Patents

Literature

141results about How to "Guaranteed processing stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

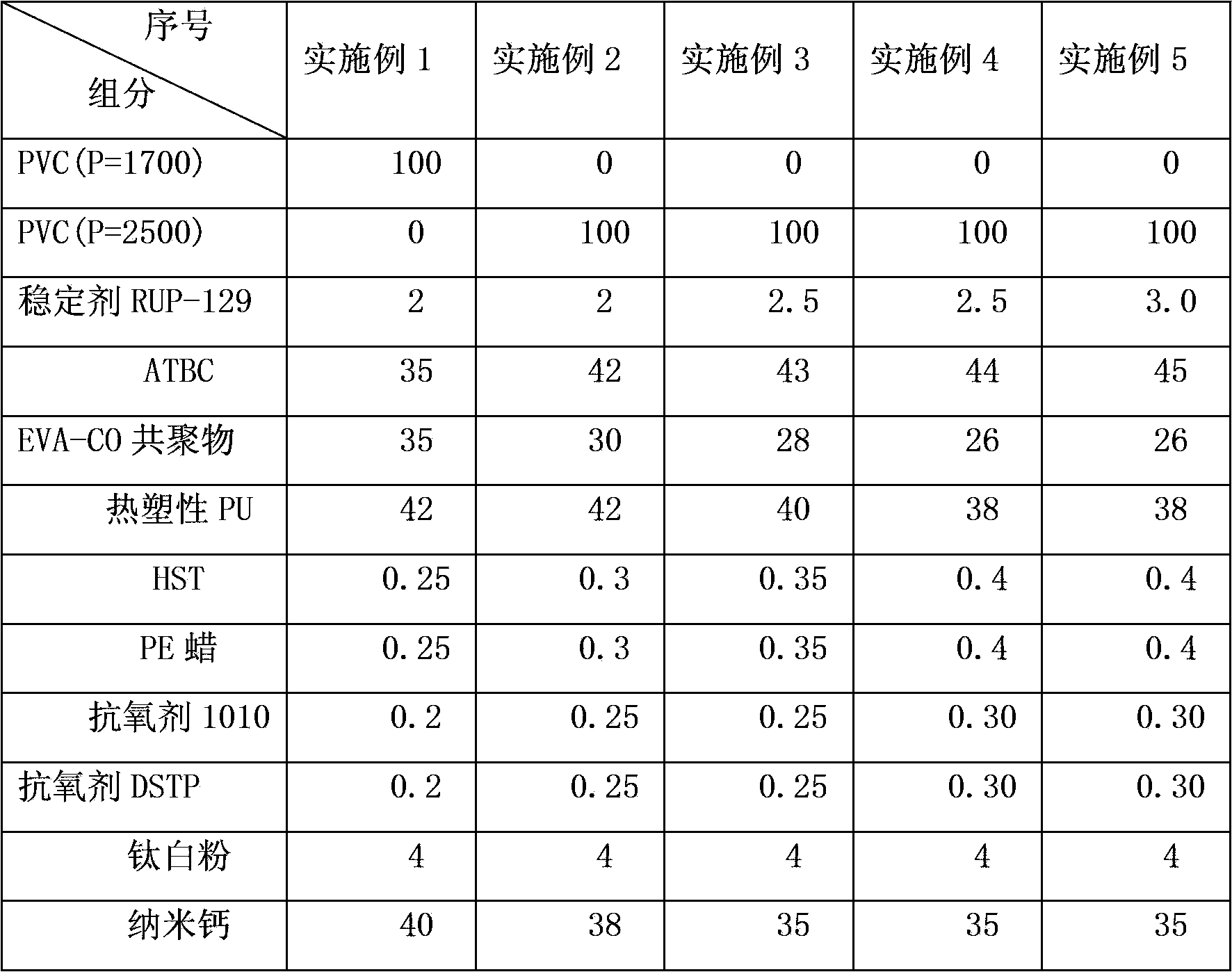

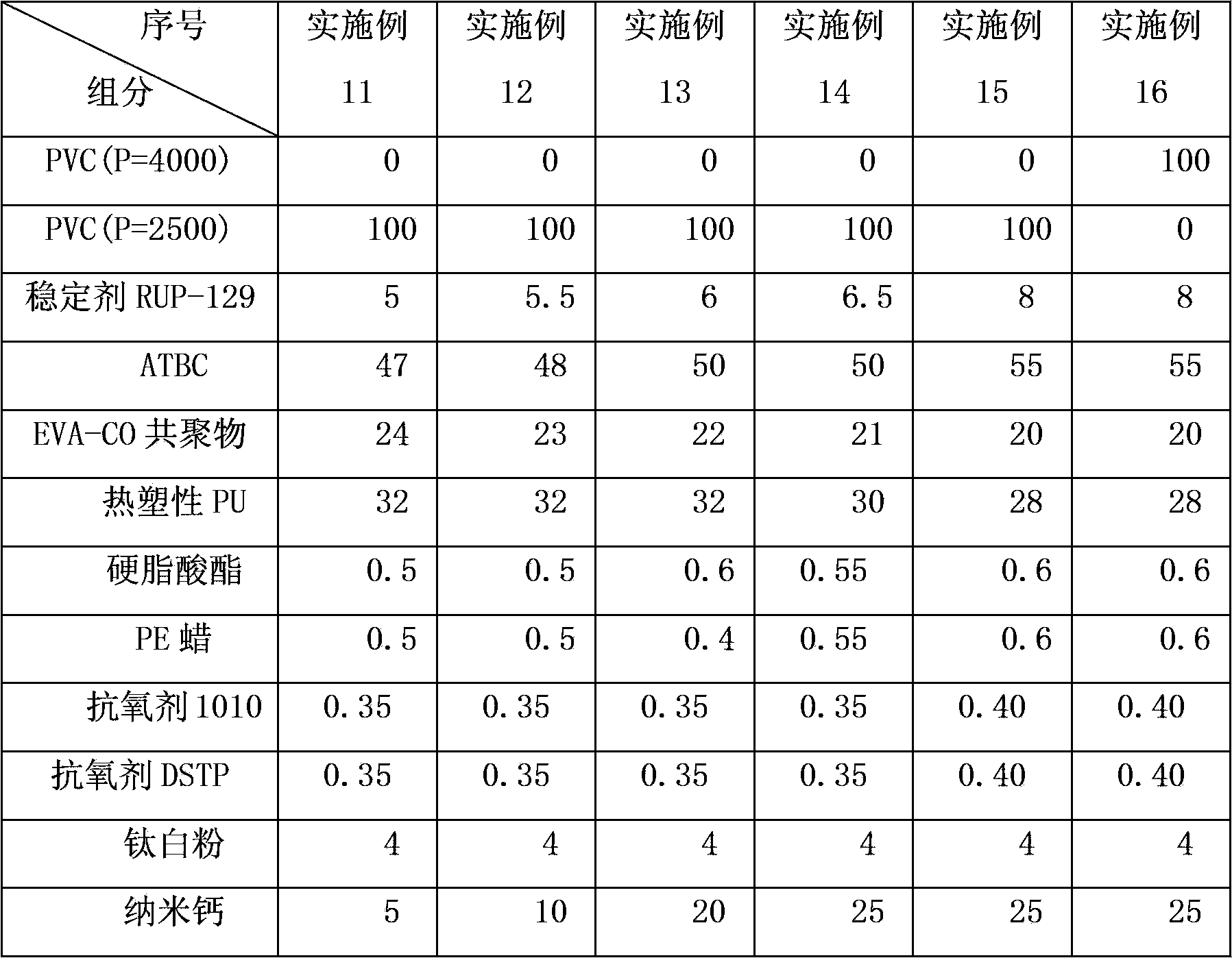

Polyvinyl chloride sealing strip composition for refrigerator

ActiveCN103524917AImprove mechanical propertiesImprove processing fluidityOther chemical processesPlasticizerPolyvinyl chloride

The invention discloses a polyvinyl chloride sealing strip composition for a refrigerator, belongs to the field of processing and application of macromolecular materials, and mainly relates to a polyvinyl chloride sealing strip composition for a refrigerator. The polyvinyl chloride sealing strip composition is prepared from the following components in parts by weight: 100 parts of polyvinyl chloride, 35-55 parts of a plasticizer, 20-35 parts of modified ethylene vinyl acetate copolymer, 28-42 parts of a thermoplastic polyurethane elastomer, 2-8 parts of a thermal stabilizer, 0.5-1.2 parts of a lubricant, 0.4-0.8 part of an antioxidant and 9-44 parts of a filling agent. A polyvinyl chloride sealing strip, produced from the polyvinyl chloride sealing strip composition, for a refrigerator is cold-resistant and oil-resistant, has good elastic resilience and durability, and is of great significance in energy conservation and consumption reduction.

Owner:CHINA PETROLEUM & CHEM CORP

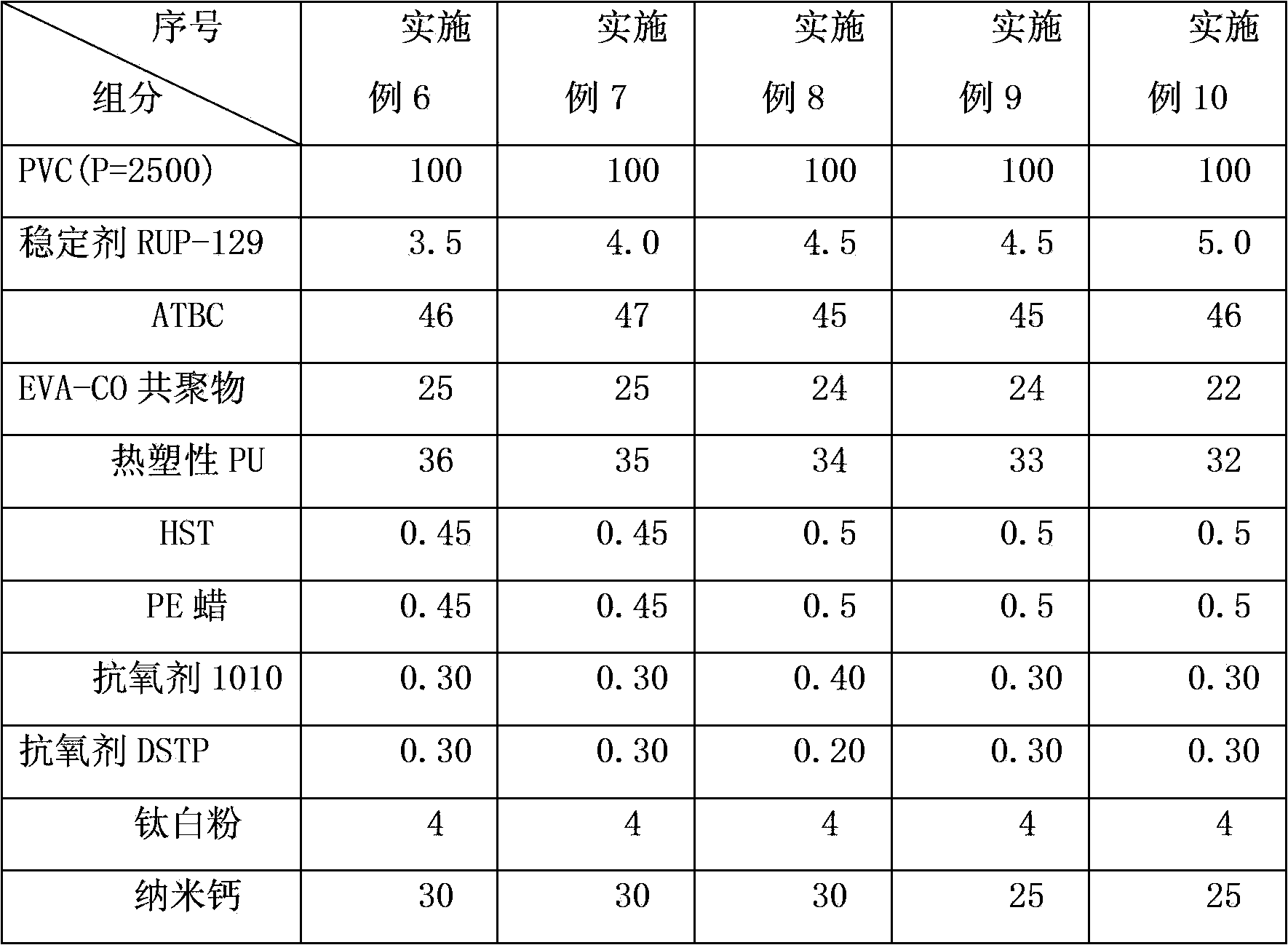

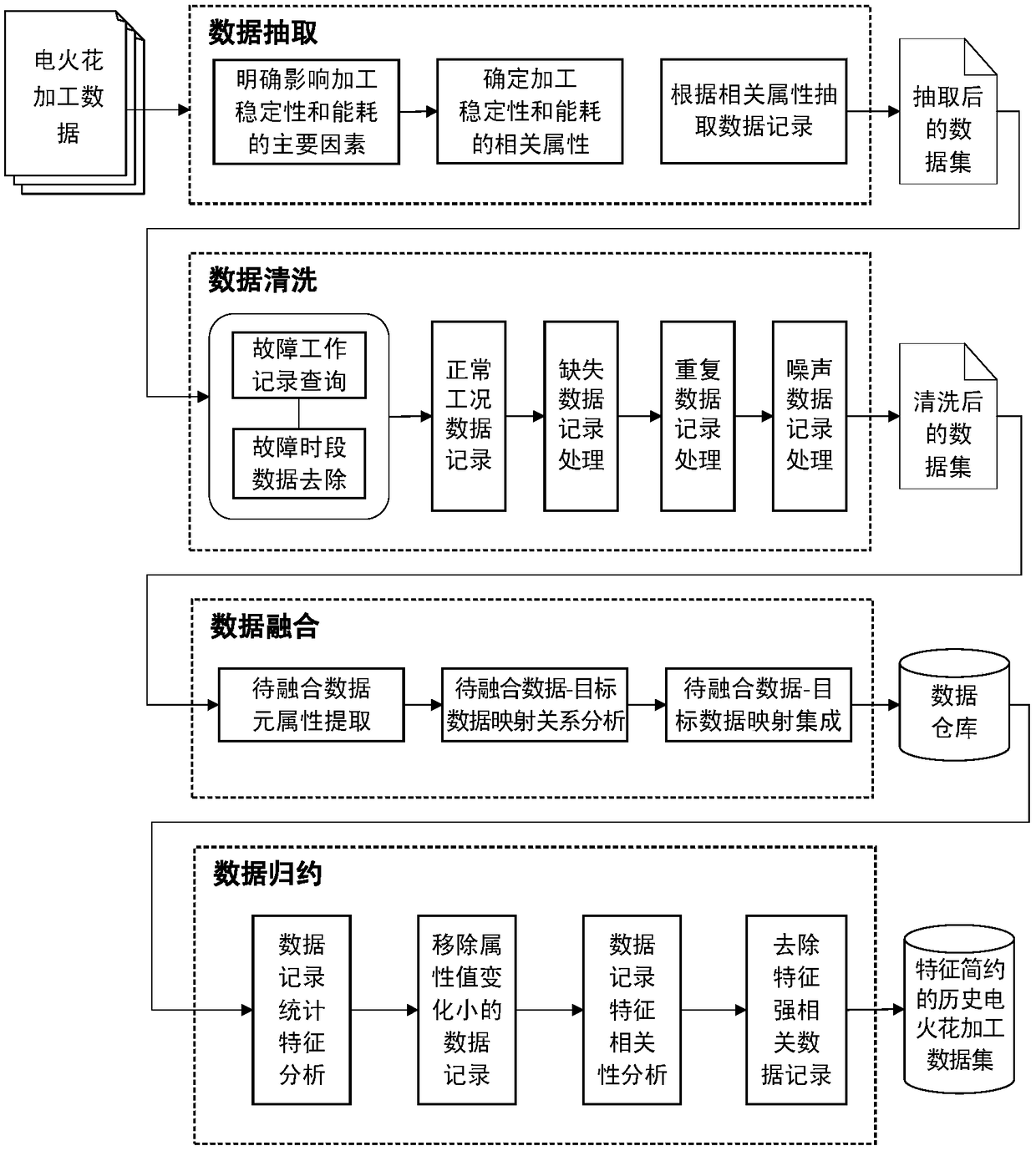

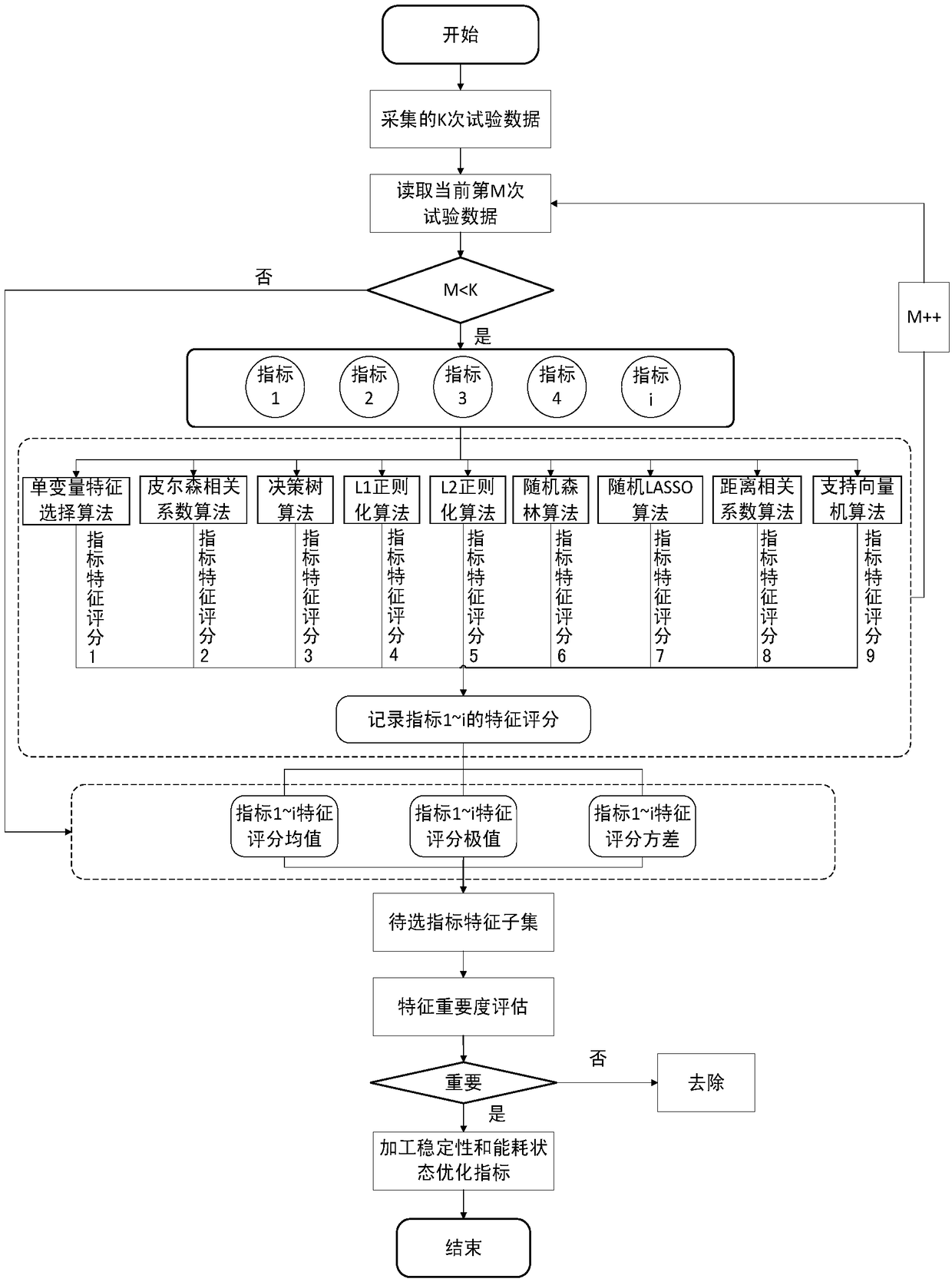

Electric spark machining stability and energy consumption state optimization decision-making system and method based on deep learning

ActiveCN109396576AImprove qualityReduce processing costsDatabase management systemsForecastingScreening methodMulti targeting

The invention discloses an electric spark machining stability and energy consumption state optimization decision-making platform based on deep learning. A characteristic screening method is used for excavating and analyzing electric spark machining data, and machining stability and energy consumption state optimization indexes are obtained; a K-medoids algorithm is used for clustering the optimization indexes, the machining stability and energy consumption state distribution condition is obtained, and a stable machining state database and an energy-saving discharge state database are built; historical electric spark machining data are used for training LSTM recurrent neural network deep learning to obtain the real-time electric spark machining state predication value, in combination with statistics characteristic value of the optimization indexes, when it is judged that the current state is the non-normal machining state, the machining stability and energy consumption state is subjected to multi-target optimization, the stability-energy saving machining state comprehensive optimal target value is obtained, and the current machining parameter value is regulated. On the basis of thedeep learning, the stability-energy saving comprehensive optimal electric spark machining parameter optimization decision-making method is given, and electric spark machining runs in the stable and energy-saving state.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

