Patents

Literature

63results about How to "Color has no effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

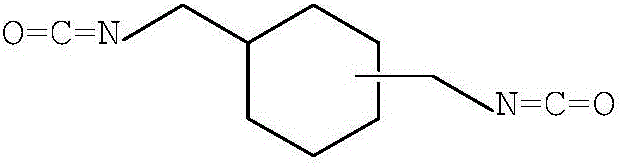

Preparation method of hydrogenated xylylene diisocynate

ActiveCN106674056AGood dispersionImprove liquidityOrganic compound preparationIsocyanic acid derivatives purification/separationXylyleneN dimethylformamide

The invention discloses a preparation method of hydrogenated xylylene diisocynate. The preparation method of the hydrogenated xylylene diisocynate comprises the following steps: (1) performing salt forming reaction on 1,3-cyclohexanol dimethylamine and concentrated hydrochloric acid in a two-phase reaction solvent to obtain amine salt, wherein the two-phase reaction solvent consists of water and an inert organic solvent insoluble in water ; (2) performing photochemical reaction on the ammonium salt obtained in the step (1) and phosgene in an inert solvent by taking N,N-dimethylformamide or N,N-dimethylacetamide as a catalyst to obtain reaction liquid, and performing aftertreatment on the reaction liquid to obtain the hydrogenated xylylene diisocynate. The preparation method of the hydrogenated xylylene diisocynate has the advantages of complete ammonium salt formation, small grain size of the ammonium salt, low viscosity of the ammonium salt, high space-time conversion rate of photochemical reaction, simple process, low cost and the like.

Owner:HUNAN HAILI CHEM IND

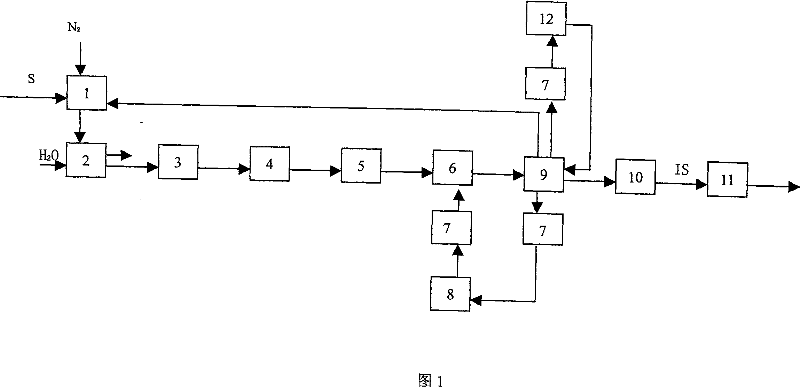

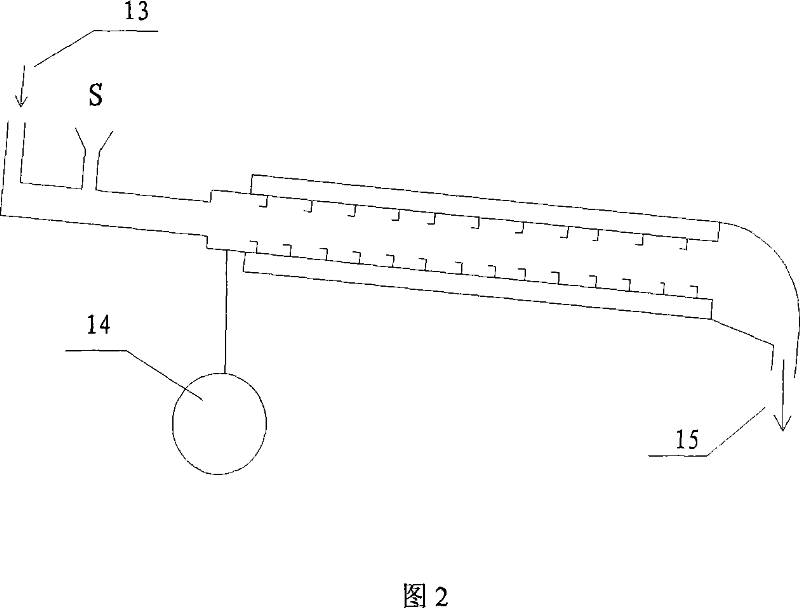

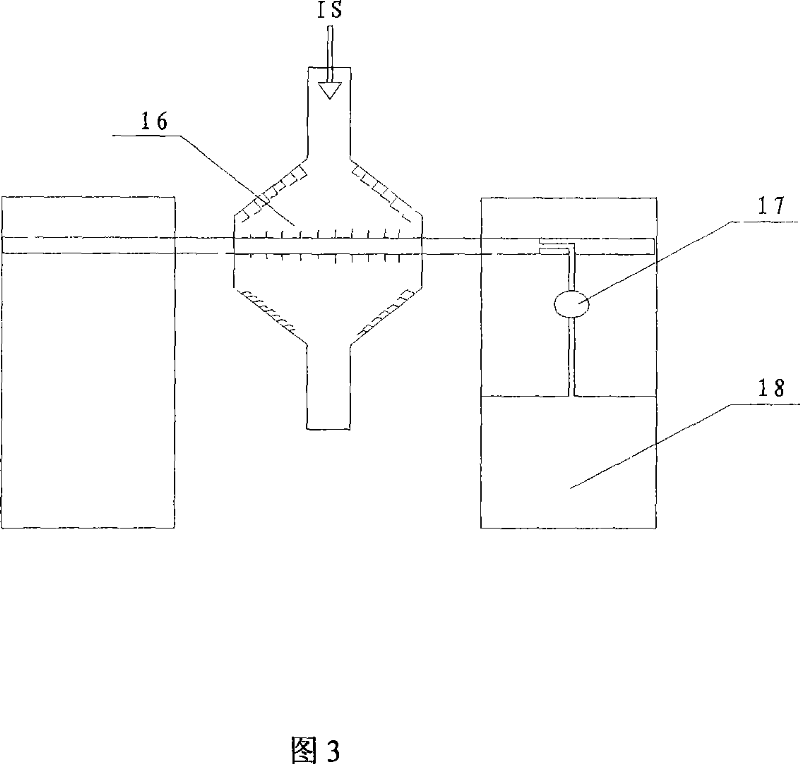

Preparation method of oil-filled insoluble sulphur

InactiveCN101037191AImprove one-way yieldColor has no effectSulfur preparation/purificationThermal insulationSolvent

The present invention relates to a preparation method of insoluble sulfur of special vulcanizing agent used for rubber, in particular to a preparation method of oil charge type insoluble sulfur, which comprises the steps of: using ordinary sulfur as raw material which is added with composite stabilizer; putting into a reaction kettle which is provided with a heating controller and a stirring device; nitrogen blanketting; melt polymerization at 200~300 DEG C; thermal insulation for 25~120 min; quenching, curing, drying, size reduction and sieving; extracting by using a mixed solvent as extractant, centrifugal separation of the liquid after extraction, fluidized drying of the residue, and then obtaining insoluble sulfur; and then executing oil charge to obtain oil charge type insoluble sulfur with high stability. The operation has a strong continuity, the recovery energy consumption of the extractant is low and the product has high thermal stability.

Owner:NANJING UNIV OF TECH

Anti-sliding glaze, anti-sliding brick and preparation method thereof

The invention discloses an anti-sliding glaze which contains the following chemical components by weight percent: 42.8%-48.5% of SiO2, 19.1%-22.8% of Al2O3, 0.1%-0.2% of Fe2O3, 7.0%-9.5% of CaO, 2.5%-5.2% of MgO, 2.1%-8.6% of Na2O, 0.9%-4.1% of K2O, 1.1%-3.3% of ZnO and 2.8%-6.2% of ZrO2. The invention also discloses an anti-sliding ceramic tile and a preparation method for the anti-sliding ceramic tile. The anti-sliding ceramic tile disclosed by the invention can achieve an excellent anti-sliding effect after a layer of anti-sliding glaze is applied to the surface of the anti-sliding ceramic tile, the technology is simple and the cost is low.

Owner:DONGGUAN CITY WONDERFUL CERAMICS IND PARK

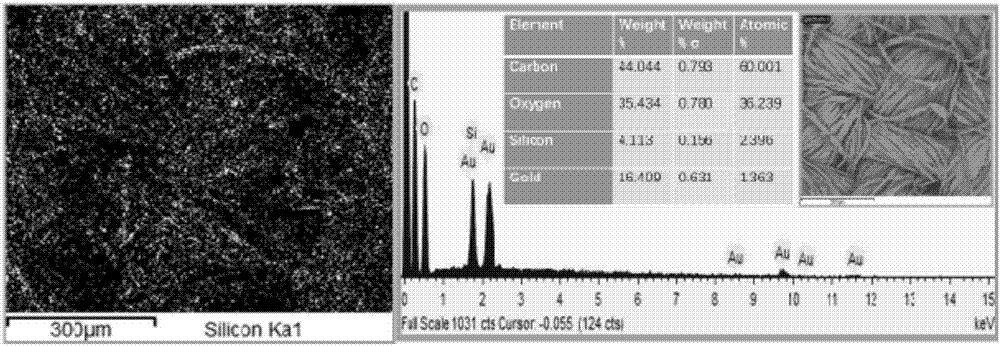

Preparation method of nano antibacterial fabric

InactiveCN1920163AImprove bindingHigh strengthFibre treatmentLiquid/gas/vapor textile treatmentFiberAntibiosis

The invention relates to a method for preparing nanometer antibiosis fabric, which uses macromolecule polymer as disperse agent and auxiliary adhesive, uses metal ion as antibiosis factor, uses nitrogen organic as the anchor agent of metal ion on the fabric, to combine the metal ion with complex bond to form nanometer particles on the fiber, to generate better antibiosis function, while the product can kill staphylococcus, bacillus coli, etc, without harmful on human skin.

