Patents

Literature

81results about "Rotary drum/kiln gasifiers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

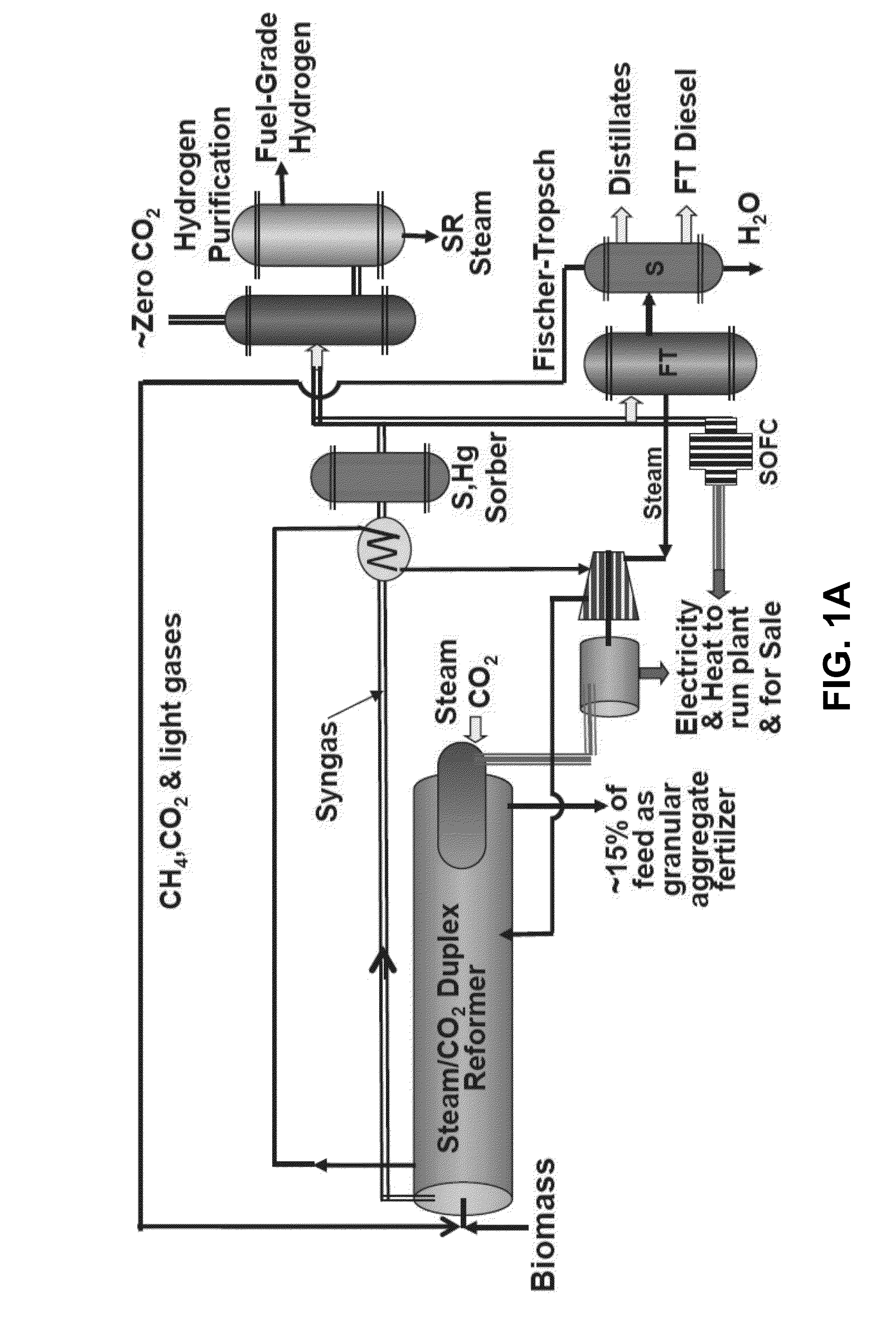

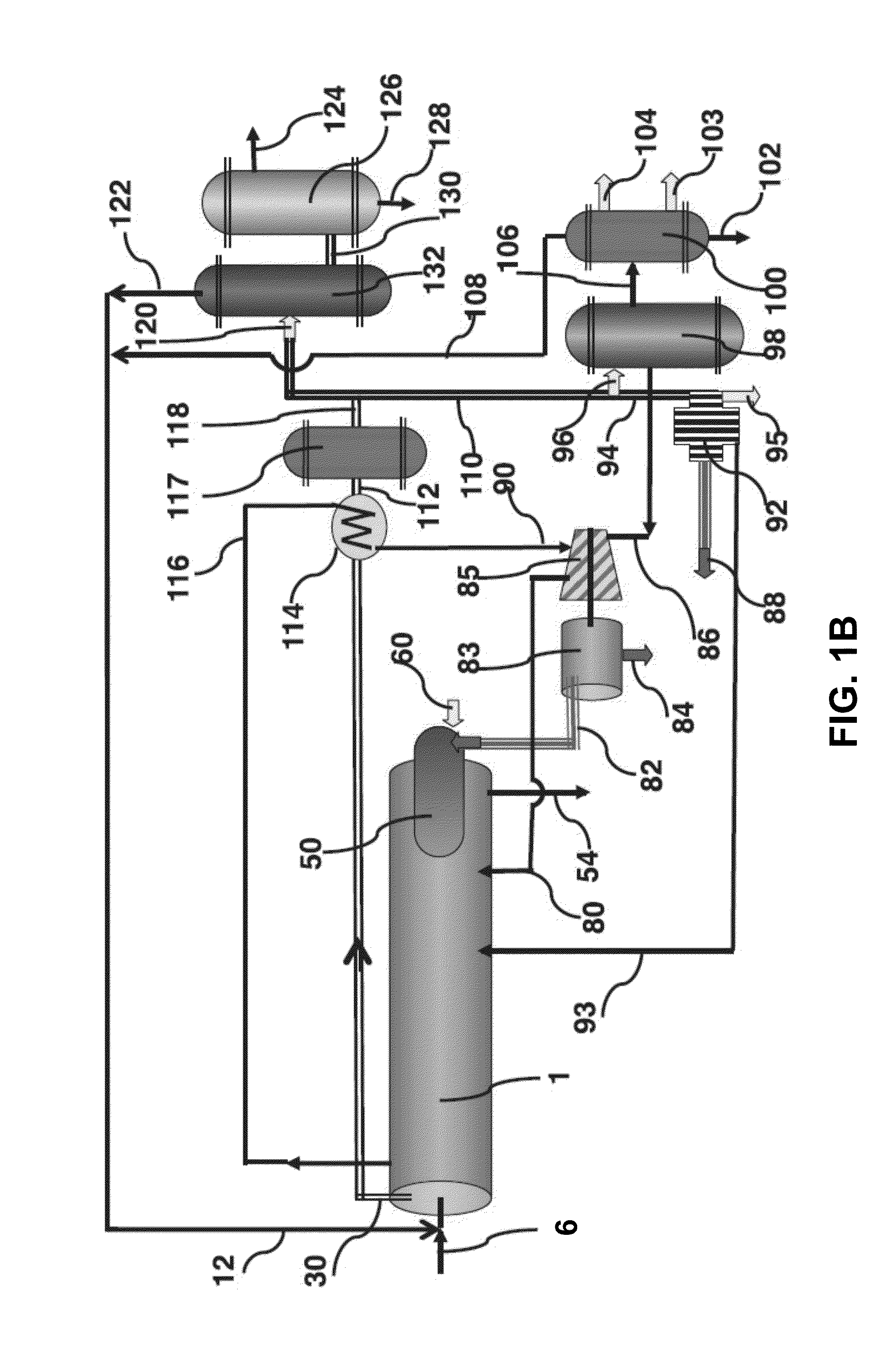

Process and system for converting carbonaceous feedstocks into energy without greenhouse gas emissions

ActiveUS20070099038A1High hydrogen contentFuel cells groupingHydrogen separation using solid contactPetroleum cokePetroleum

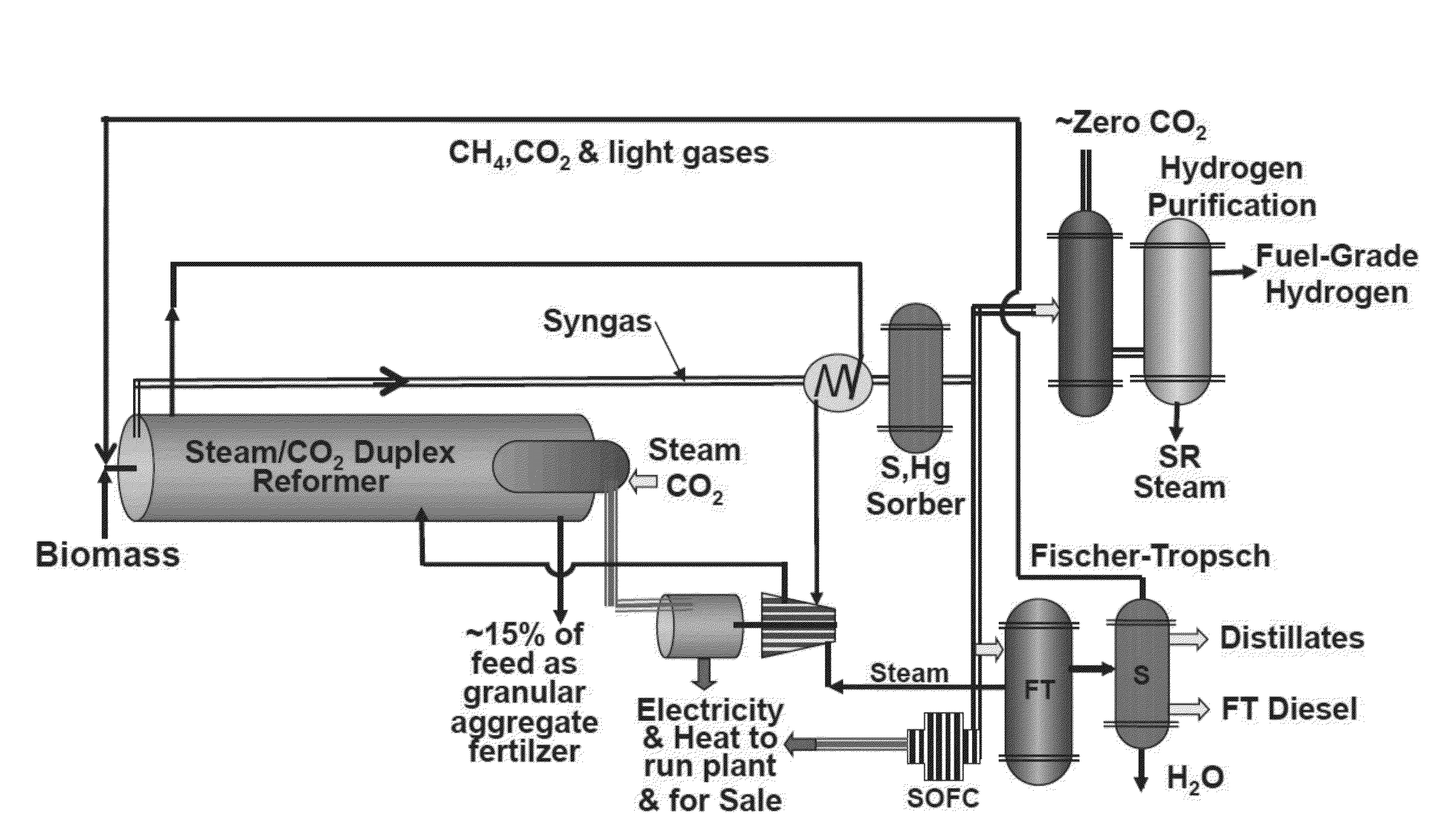

The process of the invention converts carbonaceous feedstock such as coal, hydrocarbon oil, natural gas, petroleum coke, oil shale, carbonaceous-containing waste oil, carbonaceous-containing medical waste, carbonaceous-containing military waste, carbonaceous-containing industrial waste, carbonaceous-containing medical waste, carbonaceous-containing sewage sludge and municipal solid waste, carbonaceous-containing agricultural waste, carbonaceous-containing biomass, biological and biochemical waste, and mixtures thereof into electrical energy without the production of unwanted greenhouse emissions. The process uses a steam / CO2 reformer operating in the exit range of at least 700° to about 1600° C. (1300-2900°0 F.) to convert the carbonaceous feedstock and a greenhouse gas stream into a synthesis gas comprising mostly carbon monoxide and hydrogen that contains poisons and the compounds that poison fuel cells. The syngas is sent to an interface zone to remove these poisons and other fouling compounds that are electrochemically oxidized in an electricity-producing fuel cell into an exit gas comprising carbon dioxide and water.

Owner:RAVEN SR INC

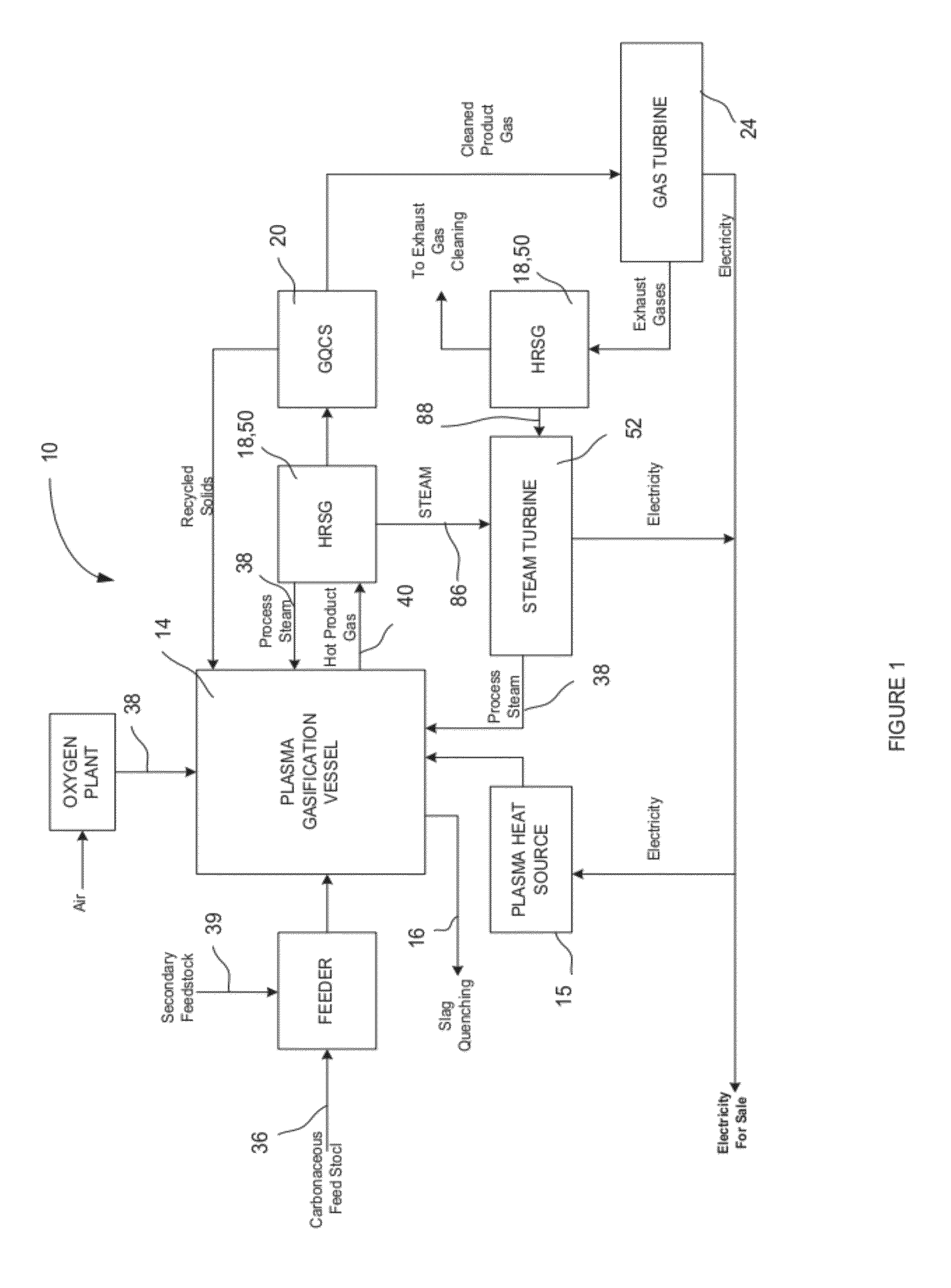

System for the Conversion of Coal to a Gas of Specified Composition

InactiveUS20080222956A1Energy inputCarburetting by solid carbonaceous material pyrolysisEnergeticsProduct gas

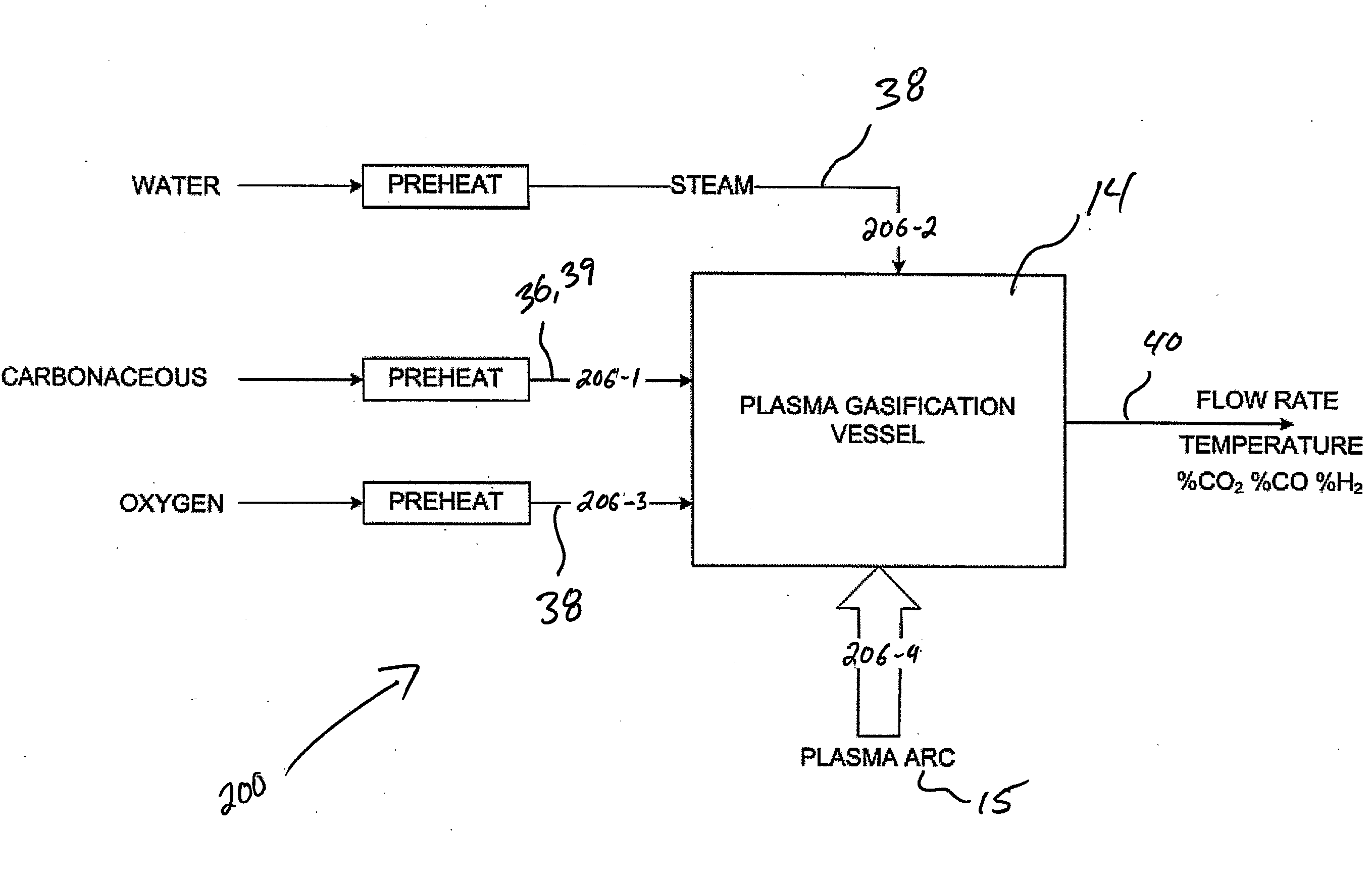

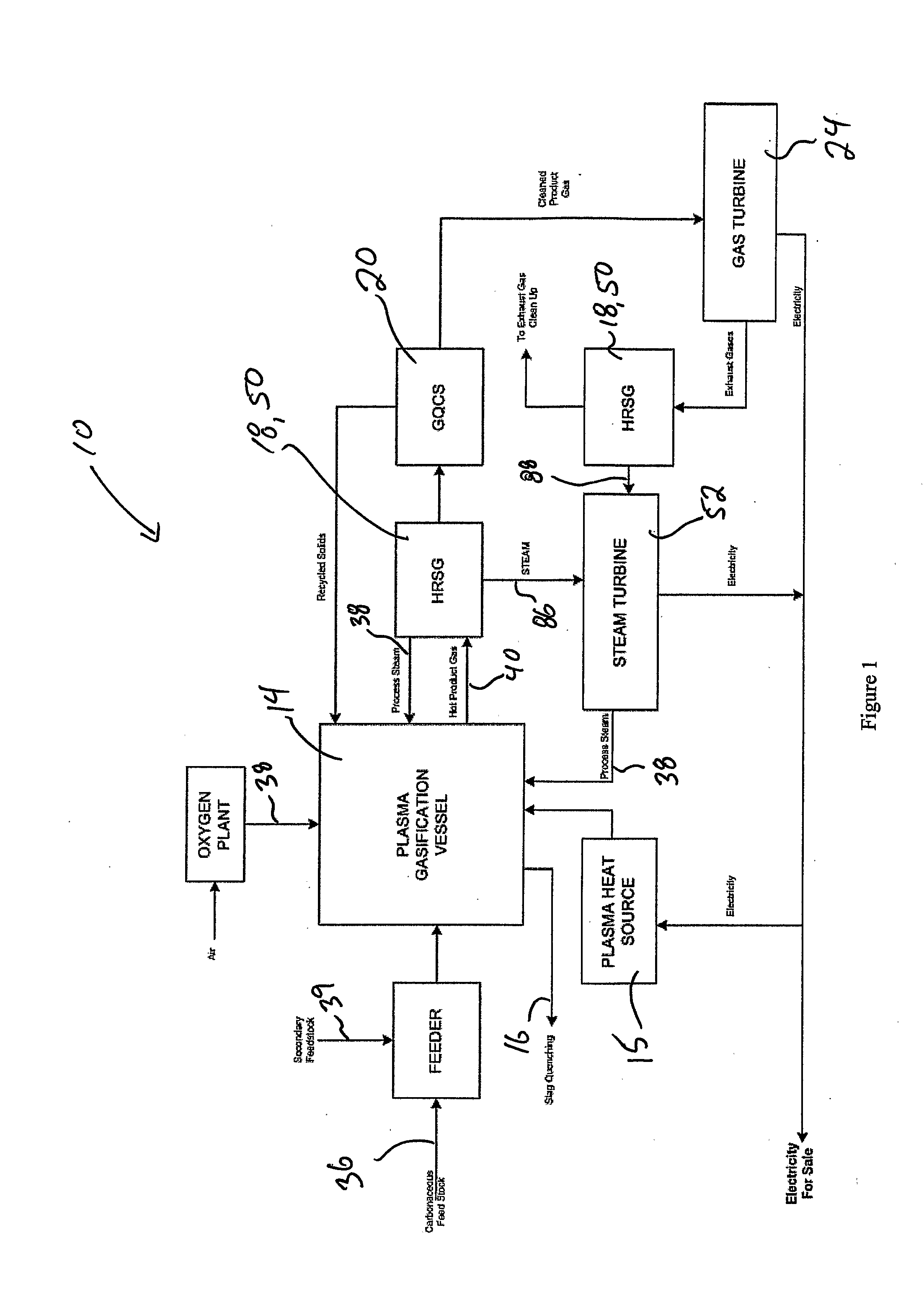

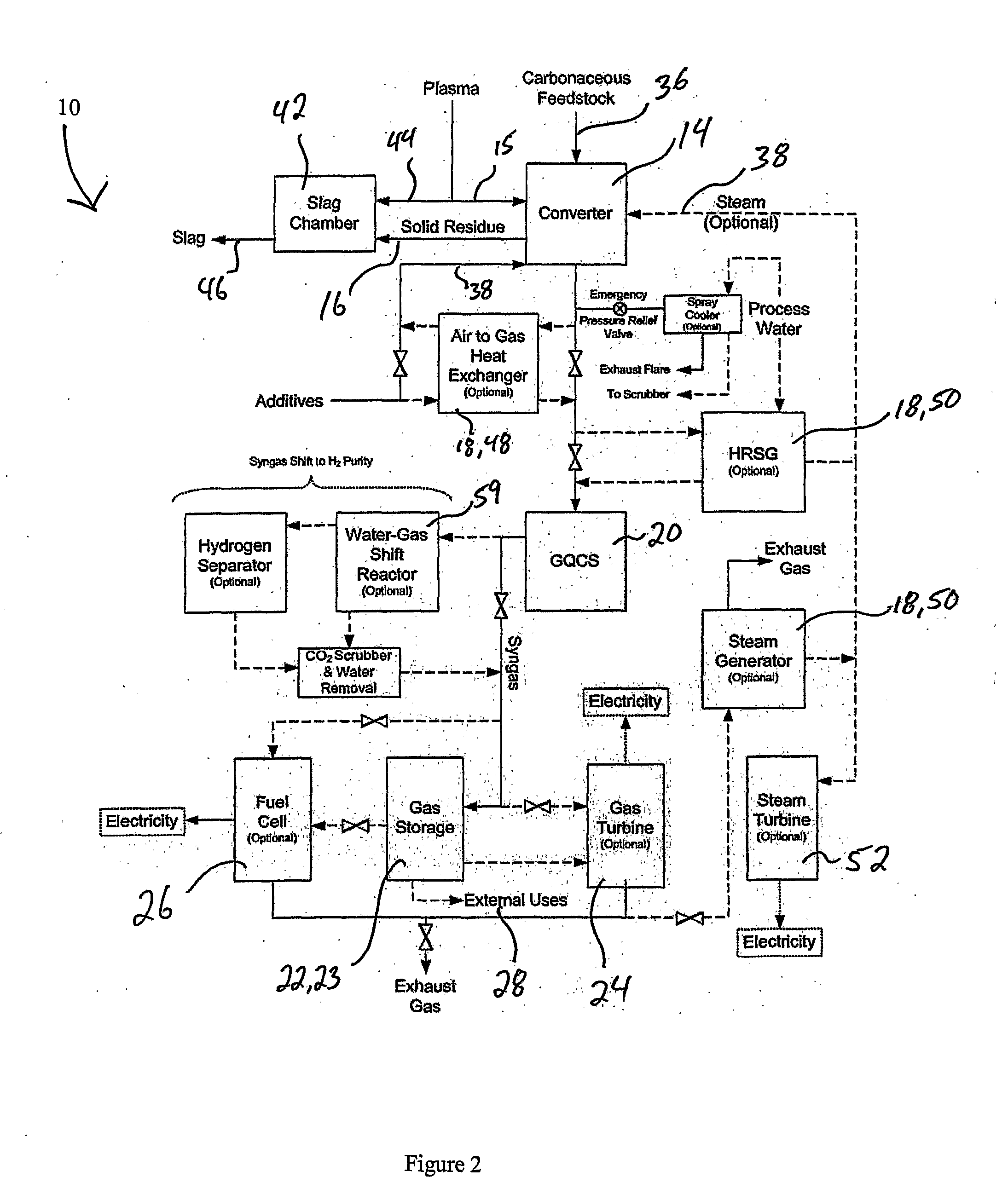

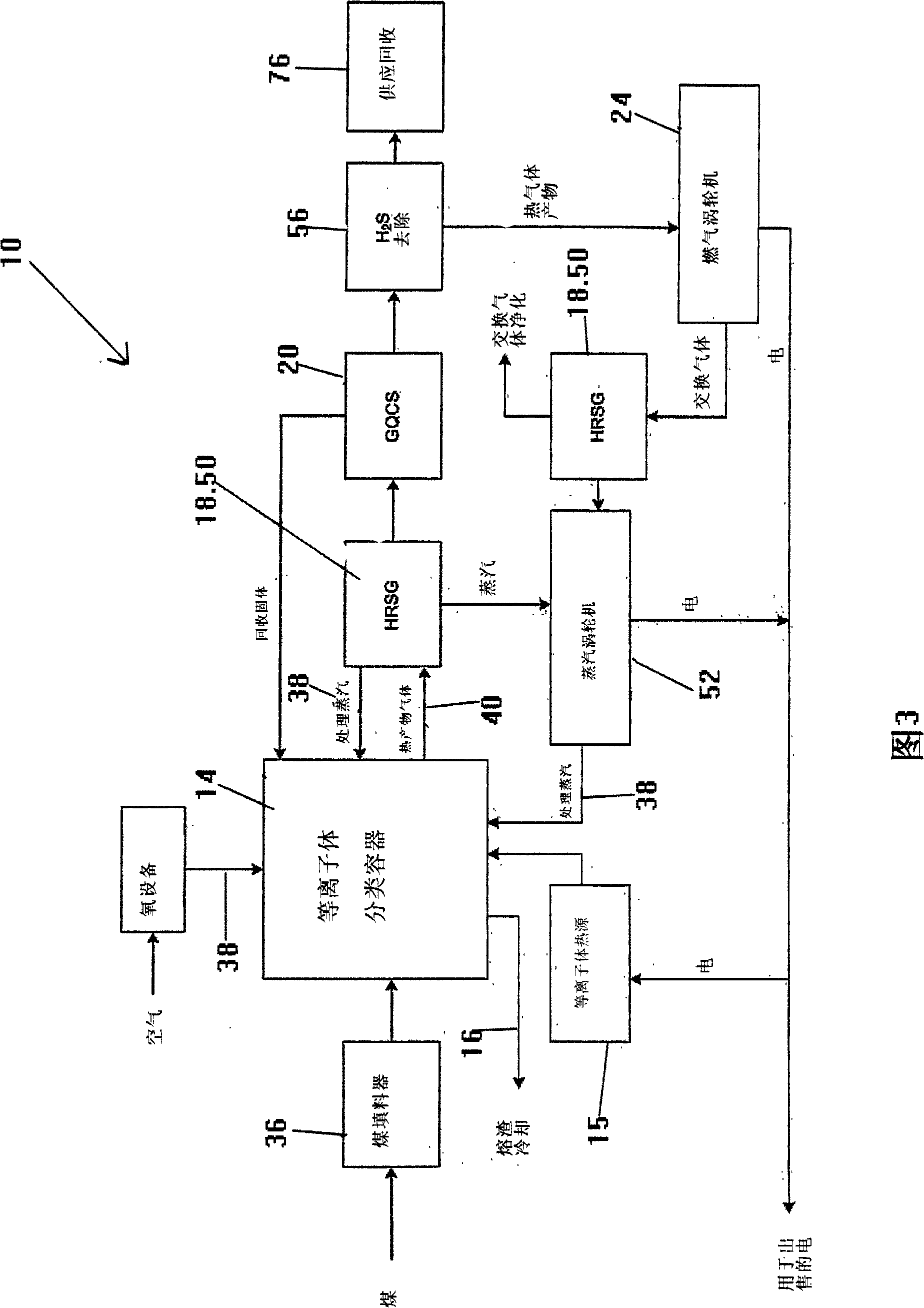

The present invention provides a coal gasification system with an integrated control subsystem. The system generally comprises, in various combinations, a gasification reactor vessel (or converter) having one or more processing zones and one or more plasma heat sources, a solid residue handling subsystem, a gas quality conditioning subsystem, as well as an integrated control subsystem for managing the overall energetics of the conversion of coal to energy and maintaining all aspects of the gasification processes at an optimal set point The gasification system may also optionally comprise a heat recovery subsystem and / or a product gas regulating subsystem.

