technical problem that steel box girder section design of internally arranging an anti-explosion and anti-impact layer needs to be provided. According to the technical scheme, a top plate is horizontally arranged, multiple U-shaped ribs are arranged at the bottom of the top plate at intervals, and a space between every two adjacent U-shaped ribs serves as a first explosion-proof and impact-proof area which is filled with a single-layer along-bridge-type truss and foamed aluminum combined member flush with the corresponding U-shaped ribs; a secondary top plate is horizontally arranged below the top plate, the vertical distance between the secondary top plate and a bottom plate is not smaller than a half of the vertical distance between the top plate and the bottom plate, the thickness of the secondary plate is 1 / 4-1 / 2 of that of the top plate, and a space between the secondary top plate and the bottoms of the U-shaped ribs of the top plate serves as a third explosion-proof and impact-proof area which is filled with at least two layers of cross-bridge-type truss and foamed aluminum combined members in the vertical direction. The steel box girder section design with the anti-explosion and anti-impact effects is applied to roads and bridges.

Owner:ZHONGBEI UNIV

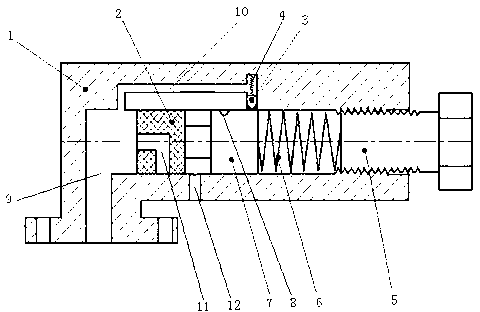

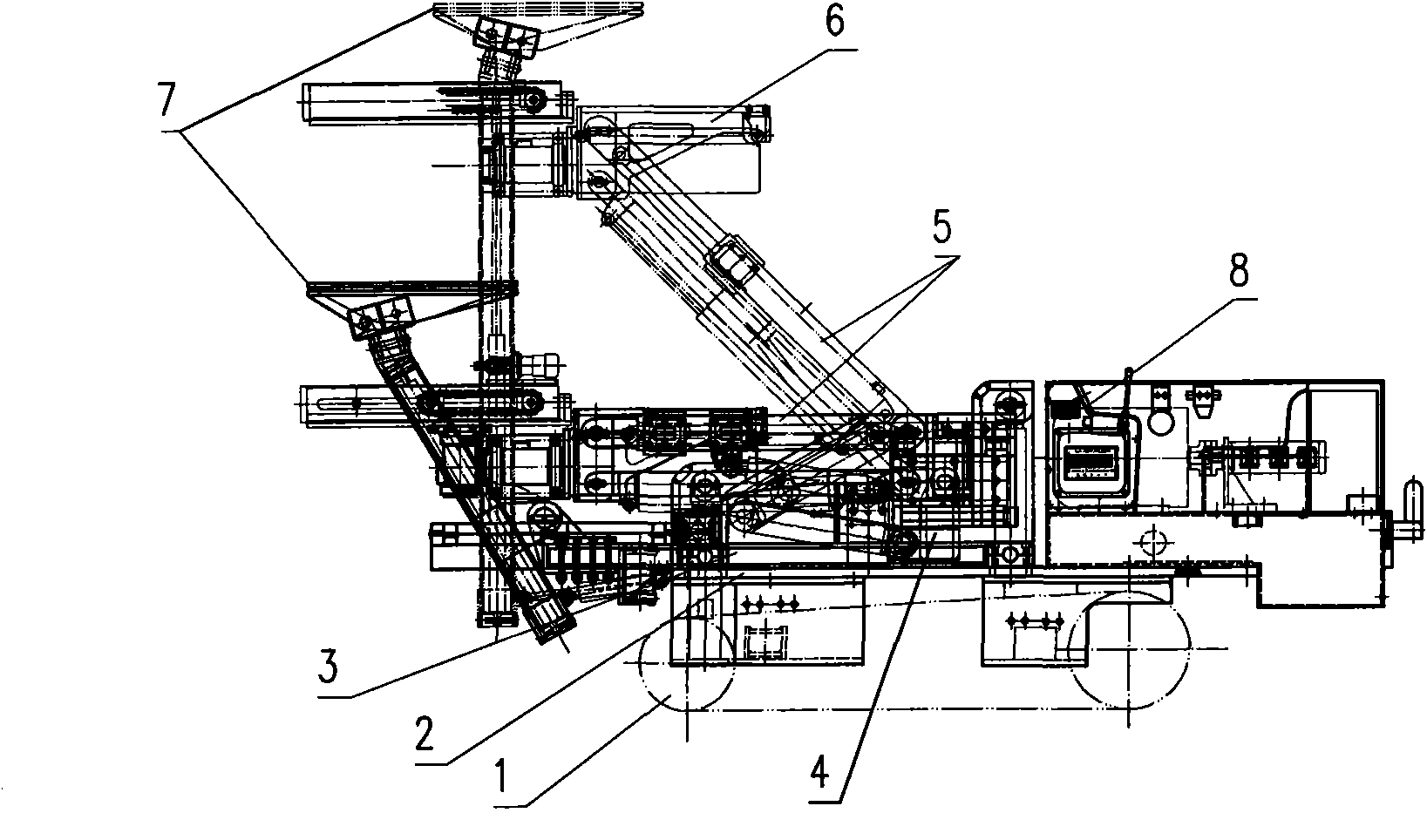

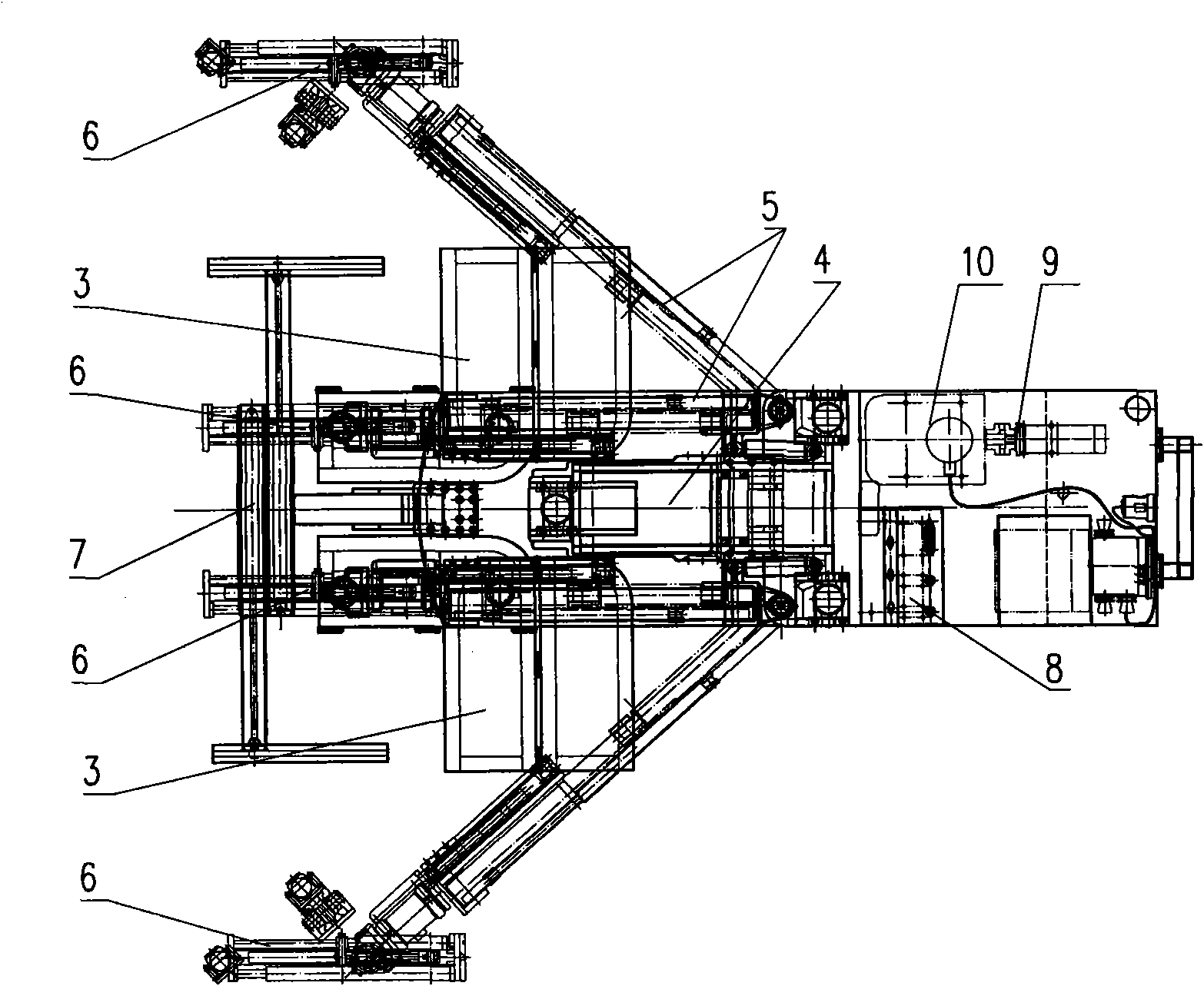

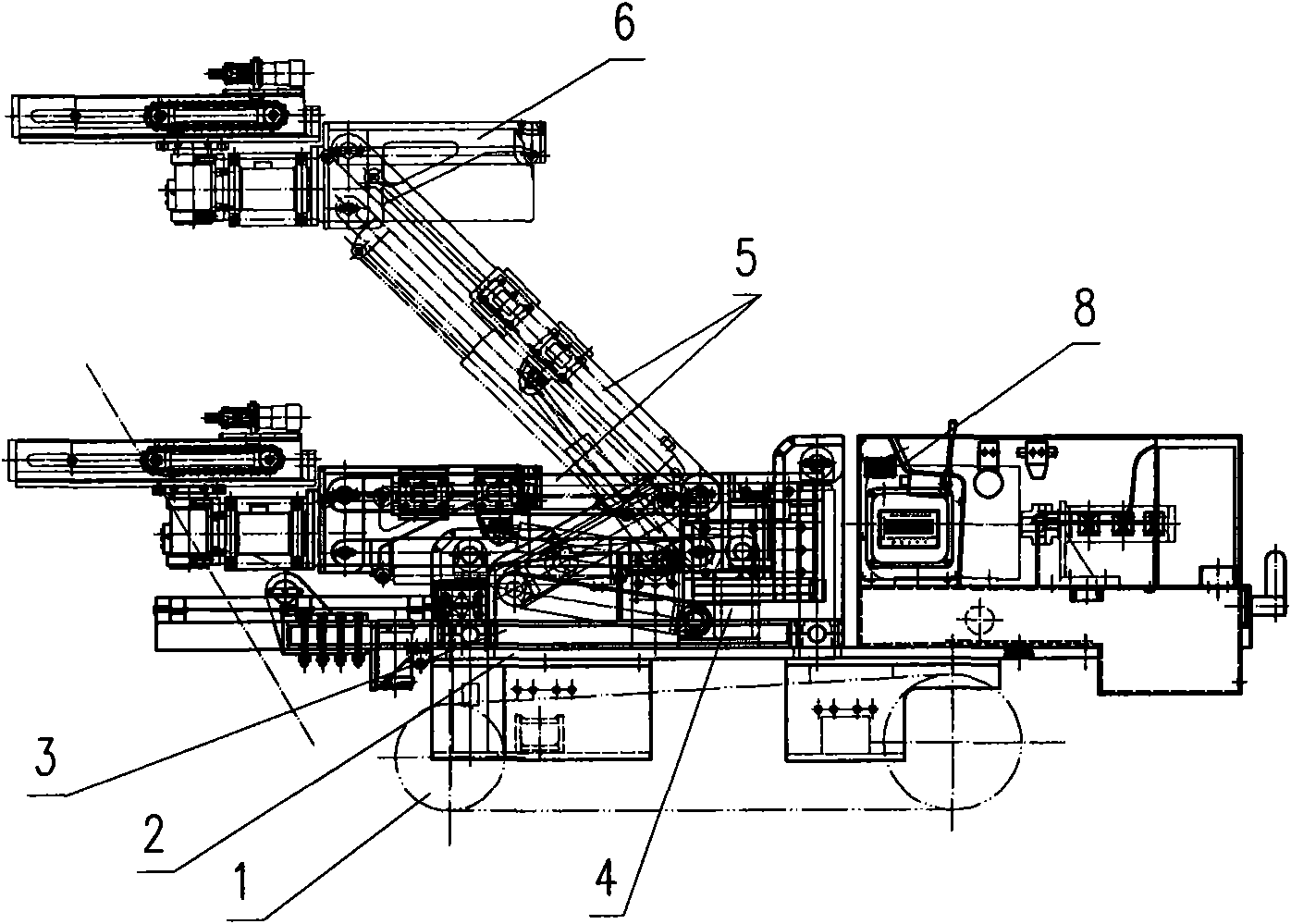

A movable lifting platform two-arm top help anchor rod anchor cable construction drilling rig

