Needle-type solid-phase extraction filter

A technology for extracting filters and needles, applied in the field of needle-type solid phase extraction filters, can solve the problems of increasing the cost of consumables, the complexity of pretreatment, the large volume of solid phase extraction columns, and the consumption of fillers and solvents, and achieves simple training. , Wide range of application, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

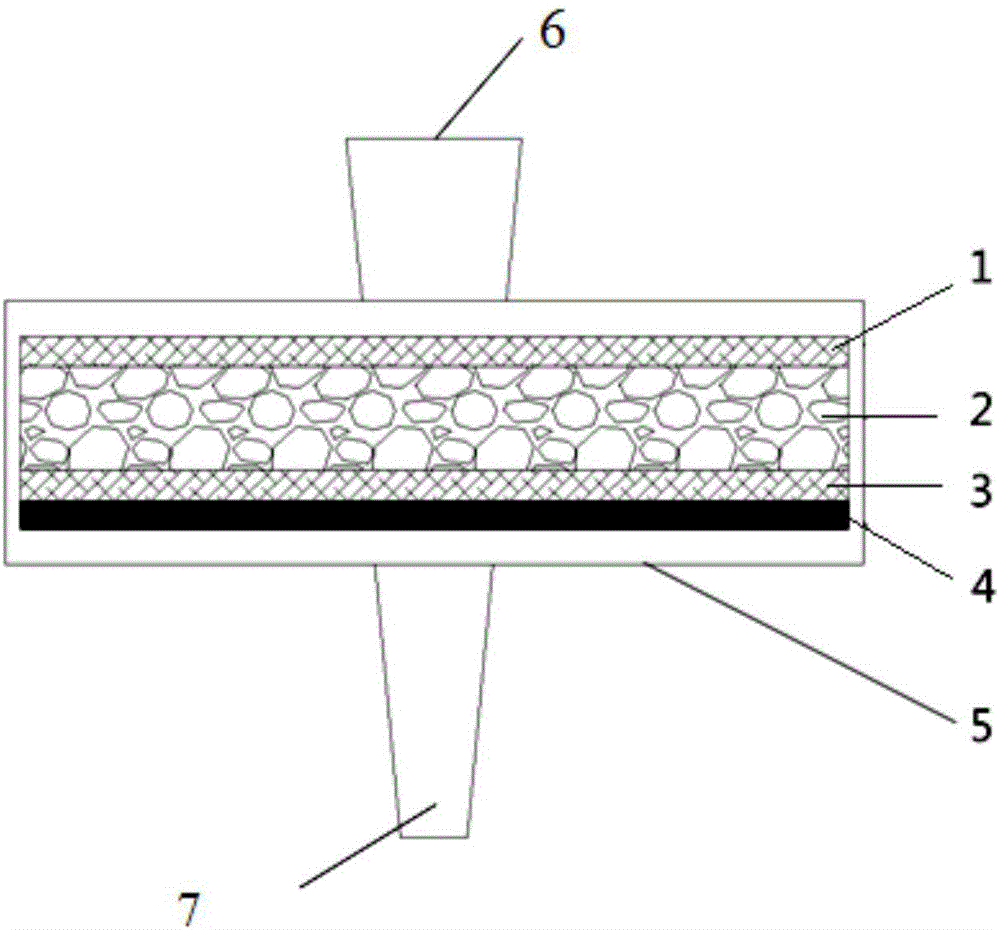

[0032] Embodiment 1, a kind of needle type solid phase extraction filter, such as figure 1 As shown, the housing 5 is included, and the syringe nipple interface 6 and the pintle interface 7 communicated with the inner cavity of the housing 5 are respectively arranged on the upper and lower sides of the housing 5; The upper sieve plate 1, the solid phase extraction filler 2, the lower sieve plate 3 and the filter membrane 4; that is, the upper sieve plate 1, the solid phase extraction filler 2, the lower sieve plate 3 and the filter membrane 4 are stacked in layers without gaps.

[0033] The upper sieve plate 1 and the lower sieve plate 3 are respectively provided with sieve holes with a diameter of 100 μm. The upper sieve plate 1 is facing the nipple interface 6 of the syringe, and the filter membrane 4 is facing the pintle interface 7 . Both the syringe nipple interface 6 and the pintle interface 7 are standard straight sockets or standard threaded ports. The octadecylchlor...

Embodiment 2

[0051] Embodiment 2, the solid-phase extraction filler 2 among the embodiment 1 is changed into octadecylsilane bonded silica gel C8, silica gel, alumina, Florisil, diatomaceous earth, gac, Diol ( diol group); the particle diameter is still 120 μm, and the rest are equal to embodiment 1.

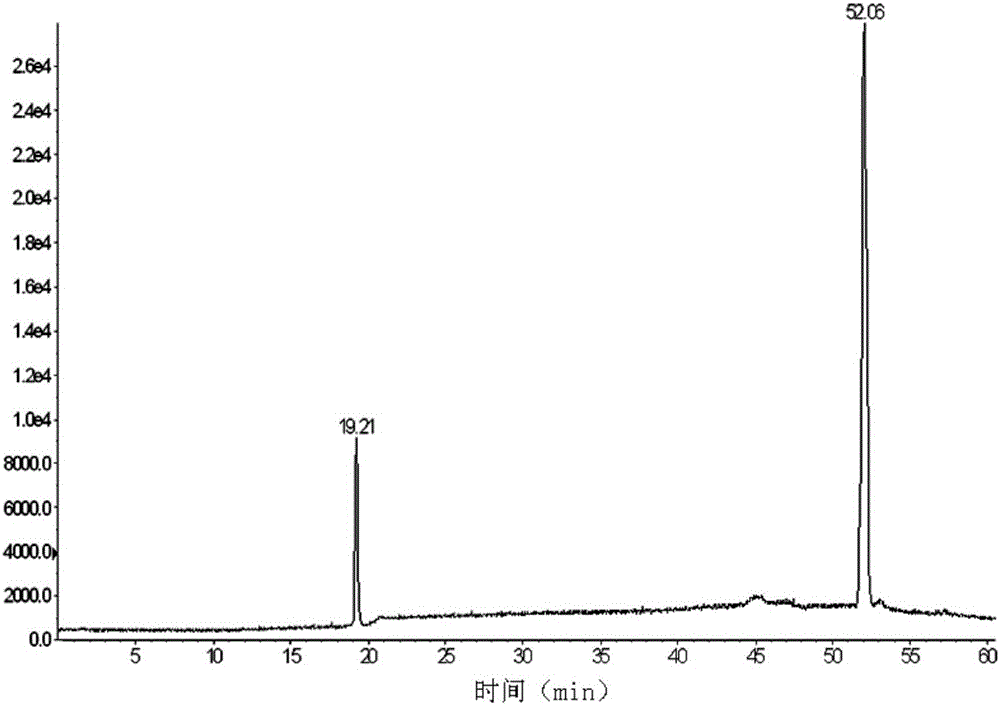

[0052] The resulting needle-type solid phase extraction filter was detected as in Experiment 1, and the quantitative parameters of phosphatidylcholine and phosphatidylethanolamine are as described in Table 2.

[0053] Table 2

[0054]

[0055]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com