Patents

Literature

44results about How to "Improve accuracy and quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

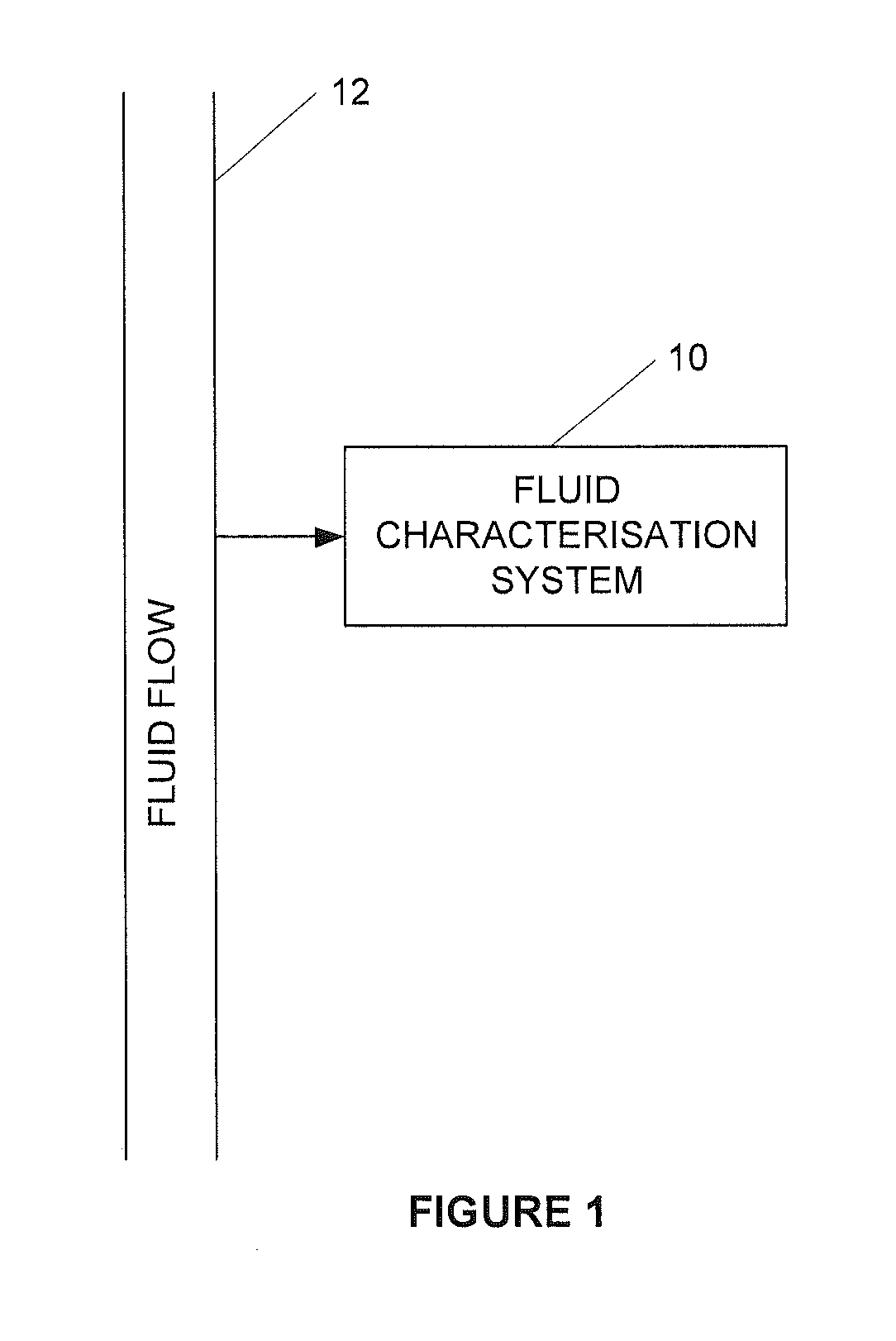

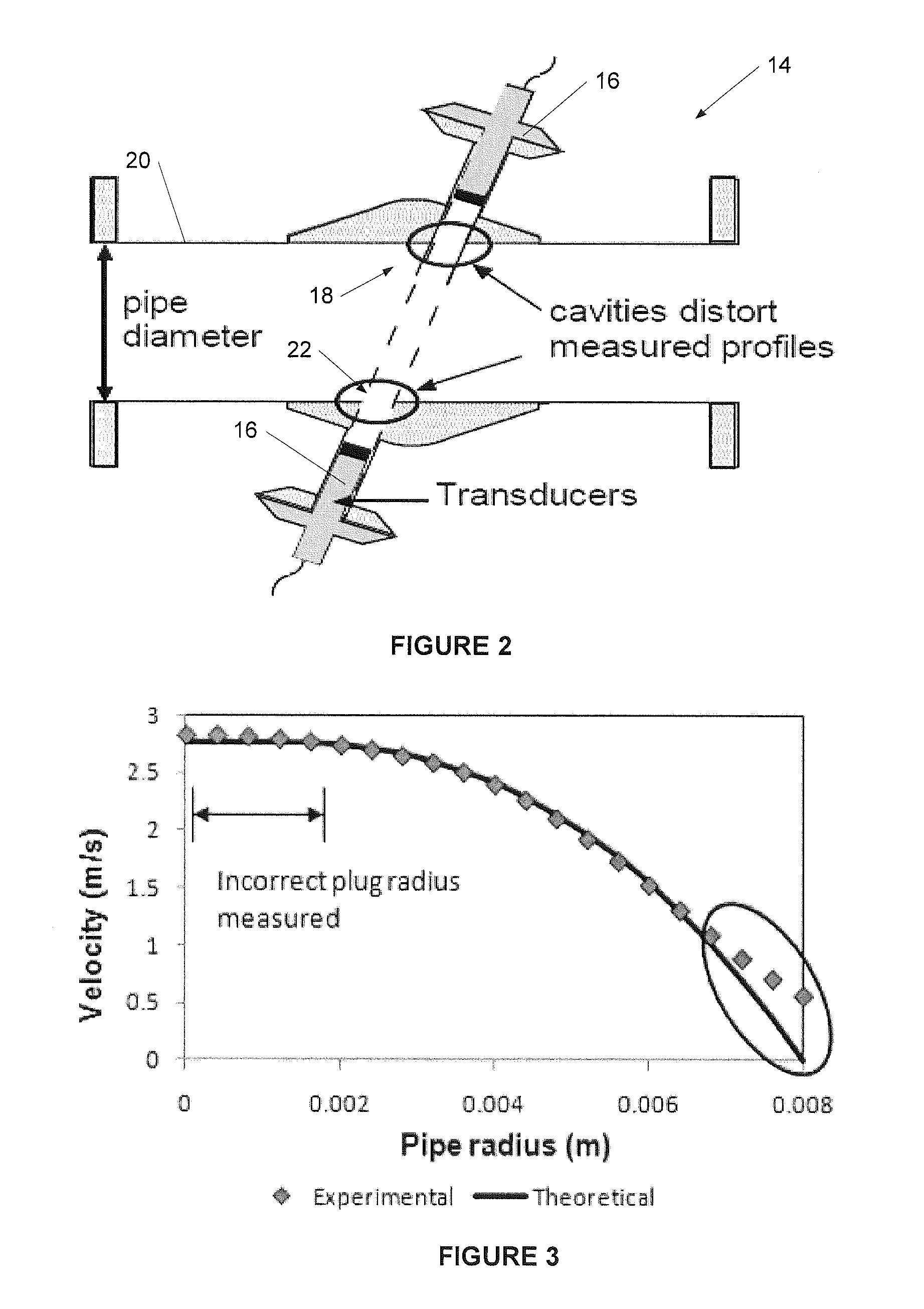

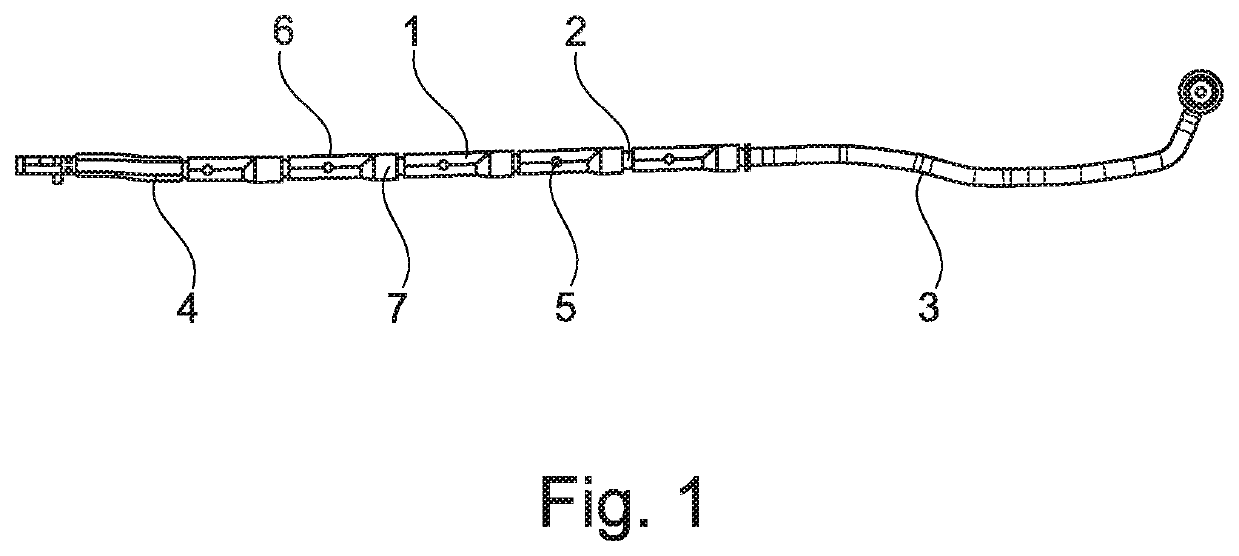

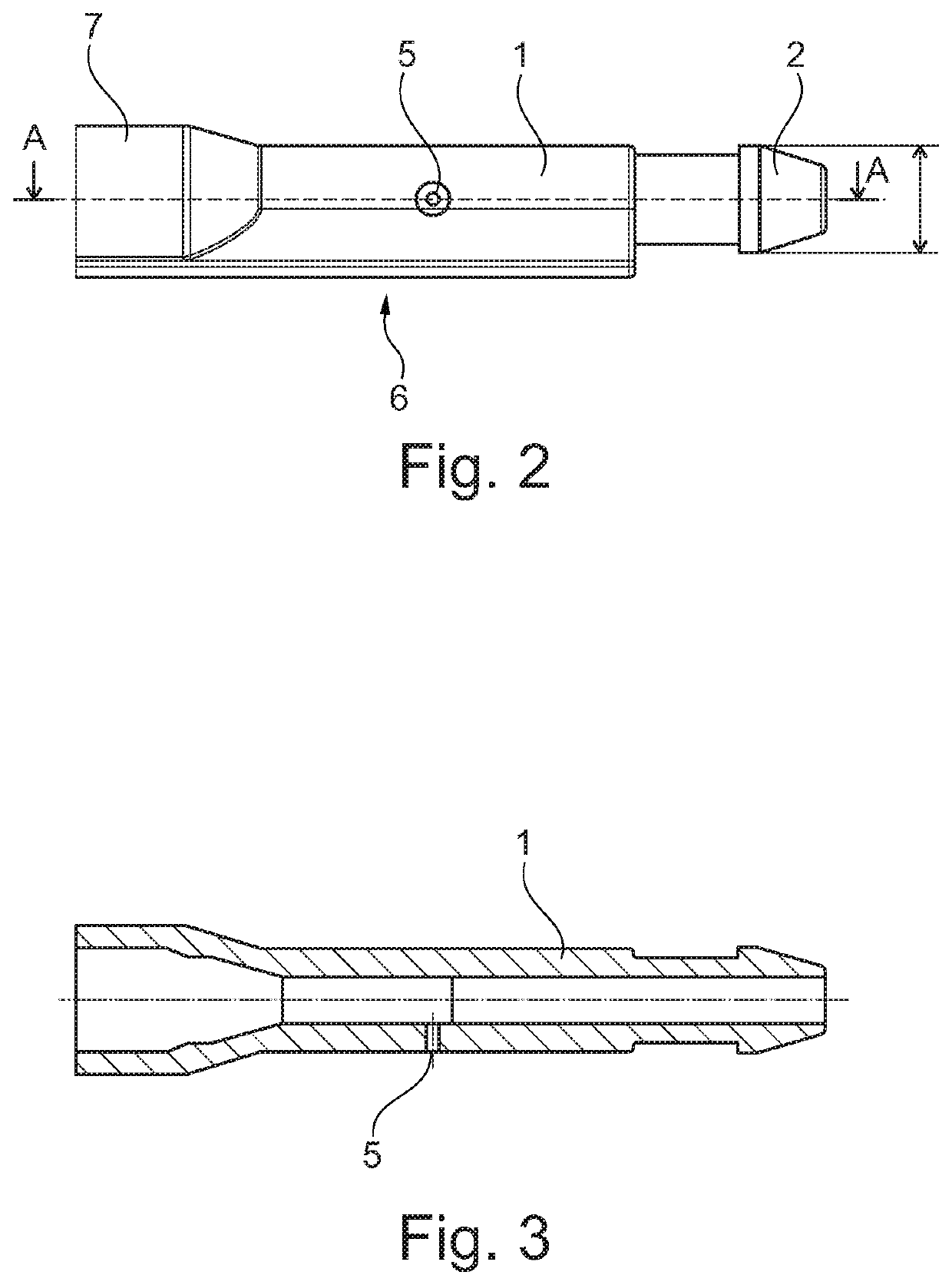

Fluid visualisation and characterisation system and method; a transducer

ActiveUS20130345994A1Reduce sensitivityCanceled outVolume meteringVolume flow measuring devicesSonificationTransducer

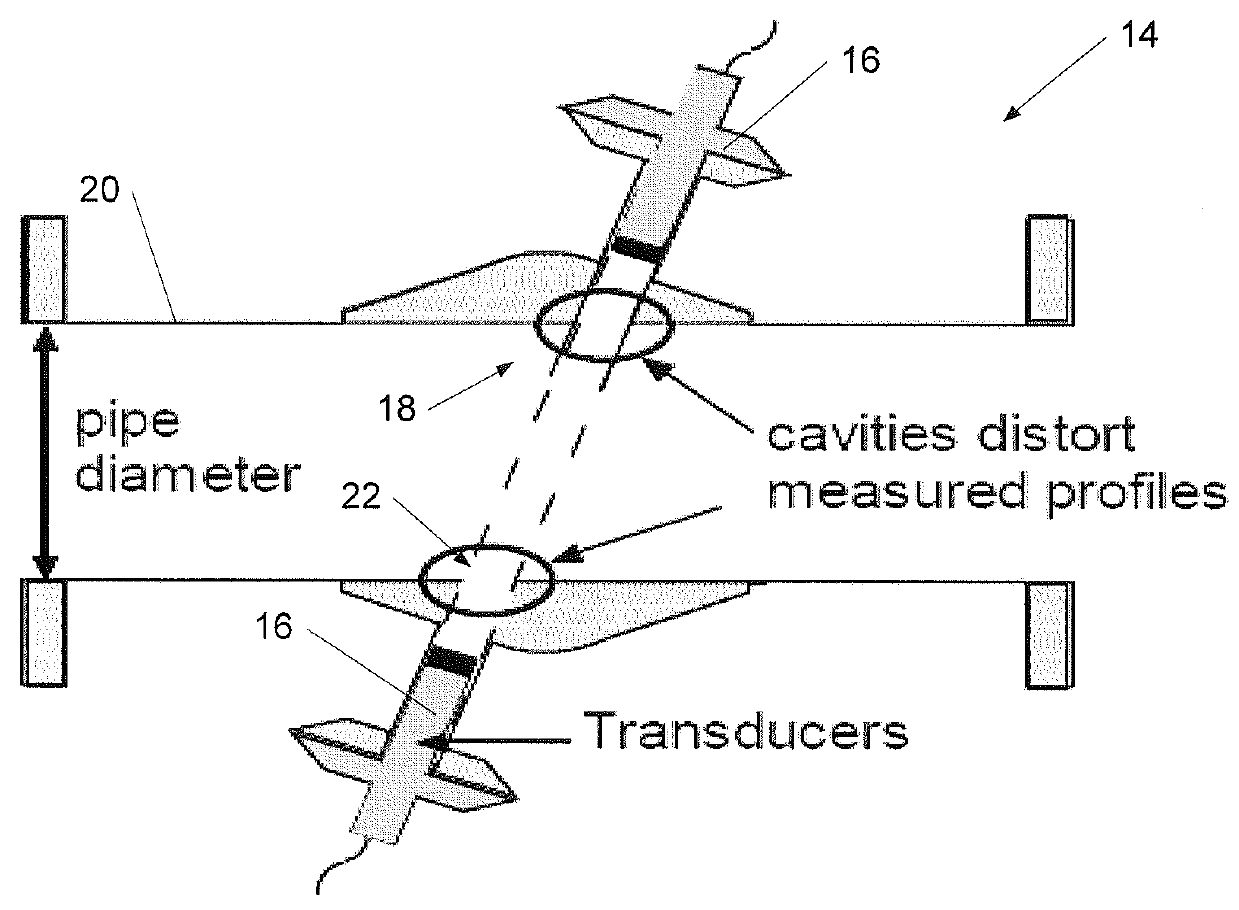

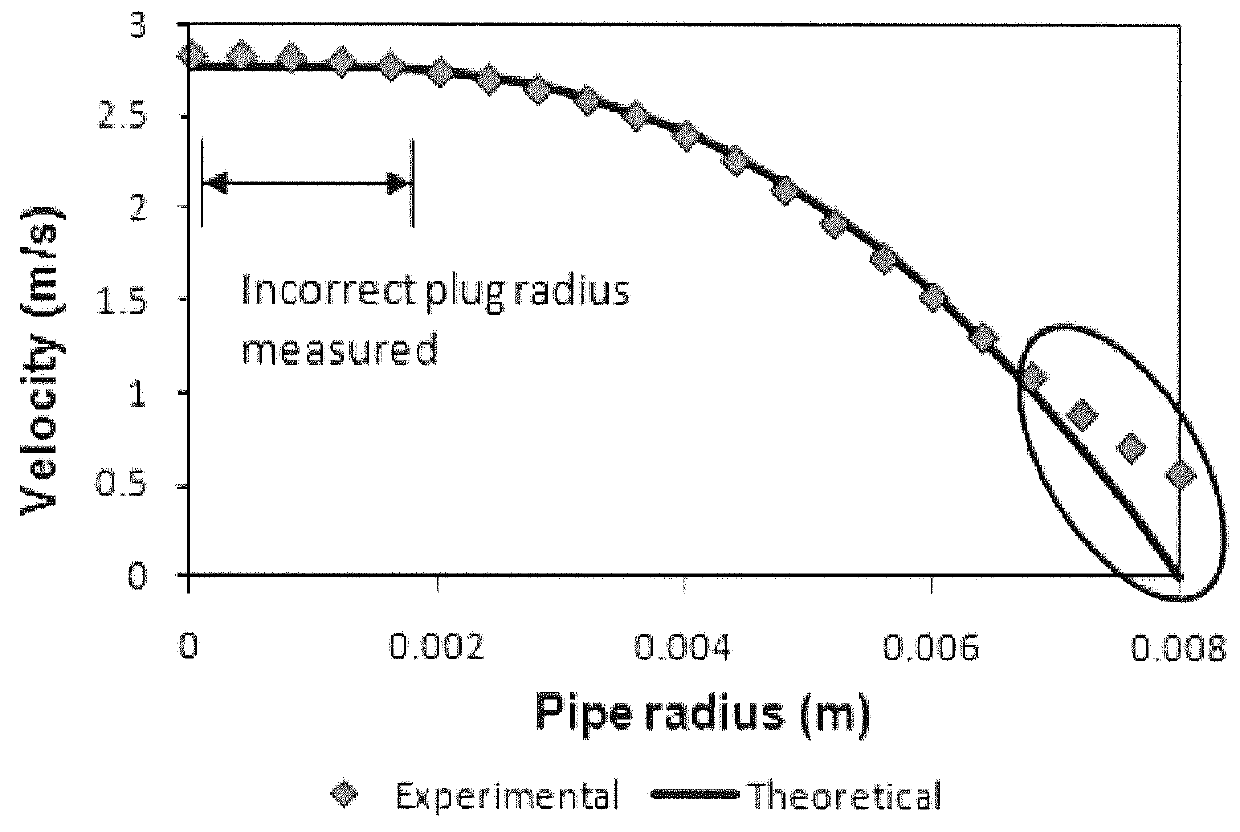

A fluid visualization and characterisation system includes a measuring section with a housing defining a fluid flow path for fluid flow. The measuring section includes one or more transducers to emit ultrasonic signals into the fluid flow, and at least one receiver to receive reflections of the ultrasonic signal from reflectors in the fluid flow. The system includes a memory for storing data and a processor operatively connected to the memory. The processor comprises several modules. A velocity estimating module is configured to apply one or more velocity estimation algorithms to received reflections of the ultrasonic signal, or data indicative thereof, to determine a velocity profile of the fluid flow. A deconvolution module is configured to apply a deconvolution algorithm at least to the determined velocity profile to determine a true velocity profile of the fluid flow. A fluid visualization and characterisation module is configured to determine characteristics of the fluid and / or fluid flow in by using the determined velocity profile and / or the true velocity profile.

Owner:SP TECHNICAL RESEARCH INSTITUTE OF SWEDEN +1

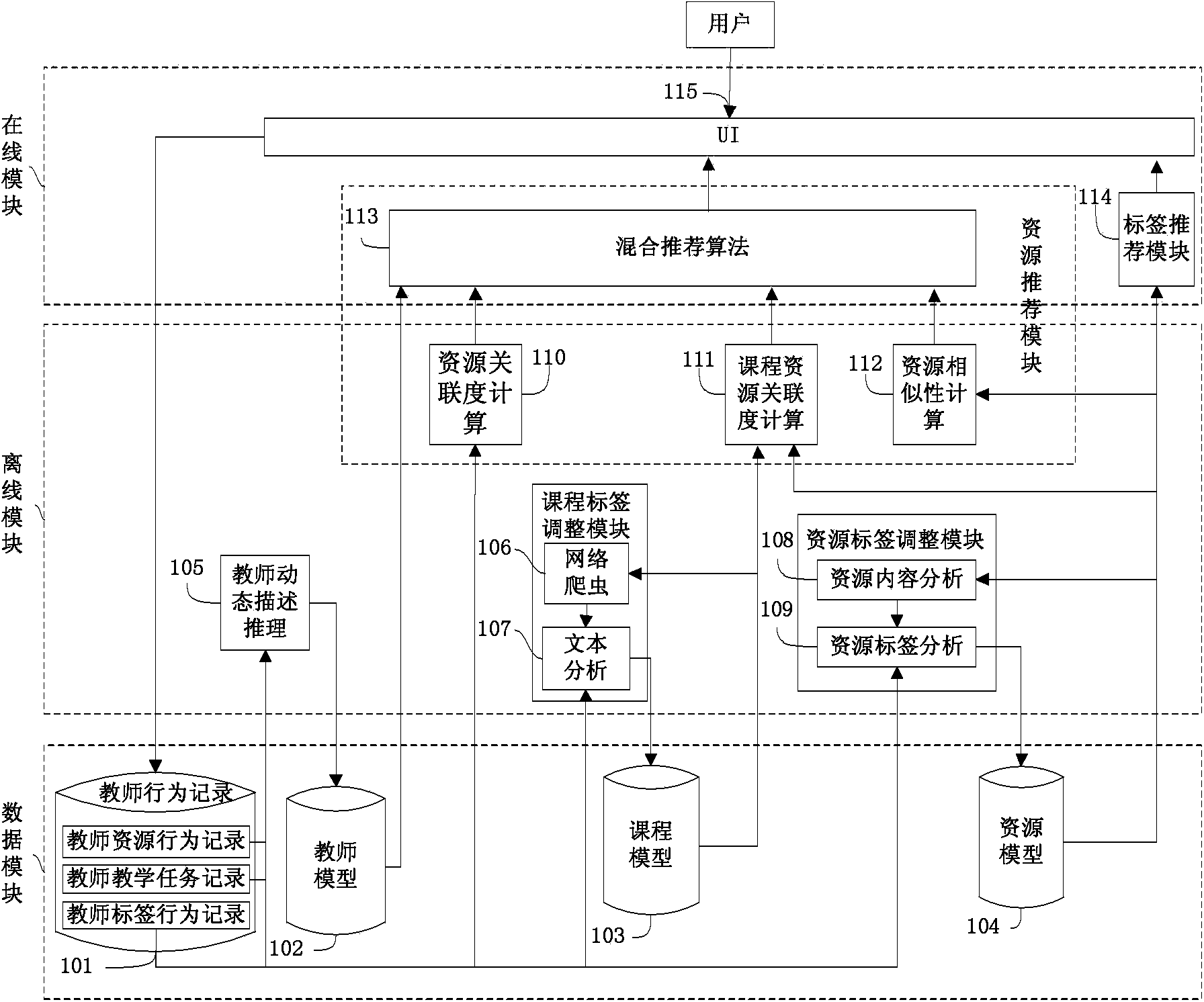

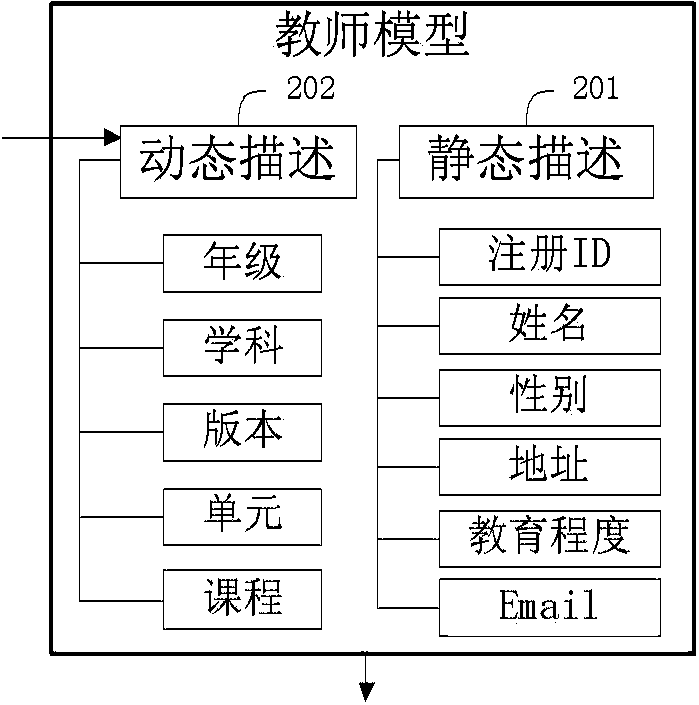

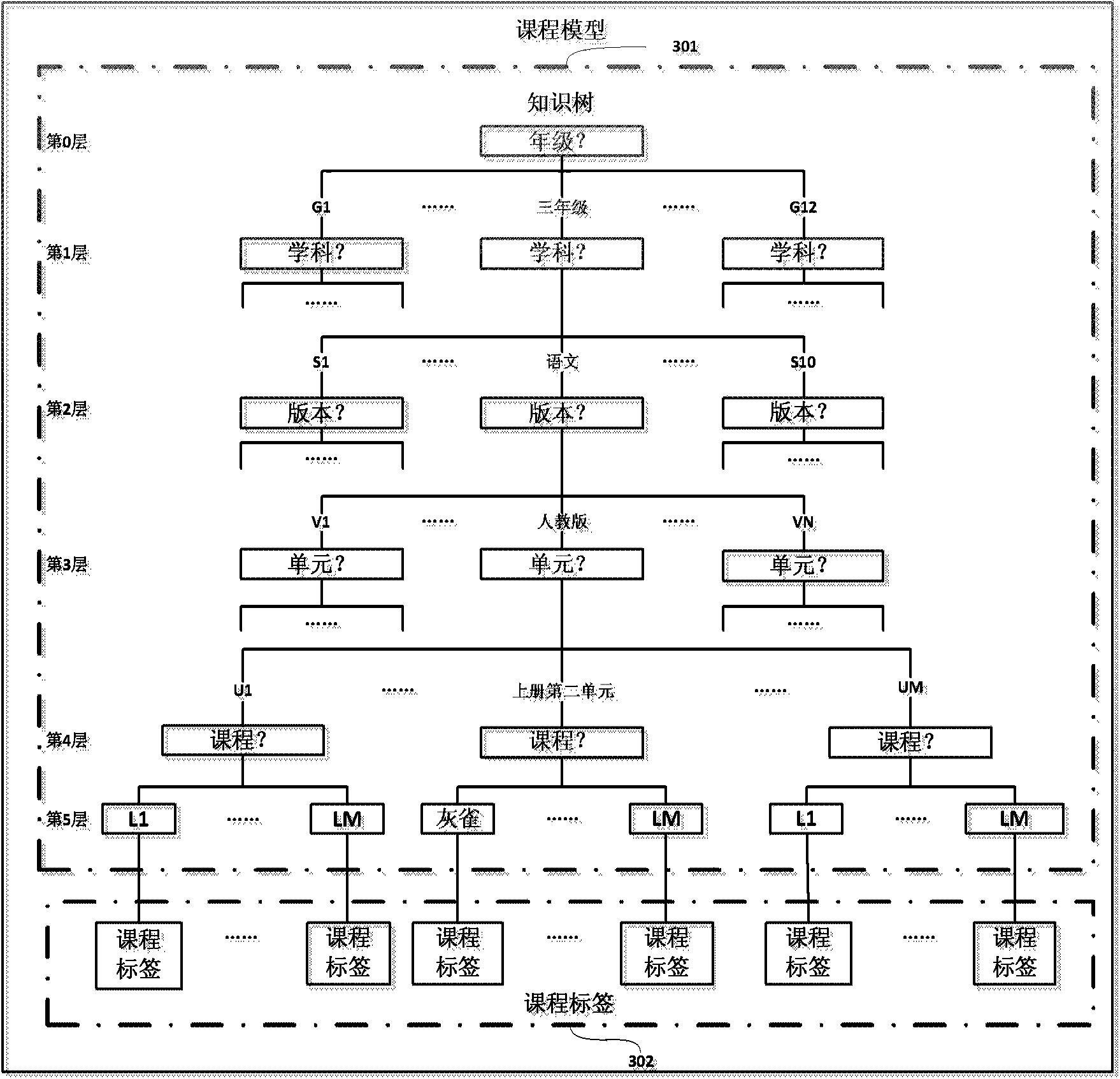

Personalization recommendation system and method of network teaching resources

InactiveCN103886054AOvercome information overloadImprove accuracy and qualitySpecial data processing applicationsData transmissionPersonalization

The invention discloses a recommendation system and method of network teaching resources. The system comprises a data establishing module, an off-line data processing module and an on-line recommendation module. The data establishing module establishes teacher behavior data, teacher model data, a course model data and resource model data. The off-line data processing module is used for initializing and adjusting course model data and resource model data, teacher behavior data are used for deducing teacher identities, the degree of association between the resources is computed according to the teacher behavior data, the similarity between the resources is computed according to the resource model data, and the degree of association between the resources and courses is computed according to the resource model data and the course model data. The on-line recommendation module describes on-line recommendation resources through the association degree between the resources, the similarity between the resources, the association degree between the courses and the resources and the dynamic states of teachers, and the on-line recommendation module transmits teacher behavior data to the teacher behavior data of the data establishing module according to the feedback recommendation resource labels of the teachers on the recommendation resources through UI interaction.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI +1

Fluid visualisation and characterisation system and method; a transducer

ActiveUS9383237B2Improve accuracy and qualityReduce gradientVolume variation compensation/correction apparatusVolume/mass flow by dynamic fluid flow effectSonificationTransducer

A fluid visualization and characterization system includes a measuring section with a housing defining a fluid flow path for fluid flow. The measuring section includes one or more transducers to emit ultrasonic signals into the fluid flow, and at least one receiver to receive reflections of the ultrasonic signal from reflectors in the fluid flow. The system includes a memory for storing data and a processor operatively connected to the memory. The processor comprises several modules. A velocity estimating module is configured to apply one or more velocity estimation algorithms to received reflections of the ultrasonic signal, or data indicative thereof, to determine a velocity profile of the fluid flow. A deconvolution module is configured to apply a deconvolution algorithm at least to the determined velocity profile to determine a true velocity profile of the fluid flow. A fluid visualization and characterization module is configured to determine characteristics of the fluid and / or fluid flow in by using the determined velocity profile and / or the true velocity profile.