Owner:RESEARCH INSTITUTE OF TSINGHUA UNIVERSITY IN SHENZHEN

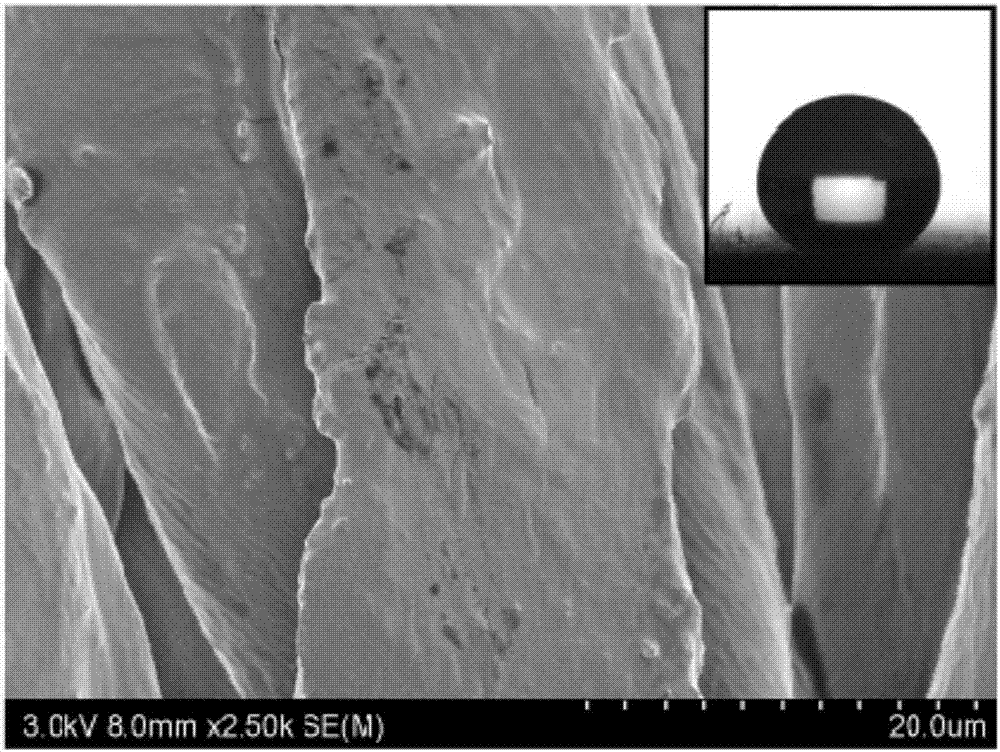

Finishing method of multifunctional textile

InactiveCN106480741AHas wash fastnessGood hydrophobic and oleophobic self-cleaning functionLiquid repellent fibresVegetal fibresCooking & bakingCross-link

The invention discloses a finishing method of a multifunctional textile. One surface of the textile has a water-and-oil-repellent antifouling function, and the other surface of the textile has oleophilic and hydrophilic moisture absorption and sweat releasing functions. The method comprises steps as follows: dip-coating of the textile in a cross-linking agent solution, spraying of oleophilic and hydrophilic components, spraying for the other surface of the textile by the oleophilic and hydrophilic components as well as pre-drying and baking for the textile after finishing. The single surface of the textile after finished with the method has a self-cleaning function, the other surface can be worn next to the skin and has the comfortable moisture absorption and sweat releasing functions, two surfaces with different functions both have certain water resistance, raw materials are widely sourced, a technology is simple and easy, the raw materials have certain compatibility with other textile finishing auxiliaries, and the method can be applied to the functional afterfinish field of the textile.

Owner:GUANGZHOU UNIVERSITY

Method for synthesizing ethylene stearamide with octadecanoic acid

InactiveCN101665447AAvoid unresponsivePerfect conversionOrganic compound preparationCarboxylic acid amide separation/purificationEthylenediamineAntioxidant

The invention discloses a method for synthesizing ethylene stearamide with octadecanoic acid, comprising the following steps: octadecanoic acid, antioxidants and catalyst phosphoric acid are added ina boiling flask, nitrogen flows in at large flow rate, and then the octadecanoic acid is heated and melted down, when the temperature is 80-100 DEG C, ethene diamine is dropwise added for reaction for0.5-1 hour, and then high-temperature reaction is carried out for obtaining finished products. The method has the advantages that: 1. the process flow is simple and the reaction condition is not strict: the ethene diamine is added to lead the octadecanoic acid to be reacted completely at the temperature of 80-100 DEG C, and the conversion of the octadecanoic acid can be improved by heat insulation. 2. The reaction time is shortened: the method adopts dehydration at low temperature and then high-temperature reaction is carried out, so as to protect color well. 3. The product has good color andluster: as BHT antioxidants and the process conditions are adopted, the color and luster of the product are kept to be well.

