Patents

Literature

114results about How to "Reduce adjustment error" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

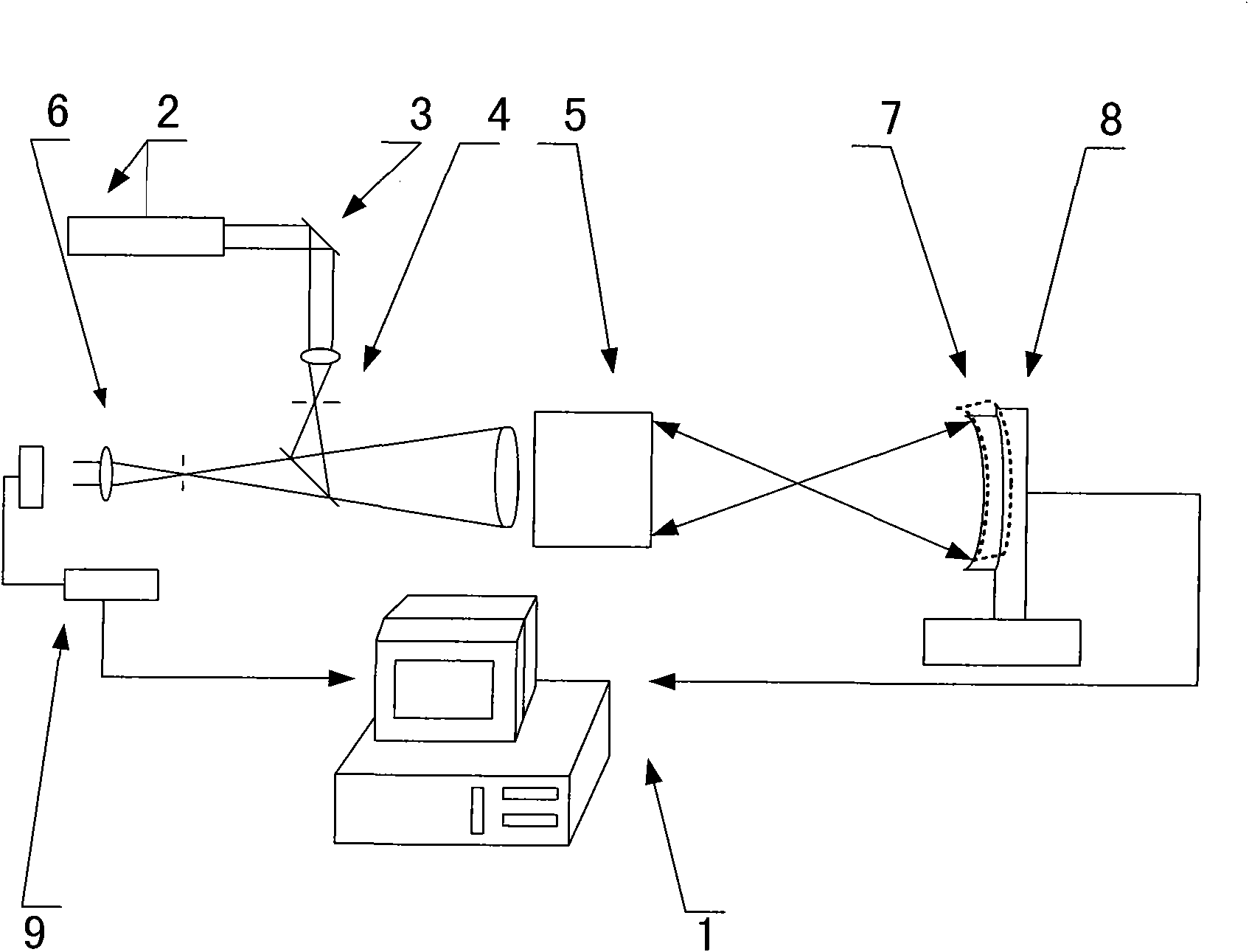

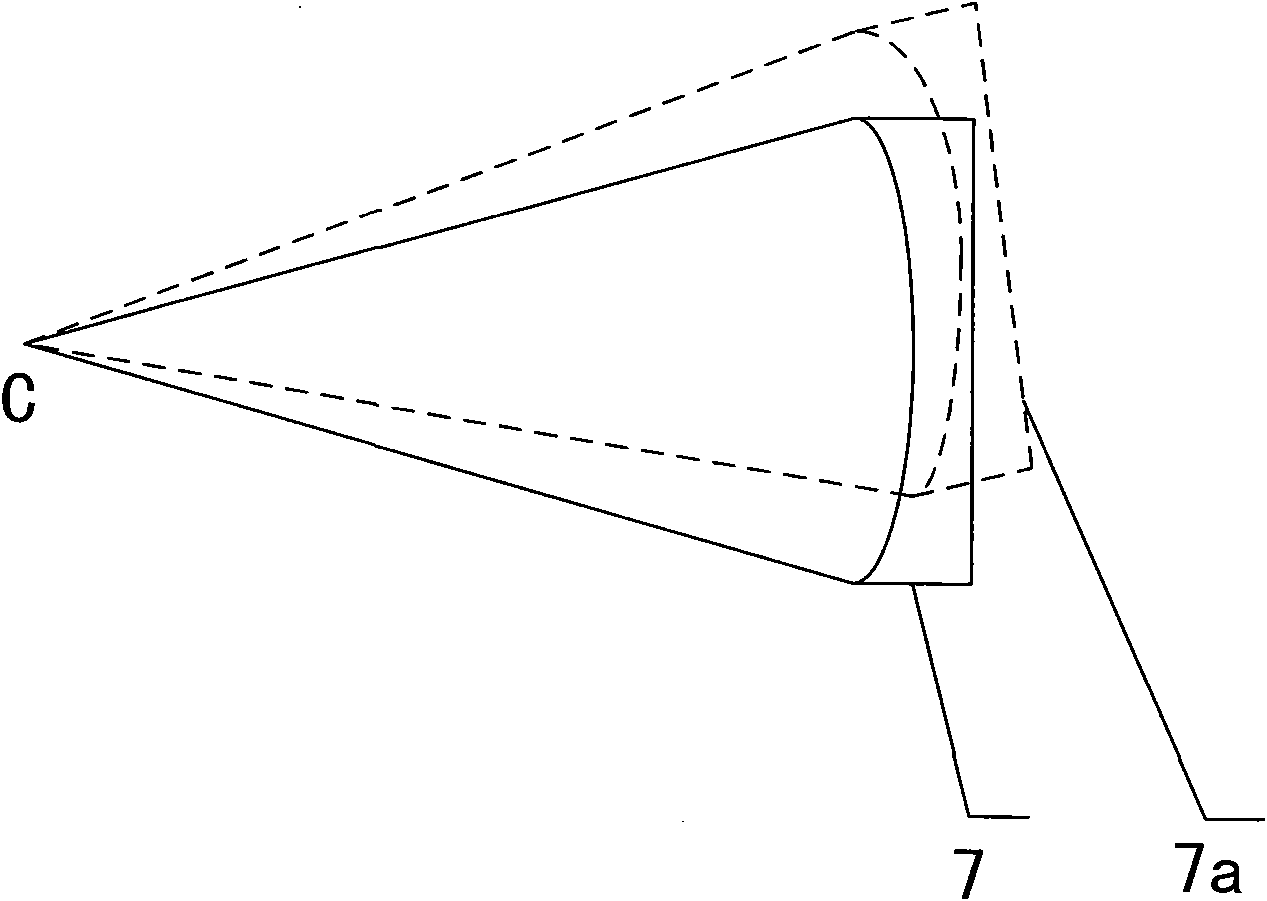

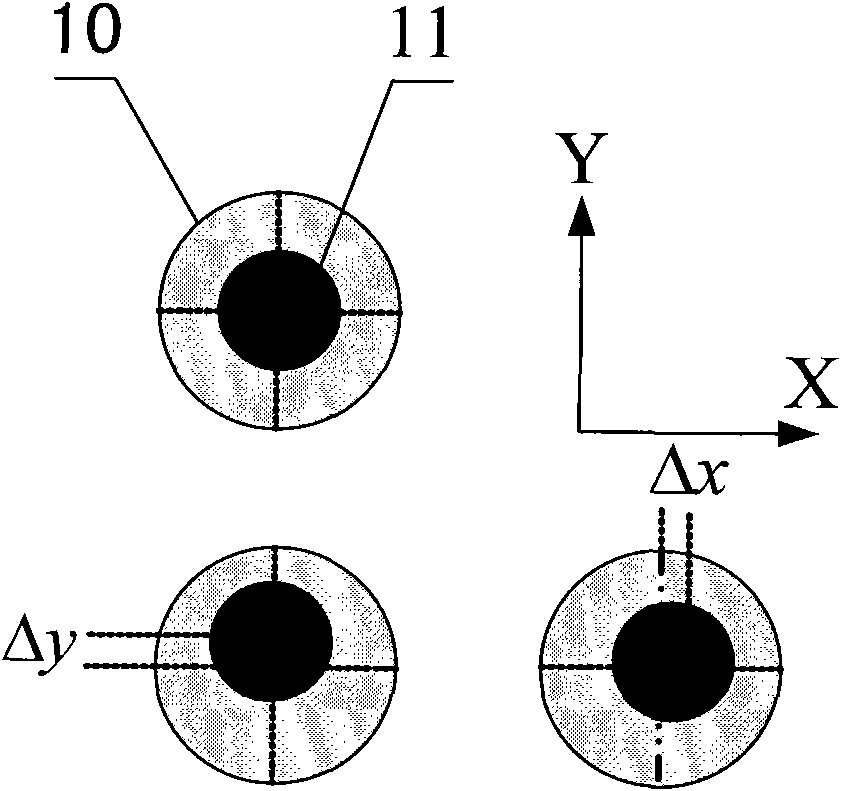

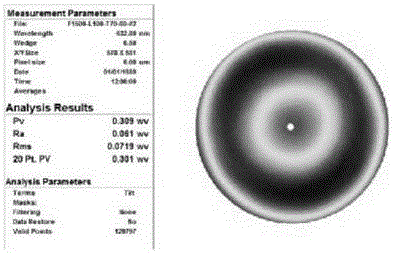

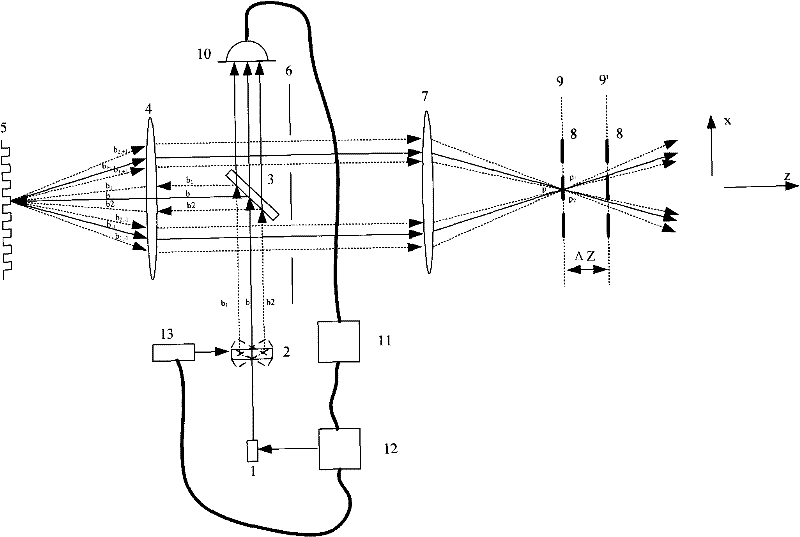

Novel spherical absolute measurement system and method thereof

ActiveCN102095385AReduce adjustment errorEliminate the effects ofUsing optical meansOptical axisData acquisition

The invention discloses a novel spherical absolute measurement system and a method thereof, wherein the system comprises a computer, a light source, a light splitting unit, a filter, a standard object lens, a measured spherical reflecting mirror, an electro-control translation stage and a data acquisition and transmission unit; the method comprises the steps of: at first, adjusting the confocal location of the measured spherical reflecting mirror on the standard object lens by the electro-control translation stage, controlling a Fizeau interferometer by the computer to perform surface detection on the measured spherical reflecting mirror once and then storing the detection data in the computer, then controlling the electro-control translation stage by the computer to enable the measured spherical reflecting mirror to generate, around the focal point, confocal shears of lambda y and lambda y in relation to an optical axis of the interferometer, and using the interferometer to perform two detections respectively and storing the detection data of the two detections in the computer, and separating the surface data of the measured spherical reflecting mirror from errors of system and reference surface by data processing software in the computer among the three detected surface data so as to obtain the absolute surface information of the measured optical mirror surface.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

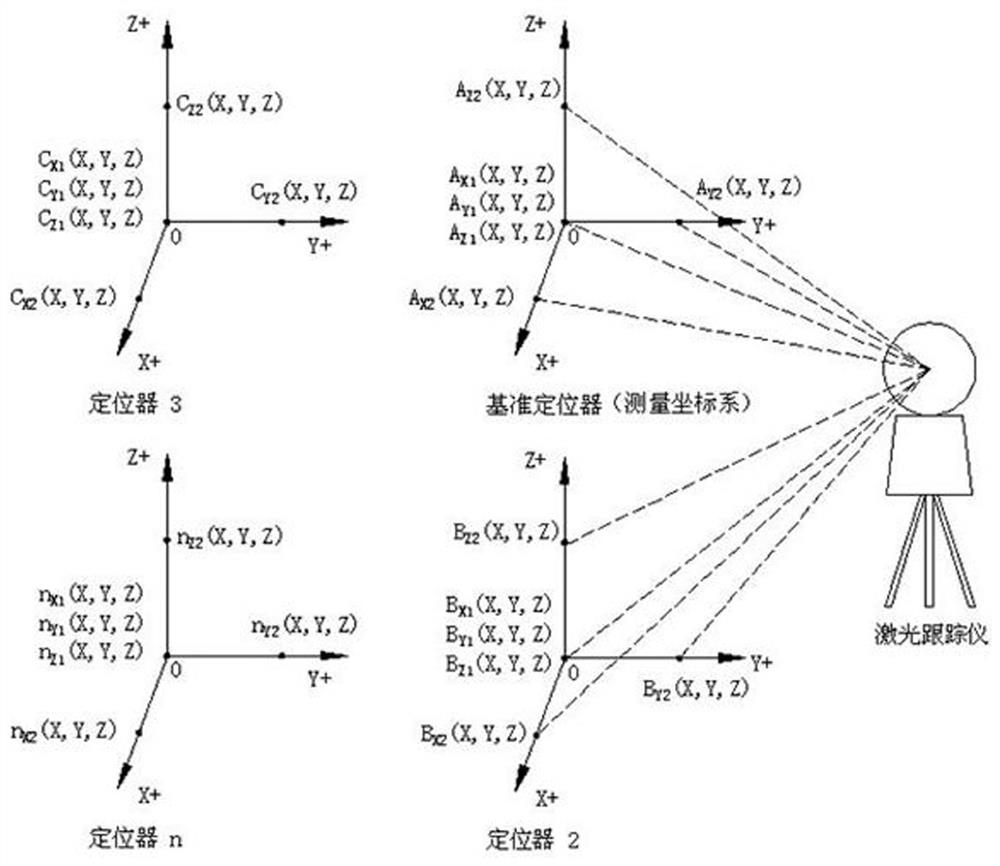

Method for adjusting housings outside single stand reversible rolling mill

ActiveCN101664760AHigh adjustment accuracyMeet the acceptance criteriaMetal rolling stand detailsMeasuring devicesEngineeringRoll center

The invention relates to a method for adjusting a single stand reversible rolling mill, in particular to a method for adjusting housings outside the single stand reversible rolling mill, which comprises the following steps: a, determining that a housing base reaches assembly accuracy, and suspending the housings to correct positions; b, hanging a steel wire, checking vertical and transverse central lines of the rolling mill; c, connecting earphones to the vertical and transverse central lines of the rolling mill by lead wires; d, moving housings on a transmission side and an operation side towards the housing base direction on a discharge side respectively by a hydraulic jack to ensure that a bracket side of the housings is close to the lateral surface of the base on an outlet side, and moving a rail rest on an inlet side towards the outlet side; e, adjusting sizes of the housing rolling center and the transverse center of the rolling mill, and fastening a foundation bolt by 70 percentof a design torque; and f, hanging steel wires on housing windows and the rolling directions of the housings, and measuring the verticality and the horizontality of the windows and the rolling directions of the housings of the rolling mill. The method uses the steel wires and the earphones to ensure numerical reading, eliminates reading errors caused by visual errors of staff, and improves the assembly accuracy of equipment.

Owner:CHINA MCC20 GRP CORP

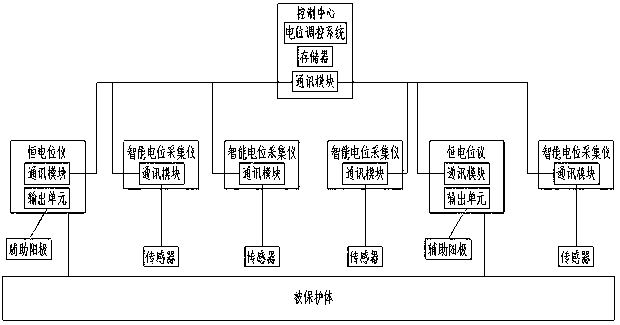

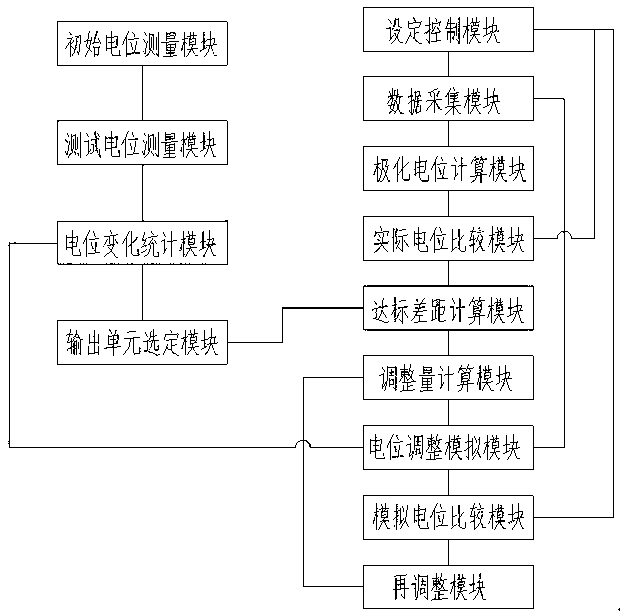

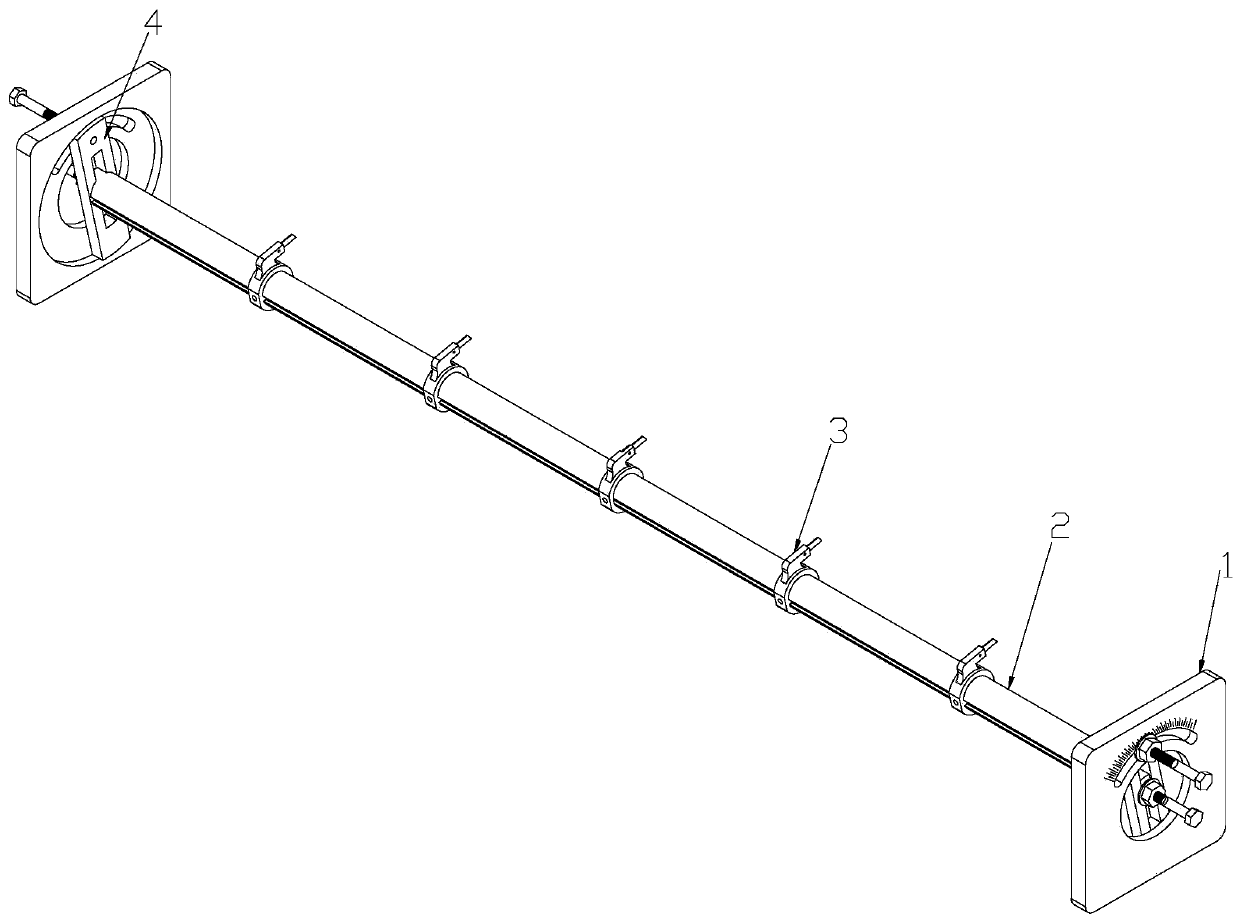

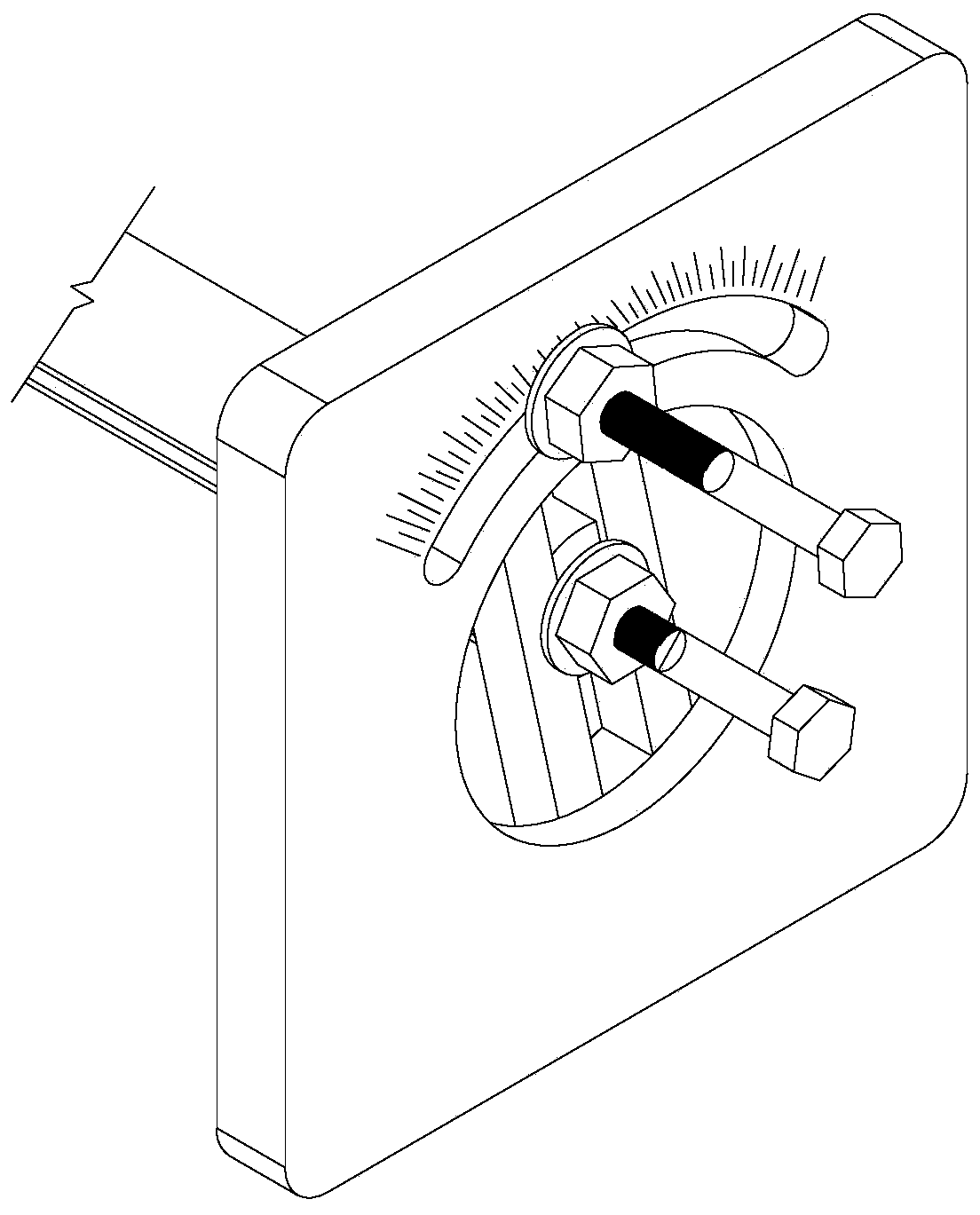

Large range long distance cathodic protection system and working method thereof

The invention relates to a large range long distance cathodic protection system which comprises a control center, constant potential rectifiers and intelligent potential collectors. A plurality of constant potential rectifiers and intelligent potential collectors are arranged. The control center is internally provided with a potential regulating system and a memory. The large range long distance cathodic protection system is provided with the constant potential rectifiers and an output unit connected with the constant potential rectifiers. The constant potential rectifiers are arranged along a protective line pipe. Output number of the constant potential rectifiers is great so that the cathodic protection is long in distance and uniform in protection. According to the large range long distance cathodic protection system provided by the invention, the output potential can be automatically adjusted, and the adjusting error is small. Automatic adjustment is realized, so that the cathodic protection at each monitoring point on the whole line pipe meets the standard or most monitoring points meet the standard.

