Equipment capable of industrially implementing entire dismantlement of waste and old circuit board component

A technology of waste circuit boards and components, applied in welding equipment, metal processing equipment, chemical instruments and methods, etc., can solve the problems of low efficiency of component removal, low heat utilization efficiency, uneven heating of components, etc., to ensure reliable The effect of reusing functions, high degree of automation, and improving disassembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

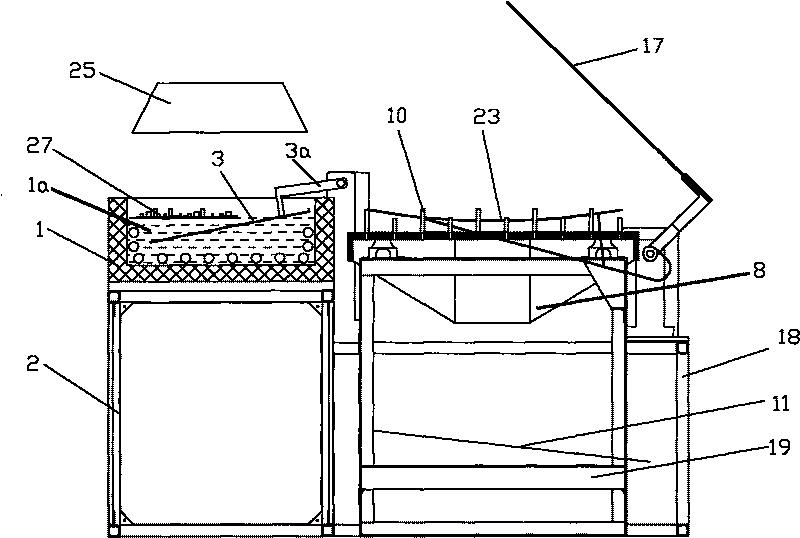

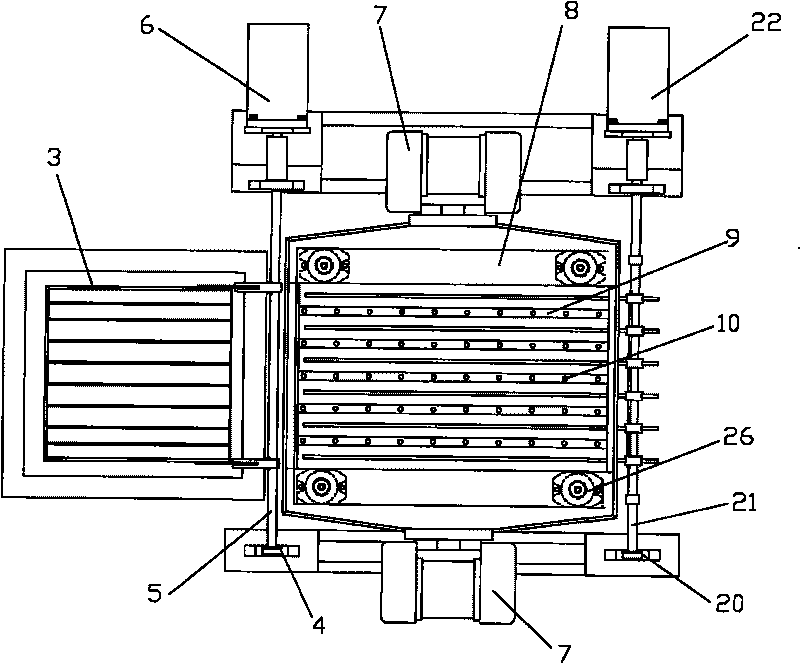

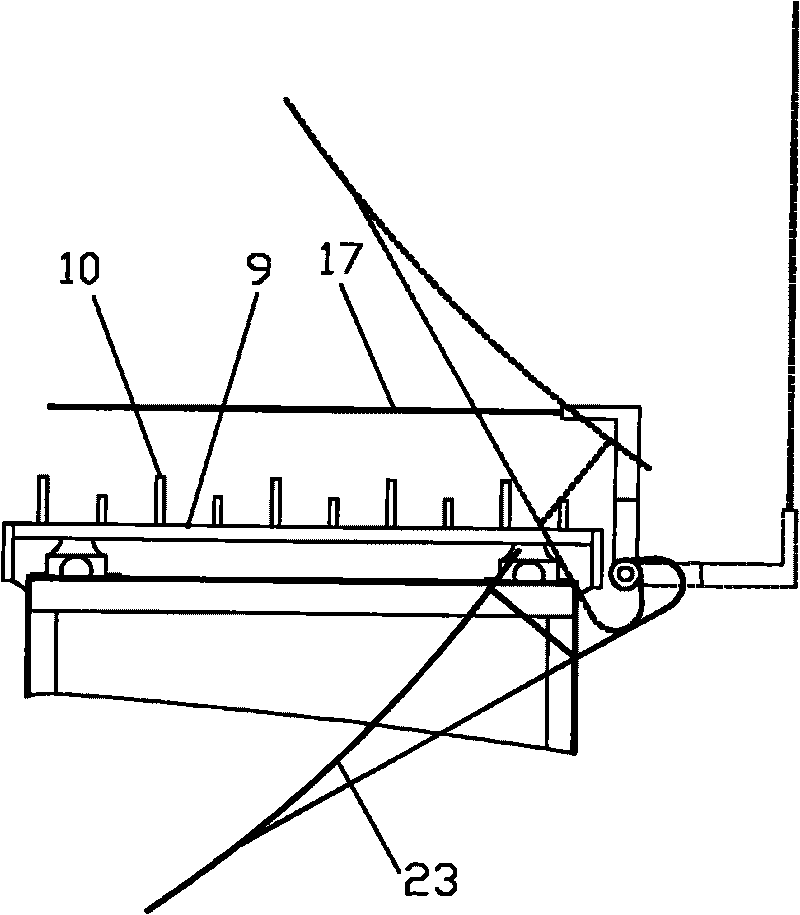

[0028] see figure 1 , figure 2 In this embodiment, the heating tank 1 and the vibrating table 8 are arranged side by side in the left and right sides. Above the heating tank 1 and the vibrating table 8, a reciprocating rotation in the vertical plane between the heating tank 1 and the vibrating table 8 is arranged, and The turning angle and speed of the turning arm 3a are adjustable, and the support frame 3 is fixedly connected to the turning arm 3a in the form of a cantilever. The height of the liquid level of the medium 1a, when the carrier 3 is turned over into the heating tank 1, the circuit board 27 to be processed floats on the liquid level of the heat-conducting medium 1a, in a heated state where the circuit board is on the bottom and the components are on top;

[0029] In specific implementation, the turning arm 3a is fixedly connected to the feeding shaft 5 in the form of a key connection, and the feeding motor 6 drives the feeding shaft 5 to rotate, thereby driving ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com