Owner:RUGAO SHUANGMA CHEM

Light gray dry-film conductive primer and preparation method thereof

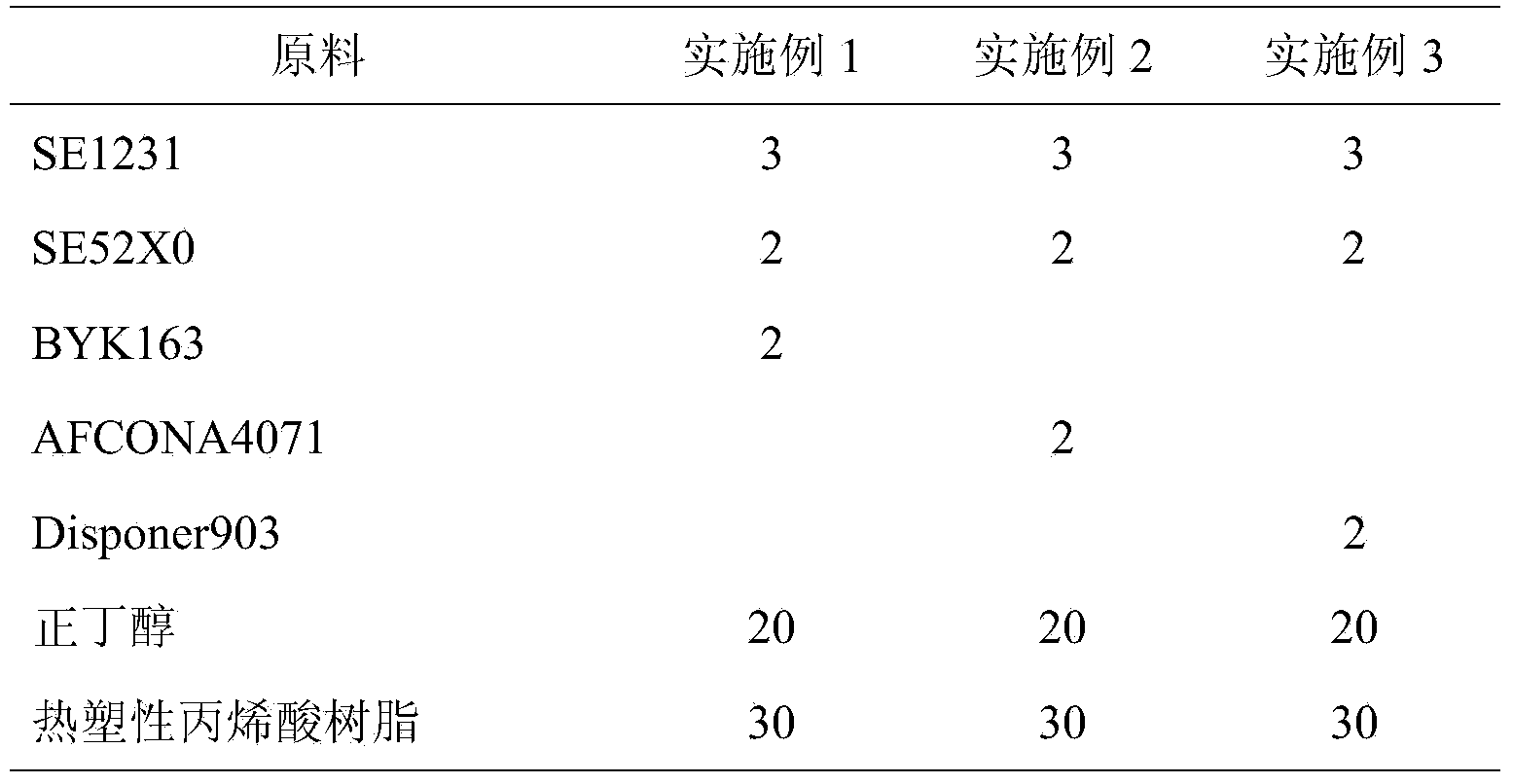

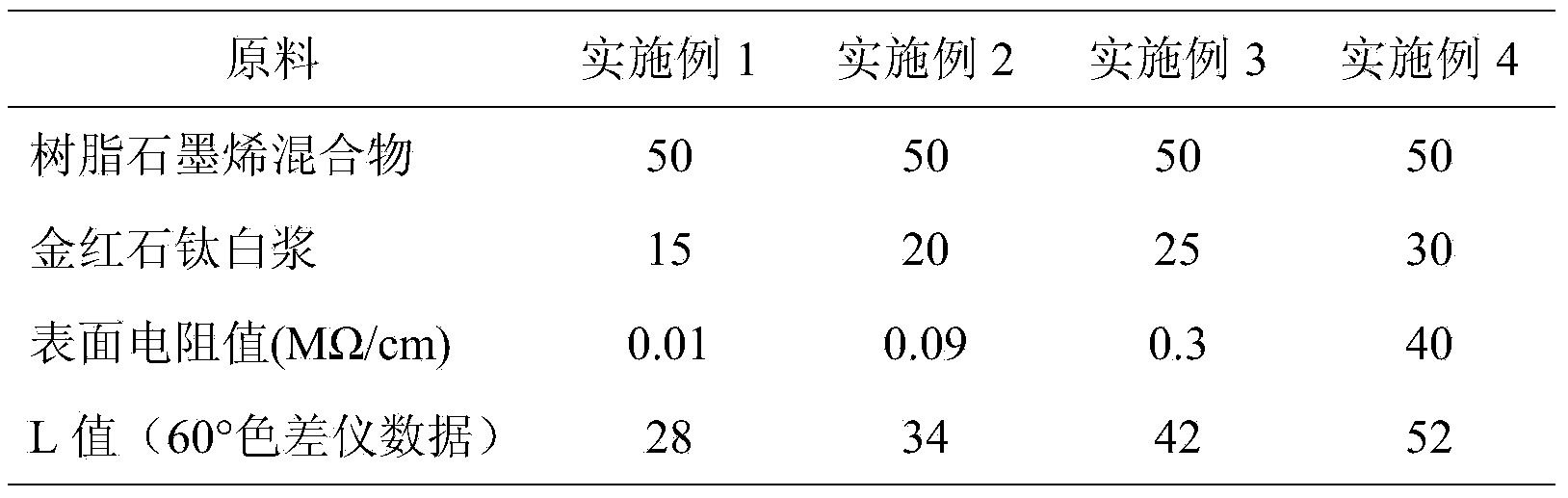

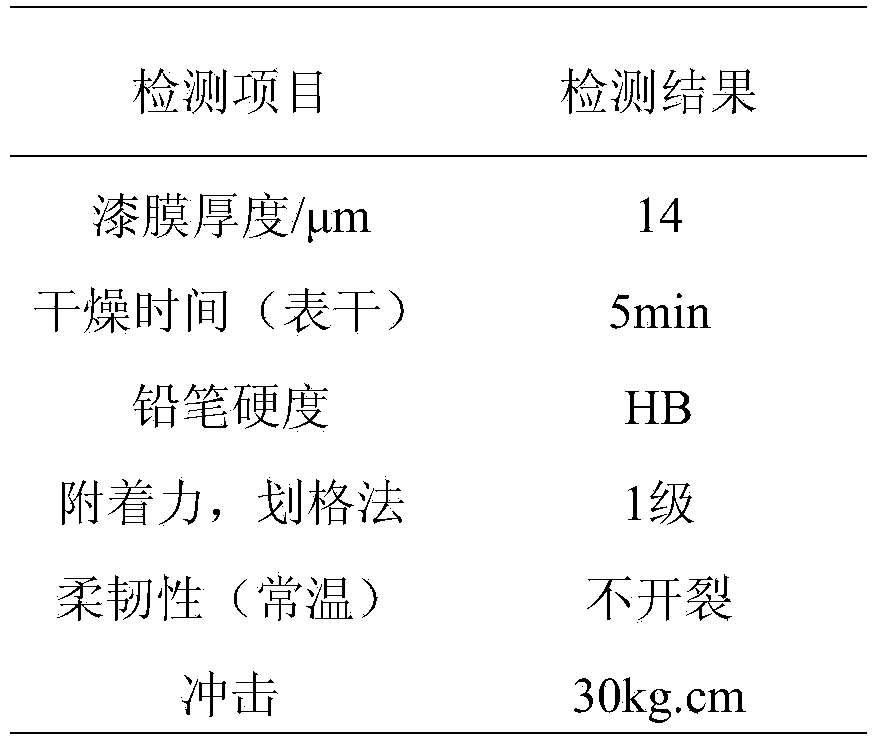

ActiveCN103666152AColor has no effectRealize electrostatic coatingElectrically-conductive paintsPolymer scienceAcrylic resin

A light gray dry-film conductive primer is mainly composed of 40-60 parts by weight of thermoplastic acrylic resin and 1-5 parts by weight of graphene. The provided light gray dry-film conductive primer is prepared by mixing surface modified graphene and thermoplastic acrylic resin and adding a solvent and rutile titanium white. The primer has the lightness (L value) more than 40 and the resistivity less than 0.3 M omega*cm. The primer has no influence on the color of a finishing coat, can help the finishing coat and varnish to realize electrostatic coating, and helps to improve the paint utilization rate and save material cost.

Owner:常州市弘可利办公用品有限公司 +1

Coating mildew-proof agent and preparation method thereof

InactiveCN107936659AGentle and non-irritating to the skinGood compatibilityAntifouling/underwater paintsPaints with biocidesSolventSodium Pyrithione

The invention discloses a coating mildew-proof agent and a preparation method thereof. The mildew-proof agent provided by the invention includes the following raw materials in percentages by weight: 25-50% of a pyrithione salt, 3%-10% of 4,5-dichloro-2-n-octyl-3-isothiazolone, 0.2%-0.6% of a dispersant, 0.02%-0.3% of a defoaming agent, 1%-2% of a consistence modifier, 0.2%-0.5% of an antioxidant,and 40-70% of a solvent; and the fineness of the pyrithione salt is not more than 2[mu]m. The coating mildew-proof agent provided by the invention is a safe, non-toxic high-efficiency and broad-spectrum coating mildew-proof agent with mildness and no irritating to skins, can be widely applied to a coating, and has good compatibility with the coating, and no effects on a plurality of properties such as color, viscosity, levelling performance and stability when the adding amount is proper; the mildew-proof agent provided by the invention can be directly added into the coating when being used, the general recommended usage amount is 0.2%-1%, and the mildew resistant level is 0; and the mildew-proof agent has obvious killing and resisting effects on moulds such as chaetomium globosum, mucor, penicillium, aspergillus terreus and aspergillus niger.

Owner:广州广微环境科技有限公司

High-temperature-resistant heat-seal adhesive applied to medicinal aluminum foil packaging

InactiveCN102796482AHigh heat sealing strengthGood oil and solvent resistancePolyureas/polyurethane adhesivesAdhesiveThermal insulation

The invention relates to high-temperature-resistant heat-seal adhesive applied to medicinal aluminum foil packaging. The high-temperature-resistant heat-seal adhesive comprises 25 to 30 percent of ethyl acetate, 20 to 30 percent of butanone, 3 to 6 percent of butyl acetate, 25 to 35 percent of polyurethane resin for printing ink and 15 to 20 percent of chloride vinyl acetate. The high-temperature-resistant heat-seal adhesive has the beneficial effects of flexibility, light weight, high heat-seat strength, high oil resistance, high solvent resistance, high temperature cooking resistance, excellent thermal insulation, excellent barrier property, high wettability and transparency to pigment, high glossiness, no influence on the color of bottom materials, no benzene solvent and high safety.