Owner:QINGDAO YAHE SCI & TECH DEV

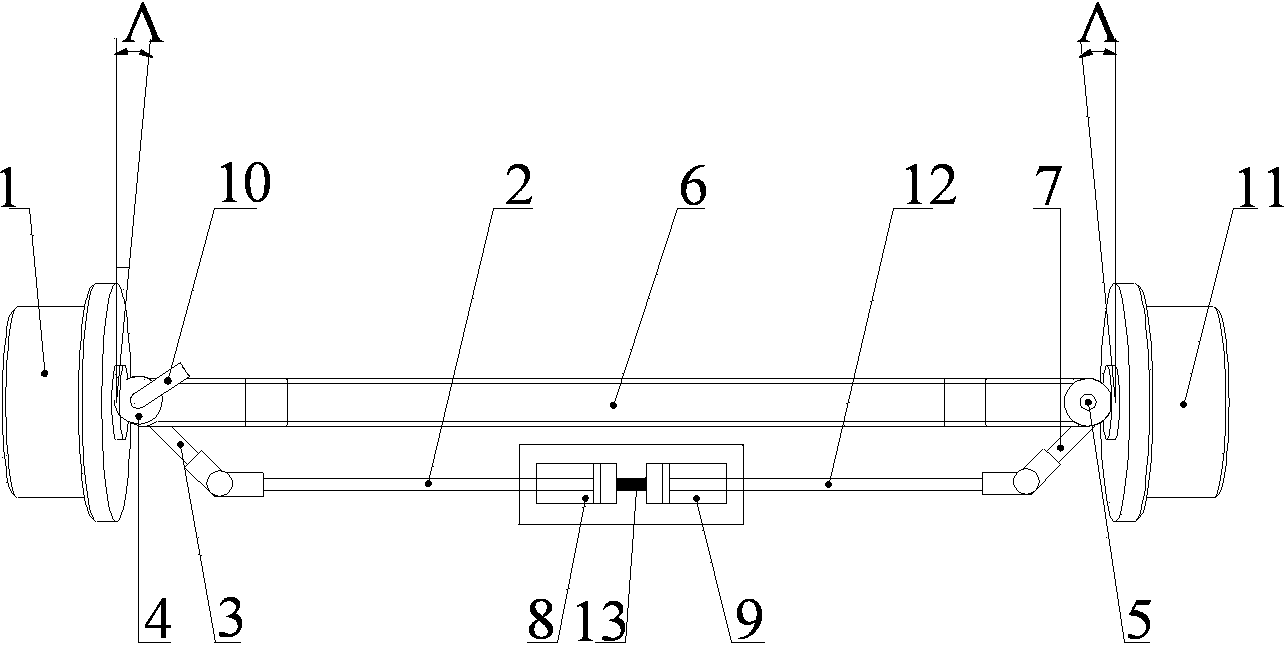

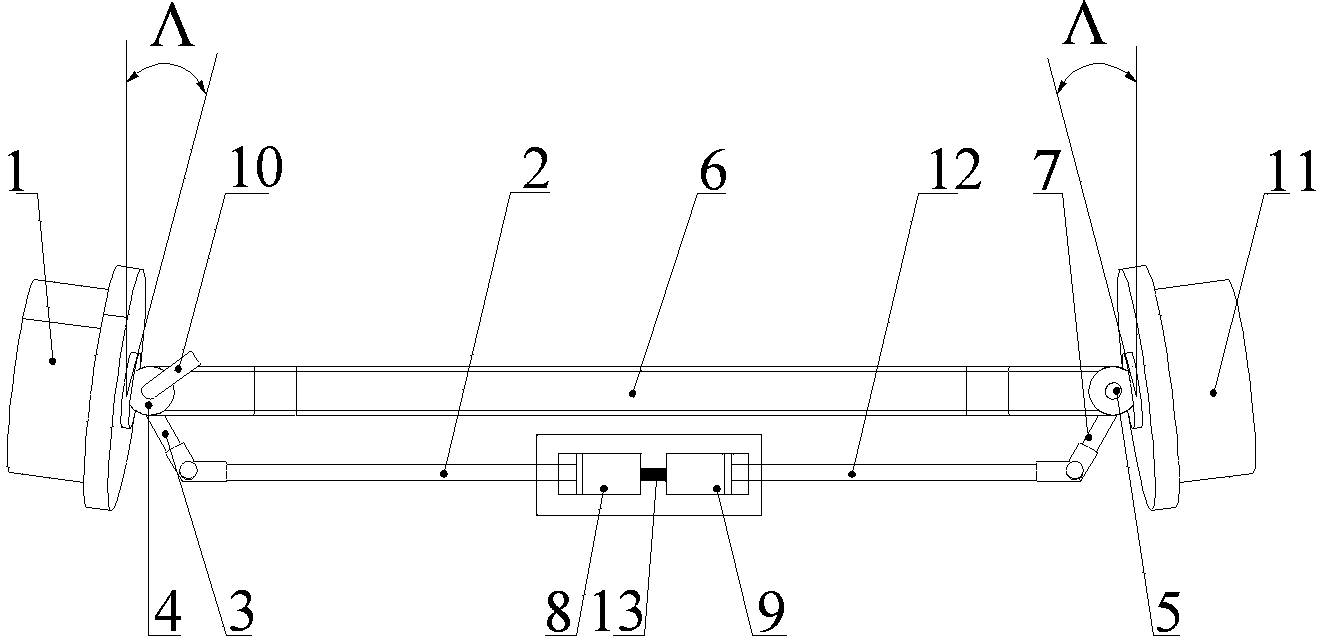

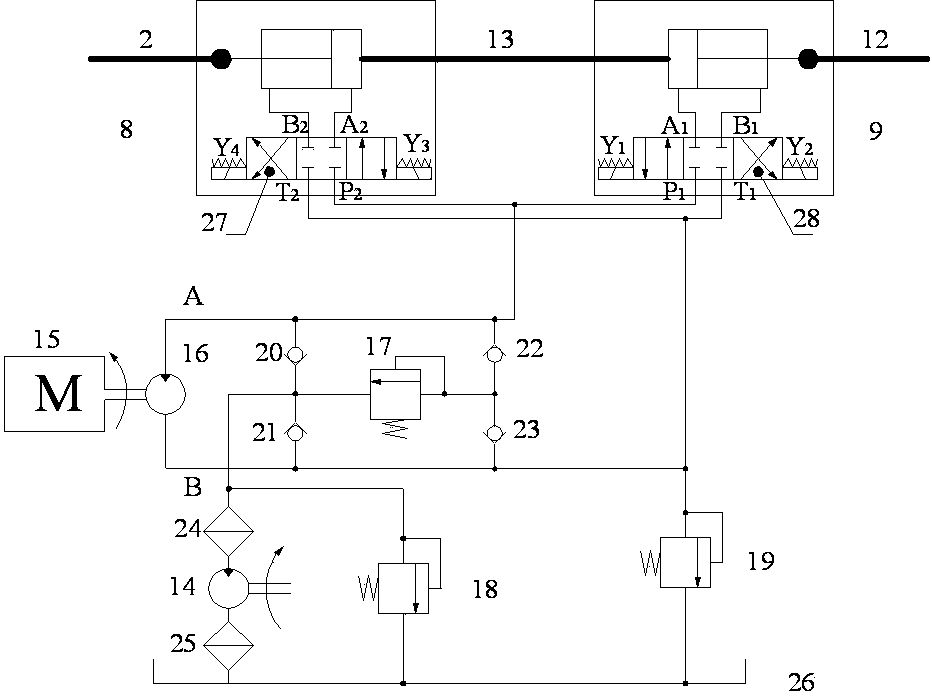

Hydraulic toe-in value adjusting mechanism for steering wheels

ActiveCN104290814AAvoid the pitfalls of length adjustment toe-inReduce adjustment errorSteering partsSteering wheelCamber angle

The invention discloses a hydraulic toe-in value adjusting mechanism for steering wheels. The hydraulic toe-in value adjusting mechanism for the steering wheels comprises a front axle, a transverse draw bar, the left steering wheel, the right steering wheel and a steering wheel toe-in value adjusting mechanism, wherein the adjusting mechanism comprises the transverse draw bar and a hydraulic mechanism; the transverse draw bar comprises a left transverse draw bar body, a right transverse draw bar body, a left electro-hydraulic servo cylinder and a right electro-hydraulic servo cylinder; and the hydraulic mechanism comprises a constant displacement pump, a stepping motor, a variable pump, a first overflow valve, a second overflow valve, a third overflow valve, four one-way valves and an oil tank. In a running process of a vehicle, the lengths of two ends of the transverse draw bar can be automatically adjusted, so that a toe-in value can be adjusted to be matched with a camber angle, the shortcoming that the lengths of two sides of the transverse draw bar are required to be respectively adjusted manually when the vehicle stops so as to adjust the toe-in value is overcome, and adjustment errors caused by artificial reasons are reduced. The length of the transverse draw bar can be accurately controlled by the electro-hydraulic servo cylinders with MR (magnetic resonance) displacement sensors, linear movement accuracy can be controlled to reach 0.1mm, and the toe-in value adjustment accuracy is improved.

Owner:HEFEI UNIV OF TECH

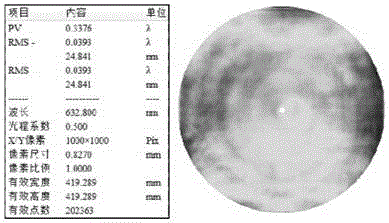

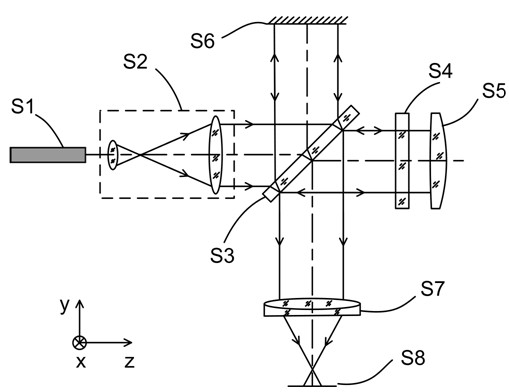

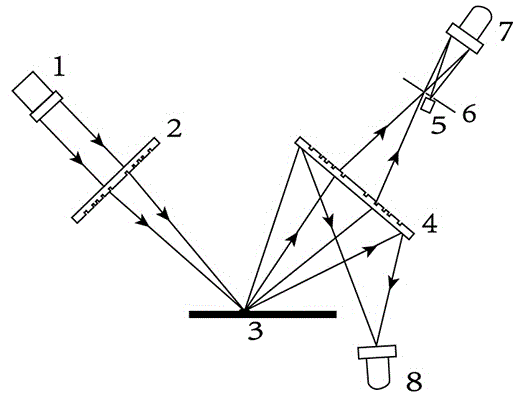

Method for aligning partial compensating lens in aspheric nonzero-digit interference detection

The invention discloses a method for aligning a partial compensating lens in aspheric nonzero-digit interference detection. The aligning device is characterized in that fine light beams emitted by a laser are expanded by a collimating beam expanding system to form parallel broad light beams; after parallel light enters a beam splitting plate plated with a semi-reflective semi-transparent film, one part of incident light is reflected, and the reflected light beam is reflected by a plane reference mirror and then returns to the beam splitting plate again; the other part of incident light is transmitted, and the transmitted light beam spreads forwards, enters an auxiliary aligning panel and then returns; the returned reflection light and the returned transmission light meet at the beam splitting plate to generate interference and form an interference pattern; the interference pattern passes through an imaging system and is imaged at a detector; and the inclination of the aligning panel and the partial compensating lens relative to the incident light is adjusted to enable the detector to obtain a zero-fringe interference pattern; and the inclined alignment of the partial compensating lens is realized by moving the aligning panel. According to the method disclosed by the invention, the problem of aligning error of the partial compensating lens in aspheric nonzero-digit interference detection is solved, and the adjustment error of the detection result caused by mistaken alignment is reduced.

Owner:ZHEJIANG UNIV

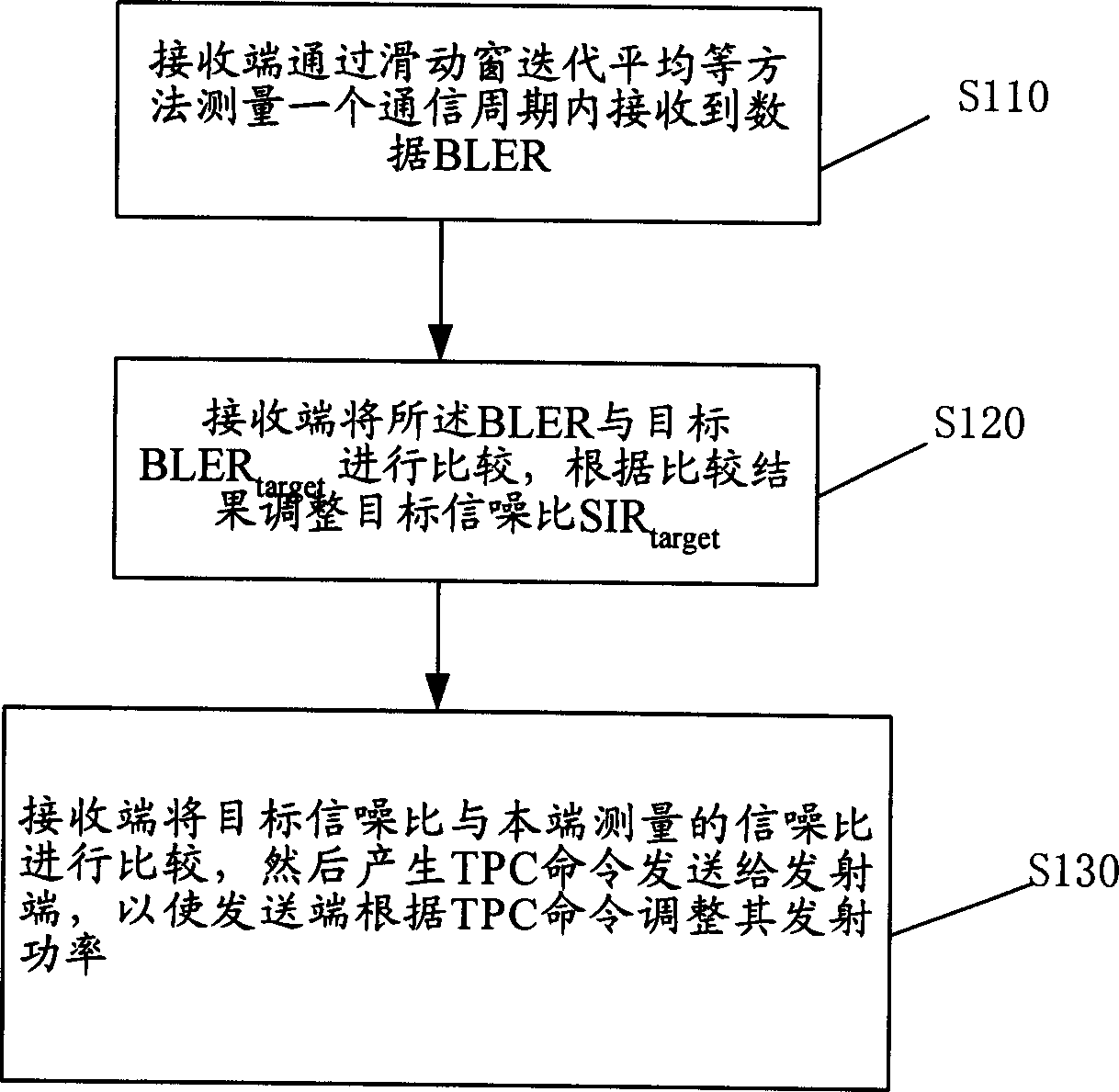

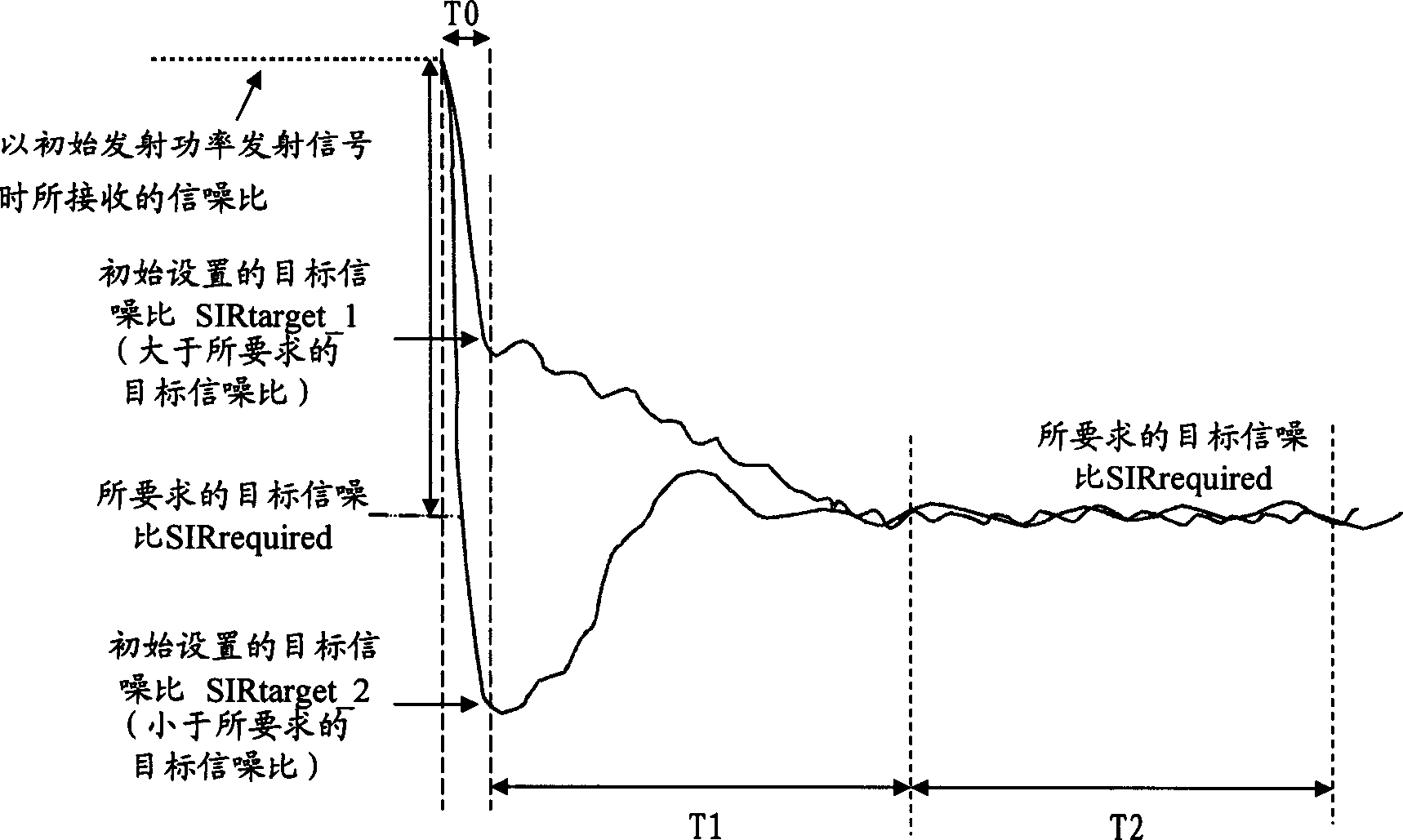

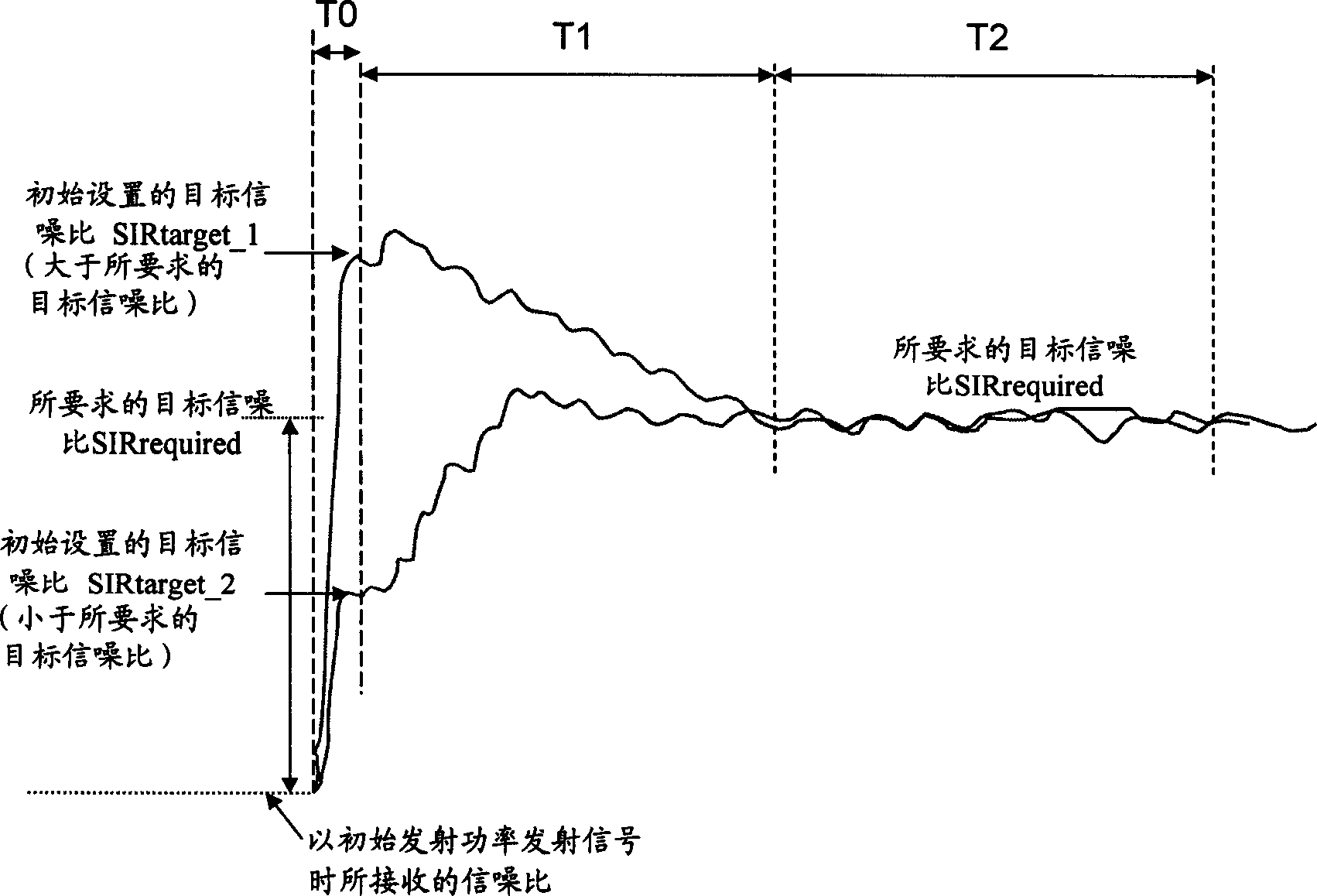

Transmitting power controlling method for realizing target signal noise ratio fast convergence

ActiveCN1773884AShorten the timeGuaranteed received signal qualityTransmission control/equalisingSignal-to-noise ratio (imaging)Target signal

A method for controlling emission power to realize object S ¿C N ratio to be quickly converged includes setting initial valve of step size, receiving data block and storing CRC calibration result, adjusting object S ¿C N ratio as per calibration result i.e. down ¿C adjusting one step size of object S ¿C N ratio if calibration result is correct or otherwise up ¿C adjusting one step size of object S ¿C N ratio, comparing object S ¿C N ratio with measured S ¿C N ratio to generate TPC command being sent to emission end for adjusting its emission power, entering said adjusting step if CRC calibration result is not changed or otherwise ending quick convergence of object S ¿C N ratio.

Owner:DATANG MOBILE COMM EQUIP CO LTD

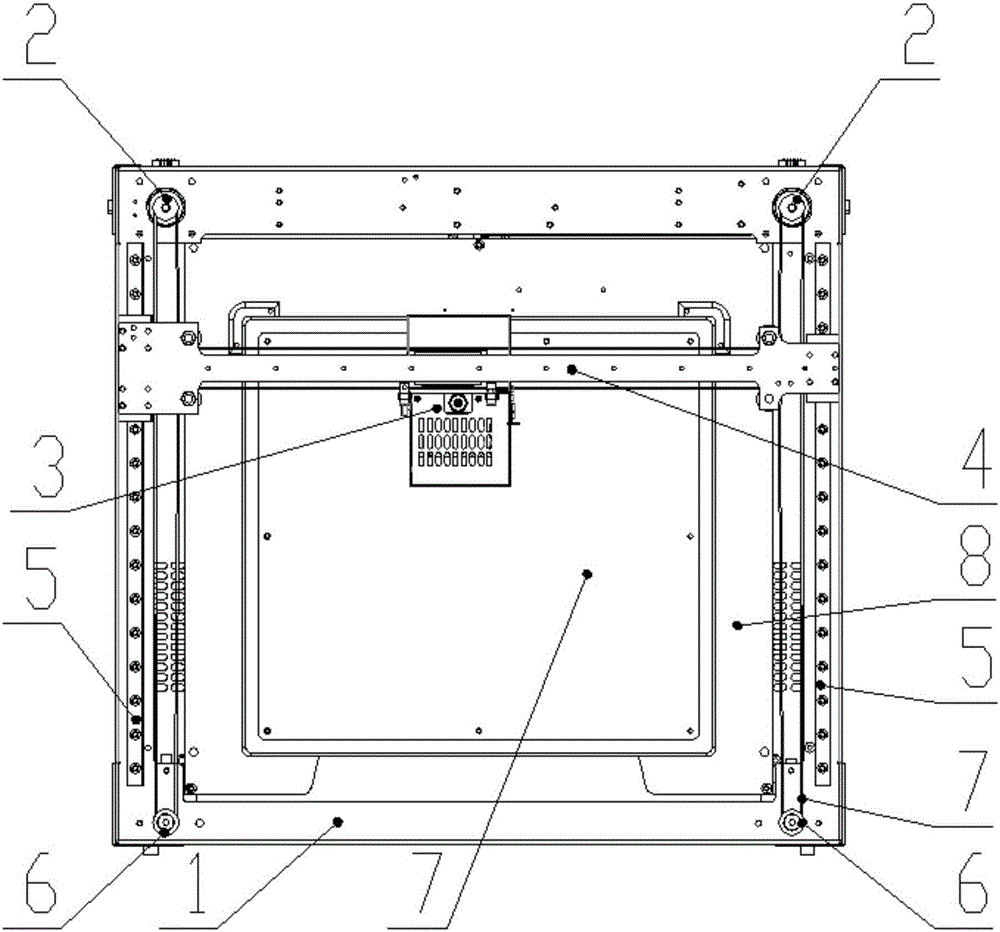

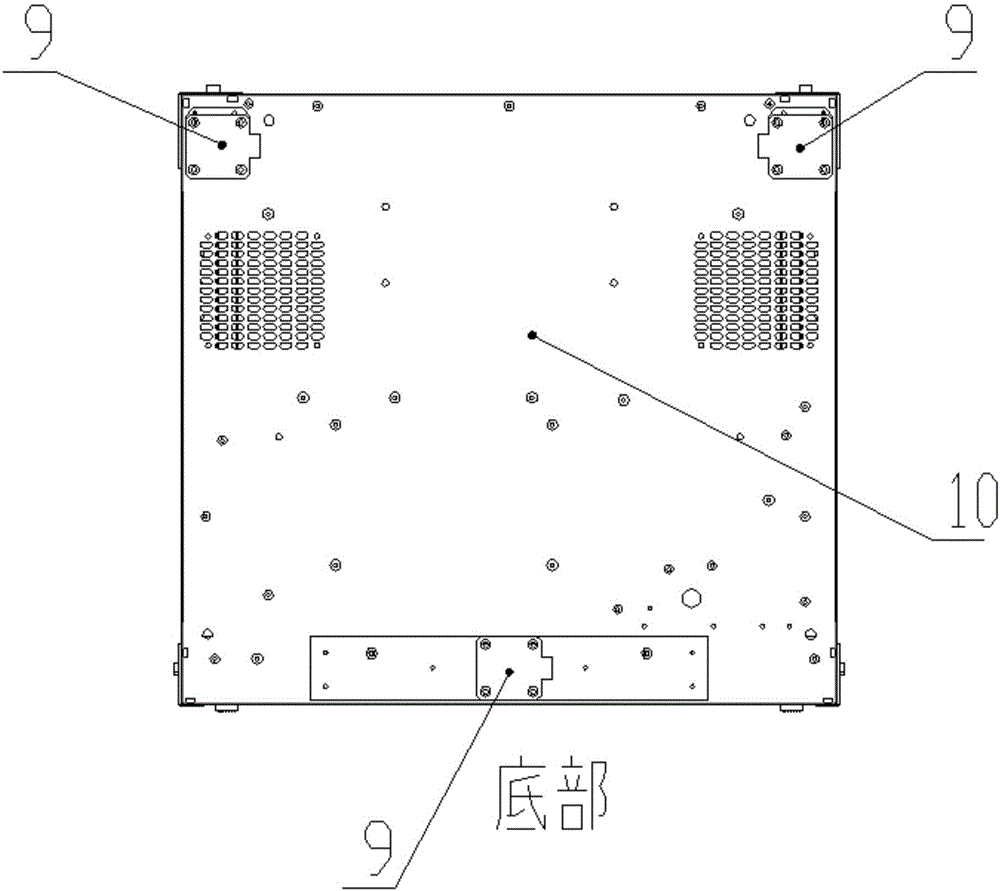

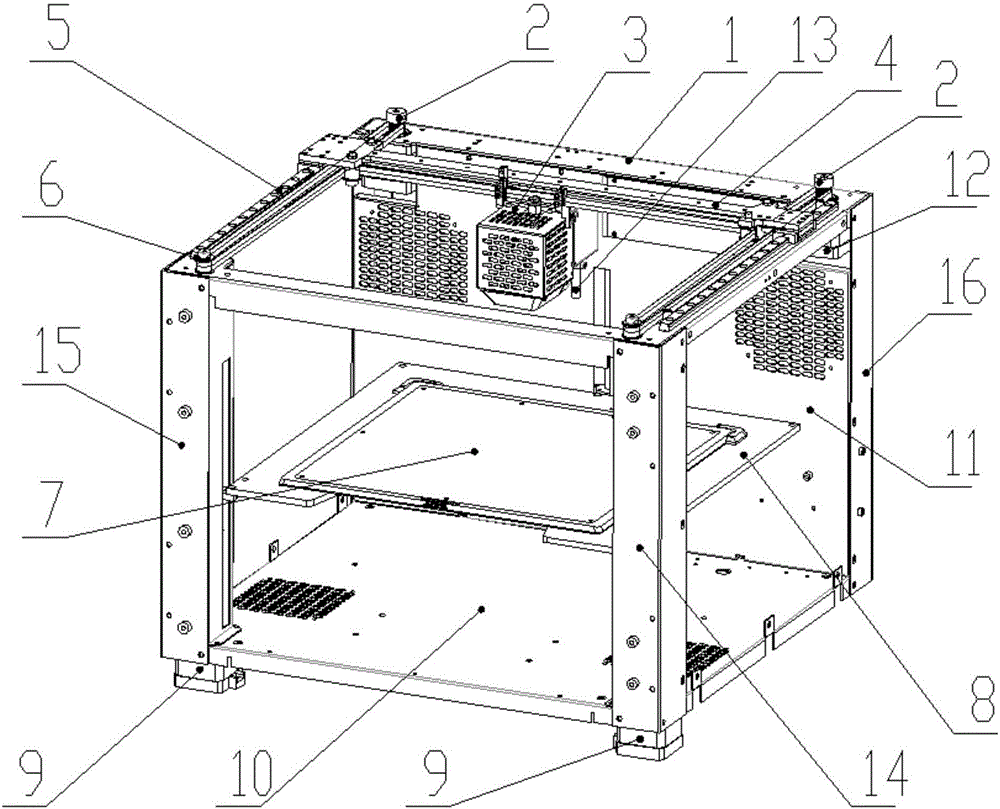

Full-automatic leveling structure for 3D printer

InactiveCN106827540ABest horizontal positionPrecisely adjust the behaviorManufacturing platforms/substratesManufacturing auxillary operations3d printMeasurement point

