Patents

Literature

293results about How to "Reduce drive costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

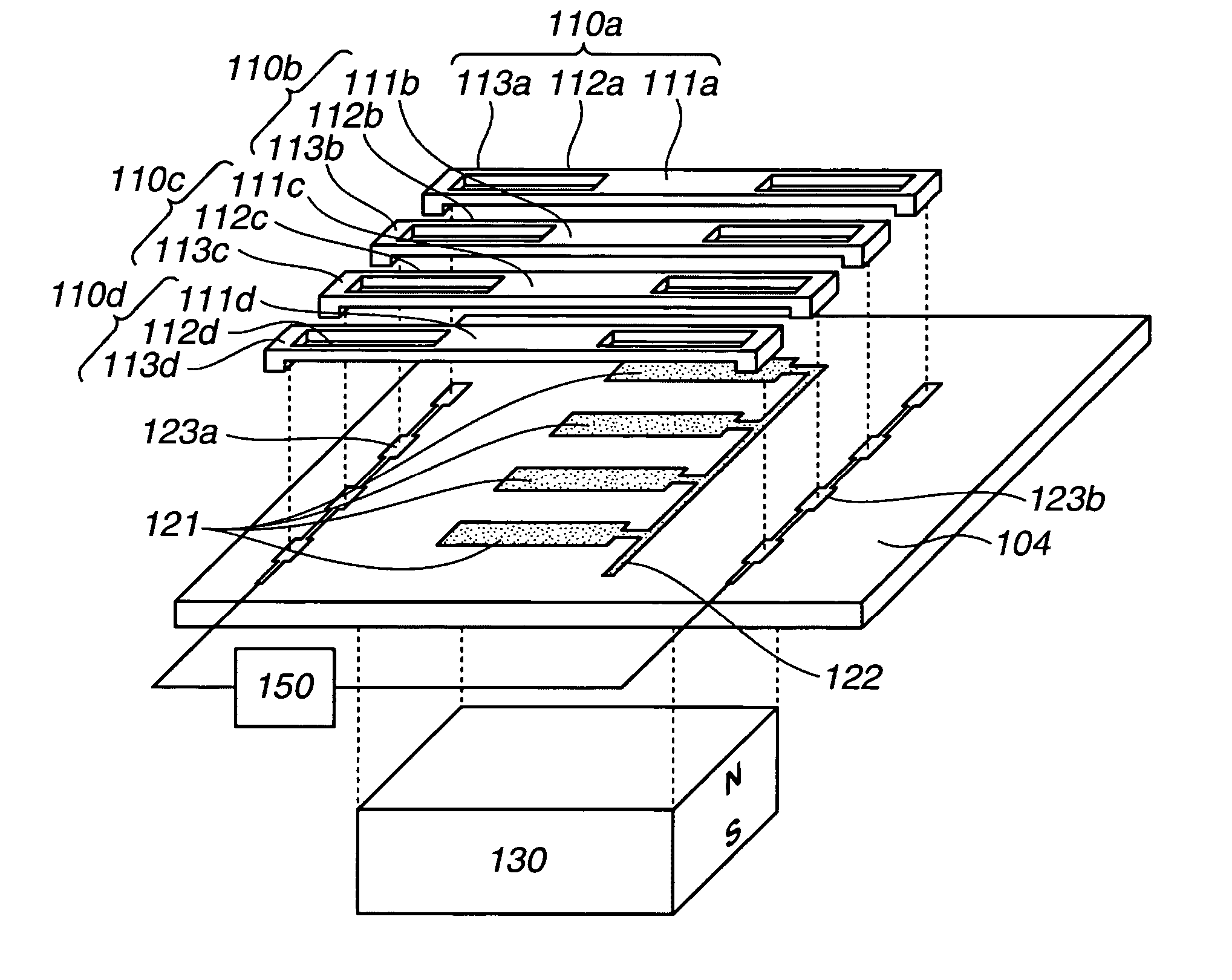

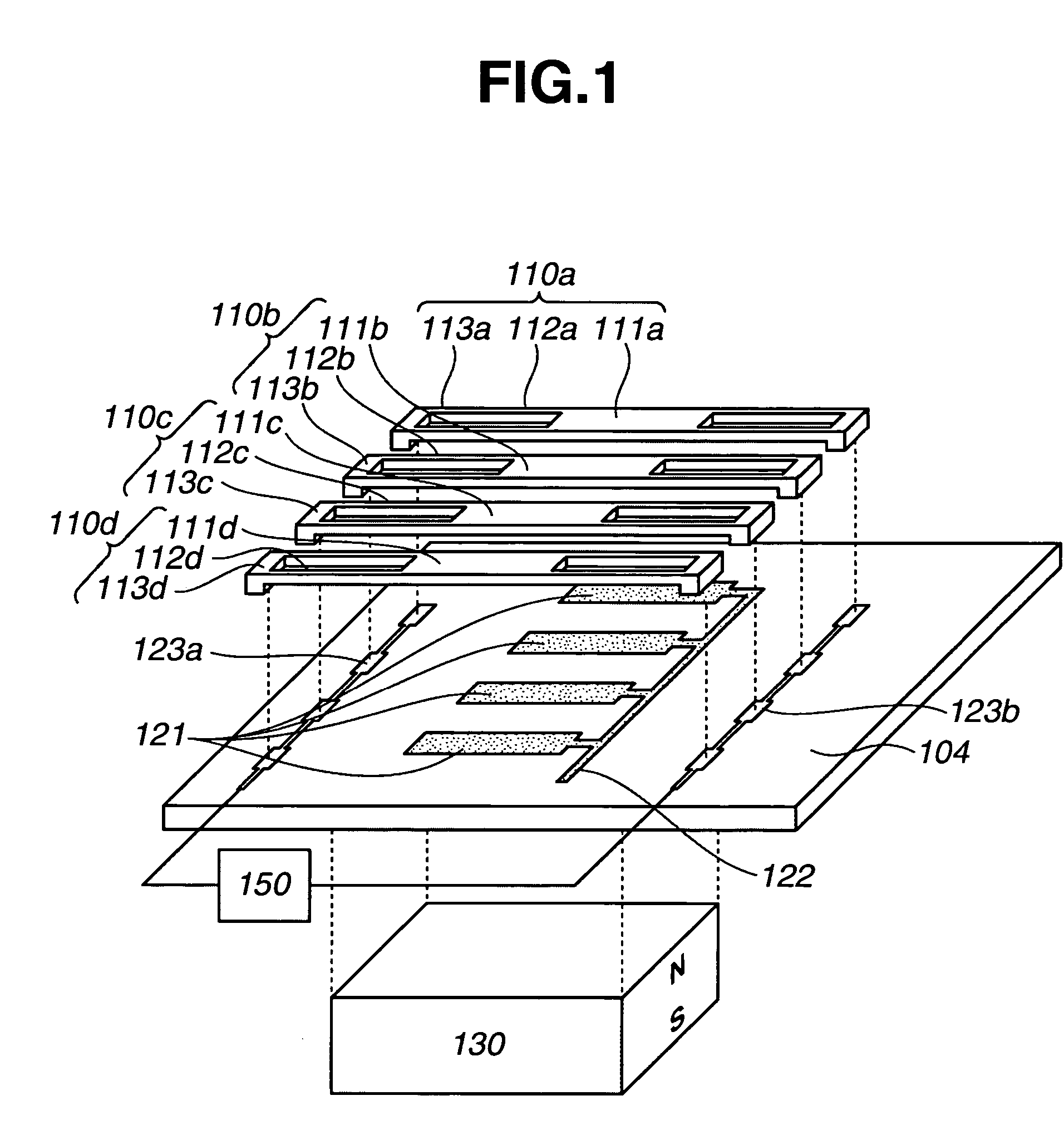

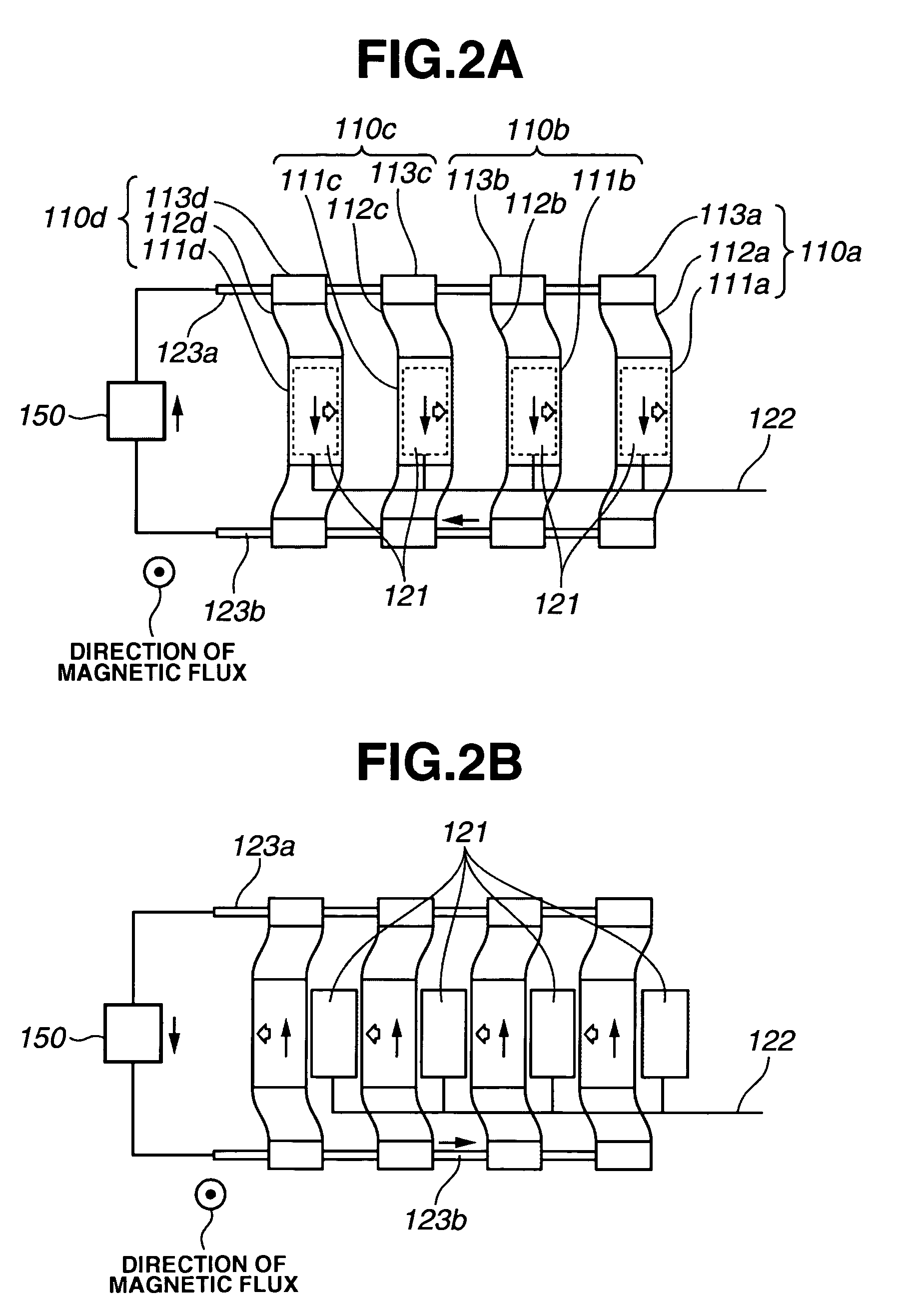

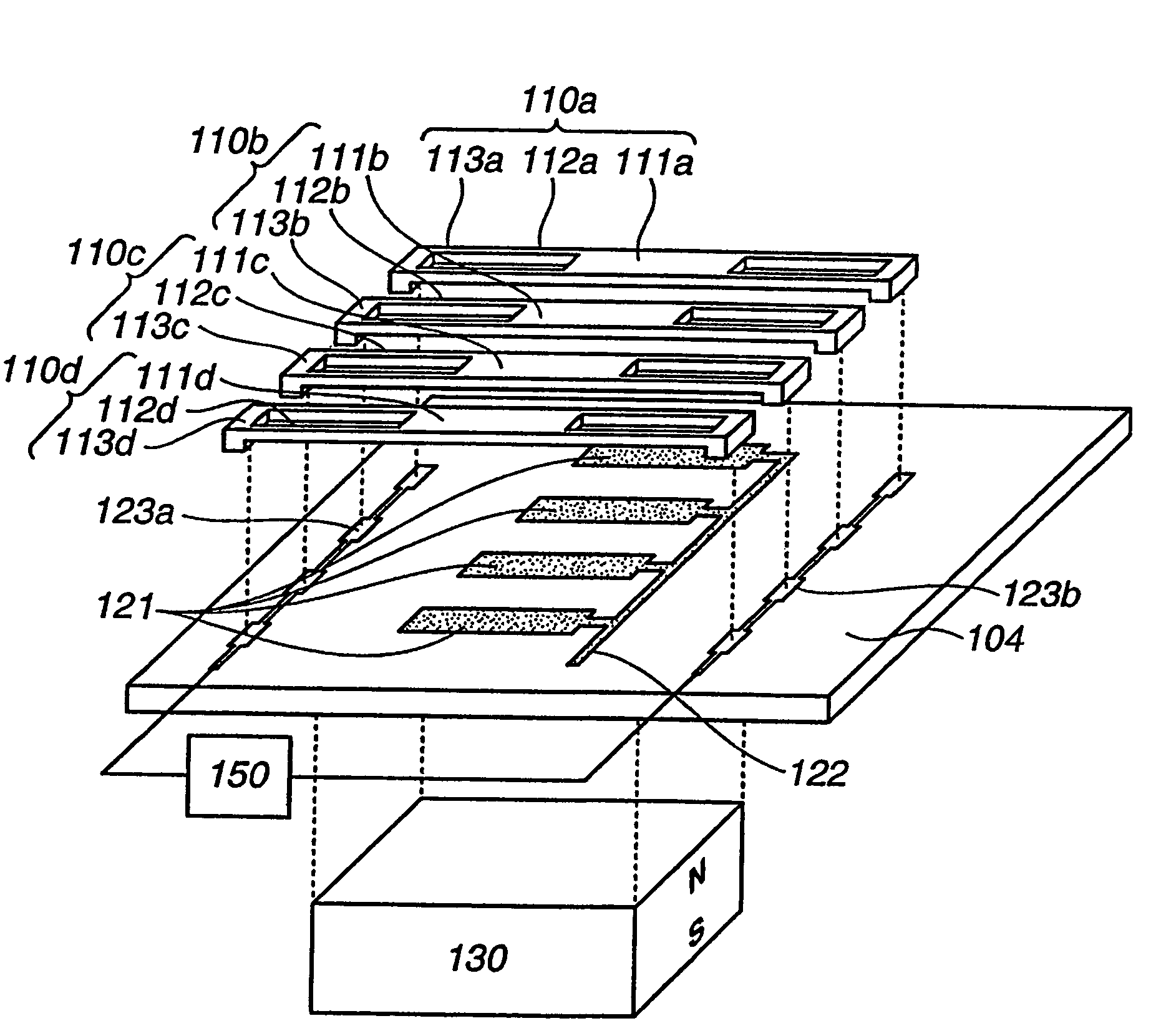

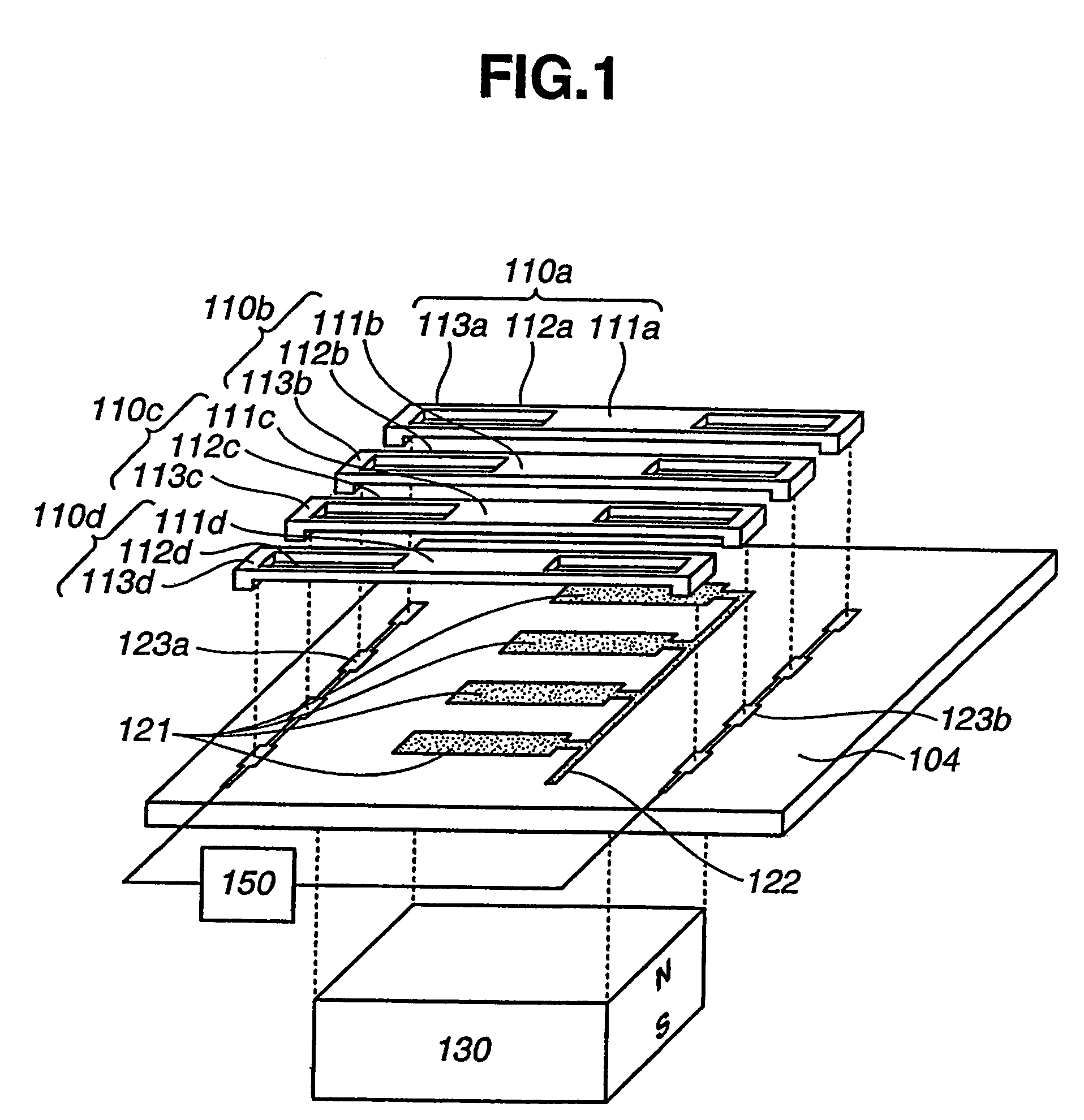

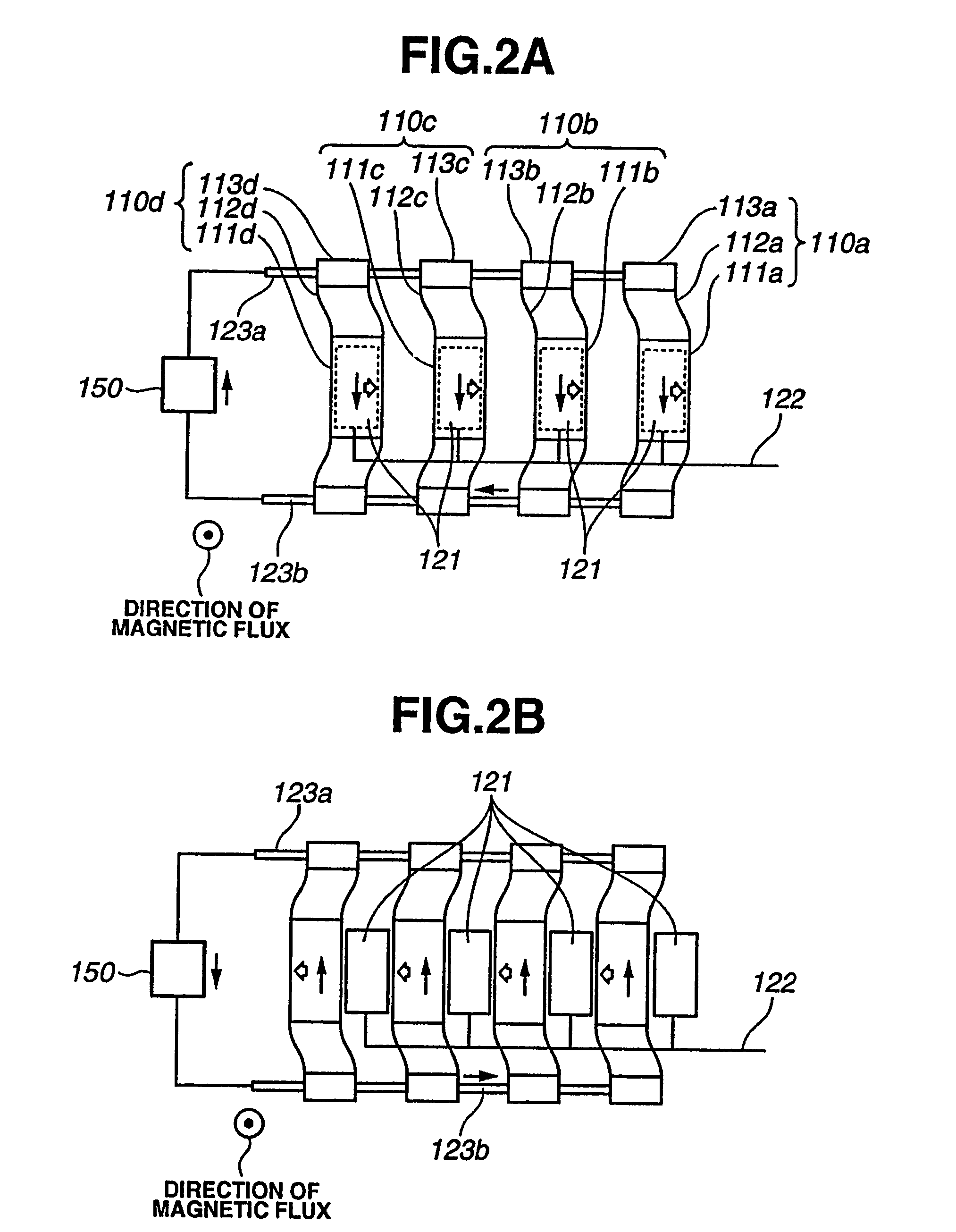

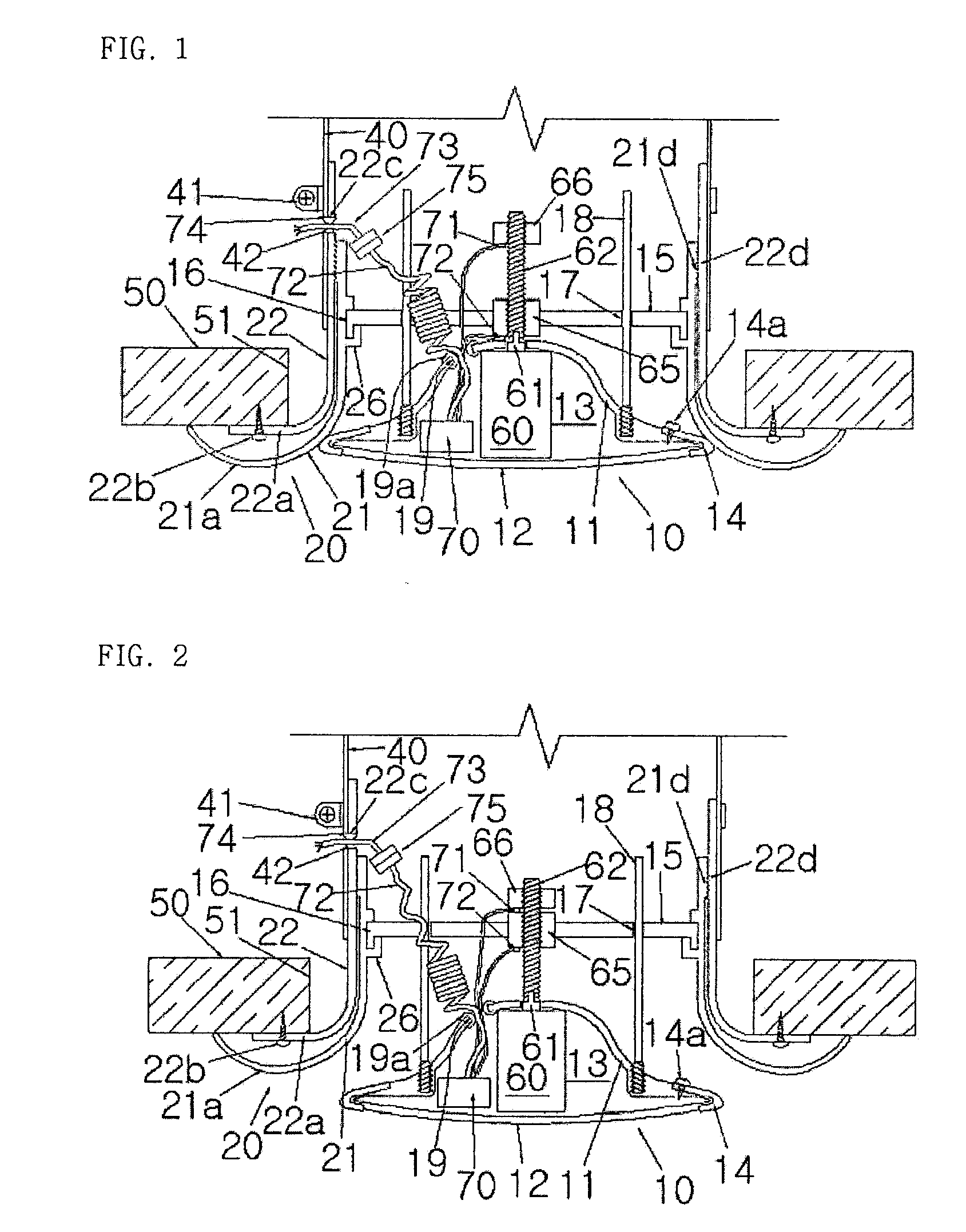

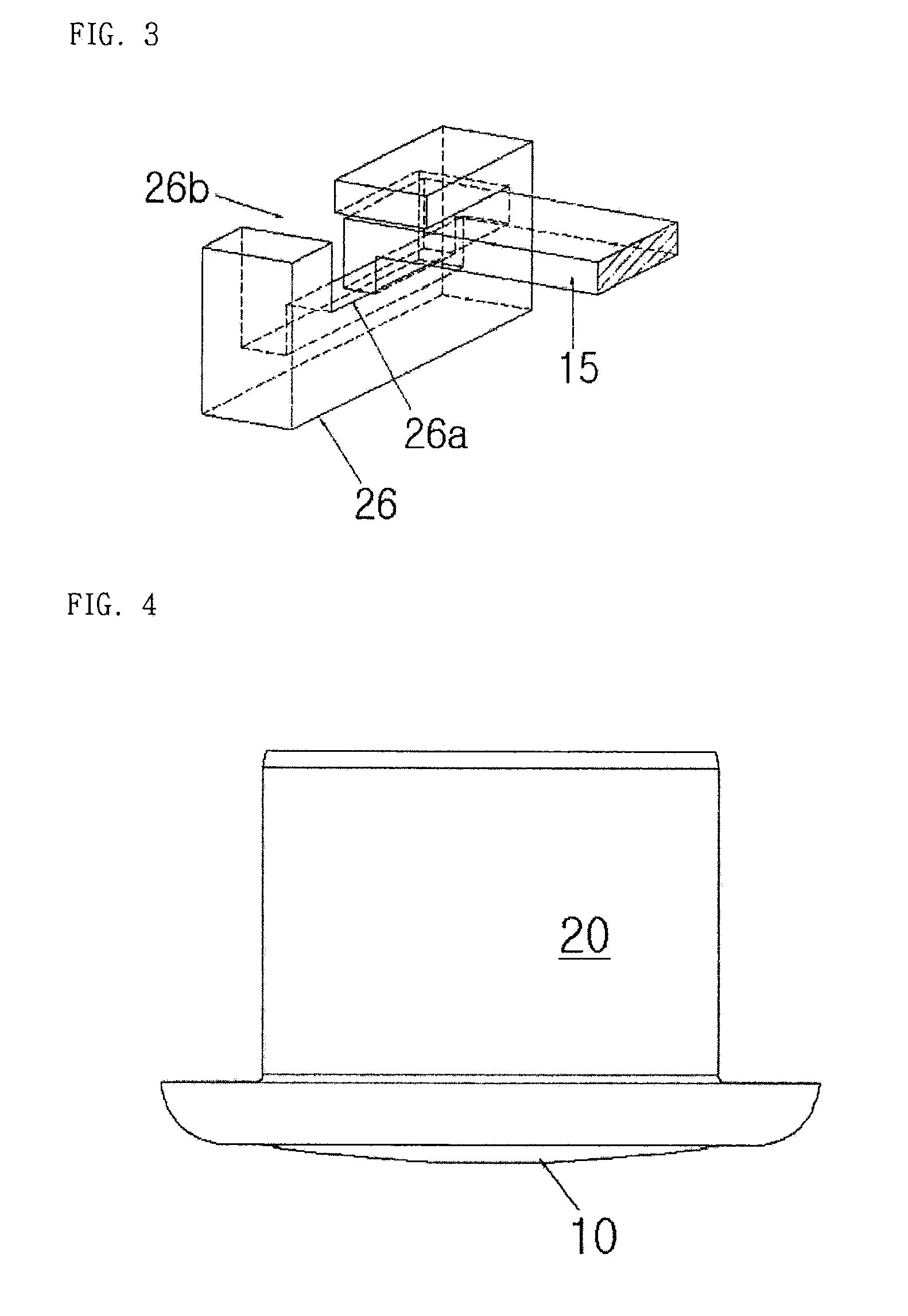

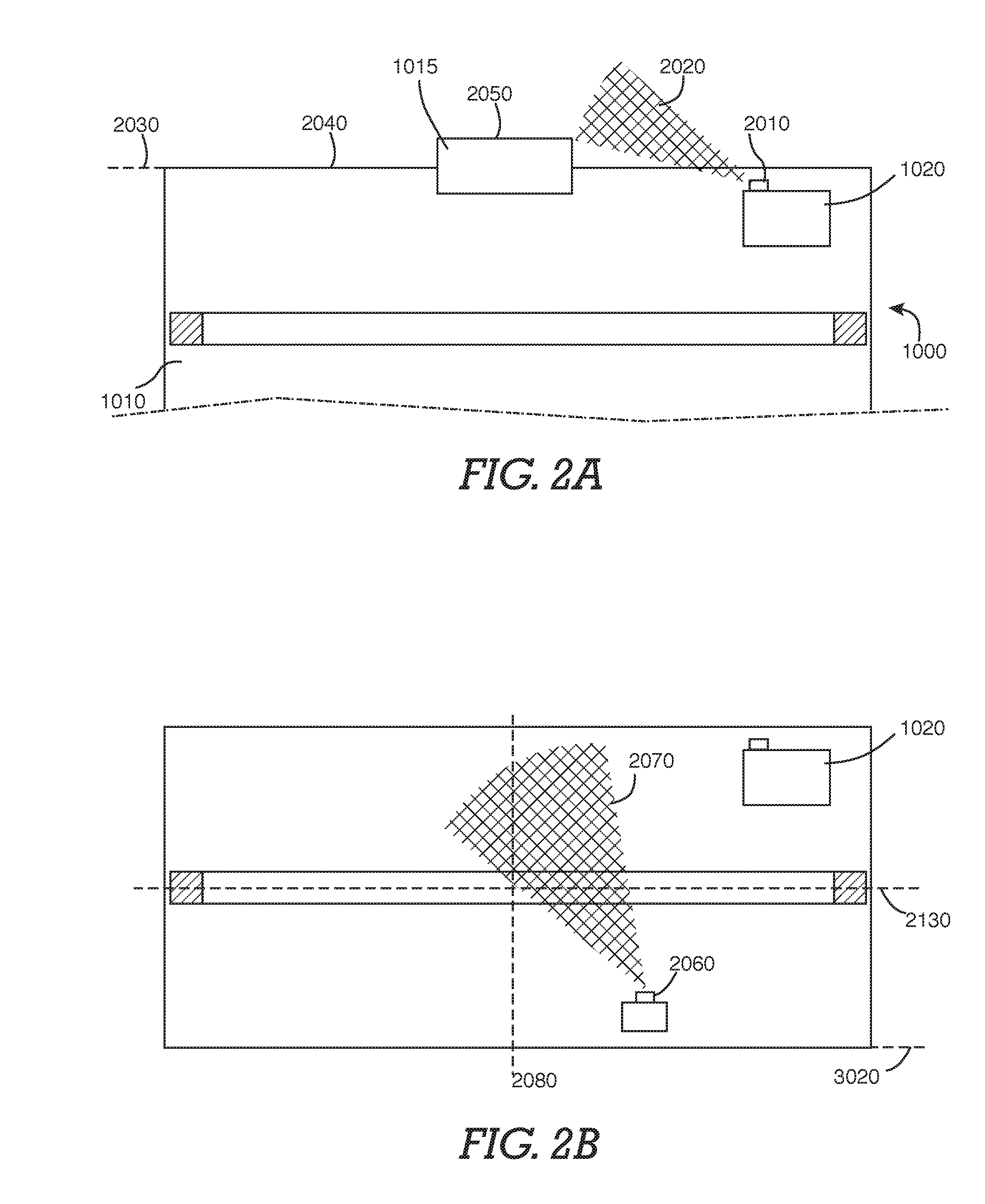

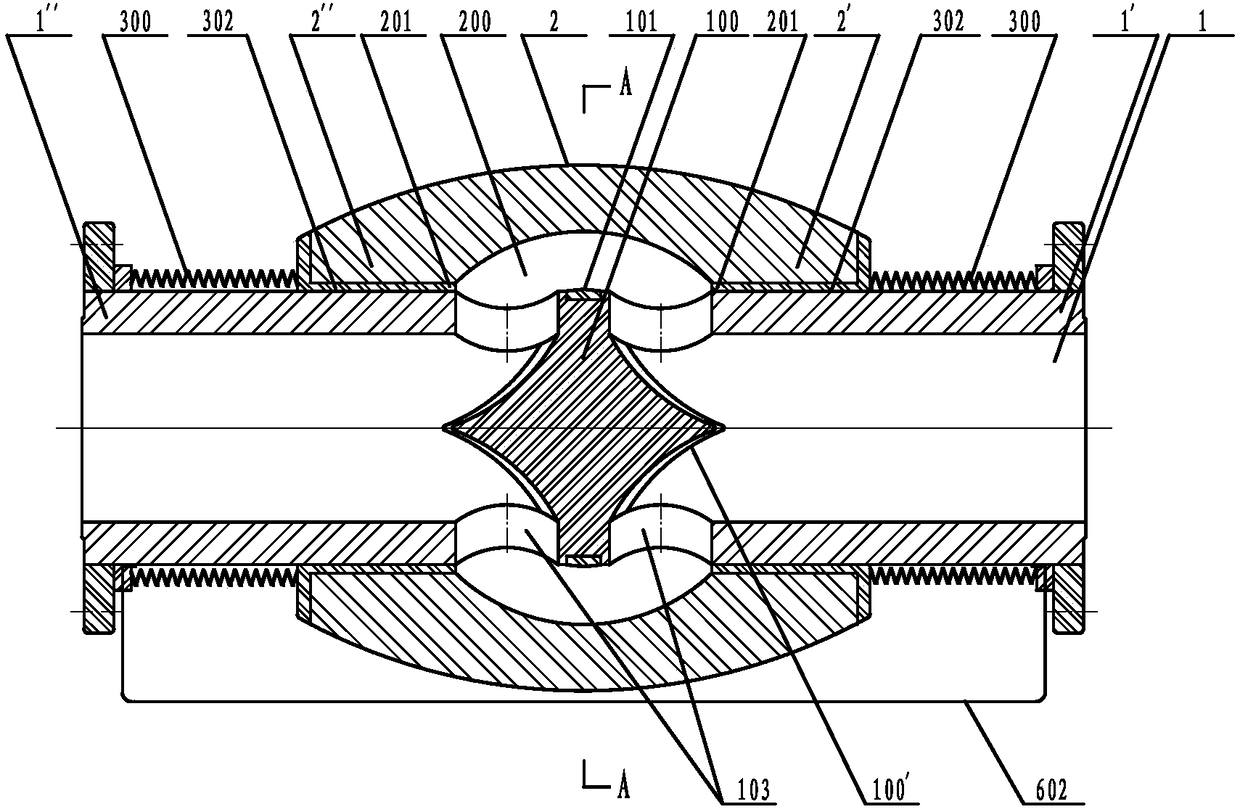

Electric potential sensor, and image forming apparatus

InactiveUS6965239B2Small sizeMass can be lightenedResistance/reactance/impedenceElectrography/magnetographyImage formationEngineering

Disclosed in a non-contacting electric potential sensor capable of being readily reduced in its size, which includes a detecting electrode, an electrically-conductive movable shutter, and a driving unit for driving the electrically-conductive movable shutter. The detecting electrode is to be placed facing a measurement object whose electric potential is to be measured. The electrically-conductive movable shutter is disposed so as to be movably located in a spacing formed between the detecting electrode and the measurement object when the detecting electrode is placed facing the measurement object, so that an exposure degree of the detecting electrode against the measurement object can be controlled. The driving unit includes a current injecting unit for selectively injecting current into the electrically-conductive movable shutter in a direction approximately perpendicular to a moving direction of the electrically-conductive movable shutter.