Owner:SP TECHNICAL RESEARCH INSTITUTE OF SWEDEN +1

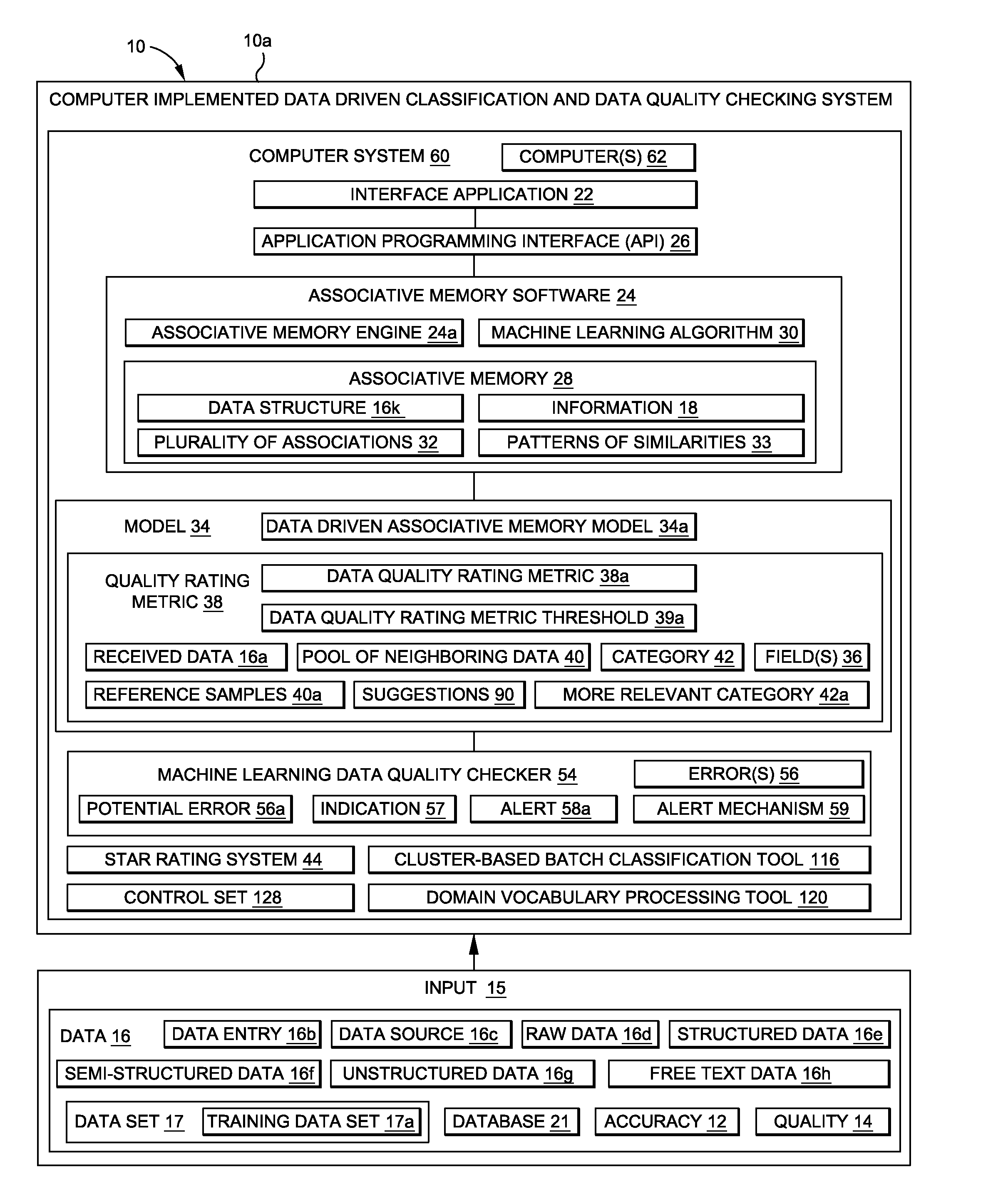

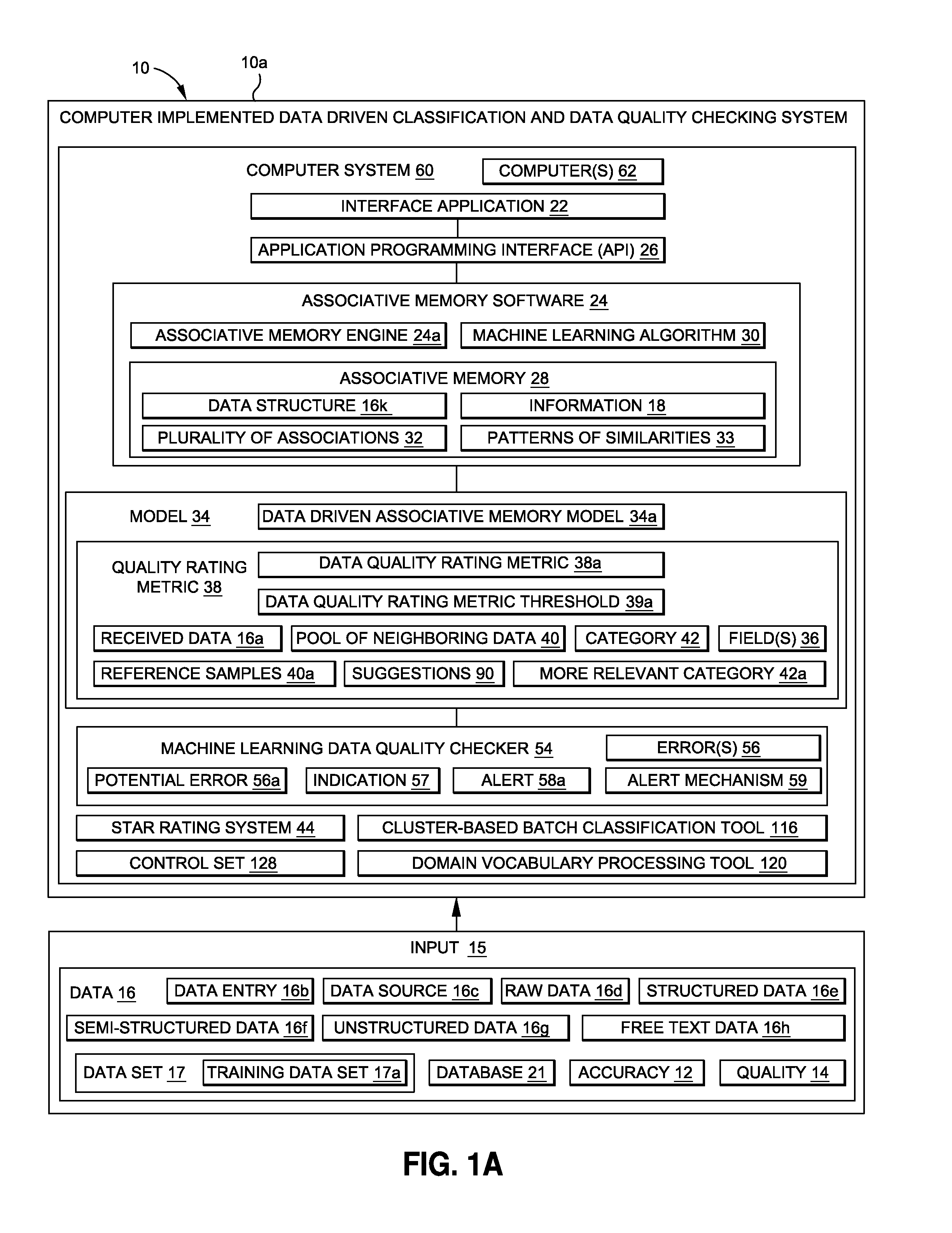

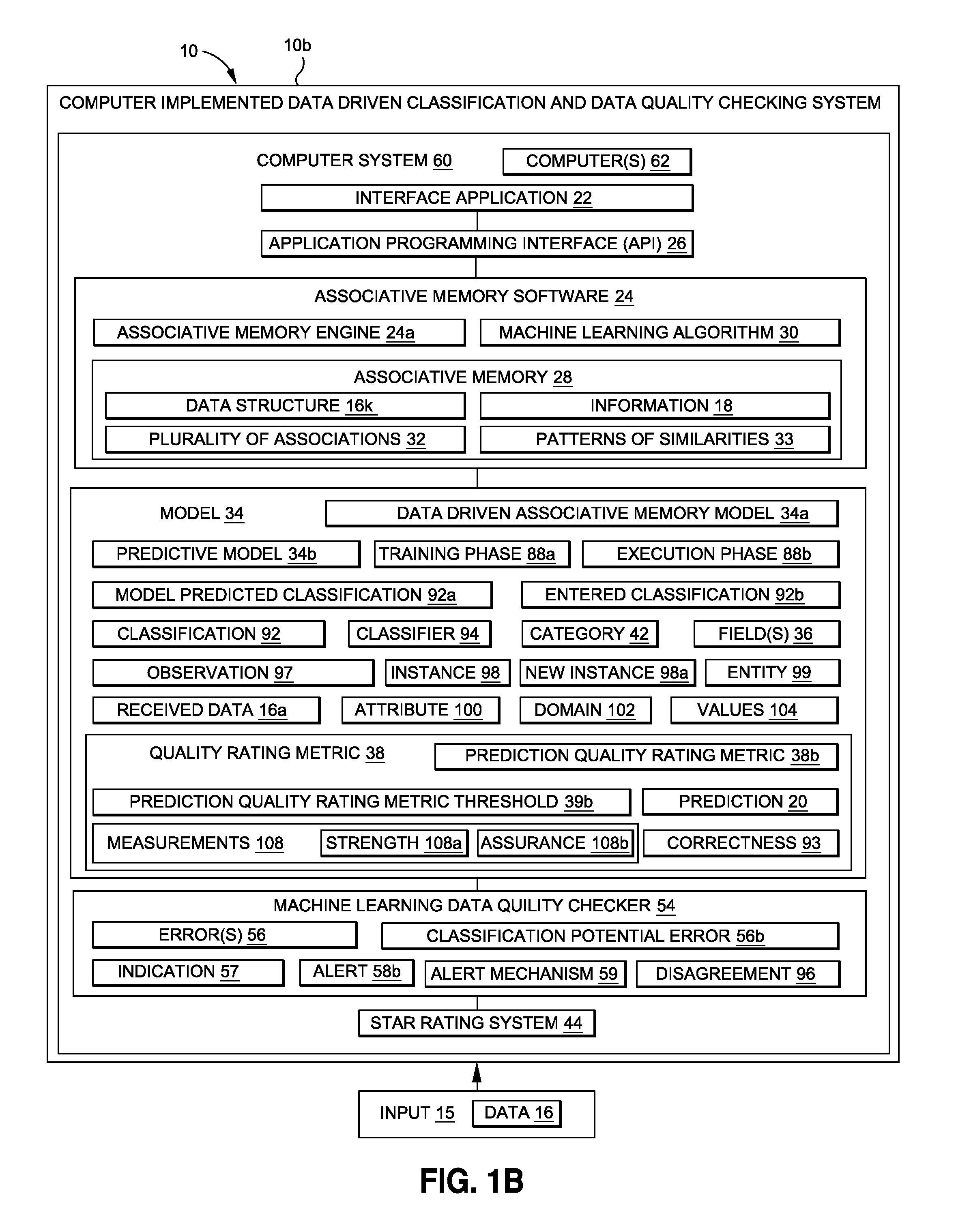

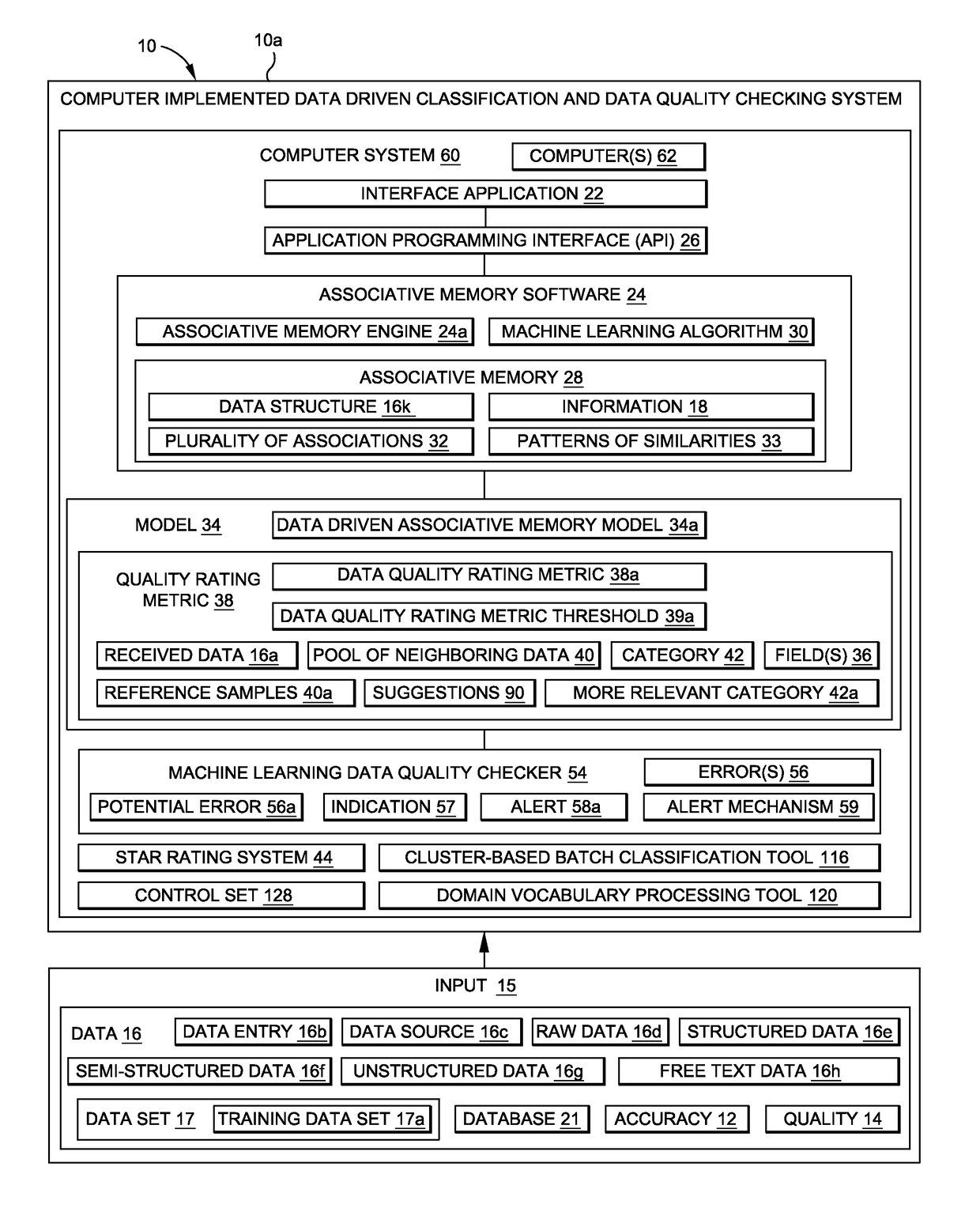

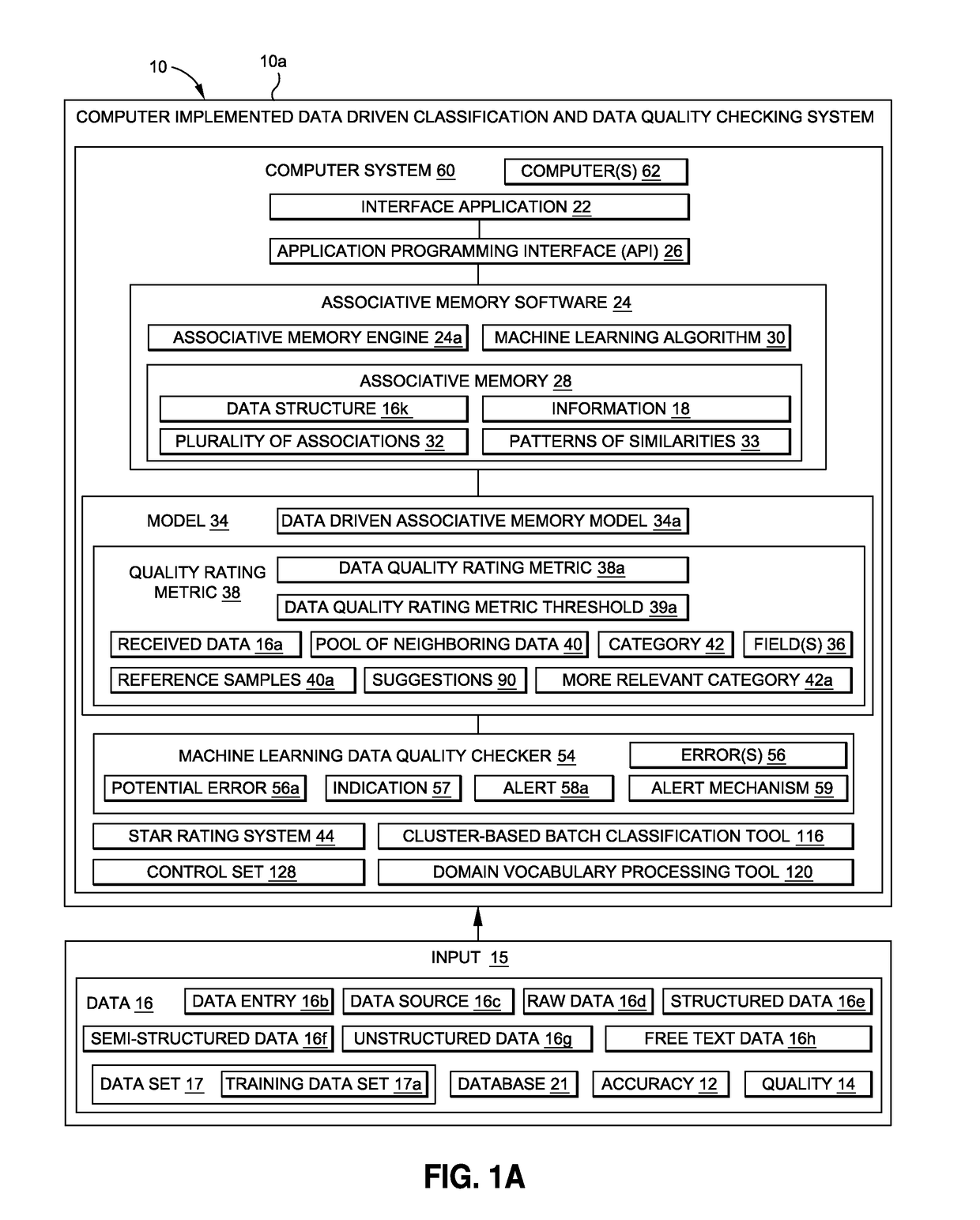

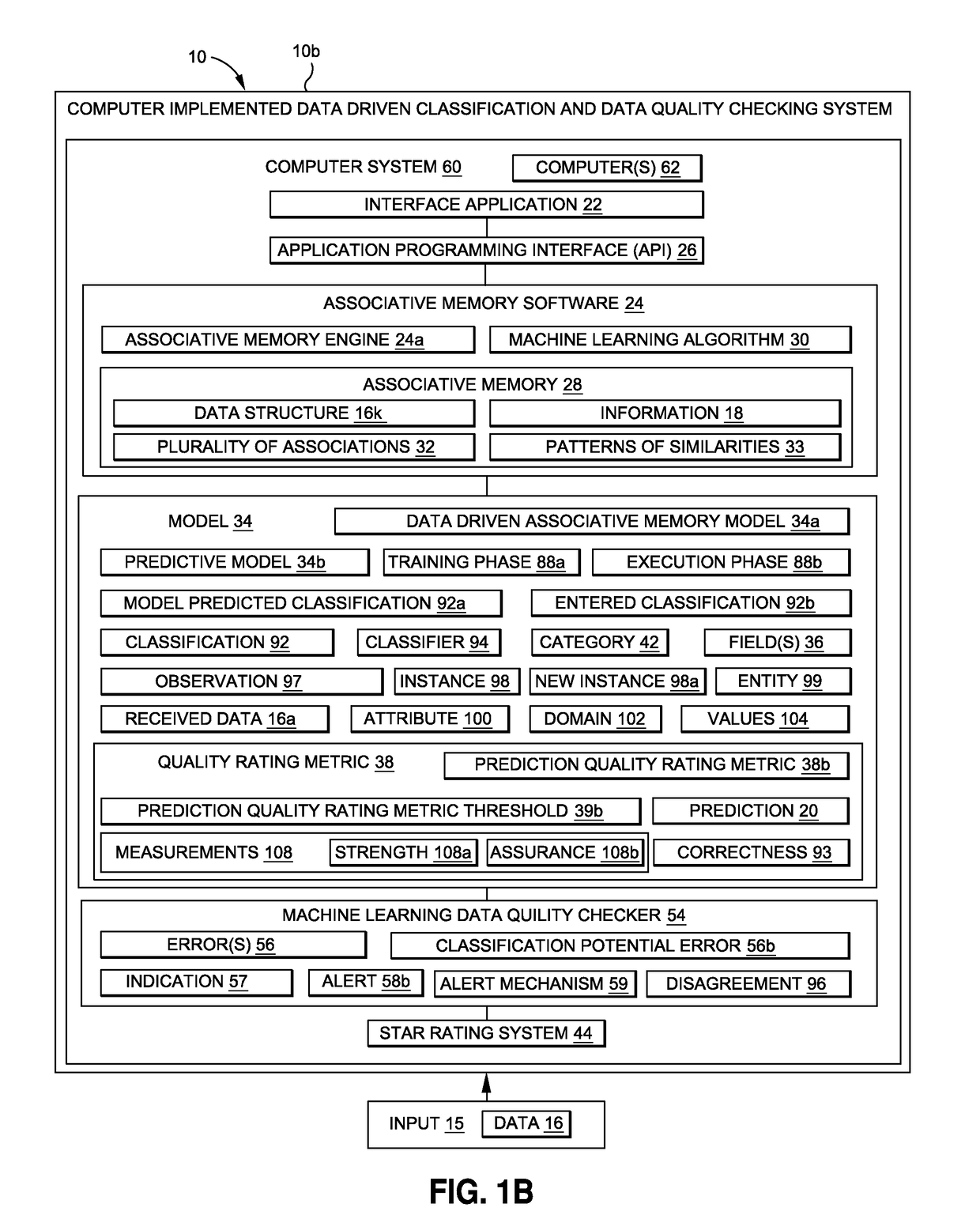

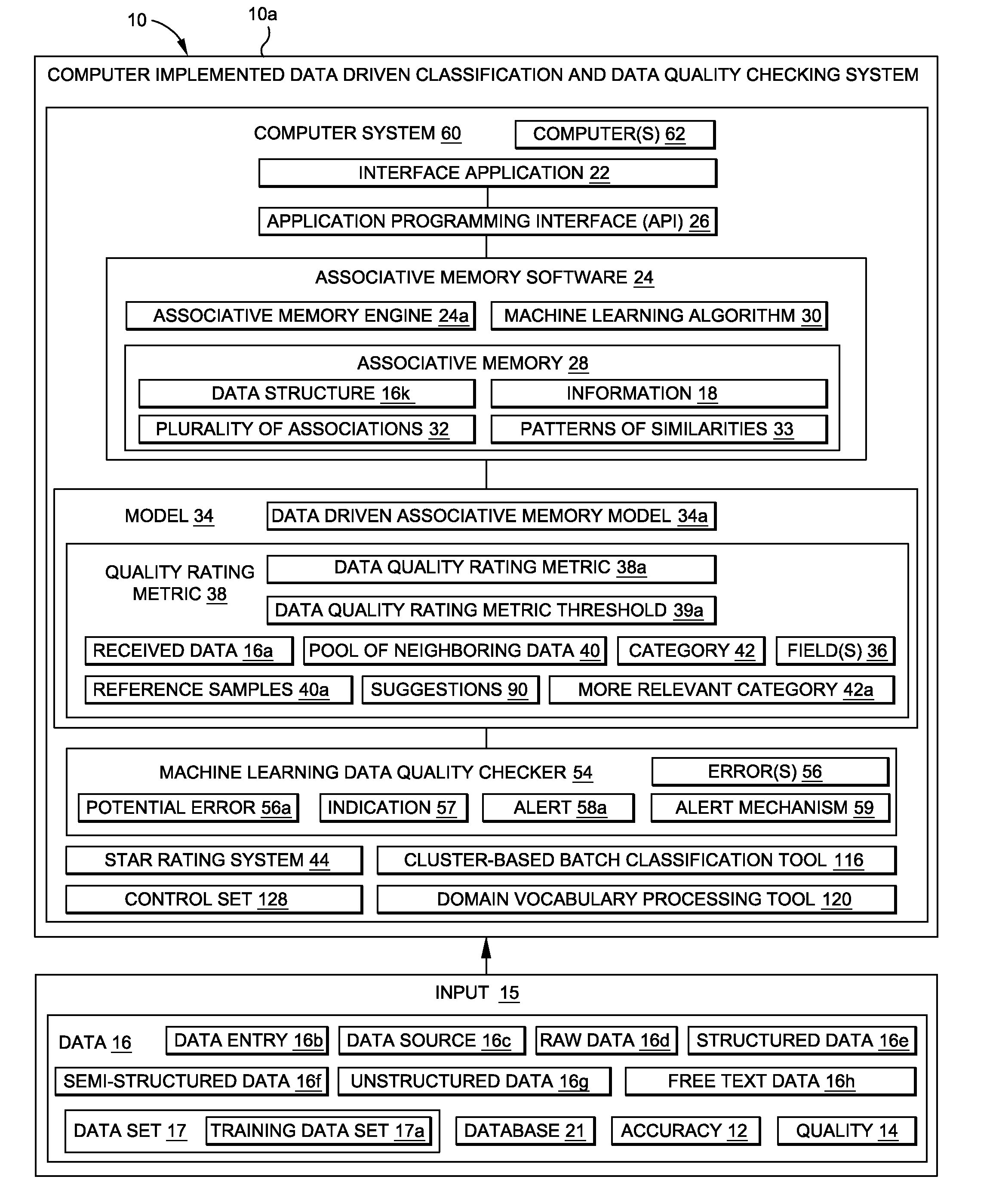

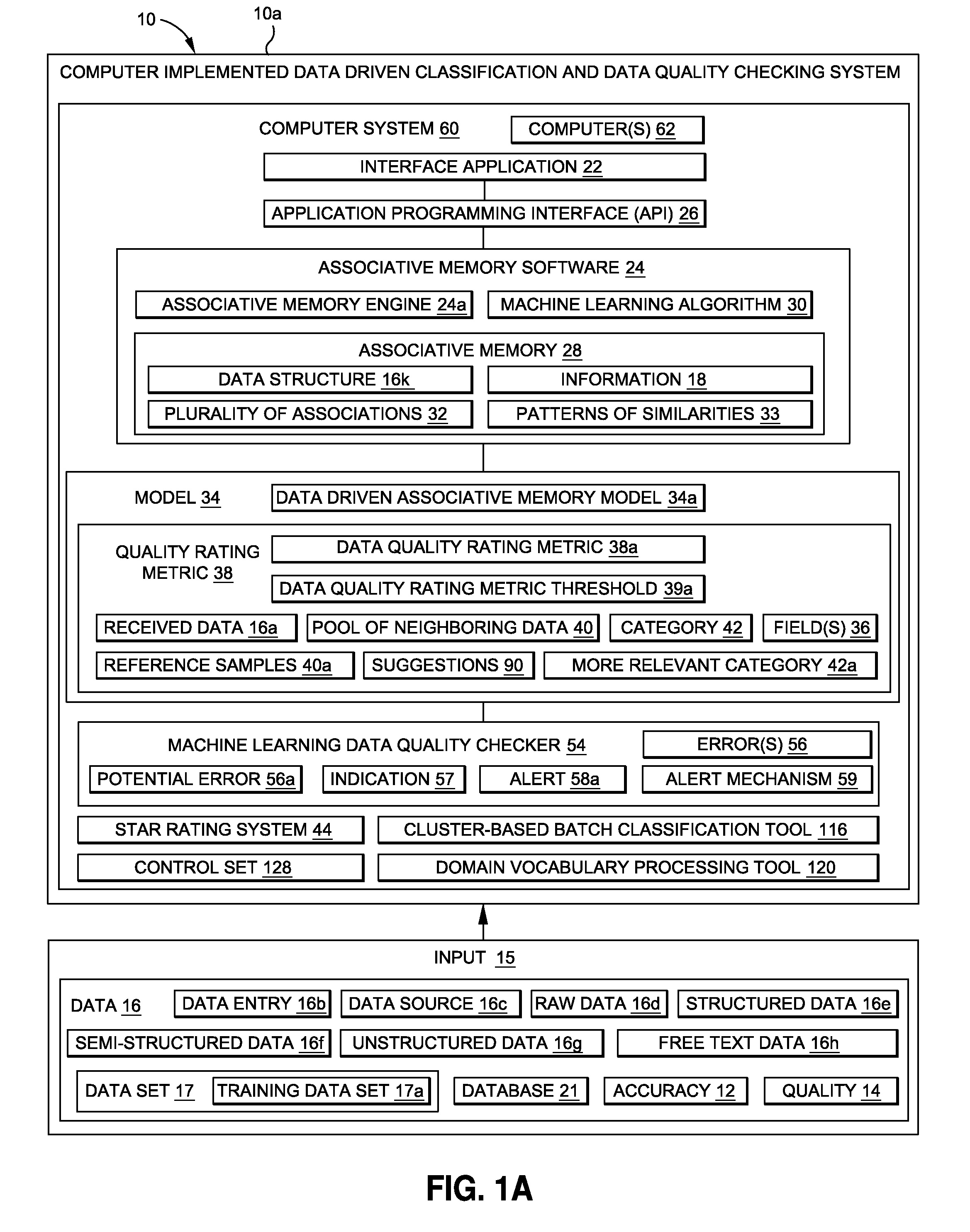

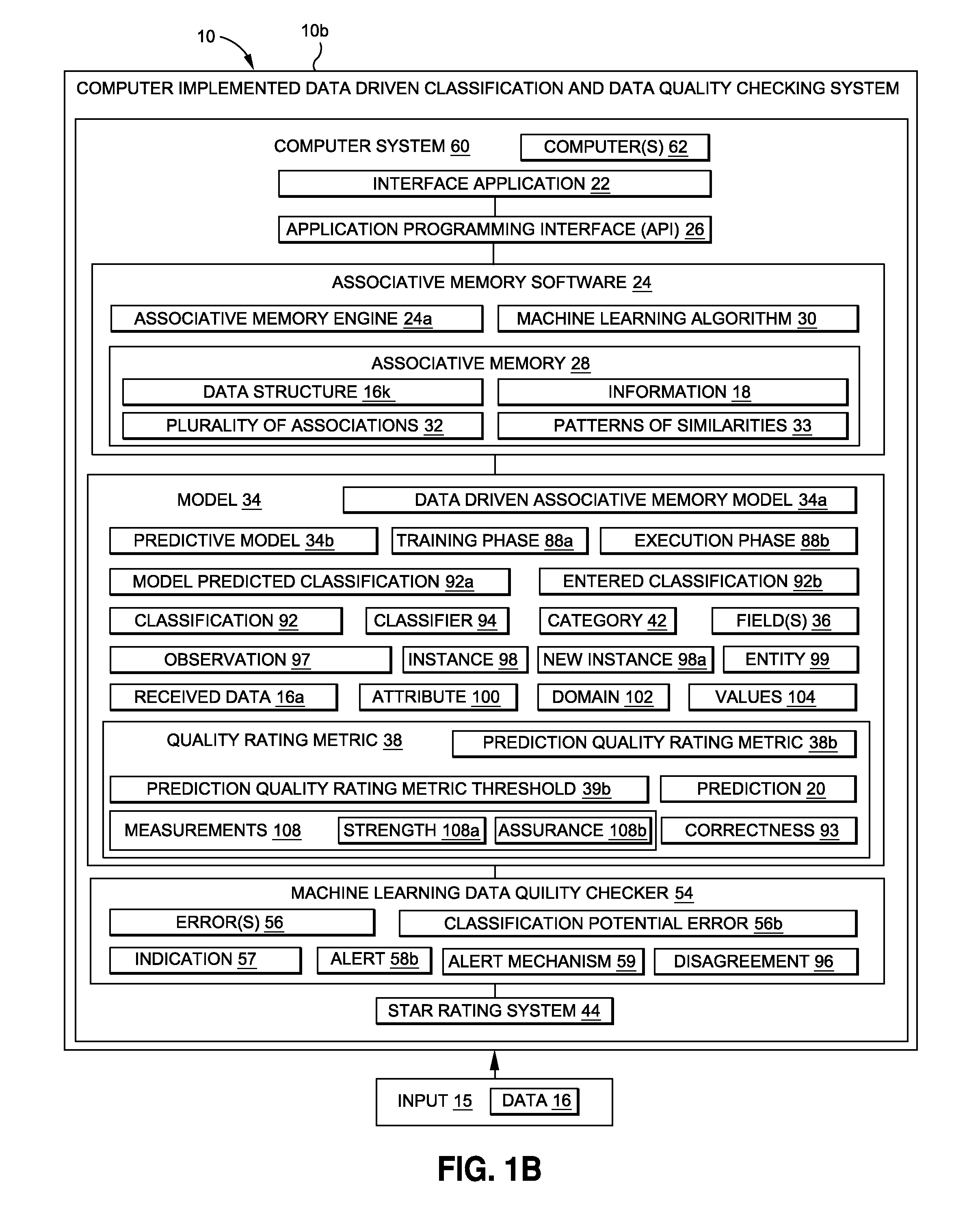

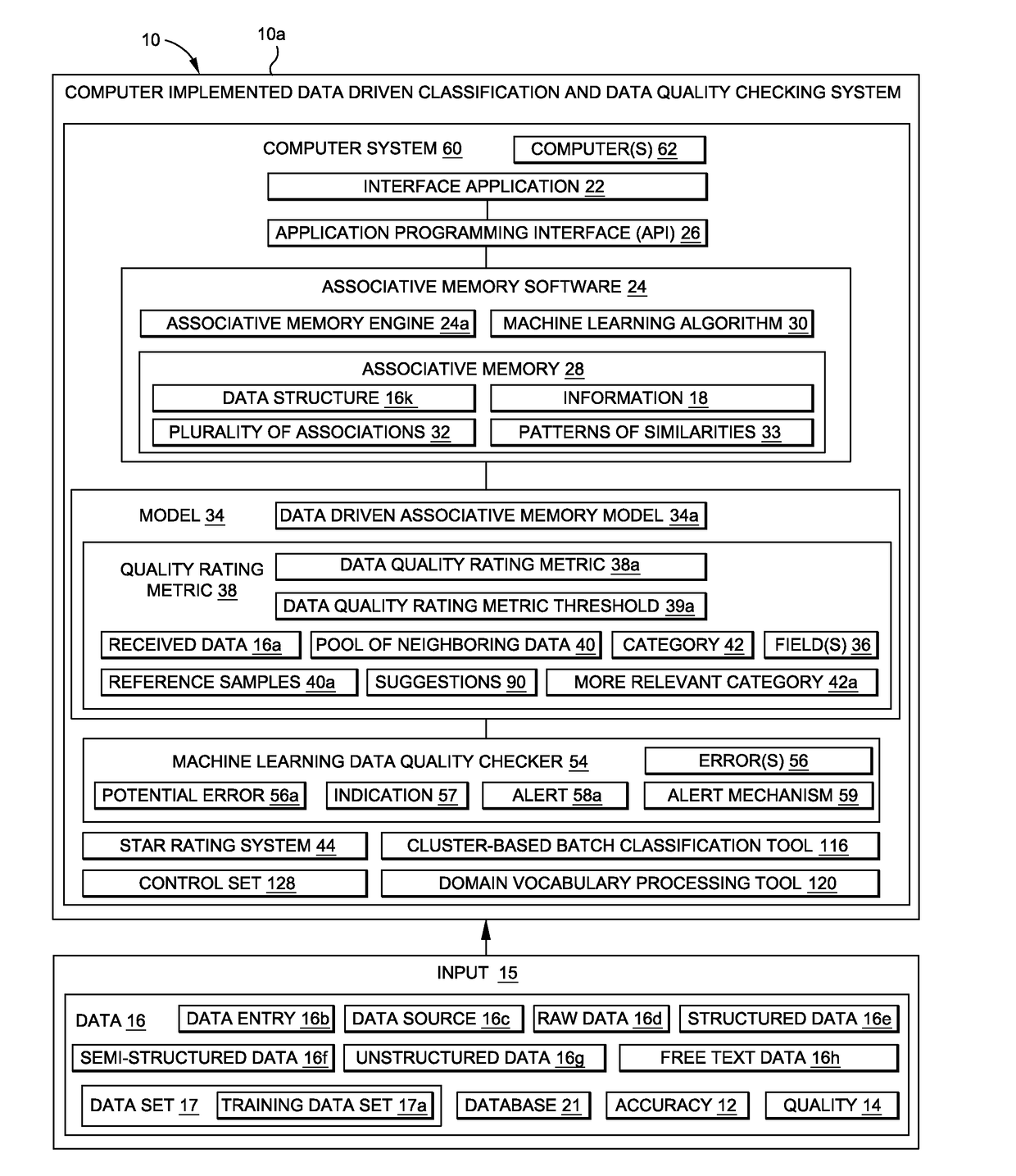

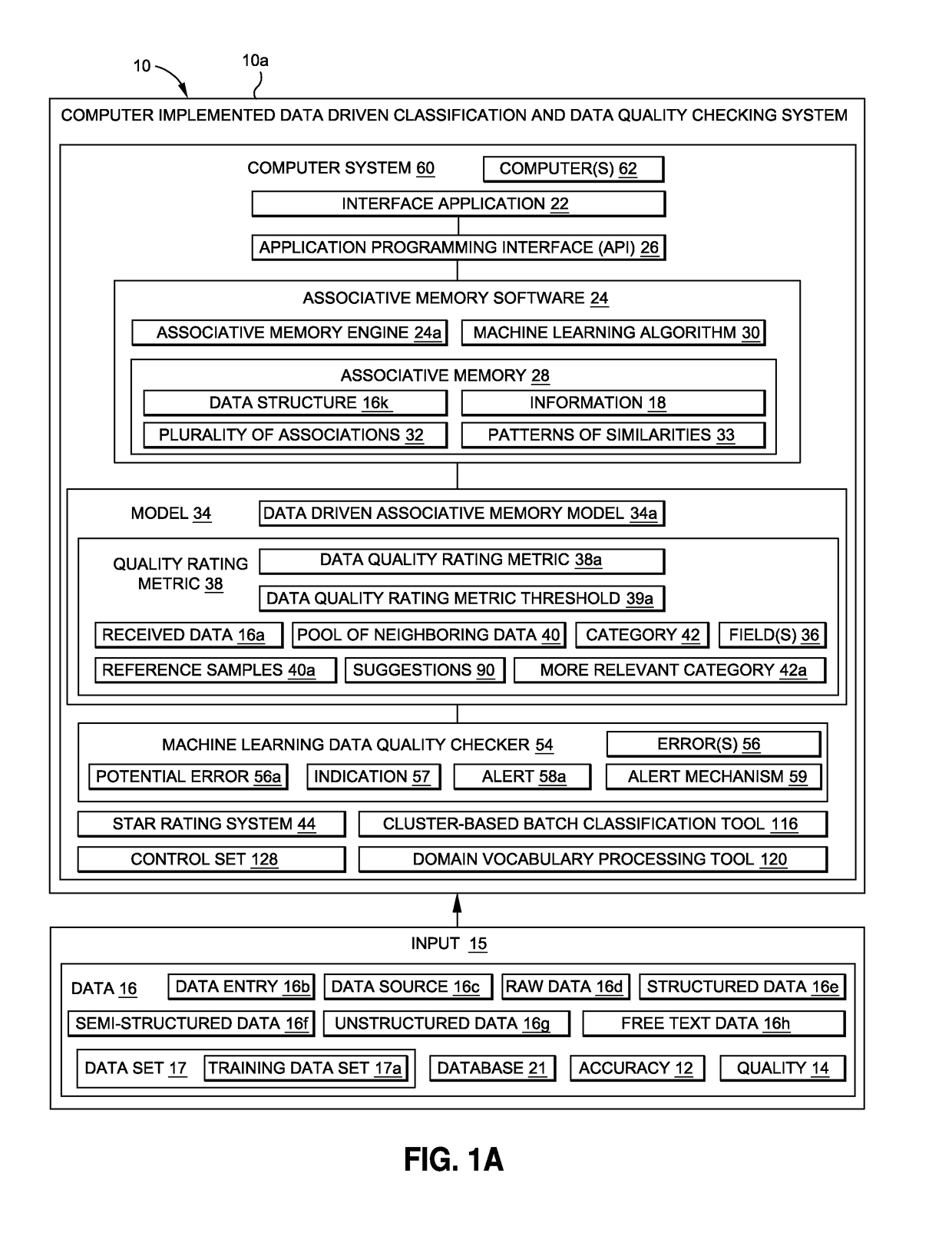

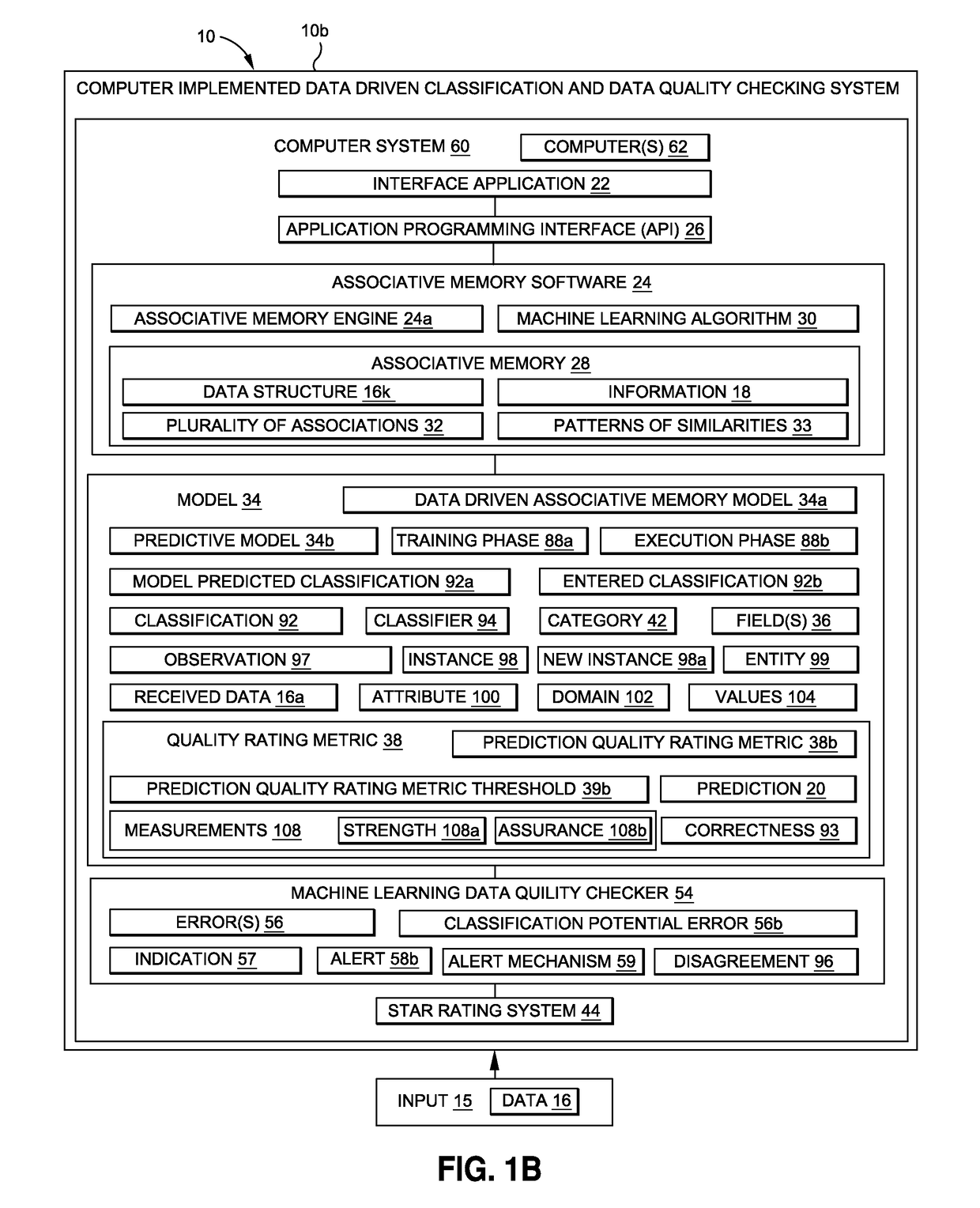

Data driven classification and data quality checking system

ActiveUS20170004413A1Improve accuracyQuality improvementRelational databasesKnowledge representationQuality ratingLearning data

A computer implemented data driven classification and data quality checking system is provided. The system has an interface application enabled to receive data and has an associative memory software. The system has a data driven associative memory model configured to categorize one or more fields of received data and to analyze the received data. The system has a data quality rating metric associated with the received data. The system has a machine learning data quality checker for the received data, and is configured to add the received data to a pool of neighboring data, if the data quality rating metric is greater than or equal to a data quality rating metric threshold. The machine learning data quality checker is configured to generate and communicate an alert of a potential error in the received data, if the data quality rating metric is less than the data quality rating metric threshold.

Owner:THE BOEING CO

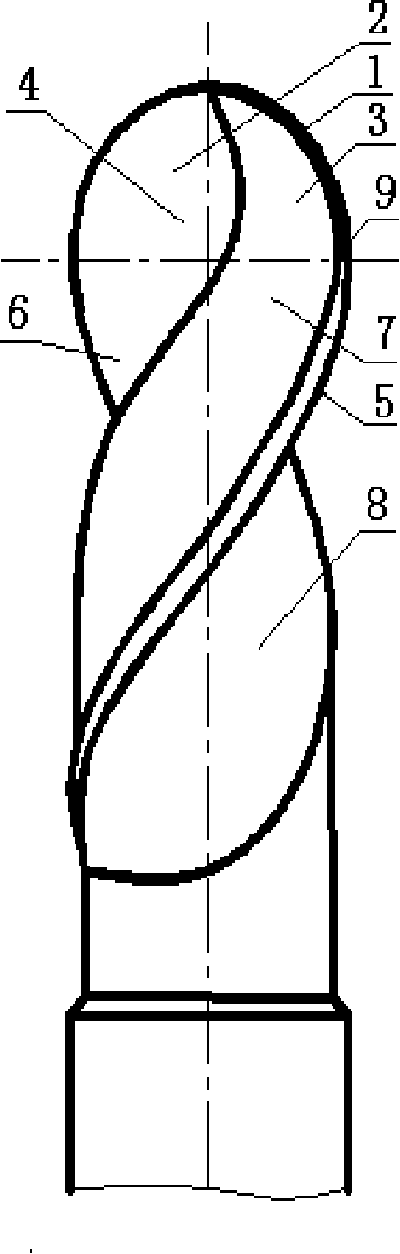

