Built-in self-capacitance touch display panel and manufacturing method thereof

一种自电容触控、显示面板的技术,应用在电数字数据处理、光学、仪器等方向,能够解决面板制程工艺难度、面板驱动成本高等问题,达到降低驱动成本的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

[0055] The present invention firstly provides an embedded self-capacitance touch display panel, including: an array substrate, a CF substrate, and a liquid crystal layer arranged between the array substrate and the CF substrate. side shot.

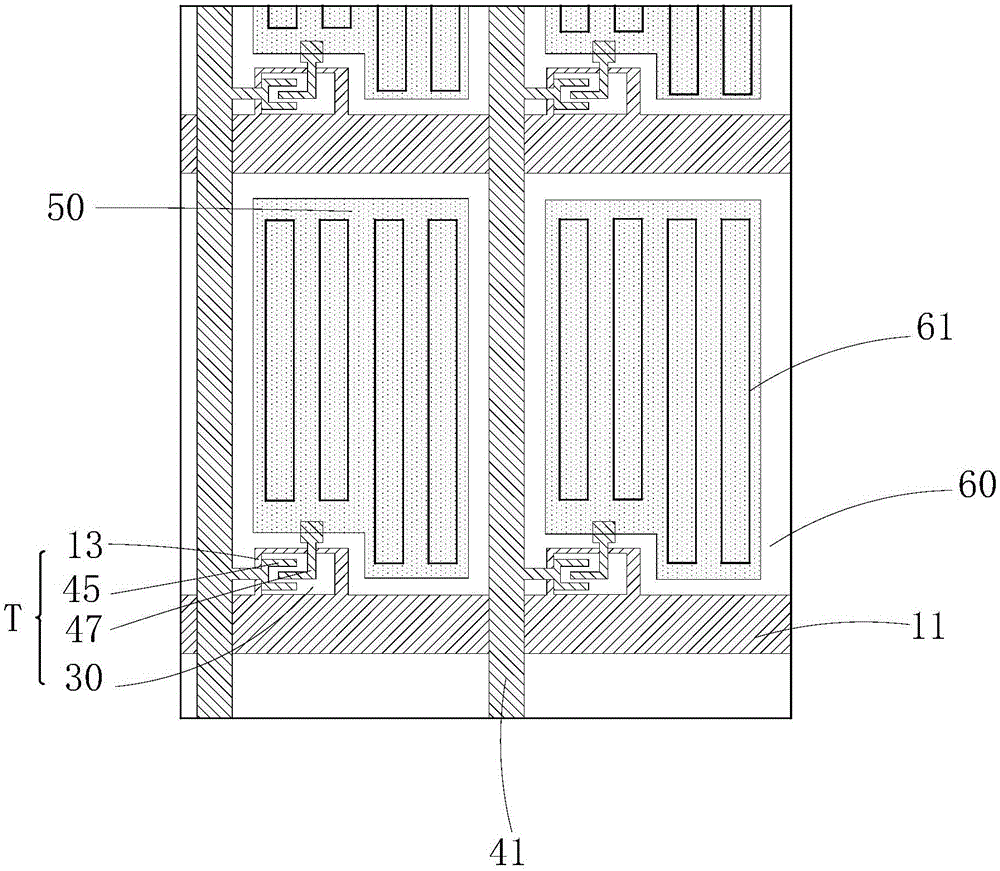

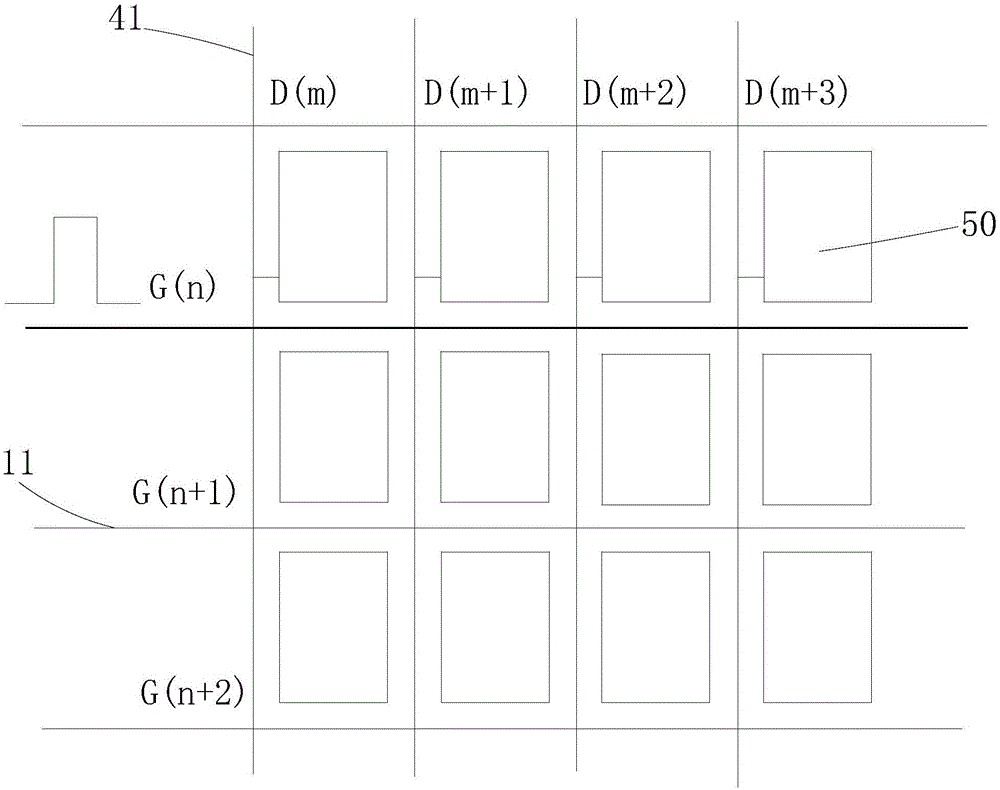

[0056] see figure 1 , the array substrate includes:

[0057] A plurality of grid scanning lines 11 arranged at intervals along the horizontal direction;

[0058] A plurality of data lines 41 arranged at intervals in the vertical direction, the plurality of gate scanning lines 11 arranged at intervals in the horizontal direction and a plurality of data lines 41 arranged at intervals in the vertical direction are insulated and interlaced with each other, dividing a plurality of sub-pixels area;

[0059] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com