Owner:CANON KK

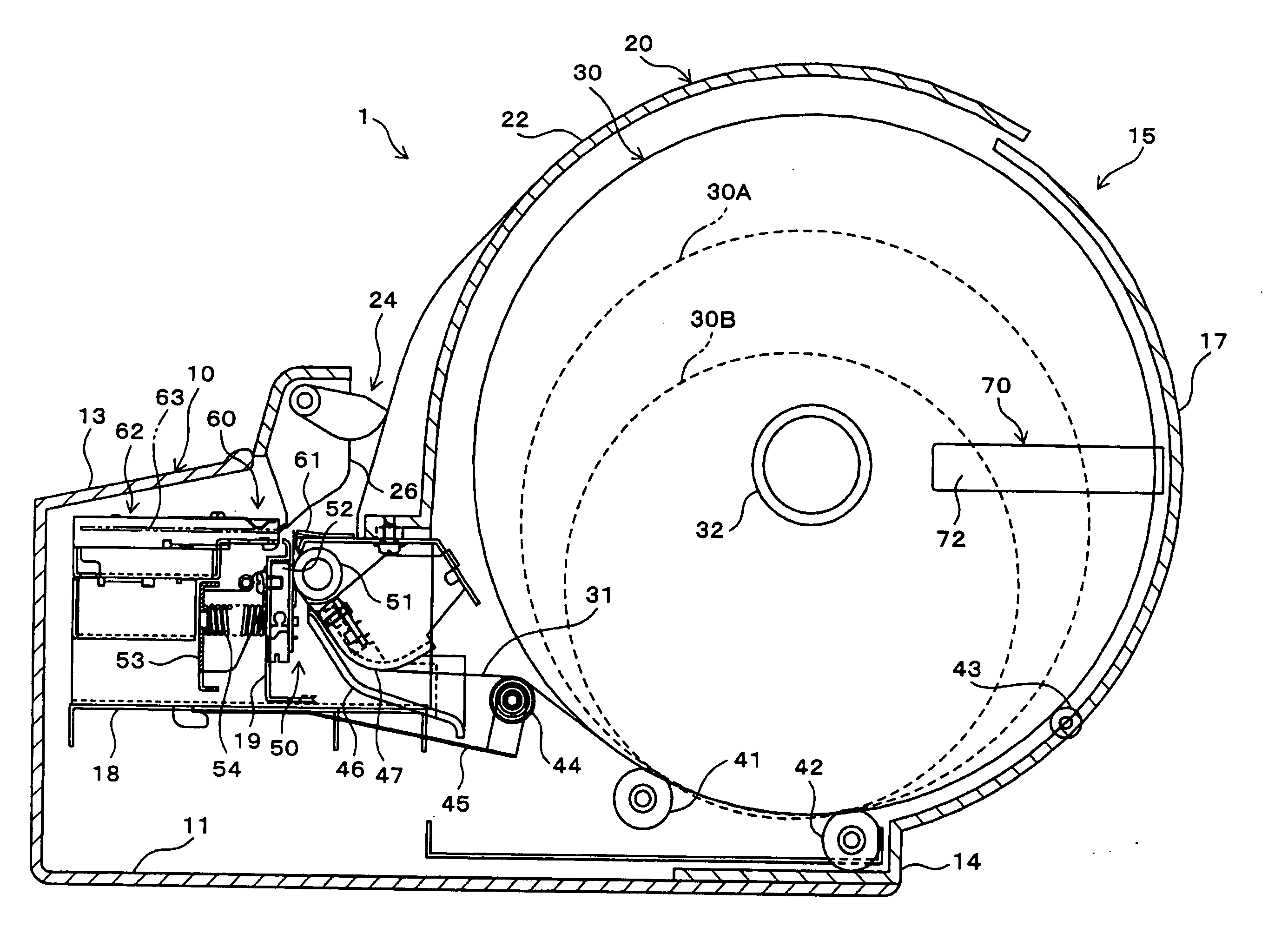

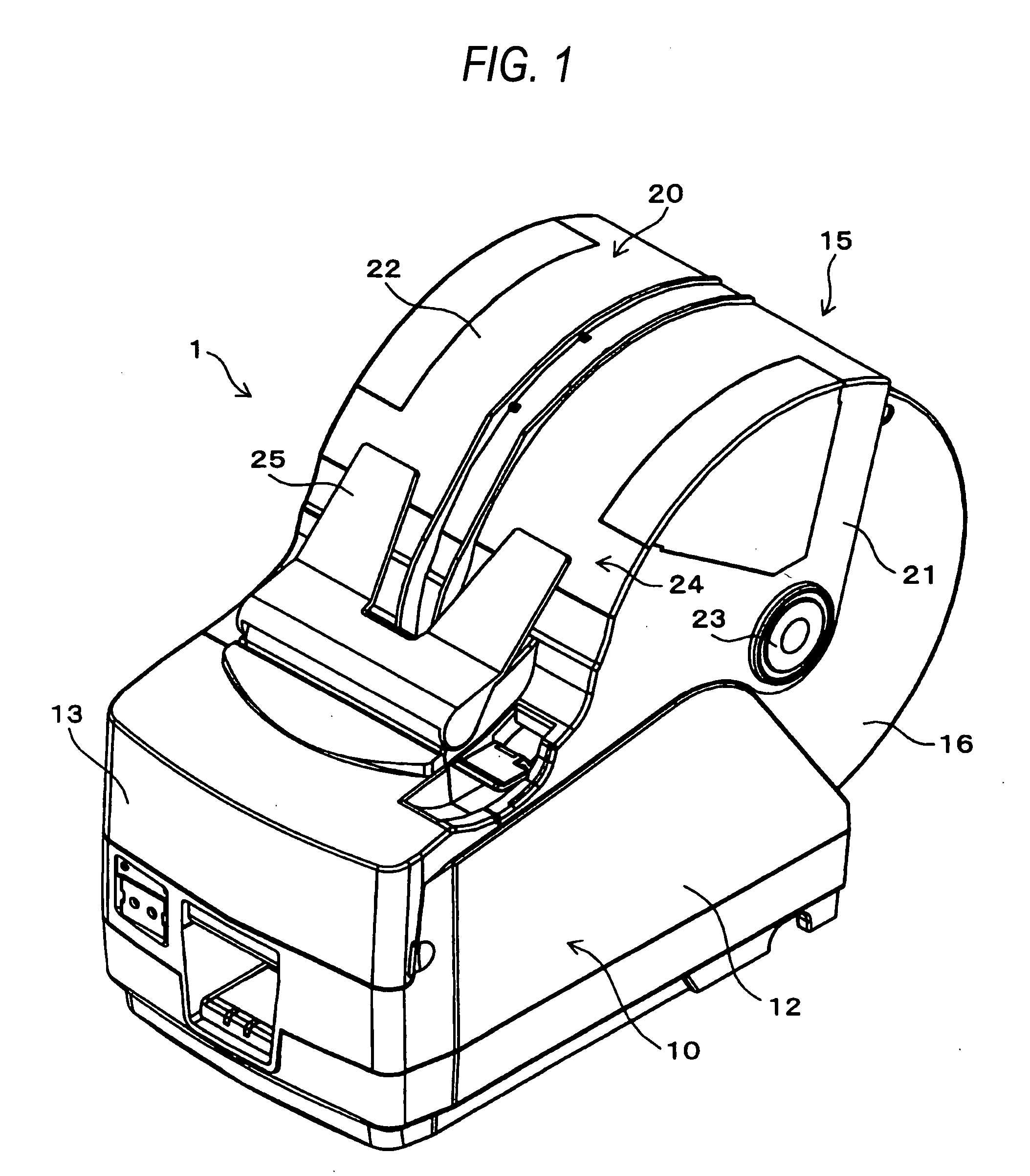

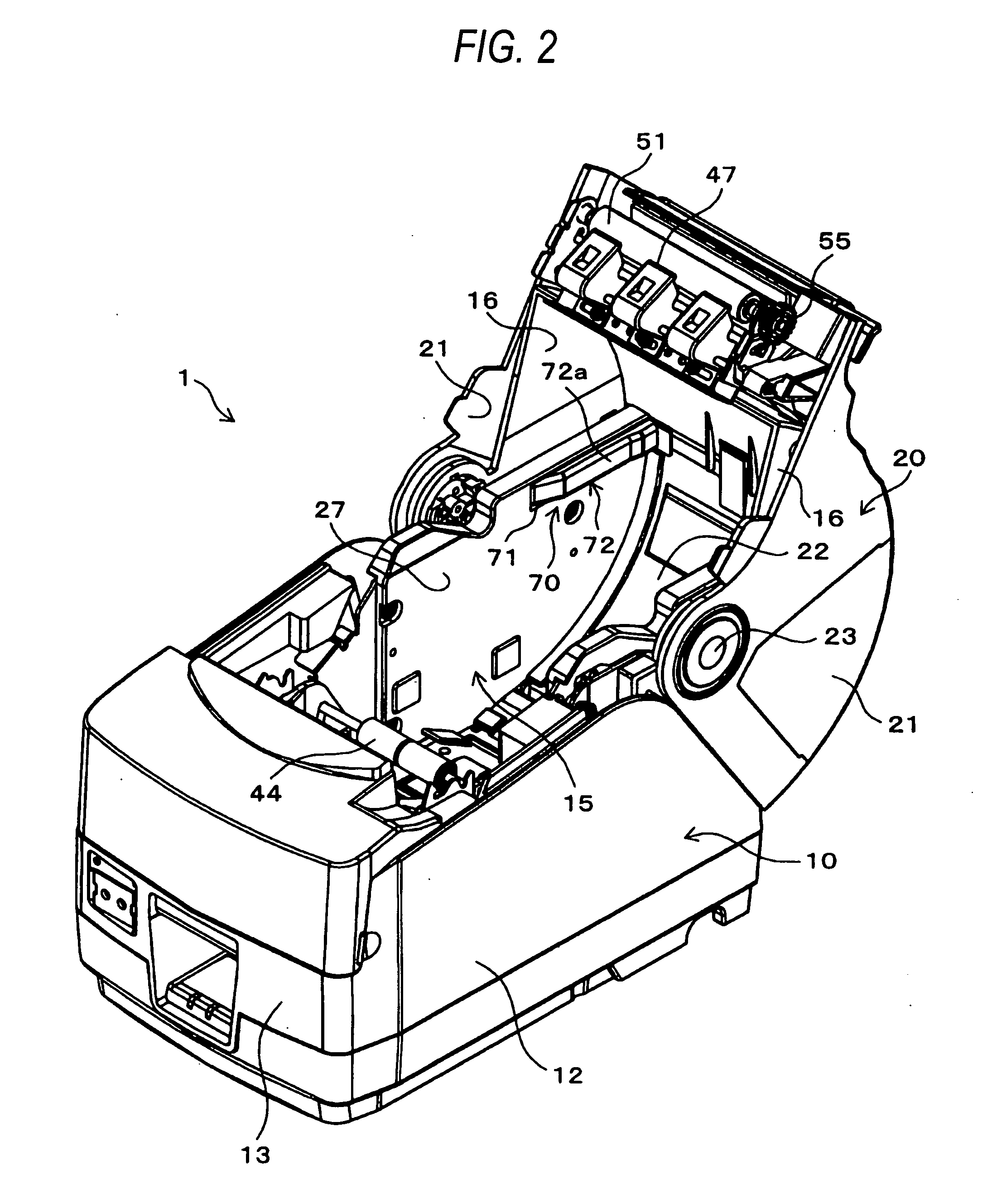

Roll paper holding mechanism and printer

InactiveUS20050232677A1Guaranteed uptimeAvoid inertia forceOther printing apparatusWebs handlingRolling paperCoil spring

Pressing plates press side faces of a roll paper loaded into a roll paper holder unit of the drop-in type, thereby preventing overrun of the roll paper caused by an inertia force from occurring. Each of the pressing plates is urged by two coil springs which are placed respectively on inner and outer circumference sides of the roll paper. The coil spring on the outer circumference side has a higher elasticity than the coil spring on the inner circumference side. According to the configuration, the pressing force of the pressing plates due to the elasticity of the coil springs is gradually reduced in accordance with reduction of a diameter of the roll paper.

Owner:STAR MICRONICS

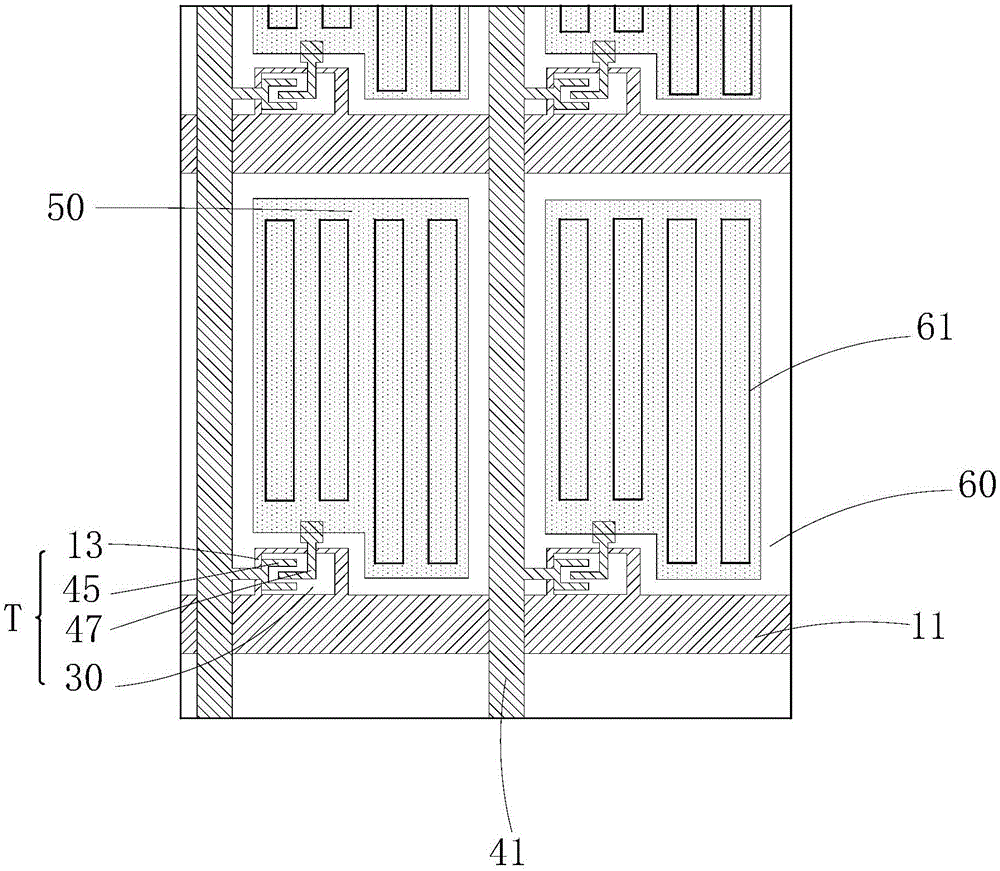

Built-in self-capacitance touch display panel and manufacturing method thereof

ActiveCN105094486AReduce drive costsRealize embedded self-capacitance touch functionNon-linear opticsInput/output processes for data processingCapacitanceComing out

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

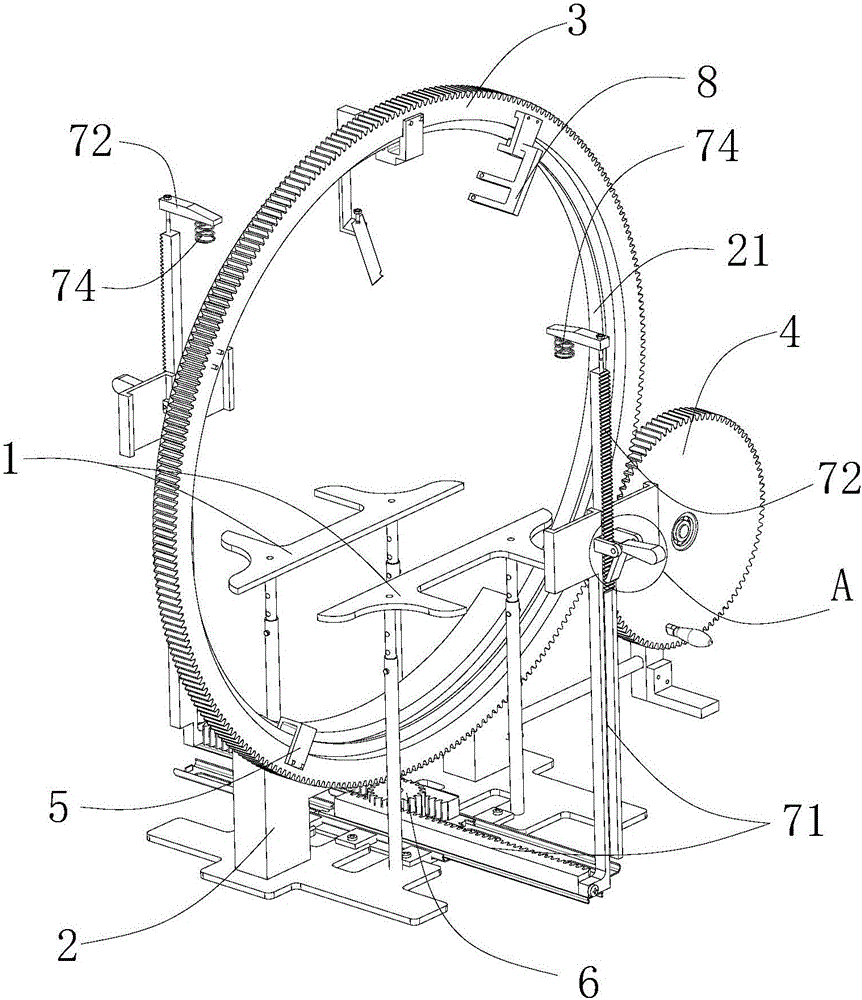

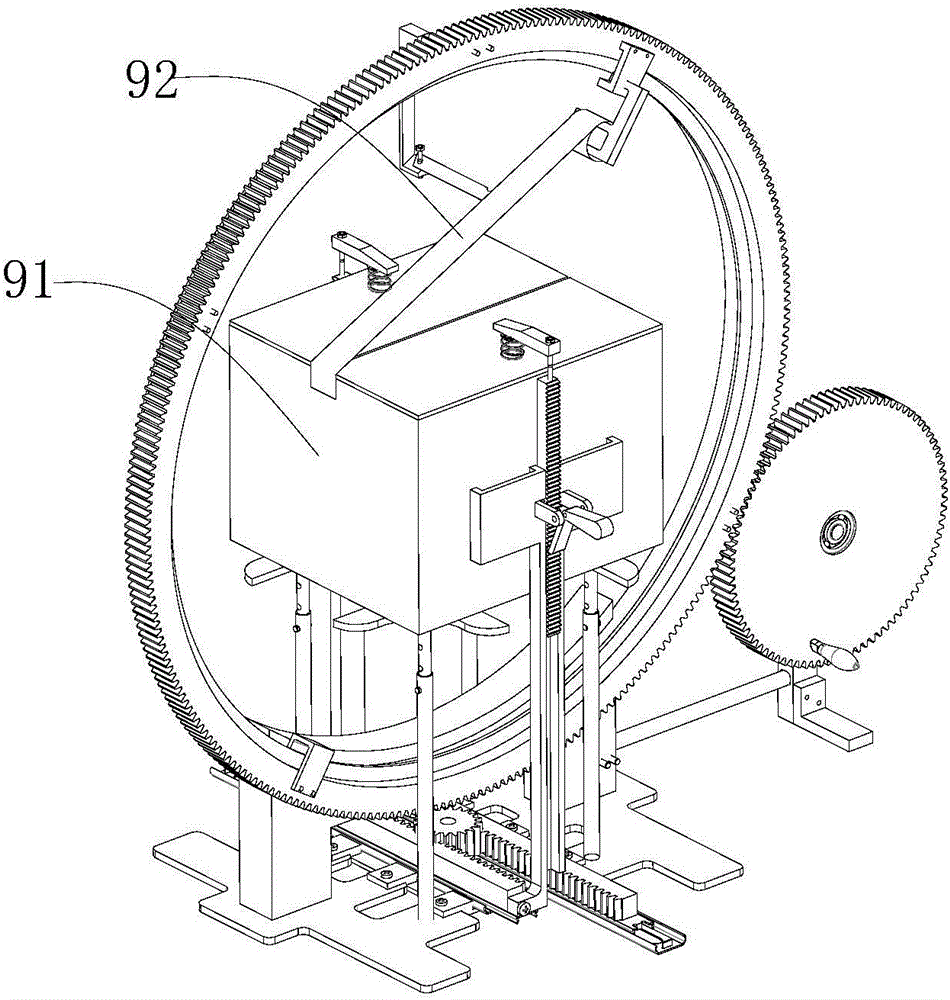

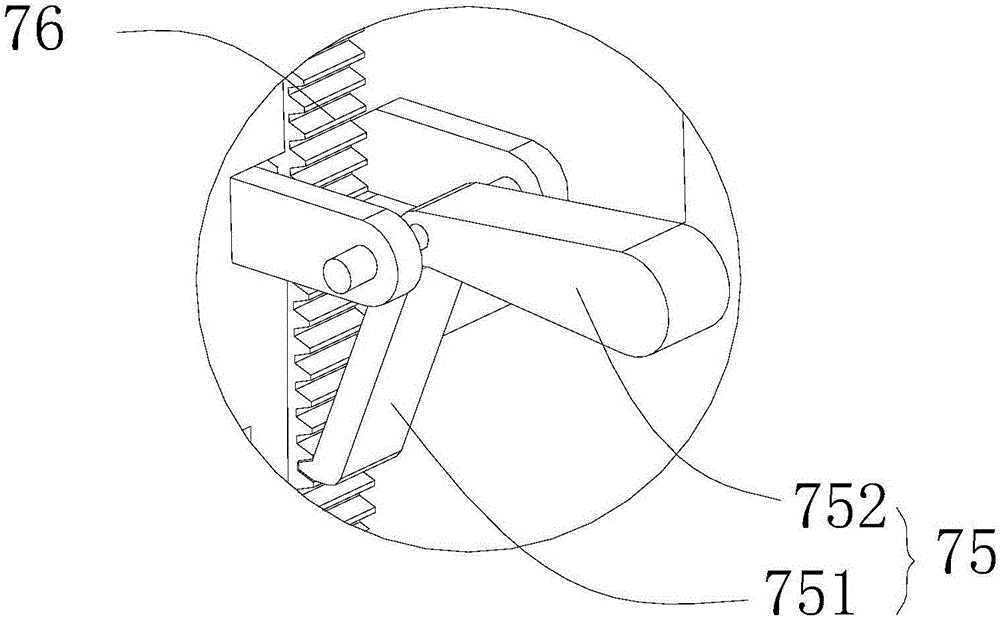

Adhesive tape box sealing device

The invention relates to the technical field of packaging, in particular to an adhesive tape box sealing device, which comprises a support frame, a packaging table and an annular gear ring, wherein the gear ring can be arranged on the support frame in a pivoting manner; the packaging table is arranged in an annular space of the gear ring. When a carton box sealed by an adhesive tape, 360-degree adhesive tape sealing of the carton box can be implemented without overturning the carton box for many times, and therefore time and labor are saved. Compared with an existing assembly line carton box sealing technique, the device has the advantages of simple structure, low cost, small occupied area, manual operability and capability of saving driving cost and energy cost.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

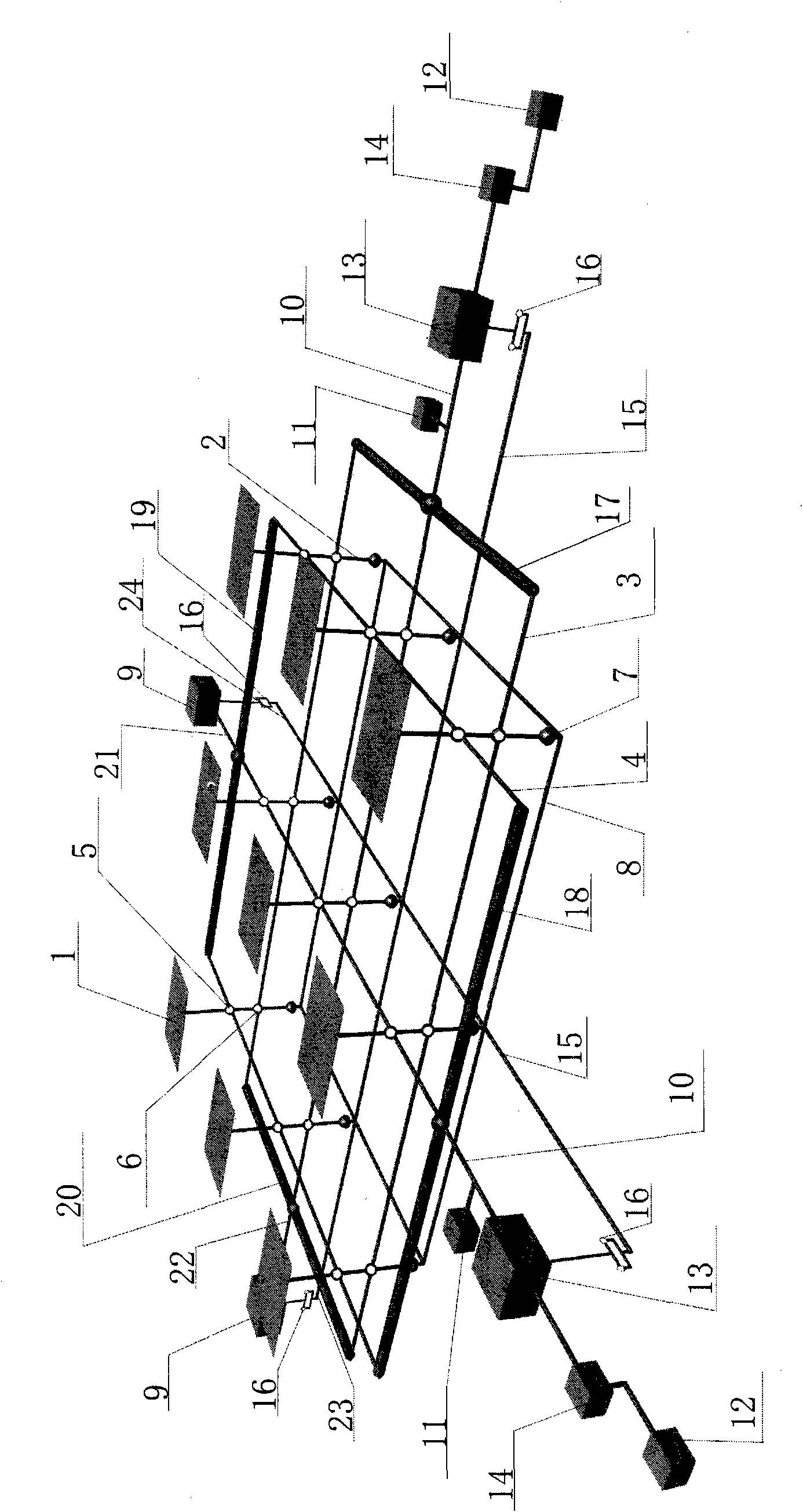

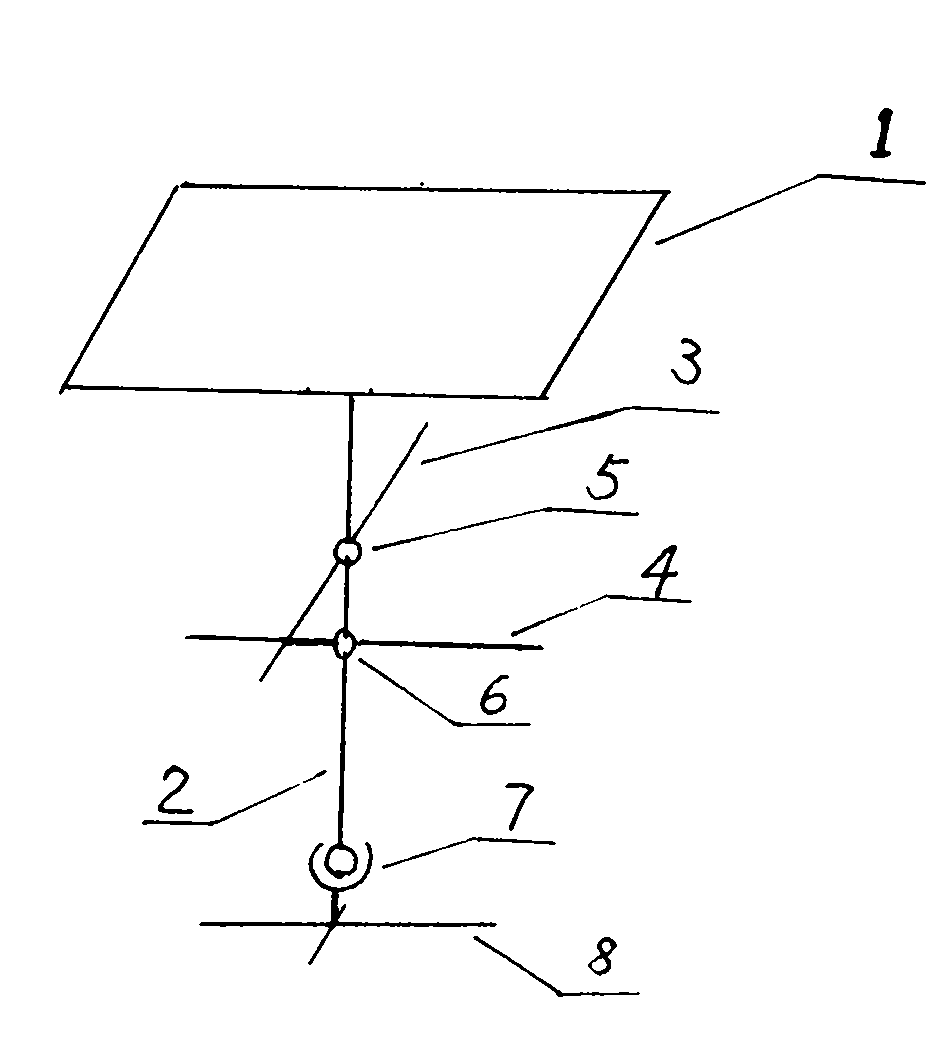

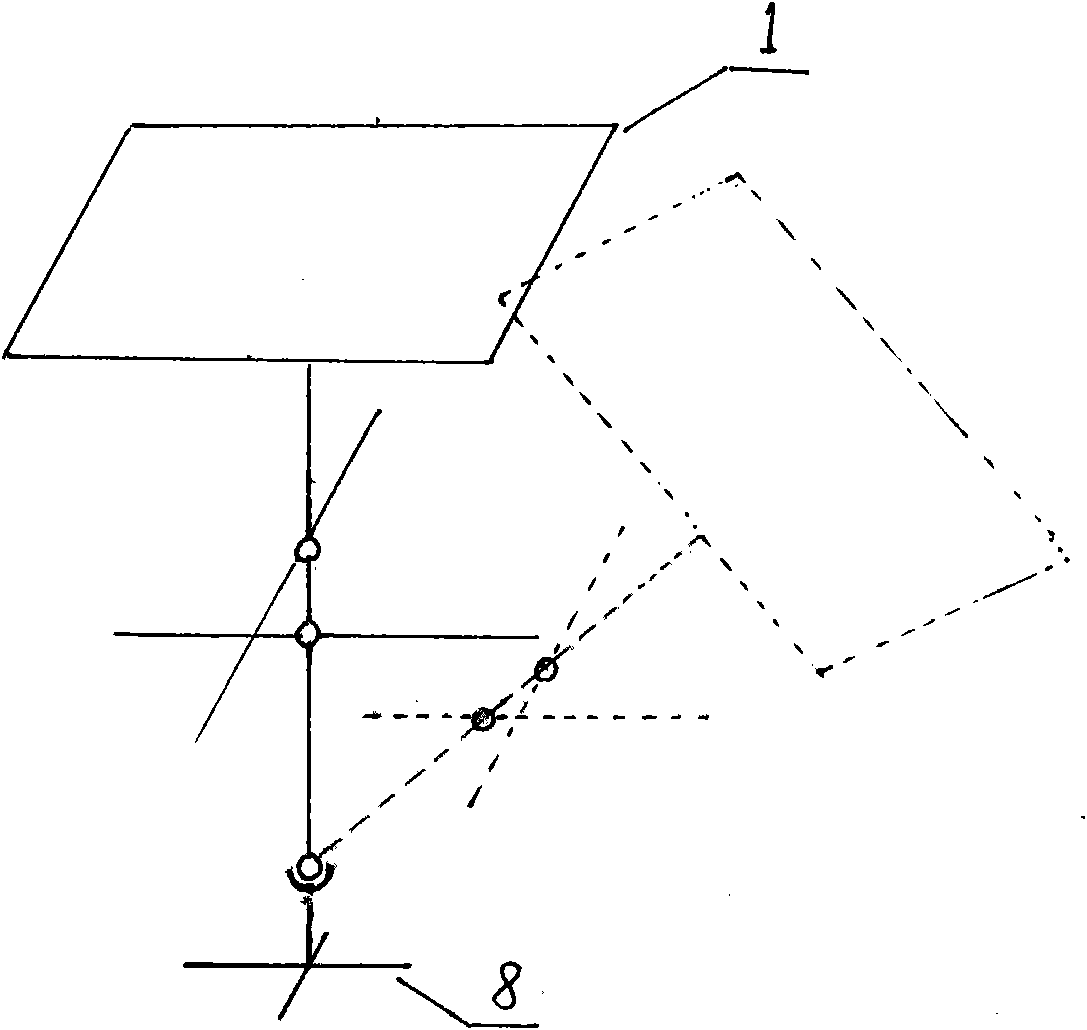

Sun tracking mechanism and application thereof

InactiveCN101976081AEven by forceLow driving powerPosition/direction controlEngineeringCell assembly

The invention relates to an automatic sun tracking device, and belongs to the technical field of solar utilization. The device comprises a condensation module array, a drive mechanism, a tracking control circuit, a sensor and the like. A set of control and drive mechanism controls and drives hundreds of to tens of thousands of sunlight receiving devices to track the sun; and the receiving devices comprise a condensation or non-condensation photovoltaic cell assembly, a heat energy receiving device, a sunlight reflector, a sunlight refractor and the like and are used for photovoltaic power generation or heat energy application and used for reflecting or refracting the sunlight to a receiver on a tower for photovoltaic power generation or heat energy application and the like. The device has simple structure, is not easy to deform, has good wind resistance, high tracking precision and low cost, and can be used for various solar utilization systems.

