Patents

Literature

423results about How to "Improve impregnation effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Epoxy resin compositions, epoxy resin compositions for fiber-reinforced composite materials, and fiber-reinforced composite materials comprising the same

InactiveUS6410127B1Improve heat resistanceImprove mechanical propertiesSynthetic resin layered productsYarnEpoxyCeiling temperature

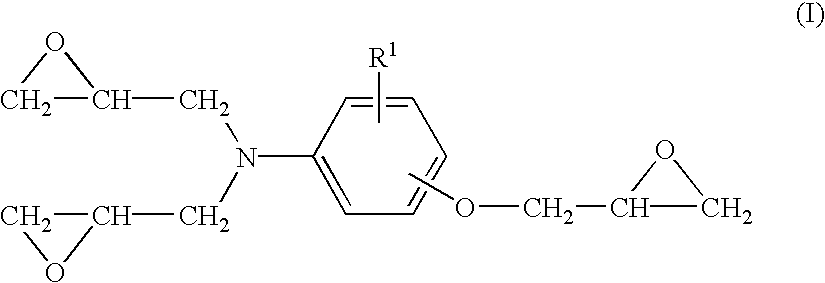

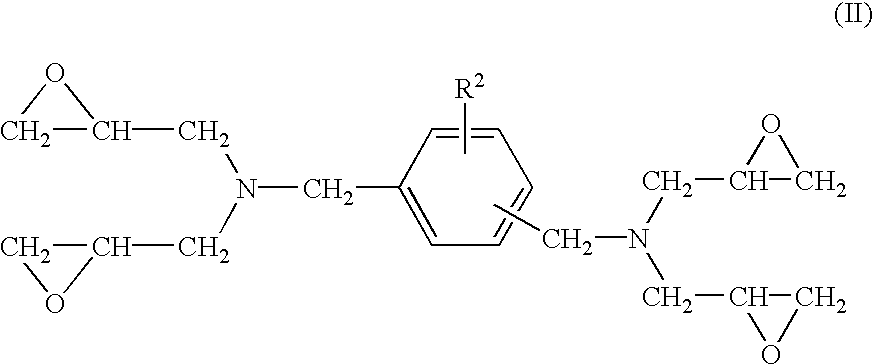

An epoxy resin composition having a low viscosity around a room temperature and excellent reinforcing fiber impregnating properties provides a composite material having excellent heat resistance and mechanical properties including compressive strength. The epoxy resin composition includes an aromatic epoxy resin having at least di-functionality, an aromatic amine compound and / or an alicyclic amine compound, wherein 5 minutes after the main agent comprising the epoxy resin and the curing agent comprising the aromatic amine compound and / or the alicyclic amine compound are mixed, the composition shows a viscosity at 25° C. in the range of from 1 to 1500 mPa sec, and Tc, tc, and Tg satisfy the following equation (1):wherein k=0 when 60<=Tc<90 and k=0.35 when 90<=Tc<=200;Tc is the highest temperature (°C.) during the curing process and is defined by the formula 60<=Tc<=200;tc is the retention time (min) at the highest temperature and is defined by the formula 1<=tc<=120; andTg is the glass transition temperature of the epoxy resin composition after a lapse of tc (min) at Tc (°C.).

Owner:TORAY IND INC

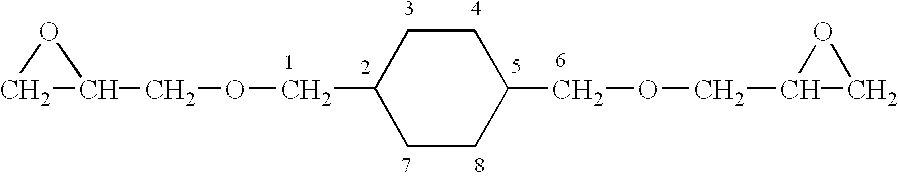

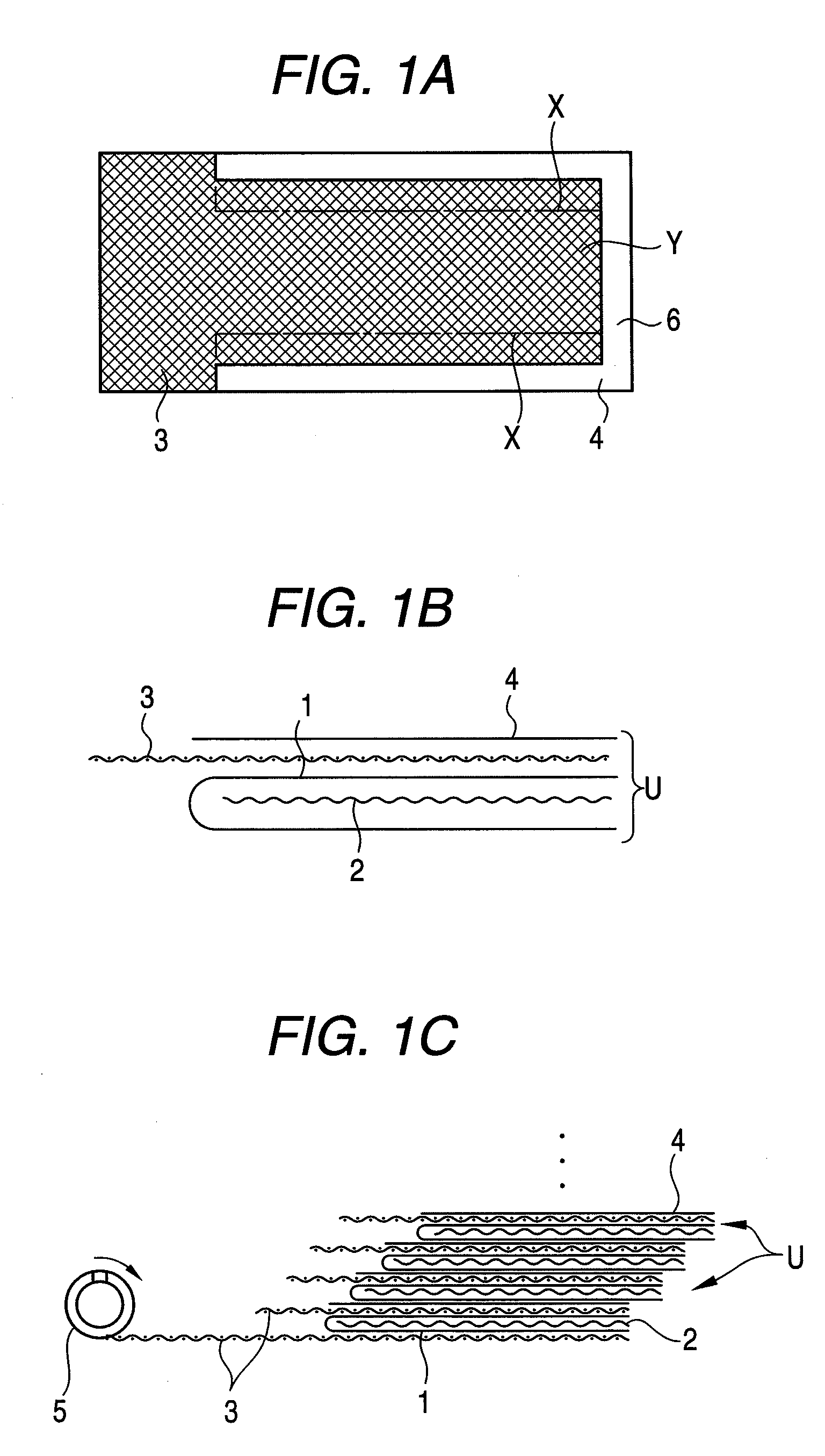

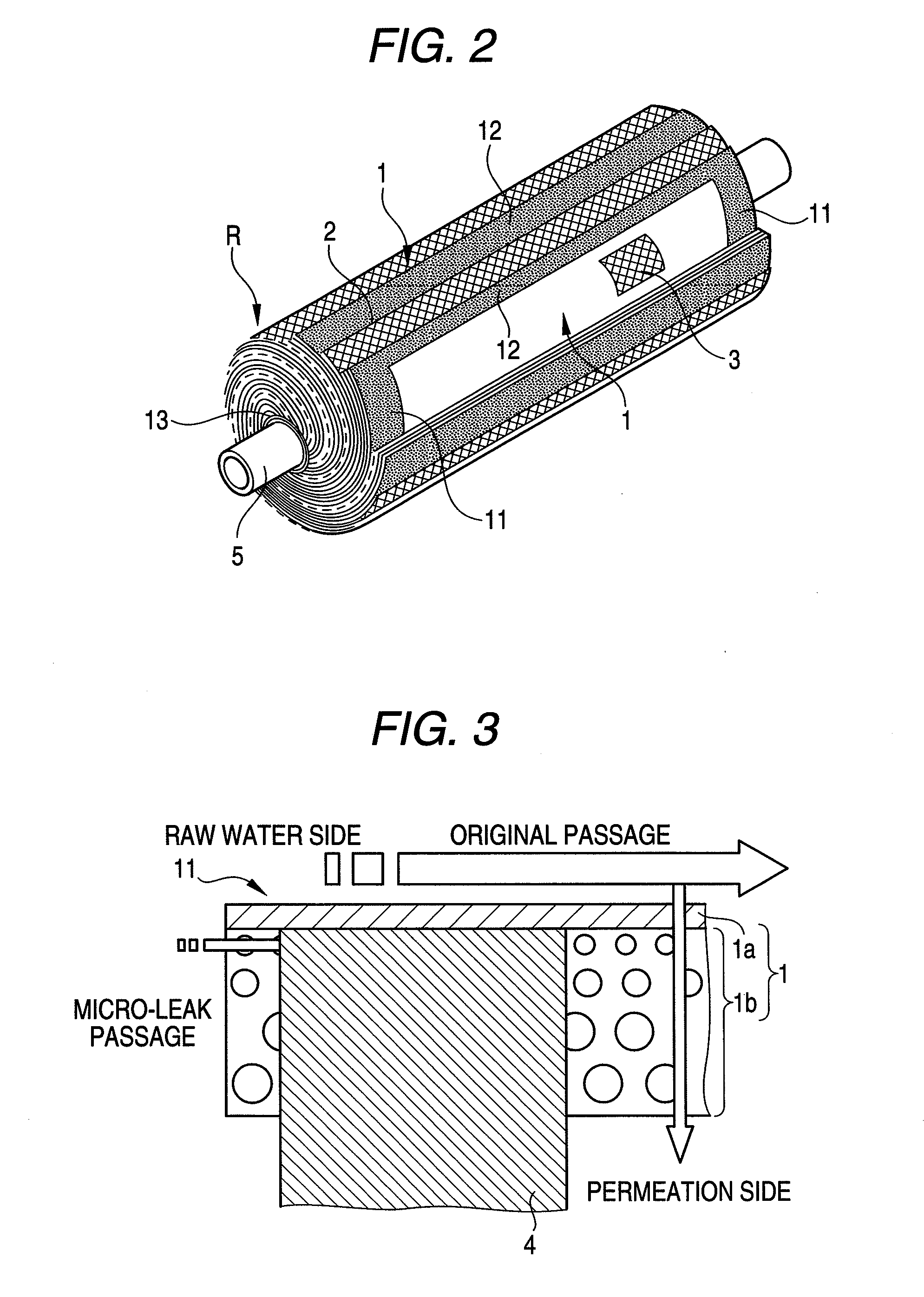

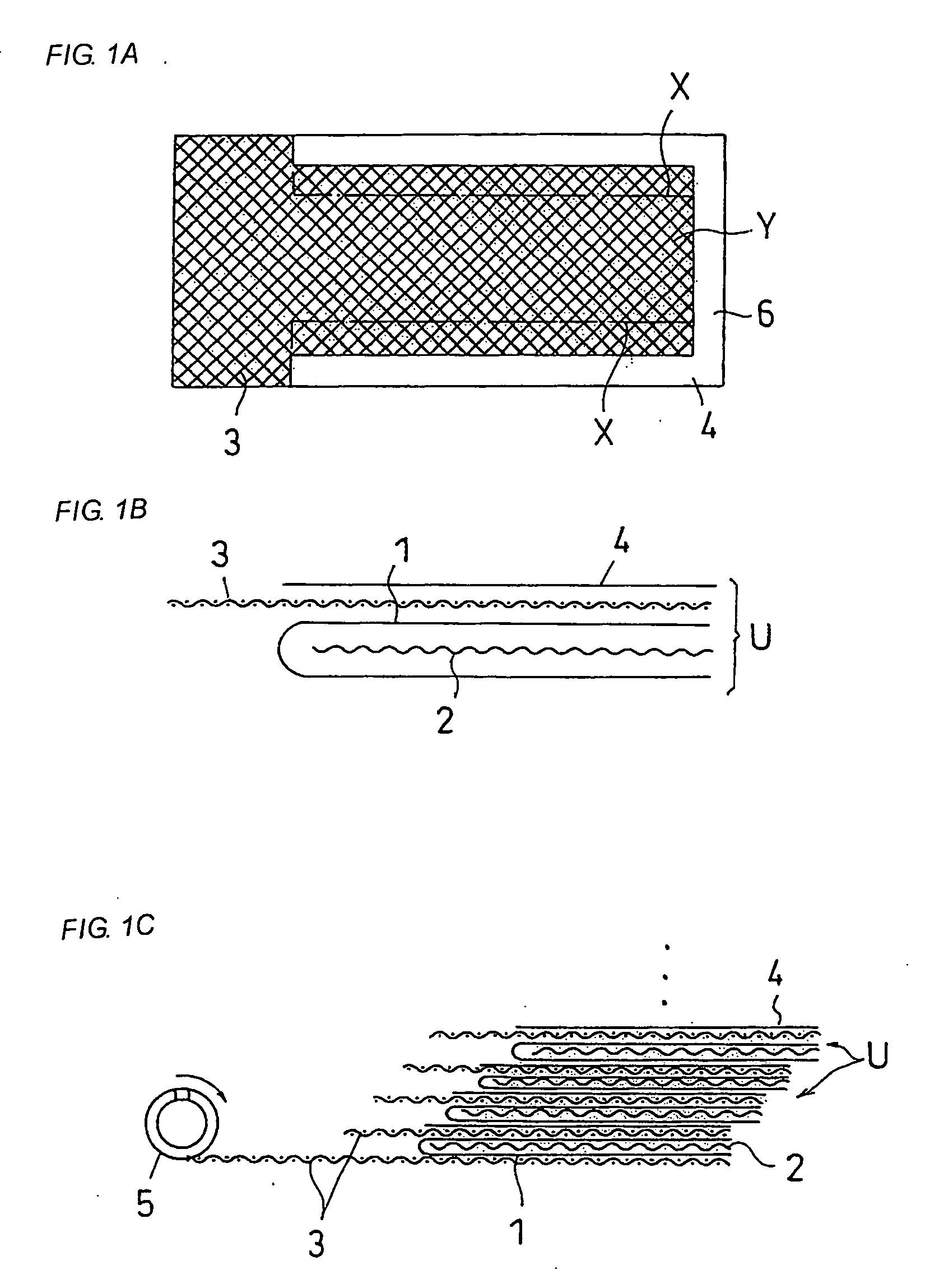

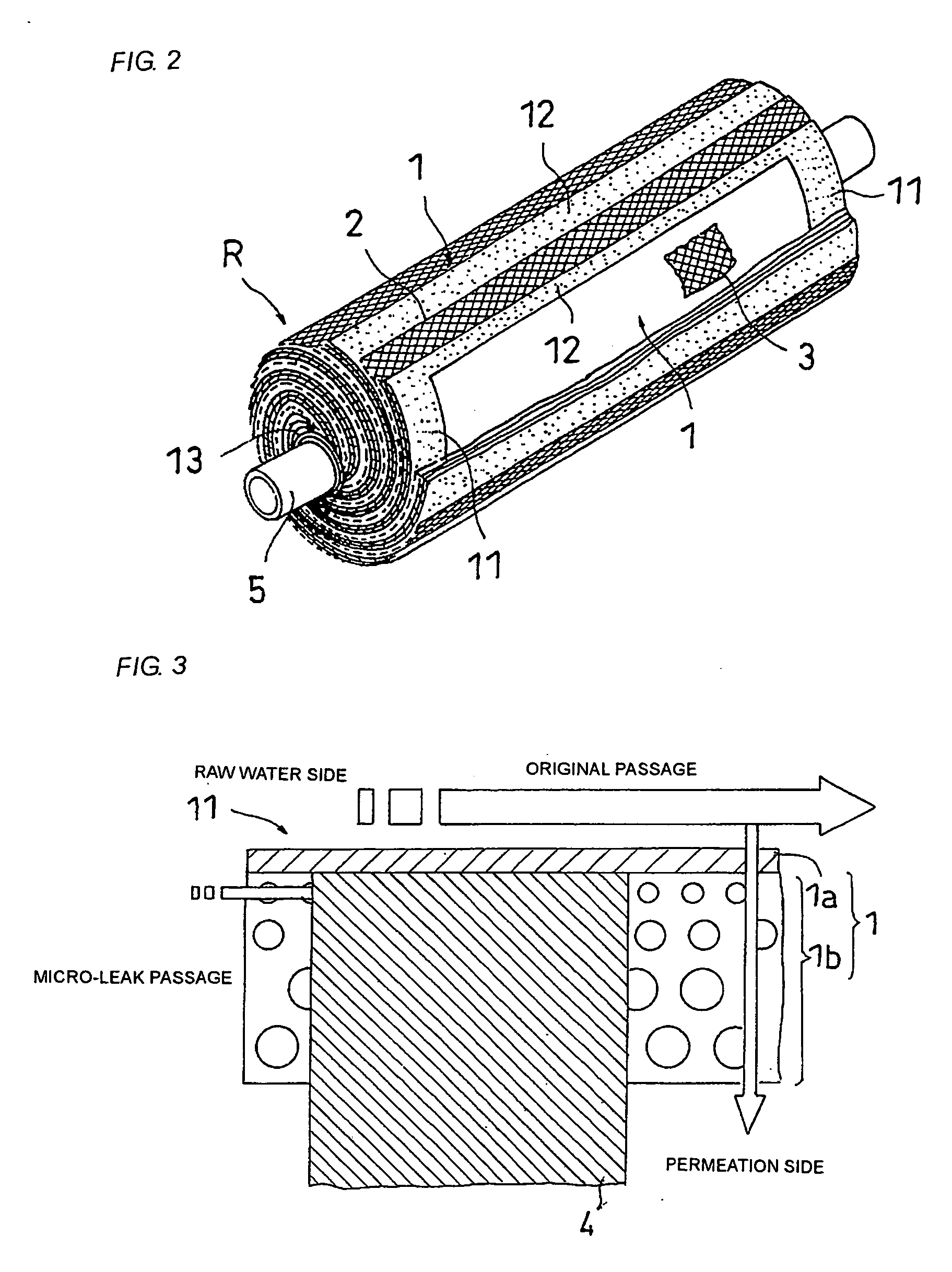

Spiral reverse osmosis membrane element, method of manufacturing the same, and its use method

ActiveUS20080295951A1Improve impregnation effectEffectively prevent micro-leaksSemi-permeable membranesPaper/cardboard wound articlesReverse osmosisPermeation

Owner:NITTO DENKO CORP

Long glass fiber reinforced recycled polypropylene material and preparation method thereof

The invention discloses long glass fiber reinforced recycled polypropylene material and a preparation method thereof. The long glass fiber reinforced recycled polypropylene material comprises components according to mass percent: 25-55% of polypropylene, 30-60% of long glass fiber, 0.4-0.8% of coupling agent, 3-8% of graft of thermoplastic elastomer, 0.1-0.3% of fused finger modifier, 0.2-0.4% ofantioxygens, 1-4% of lubricant and 1-3% of selective assistant. The preparation method is as follows: mixing and stirring components except for long glass fiber, and then adding the components exceptfor long glass fiber to a screw extruder; adding long glass fiber, mixing, extruding, cooling, air drying and pelleting; as the fused finger modifier is added, the requirements on polypropylene are reduced; various recycled polypropylene materials can be used as backing material. The preparation method is simple and has low cost; the prepared long glass fiber einforced recycled polypropylene material has good comprehensive performances and can replace a plurality of metal parts to be applied to various fields.

