Patents

Literature

702results about "Gasification apparatus details" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

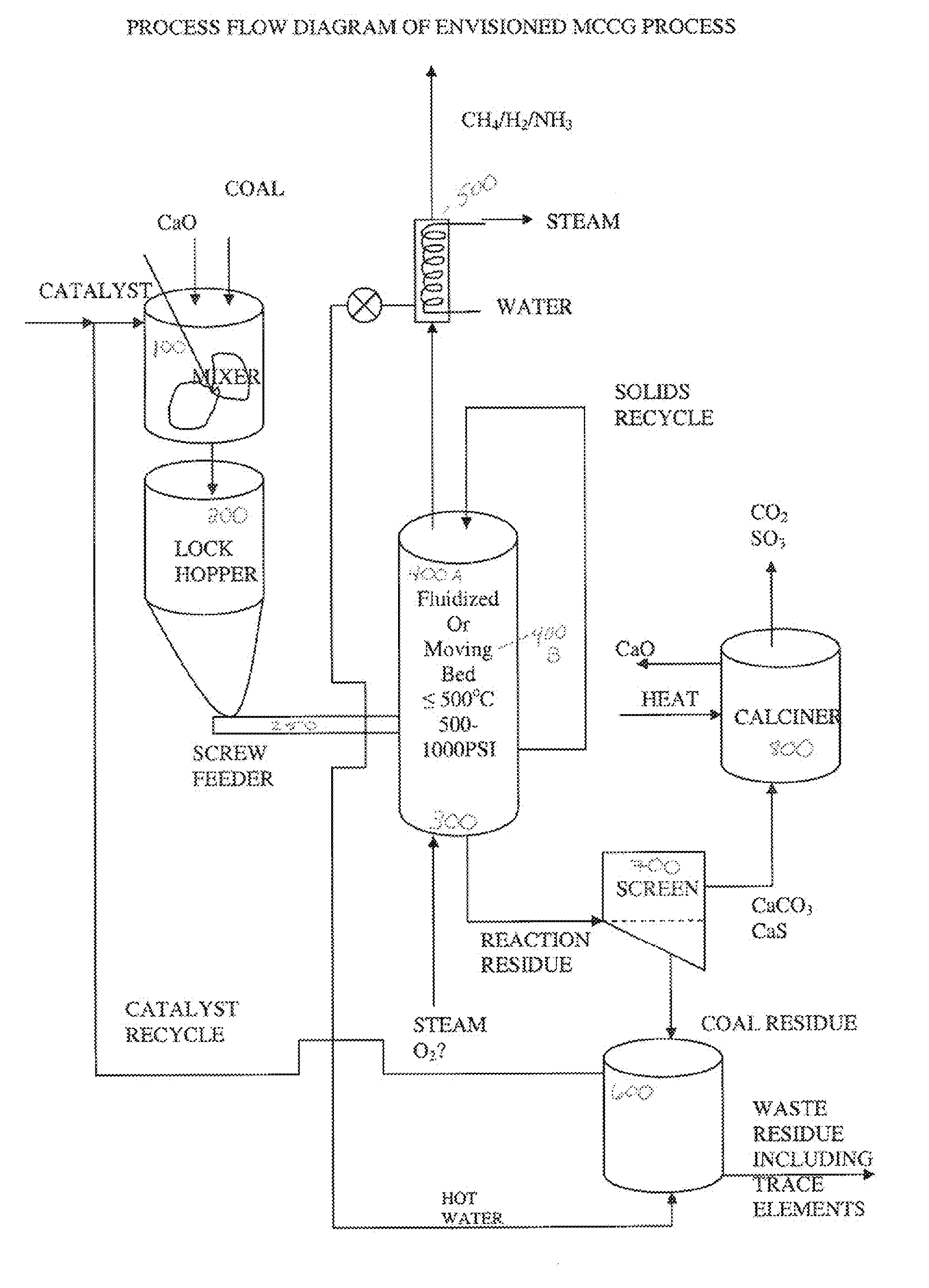

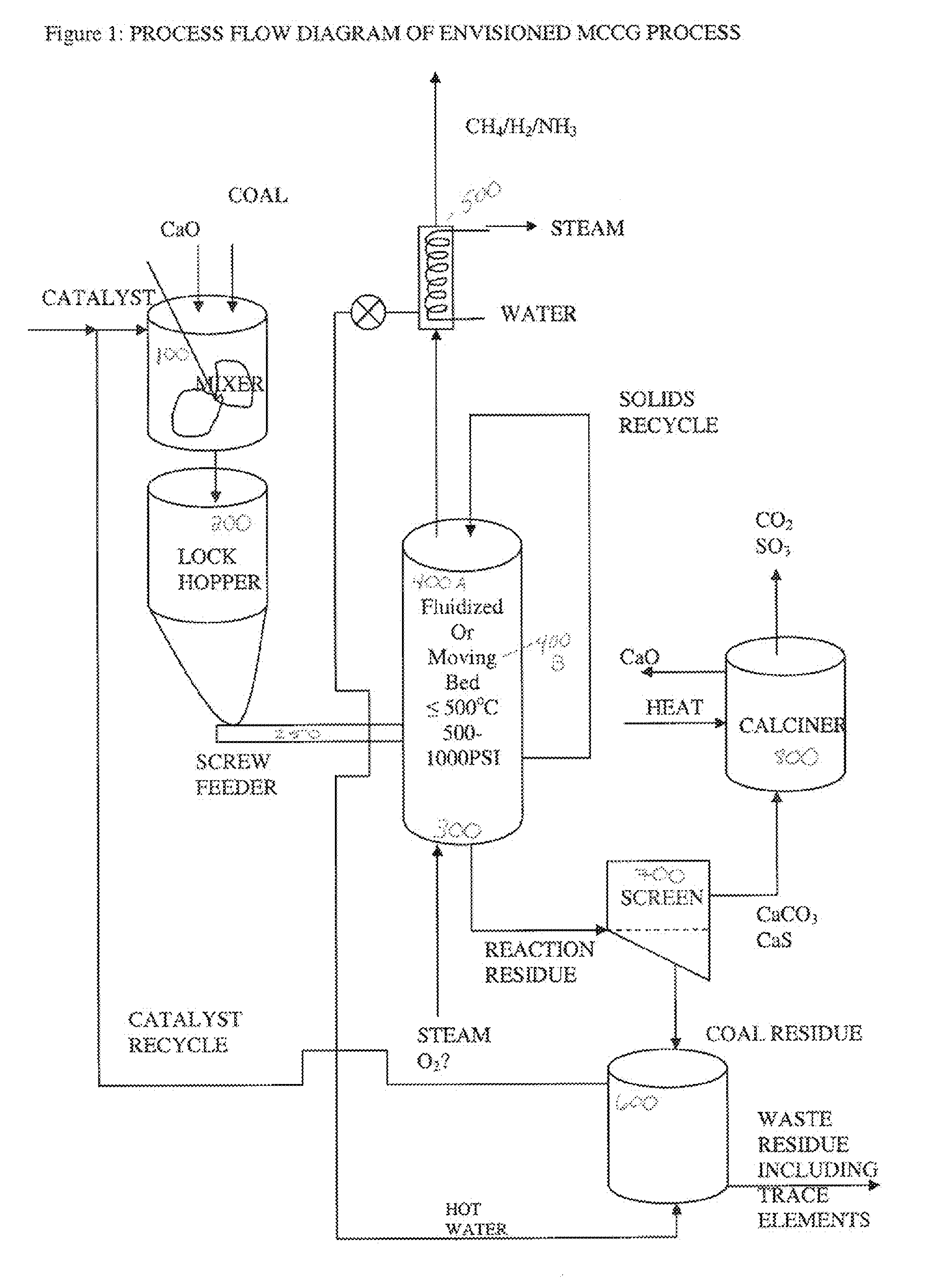

Mild catalytic steam gasification process

InactiveUS20070000177A1Great carbon conversionLittle additional treatmentGasification processes detailsCombined combustion mitigationMaceralAlkali metal

The present invention provides an improved alkali metal catalyzed steam gasification process that utilizes a CO2 trap material and / or a mineral binder material within the gasifier. The process optimally achieves over 90% carbon conversion with over 80% yield of methane. The raw gas product can be used directly as fuel. The catalyst can be recovered from the solid purge and recycled to the gasifier and / or the CO2 trap can be regenerated and recycled to the gasifier.

Owner:SURE CHAMPION INVESTMENT LTD

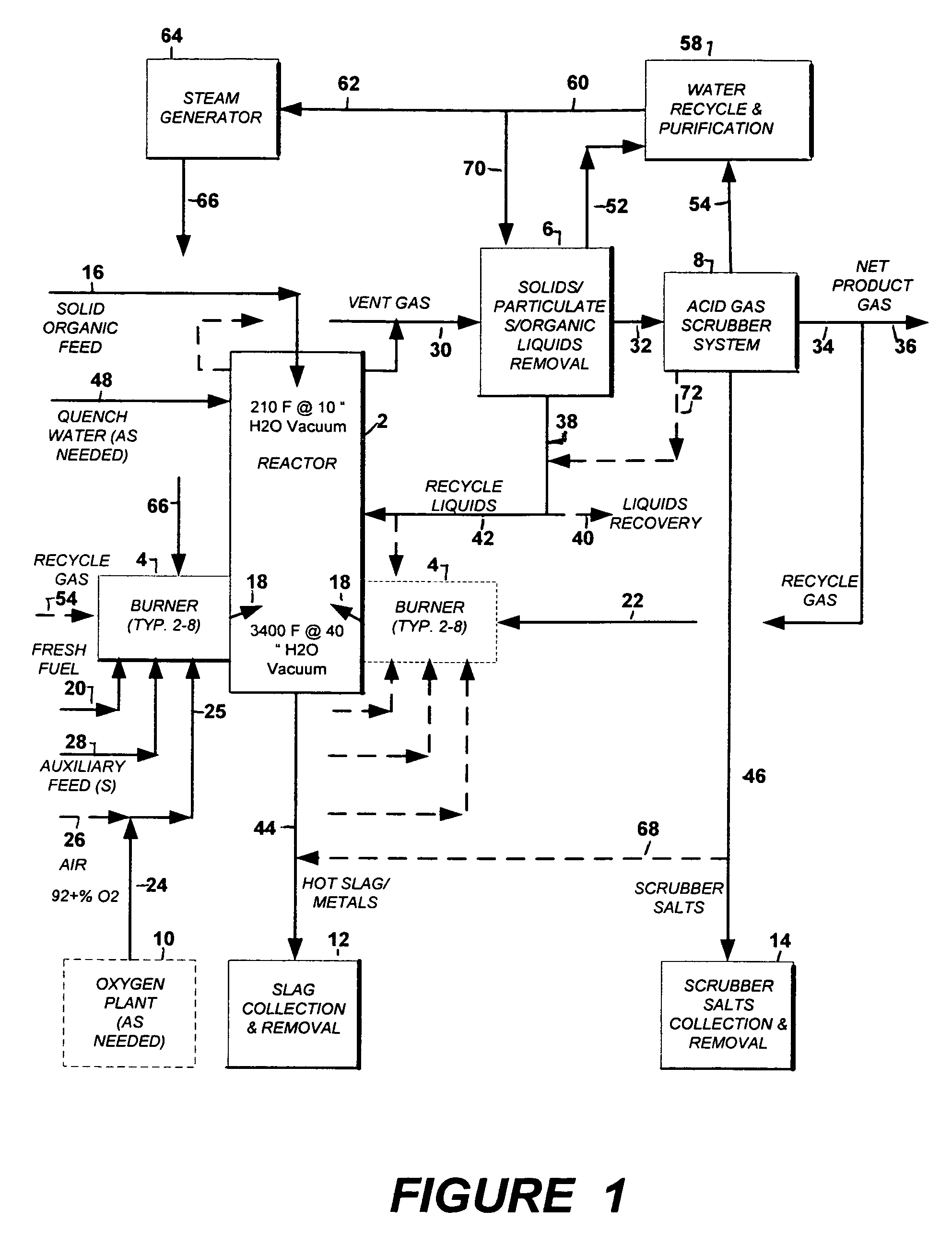

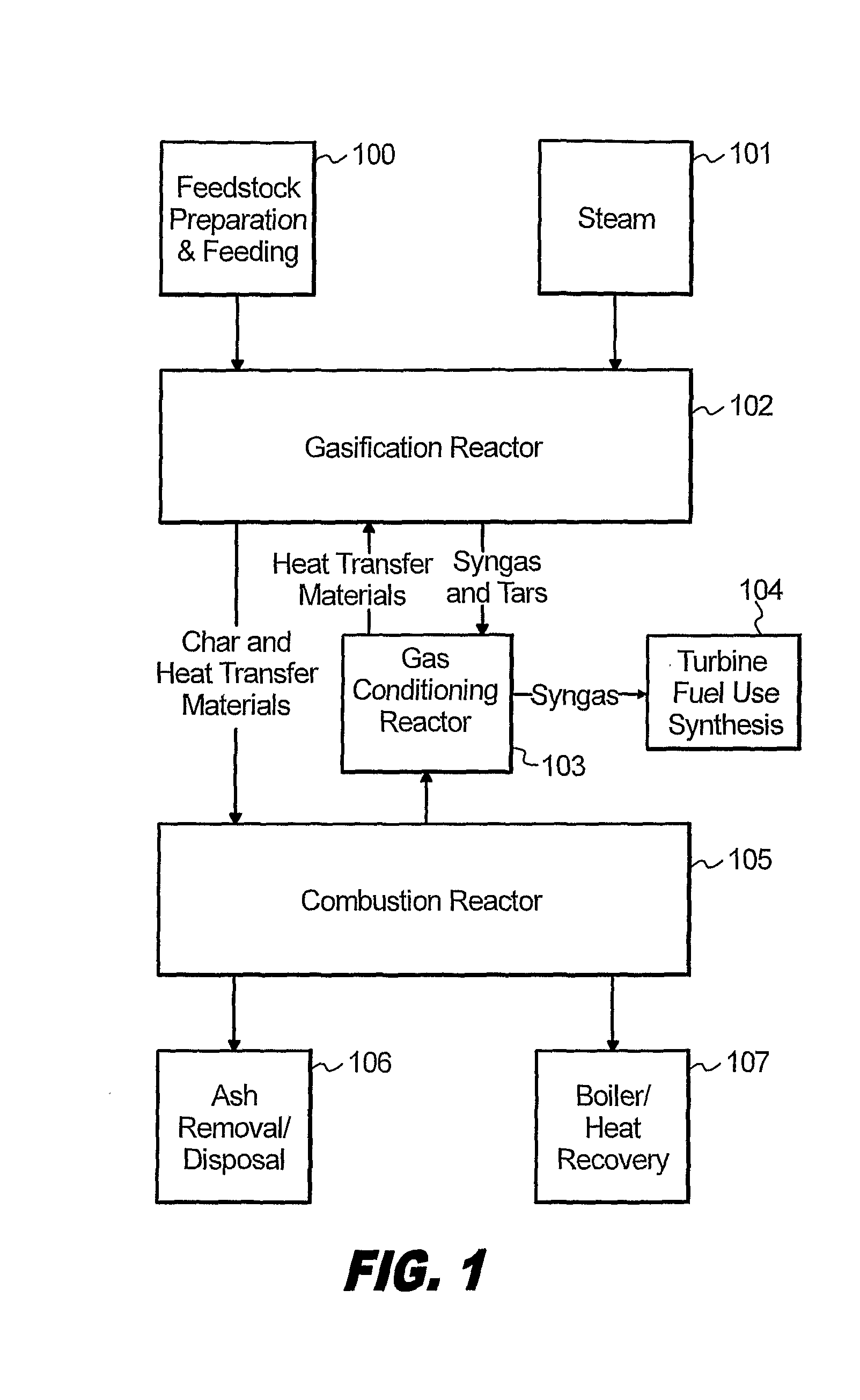

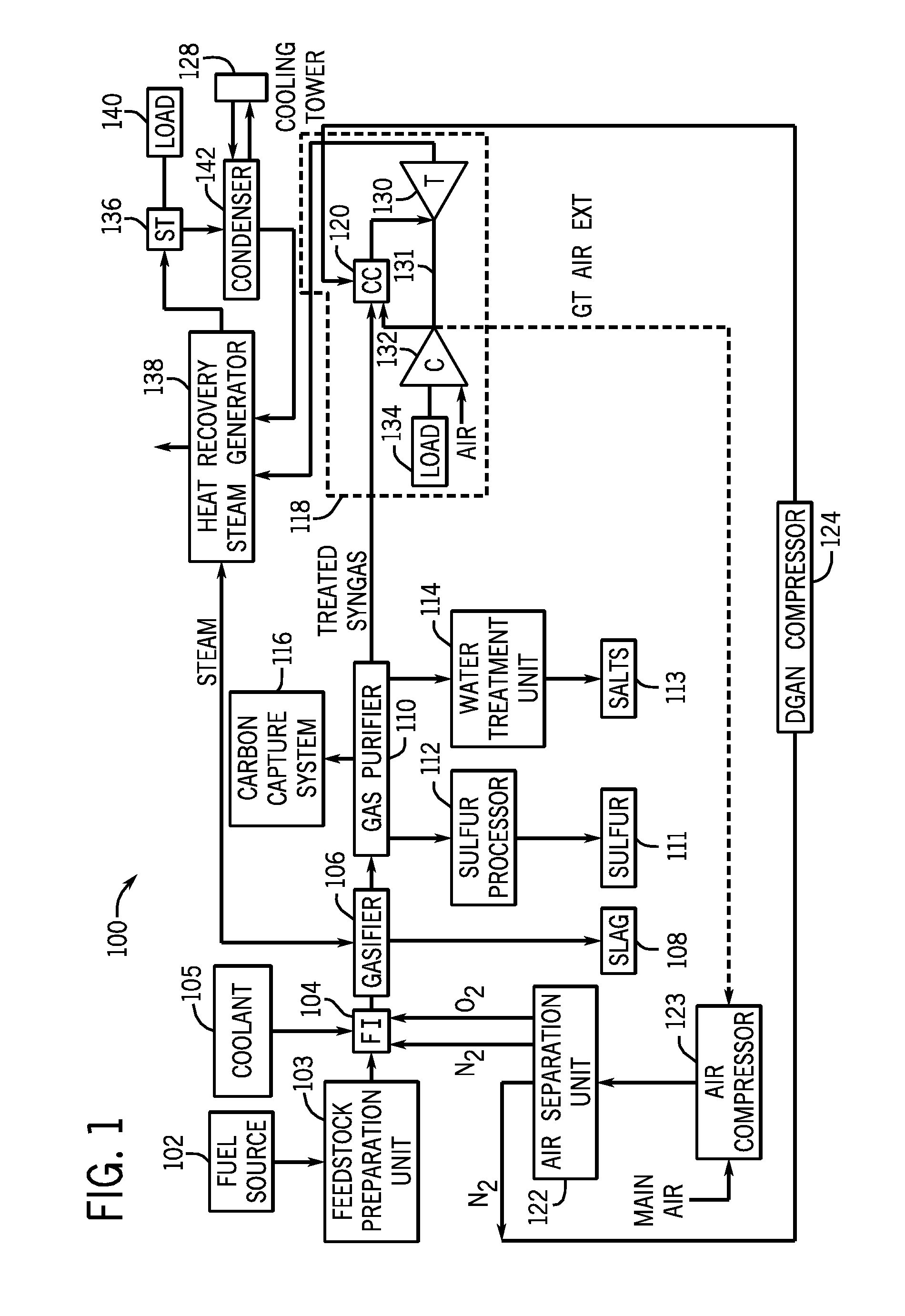

Process and system for converting carbonaceous feedstocks into energy without greenhouse gas emissions

ActiveUS20070099038A1High hydrogen contentFuel cells groupingHydrogen separation using solid contactPetroleum cokePetroleum

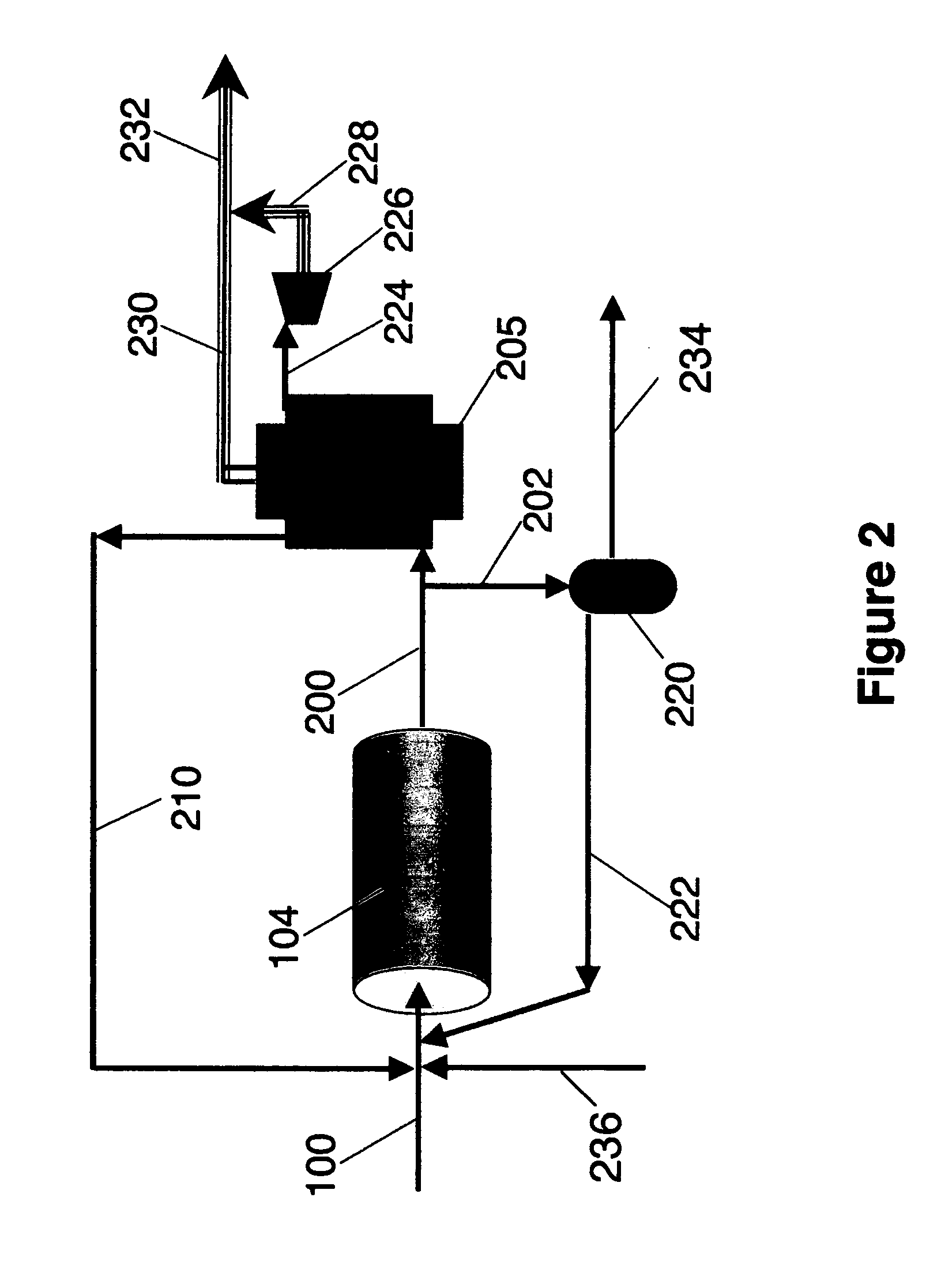

The process of the invention converts carbonaceous feedstock such as coal, hydrocarbon oil, natural gas, petroleum coke, oil shale, carbonaceous-containing waste oil, carbonaceous-containing medical waste, carbonaceous-containing military waste, carbonaceous-containing industrial waste, carbonaceous-containing medical waste, carbonaceous-containing sewage sludge and municipal solid waste, carbonaceous-containing agricultural waste, carbonaceous-containing biomass, biological and biochemical waste, and mixtures thereof into electrical energy without the production of unwanted greenhouse emissions. The process uses a steam / CO2 reformer operating in the exit range of at least 700° to about 1600° C. (1300-2900°0 F.) to convert the carbonaceous feedstock and a greenhouse gas stream into a synthesis gas comprising mostly carbon monoxide and hydrogen that contains poisons and the compounds that poison fuel cells. The syngas is sent to an interface zone to remove these poisons and other fouling compounds that are electrochemically oxidized in an electricity-producing fuel cell into an exit gas comprising carbon dioxide and water.

Owner:RAVEN SR INC

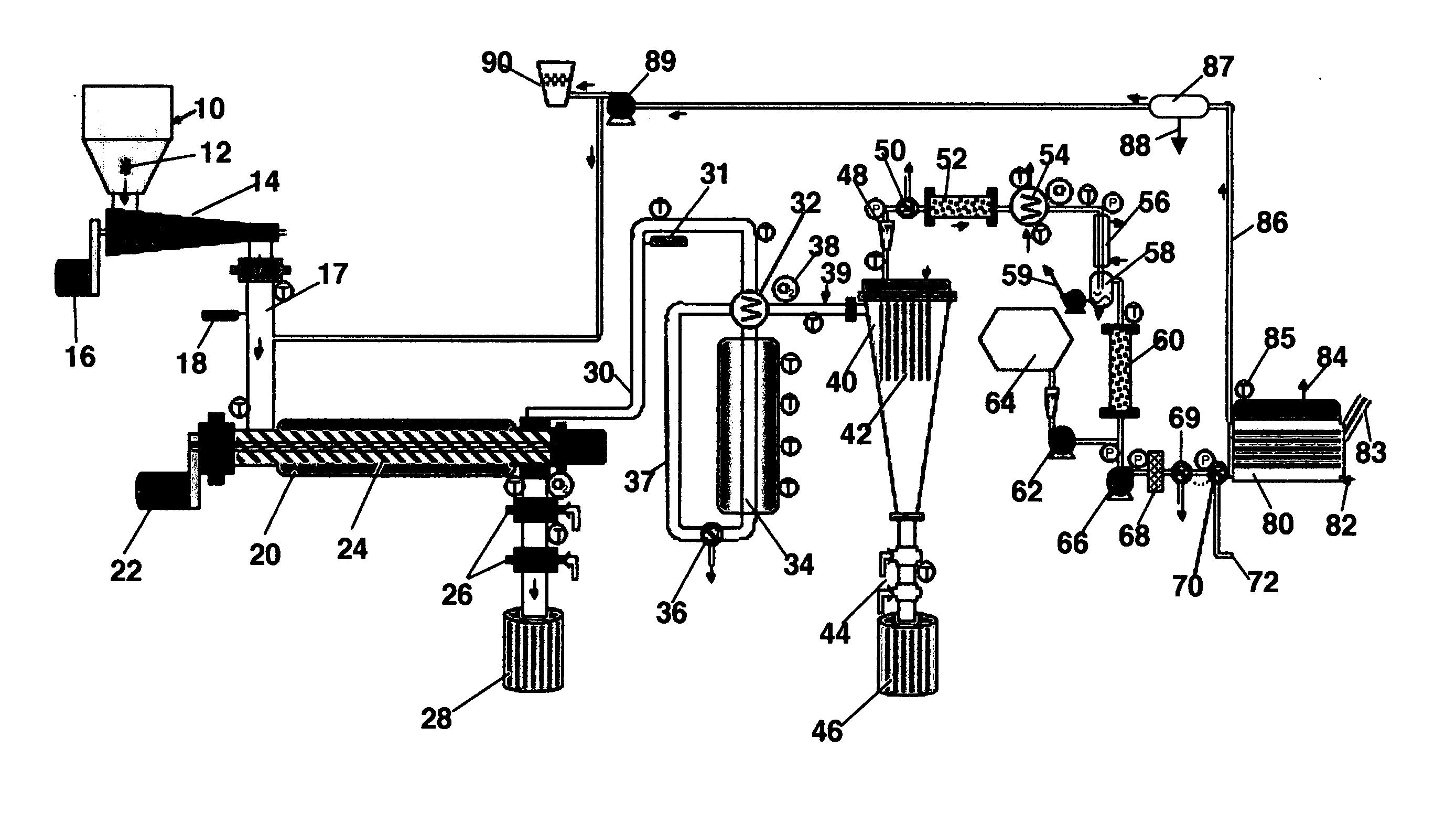

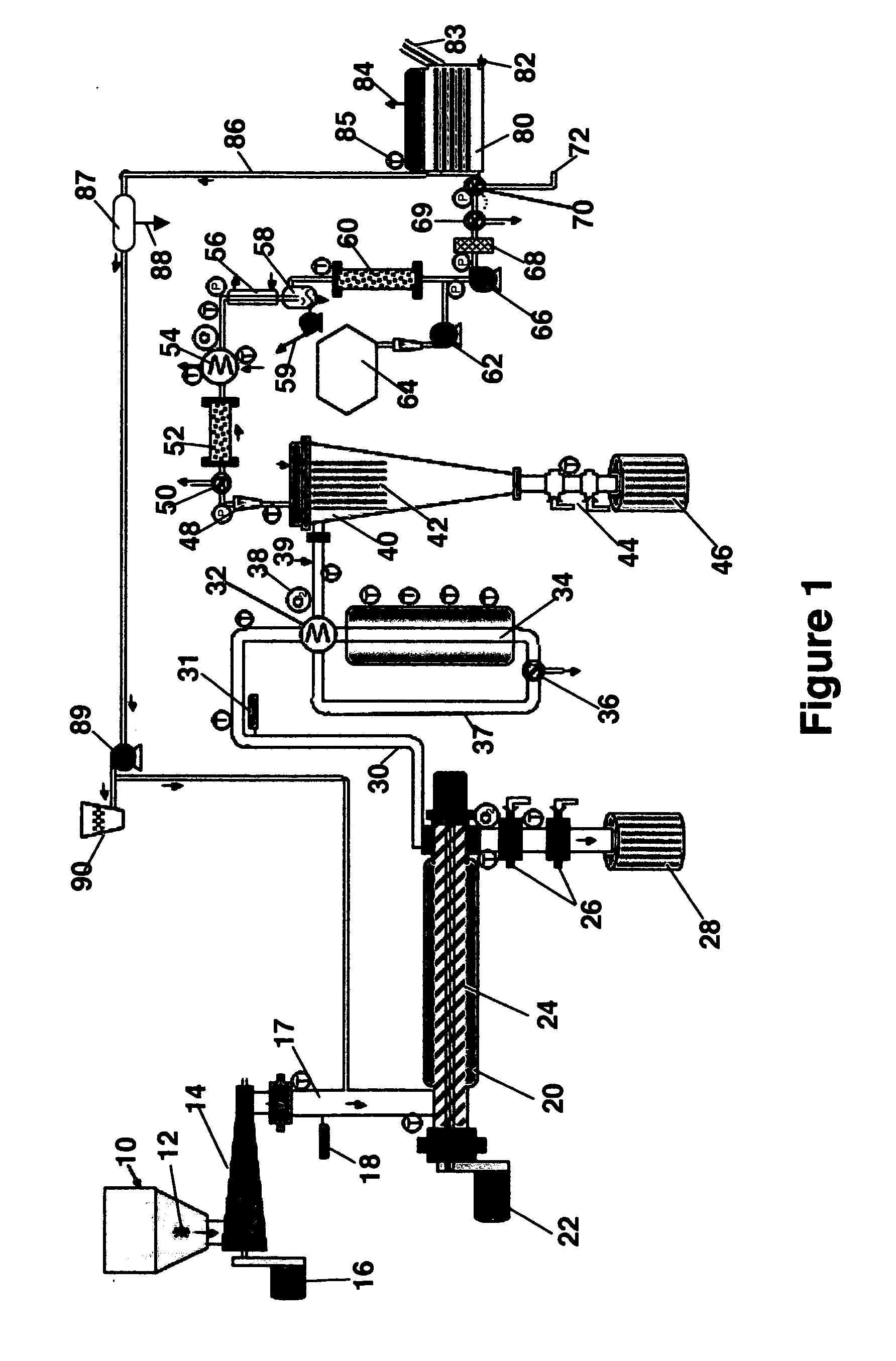

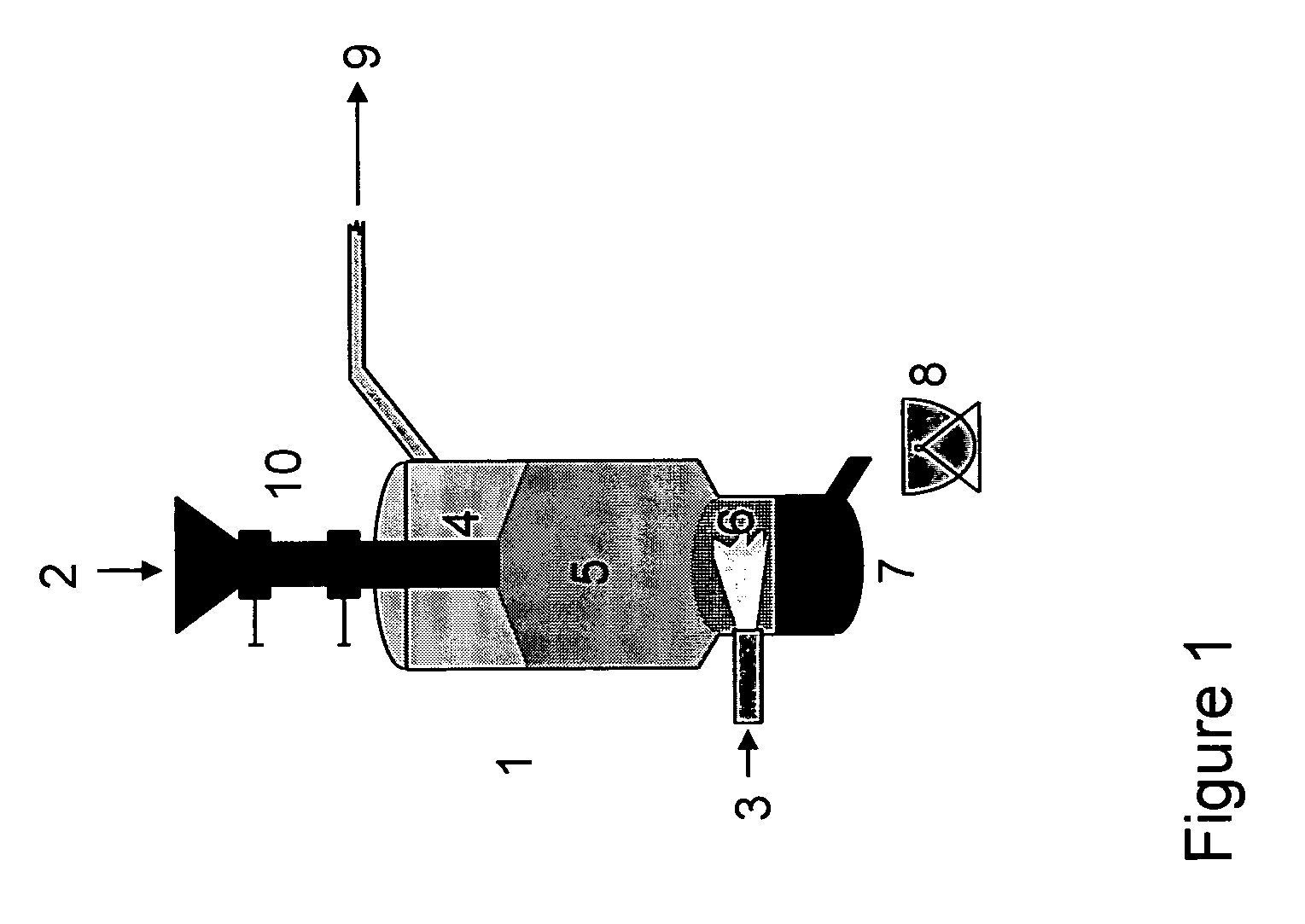

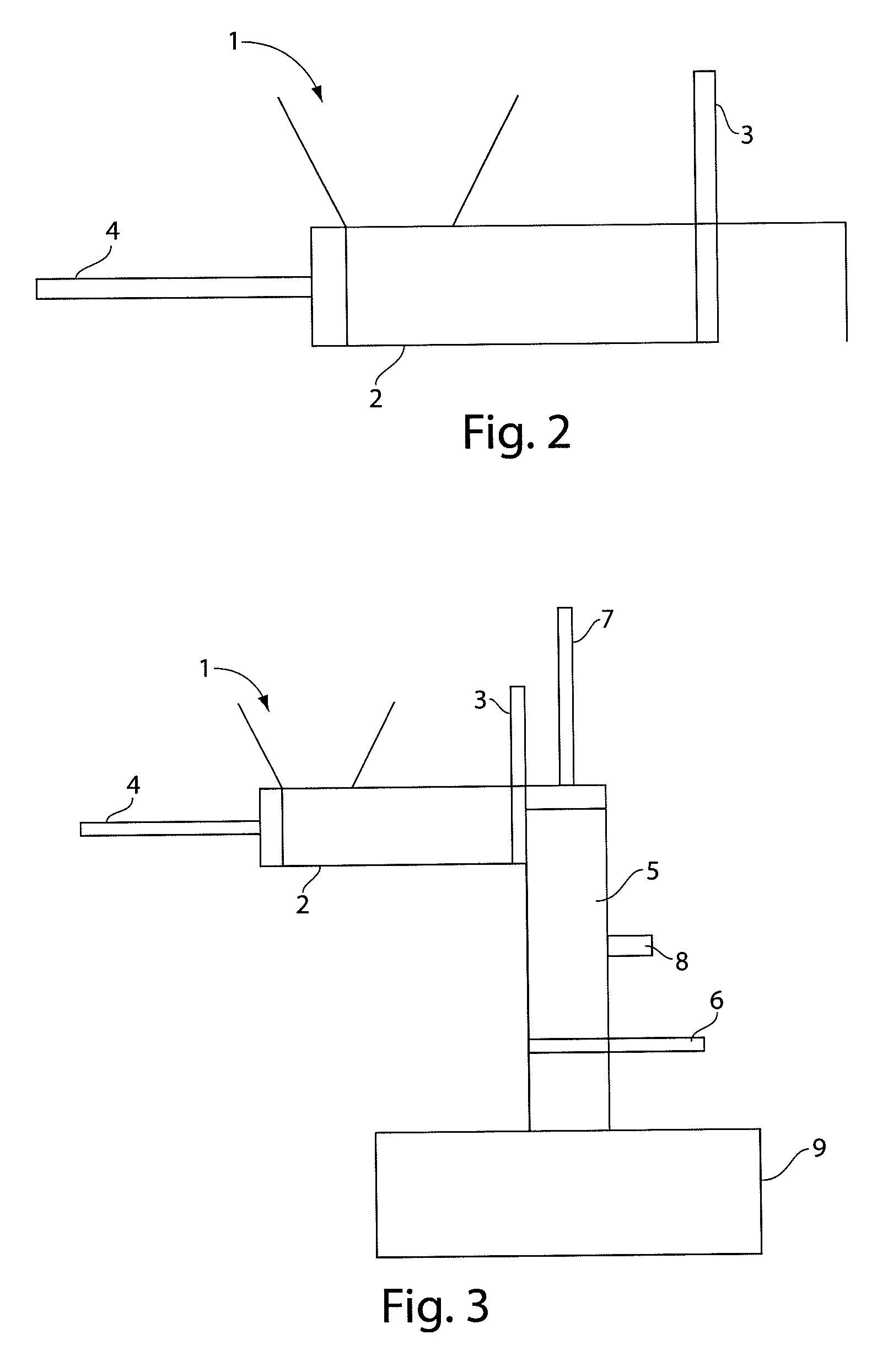

Process and system for syngas production from biomass materials

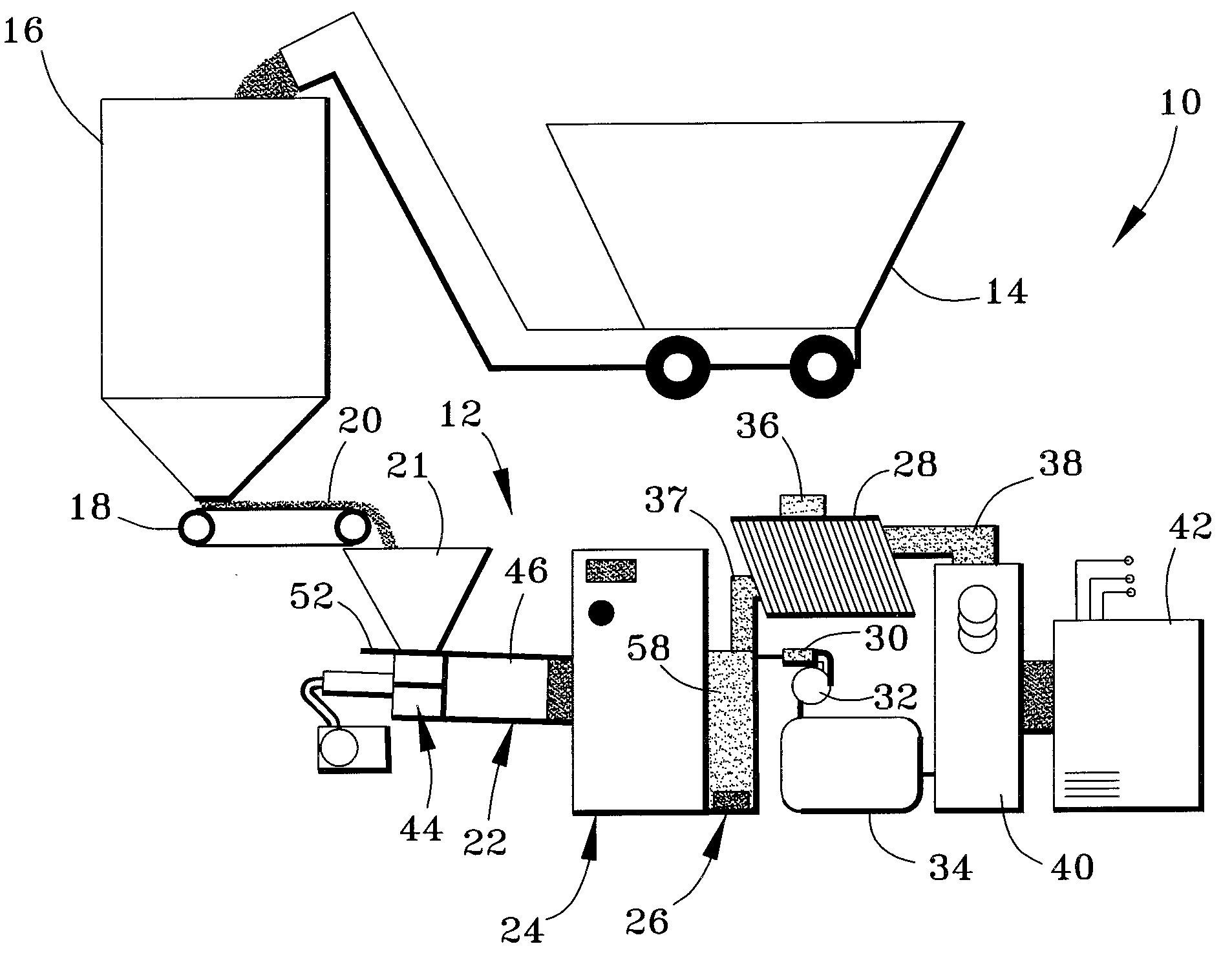

A process and system suitable for producing syngas from biomass materials. The process and system entail the compaction of a loose biomass material to remove air therefrom and form a compacted biomass material. The compacted biomass material is then introduced into a reactor and heated in the substantial absence of air so as not to combust the compacted biomass material. Instead, the compacted biomass material is heated to a temperature at which organic molecules within the compacted biomass material break down to form ash and gases comprising carbon monoxide and hydrogen gas. Thereafter, the carbon monoxide and hydrogen gas are released from the reactor, and the ash is removed from the reactor.

