Numerical control grinding machine pneumatic clamp for gear grinding

A CNC grinding machine and pneumatic fixture technology, which is applied to components with teeth, gear teeth manufacturing devices, belts/chains/gears, etc., can solve the problems that can not really meet the requirements of automatic production, low safety factor, time-consuming and labor-intensive, etc. , to achieve stability and high precision, improve the safety factor, and ensure the effect of circumferential stability and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

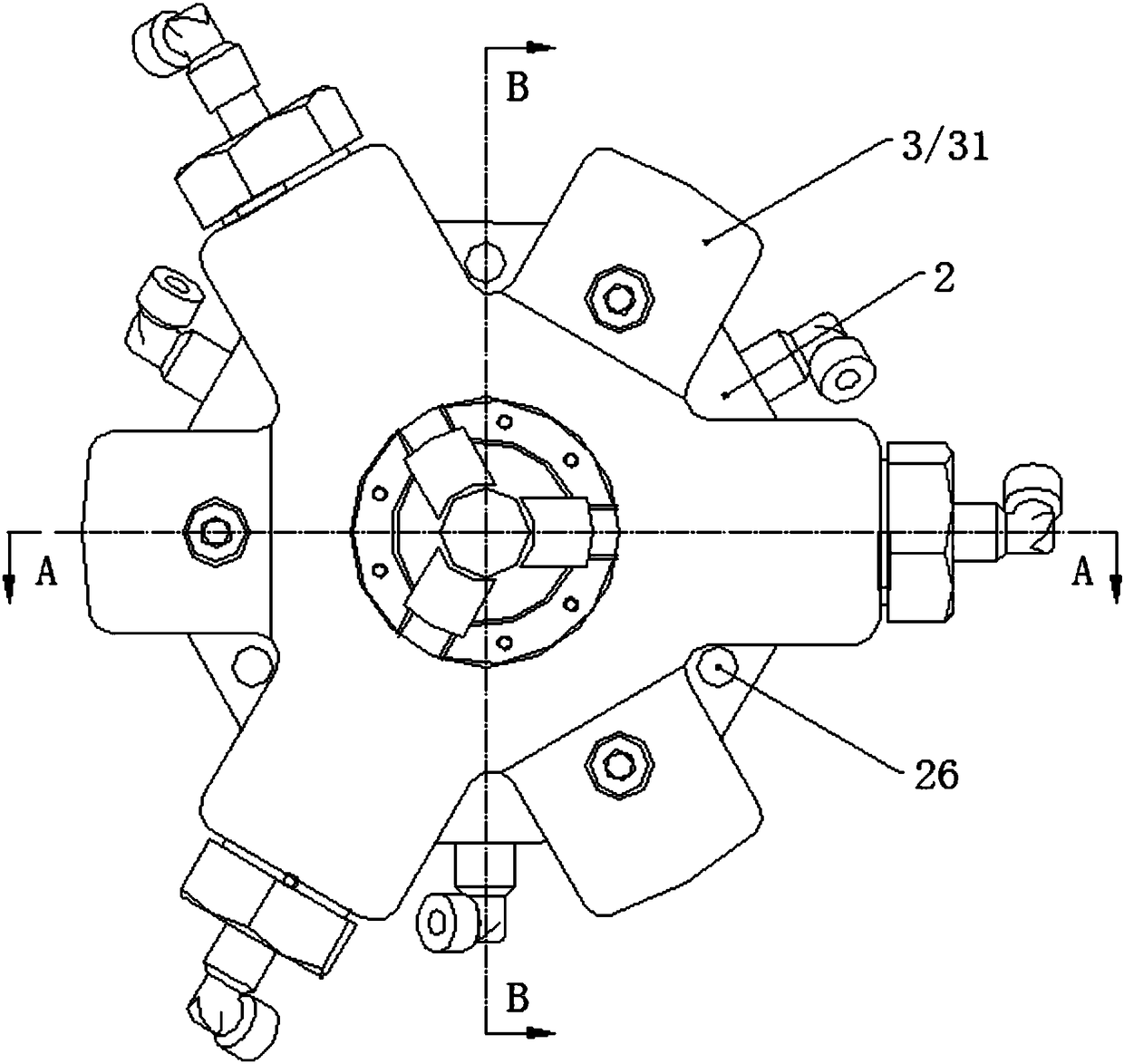

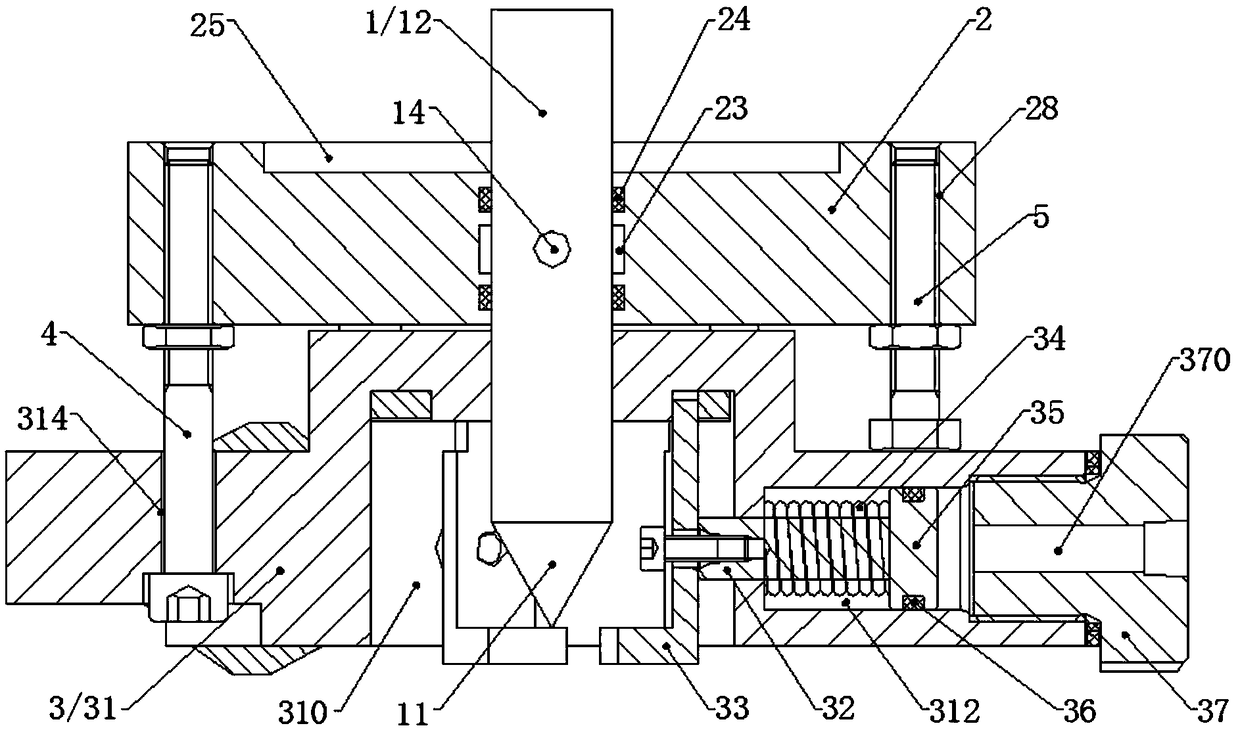

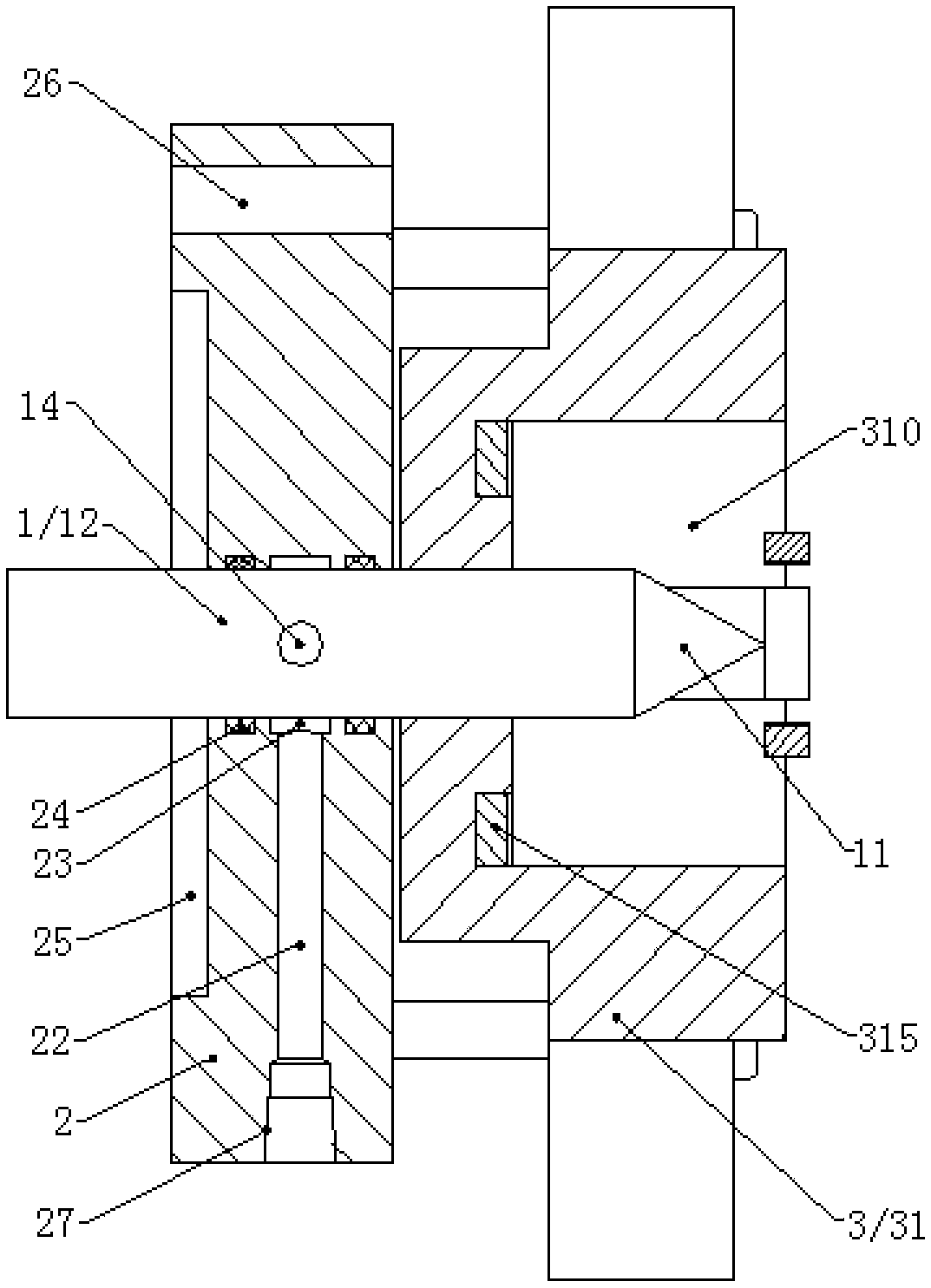

[0035] refer to Figures 1 to 10 As shown, the structural features of the pneumatic clamp for CNC grinding machine used for gear grinding are described in detail as follows:

[0036] A pneumatic fixture for a CNC grinding machine used for gear grinding, which includes a thimble 1; the fixture also includes a chassis 2 and a cylinder 3, one end of the chassis 2 is fixed on the bed base, and the cylinder 3 is fixed on the chassis 2 The other end, and the cylinder 3 includes a clamping cavity 310; the thimble 1 is set through the chassis 2, wherein, one end of the thimble 1 is fixedly connected to the bed base, and the tip 11 of the other end of the thimble 1 is placed on the cylinder 3 In the clamping chamber 310.

[0037] When the pneumatic fixture of the CNC grinding machine is used for grinding gears, the gears are placed in the clamping chamber 310 of the cylinder 3, and the circumferential stability of the gear clamping is ensured by the cylinder 3; since one end of the th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com