Owner:邱定平

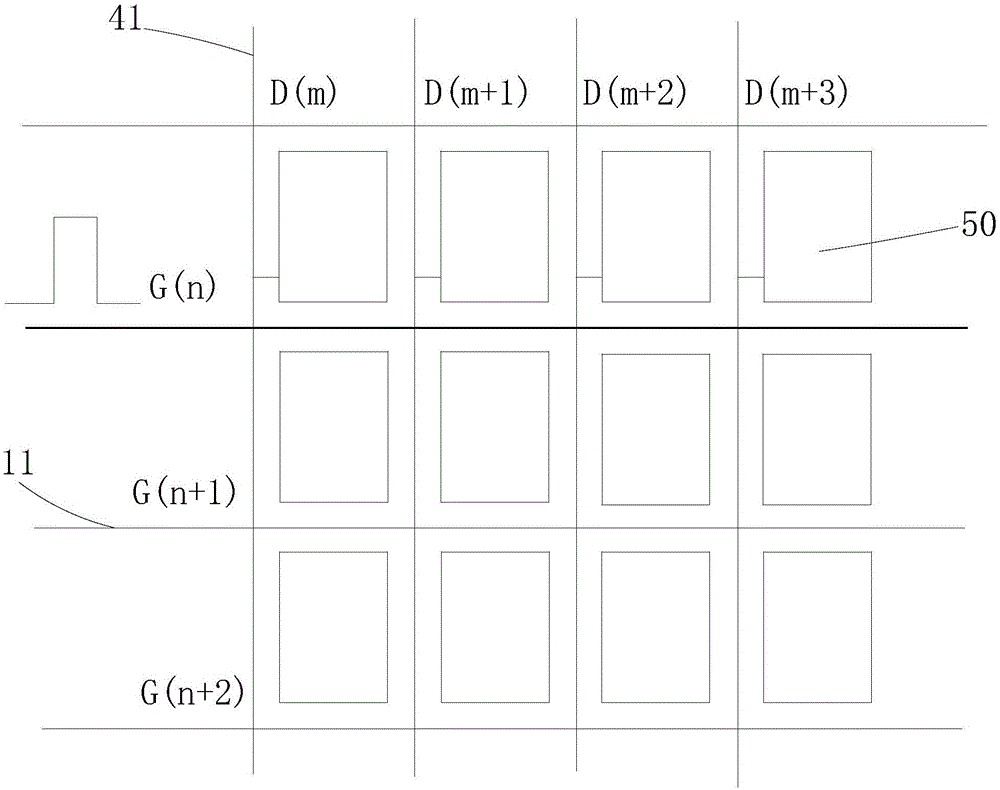

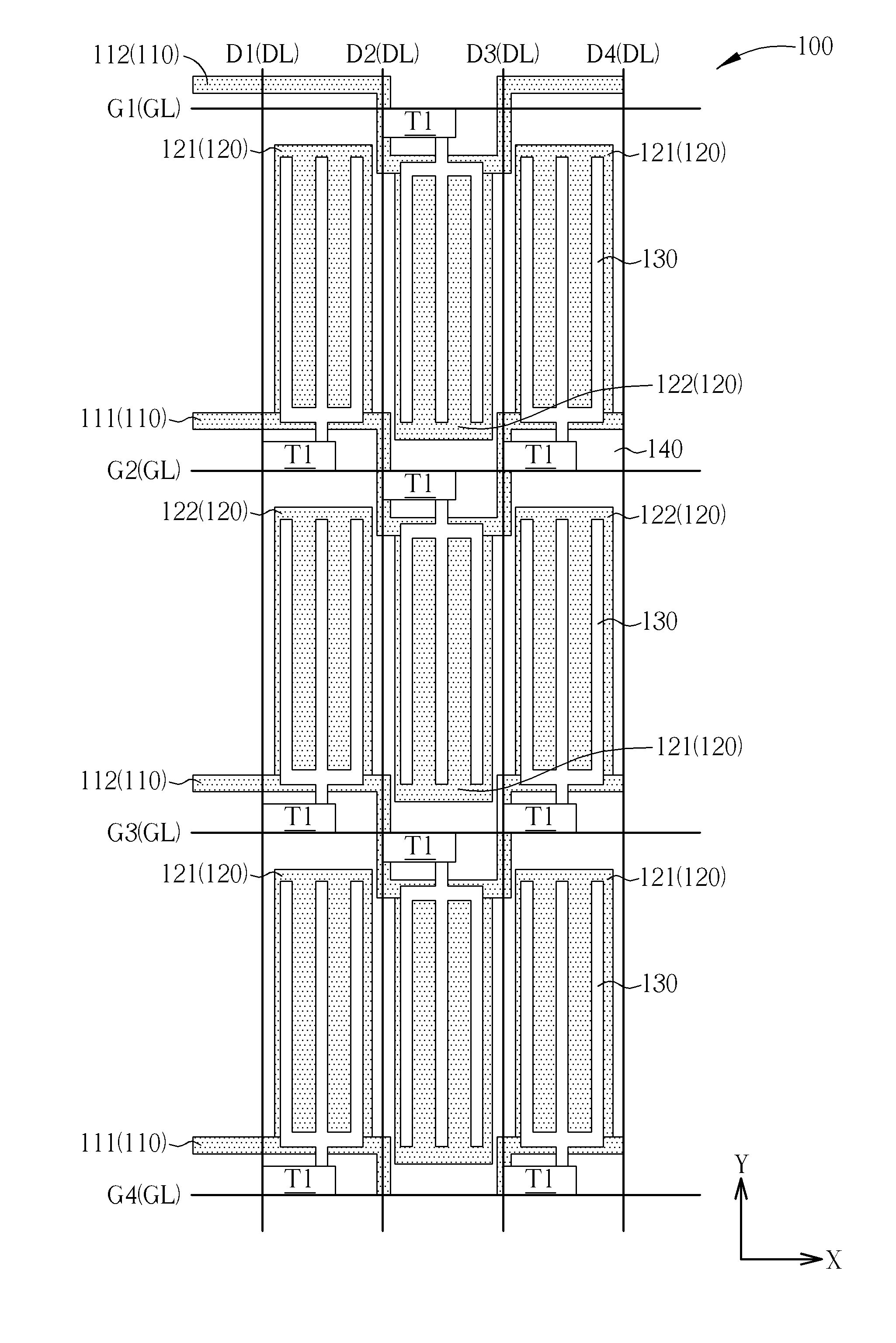

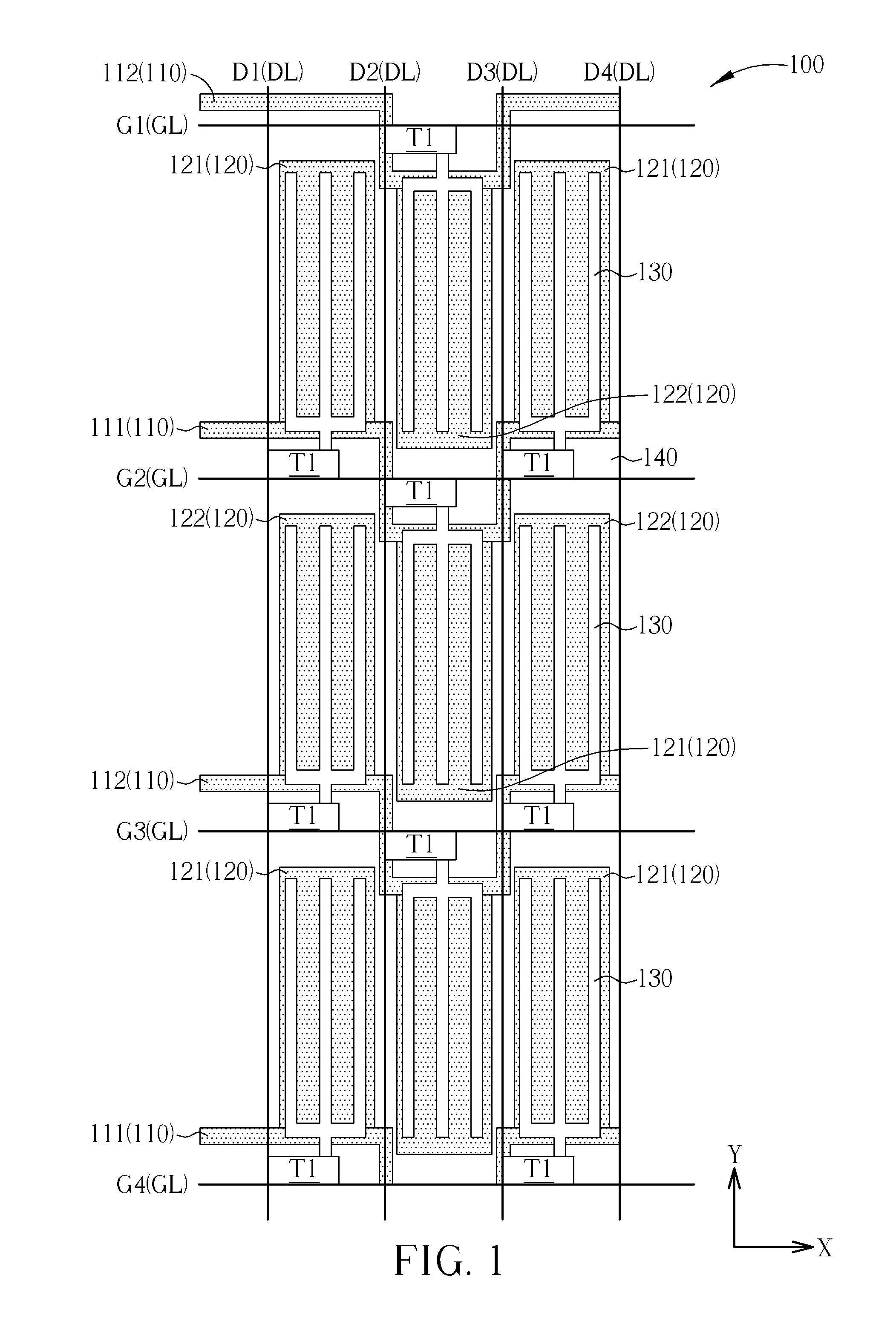

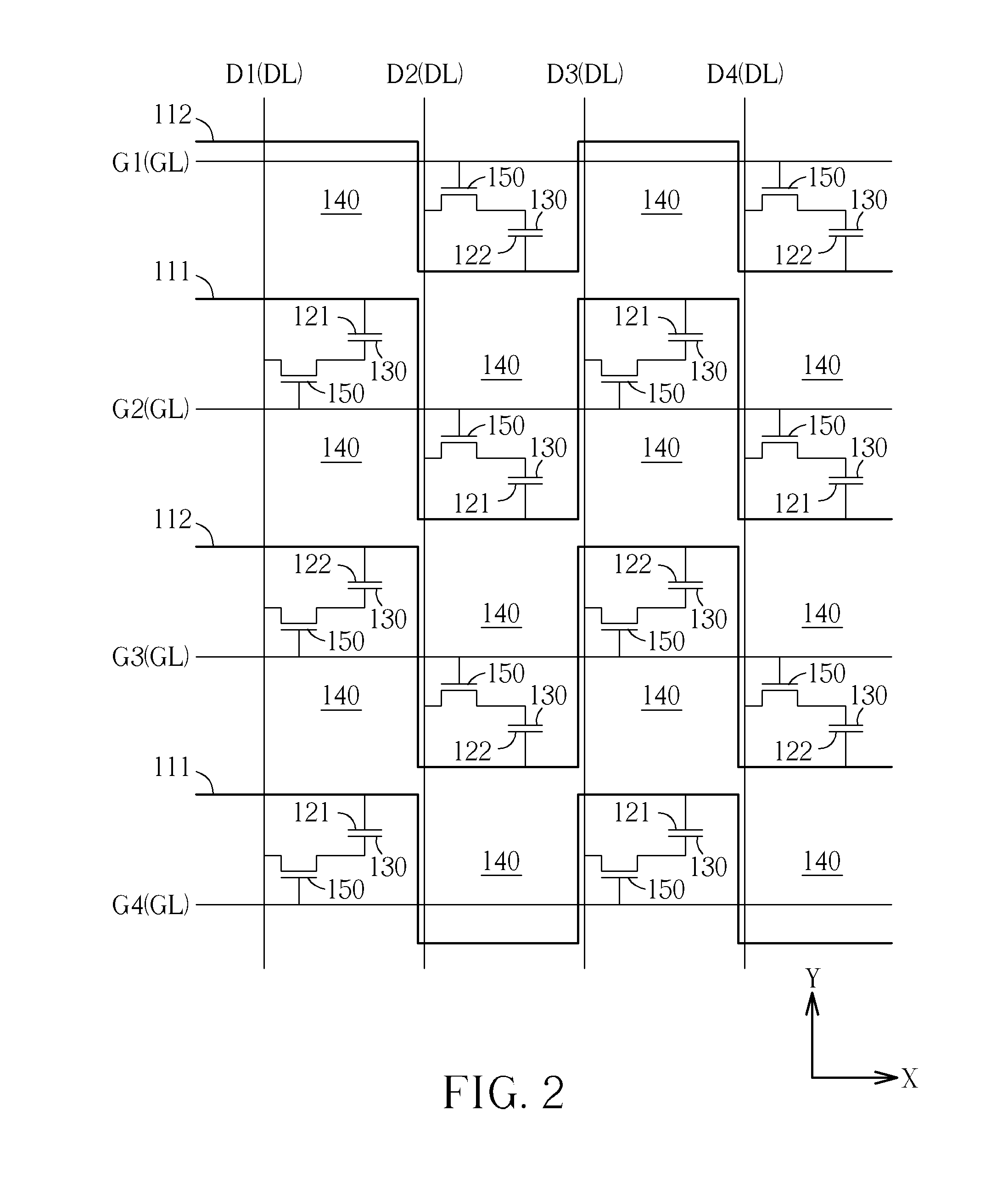

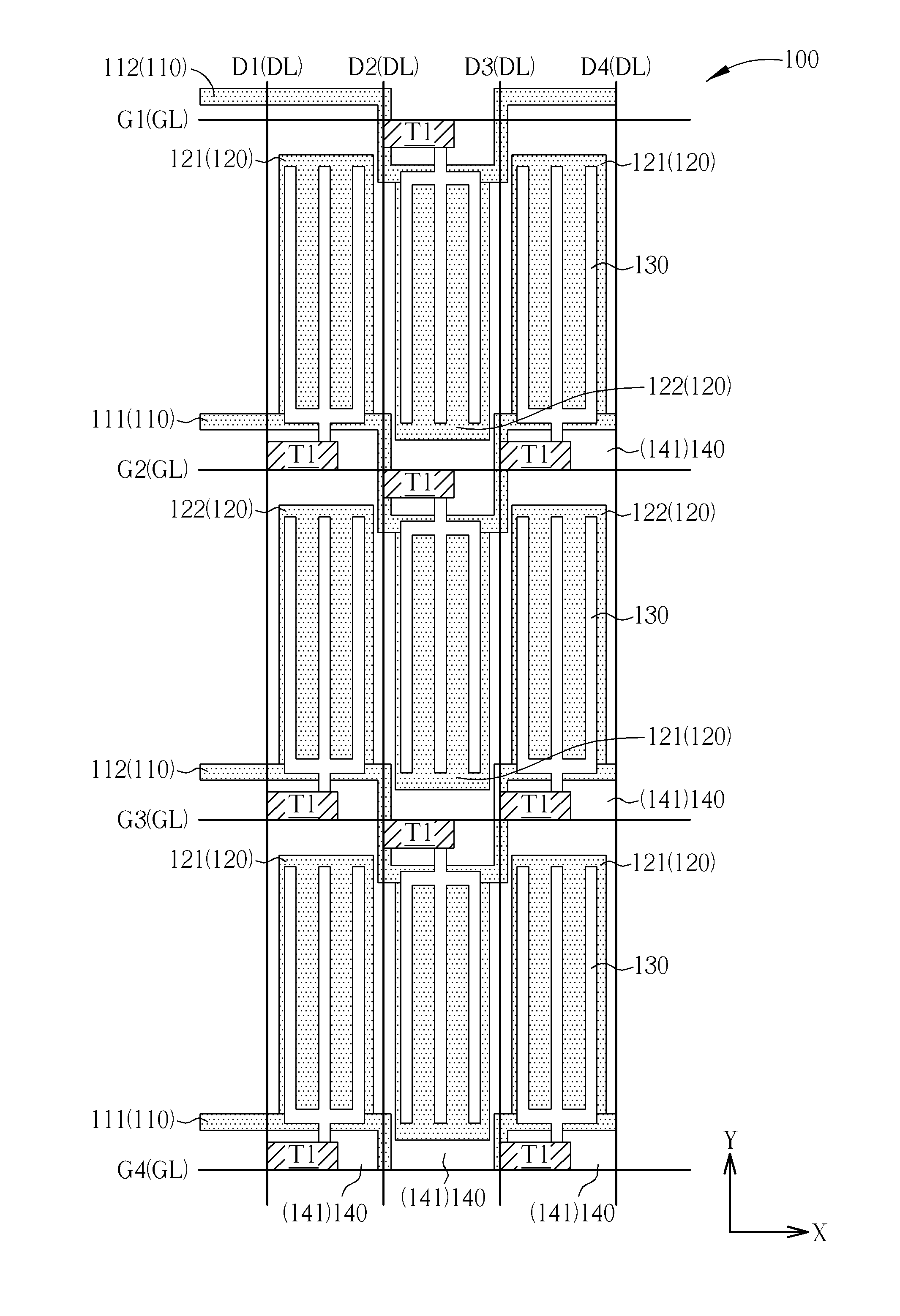

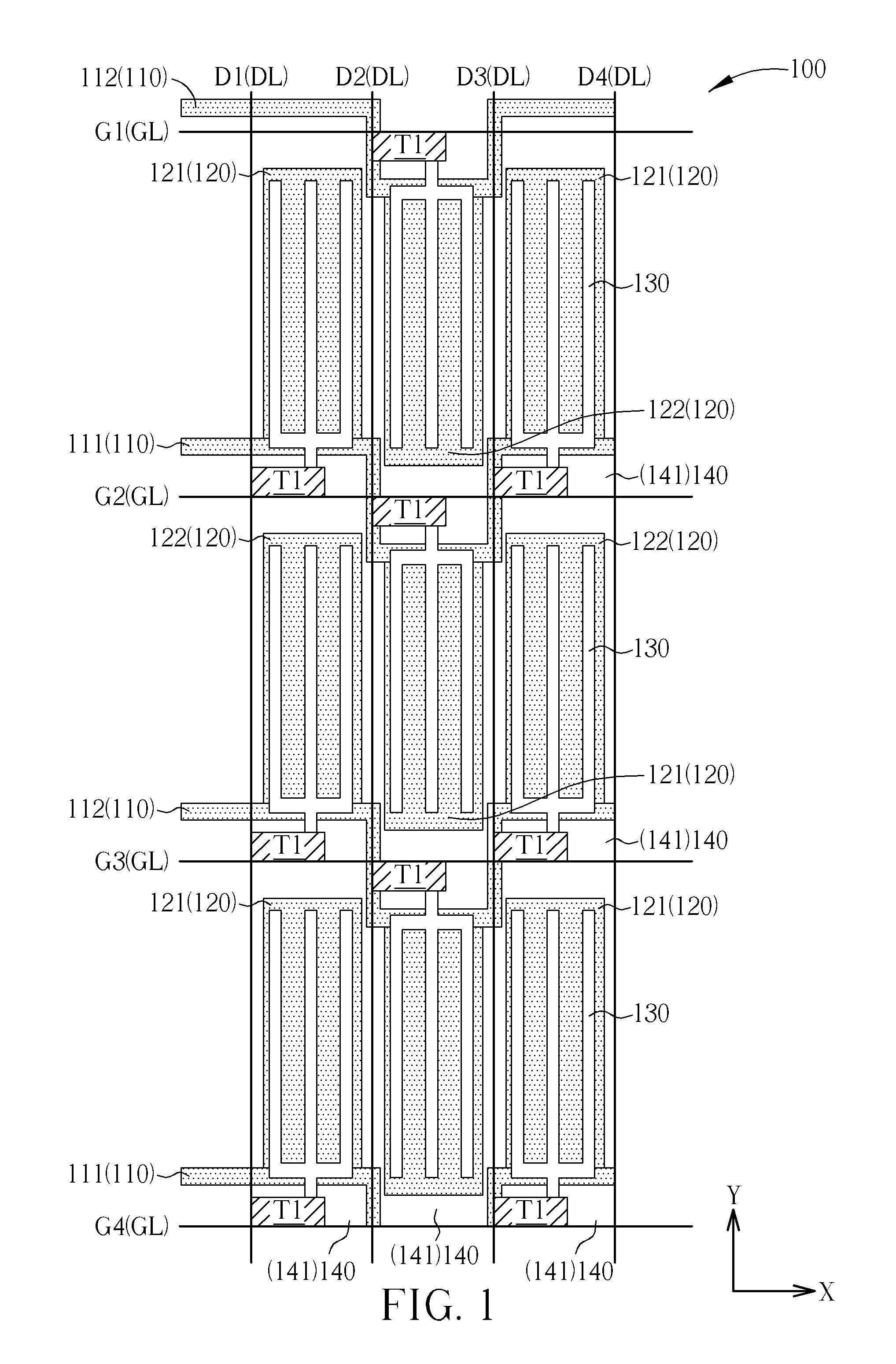

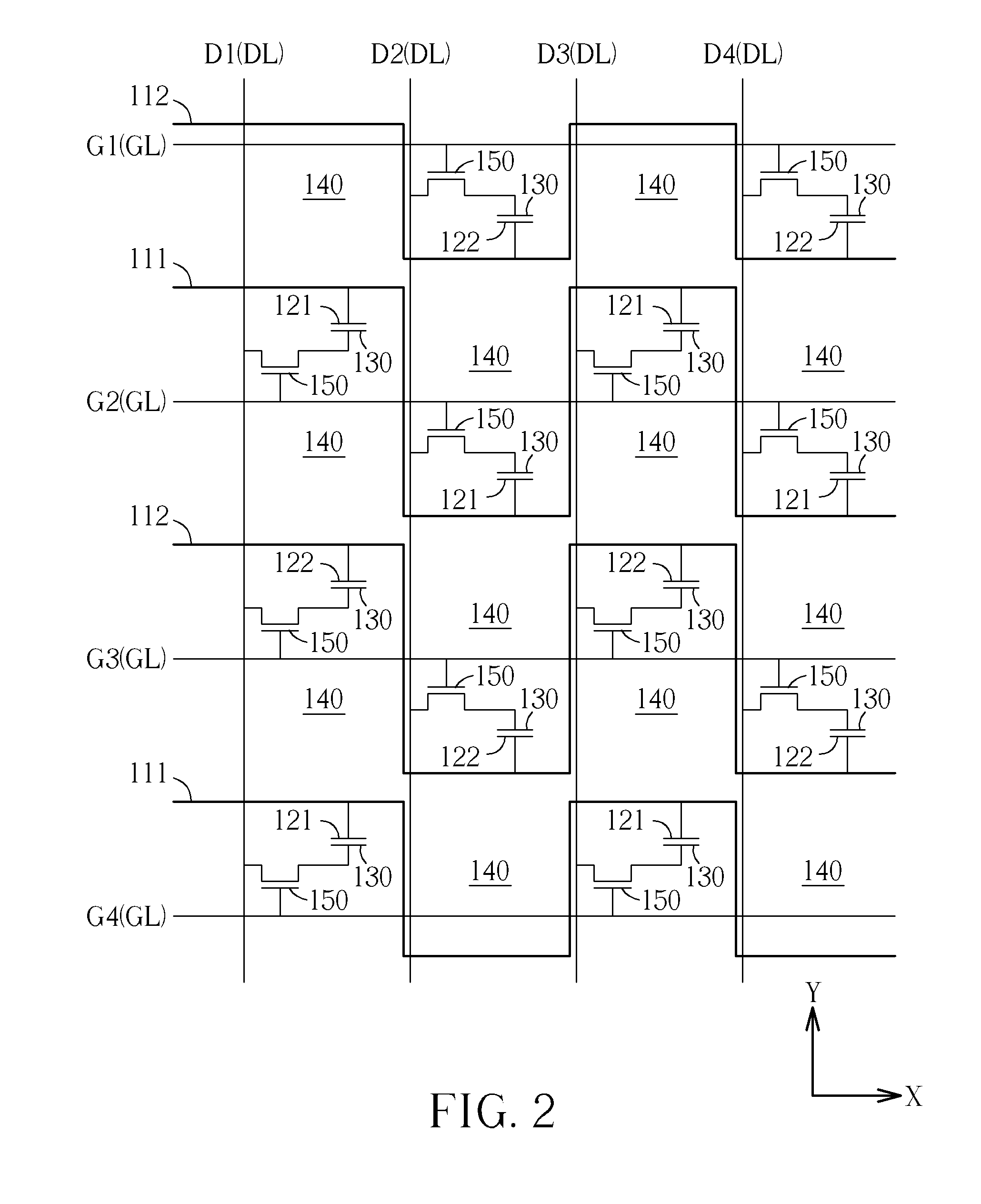

Pixel array of fringe field switching liquid crystal display panel and driving method thereof

ActiveUS20120249943A1Simple driving methodReduce drive costsStatic indicating devicesNon-linear opticsLiquid-crystal displayCommon line

A pixel array of a fringe field switching (FFS) liquid crystal display panel includes a plurality of gate lines, a plurality of data line, a plurality of pixel electrodes, and a plurality of common lines. The gate lines are disposed parallel to each other along a first direction. The data lines are disposed parallel to each other along a second direction. A plurality of sub-pixel regions is defined by the gate lines and the data lines. The common lines are disposed along the first direction and electrically isolated from each other. Each of the common lines includes a plurality of common electrodes extending along the second direction. The two adjacent common electrodes of each common line are respectively disposed in the two adjacent sub-pixel regions which are located in different rows.

Owner:AU OPTRONICS CORP

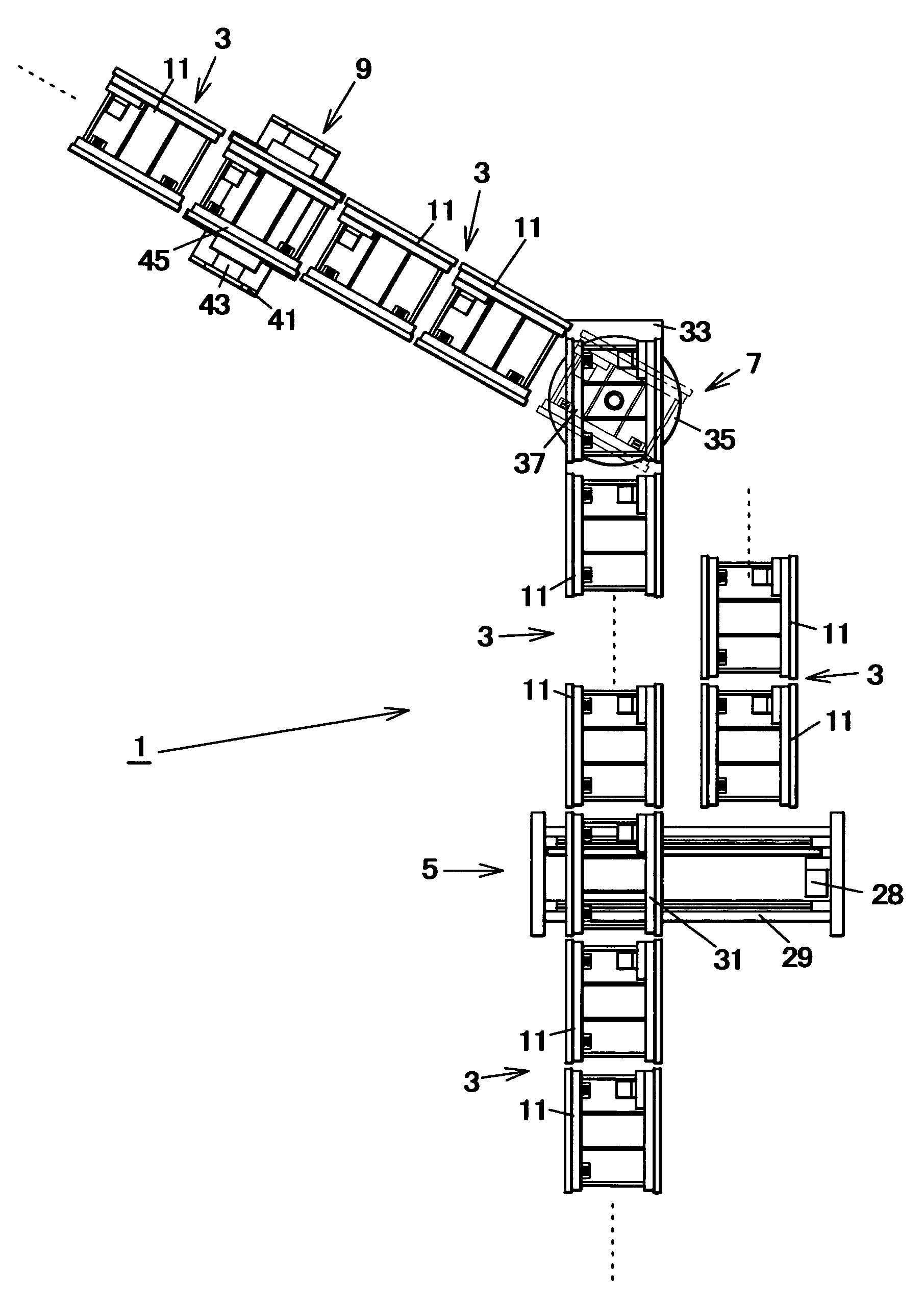

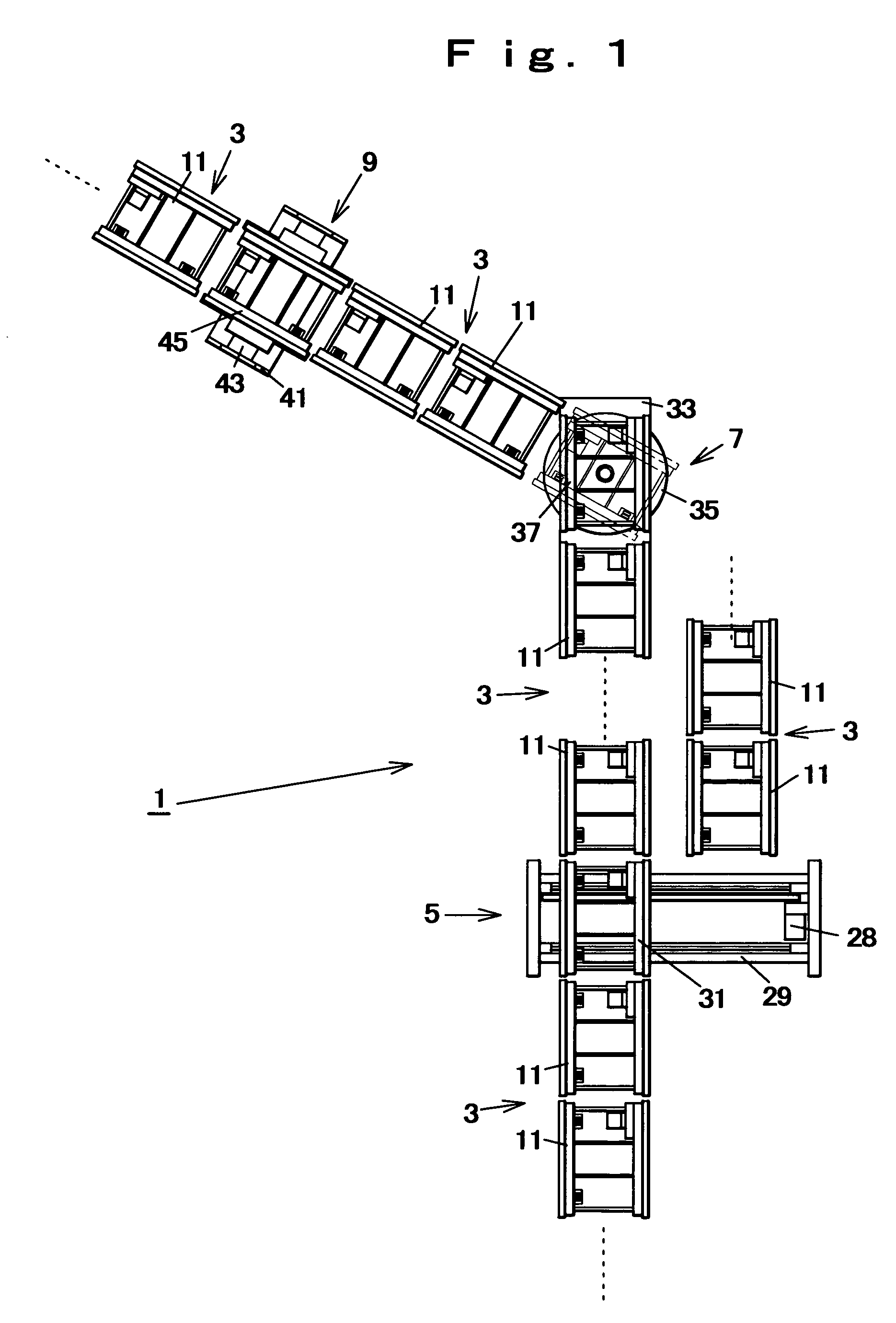

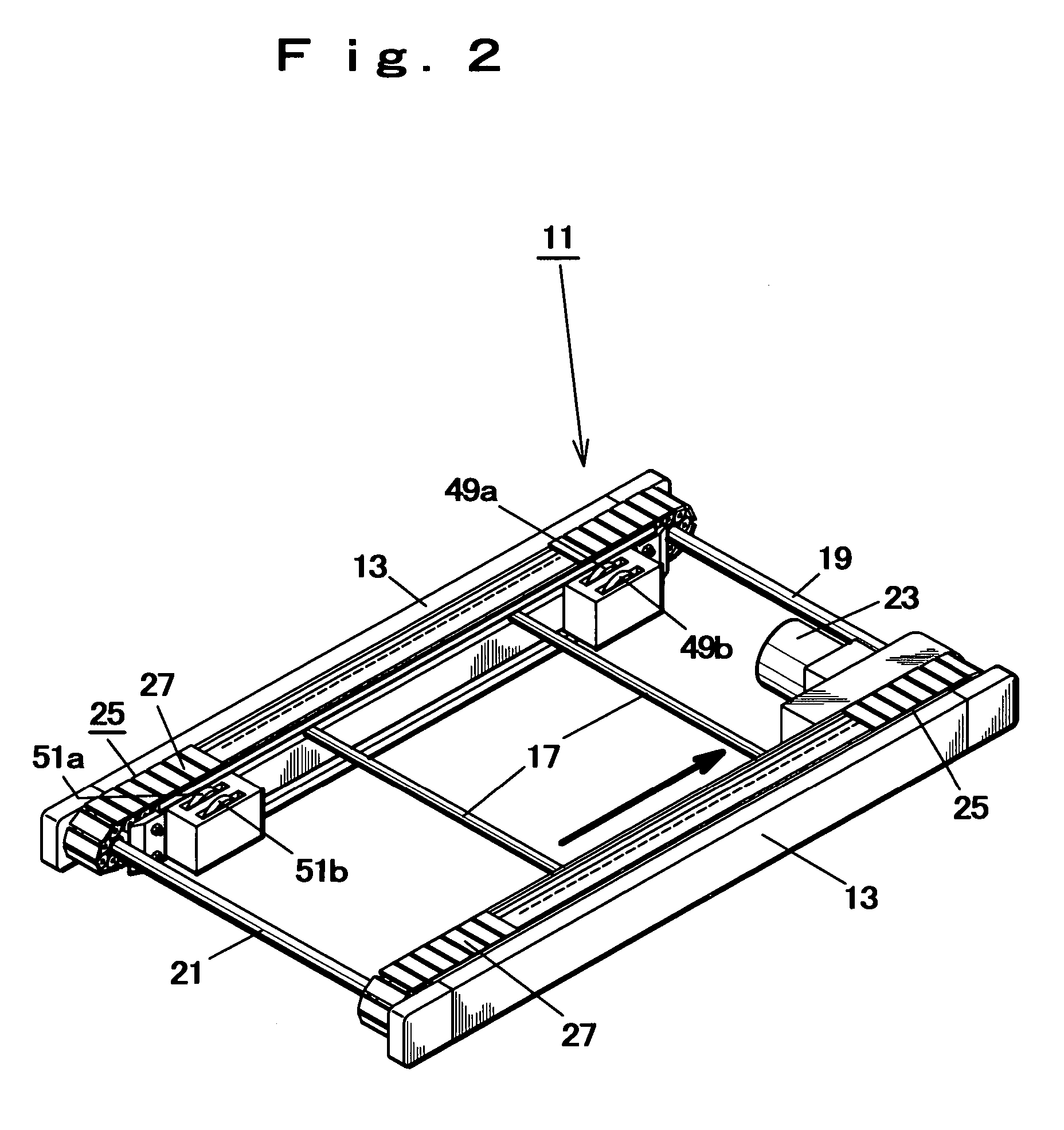

Free flow conveyance system

ActiveUS7275635B2Simplify workTroublesome workControl devices for conveyorsPackagingEngineeringMechanical engineering

A free flow conveyance system includes a plurality of linear conveyance apparatuses each having a plurality of unit conveyors linearly arranged, and a pivot conveyance apparatus having a unit conveyor which is arranged between the linear conveyance apparatuses being so arranged as to form a predetermined angle, wherein product sensors are arranged at the conveying-in side as well as at the conveying-out side of the respective unit conveyors of the linear conveyance apparatuses and the pivot conveyance apparatus, when a product is conveyed to a unit conveyor of the upstream side along the conveyance direction and product sensors of the unit conveyor become of the sensing-product state, in case respective product sensors of a unit conveyor of the downstream side along the conveyance direction are of the not-sensing-product state, these unit conveyors are driven respectively to convey the product, and when the product is consequently conveyed to the unit conveyor of the downstream side along the conveyance direction and conveying-out side product sensors thereof become of the sensing-product state, the respective adjacent unit conveyors are stopped, enabling free flow conveyance.

