Modular arranging and conveying device of reinforcing steel bar end processing production line

A transmission device and production line technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems that cannot meet the requirements of fast handling and assembly on the construction site, bulky volume, etc., to improve the degree of mechanization and automation, processing quality, and easy installation , Reduce the effect of equipment installation adjustment time and adjustment error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

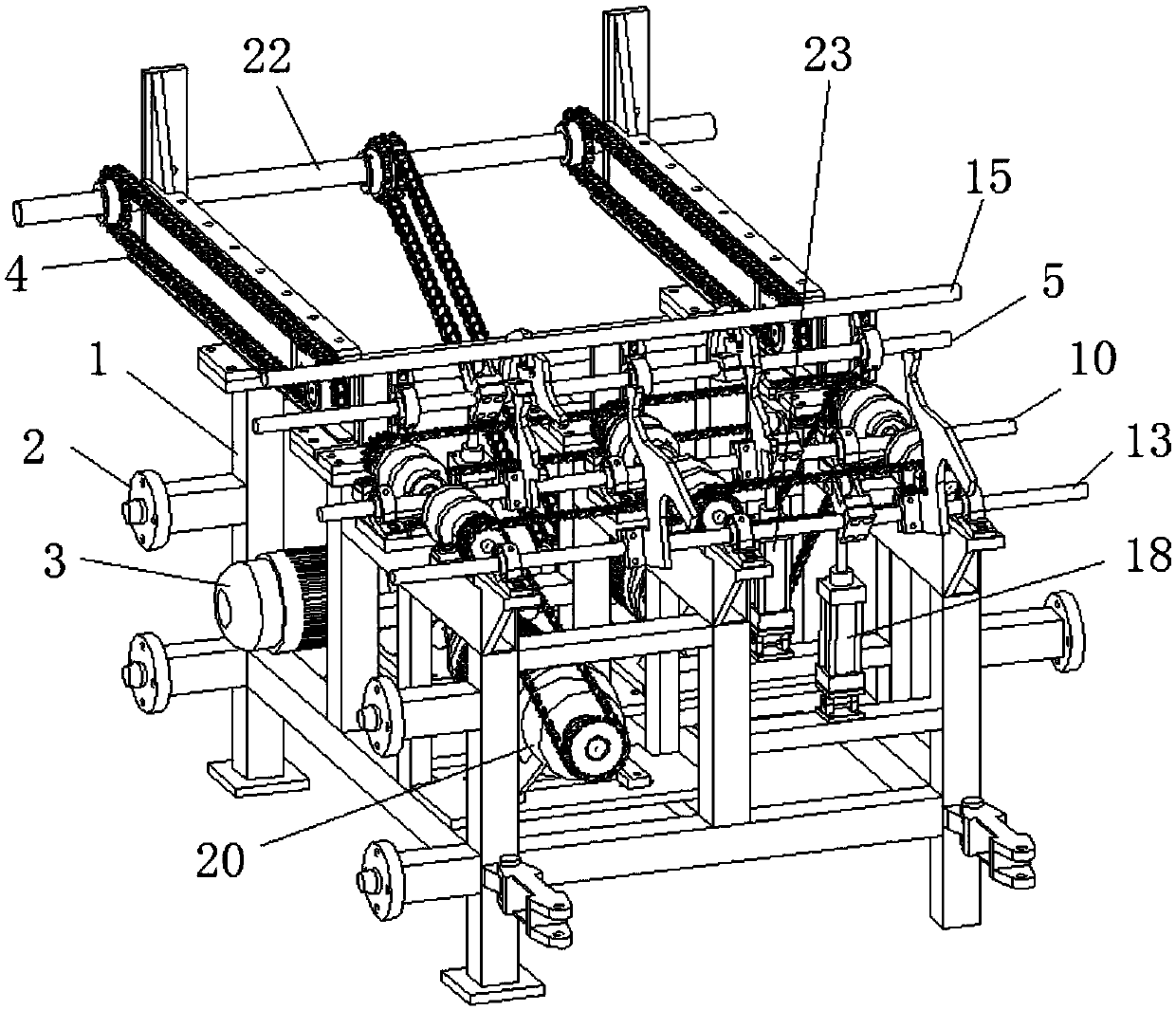

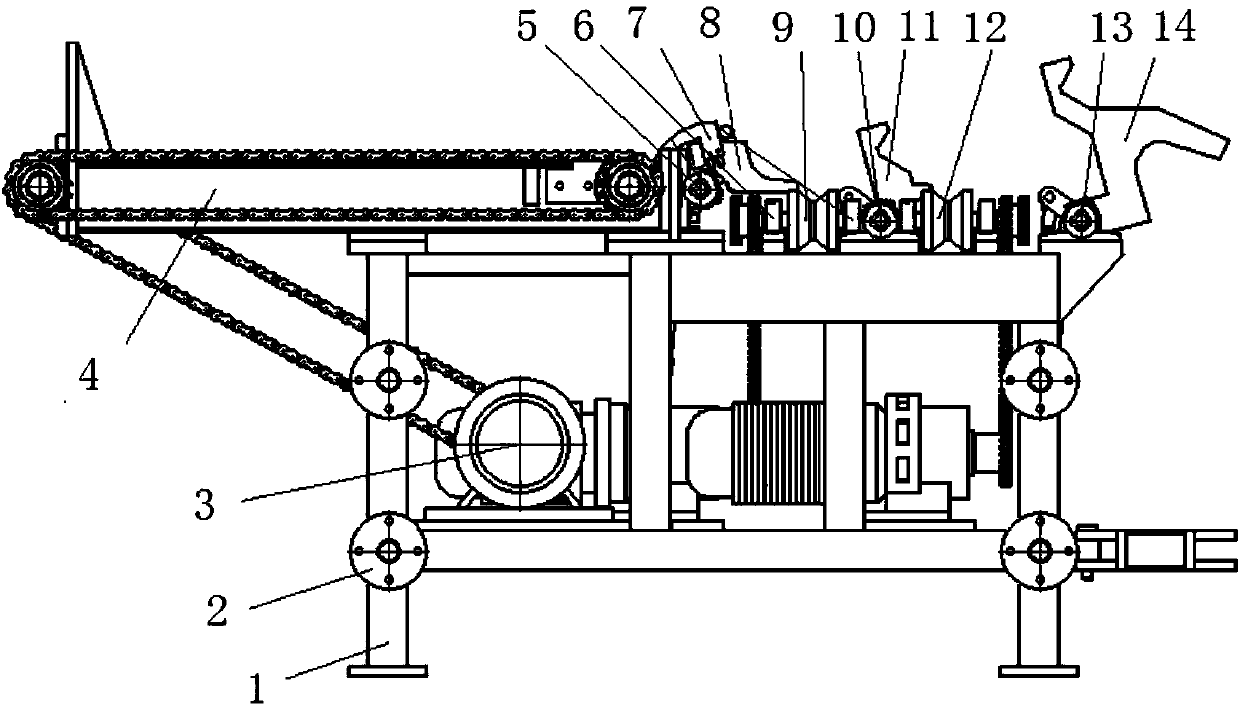

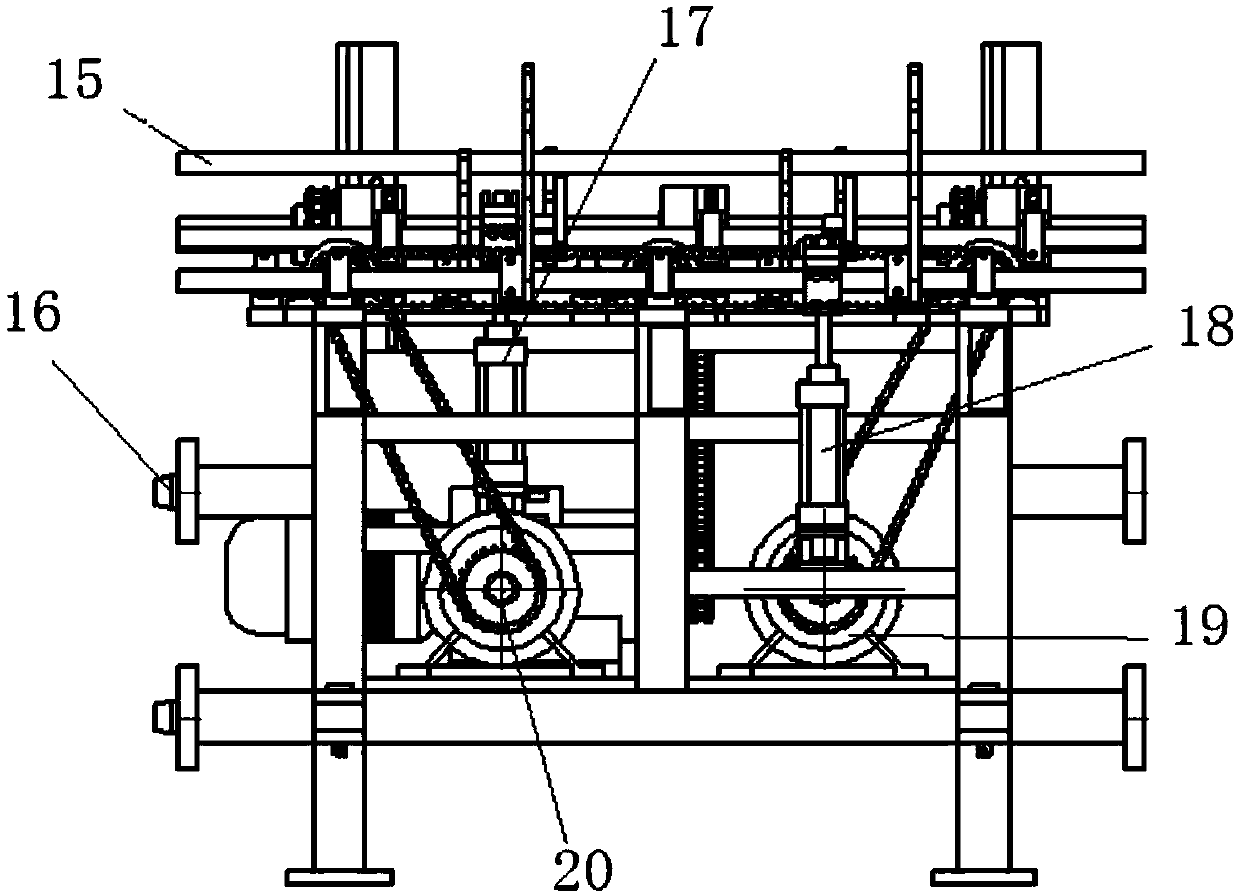

[0029]The present invention is composed of one or more standard material handling and transmission modules, which can realize on-site operations such as storage of steel bars of different lengths and diameters, automatic bulk material, single-separation, transportation between stations, and receiving materials after processing. It is equipped with advanced steel bar end processing equipment to meet the needs of different connection processes.

[0030] Each standard material transfer module is composed of frame 1, steel bar storage bulk material mechanism, single steel bar removal and turning mechanism, front roller conveying mechanism, inter-station turning and shifting mechanism, rear roller conveying mechanism, and unloading turning mechanism.

[0031] figure 1 , 2 , 3, and 4 show that each mechanism of the present invention is installed on the frame 1 respectively, and the reinforcing bar storage bulk material mechanism is positioned at the front end of the frame 1, and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com