Owner:惠东美化塑胶实业有限公司

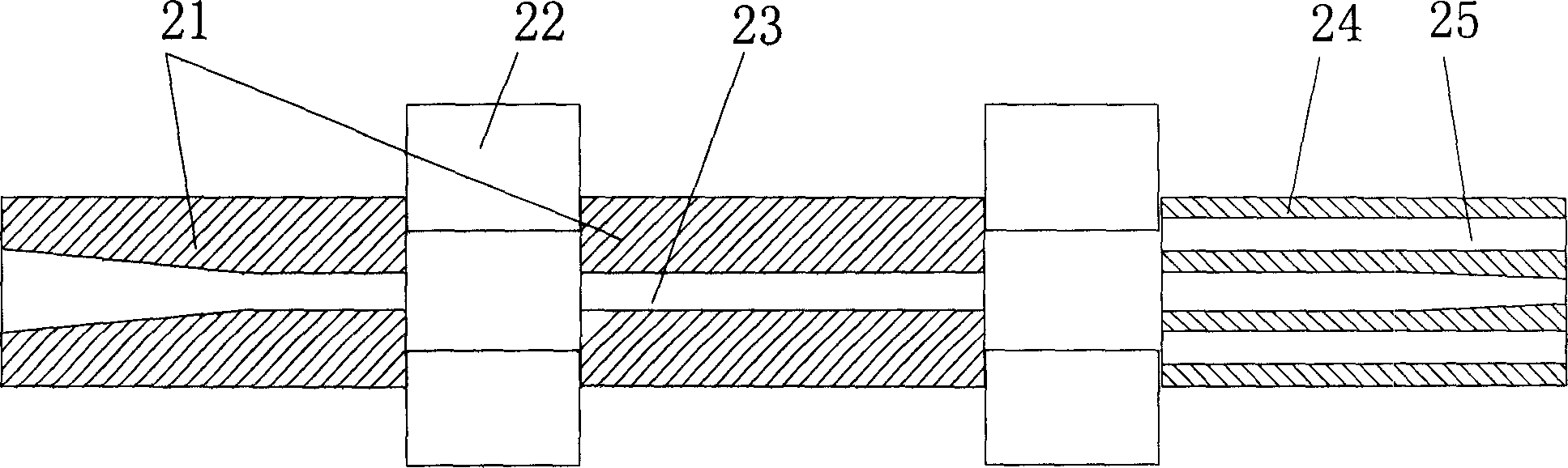

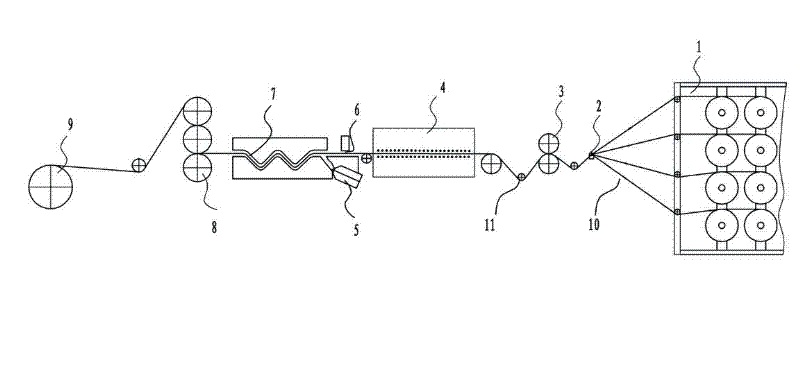

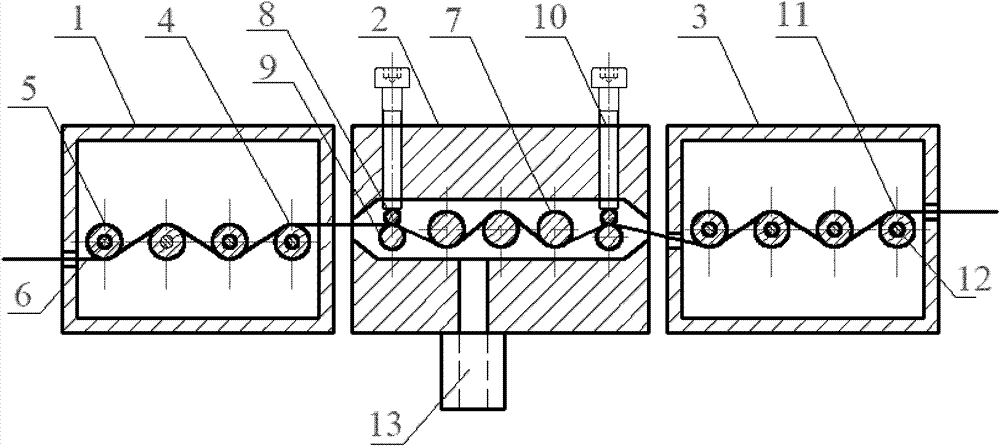

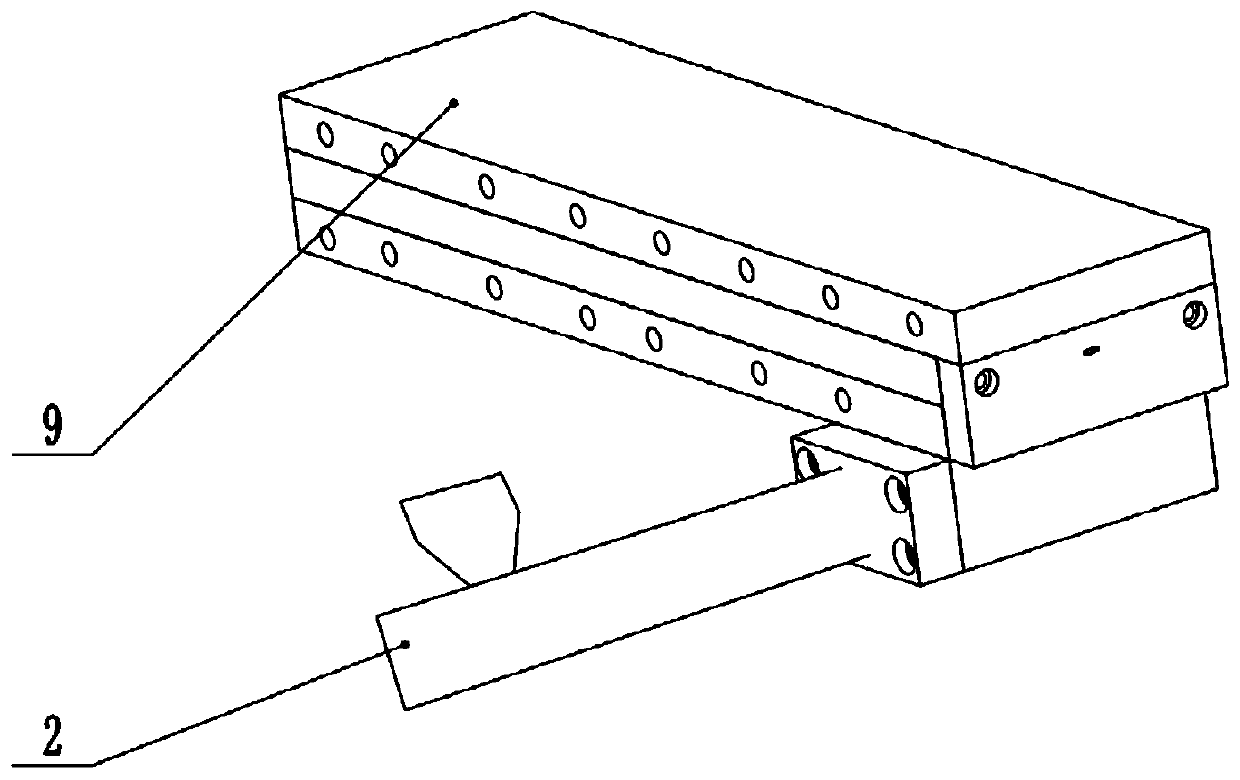

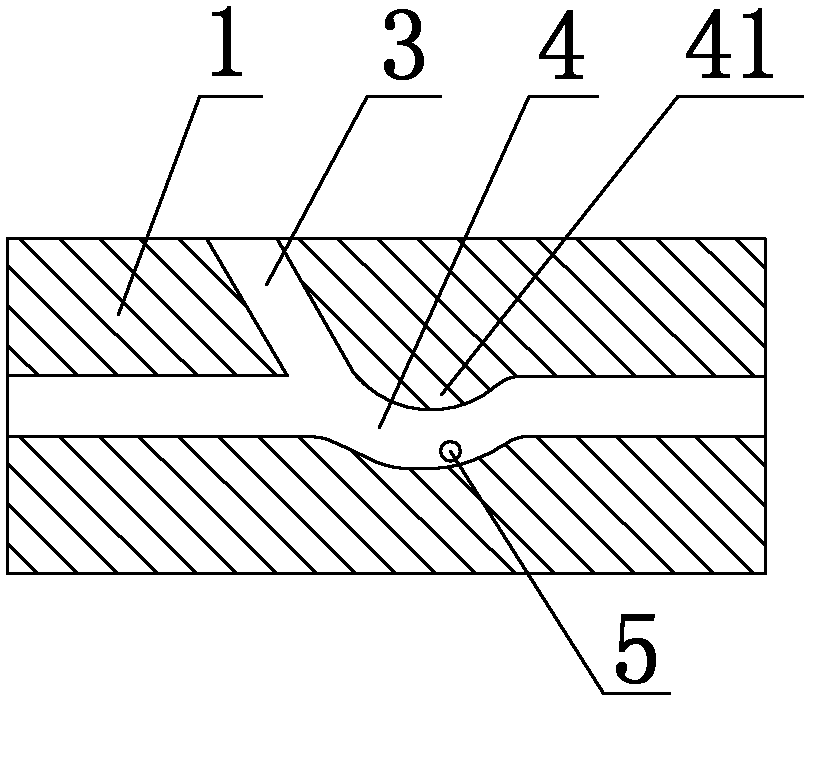

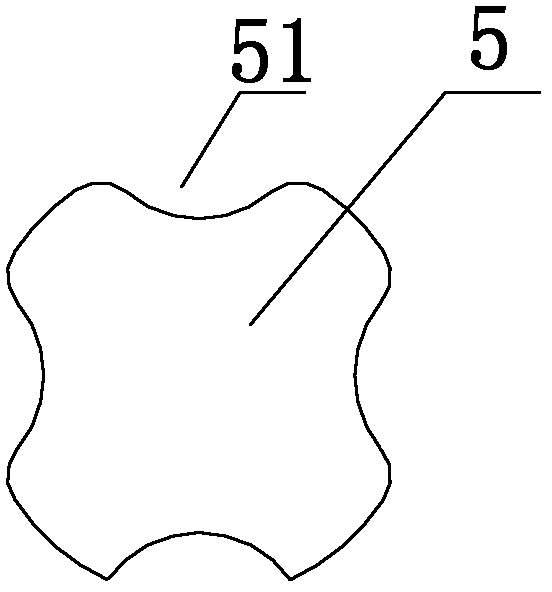

Method for shaping continuous fiber reinforced thermoplastic resin and shaping equipment thereof

ActiveCN101152767AAvoid mutual interferenceContinuous and stable productionFiber bundleFree rotation

The present invention discloses a molding method and molding equipment for a continuous fiber reinforced thermoplastic resin. The molding equipment of the present invention comprises a melting soakage mould. The melting soakage mould comprises a soakage mould outer body and a thermoplasticity resin fused mass crack flow passage, a soakage independent flow passage, a continuous fiber inlet passage and a soakage outlet which are arranged in the soakage mould outer body. The thermoplasticity resin fused mass crack flow passage is arranged on upstream end and forms an angle with the continuous fiber inlet passage. The thermoplasticity resin fused mass crack flow passage and the continuous fiber inlet passage are both communicated with the soakage independent flow passage. The soakage outlet is arranged on downstream end and is communicated with the end of the soakage independent flow passage. The soakage independent flow passage is also provided with at least one tension roller group which is capable to rotate freely. Using the molding equipment of the present invention for manufacturing continuous fiber reinforced thermoplastic resin avoids the interference and impairment between fiber bundles, guarantees the stable and continuous production and improves the dipping effect, so fiber reinforced thermoplastic resin with excellent performance can be obtained.

Owner:KINGFA SCI & TECH CO LTD +1

Pultrusion method for thermoplastic composite material and forming die thereof

InactiveCN1730270AImprove impregnation effectImprove mechanical propertiesPolymer scienceFiber bundle

The invention relates to a pultrusion method for thermoplastic composite, which takes fortifying fiber and matrix fiber as raw material, including the following steps: a. placing matrix fiber and fortifying fiber on the creel in the weight ratio of 95-20:5-80; b. loading the fortifying fiber and matrix fiber to demand scale into the preheat chamber by the thread wire and board and preheating them; c. loading the preheated mixed fiber tuft into the preforming die, so the tuft near to the entrance shape of the forming die; d. loading the preformed mixed fiber into the forming die. Certainly the performing die and forming die can be diad, with performing segment and forming segment in one die; e. after loading out from the forming die the section bar cooling and shaping to get products. The invention overcomes the socking problem of high molecular polymer, improving the socking effects of thermoplastic composites, and the mechanical property enhances dramatically.

