Patents

Literature

98results about How to "Improve weaving performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

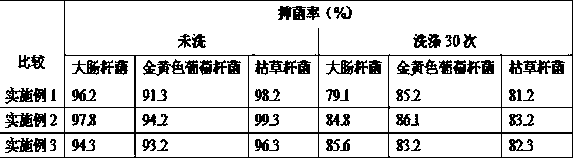

Antibacterial fabric, preparation technology thereof and textile thereof

InactiveCN103255522ANon-irritatingImprove thermal stabilityWeft knittingCarbon fibresBiotechnologyPolyester

The invention relates to the field of functional fabrics, in particular to an antibacterial fabric, a preparation technology of the antibacterial fabric and textile of the antibacterial fabric. The antibacterial fabric comprises, by weight, 10-20 parts of short fiber silk, 20-25 parts of anion polypropylene staple fibers, 15-25 parts of nano bamboo carbon fiber, 2-5 parts of nano-titanium dioxide, 5-10 parts of nano-silver fiber, 2-4 parts of anti-mite finishing agent, 3-8 parts of sweat-absorbent quick-drying processing agent, 12-18 parts of binder, 2-4 parts of dispersing agent, 3-5 parts of fabric softener and 80-85 parts of polyester cotton fiber. Due to the fact that the anion polypropylene staple fibers are added, effects of nerve stability, sleep improvement, inflammation diminishing and pain relief are provided. Due to the fact that the anti-mite finishing agent is added, trouble caused by mites to a human body can be effectively prevented. Due to the fact that the sweat-absorbent quick-drying processing agent is added, sweat generated by the body can be rapidly absorbed, discomfort can be reduced, and breeding of germs under a humid environment can be prevented. The antibacterial fabric can be applied to clothing, home textiles, sports goods, medical care, bacteria resistance and insect prevention textiles.

Owner:广东雄兴内衣实业有限公司

Preparation method of hollow fabric with radial elastic shrinkage

ActiveCN102776649AHigh tensile strengthHigh temperature resistantWoven fabricsEngineeringWear resistance

The invention discloses a preparation method of a hollow fabric with radial elastic shrinkage and relates to the preparation method of the hollow fabric. The object of the invention is to solve the problem that elastic hollow fabric available in the market does not meet the requirement of thin diameter and longitudinal elasticity and very large radial elasticity when being used in a specific task, has poor strength of bearing accidental drawing and poor wearability, as well as poor dimensional stability, and especially poor radial elasticity. The method comprises the preparation work of warp yarns, which includes selecting fine denier 75-200D aramid fiber fibers, 100-300D PBO (p-phenylene-2,6- benzobisoxazazole fiber) fibers or aramid fibers and PBO combined filament yarns as warp yarns; preparation work of weft yarns; directly winding of the weft yarns to form a pirn with a size same as that of a shuttle of a shuttle loom; and a determining and weaving process of metric portie. The hollow fabric prepared by the preparation method provided by the invention has excellent radial elastic recovery, and also the characteristics of superstrong resistance to longitudinal stretching force and wear resistance and corrosion resistance. The method is used for preparing elastic hollow fabrics.

Owner:HARBIN INST OF TECH

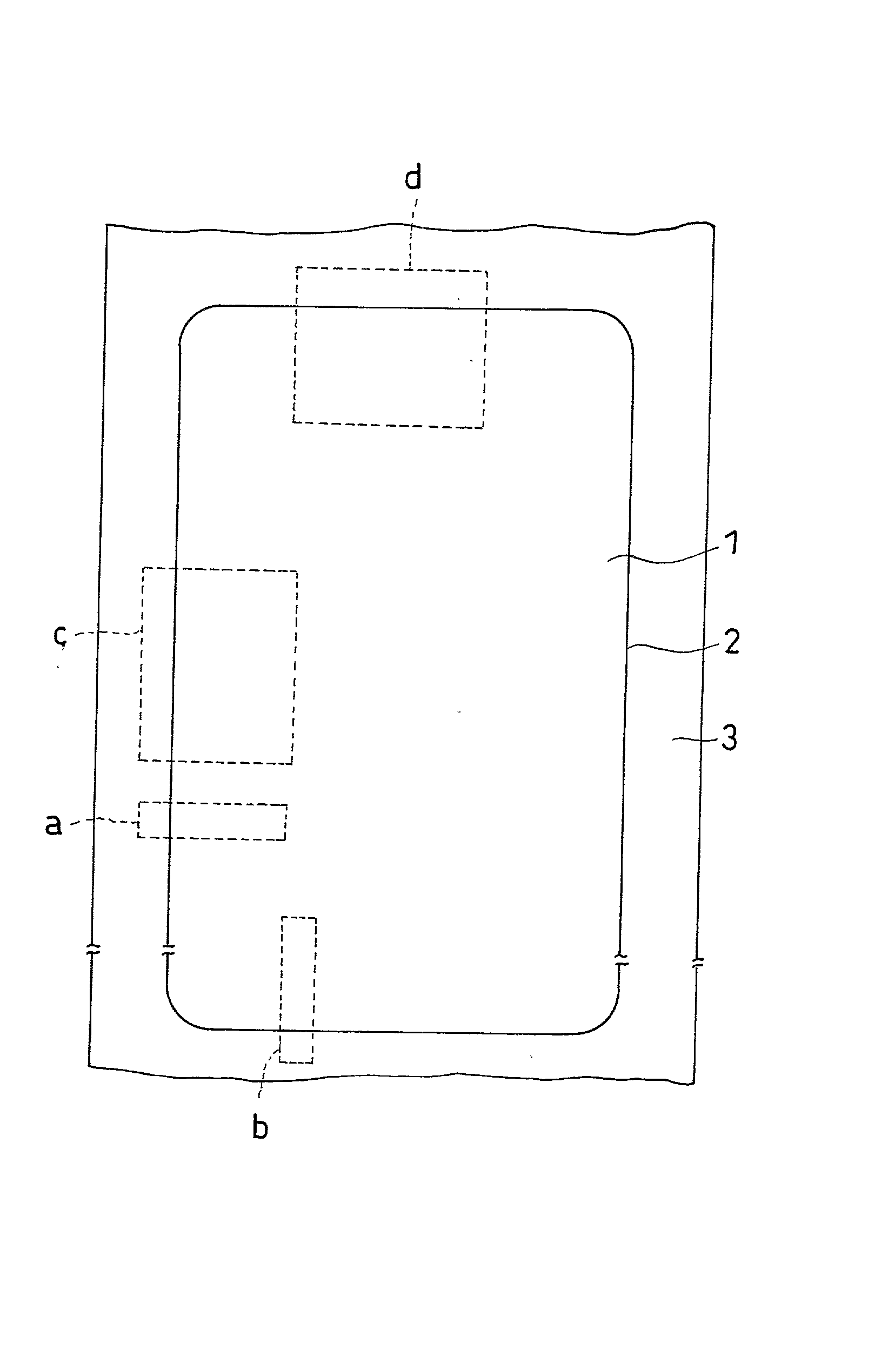

Base fabric for hollow-woven air bag and air bag

InactiveUS20020130503A1FlatnessImprove weaving performancePedestrian/occupant safety arrangementMulti-ply fabricsMechanical engineering

Owner:TOYO TOYOBO CO LTD

Ultrahigh molecular weight polyethylene fiber blended yarn

The invention discloses an ultrahigh molecular weight polyethylene fiber blended yarn, which is characterized by being formed by drawing, twisting and blending ultrahigh molecular weight polyethylene fibers and other fibers, wherein the other fibers are any one or combination of more than two of dacron, polyamide fiber and pure cotton fibers; and all the fibers are continuous fibers. Compared with the traditional blended yarn, the ultrahigh molecular weight polyethylene fiber blended yarn is simple in process, high in breaking strength, high in wear resistance, easy to color, high in knitting property and low in price.

Owner:SHANDONG ICD HIGH PERFORMANCE FIBRES CO LTD

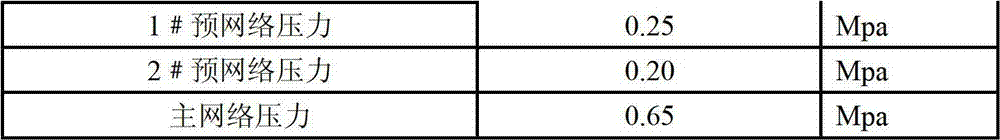

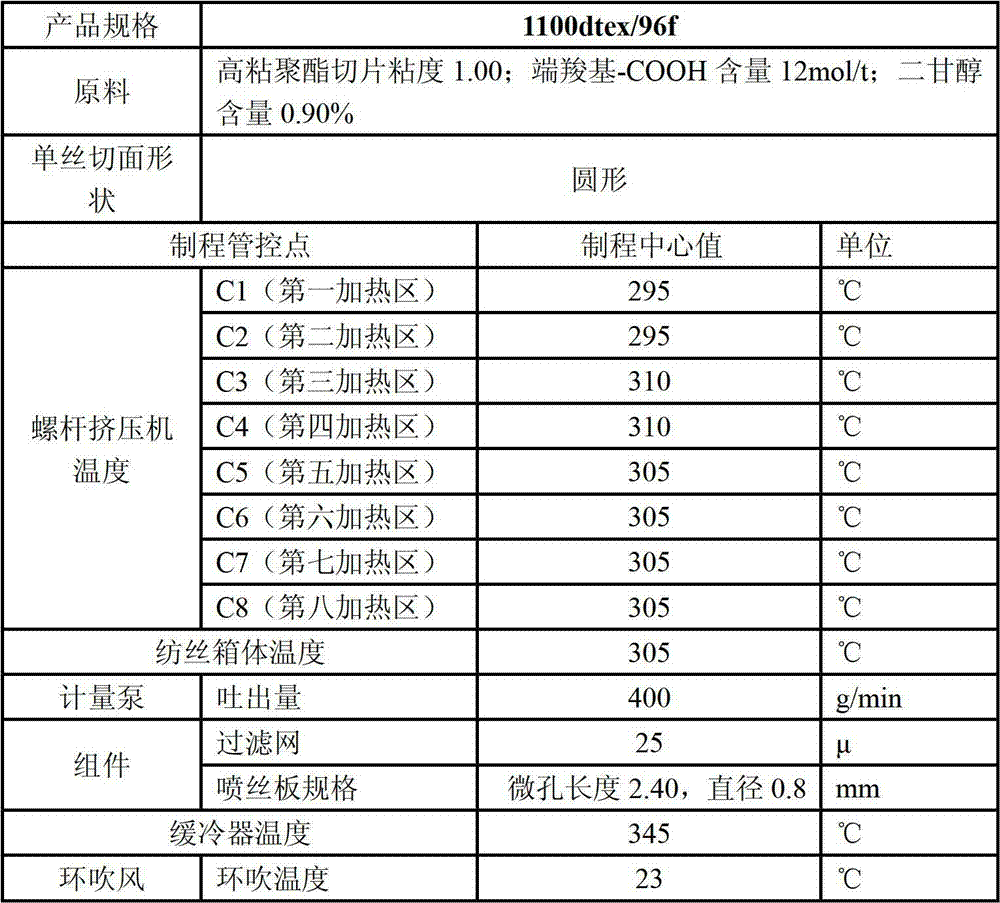

Industrial polyester filament for high-strength ultra-low-elongation safety belt and production method of industrial polyester filament

ActiveCN102808230AImprove weaving efficiencyImprove wear resistanceFilament forming substance formingNew-spun product collectionEngineeringImpurity

The invention relates to an industrial polyester filament for a high-strength ultra-low-elongation safety belt and a production method of the industrial polyester filament. The production method comprises the following steps of: A) high-viscosity polyester chip preparation; B) high-viscosity polyester chip impurity removal; C) melt spinning; and D) drafting, heat setting and winding. The number of the industrial polyester filaments produced by adopting the method is 72-144F, the fineness is 1100-2222dtex, the breaking strength can reach more than 7.80cN / dtex, the fixed-load elongation can reach 4-6 percent under a condition of 11.1KN and the controllable oil content is lower than 0.30-0.60 percent. The industrial polyester filament for the high-strength ultra-low-elongation safety belt and the production method of the industrial polyester filament have the beneficial effects that the breaking strength of the safety belt which is provided by using the obtained industrial polyester filaments can reach 35KN and is much higher than the breaking strength being 28-33KN of the existing safety belt, the physical and mechanical performance is good and the industrial polyester filament is an optimum raw material for producing front-row safety belts; the weaving performance is good, the dyeing uniformity of the safety belt is good due to lower fiber oil content, the gloss is stable, and chromatic aberration and stains do not exist; the waste polyester fibers can be recycled, the energy is saved, the environment is protected and the operating cost is reduced; and the operation is simple to conduct, the process flow is short, the automation level is high and the development space is very great.

