Patents

Literature

378results about How to "Size limit" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

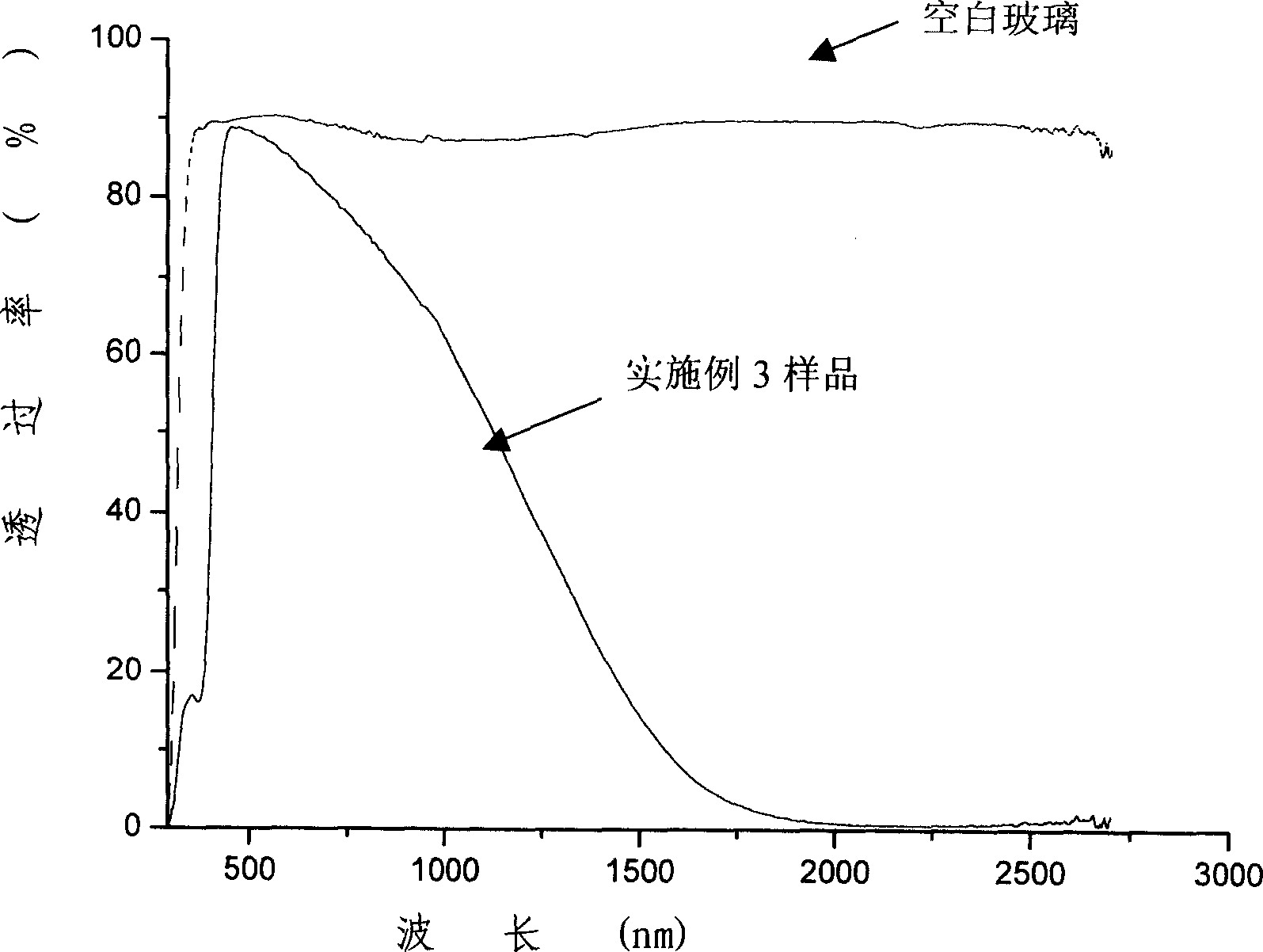

Sunlight controlled transparent film in low radiation, prepartion method and application

InactiveCN1916057AGood visible light transparencyPrevent penetrationDispersed mediaMetal oxide nanoparticles

This invention relates to a method for preparing low-radiation heat-insulating transparent film for controlling sunlight. The film is composed of: organic polymer 70-99.9 wt. %, doping metal oxide nanoparticles 0.1-30 wt. % and adjuvant 0-29.9 wt. %. The method comprises: (1) uniformly dispersing the doping metal oxide nanoparticles into a dispersing medium, mixing with the organic polymer and the adjuvant, and drying to obtain master batches; (2) plasticizing, smelting or extruding and blowing, calendaring, stretching, extruding and casting to obtain the film. The film can be used as the coating film for architecture glass, automobile window and ship window, and has such advantages as high visible-light permeability, good sunlight obstructing effect, good anti-electrostatic effect, and good electromagnetic radiation resistance.

Owner:长春迪高实业有限公司

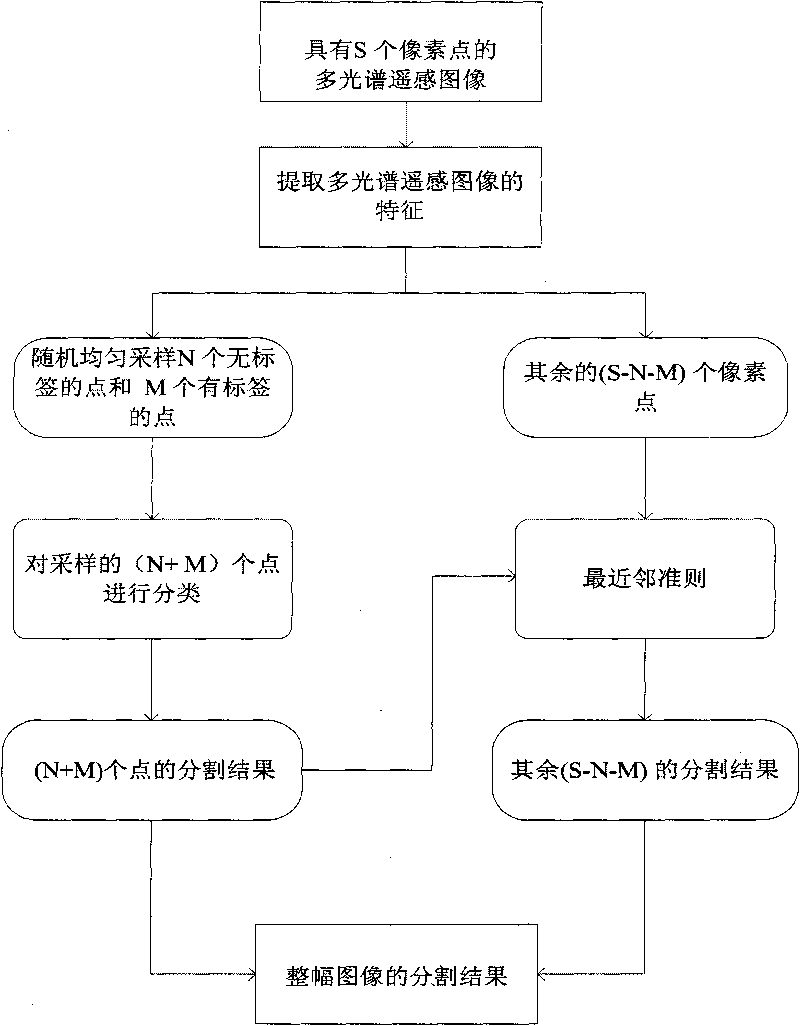

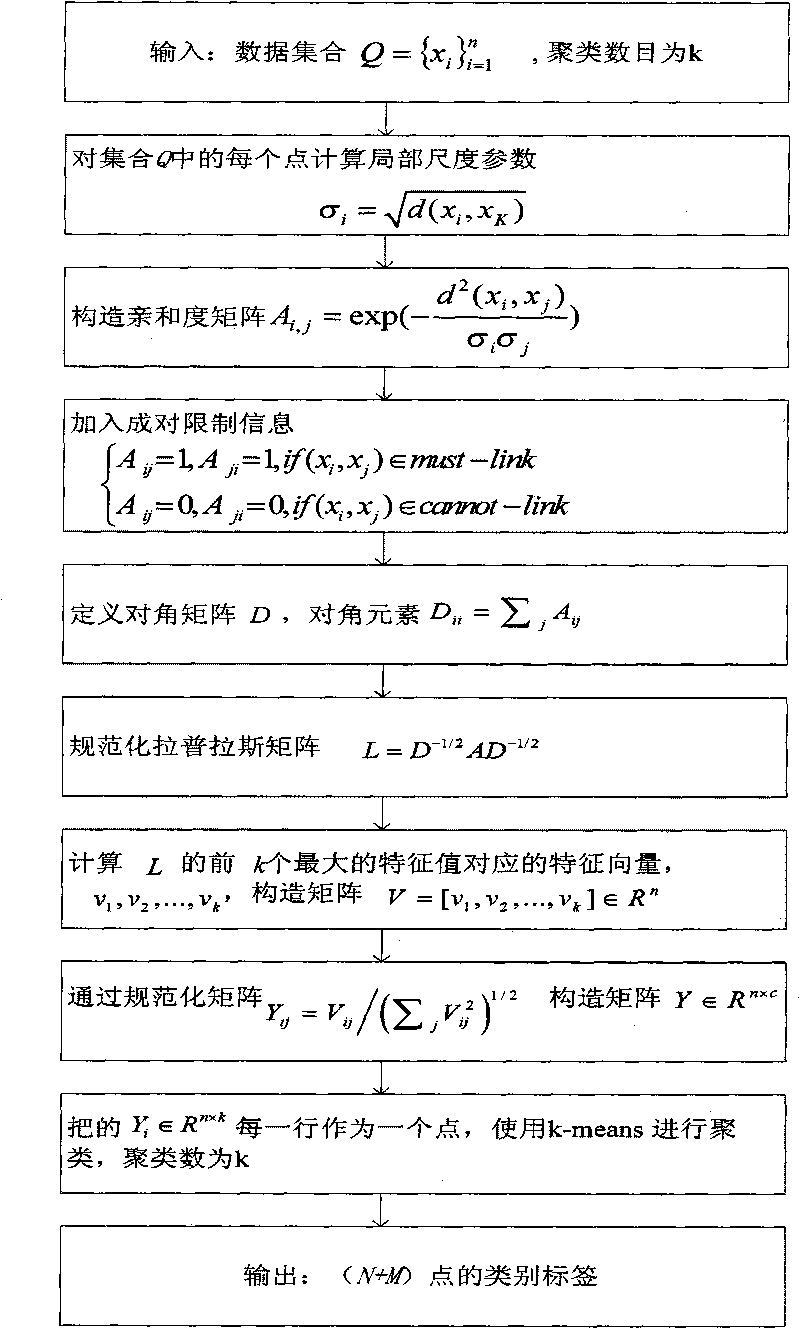

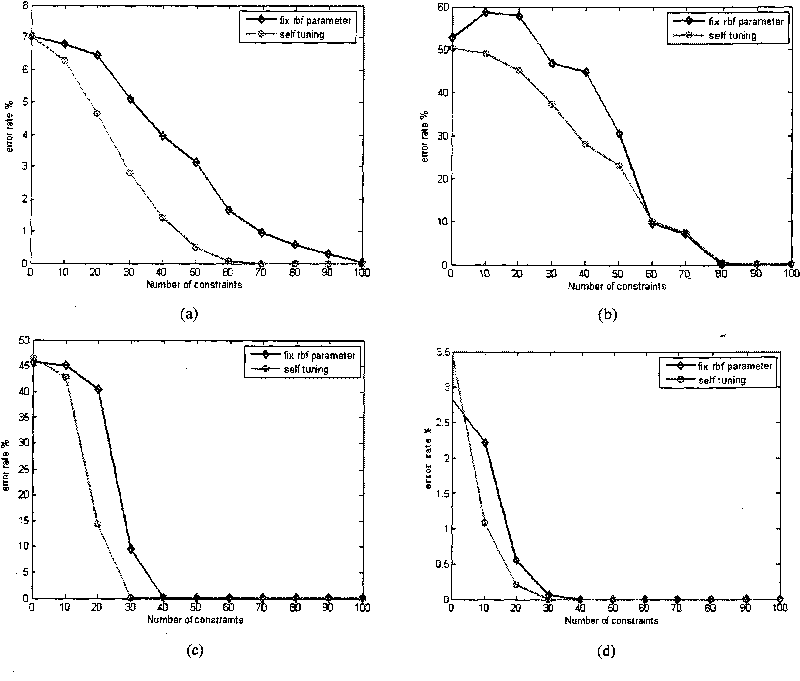

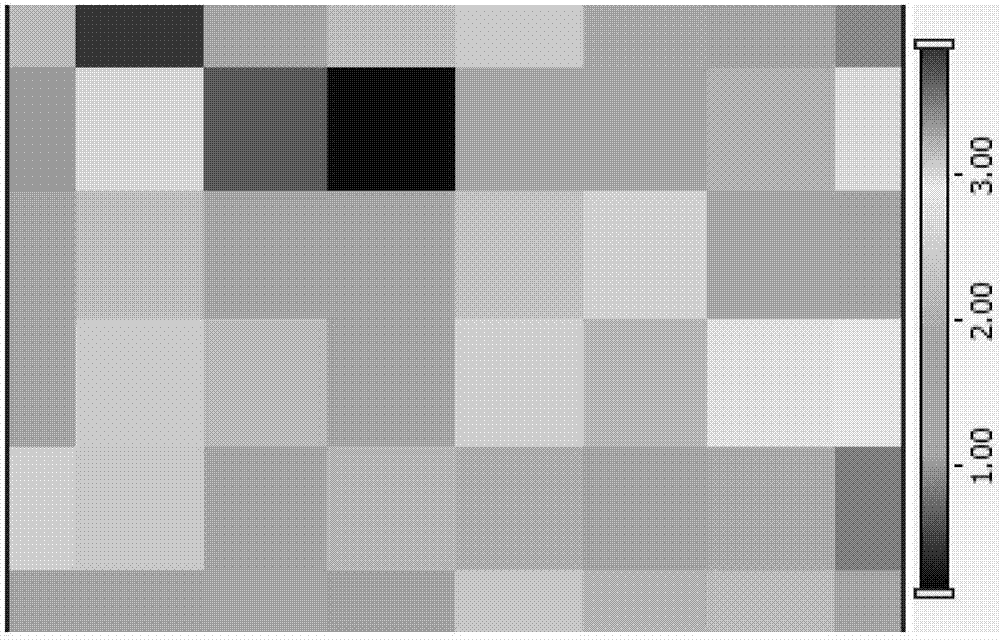

Semi-supervised multi-spectral remote sensing image segmentation method based on spectral clustering

InactiveCN101751666AAccurate identificationGood segmentation effectImage analysisWave based measurement systemsPattern recognitionNear neighbor

The invention discloses a semi-supervised multi-spectral remote sensing image segmentation method based on spectral clustering; the segmentation process includes that: (1) the characteristics inputted to the multi-spectral sensing image are extracted; (2) N points without labels and M points with labels are randomly and evenly sampled from a multi-spectral sensing image with S pixel points to form a set n which is the summation of N and M, wherein M points with labels are used for creating pairing limit information Must-link and Cannot-link sets; (3) the sampled point set is analyzed through semi-supervised spectral clustering to obtain the class labels of the n (n=N+M) points; (4) the sampled n (n=N+M) points are used as the training sample to classify the rest (S-N-M) points through nearest-neighbor rule, each pixel point is assigned with a class label according to the class of the pixel point and is used as the segmentation result of the inputted image. Compared with prior art, the invention has good image segmentation effect, strong operability, improves the classification accuracy, avoids searching the optimum parameters through repeated test, has small limit on image size and is better applicable to the segmentation of multi-class multi-spectral sensing images.

Owner:XIDIAN UNIV

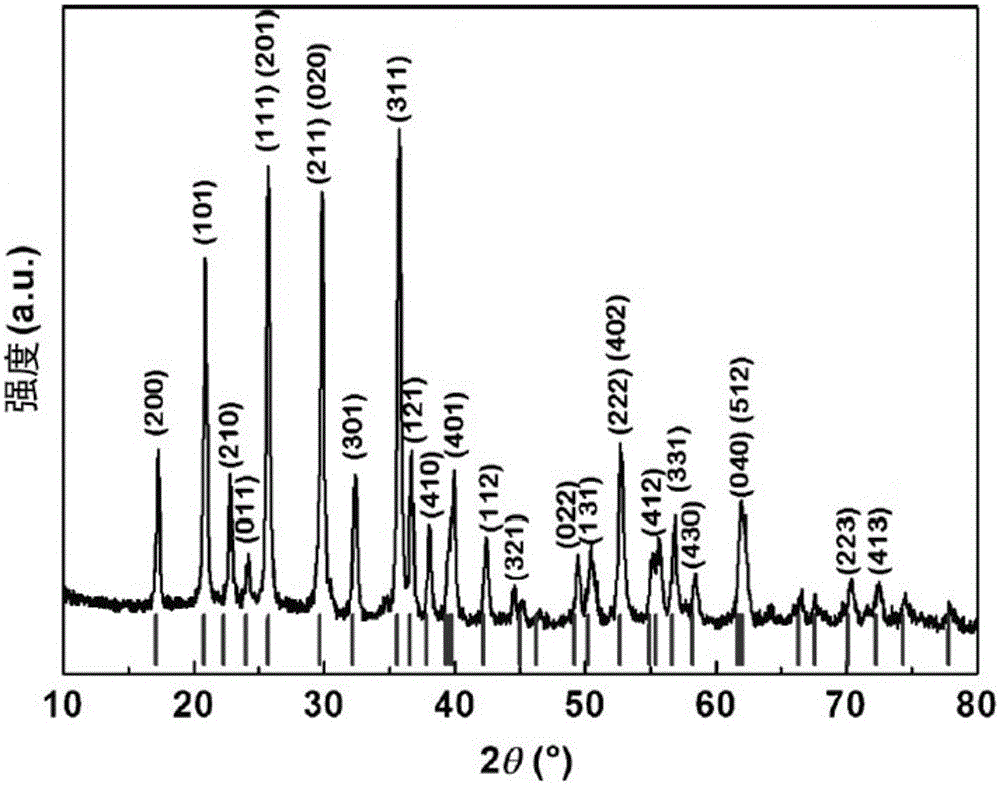

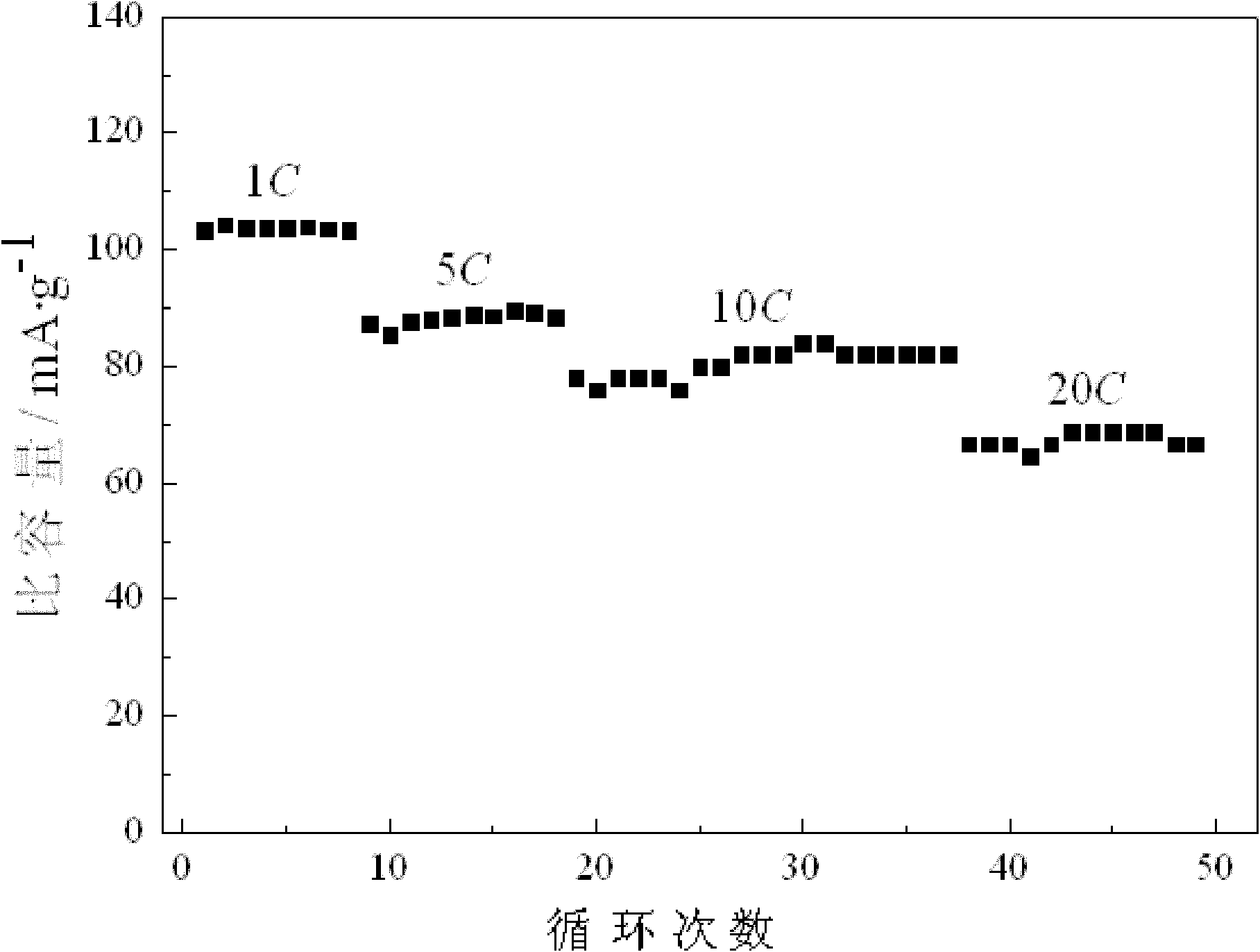

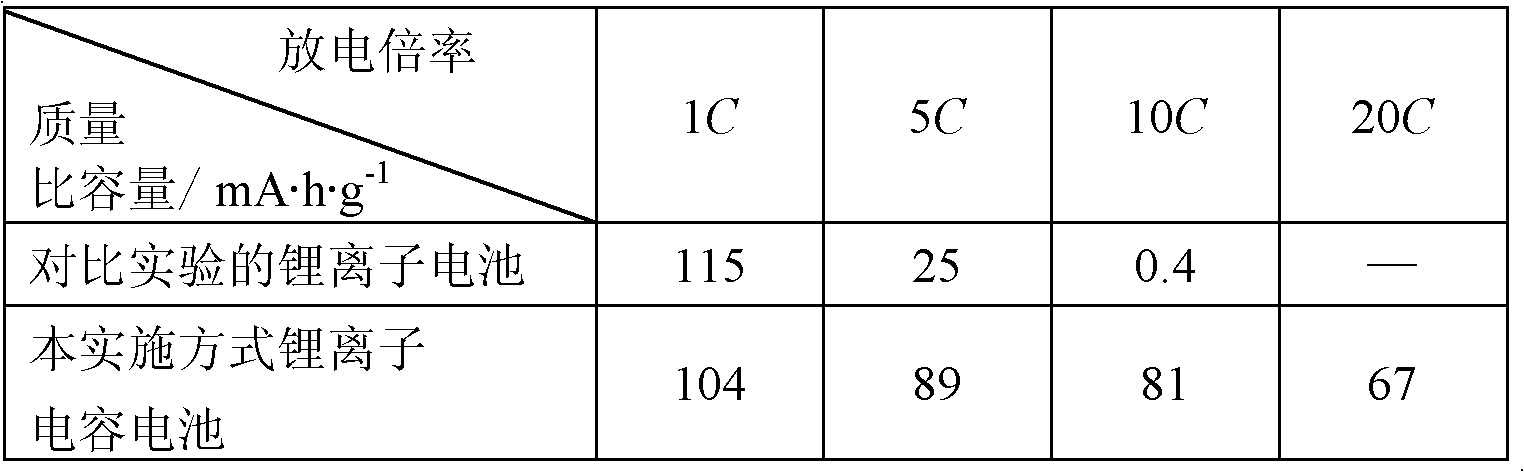

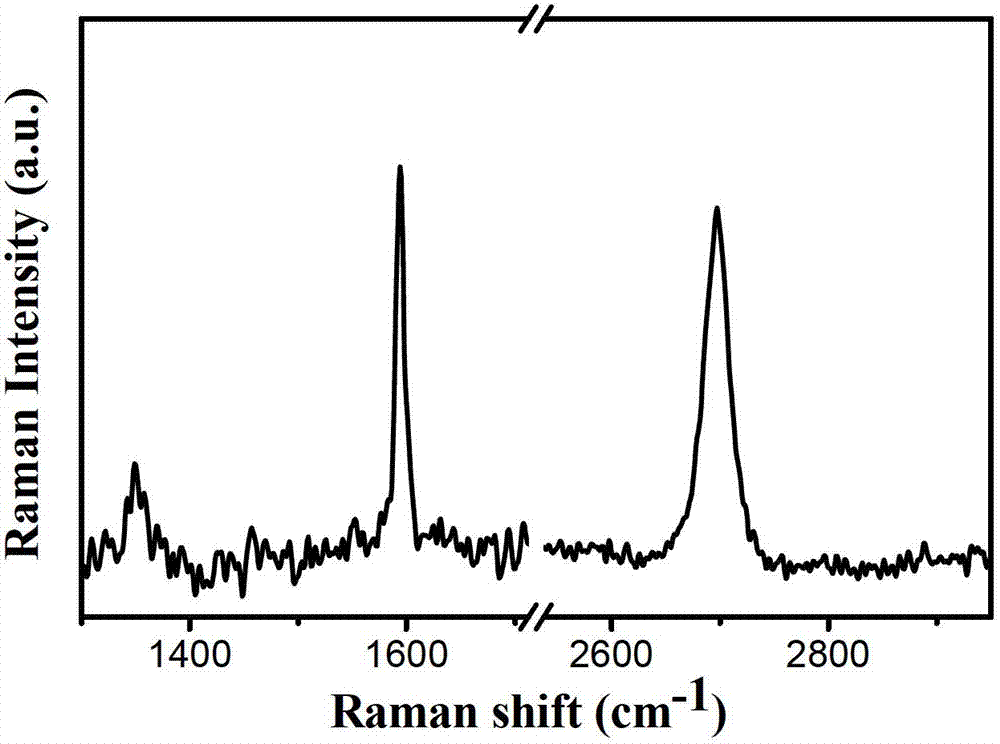

Multi-layer graphene/lithium iron phosphate intercalated composite material, preparation method thereof, and lithium ion battery adopting multi-layer grapheme/lithium iron phosphate intercalated composite material as anode material