Owner:SINOMA SCI & TECH

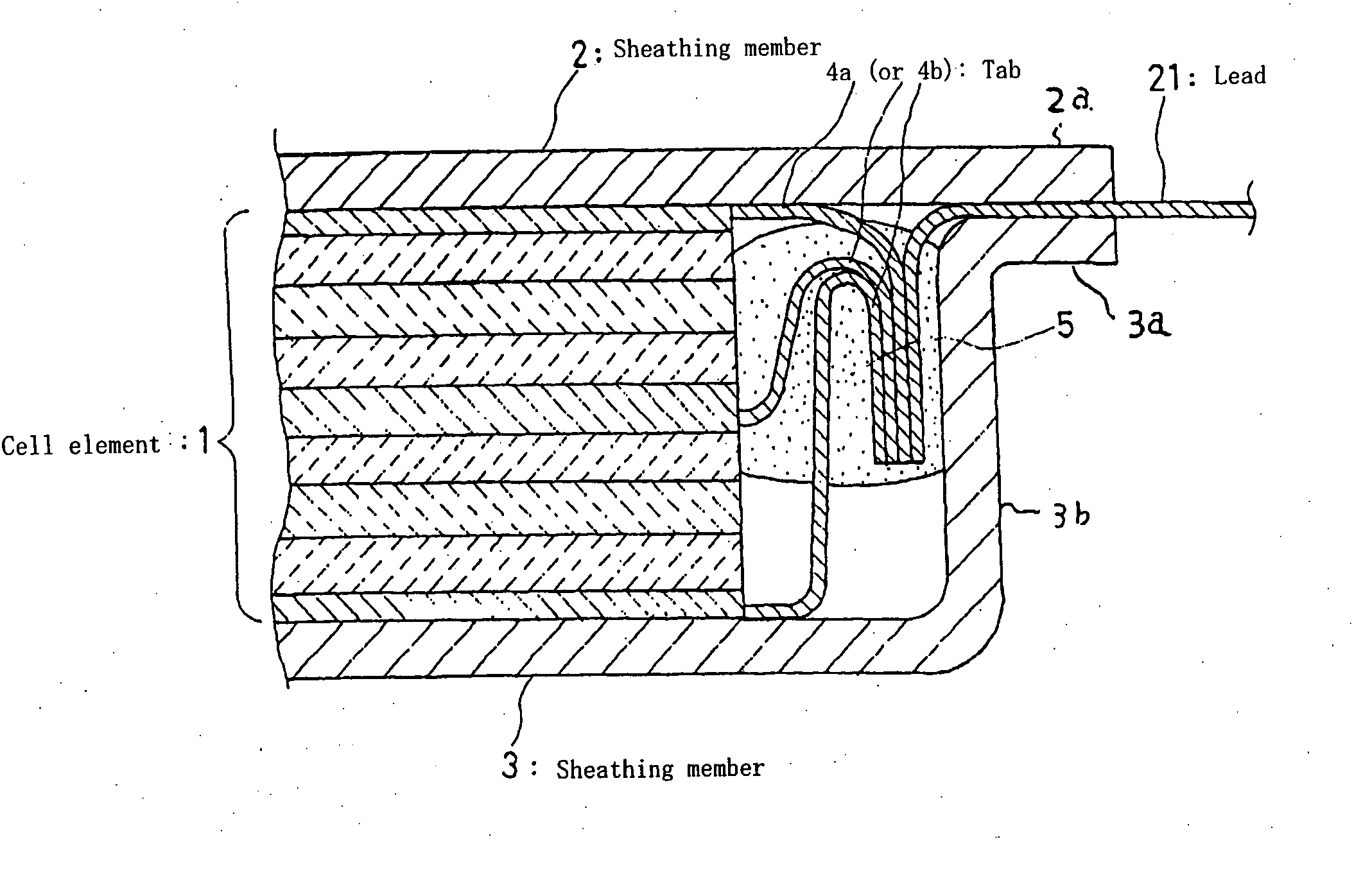

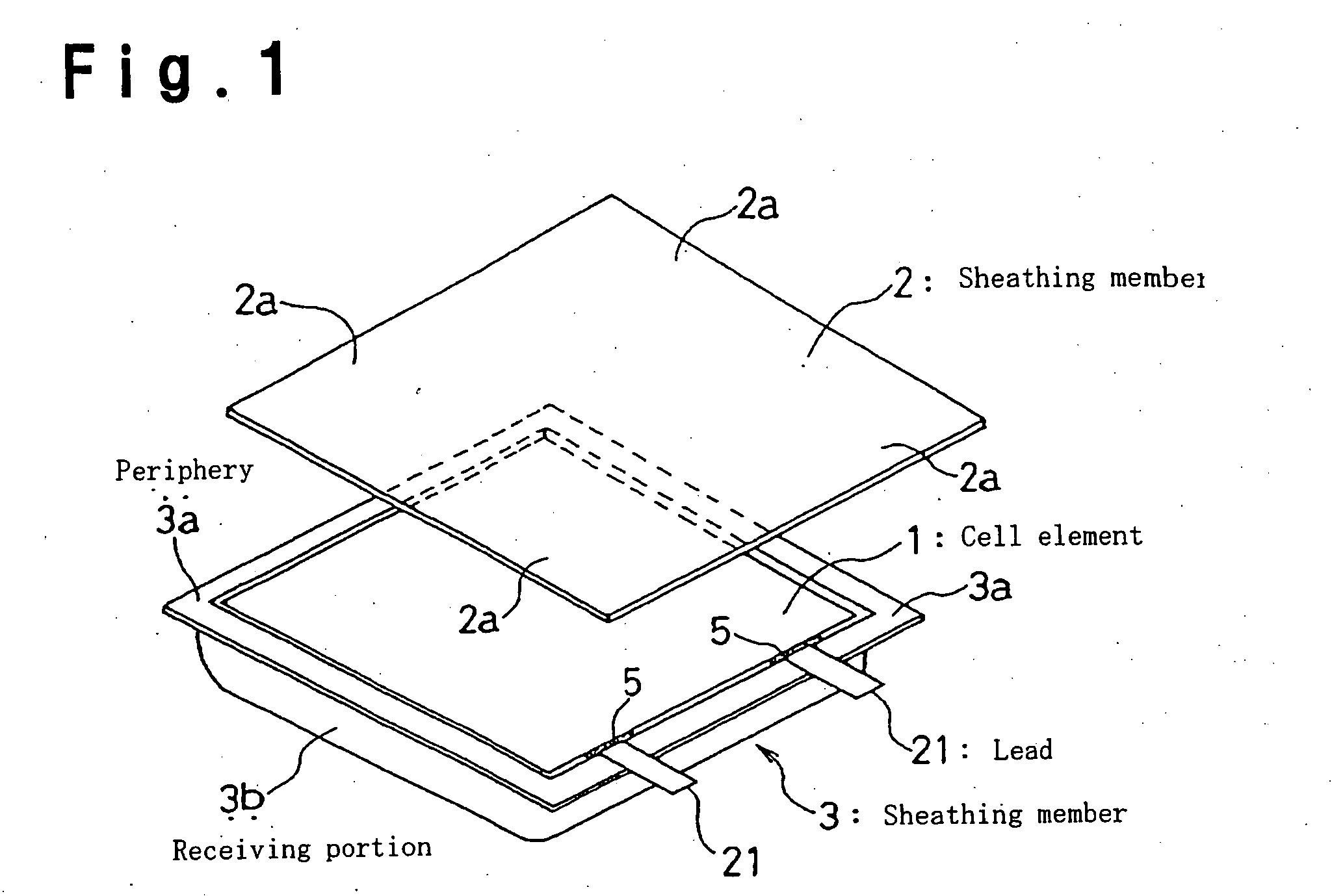

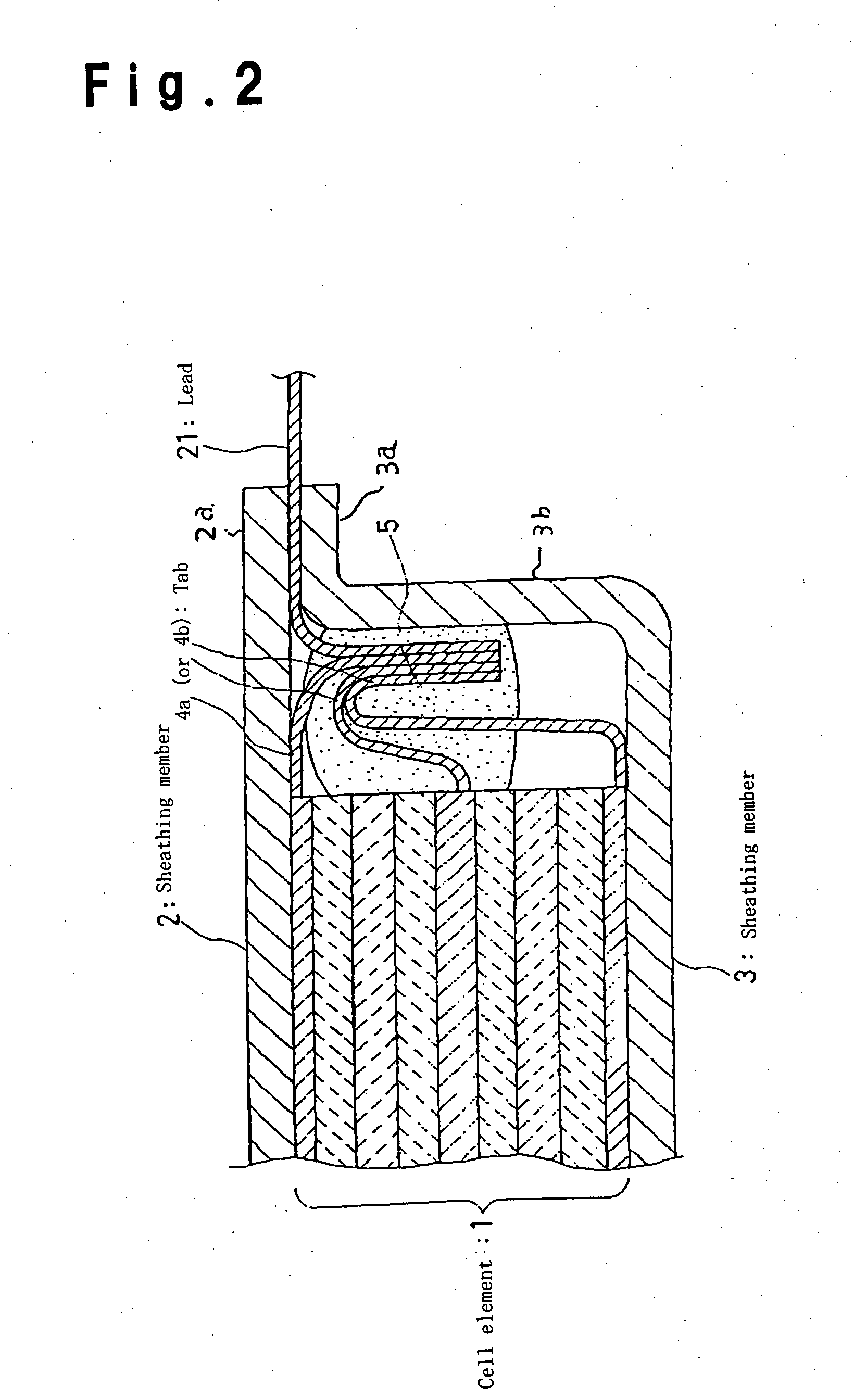

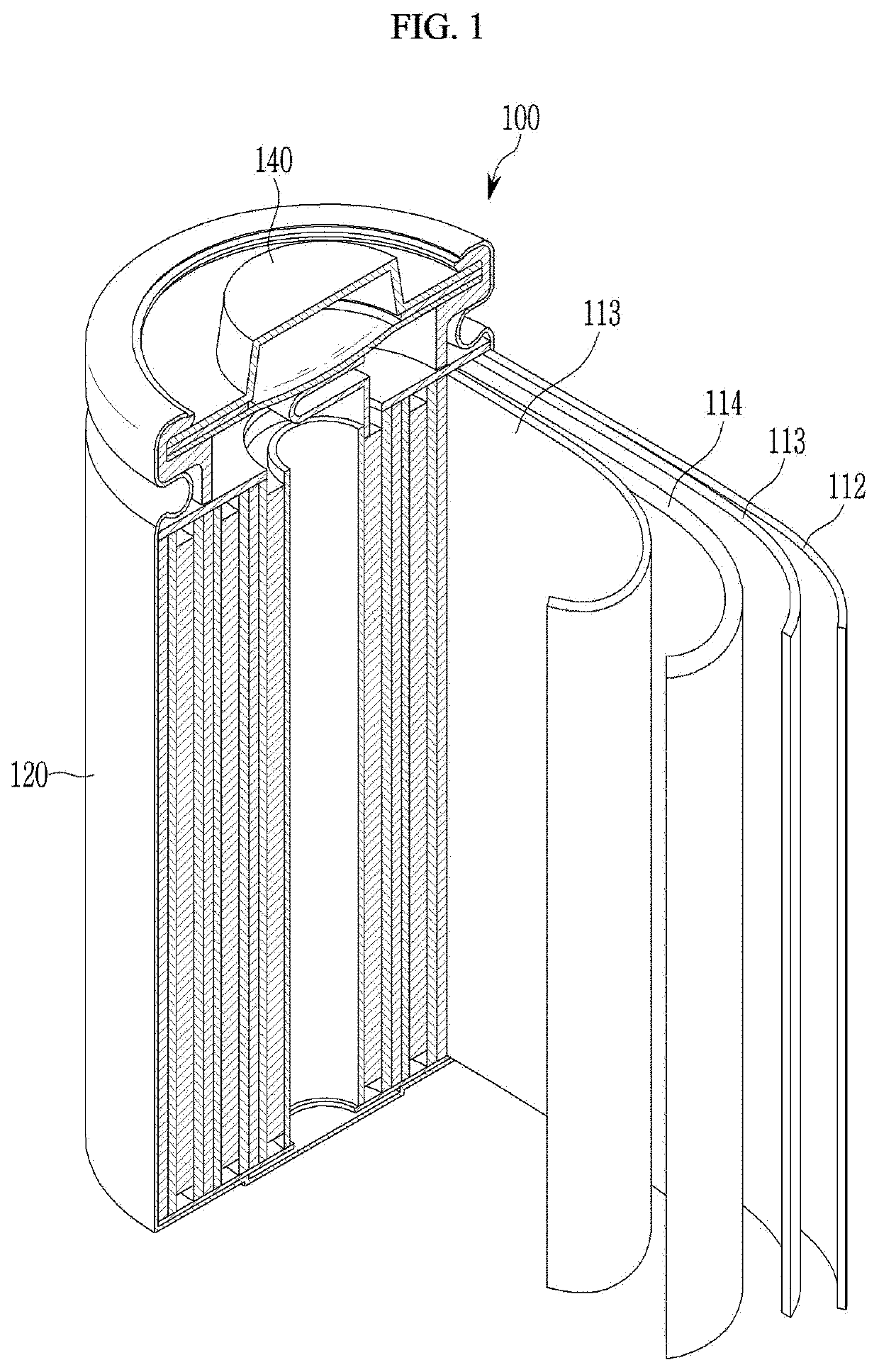

Lithium secondary cell

InactiveUS20050130044A1Improve featuresImprove rigiditySmall-sized cells cases/jacketsOrganic electrolyte cellsLithiumElectrolyte

To improve an impregnation property of an electrolyte and the cycle characteristics, which have been a problem in the case of employing a casing having a variable shape. A lithium secondary cell comprising a casing having a variable shape, and a cell element having a positive electrode, a negative electrode and an electrolyte, sealed in the casing, wherein a compound represented by following formula (1) is contained in the lithium secondary cell: A1-X-A2 (1) (wherein X is a Group VI element in the periodic table, and A1 and A2 represent an aromatic group, provided that A1 and A2 may be the same or different, and may be connected each other to constitute a ring.)

Owner:MITSUBISHI CHEM CORP

Long glass fibre reinforced nylon material and preparing method thereof

The present invention belongs to high polymer material and forming and processing field thereof, and provides a long glass fibre reinforced nylon material and preparing method thereof, wherein the constituents comprise: 29-67wt% of nylons, 30-60wt% of long glass fibre, 2-10wt% of compatilizer and 0.3-1.0wt% of antioxidants. The preparing method comprises the following steps: first mixing the nylons, compatilizer and antioxidants; adding the mixture into a double-screw extruder, wherein the processing temperature is 235-300 DEG C; extruding resin fondants into a dipping mould connected to the double-screw extruder; enabling the long glass fibre to pass through the dipping mould, wherein the dipping temperature of the dipping mould is 260-300 DEG C, dipping the long glass fibre completely in by the fondants, cooling, dragging and granulating the long glass fibre to obtain the long glass fibre reinforced nylon materials. The method of the present invention can strengthen the dipping effect of glass fibre in nylon fondant, eliminate or decrease harmful substances, reduce environmental pollution, and improve the dipping effect and mechanical property of materials effectively.

Owner:NANJING JULONG SCI&TECH CO LTD

Preparation method and preparation system for ultralight composite traction belt

ActiveCN104552988AReduce internal defectsImprove tensile propertiesRope making machinesBeltsYarnAgricultural engineering

The invention discloses a preparation method and a preparation system for an ultralight composite traction belt, and provides a preparation method and a preparation system for the ultralight composite traction belt with uniform bearing and long service life. The preparation method comprises the following steps: a twist-free continuous monofilament is led out of a fiber yarn group, unfolded uniformly, and introduced into an impregnation tank for impregnation, wherein the impregnation tank is added with a glue solution, then arrangement is performed, and composite enhanced pieces are obtained after pultrusion and curing; the composite enhanced pieces are led out respectively, preheated and introduced into a head die of an extruder, an extruding die core corresponding to the section of the traction belt is arranged in the head die, the composite enhanced pieces are uniformly coated with molten thermoplastic resin in the head die and led out of the head die of the extruder, preliminary forming is realized, and the traction belt is obtained after cooling setting and cooling. The prepared traction belt is light in weight, high in strength, easy to bend, anti-fatigue, long in service life, low in maintenance cost and more applicable to a long-distance elevator.

Owner:TIANJIN GOLDSUN WIRE ROPE

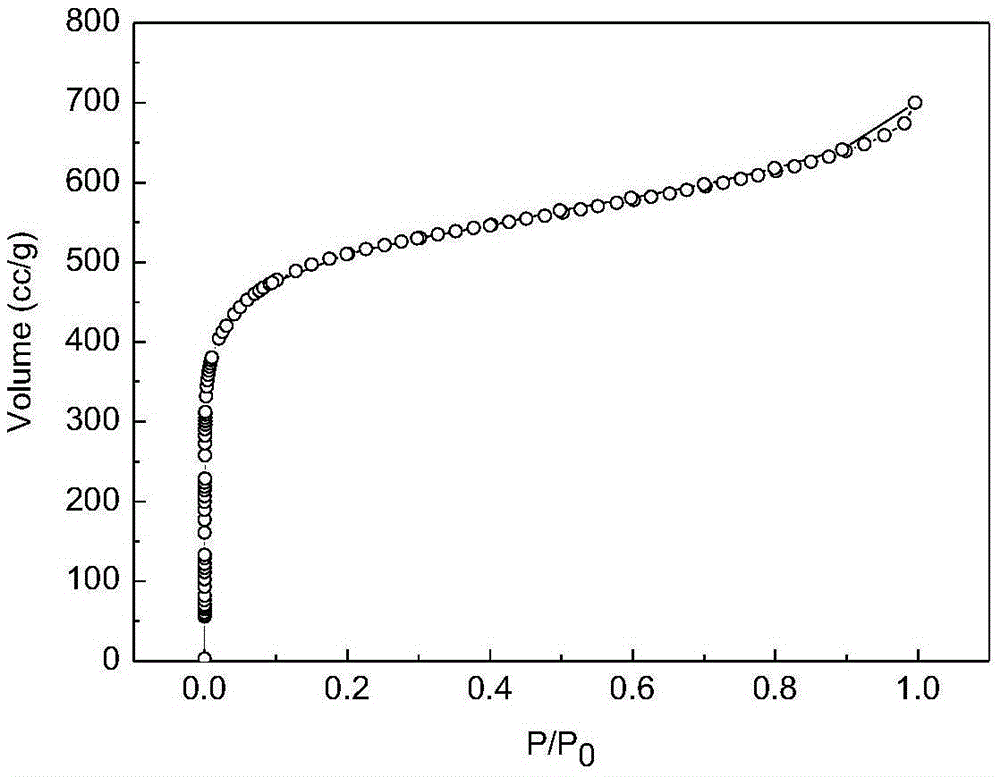

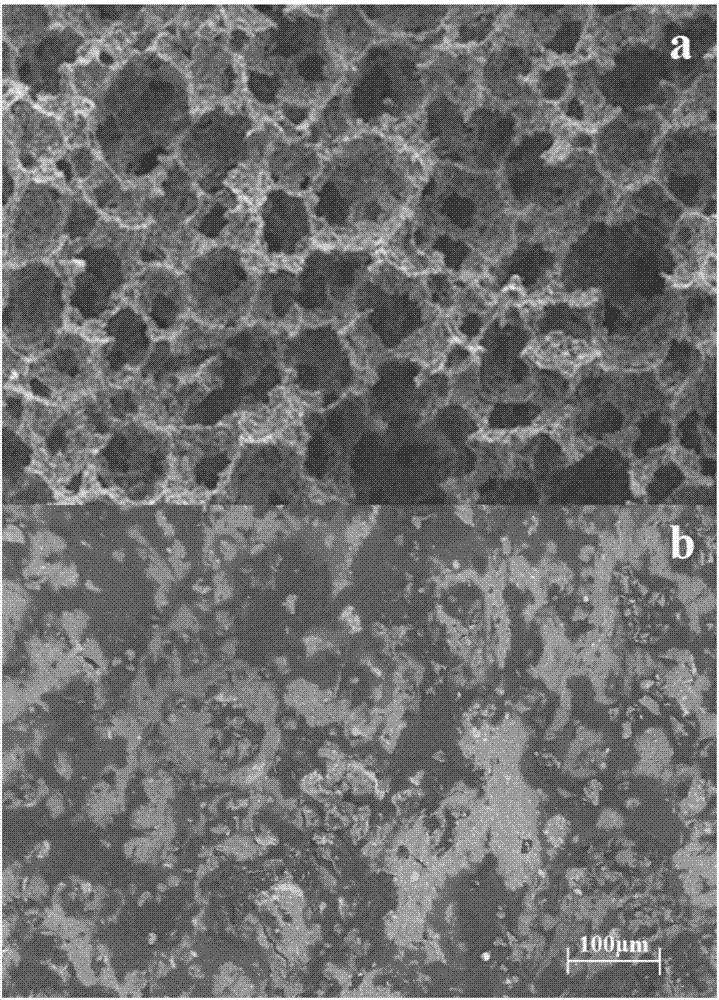

Method for efficiently preparing cotton based mesoporous activated carbon fiber

InactiveCN105480973AWide range of sourcesLow priceFibre chemical featuresChemistryHydrothermal carbonization

The invention relates to a method for efficiently preparing cotton based mesoporous activated carbon fiber. The method comprises a step (1) of washing cotton, placing the cotton in a hydrothermal reaction kettle, performing heating to 150-200 DEG C at the heating rate of 5-30 DEG C / min, performing hydrothermal carbonization, performing heat preservation for 1-3 hours and then performing cooling to room temperature; a step (2) of dipping carbonization materials obtained from the step (1) into activator solution, performing microwave-ultrasonic joint dipping for 5-30 minutes and then performing filtration, sending filtration materials to a microwave heating device, performing activation for 5-15 minutes at 250-350 DEG C and then stopping microwave output, and a step (3) of washing the activated materials to be neutral and performing drying to obtain the activated carbon fiber. According to the method, the characteristics of microwave inner heating and selective heating are fully utilized, the technological process is simple, the activation temperature is only 250-350 DEG C, the activation time is only 5-15 minutes, the mesoporous proportion of the activated carbon fiber of the product reaches 50-90%, and the adsorptive property is good.