Owner:GREEN FORTRESS ENG INC

Acid gas scrubbing apparatus and method

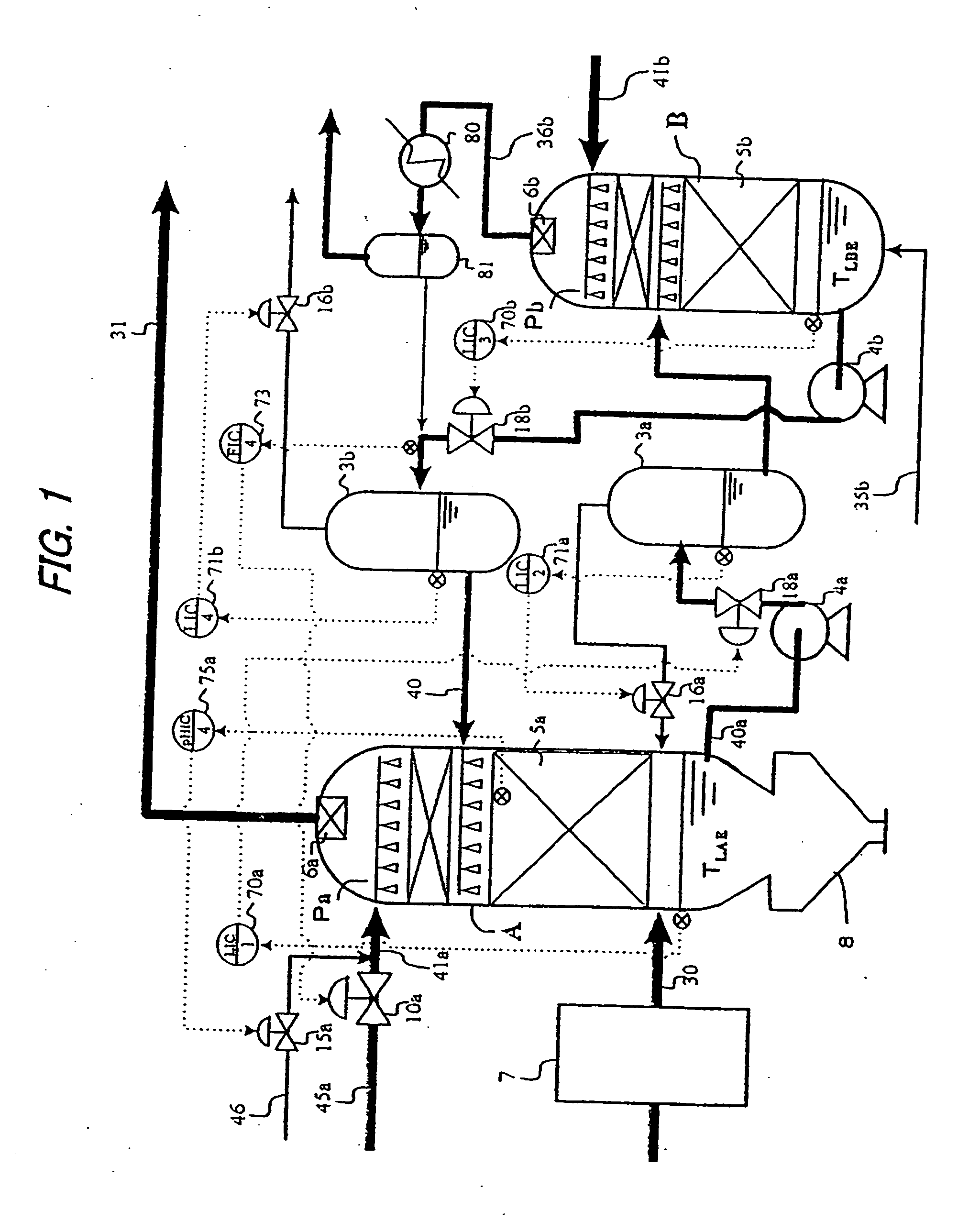

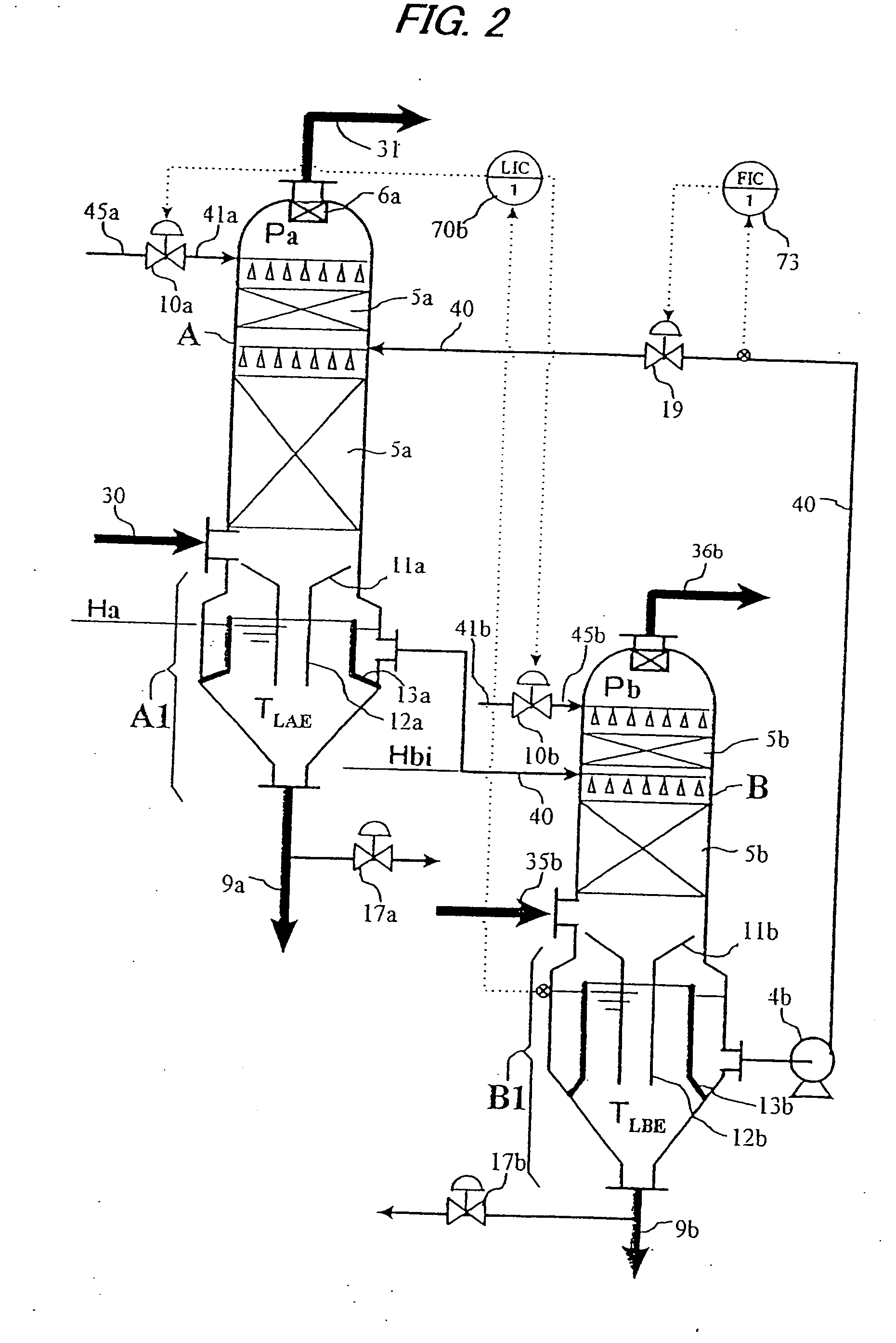

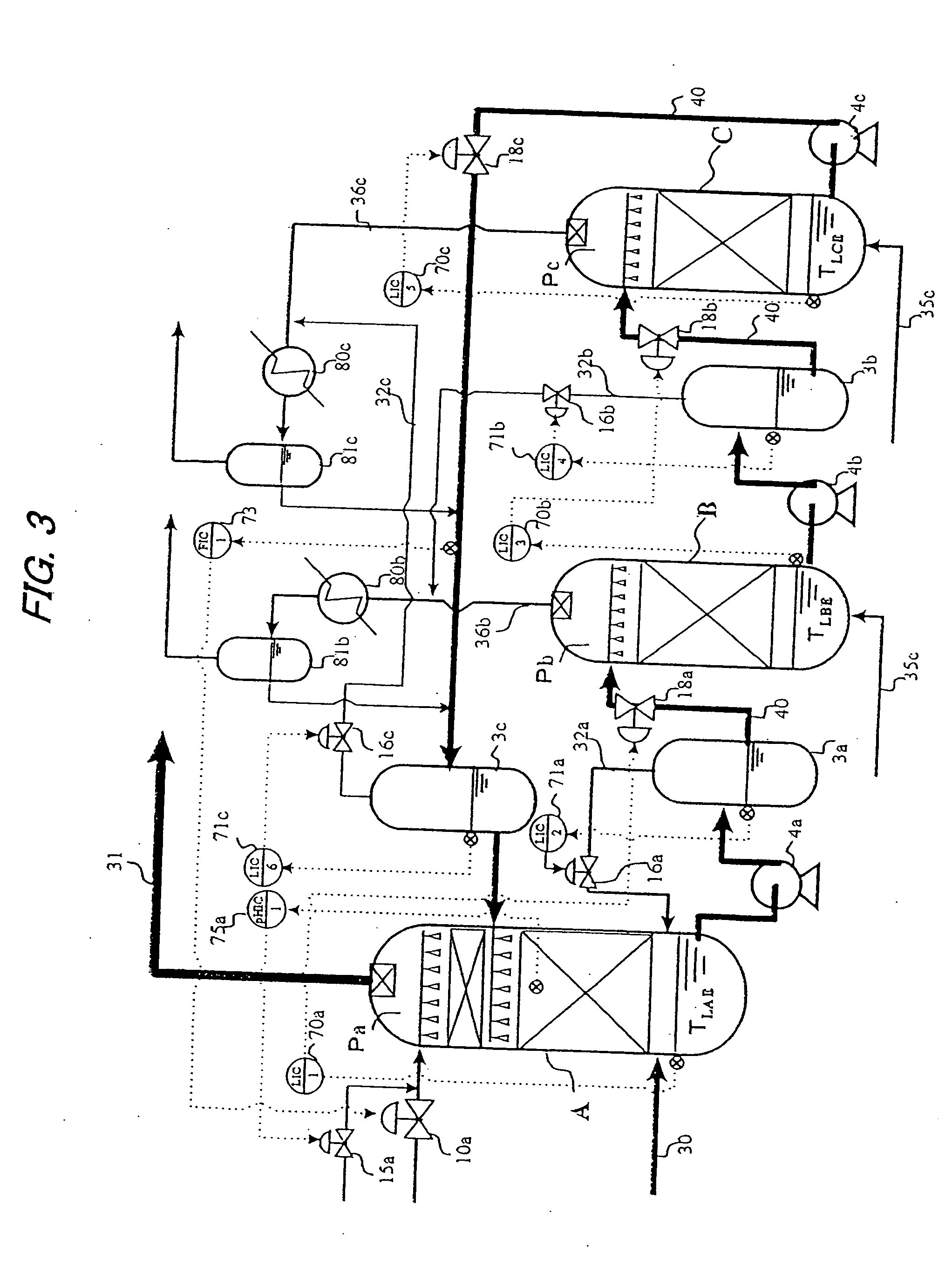

InactiveUS20050132883A1Improve energy efficiencyImprove acid gas removal capabilityUsing liquid separation agentCombustible gas catalytic treatmentScrubberCarbon dioxide

An acid gas scrubbing apparatus and method brings a gas, to be scrubbed, containing carbon dioxide into contact with a gas scrubbing liquid containing alkaline agent and cooled, and acid gases in the gas are removed. A gas scrubber removes acid gases in a gas, to be scrubbed, containing carbon dioxide by bringing the gas to be scrubbed into contact with a gas scrubbing liquid containing alkaline agent. A scrubbing liquid regenerator regenerates and cools the gas scrubbing liquid by bringing the gas scrubbing liquid into contact with a regenerating gas having components different from the gas scrubbing liquid and the gas to be scrubbed. A circulating device is provided between the gas scrubber and the scrubbing liquid regenerator for circulating the scrubbing liquid.

Owner:SU QINGQUAN +4

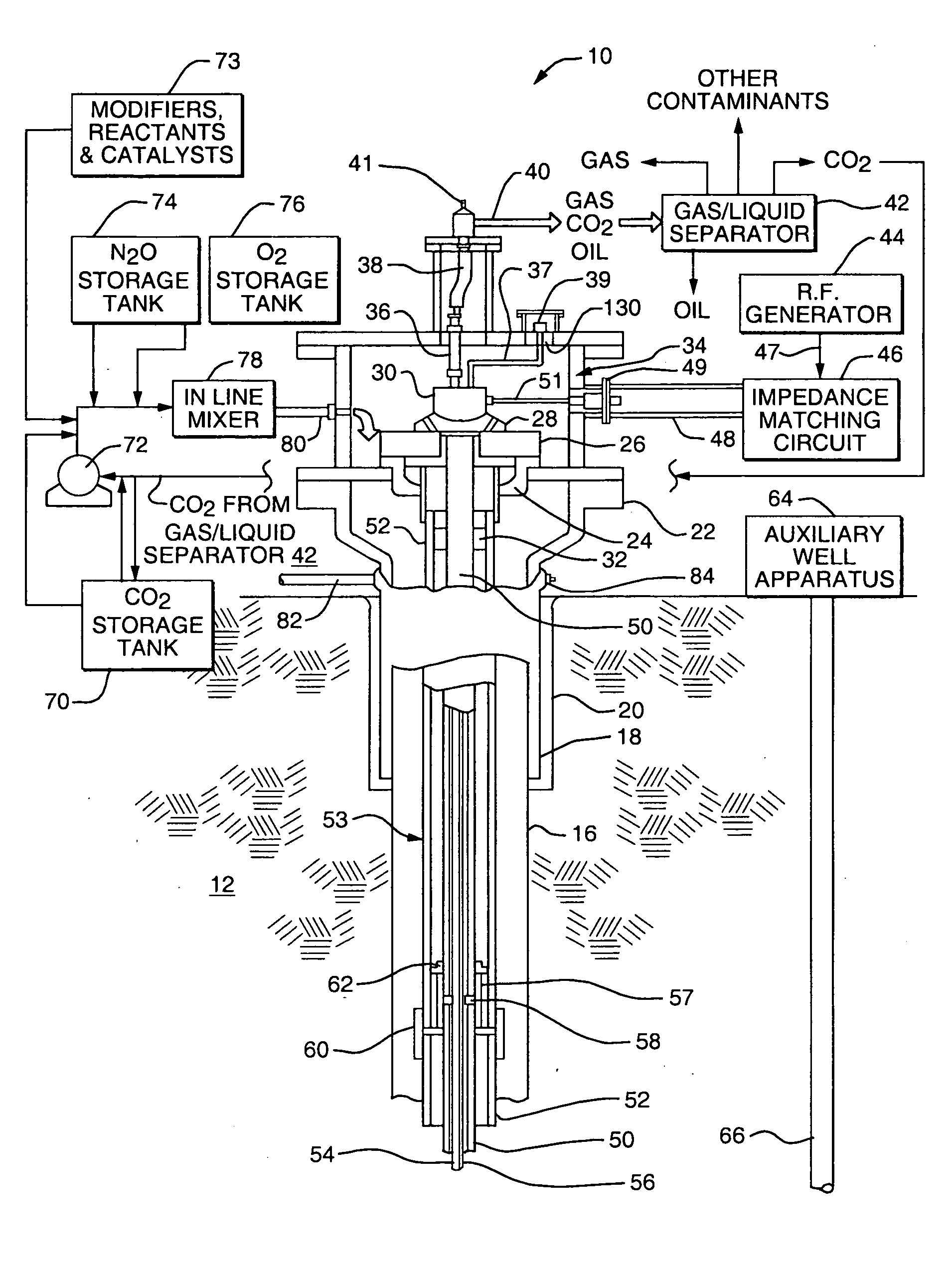

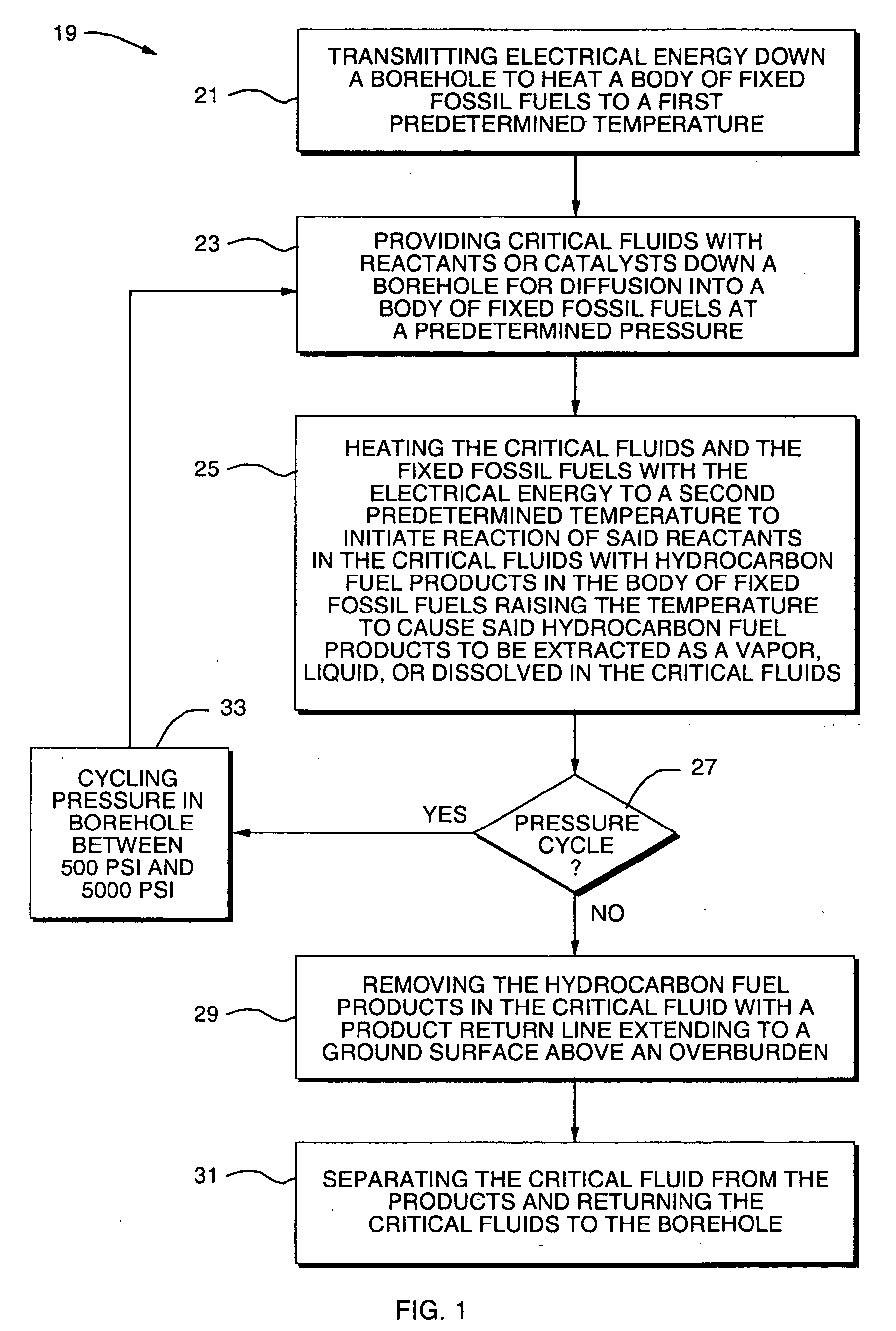

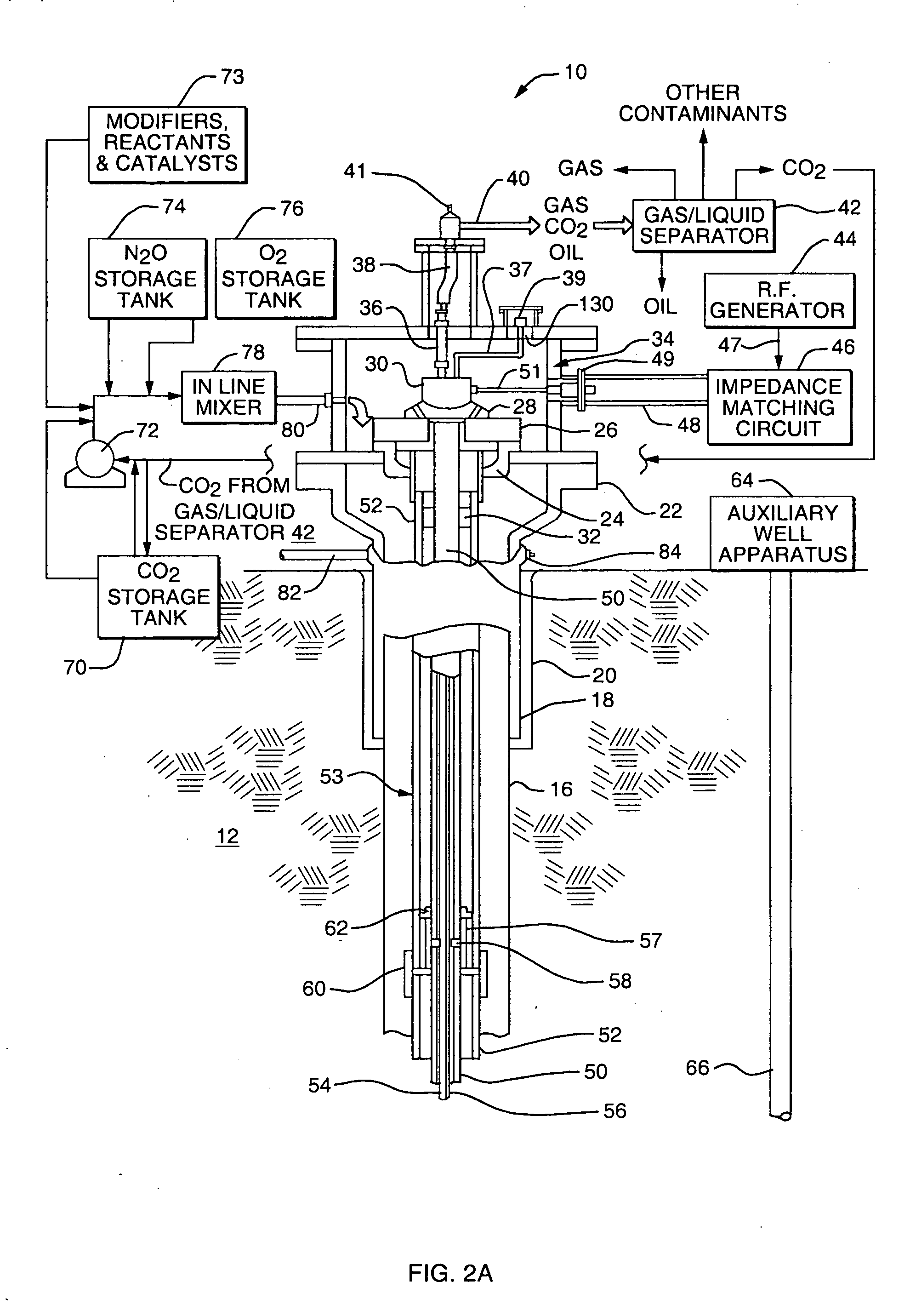

Method for extraction of hydrocarbon fuels or contaminants using electrical energy and critical fluids

ActiveUS20070137858A1Efficient heatingValid conversionSurveyHollow article cleaningVapor liquidHydrocotyle bowlesioides

The extraction of hydrocarbon fuel products such as kerogen oil and gas from a body of fixed fossil fuels such as oil shale is accomplished by applying a combination of electrical energy and critical fluids with reactants and / or catalysts down a borehole to initiate a reaction of reactants in the critical fluids with kerogen in the oil shale thereby raising the temperatures to cause kerogen oil and gas products to be extracted as a vapor, liquid or dissolved in the critical fluids. The hydrocarbon fuel products of kerogen oil or shale oil and hydrocarbon gas are removed to the ground surface by a product return line. An RF generator provides electromagnetic energy, and the critical fluids include a combination of carbon dioxide (CO2), with reactants of nitrous oxide (N2O) or oxygen (O2).