Owner:STARTECHNO

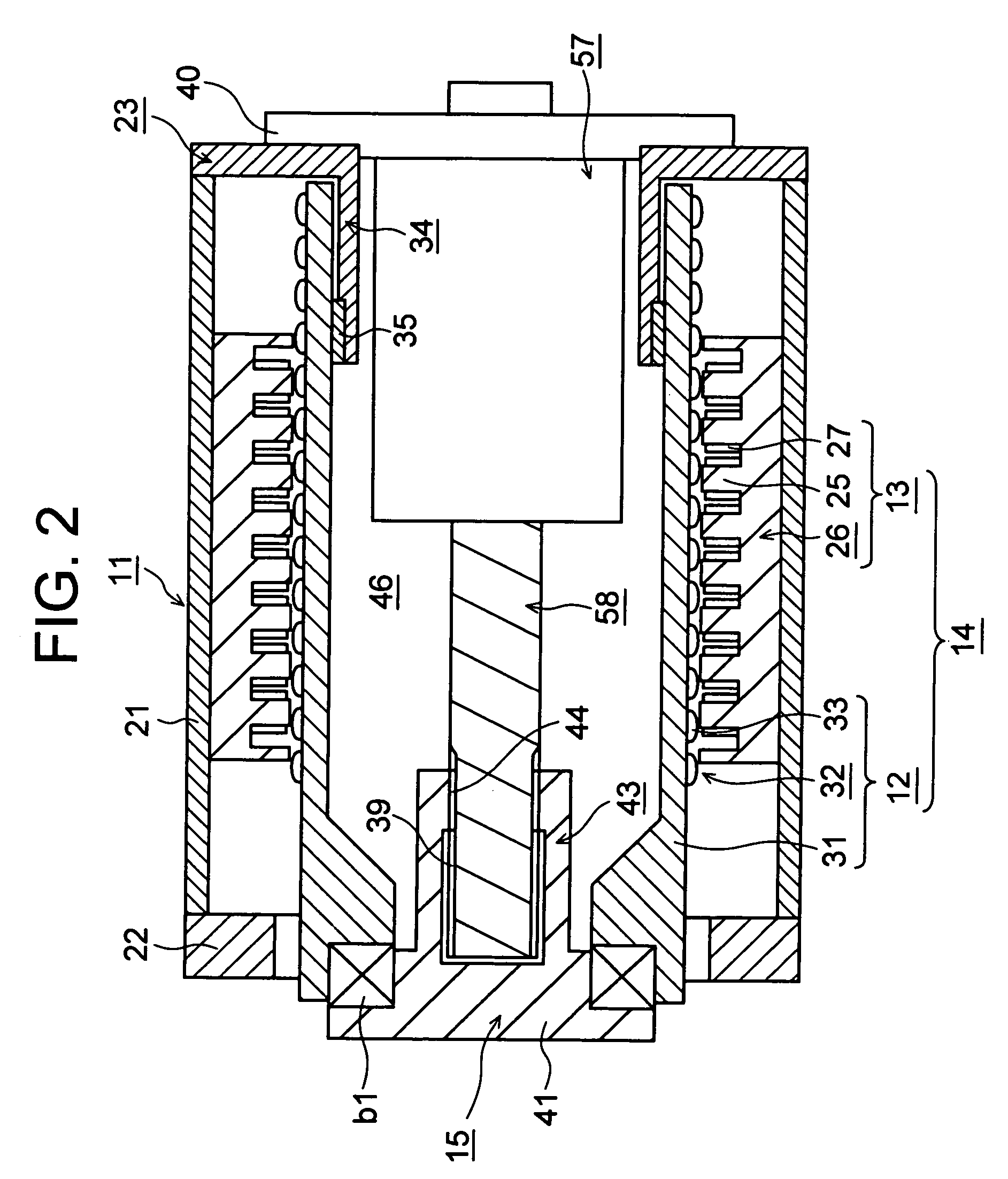

Electric potential sensor, and image forming apparatus

InactiveUS7212007B2Small sizeMass can be lightenedResistance/reactance/impedenceElectrography/magnetographyImage formationEngineering

Disclosed in a non-contacting electric potential sensor capable of being readily reduced in its size, which includes a detecting electrode, an electrically-conductive movable shutter, and a driving unit for driving the electrically-conductive movable shutter. The detecting electrode is to be placed facing a measurement object whose electric potential is to be measured. The electrically-conductive movable shutter is disposed so as to be movably located in a spacing formed between the detecting electrode and the measurement object when the detecting electrode is placed facing the measurement object, so that an exposure degree of the detecting electrode against the measurement object can be controlled. The driving unit includes a current injecting unit for selectively injecting current into the electrically-conductive movable shutter in a direction approximately perpendicular to a moving direction of the electrically-conductive movable shutter.

Owner:CANON KK

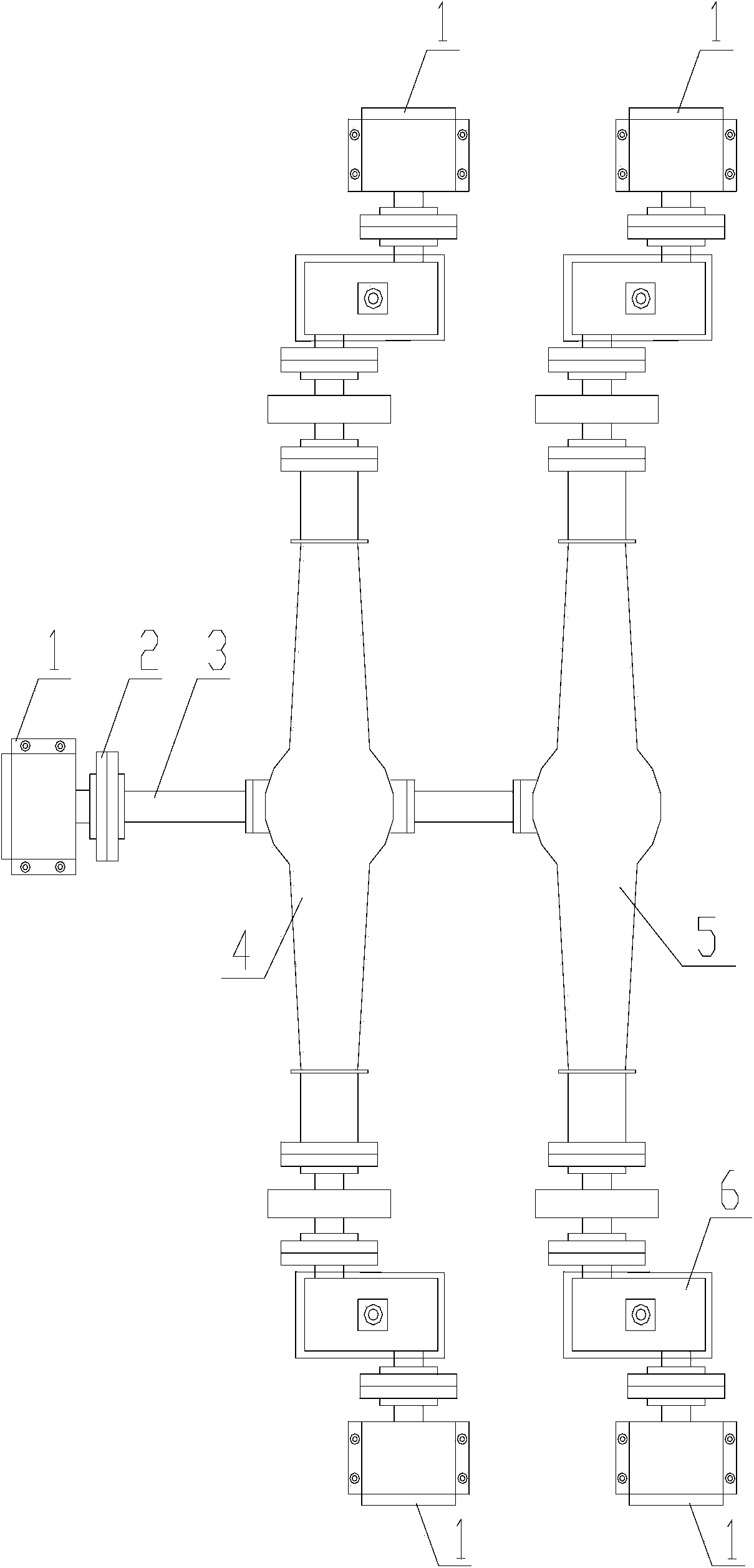

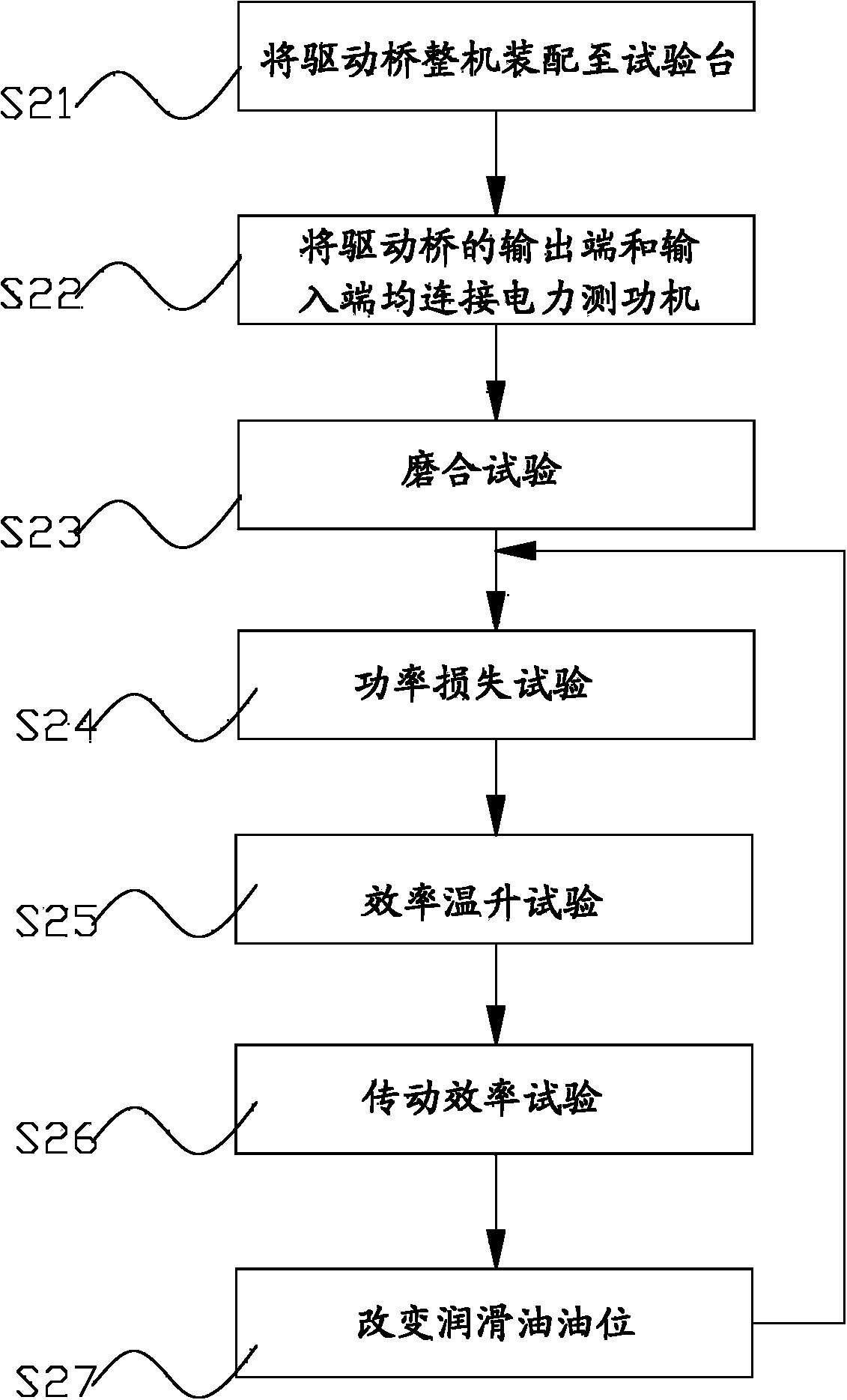

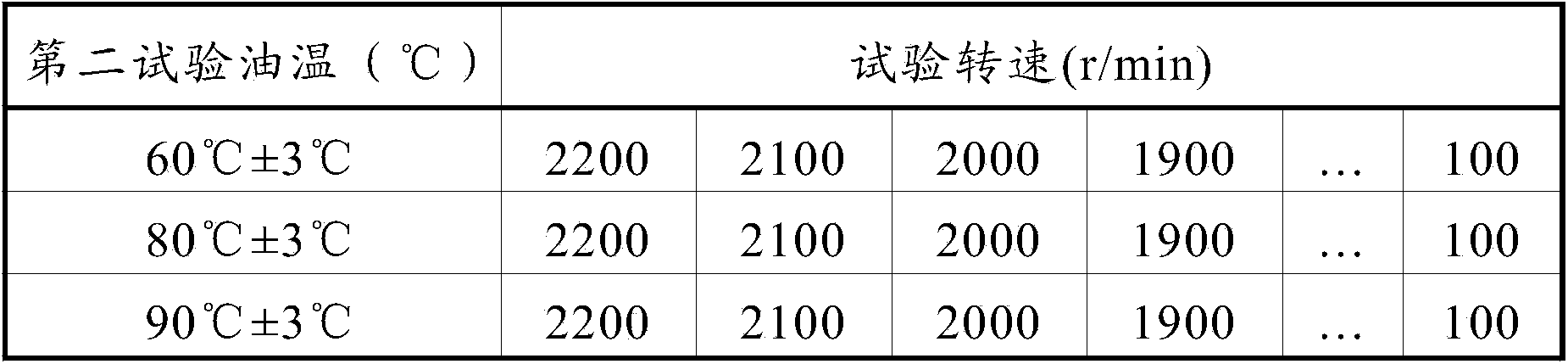

Drive axle testing method and system

ActiveCN103528815AImprove transmission efficiencyAids in comprehensive testingVehicle testingMachine gearing/transmission testingDynamometerEngineering

The invention discloses a drive axle testing method and a drive axle testing system. The method comprises the following steps of assembling the whole drive axle on a test bench; connecting the output end and the input end of the drive axle to an electric dynamometer; setting a plurality of first testing vehicle speeds and first testing input torques; detecting the output torque of the drive axle under different working conditions consisting of the set first testing vehicle speeds and the set first testing input torques to obtain the transmission efficiency of the drive axle under different working conditions. According to the drive axle testing method and the drive axle testing system, the transmission efficiency of the drive axle can be obtained, and can be used for reflecting the efficiency of transmitting the power of an engine to a wheel through the drive axle, so that the comprehensive performance detection of the drive axle before delivery is facilitated, and whether a product is qualified or not can be judged according to a more scientific standard; moreover, a user can control a vehicle to selectively work under the working condition under which the transmission efficiency is the highest according to performance parameters on the premise of meeting normal driving requirements to fulfill the aims of saving energy resources and lowering the driving cost.

Owner:WEICHAI POWER CO LTD

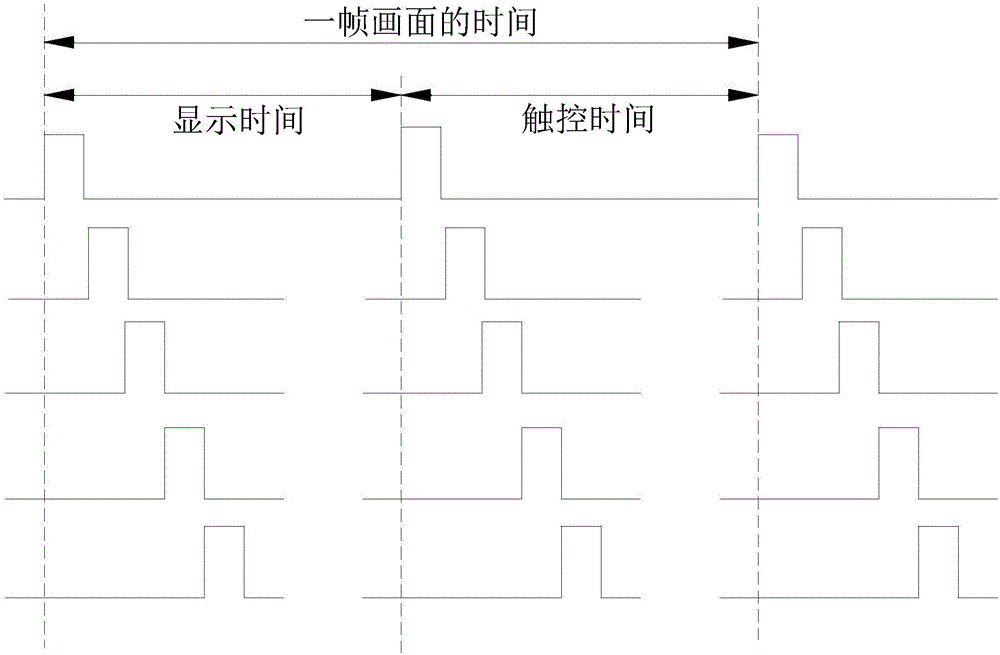

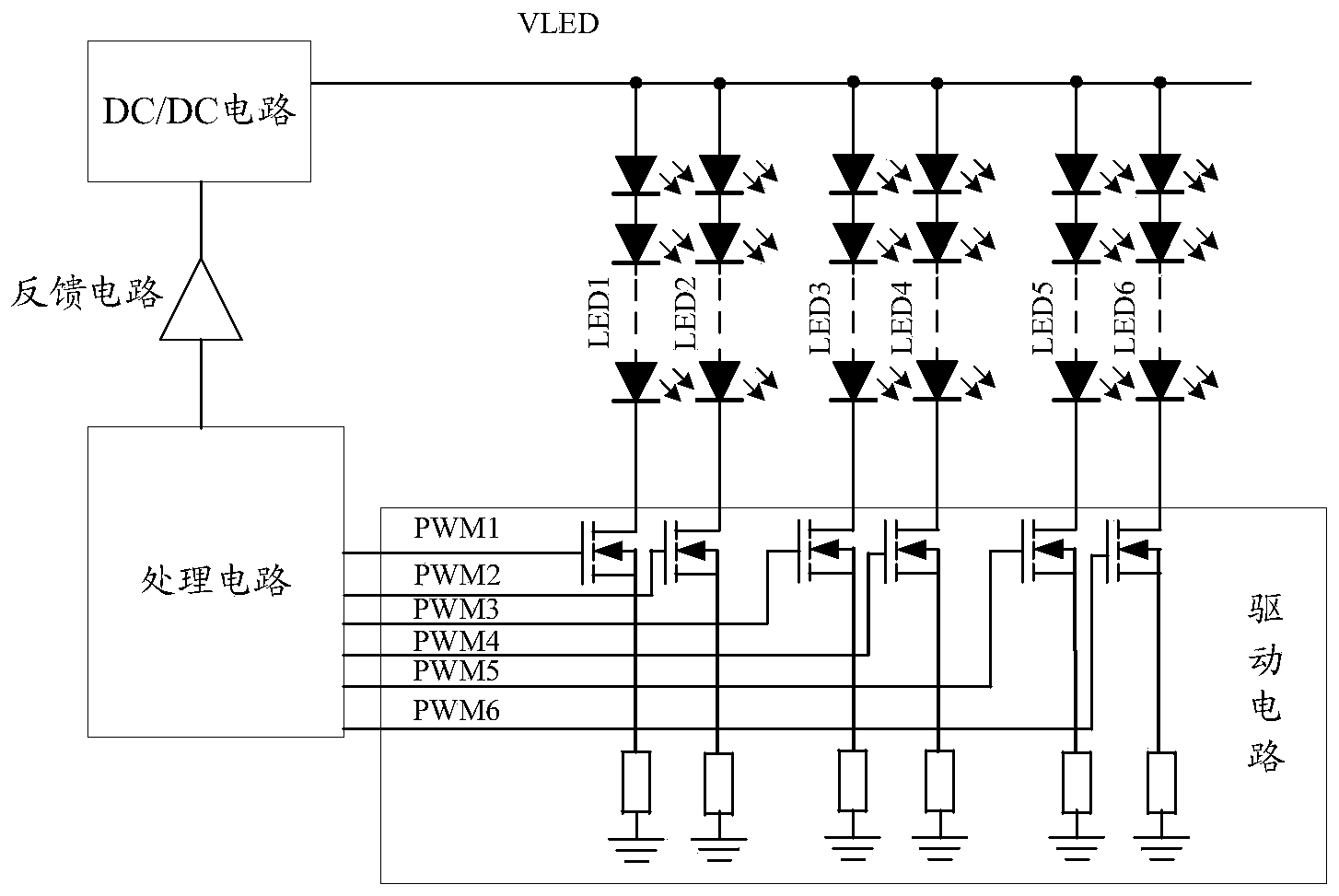

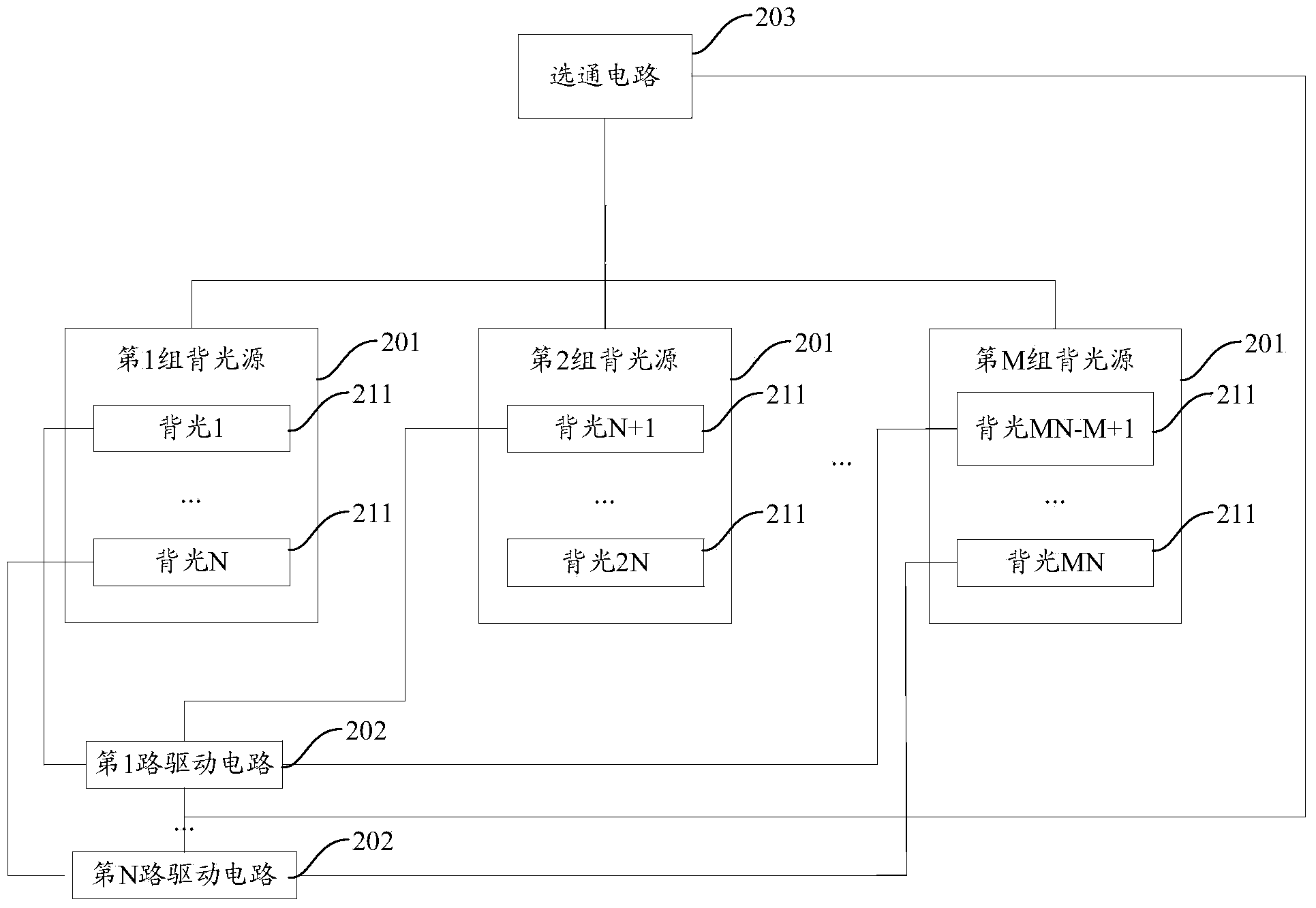

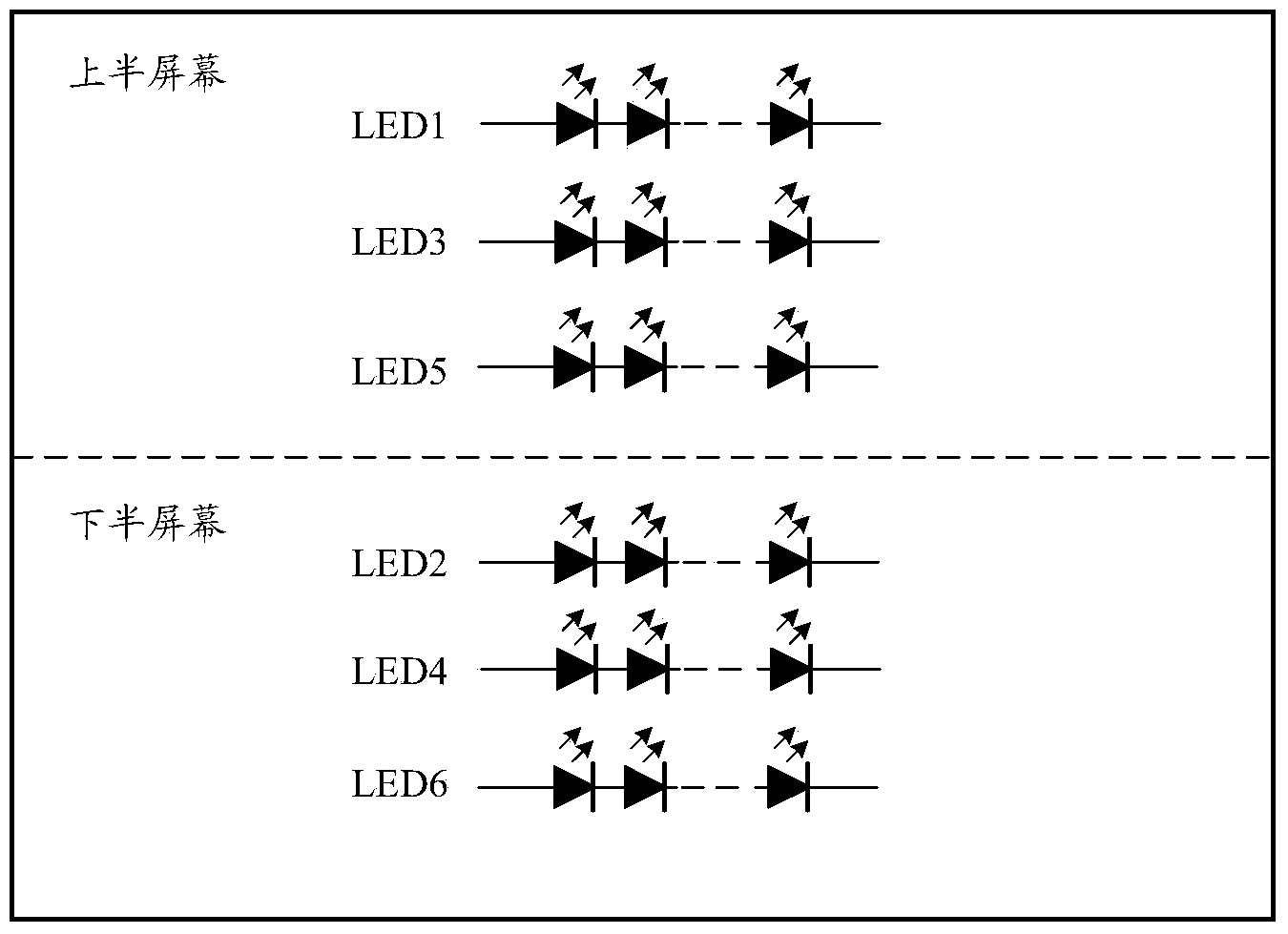

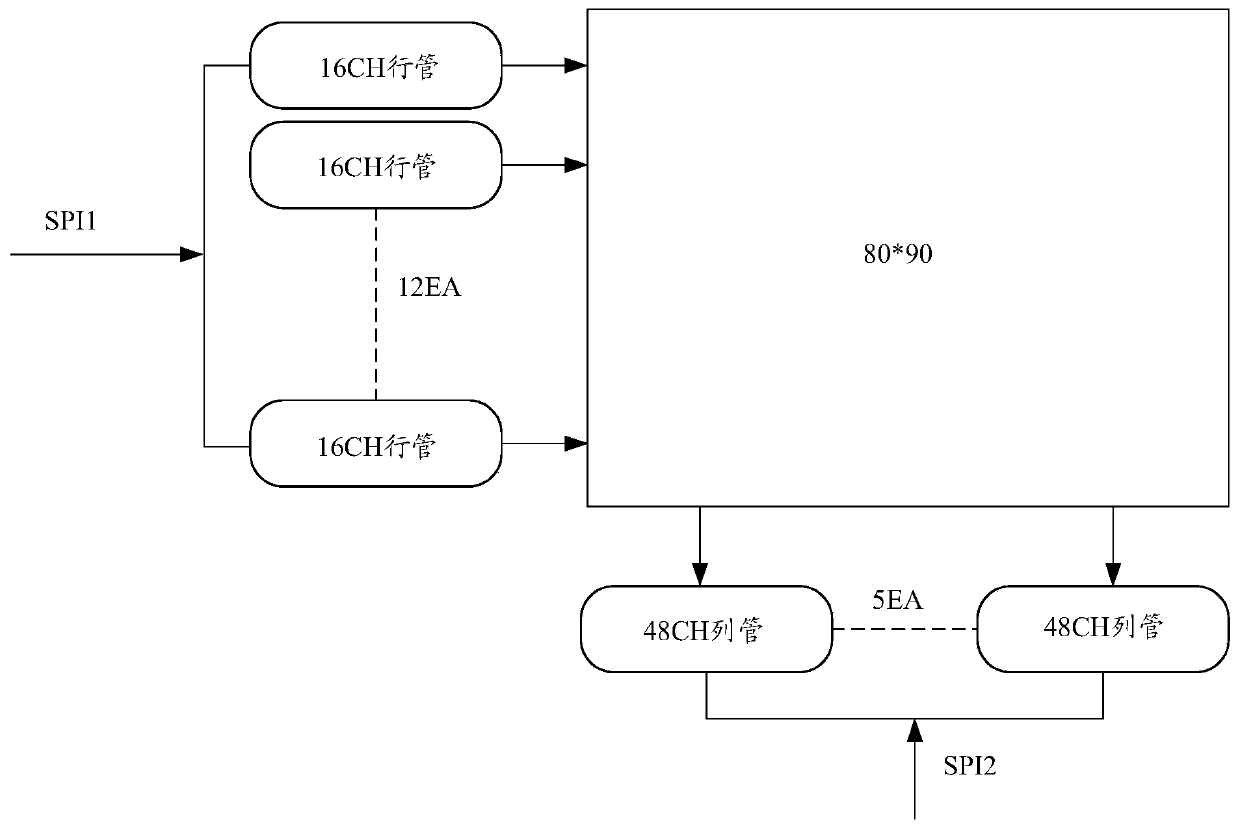

Driving system and method of backlight source

ActiveCN103839529AReduce the numberReduce complexityStatic indicating devicesComputer scienceTime Sharing Option

The invention provides a driving system and method of a backlight source. The system specifically comprises M sets of backlight sources, N paths of driving circuits and a gating circuit, wherein each set of the backlight sources comprises N paths of backlight, M is an integer larger than or equal to 2, the N paths of backlight in each set of the backlight sources are connected with the N paths of the driving circuits respectively, and the gating circuit is connected with the M sets of the backlight sources and used for carrying out time sharing option on one set of the backlight sources in the M sets of the backlight sources so as to enable the one set of the backlight sources in the M sets of the backlight sources to be driven by the N paths of the driving circuits to emit light in one scanning cycle. According to the system and method, the number of the driving circuits can be reduced.

