Magnetic steel processing device and method for production of permanent magnet synchronous motor

A permanent magnet synchronous motor and processing device technology, which is applied in the manufacture of stator/rotor bodies, etc., can solve the problems of low processing precision, low efficiency, and inability to realize automatic magnetic steel assembly and processing, and achieves improved stability and reliability. The effect of improving quality and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

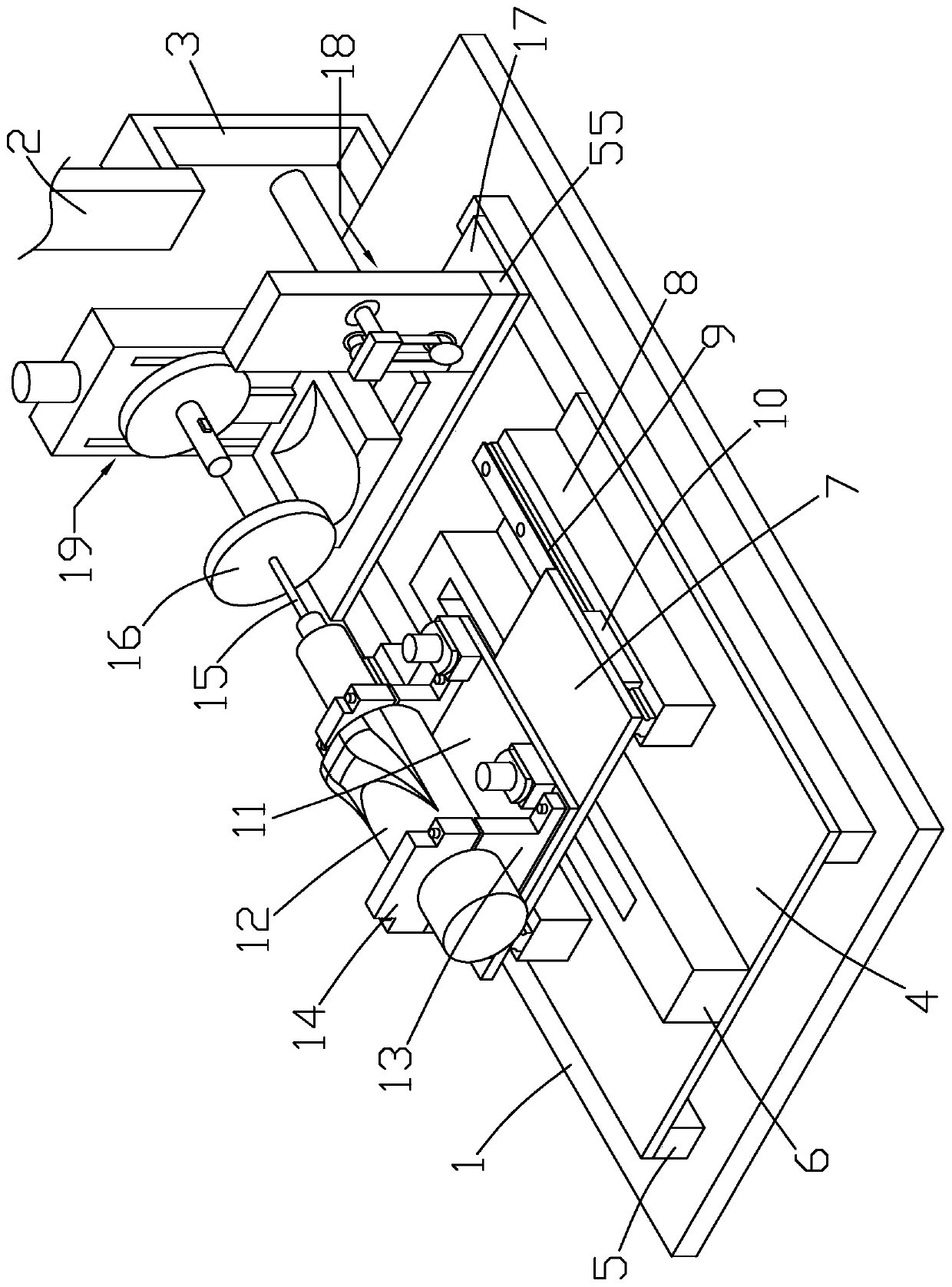