Owner:SCHLUMBERGER TECH CORP

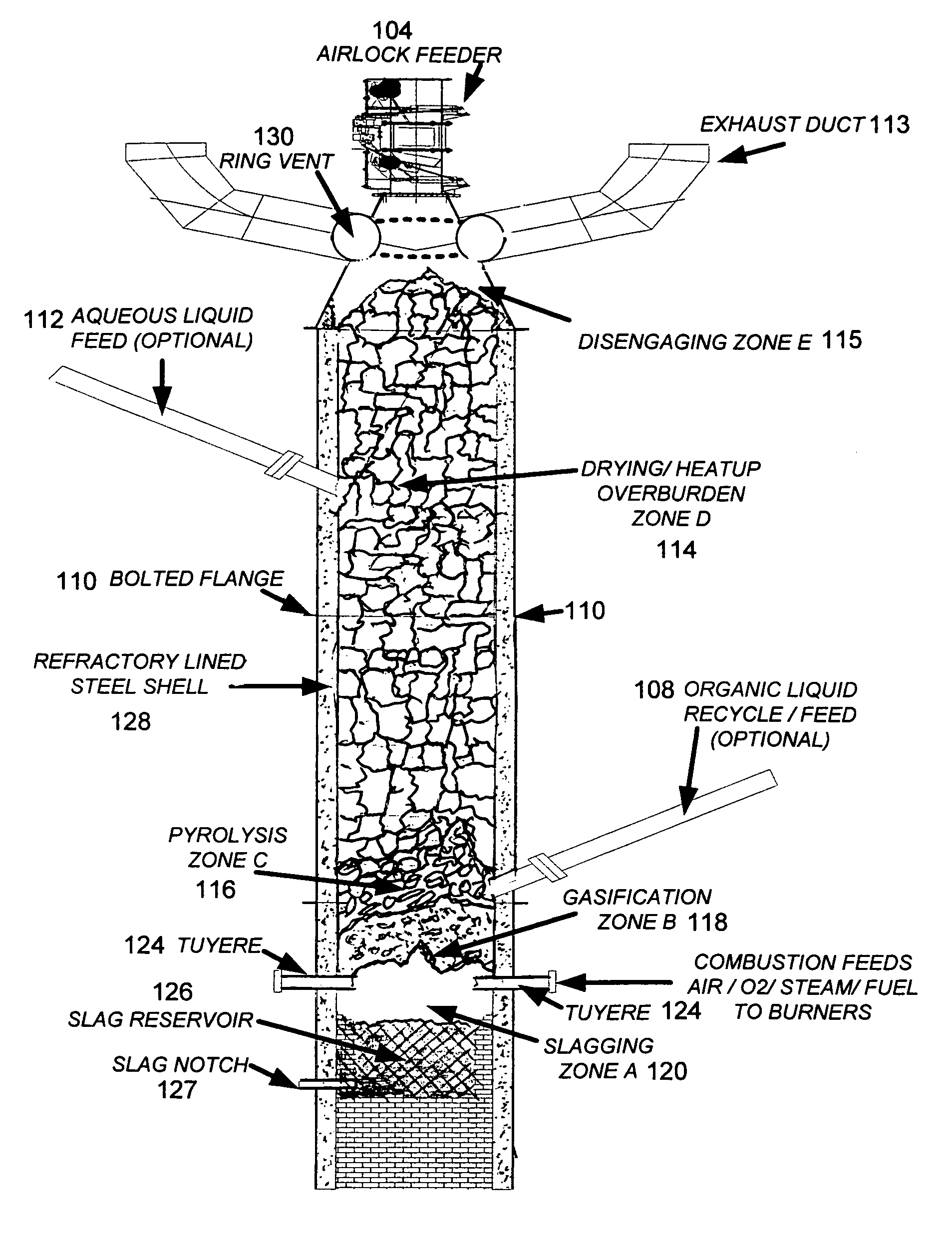

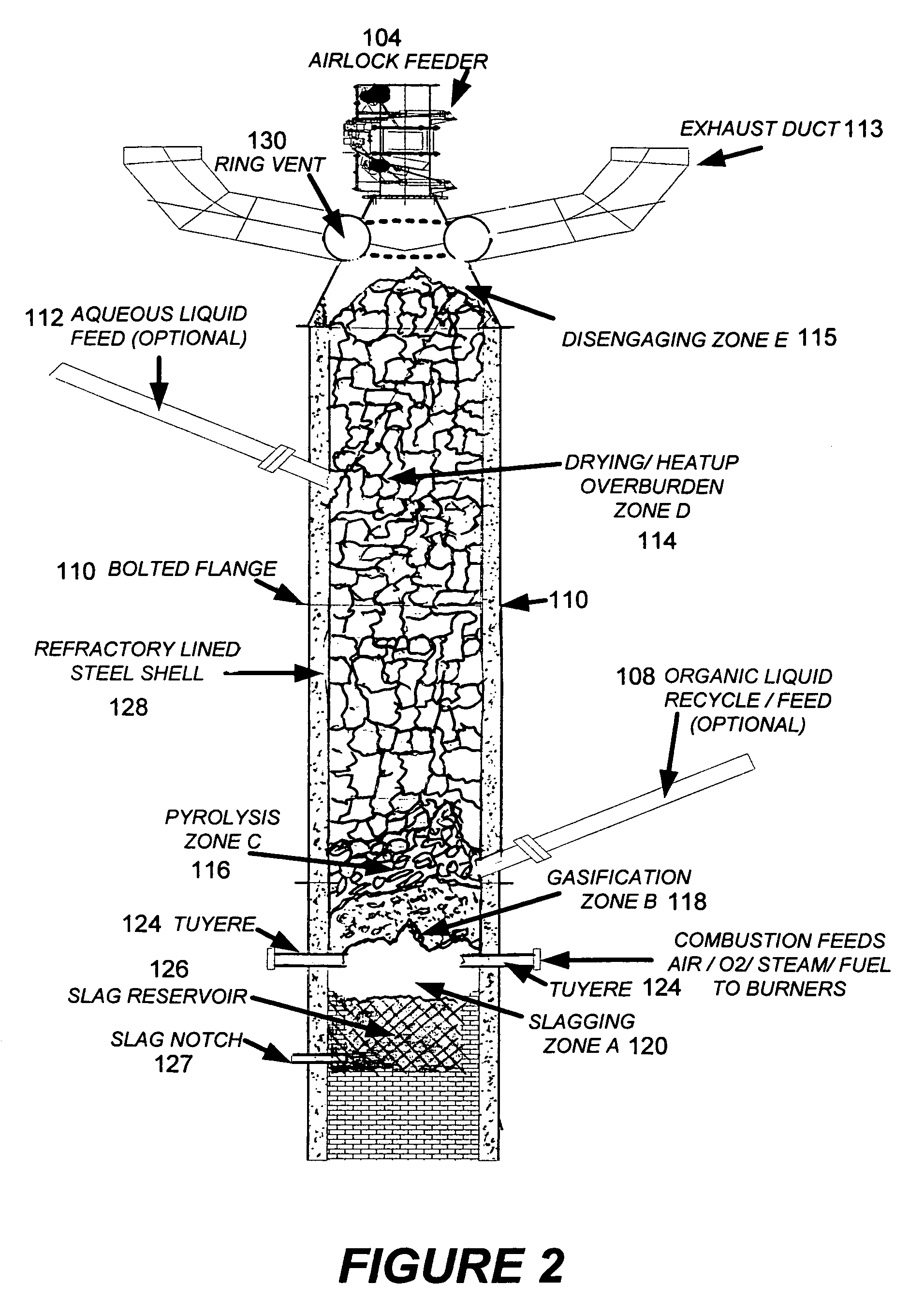

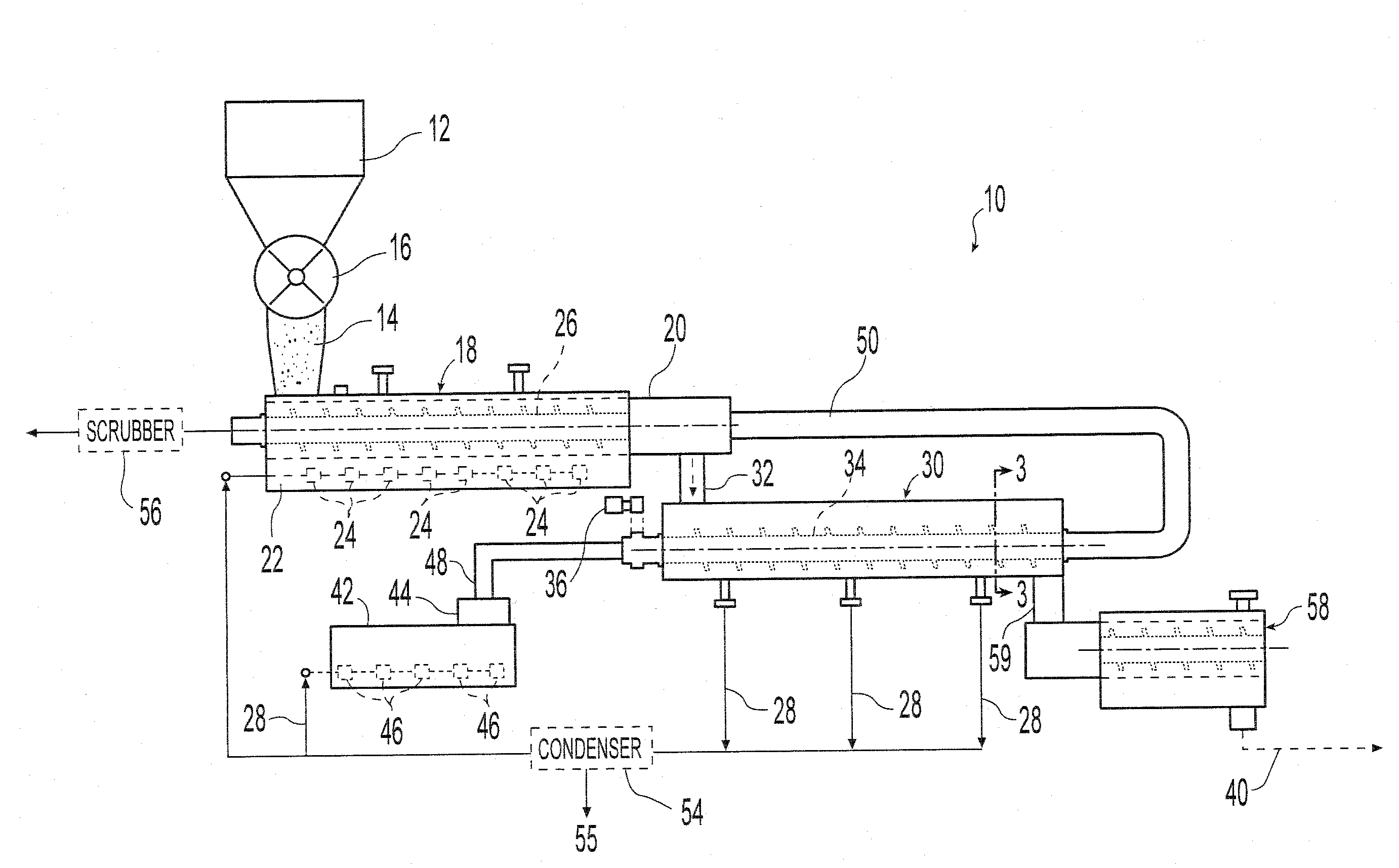

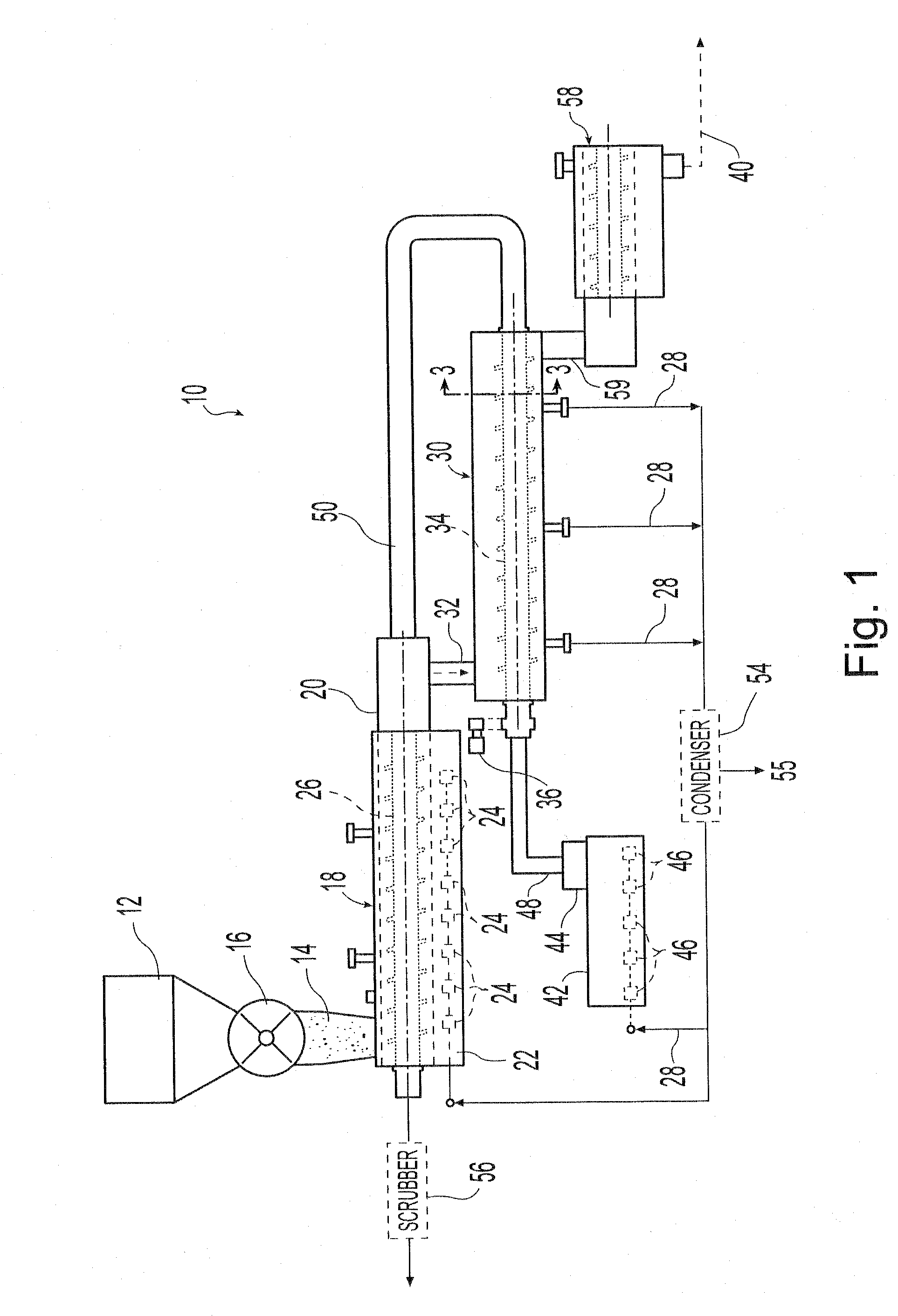

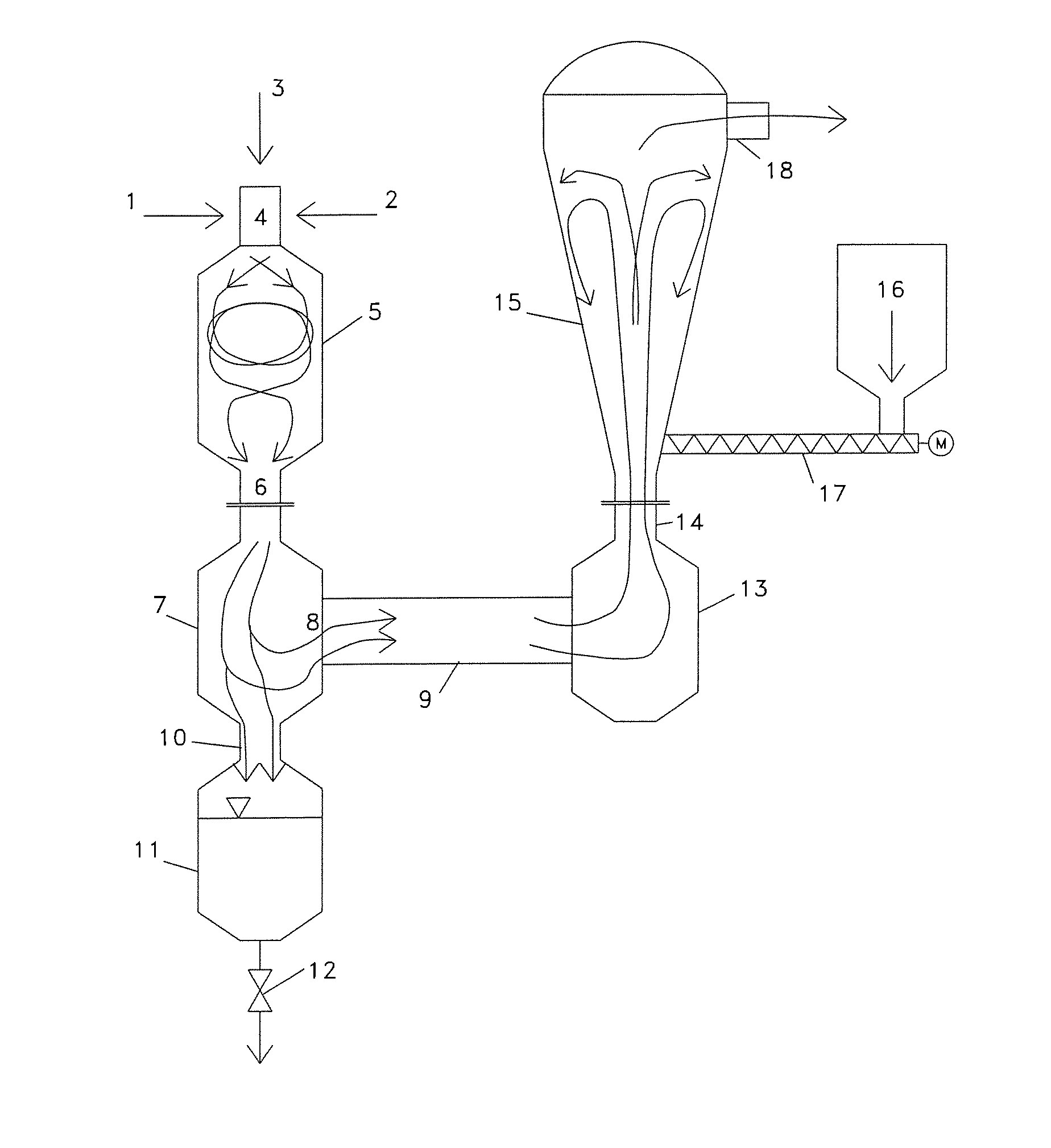

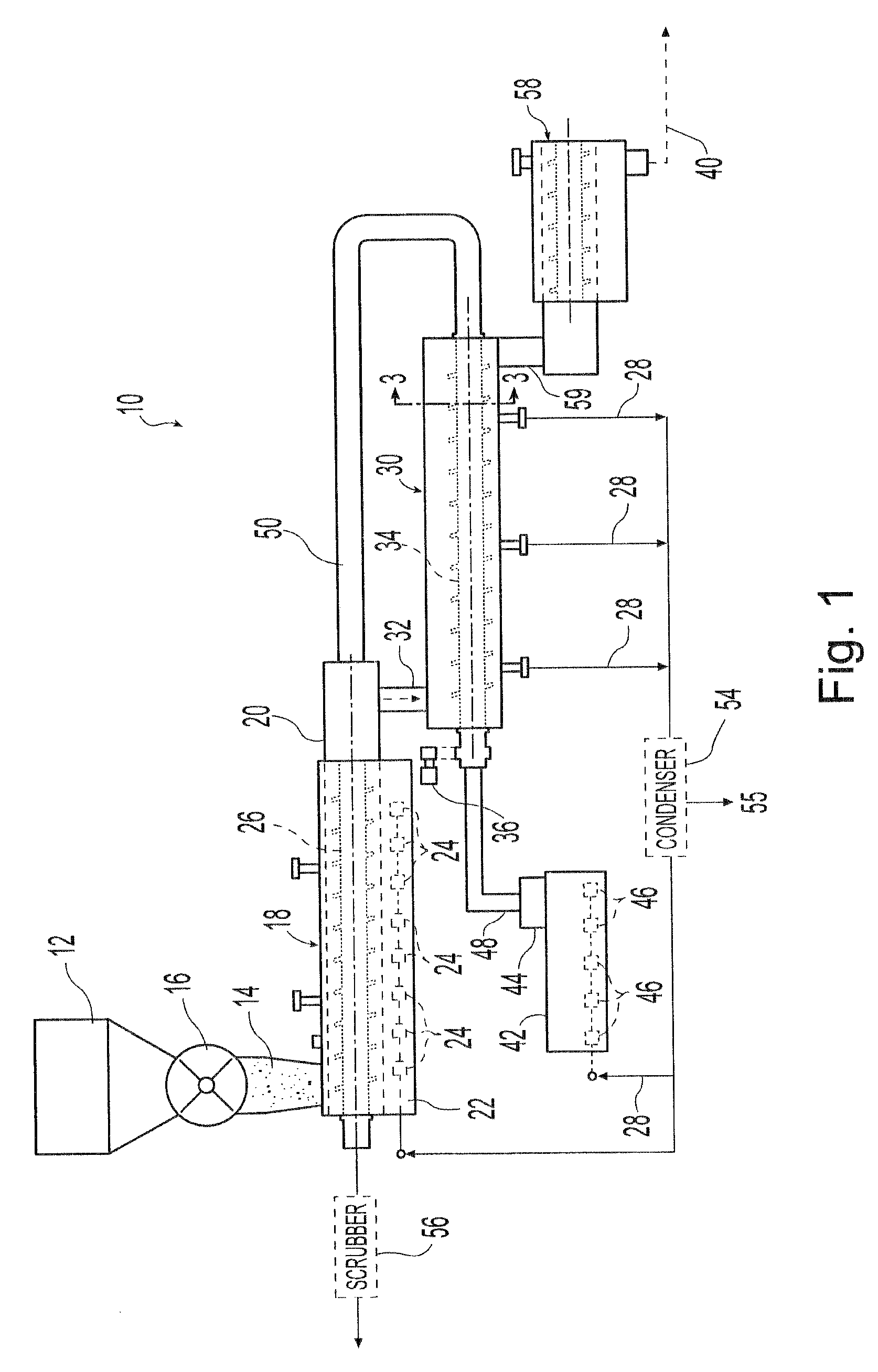

Process for pyrolytic heat recovery enhanced with gasification of organic material

InactiveUS7452392B2Improve throughputInhibition formationGas modification by gas mixingWaste based fuelThermal energyForming gas

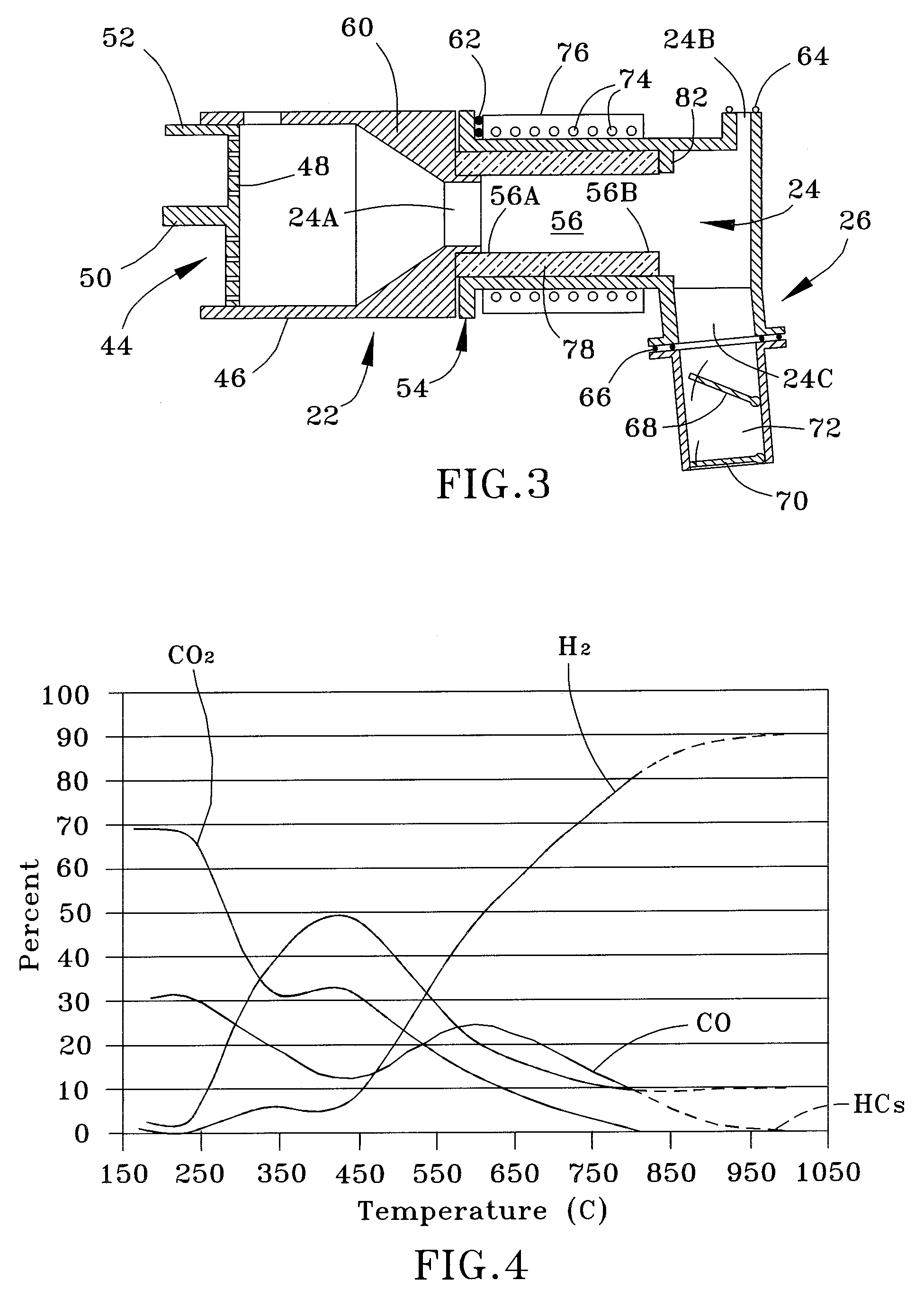

This invention is a reactor and a process for the conversion of organic waste material such as municipal trash, sewage, post-consumer refuse, and biomass to commercially salable materials.The invention produces the following:1. Maximum energy conversion from the organic material2. High volume consumption of the organic feed material3. Less pollution of gaseous products than prior art systems4. Solid residuals for disposal are minimal and non-hazardous.The conversion is accomplished by combining anaerobic gasification and pyrolysis of the feed organic material and making it into synthetic gas. The synthetic gas is a mixture of hydrocarbons (CxHy), hydrogen, and carbon monoxide with small amounts of carbon dioxide and nitrogen. An essential feature of the invention is a hot driver gas, devoid of free oxygen and rich in water, which supplies the entire thermal and chemical energy needed for the reactions. This hot driver gas is produced by complete sub-stoichiometric combustion of the fuel (CxHy) before it enters the reactor.

Owner:NICK PETER A +4

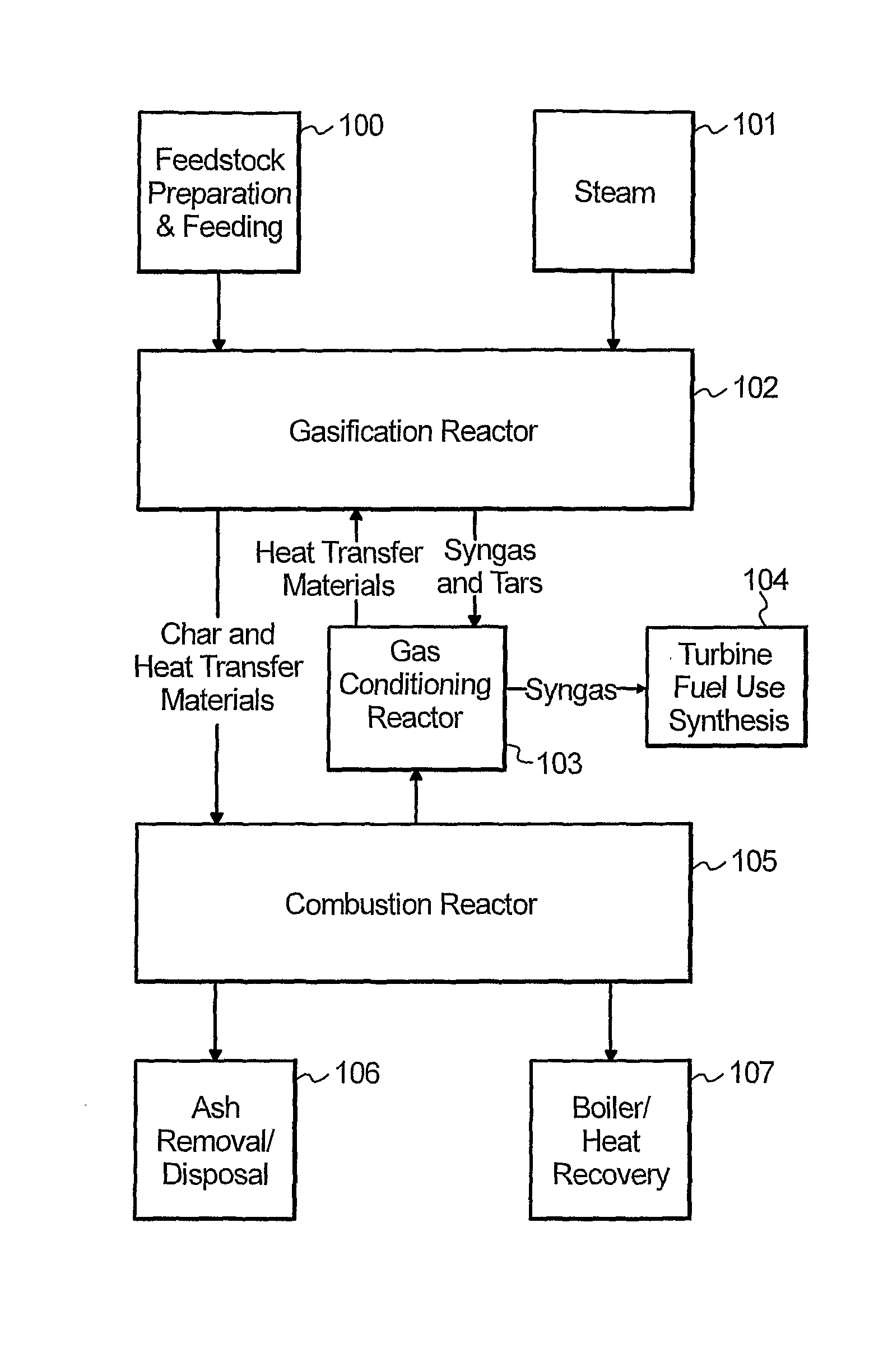

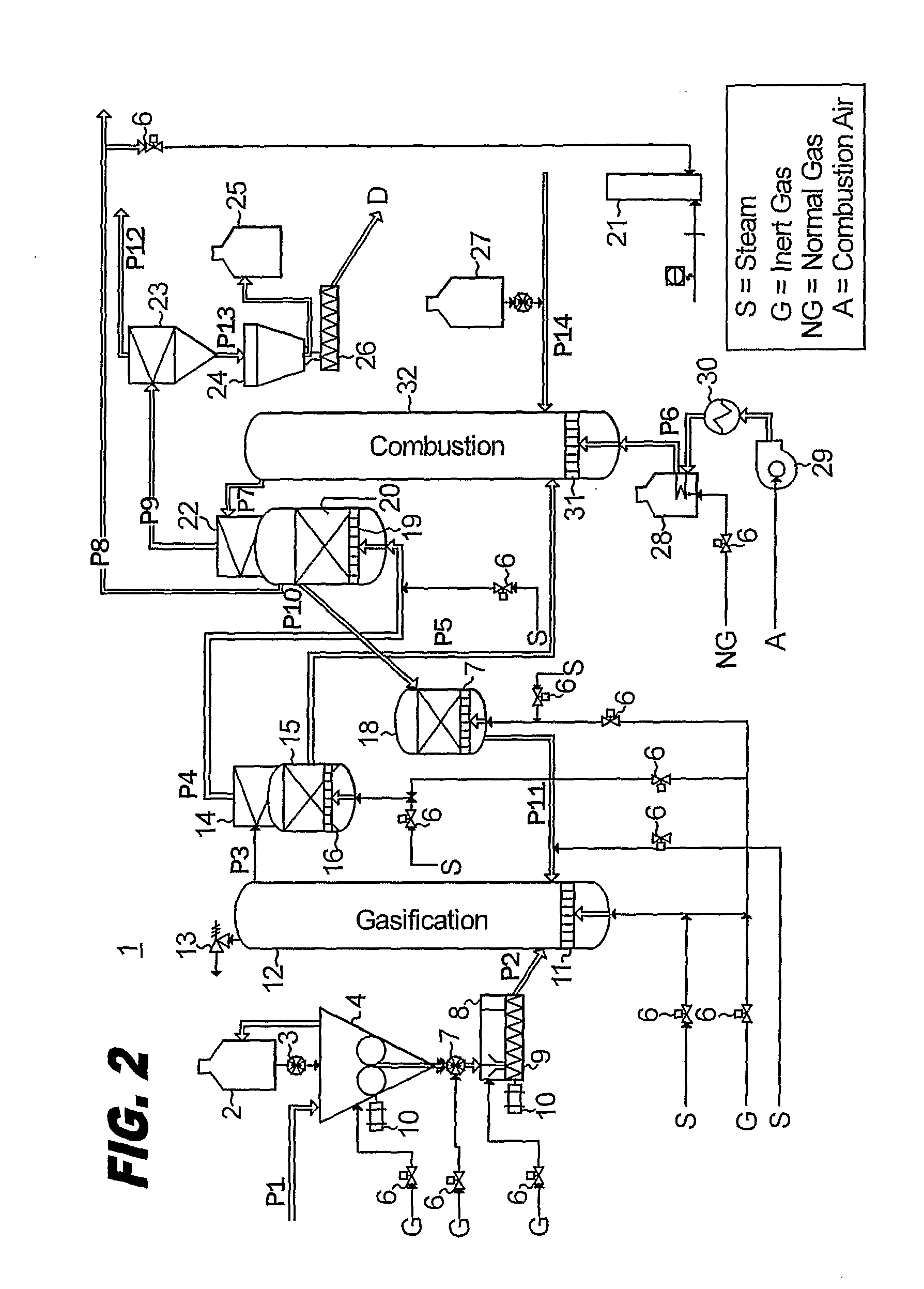

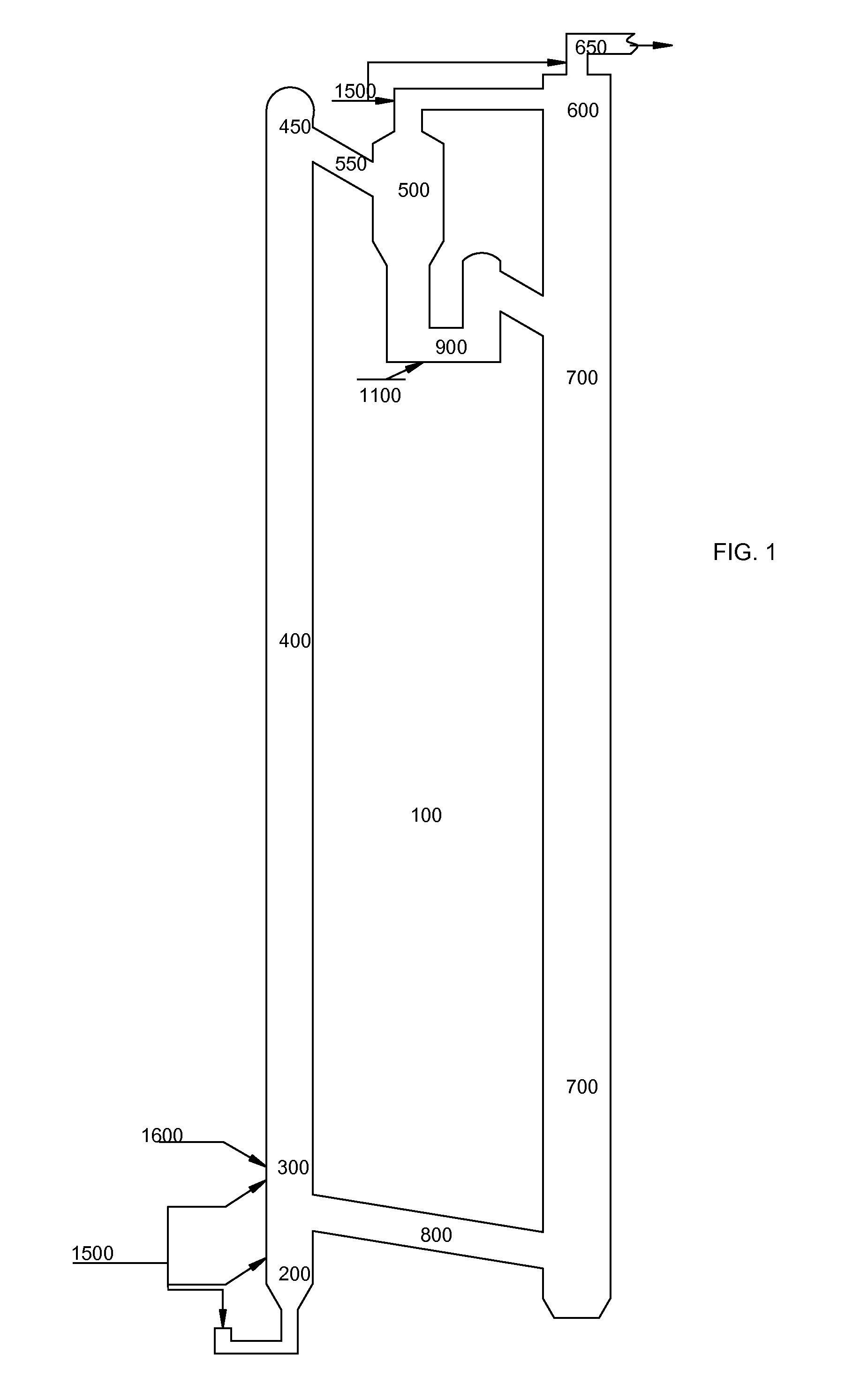

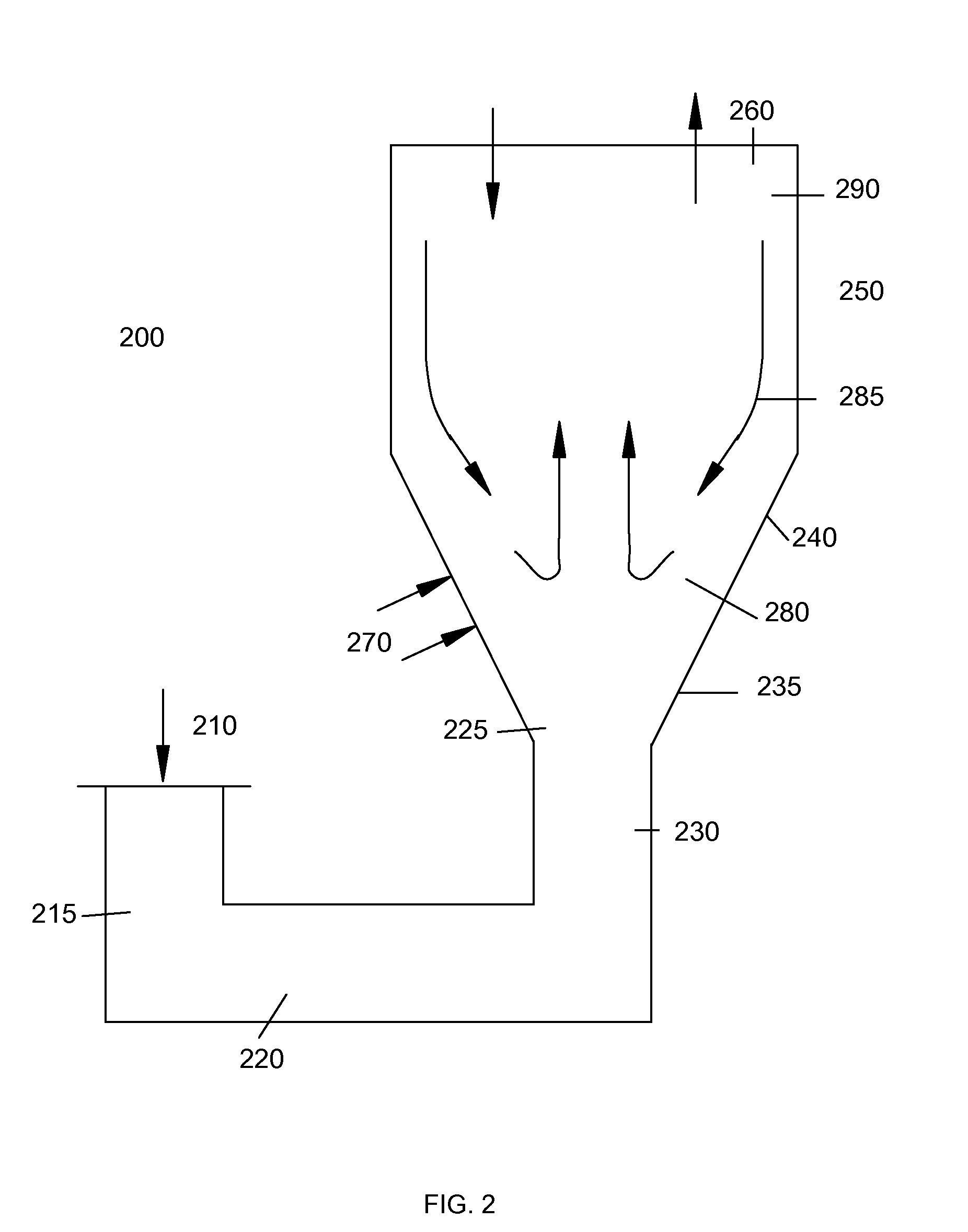

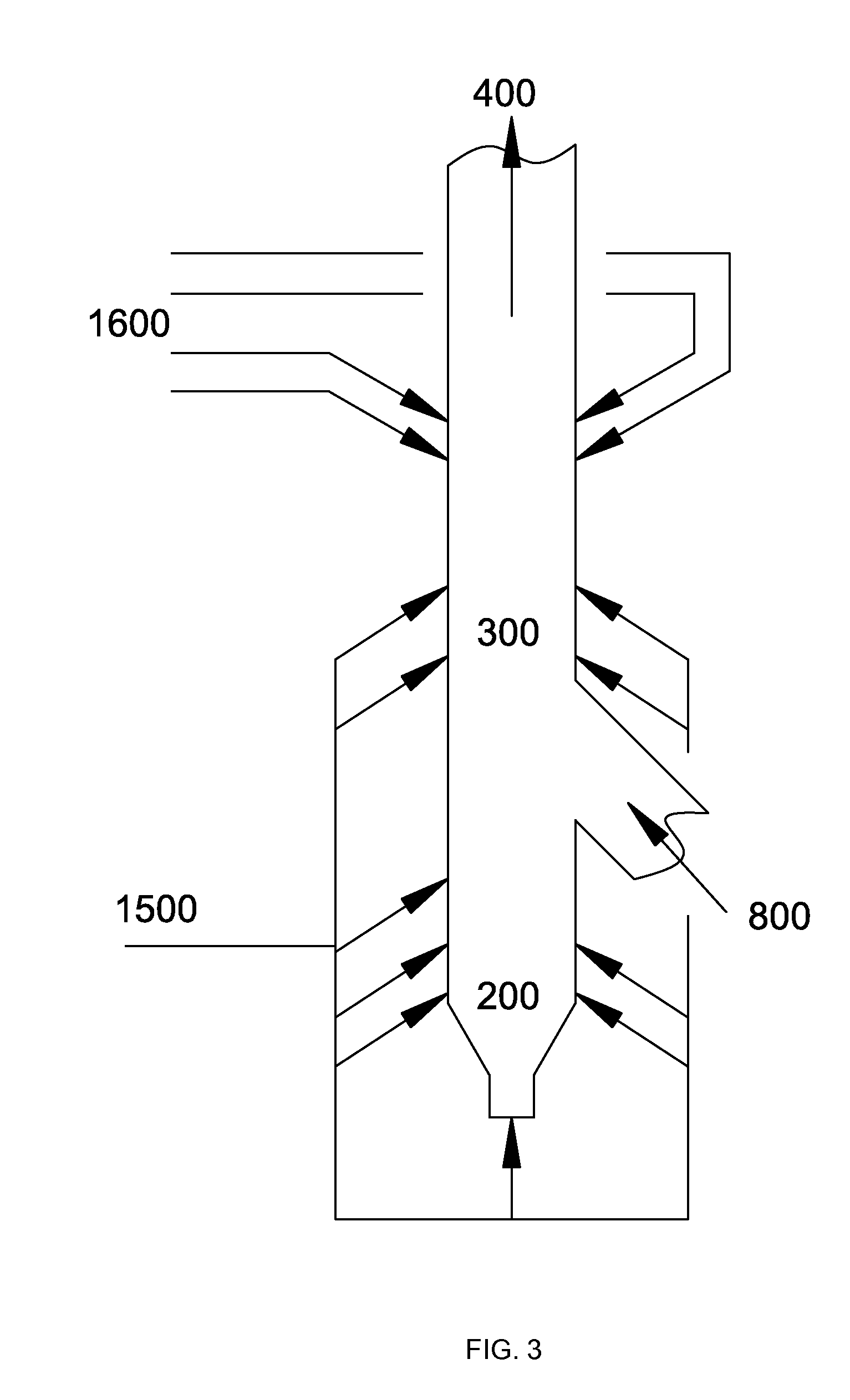

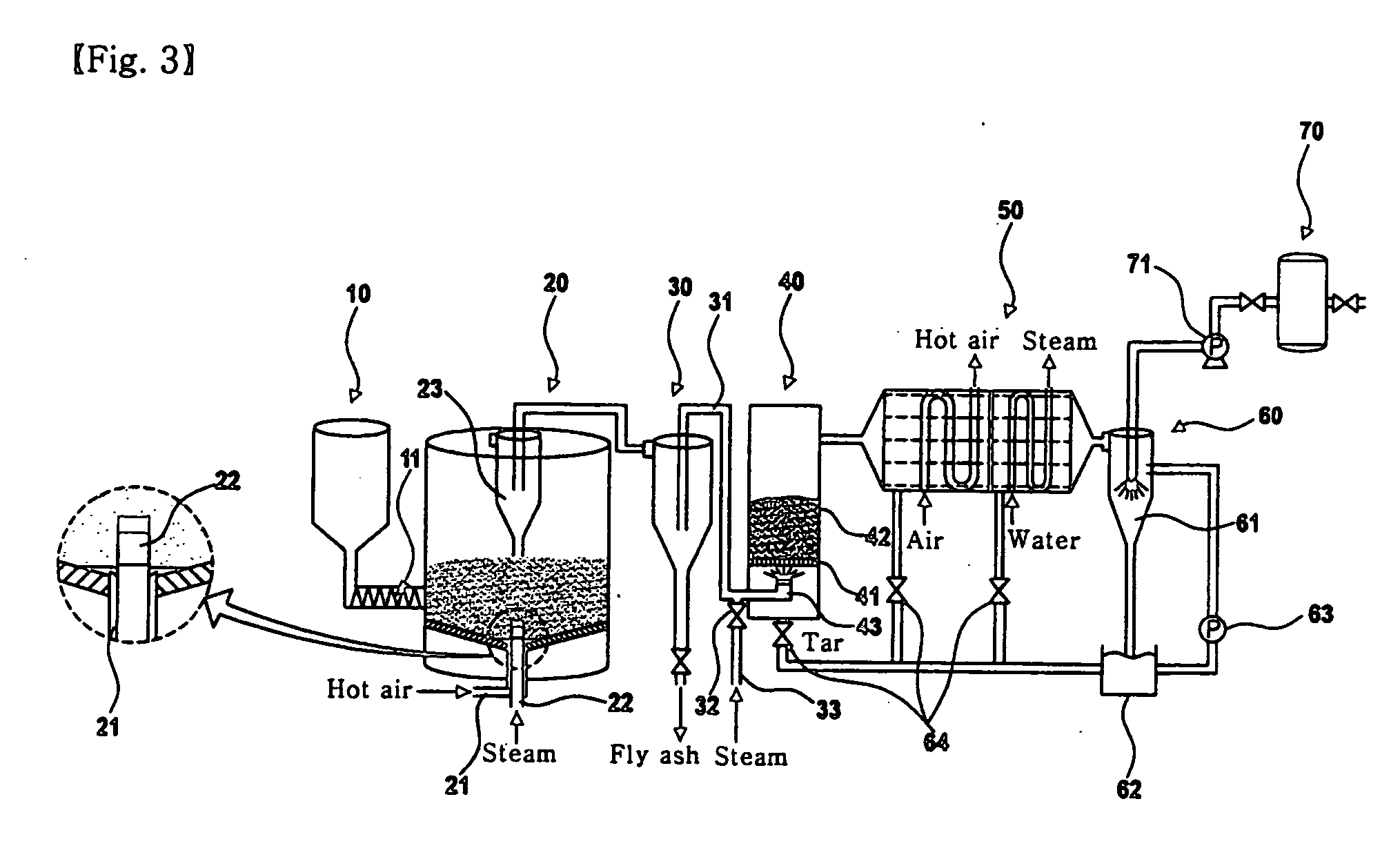

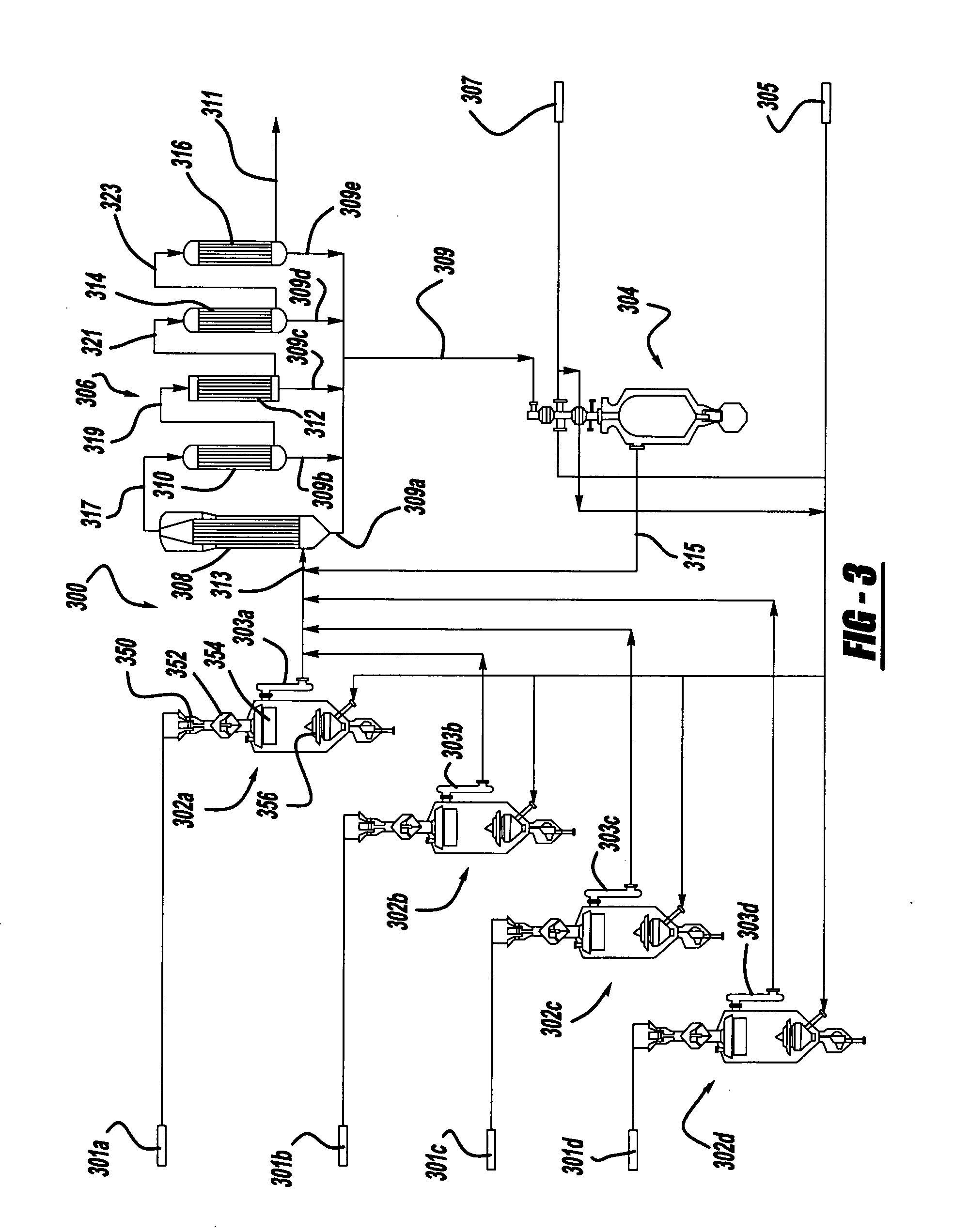

Process and System for Gasification with In-Situ Tar Removal

ActiveUS20080244976A1Simplifying downstream heat recoveryIncreased hydrogenCombustible gas catalytic treatmentCombustible gas thermal treatmentHeat carrierTar

The present invention relates to a process and system for gasifying biomass or other carbonaceous feedstocks in an indirectly heated gasifier and provides a method for the elimination of condensable organic materials (tars) from the resulting product gas with an integrated tar removal step. More specifically, this tar removal step utilizes the circulating heat carrier to crack the organics and produce additional product gas. As a benefit of the above process, and because the heat carrier circulates through alternating steam and oxidizing zones in the process, deactivation of the cracking reactions is eliminated.

Owner:TAYLOR BIOMASS ENERGY

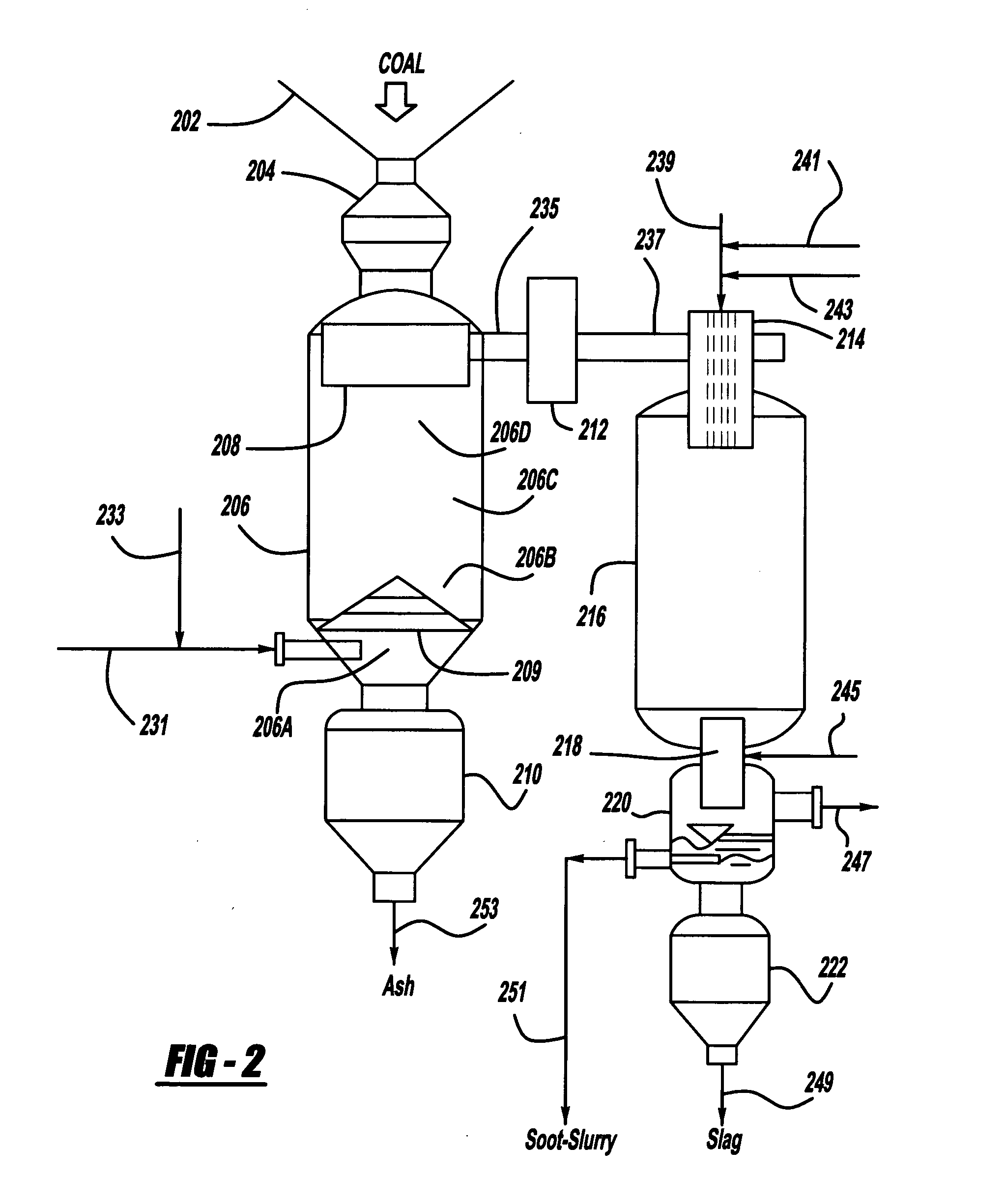

Apparatus, Components and Operating Methods for Circulating Fluidized Bed Transport Gasifiers and Reactors

ActiveUS20110146152A1Reduce and prevent reverse flow of gasOvercome problemsHydrogenFluidized bed combustionCycloneFluidized bed

The improvements proposed in this invention provide a reliable apparatus and method to gasify low rank coals in a class of pressurized circulating fluidized bed reactors termed “transport gasifier.” The embodiments overcome a number of operability and reliability problems with existing gasifiers. The systems and methods address issues related to distribution of gasification agent without the use of internals, management of heat release to avoid any agglomeration and clinker formation, specific design of bends to withstand the highly erosive environment due to high solid particles circulation rates, design of a standpipe cyclone to withstand high temperature gasification environment, compact design of seal-leg that can handle high mass solids flux, design of nozzles that eliminate plugging, uniform aeration of large diameter Standpipe, oxidant injection at the cyclone exits to effectively modulate gasifier exit temperature and reduction in overall height of the gasifier with a modified non-mechanical valve.