Owner:ORIENTAL IND SUZHOU

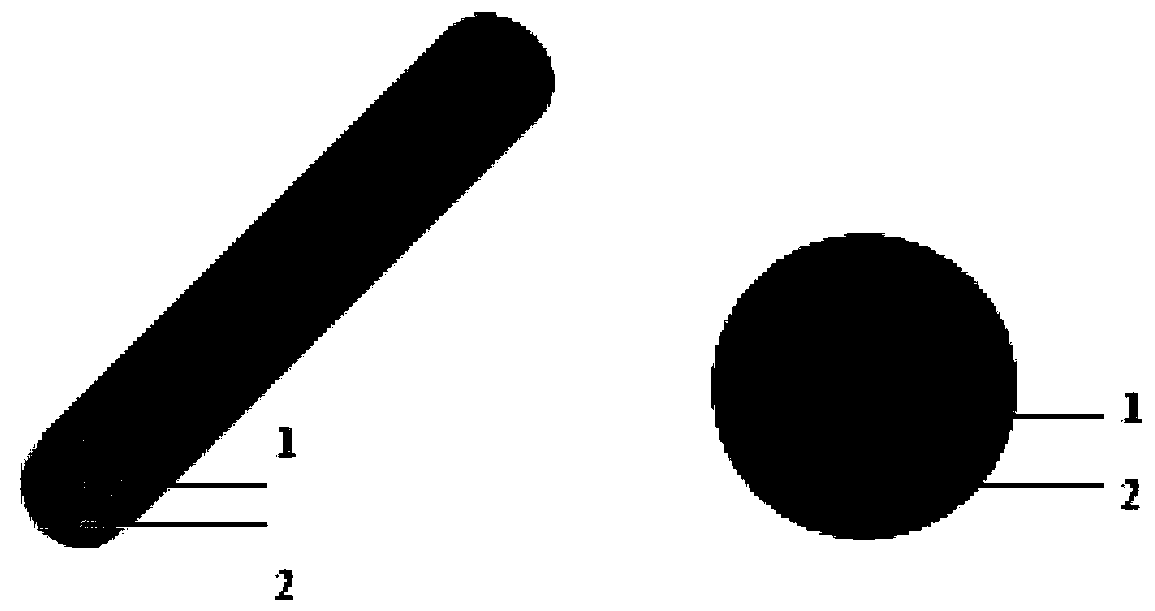

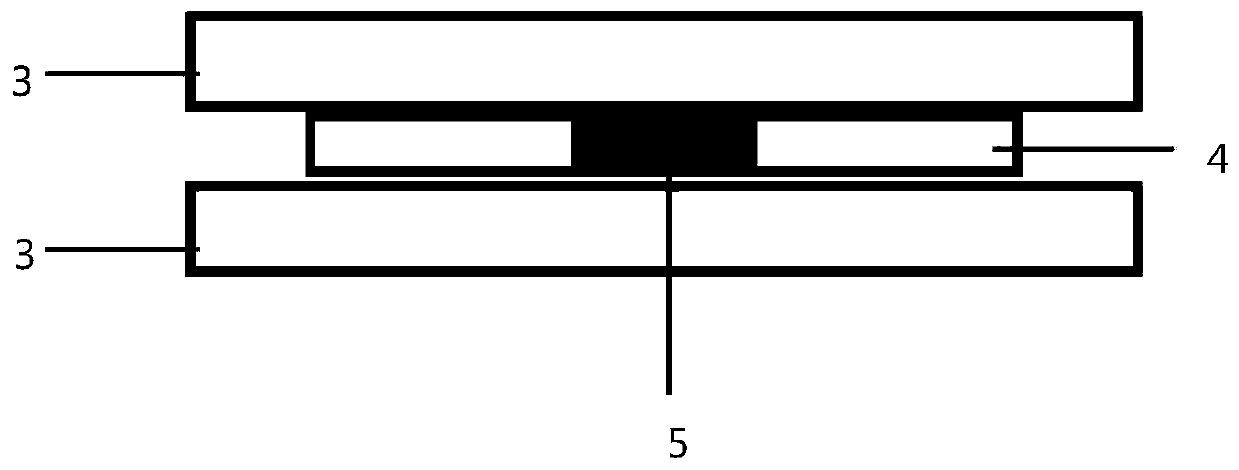

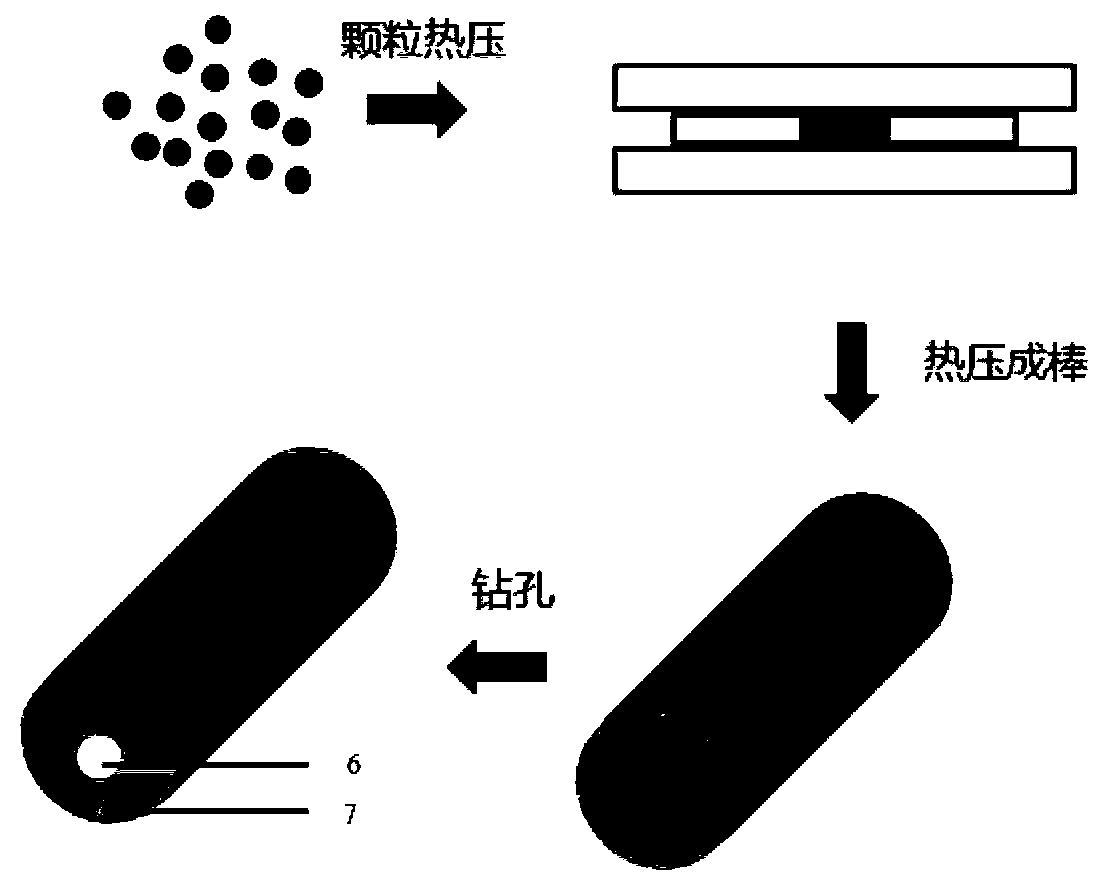

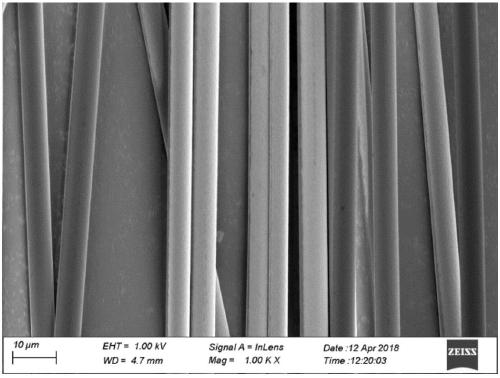

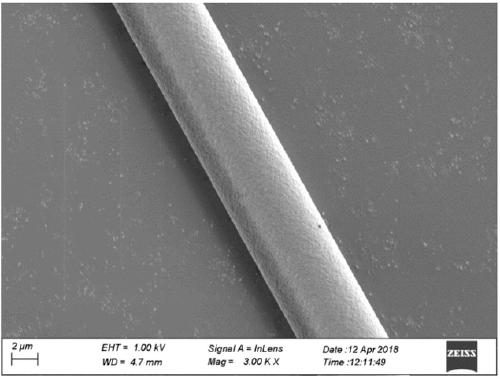

Flexible fiber electrode coated with polyetheretherketone coating layer, preparation and application thereof

ActiveCN110227208AEasy to prepareReduce material costsInternal electrodesExternal electrodesPoly ether ether ketoneBiocompatibility Testing

The present invention belongs to the field of functional fibers and more particularly relates to a flexible fiber electrode coated with a polyetheretherketone (PEEK) coating layer, a preparation and an application thereof. Firstly, a through-hole-containing polyetheretherketone prefabricated rod is obtained; then a flexible filamentary conductive material passes through a through hole of the prefabricated rod, a thermal softening drawing method is used, and the prefabricated rod and the flexible filamentary conductive material are subjected to co-drawing to obtain the flexible fiber electrodeusing the flexible filamentary conductive material as a core layer and the polyetheretherketone as the coating layer. The provided flexible fiber electrode coated with the polyetheretherketone coatinglayer is prepared mainly by a thermal drawing technology, so that the prepared flexible fiber electrode has excellent biocompatibility of the PEEK material and also has good electrical and mechanicalproperties of metal materials. The obtained flexible fiber electrode has great prospects in the field of biomedicines, especially in research of biological probes.

