Drive axle testing method and system

A test method and drive axle technology, applied in the field of vehicles, can solve the problems of not fully reflecting the actual performance of the drive axle, limited parameters, etc., and achieve the effects of saving energy, scientific judgment standards, and reducing driving costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

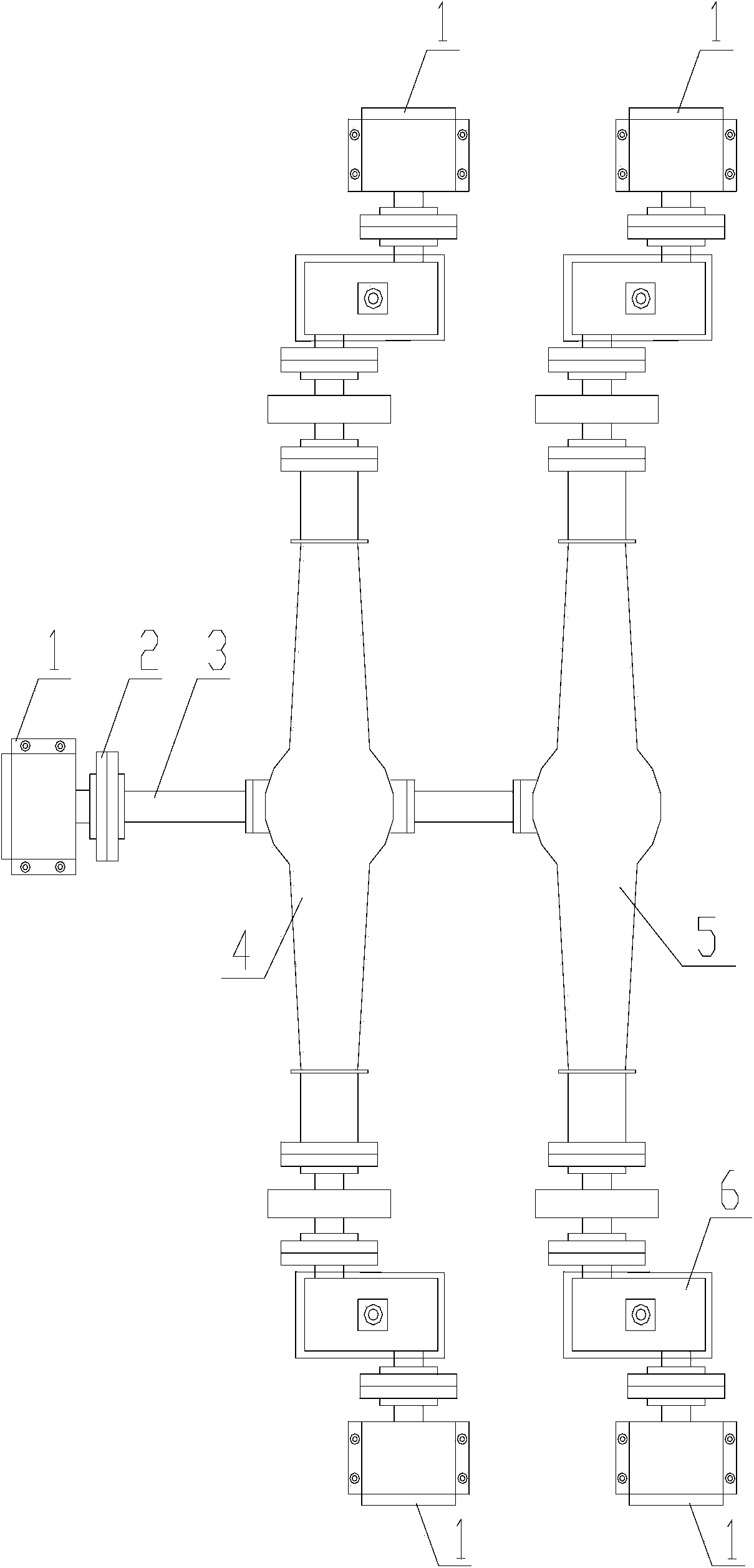

[0047] Please refer to figure 1 , figure 1 It is a structural schematic diagram of a specific embodiment of the drive axle test system provided by the present invention.