Owner:ZHENGZHOU CHENLONG ALUMINUM FOIL

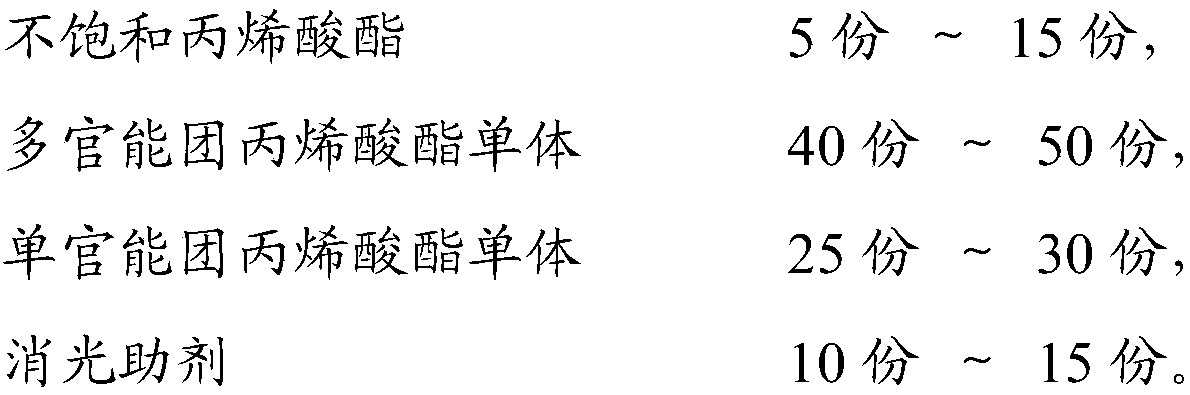

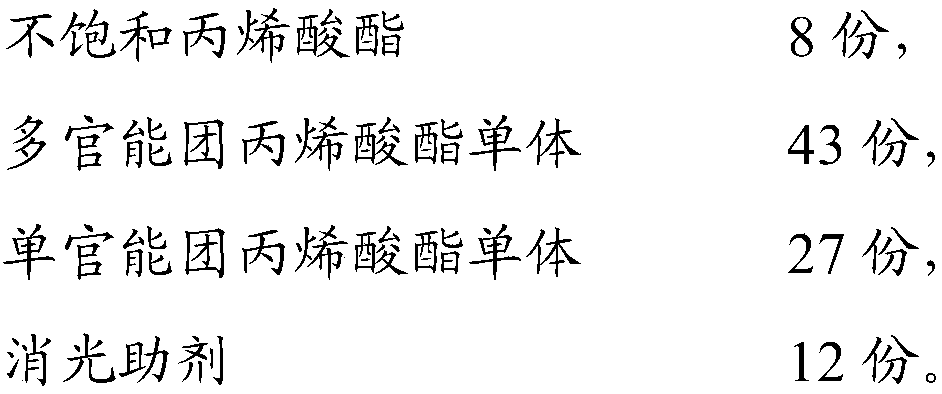

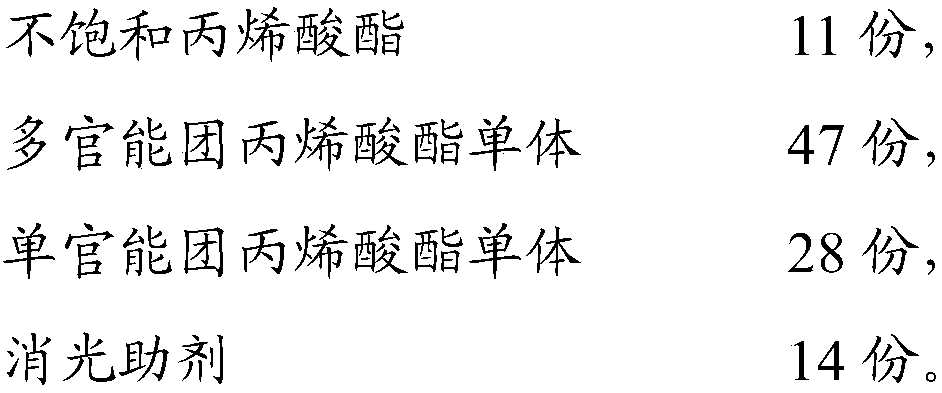

Electronic beam cured paper packaging gloss oil and curing method of printed coating

InactiveCN109666381AAvoid harmGuaranteed not to deformPretreated surfacesPolyurea/polyurethane coatingsHuman healthIrradiation

The invention provides electronic beam cured paper packaging gloss oil and a curing method of a printed coating. The electronic beam cured gloss oil comprises unsaturated acrylate, polyfunctional acrylate monomers, monofunctional acrylate monomers and extinction additive components. The electron beam curing gloss oil is obtained by uniformly mixing the unsaturated acrylate, polyfunctional acrylatemonomers, monofunctional acrylate monomers and extinction additive components. The function of the electron beam curing gloss oil is to protect an ink layer, and the electron beam curing gloss oil does not contain photoinitiators, so that a printing sample after the the electron beam curing gloss oil is cured does not contain photoinitiators, and the harm of the printed coating on human health isavoided. In addition, an electron accelerator irradiation curing process has no influence on color, and the curing at normal temperature can ensure that a printed stock is not deformed during the processing.

Owner:CGN DASHENG ELECTRON ACCELERATOR TECH

Electrolyte for realizing blackening of magnesium alloy surface and blackening process method

ActiveCN111910238AColor has no effectColor effectAnodisationProcess efficiency improvementElectrolytic agentMicro arc oxidation

The invention provides an electrolyte for realizing blackening of a magnesium alloy surface and a blackening process method. A coloring solution of a silicic acid system is adopted, and the coloring solution comprises additives such as ferric ammonium citrate and the like. In the coloring process, a magnesium alloy is subjected to down-current two-step constant-current micro-arc oxidation treatment in a prepared micro-arc oxidation solution to prepare a black ceramic membrane. In order to further improve the corrosion resistance and the stability of a membrane layer, hole sealing treatment iscarried out in hole sealing liquid. The coloring micro-arc oxidation solution is safe, environmentally friendly and high in stability, by optimizing a micro-arc oxidation manner, positive and negativecurrent density parameters are adjusted, self-repairing hole sealing is carried out on the interior of the membrane layer, the problems that the surface is loose and porous, and the thickness of a compact inner layer is small are solved, membrane layer compactness control is achieved, the membrane layer is thicker and more compact, finally the hole sealing liquid is good in stability, the influence on the color of the membrane layer does not exist, and the corrosion resistance is improved. By means of the technology, blackening treatment of the magnesium alloy is achieved, and the applicationfield of the magnesium alloy is broadened.

Owner:CHANGZHOU UNIV

Weaving of chemical synthetic fiber

InactiveCN101177796AColor has no effectImprove weaving performanceArtificial filament physical treatmentFilament/thread formingChemical synthesisDissolution

The invention provides a brand novel weaving concept of chemical synthetic fibers and a method thereof. Copper ammonia fibres, paraffin, carbon black powder, etc. are used as raw materials; the fibers spinning by dissolution method such as nitrilon, copper ammonia fibres, vinylon, etc. are used; single hole spinning is changed into compound spinning by spinning parts with a sheath-core structure when the spinning is non-compound spinning, which can obviously improve weaving performance; the outer layer of the spinning uses water-soluble paraffin and the surface of the fibers reserves concave-convex appearance caused by atoms at the same time when the paraffin is removed. The invention does not influence fiber color and has low cost and strong weaving capacity.

