Patents

Literature

269results about How to "Increase the outer surface area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

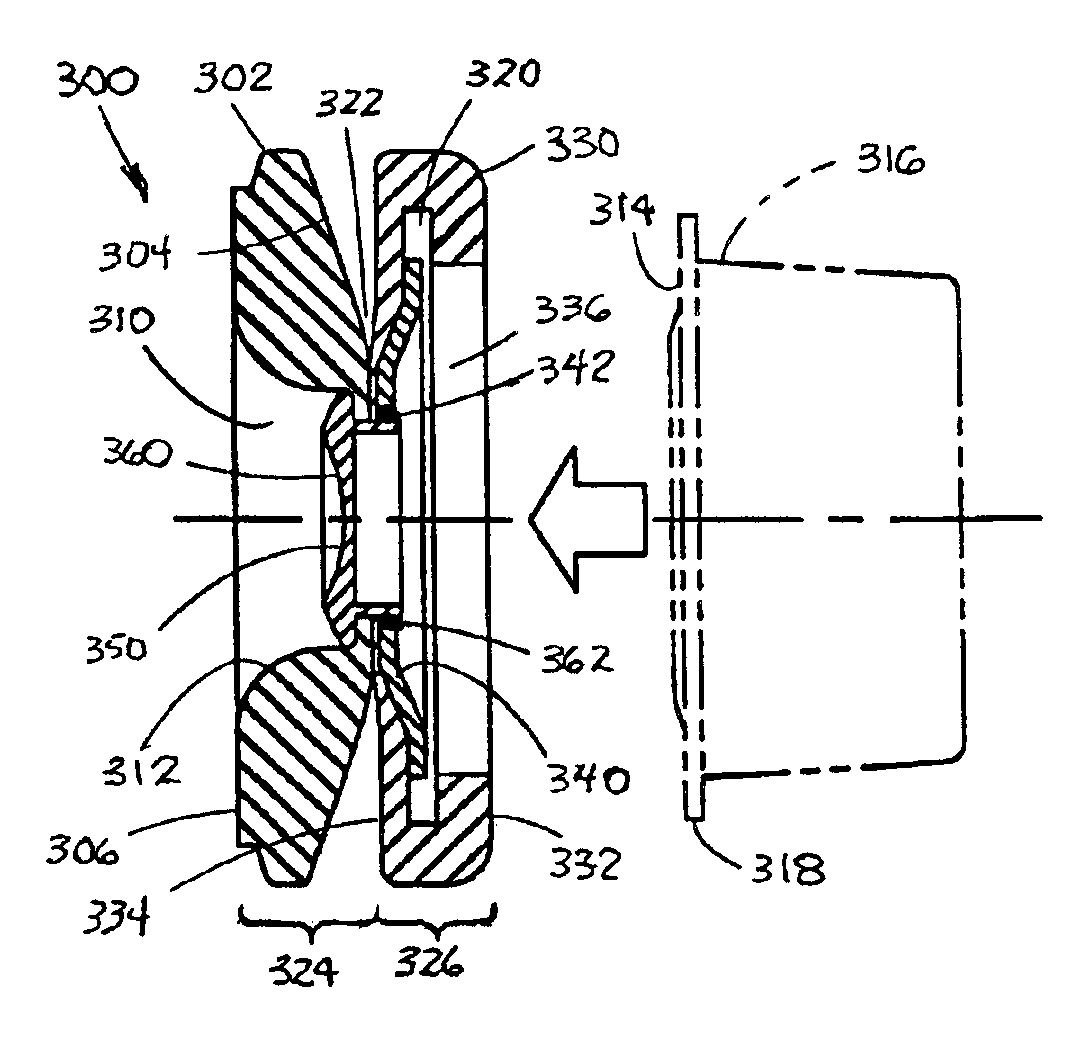

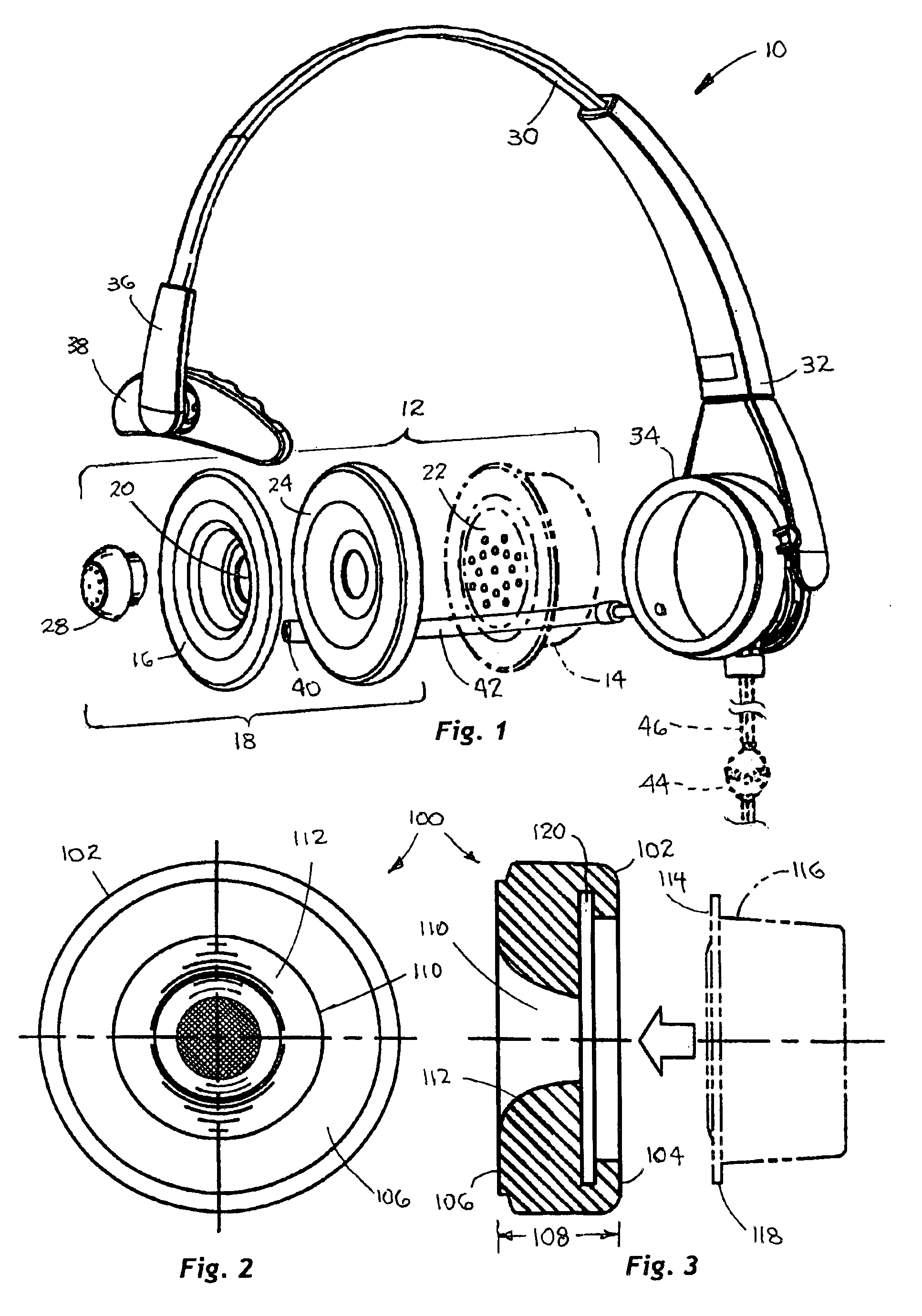

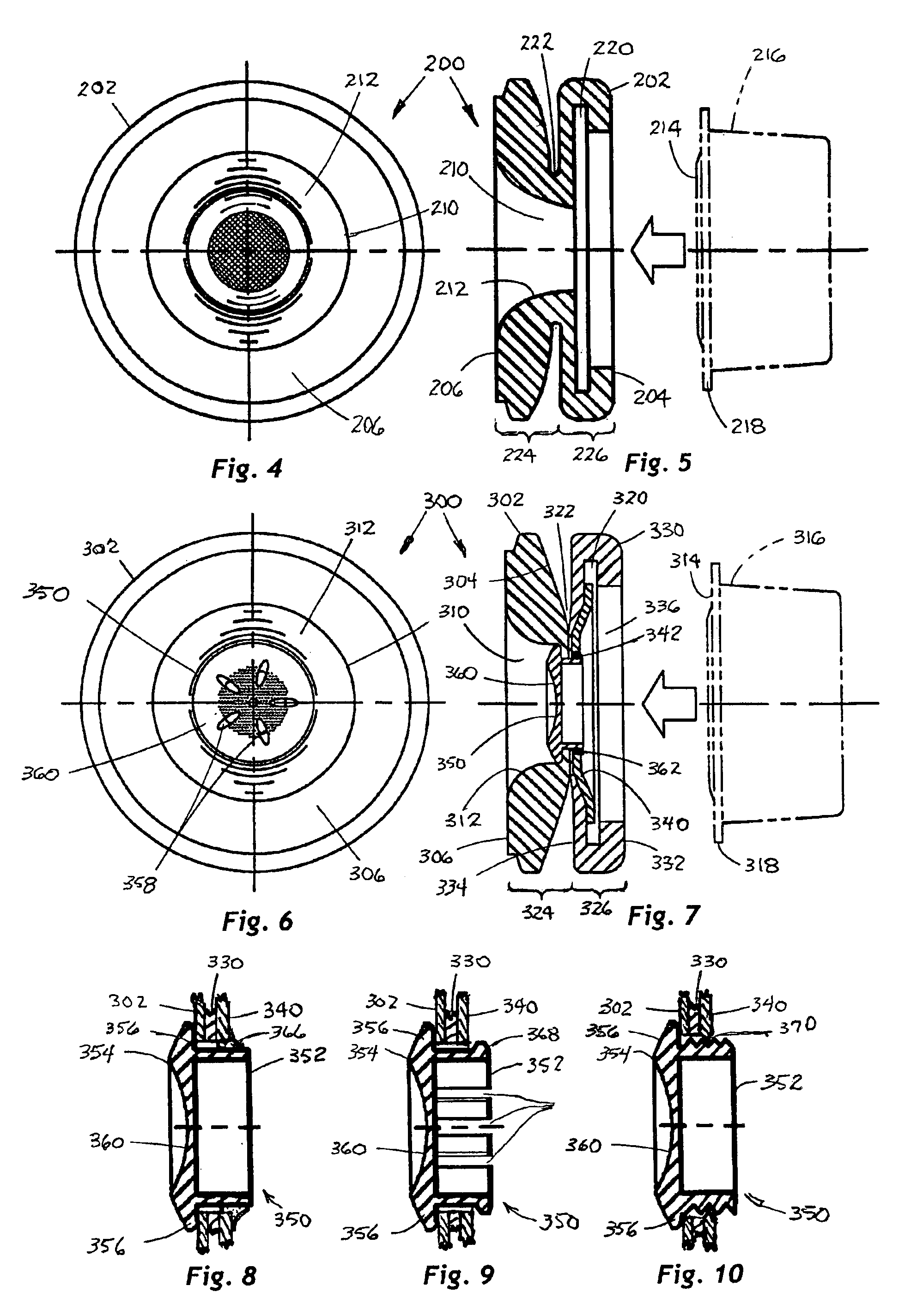

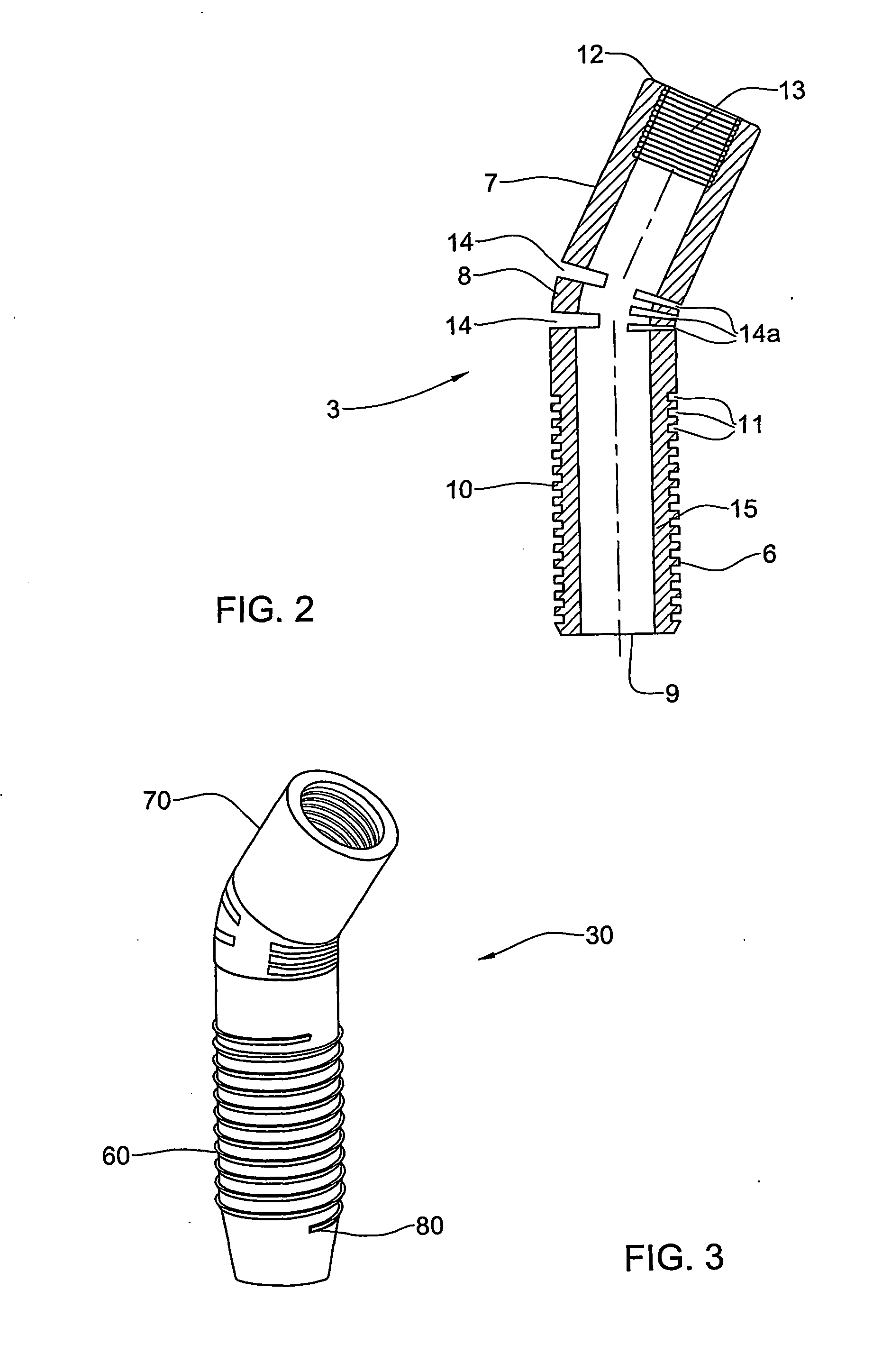

Comfortable earphone cushions

InactiveUS6856690B1Improved and long-term wearing comfortImprove cooling effectPiezoelectric/electrostrictive microphonesMicrophonesElastomerTransducer

A cushion for a headset earphone comprises a resilient ring having opposite input and output faces, and a through-opening defining an interior surface between the two faces. The input face has structure for acoustically coupling the opening to an output face of an audio speaker, and the output face is resiliently conformable to a lateral face of an external ear of a listener, thereby acoustically coupling the opening, and hence, the speaker, to the listener's ear. The interior surface of the cushion can be configured to effectively match the acoustical impedance at the output face of the speaker to the acoustical impedance at the entrance of the listener's ear. In one possible embodiment, the ring is formed of an elastomer filled with microcapsules containing a material capable of an endothermic phase changes at a constant temperature, such that the cushion more effectively conducts heat away from the ear, thereby providing long term listening comfort. In another embodiment, the through-opening is acoustically coupled to the output of the transducer with an acoustic plug such that the cushion is flexibly articulated about the plug relative to the speaker, thereby enabling the cushion to comply more easily to the listener's ear using lower contact forces between the cushion and the ear.