Owner:PLASCO ENERGY GROUP INC

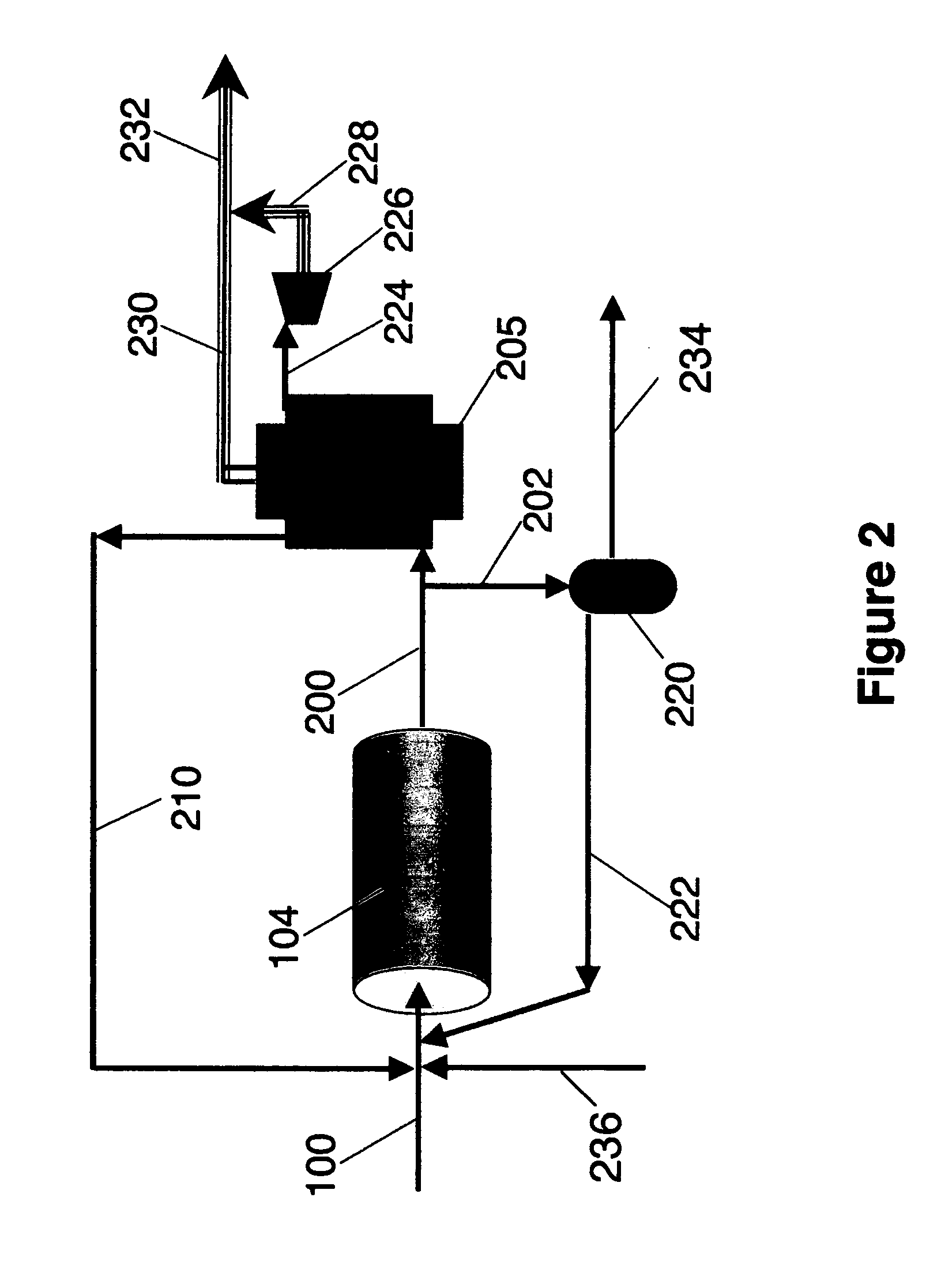

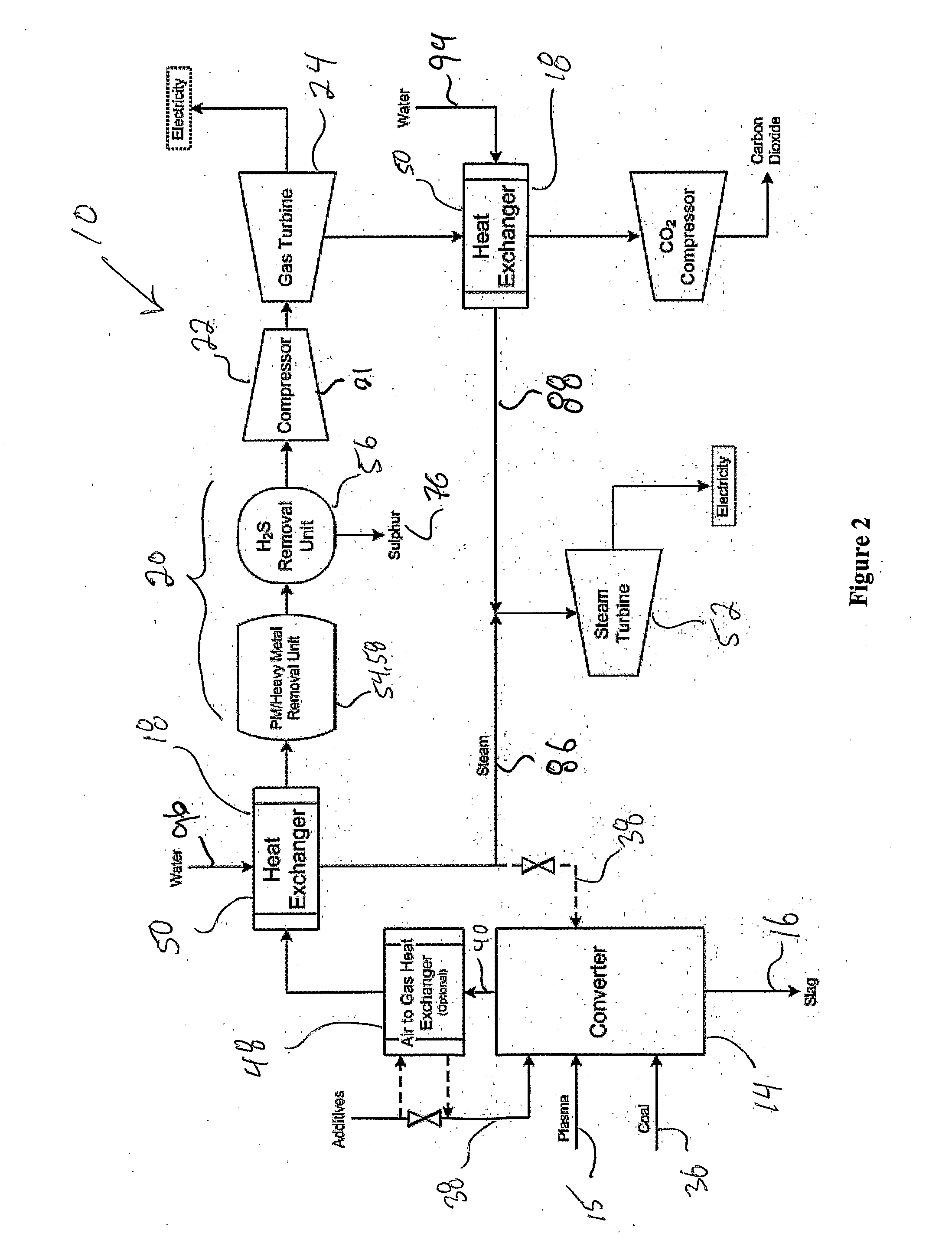

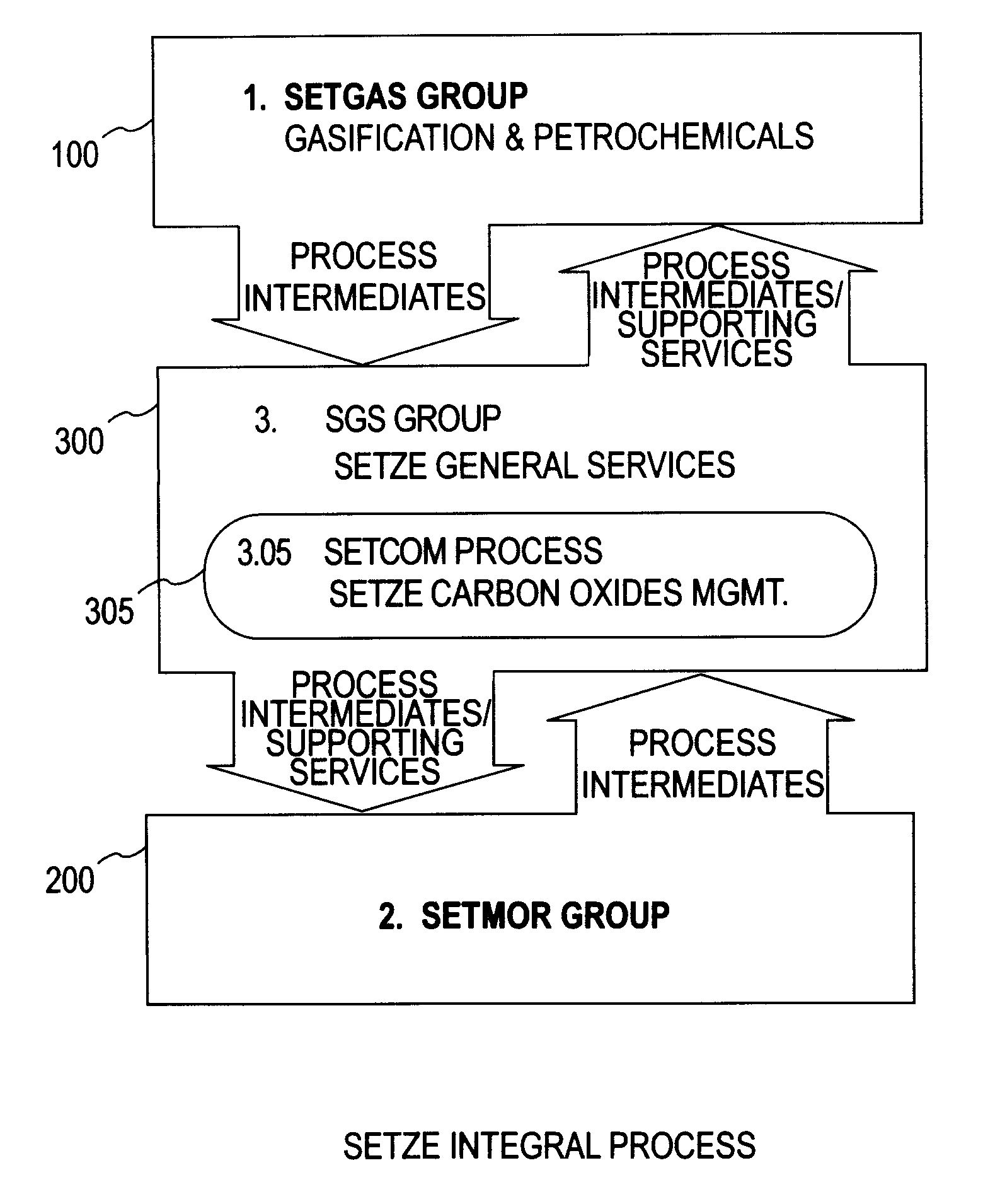

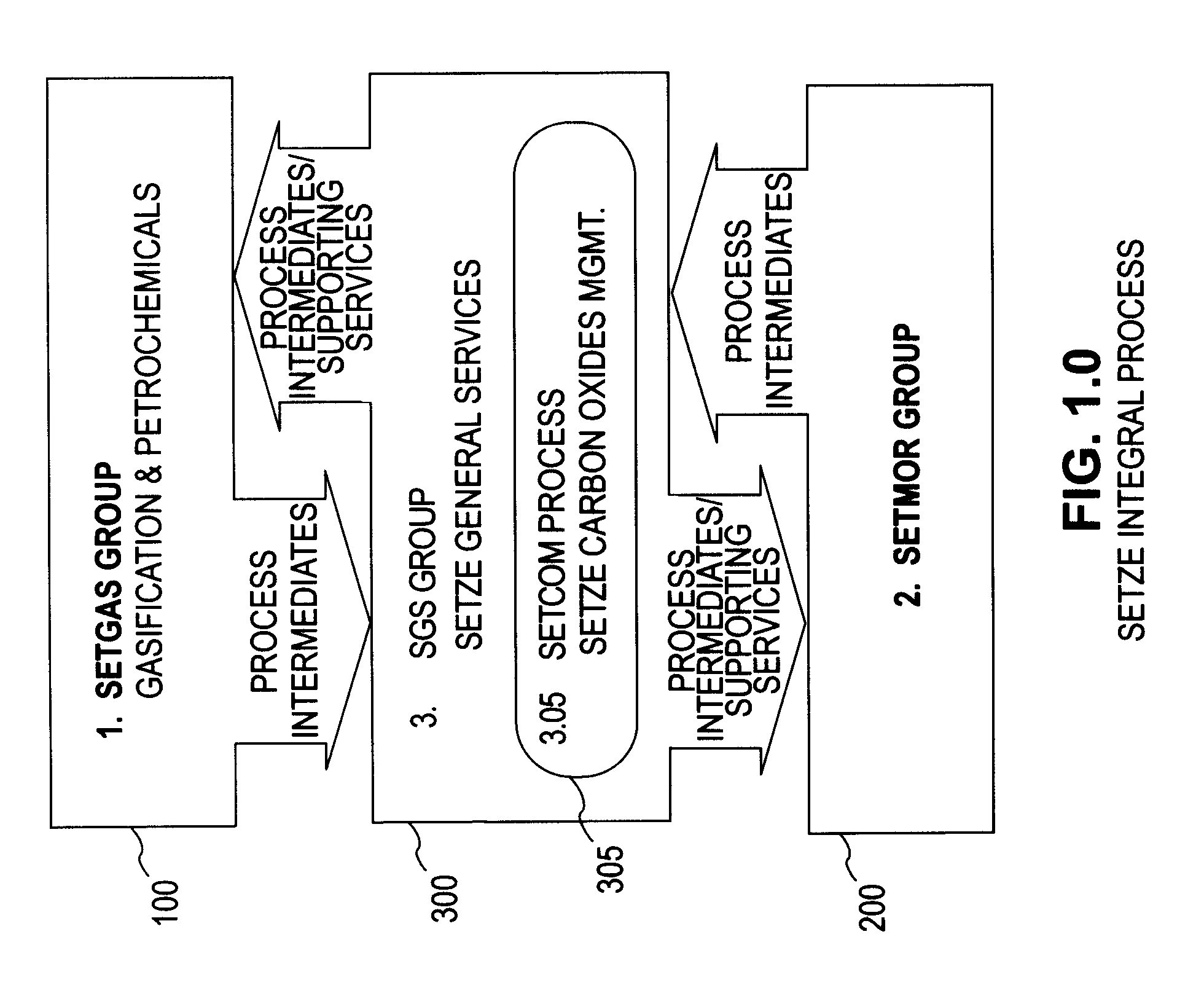

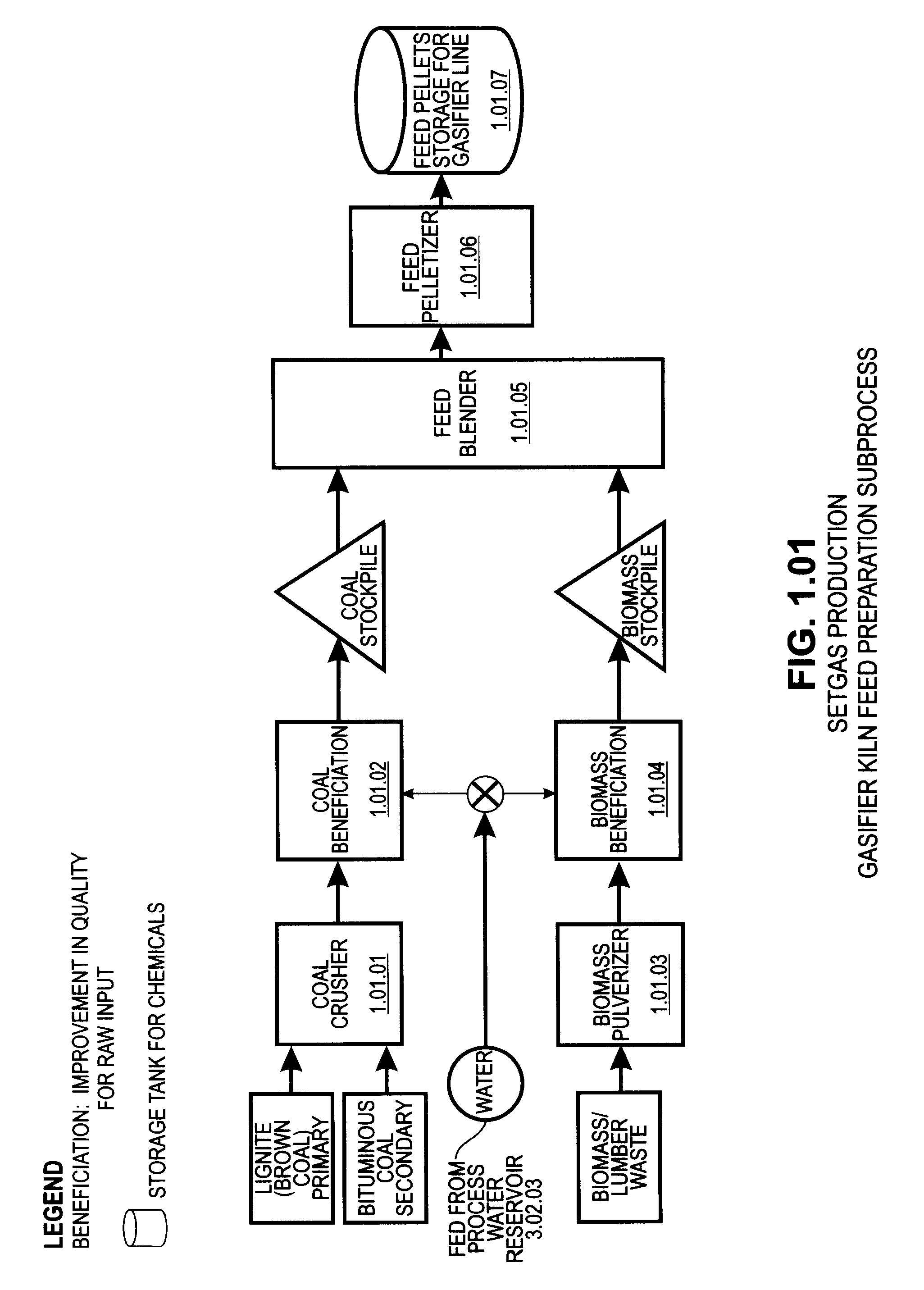

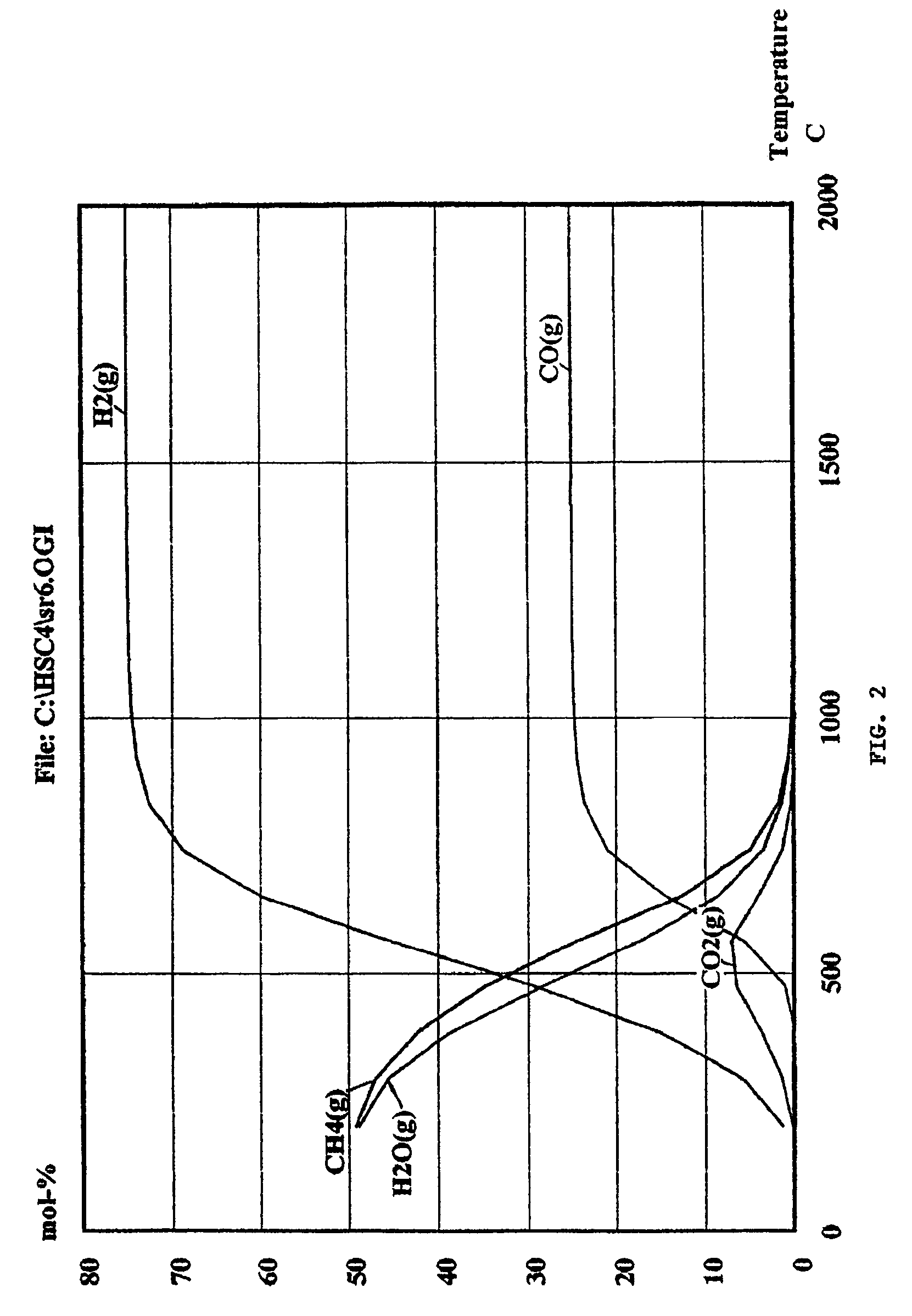

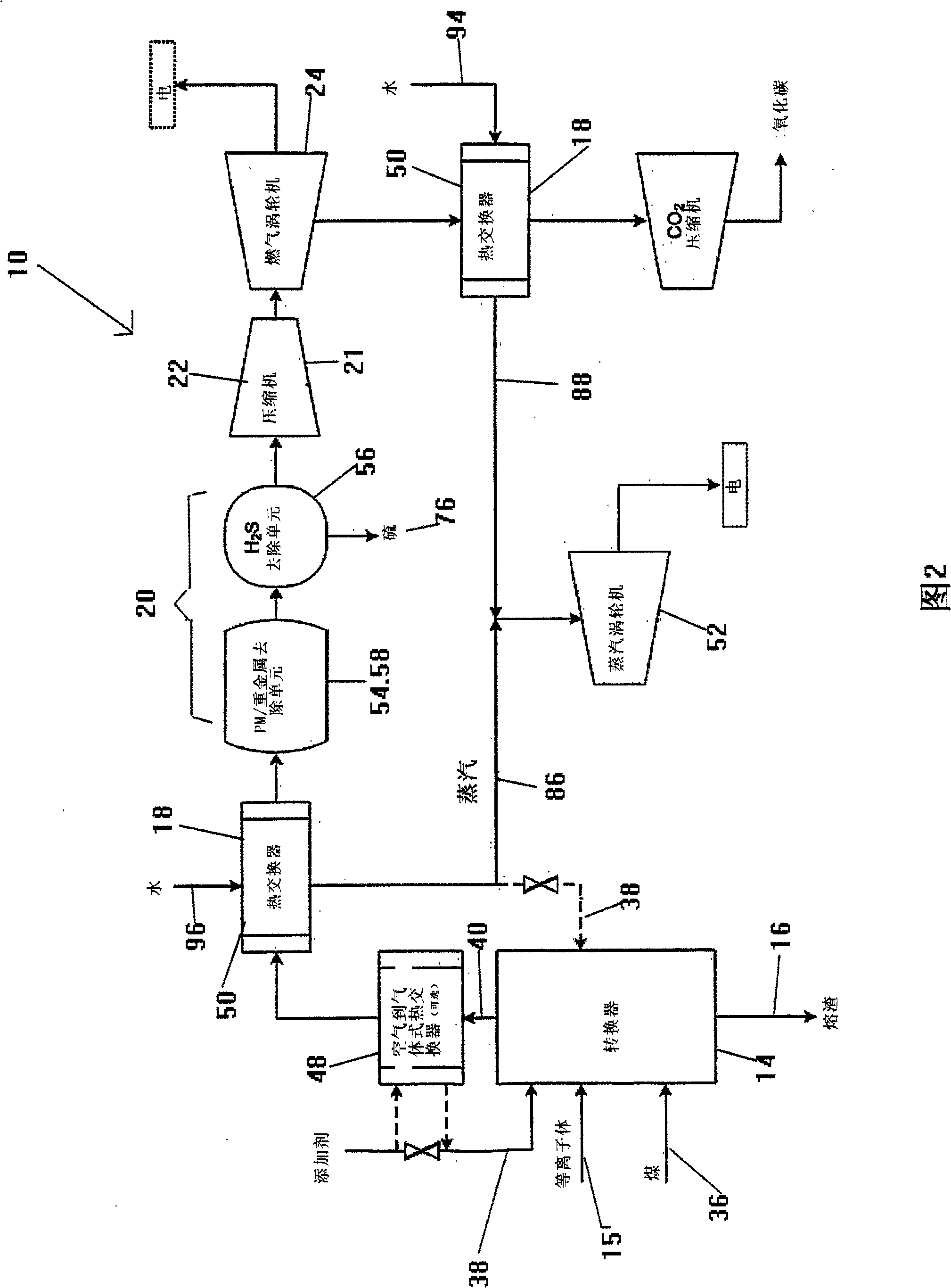

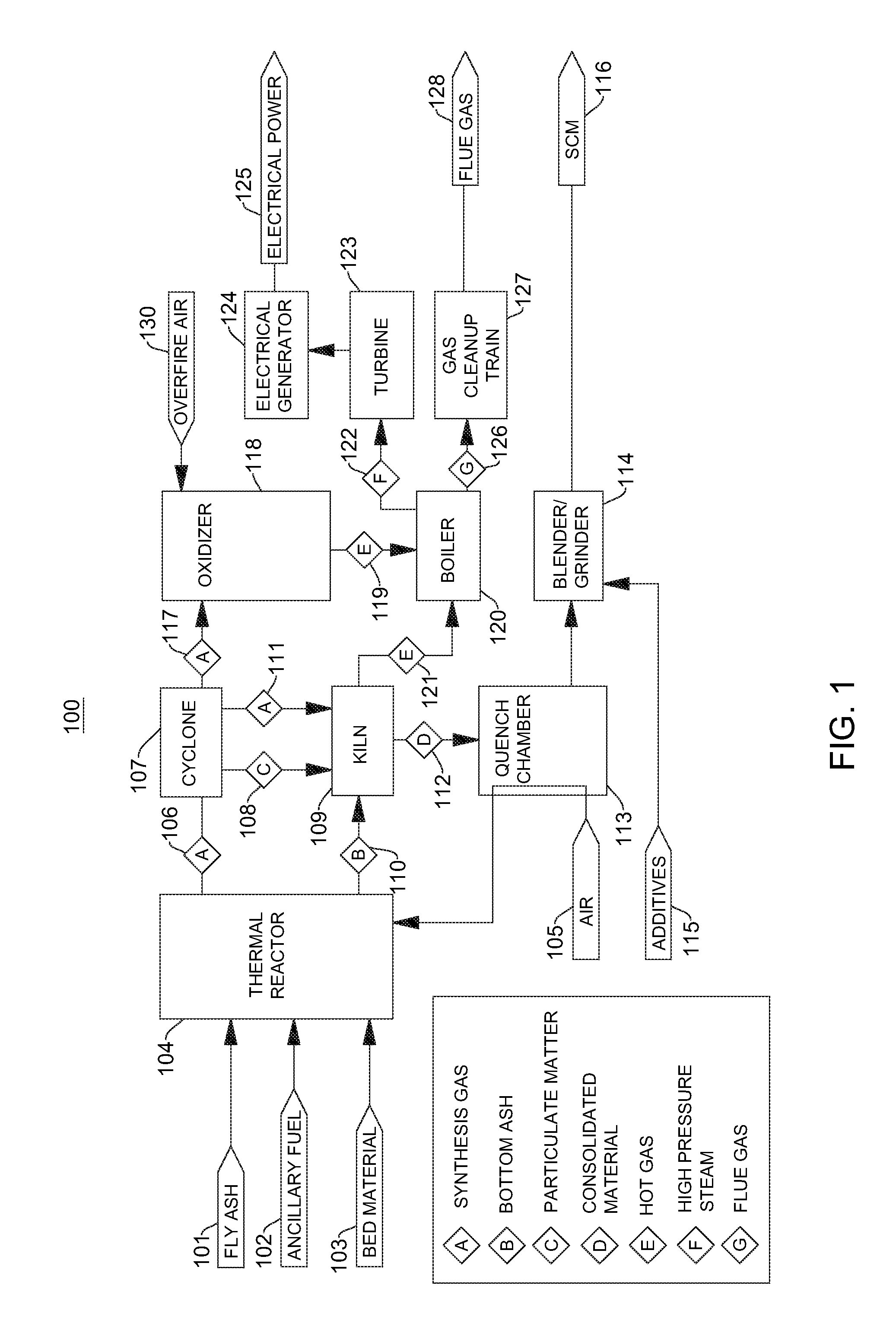

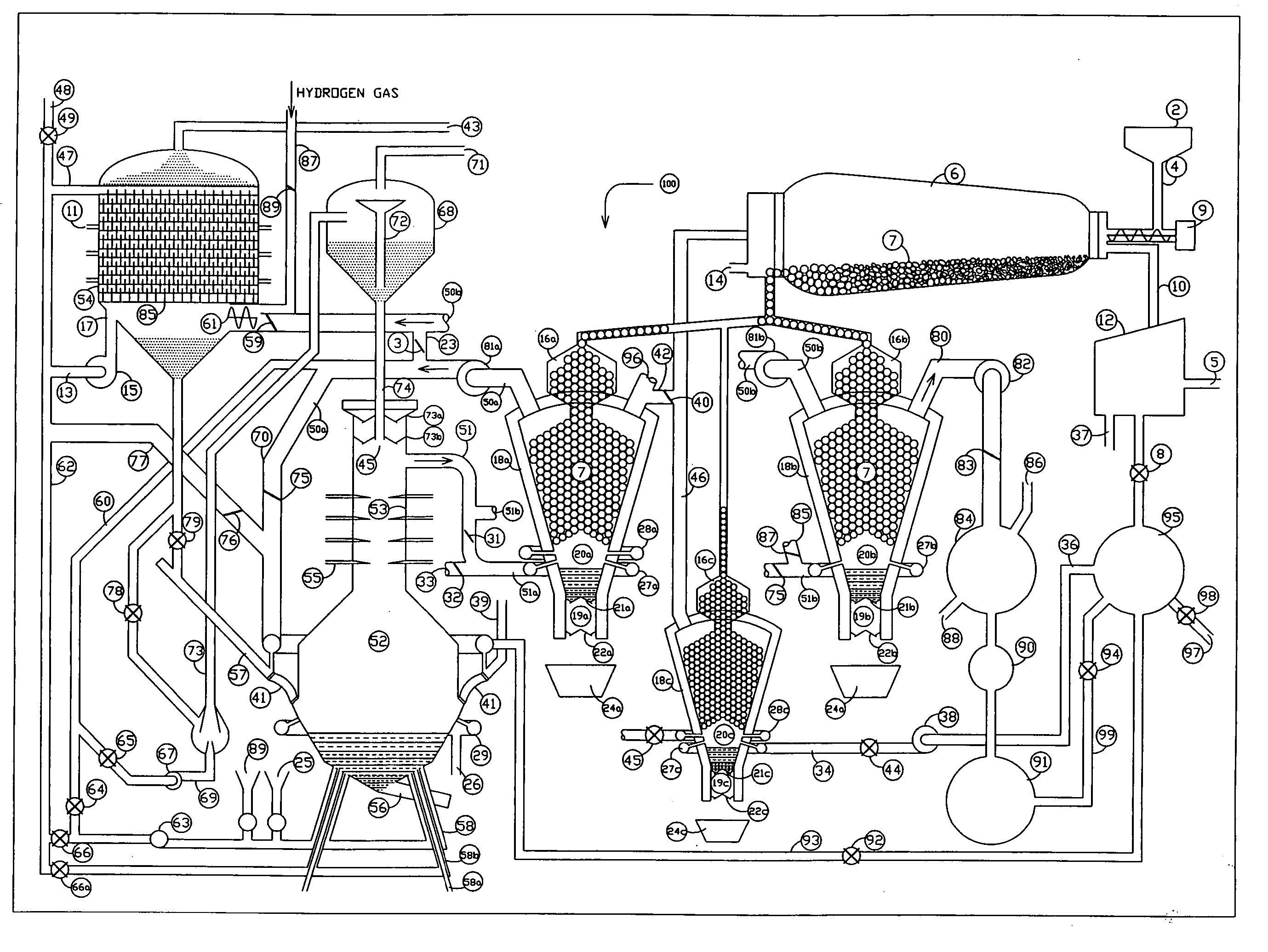

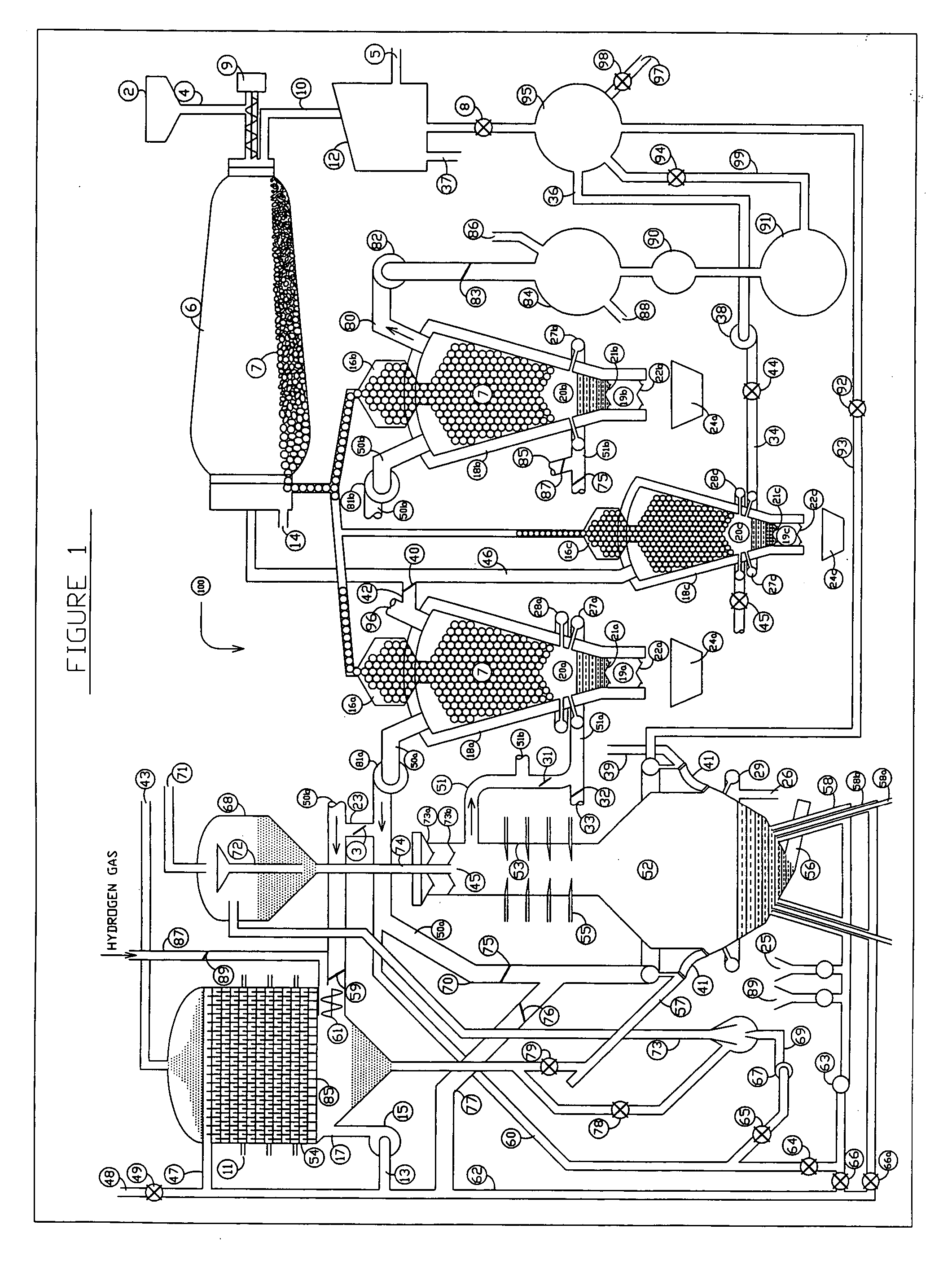

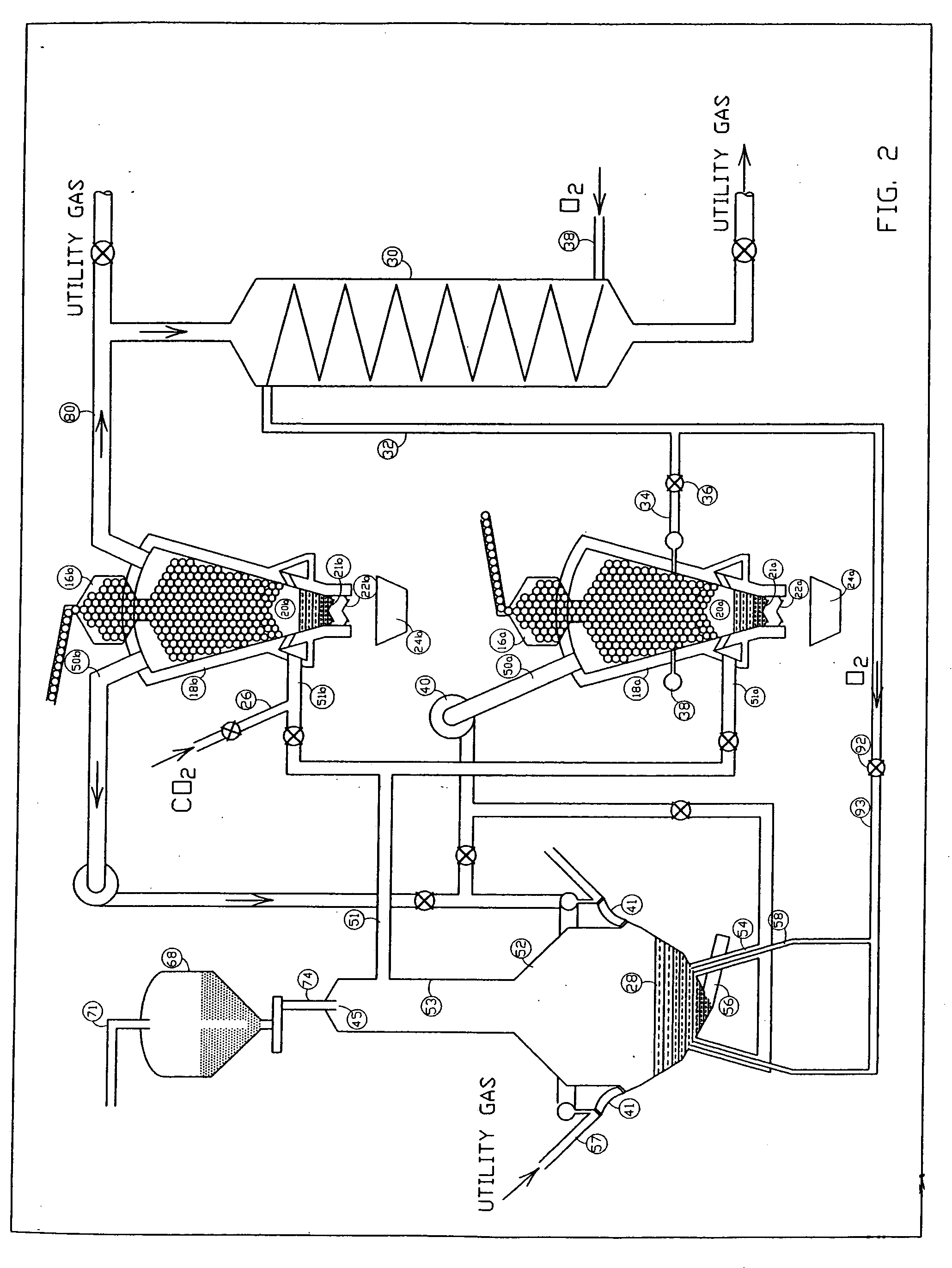

Zero emission gasification, power generation, carbon oxides management and metallurgical reduction processes, apparatus, systems, and integration thereof

ActiveUS7674443B1Improvement in individual technology componentEnhances economic performanceUsing liquid separation agentBiofuelsCyclonic separationOxygen

A system involving a two-step gasification of a carbonaceous source to produce bulk hydrogen that avoids the early formation of CO2 and obviates the traditional water gas shift (WGSR) step, carbochlorination of a metallic ore the production of metals found in the ore that utilizes carbon monoxide as an oxygen sink, rather than the traditional coke, and carbon oxides management that eliminates major impediments to emission-neutral power generation and the reduction of major metals. The gasification uses a rotary kiln reactor and gas-gas cyclonic separation process to separate synthesis gas into purified hydrogen and purified carbon monoxide. Purified bulk carbon monoxide issued in metallurgical reduction, and purified bulk hydrogen as fuel for an emission-neutral hydrogen combined cycle (HCC) turbine power generation station. The carbochlorination is integrated with: a) the concurrent separation and purification of all metal-chlorides (metchlors) and capture of CO2 for passage to the carbon oxides management system; b) the direct reduction of metchlors to nanoscale metallurgical powders and / or to dendritically-shaped particles, including metchlor reduction for the ultrahigh-performance semiconductor metals of the III-V group; and, c) the reforming of metal-oxides with improved crystalline structure from metchlors. The carbon oxides management collects, stores and directs to points of usage, carbon oxides that arise in various processes of the integrated system, and captures carbon monoxide for process enhancement and economic uses and captures carbon dioxide as a process intermediate and for economic uses.