Owner:HUAZHONG UNIV OF SCI & TECH

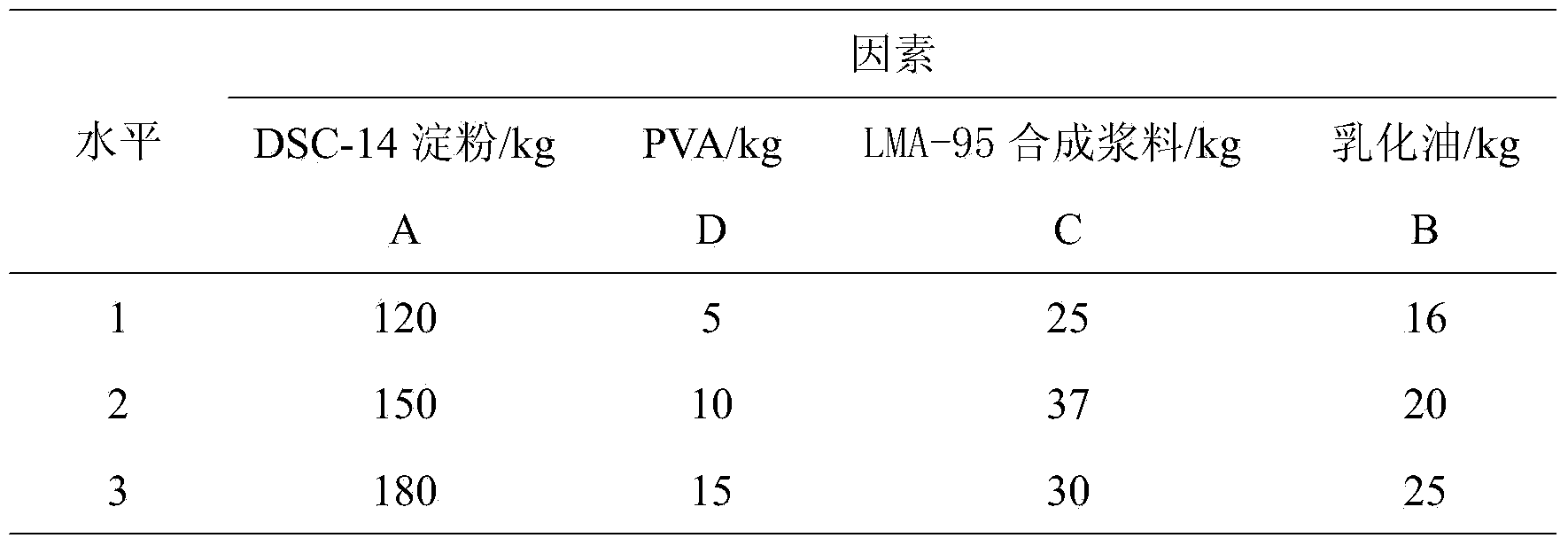

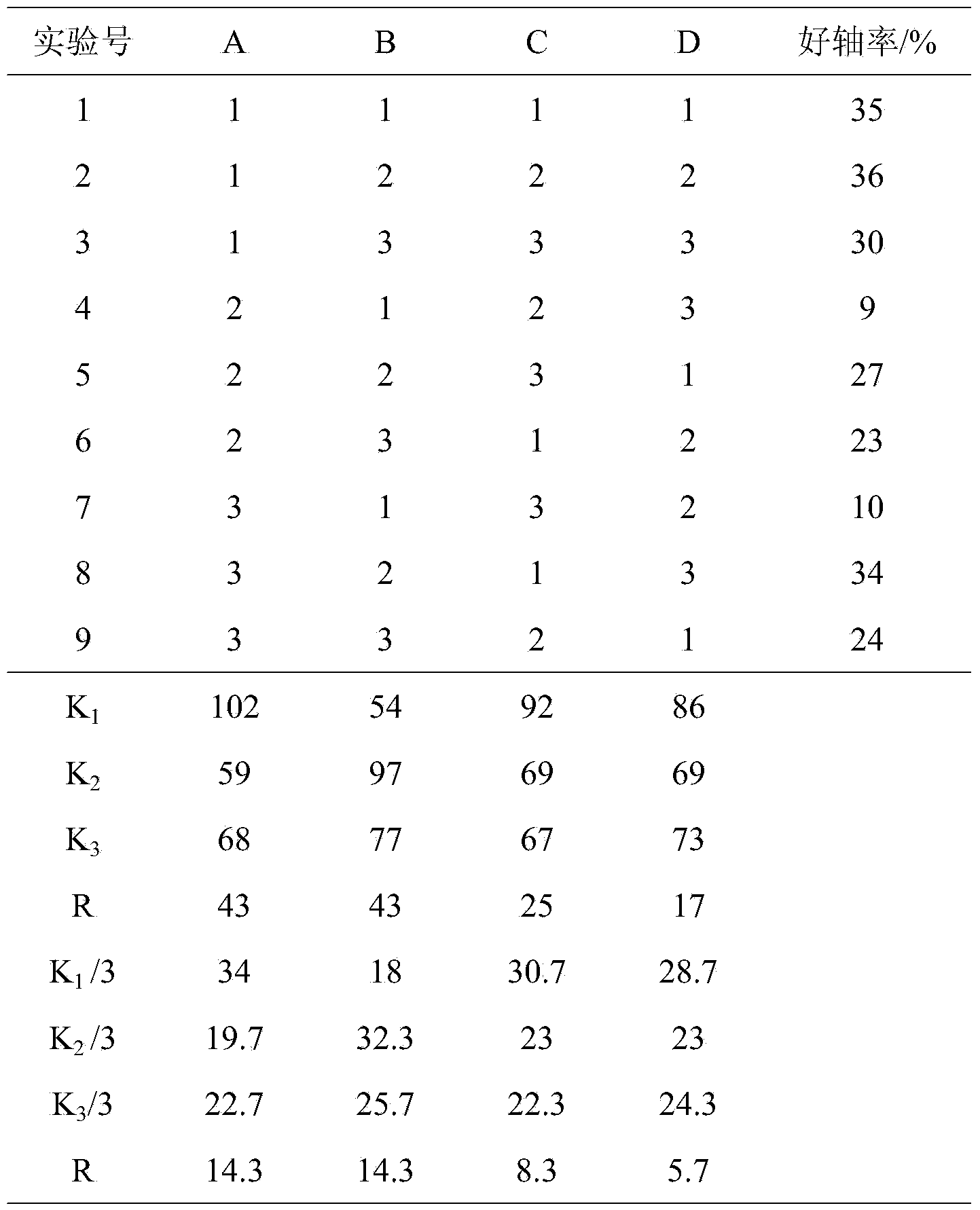

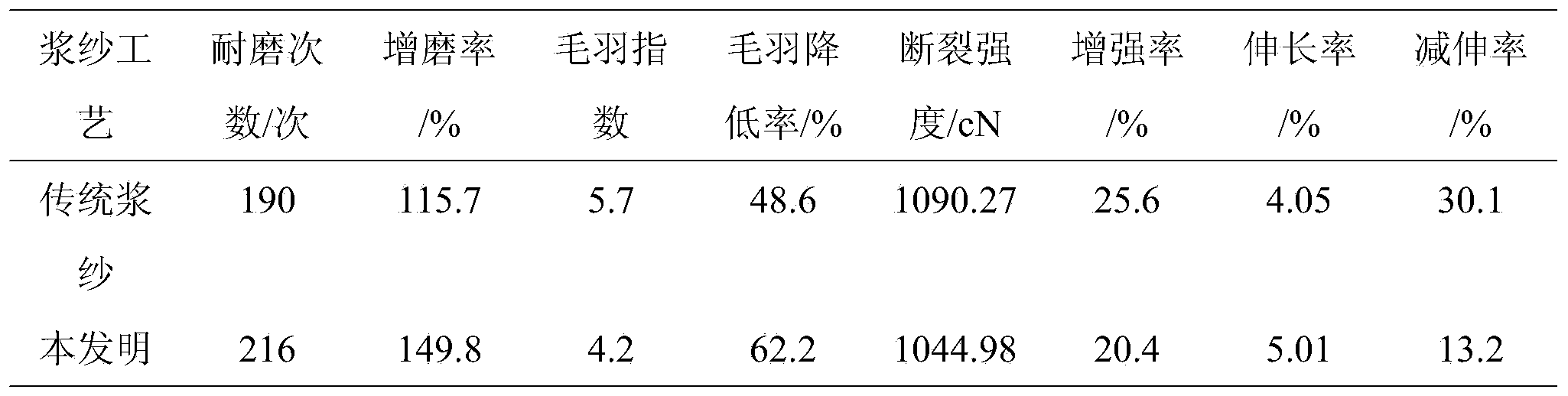

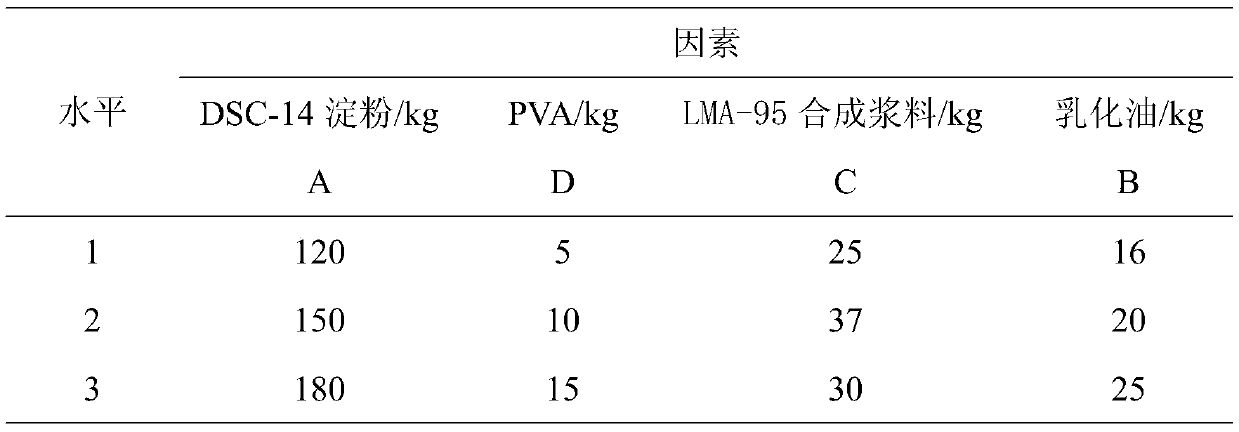

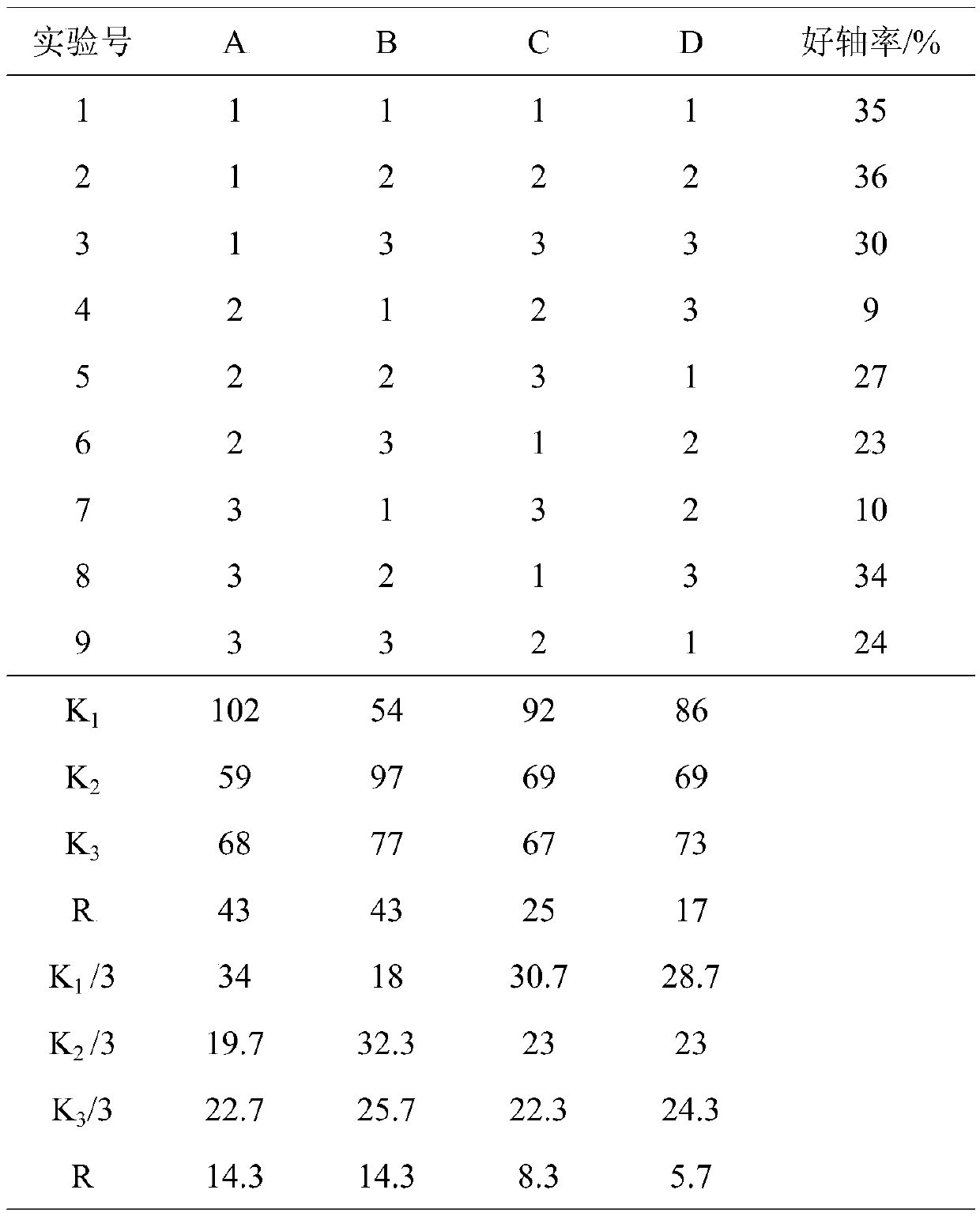

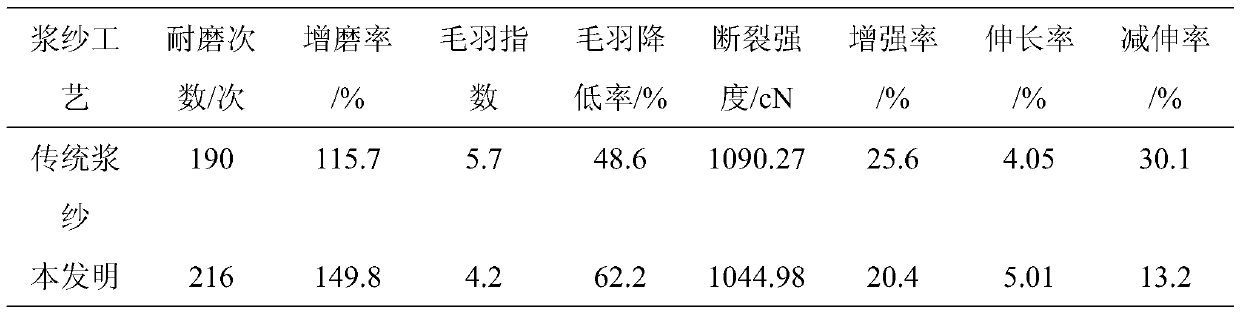

Jean warp sizing slurry and sizing process

ActiveCN103966849AImprove wear resistanceImprove surface propertiesFibre treatmentDenimProcess engineering

The invention provides a jean warp sizing slurry and a sizing process. The slurry is prepared from DSC-14 starch, PVA, LMA-95 synthesis slurry, emulsified oil and a smoothing agent. In comparison with the prior art, the sizing slurry and process ensures that the warp abrasion resistance is greatly improved, the weaving performance is enhanced and the cost is lowered. Besides, the use amount of slurry and pollution are reduced, the existing technological process does not need to be changed significantly, the investment is relatively low and the effect can be taken rapidly.