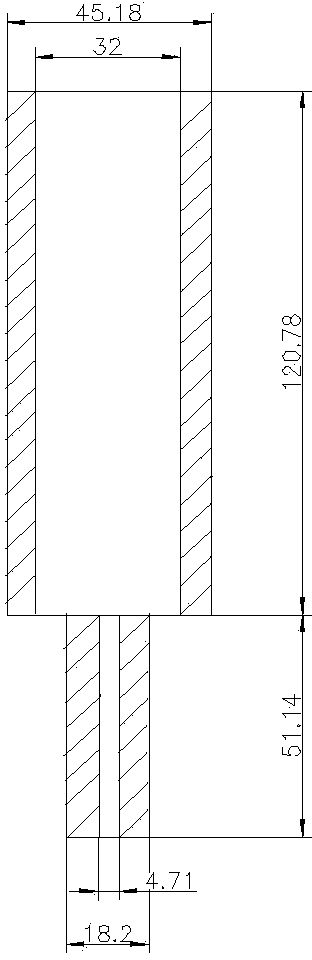

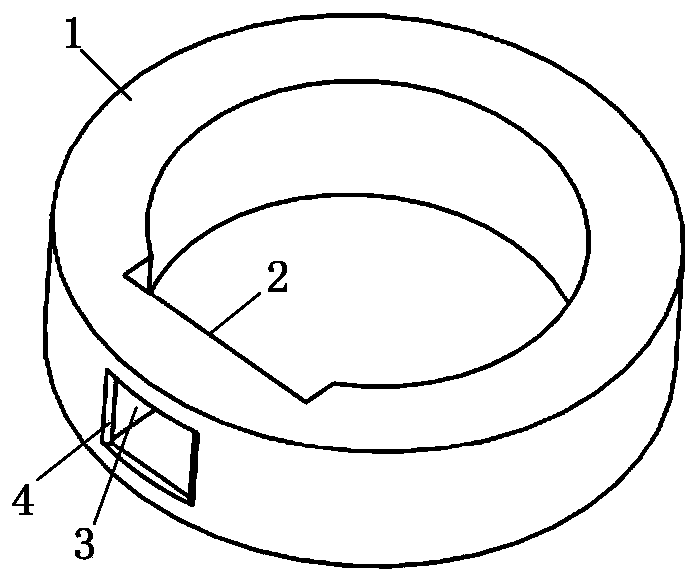

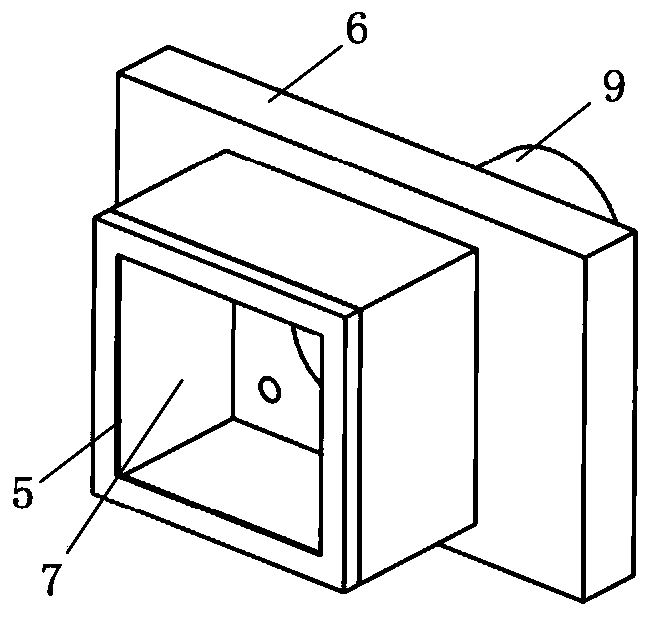

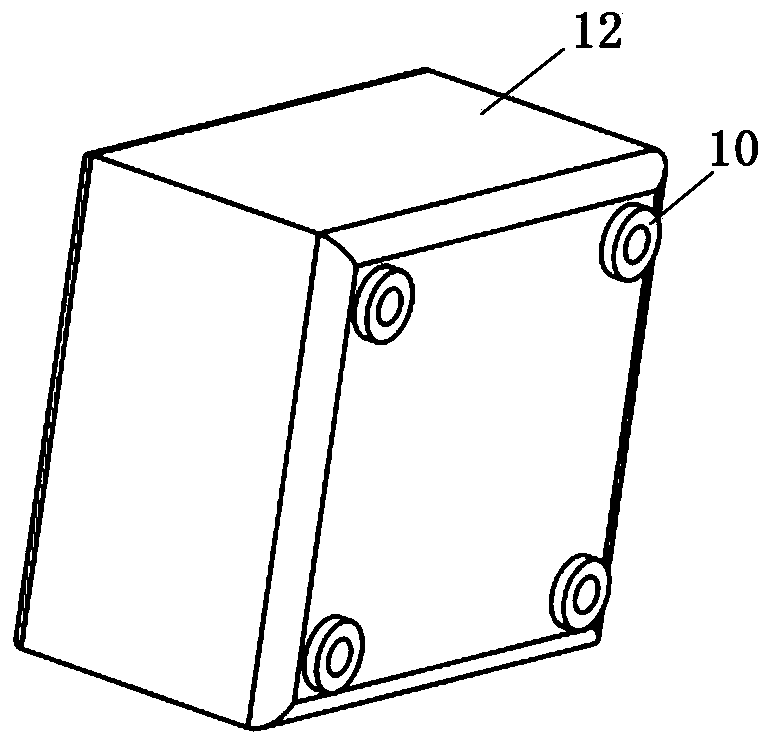

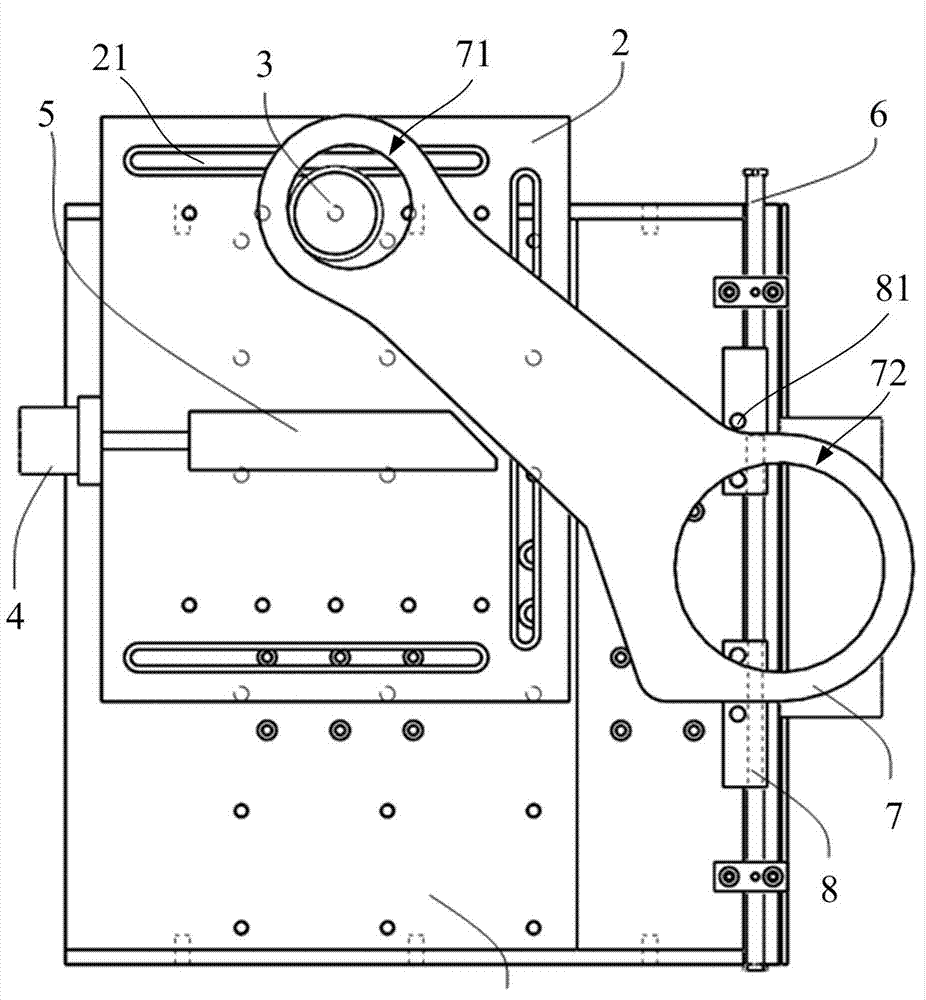

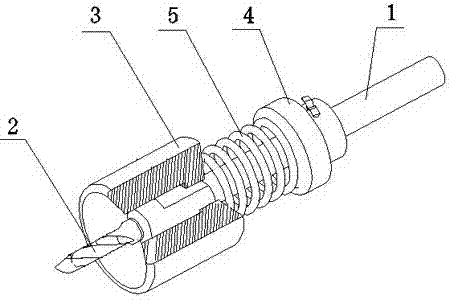

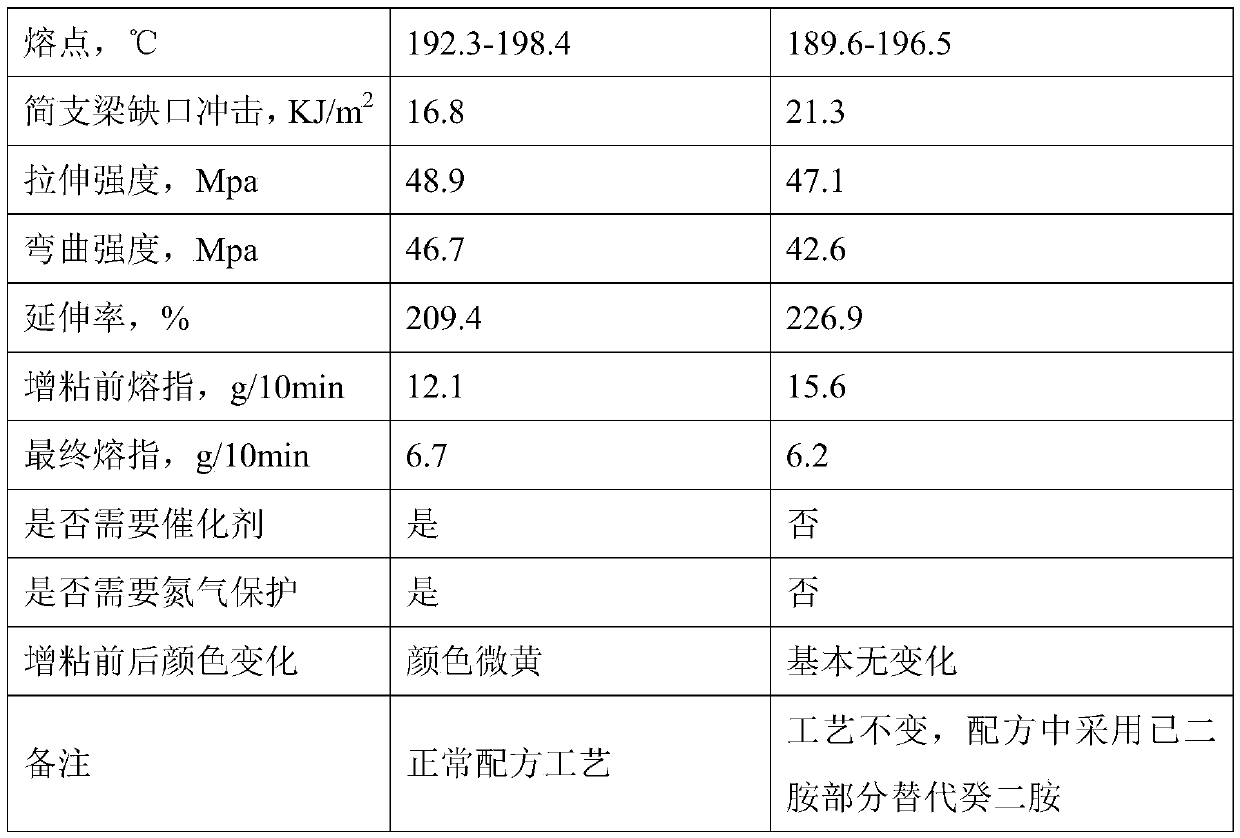

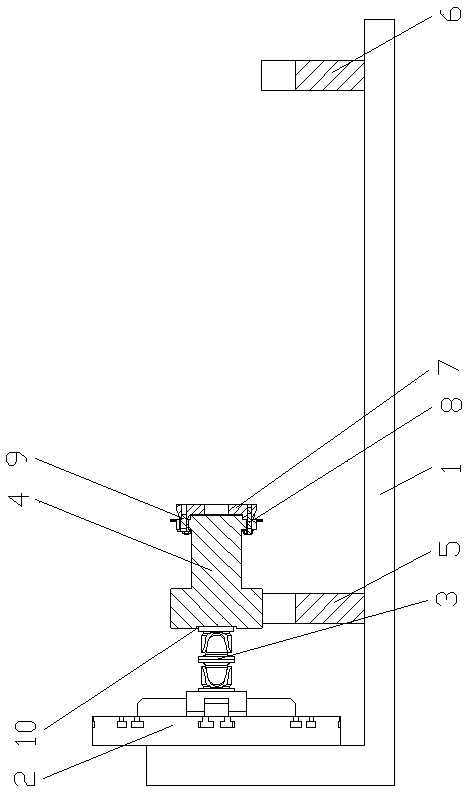

Rounding and sizing processing mould for pipe fittings

The invention relates to a rounding and sizing processing mould for pipe fittings. The rounding and sizing processing mould comprises a cap, an expanding core, mould pieces, a cover plate, a mould base and an expanding core base, wherein a ring-shaped cavity is arranged on the top of the mould base; a mounting slot is formed in the bottom of the mould base; through holes are formed inside the cap and the expanding core; a drawbar is arranged in the through holes; an oil injecting hole is formed in the top of the drawbar; a regulating gasket is arranged in front of the expanding core base and the expanding core; edges of cross sections of the plurality of mould pieces are arc-shaped, and are on the same circle D; a first elastic ring is arranged between the outer walls of the mould pieces and the mould base; the inner walls of the mould pieces are in clearance fit with conical surfaces of the expanding core; second limiting slots are formed in the inner walls of the mould pieces; limiting slide blocks are arranged between the second limiting slots and first limiting slots; and second elastic rings are arranged in grooves of the plurality of the mould pieces. The rounding and sizing processing mould is precise in structure, is reasonable in design, is convenient to dismount and maintain, can be used for simultaneously carrying out sizing, rounding and processing on pipe fittings, is stable in sizing, rounding and processing quality, is convenient and quick in oil injecting and lubricating, and is beneficial for improving processing efficiency and prolonging the service life of the mould.

Owner:ZHENJIANG HENGYUAN AUTOMOBILE COMPONENTS

Environmental self-lubricating wear-resistant copper alloy and preparation method thereof

The invention discloses environmental self-lubricating wear-resistant copper alloy, comprising the following components by mass percent: 5-13% of Sn, 2-9% of Ni and / or Co, 2-11% of Bi, 0.05-0.3% of Zr, 0.05-0.5% of RE, the balance of Cu and inevitable impurities, wherein the content of the impurity is smaller than or equal to 0.3%, the RE is Ce-La misch metal. Meanwhile, the preparation method of the environmental self-lubricating wear-resistant copper alloy is disclosed. The environmental self-lubricating wear-resistant copper alloy has the advantages that the conventional wear-resistant copper alloy containing lead is replaced, and the environmental self-lubricating wear-resistant copper alloy is the wear-resistant copper alloy material with environment-friendly and self-lubricating effects. The alloy solidification molding process is interfered by adopting a strong pulsed electromagnetic physical field in the manufacturing process, the as-cast segregation and loosening of the obtained environmental self-lubricating wear-resistant copper alloy are significantly reduced, the alloy is fine and even in as-cast structure, and high in density, the hardness of the molded casting is greater than 70HB, the tensile strength is greater than 230MPa, and the alloy density is greater than 8.7g / cm<3>. The environmental self-lubricating wear-resistant copper alloy has good overall performance, the preparation method is good in stability, and low in cost, the preparation process is green and free of pollution, and industrialization is easily achieved.

