Patents

Literature

453results about How to "Eliminate emissions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

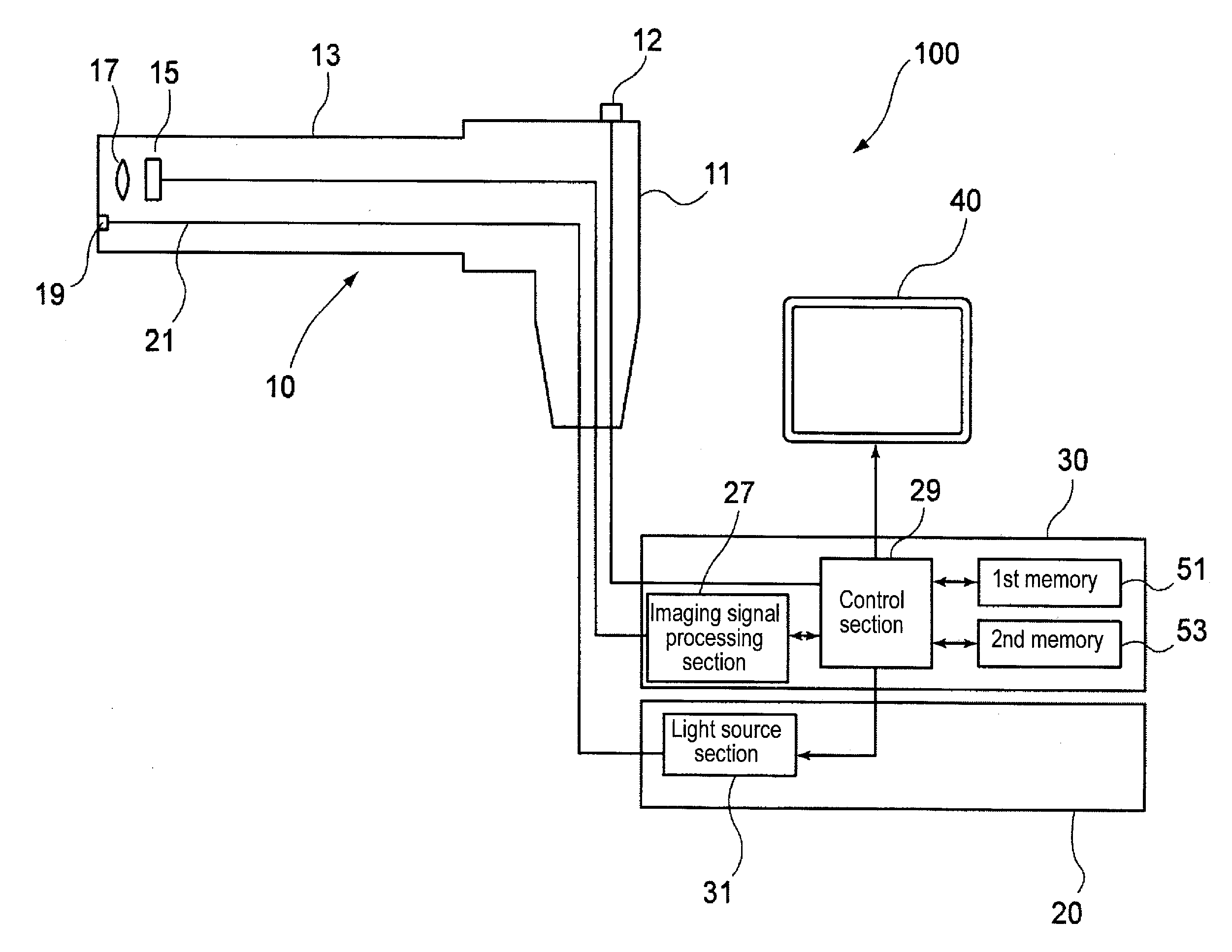

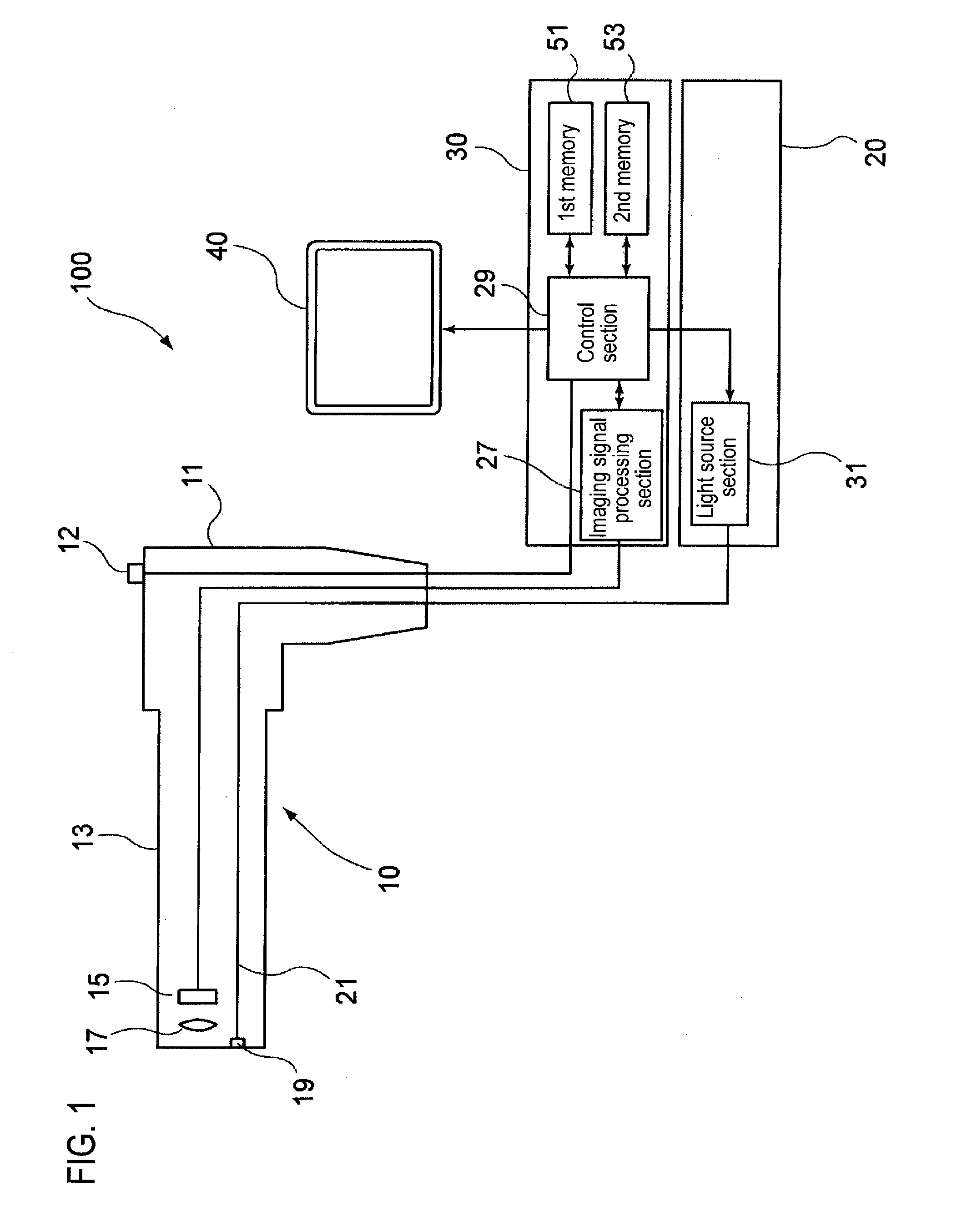

Light source device, imaging apparatus and endoscope apparatus

A light source device includes a first light source, a second light source having an emission wavelength that is different from the first light source, and a phosphor that is disposed to be distant from the first light source and the second light source and absorbs light in a predetermined excitation wavelength band to emit fluorescence. The phosphor is disposed on an emission light optical path that is shared by the first light source and the second light source. The emission wavelength of the first light source is in the predetermined excitation wavelength band. The emission wavelength of the second light source is outside of the predetermined excitation wavelength band.

Owner:FUJIFILM CORP

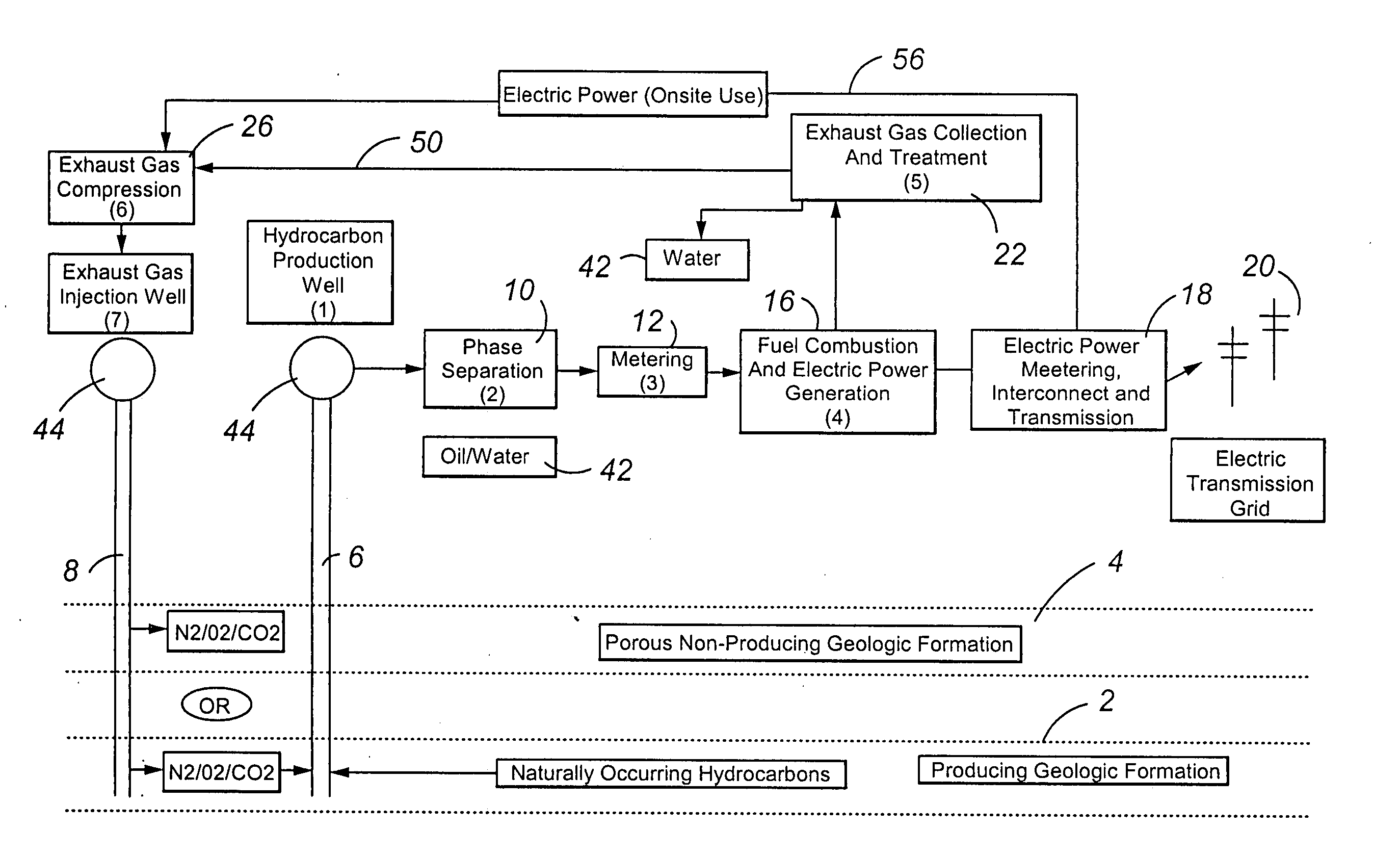

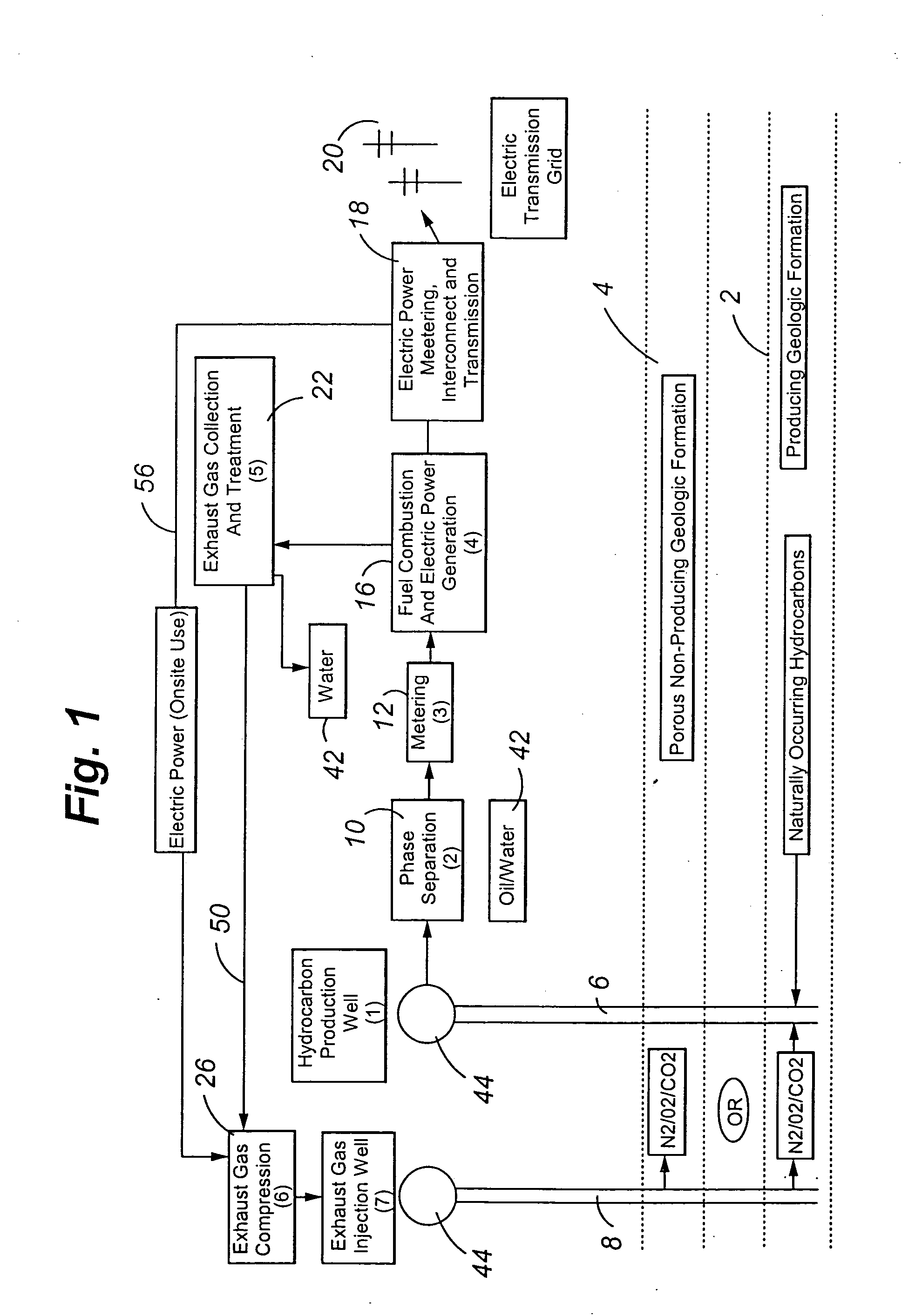

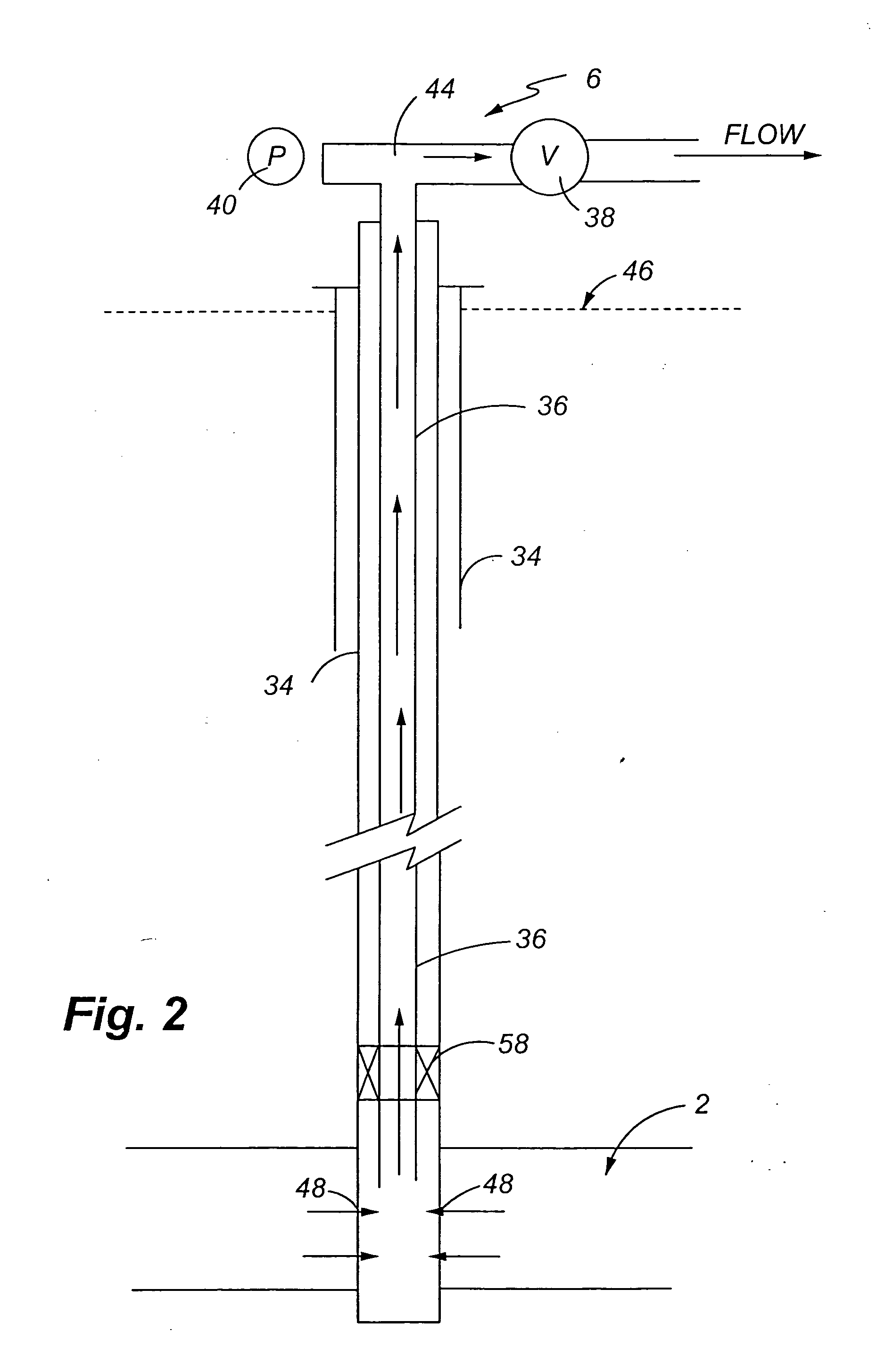

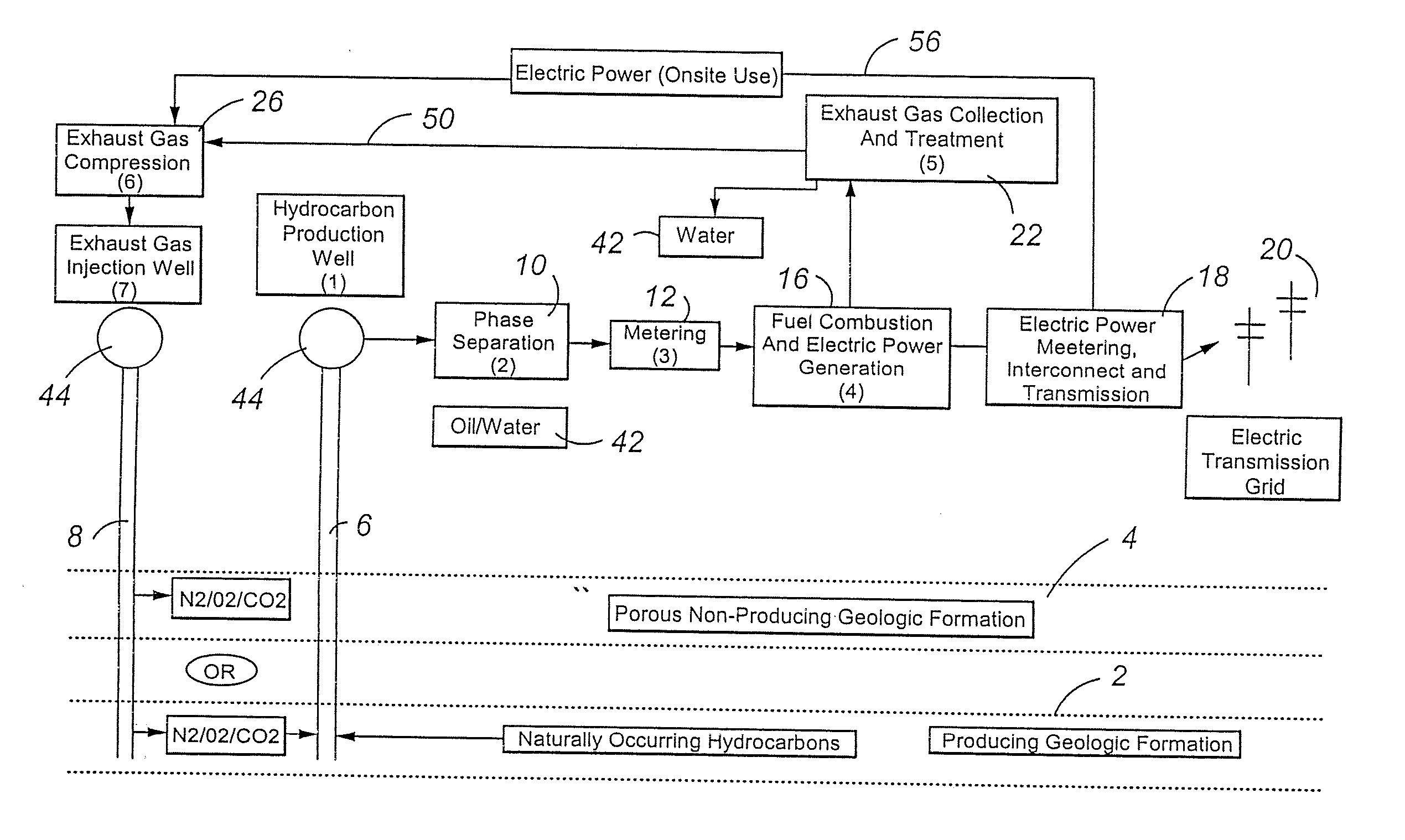

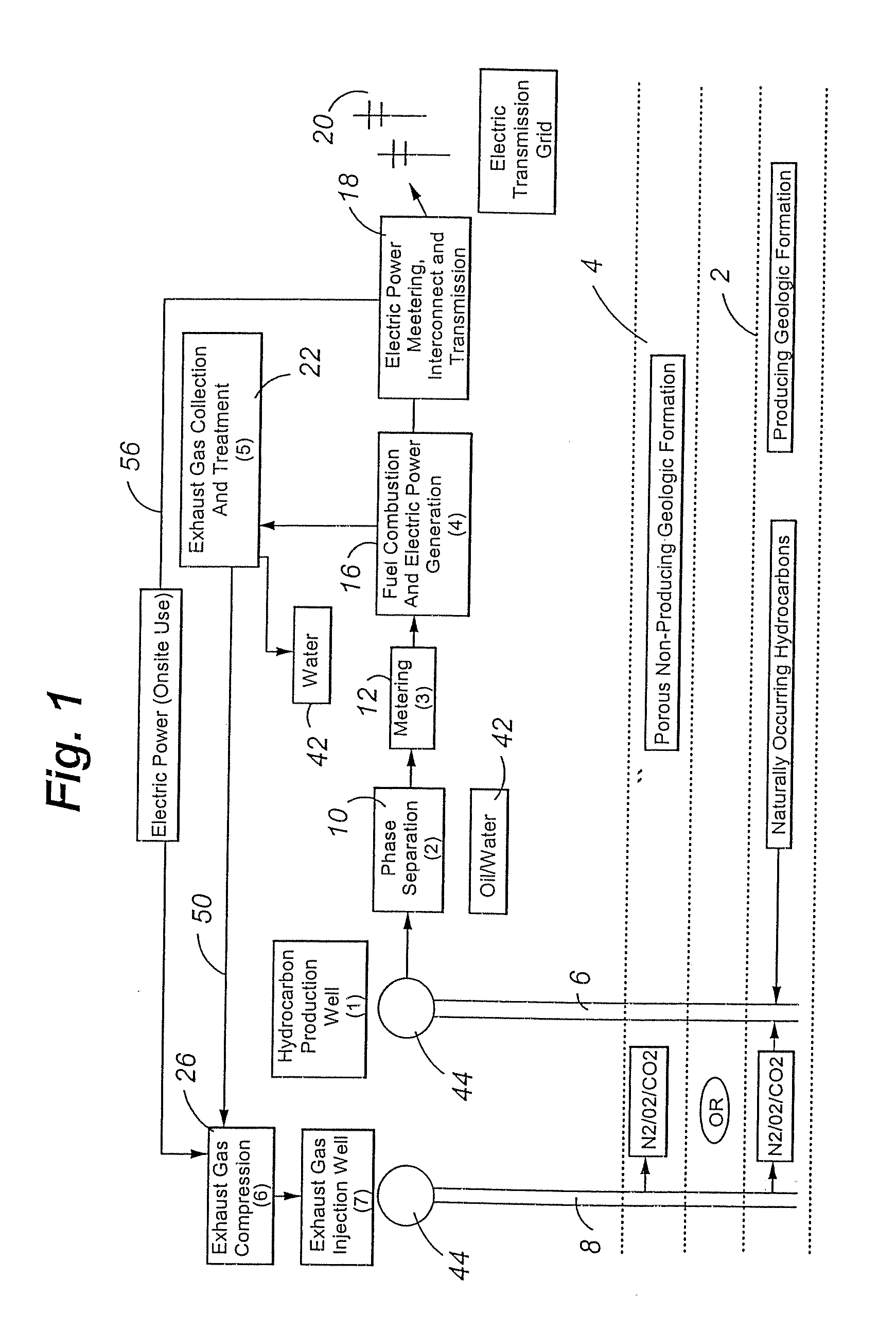

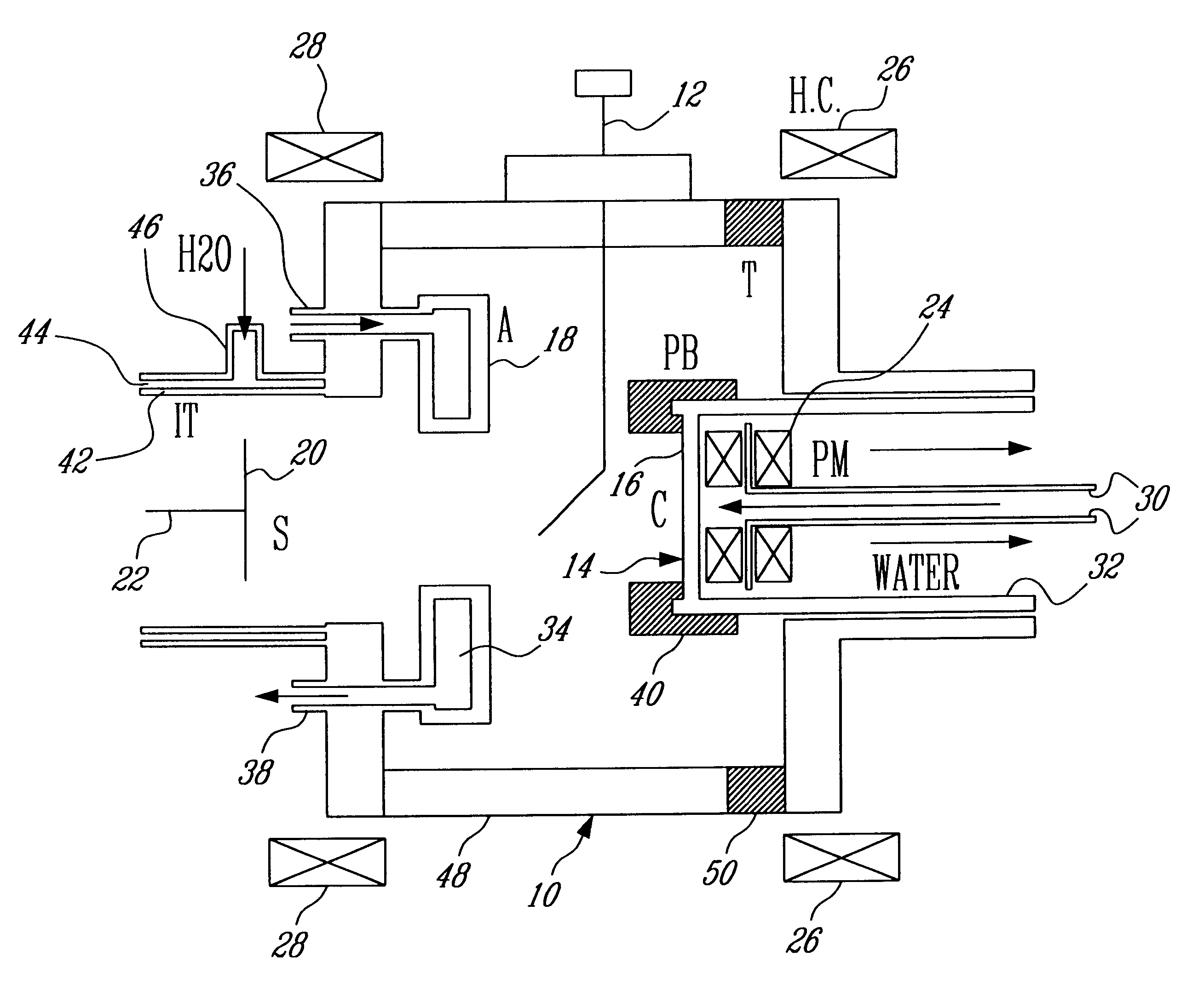

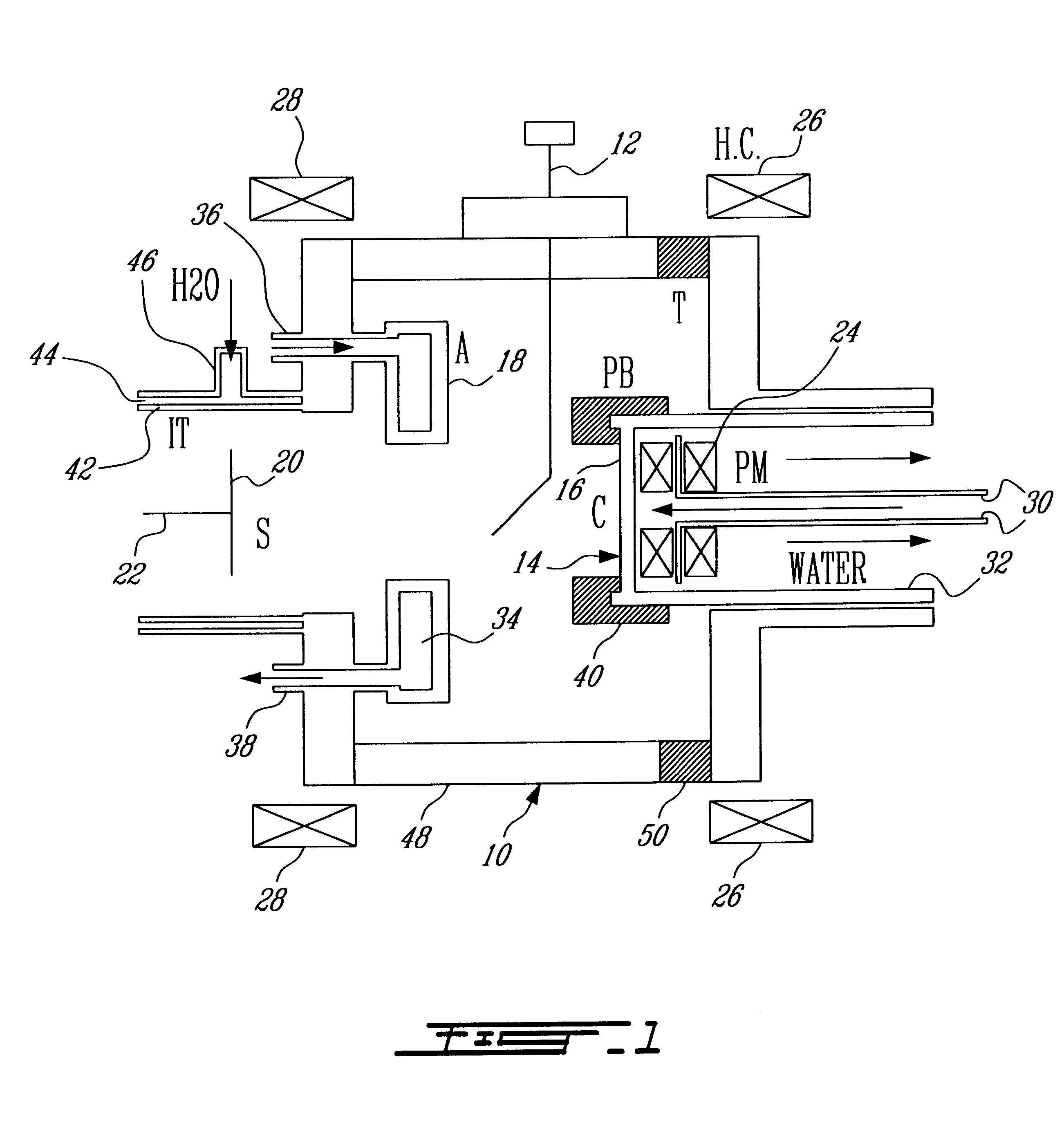

Method and apparatus for generating pollution free electrical energy from hydrocarbons

InactiveUS20060054318A1Cost effectivePollution free energyFluid removalHydrogen compoundsExhaust fumes

The present invention relates to the generation of substantially pollution free energy by utilizing hydrocarbons to create electrical energy, while reinjecting exhaust fumes or other byproducts into a subterranean formation. Thus, remote, low reserve oil and gas fields may be exploited and produced without requiring the construction of expensive gas transmission lines.