Owner:ZHEJIANG SANSEN TEXTILE

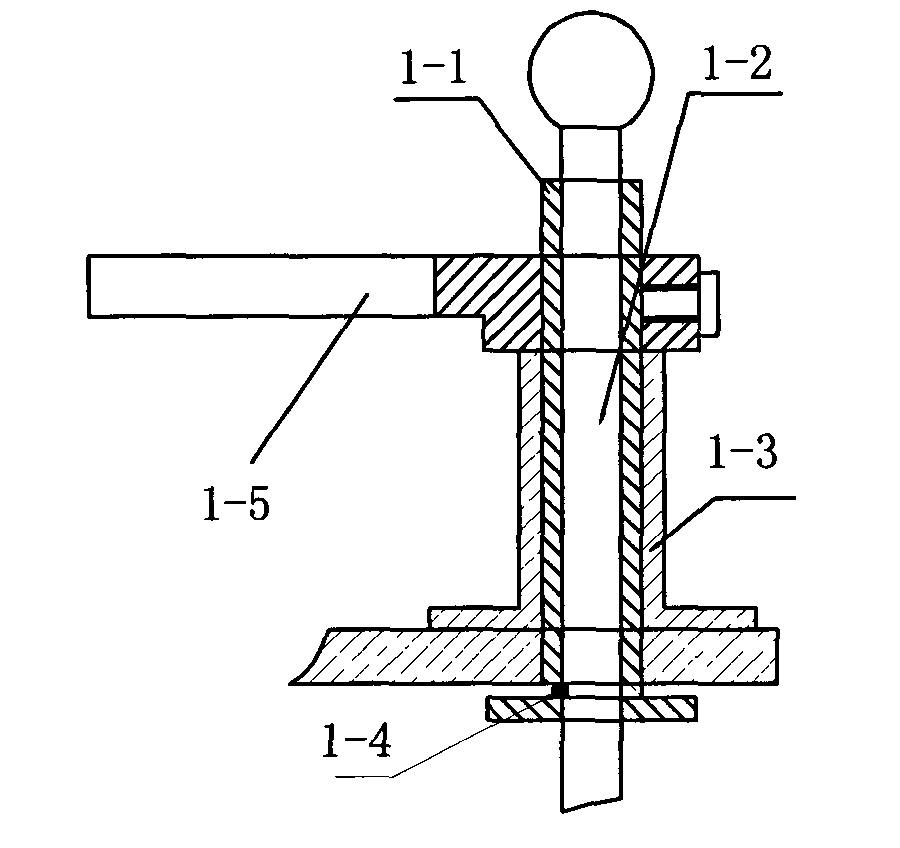

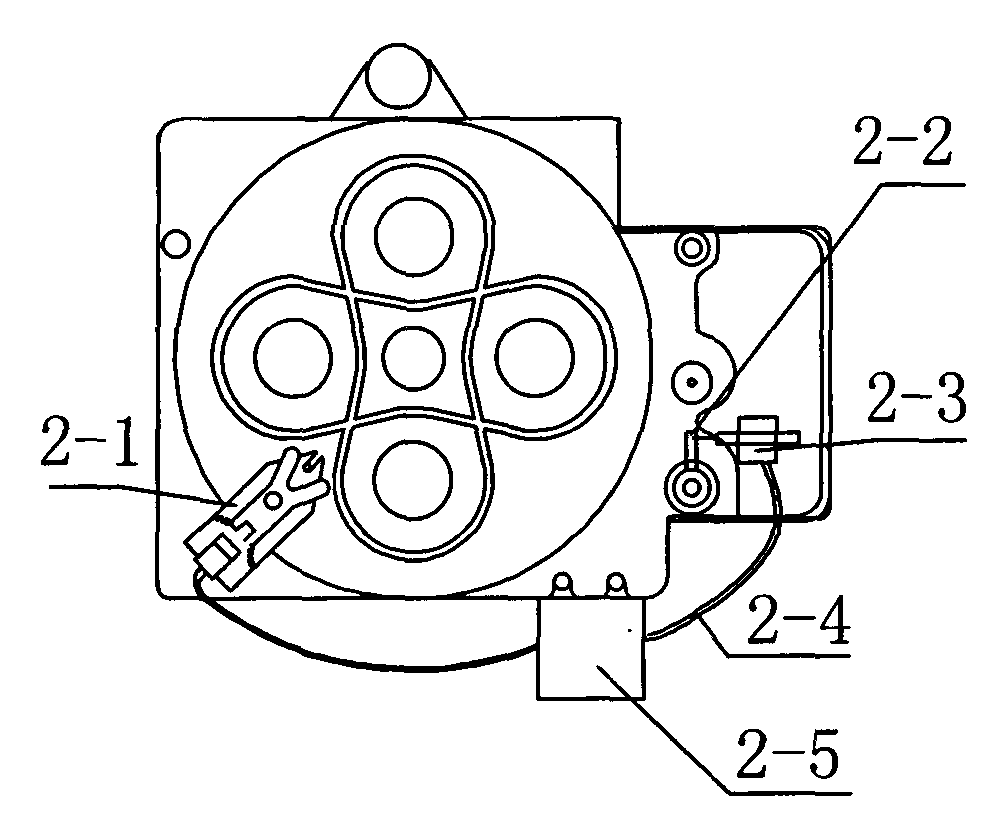

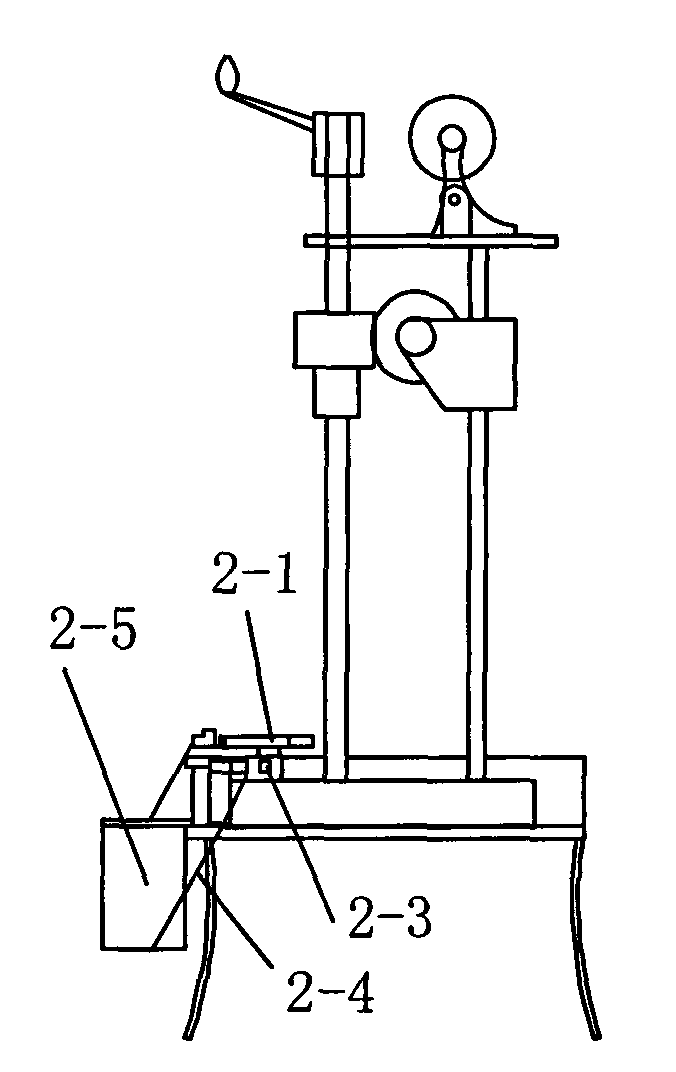

Line-breaking stoppage electronic controller of knitting machine

A line-breaking stoppage electronic controller of knitting machine belongs to the electronic controller used on the knitting machine. The electronic controller comprises a sensor device, a controllerand an electromagnetic switch, the sensor device and the electromagnetic switch are respectively connected with a controller through lead. The electromagnetic switch comprises an electromagnet and a switch handle; and the electromagnet is placed at one end of the switch handle which is positioned in the stroke of the electromagnet. The sensor device is proximity switch, microswitch, limit switch or Hall switch; or the sensor device comprises a bracket and a switch which is equipped to the bracket. The sensor device is placed at the side of B-shaped track of the knitting machine. The advantageof the invention consists in that the controller can convert a mechanical signal of the knitting machine to an electric signal which activates the electromagnet for driving the switch handle to move through the controller for driving the switch handle to move so that the clutch of the knitting machine drops off instantaneously and stop. The line-broken spindle line reel can stop immediately without collision of large load to the mechanical switch, and the component breakage of knitting machine is reduced.

Owner:韩百峰

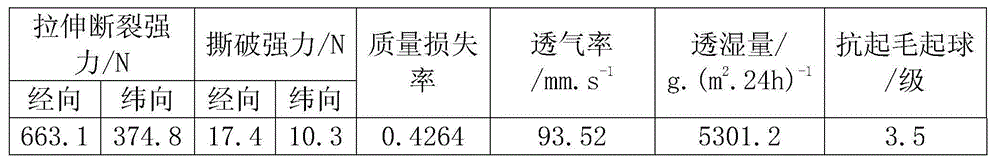

Production technology of mini-jacquard weft elastic yarn-dyed fabric made of aloe fiber

ActiveCN104947285AColors are bright without being flashyRaise the gradeSingeingSeaming textilesFiberYarn

The invention discloses a production technology of mini-jacquard weft elastic yarn-dyed fabric made of aloe fiber. The production technology comprises steps as follows: winding, warping, sizing, weaving and finishing, wherein the finishing comprises steps as follows: fabric inspection, fabric turning, sewing, singeing, desizing, setting, preshrinking and plaiting. The specification, the style and the dyed yarn arrangement of the mini-jacquard weft elastic yarn-dyed fabric made of the aloe fiber are designed, winding, warping, sizing, weaving and finishing processes are optimized, the production efficiency is up to 92%, and the rate of first-grade goods put in storage is up to 98%.

Owner:IANGSU COLLEGE OF ENG & TECH

Bismuth-containing free-cutting steel

ActiveCN103255539ANon-irritatingImprove thermal stabilitySucessive textile treatmentsWeft knittingPolyketoneUltimate tensile strength

The invention discloses bismuth-containing free-cutting steel. The bismuth-containing free-cutting steel comprises the following components in percentage by weight: 0.04%-0.15% of C, 0-0.15% of Si, 0.9%-1.6% of Mn, 0.02%-0.11%of P, 0.25%-0.45% of S, 0-0.2% of Cr, 0-0.2% of Ni, 0-0.2% of Cu, 0.05%-0.2% of Bi, 0.005%-0.05% of Ti, 0.005%-0.05% of N, 0-0.2% of impurities and the balance of Fe. According to the bismuth-containing free-cutting steel disclosed by the invention, lead is substituted by the bismuth, so that a lead pollution problem is solved; meanwhile, the thermal plasticity and the after-breakage elongation are better, so that the bismuth-containing free-cutting steel is unlikely to fracture during a rolling process. The bismuth-containing free-cutting steel disclosed by the invention has excellent comprehensive mechanical performances, cutting performances superior to those of the common free-cutting steel, and cutting performances equivalent to those of the lead-containing free-cutting steel. Meanwhile, the bismuth-containing free-cutting steel is free of lead, good in environment friendliness, and beneficial to popularization and utilization.

Owner:ZHEJIANG WANQIAN CLOTHING CO LTD

Special alkali-free direct yarn wetting agent for grinding wheel reinforcing sheets and preparation method thereof

The invention discloses a special alkali-free direct yarn wetting agent for grinding wheel reinforcing sheets and a preparation method thereof. The alkali-free direct yarn wetting agent comprises the following components in percentage by mass: 2-6% of epoxy emulsion, 1-5% of polyester emulsion, 0.2-0.6% of water-soluble epoxy resin, 0.2-0.8% of lubricant, 0.05-0.3% of antistatic agent, 0.8-1.4% of coupling agent, 0.2-2% of novel assistant A, 0.1-1% of novel assistant B, 0.1-0.5% of glacial acetic acid and the balance of deionized water. Various components are adopted to endow the yarn with high power and favorable permeation effect in the dipping treatment process. Multiple high-performance lubricants are utilized, and the two novel assistants are introduced, thereby implementing favorable weaving effect on the premise of ensuring favorable permeation effect. The two coupling agents are combined to well ensure the combination effect between the glass fiber and resin.

Owner:JIANGSU JIUDING NEW MATERIAL CO LTD

Smoothness and toughness pre-treating agent for braiding wicker and preparation method thereof

InactiveCN105437337AEasy to prepareImprove permeabilityReed/straw treatmentWood impregnation detailsFiberHigh pressure

The invention relates to the technical field of modification of braiding wicker, in particular to a smoothness and toughness pre-treating agent for braiding wicker and a preparation method thereof. The raw materials of the smoothness and toughness pre-treating agent for the braiding wicker comprise, by weight, 0.01-0.02 part of borax, 10-12 parts of silica sol with the solid content of 20-25%, 1-2 parts of starch ether, 6-8 parts of clarification limewater, 0.2-0.3 part of secondary alkyl sodium sulfonate, 0.01-0.02 part of sodium hyaluronate and 40-50 parts of water. The smoothness and toughness pre-treating agent has good permeability and is seeped into wicker fibers through high pressure when used, the clarification limewater can assist the silica sol, the starch ether and other components in adhering to plant fibers, and therefore the strength and toughness of the wicker are increased more efficiently, and the braiding performance is improved. In combination with other components, the wicker treated through the smoothness and toughness pre-treating agent is antimicrobial, resistant to corrosion and smooth and holds water, and wickerwork is longer is service life, higher in skin-friendly sense, higher in weight bearing capacity and wider in use range.