Owner:SHENGHONG GRP CO LTD

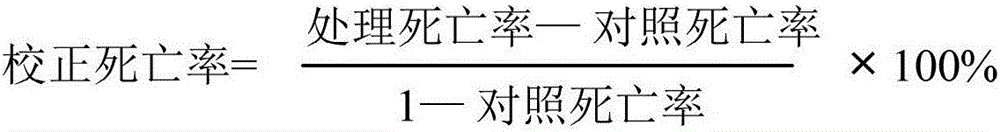

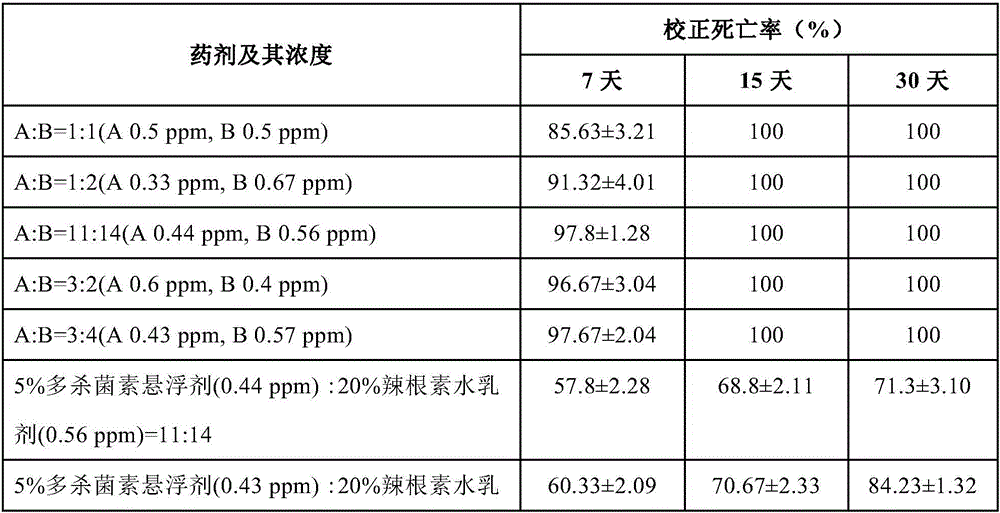

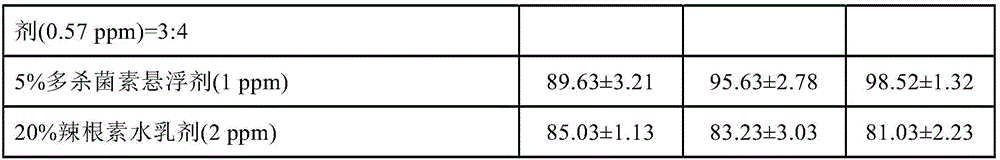

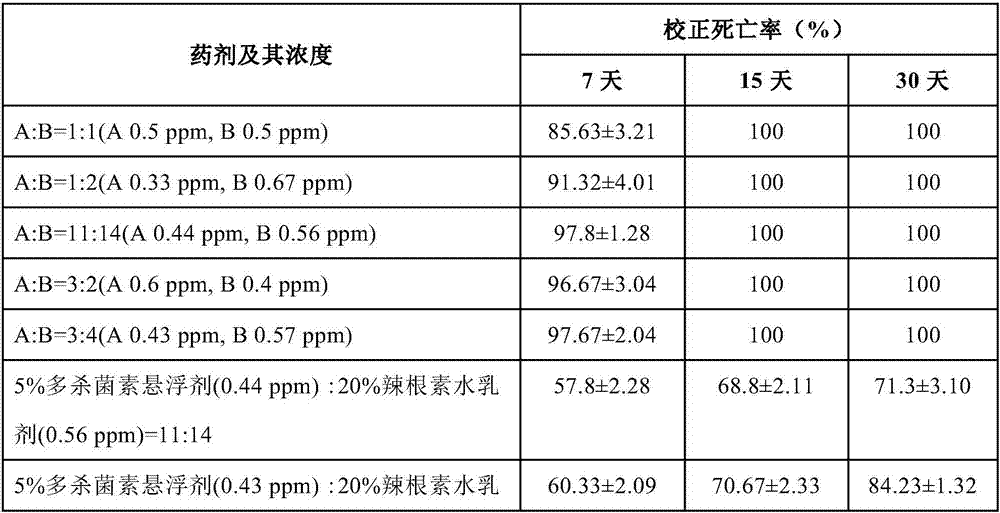

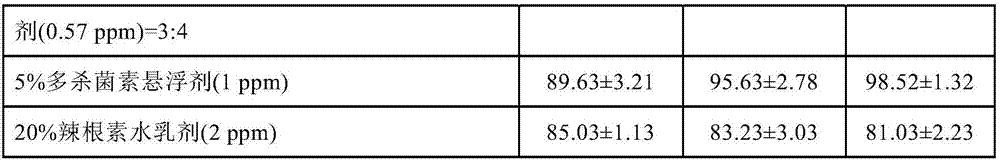

Pleocidin and athomin compounded composition and application thereof

ActiveCN105746563ALong-lasting medicineExpanding the Spectrum of Pest ControlBiocideDead animal preservationToxicityProtective Agents

The invention discloses a pleocidin and athomin compounded composition and application thereof.The effective ingredients of the compounded composition comprise pleocidin and athomin.A method in the technical field is adopted, the compounded composition can be prepared into emulsion in water or microemulsion or a suspending agent or wettable powder or water dispersible granules or the like.The pleocidin and athomin compounded composition has an obvious synergistic effect as a protective agent for grain storage, the insect killing toxicity is obviously higher than that of any single agent, the double effects of insect killing and mould preventing are achieved, and the insecticidal spectrum and the mould proof spectrum are wide.

Owner:SCI RES INST OF NAT FOOD & STRATEGIC RESERVES ADMINISTATION

Hydrophobic fixation ink and preparation process thereof

The invention discloses hydrophobic fixation ink. The hydrophobic fixation ink comprises the following components in parts by weight: 28 to 31 parts of modified adhesive material, 43 to 46 parts of amino hydrophobic pigments, 12 to 13 parts of glutaric dialdehyde, 9 parts of sodium hydroxide, 45 parts of methanol, 16 to 18 parts of oxidized starch, 8 to 10 parts of hexamethylene diisocyanate, 2 to3 parts of a defoaming agent, 3 to 4 parts of a dispersing agent, 3 to 4 parts of liquid paraffin, 1 to 2 parts of afilm forming additive, and 150 parts of ethanol. After the surface of the pigment is coated with a layer of hydrophobic composite film, the pigment has the ultrahigh hydrophobic performance; meanwhile, by introducing amino onto the composite film, the viscosity of the modified adhesive material is improved compared with the original polyvinyl alcohol adhesive materialby virtue of the polymerization of vinyl acetate and acrylamide, so that the adhesion performance is improved; and meanwhile, the amino is introduced into the adhesive material, the amino hydrophobic pigment is composited compounded onto the adhesive material under the cross-linking effect in the presence of glutaric dialdehyde, so that the whole adhesive material netted structure comprises a great amount of hydrophobic groups, and the prepared ink has ultrahigh hydrophobic capability.

Owner:汕头市光彩新材料科技有限公司

Method for preparing antistatic nano composite slurry

InactiveCN101928410APermanent antistaticColor has no effectPigment treatment with organosilicon compoundsPigment treatment with non-polymer organic compoundsSolventGlycol synthesis

The invention belongs to the technical field of PET materials, and particularly relates to a method for preparing antistatic nano composite slurry and application thereof. The method for preparing the antistatic nano composite slurry comprises the following steps of: dissolving silane coupling agent, dispersant and nano silicon nitride in a mass ratio of 1:1:4.9-5.1 into nano petroleum ether or n-hexane solvent, reacting the mixture at the temperature of between 60 and 90 DEG C, then distilling the reaction product, and drying the distilled reaction product; and mixing the dried product, ethylene, propylene and ethylene glycol in a mass ratio of 9-11:1:1:30, putting the mixture into a high-pressure crusher and dispersing the mixture to obtain the antistatic nano composite slurry. The preparation method is simple and convenient; and the antistatic nano composite slurry obtained by the method, applied in a PET material, has permanent antistatic performance and has no influence on the color of the PET material.

Owner:HEFEI KAIER NANOMETER ENERGY & TECH

New softener for cloth

InactiveCN108103783ASoft touchNo pollution in the processWrinkle resistant fibresGrip property fibresPolyvinyl butyralOleic Acid Triglyceride

The invention discloses a new softener for cloth. The new softener for the cloth comprises the following raw materials in parts by weight: 4 to 7 parts of glutaraldehyde, 5 to 8 parts of MgCl2.6H2O, 10 to 20 parts of waterborne polyurethane resin, 2 to 5 parts of a triethanolamine oleic acid soap, 3 to 7 parts of amino silicone oil, 9 to 11 parts of polyoxyethylene ether, 12 to 16 parts of dioctadecyl dimethyl ammonium chloride, 1 to 4 parts of tartaric acid, 10 to 12 parts of polyvinyl butyral, 11 to 14 parts of sodium dihydrogen phosphate, 3 to 7 parts of sodium dodecyl benzene sulfonate, 1to 4 parts of valerolactam, 4 to 6 parts of fatty acid polyoxyethylene ester, and 45 to 55 parts of deionized water. The new softener for the cloth disclosed by the invention has the beneficial effects that (1) the softer is non-toxic and harmless to human bodies, free of environmental pollution, good in safety, excellent in hygroscopicity and breathability, free of influences on the color and whiteness of the cloth, soft in handfeel, and good in crease resistance and durability; and (2) the cloth treated by the softener is high in wear resistance, good in elasticity, and convenient in production and low in cost.

Owner:ANHUI HONGYUAN NONWOVEN FABRIC

Preparation method and application of terminated-type cation water-borne polyurethane color fixing agent

The invention relates to a preparation method of a terminated-type cation water-borne polyurethane color fixing agent, belonging to the field of organic adhesives. The terminated-type cation water-borne polyurethane color fixing agent with solid content of 20-40% of and transparent or translucent yellowish appearance can be prepared by the following steps of: (1) polyurethane prepolymer reaction,(2) terminated reaction, and (3) acid neutralization and ionization reactions. In the invention, partial terminating after prepolymerization is adopted, a small number of isocyanate groups is inactivated and a self-emulsifying method is adopted to synthesize the water-borne polyurethane color fixing agent; in the color fixing process, closed active groups are released through baking at high temperature and are carried out crosslinking reaction with hydroxyl and amino groups on textile fabrics and reactive dyes so that the color fastness to washing of the textile fabric is improved.

Owner:溧阳常大技术转移中心有限公司

Aerosol can type water and oil repellent product and preparation method thereof

The invention discloses an aerosol can type water and oil repellent product. The product comprises a can body and spray in the can body, wherein the spray consists of mother liquor and propellant; the propellant is a compressed gas, and is used for providing pressure to the mother liquor to urge the ejection of the mother liquor; and the mass ratio of the mother liquor to the propellant is (0.05-6): 1. The aerosol can type water and oil repellent product can conveniently perform the local treatment for textiles, and has a quick evaporation velocity; and following procedures of drying and baking can be prevented under specific conditions to achieve the readily available purpose. The aerosol can type water and oil repellent product has little influence on colors of the textiles, and keeps the hand feel of the textiles invariable. The invention synchronously provides a preparation method of the product.