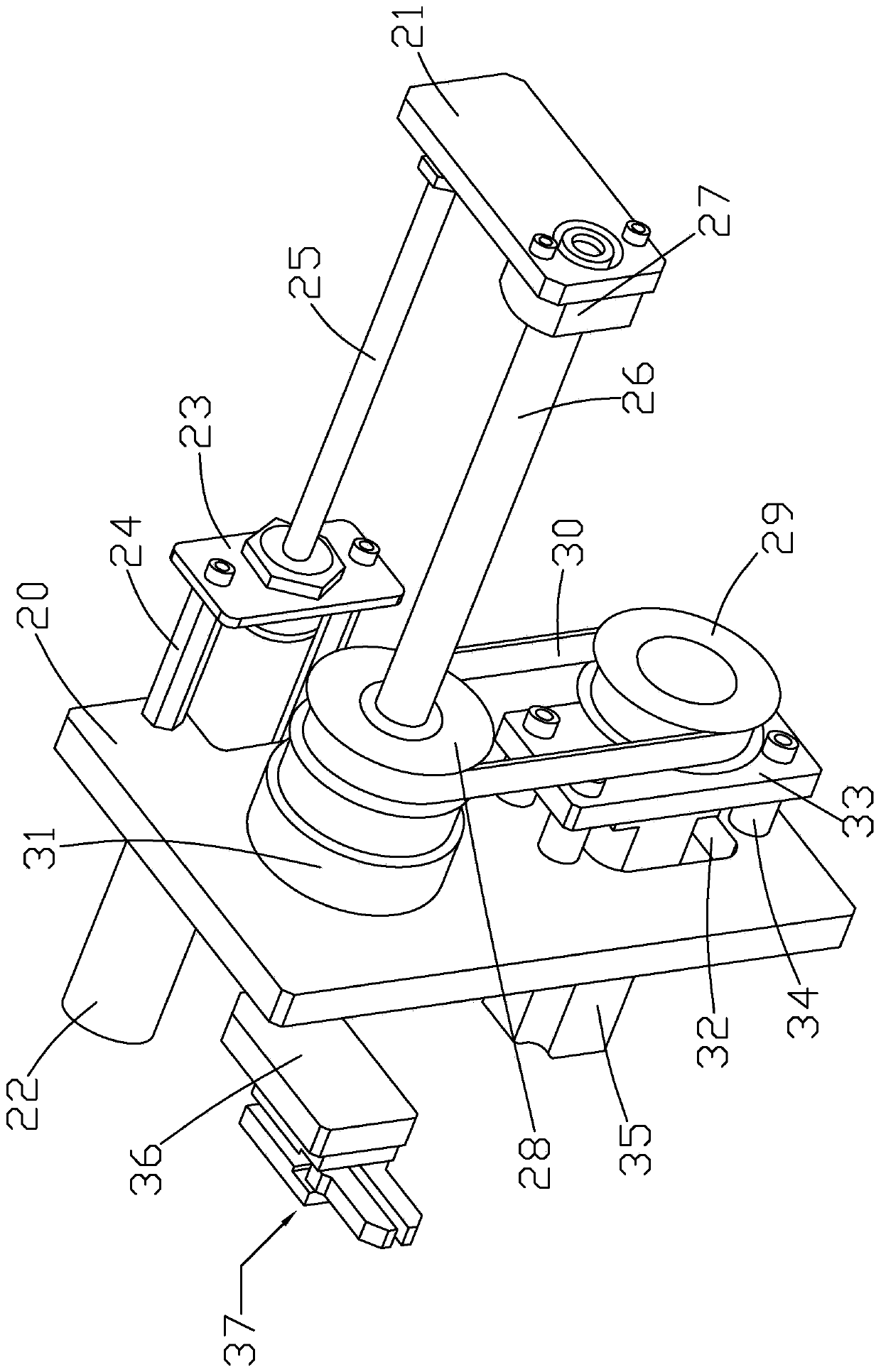

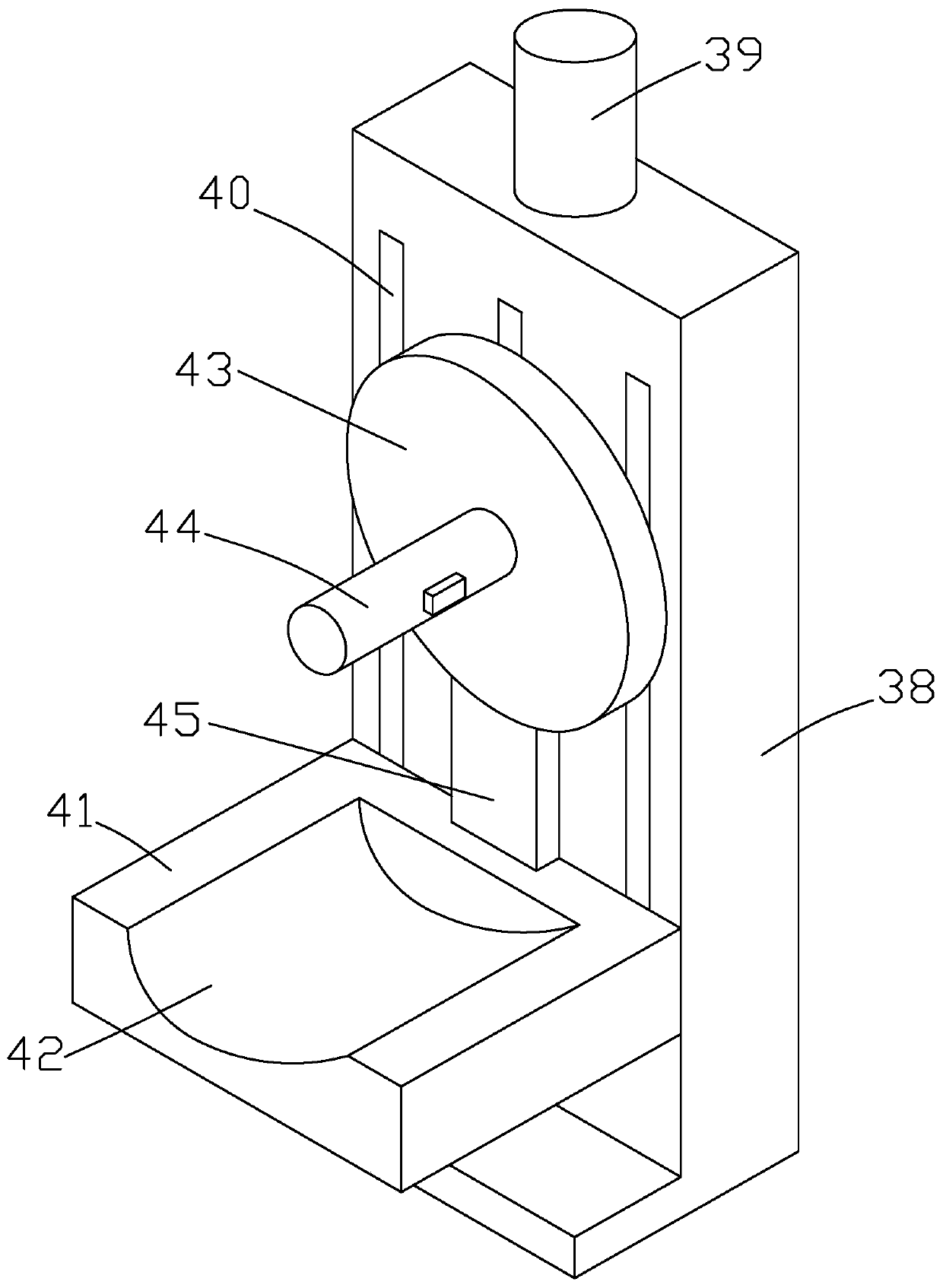

[0055] Such as Figure 1 to Figure 5 Shown, be a kind of magnet steel processing device that is used for the production of permanent magnet synchronous motor of the present invention, comprise base 1, rotor positioning mechanism 19, magnet steel extruding mechanism, magnet steel feeding mechanism 18 and feeding mechanism, base 1 Two first support bars 5 are arranged in parallel on the top surface, and a base plate 4 and a mounting plate 17 are arranged on the top surfaces of the two first support bars 5. The magnet steel extruding mechanism is connected on the top surface of the base plate 4, and the magnet steel The extruding mechanism comprises a first hydraulic cylinder 12, a booster disc 16 and a horizontally moving plate 7. The top surface of the horizontally moving plate 7 is fixedly connected with a fixed plate 11, and two lower positioning plates are arranged symmetrically on the top surface of the fixed plate 11. Block 13, the first hydraulic cylinder 12 is installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com