Owner:HEBEI UNIV OF TECH

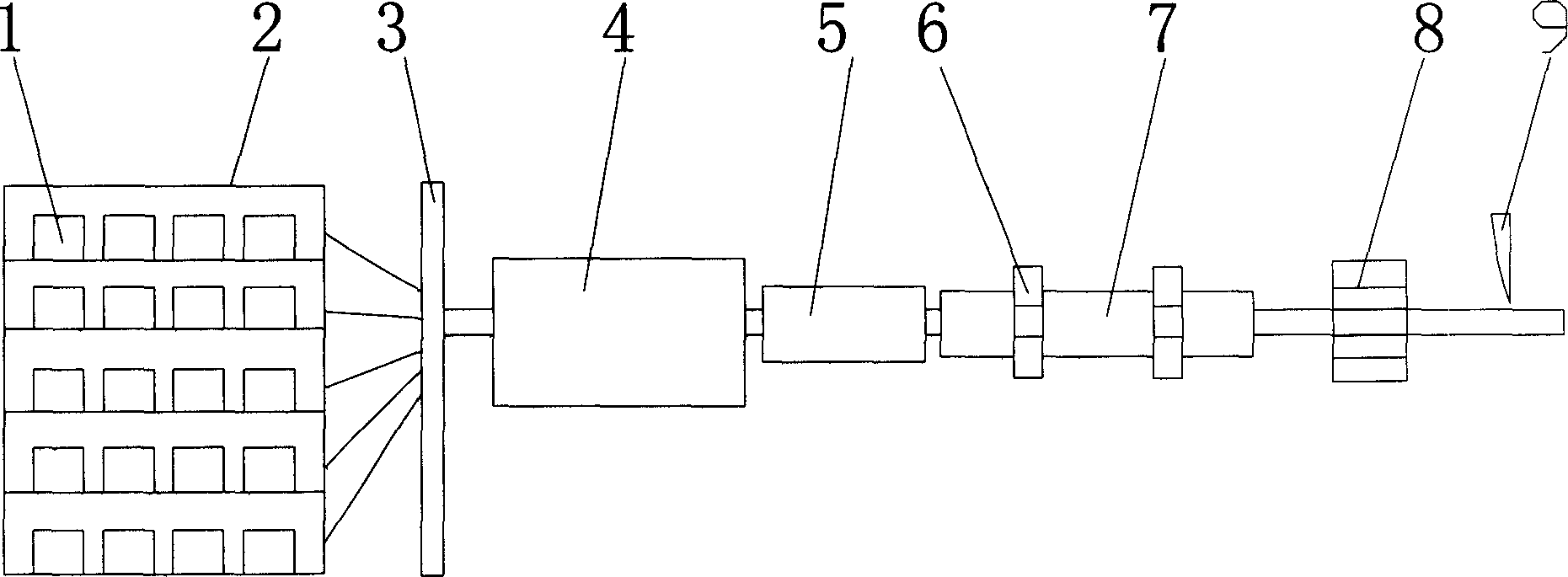

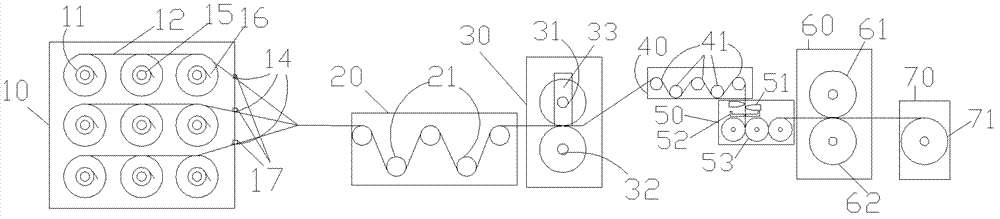

Preparation apparatus of continuous fiber reinforced thermoplastic resin prepreg tape, and its application

ActiveCN102950780AImprove impregnation effectImprove mechanical propertiesCoatingsThermoplastic compositesMaterials science

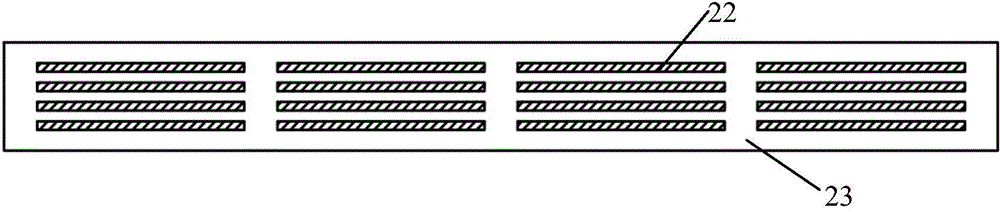

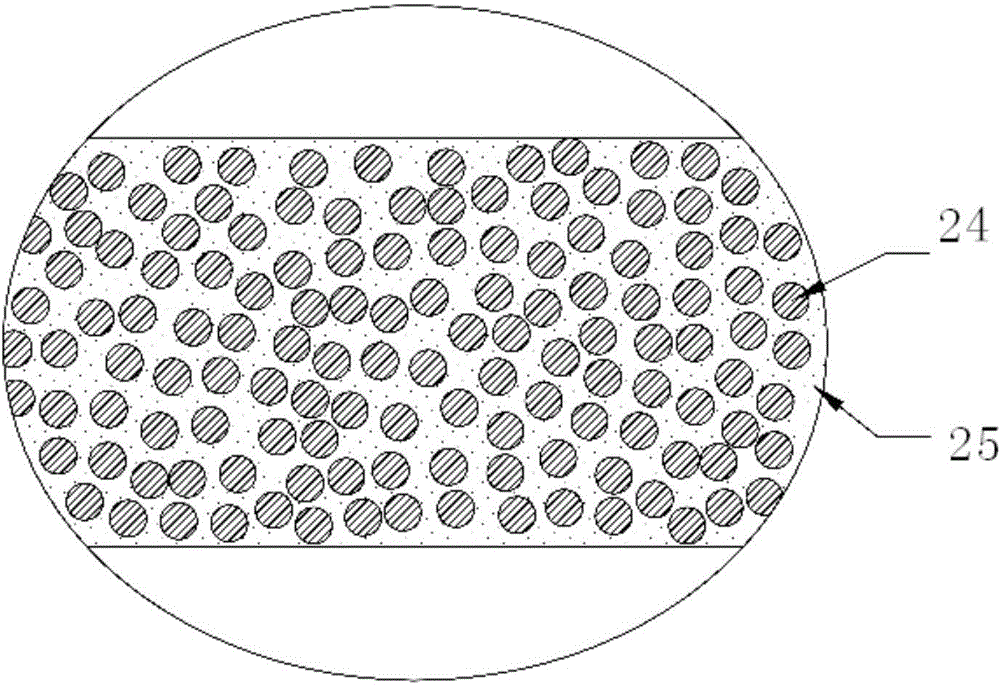

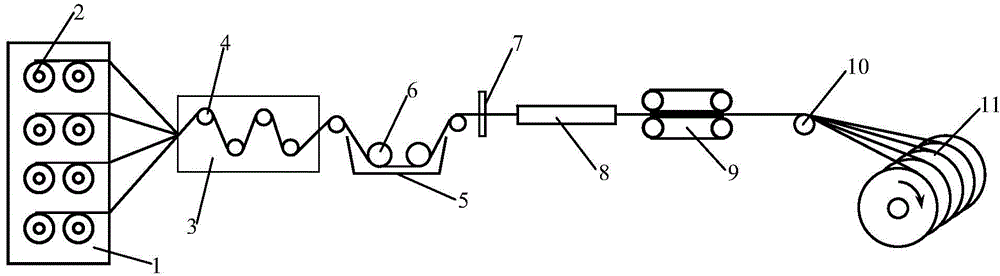

The invention belongs to technical field of composite materials, and relates to a preparation apparatus of a continuous fiber reinforced thermoplastic resin prepreg tape, and its application. The apparatus comprises a creel (10), a fiber filament tension adjusting device (20), a draw gear (30), a fiber dispersion tension adjusting device (40), a pressing molding device (60), a rolling device (70), and an impregnation compounding device (50), wherein the impregnation compounding device (50) comprises compound rollers (53), a bidirectional flame spraying head (51) and a powder recovery device (52); the compound rollers (53) are positioned in the impregnation compounding device (50); the bidirectional flame spraying head (51) is positioned above the compound rollers (53); and the powder recovery device (52) is positioned between the compound rollers (53) and the bidirectional flame spraying head (51). Compared with apparatuses in the prior art, the apparatus provided by the invention has the advantages of overcoming of a limit processing temperature problem, and low production cost.

Owner:LIAONING LIAOJIE SCI & TECH

Method and equipment for producing continuous fiber-reinforced thermoplastic composite material prepreg tape

InactiveCN102328443AImproved impregnation and workabilityEvenly dispersed fibersDischarge pressureFibre reinforcement

The invention discloses a method and equipment for producing a continuous fiber-reinforced thermoplastic composite material prepreg tape. In the method, an extrusion die head is used for extruding fused resin, preheated continuous fibers are guided into a primary tank for preliminary impregnation, and then discharge pressure is controlled to enable pre-impregnated continuous fibers to pass through a secondary impregnating tank filled with fused resin to realize a full impregnation process. Therefore, the problems of how to enable the prepreg tape to be fully impregnated and threaded and how to enable joint cleaning to become easy can be solved.

Owner:TAIZHOU JIADEBAO TECH

Method for car clutch face sheet production

InactiveCN101429977ALow priceImprove adsorption capacityAldehyde/ketone condensation polymer adhesivesFriction clutchesAdhesiveFilling materials

The invention relates to a method for producing automobile clutch facing patches, which adopts an organic vegetable fiber and other fibers to weave the organic vegetable fiber and other fibers into twill fabrics as a framework material, simultaneously mixes and stirs bonding materials such as water soluble phenol resin, filling materials and water to be prepared into slurry. The method utilizes a natural wood vegetable fiber to replace an inorganic fiber material, and the natural wood vegetable fiber is reproducible and has no pollution. The water soluble phenol resin is used to replace rubber and is taken as a bonding adhesive for preparing the clutch facing patches. Industrial naptha is not used any more. Therefore, compared with the prior art, the method has the following advantages: firstly, the method has the characteristic of environmental protection; and secondly, the method is favorable for reducing the production cost of the automobile clutch facing patches, and solving the problem of product performance fluctuation.

Owner:ZHEJIANG DUALRAY FRICTION MATERIAL

Method for preparing continuous carbon fiber-reinforced thermoplastic resin composite material

The invention discloses a method for preparing a continuous carbon fiber-reinforced thermoplastic resin composite material, which comprises the following steps: mixing N,N-dimethylacetamide and acetone at the mass ratio of (1-5):1 to obtain mixed solvent; dissolving 1-5 parts by weight of polyether sulfone into 30-60 parts by weight of mixed solvent to be fully dissolved so as to obtain polyethersulfone solution; adding 0.5-2.5 parts by weight of indissolvable thermoplasticity powdered resin into the polyether sulfone solution by mechanical stirring or ultrasonic vibration to obtain suspension with stable performance, wherein the added thermoplasticity resin powder is evenly distributed; dipping the continuous carbon fiber into mixed thermoplasticity resin suspension at the temperature of 18-22DEG C to obtain prepreg; and carrying out hot pressing and shaping to the prepreg to obtain a product. The method for preparing the continuous carbon fiber-reinforced thermoplastic resin composite material has the advantages of low cost, simple technology and small solvent toxicity.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Manufacturing method of impregnated bond paper for low formaldehyde furniture

ActiveCN105369687AIncrease crosslink densityPromote chemical reactionSpecial paperPaper/cardboardPulp and paper industryWetting

The invention discloses a manufacturing method of impregnated bond paper for low formaldehyde furniture. The method comprises the steps of raw paper selection and treatment, uncoiling, pre-wetting, impregnation, first time drying, gluing, preparation of coating glue, second time drying, deviation adjustment traction and cutting. The manufacturing method has the advantages that the quality of the impregnated bond paper prepared with the method is high, the content of formaldehyde is further reduced, the uniformity of impregnation and gluing of the impregnated bond paper is guaranteed in the manufacturing process, the flexibility of a glue layer and the sealing performance of the surface of the glue layer are guaranteed, and accordingly, the problems that the content of formaldehyde is high and the quality is not high in impregnated bond paper are fundamentally solved.

Owner:成都建丰新材料股份有限公司

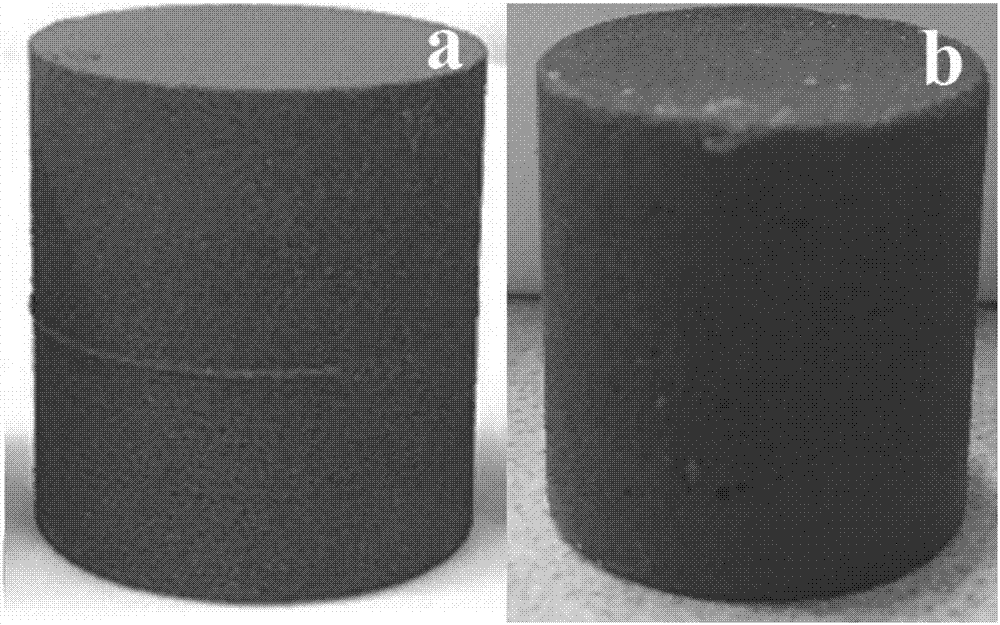

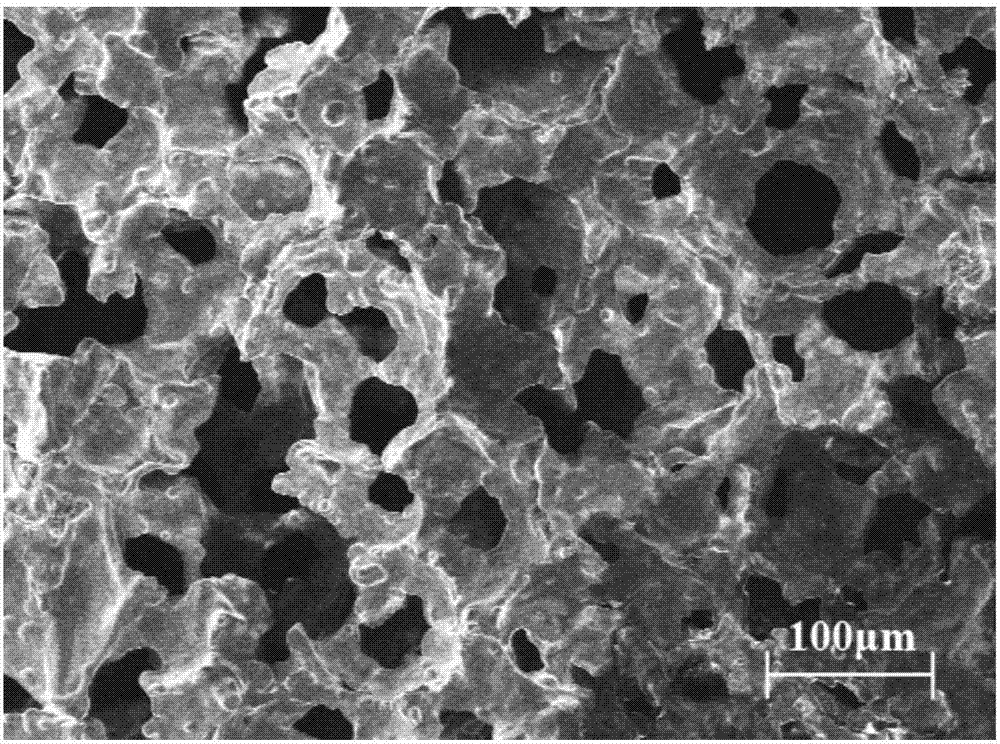

Paraffin/iron tailing ceramic composite phase change energy storage material and melt and infiltration preparation method thereof

ActiveCN107011868AIncrease profitHigh phase change material contentHeat-exchange elementsCeramic materials productionEcological environmentCeramic composite

The invention discloses a paraffin / iron tailing ceramic composite phase change energy storage material and a melt and infiltration preparation method thereof. The composite material is prepared from the following raw materials in percentage by volume: 70 to 85 percent of paraffin and the balance of iron tailings. The composite phase change energy storage material provided by the invention has the advantages of high solid waste utilization rate, high phase change material content, high energy storage density, good mechanical property, low cost and the like; after large-scale application, the peak load shifting of energy sources can be realized; the pressure of the iron tailings on ecological environment is relieved; meanwhile, the heat conduction performance and the energy storage efficiency of the phase change material are effectively improved. The invention also discloses a melt and infiltration preparation method of the paraffin / iron tailing ceramic composite phase change energy storage material. The process parameters of the method are controllable; the operation is simple; the production period is short; products with complicated structures can be prepared.

Owner:BEIJING JIAOTONG UNIV

Spiral reverse osmosis membrane element, method of manufacturing the same, and its use method

ActiveUS20060043013A1Avoid dippingEasy to separateSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisReverse osmosisPermeation

A spiral reverse osmosis membrane element that improves impregnation property of a sealing resin at edges of a membrane leaf and can effectively prevent micro-leaks, by using, for example, a porous support having a structure capable of sufficiently impregnating therein a sealing resin, a method for manufacturing the same, and a use method of the same are disclosed. The spiral reverse osmosis membrane element comprises a cylindrically wound body comprising a perforated core tube and, spirally wound therearound, a separation membrane, a feed-side passage material and a permeation-side passage material in a laminated state, and a sealing portion for preventing a feed-side liquid and a permeation-side liquid from being mixed together, wherein the separation membrane facing through the permeation-side passage material has a structure that a porous support and a skin layer are successively laminated on a non-woven fabric layer, and the sealing portion sealed with a sealing resin is provided at the edges of the separation membrane, wherein the separation membrane is impregnated with the sealing resin at least up to the vicinity of the skin layer through the porous support.

