Low-smoke zero-halogen flame-retardant polyolefin oxygen barrier material

A polyolefin and oxygen barrier technology, applied in the field of low-smoke halogen-free flame retardant polyolefin oxygen barrier material, can solve the problem that slow extrusion current limits cable production efficiency, cannot effectively isolate and protect insulating layers, and cables cannot meet the requirements of combustion. Grade requirements and other issues to achieve the effect of reducing the heat release rate and total heat release, reducing smoke production and ensuring processing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Below in conjunction with the examples, the specific implementation of the present invention will be further described in detail. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

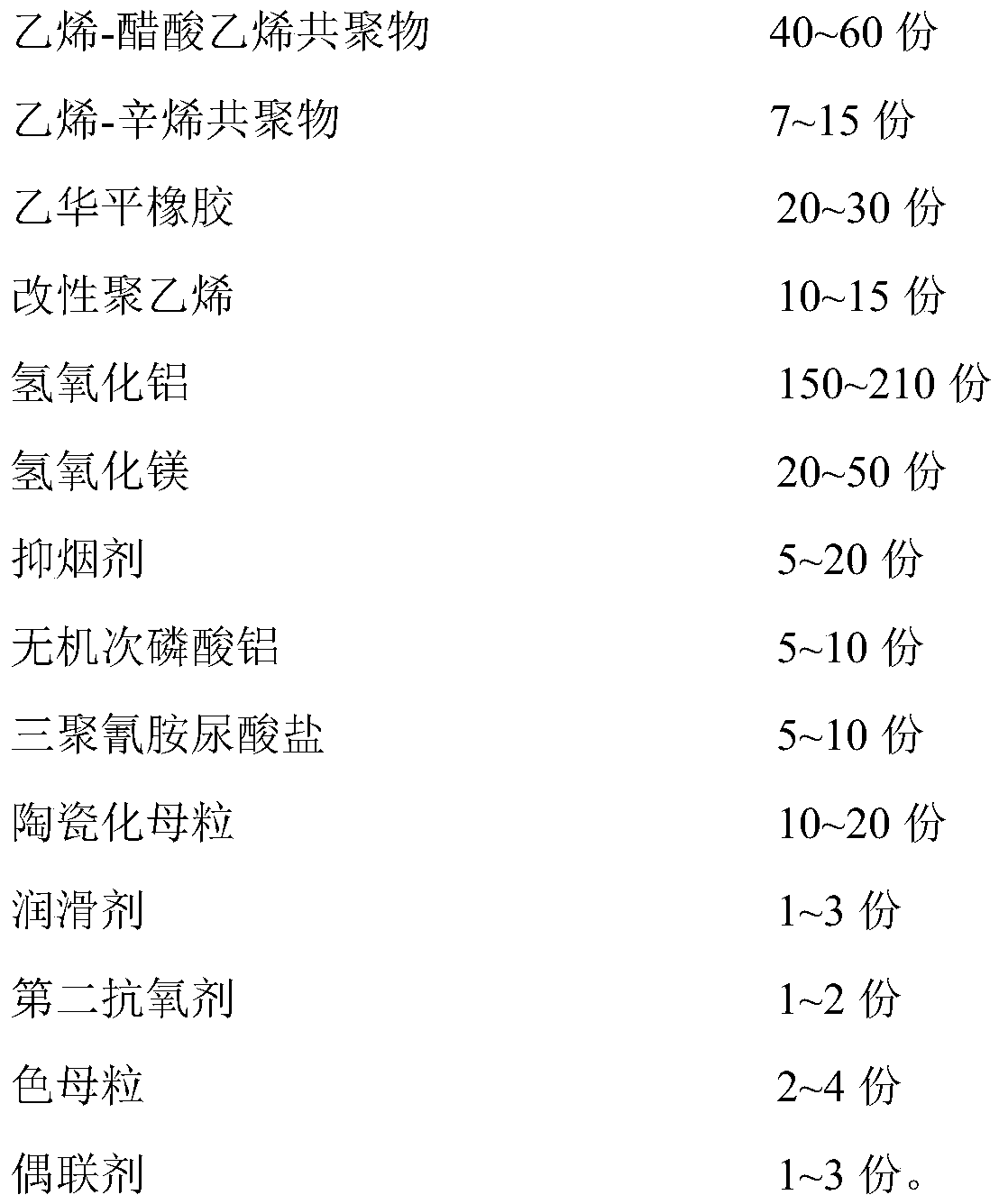

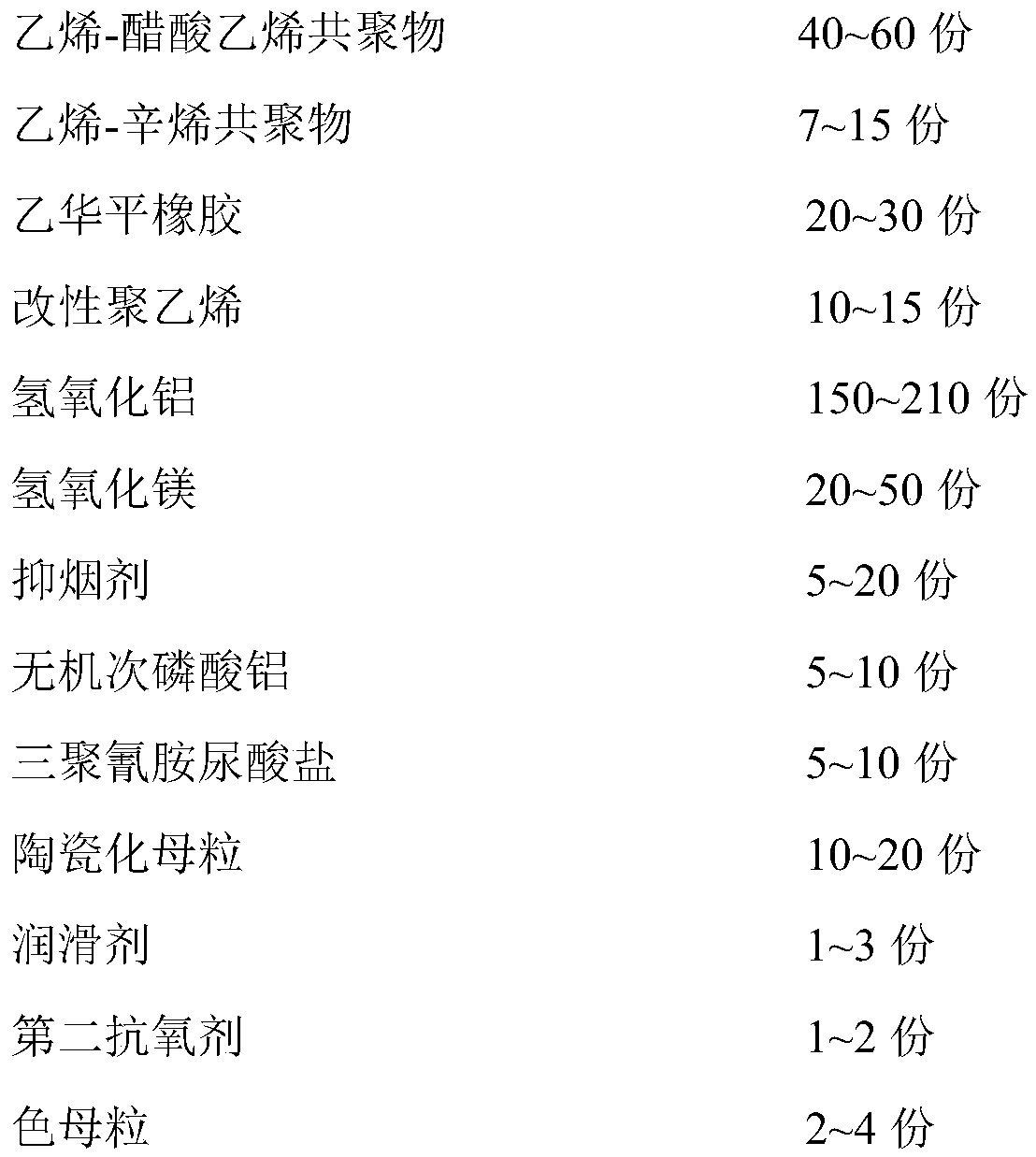

[0042] The product of the present invention is based on ethylene-vinyl acetate copolymer, Evapine rubber, modified polyethylene and ethylene-octene copolymer, with aluminum hydroxide, magnesium hydroxide, zinc borate, melamine urate (MCA) 1. One or more of the inorganic aluminum hypophosphite is the main flame retardant, adding vitrified masterbatch, and then adding a certain amount of lubricant, antioxidant, color masterbatch and other functional additives. After being uniformly mixed by an internal mixer, it is then extruded and granulated by a two-stage extruder unit to finally produce a low-smoke, halogen-free polyolefin oxygen barrier with low heat release, high coke formation, and excellent extrusion p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com