InactiveCN102278110AImprove performanceReduce maintenance costsDerricks/mastsMine roof supportsDrillTelescopic cylinder

The invention relates to a drilling rig for construction of anchor rods and cables with two arms on a movable lifting platform, which includes a crawler walking part, a body platform, a lifting platform, a platform lifting device, a drilling arm part, a hydraulic drilling rig part, a temporary support device, a hydraulic The operating system, the pumping station part and the main motor; the main feature is that there are two stages of pedals on the lifting platform, which are respectively a primary rotary pedal and a secondary flip pedal; the temporary support device includes a column, an angle adjustment cylinder, and a beam , telescopic oil cylinder, telescopic beam and supporting part; and the lifting platform adopts three lifting oil cylinders and three-point support, four-link integral top beam, parallel movement, vertical lifting and other structures; It also has the functions of construction blasthole, gas discharge hole, water exploration and discharge drilling, better temporary support capacity, ultra-high roadway support and other functions, adopts full hydraulic system transmission, explosion-proof performance and safety Good performance.

Owner:马晓山

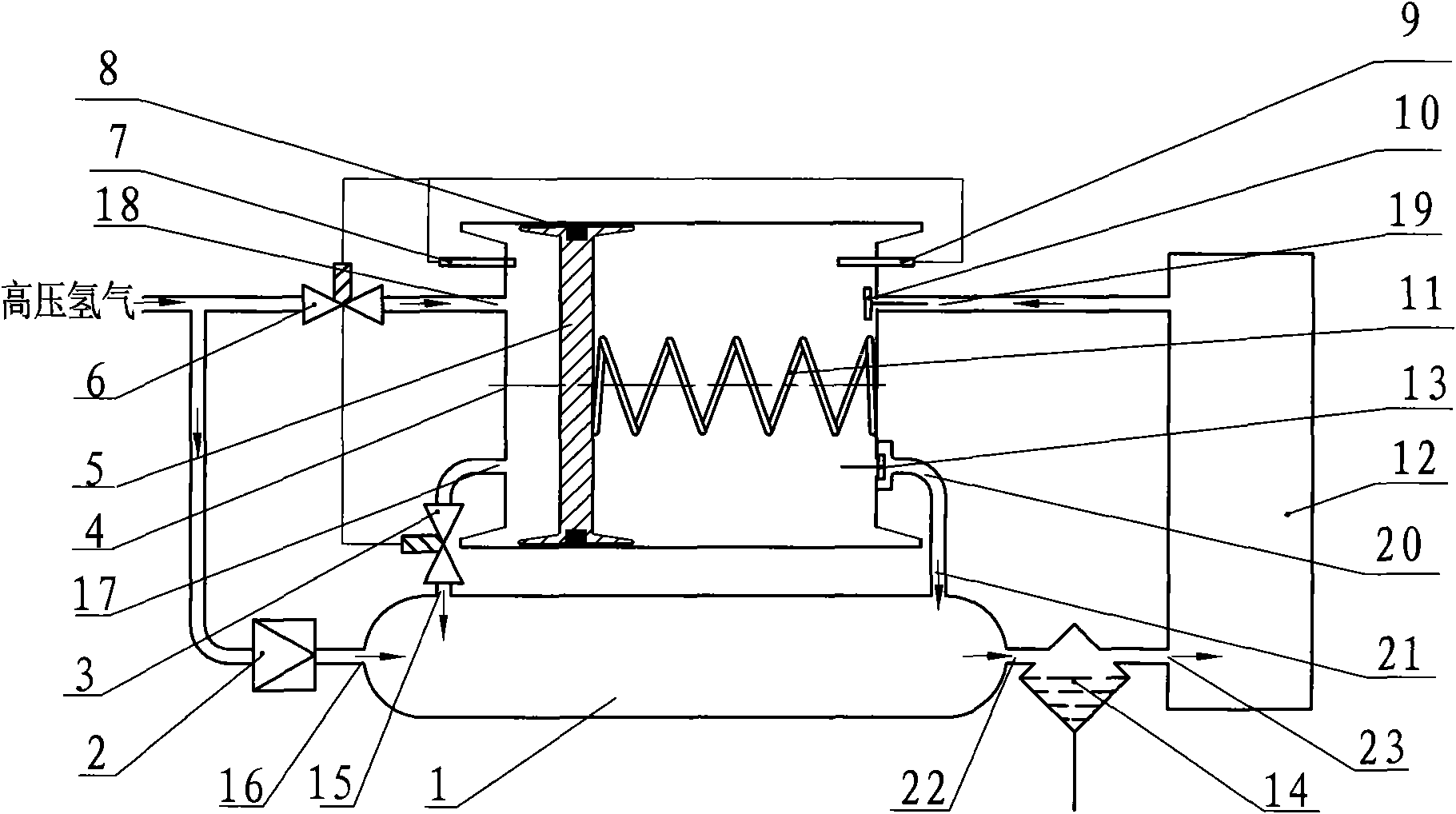

Piston type hydrogen conveyor for fuel cell

ActiveCN101645513ASave electricityGood explosion-proof effectFinal product manufactureFuel cell auxillariesHigh pressure hydrogenCorrosion

The invention discloses a piston type hydrogen conveyor for a fuel cell. The cylinder bodies on both sides of a cylinder piston are respectively provided with position sensors and are respectively provided with a hydrogen inlet and a hydrogen outlet; the hydrogen outlet of a buffer tank is connected with the hydrogen inlet of the fuel cell by a water segregator; the hydrogen inlet of the buffer tank is connected with a path of pipeline of a high-pressure hydrogen source, the other path of pipeline of the high-pressure hydrogen source is connected with the hydrogen inlet at one side of the cylinder by a hydrogen inlet solenoid valve, the hydrogen outlet on the same side of the cylinder body is connected with the buffer tank by a hydrogen outlet solenoid valve, the hydrogen inlet on the cylinder body on the other side of the cylinder piston is connected with the hydrogen tail discharge port of the fuel cell by the hydrogen inlet one-way valve, the hydrogen outlet at the same side of thecylinder body is connected with the buffer tank through a hydrogen outlet one-way valve, and the position sensor is connected with the solenoid valve through a signal wire. The invention has the advantages of electricity saving, good ability of utilizing the energy of high-pressure hydrogen to cause discharged tail hydrogen to flow back, simple structure, easy manufacture, low noise, no oil and corrosion, and high security and reliability.