Owner:DAVIS OLUMIJI B +1

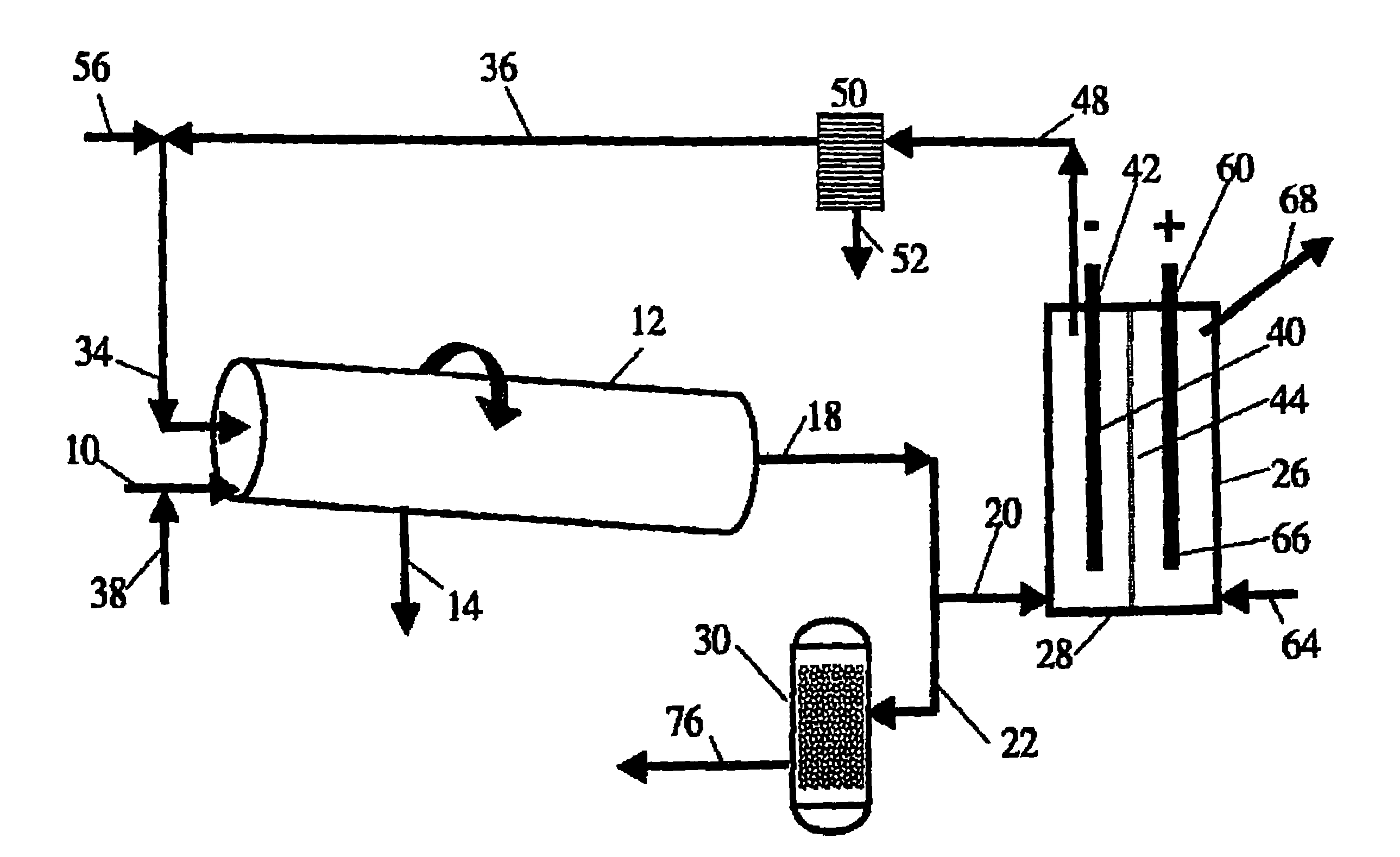

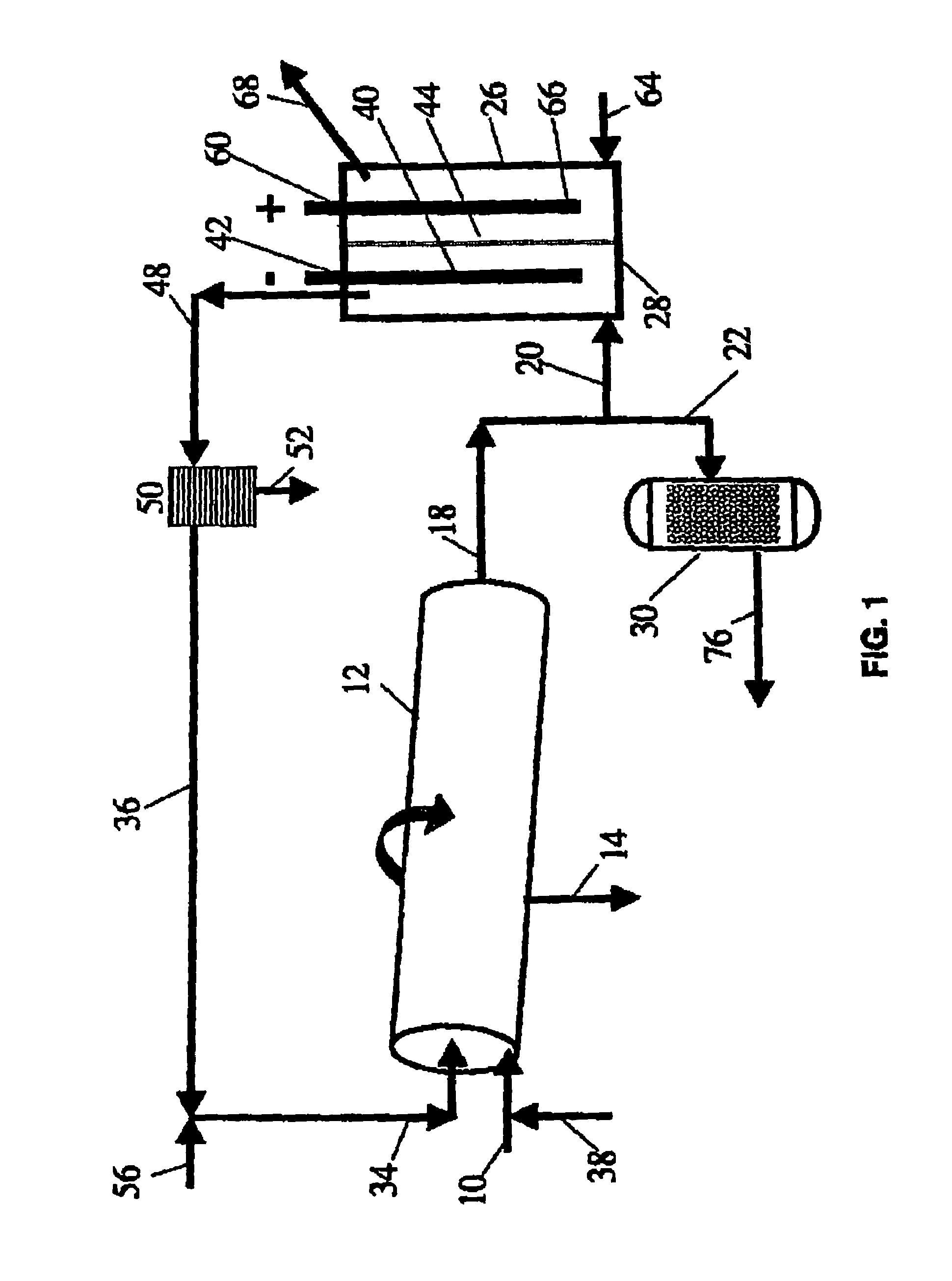

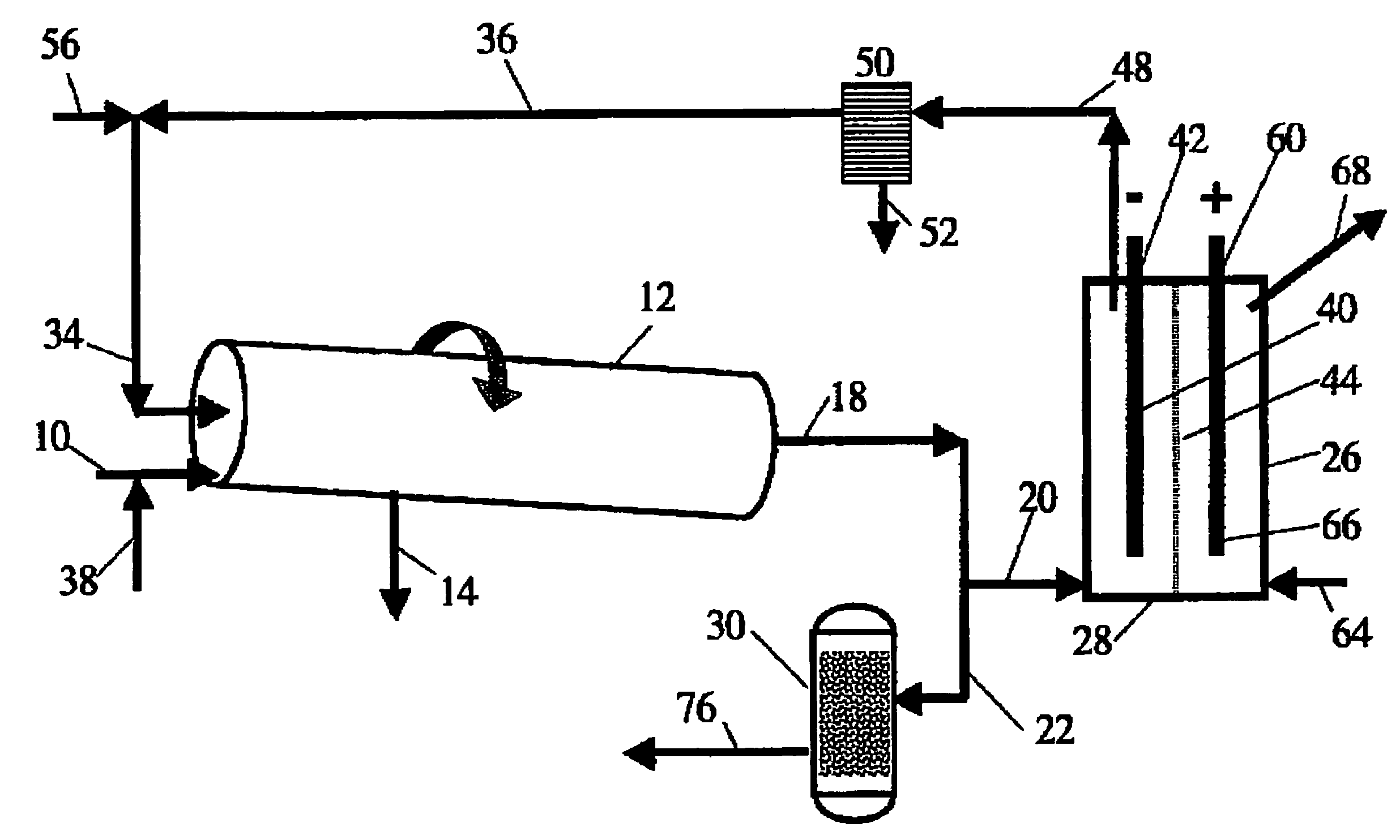

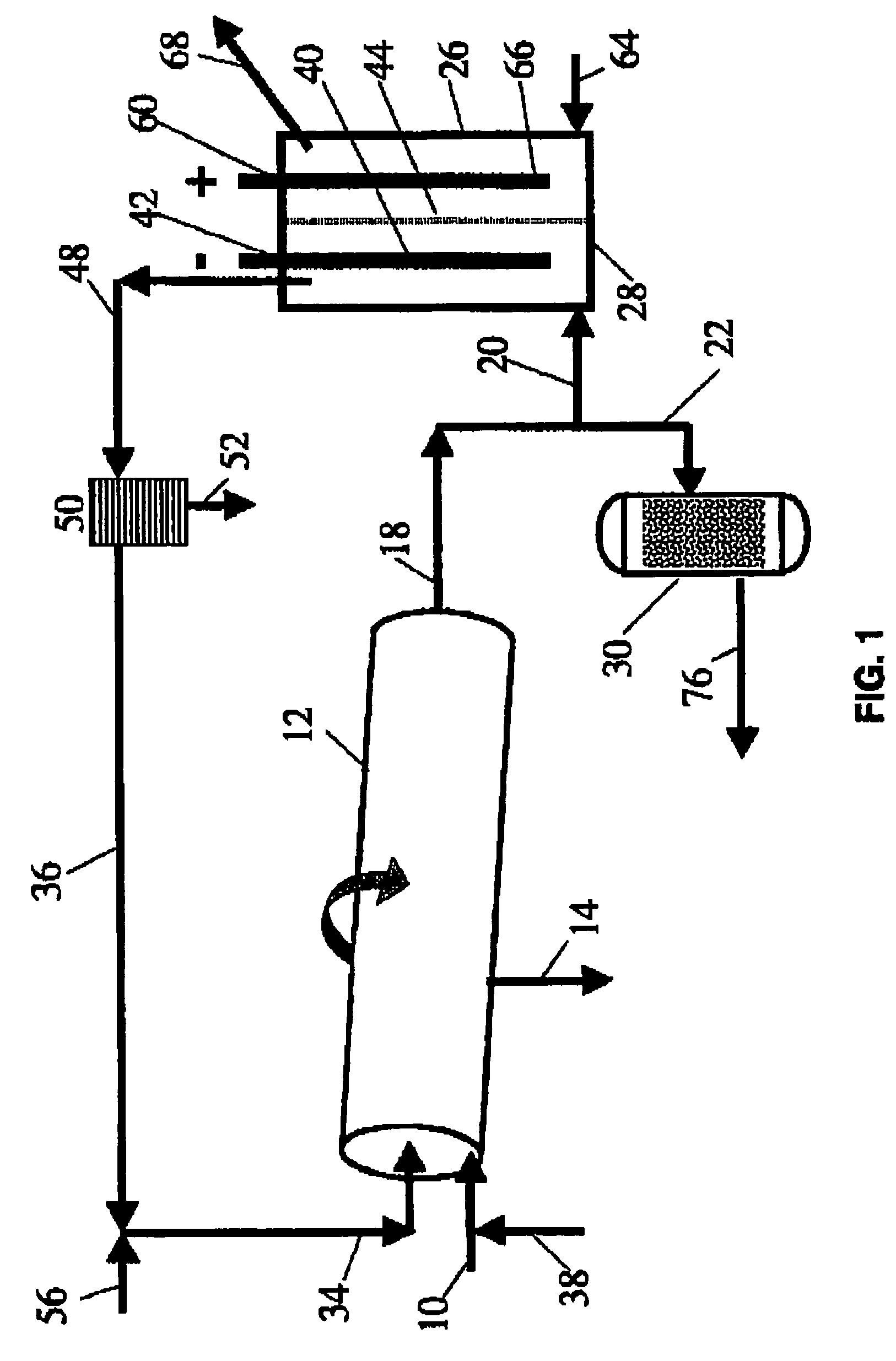

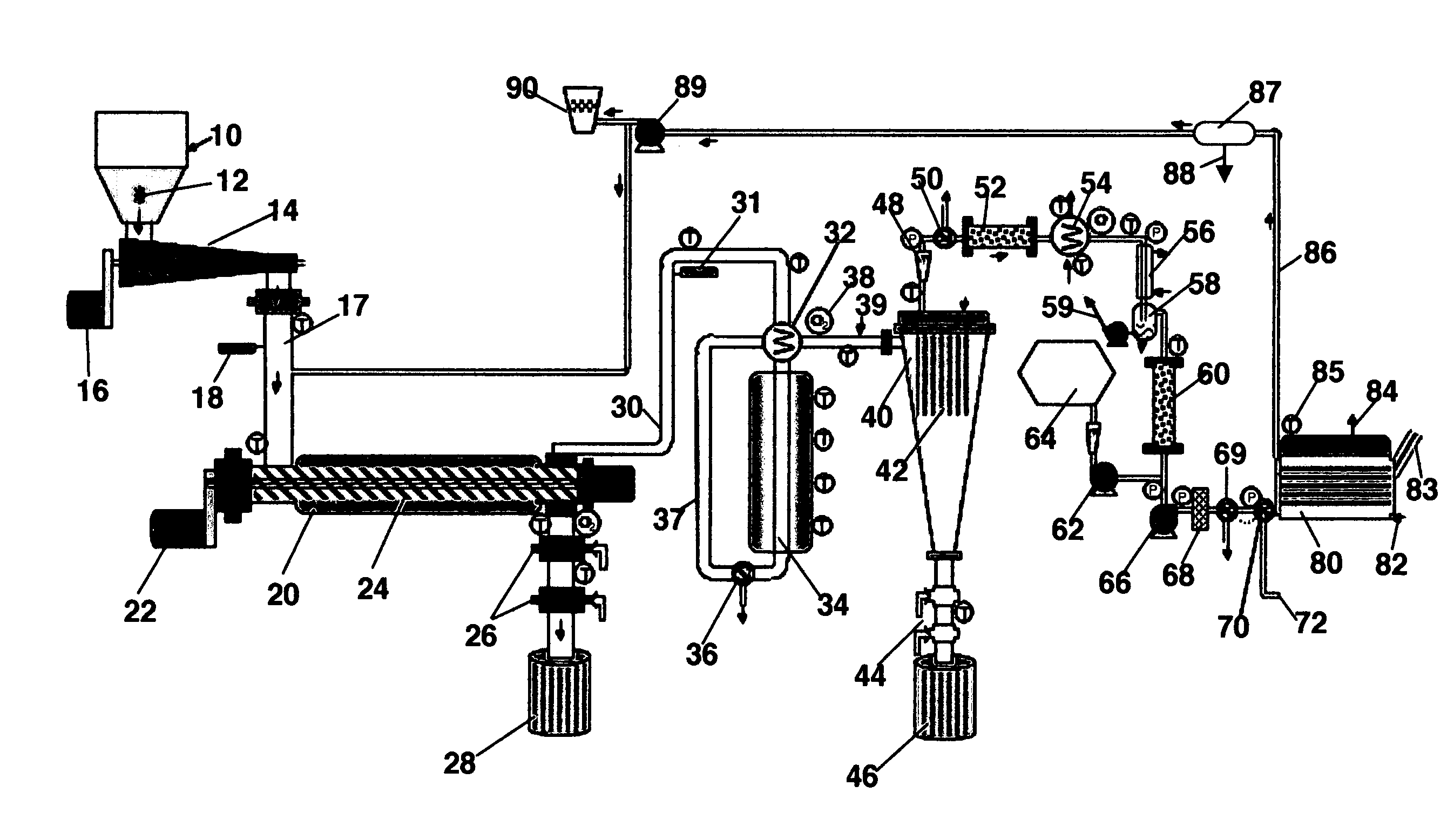

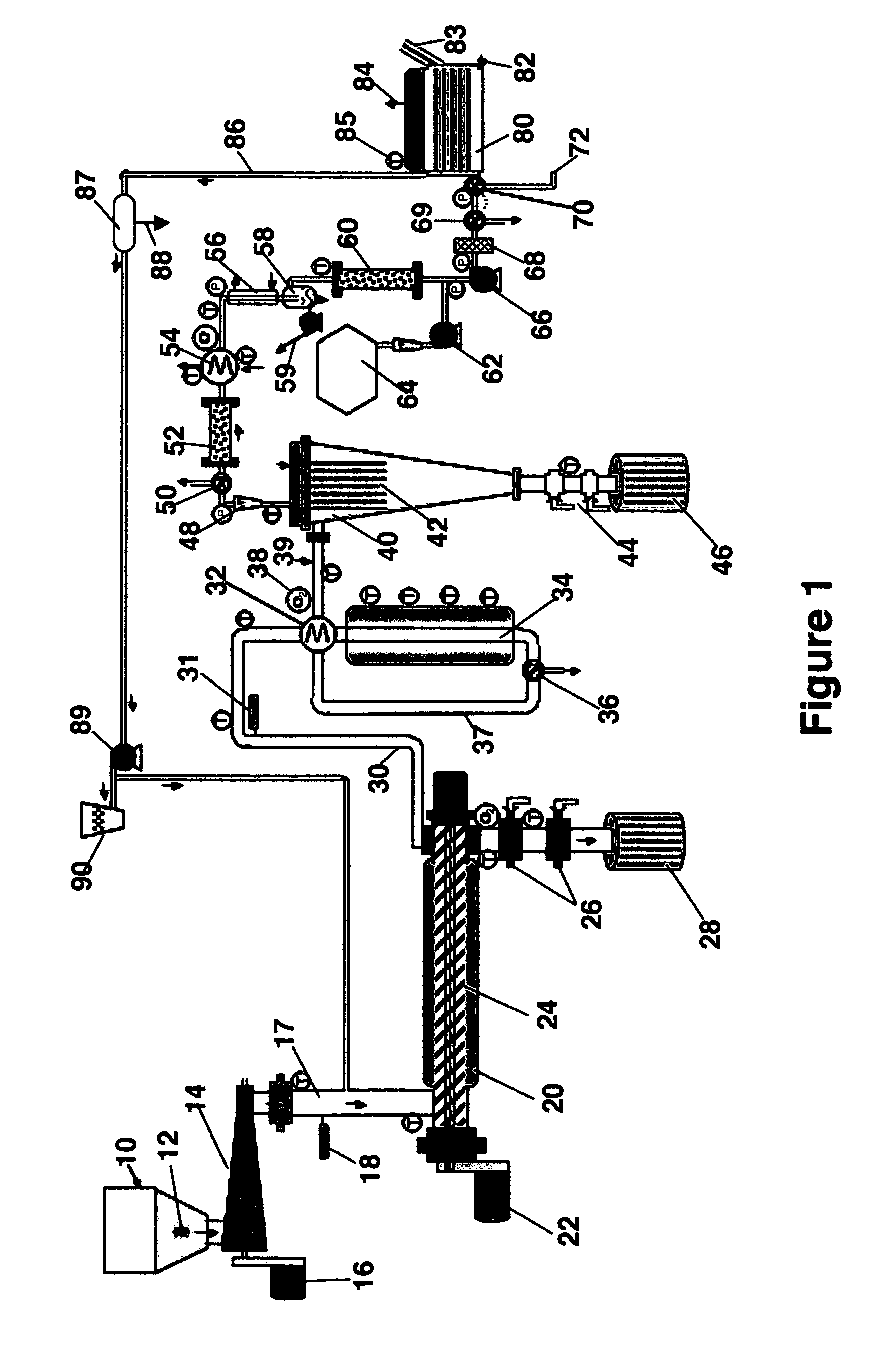

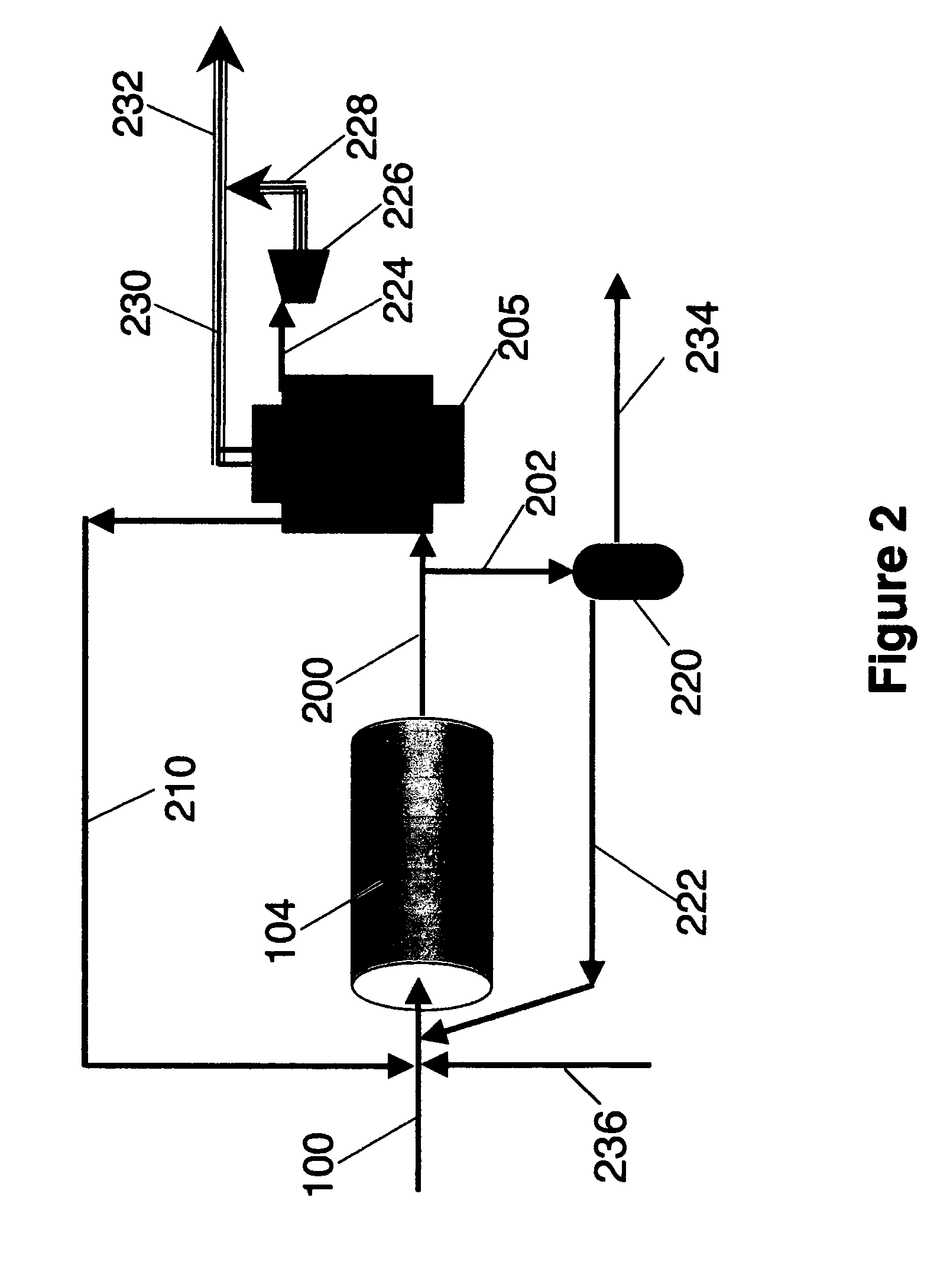

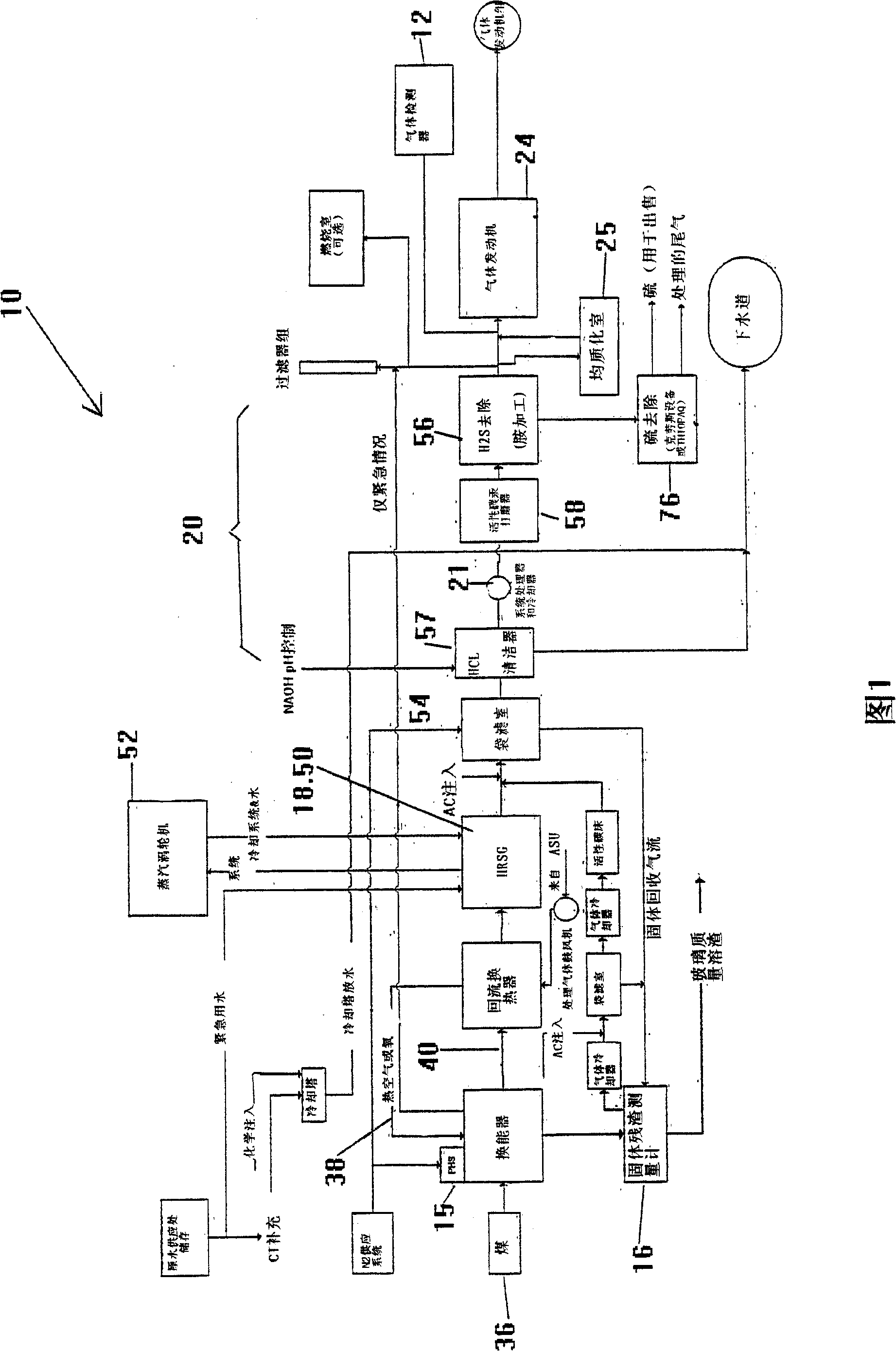

Process and system for converting carbonaceous feedstocks into energy without greenhouse gas emissions

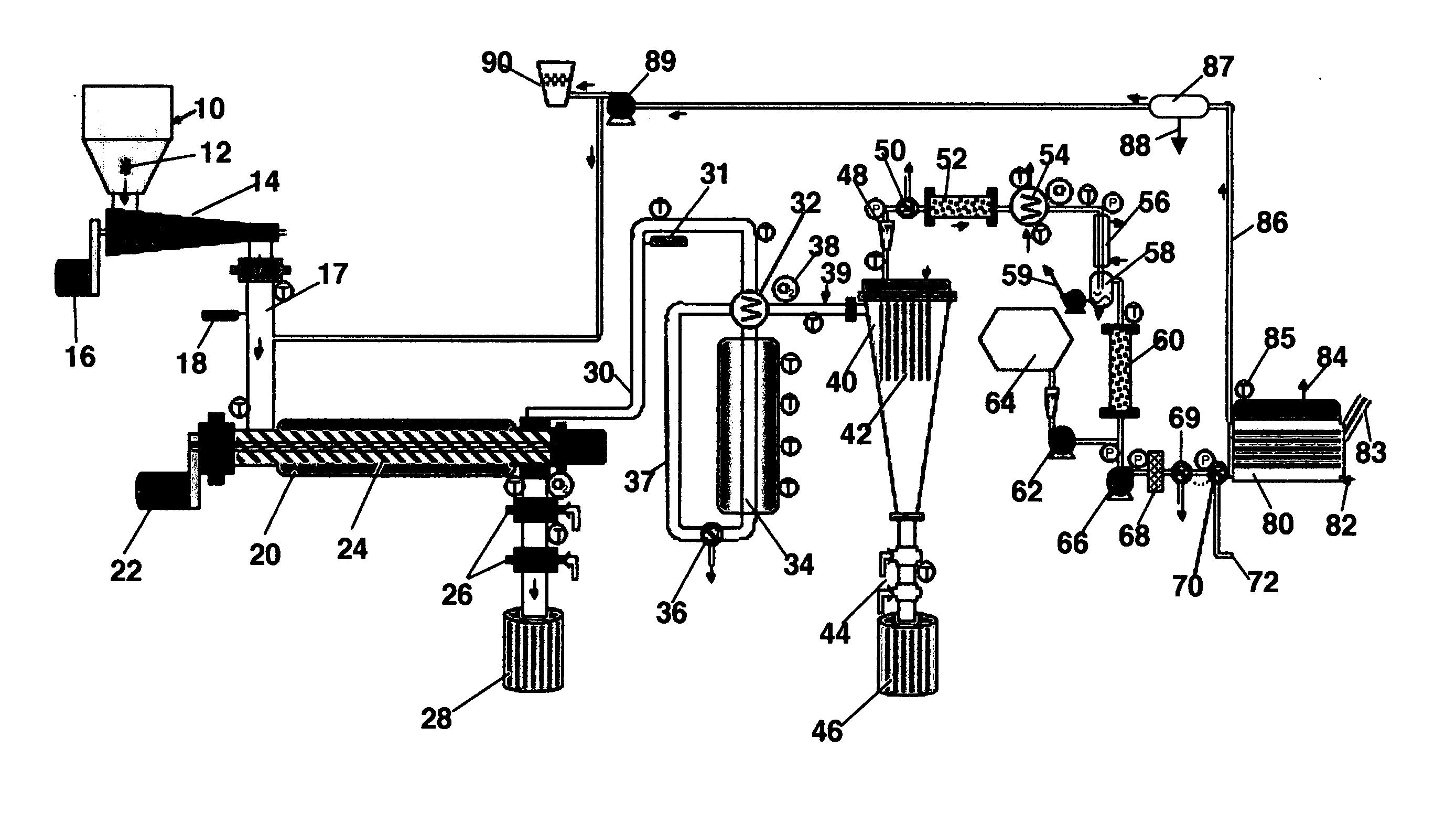

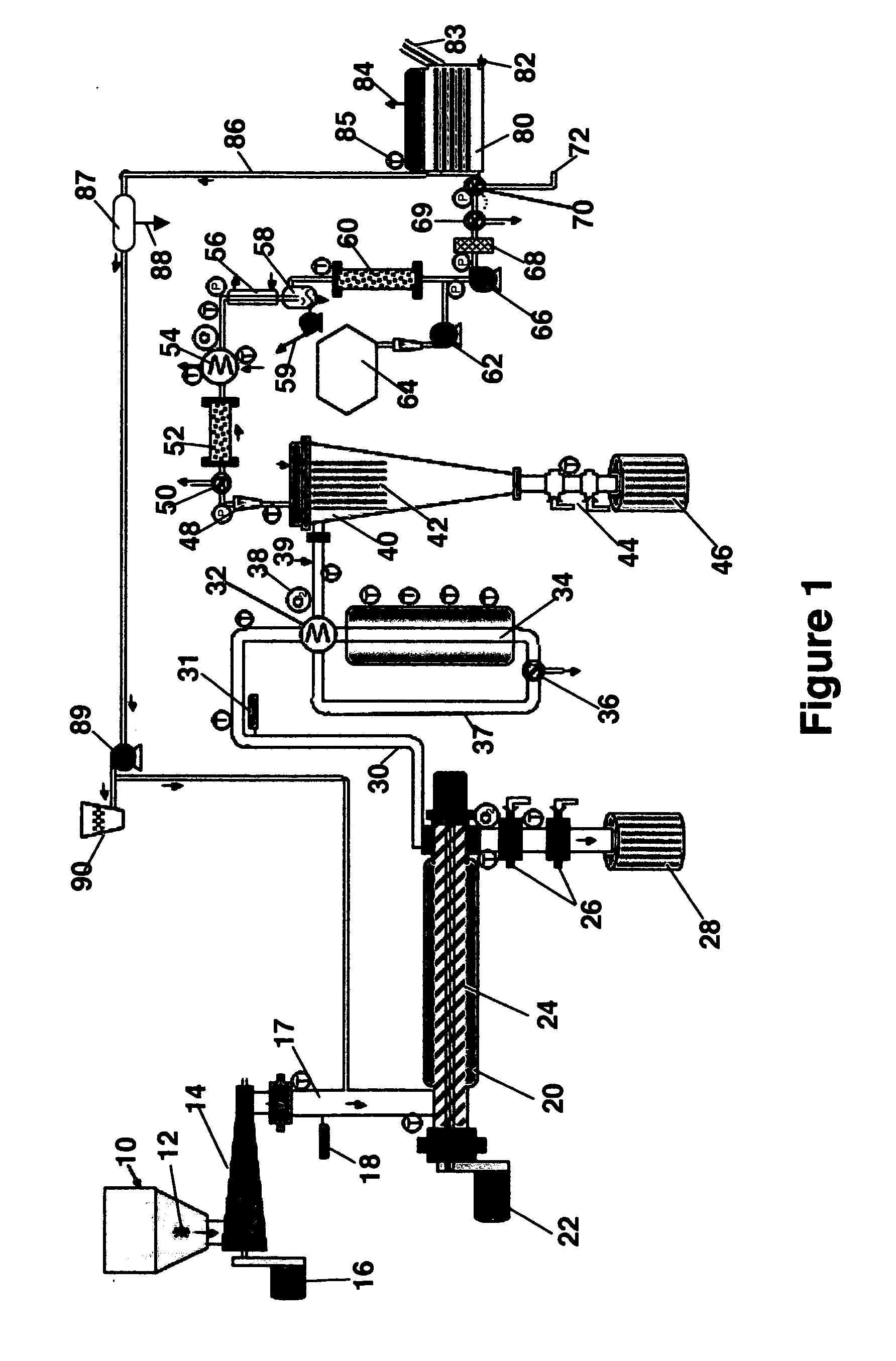

InactiveUS7220502B2Improve efficiencyHigh hydrogen contentFuel cell auxillariesWaste based fuelPetroleum cokeToxic industrial waste

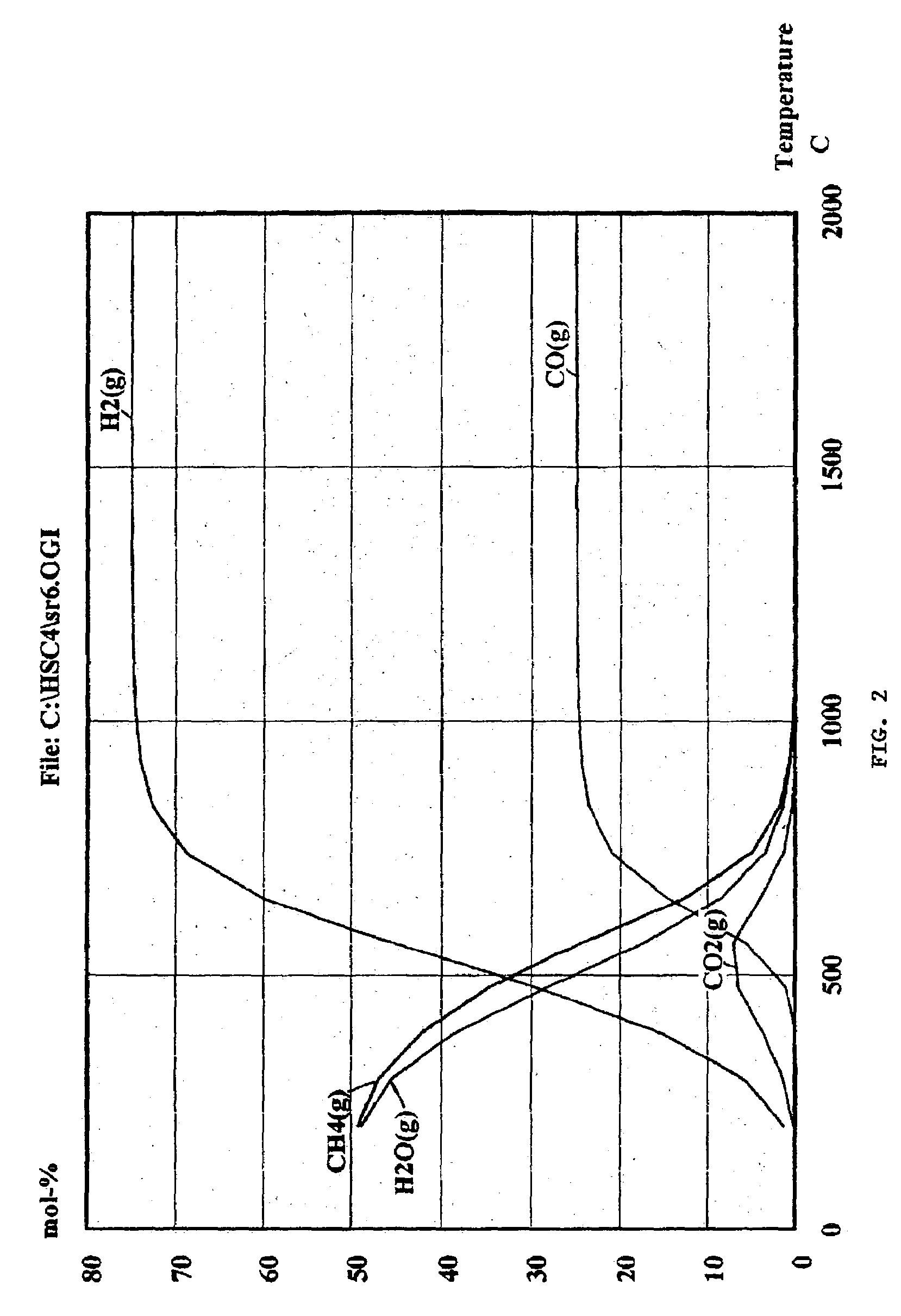

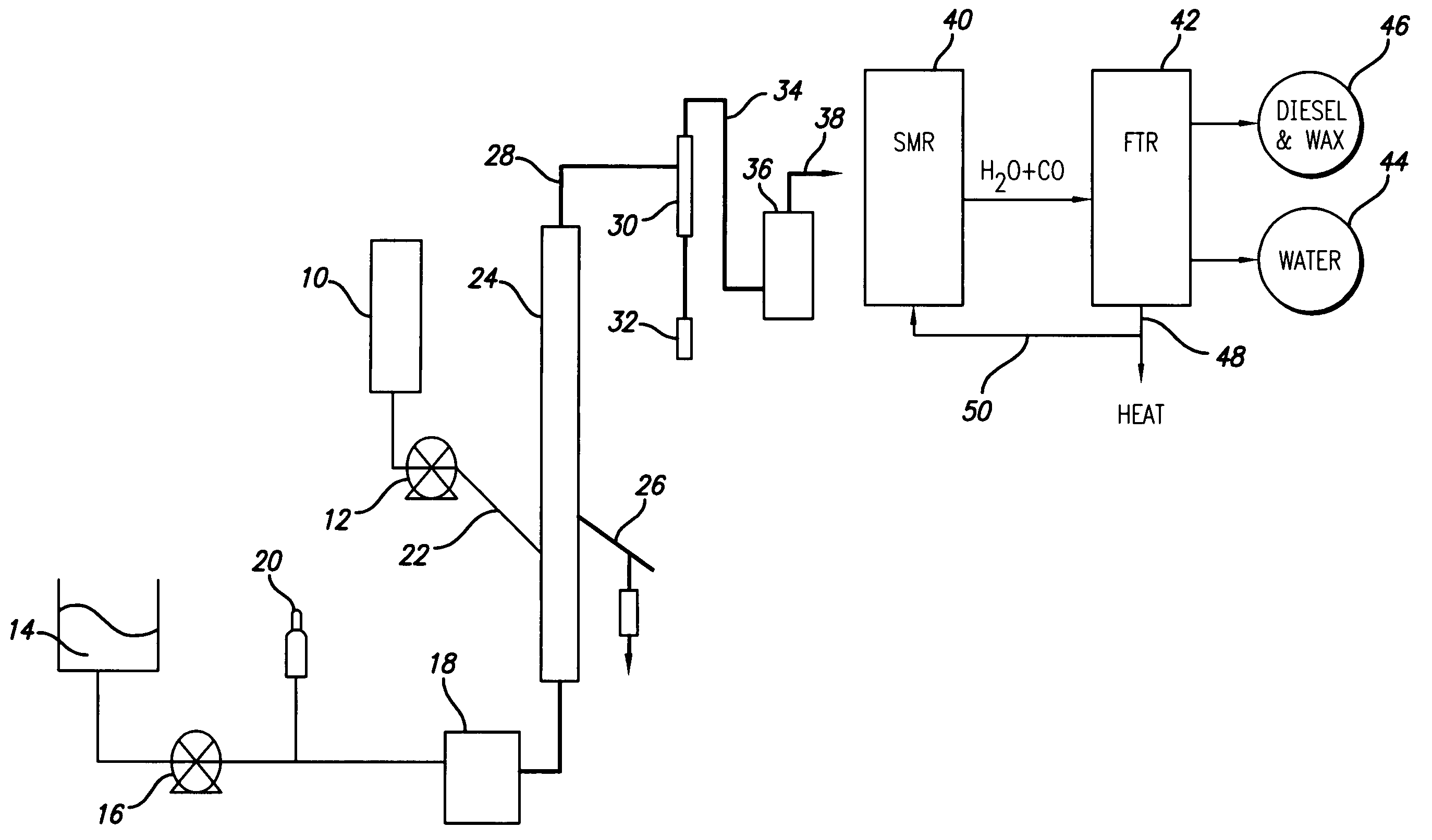

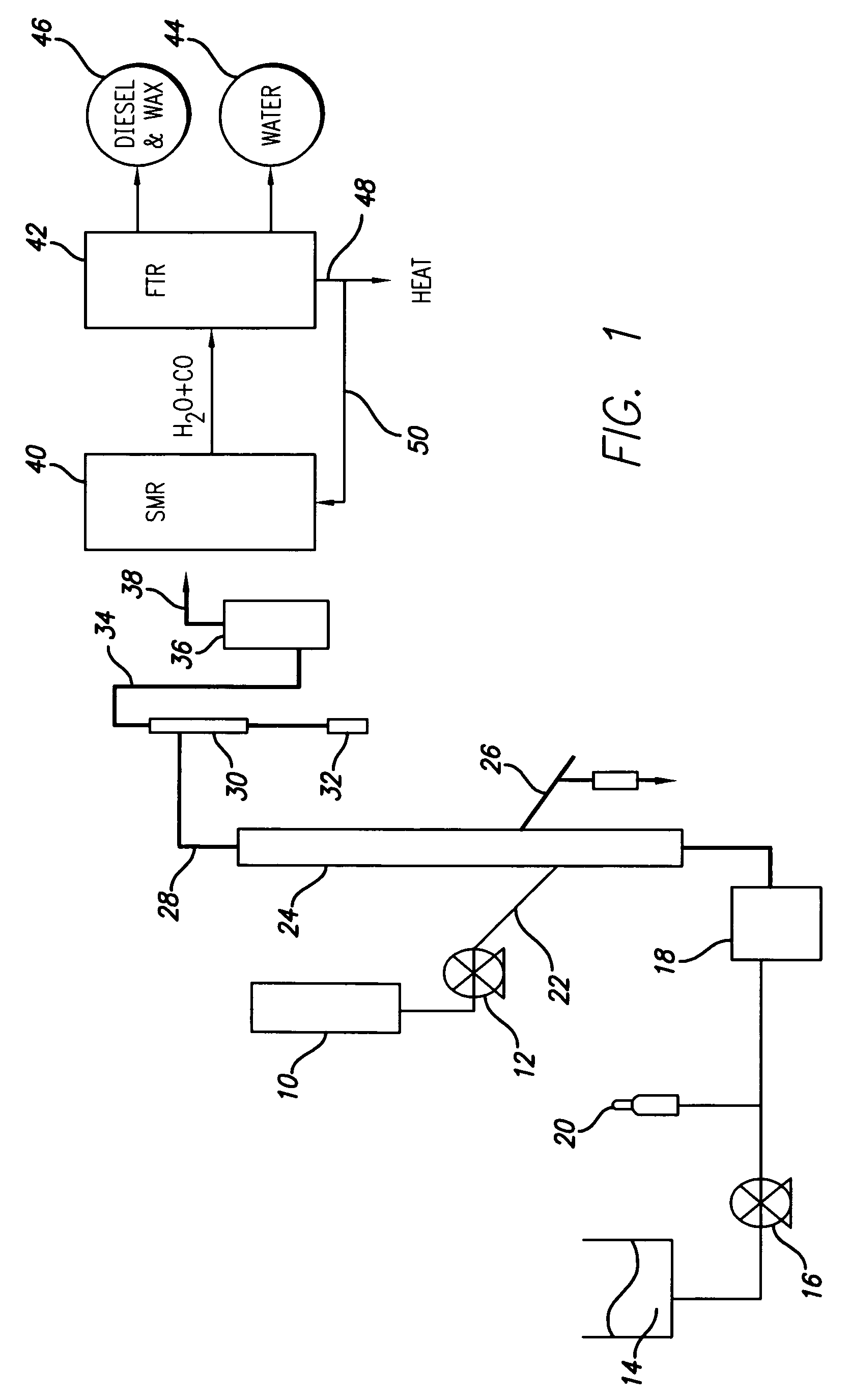

The process and system of the invention converts carbonaceous feedstock such as coal, hydrocarbon oil, natural gas, petroleum coke, oil shale, carbonaceous-containing waste oil, carbonaceous-containing medical waste, carbonaceous-containing military waste, carbonaceous-containing industrial waste, carbonaceous-containing medical waste, carbonaceous-containing sewage sludge and municipal solid waste, carbonaceous-containing agricultural waste, carbonaceous-containing biomass, biological and biochemical waste, and mixtures thereof into electrical energy without the production of unwanted greenhouse emissions. The process and system uses a combination of a gasifier, e.g., a kiln, operating in the exit range of at least 700° to about 1600° C. (1300-2900° F.) to convert the carbonaceous feedstock and a greenhouse gas stream into a synthesis gas comprising mostly carbon monoxide and hydrogen without the need for expensive catalysts and or high pressure operations. One portion of the synthesis gas from the gasifier becomes electrochemically oxidized in an electricity-producing fuel cell into an exit gas comprising carbon dioxide and water. The latter is recycled back to the gasifier after a portion of water is condensed out. The second portion of the synthesis gas from the gasifier is converted into useful hydrocarbon products.

