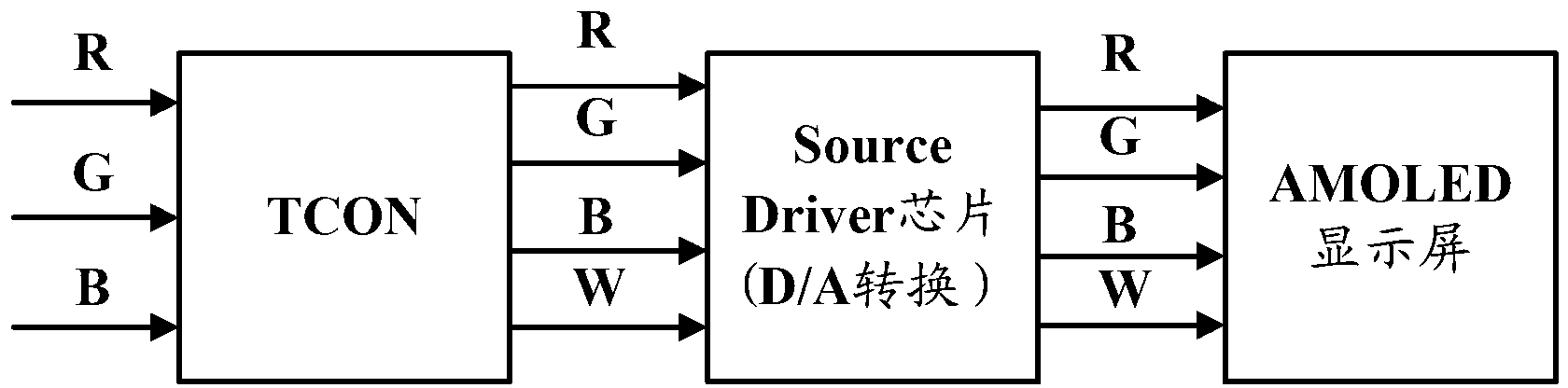

Driving system and method applicable to red, green, blue and white (RGBW) sub-pixel display screen

A technology for driving systems and sub-pixels, applied in static indicators, instruments, etc., can solve the problems of high driving cost, high system complexity, and large data transmission volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