Owner:HISENSE VISUAL TECH CO LTD

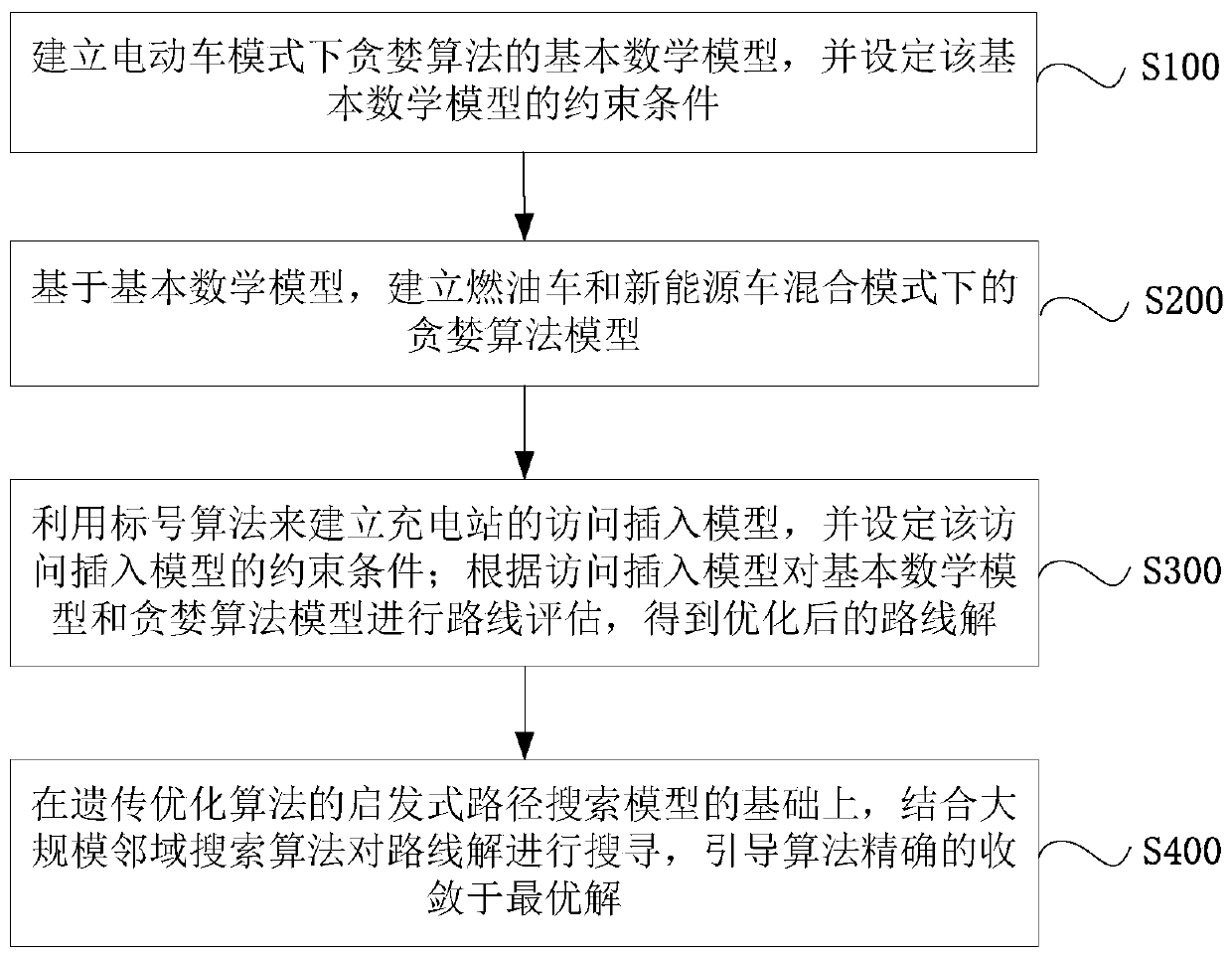

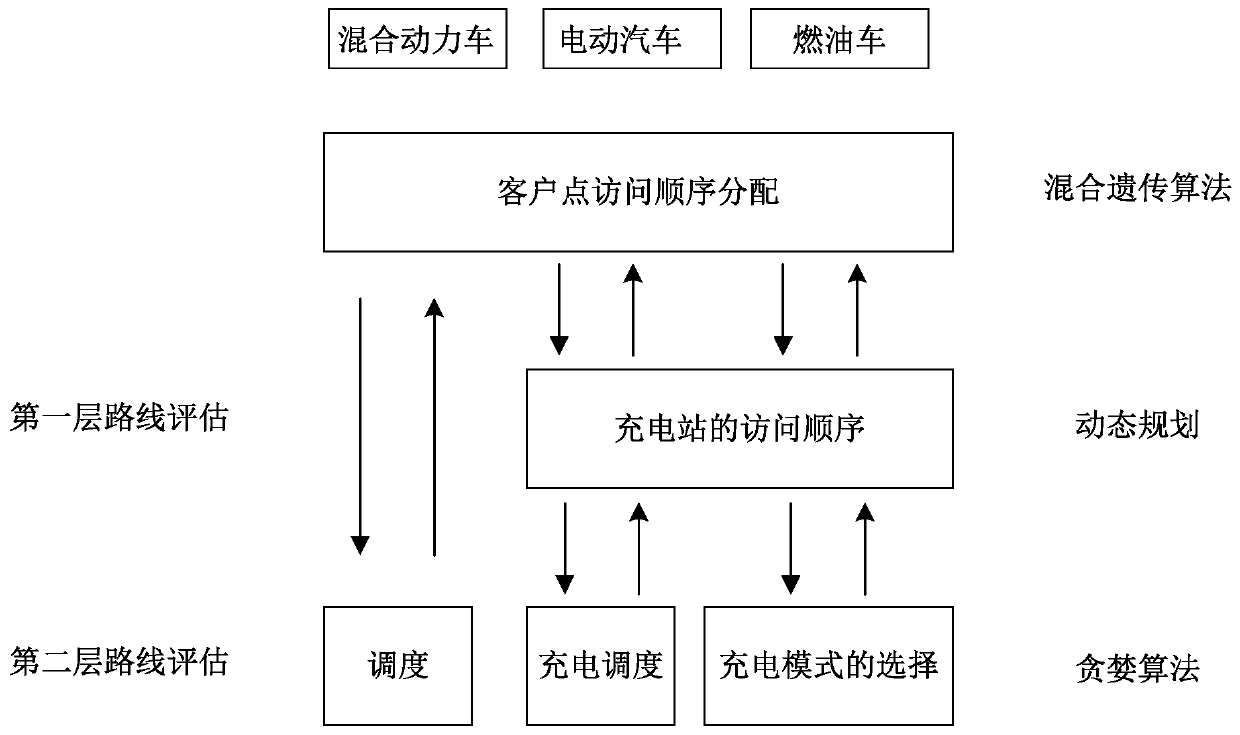

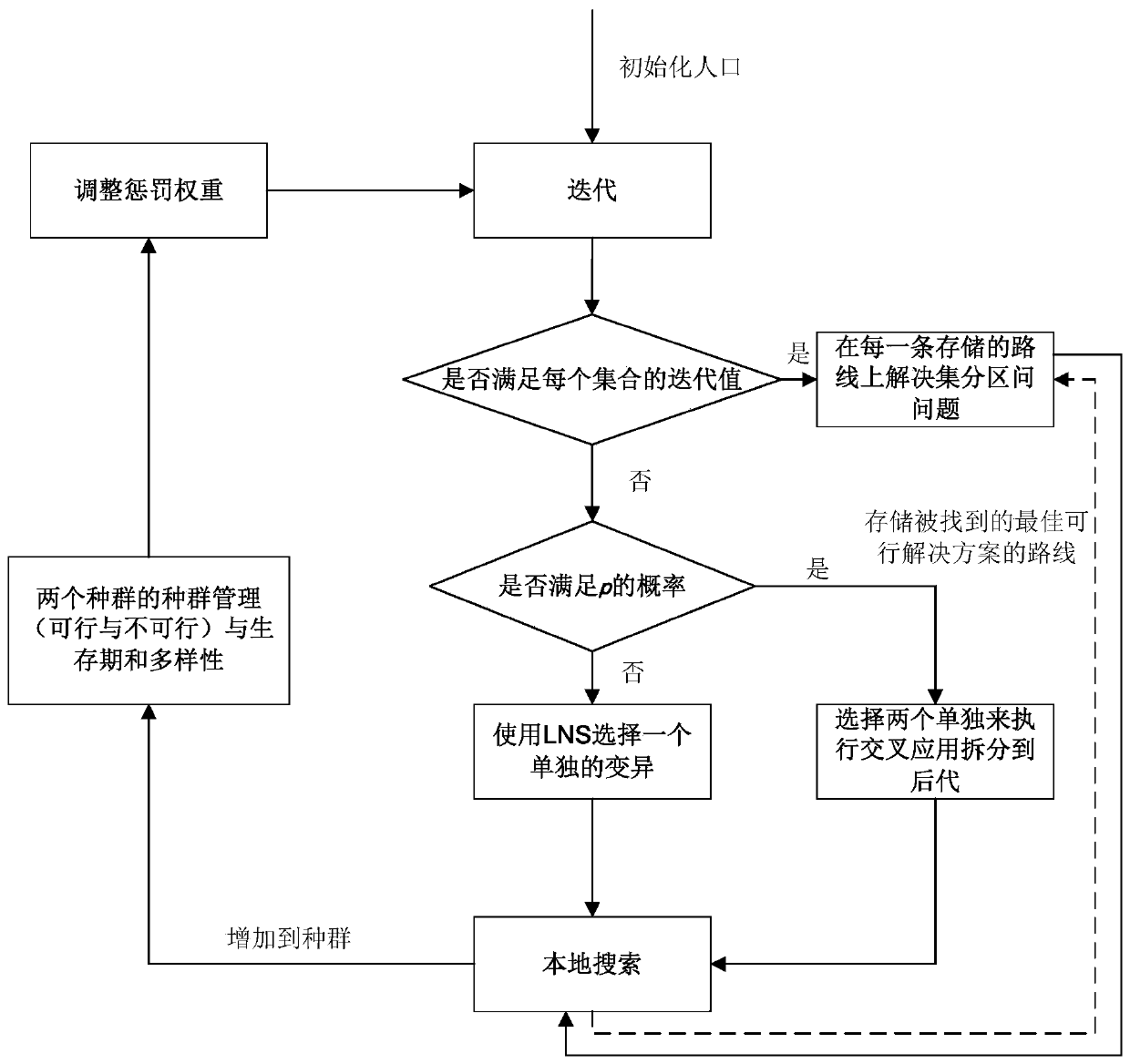

Fuel vehicle and new energy vehicle collaborative distribution scheduling method

InactiveCN110059934AReduce usageSolve the problem of accessInternal combustion piston enginesForecastingNeighborhood searchMathematical model

The invention discloses a fuel vehicle and new energy vehicle collaborative distribution scheduling method, and the method comprises the steps: building a basic mathematical model of a greedy algorithm in an electric vehicle mode, and setting constraint conditions of the basic mathematical model; based on the basic mathematical model, establishing a greedy algorithm model of the fuel vehicle and the new energy vehicle in a mixed mode; establishing an access insertion model of the charging station by utilizing a labeling algorithm, and setting constraint conditions; performing route evaluationon the basic mathematical model and the greedy algorithm model according to the access insertion model to obtain an optimized route solution; on the basis of a heuristic path search model of a geneticoptimization algorithm, searching a path solution in combination with a large-scale neighborhood search algorithm, and guiding an algorithm to be accurately converged to an optimal solution. The cooperative distribution route of the fuel vehicle and the new energy vehicle can be reasonably arranged, the access frequency of the charging station is reduced, and therefore pollution of carbon emission to the environment is reduced.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

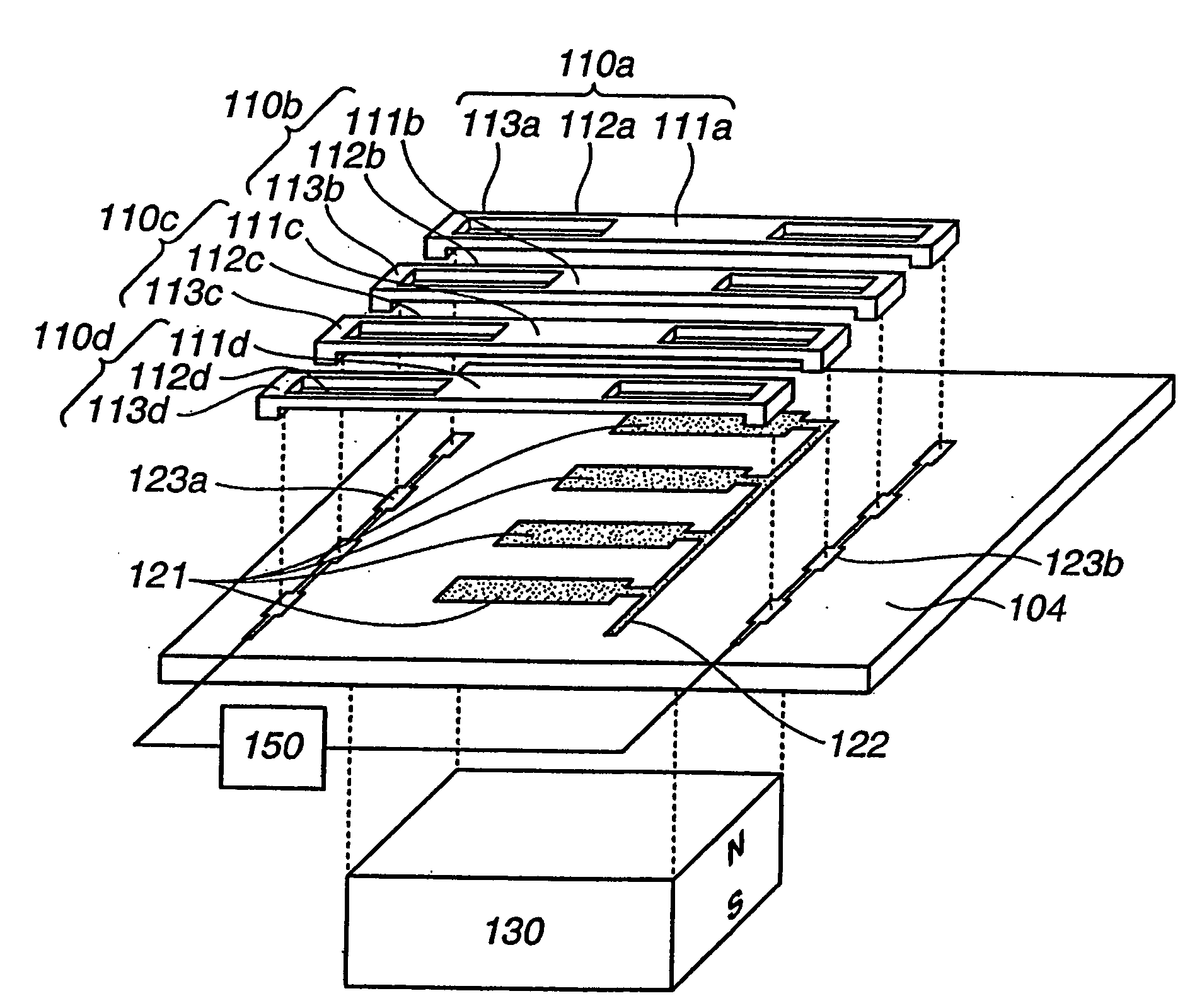

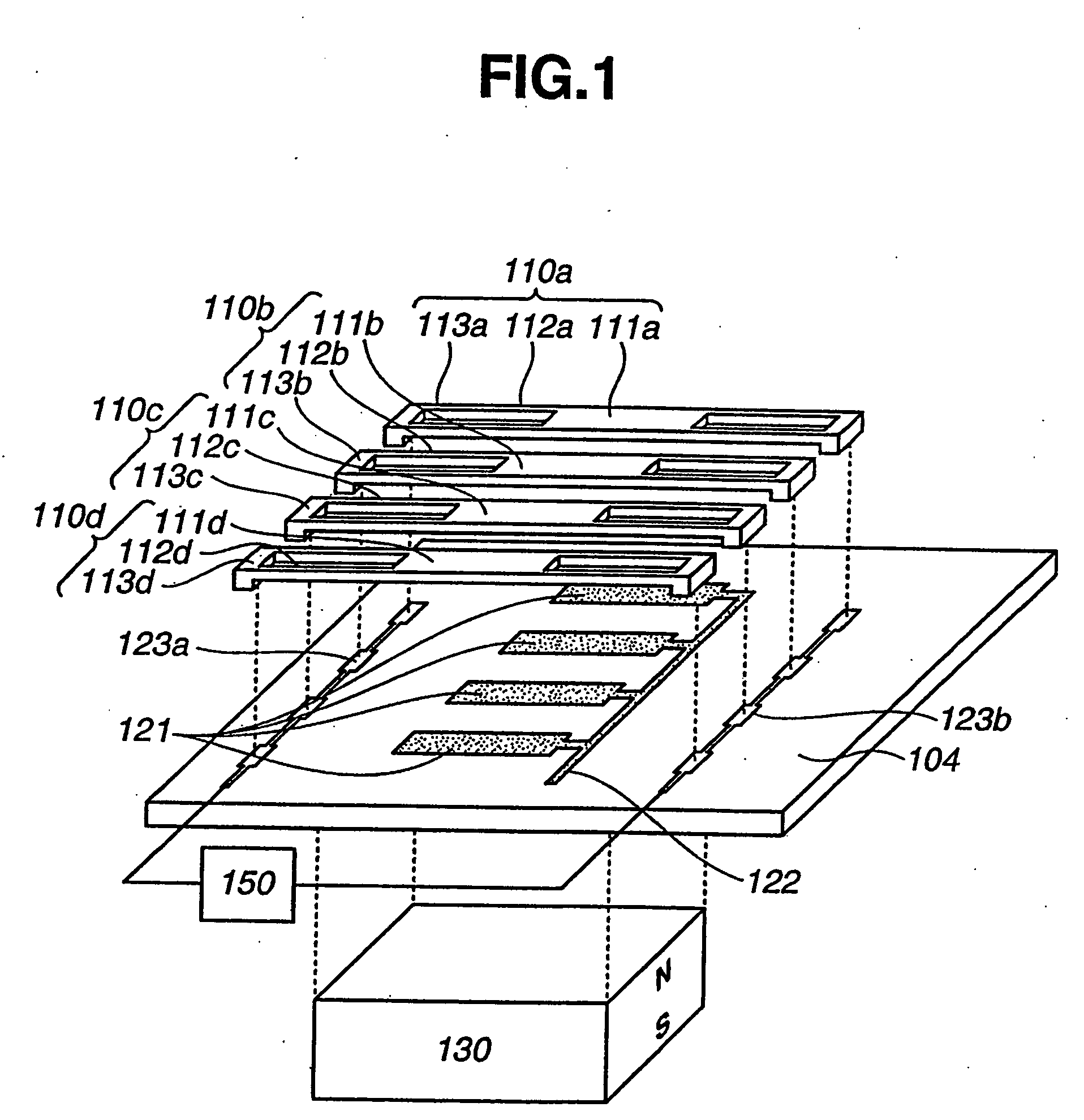

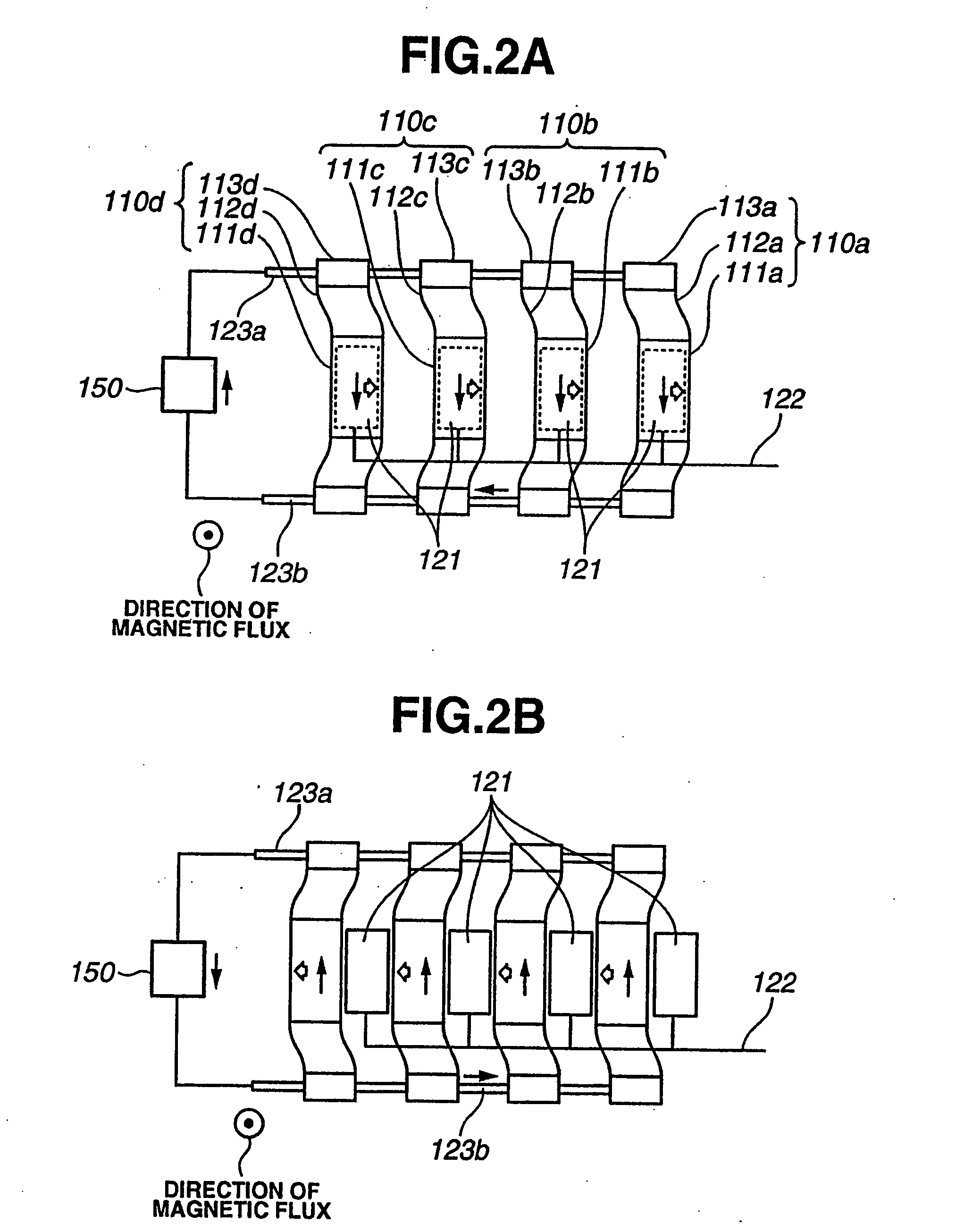

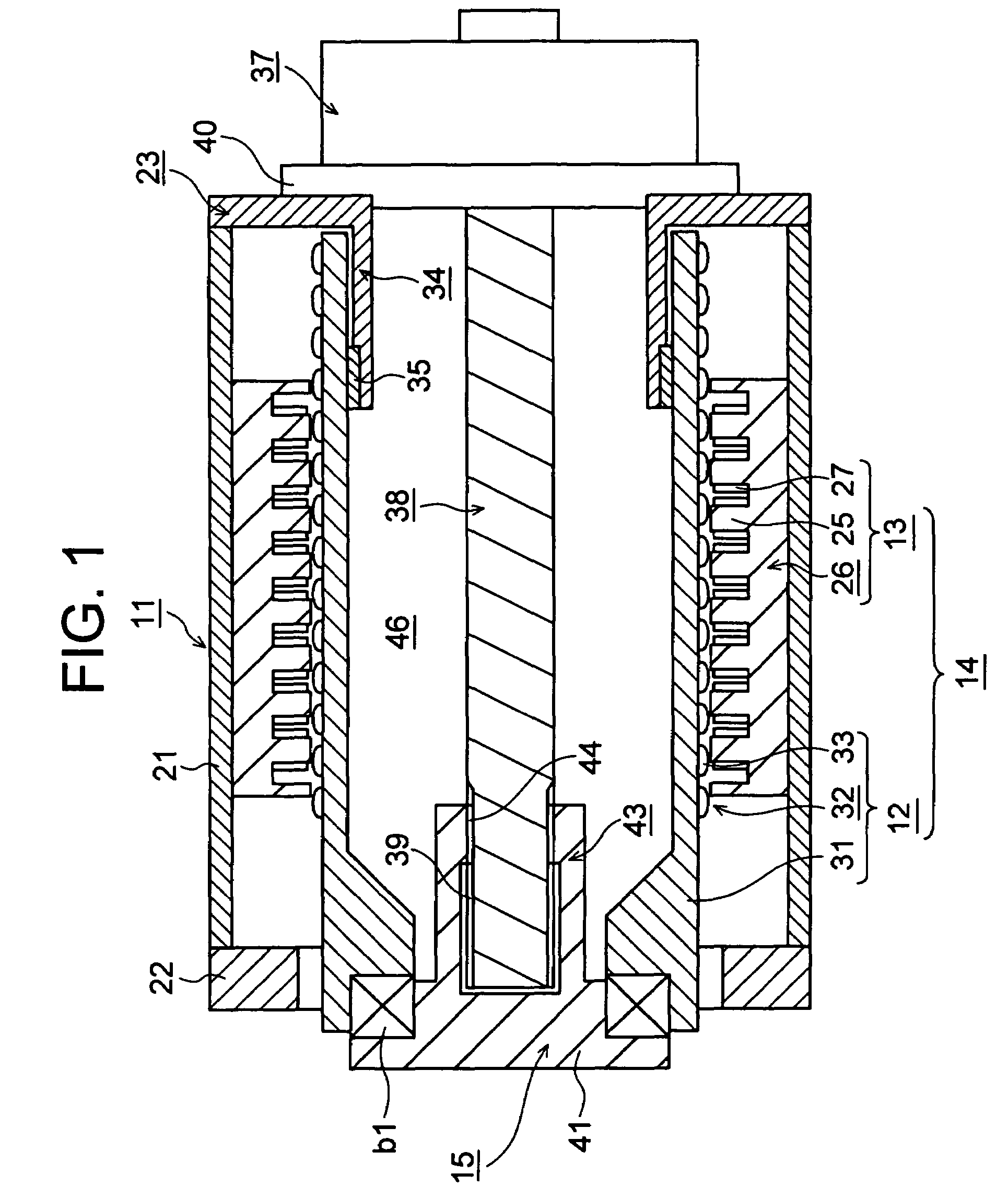

Electric potential sensor, and image forming apparatus

InactiveUS20060001432A1Small sizeMass can be lightenedResistance/reactance/impedenceElectrography/magnetographyImage formationEngineering

Disclosed in a non-contacting electric potential sensor capable of being readily reduced in its size, which includes a detecting electrode, an electrically-conductive movable shutter, and a driving unit for driving the electrically-conductive movable shutter. The detecting electrode is to be placed facing a measurement object whose electric potential is to be measured. The electrically-conductive movable shutter is disposed so as to be movably located in a spacing formed between the detecting electrode and the measurement object when the detecting electrode is placed facing the measurement object, so that an exposure degree of the detecting electrode against the measurement object can be controlled. The driving unit includes a current injecting unit for selectively injecting current into the electrically-conductive movable shutter in a direction approximately perpendicular to a moving direction of the electrically-conductive movable shutter.

Owner:CANON KK

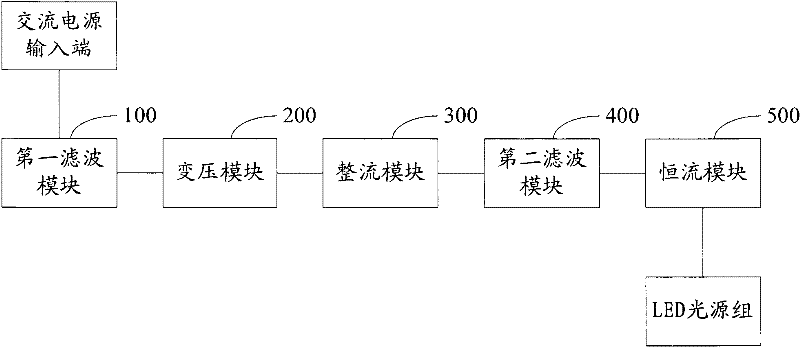

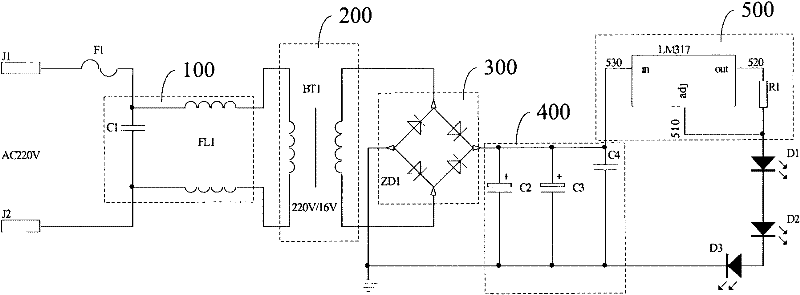

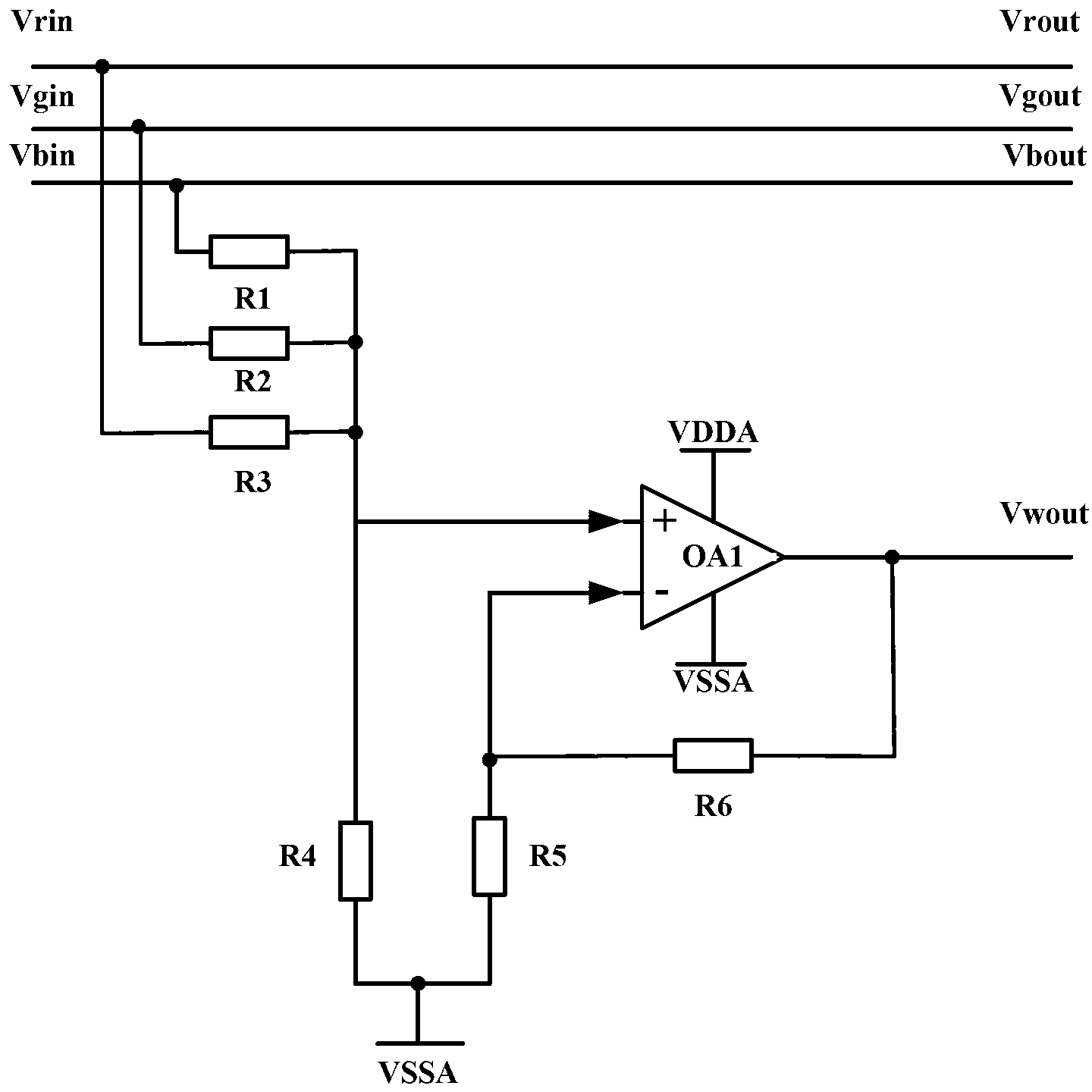

LED (light-emitting diode) constant-current driving circuit and LED lamp

InactiveCN102413599AReduce drive costsSimple structureElectric light circuit arrangementPower conversion systemsEngineeringLED lamp

The invention relates to an LED (light-emitting diode) constant-current driving circuit which comprises a first filtering module, a voltage transformation module, a rectifying module, a second filtering module and a constant-current module, wherein the input end of the first filtering module is connected with the input end of an alternating-current power supply and used for filtering electromagnetic interference between the alternating-current power supply and the driving circuit; the voltage transformation module carries out voltage reduction on an alternating current signal filtered by the first filtering module; the rectifying module is used for receiving an alternating current signal output by the voltage transformation module, rectifying the alternating current signal into a direct current signal and providing the direct current signal to the second filtering module; the second filtering module is used for carrying out voltage stabilization on the direct current signal and outputting to direct current signal subjected to voltage stabilization to the constant-current module; and the constant-current module is connected with the second filtering module and used for receiving an electrical signal subjected to voltage stabilization and providing constant currents to an LED light source group. The invention also relates to an LED lamp. In the LED constant-current driving circuit, the first filtering module is arranged at the input end of the alternating-current power supply and used for filtering the high-frequency electromagnetic interference between the alternating-current power supply and the driving circuit, thereby eliminating the influence of the electromagnetic interference on electronic equipment and safely and reliably driving the LED lamp to work.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

Motorized diffuser

InactiveUS20110275306A1Beautifully configuredSimple configurationDucting arrangementsLighting heating/cooling arrangementsEnergy expenditureHeating system

Disclosed is a motorized diffuser which is shut when not in use and which reduces energy consumption in a building, eliminates the necessity of a maintenance hole, prevents contamination, has a simple configuration, and enables easy maintenance when applied in a cooling / heating system adopting a proportional air flow control scheme. According to the disclosed diffuser, a diffuser cone includes: a diffuser cone body which forms a fluid passage on the outer surface thereof which is disposed between the diffuser cone body and a diffuser casing when the diffuser cone is opened; a diffuser cone cover fixed to the diffuser cone body such that the diffuser cone cover can be assembled / disassembled to / from the diffuser cone body with a space therebetween; and a motor means fixedly installed in the space.