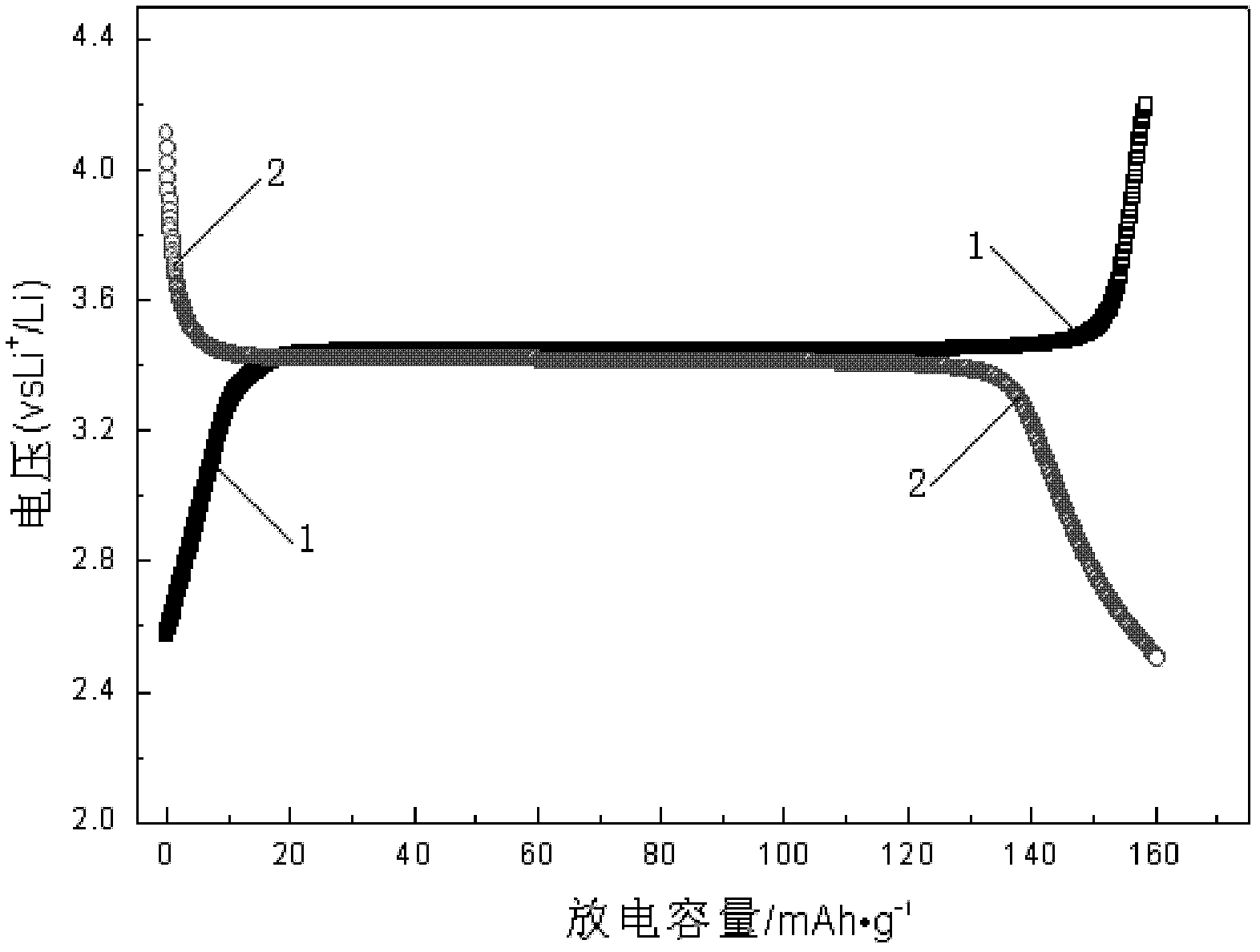

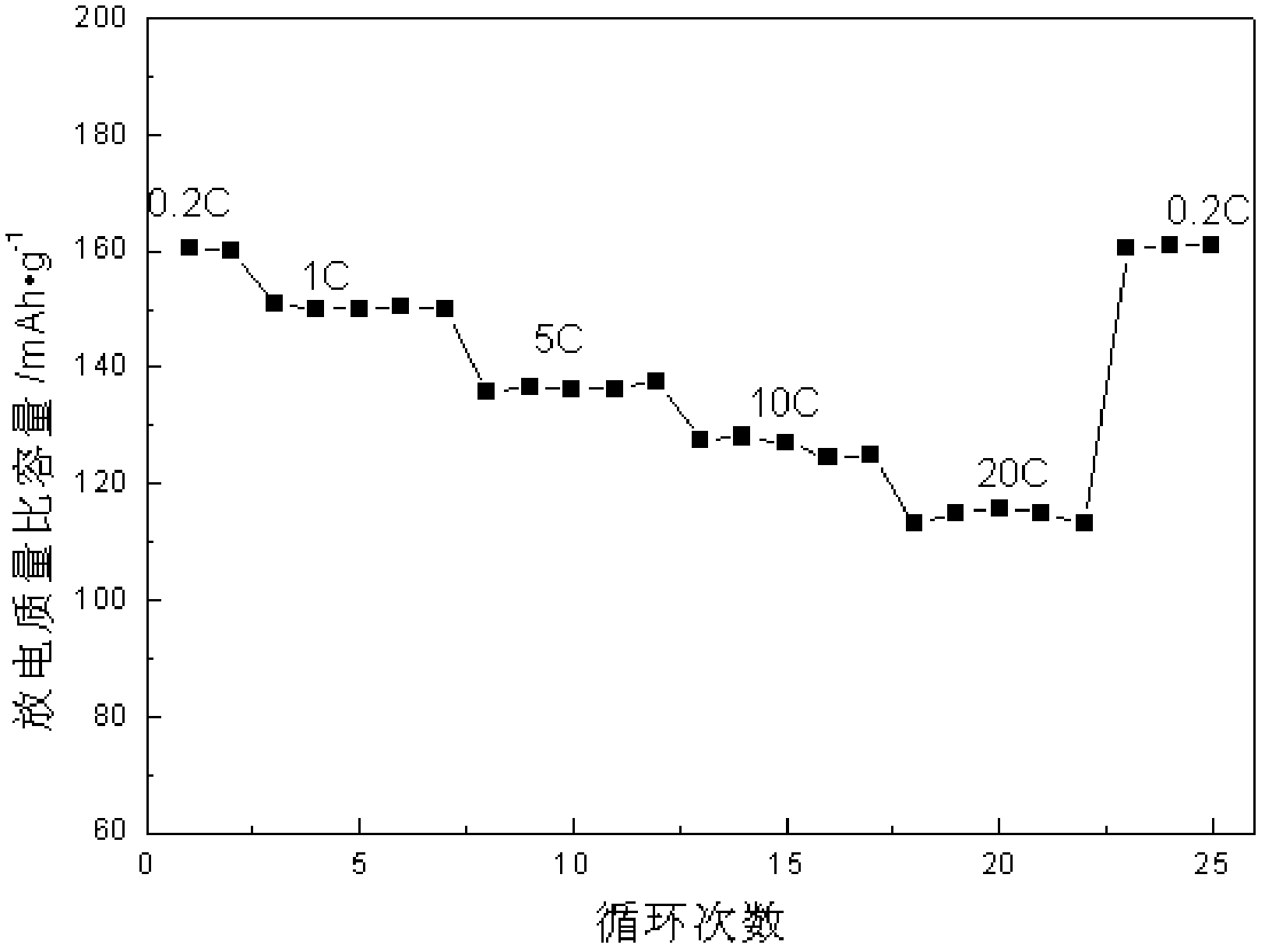

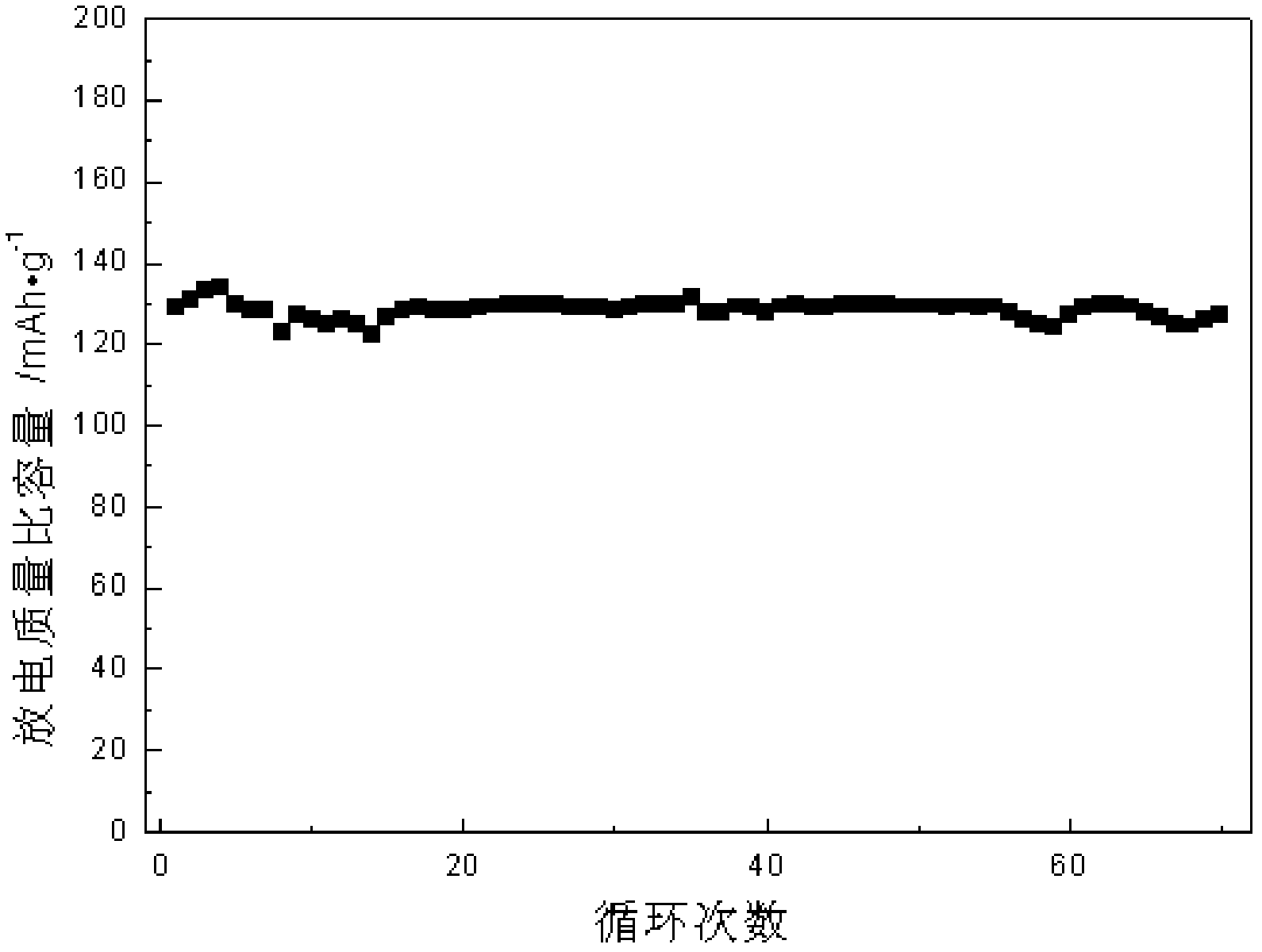

InactiveCN102306783AImprove electronic conductivityReduced Diffusion ResistanceCell electrodesSecondary cellsHigh rateSlurry

The invention relates to a lithium iron phosphate intercalated composite material, a preparation method thereof and a lithium ion battery adopting the multi-layer graphene / lithium iron phosphate intercalated composite material as an anode material. In the prior art, the electronic conductivity of the lithium iron phosphate material is poor, high-rate charging / discharging capacity of the lithium ion battery adopting the lithium iron phosphate material as the anode material is poor. The purpose of the present invention is to solve the problems in the prior art, and improve the rapid charging capacity of the power lithium ion battery so as to meet the requirements of the pure electrocar. The composite material is prepared through the following steps that: a rheological phase reaction method is adopted for multi-layer graphene, a trivalent iron salt, a phosphorus compound, a lithium compound and carbon source of small organic molecule to obtain a composite precursor, then the precursor is sintered to obtain the multi-layer graphene / lithium iron phosphate intercalated composite material. The anode slurry of the lithium ion battery anode plate comprises the composite material, a conductive agent and polyvinylidene difluoride. The composite material is an intercalated structure, wherein the lithium iron phosphate particles are intercalated between the multi-layer graphene to form the intercalated structure. The trivalent iron salt is adopted as the raw material, such that the cost is reduced. The lithium ion battery has good charging / discharging cycle performance, wherein the specific capacity is more than 60 mA.h.g<-1> at the rate of 20C.

Owner:HARBIN INST OF TECH

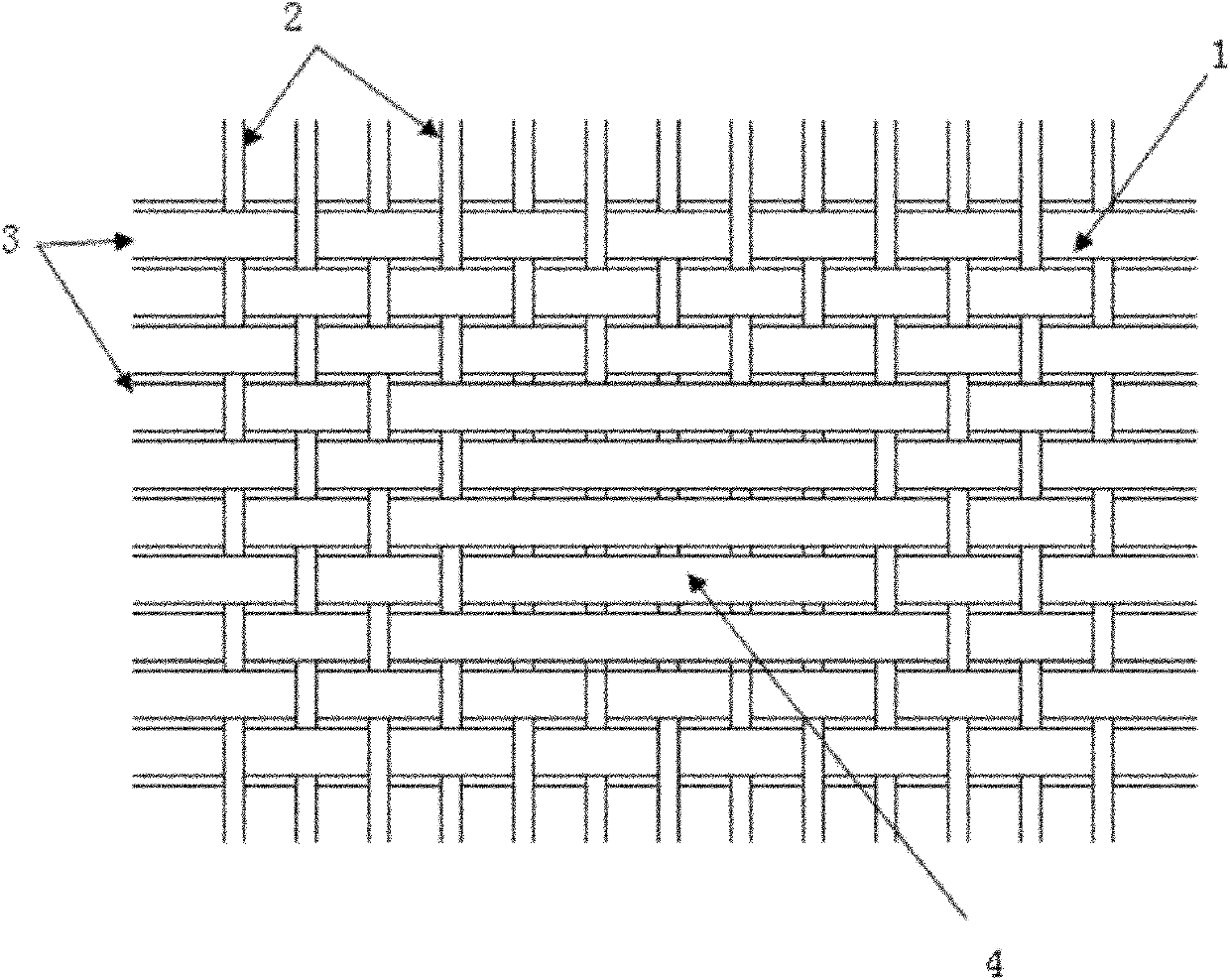

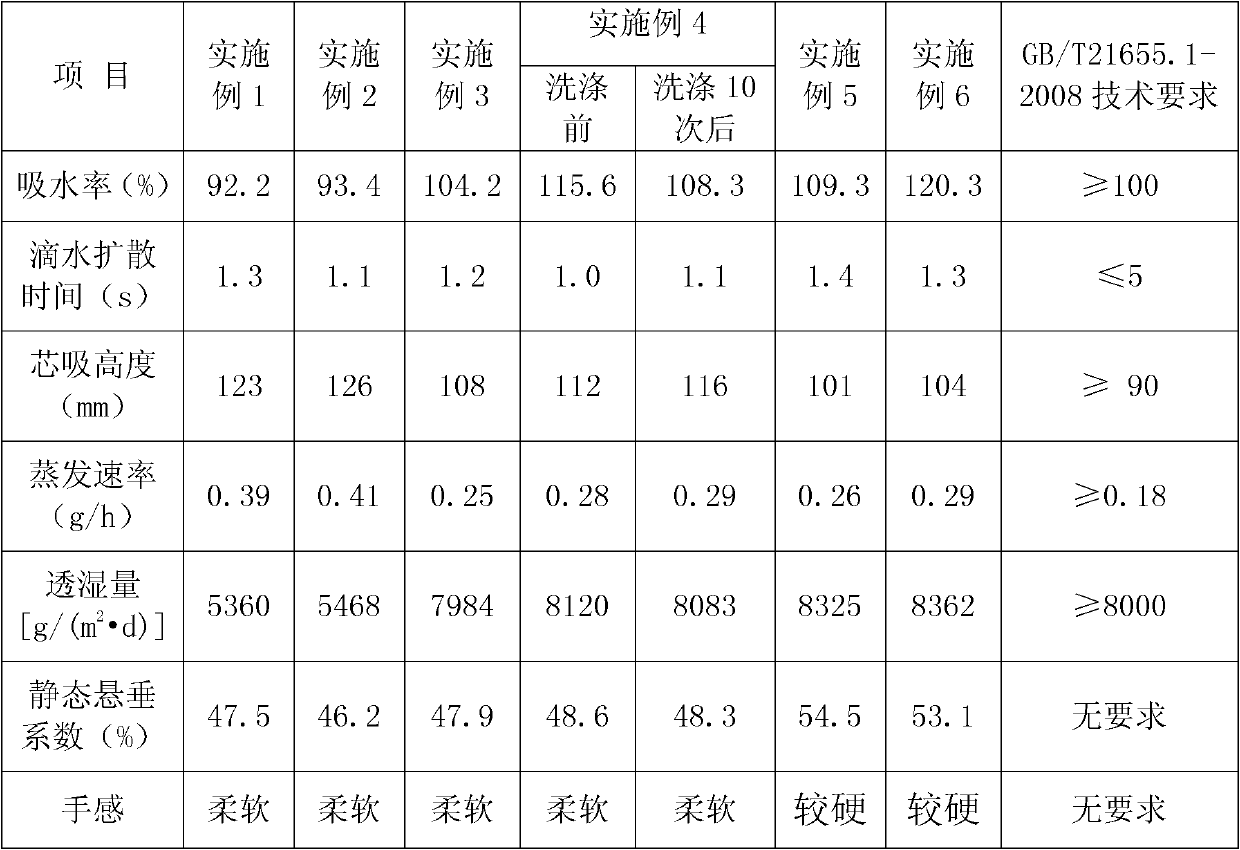

Moisture-absorbing quick-drying type jacquard fabric as well as hydrophilic quick-drying finishing agent and post processing method thereof

ActiveCN101994192ASoft and comfortableEasy to manufactureFibre treatmentWoven fabricsPolymer sciencePolymer chemistry

The invention relates to a moisture-absorbing quick-drying type jacquard fabric as well as a hydrophilic quick-drying finishing agent and a post processing method thereof. The moisture-absorbing quick-drying type jacquard fabric comprises a base cloth area and jacquard areas, wherein the jacquard areas are distributed in the base cloth area; the base cloth area is formed by mutually wavily interlacing warps and wefts; the waving intervals of the warps and the wefts of the jacquard areas are more than or equal to two; the warps are modified chinlon, and the wefts are fine denier cross-shaped sectional polypropylene fibers. Body surface moisture is rapidly delivered and dispersed to an external layer by utilizing the wicking action of the fine denier cross-shaped sectional polypropylene fibers when the jacquard surface of the fabric contacts with a human body and then evaporates without being absorbed by internal fibers; and in addition, the modified chinlon which is positioned on the surface layer of the fabric and has high hydrophilcity can further increase the transferring, dispersing and evaporating speed of the moisture so as to keep skin dry and comfortable.

Owner:ZHEJIANG TAIHUA NEW MATERIAL

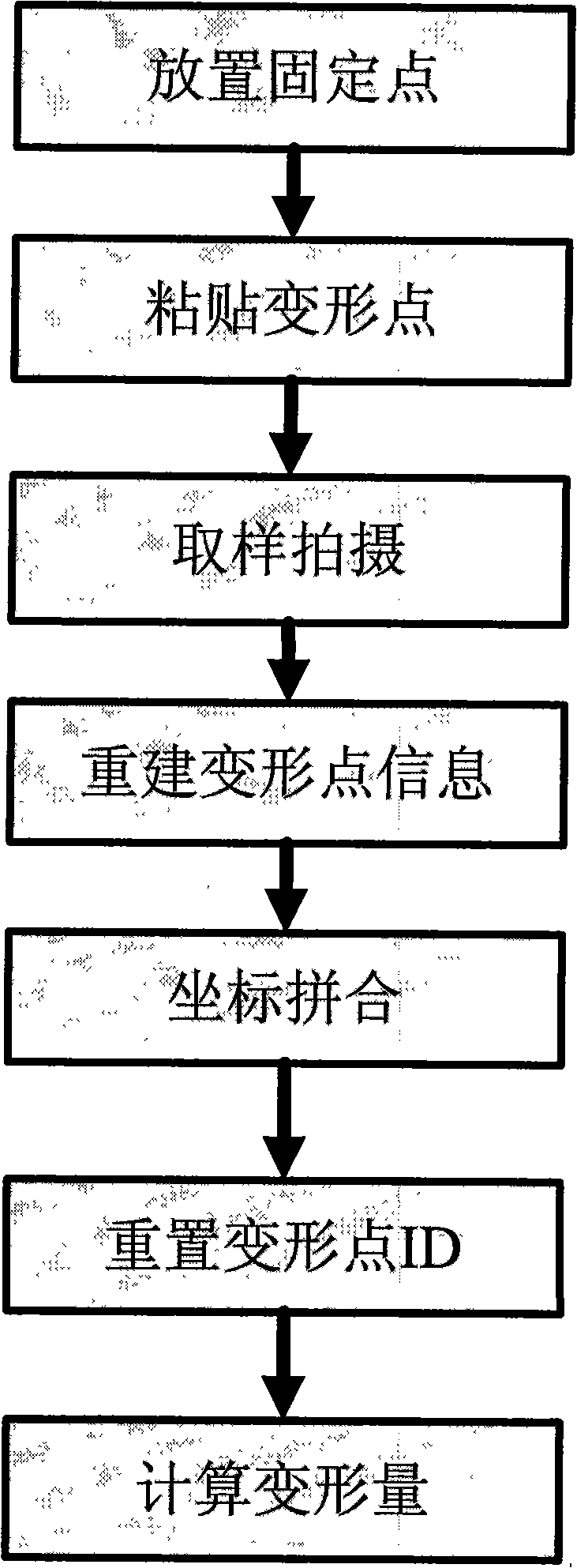

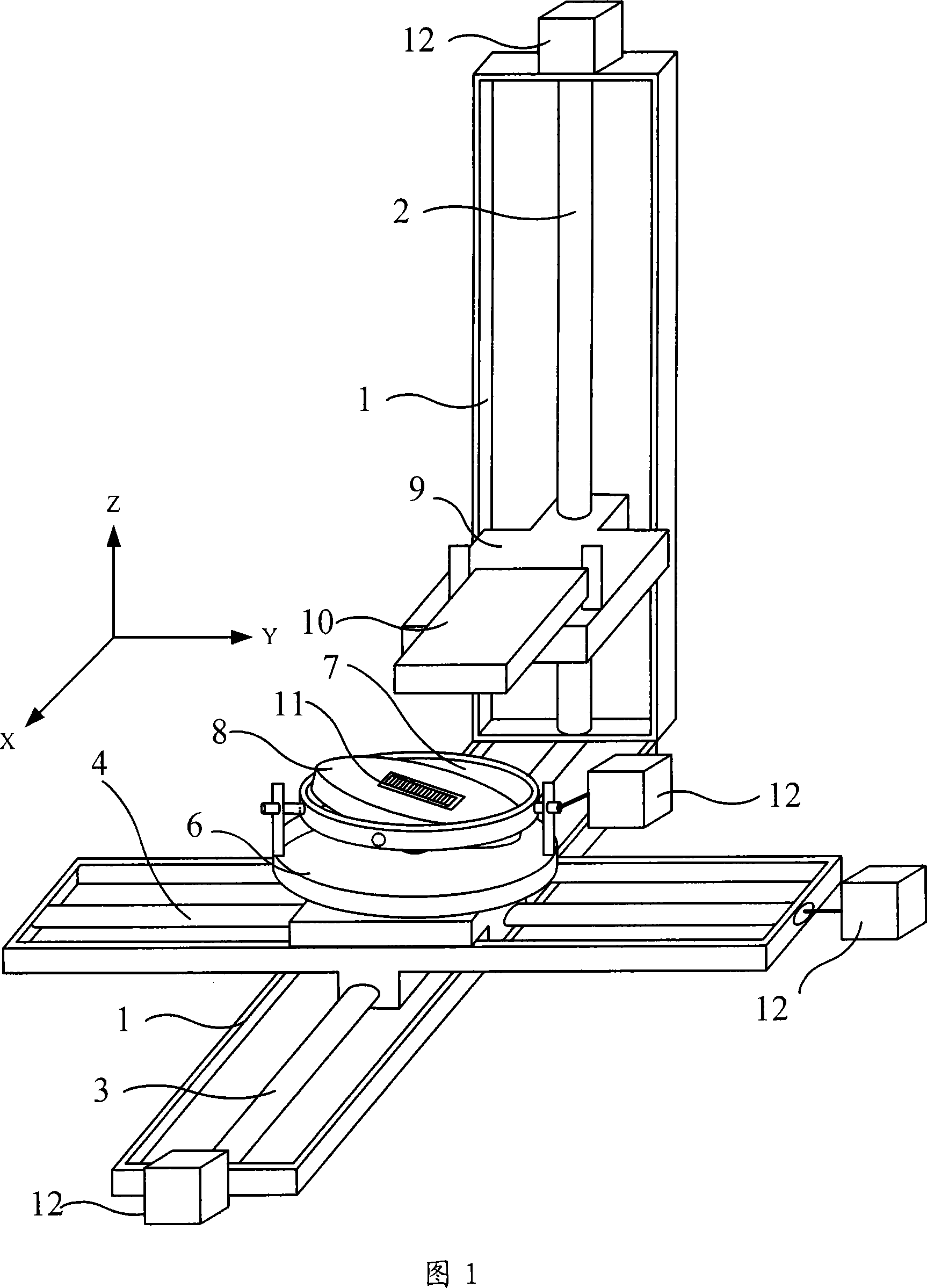

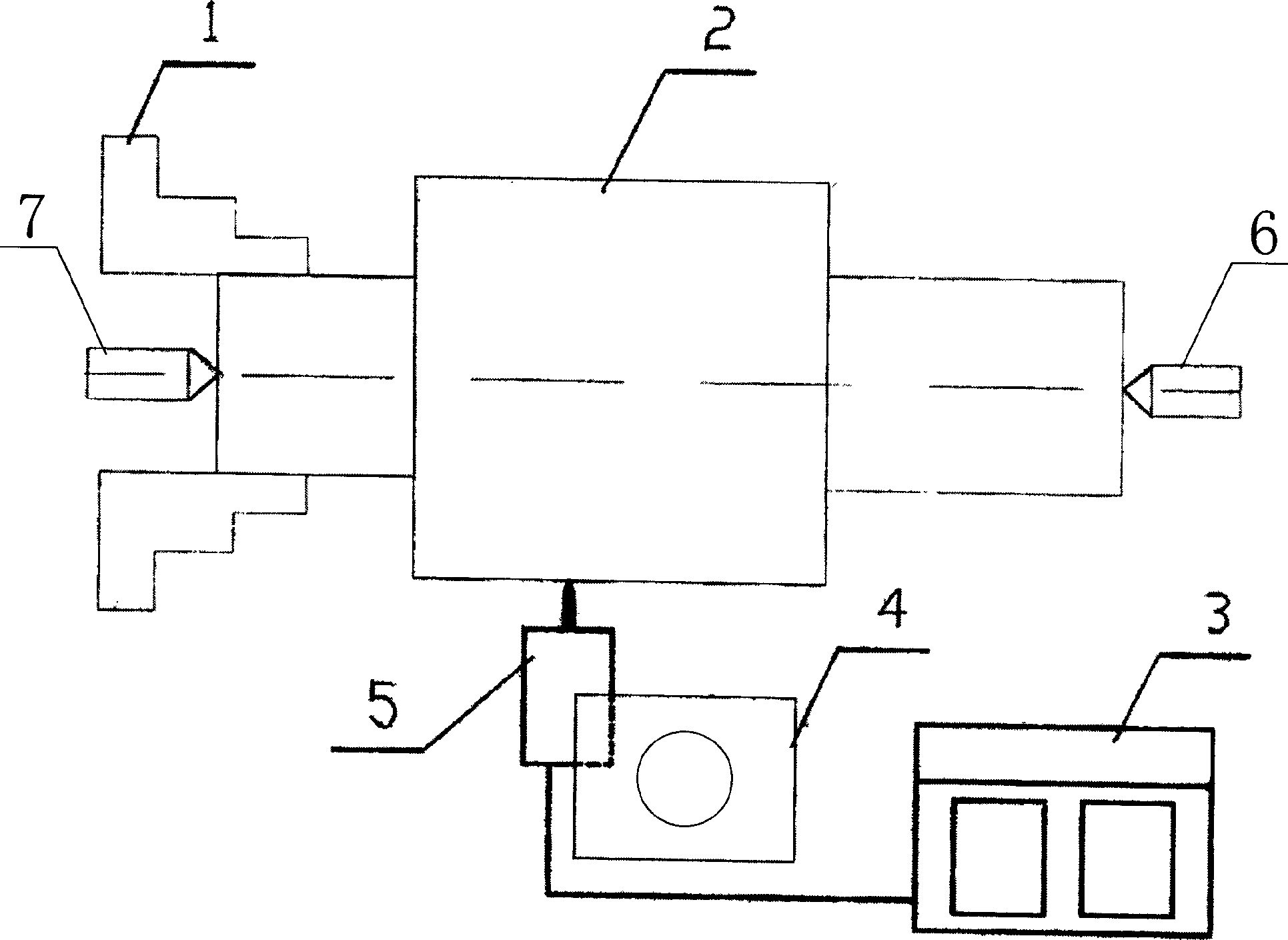

Method for measuring the deformation of large-sized workpiece

The invention discloses a method for measuring the deformation of a large-sized work-piece, which comprises the following steps of: firstly, placing a fixed point; secondly, sticking a deformation point; thirdly, sampling and shooting a picture; fourthly, rebuilding the information of the deformation point; fifthly, combining the coordinates; sixthly, resetting the ID of the deformation point; and seventhly, calculating the deformation quantity. By the operation steps, the invention can measure the direction and size of the three dimensional deformation of the large-size workpiece, which is caused by the applied force load, thermal load, etc. The method has the characteristics of easy operation, no restriction of the size of the workpiece, abundant measurement information, precise and reliable results, high efficiency and non-contact measurement.