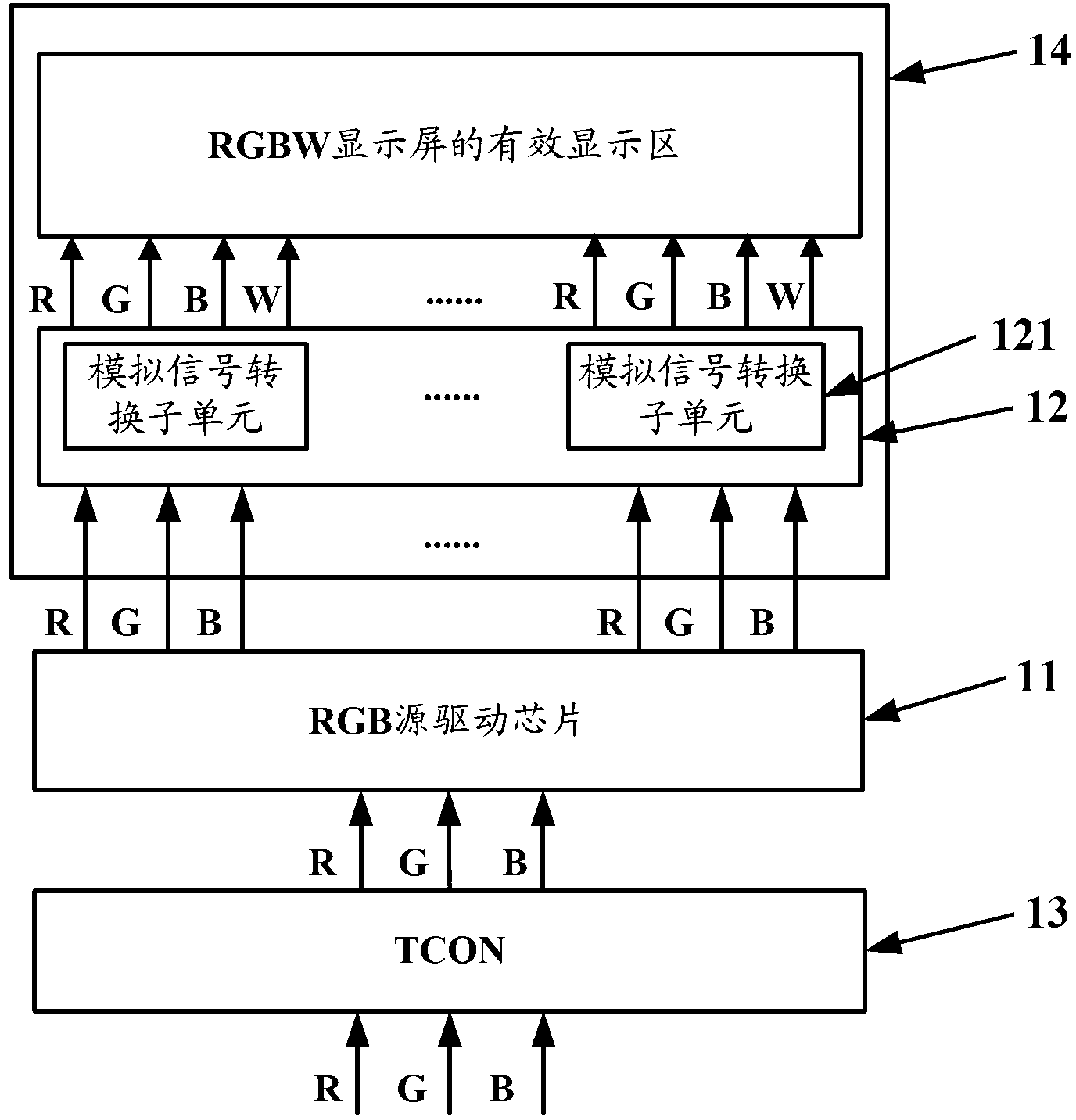

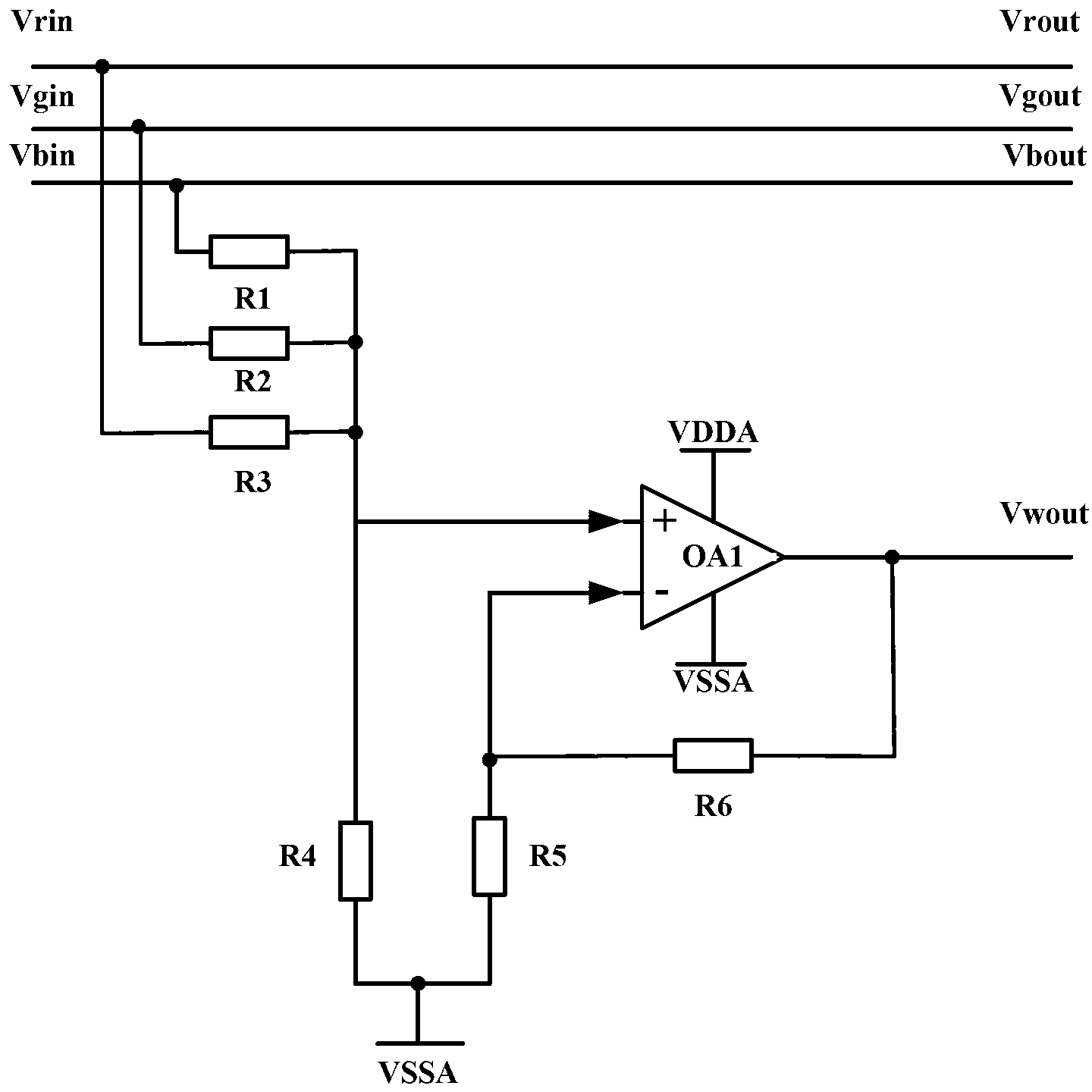

[0026] Such as figure 2 As shown, it is a schematic structural diagram of a driving system suitable for RGBW four-color sub-pixel display screens in Embodiment 1 of the present invention. The driving system includes an RGB source driving chip 11 and an analog signal conversion unit 12, and may also include a It is used to receive the RGB digital driving signal from the external system, and output the received RGB digital driving signal to the TCON13 of the RGB source driver chip 11 and the RGBW four-color sub-pixel display screen 14, etc., wherein:

[0027] The RGB source driver chip 11 is used to receive RGB digital drive signals from TCON13, and perform digital-to-analog conversion on every N groups of RGB digital drive signals received from TCON13 to obtain N groups including R, G, and B tricolors. An analog driving signal of the pixel driving voltage, and outputting the N groups of analog driving signals including R, G, and B three-color sub-pixel driving voltages to the ...

Embodiment 2

[0048] Such as Figure 4 As shown, it is a schematic flowchart of a driving method suitable for RGBW four-color sub-pixel display screens described in Embodiment 2 of the present invention. The RGBW four-color sub-pixel display screens (referred to as RGBW display screens) can be AMOLED display screens, etc. , the embodiment of the present invention does not make any limitation on this, specifically, the driving method may include the following steps:

[0049] Step 101: The analog signal conversion unit receives N groups of analog driving signals including sub-pixel driving voltages of R, G, and B colors output by the RGB source driving chip, wherein N is a positive integer.

[0050] Specifically, the RGB source driver chip outputs the N groups of analog drive signals including R, G, and B three-color sub-pixel drive voltages. The RGB source driver chip performs digital-to-analog conversion on the RGB digital drive signals received from TCON. obtained after.

[0051] Specifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com