Owner:PRODN RESOURCES

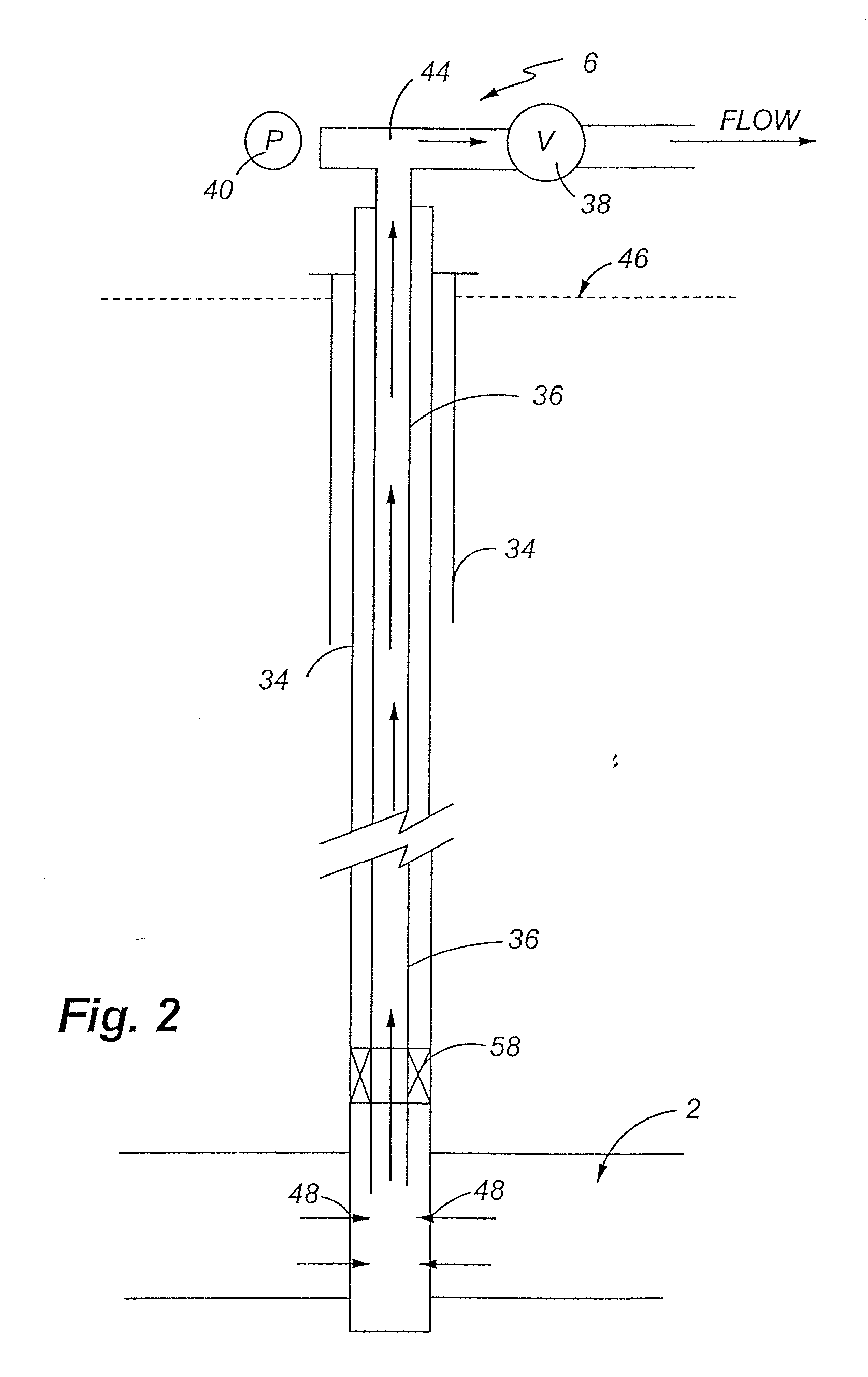

Method and apparatus for generating pollution free electrical energy from hydrocarbons

InactiveUS20080017369A1Cost effectivePollution free energyFluid removalThermal energyHydrocotyle bowlesioides

The present invention relates to the generation of substantially pollution free energy by utilizing hydrocarbons to create electrical energy, while reinjecting exhaust fumes or other byproducts into a subterranean formation. The present invention further relates to managing and supplying this electrical energy to at least one of a variety of subprocesses for producing a fuel product, such as hydrogen or ethanol. Alternatively, electrical power can be generated from a non-hydrocarbon source such as thermal, solar, wind or other power source to produce electrical energy, which in turn may be used to produce fuel products or other forms of usable energy. Thus, remote, low reserve oil and gas fields may be exploited and produced without requiring the construction of expensive gas transmission lines.

Owner:PRODN RESOURCES

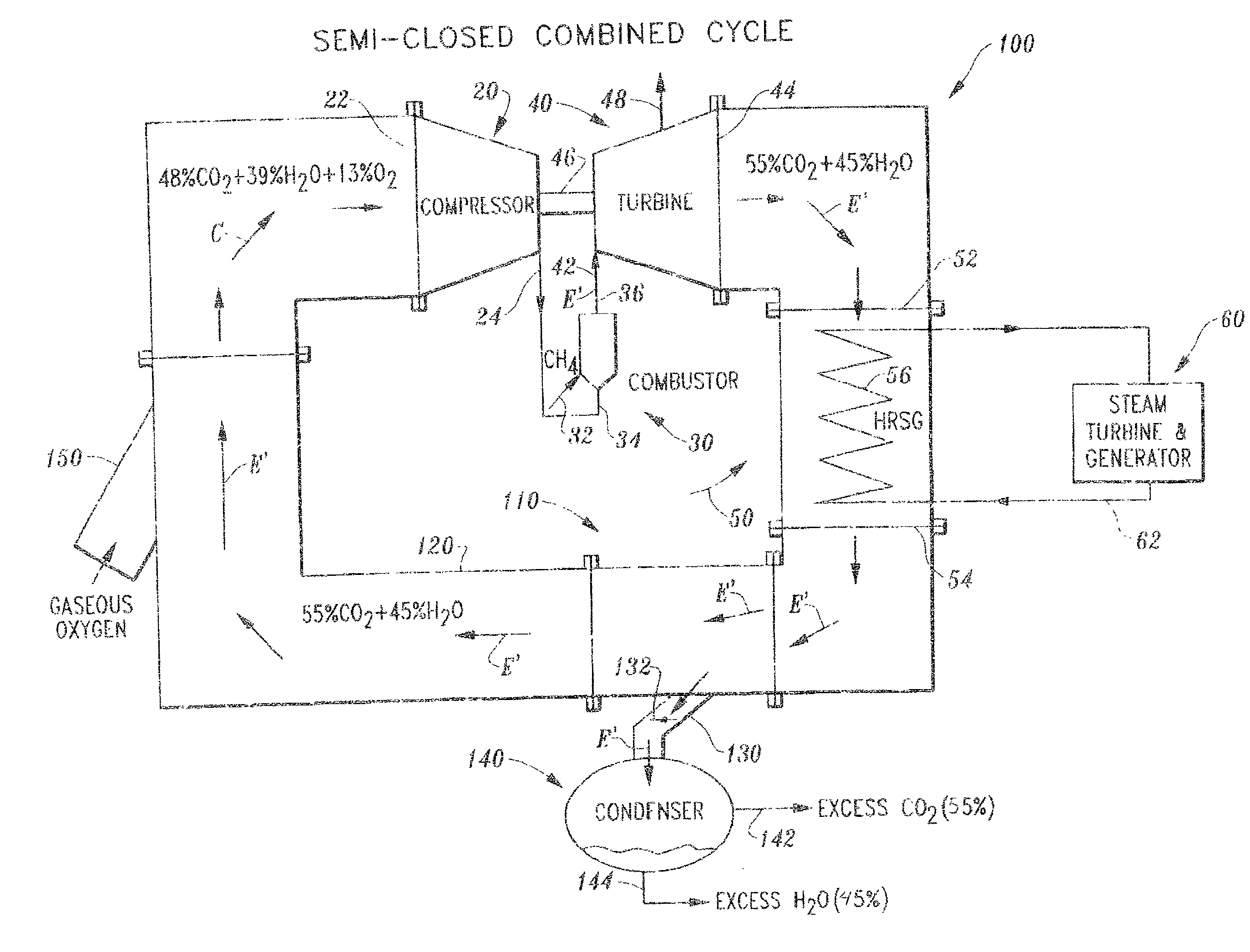

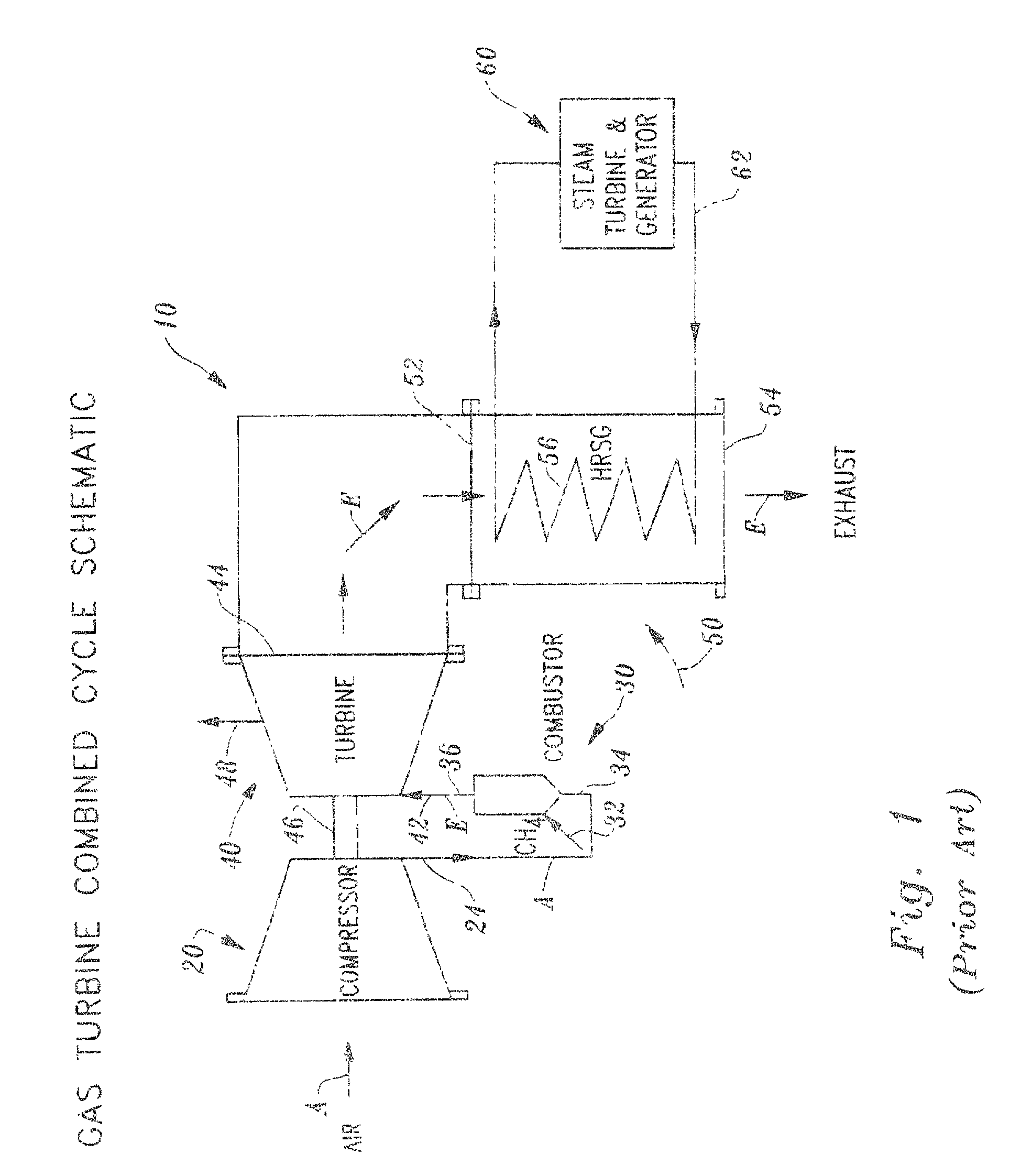

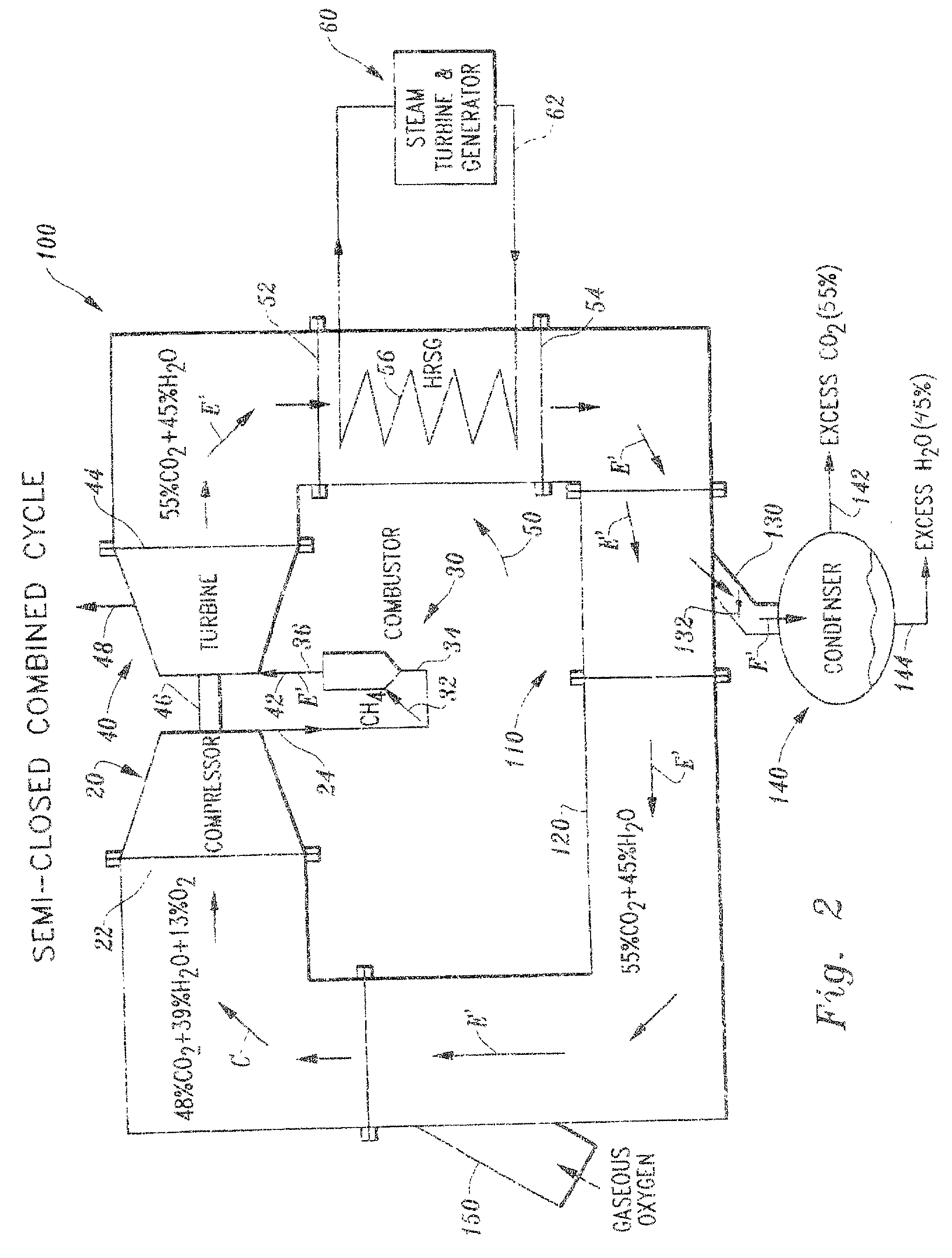

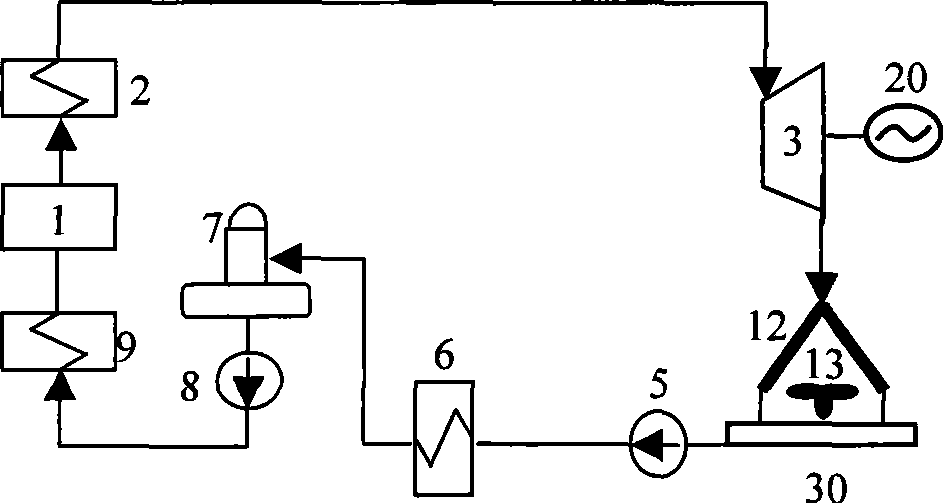

Semi-closed brayton cycle gas turbine power systems

InactiveUS20020023423A1Efficient collectionEliminate emissionsEnergy industryEfficient propulsion technologiesAtmospheric airElectric power system

A semi-closed combined cycle power system 100 is provided which can also convert an open combined cycle gas turbine 10 into a non-polluting zero emissions power system. The prior art open combined cycle gas turbine 10 includes a compressor 20 which compresses air A' and combusts the air A' with a fuel, such as natural gas. The products of combustion and the remaining portions of the air form the exhaust E' which is expanded through the turbine 40. The turbine 40 drives the compressor 20 and outputs power. The exhaust E' exits the turbine 40 and then can optionally be routed through a heat recovery steam generator 50 to function as a combined cycle. According to this invention, the exhaust E' is not emitted into the atmosphere, but rather is routed to a divider 110. The divider 110 includes two outlets for the exhaust E' including a return duct 120 and a separation duct 130 which both receive a portion of the exhaust E'. The return duct 120 routes a portion of the exhaust E' back to the compressor 20. Before reaching the compressor 20, an oxygen duct 150 adds additional oxygen to the exhaust E' to form a gas mixture C which includes CO2 and steam from the exhaust E' and oxygen from the oxygen duct 150. This gas mixture C has characteristics which mimic those of air, so that the compressor 20 need not be modified to effectively compress the gas mixture C. The gas mixture C is compressed within the compressor 20 and routed to the combustor 30 where the fuel combusts with the oxygen of the gas mixture C' and produces exhaust E' which is substantially entirely CO2 and steam. This exhaust E' is routed through the turbine 40 and expanded to drive the compressor 20 and output power. The exhaust E' exits the turbine 40 and is routed back to the divider 110, preferably by way of a heat recovery steam generator 50 or other heat removal device, so that the semi-closed cycle operates as a combined cycle power system 100. The divider 110 directs a portion of the exhaust E' to a separation duct 130 which leads to a condenser 140. In the condenser 140 the exhaust E' is separated by condensation of the steam / water portion of the exhaust and removal of the remaining CO2 as gas from the condenser 140. The only exhaust from the semi-closed power system 100 is water and CO2 from the condenser. The CO2 exhaust is substantially pure and ready for appropriate further handling and disposal. Hence, no pollutants are emitted from the semi-closed power system 100. The return duct 120 can

Owner:CLEAN ENERGY SYST

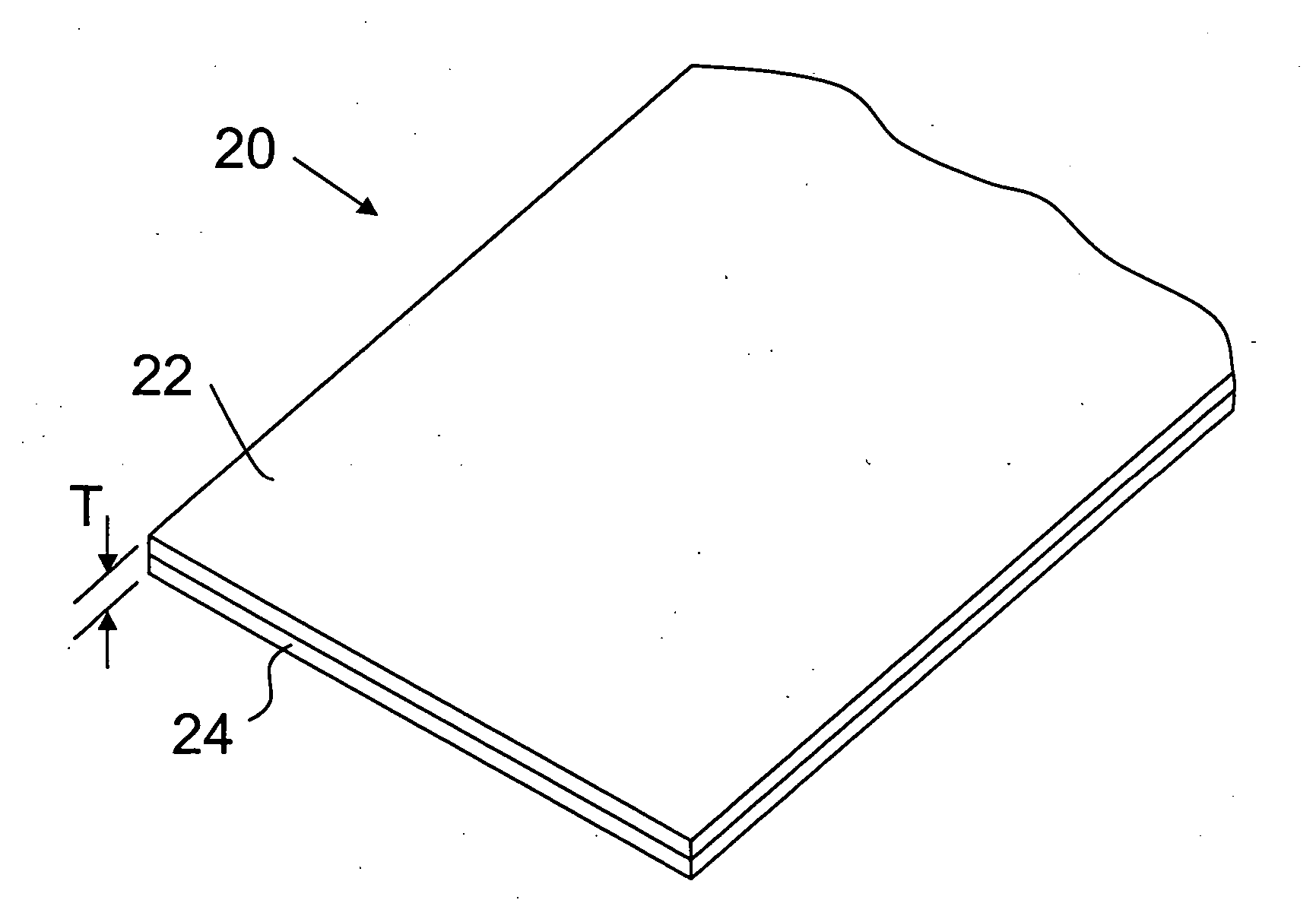

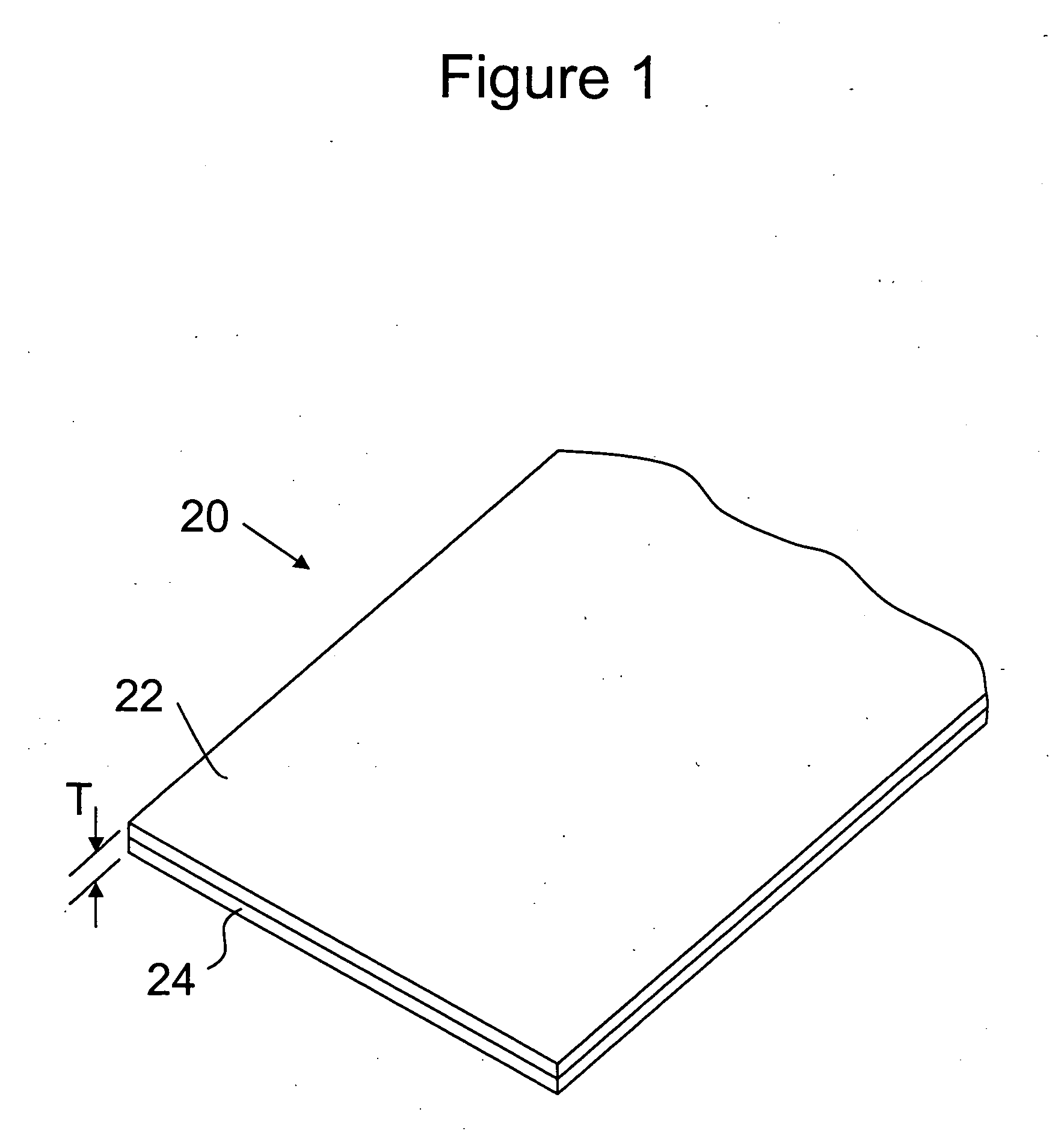

Tire with low hydrocarbon emission rubber combination of tread and sidewall components with compositional limitations

InactiveUS7214731B2Eliminate emissionsEmission reductionSpecial tyresInflatable tyresElastomerHydrophobic silica

The invention relates to a tire of a structural combination of tire tread and sidewall components with compositional limitations containing minimal, if any, of in situ formed alcohol and methyl isobutyl ketone byproducts. The tread component rubber composition contains pre-hydrophobated silica reinforcement. The sidewall component contains low unsaturation EPDM or brominated copolymer of isobutylene and p-methylstyrene and may contain pre-hydrophobated silica reinforcement. The silica reinforcement for said tread and sidewall components is a pre-hydrophobated precipitated silica. The pre-hydrophobated silica is prepared, prior to mixing with the elastomer(s), by reacting hydroxyl groups (e.g. silanol groups) contained on the surface of a precipitated silica with an alkoxyorganomercaptosilane or a combination of an alkoxyorganomercaptosilane and a substituted alkylsilane or with a bis-3(trialkoxysilylalkyl) polysulfide which contains an average of from 2 to 4 connecting sulfur atoms in its polysulfidic bridge to form a composite thereof. The alcohol byproduct therefrom is removed from the composite prior to its introduction into the rubber composition(s). In another aspect of the invention, the connecting sidewall rubber composition, and optionally the tread composition is free of N-(1,3-dimethylbutyl)-N′-phenyl-p-phenylenediamine antidegradant (referred herein to as 6PPD) in order to prevent in situ formation of methyl isobutyl ketone byproduct from the reaction of 6PPD with atmospheric oxygen and / or ozone.

