Polymer processing method and device thereof

A processing method and processing device technology, applied in the direction of coating, etc., can solve problems such as raw material coking, and achieve the effects of avoiding waste of energy, fast mold clamping action, and shortening mold clamping stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The following examples illustrate possible implementations of the present invention, but they are not intended to limit the protection scope of the present invention and are described in advance.

[0057] Hereinafter, two preferred embodiments of the present invention are given together with the drawings for further description.

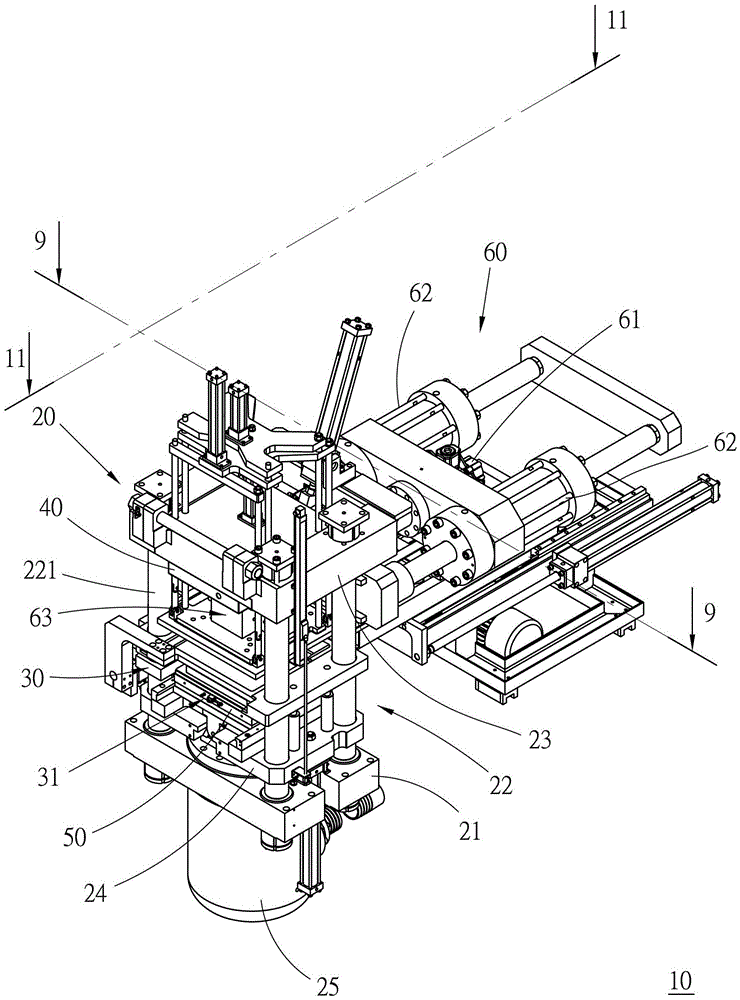

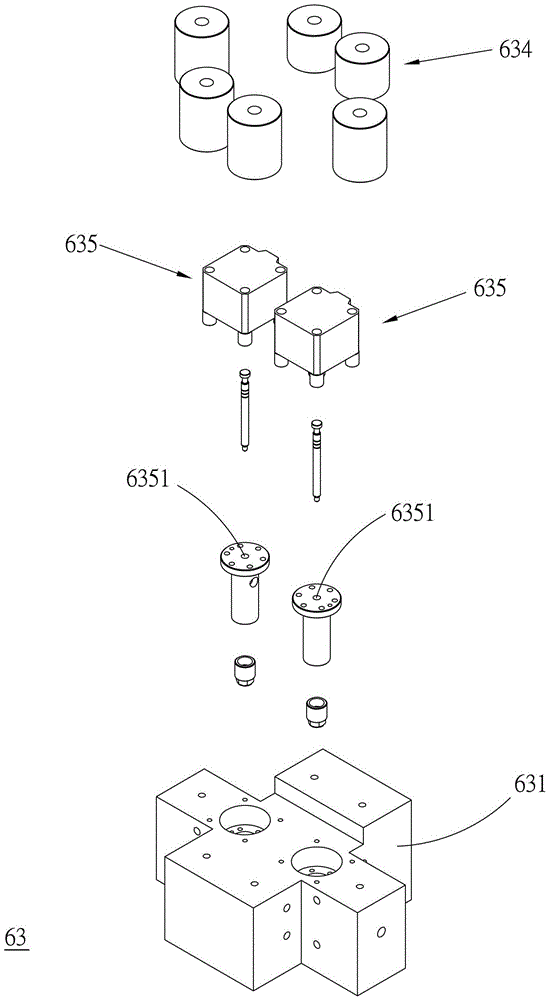