The invention discloses a fully automatic leveling structure for a 3D printer, which includes a frame, a nozzle and a heated bed plate. The frame is provided with an XY platform, and the XY platform is provided with an active synchronous wheel, a passive synchronous wheel, a guide rail and an X-axis fixed plate. The two ends of the lower part of the X-axis fixed plate are provided with guide rail grooves, the guide rail grooves are erected on the guide rails, the active synchronous wheel and the passive synchronous wheel are connected with a belt, and the belt drives the X-axis fixed plate to move back and forth on the Y-axis. The beneficial effects of the present invention are : The automatic leveling system can complete the automatic leveling of the large-format 3D printer printing platform. This method completes the distance measurement through the distance sensor, measures three points, compares the data, and uses the distance between the first support column and the second support column. The measurement distance between the measurement points is used as the reference to adjust, the measurement points are few, and the speed is fast.

Owner:深圳市极光创新科技股份有限公司

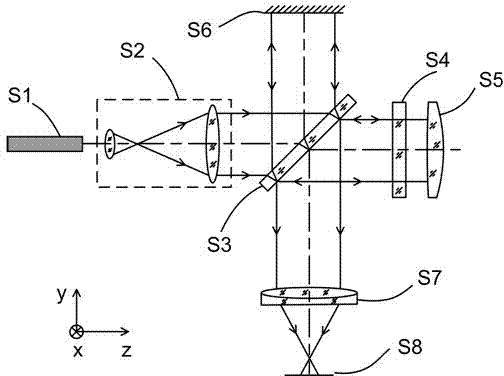

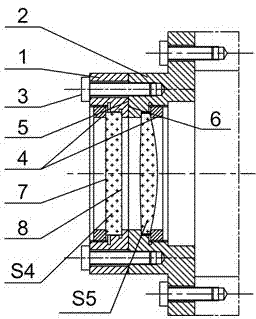

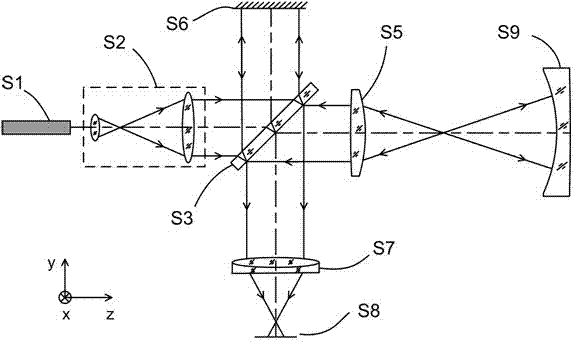

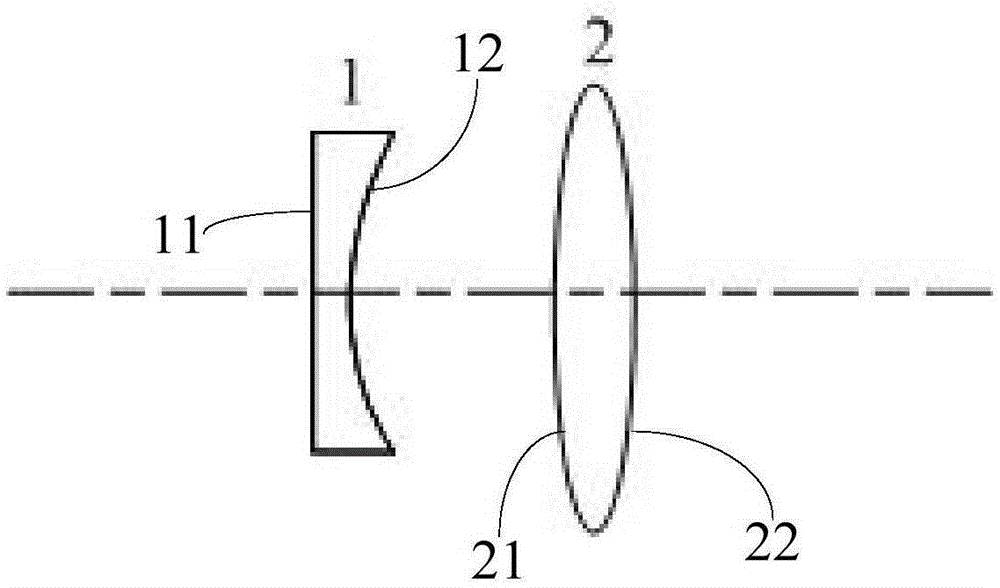

Detection device and detection method for measuring long-focal-length lens transmission wavefront by computer-generated holography

ActiveCN106441816ASimple structureEasy to adjustRefractive power measurementOptical pathLight Testing

The invention discloses a detection device and detection method for measuring long-focal-length lens transmission wavefront by a computer-generated holography, and belongs to the technical field of optical measurement. The detection device is mainly characterized in that an interferometer, a measured long-focal-length lens and a Fresnel wave zone plate form a Fizeau interference optical path; when collimated parallel light output by the interferometer passes through a standard plane mirror, one beam is reflected by a reference surface of the standard plane mirror to form a standard reference light beam; the other beam penetrates through the measured long-focal-length lens to be transmitted and is reflected through the wave zone plate to return along the original path for forming a test light beam; the test light beam and the standard reference light beam generate interference; the tested long-focal-length lens is regulated, so that interferometric fringes are minimum; the transmission wavefront of the tested long focal-length lens can be obtained through measurement. The method and the device provided by the invention are applicable to the detection of the long-focal-length lens transmission wavefront.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