Owner:OMNIVENT CORP

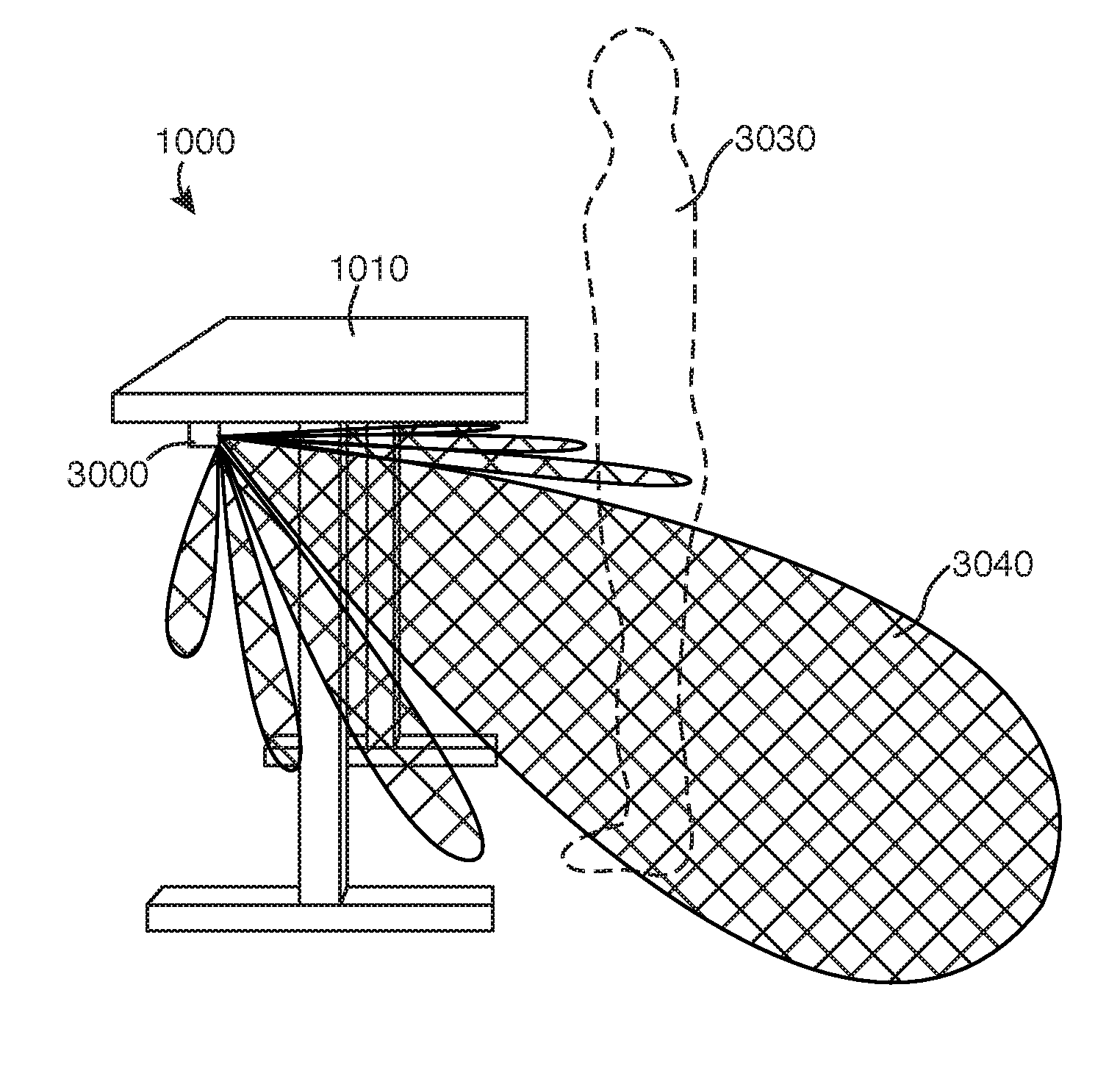

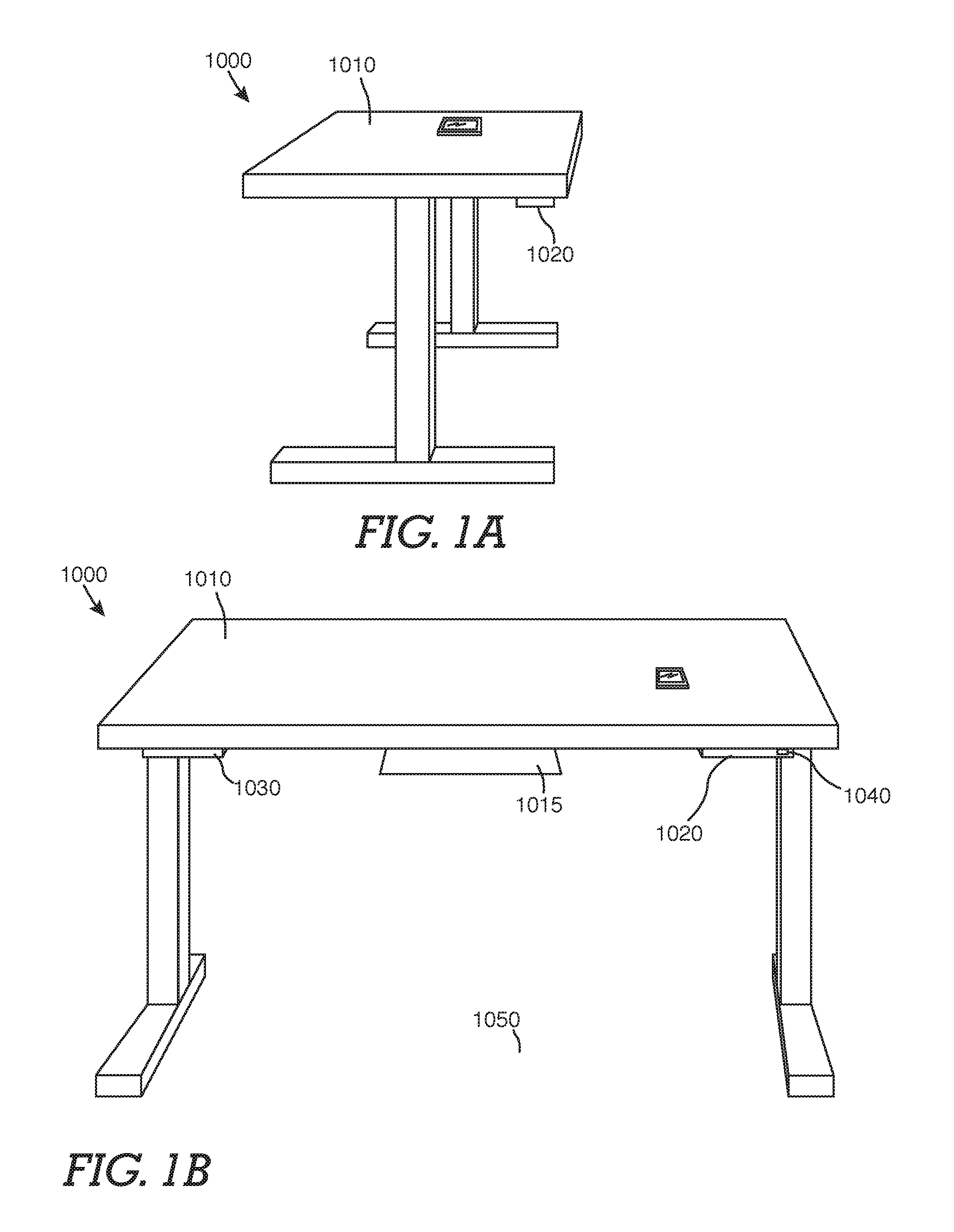

System, method and apparatus for user interaction with a workstation

InactiveUS20160231731A1Low health related costIncrease profitabilityProgramme controlOffice tablesThird partyAs Directed

The present invention pertains in general to a system, method and apparatus to track a user's interaction with a workstation surrounding the sensing of user presence, user orientation workstation height for association with an identified user and providing notifications to the user for the purposes of recommending standing or seated user orientation as directed by system analysis and allowing access and tacking of such tracking and notifications by users, employers or other predetermined third-parties.

Owner:STANDLOGIX INC

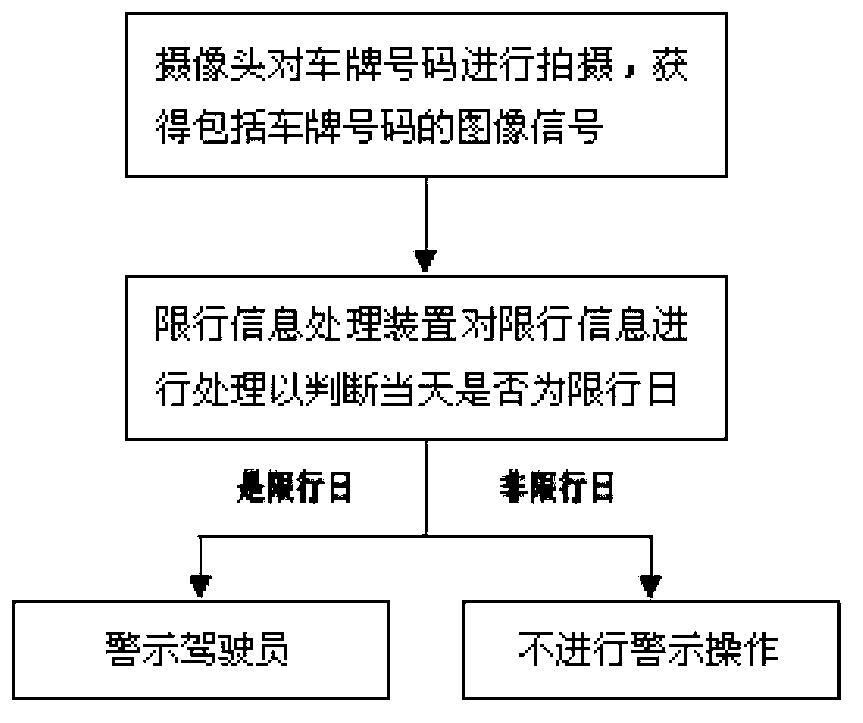

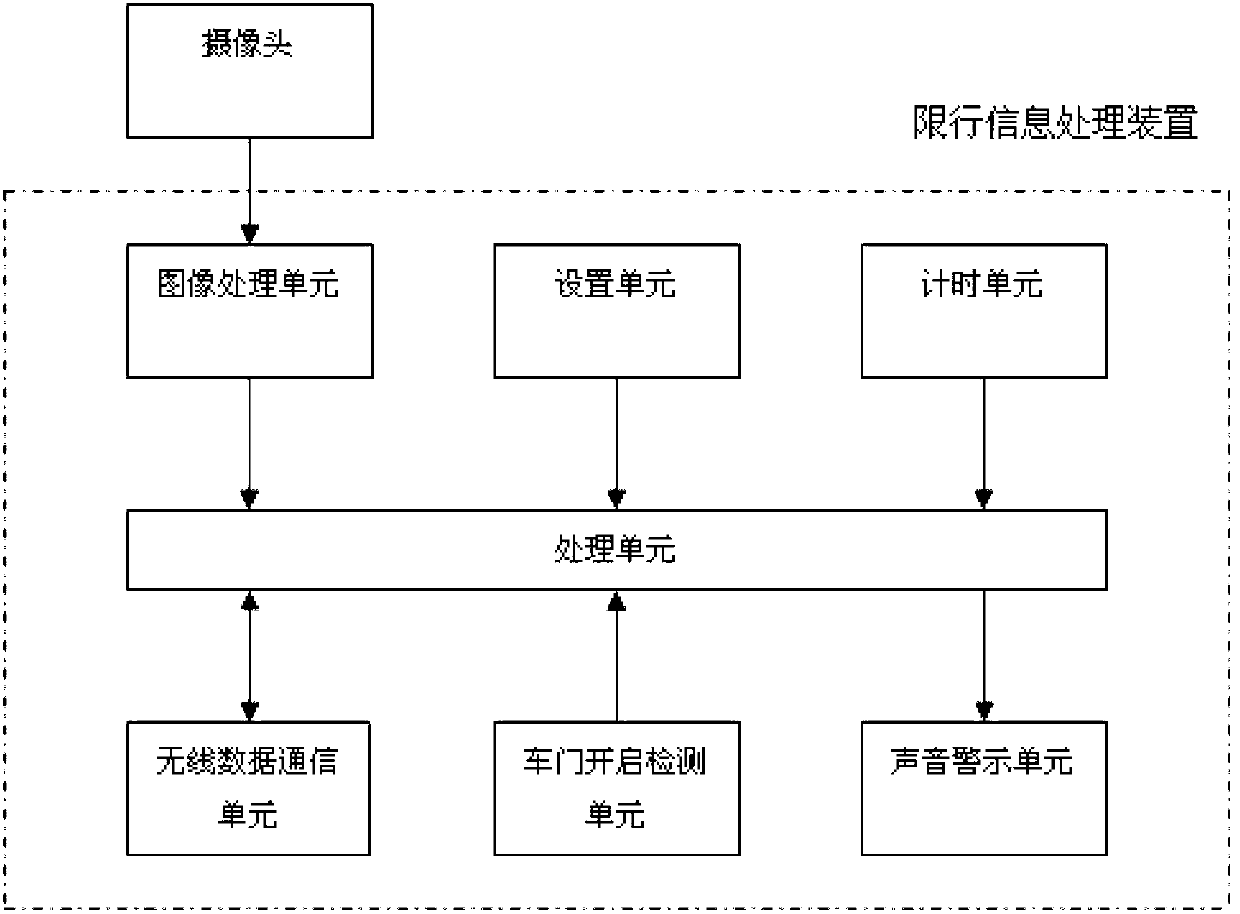

Traffic restriction warning method of automobile

InactiveCN102991415AAvoid traffic violationsReduce drive costsAcoustic signal devicesInformation processingCar driving

The invention relates to a traffic restriction warning method of an automobile. The traffic restriction warning method comprises the following steps of: photographing a license plate number by a camera mounted at the tail of the automobile and located above a license plate at the tail of the automobile, and acquiring an image signal including the license plate number; and processing traffic restriction information by connecting a traffic restriction information processing device of the camera to judge that whether the day is a traffic restriction day, when judging that the day is the traffic restriction day, warning a driver, and when the day is not the traffic restriction day, giving up a warning operation. With the adoption of the traffic restriction warning method of the automobile, the driver of the automobile is guaranteed not to misuse a traffic restriction vehicle in the traffic restriction day, and the unnecessary regulation breaking and fining are avoided.

Owner:YUYAO DECHENG TECH CONSULTING

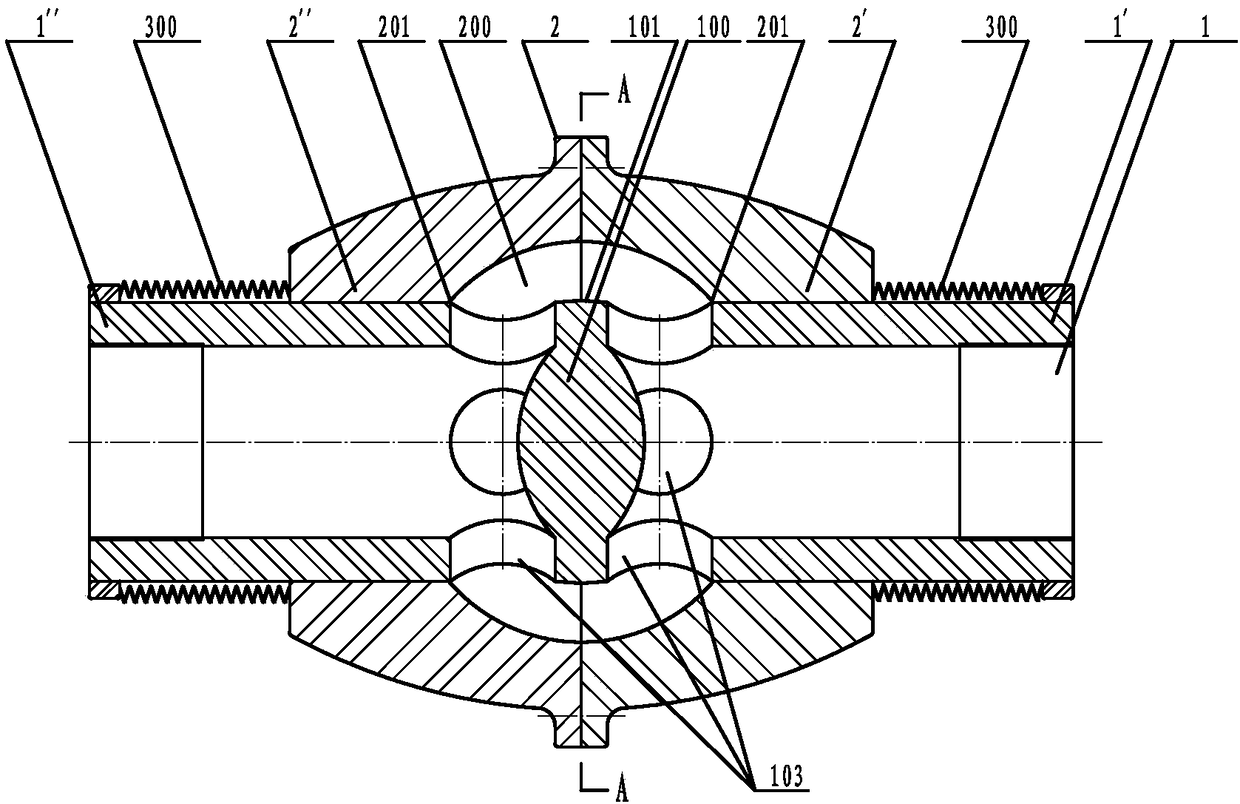

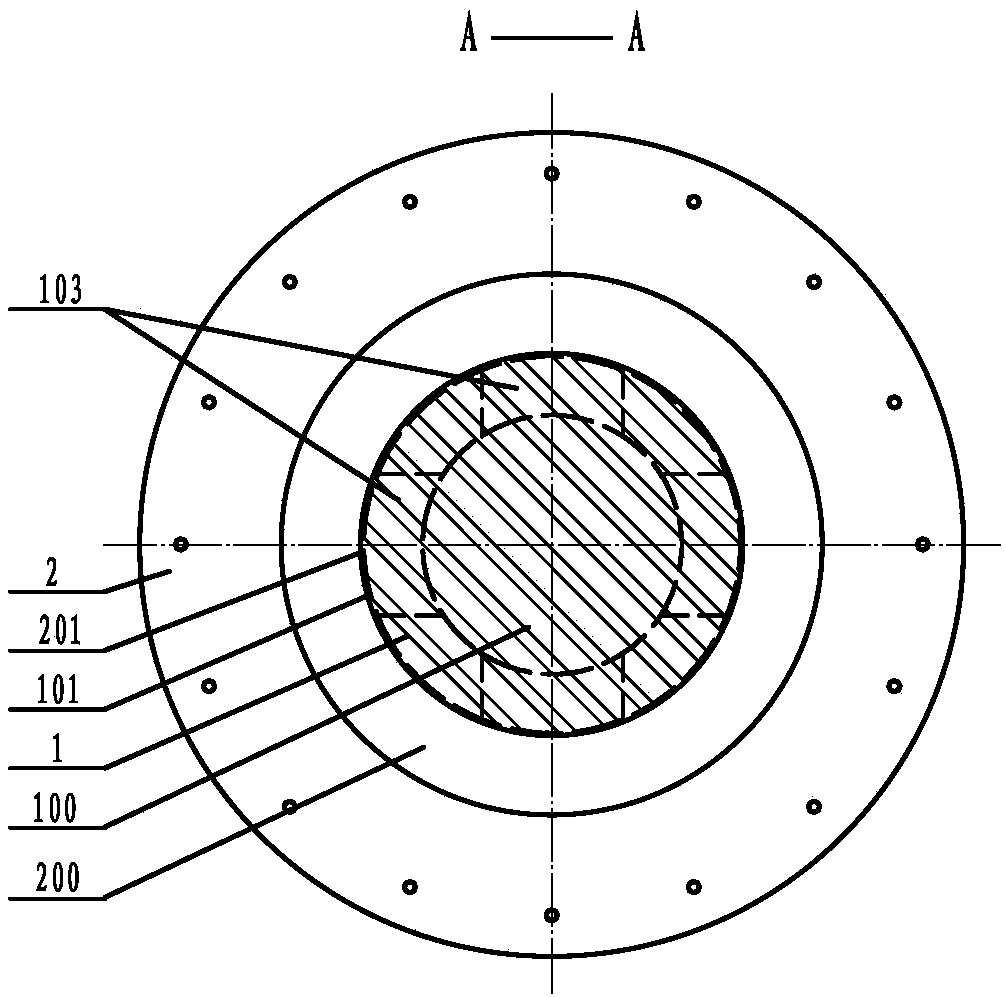

Core pipe valve

ActiveCN108488403AFacilitate smart manufacturingSmart manufacturing benefitsOperating means/releasing devices for valvesSlide valveEngineeringPressure reduction

The invention provides a core pipe valve, and belongs to the field of valves. The core pipe valve is an original brand-new-structure valve, and refers to starting and stopping, pressure starting and stopping, adjustment, safety, decompression, returning stopping, pressure reduction, emergency cutting-off and the like. A valve element pipe is a fixing piece and coaxially penetrates through a sleeveI of a valve body, a valve body cavity and a sleeve II of the valve body; an axial partition is arranged in the middle of the valve element pipe, and two adjacent sides of the partition in the axialdirection are separately at least one radial circulating hole of a pipe section I and at least one radial circulating hole of a pipe section II; an annular valve element which surrounds the partition,an annular valve seat of at least one sleeve throat of the sleeve I and an annular valve seat of at least one sleeve throat of the sleeve II form a sealing pair; the difference between the outer diameters of the pipe section I and the pipe section II is greater than or equal to 0, the pipe section I is in shaft hole type fit with the sleeve I, the pipe section II is in shaft hole type fit with the sleeve II, and at least one combined portion is provided with a seal; and under the effect of two direction potential energy, the valve body axially moves in an axial direction relative to the valveelement pipe to implement starting and stopping and function transformation. The core pipe valve is simple in structure, convenient to manufacture, low in starting and stopping resistance and good insafety, reliability and sensitivity, and adapts to various working conditions, and the efficiency is improved.

Owner:卢星霖

Pixel array of fringe field switching liquid crystal display panel and driving method thereof

ActiveUS20120249496A1Simple driving methodReduce drive costsCathode-ray tube indicatorsNon-linear opticsLiquid-crystal displayCommon line

A pixel array of a fringe field switching (FFS) liquid crystal display panel includes a plurality of gate lines, a plurality of data line, a plurality of pixel electrodes, a plurality of common lines, and a plurality of pixel units aligned in an array configuration. The gate lines are disposed parallel to each other along a first direction. The data lines are disposed parallel to each other along a second direction. Each of the pixel units includes at least one sub-pixel region. The common lines are disposed along the first direction and electrically isolated from each other. Each of the common lines includes a plurality of common electrodes extending along the second direction. The two adjacent common electrodes of each common line are respectively disposed in the two adjacent pixel units which are located in different rows.

Owner:AU OPTRONICS CORP

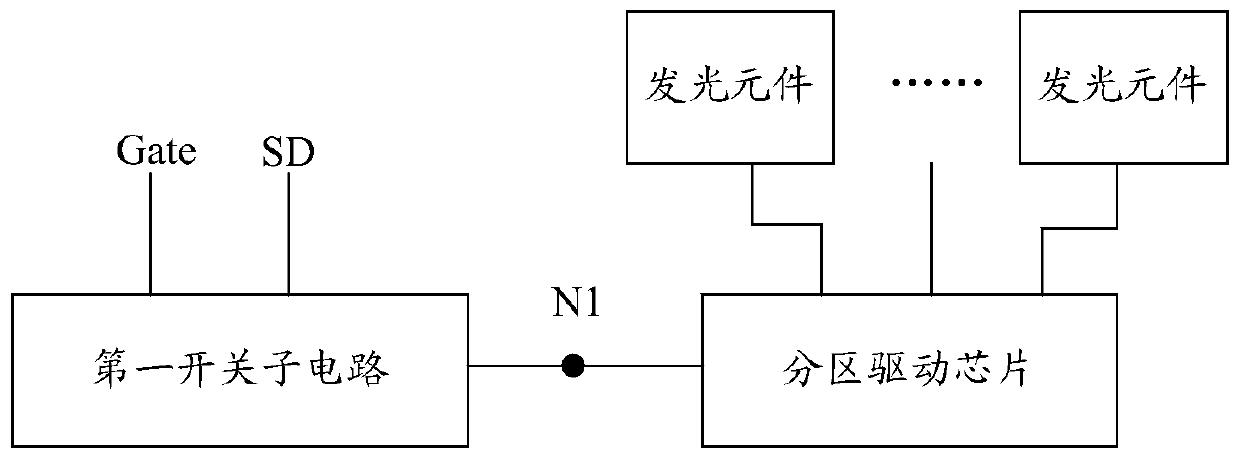

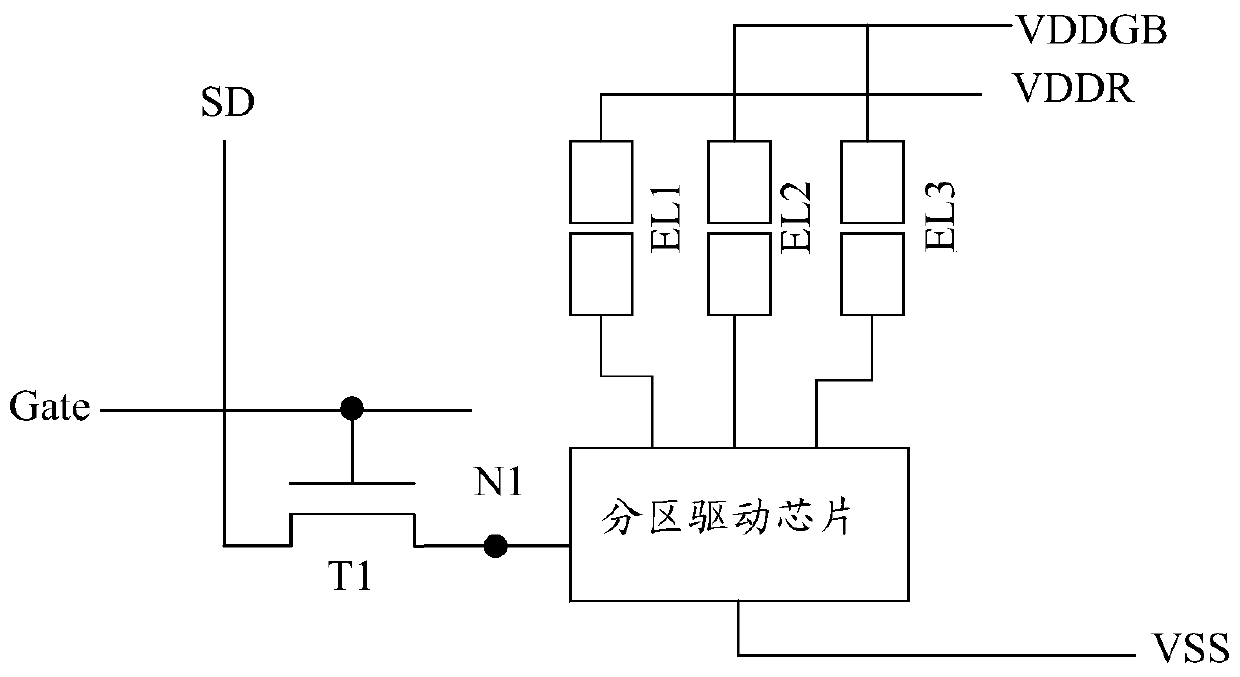

Pixel circuit, driving method thereof and display device

ActiveCN111243496AReduce the number of tracesReduce drive power consumptionStatic indicating devicesScan lineDisplay device

The invention discloses a pixel circuit, a driving method thereof and a display device. The pixel circuit comprises a first switch sub-circuit, a partition driving chip and a plurality of light-emitting elements. The first switch sub-circuit is respectively connected with a scanning line, a data line and a first node and is used for writing a data voltage signal of the data line into the first node under the control of the scanning line; and the partition driving chip is connected with the first node and the plurality of light-emitting elements respectively and is used for judging driving timecorresponding to each light-emitting element according to a data voltage signal input by the first node, and driving the light-emitting elements to emit light by using the data voltage signal withinthe corresponding driving time. Active site selection driving is realized through the first switch sub-circuit and the partition driving chip, so that the number of glass-based wires is effectively reduced, the difficulty of a side edge wire routing process is greatly reduced, the driving power consumption and the driving cost of the whole display module are reduced, and the competitive advantageof a product is greatly improved.