Owner:THE GOODYEAR TIRE & RUBBER CO

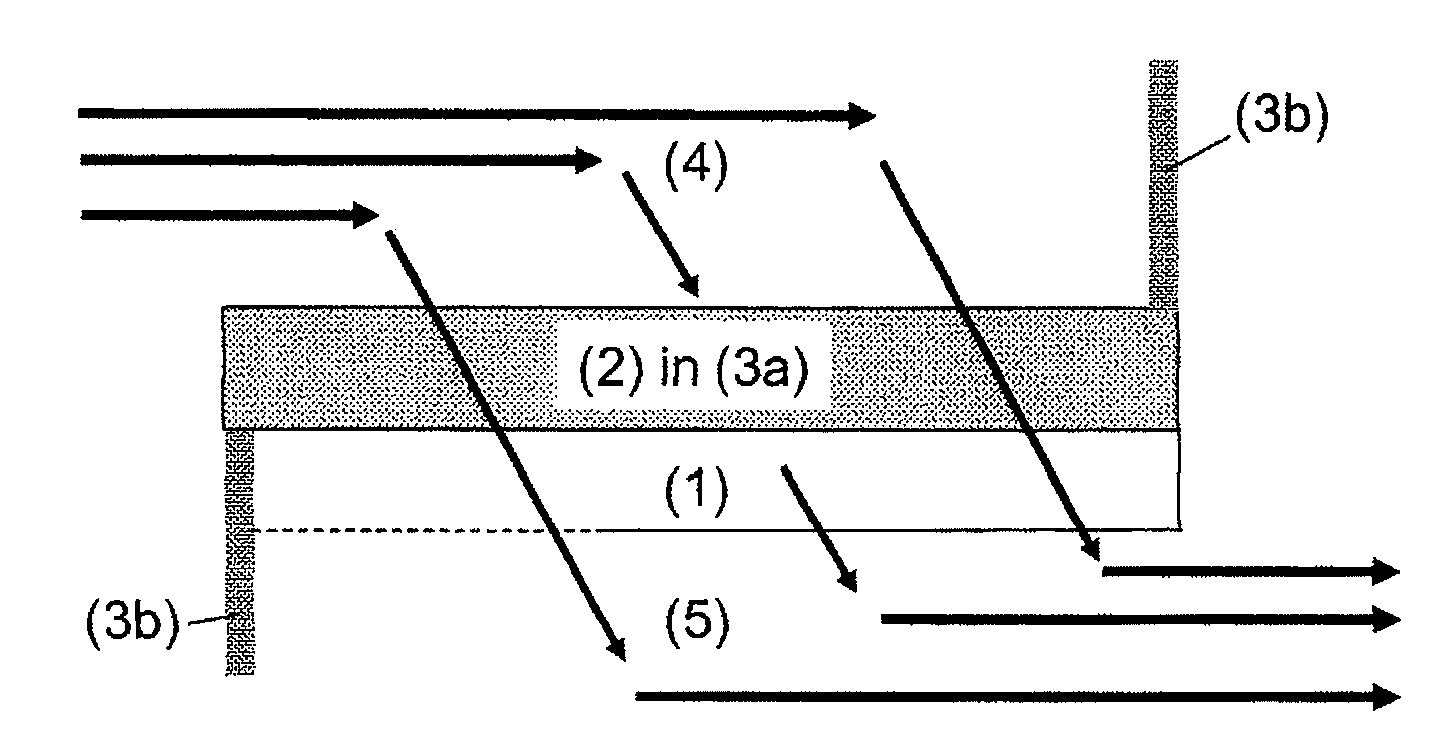

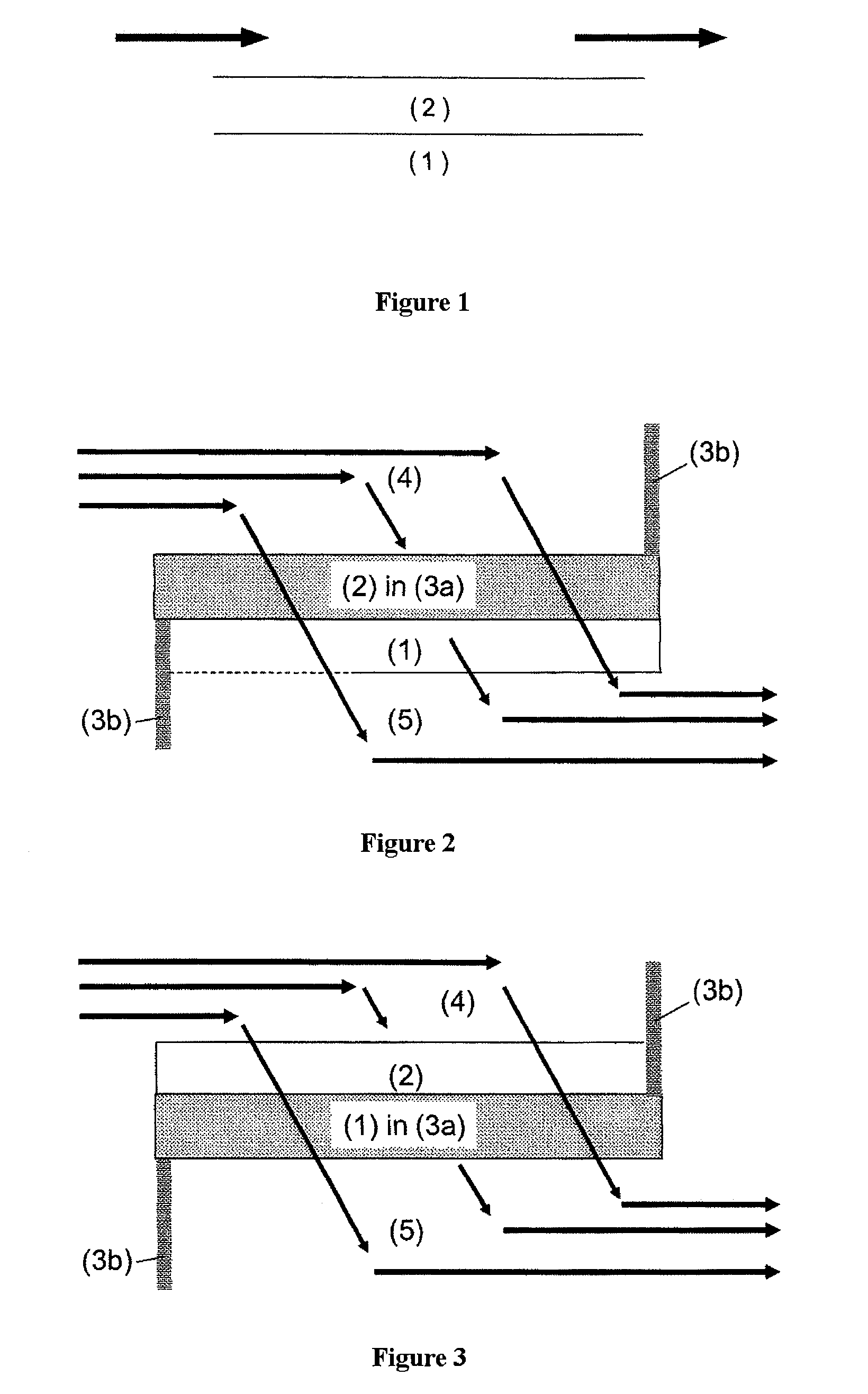

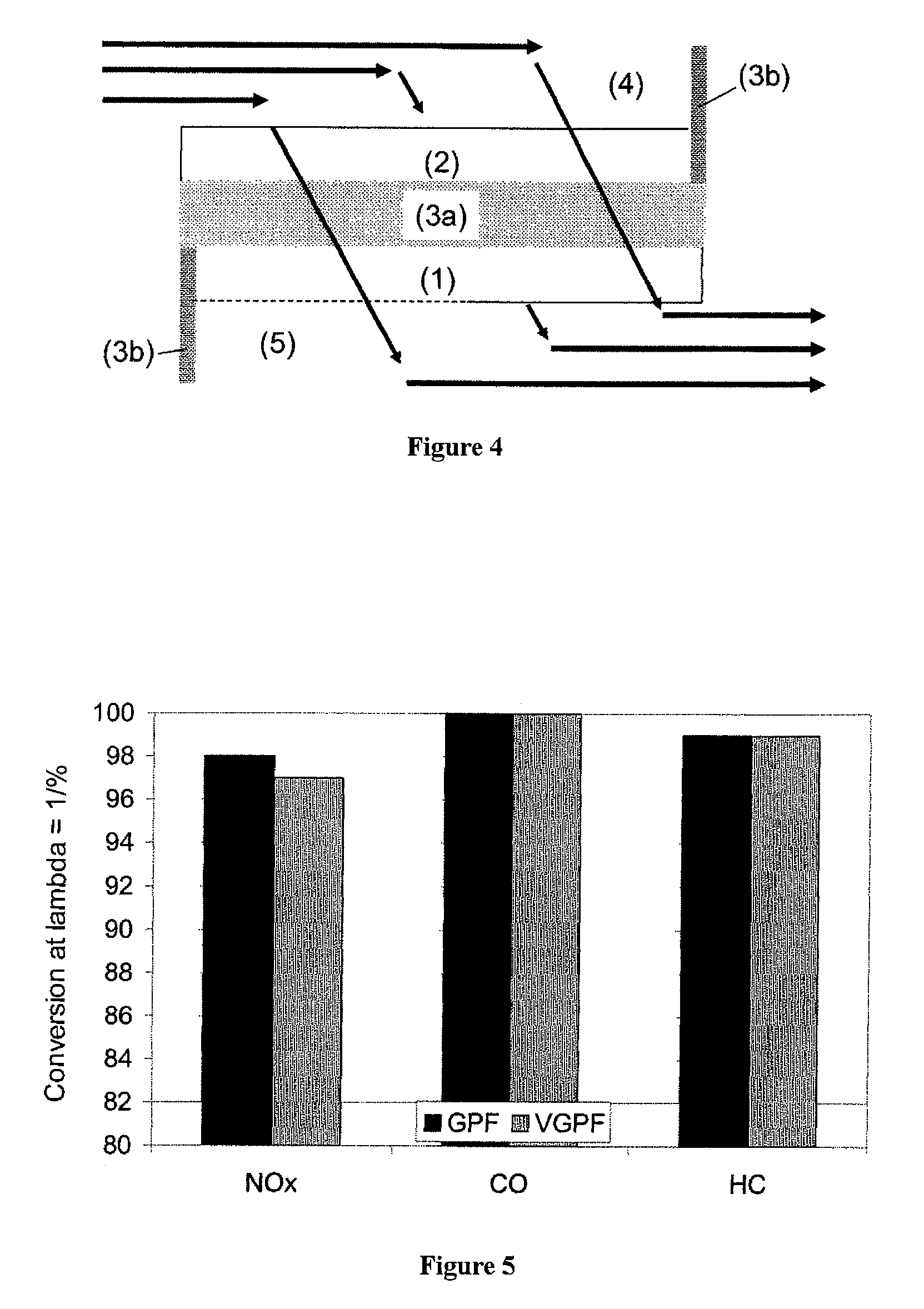

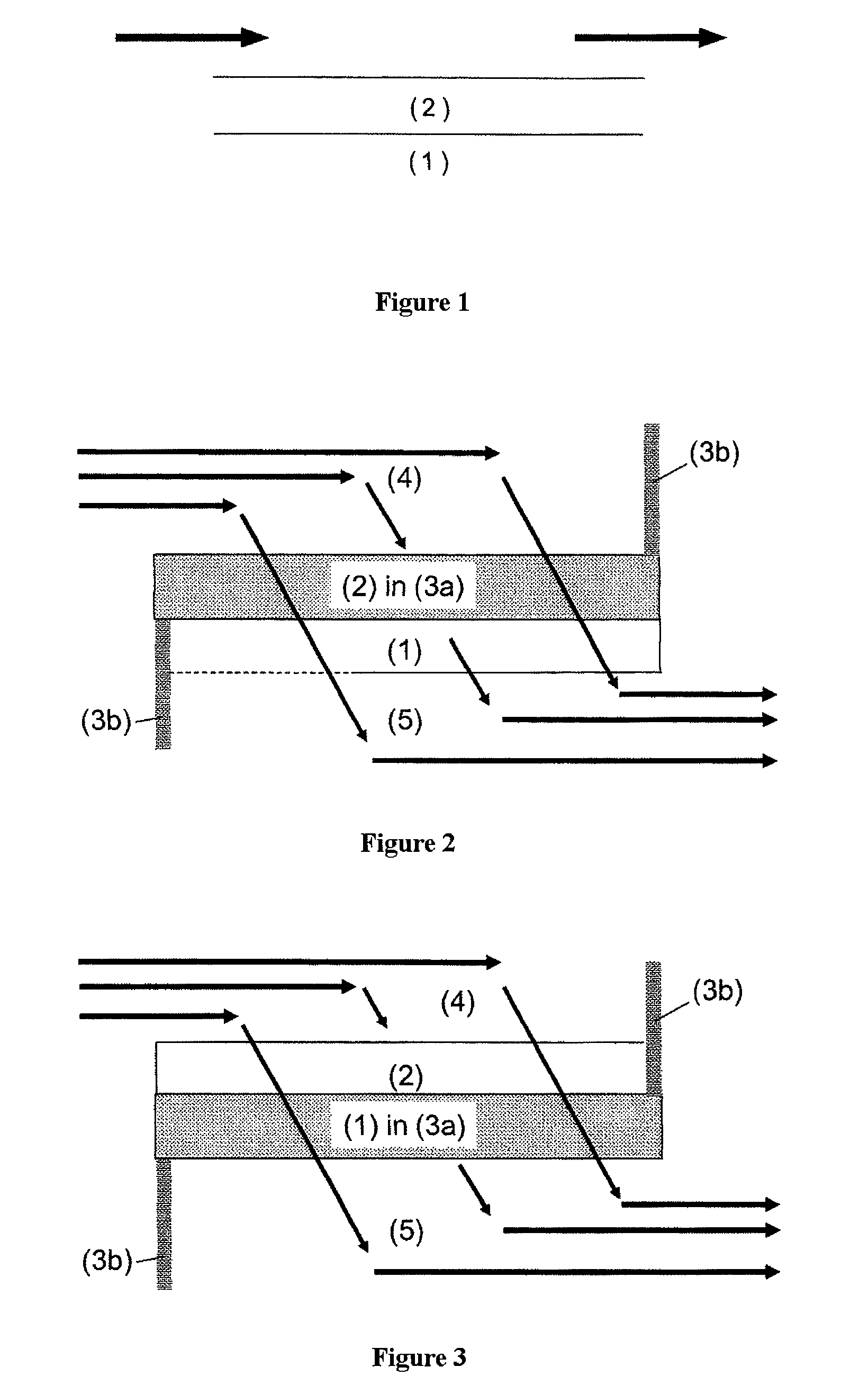

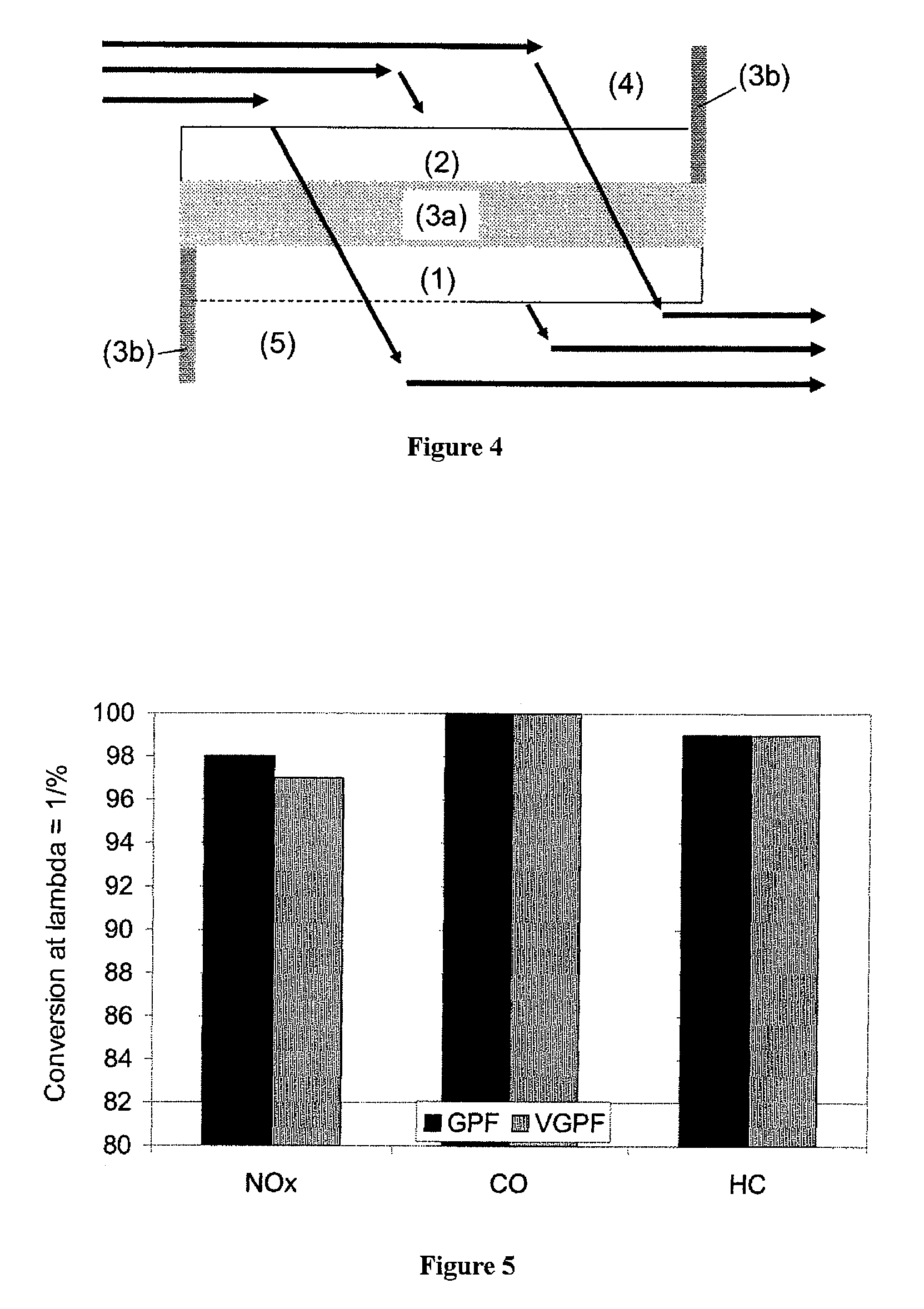

Removal of particulates from the exhaust gas of internal combustion engines operated with a predominantly stoichiometric air/fuel mixture

ActiveUS20090087365A1Sufficient thermal aging stabilityImproved thermal cycling stabilityCombination devicesOrganic chemistryExternal combustion engineEngineering

The exhaust gas of internal combustion engines operated with a predominantly stoichiometric air / fuel mixture contains, as well as the gaseous hydrocarbon (HC), carbon monoxide (CO) and nitrogen oxide (NOx) pollutants, also ultrafine particulates. The introduction of the EU-5 exhaust gas standard in Europe in 2010 will for the first time impose a legal limit to these particulate emissions for gasoline vehicles. Future exhaust gas cleaning concepts for these vehicles must include devices for removing these particulates.A catalytically active particulate filter, an exhaust gas cleaning system and a process for cleaning the exhaust gases of predominantly stoichiometrically operated internal combustion engines are presented, which are suitable, as well as the gaseous CO, HC and NOx pollutants, also for removing particulates from the exhaust gas. The particulate filter comprises a filter body and a catalytically active coating consisting of two layers. Both layers contain alumina. The first layer contains palladium. The second layer contains rhodium. The latter is disposed above the first layer.

Owner:UMICORE AG & CO KG

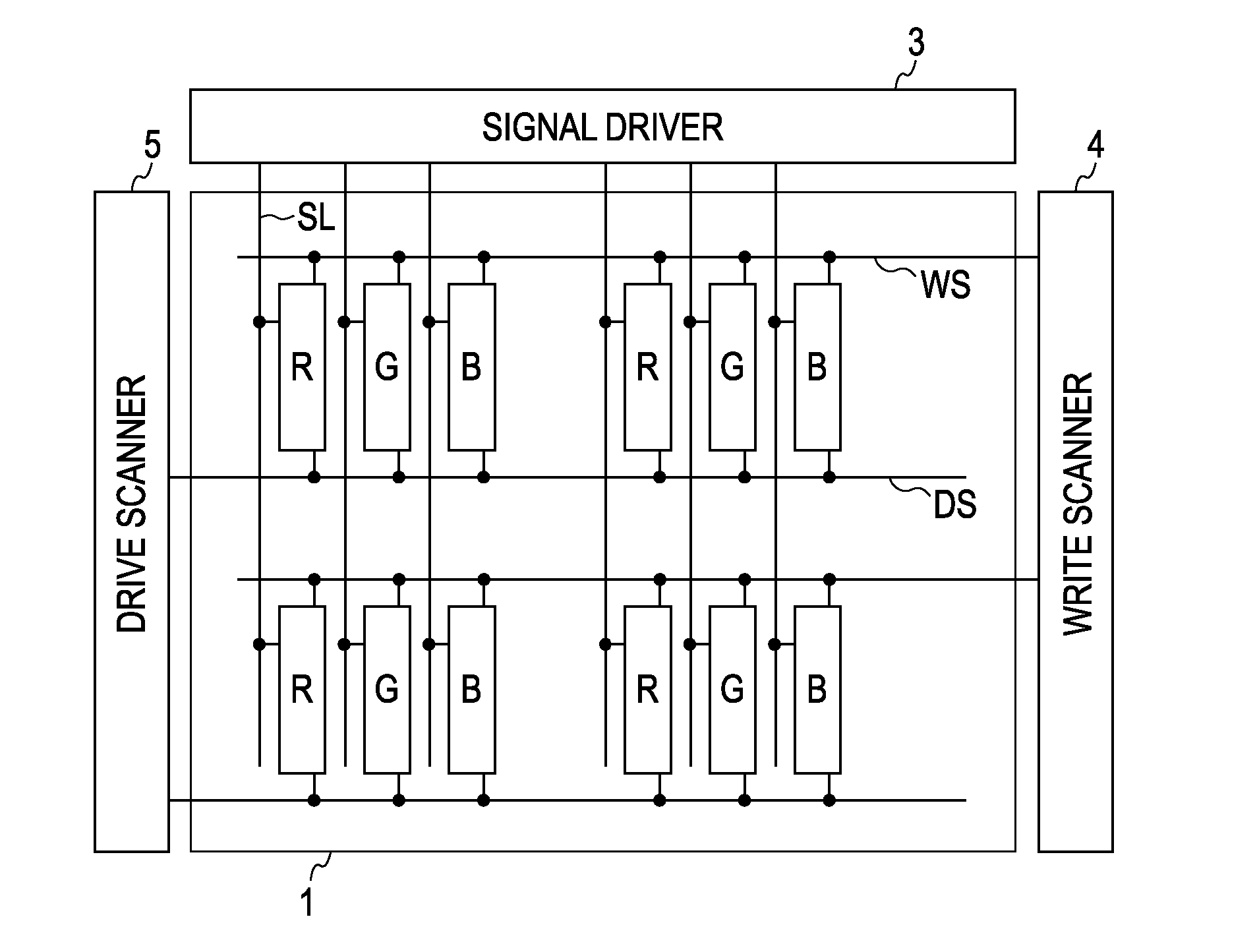

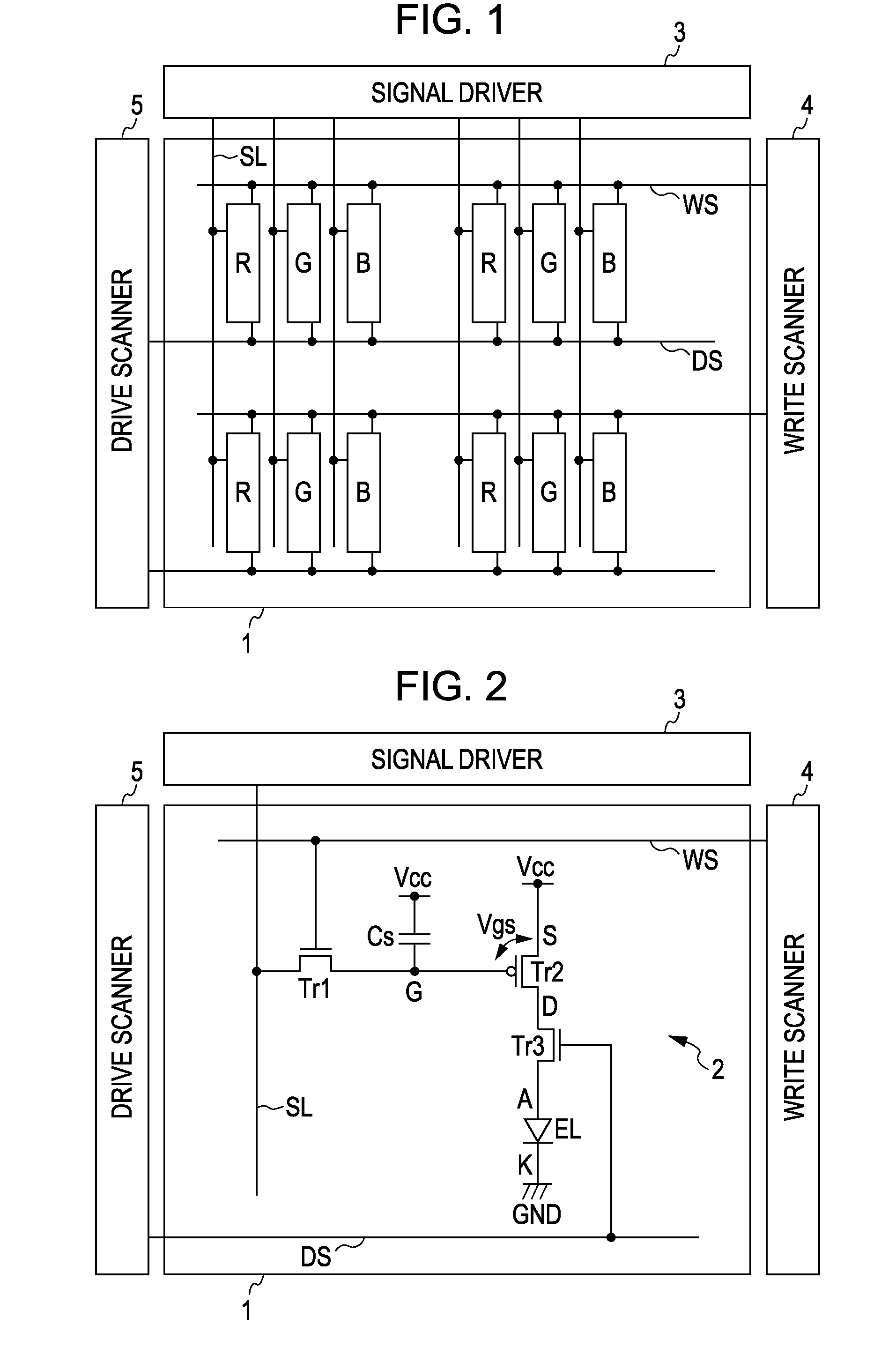

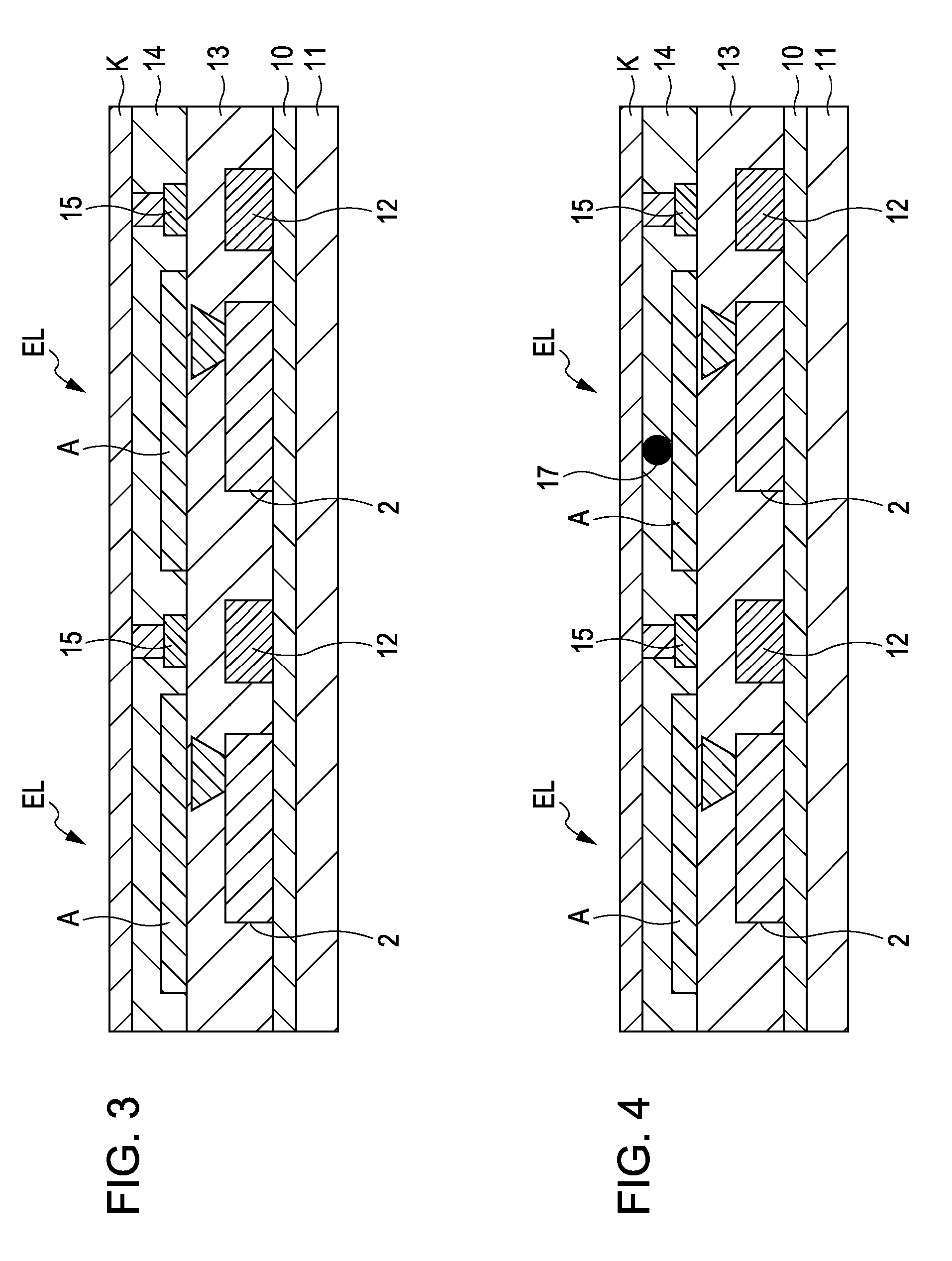

Active matrix display apparatus and electronic apparatus

InactiveUS20080062096A1Dark spot defect is corrected with easeProbability of generation of a short-circuit defect due to adhesion of a contaminant particleStatic indicating devicesSolid-state devicesDriving currentActive matrix

An active matrix display apparatus includes a substrate having scanning lines, signal lines, and pixels thereon. Each of the pixels includes a sampling transistor for taking in a video signal, a drive transistor for generating a driving current, and a light-emitting device which emits light with luminance in accordance with the video signal. The two-terminal thin-film light-emitting device includes an anode and cathode electrodes, and a light-emitting layer arranged therebetween. At least one of the electrodes is divided into pieces whereby the light-emitting device is divided into sub-light-emitting devices. The sub-light-emitting devices receive the driving current from a driving transistor and emit light with luminance in accordance with the video signal. A sub-light-emitting devices including a short-circuit defect is separated from the corresponding one of the pixels and the driving current is supplied to the remaining sub-light-emitting devices, whereby the luminance in accordance with the video signal is maintained.

