Liquid continuous slag-removal fixed bed gasification furnace and gasification method thereof

A fixed bed gasifier, liquid technology, applied in chemical instruments and methods, gasification process, gasification device details, etc., can solve the problem of high cost of coal water slurry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

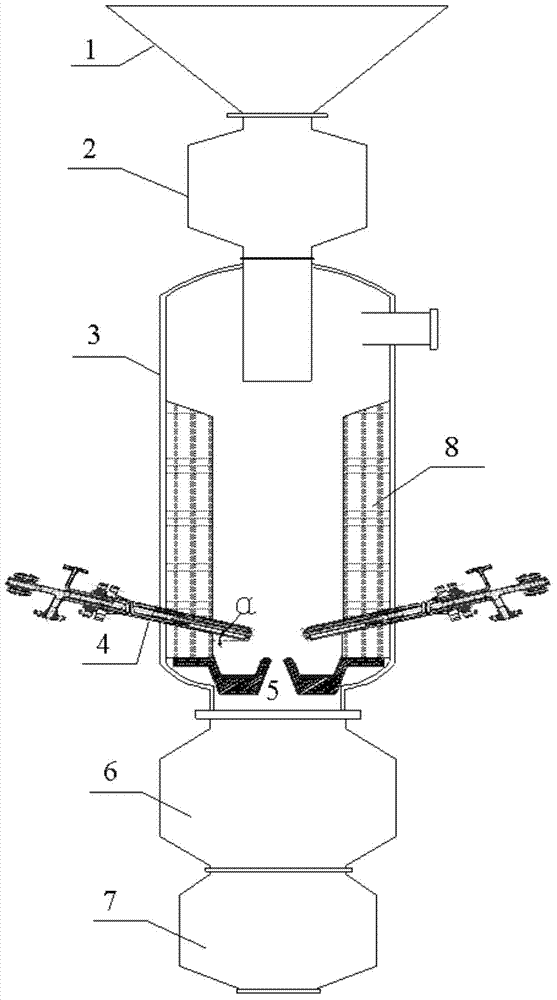

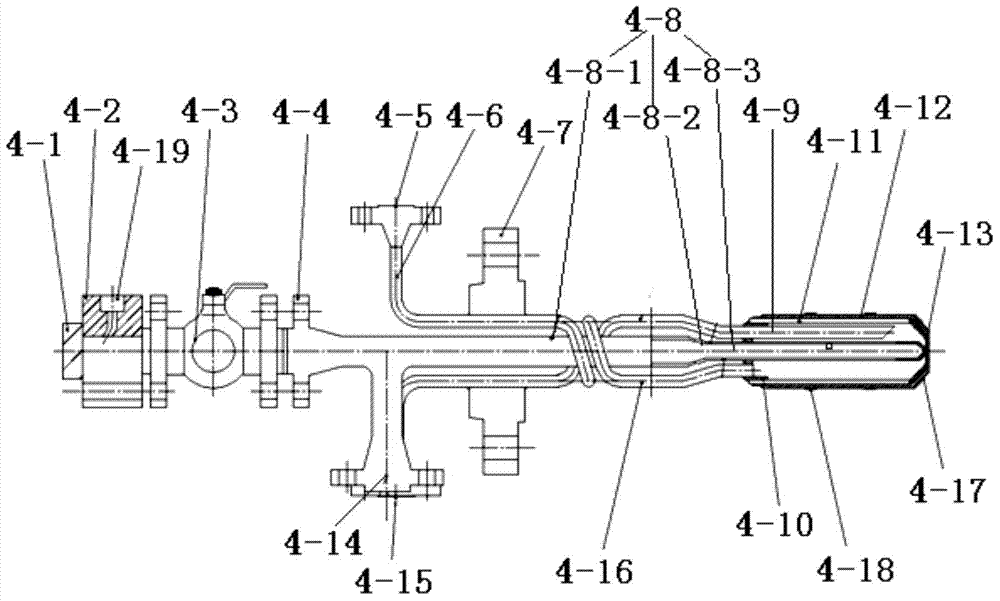

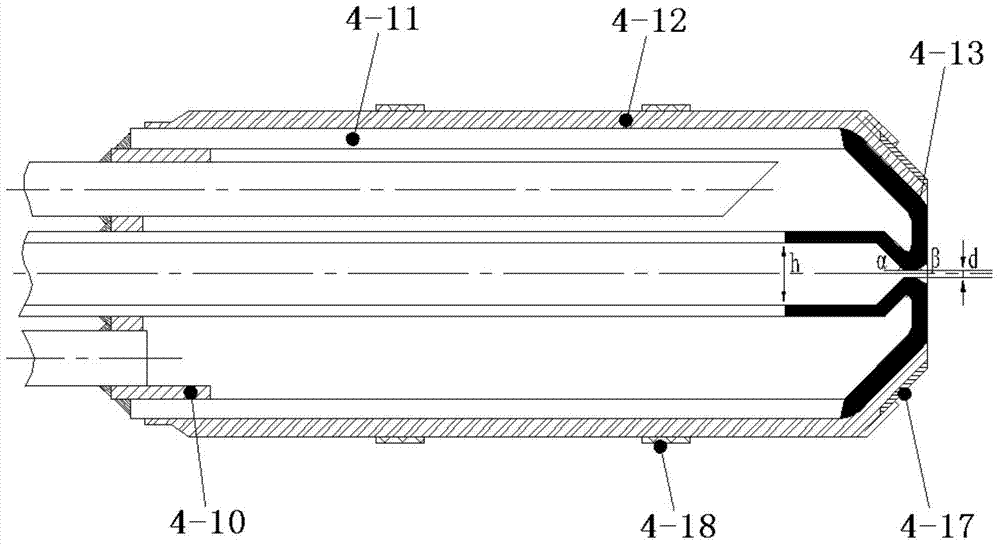

[0110] The gasifier used in the test has an inner diameter of 2.0m and four nozzles. The effective volume of the gasification chamber is 30m 3 , the height-to-diameter ratio is 6, the nozzles are evenly arranged in the circumferential direction of one layer, the axial deflection angle α is 19°, and the vertical distance from the intersection of the extension lines of the nozzles to the slag discharge port at the upper end of the slag discharger is 0.2 times the diameter of the furnace body. The furnace lining in the upper area of the furnace body has a two-layer structure, the outer layer is a jacket, and the inner layer is clay bricks. The furnace lining in the lower area has a four-layer structure, the outer layer is a jacket, and the inner layer is a ramming material layer, a water wall, and a refractory material layer. Among them, the water-cooled wall is assembled in blocks, consisting of 8 water-cooled walls. The wall thickness of the water-cooled wall is 150mm, and t...

Embodiment 2

[0132] The gasifier used in the test has an inner diameter of 3.6m and six nozzles. The effective volume of the gasification chamber is 180m 3 , the height-to-diameter ratio is 5, the nozzles are evenly arranged in the circumferential direction of one layer, the axial deflection angle α is 19°, and the vertical distance