Owner:阜南县铭钰柳木工艺品有限公司

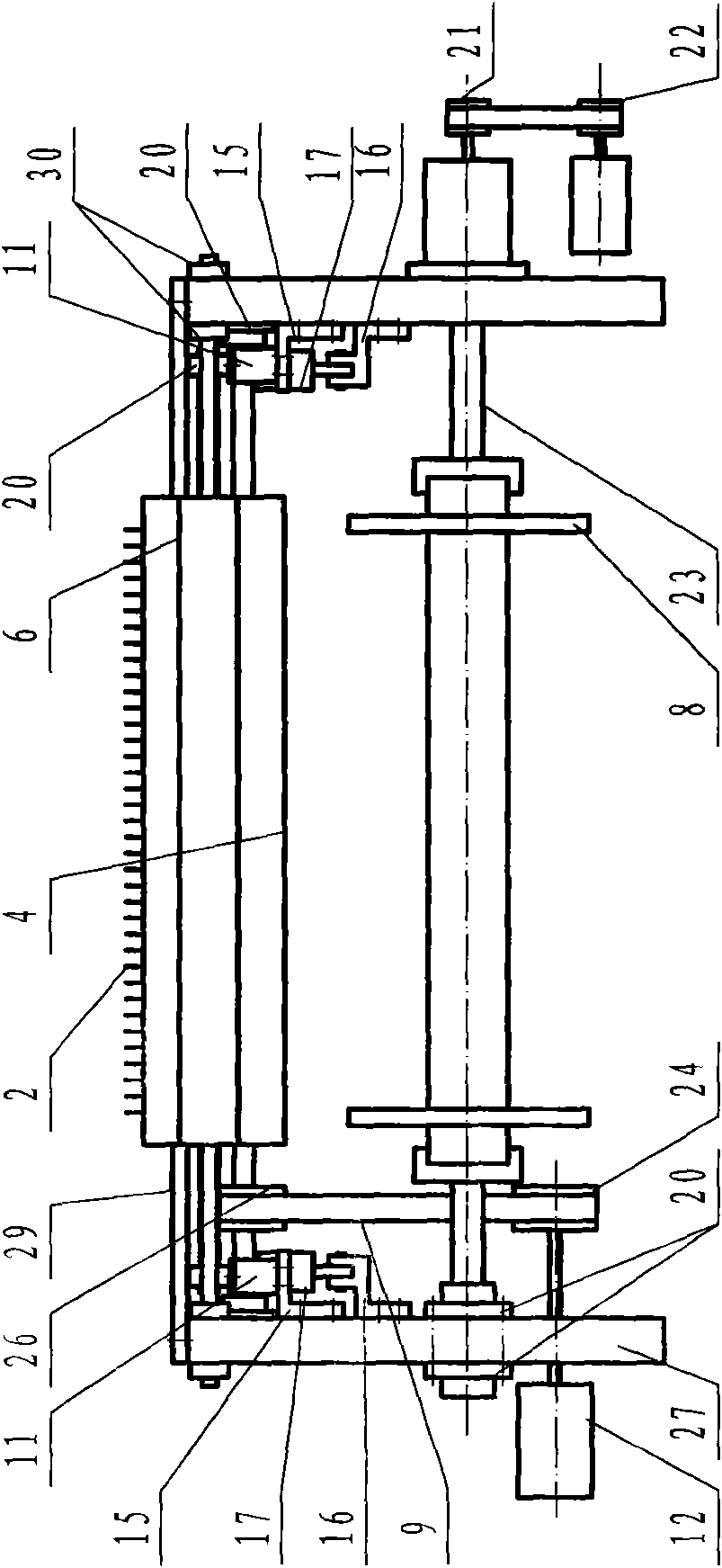

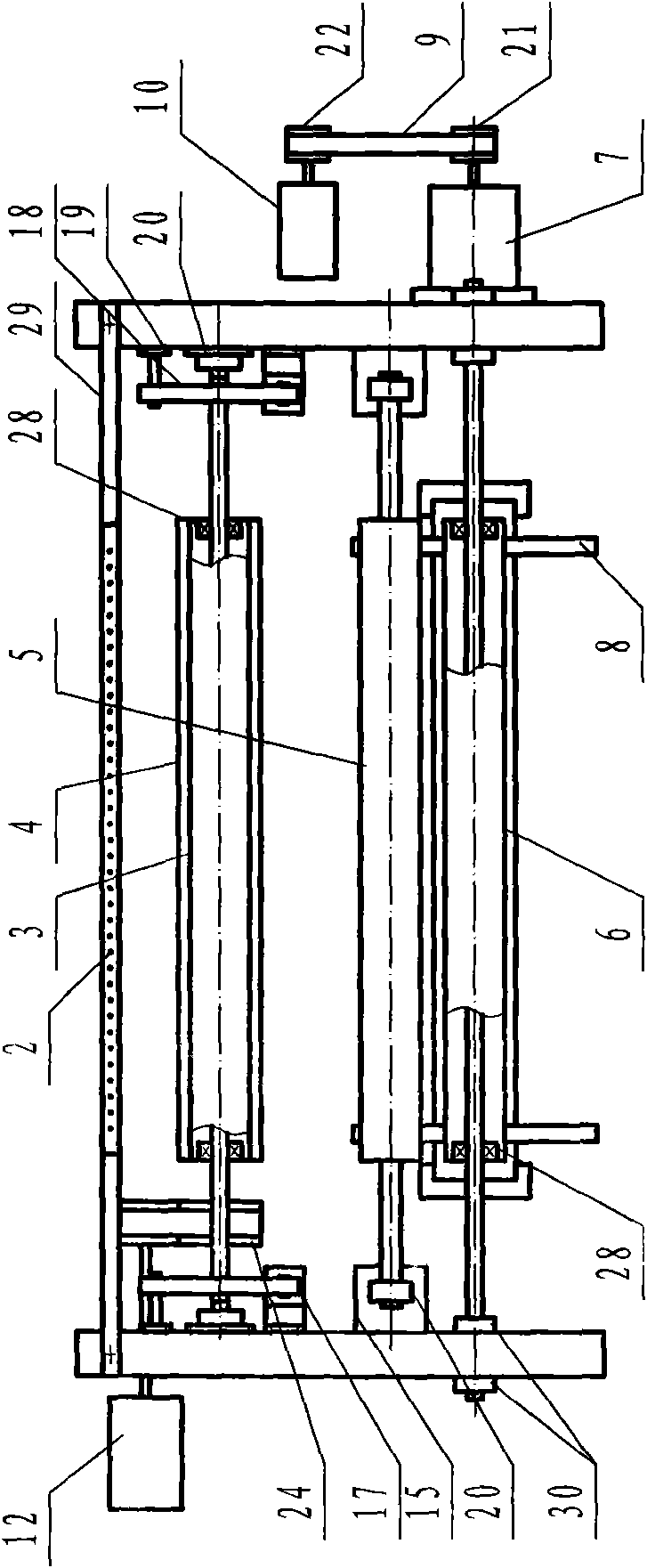

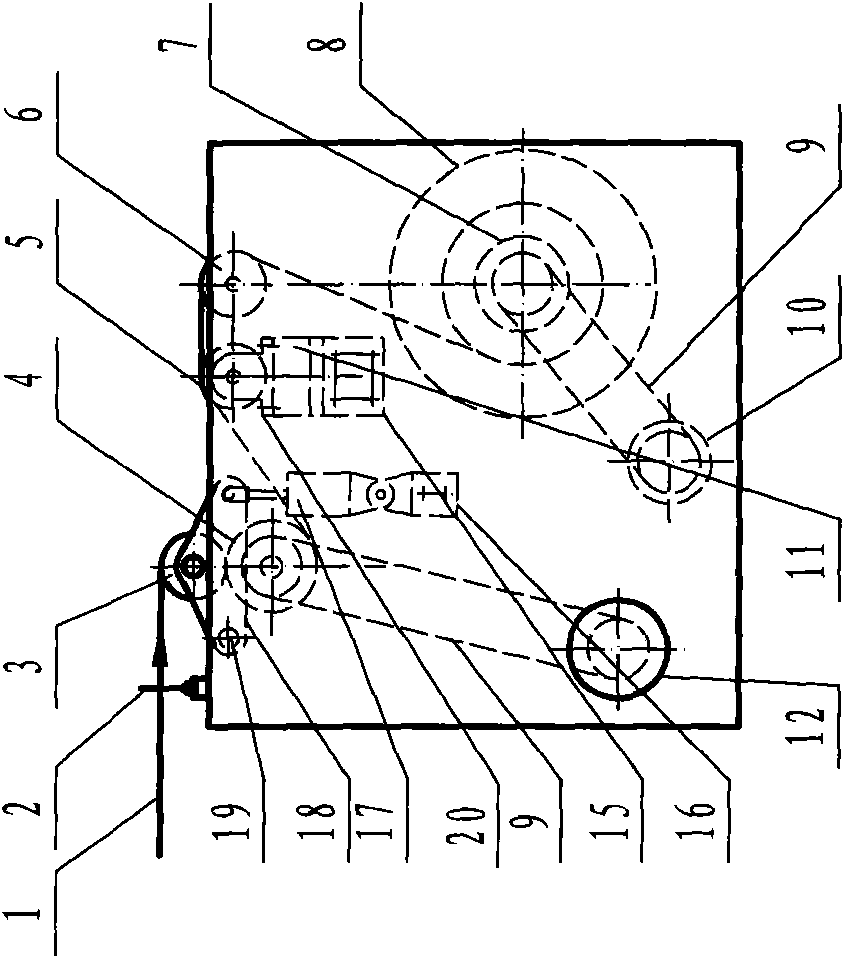

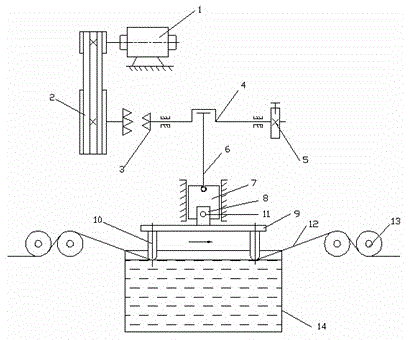

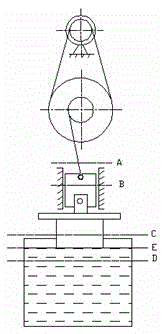

Glass fiber warping machine

InactiveCN101643957AReduce tensionImprove weaving performanceWarping machinesOther manufacturing equipments/toolsYarnTension control

The invention relates to a glass fiber warping machine. The glass fiber warping machine is characterized in that tension-controlling equipment is arranged on a rack between a reed and a thread guide roller; the equipment comprises a pressure roller, a towing rubber roller and a force-measuring roller, wherein, the pressure roller is arranged above the thread guide roller, and a tension sensor is arranged below the force-measuring roller; the equipment drives the towing rubber roller to rotate by taking a towing electric machine as towing power, enabling that the film yarn, after passing through the reed, winds from the top of the pressure roller to the bottom, gets through between the pressure roller and the towing rubber roller and winds into an 'S' shape, then the film yarn is led to thetop of the force-measuring roller and enters into a warp beam after passing through the thread guide roller; the winding electric machine is warp beam winding power, and the traction electric machineand winding electric machine work simultaneously. The invention is able to obviously improve the tensile force of the film yarn, detect the tensile force and ensure that the film yarn which is increased in tensile force keeps constant tensile force in the whole winding process. The fact proves that the film yarn wound by the glass fiber warping machine has fine weaving effect on the loom, thus deserving widespread popularization and application.

Owner:射阳县杰力纺织机械有限公司

Method for processing osiers for weaving kennel

InactiveCN106272815AImprove antibacterialReduce chewing behaviorWood treatment detailsReed/straw treatmentPre treatmentCanis lupus familiaris

The invention discloses a method for processing osiers for weaving a kennel. The method provided by the invention comprises the following steps: (1), osier preprocessing; (2), drying treatment; (3), osier decocting; (4), secondary drying; (5), poikilothermic treatment; and (6), insulation weaving. The kennel formed by weaving osiers processed by method is relatively good, an impetuous emotion of a pet dog can be relieved, the morbidity of the pet dog is lowered, the service life of the kennel is prolonged by 2 to 3 years, and an excellent use value is achieved.

