Patents

Literature

75results about How to "Solve filterability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

RFID/VFID (Radio Frequency Identification Device/Video Frequency Identification Device) comprehensive comparison intelligent vehicle management system and method

ActiveCN102542807AHigh resolutionWith intelligent imagingRoad vehicles traffic controlCo-operative working arrangementsDigital signal processingIdentification device

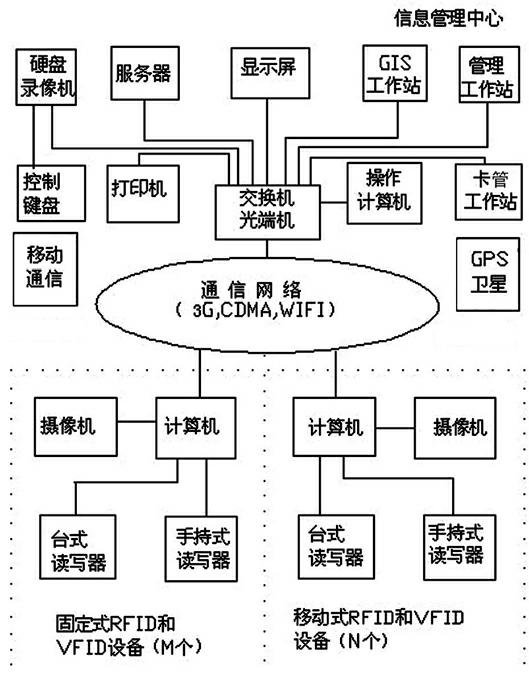

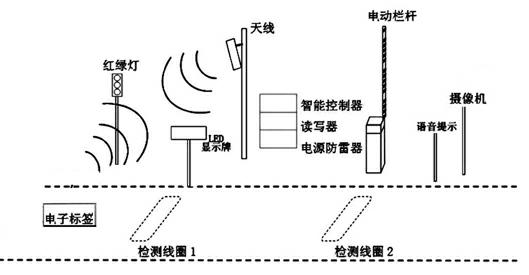

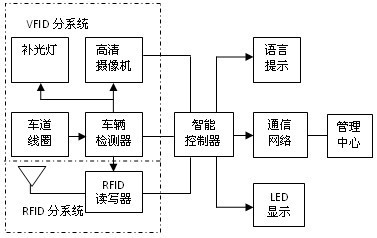

The invention discloses a RFID / VFID (Radio Frequency Identification Device / Video Frequency Identification Device) comprehensive comparison intelligent vehicle management system and a method. The system comprises one or more automatic vehicle identifying fixed station, one or more automatic vehicle identifying moving station, a communication network and a management center, wherein the fixed station and the moving station are respectively connected with the management center through the communication network; the fixed station and the moving station comprise one or more RFID subsystem, one or more VFID subsystem and one or more intelligent controller; the RFID subsystem and the VFID subsystem are respectively connected with the intelligent controller; and the VFID subsystem comprises a light-supplementing lamp, a high definition camera and a DSP (Digital Signal Processing) module, which are connected one another, wherein the DSP module is embedded in the high definition camera. The problems of finding and trigger starting when a vehicle passes in the absence of a lane coil and the problems of comprehensive comparison and filtering under the conditions of multi-path interference and cloned license plate are solved by using the system provided by the invention. The system provided by the invention has significance for resisting interference, preventing fake and saving energy.

Owner:四川新源现代智能科技有限公司

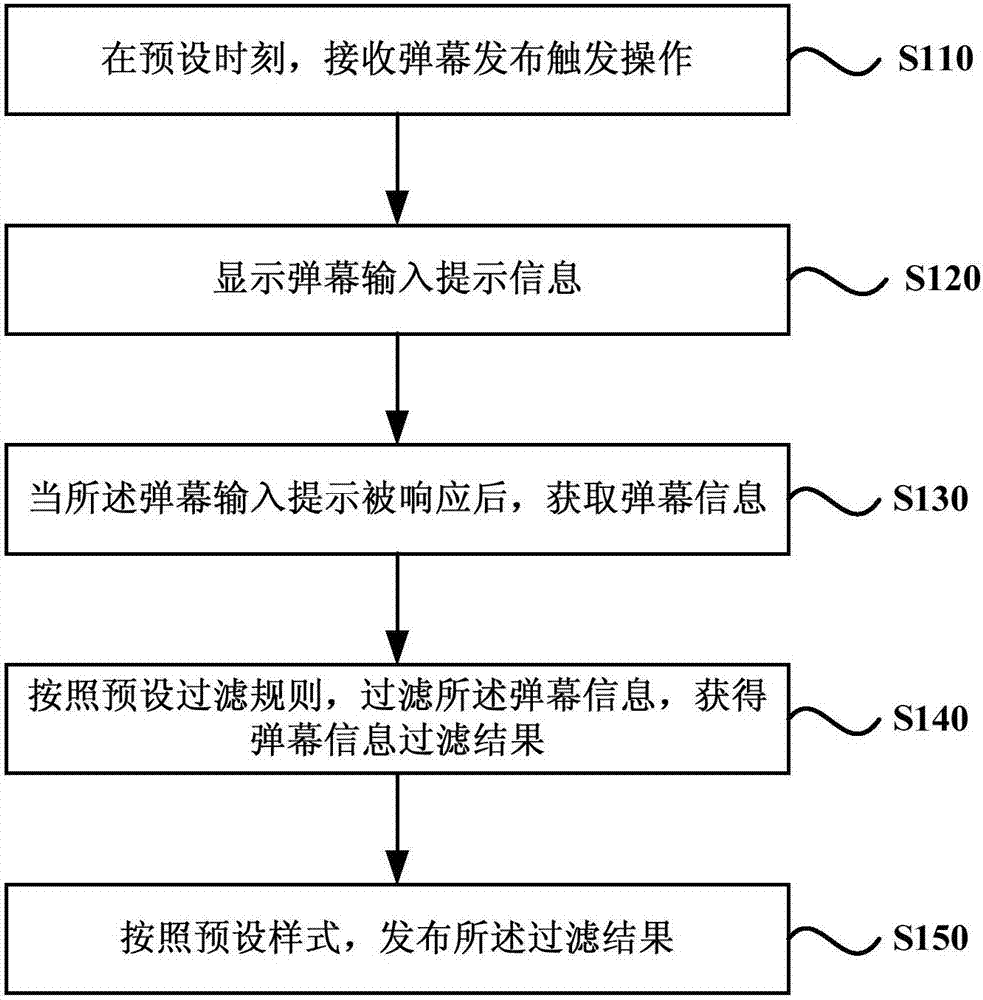

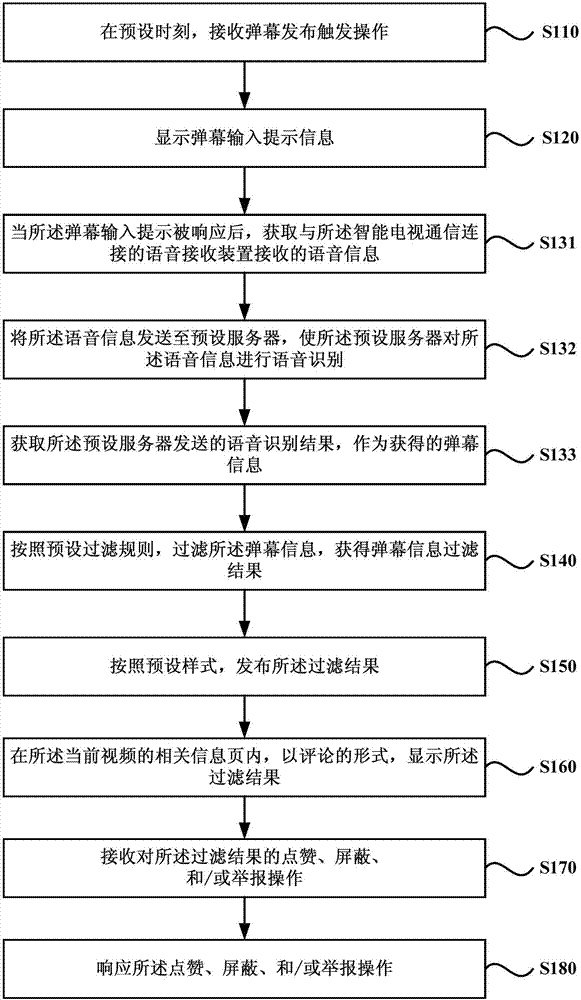

Bullet screen release method and device

InactiveCN106921868AQuick releaseRelease securitySelective content distributionComputer hardwareFiltering rules

Owner:SHENZHEN SKYWORTH DIGITAL TECH CO LTD

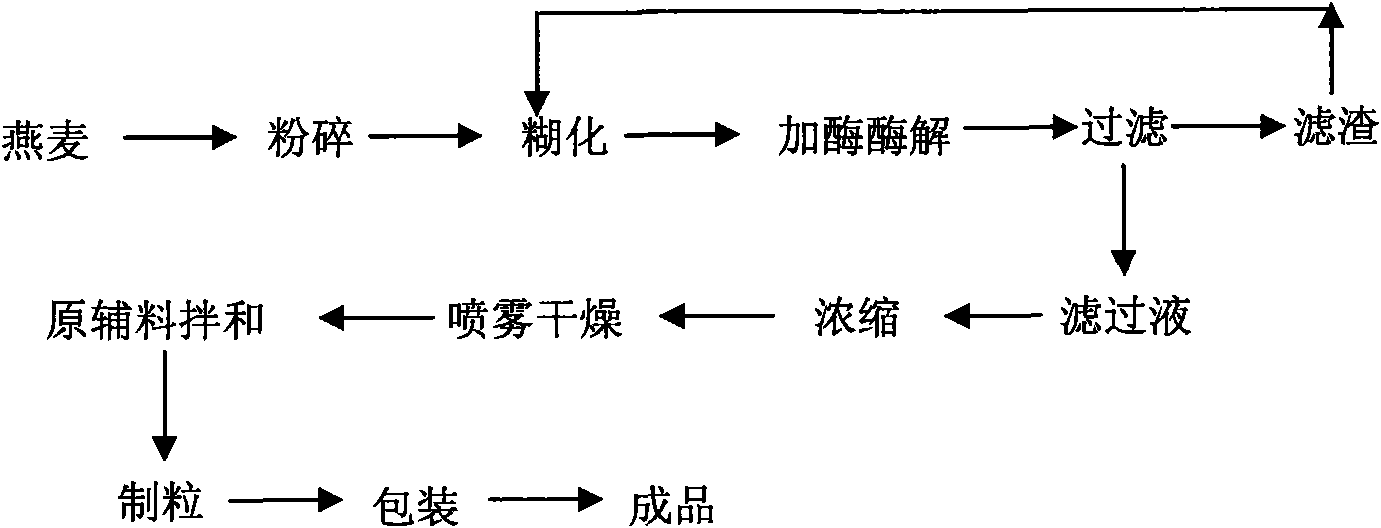

Method for producing oat solid beverage

The invention relates to a method for producing an oat solid beverage, belonging to the manufacture field of solid beverages. The production method comprises the following steps: grinding oats into 60-80 meshes by a dry method; adding 3-15 times of water by mass in a pasting tank or a saccharifying tank provided with a stirrer; adding 5-20 thousand U / kg of high-temperature resistant amylase of oatpowder; heating to boil and keeping the temperature for 10-60min; lowering the temperature to 45-60 DEG C, adding 2-12 thousand U / kg of pectase of oat powder; filtering to obtain primary filter liquid and filter residual; adding 1-4 times of water in the filter residual; soaping for 10-40min for secondary filtering; merging the primary filter liquid and the secondary filter liquid; carrying out vacuum concentration until soluble solid matter reaches more than 40%; atomizing and drying to obtain the oat beverage power; adding 20-40% of auxiliary materials by weight of oat power; and palletizing to obtain the pellet oat solid beverage. The oat solid beverage produced in the invention has the advantages of special flavor and taste of oats, smooth taste, uniform milk white color, good productstability, no precipitation or stratification within one day after being poured, abundant nutrition and content of beta-glucosan being as high as 6%.

Owner:JIANGSU UNIV +1

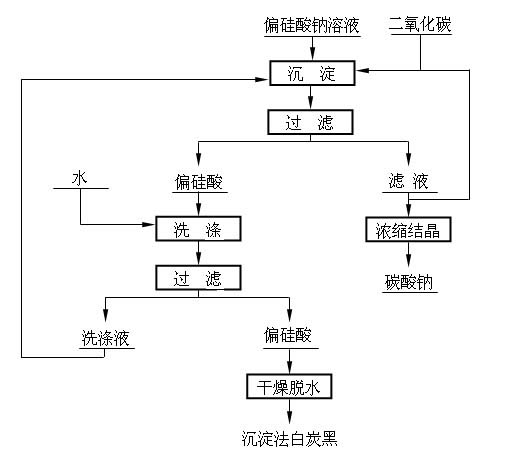

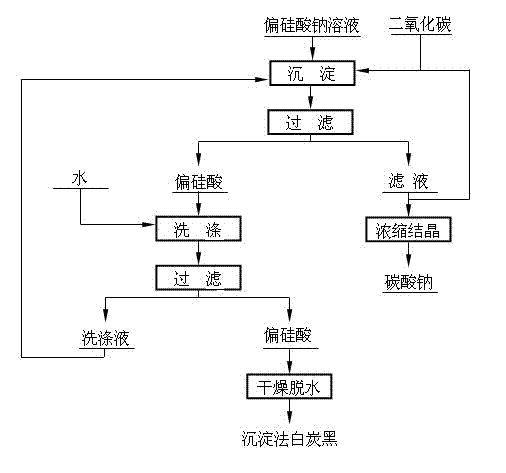

Process for preparing precipitated white carbon black by adopting carbon dioxide for decomposition

The invention relates to a process for preparing precipitated white carbon black by adopting carbon dioxide for decomposition. The process comprises the following steps: introducing the precipitator carbon dioxide into industrial sodium metasilicate solution with the pH value of 12.5-13.5 to react, stopping introducing the carbon dioxide when the pH value of the solution is 8.5-9.0, filtering the reactant to obtain metasilicic acid filter residues and filtrate containing sodium carbonate; adding water to metasilicic acid according to the liquid solid mass ratio of 6:1, stirring and washing the mixture, filtering the mixture and then washing entrained sodium carbonate solution, and drying the product to obtain the precipitated white carbon black; and returning one half of the filtrate containing sodium carbonate to the sodium metasilicate solution to be dissolved again to precipitate the metasilicic acid and concentrating and crystallizing the other half of the filtrate to obtain sodium carbonate product. The process has the following advantages: the carbon dioxide is adopted to replace the acid to precipitate the metasilicic acid in the sodium metasilicate solution, thus solving the filtering performance of the precipitate metasilicic acid in the traditional precipitation process; meanwhile, the liquid after precipitation is ensured to be the sodium carbonate solution with high additional value, thus completely eliminating discharge of waste water in the precipitation process; and besides, carbon is utilized.

Owner:KUNMING METALLURGY INST

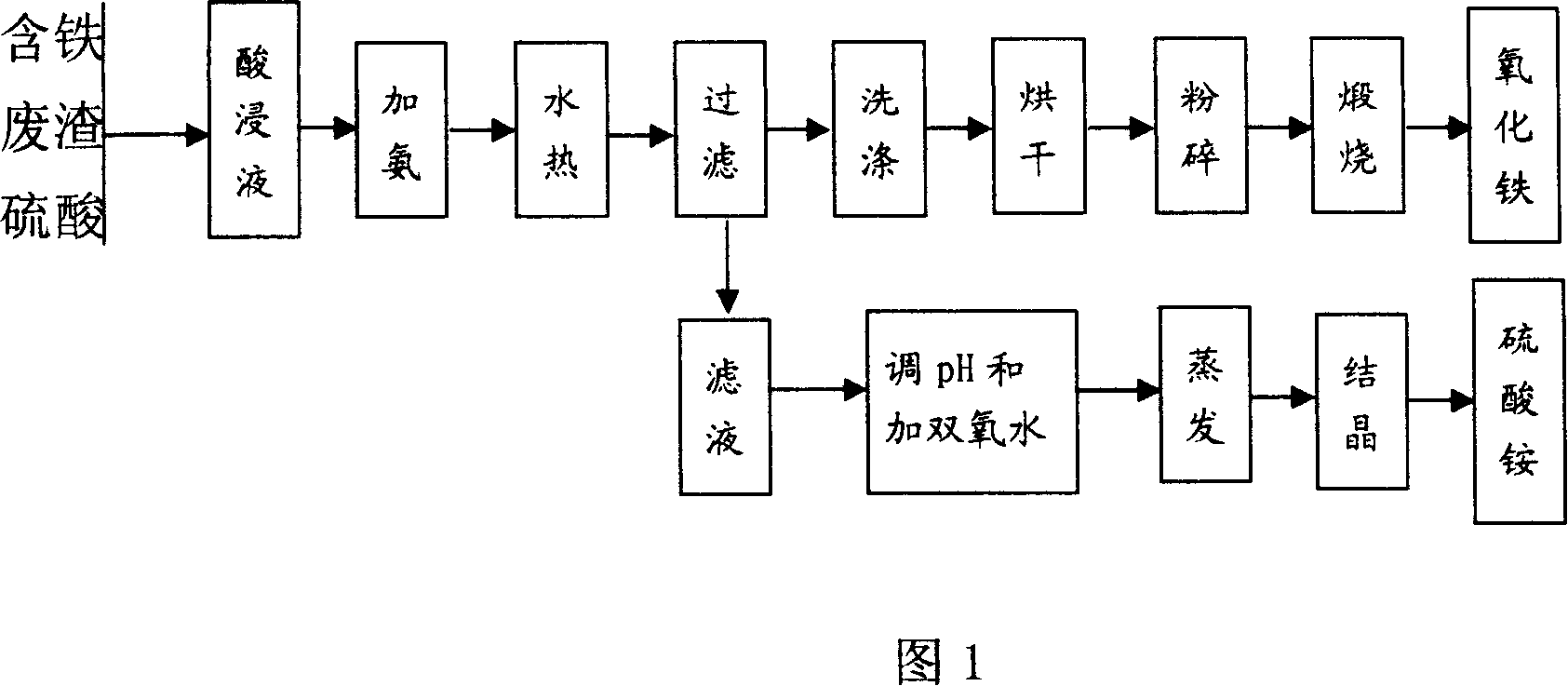

Method for manufacturing iron oxide with waste slag containing iron

A method that the ferriferous residue prepares the ferric oxide. The pyrite cinder reacts with the sulfuric acid to gain the pickle liquor. The pickle liquor reacts with the ammonia or ammonia liquid. The amount ratio of the substance between Fe2+ and Fe3+ in the pickle liquor is 0 to 2, the pH value of the reaction solution is 3 to 14, the hydrothermal temperature is 100 DEG C. to 350 DEG C. and the reaction time is 0.5 hour to 24 hours. The filter cake is washed and dried to gain the crude product ferric oxide and the ferric oxide crude product is calcined under 300 DEG C. to 1000 DEG C. to gain the ferric oxide. The ammonium sulfate filtrate is evaporated, condensed and crystallized to gain the solid ammonium sulfate. The invention adopts the ferriferous residue to prepare the ferric oxide with environmental benefit and economic benefit and adopts the pickle liquor gained by the ferriferous residue with simple process and low temperature of synthesizing the ferric oxide, which lowers the cost of the ferric oxide and solves the difficult problem that the colloidal substance produced before is difficult to filter and wash.

