Differential three-screw extruder with triangularly-arranged screws

A triangular, extruder technology, applied in the field of differential three-screw extruders, can solve the problems of low efficiency, inability to operate continuously, and not suitable for extrusion molding, granulation, mixing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

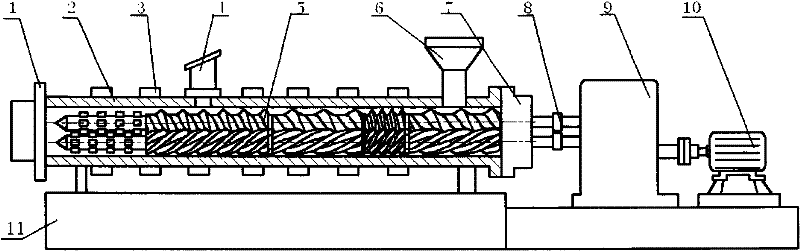

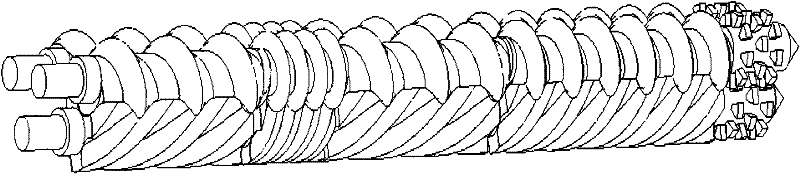

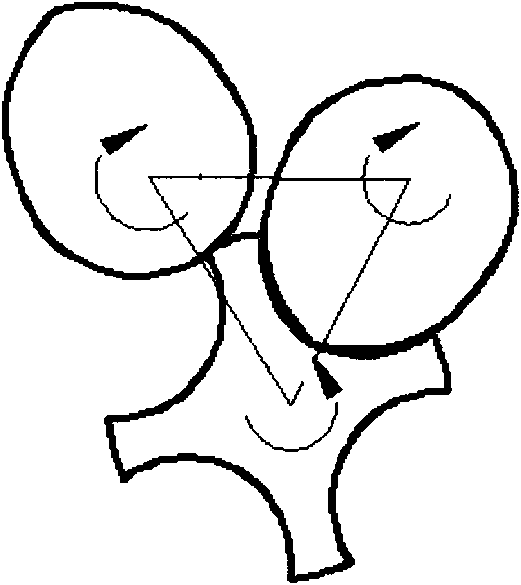

[0022] according to figure 1 Design a differential three-screw extruder with a triangular arrangement of screws, and the three screws engage like figure 2 . Three screw rods 5 in the extruder adopt image 3 , Figure 4 or Figure 5 equal arrangement. Among them, in the thread meshing area, the number of screw heads of the male rotor is 1, and the number of screw heads of the female rotor is 4. The high-speed motor distributes the torque to the male and female rotors through the reduction box 9 and the coupling 8. The speed ratio is 1 / 4. The two male rotors rotate in the same direction, while the female rotor and the male rotor rotate in different directions. The screw 5 is assembled and placed in the barrel 2 fixed on the mounting base 7. The barrel 2 has an exhaust port 4, and the temperature is adjusted through the external heating and cooling device 3. The barrel 2, the reduction box 9 and the motor are directly installed on the frame. 11 on.

[0023] Add the materi...

Embodiment example 2

[0025] A differential three-screw extruder is formed similarly to Example 1. The difference is that the screw is in the mixing section close to the machine head 1, using Figure 7 and Figure 8 Engagement disc form shown. The non-staggered area of the screw toothed disc can divide the material, increase the interface, provide the minimum energy input, facilitate the distribution and mixing, and generate a lower temperature; the shearing of the material perpendicular to the flow direction in the interlaced area is also beneficial Distribution mixing makes up for the shortcoming of insufficient distribution mixing ability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com