Owner:TEXLABS TECH CO LTD

Traditional Chinese herbal grain mildew-proof insecticide

A traditional Chinese herbal grain mildew-proof insecticide comprises the components: sulfur, radix stemonae, fructus caryophylli, lignum dalbergiae odoriferae, and fructus evodiae. The insecticide has no toxic or side effect, has no effect on flavors, colors and grades of stored grains, is safer, is rich in various raw material sources, low in price and long in effect lasting time, adapts to storage of various grains, is convenient and environmentally friendly, has no pollution to human and livestock when used for long-term storage of the grains, also can keep the grains dried and non-mildew, and has relatively good social benefits.

Owner:叶维谦

Preparation method of fresh keeping agent for fish meat

InactiveCN107410441AAvoid breedingInhibition of reproductionMeat/fish preservation using chemicalsZeaxanthinApple extract

The invention discloses a preparation method of a fresh keeping agent for fish meat. The technical scheme of the preparation method disclosed by the invention is realized in the following manner that the fresh keeping agent is prepared through the following steps of organically mixing plant essential oil with nisin, acetamino, carboxymethyl chitin, lactobacillus reuteri, zeaxanthin, an apple extract, sodium benzoate, a silybum marianum extract, chitin, sodium diacetate, bamboo-leaf flavone and water through scientific compatibility.

Owner:HUNAN YIKE BIOLOGICAL ENG CO LTD

Method for processing mellow-thick green tea

InactiveCN106031395APromote dissolutionNo change in colorPre-extraction tea treatmentMicrowaveHigh power density

The invention discloses a method for processing mellow-thick green tea, and relates to a tea processing method. The method aims at achieving the aim that on the basis of keeping the quality of traditional tea, the concentration of tea soup of upscale green tea is increased. The processing method includes the following steps that fresh leaves are fixed through a fixing machine, then tissue cracking is conducted through microwaves, the cracked tea is quickly frozen and cooled, the quickly-frozen tea is shaped, and finally refiring is carried out till the tea is adequately dry. The method has the advantages that the fixed leaves are heated through the high-power-density microwaves, moisture contained in cells of the fixed leaves is rapidly heated and gasified, cell walls are broken through gasifying, tea cell contents can be conveniently dissolved out during brewing, and therefore the effect of increasing the concentration of the tea soup is achieved.

Owner:孙永华

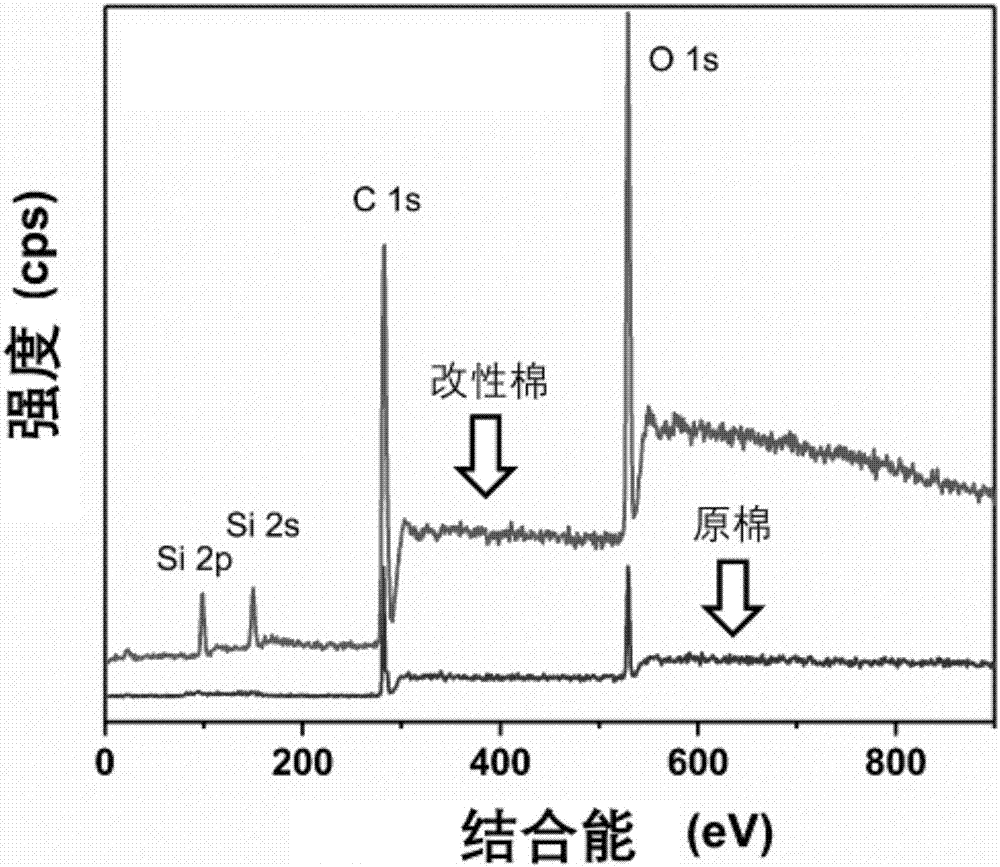

Synthesizing and finishing method of environment-friendly fluoride-free hydrophobic coating liquid

InactiveCN107130435ALow costSimple processLiquid repellent fibresVegetal fibresEmulsionHigh wear resistance

The invention discloses a synthesizing and finishing method of an environment-friendly fluoride-free hydrophobic coating liquid. A stable hydrophobic coating liquid emulsion is prepared firstly; a transparent ultra-hydrophobic finishing effect can be realized on the surface of a substrate by a soaking method. The method has the advantages of simple process, low energy cost, low raw material cost and environmental friendliness, and is suitable for various material substrates; an obtained product has very high wear resistance, soaping resistance, and acid, salt and alkali resistance, and can be directly applied to large-scale industrial production and market popularization.

Owner:SUZHOU RONGLYU NANO SCI & TECHOGY

A kind of high-temperature resistant heat-sealing adhesive applied to pharmaceutical aluminum foil packaging and preparation method thereof

ActiveCN103952095BHigh transparencyImprove wettabilityNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesAdhesiveAcrylonitrile

The invention discloses high temperature-resistant heat-sealing glue for medicinal aluminum foil package and a preparation method thereof. The high temperature-resistant heat-sealing glue is prepared from 12-14 parts by weight of dimethyl dichlorosilane, 24-26 parts by weight of ethyl acetate, 12-14 parts by weight of ethyl methyl ketone, 20-24 parts by weight of EVA emulsion, 1-2 parts by weight of iso-tridecanol polyoxyethylene ether, 2-3 parts by weight of anilino-methyl-triethoxysilane, 1-2 parts by weight of tert-butyl hydroperoxide, 4-5 parts by weight of acrylonitrile, 6-7 parts by weight of isoprene, 1-2 parts by weight of rosin-polythylene oxide ester and 4-5 parts by weight of a tackifying promoter. The high temperature-resistant heat-sealing glue is soft, has light weight, high heat-sealing strength, good oil resistance and solvent resistance, good high-temperature stewing resistance, excellent heat insulation and barrier properties, good wetability to pigment, good transparency, high glossiness and no influence on a substrate color, does not contain a benzene-like solvent and has good safety.