Owner:SONY CORP

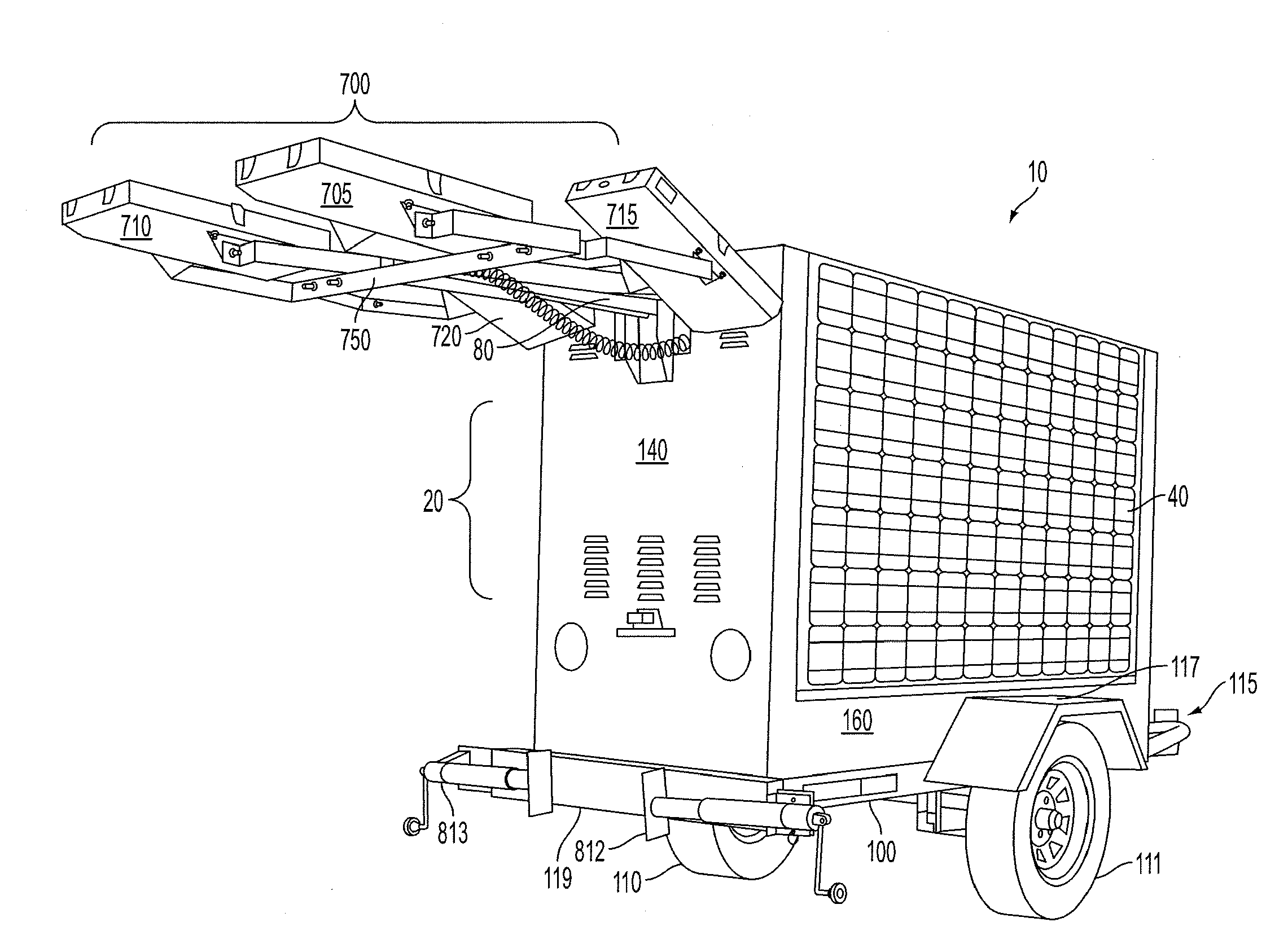

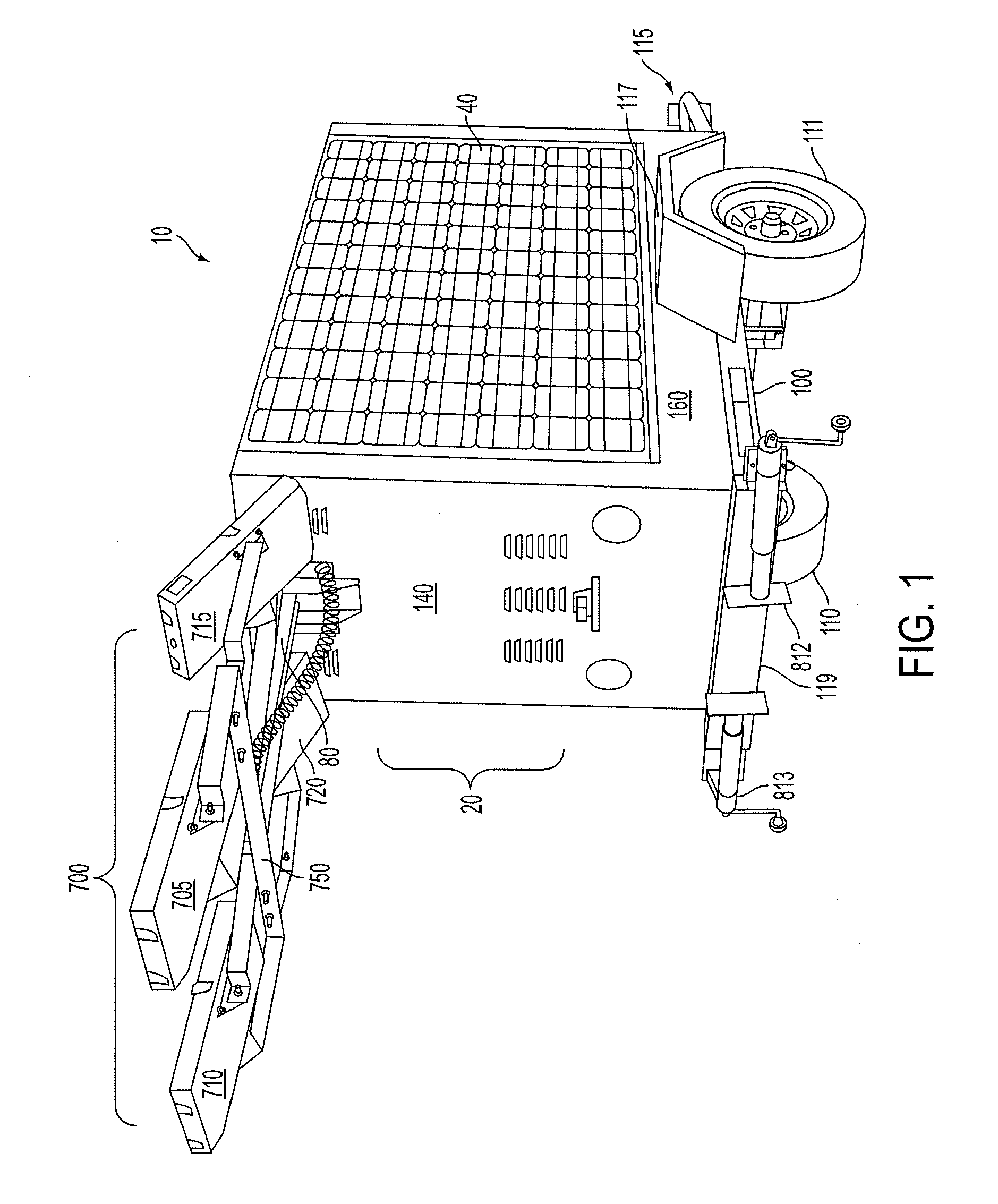

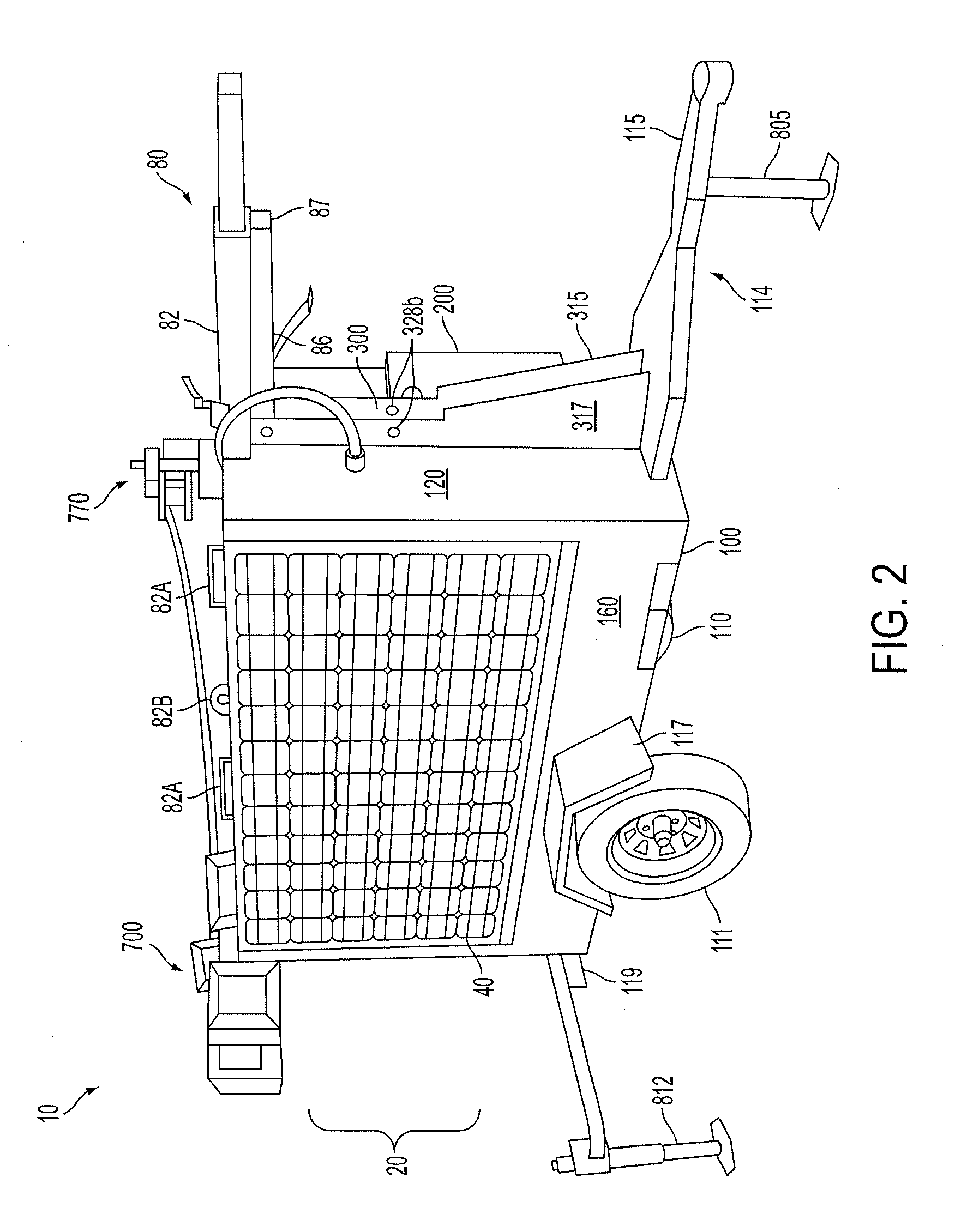

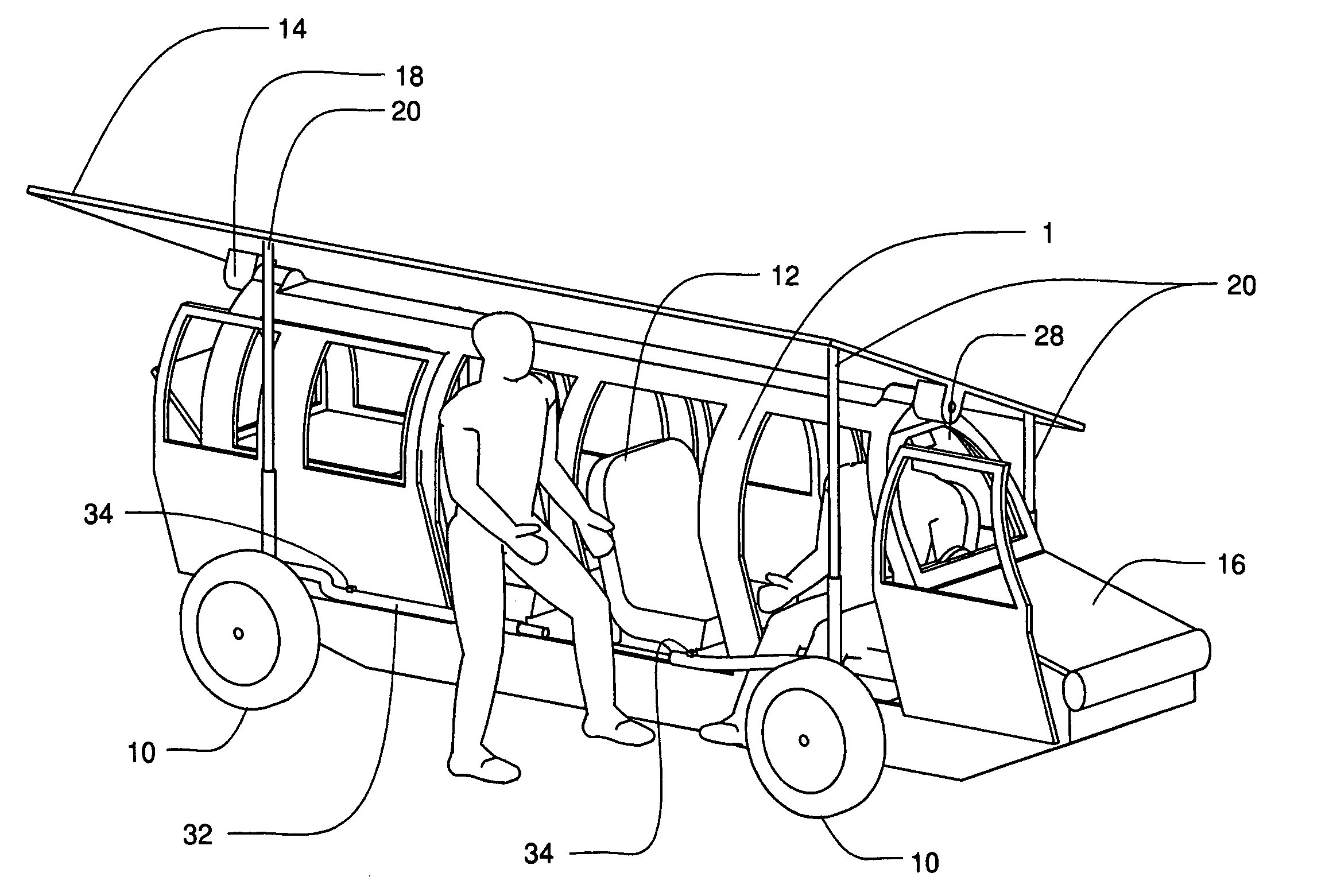

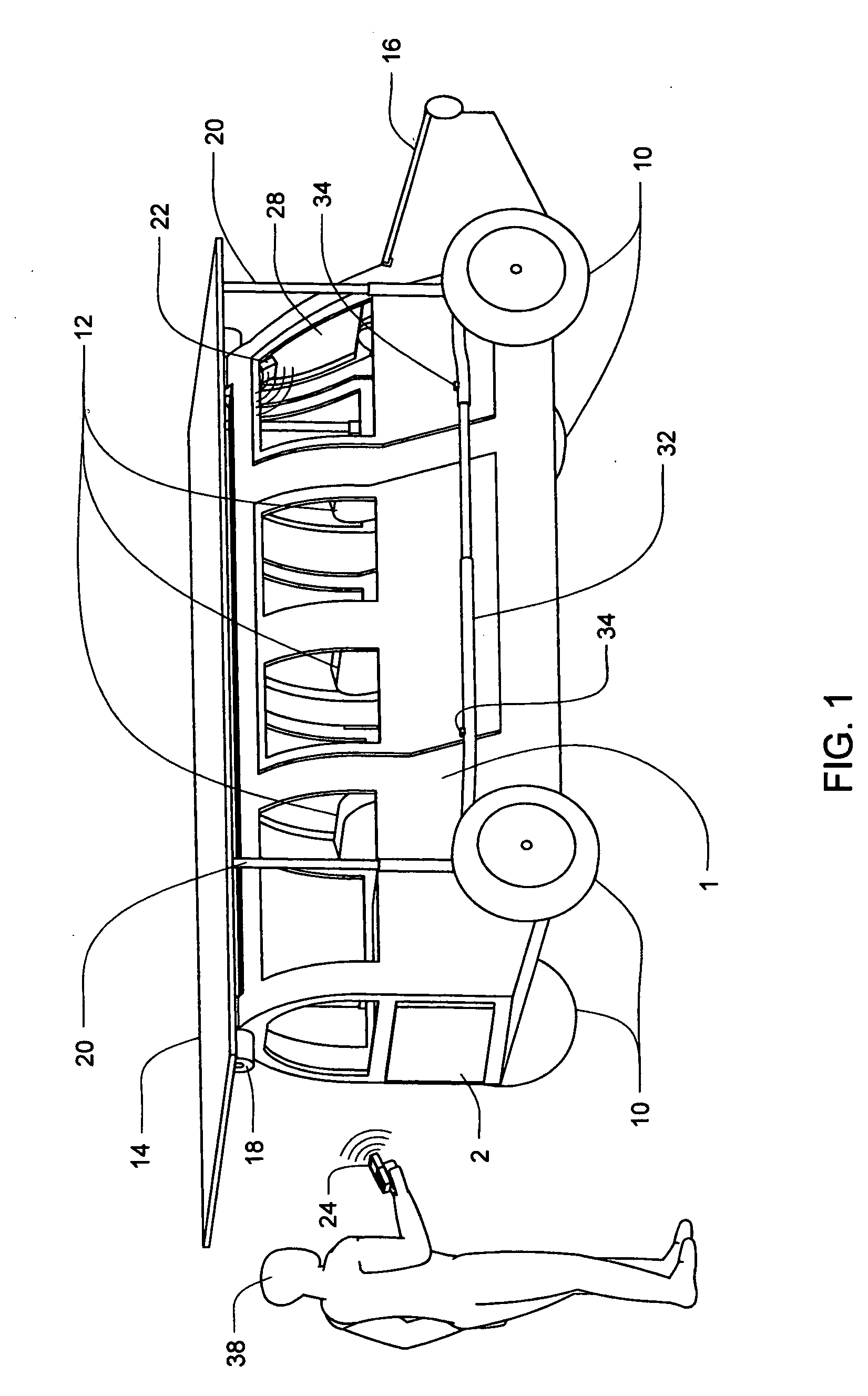

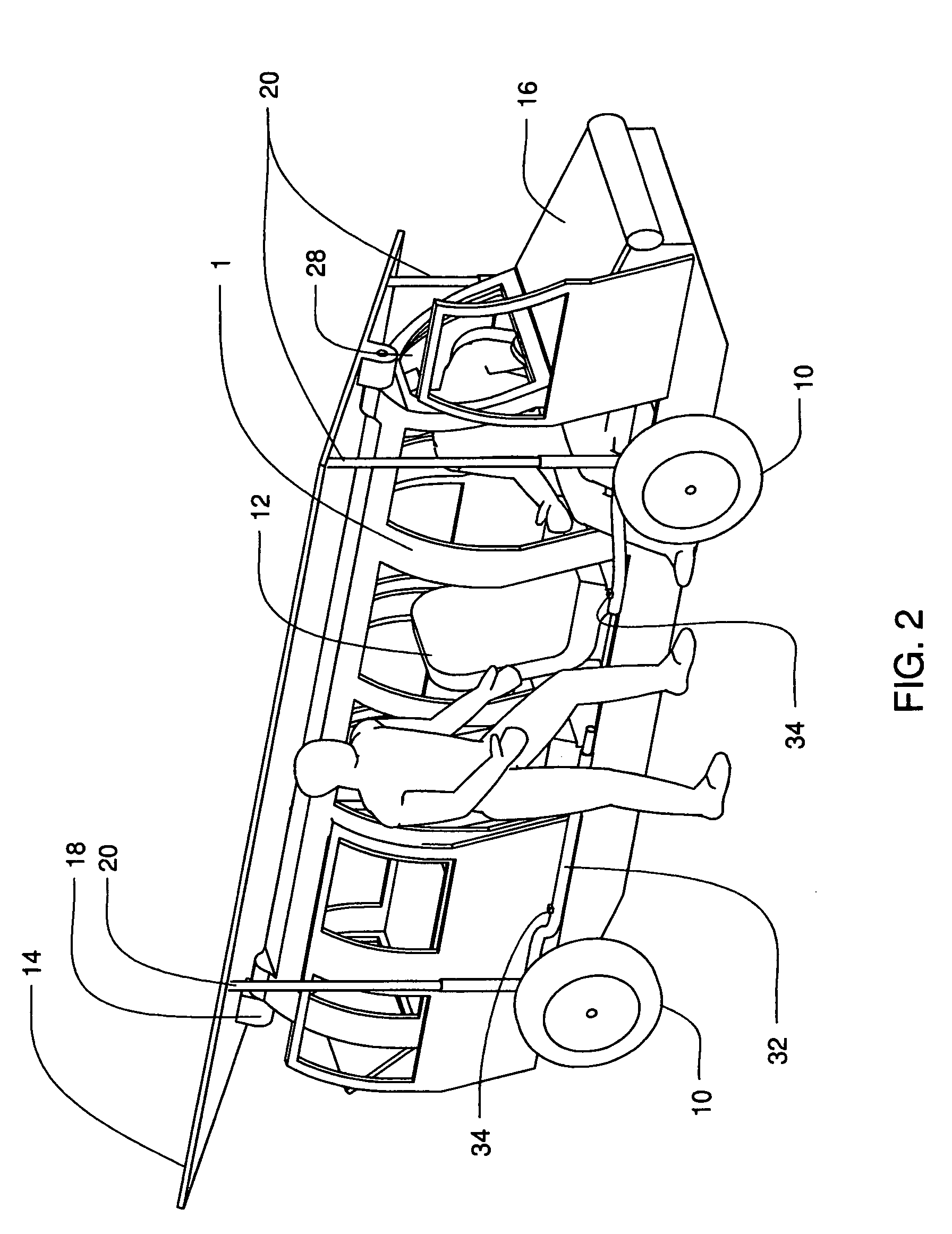

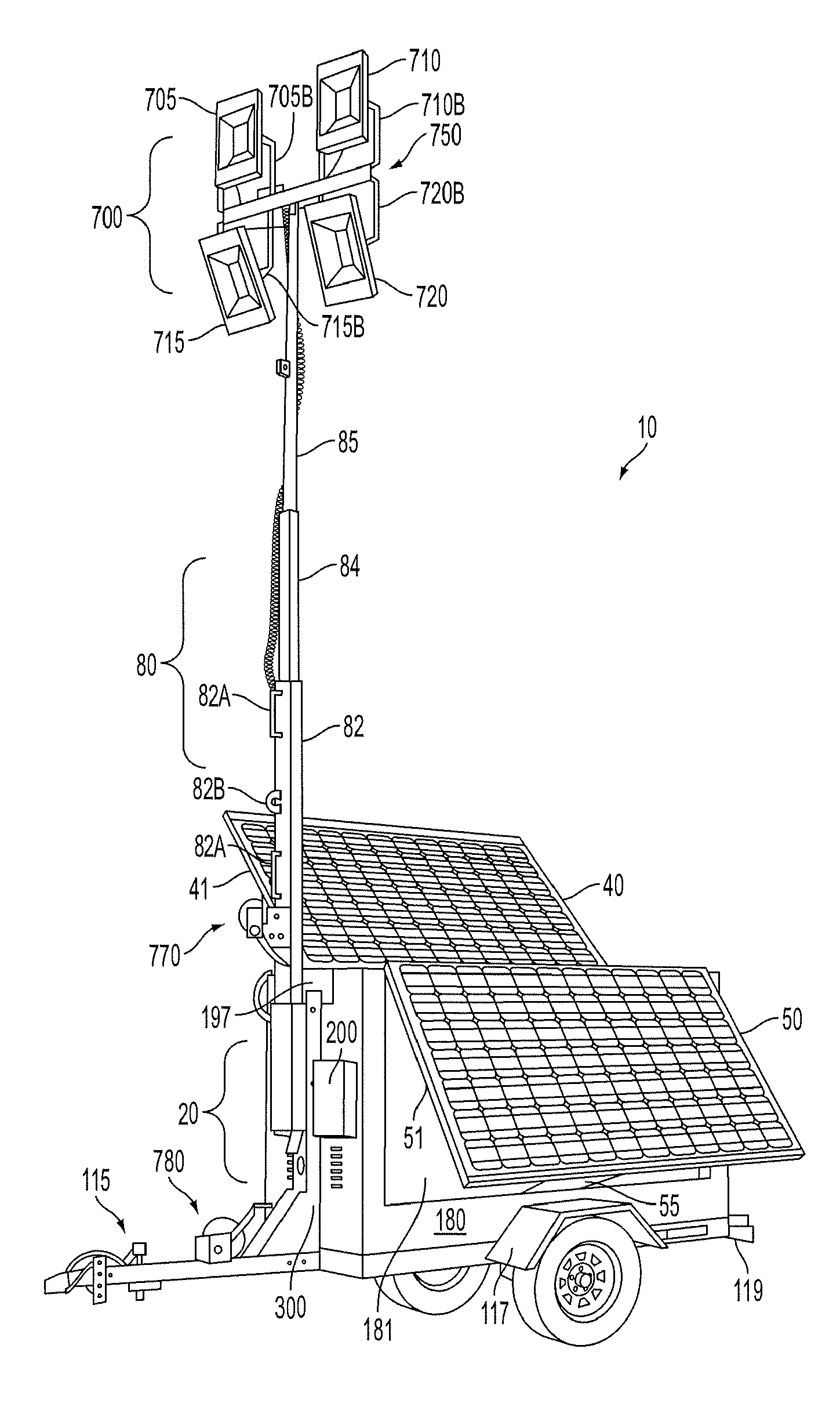

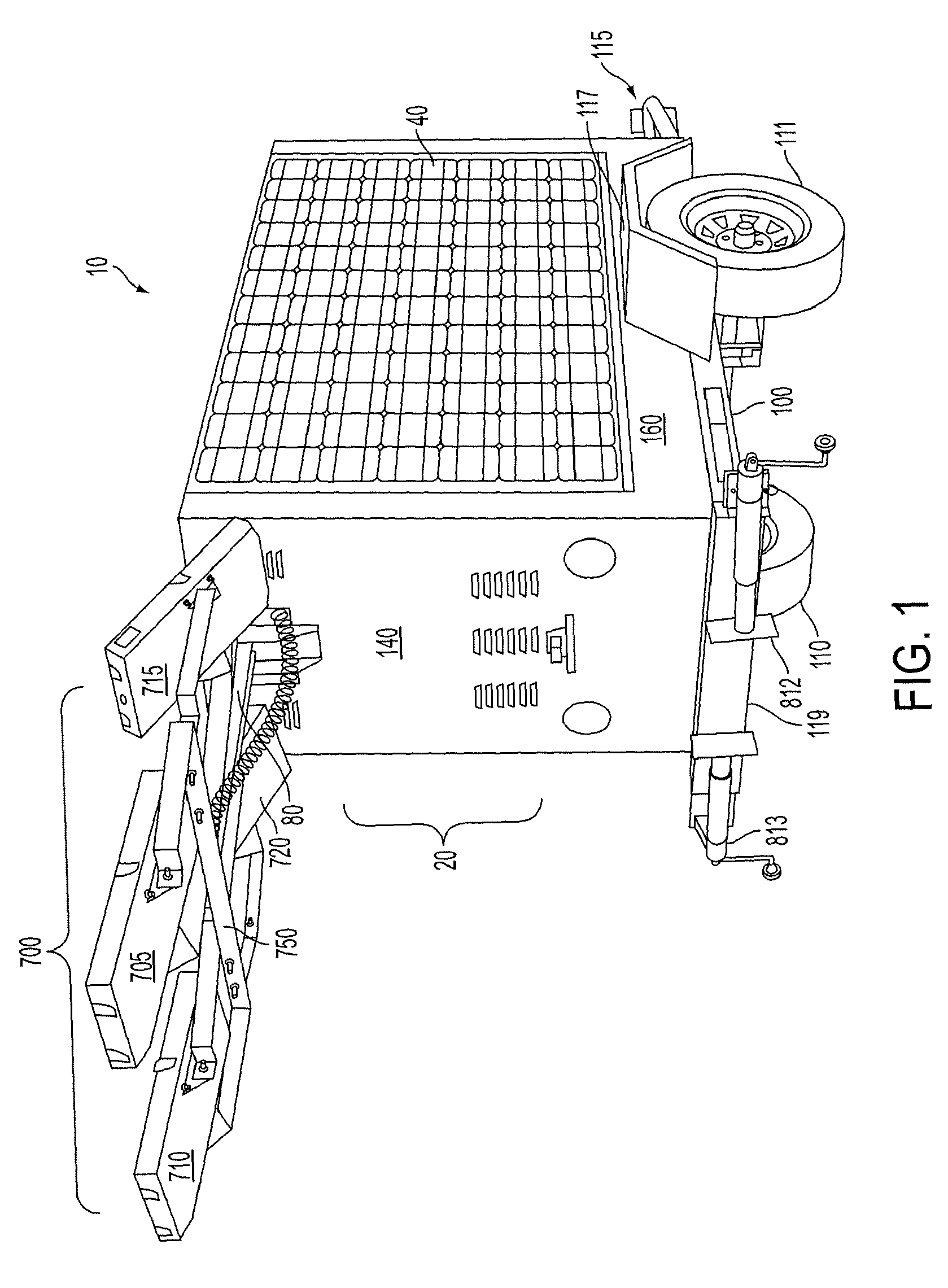

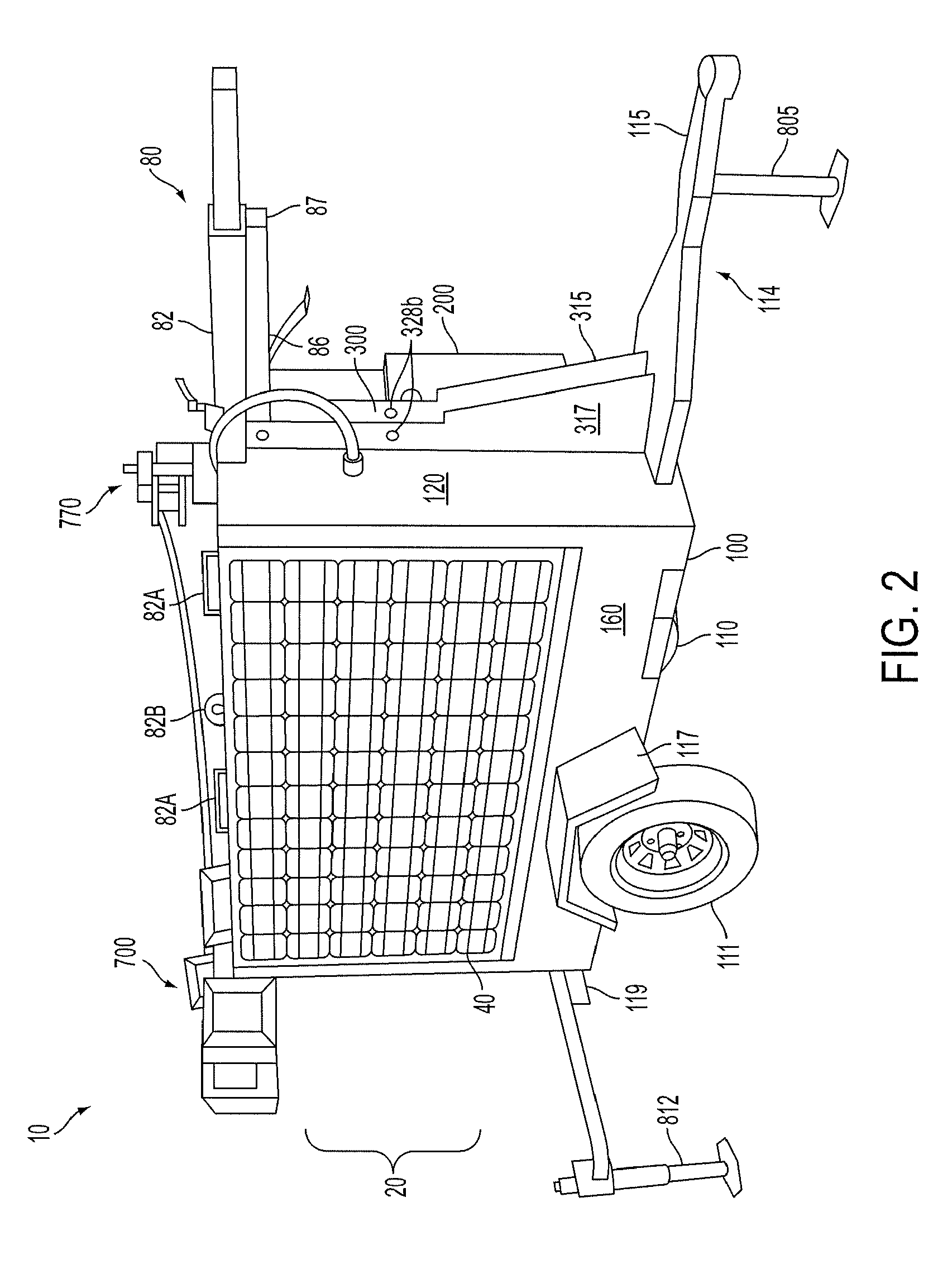

Mobile solar-powered light tower

ActiveUS20120201016A1Excellent and useful lightingRemove carbon emissionsMechanical apparatusLighting support devicesLight equipmentElectrical battery