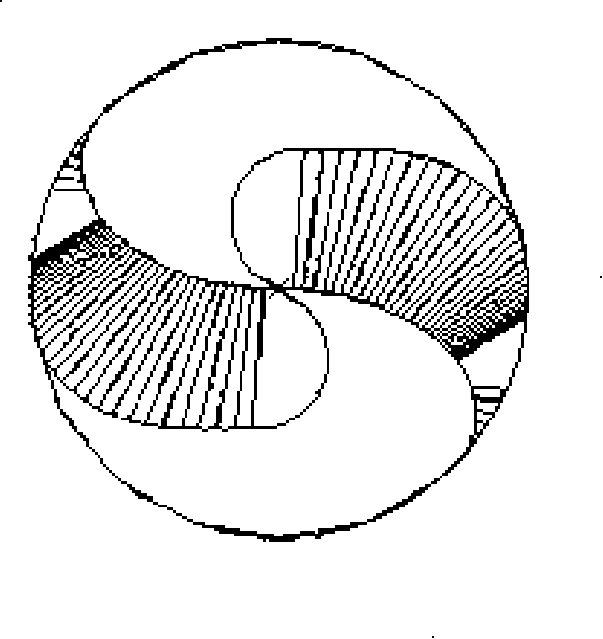

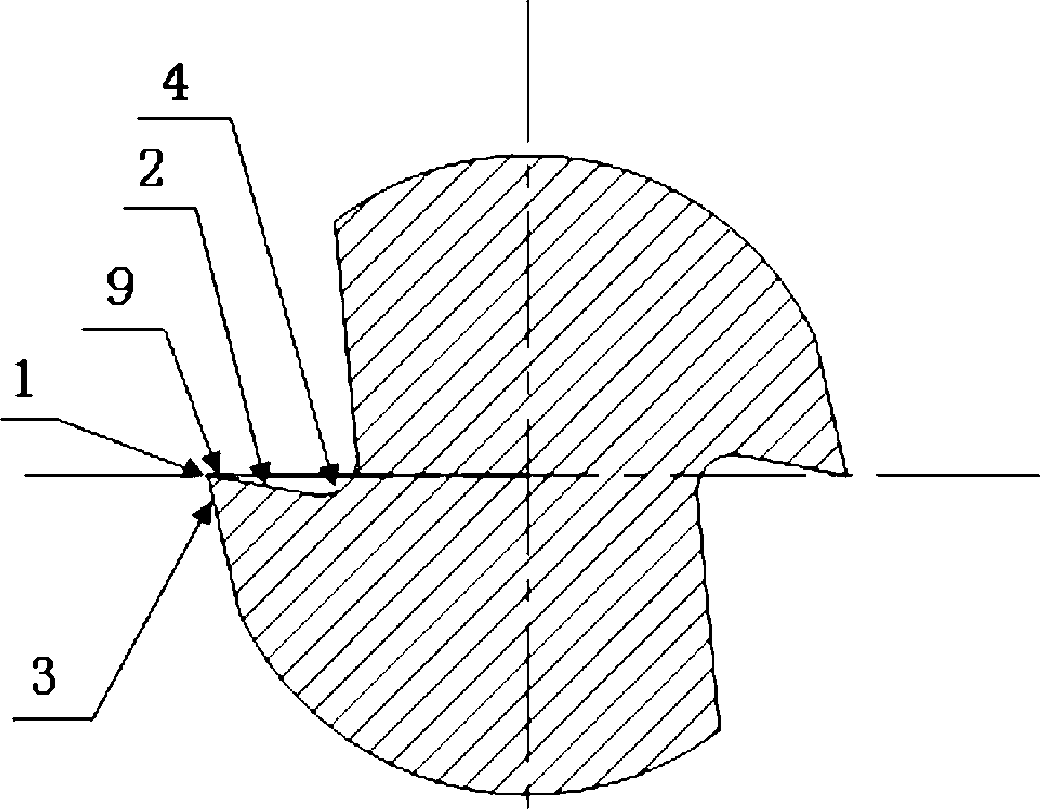

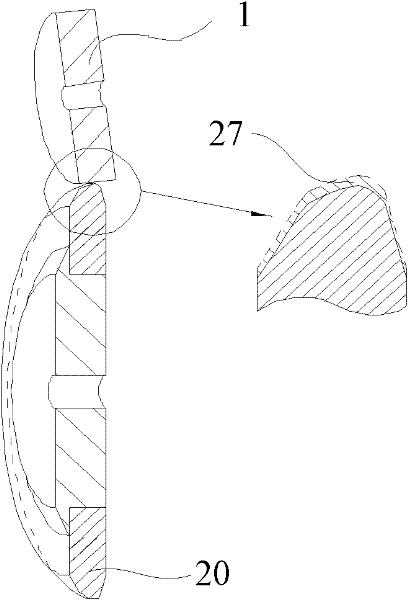

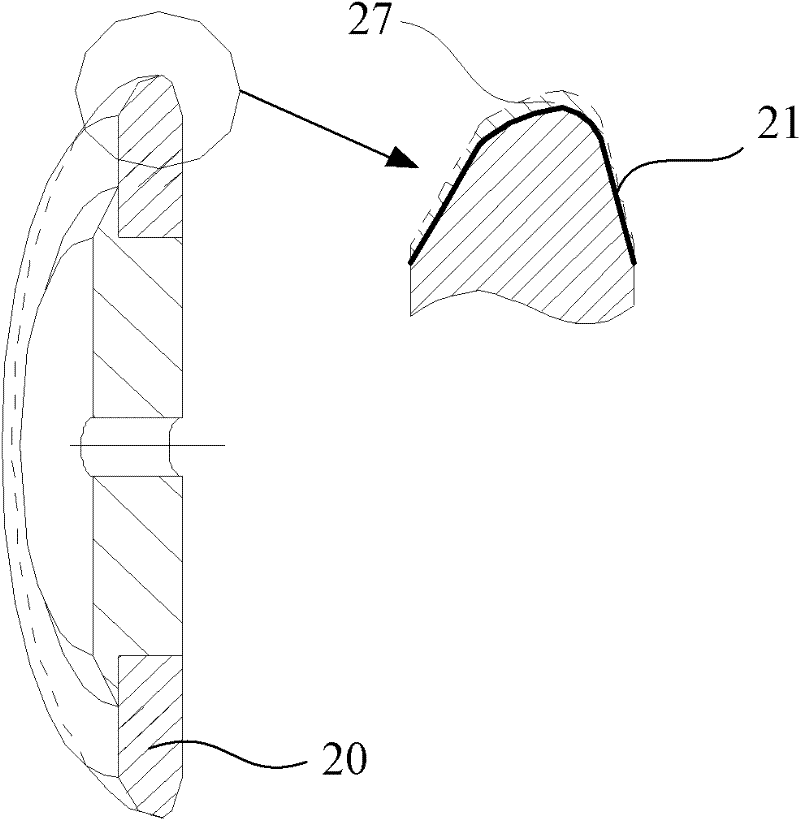

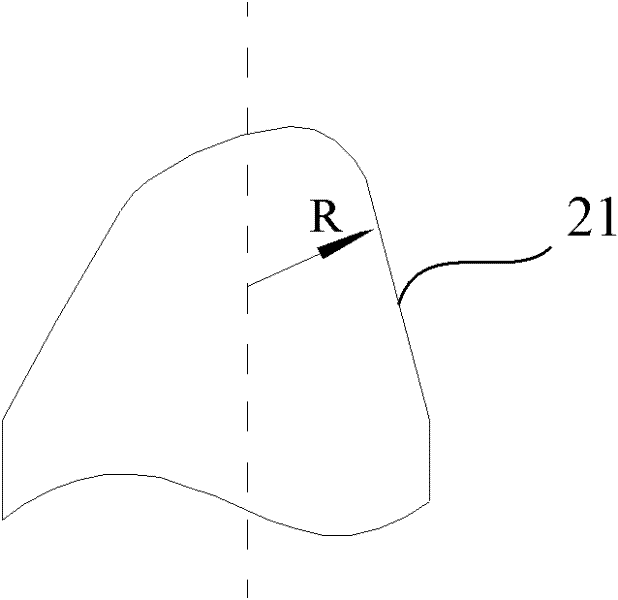

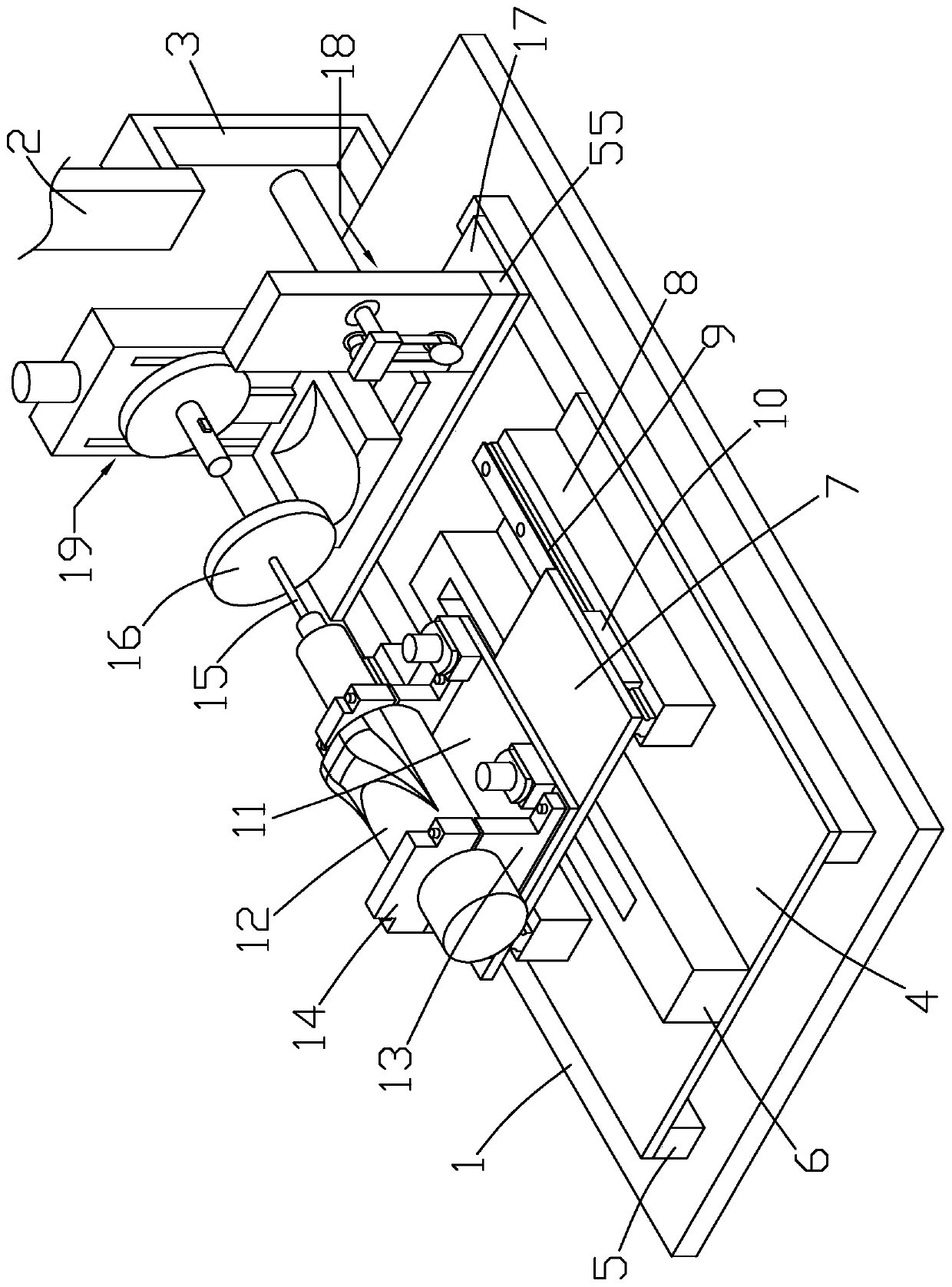

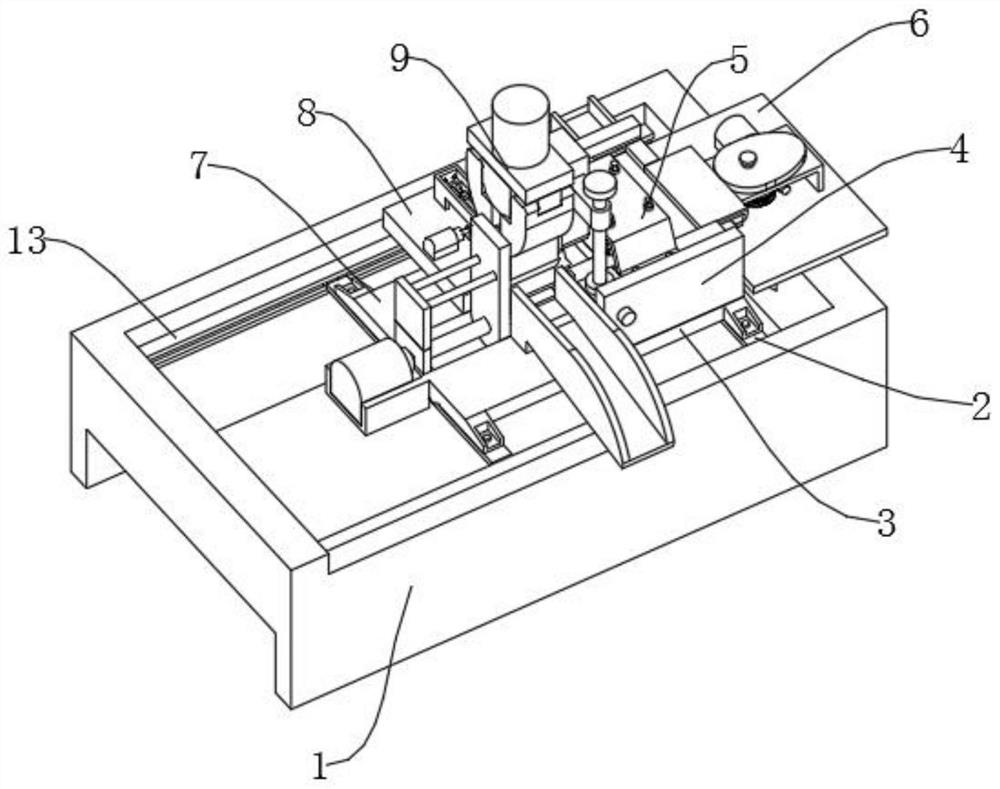

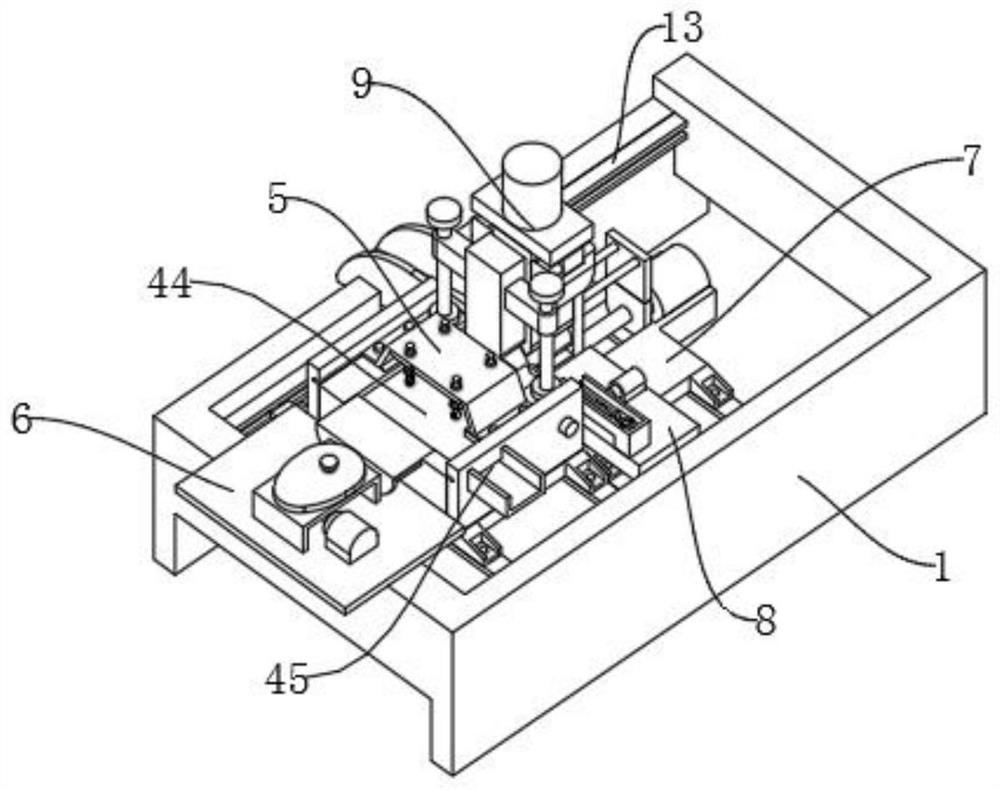

Bulb slotting cutter and its abrasive machining four-shaft linkage equipment

InactiveCN101239406AImprove accuracy and qualityWide range of applicationsMilling cuttersAgricultural engineeringMilling cutter

The invention discloses a bulb end milling cutter and a milling processing four-shaft associated device thereof. An S-shape bulb edge (1) is connected with a spiral circumferential edge (5), a bulb edge front face is connected smoothly with the circumferential edge front face (6), the bulb rear face (3) is connected with the circumferential edge rear face (7), and the bulb edge spiral groove (4) is connected with the circumferential edge spiral groove (8); the front angle of the bulb edge front face (2) is a rather big positive front angle, and is distributed with a small-big-small mode from inside to outside; the milling processing four-shaft associated device of the bulb end milling cutter comprises a latch bed (10), a horizontal longitudinal X axis straight-line motion flat stage (11), a horizontal transversal Y-axis straight-line motion flat stage (12), a vertical Z axis straight-line motion flat stage (13), a workpiece rotating shaft (14), and a front tool face milling head (15), and a rear tool face milling head (16). The invented devices are provided with characteristics of stable milling, smooth chip removal, simple structure, low cost, moderate price, and economic.