Owner:CENT SOUTH UNIV +1

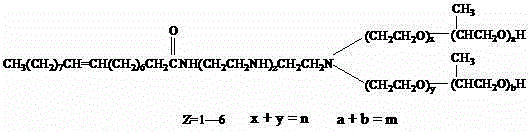

Synthesis method and application of oleic acid-polyethylene polyamine polyether

ActiveCN104479125AGuaranteed smooth productionGood flexibilityMonocomponent cellulose artificial filamentCelluloseSulfonate

The invention provides a synthesis method and application of oleic acid-polyethylene polyamine polyether. The synthesis method is mainly characterized in that the equation is shown in the specification, wherein z is any integer from 1 to 6, n is any integer from 1 to 20, and m is any integer from 0 to 15. Through the synthesis of an oleic acid-polyethylene polyamine polyether intermediate, the synthesis of oleic acid-polyethylene polyamine polyether and product compounding, the oleic acid goes through an amidation reaction with polyethylene polyamine and then is synthesized through etherification with ethylene oxide and propylene oxide to obtain a functional additive of the cellulose viscose production technology, and the decomposition of sulfonate and deposition of elemental sulfur or sulfide are prevented in the processes of spinning and forming and drafting of Modal viscose, so that the viscose is clear and the filtering property is improved; and moreover, the interfacial tension of the viscose is reduced to prevent blocking of spinneret orifices, the spinning and forming effect is good, and the product quality is stable. The synthesis method has the advantages of simple technology, high product purity, few imidazoline byproducts and good effect.

Owner:沈阳新意精细助剂有限公司

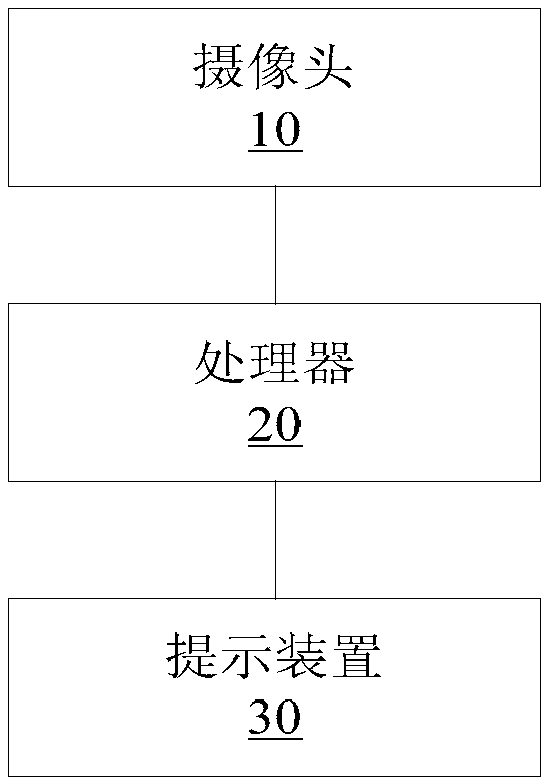

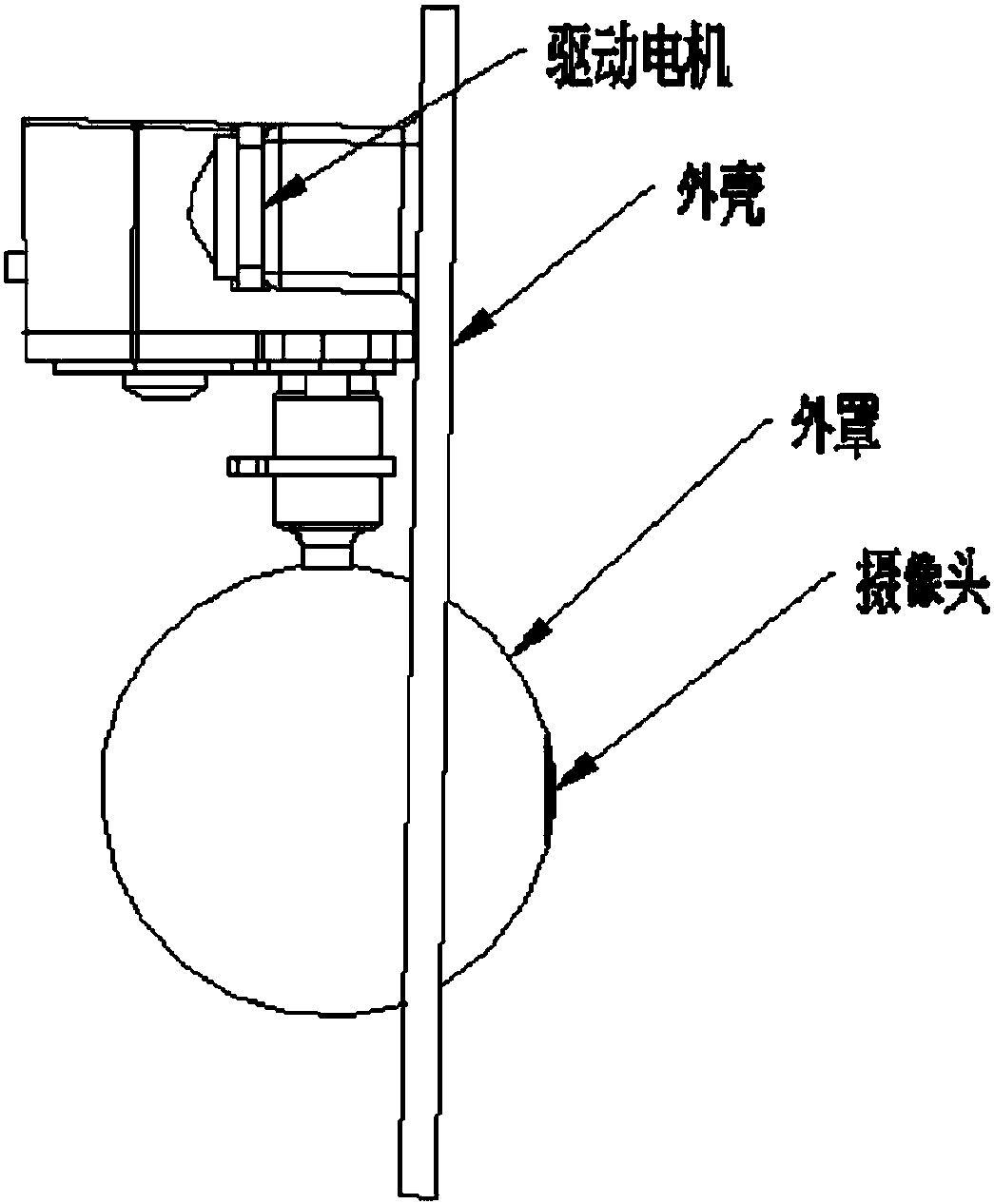

Monitoring equipment and method for air-conditioner and air-conditioner

PendingCN107606744ACan't solveSolve filterabilityMechanical apparatusImaging FeatureMonitor equipment

Owner:GREE ELECTRIC APPLIANCES INC

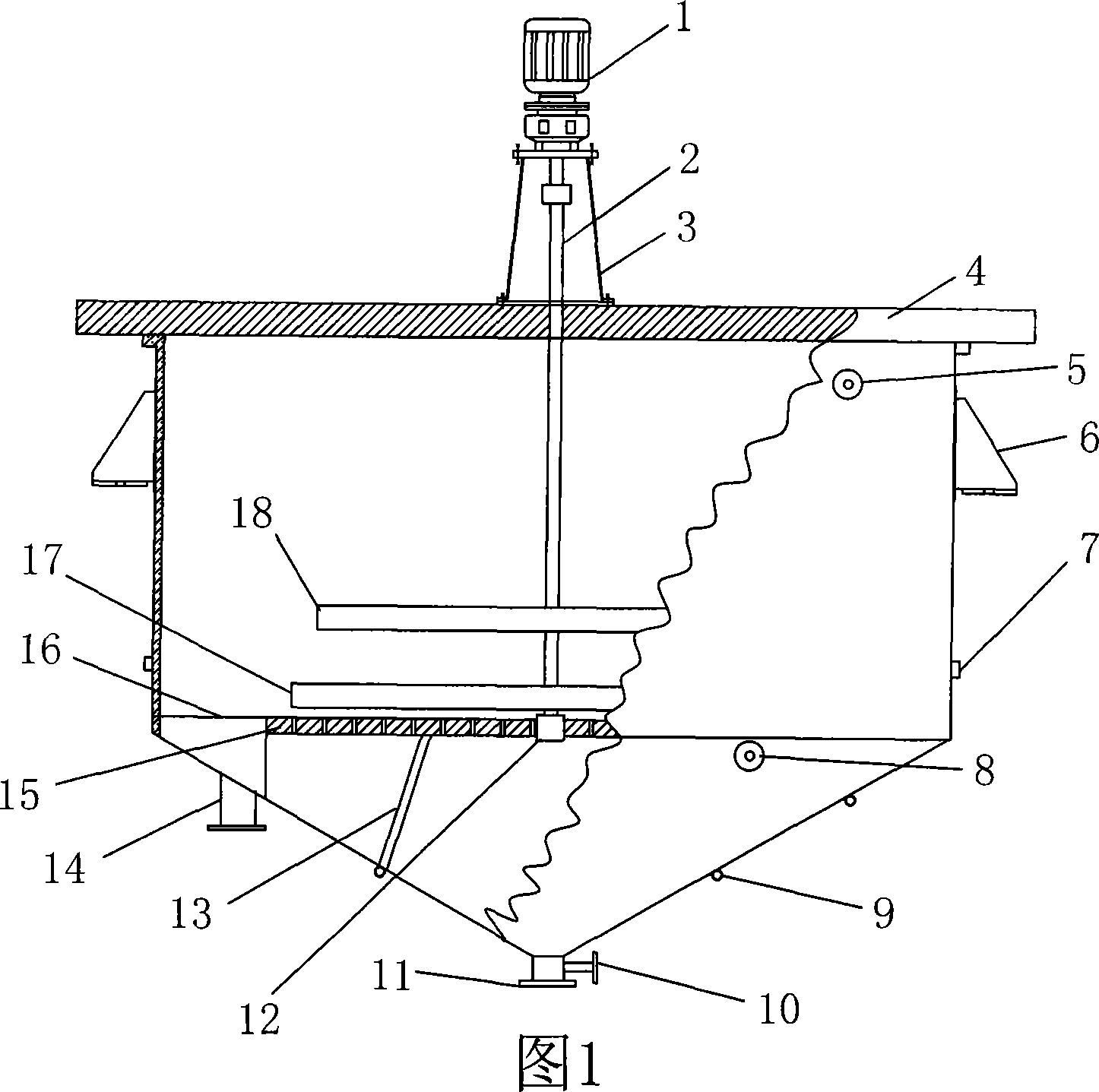

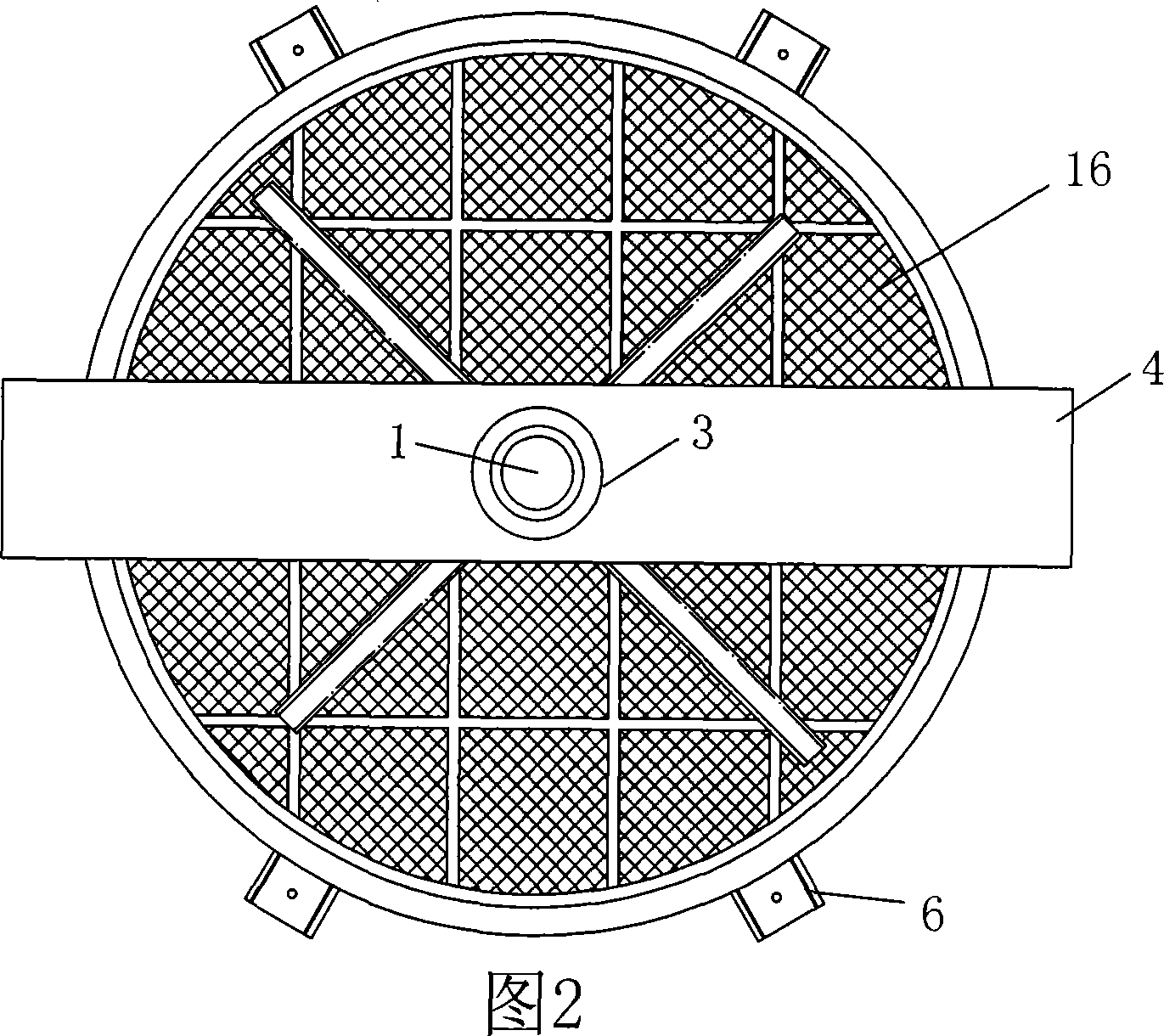

Agitation filtering pot for rapessed cake dreg de-toxin reaction

InactiveCN101073726AResolution timeSolve filterabilityRotary stirring mixersChemical/physical/physico-chemical stationary reactorsFiltrationPhytic acid

The invention is concerned with a kind of rapeseed cakes detoxification reaction mixing filter pot. It relates to electromotor, griddle net and mixing framework inside of the upper pot driven by electromotor. The griddle net set on the inner bottom of upper pot through supporting plate. The upper pot is a column, the down pot is a taper, and the both connect into a whole and each of them has an in-fall, while the down pot has a material exit and a liquid exit. This solves the problem that long filtration time, awfully effect and lots lost of materiel, and so on. Through owning reaction, mixing and filtration, it commendably completes the core technology to prepare concentrated albumen of deep process to rapeseed cakes. Meanwhile, it removes some kinds of poisonous of anti-nutrition matters, such as glucosinolate, polyphenol and phytic acid to get rapeseed concentrated albumen with the nutrition value like fishmeal. It can be added into assorted feed to breed valuable fish.

