Rotating bed gasifier

a gasifier and rotating bed technology, applied in the direction of gasifier mechanical details, fuel gas production, combustible gas production, etc., can solve the problems of limiting the size of the gasifier which can be constructed, uneven gasification, and questionable primary energy generation, so as to reduce the size limitations, improve efficiency, and improve the effect of air flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

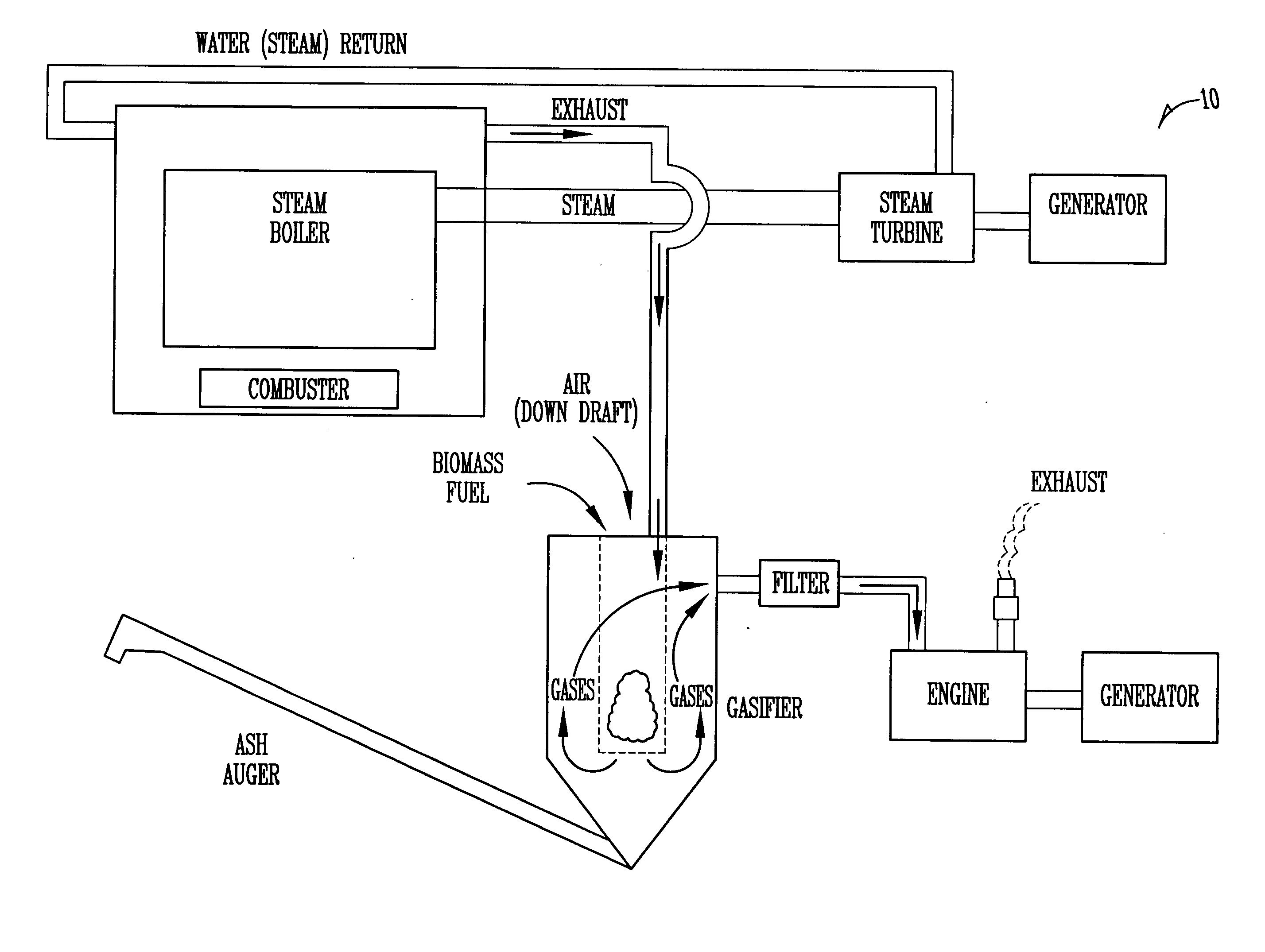

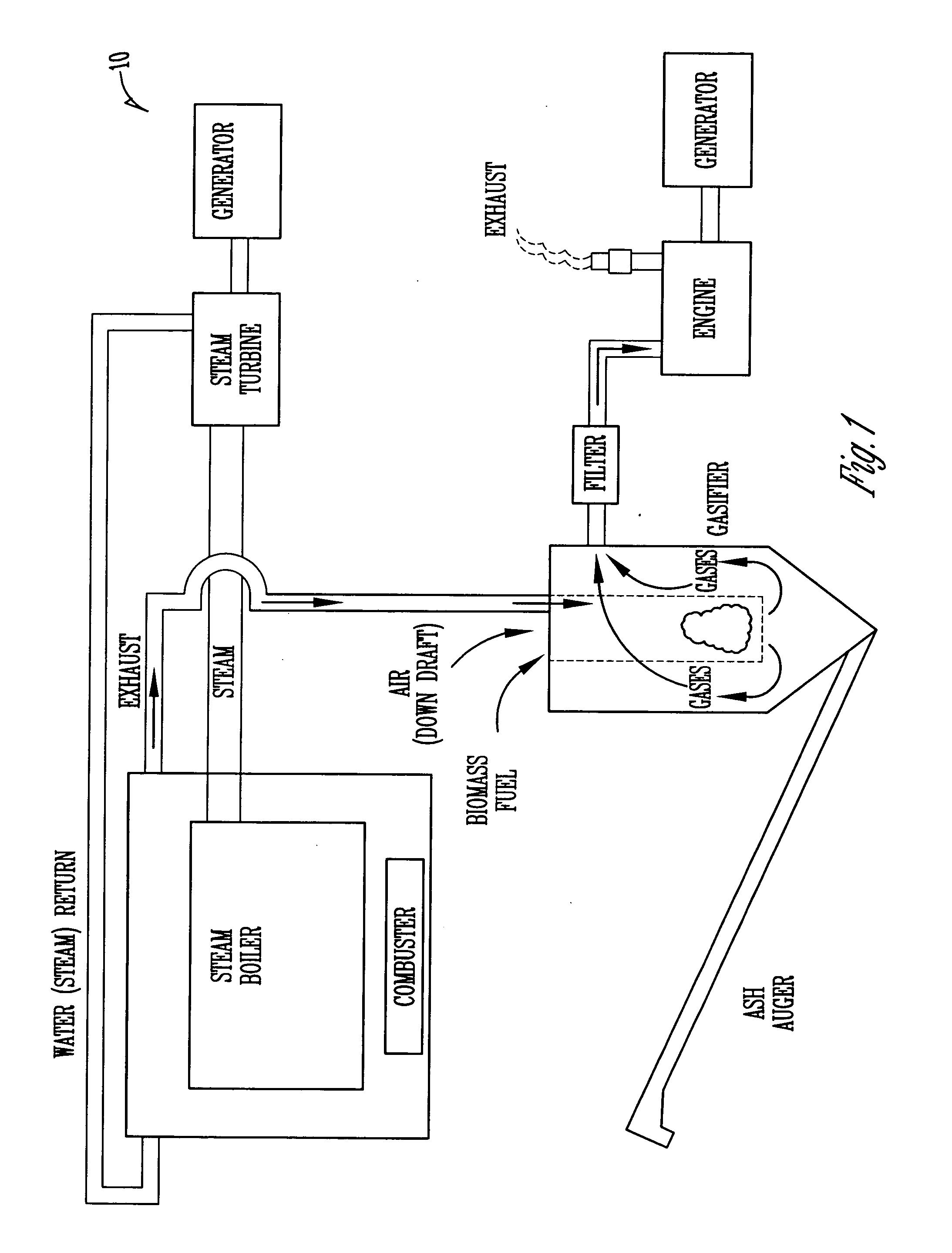

[0027] The present invention relates to a rotating bed gasifier. The present invention can be used in a system such as the system 10 as shown in FIG. 1. However, the present invention can be used in any type of system where a gasifier for gasifying solid fuels is desired.