Owner:SOUTHERN COMPANY SERVICES

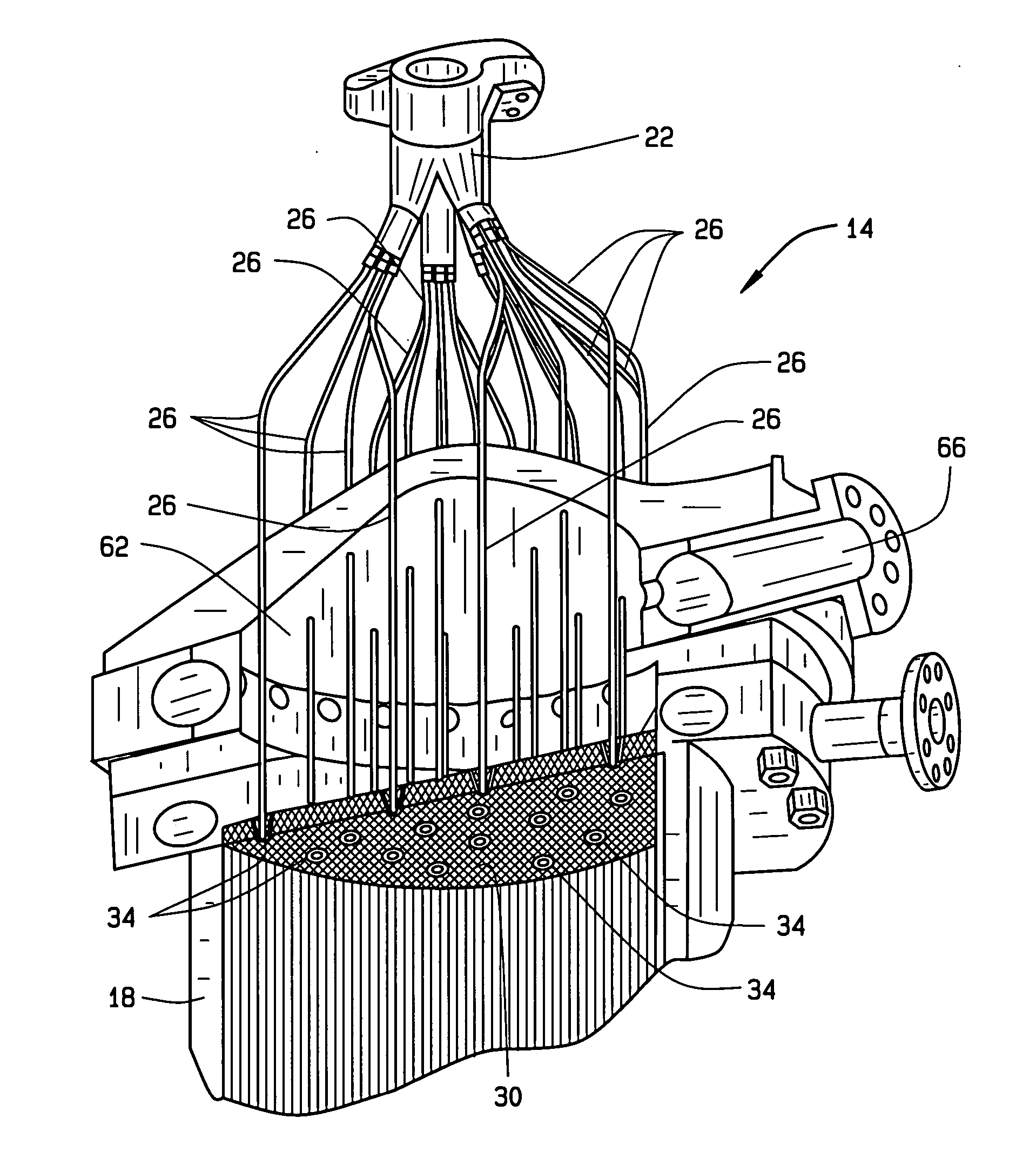

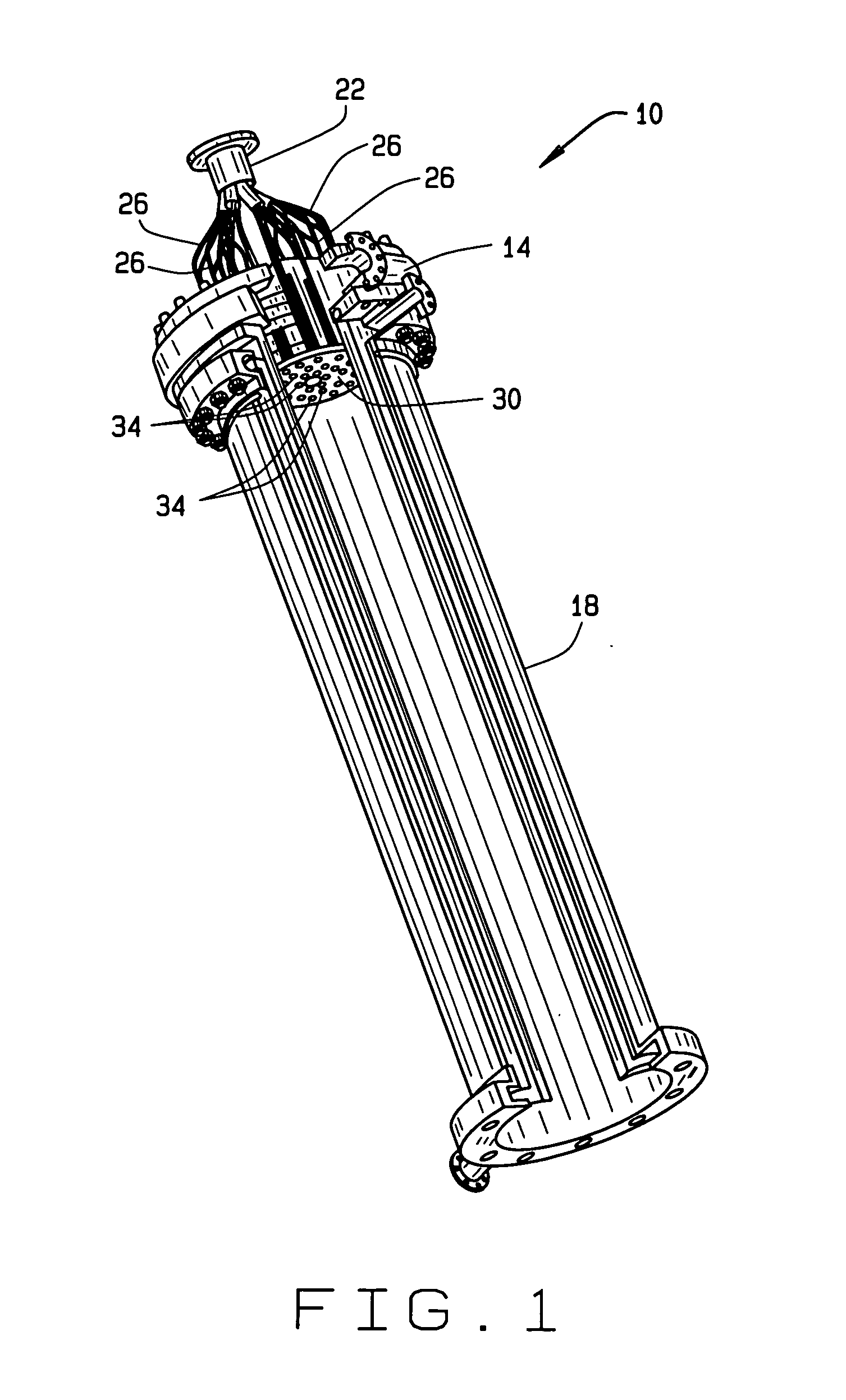

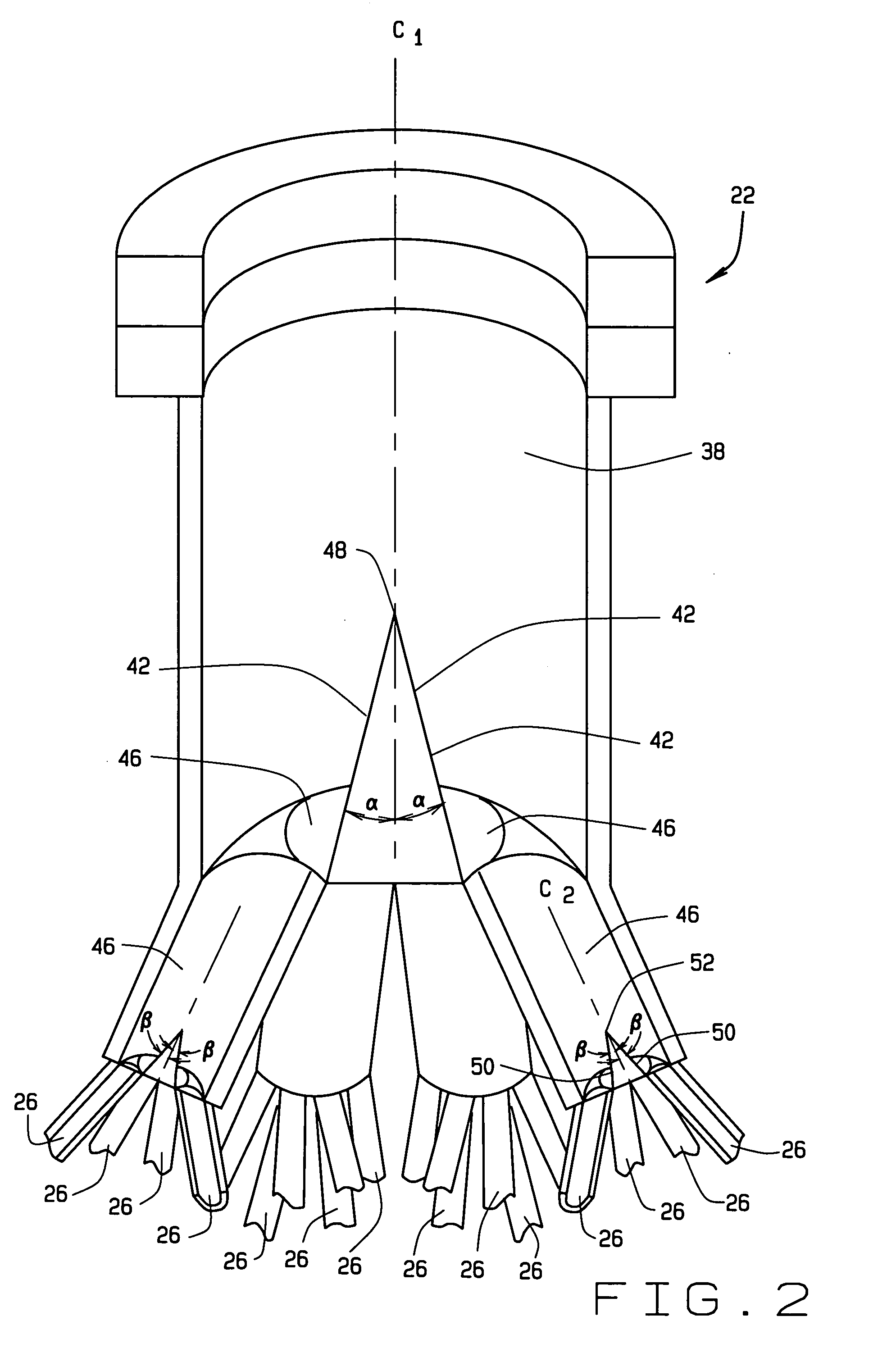

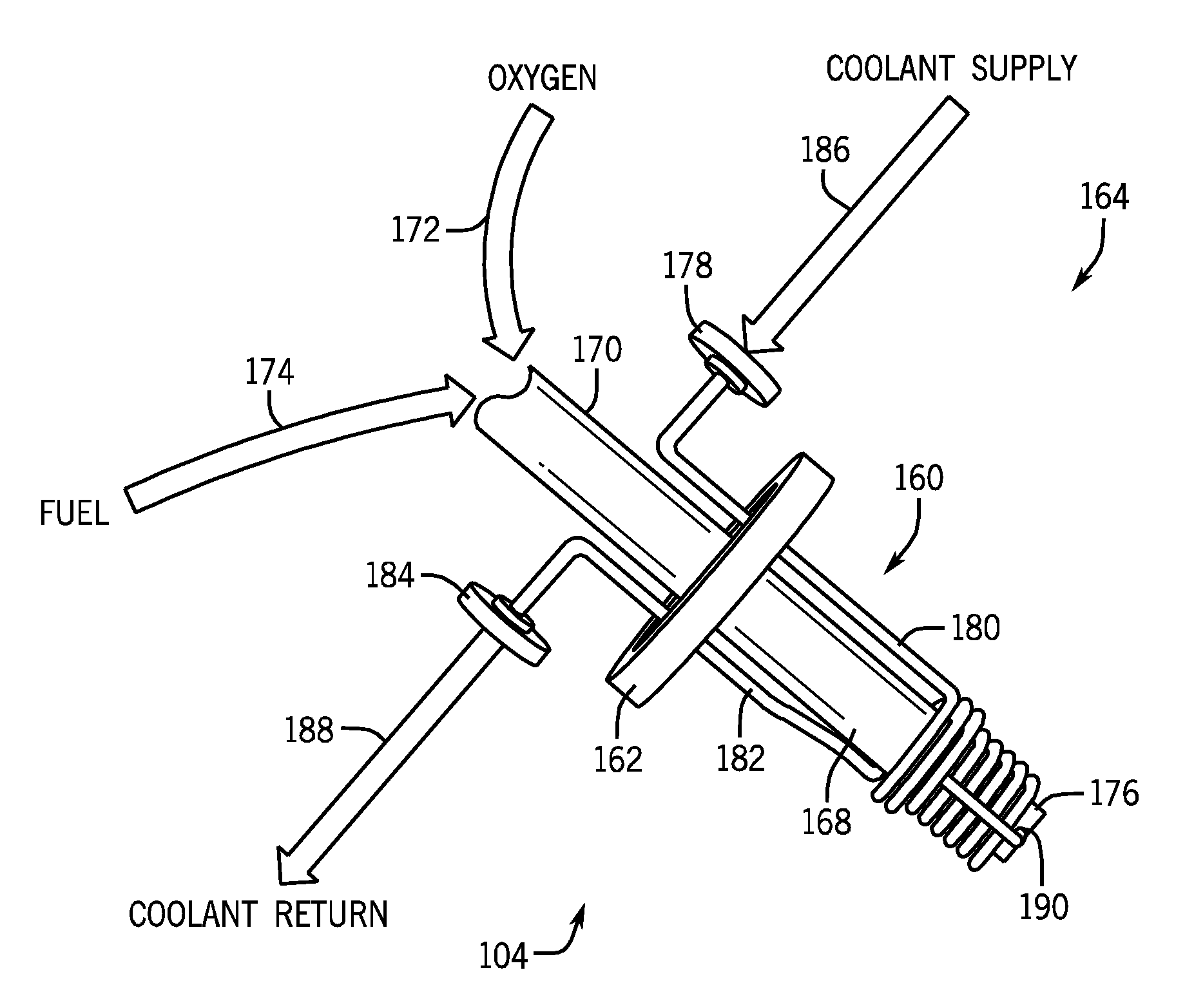

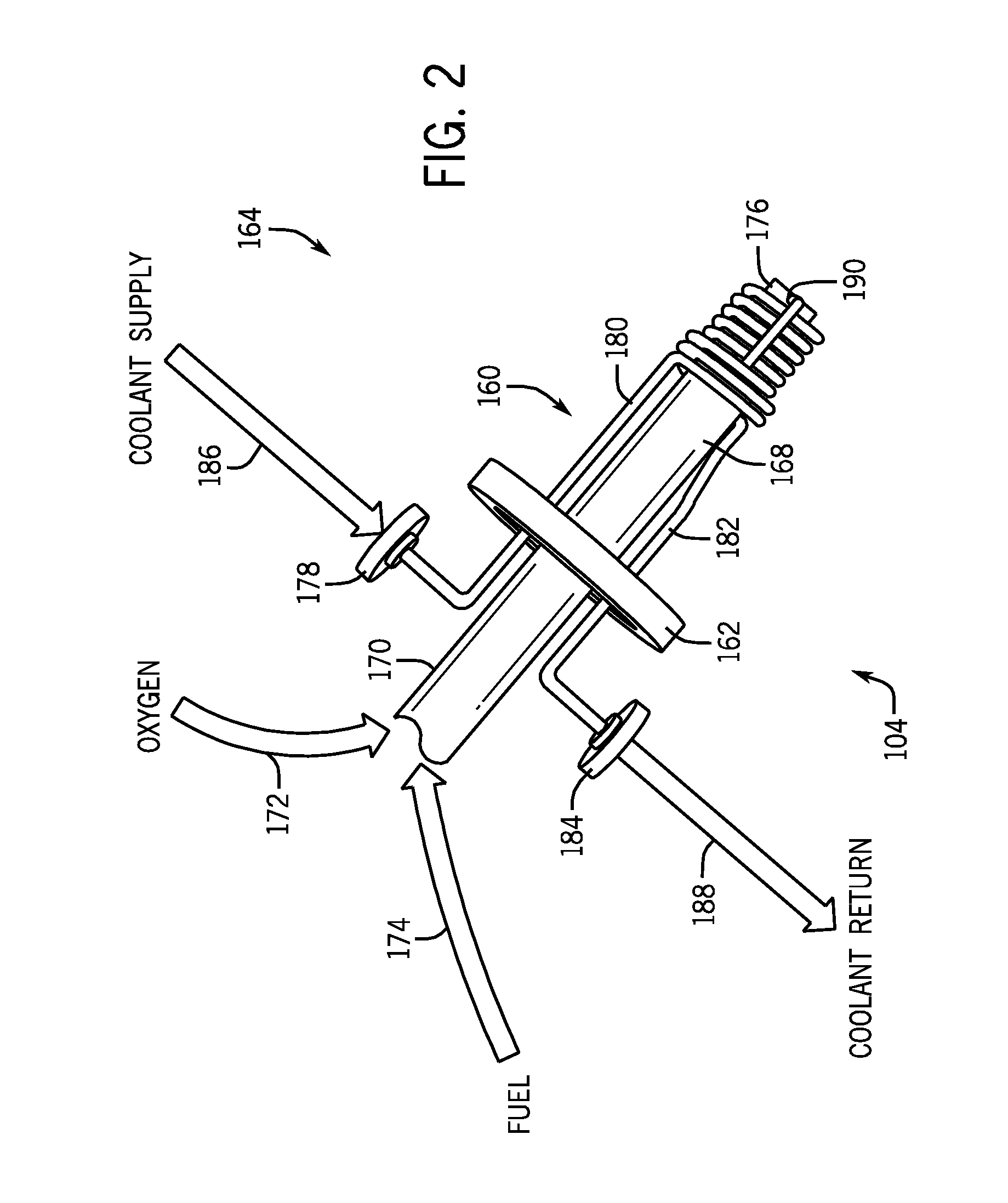

Gasifier injector

ActiveUS20060242907A1Reduce and prevent damageHigh-temperatures and abrasive matterDust removalFire preventionEngineeringHigh pressure

A gasifier injection module includes a two-stage slurry splitter and an injector face plate with a coolant system incorporated therein. The two-stage slurry splitter includes a main cavity into which a main slurry flow is provided. The main cavity includes a plurality of first stage flow dividers that divide the main slurry flow into a plurality of secondary slurry flows that flow into a plurality of secondary cavities that extend from the main cavity. Each secondary cavity includes a plurality of second stage flow dividers that divide each secondary slurry flow into a plurality of tertiary slurry flows that flow into a plurality of slurry injection tubes extending from the secondary cavities. The tertiary flows are injected as high pressure slurry streams into the gasification chamber via the slurry injection tubes. A reactant is impinged at high pressure, as an annular shaped spray, on each high pressure slurry stream via a plurality of annular impinging orifices incorporated into the injector face plate. The coolant system incorporated within the injector face plate maintains the injector face plate at a temperature sufficient to substantially reduce or prevent damage to the injector face plate by high temperatures and / or abrasive matter created by the resulting gasification reaction.

Owner:GAS TECH INST +1

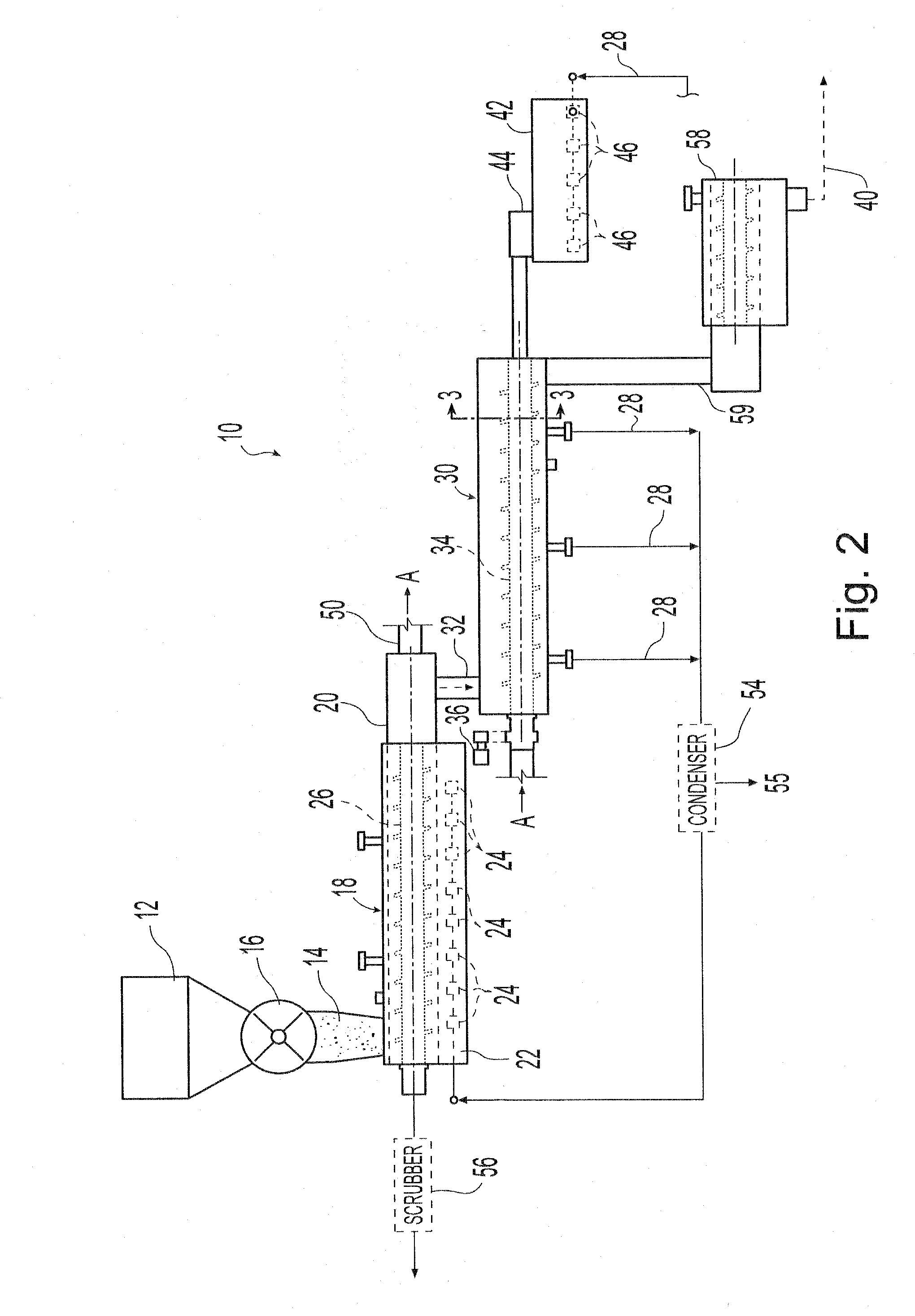

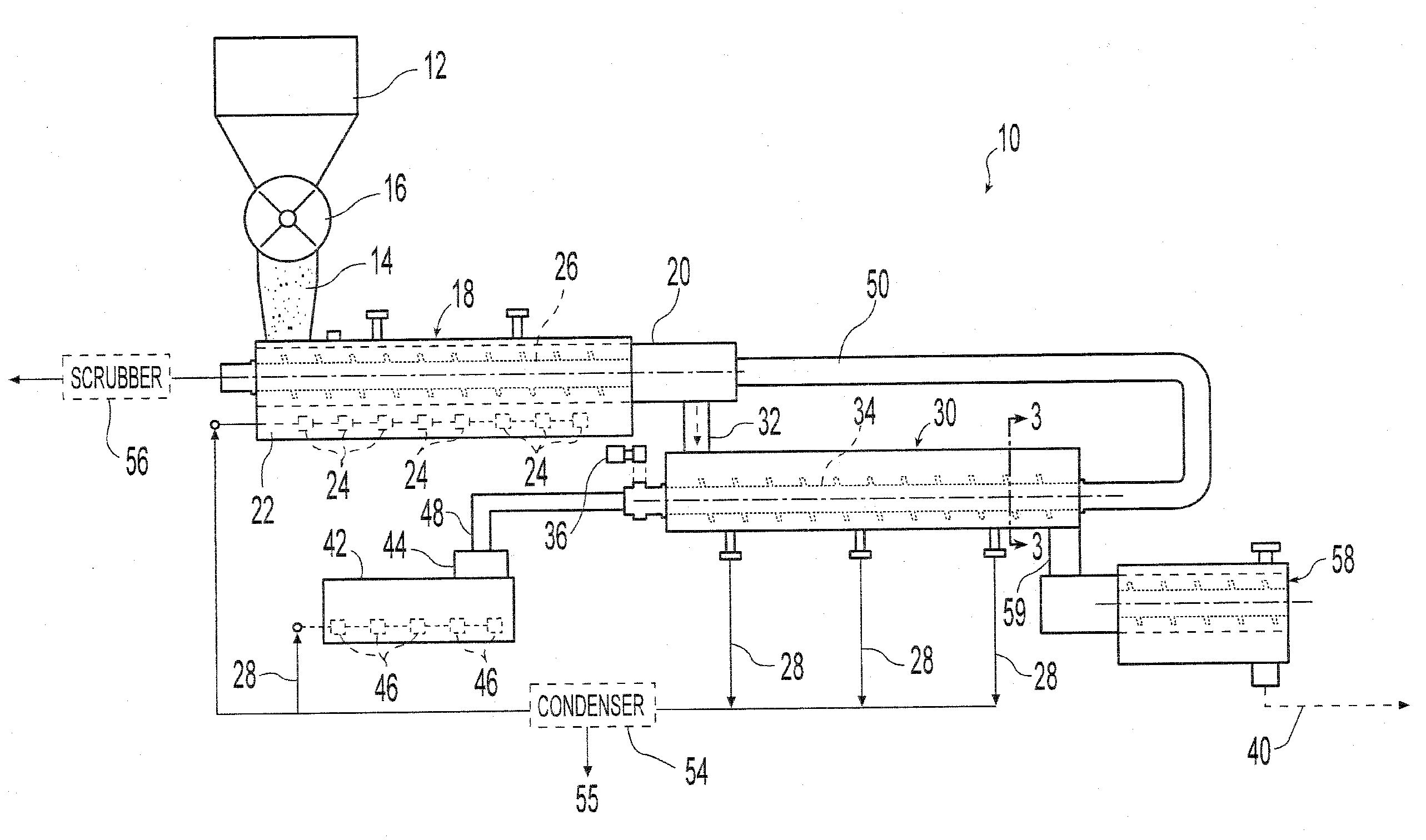

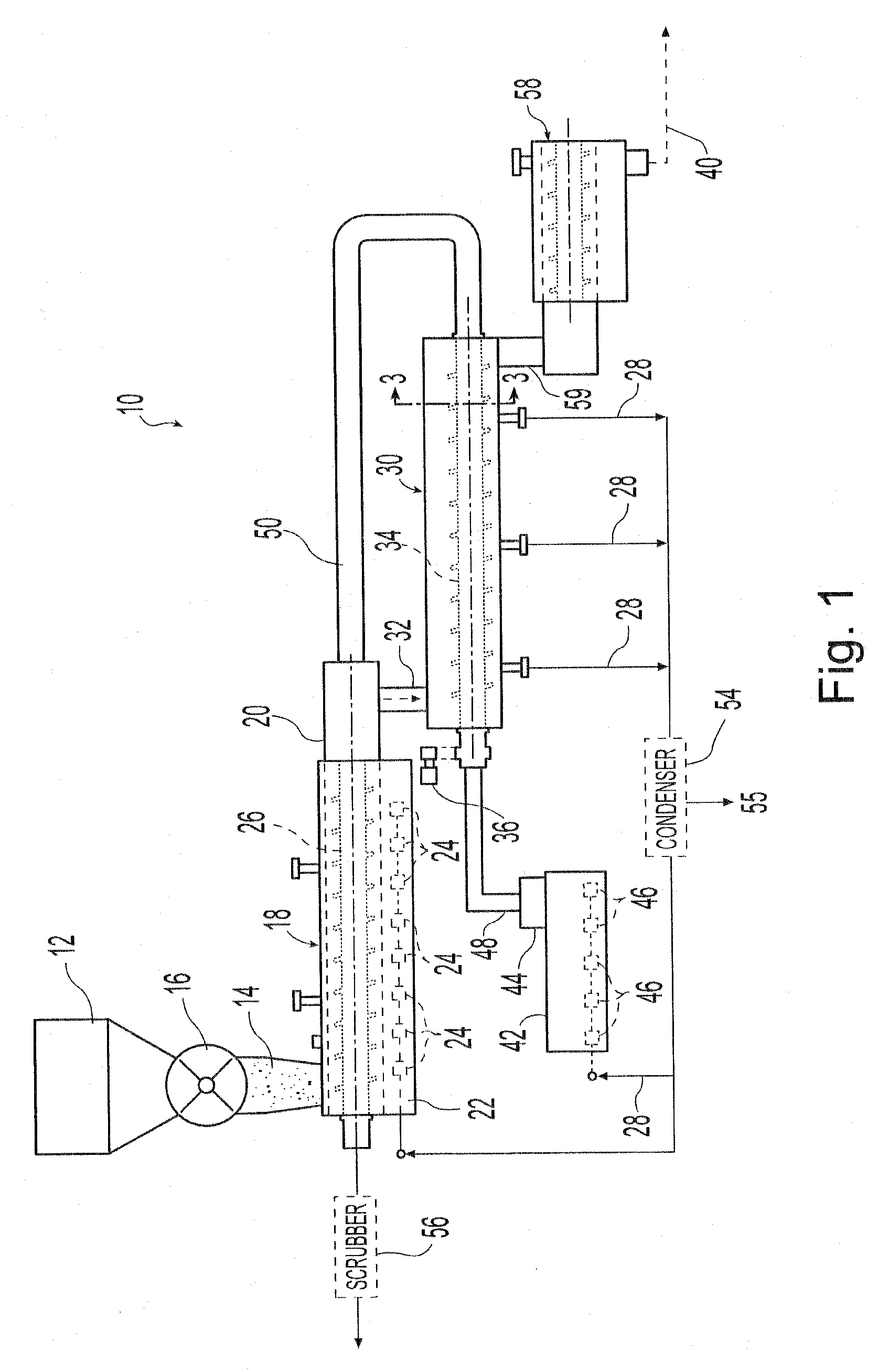

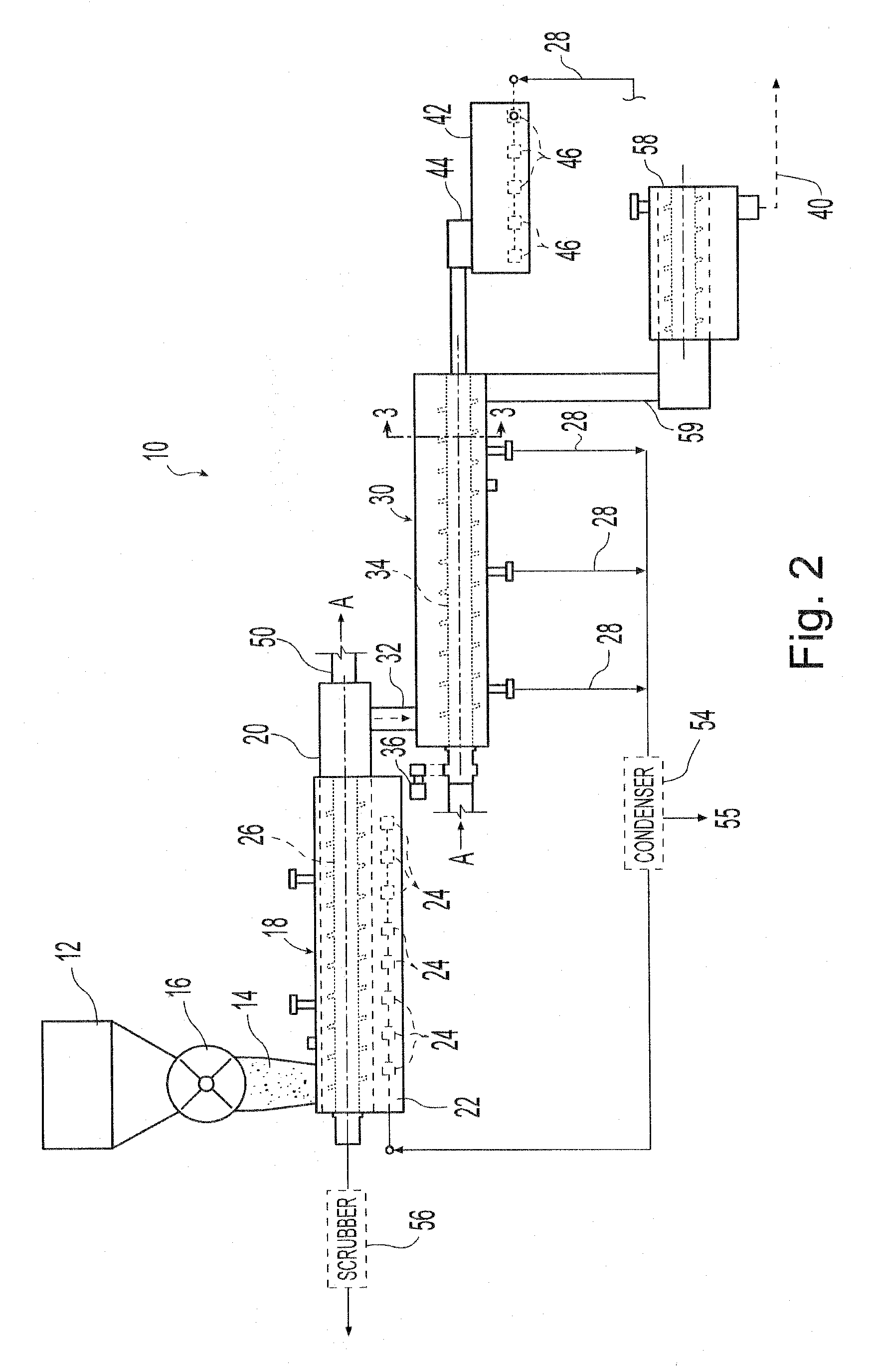

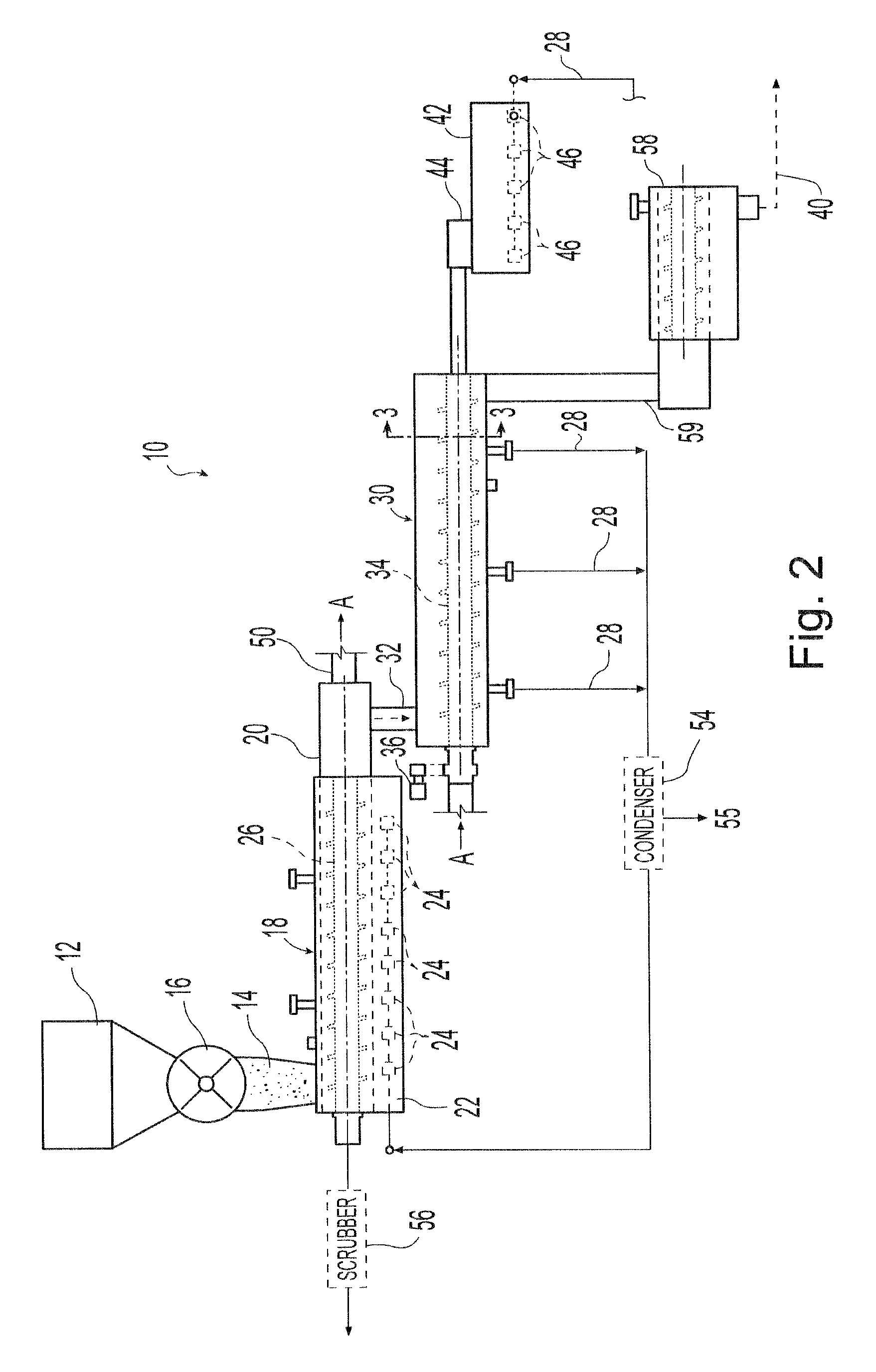

Pyrolyzer furnace apparatus and method for operation thereof

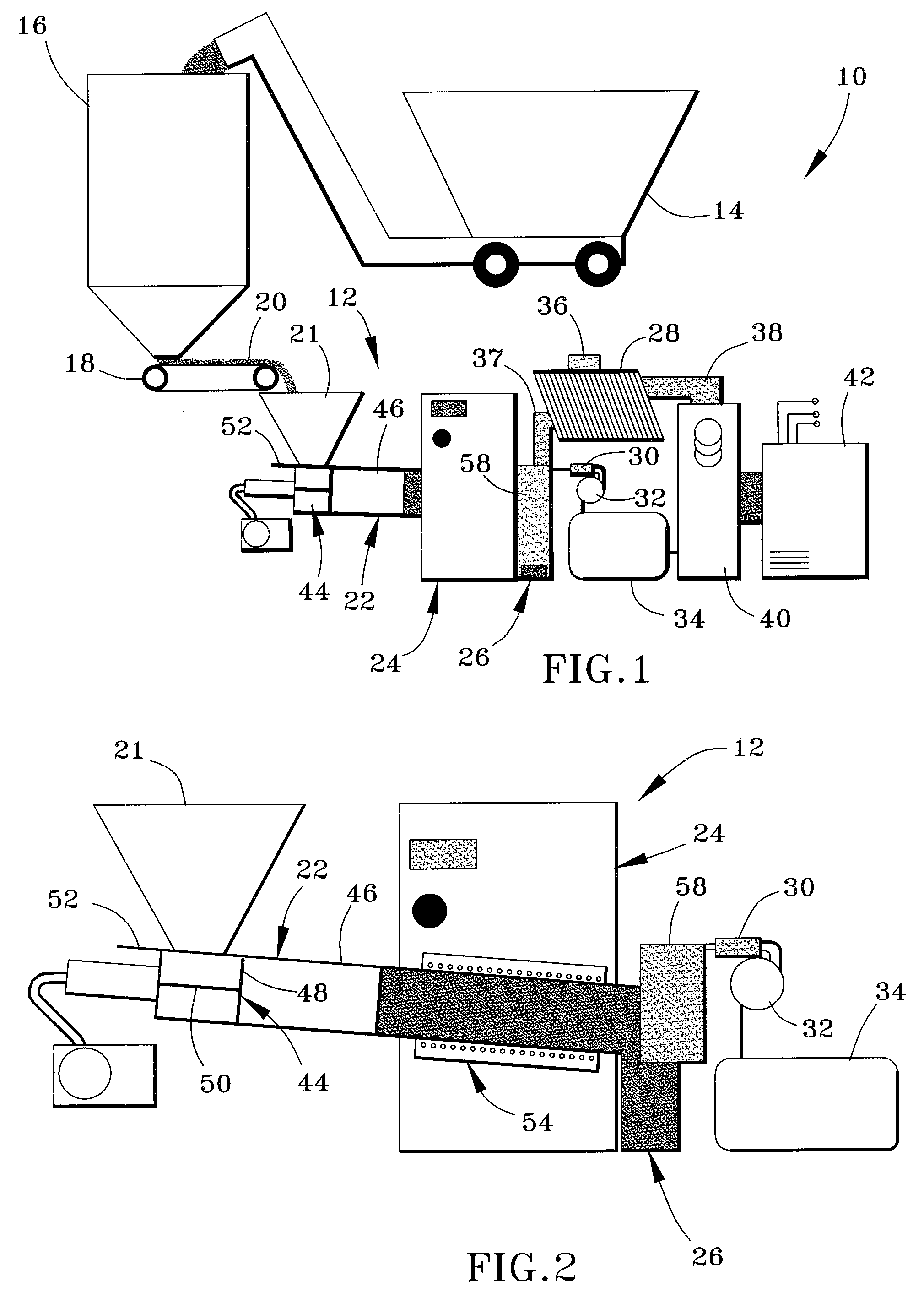

InactiveUS20080149471A1Weaken energyLower Level RequirementsMechanical conveying coke ovensDirect heating destructive distillationCombustion chamberDrive shaft

A pyrolyzer and method is provided for devolatizing coal and other volatile materials. The pyrolyzer has a pyrolyzer furnace housing having at least two screws laterally positioned adjacent and overlapping rotatably mounted within the furnace for moving volatile material through the pyrolyzer furnace housing. The screws have hollow drive shafts with a diverter inside for converging heated fluid to heat the volatile material moving through the pyrolyzer furnace housing. A combustion chamber combusts fuel to create heated exhaust gas for directing through the hollow drive shafts to heat the volatile material. The pyrolyzer furnace housing may have a double wall with a cavity between, capable of receiving heated fluid for further heating of volatile material moving through the pyrolyzer furnace housing.