Owner:RAVEN SR INC

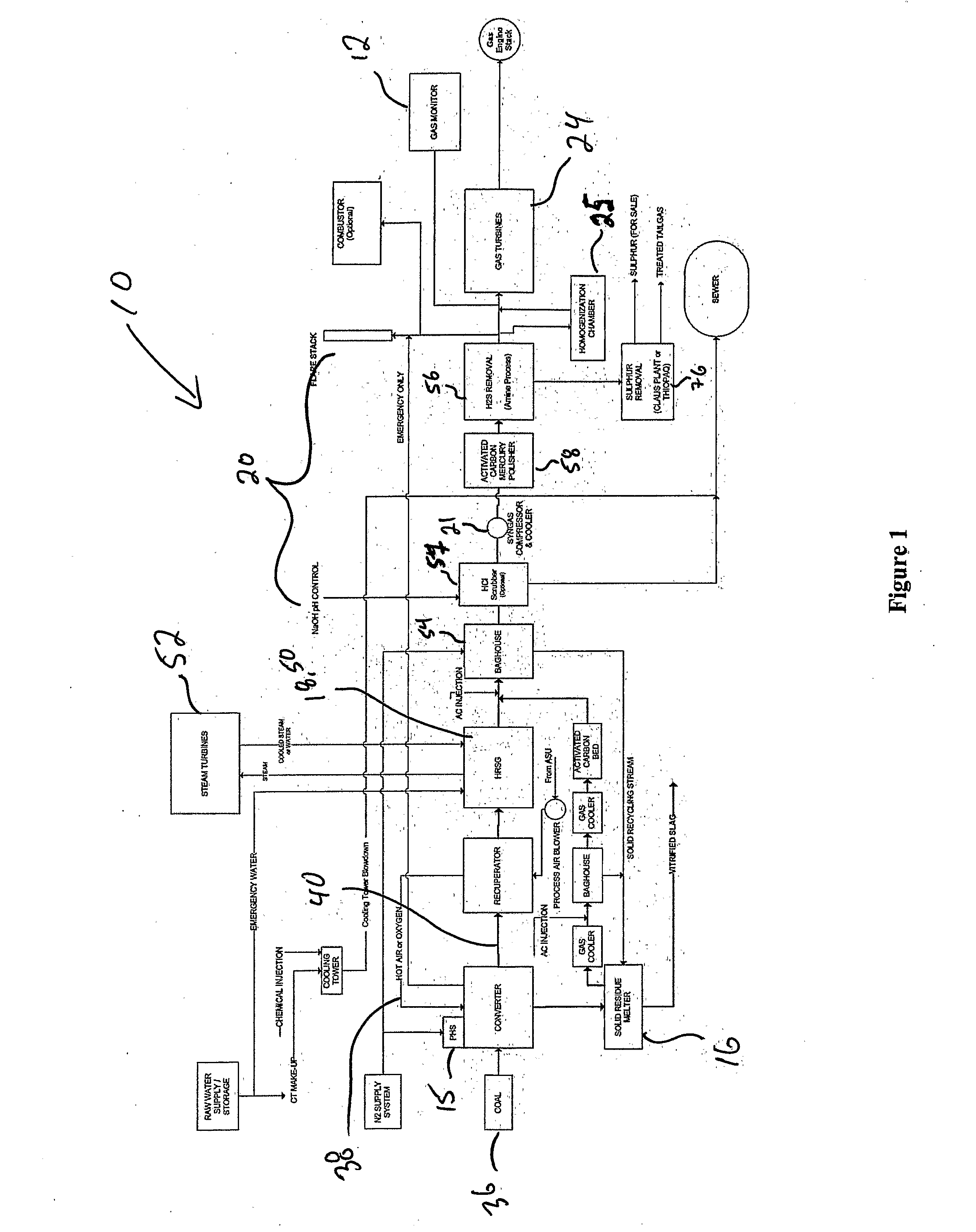

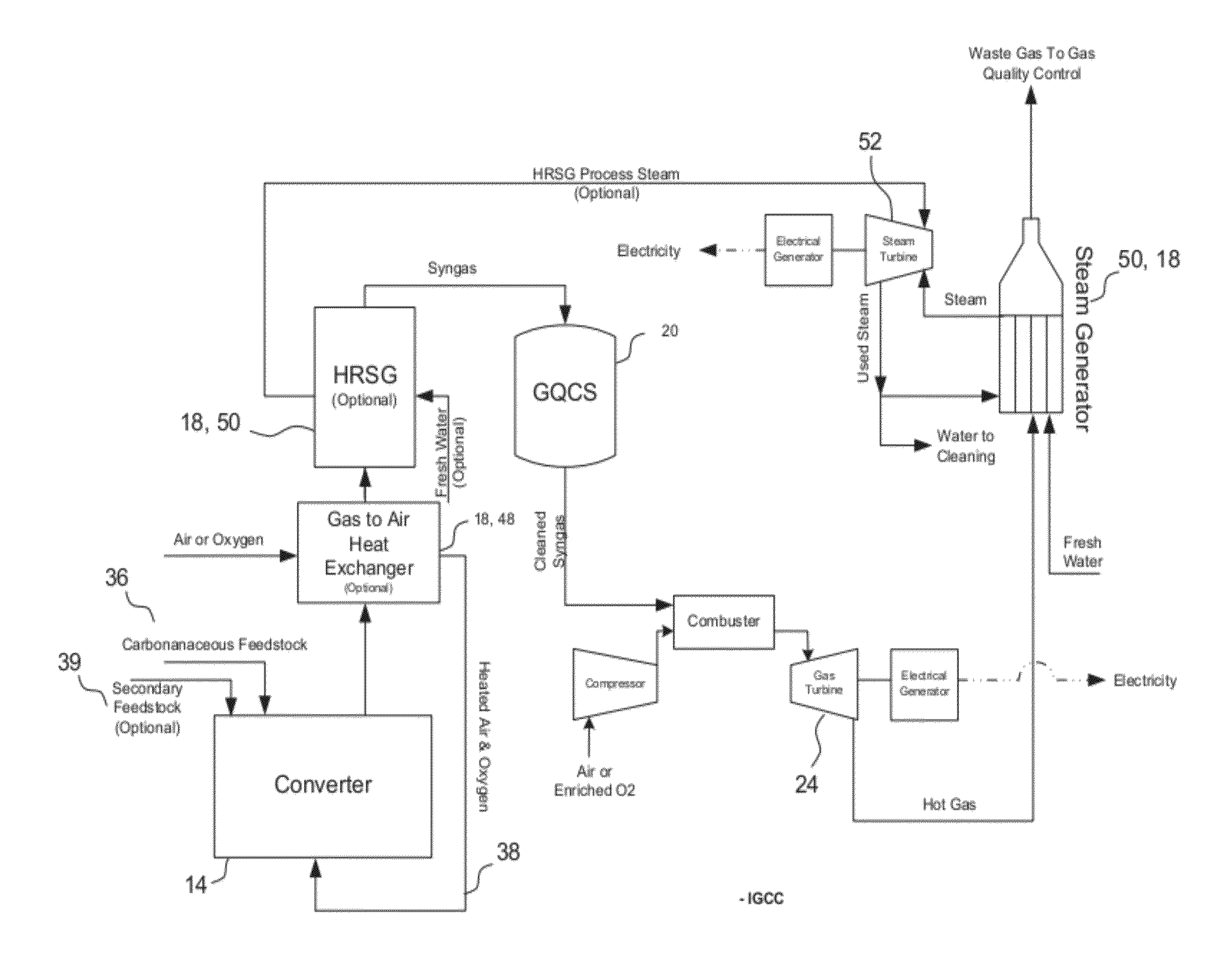

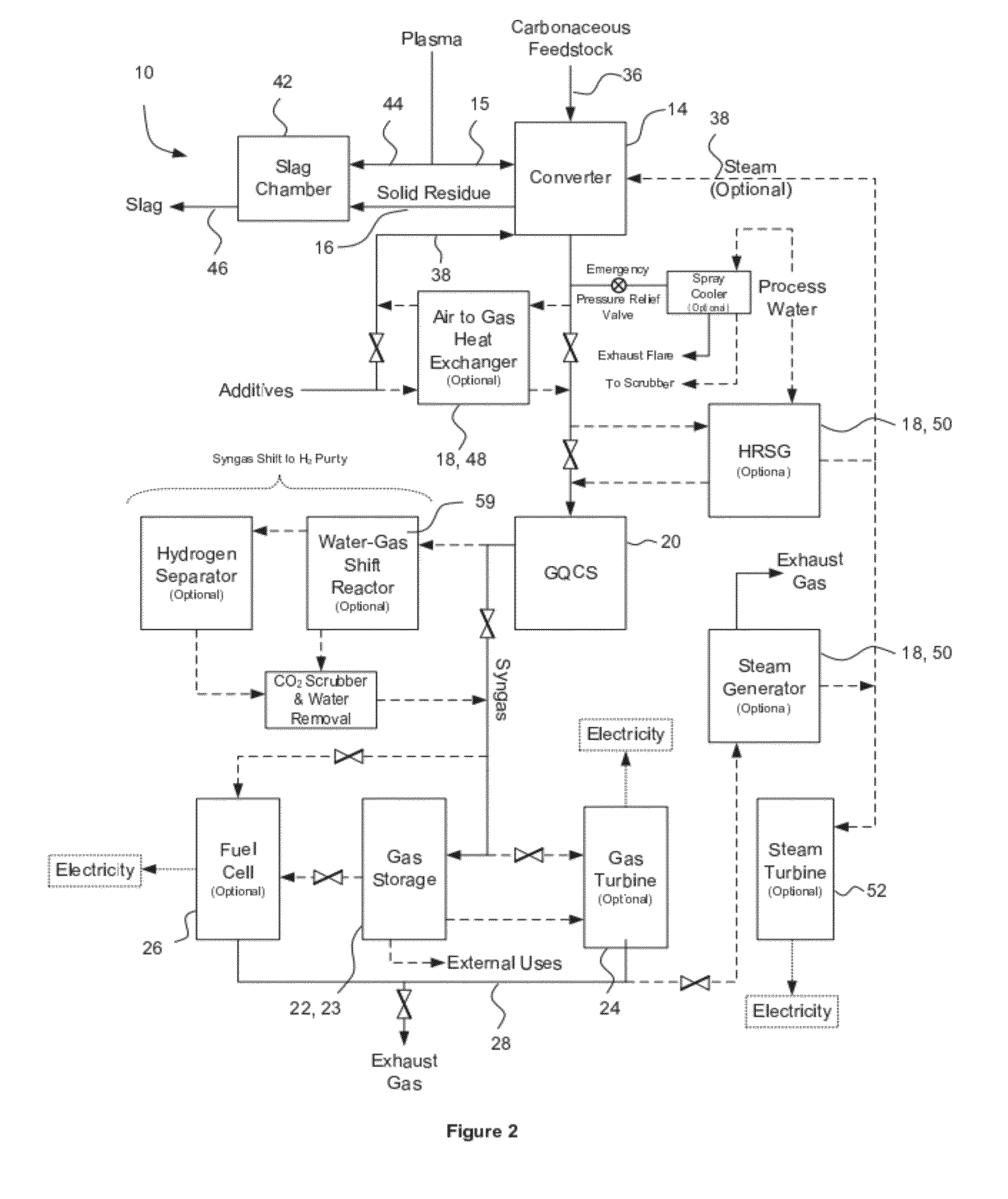

System For the Conversion of Carbonaceous Fbedstocks to a Gas of a Specified Composition

The present invention provides a carbonaceous feedstock gasification system with integrated control subsystem. The system generally comprises, in various combinations, a gasification reactor vessel (or converter) having one or more processing zones and one or more plasma heat sources, a solid residue handling subsystem, a gas quality conditioning subsystem, as well as an integrated control subsystem for managing the overall energetics of the conversion of the carbonaceous feedstock to energy, as well as maintaining all aspects of the gasification processes at an optimal set point. The gasification system may also optionally comprise a heat recovery subsystem and / or a product gas regulating subsystem.

Owner:PLASCO ENERGY GROUP INC

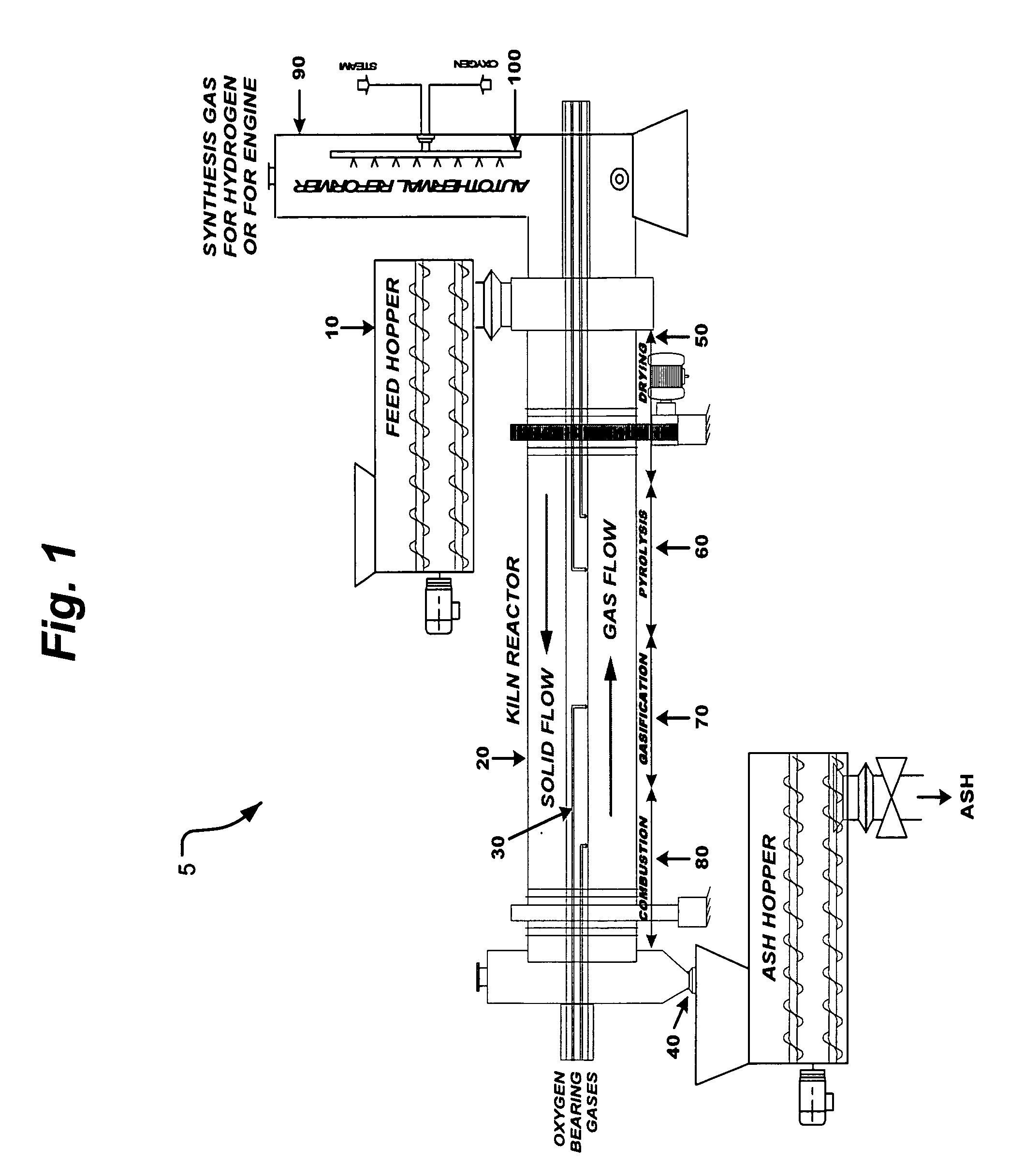

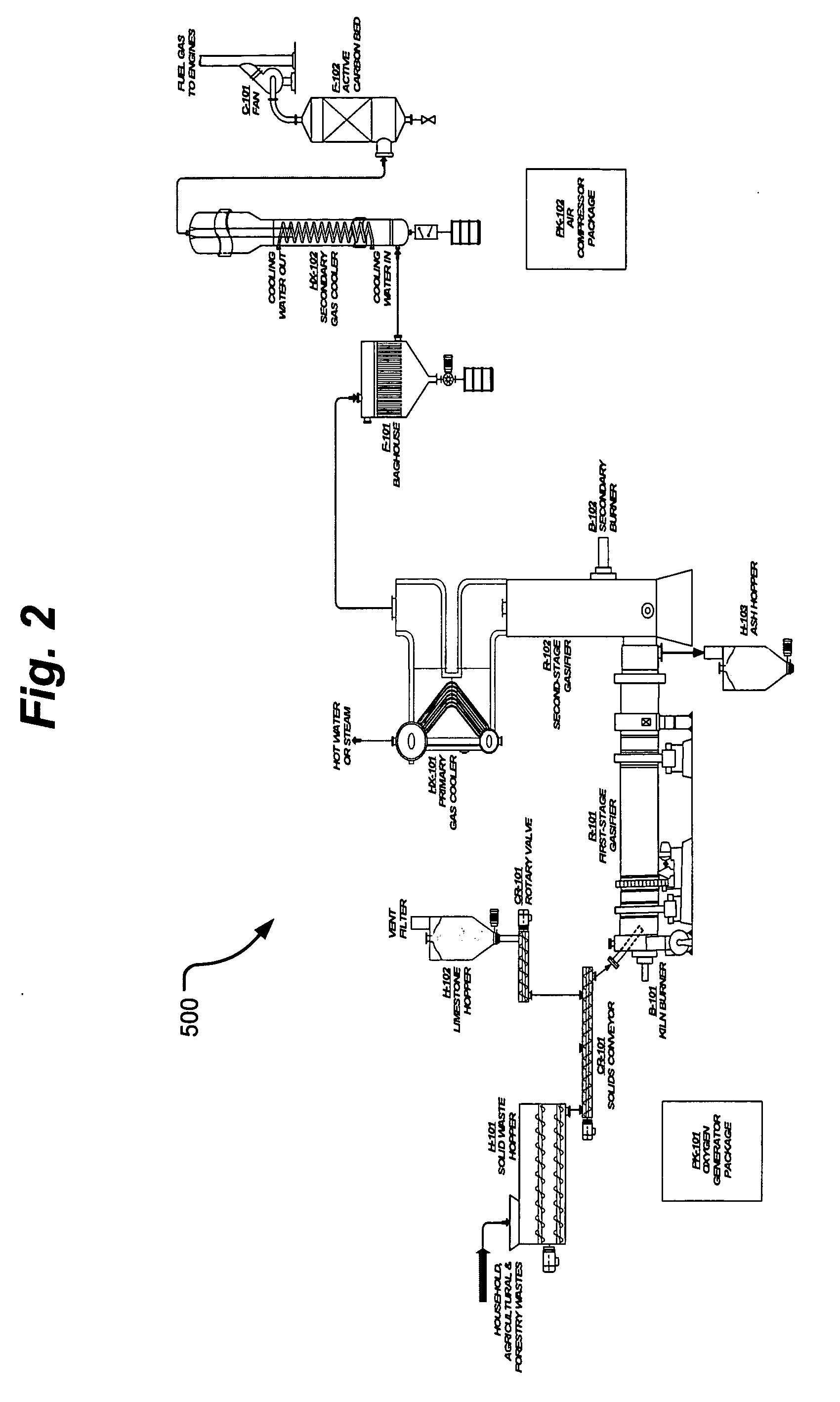

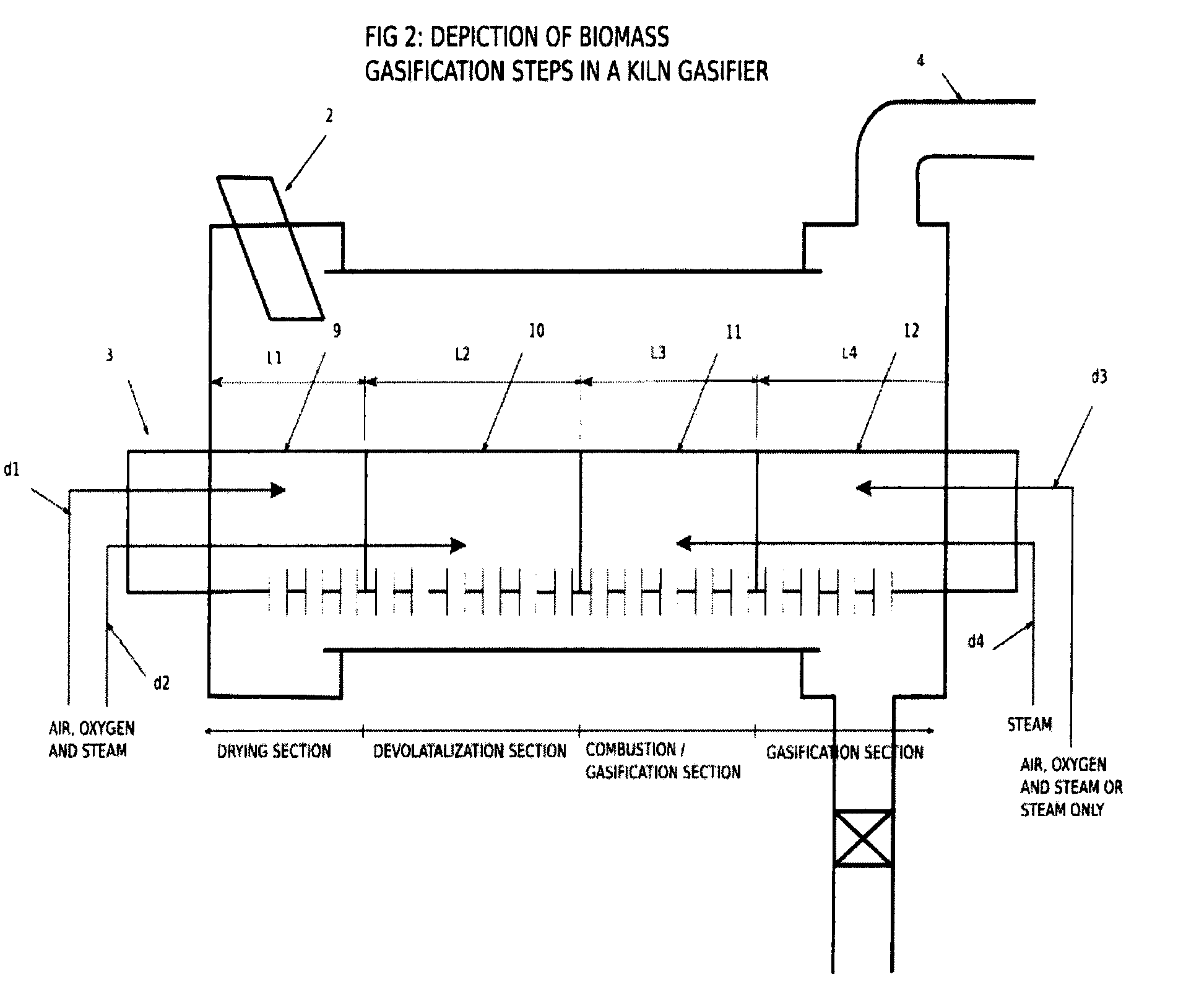

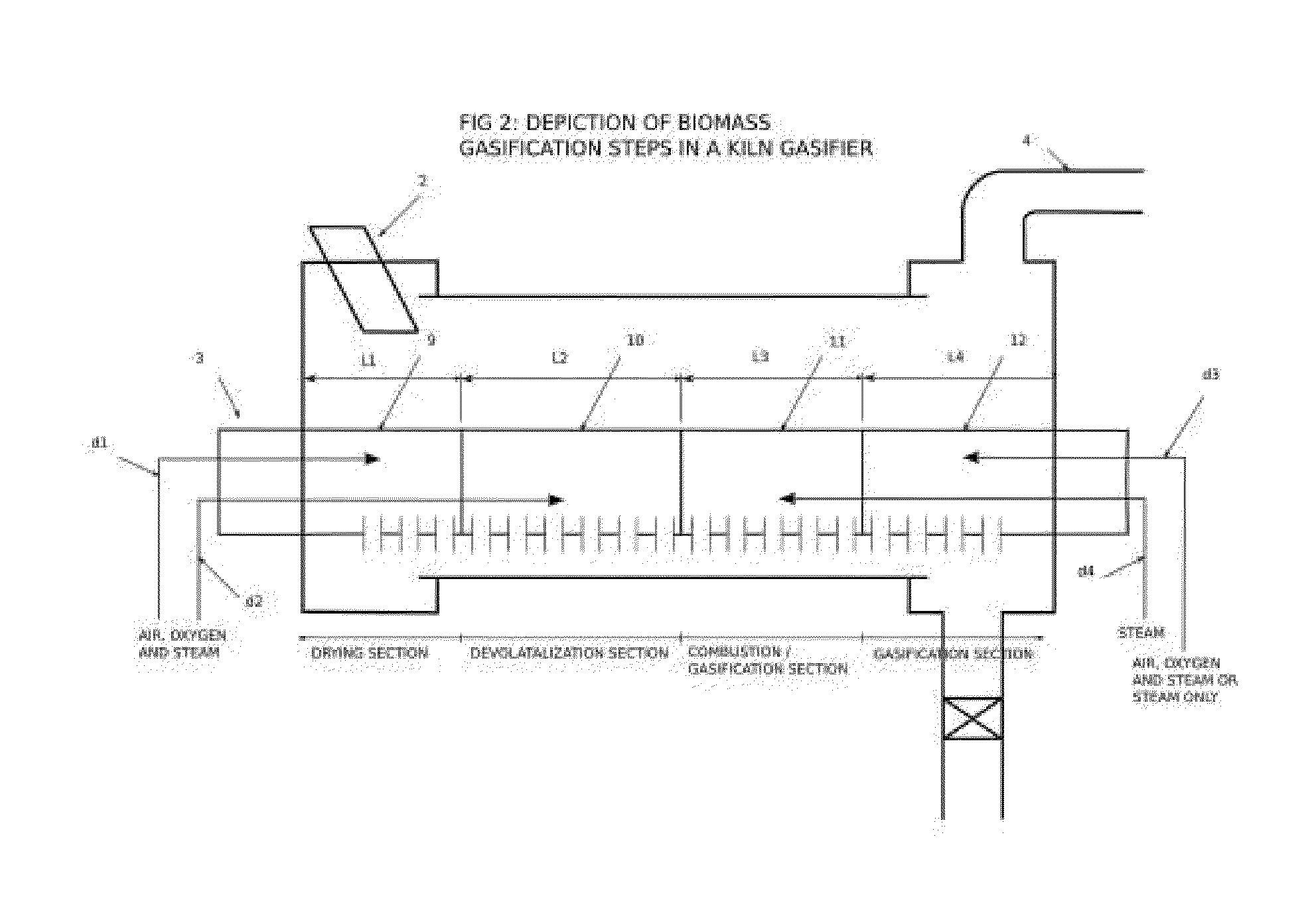

Process and apparatus for biomass gasification

InactiveUS20050095183A1Oxygen-containing compound preparationGasifier mechanical detailsForming gasTar

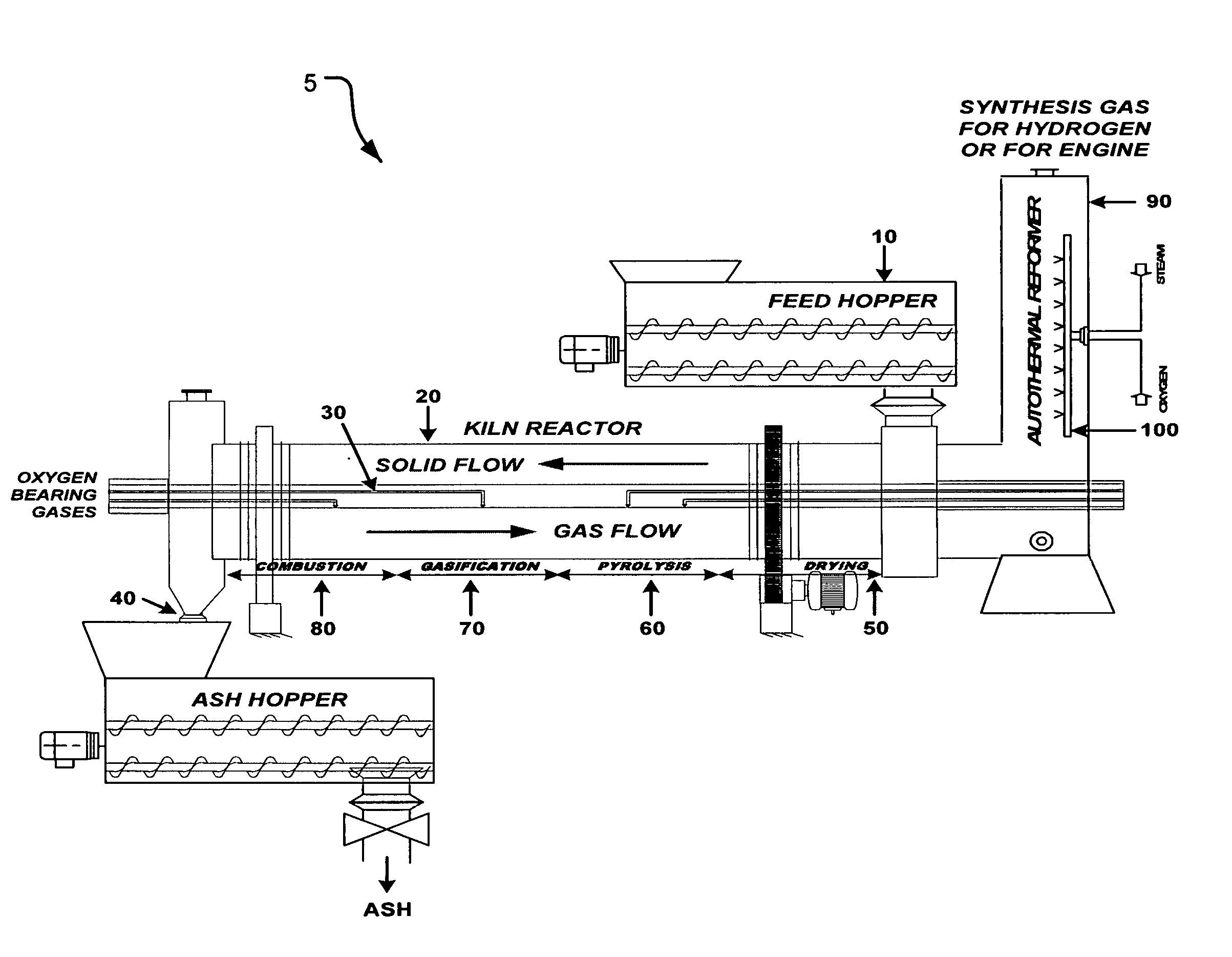

A waste-to-synthesis gas system including: a first gasifier for receiving biomass; a gas distributor for delivering reactant gas and oxygen into the first gasifier in a countercurrent direction to the biomass flow and to define a plurality of reaction regions including a drying region, a pyrolysis region, a gasification region and a combustion region; and, a second gasifier for receiving gases from the plurality of regions of the first gasifier and a gas distributor for delivering reactant gas and oxygen into the second gasifier in a concurrent direction to the flow of gases from the first gasifier. As a result, no carbon chars, oils or tars are expected to be present in the synthesis gas produced.

Owner:BIOMASS ENERGY SOLUTIONS

Process and system for converting carbonaceous feedstocks into energy without greenhouse gas emissions

ActiveUS7132183B2Improve efficiencyHigh hydrogen contentFuel cell auxillariesGasification processes detailsWaste oilHigh pressure

The process and system of the invention converts carbonaceous feedstock such as coal, hydrocarbon oil, natural gas, petroleum coke, oil shale, carbonaceous-containing waste oil, carbonaceous-containing medical waste, carbonaceous-containing hazardous waste, carbonaceous-containing medical waste, and mixtures thereof into electrical energy without the production of unwanted greenhouse emissions. The process and system uses a combination of a gasifier, e.g., a kiln, operating in the exit range of at least 700° to about 1600° C. (1300–2900° F.) to convert the carbonaceous feedstock and a greenhouse gas stream into a synthesis gas comprising mostly carbon monoxide and hydrogen without the need for expensive catalysts and or high pressure operations. One portion of the synthesis gas from the gasifier becomes electrochemically oxidized in an electricity-producing fuel cell into an exit gas comprising carbon dioxide and water. The latter is recycled back to the gasifier after a portion of water is condensed out. The second portion of the synthesis gas from the gasifier is converted into useful hydrocarbon products.

