Blowback fast explosion suppression device for coal mining working face

A recoil-type technology for mining working faces, which is applied in mining equipment, safety devices, mining equipment, etc., can solve the problem of being unable to effectively prevent explosion shock waves and flames, and achieve fast closing action, good effect, and strong explosion-proof performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

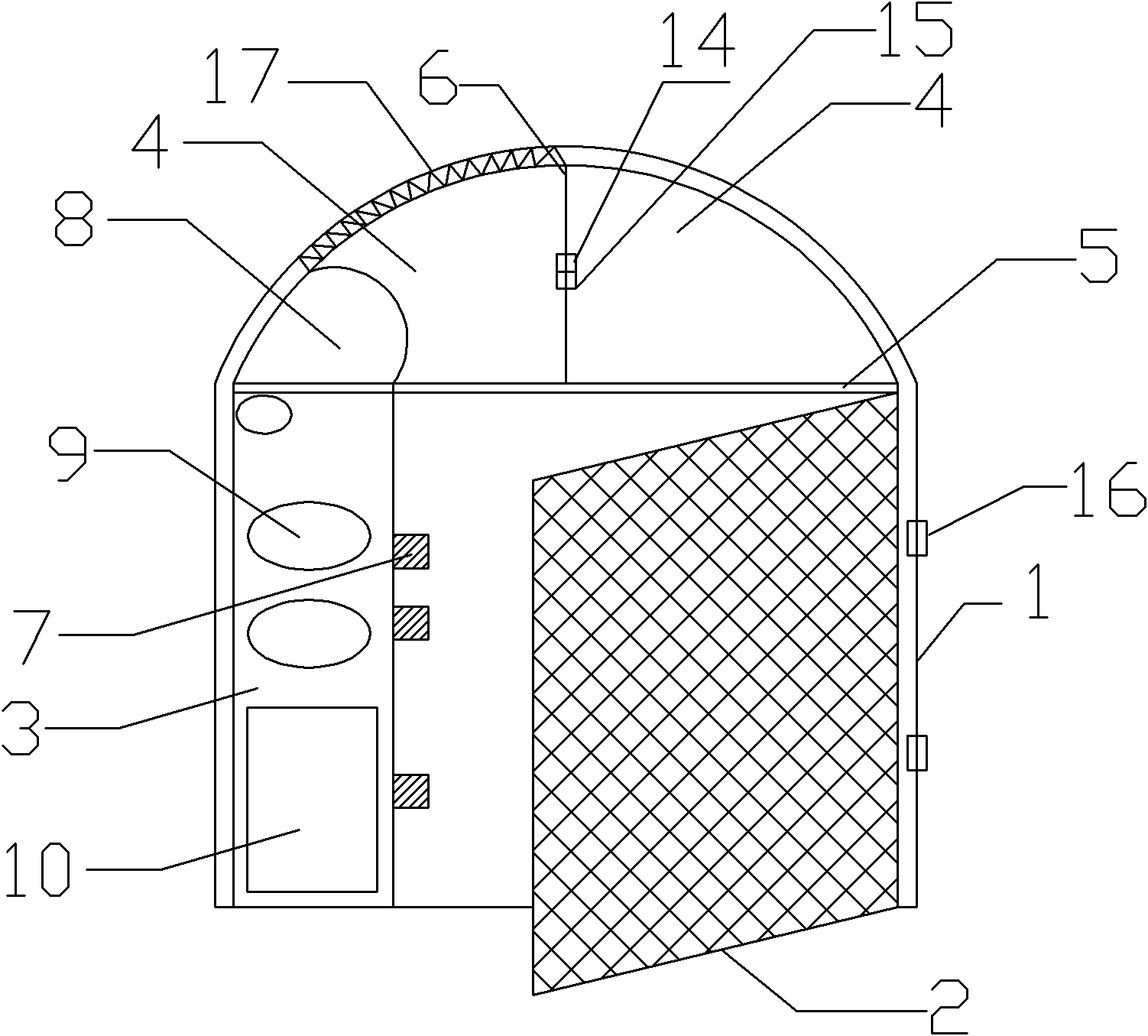

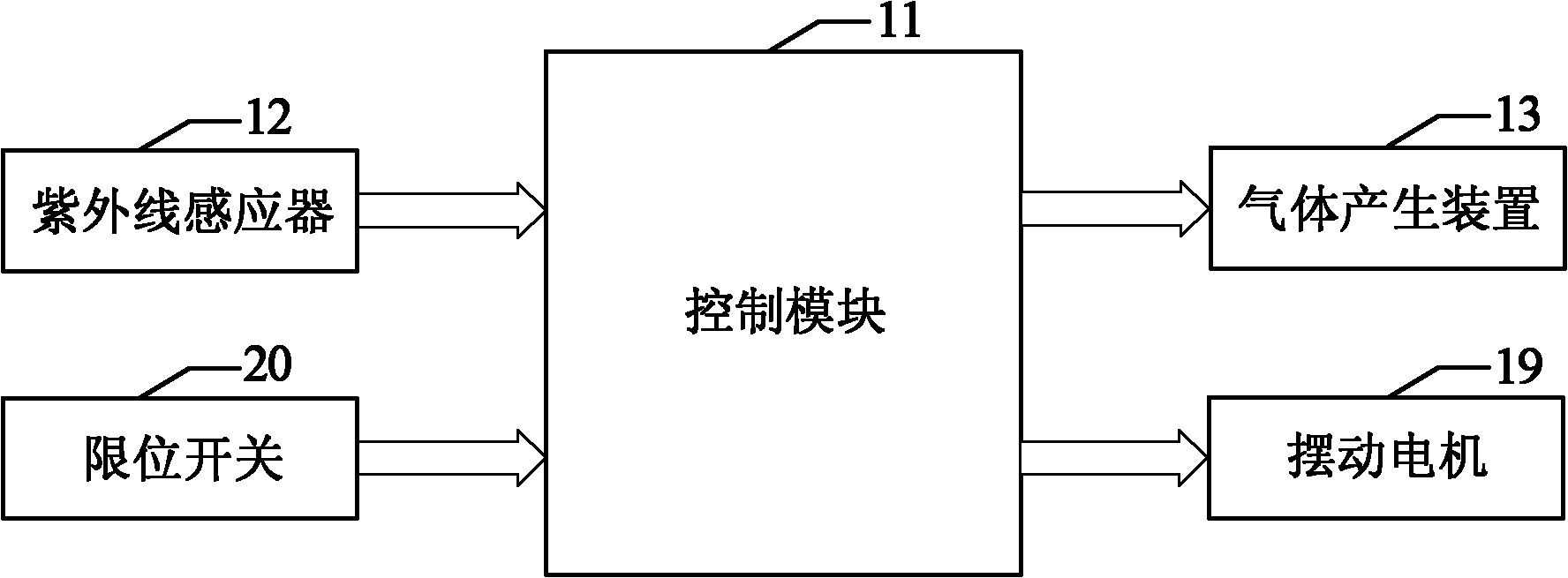

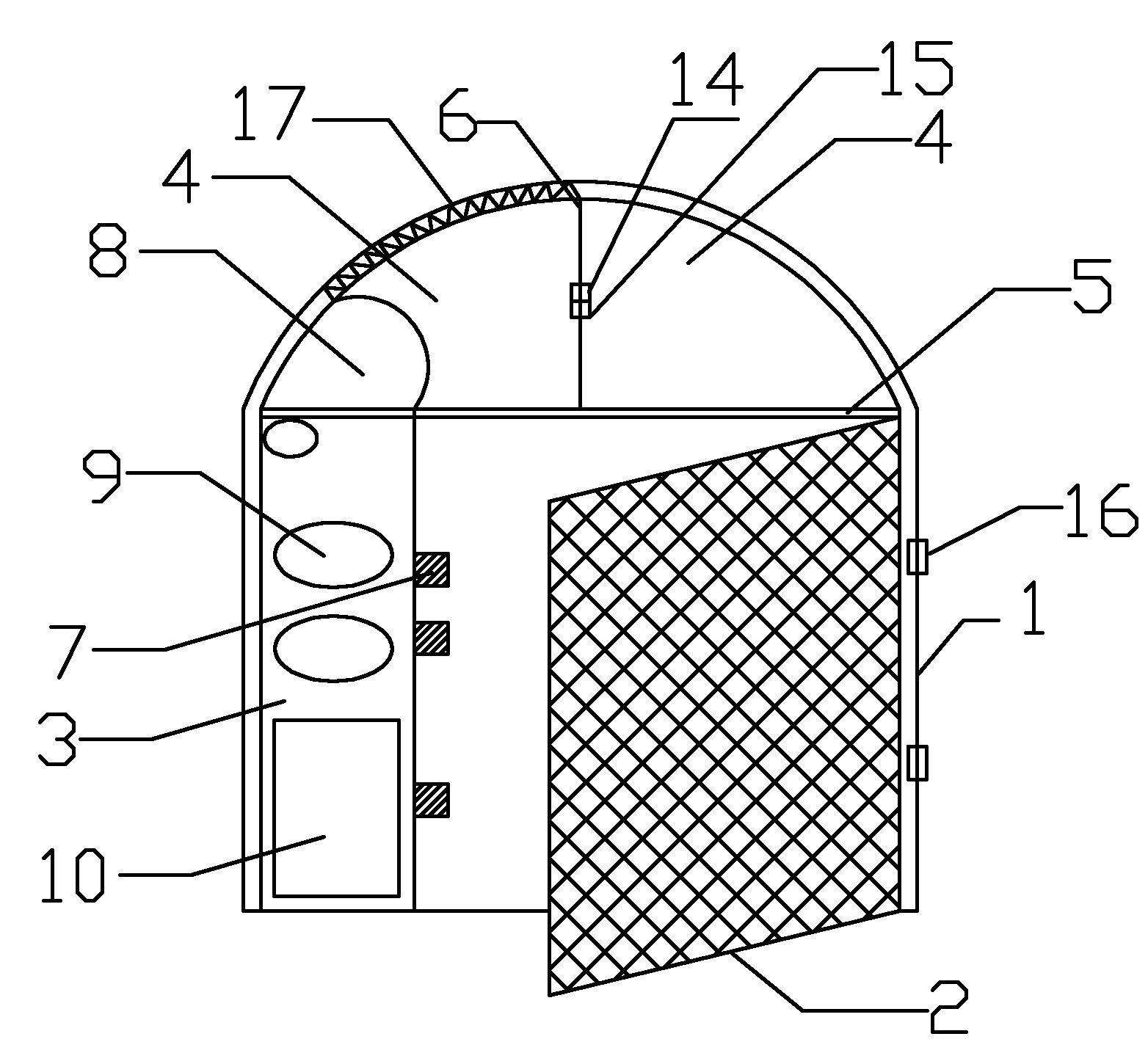

[0010] Specific implementation mode 1. Combination figure 1 and figure 2 Illustrate this specific embodiment, the gas recoil type fast explosion-proof device of coal mine excavation working face, it comprises support frame 1, explosion-proof door 2, explosion-proof plate 3, two fan explosion-proof windows 4, crossbeam 5, vertical suspension beam 6, electromagnetic Armature 14, spring 15 and control system, support frame 1 is divided into upper and lower parts by beam 5, the left