Owner:XI AN JIAOTONG UNIV

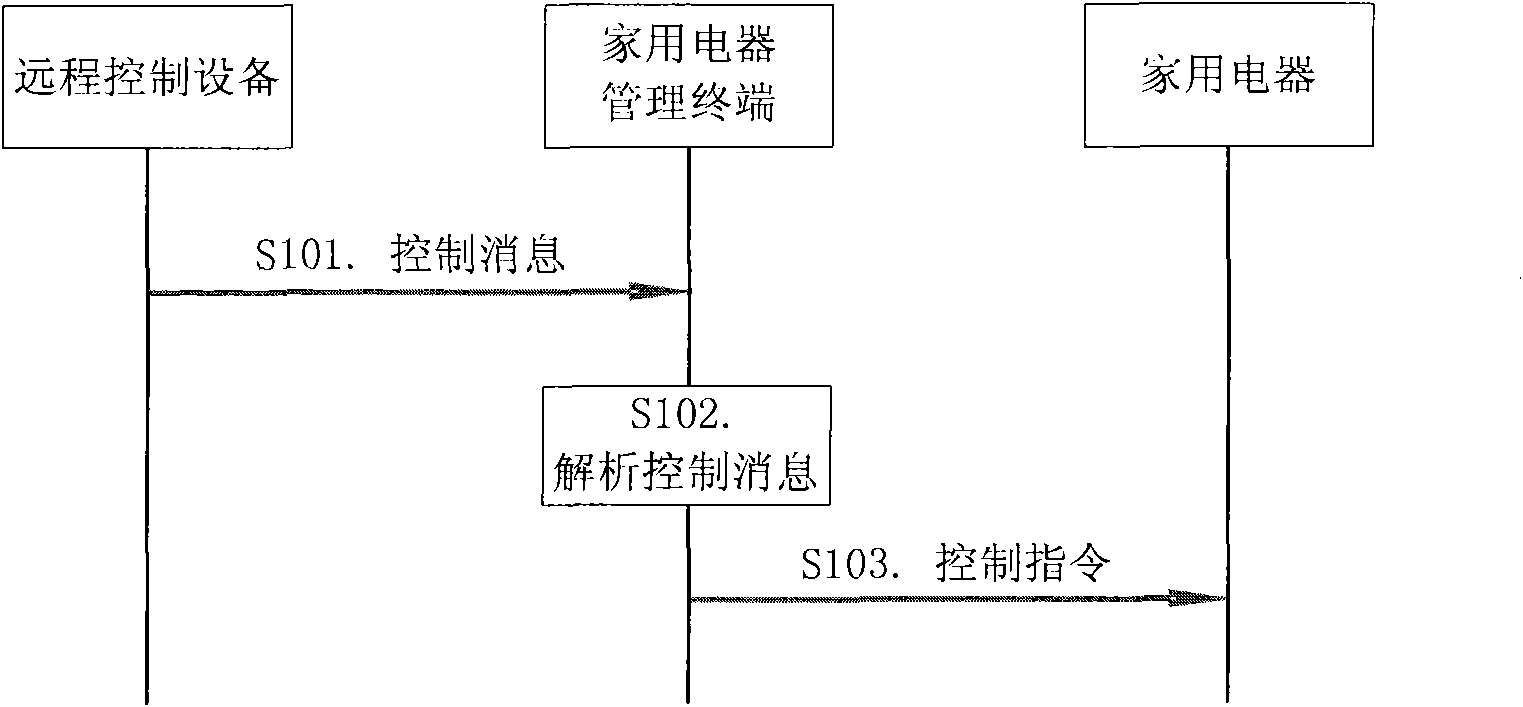

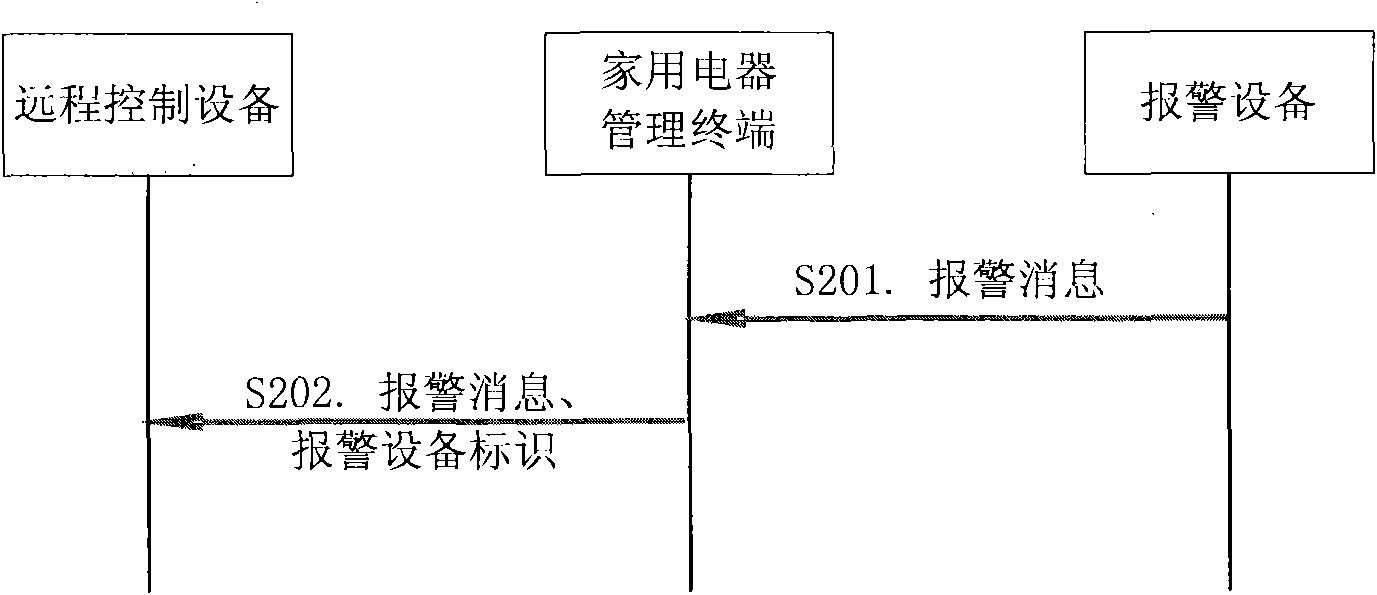

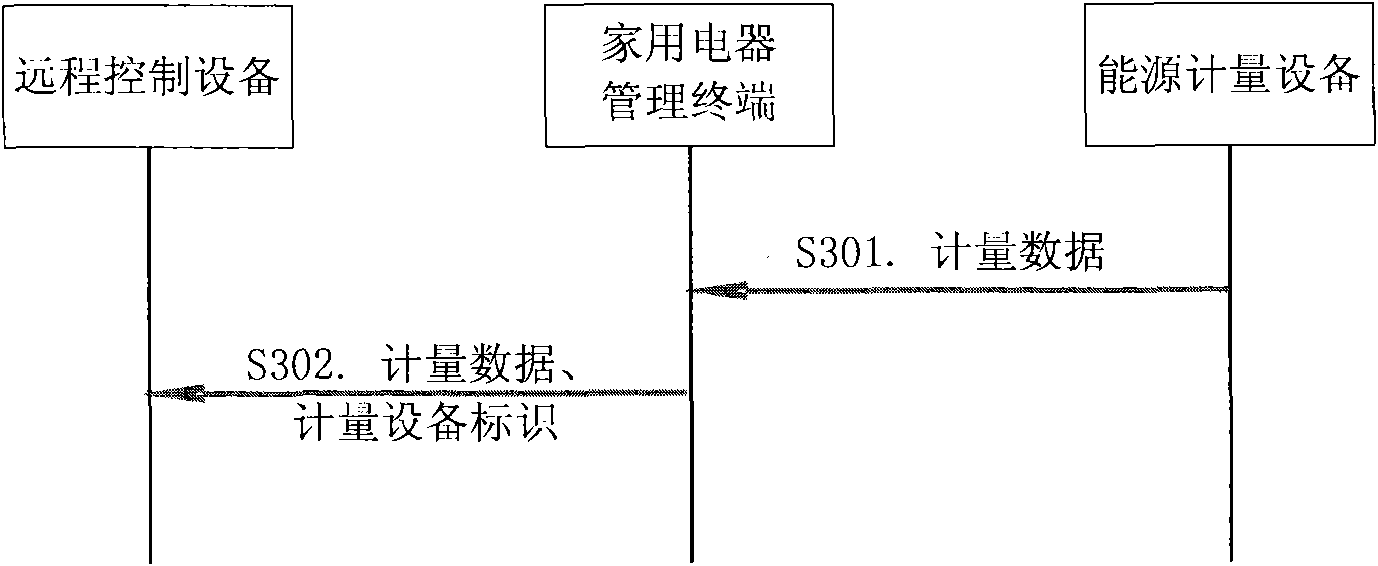

Home appliance management method, terminal and system

InactiveCN101673113AAutomate managementSize limitAlarmsProgramme total factory controlRemote controlOutput device

The request discloses a home appliance management method, a terminal and a system. The method comprises the following steps: receiving a control message sent by a remote control device; analyzing thecontrol message to obtain the label and control behavior of the target appliance; sending a control command corresponding to the control behavior to the target appliance; and generating executive information in real time according to execution of the above steps and sending the executive information to a display output device, wherein, the remote control device comprises a remote user terminal and / or a remote management server.

Owner:STATE GRID INFORMATION&TELECOMM

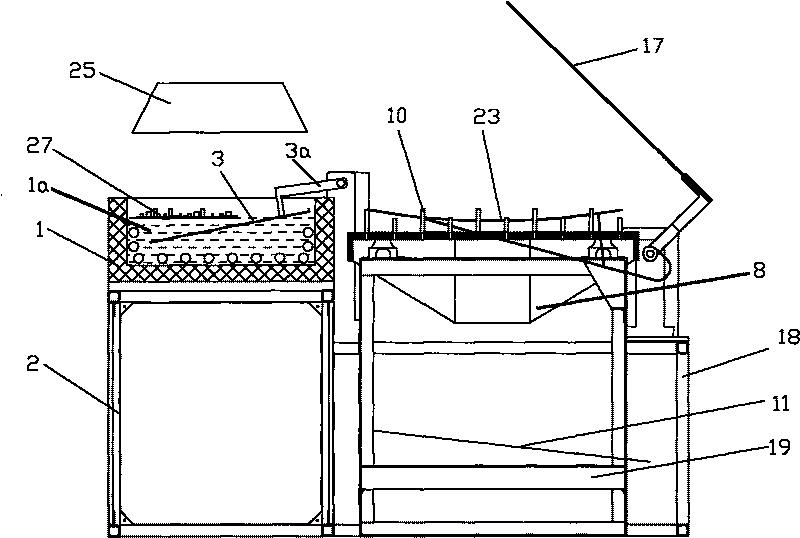

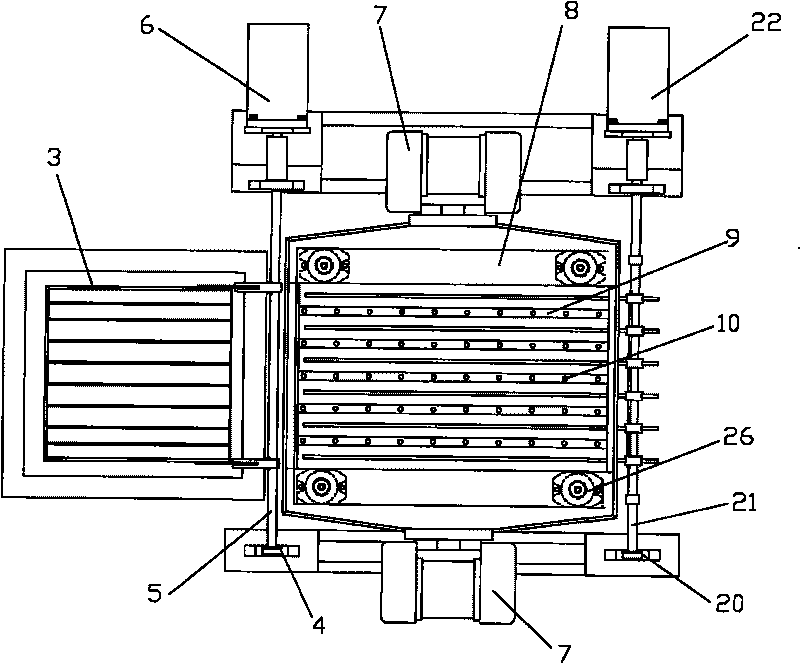

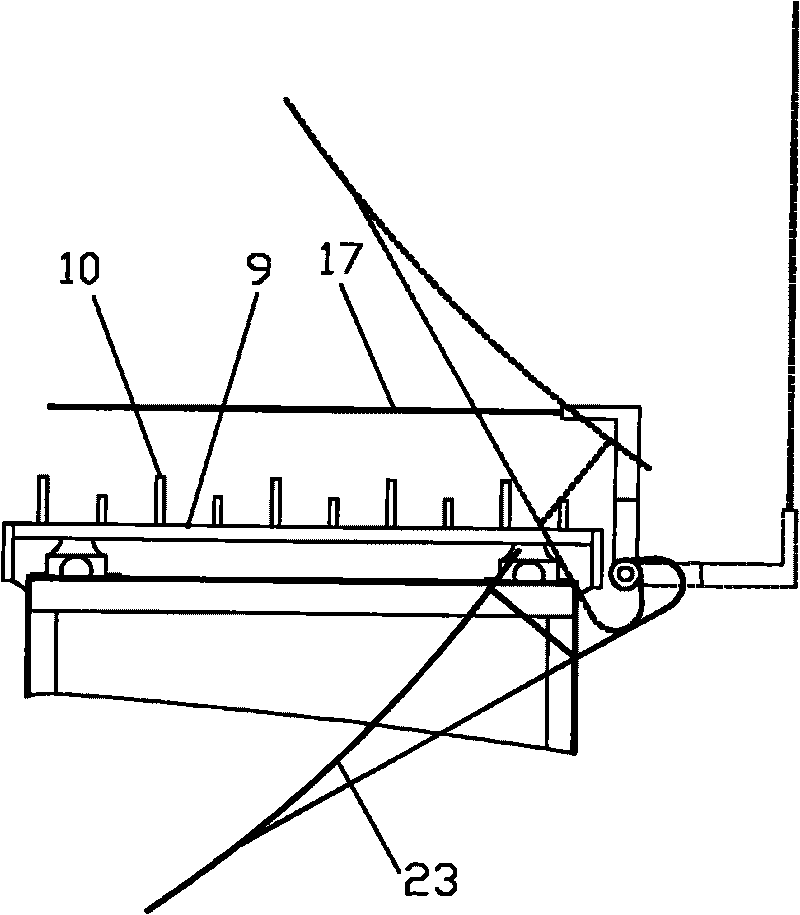

Equipment capable of industrially implementing entire dismantlement of waste and old circuit board component

The invention relates to equipment capable of industrially implementing the entire dismantlement of a waste and old circuit board component. The equipment is characterized in that a heating groove and a vibrating table are arranged in parallel at the left and the right, an overturning arm capable of rotating left and right is arranged above the heating groove and the vibrating table and a supporting frame is fixedly connected to the overturning arm in a cantilever mode; the vibrating table is supported on a vibrating frame by a rubber damper; a vibrating screen gaze is arranged below the vibrating table towards the discharge side; a soldering flux collector is arranged at the bottom of the vibrating frame, the dismantled component is held by the vibrating screen gaze and granular solder fluxes fall into the solder flux collector through the vibrating screen gaze; a blanking rack consists of a row of support rods, a circuit board can be supported on the blanking rack, and the dismantled component and solder flux can fall off through the blanking rack; and a cover plate is linked with the blanking rack and the blanking rack and the cover plate are overturned towards the blanking side by the rotation of a blanking rotating shaft. The equipment is simple and practical and can be industrially produced.

Owner:HEFEI UNIV OF TECH

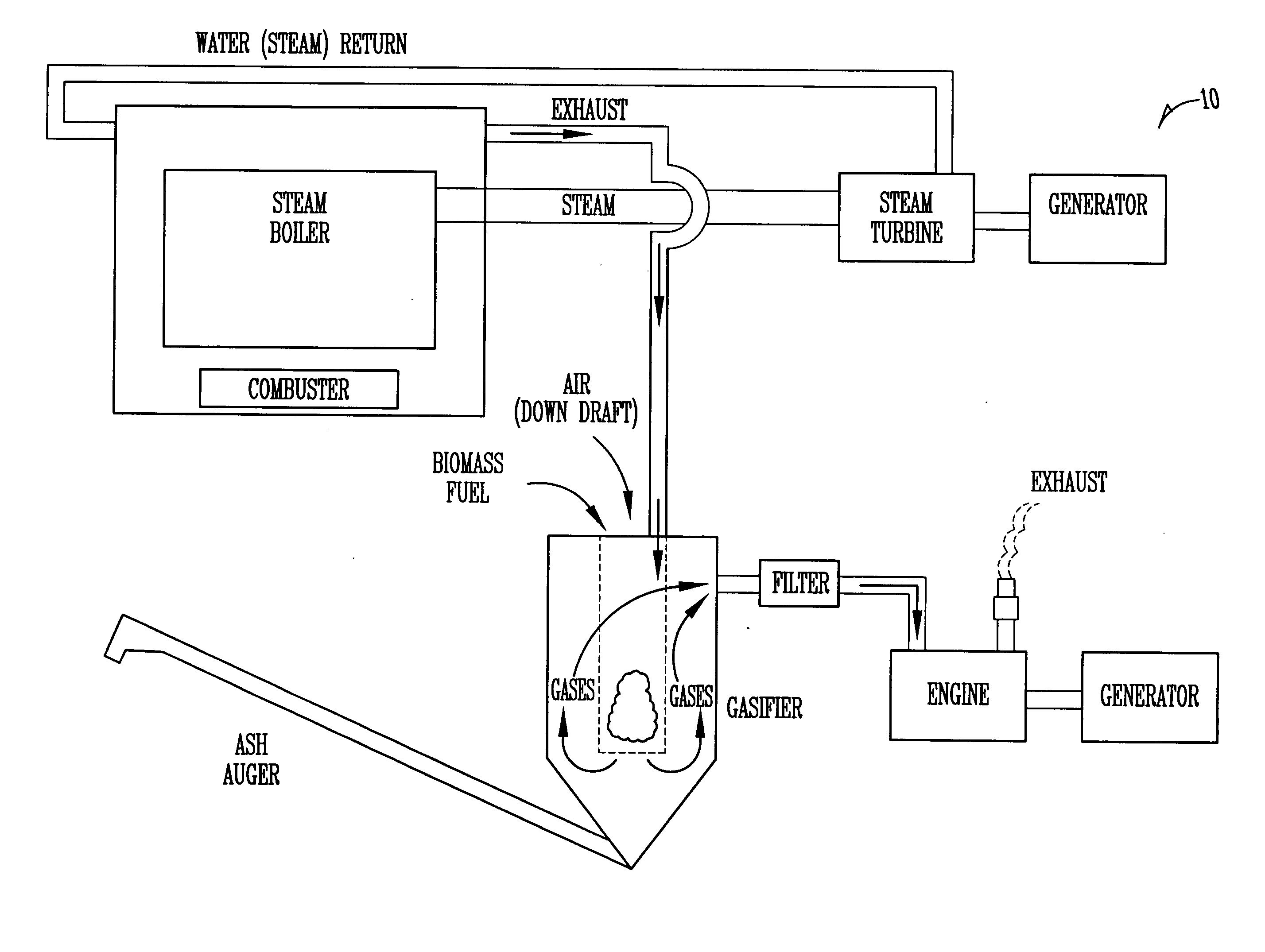

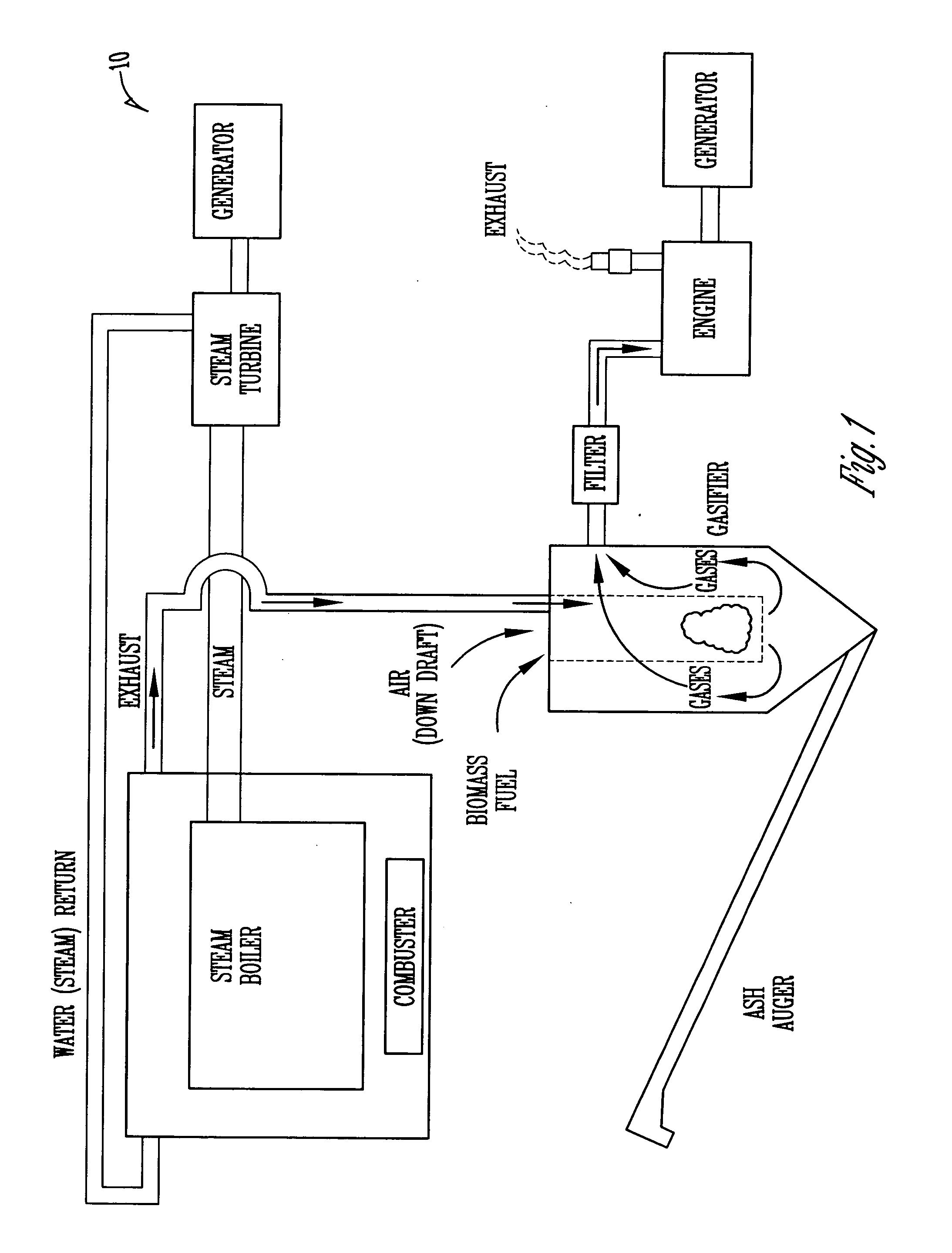

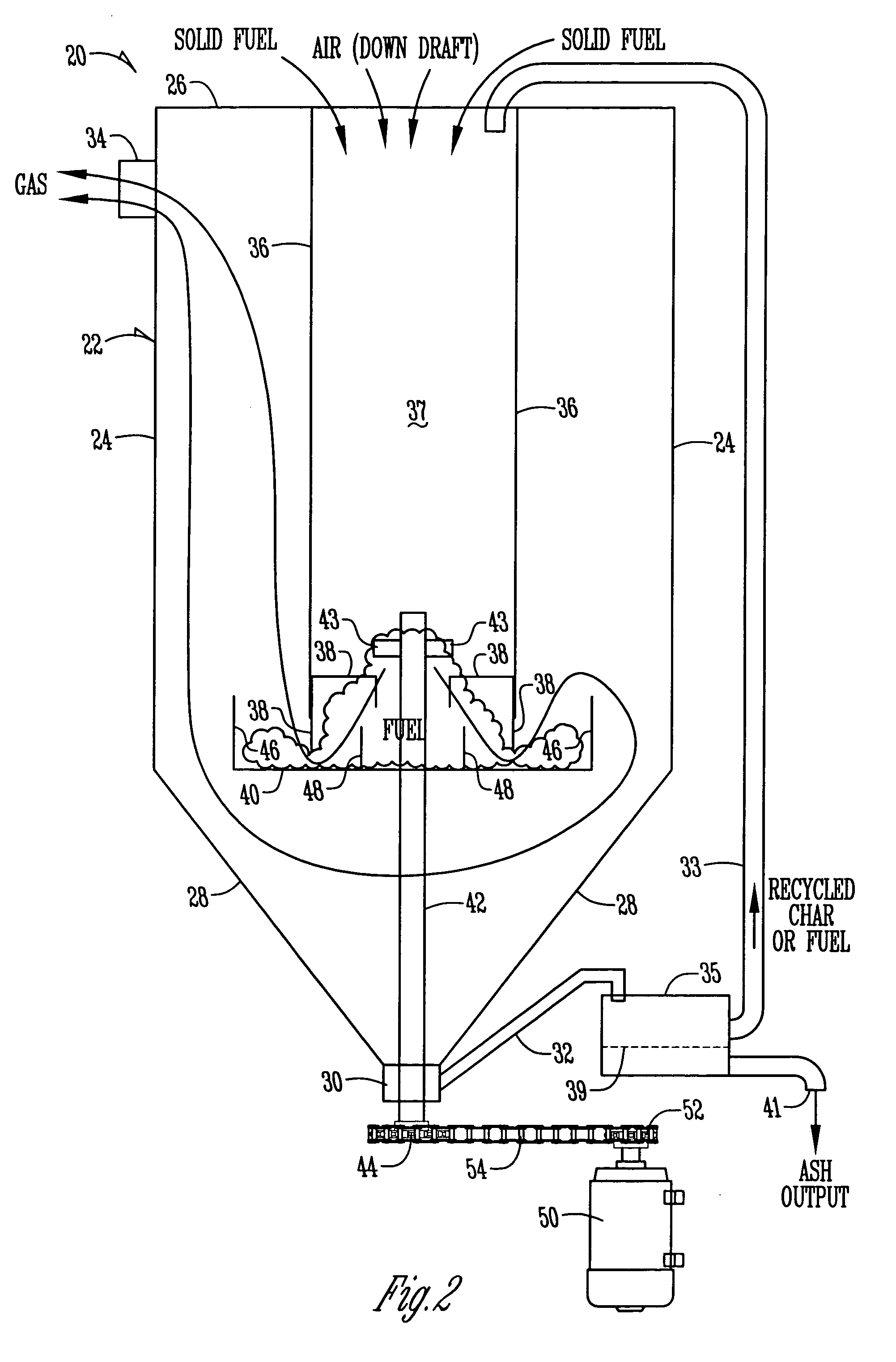

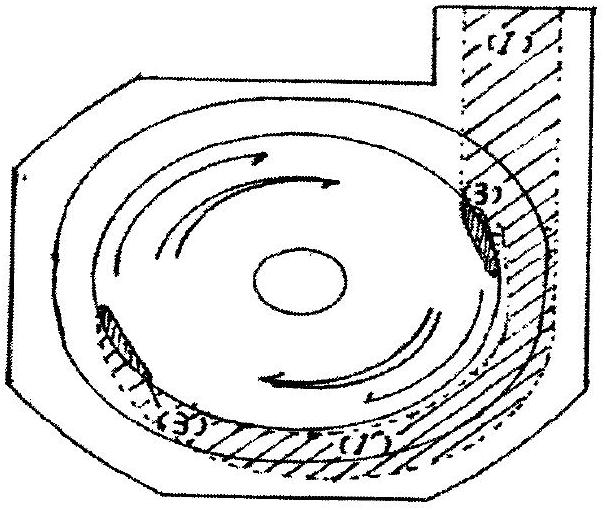

Rotating bed gasifier

InactiveUS20070169411A1Size limitImprove efficiencyGasifier mechanical detailsGasification processes detailsEngineeringMechanical engineering

The present invention includes a gasifier for gasifying fuels having a container with a top, sidewalls and a bottom for facilitating the gasifying process. One or more open vertical shafts extend downward inside the container for allowing a downdraft or updraft of air and fuel for the gasifying process. A rotating bed is preferably included inside the container and below the one or more shafts for receiving the fuel. The bed rotates essentially perpendicular to the shaft to facilitate even heating and gasifying of the fuel.

Owner:THIESSEN RANDALL J +1

C3N4-carbon-coated lithium iron phosphate composite anode material and preparation method thereof

ActiveCN105206809AImprove electronic conductivityExcellent rate performanceCell electrodesLithium iron phosphateCarbon coated

The invention discloses a C3N4-carbon-coated lithium iron phosphate composite anode material. The C3N4-carbon-coated lithium iron phosphate composite anode material consists of a layered material C3N4 and carbon-coated lithium iron phosphate, wherein the weight percent of the C3N4 is 0.5 to 10 percent, the weight percent of non-C3N4 carbon is 0.2 to 10, and the weight percent of lithium iron phosphate is 80 to 99.3 percent. The preparation method comprises the following steps: preparing C3N4 in a sintering manner, ultrasonically stripping, and carrying out the nanocrystallization; adding an iron source and a phosphorus source into a C3N4 suspension solution, and filtering and washing a mixture precipitate; uniformly mixing a precipitate product with a lithium source and a carbon source, and calcining the mixture under the protection of inert gas at a high temperature to obtain the C3N4-carbon-coated lithium iron phosphate composite anode material. The anode material prepared in the method is small in primary particle size, high in ion electric conductivity and electron electric conductivity, high in discharge capacity and excellent in rate capability and cycling performance.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

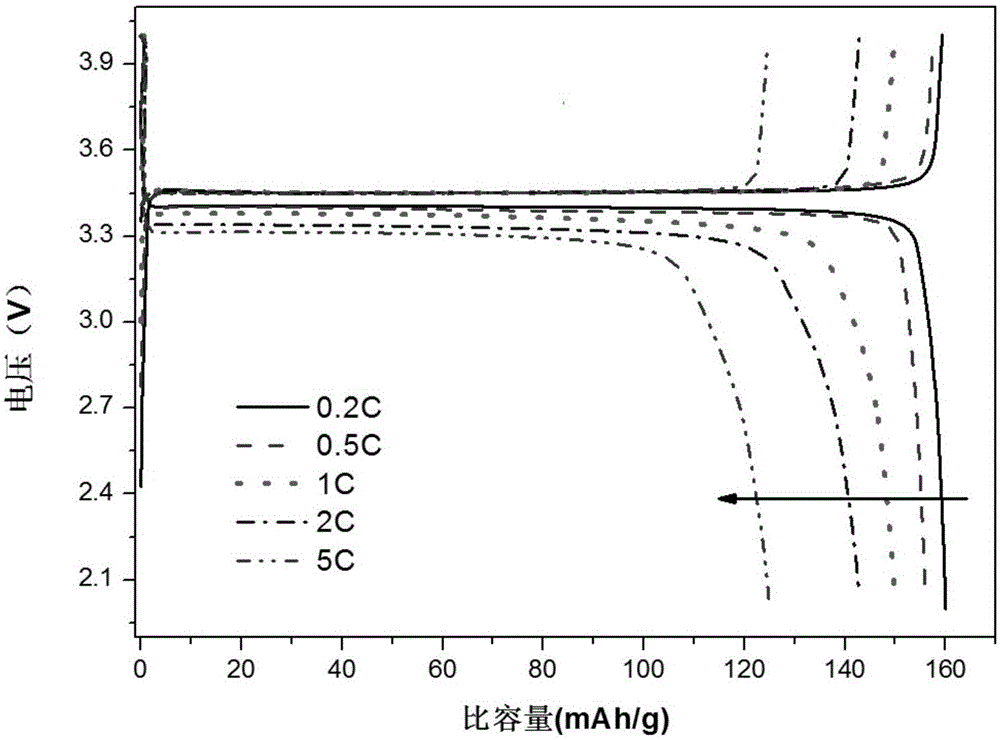

Capacitor carbon/lithium iron phosphate composite material, preparation method thereof and lithium-ion capacitor battery using same as cathode material

InactiveCN101944588AImprove high rate charge and discharge performanceIncrease surface areaElectrolytic capacitorsNon-aqueous electrolyte accumulator electrodesCapacitanceElectrical battery

The invention discloses a capacitor carbon / lithium iron phosphate composite material, a preparation method thereof and a lithium-ion capacitor battery using the same as a cathode material and relates to a lithium iron phosphate material, a preparation method and a lithium-ion capacitor battery using the lithium iron phosphate material as a cathode material, solving the problems of higher preparation cost of the traditional lithium iron phosphate and poor high-magnification charge / discharge properties of the lithium-ion batteries prepared from the traditional lithium iron phosphate. The composite material is formed by loading the lithium iron phosphate on activated carbon. The preparation method comprises the following steps of: preparing a lithium iron phosphate precursor by using a trivalent ferric salt, a phosphorus compound, a lithium source compound and an organic micromolecule carbon source as raw materials; and then mixing the precursor with the activated carbon and sintering. In the invention, the cathode sizing agent of the lithium-ion capacitor battery comprises the capacitor carbon / lithium iron phosphate composite material, a conductive agent and a bonding agent; the particle size distribution of the composite material is uniform; the trivalent ferric salt is used as a raw material, and the cost on the preparation is low; and the capacitor battery has good charge / discharge cycle performances and the mass specific capacity larger than 60mA.h.g<-1> under 20C magnification.