Owner:BOE TECH GRP CO LTD +1

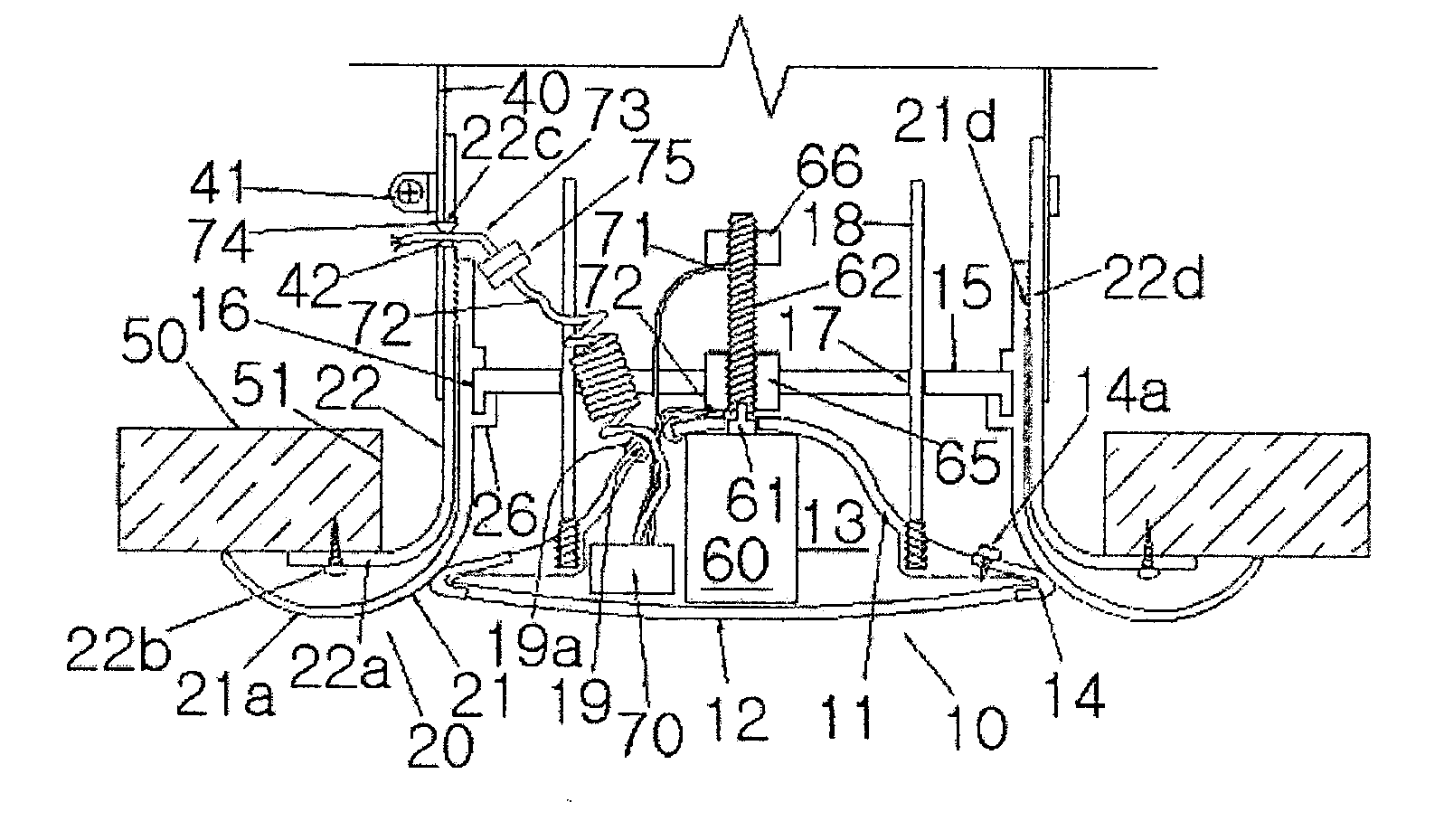

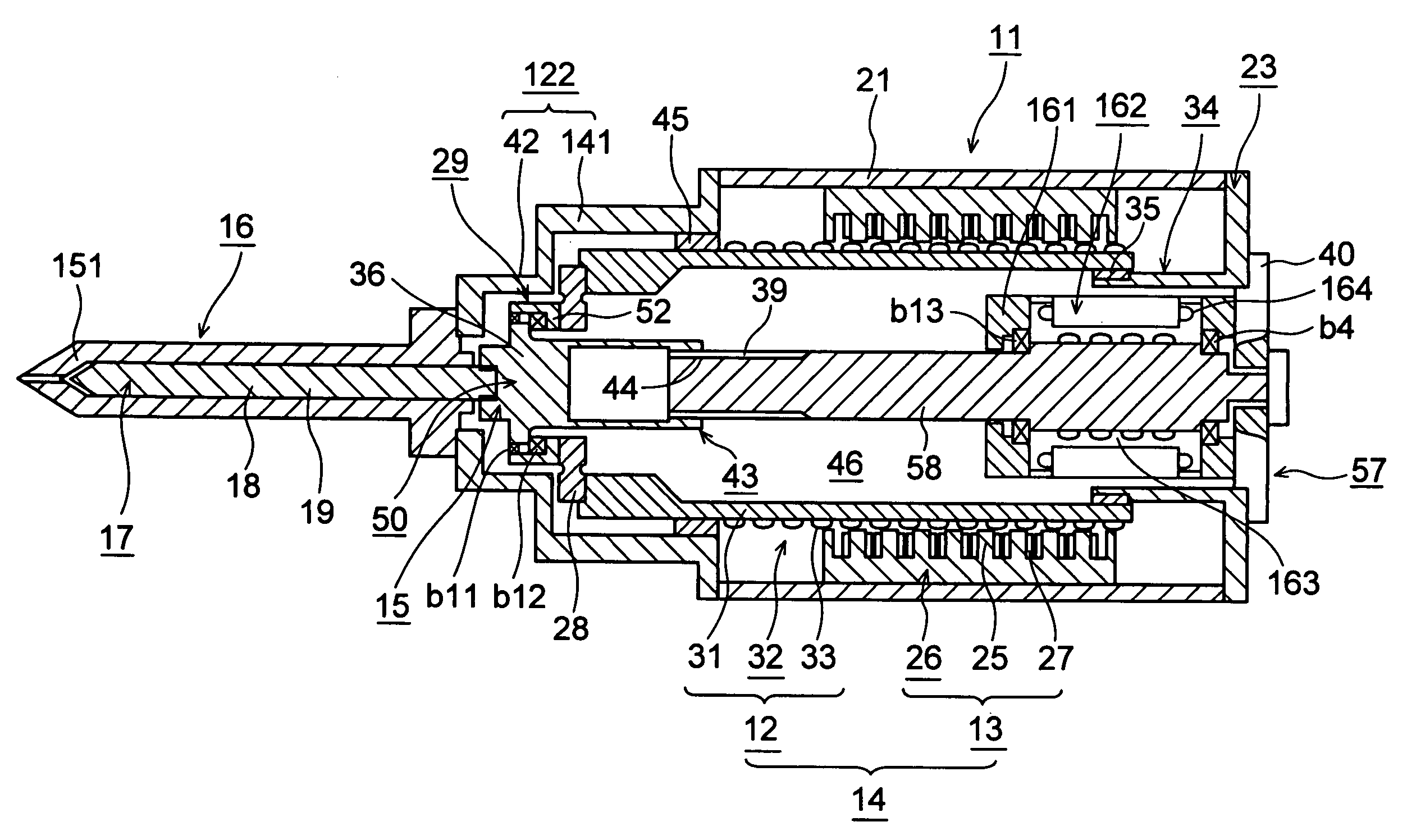

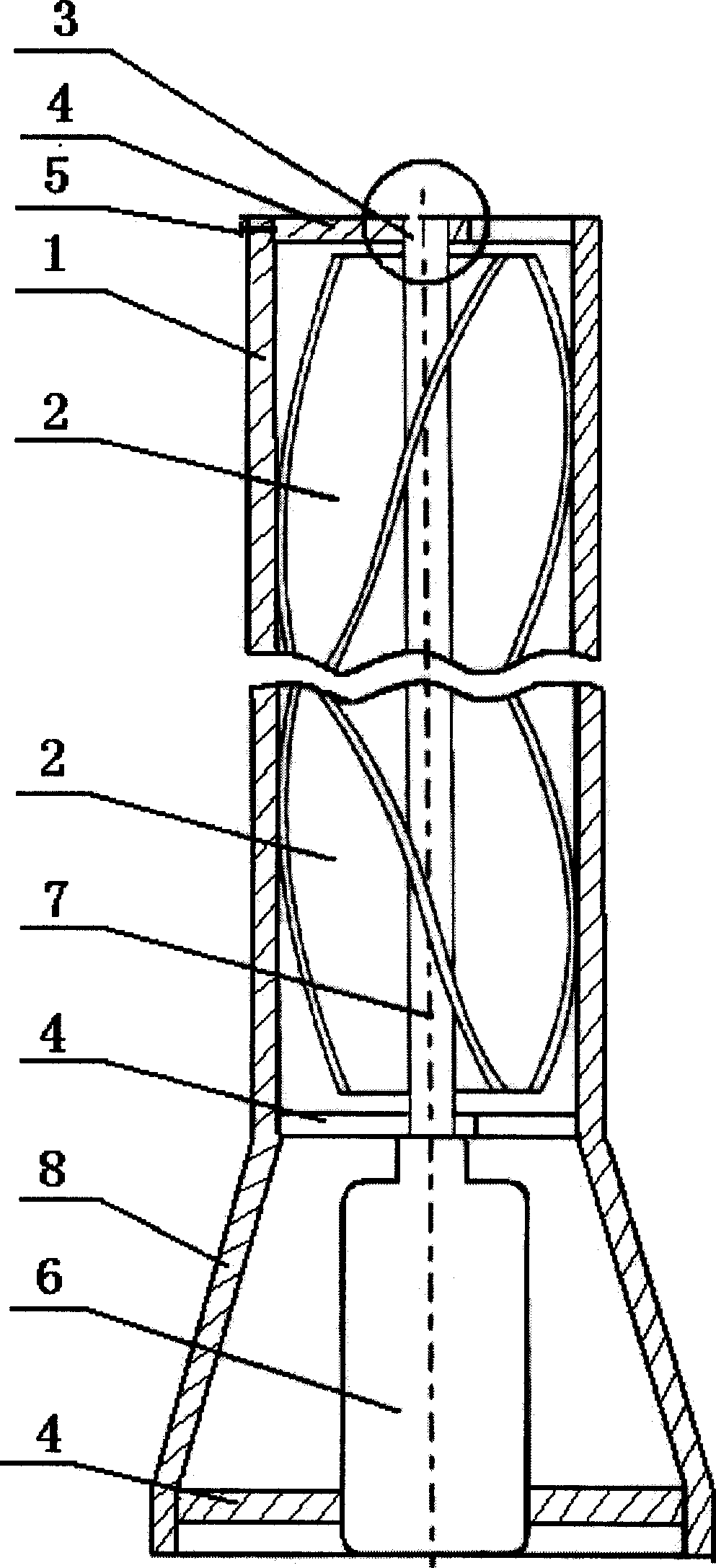

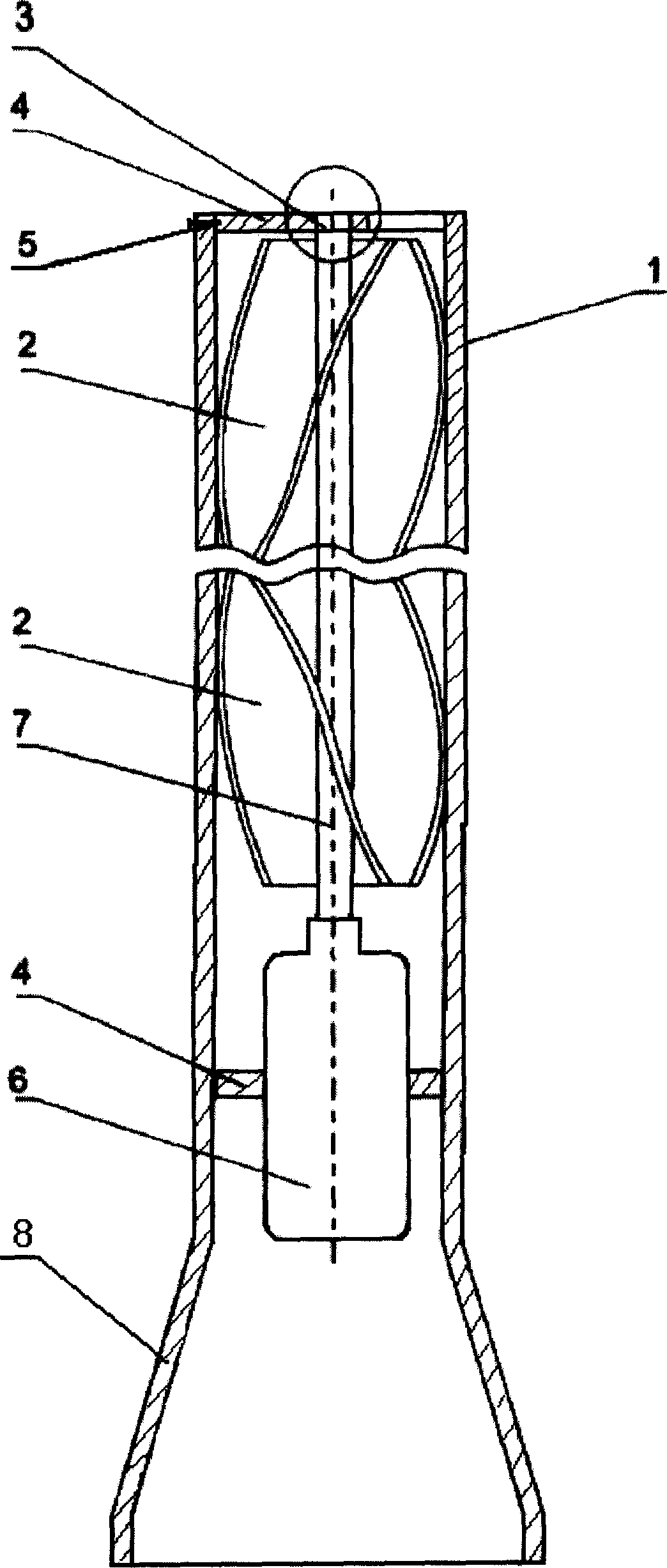

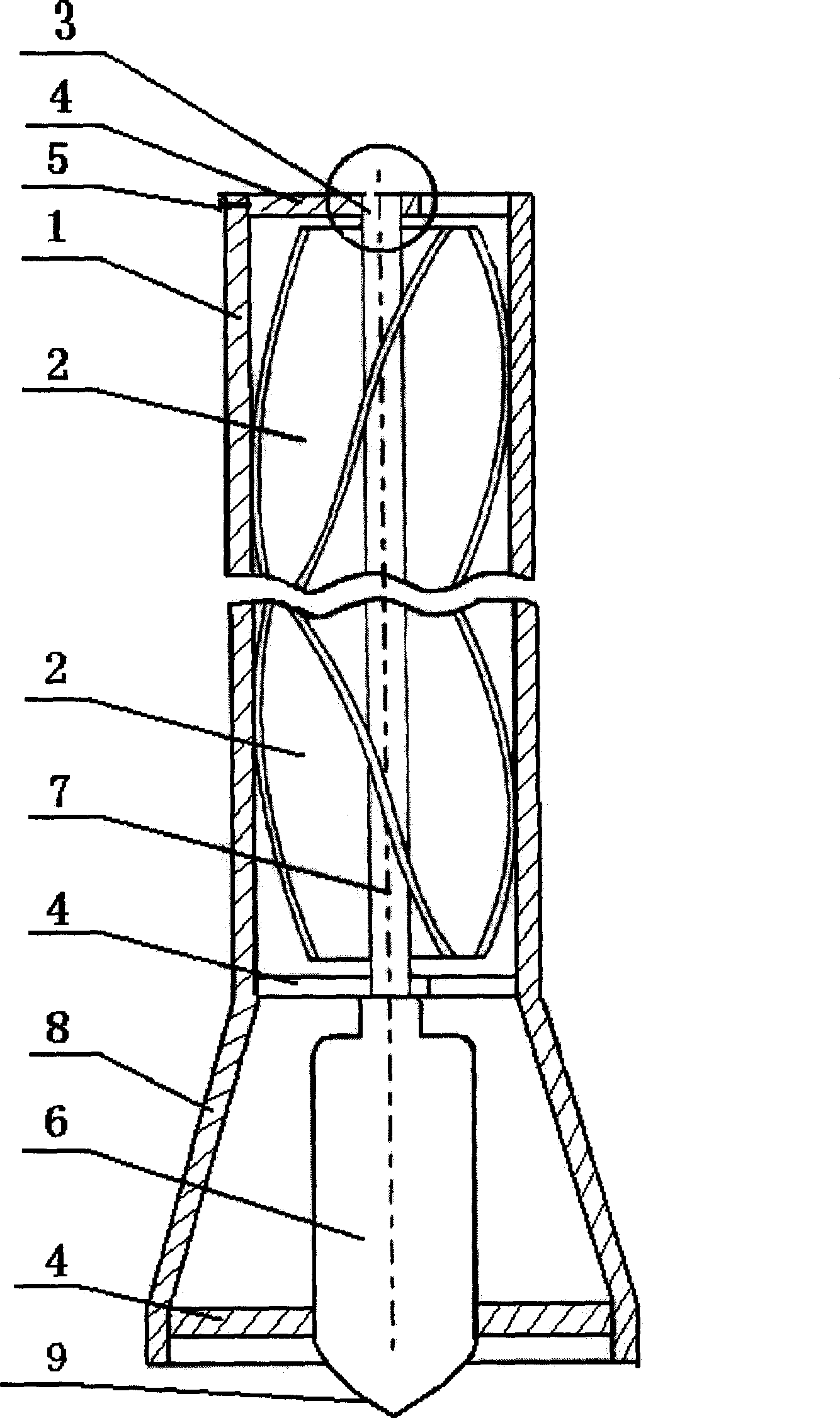

Drive apparatus for injection molding machine, injection apparatus, and mold clamping apparatus

InactiveUS7442022B2Large thrustIncrease capacityMagnetic circuitSynchronous machinesTubular linear motorEngineering

An object is to provide a drive apparatus for an injection molding machine which can generate a large thrust force and can provide short-cycled continuous drive. The drive apparatus includes a housing (11); a tubular linear motor (14) including a movable element (12) disposed within the housing (11) in a manner capable of advancing and retreating, and a stationary element (13) attached to the housing (11), the linear motor (14) serving as a first drive section; a member-to-be-driven (15) caused to advance and retreat together with the movable element (12); and a second drive section attached to the housing (11) and disposed such that at least a portion of the second drive section overlaps the linear motor (14) along the axial direction. By merely a slight increase in a radial dimension, the area of a permanent magnet (23) of the movable element (12) can be sufficiently increased, and the capacity of the linear motor (14) can be increased.

Owner:SUMITOMO HEAVY IND LTD

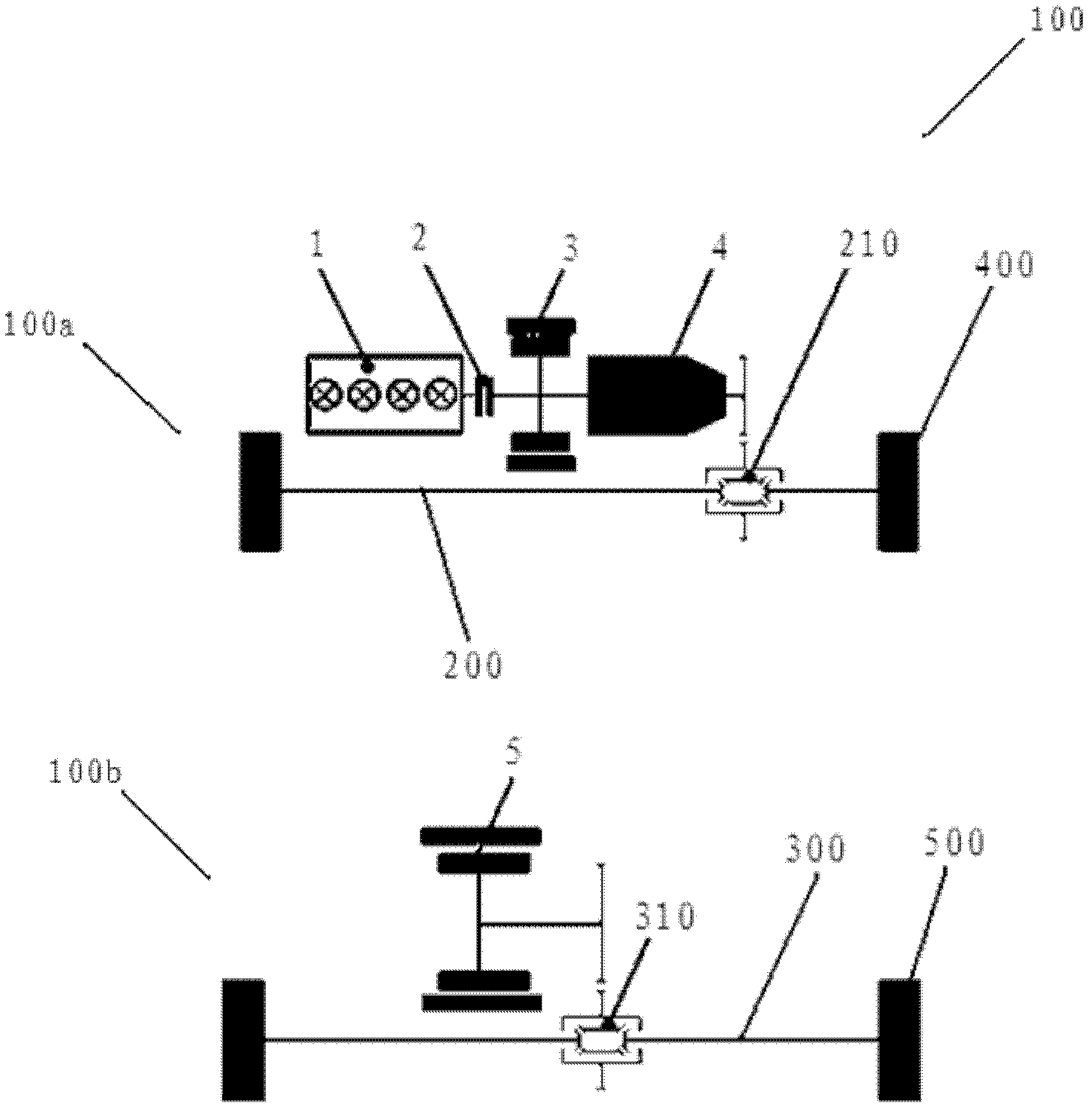

Driving assembly used for hybrid electric automobile

InactiveCN103158524AImprove operational stabilityImprove fuel economyHybrid vehiclesGas pressure propulsion mountingStarter generatorAutomatic transmission

The invention discloses a driving assembly used for a hybrid electric automobile. The driving assembly comprises a front axle driving assembly, a rear axle driving assembly and a control unit. The front axle driving assembly comprises an engine, an automatic clutch, an integrated starter generator (ISG) motor and an automatic speed changer, wherein the engine is connected or disconnected with the ISG motor through the automatic clutch, and the ISG engine is connected with a front axle main speed reducer through the automatic speed changer so as to transmit motive power of the engine and / or the ISG motor to front wheels of the automobile. The rear axle driving assembly comprises a main motor, wherein the main motor is connected with a rear axle main speed reducer so as to transmit motive power of the main motor to rear wheels of the automobile. According to the driving assembly for the hybrid electric automobile, driving status of the automobile can be changed according to actual situations, power performance is good, passage capacity is strong, operation stability of a finished automobile is improved, and braking energy of the front wheels and the rear wheels during braking of the automobile can be recovered.

Owner:BEIQI FOTON MOTOR CO LTD

Vehicle restriction warning system

InactiveCN103000038AAvoid traffic violationsReduce drive costsRoad vehicles traffic controlLicense numberInformation processing

The invention relates to a vehicle restriction warning system. The vehicle restriction warning system comprises a camera and a vehicle restriction information processing device, the camera is installed at the tail of a vehicle, located above a vehicle tail license plate and used for shooting license numbers so as to obtain an image signal, the vehicle restriction information processing device is connected with the camera and used for processing vehicle restriction information to determine whether the day is a vehicle restriction date or not, if the day is the vehicle restriction date, a driver is warned, and if the day is not the vehicle restriction date, the driver is not warned. By means of the vehicle restriction warning system, a restricted vehicle can not be misused in the vehicle restriction date by the driver, and unprovoked violation of laws and fine can be avoided.

Owner:杨伟

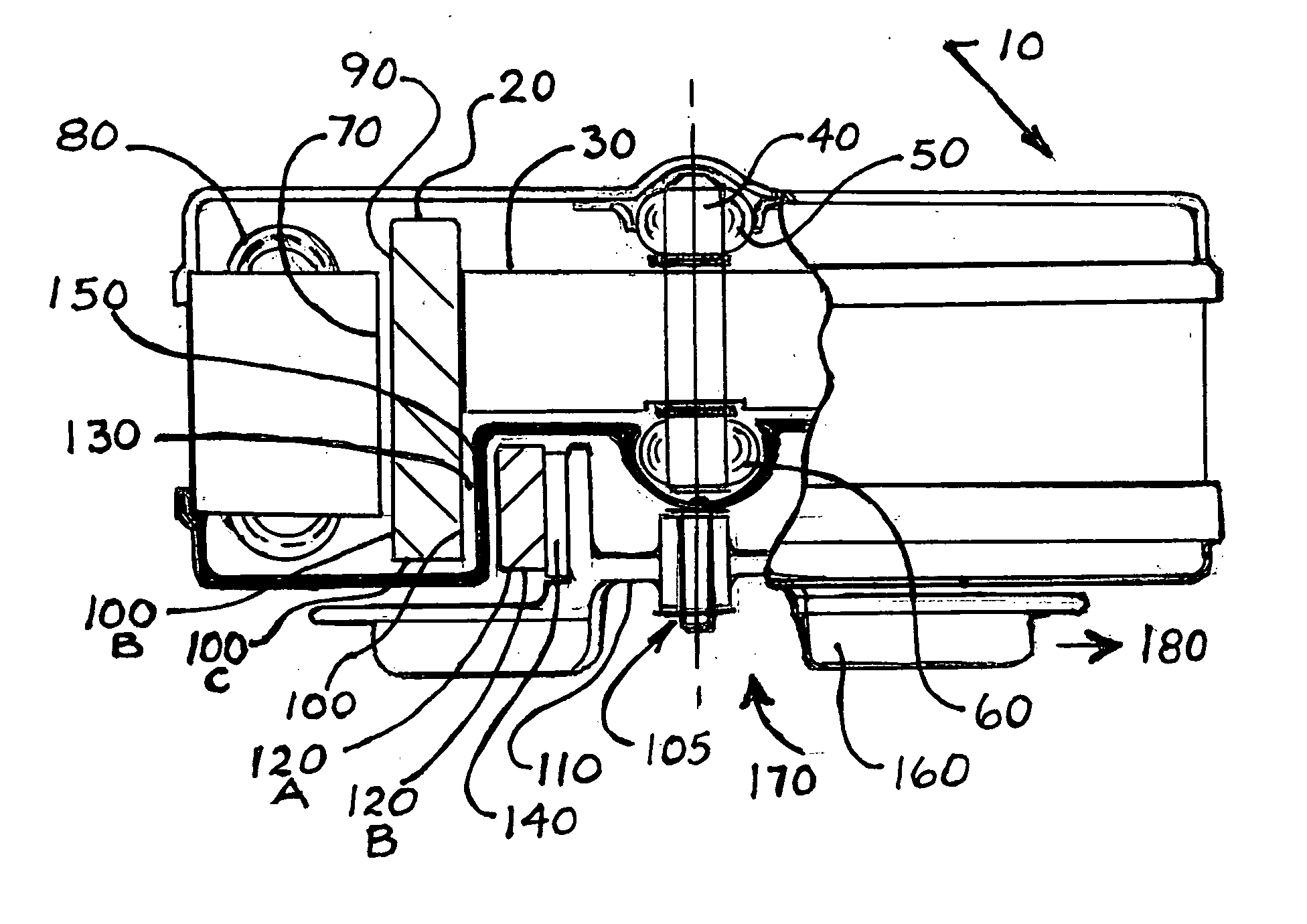

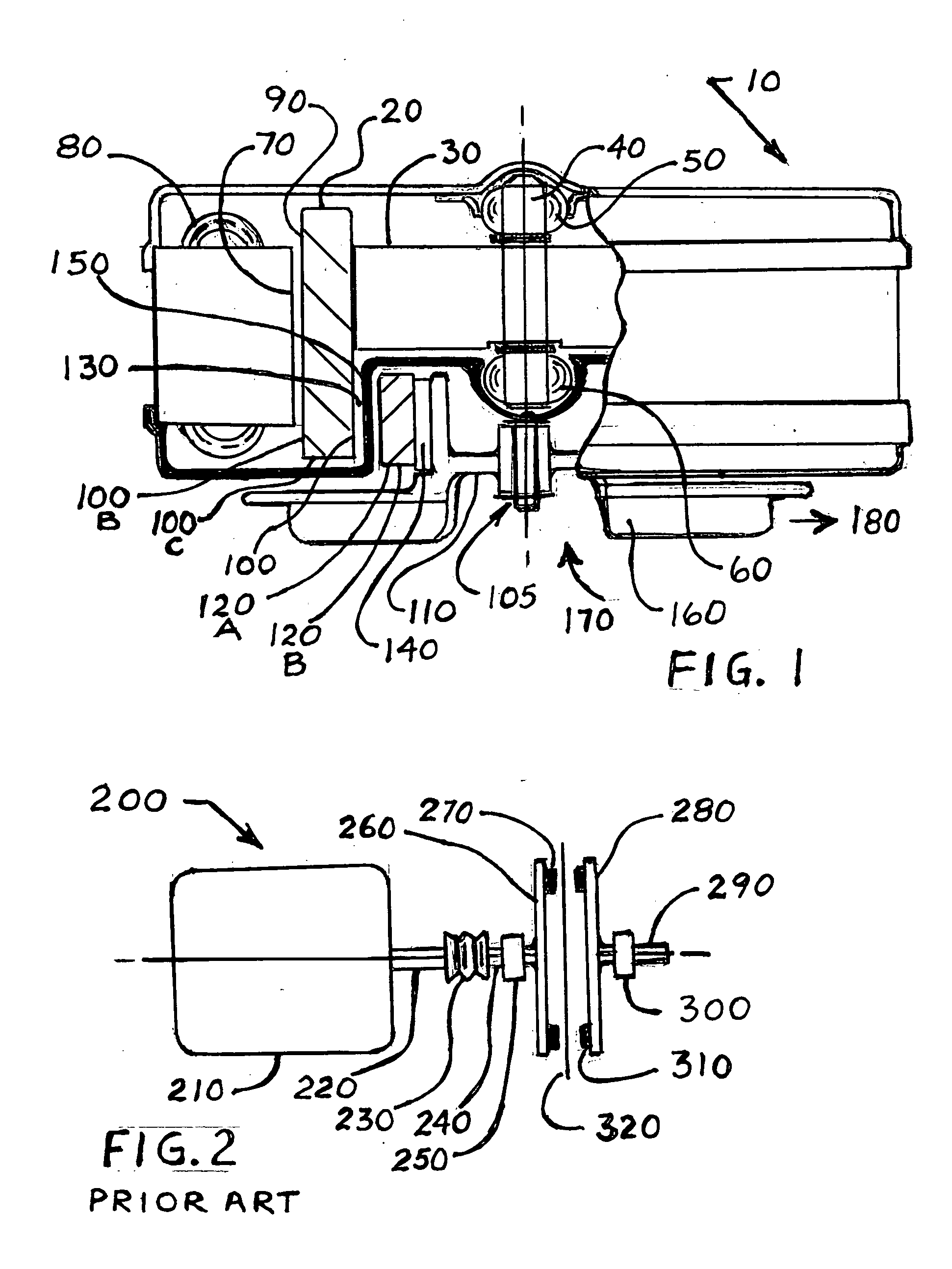

Magnetic coupling using magnets on a motor rotor

InactiveUS20050099077A1Reduce friction lossPresent inventionPermanent-magnet clutches/brakesMechanical energy handlingElectric machineCoupling

A simplified magnetic coupling utilizing the available rotating permanent magnets on an electric motor rotor to be the “drive” component in the magnetic coupling of the present invention. The “driven part of the magnetic coupling is a co-axially journalled second rotor, driven by magnetic flux from the rotating permanent magnets on the motor rotor mentioned above. A membrane between these two rotors can hermetically separate the drive part from the driven part. This invention has fewer parts, has both less costly parts and assembly and is also more compact then related art.

Owner:GERFAST STEN R

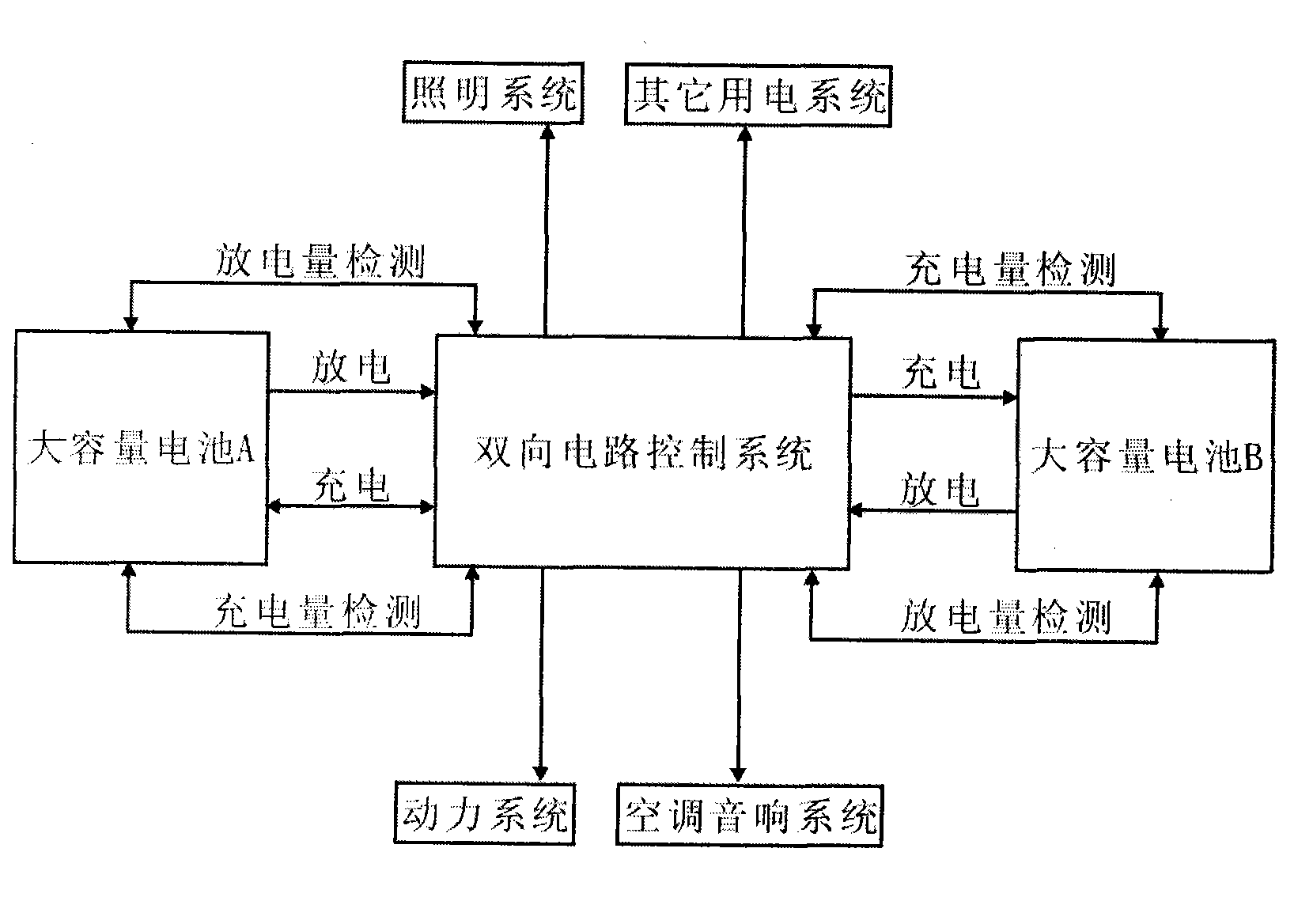

Double-battery mutually-rechargeable electric automobile

InactiveCN101612898AThe Cons of Avoiding the Hassle of ChargingSolve the limitation of driving mileageVehicular energy storageElectric propulsionElectrical batteryAir conditioning

The invention relates to an energy supply system of an electric automobile, which comprises two same high-capacity batteries A and B and a bilateral circuit control system, wherein the high-capacity battery A transmits electric energy to a power system, a lighting system, an air conditioning audio-video system and the like through the bilateral circuit control system, and simultaneously charges the high-capacity battery B through the bilateral circuit control system; and when detecting that the electric energy of the high-capacity battery A is lower than an approved standard, the bilateral circuit control system automatically changes the high-capacity battery B into a supply battery to charge the large-capacity battery A while supplying electric quantity to other systems. The energy supply system implemented through the technical scheme needs no external power supply for battery charging under normal condition to avoid the abuse that the prior electric automobile is troublesome to charge.