Owner:HUBEI WEIPU BIOLOGICAL TECH

Preparation method of firmly-combined sandwich type purification material

InactiveCN103191604ALarge specific surface areaImprove filtration efficiencyFiltration separationFiberGlass fiber

The invention discloses a novel preparation method of a firmly-combined sandwich type nano / submicron super-purification material. The preparation method disclosed by the invention comprises the following steps of: dissolving various natural or artificial polymers with melting points being higher than 175 DEG C by adopting appropriate solvents to prepare a polymer spinning solution with a certain concentration, electromagnetically stirring the polymer spinning solution for later use; cleaning and drying industrial filtering cloth, and electrically spinning various natural or artificial polymer fibers with melting points being lower than 175 DEG C to the industrial filtering cloth by adopting a fusion electrostatic spinning technology firstly; then electrically spinning the polymer spinning solution to the industrial filtering cloth of the natural or artificial polymer fibers with the melting points being lower than 175 DEG C via a solution electrostatic spinning technology; and hot pressing and forming the industrial filtering cloth with two fibers with glass fiber by adopting a hot pressing device, and preparing the sandwich type purification material.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

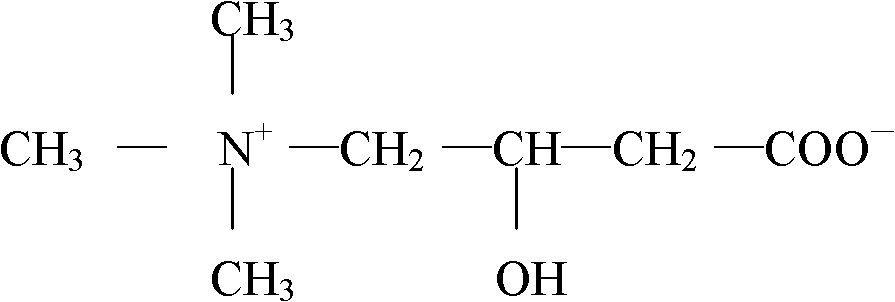

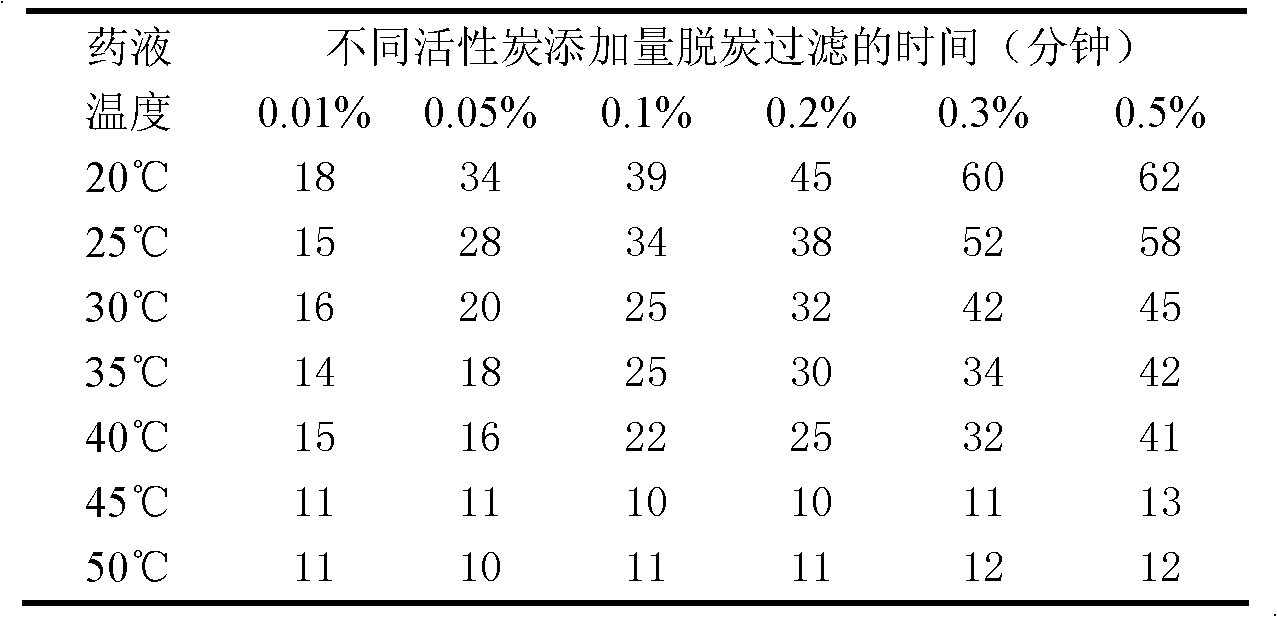

Levocarnitine composition for injection and preparation method of levocarnitine composition

ActiveCN102327238AReduce dosageReduce skeletonOrganic active ingredientsPowder deliveryPorosityFreeze-drying

The invention relates to a levocarnitine composition for injection and a preparation method of the levocarnitine composition; the levocarnitine composition is lyophilized powder containing levocarnitine and mannitol, wherein the weight ratio of the levocarnitine to the mannitol is 1:(0.75-1.25); the average particle diameter of the lyophilized powder is 90-130 nm, and the porosity is 94-98%. The preparation method comprises the steps of: 1) preparing: weighing levocarnitine and mannitol, putting the levocarnitine and the mannitol in a preparing tank, adding injection water, agitating to enable the levocarnitine and the mannitol to be completely dissolved and uniformly mixing, regulating the pH to 5.7-6.3 through a 0.1mol / L hydrochloric acid solution; 2) decarburizing and sterile filtering; 3) sterile packaging; 4) vacuum freeze drying to obtain the levocarnitine composition . The levocarnitine composition has the advantages of simple preparation, advanced technique, uniform quality, excellent stability, better redissolution capability and clinic medicine application safety.

Owner:JIANGSU AOSAIKANG PHARMA CO LTD

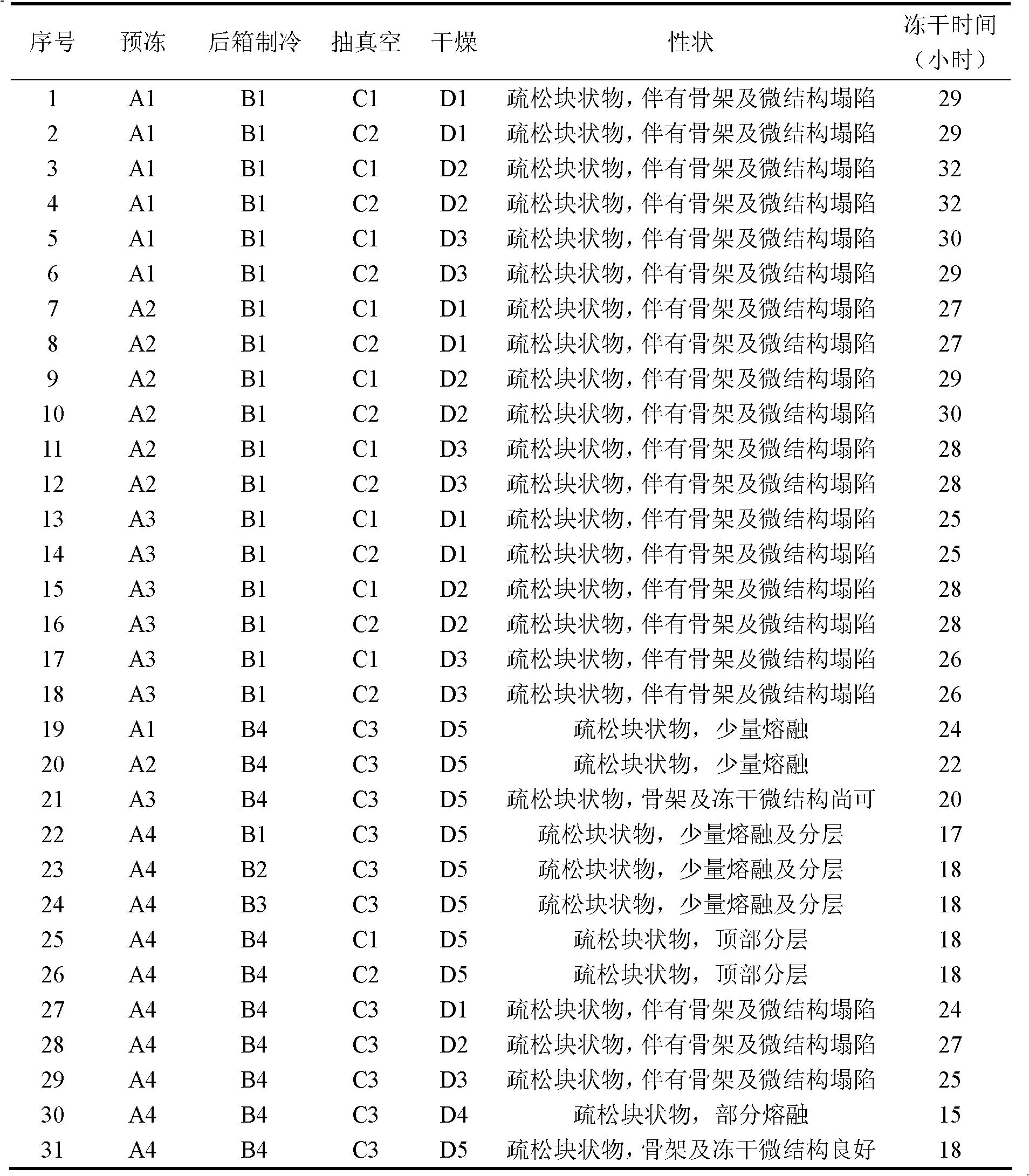

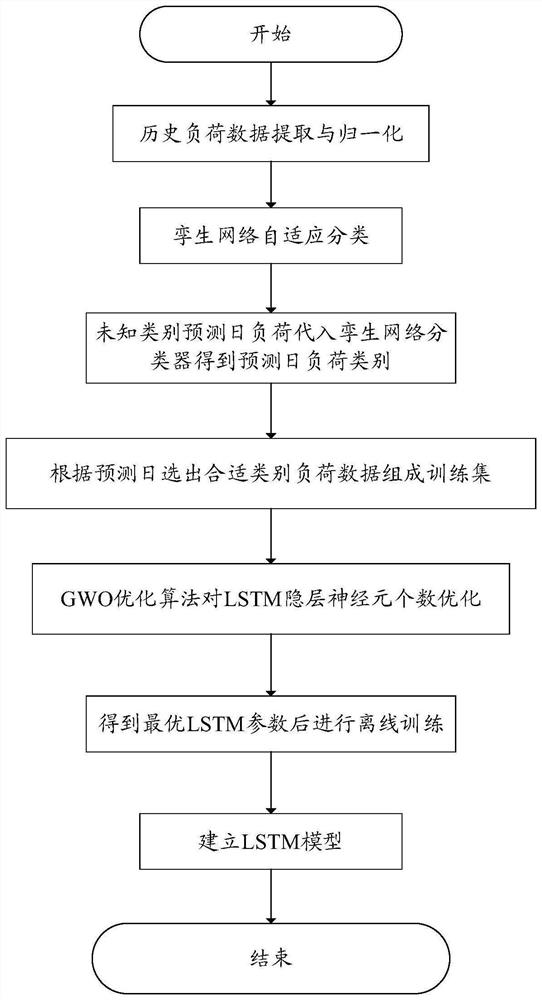

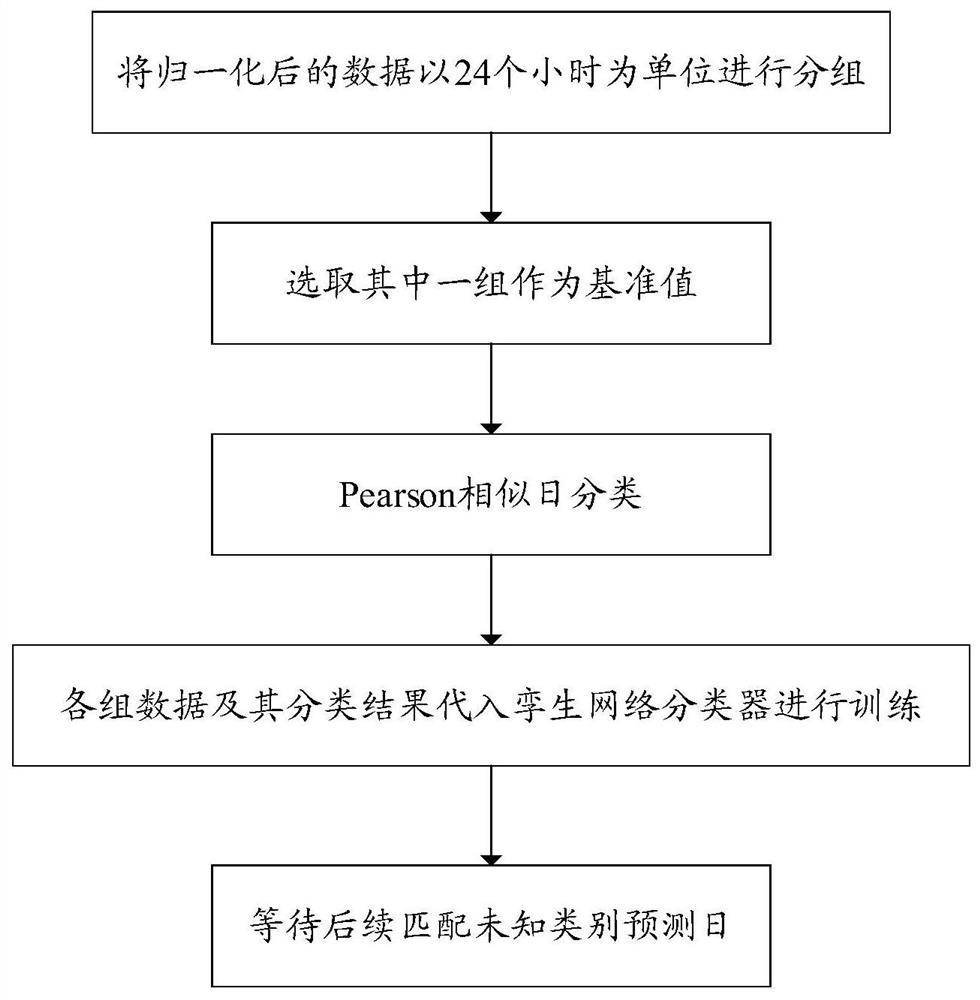

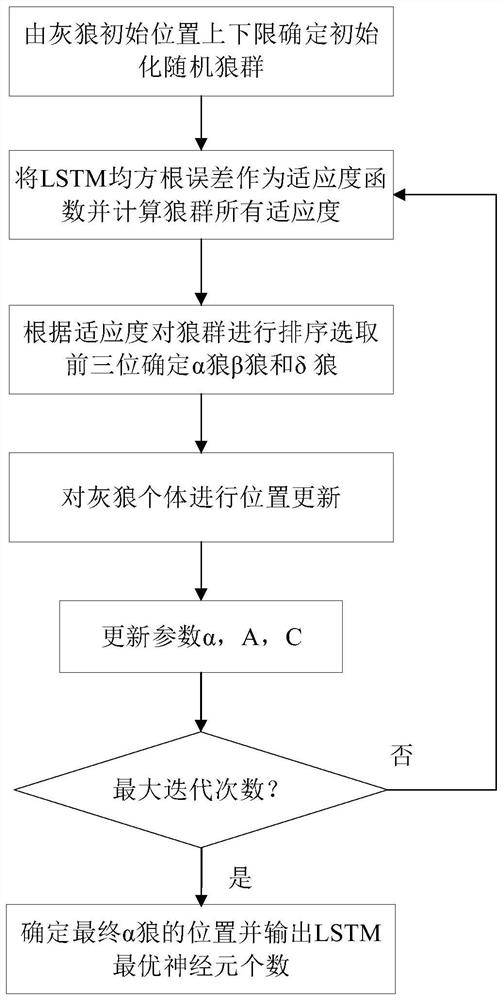

Regional power distribution network short-term load prediction method

ActiveCN112116144ASolve the problem of selectivitySolve filterabilityLoad forecast in ac networkForecastingLoad forecastingEngineering

The invention belongs to the technical field of power load prediction, and particularly discloses a regional power distribution network short-term load prediction method based on a twin network classification method, a grey wolf algorithm and a long-short-term memory network. The load prediction method comprises the following steps: firstly, extracting and classifying historical load data by applying the twin network classification method, determining the category of input characteristics according to the load condition of a prediction day, and extracting a load with strong correlation to theload of the prediction day as input; the problems that the current effective input variable is difficult to select and the calculation steps are tedious are solved; and then parameter optimization selection is performed on the long-short-term memory network prediction model by applying a grey wolf algorithm, inputting an optimal parameter, and training and testing the long-short-term memory network prediction model to obtain a load prediction value under the prediction day. The method effectively solves the problems that an existing prediction model is low in efficiency, high in operation costand lack of self-adaptive capacity.