Owner:PLANTRONICS

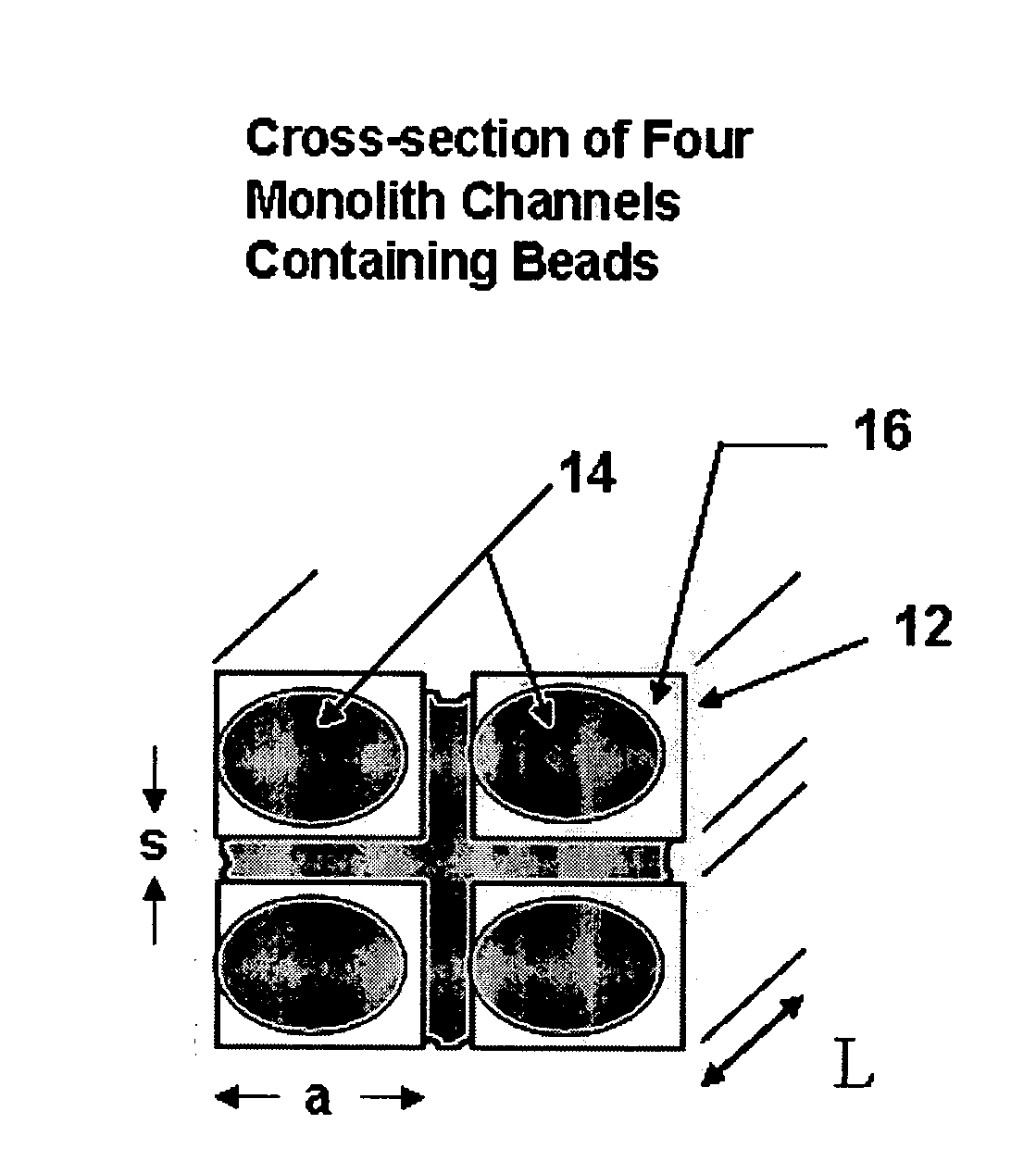

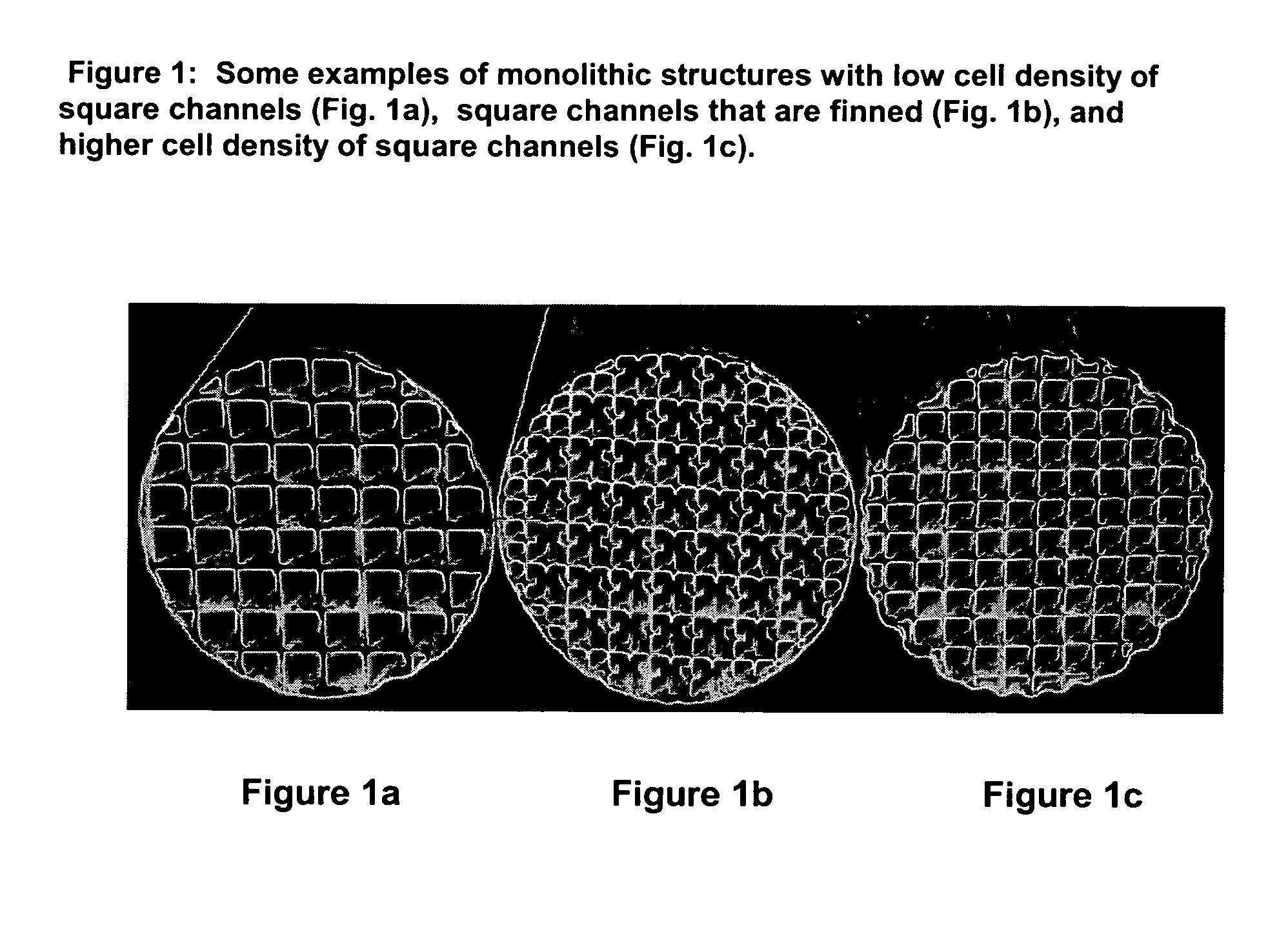

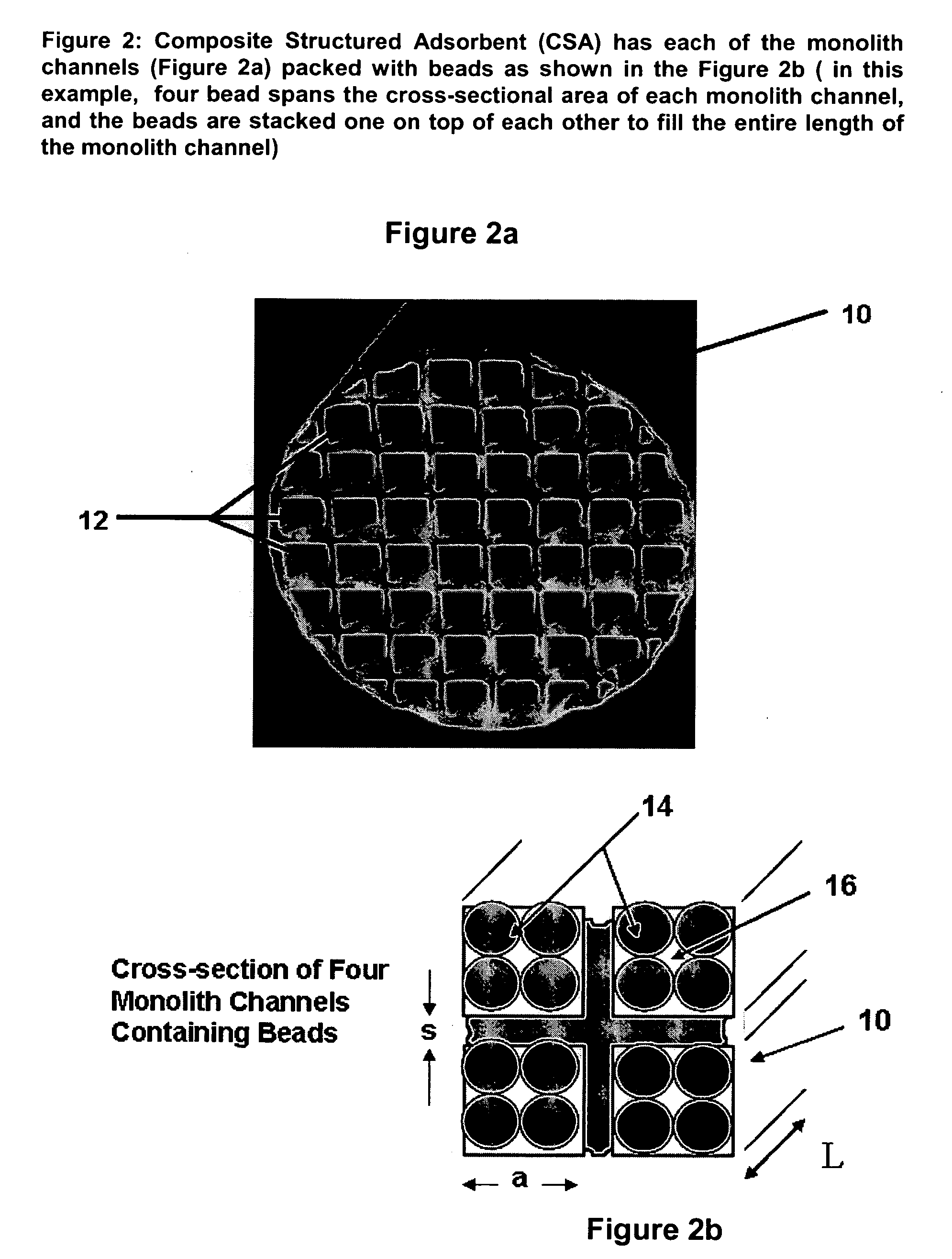

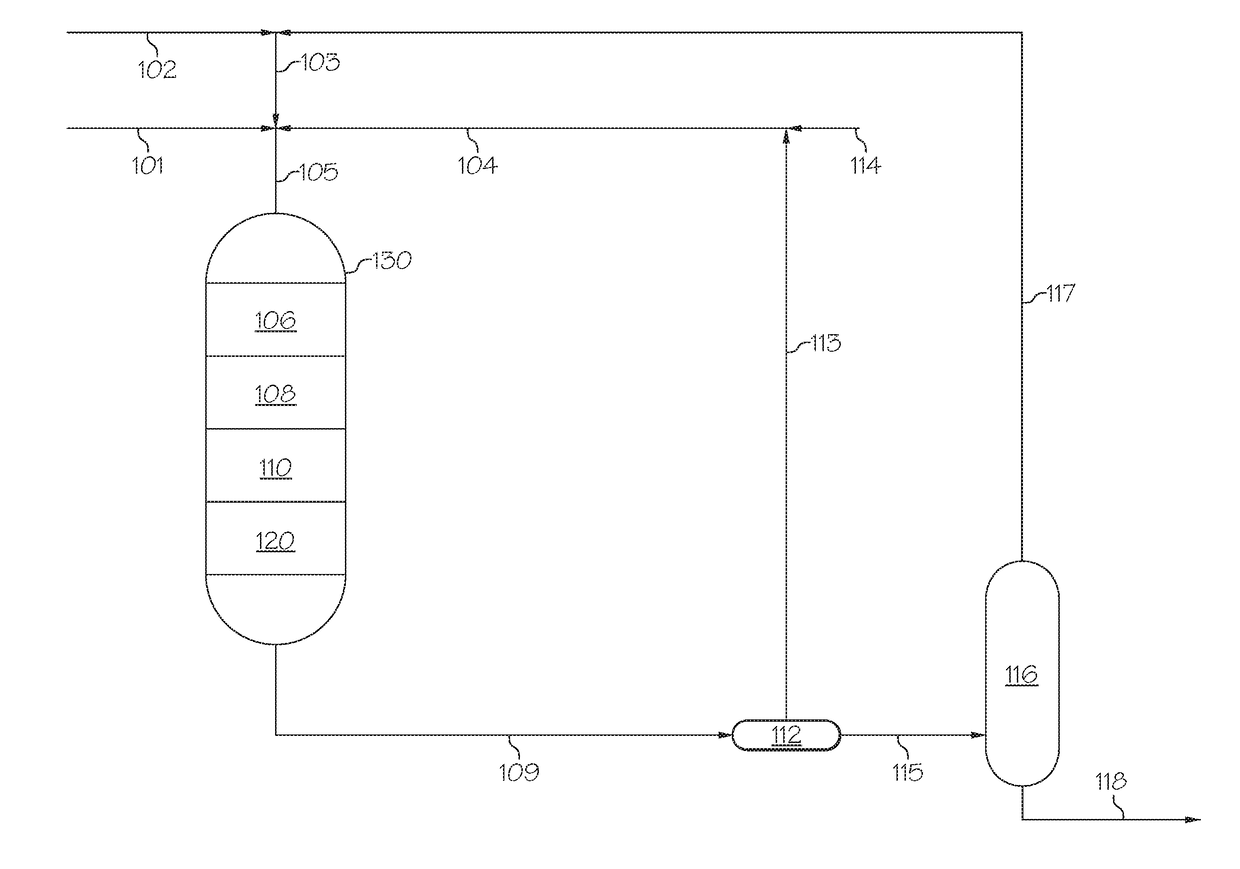

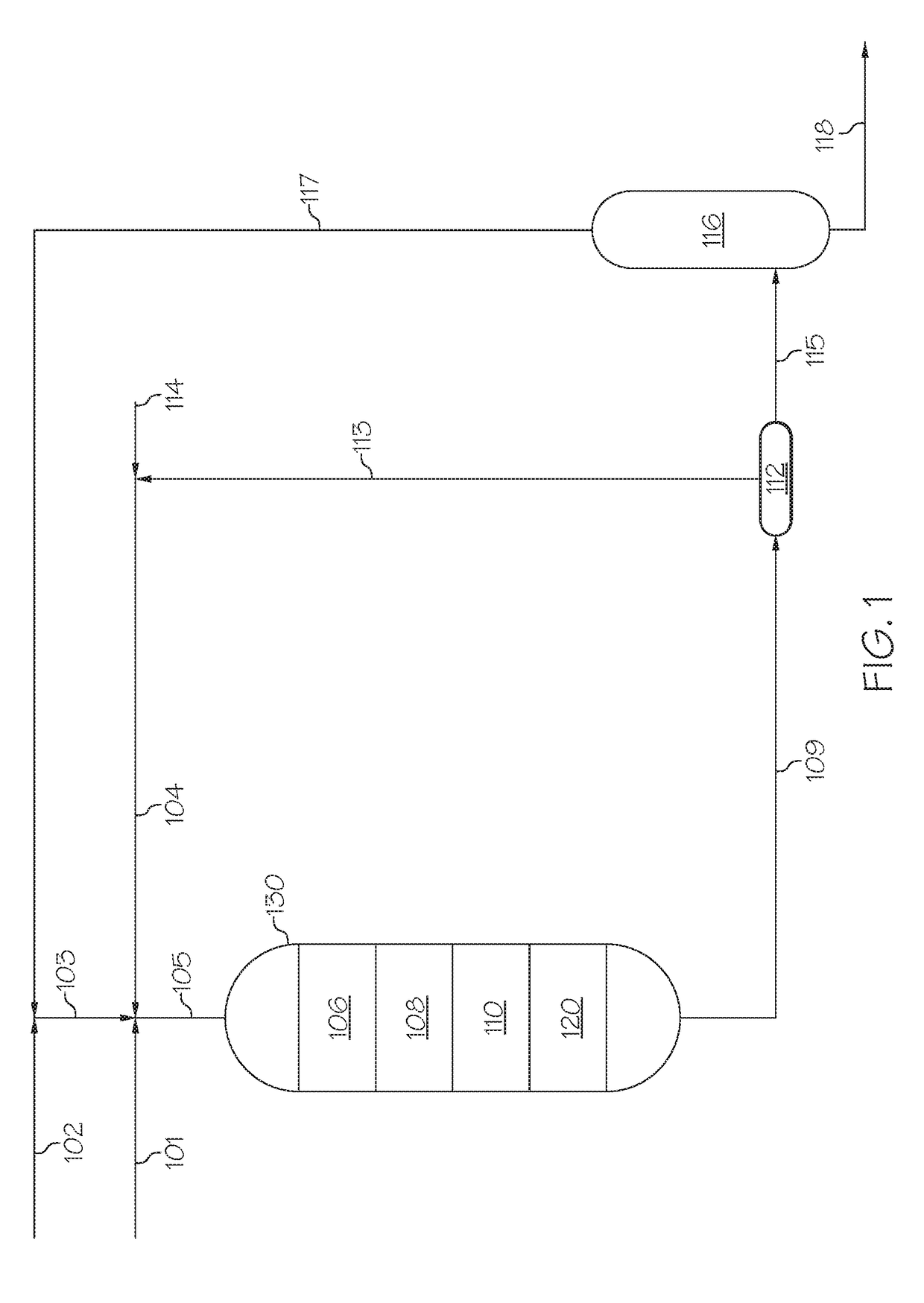

Composite structured adsorbents

InactiveUS20080148936A1Lower overall pressure dropReduce power consumptionGas treatmentIsotope separationVacuum pressureSorbent

The present invention relates to composite structured adsorbents and methods of use therefor. The invention more particularly relates to composite structured adsorbents that can include a multi-channel framework (e.g., monoliths), the channels of the multi-channel framework containing adsorbent beads particles therein, with a channel-to-particle diameter ratio in the range of 1 to 10, more preferably 1 to 7 and even more preferably 1 to 5. In the case of non-spherical particles, the hydraulic diameter is used in the calculation of the channel-to-particle diameter. The composite structured adsorbents of the present invention can be used in various industrial applications, for example in pressure swing adsorption (PSA) or vacuum pressure swing adsorption (VPSA) processes to produce O2 from air.

Owner:PRAXAIR TECH INC

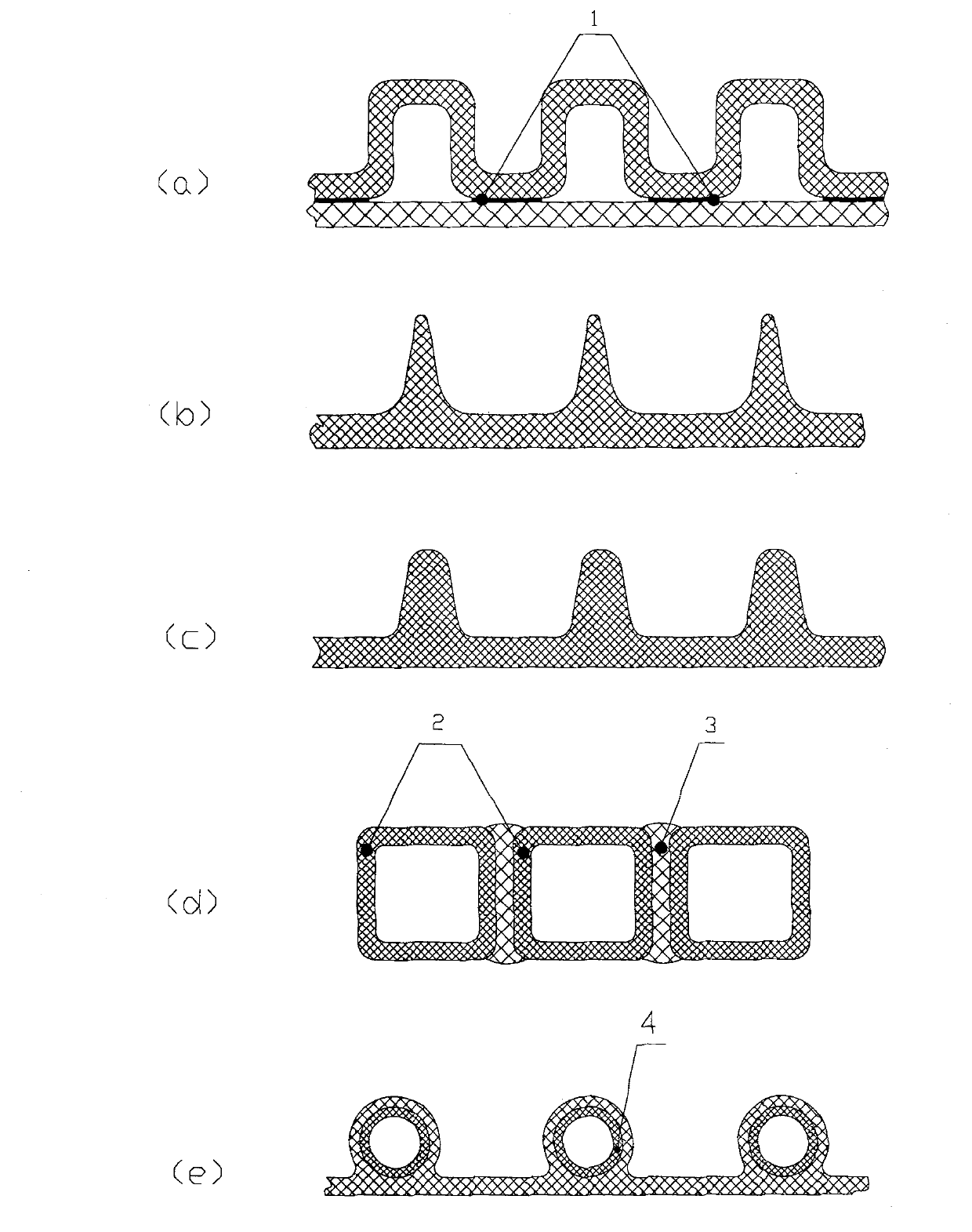

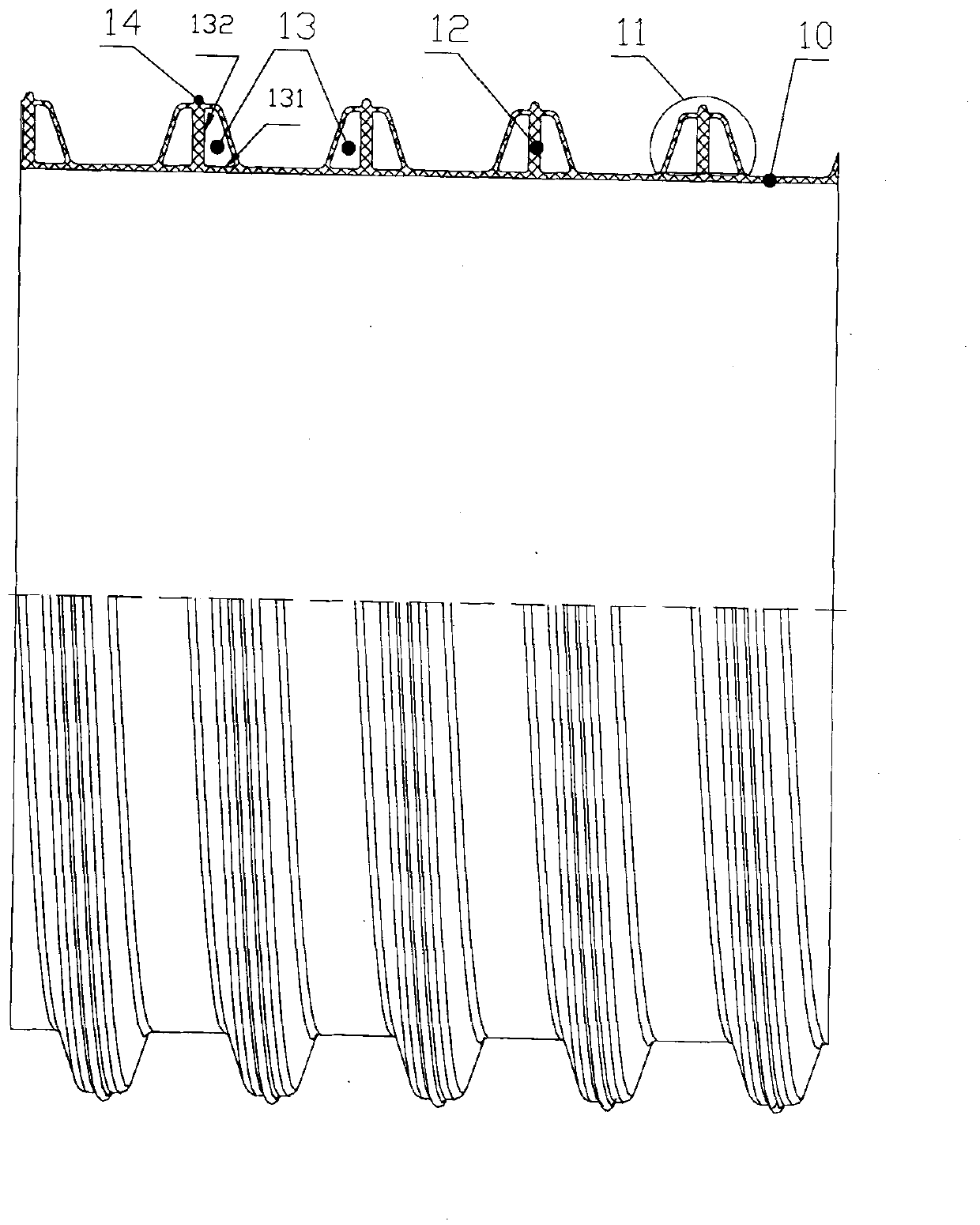

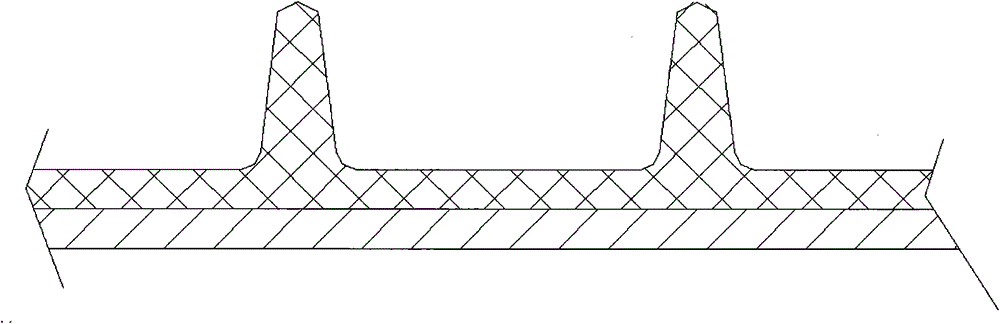

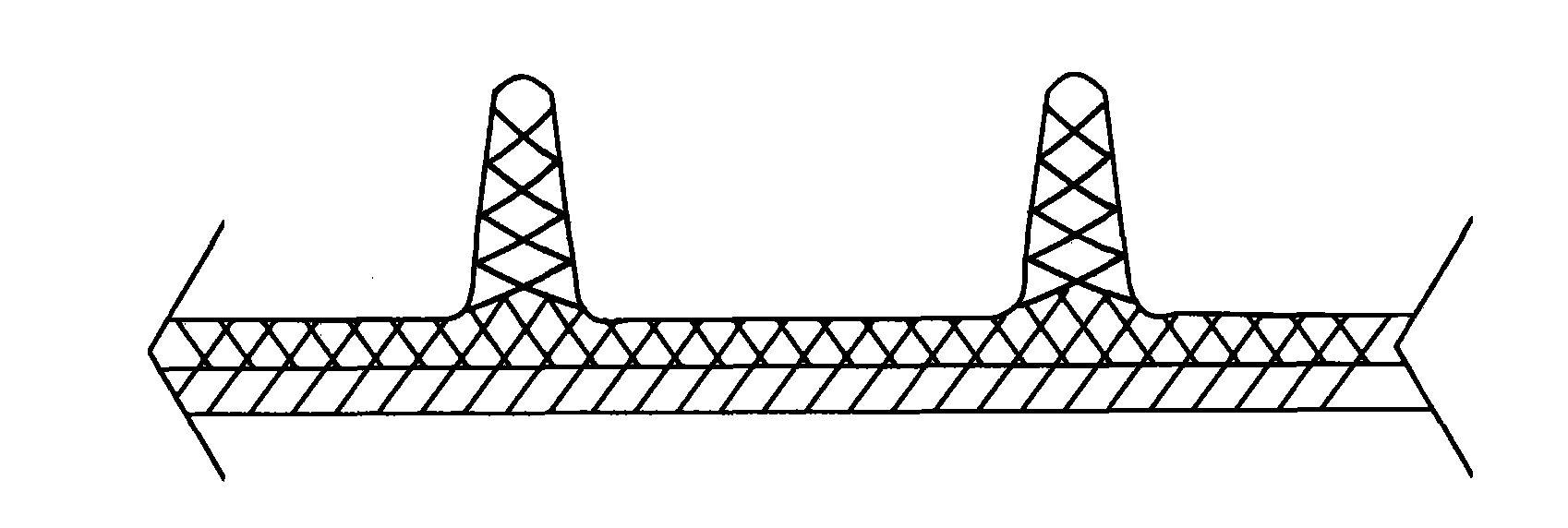

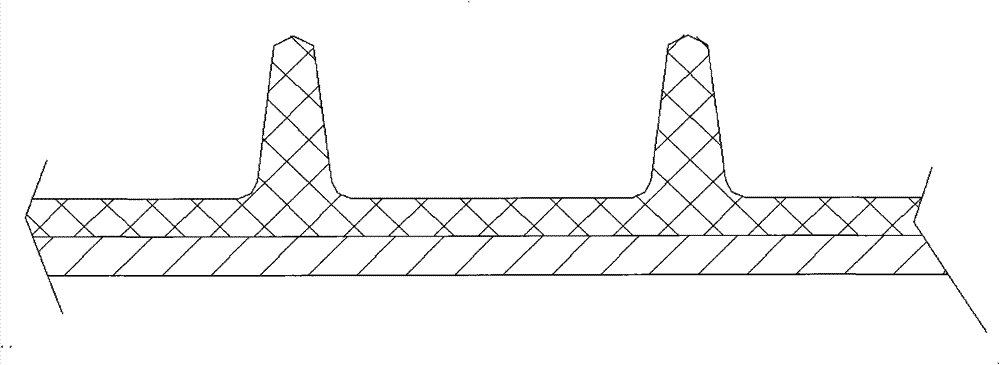

Internal rib reinforcing outer ripple type plastic twining structured wall pipe and manufacturing method thereof

InactiveCN101907207AIncrease the outer surface areaGood synergyRigid pipesTubular articlesMechanical engineeringHot-melt adhesive

The invention relates to an internal rib reinforcing outer ripple type plastic spirally twining structured wall pipe, which comprises a cylindrical surfaced pipe main body and a reinforcing rib wound outside of the pipe main body. The reinforcing rib contains an inner reinforcing rib vertical to the pipe wall, wherein the inner rib divides the reinforcing rib into two parallel hollow cavities. The upper part of the reinforcing rib and the top of the inner rib are both provided with a solid bulge. A method for manufacturing the plastic reinforcing pipe of the invention comprises the steps of: continuously extruding a plastic abnormal strip with two tubular bulges and containing a hollow cavity inside through a first plastic extruder, continuously, regularly, spirally twining the plastic abnormal strip on a formed roller in parallel, at the same time, extruding fused plastic gel in a clearance between adjacent side walls of the spirally wound plastic abnormal strip through a second plastic extruder, rolling two projected tubular cavities corresponding to two sides of the clearances connected by fusing the adjacent plastic abnormal pipe through a rolling wheel which is arranged at the corresponding part on the periphery of the formed roller with a slot structure, forming an outer projected reinforcing rib of the pipe outer wall by fusing the two tubular bulges, and extruding the residual fused gel in the clearance by the rolling wheel so as to form the solid bulge.

Owner:戴爱清

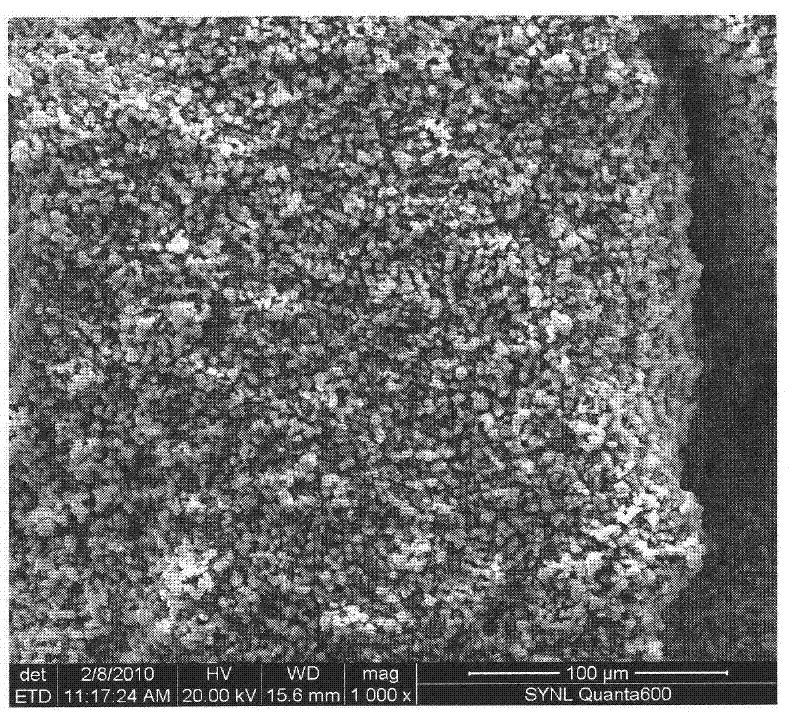

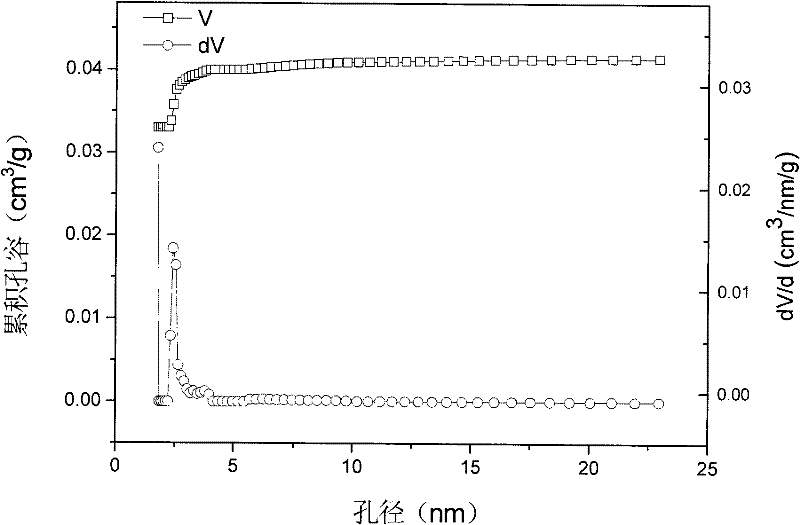

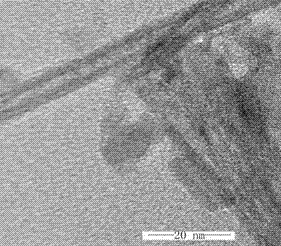

Small dense microporous solid support materials, their preparation, and use for purification for large macromolecules and bioparticles

InactiveUS20050269257A1High densityLow porosityBioreactor/fermenter combinationsBiological substance pretreatmentsMaceralOxide matrix

The present invention provides small, dense mineral oxide solid supports or microbeads, comprising dense microporous mineral oxides matrices in which a skin of polymers is rooted, and their use in downstream processing, especially for fluidized bed purification of bioparticles or high molecular weight macromolecules.

Owner:PALL CORP

Zeolites, the production thereof, and their uses for upgrading heavy oils

ActiveUS20180333708A1Low costLess expensiveCatalytic crackingMolecular sieve catalystsFuel oilChemistry

According to one or more embodiments, a nano-sized, mesoporous zeolite particle may include a microporous framework comprising a plurality of micropores having diameters of less than or equal to 2 nm and a BEA framework type. The nano-sized, mesoporous zeolite particle may also include a plurality of mesopores having diameters of greater than 2 nm and less than or equal to 50 nm. The zeolite particles may be integrated into hydrocracking catalysts and utilized for the cracking of heavy oils in a pretreatment process.