Owner:GUIZHOU UNIV

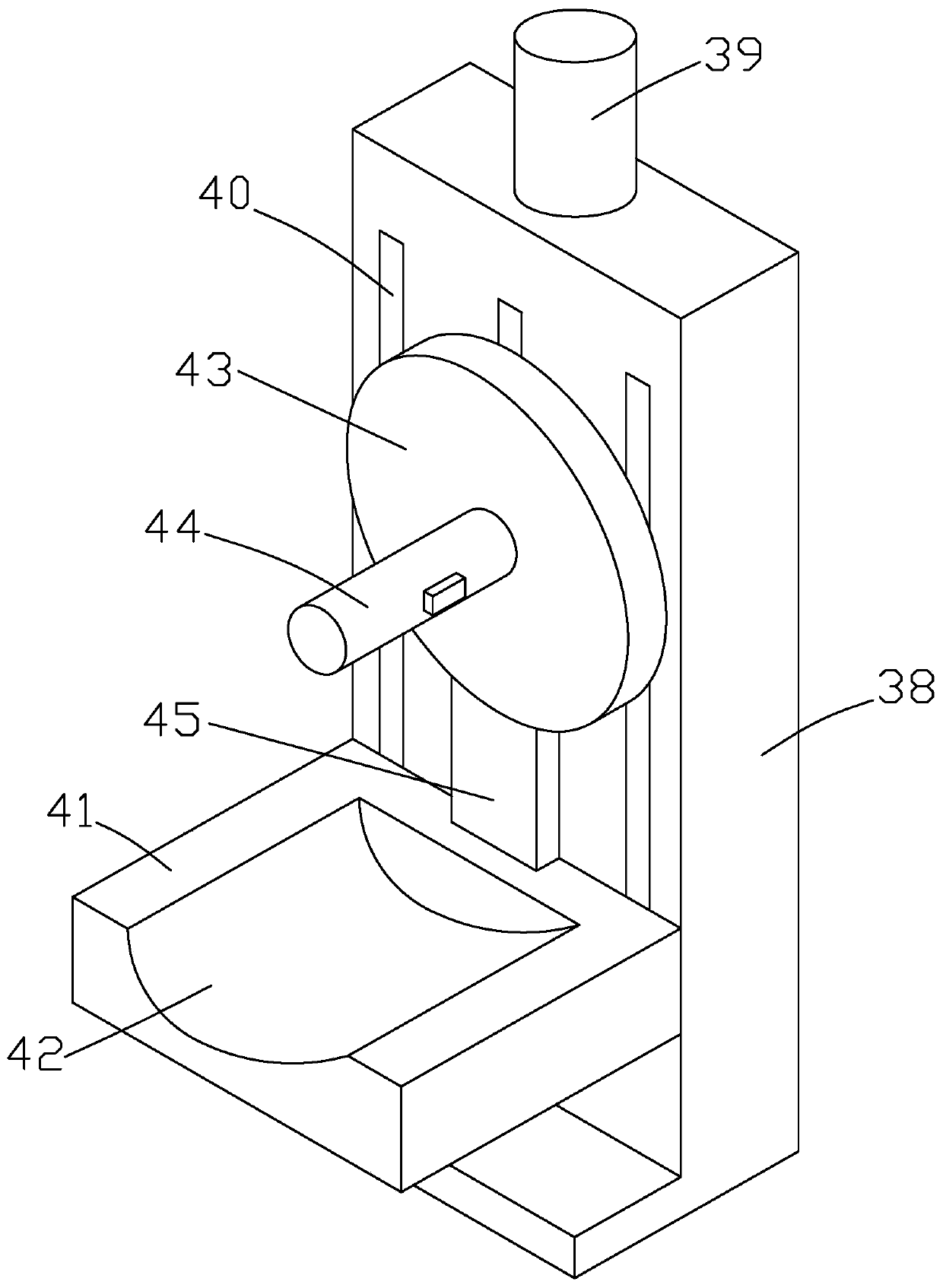

Method for polishing grinding wheels

InactiveCN102601734AAvoid errorsImprove accuracy and qualityAbrasive surface conditioning devicesLaser cuttingEngineering

The invention discloses a method for polishing grinding wheels, which comprises the following steps: the parts to be removed on the grinding wheels to be polished are cut by laser to form preset curved surfaces on the grinding wheels. The grinding wheels are polished by the laser, so as to realize the accurate polishing for the grinding wheels through the accurate control on cutting tracks of a laser beam and accurately obtain the curved surfaces of the required grinded parts of the grinding wheels, thereby avoiding the errors caused by the manual polishing, improving the accuracy and the quality of the curved surfaces at the edges of the grinding wheels and improving the success rate of polishing; meanwhile, the parts of the grinding wheels, on which the focuses of the laser can arrive, can be cut, however, the laser beam can not be damaged, the laser cutting tracks can not be lost, so that the cutting output of the laser for the grinding wheels can not cause errors in the polishing process, namely, the cutting errors can be reduced to a lower level so as to improve the polishing accuracy of the grinding wheels, batch polishing can be realized for the grinding wheels in the same type, and extremely good consistency among a plurality of grinding wheels can be kept. In addition, for the mode of laser grinding for the grinding wheels, the speed is higher, the working efficiency of grinding the grinding wheels is improved, and the cost of manual polishing is saved.

Owner:SHENZHEN JINZHOU PRECISION TECH

Data driven classification and data quality checking system

ActiveUS10089581B2Improve accuracy and qualityEfficient and reliableRelational databasesMachine learningQuality ratingLearning data

A computer implemented data driven classification and data quality checking system is provided. The system has an interface application enabled to receive data and has an associative memory software. The system has a data driven associative memory model configured to categorize one or more fields of received data and to analyze the received data. The system has a data quality rating metric associated with the received data. The system has a machine learning data quality checker for the received data, and is configured to add the received data to a pool of neighboring data, if the data quality rating metric is greater than or equal to a data quality rating metric threshold. The machine learning data quality checker is configured to generate and communicate an alert of a potential error in the received data, if the data quality rating metric is less than the data quality rating metric threshold.

Owner:THE BOEING CO

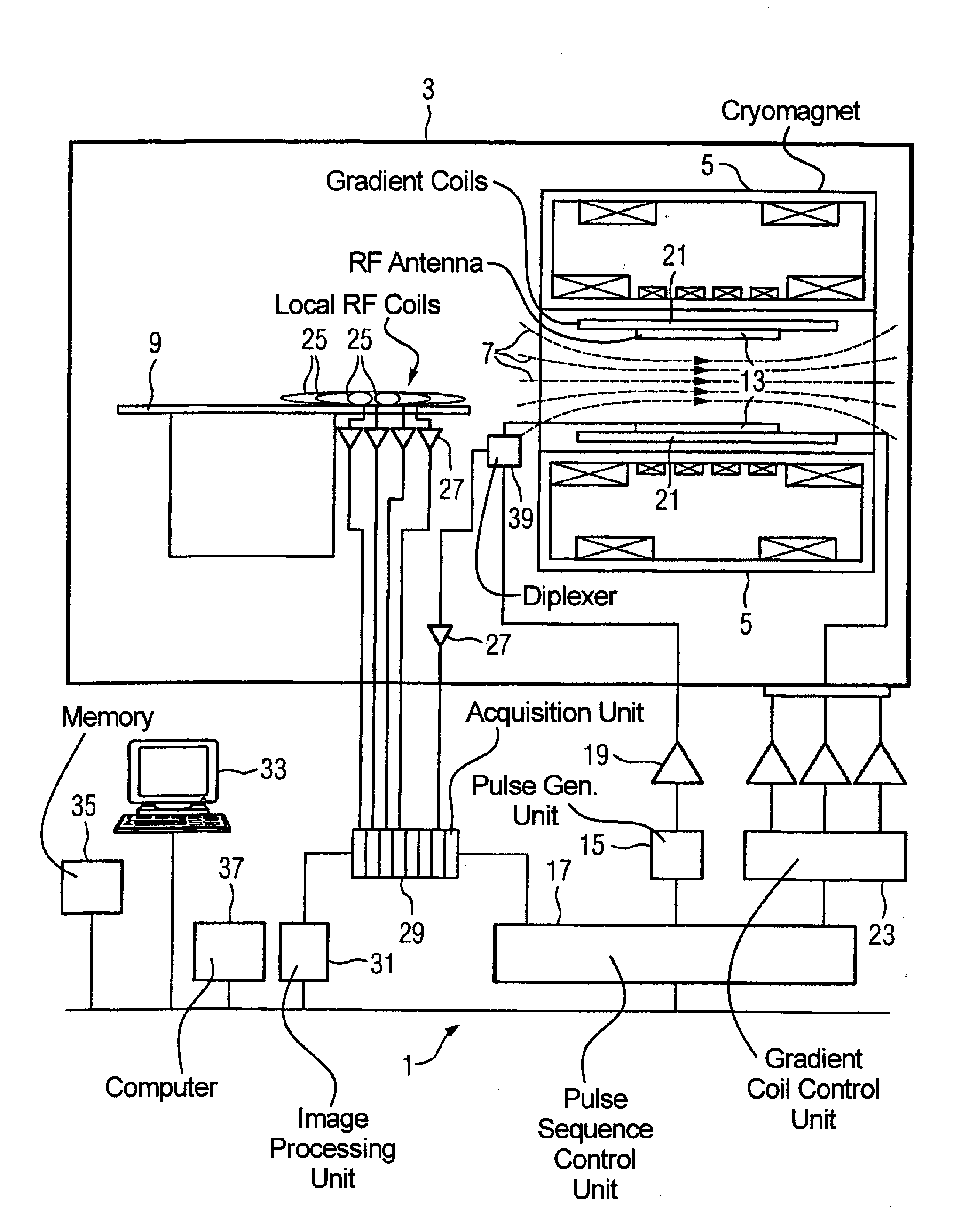

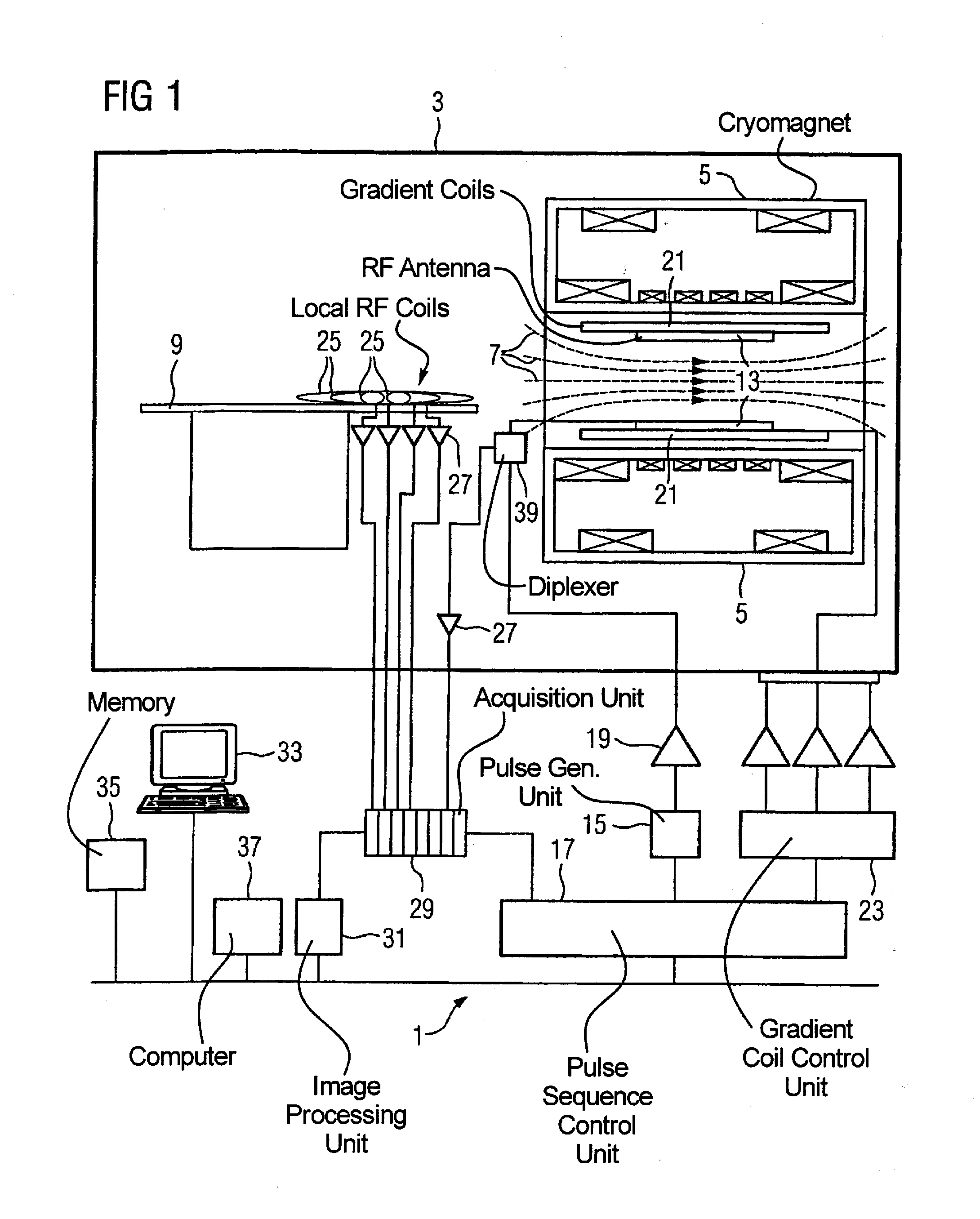

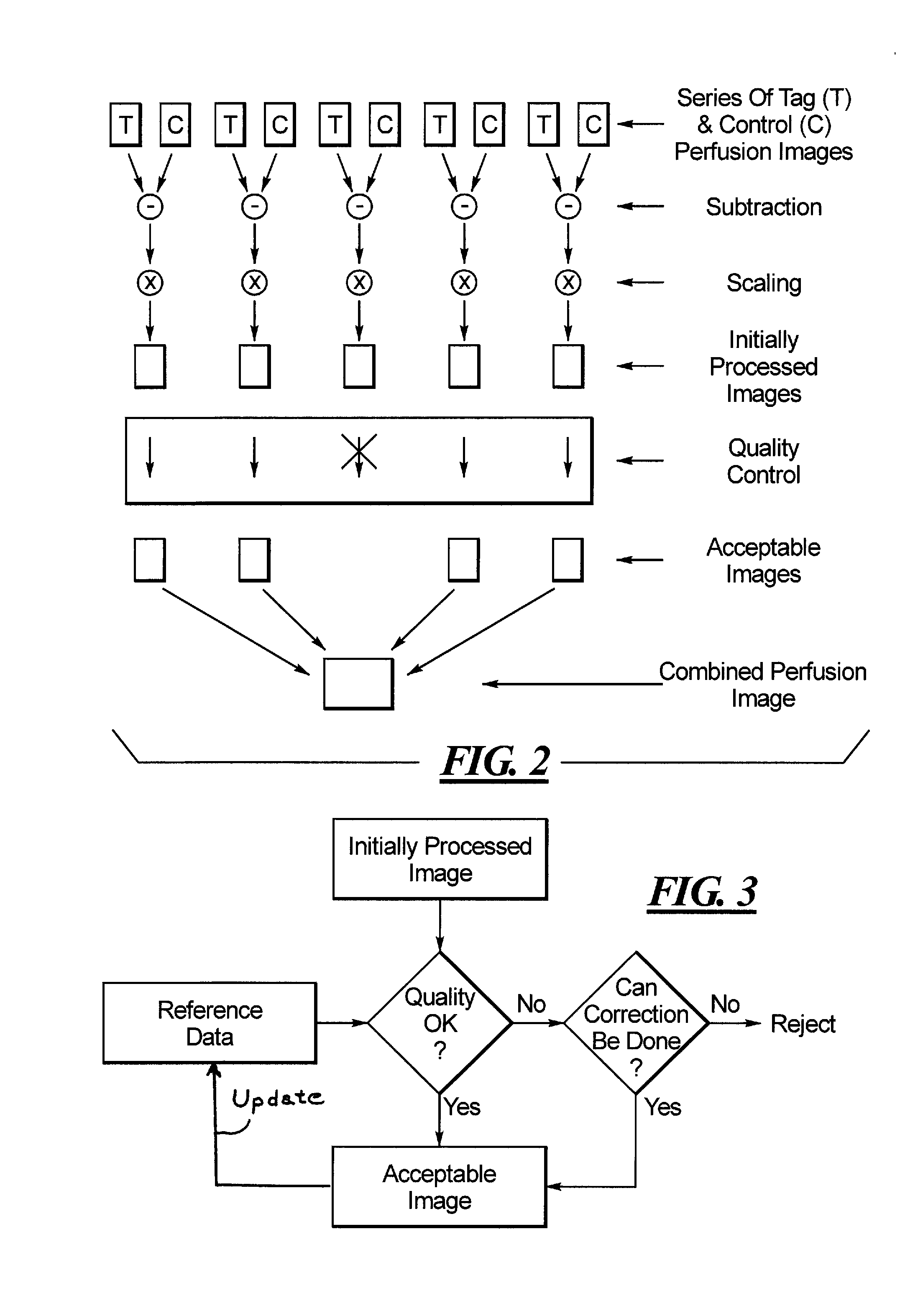

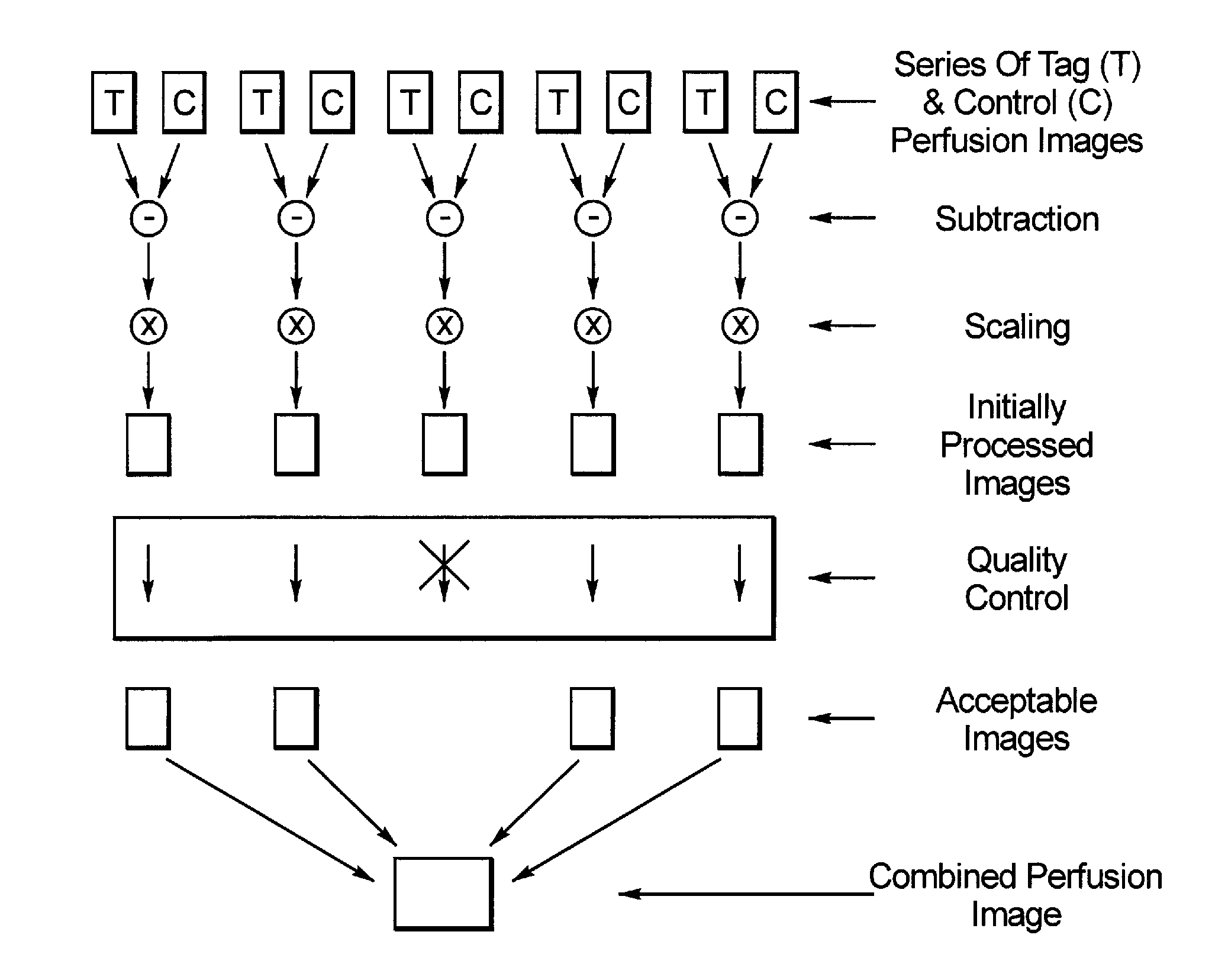

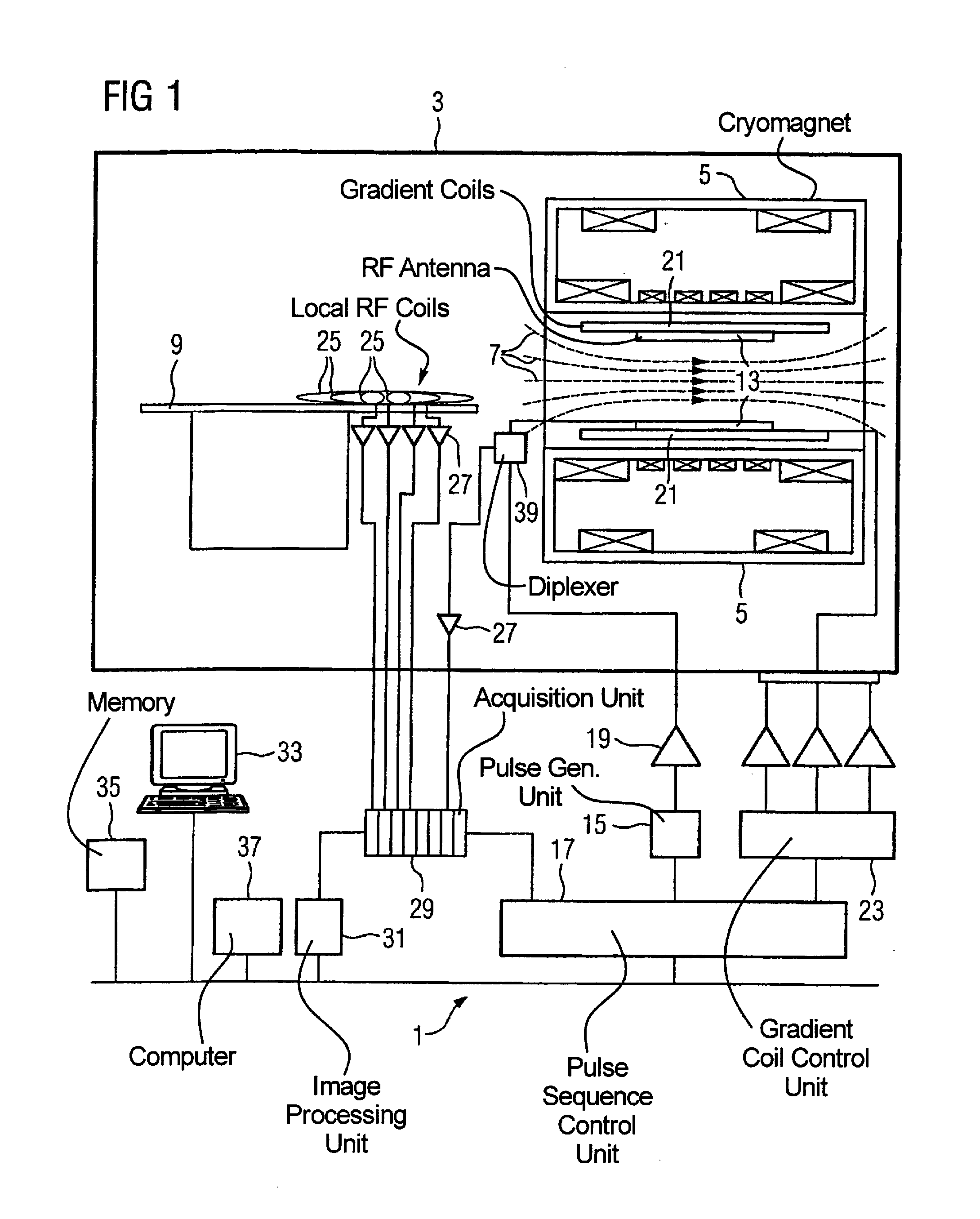

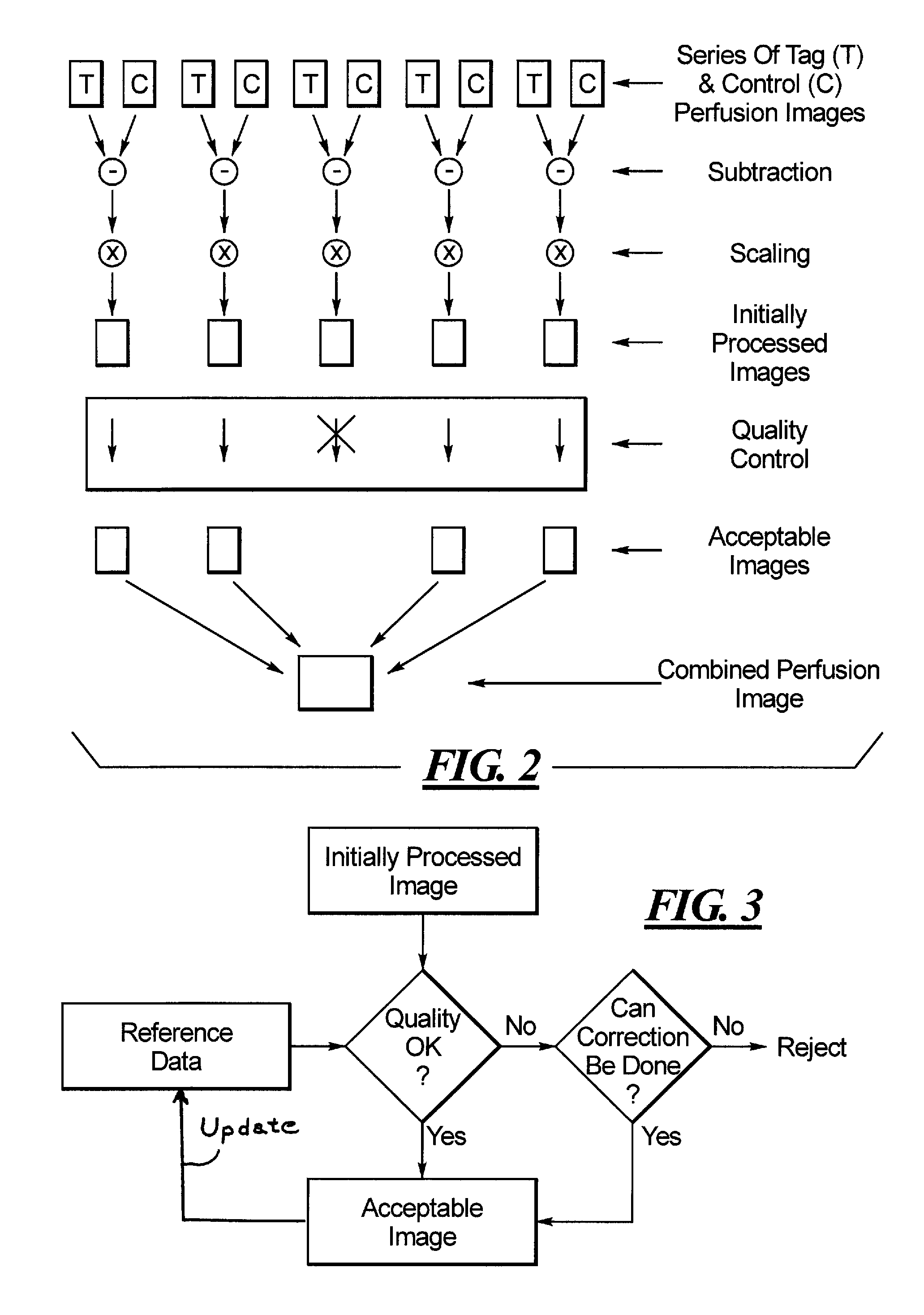

Magnetic resonance method and apparatus for generating a perfusion image

ActiveUS20100036234A1Improve accuracyQuality improvementImage enhancementImage analysisResonanceImaging quality

In a magnetic resonance method and apparatus for generating perfusion images, a perfusion series of magnetic resonance perfusion images is acquired that includes tag images and at least one control image, that are grouped in pairs. From each pair an initially processed perfusion image is obtained, such as by subtraction. Each initially processed image is subjected to a quality control review by analysis with respect to at least one image quality criterion. Any initially processed image that does not satisfy the quality criterion is rejected. Only initially processed images that satisfy the quality criterion are combined to form a resultant magnetic resonance perfusion image. Artifacts in the resultant perfusion image are thereby reduced or avoided.

Owner:SIEMENS MEDICAL SOLUTIONS USA INC

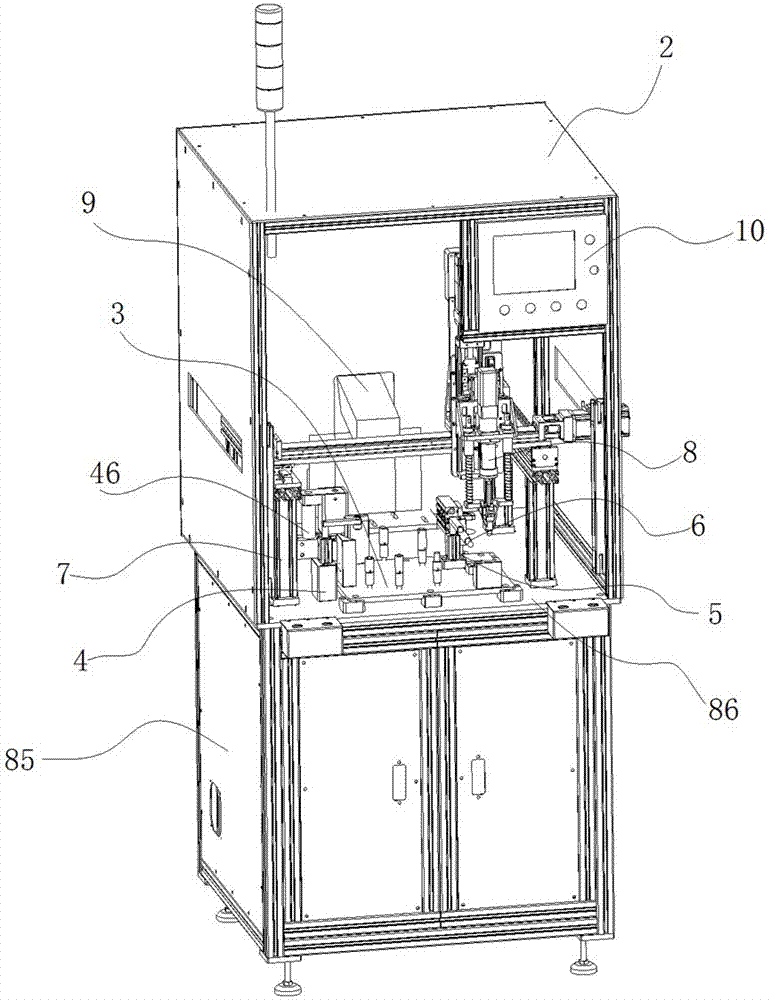

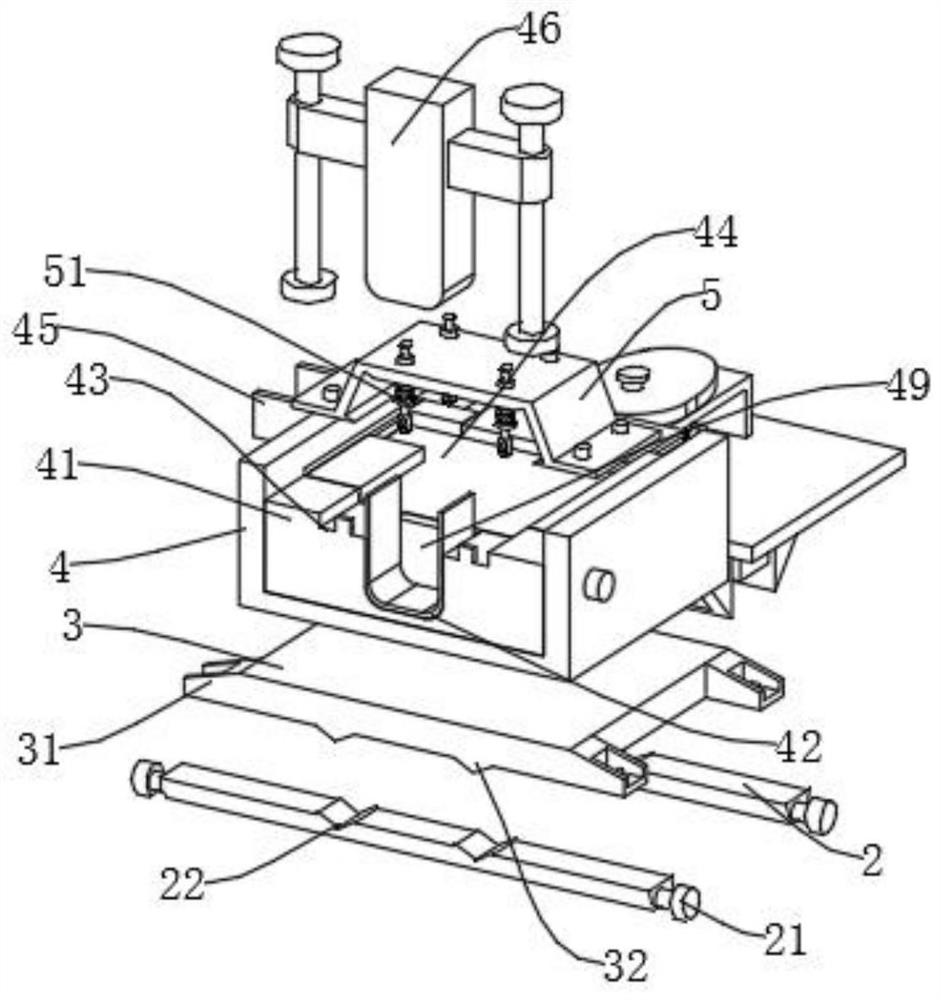

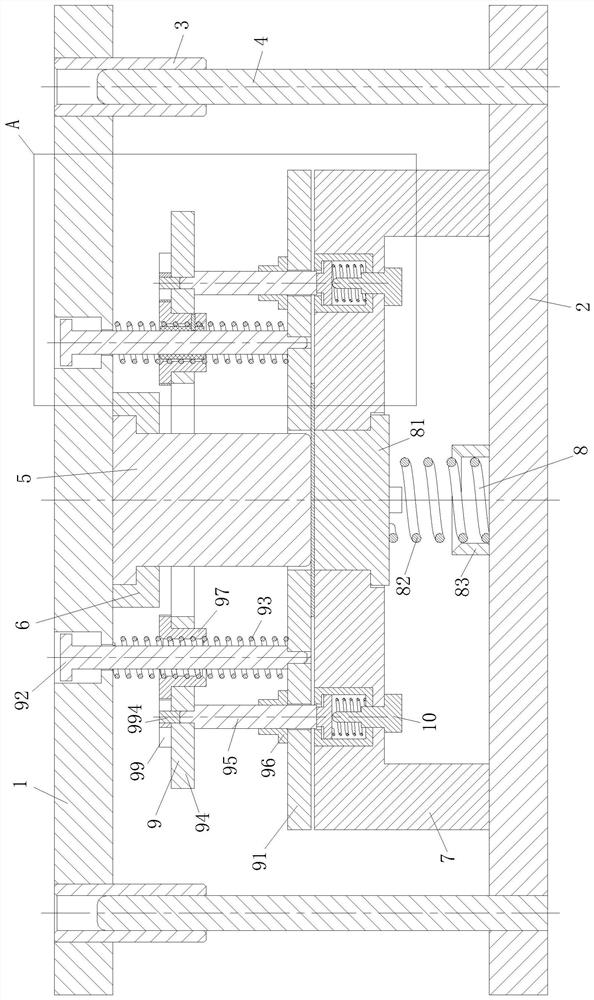

Magnetic steel processing device and method for production of permanent magnet synchronous motor

ActiveCN109802531AImprove accuracy and qualityImprove stability and reliabilityManufacturing stator/rotor bodiesMagnetPermanent magnet synchronous motor

The invention discloses a magnetic steel processing device and method for the production of a permanent magnet synchronous motor. The device comprises a pedestal, a rotor positioning mechanism, a magnetic steel extrusion mechanism, a magnetic steel feeding mechanism and a feeding mechanism. Two first supporting strips are arranged on the top face of the pedestal in a parallel manner. A bottom plate and a mounting plate are arranged on the top faces of the two first supporting strips, and the magnetic steel extrusion mechanism is connected to the top face of the bottom plate. The rotor positioning mechanism is fixedly connected to the top face of the mounting plate, and the magnetic steel feeding mechanism is movably connected to a guide strip, wherein the guide strip is fixedly connected to the mounting plate. The feeding mechanism is fixedly connected to a side face of the pedestal. The method comprises the steps of installation of the magnetic steel extrusion mechanism, installationof the rotor positioning mechanism, installation of the magnetic steel feeding mechanism, installation of the feeding mechanism and magnetic steel assembly. The device increases the magnetic steel assembling speed and machining precision, and the machining method is simple in step. The device can meet the rotor machining requirements of permanent magnet synchronous motors of different sizes, improves the magnetic steel assembling precision and quality, and improves the machining efficiency.