side of explosion-proof plate 3 is fixed on the left side of the lower part of support frame 1, and the explosion-proof plate The right side of 3, the crossbeam 5 and the right side of the supporting frame 1 form a door frame, and the blast door 2 is hinged with the door frame; The other end is in contact with the upper surface of the crossbeam 5; the upper part of the support frame 1 is divided into left and right parts by the vertical suspension beam 6, and the two explosion-proof windows 4 are res...

specific Embodiment approach 2

[0015] Embodiment 2. The difference between this embodiment and the gas recoil type rapid explosion arresting device for coal mine mining face described in Embodiment 1 is that the explosion arrester 2 is composed of a foam ceramic base layer 21 and a barbed wire layer 22. The barbed wire layer 22 is covered and fixed on the inner and outer surfaces of the ceramic foam base layer 21 .

[0016] In this embodiment, the material of the explosion-proof plate 3 and the explosion-proof door 2 is the same.

[0017] In this embodiment, the function of the coal mine gas and coal dust automatic barrier explosion isolation device is to eliminate the hazards and influences of high-temperature burning of the flame front, shock wave overpressure damage, and poisonous and harmful gases in shafts during gas and coal dust explosions. At the same time, it should have repeated functions. And usability, it can play a role in preventing secondary explosions or multiple explosions after underground...

specific Embodiment approach 3

[0018] Specific Embodiment Three. The difference between this specific embodiment and the gas recoil type rapid explosion arresting device for coal mining face described in specific embodiment one or two is that it also includes N anti-collision liners 7, and the N The anti-collision liner 7 is distributed and fixed on the right side of the explosion-proof plate 3, and the N is a positive integer.

[0019] The crash pad 7 in this embodiment is a copper crash pad.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com