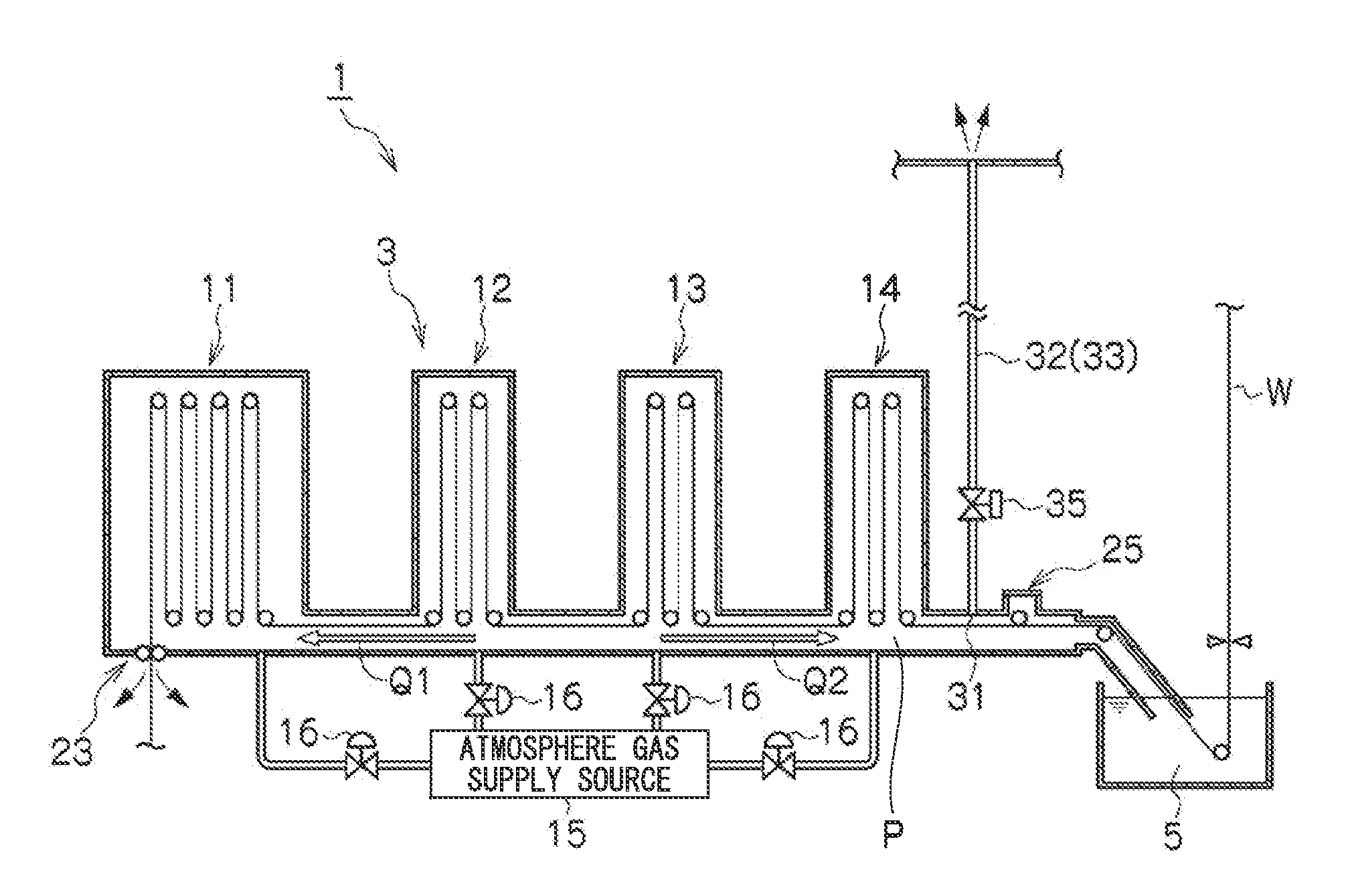

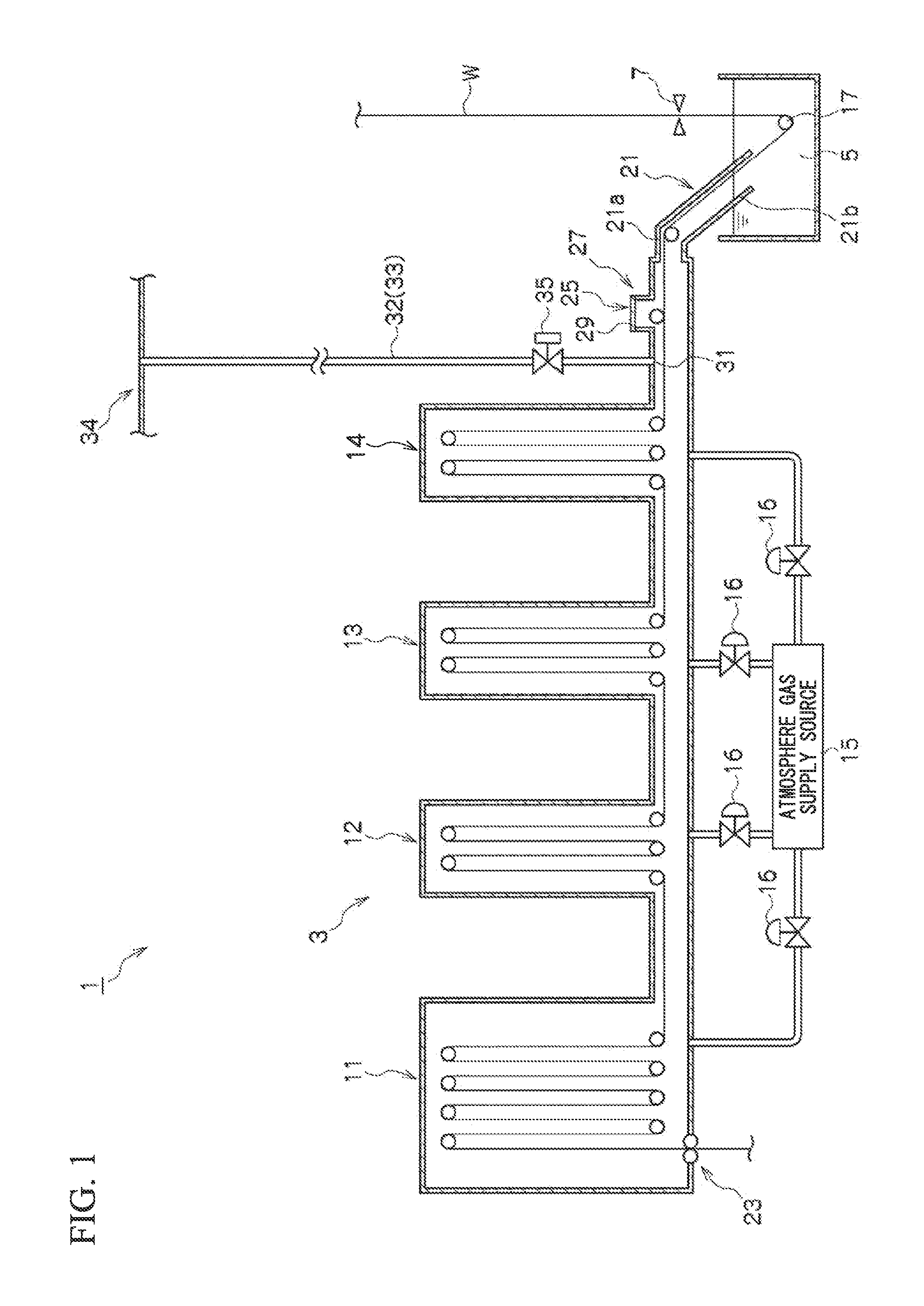

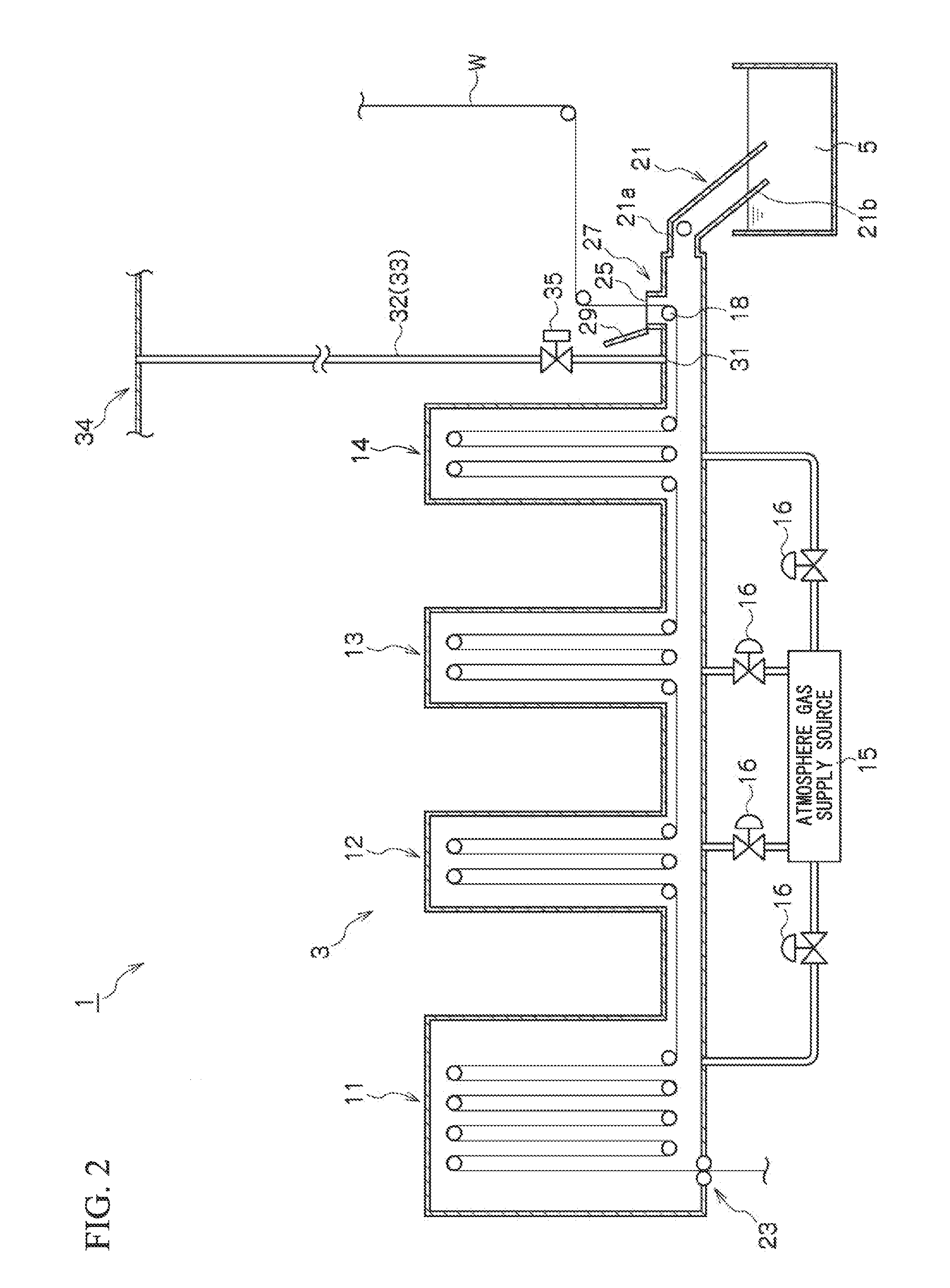

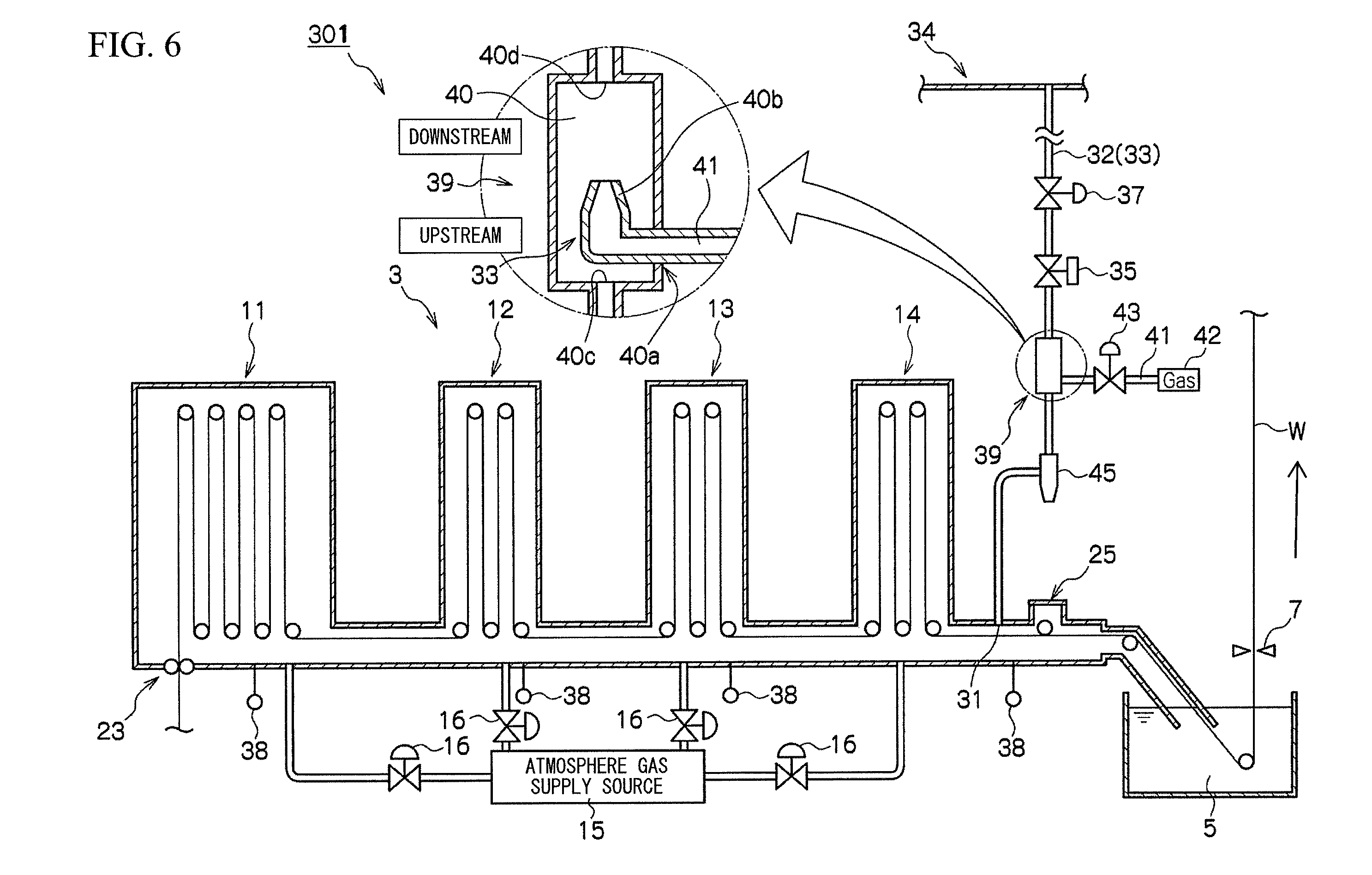

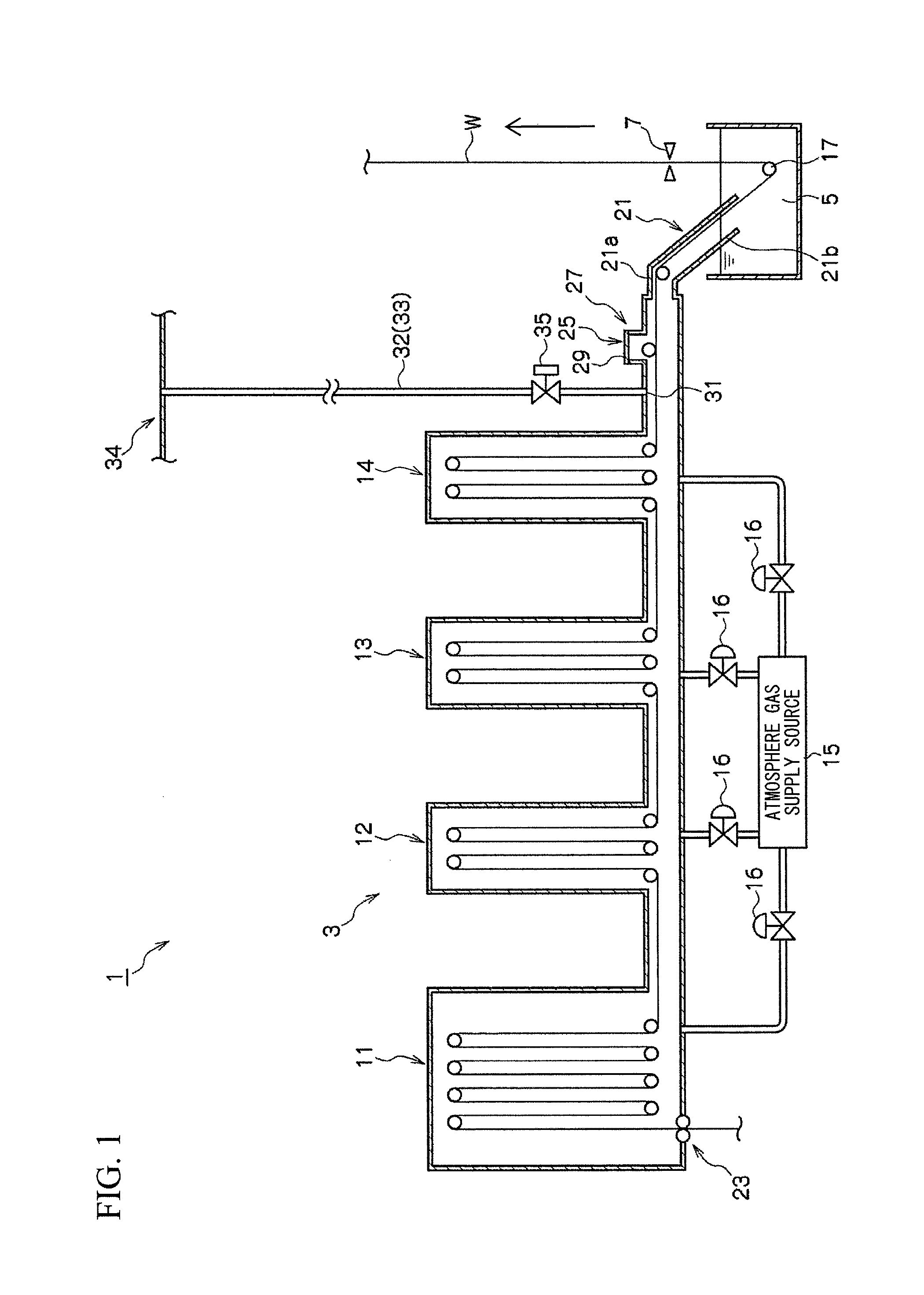

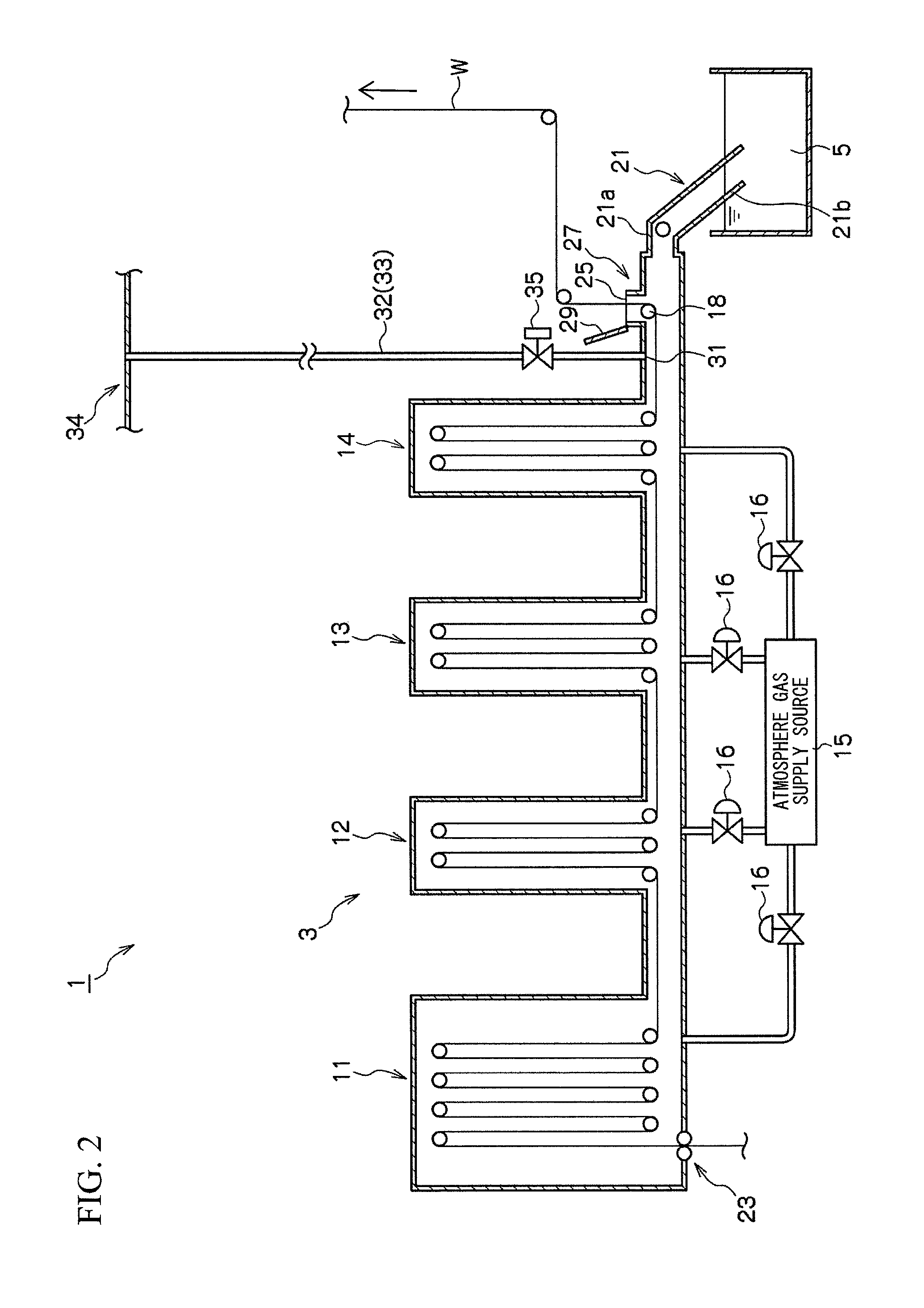

Dual-purpose facility of continuous hot-dip coating and continuous annealing

ActiveUS20120180721A1Conducive to simplificationStable pressure balanceHot-dipping/immersion processesLiquid surface applicatorsProduction lineMetallurgy

A dual-purpose facility of continuous hot-dip coating and continuous annealing is configured so as to be switched between a continuous hot-dip coated material production line and a continuous annealed material production line, and includes a gas discharge path that discharges atmosphere gas in an annealing furnace from a gas discharge port provided in an outlet side of the annealing furnace out of the annealing furnace and a path opening and closing unit for opening and closing the gas discharge path. The path opening and closing unit opens the gas discharge path when the dual-purpose facility is used as the continuous hot-dip coated material production line and closes the gas discharge path when the dual-purpose facility is used as the continuous annealed material production line.

Owner:NIPPON STEEL CORP

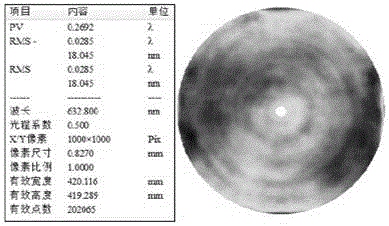

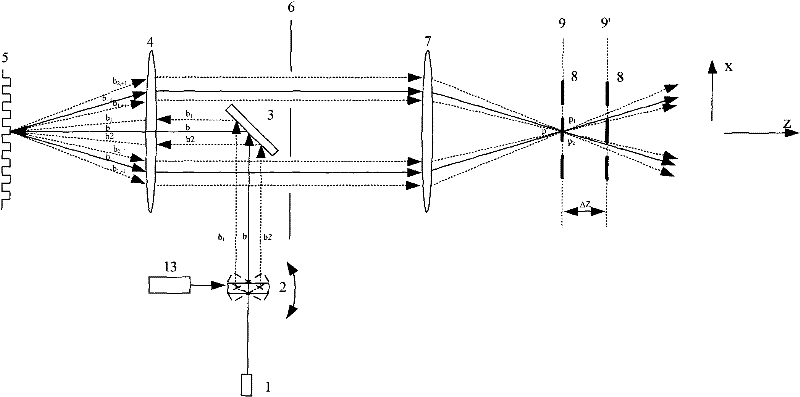

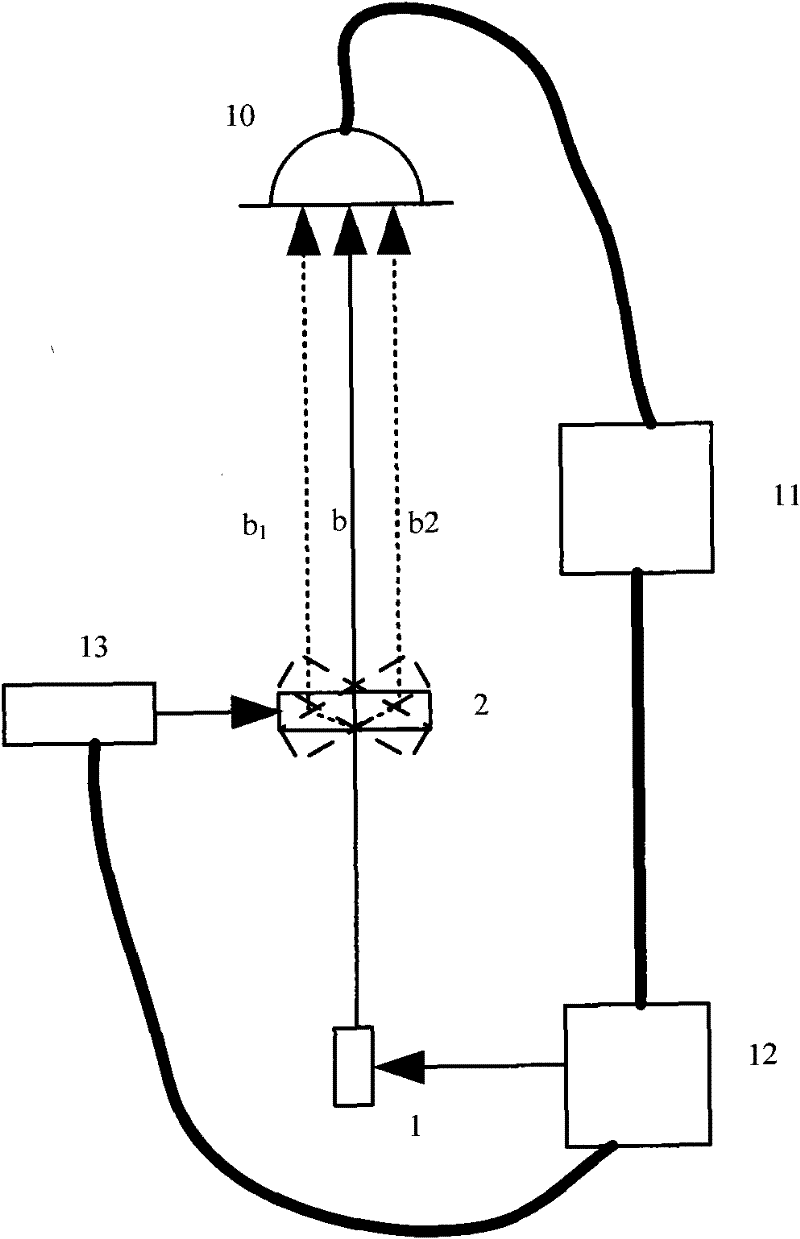

Aligning device and aligning method for partial compensating lens during detection of aspheric surface and nonzero digit interference

InactiveCN102591031ASolve the tiltSolve the errorUsing optical meansOptical elementsLight beamOptoelectronics

The invention discloses an aligning device and an aligning method for a partial compensating lens during detection of aspheric surface and nonzero digit interference. The aligning device is characterized in that a fine light beam emitted by a laser is expanded by a collimating beam expanding system to form parallel broad light beams; after parallel light enters a beam splitter on which a part reflective semitransparent film is plated, one part of incident light is reflected and the reflected light beam is reflected by a plane reference mirror and then returns to the beam splitter again; the other part of incident light is transmitted and the transmitted light beam forwards spreads and enters an auxiliary aligning panel and then returns; the returned reflection light and the returned transmission light meet at the beam splitter to generate interference and form an interference pattern; the interference pattern passes through an imaging system and images at a detector; and the inclination of the aligning panel and the partial compensating lens, which are relative to the incident light, is adjusted, so that the detector obtains a zero-fringe interference pattern; and the inclined alignment of the partial compensating lens is realized by moving the aligning panel. According to the aligning device and the aligning method disclosed by the invention, the problem of aligning error of the partial compensating lens during detection of the aspheric surface and nonzero digit interference is solved and the adjustment error of the detection result caused by mistaken alignment is reduced.

Owner:ZHEJIANG UNIV

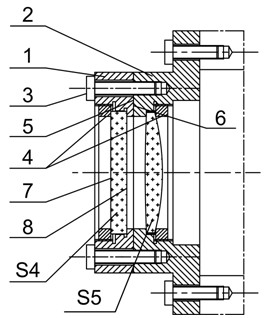

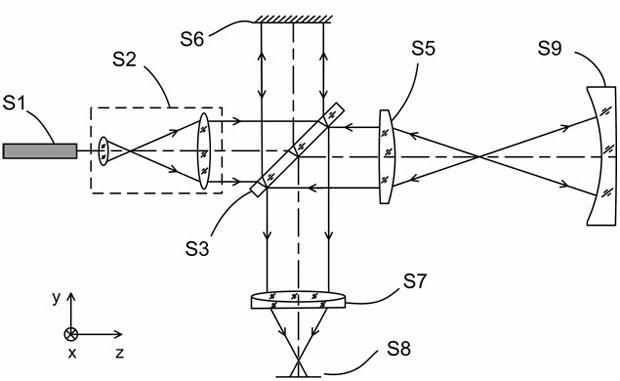

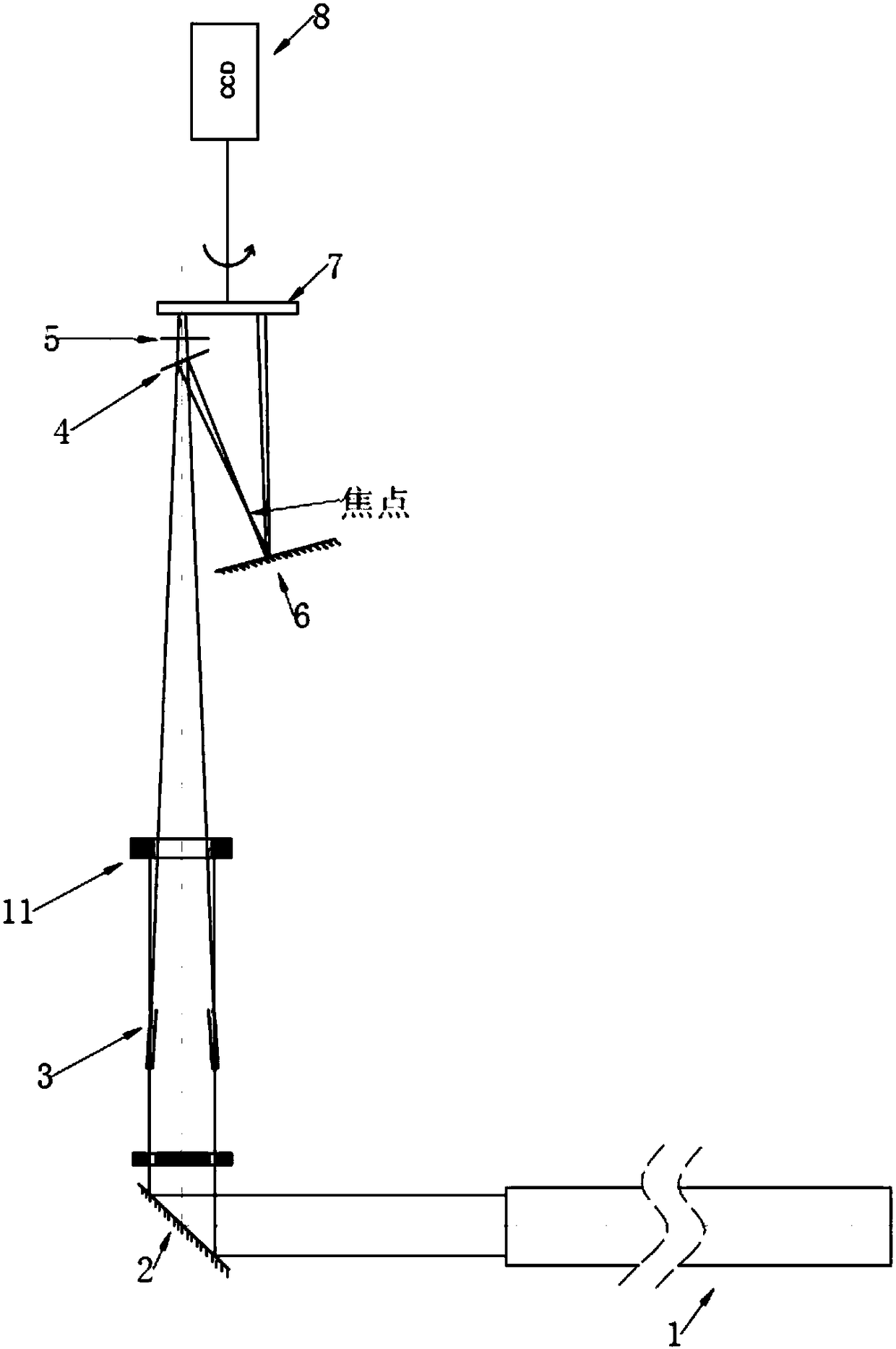

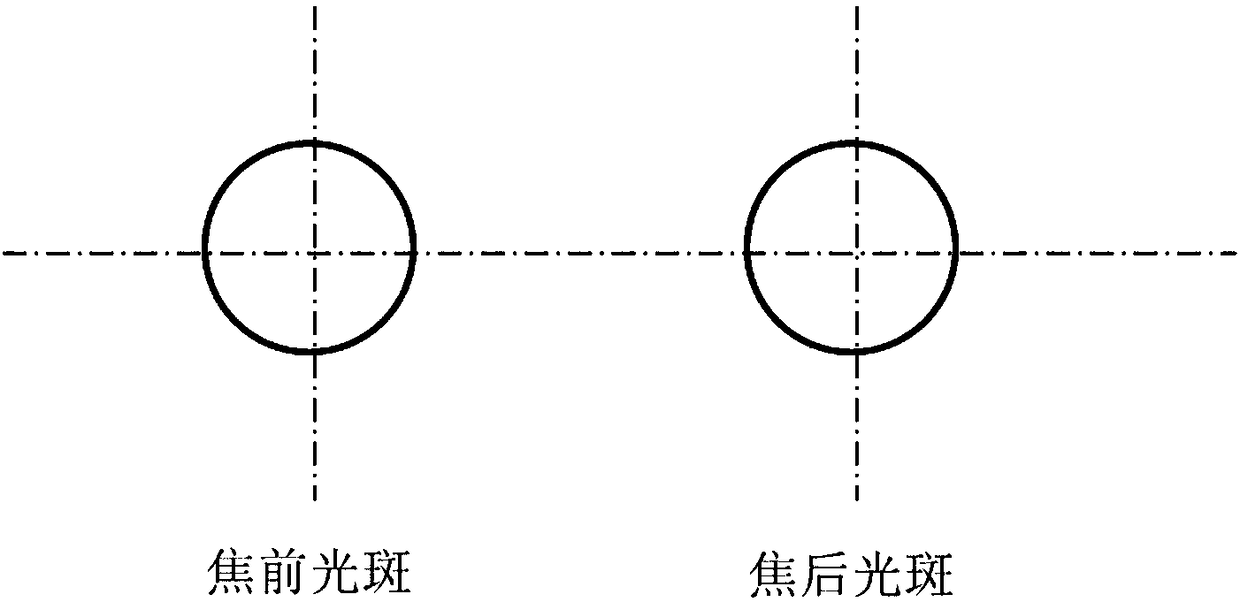

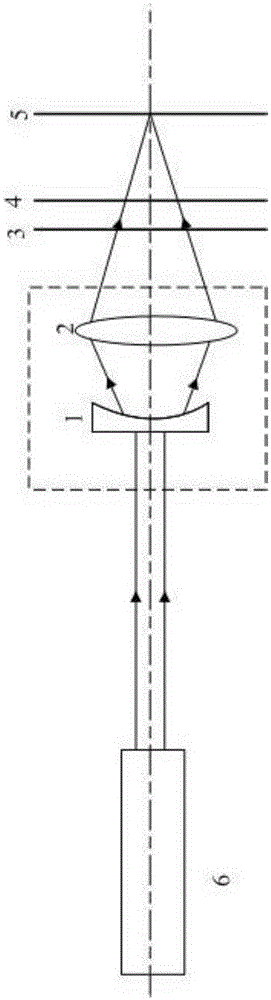

X-ray focus lens vertical installation and adjustment system and method

PendingCN108375453AQuick SetupPrecise adjustmentStatic/dynamic balance measurementBeam deviation/focusing by electric/magnetic meansMicrometerX-ray

The invention relates to an X-ray focus lens vertical installation and adjustment system and method, which solves the problems that the gravity introduced in the assembling process of a focus lens tube influences a facial form and the assembling precision is relatively low. The X-ray focus lens vertical installation and adjustment system comprises a parallel light tube, a focus lens tube, a focuslens installation and adjustmentassembling system, a semitransparent semi-reflective mirror, a reflection mirror, a receiving screen, a CCD camera and a computer; the focus lens installation and adjustmentassembling system comprises a fixed disc, a micrometer head, a suspension rope and a pulley, the pulley is fixedly arranged on the fixed disc, one end of the suspension rope is connected with themicrometer head, and the other end is connected with the focus lens tube; and the outgoing light of the parallel light tube perpendicularly enters the focus lens tube, the outgoing light of the focuslens tube is divided into two beams by virtue of the semitransparent semi-reflective mirror, one beam directly enters the receiving screen, the other beam is reflected by the reflection mirror to receiving the screen, the two beams of light form the centroid of focal spot in front of and behind a focus, and the CCD camera records and transfers the centroid of focal spot to the computer. The invention also provides an installation and adjustmentassembling method based on the system.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