Owner:SUNRISE POWER CO LTD

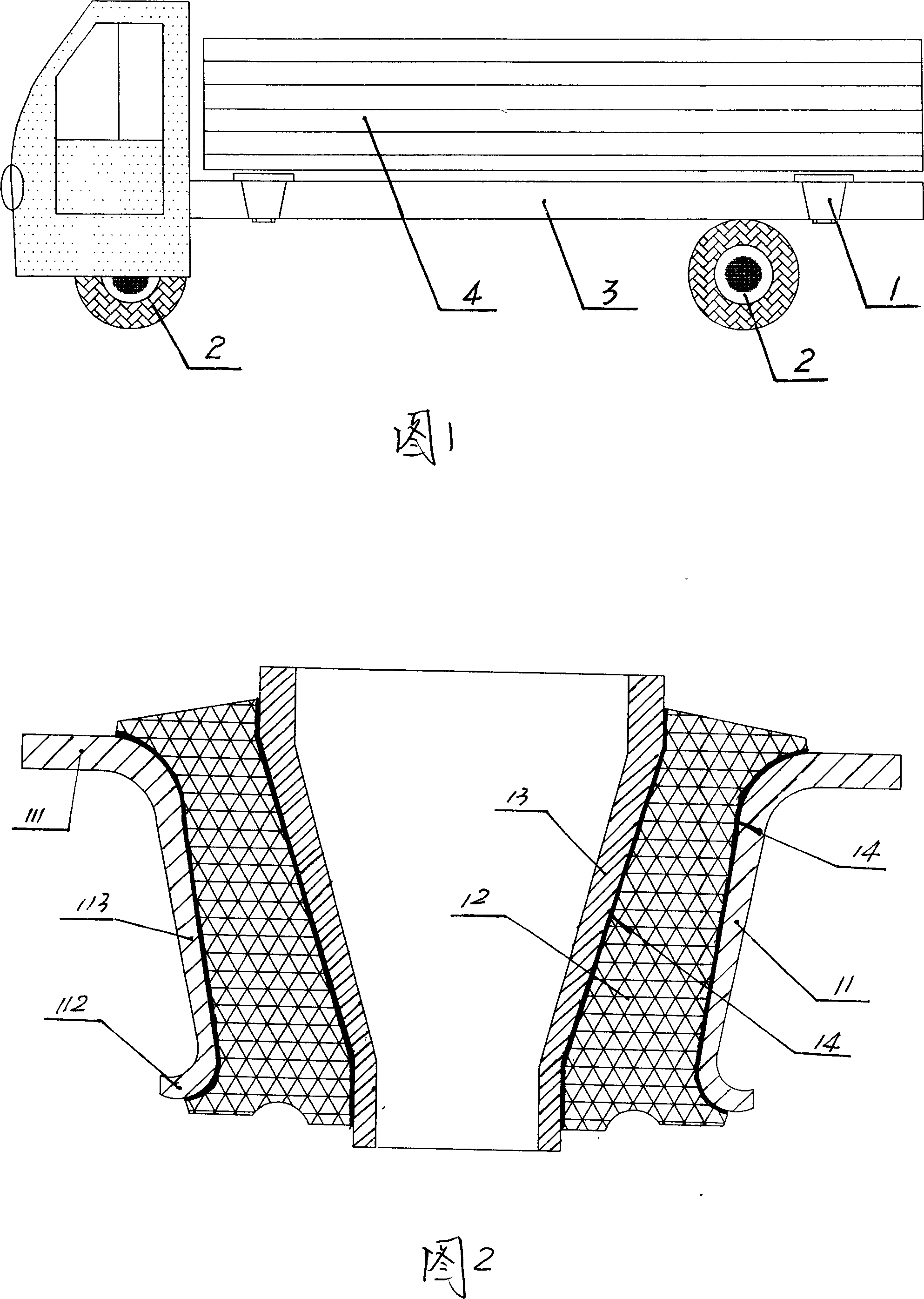

Conical vibration absorber of mine vehicle

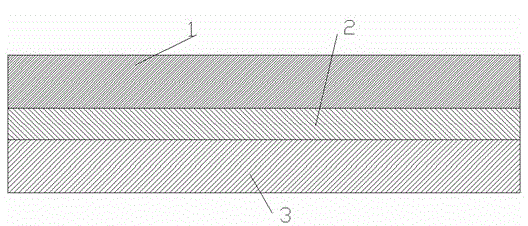

InactiveCN100999233AImprove explosion-proof performanceShock vibration can be mitigatedRubber-like material springsLoading-carrying vehicle superstructuresBody compartmentEngineering

The present invention relates to a conical vibration damper for mine car. It includes the following several portions: metal case shell, electric conductive rubber layer and metal neck bush. The electric conductive rubber layer is placed between metal case shell and metal neck bush. The upper end of the described metal case shell is equipped with upwards flange and its lower end is equipped with downwards flange, its middle portion is made into the form of conical face. The metal neck bush is made into the form of funnel. Said metal case shell, electric conductive rubber layer and metal neck bush are connected into one body. Said vibration damper can be used between the compartment and chassis.

Owner:蒋一忠

LED anti-explosion lamp

InactiveCN101706050AAvoid explosionImprove cooling effectPoint-like light sourceElectric circuit arrangementsDust explosionEngineering

The invention relates to an LED anti-explosion lamp which comprises a shell, wherein the LED anti-explosion lamp consists of a front light source cavity, a rear electric appliance cavity and a heat radiating cavity positioned between the front light source cavity and the rear electric appliance cavity, the light source cavity and the electric appliance cavity are closed cavities and are capable of preventing electric sparks from leaking, heat radiating through holes are arranged on the circumferential wall of the heat radiating cavity, the light source cavity is internally provided with an LED module, the electric appliance cavity is internally provided with a power supply driver adapted with the LED module, an electric wire connected with the power supply driver and the LED module is led to the light source cavity from the electric appliance cavity after passing through a sealing sleeve membrane; and a heat radiating sheet is connected to the LED module in the light source cavity, and the rear end of the heat radiating sheet is communicated with the heat radiating cavity. The invention has the advantages of good heat radiation effect, dust explosion prevention, high safety and long service life of the LED lamp.