Owner:JINING XINRUIDA INFORMATION TECH CO LTD

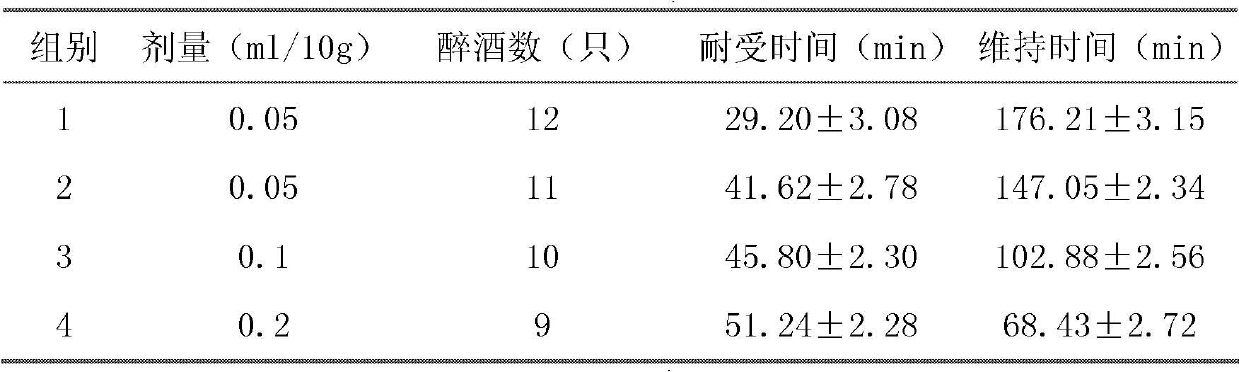

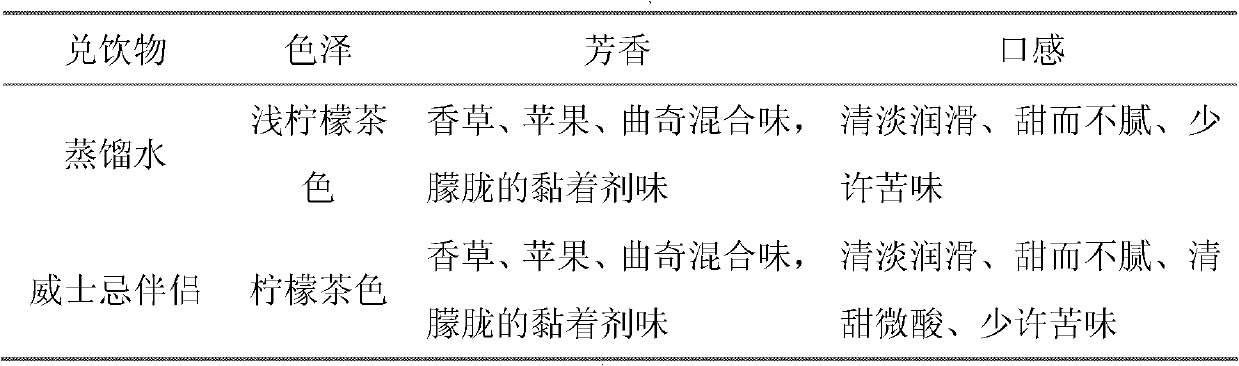

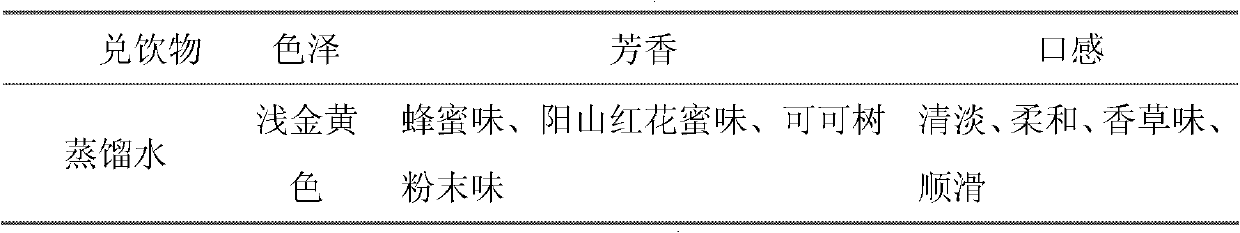

Beverage used for blending and diluting whisky and preparation method thereof

The invention relates to a beverage used for blending and diluting whisky and a preparation method thereof. The beverage is composed of 50-55 parts of leaching solution of malus hupehensis leaves, 30-35 parts of kudzuvine flower leaching solution and 10-15 parts of an auxiliary material. The preparation method comprises the following steps: respectively washing, drying, crushing, heating and lixiviating malus hupehensis leaves and kudzuvine flowers, mixing and cooling the obtained leaching solution, adding the auxiliary material, homogenizing, cooling, filtering and sterilizing to finally obtain the beverage used for blending and diluting whisky. The beverage of the invention is golden yellow, uniform, fresh and sweet and sourish, clear and bright, and the beverage has gentle taste and health-care effects of relieving heat and quenching thirst, resisting fatigue, reducing alcoholic toxicity and the like on a human body.

Owner:HUBEI UNIV OF TECH

Environmental protection type moth-proof and mould-proof dust

An environment protection type mothproofing antimildew powder for leather, wool, fibrous fabrics, cultural relics, book, archives, etc is prepared from empenthrin or high d-trans-furamethrin, dimethyl fumarate or p-chlorometaxylenol, and the excipient prepared from diatomite, quartz sand and talc powder.

Owner:陈连

Plastic part and manufacturing method thereof

InactiveCN103158308AWith electromagnetic shieldingConductivity has no effectMagnetic/electric field screeningSynthetic resin layered productsColor ScaleAluminum composites

A plastic part comprises a plastic base and non-conducting coating film layer formed in the plastic base. The non-conducting coating film layer is a silicon-aluminum composite layer, and an L* coordinate, an a* coordinate and a b* coordinate of a chromaticity area of the silicon-aluminum composite layer in the CIE LAB color scale system respectively are 70-75, 0-0.5 and 0-0.5. The invention further provides a manufacturing method of the plastic part.

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD

A compound composition of spinosyn and horseradish and its application

ActiveCN105746563BDelay drug resistanceNo impact on qualityBiocideDead animal preservationSpinosadGrain storage

The invention discloses a pleocidin and athomin compounded composition and application thereof.The effective ingredients of the compounded composition comprise pleocidin and athomin.A method in the technical field is adopted, the compounded composition can be prepared into emulsion in water or microemulsion or a suspending agent or wettable powder or water dispersible granules or the like.The pleocidin and athomin compounded composition has an obvious synergistic effect as a protective agent for grain storage, the insect killing toxicity is obviously higher than that of any single agent, the double effects of insect killing and mould preventing are achieved, and the insecticidal spectrum and the mould proof spectrum are wide.

Owner:ACAD OF NAT FOOD & STRATEGIC RESERVES ADMINISTRATION

A non-destructive removal method for photographs bonded to glass surfaces

ActiveCN108466473BAchieve lossless extractionMechanical strength has no effectLamination ancillary operationsLaminationNon destructiveAlcohol

The invention discloses a non-destructive peeling method for a picture adhered to the surface of glass. The method comprises the following step: directly soaking a picture adhered to a piece of glassand the glass together into absolute ethyl alcohol at a normal temperature, thereby non-destructively peeling off the picture from the glass. The method disclosed by the invention is simple to operate, image information of the peeled picture can be clear and complete without deformation, in addition, the absolute ethyl alcohol is safe and environmental-friendly to use, and the mechanical strength,the gloss and the color of the picture are not affected.