Provided is a mobile lighting device that can derive power from a renewable energy source, such as solar power. The device can comprise a mobile base unit that can house one or more components of the device. The device further can comprise a solar power module associated with the mobile base unit that converts solar energy into electrical current. The device also can comprise a lighting module associated with the mobile base unit that is at least partially powered either directly or indirectly using the electrical current from the solar power module. The device further can comprise a solar power storage module, such as comprising one or more batteries, for storing energy and discharging as electrical current for powering the lighting module, which can be positioned atop a mast that can be extendable, pivotable, and / or rotatable. The invention also provides methods and systems for illuminating areas.

Owner:RENEWABLE ENERGY HLDG

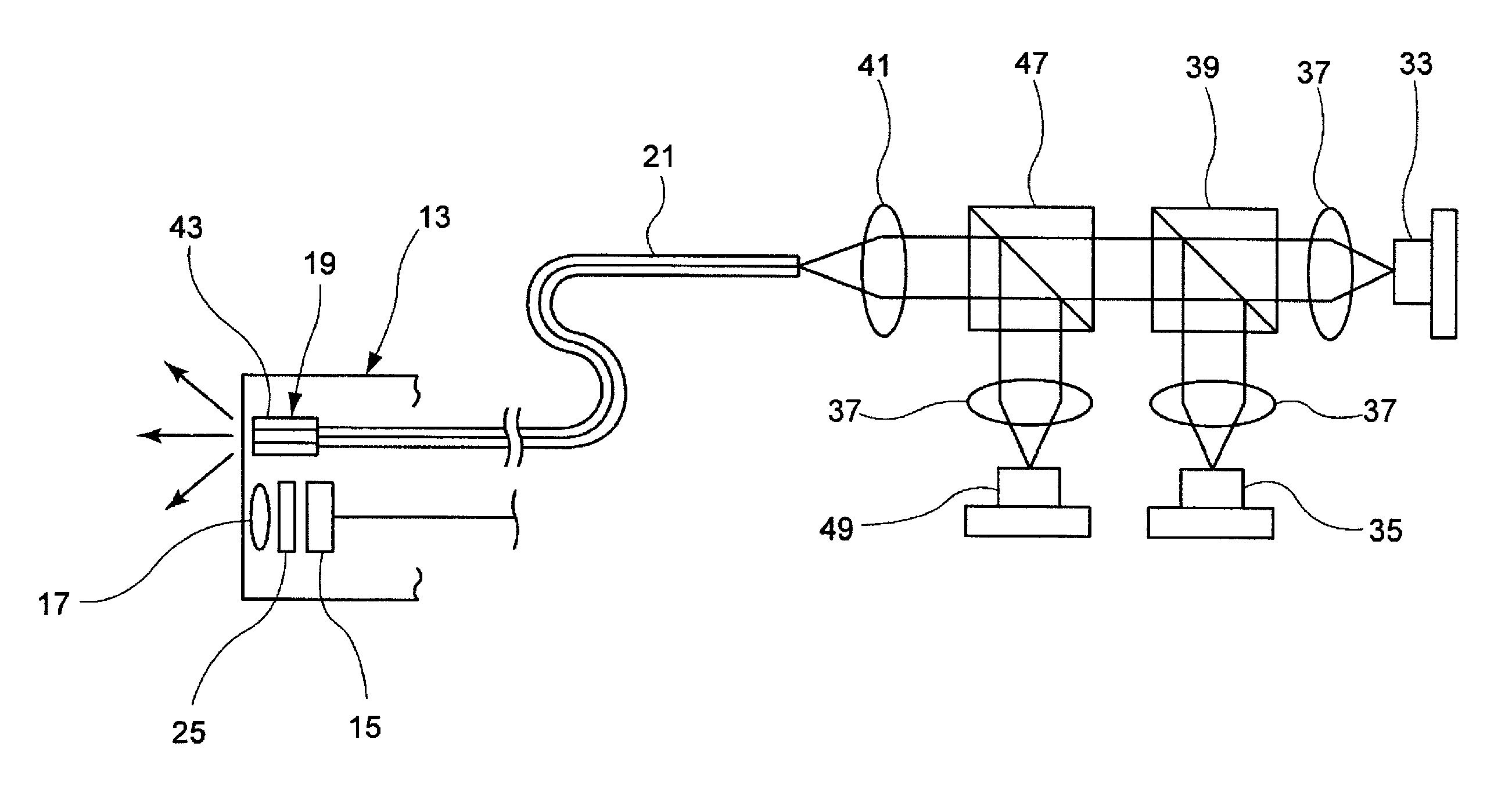

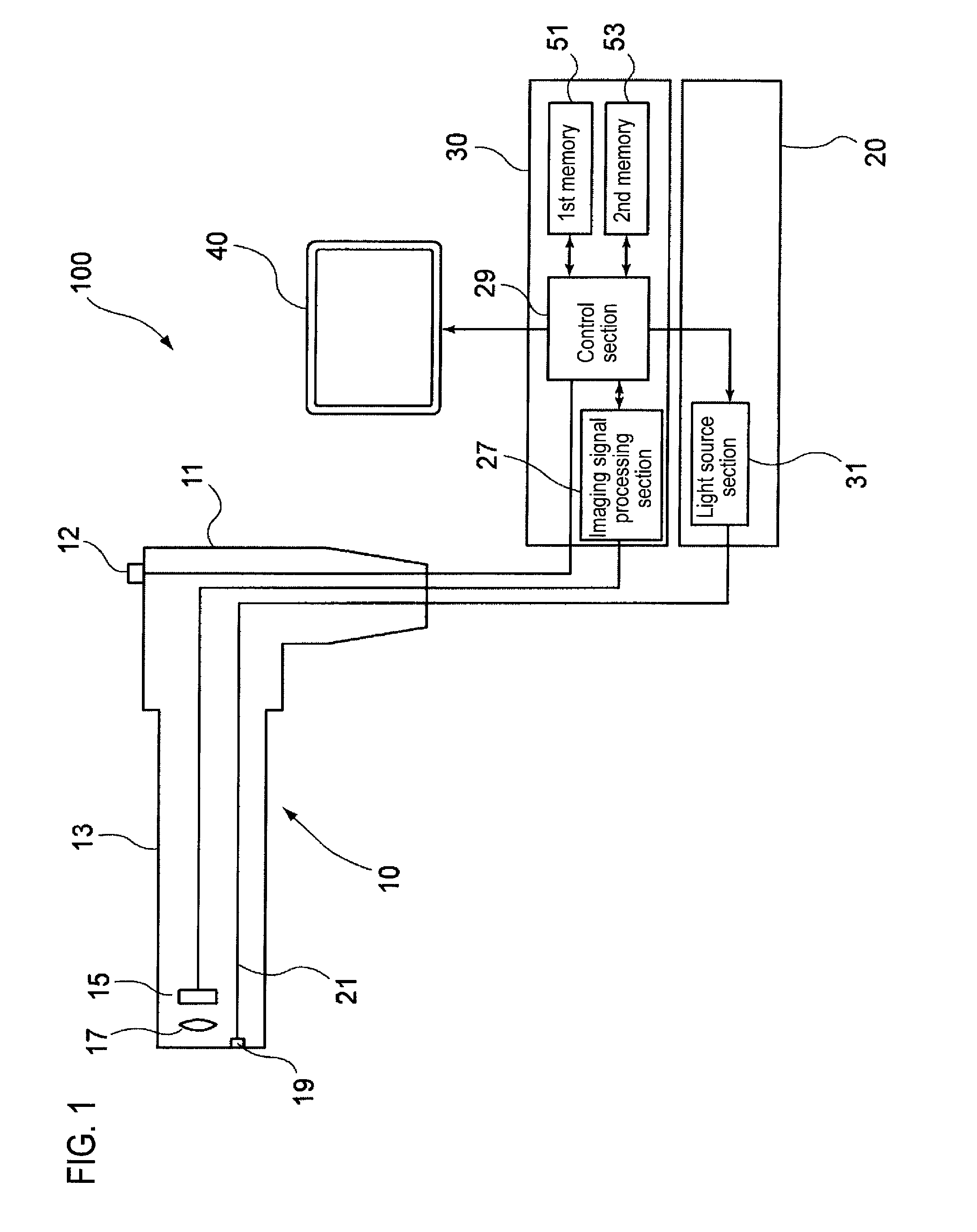

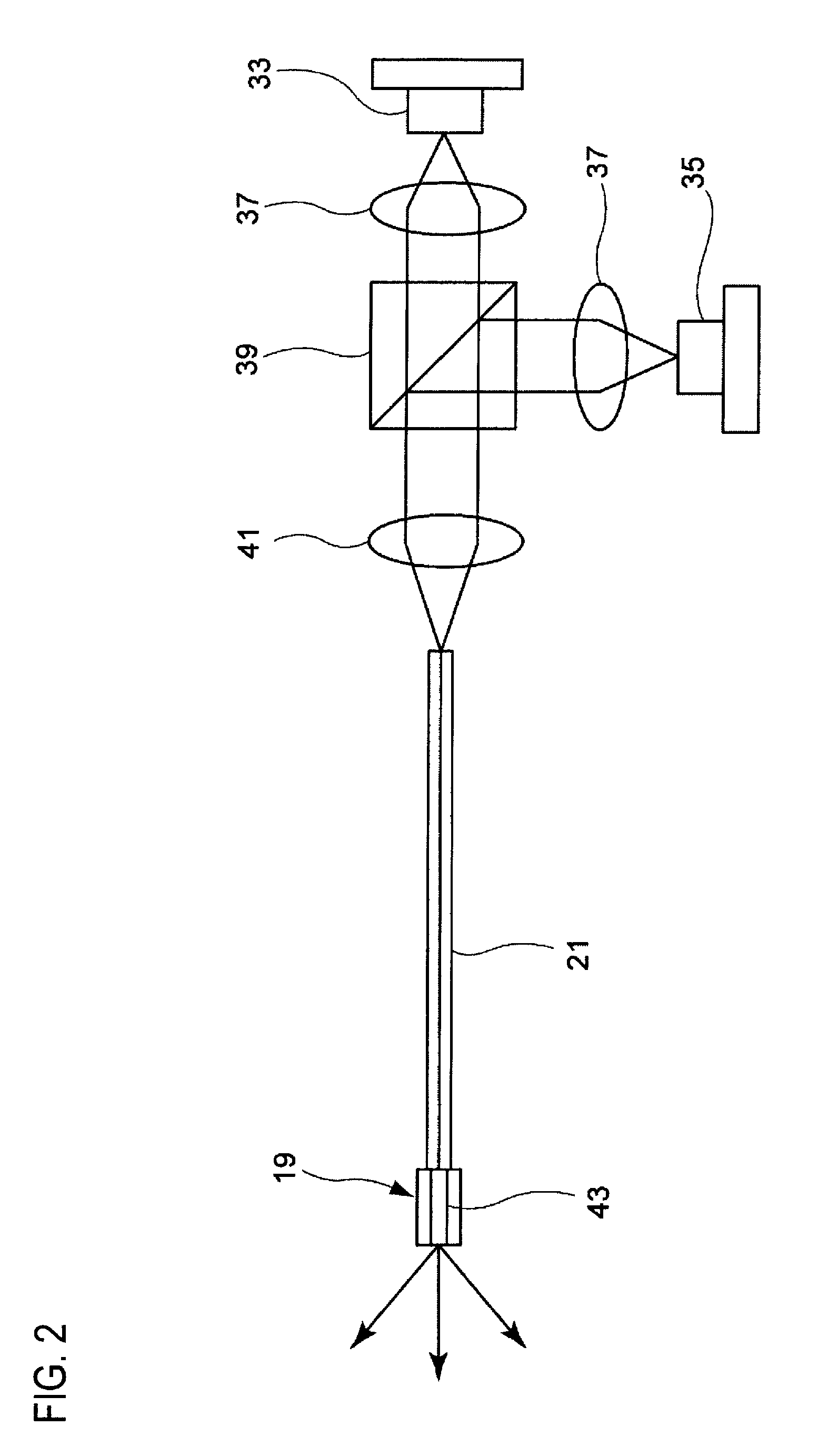

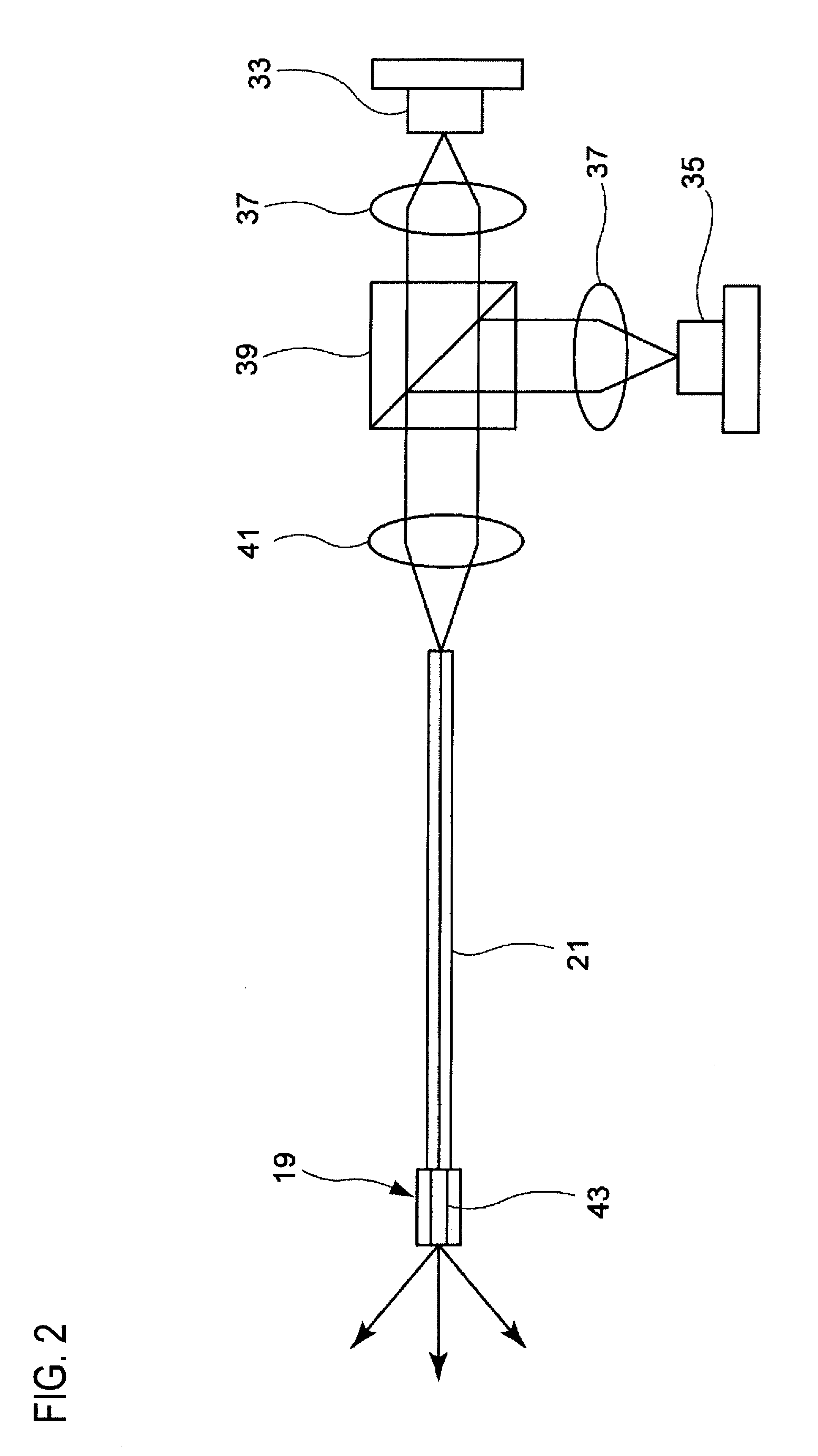

Light source device, imaging apparatus and endoscope apparatus

InactiveUS20090312607A1Improve accuracySimple designTelevision system detailsCladded optical fibrePhosphorLength wave

A light source device includes a first light source 33, a second light source 35 having an emission wavelength that is different from the first light source 33, and a phosphor 43 that is disposed to be distant from the first light source 33 and the second light source 35 and absorbs light in a predetermined excitation wavelength band to emit fluorescence. The phosphor 43 is disposed on an emission light optical path that is shared by the first light source 33 and the second light source 35. The emission wavelength of the first light source 33 is in the predetermined excitation wavelength band. The emission wavelength of the second light source 35 is outside of the predetermined excitation wavelength band.

Owner:FUJIFILM CORP

Removal of particulates from the exhaust gas of internal combustion engines operated with a predominantly stoichiometric air/fuel mixture

ActiveUS8066963B2Eliminate emissionsSmall sizeCombination devicesOrganic chemistryExternal combustion engineChemical measurement

The exhaust gas of internal combustion engines operated with a predominantly stoichiometric air / fuel mixture contains, as well as the gaseous hydrocarbon (HC), carbon monoxide (CO) and nitrogen oxide (NOx) pollutants, also ultrafine particulates. There is disclosed a catalytically active particulate filter, an exhaust gas cleaning system and a process for cleaning the exhaust gases of predominantly stoichiometrically operated internal combustion engines, as well as the gaseous CO, HC and NOx pollutants, also for removing particulates from the exhaust gas. The particulate filter comprises a filter body and a catalytically active coating consisting of two layers. Both layers contain alumina. The first layer contains palladium. The second layer contains rhodium. The latter is disposed above the first layer.

Owner:UMICORE AG & CO KG

Electric car with maximized solar assist

InactiveUS20100193260A1Eliminate emissionsReduce threatAuxillary drivesVehicular energy storageElectricityContinuous flow

The present invention is an electric car with a maximized solar panel assist. Since batteries are normally charged at night while solar energy is created during the day, this system creates an almost continuous flow of electricity to the batteries. Since the weight and cost of the batteries are the main handicap for electric cars and a continuous flow of electricity minimizes the need for a large and expensive battery system, this is the most logical way to build a viable electric car.

Owner:FREEMAN BENJAMIN

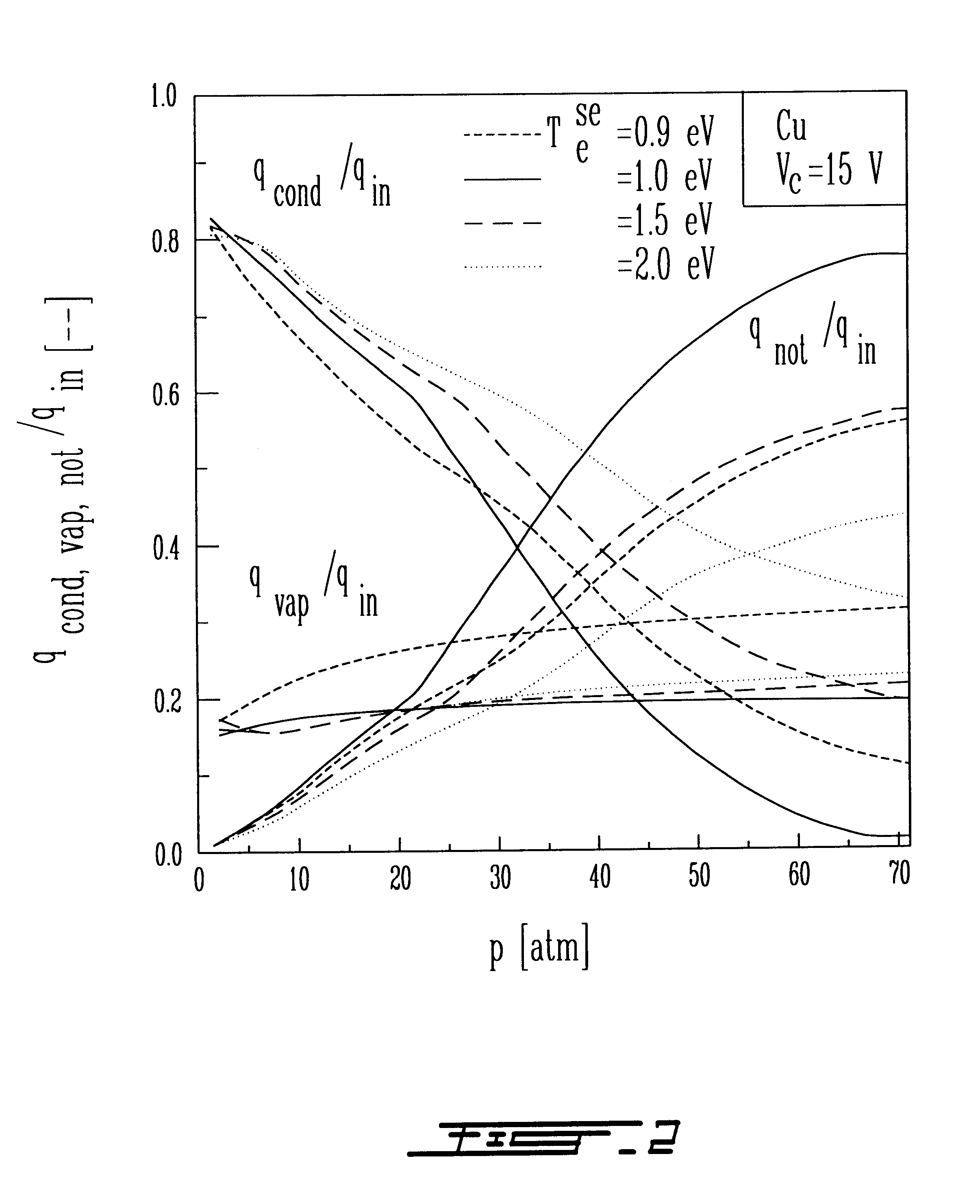

Particle-free cathodic arc carbon ion source

A method and apparatus for vacuum arc deposition of carbon on a substrate inhibits or eliminates emission of contaminating carbon particles in the ion plasma by maintaining an elevated local plasma pressure at the cathode or target surface, thereby minimizing the role of heat conduction in the creation of the particles and strongly increasing the electron emission cooling effects.

Owner:MCGILL UNIV

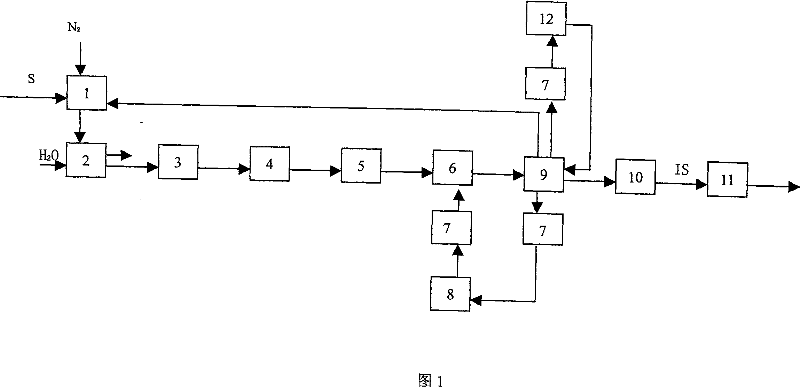

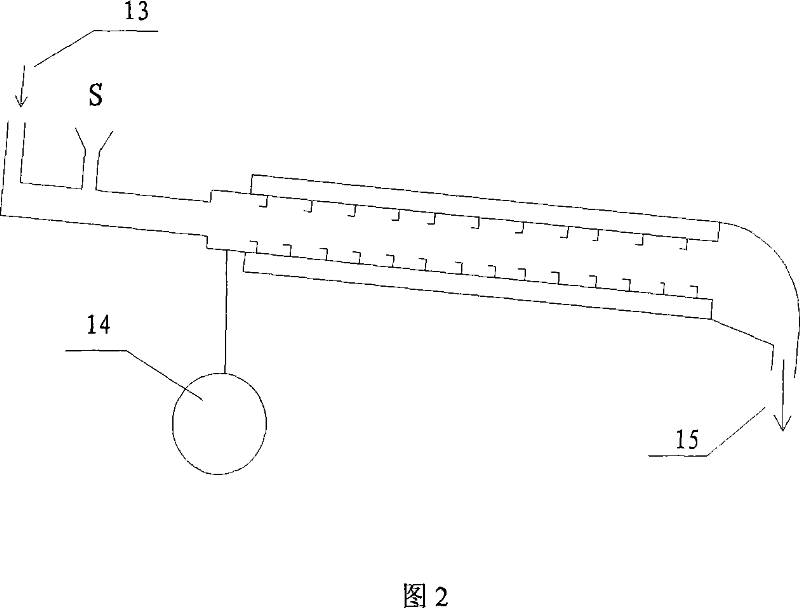

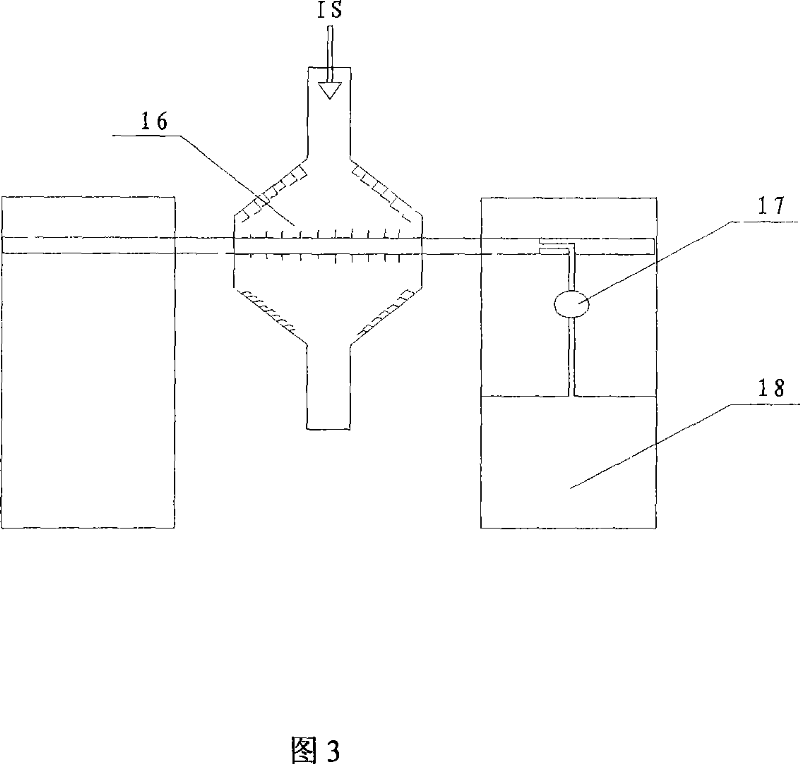

Preparation method of oil-filled insoluble sulphur

InactiveCN101037191AImprove one-way yieldColor has no effectSulfur preparation/purificationThermal insulationSolvent

The present invention relates to a preparation method of insoluble sulfur of special vulcanizing agent used for rubber, in particular to a preparation method of oil charge type insoluble sulfur, which comprises the steps of: using ordinary sulfur as raw material which is added with composite stabilizer; putting into a reaction kettle which is provided with a heating controller and a stirring device; nitrogen blanketting; melt polymerization at 200~300 DEG C; thermal insulation for 25~120 min; quenching, curing, drying, size reduction and sieving; extracting by using a mixed solvent as extractant, centrifugal separation of the liquid after extraction, fluidized drying of the residue, and then obtaining insoluble sulfur; and then executing oil charge to obtain oil charge type insoluble sulfur with high stability. The operation has a strong continuity, the recovery energy consumption of the extractant is low and the product has high thermal stability.