Owner:安徽省阜南志峰工艺品有限公司

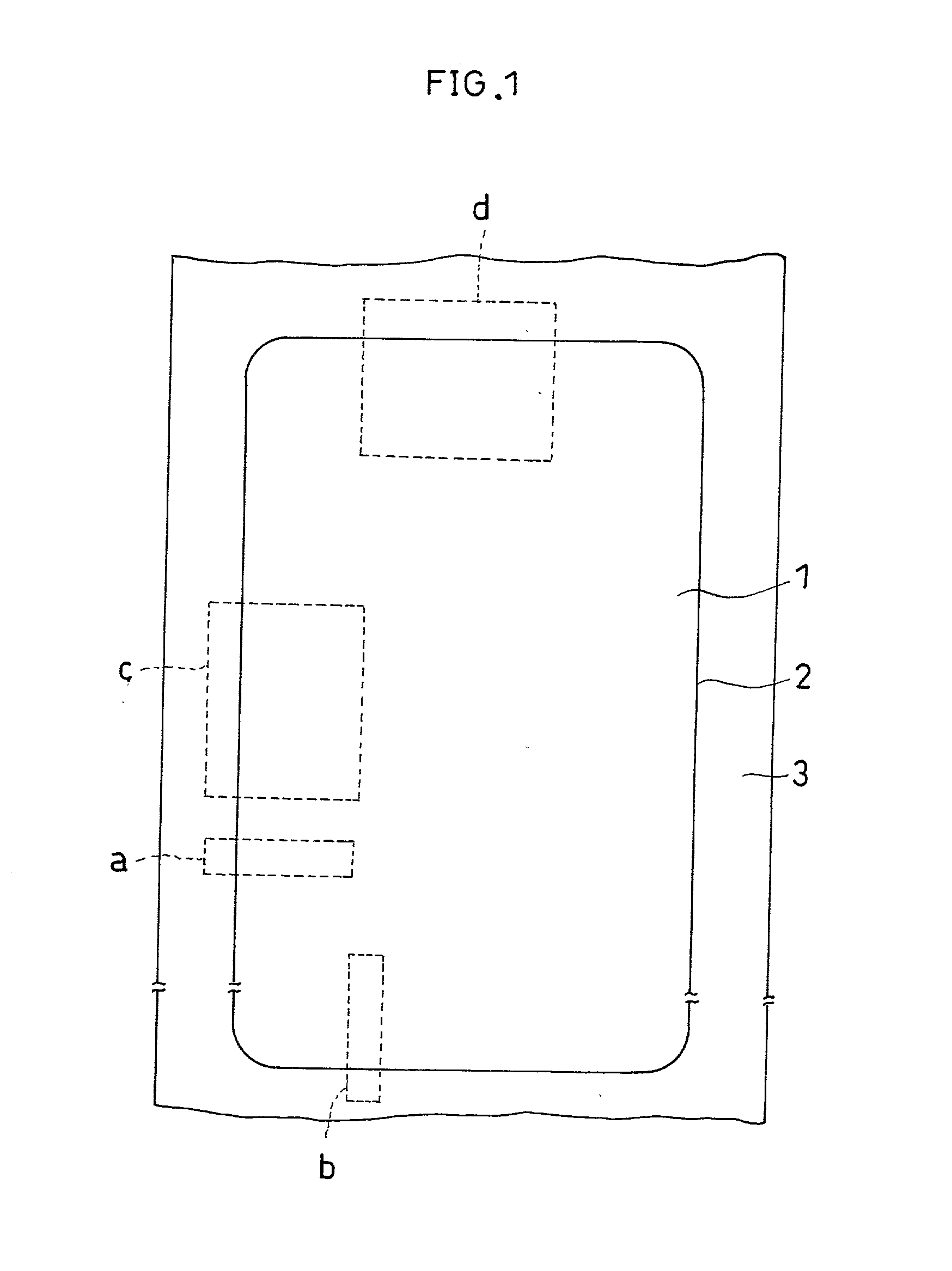

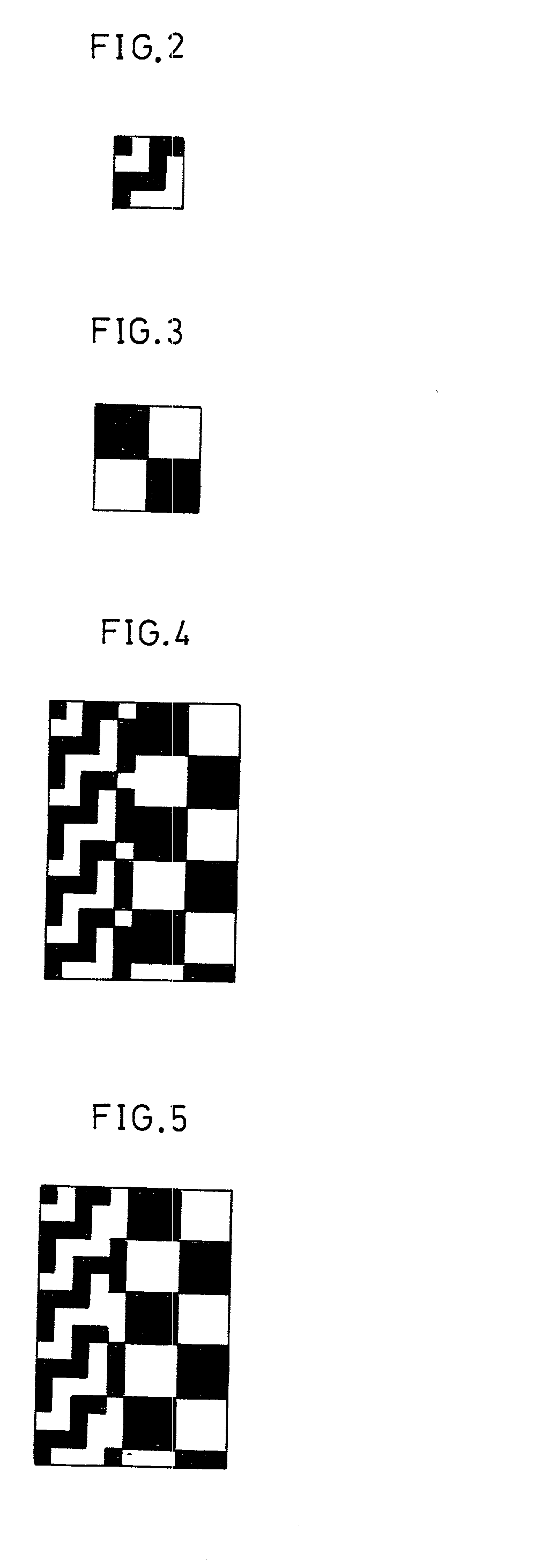

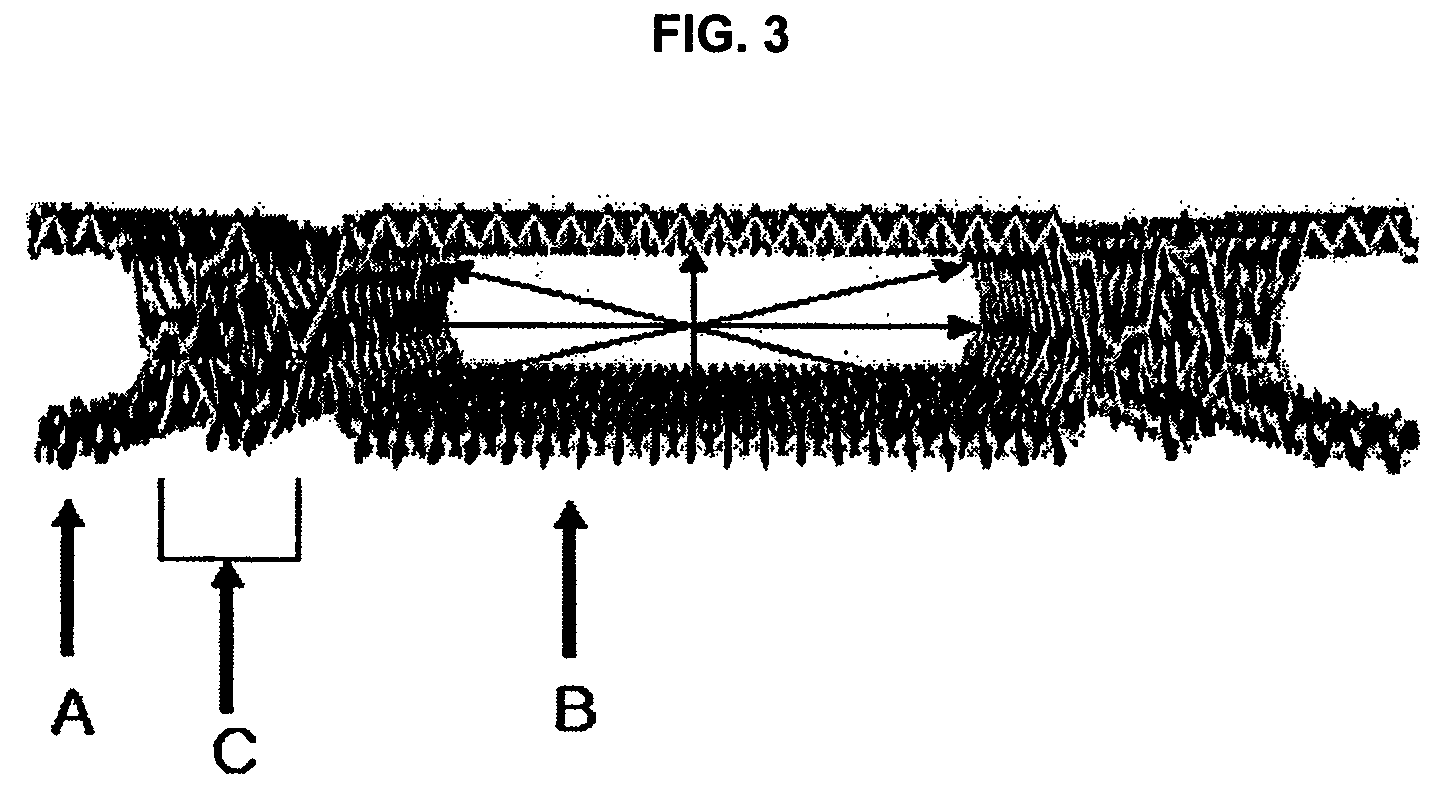

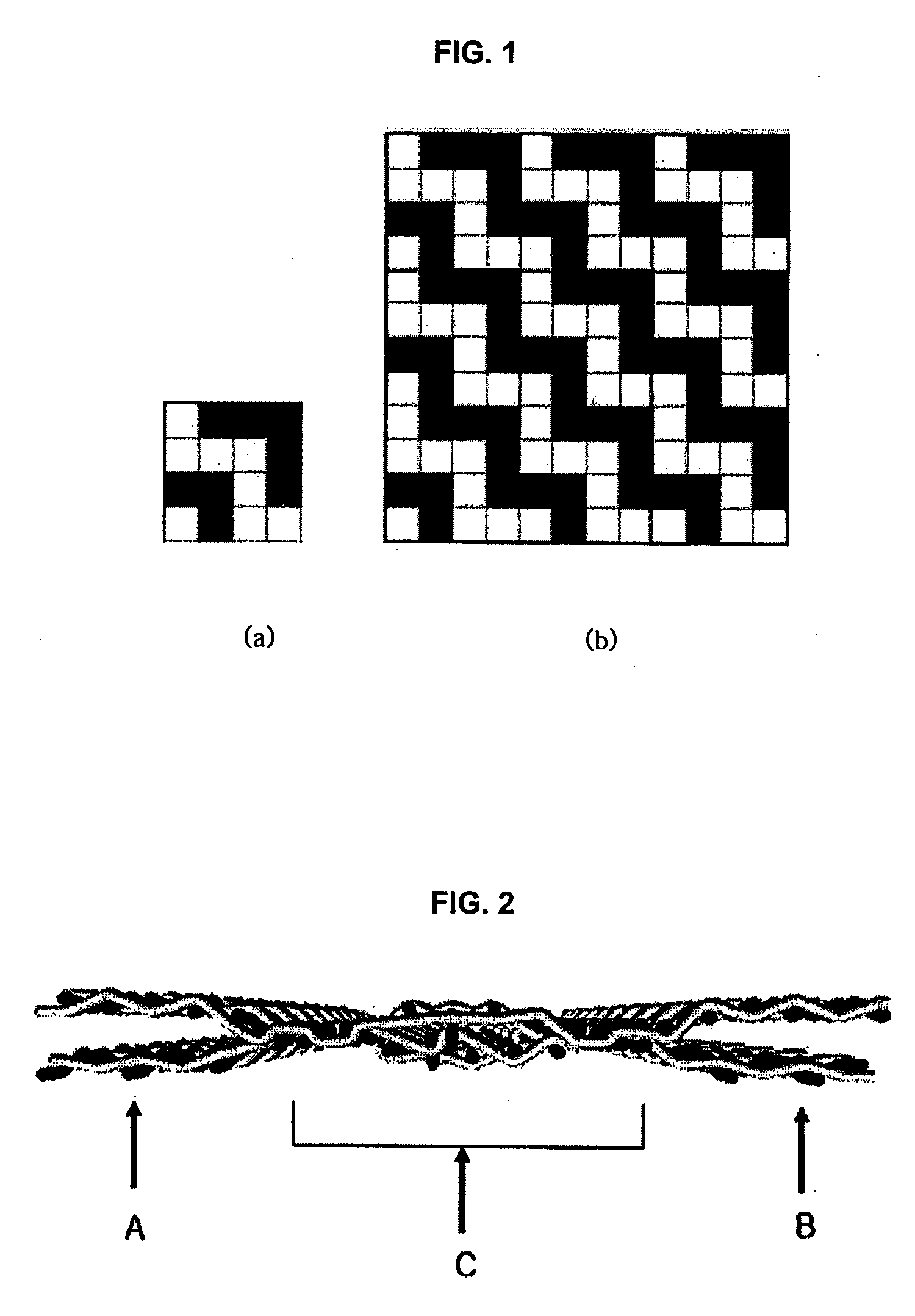

Inflatable two-layer fabrics by gas

ActiveUS7681602B2Improve suppression propertiesArea minimizationPedestrian/occupant safety arrangementWoven fabricsYarnEngineering

Provided is an inflatable fabric containing two separated fabric layers which are woven at the same time using a weaving machine, and at least one an attachment area where a single layer of fabric is formed. The attachment area is formed from at least a weave pattern of at least 13 yarns, air leakage can be minimized during inflation. The fabric can be utilized for shock-absorbing products such as an airbag when coated with synthetic resins.

Owner:KOLON IND INC

Moth-resistant treating method for wicker straw

InactiveCN106272816AIncrease storage capacityHigh bonding strengthRadiation/waves wood treatmentWood treatment detailsMedicinePre treatment

The invention discloses a moth-resistant treating method for wicker straw. The method comprises the following steps: (1) pretreating straw raw materials; (2) preparing a moth-resistant treating solution; (3) modifying; (4) treating at low temperature; (5) repeatedly treating for the second time; (6) weaving at constant temperature. The straw treated according to the method provided by the invention has better moth-resistant and mold-proof characteristics, excellent flexibility, folding resistance, tensile strength and weaving property; the prepared products have the characteristics of environmental protection, safety and no harm to a human body; the service life of the products is 2-3 years longer than that of the products prepared according to the conventional method; the popularization value is higher.

Owner:FUNAN YONGXING ARTS & CRAFTS

Bali voile weaving

InactiveCN101187098ANo pollution in the processImprove weaving performanceBiochemical fibre treatmentWoven fabricsSocial benefitsYarn

The invention provides a novel weaving idea of a voile variety fabric and process, voile yarn is twisted into yarn and is done a reprocessing on a bidirectional coating spinning machine, after the voile yarn is twisted into the yarn, heat set twist only needs to be done one time, folded yarns use a hollow mesh pagoda cone to do the heat wet wet, the temperature of yarn steaming is controlled at 95 DEG C, the time of yarn steaming is 1.5 hour, the set twist rate is capable of achieving above 60 percent, and then the reprocessing is done on the bidirectional coating spinning machine, when processing, the voile yarn is used as a yarn core to enter, thereby the voile yarn has the characteristics of excellent and thin texture, excellent hand feeling, clear hole arrangement, transparent and breathability, and has excellent economic and social benefits.

Owner:SHENGHONG GRP CO LTD

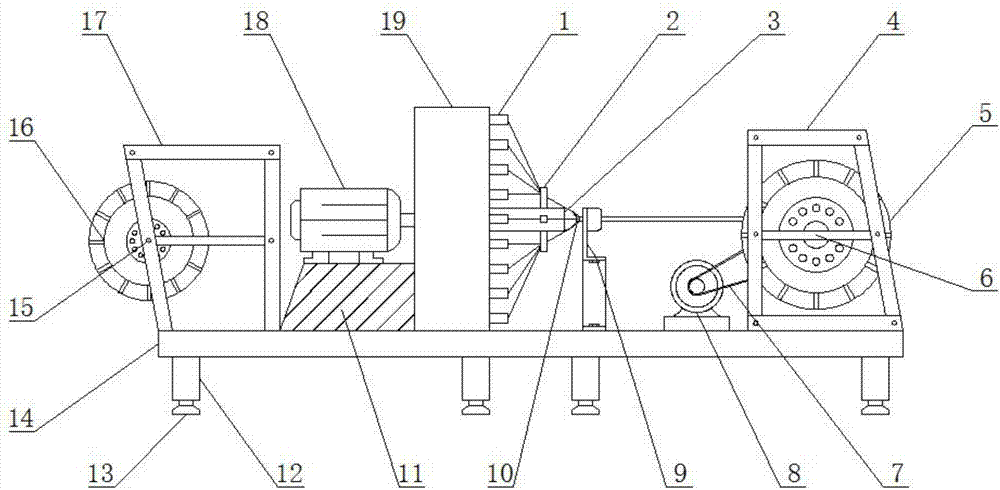

Horizontal cable high-speed braiding machine

InactiveCN107359021AReduce the temperatureReduce frictionCable/conductor manufactureEngineeringFriction force

The invention discloses a horizontal cable high-speed braiding machine. The horizontal cable high-speed braiding machine comprises a smooth skin cable, braiding machine support feet, spindle rotation shafts and ceramic ball support racks, wherein braiding machine support legs are arranged on the braiding machine support feet, a braiding machine body is arranged on the braiding machine support legs, a smooth skin cable disc rack is arranged at a part above a left end of the braiding machine body, and a smooth skin cable disc is arranged at an intermediate position of a left end of the smooth skin cable disc rack. The ceramic is relatively low in friction force, the friction of a braiding line is reduced, the temperature of an outgoing line hole is reduced, and the braiding line is prevented from being broken due to high temperature of the outgoing line hole; a tension wheel is arranged outside a cable passage pipe, so that each braiding line can pass through the tension wheel, the tension degree can be consistent when the braiding line bears a tension force, and the braiding effect during braiding can be better; and moreover, line breakage due to inconsistent tension degree can be prevented, the line breakage frequency of the braiding machine during braiding is reduced, and the production efficiency is improved.

Owner:杨桂芝

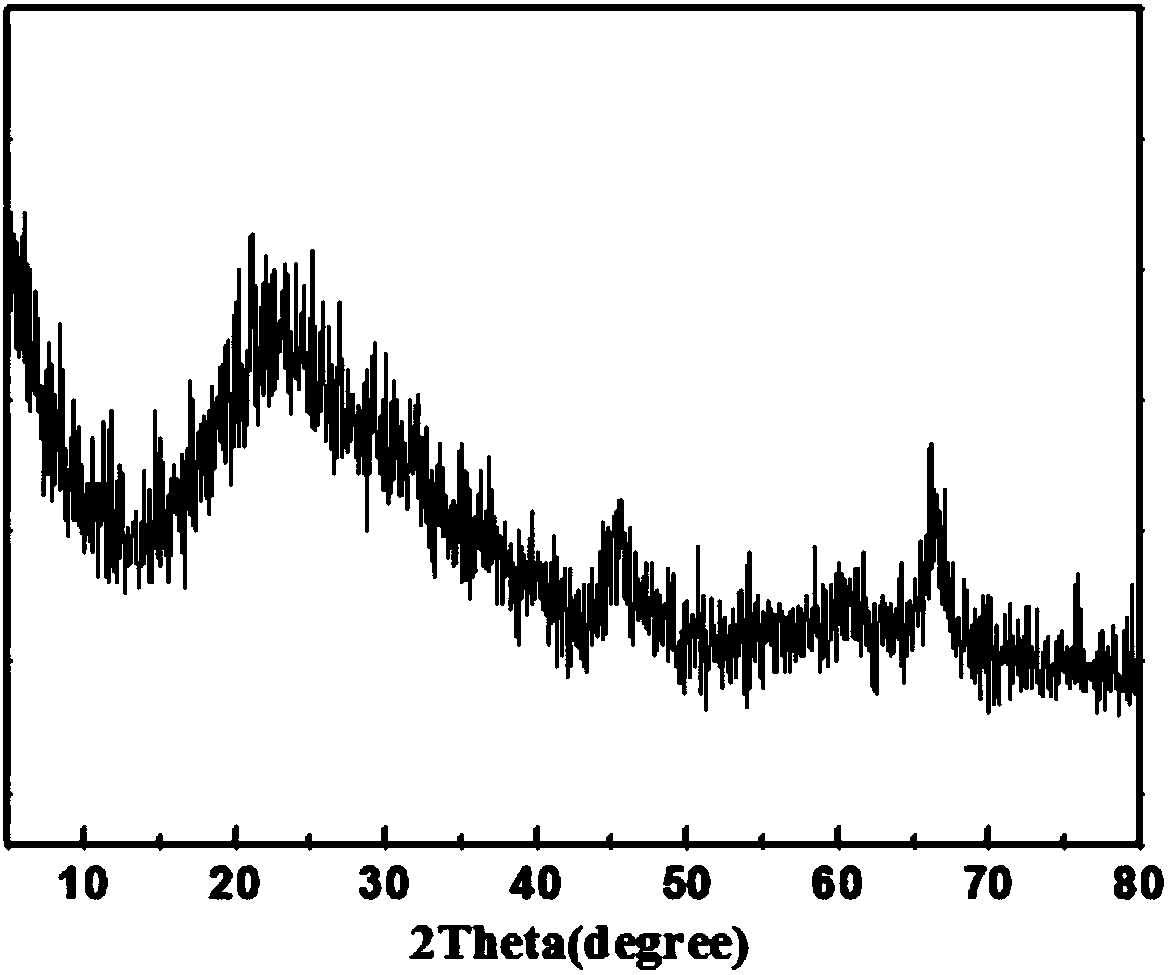

Preparation method for aluminum oxide-based ceramic continuous fiber containing 1-5 wt% of B2O3

ActiveCN109437862AImprove stabilityImprove tensile propertiesInorganic material artificial filamentsFiberTemperature resistance

The invention provides a preparation method for an aluminum oxide-based ceramic continuous fiber containing 1-5 wt% of B2O3. The method comprises the following steps that alumina sol containing Al13 colloidal particles, a pseudo-boehmite nano-dispersion, silica sol, a boric acid aqueous solution and a high-molecular spinning auxiliary are mixed so as to obtain a mixed solution; then aging and concentrating are carried out until the viscosity of a system is 500-1000 Pa*s so as to obtain spinnable precursor sol; and dry spinning, drying and calcining are carried out so as to obtain the aluminumoxide-based ceramic continuous fiber. According to the preparation method, the electron deficiency effect of boron is utilized, and addition reaction of water is carried out on the boric acid to formB(OH)4<->, so that the boric acid can be stably combined with polyhydroxyl pseudo-boehmite nano-particles so as to prepare the spinnable precursor sol and the fiber with excellent properties. The method has the advantages that the raw materials are easy to obtain, and industrialized application is easy to realize; and the diameter of the prepared fiber is 5-8 microns, the strength of the single fiber can reach 2.0 GPa, the modulus can reach 149 GPa, and various excellent performances such as high temperature resistance, flexibility and spinnability are achieved.