Owner:镇江金鑫有色合金有限公司 +2

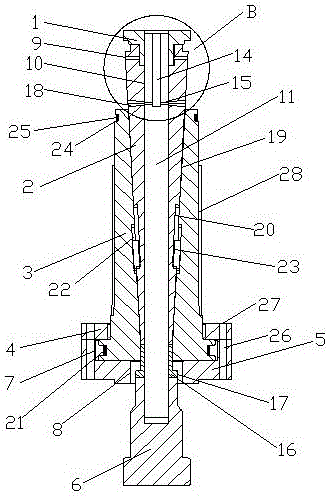

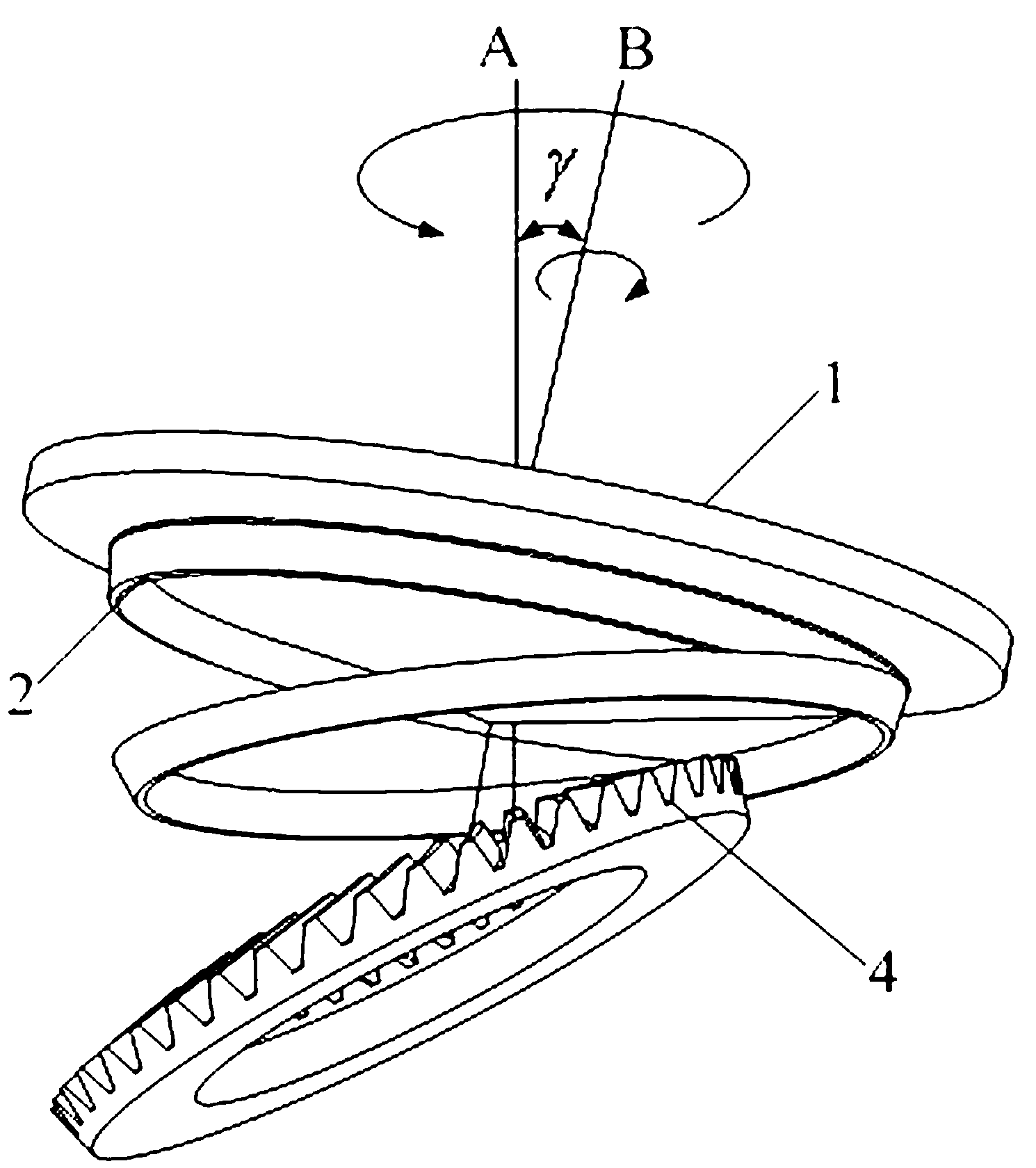

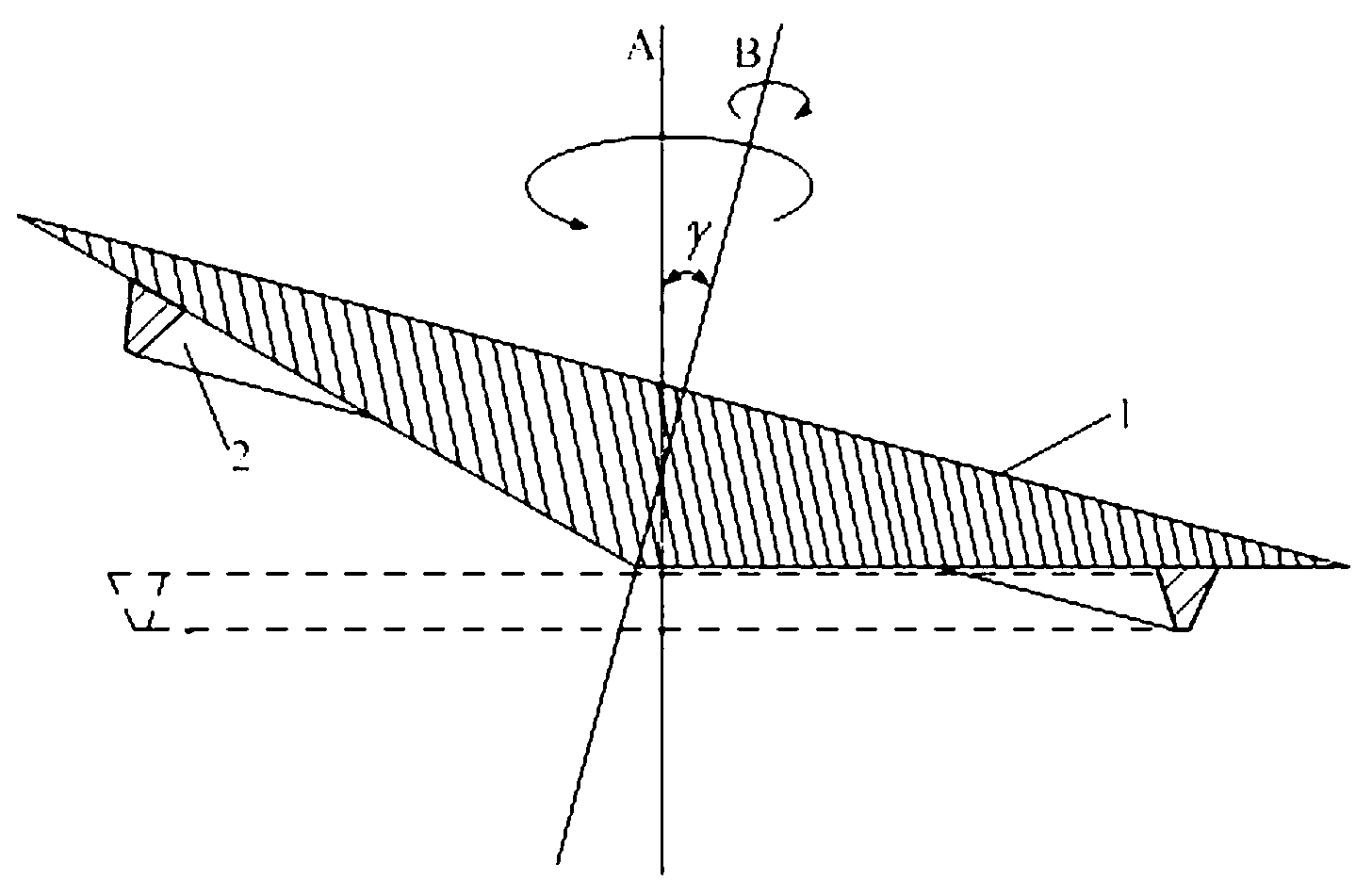

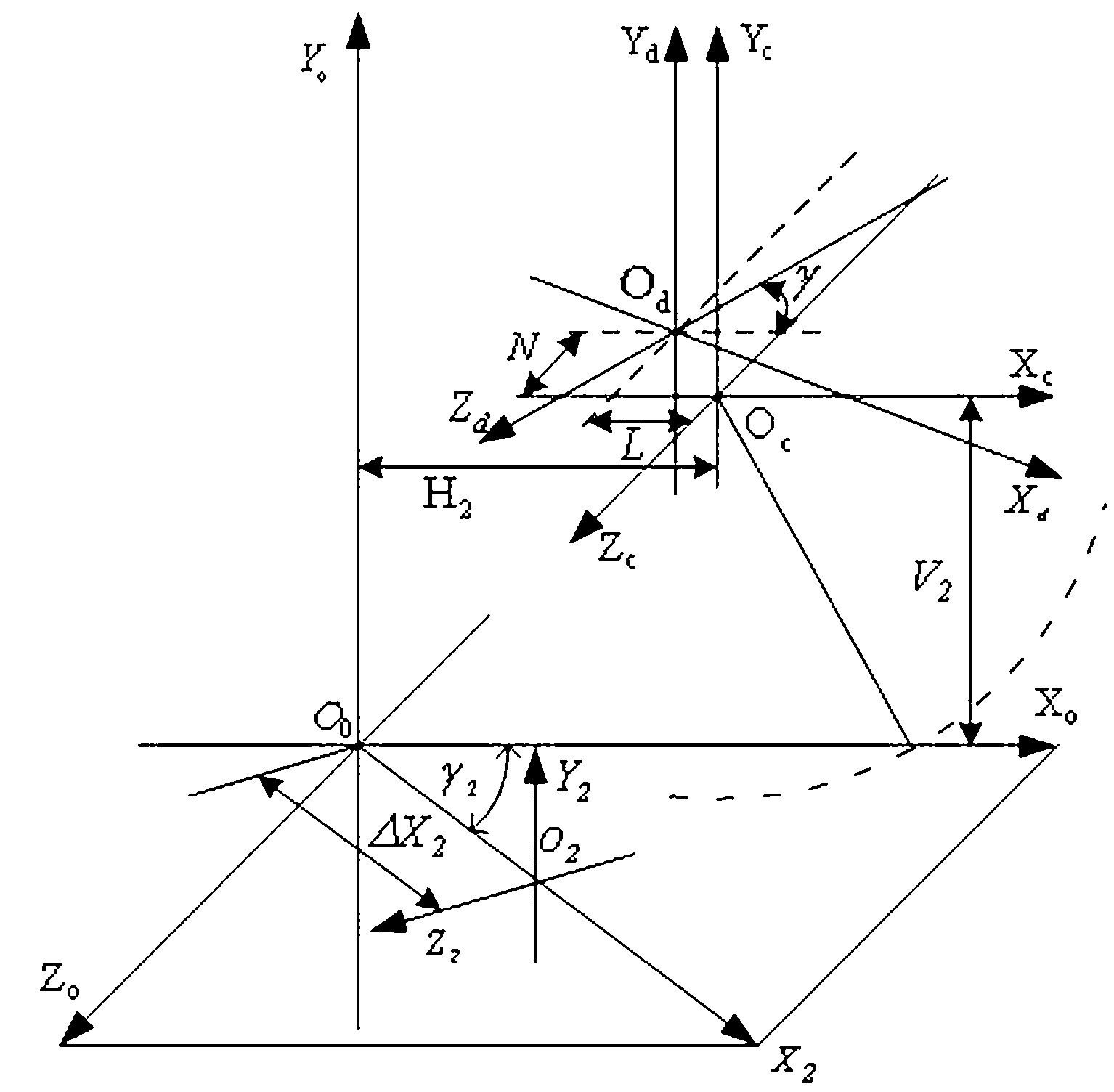

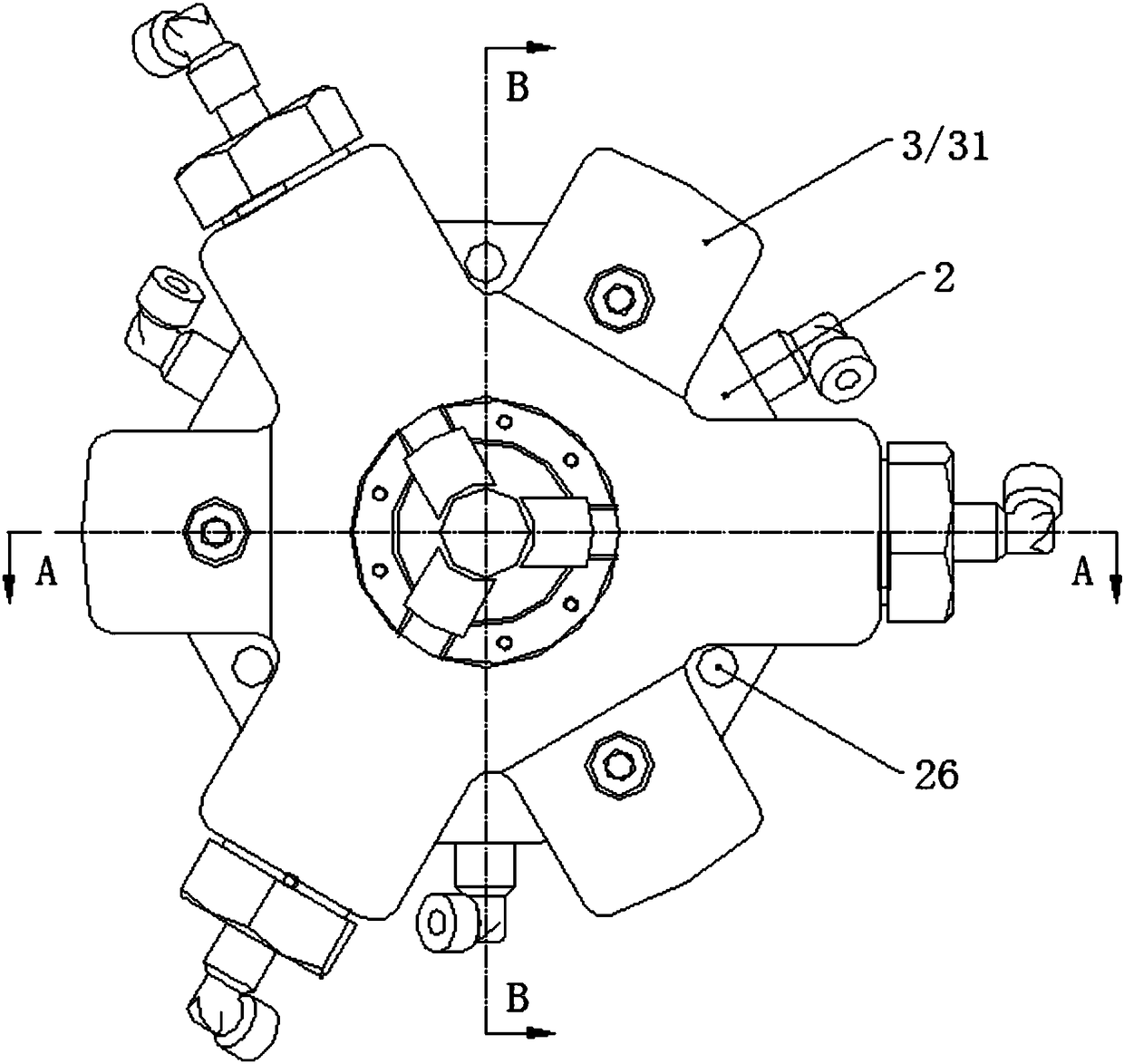

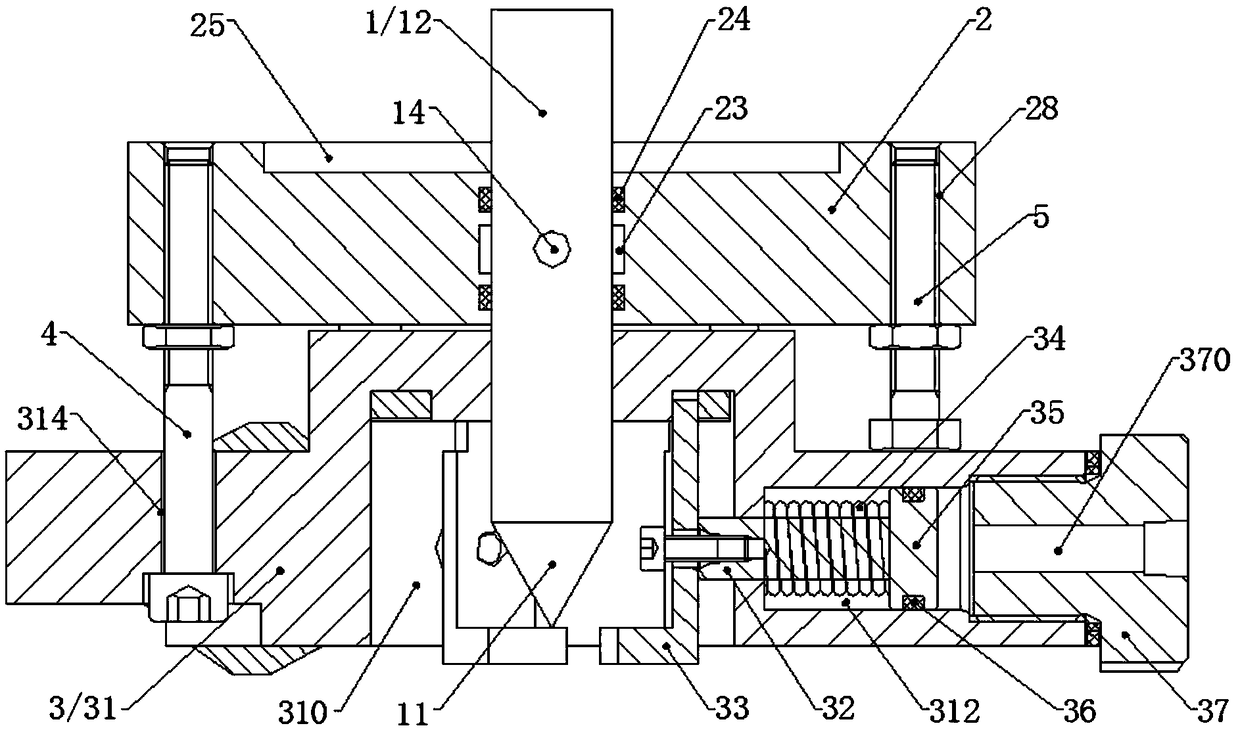

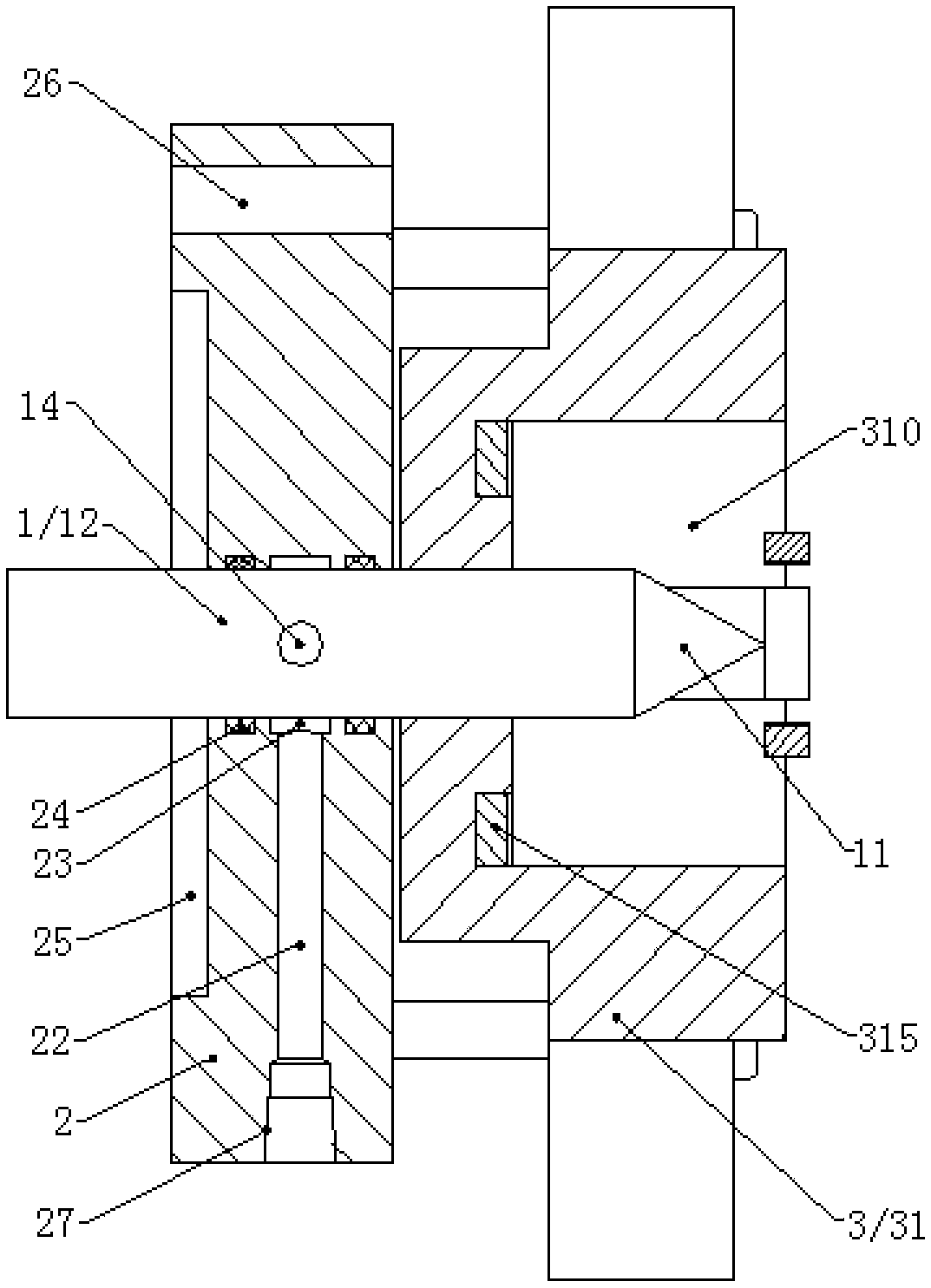

Hypoid gear rotary forging processing device and method for processing hypoid gear

Owner:HENAN UNIV OF SCI & TECH

Joint glue for corner part of sealing strip for car door and preparation method

The invention discloses joint glue for a corner part of a sealing strip for a car door and a preparation method. The joint glue adopts the technical scheme that the joint glue is prepared by the following materials in parts by mass: 100-160 parts of ethylene propylene diene terpolymer rubber K4869, 20-50 parts of ethylene propylene diene terpolymer rubber 4045M, 3-8 parts of zinc oxide, 1-3 parts of stearic acid, 1-3 parts of dispersant L-24, 2-5 parts of polyethylene glycol, 60-100 parts of FEF (Fast Extruding Furnace) level carbon black N550, 20-80 parts of light calcium carbonate, 40-70 parts of paraffin oil, 3-8 parts of moisture absorbent, 0.1-0.5 parts of anti-scorching agent, 0.8-1.6 parts of sulfur and 1.7-4.7 parts of accelerant. The mooney viscosity of the joint glue is increased to be 16; the tensile strength is improved to be 12.3MPa; a shearing force during mixing is increased obviously; the dispersity of a packing is improved; skidding during the mixing of the glue is precluded; and the production efficiency is improved.

Owner:GREAT WALL MOTOR CO LTD

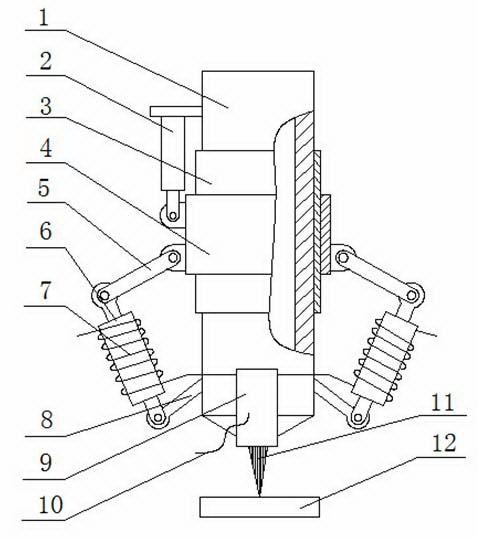

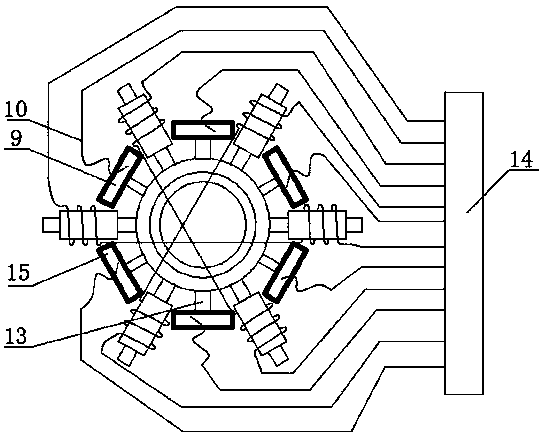

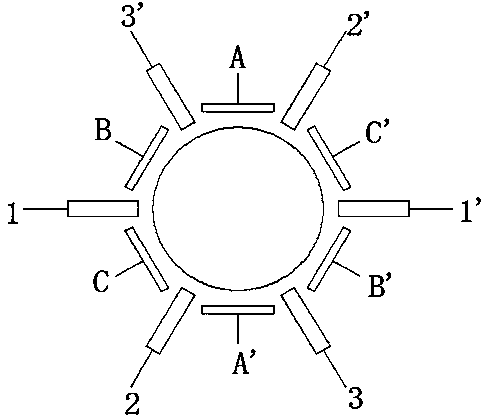

Device for assisting in laser drilling with rotating electric field

ActiveCN104043905ADoes not affect positional accuracyGuaranteed processing stabilityWelding/soldering/cutting articlesLaser beam welding apparatusHydraulic cylinderEngineering

The invention discloses a device for assisting in laser drilling with a rotating electric field. N pairs of iron cores are distributed along the circumference of a laser head uniformly at intervals, the upper and lower ends of each iron core are respectively hinged to a connecting rod and a supporting rod fastened at the lower end of the laser head, the other end of each connecting rod is hinged to a guide sleeve, the guide sleeve sleeves the outer wall of a guide pillar coaxially fixed on the laser head, the upper end of the guide sleeve is connected with a hydraulic cylinder fixed on the upper end of the laser head, the guide sleeve can move up and down along the guide pillar, N pairs of coil windings respectively sleeve the N pairs of iron cores and are connected with a controller, N pairs of electroplates are respectively fixed on the lower end of the laser head through N pairs of electroplate supports, the N pairs of electroplates are located on the same plane and each electroplate is located at the central position of an included angle formed by two corresponding adjacent coil windings, and the electroplates of which the surfaces are coated with insulated layers are connected with the controller through conducting wires. According to the device, the drilling efficiency can be improved, and the device is applicable to laser drilling processing on all materials.

Owner:JIANGSU UNIV

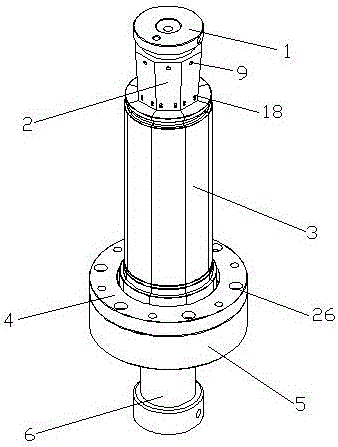

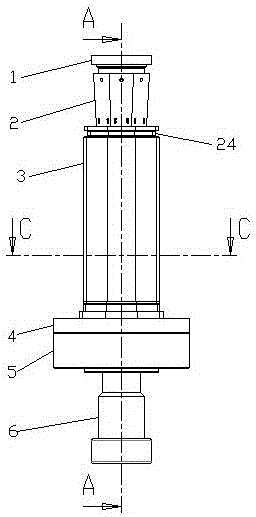

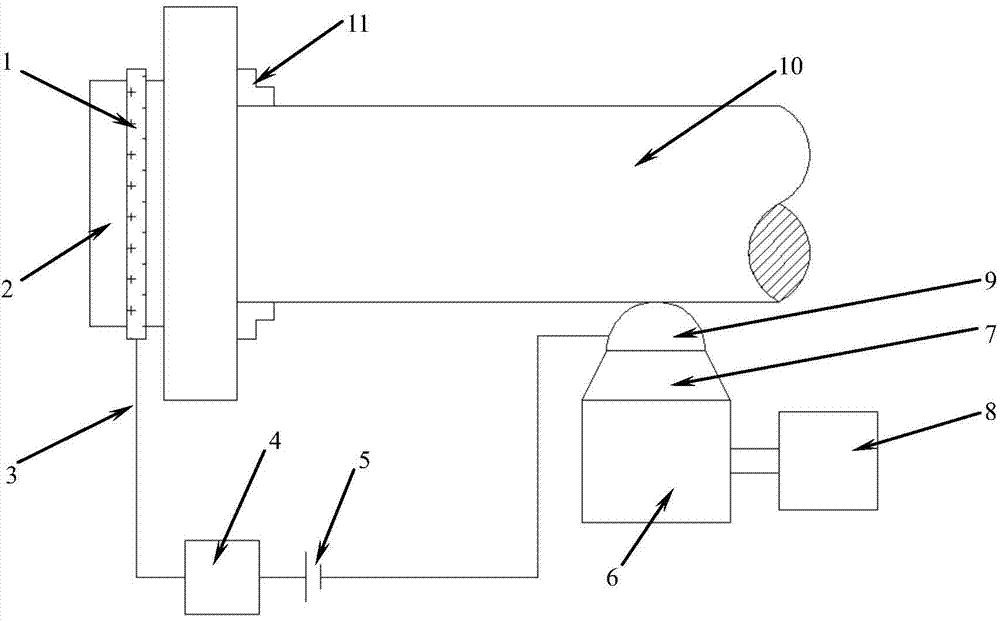

Ultrasonic-vibration surface-enhanced and finishing processing device with electric-contact heating assistance

The invention discloses an ultrasonic-vibration surface-enhanced and finishing processing device with electric-contact heating assistance. The ultrasonic-vibration surface-enhanced and finishing processing device comprises an electric brush, a main shaft, a guide line, an arc-extinguishing device, a power supply, an ultrasonic-vibration generation device, a workpiece and a chuck, wherein a knife head of the ultrasonic generation device, the power supply, the arc-extinguishing device, the electric brush sheathed on the main shaft, the main shaft, the chuck and the workpiece are connected in sequence and in series to form a conducting loop; current generated in the conducting loop is utilized to enable a material of the contact part between the surface of the workpiece and the knife head to generate joule heat for instantaneous warming and softening, and by combination of ultrasonic vibration, finishing processing, surface enhancement, fine-grain enhancement and residual stress elimination are realized. The invention also discloses an ultrasonic-vibration surface-enhanced and finishing processing method with the electric-contact heating assistance utilizing the device. The ultrasonic-vibration surface-enhanced and finishing processing device and method disclosed by the invention have the advantages that the structure is simple, the precise finishing processing and surface enhancement of various conducting materials can be realized, the quality of the processed surface can be improved, the surface roughness is reduced, the surface residual stress can be eliminated, and the ultrasonic vibration also can play a role in enhancing fine grains of the material of the surface of the workpiece.

Owner:SHANDONG UNIV

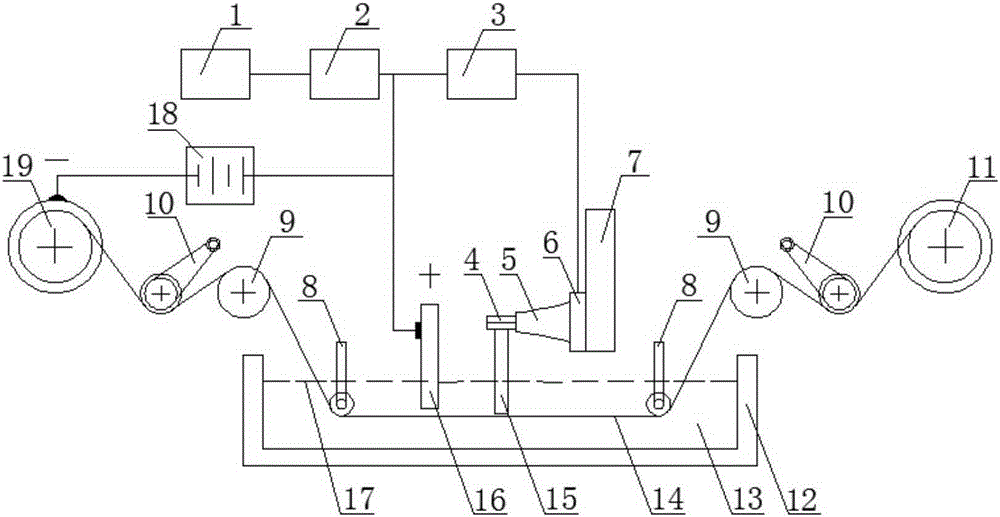

Ultrasonic vibration auxiliary micro-electrochemical electrical discharge wire-cutting machining method and device

The invention belongs to the field of combined micro-machining and relates to an ultrasonic vibration auxiliary micro-electrochemical electrical discharge wire-cutting machining method and device for non-conductive hard and brittle material machining. The machining method comprises the steps that ultrasonic vibration is utilized for exciting a workpiece in the axial direction of an electrode wire, the electrode wire and an auxiliary electrode are subjected to an electrolytic reaction in an electrolytic solution so that hydrogen gas is separated out around the electrode wire, and then a gas film is formed so that the electrode wire and the electrolytic solution can be insulated. The machining device comprises a machine tool bed, an electrolysis-electrical discharge wire cutting device, an ultrasonic vibration unit and a workbench. A wire storage cylinder, a driving wheel, a tensioning device and a guide wheel support are arranged on the machine tool bed. The electrolysis-electrical discharge wire cutting device comprises a clamping device for fixing the workpiece, the workpiece, a main shaft, a wire driving device, the electrode wire, a working solution box containing the electrolytic solution, an auxiliary electrode and an electrolysis-electrical discharge power source. The auxiliary electrode is connected with a positive electrode of the electrolysis-electrical discharge power source. The electrode wire is connected with a negative electrode through an external wire feeding device. According to the method and device, implementation is easy, the production cost is lowered while the precision and efficiency are ensured, and the method and device can be widely applied to micro-machining of various non-conductive hard and brittle materials.