Owner:叶进华

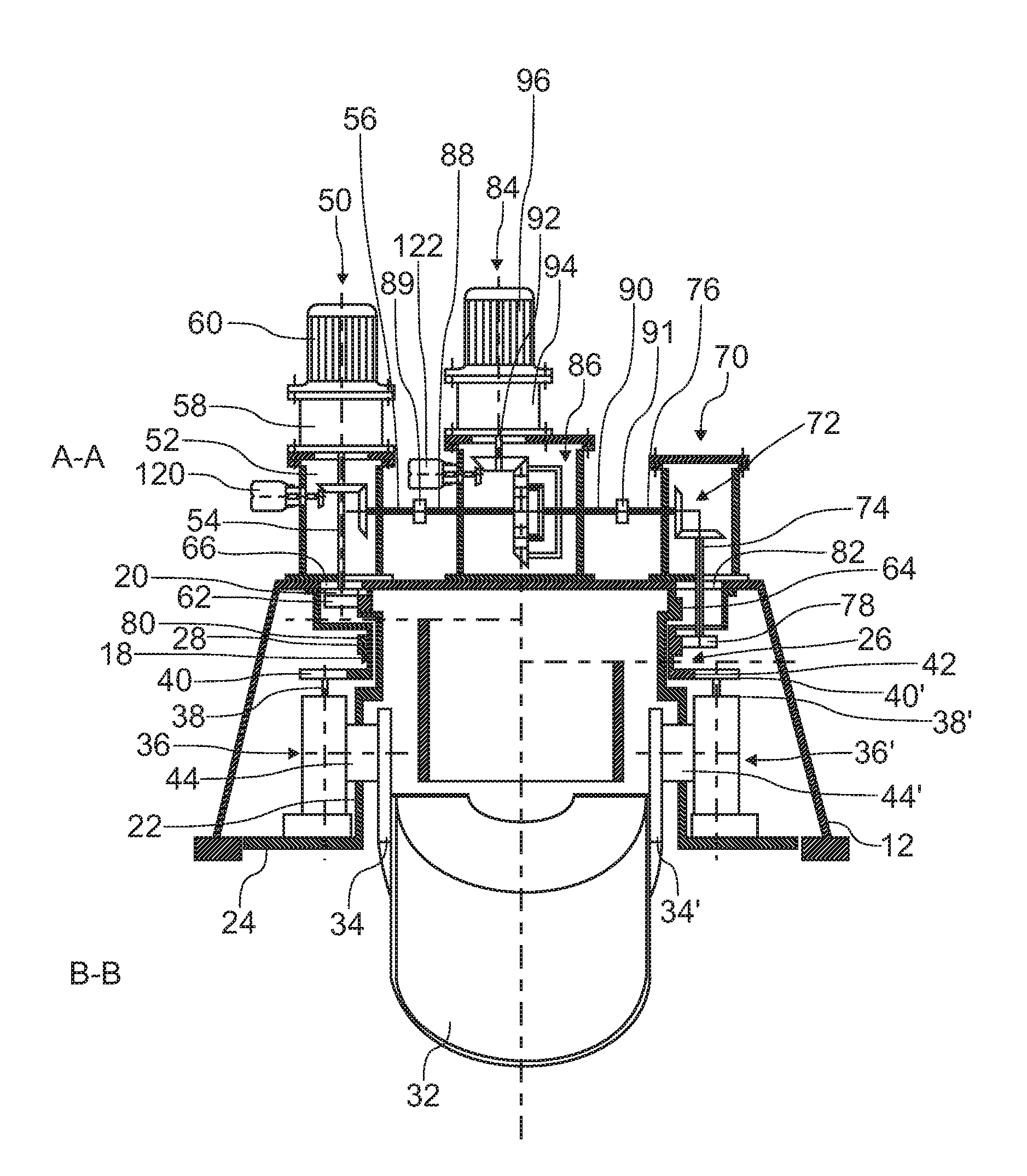

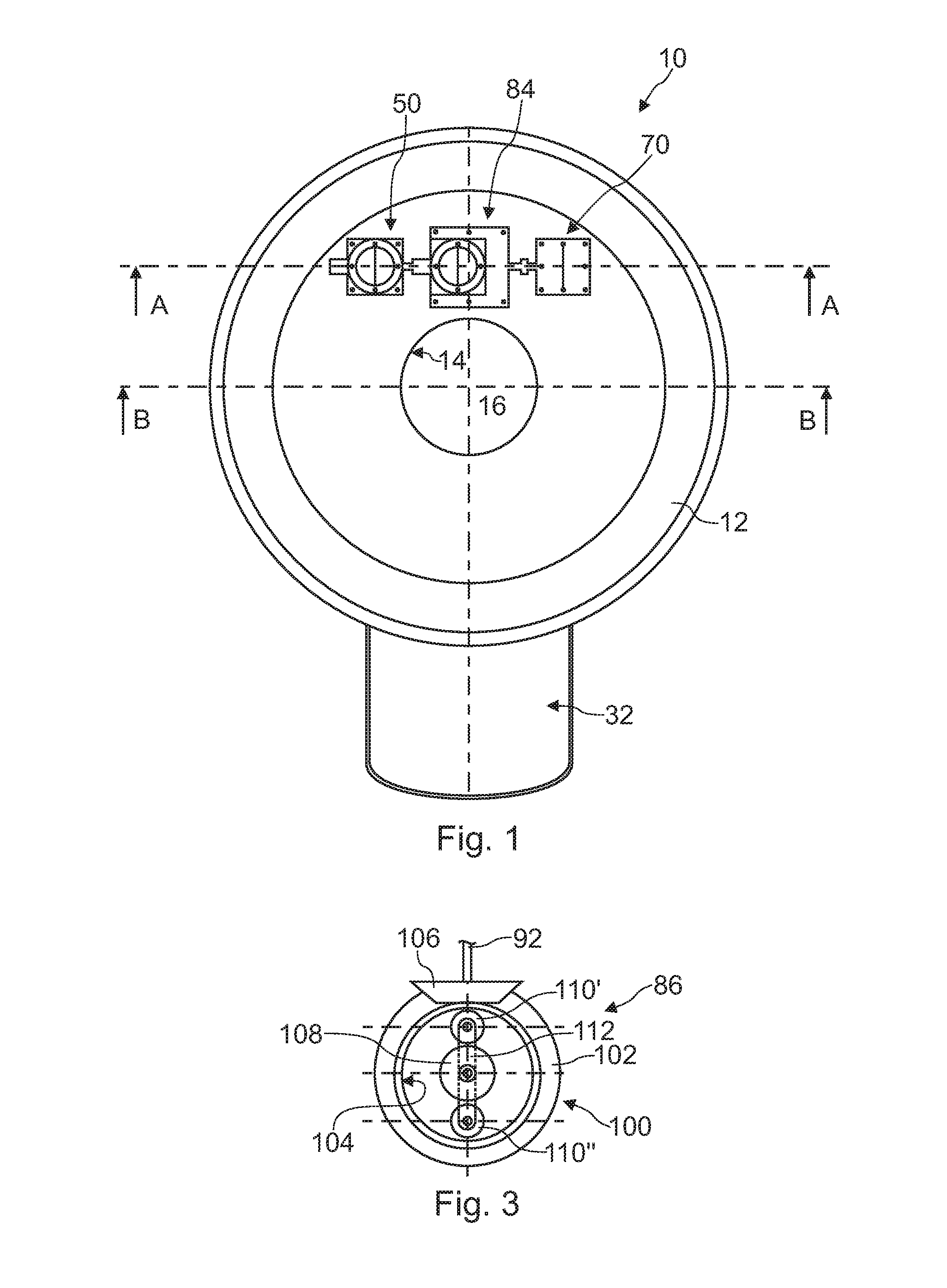

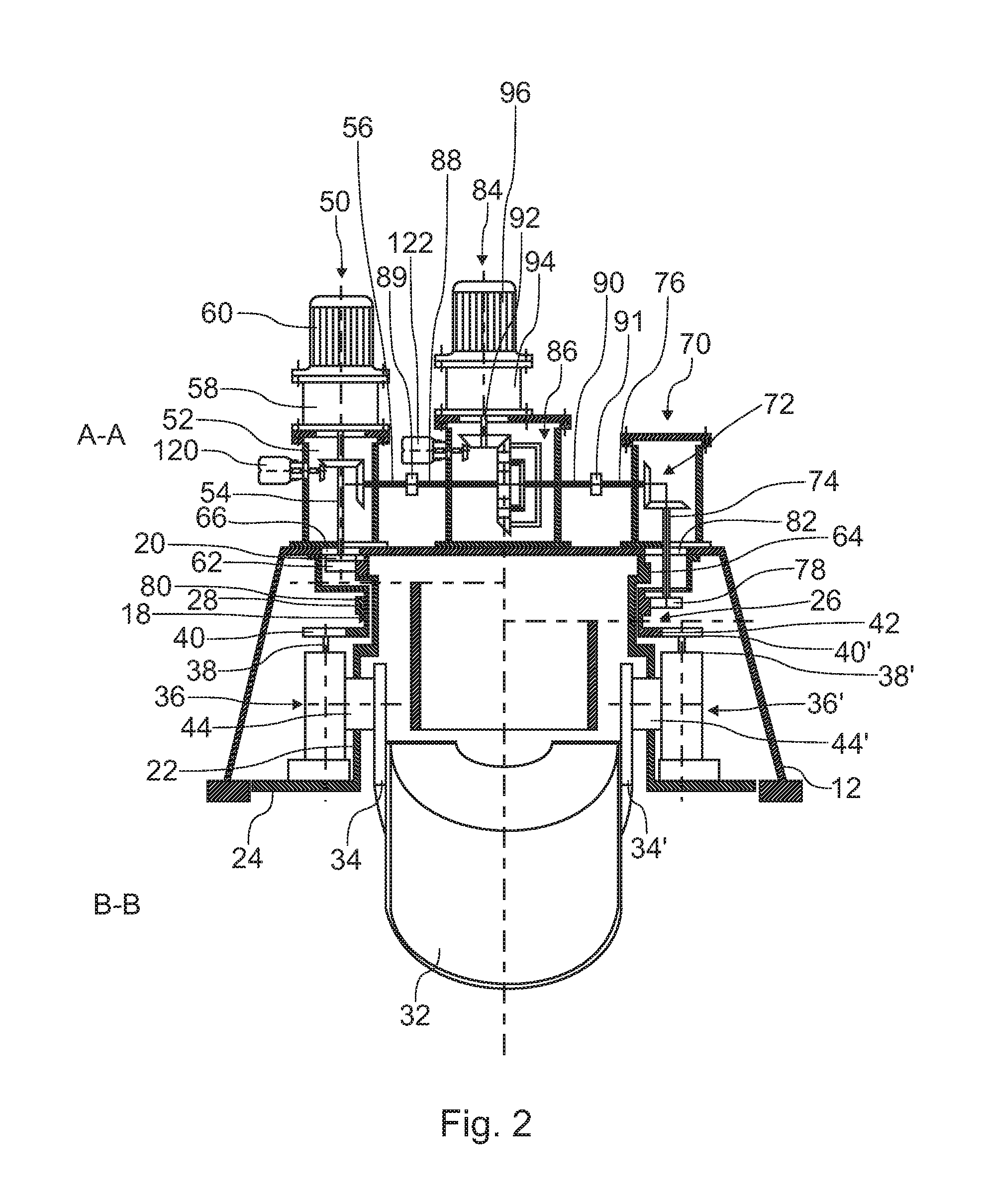

Device for distributing charge material in a shaft furnance

InactiveUS20120070253A1High positioning flexibilityImprove toleranceConveyorsGearingEngineeringShaft furnace

A device (10) for distributing charge material into a shaft furnace comprises a main housing (12), a distribution chute, a suspension rotor (18) and an adjustment rotor (26), which are rotatable about a substantially vertical axis. The chute (32) is suspended to the suspension rotor (18) to rotate therewith for circumferential distribution of charge material and adjustable in orientation through the adjustment rotor (26) for radial distribution of charge material. A differential gear (86) interconnects the suspension rotor (18) and the adjustment rotor (26) and is configured to transmit to the adjustment rotor the same speed of rotation that is imparted to the suspension rotor by a main rotation drive (60) unless an adjustment drive (96) imparts, through the differential gear, a differential rotation to the adjustment rotor. According to the invention, the device includes: a first casing (50) arranged on the main housing (12) and enclosing an angular transmission (52) between a substantially vertical output shaft (54), which protrudes from the first casing (50) into the main housing and is connected to a gearwheel (62) that meshes with a first gear ring (64) on the suspension rotor (18), and a connecting shaft (56), which protrudes from the first casing (50) at an angle, in particular perpendicularly, with respect to the output shaft (54); a second casing (70) arranged on the main housing (12) and enclosing an angular transmission (72) between a substantially vertical output shaft (74), which protrudes from the second casing (70) into the main housing and is connected to a gearwheel (78) that meshes with a second gear ring (80) on the adjustment rotor (26), and a connecting shaft (76(, which protrudes from the second casing (70) at an angle, in particular perpendicularly, with respect to the output shaft (74); a third casing (84) that is spaced apart from the first and second casings (50, 70) and encloses the differential gear (86), the differential gear being connected to a first shaft (88), which is coupled to the connecting shaft (56) of the first casing (50), and to a second shaft (90), which is coupled to the connecting shaft (76) of the second casing (70).

Owner:PAUL WURTH SA

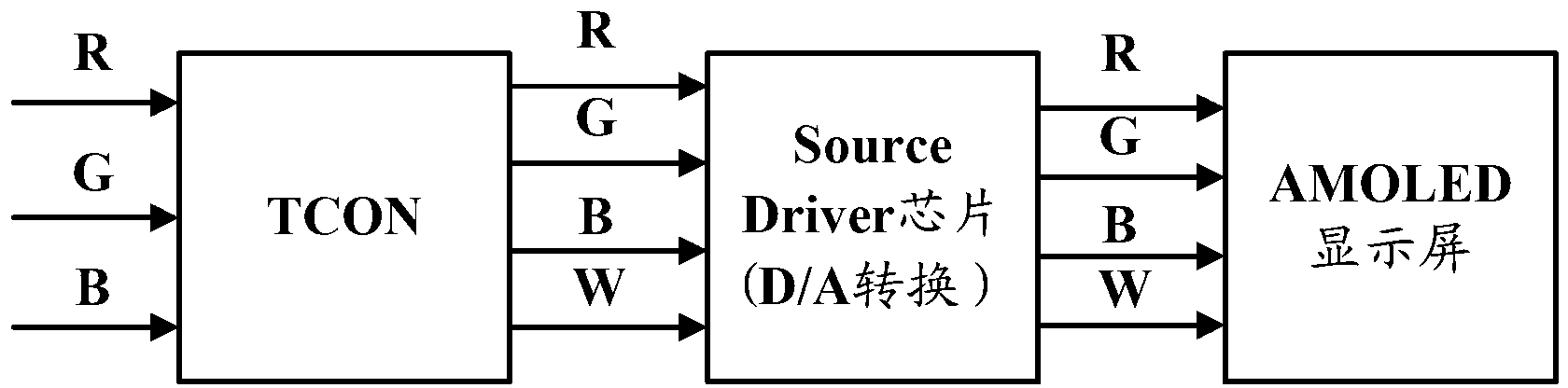

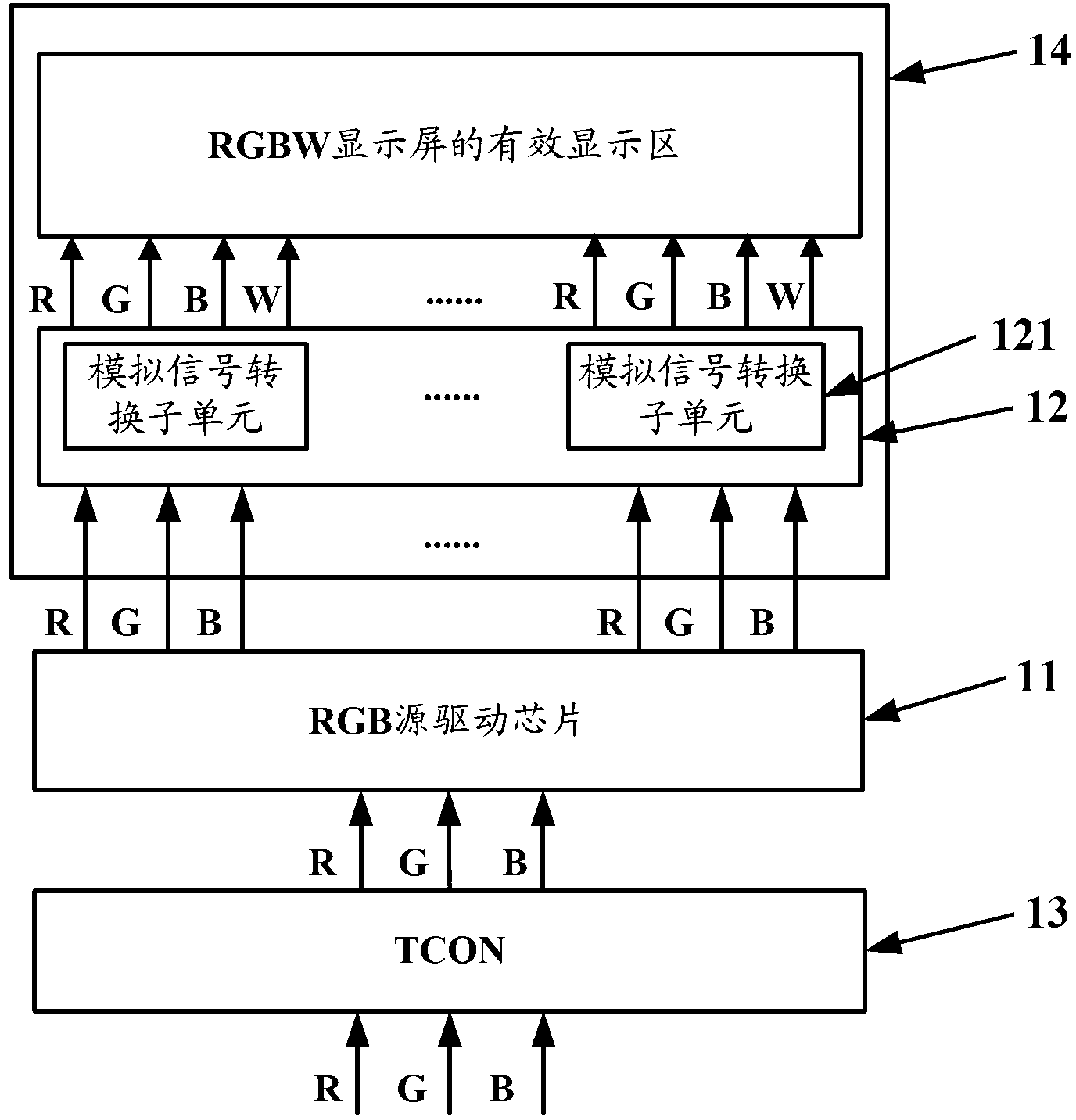

Driving system and method applicable to red, green, blue and white (RGBW) sub-pixel display screen

ActiveCN103021316ASimplify complexityReduce complexityStatic indicating devicesTime scheduleAnalog signal

The invention discloses a driving system and method applicable to a red, green, blue and white (RGBW) sub-pixel display screen. The driving system comprises a RGB source driving chip and an analog signal conversion unit. The RGB source driving chip is used for converting received each N group of RGB digital driving signals coming from a time schedule controller to N groups of analog driving signals comprising RGB sub-pixel driving voltage and outputting the analog driving signals to the analog signal conversion unit. The analog signal conversion unit is used for converting each N group of the analog driving signals comprising RGB sub-pixel driving voltage to N groups of the analog driving signals comprising RGBW sub-pixel driving voltage and outputting the analog driving signals comprising RGBW sub-pixel driving voltage to an effective display area of the RGBW sub-pixel display screen, wherein N is a positive integer. According to the driving system and method, the effect of using the RGB source driving chip to drive the RGBW display screen can be achieved, system complexity is simplified, and system driving cost is saved.

Owner:BOE TECH GRP CO LTD

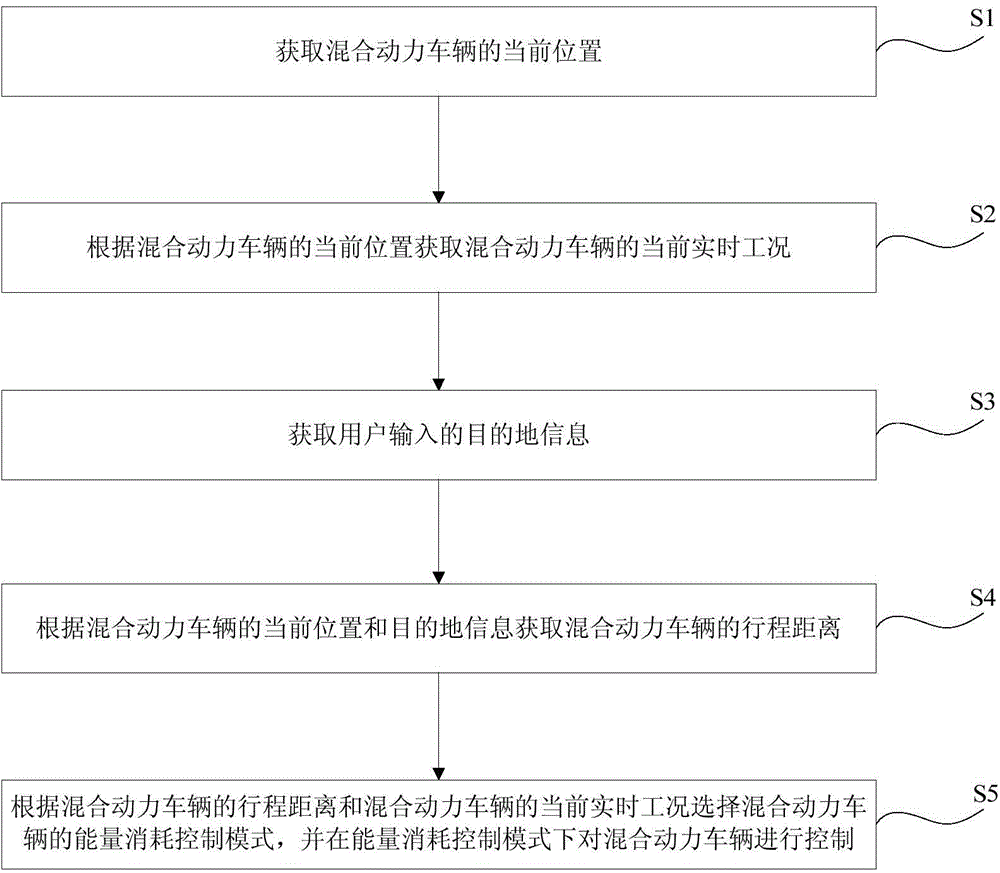

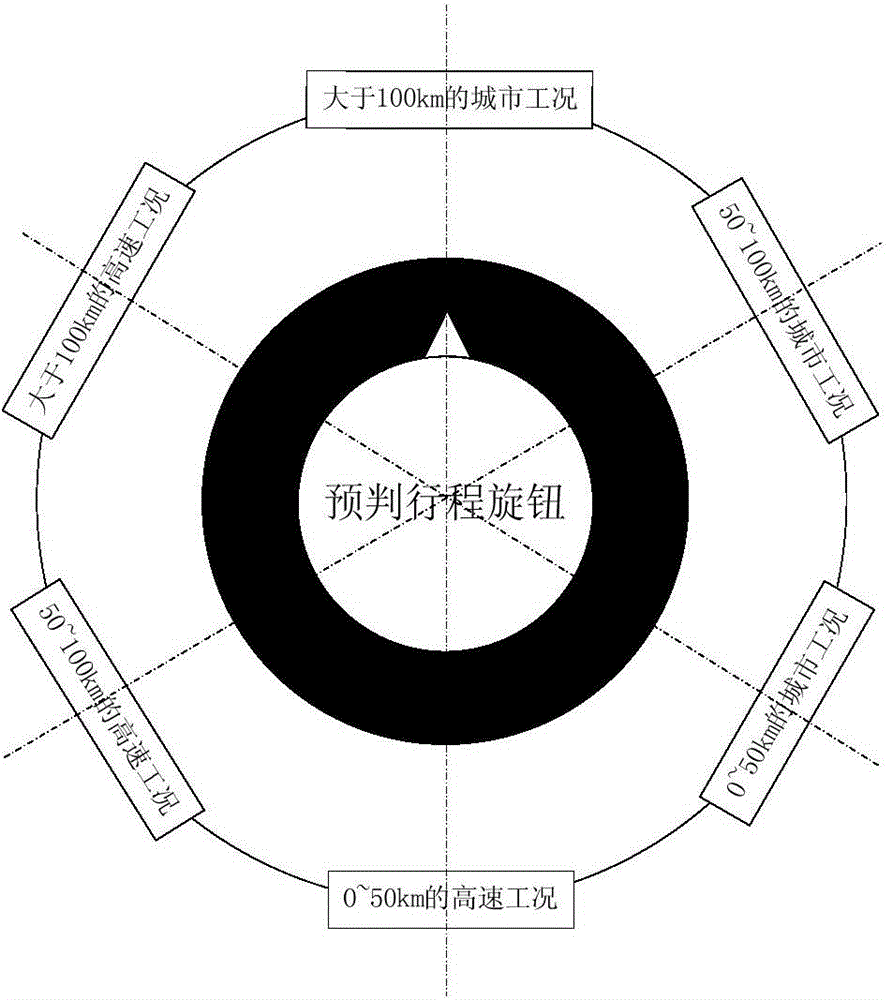

Energy consumption mode selection method and system of hybrid electric vehicle (HEV)

InactiveCN104828075AReduce driving costsEmission reductionHybrid vehiclesOther vehicle parametersSimulationSelection system

The invention discloses an energy consumption mode selection method of a hybrid electric vehicle (HEV). The method comprises the steps of obtaining the current position of the HEV; obtaining the current real-time working condition of the HEV according to the current position of the HEV; obtaining destination information input by a user; obtaining the stroke distance of the HEV according to the current position of the HEV and the destination information; and selecting an energy consumption control mode according to the current real-time working condition of the HEV and the stroke distance of the HEV, and performing control over the HEV under the energy consumption control mode. According to the invention, the most suitable energy consumption control mode can be automatically selected according to the stroke distance and the current real-time working condition, to control the proportion ratio of motor driving to engine driving, and thus emissions and driving consumption costs of users are greatly reduced. The invention also discloses an energy consumption mode selection system of the HEV.

Owner:BEIJING BORGWARD AUTOMOBILE CO LTD

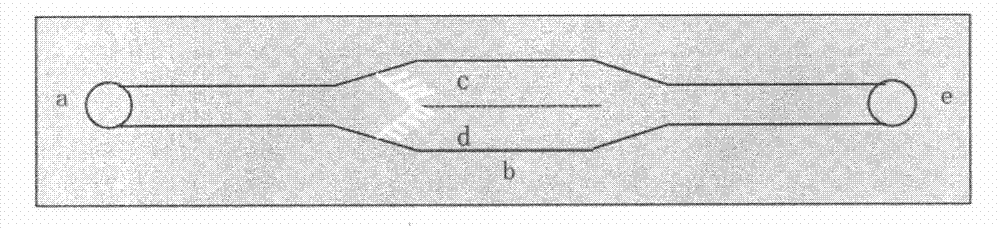

Micro-fluidic chip-based pH (Potential of Hydrogen) response micro valve and preparation method thereof

InactiveCN103075572AEasy to controlReduce drive costsValve arrangementsDecorative surface effectsMicro structureChromatographic separation

The invention relates to a micro-fluidic chip-based pH (Potential of Hydrogen) response micro valve and a preparation method thereof. A micro-structure and a micro-passage are arranged on the surface of a micro-fluidic chip; the main micro-passage is provided with a hydrophilic / hydrophobic gate controlled switch; the surface of the micro-passage is modified through pH responsive molecules; change in surface wettability is caused by reversible changes of surface topography and chemical configuration of the micro-passage under stimulation of different pHs; and motion of micro-fluid on the surface of the micro-passage is controlled, so that an intelligent micro-valve for controlling the flow of micro-fluid is realized. The valve is mainly applied to the related fields such as electrophoretic separation, chromatographic separation and immunoassay. The micro-fluidic chip realizes intelligent driving and control of the micro-fluid, the micro-fluid driving and control cost is greatly reduced, the valve has the characteristics of portability, economy, quickness and high efficiency, and a completely new analysis technology is provided for micro-fluid driving and control.

Owner:SUZHOU WENHAO MICROFLUIDIC TECH CO LTD

Horn mouth drum type screw wind power generator

InactiveCN1900514AReduce volumeReduce drive costsWind motor supports/mountsWind motor combinationsWind drivenBall bearing

The invention is especially related to drum type helix wind driven generator in shape of bell mouth applicable to car, train, airplane, and ship etc. Technical scheme is that the product is composed of outer cover, generator, blades, and transmission shaft; being installed on up part of the outer cover, helix type blades and trench type ball bearings through bolts are connected to the outer cover, and through transmission shaft are connected to generator and bracket at lower part; windward end of the outer cover is designed as shape of bell mouth; generator is positioned inside straight tube or inside bell mouth. Features are: reduced volume of generator compared under same power, and reduced space usage. Structure of bell mouth increases air input.

Owner:单建锡

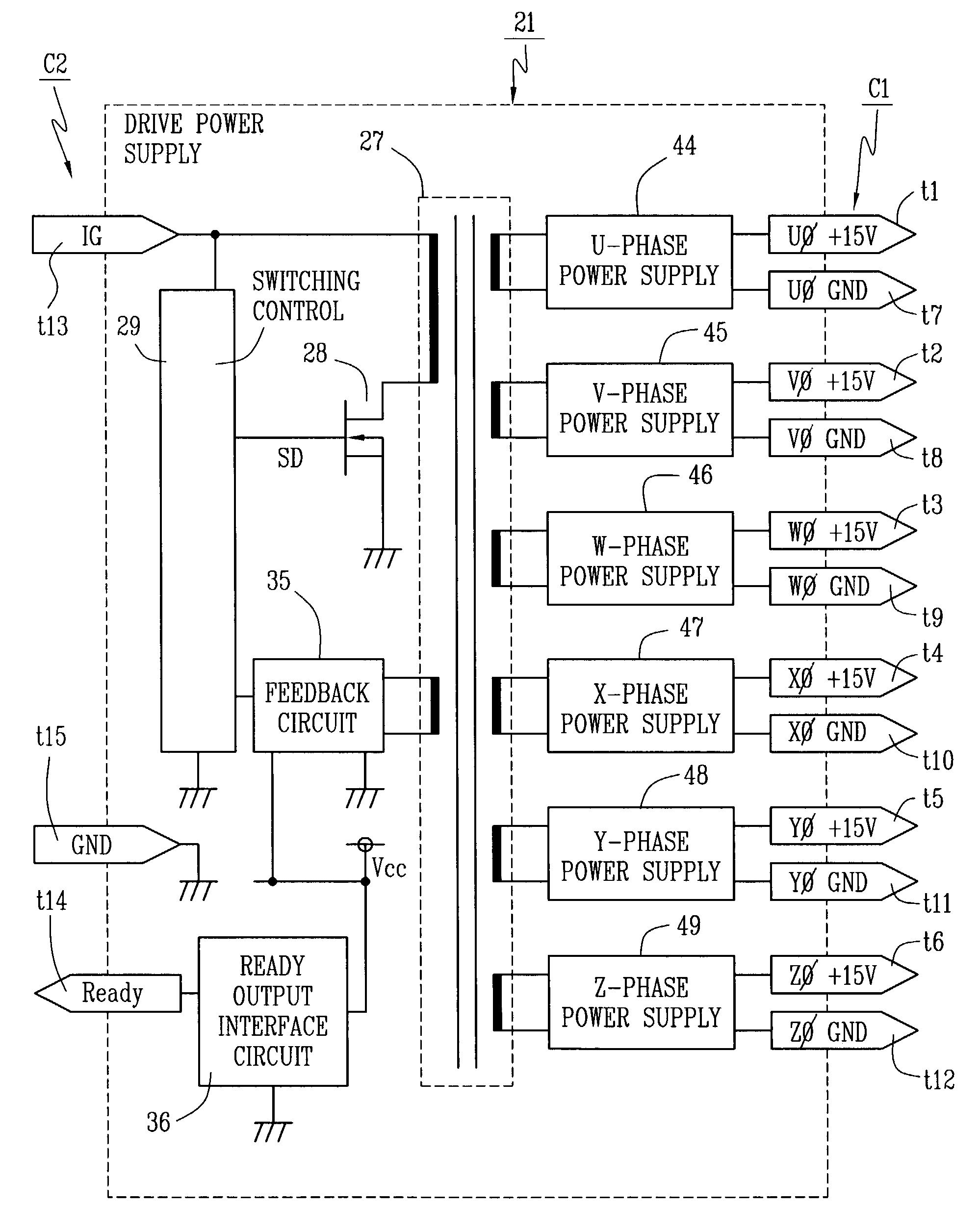

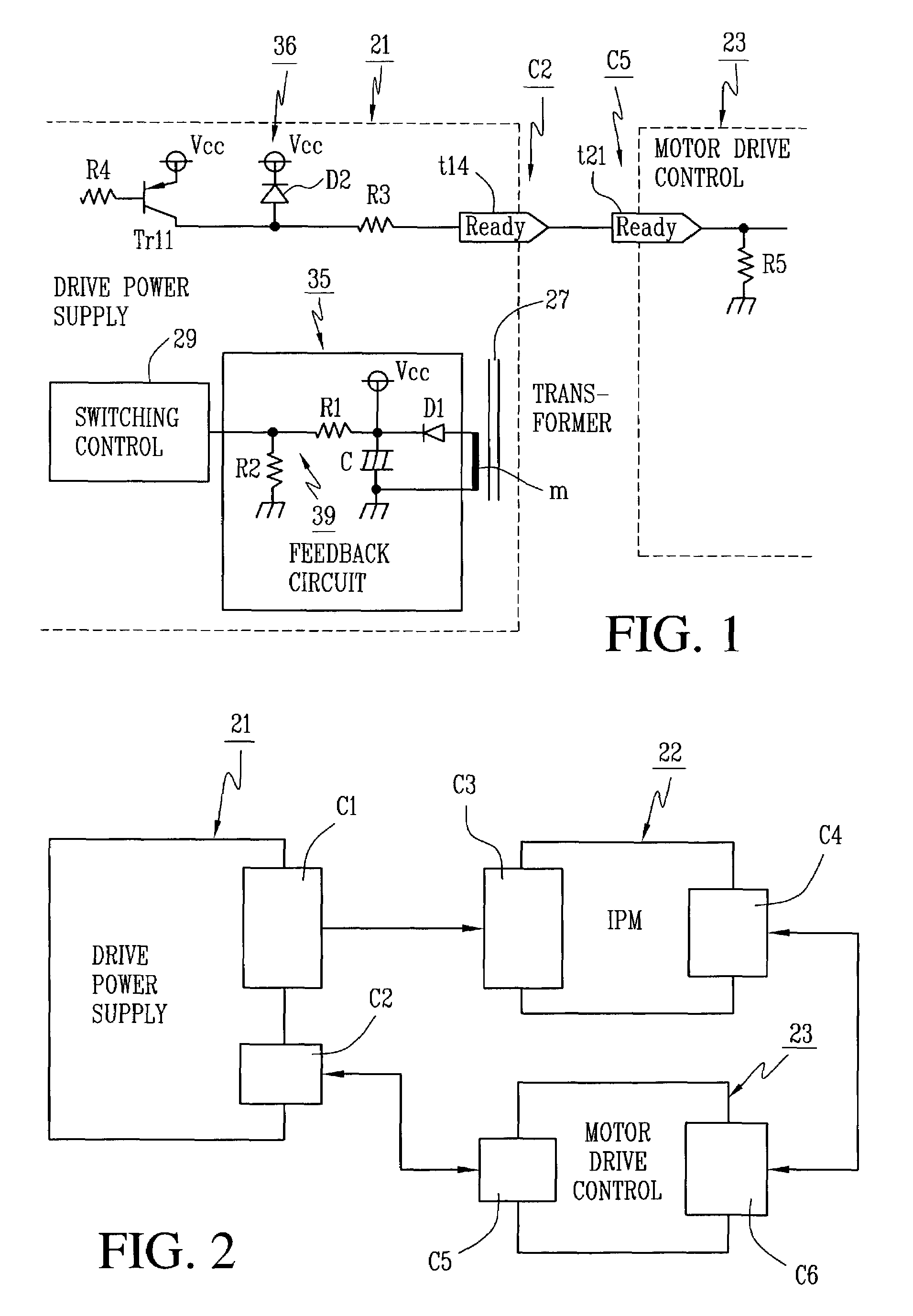

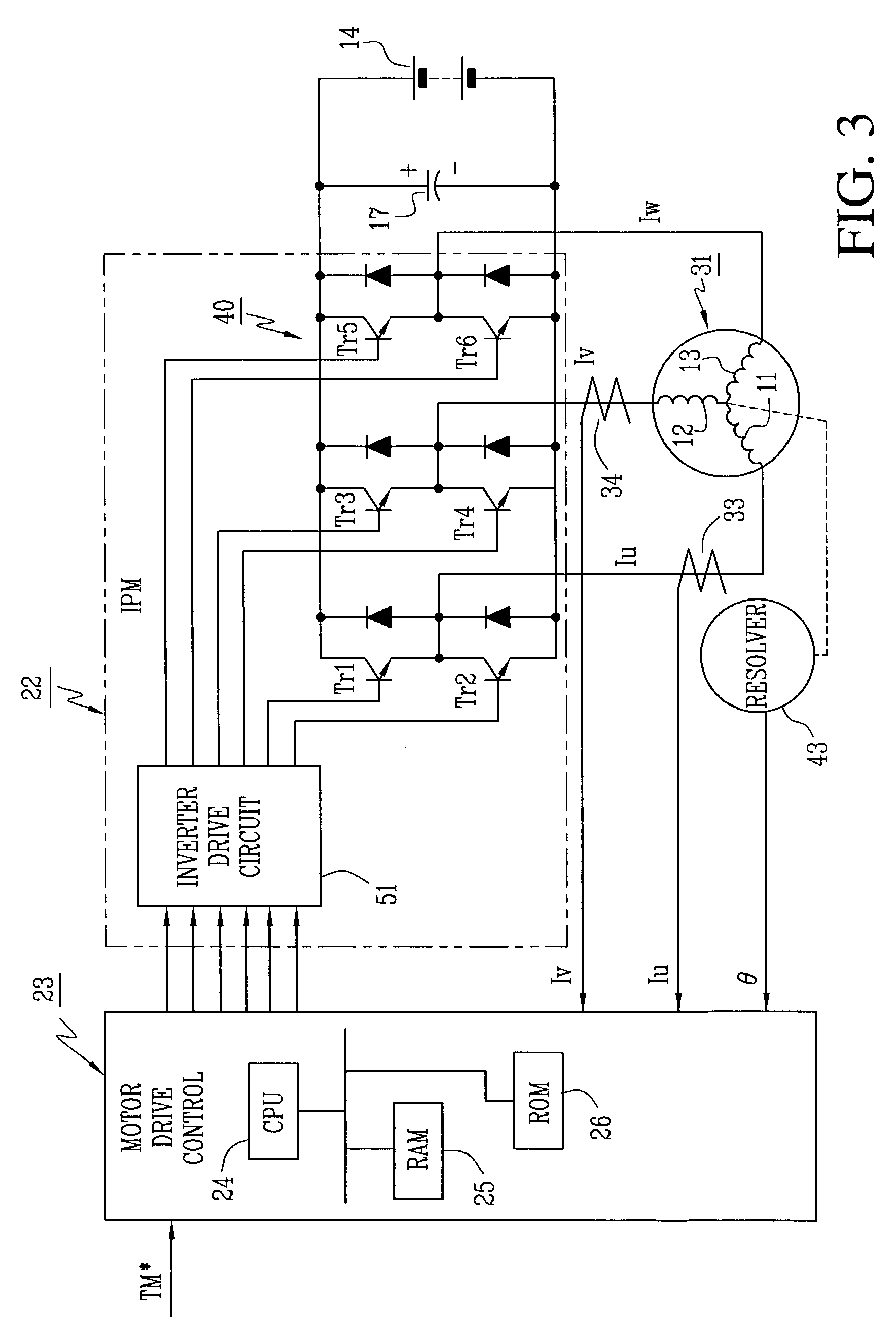

Drive power supply and fail determination method

ActiveUS7236337B2Low costSimple supplyVector control systemsEmergency protective arrangements for automatic disconnectionAnomaly detectionFeedback circuits

A drive power supply for generating inverter drive voltages has a switching control circuit that switches a switching element on a primary side of a transformer to generate drive voltages on the secondary side in connection with the switching of switching elements of the inverter. A feedback circuit generates a feedback voltage corresponding to the drive voltages and supplies the feedback voltage to the switching control circuit to control the drive voltages. An abnormality detecting portion changes the feedback voltage when the voltage of a predetermined terminal fluctuates. Thus when an IG short involving the predetermined terminal occurs, the drive voltages are changed by the switching control circuit sensing the change in the feedback voltage. Since any change in the drive voltages is detected to reliably determine an abnormality, an IG short is detected as an abnormality even though the abnormality has been generated in the drive power supply independent of any prior change in the actual drive voltages.

Owner:AISIN AW CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com