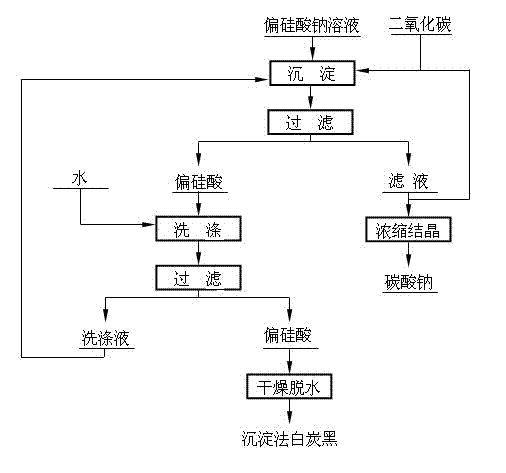

Process for preparing precipitated white carbon black by adopting carbon dioxide for decomposition

A precipitation method of white carbon black and carbon dioxide technology, applied in the direction of silicon dioxide, silicon oxide, etc., can solve the problems of low recovery value of sodium sulfate solution, difficulty in recycling and environmental pollution, etc., and achieve uniform particles, good filtration performance, and smelting. Simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Example 1 1. The aluminum content in industrial sodium metasilicate is 0.50g / l, the iron content is 0.60g / l, and the titanium content is 0.07g / l. The sodium metasilicate is first neutralized and decontaminated, and filtered to obtain an industrial sodium metasilicate solution with a pH of 12.5-13.5.

[0015] Pass carbon dioxide gas into the obtained industrial sodium metasilicate solution, the solution temperature during ventilation is 50~55°C, the carbon dioxide concentration is 10~15%, and the flow rate is 20~25m 3 / h; when the pH of the sodium metasilicate solution drops to 8.5~9.0, stop feeding carbon dioxide gas, continue to stir for 30min~40min, stop stirring, and filter. The filter residue is metasilicate, and the filtrate is a solution containing sodium carbonate. Put metasilicate into 4 m 3 Add pure water according to the liquid-solid mass ratio of 6:1, raise the temperature to 50~65°C, stir and wash for 30min, and filter. After filtering, rinse with pure ...

Embodiment 2

[0018] Example 2 1. The aluminum content in industrial sodium metasilicate is 0.65g / l, the iron content is 0.72g / l, and the titanium content is 0.043g / l. The sodium metasilicate is first neutralized and decontaminated, and filtered to obtain an industrial sodium metasilicate solution with a pH of 12.5-13.5.

[0019] Infuse carbon dioxide gas into the obtained industrial sodium metasilicate solution, the temperature of the solution is 60~65°C, the concentration of carbon dioxide is 15~20%, and the flow rate is 15~20m 3 / h; when the pH of the sodium metasilicate solution drops to 8.5~9.0, stop feeding carbon dioxide gas, continue to stir for 30min~40min, stop stirring, and filter. The filter residue is metasilicate, and the filtrate is a solution containing sodium carbonate. Put metasilicate into 4 m 3 Add pure water to the mixing tank according to the liquid-solid mass ratio of 6:1, raise the temperature to 55~60°C, stir and wash for 30min, and filter. After filtering, rin...

Embodiment 3

[0022] Example 3 1. The aluminum content in the industrial sodium metasilicate solution is 0.35g / l, the iron content is 0.56g / l, and the titanium content is 0.04g / l. The sodium metasilicate is first neutralized and decontaminated, and filtered to obtain a sodium metasilicate solution with a pH of 12.5-13.5.

[0023] Pass carbon dioxide gas into the obtained industrial sodium metasilicate solution, the solution temperature during ventilation is 55~60°C, the carbon dioxide concentration is 20~25%, and the flow rate is 10~15m 3 / h; when the pH of the sodium metasilicate solution drops to 8.5~9.0, stop feeding carbon dioxide gas, continue to stir for 30min~40min, stop stirring, and filter. The filter residue is metasilicate, and the filtrate is a solution containing sodium carbonate. Put metasilicate into 4 m 3 Add pure water according to the liquid-solid ratio of 6:1, raise the temperature to 50~55℃, stir and wash for 30min, and filter. After filtering, rinse with pure water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com