Owner:NUCOR CORP

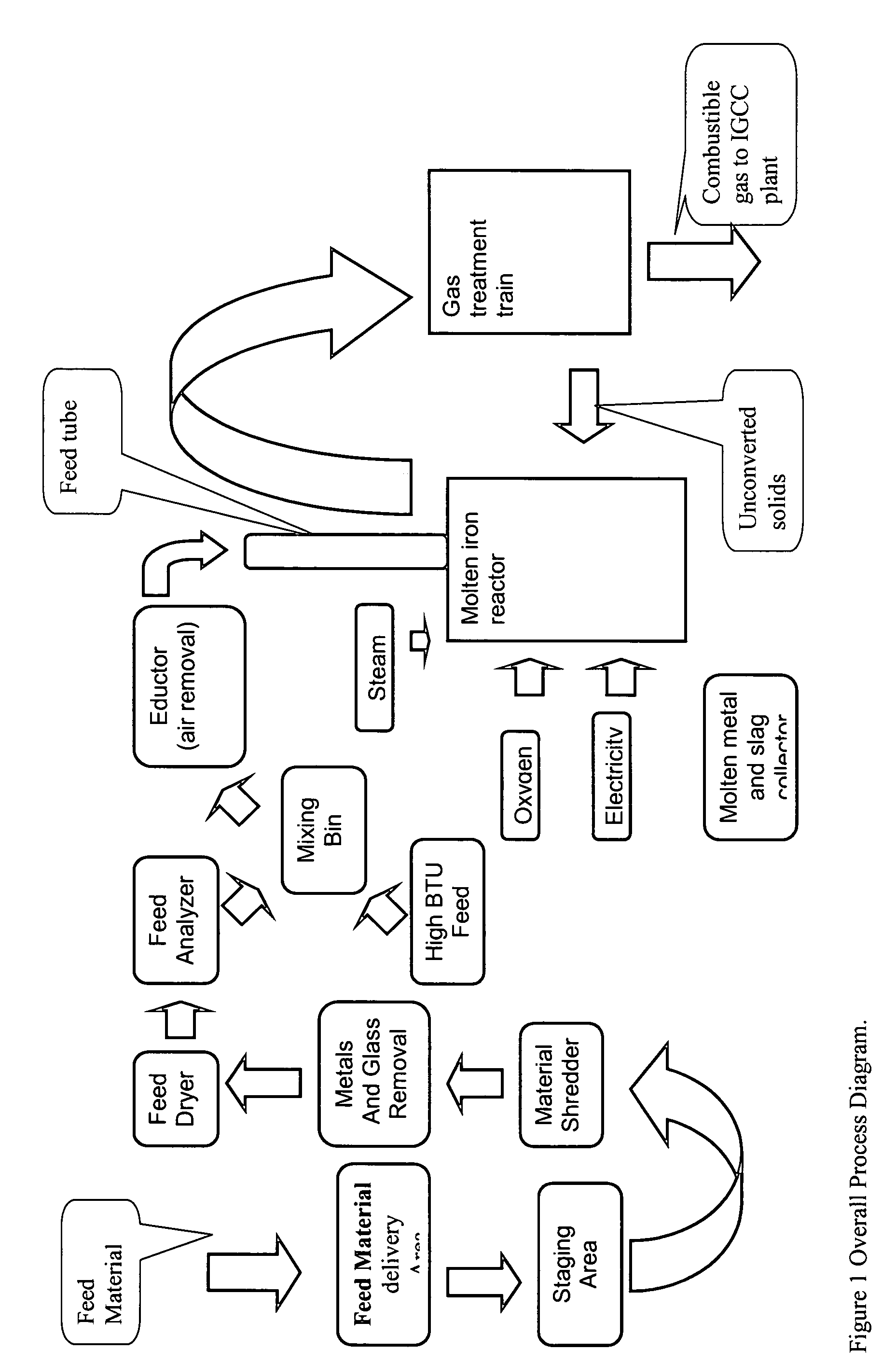

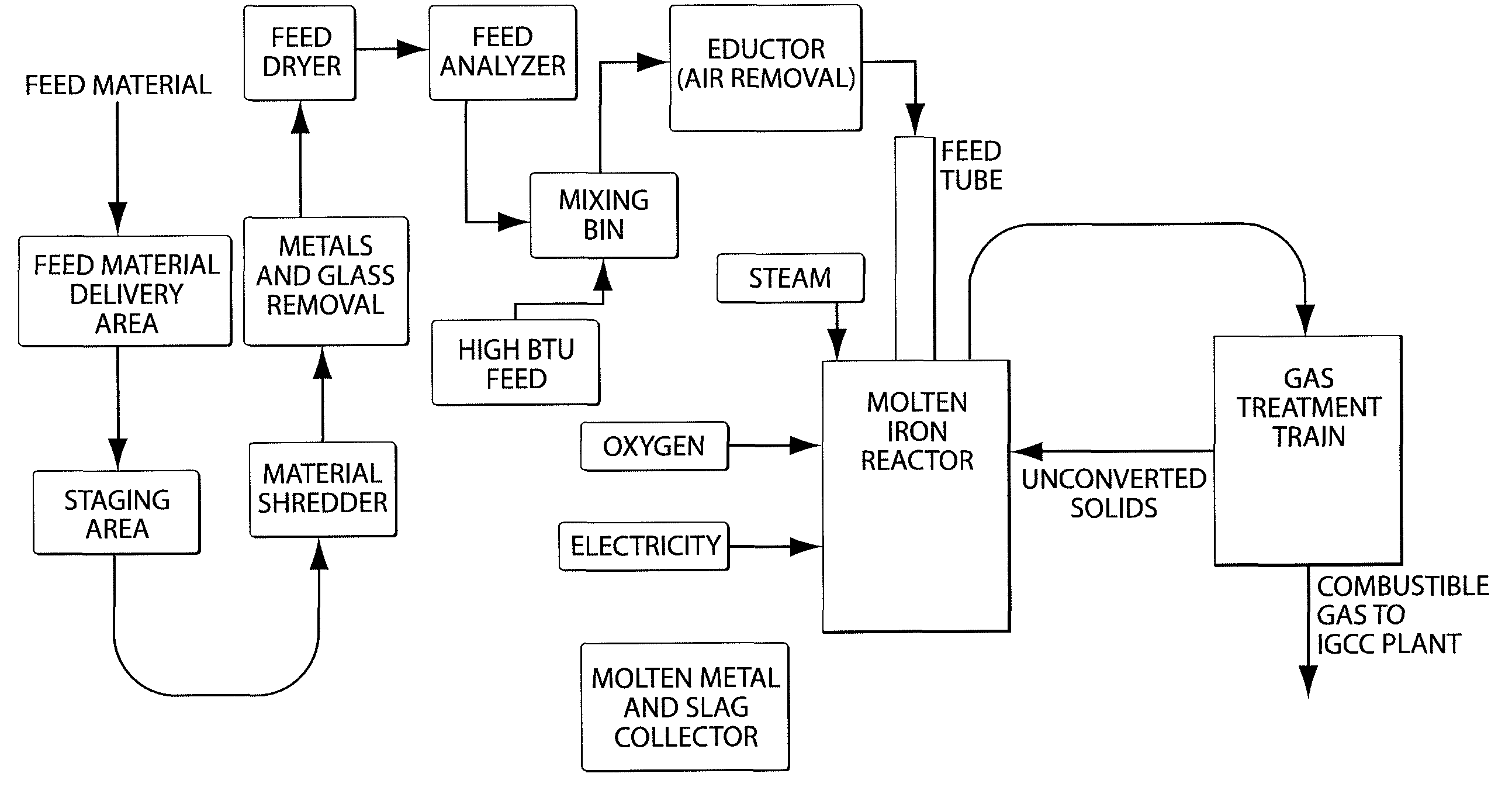

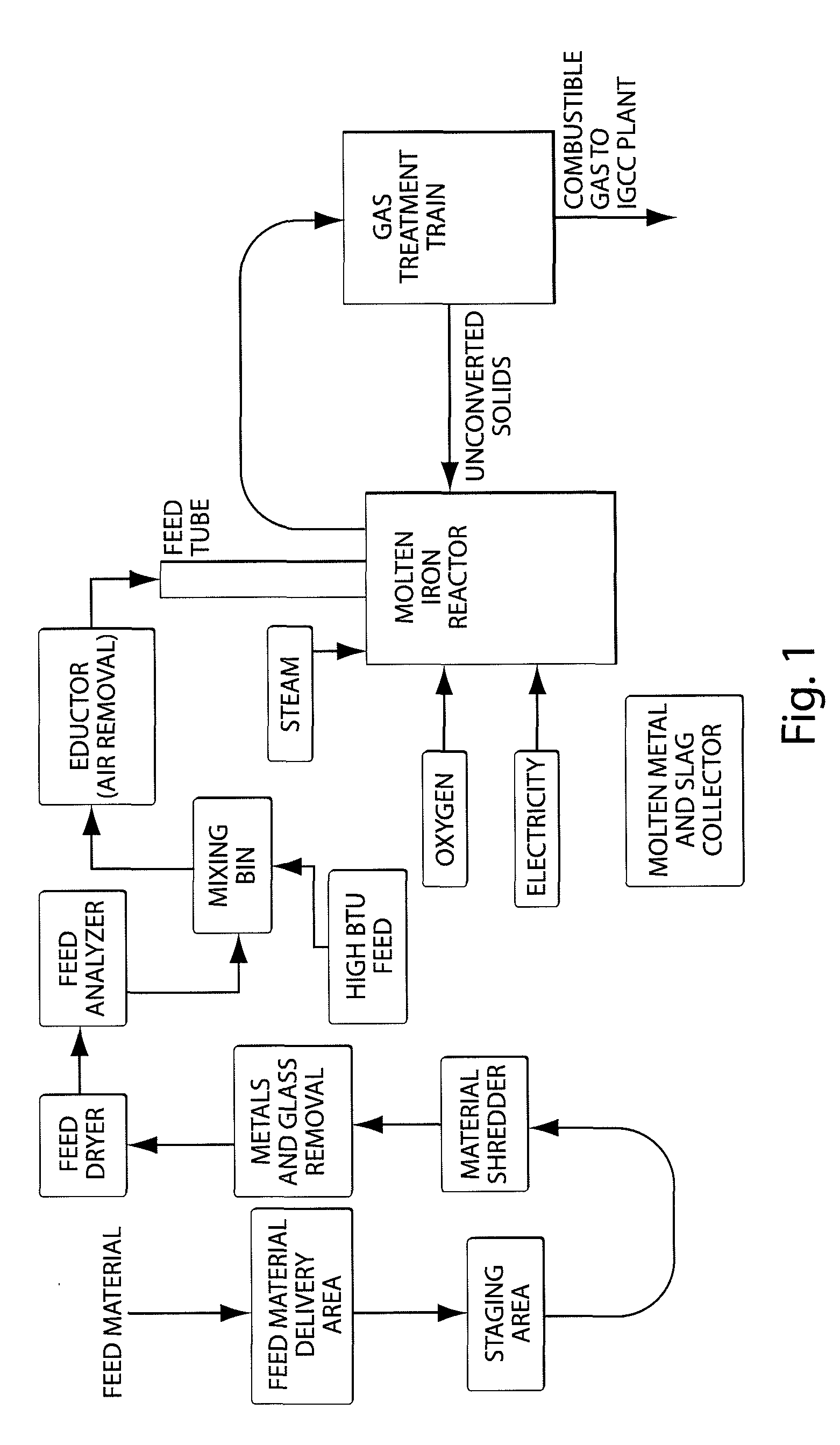

Process and apparatus using a molten metal bath

Processes and apparatus for treating organic and inorganic materials in a metal bath contained in a high temperature reactor to produce synthesis gas are provided. The feed materials are prepared and analyzed for heat value prior to injection and the composition of materials in and exiting the reactor are monitored. Based upon the results of the analysis and monitoring, oxygen, steam, and / or other feed materials are also injected into the reactor, to control processing and synthesis gas quality.

Owner:ZE-GEN

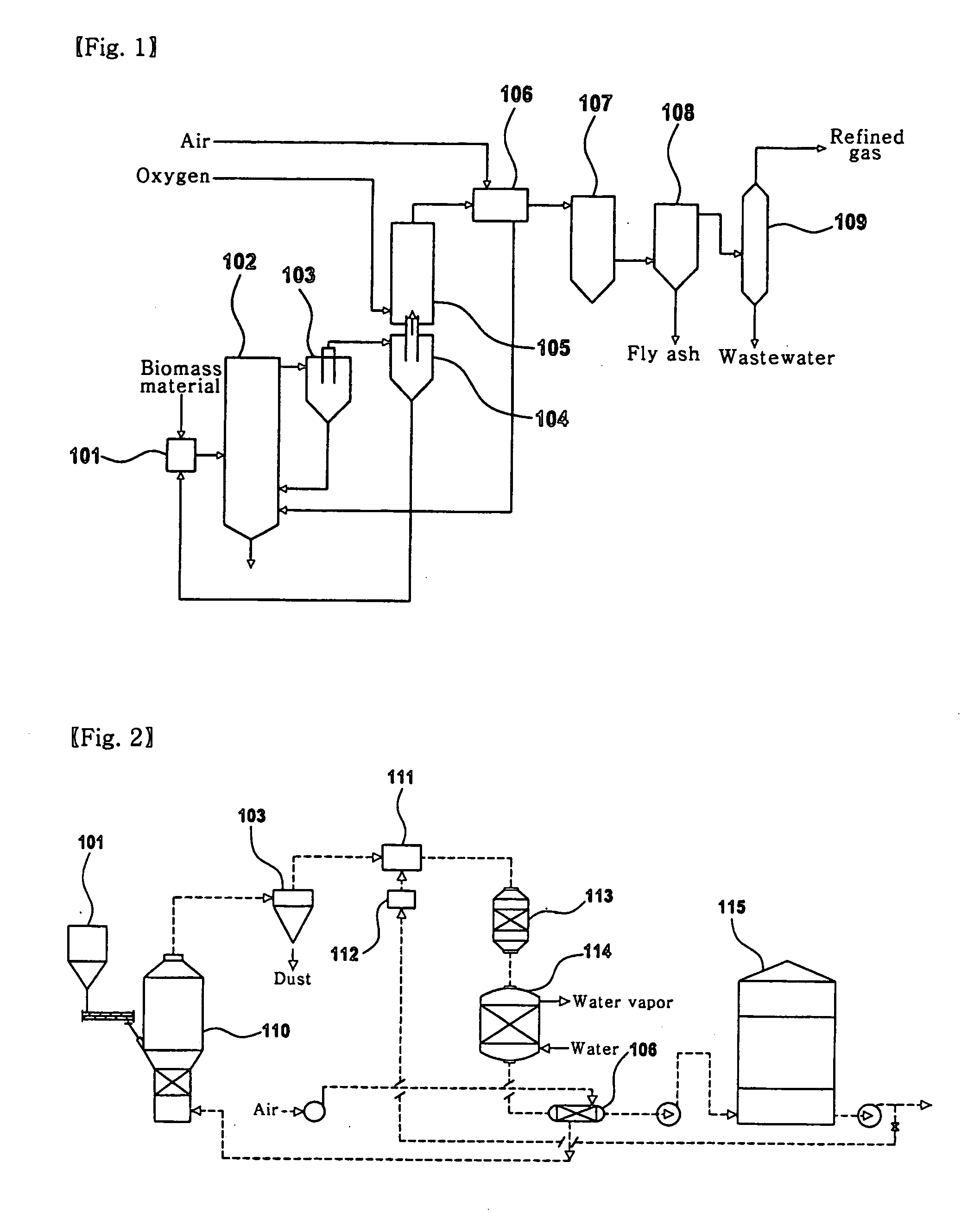

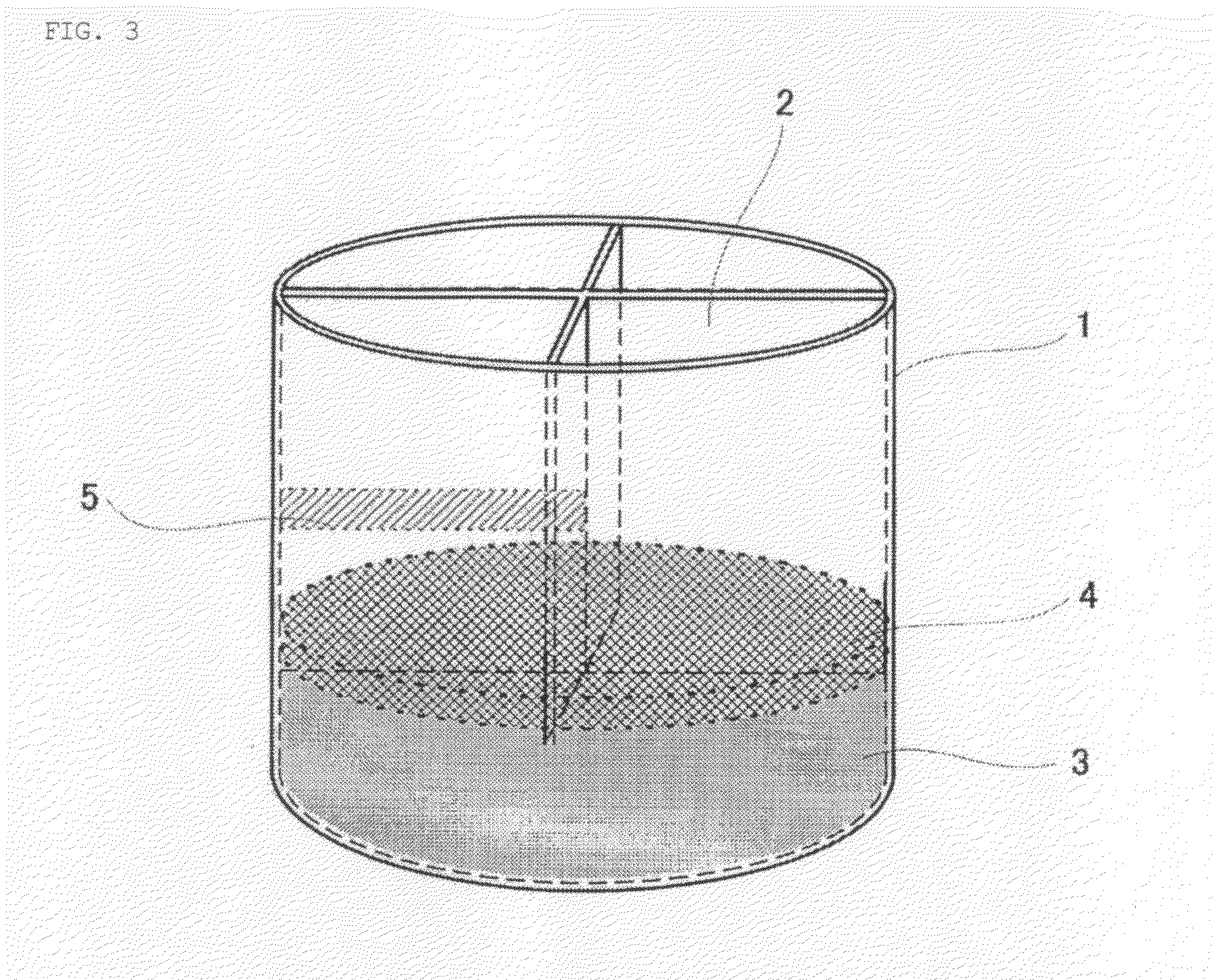

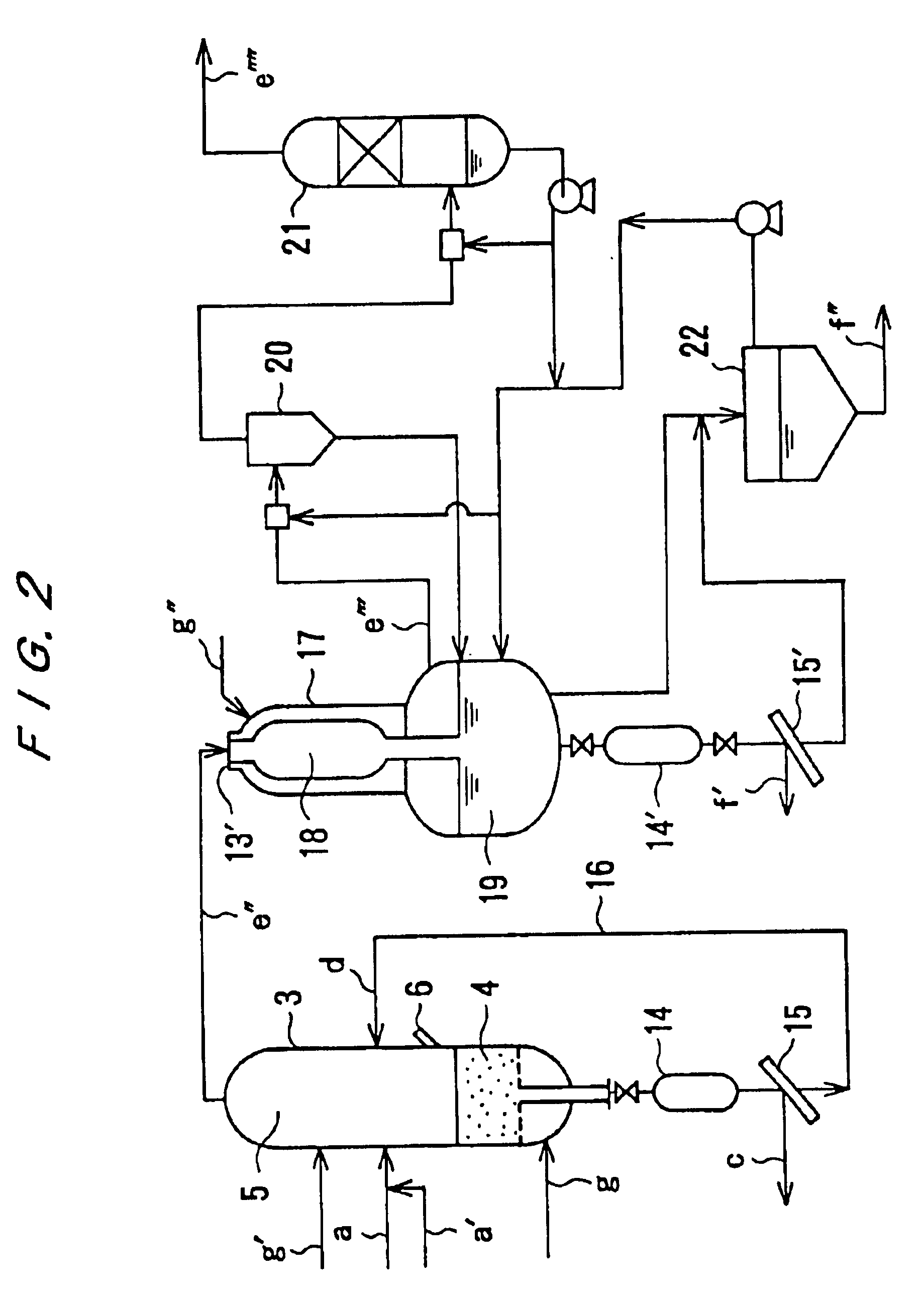

Apparatus of catalytic gasification for refined biomass fuel at low temperature and the method thereof

InactiveUS20070094929A1Low production costCompactCombustible gas catalytic treatmentLiquid hydrocarbon mixture productionCatalytic reformingFluidized bed

Disclosed is a gasification technique for converting biomass, which is difficult to treat, into clean gas fuel able to be burned in a cogeneration system. The gasification technique includes first stage fluidized-bed catalytic gasification, and second stage gasification of tar and catalytic reforming to convert nitrogen in tar, and HCN in a flammable gas into NH3, unlike conventional gasification techniques. In addition, since the temperature of a total gasification process is lower than a melting point of ash, powdery ash is generated and thus easily treated. Also, little heat is released due to the low process temperature, and therefore, a compact reactor may be designed to produce gas having a high caloric value. Further, the generated tar is recovered and reused in other processes, and the gas fuel contains a small amount of ammonia.

Owner:KOREA INST OF ENERGY RES

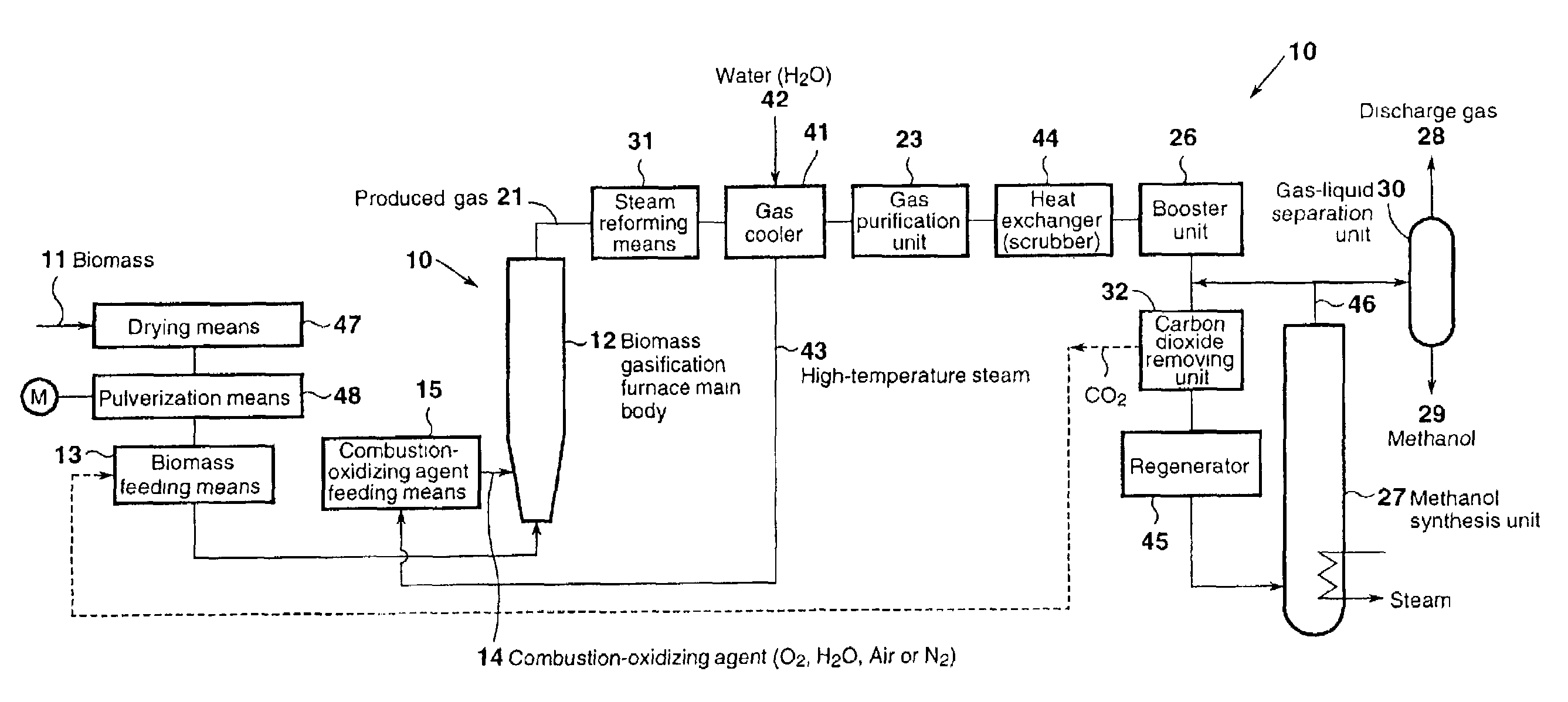

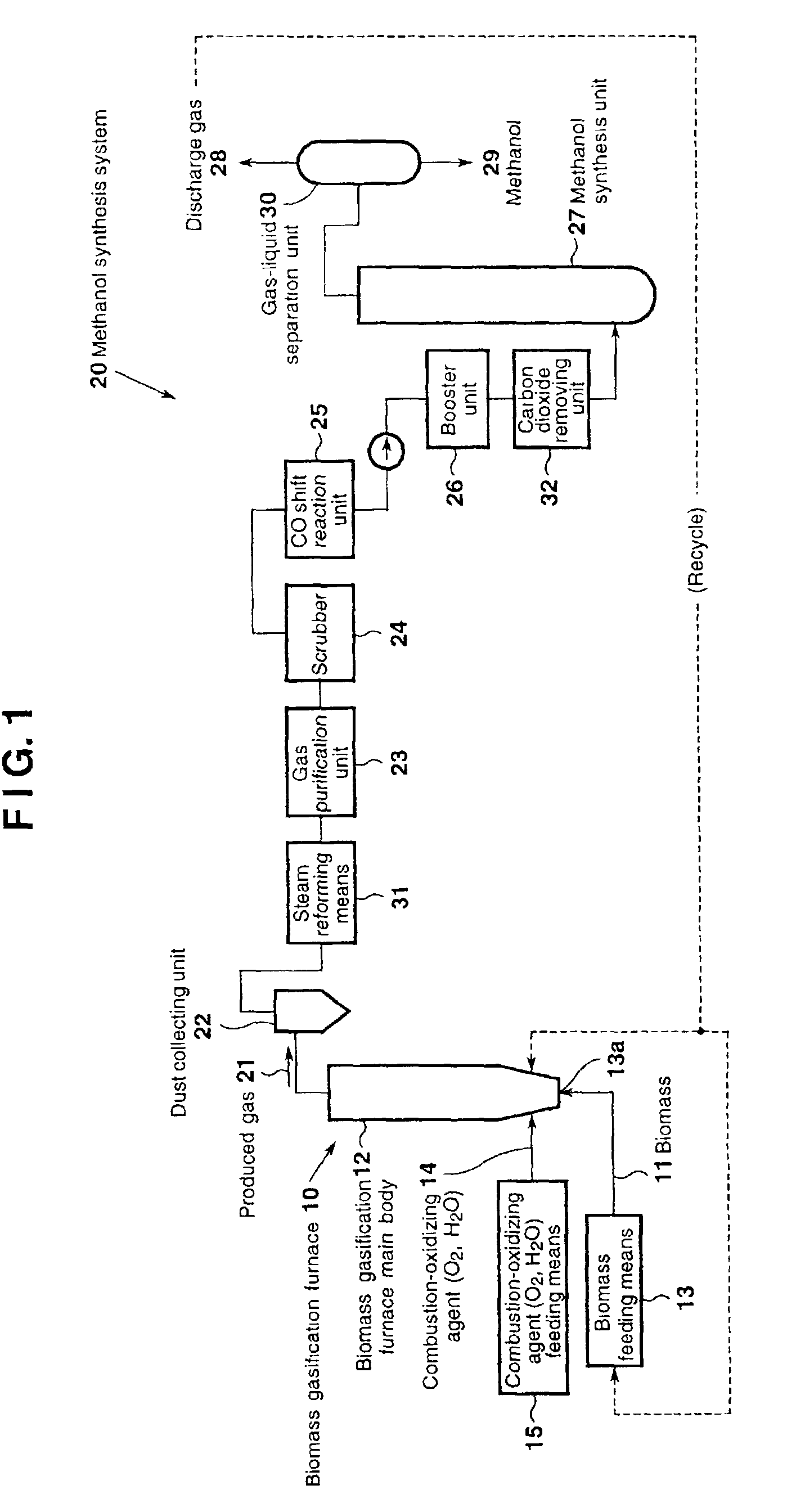

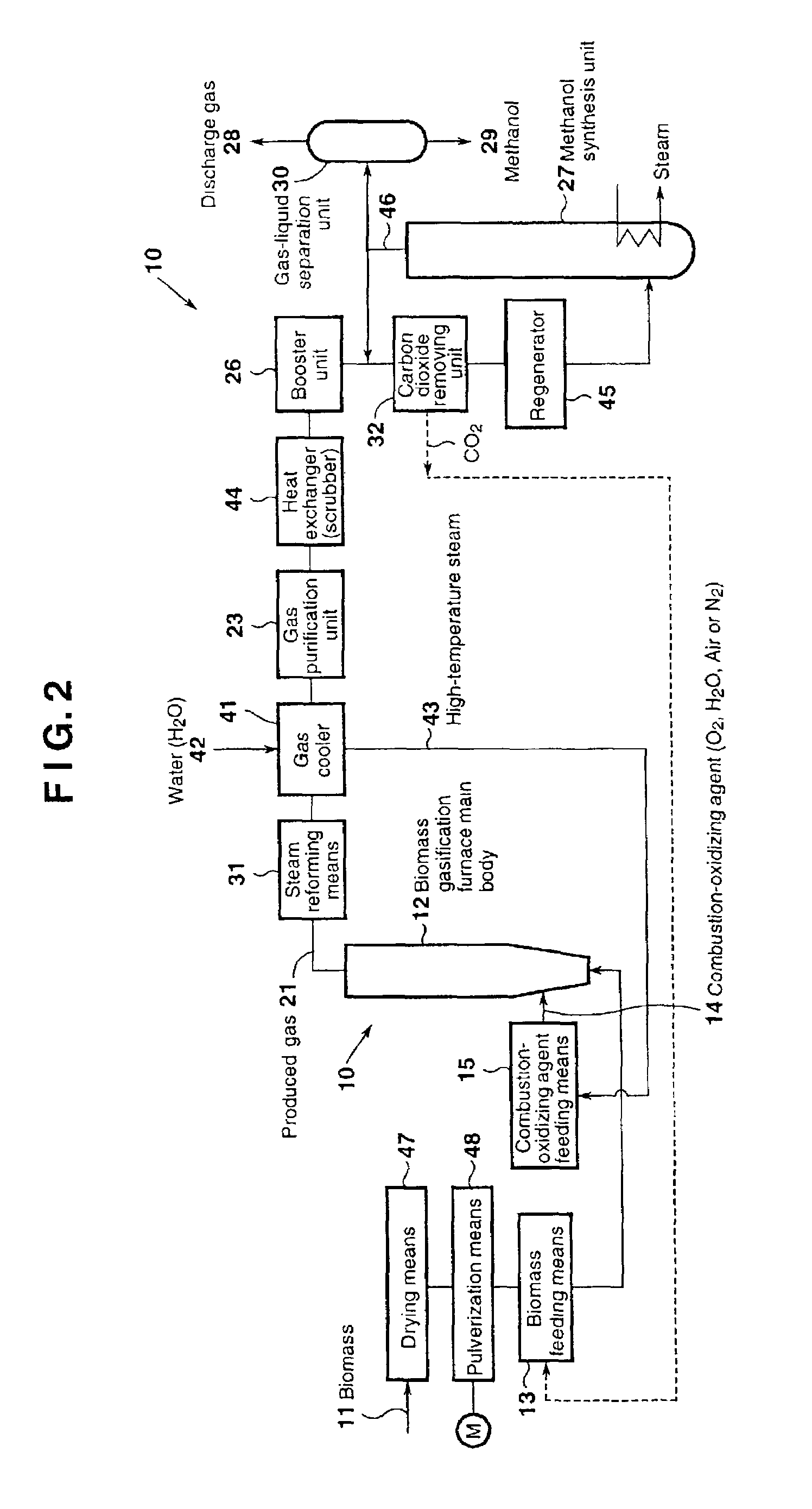

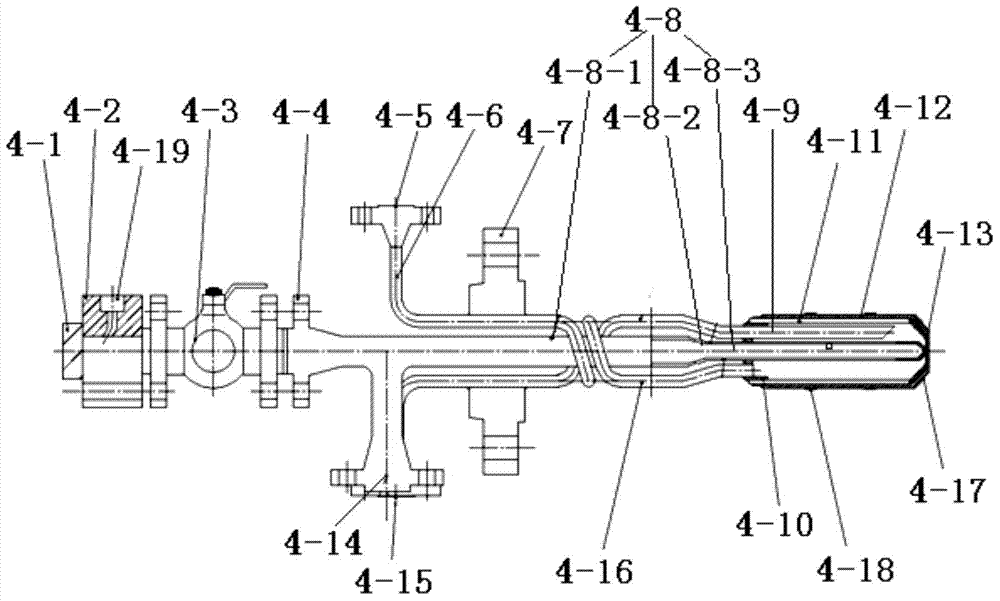

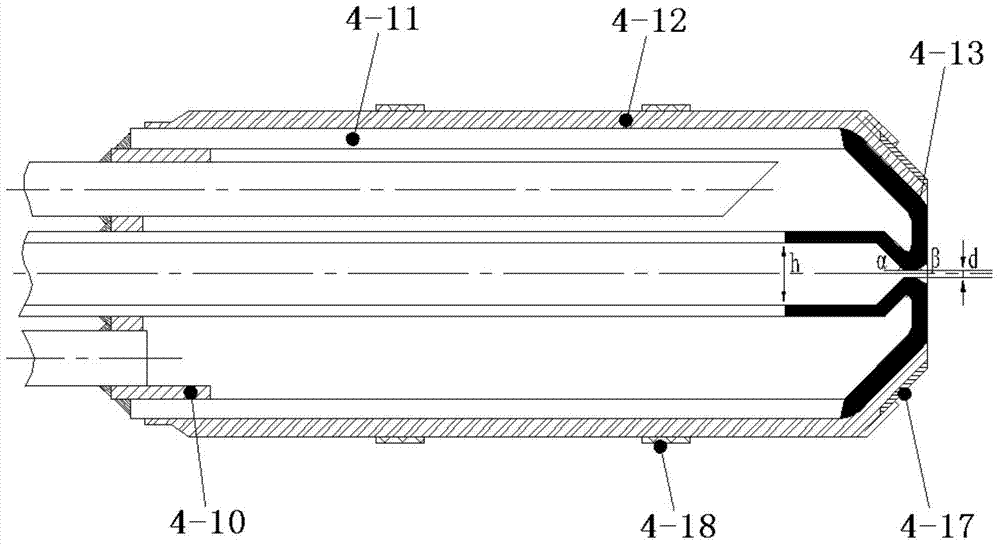

Biomass gasifycation furnace and system for methanol synthesis using gas produced by gasifying biomass

InactiveUS6991769B2Eliminate compression and entanglementCombustible gas catalytic treatmentBiofuelsCombustionProcess engineering

Methanol is synthesized from a gas produced through gasification of biomass serving as a raw material, making use of a biomass feeding means for feeding biomass into a furnace main body and, located above the biomass feeding means, combustion-oxidizing-agent-feeding means for feeding into the furnace main body a combustion-oxidizing agent containing oxygen or a mixture of oxygen and steam.

Owner:MITSUBISHI HEAVY IND LTD

Process and plant for production of biofuels

InactiveUS20100216898A1Easy to useHigh yieldDirect heating destructive distillationCombustible gas catalytic treatmentSyngasCellulose

The invention concerns a method and a plant for producing hydrocarbon based fuels from waste and biomass including wood and / or other cellulose containing biomass, where biomass and / or waste is gasified in anaerobic conditions, heating the formed syngas in for decomposition and subsequent condensation in anaerobic conditions, subjecting the heat treated biosyngas to cleaning measures for removing elements / compounds which are poisonous towards the catalysts of the Fischer-Tropsch synthesis, and passing the cleaned heat treated biosyngas through a Fischer-Tropsch synthesis for production of biofuels.