Owner:SHANDONG UNIV OF SCI & TECH +1

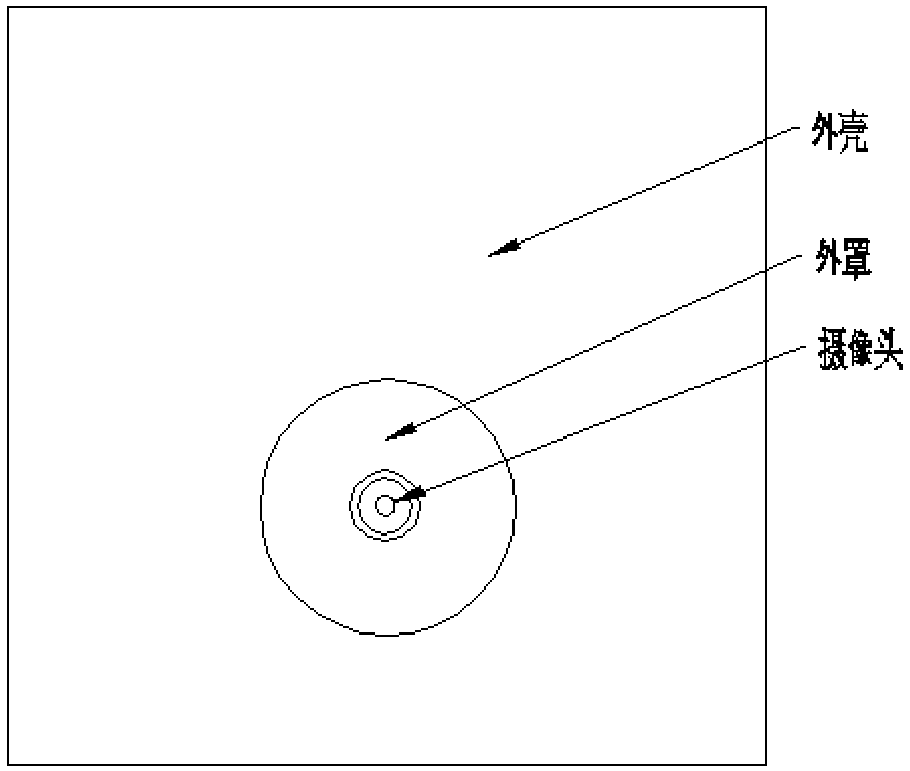

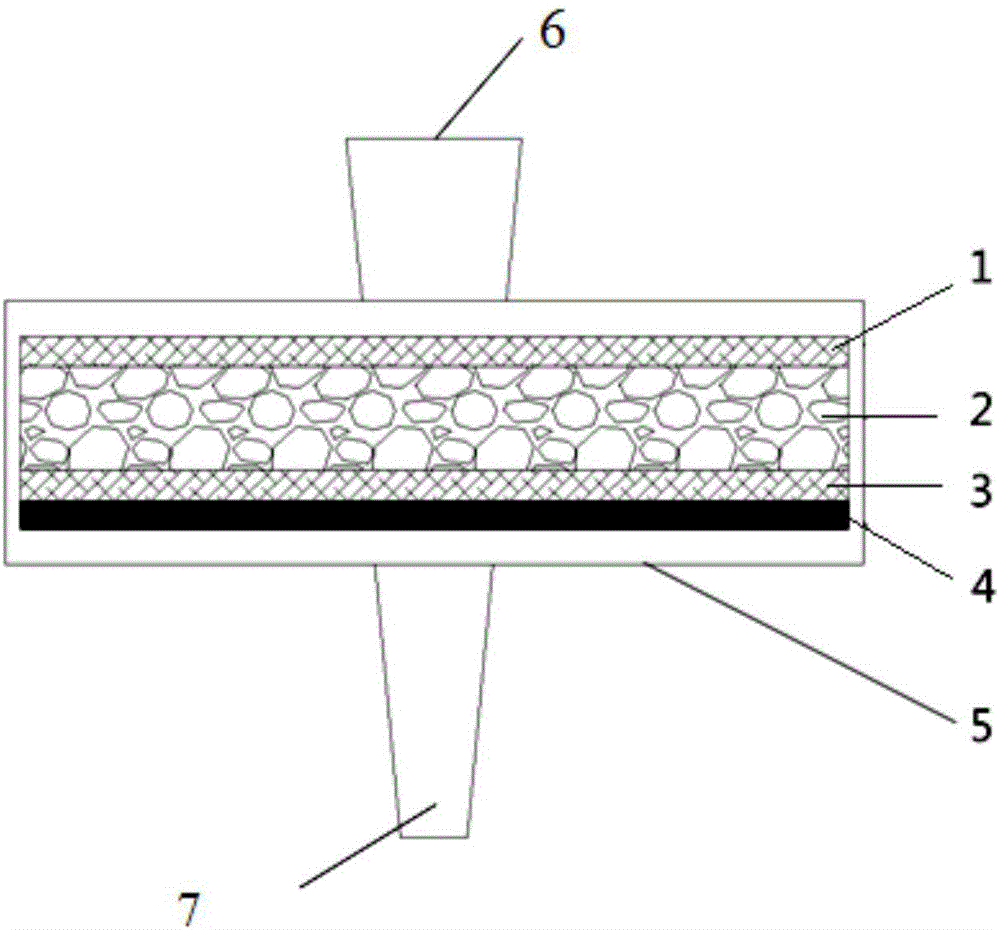

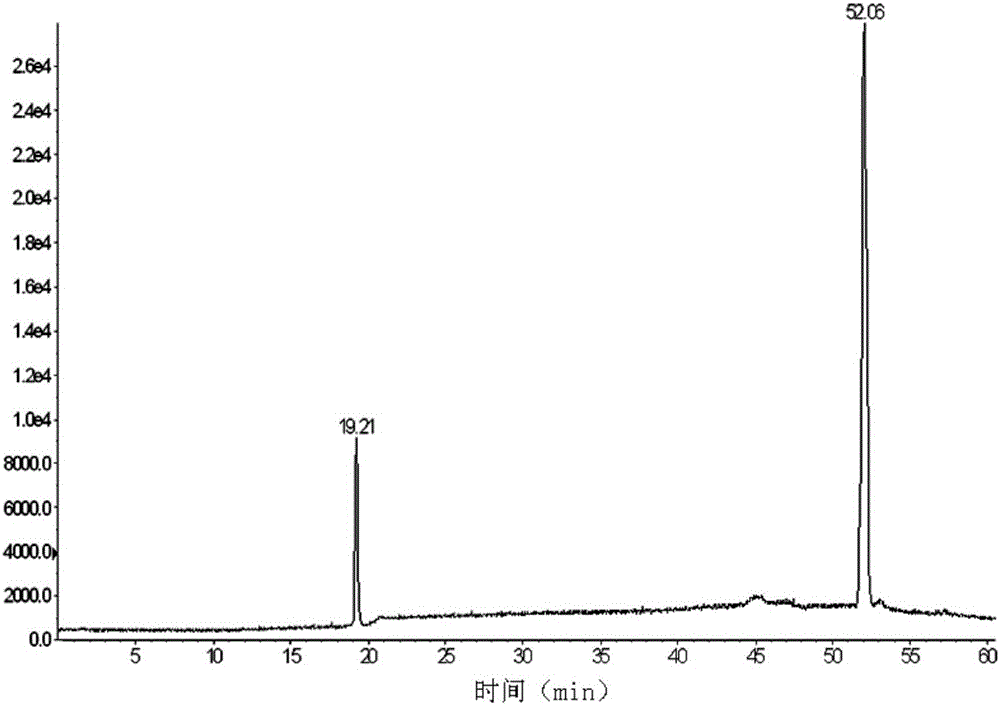

Needle-type solid-phase extraction filter

The invention discloses a needle-type solid-phase extraction filter. The needle-type solid-phase extraction filter comprises a shell, and the upper side and the lower side of the shell are provided with an injector nipple connector and a pintle connector which are communicated with an inner cavity of the shell respectively; an upper sieve plate, solid-phase extraction filler, a lower sieve plate and a filter membrane are sequentially arranged in the inner cavity of the shell from top to bottom, the upper sieve plate and the lower sieve plate are each provided with sieve holes of which the hole diameters range from 95 micrometers to 105 micrometers, and the particle size of the solid-phase extraction filler ranges from 110 micrometers to 130 micrometers. According to the needle-type solid-phase extraction filter, solid-phase extraction and membrane filtration are combined in one device for the first time, the operation steps are greatly simplified, the solvent and the filler are saved, and the operation cost is reduced; the needle-type solid-phase extraction filter can be suitable for different samples and solvents and is wide in application range and good in effect.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

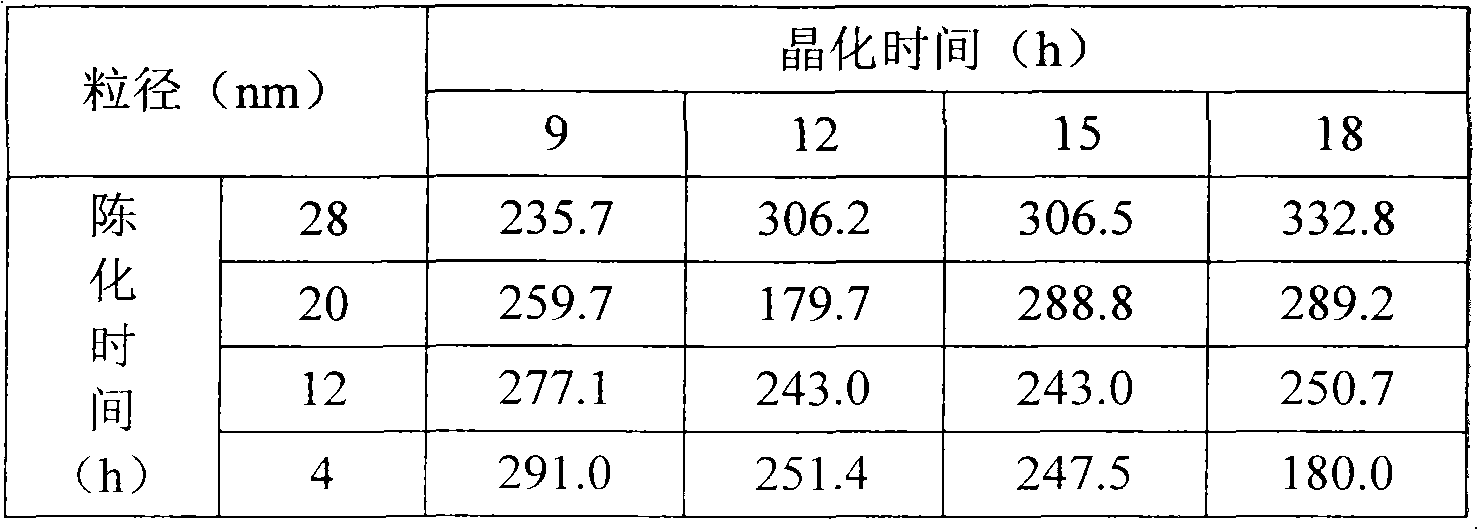

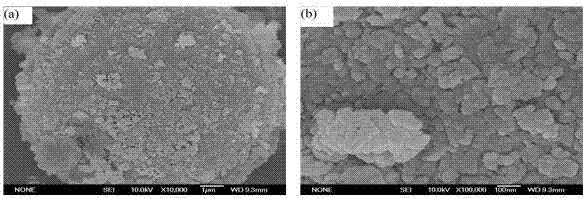

Preparation method of high-medium oil selective hydrocracking catalyst

InactiveCN101844085ASolve reunionSolve filterabilityMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveActive component

The invention relates to a preparation method of a high-medium oil selective hydrocracking catalyst. The invention firstly provides a preparation method of a Y-molecular sieve / Si-Al oxide composite catalytic material, comprising the steps of: synthesizing a Y-molecular sieve by a guide agent method, controlling the synthesis temperature of mother solution to be below 0 DEG C, the ageing time to be 4-8h, the crystallization temperature to be 90-95 DEG C and the crystallization time to be 9-18h, and obtaining slurry formed by the Y-molecular sieve and the rest crystallization liquid; carrying out ammonium exchange treatment on the Y-molecular sieve, and obtaining the mixed solution; and adding an Al source and a Si source into the mixed solution, adjusting the pH value to be 6-10 to form gel, drying the gel, and obtaining the composite catalytic material. The invention also provides the preparation method of the high-medium oil selective hydrocracking catalyst, comprising the following steps of: preparing the Y-molecular sieve / Si-Al oxide composite catalytic material according to the method; taking the composite catalytic material as a carrier for carrying active components; and obtaining the high-medium oil selective hydrocracking catalyst by drying and calcining.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

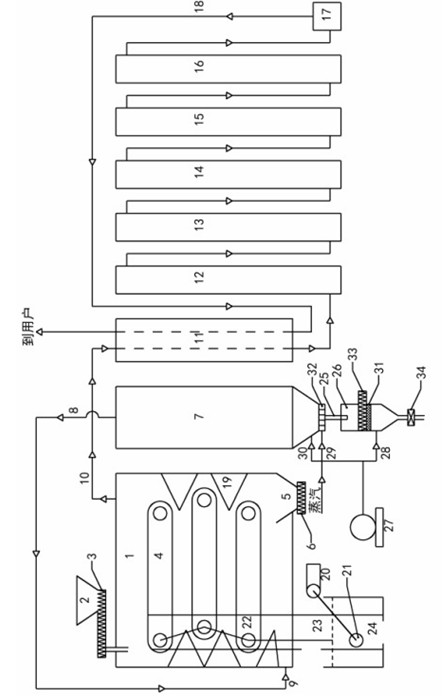

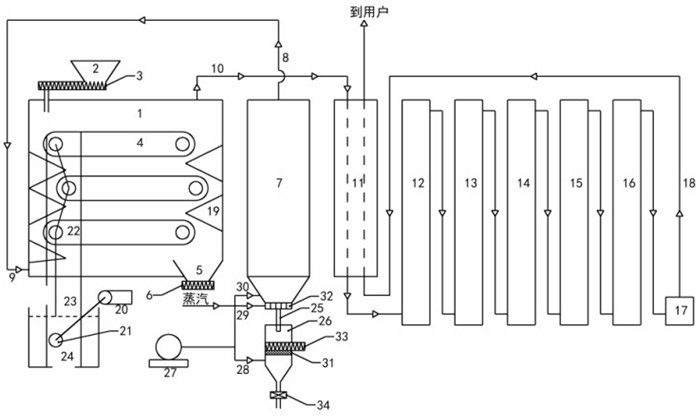

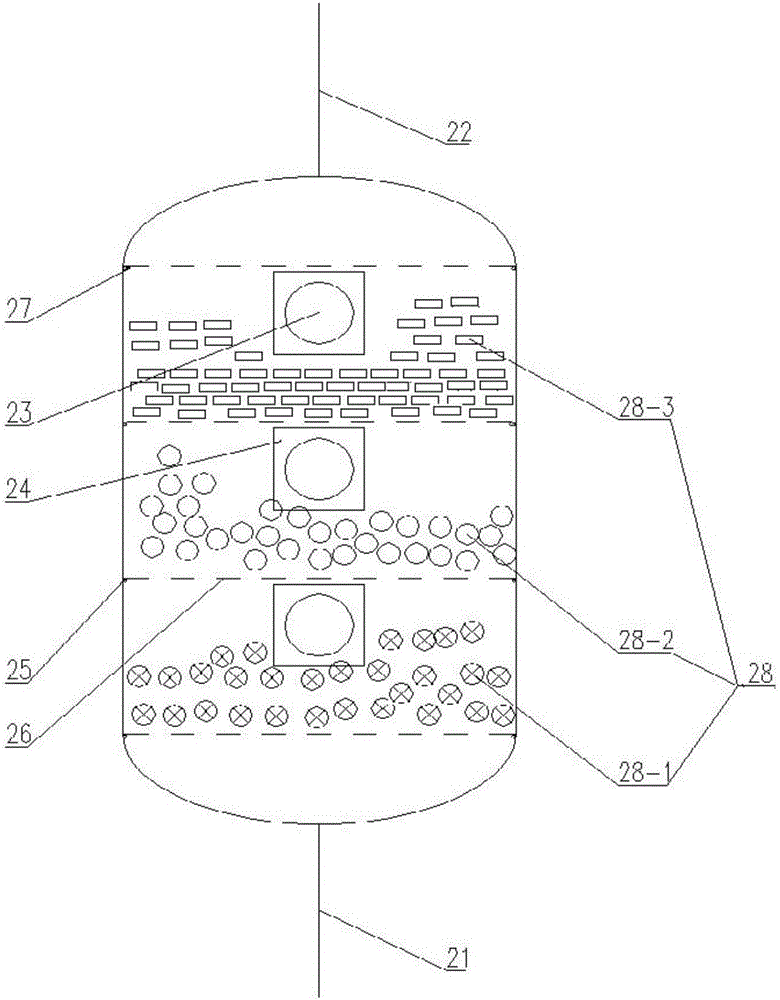

Two-step method for gasification of pulverized coal fluidized bed and device utilizing method

InactiveCN102517090AGuarantee explosion-proof safetyImprove sensible heat utilizationChemical industryDirect heating destructive distillationFluidized bedProduct gas

The invention relates to a two-step method for gasification of a pulverized coal fluidized bed and a device utilizing the method. The two-step method for gasification of the pulverized coal fluidized bed includes: the first step, gas generated from a gasification furnace is led into a dry distillation column and runs through a feed coal layer in the dry distillation column to heat, dry and distill feed coal, so that temperature of the feed coal raises and water content thereof is evaporated and separated, high-heating-value gas such as CH4, H2 and the like are decomposed from the feed coal, most carbon-bearing flyash carried by gas can be adsorbed and filtered by the feed coal layer when flowing through the feed coal layer, and accordingly gas can be purified; the second step, the feed coal is dehydrated, dried and distilled to be hot semi-coke, the hot semi-coke is fed into the gasification furnace to be gasified, carbon-bearing flyash enters the gasification furnace to be gasified along with the semi-coke, and accordingly carbon conversion efficiency is improved. By the two-step method, carbon-bearing flyash carried with gas can be filtered and fed into the gasification furnace to be gasified circularly during the gasification process of the fluidized bed utilized for any coal types, so that carbon conversion efficiency is increased greatly, heating value of gas is increased, utilization of sensible heat of gas is improved, and pollution of flyash to environments is decreased.