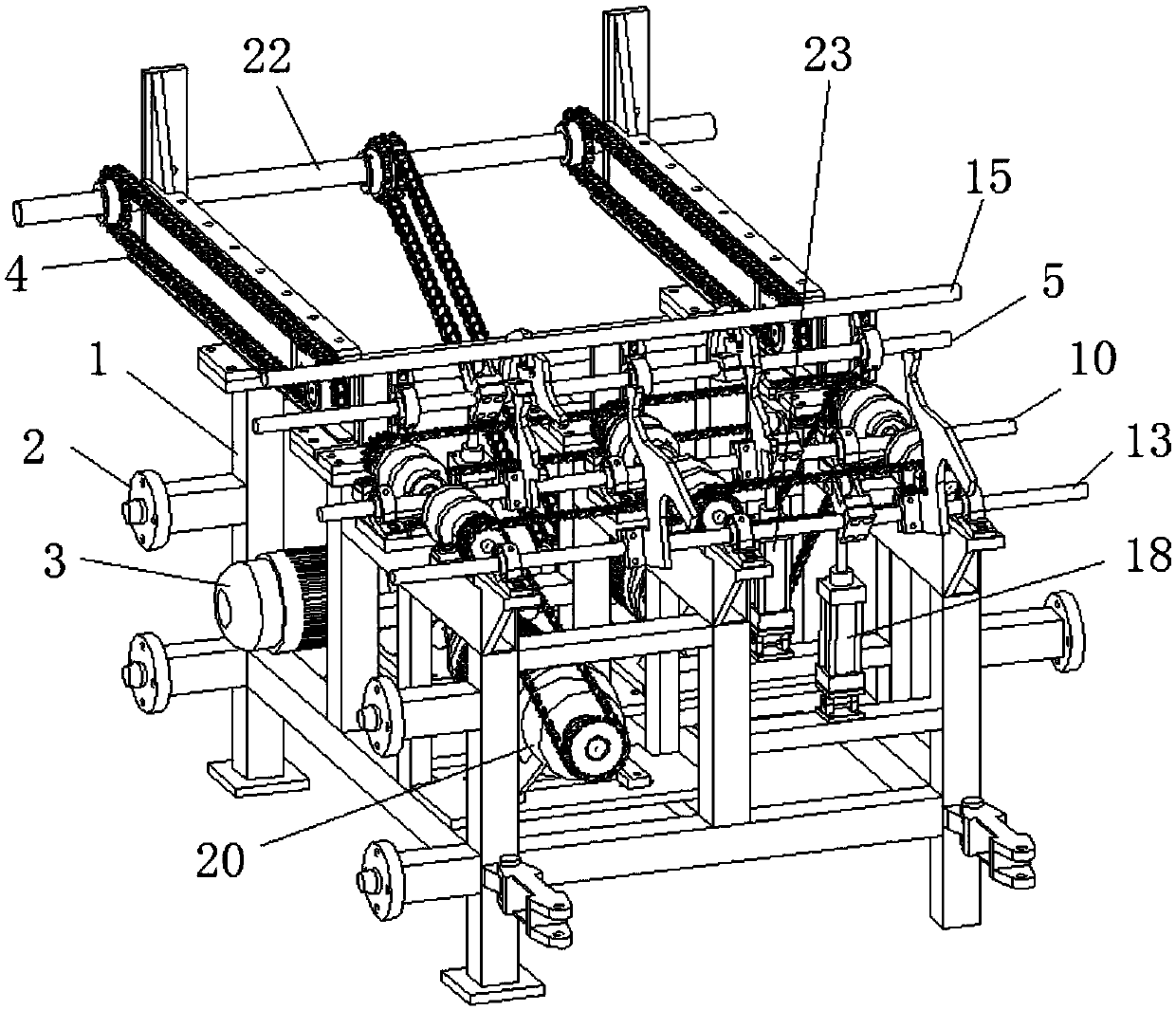

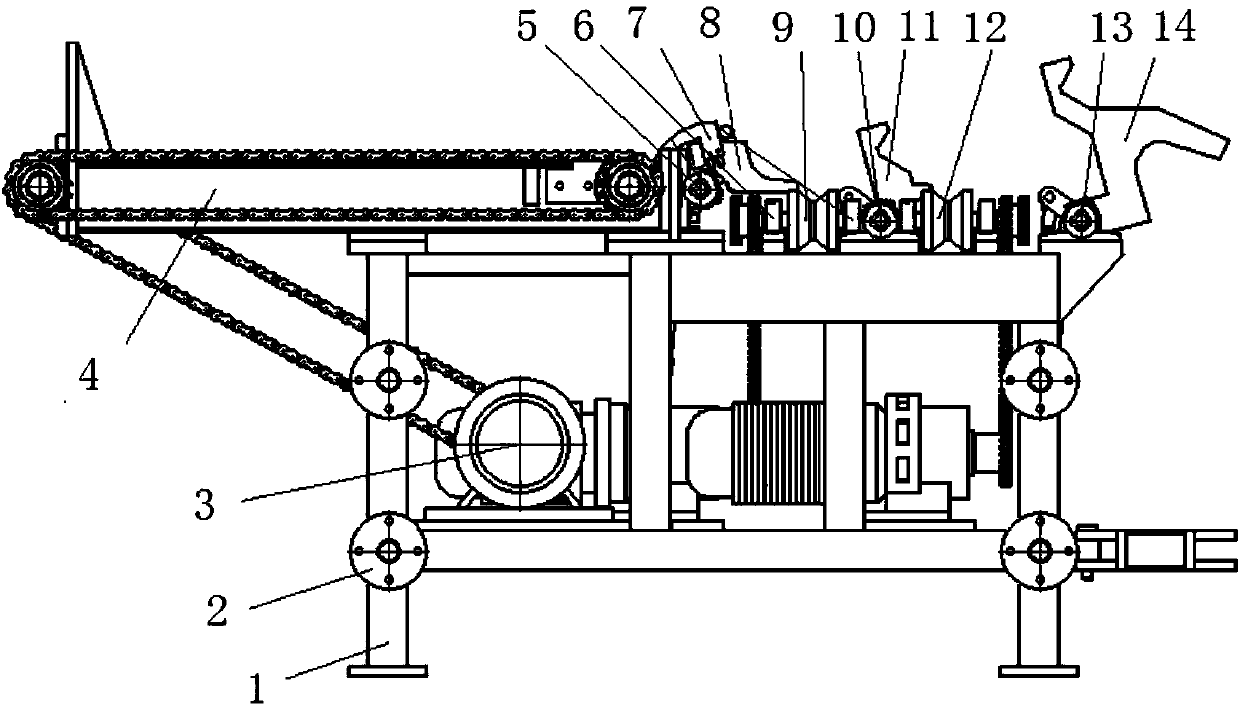

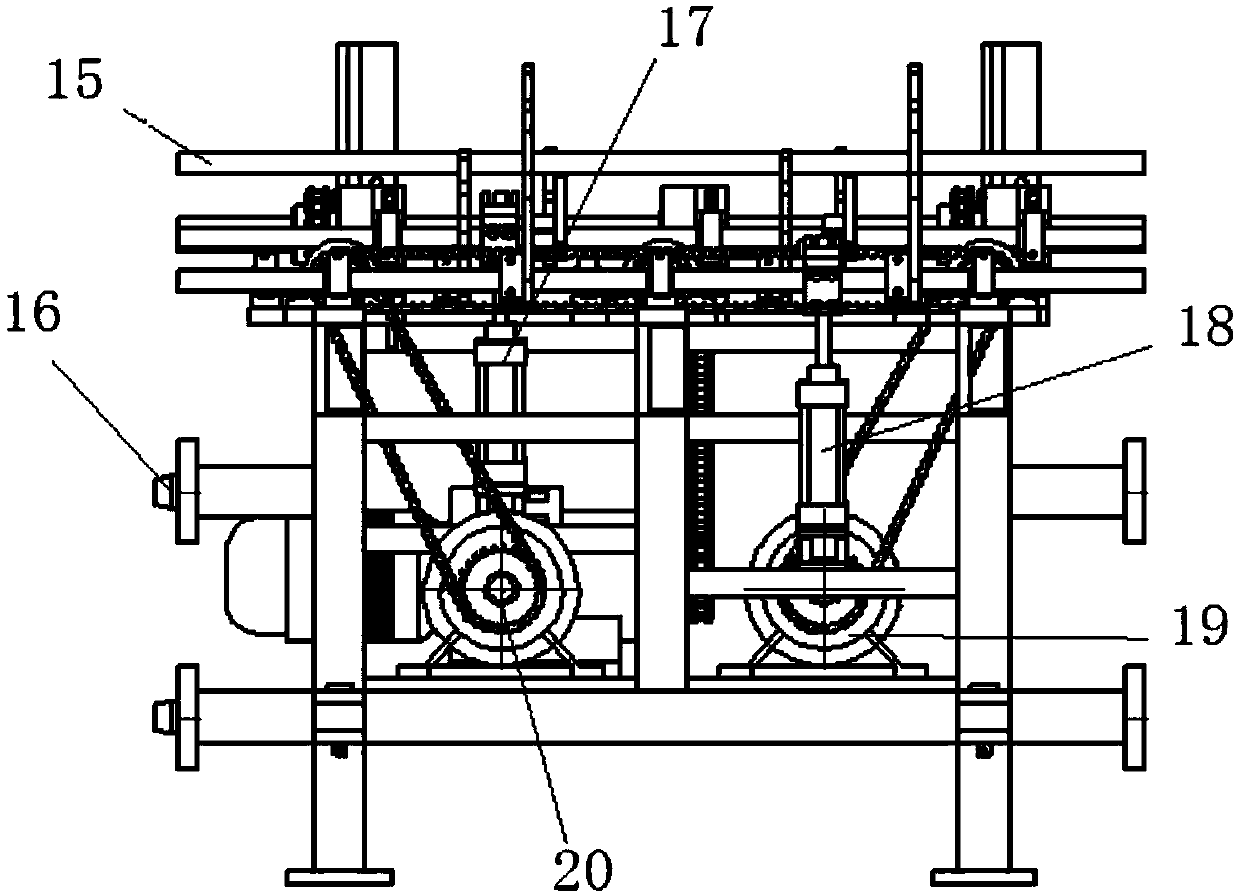

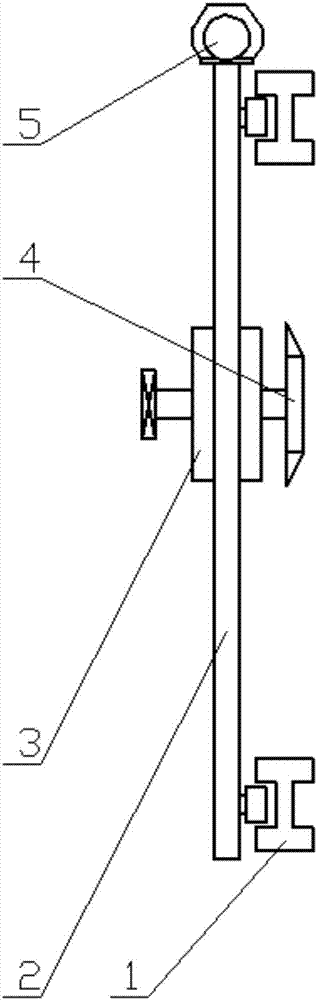

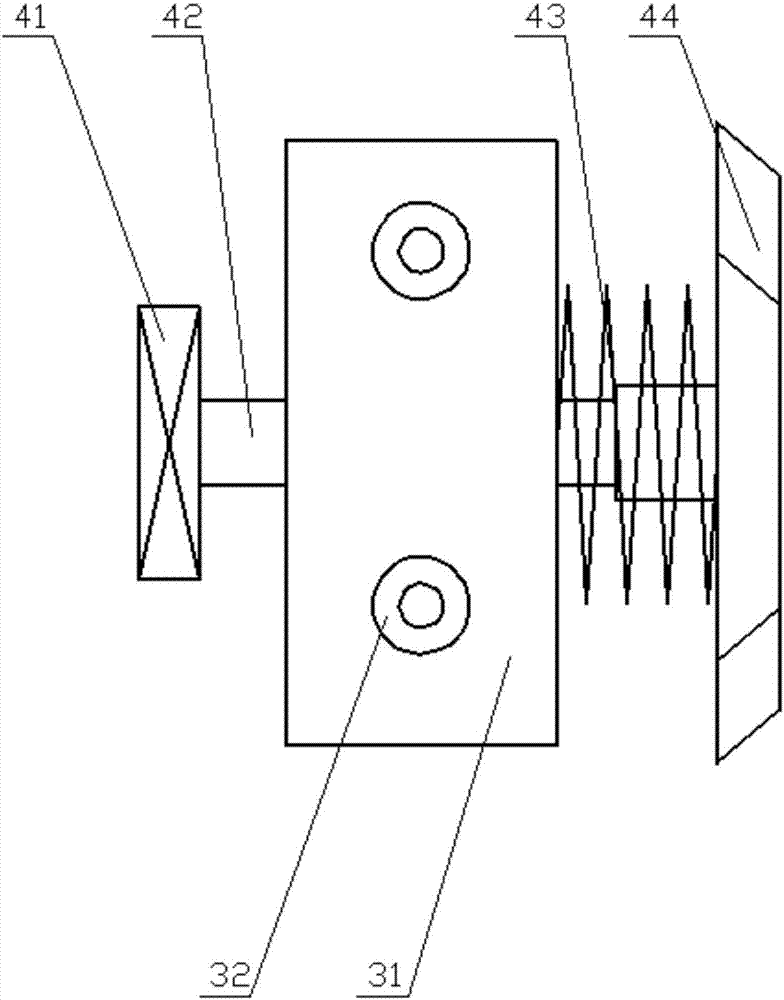

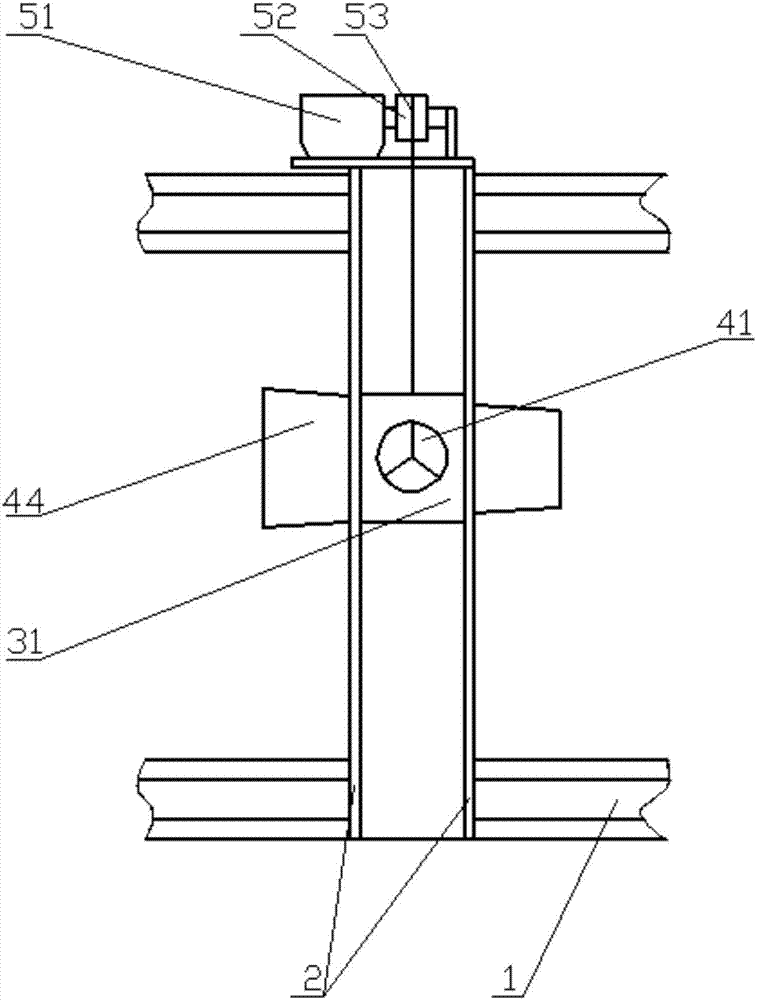

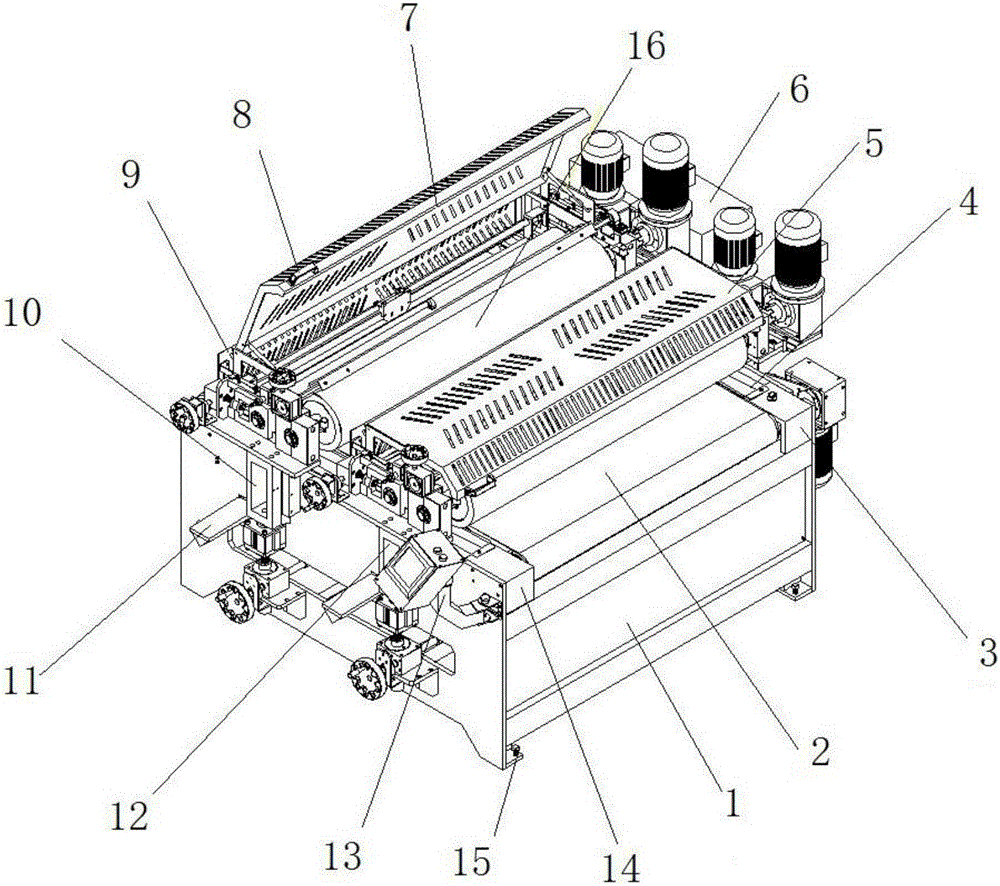

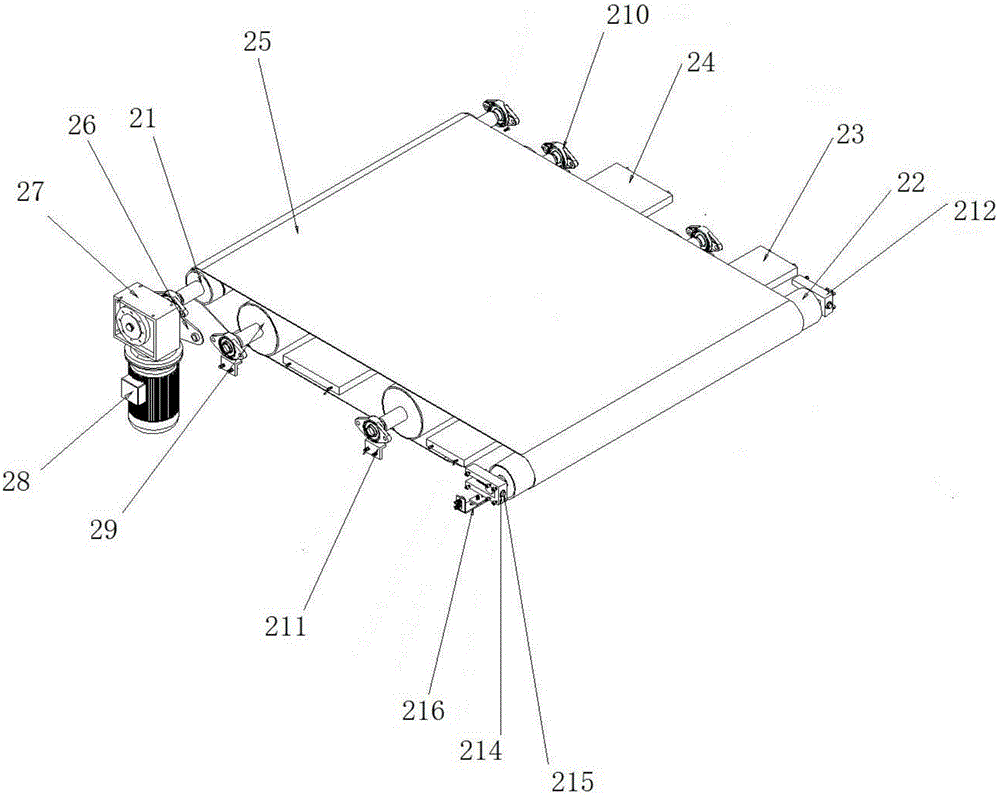

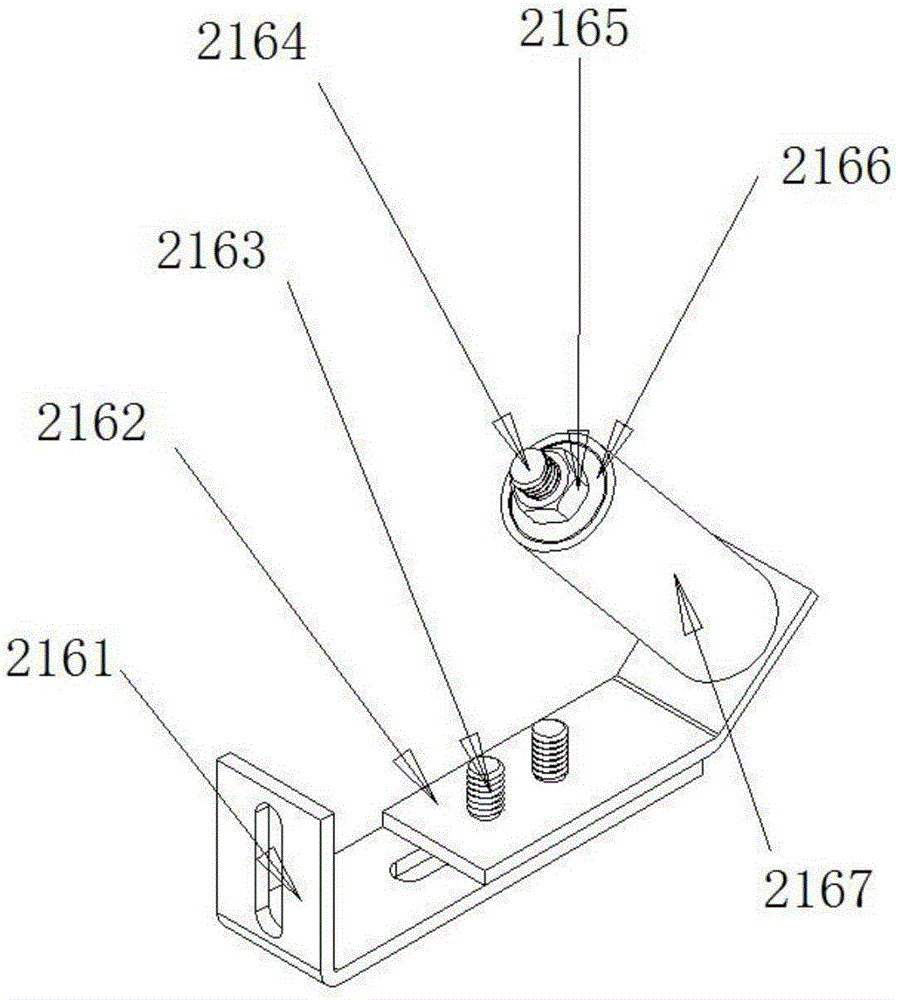

Modular arranging and conveying device of reinforcing steel bar end processing production line

PendingCN107651429ARealize isolated deliveryHigh degree of mechanical automationConveyor partsProduction lineRebar

The invention discloses a modular arranging and conveying device of a reinforcing steel bar end processing production line, belongs to the technical field of reinforcing steel bar processing equipment, and is used for arrangement and conveyance of ribbed reinforcing steel bar end processing production lines. According to the technical scheme, the modular arranging and conveying device comprises one or more standard arranging and conveying modules; each standard arranging and conveying module comprises a rack, a reinforcing steel bar storing and dispersing mechanism, a single reinforcing steelbar taking-out and turning-over mechanism, a front roller conveying mechanism, an inter-station turning-over and shifting mechanism, a back roller conveying mechanism and a discharging and turning-over mechanism, and the mechanisms are sequentially mounted on the rack; and when the standard arranging and conveying modules are connected, the mechanisms are correspondingly connected. With the modular arranging and conveying device, field operations such as storage, automatic dispersion, single separation, inter-station conveyance, collection after processing and the like of multiple reinforcingsteel bars can be realized, the device can be matched with different reinforcing steel bar end processing devices, different connection technology requirements can be met, and the mechanical and automatic degree and the processing quality of the processing production line can be improved.

Owner:HEBEI YIDA REINFORCING BAR CONNECTING TECH

Simple concrete wall surface trowelling machine

InactiveCN107143115AImprove uniformityImprove smoothnessBuilding constructionsEngineeringUltimate tensile strength

The invention discloses a simple concrete wall surface trowelling machine comprising the following structures: a transverse track; a vertical track capable of sliding left and right in the transverse track; a mobile rack including a rack body and a plurality of first roller wheels, wherein the plurality of first roller wheels are respectively arranged on two sides of the rack body, and the first roller wheels can reciprocate and elevate in the vertical track; a trowelling device comprising a trowelling plate and a push mechanism, wherein the push mechanism is arranged on the rack body, the trowelling plate is arranged in the front end of the push mechanism, and the push mechanism can drive the trowelling plate to move back and forth; a lifting device arranged on the top of the vertical track, and the lifting device can drive the mobile rack to reciprocate and elevate in the vertical track. The lifting device can drive the trowelling device to reciprocate and elevate on the wall surface, thus trowelling the wall surface, and reducing the personnel working intensity; the trowelling device can move left and right along the vertical track, thus improving the wall surface evenness and smoothness.

Owner:防城港市泽农工程设计活动有限公司

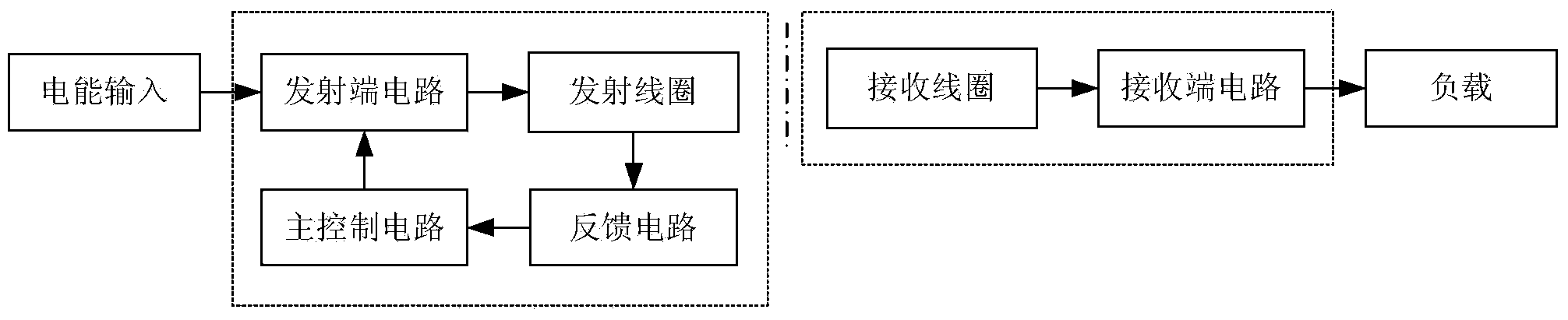

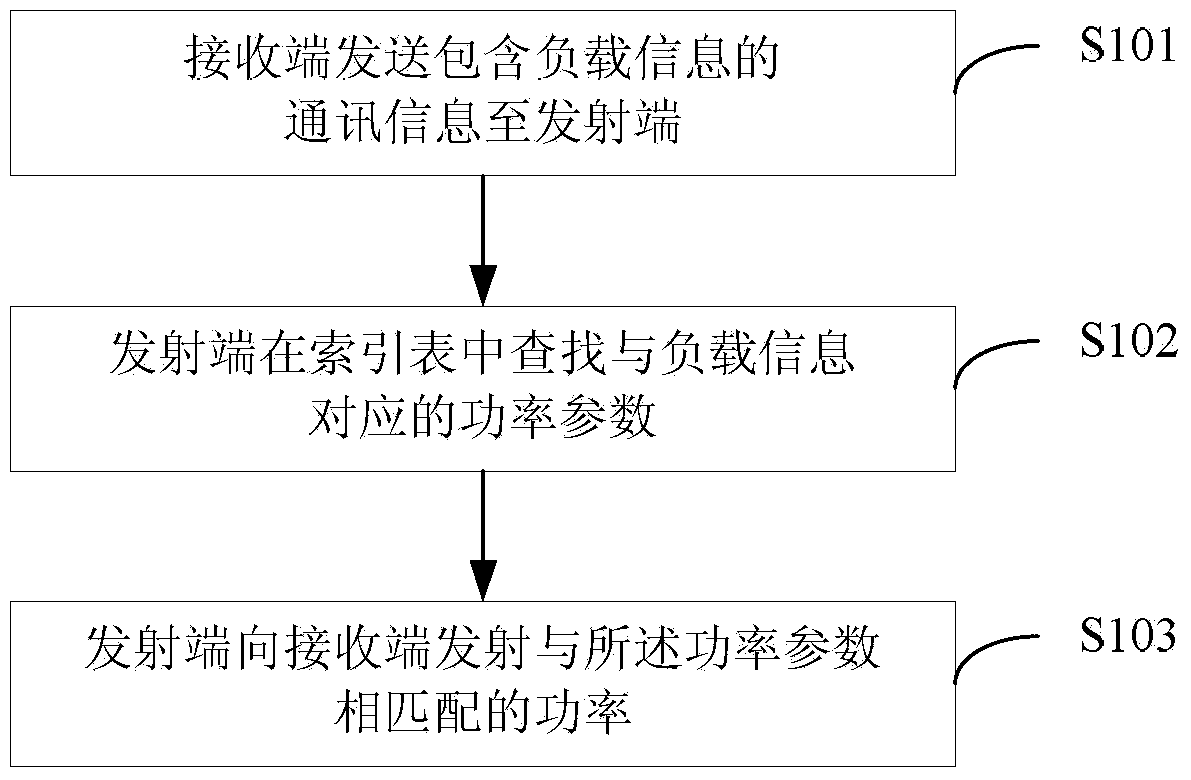

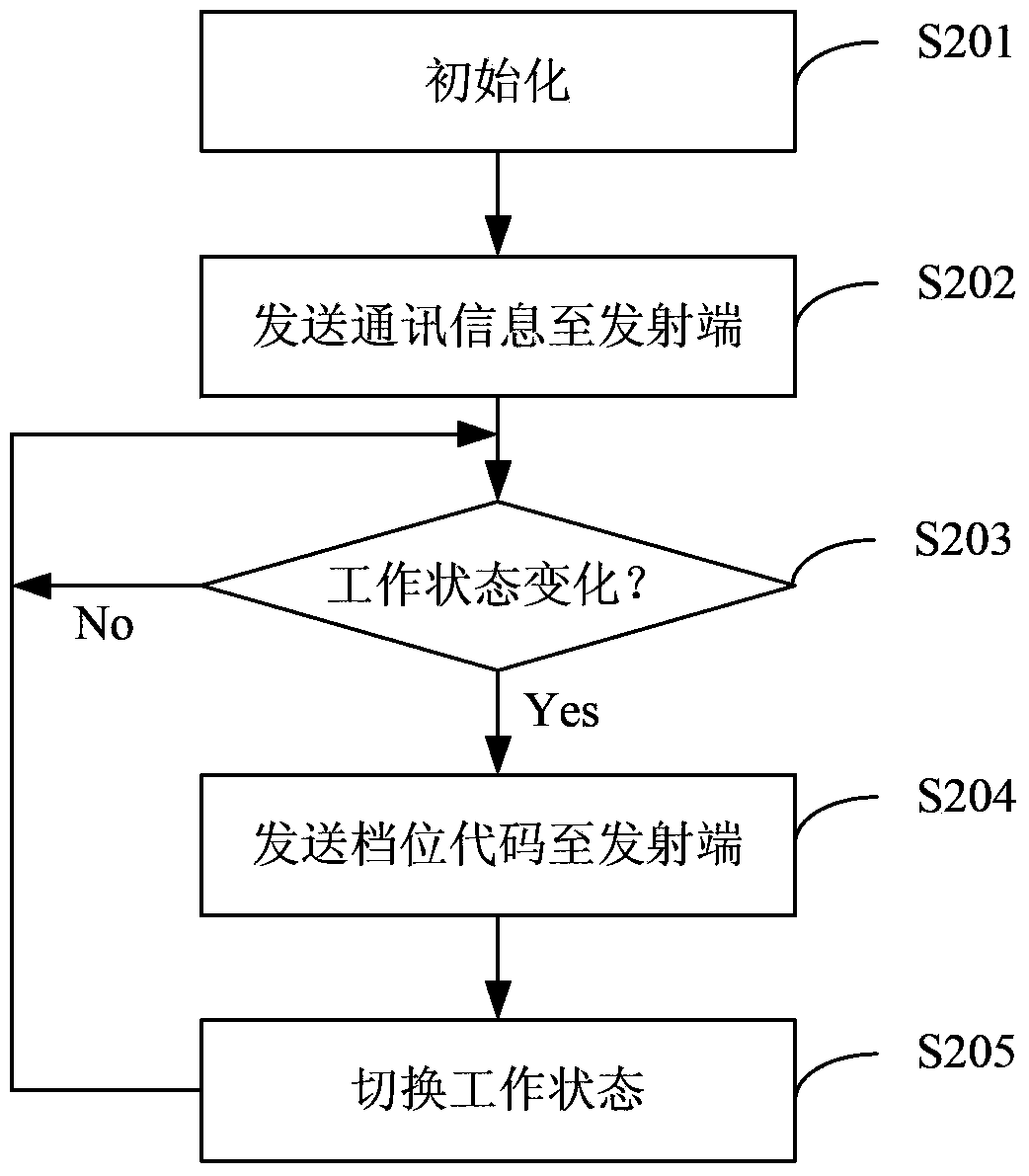

Power adjustment method of wireless power transmission system and system thereof

ActiveCN104124765AShorten adjustment timeReduce adjustment errorElectromagnetic wave systemTransmission systemsCurrent loadPower parameter

The invention discloses a power adjustment method of a wireless power transmission system and a system thereof. The method comprises the following steps that a receiving end of the wireless power transmission system sends communication information comprising current load information to a transmitting terminal of the wireless power transmission system; the transmitting terminal of the wireless power transmission system searches a power parameter corresponding to the load information in an index table; the transmitting terminal of the wireless power transmission system emits power which matches with the power parameter to the receiving end of the wireless power transmission system. The transmitting terminal in the invention is switched to different power gear directly according to the communication information fed back by the different receiving ends so that control precision of the system is greatly increased and simultaneously adjustment time is shortened.

