A method of extruding activated carbon materials using a reactive twin-screw extrusion system

A twin-screw extrusion and reactive technology, applied in the field of porous materials, can solve the problems of incapable of continuous production and preparation process efficiency, limitation of mass transfer and heat transfer process of activated carbon materials, etc. hole effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

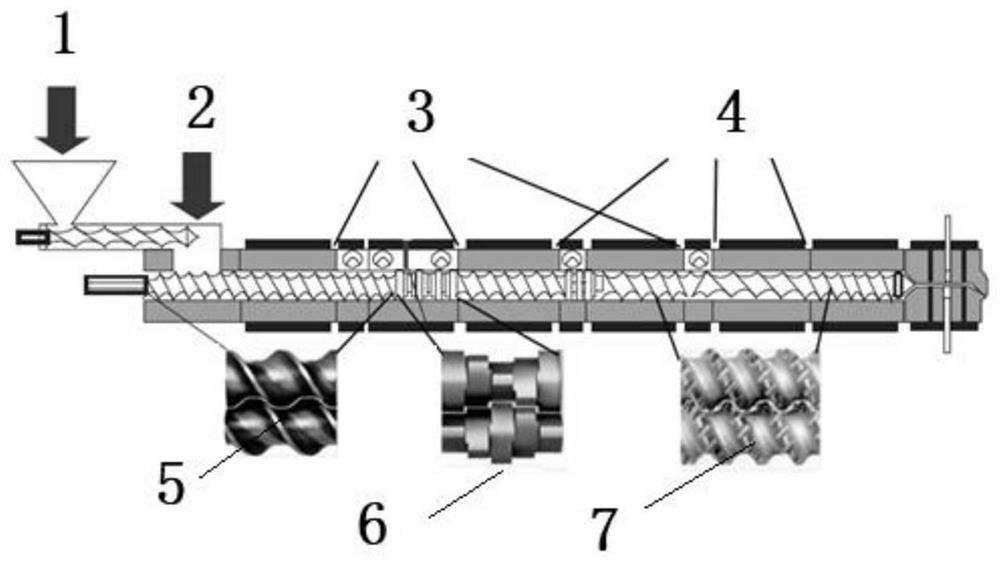

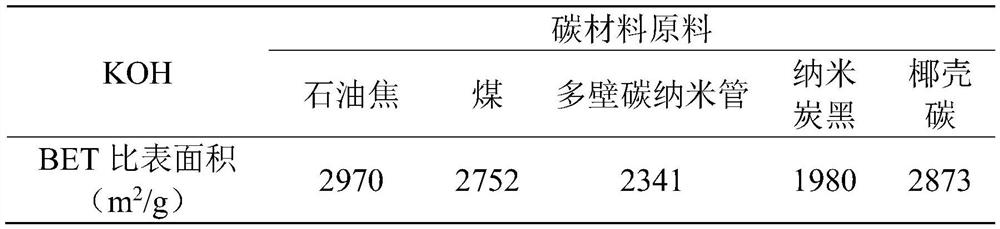

[0069] 100 g of pre-carbonized carbon material raw materials (the types of carbon material raw materials are listed in Table 1) and 300 g of KOH powder were stirred and mixed evenly, and the screw-in speed of the reactive twin-screw extrusion system was 20 r / min. The flow rate of the reactive twin-screw extrusion system is 0.4kg / h. The axial distance of the reactive twin-screw extrusion system is 26mm, the diameter of the screw shaft is 31mm, and the total length of the screw shaft is 12000mm; the reactive twin-screw extrusion system has three functional areas along the axial direction: the propulsion area with a temperature of 400°C 5, The kneading zone 6 with a temperature of 600°C and the high-temperature distribution mixing zone 7 with a temperature of 800°C; the cooled sample is mixed and eluted three times with 2.0kg deionized water, and the treatment time in ultrasonic cleaning is 20 minutes each time, and the solid Samples were filtered and dried. The porosity propert...

Embodiment 2

[0073] 100 g of pre-carbonized carbon material raw materials (the types of carbon material raw materials are listed in Table 2) and 300 g of NaOH powder were stirred and mixed evenly, and the screw-in speed of the reactive twin-screw extrusion system was 20 r / min. The flow rate of the reactive twin-screw extrusion system is 0.4kg / h. The axial distance of the reactive twin-screw extrusion system is 26mm, the diameter of the screw shaft is 31mm, and the total length of the screw shaft is 12000mm; the reactive twin-screw extrusion system has three functional areas along the axial direction: the propulsion area with a temperature of 400°C 5, The kneading zone 6 with a temperature of 600°C and the high-temperature distribution mixing zone 7 with a temperature of 800°C; the cooled sample is mixed and eluted three times with 2.0kg deionized water, and the treatment time in ultrasonic cleaning is 20 minutes each time, and the solid Samples were filtered and dried. The porosity proper...

Embodiment 3

[0077] 100g of pre-carbonized carbon material raw materials (the types of carbon material raw materials are listed in Table 3) and 300g of NaOH / KOH (1:1) powder were stirred and mixed evenly, and the screw-in speed of the reactive twin-screw extrusion system was 20r / min. The flow rate of the reactive twin-screw extrusion system is 0.4kg / h. The axial distance of the reactive twin-screw extrusion system is 26mm, the diameter of the screw shaft is 31mm, and the total length of the screw shaft is 12000mm; the reactive twin-screw extrusion system has three functional areas along the axial direction: the propulsion area with a temperature of 400°C 5, The kneading zone 6 with a temperature of 600°C and the high-temperature distribution mixing zone 7 with a temperature of 800°C; the cooled sample is mixed and eluted three times with 2.0kg deionized water, and the treatment time in ultrasonic cleaning is 20 minutes each time, and the solid Samples were filtered and dried. The porosity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com