Owner:TONSETH ERIK

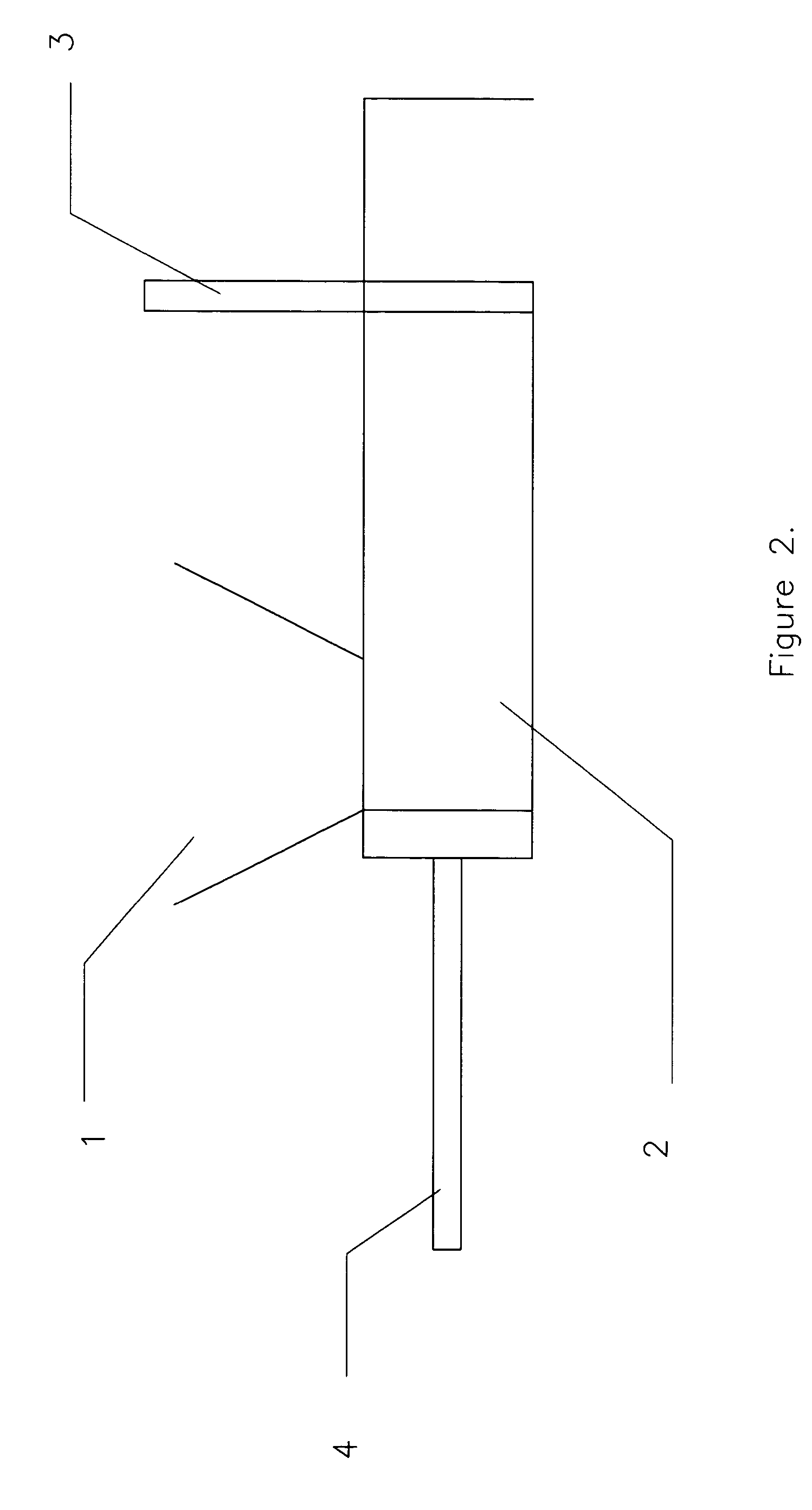

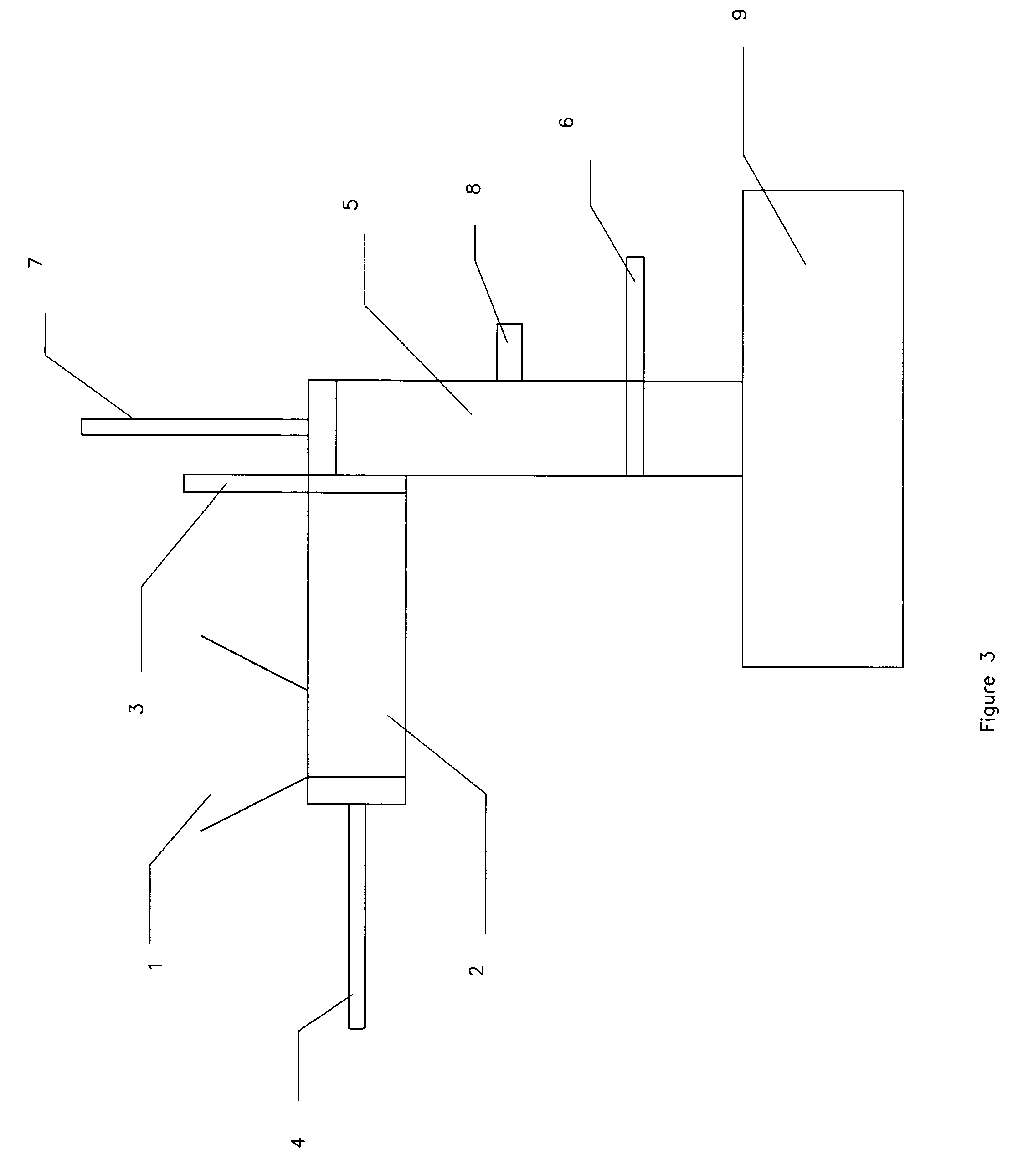

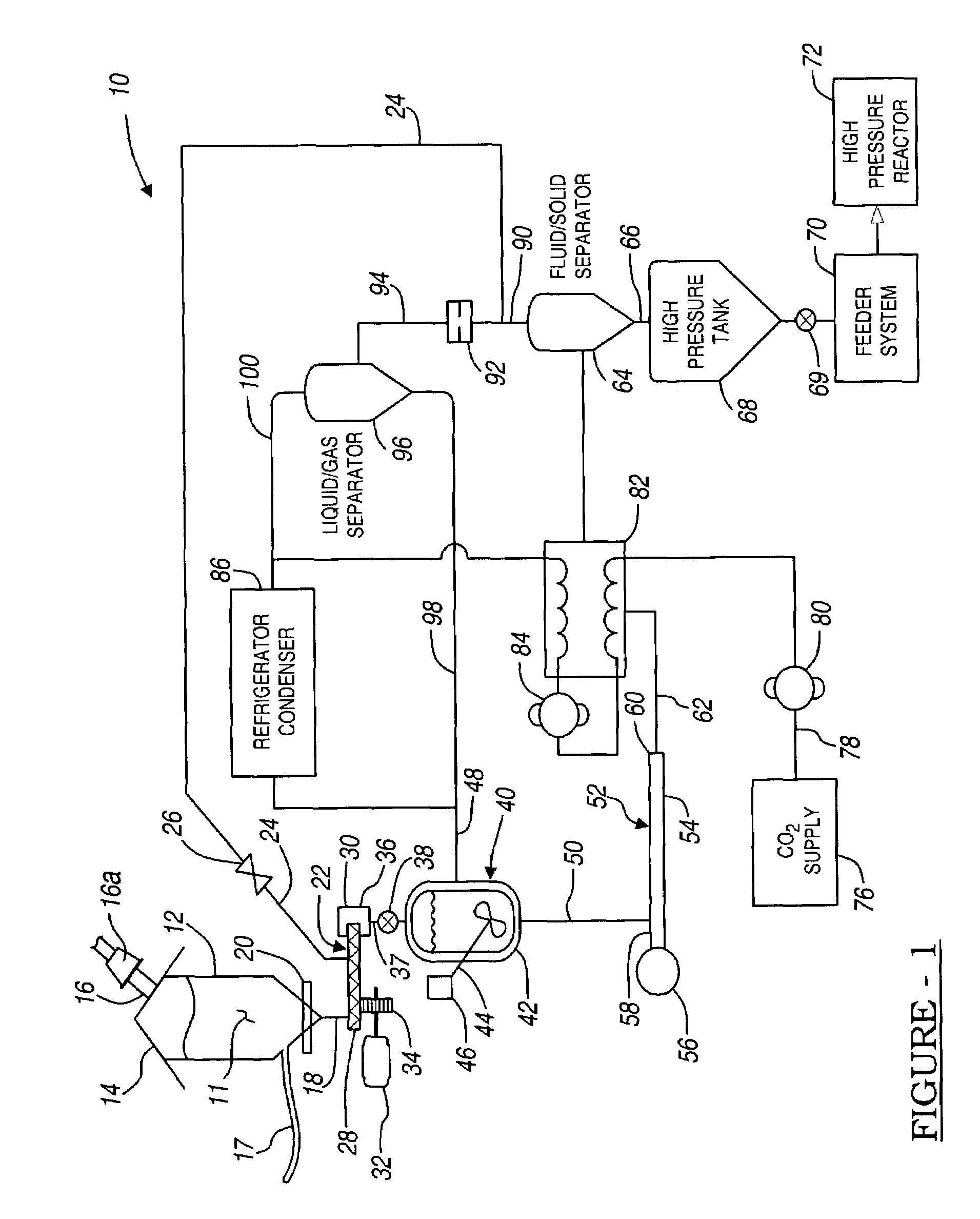

Method and apparatus for continuously feeding and pressurizing a solid material into a high pressure system

A system for substantially continuously providing a solid material, for example pulverized coal, to a pressurized container. The system provides the solid material to a first container of a first pressure elevated above an initial pressure of the solid material. Generally, a screw conveyor augmented with a jet port is used to move the material where the jet port provides a gas to provide a make-up volume of the solid material. The system also provides the material to a second high pressure container after the material has been formed into a slurry. Therefore, the solid material may be substantially continuously provided in a system to a high pressure container.

Owner:THE BOEING CO +1

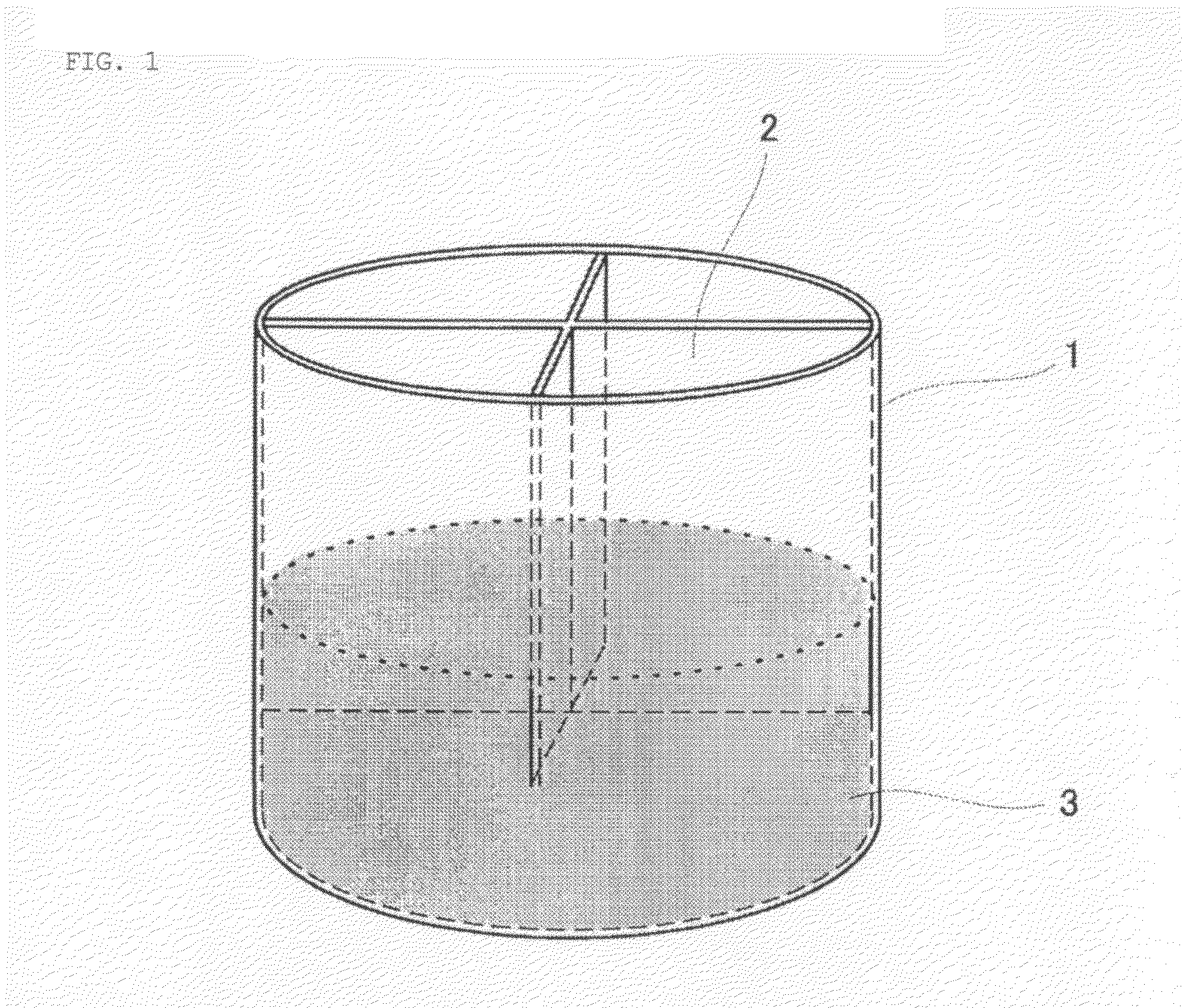

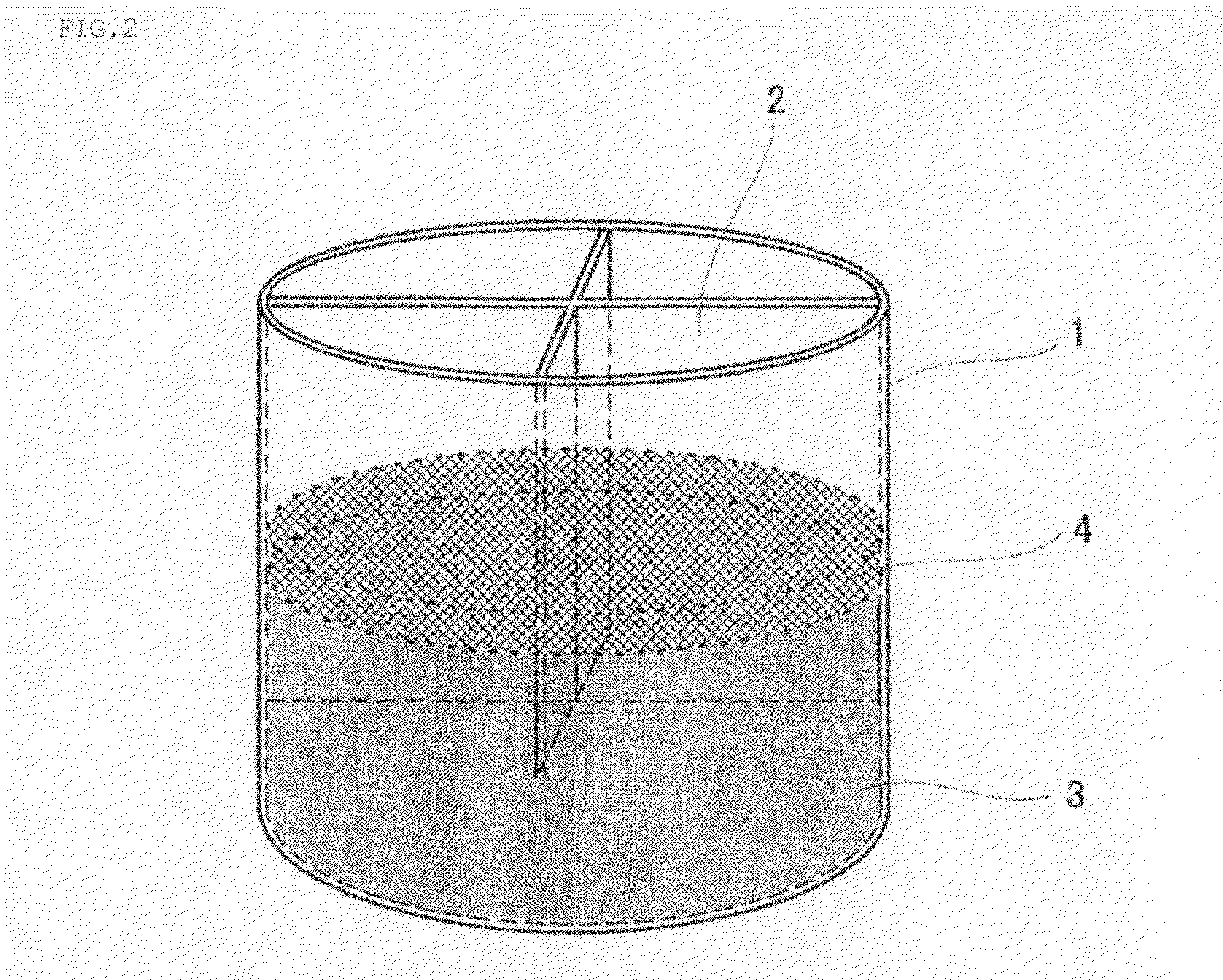

Lock hopper

ActiveUS20110206469A1Large transfer amountSmall particle sizeDispersed particle separationLarge containersWaste managementEngineering

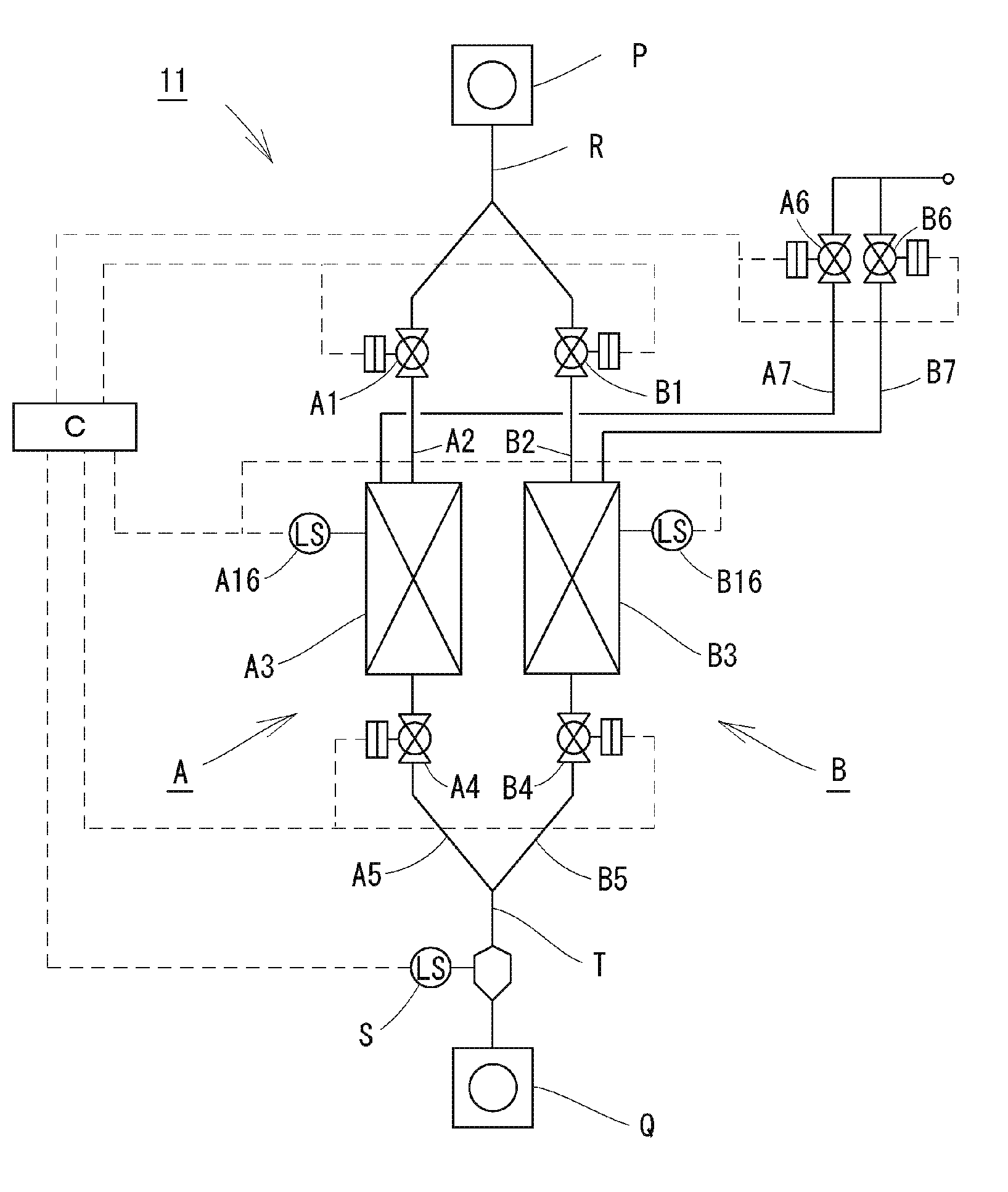

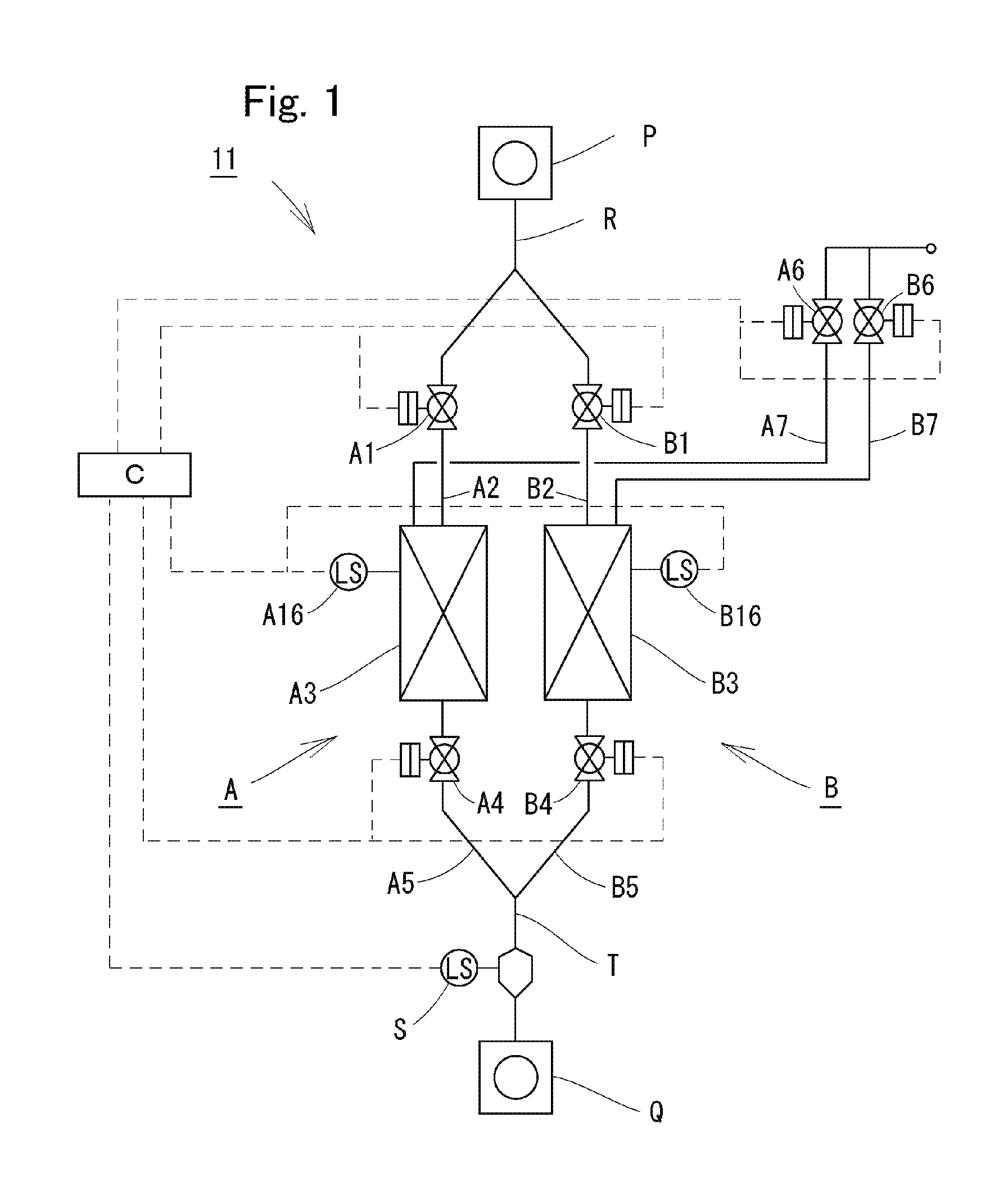

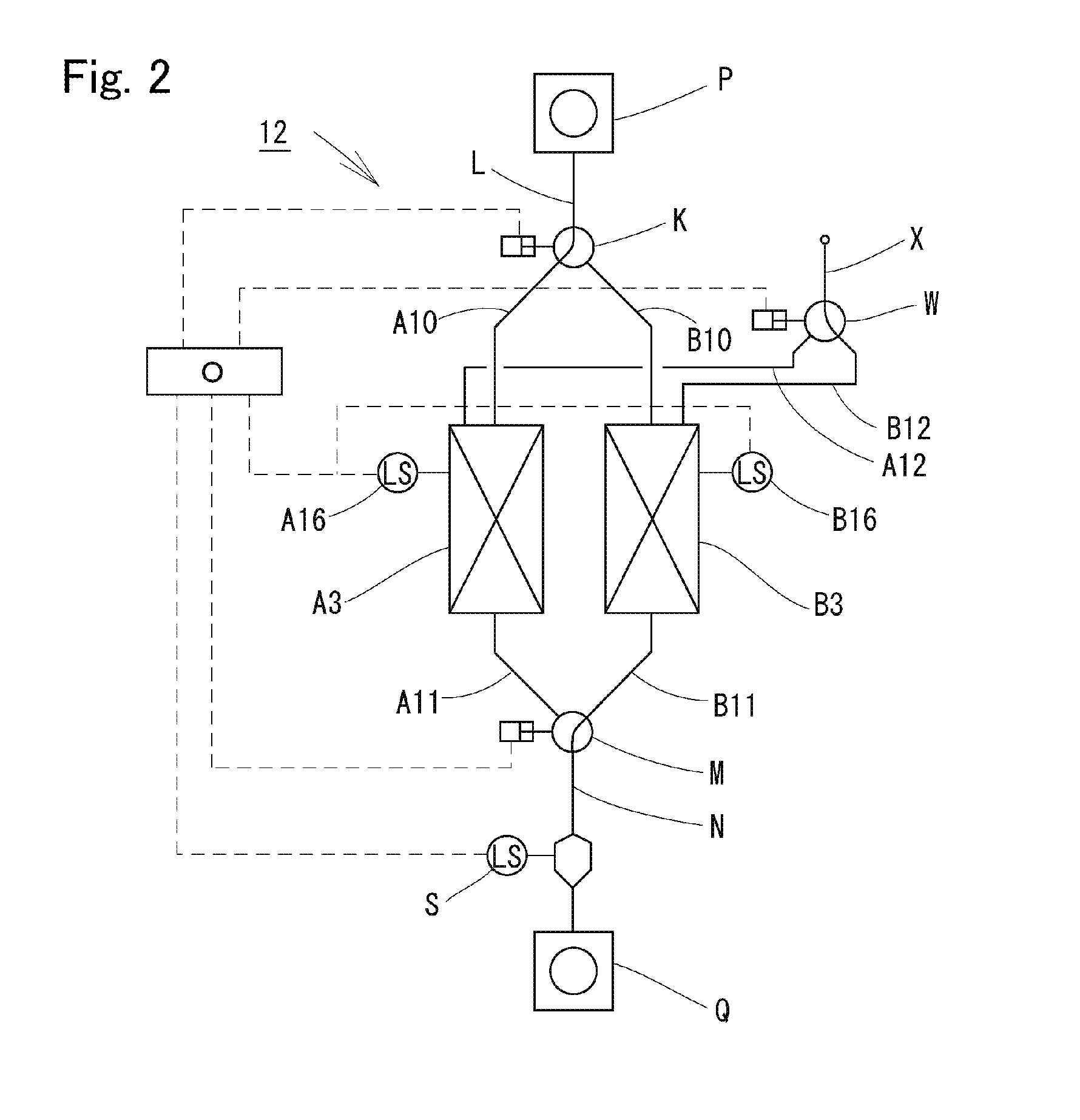

The present invention relates toA lock hopper (11) provided with air-tight hoppers (A3, B3) arranged side by side with entrance valves (A1, B1) arranged above the air-tight hoppers (A3, B3) and exit valves (A4, B4) arranged below the air-tight hoppers (A3, B3).The lock hopper (11) performs control which alternately repeats the following states: a state in which granular substances in an upper system are placed in one of the hoppers and gas is supplied into the other hopper to discharge granular substances from the inside of the other hopper to a lower system and a state in which the granular substances in the upper system are placed in the other hopper and gas is supplied to said hopper to discharge granular substances from the inside of said hopper to the lower system.Also provided is a method of transferring granular substances in an upper system to a lower system by using above-described lock hopper, wherein gas having a volume corresponding to the volume of at least the granular substances to be discharged to the lower system is supplied to a hopper in a state in which the granular substances are being discharged from the hopper to the lower system.

Owner:J POWER ENTECH

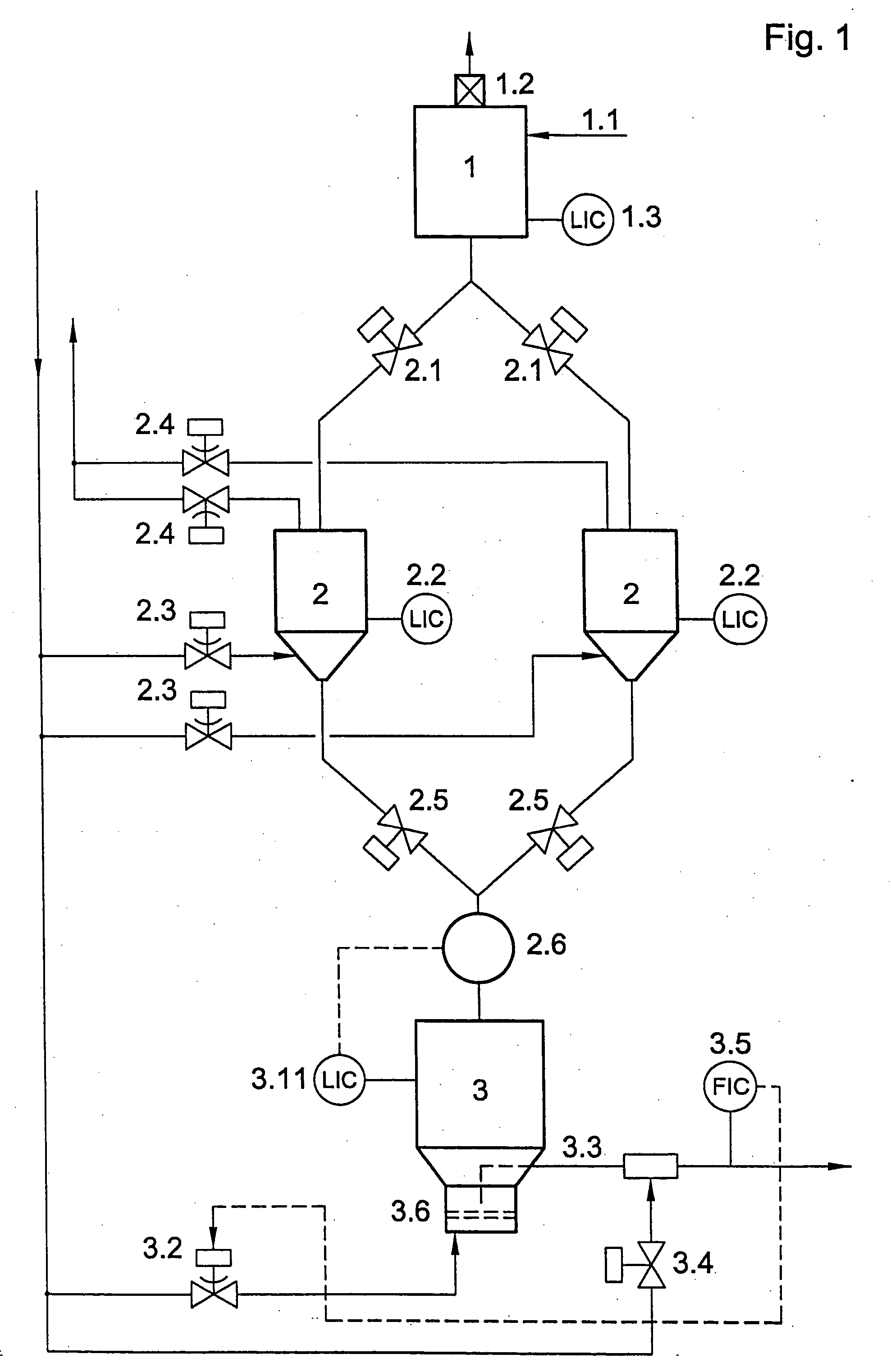

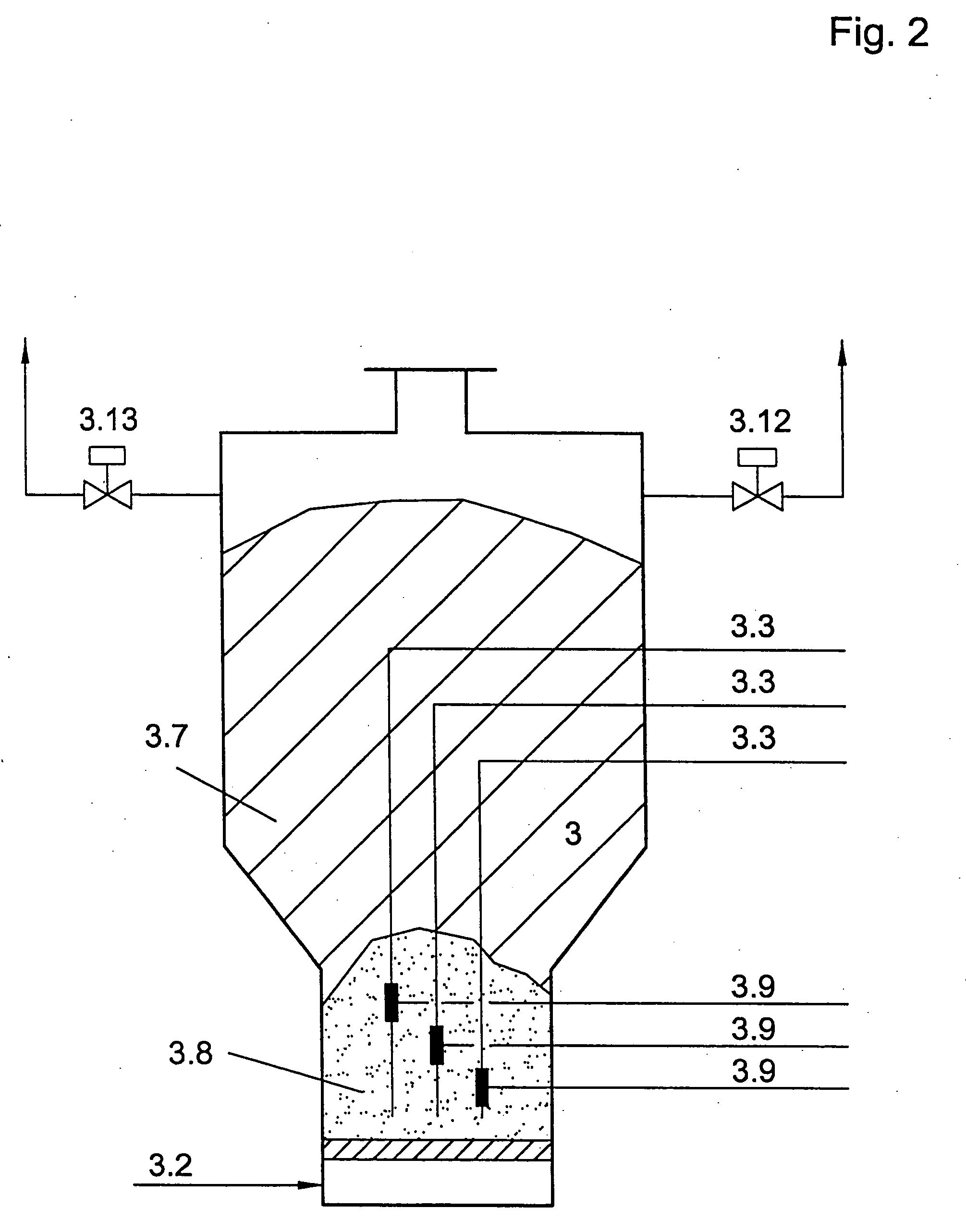

Method and device for the regulated feed of pulverized fuel to an entrained flow gasifier

ActiveUS20070074643A1Constant flowDouble gratePulverulent fuel combustion burnersCombustorFluidized bed

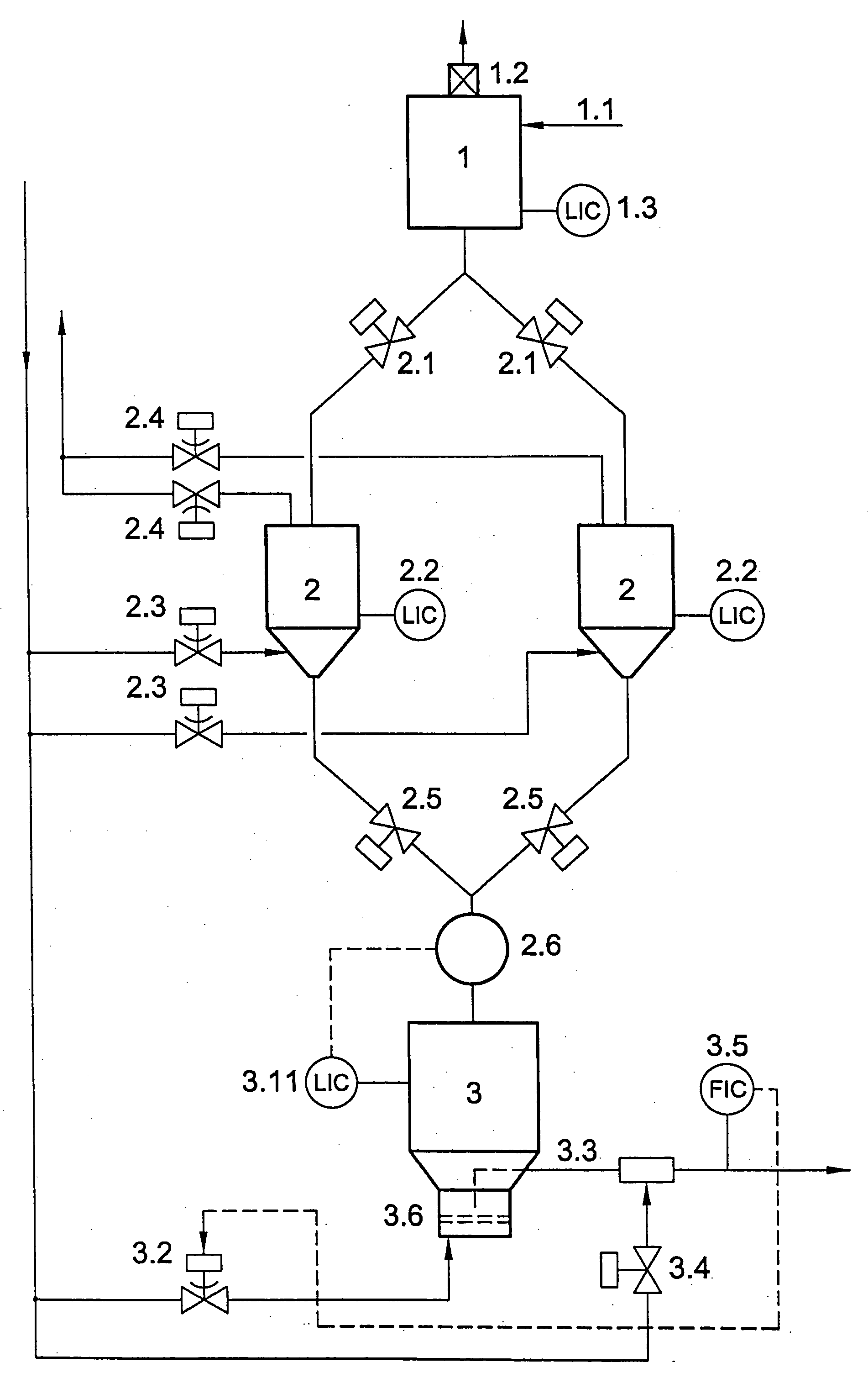

A method and device for metering and feeding pulverized fuels under pressure into gasification reactors, with the pulverized fuel being supplied alternately from an operational bunker through pressurized sluices to a metering tank, in the bottom of which a dense fluidized bed is formed by introducing fluidizing gas through a turbulence plate, with transport pipes immersed in the fluidized bed horizontally or vertically, by which the fluidized fuel is fed continuously through burners to a pressurized gasification reactor. By feeding in auxiliary gas in the immediate vicinity of the transport line inlet into the metering tank or the transport lines, the pressure differential between the metering tank and the gasification reactor is controlled and is utilized as a control parameter for pulverized fuel transport.