Owner:RAVEN SR INC

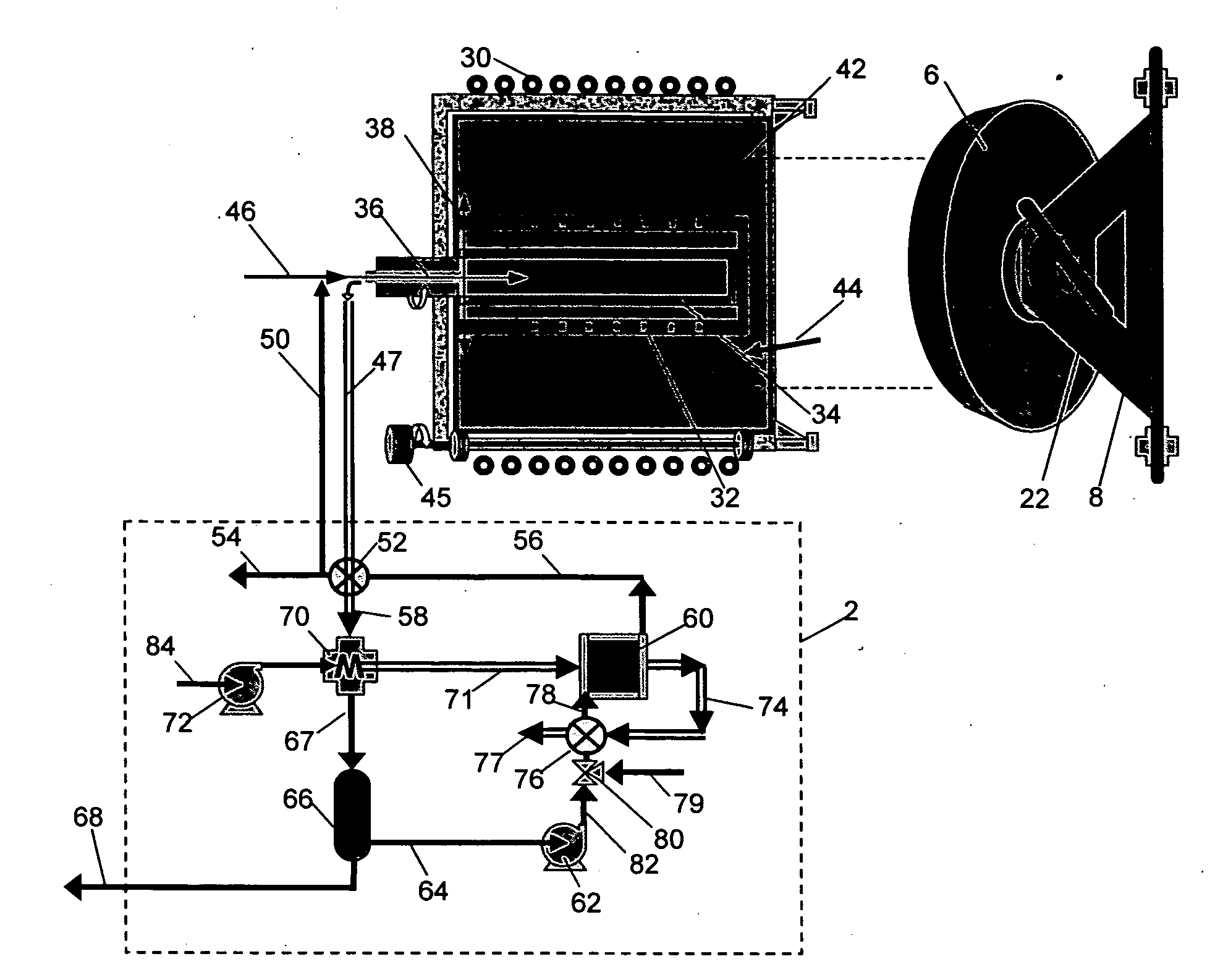

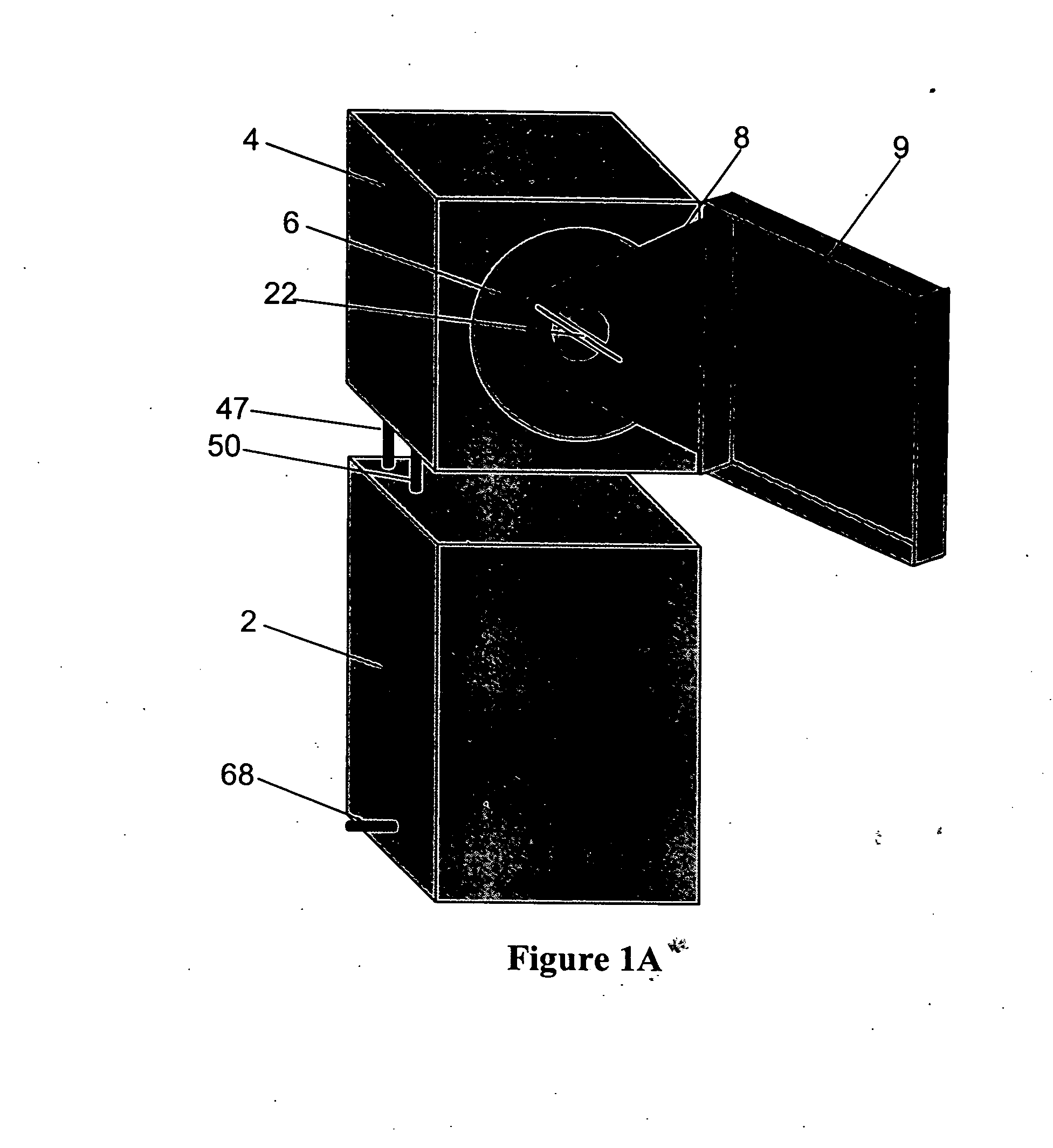

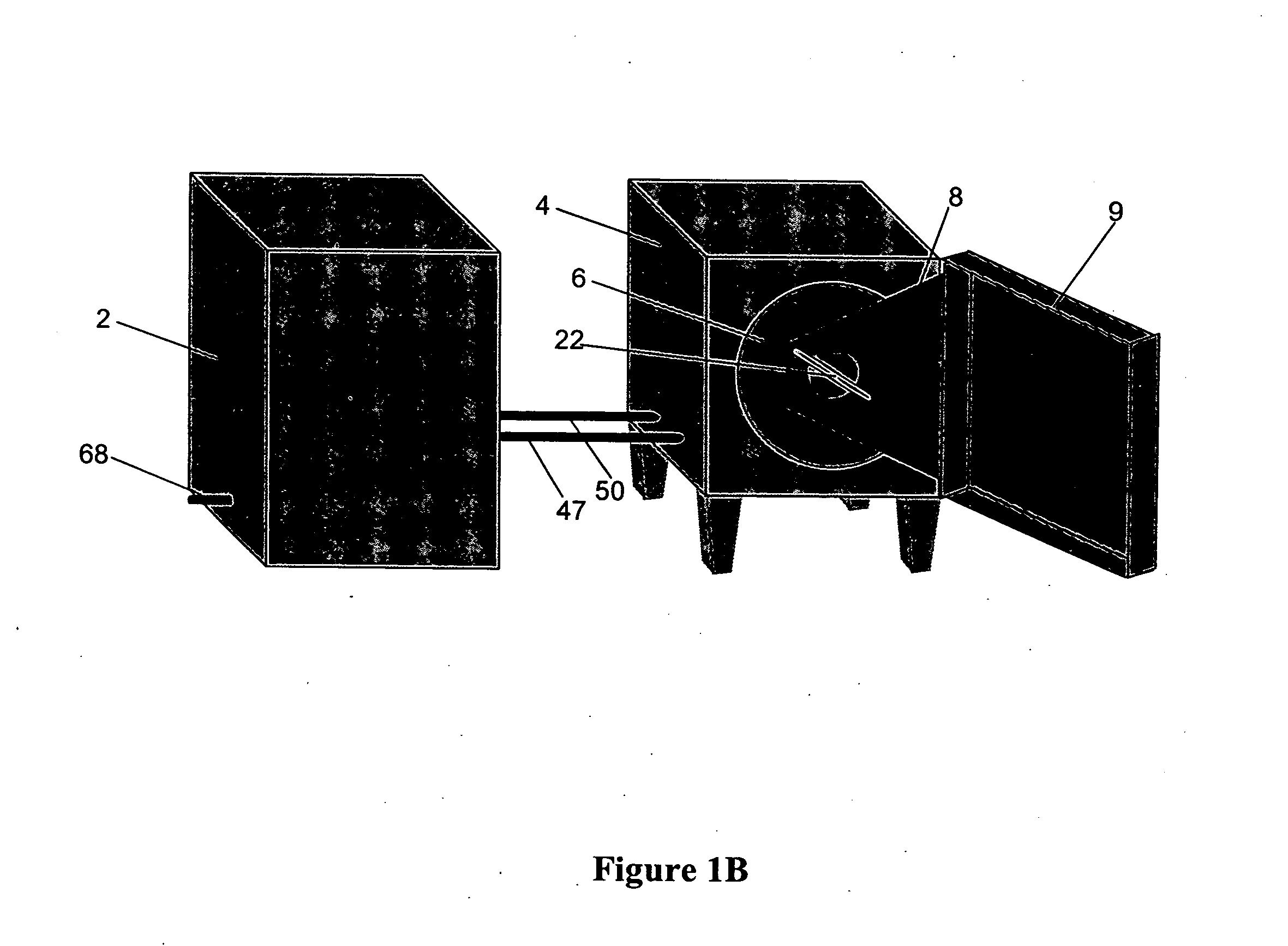

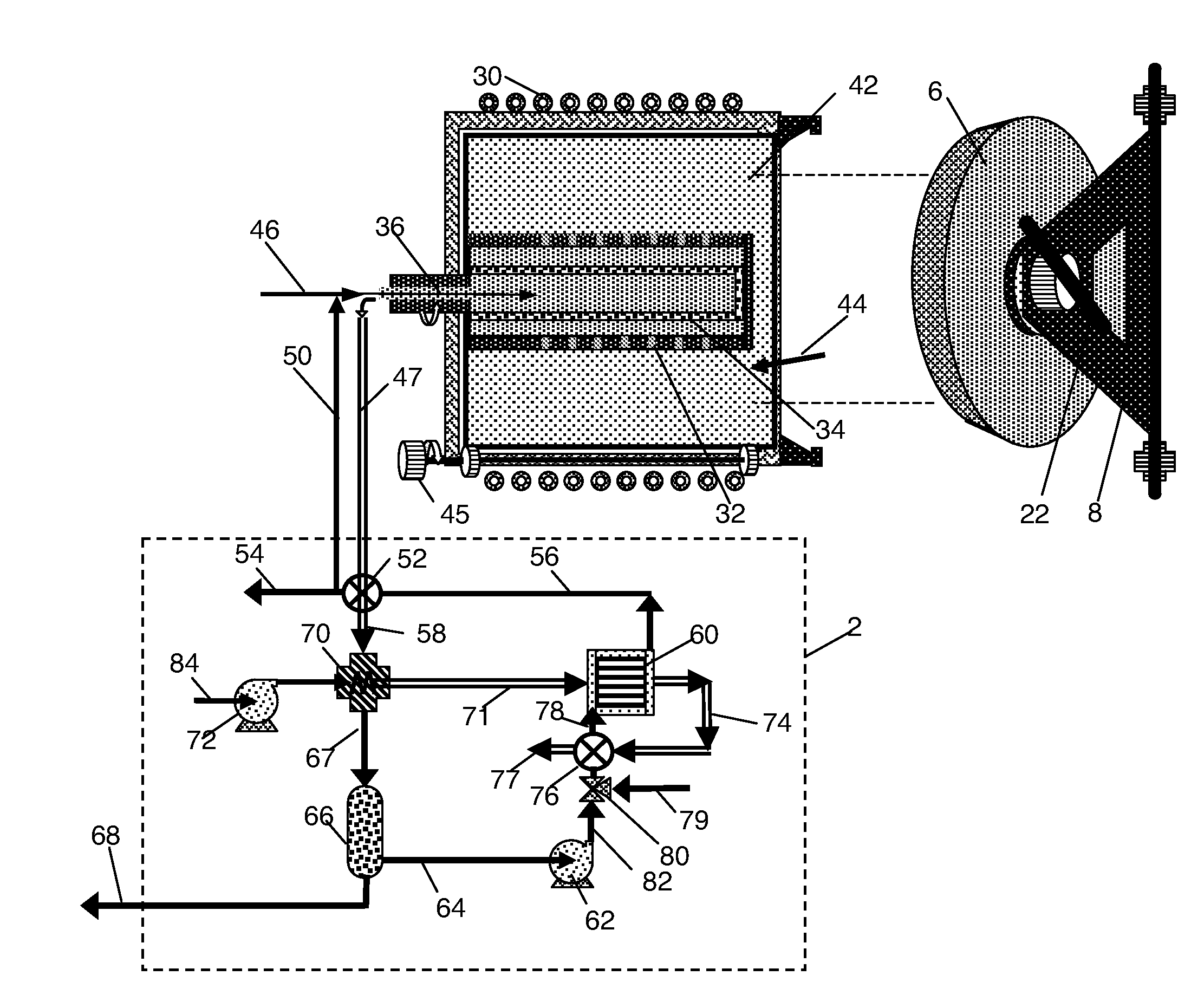

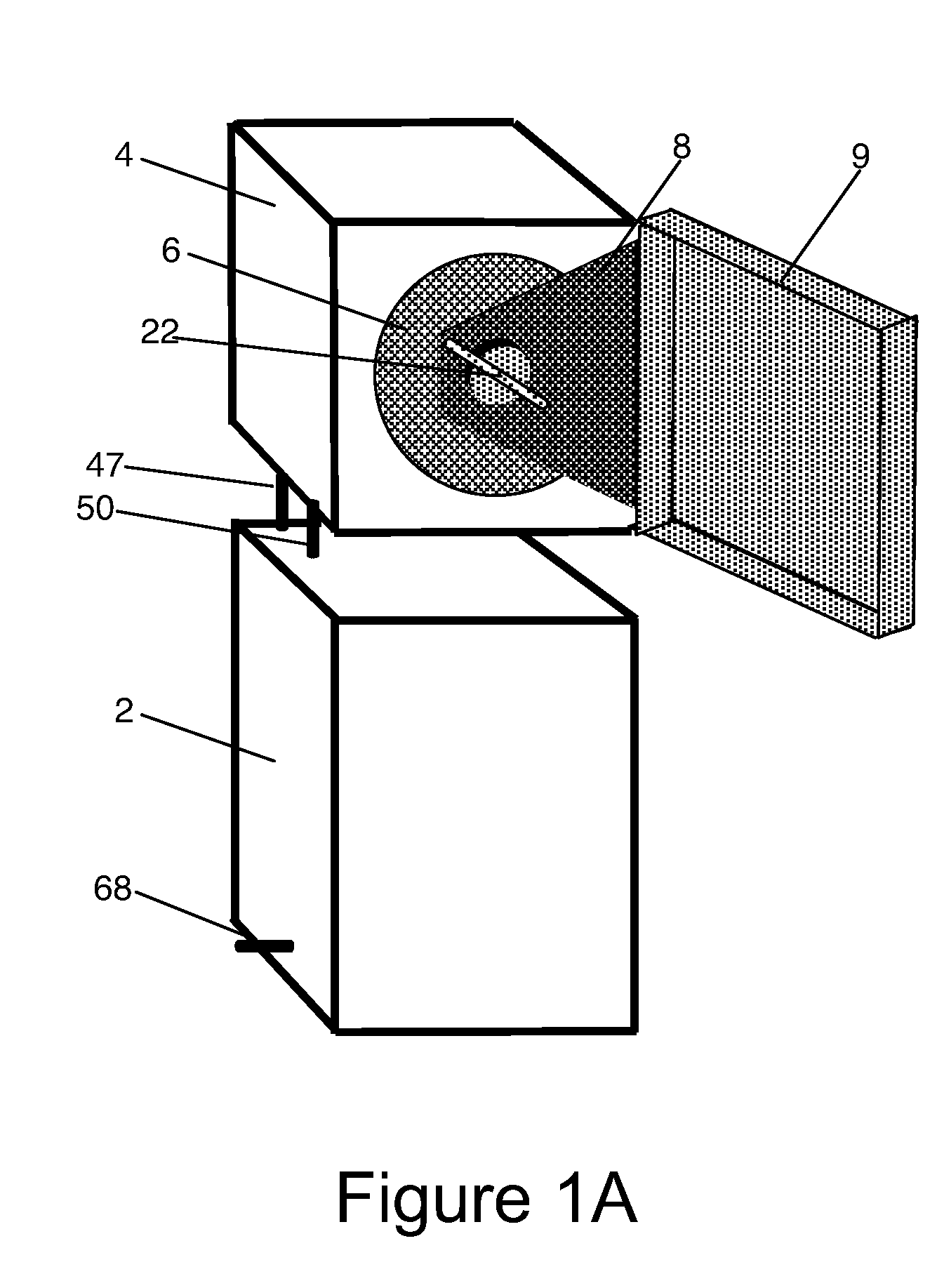

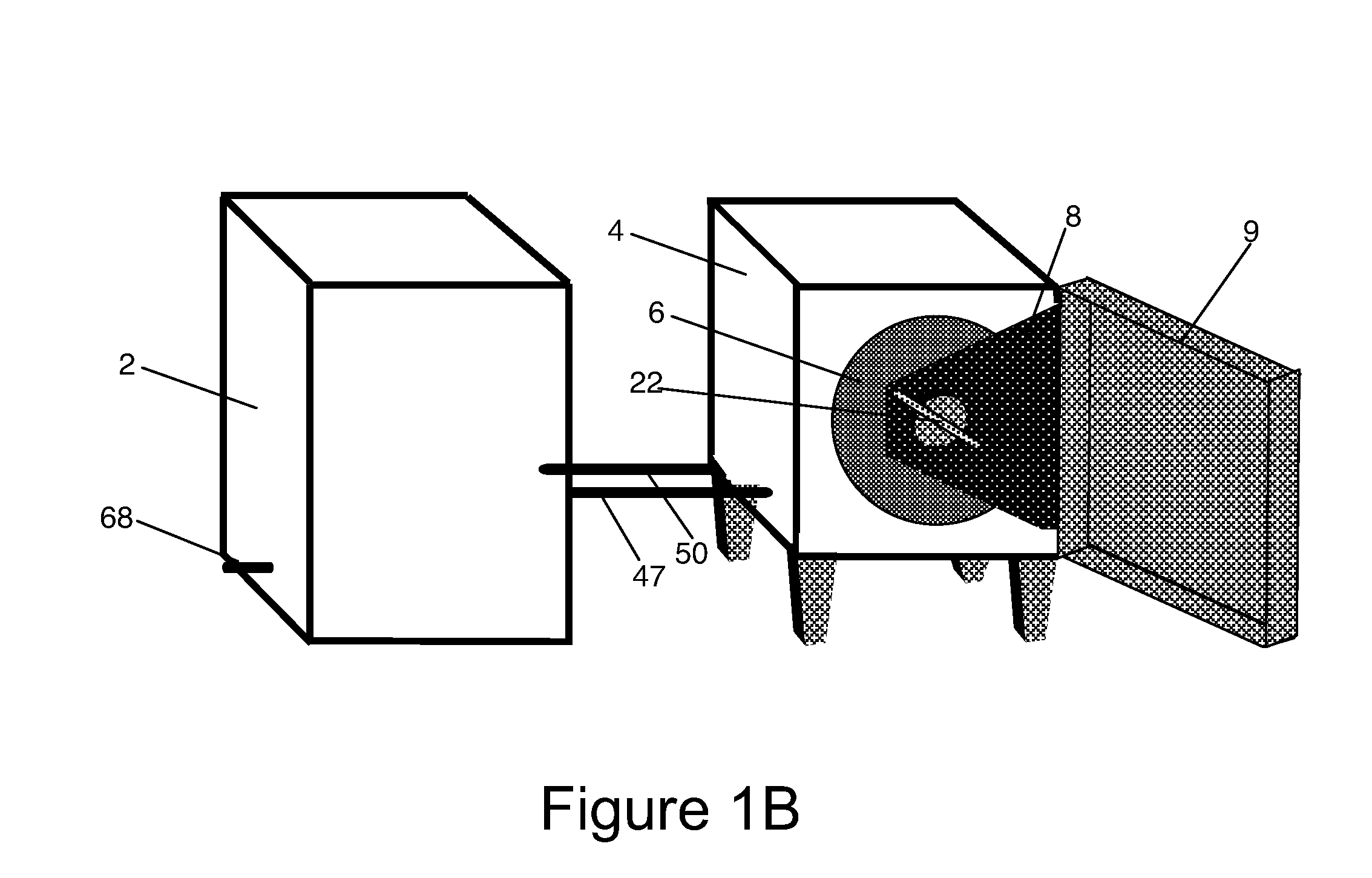

Appliance for converting household waste into energy

ActiveUS20070099039A1Reduce the total massEliminating garbage requiring landfillsFuel cell heat exchangeSolid waste disposalSteam reformingNuclear engineering

A method and reactor system is configured as an appliance for the destruction of residential and building waste to form hydrogen-rich syngas. This syngas is used to power a fuel cell for the generation of electric power, steam and heat or cooling for use in residences and buildings as well as hydrogen fuel for vehicles. The waste conversion rector that carries out the endothermic reactions of steam reforming is heated with the waste heat and electrical power. Alternatively, this reactor can be heated by a natural gas burner. This reactor is designed as a rotary drum, into which are placed bags of waste that can consist of normal garbage as well as toilet solid waste. Glass and metal are not melted in this drum and are recovered as completely sterilized at the end of the process cycle.

Owner:RAVEN SR INC

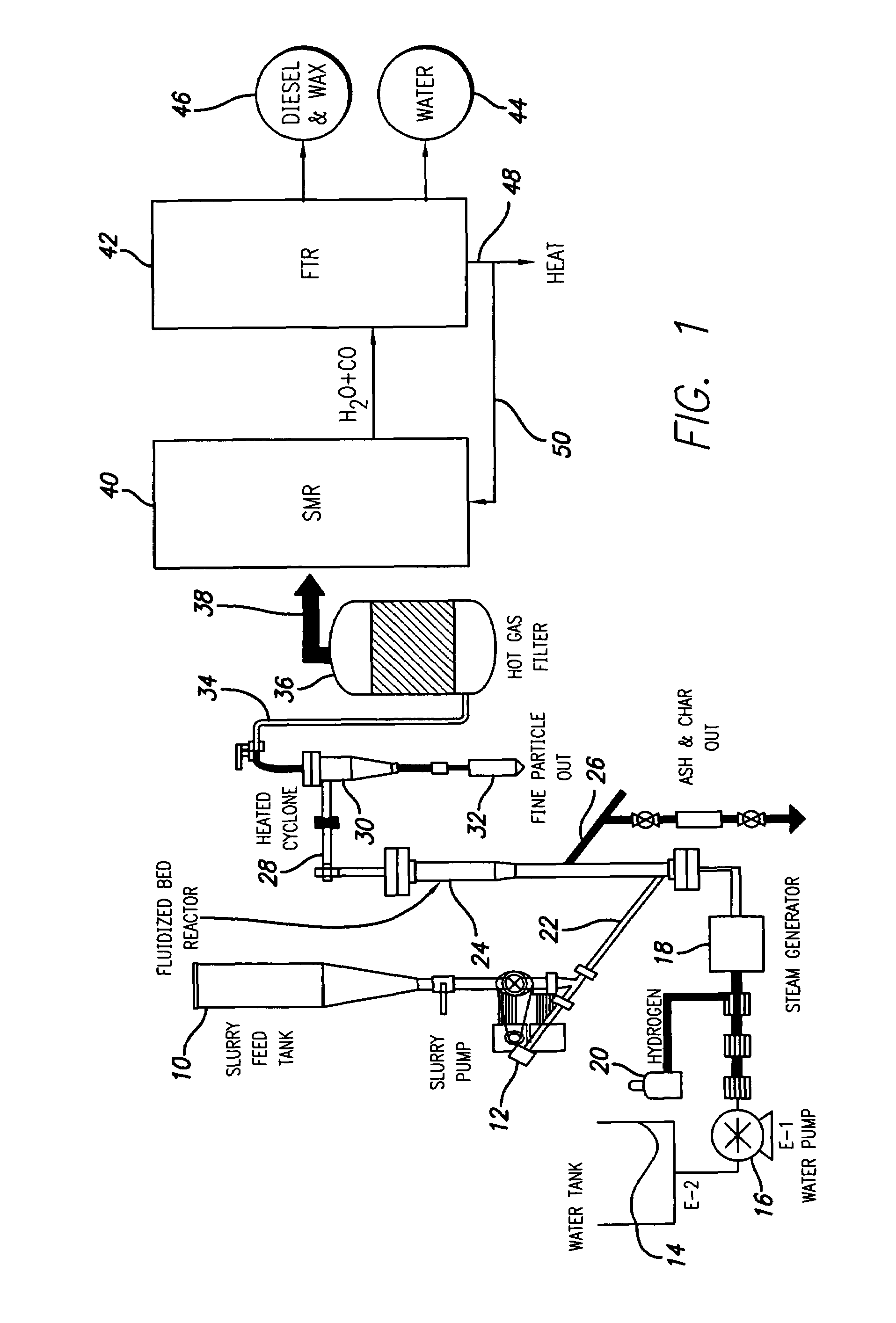

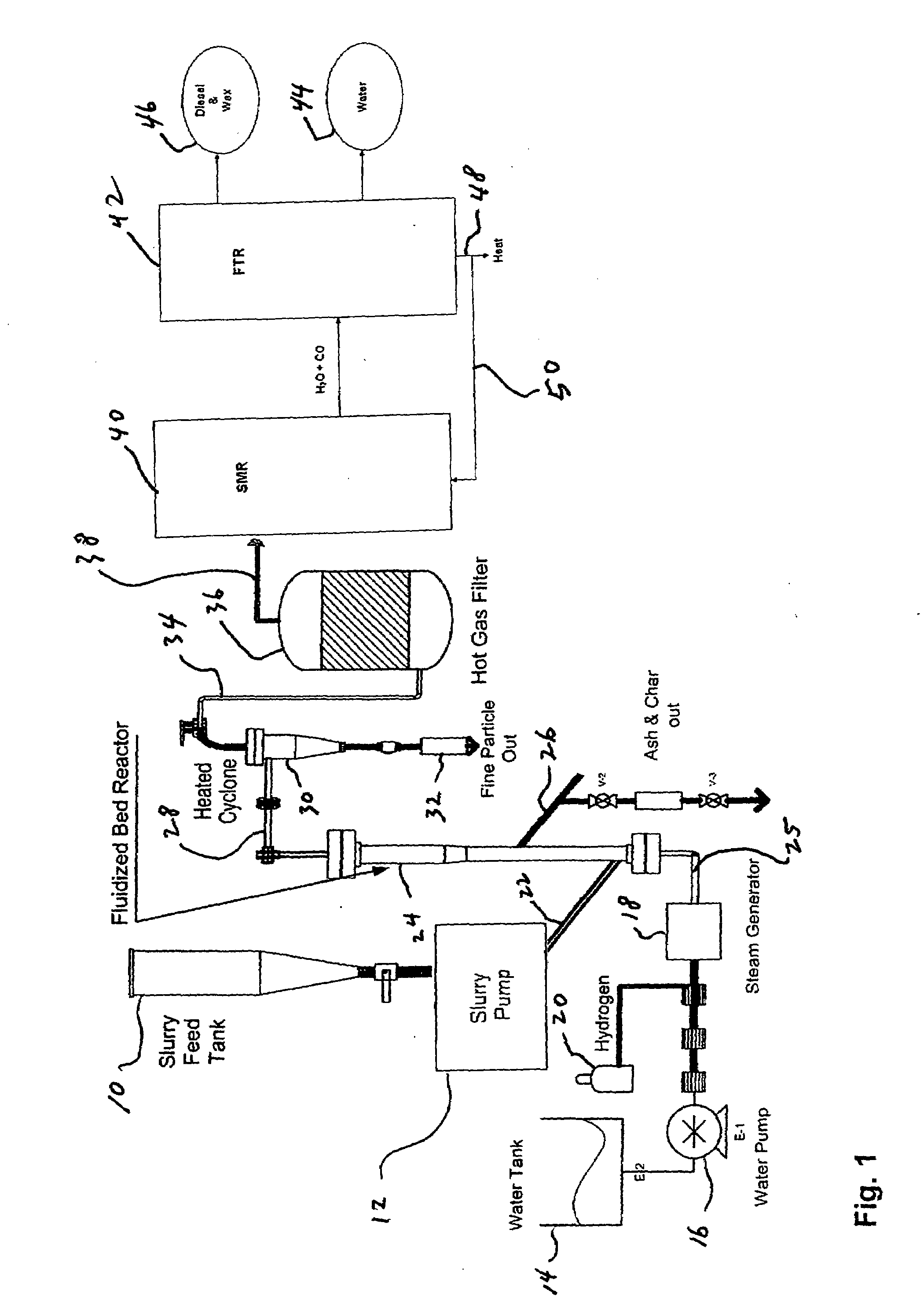

Method and apparatus for steam hydro-gasification in a fluidized bed reactor

InactiveUS20080021123A1Well mixedIncrease conversion rateCombustible gas chemical modificationHydrogenHydrogenFluidized bed