Owner:NANJING UNIV OF TECH

Reducing Emissions in Polyurethane Foam

ActiveUS20130137787A1Emission reductionMinimizing isocyanateOrganic-compounds/hydrides/coordination-complexes catalystsCatalytic reactionsCarboxylic acidMechanical property

Owner:EVONIK OPERATIONS GMBH

Mobile solar-powered light tower

ActiveUS8833985B2Excellent and useful lightingEliminates the dependency on fossil fuelNon-electric lightingMechanical apparatusLight equipmentElectrical battery

Provided is a mobile lighting device that can derive power from a renewable energy source, such as solar power. The device can comprise a mobile base unit that can house one or more components of the device. The device further can comprise a solar power module associated with the mobile base unit that converts solar energy into electrical current. The device also can comprise a lighting module associated with the mobile base unit that is at least partially powered either directly or indirectly using the electrical current from the solar power module. The device further can comprise a solar power storage module, such as comprising one or more batteries, for storing energy and discharging as electrical current for powering the lighting module, which can be positioned atop a mast that can be extendable, pivotable, and / or rotatable. The invention also provides methods and systems for illuminating areas.

Owner:RENEWABLE ENERGY HLDG

Method for preparing jade type microcrystalline glass with high-temperature furnace slag

The invention discloses a method for preparing jade type microcrystalline glass with high-temperature furnace slag, which comprises the steps of: taking molten furnace slag as main materials; adding auxiliary materials such as fluxing clarifying agent and additive, and the like; further melting and clarifying in a high-temperature furnace to form glass liquid; pouring or calendaring the glass liquid to form basic glass; heat processing the basic glass by means of crystallization to obtain the rough product of the jade type microcrystalline glass; and finish machining to obtain the finished product of the jade type microcrystalline glass. The method not only effectively utilizes the molten high-temperature furnace slag, but also sufficiently utilizes heat energy stored in the high-temperature furnace slag, and prevents the high-temperature furnace slag from generating huge amounts of corrosive hot steam in the process of discharging. The jade type microcrystalline glass prepared by the method is in the status of semitransparent wax, exactly looks like natural jade, has good cutting performance, high intensity and good tenacity, can be used for replacing natural stones in construction industry, and can be used for replacing natural rare jades in machining artware.

Owner:TSINGHUA UNIV

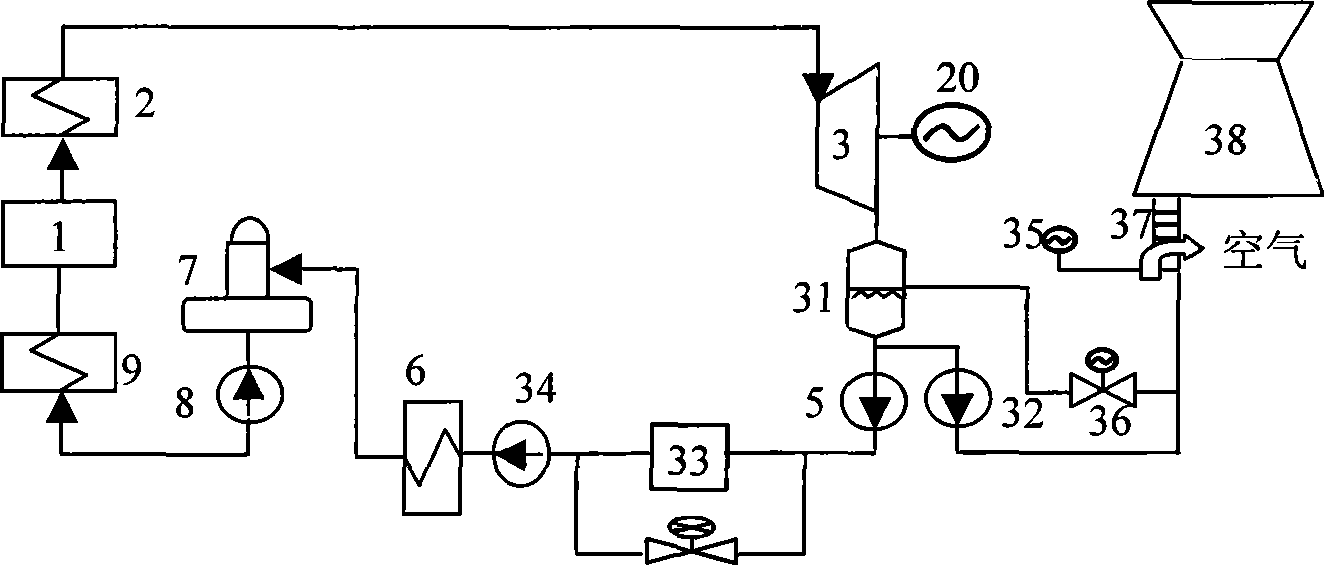

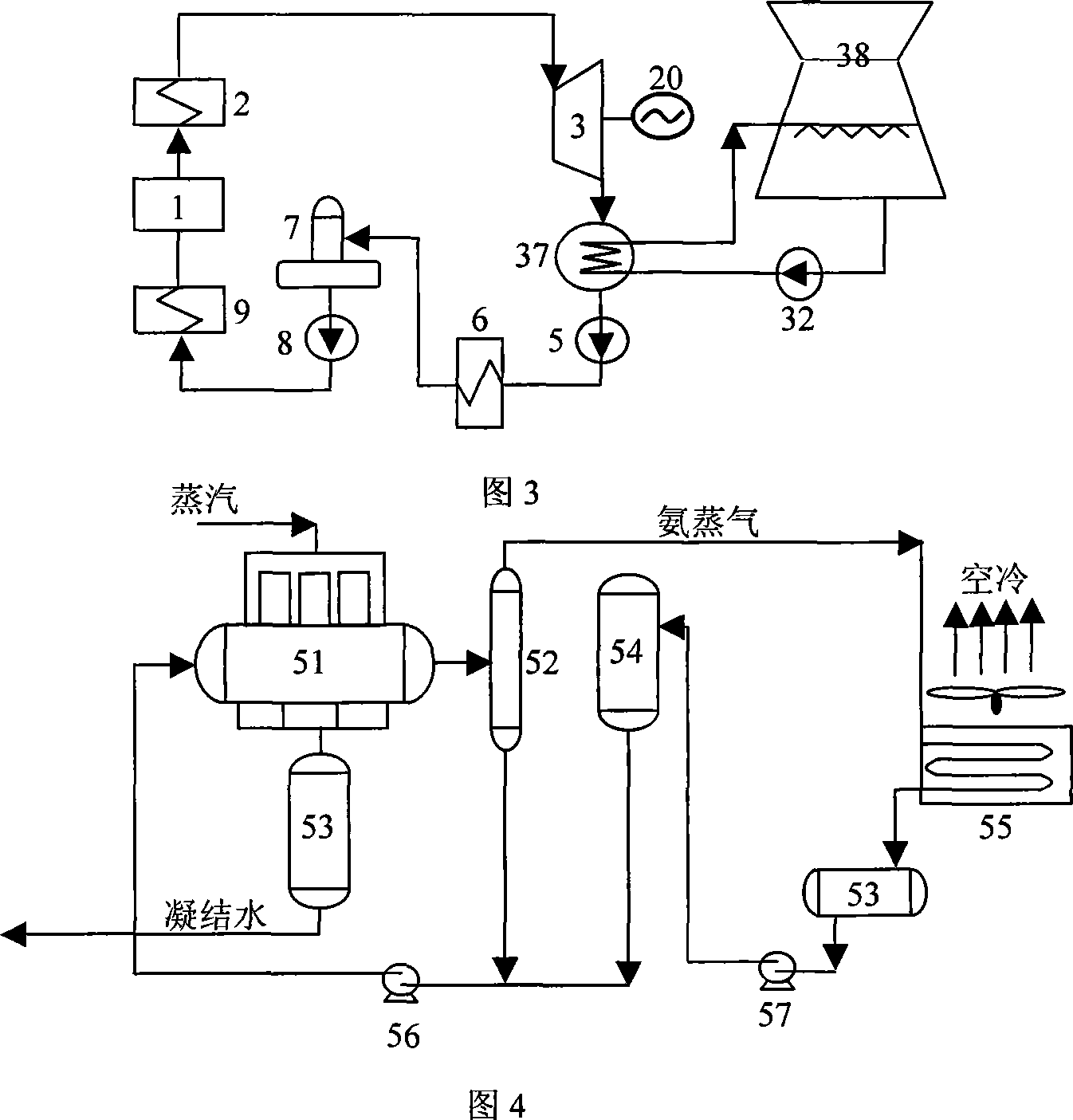

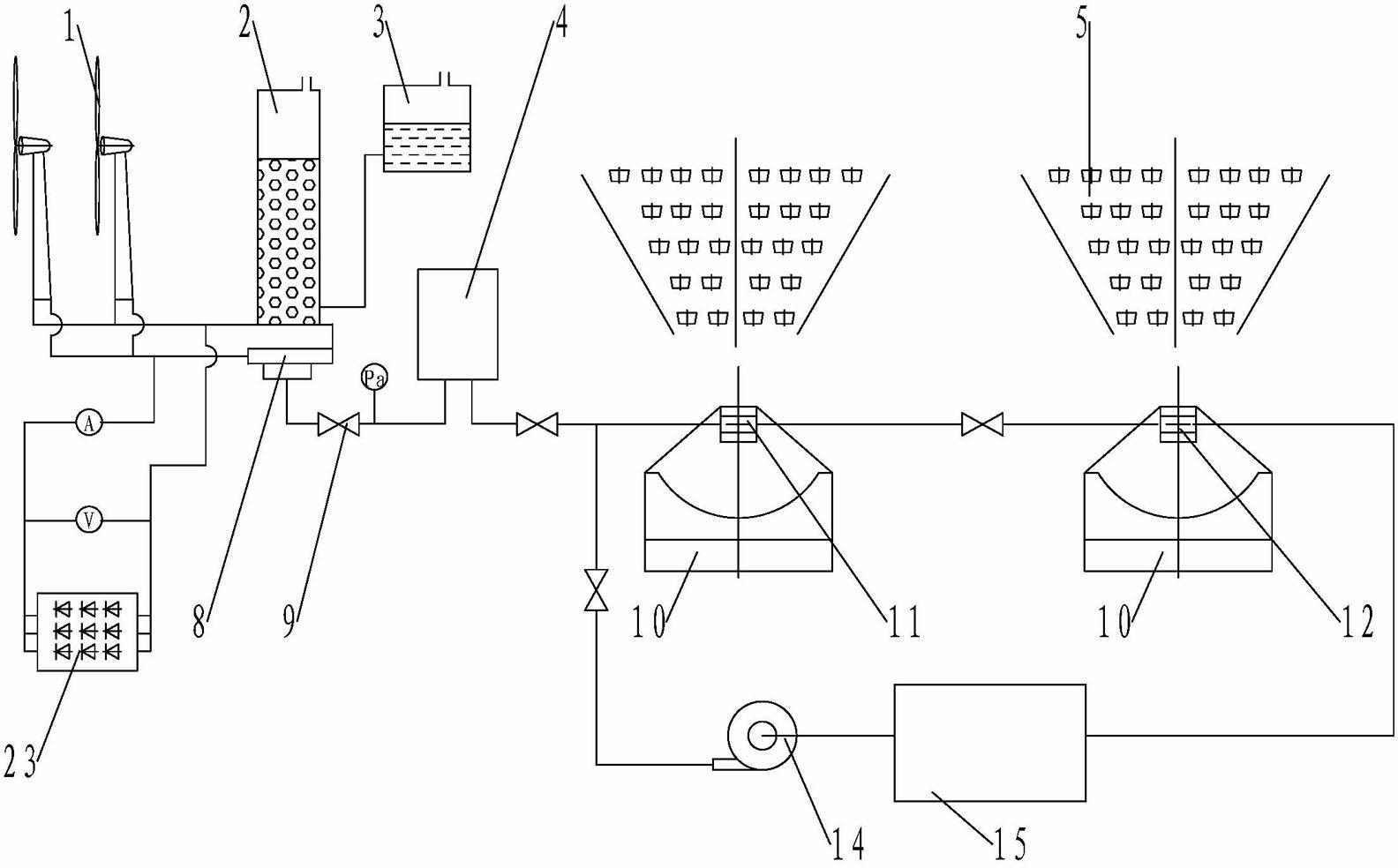

Indirect air cooling method and system for working medium adopting parallel-connection positive and reverse refrigeration cycle

InactiveCN101368767AEasy to implementNovel ideaCompression machines with reversible cycleWorking fluidNuclear power

The invention discloses an indirect air cooling method and a system with the working fluid of parallel-connected obverse and inverse refrigeration cycles. Based on the phase transition in the working fluid cooling process, a double-phase transition heat exchanger and a single-phase transition heat exchanger are respectively coupled with an obverse refrigeration cycle and an inverse refrigeration cycle which are connected in parallel; the saturated gaseous refrigerant from the phase-transition heat exchangers is compressed, boosted and then sent to an air-cooled radiator for exothermic condensation, then the condensed refrigerant enters a liquid storage tank and is decompressed through a throttle valve and sent to the phase-transition heat exchangers so as to complete the obverse refrigeration cycle; or the saturated gaseous refrigerant from the phase-transition heat exchangers is throttled and decompressed through a thermal expansion valve and then sent to the air-cooled radiator and the liquid storage tank, pressurized by a booster pump and finally sent back to the phase-transition heat exchangers so as to complete the inverse refrigeration cycle. The method and the system can be widely applied to the cooling systems of the condensers in thermal power, nuclear power and other turbine-generator units or the cooling systems of the intercoolers in petroleum, chemical and other industries to reduce energy consumption, save investments, as well as improve water-saving rate and the adaptability of the cooling system to the environment; therefore, the method and the system are provided with promotional values and can produce larger social environmental benefits and economic benefits after implementation.

Owner:NORTHEAST DIANLI UNIVERSITY

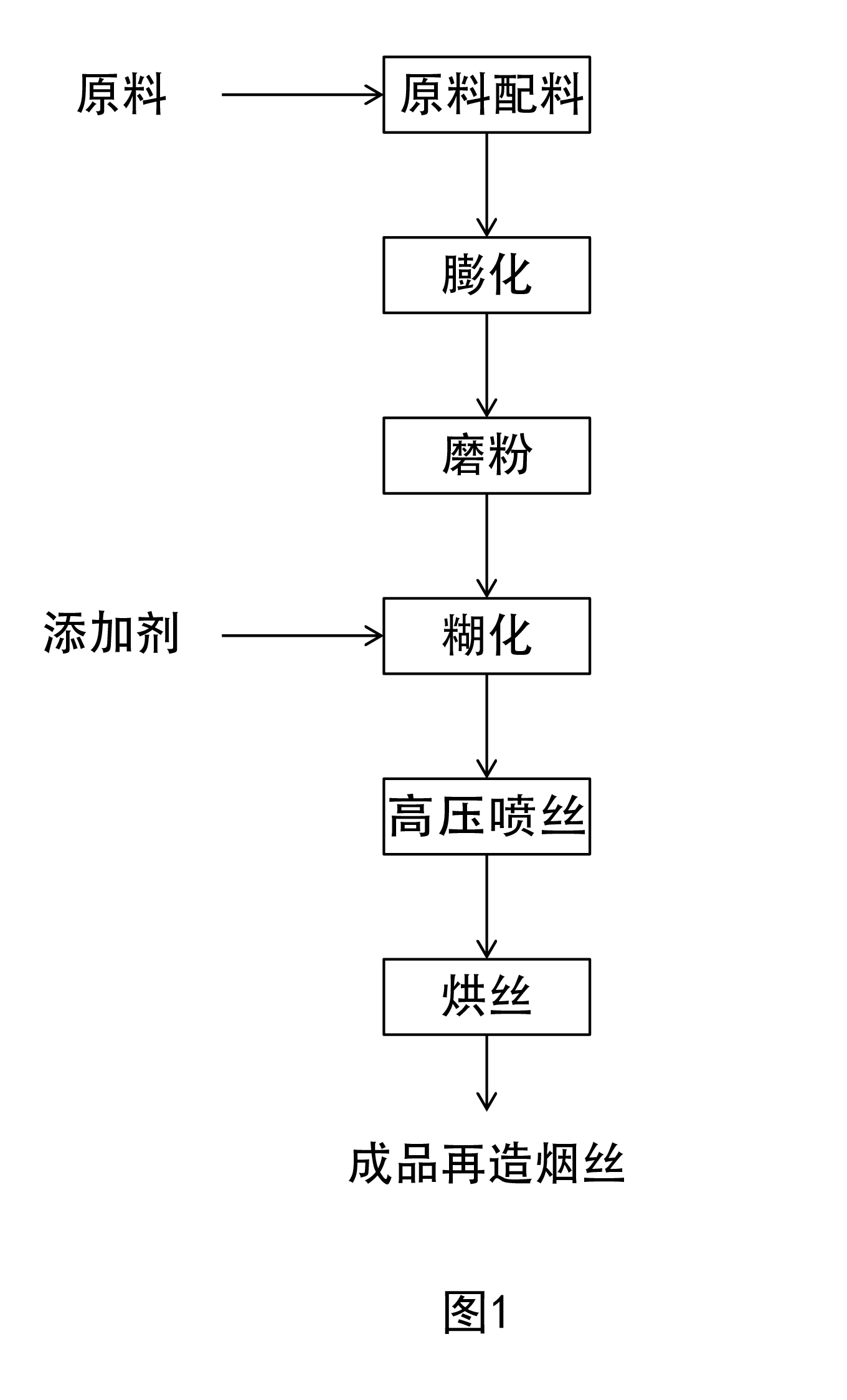

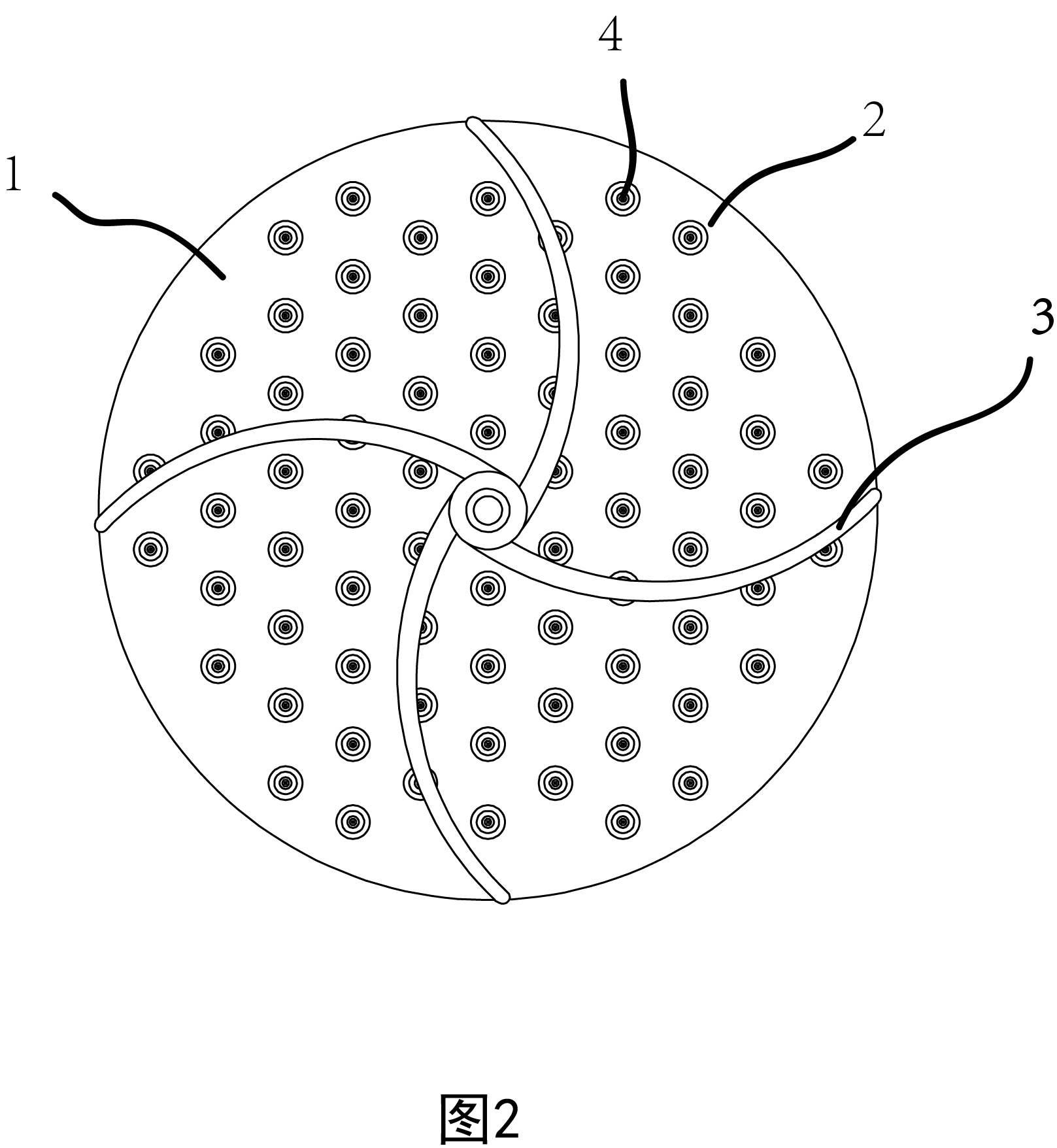

Tobacco remanufacturing process by spinning method

The invention relates to a tobacco remanufacturing process by a spinning method, belonging to the chemical technology of tobacco, in particular to a tobacco remanufacturing process for remanufacturing the tobacco and tobacco shreds by utilizing smoked sheets, tobacco waste and tobacco stalks. The tobacco remanufacturing process is characterized in that the remanufactured tobacco shreds with different shapes and structures are produced by carrying out the procedures of blending, bulking, grinding, gelatinizing, high-pressure spinning and shred baking on raw materials, and comprise hollow remanufactured tobacco shreds. Compared with the traditional processes such as a thick slurry method, a rolling method and a papermaking method, the tobacco remanufacturing process has the benefits that the utilization ratio of the tobacco is improved from 85%-95% to be close to 100%, no sewage and waste are discharged, the quality of the tobacco shreds is improved, the application range of the remanufactured tobacco shreds is expanded, the process flow is simple and easy to control, the automatic production is easy to be realized and the sensing quality and the production efficiency are improved.

Owner:侯明

Alloy material suitable for inert anode of metal fused-salt electrolysis cell

InactiveCN101717969AReduce consumptionEliminate emissionsElectrodesAluminium electrolysisMolten salt

The invention relates to an alloy material suitable for an inert anode of a metal fused-salt electrolysis cell, relating to metal fused-salt electrolysis, in particular to a carbon-free metal-base alloy inert anode of an aluminium electrolysis cell. The carbon-free metal-base alloy inert anode of the aluminium electrolysis cell is characterized in that the alloy material comprises the following components in percentage by weight: 5-30% of Ni, 5-20% of Al, and the balance of Cu. The alloy material suitable for the inert anode of the metal fused-salt electrolysis cell is suitable for a lower-temperature (700 DEG C-850 DEG C) electrolyte system; in addition, the alloy inert anode has good high-temperature oxidation resistance and electrolyte corrosion resistance in the electrolytic processes, and electrolyzed aluminium products reach the quality more than 99.7 percent.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Air filtration media

InactiveUS20060101796A1Eliminate emissionsSimilar characteristicDispersed particle filtrationLoose filtering material filtersGlass fiberAir filtration

The present invention relates to an air filtration media made from very fine glass fibers having an average fiber diameter within a range from 3×10−5 to 2×10−4 inches, with the media comprising a formaldehyde-free binding agent comprised of a polycarboxy polymer and a polyol to bind the glass fibers together.

Owner:JOHNS MANVILLE CORP

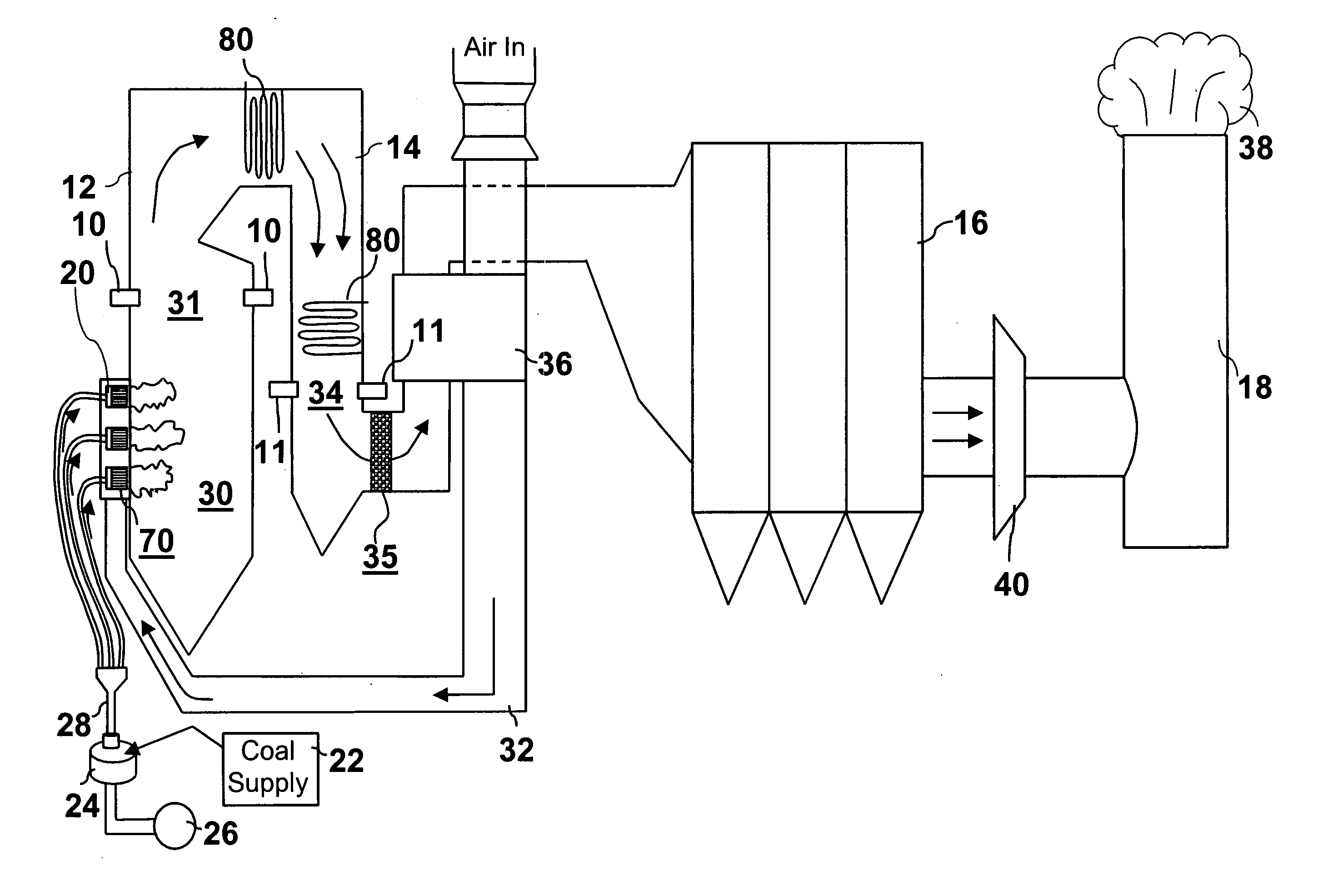

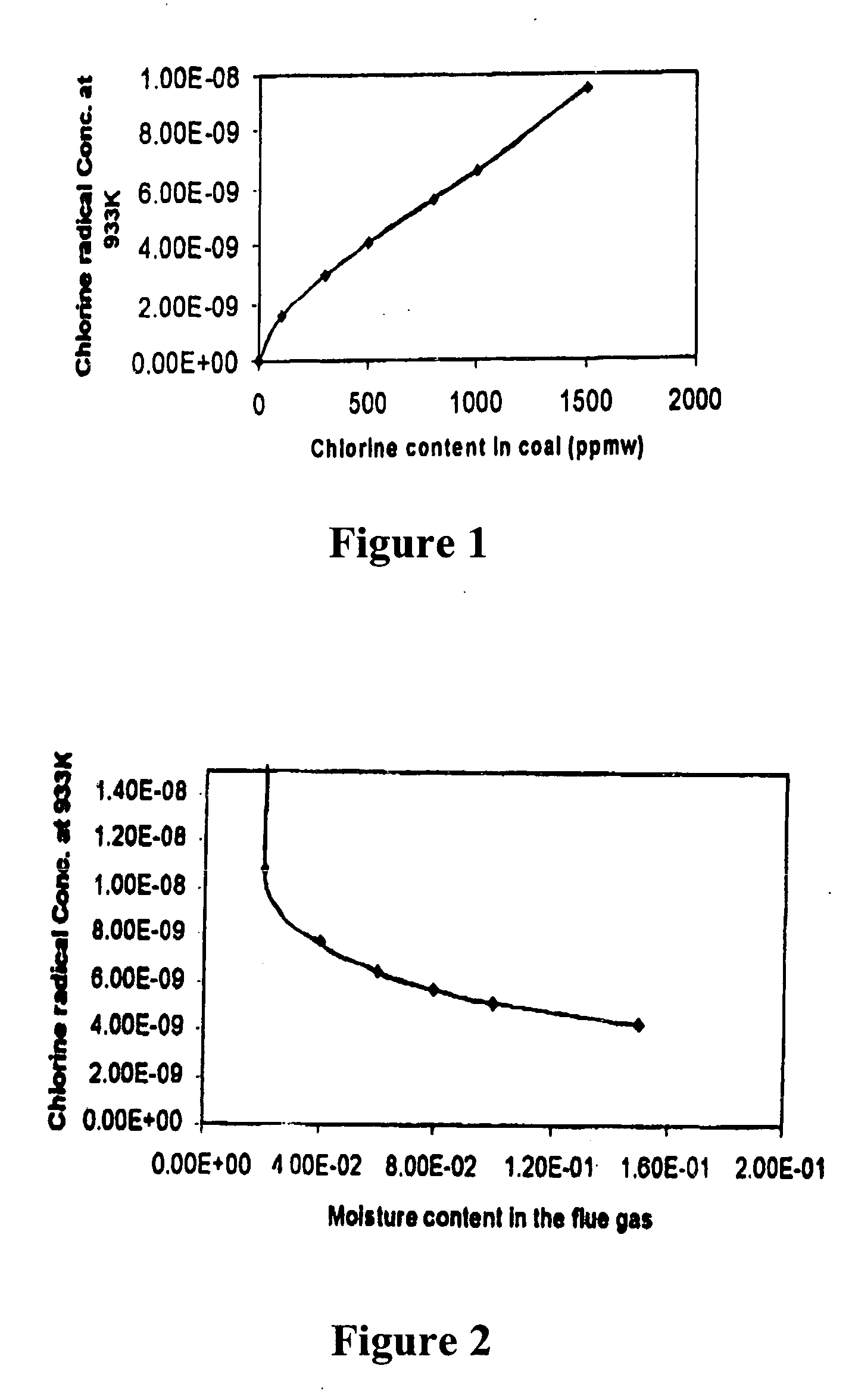

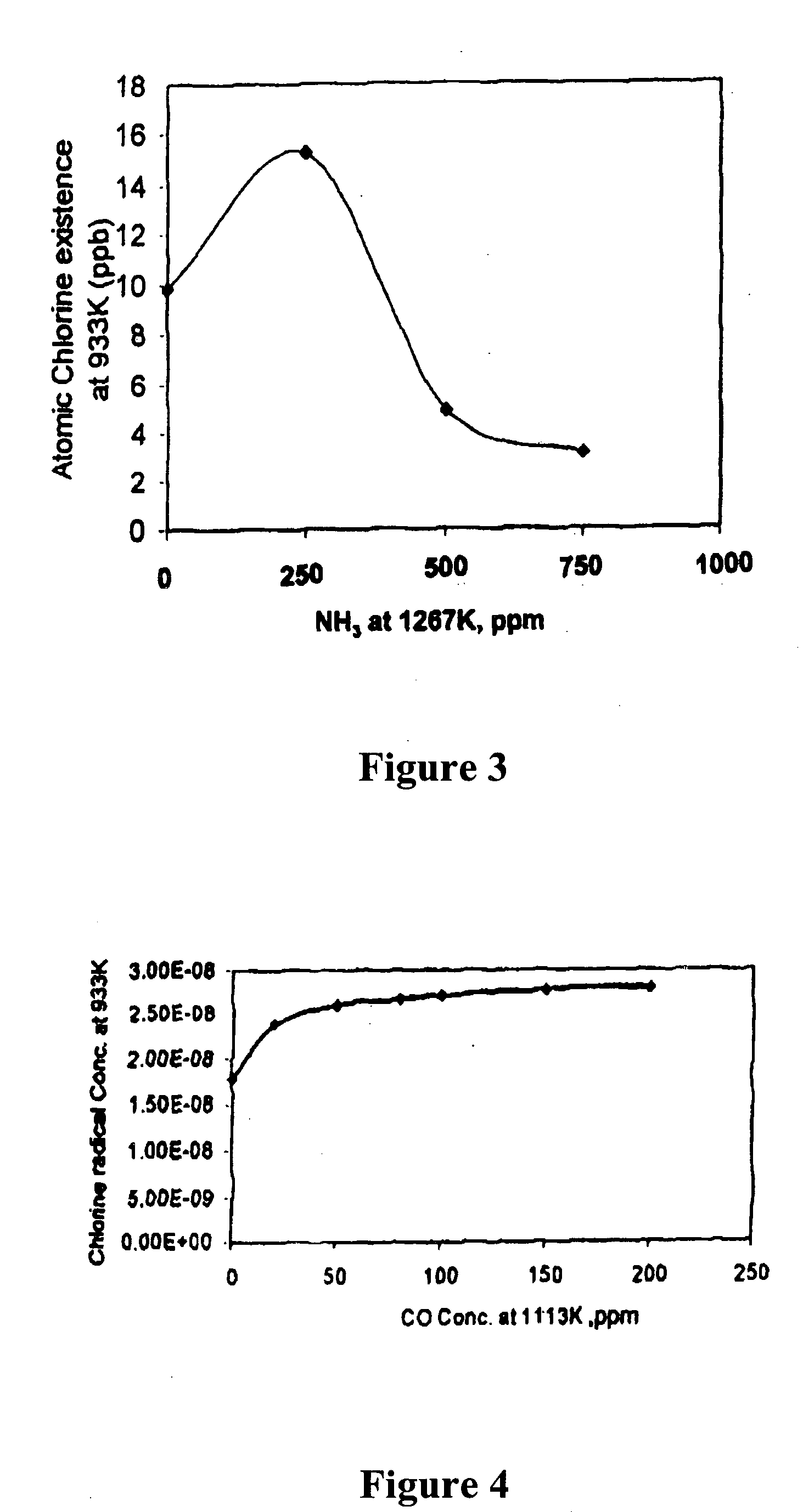

Control of mercury and other elemental metal emissions using reaction stabilization device