Owner:HAIER GROUP TECHN R&D CENT +1

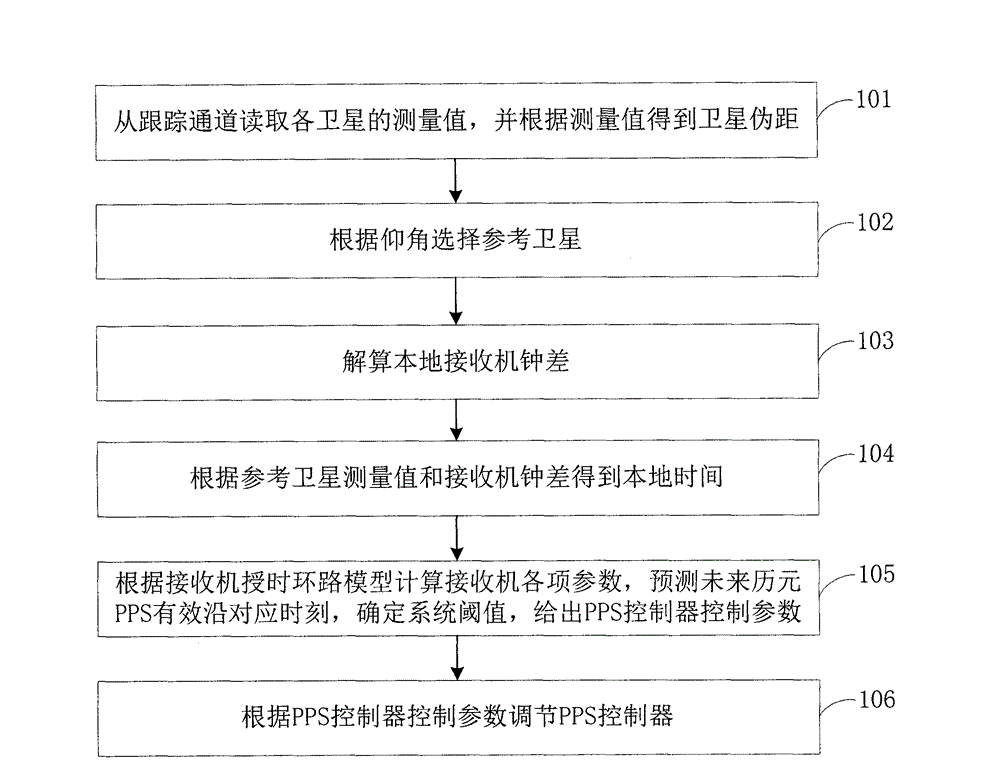

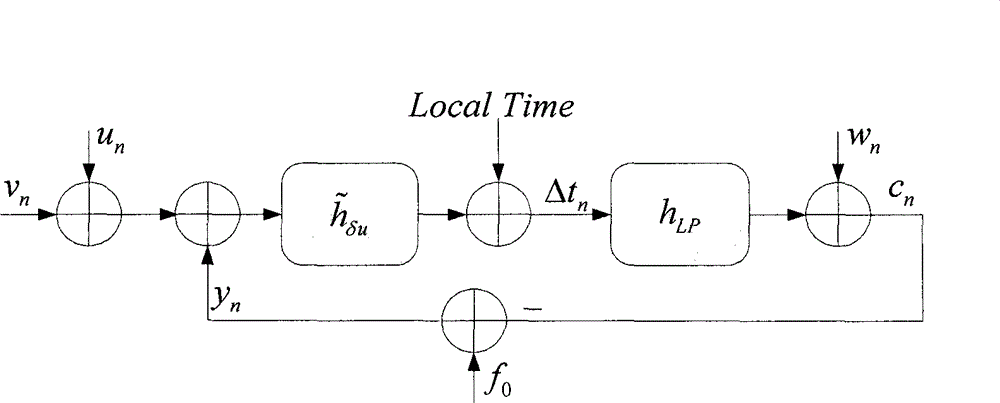

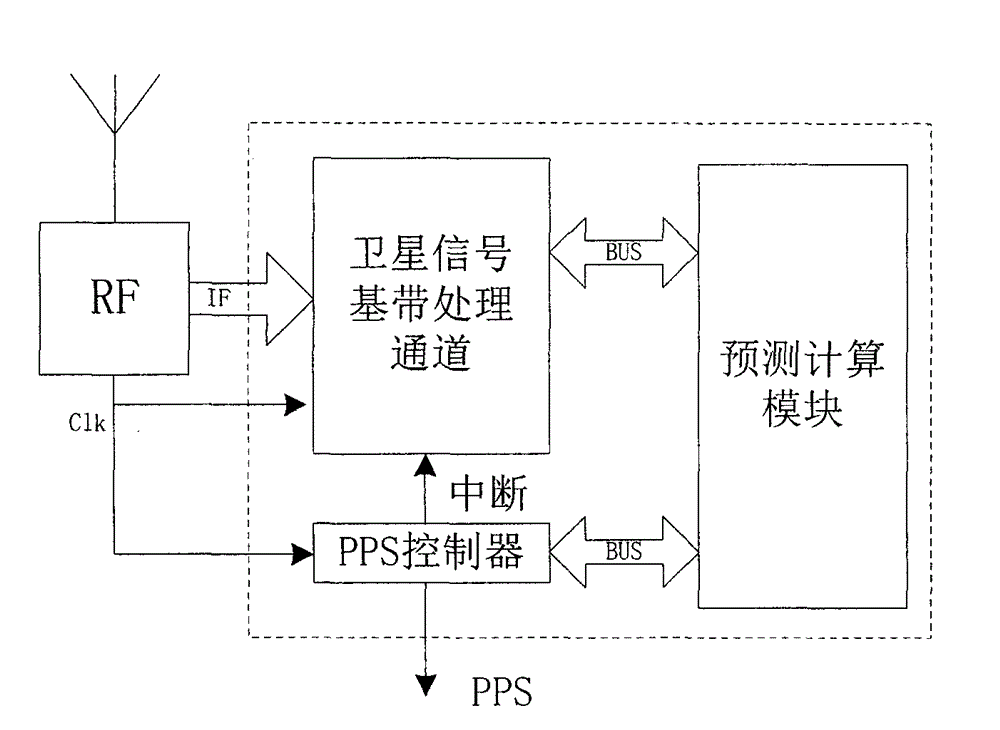

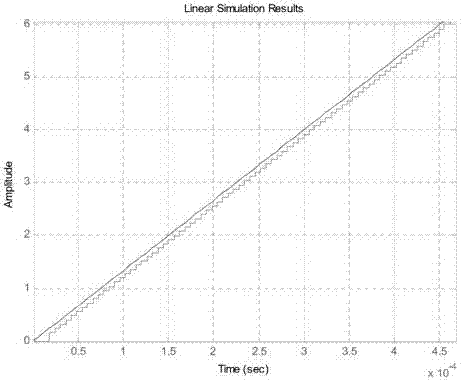

Pulse per second (PPS) generating method and device

InactiveCN104808480ASmall standard deviationReduce adjustment errorRadio-controlled time-piecesTime informationPhase difference

The invention discloses a pulse per second (PPS) generating method. The method includes the following steps that: satellite observation values are read from a satellite baseband signal processing channel so as to form local UCT time information; information such as satellite time, local time, PPS controller parameters and crystal oscillator parameters is utilized to predict future epoch PPS effective edge time phase difference; and information such as the crystal oscillator parameters and receiver parameters are utilized to determine the current status of a receiver loop, so that a PPS effective edge hopping constraint threshold value can be dynamically adjusted. With the method adopted, the long-term stability of a crystal oscillator can be ensured, and short-term random phase jitter of satellite navigation signals tracked by the receiver can be eliminated, and PPS output accuracy can be improved. The invention also provides a device for realizing the above method. With the device of the invention adopted, the high-precision time information of GNSS can be fully utilized, and timing accuracy of the satellite navigation system can be improved. The pulse per second (PPS) generating method and device of the invention can have higher commercial value.

Owner:PEKING UNIV

Off-axis phase waveband plate-based interference microscopic detection apparatus

InactiveCN106323981AReduce processing difficultyReduce processing costsOptically investigating flaws/contaminationTest sampleField analysis

The invention discloses an off-axis phase waveband plate-based interference microscopic detection apparatus including a 13.5nm extreme ultraviolet light source, a focusing waveband plate, a five-dimensional precision micro adjustment table, an off-axis waveband plate, an optical fiber point diffraction device, an extreme ultraviolet bright field CCD and an extreme ultraviolet dark field CCD. The off-axis waveband plate is a hollow phase type structure, can realize modulation of + 1 level diffraction light, when the light is incident on sample surface, scattering and reflection occur simultaneously, the off-axis waveband plate takes effect on reflected light and scattered light, the reflected light is modulated into axial focusing, and the scattered light is reflected to the dark field CCD; the optical fiber point diffraction device provides reference light for testing light, interference of the reference light and the testing light is realized, an interferogram enters the bright field CCD, and the interferogram is interpreted by a computer for reduction of contour information of a to-be-tested sample. The off-axis phase waveband plate-based interference microscopic detection apparatus has the advantages of simple structure, good vibration resistance, high precision, low system cost, simultaneous bright field and dark field analysis and timely positioning and analysis of phase defects, and can obtain defect contour information.

Owner:NANJING UNIV OF SCI & TECH

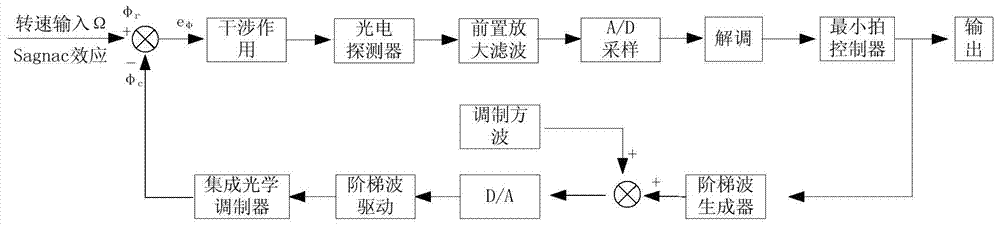

Closed loop fiber optic gyroscope minimum step control method

ActiveCN104713538AShorten adjustment timeReduce adjustment errorSagnac effect gyrometersPosition/direction controlFiberControl system

The invention belongs to a fiber optic gyroscope technology, and relates to a closed loop fiber optic gyroscope minimum step control method. The method comprises the following steps: establishing accurate model parameters according to the work principle and framework of a digital closed loop fiber optic gyroscope; establishing the discrete control model of the whole control system of the closed loop fiber optic gyroscope, and obtaining the control model of the controlled object of the gyroscope; calculating based on the principle of a minimum time response controller according to the type of an input signal to obtain a minimum step controller of the fiber optic gyroscope; and designing the corresponding minimum step controller directed against a step input signal and a slope input signal as needed to make the gyroscope trace input signals after 2 and 3 control periods. The minimum step closed loop fiber optic gyroscope controller disclosed in the invention reduces the trace delay time of the fiber optic gyroscope to dynamic signals, reduces the dynamic trace error, improves the use performance of the fiber optic gyroscope in dynamic input environment, and improves the environment adaptability of the fiber optic gyroscope.

Owner:FLIGHT AUTOMATIC CONTROL RES INST

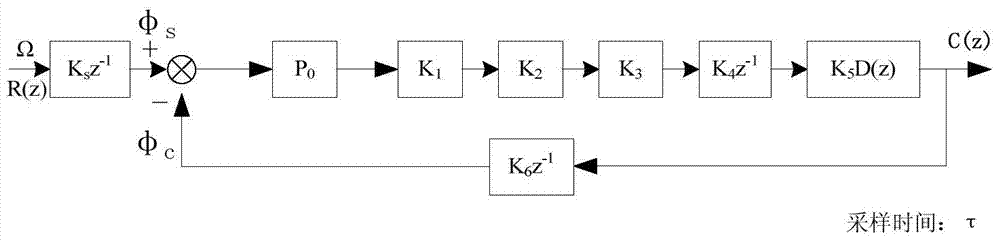

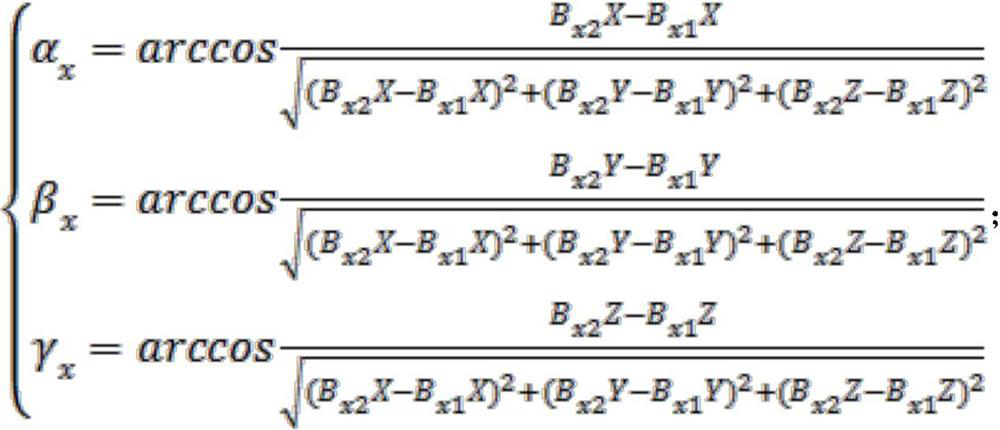

Method for measuring and adjusting spatial position relationship of multiple positioners

ActiveCN112361957AGuaranteed accuracyReduce mistakesUsing optical meansIncline measurementControl theoryMechanical engineering

The invention discloses a method for measuring and adjusting the spatial position relationship of multiple positioners. The method comprises the steps of: respectively measuring the coordinates of a positive limiting point and the coordinates of a negative limiting point on a reference X axis, a reference Y axis and a reference Z axis through a reference positioner, obtaining the spatial positionsof the reference X axis, the reference Y axis and the reference Z axis, and building a reference coordinate system; measuring the coordinates of the positive limiting point and the coordinates of thenegative limiting point on a positioner X-axis, a positioner Y-axis and a positioner Z-axis respectively through an adjustment positioner, and then obtaining the spatial position relations between the positioner X-axis and the reference X-axis, between the positioner Y-axis and the reference Y-axis, and between the positioner Z-axis and the reference Z-axis, and calculating the adjustment amountsbetween the positioner X-axis and the reference X-axis, between the positioner Y-axis and the referenceY-axis, and between the positioner Z-axis and the reference Z-axis respectively, and then accurately, conveniently and quantitatively adjusting the spatial positions of the positioner X-axis, the positioner Y-axis and the positioner Z-axis so as to enable errors among positioners to reach standards.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

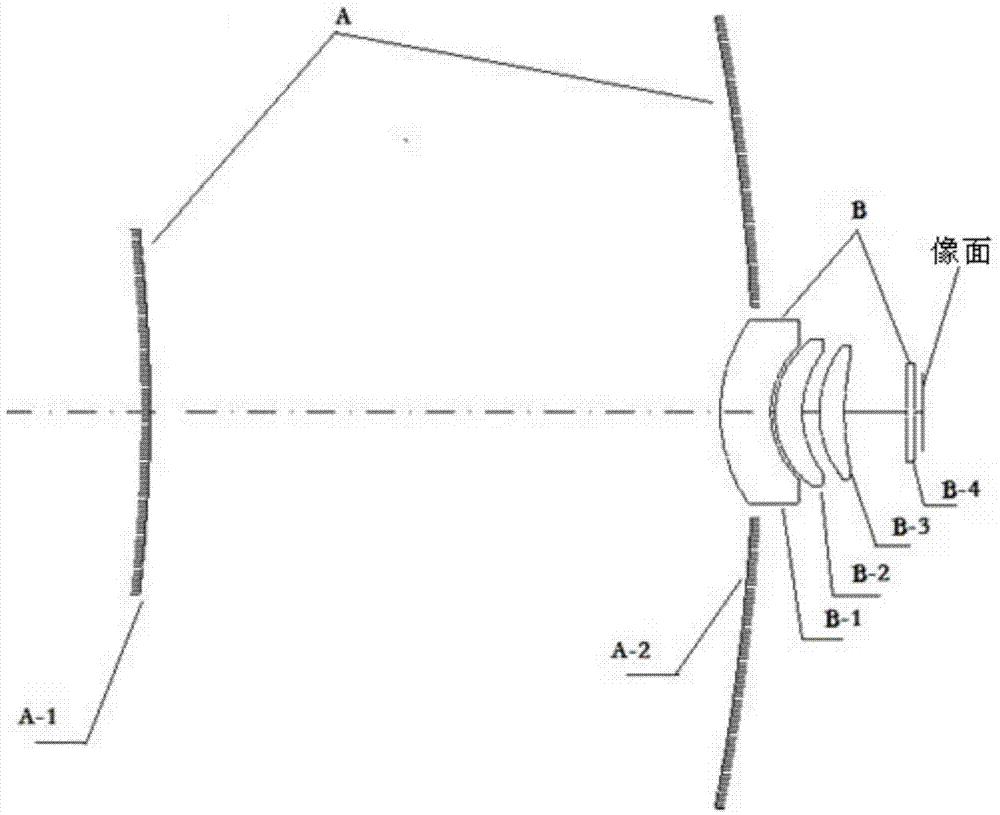

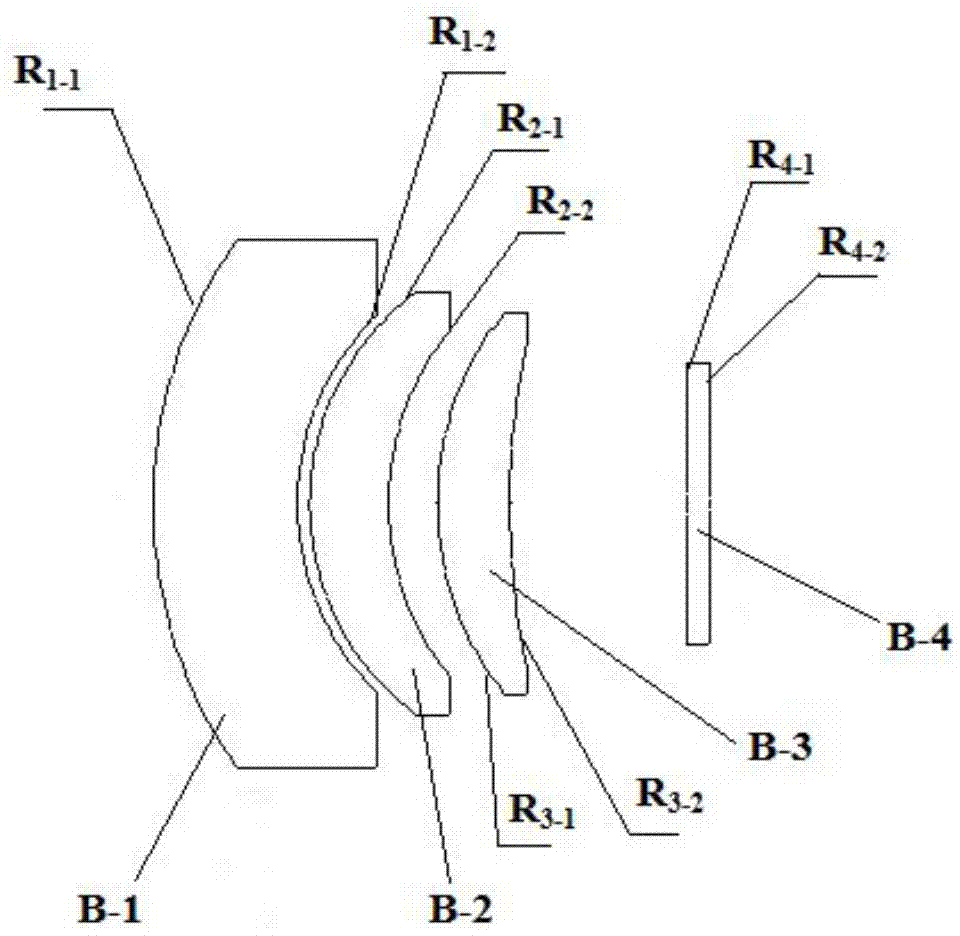

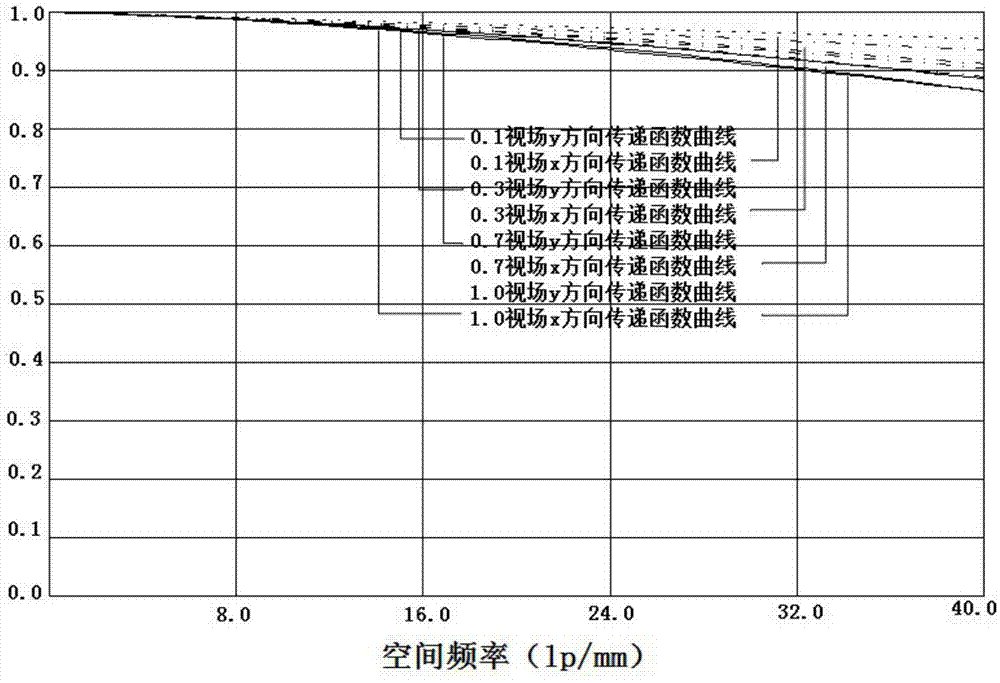

Large-relative-aperture high-precision refraction-reflection star sensor optical system

ActiveCN104501805AEasy to correctReduce the pressure of aberration correctionNavigation by astronomical meansFlat glassParallel plate

The invention relates to a large-relative-aperture high-precision refraction-reflection star sensor optical system, which belongs to the technical field of optical systems, and overcomes the problems of the prior art. The optical system is provided with a front mirror group with positive focal power and a rear mirror group with a positive focal power, which are arranged in sequence according to the incidence direction of the light, wherein the front mirror group consists of a secondary reflecting mirror and a main reflecting mirror; the rear mirror group consists of a first convex-concave lens, a second convex-concave lens, a third convex-concave lens and parallel plate glass, and the first convex-concave lens, the second convex-concave lens and the third convex-concave lens are all spherical lenses; an air interval between the secondary reflecting mirror and the first convex-concave lens is 68.034, the air interval between the secondary reflecting mirror and the main reflecting mirror is 72mm, the air interval between the first convex-concave lens and the second convex-concave lens is 0.5mm, the air interval between the second convex-concave lens and the third convex-concave lens is 2.013mm, and the air interval between the third convex-concave lens and the parallel plate glass is 7.328mm.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

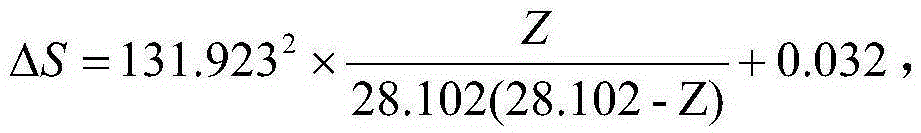

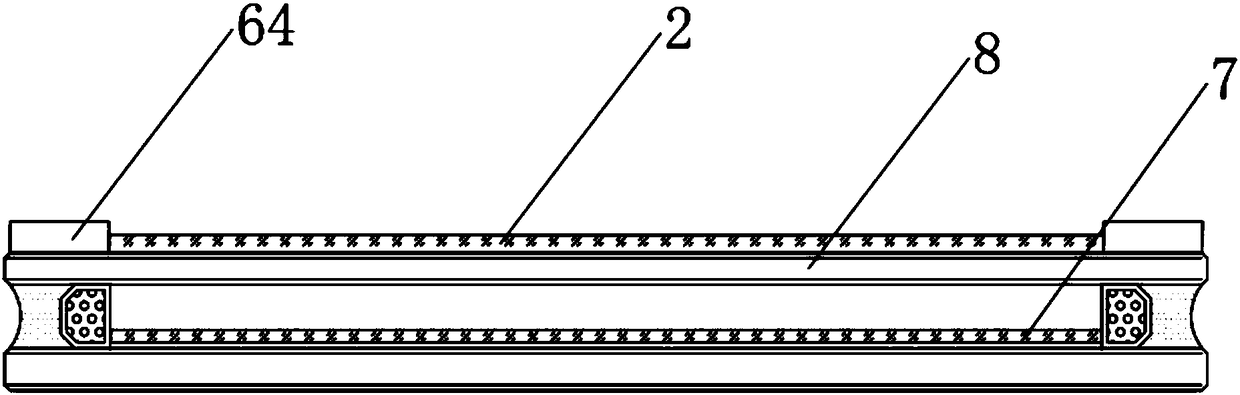

Focusing lens and vibrating mirror type laser scanning system

The invention discloses a focusing lens and a vibrating mirror type laser scanning system. The focusing lens comprises a flat concave lens and a convex lens, the flat concave lens comprises a plane and a concave surface arranged opposite to the plane, and the convex lens which is arranged fixedly comprises a first convex surface and a second convex surface arranged opposite to the plane; the flat concave lens can move in the axis, and light is input via the plane of the flat concave lens, passes the concave surface of the flat concave lens and the first convex surface of the convex lens successively, and is output via the second convex surface of the convex lens. The focusing lens is simple in structure and low in the adjusting error; the focusing lens has no real focus and thus, can be kept in a relatively low temperature; and when the waist radius of an input laser beam of the vibrating mirror type laser scanning system is greater than 7.5mm, the distance between a laser and the focusing lens does not influence the focusing effect.

