Non-stick aluminum castable

A castable, non-stick aluminum technology, applied in the field of refractory materials, can solve the problems of high cost, achieve the effects of prolonging service life, improving product competitiveness, and large wetting angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

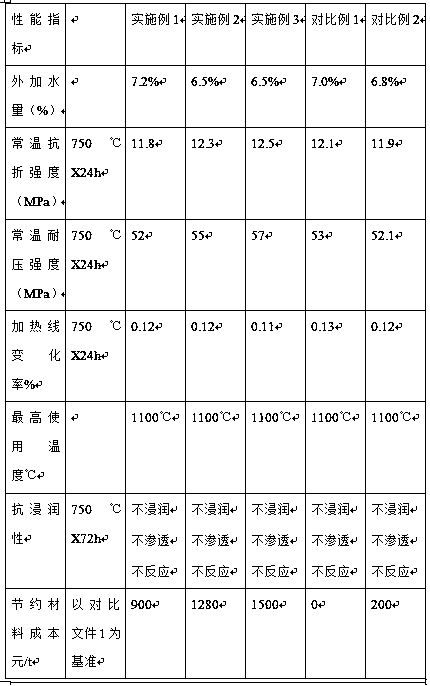

Examples

Embodiment 1

[0023] The proportion of main materials for pouring is as follows: fused silica particles 3~5mm, 20%; aluminum silicate fiber slag balls 0~3mm, 30%; fused silica powder 200 mesh, 13%; aluminate cement CA80, 8%; Sodium phosphate, 0.2%; corundum powder 200 mesh, 10%; composite additives: cryolite 6000 mesh 2%, 320 mesh calcium fluoride powder 8%, activated alumina 6% with particle size less than or equal to 5 microns, particle size less than or equal to 10 micron zircon powder 2.8%.

[0024] The admixture is based on the weight of the pouring main material, and the proportion is as follows: polypropylene explosion-proof fiber 0.3%, citric acid 0.05%.

Embodiment 2

[0026] Fused silica particles 3~5mm, 25%; aluminum silicate fiber slag balls 0~3mm, 35%; fused silica powder 200 mesh, 14%; aluminate cement CA80, 3%; sodium tripolyphosphate, 0.2%; corundum Powder 200 mesh, 10%; composite additive, cryolite 6000 mesh, 2%, 320 mesh calcium fluoride powder 4%, activated alumina with particle size less than or equal to 5 microns, 4%, zircon with particle size less than or equal to 10 microns Stone powder, 2.8%.

[0027] The admixture is based on the weight of the pouring main material, and the proportion is as follows: polypropylene explosion-proof fiber 0.1%, citric acid 0.05%.

Embodiment 3

[0029] The proportion of main materials for pouring is as follows: fused silica particles 3~5mm, 18%; aluminum silicate fiber slag balls 0~3mm, 40%; fused silica powder 200 mesh, 14%; aluminate cement CA80, 8%; Sodium phosphate, 0.2%; corundum powder 200 mesh, 10.8%; composite additives: cryolite 6000 mesh, 1%, 320 mesh calcium fluoride powder 3%, activated alumina with particle size less than or equal to 5 microns, 3.0%, particle size Zircon powder less than or equal to 10 microns, 2.0%.

[0030] The admixture is based on the weight of the pouring main material, and the proportion is as follows: polypropylene explosion-proof fiber 0.4%, citric acid 0.01%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com