InactiveUS20060011115A1Reduce levelEliminate emissionNitrogen compoundsDispersed particle filtrationChemistryDecomposition

Ammonia and optionally carbon monoxide are injected into the flue gas containing metals such as mercury in a manner so that there are sufficient amounts of these materials in the flue gas when the flue gas is at a temperature of from 900° F. to 1,450° F. to oxidize the metals within the flue gas. The oxidized metals are then attracted to particulates present in the flue gas. Oxidation is facilitated by a reaction zone stabilizer through which the flue gas flows. The stabilizer provides a stable continuous ignition front. These particulates bound with oxidized metals are removed from the flue gas by a particulate removal device such as an electrostatic precipitator or baghouse. After the ammonia is injected, the flue gas can be rapidly cooled to a temperature below 500° F. to minimize decomposition of oxidized metals in the flue gas.

Owner:BREEN ENERGY SOLUTIONS

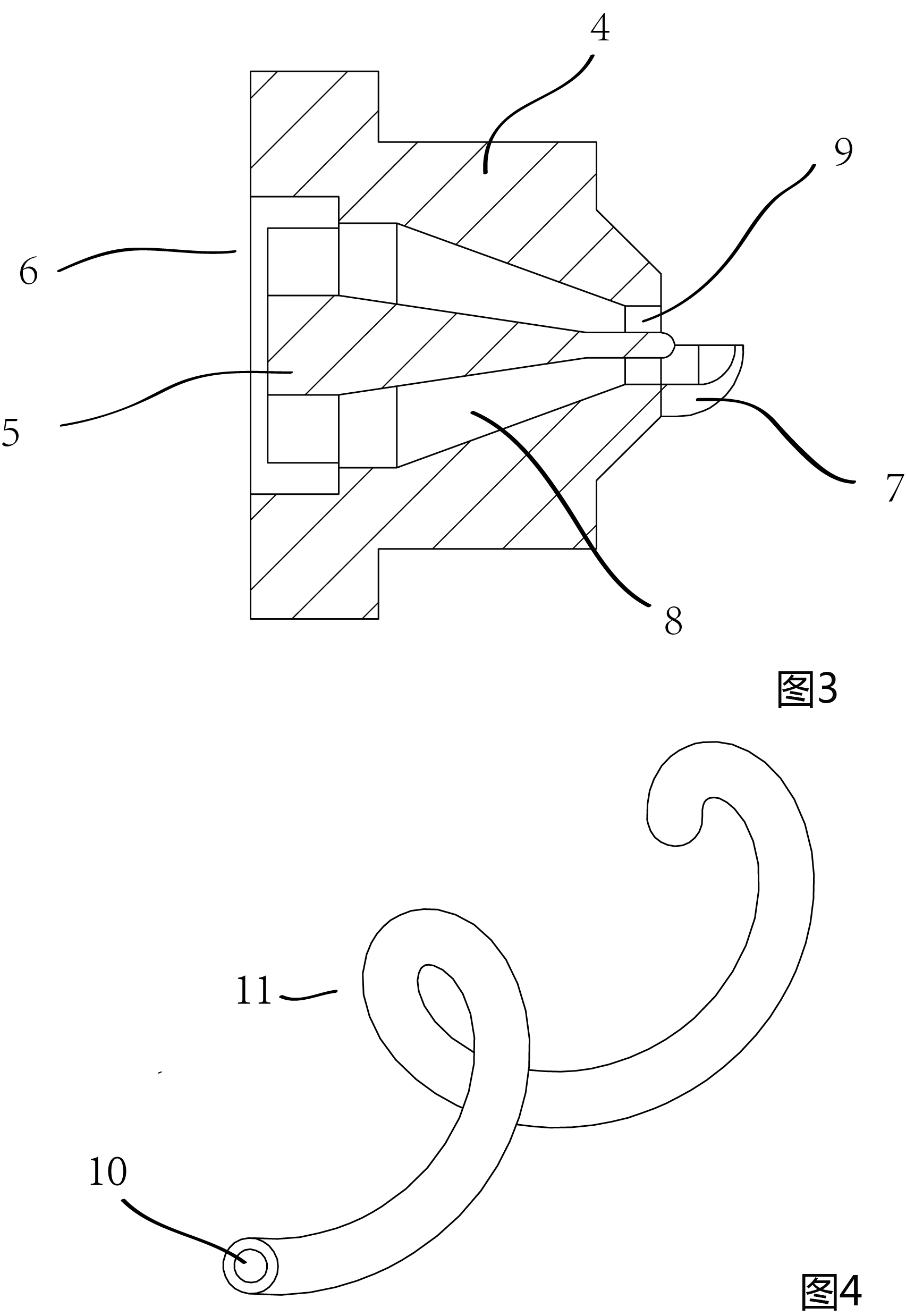

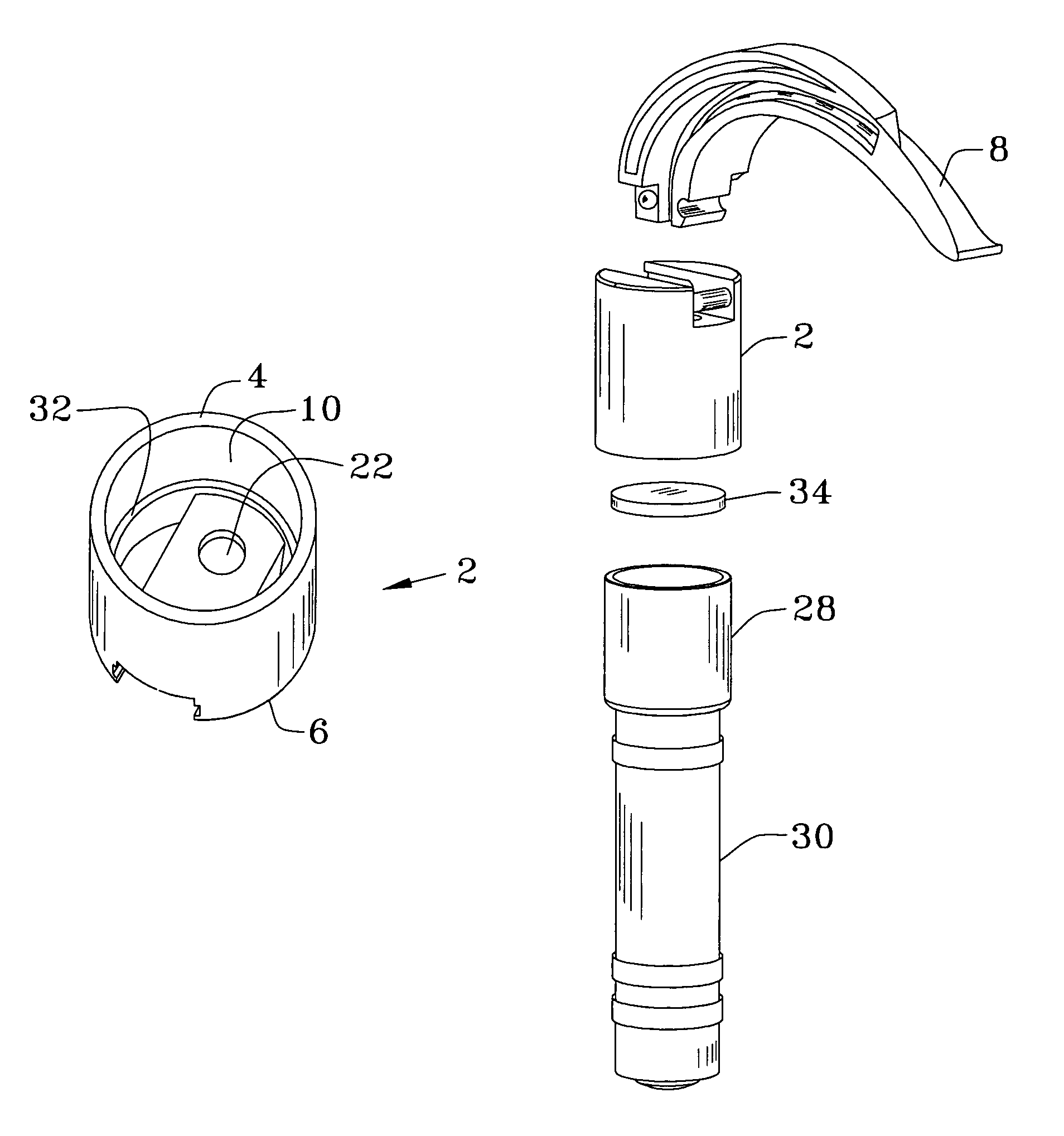

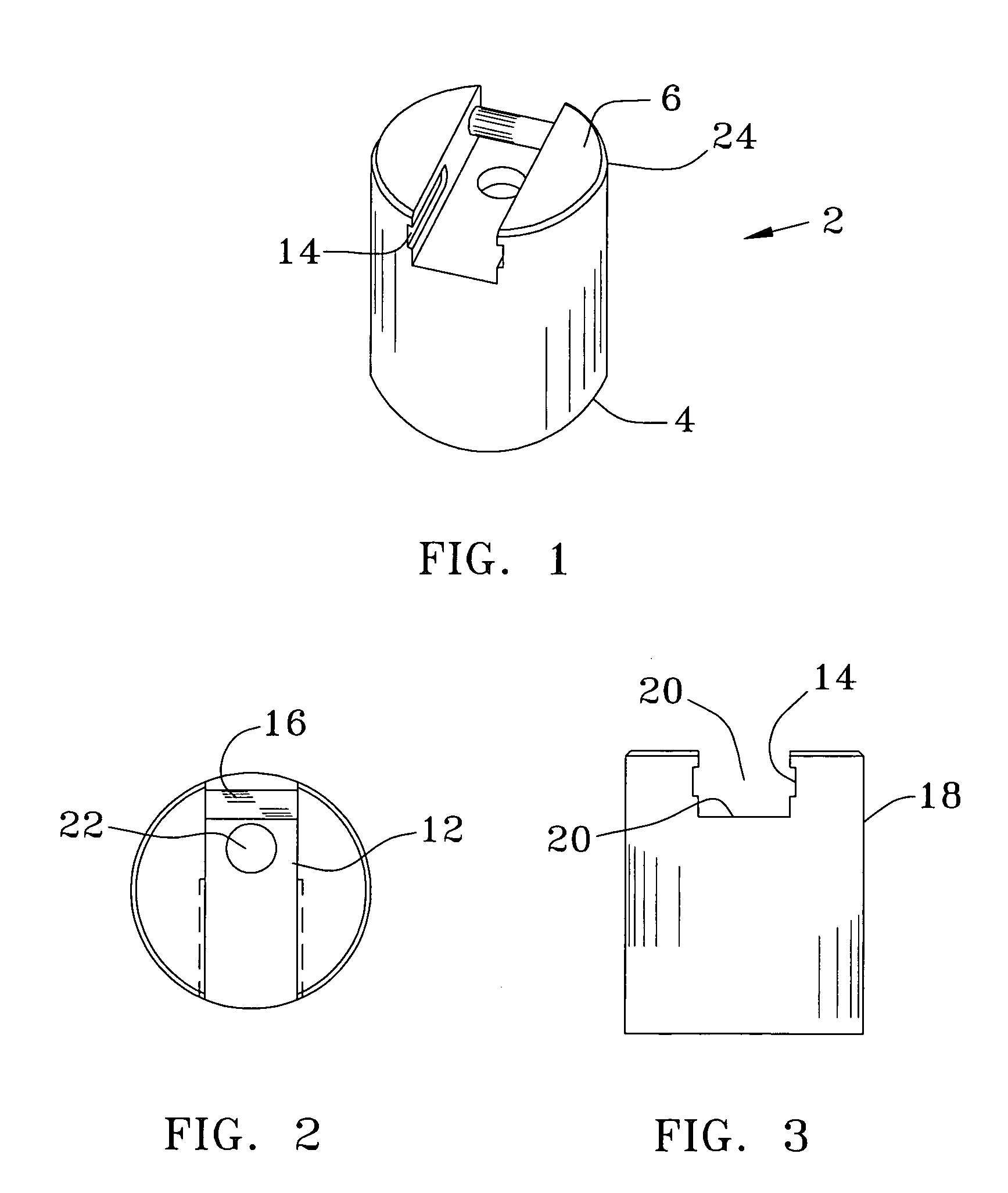

Battlefield laryngoscope adaptor cap for flashlight

InactiveUS8394017B2Eliminate emissionsSatisfy safety performance requirementsBronchoscopesLaryngoscopesNight visionEndotracheal intubation

A laryngoscope adaptor cap for use with existing government issue military flashlights designed for use in night time battlefield conditions. A filter disc filters out visible light and a light seal design prevents leakage of visible light from an assembled laryngoscope. The adaptor cap is crush resistant, impact resistant, has a high melting temperature, is disposable and allows the attachment of conventional laryngoscope paddles. It allows for night time endotracheal intubation in conjunction with military issue night vision goggles in the absence of visible light.

Owner:KIEFFER LUCAN MILES

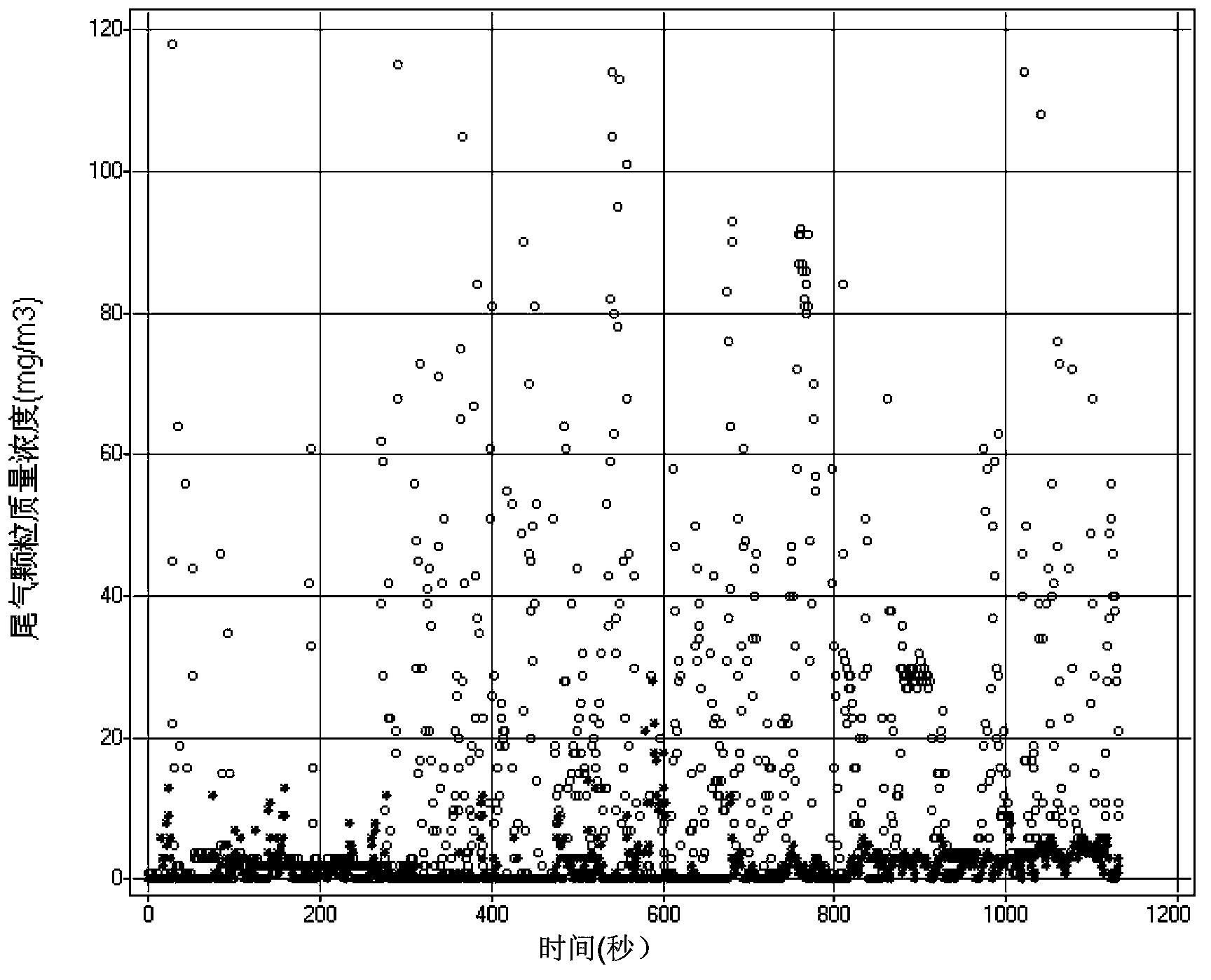

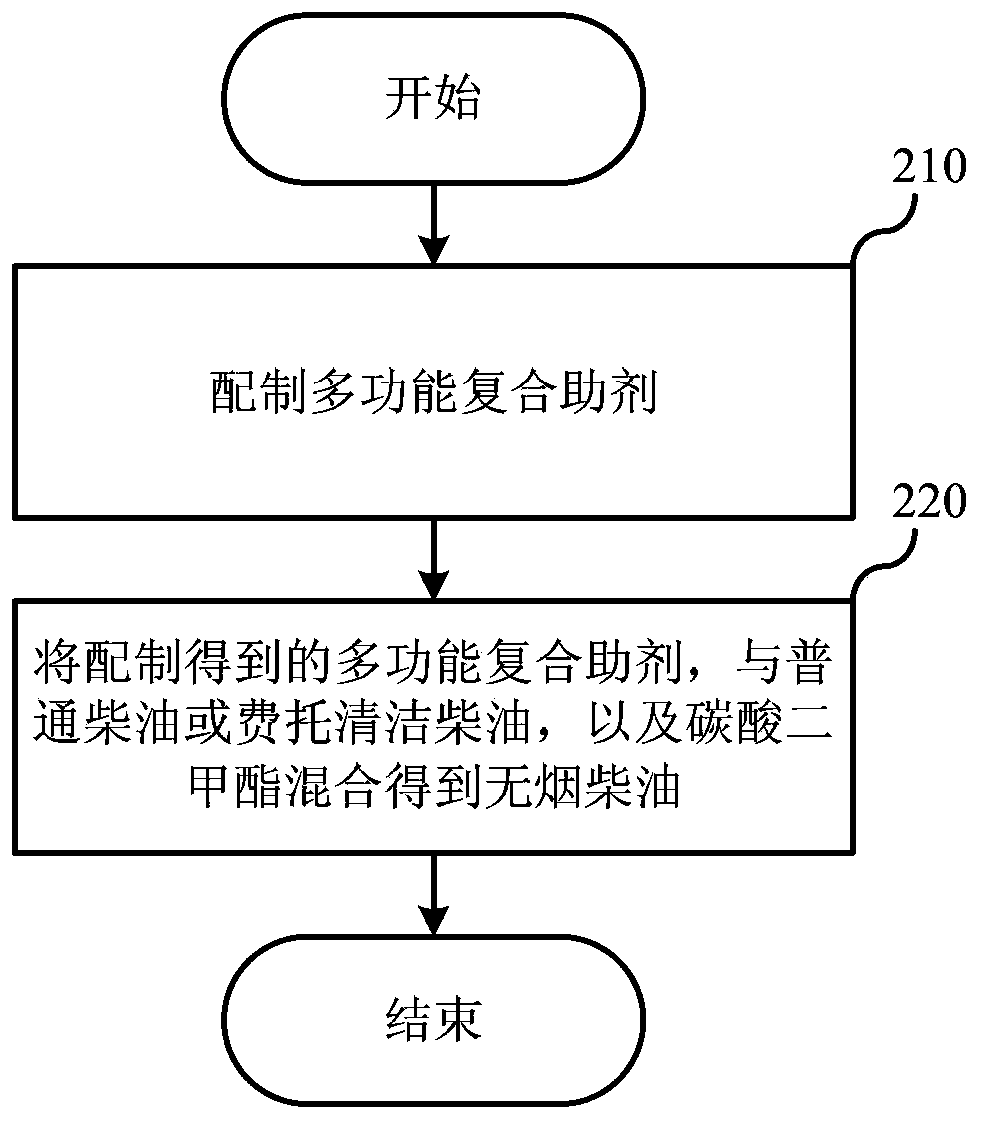

Smokeless diesel oil and preparation method thereof

ActiveCN103805297AEliminate emissionsImprove combustion effectLiquid carbonaceous fuelsParticulatesMethyl carbonate

The invention relates to the field of fuels, and discloses smokeless diesel oil and a preparation method thereof. The smokeless diesel oil comprises 70-95wt% of common diesel oil, 2-25wt% of dimethyl carbonate and 0-10wt% of a multifunctional compound additive. According to the smokeless diesel oil provided by the invention, particulate matter emission in the using process of means of conveyance (comprising various motor vehicles and ships) taking diesel oil as a fuel and machinery for engineering, mining and agriculture and forestry taking diesel engines as power can be greatly reduced or even eliminated without affecting other emission indexes. The smokeless diesel oil is clean and environment-friendly diesel oil, and is simple and convenient and feasible. The fuel system of the diesel engine needs not to be changed.

Owner:YASHENTECH CORP

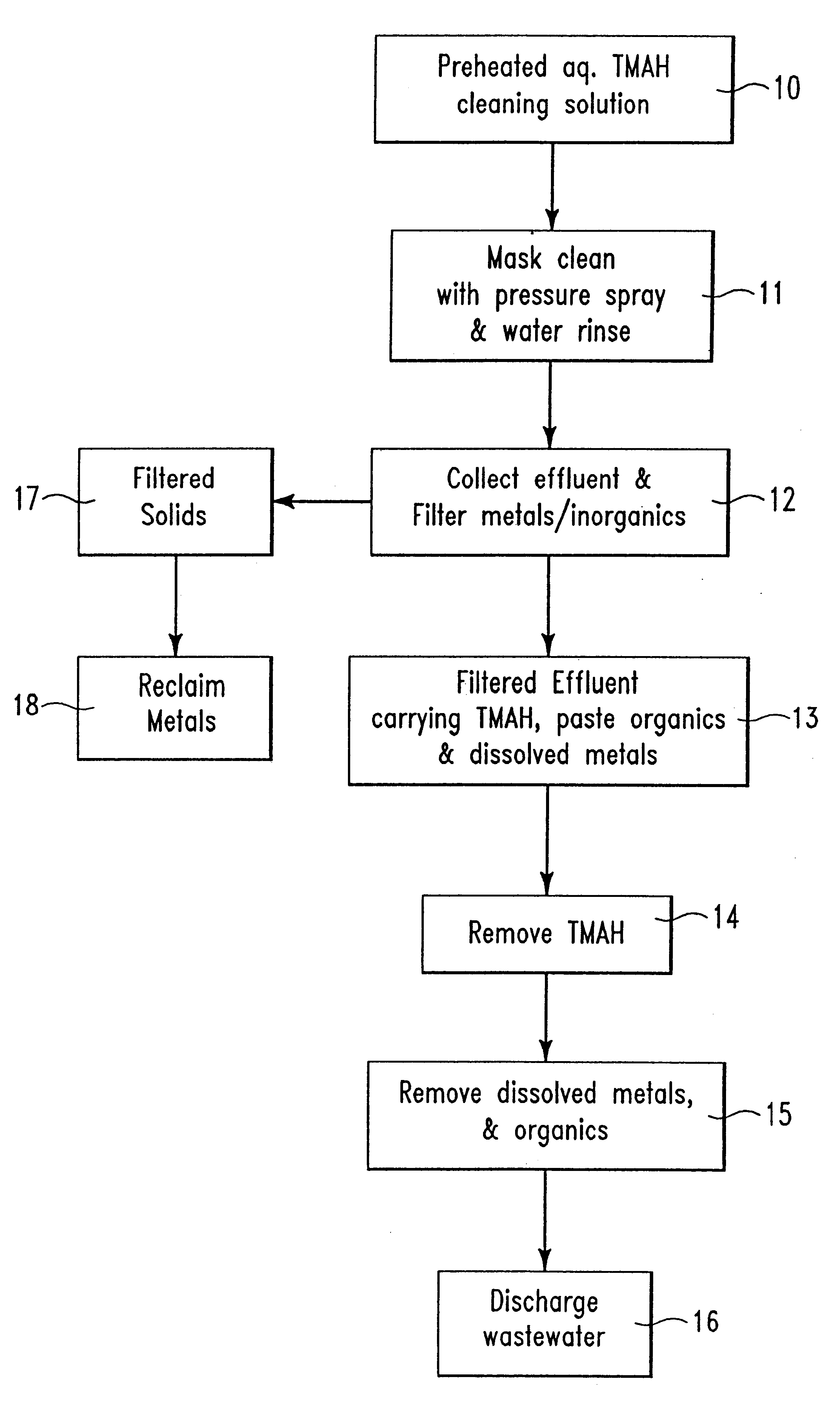

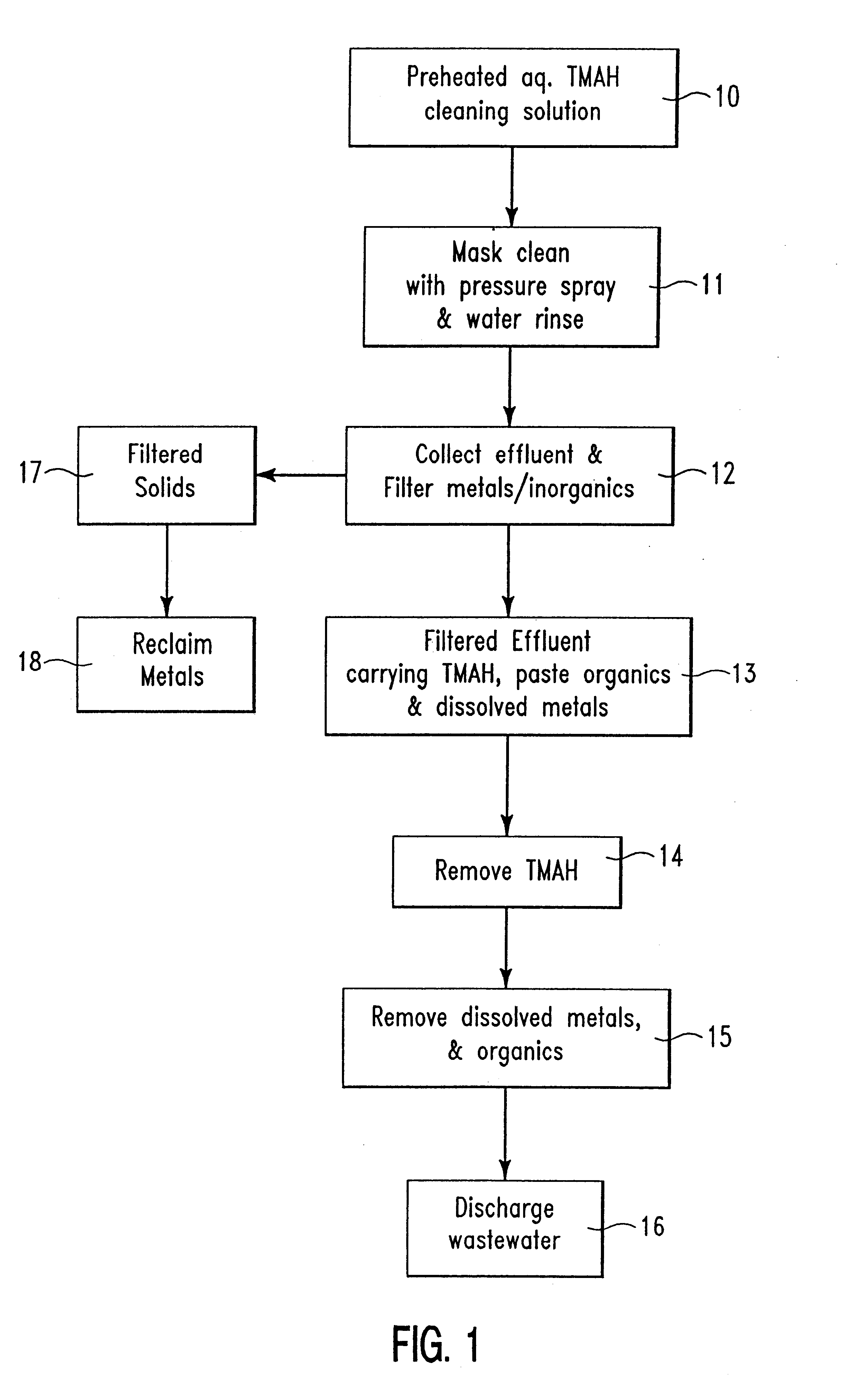

Aqueous quaternary ammonium hydroxide as a screening mask cleaner

InactiveUS6280527B1Effective cleaningHigh efficiencyDetergent mixture composition preparationSemiconductor/solid-state device manufacturingAmmonium hydroxideChemistry

This invention relates to the cleaning of objects that relate to semiconductor printing, such as, for example, screening masks. This invention is basically directed to removing, for example, an organic polymer-metal composite paste from screening masks used in printing conductive metal patterns onto ceramic green sheets in the fabrication of semiconductor packaging substrates. More particularly, this invention is concerned with the automated in-line cleaning of paste screening masks with an aqueous alkaline solution of a quaternary ammonium hydroxide as a more environmentally friendly alternative to non-aqueous organic solvents-based cleaning in screening operations for the production multilayer ceramic (MLC) substrates.