Owner:SHAANXI NORMAL UNIV

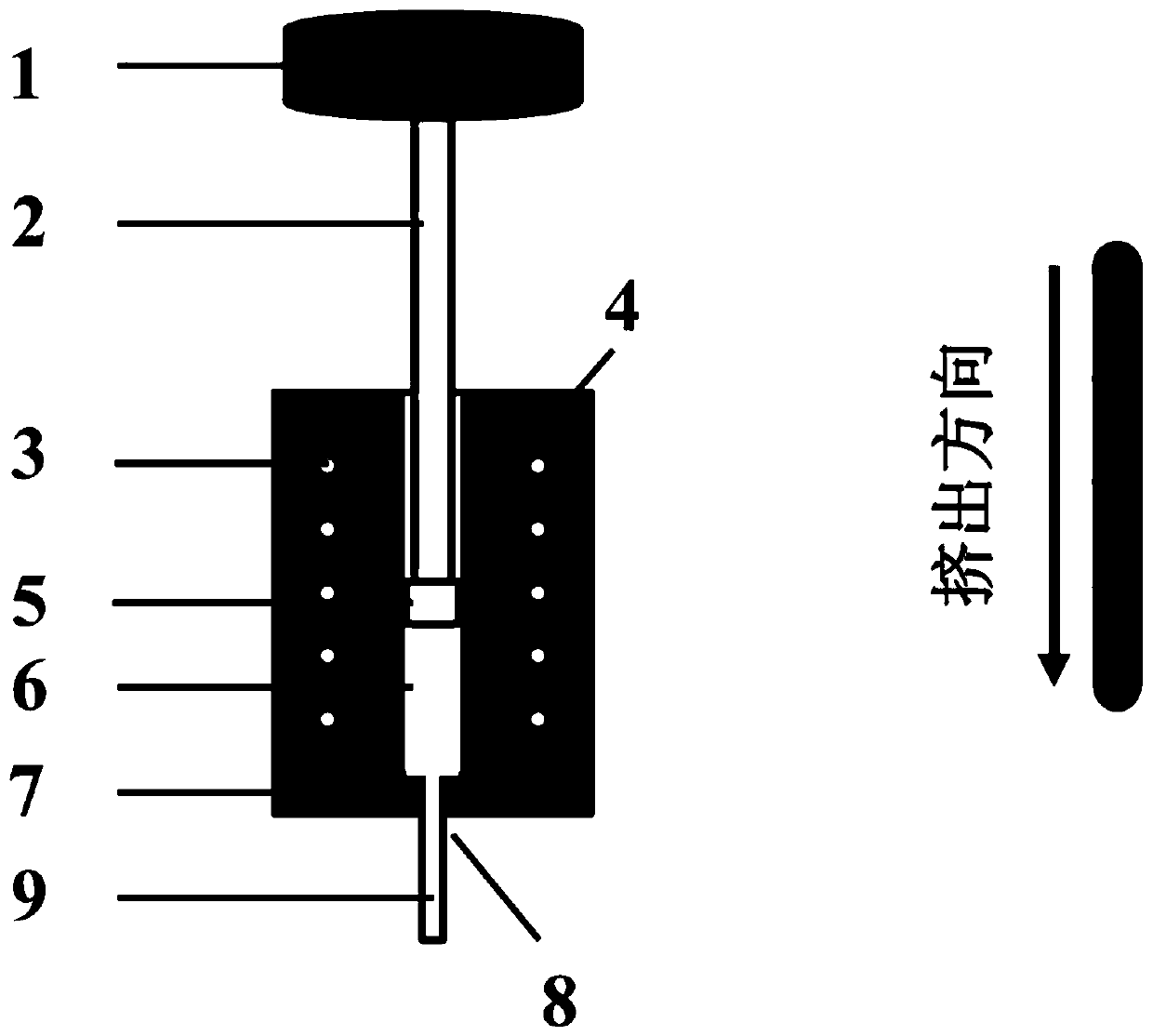

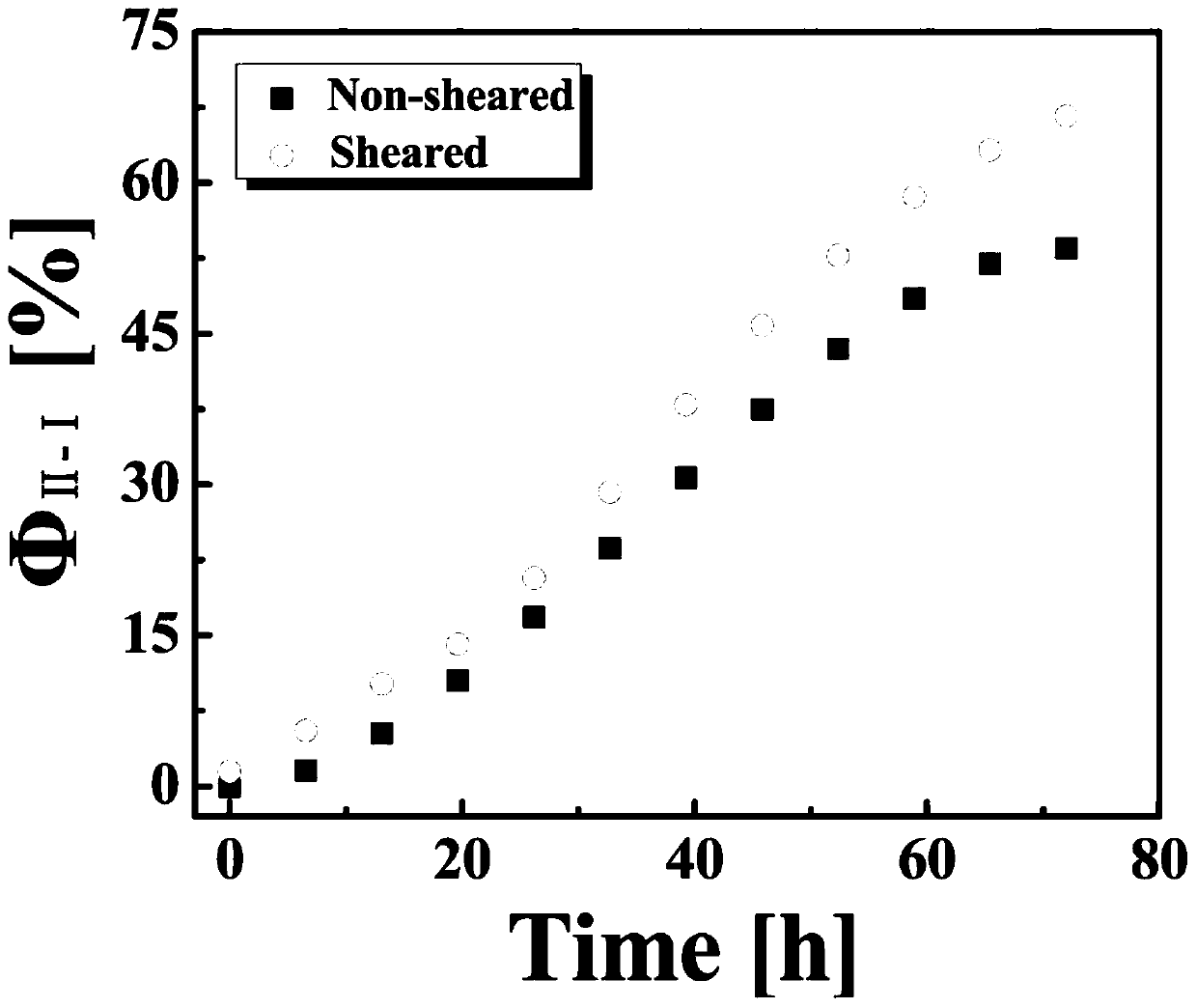

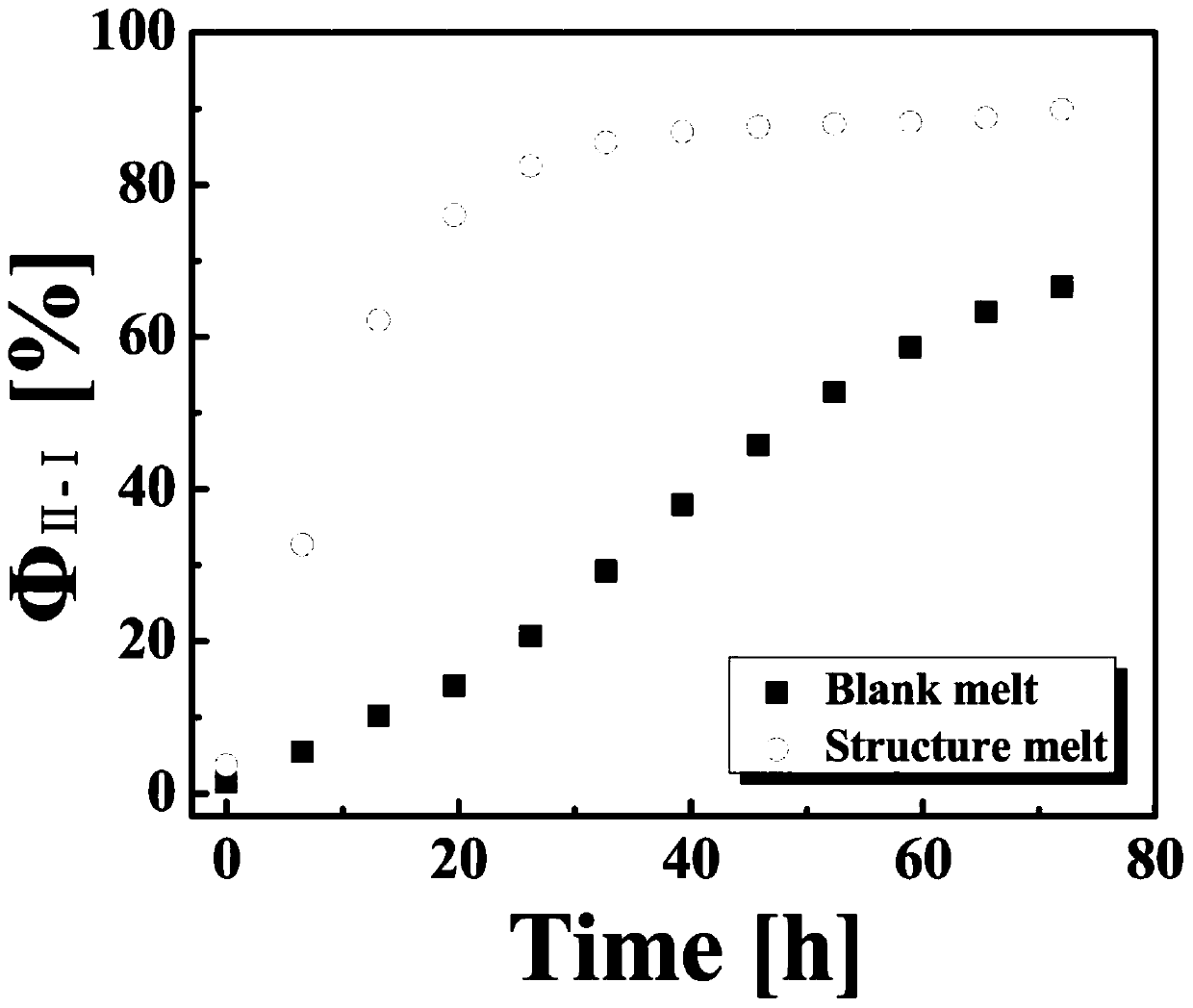

A method for accelerating the transformation of crystal form II to crystal form I by applying flow shear to isotactic polybutene-1 structure melt

Owner:ZHENGZHOU UNIV

Preparation method of high-aroma type sachima

InactiveCN102165985BHigh aroma intensityColor has no effectConfectionerySweetmeatsGlucose-Fructose SyrupVegetable oil

The invention discloses a preparation method of high-aroma type sachima, which comprises the following steps: evenly mixing flour, fresh eggs, a leavening agent, wheat gluten lactalbumin hydrolysate and water, fermenting, cutting into predetermined shape, deep frying in vegetable oil at 130-150 DEG C for 1-5 min, and then obtaining fried twisted dough sticks; and after boiling grape syrup to 100-106 DEG C, mixing the grape syrup with the fried twisted dough sticks, pressing flat, cutting, molding and obtaining the high-aroma type sachima. In the preparation method, by adding the wheat gluten lactalbumin hydrolysate, the aroma intensity of sachima can be significantly improved under the process conditions without affecting the color and luster of the product.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com