Owner:NITTO DENKO CORP

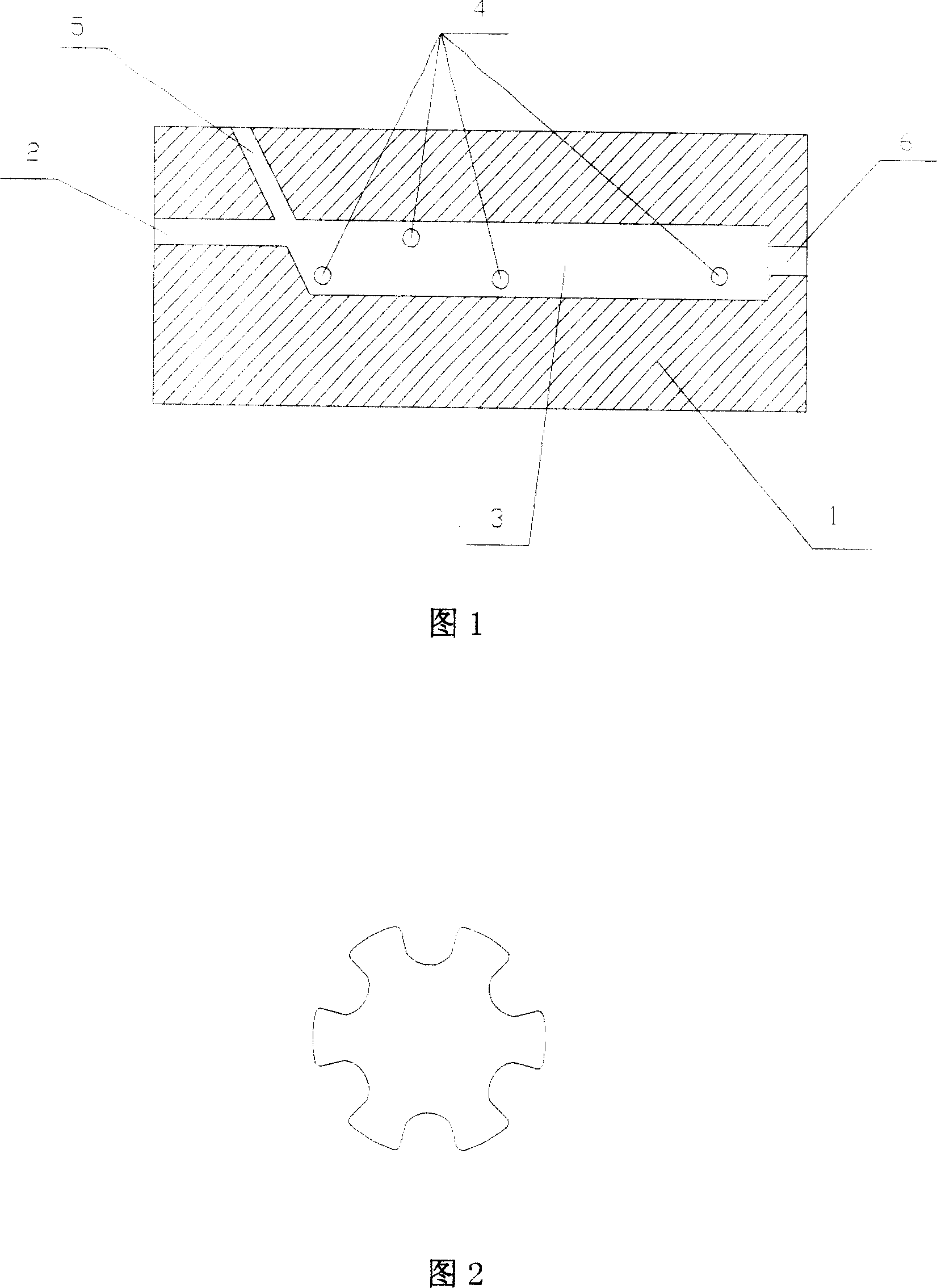

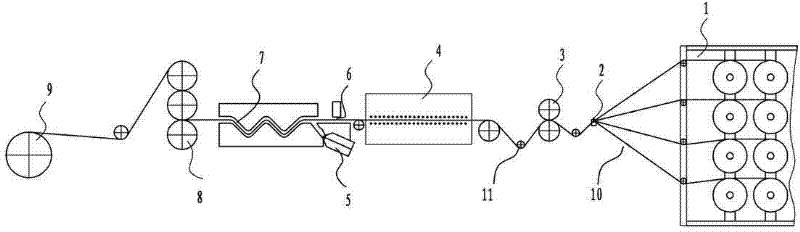

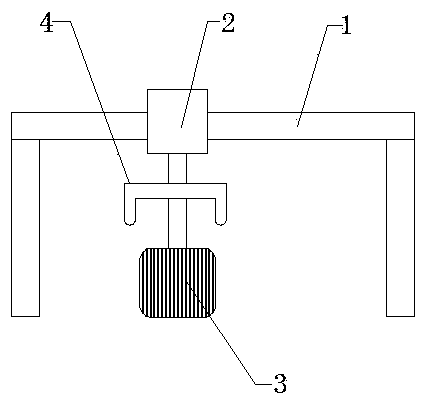

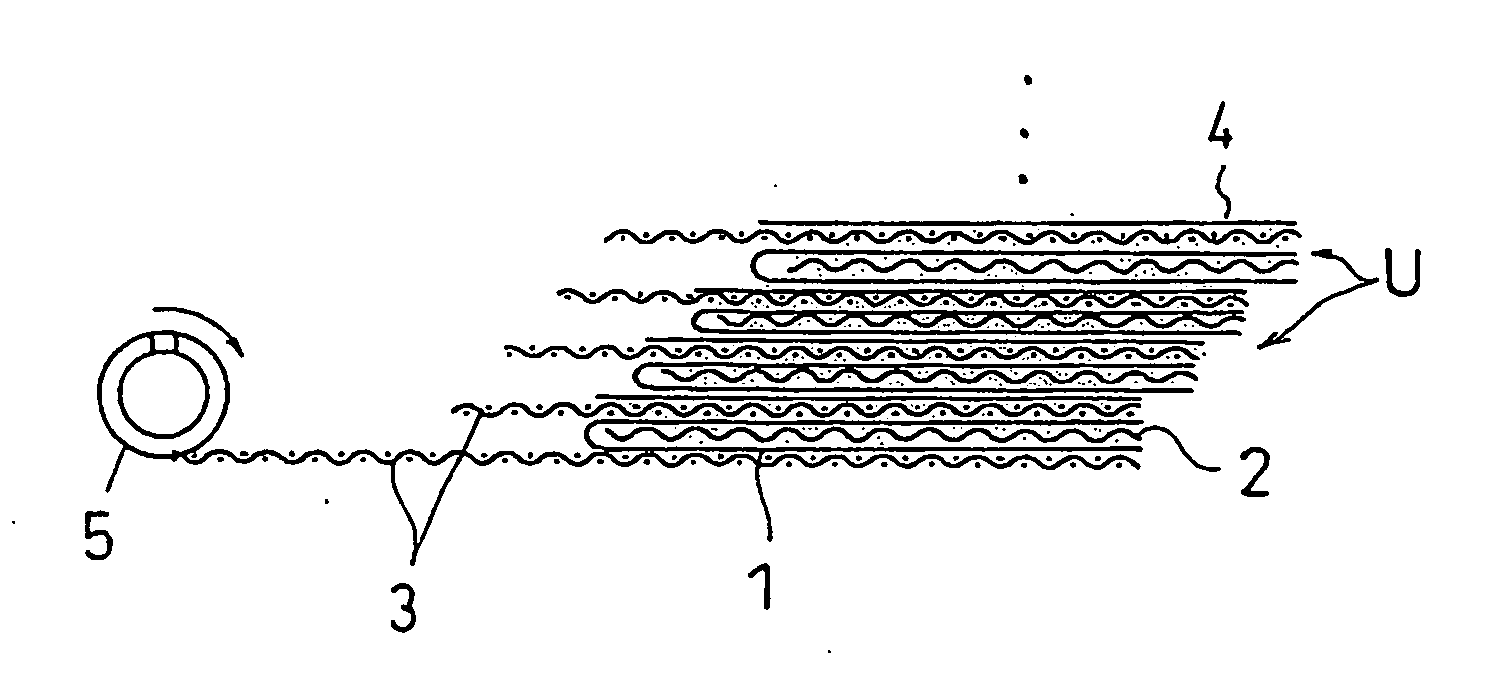

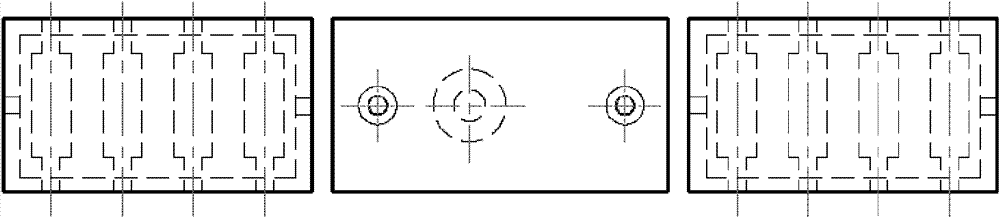

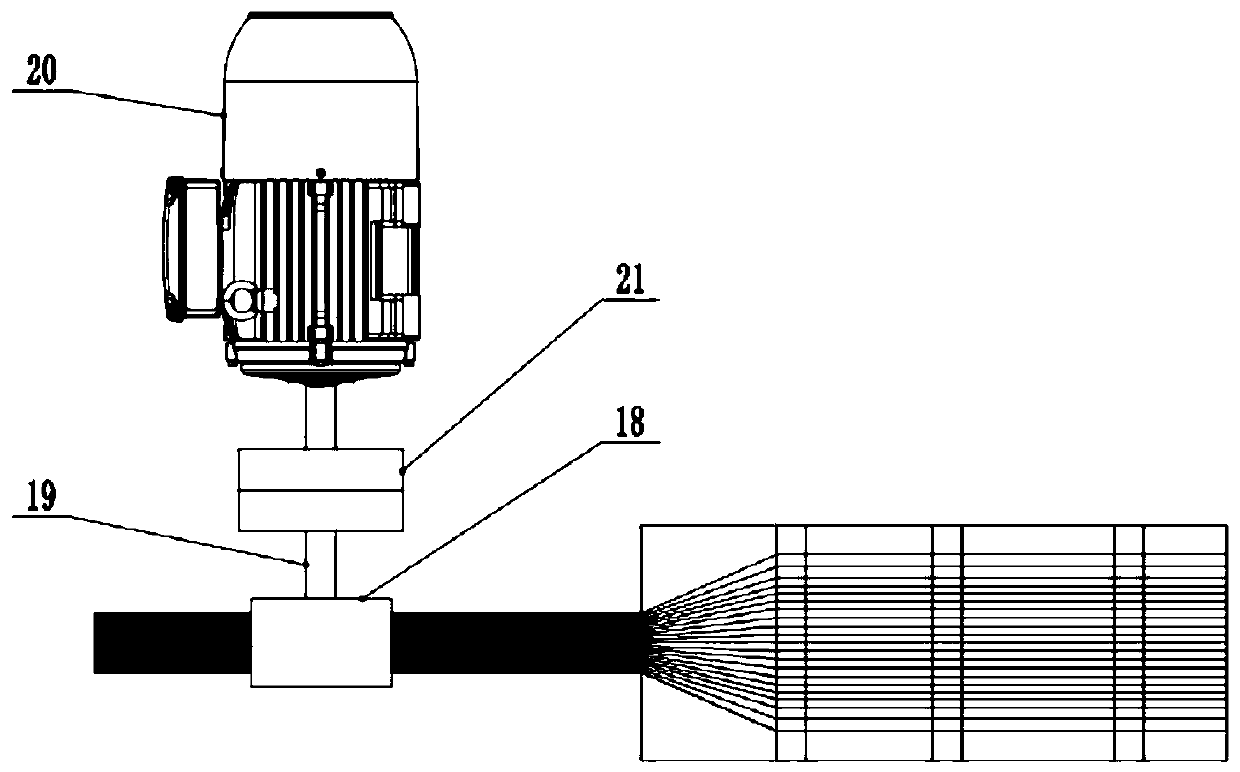

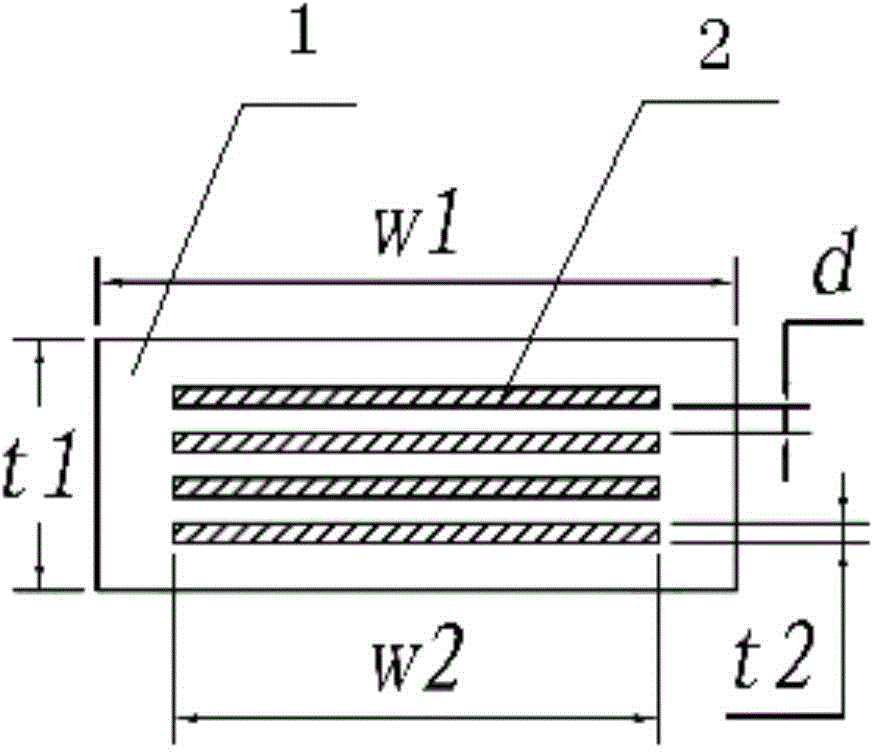

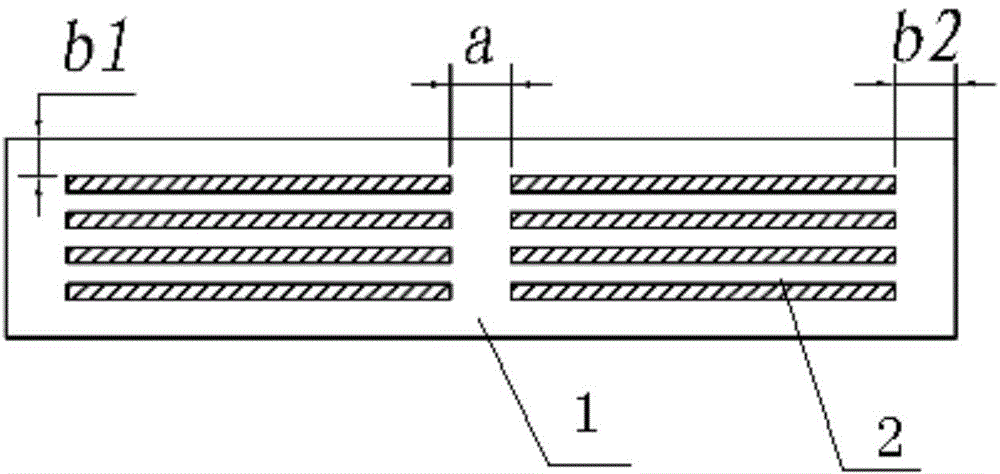

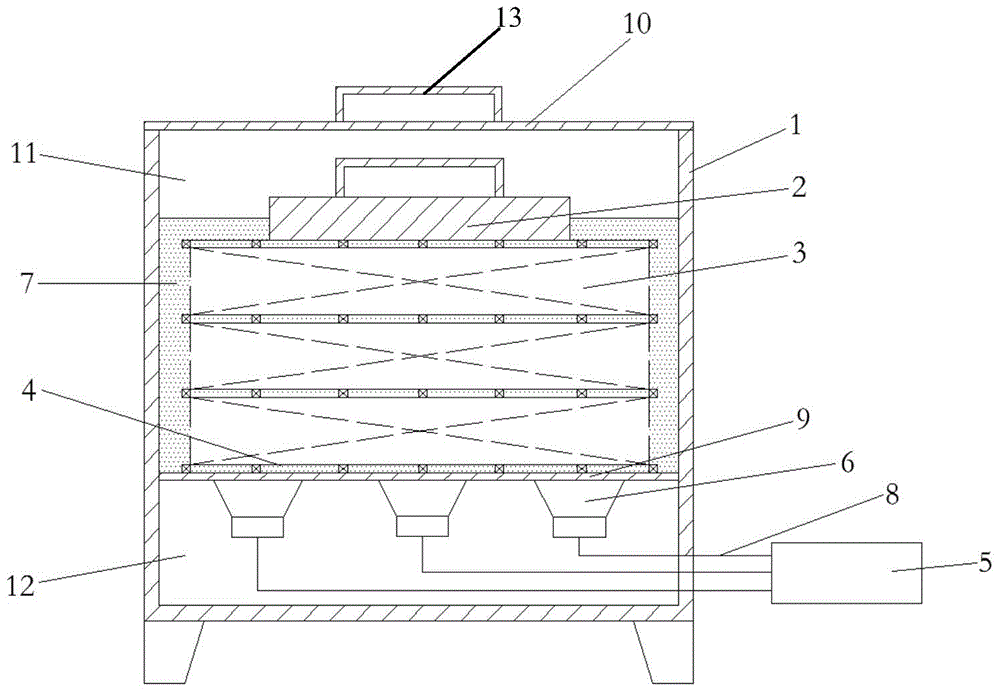

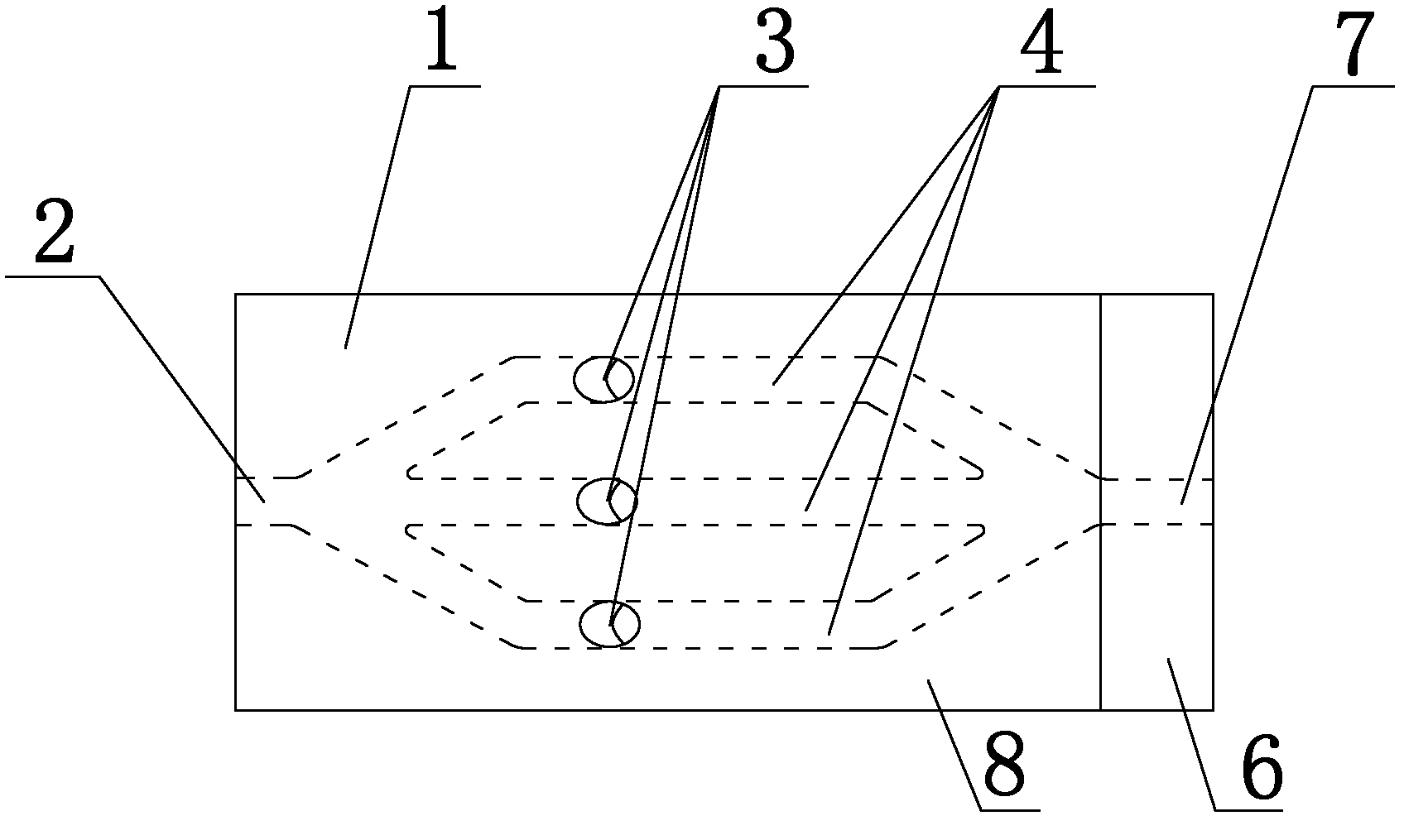

Continuous long fiber-reinforced thermoplastic resin and its preparation method and molding equipment