Owner:HARBIN INST OF TECH

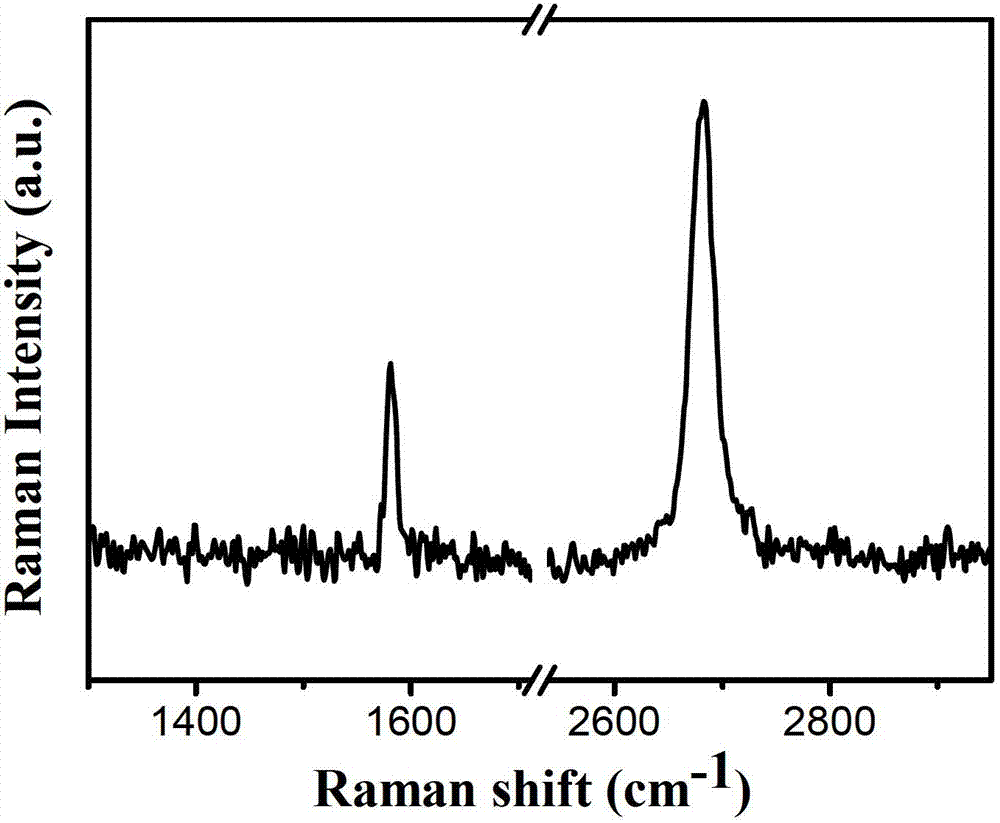

Layer-number-controllable graphite film based on nickel-copper composite substrate and preparation method of film

ActiveCN102828244ALess restricted shape and sizeStrong ability to control the number of layersPolycrystalline material growthGrapheneCvd grapheneComposite substrate

The invention relates to the field of graphite film preparation, and in particular relates to a layer-number-controllable graphite film based on a nickel-copper composite substrate and a preparation method of the film. The preparation method comprises the following steps of: 1) preparing the nickel-copper composite substrate; 2) carburizing, namely heating the nickel-copper composite substrate to 200-300 DEG C, then introducing a carbon source gas and a carrier gas, and carrying out heat preservation for 30-240 minutes for carburization of a nickel layer; and 3) depositing carbon, namely cutting off the supply of the carbon source gas, raising the temperature of the nickel-copper composite substrate to 300-1000 DEG C, introducing the carrier gas, and carrying out heat preservation for 10-180 minutes so as to obtain the graphite film based on the nickel-copper composite substrate. The preparation method has the beneficial effects that a novel preparation process is provided, the layer number of graphite is controlled more easily, the problem that the existing composite substrate is high in preparation cost, and a graphite film material which is low in cost, simple in preparation method, easy to control, good in product quality and large in area is obtained.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

Mobile terminal

InactiveCN108600457ASize limitGuaranteed display areaTelephone set constructionsSound productionComputer engineering

The embodiment of the invention provides a mobile terminal, applied to the technical field of communication. The mobile terminal comprises a screen component, a vibrator and a middle frame, wherein the screen component comprises a display screen and a display screen cover plate laid on the front surface of the display screen; the vibrator is arranged on the back surface of the display screen; thedisplay screen in the screen component is connected with the middle frame; the middle frame is provided with a first opening, and the vibrator penetrates through the first opening and is connected with the back surface of the display screen; and the hole wall of the first opening is spaced apart from the vibrator. The embodiment of the invention aims to solve the problem that the structure of a sound generator affects the proportion of the display screen in the prior art, the vibrator is arranged below the display screen, thereby, compared with the prior art, the sound production function of the screen can be ensured, the phenomenon that the vibrator occupies the extension space of the display screen and limits the size of the display screen can also be avoided, and a display area of the display screen can be ensured.

Owner:VIVO MOBILE COMM CO LTD

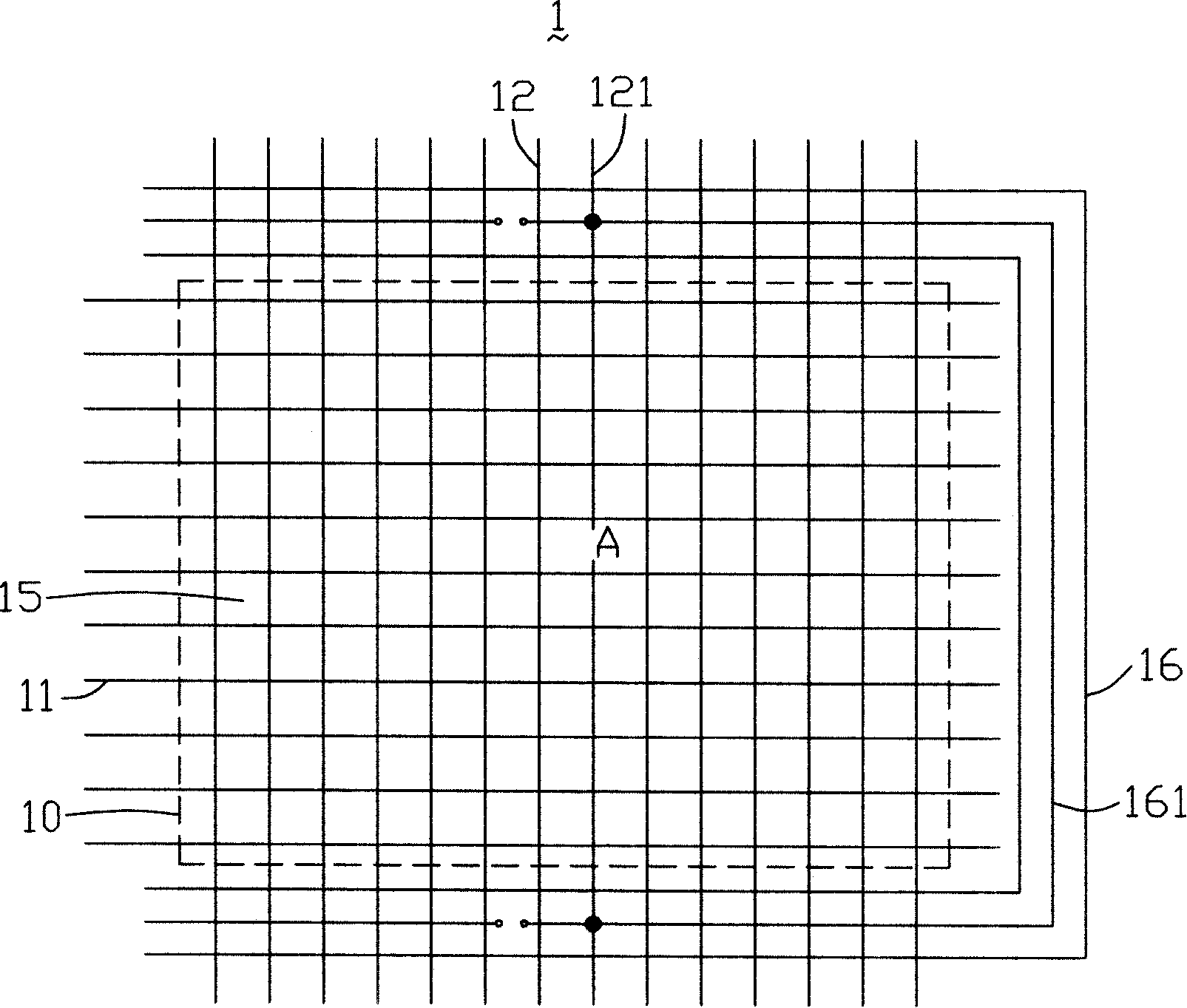

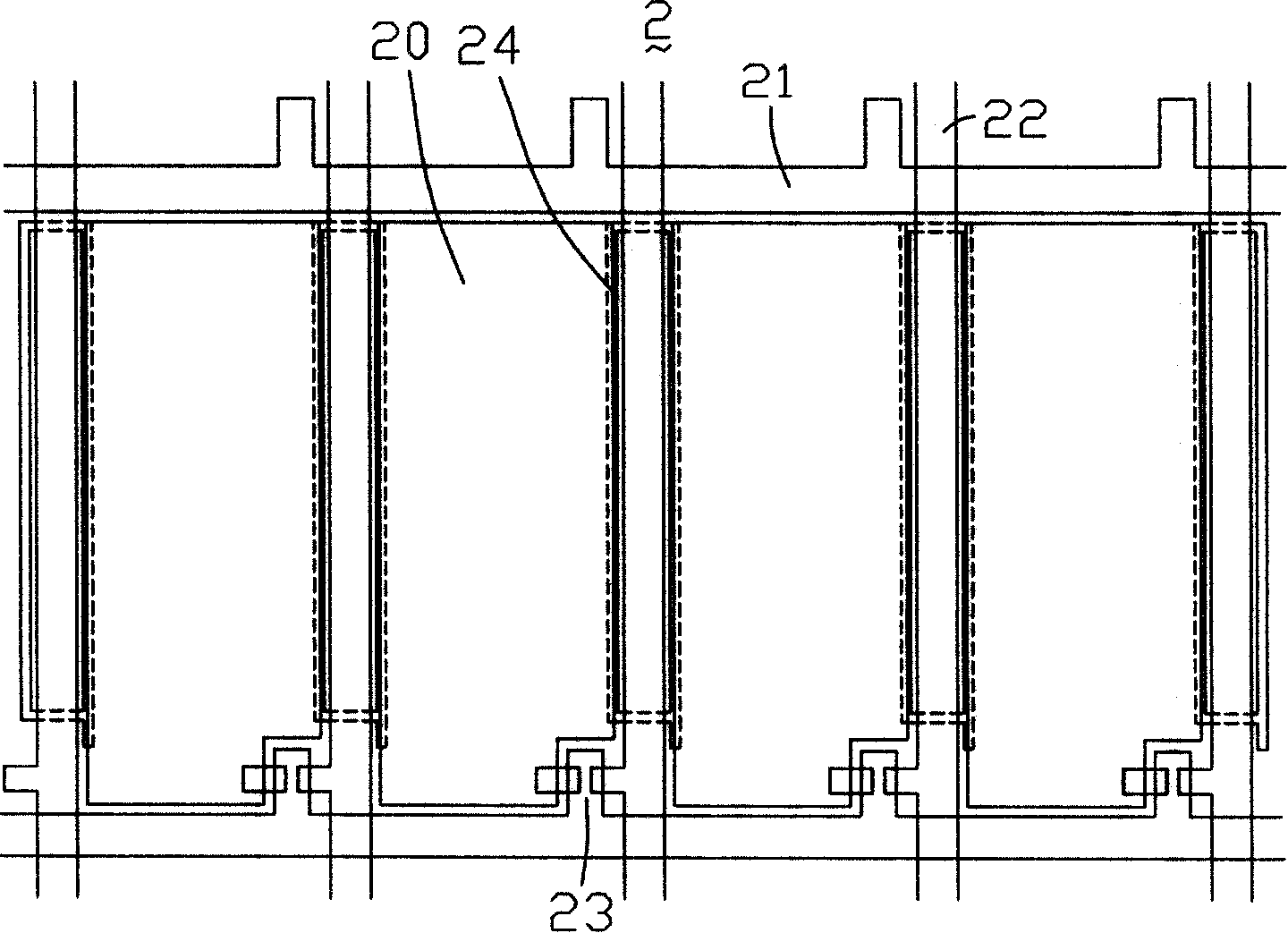

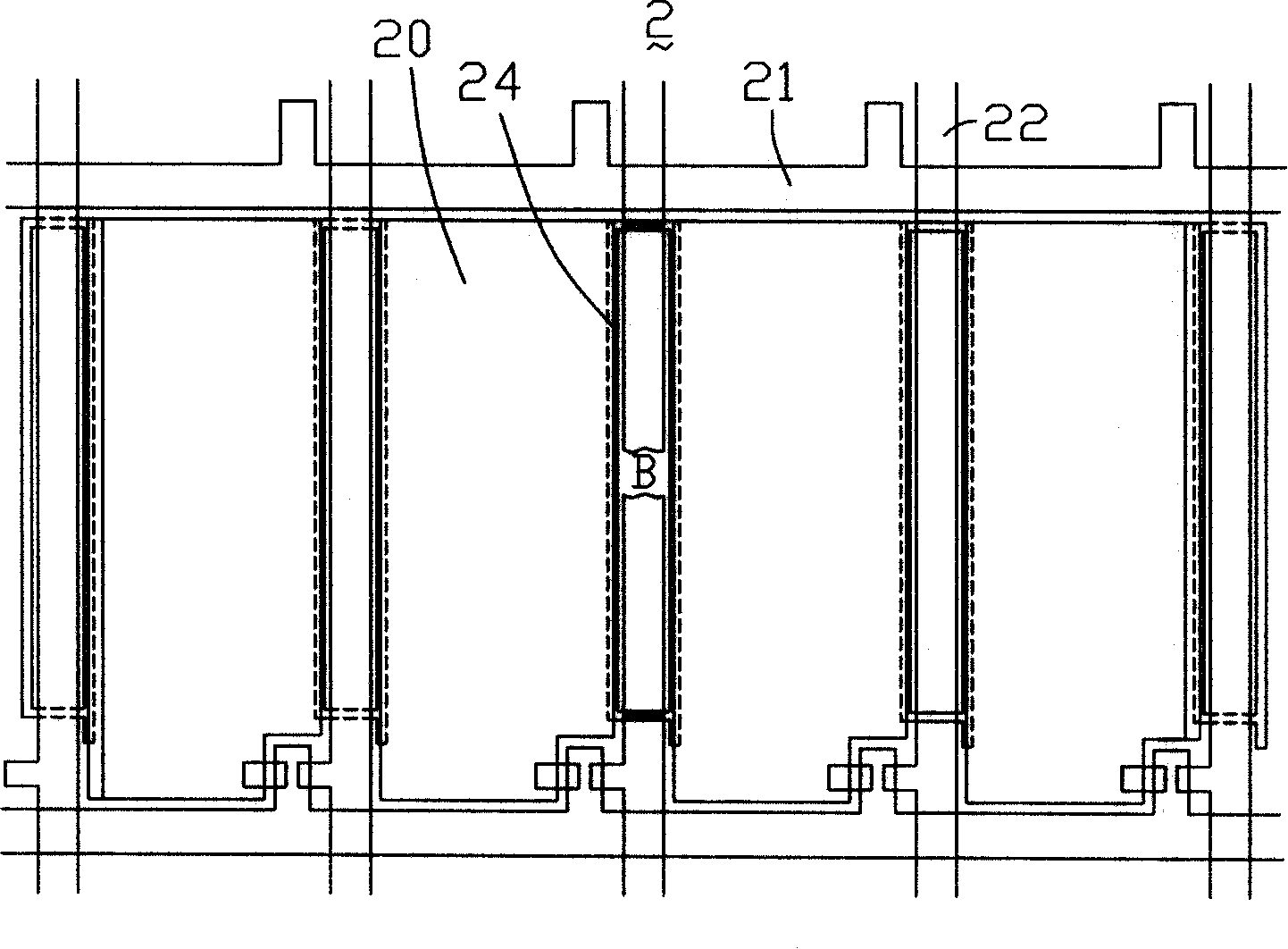

Liquid crystal display board and repairing method thereof

ActiveCN101201469AHigh resolutionThere will be no phenomenon that affects the display effectStatic indicating devicesNon-linear opticsLiquid-crystal displayEngineering

The invention provides a liquid crystal display panel and its repairing method. The liquid crystal display panel comprises a plurality of parallel scanning lines, a plurality of data lines perpendicular to the scanning lines in an insulation way and a plurality of pixel areas circled by the scanning lines and the data lines; each pixel area comprises a pixel electrode, wherein, a long annular repair line is arranged between the adjacent pixel electrodes; the two ends of the long annular repair line respectively intersect with the data lines in an insulation way. The display quality of the liquid crystal display panel cannot be affected after repair and the repair of the panel is not limited by the size of the panel.

Owner:INNOCOM TECH SHENZHEN +1

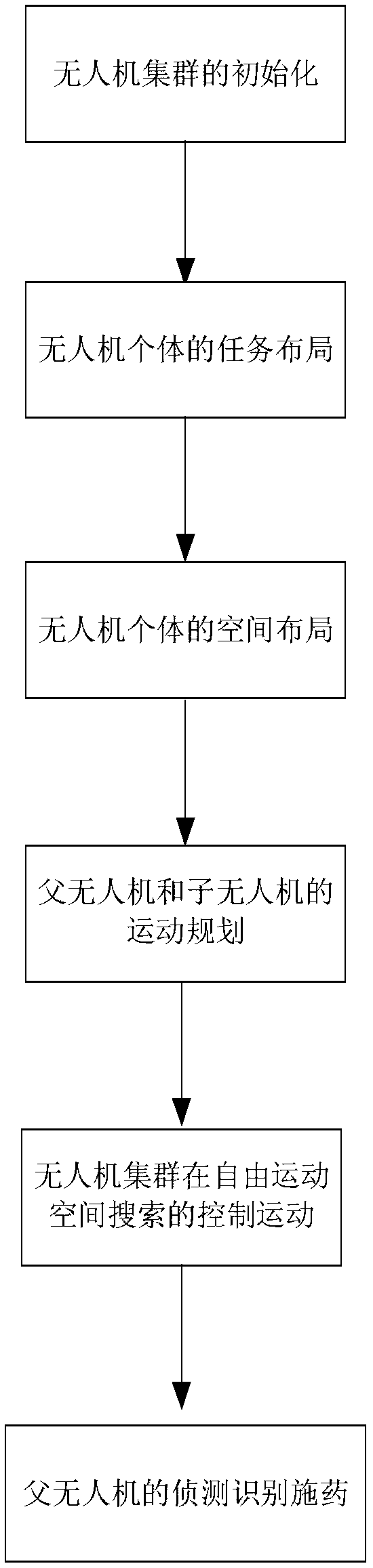

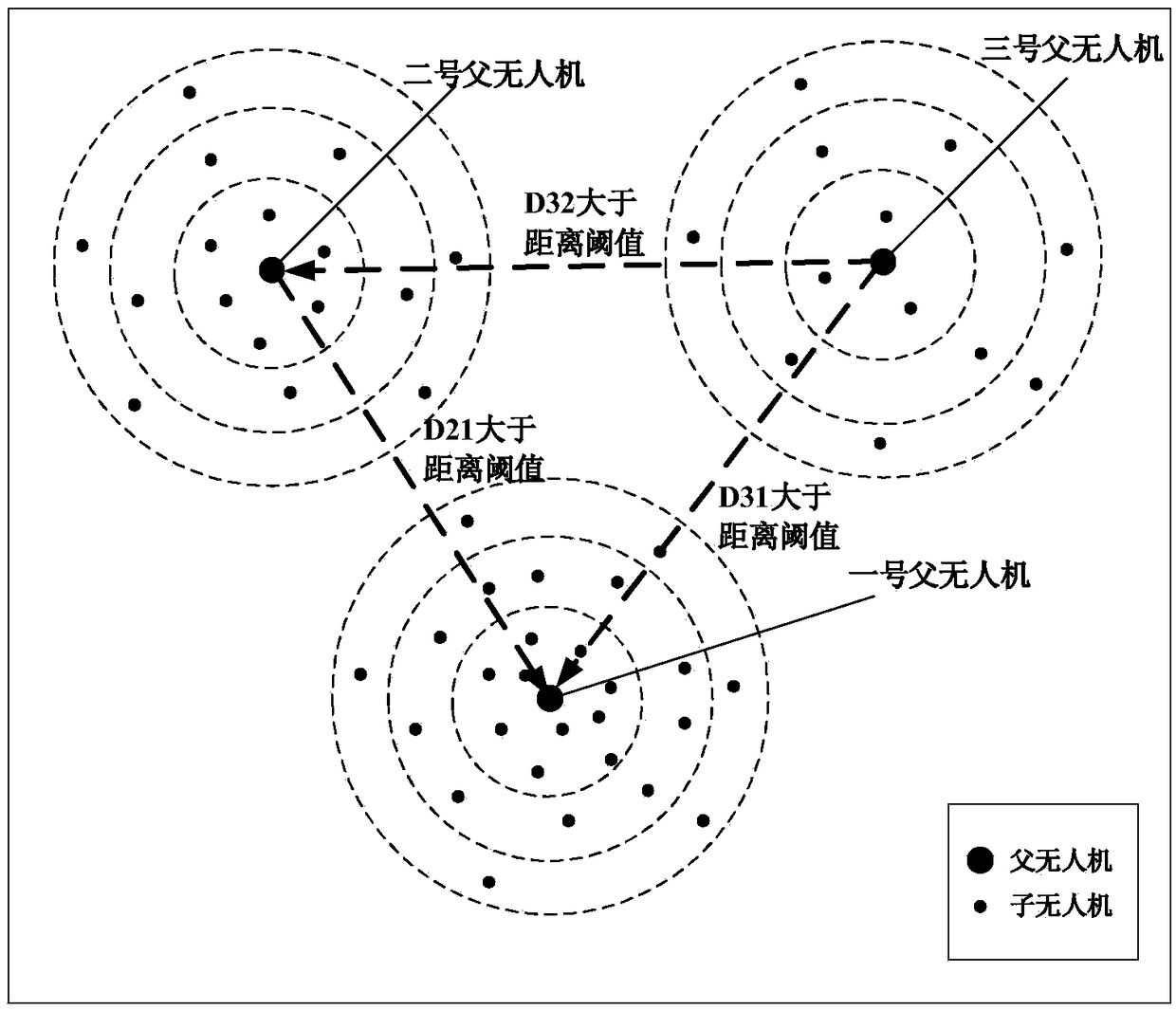

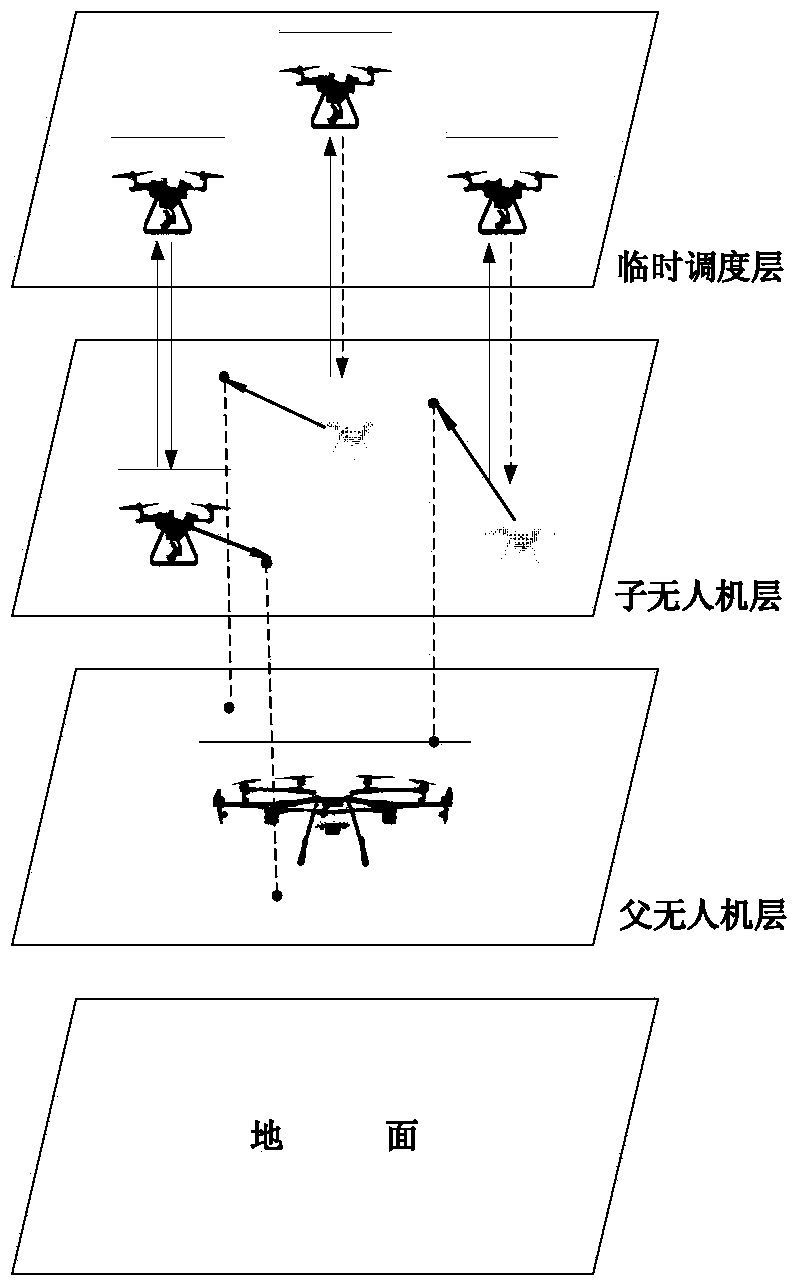

Plant protection UAV (unmanned aerial vehicle) cluster cooperative control method

ActiveCN108983823ARealize collaborative controlSize limitPosition/course control in three dimensionsRelationship - FatherAutomatic train control

The invention relates to a plant protection UAV (unmanned aerial vehicle) cluster cooperative control method. Compared with the prior art, the method irons out a defect that a plant protection UAV cluster method cannot achieve the automatic cooperative control for the agricultural pest monitoring and pesticide application. The method comprises the following steps: initialization of the UAV cluster; task overall arrangement of individual UAVs; the space overall arrangement of the individual UAVs; the motion planning of a father UAV and a son UAV; the control motion of the search of the UAV cluster in a free motion space; the detection, recognition and pesticide application through the father UAV. The method achieves the cooperative control of the plant protection UAV cluster, enables the UAV cluster to perform the automatic pesticide application after the pest recognition through a conventional mature pest image recognition method.