Owner:SAUDI ARABIAN OIL CO

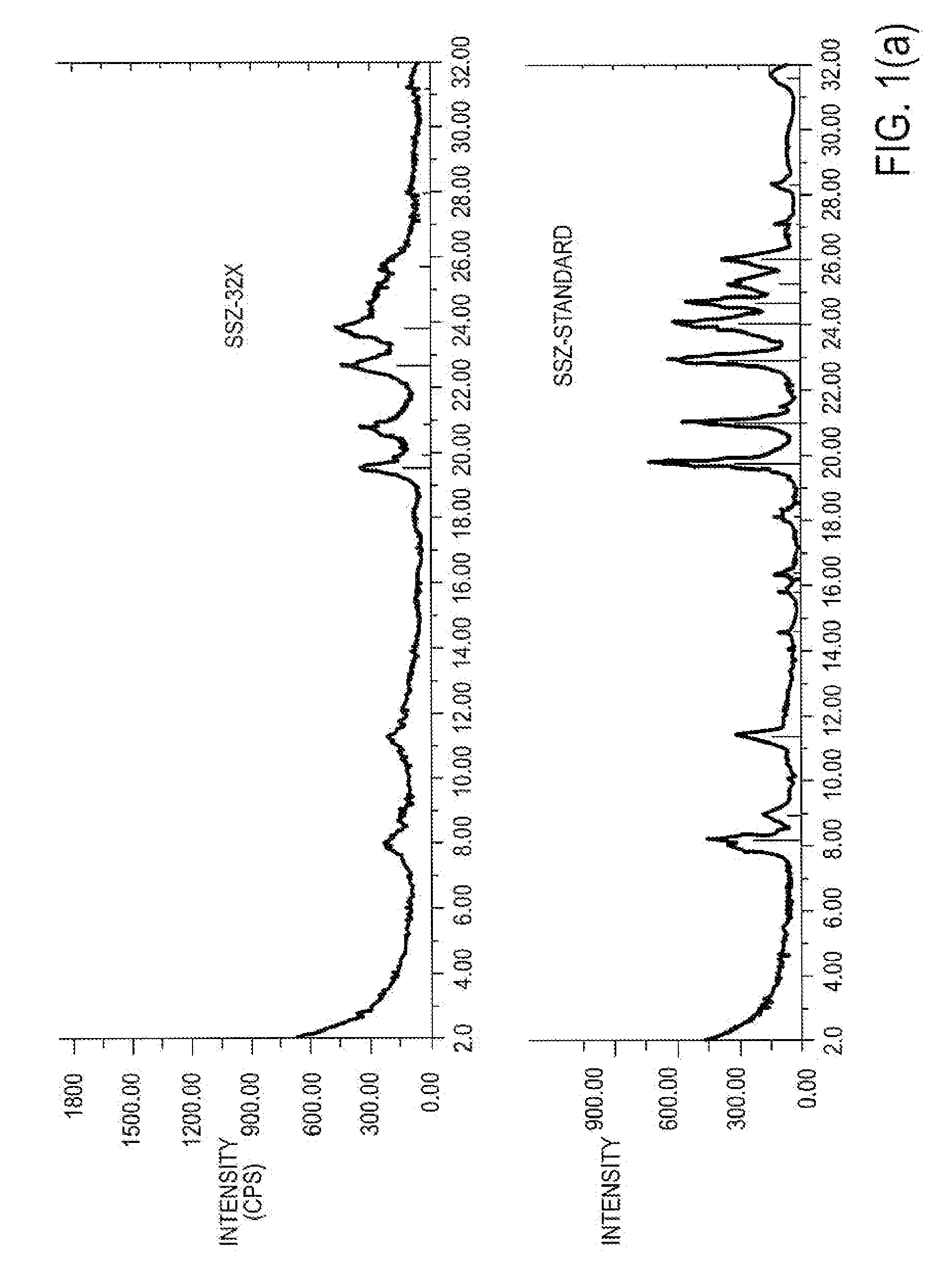

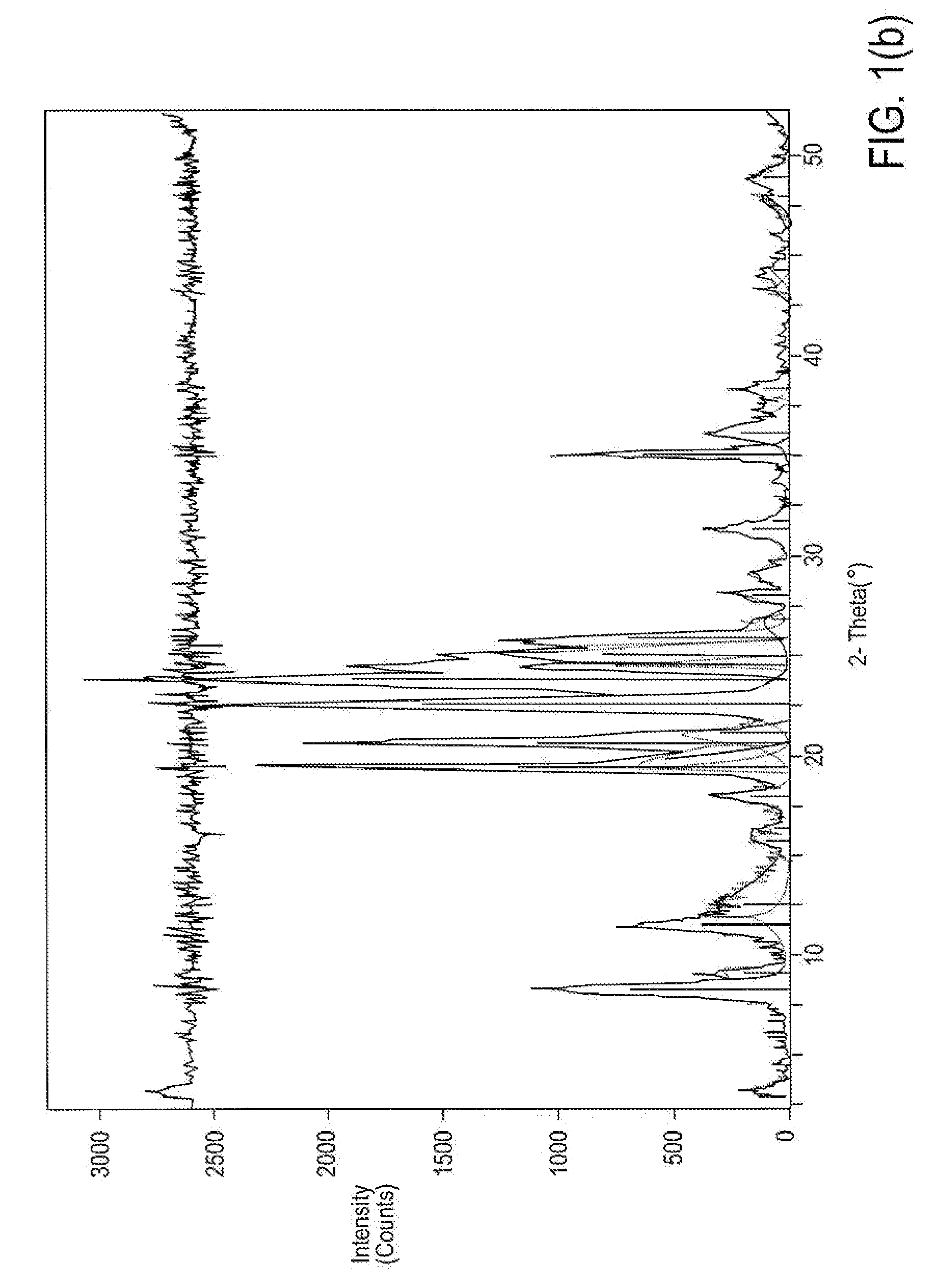

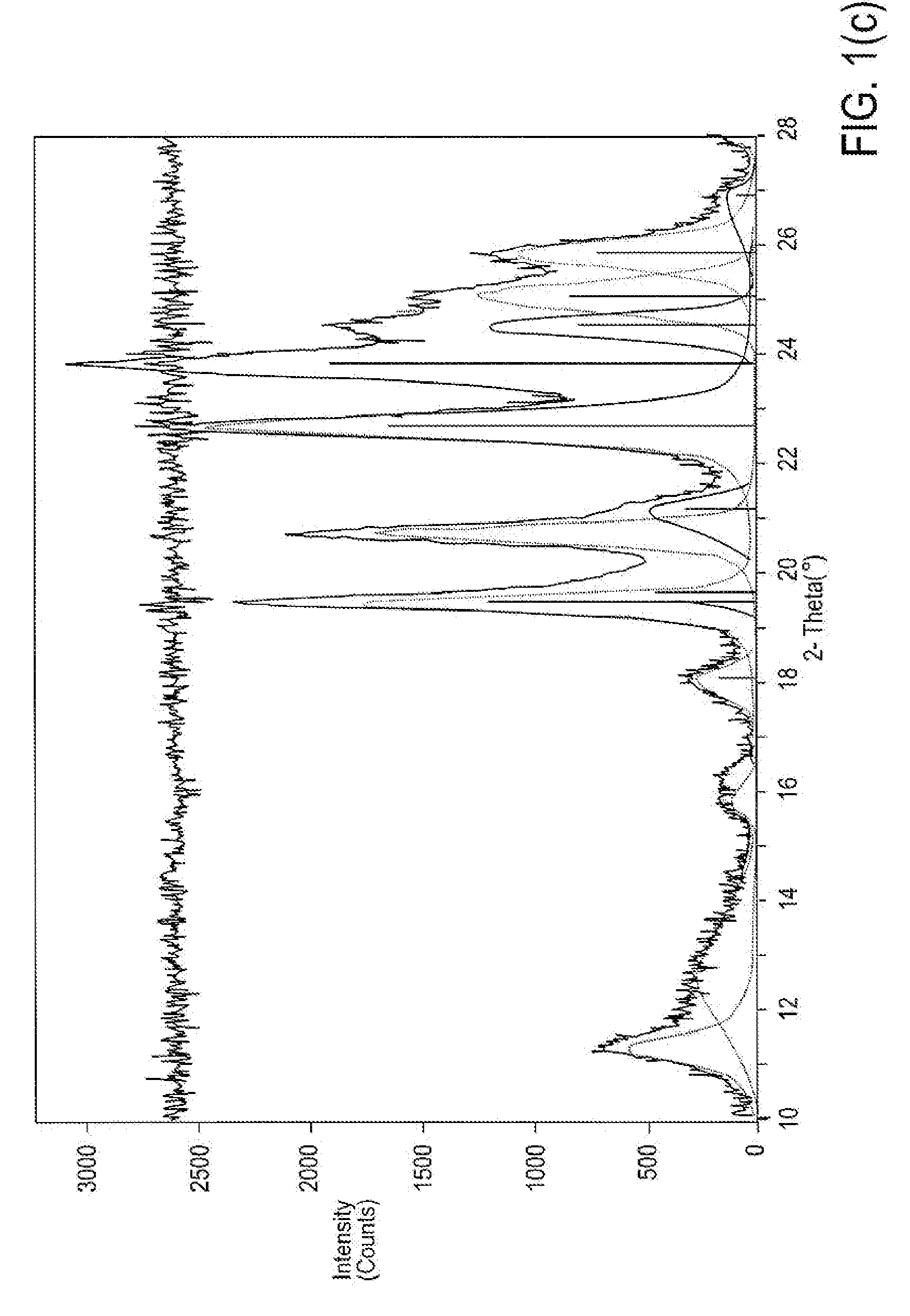

Preparing small crystal SSZ-32 and its use in a hydrocarbon conversion process

ActiveUS20070041898A1Less crystallinityAltered adsorption ratioAluminium compoundsMolecular sieve catalystsIsomerizationPhotochemistry

The invention is directed to a method of making a small crystal SSZ-32 zeolite, known as SSZ-32X. The catalyst is suitable for use in a process whereby a feed including straight chain and slightly branched paraffins having 10 or more carbon atoms is dewaxed to produce an isomerized product, with increased yield of isomerized material and decreased production of light ends.

Owner:CHEVROU USA INC

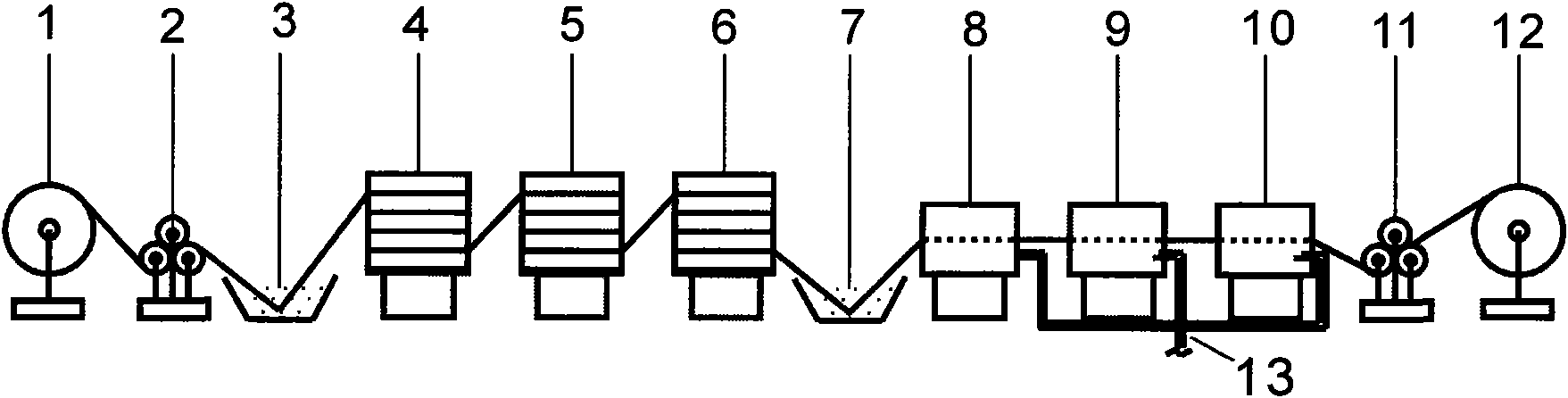

Device for continuously fabricating carbon fiber felt production line and technique thereof

InactiveCN101597848AHigh densityIncrease productivityFibre treatmentHeating/cooling textile fabricsThermal conductivityElectric heating

The invention discloses a device for continuously fabricating carbon fiber felt production line and a technique thereof, which is implemented by a production line support device, a dynamical system, an electric heating and temperature controlling system and a felt material dipping system. The invention is characterized in that one end which is rolled into a felt blank roll is put into a felt material dipping pool along a felt containing machine; then the end sequentially enters a low-temperature oxidation furnace, an intermediate-temperature oxidation furnace and a high-temperature oxidation furnace; the end enters a lower-temperature carbide furnace, a middle-temperature carbide furnace and a high-temperature carbide furnace after passing through an oxidation felt dipping pool; at last, the end extends out and enters a felt receiving machine and a felt shelf disk shelf to be rolled to obtain finished products; the width of the product is 900-1200mm, the thickness is 3-12mm, tensile strength (N / 25mm) longitude / latitude is 14 / 16, surface density (g / m) is 1500-1800, carbon content is 86-94%, square resistance (omega / 25mm) (11) is 0.1, and thermal conductivity (J / cm.s DEG C) is 4.6*10 52 DEG C. The invention can achieve the aim of continuously fabricating carbon fiber felts.

Owner:肖颖

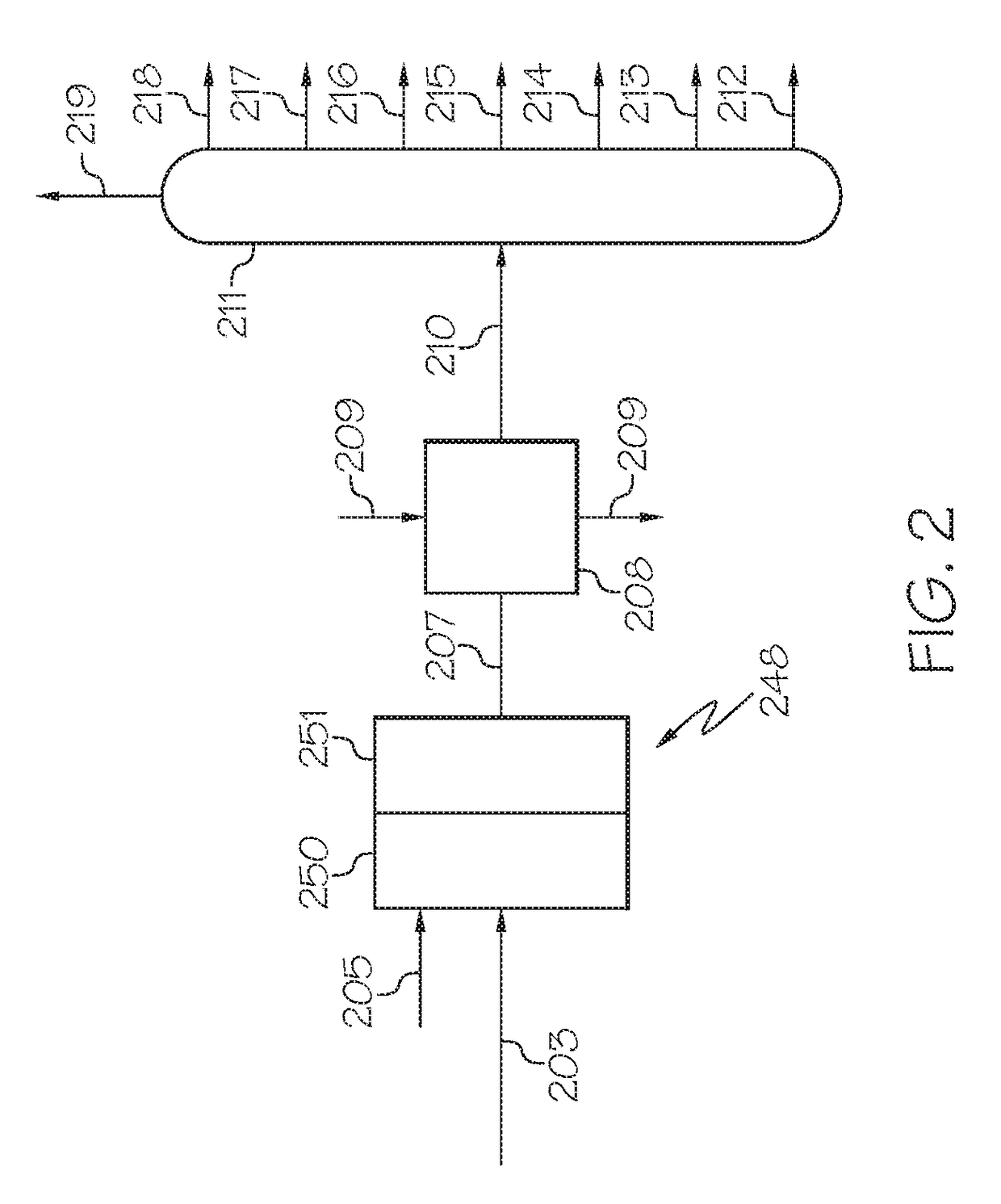

Shaped catalysts for transalkylation of aromatics for enhanced xylenes production

InactiveUS7202189B2Increase the outer surface areaHigh activityMolecular sieve catalystsMolecular sieve catalystMordeniteMetal

A catalyst, a process for using the catalyst whereby the catalyst effectively transalkylates C7, C9, and C10 aromatics to C8 aromatics are disclosed. The catalyst comprises a support such as mordenite plus a metal component. The catalyst provides an enhanced life and activity for carrying out the transalkylation reactions at relatively low temperatures. This is achieved by reducing the maximum particle diameter of cylindrical pellets to 1 / 32 inch (0.08 cm) or a trilobe to 1 / 16 inch (0.16 cm).