Owner:浙江晋一特种电机有限公司

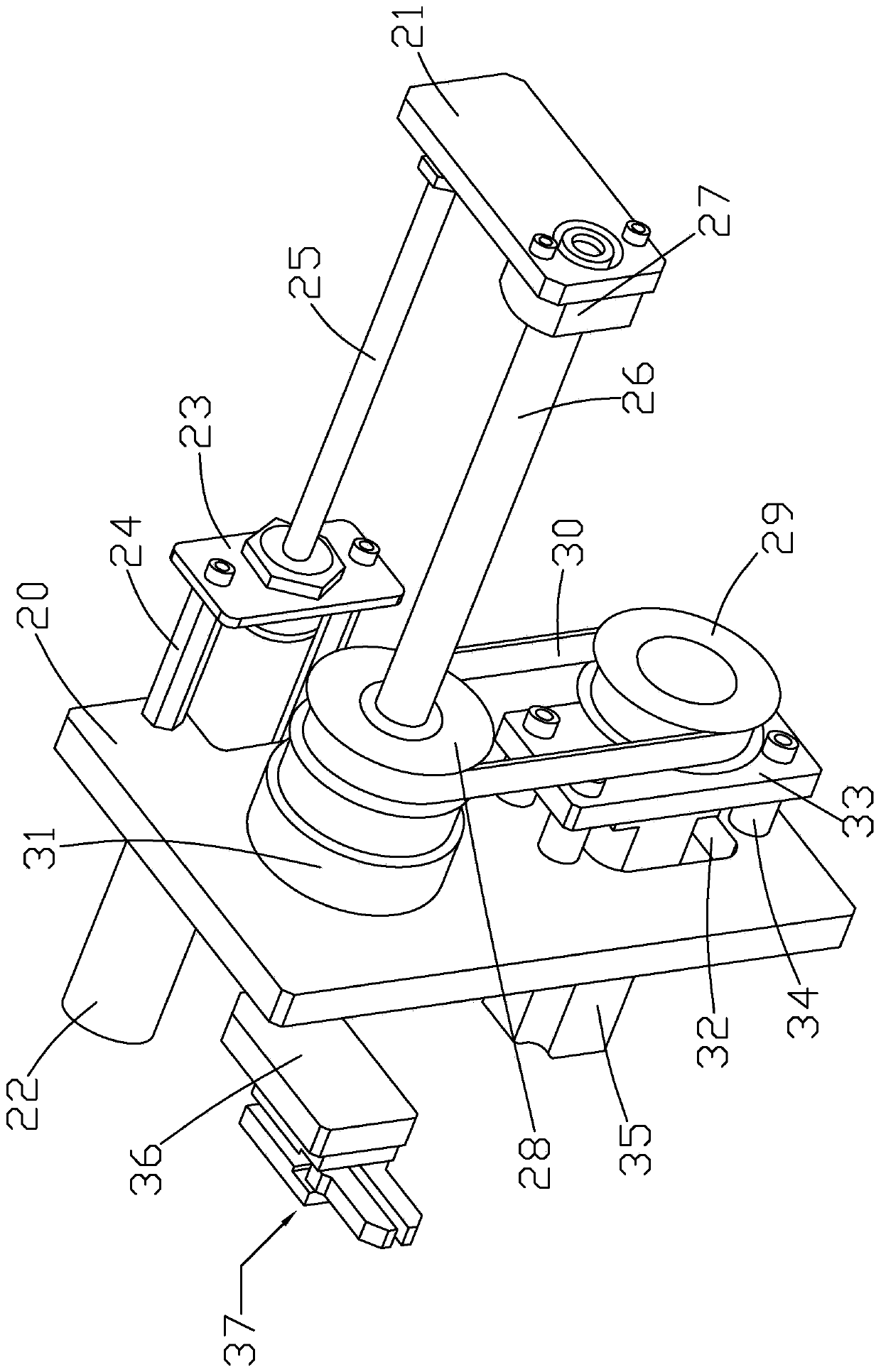

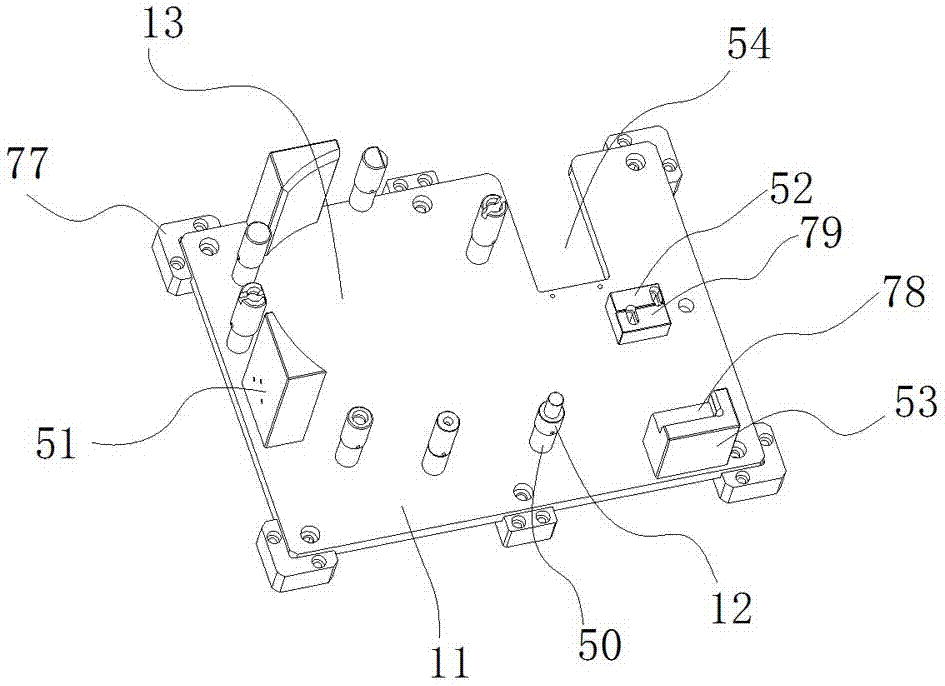

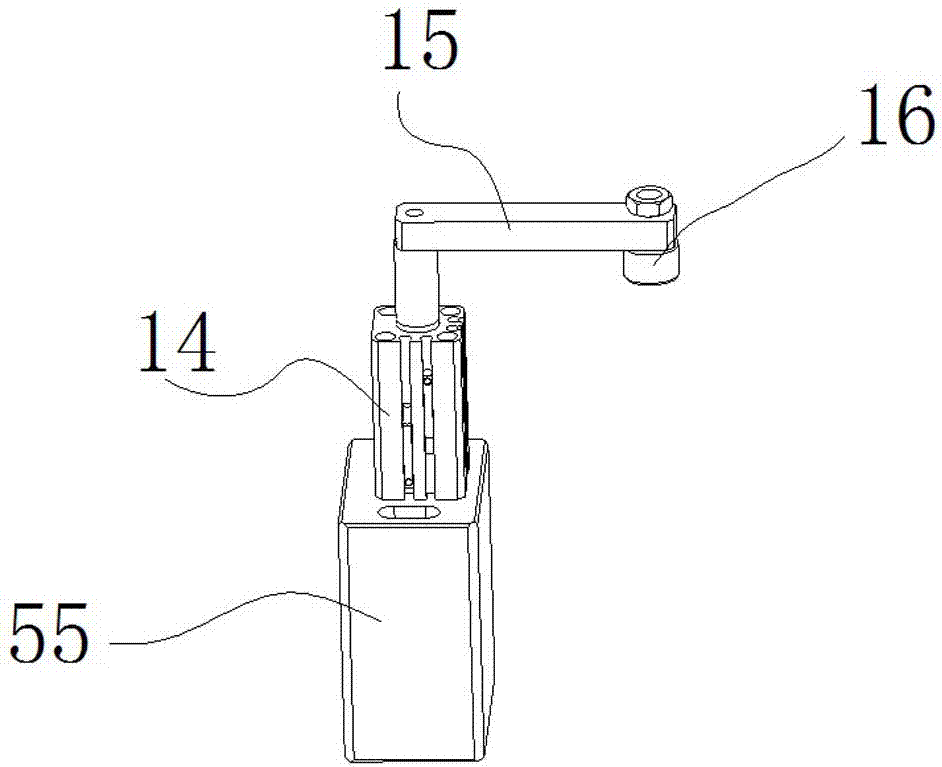

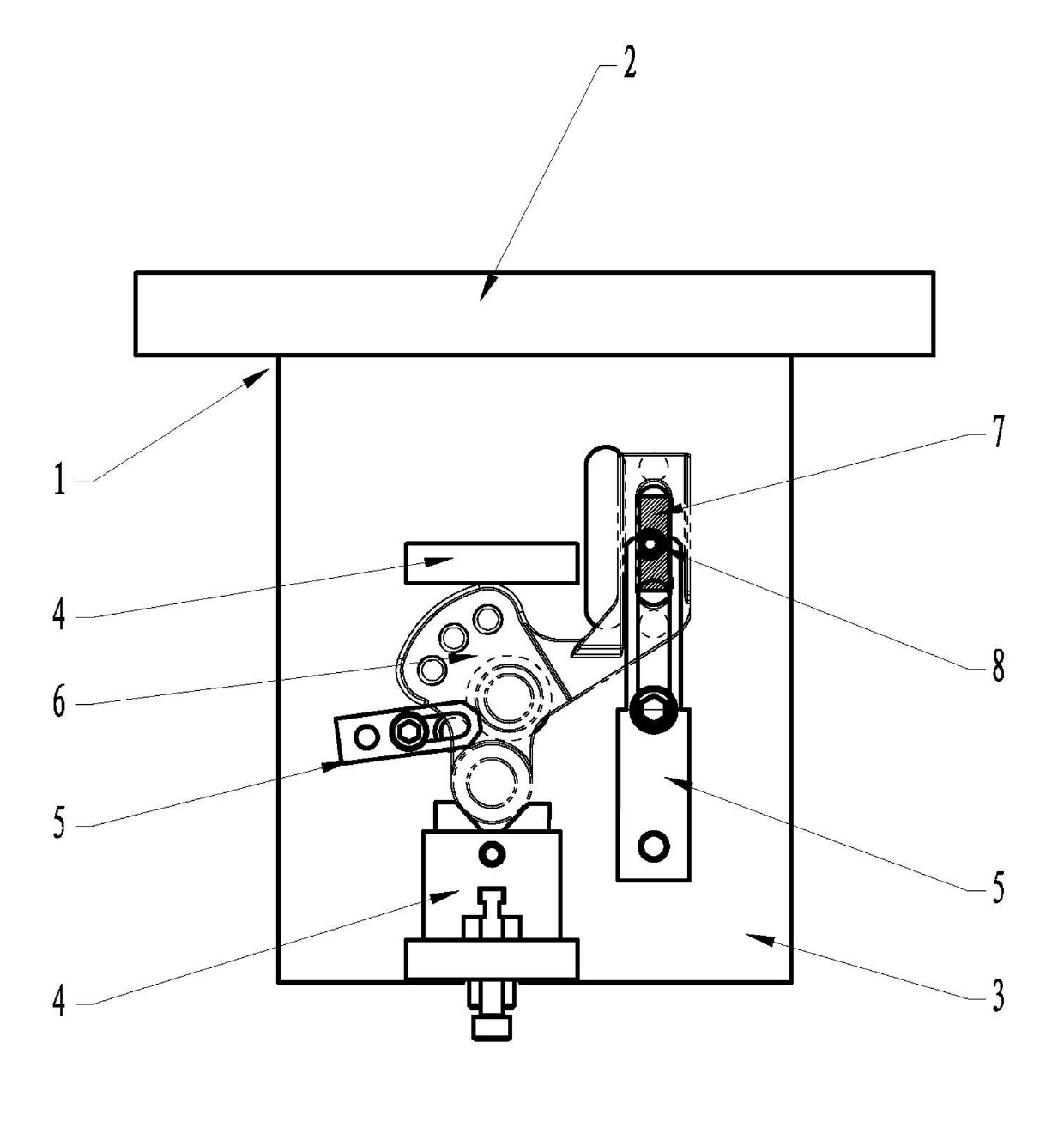

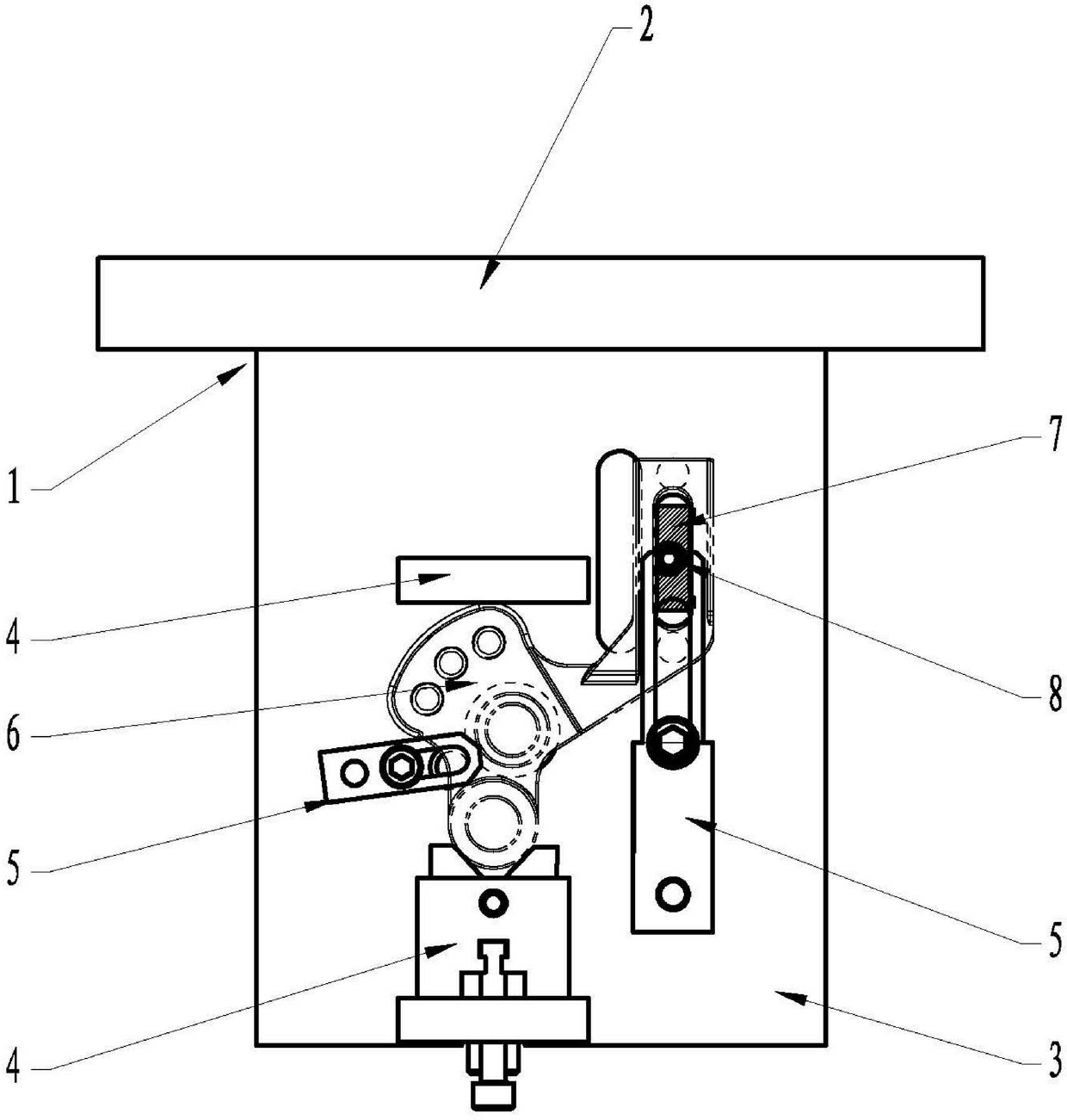

Automatic locking screw machine and operation method thereof

ActiveCN106914747AImprove assembly efficiencyImprove accuracy and qualityMetal working apparatusMechanical engineering

The invention relates to a screw machine, and especially relates to an automatic locking screw machine and an operation method thereof. The screw machine comprises a screw feeding mechanism, and also comprises a rack. The rack is provided with a supporting mechanism, a left clamping mechanism, a right clamping mechanism, a side surface clamping mechanism, and a transverse motion mechanism. The left side of the supporting mechanism is provided with the left clamping mechanism which is fixed with the rack. The right side of the supporting mechanism is provided with the right clamping mechanism and the side surface clamping mechanism fixed with the rack. The transverse motion mechanism fixed with the rack is arranged on the supporting mechanism. The transverse motion mechanism is internally provided with a new lock screw mechanism which can move. The rack is internally provided with a screw feeding mechanism which is connected with the new lock screw mechanism. The supporting mechanism, the left clamping mechanism, the right clamping mechanism, the side surface clamping mechanism, the transverse motion mechanism, the new lock screw mechanism, and the screw feeding mechanism are controlled through a control end. The automatic locking screw machine is compact in structure, and the automatic locking screw machine and the operation method thereof improve efficiency and improve quality.

Owner:HANGZHOU TAISHANG INTELLIGENT EQUIP CO LTD

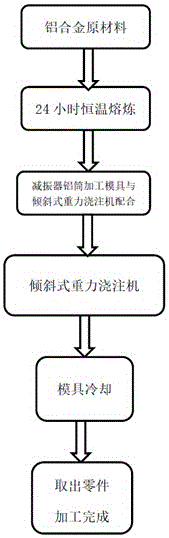

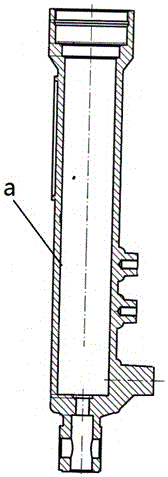

Manufacturing method for shock absorber aluminum barrel

InactiveCN106513588AImprove accuracy and qualityReduce manufacturing costFoundry mouldsFoundry coresAluminium alloySmelting

The invention belongs to the technical field of mechanical manufacturing, and particularly relates to a manufacturing method for a shock absorber aluminum barrel. According to the technical scheme adopted by the invention, the manufacturing method for the shock absorber aluminum barrel comprises the steps that (1) aluminum alloy raw materials are placed into a 24-hour constant-temperature smelting furnace; (2)a shock absorber aluminum barrel machining mould and a tilting gravity casting machine are used in cooperation; (3) molten aluminum obtained after aluminum alloy is smelted is poured into the tilting gravity casting machine; (4) the shock absorber aluminum barrel is formed in the tilting gravity casting machine; (5) the mould is cooled; and (6) the part is taken out of the mould. The manufacturing method for the shock absorber aluminum barrel has the advantages that a brand new production method is provided and adopted, the part quality and precision are greatly improved, the production cost is lowered, the service lives of the part and the equipment are prolonged, and the production efficiency and part use safety are effectively improved.

Owner:JIANGSU JINTAIBAO MACHINERY

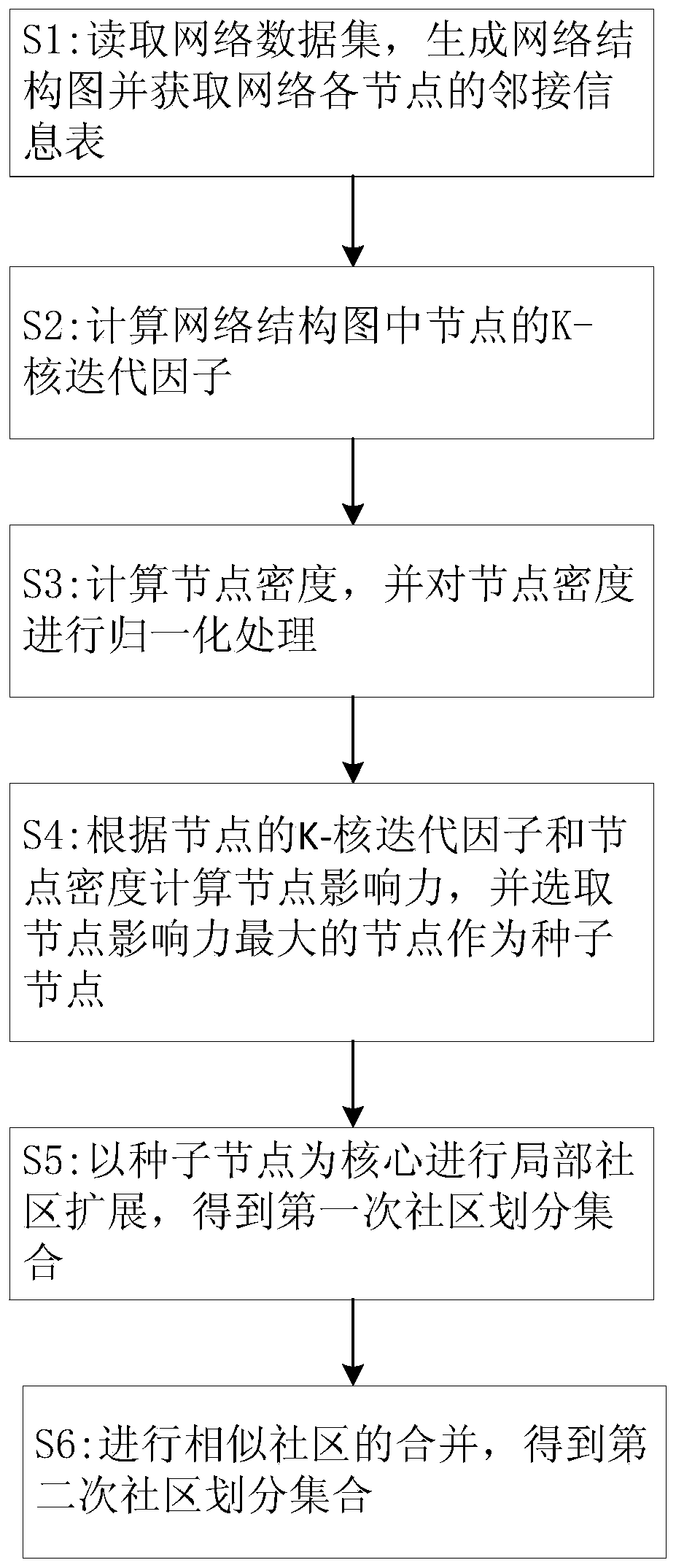

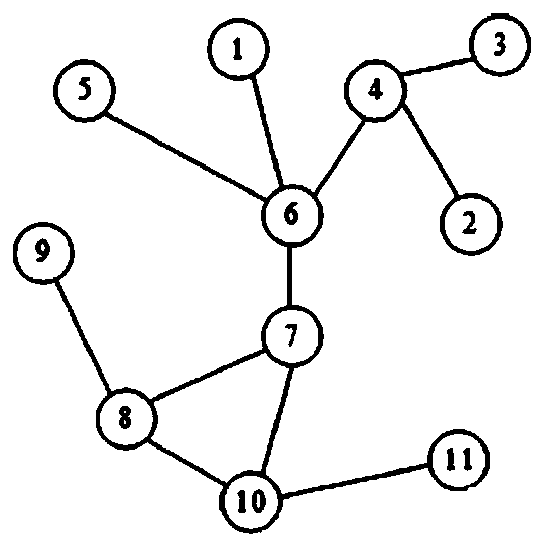

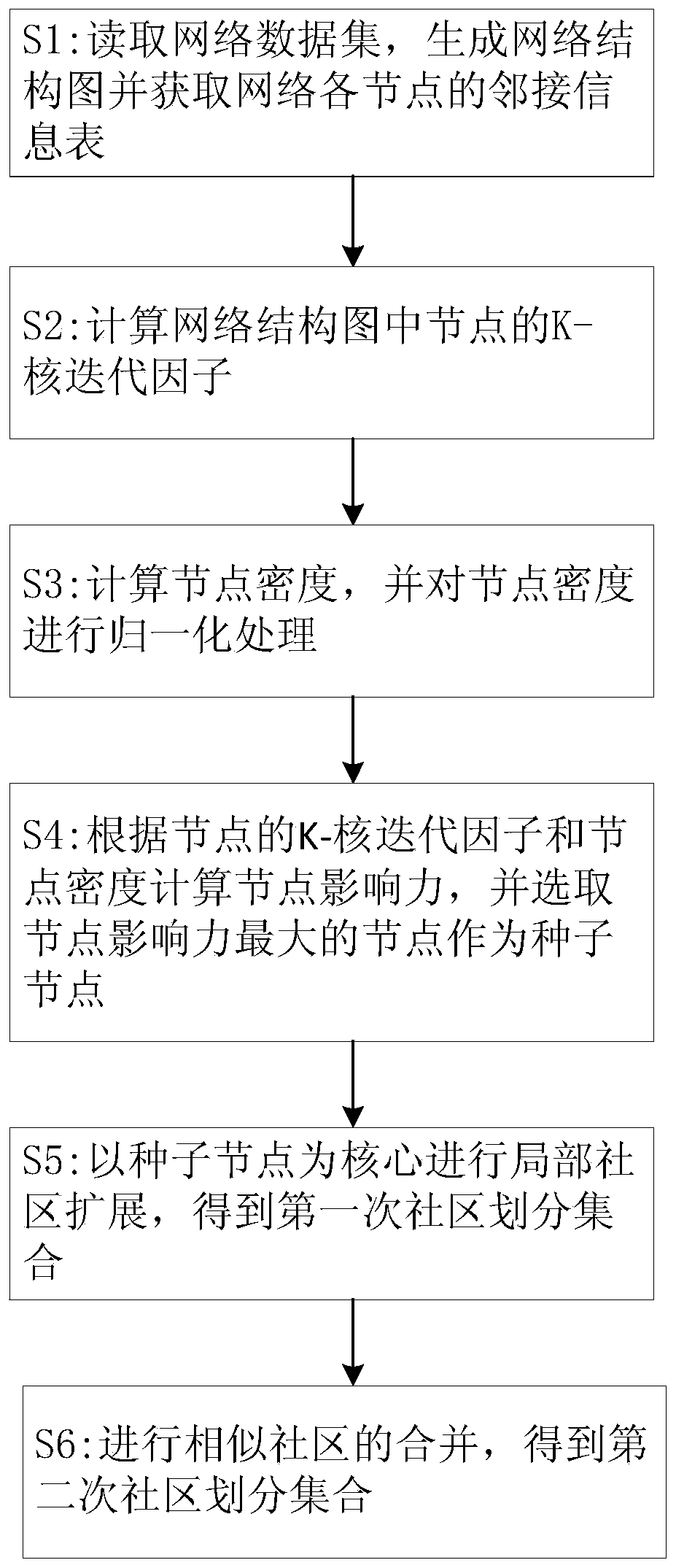

Overlapped community division method based on K-core iteration factor and community membership degree

PendingCN109978710AImprove accuracy and qualityImprove accuracy and stabilityData processing applicationsOther databases indexingAlgorithmNetwork structure

The invention discloses an overlapped community division method based on a K-core iteration factor and a community membership degree, and the method comprises the following steps of S1, reading a network data set, generating a network structure diagram G, and obtaining an adjacent information table Nij of each node of a network; s2, calculating a K-core iteration factor of each node in the networkstructure chart G; S3, calculating the node density of each node in the network structure diagram G, and carrying out normalization processing on the node density; s4, calculating the node influenceby combining the K-core iteration factor and the node density, and selecting the node with the maximum node influence as a seed node; S5, carrying out local community expansion by taking the seed nodeas a core to obtain a sub-community, thereby obtaining a first community division set; and S6, combining the sub-communities in the first community division set to obtain a second community divisionset.

Owner:CHONGQING UNIV

Data driven classification and data quality checking method

InactiveUS20170004414A1Improve accuracyQuality improvementBiological modelsInference methodsLearning dataData-driven

A method for improving accuracy and quality of received data is provided. The method provides a computer implemented data driven classification and data quality checking system. The method uses the associative memory software to build a data driven associative memory model that enables a machine learning data quality checker for receiving data. The method categorizes one or more fields of received data, analyzes the received data, and calculates a data quality rating metric, by comparing the received data with a pool of neighboring data in the category of field of the received data. The method accepts and adds the received data, if the data quality rating metric is greater than or equal to a data quality rating metric threshold, and generates and communicates an alert of a potential error in the received data, if the data quality rating metric is less than the data quality rating metric threshold.