Owner:RGT UNIV OF CALIFORNIA

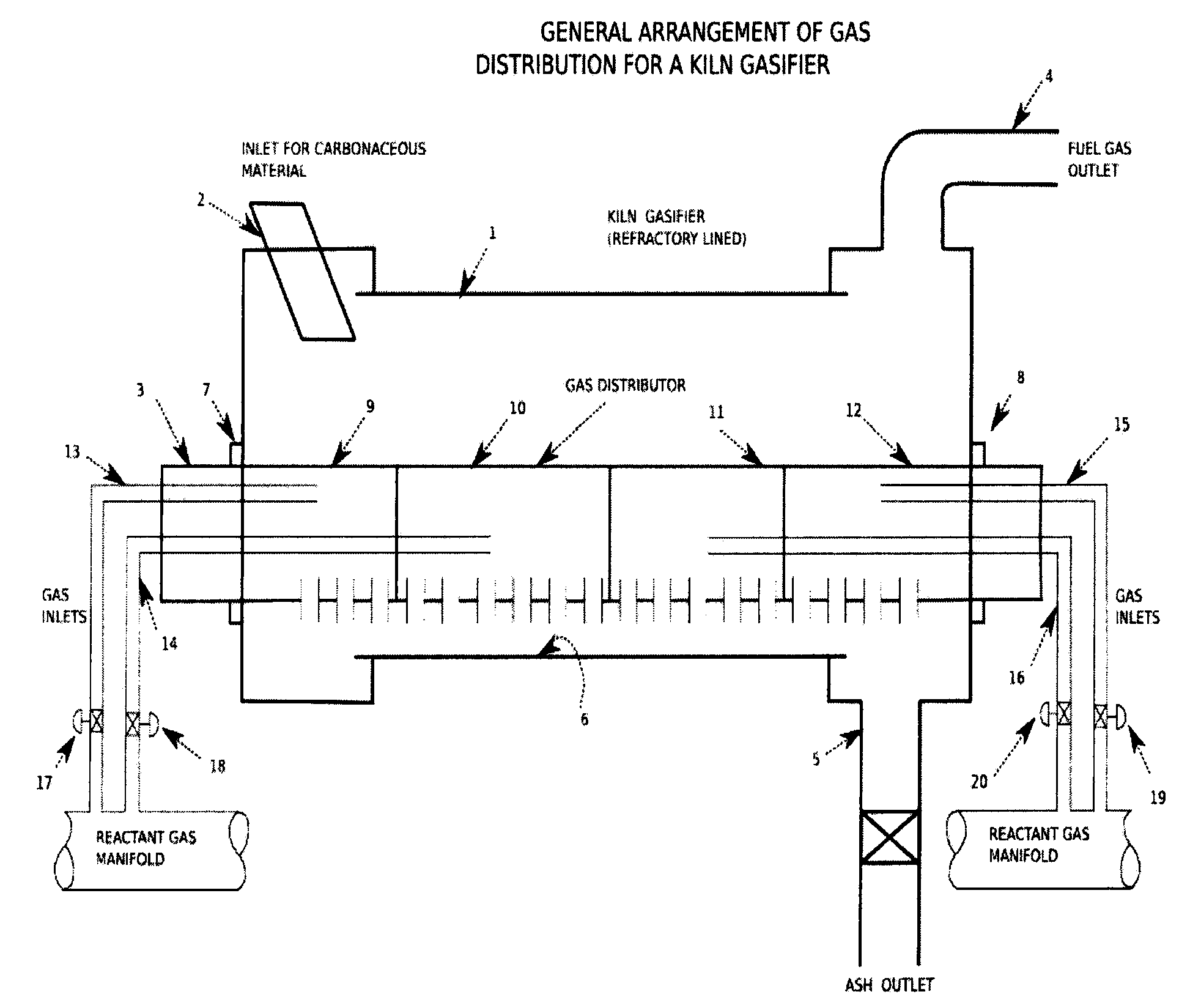

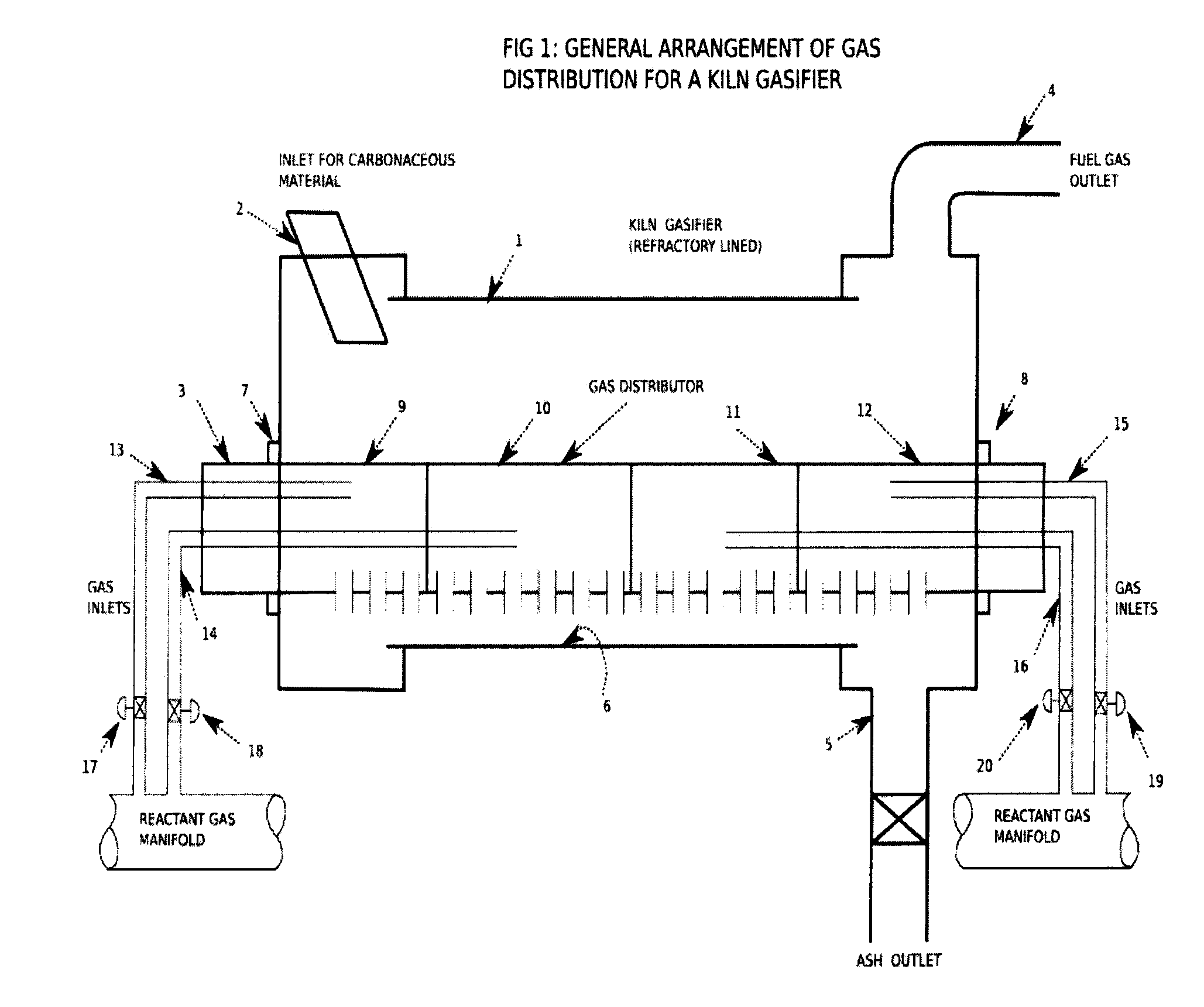

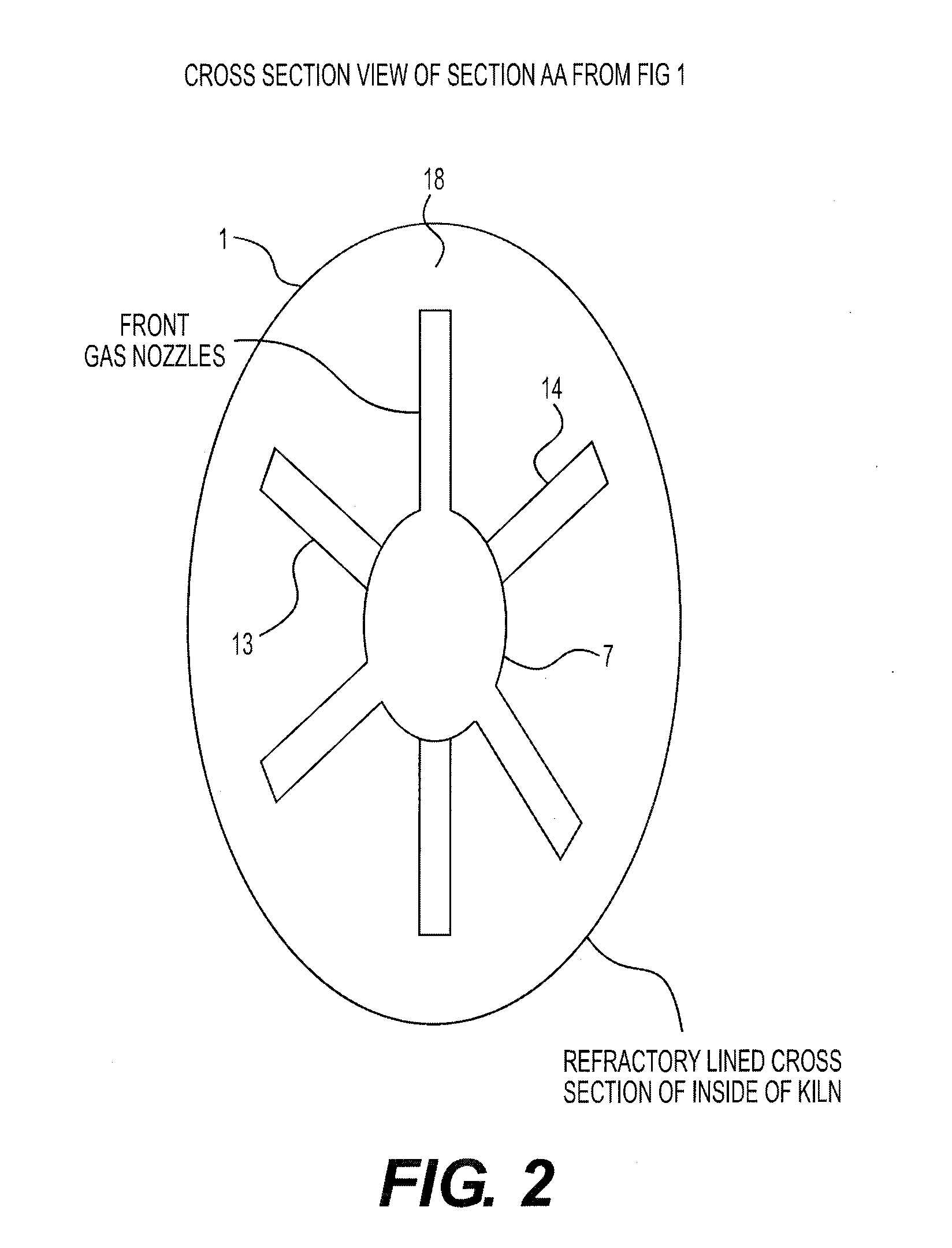

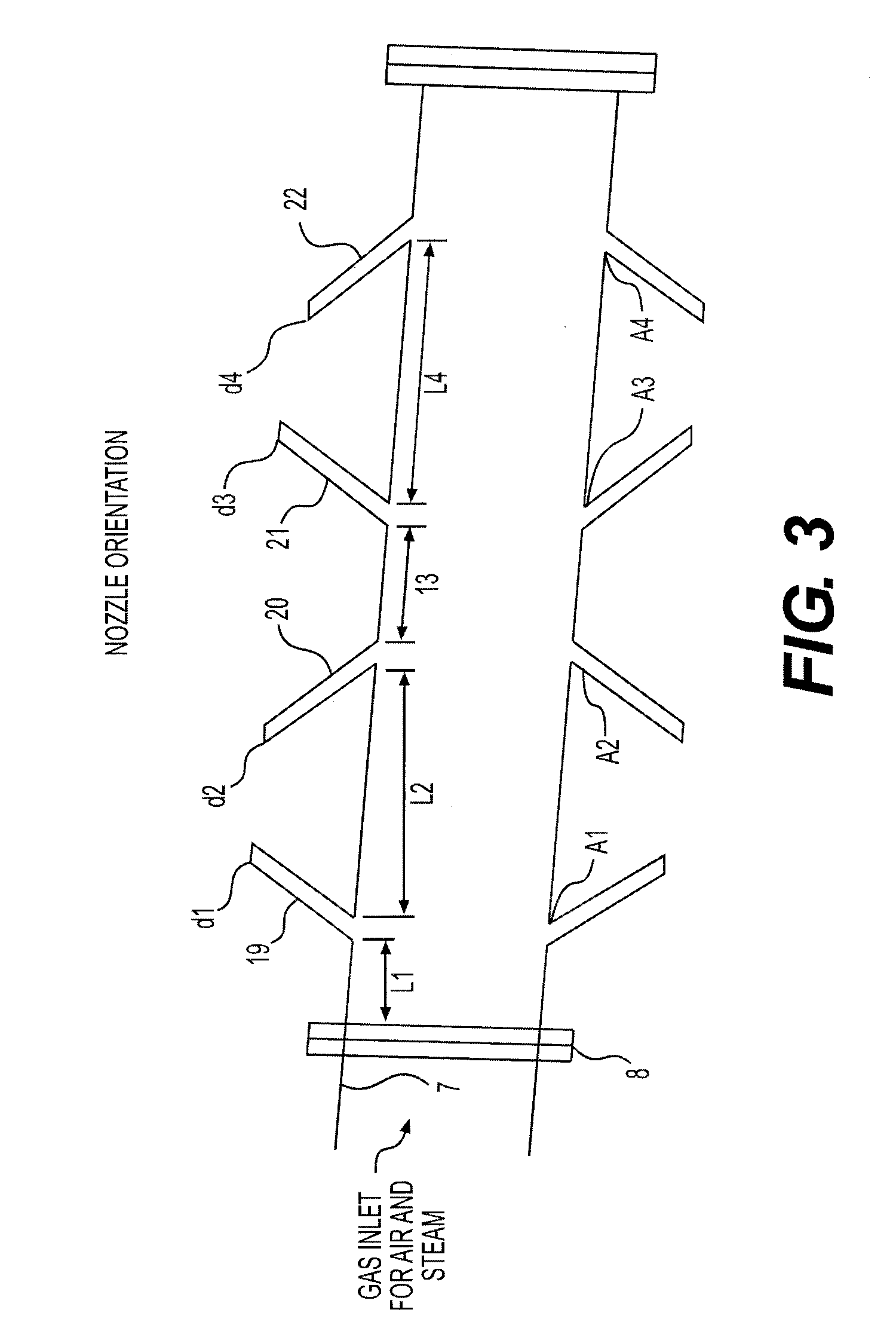

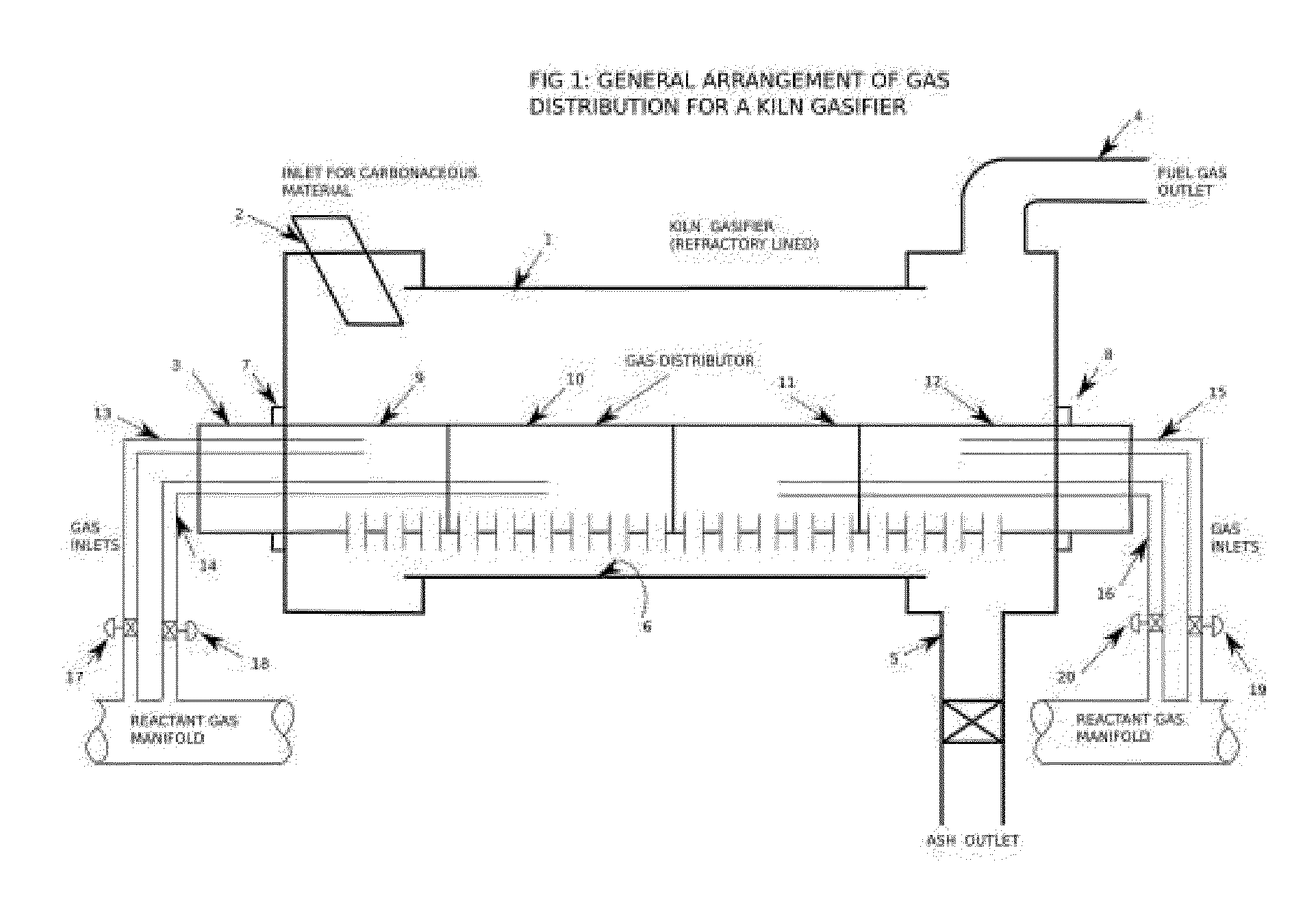

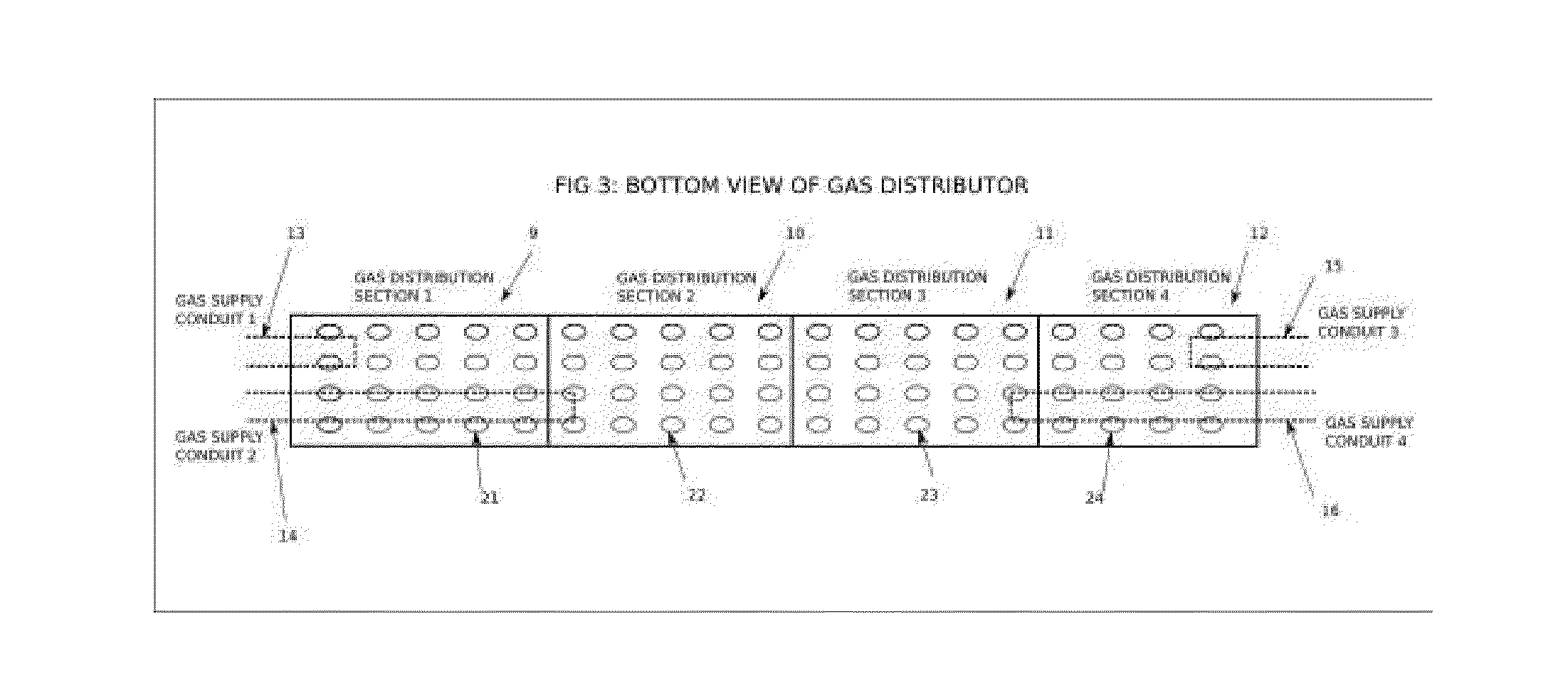

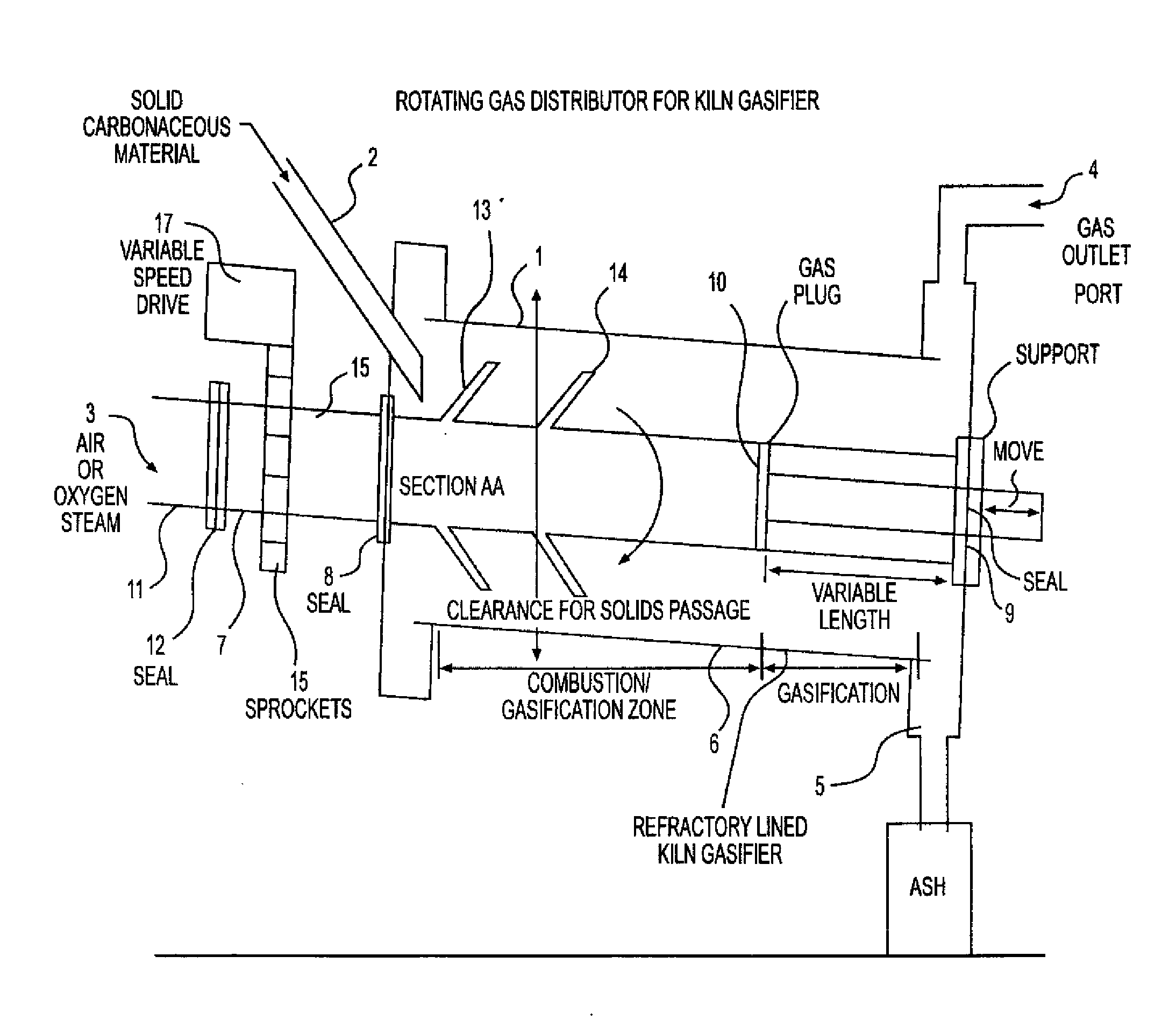

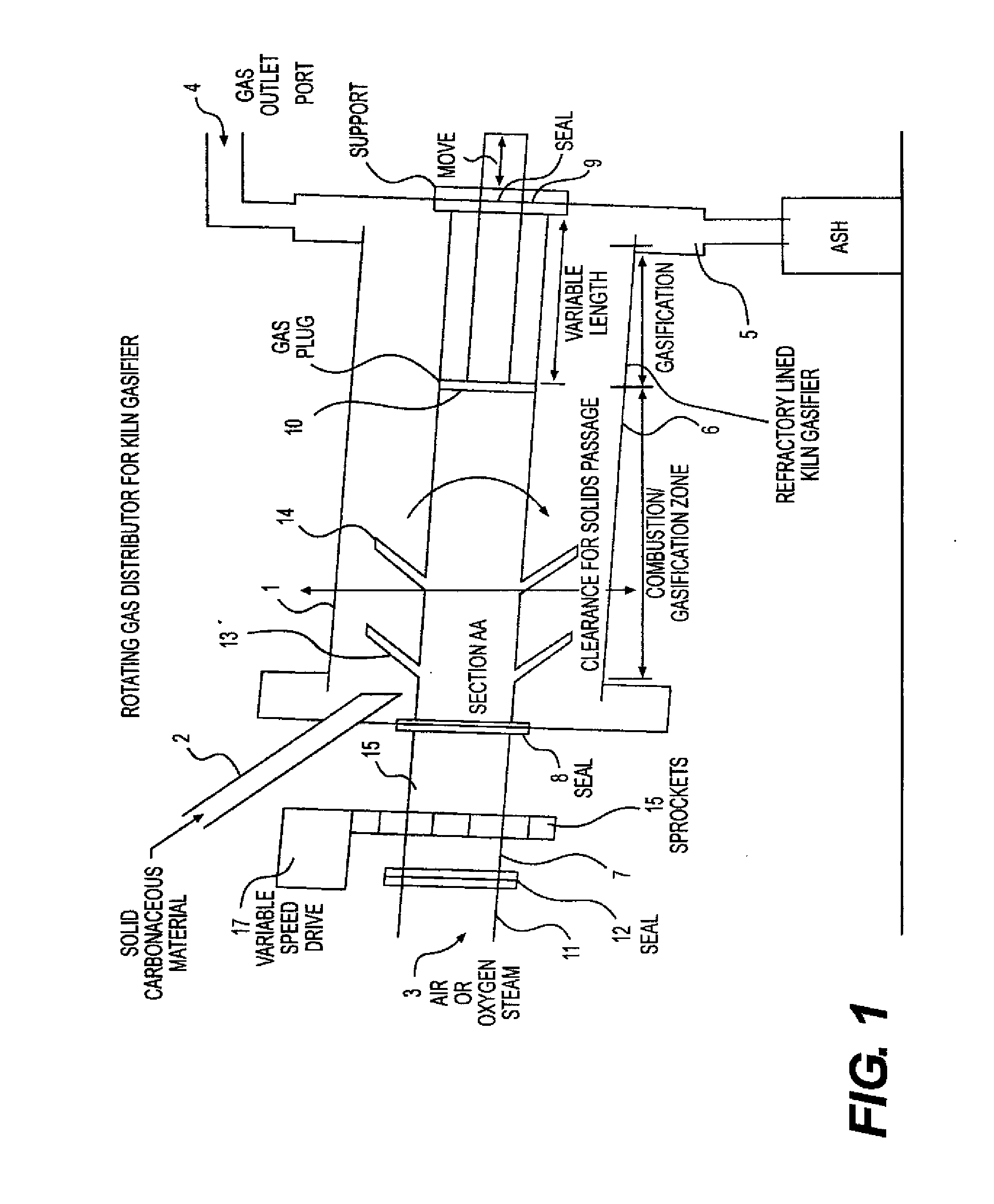

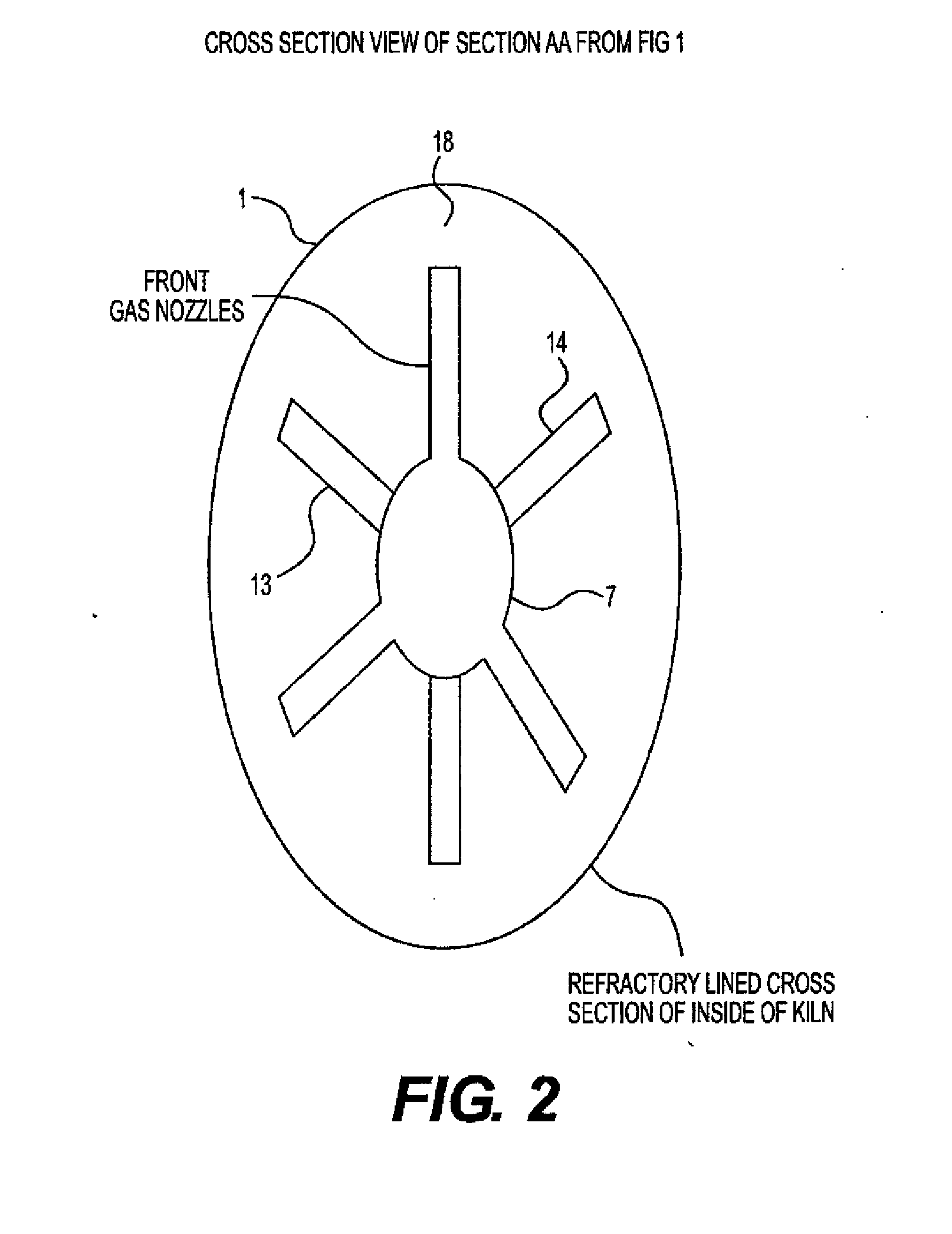

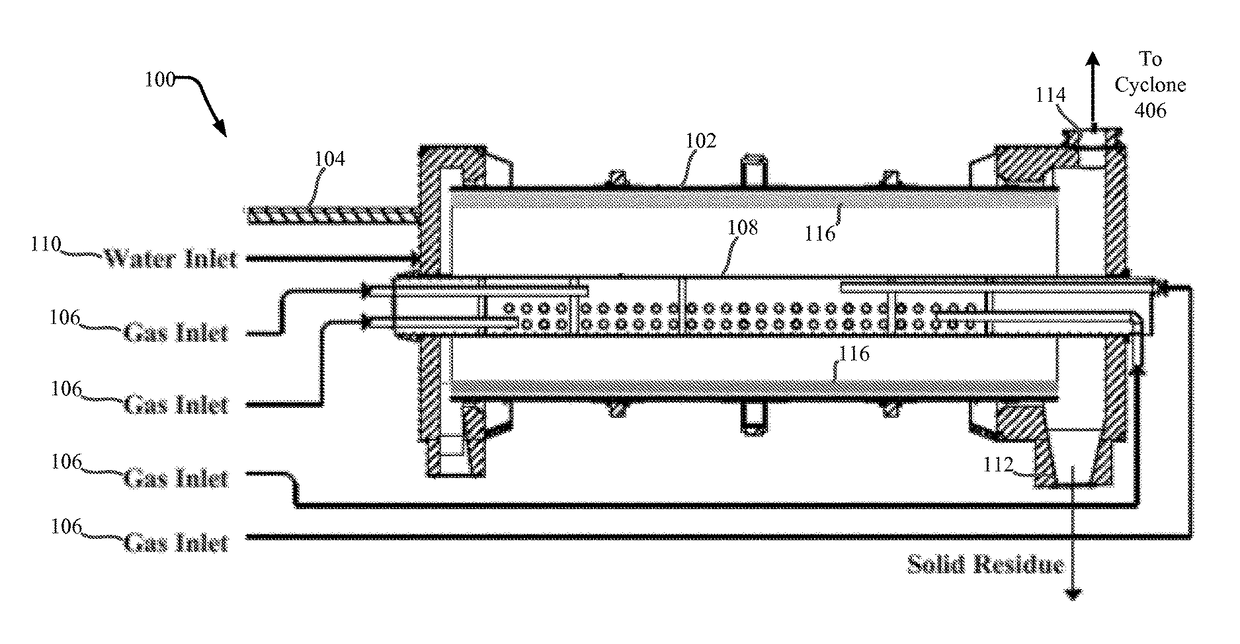

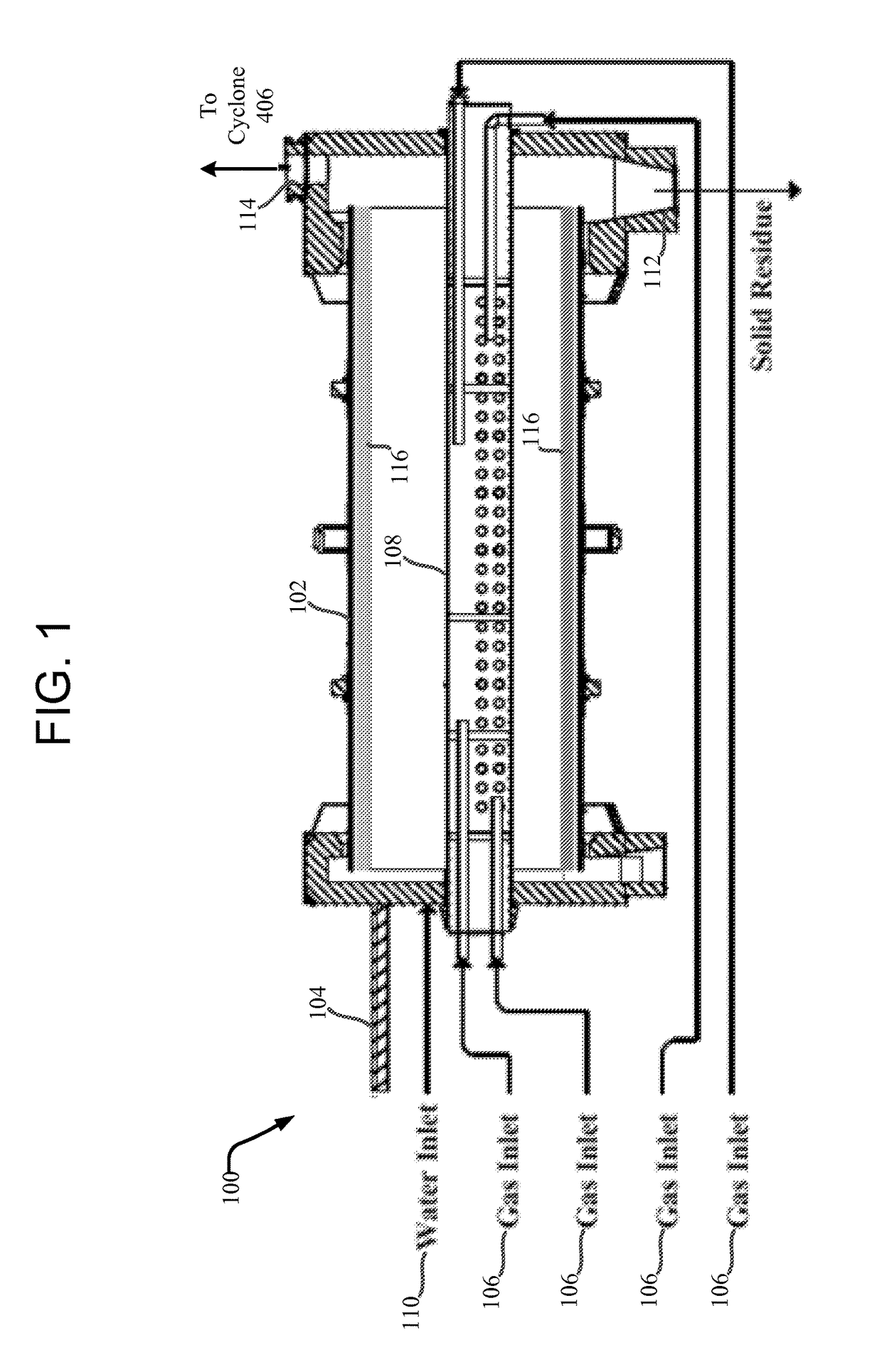

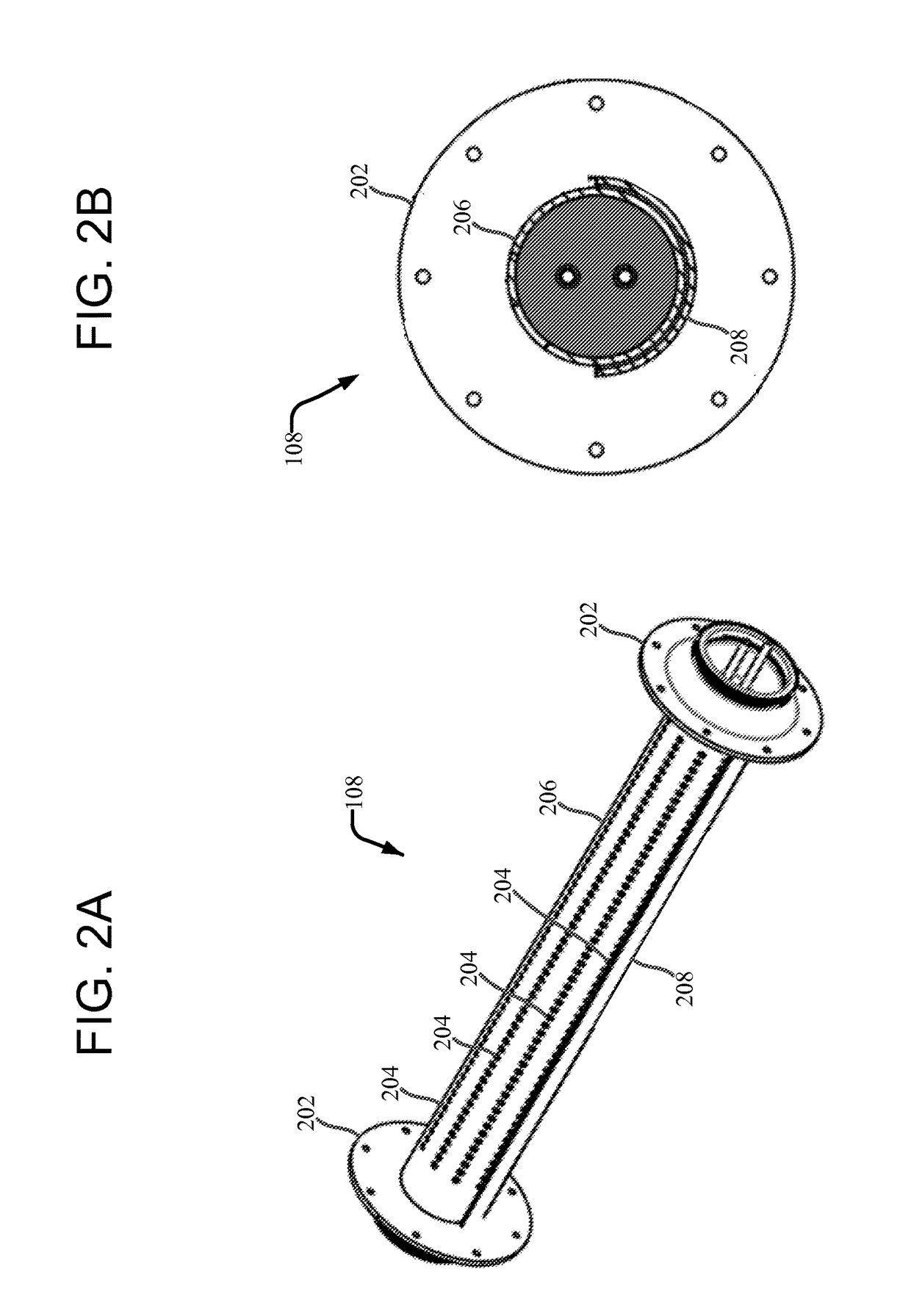

Gas distribution arrangement for a rotary reactor

InactiveUS20090277090A1Prevent escapeWell mixedHydrogenHydrocarbon from carbon oxidesProduct gasGuide tube

A port assembly for controlling the delivery of gases into the horizontal rotating reactor such as kiln gasifier is disclosed for introducing reactant gases. The port assembly comprises a cylindrical conduit is divided into noncommunicating four or more sections extending through the entire length of the kiln and supported by the stationary end plates of the rotating kiln gasifier. Each section of the conduit communicates with external supply of the reactant gases and each supply of reactant gases is independently controlled in terms of the composition and quantity. Each section of the port assembly communicates with the interior of the kiln gasifier through the plurality of nozzles are confined in the lower part of the conduit. The number and the size of the nozzles in individual section of the conduit is based on the desired flow of gases and available pressure for the supply of the reactant gases.

Owner:REHMAT AMIRALI GULAMHUSSEIN +4

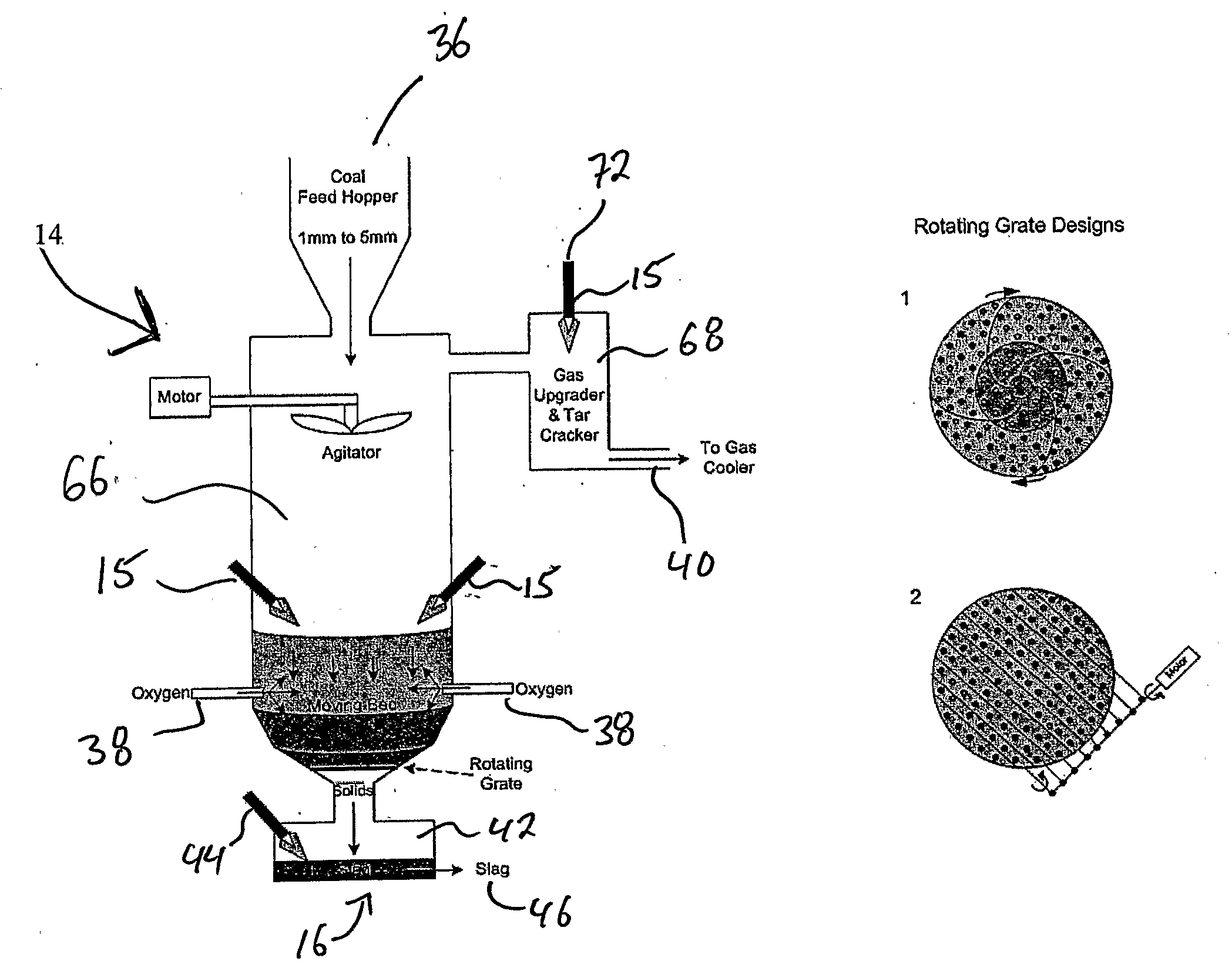

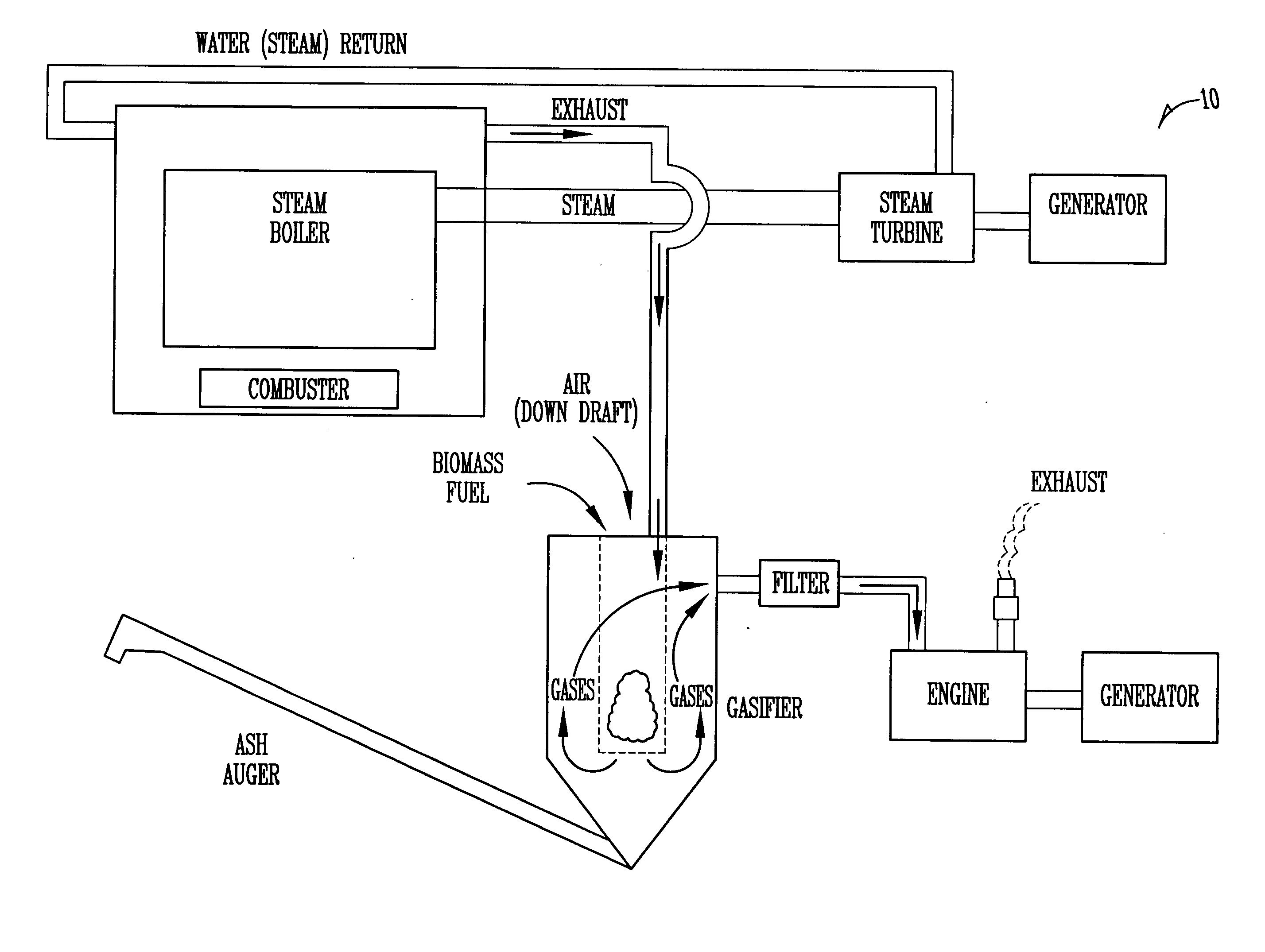

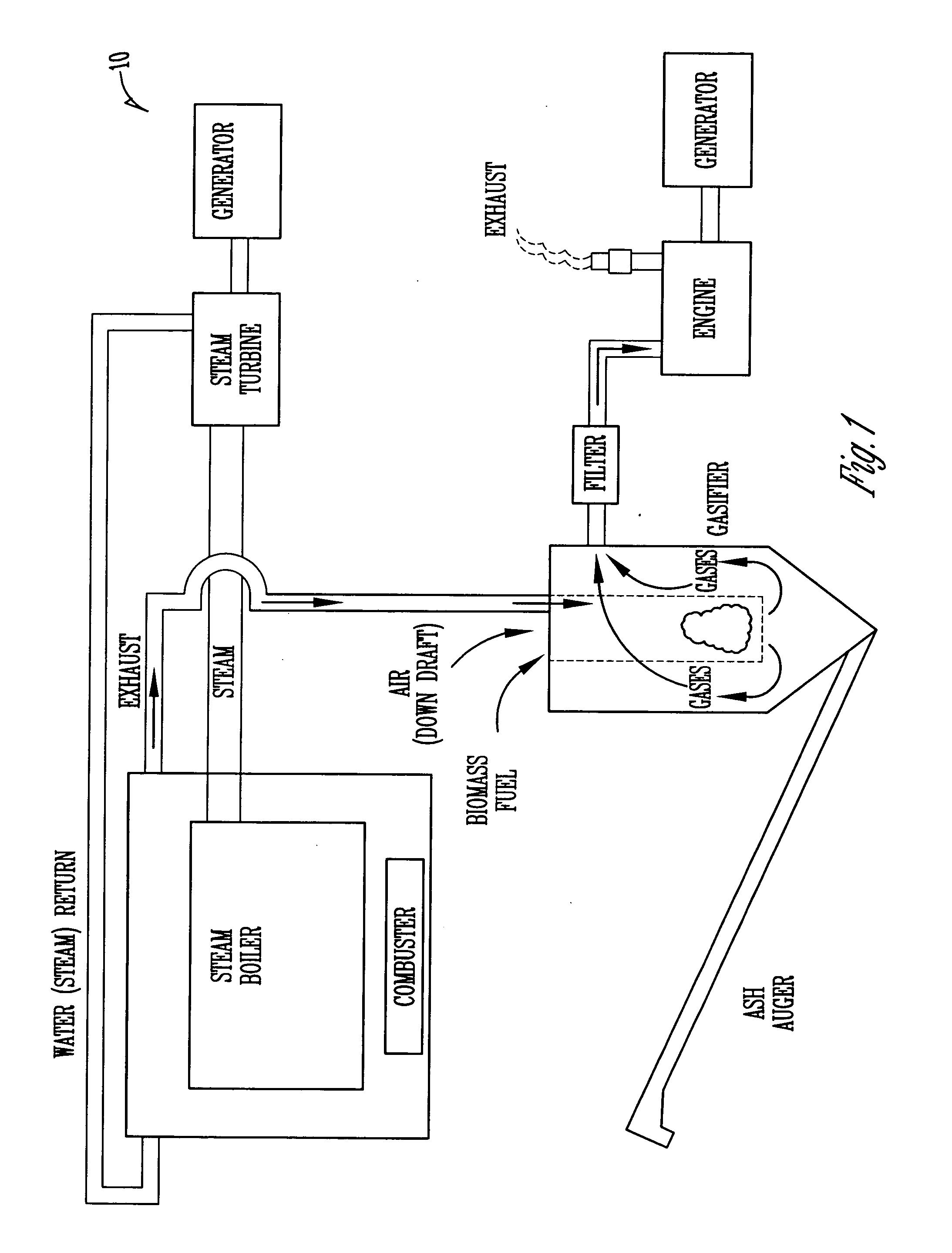

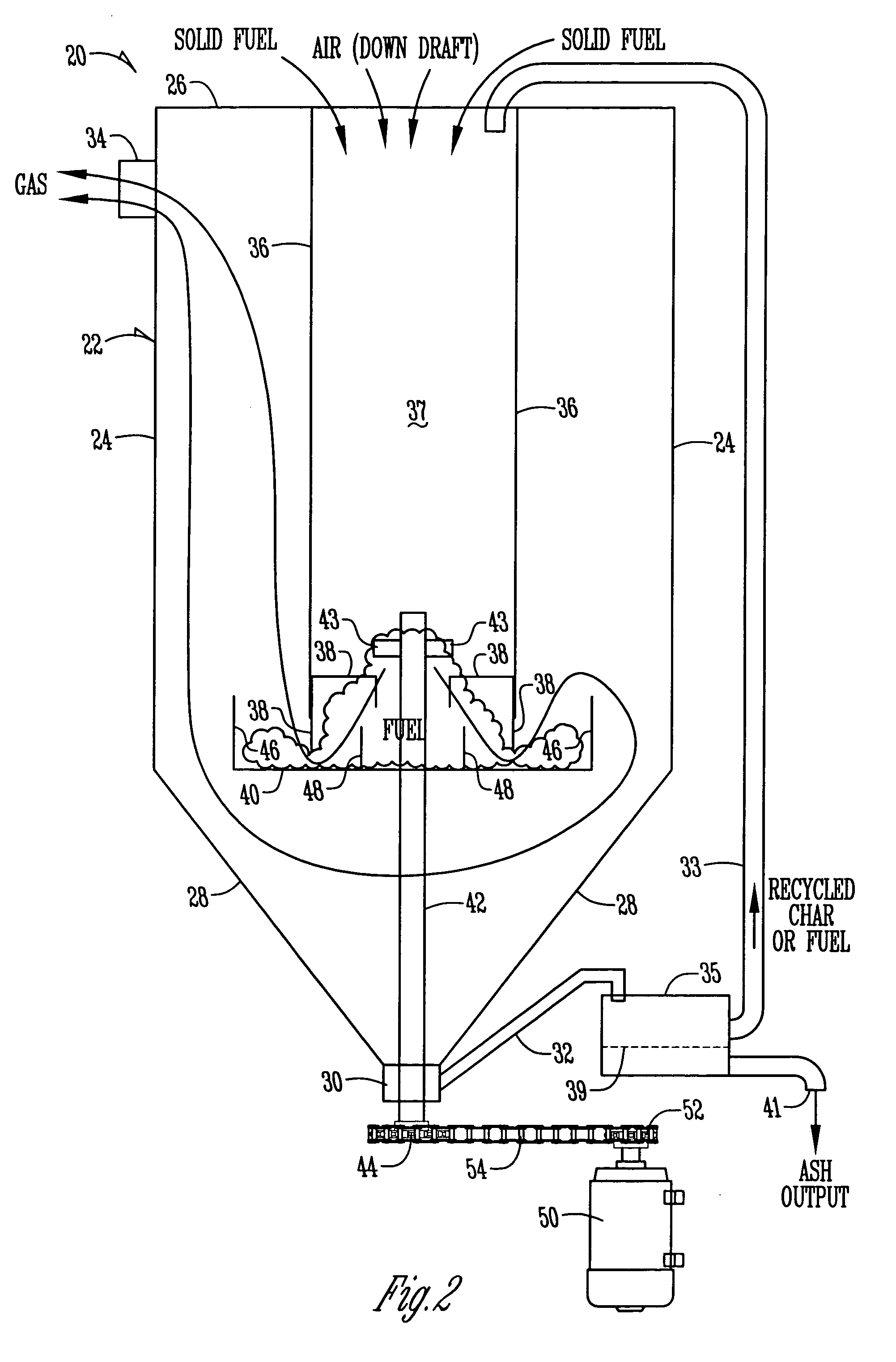

Rotating bed gasifier

InactiveUS20070169411A1Size limitImprove efficiencyGasifier mechanical detailsGasification processes detailsEngineeringMechanical engineering

The present invention includes a gasifier for gasifying fuels having a container with a top, sidewalls and a bottom for facilitating the gasifying process. One or more open vertical shafts extend downward inside the container for allowing a downdraft or updraft of air and fuel for the gasifying process. A rotating bed is preferably included inside the container and below the one or more shafts for receiving the fuel. The bed rotates essentially perpendicular to the shaft to facilitate even heating and gasifying of the fuel.