Owner:UOP LLC

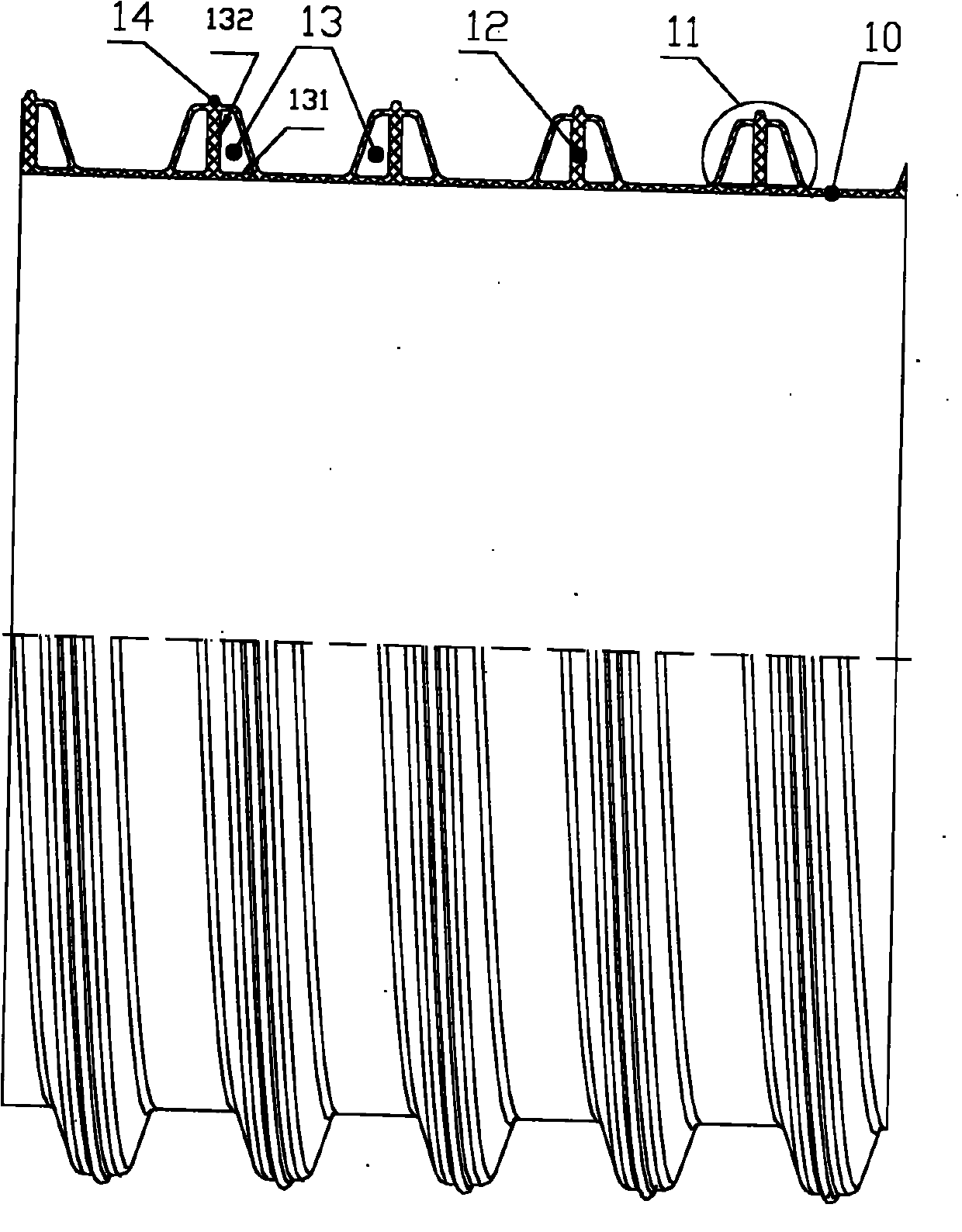

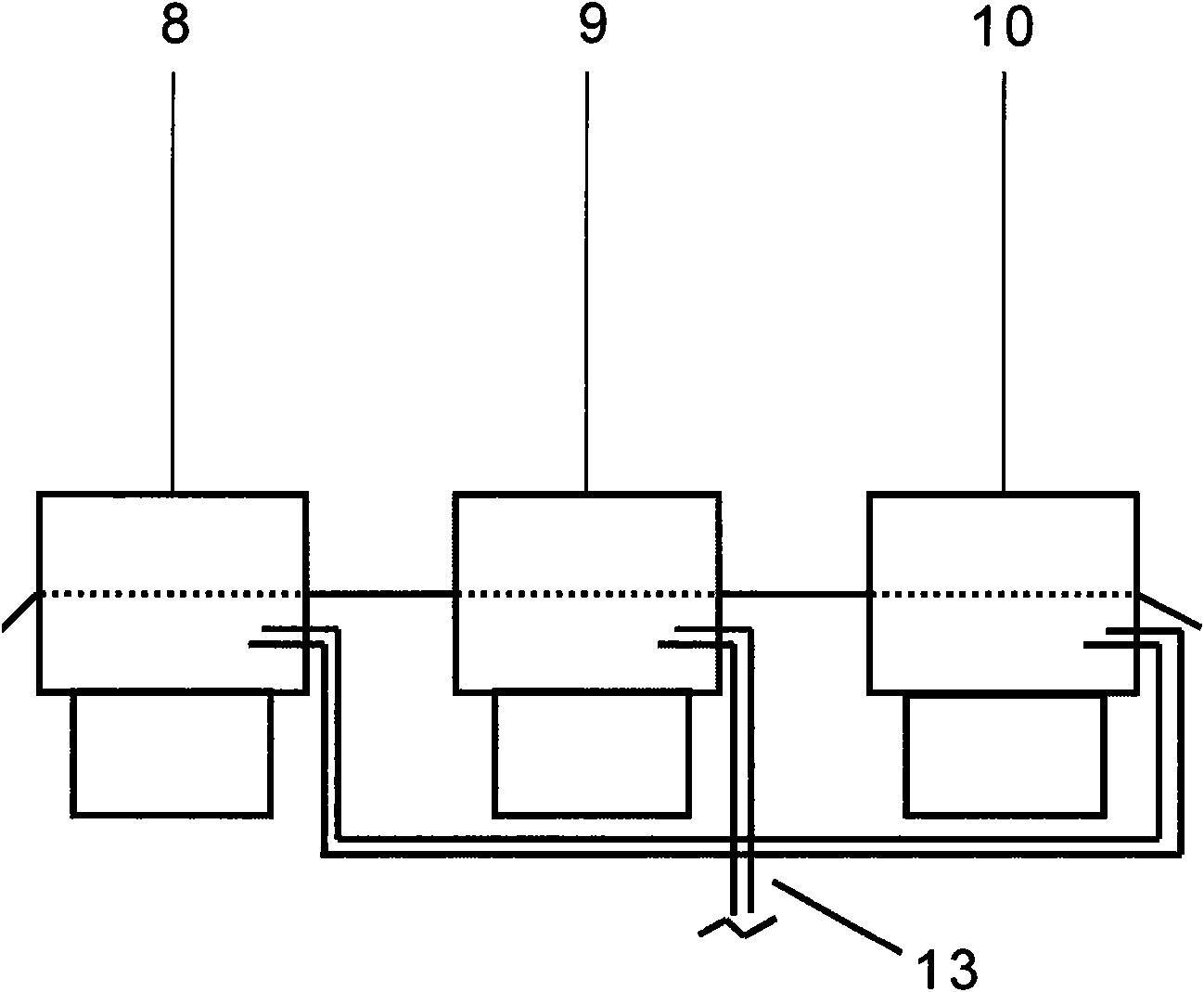

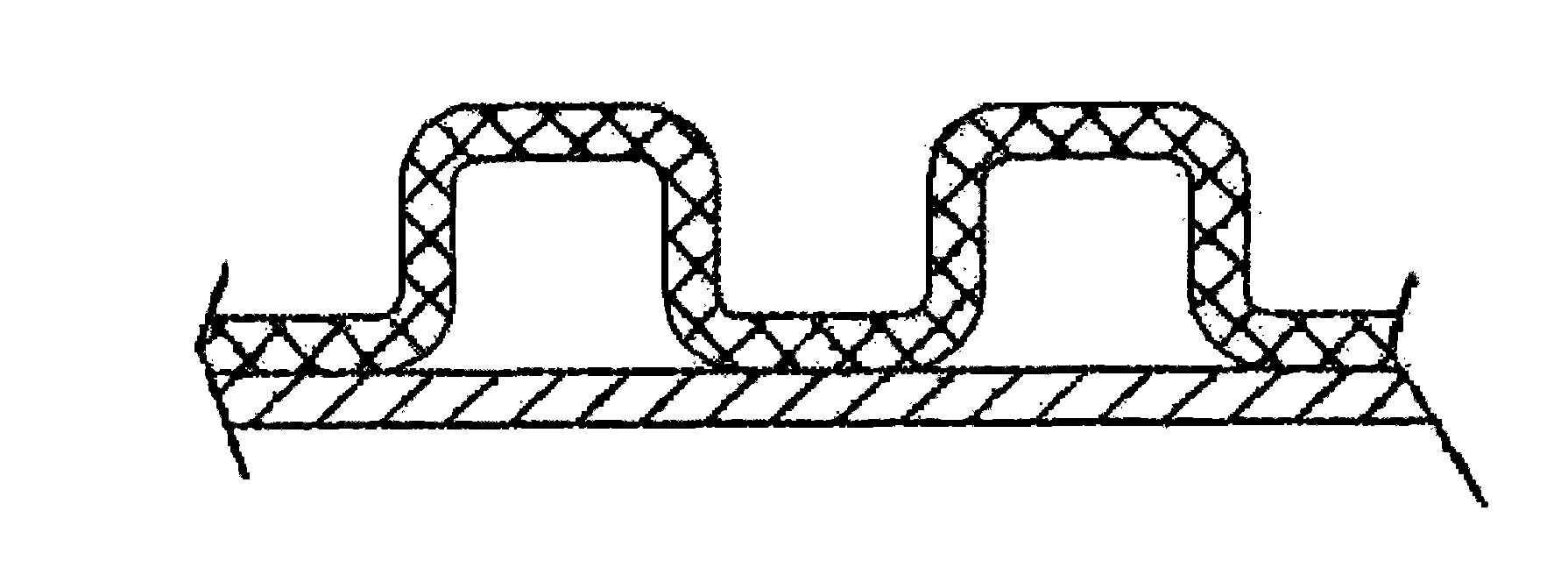

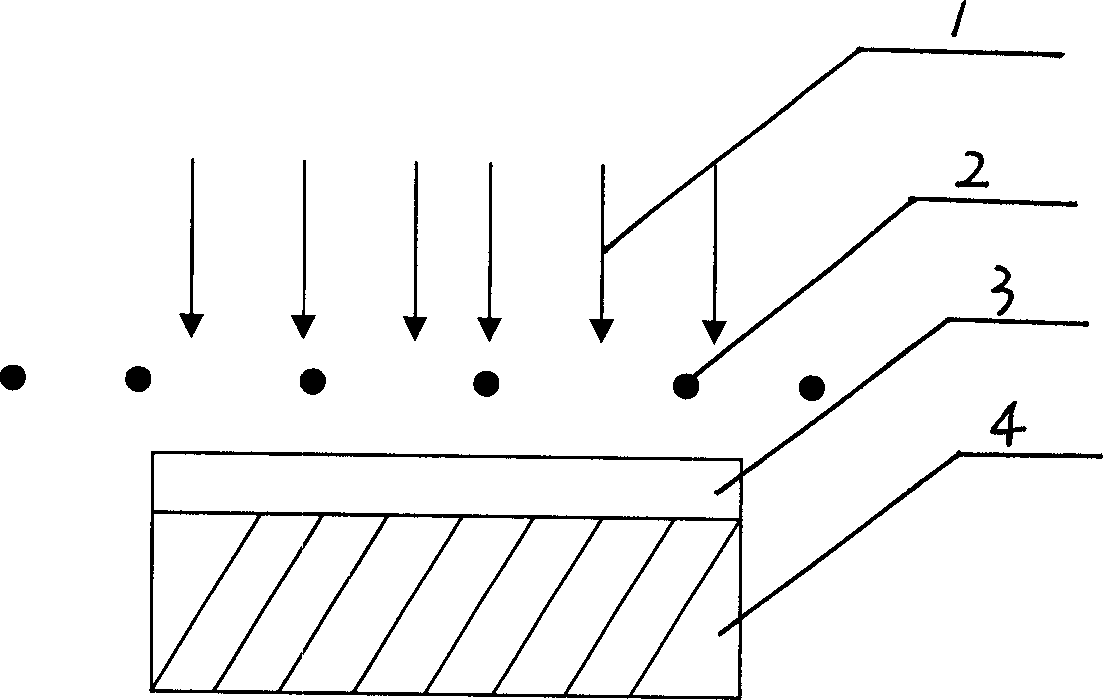

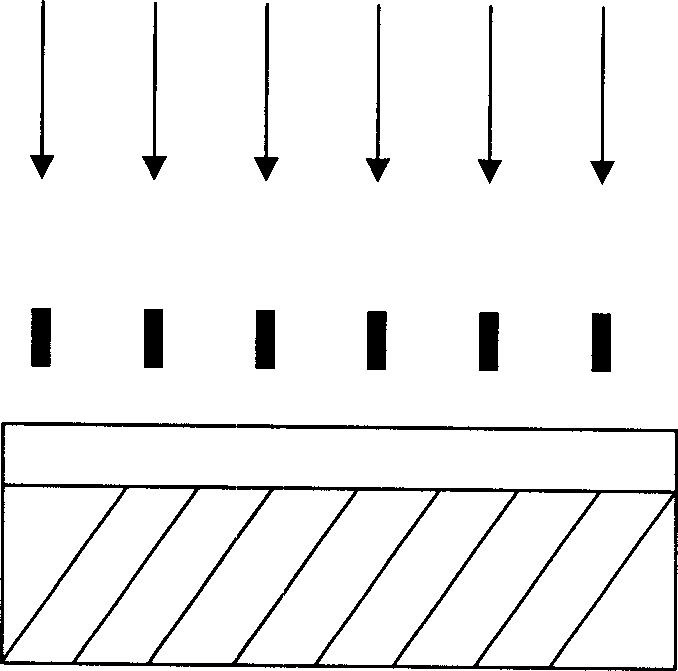

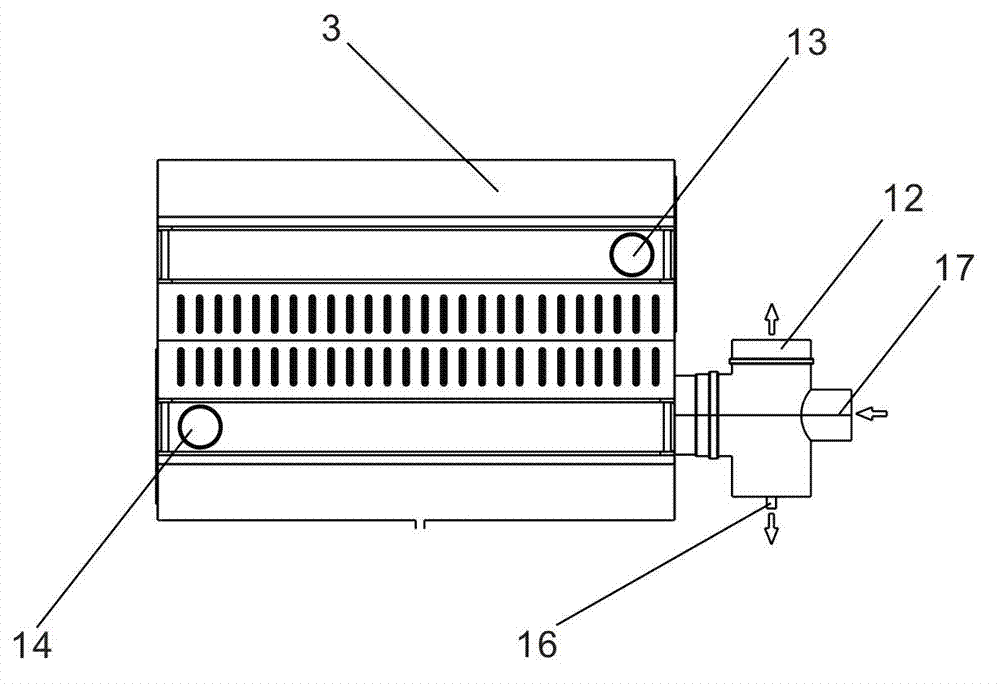

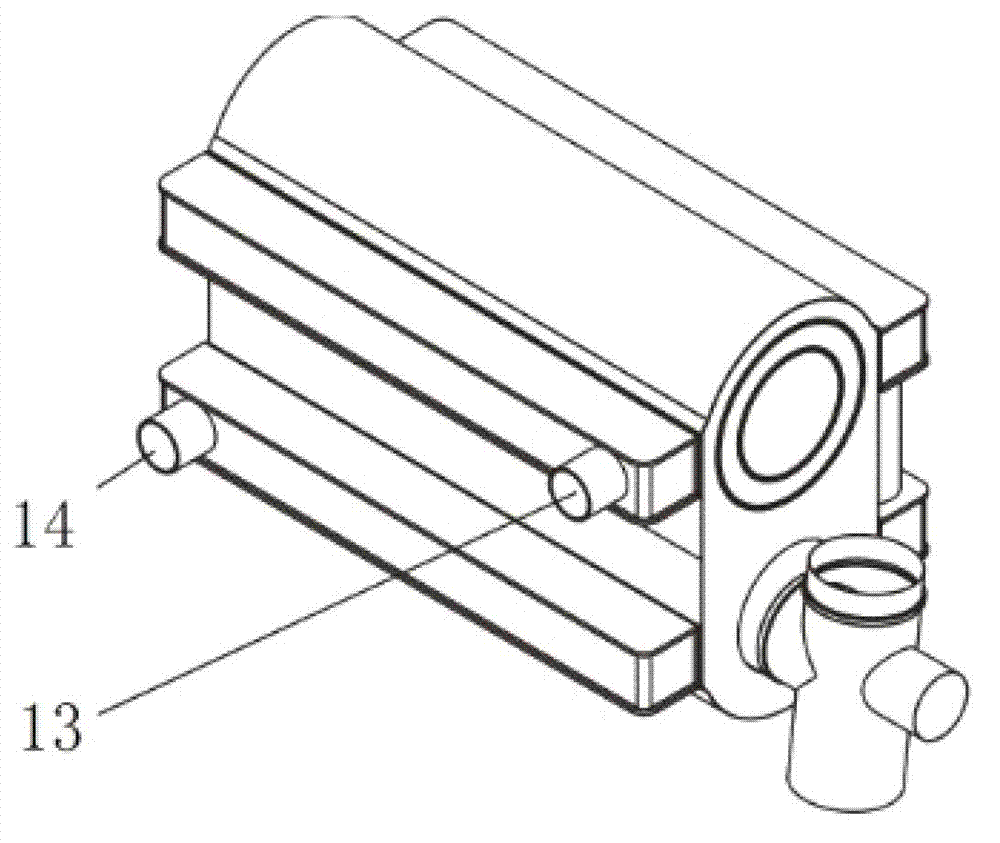

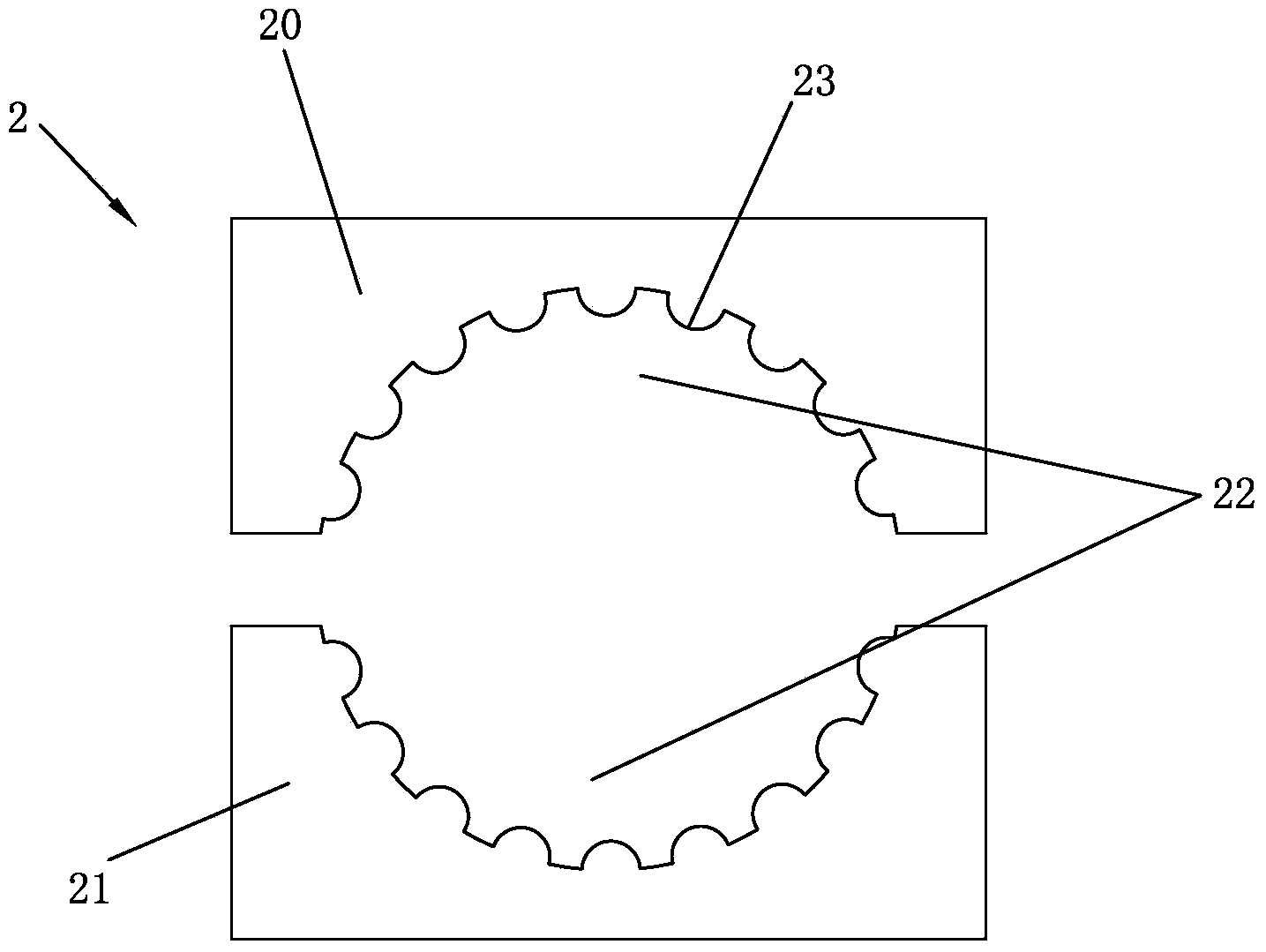

Continuous twining reinforced structure wall pipe, manufacturing equipment and manufacturing method

InactiveCN104061378AIncrease the outer surface areaGood synergyRigid pipesSolid wallPlastic materials

The invention provides a continuous twining reinforced structure wall pipe. The pipe wall of the continuous twining reinforced structure wall pipe is a spiral circumference; a center line is considered as an axis for specific strip-shaped plastic materials to twine in a spiral manner; the edges of the each adjacent specific strip-shaped plastic materials are overlapped to be integrated with each other to form a continuous solid wall pipe-shaped structure; reinforced adhesive materials which has the same spiral twining form is straddled and pressed on the positions on which overlapping joints of the adjacent specific strip-shaped materials are positioned; a specific single wall corrugated pipe which has the same spiral twining form is straddled and pressed on the reinforced adhesive materials; a strip-shaped material which has the same spiral twining form straddles the specific single wall corrugated pipe in a pressing manner, and adhesive to the pipe wall through a pressing wheel mechanism.

Owner:戴爱清 +1

Method for preparing carbon fiber reinforced thermoplastic composite material

The invention discloses a method for preparing a carbon fiber reinforced thermoplastic composite material, which comprises the following steps: 1)alternatively paving carbon fiber and thermoplastic resin in a die, wherein a bottom layer and a top layer of the die are thermoplastic resin, closing the die and applying pressure; 2)accessing power supply to a carbon fiber layer, rapidly heating under current effect, when the temperature is higher than the melting point of thermoplastic resin, fusing thermoplastic resin, dipping carbon fiber under pressure; and 3)breaking power, cooling the die, and then opening the die to obtain the carbon fiber reinforced thermoplastic composite material. The method takes carbon fiber as a heat-generating body, the electrothermal conversion efficiency can reach as high as more than 90%, and the energy saving effect is obvious; simultaneously, carbon fiber is capable of melting thermoplastic resin and completing dipping, and has the advantages of short moulding time and good dipping effect, formation of good cross section of thermoplastic resin and fiber can be realized, composite material performance is increased, and processing of product with large thickness can be realized in short time.

Owner:蓝星纤维(北京)有限公司

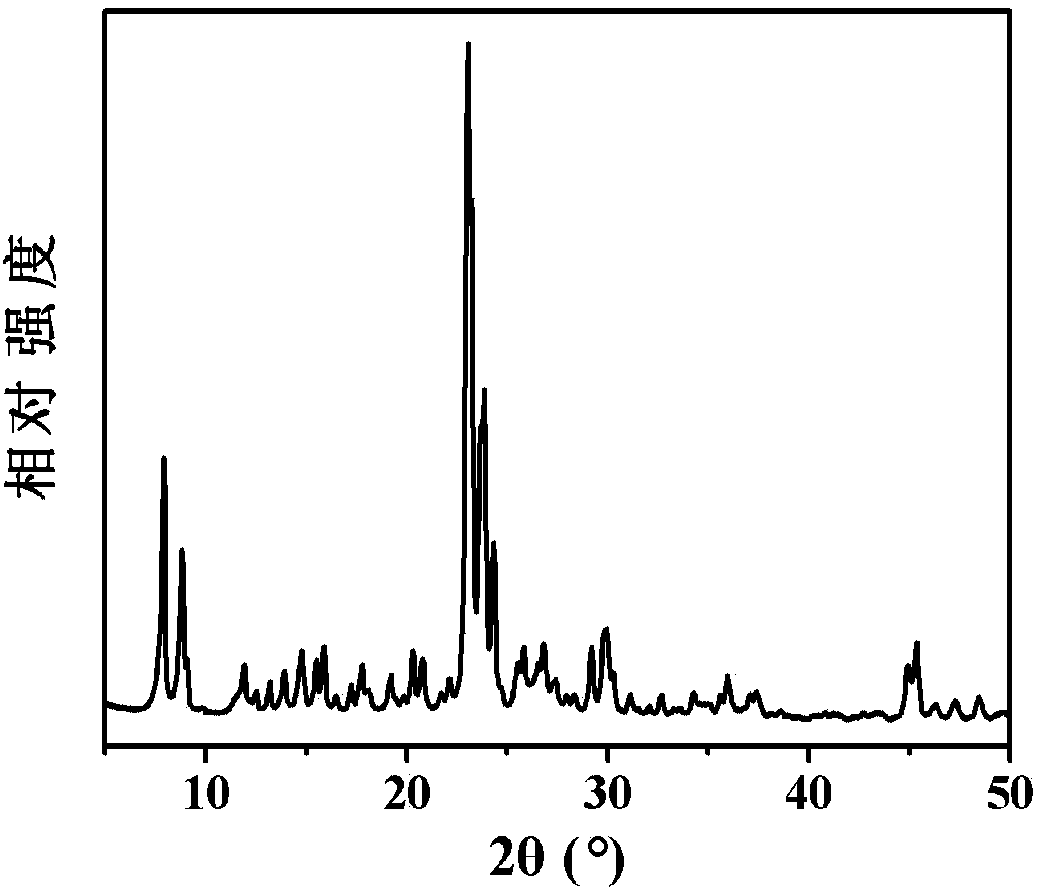

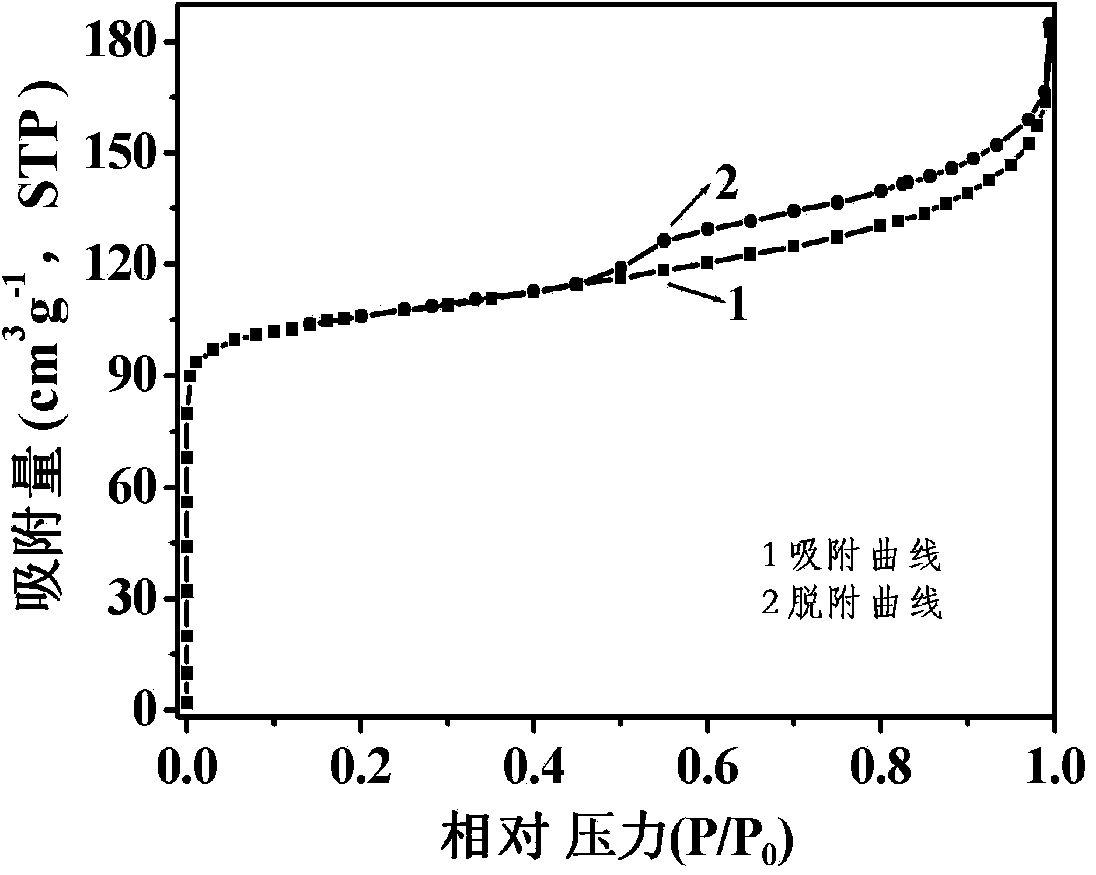

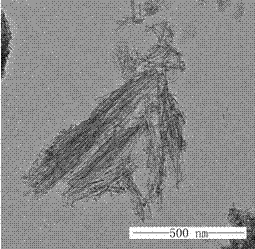

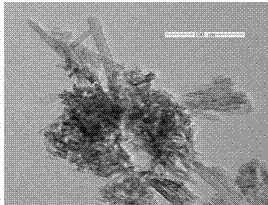

Preparation method of house-of-cards-like hierarchical porous ZSM-5 molecular sieve

ActiveCN104261427AIncrease the outer surface areaStrong acidMaterial nanotechnologyPentasil aluminosilicate zeoliteIonHierarchical porous

The invention belongs to the technical field of synthesis of inorganic porous materials and particularly relates to a preparation method of a house-of-cards-like hierarchical porous ZSM-5 molecular sieve which is low in cost, environment-friendly and fast. The preparation method comprises the following steps: adding an inorganic alkali source and an aluminum source into deionized water, and adding a proper amount of N-methyl-2-pyrrolidone (NMP); then, slowly adding a silicon source; fully and uniformly stirring; and synthesizing a house-of-cards-like hierarchical porous HCL-ZSM-5 molecular sieve by a one-step hydrothermal method. The molecular sieve has remarkable hierarchical porous structural characteristics, is large in external surface area, strong in acidity and good in stability, and has wide application prospects in the fields of catalysis, adsorption, separation and the like. In an alkaline ZSM-5 synthetic system without an organic template, by using non-toxic and cheap NMP as a structural guiding agent which is used for replacing an expensive macromolecular organic template, the method is an economic, efficient and environment-friendly synthetic method which is expected to be applied to large-scale commercial production.

Owner:JILIN UNIV

Zeolite coating material with high intercrystalline porosity on the surface of porous silicon carbide support and its preparation

InactiveCN102274743ASmall external areaIncrease the outer surface areaMolecular sieve catalystsOther chemical processesHoneycomb structureSupport surface

The invention which belongs to the technical field of structured catalysts and application technologies thereof concretely relates to a high intercrystal poriness zeolite coating material on the surface of a porous silicon carbide carrier and a preparation method thereof. The porous silicon carbide carrier involved by the material has a macroscopic porous structure, for example a foamy structure,and a honeycomb structure. The zeolite coating has a high intercrystal poriness. According to the preparation method, the surface of the porous silicon carbide carrier is modified by a colloidal zeolite guiding agent to realize the preferred growth of zeolite crystal on the surface of the porous silicon carbide carrier; and the alkalinity of a secondary growth solution, the concentration of nutrients, and the addition of alkali metal ions are controlled to control the intercrystal poriness of zeolite. The coating material has the advantages of high intercrystal poriness, small zeolite crystaldimension, good molecular diffusion ability, large zeolite load capacity, adjustable silica-alumina ratio of the zeolite crystal and zeolite coating thickness, and good binding ability of the zeolitecrystal with the surface of the porous silicon carbide carrier. The structured catalyst which is in favor of mass and heat transfer reinforcement has wide application prospects in fields of catalysis, adsorption, separation and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