Owner:THE BOEING CO

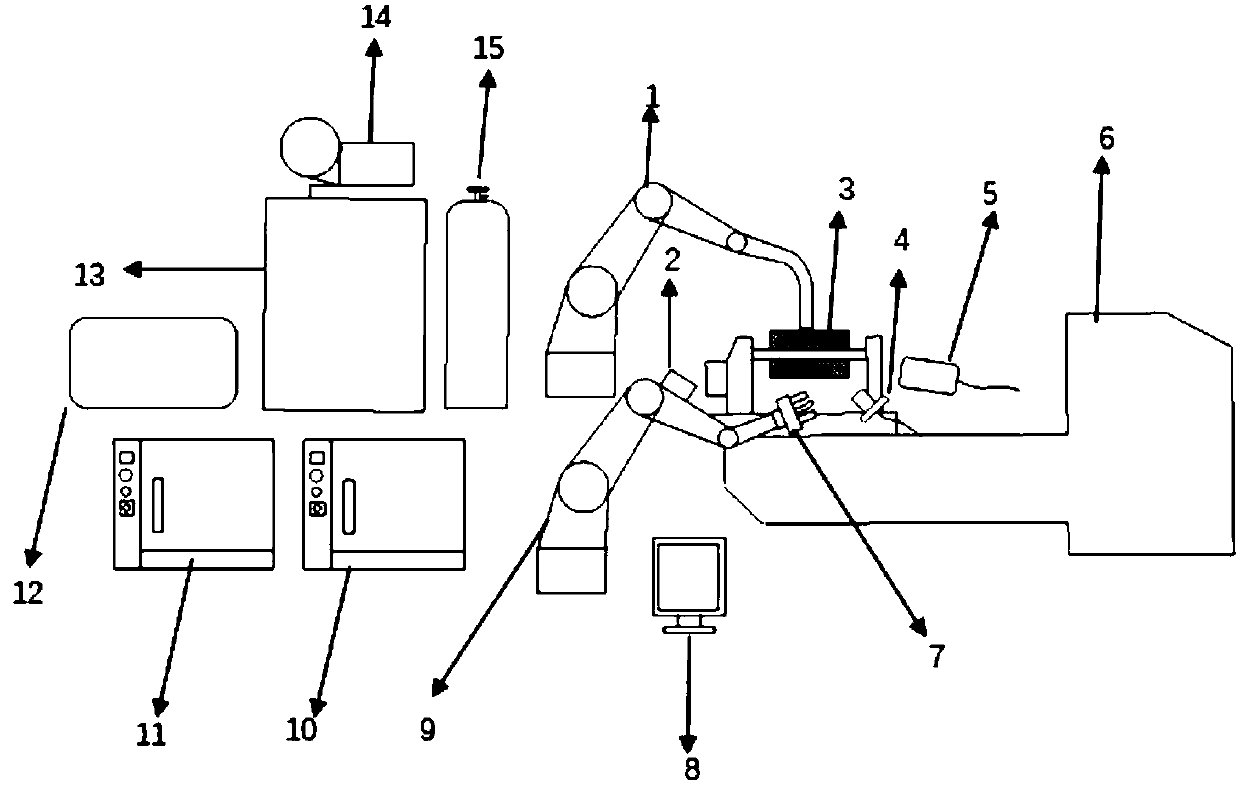

Material adding and reducing coordinated manufacturing method

ActiveCN109623105AImprove accuracy and qualityControl interlayer cooling temperatureOther manufacturing equipments/toolsPlasma welding apparatusThermal deformationElectric arc

The invention discloses a material adding and reducing coordinated manufacturing method. According to the method, model building is performed through CAD, and a computer is used for automatically generating a material adding trajectory; a power source is switched on, a base plate is installed and cleaned, and a material adding robot performs material adding on the front side of the base plate; thebase plate is overturned by 180 degrees; the material adding robot performs material adding on the front side of the base plate, and a material reducing robot performs material reducing on the back side of the base plate, air cooling is performed through an air gun, and an infrared thermometer monitors the back side temperature of the base plate in real time; overturning is performed again aftermachining of material adding and reducing and back side cooling are completed; and the steps are repeated till material adding manufacturing is completed. In the manufacturing method, material addingmanufacturing and material reducing machining are performed in a coordinated manner, the temperature of the base plate is monitored and controlled in real time, thermal deformation of the base plate is greatly reduced, the forming precision and quality of an obtained material adding structural part is improved, and the manufacturing period of electric arc material adding is shortened.

Owner:NANJING UNIV OF SCI & TECH

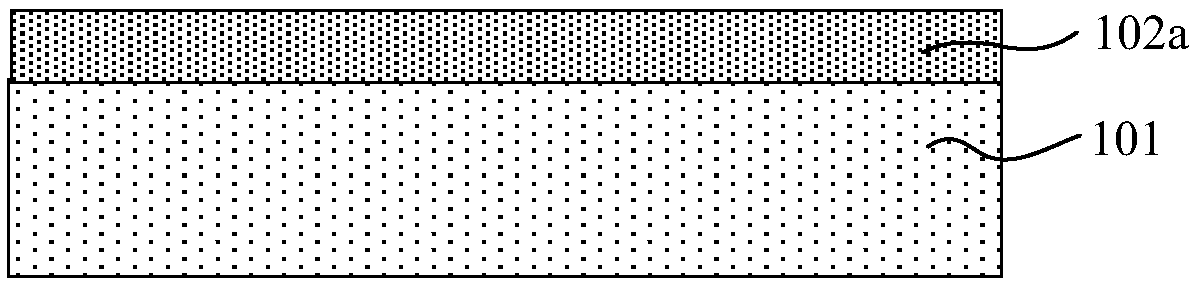

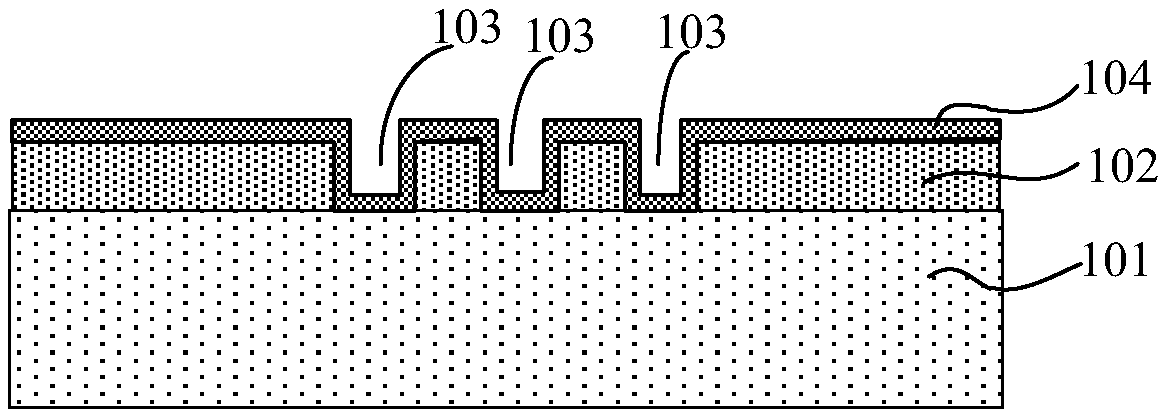

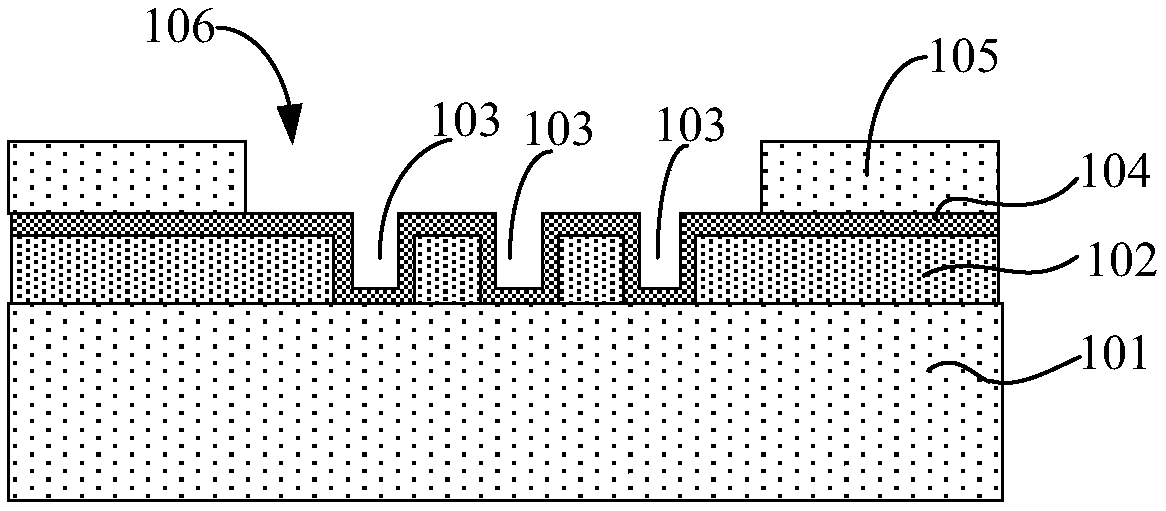

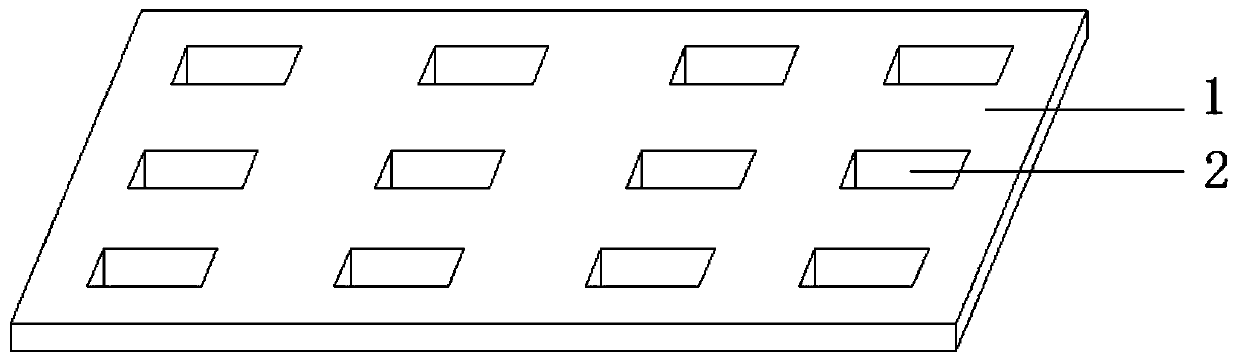

Mask and manufacturing method thereof

ActiveCN108649142AImprove limitImprove accuracy and qualitySolid-state devicesVacuum evaporation coatingEXPOSESemiconductor

The invention provides a mask and a manufacturing method thereof. The mask comprises a substrate and a mask pattern layer positioned on the first surface; the substrate has a first surface and a second surface which are arranged oppositely; multiple openings for running through the substrate are formed in the substrate; the substrate material is a material which can be subjected to a semiconductoretching process; the mask pattern layer material is a material which can be subjected to a semiconductor etching process; the mask pattern layer has pattern regions and shielding regions; at least one through hole is formed in each pattern region; the openings expose the pattern regions; each opening is opposite to one pattern region and exposes all through holes in the corresponding pattern region; and the shielding regions are positioned outside the pattern regions and opposite to the substrate. The mask is high in quality and higher in precision; and when the mask is used for an evaporation process of an organic layer, the deposition quality of the organic layer can be improved, and quality of a post-period product is improved.

Owner:NINGBO SEMICON INT CORP

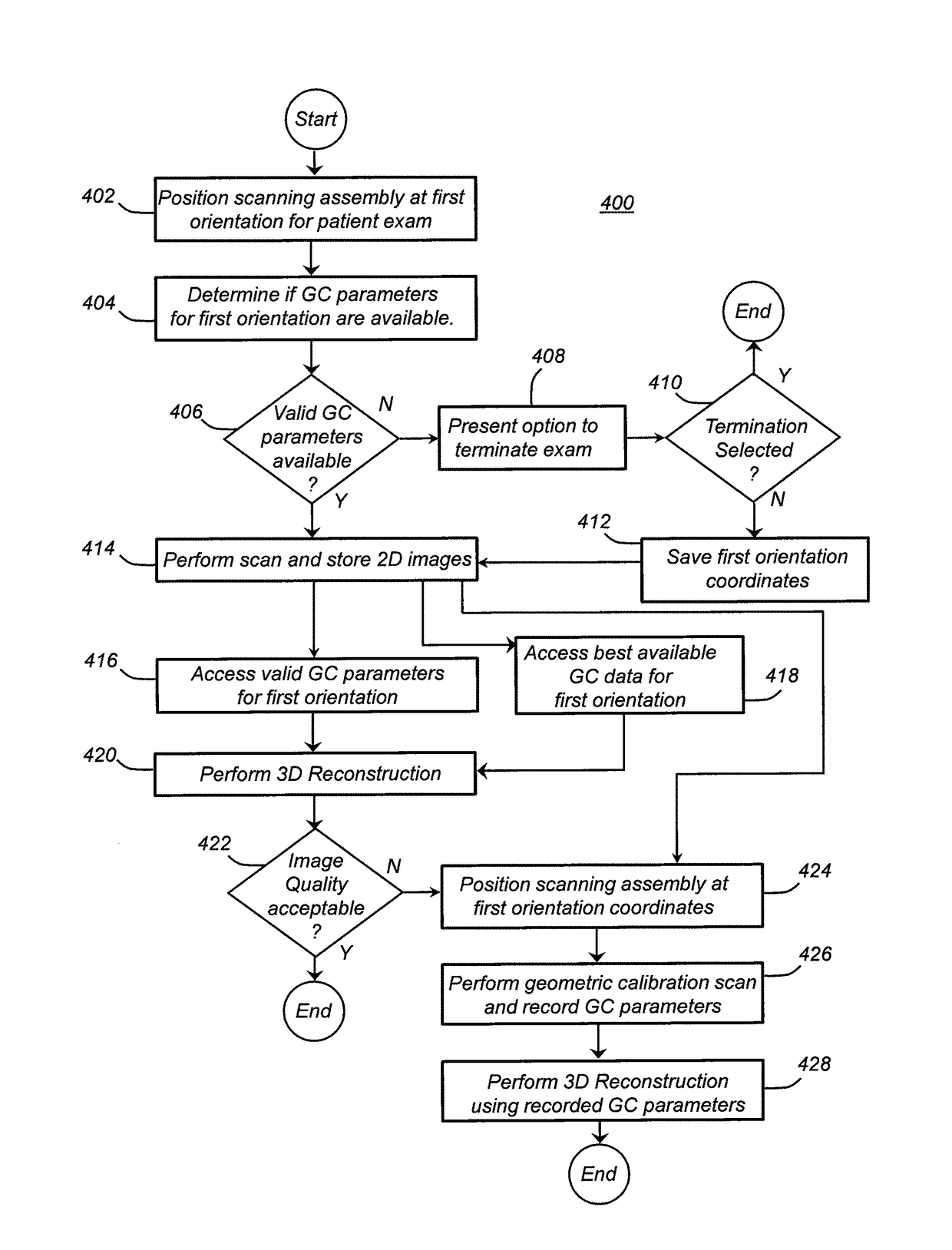

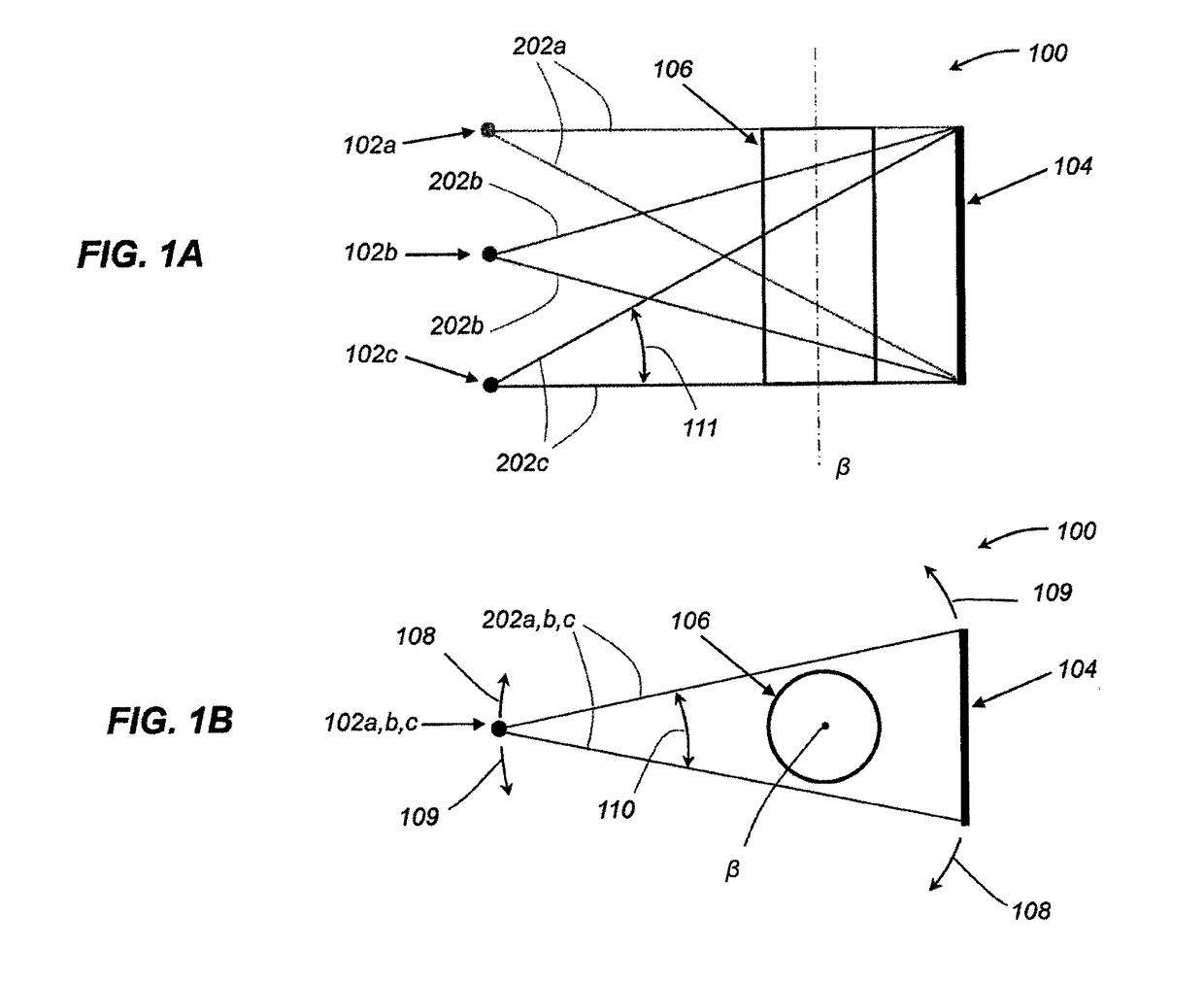

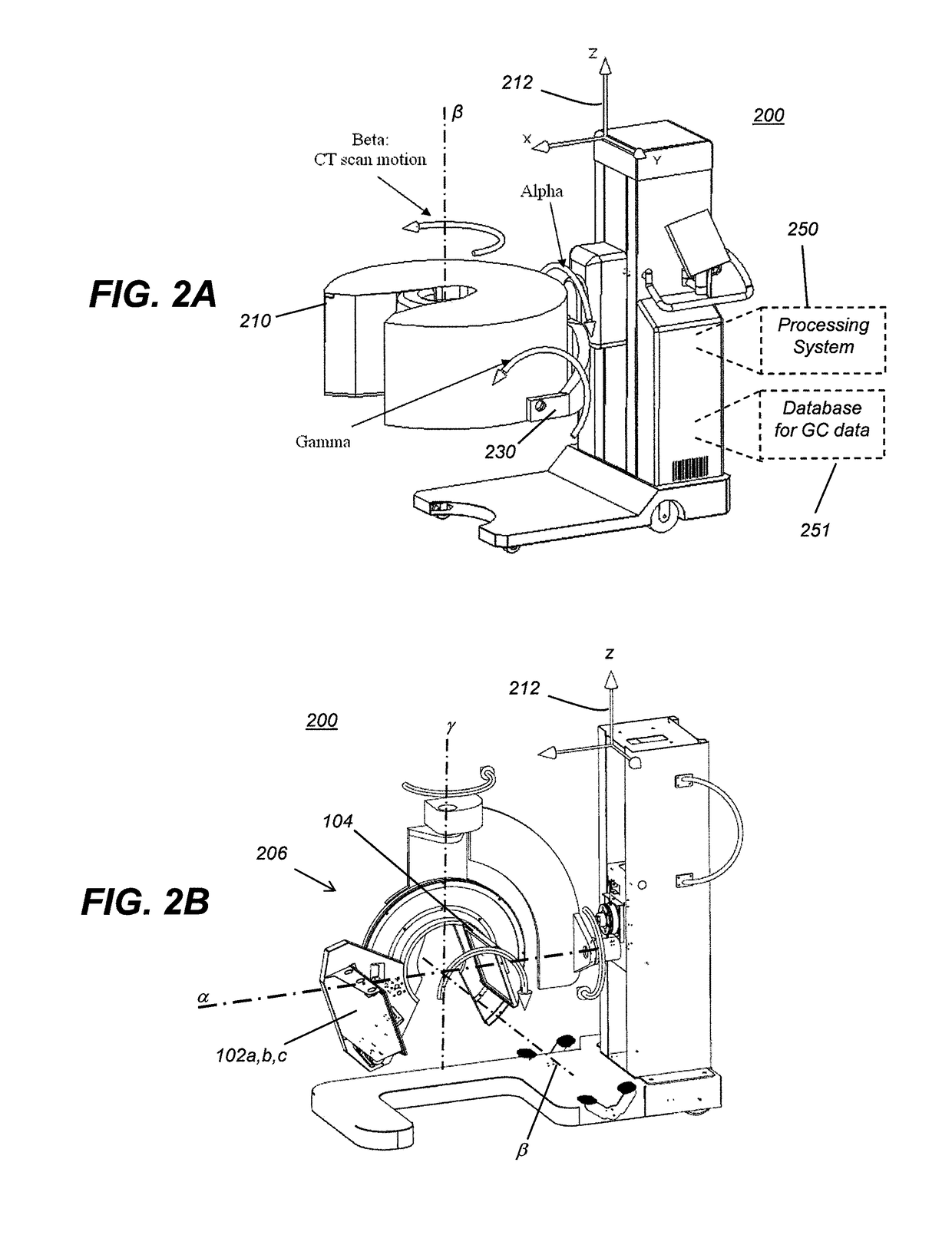

Post acquisition calibration

InactiveUS20170296137A1Improved radiographic image qualityImprove accuracyImage enhancementReconstruction from projectionComputer vision

A method of operating a tomographic imaging system whereby a plurality of radiographic images of an object are captured at a first orientation of the system's source and detector. After the radiographic images are captured and stored, geometric calibration data for the system is measured, corresponding to the first orientation of the system. A three dimensional image of the object is reconstructed using the measured geometric calibration data corresponding to the first orientation.

Owner:CARESTREAM HEALTH INC

Blast furnace roof flange installing method

InactiveCN109759734AImprove accuracy and qualityUniform deformationWelding/cutting auxillary devicesAuxillary welding devicesWelding deformationSpot welding

The invention relates to a blast furnace roof flange installing method. Preheating is conducted to 190-210 DEG C before welding; rib plates are adopted for strengthening a flange for restraining deformation, and the rib plates are arranged along the periphery of a furnace roof at equal intervals; preliminary leveling is conducted on the flange, and after leveling, welding lines between the rib plates and a furnace body are leveled; accurate leveling is conducted on the flange, four-point leveling is conducted on the flange along the flange center according to cross symmetry, vertical welding lines between the corresponding rib plates in the four-point direction and the flange are subjected to spot welding, and after accurate flange leveling and spot welding of the vertical welding lines between all the rib plates and the flange are gradually finished according to the above manner, the vertical welding lines between all the rib plates and the flange are welded through a skip reverse welding method; and during flange welding, welding is synchronously conducted along the flange center according to the four-point positions of the cross center line, a segmented reverse welding method isadopted in welding, and synchronous reversing is conducted in the welding process. In the flange welding process, a balance level and an invar ruler are adopted for welding deformation monitoring. Bymeans of the blast furnace roof flange installing method, the flange installing quality can be improved, the construction period is shortened, and the construction cost can be better reduced.

Owner:SHANGHAI ERSHIYE CONSTR CO LTD +1

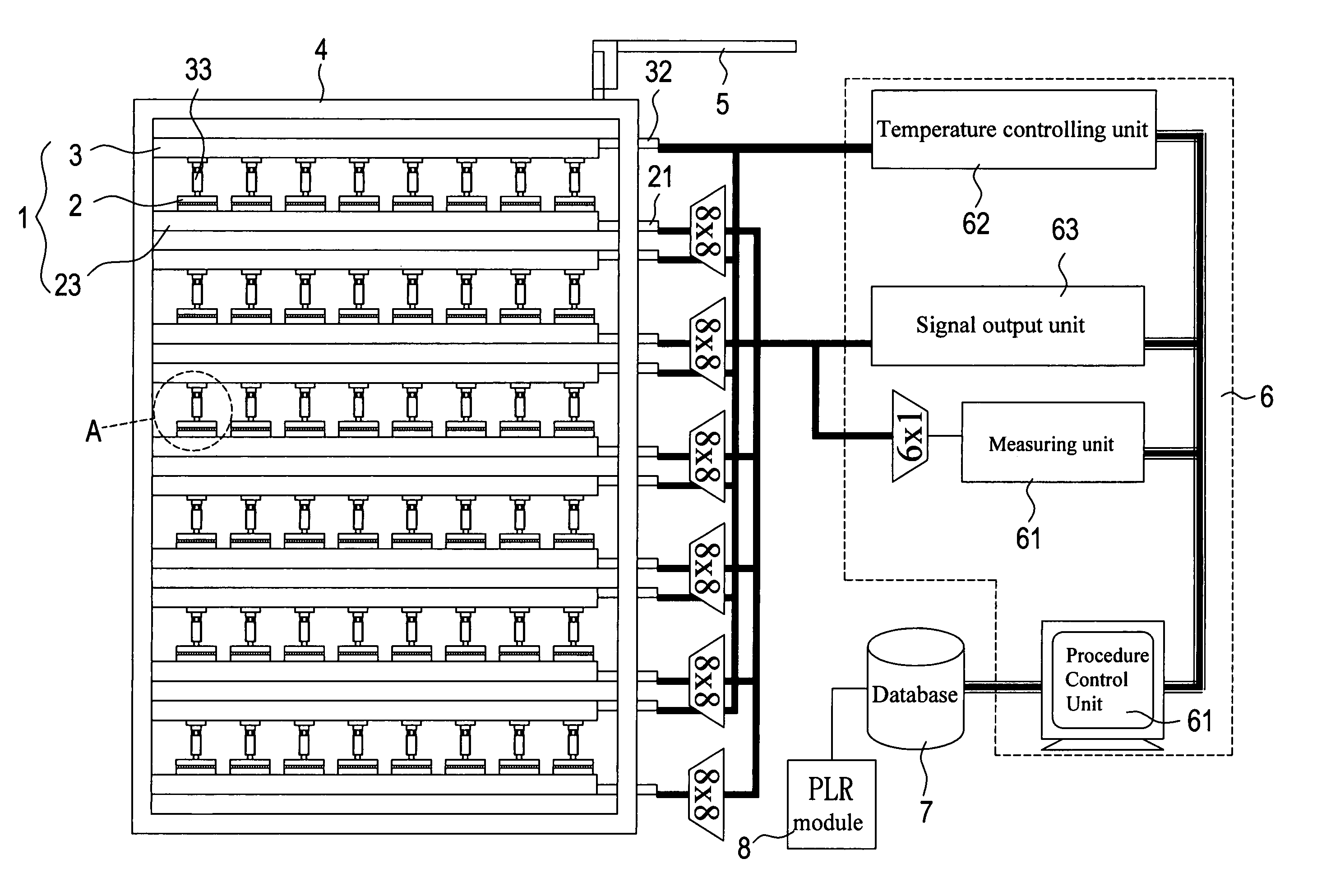

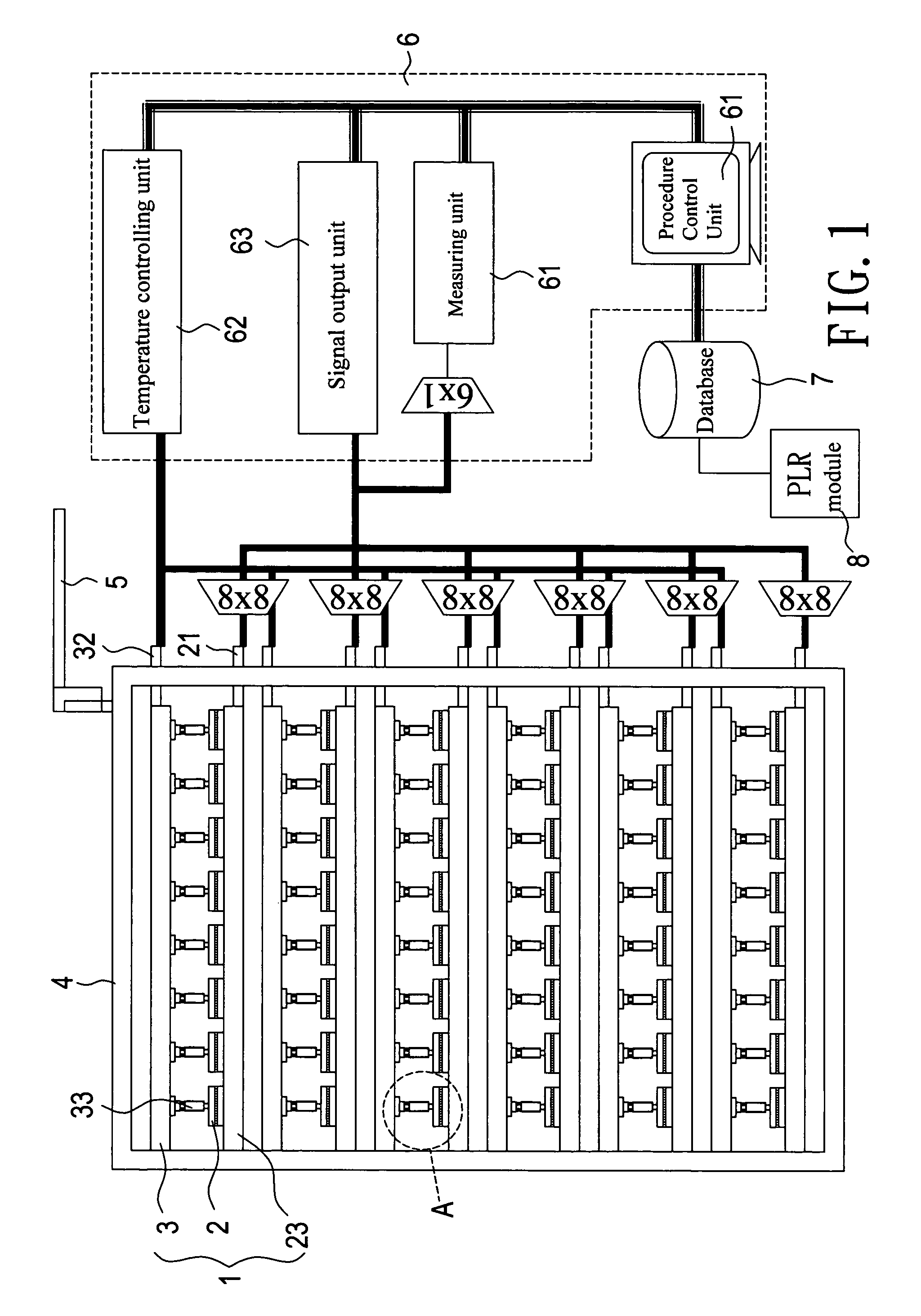

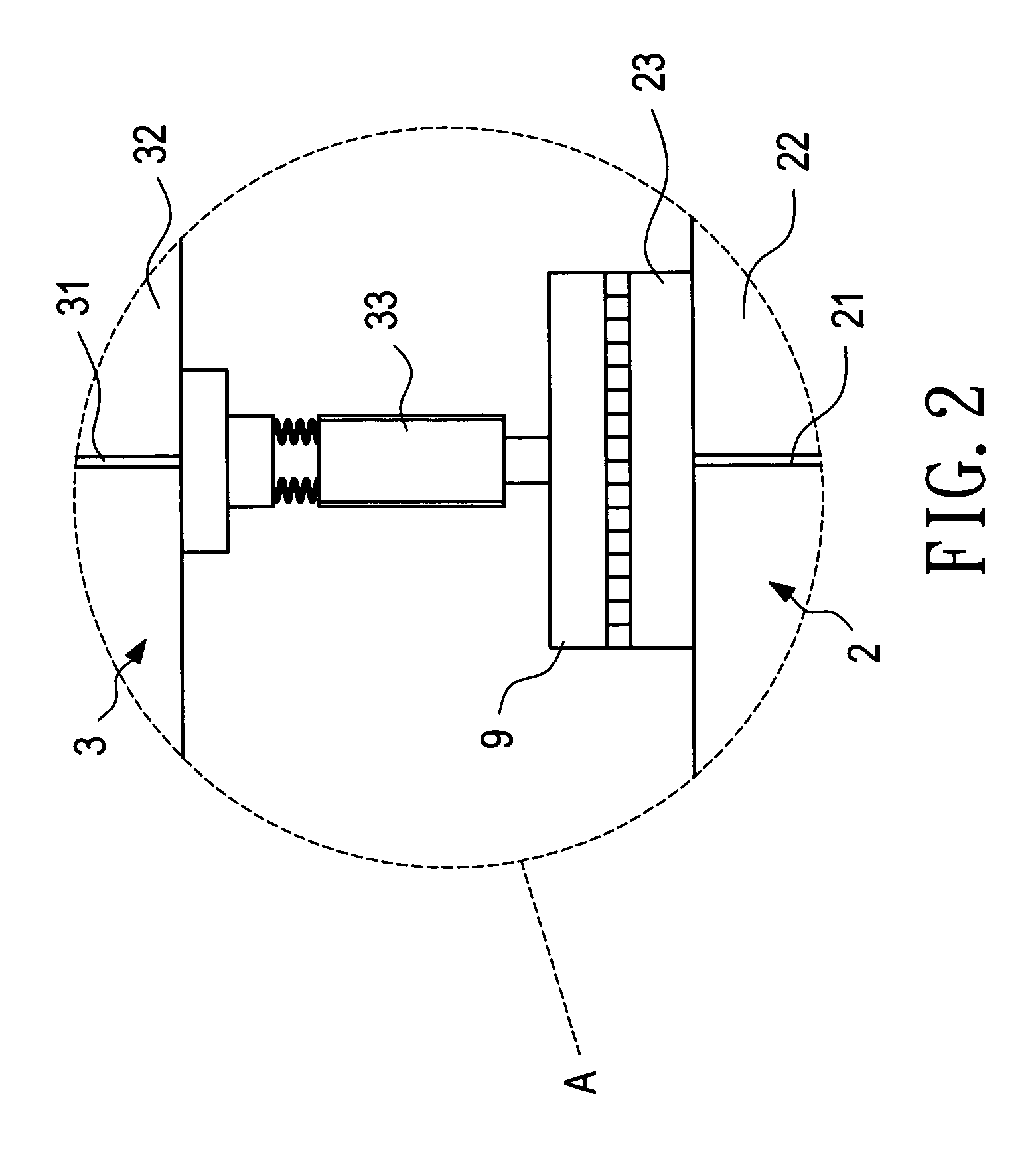

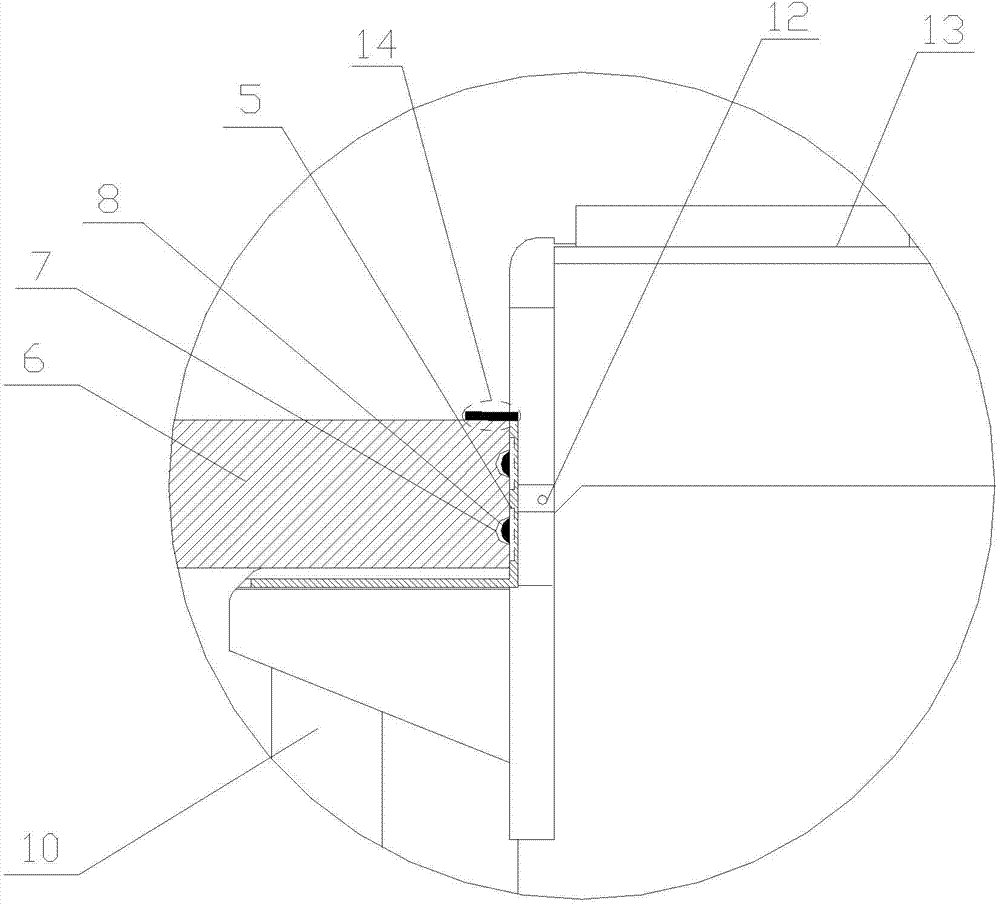

System for testing integrated circuits

InactiveUS6973402B1Improve accuracy and qualityConserve costResistance/reactance/impedenceElectronic circuit testingTemperature controlEngineering

A system for testing integrated circuits by testing the change of integrated circuits under various temperatures comprises: at least one two-dimensional matrix testing module which includes a testing section having arrays for plugging integrated circuits to be tested, a heating section corresponding with the above testing section for heating integrated circuits respectively; a computer mainframe for connecting said two-dimensional matrix testing module and controlling the whole operations of the testing system, and a database. With the above-described structure, said database and said two-dimensional matrix testing module can be connected with the computer mainframe such that the temperature control information can be transmitted to provide each heater of said heating section to generate a suitable temperature, heat the integrated circuit to be tested, and store the test information.