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

Process for gasification of low rank carbonaceous material

A process for the gasification of low rank carbonaceous material, including the steps: (a) subjecting said low rank carbonaceous material to shearing stresses in order to cause attritioning of the microporous structure of said low rank carbonaceous material and release of water contained in the micropores; (b) continuing the shearing attritioning of step (a) until the low rank carbonaceous material forms into a plastic mass; (c) compacting the plastic mass of step (b) into compacted bodies; (d) heating the compacted bodies at temperatures sufficient to thermally decompose the compacted bodies to produce a reactive carbonaceous product; (e) reacting the reactive carbonaceous product with water vapour at a temperature sufficient to produce hydrogen and carbon monoxide containing gas.

Owner:PACIFIC EDGE HLDG PTY LTD

Process for producing molten iron

InactiveUS20110154951A1Efficient productionIncrease productionGasification processes detailsManufacturing convertersChemical compositionCarbon source

The object of the present invention is to provide a process for producing molten iron through the efficient reduction of iron oxide having various chemical compositions and various shapes, or through the efficient melting of scrap iron or reduced iron having various shapes and various chemical compositions, the process being used in cases where the amount of iron necessary per furnace is not so large as in blast furnace processes. Specifically, the present invention provides a process for producing molten iron comprising the steps of: supplying carbon-containing molten iron to a holding container, heating the molten iron using heat of a combustion reaction of a gas mixture containing a fuel gas and a combustion-supporting gas, thereby storing the heat therein, and adding a carbon source and an iron-containing material that contains iron oxide and / or scrap iron to the heated and heat-stored molten iron, thereby converting the iron-containing material to molten iron.

Owner:ISTC

Method for controlling syngas production in a system with multiple feed materials using a molten metal bath

Processes and apparatus for treating organic and inorganic materials in a metal bath contained in a high temperature reactor to produce synthesis gas are provided. Two or more feed materials that possess differing syngas generation potentials are mixed in a mixer and fed as a composite feed stream into a gasifier to produce syngas. The feed materials are prepared and analyzed for heat value prior to injection and the composition of materials in and exiting the reactor are monitored. By controlling the feed rate of the mixture into the gasifier as well as the feed rates of one or more of the individual feed materials into the mixer, the syngas is produced at a target production rate, with target energy content (BTU). Based upon the results of the analysis and monitoring, oxygen, steam, and / or other feed materials are also injected into the reactor, to control processing and synthesis gas quality. Potential feed materials include, but are not limited to, construction and demolition (C&D) debris, municipal solid waste (MSW), other sewage-related solids, waste tires, and other substances that contain varying levels of organic compounds capable of producing a syngas.

Owner:ZE-GEN

System for gasification fuel injection

A system includes a gasification fuel injector, which includes a first fuel conduit configured to inject a first fuel flow from a first fuel tip, a second fuel conduit configured to inject a second fuel flow from a second fuel tip, a first gas conduit configured to inject a first gas flow from a first gas tip, a second gas conduit configured to inject a second gas flow from a second gas tip, and a third gas conduit configured to inject a third gas flow from a third gas tip. At least one of the first fuel tip, the second fuel tip, the first gas tip, the second gas tip, or the third gas tip is recessed a distance away from an outlet of the gasification fuel injector. The first and second fuel conduits and the first, second, and third gas conduits are coaxial with one another.

Owner:AIR PROD & CHEM INC

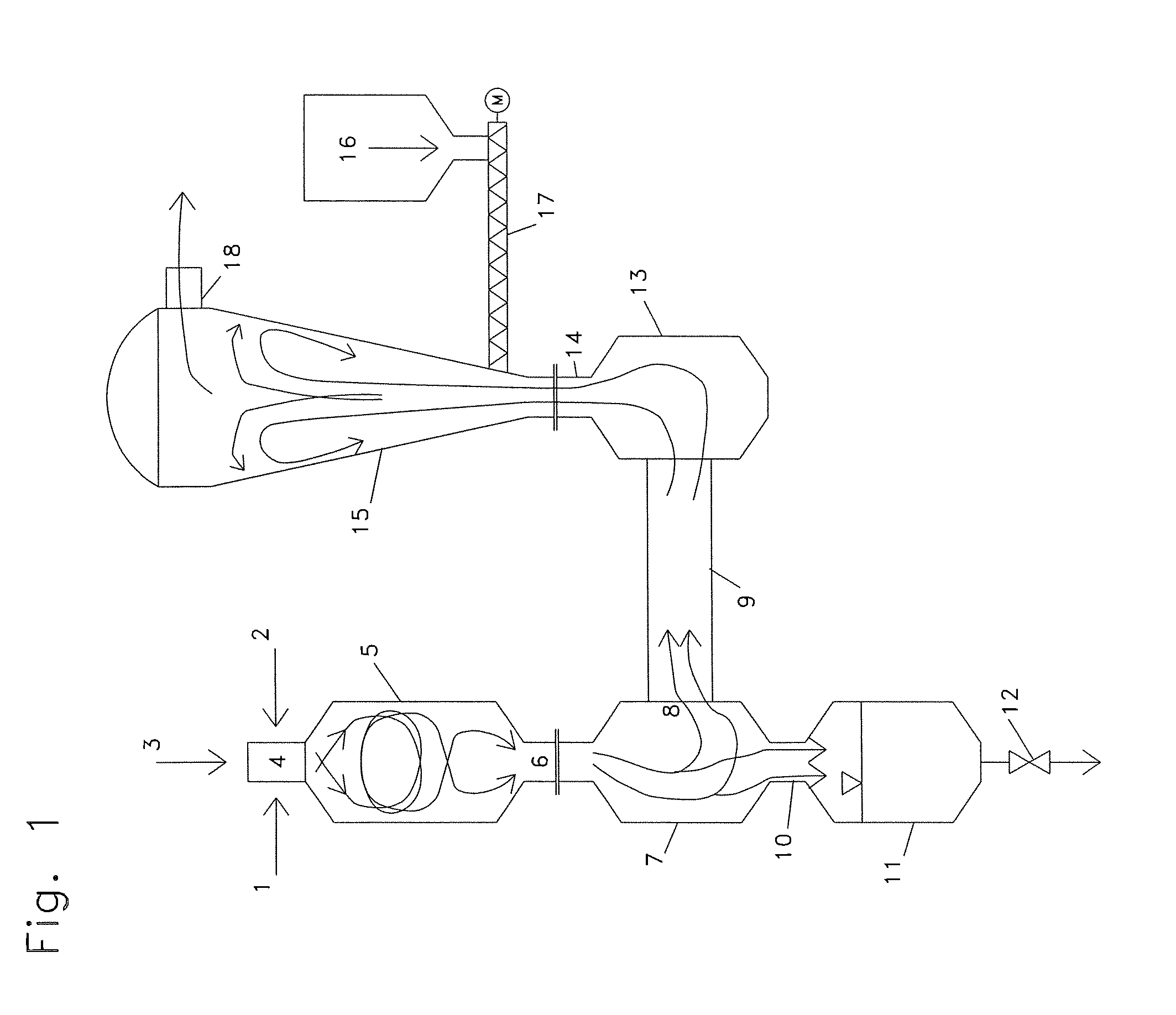

Process and apparatus for the endothermic gasification of carbon

InactiveUS7776114B2Improve fuel efficiencyGreat differenceHydrogenGasification processes detailsSolid carbonPartial oxidation

A process for the endothermic gasification of solid carbon in an entrained bed facility comprises partial oxidation of fuel(s) and endothermic gasification of solid carbon, preferably preceded by low temperature carbonization such that the carbonization gas is passed to the partial oxidation and the carbonization coke is passed to the endothermic gasification. The hot gas streaming downwardly from the combustion chamber is deflected to produce separation of the liquid slag and is then passed to the endothermic gasification that operates with a rising gas stream and with addition of solid carbon having a grain diameter of up to 20 mm. The speed of the gas at the carbon inlet is higher than, and the speed of the gas at the end of the endothermic gasification is lower than, the suspension rate of the reactive carbon particles, to produce an increase of the relative speed difference between the gas and the carbon particles. Apparatus is also disclosed for carrying out the process.

Owner:LINDE AG

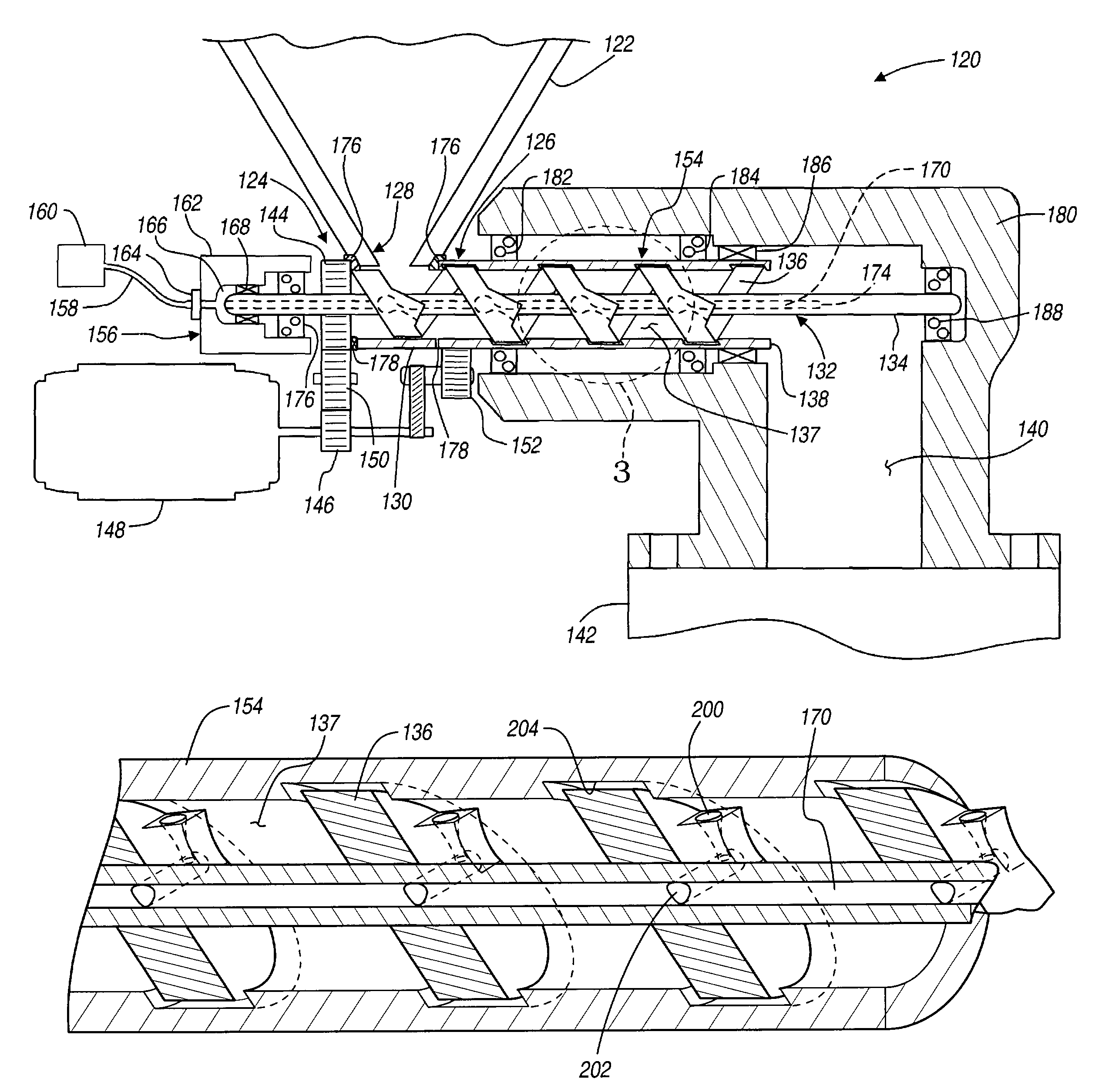

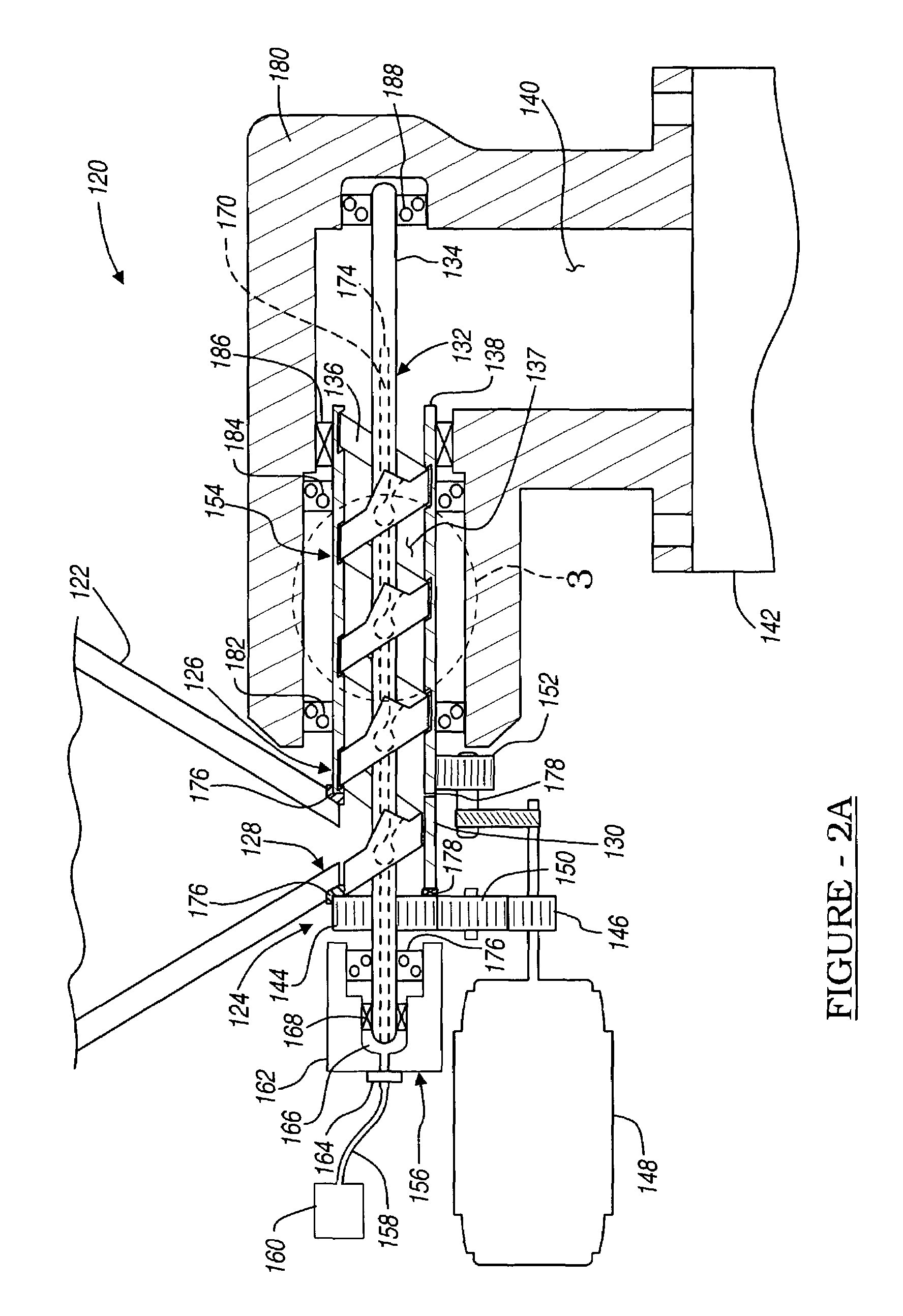

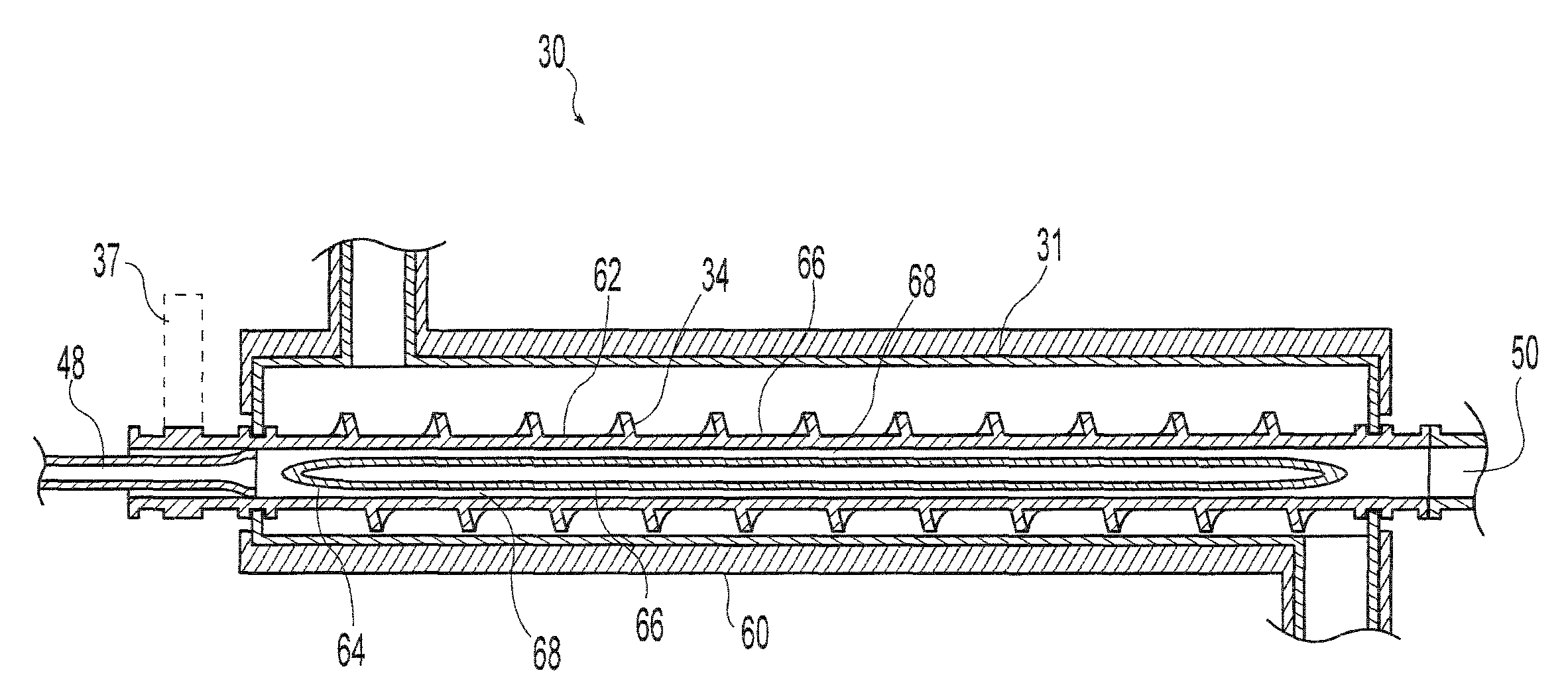

Pyrolyzer furnace apparatus and method for operation thereof

InactiveUS20130240343A1Reduce the cross-sectional areaWeaken energyCombustible gas coke oven heatingCoal charges mechanical treatmentCombustion chamberMechanical engineering

A char making apparatus comprises a longitudinal pyrolyzer furnace housing wherein coal-bearing material may be heated to a temperature to fluidize volatile materials therein and plasticize coal in the coal-bearing material. At least two rotatable drive screws are laterally positioned and interleaved within the longitudinal furnace housing and capable of conveying coal-bearing materials through the pyrolyzer furnace housing, each drive screw having a hollow drive shaft and a diverter positioned within the drive shaft to provide heating to the coal-bearing material. A heating jacket about the longitudinal furnace housing provides additional heating to the coal-bearing material. Multiple combustion chambers adjacent the heating jacket and hollow drive shaft burn fluidized volatile materials and exhaust combustion fluids through the jacket and shaft.

Owner:NUCOR CORP

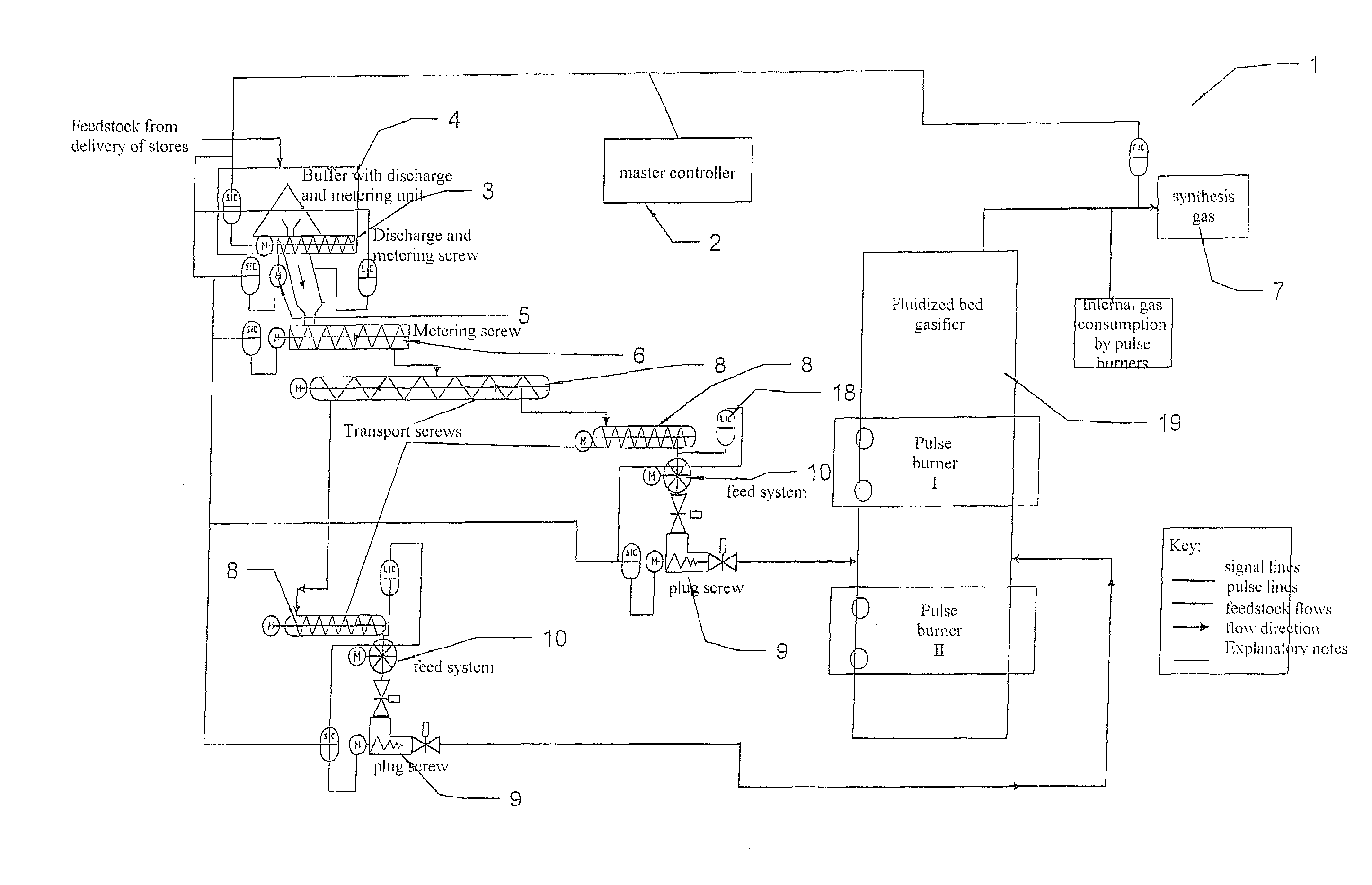

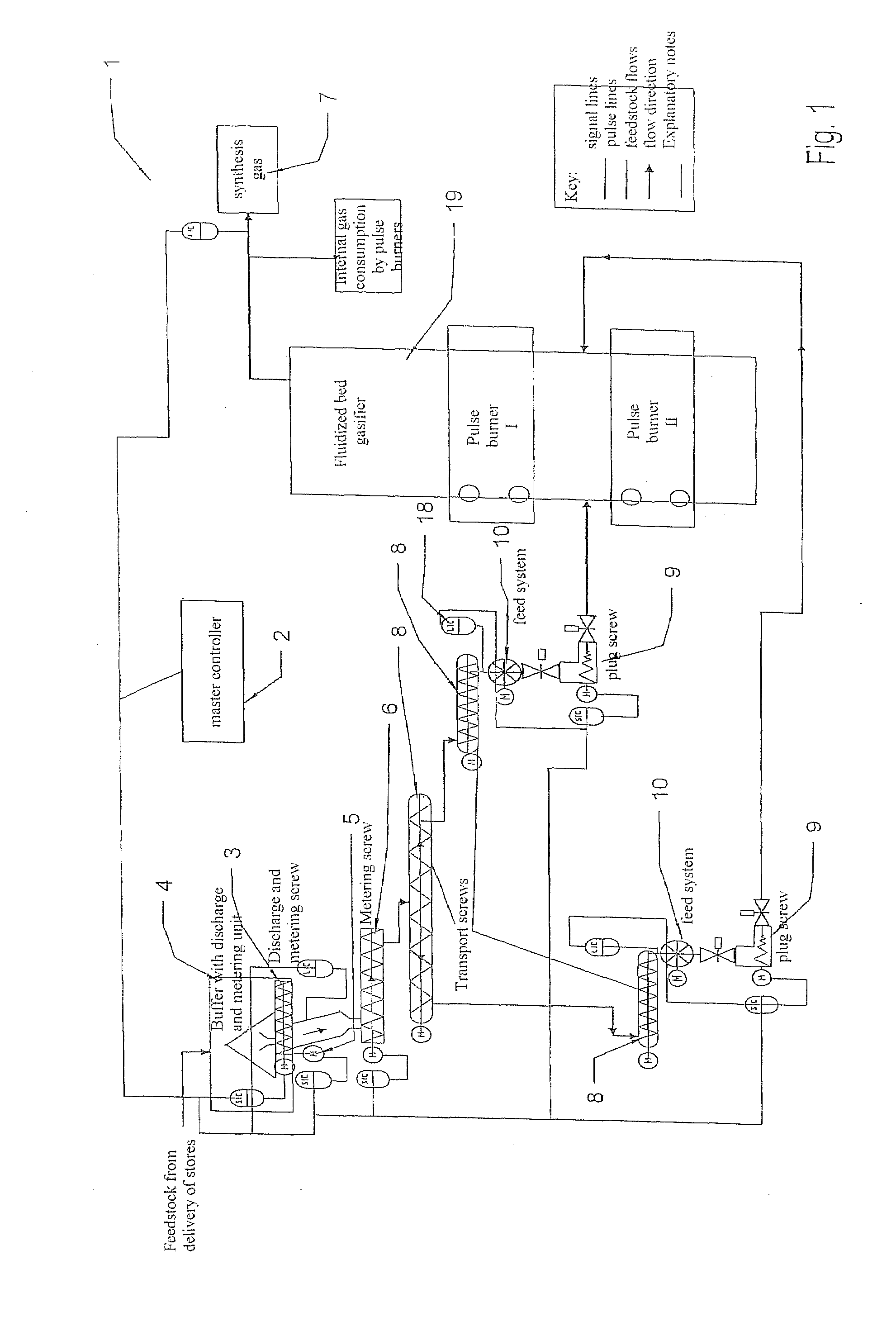

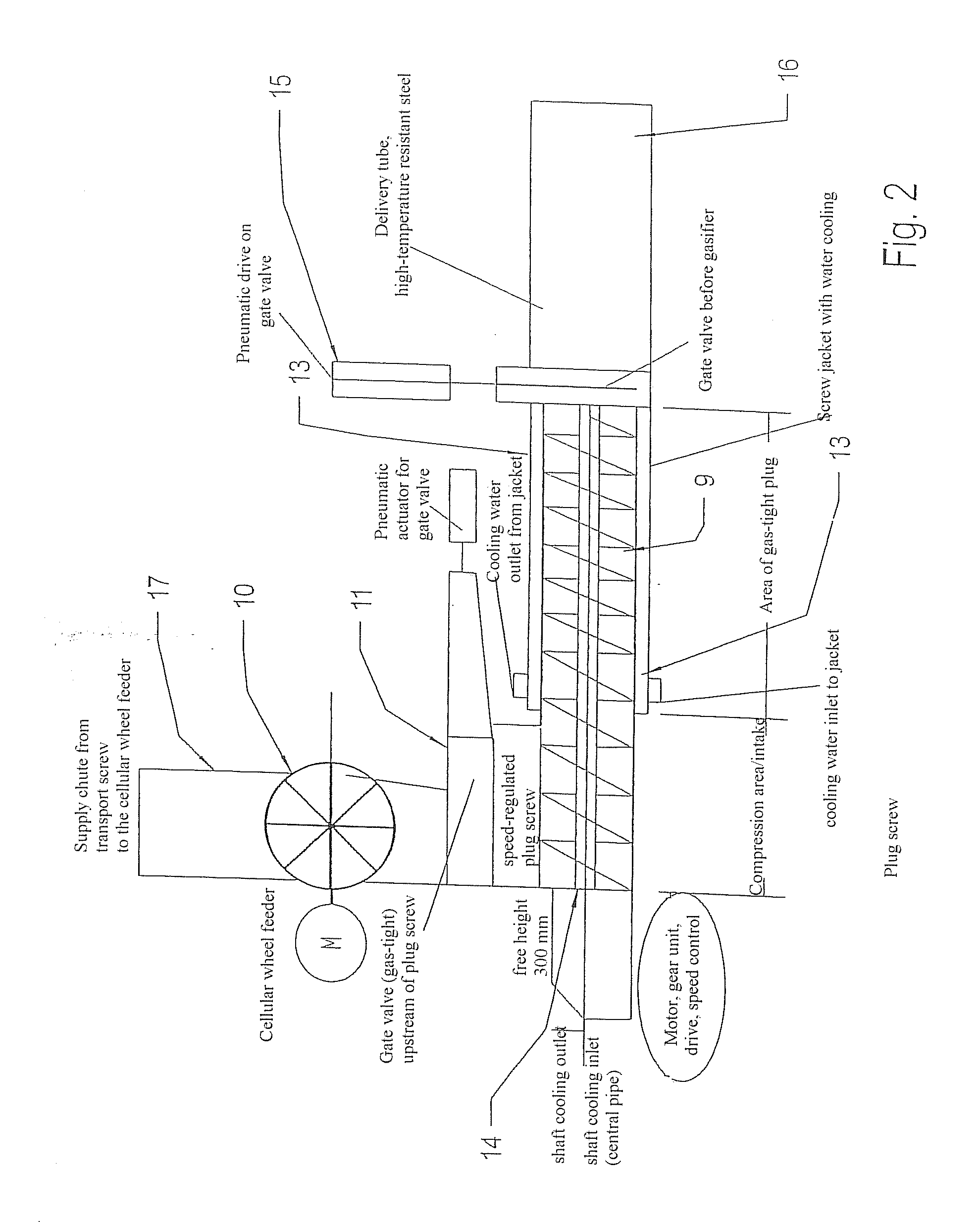

Feed System

InactiveUS20090173005A1Prevent backflowEfficient deliveryHydrogenGasification processes detailsTransport systemDelivery system

Transport system for the introduction of biomass into a gasifier comprising: a plug screw that forces the biomass into the gasifier, wherein the plug screw is formed such that the biomass is compressed in order on the one hand for it to be conveyed against a pressure in the gasifier and, on the other hand, to leave the gas and bed material in the gasifier, having a gate valve adjacent to the plug screw and which closes when the plug screw stops so that heat, vapour and gas cannot escape.

Owner:SPIRIT OF TECH

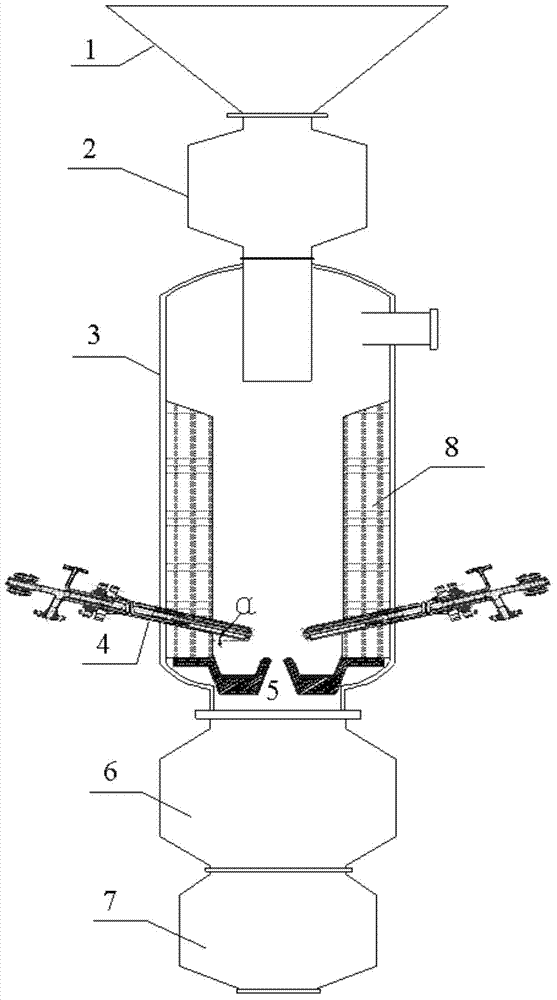

Liquid continuous slag-removal fixed bed gasification furnace and gasification method thereof

ActiveCN104327881AExtended service lifeAvoid overall overheatingHydrogenGasification processes detailsFixed bedQuenching

The invention relates to a liquid continuous slag-removal fixed bed gasification furnace and a gasification method thereof, the liquid continuous slag-removal fixed bed gasification furnace is characterized in that: the liquid continuous slag-removal fixed bed gasification furnace from top to bottom in turn comprises a raw material bin, a material lock hopper, a furnace body, a plurality of gasification agent nozzles, a slag-removal device, a molten slag quenching chamber and a slag lock; the raw material bin is funnel-shaped, the lower end of the raw material bin is in fastening connection with the upper end of the raw material lock hopper; the raw material lock hopper is in fastening connection with an upper end port of the furnace body, the upper part of the furnace body is provided with a crude gas outlet, the furnace body inner wall located below the crude gas outlet is provided with a layer of furnace lining; the plurality of gasification agent nozzles are in fastening connection with the lower part of the furnace body and are arranged uniformly along the circumferential direction of the furnace body, the outlet of each gasification agent nozzle passes through the furnace body furnace wall and the furnace lining and extends into the furnace body; the slag-removal device is installed in the furnace body located below the furnace lining, the lower end of the furnace body is in fastening connection with the upper end of the molten slag quenching chamber, and the lower end of the molten slag quenching chamber is in fastening connection with the upper end of the slag lock. The gasification agent nozzles adopt a single channel structure only conveying a gasifying agent, the service life of the gasification agent nozzles is improved, and an overflow type slag pool can effectively ensure the smooth slag removal, and improves the operation efficiency of the fixed bed molten slag gasification furnace.

