A long-span beam-type positioning frame suitable for ribs

A positioning frame and positioning frame technology, applied in the direction of manufacturing tools, workpiece clamping devices, etc., can solve the problems of scrapped parts, poor economy, high cost, etc., to achieve the effect of ensuring positioning accuracy and saving manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

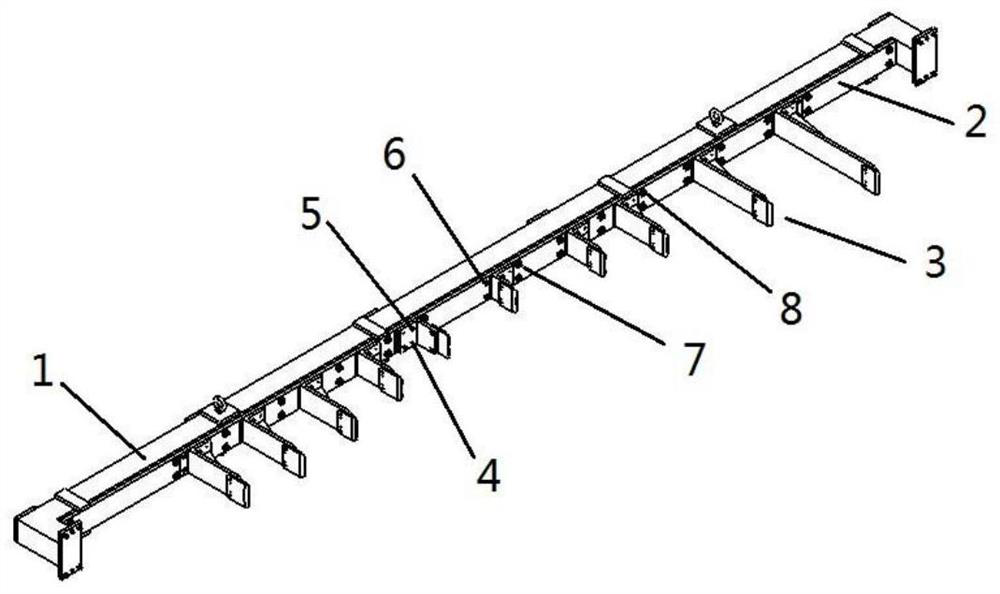

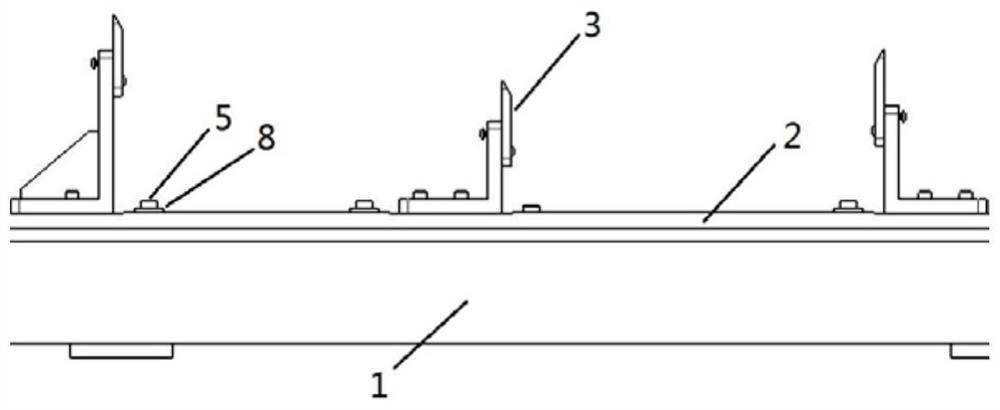

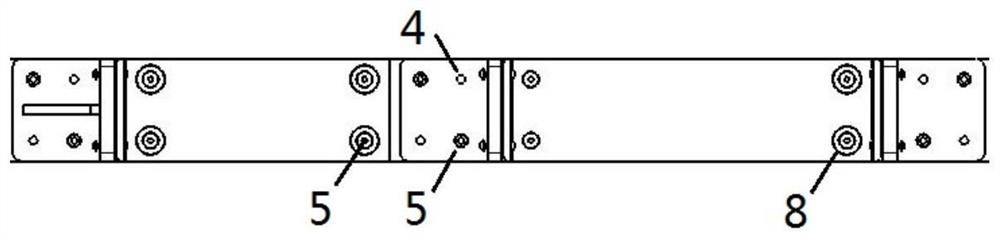

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings. Such as figure 1 As shown, the device includes an upper positioning block 1, a lower positioning block 2 and a mold support 3. The upper positioning block is a C-shaped metal module with chamfers on the inner surface, and the lower positioning block is a T-shaped metal module with chamfers on the outer surface. There is a cooperative relationship between the chamfer of the upper positioning block and the chamfering of the lower positioning block. The inner surface of the upper positioning block matches the outer surface of the lower positioning block. Corresponding to the groove, the lower positioning block is installed in the groove through the positioning block and the round rod 4, so that the lower positioning block rotates around the round rod between 0 and 90 degrees. When the device is applied to the combined mold, the upper positioning block It is fixed on each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com