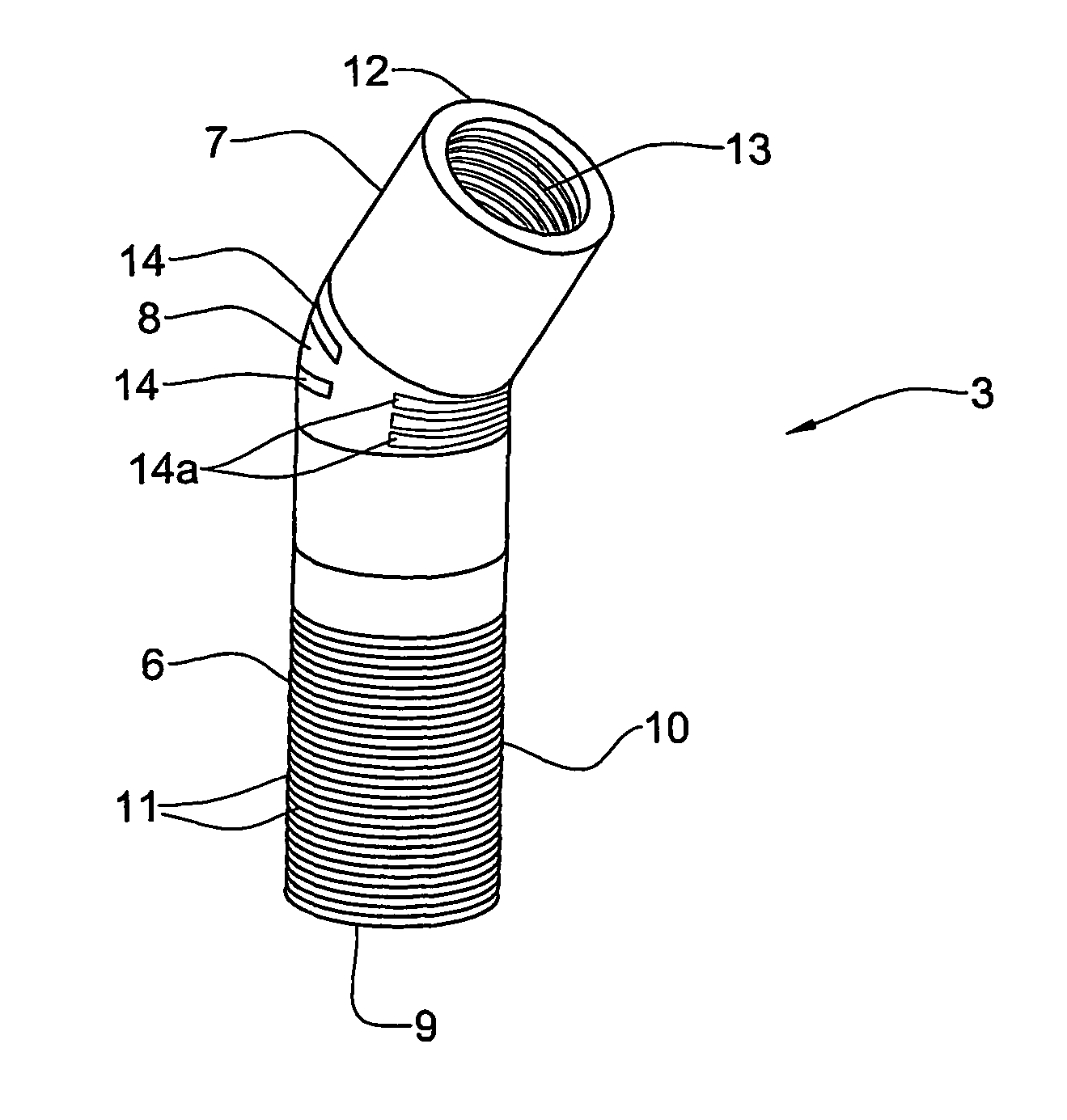

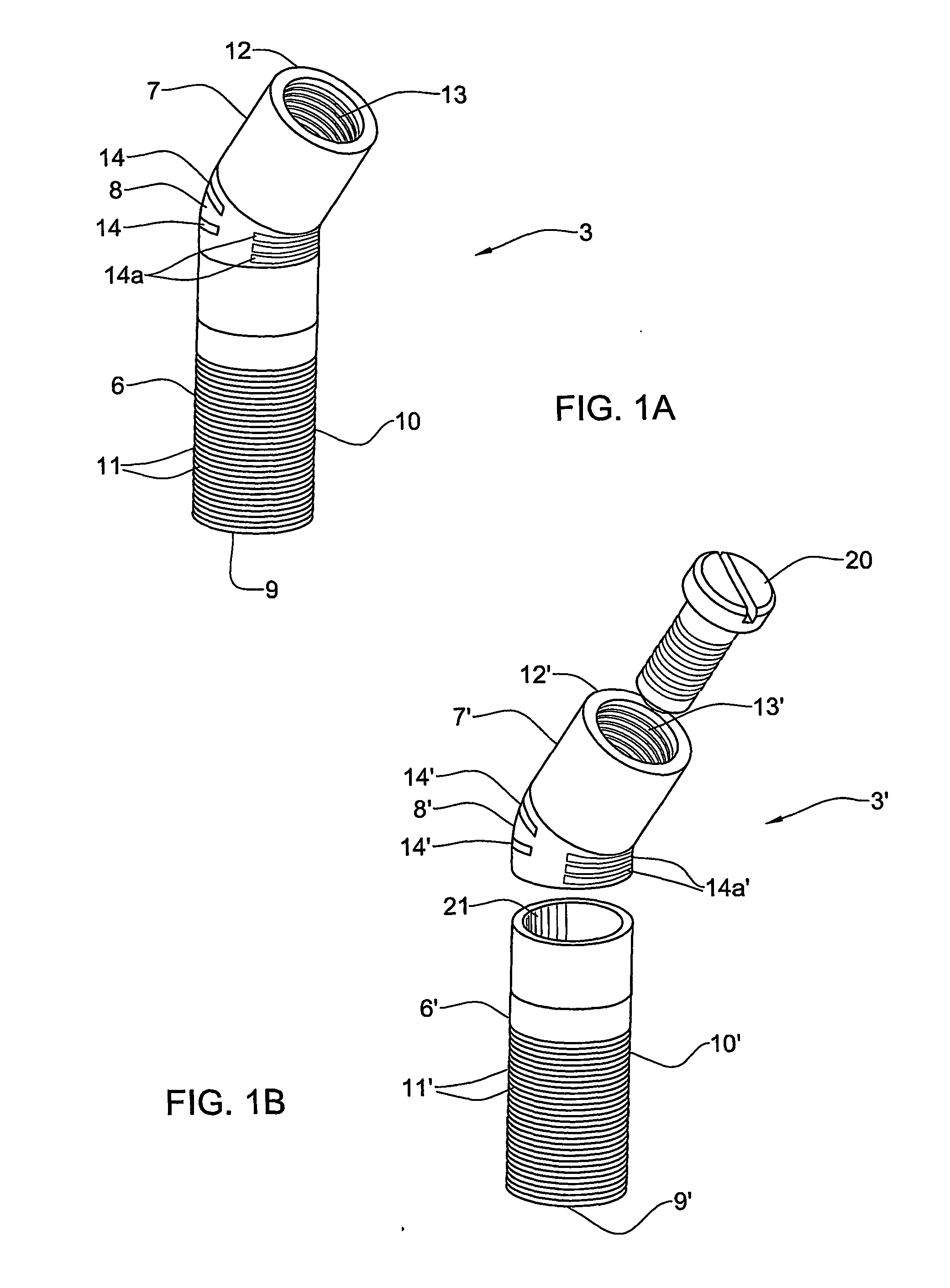

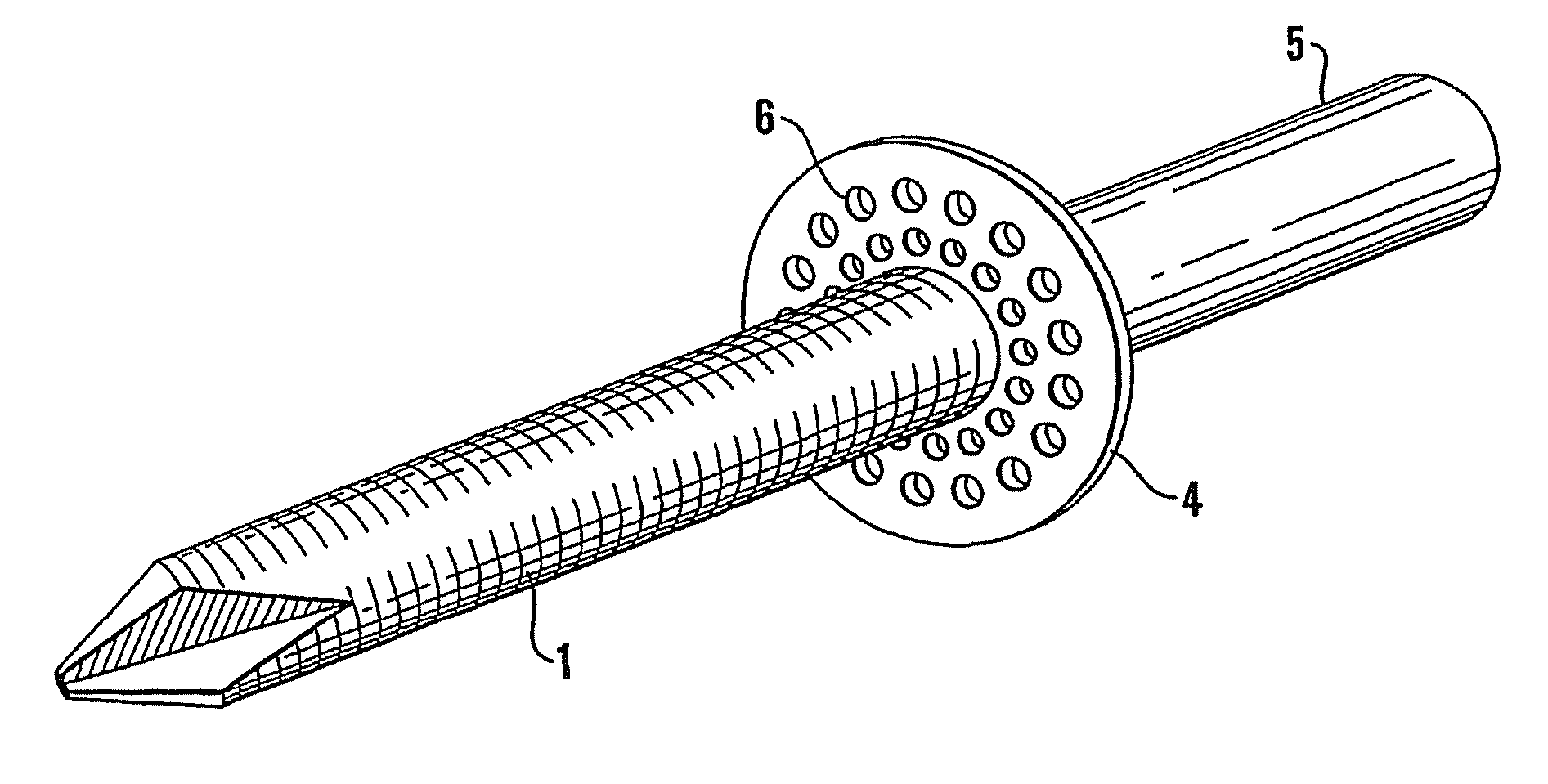

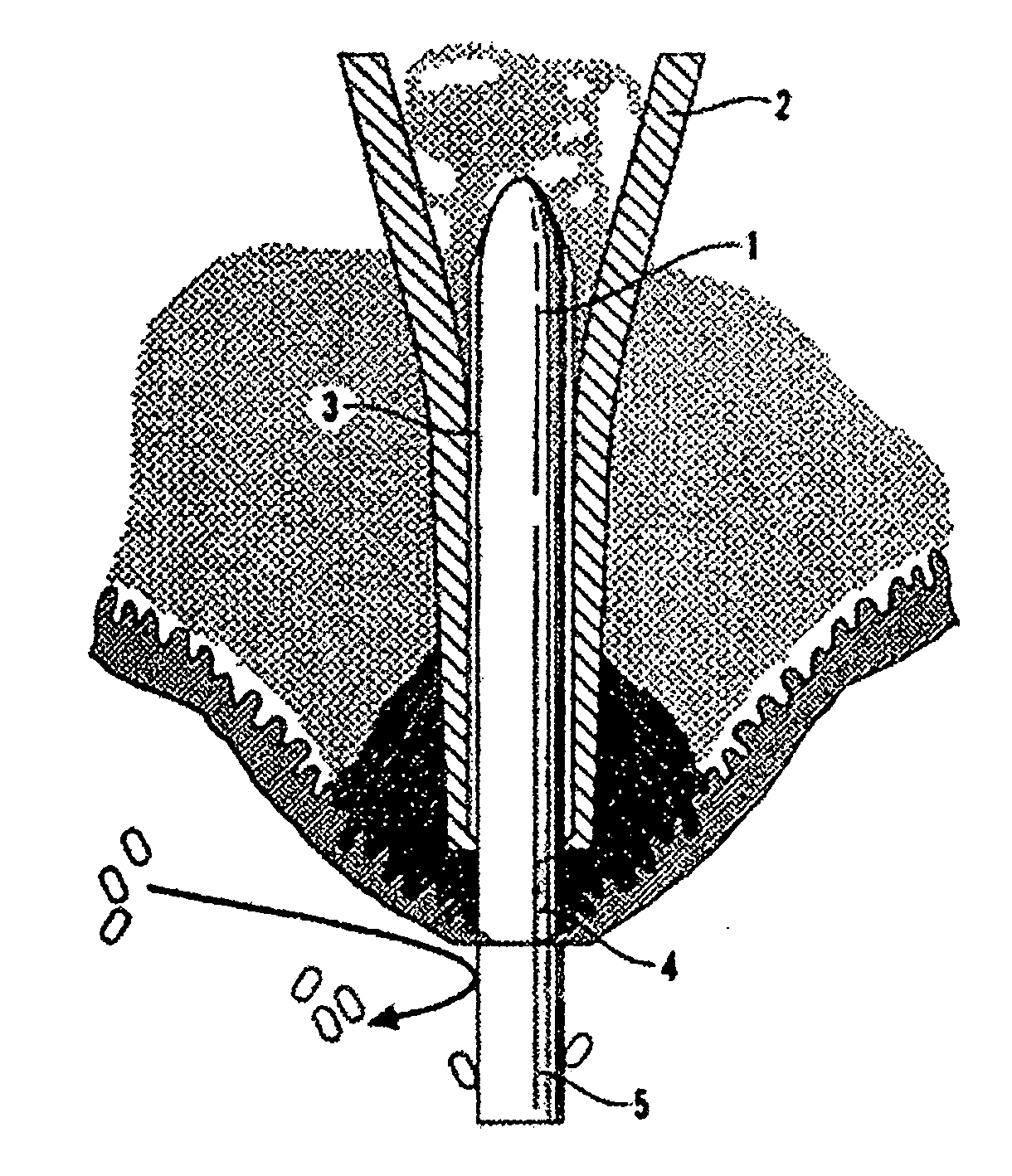

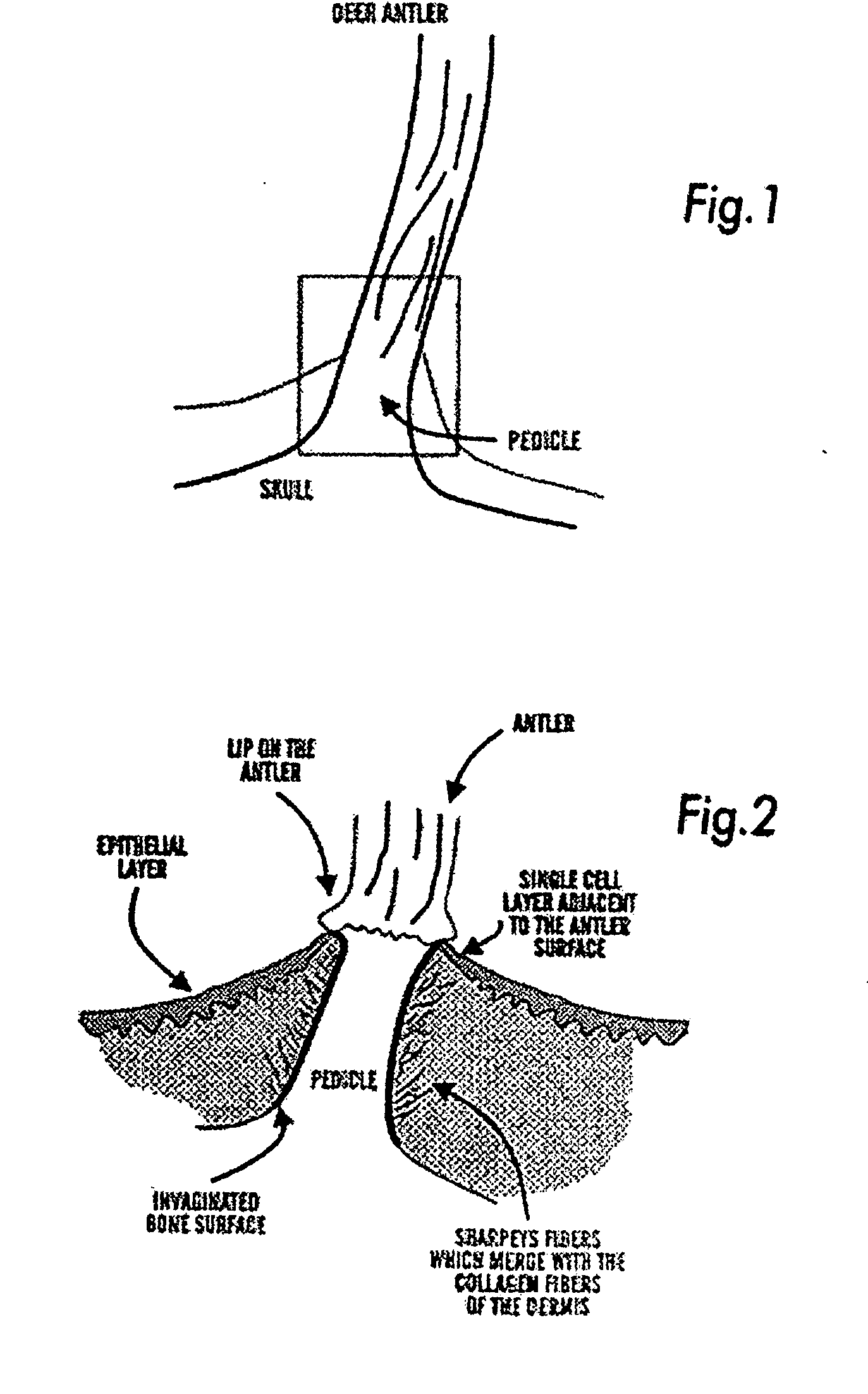

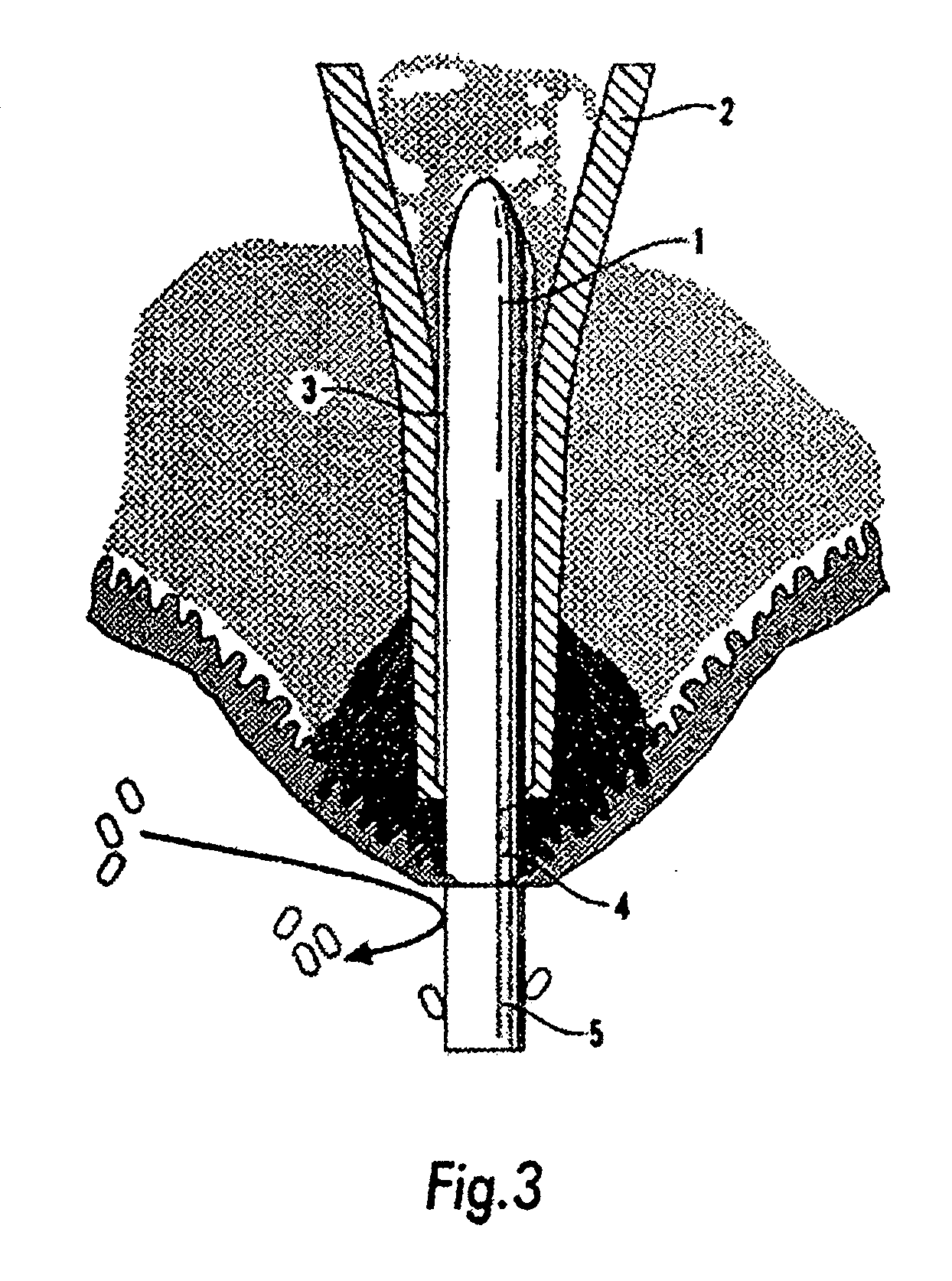

Implant having integral flexible abutment portion and method for use thereof

InactiveUS20070099151A1Improve easeImprove convenienceDental implantsInternal osteosythesisDental implantBiomedical engineering

The present invention concerns an implant, in particular a dental implant, having a below-shaped adjustable bendable portion and a cavity extending throughout the bendable portion and having an opening. The invention further concerns a method wherein the implant is placed in the bone, the adjustable bending portion is bended to the desired angle and the cavity is filled with a composition that can fix the portion at a desirable angle.

Owner:POLYDENT MEDICAL DEVICES

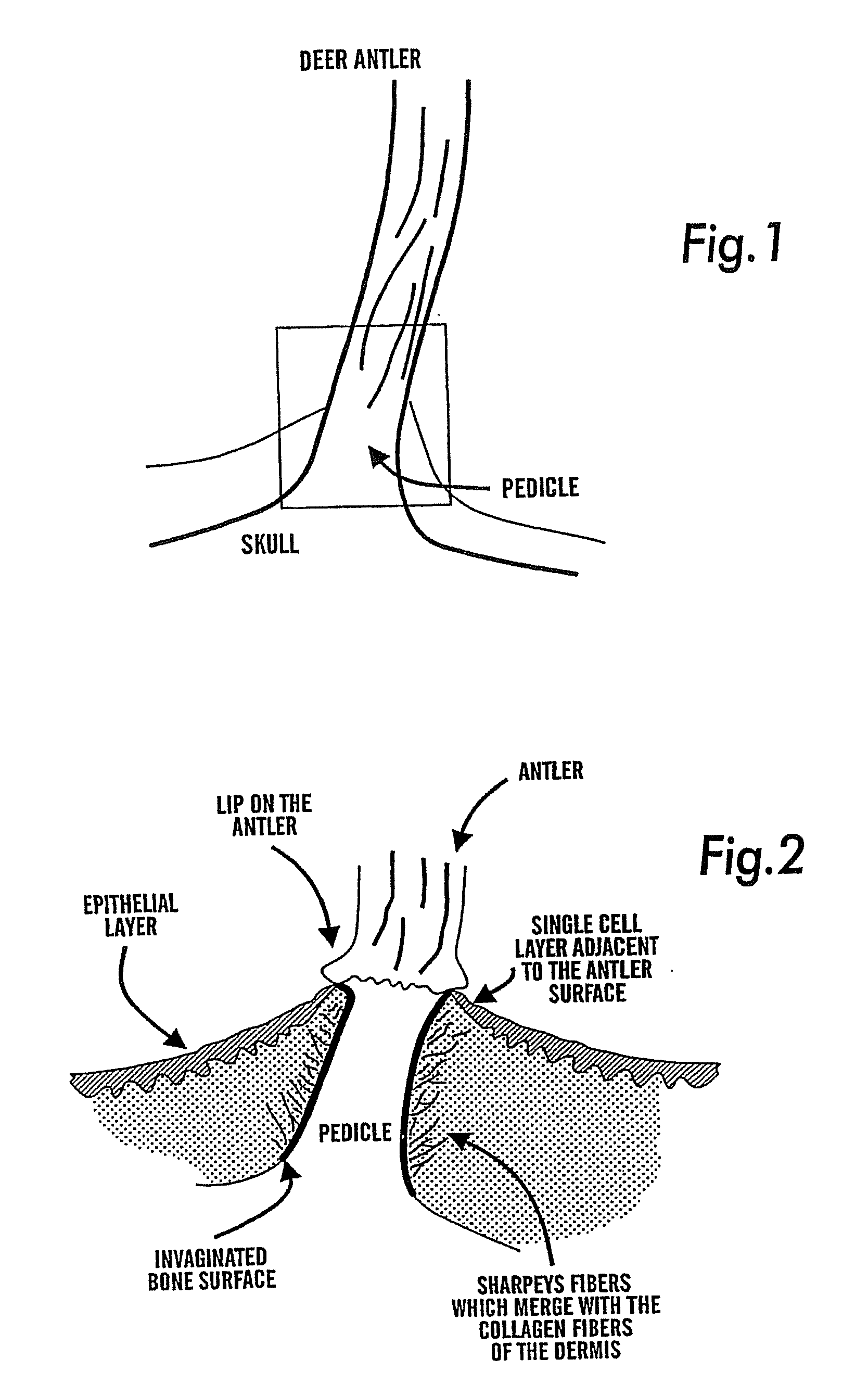

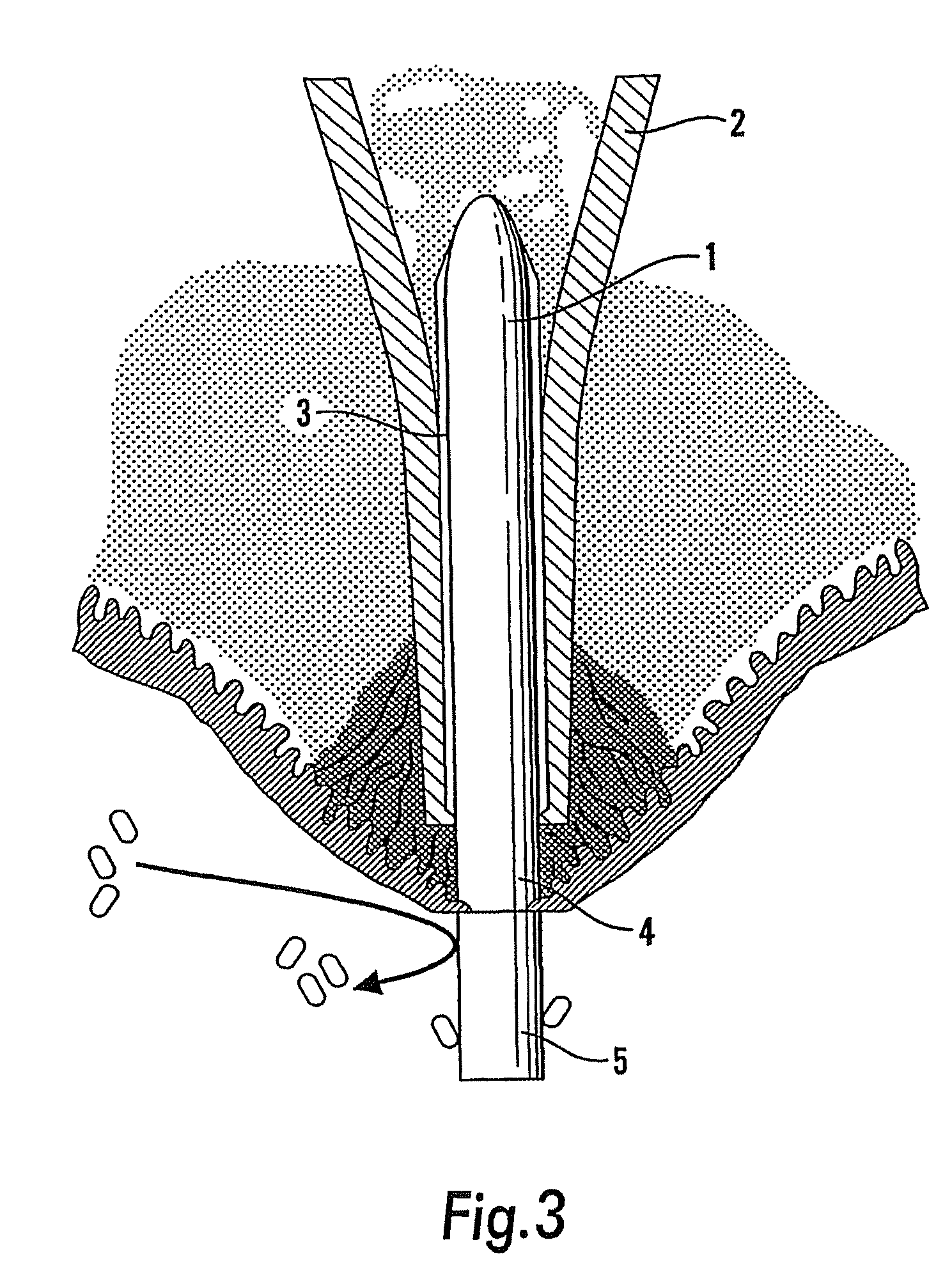

Transcutaneous prosthesis

InactiveUS20090149966A1More powerAid adhesionDental implantsInternal osteosythesisBacterial AdhesionsProsthesis

A transcutaneous prosthesis includes a first component configured for attachment to a bone, the first component including flutes or grooves on a surface thereof for deterring rotation of the prosthesis within a bone; a second component adapted for location between the bone and the skin, the second component having a surface treatment for stimulation of fibroblastic cell proliferation and attachment of epithelial cells; and a third component adapted for location to extend from the skin surface and is adapted to extend directly from the skin surface in use, the third component having a coating of a non-stick material on an outer surface thereof, the coating having a surface energy that is lower than a surface energy of the first and second components and which is low enough to deter bacterial adhesion.

