Touch display device integrated on displayer

A touch display device and display technology, which is applied in the input/output process of instruments, data processing, electrical digital data processing, etc., can solve the problem of high cost, large size, and inability to develop and Market application and other issues, to achieve the effect of fast detection speed, simplified structure, and improved position detection ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

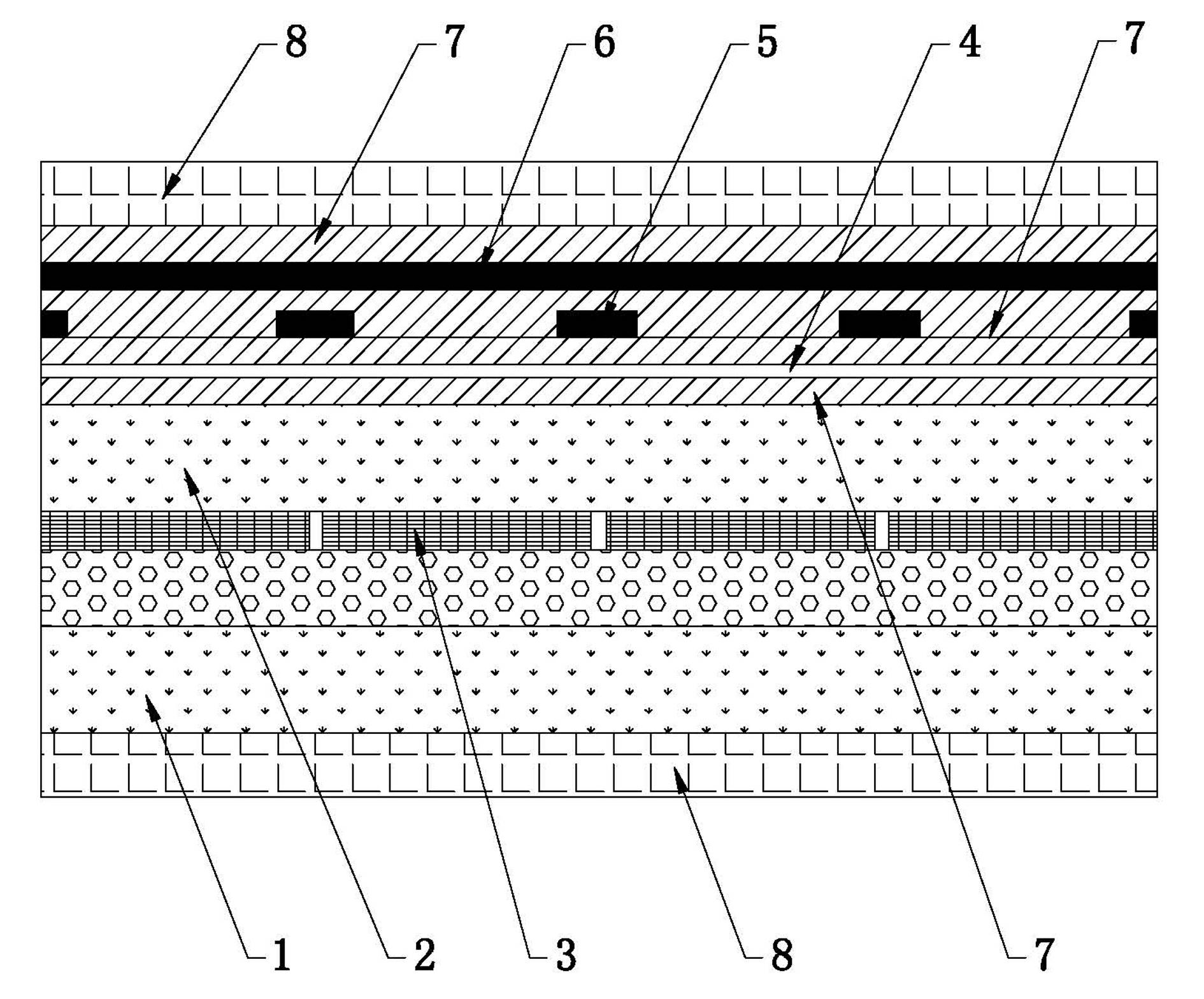

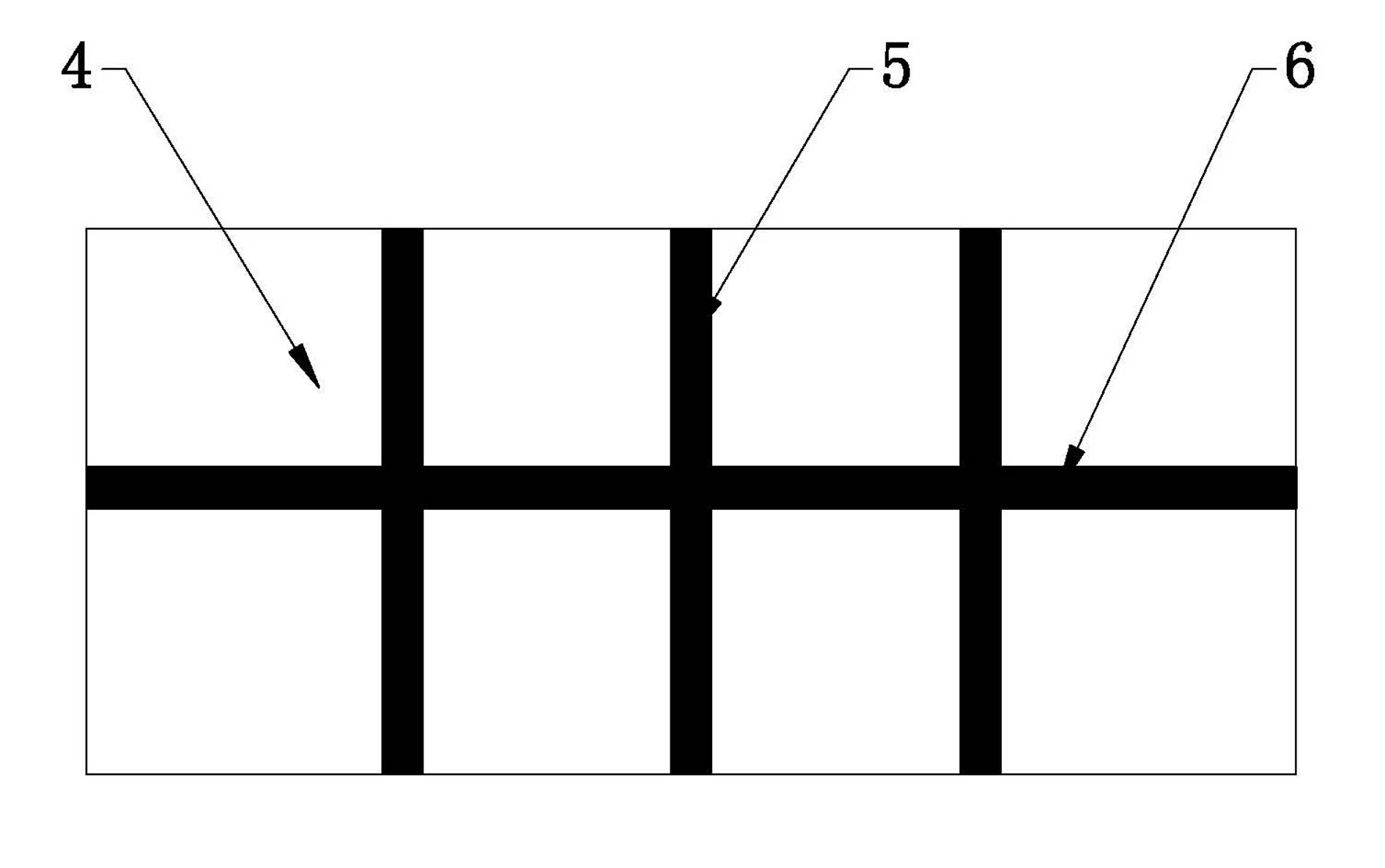

[0030] figure 1 For the integration of capacitive touch technology and liquid crystal display to form a touch screen, the On-Cell structure made on the glass substrate of the liquid crystal cell, such as figure 1As shown, the first substrate 1 is the array substrate of the liquid crystal display, and the second substrate 2 is the color filter substrate of the liquid crystal display. The space between the color filter substrate and the array substrate is filled with liquid crystal, and the surrounding is sealed with Seal. For a color liquid crystal display, RGB color layers 3 composed of red, green and blue color resist patterns are distributed on the color filter substrate, and corresponding pixel units are arranged at the corresponding positions of the array substrate; on the upper side of the color filter substrate Distributed planar transparent electrode layer 4 and criss-cross first metal layer 5, second metal layer 6, between planar transparent electrode layer 4 and first...