Owner:SHANDONG UNIV

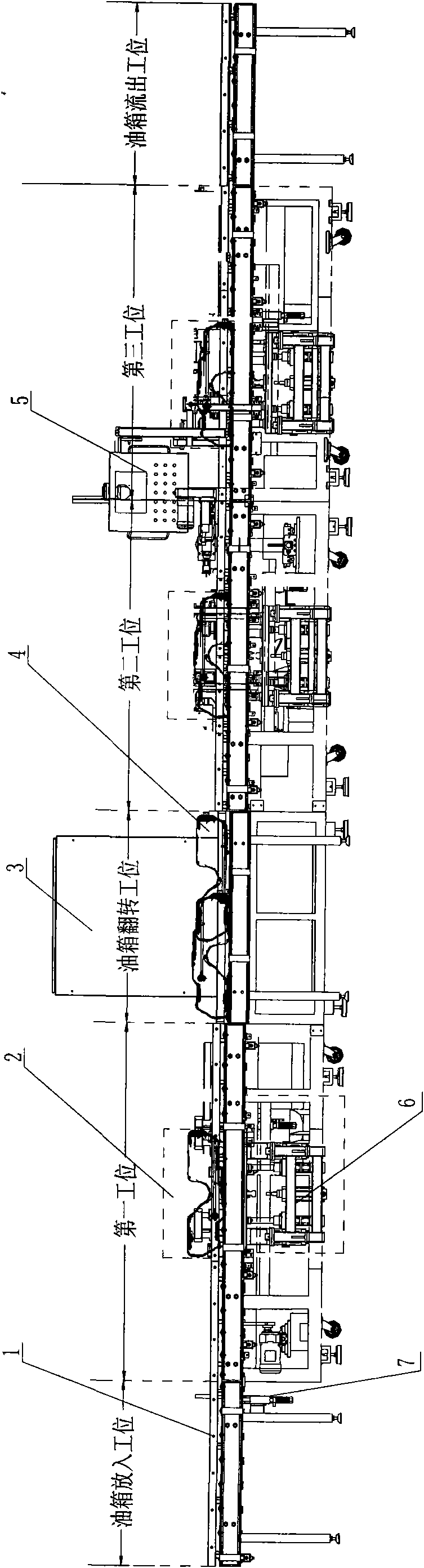

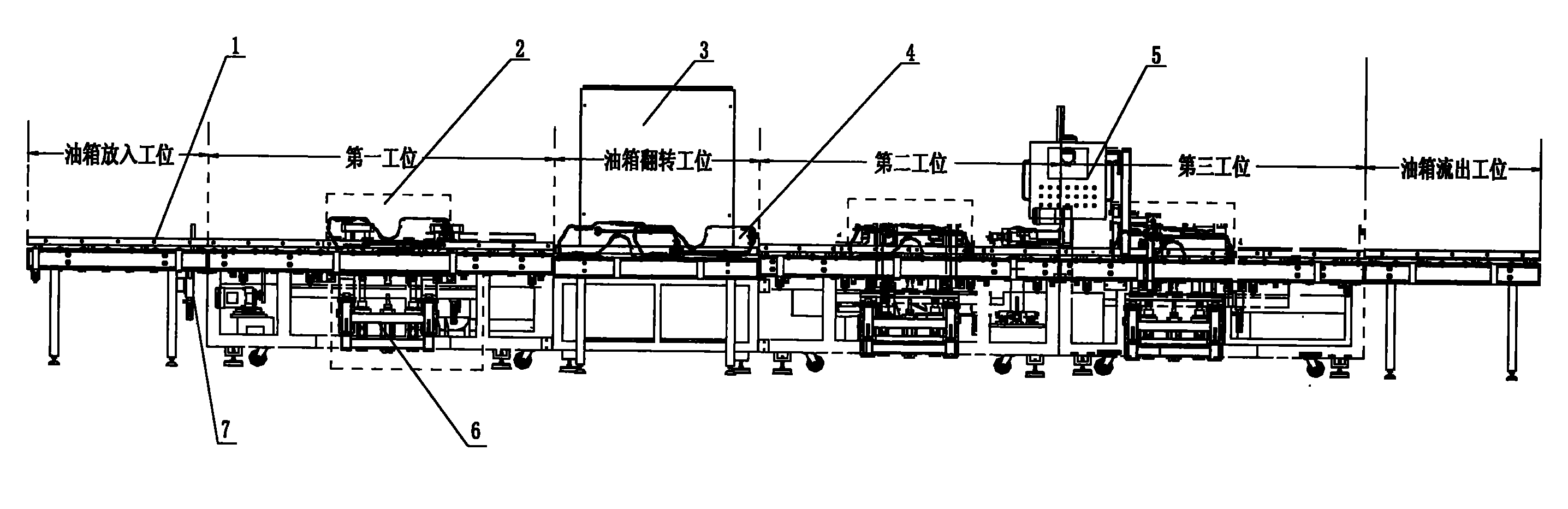

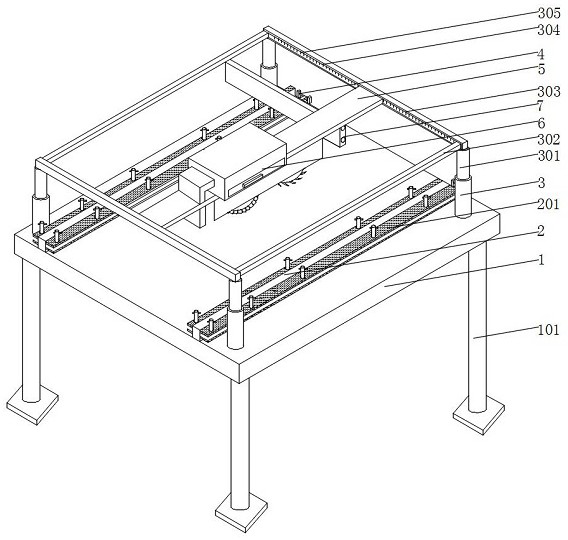

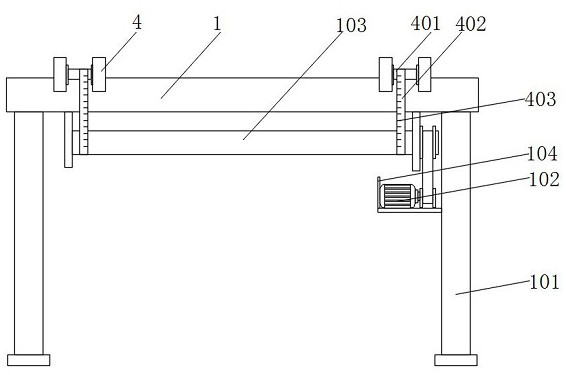

Method and equipment for processing pipeline through plastic oil tank

ActiveCN101850716AReduce processing timeImprove processing efficiencyUnderstructuresFuel tankPetroleum engineering

The invention discloses a method for processing a pipeline through plastic oil tank and processing equipment for implementing the same. The technical scheme adopted by the processing method is as follows: an oil tank is processed by a pipeline operation method, the pipeline is provided with a plurality of oil tank processing stations, each processing station can perform different treatments on the oil tank thereon simultaneously, and the oil tank flows through all the processing stations to finish the process. The technical scheme adopted by the processing equipment is characterized by comprising the pipeline and the plurality of the processing stations, wherein each processing station is provided with station processing equipment which can perform different treatments on an oil tank simultaneously. As each processing station can process the oil tank thereon simultaneously, the average processing time of each oil tank is one station time which equals to the consumed time of a certain specific station with the most consumed time on the pipeline, thus greatly lowering the average processing consumed time of the oil tank and improving the processing efficiency of the oil tank.

Owner:深圳市远望工业自动化设备有限公司

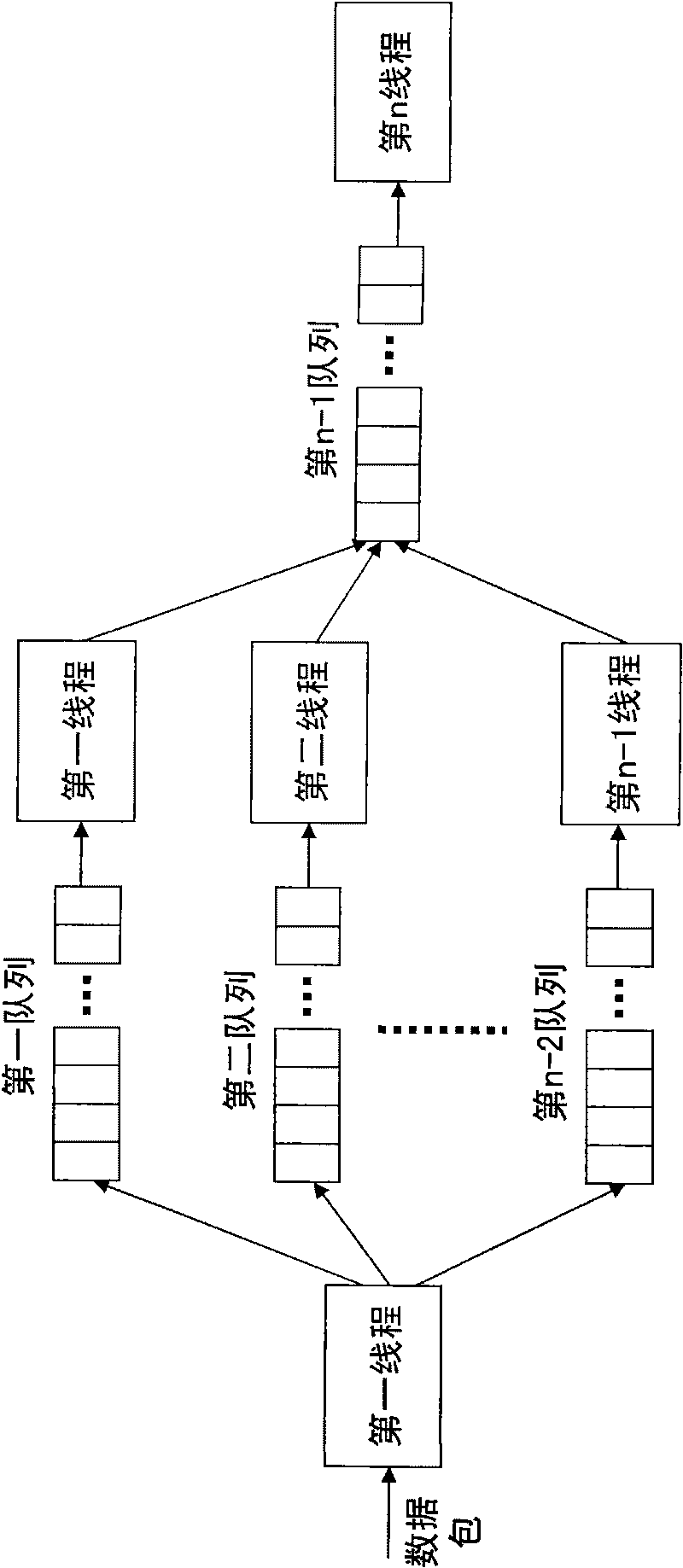

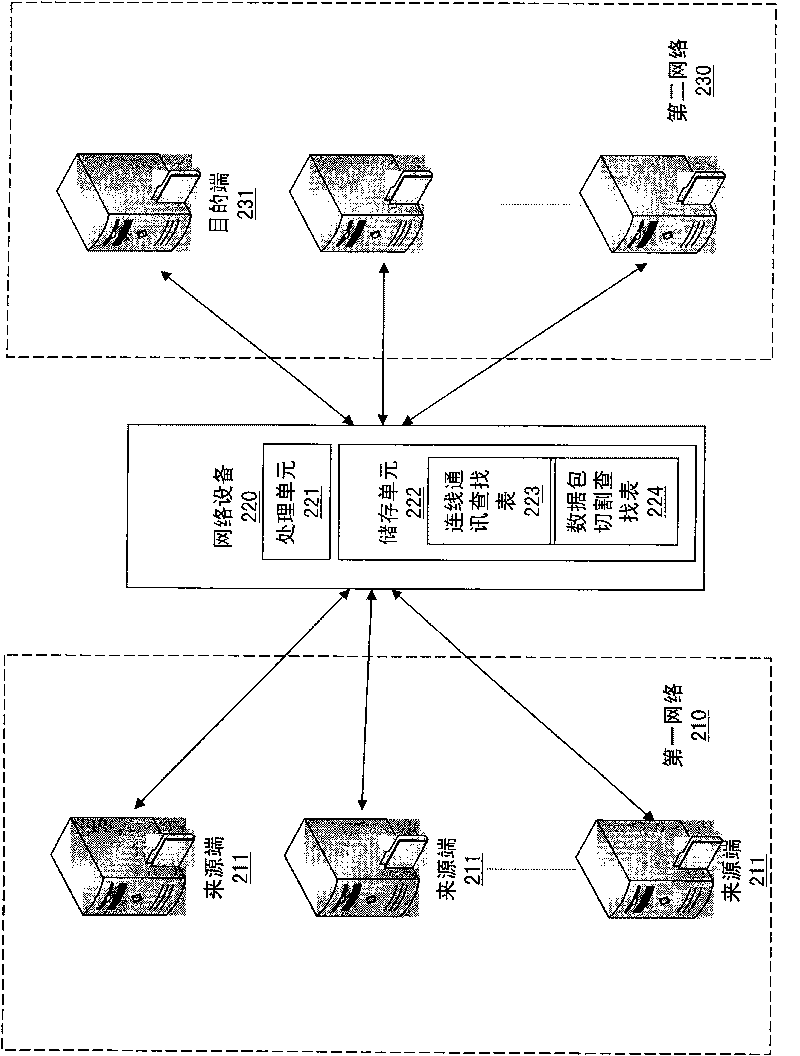

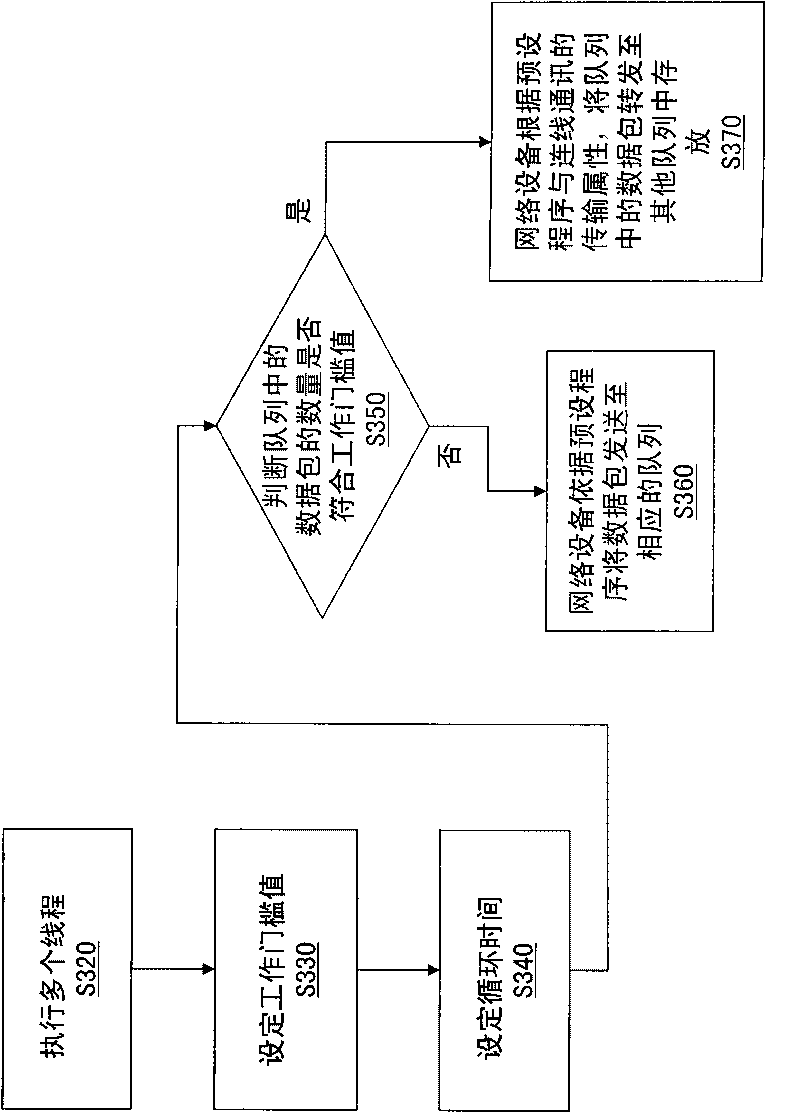

Method for balancing network flow load

InactiveCN101741691AGuaranteed processing stabilityPreserve integrityData switching networksBalancing networkTraffic capacity

The invention discloses a method for balancing a network flow load, which balances the load of the connection communication of packet handler threads in network equipment. The method comprises the following steps of: executing a plurality of packet handler threads and designing a queue to each thread to store the received packets, wherein the threads read the packets from the queue and handle the packets; and judging whether the number of the packets in the queue meets a threshold value of a flow or not, wherein when the number of the packets in a certain queue meets the working threshold value, the network equipment dispatches the new packets to other queues under the principle that the integrity of the connection communication is not affected. The method not only can keep the integrity of the connection communication but also ensure the accordant load of the packet handler threads.

Owner:INVENTEC CORP

Fully biodegradable polyester material, and preparation method and application thereof

The invention belongs to the technical field of biodegradable polyester material, and discloses fully biodegradable polyester material in composting conditions, and a preparation method and the application thereof. The polyester material comprises the following constituents by mass percent: 93 to 99.5 percent of long chain branched polyester, 0.1 to 3 percent of a chain extender, 0.1 to 1 percent of an antioxidant, 0.1 to 1 percent of a lubricant, 0.1 to 1 percent of a stabilizer, and 0.1 to 1 percent of a nucleating agent. The material adopts the efficient chain extender to be mixed with aliphatic-aromatic copolyester and various types of additives, utilizes unique screw combination design and side feeding refueling design, improves the ageing property and the processing property of PBSA products, and meanwhile ensures that the fully biodegradable polyester material has excellent degradation property and aging property. The biodegradability of the material meets the use requirements of biodegradable plastics EN13432, and excellent membrane material mechanical property can be guaranteed after membrane blowing forming processing is performed.