Owner:绍兴晶彩光电技术有限公司 +1

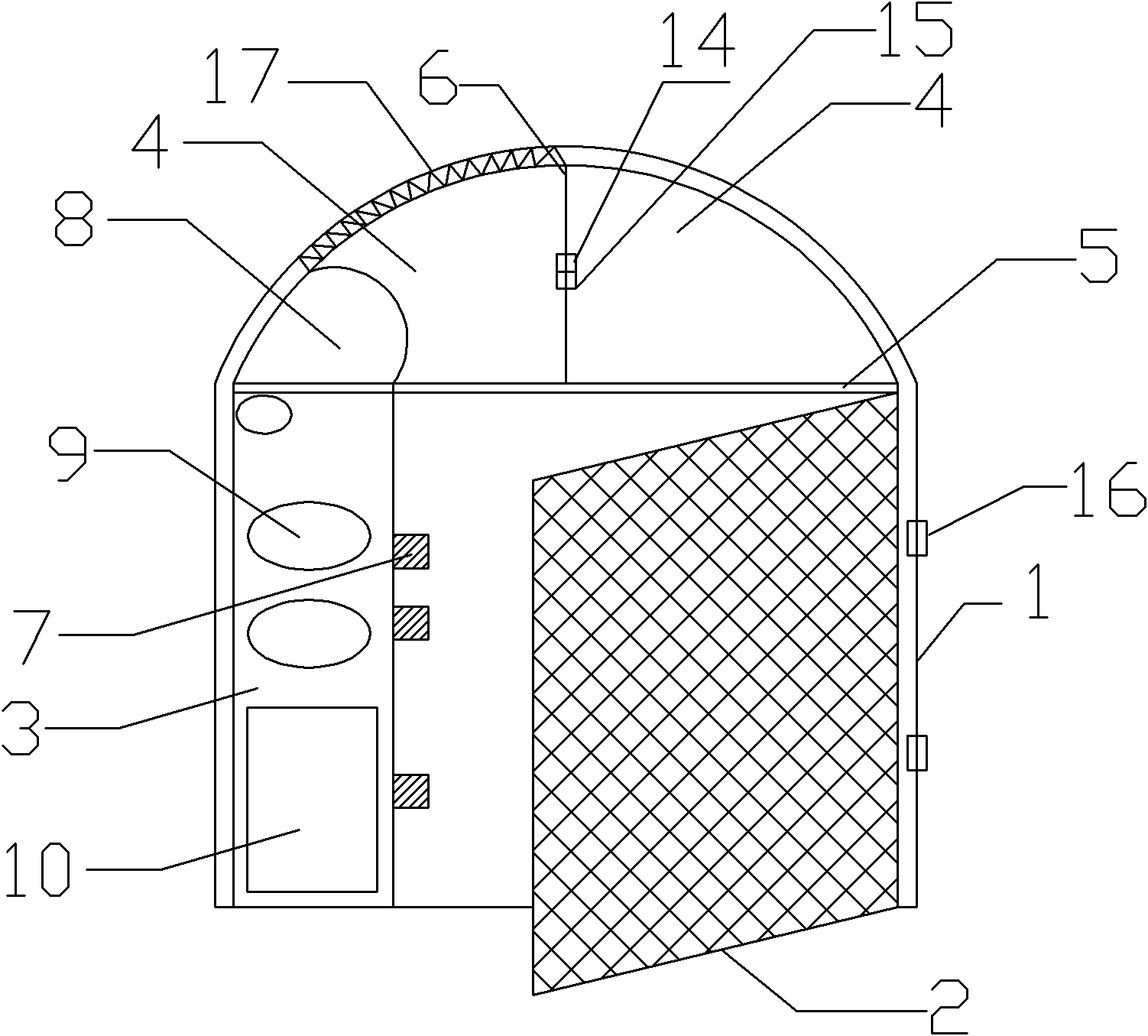

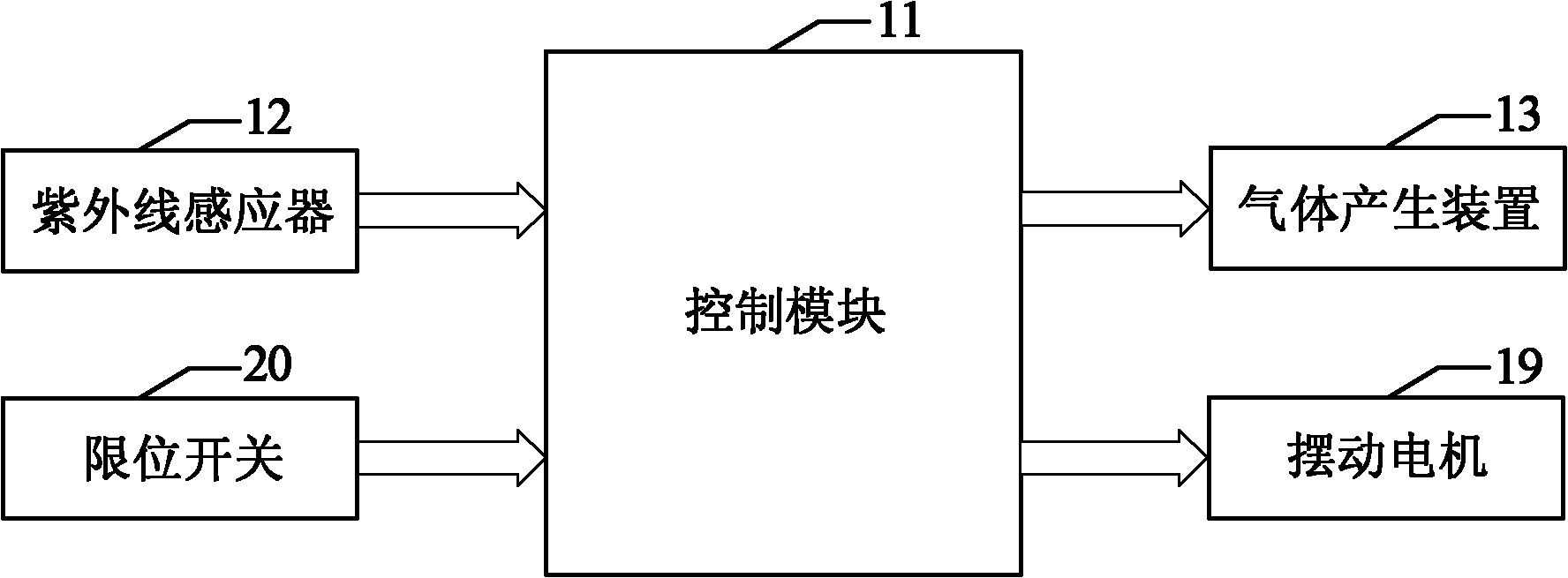

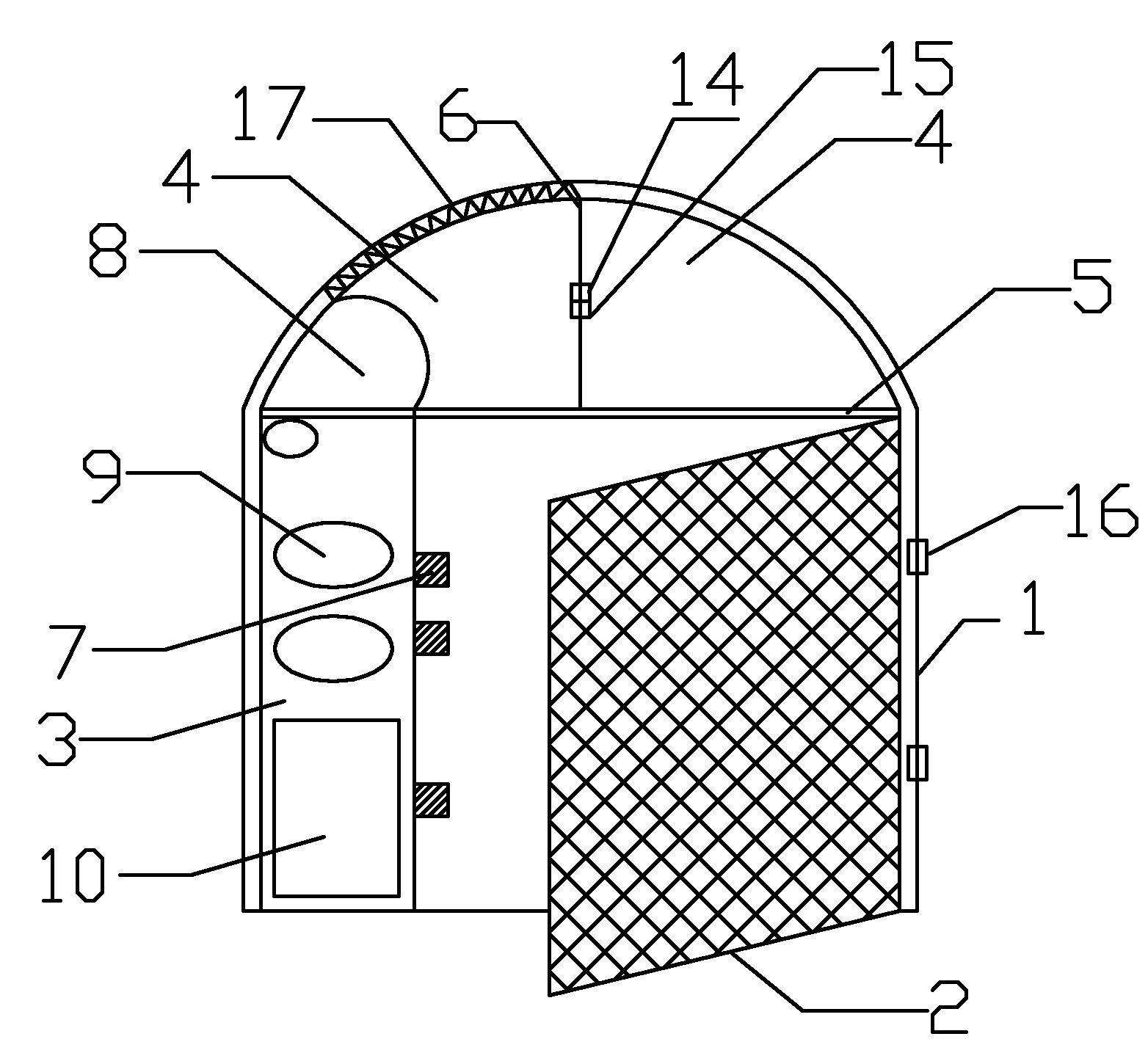

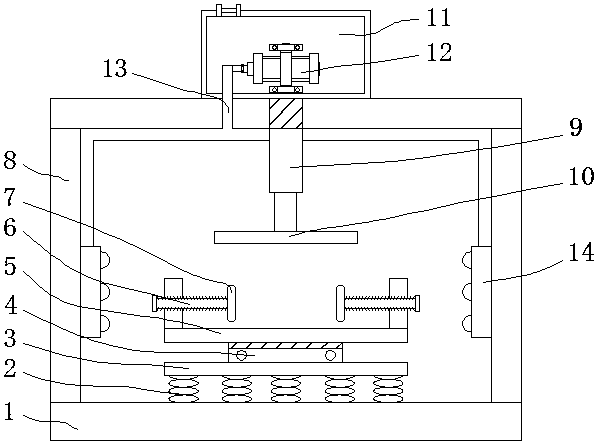

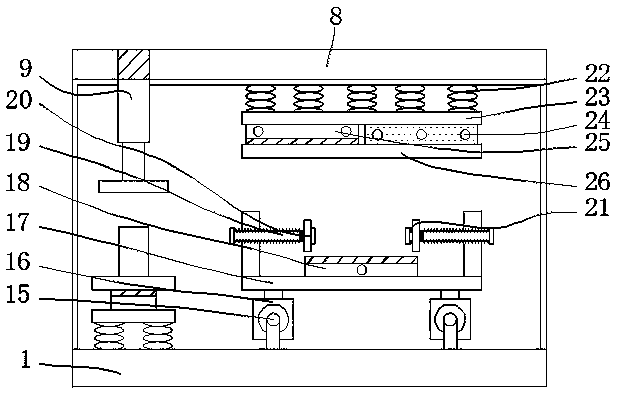

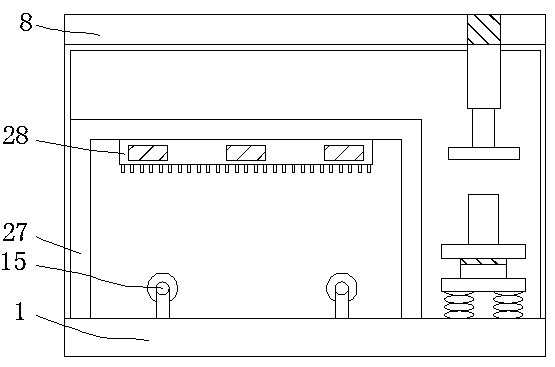

Explosion-proof performance detecting device with fire extinguishing function for battery production

InactiveCN109283468APlay a buffer rolePrevent crushingElectrical testingMaterial strength using tensile/compressive forcesElectrical batteryEngineering

The invention relates to an explosion-proof performance detecting device with a fire extinguishing function for battery production, and relates to the technical field of an explosion-proof performancedetecting device for battery production. The explosion-proof performance detecting device comprises a bottom plate and a first spring plate; the upper end of the bottom plate is provided with first springs; the first spring plate is disposed at upper ends of the first springs; and a first pressure sensor is embedded in the upper end of the first spring plate. The beneficial effects of the invention are that the first spring plate is connected to the bottom plate by using the first springs, when the pressure plate starts to exert pressure to a battery and a first tray apply, the first spring plate is elastically lowered by the first springs on the bottom plate after being pressed, so that the first pressure sensor can be buffered, and when the applied pressure and the first pressure sensorpair are utilized to detect the explosion-proof performance of the battery, the first pressure sensor can be simultaneously protected to prevent the applied pressure from being excessively large to cause the first pressure sensor to be crushed.