Owner:李叔锟

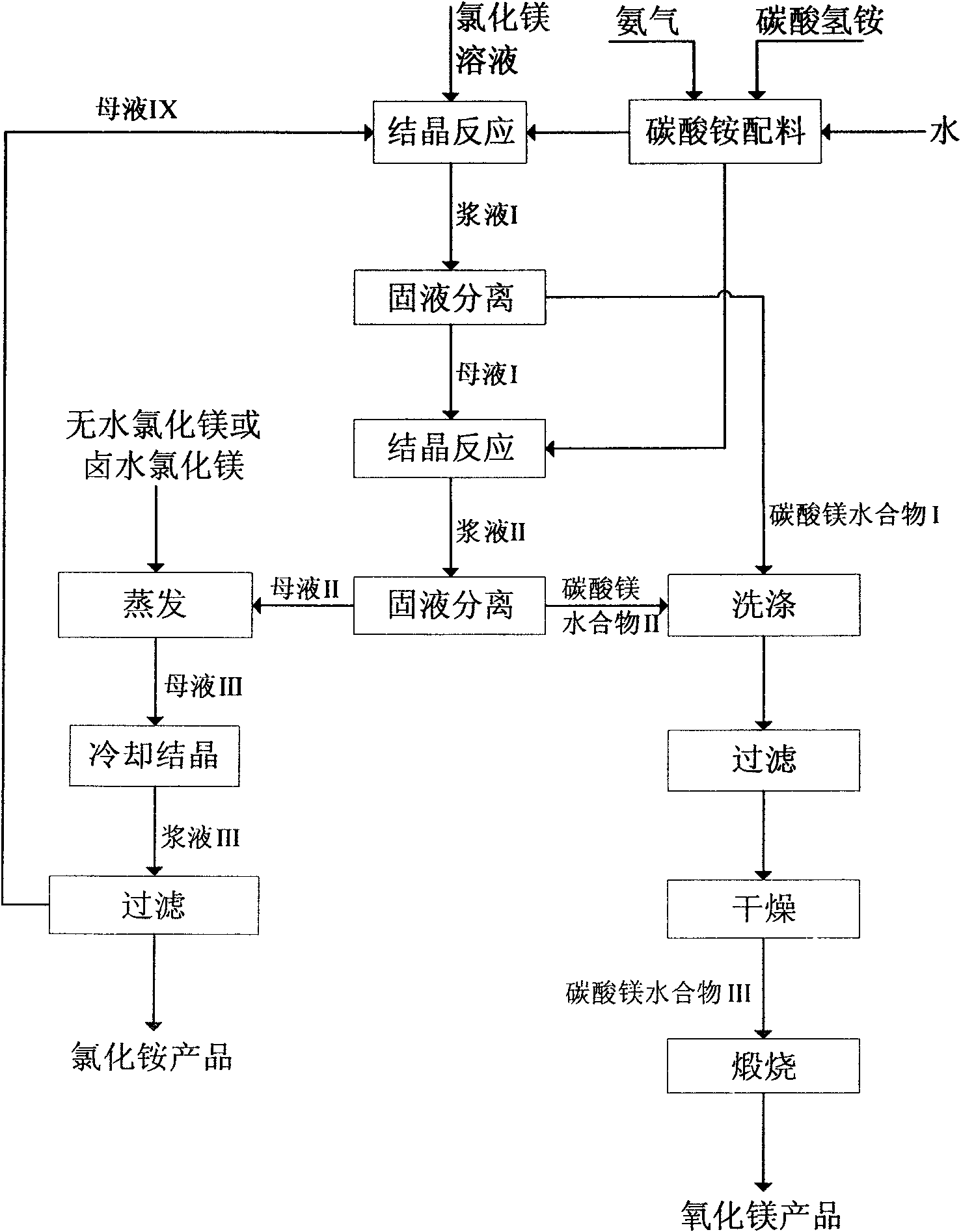

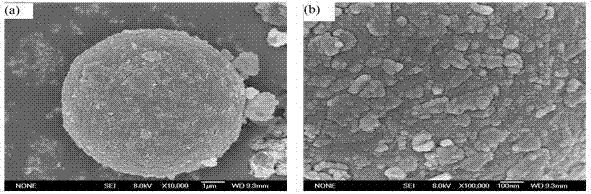

Method for producing magnesium oxide with co-production of ammonium chloride by taking magnesium carbonate hydrate as intermediate

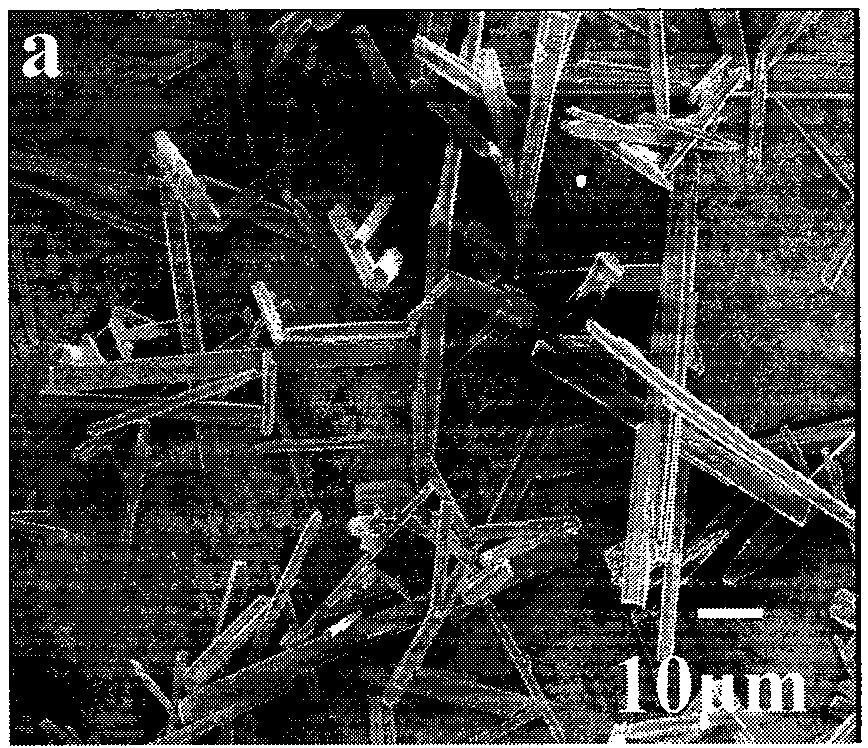

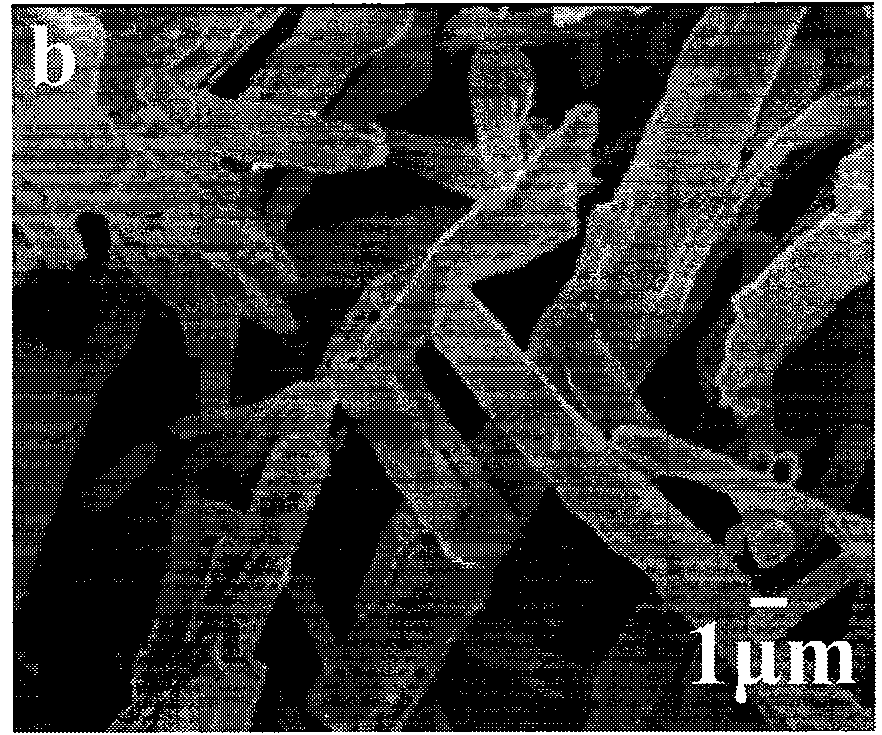

InactiveCN101993097AHigh purityGood filtration propertiesMagnesium carbonatesAmmonium halidesMagnesium saltSeawater

The invention belongs to the field of inorganic salt chemical industry and fertilizer production, particularly relates to a method for producing magnesium oxide with co-production of ammonium chloride by taking magnesium carbonate hydrate as an intermediate. The method comprises the following steps of: with anhydrous magnesium chloride or bittern magnesium chloride as a raw material and with ammonia and ammonium bicarbonate as precipitating agents, obtaining the magnesium carbonate hydrate intermediate (the purity reaches 97-99 percent) with favorable crystal form by controlling process conditions; calcining the obtained magnesium carbonate hydrate intermediate to prepare magnesium oxide (the purity reaches 95-99 percent); adding salt to mother liquor enriched with ammonium salts and evaporating, salting out and cooling to separate out ammonium chloride, and filtering to obtain the ammonium chloride, wherein the mother liquor is circularly taken as a raw material. The method aims at producing needle-shaped or spherical magnesium carbonate hydrate by utilizing rich magnesium chloride brine from salt lakes, or magnesium chloride brine from seawater, or anhydrous magnesium chloride used for producing titanium sponge by-products, and other magnesium salt materials, thereby preparing high-purity magnesium oxide with the simultaneous co-production of ammonium chloride fertilizer. The method of the invention has strong maneuverability and is easy to realize industrialization.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

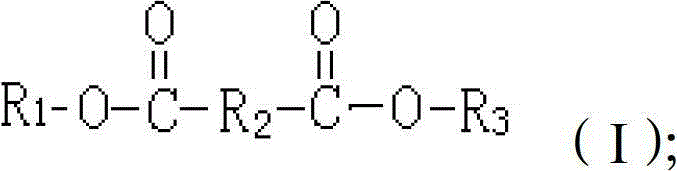

Synthetic lubricating oil composition for air compressor and preparation method thereof

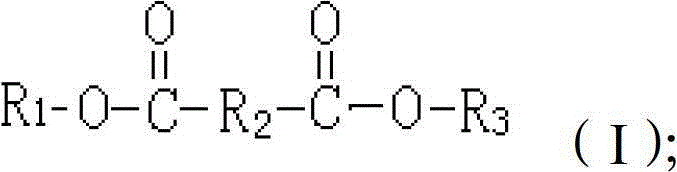

ActiveCN102911766AMeet the use requirementsExcellent coke cleaning functionAdditivesTO-18Chemical composition

The invention provides a synthetic lubricating oil composition for an air compressor. The synthetic lubricating oil composition comprises 0.1 to 10wt% of tackifier, 2 to 7wt% of antioxygen, 0.05 to 1wt% of corrosion inhibitor, 1 to 8wt% of extreme pressure anti-wear agent, 0.0001 to 0.05wt% of antifoaming agent, and the balance of ester oil. The ester oil is provided with a structure shown as formula (I), wherein R1 and R3 are independently selected from alkyl with 5 to 20 carbon atoms; and R2 is the alkylene with 5 to 18 carbon atoms. The ester oil is provided with a special molecular structure, so that the synthetic lubricating oil composition for the air compressor is excellent in function of cleaning the coking material, and original oil sludge and coking matter of the compressor system can be cleaned and carried out; and the synthetic lubricating oil composition for the air compressor is higher in coking resistance. The invention also provides a preparation method of the synthetic lubricating oil composition for the air compressor.

Owner:CHINA PETROLEUM & CHEM CORP

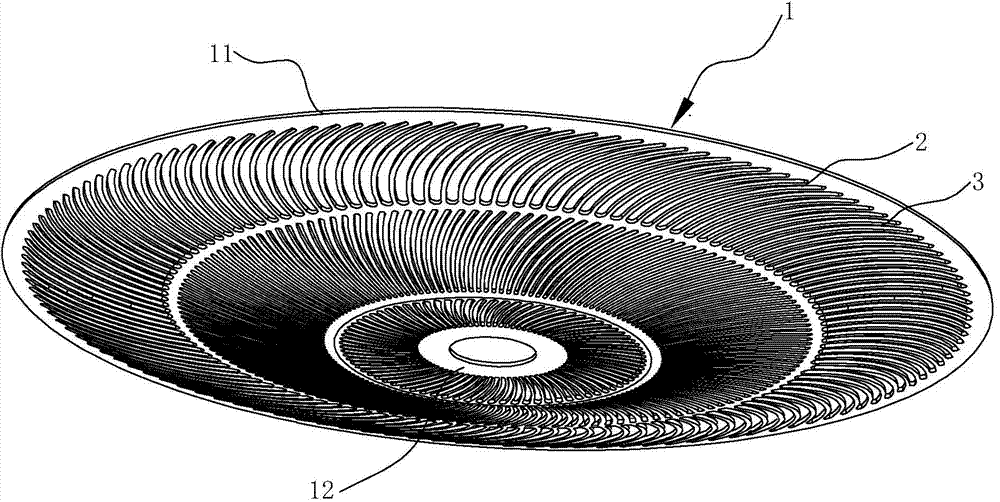

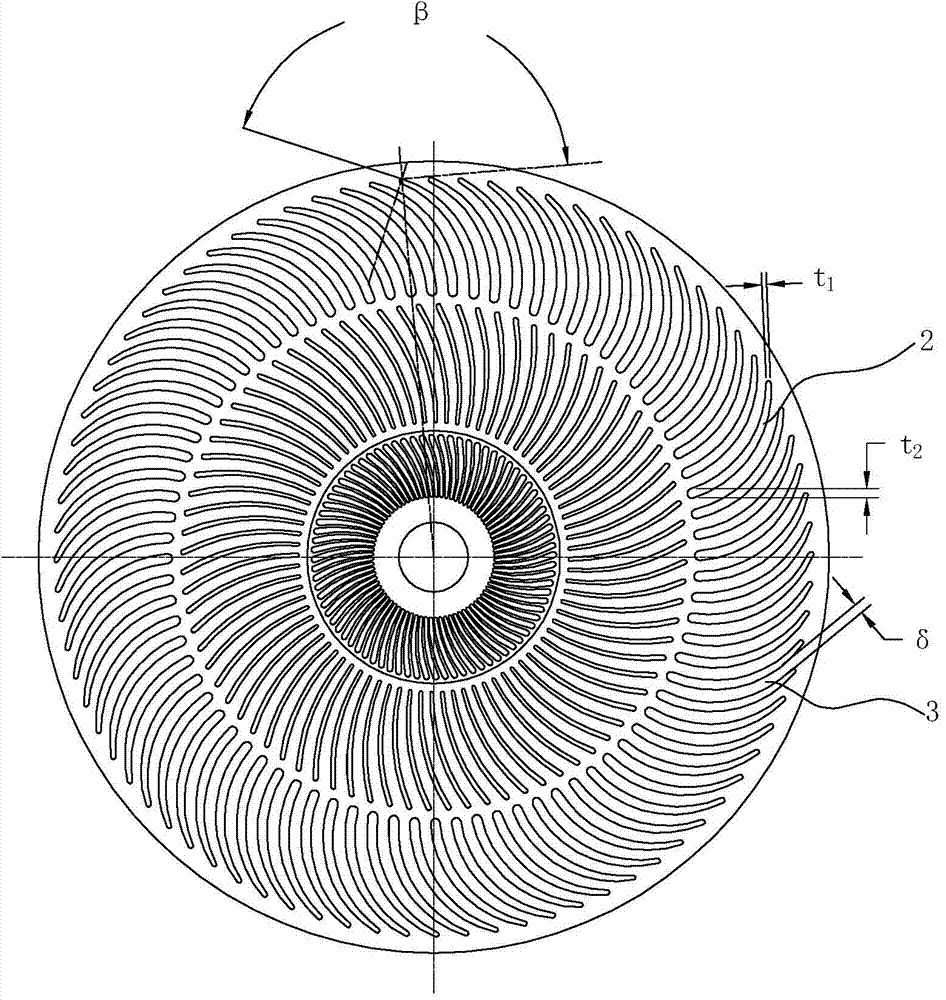

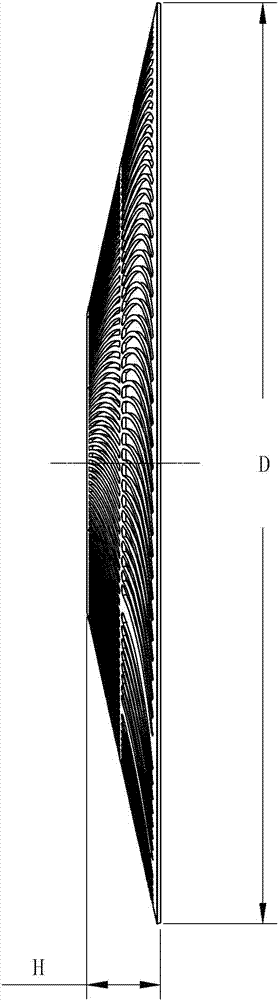

Oil flinger for blower of range hood

ActiveCN104748184AImprove interception efficiencyIncrease the degree of actionDomestic stoves or rangesLighting and heating apparatusFiltrationEngineering

The invention discloses an oil flinger for a blower of a range hood. The oil flinger comprises an oil flinger main body and is characterized in that the surface of the oil flinger main body is provided with arc-shaped grooves which are in central symmetry and are in array arrangement; each groove extends in the radial direction; the surface of the disc main body is provided with at least two layers of groove arrays;each layer of groove array is in a circular ring shape; spokes are formed among the adjacent grooves in each layer on the surface of the oil flinger main body. By virtue of radially-extending arc-shaped grooves, when contacting with the oil flinger main body, oil drops can flow from inside to outside smoothly, a greater centrifugal force is obtained and then efficiency non-fluid oil centrifugal separation is realized; furthermore, multiple layers of groove arrays are formed, so that on the one hand, the rigidity of the oil flinger is improved, on the other hand, the optimal width size is obtained by freely distributing the grooves and spokes in each layer according to the actual fume concentration distribution characteristic after specifically selecting a blower system without influence of the grooves in the other layers, and the filtration effect is improved as much as possible.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

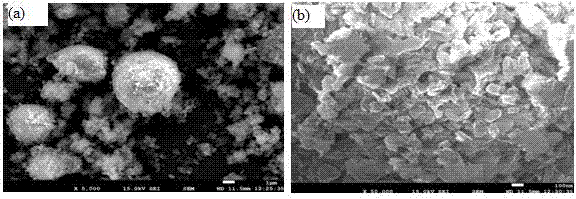

Composite powder material of fly ash hollow microspheres with surfaces cladded with nanometer magnesium hydroxide and preparation method thereof

InactiveCN107446163ADifficult to disperseSolve filterabilityWater treatment compoundsWater/sewage treatmentWater bathsDepolymerization

The invention discloses a composite powder material of fly ash hollow microspheres with surfaces cladded with nanometer magnesium hydroxide and a preparation method thereof. A calcined sample of fly ash hollow microspheres is adopted as a raw material, sodium hydroxide and magnesium sulfate are adopted as a cladding agent, and the composite powder material is prepared by adopting a heterogeneous nucleation method. The preparation method specifically comprises the following steps: (1) calcinating the fly ash hollow microspheres; (2) adding water into the calcined fly ash hollow microspheres for stirring dispersion, and performing water-bath heating to obtain suspension liquid; (3) adding a solution of the sodium hydroxide and the magnesium sulfate into the suspension liquid, and performing precipitation reaction to clad the surfaces of the fly ash hollow microspheres with magnesium hydroxide; (4) after addition of the solution of the sodium hydroxide and the magnesium sulfate is finished, regulating the pH with sodium hydroxide, continuing reaction, and performing heat preservation and aging; (5) performing filtering, washing, drying and depolymerization on a reaction product to obtain the composite powder material. According to the composite powder material, the problems of low whiteness, poor compatibility, high abrasion and poor flame retardancy of a hollow microsphere filled polymer and the difficulty in dispersion of a nanometer magnesium hydroxide filled polymer are solved.