Owner:WUHAN JINFA TECH CO LTD

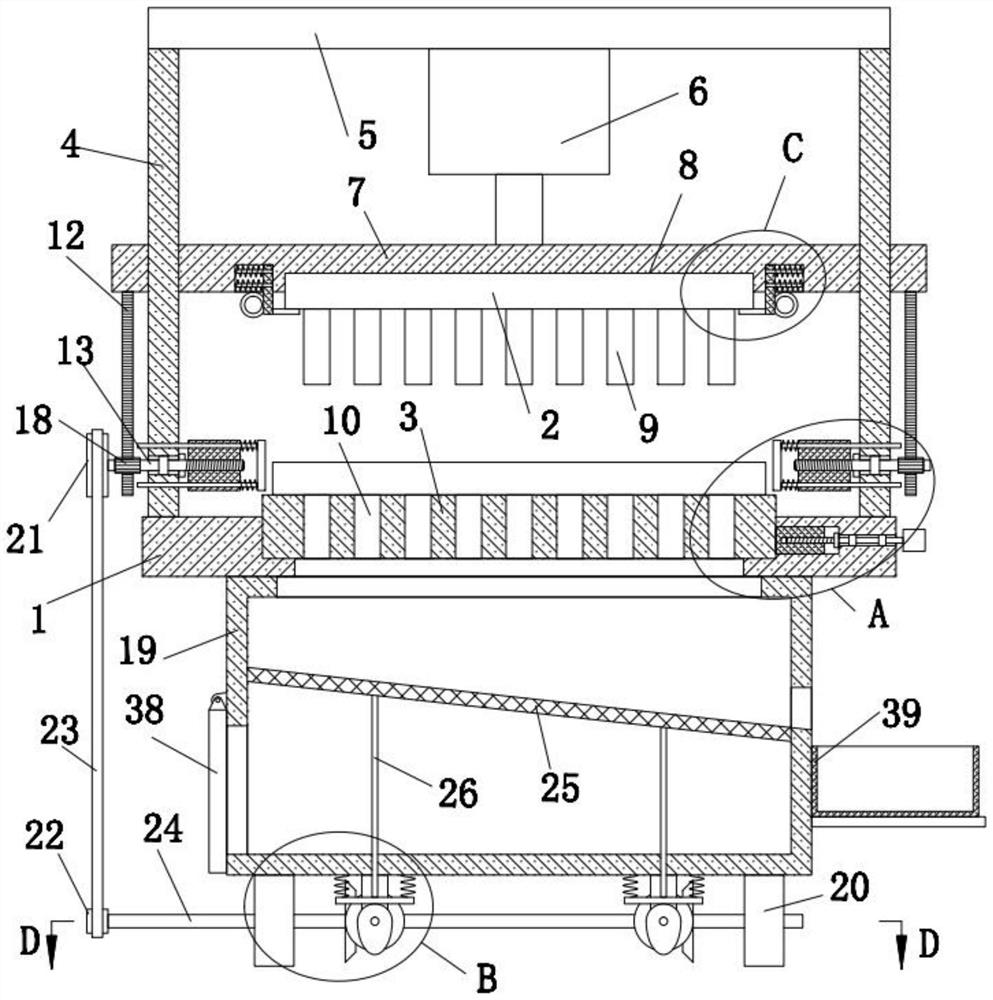

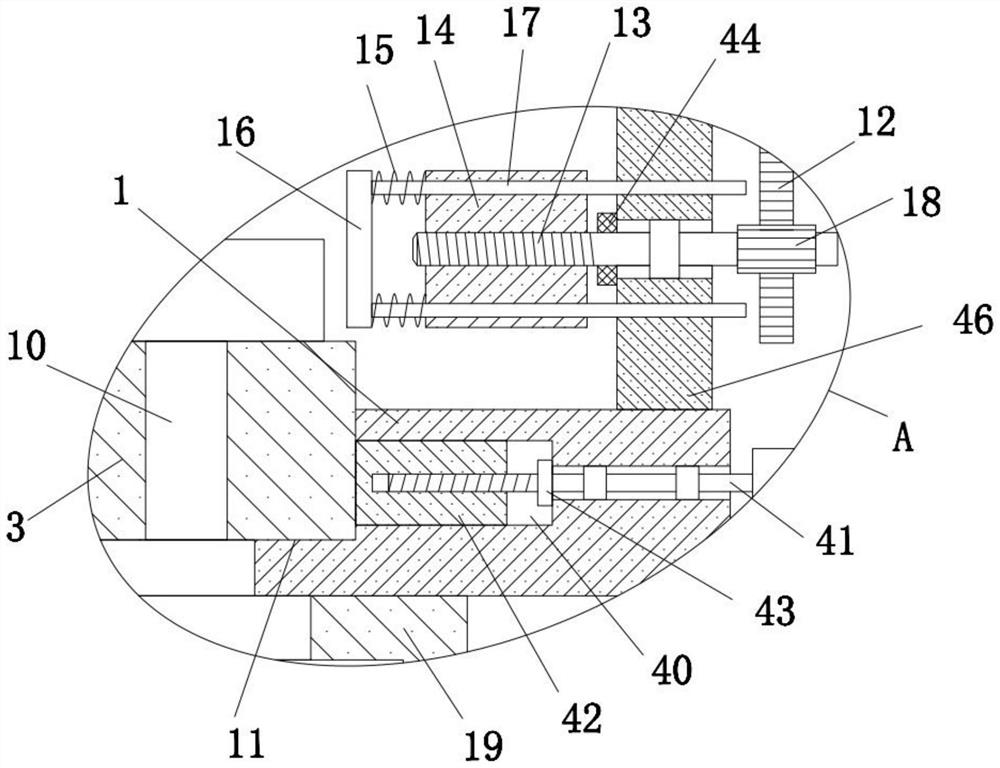

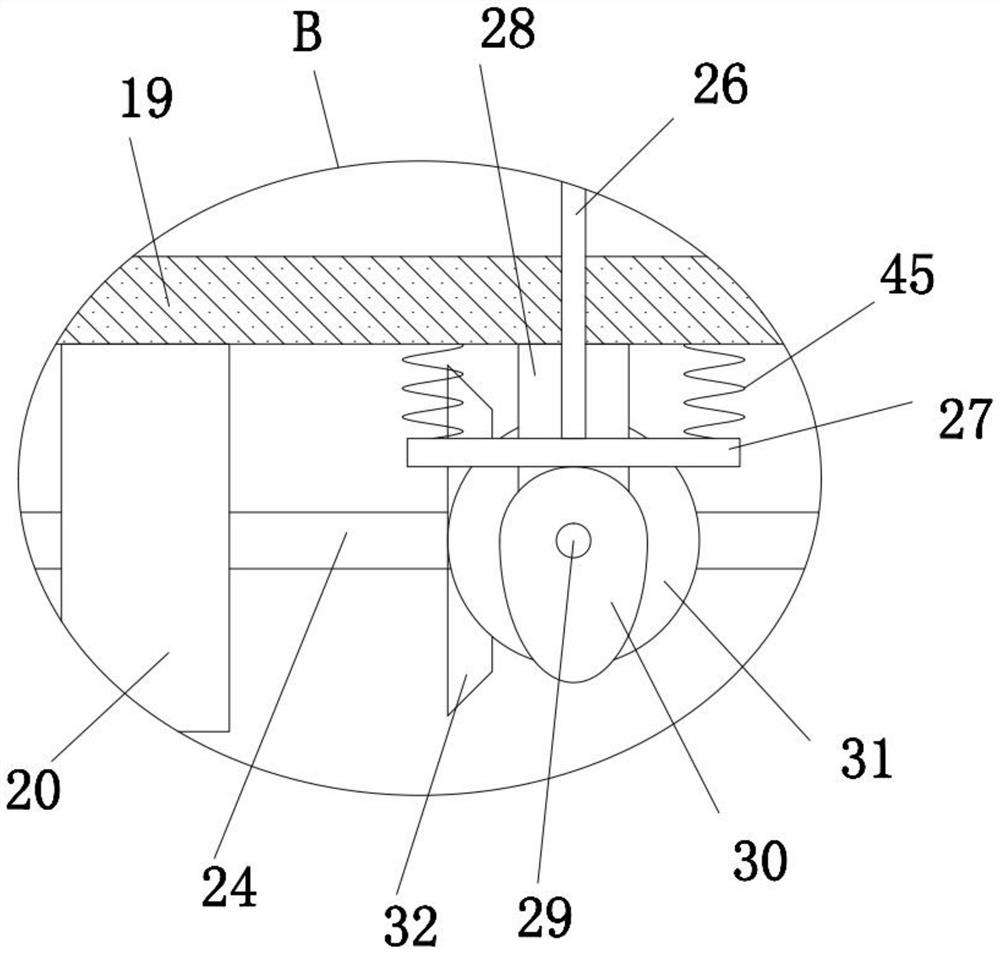

Multi-specification aluminum alloy stamping device

PendingCN112676440AReasonable structural designGuaranteed processing stabilitySievingShaping toolsHydraulic cylinderPunching

The invention belongs to the technical field of stamping equipment, particularly relates to a multi-specification aluminum alloy stamping device, and aims to solve the problems that existing aluminum alloy punching equipment is simplex in function, the punching quality is poor as an aluminum alloy plate cannot be clamped and positioned during impact work, and the machining efficiency is affected as punching waste cannot be automatically removed after punching is completed. According to the following scheme, the multi-specification aluminum alloy stamping device comprises a workbench, an upper die and a lower die, vertical plates are fixed to the two sides of the top of the workbench, an identical top plate is fixedly installed at the tops of the two vertical plates, and a hydraulic cylinder is fixedly installed at the bottom of the top plate. In the stamping process of the stamping device, two clamping plates are driven to move close to each other to clamp and position an aluminum alloy plate, so as to guarantee the machining stability of the aluminum alloy plate, a screen can be driven to vibrate up and down at the same time so that waste generated by aluminum alloy stamping machining can be screened for classification treatment, and thus the working efficiency is improved.

Owner:廖日豪

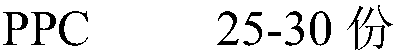

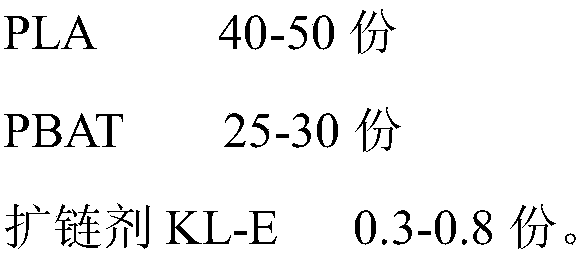

PPC/PLA/PBAT blend modified biodegradable resin prepared with chain extender and preparation method thereof

InactiveCN109535674AGood compatibilityRaise the crystallization temperatureAcetic acidPolymer science

The invention discloses a PPC / PLA / PBAT blend modified biodegradable resin prepared with a chain extender. The PPC / PLA / PBAT blend modified biodegradable resin is prepared from the following raw materials by weight: 25-30 parts of PPC; 40-50 parts of PLA; 25-30 parts of PBAT; and 0.3-0.8 part of a chain extender KL-E. The invention also discloses a preparation method of the resin. The chain extenderis added during blending to play a modification role during chain extension, thus improving the material compatibility. The method adopts a two-step process, firstly PPC and PBAT are subjected to blending granulation in a twin-screw extrusion granulator, then the obtained blend is mixed with PLA particles, the chain extender KL-E is dissolved into an ethyl acetate solution, by means of spraying,the chain extender KL-E can be evenly distributed in the mixed particles of PLA and PPC / PBAT and increase the compatibility of the three, the small chain molecules and free molecules in the three canbe extended into macromolecular materials, thus eliminating the disadvantage of easy hydrolysis of aliphatic resin structurally, at the same time enhancing the melt strength of the three, and guaranteeing the processing stability.

Owner:NANJING WURUI BIODEGRADABLE NEW MATERIAL RES INST CO LTD

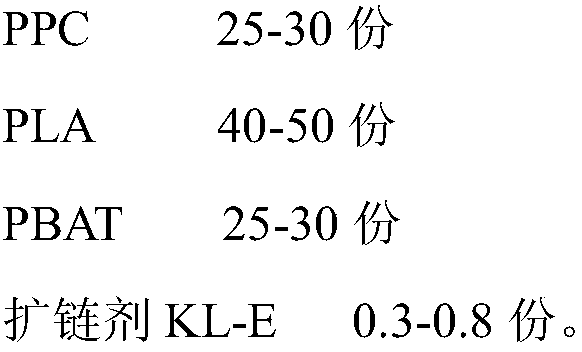

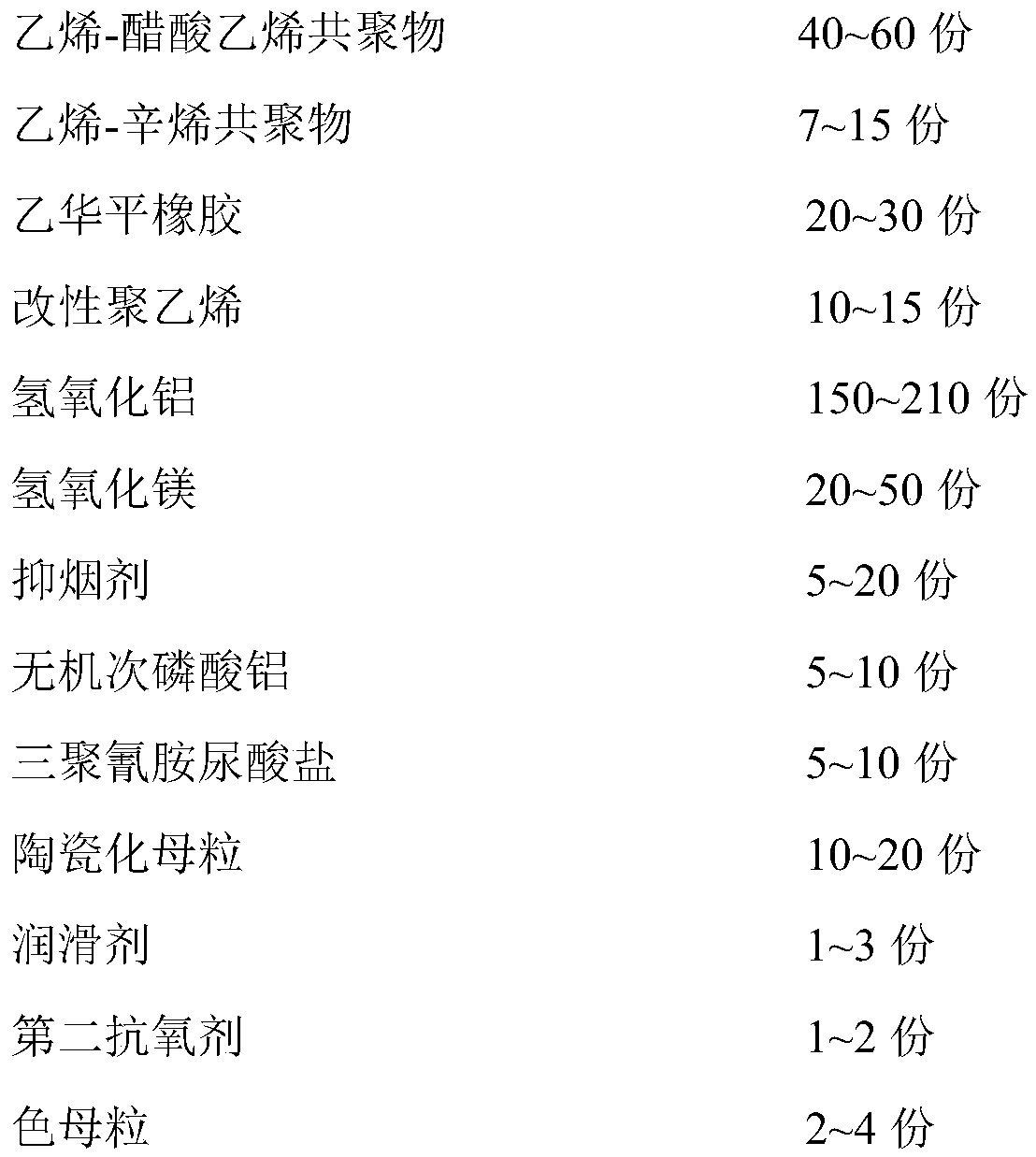

Low-smoke zero-halogen flame-retardant polyolefin oxygen barrier material

The invention relates to a low-smoke zero-halogen flame-retardant polyolefin oxygen barrier material with low heat release and high coking property, which comprises Levapren rubber and a ceramic master batch. The VA content of the Levapren rubber is greater than or equal to 50%, and at 100 DEG C, the mooney viscosity of the Levapren rubber is 20-30; based on the total weight of the ceramic masterbatch, the ceramic master batch comprises the following components in percentage by mass: 40-60% of ceramic powder, 40-60% of polyethylene resin, 0.1-0.3% of first antioxidant, 0.1-0.5% of polyethylene wax and 0.2-0.6% of silicone powder. The polyolefin oxygen barrier material disclosed in the invention has low heat release property, high coking property and excellent extrusion machinability.

Owner:中广核高新核材科技(苏州)有限公司

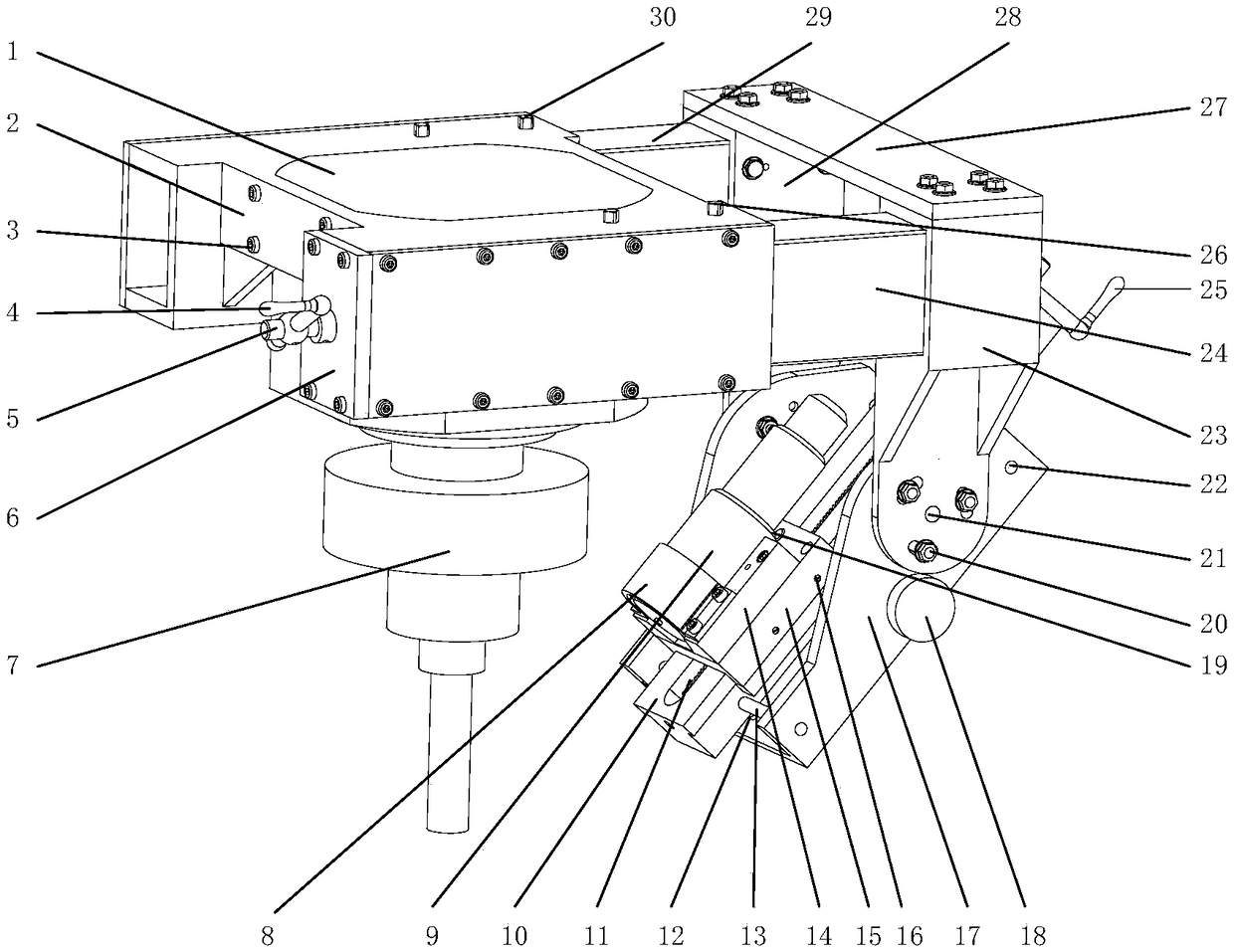

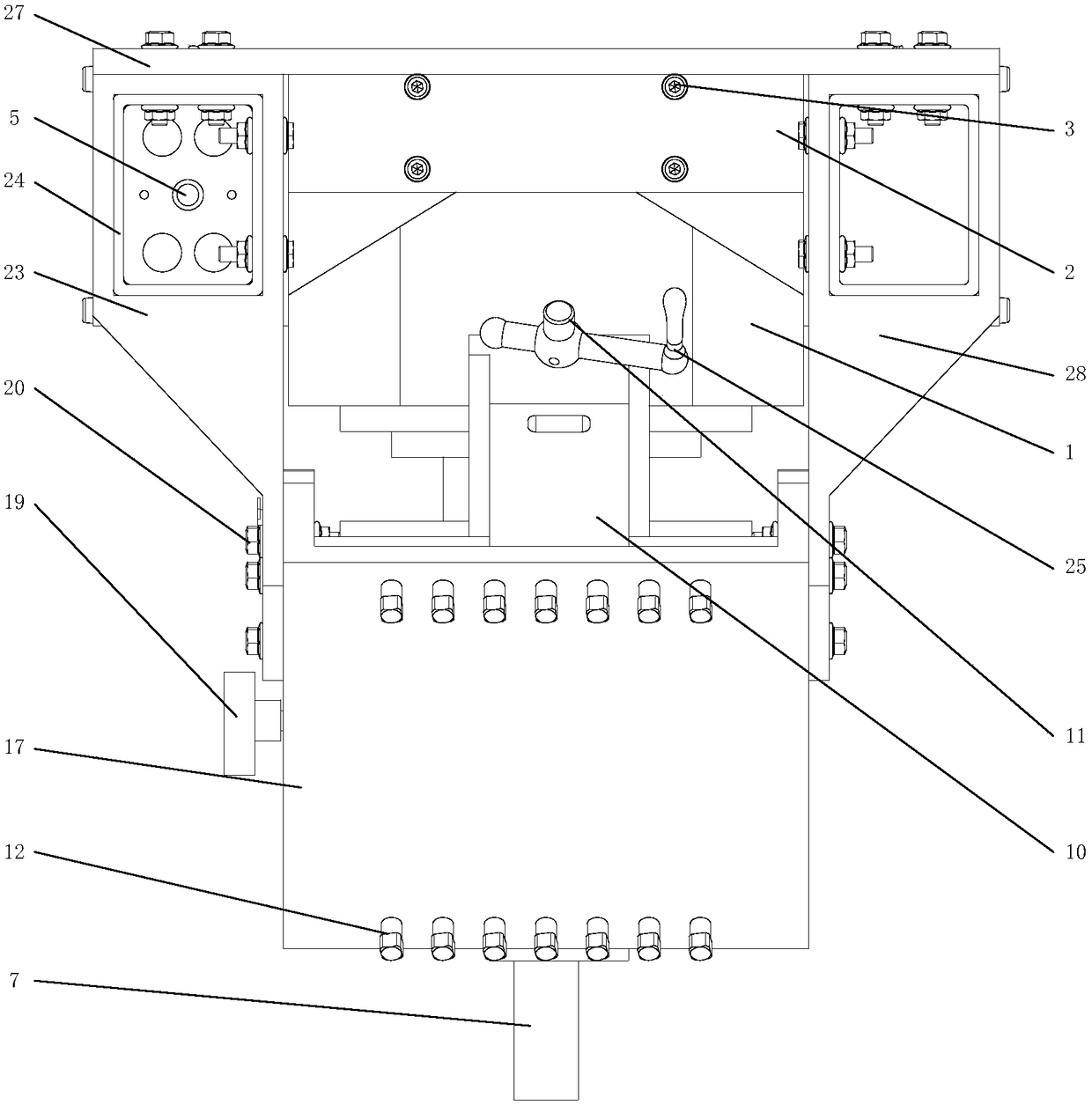

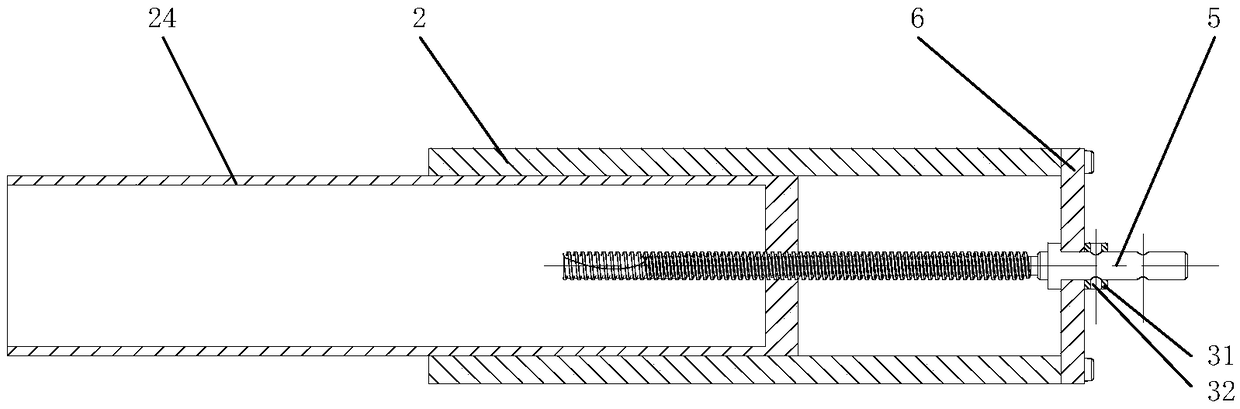

Collimator position and posture adjustment device and method for laser assisted milling

ActiveCN108838689AEasy to adjustImprove structural rigidityMilling equipment detailsMetal working apparatusLaser assistedEngineering

The invention belongs to the field of collimator position and posture adjustment, and particularly discloses a collimator position and posture adjustment device and method for laser assisted milling.The collimator position and posture adjustment device comprises a fixed supporting plate, a pair of parallel square slide rails, a U-shaped movable supporting back and a cross slide platform mechanism, wherein the pair of parallel square slide rails is installed on both sides of the fixed supporting plate, and two fixed supporting backs are correspondingly mounted at the ends, away from the fixedsupporting plate, of the two square slide rails; and the two fixed supporting backs are connected with the U-shaped movable supporting back in pivoted and rotating modes so as to form a rotary pair, the cross slide platform mechanism is mounted on the U-shaped movable supporting back, and a collimator is mounted on the cross slide platform mechanism. The method is performed by using the collimatorposition and posture adjustment device to achieve the adjustment of the laser incident angle, spot size, and the relative position between a laser spot and a tool. The collimator position and postureadjustment device can effectively adjust the position and posture of the collimator, has a compact overall structural layout, small size and small space occupation.