Owner:ANHUI AGRICULTURAL UNIVERSITY

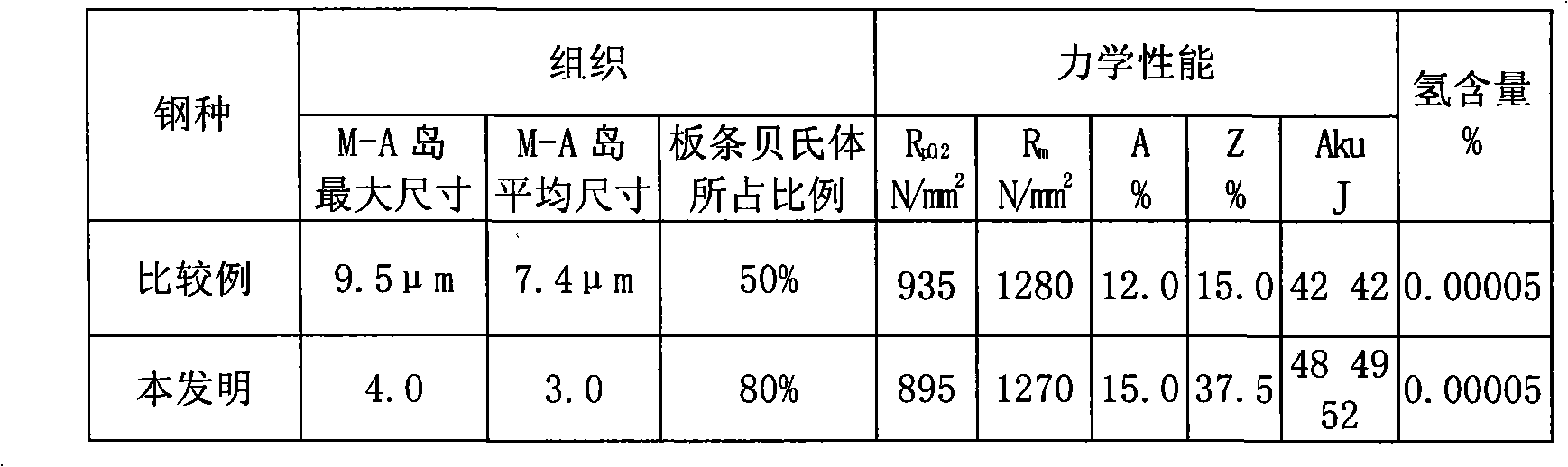

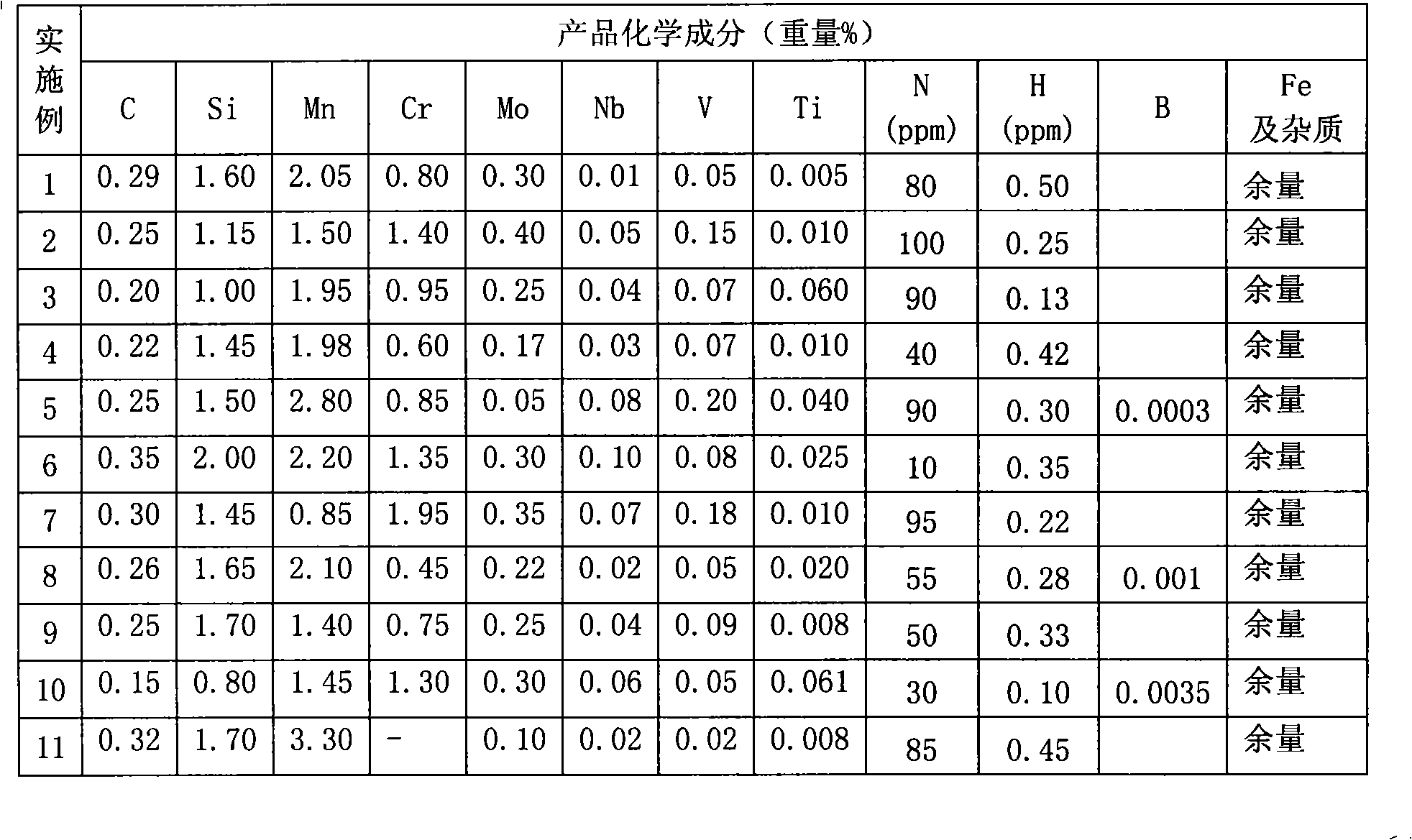

Hot rolled bainite steel rail and production process

The invention discloses a hot rolled bainitic steel rail and a production process. The hot rolled bainitic steel rail comprises the following chemical compositions in percentage by weight: 0.10 to 0.35 percent of C, 0.80 to 2.00 percent of Si, 0.80 to 3.30 percent of Mn, less than 2.00 percent of Cr, 0.0010 to 0.0100 percent of N, 0.01 to 0.10 percent of Nb, 0.02 to 0.2 percent of V, 0.005 to 0.06 percent of Ti, 0.10 to 0.40 percent of Mo, less than 0.00005 percent of H and the balance of Fe and inevitable impurities. The process is characterized in that: a hole pattern method is adopted for the rough rolling of the steel rail, a universal method is adopted for the precision rolling of the steel rail, the rolling interval of adjacent passes in the rough rolling is controlled to more than 5 seconds and not more than 35 seconds, and the steel rail after the rolling is naturally cooled in the air to room temperature. The production process limits the size of residual austnesite in M-A islands and between lath bainitic ferrite; the proportion of the lath bainitic ferrite is over 75 percent; comprehensive indexes of performance such as specific elongation and the like are improved; and the production process can be also applied to turnout bainitic steel rails and bainitic AT rails.

Owner:ANGANG STEEL CO LTD

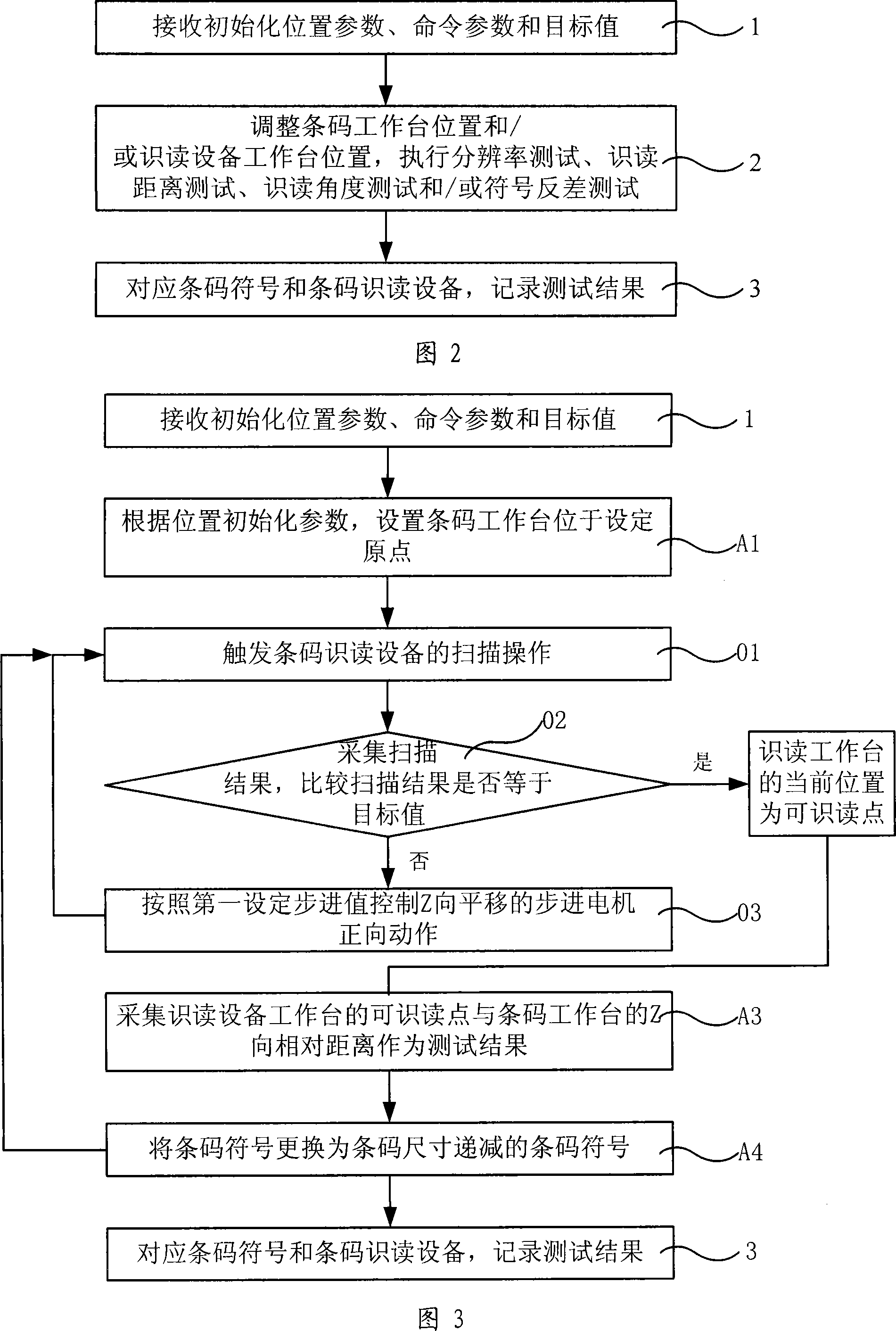

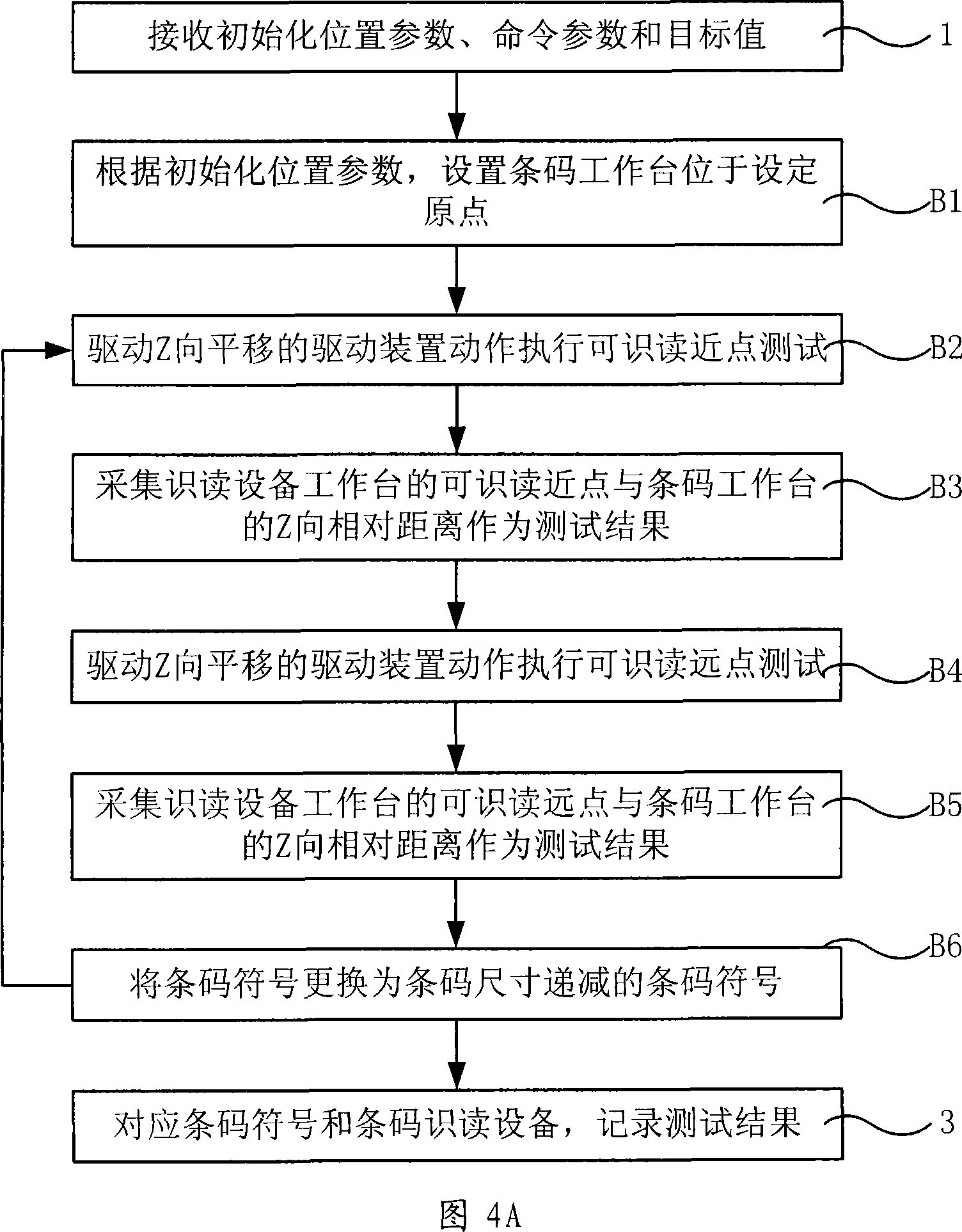

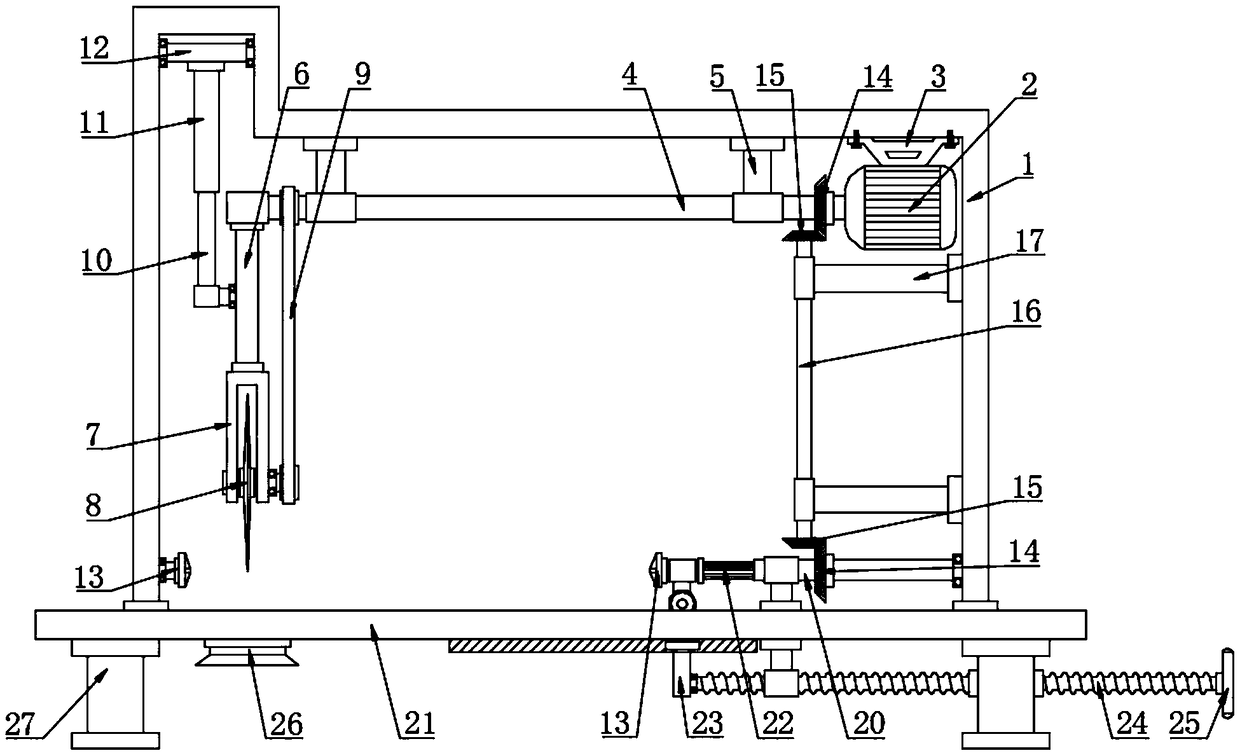

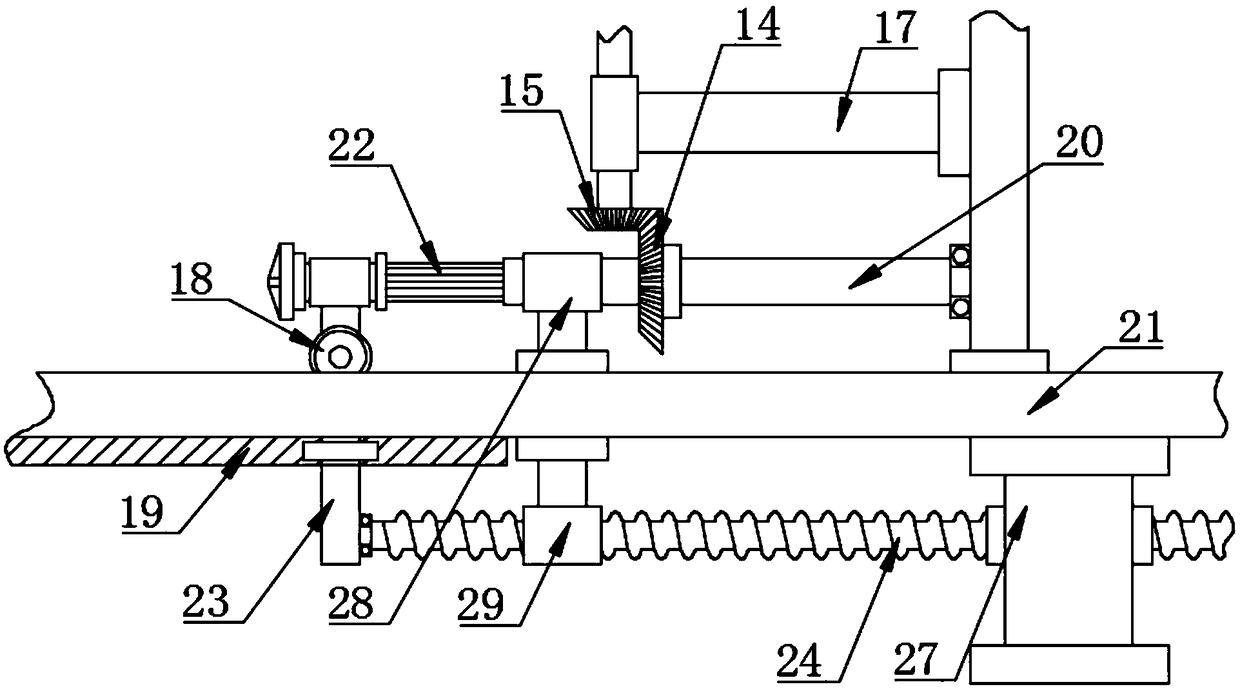

Method and system for controlling the test of bar-code recognizing device

ActiveCN101162497ASize limitSolve the problem of lack of detection and control methodsSensing by electromagnetic radiationProgramming languageAlgorithm

The invention relates to a detection and control method and a system of bar code reading equipment, wherein, the method includes the following steps: initialized location parameter, command parameter and target value is received; according to the initialized location parameter, each drive unit is controlled to work and the location of a bar code worktable and / or a reading equipment worktable is adjusted; according to the command parameter and the target value, resolution test, reading distance test, reading angle test and / or symbol contrast test are executed; finally, test result is recorded through comparing bar code symbol and the bar code reading equipment. The system comprises an initialized module, a testing item module and a result processing module which complete the steps of the method, wherein, the testing item module comprises a resolution test unit, a reading distance test unit, a reading angle test unit and / or a symbol contrast test unit. The invention which can adapt to bar code reading equipment of different dimensions and models tests the reading distance of the equipment and plots the reading graphic; moreover, the invention has strong versatility and wide application.

Owner:ARTICLE NUMBERING CENT OF CHINA

Industrial pipe ring cutting device

ActiveCN109049073AImprove cutting efficiencyHigh degree of automationMetal working apparatusDrive motorThrough transmission

The invention discloses an industrial pipe ring cutting device. The right side of the upper end of a device body is provided with a driving motor, and the left side of the driving motor is rotationally connected with a driving shaft; the left end of the driving shaft is in sleeving connection with the upper end of a swing arm, and the lower end of the swing arm is fixedly connected with a U-shapedframe; the middle of the lower end of the U-shaped frame is rotationally connected with a rotary shaft, and the rotary shaft is fixedly connected with a cutter; the middle of the swing arm is rotationally connected with the lower end of a piston rod through a bearing; and the upper portion of the piston is slidably connected to the lower portion of a hydraulic cylinder in a sealing mode. According to the industrial pipe ring cutting device, a transmission belt is driven to roll, accordingly, the cutter is driven to rotationally cut, a sleeve and the driving shaft are reverse in rotation direction through transmission of a first bevel gear and a second bevel gear while cutting is conducted, the sleeve drives a conical roller and a pipe to synchronously and reversely rotate, that is, the pipe is reversely rotated to be cut while the cutter conducts rotary cutting, meanwhile, height adjusting of the cutter is achieved under action of the hydraulic cylinder and the piston rod, and pipes different in pipe diameter and wall thickness can be cut; and by adopting the ring cutting mode, limitation to the size of a traditional cutter is overcome.

Owner:ZHEJIANG HOWHI PIPE IND CO LTD

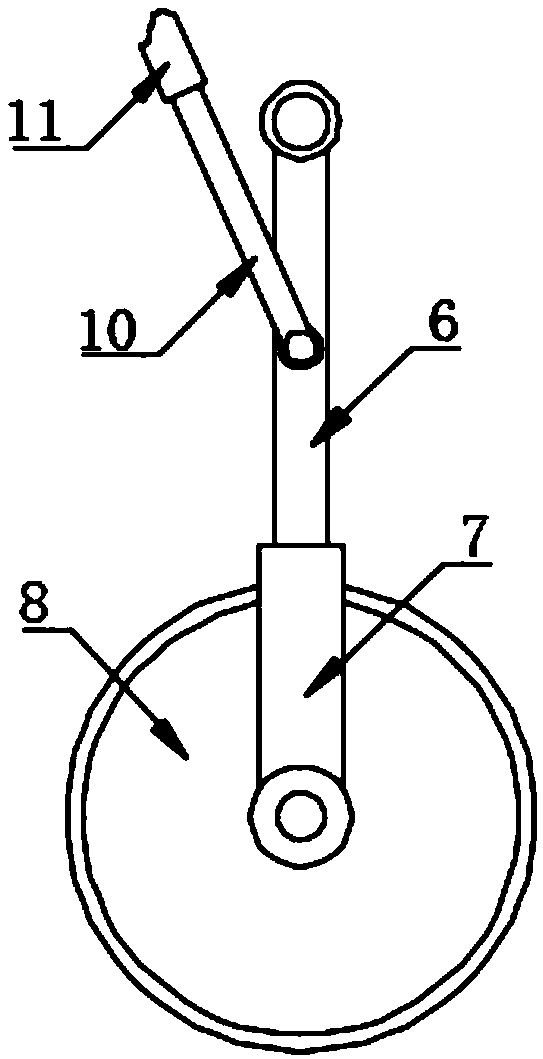

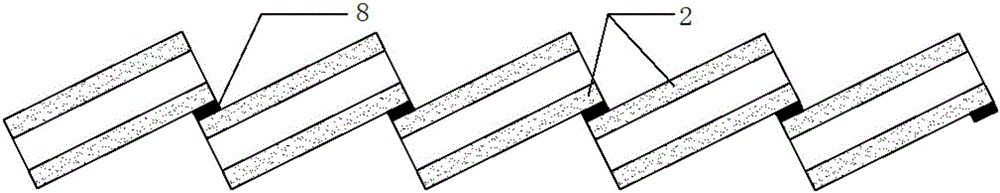

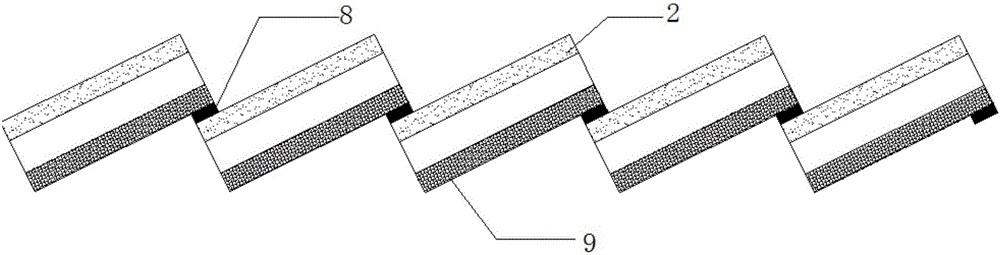

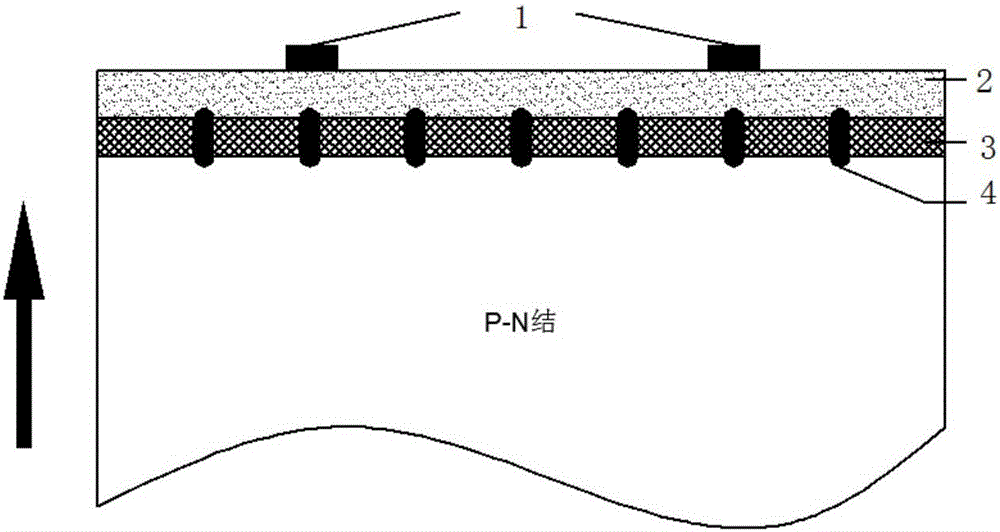

Connecting structure of crystalline silicon photovoltaic cell with transparent electrodes

ActiveCN105870216AIncrease the area that can generate electricityHigh power outputPhotovoltaic energy generationSemiconductor devicesComposite electrodeTransparent conducting film

The invention discloses a connecting structure of a crystalline silicon photovoltaic cell with transparent electrodes. Front electrodes of cell pieces forming a cell pack string are transparent conductive film-metal composite electrodes, and back electrodes are transparent conductive film-metal composite electrodes or back metal electrodes. The adjacent crystalline silicon photovoltaic cells are connected in series in the mode that the front electrodes and the back electrodes are overlapped, and joints are filled with a conductive binding agent so as to make a cell pack string circuit closed. The transparent conductive film-metal composite electrodes are adopted for the front and / back electrodes of the cells forming a photovoltaic assembly, so that the using amount of metal for making solar cell electrodes is greatly reduced, metal can even be not used at all, the light shielding area is reduced, and the production cost is reduced. The power generating area of the assembly is further increased through overlapped connection of the cells, and thus the power output of the assembly is increased.