from the intersection of the extension lines of the nozzles to the slag discharge port at the upper end of the slag discharger is 0.1 times the diameter of the furnace body. The furnace lining in the upper area of the furnace body has a two-layer structure, the outer layer is a jacket, and the inner layer is clay bricks. The furnace lining in the lower area has a four-layer structure, the outer layer is a jacket, and the inner layer is a ramming material layer, a water wall and a refractory material layer. Among them, the water cooling wall is assembled in blocks, a total of 12 pieces, the thickness of the water cooling wall is 150mm, the height is 1850mm, a...

Embodiment 3

[0155]The gasifier used in the test has an inner diameter of 5.0m and eight nozzles. The effective volume of the gasification chamber is 450m3, the height-to-diameter ratio is 5, the nozzles are evenly arranged in the circumferential direction of one layer, the axial deflection angle α is 19°, and the vertical distance from the intersection of the nozzle extension lines to the slag discharge port at the upper end of the slag discharger is 0.1 times furnace diameter. The furnace lining in the upper area of the furnace body has a two-layer structure, the outer layer is a jacket, and the inner layer is clay bricks. The furnace lining in the lower area has a four-layer structure, the outer layer is a jacket, and the inner layer is a ramming material layer, a water wall and a refractory material layer. Among them, the water cooling wall is assembled in blocks, a total of 18 pieces, the thickness of the water cooling wall is 150mm, and the height is 1850mm. The water cooling wall...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Softening temperature | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com