Owner:TAIYUAN UNIV OF TECH

Method for preparing threonine crystal by threonine fermentation liquid

InactiveCN101759580AQuality improvementHigh yieldOrganic compound preparationAmino-carboxyl compound preparationUltrafiltrationThreonine

The invention relates to a method for preparing threonine crystal by threonine fermentation liquid, comprising the steps of: sterilizing the threonine fermentation liquid, and the carrying out plate-type or tube-type film ultrafiltration, concentration, azeotropic crystallization and other steps to prepare the threonine crystal; and the prepared threonine crystal has the purity of 98.5%, the threonine film ultrafiltration yield of more than 96%, and the azeotropic crystallization yield of more than 95%. The preparation method is an environment-friendly new production technique which has high efficiency, low energy consumption, low cost, simple method and easy popularization.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

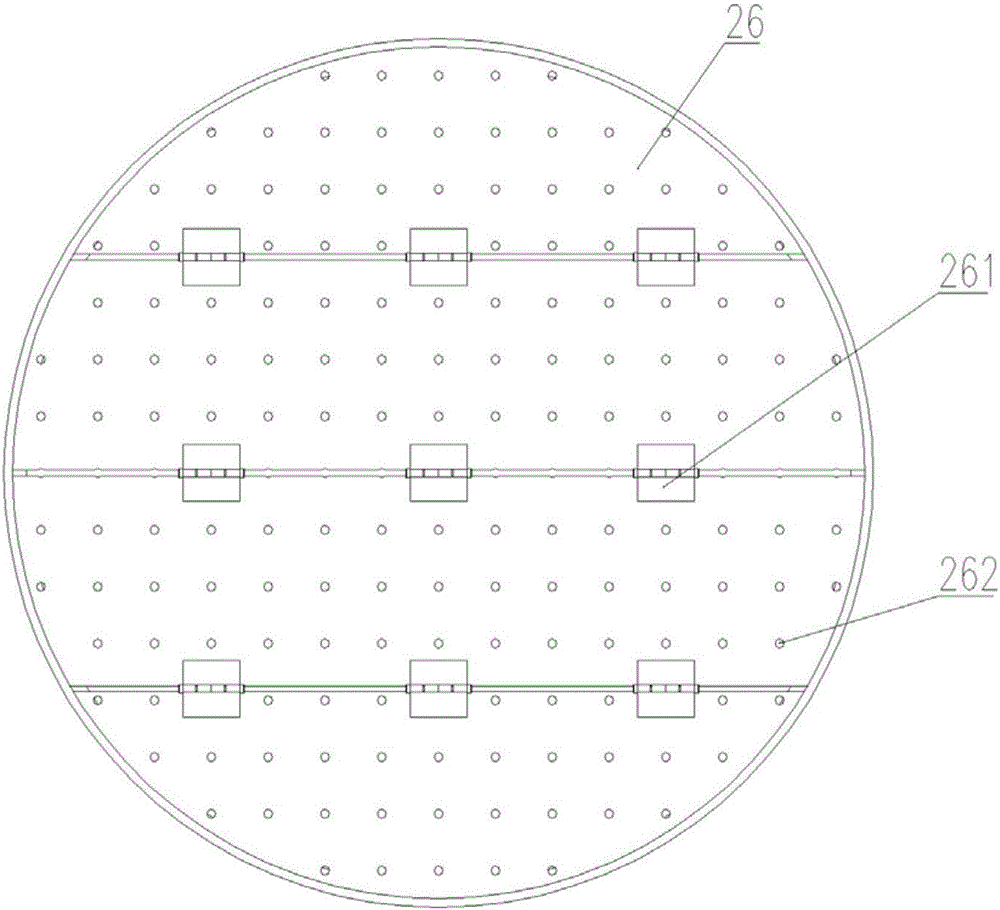

Integrated filtering water-purifying system based on modularized separating component

ActiveCN105879441AMiniaturizationSingle performance solutionTreatment involving filtrationMembrane filtersMiniaturizationWater quality

The invention provides an integrated filtering water-purifying system based on a modularized separating component and belongs to the technical field of water purification. The system comprises a conveying part, a filtering water purifier, an online monitoring part and a PLC control part and is characterized in that the filtering water purifier, the online monitoring part and the PLC control part are connected into a normal running loop and a filtering water-purifying module regenerating loop through the conveying part; the separating component formed by various modularized parts is arranged in the filtering water purifier. According to the integrated filtering water-purifying system based on the modularized separating component, the water purifying modules with different filtering water-purifying features are assembled in one filtering water purifier through the modularizing treatment for the separating component, so that the miniaturization of multilayer filtering water-purifying function is realized and the problems of single property, insufficient water quality adaptability, frequency and inconvenience in exchanging filtering water-purifying material, and the like, of the single filtering water-purifying material are solved.

Owner:鄂尔多斯市紫荆低碳生产力促进中心有限公司

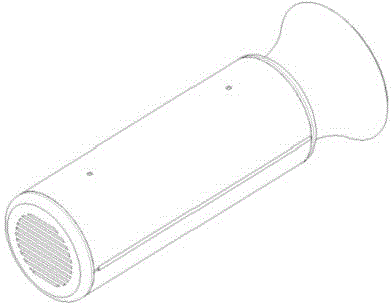

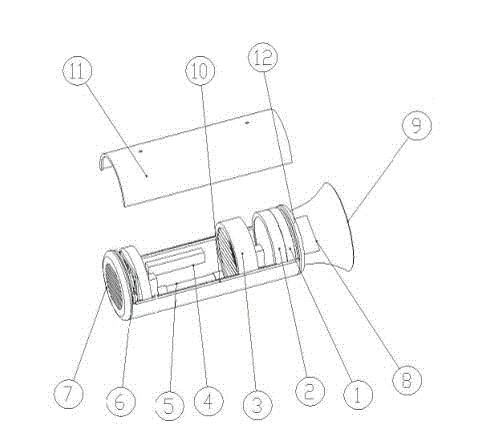

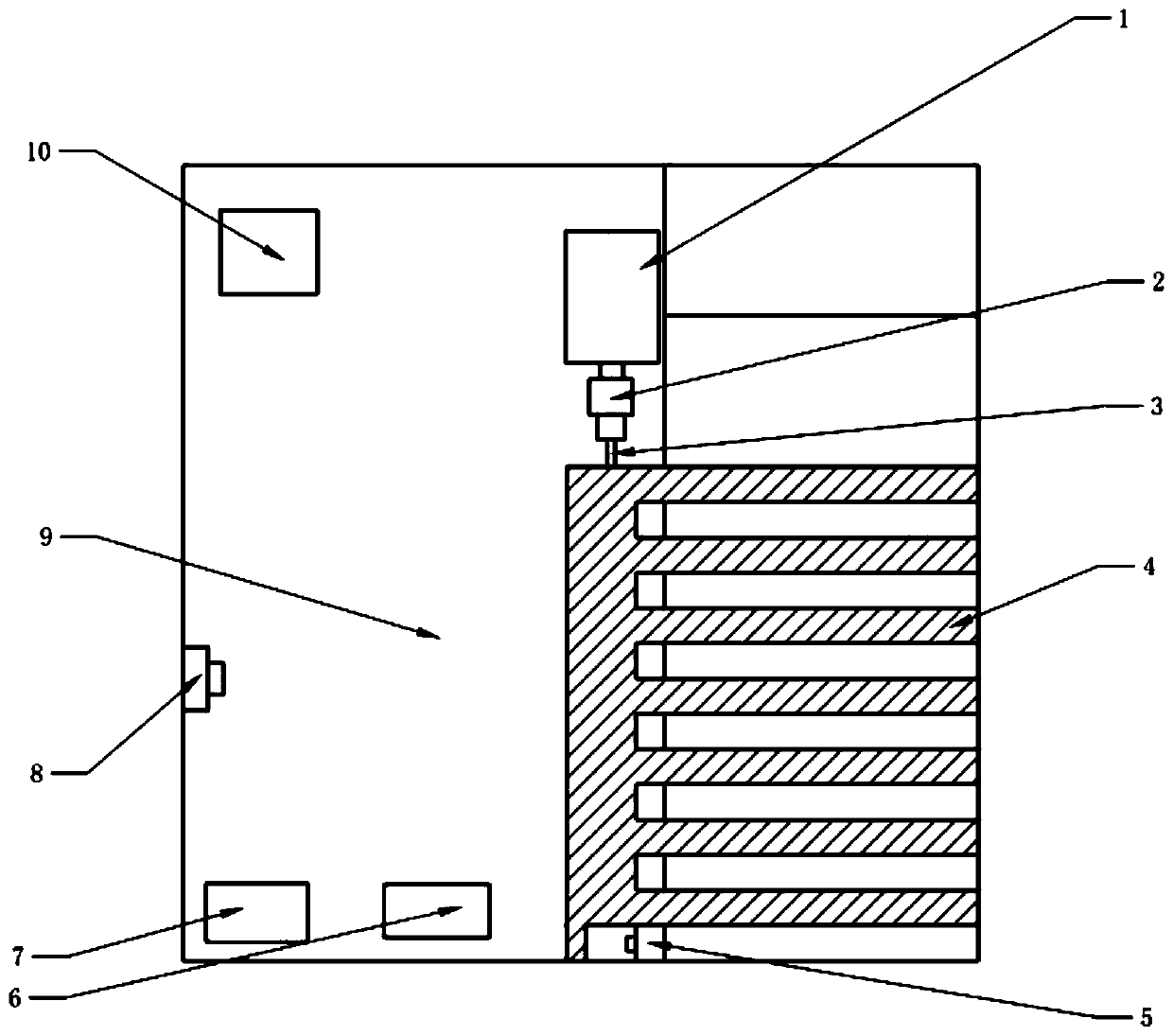

Air cleaner for fresh air system

InactiveCN104006464ASolve filterabilitySolve the purificationLighting and heating apparatusAir conditioning systemsParticulatesAir filter

The invention relates to an air cleaner for a fresh air system. The air cleaner for the fresh air system comprises a high efficiency particulate air filter, an activated carbon filter net, an aluminum-based plasma electrostatic net, a high voltage electrostatic generator, an ultraviolet lamp, a fan, a rear outer shell, a front outer shell, a movable handle, an exterior matching air inlet, a lower outer shell and an upper outer shell. The air cleaner can be installed at an air inlet of the fresh air system, and can effectively intercept, thoroughly purify, disintegrate, deodorize and sterilize pollutants, bacteria and viruses in outdoor air, and at last send fresh air which is purified completely into a room through a fresh air system pipeline.

Owner:JIANGSU THAMES EP TECH

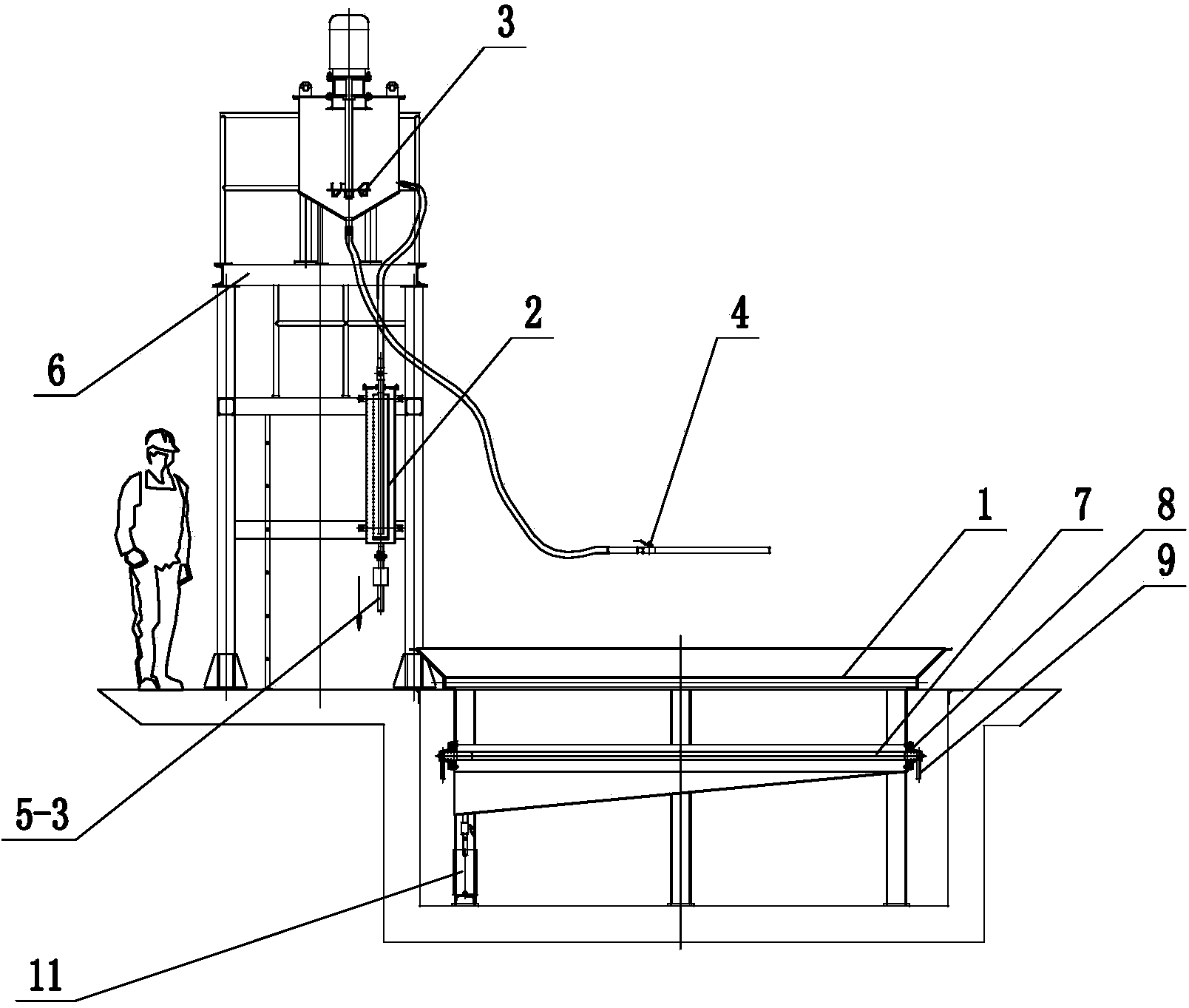

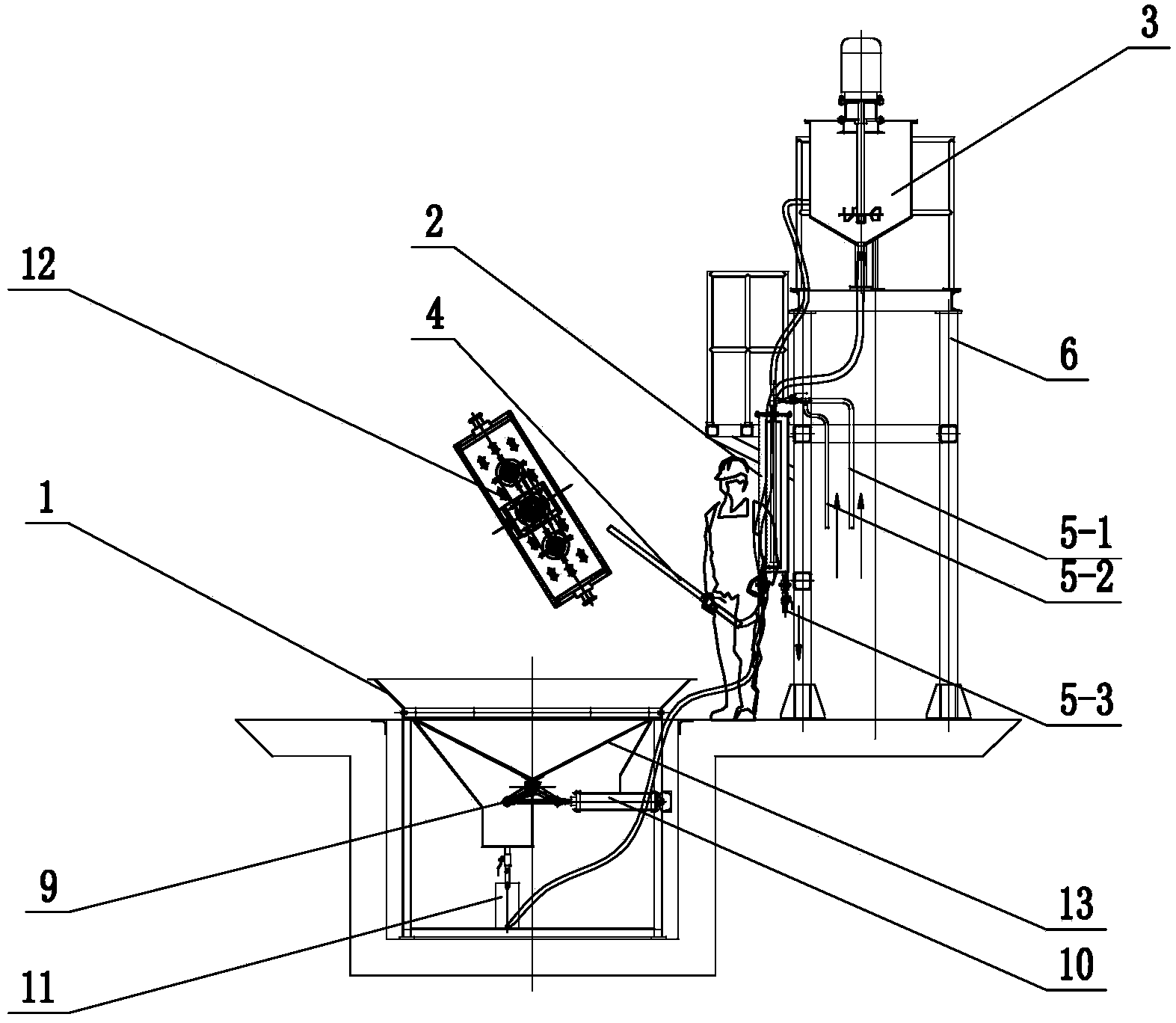

Cast flow coating system

The invention relates to a cast flow coating system, which comprises a coating tank below a sand mould, and the cast flow coating system is characterized in that a high-altitude platform is arranged on one side of the coating tank, a stirring barrel is arranged at the top of the high-altitude platform, and a discharge outlet in the bottom of the stirring barrel is connected with a flow coating gun through a pipeline; the coating tank consists of a left-side tank body and a right-side tank body, the left-side tank body has a flat bottom and an inclined side part, the bottom of the left-side tank body is connected with a diaphragm pump through a discharge opening, the diaphragm pump is connected with a feed inlet of a filter through a pipeline, and a discharge outlet of the filter is connected with the stirring barrel. The cast flow coating system can evenly and naturally flow-coats the sand mould, the flow coating quality is good, the production efficiency is high, and the coating plugging of the system can be effectively prevented; the cast flow coating system is widely applied to flow coating of moulding line sand boxes, the labor force of workers can be greatly reduced, the production efficiency can be increased, and the high-quality flow coating of the sand mould in the casting process can be realized.