Owner:UNIV COLLEGE OF LONDON

Forced finned straight pipe condensation heat-supply heat exchanger

ActiveCN102901221AImprove heat transfer efficiencyImprove heat transfer effectEnergy efficient heating/coolingAir heatersPlate heat exchangerCombustor

The invention discloses a forced finned straight pipe condensation heat-supply heat exchanger, which comprises a shell, a combustor and a plurality of finned straight pipes, wherein the combustor is positioned on the upper part of the shell; the periphery of the combustor is provided with a group of finned straight pipe bundles consisting of a plurality of finned straight pipes which are tightly and uniformly distributed along the circumference; a smoke exhaust pipeline which consists of the shell and a plurality of tightly arranged finned straight pipes is arranged below the combustor; the smoke exhaust pipeline is emptied through a smoke outlet; two ends of the finned straight pipes are respectively front water main pipes and rear water main pipes; clapboards are arranged in the rear water main pipes; the rear water main pipes are separated into a water inlet area and a water outlet area through the clapboards; and water flow enters part of the finned straight pipes through the water inlet area, reaches the front water main pipes and enters the water outlet area of the rear water main pipes through the other part of the finned straight pipes. The inwards folded finned straight pipes serve as basic elements of the forced finned straight pipe condensation heat-supply heat exchanger, and the heat exchange efficiency is obviously improved.

Owner:SUZHOU CQ HEAT EXCHANGER

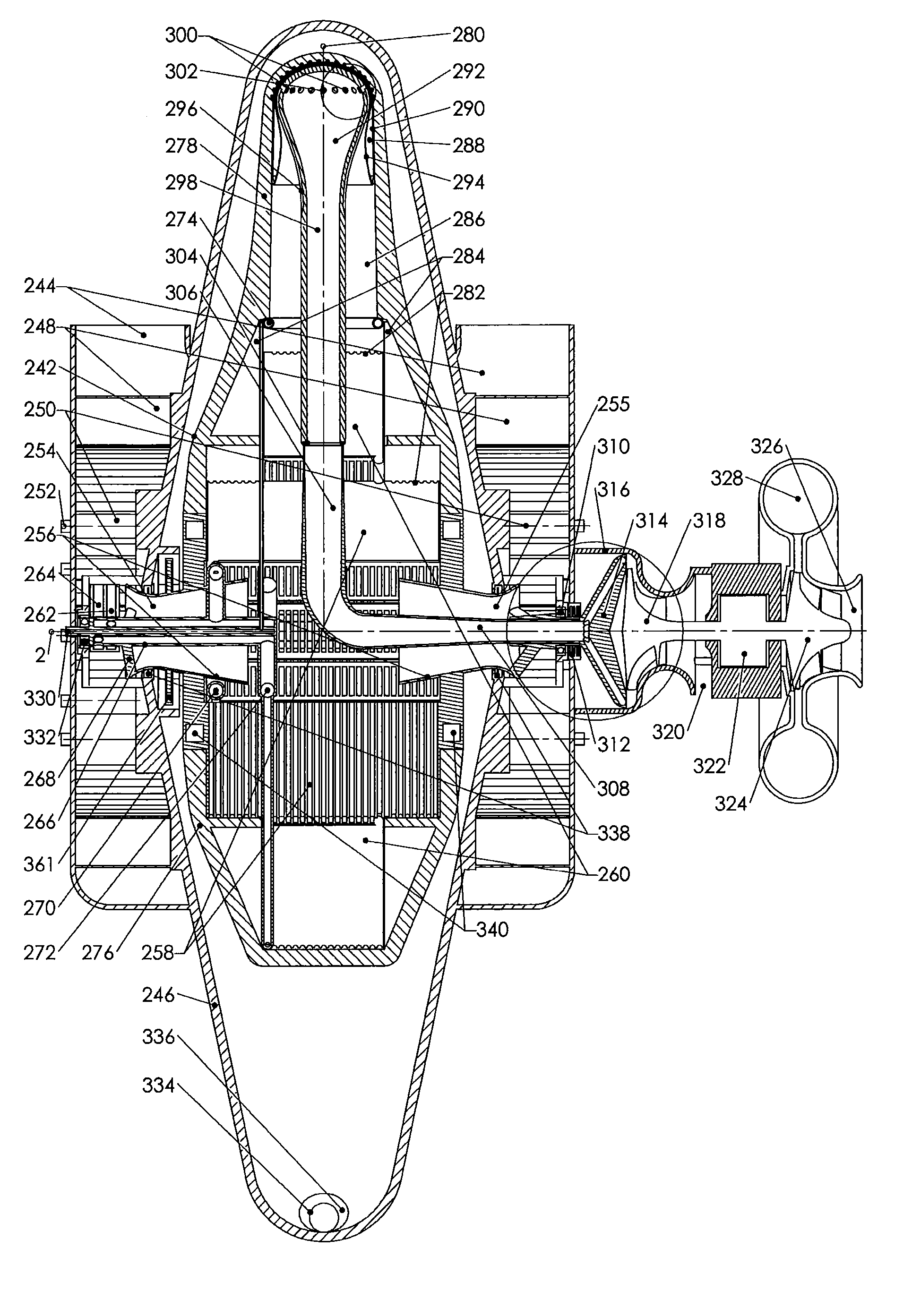

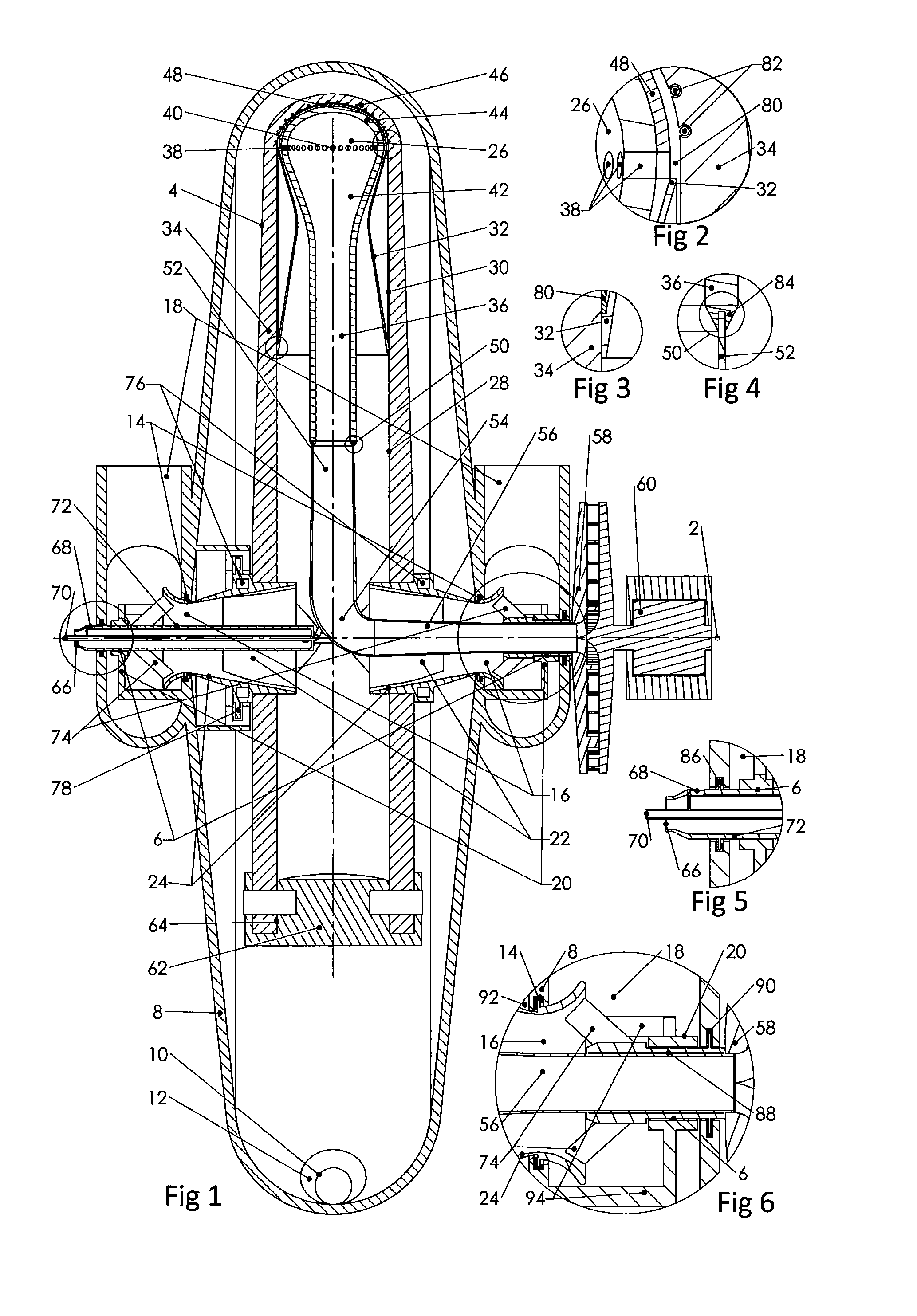

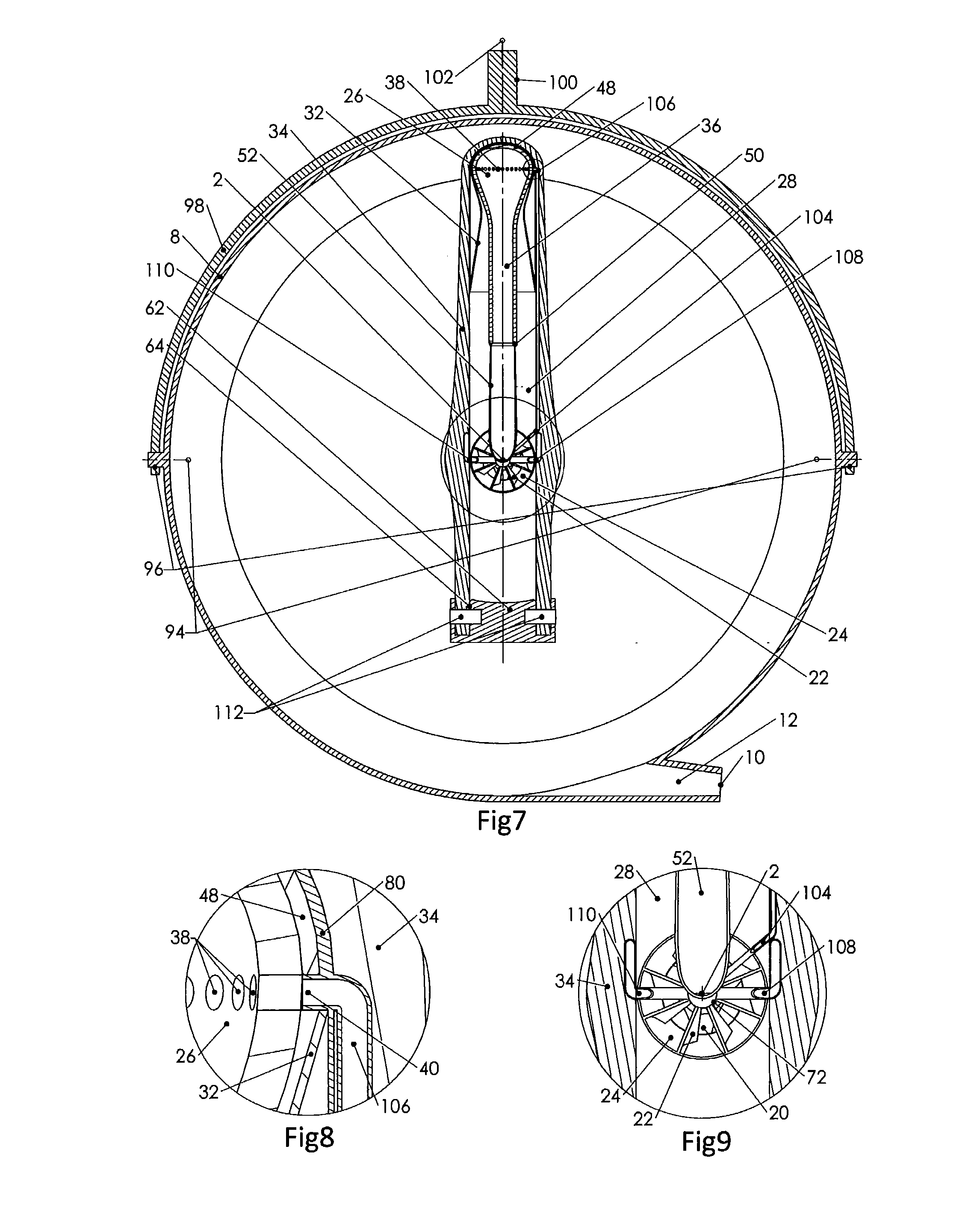

A rotor assembly for an open cycle engine, and an open cycle engine

ActiveUS20160102608A1Increase ratingsIncrease the outer surface areaContinuous combustion chamberTurbine/propulsion fuel flow conduitsCombustion chamberEngineering

A rotor assembly for an engine, comprising: a rotor, supported on bearings for axial rotation, a rotor portion forming a compression passage extending outwards from the axis, gases entering the rotor through inlets at the axis and flowing outwards through the compression passage; a combustion chamber supported within the compression passage near the maximum radius of the rotor having a closed outer end and combustion chamber gases inlets through which gases enter the combustion chamber, each combustion chamber having a fuel inlet, and; one or more expansion passages in fluidic connection with and extending radially inwards from the combustion chamber within a compression passage and fluidically connecting at or near the rotor axis to a combustion gas outlet tube that extends along the rotor axis, combustion gases created by combustion of fuel with inlet gases within the combustion chamber expanding as they flow inwards through the expansion passage.

Owner:XEICLE

Hierarchical-hole molecular sieve catalyst for preparation of ethylene through dehydration of low-concentration ethanol, and preparation method and application thereof

InactiveCN106540736AUnobstructed pore size distributionImprove featuresMolecular sieve catalystsHydrocarbon from oxygen organic compoundsMolecular sieveHigh activity

The invention relates to a hierarchical-hole HZSM-5 catalyst suitable for a reaction for preparation of ethylene through dehydration of low-concentration ethanol, and is used for mainly solving the problems of low catalyst activity, poor catalyst stability, easy loss of active metals and the like existing in the prior art. The invention also relates to preparation of the modified catalyst and an application of the modified catalyst in the reaction for preparation of ethylene through dehydration of low-concentration ethanol. The molecular sieve catalyst can convert ethanol into ethylene with high conversion rate and high selectivity, and has the advantages of high activity at low temperature, good stability, high selectivity of ethylene, long catalytic life and the like.

Owner:TAIYUAN UNIV OF TECH

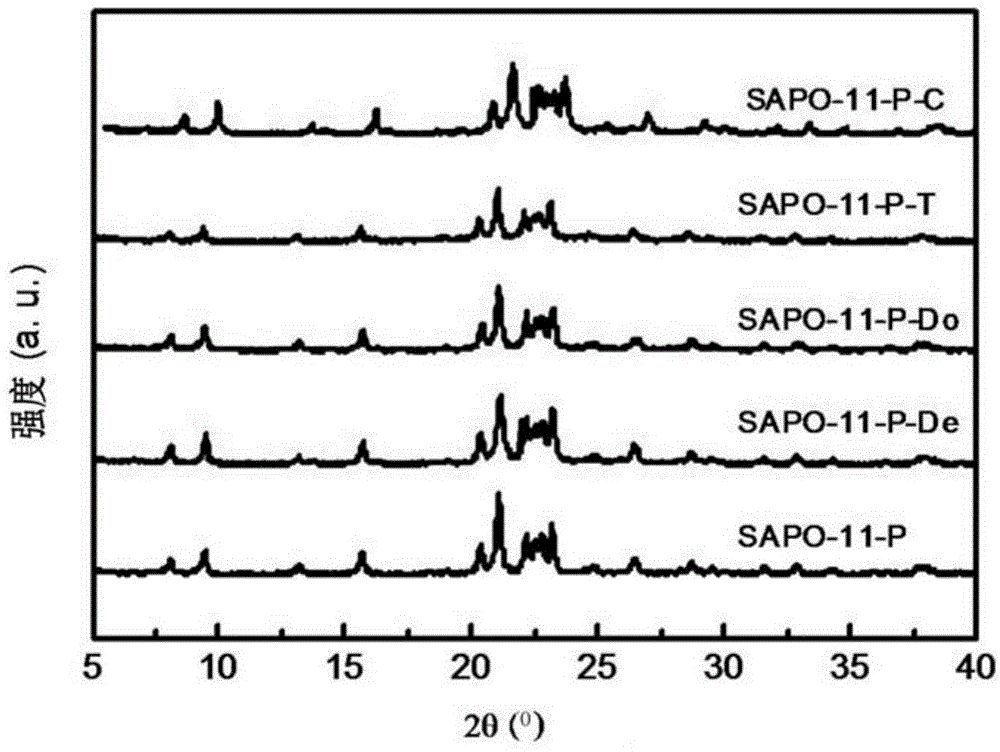

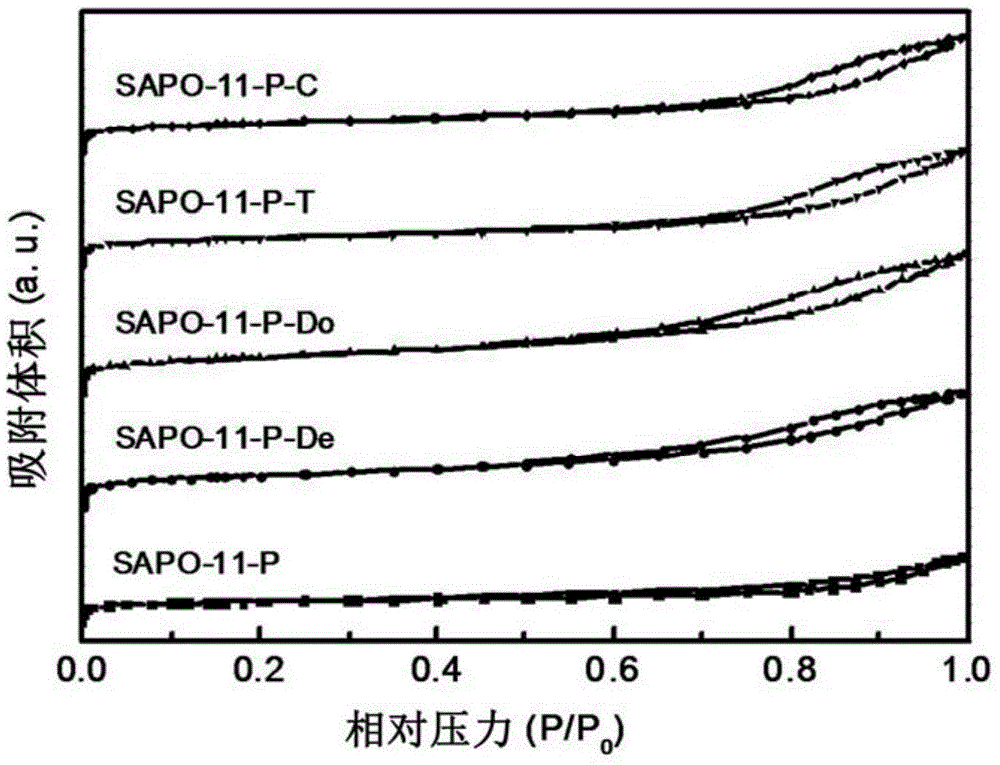

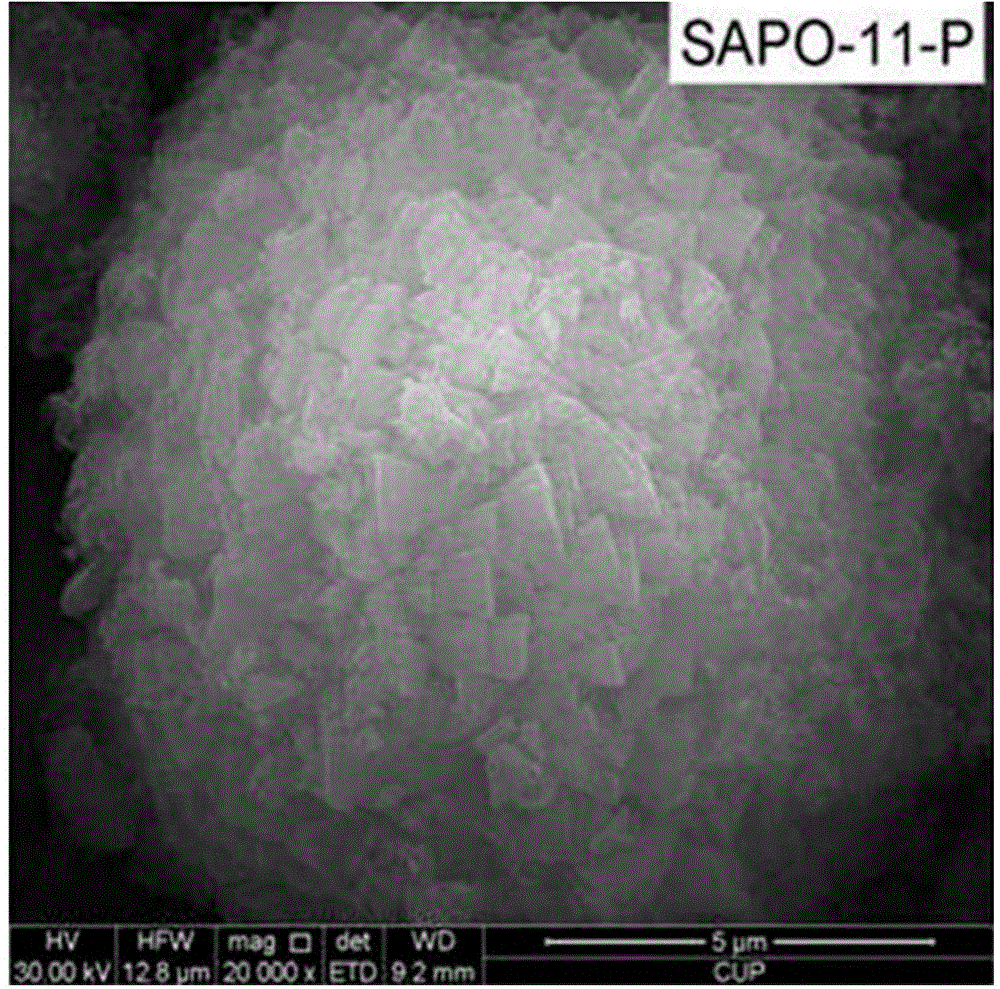

Small crystal grain stepwise pore SAPO-11 molecular sieve and hydrocarbon isomerization catalyst and their preparation methods

ActiveCN105800632APolyacid active siteExposed acid sitesHydrocarbon by isomerisationMolecular sieve catalystsMolecular sievePtru catalyst

The invention provides a small crystal grain stepwise pore SAPO-11 molecular sieve and a hydrocarbon isomerization catalyst and their preparation methods. The preparation method of the molecular sieve comprises dissolving a phosphorus source in water, carrying out stirring, orderly adding at least one aluminum source, at least one silicon source, at least one template, at least one cationic surfactant and at least one cosolvent into the solution, carrying out dissolution and crystallization to obtain crystals, cooling the crystals, carrying out centrifugation, washing and drying to obtain small crystal grain stepwise pore SAPO-11 molecular sieve raw powder, and roasting the small crystal grain stepwise pore SAPO-11 molecular sieve raw powder in air to obtain the small crystal grain stepwise pore SAPO-11 molecular sieve. The invention also provides the small crystal grain stepwise pore SAPO-11 molecular sieve obtained by the preparation method. The invention also provides the hydrocarbon isomerization catalyst with the small crystal grain stepwise pore SAPO-11 molecular sieve as a carrier and a preparation method thereof.