Owner:SHANDONG UNIV

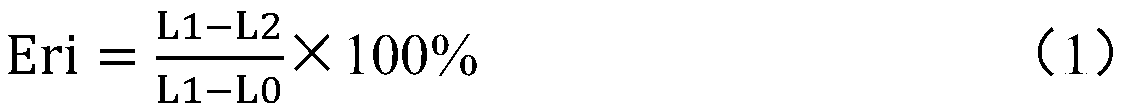

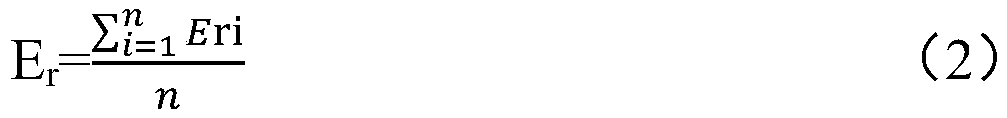

High-strength and high-resiliency spandex fiber and preparation method thereof

PendingCN111394821AHigh strengthIncrease elasticityMonocomponent polyurethanes artificial filamentFiberPolymer science

The invention belongs to the field of polymer chemistry, and particularly relates to a high-strength and high-resiliency spandex fiber and a preparation method thereof. The preparation method includesthe following steps that a prepolymer is prepared by reacting polyhydric alcohols with isocyanate; the prepolymer and a chain extender are subjected to secondary polymerization, a chain terminator isadded to end polymerization, and accordingly a polymer dope of polyurethane urea is obtained; an annexing agent is optionally added into the polymer dope of the polyurethane urea to be evenly stirred, then spinning is conducted, and the spandex fiber is obtained; and the isocyanate refers to a mixture containing the isocyanate modified through diisocyanate and carbodiimide. The spandex fiber disclosed by the invention has the high-strength and high-resiliency properties at the same time, the strength is 1.70-2.00g / d or above, the stress at definite elongation is 10.5-13.5cN, the elongation atbreak is 520-600cN or above, the elastic recovery rate is 93%-95% or above, and the weaving performance of spandex fabrics in the high-resiliency field is greatly improved.

Owner:WANHUA CHEM GRP CO LTD

Weaving of functional non-woven fabric

InactiveCN101177843AJoin flexibleSuitable for multi-variety productionNon-woven fabricsPolyesterEngineering

The invention provides a novel weaving concept of functional non-woven fabrics and a method thereof. Common natural staple fibers are combed into a net through air current or polymer fibers are melted and extruded into a net; the fiber net, after prewet out in a parallel laying or folding laying way, is in a spun-laced way consolidated and dried, then further consolidated by chemical adhesion or thermal adhesion. The functional particle of the fiber net can be added flexibly, and is suitable for multi-product production; the invention has simple technology, requires no dramatic alteration to the present equipment and can obviously improve weaving performance and improve weaving efficiency.

Owner:SHENGHONG GRP CO LTD

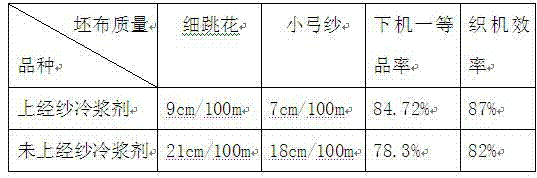

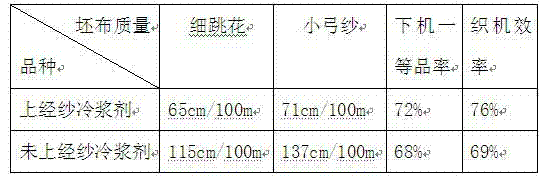

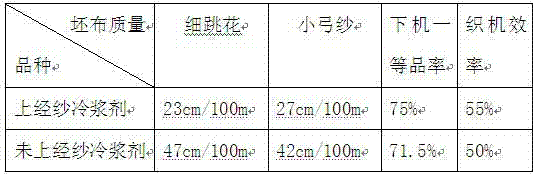

Pulp coolant for cotton spinning and wool spinning fibers

The invention provides pulp coolant for cotton spinning and wool spinning fibers. The pulp coolant contains emulsifier TX-40, emulsifier EL-40, fatty alcohol-polyoxyethylene ether, coconut diethanol amide, PEG-6000, methyl acrylate, acrylic acid, acrylamide, ammonium persulfate, potassium peroxodisulfate, water and diethanol amine. The emulsifiers TX-40 and EL-40, the fatty alcohol-polyoxyethylene ether, the coconut diethanol amide, the PEG-6000, the methyl acrylate, the acrylamide and water are mixed and heated to 65 DEG C for 3 hours and then cooled to 30 DEG C, and a target product is obtained by adding the diethanol amine to regulate the PH value to 6-7. The product has excellent permeability and antistatic property, is applicable to cotton spinning and chemical spinning, and is also applicable to all wool and wool blended yarns; weaving performance of thin yarns is improved, flyings, adhesion and skips during the weaving process are reduced, strength of single yarns and strength of under-twisted yarns are improved, the product is convenient to use, contains no APEO or phosphorus and is green, and the product is easy to wash after weaving.

Owner:如皋市西林化工有限公司

Weaving of chemical synthetic fiber

InactiveCN101177796AColor has no effectImprove weaving performanceArtificial filament physical treatmentFilament/thread formingChemical synthesisDissolution

The invention provides a brand novel weaving concept of chemical synthetic fibers and a method thereof. Copper ammonia fibres, paraffin, carbon black powder, etc. are used as raw materials; the fibers spinning by dissolution method such as nitrilon, copper ammonia fibres, vinylon, etc. are used; single hole spinning is changed into compound spinning by spinning parts with a sheath-core structure when the spinning is non-compound spinning, which can obviously improve weaving performance; the outer layer of the spinning uses water-soluble paraffin and the surface of the fibers reserves concave-convex appearance caused by atoms at the same time when the paraffin is removed. The invention does not influence fiber color and has low cost and strong weaving capacity.

Owner:SHENGHONG GRP CO LTD

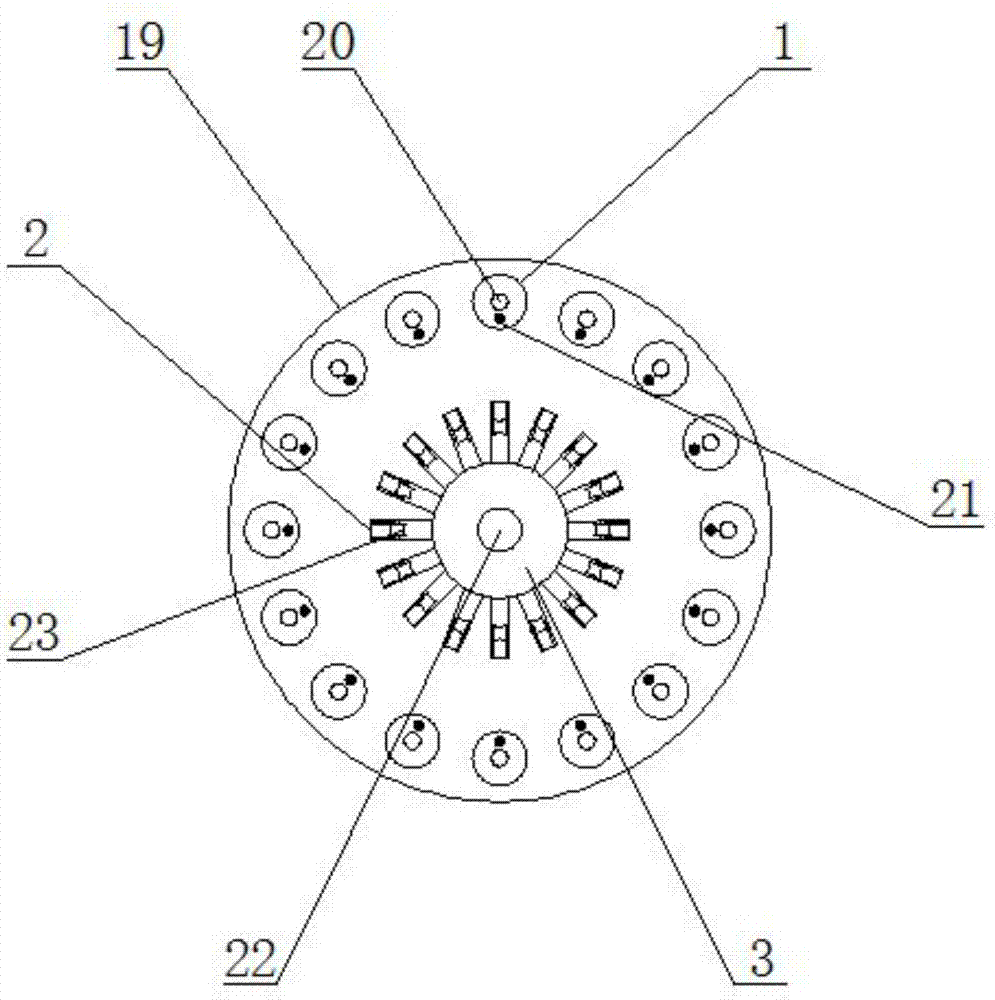

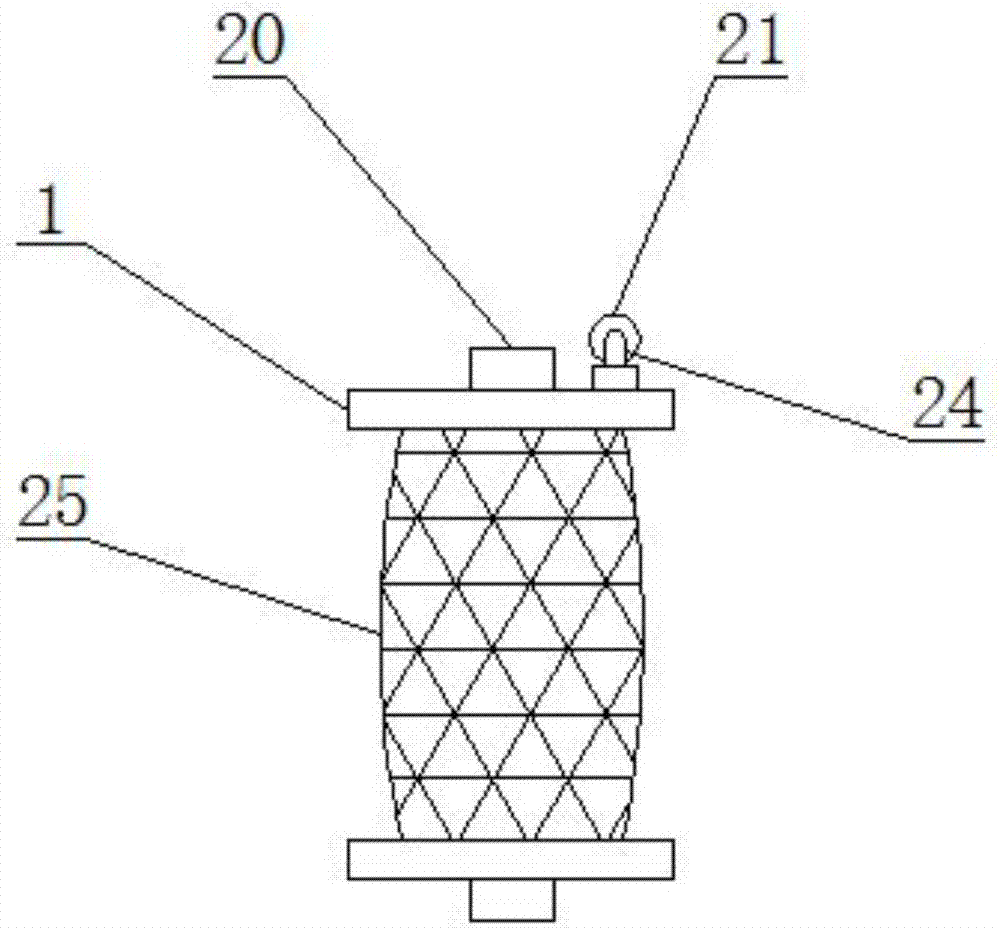

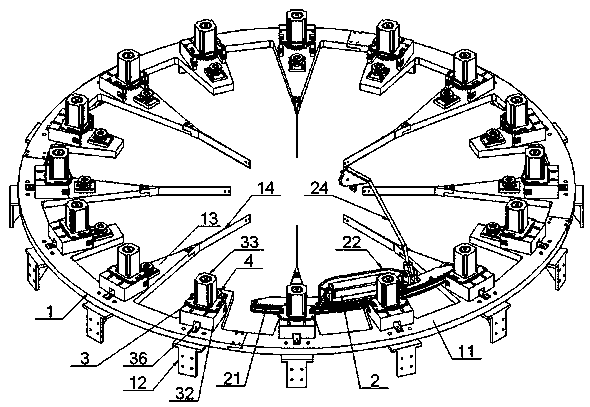

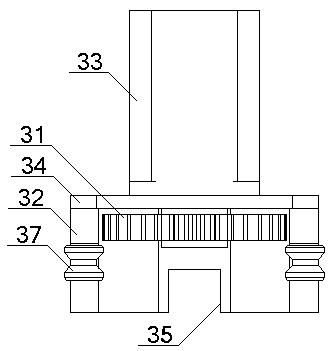

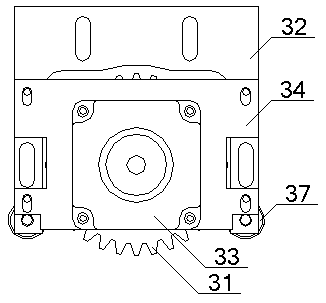

Weft-guiding mechanism for multi-layer cylindrical weaving machine

ActiveCN108677354AThe disadvantage that optimization cannot be applied to multi-layer circular loomsRealize automatic weft insertionCircular loomsTextile/flexible product manufactureYarnScrew position

Provided is a weft-guiding mechanism for a multi-layer cylindrical weaving machine. The weft-guiding mechanism comprises a weft-guiding fixing board and a weft-guiding shuttle. Multiple groups of transmission devices and multiple shuttle limiting wheels are uniformly arranged along the peripheral direction of the weft-guiding fixing board. The weft-guiding shuttle comprises an arc rack, a yarn-carrying device and a stirring rod. The yarn-carrying device and the stirring rod are arranged on the arc rack. The arc rack is meshed with gears of the transmission devices. The transmission devices comprise fixing seats and stepping motors. Locating holes are arranged in the gears and internally equipped with screws. The gears are fixed in shafts of the stepping motors through screws. Notches are arranged in lower ends of fixing seats and equipped with sensors. The sensors are used for sensing positions of the gears by sensing positions of the screws. Rollers are arranged on the fixing seats. The lower end of the arc rack is equipped with a limiting bottom board. Two sides of the limiting bottom board match the shuttle limiting wheels and the rollers. The weft-guiding shuttle finishes weft-guiding operation by moving along the peripheral direction of the weft-guiding fixing board. The weft-guiding mechanism for the multi-layer cylindrical weaving machine is high in weft-guiding efficiency, good in weaving effect and great in reliability.