Owner:LONGI SOLAR TECH CO LTD

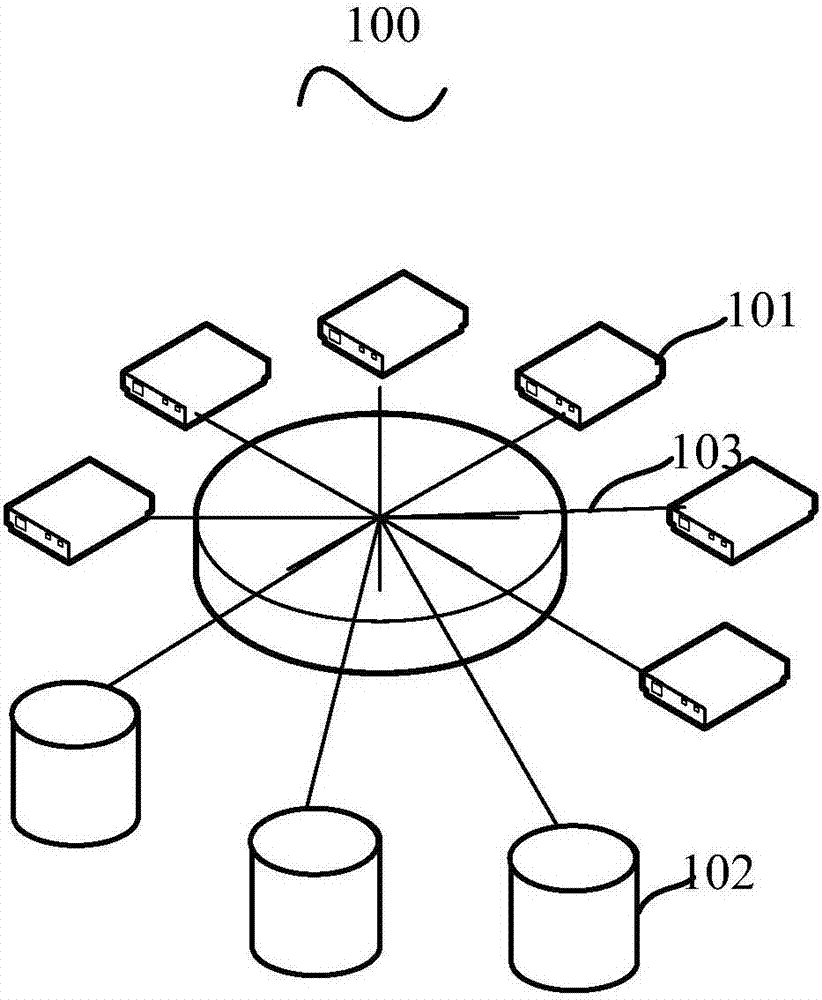

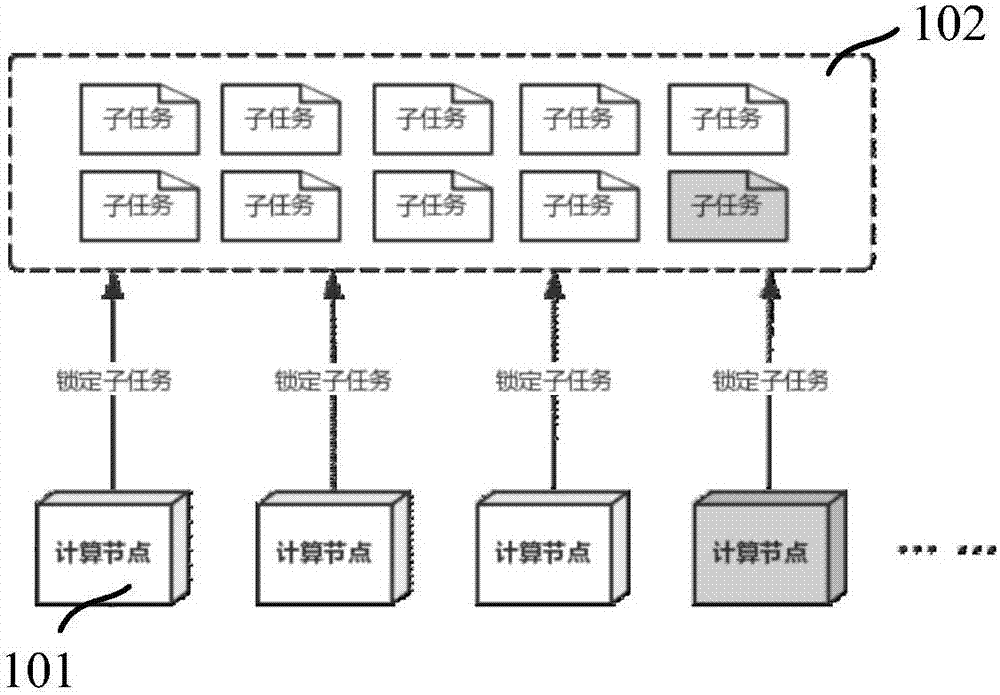

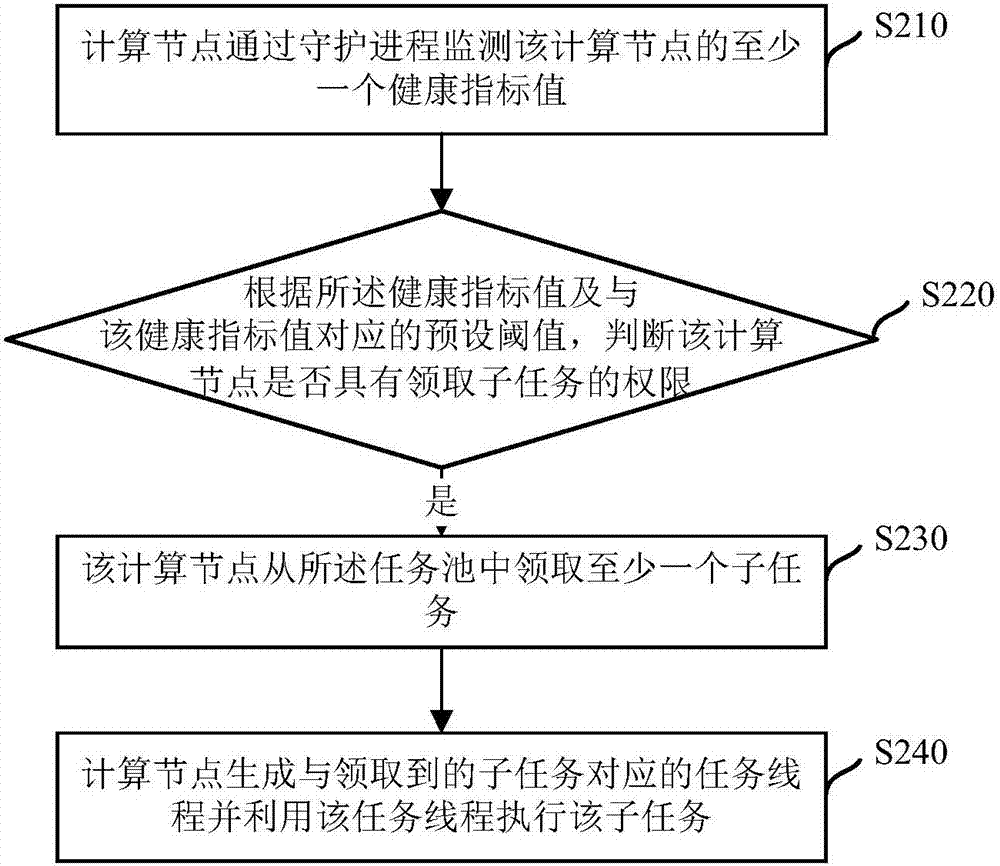

Distributed task processing method and device

The embodiment of the invention discloses a distributed task processing method and device. The distributed task processing method comprises the steps that calculating nodes monitor at least one health index value of the calculating node through a daemon process; the calculating nodes judge whether the calculating node has the permission of taking subtasks from a task pool prestored with a plurality of subtasks or not according to the health index values and preset threshold values corresponding to the health index values; if yes, the calculating nodes take at least one subtasks from the task pool prestored with a plurality of subtasks; the calculating nodes generate task threads corresponding to the taken subtasks and utilize the task threads to execute the subtasks. By utilizing the embodiment, the problem that in an existing distributed task processing technology, the scale of calculating node groups is limited due to the fact that the subtasks are dispatched to a plurality of calculating nodes through connection between control nodes and a plurality of calculating nodes and through the control nodes can be solved.

Owner:ALIBABA GRP HLDG LTD

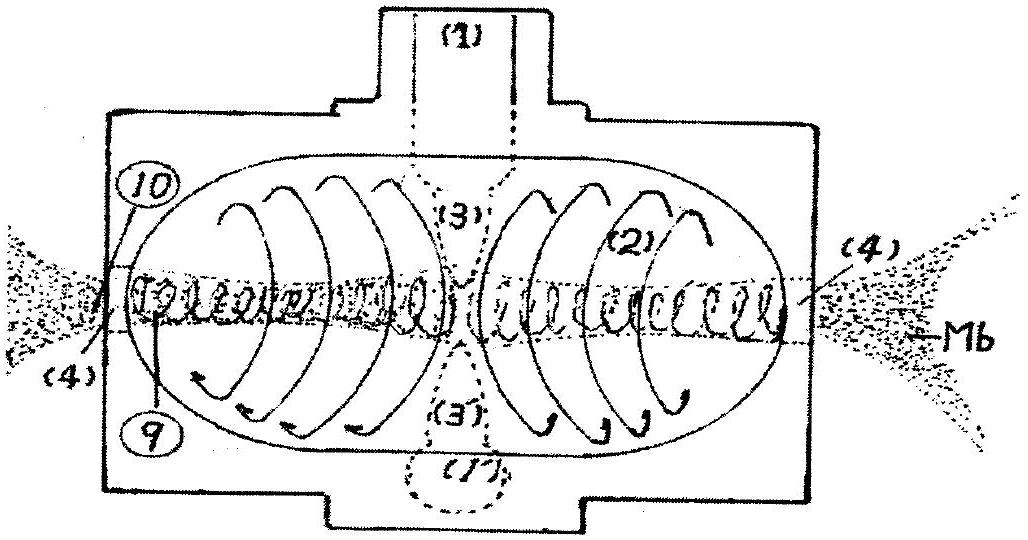

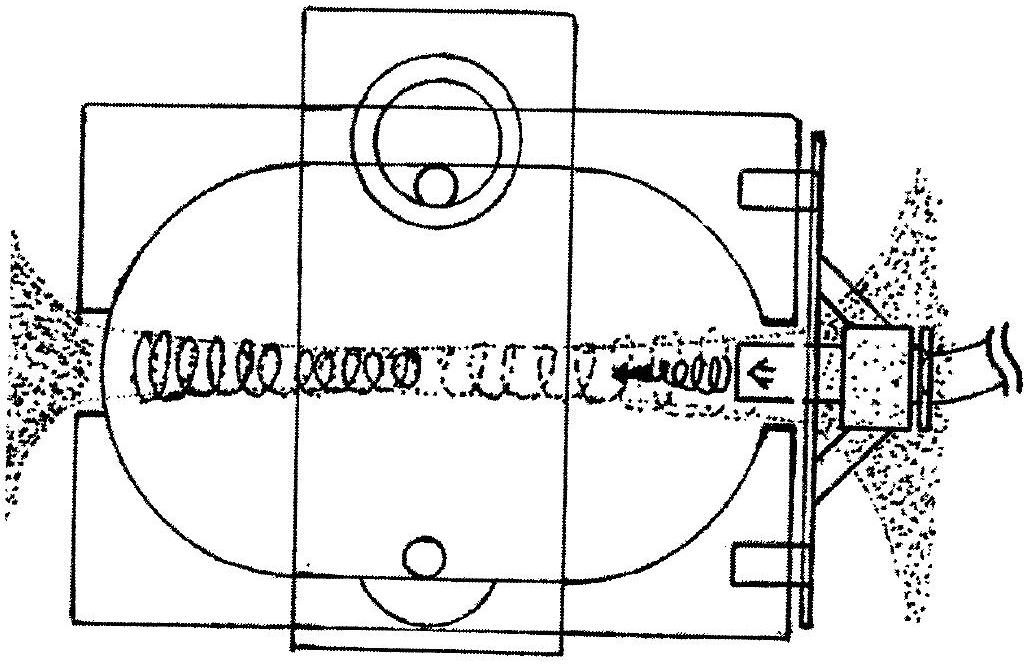

High-speed cyclic gas-liquid mixed micro-nano foam generating device

InactiveCN102688709ALarge amount of bubblesUniform amount of air bubblesFlow mixersMixing methodsMicro nanoHybrid type

The invention discloses a high-speed cyclic gas-liquid mixed micro-nano foam generating device, which consists of two hemispherical containers and a cylindrical container which is connected with a water inlet pipe, hollow C-shaped pipes (3) and (3') are arranged on the cylindrical inner surface, and a circular hole (4) for spraying liquid to achieve the effects of micro-nano foam and an air conduit is formed at each of two hemispherical ends. Due to the hollow C-shaped pipes, the rotating speed of liquid is improved (so that super-micro thinning of foam is promoted), and the superfine foam generating rate is improved by 25 percent compared with the conventional superfine foam generating rate.

Owner:金强

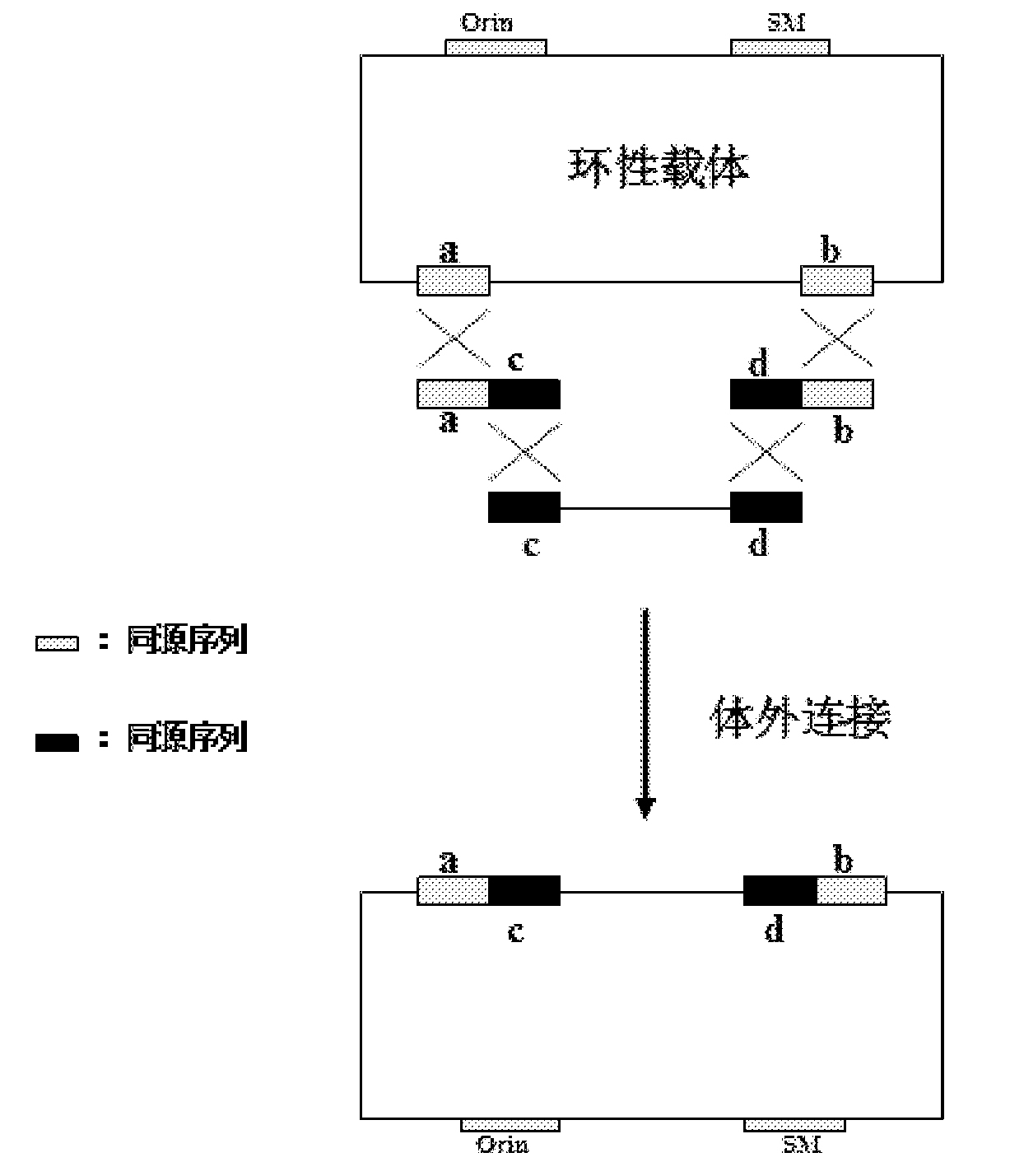

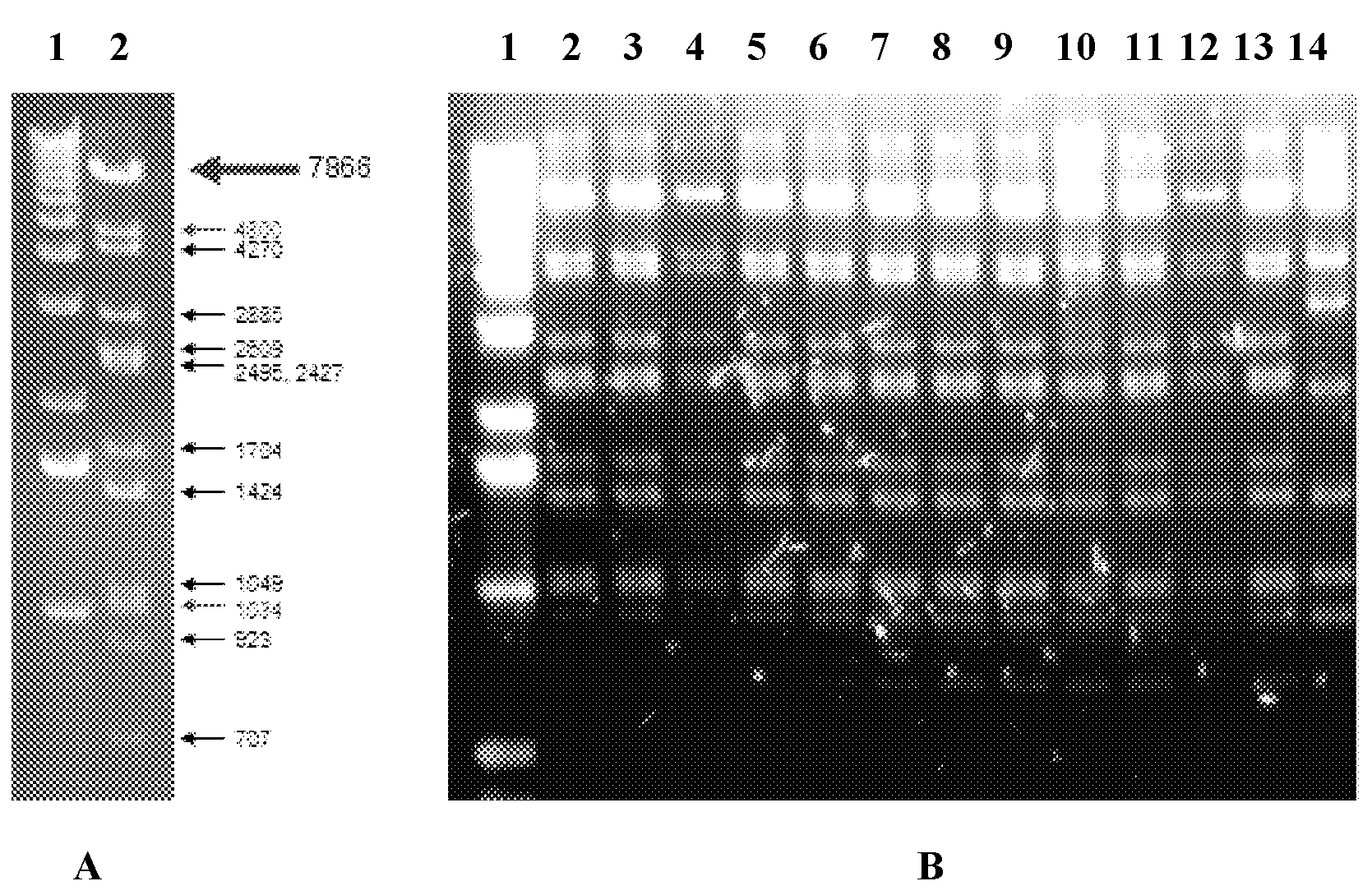

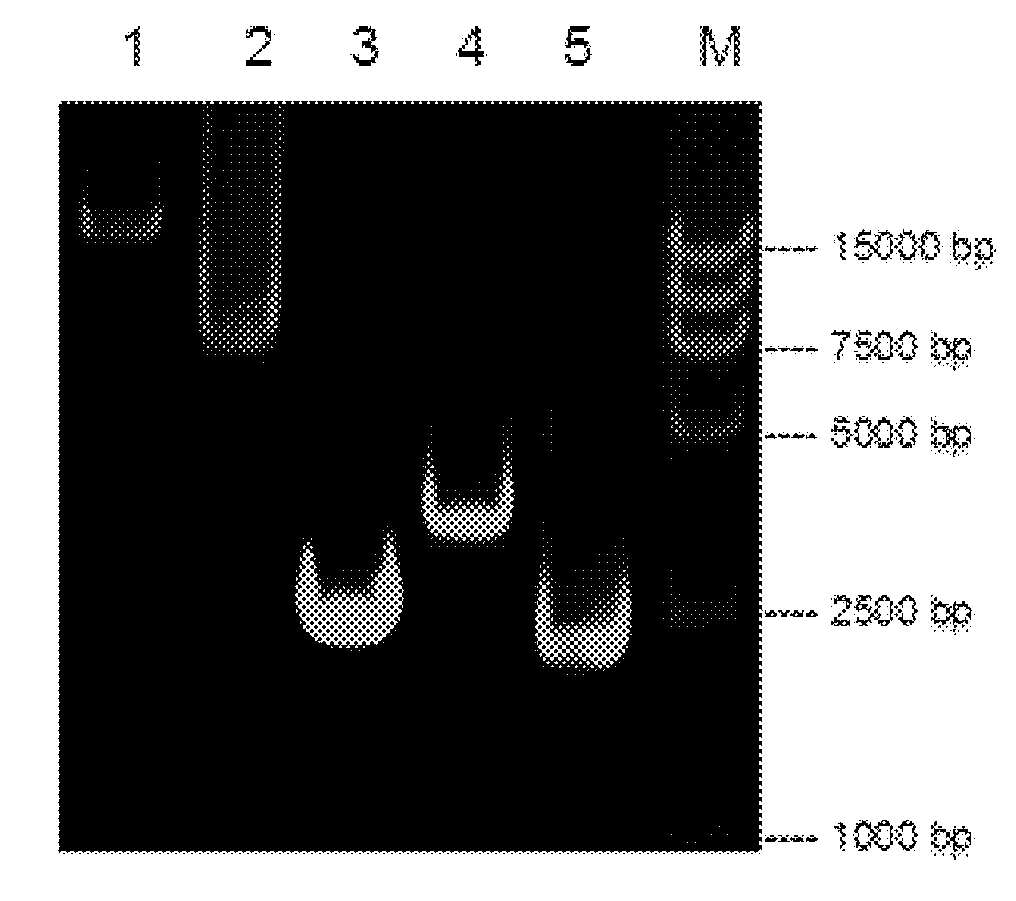

Nucleic acid molecular cloning method and related kit based on homologous recombination

InactiveCN102634534ASize limitAvoid the contradiction of low conversion rateVector-based foreign material introductionDNA preparationNucleotideMolecular cloning

The invention provides a nucleic acid molecular cloning method based on homologous recombination. According to the method provided by the invention, a target DNA is cloned to a vector by the homologous recombination through providing a linearizing vector with two ends respectively added with sequences(namely specific homologous arm of the target DNA) homologous with sequences at the two ends of the target DNA or the flanking sequence of the target DNA or utilizing a connecting section containing the specific homologous arm of the target DNA as well as the specific homologous arm of the vector (sequence homologous with the specific region of the vector). The nucleic acid molecular cloning method provided by the invention is especially suitable for the clone of large DNA section and polymorphism researches of mononucleotide. The invention further provides a related kit.

Owner:SHENZHEN ZHONGLIAN BIOLOGICAL TECH DEV

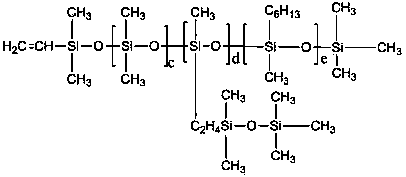

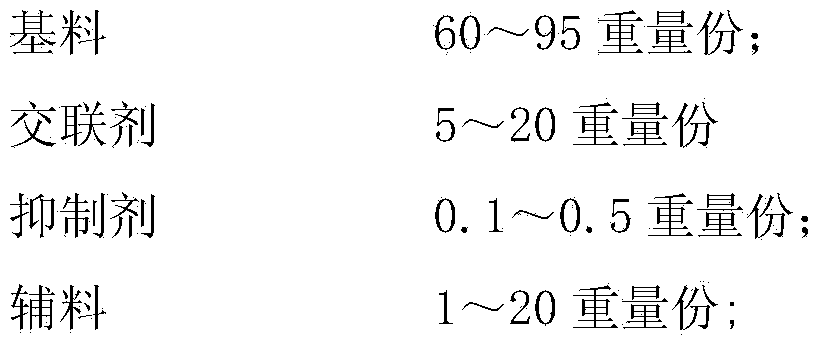

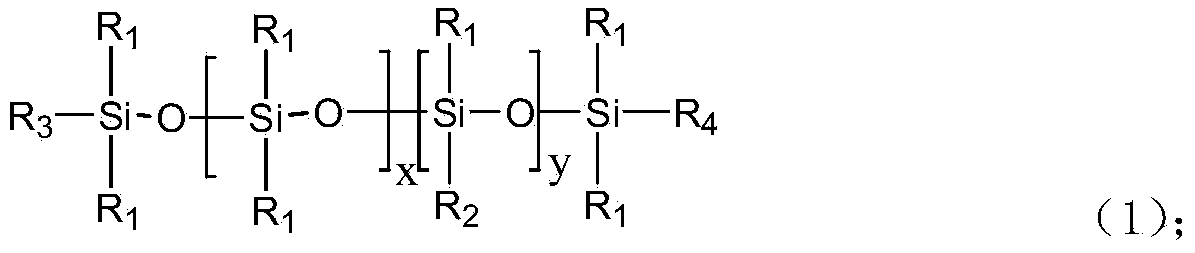

Organic silica gel optical adhesive film and production technology thereof

InactiveCN104004460AReduce manufacturing costEasy to useFilm/foil adhesivesMacromolecular adhesive additivesSilicone GelsMechanical equipment

The invention provides an organic silica gel optical adhesive film. The organic silica gel optical adhesive film comprises an upper-layer release film and a lower-layer release film, wherein an organic silica gel layer is also arranged between the upper-layer release film and the lower-layer release film, and the organic silica gel layer comprises transparent organic silica gel adhesive and is obtained by mixing a component A with a component B in mass ratio of 1:1. The organic silica gel optical adhesive film has the advantages that organic silica gel is clamped between two release films, the silica gel can not be hardened under normal temperature condition, so that only one release film is firstly uncovered and bonded on a base plate to be laminated when the organic silica gel optical adhesive film is used, then the other release film is uncovered, an optical element to be laminated is pasted, thereby being convenient; meanwhile, the organic silica gel optical adhesive film can be cut at will and can not be limited by a mould and mechanical equipment, usable range is more broad, and production cost of an optical transparent element can be effectively reduced.

Owner:SUZHOU TONGLI PHOTOELECTRIC CO LTD

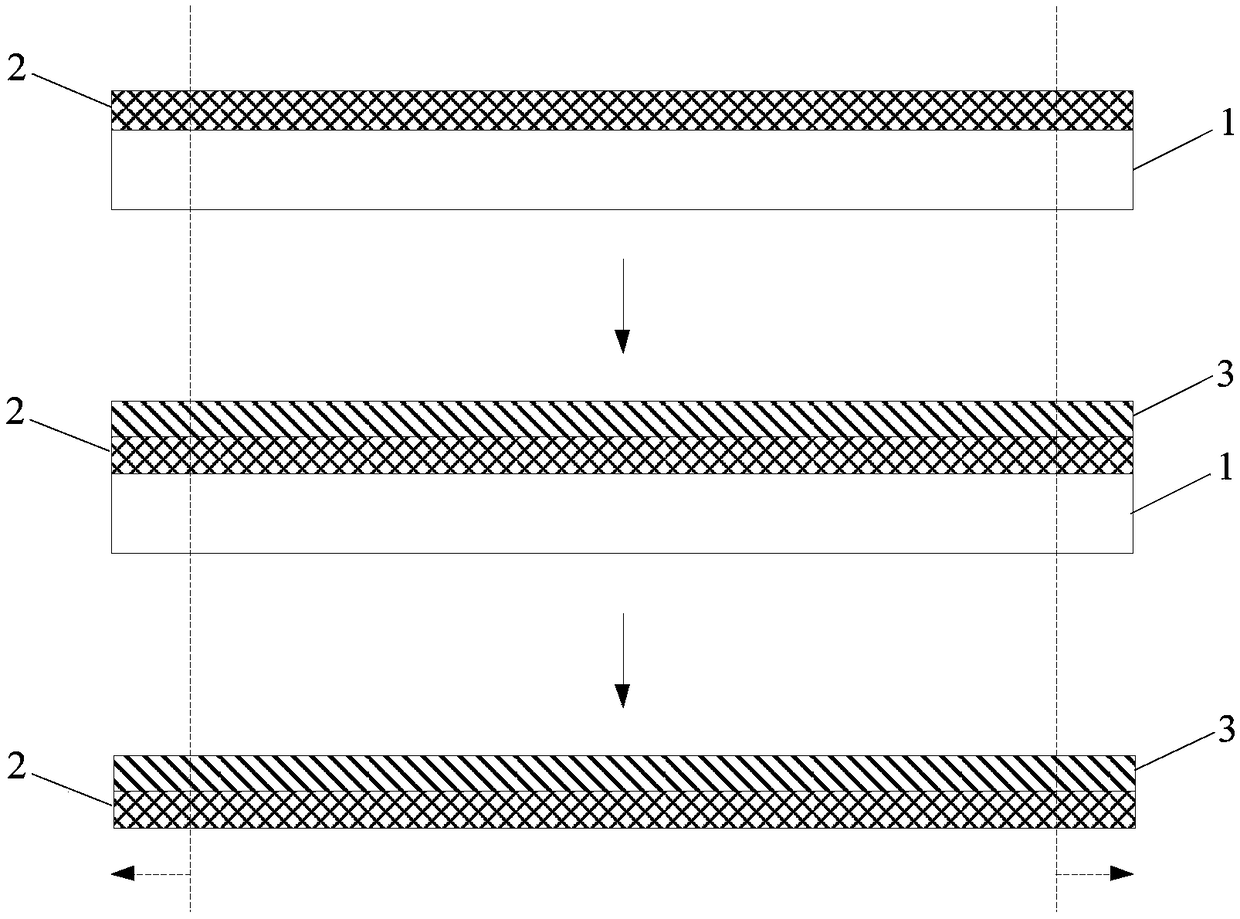

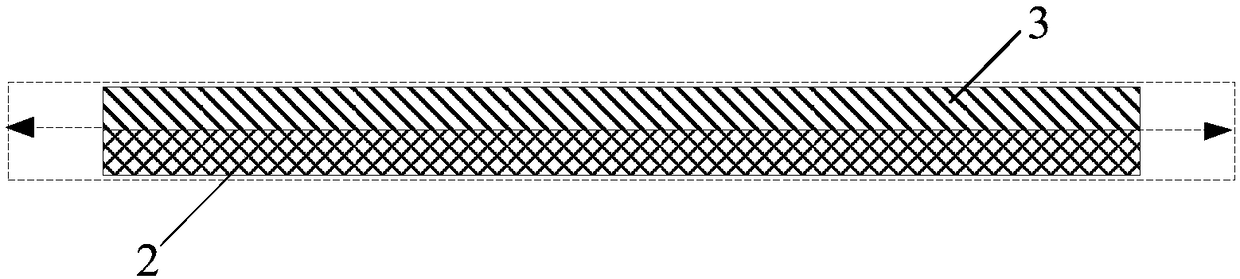

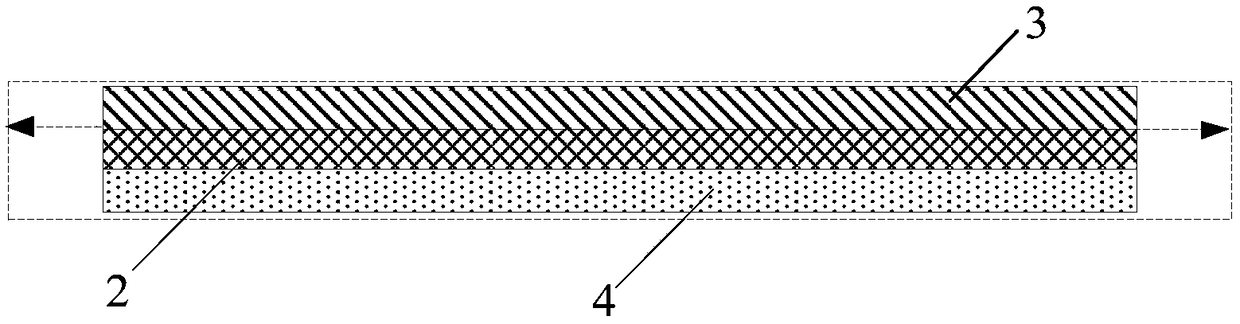

Pre-stretching base and manufacture method thereof and electron device and manufacture method thereof

ActiveCN108597376AUniform thermal expansionGuaranteed uniformityLamination ancillary operationsSolid-state devicesElectronMaterials science

The invention discloses a pre-stretching base and a manufacture method thereof and an electron device and a manufacture method thereof, and relates to the technical field of base pre-stretching. In order to solve the problem that an existing pre-stretching base manufacture method can not form the pre-stretching base with a large area and even pre-stretching quantities, the manufacture method of the pre-stretching base includes the following steps that under the environment with temperature high than preset temperature, at least two layers of films are successively formed on a carrier plate, and thermal expansivity coefficients of the at least two layers of films are different; and the at least two layers of films are separated from the carrier plate, and the pre-stretching base is obtained. The manufacture method of the pre-stretching base is used for manufacturing the pre-stretching base.

