Method for preparing continuous carbon fiber-reinforced thermoplastic resin composite material

A technology for resin composite materials and thermoplastic enhancement, which is applied in the field of resin composite material preparation, can solve the problems of high melting point of mixed solvent, complex preparation process and difficult removal, and achieves widening the scope of thermoplastic resin, strong process controllability and impregnation effect. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1 part by mass of polyethersulfone (PES) was dissolved in 30 parts by mass of a mixed solvent of N,N dimethylacetamide (DMAc) and acetone, wherein the mass ratio of DMAc to acetone was 1:1. Add 0.5 parts by mass of polyphenylene sulfide powder into the PES-DMAc solution, mechanically stir at a lower stirring rate for 60 minutes, impregnate the prepreg made of continuous carbon fiber, and perform the following processing according to the processing technology of hot pressing :

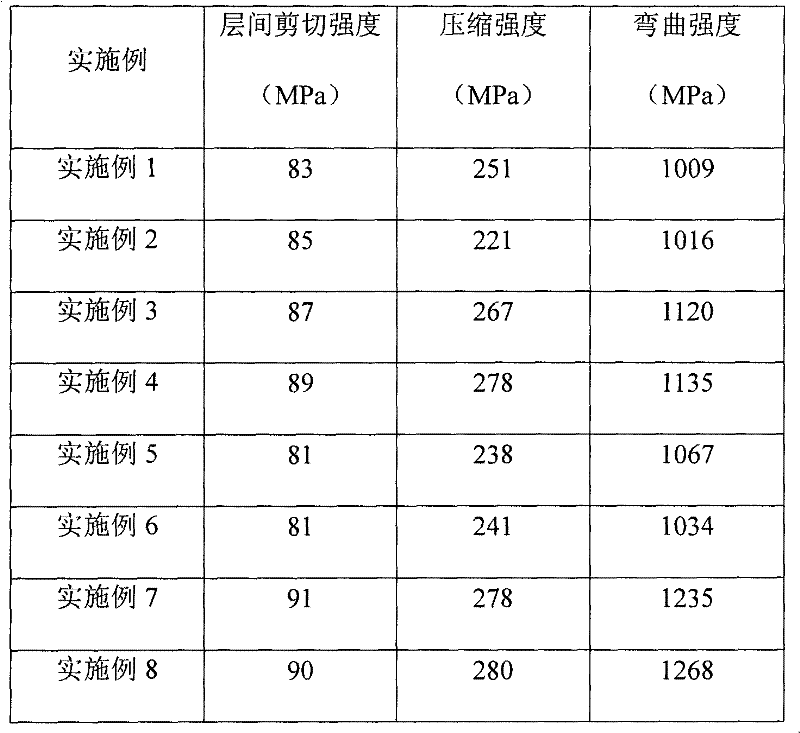

[0024] Cold pressing: 10MPa / room temperature / 60Min+hot pressing: 15MPa / 225°C / 60Min+15MPa / 350°C / 120Min+cooling: 80°C / water cooling+pressure relief and demoulding. The continuous carbon fiber reinforced composite material prepared by the above process has excellent comprehensive mechanical properties and can meet the requirements of general industrial use. Please see attached table 1 for specific performance test values.

Embodiment 2

[0026] 2 parts by mass of polyethersulfone (PES) were dissolved in 40 parts by mass of a mixed solvent of N,N dimethylacetamide (DMAc) and acetone, wherein the mass ratio of DMAc to acetone was 2:1. Add 0.75 parts by mass of polyphenylene sulfide powder into the PES-DMAc solution, oscillate ultrasonically for 60 minutes, impregnate the prepreg made of continuous carbon fiber, and perform the following processing according to the processing technology of hot pressing:

[0027] Cold pressing: 8MPa / room temperature / 50Min+hot pressing: 13MPa / 210°C / 50Min+13MPa / 320°C / 100Min+cooling: 80°C / water cooling+pressure release. The continuous carbon fiber reinforced composite material prepared by the above process has excellent comprehensive mechanical properties and can meet the requirements of general industrial use. Please see attached table 1 for specific performance test values.

Embodiment 3

[0029] 3 parts by mass of polyethersulfone (PES) was dissolved in 50 parts by mass of a mixed solvent of N,N dimethylacetamide (DMAc) and acetone, wherein the mass ratio of DMAc to acetone was 4:1. Add 1 mass part of polyphenylene sulfide powder into the PES-DMAc solution, mechanically stir at a low stirring rate for 60Min, impregnate the prepreg made of continuous carbon fiber, and perform the following processing according to the processing technology of hot pressing :

[0030] Cold pressing: 6MPa / room temperature / 40Min+hot pressing: 12MPa / 200°C / 40Min+11MPa / 290°C / 80Min+cooling: 80°C / water cooling+pressure release and demoulding. The continuous carbon fiber reinforced composite material prepared by the above process has excellent comprehensive mechanical properties and can meet the requirements of general industrial use. Please see attached table 1 for specific performance test values.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com