Owner:SHENZHEN INST OF ADVANCED TECH

Single-roller coating machine capable of being suitable for non-planar plate

InactiveCN106423711AReduce adjustment errorHigh adjustment accuracyLiquid surface applicatorsCoatingsEngineeringSoft materials

The invention provides a single-roller coating machine capable of being suitable for a non-planar plate. The single-roller coating machine comprises a coating machine base. A conveying device is arranged on the upper side of the coating machine base. The coating machine base on the lower side of the conveying device is provided with a main loop oil groove. Oil grooves are formed in the left side and the right side of the conveying device. A front side lifting device is installed on the side, with a feeding port, on the conveying device. A rear side lifting device is installed on the side, with a discharging port, of the conveying device. The upper end of the front side lifting device and the upper end of the rear side lifting device are provided with coating devices. The left side of the coating machine base is provided with an operation panel assembly, and the right side of the coating machine base is provided with a distribution box. According to the single-roller coating machine capable of being suitable for the non-planar plate, soft materials such as polyurethane or silica gel or the like can be selected for wrapping a rubber roller according to different demands, the single-roller coating machine can well adapt to surface roller coating of the non-planar plate, the deepest non-planar roller coating size can reach 1 cm, in addition, the manner that a dovetail is matched with a screw rod lifter is adopted in a lifting mechanism of the single-roller coating machine and an air cylinder automatic compensation manner is adopted, the adjusting error is greatly reduced, and the adjusting precision is improved.

Owner:安徽纪兴源科技股份有限公司

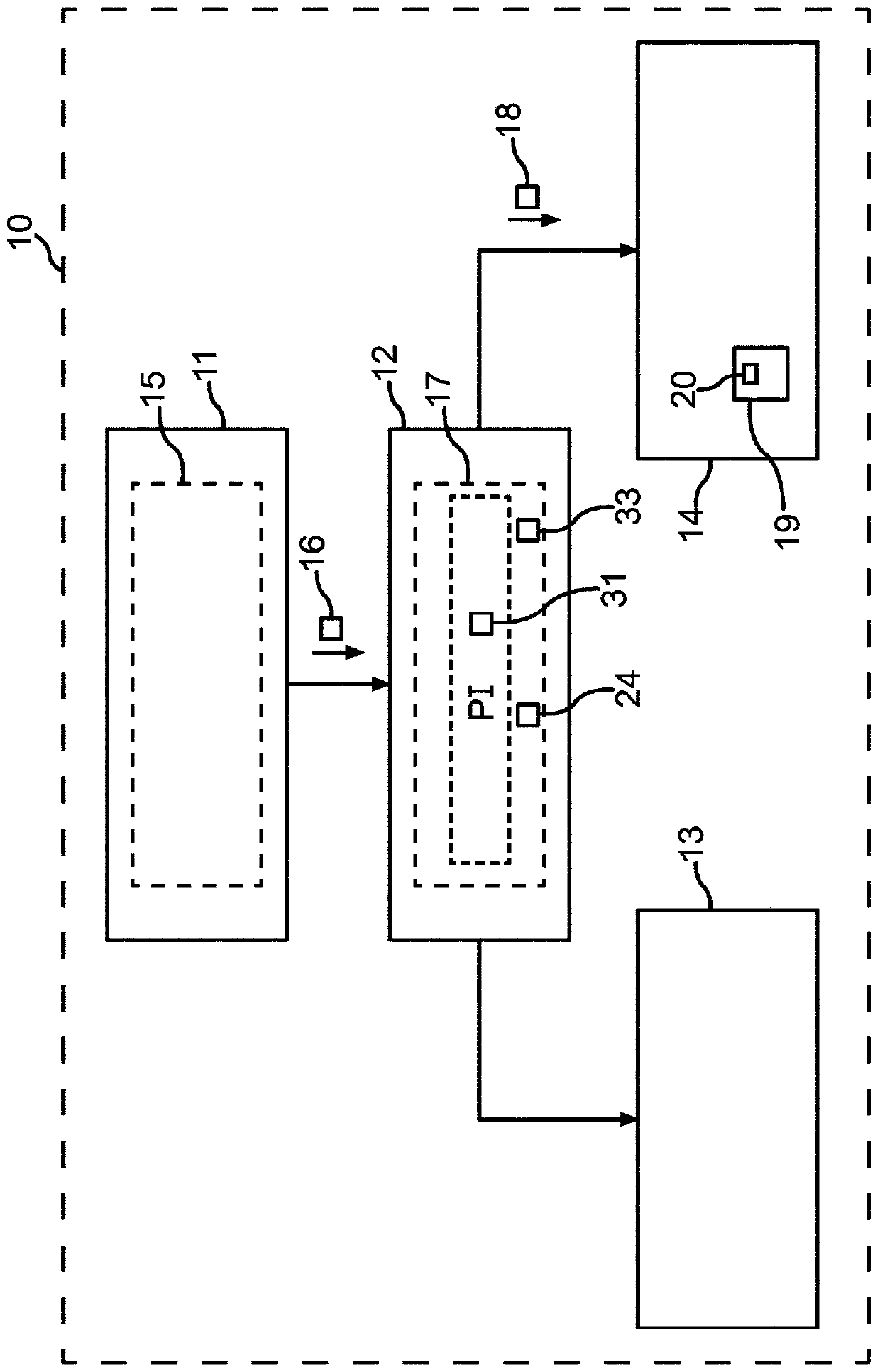

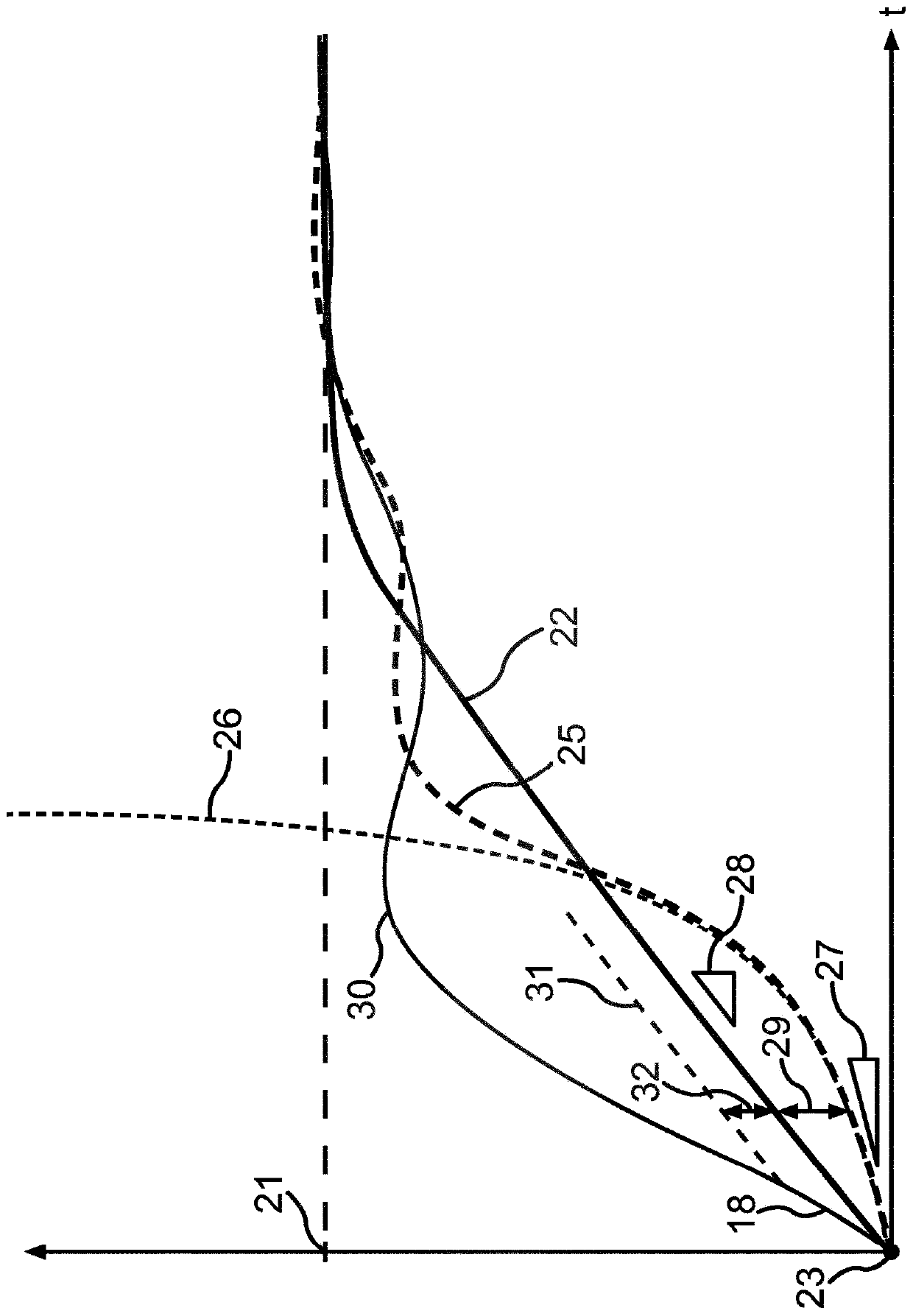

Method for operating a control device for a braking system of a motor vehicle, control device and motor vehicle,

ActiveCN110402212AGuaranteed changePortion limitBrake system interactionsBraking action transmissionDriver/operatorBraking system

The invention relates to a method for operating a control device (12) for a braking system (14) of a motor vehicle (10), wherein the control device (12) receives a braking request (16) from a driver assistance system (11) and determines a target value (21) of a braking operation parameter of the braking system (14) and determines an ideal temporal process (22) for the braking operation parameter,which gradually leads to the target value (21), complying with a predetermined jerk criterion (24), and a determines a control fault (29) of an actual value (25) of the braking operation parameter inrelation to the ideal process (22) and determines a request value (18) for a controller (20) of a brake pressure pump (19) of the braking system (14) from the control fault (29) on the basis of a controller unit (PI). According to the invention, the control device (12) determines a maximum achievable temporal gradient (27) of the braking operation parameter by means of the brake pressure pump (19)and examines whether the gradient (27) fulfills a freezing criterion (33) and, in the case of the freezing criterion being fulfilled, limits at least one control operation parameter (31) of the controller unit (PI) and / or a gradient of the brake request (16).

Owner:VOLKSWAGEN AG

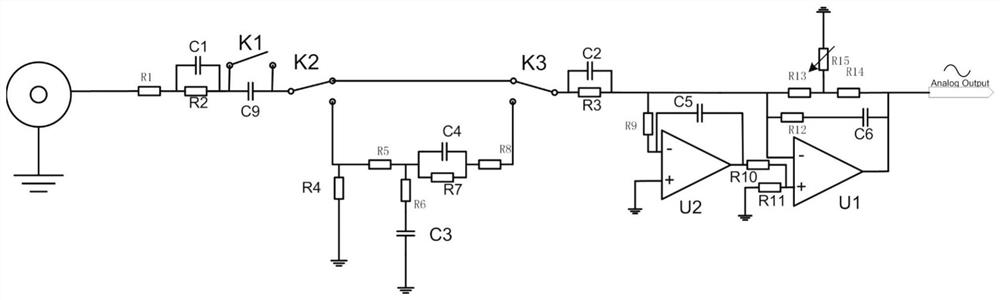

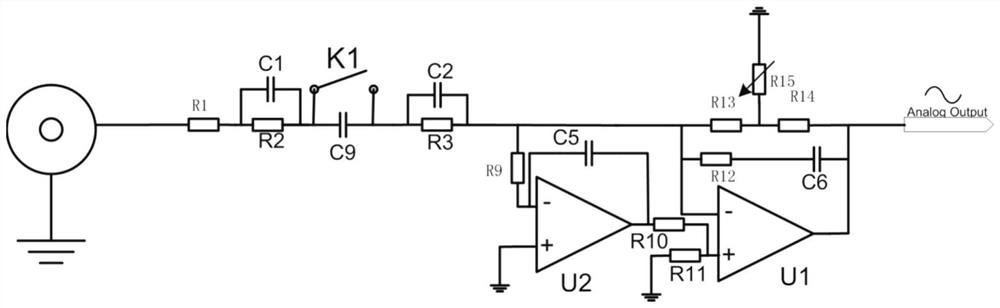

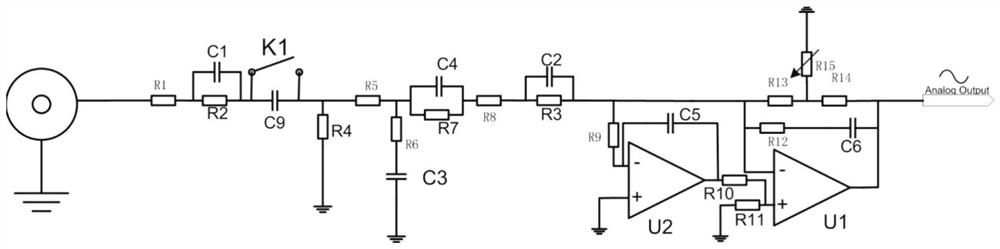

Signal conditioning circuit capable of program-controlled compensation

ActiveCN111865262ARealize program-controlled adjustmentEasy to adjustImpedence convertorsFrequency-independant attenuatorsSignal conditioning circuitsCapacitance

The embodiment of the invention discloses a signal conditioning circuit capable of program-controlled compensation. According to the signal conditioning circuit provided by the embodiment of the invention, the T-shaped network is arranged on an impedance conversion network branch, an adjustable resistor of the T-shaped network is used for adjusting the low-frequency gain at a feedback end of an operational amplifier, so program-controlled adjustment of signals can be realized, and the adjustment effect is optimized. Moreover, the influence of the port capacitance of the digital potentiometer on the circuit bandwidth can be reduced through the T-shaped network, an adjustment error is reduced, and the adjustment effect is further optimized.

Owner:GUANGZHOU ZHIYUAN ELECTRONICS CO LTD

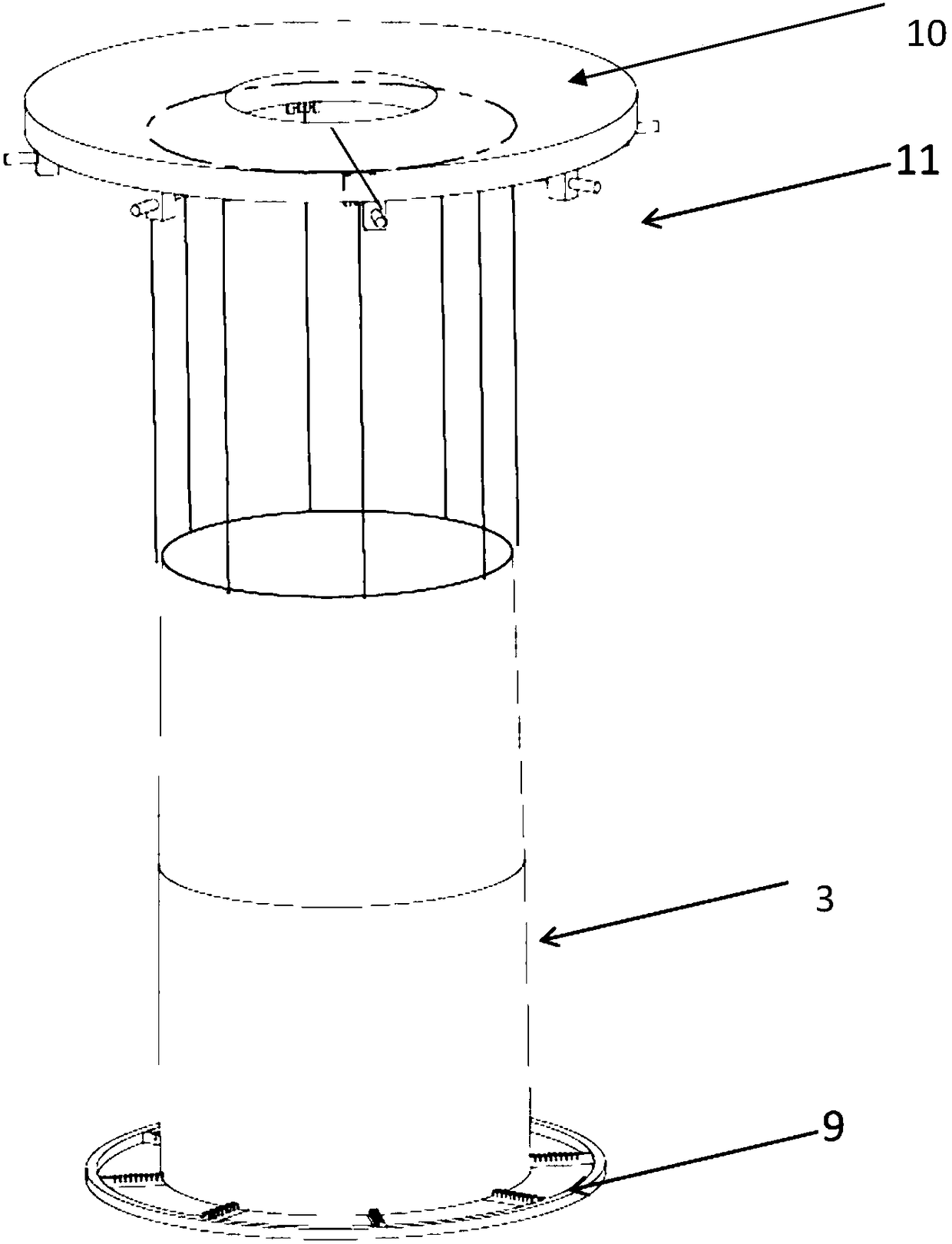

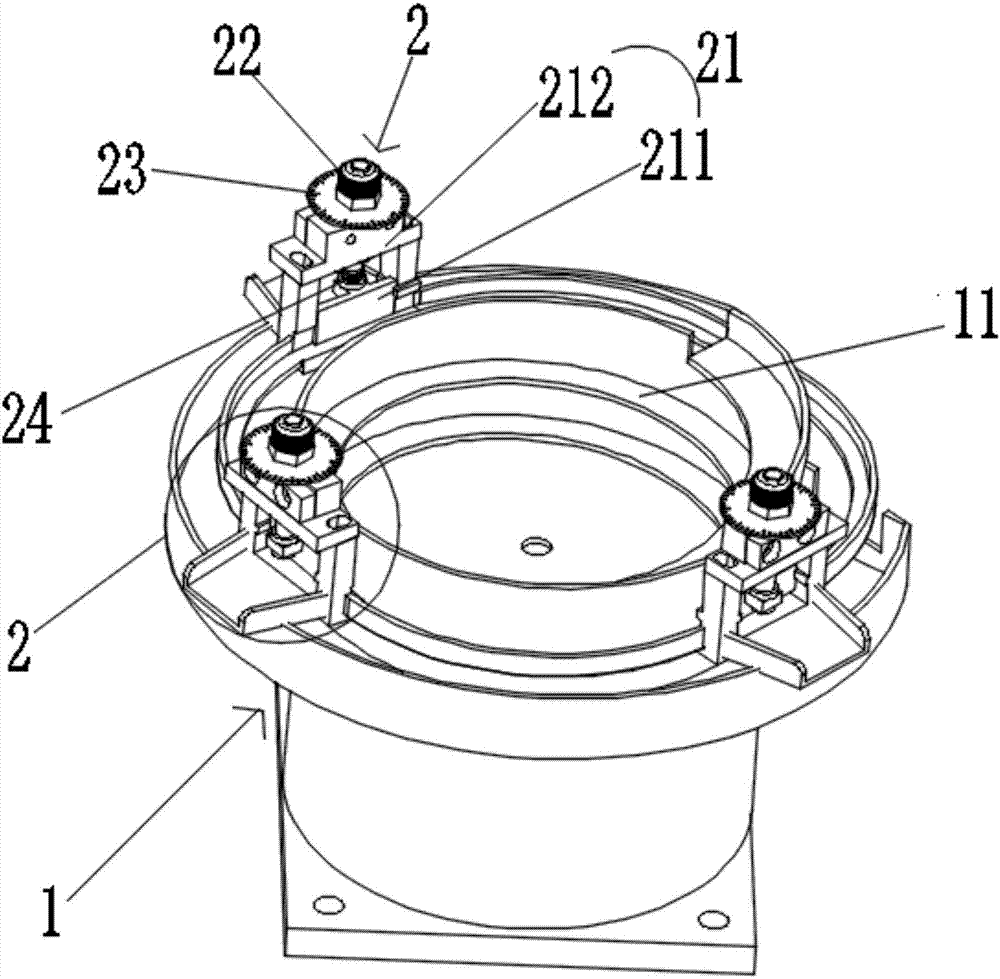

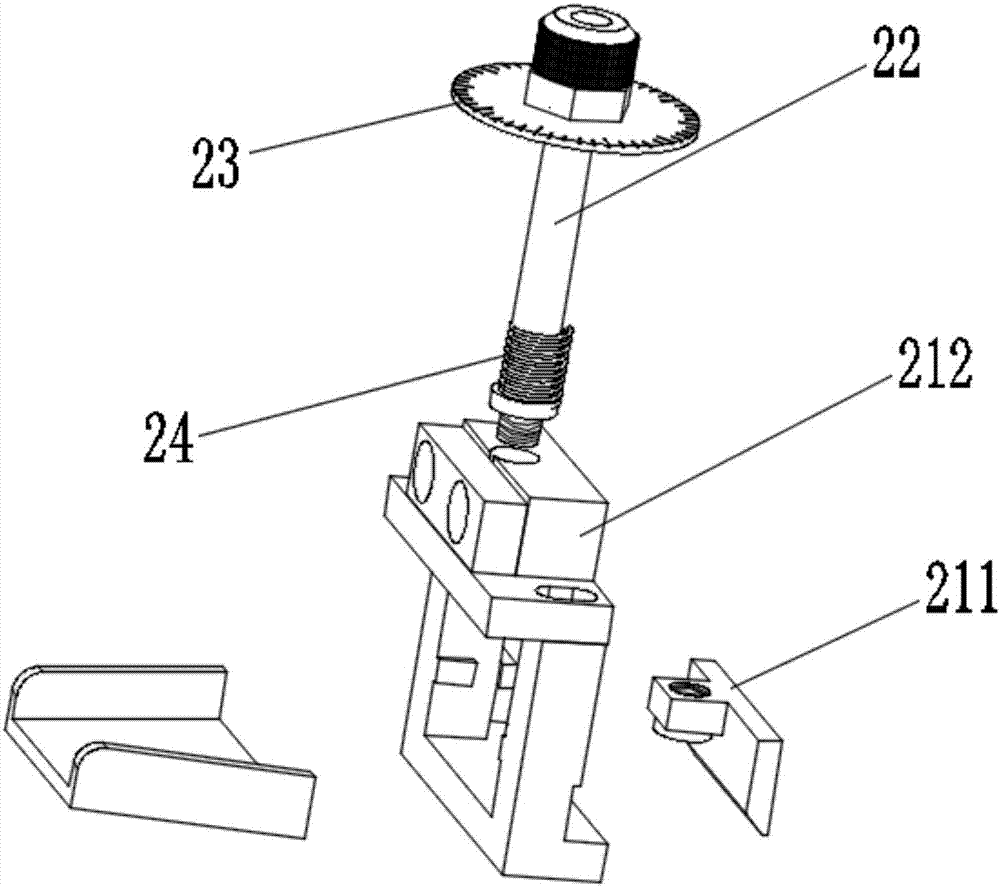

Sorting height adjustable vibration disk

InactiveCN106881272AImprove versatilityImprove sorting efficiencySortingEngineeringMaterial resources

The invention discloses a sorting height adjustable vibration disk. The sorting height adjustable vibration disk comprises a vibration disk body and at least one sorting unit. The vibration disk body internally comprises a spiral material distributing track, and the sorting units are arranged on the outer circle of the spiral material distributing track. Each sorting unit comprises a gate, an adjusting threaded rod and a dial, wherein the gate comprises a gate body and a gate frame, the gate frame is arranged on the outer circle of the spiral material distributing track, the gate body is arranged in the gate frame, a sorting opening is formed by the gate body and the spiral material distributing track, the gate frame and the gate body are provided with internal threads matched with the adjusting threaded rod, the lower end of the adjusting threaded rod penetrates the internal thread of the gate frame and the internal thread of the gate body and is used for adjusting the opening size of the sorting opening, and the dial is fixed to the threaded rod. The sorting height adjustable vibration disk has the beneficial effects of being high in universality and sorting efficiency; and meanwhile, the adjusting threaded rods are matched with the dials, the heights of the sorting openings can be adjusted more precisely, and the sorting height adjustable vibration disk has the beneficial effects of being small in error and capable of saving manpower and material resources.

Owner:厦门宏发精密机械有限公司

Film cutter capable of being adjusted in multiple directions

PendingCN111421600AAchieve regulationReduce adjustment errorMetal working apparatusStructural engineeringMechanical engineering

Owner:YANGZHOU STRVALUE INFORMATION TECH CO LTD

Dual-purpose facility of continuous hot-dip coating and continuous annealing

ActiveUS8714104B2Conducive to simplificationStable pressure balanceHot-dipping/immersion processesMaintainance of heating chambersProduction lineDual purpose

A dual-purpose facility of continuous hot-dip coating and continuous annealing is configured so as to be switched between a continuous hot-dip coated material production line and a continuous annealed material production line, and includes a gas discharge path that discharges atmosphere gas in an annealing furnace from a gas discharge port provided in an outlet side of the annealing furnace out of the annealing furnace and a path opening and closing unit for opening and closing the gas discharge path. The path opening and closing unit opens the gas discharge path when the dual-purpose facility is used as the continuous hot-dip coated material production line and closes the gas discharge path when the dual-purpose facility is used as the continuous annealed material production line.