Owner:BOE TECH GRP CO LTD

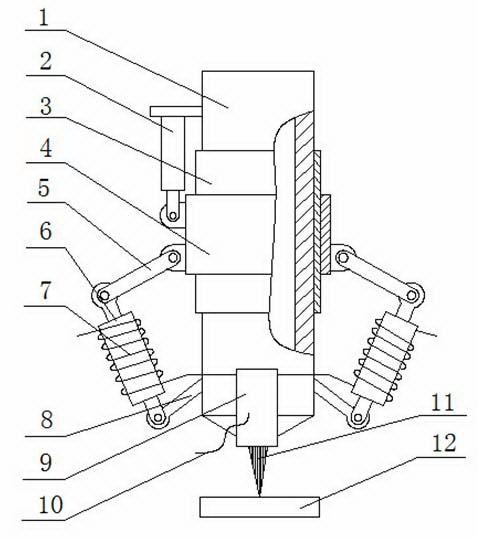

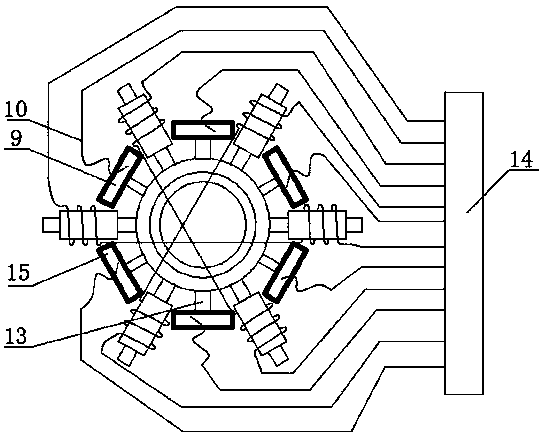

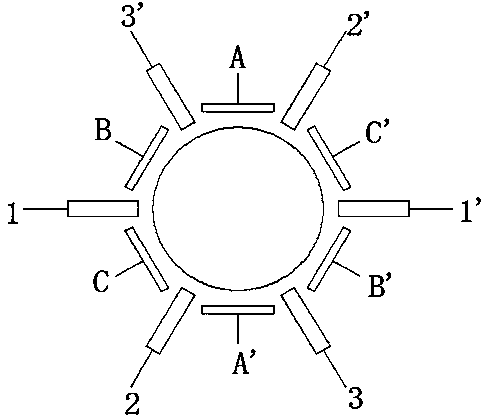

Device for assisting in laser drilling with rotating electric field

ActiveCN104043905ADoes not affect positional accuracyGuaranteed processing stabilityWelding/soldering/cutting articlesLaser beam welding apparatusHydraulic cylinderEngineering

The invention discloses a device for assisting in laser drilling with a rotating electric field. N pairs of iron cores are distributed along the circumference of a laser head uniformly at intervals, the upper and lower ends of each iron core are respectively hinged to a connecting rod and a supporting rod fastened at the lower end of the laser head, the other end of each connecting rod is hinged to a guide sleeve, the guide sleeve sleeves the outer wall of a guide pillar coaxially fixed on the laser head, the upper end of the guide sleeve is connected with a hydraulic cylinder fixed on the upper end of the laser head, the guide sleeve can move up and down along the guide pillar, N pairs of coil windings respectively sleeve the N pairs of iron cores and are connected with a controller, N pairs of electroplates are respectively fixed on the lower end of the laser head through N pairs of electroplate supports, the N pairs of electroplates are located on the same plane and each electroplate is located at the central position of an included angle formed by two corresponding adjacent coil windings, and the electroplates of which the surfaces are coated with insulated layers are connected with the controller through conducting wires. According to the device, the drilling efficiency can be improved, and the device is applicable to laser drilling processing on all materials.

Owner:JIANGSU UNIV

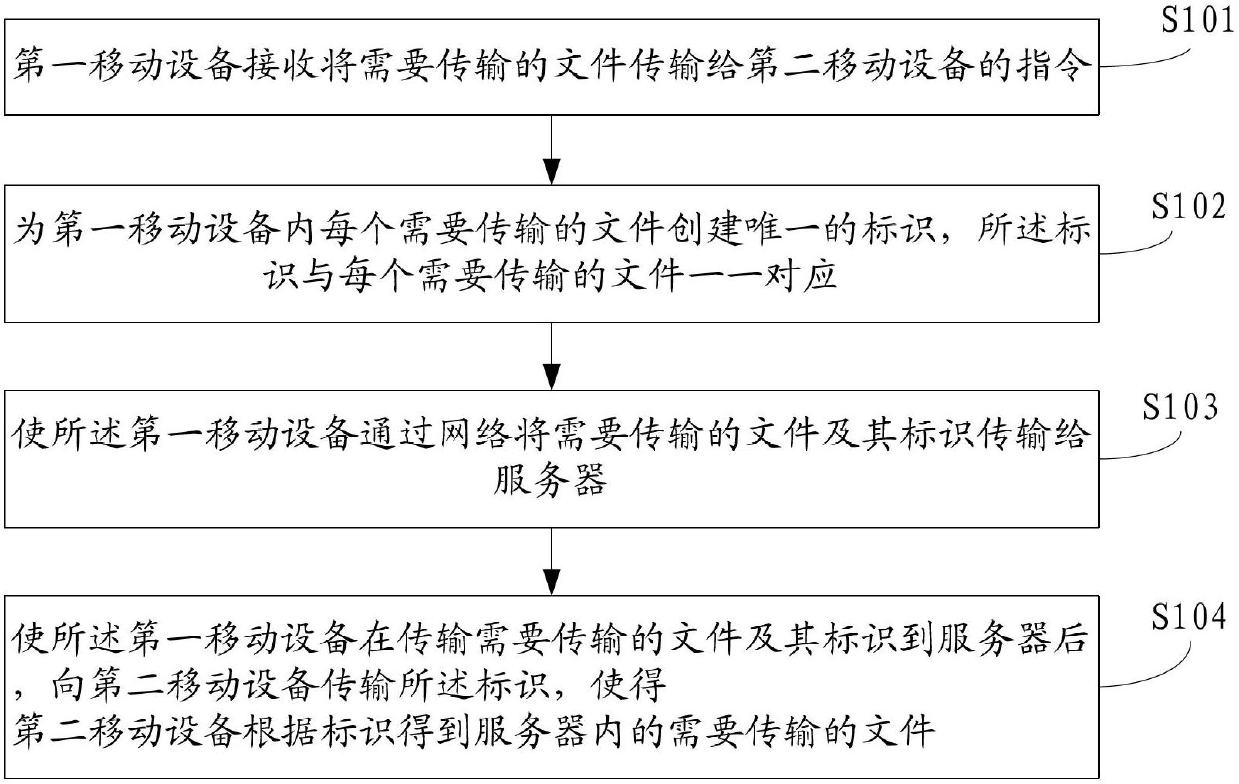

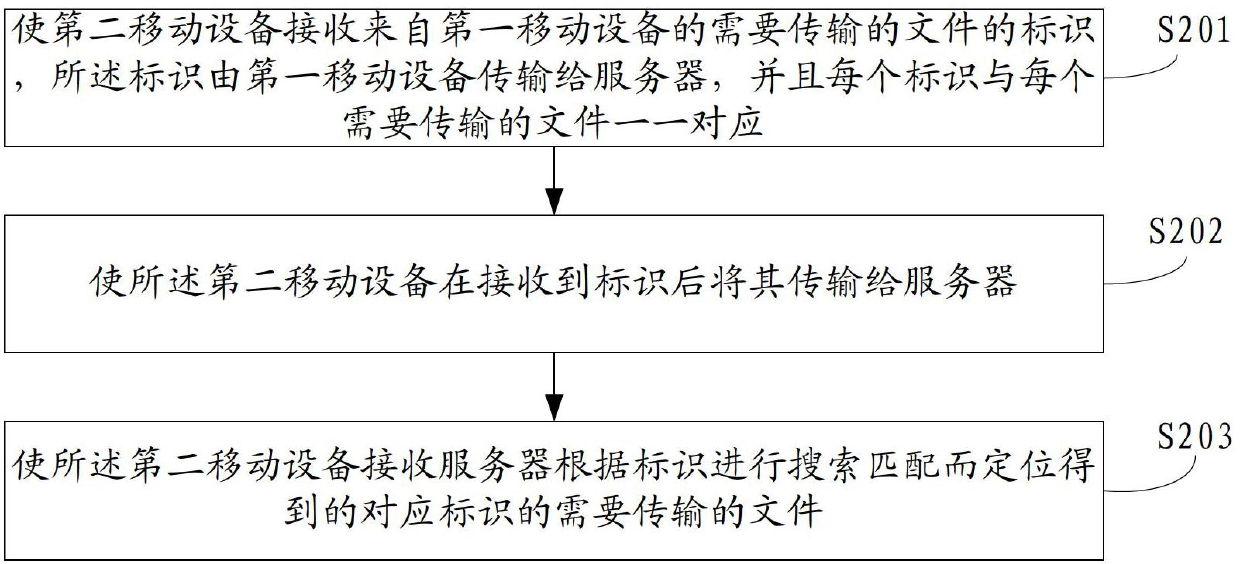

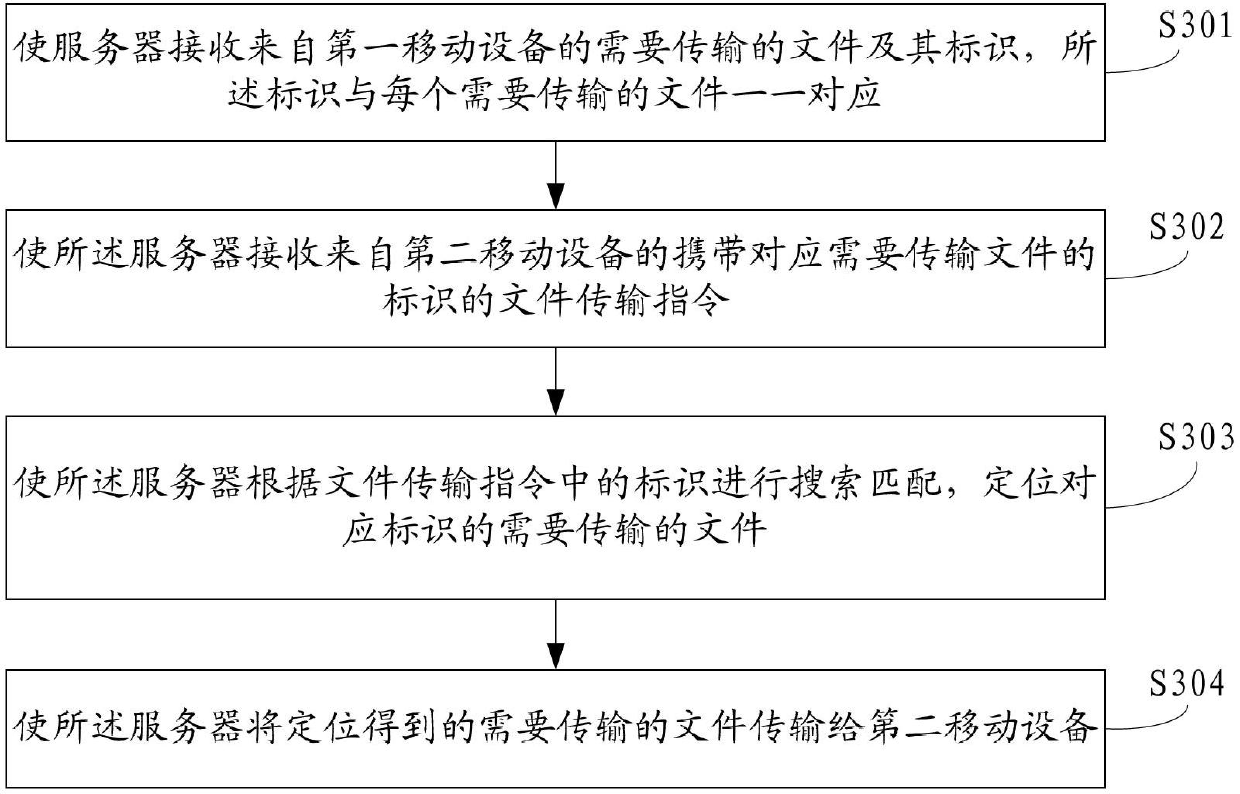

File transmission method, mobile equipment, server and file transmission system

InactiveCN102638587ASize limitGuaranteed normal transmissionTransmissionSpecial data processing applicationsFile transmissionUnique identifier

The invention discloses a file transmission method, mobile equipment, a server and a file transmission system. The method comprises the steps of creating a unique identifier for each file needing to be transmitted in first mobile equipment; enabling the first mobile equipment to transmit the files needing to be transmitted and the identifiers thereof to the server through a network; after the first mobile equipment transmits the files needing to be transmitted and the identifiers thereof to the server, enabling the first mobile equipment to transmit the identifiers to second mobile equipment; enabling the second mobile equipment to receive the identifiers and to transmit the identifiers to the server; and enabling the server to conduct searching and matching according to the identifiers, position the files to be transmitted corresponding to the identifiers and transmit the files needing to be transmitted to the second mobile equipment. By adopting the method, the operation of file transmission can be completed efficiently, reliably and conveniently.

Owner:BEIJING ERENEBEN INFORMATION TECH

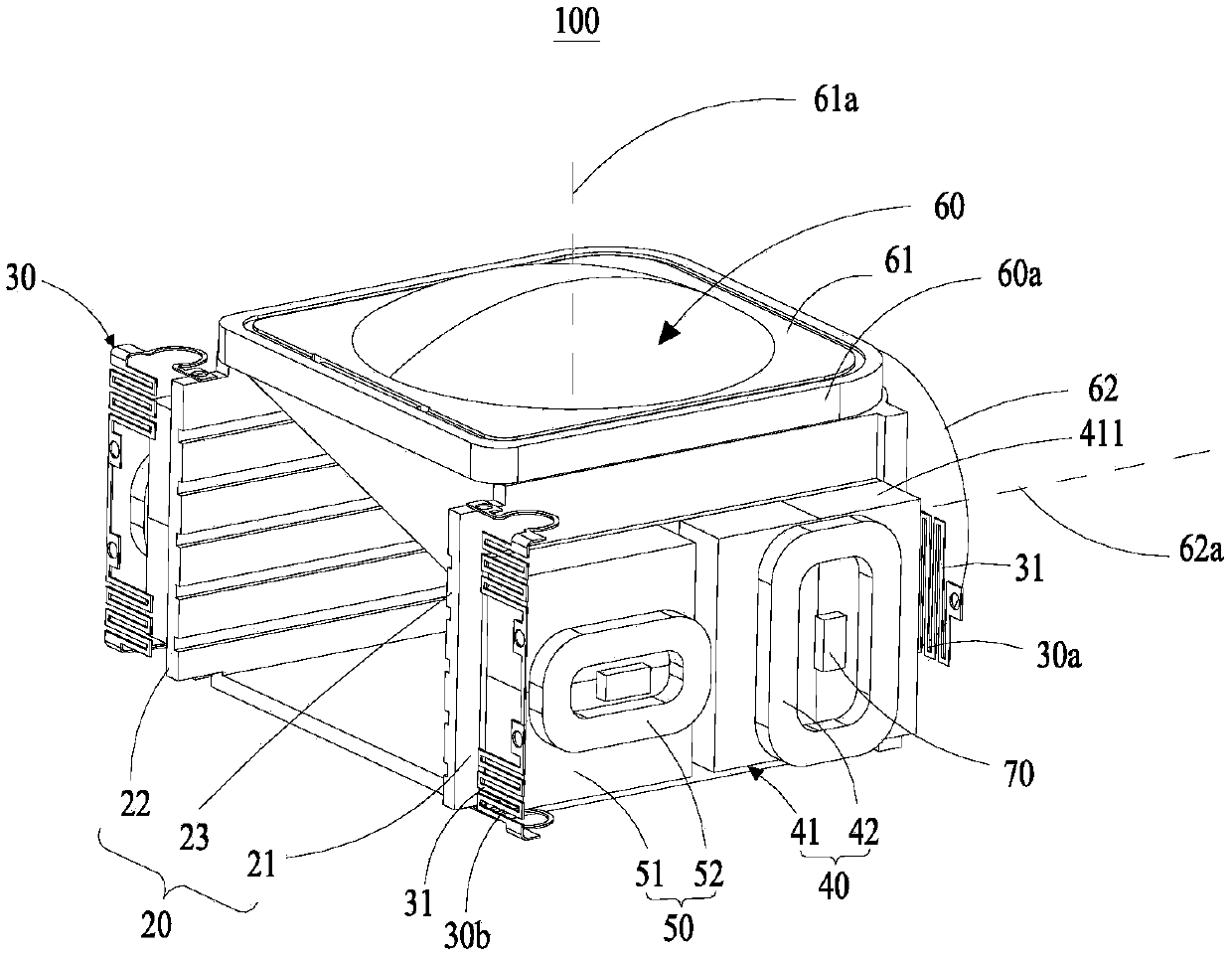

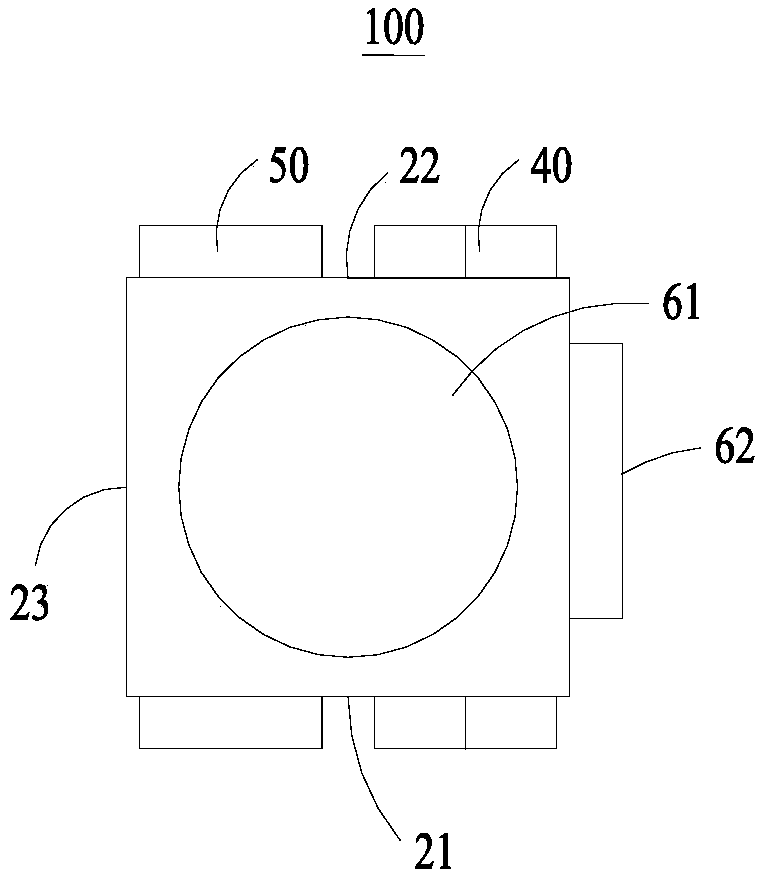

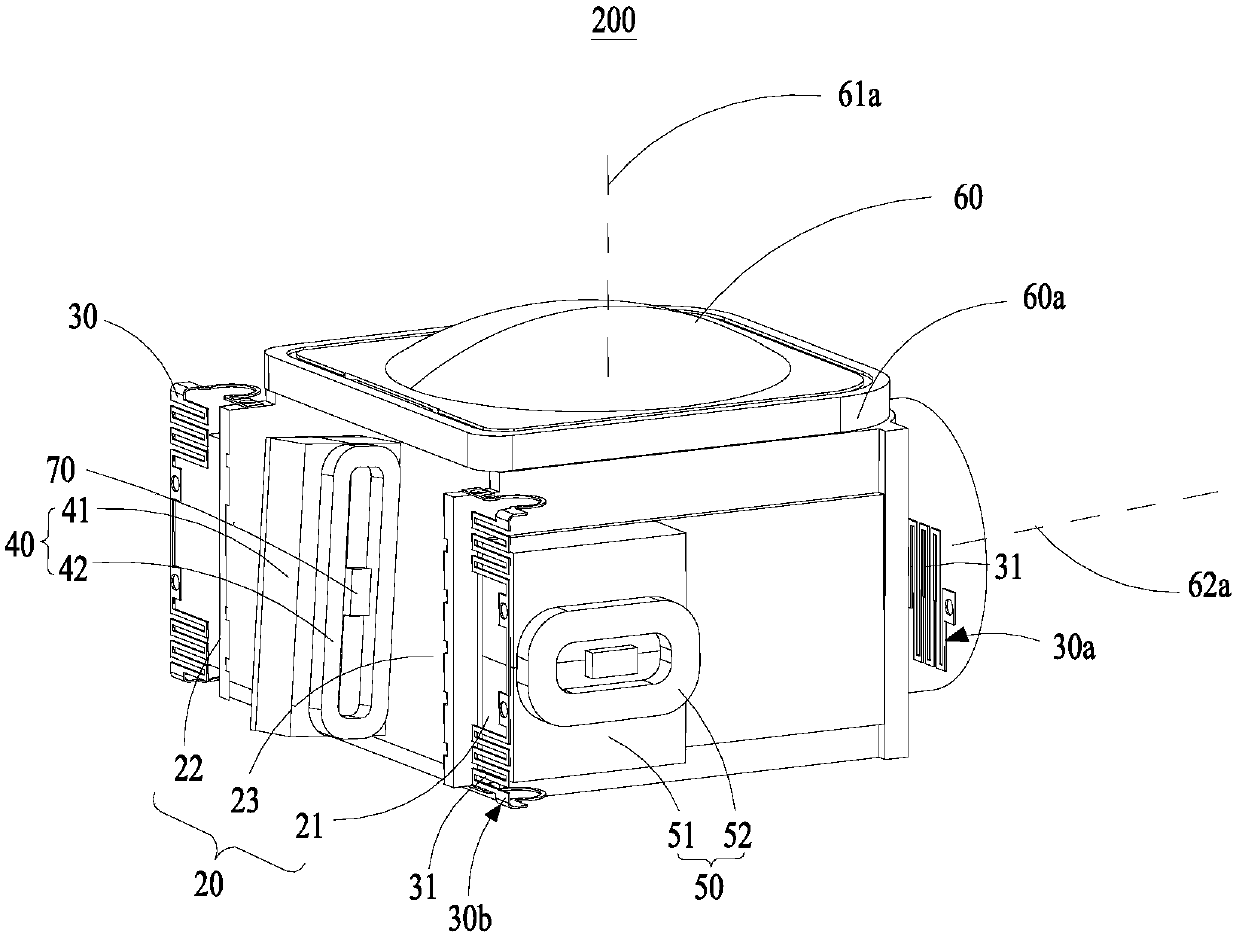

Lens actuating device, periscopic shooting module and shooting equipment

InactiveCN111367036ATurn easilyPrevent rotationTelevision system detailsPrintersEngineeringOptical axis

The invention provides a lens actuating device, a periscopic lens module comprising the lens actuating device and shooting equipment comprising the periscopic lens module. The light enters a lens group after being reflected, so the optical axis direction of the lens group is different from the thickness direction of the shooting equipment, the limitation of the optical axis direction length of thelens group on the thickness of the shooting equipment is eliminated, and thinning of the shooting equipment is realized. By arranging a translation type motor and a tilt-shift type motor on a supportof the lens actuating device, focusing and shake prevention of the periscopic lens module comprising an optical component and the lens actuating device are achieved. The translation type motor and the shaft-moving type motor are independent individuals, so the translation type motor and the shaft-moving type motor can work at the same time, control efficiency is higher, moreover, rotation of thesupport is realized through matching of shaft moving type motors and elastic pieces, and the motors which are symmetrical pairwise do not need to be arranged around the support, so the number of the motors arranged around the support can be reduced.