Owner:PETROCHINA CO LTD +1

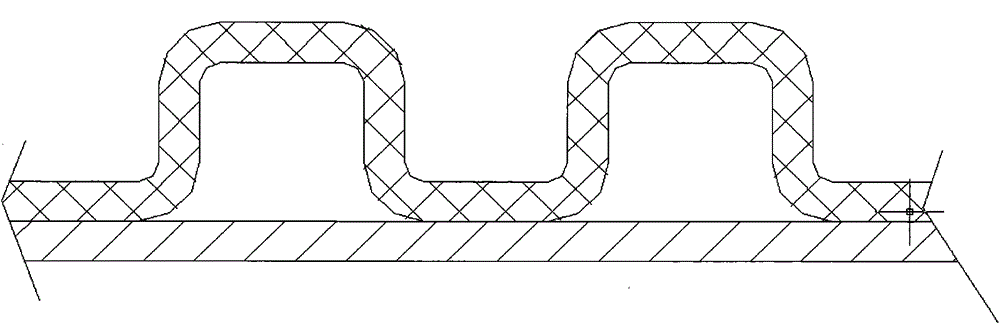

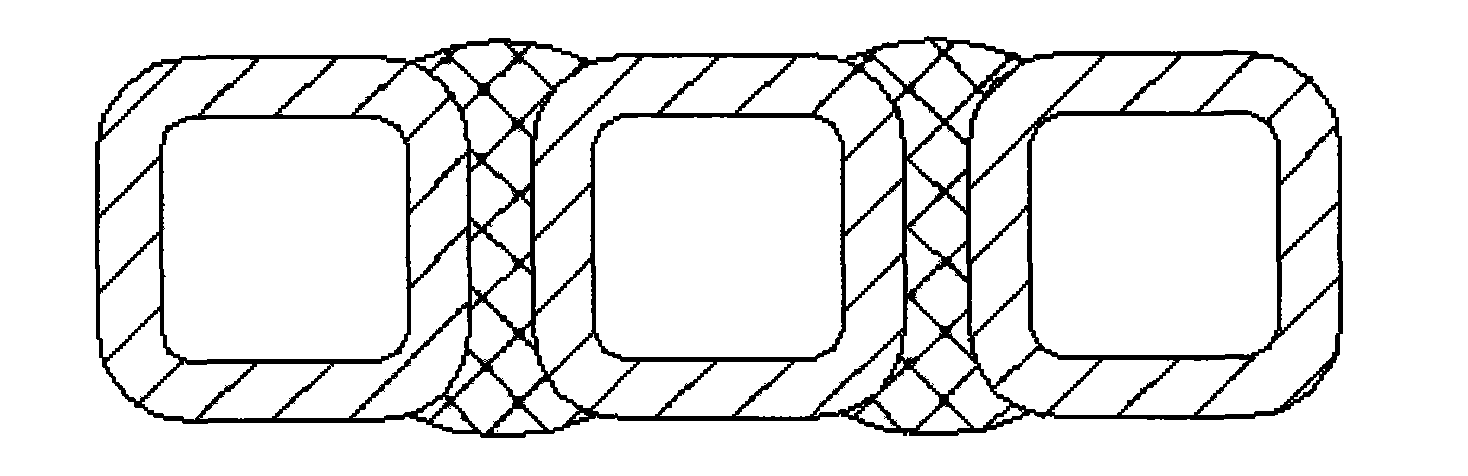

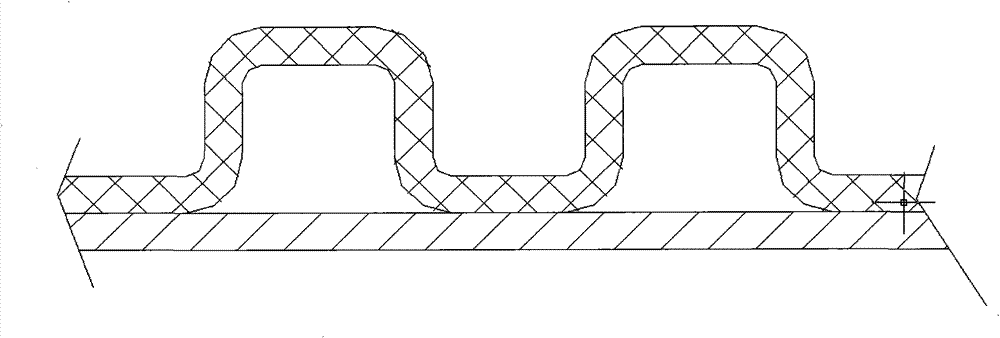

Continuously wound reinforced corrugated pipe and manufacturing method thereof

ActiveCN104279379AIncrease the outer surface areaIncreased structural wall thicknessCorrugation articlesFlexible pipesSolid wallAdhesive

The invention discloses a continuously wound reinforced corrugated pipe and a preparation method thereof. The pipe comprises a continuous solid-wall cylindrical pipe body formed by lapping and fusing a plurality of spirally wound special rods of which the two sides are provided with butting wings through the wings; a plurality of hollow reinforcing ribs are spirally wound on the pipe wall of the cylindrical pipe body; each hollow reinforcing rib comprises at least one special single-wall corrugated reinforcement pipe which is spirally wound on the pipe wall of the cylindrical pipe body through a reinforcement adhesive layer, and an outer reinforcement layer which is spirally wound, spans and presses on the special single-wall corrugated reinforcement pipe and of which two ends are adhered to the pipe wall of the cylindrical pipe body; the center line of each hollow reinforcing rib is overlapped with the center line of a lapping and fusing part of wings of an adjacent special rod. The pipe is high in stability and welding effect, the crest height of the pipe is higher than that of a double-wall corrugated pipe, the continuously wound reinforced corrugated pipe can be produced by matching common wound pipe production equipment with a suitable die, and equipment investment is small.

Owner:戴爱清 +1

Nanometer material and application and method for repairing soil cadmium pollution under combination of nanometer material, plants and microorganisms

InactiveCN106216371ARepair Cd contaminationReduced total cadmium contentContaminated soil reclamationMicroorganismSoil cadmium

The invention provides a method for repairing vegetable garden soil cadmium pollution. Nano-zeolite with the soil weight being 0.5% to 1.0% and nano-magnesium hydroxide with the land fertilizer amount being 0.1% to 0.5% are used and are sufficiently and evenly mixed with soil through broadcasting, furrow dressing and hole application, the soil turning depth ranges from 15 cm to 20 cm, and after balance is conducted for 5 days to 7 days, vegetables or other crops are transplanted. According to the method, multiple repairing technologies such as in-situ passivation, plant repairing and microorganism repairing are organically combined, and soil Cd pollution is effectively repaired through a synergistic effect.

Owner:SOUTHWEST UNIVERSITY

Transcutaneous Prosthesis

InactiveUS20070073412A1Increase the outer surface areaMore powerDental implantsInternal osteosythesisBacterial AdhesionsProsthesis

A transcutaneous prosthesis includes a first component shaped for implantation into a bone, the first component including flutes or grooves on a surface thereof for deterring rotation of the prosthesis within a bone; a second component adapted for location between the bone and the skin, the second component having a surface treatment for stimulation of fibroblastic cell proliferation and attachment of epithelial cells; and a third component adapted for location to extend from the skin surface and is adapted to extend directly from the skin surface in use, the third component having a coating of a non-stick material on an outer surface thereof, the coating having a surface energy that is lower than a surface energy of the first and second components and which is low enough to deter bacterial adhesion.

Owner:UNIV COLLEGE OF LONDON

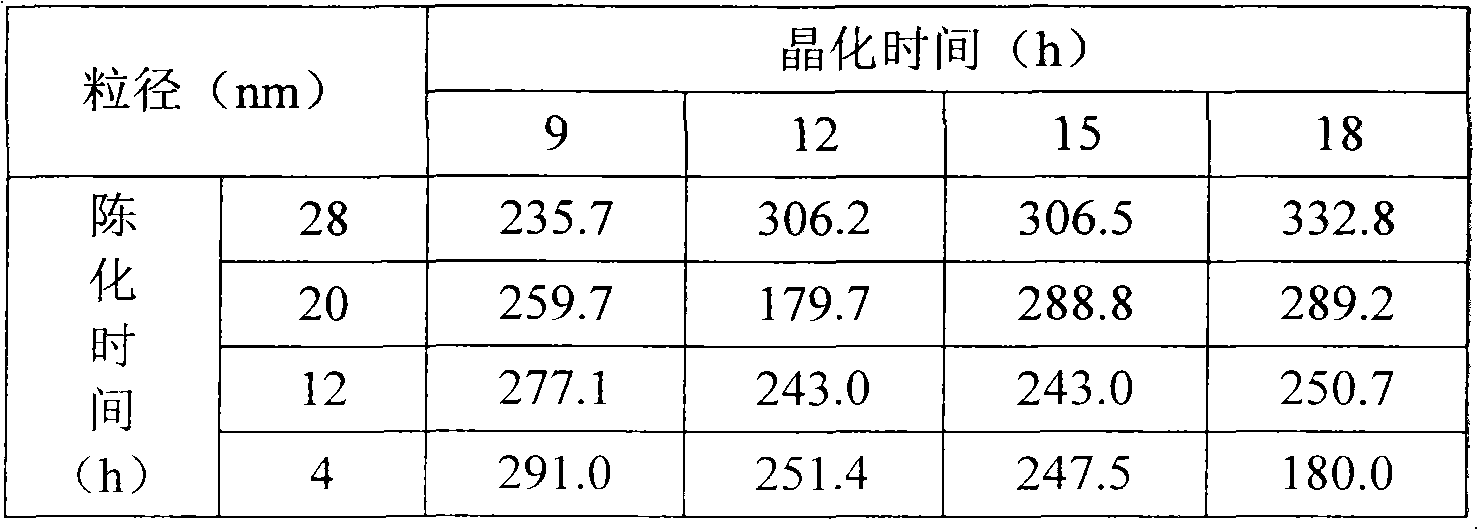

Preparation method of high-medium oil selective hydrocracking catalyst

InactiveCN101844085ASolve reunionSolve filterabilityMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveActive component

The invention relates to a preparation method of a high-medium oil selective hydrocracking catalyst. The invention firstly provides a preparation method of a Y-molecular sieve / Si-Al oxide composite catalytic material, comprising the steps of: synthesizing a Y-molecular sieve by a guide agent method, controlling the synthesis temperature of mother solution to be below 0 DEG C, the ageing time to be 4-8h, the crystallization temperature to be 90-95 DEG C and the crystallization time to be 9-18h, and obtaining slurry formed by the Y-molecular sieve and the rest crystallization liquid; carrying out ammonium exchange treatment on the Y-molecular sieve, and obtaining the mixed solution; and adding an Al source and a Si source into the mixed solution, adjusting the pH value to be 6-10 to form gel, drying the gel, and obtaining the composite catalytic material. The invention also provides the preparation method of the high-medium oil selective hydrocracking catalyst, comprising the following steps of: preparing the Y-molecular sieve / Si-Al oxide composite catalytic material according to the method; taking the composite catalytic material as a carrier for carrying active components; and obtaining the high-medium oil selective hydrocracking catalyst by drying and calcining.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

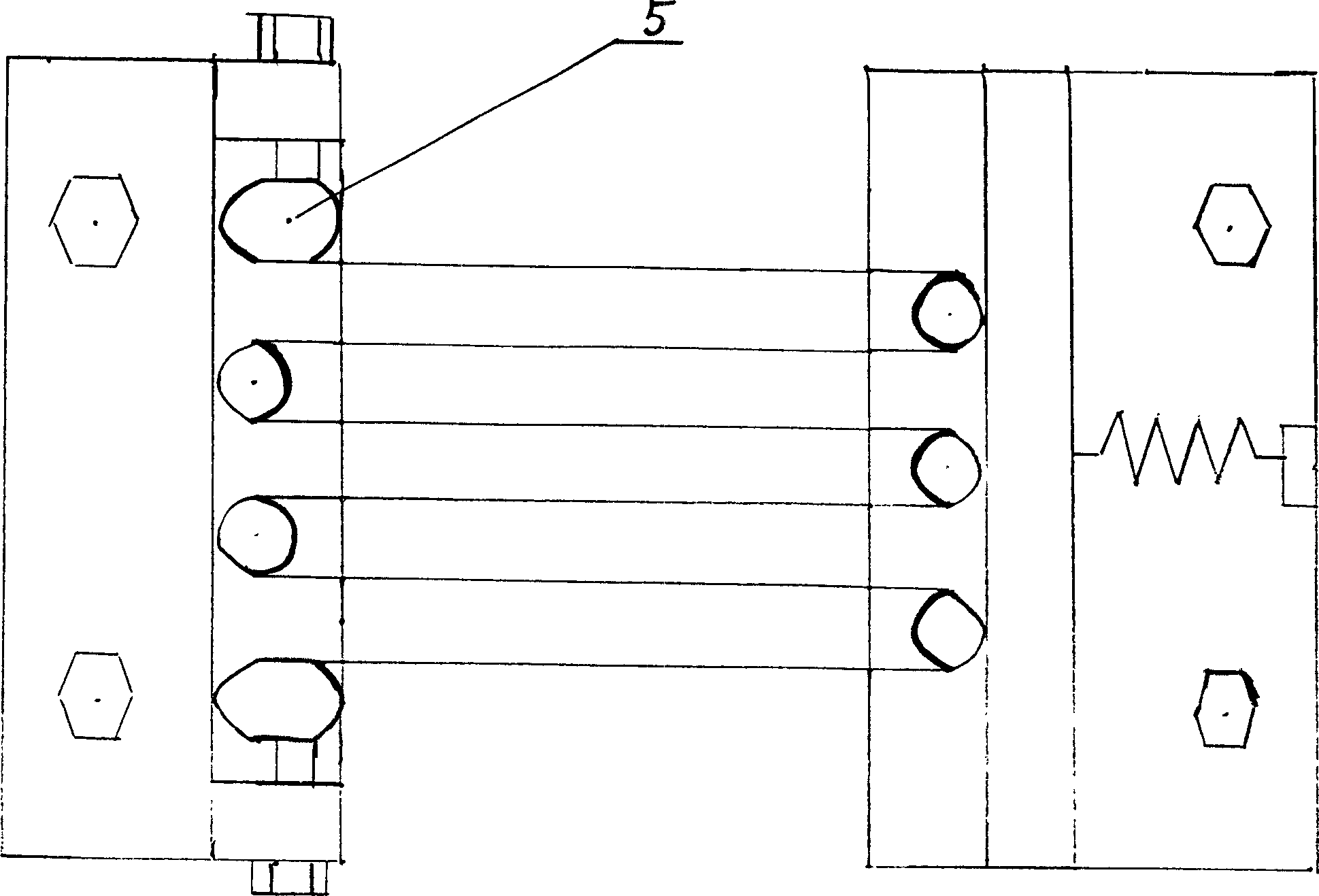

Hot wire for diamond film growth device and electrode structure thereof

InactiveCN1844450AReduced blocking cross sectionEasy to pass throughOhmic-resistance electrodesChemical vapor deposition coatingEngineeringProduct gas

This invention relates to the heater and electrode structure of diamond film growth device. This invention mainly includes a fixing electrode, a mobile electrode and corresponding heater, the character as follows: the fixing electrode is arranged with a group of electrode poles in equal space; and the mobile electrode is also arranged with a group of electrode poles, and the space is equal to the electrode pole space of the fixing electrode, the electrode pole is half space away from the electrode pole on the fixing electrode; the heater is a flat-shape heater, which is wrapped around the electrode pole of the fixing electrode and mobile electrode to form heater array. Comparing to the circular silk, the flat-shape structure increases the contact area and time of the reaction gas and heater, and improves the reaction gas decomposing rate, and save electric energy to decrease the growth cost of the diamond film.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