Owner:NIPPON STEEL CORP

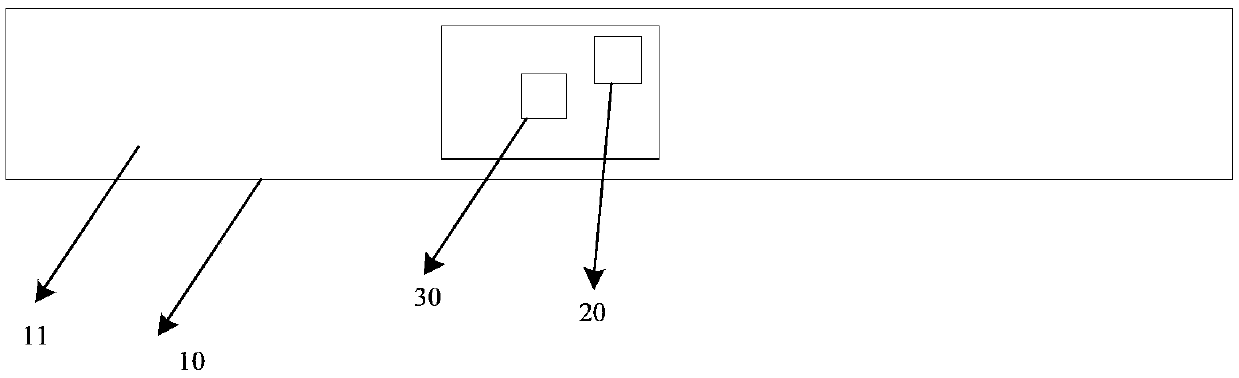

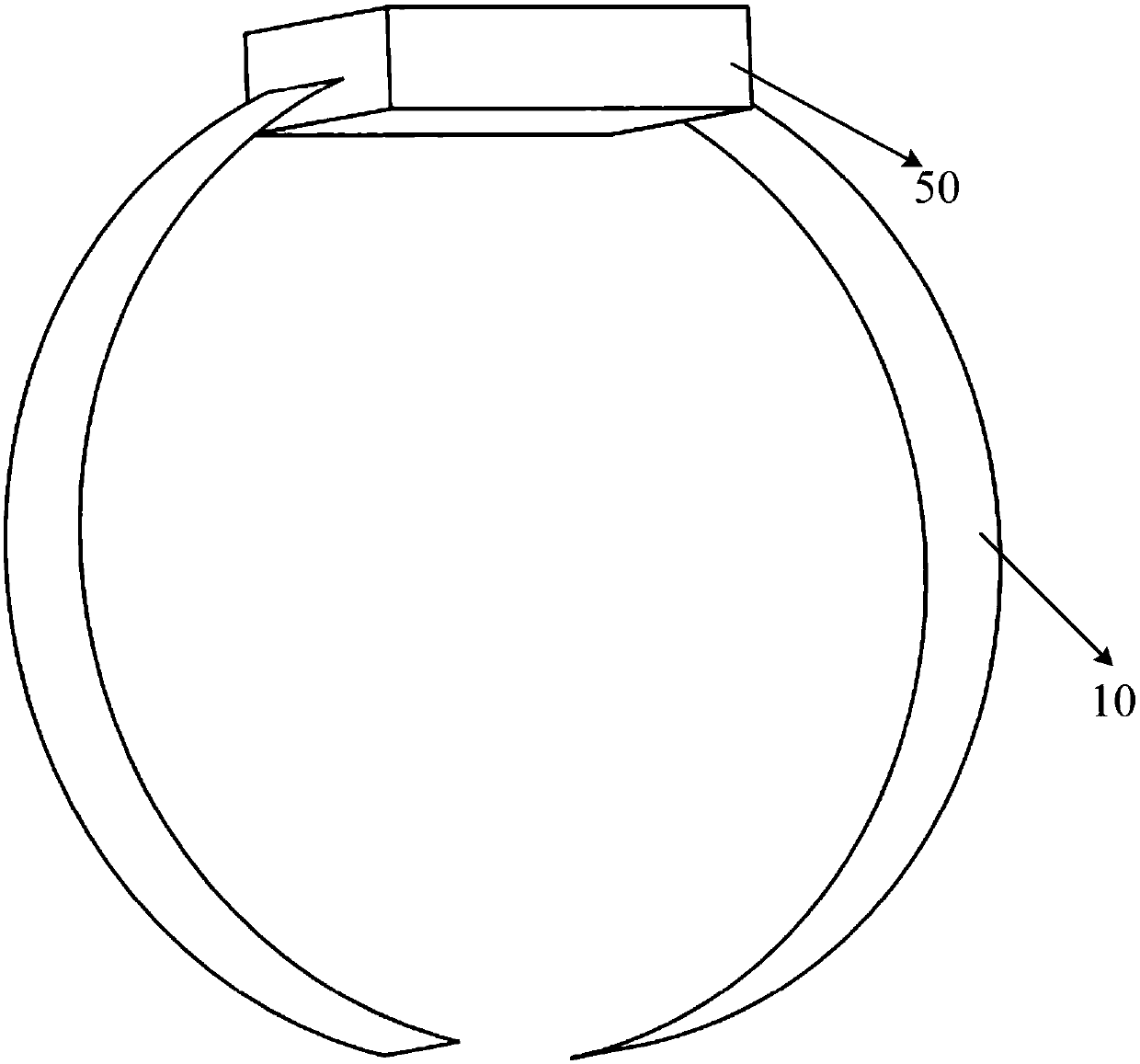

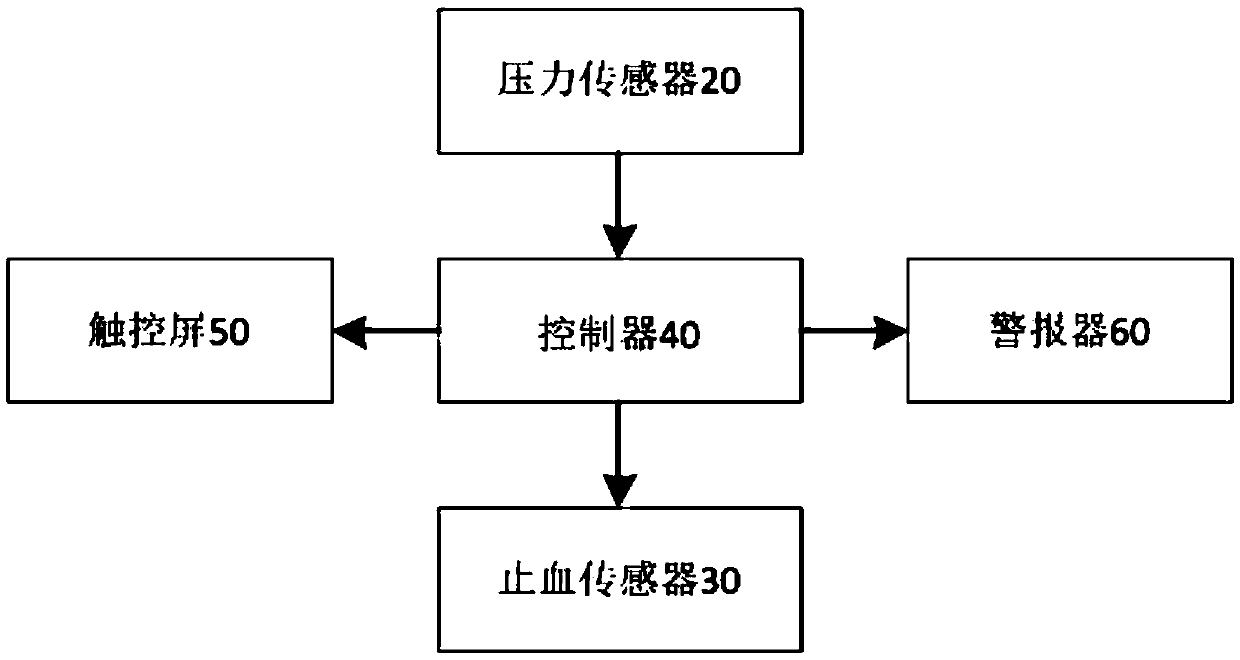

Intelligent internal fistula bandage

InactiveCN109674504AAccurate and standardized pressure regulationAdjustment accuracy and standardizationCatheterDiagnostic recording/measuringBlood pressureElectrical bonding

The invention discloses an intelligent internal fistula bandage. The intelligent internal fistula bandage comprises a bandage body, a pressure sensor, a blooding sensor, a controller and a touch screen, wherein the pressure sensor and the blooding sensor are arranged on a first surface and are connected with the controller electrically; the touch screen is arranged on a second surface and is connected with the controller electrically; the controller comprises a memory and a processor; an executable code is stored in the memory; and the executable code can complete the following steps through execution by the processor: obtaining the current pressure value of the patient through the touch screen, creating a pressure adjusting scheme for the patient according to the pressure value and displaying the pressure value in current hemostasis stage and the time remaining through the touch screen, and specifically, the pressure adjusting scheme includes a reference pressure value and time of duration for each hemostasis phase of the patient. According to the bandage, more accurate and more standard pressure adjustment is achieved; the pressure adjustment does not depend on the experience ofusers and the adjustment error is small.

Owner:ZHONGSHAN HOSPITAL XIAMEN UNIV

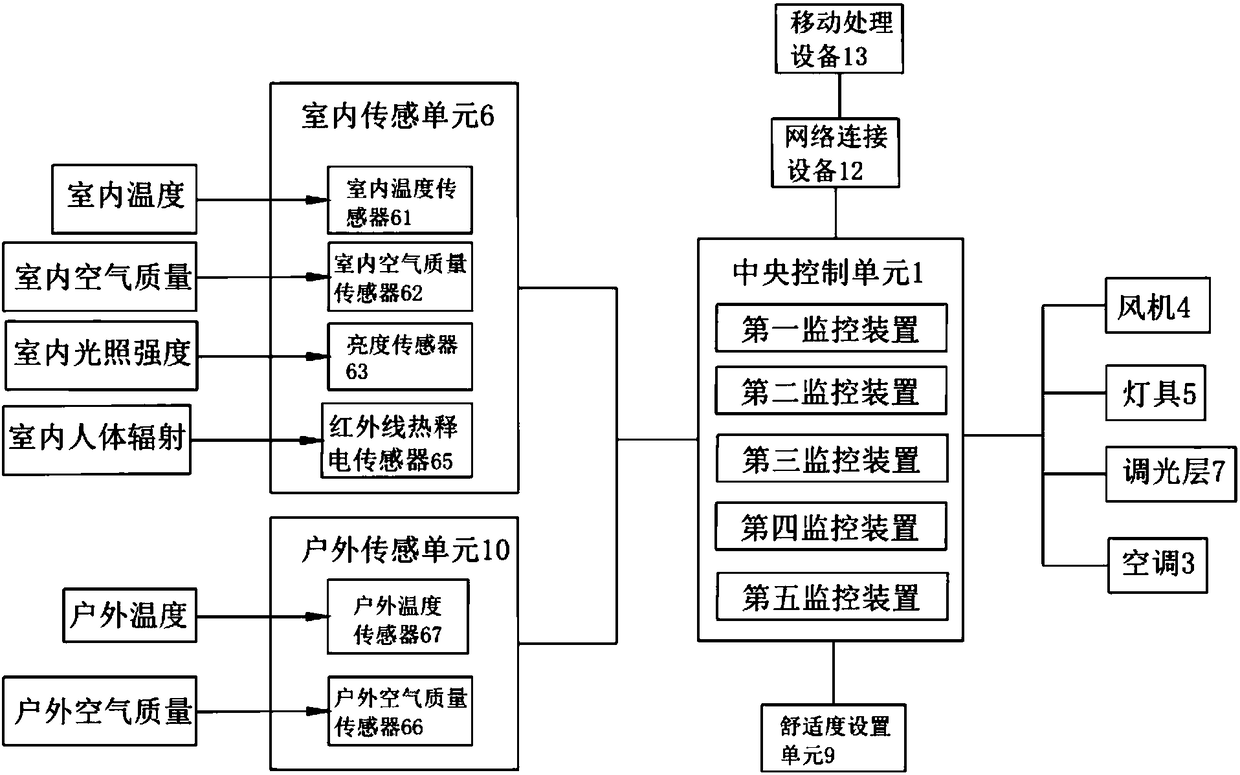

Energy-saving comfortable intelligent building system

PendingCN108286782ARealize remote controlAchieve observationMechanical apparatusEfficient regulation technologiesEngineeringOutdoor air quality

The invention relates to an energy-saving comfortable intelligent building system. The building system comprises a glass curtain wall, a ventilation or air purifying unit, a temperature adjusting unitand an illuminating unit, further comprises a barrier film and a dimming layer combined with the glass curtain wall, and further comprises an outdoor sensing unit, an indoor sensing unit and a central control unit for controlling at least one of the ventilation or air purifying unit, the temperature adjusting unit, the illuminating unit and the dimming layer according to signals provided by the outdoor sensing unit and the indoor sensing unit; the indoor sensing unit comprises an indoor temperature sensor, an indoor air quality sensor and a brightness sensor; and the outdoor sensing unit comprises an outdoor temperature sensor and an outdoor air quality sensor. The building system can greatly reduce consumed resources needed to keep comfortable environments for buildings, achieves higherenergy saving effect, and can radically promote the energy resource saving and reasonable utilization.

Owner:深圳市盈科幕墙设计咨询有限公司

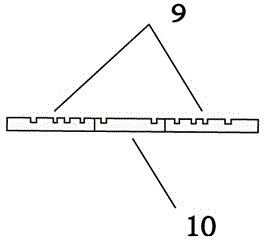

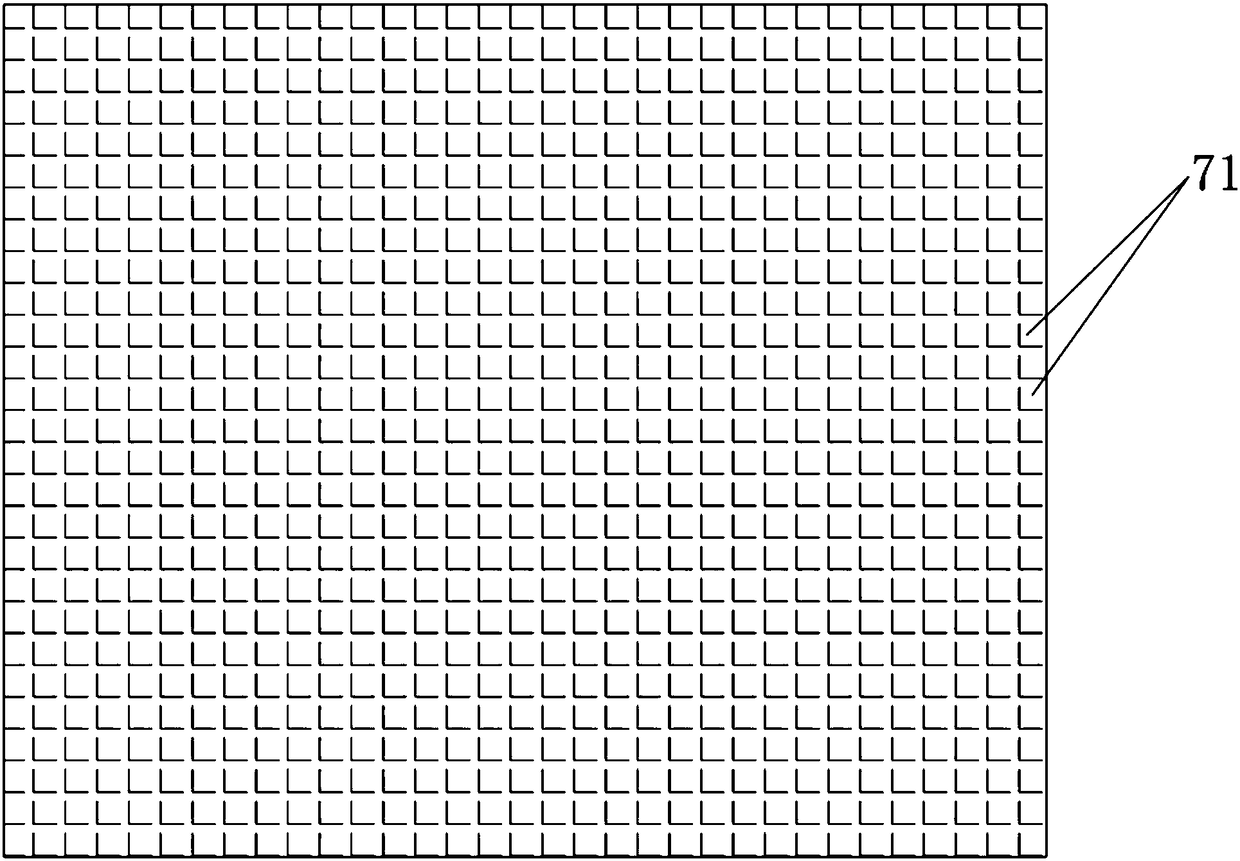

Device and method for installing and adjusting reference grating of lithography equipment

ActiveCN102540743AAdjust output light intensityReduce adjustment errorPhotomechanical exposure apparatusMicrolithography exposure apparatusGratingLithographic artist

The invention discloses a device and a method for installing and adjusting reference grating of lithography equipment. The device sequentially comprises a laser source, a vibrating mirror, a reflecting mirror, a first lens group, a diaphragm and second lens group according to the light beam propagation direction, which are used for adjusting the reference grating to the focal plane, and the device further comprises a light intensity adjusting and calibrating unit which is used for adjusting the intensity of the light beam outputted by the laser source..

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

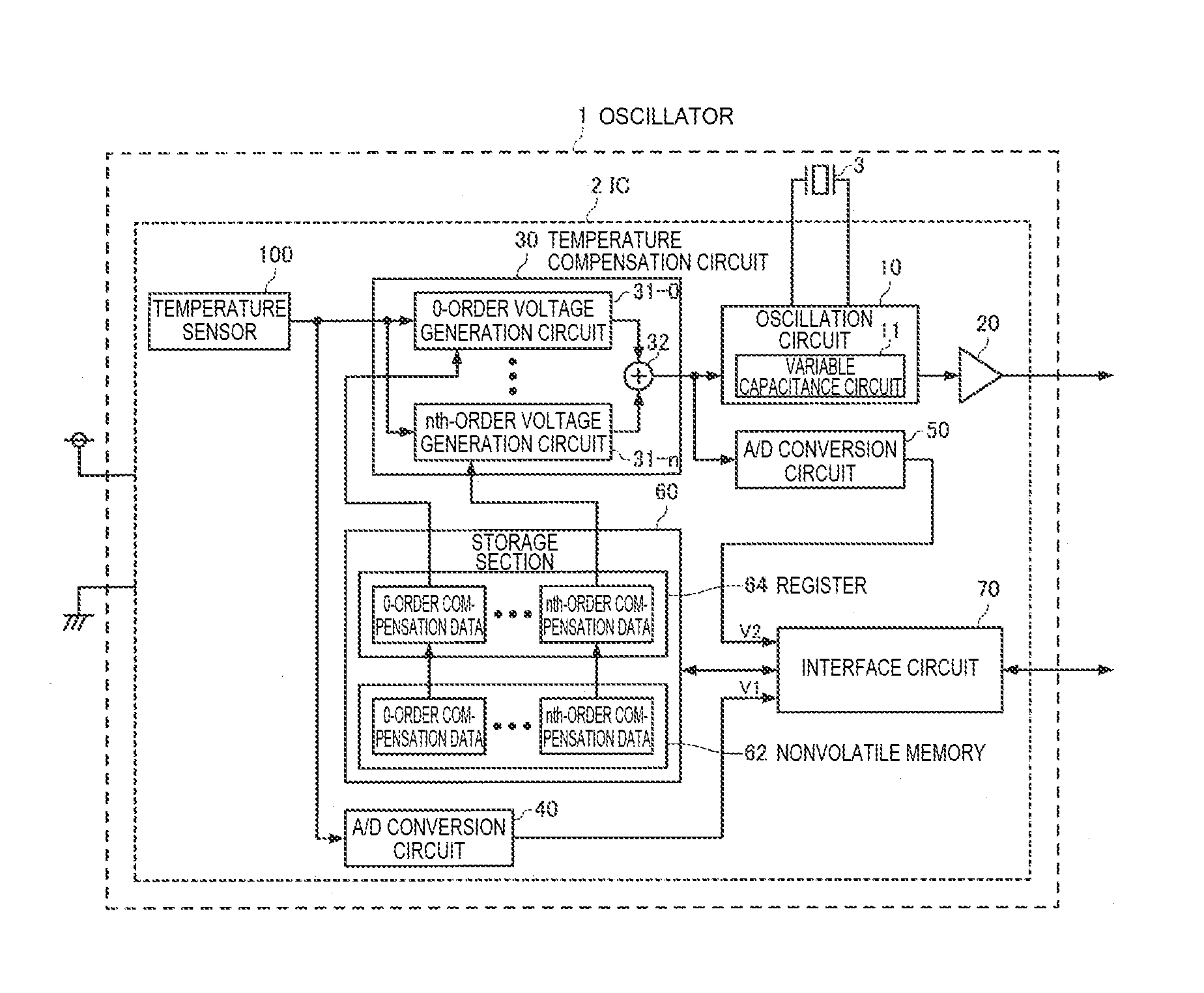

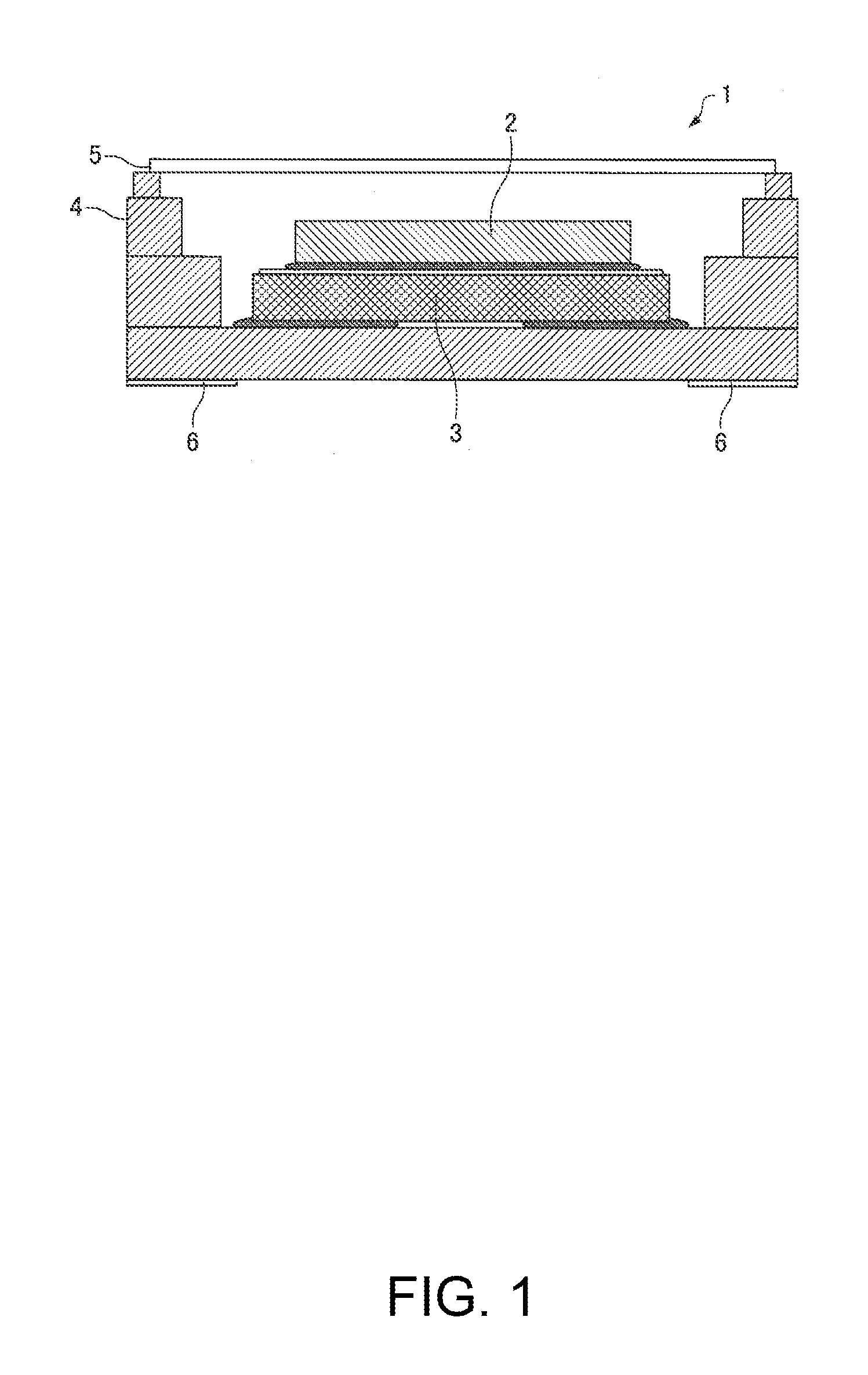

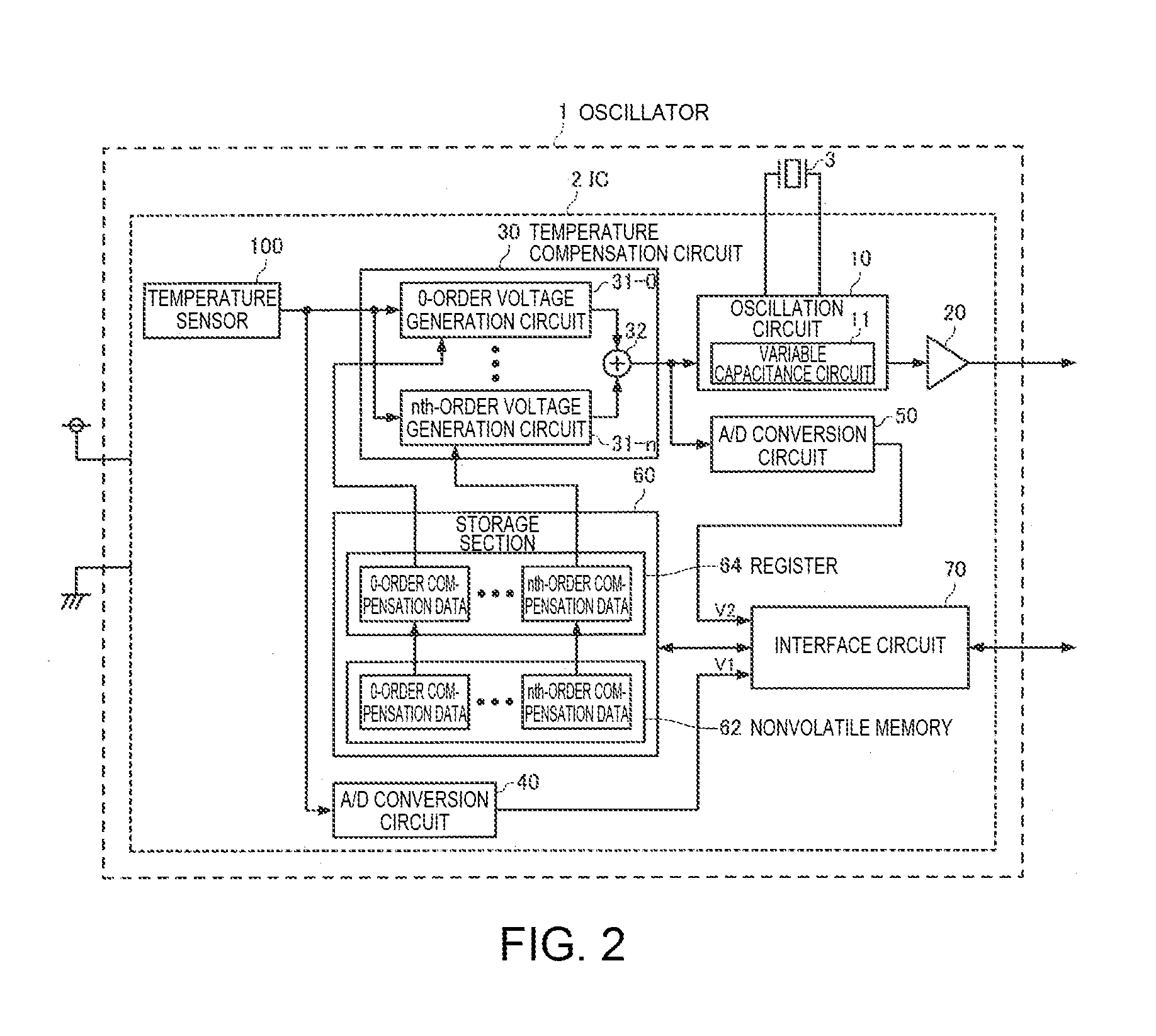

Electronic device, method of manufacturing electronic device, electronic apparatus, and moving object

ActiveUS20170063379A1Reduce adjustment errorImprove accuracyPulse automatic controlGenerator stabilizationAnalog signalElectron

An electronic device includes a drive section, a detection signal output section adapted to generate a first analog signal having a value varying in accordance with a physical quantity, and a control section adapted to generate a second analog signal controlled based on the first analog signal, and adapted to control a drive state of the drive section, at least the detection signal output section and the control section are provided to a substrate, and a first digital signal obtained by digitalizing the first analog signal and a second digital signal obtained by digitalizing the second analog signal can be output from the substrate.

Owner:SEIKO EPSON CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com