Owner:HUAZHONG UNIV OF SCI & TECH

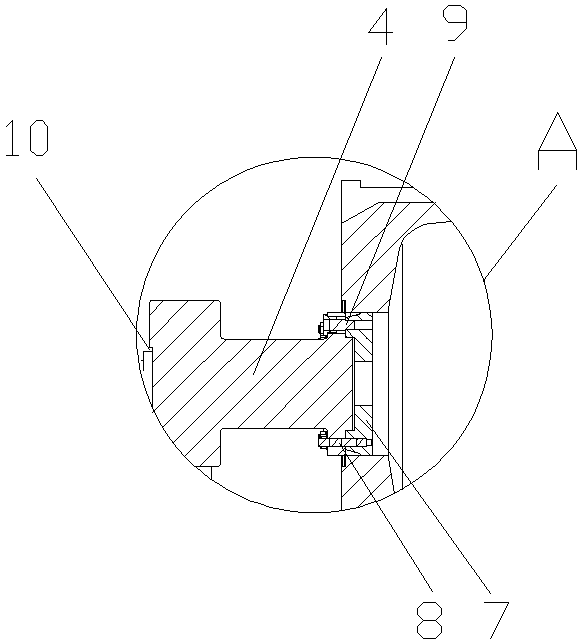

Revolving body surface high boss electrolytic machining tool electrode assembly and electrolytic machining method

ActiveCN110605444AAvoid electric field concentrationReduction of stray corrosionMachining electrodesMachining working media supply/regenerationElectrolysisEngineering

The invention provides a revolving body surface high boss electrolytic machining tool electrode assembly and an electrolytic machining method, and belongs to the technical field of electrolytic machining. The method is characterized in that the tool electrode assembly comprises a tool cathode, a first insulating cavity and a second insulating cavity; and the tool cathode is of a revolving body structure, the surface of the tool cathode is provided with a hollowed-out groove structure, and an opening of the groove structure is of a protruding guide circle structure; the outer side of the firstinsulating cavity is fixedly attached to the inner wall of the protruding guide circular structure, the side wall of the groove structure and the inner side plane of the tool cathode, and the other end of the first insulating cavity is of a tubular structure; the outer side corner of the second insulating cavity is in an arc transition, and the second insulating cavity is fixed in the first insulating cavity through a bottom mounting seat and forms an electrolyte flow channel with the first insulating cavity. According to the method, the electrolyte flowing from the side surface through a first electrolyte inlet can provide a stable flow field for the processing region at the revolving surface, and the electrolyte flowing from the inner side of the groove structure through a second electrolyte inlet can ensure the uniformity of the flow field of the machining region at the side wall of the boss, so that the electrolytic machining stability of the high boss on the surface of the revolving body is ensured.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

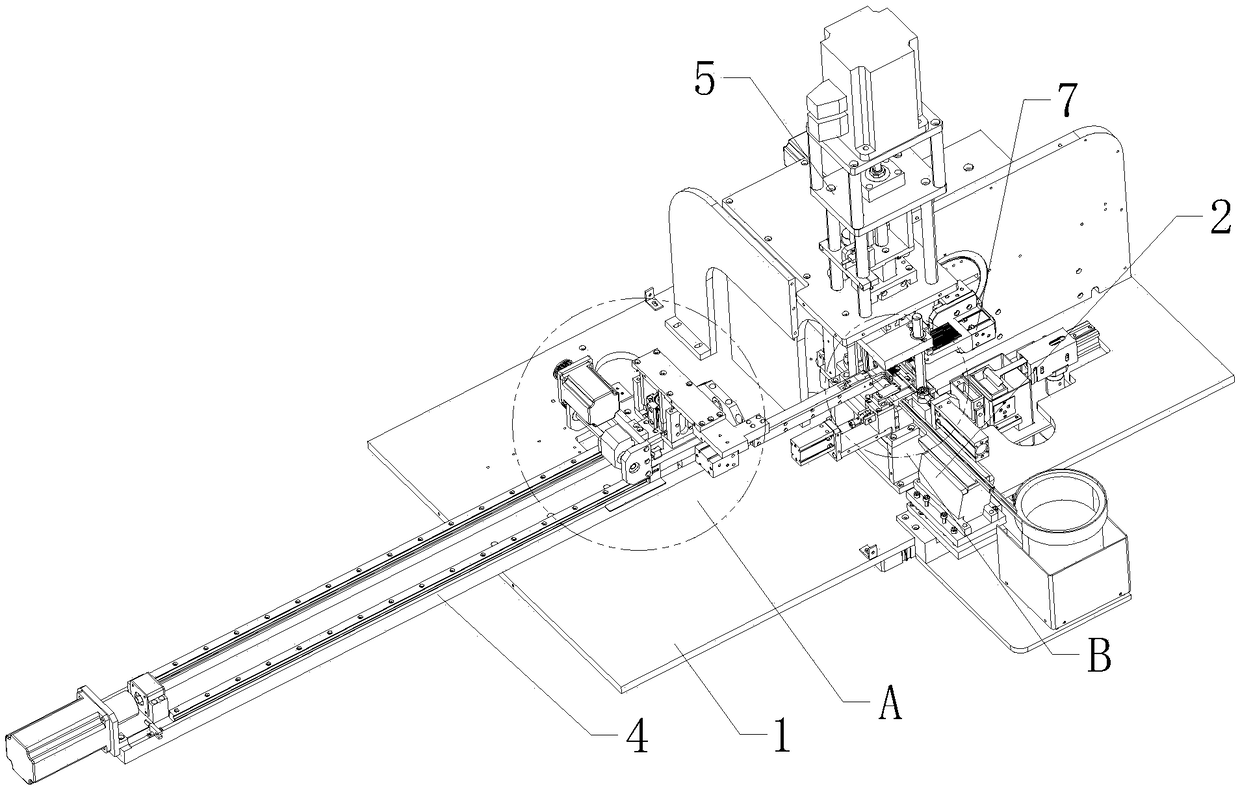

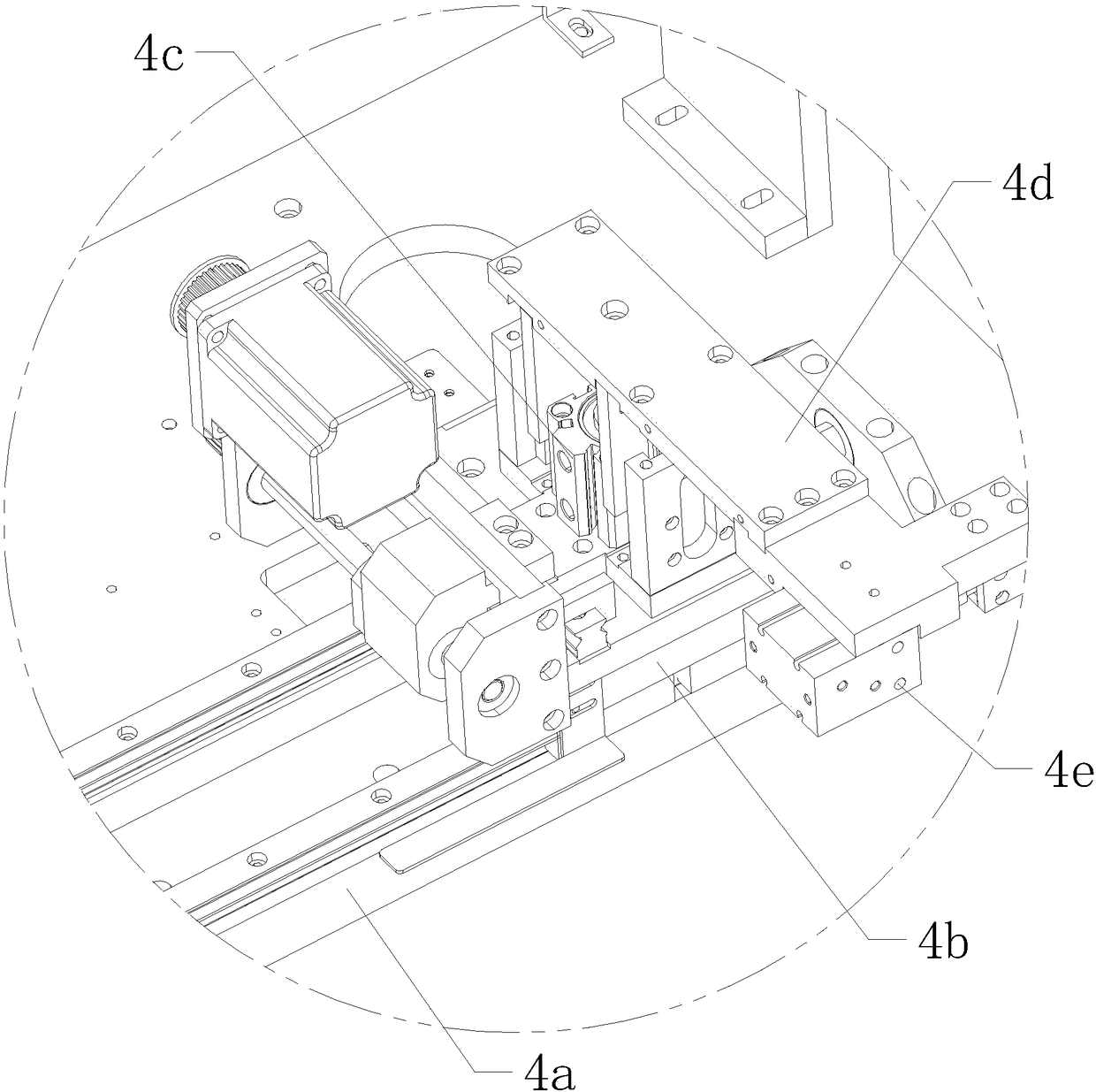

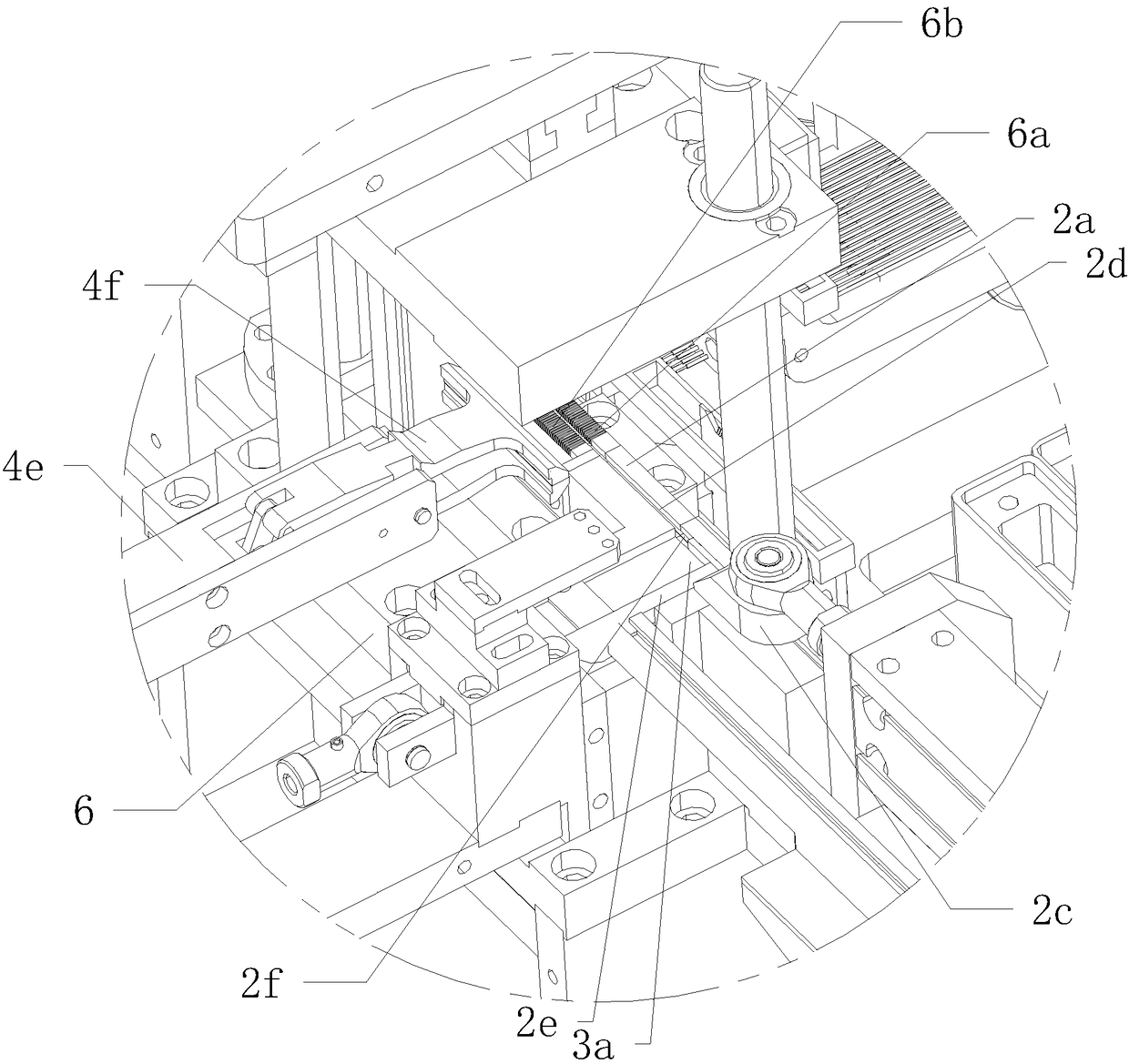

Rapid clamping device for machining split grooves of oblique connecting rod of automobile by linear cutting

ActiveCN107052487ARapid positioningPrecise positioningElectrical-based auxillary apparatusEngineeringMachining process

The invention discloses a rapid clamping device for machining split grooves of an oblique connecting rod of an automobile by linear cutting. The rapid clamping device comprises a horizontally arranged large bottom plate and a small bottom plate connected to the top surface of the large bottom plate; the top surface of the small bottom plate is connected to a small head hole positioning pin capable of abutting against the inner hole wall of a small head hole of the oblique connecting rod, and the edge of the large bottom plate is provided with a pair of large head hole positioning pins capable of abutting against the inner hole wall of a large head hole of the oblique connecting rod. Compared with the prior art, the technical solution of the invention has the advantages that by adjusting the position of positioning pin sliding blocks, the position of the large head hole of the oblique connecting rod can be fixed in advance, rapid and precise positioning can be realized, and consistency between the depths and perpendicularities of split grooves in the two sides can be ensured. By using the small head hole positioning pin and the large head hole positioning pins to limit and fix three positions of the oblique connecting rod, a rubber push block ensures positioning accuracy and stability in a machining process, such that the quality of the split grooves is higher. The small head hole positioning pin and the positioning pin sliding blocks can be moved, such that the rapid clamping device is suitable for clamping of the oblique connecting rods of various types, and thus has greater universality.

Owner:GUANGDONG UNIV OF TECH

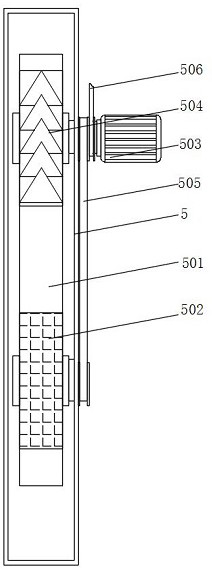

Automatic-puncturing terminal crimping tin dipping machine

PendingCN108616024AImprove stabilityImprove efficiencyContact members penetrating/cutting insulation/cable strandsConnection formation by deformationEngineeringTin

An automatic-puncturing terminal crimping tin dipping machine comprises a processing table, a terminal transfer device, a tin dipping device and a clamping device, wherein the terminal transfer deviceis arranged at a front side of the processing table, the tin dipping device and the clamping device are arranged at a left end and a right end of the processing table, a crimping device is arranged on the processing table, a line arrangement rack module is arranged at an outer side of the processing table, a stabilization block is arranged on the processing table, a peeling and twisting knife holder module is arranged below the processing table, the stabilization block is arranged right below the crimping device, a lower die cutting knife holder and a lower die terminal avoidance block are symmetrically arranged at the top of the stabilization block, an accommodating cavity is formed between the lower die cutting knife holder and the lower die terminal avoidance block and is used for placing a terminal, a tin furnace is arranged below the tin dipping device, the tin dipping device comprises a limitation block, a plurality of line through pipes and a power assembly, the plurality of line through pipes are arranged at the top of the limitation block along a straight line, and the power assembly is used for driving the limitation block to move in a cross way. By the automatic-puncturing terminal crimping tin dipping machine, a terminal line can be automatically dipped with tin instead of manual operation and is crimped with the terminal, the efficiency is improved, and meanwhile,body harm to a worker brought by manual operation is prevented.

Owner:傅炳荣

Computer case glass processing device with protection function

InactiveCN112817390AWith antistatic functionRolling is successfully realizedEdge grinding machinesGrinding drivesEngineeringMachining process

The computer case glass processing device with the protection function comprises a working platform, positioning frames, a processing plate and an anti-static processing plate; the positioning frames are fixed to the four corners of the top of the working platform, a cross rod is welded to the top of a telescopic column, a sliding groove is formed in the cross rod, a machining plate is slidably connected into the sliding groove, a cleaning box is fixed to the top of the machining plate, an anti-static machining plate is fixed to the bottom of the machining plate, a stretching frame is fixed to the back face of the working platform, a set of parallel clamps are installed at the top of the working platform, and the clamps are located on one side of the positioning frame. A series of elements are arranged, the device can be assisted in achieving longitudinal and transverse double-axis positioning in the machining process, synchronous cutting and grinding operation can be conducted on raw glass sheets, the machining efficiency of the device is improved, and the raw glass sheets can be subjected to antistatic film attaching machining, so that the invention has the antistatic function, and the use safety of the computer case is guaranteed.

Owner:东莞市信恒智能装备科技有限公司

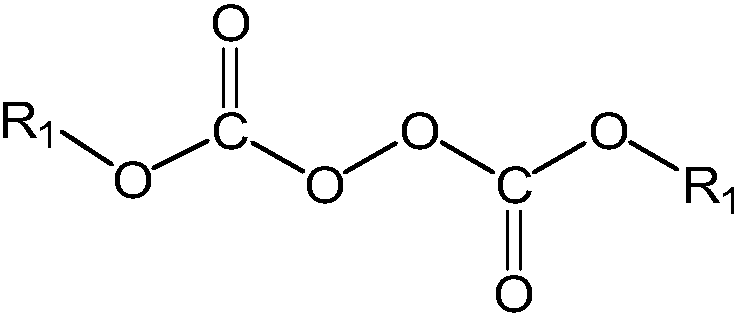

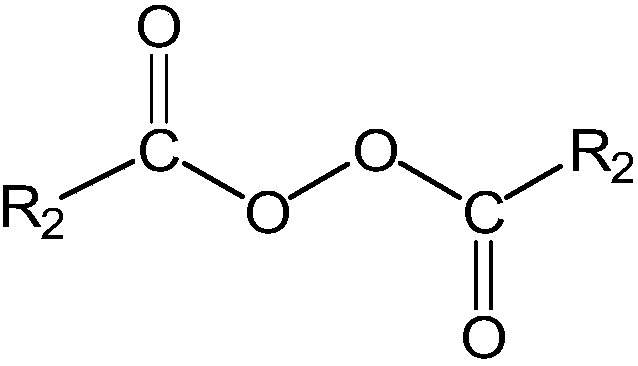

Modified cellulose diacetate as well as preparation method and application thereof

ActiveCN109503892AIncrease melt viscosityFeel comfortableAdditive manufacturing apparatusCellulose diacetateCellulose acetate

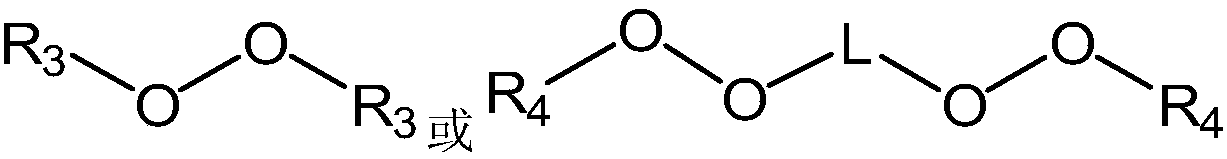

The invention belongs to the field of cellulose diacetate products, and particularly relates to a modified cellulose diacetate product as well as a preparation method and application thereof to 3D printing and other fields. The modified cellulose diacetate provided by the invention is prepared by mixing cellulose diacetate, a plasticizer, a hindered phenol antioxidant, a phosphite antioxidant andperoxide. The cellulose diacetate can be used as a 3D printing material for preparing products by adopting a 3D printing method.

Owner:SICHUAN PUSH CELLULOSE ACETATE CO LTD

Numerical control grinding machine pneumatic clamp for gear grinding

PendingCN108406010AGuaranteed axial stabilityGuaranteed sizeGear-cutting machinesGear teethNumerical controlGear grinding

The invention discloses a numerical control grinding machine pneumatic clamp for gear grinding. The numerical control grinding machine pneumatic clamp comprises a centre. The clamp further comprises abase plate and an air cylinder. One end of the base plate is fixedly arranged on a lathe bed base, and the air cylinder is fixedly arranged at the other end of the base plate and comprises a clampingcavity. The centre penetrates the base plate. One end of the centre is fixedly connected with the lathe bed base, and a tip at the other end of the centre is located in the clamping cavity of the aircylinder. The numerical control grinding machine pneumatic clamp for gear grinding can achieve automatic workpiece clamping, and automatic mechanical arm clamping is achieved; the workpiece machiningefficiency is effectively improved, and economic benefits are good; the safety coefficient in the workpiece machining process is improved, and protection to an operator is effectively guaranteed; thegear machining stability and precision are guaranteed, and the gear workpiece fly-out accident and the gear workpiece loosening situation are avoided; and the structure is simple, and the appearanceis exquisite.

Owner:HEFEI CHANGYUAN HYDRAULICS

Cutting tool for finishing end portion of hose

InactiveCN103084632AIncrease productivityGood qualityTransportation and packagingTrepanning drillsDrill bitEngineering

The invention relates to a cutting tool for finishing the end portion of a hose. The cutting tool for finishing the end portion of the hose comprises a drill stem, a drill bit installed at the front end of the drill stem, a floating grinding head, a spring and a spring seat fixed on the rear portion of the drill stem. A through hole is formed in the middle portion of the floating grinding head, a forming grinding end face is arranged at the front end of the through hole, and the floating grinding head is sleeved on the drill stem in a circumferential limiting mode and is connected with the molded surface of the drill stem. The spring is movably sleeved on the drill stem between the floating grinding head and the spring seat. The cutting tool for finishing the end portion of the hose can remove flanging and burrs at the same time, and is high in producing efficiency, low in labor intensity, and good in product quality.

Owner:山西机电职业技术学院

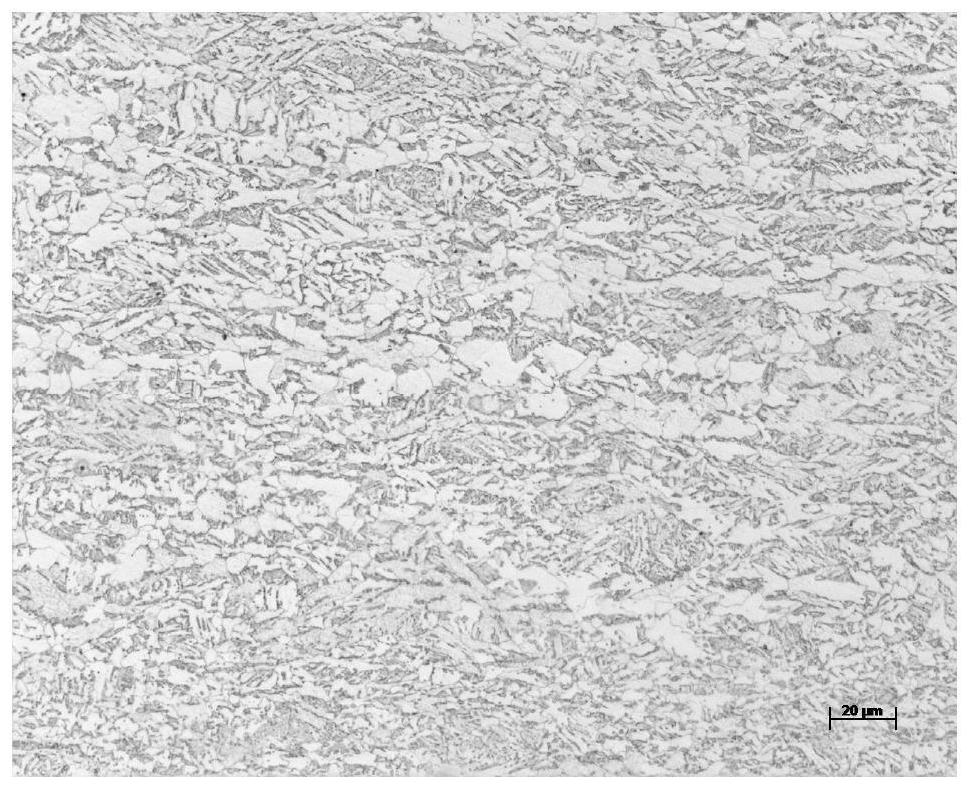

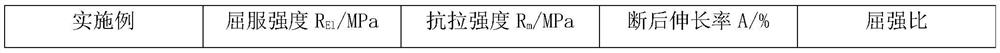

Q370qE-HPS bridge steel with low cost and high performance, and production method

ActiveCN112195406APromote formationFacilitate organizational transformationTemperature control deviceManufacturing convertersMetallurgyYield ratio

The invention discloses Q370qEHPS bridge steel with low cost and high-performance, and relates to the technical field of steel production. The Q370qEHPS bridge steel comprises the following chemical components by mass: 0.05%-0.08% of C, 0.10%-0.40% of Si, 1.61%- 1.70% of Mn, no more than 0.015% of P, no more than 0.0030% of S, 0.030%-0.050% of Nb, 0.010%-0.018% of Ti, no more than 0.05% of residual Ni, 0.20%-0.30% of Cr, no more than 0.05% of residual Mo, no more than 0.05% of residual Cu, no more than 0.05% of residual B, no more than 0.005% of N, 0.020%-0.050% of Al, and the balance Fe and impurities. A TMCP rolling process is adopted, so that the bridge steel plate which is low in yield ratio, excellent in welding performance and capable of meeting standard requirements is obtained, andthe market competitiveness of enterprises is improved.