InactiveCN102729483ARaise the contact temperatureImprove impregnation effectLong-fiber-reinforced thermoplasticFibre reinforcement

The invention discloses a continuous long fiber-reinforced thermoplastic resin and its preparation method and molding equipment. The molding equipment comprises a fiber preheating device 1, a melt impregnation mold 2 and a secondary rolling device 3. The preparation method comprises the following steps of 1, alternately bypassing dispersion rollers (4) with continuous long fibers, and simultaneously heating dispersion roller electrically-heating rods (5) so that preliminary dispersion of the continuous long fibers is realized, 2, alternately bypassing tension rollers (7) with the treated continuous long fibers, and simultaneously feeding thermoplastic resin melt into the melt impregnation mold 2 from an extruder connection device (13) so that the continuous long fibers and the thermoplastic resin melt are subjected to melt impregnation, and 3, alternately bypassing rollers (11) with the continuous long fibers and the thermoplastic resin melt treated by the step 2, and carrying out rolling to obtain the continuous long fiber-reinforced thermoplastic resin. The continuous long fiber-reinforced thermoplastic resin prepared by the molding equipment has the advantages of good impregnation effects, high impregnation efficiency and excellent performances.

Owner:CHINA NAT OFFSHORE OIL CORP +2

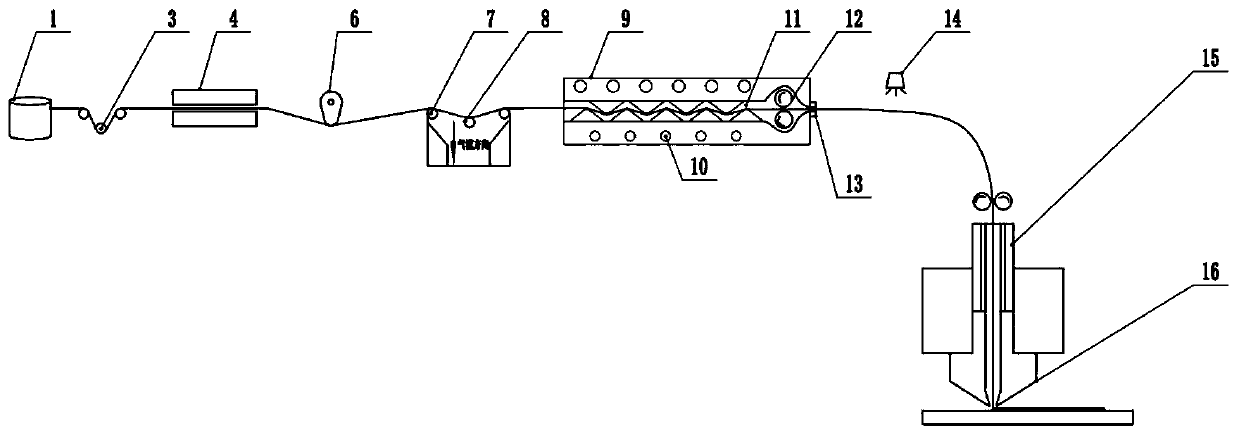

Continuous fiber melt impregnation 3D printing device and process

ActiveCN111186138AHigh molding pressureEnough molding pressure3D object support structuresApplying layer means3d printPolymer science

The invention relates to a continuous fiber reinforced thermoplastic resin melt impregnation 3D printing device and a method, wherein thermoplastic resin is used as a matrix, and continuous glass fiber or carbon fiber is used as a reinforcement. The 3D printing device comprises an extruder, an unwinding roller, a pre-tensioning roller, an infrared radiation device, a gas-assisted swinging device,a wire wetting mold, a cooling device and a 3D printer. A continuous fiber bundle is firstly pre-dispersed by the pre-tensioning roller, the upper surface and the lower surface of the continuous fiberare pre-heated by the infrared radiation device, the pre-heated continuous fiber is unfolded to a certain width under the action of the gas-assisted swinging device, then the pre-heated continuous fiber enters the wire wetting mold, the wetting process of the resin matrix on the fiber bundle is completed under the action of a wave-shaped runner, the fiber bundle is conveyed forwards by the traction of an inner traction roller and passes through a circular shaping die to form continuous fiber prepreg filaments which can be used for 3D printing, and cooling, feeding and printing are carried outto finally obtain the 3D printed product of the continuous fiber reinforced thermoplastic composite material. According to the device and the method, uniform dispersion and full impregnation of the continuous fiber in the resin matrix can be realized, the 3D printing continuous fiber reinforced thermoplastic composite material product with good interface bonding and excellent performance can be prepared, and meanwhile real-time integrated forming of continuous fiber consumables and the 3D printing composite material product can be realized.

Owner:BEIJING UNIV OF CHEM TECH

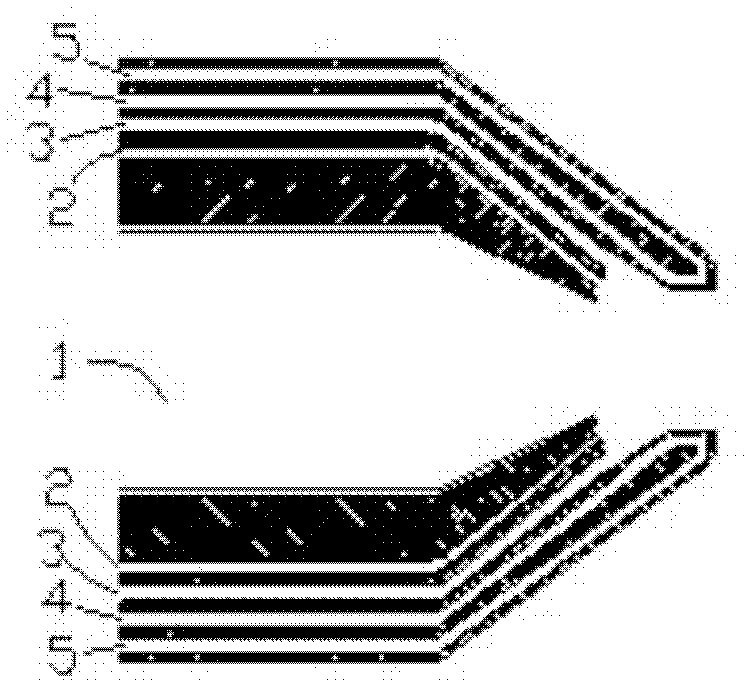

Dragging belt of composite materials

InactiveCN104528498AReduce the bending radius of curvatureEasy to bendRope making machinesElevatorsFiberThermoplastic polyurethane

The invention discloses a dragging belt of composite materials. The dragging belt is light in weight and good bending performance. The dragging belt comprises a plurality of inner bearing body layers and abrasion-resisting elastic bodies wrapped outside the inner bearing body layers. The inner bearing bodies are in a sheet shape which is continuous in the single length direction of the dragging belt. Each inner bearing body comprises a base body. A plurality of nonmetal non-twist continuous fiber monofilaments are arranged in the base bodies, the nonmetal non-twist continuous fiber monofilaments are not in contact, the base bodies of inner bearing body layers are made of thermosetting resin materials or thermoplastic resin materials, the abrasion-resisting elastic bodies are thermoplastic polyurethane or rubber elastic bodies. At least two inner bearing body layers are arranged in the thickness direction of the dragging belt. The thickness of the inner bearing body layers of the sheet-shaped structure of the dragging belt is small, under the premise that good bearing is achieved, bending curvature radius is greatly lowered, the obtained dragging belt is light in weight, high in intensity and easy to bend, abrasion resistance and whether resistance are achieved, anti-fatigue performance is achieved, service life is long, maintaining cost is low, and the dragging belt can be used for lifting of long-distance heavy objects.

Owner:TIANJIN GOLDSUN WIRE ROPE

Pretreatment device for improving wood impregnation efficiency and wood impregnation treatment method

InactiveCN104416635AExpand the effective channel areaIncrease drug intakeWood treatment detailsWood impregnation detailsCavitationPre treatment

The invention discloses a pretreatment device for improving wood impregnation efficiency and a method for impregnating woods by utilizing the device. The device comprises a wood pretreatment chamber in which a cavity is formed, an ultrasonic treatment system and pretreatment liquid, wherein to-be-treated woods are subjected to ultrasonic pretreatment. The method disclosed by the invention comprises the following steps: pretreating to-be-impregnated woods by using ultrasonic waves under normal pressure, and getting through a liquid moving channel in the woods by utilizing a cavitation effect of the ultrasonic waves, so that the liquid permeability of the to-be-impregnated woods is enhanced, and the effective channel area inside the woods is enlarged; impregnating the woods, and impregnating a wood impregnation modifier into the woods, so that the absorption dose of the impregnated woods is improved, the agent penetration depth is increased, the impregnation period is shortened, and the impregnation effect is improved. The treatment device disclosed by the invention is simple, convenient to operate and is suitable for treating various woods, and process treatment conditions are controllable.

Owner:BEIJING FORESTRY UNIVERSITY

Long glass fibre reinforced polypropylene material and preparation method thereof

The invention belongs to field of a polymer material and shaping thereof, in particular to a long glass fiber reinforced polypropylene material and a preparation method thereof. The long glass fiber reinforced polypropylene material is prepared from the following components: 35-68wt% of polypropylene, 30-60wt% of long glass fiber, 1-5wt% of compatilizer and 0.3-1.0wt% of antioxidant, wherein the polypropylene is polypropylene with a melt index as high as 50-500g / 10min. The preparation method comprises the following steps: mixing the polypropylene, the compatilizer and the antioxidant; feeding the mixture in a double-screw extruder; enabling the long glass fiber to be fully soaked by melts through a soaking die; and cooling, drawing and pelletizing the fully soaked long glass fiber to obtain the long glass fiber reinforced polypropylene material. By the invention, the soaking effect of the glass fiber in polypropylene melts can be reinforced, substances harmful to human bodies can be eliminated or reduced, the odor is lightened, and the soaking effect and mechanical property of the material can be effectively improved.

Owner:NANJING JULONG SCI&TECH CO LTD

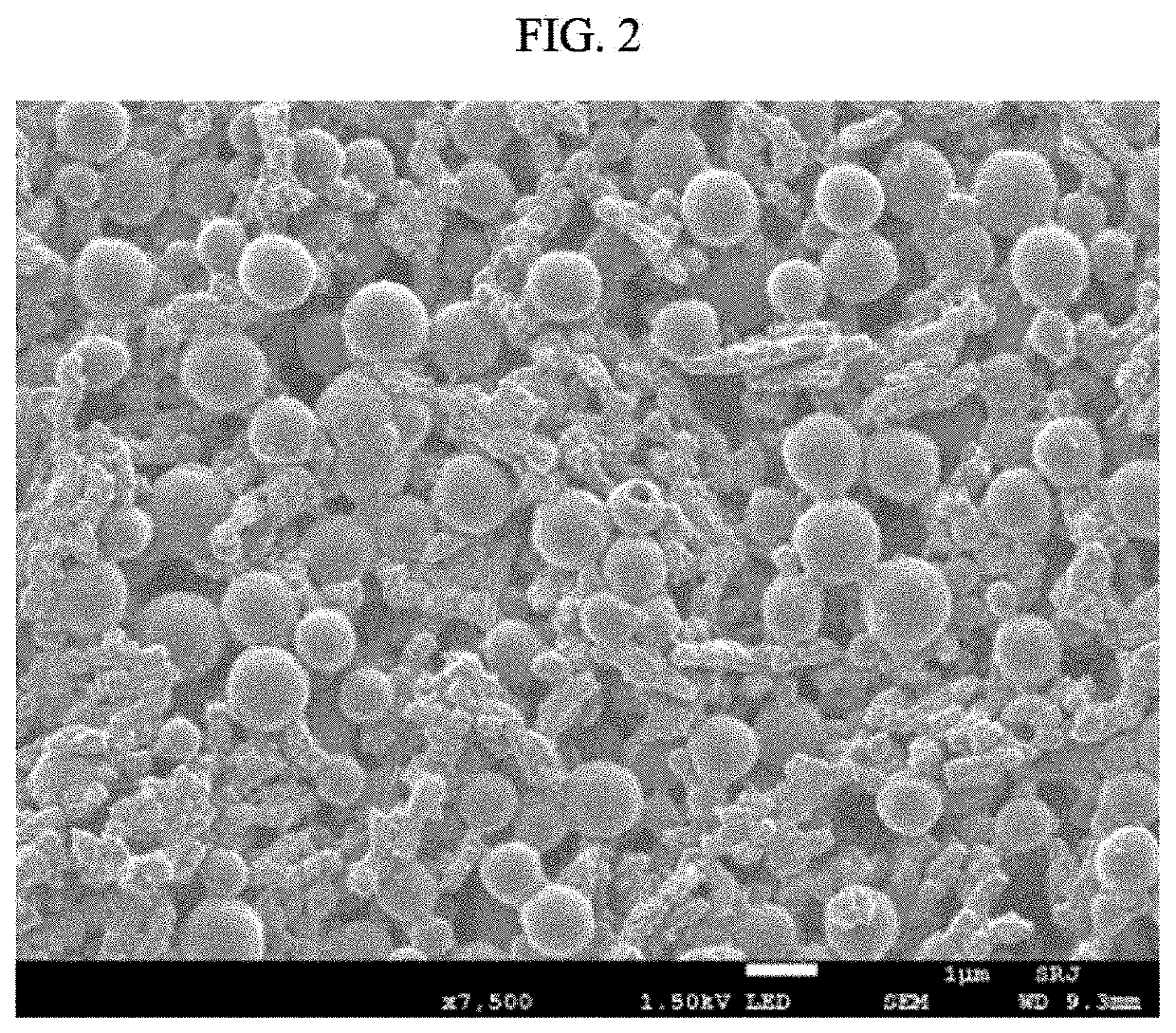

Rechargeable lithium battery

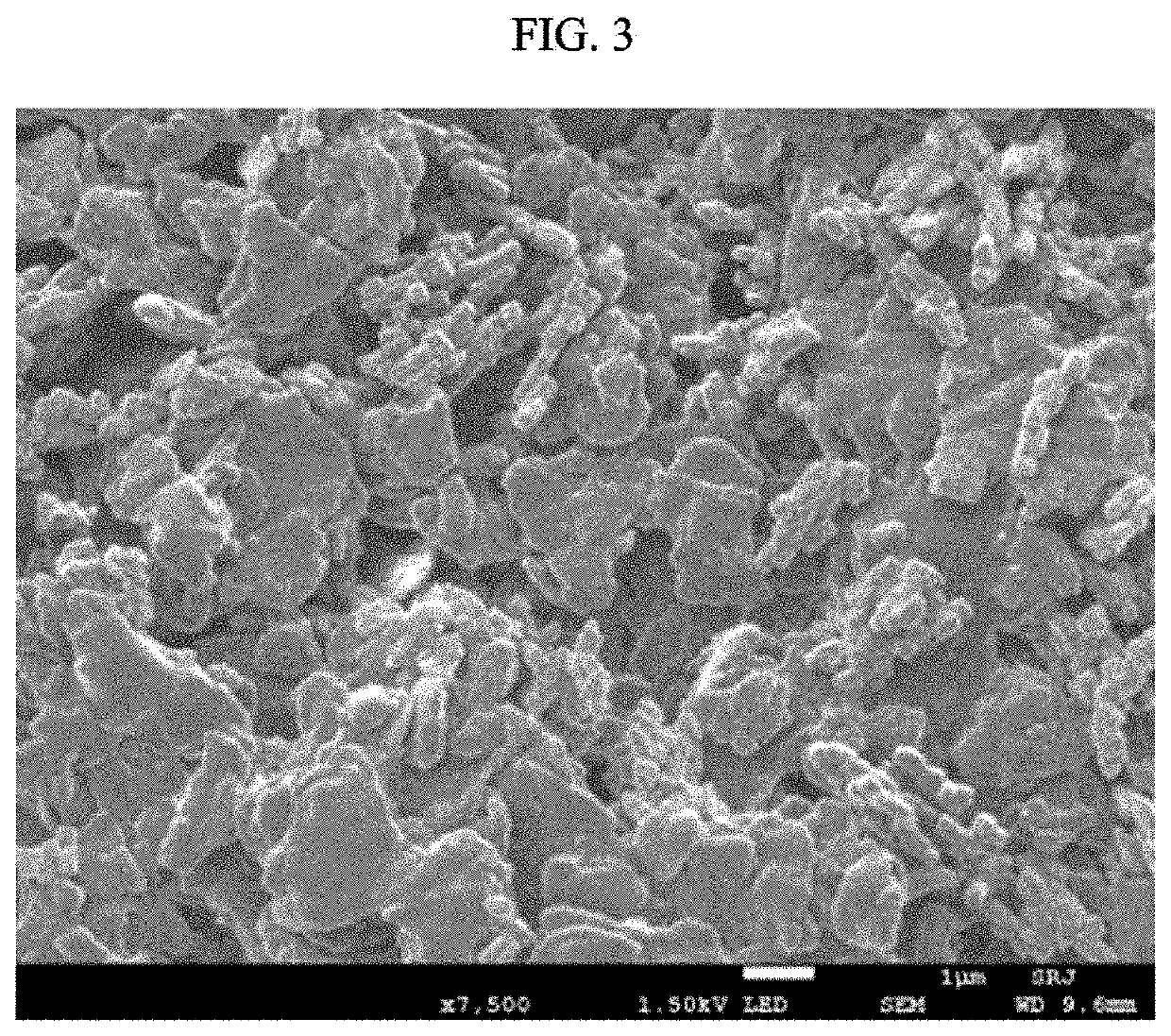

ActiveUS20200350632A1Improve stabilityImproving impregnation of electrolyteNegative electrodesPositive electrodesElectrolytic agentOrganic solvent

Rechargeable lithium battery includes a negative electrode including a negative active material layer and a negative electrode functional layer disposed on the negative active material layer; a positive electrode including a positive active material; an electrolyte solution, wherein the negative electrode functional layer includes flake-shaped polyethylene particles, the electrolyte solution includes a lithium salt and a non-aqueous organic solvent, and the non-aqueous organic solvent includes about 60 volume % to about 80 volume % of a propionate-based solvent and about 20 volume % to about 40 volume % of a carbonate-based solvent.