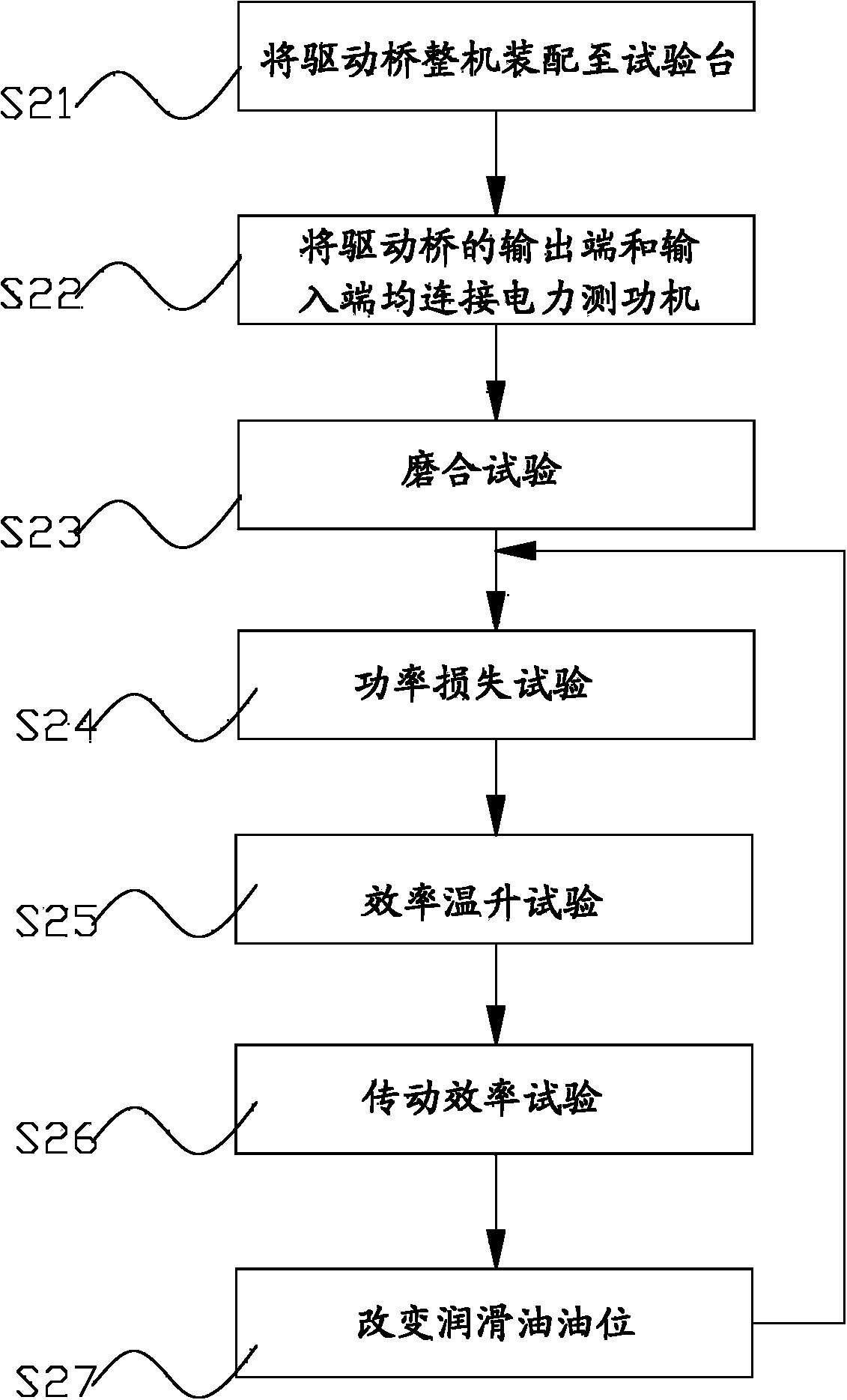

[0048] The drive axle test method specifically comprises the following steps:

[0049] S11, assembling the drive axle complete machine to the test bench;

[0050] S12. Connect the output end and the input end of the driving axle to the electric dynamometer 1;

[0051] The test bench mainly includes electric dynamometer 1, transmission shaft 3, electrical control system and other components. When assembling the driving axle, the driving axle can be fixed on the test bench according to the assembly method of assembling on the whole machine, that is, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com