Owner:WUXI XINAN FOUNDARY MACHINERY

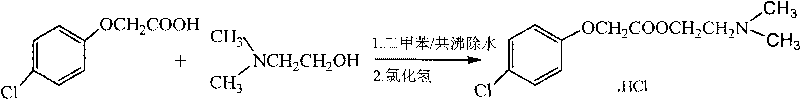

Method for preparing meclofenoxate hydrochloride sterile bulk drug

InactiveCN101747215AReduce moistureQuality improvementOrganic active ingredientsNervous disorderFiltrationChemistry

The invention relates to a method for preparing a meclofenoxate hydrochloride sterile bulk drug, which is characterized in that a meclofenoxate hydrochloride sterile finished product is obtained by the following steps: dissolving meclofenoxate hydrochloride in isopropanol in a certain mixture ratio, then decoloring and carrying out aseptic filtration and decompression concentration, and then devitrifying, filtering and drying. The product prepared by the method has more stable quality and simple process, thereby being suitable for industrial big production.

Owner:YAOPHARMA CO LTD

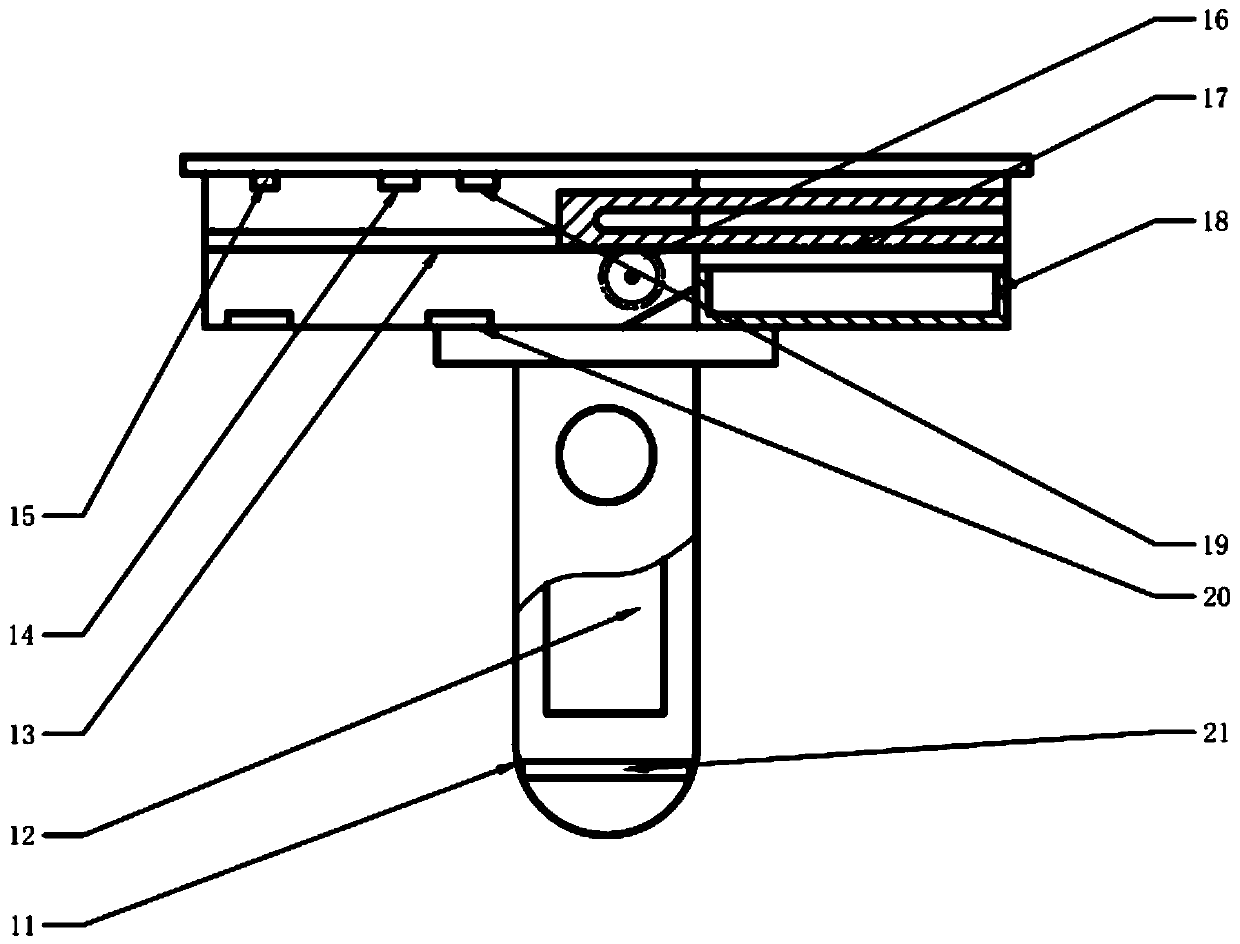

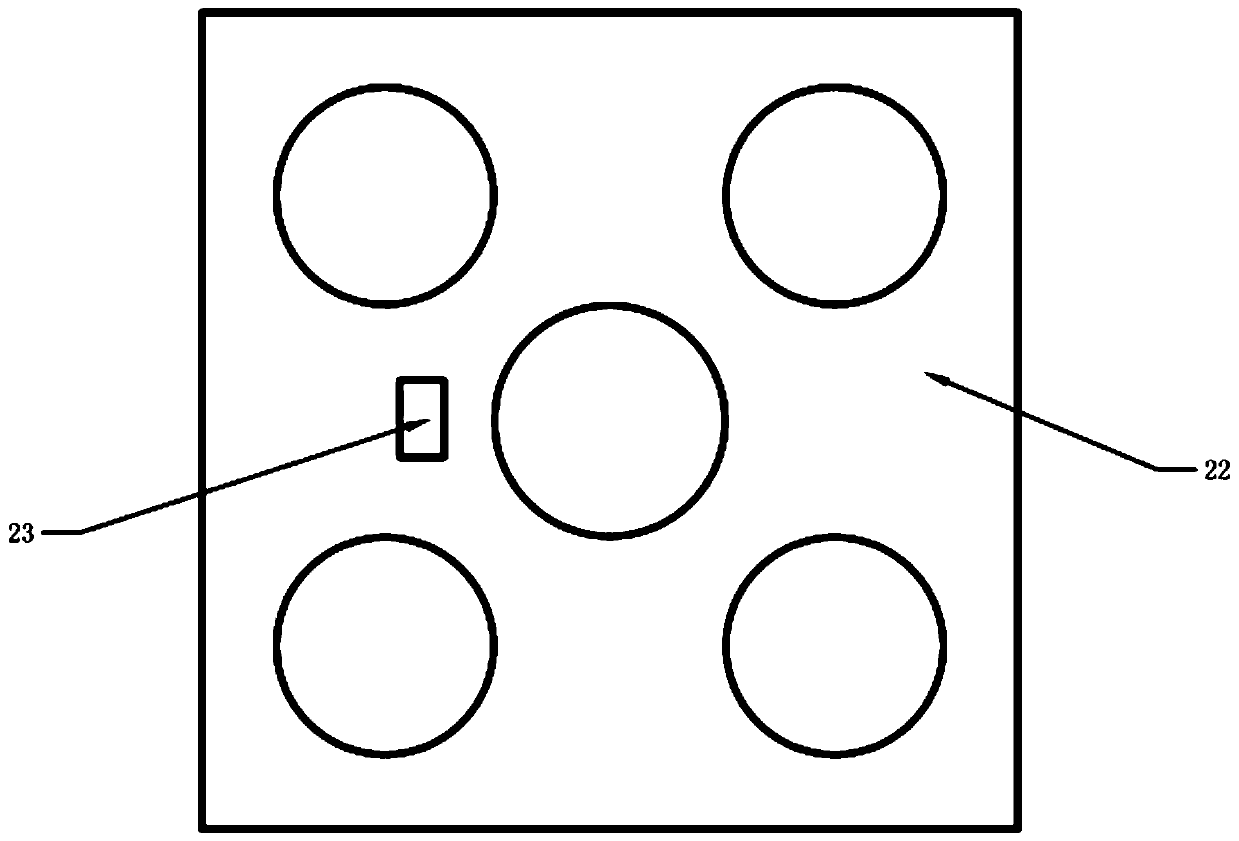

Ground leakage with low energy consumption and easy to clean

The invention relates to a ground leakage with low energy consumption and easy to clean. The ground leakage with the low energy consumption and easy to clean comprises a gear motor, a coupling, a driving shaft, a comb tooth filtering net, a limiting switch A, a power supply module, a storage battery, a limiting switch B, a modularized box body, a micro-controller, a drainage pipe outer pipe, a drainage pipe inner pipe, a sliding guide rail, a buzzer, a piezoelectric ceramic vibration sensor, a gear, a rack, a collecting basket, a magnetically controlled switch, a protective cover plate and a tiny magnet. According to the ground leakage with the low energy consumption and easy to clean, the separated comb-shaped movable double-layer filtering net is adopted, hairs are cleared through horizontal moving of the comb tooth filtering net, the problems that the filtering effect of the filtering net on hairs is not good, and the hairs wound around the filtering net are difficult to clear are solved to a certain extent. According to the ground leakage with the low energy consumption and easy to clean, the energy consumption is low, the technology of vibration information monitoring is adopted, and the problem that the buzzer prompts when nobody exists is avoided.

Owner:HEBEI UNIV OF TECH

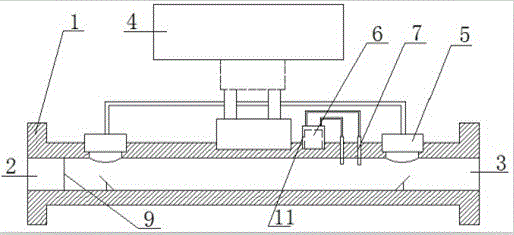

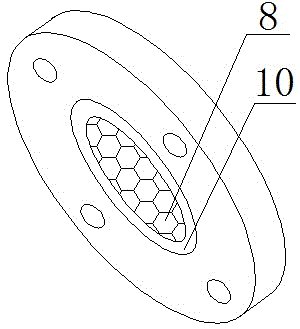

Ultrasonic calorimeter capable of detecting content of heavy metals and filtering impurities

InactiveCN104655328ASolve the inability to measure heavy metal content in waterSolve filterabilityTesting waterCalorimeterWater flowTransducer

The invention provides an ultrasonic calorimeter capable of detecting the content of heavy metals and filtering impurities. The ultrasonic calorimeter comprises a calorimeter body, a copper pipe, an energy converter on the copper pipe, a water inlet and a water outlet, wherein the water inlet and the water outlet are formed in the two ends of the copper pipe; a placing cavity of a heavy metal detection instrument is formed in the copper pipe, close to the water outlet, between the calorimeter body and the energy converter and is fixedly connected with the copper pipe in a welding way; a high-temperature-resistant filter screen I is arranged at a pipe orifice of the water inlet. Therefore, the ultrasonic calorimeter solves the problem that an existing ultrasonic calorimeter cannot detect the content of the heavy metals and the filtering impurities in water; when people need to detect the content of the heavy metals in the water, the heavy metal detection instrument on the ultrasonic calorimeter can be used for observing data, and measures to protect the copper pipe are timely taken; in addition, the filter screen in the copper pipe can block part of impurities and cannot cause great influence on water flow speed, so that the normal use of the ultrasonic calorimeter is ensured.

Owner:XIAN TRIONES DIGITAL INFORMATION

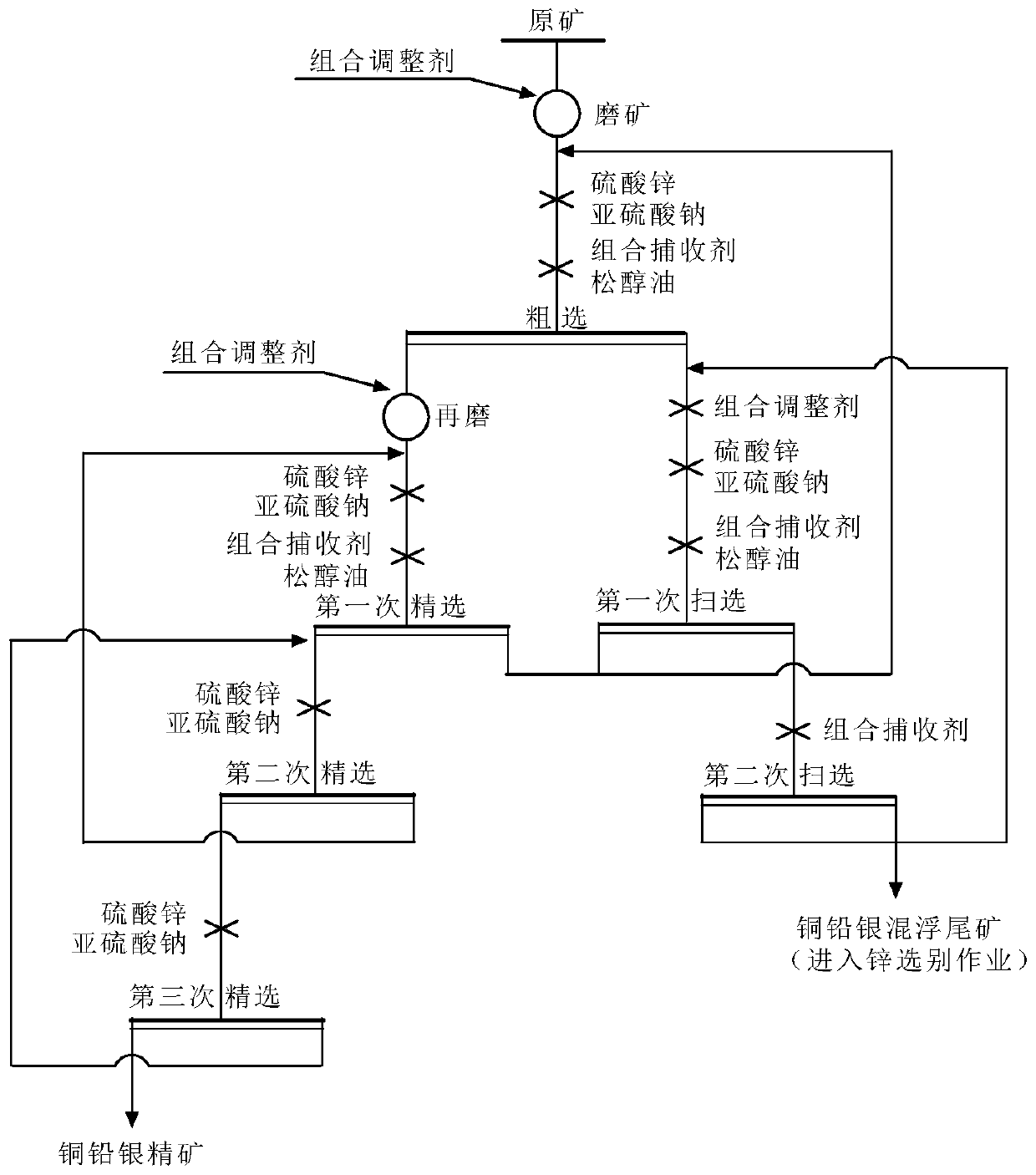

Combined collecting agent and beneficiation method for recovering copper, lead and silver from copper lead zinc and silver polymetallic ore

The invention discloses a combined collecting agent and a beneficiation method for recovering copper, lead and silver from copper lead zinc and silver polymetallic ore. The combined collecting agent is prepared by mixing dianilinodithiophosphoric acid, sodium carbonate and ethyl thio carbamate in a mass ratio of (3.0 to 5.0):(2.0 to 3.0):(1.0 to 2.0). The beneficiation method comprises the steps that a combined regulator is added into raw ore for grinding to prepare raw ore slurry; zinc sulfate, sodium sulfite, the combined collecting agent and terpineol oil are added into the raw ore slurry in turn for rough separation to obtain copper-lead mixed coarse concentrate; the copper-lead mixed coarse concentrate is subjected to thickening and dewatering, and then the combined regulator is addedfor grinding to prepare regrinding slurry; and the zinc sulfate, the sodium sulfite, the combined collecting agent and the terpineol oil are added into the regrinding slurry in turn, then fine separation is conducted, and thus copper-lead-silver mixed concentrate is obtained. According to the combined collecting agent and the beneficiation method for recovering the copper, the lead and the silverfrom the copper lead zinc and silver polymetallic ore, copper lead silver mineral in the high sulfur high arsenic copper lead zinc and silver polymetallic ore can be efficiently recovered.