Owner:GLOBALFOUNDRIES INC

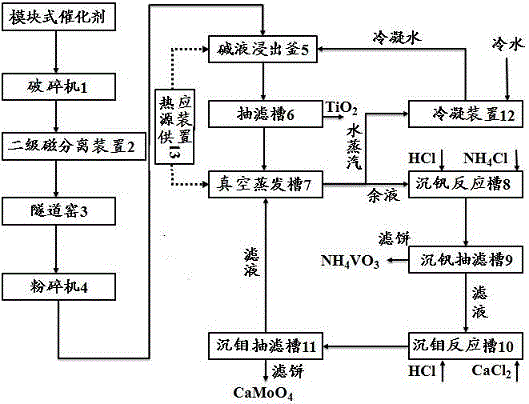

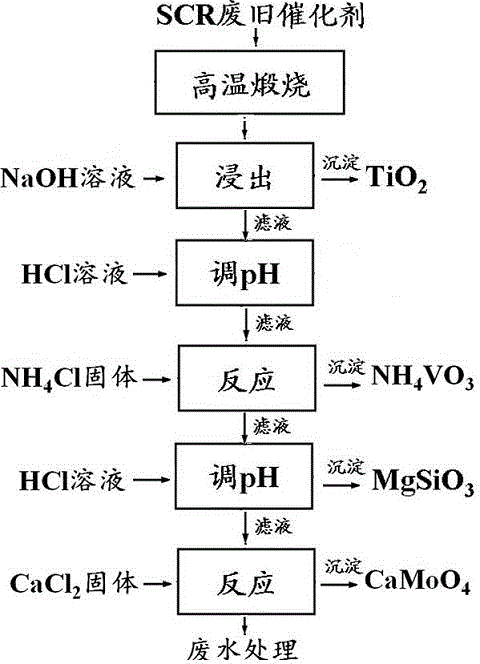

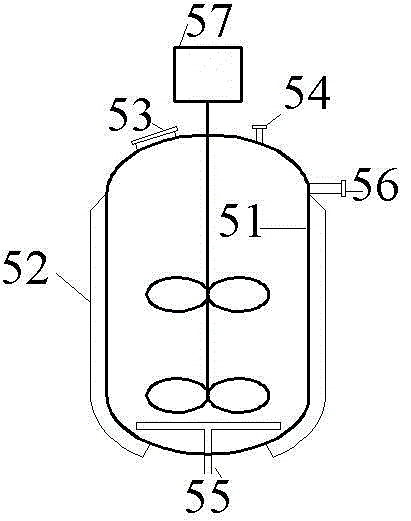

Continuous recovery device and continuous recovery process of vanadium, molybdenum and titanium in SCR (selective catalytic reduction) waste catalyst

The invention discloses a continuous recovery device and a continuous recovery process of vanadium, molybdenum and titanium in an SCR (selective catalytic reduction) waste catalyst, wherein a crusher is connected with a secondary magnetic separation device, the secondary magnetic separation device is connected with a tunnel kiln, the tunnel kiln is connected with a smasher, the smasher is connected with an alkaline leaching kettle, the alkaline leaching kettle is connected with a suction filtration groove, the suction filtration groove is connected with a vacuum evaporation tank, the vacuum evaporation tank is connected with a vanadium sedimentation reaction tank, and the vanadium sedimentation reaction tank is connected with a molybdenum sedimentation suction filtration groove; the alkaline leaching kettle is clamped outside the reaction kettle, a top overflow opening is positioned in the upper side of the jacket, a charging opening and a filling opening are positioned in the upper part of the reaction kettle, and the filling opening is guided to the middle part of the reaction kettle by virtue of a guide pipe. According to the continuous device disclosed by the invention, the production efficiency is effectively improved, thereby facilitating subsequent automatic and continuous production. A flat plate type flue gas denitrification catalyst is continuously recovered, infiltrating water is recycled, and the water yield is greatly saved.

Owner:DATANG NANJING ENVIRONMENTAL PROTECTION TECH

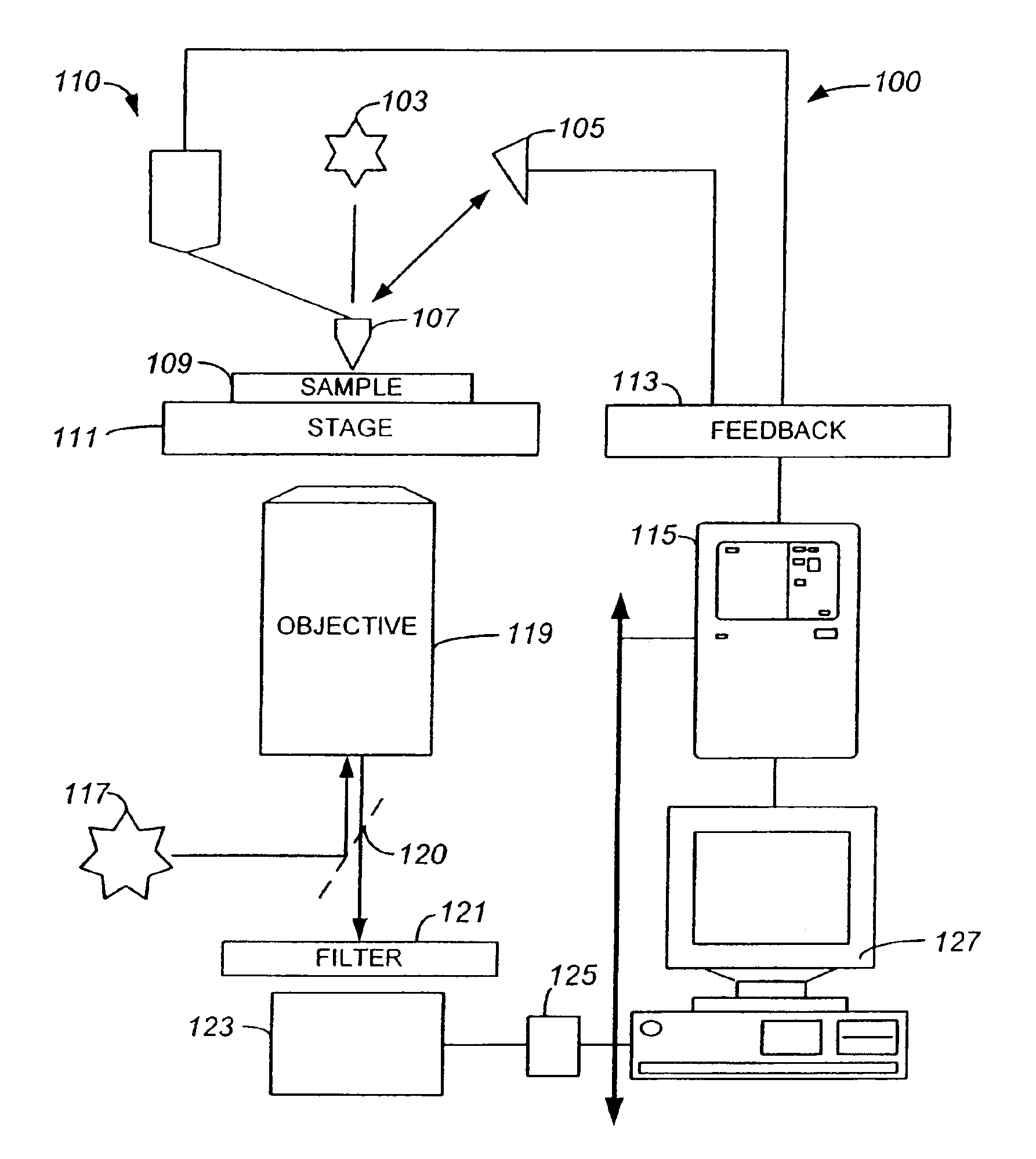

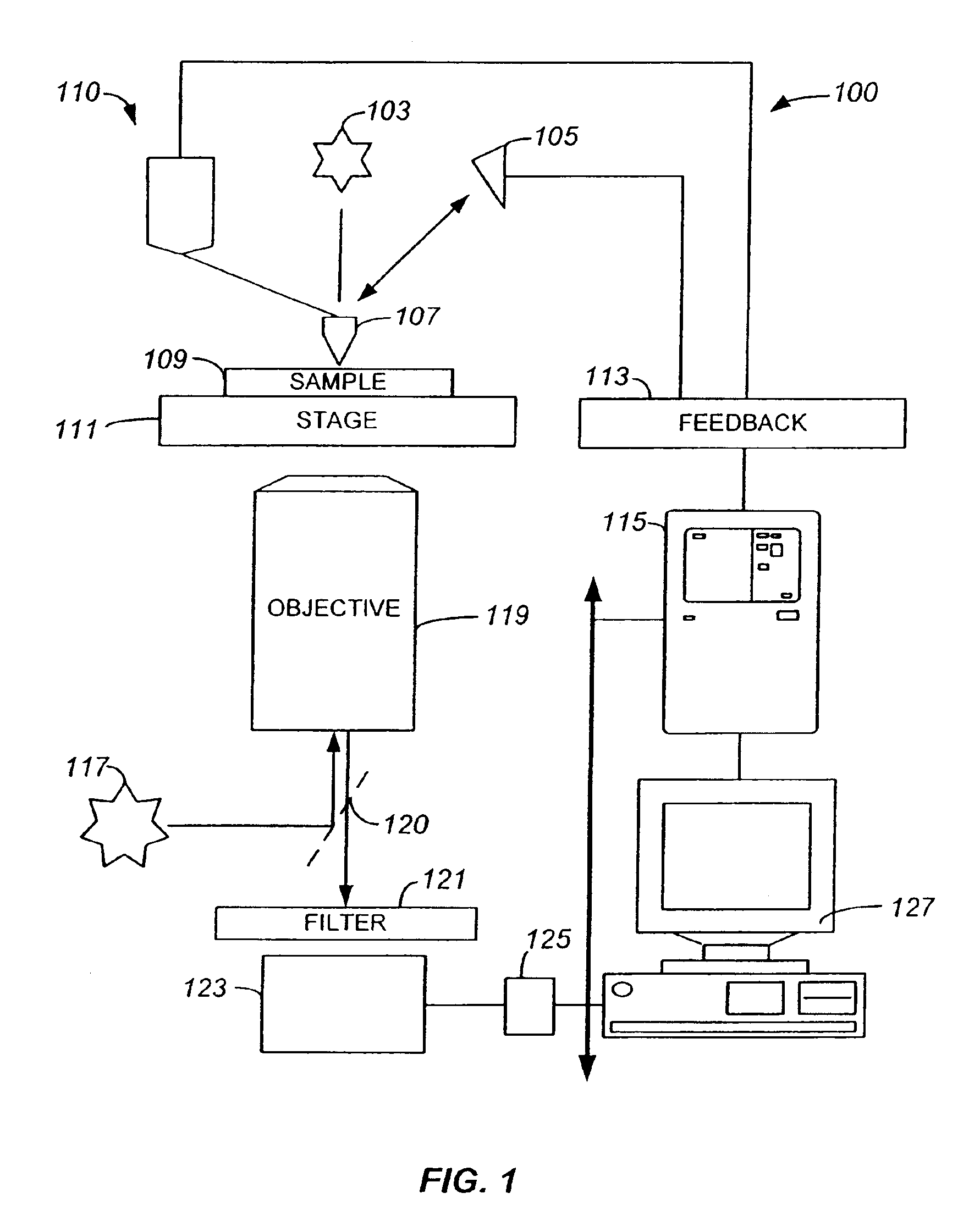

Method and system for scanning apertureless fluorescence microscope

InactiveUS6953927B2Narrow transmission widthEnhanced spontaneous emissionNanoinformaticsMaterial analysis by optical meansFluorescence microscopeCantilever

Methods and systems for operating an apertureless microscope for observing one or more features to a molecular sensitivity on objects are described. More particularly, the method includes moving a tip of a probe coupled to a cantilever in a vicinity of a feature of a sample, which emits one or more photons at a detected rate relative to a background rate of the sample based upon the presence of the tip of the probe in the vicinity of the feature. The method modifies the detected rate of the feature of the sample, whereupon the modifying of the detected rate causes the feature of the sample to enhance relative to background rate of the feature.

Owner:CALIFORNIA INST OF TECH

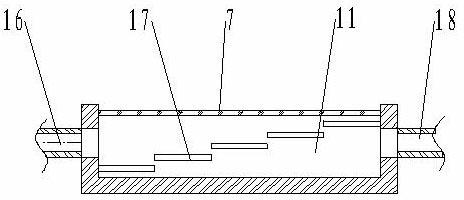

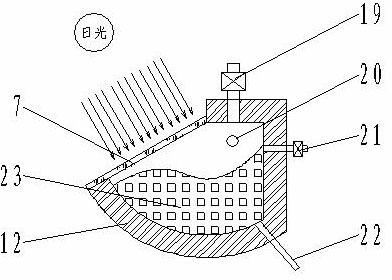

Method and device for solar reduction iron making

ActiveCN102424873AIncrease productivityAvoid emissionsProcess efficiency improvementGas emission reductionHeliostatHydrogen

The invention discloses a method and a device for solar reduction iron making. The device comprises a solar photovoltaic cell, a wind driven generator, an electrolyzer, a hydrogen heating chamber, a solar reduction furnace and gas treatment equipment. The hydrogen heating chamber and the reduction furnace are provided with a composite optical heating system consisting of a condenser, a heliostat and heat absorbing equipment. In the process of solar reduction iron making, hydrogen prepared by electrolyzing water is used as a reducing agent, the hydrogen is preheated and heat is provided for iron oxide reduction through a photo-thermal principle, the preheated hydrogen is introduced into the solar reduction furnace for reduction reaction so as to generate iron, the iron is smelted into molten iron, and the rest hydrogen is purified, and fed into a system for recycle through a circulating fan. Through the solar reduction iron making, non-renewable energy resources are saved, and the emission of greenhouse gases such as CO2 and the like is avoided. The electrolyzed hydrogen does not contain any harmful impurities, the temperature required by reduction in the reduction iron making process taking the hydrogen as the reducing agent is low, the reaction time is short, carbon dioxide is not generated, and the reduced iron has good quality.

Owner:SHIJIAZHUANG XINHUA IND FURNACE CO LTD

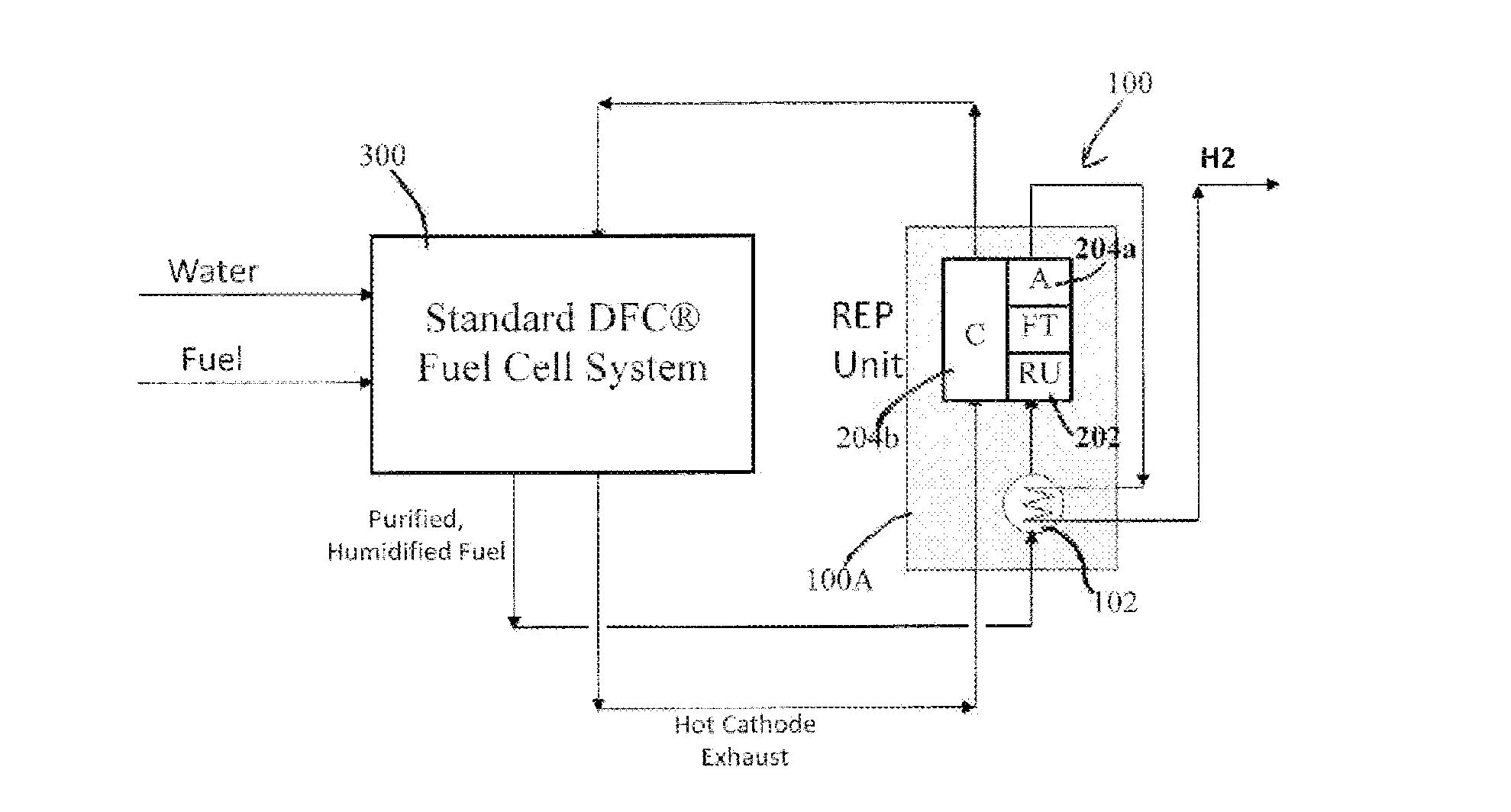

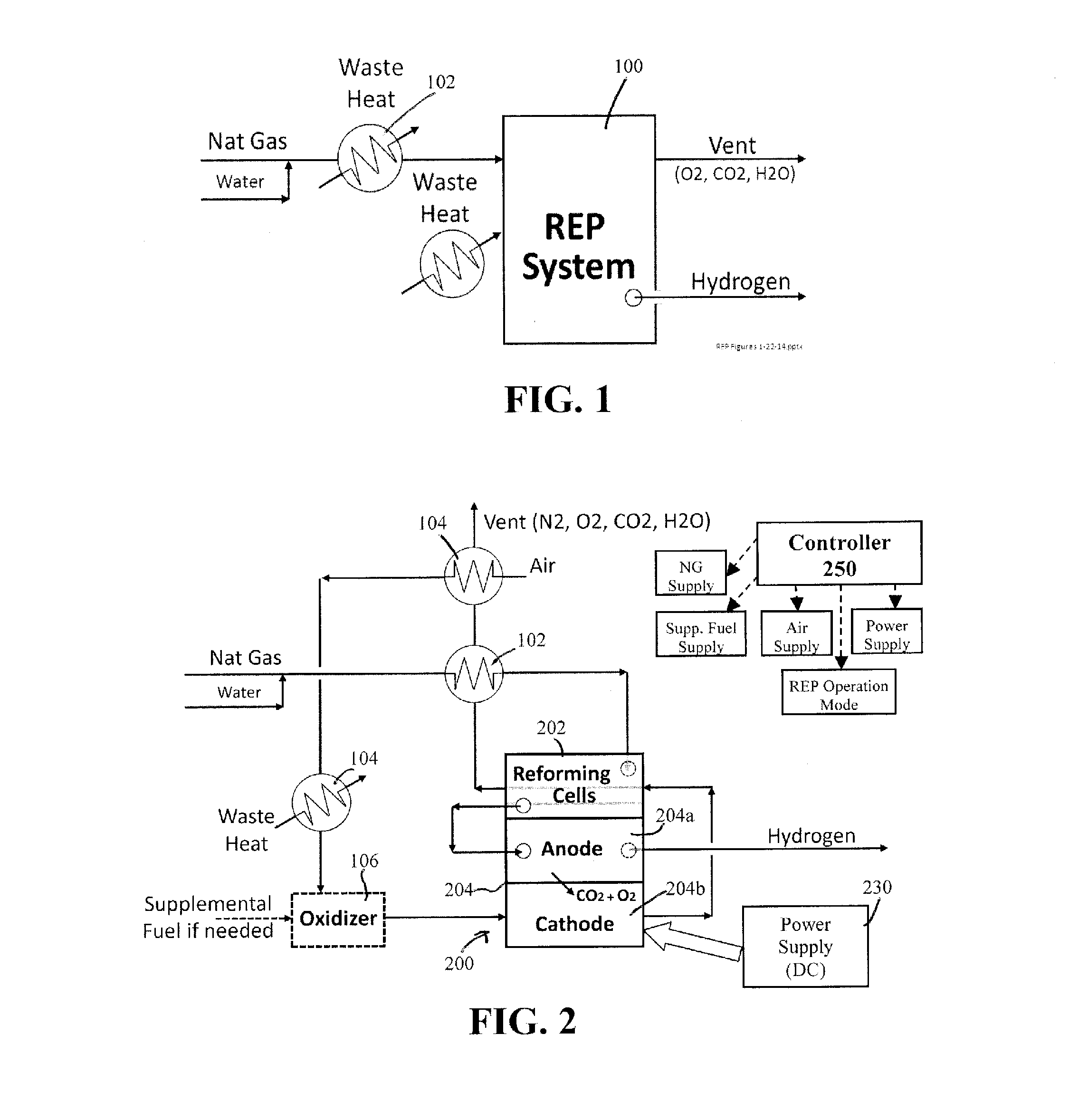

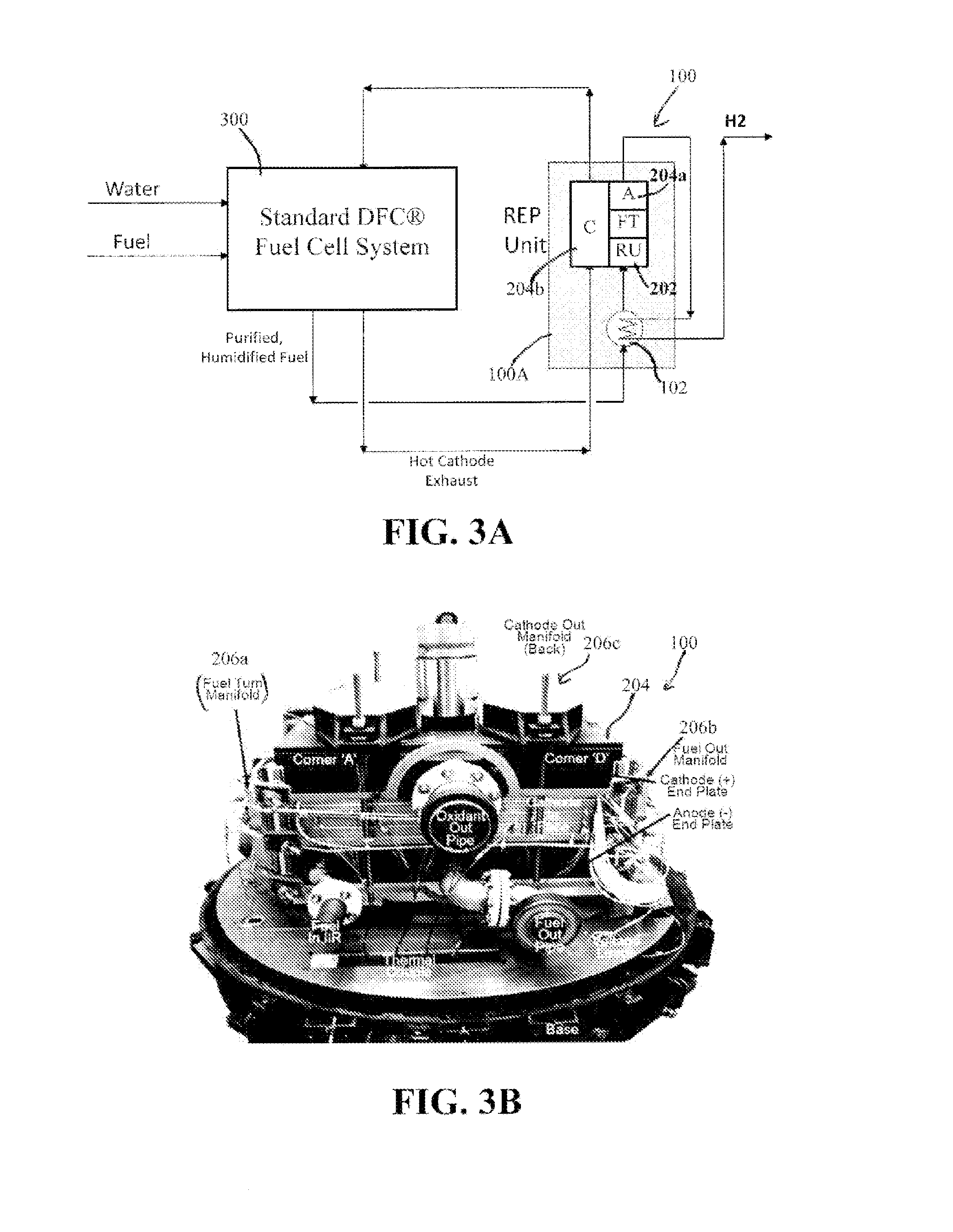

Reformer-electrolyzer-purifier (REP) assembly for hydrogen production, systems incorporating same and method of producing hydrogen

ActiveUS20160351930A1Low costEmission reductionElectrolysis componentsRegenerative fuel cellsFuel cellsProcess engineering

A high temperature electrolyzer assembly comprising at least one electrolyzer fuel cell including an anode and a cathode separated by an electrolyte matrix, and a power supply for applying a reverse voltage to the at least one electrolyzer fuel cell, wherein a gas feed comprising steam and one or more of CO2 and hydrocarbon fuel is fed to the anode of the at least one electrolyzer fuel cell, and wherein, when the power supply applies the reverse voltage to the at least one electrolyzer fuel cell, hydrogen-containing gas is generated by an electrolysis reaction in the anode of the at least one electrolyzer fuel cell and carbon dioxide is separated from the hydrogen-containing gas so that the at least one electrolyzer fuel cell outputs the hydrogen-containing gas and separately outputs an oxidant gas comprising carbon dioxide and oxygen.

Owner:FUELCELL ENERGY INC

Method for preparing fatty acid methyl ester by using waste edible oil

InactiveCN103013681ASimple processEliminate lossFatty acid esterificationReaction temperatureGlycerol

The invention aims to provide a process for preparing fatty acid methyl ester. According to the process, glycerol is used for replacing methanol, no acid catalyst is added, and direct esterification is carried out for deacidifying and deodorizing waste oil through gas stripping dehydration by using an inert gas. The process is a clean production method which is characterized in that raw materials do not need to be pretreated, water generated during reaction is taken out of a reaction system during reaction, the yield of the fatty acid methyl ester is increased, and no waste water or waste gas is emitted. The process comprises the steps of mixing the waste edible oil (acid value of 30-160mgKoH / g) with glycerol in a molar ratio of fatty acid of 1:(1-2) and adding the mixture into a reaction kettle, introducing the inert gas nitrogen, reacting for 1-4h under the conditions that the reaction temperature is 140-200 DEG C and the vacuum pressure of the reaction kettle is 30-50 KPa, reducing the acid value of an esterification product to be below 3.0mgKoH / g; and preparing the fatty acid methyl ester from materials by adopting the traditional base catalysis ester exchange reaction after the esterification is ended. Because a process of directly esterifying the waste edible oil through acid-free catalysis is adopted, the conversion rate of fatty acid is high, the content of the fatty acid in the waste edible oil is low, and the base catalysis ester exchange is complete.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

Tire with low hydrocarbon emission rubber combination of tread and sidewall components with compositional limitations

InactiveUS20040192825A1Improve tire performanceEliminate emissionsSpecial tyresInflatable tyresElastomerSilicon dioxide

The invention relates to a tire of a structural combination of tire tread and sidewall components with compositional limitations containing minimal, if any, of in situ formed alcohol and methyl isobutyl ketone byproducts. The tread component rubber composition contains pre-hydrophobated silica reinforcement. The sidewall component contains low unsaturation EPDM or brominated copolymer of isobutylene and p-methylstyrene and may contain pre-hydrophobated silica reinforcement. The silica reinforcement for said tread and sidewall components is a pre-hydrophobated precipitated silica. The pre-hydrophobated silica is prepared, prior to mixing with the elastomer(s), by reacting hydroxyl groups (e.g. silanol groups) contained on the surface of a precipitated silica with an alkoxyorganomercaptosilane or a combination of an alkoxyorganomercaptosilane and a substituted alkylsilane or with a bis-3(trialkoxysilylalkyl) polysulfide which contains an average of from 2 to 4 connecting sulfur atoms in its polysulfidic bridge to form a composite thereof. The alcohol byproduct therefrom is removed from the composite prior to its introduction into the rubber composition(s). In another aspect of the invention, the connecting sidewall rubber composition, and optionally the tread composition is free of N-(1,3-dimethylbutyl)-N'-phenyl-p-phenylenediamine antidegradant (referred herein to as 6PPD) in order to prevent in situ formation of methyl isobutyl ketone byproduct from the reaction of 6PPD with atmospheric oxygen and / or ozone.

Owner:THE GOODYEAR TIRE & RUBBER CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com