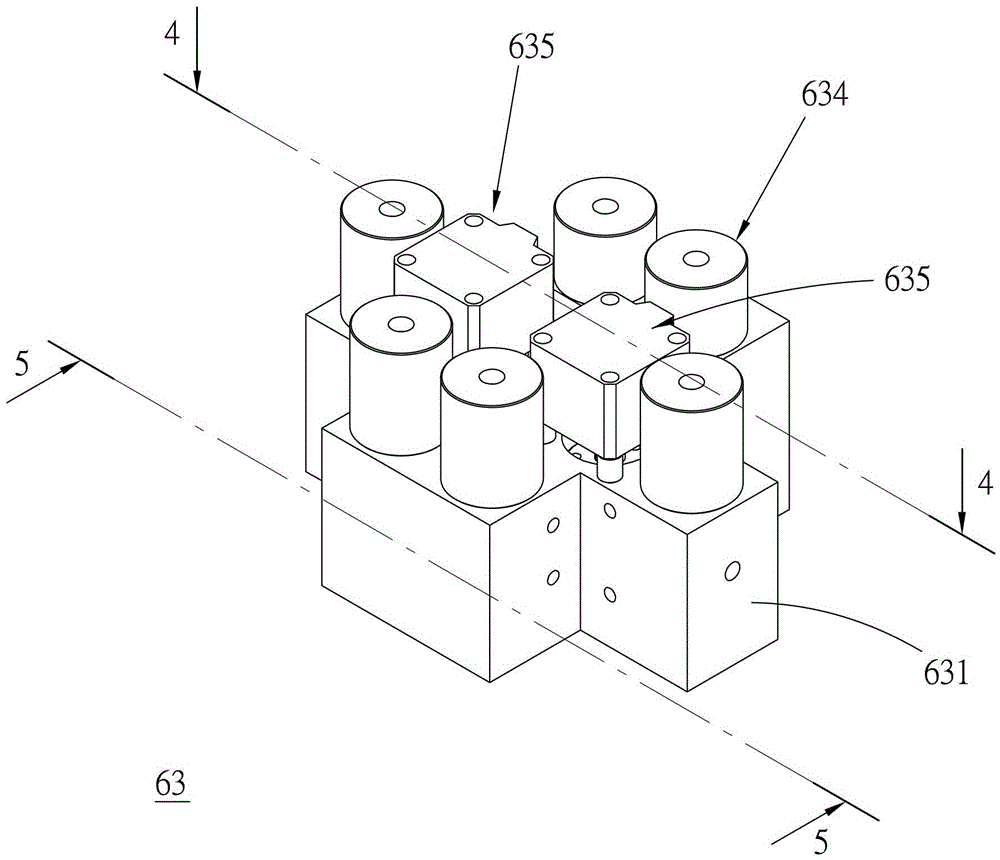

[0058] see Figure 1 to Figure 11 As shown, the polymer processing device 10 provided in a preferred embodiment of the present invention mainly includes a clamping mechanism 20, a module 30, an upper heating part 40, a lower heating part 50 and an injection Feeding mechanism 60.

[0059] The mold clamping mechanism 20 belongs to the known vertical mold clamping technology. Generally speaking, it mainly has a base 21, and a guide 22 composed of four guide columns 221 is erected at the bottom of the column shaft. Fixed on the base 21, a plate-shaped fixed end piece 23 is bridged and fixed on the top of the column shaft of each guide post 221, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com