Owner:BEIJING MINING & METALLURGICAL TECH GRP CO LTD

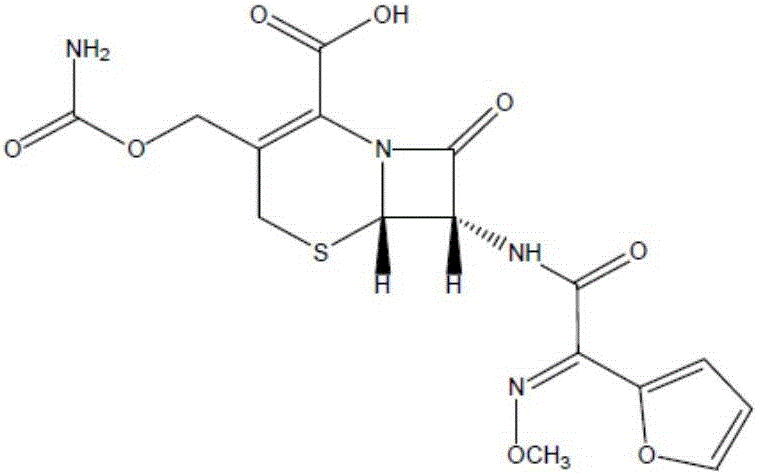

Preparation process for cefuroxime acid crystallization

The invention belongs to the technical field of crystallization of pharmaceutical intermediates, and discloses a preparation process for cefuroxime acid crystallization. The process provided by the invention comprises the following concrete steps: adding a cefuroxime acid material liquid prepared in an upstream process into a crystallizer, adding a proper amount of a crystal modifier, adjusting a certain temperature and stirring rate; dropwise adding hydrochloric acid and adjusting the pH value of the mixed solution to a certain value, adding a proper amount of seed crystals, and allowing crystals to grow; adjusting the stirring rate and the hydrochloric acid dropwise adding rate, continuously dropwise adding the hydrochloric acid, and after the completion of dropwise adding, allowing the crystals to grow again; and carrying out filtering, washing and vacuum drying so as to obtain a cefuroxime acid crystallization product. The cefuroxime acid crystal obtained by using the crystallization process provided by the invention has high purity, complete crystal habits and proper particle sizes and particle-size distribution, solves common problems like small product particle size, large crystal slurry viscosity, difficult filtration and drying in the production process of cefuroxime acid in the prior art, shortens the production cycle of products, and reduces production cost.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

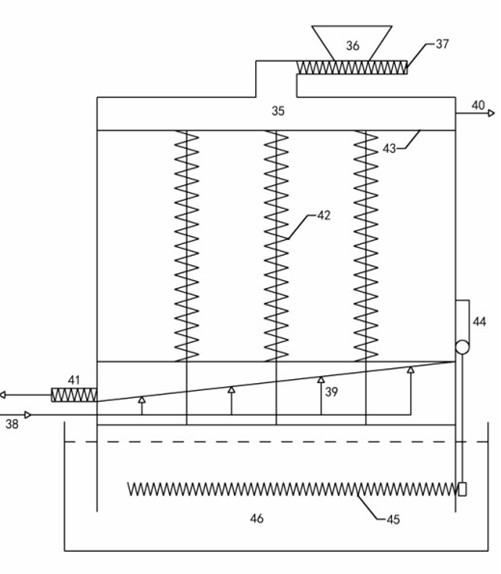

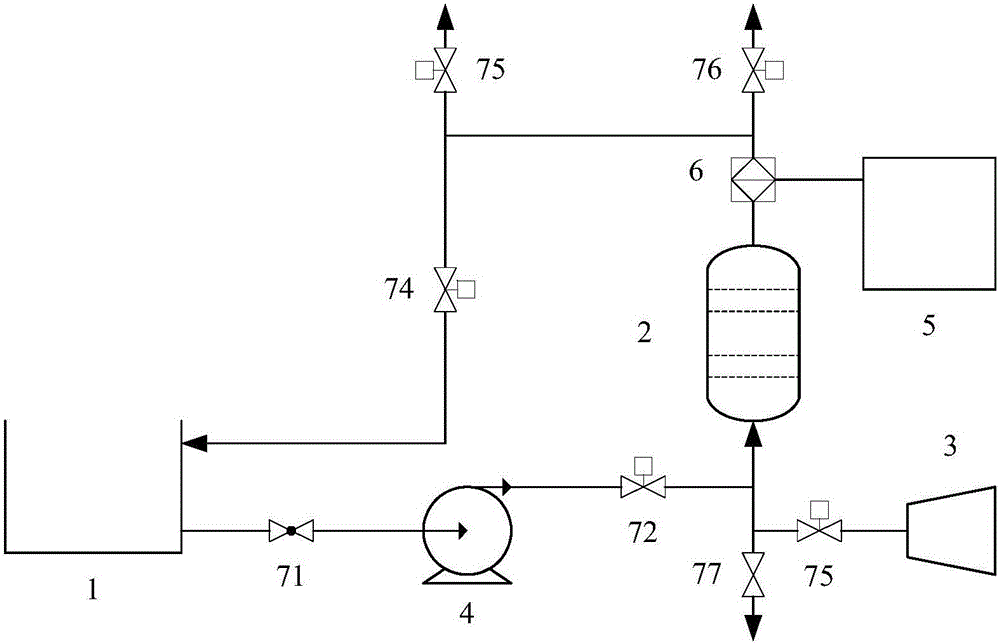

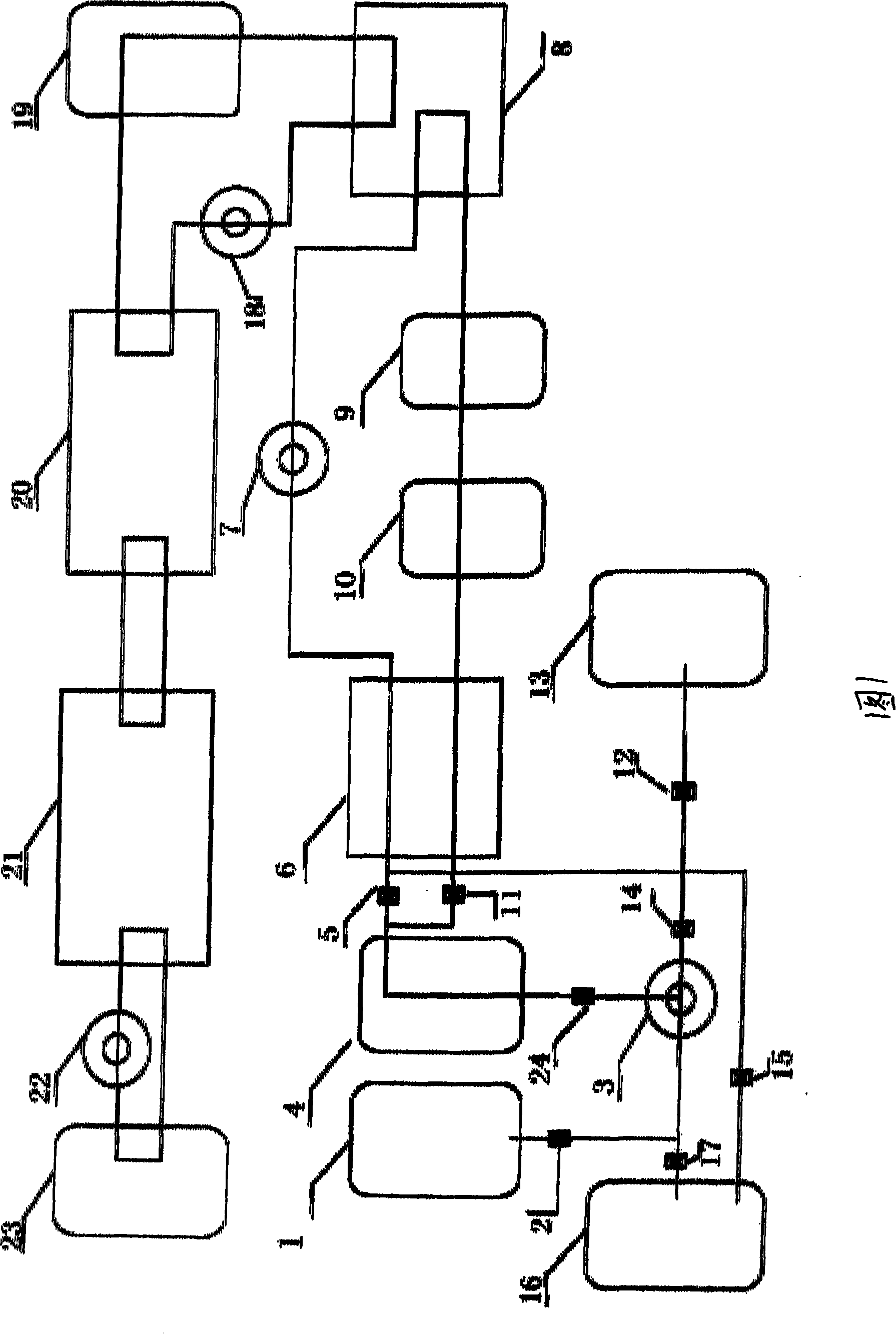

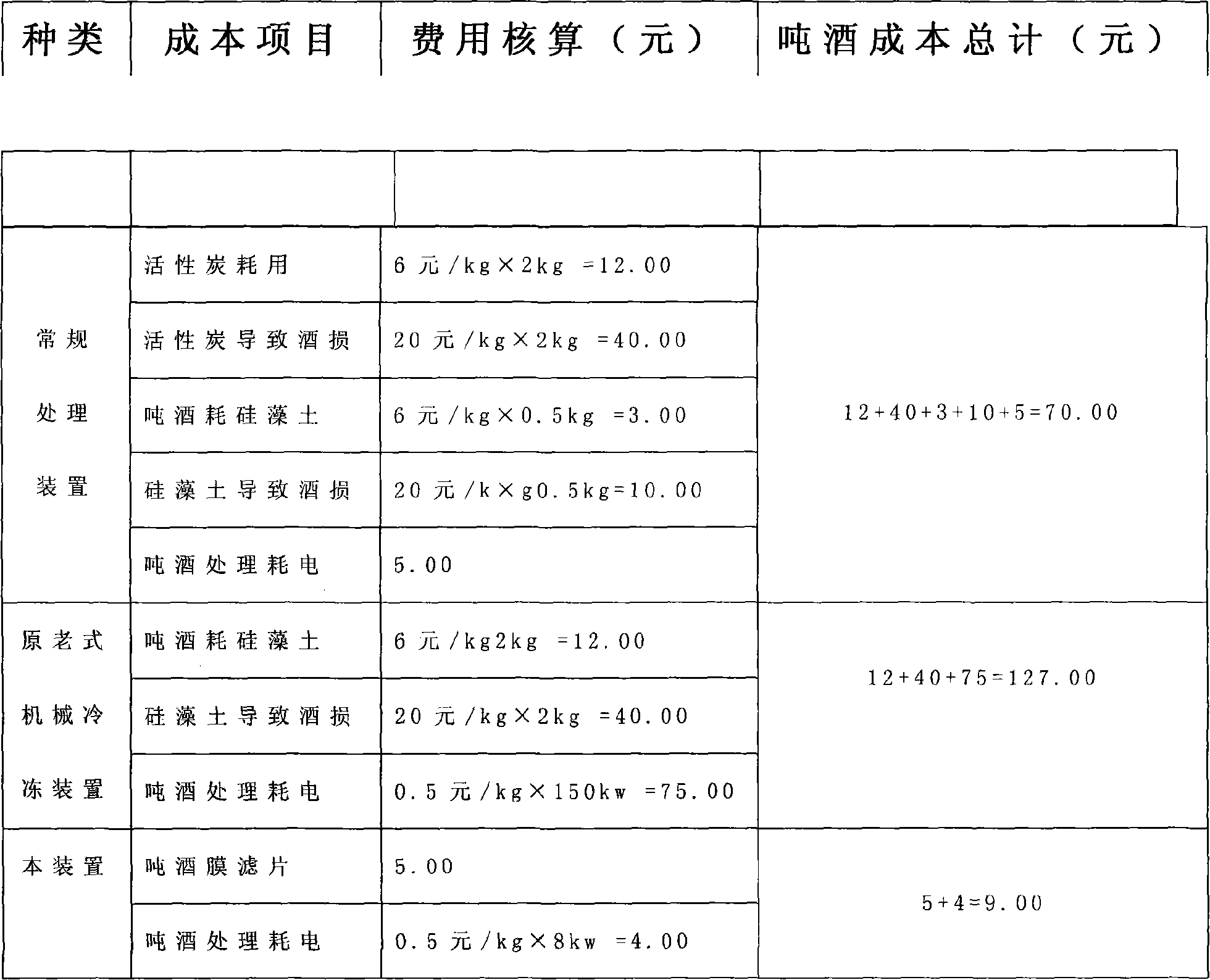

Energy-saving and environment-friendly comprehensive processing device for wines and its technique

InactiveCN101157888ASolve the problem of removing turbidityAddress operational complexityAlcoholic beverage preparationAlcoholFiltration

The invention relates to an alcoholic energy conservation, environment protection, and comprehensive treatment device and a technique. By a refrigerant, a refrigerating machine (21) is communicated with a refrigerant cool heat exchanger (20), a refrigerant pump (18), a cooling catalyst and a brut cool heat exchanger (8) and a cooling catalyst tank (19) to cool down. A brut tank (1) is communicated with a pure wine tank (13) by a valve(2), a wine pump(3), a primary filter (4) , a valve (5), a brut and pure wine cool heat exchanger (6), a wine pump(7), the cooling catalyst and the brut cool heat exchanger (8), an anti-low temperature filter (9), an anti-hydrolytic filter (10), the brut and pure wine cool heat exchanger (6), a valve (12) to carry out an anti-low temperature anti-turbid and anti-hydrolytic filtration. Alcohol in an alcohol tank (16) goes back to the alcohol tank (16) to backwash circularly through a valve (17), the wine pump(3), the primary filter (4), a valve(11), the brut and pure wine cool heat exchanger (6), the anti-hydrolytic filter (10), the anti-low temperature filter (9), the cooling catalyst and brut cool heat exchanger (8), the wine pump(7), the brut and pure wine cool heat exchanger (6) and a valve(15). The quality of the alcohol treated by the device is stable, which realizes environmental protection by zero emission.

Owner:晋中开发区华德净化技术有限公司

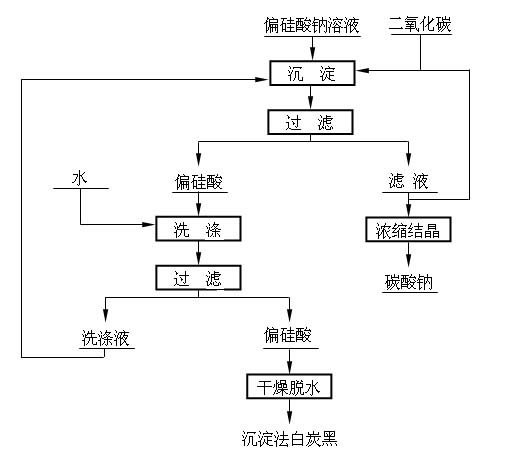

Process for preparing precipitated white carbon black by adopting carbon dioxide for decomposition

ActiveCN102040225BEliminate emissionsSolve filterabilitySilicaSodium metasilicateEnvironmental engineering

The invention relates to a process for preparing precipitated white carbon black by adopting carbon dioxide for decomposition. The process comprises the following steps: introducing the precipitator carbon dioxide into industrial sodium metasilicate solution with the pH value of 12.5-13.5 to react, stopping introducing the carbon dioxide when the pH value of the solution is 8.5-9.0, filtering thereactant to obtain metasilicic acid filter residues and filtrate containing sodium carbonate; adding water to metasilicic acid according to the liquid solid mass ratio of 6:1, stirring and washing the mixture, filtering the mixture and then washing entrained sodium carbonate solution, and drying the product to obtain the precipitated white carbon black; and returning one half of the filtrate containing sodium carbonate to the sodium metasilicate solution to be dissolved again to precipitate the metasilicic acid and concentrating and crystallizing the other half of the filtrate to obtain sodium carbonate product. The process has the following advantages: the carbon dioxide is adopted to replace the acid to precipitate the metasilicic acid in the sodium metasilicate solution, thus solving the filtering performance of the precipitate metasilicic acid in the traditional precipitation process; meanwhile, the liquid after precipitation is ensured to be the sodium carbonate solution with high additional value, thus completely eliminating discharge of waste water in the precipitation process; and besides, carbon is utilized.

Owner:KUNMING METALLURGY INST

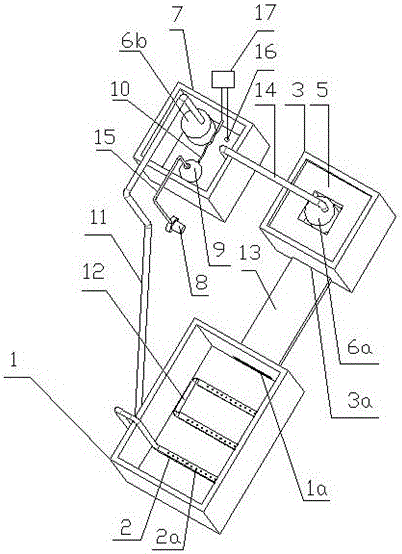

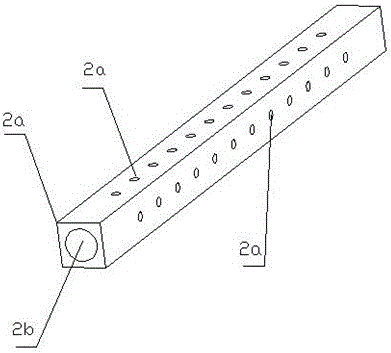

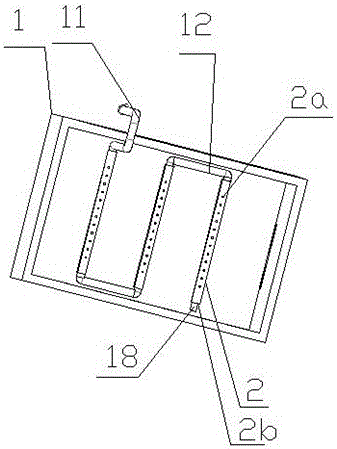

Fish tank

InactiveCN106172159AAchieve dischargeSolve dirt depositsPisciculture and aquariaActivated carbonEngineering

The invention relates to a fish tank which comprises a fish tank body (1). The fish tank is characterized in that a group of spraying strips (2) are arranged at the bottom of the fish tank body (1), the fish tank body (1) is connected with a filter tank (3) through a hose, a filter screen (4) is arranged on the lower portion of the filter tank (3), activated carbon (5) is placed on the filter screen (4), a first submersible pump (6a) is arranged among the activated carbon (5), an outlet of the first submersible pump (6a) is connected with a first water pipe (14) and stretches into an adjusting tank (7), and a second submersible pump (6b) is arranged in the adjusting tank (7) and communicated with the spraying strips (2) through a water delivery hose. According to the technical scheme, dirt in the fish tank can be discharged on the premise that water is not replaced, the problems of depositing and filtering dirt in the fish tank are solved, use is convenient, the structure is simple, and health of aquarium fishes is guaranteed.

Owner:黄玉 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com