Owner:SAMSUNG SDI CO LTD

Process for impregnating porous mineral substrates

InactiveUS7611753B2Improve impregnation effectEasy to operateDomestic plumbingPretreated surfacesProduct gasMineral matrix

A process is provided for impregnating porous mineral substrates by a spray technique in which use is made of a gas-supported spraying assembly to apply liquid impregnating agent in a controlled manner to the substrate surface, the amount consumed being markedly less than the amount consumed in a conventional method of application by a flow-coating process.

Owner:EVONIK DEGUSSA GMBH

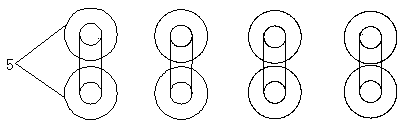

Equipment and method for impregnating continuous long fiber reinforced thermoplastics

The invention discloses equipment and a method for impregnating, and particularly relates to equipment and a method for impregnating continuous long fiber reinforced thermoplastics. The invention provides the equipment and the method for impregnating the continuous long fiber reinforced thermoplastics of which the fiber bundles are not interfered with one another, which comprise an equipment outer body, wherein a melt inlet is arranged at the upstream end of the equipment outer body, an extruding outlet is arranged at the downstream end of the equipment outer body, impregnating runners are arranged in the equipment outer body, the two ends of the impregnating runners are respectively communicated with the melt inlet and the extruding outlet, at least two impregnating runners are arranged in parallel, and long fiber feed ports which have the same number as that of the impregnating runners are arranged on the side wall of the equipment outer body and are respectively communicated with each impregnating runner. Because each impregnating runner is separately arranged, fibers can be separately impregnated and fed, and are not interfered with one another, so the production can be ensured to be stable.

Owner:SICHUAN UNIV

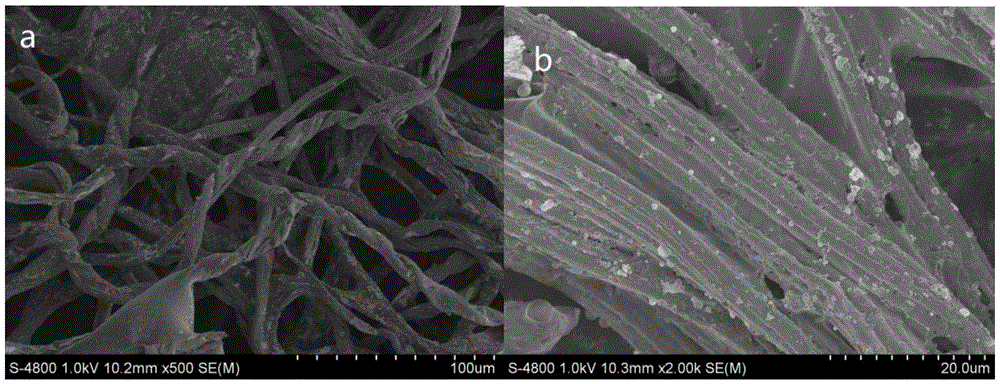

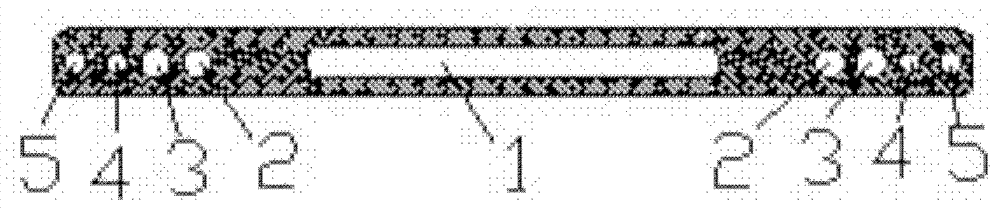

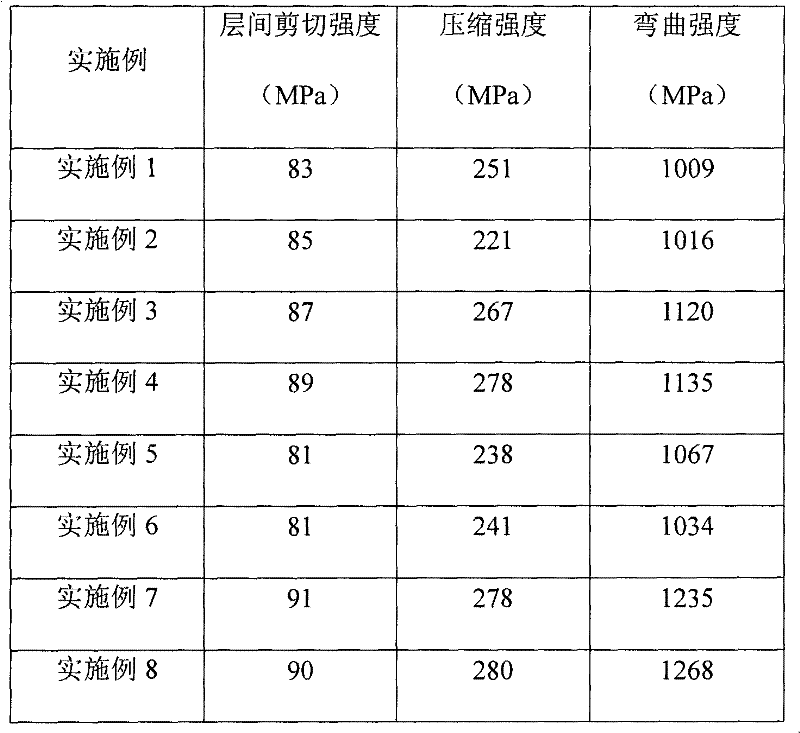

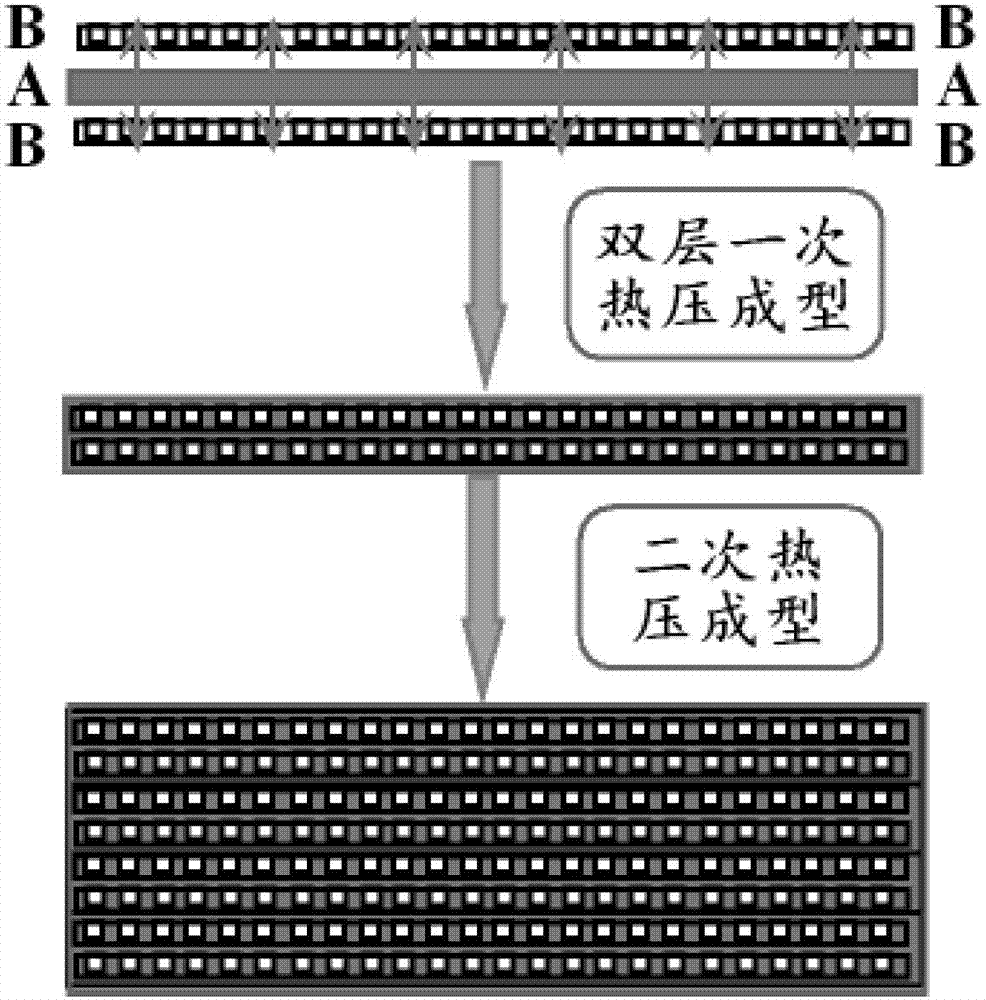

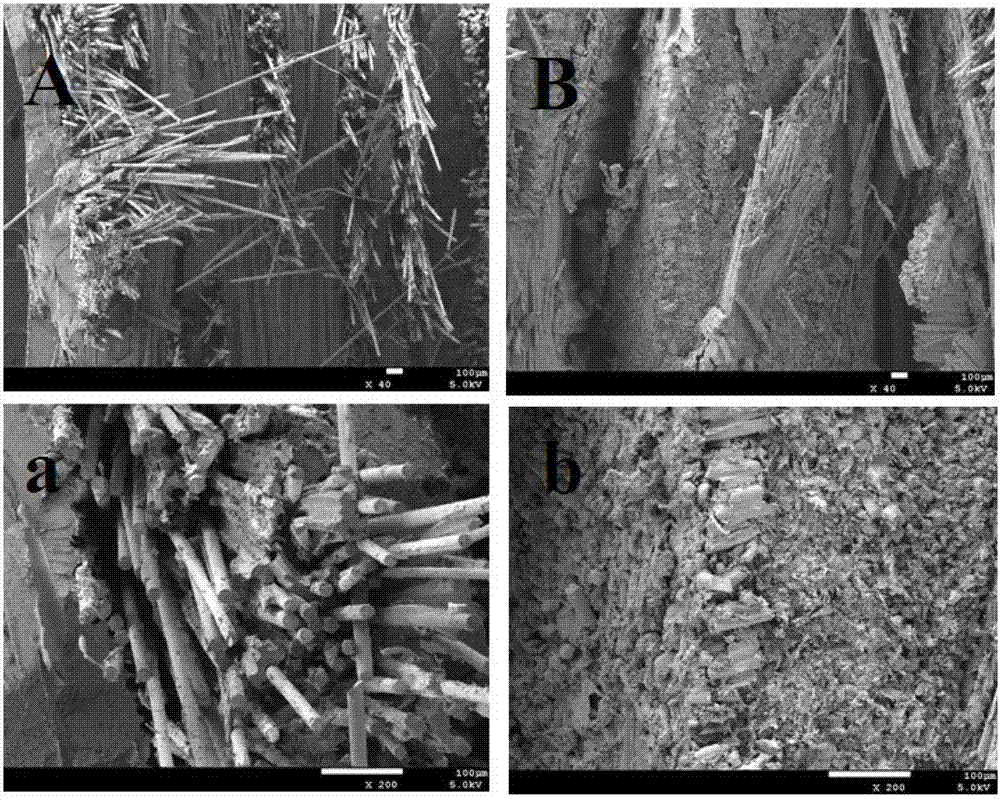

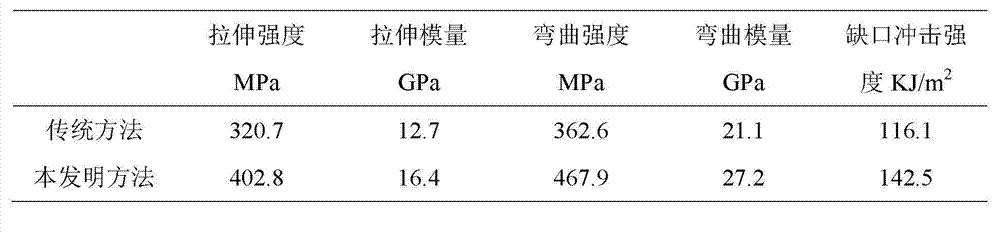

Method for improving impregnation effect of fiber cloth enhanced thermoplastic composite material

The invention discloses a preparation method for improving an impregnation effect of a fiber cloth enhanced thermoplastic composite material, wherein the fiber cloth enhanced thermoplastic composite material is prepared by a secondary hot press molding method. The method for improving the impregnation effect of the fiber cloth enhanced thermoplastic composite material comprises preparation of a monolayer sheet and overlapping combination of multiple monolayer sheets, wherein the monolayer is obtained by overlapping three layers of the fiber cloths, the resin matrixes and the fiber cloths at 2 to 10 MPa under the conditions that the fiber mass content is 30% to 80% and the arranging way is the fiber cloths, the resin matrixes and the fiber cloths; and the overlapping of multiple monolayer sheets is that each monolayer sheet is pressed and moulded after being overlapped in sequence under the conditions that the temperature is 290 to 400 DEG C and the pressure is 10 to 40 MPa. Therefore, the composite material has good impregnation effect and mechanical property.

Owner:SICHUAN UNIV

Technological process for producing viscose fiber filament by secondary impregnation production

InactiveCN101372766AImprove impregnation effectImprove the quality of alkali celluloseArtificial filaments from viscoseChemistryCarbon bisulfide

The invention discloses a technique method for producing viscose fiber filaments by adopting secondary dipping. In the method, the secondary dipping technology is adopted based on the technique of primary dipping for producing viscose fiber filaments; besides, the concentration difference of free bases in secondary alkali liquid and soda cellulose are utilized to separate out partial free bases; simultaneously the semi-fiber content of the soda cellulose is reduced; under the situation of not affecting the amount of the combined soda, the secondary reactions during an etiolation process are reduced; the adding amount of carbon bisulfide is reduced; the viscose quality is ensured; and the dipping effect is improved by adding a novel addition agent in the secondary dipping process; proper aging, etiolation, ripening and spinning techniques are selected to produce the viscose filaments with high quality; besides, the production cost is reduced; the production efficiency is improved and the environment pollution is reduced.

Owner:CHTC HELON

A coating-treatment surface modification method for ultrahigh molecular weight polyethylene fibers

InactiveCN105544180AOptionalUniform concentrationFibre typesUltrasonic/sonic fibre treatmentFiberPolymer science

The invention belongs to the field of materials and particularly relates to a coating-treatment surface modification method for ultrahigh molecular weight polyethylene fibers and fabric of the fibers. To improve adhesion properties of an interface between a resin substrate and the ultrahigh molecular weight polyethylene fibers as well as the fabric thereof and to eliminate or weaken timeliness of material surface plasma treatment, the surface of the ultrahigh molecular weight polyethylene is treated with low-temperature plasma and the fibers or the fabric are then immediately dipped into a coating solution containing epoxy resin, cyanate esters, bismaleimide resin, and the like so as to artificially introduce a designable "composite material interface layer" before compositing the ultrahigh molecular weight polyethylene fibers and the resin substrate, thus enhancing interface adhesive strength with the resin substrate and improving comprehensive properties.

