High-precision control gate for waste water backflow

A backflow control, high-precision technology, applied in the direction of sliding valves, engine components, mechanical equipment, etc., can solve problems such as poor fit and clogged valves, and achieve the effects of controllable opening, rapid closing action, and short stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

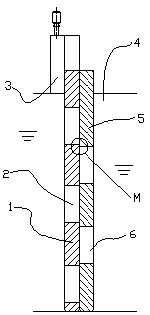

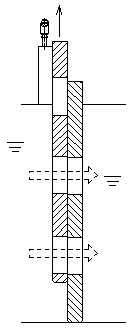

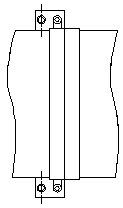

[0020] Such as Figure 1-5 As shown, the present invention includes a controller, a fixed door 5, a movable door 1 and a lifting device 3 for the movable door 1, the fixed door 5 and the movable door 1 are liquid-tightly bonded to each other, and the fixed door 5 and the movable door 1 are A number of panes are respectively provided, which are fixed door panes 6 and movable door panes 2. The panes 6 on the fixed door and the panes 2 on the movable door are mutually staggered in height. The above-mentioned dodge door 1 is connected. When the fixed door pane 6 and the movable door pane 2 do not match each other, the movable door 1 and the fixed door 5 of the present invention work together to cut off the liquid in the channel 4 . After the dodge door 1 is lifted, the panes between the two doors engage with each other (full engagement, partial engagement), such as figure 2 As shown, channel 4 is turned on.

[0021] The lower opening of the movable door pane 2 towards the fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com