Owner:NANJING IRON & STEEL CO LTD

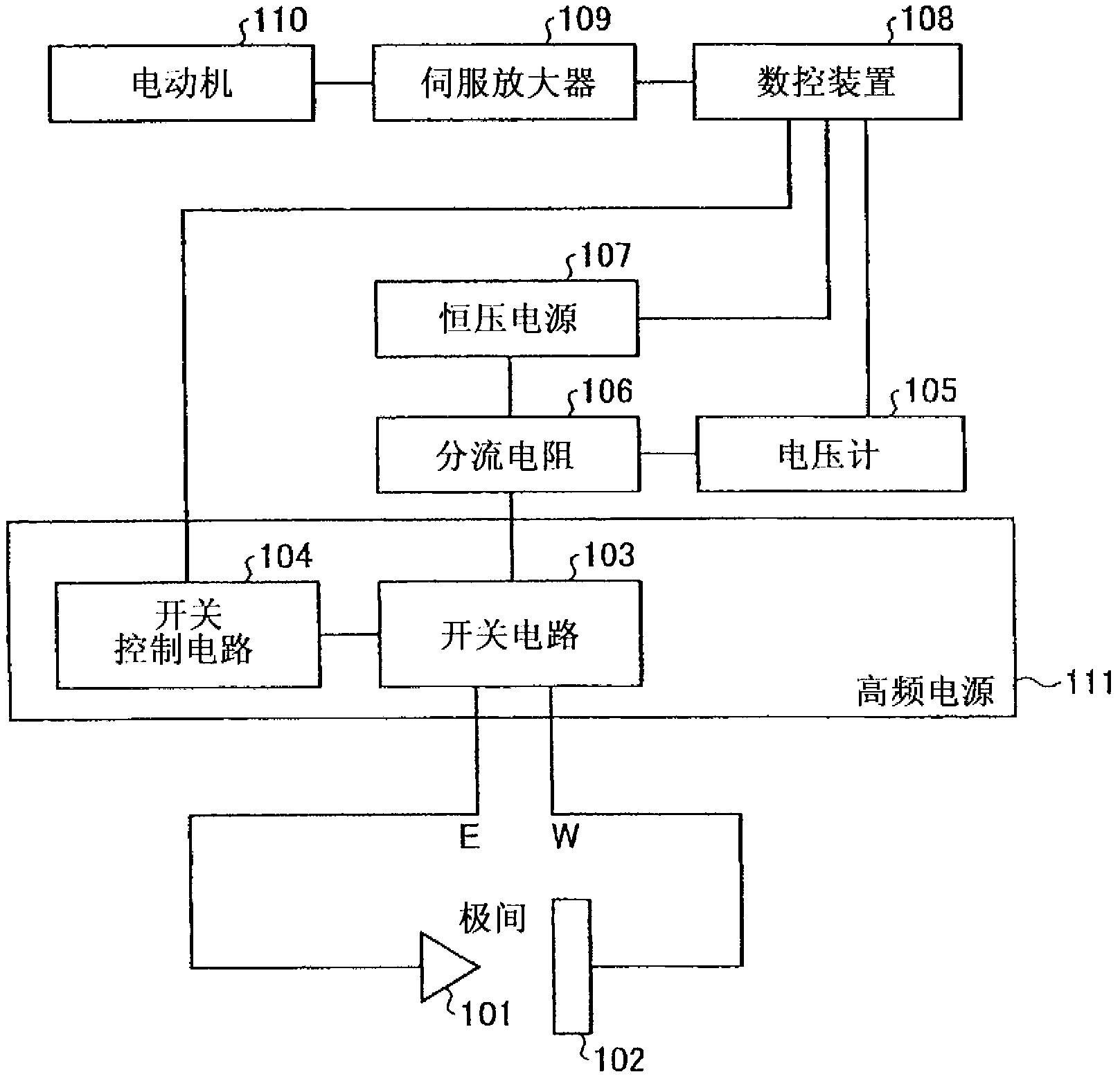

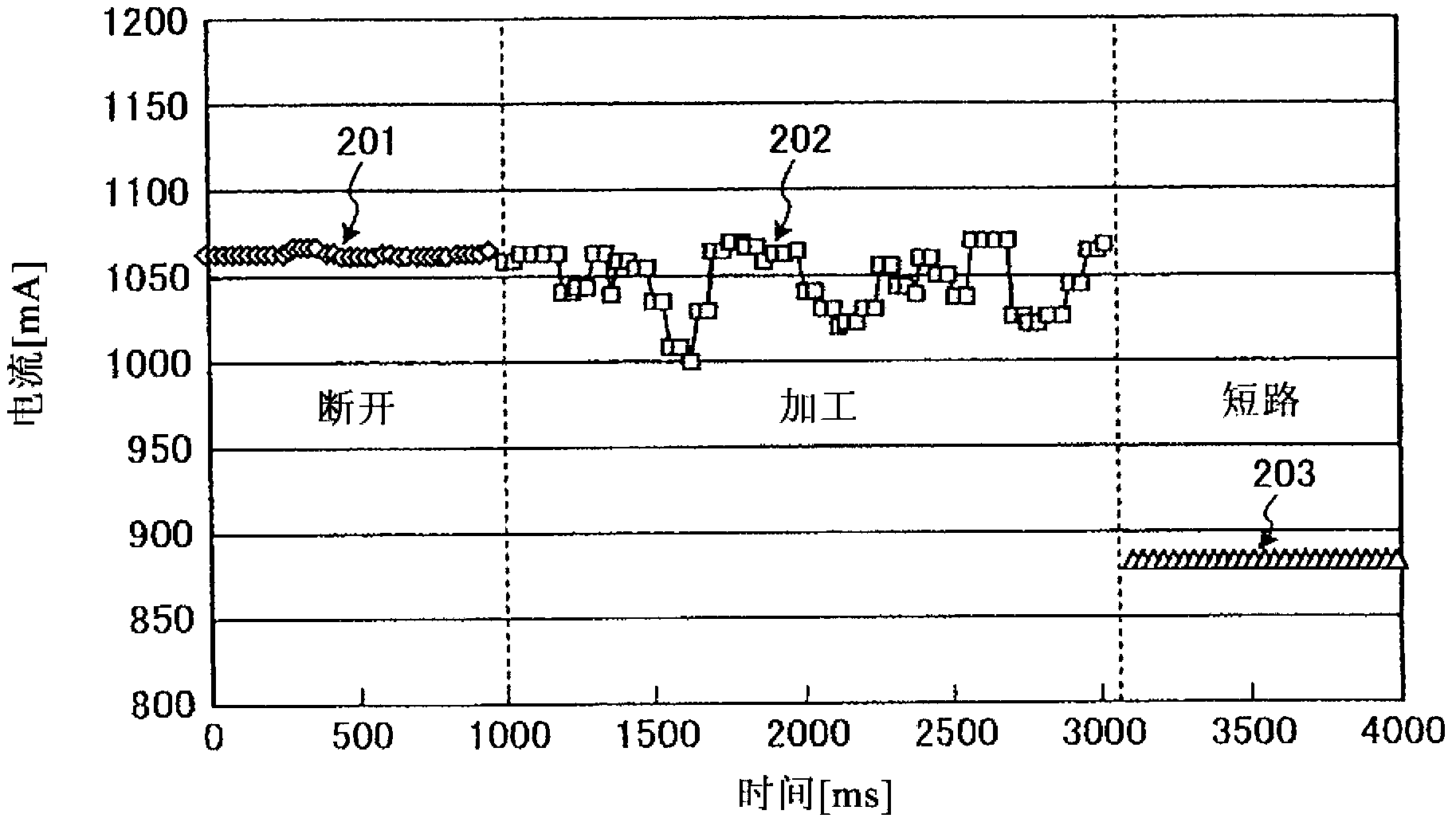

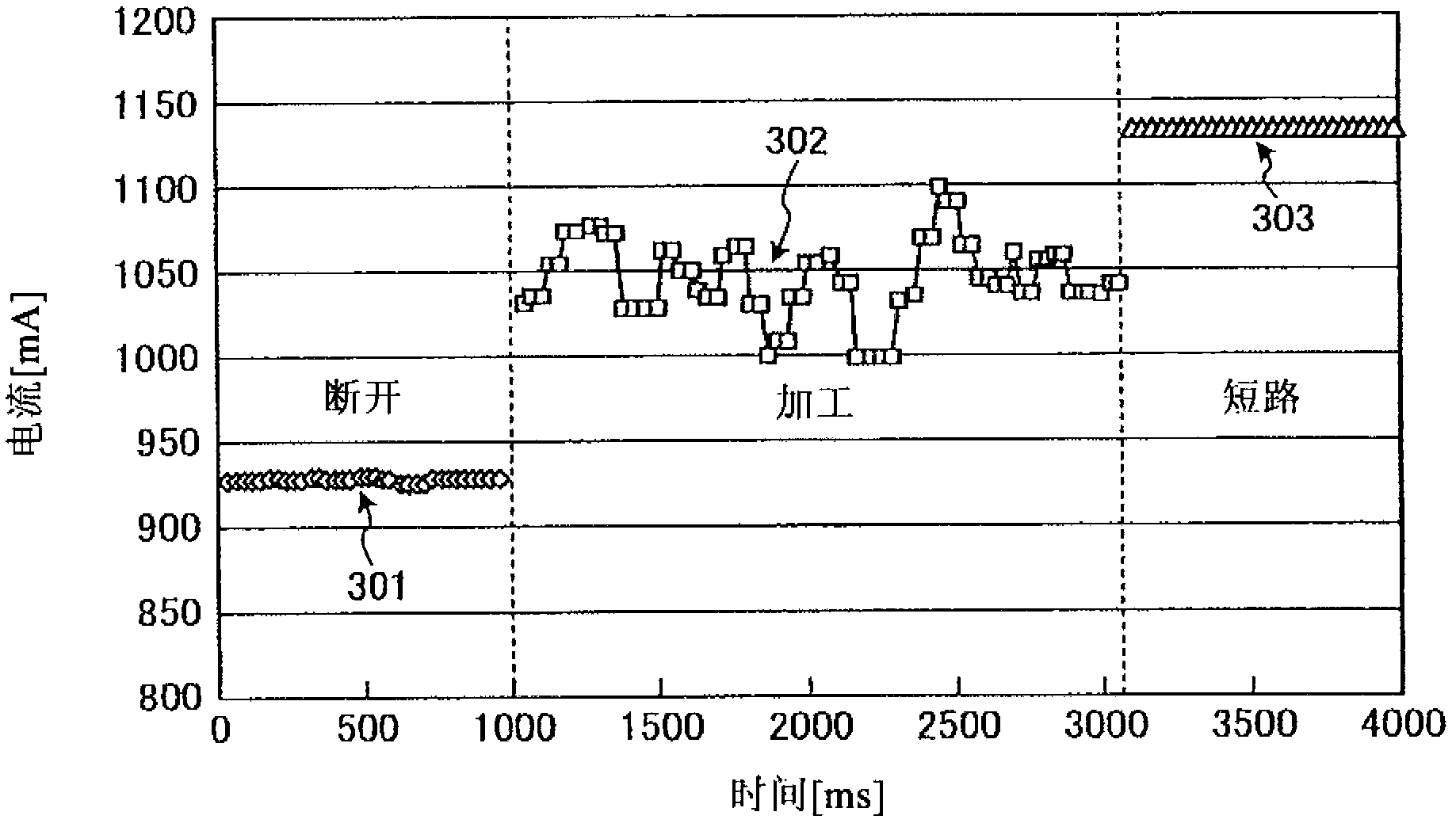

Wire electric discharge machining device

InactiveCN102905832AGuaranteed processing stabilityPrevent deterioration of surface roughnessElectric dischargeEngineering

A wire electric discharge machining device comprises a wire electrode disposed spaced from an object to be machined and a constant voltage power supply for supplying a high-frequency voltage between the object to be machined and the wire electrode, and generates electric discharge between the object to be machined and the wire electrode by the application of the high-frequency voltage to machine the object to be machined. The wire electric discharge machining device further comprises: a current measuring means for measuring the value of current flowing from the constant voltage power supply; a determination means for, based on the measured current value and the variation value of the current value, determining an inter-electrode state that is a state between the object to be machined and the wire electrode; and a control means for, based on the determined inter-electrode state, controlling the space between the object to be machined and the wire electrode.

Owner:MITSUBISHI ELECTRIC CORP

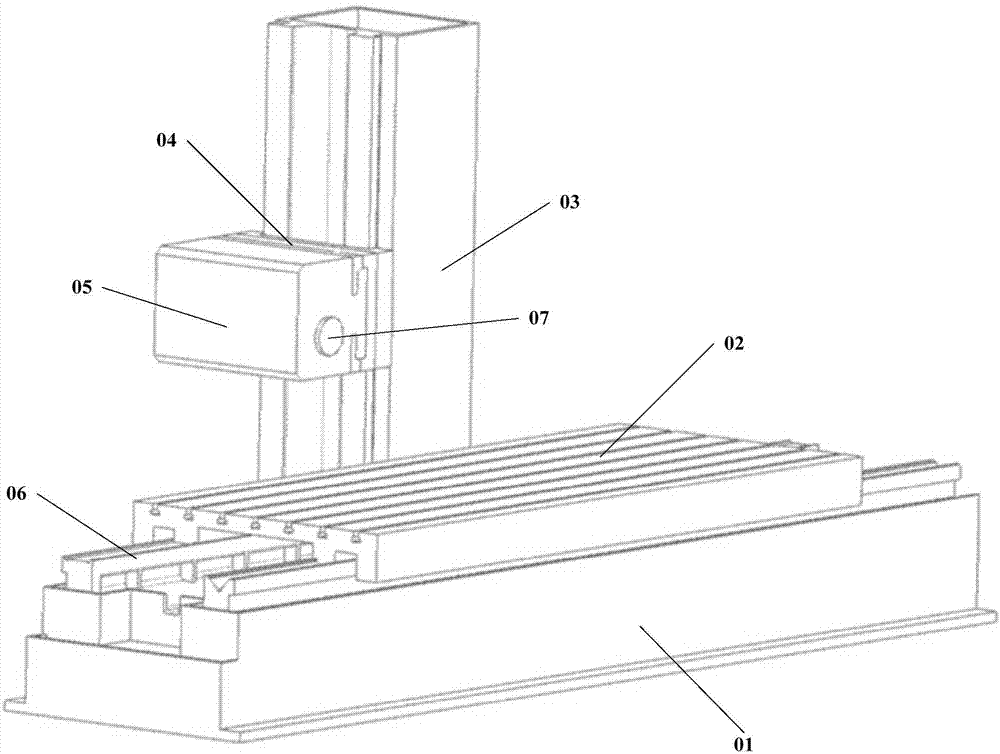

Horizontal type finish milling machine

InactiveCN104325181AGuaranteed machining accuracyGuaranteed processing stabilityMilling machinesFeeding apparatusMilling cutterMechanical engineering

The invention discloses a horizontal type finish milling machine. Two sets of guide rails are arranged on the end face of a base; a worktable is located on the first set of guide rails, and a stand column is located on the second set of guide rails; the side wall of the stand column is provided with a planker which is connected with the stand column in a sliding manner; the end face, facing the worktable, of the planker is connected with a milling cutter by a main shaft; the first set of guide rails are vertical to the end face of the milling cutter; the second set of guide rails are parallel to the end face of the milling cutter; or the first set of guide rails are parallel to the end face of the milling cutter, and the second set of guide rails are vertical to the end face of the milling cutter. Compared with the prior art, the horizontal type finish milling machine disclosed by the invention has the advantages that the stand column slides along the guide rails and the sliding of a milling power head along the horizontal direction of a ram is replaced; and a condition that abrasion is generated when the milling power head slides along the ram is avoided, so that the machining precision and the stability of the horizontal type finish milling machine can be guaranteed.