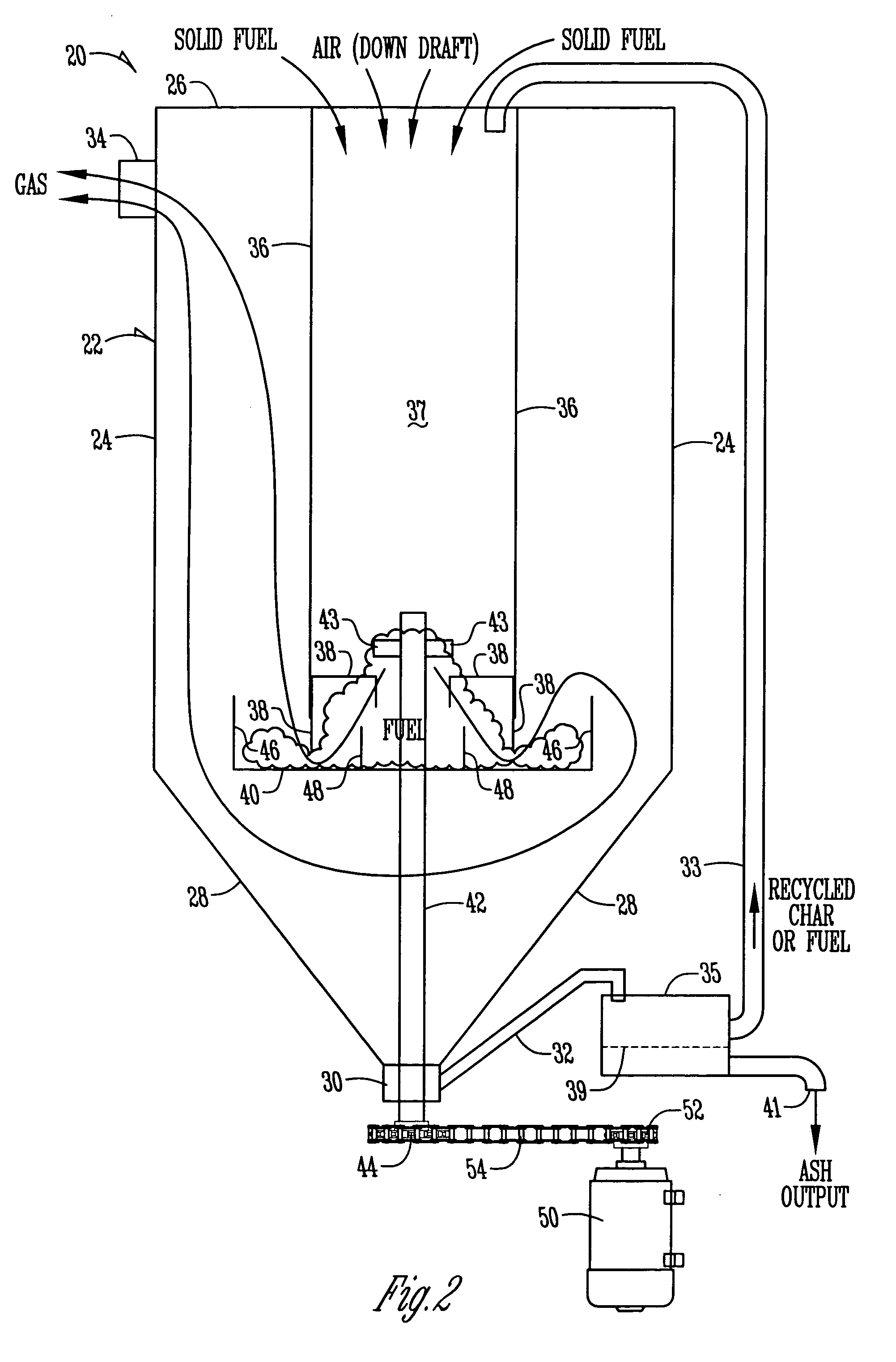

[0028] Referring now to FIG. 2, a cut away side view of one embodiment of a rotating bed gasifier assembly 20 is shown. The gasifier assembly 20 begins with a gasifier container assembly 22. The gasifier container assembly 22 generally has a cylindrical shaped sidewall 24. However, the sidewall 24 can be in any shape. Connected to the sidewall 24 is a top 26 and a bottom 28. Preferably, the bottom 28 is an inverted cone-shaped piece of metal to allow used ashes and overflow fuel or char to fall to a central point of an ash sump 30.

[0029] The ash sump 30 is connected to the bottom 28 of the gasifier container assembly 22 preferably is connected to an ash auger 32 for removing the fuel and ashes after they have been...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| bed rotation | aaaaa | aaaaa |

| energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com