Owner:THIESSEN RANDALL J +1

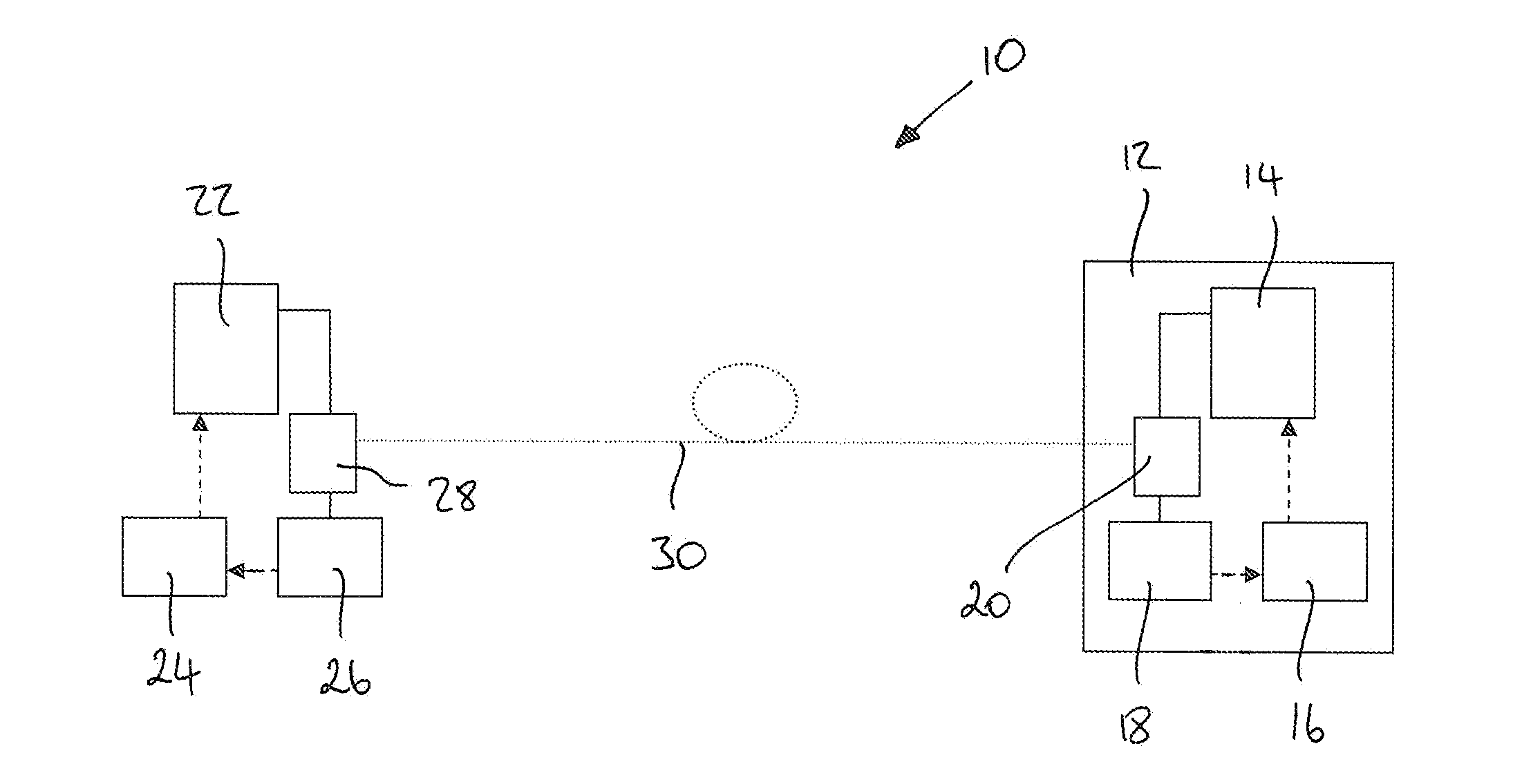

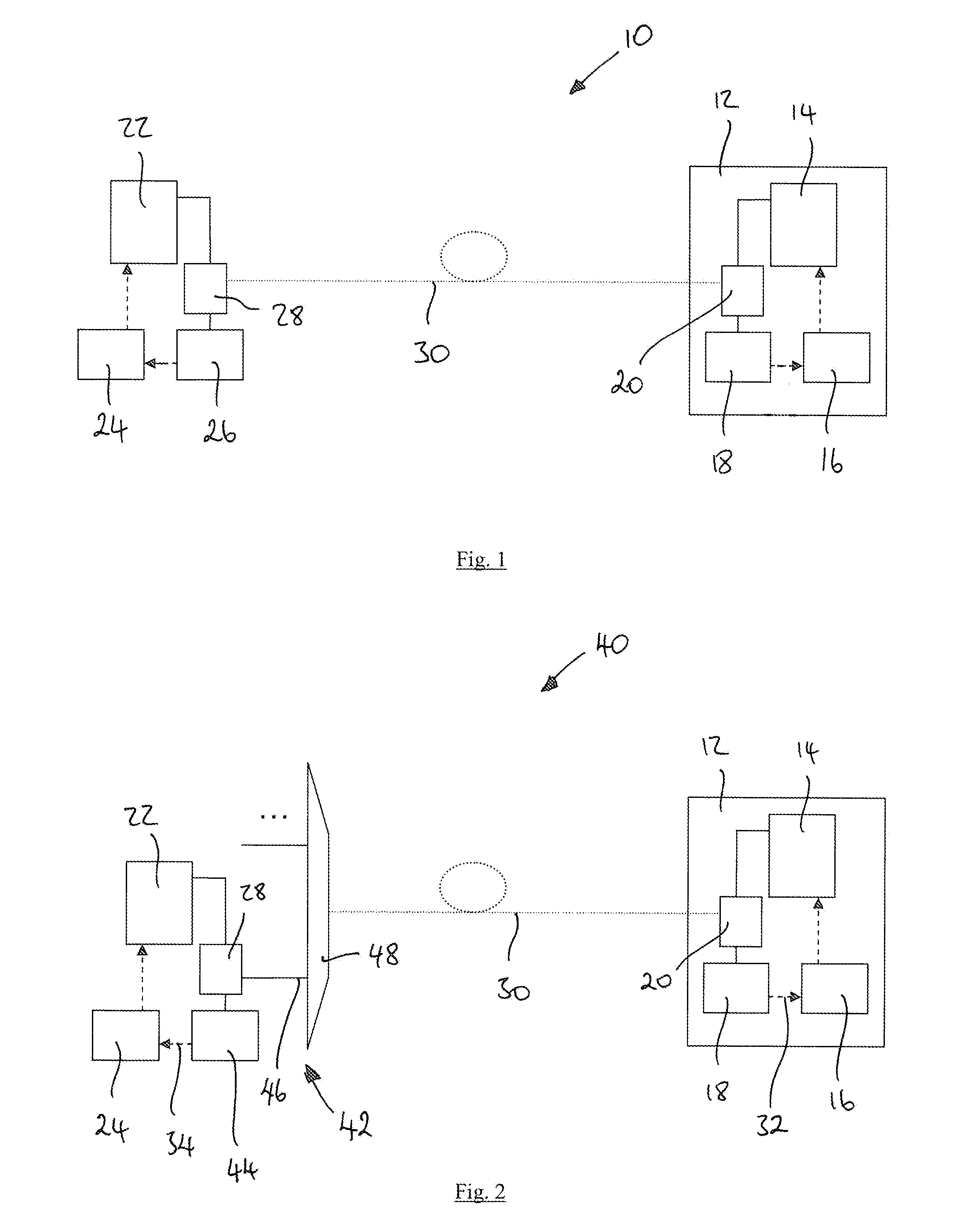

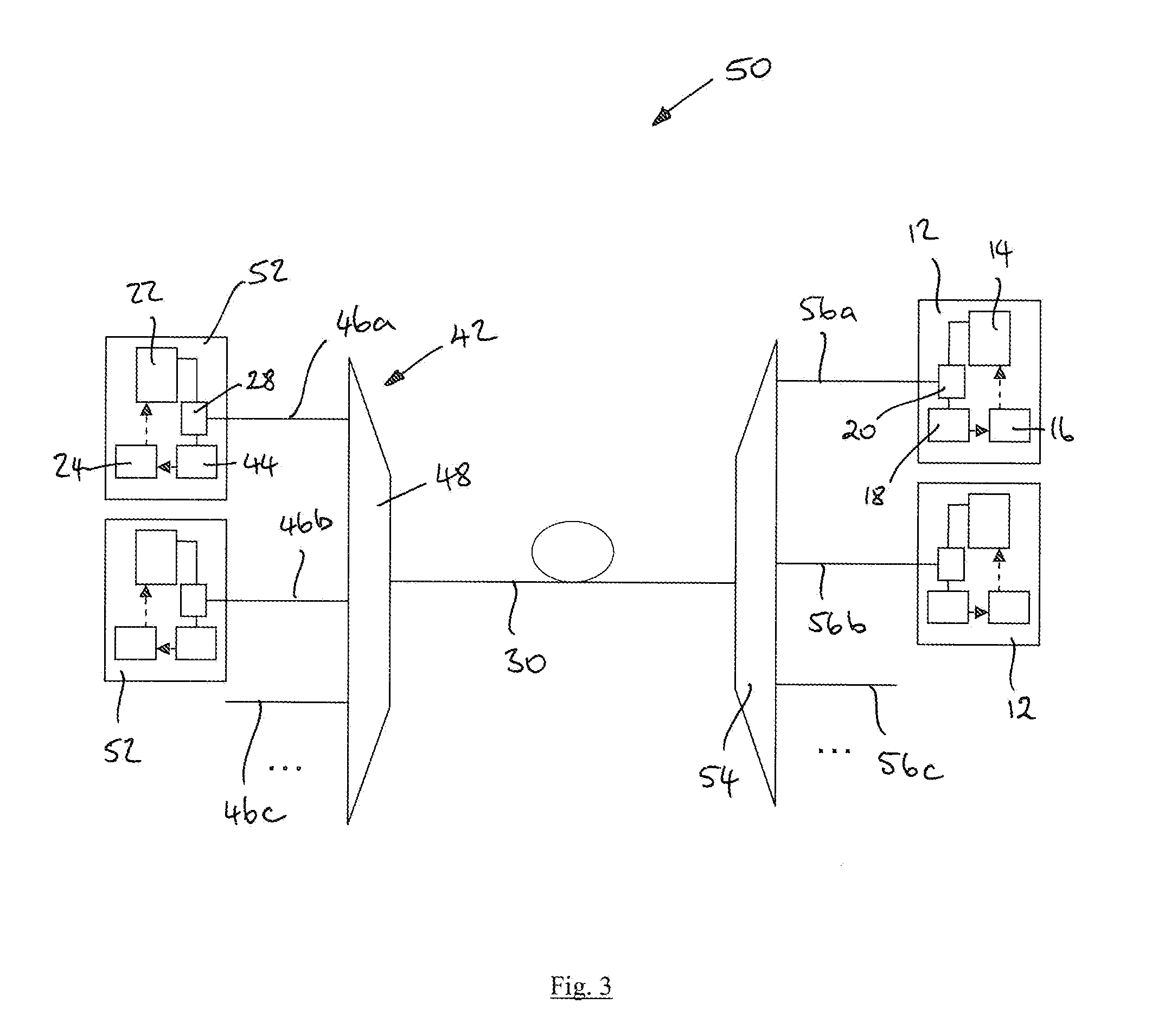

Optical networks

ActiveUS20120224850A1Control power consumptionRotary drum/kiln gasifiersCalcinationLength waveOptical transmitter

An optical network (10) comprising an optical network element (12) comprising a first optical transmitter (14), a first controller (16), an optical receiver (18), a second optical transmitter (22), a second controller (24) and optical receiver apparatus (26). Said first controller is arranged to control said first optical transmitter to generate and transmit a first optical signal in response no second optical signal being detected. Said first controller is arranged to iteratively generate and transmit said first optical signal at different wavelengths of a plurality of wavelengths until said second optical signal is detected, and is further arranged to subsequently maintain generation and transmission of said first optical signal at said wavelength at which said second optical signal is detected. Said second controller is arranged to control said second optical transmitter to generate and transmit said second optical signal following detection of said first optical signal by said optical receiver apparatus.

Owner:TELEFON AB LM ERICSSON (PUBL)

System For The Conversion Of Carbonaceous Feedstocks To A Gas Of A Specified Composition

The present invention provides a carbonaceous feedstock gasification system with integrated control subsystem. The system generally comprises, in various combinations, a gasification reactor vessel (or converter) having one or more processing zones and one or more plasma heat sources, a solid residue handling subsystem, a gas quality conditioning subsystem, as well as an integrated control subsystem for managing the overall energetics of the conversion of the carbonaceous feedstock to energy, as well as maintaining all aspects of the gasification processes at an optimal set point. The gasification system may also optionally comprise a heat recovery subsystem and / or a product gas regulating subsystem.

Owner:PLASCO ENERGY GROUP INC

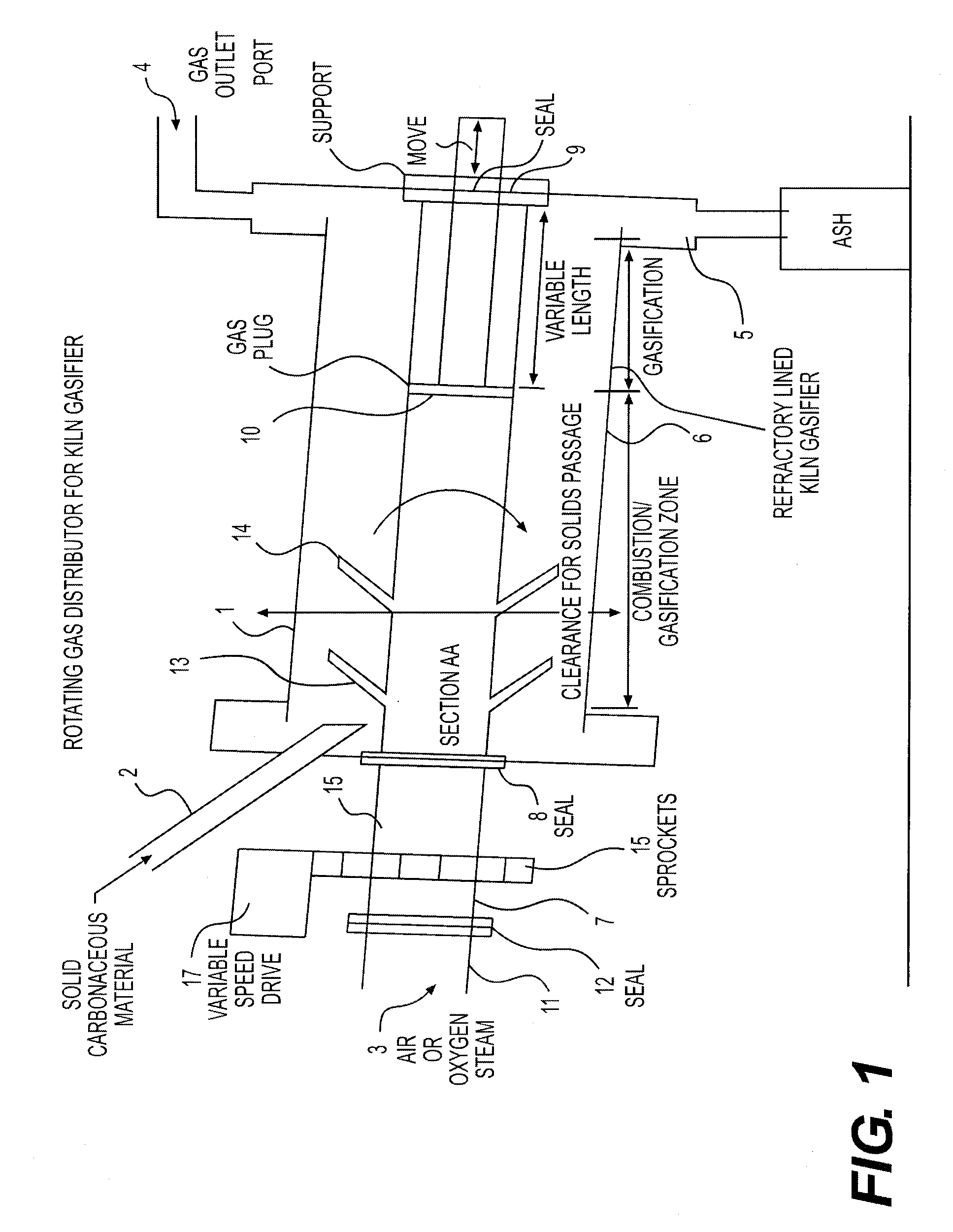

Gas distributor for a rotary kiln

InactiveUS20110116984A1Lower overall pressure dropReduce direct impactSolid waste disposalRotary drum furnacesProduct gasProcess engineering

A rotating air distributor for rotary reactors such as rotary kilns for the gasification of biomass and other carbonaceous materials for efficient mixing and maximum conversion of solid biomass and other carbonaceous materials into synthesis fuel gas is disclosed. The invention includes a gas distribution port comprises of one main supply from which several discharge nozzles emerge at different angles and at different locations along the length of the reactor to provide distribution of gas throughout the intended length of the reactor. The discharge of gas from the gas distribution port is adjusted by the variable position of a plug inside the port that can be adjusted during the operation of the kiln to achieve optimum gas-solid interaction along the length of the reactor. The rotating action of the gas distribution port also facilitates and eases the passage of reacted biomass solid and other carbonaceous material residue through the reactor.

Owner:REHMAT AMIRALI GULAMHUSSEIN +4

Process and system for converting carbonaceous feedstocks into energy without greenhouse gas emissions

ActiveUS7753973B2High hydrogen contentEasy to separateFuel cells groupingHydrogen separation using solid contactSludgeWaste oil

The process of the invention converts carbonaceous feedstock such as coal, hydrocarbon oil, natural gas, petroleum coke, oil shale, carbonaceous-containing waste oil, carbonaceous-containing medical waste, carbonaceous-containing military waste, carbonaceous-containing industrial waste, carbonaceous-containing medical waste, carbonaceous-containing sewage sludge and municipal solid waste, carbonaceous-containing agricultural waste, carbonaceous-containing biomass, biological and biochemical waste, and mixtures thereof into electrical energy without the production of unwanted greenhouse emissions. The process uses a steam / CO2 reformer operating in the exit range of at least 700° to about 1600° C. (1300-2900° F.) to convert the carbonaceous feedstock and a greenhouse gas stream into a synthesis gas comprising mostly carbon monoxide and hydrogen that contains poisons and the compounds that poison fuel cells. The syngas is sent to an interface zone to remove these poisons and other fouling compounds that are electrochemically oxidized in an electricity-producing fuel cell into an exit gas comprising carbon dioxide and water.

Owner:RAVEN SR INC

Gas distribution arrangement for rotary reactor

InactiveUS20140202079A1Prevent escapeFacilitate intimate mixingHydrogenMuffle furnacesSpray nozzleEngineering

A port assembly for controlling the delivery of gases into the horizontal rotating reactor such as kiln gasifier is disclosed for introducing reactant gases. The port assembly comprises a cylindrical conduit is divided into noncommunicating four or more sections extending through the entire length of the kiln and supported by the stationary end plates of the rotating kiln gasifier. Each section of the conduit communicates with external supply of the reactant gases and each supply of reactant gases is independently controlled in terms of the composition and quantity. Each section of the port assembly communicates with the interior of the kiln gasifier through the plurality of nozzles are confined in the lower part of the conduit. The number and the size of the nozzles in individual section of the conduit is based on the desired flow of gases and available pressure for the supply of the reactant gases.

Owner:SIMPLE APPROACH SYST

Catalyst for reforming tar-containing gas, method for preparing catalyst for reforming tar containing gas, method for reforming tar-containing gas using catalyst for reforming tar-containing gas, and method for regenerating catalyst for reforming tar-containing gas

ActiveUS20120058030A1Highly efficiently and stably convertedHigh tar-containing gas reformation activityMaterial nanotechnologyUsing liquid separation agentCeriumTar

Owner:NIPPON STEEL CORP

Gas distributor for a rotary kiln

ActiveUS20130119315A1Well mixedLower overall pressure dropSolid waste disposalRotary drum furnacesThermodynamicsProcess engineering

A rotating air distributor for rotary reactors such as rotary kilns for the gasification of biomass and other carbonaceous materials for efficient mixing and maximum conversion of solid biomass and other carbonaceous materials into synthesis fuel gas is disclosed. The invention includes a gas distribution port comprises of one main supply from which several discharge nozzles emerge at different angles and at different locations along the length of the reactor to provide distribution of gas throughout the intended length of the reactor. The discharge of gas from the gas distribution port is adjusted by the variable position of a plug inside the port that can be adjusted during the operation of the kiln to achieve optimum gas-solid interaction along the length of the reactor. The rotating action of the gas distribution port also facilitates and eases the passage of reacted biomass solid and other carbonaceous material residue through the reactor.

Owner:SIMPLE APPROACH SYST

System for the conversion of coal to a gas of specified composition

The present invention provides a coal gasification system with an integrated control subsystem. The system generally comprises, in various combinations, a gasification reactor vessel (or converter) having one or more processing zones and one or more plasma heat sources, a solid residue handling subsystem, a gas quality conditioning subsystem, as well as an integrated control subsystem for managing the overall energetics of the conversion of coal to energy and maintaining all aspects of the gasification processes at an optimal set point The gasification system may also optionally comprise a heat recovery subsystem and / or a product gas regulating subsystem.

Owner:PLASCOENERGY IP HLDG SL

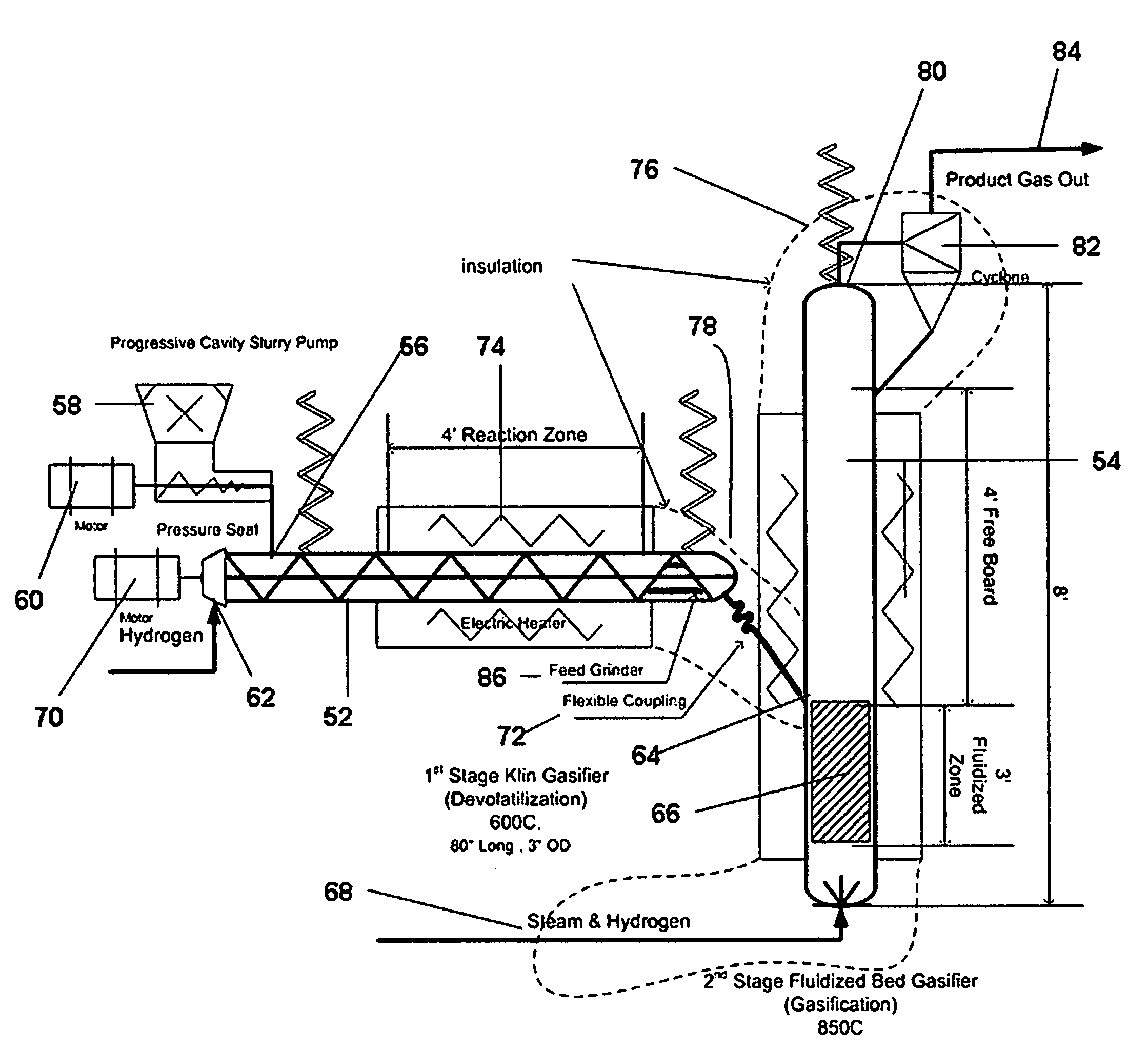

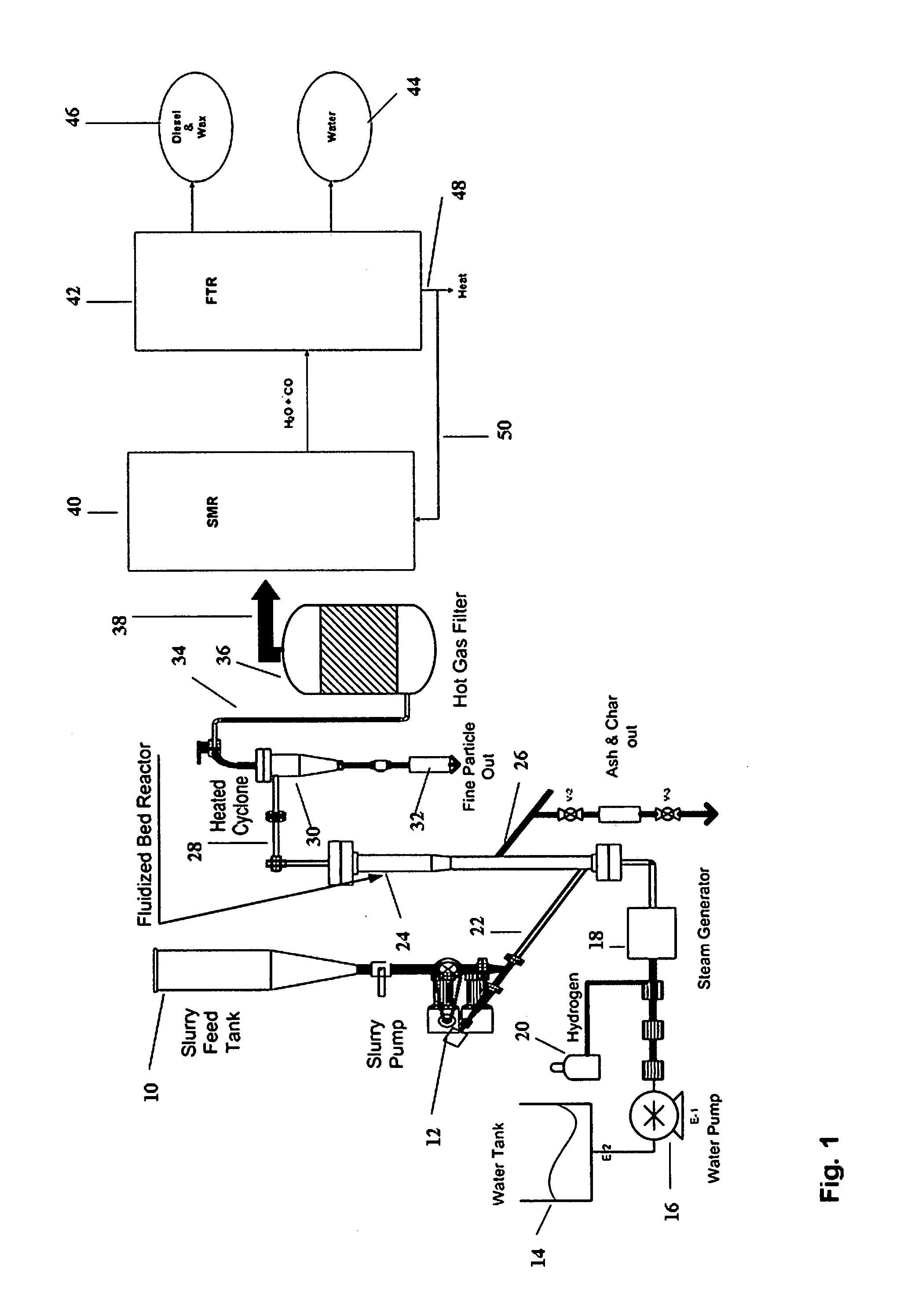

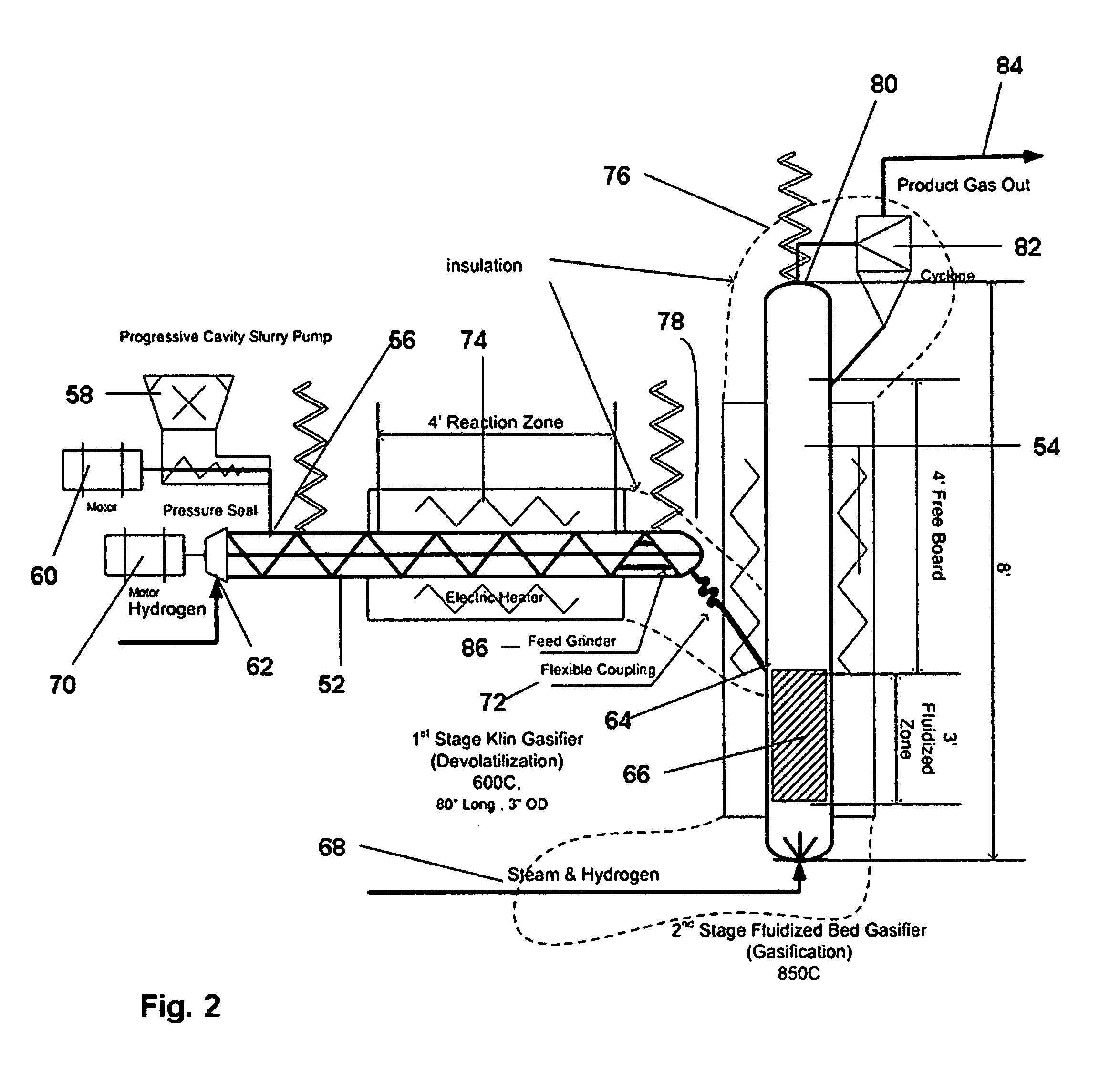

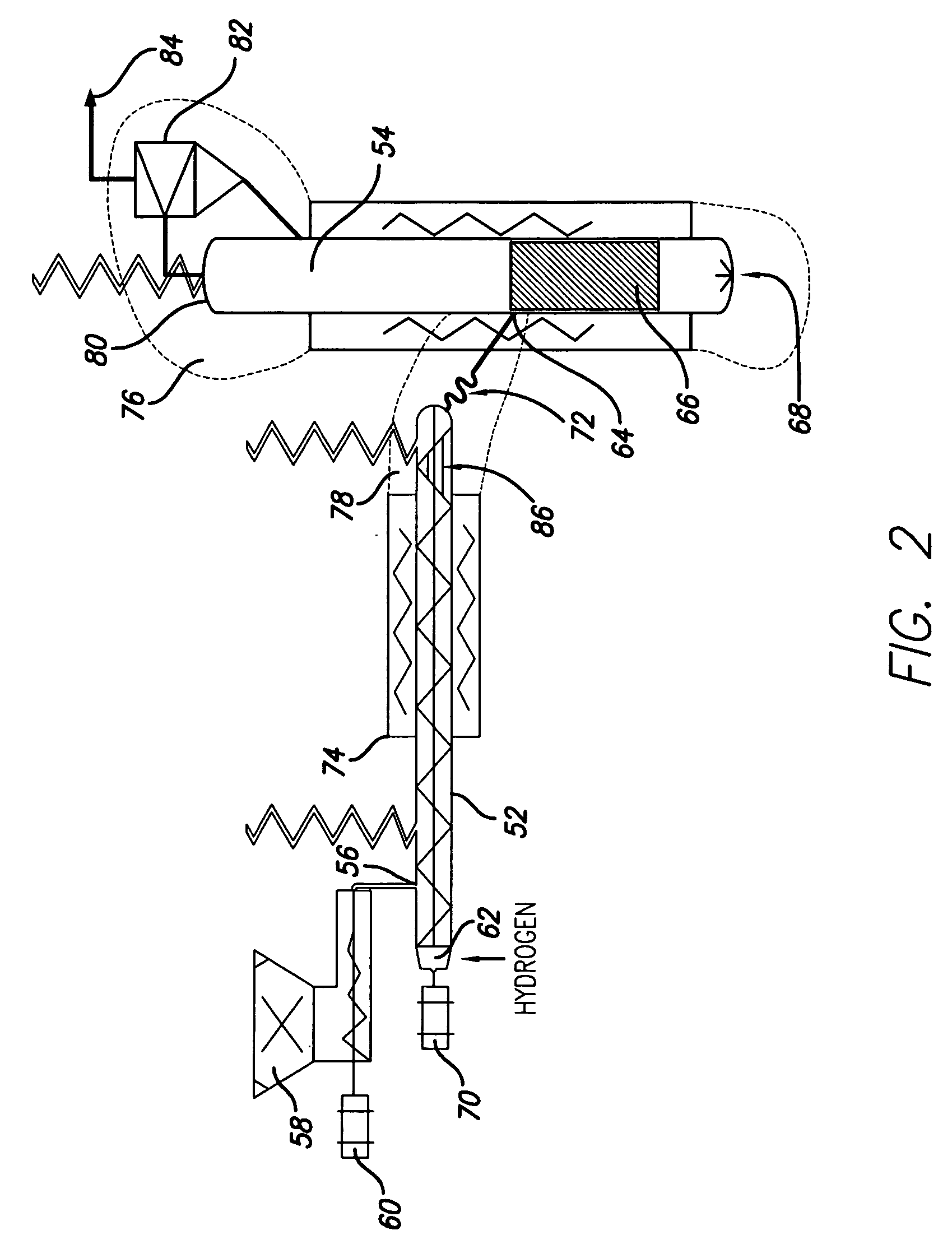

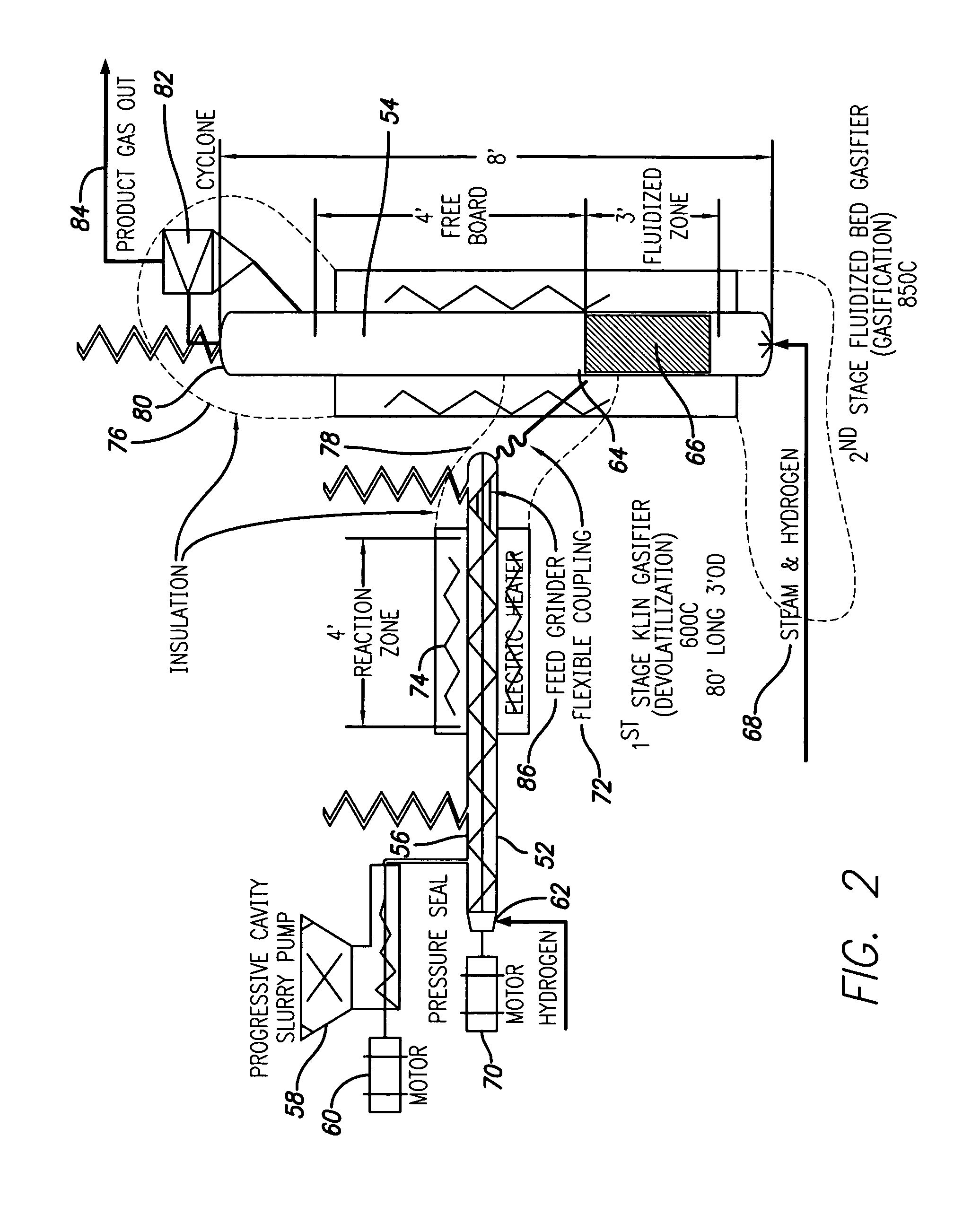

Method and apparatus for steam hydro-gasification with increased conversion times

ActiveUS20080312348A1Increase conversion timeImproved and economicalLiquid hydrocarbon mixture productionRotary drum/kiln gasifiersHydrogenFluidized bed

A method and apparatus for converting carbonaceous material to a stream of carbon rich gas, comprising heating a slurry feed containing the carbonaceous material in a hydrogasification process using hydrogen and steam, at a temperature and pressure sufficient to generate a methane and carbon monoxide rich stream in which the conversion time in the process is between 5 and 45 seconds. In particular embodiments, the slurry feed containing the carbonaceous material is fed, along with hydrogen, to a kiln type reactor before being fed to the fluidized bed reactor. Apparatus is provided comprising a kiln type reactor, a slurry pump connected to an input of the kiln type reactor, means for connecting a source of hydrogen to an input of the kiln type reactor; a fluidized bed reactor connected to receive output of the kiln type reactor for processing at a fluidizing zone, and a source of steam and a source of hydrogen connected to the fluidized bed reactor below the fluidizing zone. Optionally, a grinder can be provided in the kiln type reactor.

