A Mechanical Seal Structure Suitable for Fuel Cooling Turbine

A technology of mechanical sealing and cooling turbine, applied in the direction of engine sealing, gas turbine device, mechanical equipment, etc., can solve the problems of seal failure, rubber ring failure, poor sealing effect, etc., to reduce the degree of runout, good sealing effect, working temperature low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

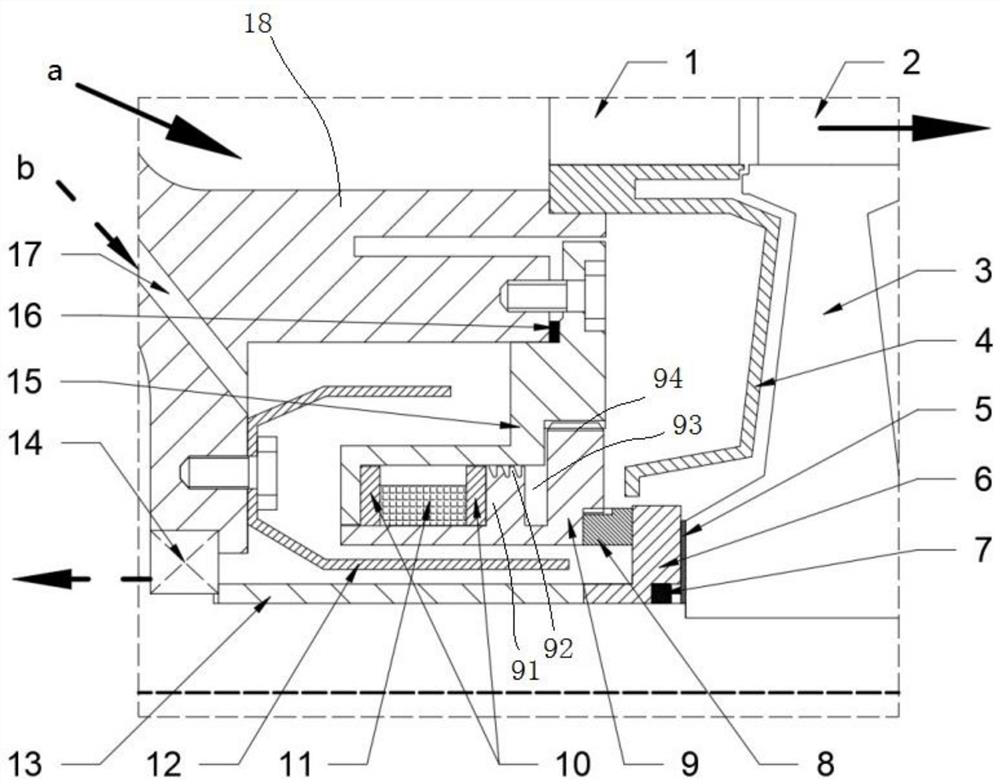

[0033] figure 1 It is a schematic main cross-sectional view of a mechanical seal structure suitable for a fuel-cooled turbine according to an embodiment of the present application, wherein a is the flow direction of the mainstream gas working medium, and b is the cooling oil flow inlet and outlet. This embodiment provides a mechanical seal structure suitable for fuel-cooled turbines, wherein the turbine includes a stationary casing 18, a bearing 14 and a sleeve 13 sleeved in the stationary casing 18, and a The turbine guide vane 1, the turbine rotor blade 2, the turbine disk 3 and the disk chamber baffle plate 4 in the casing 18. The sleeve 13 is in contact with the inner ring of the bearing 14 . The upper end of the disk cavity baffle plate 4 is connected to the base of the turbine guide vane 1, and plays a role in blocking the leakage of hot gas in the rotating and static gap in the turbine disk cavity, which can not only play the role of heat insulation, protect the sealin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com