Owner:THE RES INST FOR SPECIAL STRUCTURES OF AERONAUTICAL COMPOSITE AVIC

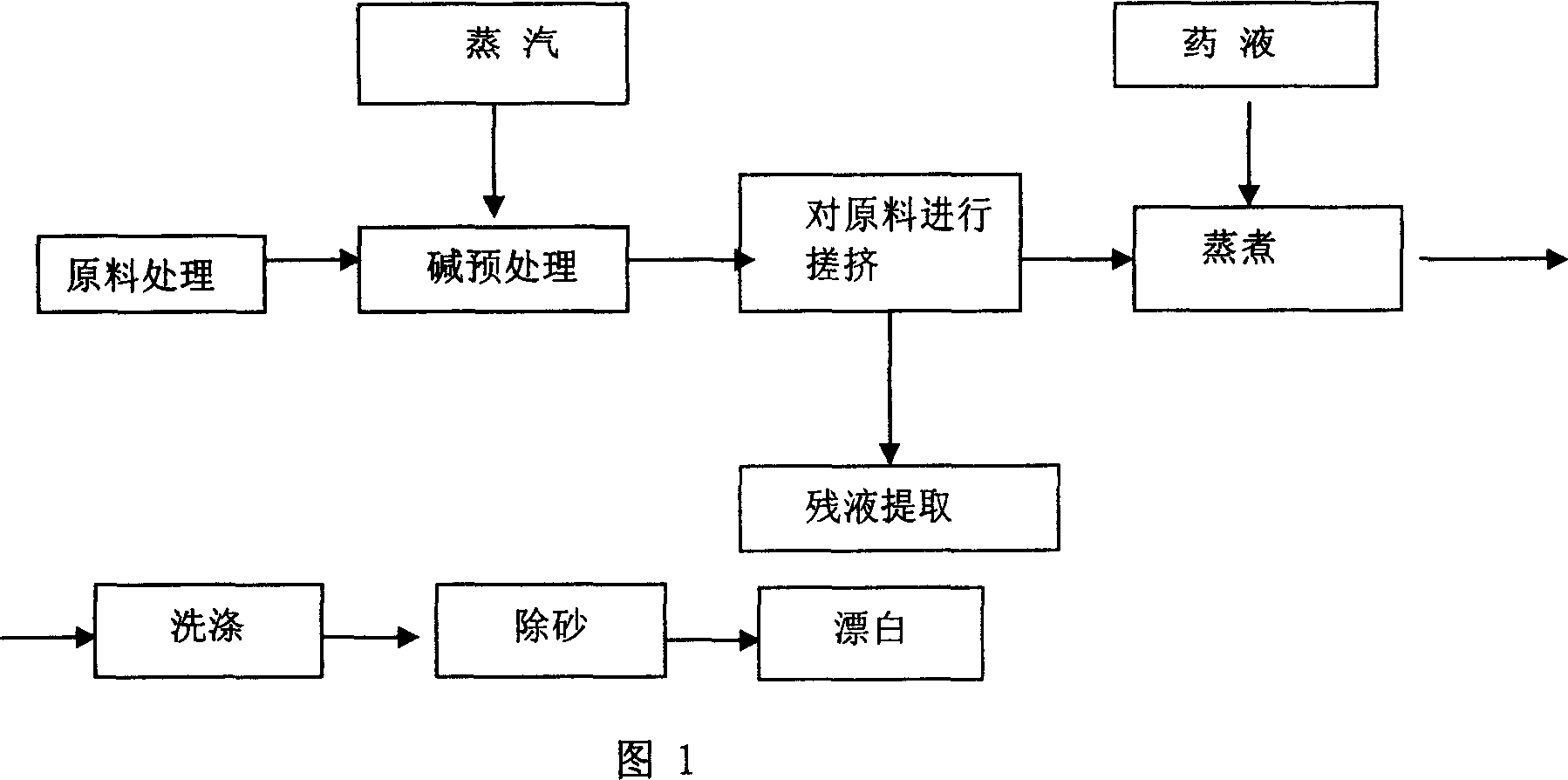

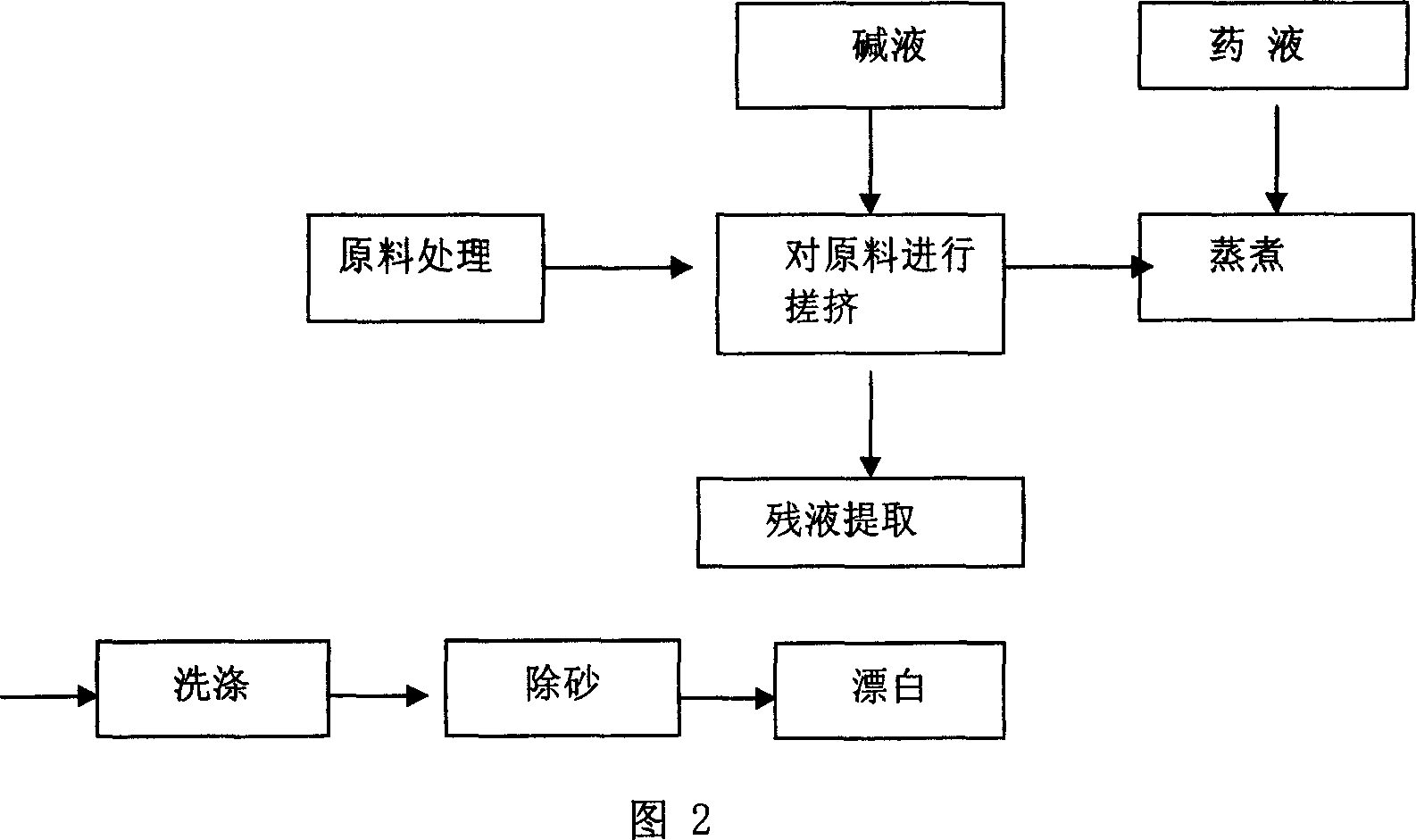

Method for producing chemical fiber pomace with fiber as raw material

InactiveCN1974922APerformance activationImprove impregnation effectCellulosic pulp after-treatmentDigestersBlack liquorPlant fibre

The present invention relates to a method for producing chemical fibre pulp by using plant fibre as raw material. Said method includes the following several steps: raw material treatment, making the treated raw material undergo the processes of rubbing and extruding, cooking, washing, removing sand and bleaching treatment. It is characterized by that in the preparation process of said chemical fibre pulp a screw extruding machine and a rubbing-extruding machine are adopted.

Owner:湖南吉湘生物科技有限公司

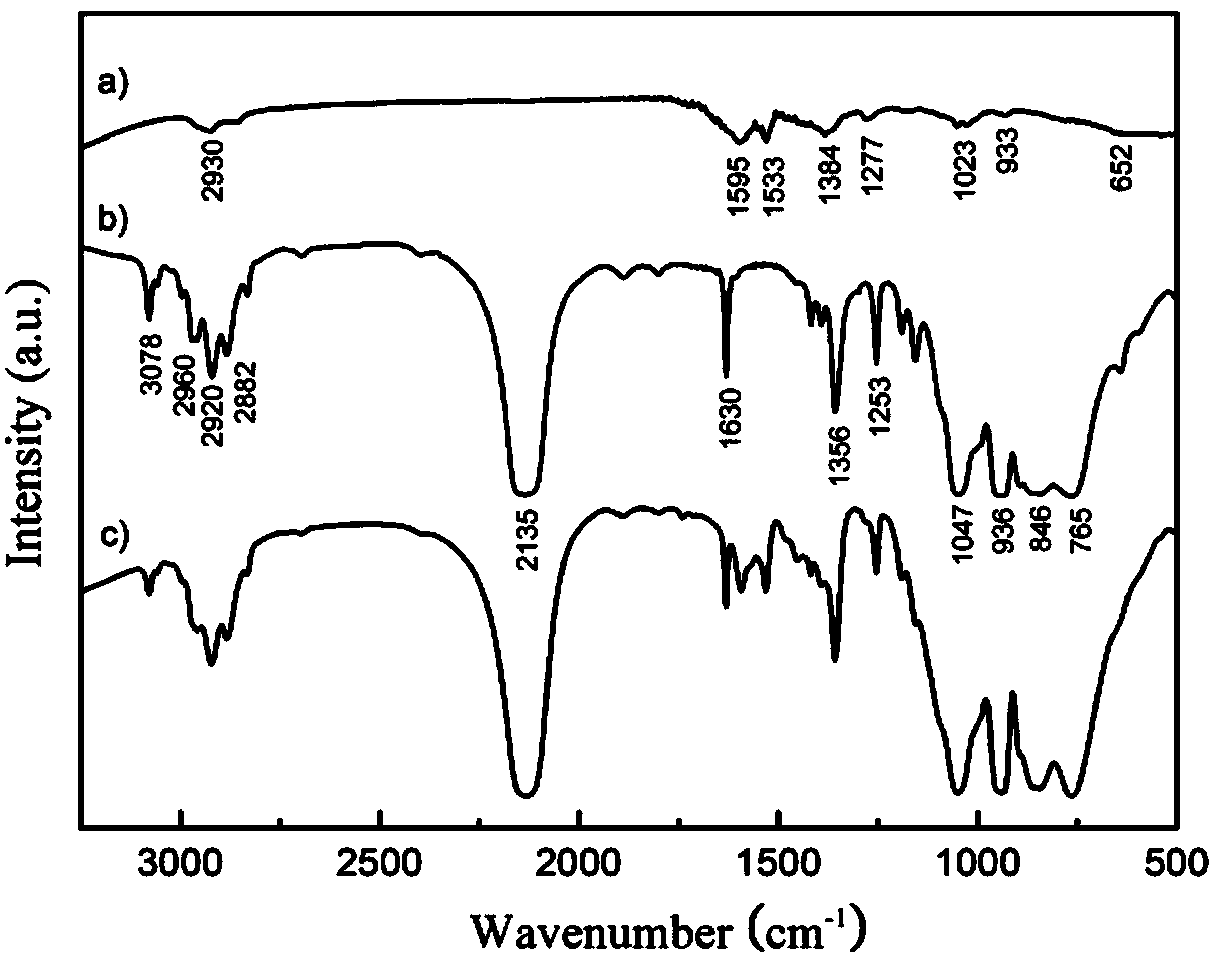

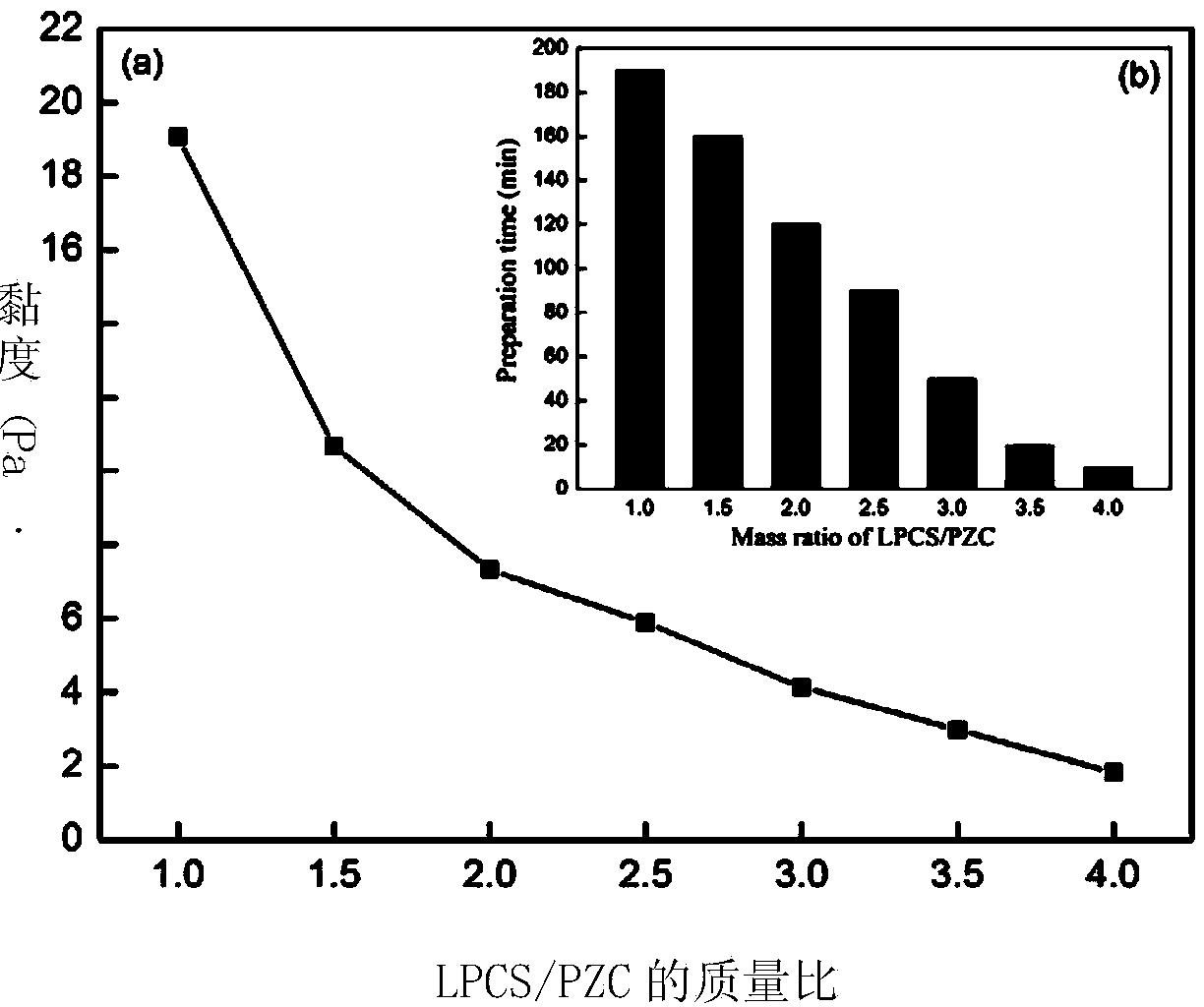

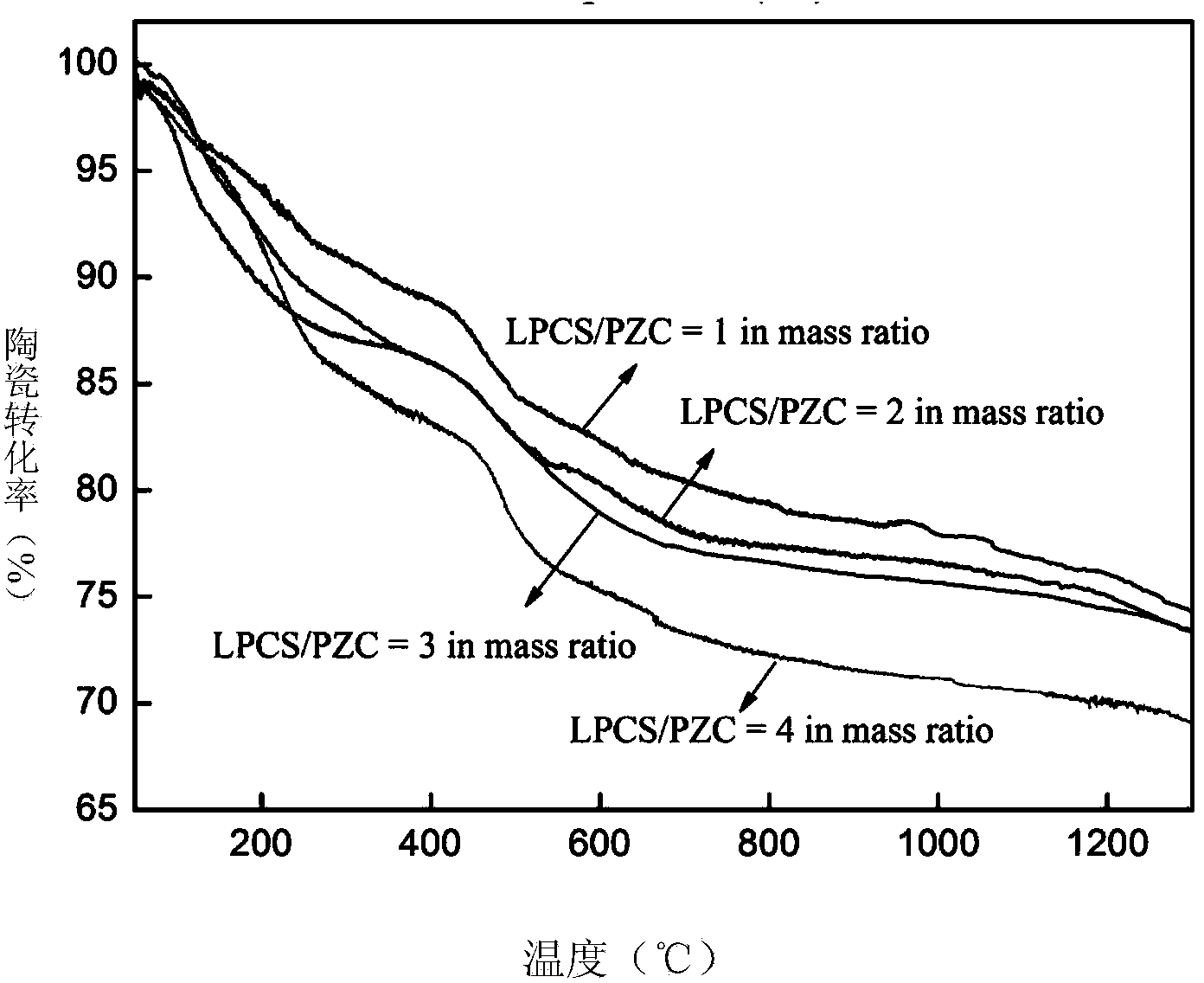

Hybridization liquid precursor, preparing method and method for preparing ZrC-SiC superhigh temperature ceramics and composite materials of ZrC-SiC superhigh temperature ceramics through hybridization liquid precursor

The invention relates to hybridization liquid precursor, a preparing method and a method for preparing ZrC-SiC superhigh temperature ceramics and composite materials of the ZrC-SiC superhigh temperature ceramics through the hybridization liquid precursor. Solid PZC precursor and carbon-rich vinyl adopted to replace liquid polycarbosilane (LPCS) precursor serve as raw materials for the first time and are processed in a hybridization mode to synthesize the brand new hybridization liquid precursor which is low in viscosity, adjustable in component, low in solidifying temperature, good in dipping performance, free of toxicity, harmless and high in productivity, organic solvent does not need to be added to the hybridization liquid precursor, the hybridization liquid precursor can be used for preparing the ZrC-SiC superhigh temperature ceramics and the composite materials of the ZrC-SiC superhigh temperature ceramics, and according to the thermogravimetric analysis, the ceramic productivity of the hybridization liquid LPCS-PZC ceramic precursor is more than 69 percent. The percent conversion of the ZrC-SiC superhigh temperature ceramics or the percent conversion of the fiber-reinforced ZrC-SiC superhigh temperature ceramic composite material ceramic is high, the technology is simple, and the high-temperature oxidation resistance of the obtained materials is good.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

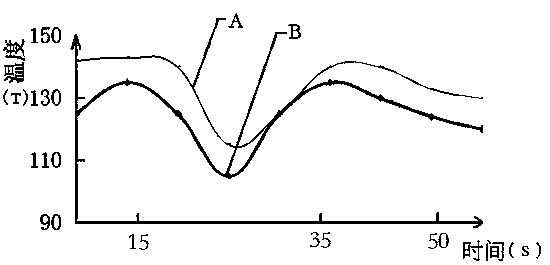

Method for preparing carbon fiber reinforced thermoplastic composite material

The invention discloses a method for preparing a carbon fiber reinforced thermoplastic composite material, which comprises the following steps: 1)alternatively paving carbon fiber and thermoplastic resin in a die, wherein a bottom layer and a top layer of the die are thermoplastic resin, closing the die and applying pressure; 2)accessing power supply to a carbon fiber layer, rapidly heating under current effect, when the temperature is higher than the melting point of thermoplastic resin, fusing thermoplastic resin, dipping carbon fiber under pressure; and 3)breaking power, cooling the die, and then opening the die to obtain the carbon fiber reinforced thermoplastic composite material. The method takes carbon fiber as a heat-generating body, the electrothermal conversion efficiency can reach as high as more than 90%, and the energy saving effect is obvious; simultaneously, carbon fiber is capable of melting thermoplastic resin and completing dipping, and has the advantages of short moulding time and good dipping effect, formation of good cross section of thermoplastic resin and fiber can be realized, composite material performance is increased, and processing of product with large thickness can be realized in short time.

Owner:蓝星纤维(北京)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com