Owner:DONGGUAN UNIV OF TECH

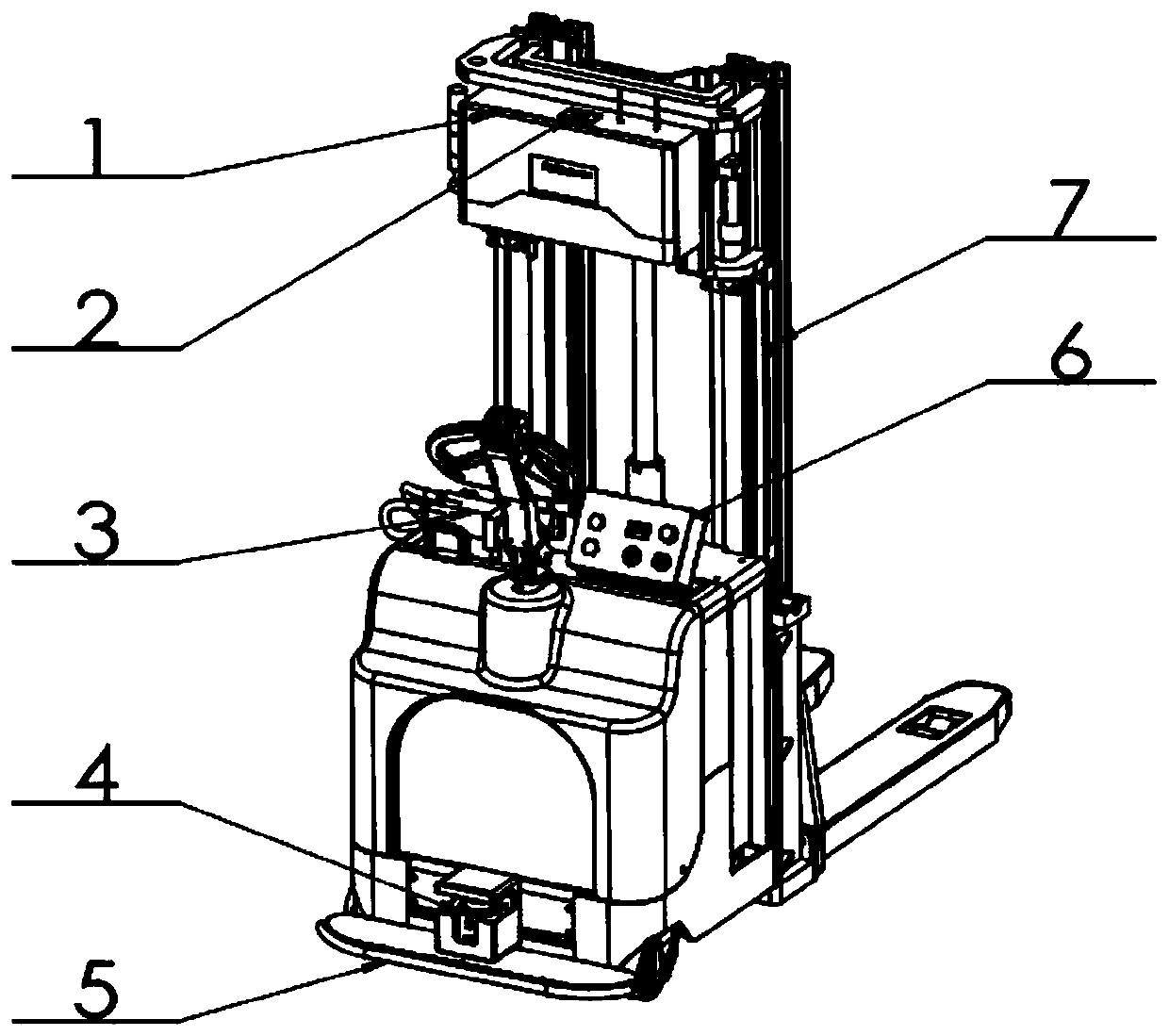

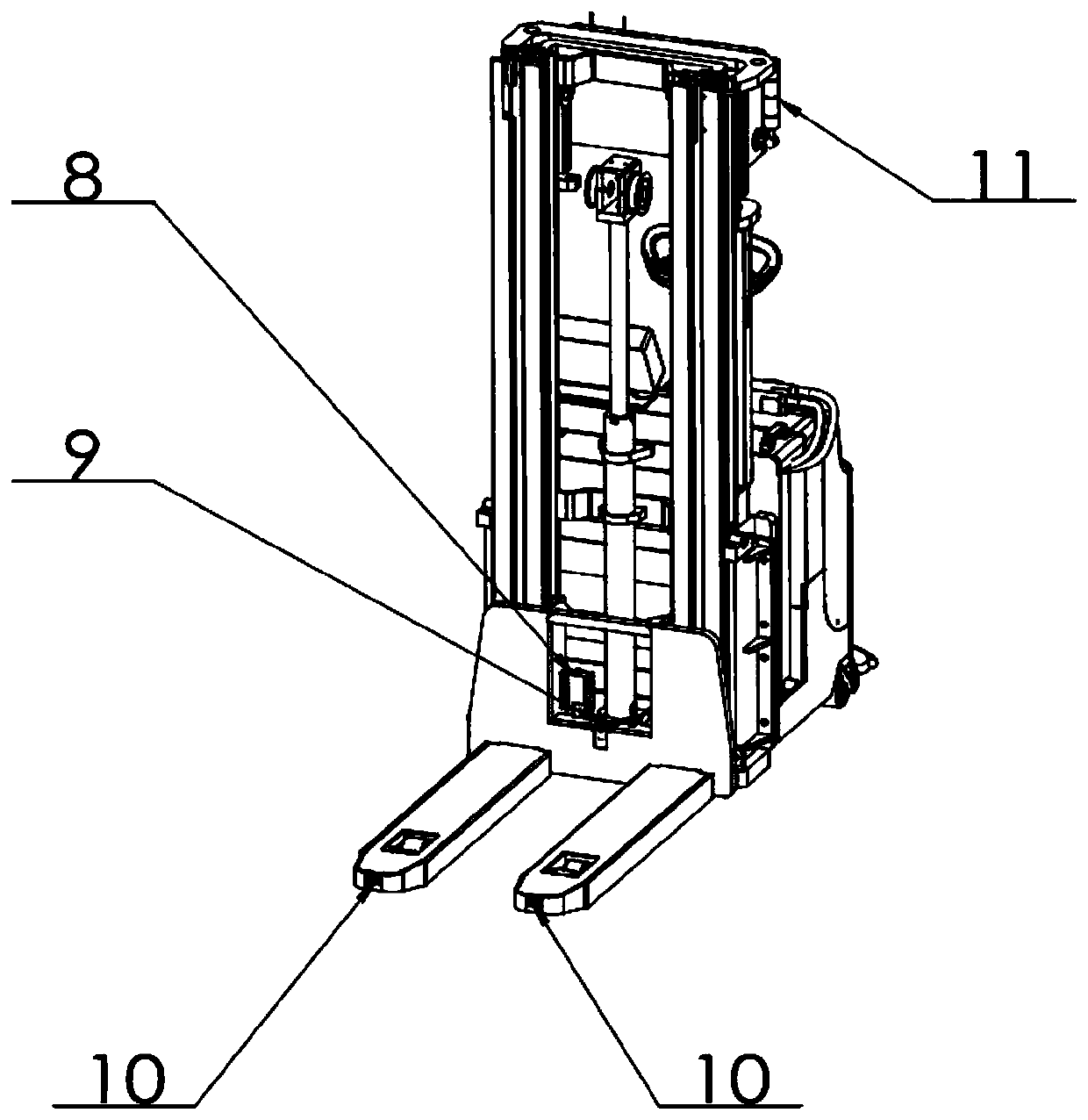

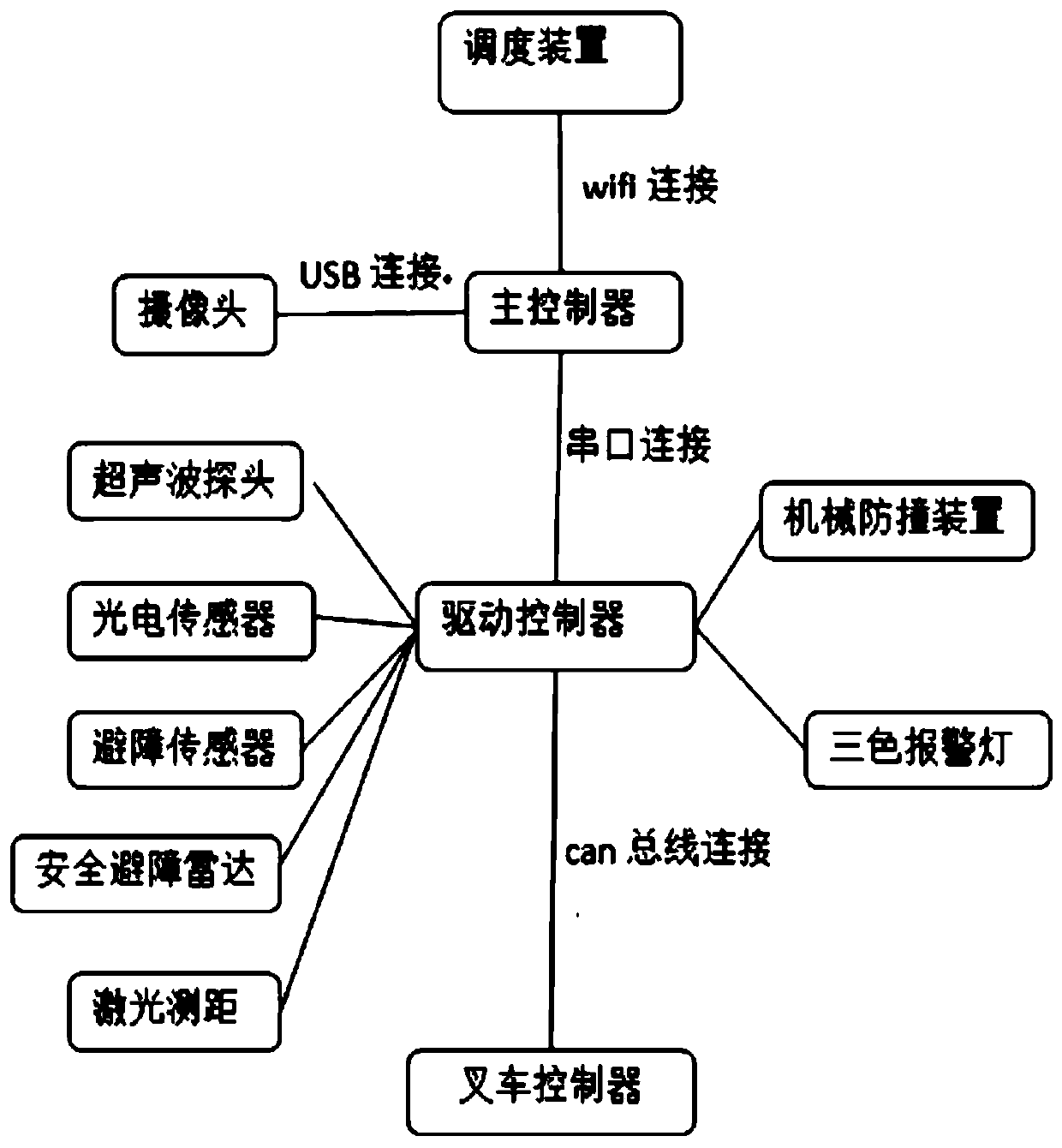

Passive vision navigation unmanned forklift system for explosion-proof warehouse and navigation method

ActiveCN110028017AHealth hazardMechanizationLifting devicesPosition/course control in two dimensionsWork periodInductor

The invention discloses a passive vision navigation unmanned forklift system for an explosion-proof warehouse. The passive vision navigation unmanned forklift system comprises a forklift body, a dispatching device, an explosion-proof camera, an explosion-proof controller, an inductor, an alarm and a mechanical anti-collision device. The real-time position of a forklift is determined by processingand analyzing the real-time beacon information of the forklift and stored corresponding beacon information, and the optimal path selection is continuously carried out on a path until the target position is reached during the traveling. The passive vision navigation unmanned forklift system realizes unmanned operation of passive visual navigation in the explosion-proof warehouse, endangering of human health is avoided, the manpower investment is reduced, the operation efficiency is improved, and working time is shortened.

Owner:杭州国辰牵星科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com