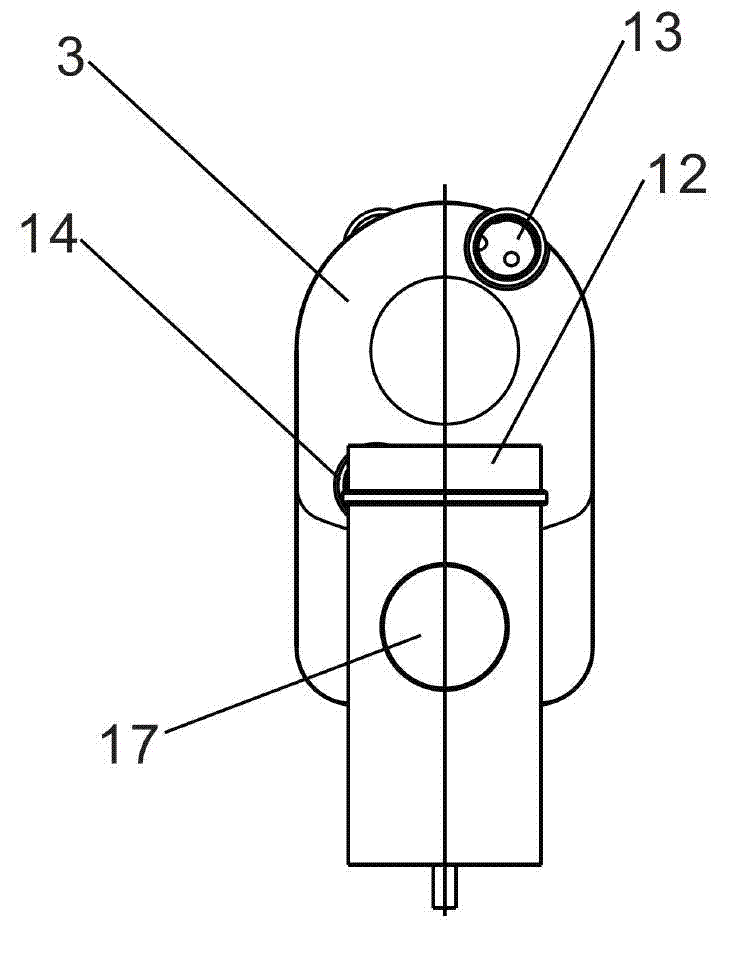

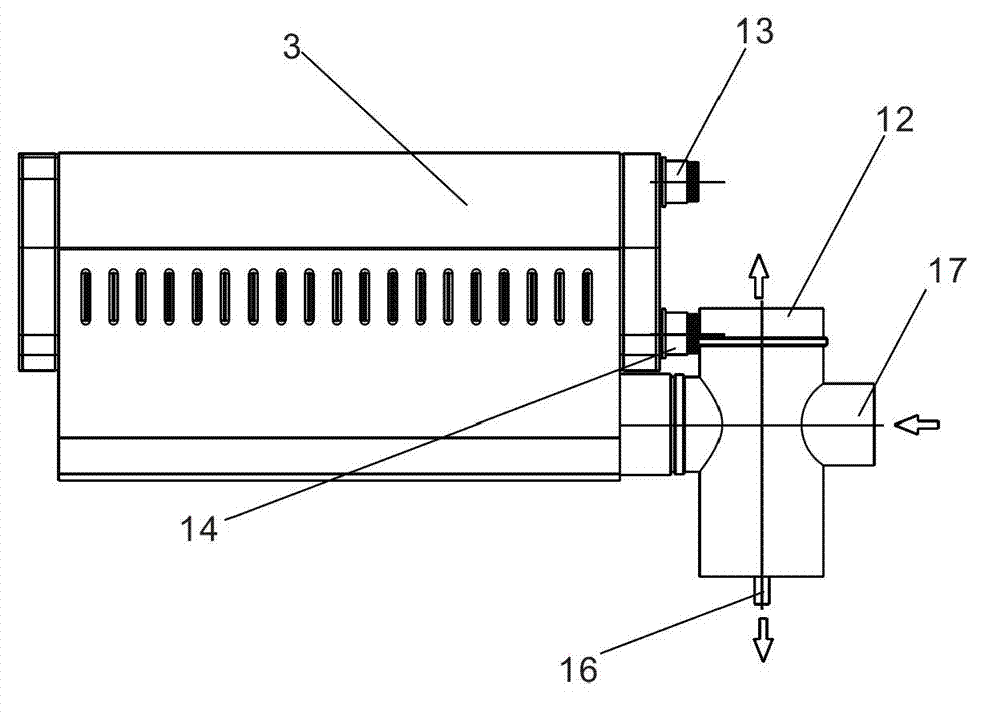

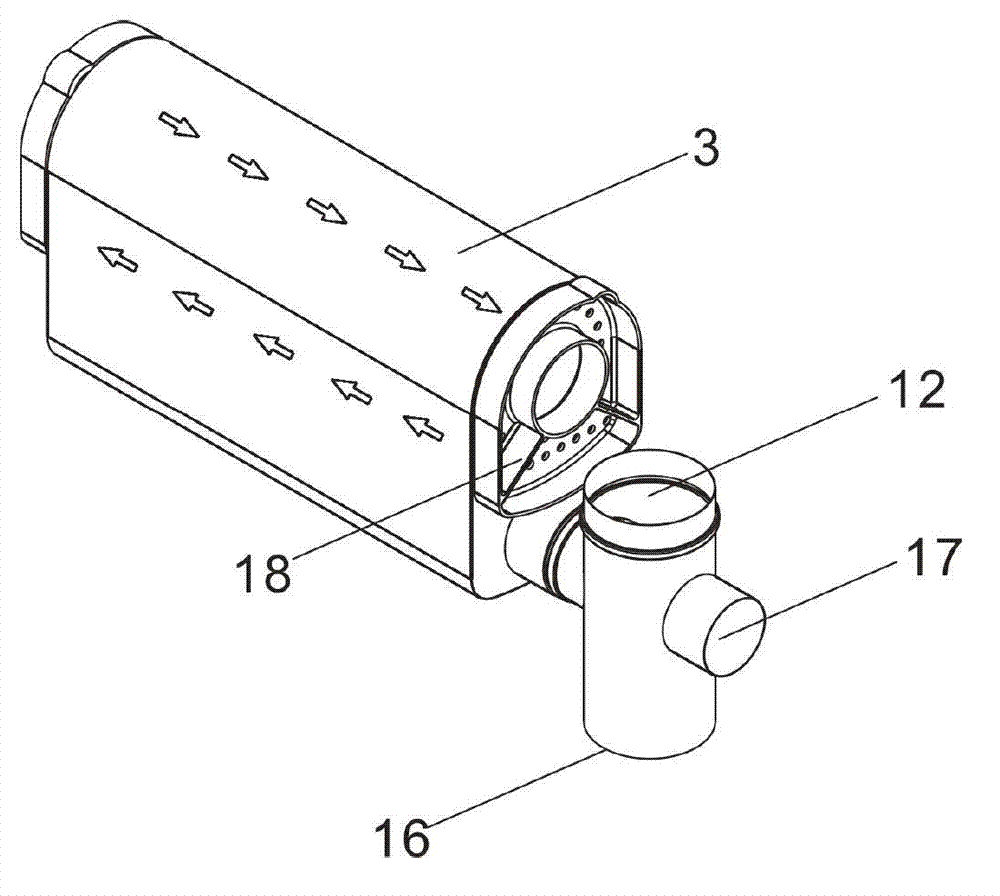

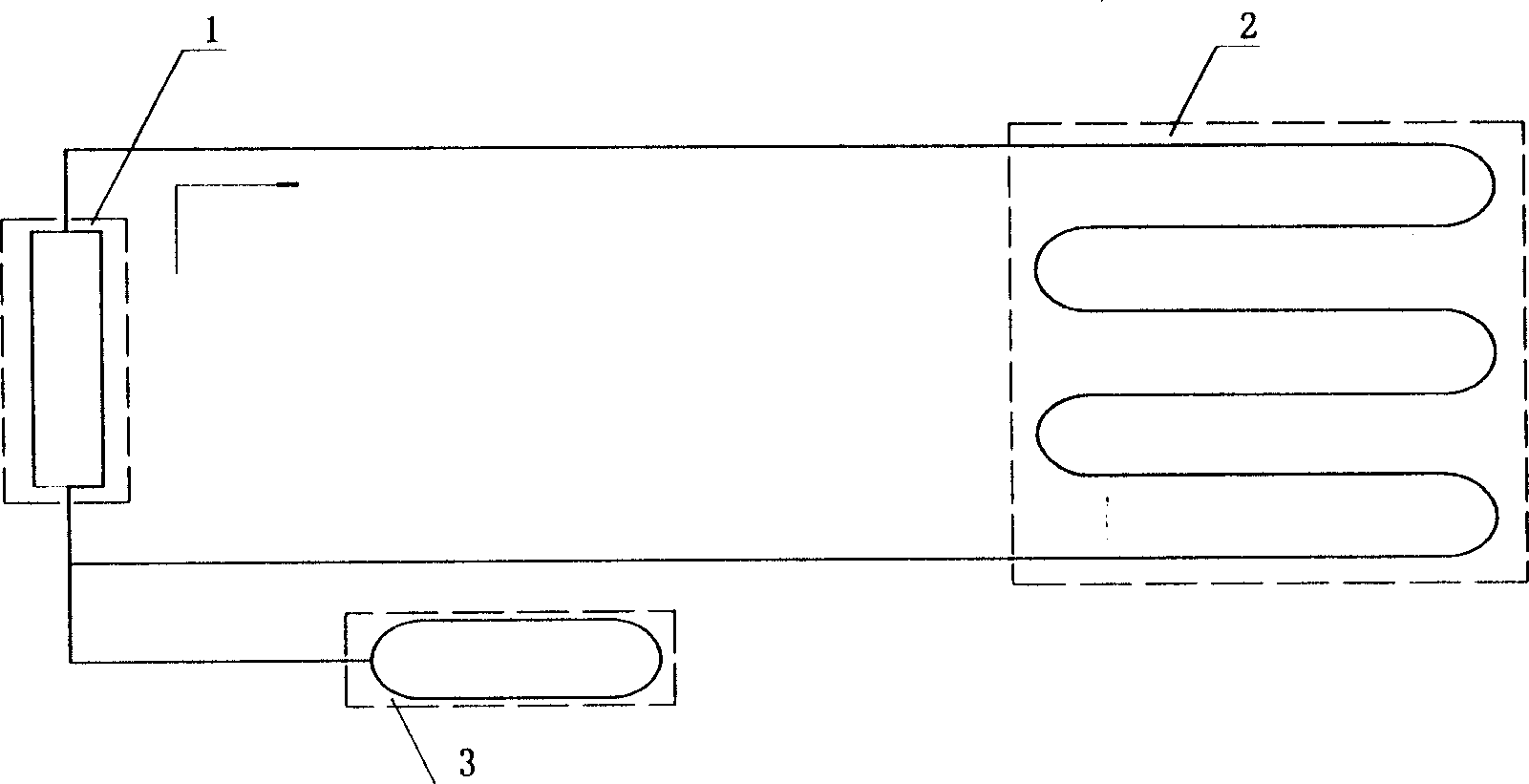

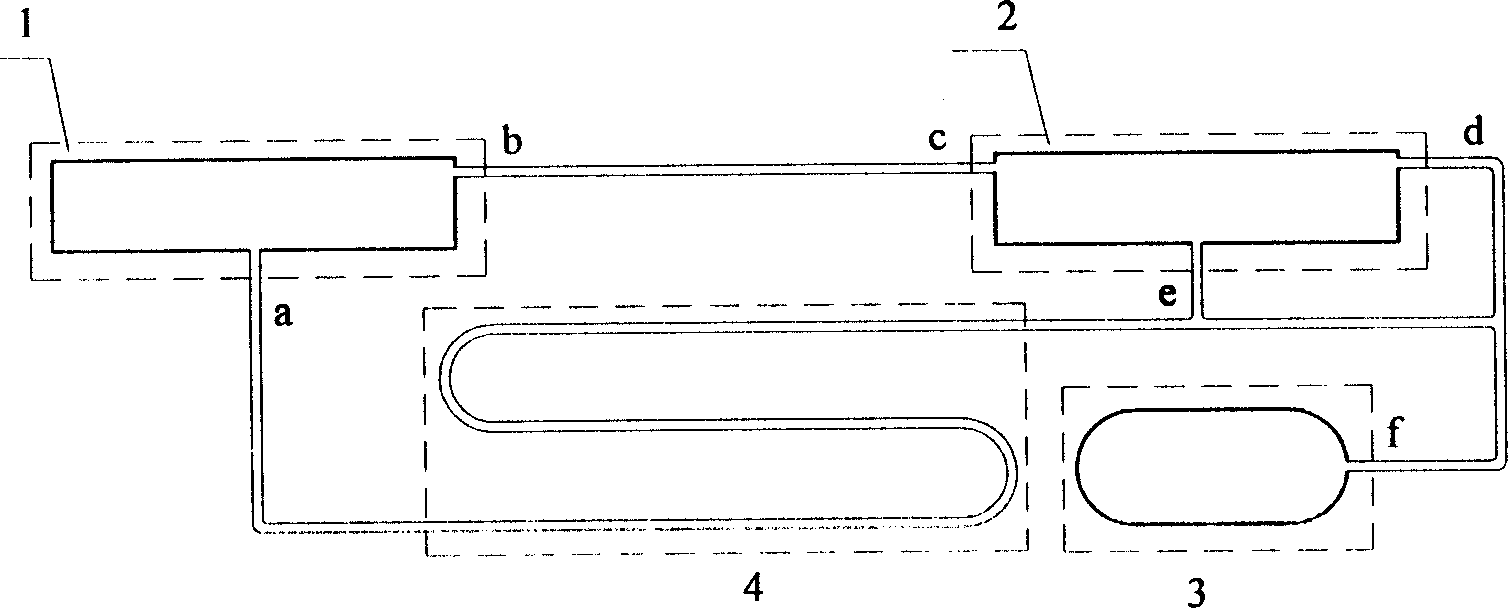

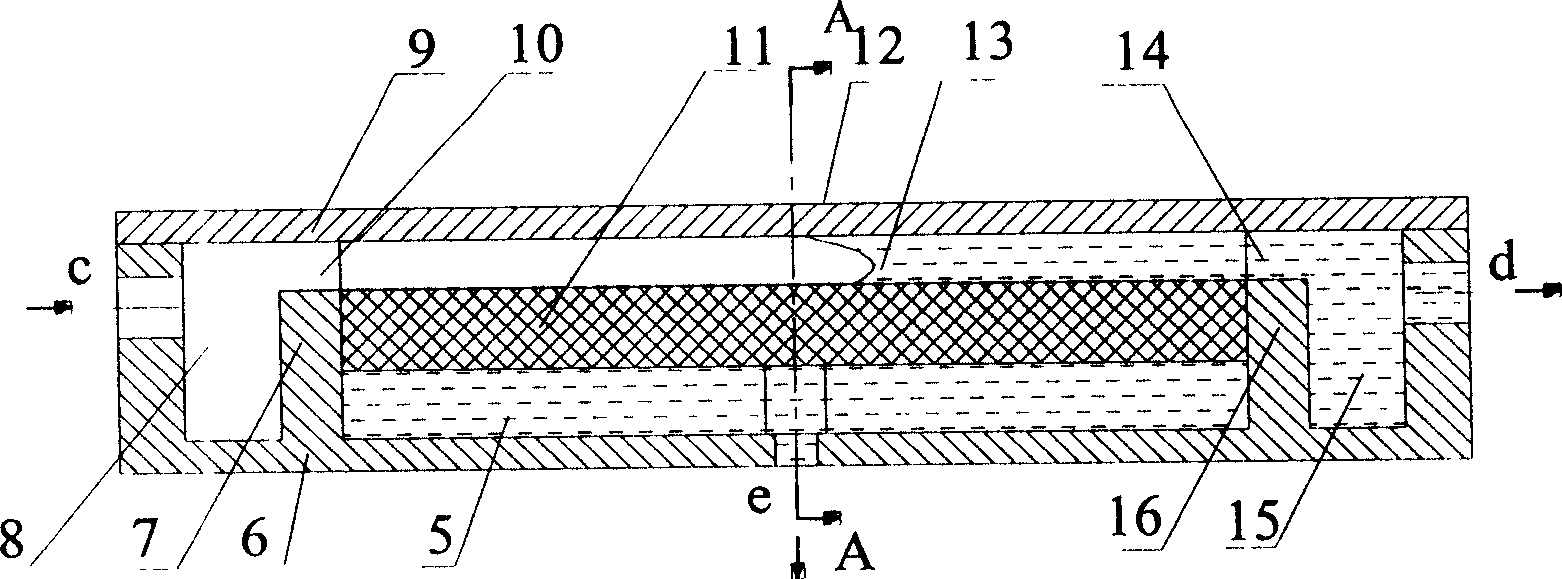

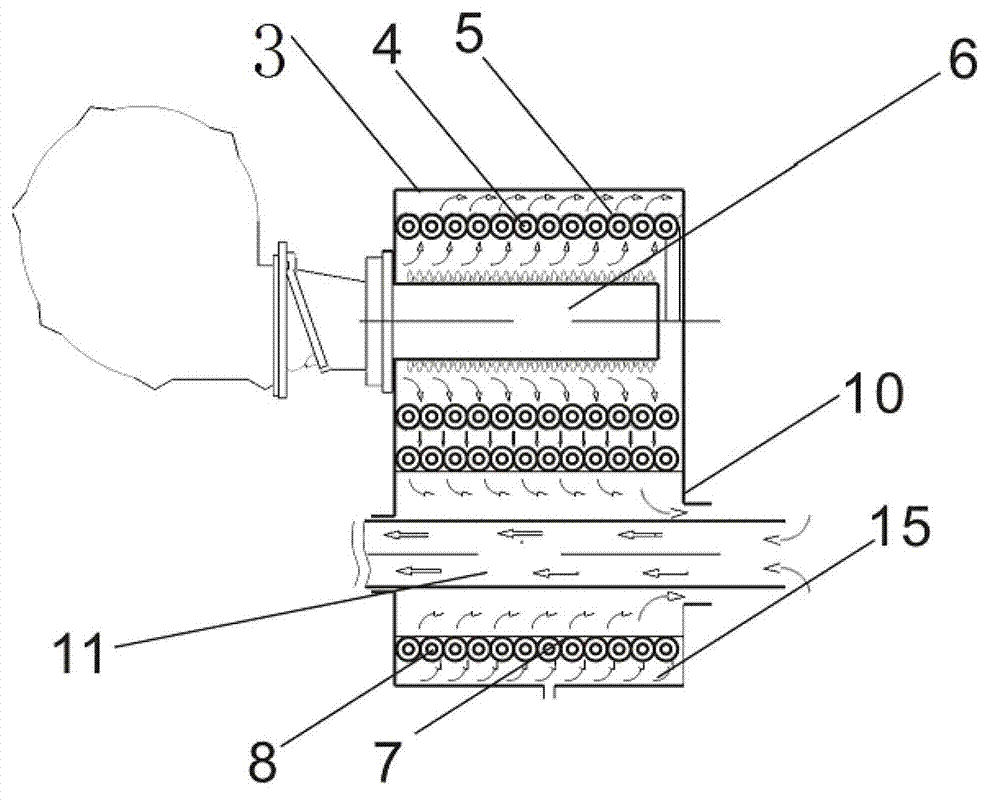

CPC system having plane type capillary core evaporator and condenser

The present invention discloses a CPL system with plane type capillary core evaporator and condenser. Its structure is characterized by that the steam outlet of its evaporator is connected with steam inlet of its condenser, and the liquor storage device is connected with condensate outlet of condenser, the described evaporator is a plane type capillary core evaporator, and the condenser is a plane type capillary core condenser, said liquor storage device is connected with liquor-discharging outlet of condenser, and the condensate outlet of condenser is connected with return flow liquor inlet of evaporator by means of subcooler.

Owner:HUAZHONG UNIV OF SCI & TECH

Hydrogenated titanium dioxide nanotube/nano-particle composite photocatalytic material and preparation method thereof

ActiveCN103877959AIncrease the outer surface areaImprove photocatalytic activityMaterial nanotechnologyPhysical/chemical process catalystsNitrogen gasPhenol

The invention provides a preparation method of a titanium dioxide nanotube / nano-particle composite photocatalytic material with a hydrogenated surface. The preparation method comprises the following steps of adding titanium dioxide into a NaOH solution, ultrasonically dispersing and stirring the titanium dioxide and the NaOH solution in a dark place, carrying out the hydrothermal reaction, cooling, washing and drying to obtain a solid product; grinding the solid product, placing the ground product into a quartz tubular furnace, introducing hydrogen-nitrogen mixed gas, and heating the to 400 to 600 DEG C, sintering the ground product for 1h to 6h; stopping the introduction of the mixed gas when the tubular furnace is cooled to 100DEG C to obtain the hydrogenated titanium dioxide nanotube / nano-particle photocatalysis composite material. The photocatalysis material is compounded of hydrogenated cavity titanium dioxide nanotube and titanium dioxide nano particles, so that the outer surface area is high, the cavity nanotube which easily adsorbe hydrogen is provided, the hydrogenation is easily realized, and therefore the photocatalytic activity is higher; in addition, the titanium dioxide nanotube / nano-particle composite photocatalytic material not only can be used for treating phenol pollutants in the water, but also can be used for treating dye and phenolic derivatives.

Owner:NATURAL ENERGY INST GANSU ACAD OF SCI

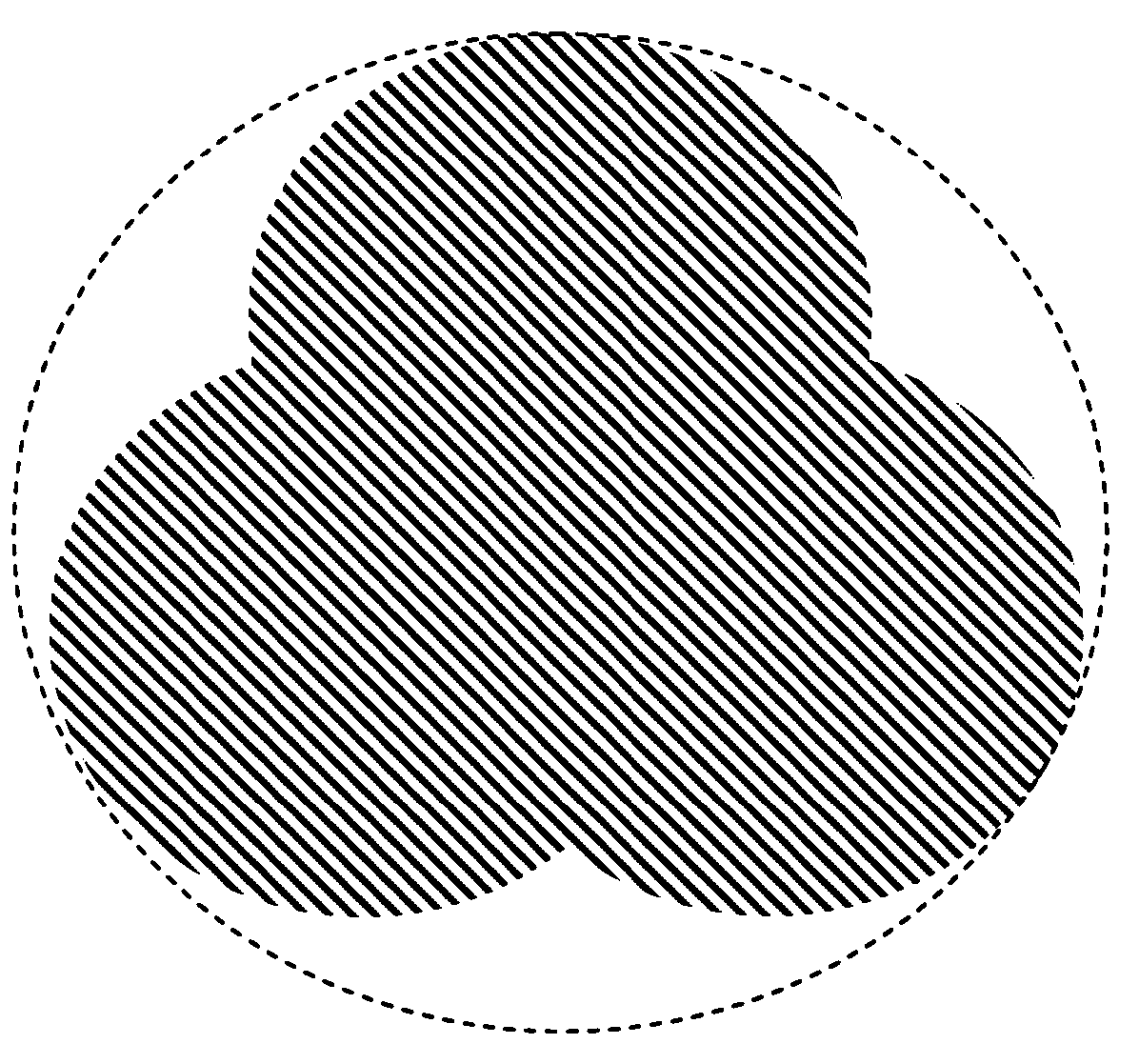

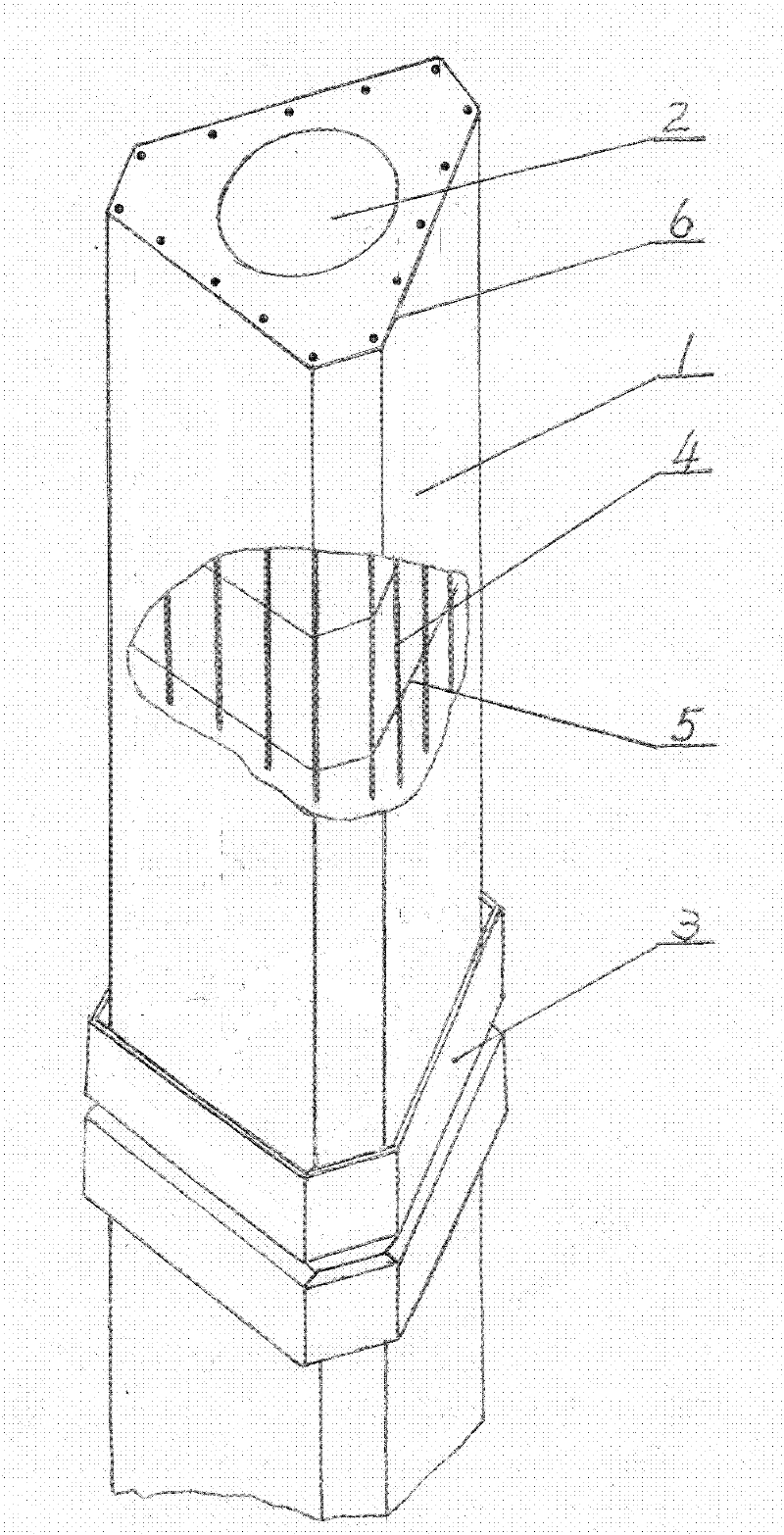

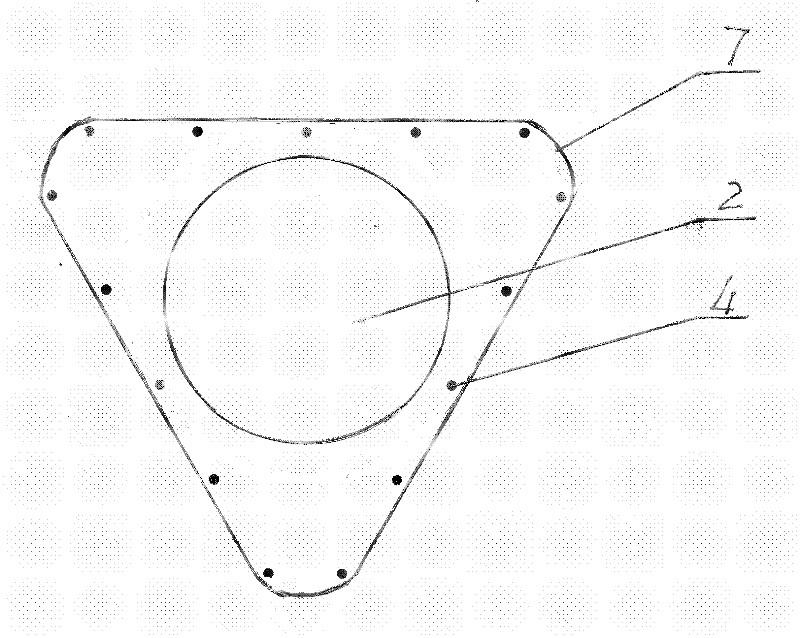

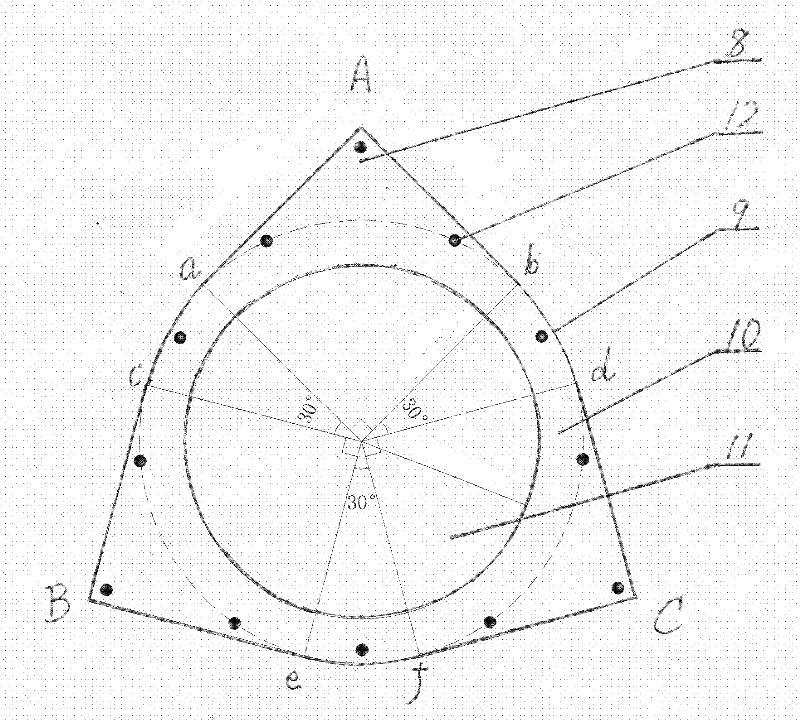

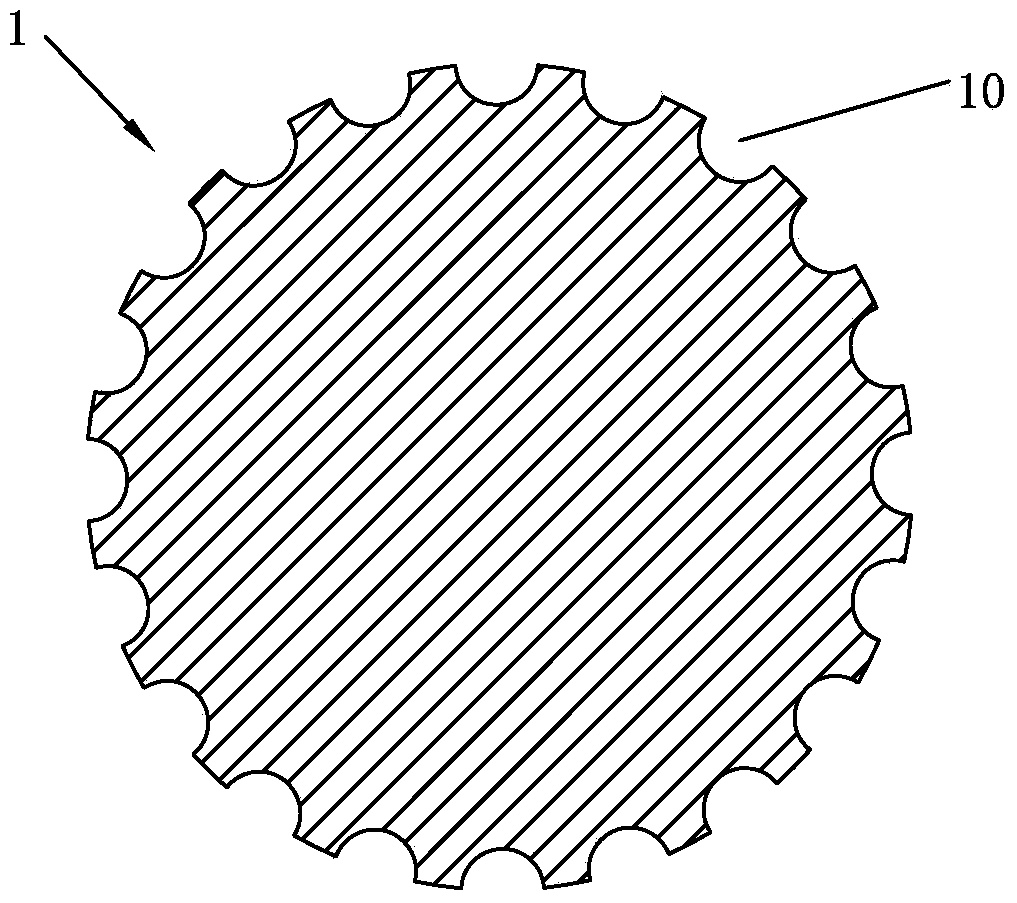

Prestressed reinforced concrete special-shaped precast pile

InactiveCN102505680AIncrease the outer surface areaImprove bearing capacityBulkheads/pilesReinforced concretePile cap

The invention relates to a prestressed reinforced concrete special-shaped precast pile, wherein the concrete precast pile is special in shape, the center of the concrete precast pile is provided with a center hole, two ends of the concrete precast pile are respectively provided with a pile cap made from a steel plate, the shape of each pile cap is the same as the cross section shape of the concrete precast pile, one end of each pile cap is provided with a 45-degree groove, the pile caps and the precast pile are fixed by bolts, and every two concrete precast piles are connected with one another into a whole in a welding way by virtue of the pile caps; and the cross section of the special-shaped precast pile is a hexagon with three long edges and three short edges formed by cutting off three top angles of equilateral triangle or three external angles formed by outwards extending three tangent lines with arc or circular pile-shaped short edges, and the external angles are acute angles, 90-degree angles or obtuse angles. The prestressed reinforced concrete special-shaped precast pile has the advantages that the external surface area of the special-shaped precast pile is increased, so that the vertical frictional force and the vertical bearing capacity can be greatly improved; and simultaneously, the cross section is increased, so that the bending resistance of a pile body can be correspondingly increased as well, i.e., the bearing capacity of the whole pile body can be effectively improved.

Owner:天津开发区福林发展有限公司

Forced spiral finned coil pipe condensation heat-supply heat exchanger

ActiveCN102901225AImprove heat transfer efficiencyImprove heat transfer effectEnergy efficient heating/coolingAir heatersCombustorPlate heat exchanger

The invention discloses a forced spiral finned coil pipe condensation heat-supply heat exchanger, which comprises a shell, a combustor arranged in the shell and a plurality of spiral finned coil pipes, wherein a water inlet, a water outlet and a smoke outlet are formed on the shell; the combustor is connected with an air and gas inlet device; the combustor is positioned on the upper part of the shell; the periphery of the combustor is coaxially provided with a group of pipe bundles consisting of a plurality of spiral finned coil pipes; a smoke exhaust pipeline which consists of a plurality of tightly arranged spiral finned coil pipes is arranged below the combustor; the smoke exhaust pipeline is emptied through a smoke outlet; the water inlet is communicated with the spiral finned coil pipes which are tightly arranged below the combustor; the spiral finned coil pipes which are tightly arranged below the combustor are communicated with the spiral finned coil pipes at the periphery of the combustor; and the spiral finned coil pipes at the periphery of the combustor are communicated with the water outlet. The inwards folded finned straight pipes serve as basic elements of the heat exchanger, the heat exchange on the smoke side is intensified, and the size of the whole heat exchanger is further reduced.

Owner:SUZHOU CQ HEAT EXCHANGER

Preparation method for hydrocracking catalyst

ActiveCN104826645AImprove cracking capacityHigh activityCatalyst carriersMolecular sieve catalystsMolecular sievePtru catalyst

The invention discloses a preparation method for a hydrocracking catalyst. The method comprises the following steps: subjecting a small-grain Y type molecular sieve, amorphous silicon-aluminum and a binder prepared from alumina to mechanical mixing and molding and then carrying out drying and roasting so as to prepare a catalyst carrier; and loading a hydrogenation active metal component on the catalyst carrier and then carrying out drying and roasting so as to prepare the catalyst. According to the method, a NaY type molecular sieve raw material with a high silica-alumina ratio, a high degree of crystallization and good stability is employed and successively undergoes ammonium exchange, primary hydro-thermal treatment, treatment with an alkali-containing solution, secondary hydro-thermal treatment and treatment with a mixed solution of acid and an ammonium salt; and the obtained small-grain Y type molecular sieve has a high SiO2 / Al2O3 mol ratio and a high proportion of secondary pores, retains the stability of the molecular sieve and has a high specific surface area and a high degree of crystallization. The hydrocracking catalyst provided by the invention is applicable as a hydrocracking catalyst for high and medium oil and has good activity, medium oil selectivity and product properties.

Owner:CHINA PETROLEUM & CHEM CORP +1

Phosphor copper ball with grooves at surface and preparation method thereof

The invention discloses a phosphor copper ball with grooves at the surface and a preparation method thereof. The phosphor copper ball comprises a phosphor copper ball body, and grooves arranged at the surface of the phosphor copper ball body at intervals, and the height difference between the bottoms of the grooves and the surface of the phosphor copper ball body is 1-3mm. Compared with the existing solid phosphor copper ball which is smooth and flat in surface, the phosphor copper ball with the grooves at the surface provided by the invention has large superficial area, can bear greater current, discharges more copper ions in the electroplating process, and is high in usage rate.

Owner:东又悦(苏州)电子科技新材料有限公司

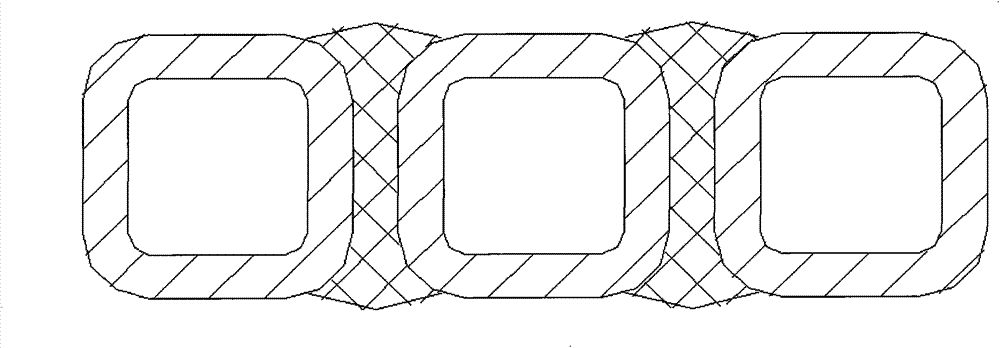

Enhancement structure wall pipe material and manufacturing device and method thereof

ActiveCN103925428AIncrease the outer surface areaGood synergyFlexible pipesRigid pipesSolid wallLap joint

The invention provides an enhancement structure wall pipe material. The pipe wall is in a spiral circumference shape formed by spirally winding special-shaped strip-shaped plastic sectional materials by taking the central line as the axis, the edges of the adjacent special-shaped strip-shaped plastic sectional materials are integrated in a lap-joint mode to form a continuous solid wall tubular structure, an enhancement bonding sectional material in the same spiral winding type is pressed above the portions of lap-joint integrating lines of the edges of the adjacent special-shaped strip-shaped plastic sectional materials on the pipe wall in a crossed mode, and a polypropylene and polyethylene composite enhanced pipe in the same spiral winding type is pressed above the enhancement bonding sectional material in a crossed mode and is bonded with the pipe wall through a pressing wheel mechanism. The structure mode of the material is provided with the outer ripples, the outer surface area of the pipe material is improved, in the use process, the formed pipeclay joint effect is superior to that of a pipe A of the pipe material of the polyethylene winding structure, and in addition, due to the fact that the structural wall height is large, the pipeclay joint effect is better than that of a common double-wall corrugated pipe.

Owner:青岛北塑机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com