Owner:HUAWEI TECH CO LTD

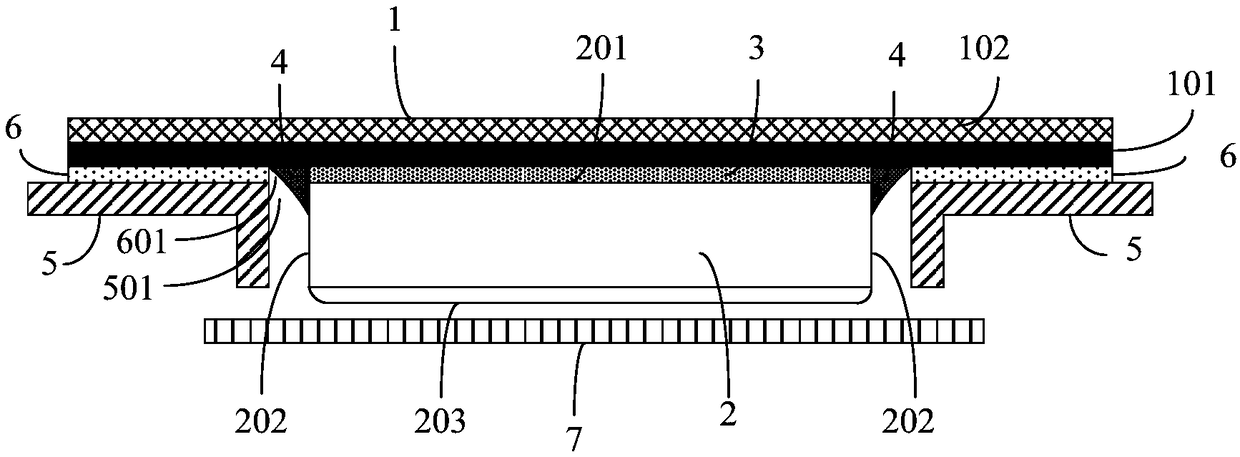

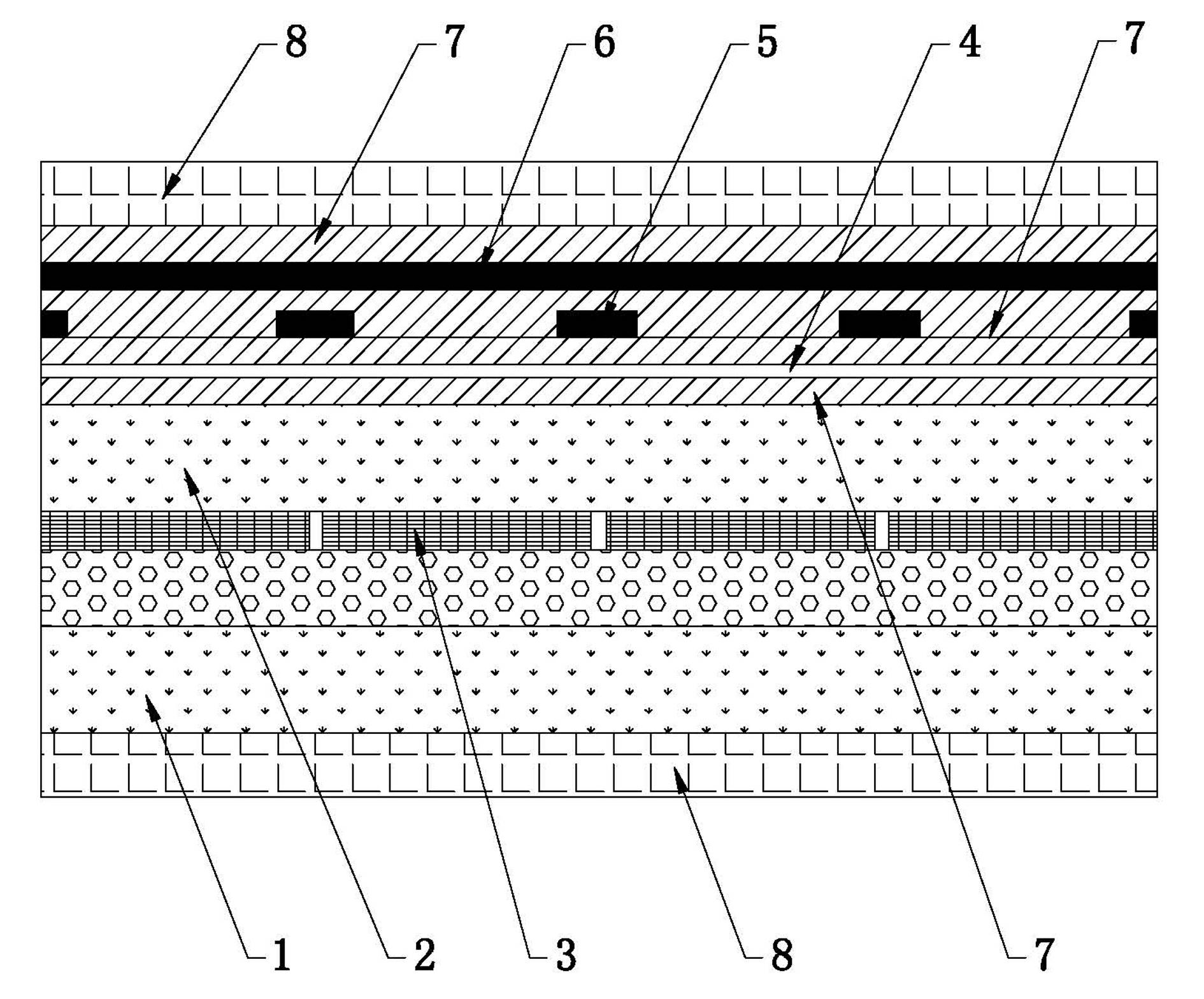

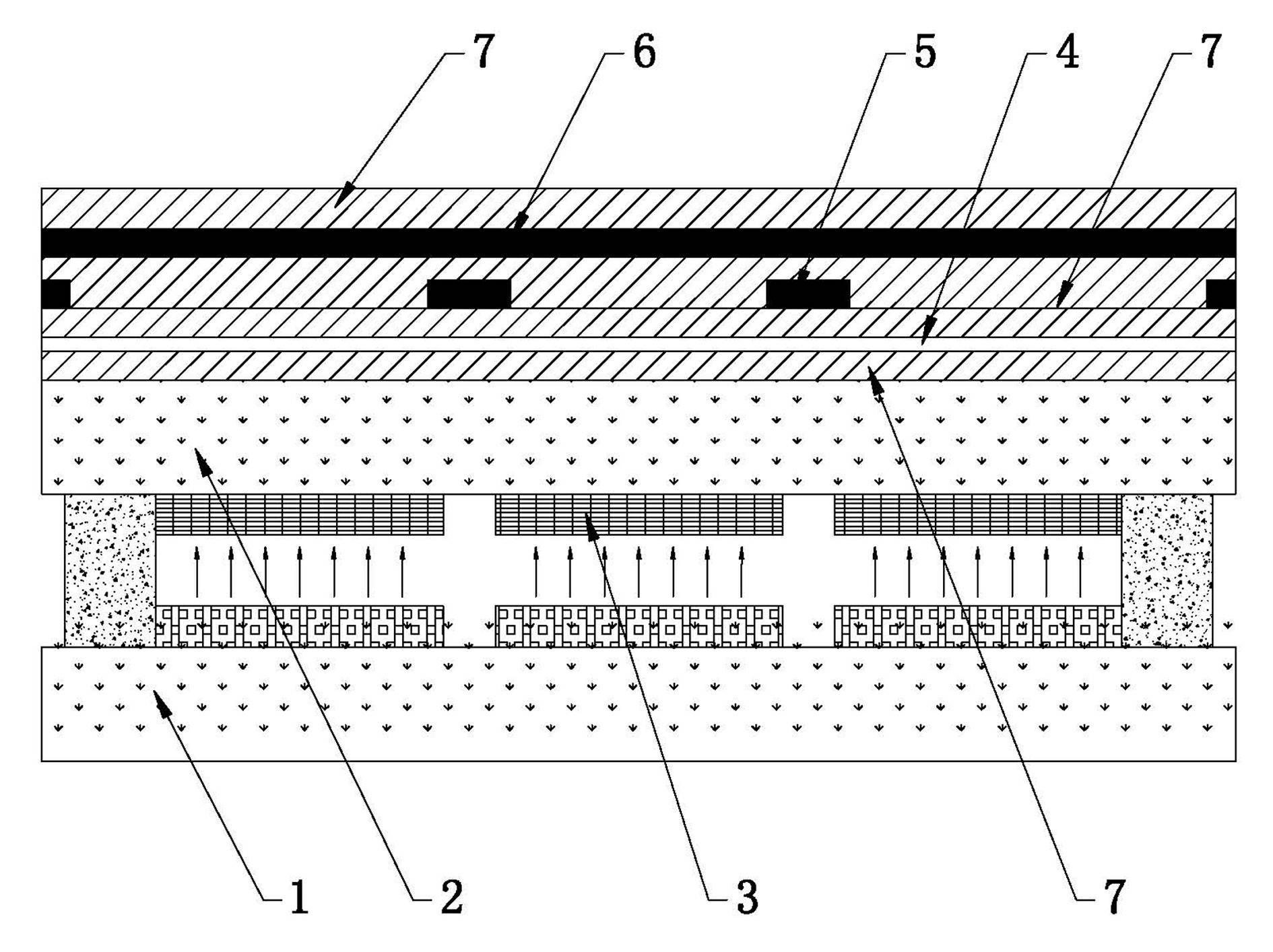

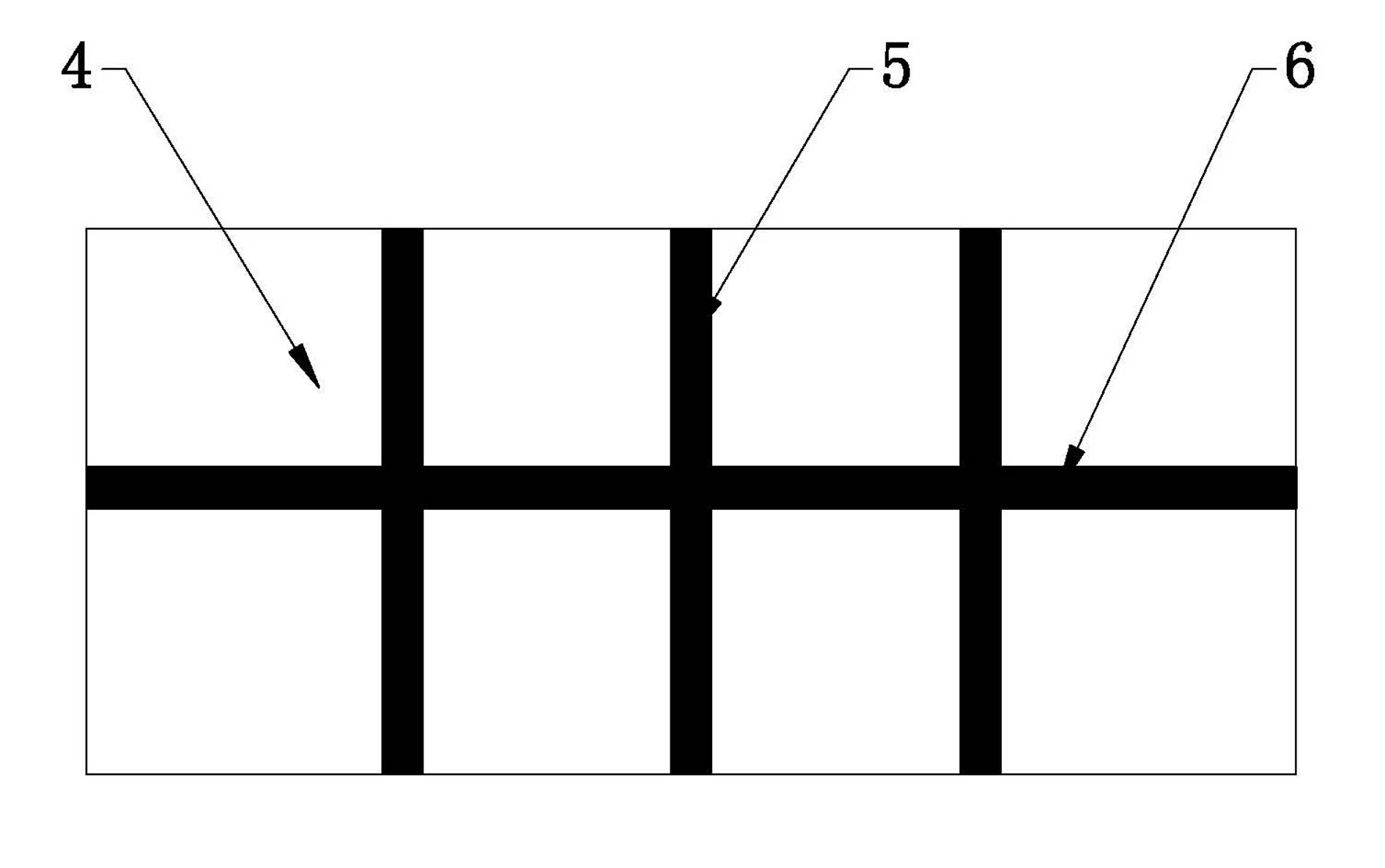

Touch display device integrated on displayer

InactiveCN102646006AImproved position detection capabilitySize limitInput/output processes for data processingDisplay deviceOptoelectronics

The invention discloses a touch display device integrated on a displayer, which comprises a first substrate (1) and a second substrate (2) integrating an electric control unit, wherein the first substrate (1) and the second substrate (2) are oppositely arranged, a red, green and blue (RGB) color layer (3) is arranged on one side of the second substrate (2) facing to the first substrate (1), a faceted transparent electrode layer (4) and a first metal layer (5) and a second metal layer (6) which are arranged in staggered mode are sequentially arranged on one side of the second substrate (2) back on to the first substrate (1), and the first metal layer (5) is located between the faceted transparent electrode layer (4) and the second metal layer (6). The touch display device integrated on the displayer conducts position detection of touch points through the faceted transparent electrode layer and metal electrodes, avoids optical interference caused by patterning of the transparent electrode layer, greatly improves capability of touch point position detection, has the advantages of being fast in detection and low in driving cost, and can achieve production of high-fineness and large-size touch panels.

Owner:NANJING CEC PANDA LCD TECH

High small ultrasonic polishing, collating equipment in use for parts of axes, and processing method

InactiveCN1915592AChange performanceHigh strengthSuperfinishing machinesBiomedical engineeringUltrasonic generator

An efficient ultrasonic polishing apparatus for the axle-type parts is composed of a HF (200000-300000 H2) ultrasonic generator and a grinding head, and is installed to the cutting-tool carrier. Its polishing method features that the part to be polished is fixed to a lathe.

Owner:CITIC HEAVY INDUSTRIES CO LTD

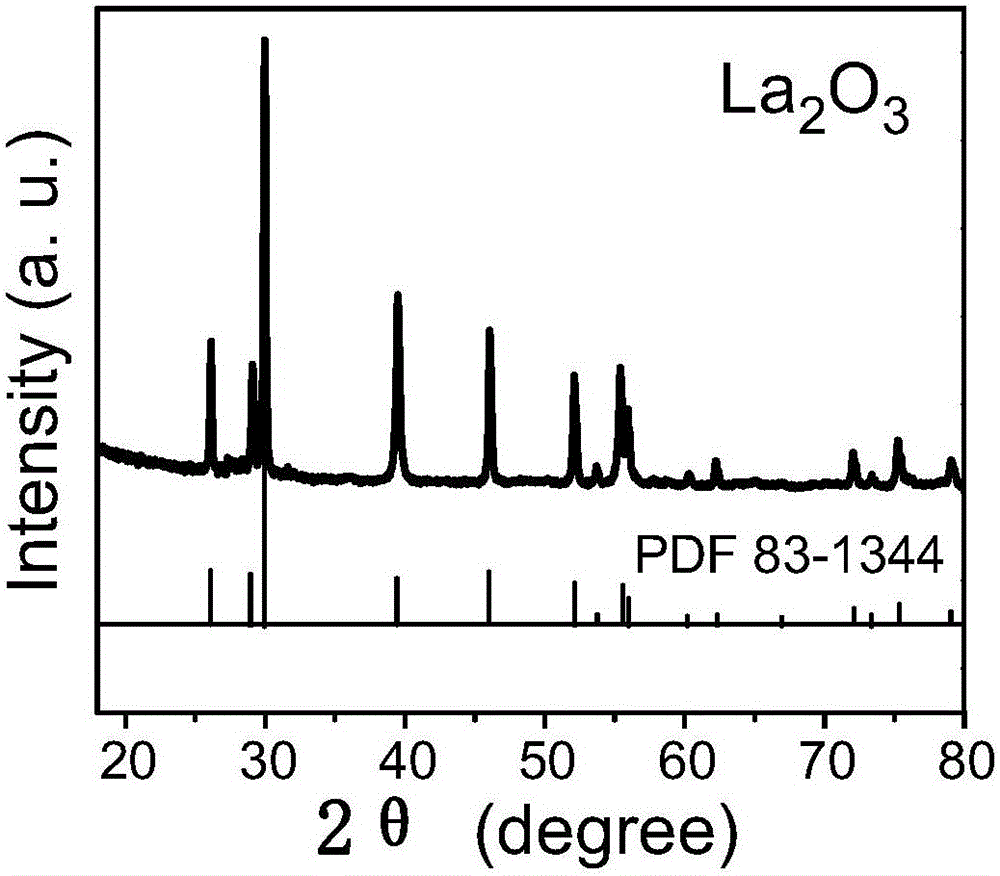

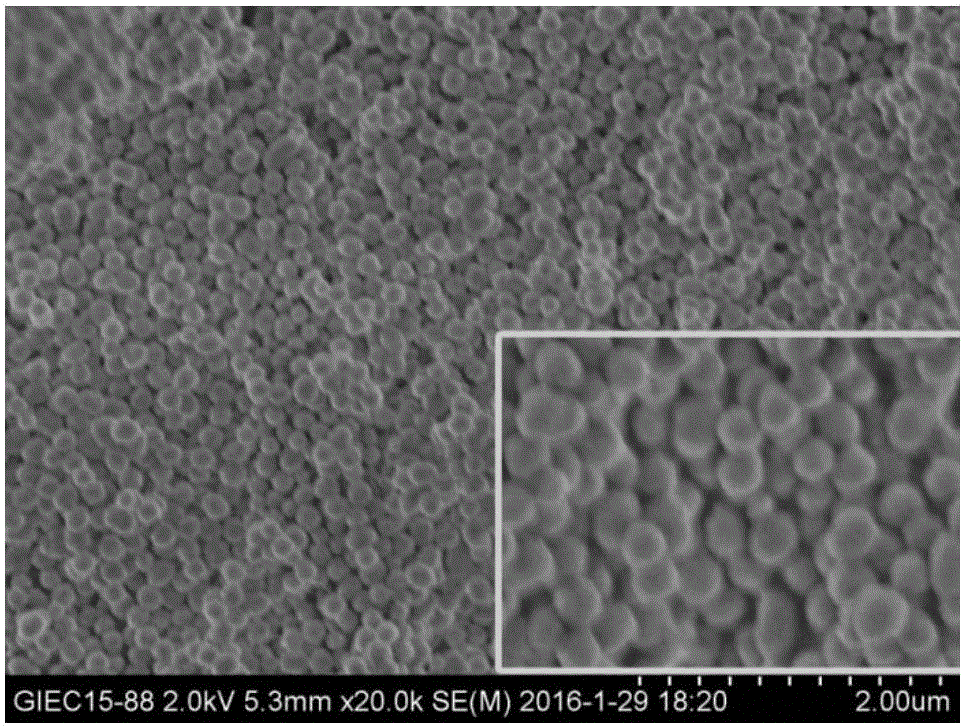

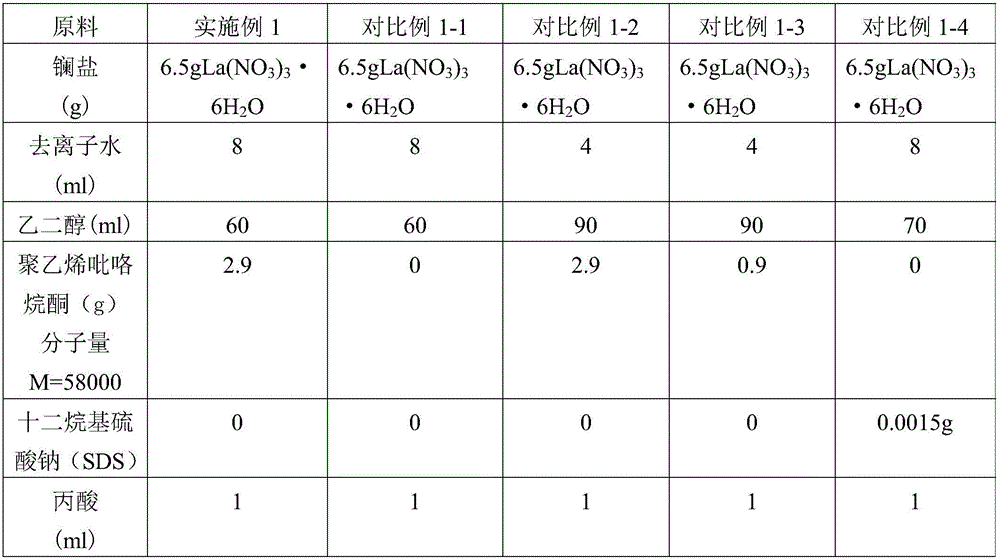

Spherical lanthanum oxide

ActiveCN105948098AShort reaction timeSimple and fast operationRare earth metal oxides/hydroxidesOrganic acidLanthanum

The invention discloses a spherical lanthanum oxide. The average particle size of spherical lanthanum oxide is 150 nm-1.2 mum, the specific surface area after roasting at 1000 DEG C is 1-7 m<2> / g, and the specific surface area after roasting at 500 DEG C is 120-144 m<2> / g. The invention also discloses a preparation method of the spherical lanthanum oxide, and the method includes the following steps: (1) mixing lanthanum salt, hydrous ethylene glycol, polyvinylpyrrolidone, and short-chain organic acid, stirring the mixture, dissolving the mixture, and performing a hydrothermal reaction; and (2) subjecting the mixture to the reaction for 1-8 hours at 160-240 DEG C, cooling the mixture to obtain the precipitate, and drying the precipitate to obtain the spherical lanthanum oxide. The lanthanum oxide prepared by the invention is spherical, has uniform morphology, good degree of crystallization, good dispersibility, high heat stability, and big specific surface area, and is suitable for the application on the motor vehicle exhaust.

Owner:GUANGDONG UNIV OF TECH +1

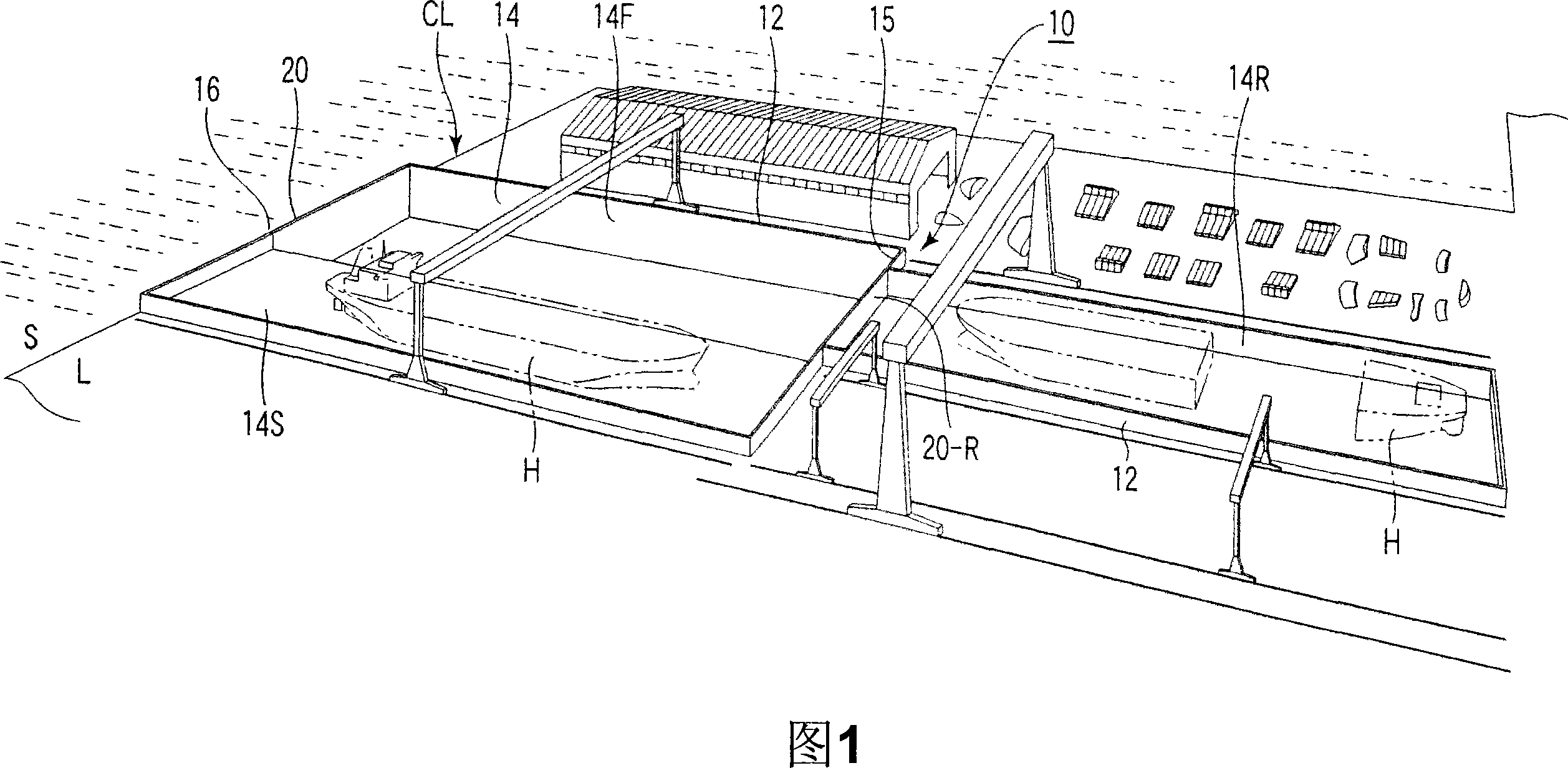

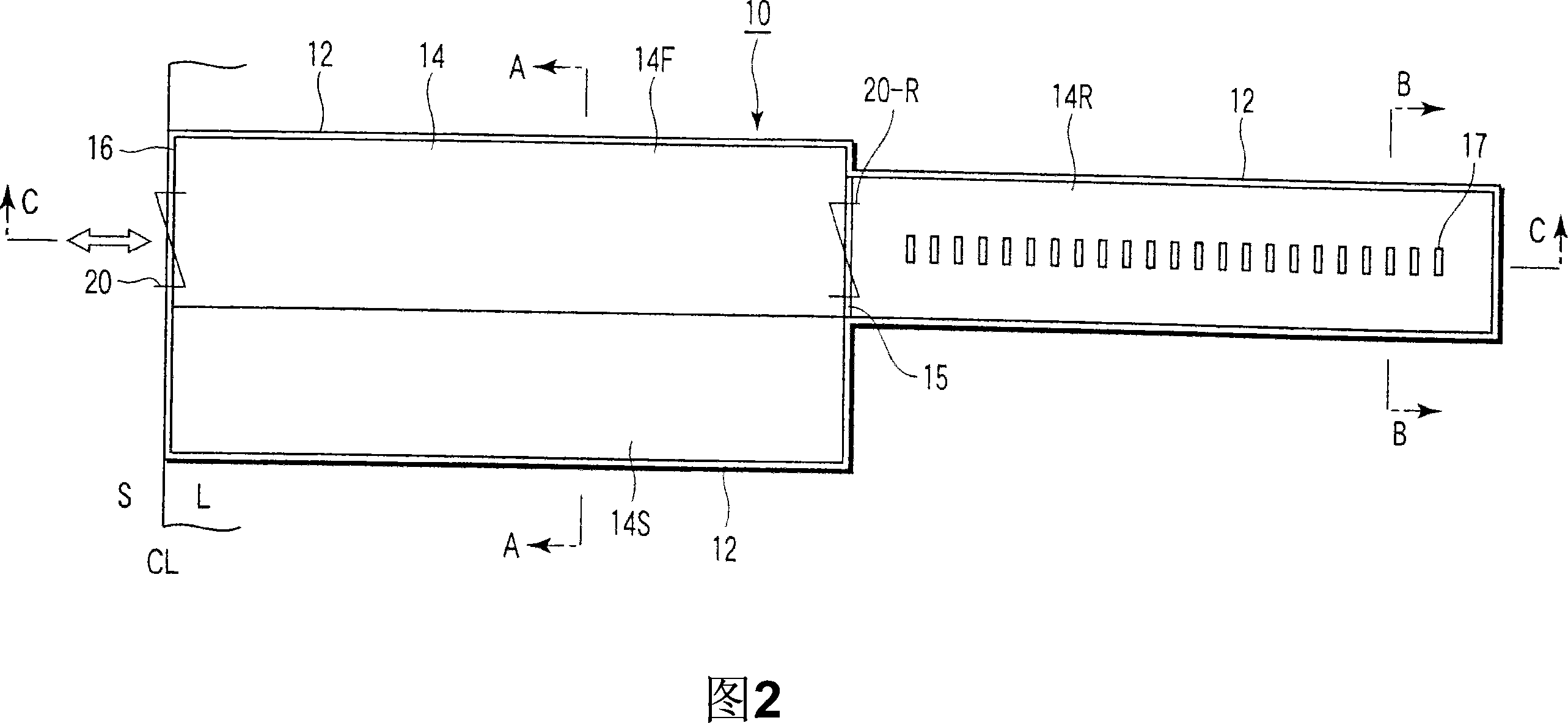

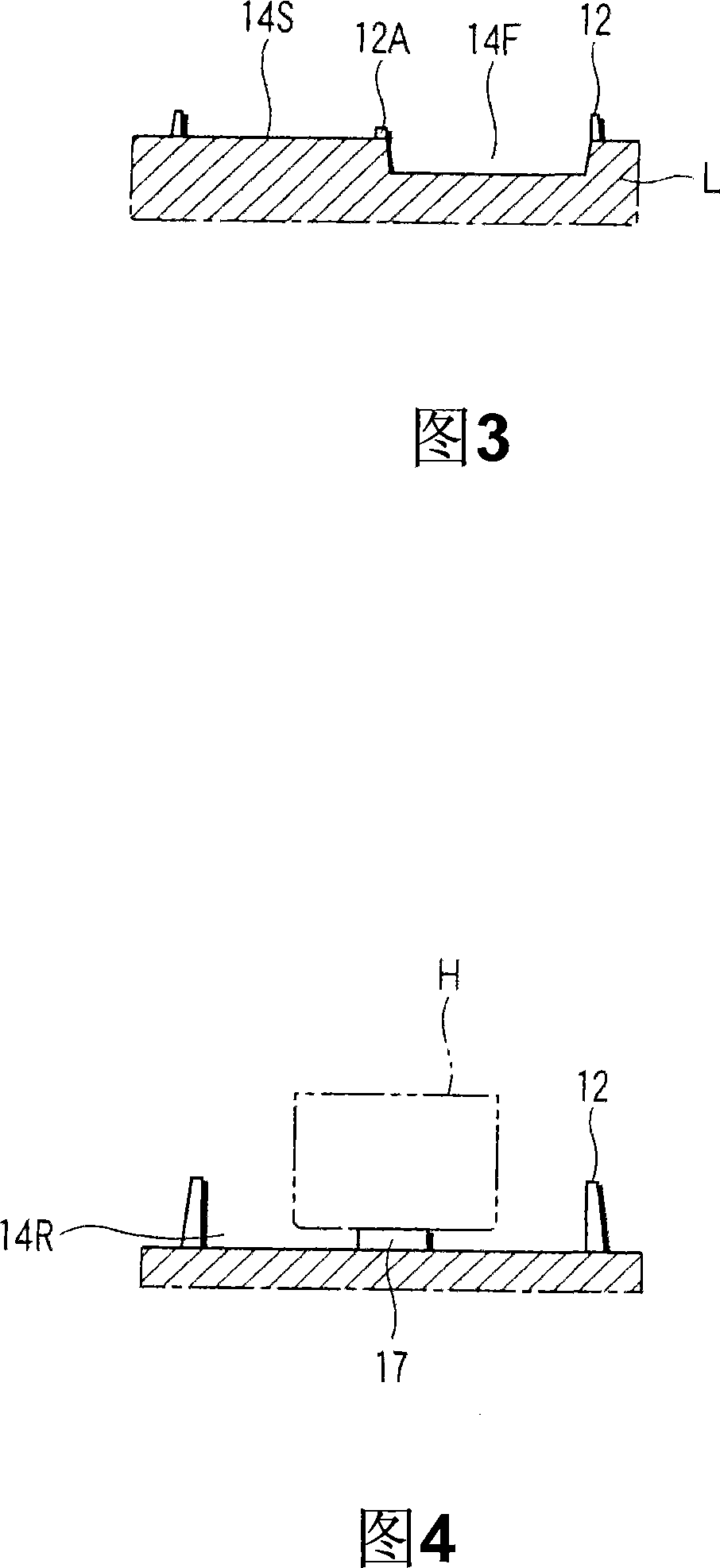

Boatbuilding system

A ship building system (10) or method includes a boatyard with preset depth. The boatyard (14) can sustain a certain water level with the external circumstance wall (12) and is provided with a in / out openable door (20) which can communicated with the coastal sea area (S). The water level in the dock basin (14) is adjusted to same at the coastal sea area (S) by injecting seawater to the boatyard (14) or discharging seawater from the boatyard (14) thereby allowing the movement of the watercraft (H). The lower subsequent boatyard (14-1 to 14-5) connected to the boatyard (14) is arranged and the constructing space is formed by controlling the water level in the subsequent boatyard (14-1 to 14-5).

Owner:MINAMINIPPON SHIPBUILDING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com