Owner:PROGENIC TECH

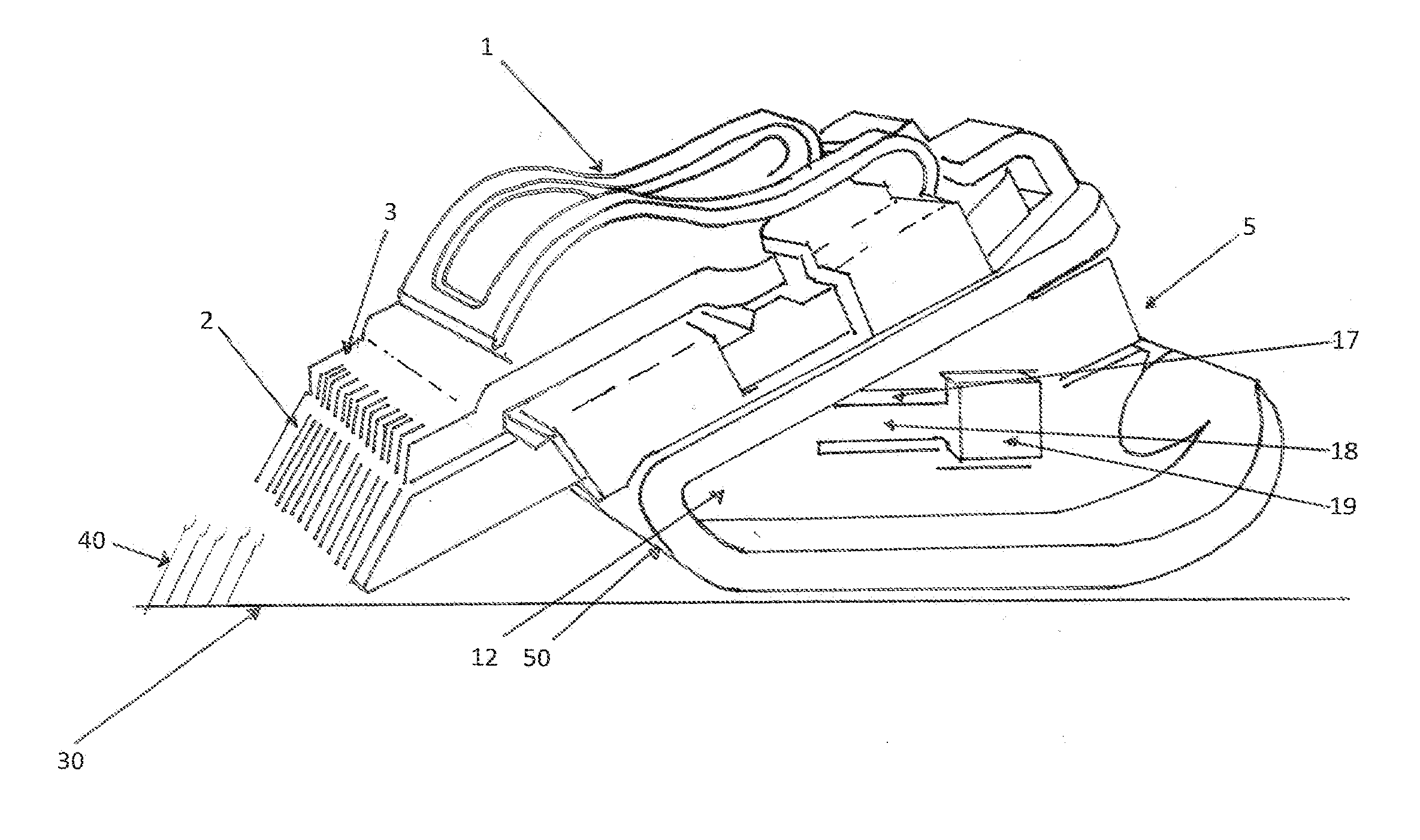

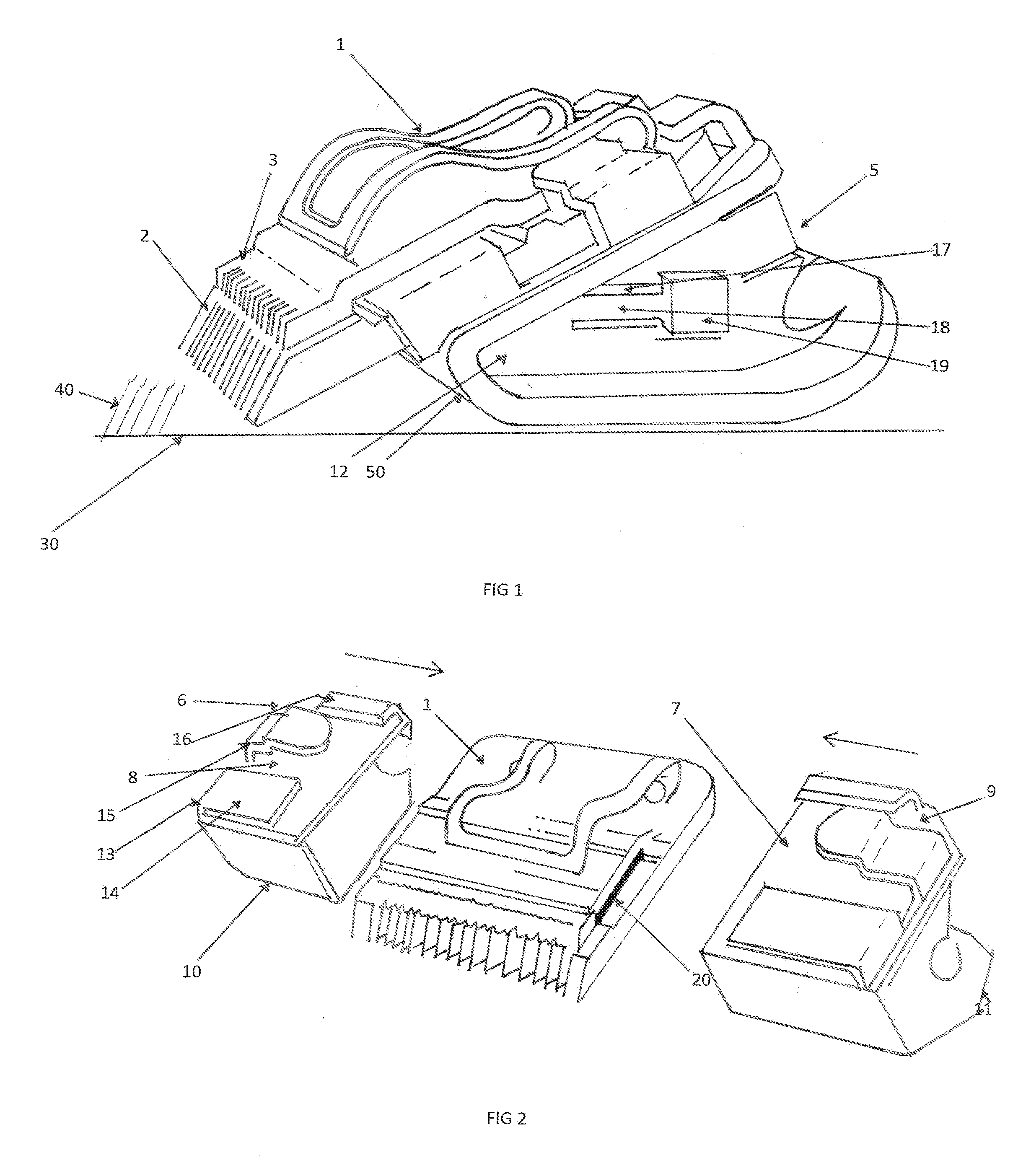

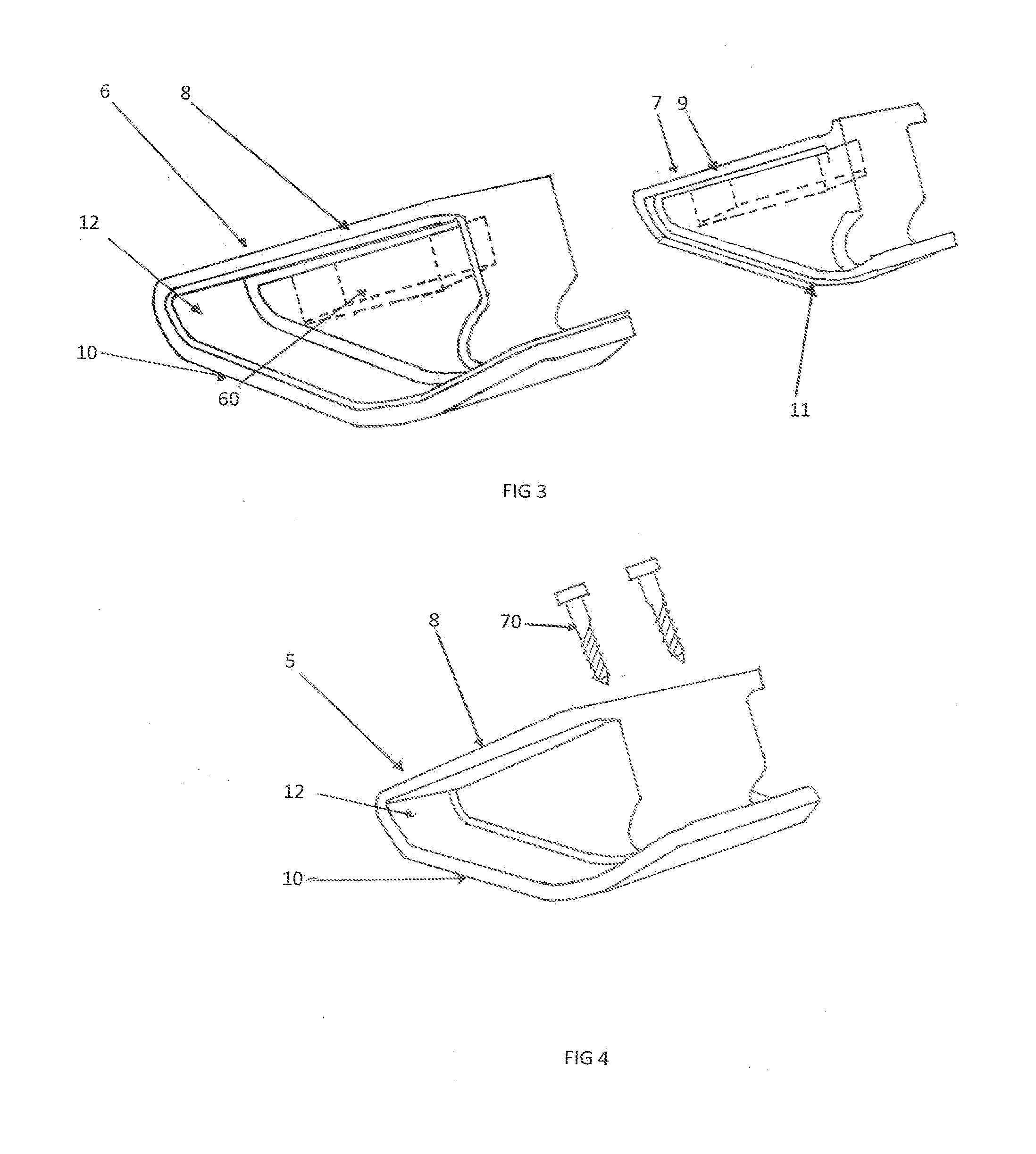

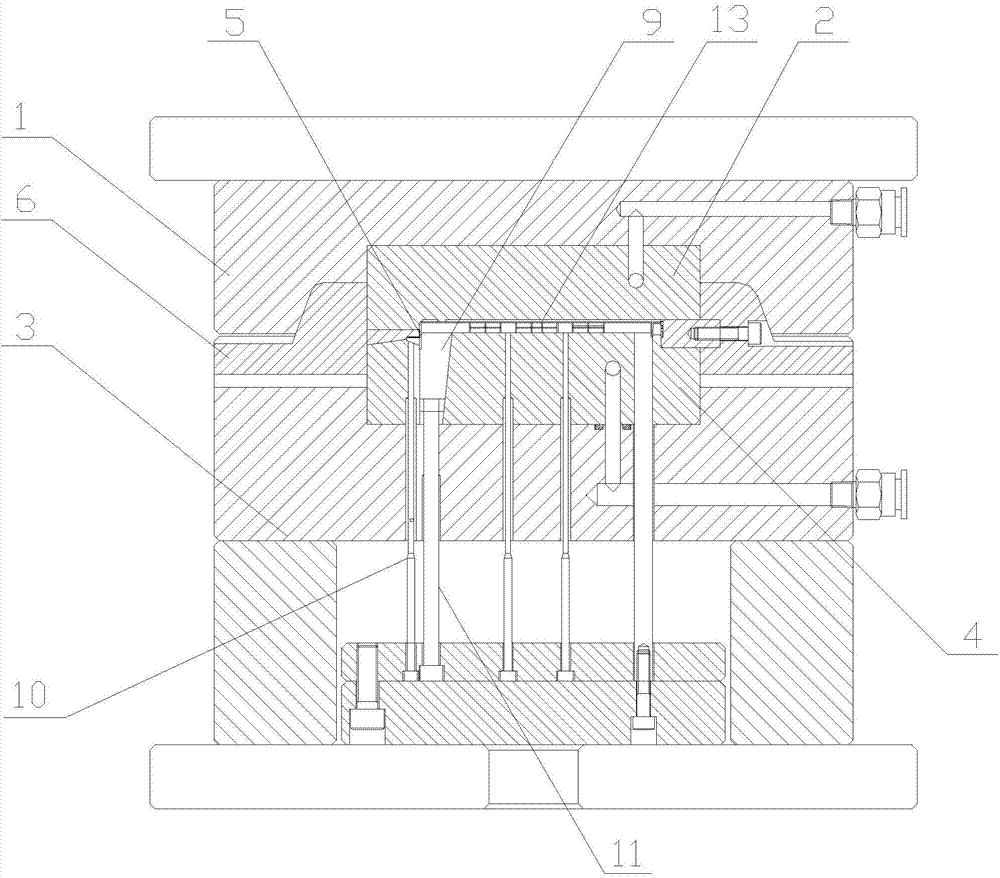

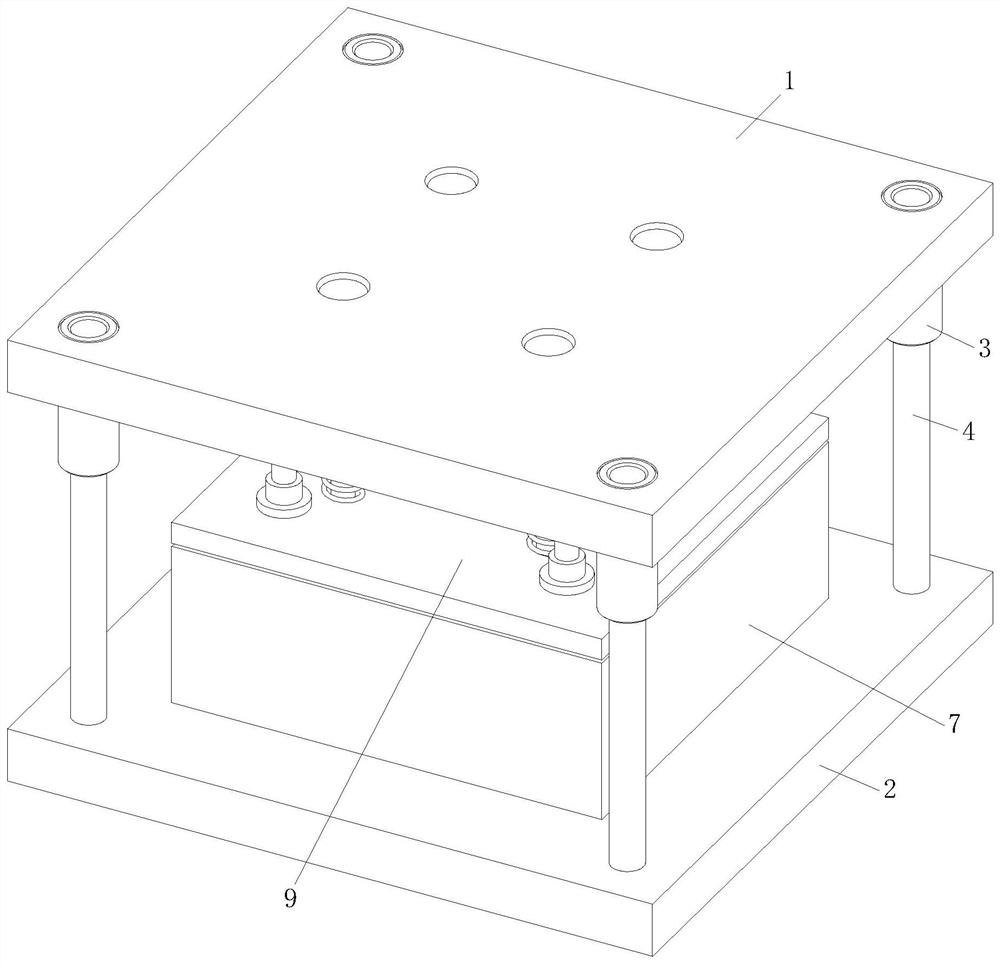

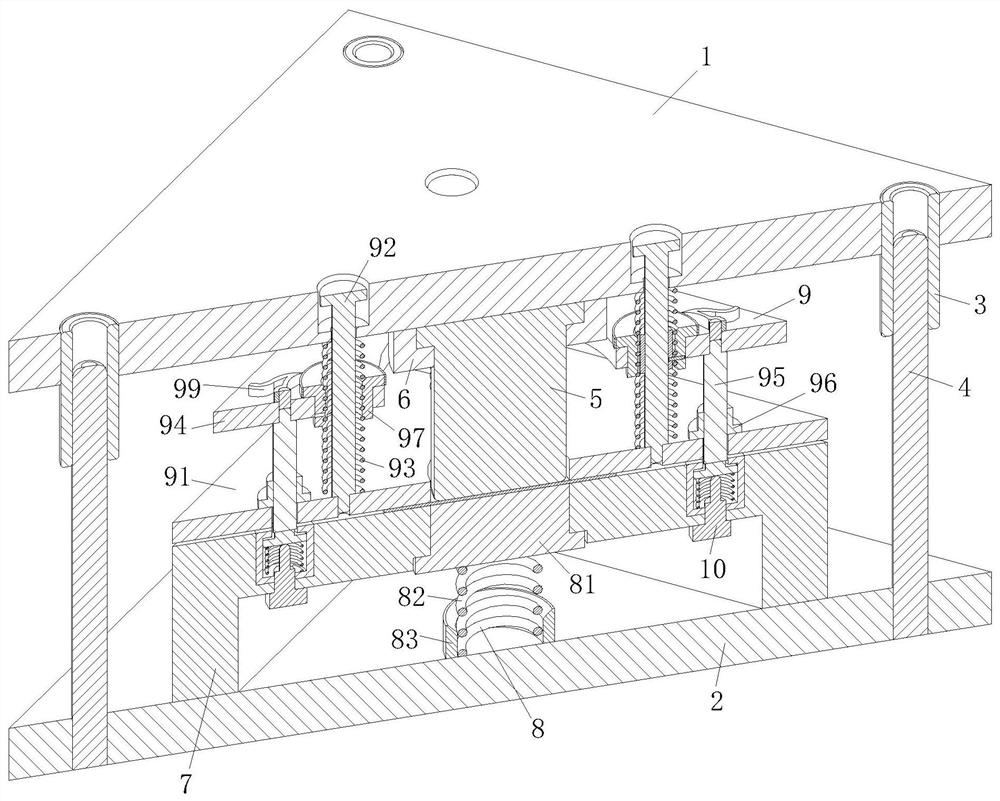

Injection molding and buried injection molding die set

ActiveCN103895172APrevents misalignment of insertsImprove accuracy and qualityPlastic cementEngineering

The invention relates to an injection molding and buried injection molding die set. The injection molding and buried injection molding die set comprises a dynamic die, and a stationary die which is matched with the dynamic die; the stationary die comprises a stationary die plate and a dynamic die core; the dynamic die comprises a dynamic die plate and a dynamic die core; the stationary die plate and the dynamic die plate form a complete die plate set; the stationary die core and the dynamic die core form a complete die core set; an embedding part which forms an integrated product with a part needing injection molding is also arranged in an inner cavity of the die core set; a sliding block for assisting to locate the embedding part is arranged between the die core set and the die plate set; the embedding part is arranged on the sliding block in a buckling manner; a corresponding locating groove is formed in the side locating surface of the sliding block, corresponding to the embedding part; a boss structure matched with the locating groove is arranged on the side locating surface of the embedding part; an initial locating structure for assisting to locate the embedding part on the sliding block is also added to the embedding part structure. According to the mode, the injection molding and buried injection molding die set has the advantages that the embedding part can be precisely located during molding according to the die structure design; in addition, the offset of the embedding part caused by the rebound deformation of the embedding part or the plastic cement flowing impact during molding can also be prevented, and thus the molding quality and precision can be greatly improved.

Owner:苏州方蒯精密科技有限公司

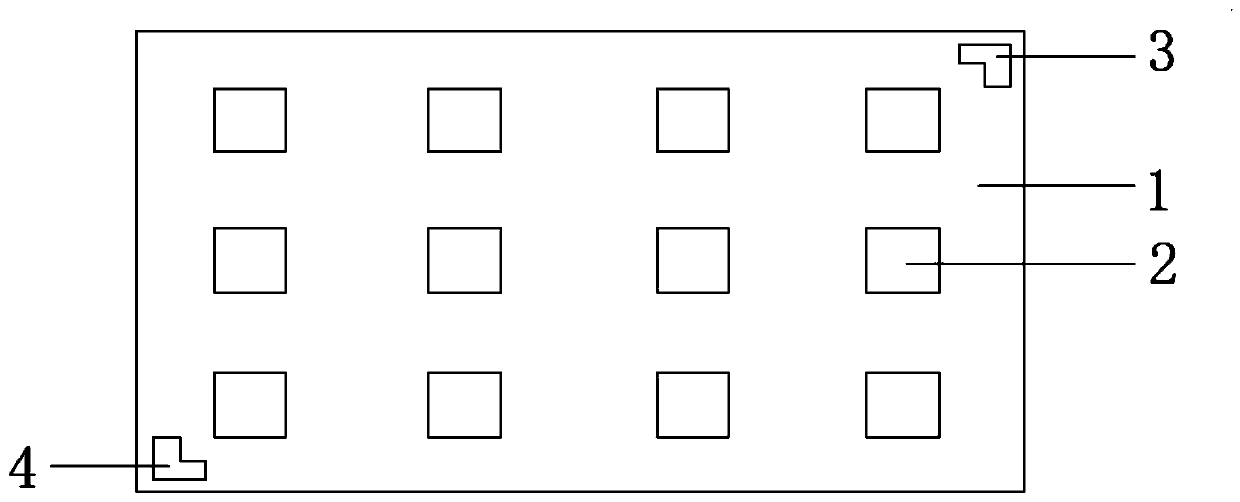

Clamp for mounting a plurality of laser chips

InactiveCN110890295APrevent reference position shiftingImprove accuracy and qualitySemiconductor/solid-state device manufacturingPhysicsErbium lasers

The invention discloses a clamp for mounting a plurality of laser chips. The clamp comprises a substrate and a spring block, a through hole is formed in the surface of the substrate, and an optical positioning point a is arranged above the right side of the top surface of the substrate. An optical positioning point b is arranged below the right side of the top surface of the substrate, and the optical positioning point a and the optical positioning point b are both L-shaped structures. A limiting block a is arranged above the left side of the through hole, a rubber layer is arranged at the bottom end of the limiting block a, and the rubber layer is made of anti-static rubber. A chamfer is arranged at the right side of the rubber layer, and through the chamfer, the surface of the chip can be prevented from being abraded during the chip clamping process. A limiting block b is arranged at the right side of the limiting block a, a spring block is arranged in the middle at the bottom end ofthe through hole, and the limiting block a, the limiting block b and the spring block are all fixed to the back of the substrate. A protruding block is arranged above the interior of the spring blockand can move up and down in the spring block, and a spring is arranged at the bottom end of the protruding block. The clamp has the advantages of being capable of clamping a plurality of chips, and being accurate in positioning and firm in clamping.

Owner:湖南红鑫通信技术有限责任公司

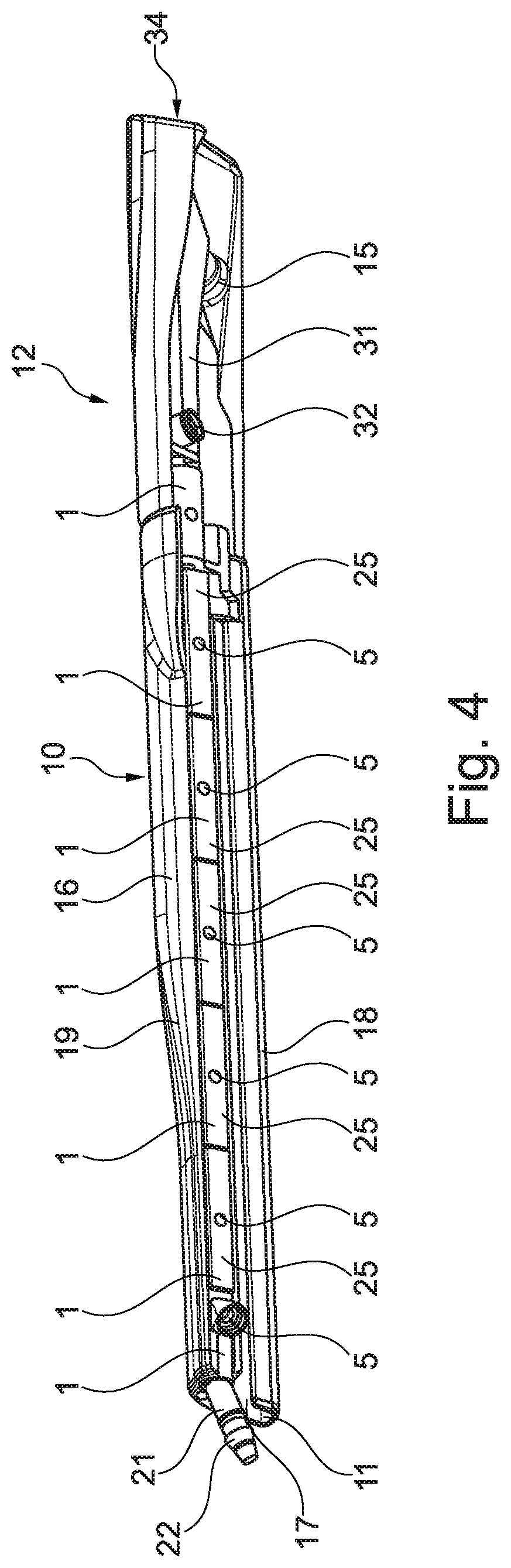

Arrangement of nozzle units for a wiper arm, wiper arm and use of a nozzle unit

ActiveUS20200398796A1Facilitate assemblySimple form-fitting connectionVehicle cleaningPhysicsAutomotive engineering

Disclosed is an arrangement of nozzle units for a wiper arm, wherein at least one nozzle unit comprises a rigid body, has a channel through which liquid can flow into the nozzle unit and / or out of the nozzle unit, and comprises a nozzle, which is connected to the channel. The nozzle units are in communication with each other in series such that a liquid can flow from a nozzle unit into a following nozzle unit in the series, wherein at least one nozzle unit has a contact surface which is formed such that the nozzle unit cannot rotate about the longitudinal axis thereof if the contact surface contacts a surface of a wiper arm. A wiper arm comprising the arrangement is also disclosed.

Owner:A RAYMOND & CO

Data driven classification and data quality checking method

InactiveUS10083403B2Improve accuracy and qualityEfficient and reliableBiological modelsInference methodsLearning dataQuality rating

A method for improving accuracy and quality of received data is provided. The method provides a computer implemented data driven classification and data quality checking system. The method uses the associative memory software to build a data driven associative memory model that enables a machine learning data quality checker for receiving data. The method categorizes one or more fields of received data, analyzes the received data, and calculates a data quality rating metric, by comparing the received data with a pool of neighboring data in the category of field of the received data. The method accepts and adds the received data, if the data quality rating metric is greater than or equal to a data quality rating metric threshold, and generates and communicates an alert of a potential error in the received data, if the data quality rating metric is less than the data quality rating metric threshold.