Owner:CCTEG CHINA COAL RES INST

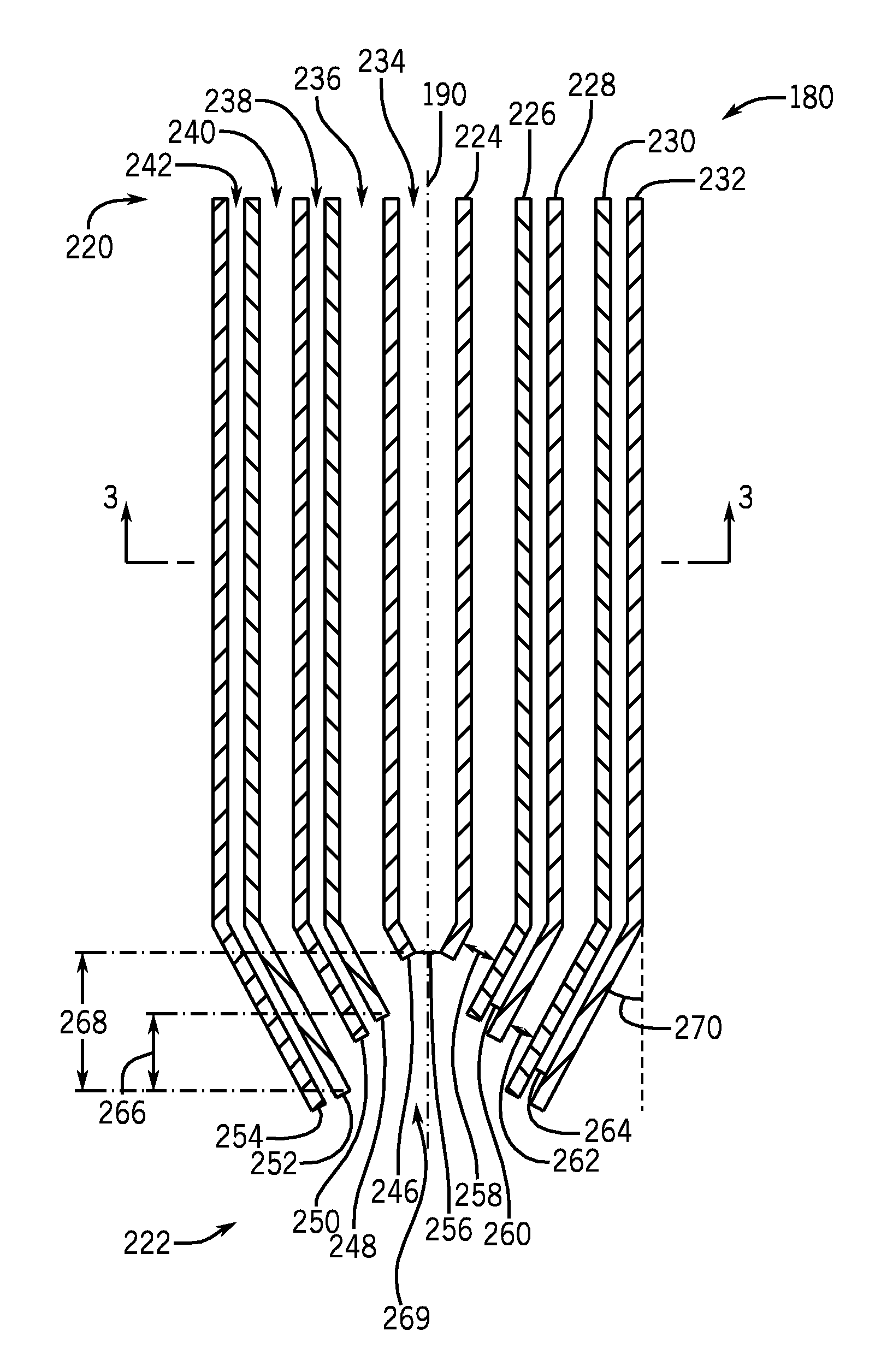

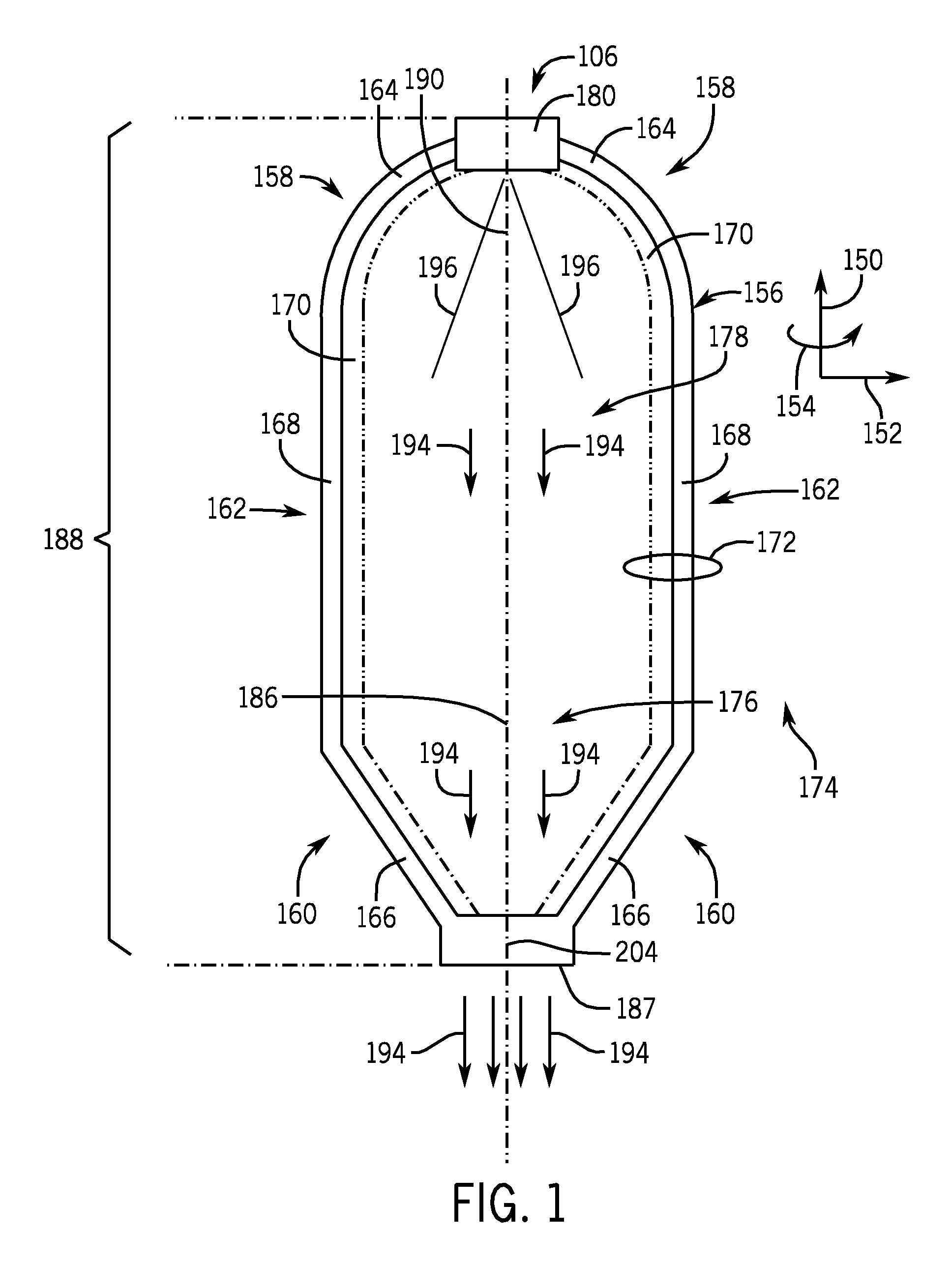

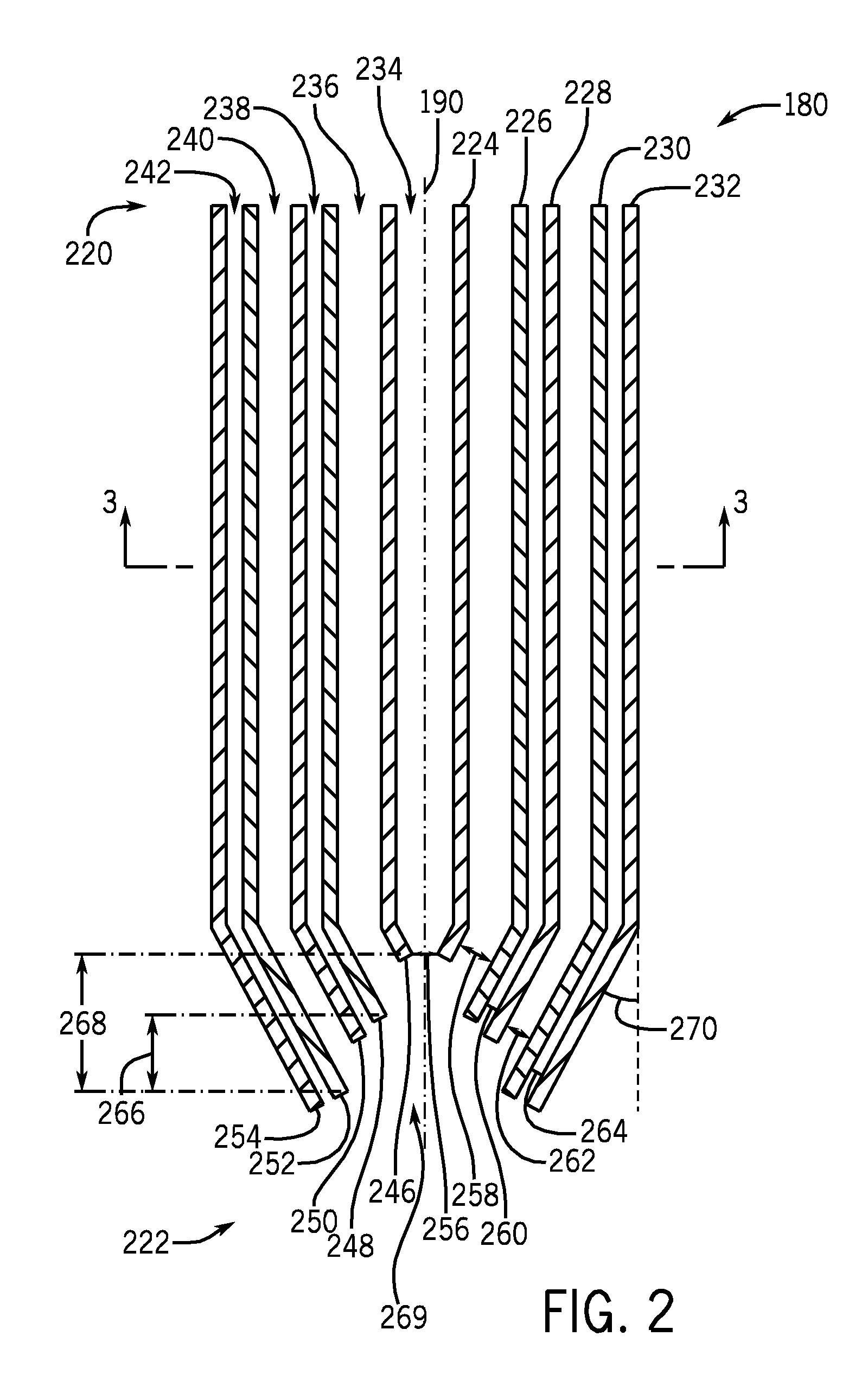

Pyrolyzer furnace apparatus and method for operation thereof

InactiveUS9045693B2Weaken energyLower Level RequirementsCombustible gas coke oven heatingCoal charges mechanical treatmentCombustion chamberDrive shaft

A char making apparatus comprises a longitudinal pyrolyzer furnace housing wherein coal-bearing material may be heated to a temperature to fluidize volatile materials therein and plasticize coal in the coal-bearing material. At least two rotatable drive screws are laterally positioned and interleaved within the longitudinal furnace housing and capable of conveying coal-bearing materials through the pyrolyzer furnace housing, each drive screw having a hollow drive shaft and a diverter positioned within the drive shaft to provide heating to the coal-bearing material. A heating jacket about the longitudinal furnace housing provides additional heating to the coal-bearing material. Multiple combustion chambers adjacent the heating jacket and hollow drive shaft burn fluidized volatile materials and exhaust combustion fluids through the jacket and shaft.

Owner:NUCOR CORP

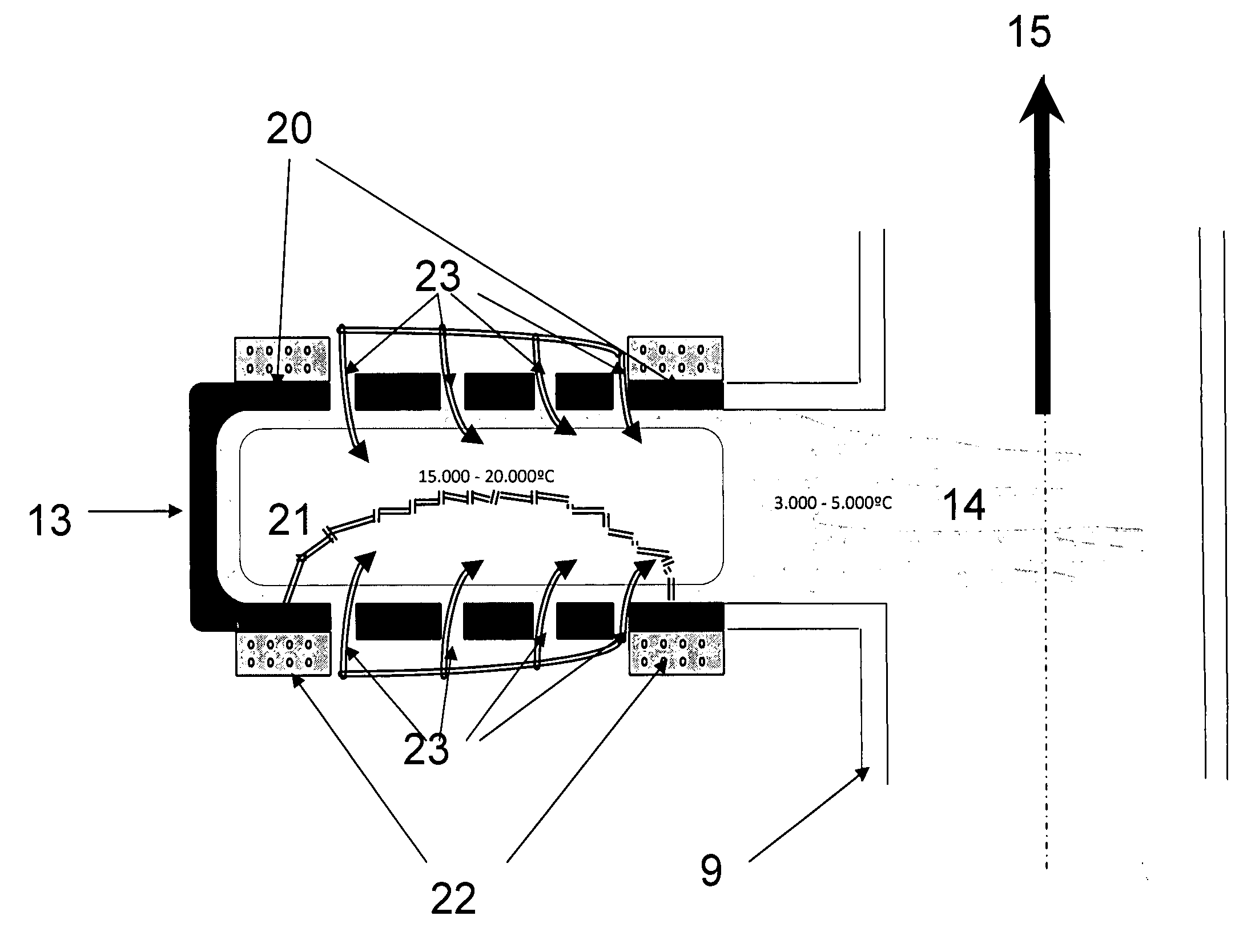

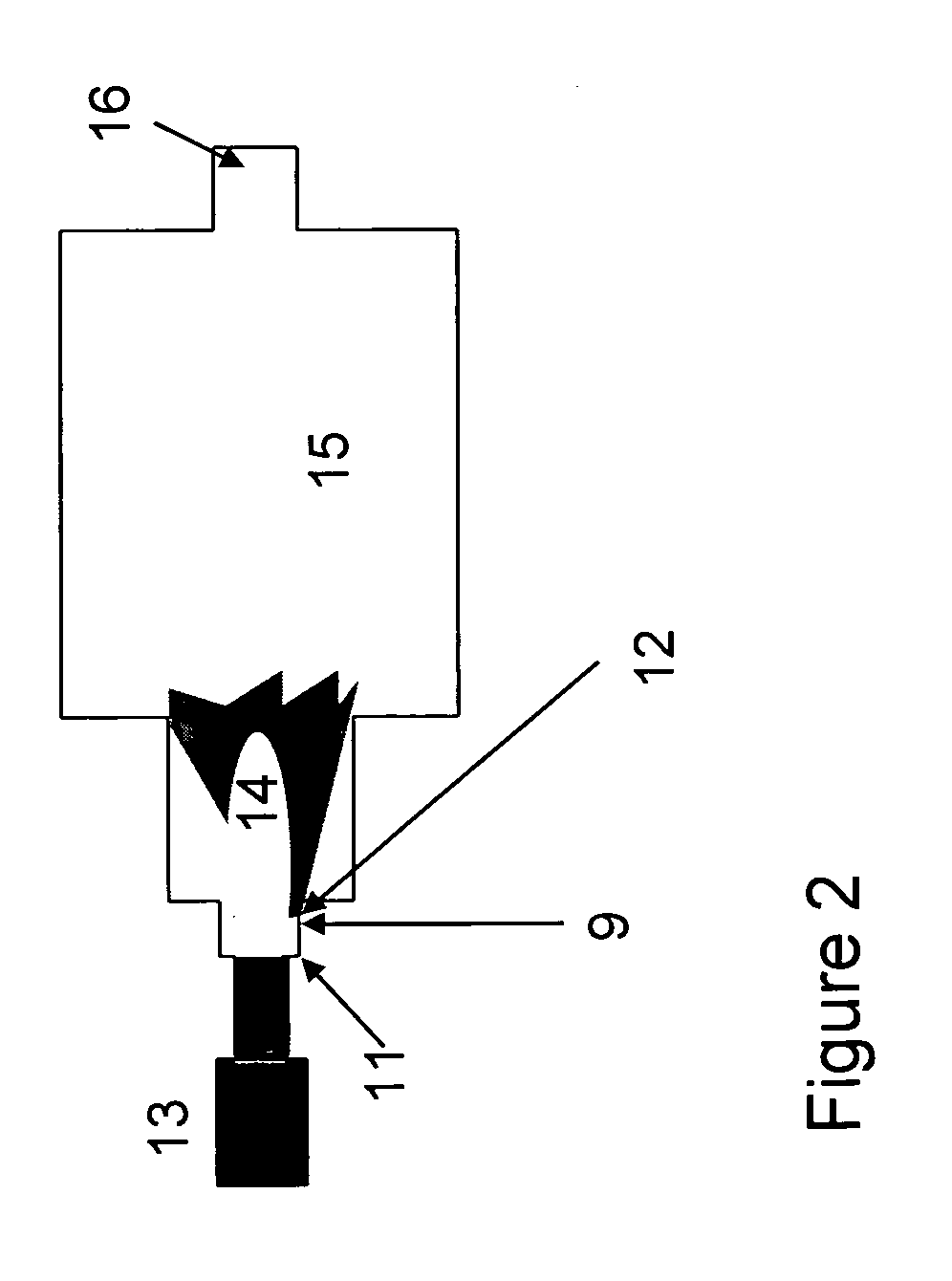

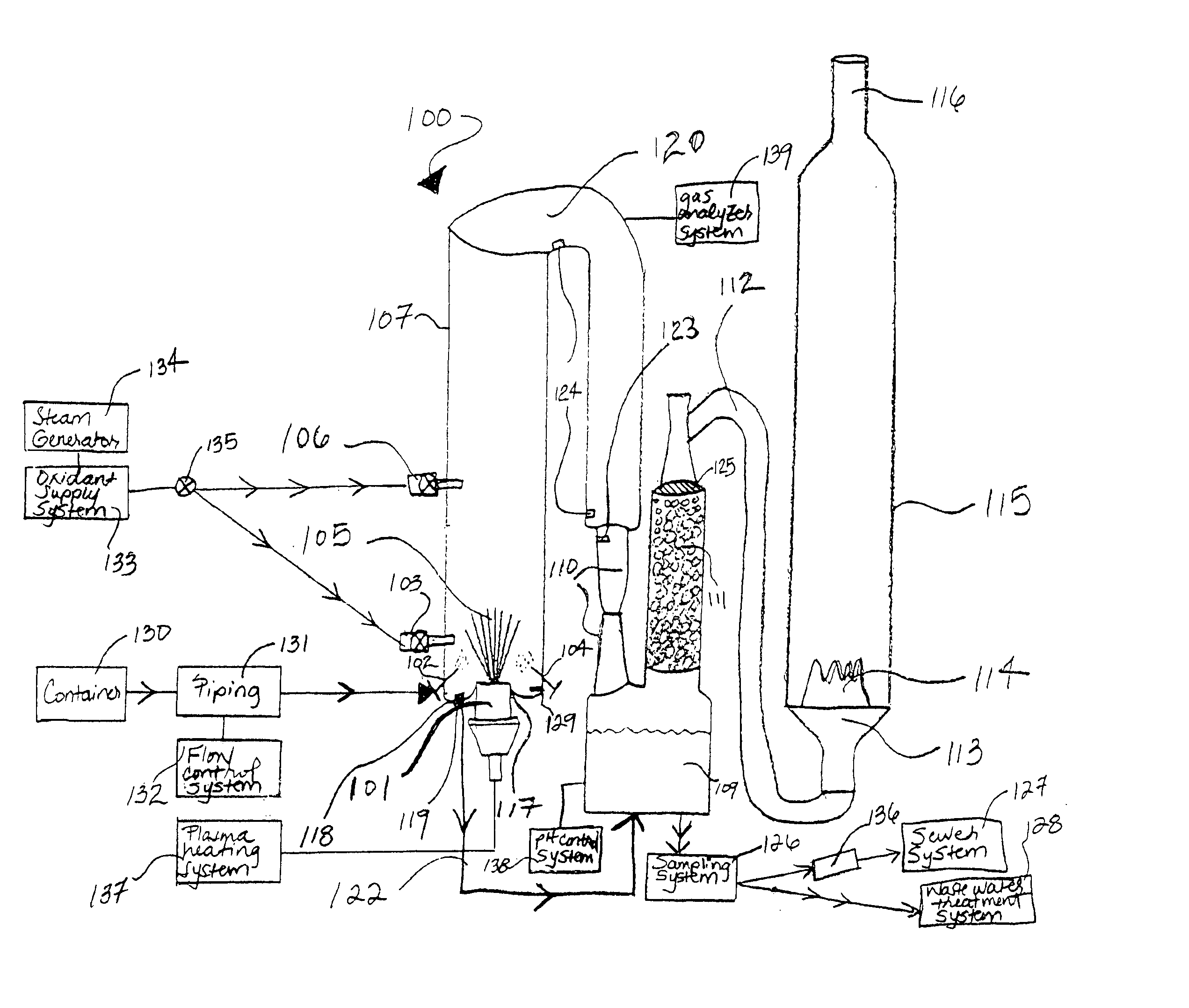

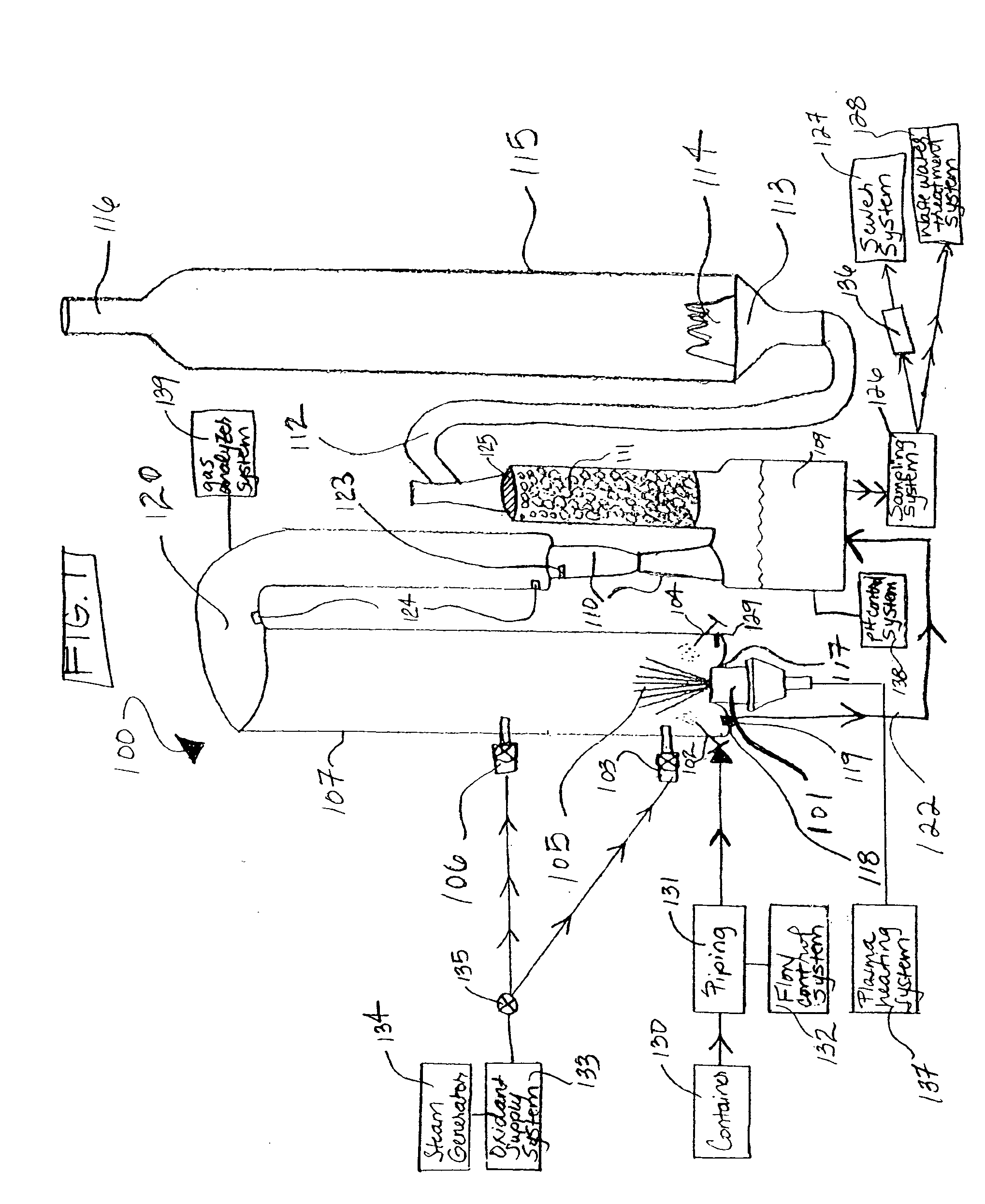

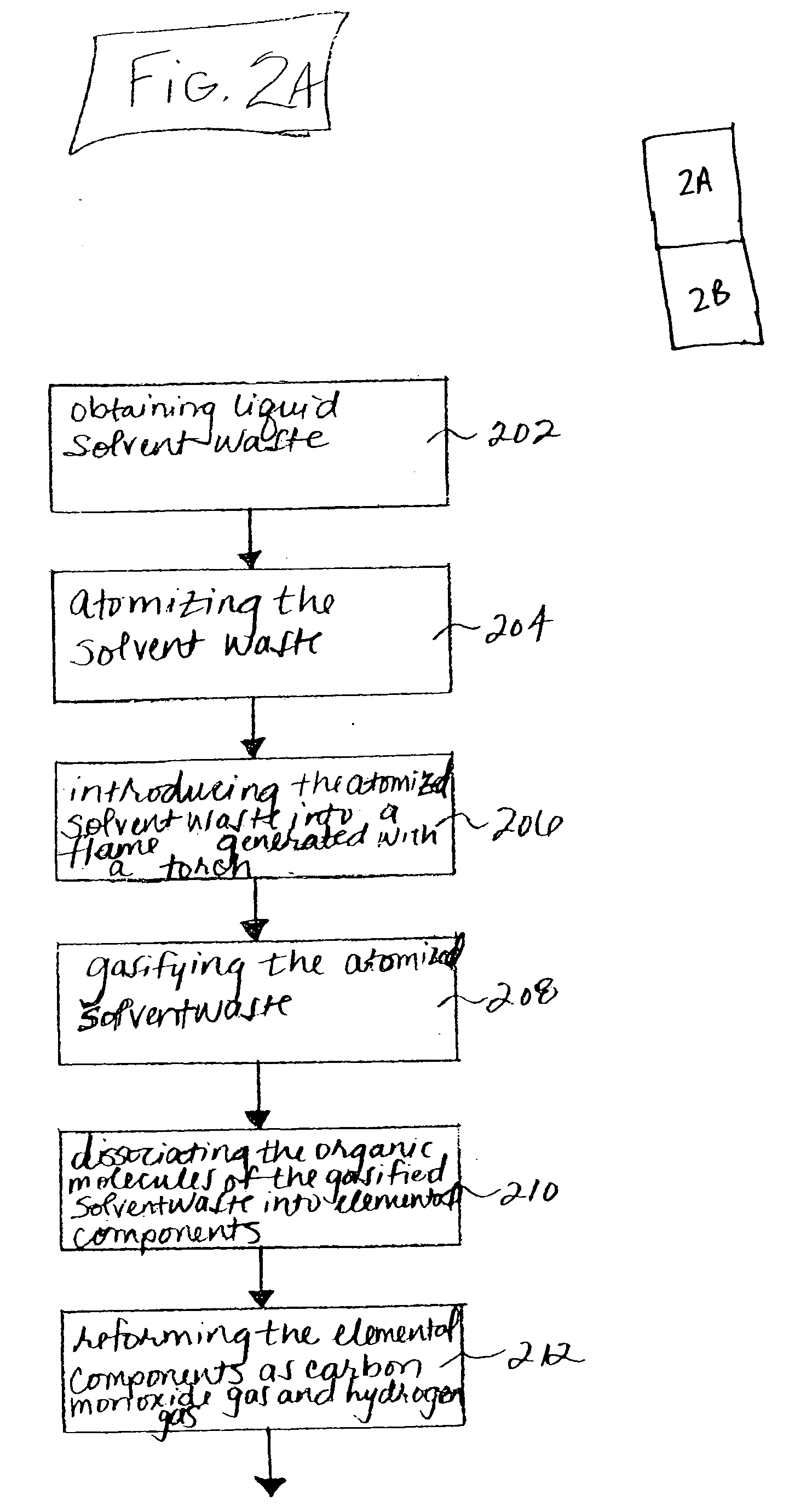

Method and apparatus for treating liquid waste

An apparatus for treating liquid waste includes a vessel, an AC plasma torch mounted with the vessel, and at least one nozzle mounted in the vessel. The nozzle is positioned so that liquid waste introduced through the nozzle into the vessel will be sprayed into or above a flame emitted by the AC plasma torch. Liquid waste is atomized by the nozzle and sprayed into the flame. The energy from the flame causes the organic portion of the atomized liquid waste to gasify and dissociate into elemental components. This dissociation destroys any hazardous or toxic constituency of the waste material.

Owner:PEAT INT INC

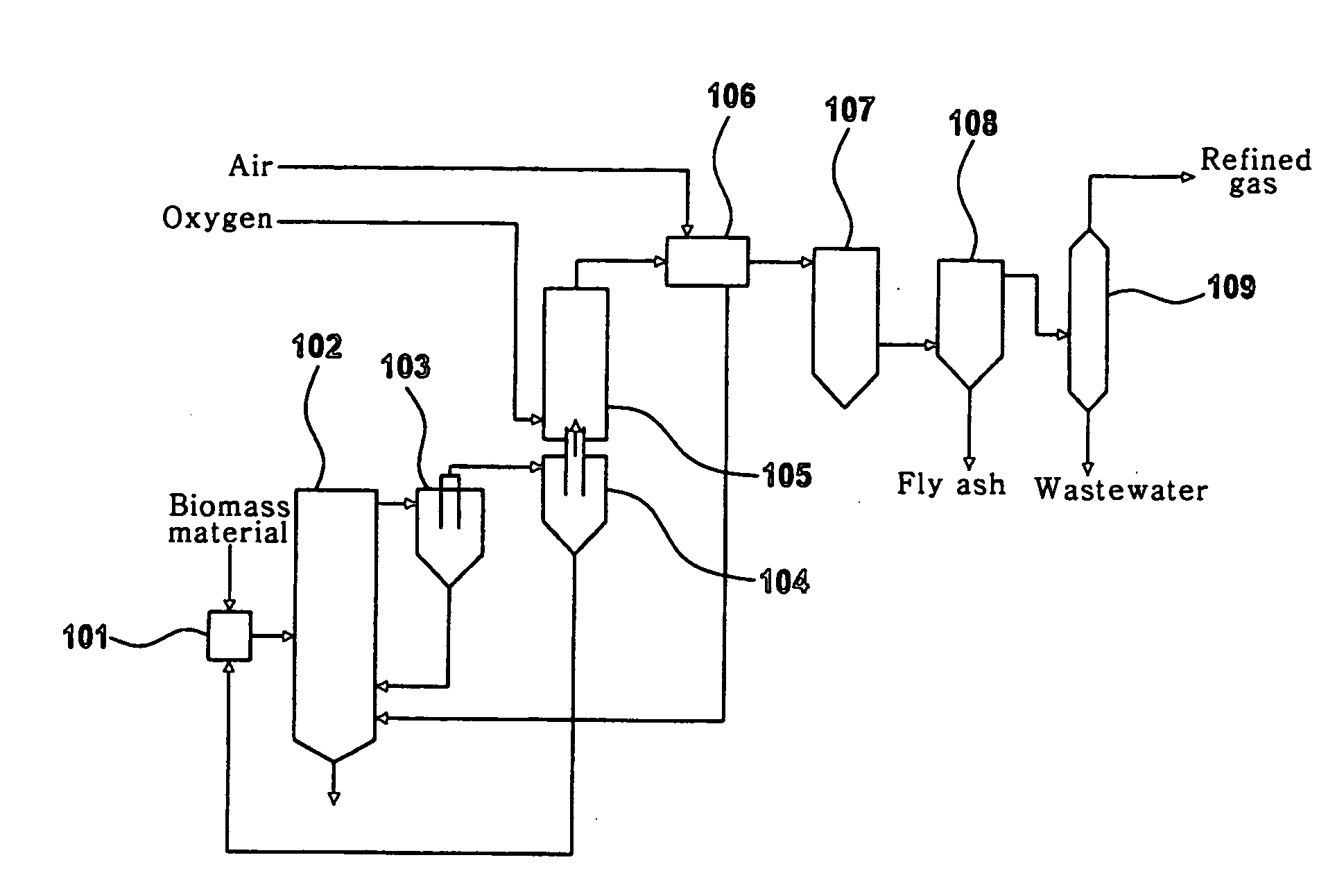

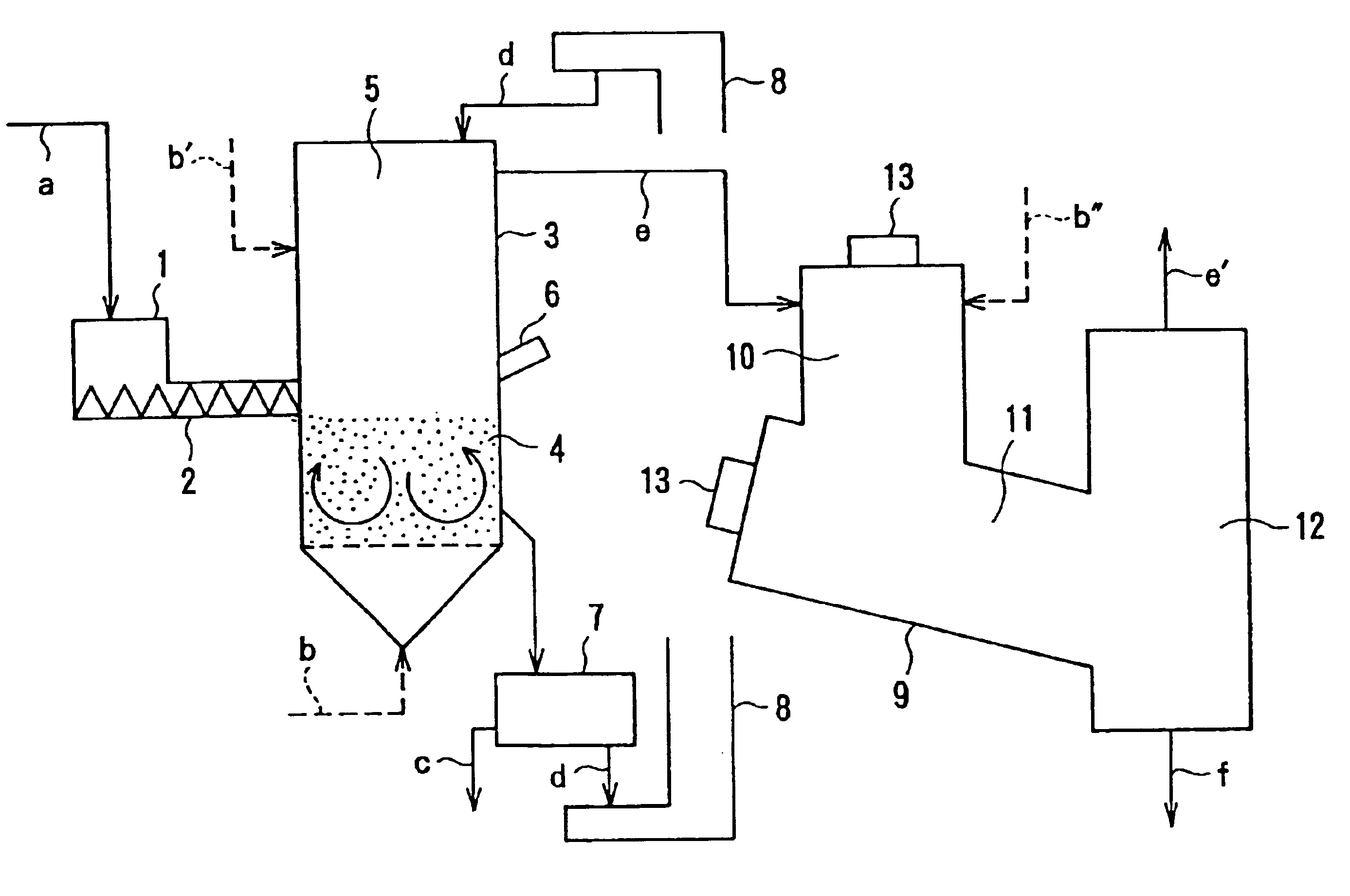

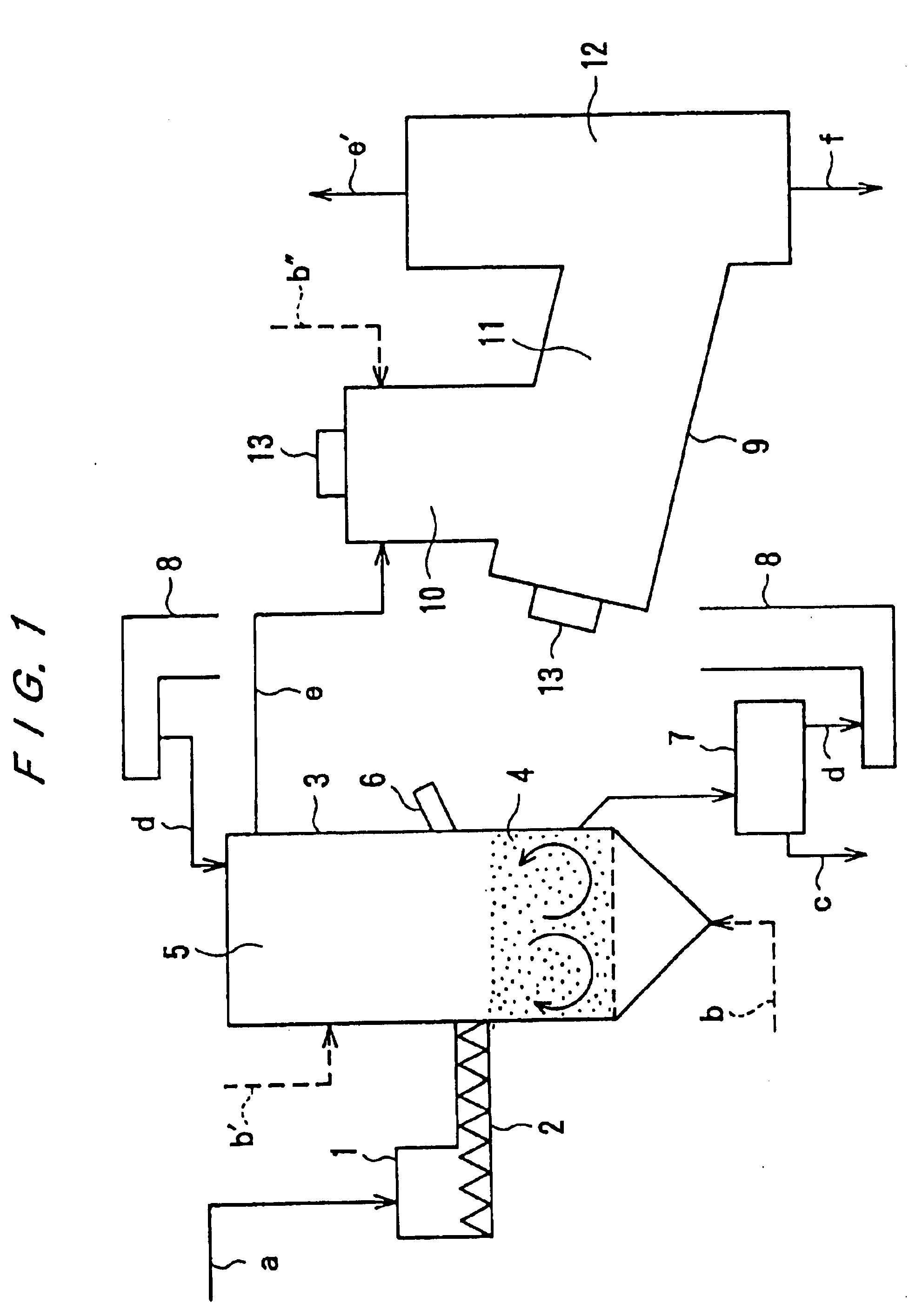

Apparatus for treating wastes by gasification

InactiveUS6902711B1Low costVarious problemCombustible gas catalytic treatmentCombustible gas thermal treatmentSyngasFluidized bed

An apparatus for treating wastes includes a fluidized bed reactor for partially combusting the wastes at a relatively low temperature, and a separate relatively high temperature reactor for separate gasification of gaseous material and char from the first gasification. This synthesis gas thus formed is cooled, subjected to a conversion operation in a converter to produce hydrogen.

Owner:EBARA CORP +1

Fuel injector having tip cooling

According to various embodiments, a system includes a gasification fuel injector. The gasification fuel injector includes a tip portion, an annular coolant chamber disposed in the tip portion, a recessed surface for cooling control and a first structural support extending through the annular coolant chamber. The first structural support divides the annular coolant chamber into a first passage and a second passage.

Owner:AIR PROD & CHEM INC

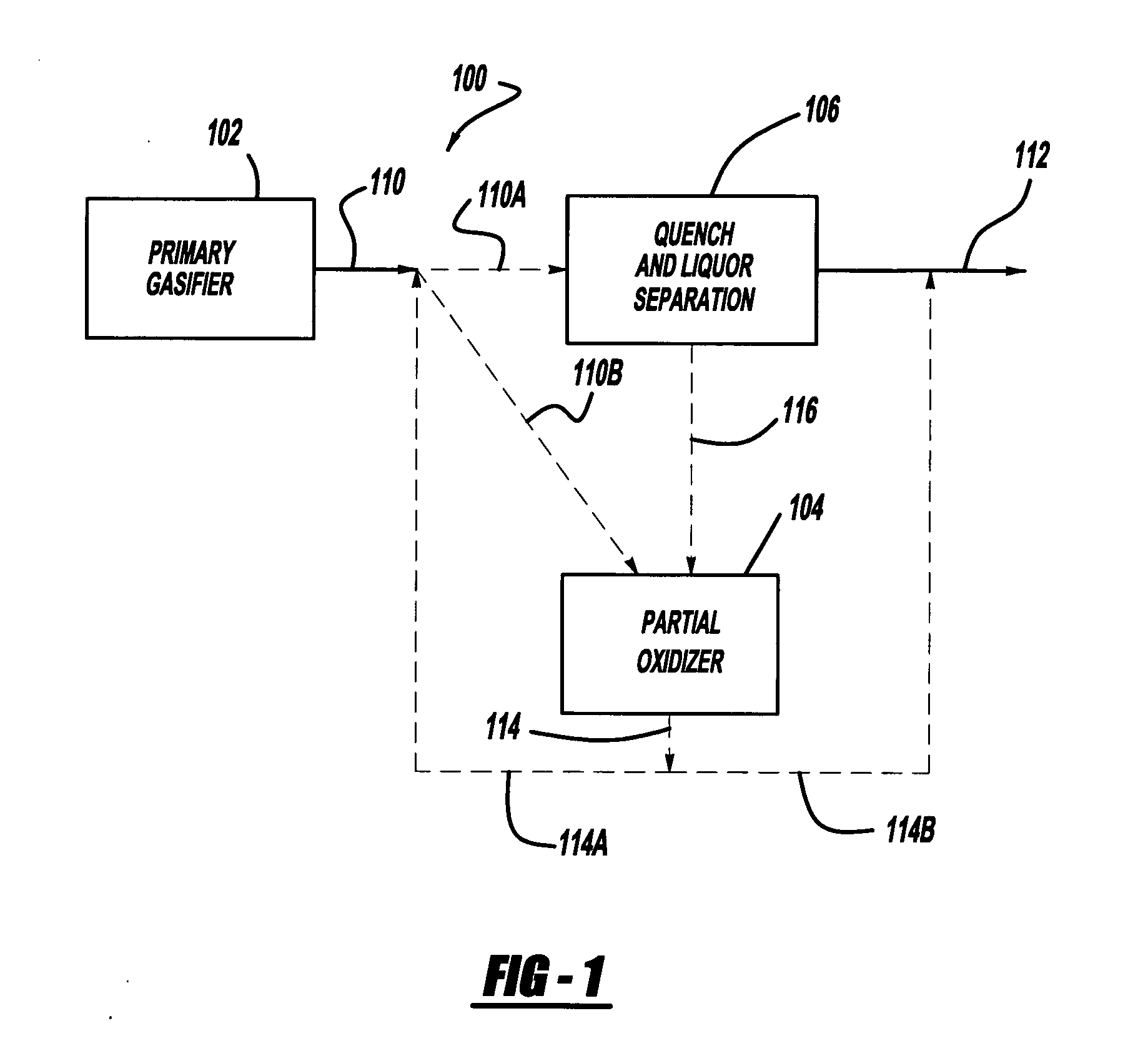

Apparatus and method for coal gasification

InactiveUS20060101715A1HydrogenGasification processes detailsPartial oxidationHydrocotyle bowlesioides

A process and apparatus for converting a coal into a substitute natural gas generates raw gas in a conventional coal gasification unit and passes at least a portion of the raw gas into a partial oxidation unit to convert the at least portion of the raw gas into a secondary raw synthesis gas substantially devoid of higher hydrocarbons. Optionally, the raw gas is quenched and only the resulting condensate is passed to the partial oxidation unit for conversion to the secondary raw synthesis gas.

Owner:COGAS LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com