Owner:湖南坤鼎数控科技有限公司

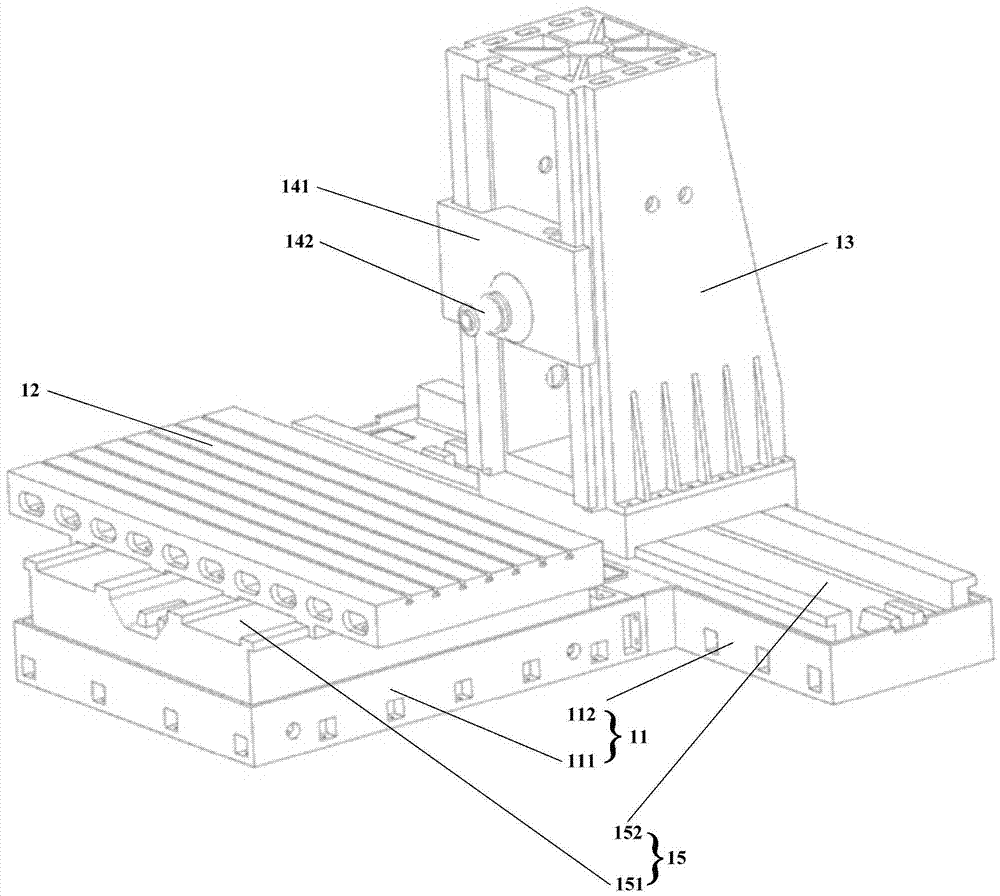

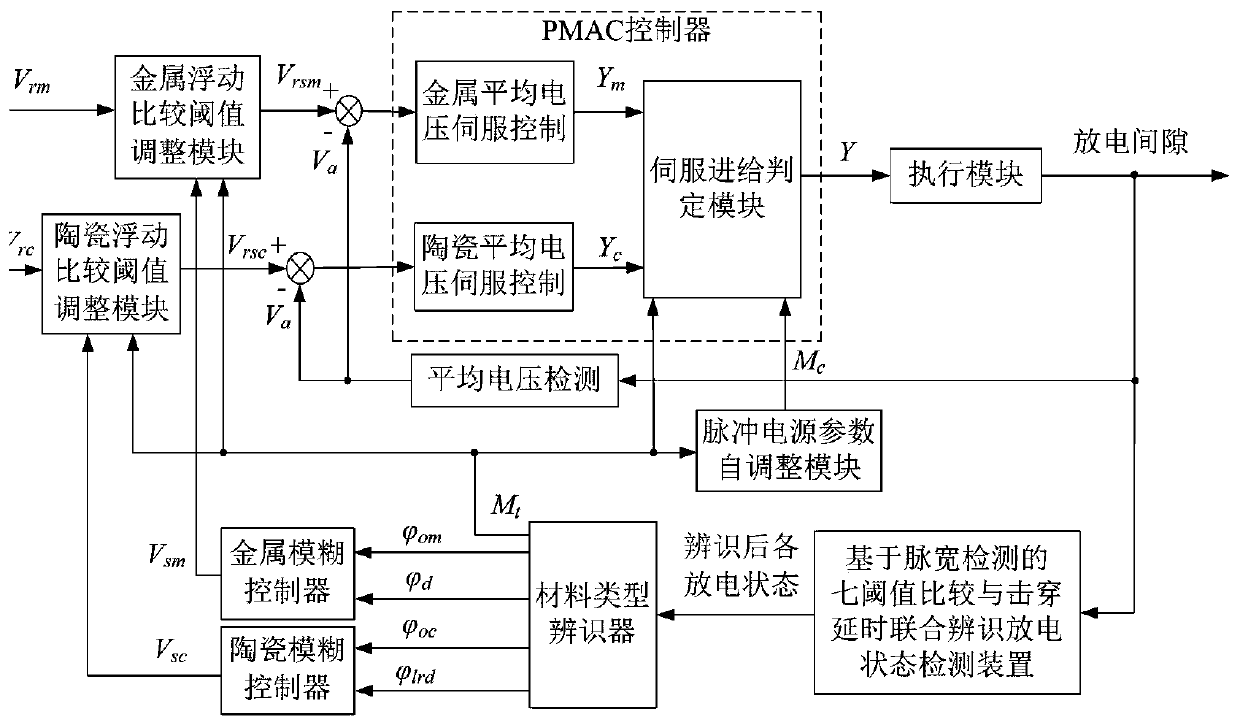

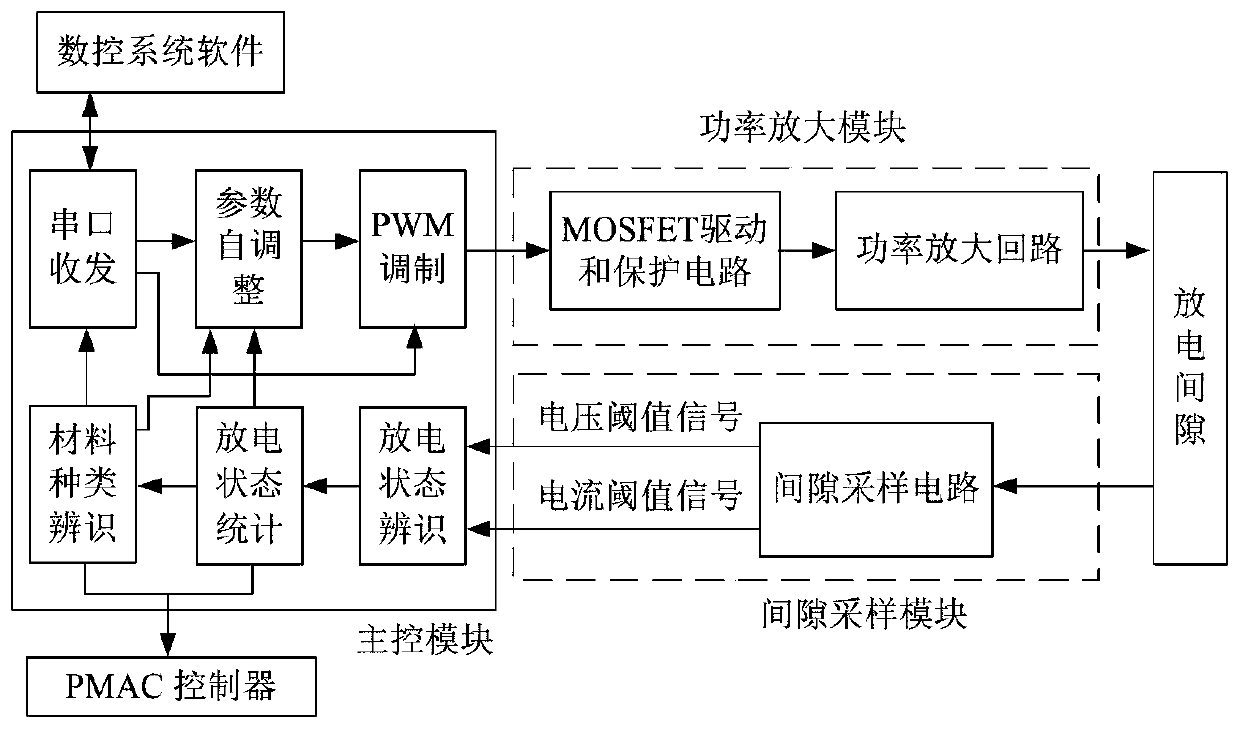

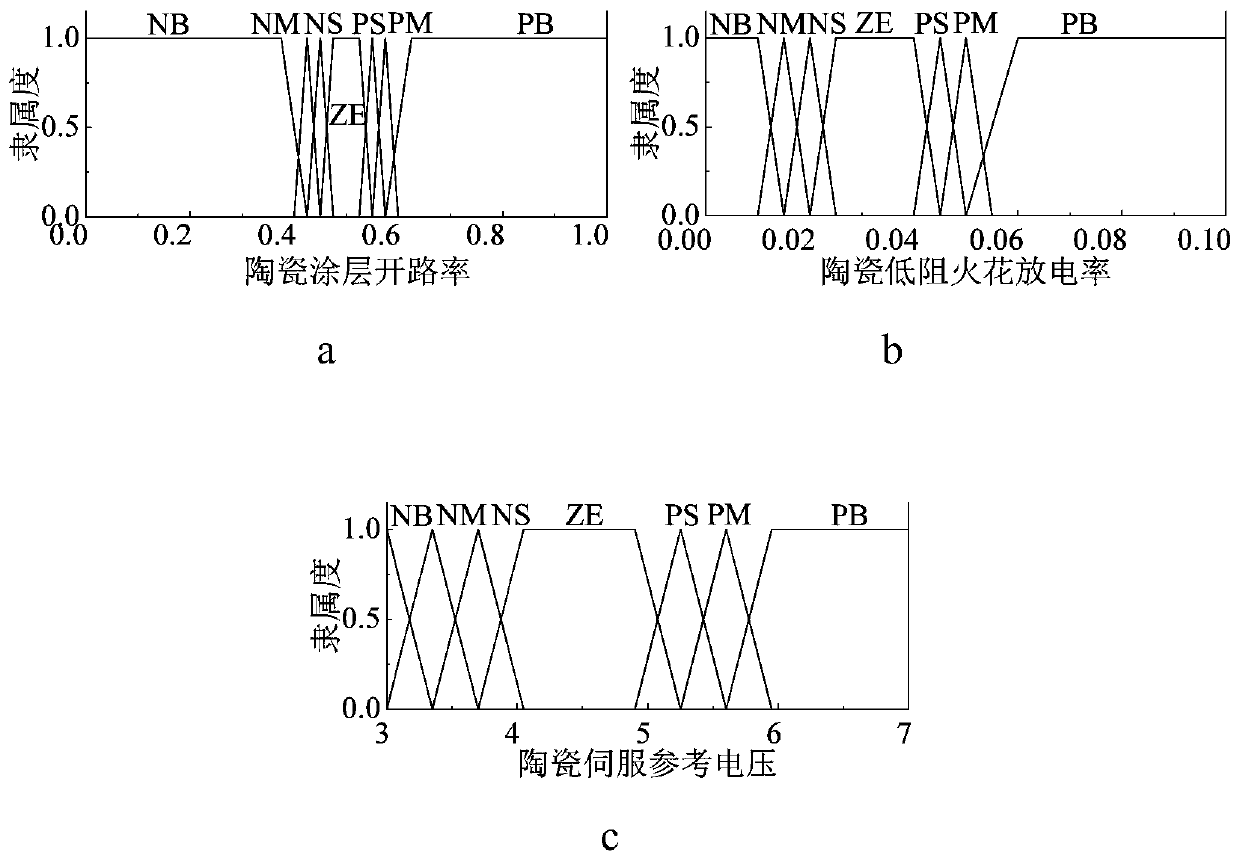

Fuzzy servo control system and method for material identification of insulating ceramic coating-metal electric spark machining

ActiveCN110181132AImprove processing efficiencyImprove processing qualityElectric circuitsElectricityMaterial type

The invention discloses a fuzzy servo control system and method for material identification of insulating ceramic coating-metal electric spark machining. The fuzzy servo control system involves an average voltage detection module, a pulse power supply parameter self-adjusting module, a PMAC controller, a metal floating comparison threshold value adjusting module, a ceramic floating comparison threshold value adjusting module, a metal fuzzy controller, a ceramic fuzzy controller, a material type identifier, a seven-threshold comparison and breakdown delay combined discharge state identificationdetection device based on pulse width detection and an execution module. According to the system and the method, a material type can be identified in the processing process, and a floating comparisonthreshold value of an insulating ceramic coating or metal can be adjusted on line according to the material type, so that the effective adjustment of discharge gaps of the ceramic coating and the metal is realized, and the electric spark machining efficiency and quality of the insulating ceramic coating-metal material are improved.

Owner:HARBIN INST OF TECH

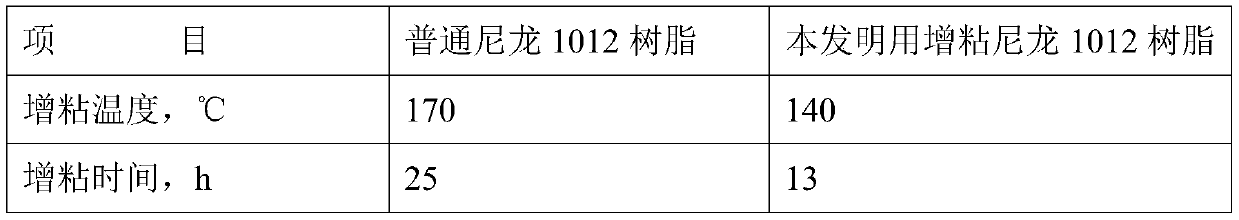

Special flame-retardant nylon material for cable sheaths of new energy vehicles, and preparation method thereof

InactiveCN110204895AGuaranteed processing stabilityGood flexibilityPlastic/resin/waxes insulatorsElastomerNew energy

The invention discloses a special flame-retardant nylon material for cable sheaths of new energy vehicles, and a preparation method thereof. The special flame-retardant nylon material for cable sheaths of new energy vehicles, having a good flexibility, excellent processing performances, excellent adhesion to metals and new energy vehicle cable sheath requirement-meeting environmental protection and flame retardation performances, is prepared by using self-synthesized tackifying nylon 1012 resin as a base material, adding proper amounts of assistants such as a toughening agent (a nylon 12 elastomer or a maleic anhydride-grafted elastomer), a flame retardant and a compounded lubricant and using a self-designed screw rod; and the performances of the product are as follows: the tensile strength being more than 30 MPa, the elongation percentage being more than 150%, the bending strength being less than 40 MPa, the charpy notched impact strength being NB, and the flame retardation level being not less than FV-2 (thickness 1.6 mm).

Owner:SHANDONG DONGCHEN ENG PLASTIC

Method for machining bottle-shaped shaft of large pumped storage generator motor

ActiveCN111421308AReduce mistakesMeet the requirements of beating high precisionMagnetic circuit rotating partsNumerical controlEngineering

The invention discloses a method for machining a bottle-shaped shaft of a large pumped storage generator motor, and belongs to the technical field of motor shaft machining. The method is characterizedby comprising the following steps of a, boring a matching hole of the center of a large end and a transition connecting plate; b, turning an outer circle and a welding groove of the transition connecting plate, and assembling and welding the transition connecting plate into a shaft center hole in the large end of the bottle-shaped shaft; c, mounting a process dummy shaft at the large end of the bottle-shaped shaft; d, turning the process dummy shaft; e, on a working platform of a numerical control boring machine, erecting and installing the process dummy shaft to be parallel to the numericalcontrol boring machine by using angle iron, pressing a workpiece, checking by using a height gauge according to a line, pressing a gauge on the lower side surface of the machined groove by using a dial gauge, moving the machine tool away along an X axis, checking by using the height gauge according to the line, and machining a magnet yoke key groove to obtain a bottle-shaped shaft finished product. The chuck precision of a horizontal lathe does not affect the rotation center of the bottle-shaped shaft, the machining difficulty is reduced, the machining stability is guaranteed, the machining precision is improved, and machining operation is more convenient.

Owner:DONGFANG ELECTRIC MACHINERY

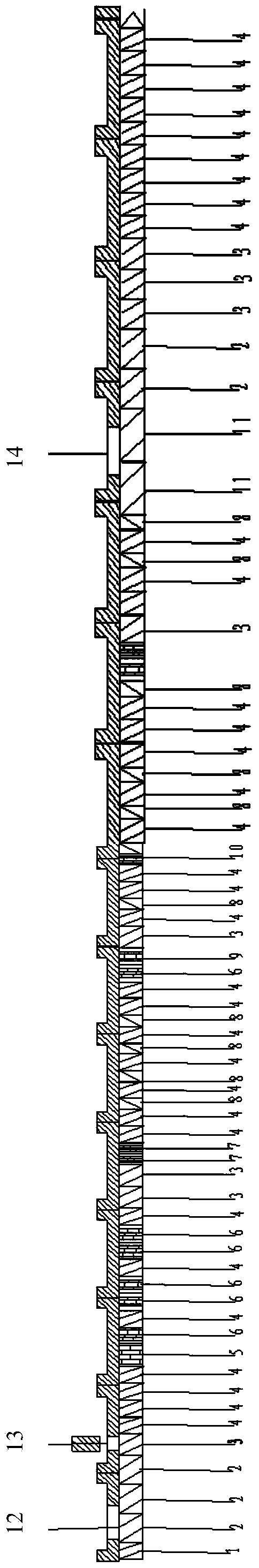

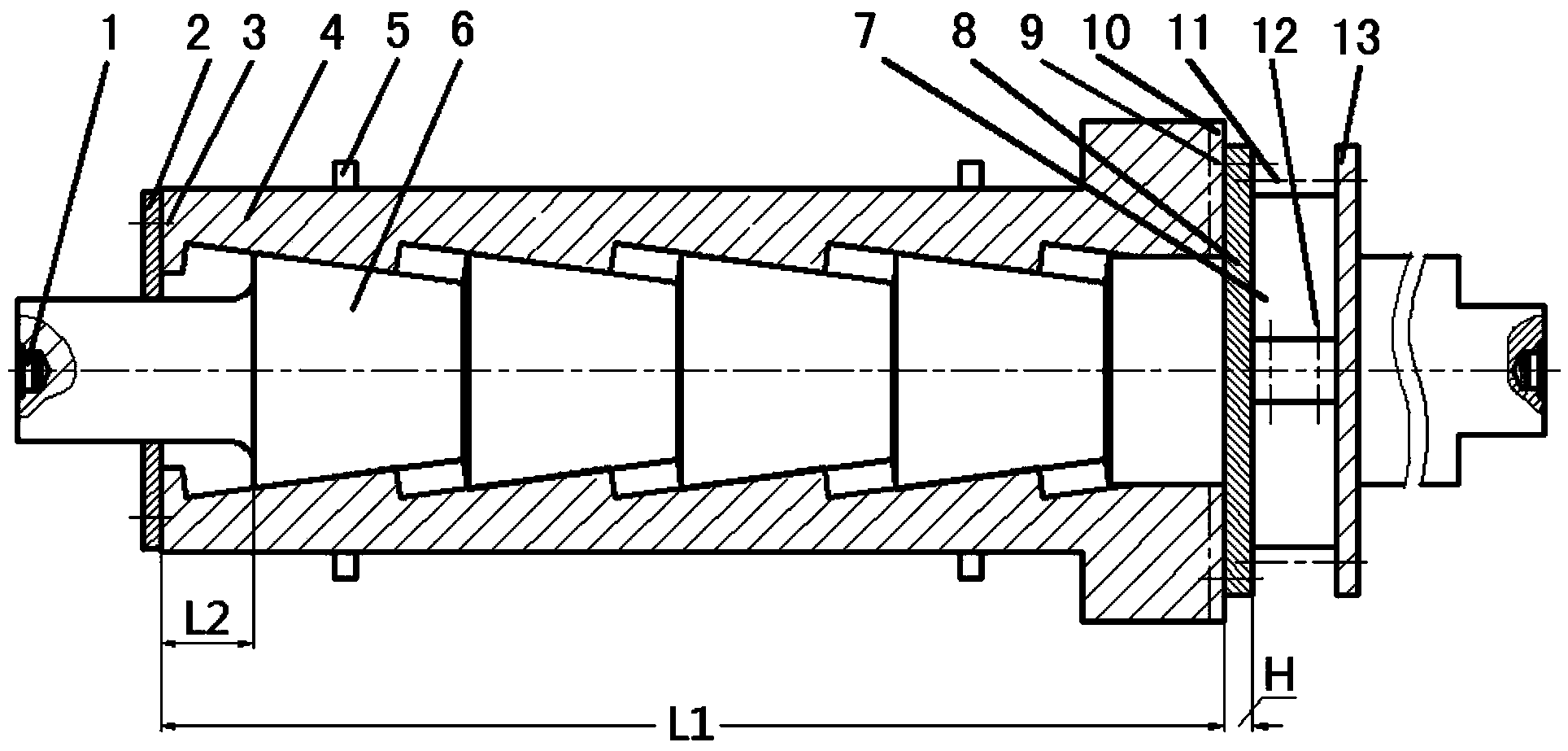

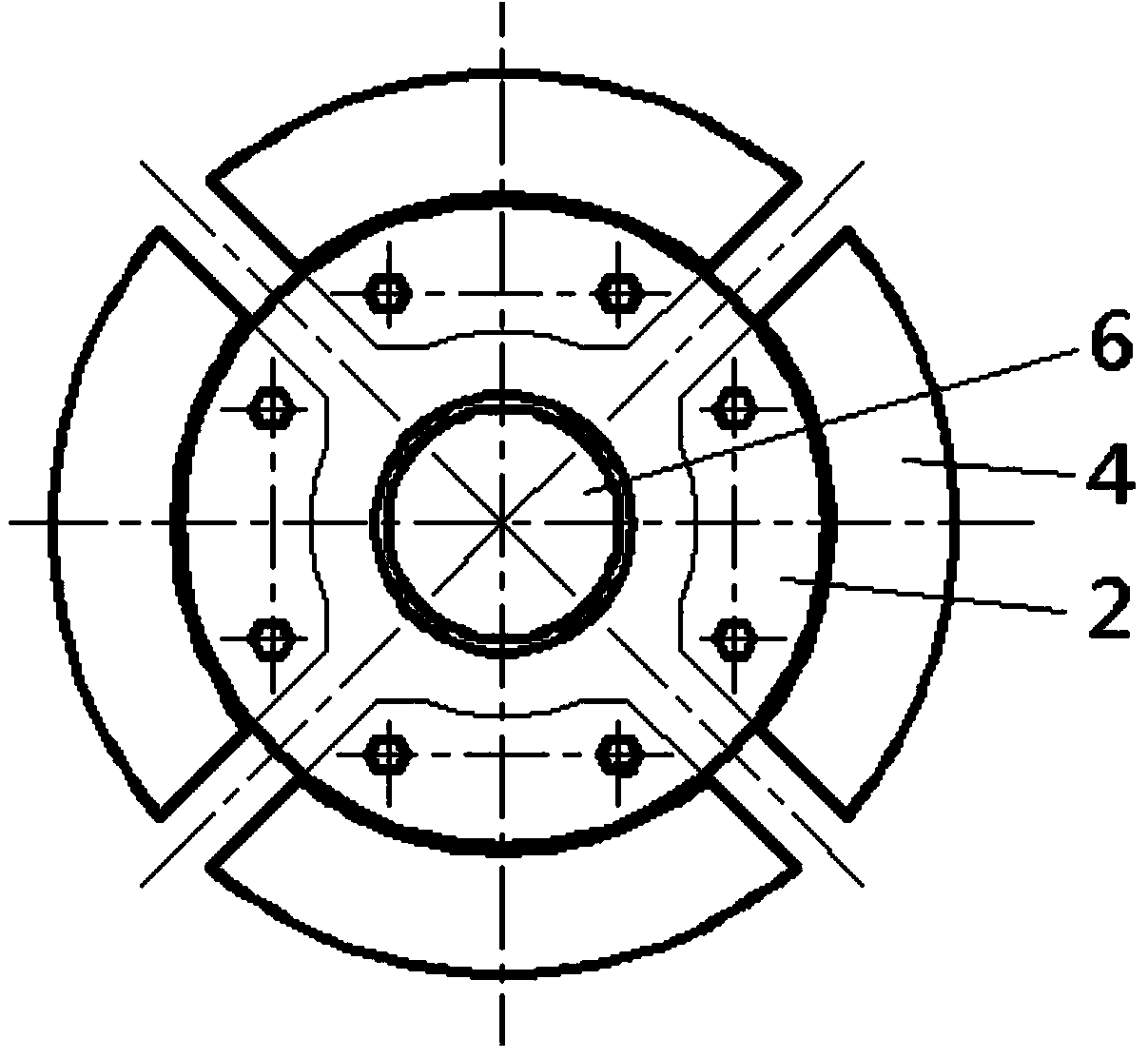

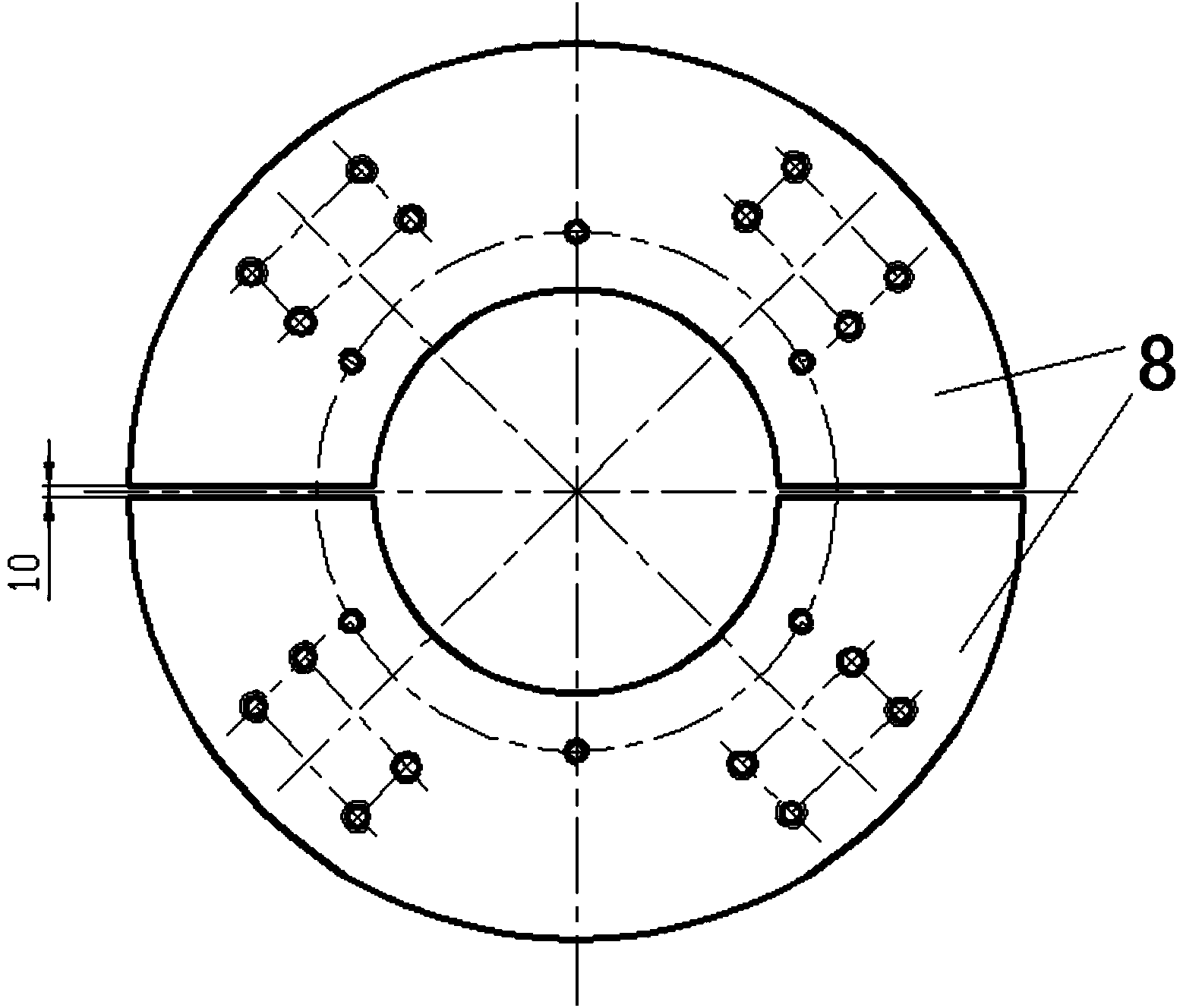

Method for machining fan-shaped plate outer circle by utilizing split base plate

ActiveCN103522094ARealize processing positioningAchieve axial positioningPositioning apparatusGrinding work supportsEngineeringMechanical engineering

The invention discloses a method for machining a fan-shaped plate outer circle by utilizing a split base plate. The method comprises the steps that a positioning body is combined on a main shaft, an upper lathe is positioned through inserting blocks which are arranged at the two ends, the two end faces of the positioning body are machined, the length size L of the installing space of fan-shaped plates is controlled in the range of + / -0.2mm, the two end faces of the positioning body are perpendicular to the axis of the main shaft, and the two end faces of the positioning body are parallel to each other. The four fan-shaped plates are arranged into the main shaft and are respectively clamped through the cooperation of two sets of clamps and jack screws, the base plate and the large ends of the fan-shaped plates are fixed through a tool base plate, and the small ends of the fan-shaped plates are connected with a shaft end baffle. A pull plate is connected with the base plate through a long screw rod but not held tightly, the planeness of the end face of the base plate is checked, and gaps between the two end faces of the base plate and the fan-shaped plates and between the two end faces of the base plate and the end face of the positioning body are rechecked. The long screw rod is held tightly, and the outer circle of the fan-shaped plates is machined. The method solves the problem that the positioning cannot be achieved in the radial direction when the outer circle of the fan-shaped plates is machined.

Owner:MCC SFRE HEAVY IND EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com