Owner:RGT UNIV OF CALIFORNIA

Method and apparatus for steam hydro-gasification in a fluidized bed reactor

InactiveUS7619012B2Well mixedImproved and economicalCombustible gas chemical modificationHydrogenHydrogenFluidized bed

Owner:RGT UNIV OF CALIFORNIA

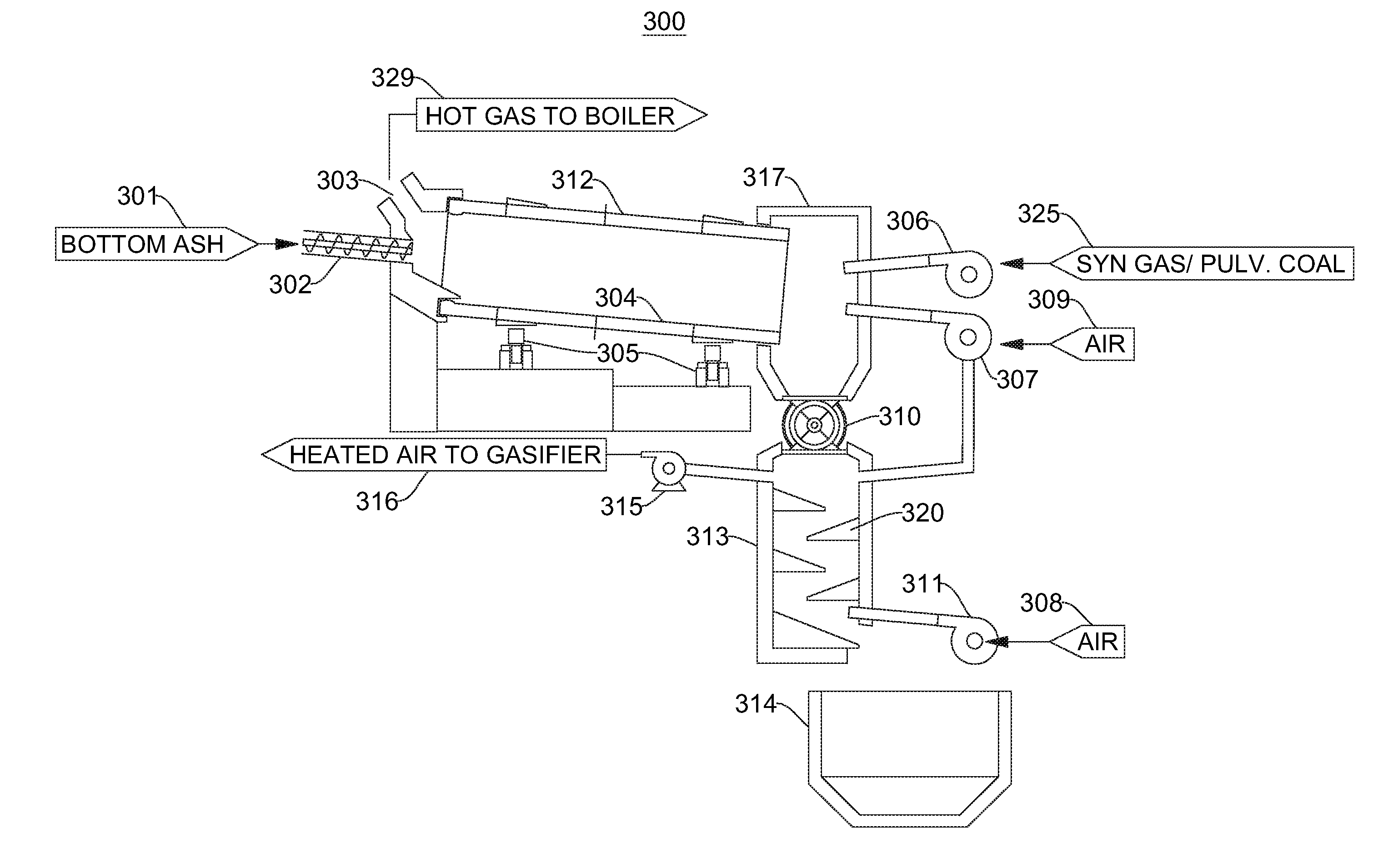

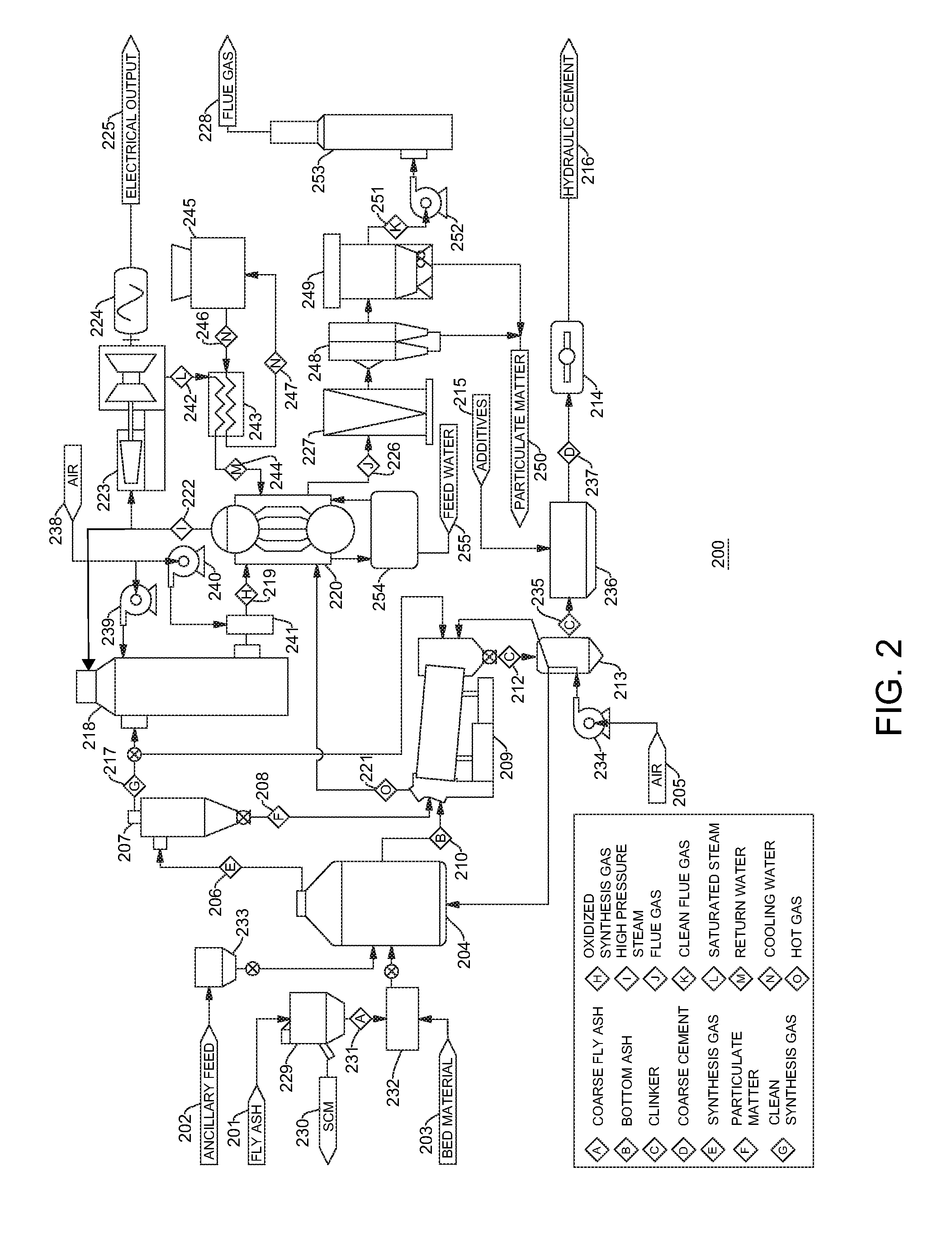

System for reprocessing carbonaceous waste materials to produce energy and carbon-free materials

InactiveUS20160194567A1Improve early compressive strengthHigh strengthEnergy inputGasification processes detailsRefuse-derived fuelThermal energy

The invention provides an apparatus that thermally processes solid waste such as municipal solid waste to generate heat for production of steam that is employed to generate electrical power. The apparatus provides clean efficient gasification of refuse derived fuel to minimize air pollutants such as nitrogen oxides and uses released thermal energy to produce steam for electricity. Carbon in the solid waste is converted to synthesis gas or syngas that is combusted to generate steam or electricity. The apparatus recovers energy from residual carbon that is normally rejected by air fed gasifiers and partially recycles the flue gas to control combustion temperature and oxygen content in the fuel gas burner. The apparatus extends boiler service life by reducing the temperature of hot gases entering the boiler and produces clean electrical energy from materials that otherwise would be discarded as environmentally damaging waste.

Owner:MOBIL TENSOR HLDG LLC

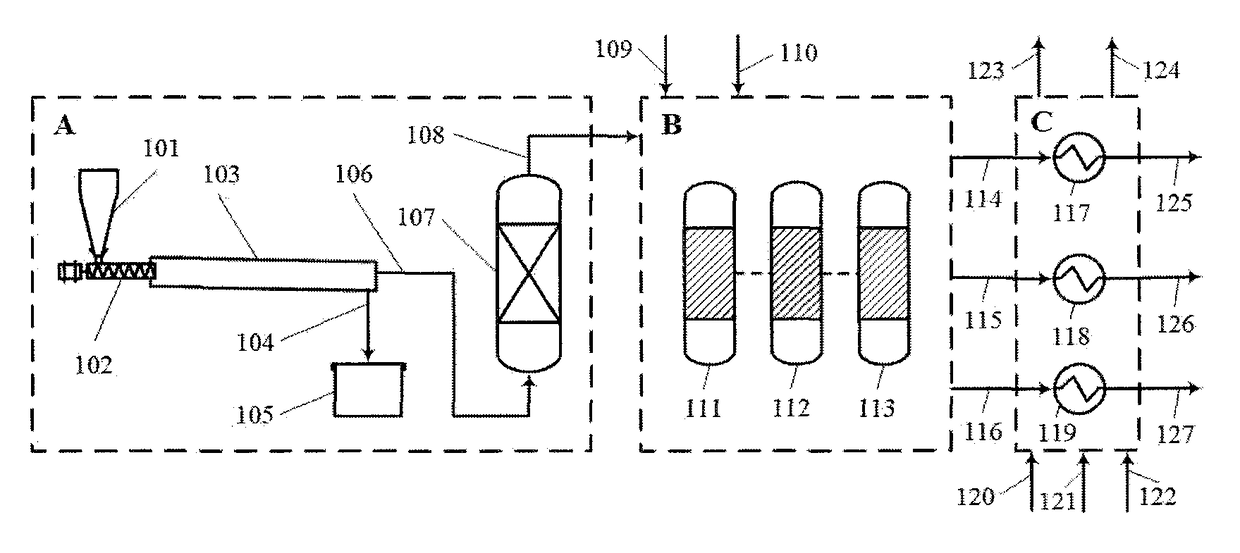

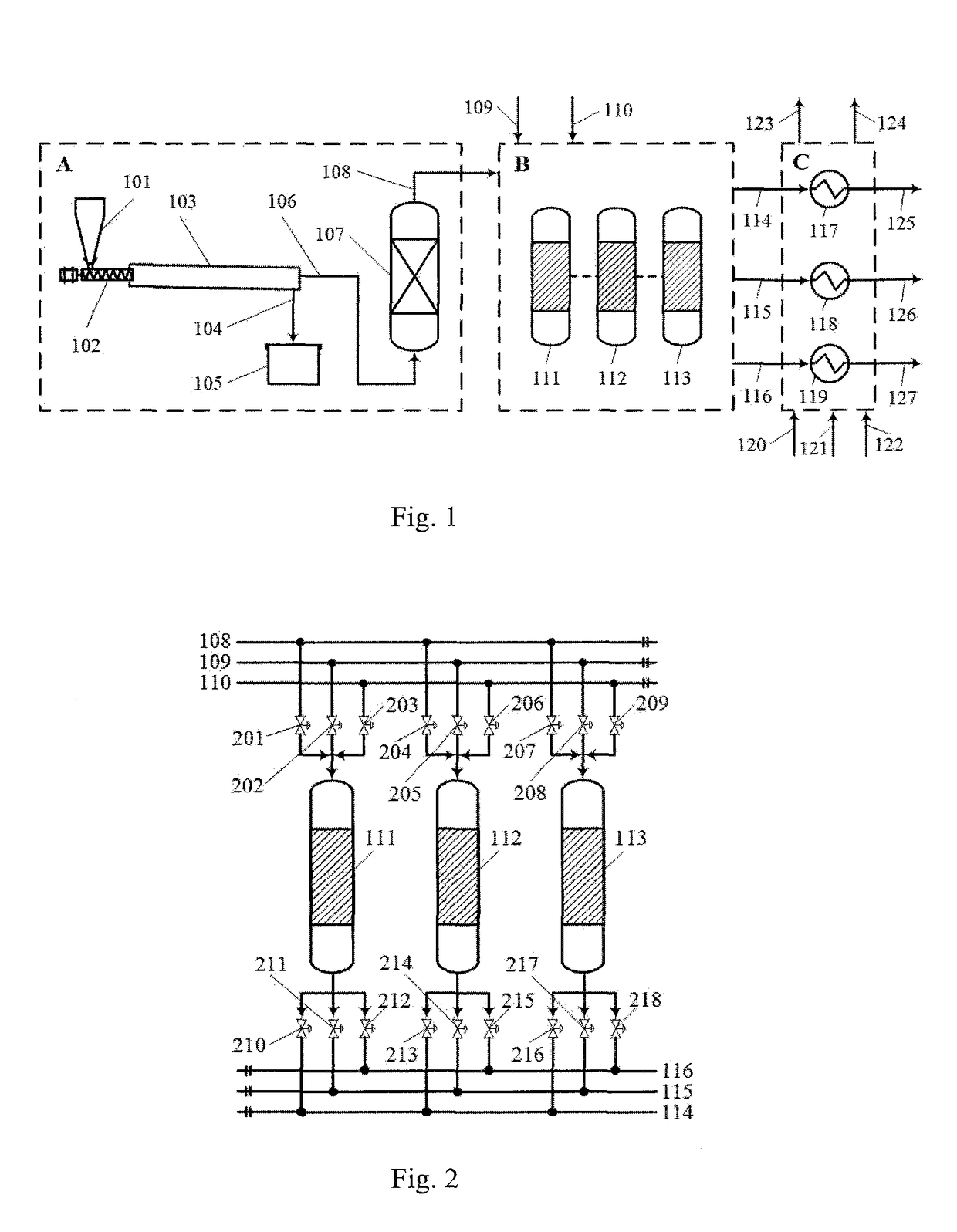

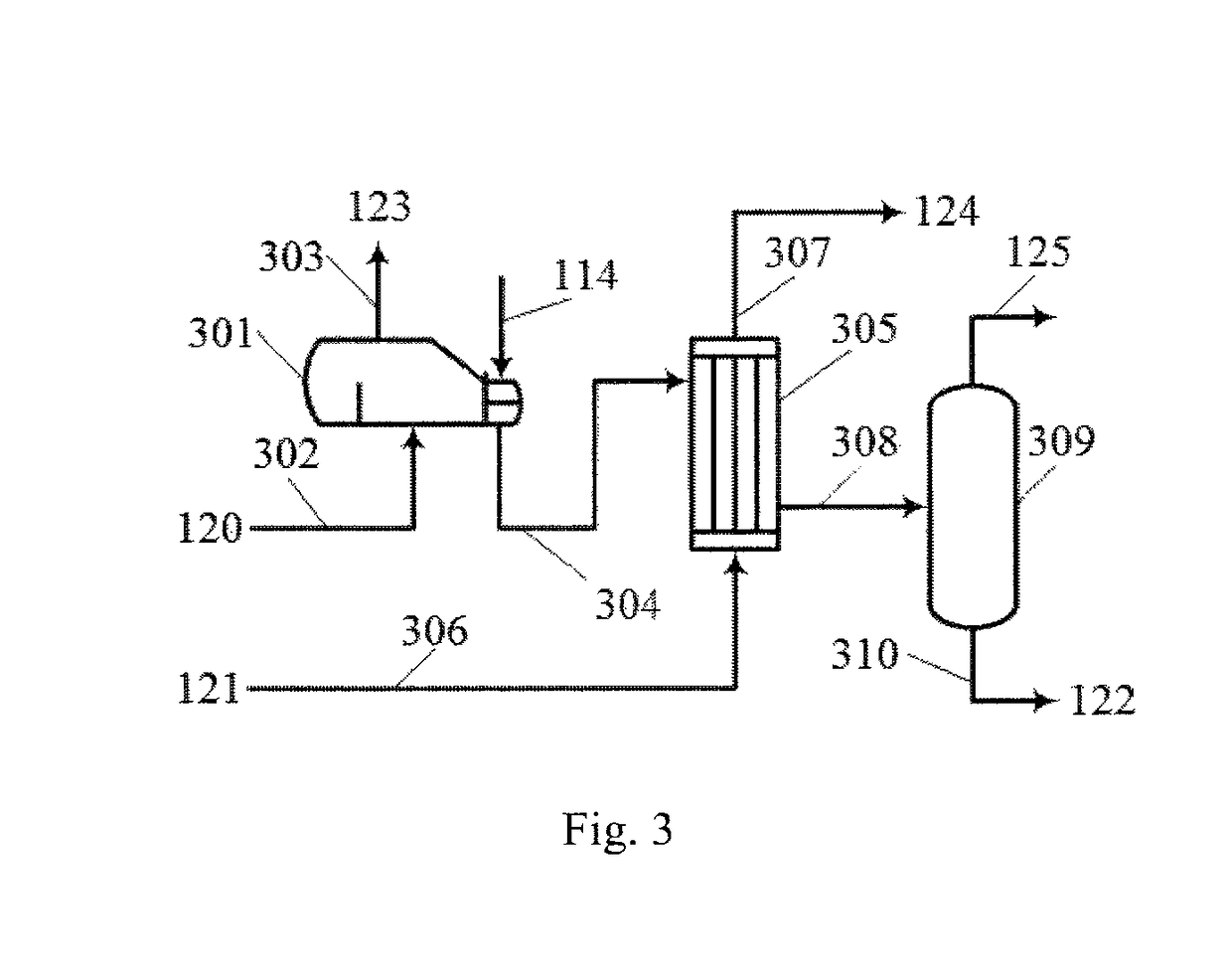

Device and method for generating high-purity hydrogen by biomass pyrolysis-chemical looping combustion

ActiveUS20180002174A1Simple condensationSimple water removalHydrogenBiofuelsWaste heat recovery unitVapor–liquid separator

The present invention discloses a device and method for generating high-purity hydrogen by biomass pyrolysis-chemical looping combustion. The device comprises a biomass pyrolysis unit, a chemical looping hydrogen generation unit and a waste heat recovery unit; the biomass pyrolysis unit comprises a vertical bin, a screw feeder, a rotary kiln pyrolysis reactor and a high temperature filter; the chemical looping hydrogen generation unit comprises a path switching system of intake gas end, at least one packed bed reactor and a path switching system of tail gas end, wherein the packed bed reactor is composed of three parallel packed bed reactors I, II and III, which are continuously subjected to fuel reduction-steam oxidation-air combustion stages (steam purging stage) successively; the waste heat recovery unit comprises a waste heat boiler, a cooler and a gas-liquid separator. According to the present invention, a process flow of generating hydrogen from biomass is short, high-purity hydrogen can be obtained by simple condensation and water removal of a hydrogen-containing product that is generated after entrance of a pyrolysis gas into the chemical looping hydrogen generation unit, no complex gas purification device is employed, and the costs for hydrogen generation are low.

Owner:HYLOOP TECH (BEIJING) CO LTD

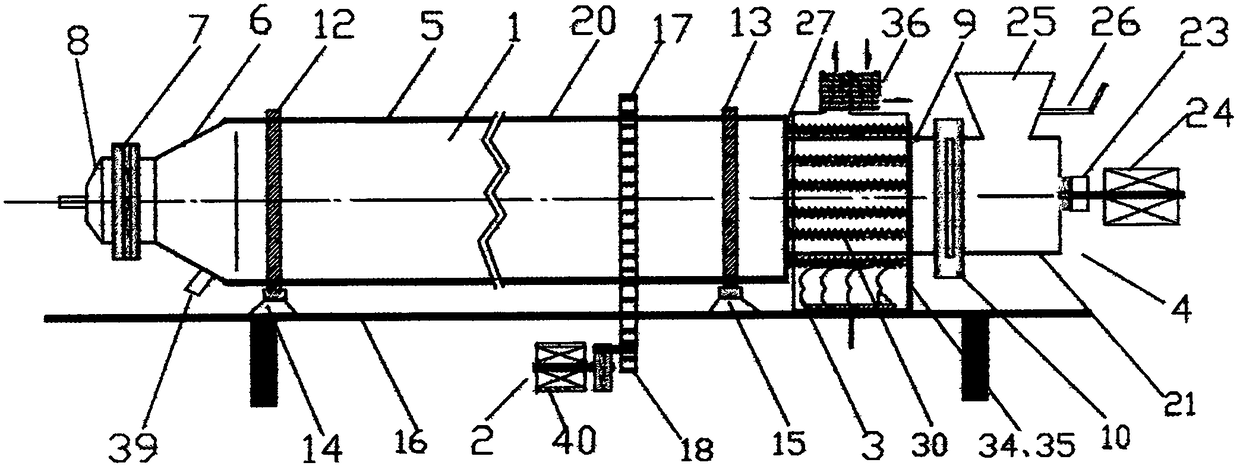

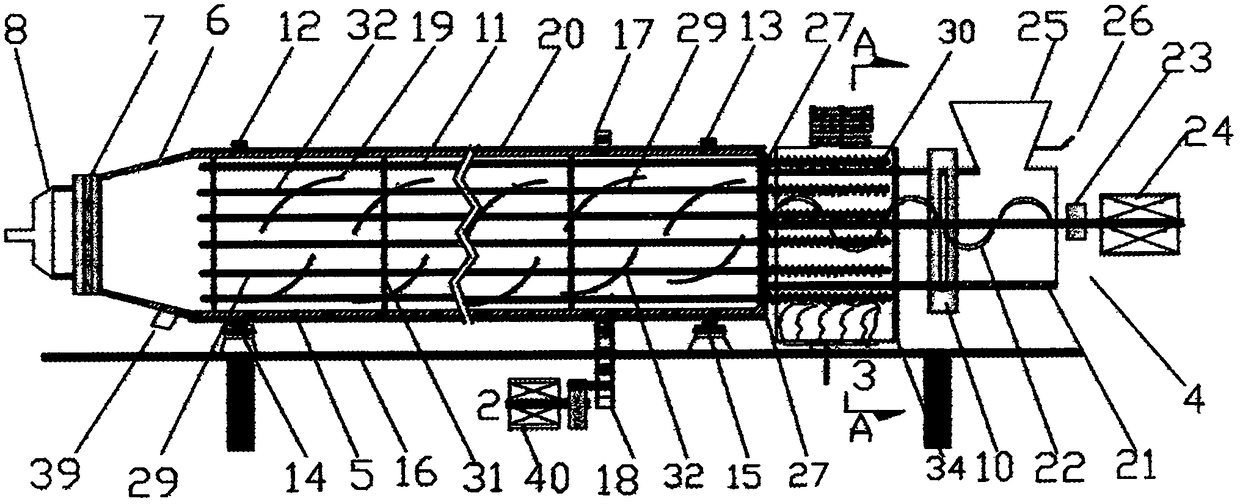

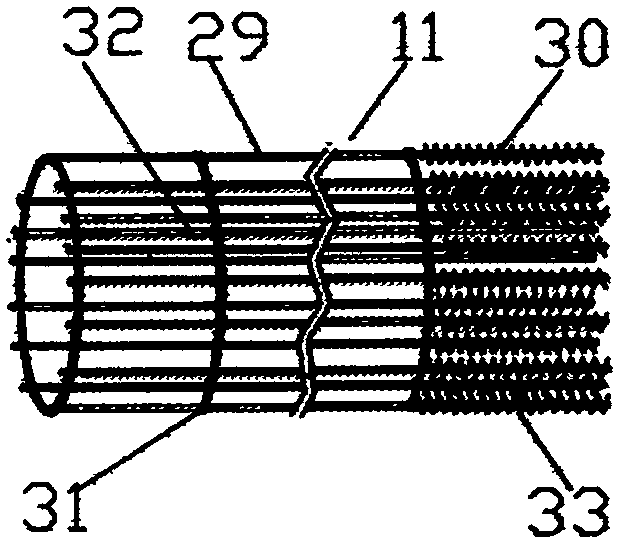

Rotary high-temperature superconducting-tube pyrogasification furnace for garbage

InactiveCN109423339AHigh pyrolysis gasification efficiencyImprove thermal conductivityGasification processes detailsRotary drum/kiln gasifiersFurnace temperatureSocial benefits

The invention relates to a rotary high-temperature superconducting-tube pyrogasification furnace for garbage. The rotary high-temperature superconducting-tube pyrogasification furnace is composed of four parts, i.e., a circular cylinder rotary furnace body, a rotary furnace body driver, a heater and a feeding machine. The rotary high-temperature superconducting-tube pyrogasification furnace is characterized in that the inner wall of the circular cylinder rotary furnace body is filled with metal stirring plates and a high-temperature mouse-cage-type superconducting heat transmitter. The heateruses gas produced by the cracking furnace for heating the superconducting-tube evaporation section of the high-temperature mouse-cage-type superconducting heat transmitter in the exterior of the furnace body, and generated radiant heat can be rapidly transmitted to garbage stirred in the furnace via high-temperature superconducting heat-transmitting pipes, thereby completing rapid, high-efficiencyand continuous pyrogasification of the garbage. The pyrogasification furnace provided by the invention has high temperature and balanced furnace temperature, so the dangers of bonding, bulging, block-forming and coking of the garbage caused by local overheating in the furnace are effectively solved, the generation of flue gas is avoided, pollution of harmful substances released by cracked substances to the environment are shielded, and the generation of dioxin is suppressed; and solid residues produced after cracking can be used as a chemical raw material for manufacturing of active carbon, and social benefits and economic benefits are significantly improved.

Owner:西安美润环保工程技术有限公司 +1

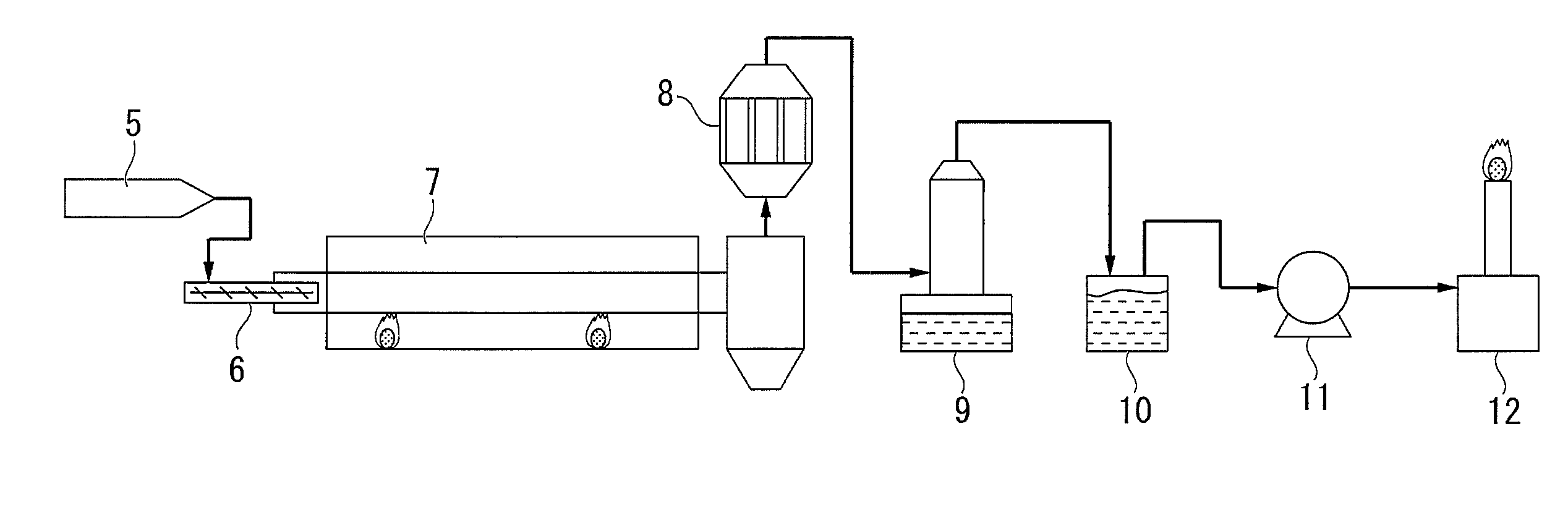

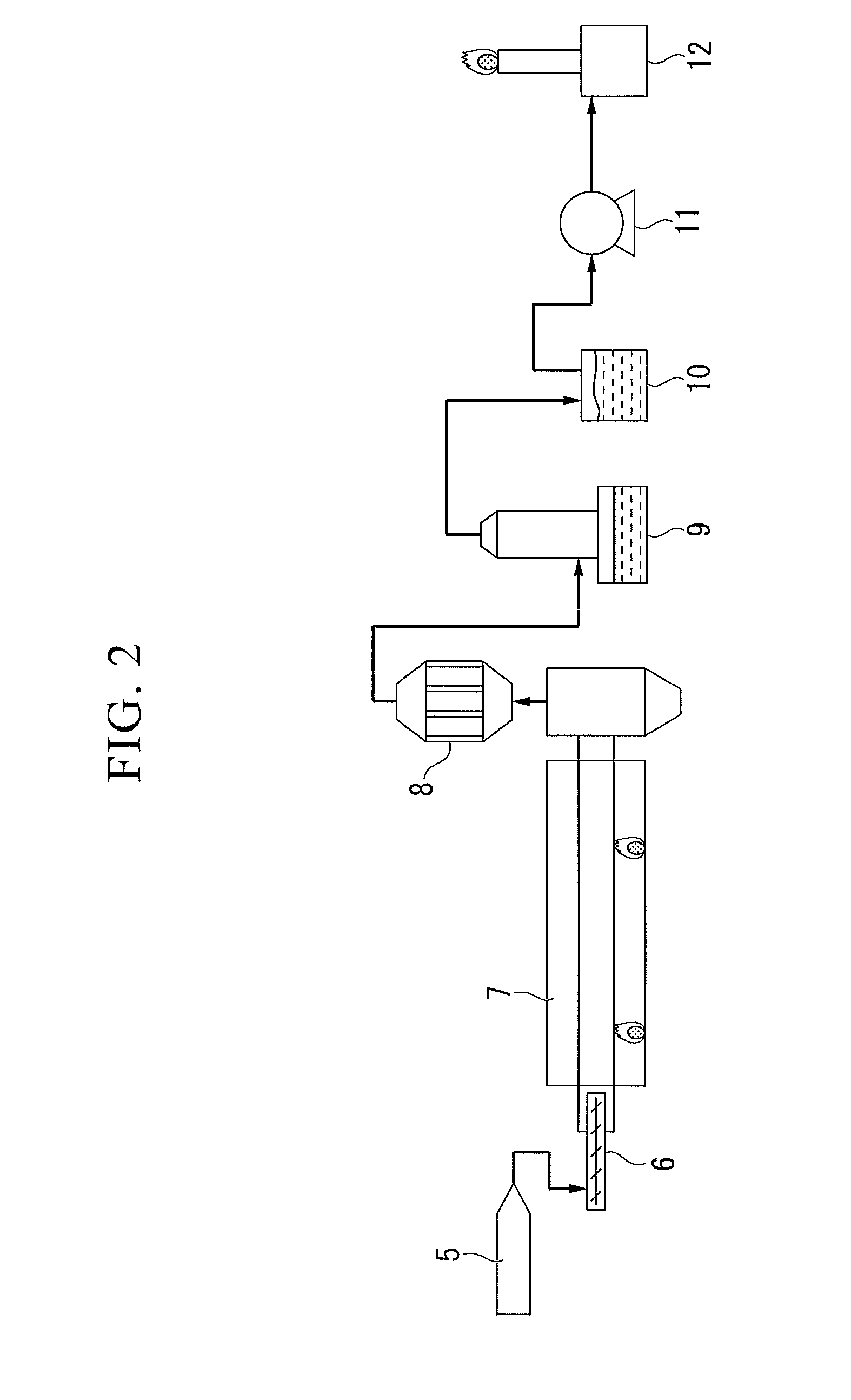

Process and system for duplex rotary reformer

ActiveUS20160130513A1Minimize GHG emissionEmission minimizationGasifier mechanical detailsWaste based fuelSyngasProcess engineering

Methods apparatus for producing fuel and power from the reformation of organic waste. Various embodiments include the use of steam to produce syngas in a Fischer-Tropsch reaction, followed by conversion of that syngas product to hydrogen. Some embodiments include the use of a heated auger both to heat the organic waste and further to cool the syngas.

Owner:RAVEN SR INC

Thermal synthesis production of steel

A process for producing liquid steel is disclosed. Carbon monoxide and oxygen may be combusted in a high temperature reactor. Iron and iron oxide materials, along with scrap steel if desired, may be placed in the high temperature reactor. Carbon dioxide produced in the high temperature reactor may be circulated through a back reactor vessel. Coke masses may be placed in the back reactor vessel. The coke may be formed by circulating heated carbon monoxide counter current to crushed coal in a rotary kiln. The carbon dioxide circulated through the back reactor vessel reacts with the coke to form carbon monoxide. The carbon monoxide may be conveyed to the high temperature reactor to be combusted with oxygen to produce the heat for forming the liquid steel.

Owner:PETERSON OREN V

Apparatus, system, and method for converting varied source industry waste into energy

InactiveUS20170275542A1Improve the environmentConsiderable savingEnergy inputRaised temperature/pressure usageProcess engineeringDistributor

An apparatus, system, and method for processing hydrocarbon-containing wastes are described. The system and method include the use of a gasification apparatus comprising a rotary kiln reactor and a gas distributor. The rotary kiln reactor and gas distributor are configured to generate multiple reaction environments within the gasification apparatus. Each of the reaction environments has unique temperature reaction conditions to suit various physical and chemical properties associated with processing of the varied-source hydrocarbon-containing wastes.

Owner:SIMPLE APPROACH SYST

Operation of a steam hydro-gasifier in a fluidized bed reactor

InactiveUS20080021120A1Well mixedIncrease conversion rateCombustible gas chemical modificationHydrogenMethane reformerSyngas

Carbonaceous material, which can comprise municipal waste, biomass, wood, coal, or a natural or synthetic polymer, is converted to a stream of methane and carbon monoxide rich gas by heating the carbonaceous material in a fluidized bed reactor using hydrogen, as fluidizing medium, and using steam, under reducing conditions at a temperature and pressure sufficient to generate a stream of methane and carbon monoxide rich gas but at a temperature low enough and / or at a pressure high enough to enable the carbonaceous material to be fluidized by the hydrogen. In particular embodiments, the fluidizing mixture can be a combination of hydrogen and steam. The stream of methane and carbon monoxide rich gas can be subjected to steam methane reforming under conditions whereby synthesis gas comprising hydrogen and carbon monoxide is generated. Synthesis gas generated by the steam methane reforming is fed into a Fischer-Tropsch reactor under conditions whereby a liquid fuel is produced. Excess hydrogen from the steam methane reformer can be fed back to the fluidized bed reactor. Exothermic heat from the Fischer-Tropsch reaction can be transferred to the hydro-gasification reactor.

Owner:RGT UNIV OF CALIFORNIA

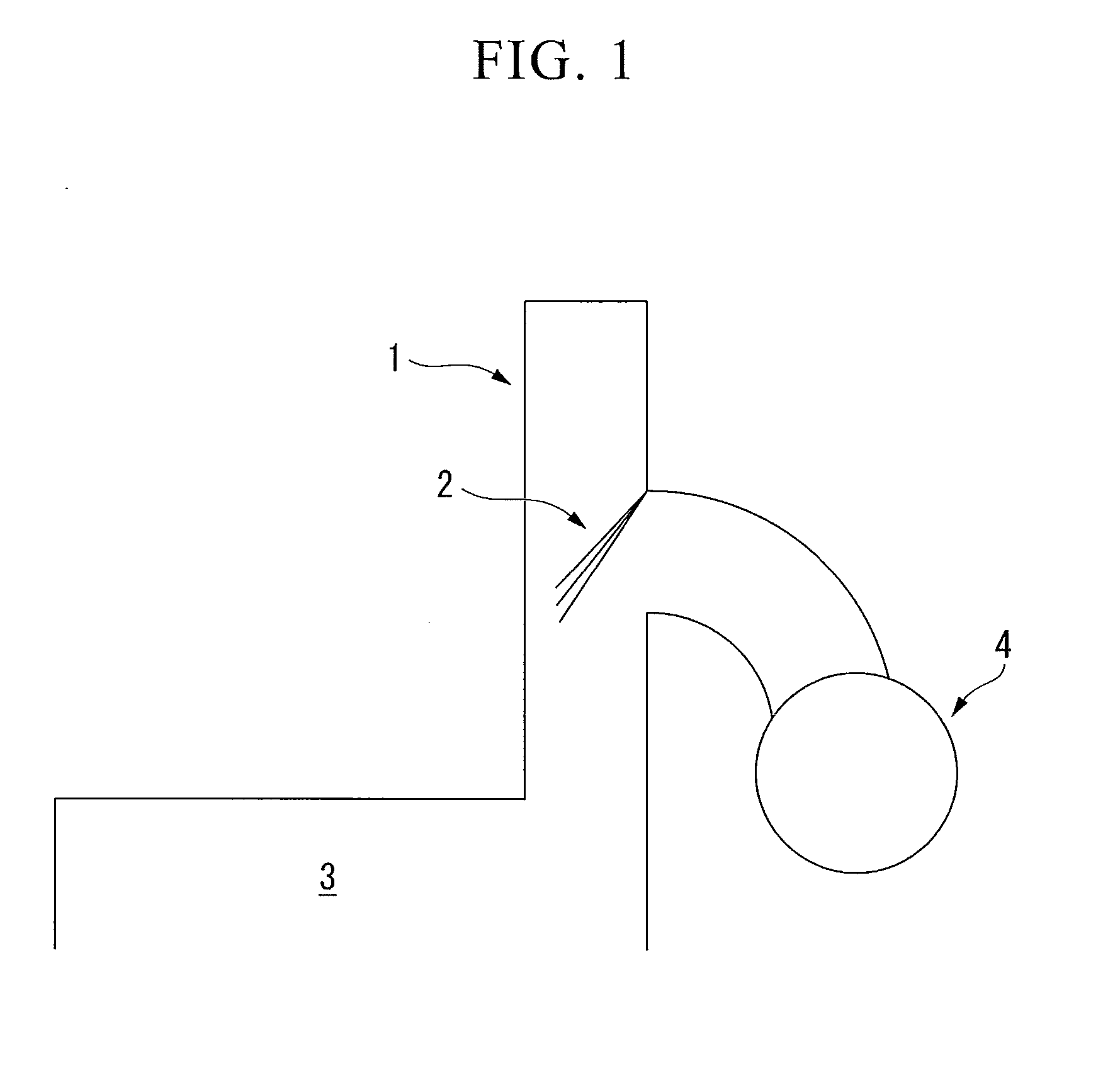

Appliance for converting household waste into energy

ActiveUS7998226B2Reduce the total massEliminating garbage requiring landfillsFuel cell heat exchangeSolid waste disposalSteam reformingFuel cells

An appliance is provided having a waste receptor module and an energy generation module for converting household waste into energy. The receptor module has a rotary drum with an opening for receiving the household waste and a steam reforming means for converting the waste into synthesis gas. A swing arm is attached adjacent to the opening in the rotary drum and a sealing door is mounted on the swing arm for sealing the opening when the waste receptor module is in operation. An outer door is used to cover the sealing door. The steam reforming means includes a tube mounted within the rotary drum for receiving the volatilized organic waste and an internal heater for heating the organic waste to temperatures to convert the waste into the synthesis gas. The energy generation module has an inlet in fluid communication with the waste receptor module for receiving the synthesis gas and a fuel cell for converting the synthesis gas into electrical energy.

Owner:RAVEN SR INC

Method for lowering molecular weight of organic substance

ActiveCN104136580ALess carbonImplement chemical reuseSolid waste disposalCombustible gas catalytic treatmentHydrogenWater vapor

An organic substance is reformed and lowered in molecular weight by: producing a mixed gas (g) by mixing water vapor to a gasification melting furnace-generated exhaust gas (g0) that contains carbon dioxide and hydrogen; or adding an excessive amount of water vapor to a gasification melting furnace-generated exhaust gas (g1) that contains carbon monoxide and hydrogen to cause a shift reaction, and thereby producing a mixed gas (g) that contains the hydrogen contained in the exhaust gas (g1), carbon dioxide and hydrogen produced by the shift reaction, and the water vapor that was not consumed by the shift reaction; and bringing said mixed gas (g) into contact with said organic substance.

Owner:JFE STEEL CORP

Popular searches

Screw type gasifiers Cell component details Hydrogen/synthetic gas production Petrochemical industry Combined combustion mitigation Gasification apparatus details Granular/pulverulent flues gasification Gas purification with selectively adsorptive solids Incinerator apparatus Gas contaminants removal

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com