200MPa grade anti-bursting reactive powder concrete under construction site curing conditions and preparation method thereof

An active powder, construction site technology, applied in the field of building materials, can solve problems such as easy bursting, achieve good burst resistance, improve strength and compactness, and protect the environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

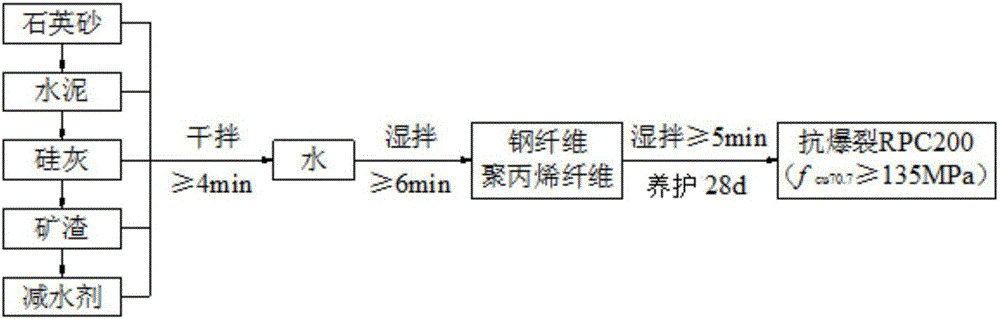

Method used

Image

Examples

Embodiment 1

[0036] A kind of 200MPa explosion-proof cracking-proof reactive powder concrete under the condition of maintenance on the construction site, each component is weighed according to the following mass parts:

[0037] Cement: 1 part, modified silica fume: 0.25 parts, finely ground slag: 0.20 parts, quartz sand: 1.15 parts, early-strength polycarboxylate superplasticizer: 0.035 parts, steel fiber: 0.15 parts, polypropylene fiber: 0.00175 parts, water: 0.18 parts.

[0038] Among them, the cement is P.O52.5 ordinary Portland cement; the specific surface area of modified silica fume should be greater than 15000m 2 / kg, the 7-day activity index should be greater than 110%; the specific surface area of the ground slag should be greater than 600m 2 / kg, 28d activity index should be greater than 115%; the main component of modified silica fume and ground slag is active SiO 2 ; SiO in quartz sand 2 The content is greater than 90%, the mass ratio of particle size 0.18-0.36mm to part...

Embodiment 2

[0041] A kind of 200MPa explosion-proof cracking-proof reactive powder concrete under the condition of maintenance on the construction site, each component is weighed according to the following mass parts:

[0042] Ordinary Portland cement (P.O 52.5): 1 part, modified silica fume: 0.30 parts, ground slag: 0.20 parts, quartz sand: 1.50 parts, early-strength polycarboxylate superplasticizer: 0.0375 parts, steel fiber : 0.20 parts, polypropylene fiber: 0.0025 parts, water: 0.20 parts.

[0043] Among them, the specific surface area of modified silica fume should be greater than 15000m 2 / kg, the 7-day activity index should be greater than 110%; the specific surface area of the ground slag should be greater than 600m 2 / kg, the 28-day activity index should be greater than 115%; the main component of modified silica fume and ground slag is active SiO 2 ; SiO in quartz sand 2 The content is greater than 90%, the mass ratio of particle size 0.18-0.36mm to particle size 0.36-0.6...

Embodiment 3

[0046] A kind of 200MPa explosion-proof cracking-proof reactive powder concrete under the condition of maintenance on the construction site, each component is weighed according to the following mass parts:

[0047] Ordinary Portland cement (P.O 52.5): 1 part, modified silica fume: 0.35 parts, ground slag: 0.35 parts, quartz sand: 1.50 parts, early-strength polycarboxylate superplasticizer: 0.040 parts, steel fiber : 0.25 parts, polypropylene fiber: 0.003 parts, water: 0.25 parts.

[0048] Among them, the specific surface area of modified silica fume should be greater than 15000m 2 / kg, the 7-day activity index should be greater than 110%; the specific surface area of the ground slag should be greater than 600m 2 / kg, the 28-day activity index should be greater than 115%; the main component of modified silica fume and ground slag is active SiO 2 ; SiO in quartz sand 2 The content is greater than 90%, the mass ratio of particle size 0.18-0.36mm to particle size 0.36-0.60m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com