Embodiment 2

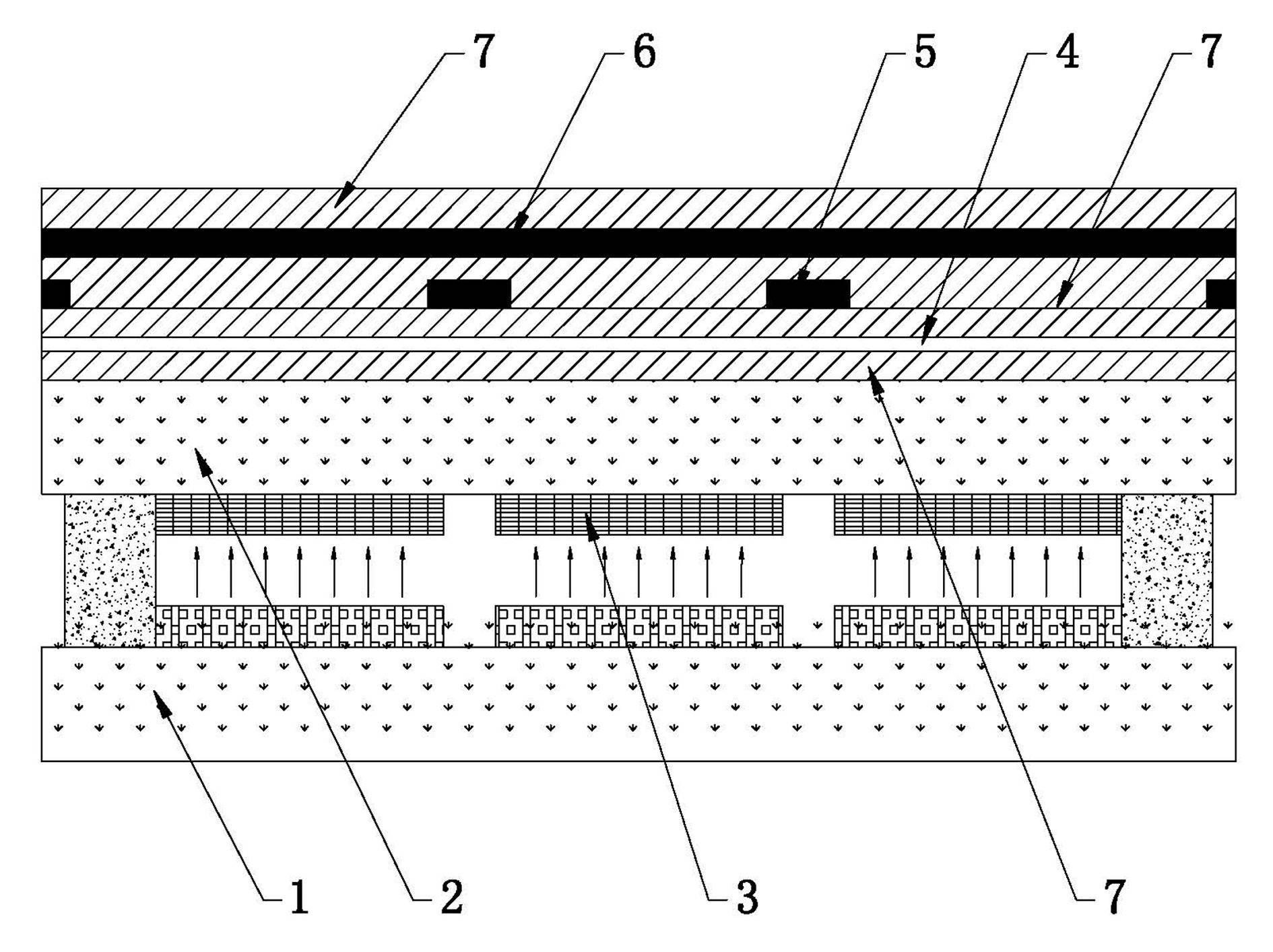

[0032] figure 2 It is a structural diagram of integrating touch technology on a field emission display. exist figure 2 Among them, the first substrate 1 is a cathode substrate with an electron source, and the second substrate 2 is an anode substrate with phosphor powder. The RGB color resist layer 3 is arranged on the lower side of the second substrate 2, and the upper side of the second substrate 2 is distributed with the planar transparent electrode layer 4 and the first metal layer 5 and the second metal layer 6 which criss-cross. A transparent insulating layer 7 is also provided between the transparent electrode layer 4 and the first metal layer 5 , and between the first metal layer 5 and the second metal layer 6 , and the black matrix may not be used between the RGB color resist layers 3 . in addition figure 1 In addition, a transparent insulating layer 7 is provided between the second substrate 2 and the planar transparent electrode layer 4 and outside the second me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com