Owner:THE BOEING CO

High-precision stamping die for sheet metal part machining

InactiveCN113617941AImprove accuracy and qualityRealize automatic feedingShaping toolsMetal-working feeding devicesStampingMaterials science

The invention belongs to the technical field of sheet metal machining, and discloses a high-precision stamping die for sheet metal part machining, which comprises a die bottom frame, wherein a mounting top groove is formed in one end of the top of the die bottom frame, a position adjusting sliding groove is formed in the other end of the top of the die bottom frame, and a bearing support frame is integrally arranged on the inner side of the top of the die bottom frame; a bearing tooth groove is formed in the inner side of the bearing support frame, a bearing bottom column is slidably installed on the inner side of the bearing tooth groove, driving mechanisms are installed at the two ends of the bearing bottom column through connecting shafts, and the driving mechanisms and the bearing tooth groove move in an engaged mode; a servo motor drives the gear and the rack to rotate so as to drive a transportation pushing piece to slide in a reciprocating mode, the transportation pushing piece pushes extruded sheet metal parts and moves the extruded sheet metal parts to the inner side of a transportation sliding frame, then the sheet metal parts slide directionally and are collected in a centralized mode, so that the problems that an existing device needs manual collection, and safety and production efficiency are low are solved. The device can stretch the sheet metal parts while stamping the sheet metal parts, and is rich in function and high in efficiency.

Owner:万腾钣金(深圳)有限公司

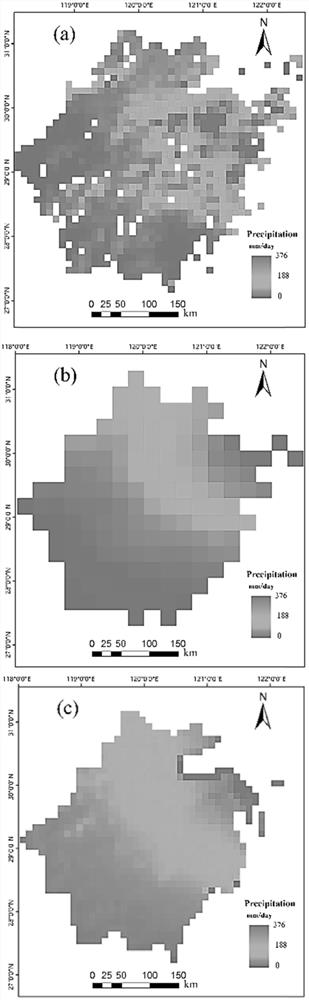

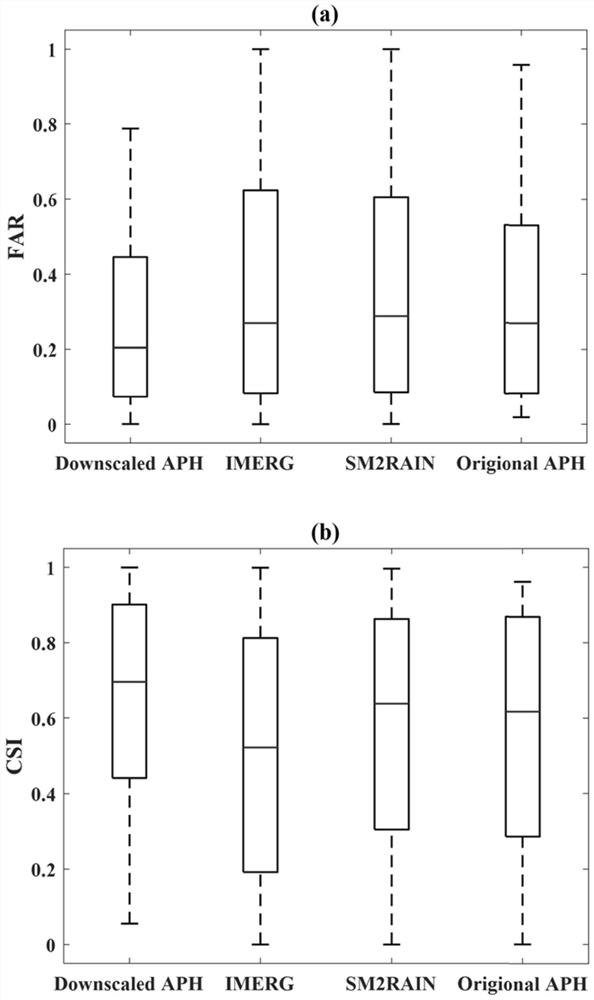

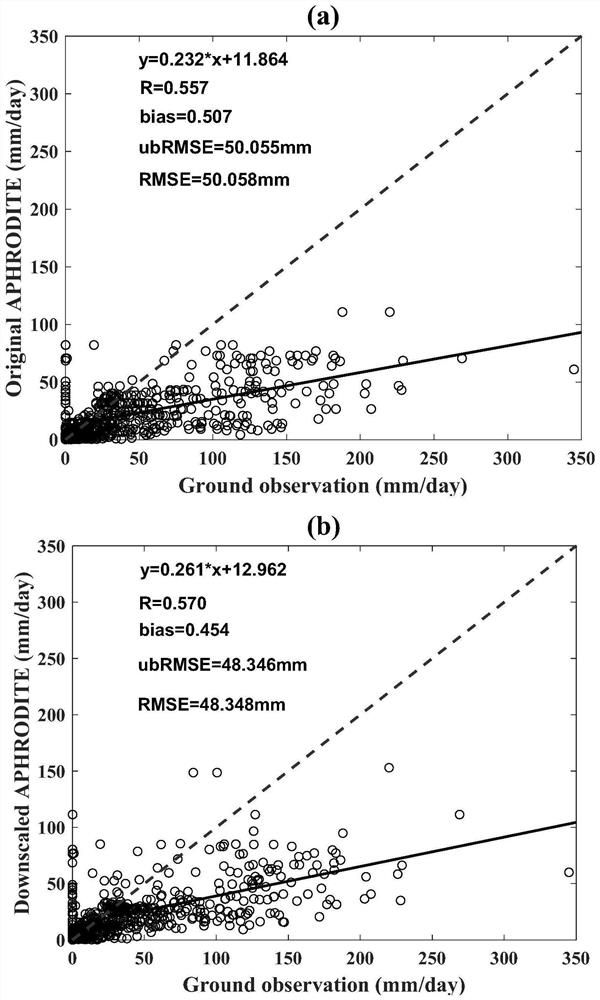

Downscaling method for APHRODITE rainfall data

ActiveCN112285808AImprove accuracy and qualityQuality improvementRainfall/precipitation gaugesWeather condition predictionIndependent predictorAtmospheric sciences

The invention discloses a downscaling method for APHRODITE rainfall data. The method comprises the steps of acquiring a GPM-IMERG data set, an SM2RAIN-ASCAT data set and an APHRODITE day-by-day rainfall data set which are used for describing the same object, obtaining an environmental factor auxiliary data set which is the same as the three data set description objects, respectively matching the four data sets based on different observation dimensions, and carrying out total amount control processing on the APHRODITE data set, based on the spatial dimension, establishing a regression model bytaking the low-resolution GPM-IMERG data set, the SM2RAIN-ASCAT data set and the auxiliary data set obtained in the step S22 as independent variables and taking the APHRODITE data set obtained in thestep S24 as a dependent variable, and S3, based on the spatial dimension, taking the high-resolution GPM-IMERG data set obtained in the step S21, the high-resolution SM2RAIN-ASACAT data set obtained in the step S23 and the high-resolution auxiliary data set obtained in the step S22 as input variables, and inputting the input variables into a regression model to obtain a high-resolution APHRODITE day-by-day precipitation data set. The rainfall data obtained through the method is high in result precision and quality and has certain theoretical and practical significance and application and popularization value.

Owner:ZHEJIANG UNIV

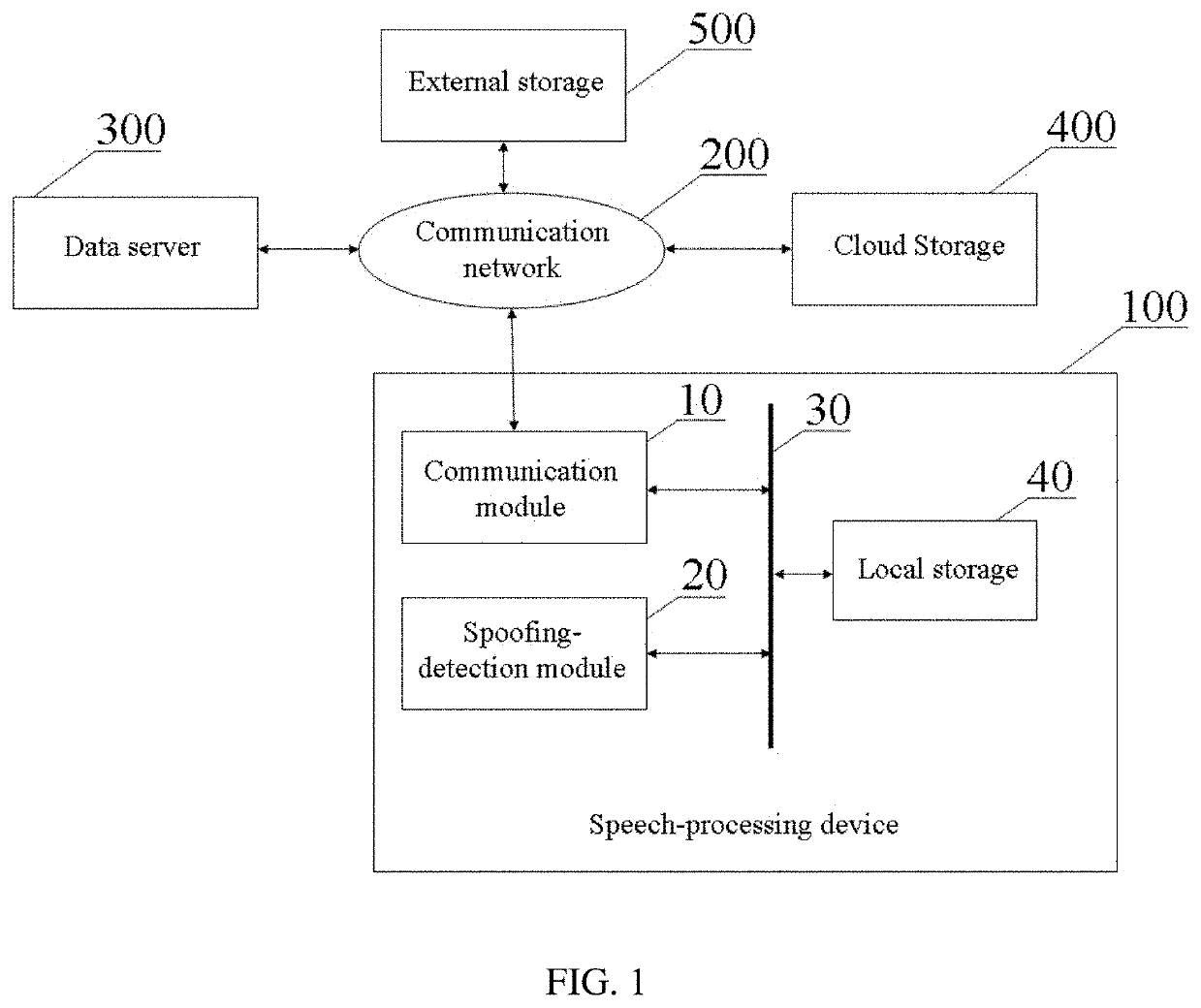

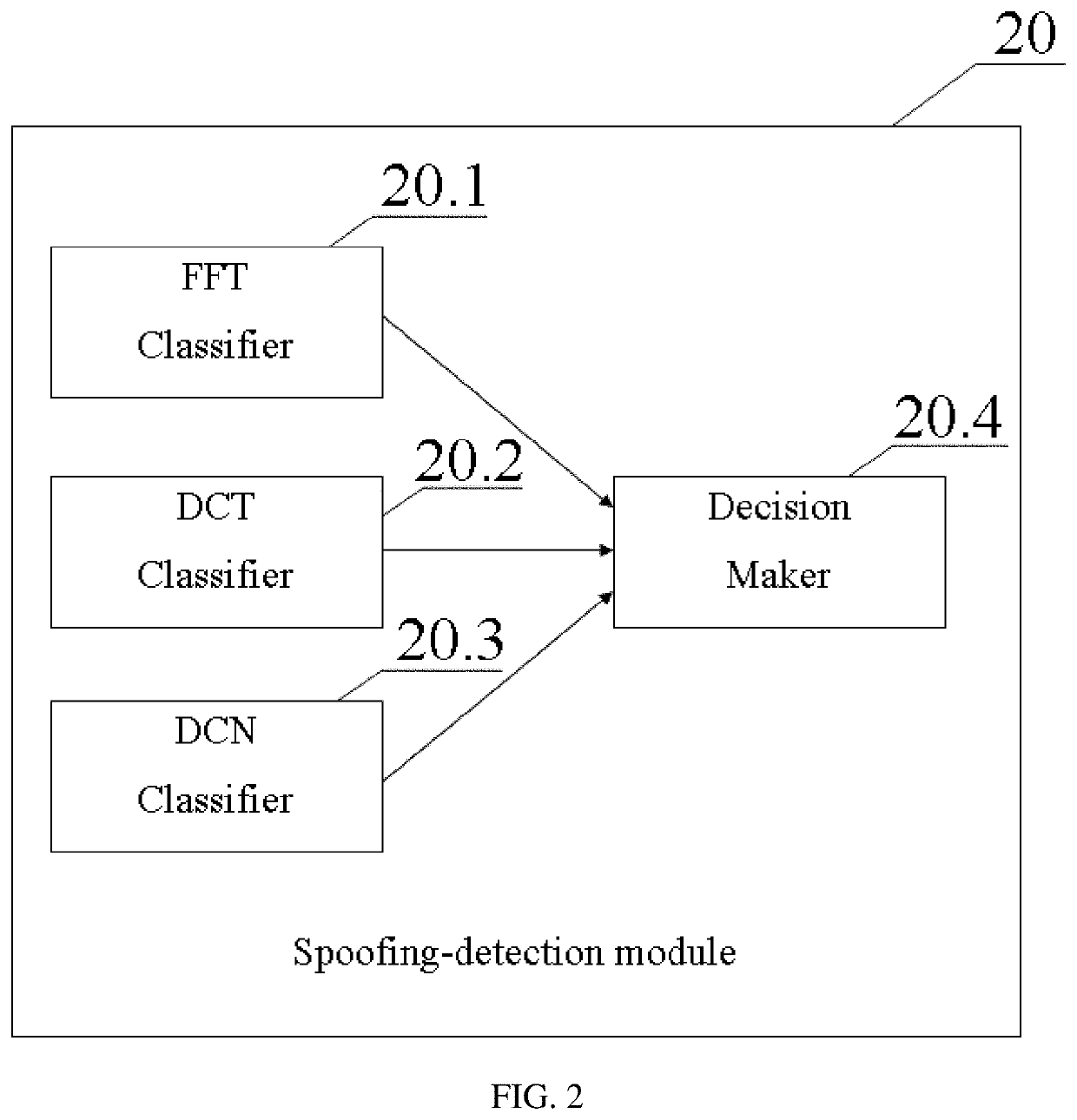

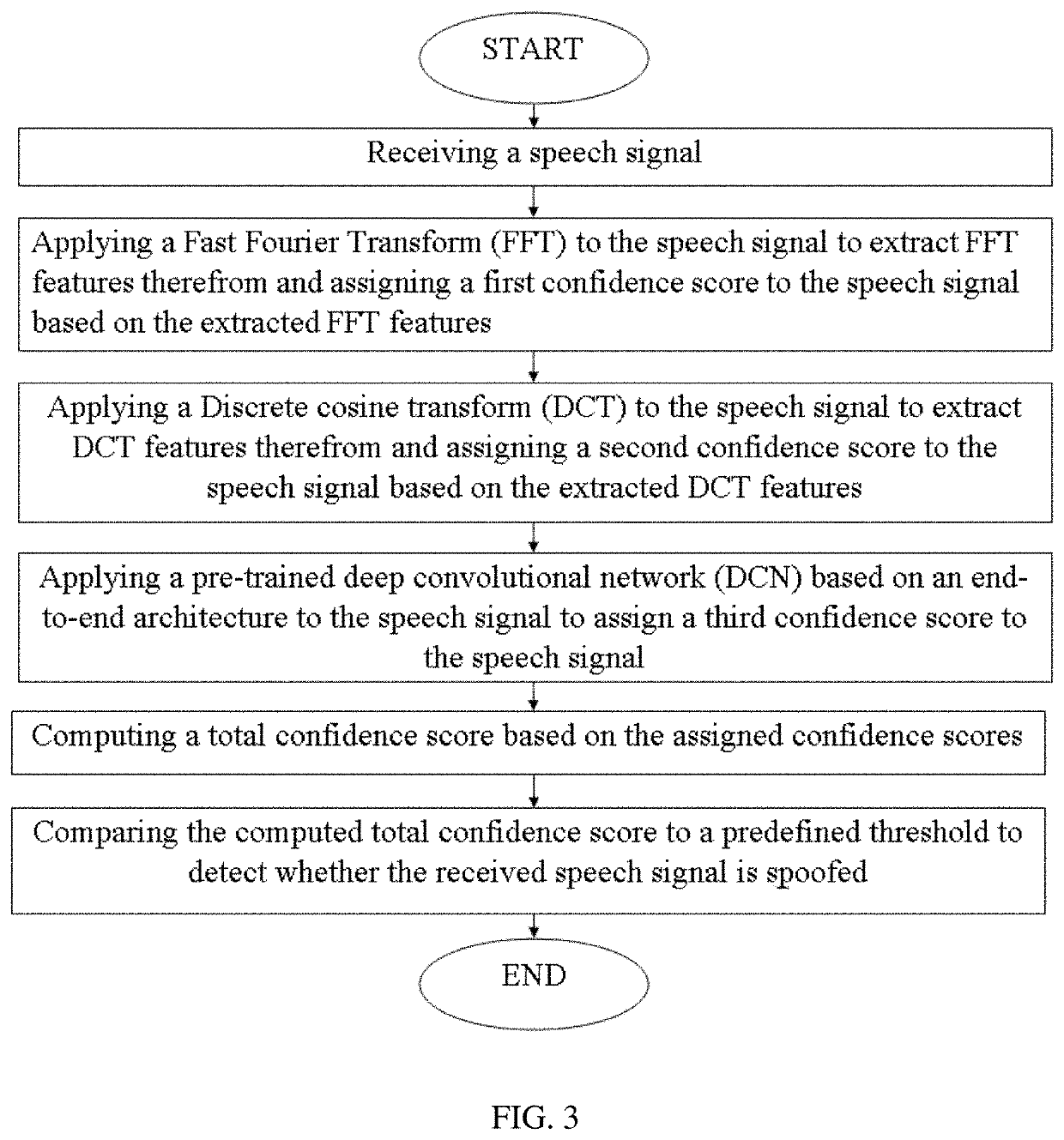

Methods and devices for detecting a spoofing attack

ActiveUS20220070207A1Effective attackPerformance requirementSpeech recognitionTransmissionPattern recognitionFast Fourier transform

Methods and devices for detecting a spoofing attack are provided. The method includes receiving a speech signal; applying a Fast Fourier Transform (FFT) to the speech signal to extract FFT features therefrom and feeding the extracted FFT features to a pre-trained deep neural network to assign a first confidence score to the speech signal; applying a Discrete cosine transform (DCT) to the speech signal to extract DCT features therefrom and feeding the extracted DCT features to a pre-trained deep neural network to assign a second confidence score to the speech signal; applying a pre-trained deep convolutional network (DCN) based on an end-to-end architecture to the speech signal to assign a third confidence score to the speech signal; computing a total confidence score based on the assigned confidence scores; and comparing the computed total confidence score to a predefined threshold to detect whether the received speech signal is spoofed.

Owner:ID R&D INC

Magnetic resonance method and apparatus for generating a perfusion image

ActiveUS8203340B2Improve accuracy and qualityReduce impactImage enhancementImage analysisImaging qualityResonance

Owner:SIEMENS MEDICAL SOLUTIONS USA INC

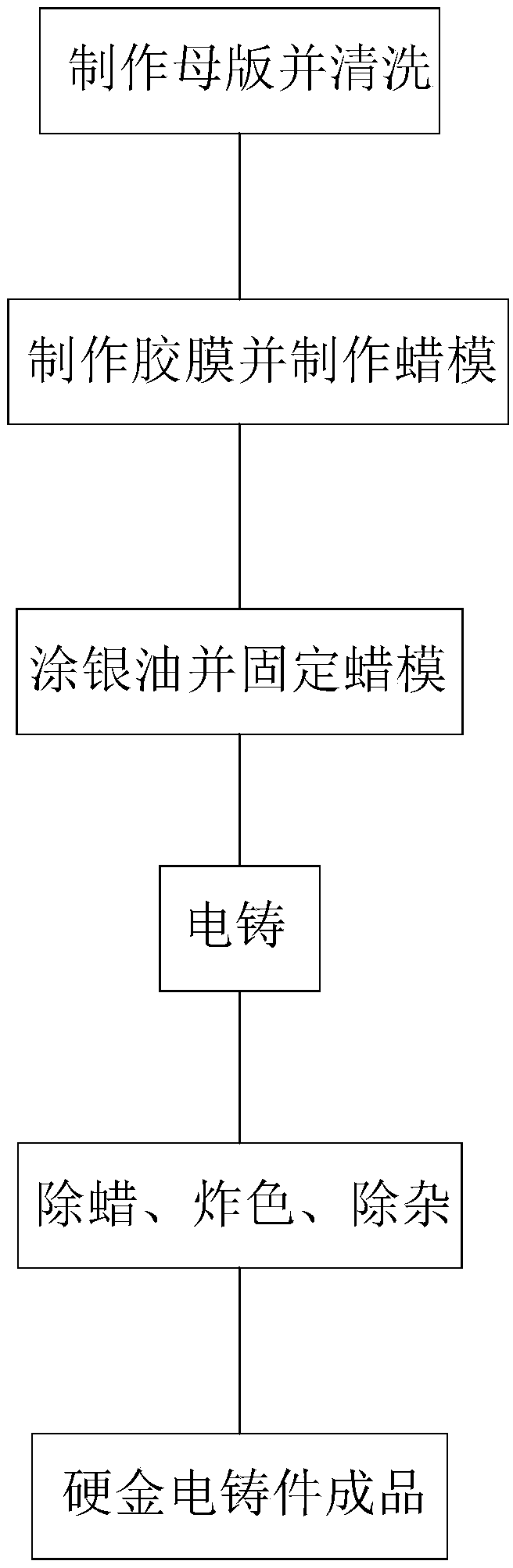

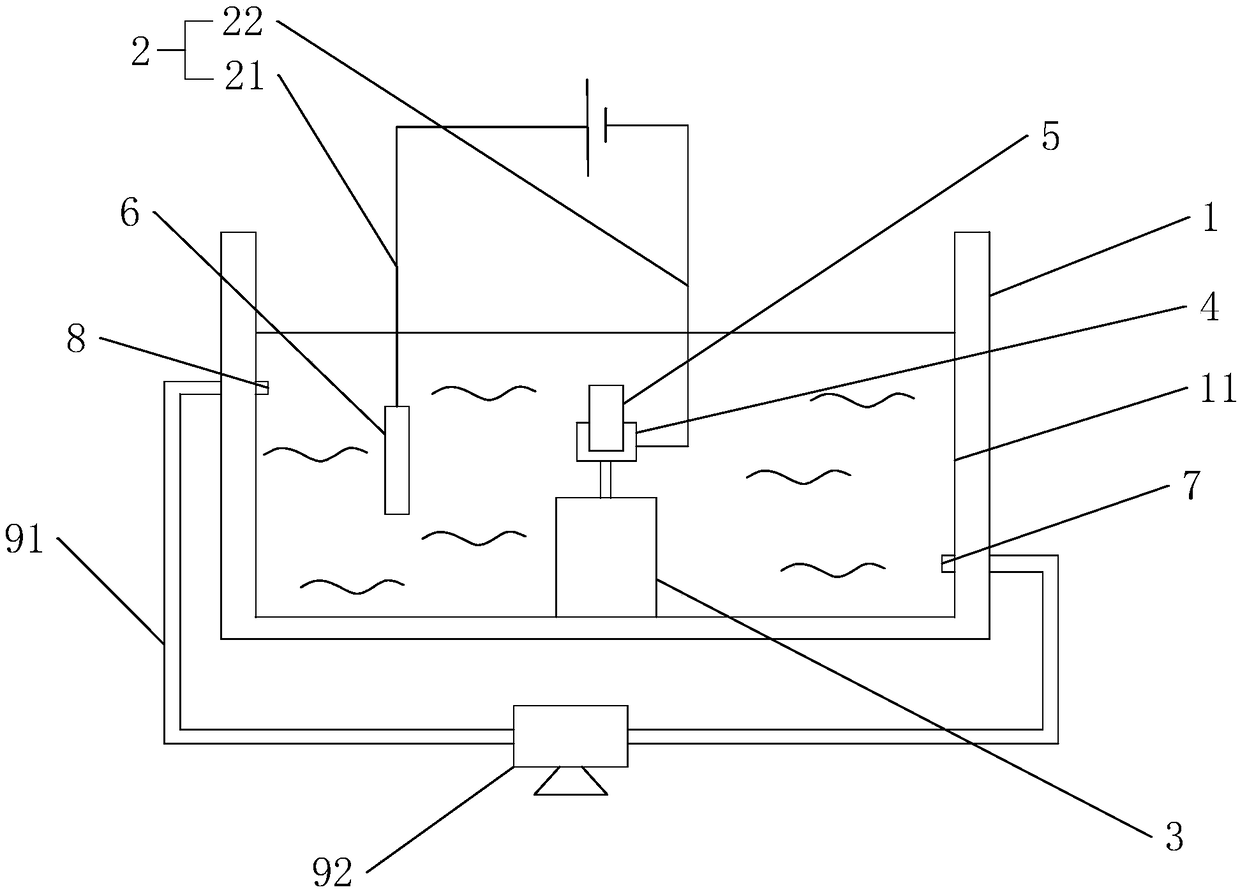

3D hard gold process

InactiveCN109183080AImprove accuracy and qualityHigh activity3D structure electroformingWaxWork in process

The invention relates to the technical field of precious metal processing and discloses a 3D hard gold process. The 3D hard gold process comprises the steps of S1, making a master mask and washing themaster mask; S2, using the master mask made in the step S1 to make a glue film, using the glue film to make a wax mould capable of copying the appearance of the master mask, and repairing the wax mould; S3, coating silver oil to the wax mould, hanging the wax mould on a workpiece fixing rack of electroforming cylinder so that the wax mould rotates with the workpiece fixing rack in the electroforming process; S4, starting the electroforming cylinder to perform electroforming so as to obtain an electroforming part; S5, forming a wax in the electroforming part, removing wax, enhancing the glossof the electroforming part and removing impurities from the electroforming part; and S6, carrying out a finishing process, a sand-blasting process and a calendaring process on a jewelry semi-finishedproduct in the step 5 in sequence. According to the 3D hard gold process, as the master mask is washed after being made and impurities in the master mask are removed, the accuracy and quality of the electroforming part are obviously improved.

Owner:浙江明牌珠宝科技有限公司

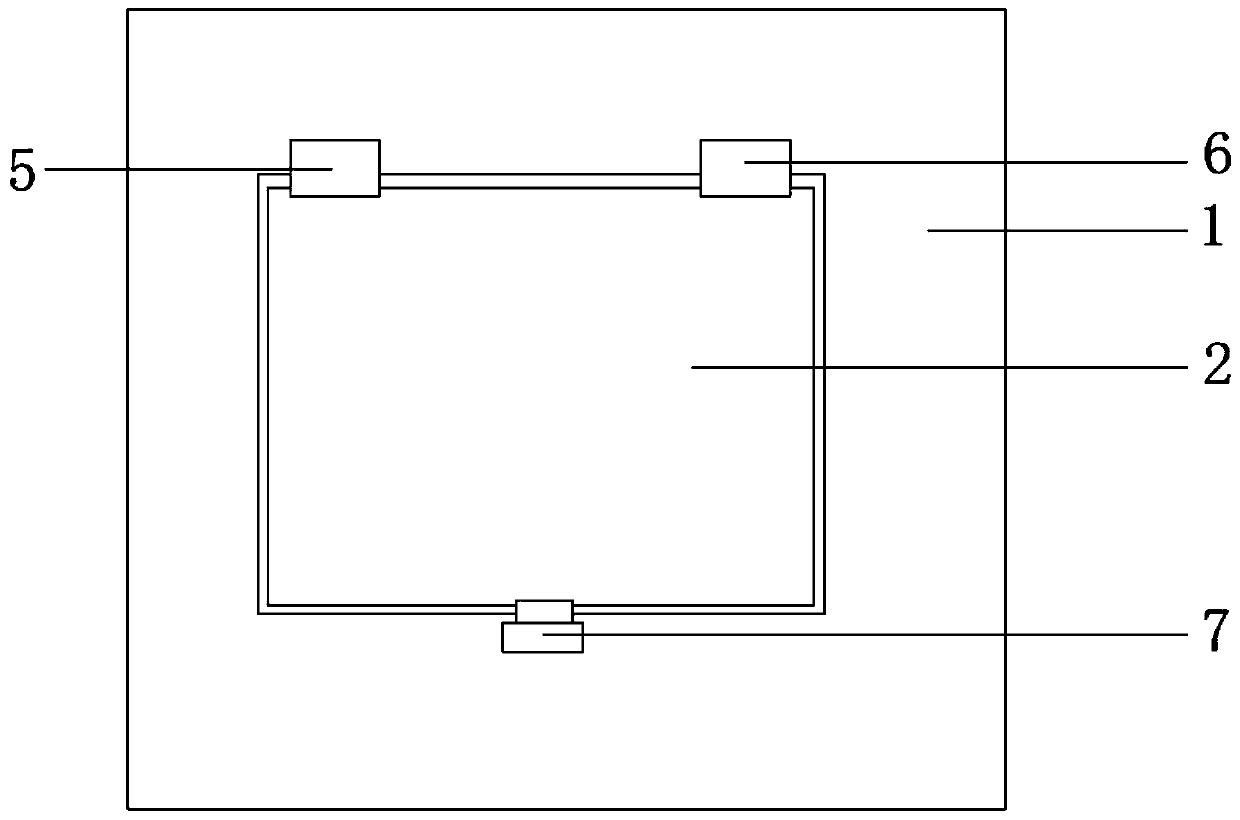

Positioning locking mechanism for workpiece U-shaped groove

ActiveCN102672506AReduce the production of non-conforming productsImprove accuracy and qualityPositioning apparatusMetal-working holdersCamEnergy consumption

The invention discloses a positioning locking mechanism for a workpiece U-shaped groove. The positioning locking mechanism comprises a tooling body (1) comprising a base plate connection part (2), a processing platform (3), an external positioning structure (4) and a pressing plate (5). The processing platform (3) is fixedly arranged on the lateral wall of the base plate connection part (2), the external positioning structure (4) and the pressing plate (5) are installed on the processing platform (3), and the outer wall of a processing part (6) is fixed on the processing platform (3) through the external positioning structure (4) and the pressing plate (5). A limit block (7) is fixedly arranged on the processing platform (3) and located at the position of a U-shaped groove of the processing part (6), and a cam bolt (8) is arranged on the limit block (7). By means of the limit block and the cam bolt, product deflection is avoided, the number of unqualified produces is reduced, accuracy and quality of products are improved simultaneously, and energy consumption is reduced. Therefore, the positioning locking mechanism for the workpiece U-shaped groove is suitable for popularization and application.

Owner:鹰普机械(宜兴)有限公司

Deep drawing die based on variable blank holder force control

InactiveCN111618155APrevent cracking of the blank holderImprove accuracy and qualityShaping toolsThin slabStructural engineering

The invention belongs to the technical field of punching dies, and specifically provides a deep drawing die based on variable blank holder force control. The deep drawing die comprises an upper fixedplate, a lower fixed plate, guide sleeves, guide columns, a male die, a fixed base, a female die, an ejecting mechanism and a pressing mechanism. The pressing mechanism comprises a pressing plate, guide rods, second springs, a regulation plate, limiting ejection rods and guide sleeves. In the deep drawing die, the pressing plate in the pressing mechanism makes contact with a to-be-punched plate, then the edge of the to-be-punched plate is pressed, then the limiting ejection rods make contact with the upper surface of the female die, and therefore the regulation plate is limited to continue toget close to the pressing plate, the second springs between the regulation plate and the pressing plate are limited to continue to be compressed, the extrusion force provided by the second springs islimited to continue to increase, it is ensured that the blank holder force provided by the pressing plate for the to-be-punched plate cannot be increased along with increase of the deep drawing height, the problem of blank holder fracture caused by excessively-large blank holder force is prevented, and precision and quality of thin plate punching are improved.

Owner:ANHUI TECHN COLLEGE OF MECHANICAL & ELECTRICAL ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com