Photoelectric telescope dust cover based on special-shaped spring drive and memory alloy wire brake

A technology of memory alloy wire and photoelectric telescope, applied in the direction of telescope, optics, optical components, etc., can solve the problems of slow opening and closing, poor dustproof effect, large gap, etc., and achieve reliable closing action, high reliability, and small size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

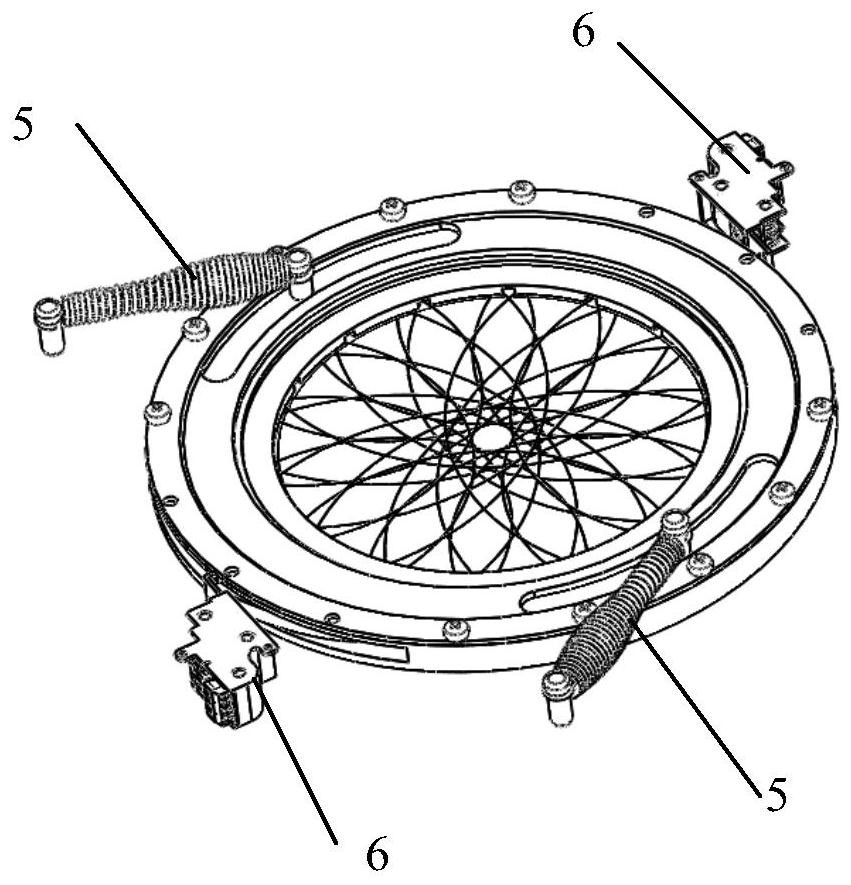

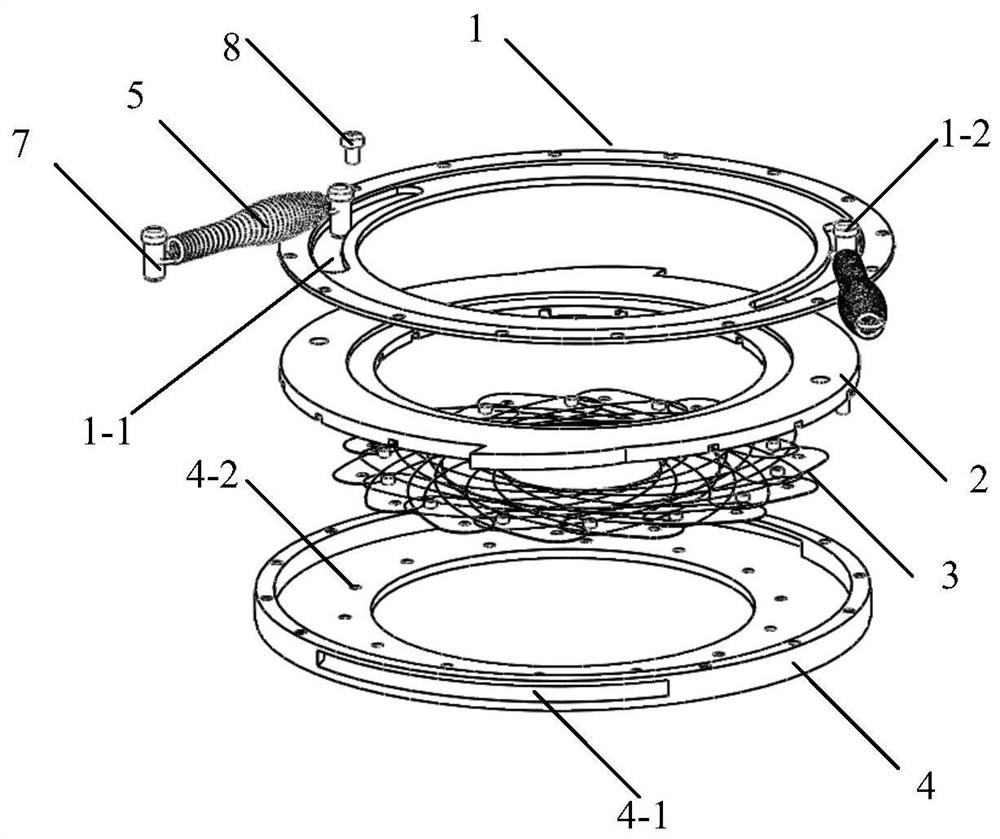

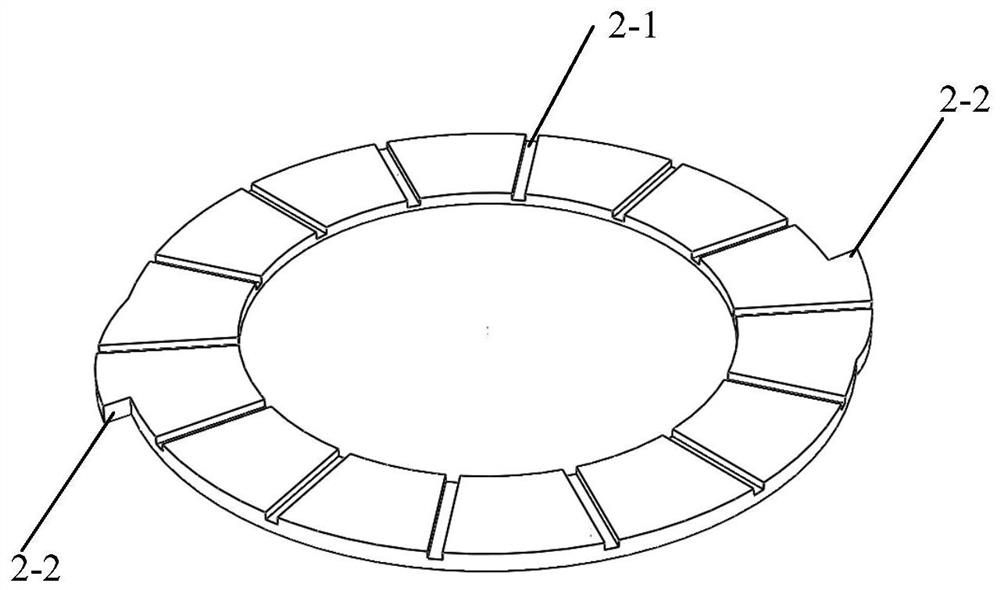

[0030] Specific implementation mode 1. Combination Figure 1 to Figure 9 Describe this embodiment, the photoelectric telescope dust cover based on special-shaped spring drive and memory alloy wire brake, includes coaxially installed upper cover 1, rotating disk 2, dust-proof blade 3 and mounting seat 4; also includes special-shaped spring 5 and Braking / locking module 6 of SMA memory alloy;

[0031] Such as figure 1 and figure 2 As shown, the upper cover 1 is a stepped ring, and arc-shaped through holes 1-1 are symmetrically arranged on the lower stepped ring surface, and each arc-shaped through hole 1-1 is provided with a The fixed holes on the surface are fixed with pins 1-2, each pin 1-2 is connected with special-shaped spring 5; the big end of one special-shaped spring 5 is connected with pin 1-2, the small end is connected with fixed pin 7, and the other symmetrically arranged The small end of spring 5 is connected with pin 1-2, and the large end is connected with fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com