Device for assisting in laser drilling with rotating electric field

A technology that assists lasers and electromagnetic fields. It is used in laser welding equipment, welding/welding/cutting items, manufacturing tools, etc. It can solve the problem of not being able to increase the unit plasma energy, and achieve the effect of ensuring processing stability and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

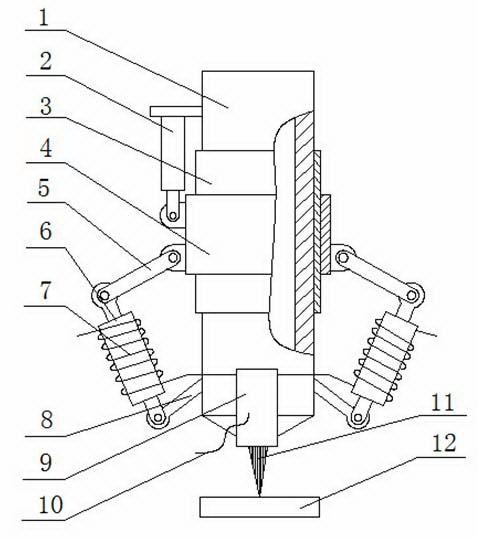

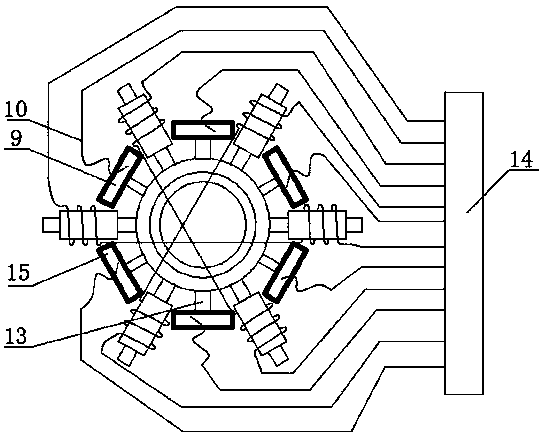

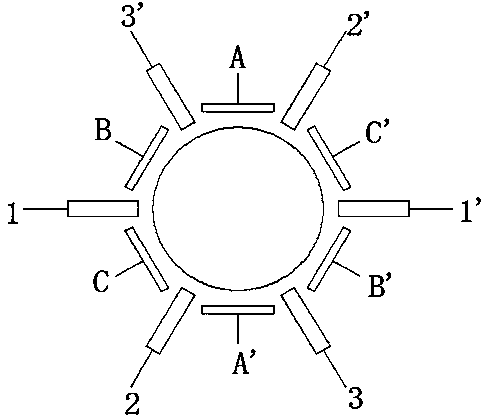

[0035] A device for rotating electromagnetic field assisted laser drilling using the present invention such as figure 1 and figure 2 The shown includes a laser head 1 and a rotating electromagnetic field generating device. The rotating electromagnetic field generating device is installed on the laser head 1 and is coaxial with the laser head; the rotating electromagnetic field generating device includes a hydraulic cylinder 2, a guide post 3, a guide sleeve 4, and three pairs of Connecting rod 5, three pairs of iron cores 6, three pairs of coil windings 7, three pairs of support rods 8, three pairs of electric boards 9, wires 10, controller 14 and three pairs of electric board supports 13; three pairs of iron cores 6 along the laser The head 1 is evenly distributed in the circumferential direction. The upper and lower ends of the iron core 6 are respectively hinged with one end of the connecting rod 5 and the support rod 8 fastened to the lower end of the laser head 1. The o...

Embodiment 2

[0049] see figure 1 and figure 2 , the device of this embodiment is the same as that of Embodiment 1, except that two pairs of connecting rods 5, two pairs of iron cores 6, two pairs of coil windings 7, two pairs of support rods 8, two pairs of electric plates 9 and two pairs of The electric plate supports 13, and the number of turns of the coil winding 7 is 600 turns.

[0050] The controller 14 adjusts the excitation current to 1.8A, the voltage between the plates to 60V, and the current-voltage change frequency to 100Hz, so that the rotating electromagnetic field generating device generates a rotating electromagnetic field with a certain intensity and frequency; at the same time, by adjusting the extension length of the hydraulic cylinder 2 , to drive the connecting rod 5 and the iron core 6 to rotate, so that the angle between the two opposing coil windings 7 is 120°.

Embodiment 3

[0052] see figure 1 and figure 2 , the device of this embodiment is the same as that of Embodiment 1, except that eight pairs of connecting rods 5, eight pairs of iron cores 6, eight pairs of coil windings 7, eight pairs of support rods 8, eight pairs of electric plates 9 and eight pairs of The electric plate supports 13, and the number of turns of the coil winding 7 is 700 turns.

[0053] The controller 14 adjusts the excitation current to 2A, the voltage between the plates to 100V, and the current-voltage change frequency to 200Hz, so that the rotating electromagnetic field generating device generates a rotating electromagnetic field with a certain intensity and frequency; at the same time, by adjusting the extension length of the hydraulic cylinder 2, Drive the connecting rod 5 and the iron core 6 to rotate, so that the included angle between the two opposing coil windings 7 is 90°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com