Owner:WUHAN TEXTILE UNIV

Dyeing technology utilizing spaced dyeing fancy yarn cheese dyeing device

ActiveCN105544120AUniform colorMeet the requirementsBiochemical treatment with enzymes/microorganismsDyeing processBobbinEngineering

The invention discloses a dyeing technology utilizing a spaced dyeing fancy yarn cheese dyeing device. The dyeing technology includes the following steps that pure cotton grey cotton is prepared, a bobbin is loosened through the spaced dyeing fancy yarn cheese dyeing device, preprocessing is performed, the dyeing technology is performed, postprocessing is performed, the bobbin is tightened, and packaging is performed. According to the fasteness index of dyed fabric, the water washing fasteness is at the 4-5 level, the friction fasteness is at the 4-5 level, and a large-production dyeing result shows that the technological process is short, pure cotton fancy yarn is uniform in color, no dyeing defects exist, no inner and outer layer difference exists, and the yarn disorder and breakage phenomenon is avoided, the hand feeling is soft, and the product level is high. Besides, pure cotton yarn subjected to ecological preprocessing is woven, weaving performance is good, and yarn strength, color fasteness and the like all meet customer requirements.

Owner:南通虹纬纺织有限公司

Lubrication glass fiber impregnating agent

The invention discloses a lubrication glass fiber impregnating agent. The lubrication glass fiber impregnating agent is prepared from, by weight, 40-50 parts of polyvinyl acetate, 20-30 parts of waterborne polyurethane, 5-8 parts of castor oil, 3-5 parts of a coupling agent, 0.5-2 parts of nonionic lubricant, 0.5-1 part of a pH conditioning agent, 0.5-1 part of an emulsifier, 0.5-2 parts of a cation lubricant, 0-0.5 part of an antistatic agent, 0.5-1 part of a defoaming agent and a proper amount of deionized water. The better strength is given to yarn, and the impregnating effect in the impregnating process is improved. Various high-performance lubricants are adopted, and the good weaving effect is achieved while the good impregnating effect is ensured. Three coupling agents are adopted in a combination mode, and the combination effect between the glass fiber and resin is well ensured; the components are wide in source, the moisturizing performance and heat stability are good, and the agent is applicable to glass fiber moisturizing under various conditions, environmental pollution will not be caused, and the impregnating agent is simpler in formula component, the compatibility with resin is good, and the better mechanical property is given to composite materials.

Owner:TONGCHENG GLASS FIBER OF ANHUI DANFENG GROUP

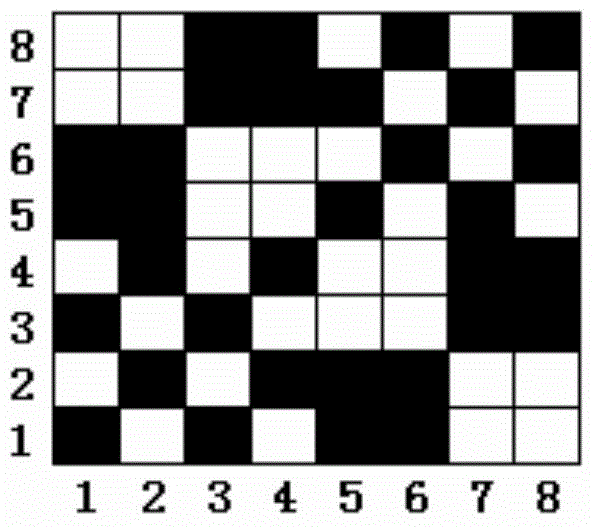

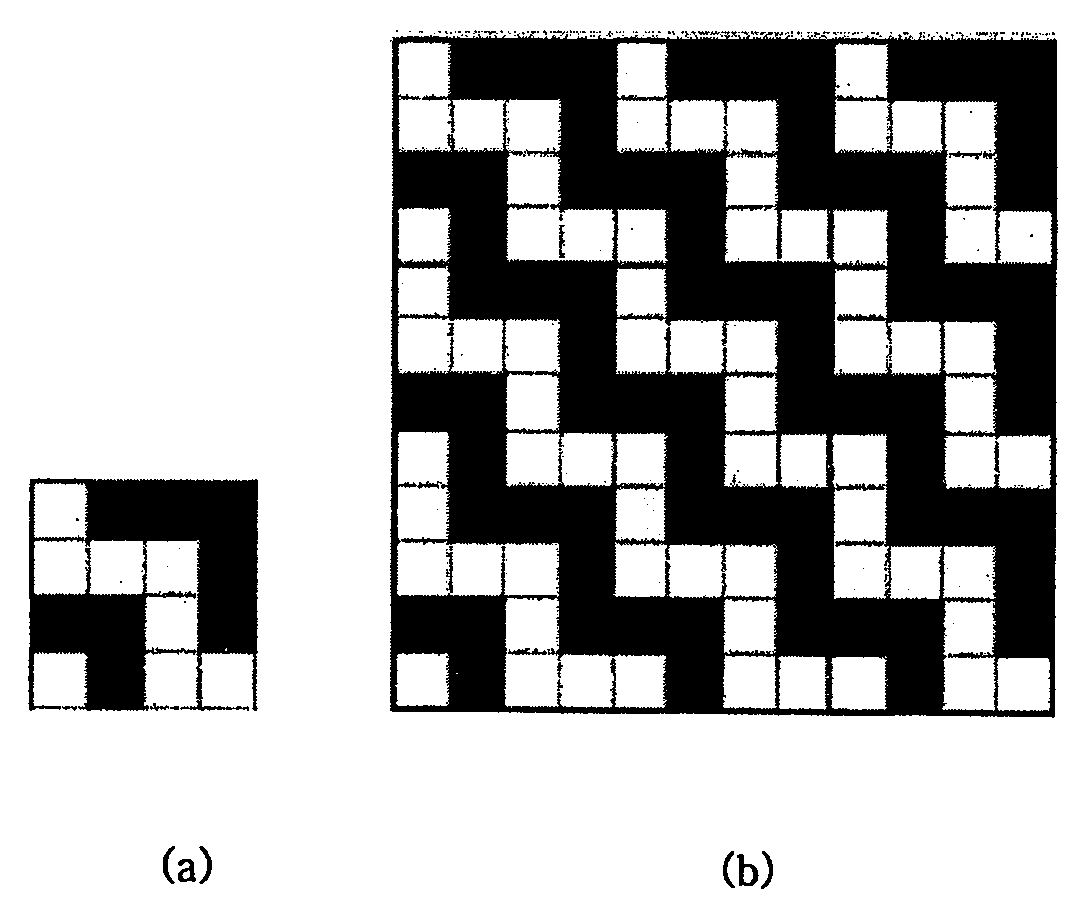

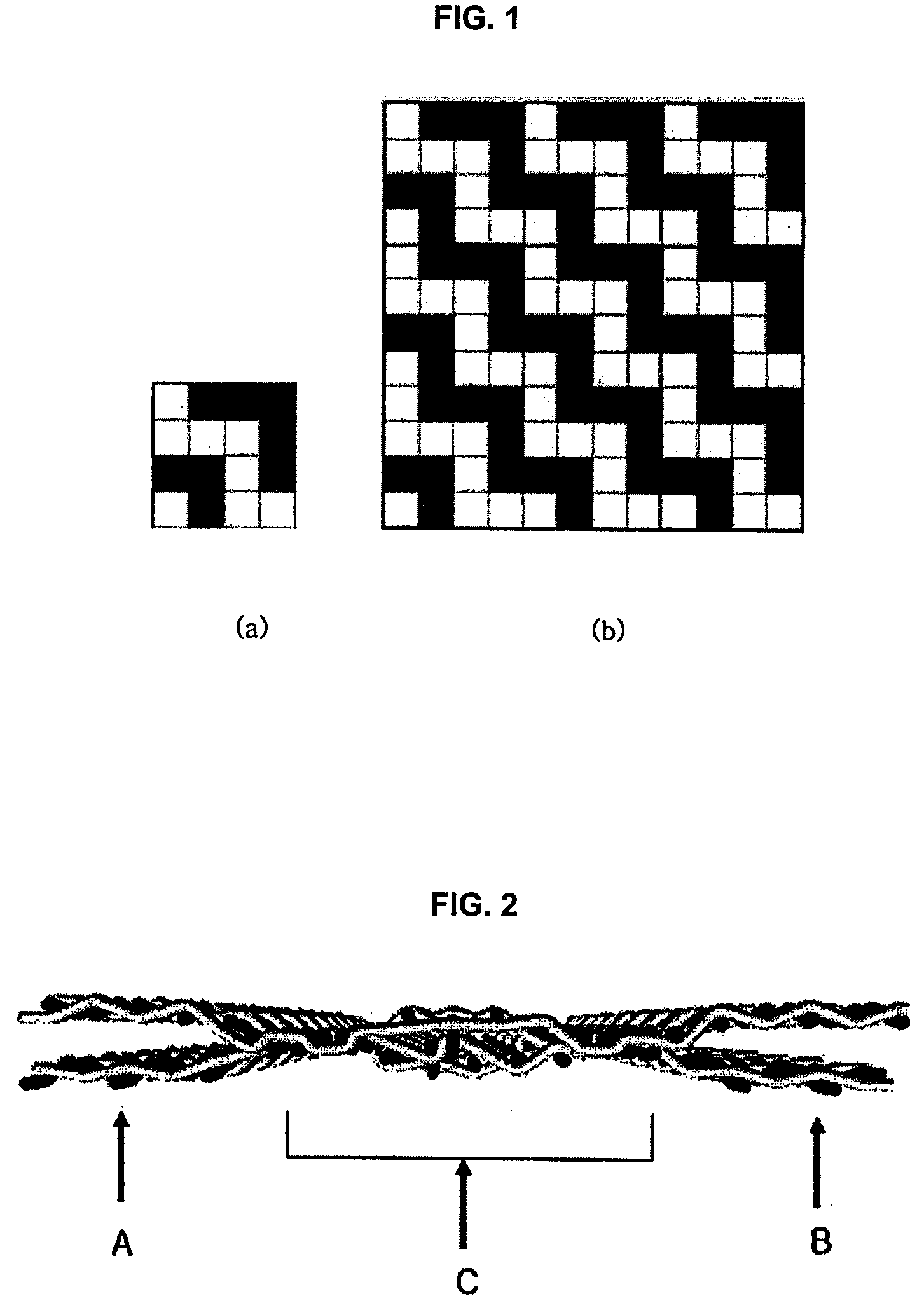

Inflatable Two-Layer Fabrics By Gas

ActiveUS20080231025A1Improve suppression propertiesMinimization of attachment areaLayered productsPedestrian/occupant safety arrangementYarnEngineering

The present invention relates to an inflatable fabric, and more particularly to an inflatable fabric comprising two separated fabric layers which are woven at the same time using a weaving machine, and at least one an attachment area where a single layer of fabric is formed, wherein said attachment area is formed from at least a weave pattern of at least 13 yarns selected from the group consisting of a 2 / 2 basket weave pattern, a satin weave pattern, a partial attaching weave of a double layer weave pattern, and a combination thereof Since the attachment area of the inflatable fabric of the present invention comprises at least 13 yarns, air leakage can be minimized during inflation. Also, because sewing is unnecessary, manufacture cost of shock-absorbing products including an airbag can be reduced. Further, with a superior weaving property and surface smoothness, the fabric of the present invention can be utilized for shock-absorbing products when coated with synthetic resins.

Owner:KOLON IND INC

Flame-retardant yarn weaving

The invention provides a novel weaving idea of a flame retardant yarn variety fabric and process, through a reciprocating automatic plucker to clean cotton, using the processes of mixing a head and a channel, and twice drawing, a drawing sliver which is spun into yarn through roving yarn and spun yarn, after being twisted, the yarn is changed into wire. Using the fiber blending, the comfortable wear is guaranteed and the flame retardant efficacy is possessed, simultaneously, the cost is properly reduced, the weaving performance is capable of being obviously improved, the weaving effect is improved above 92 percent, simultaneously, the strength of the fiber is increased, the brittleness is increased, the wear comfort is excellent, the production process is simple, the weaving effect is high, the production value of a product is improved, and the economic and social benefits are excellent.

Owner:SHENGHONG GRP CO LTD

A kind of denim warp yarn sizing size and sizing process

ActiveCN103966849BImprove wear resistanceImprove surface propertiesFibre treatmentSlurryPulp and paper industry

The invention provides a jean warp sizing slurry and a sizing process. The slurry is prepared from DSC-14 starch, PVA, LMA-95 synthesis slurry, emulsified oil and a smoothing agent. In comparison with the prior art, the sizing slurry and process ensures that the warp abrasion resistance is greatly improved, the weaving performance is enhanced and the cost is lowered. Besides, the use amount of slurry and pollution are reduced, the existing technological process does not need to be changed significantly, the investment is relatively low and the effect can be taken rapidly.

Owner:ZHEJIANG SANSEN TEXTILE

Glass fiber yarn efficient impregnating agent

The invention relates to the technical field of glass fiber, in particular to a glass fiber yarn efficient impregnating agent. The glass fiber yarn efficient impregnating agent provided by the invention comprises the following components: 13 to 21 percent of epoxy resin emulsion, 16 to 24 percent of polyacrylic ester, 1 to 2 percent of ammonia water, 0.2 to 0.8 percent of a silane coupling agent,0.05 to 0.5 percent of an organosilicon lubricating agent, 0.05 to 0.7 percent of a cationic lubricating agent, 0.3 to 1.3 percent of a non-ionic lubricating agent, 0.5 to 1 percent of sodium dodecylbenzene sulfonate, 0.5 to 1 percent of imidazoline, 4 to 8 percent of gasoline, 0.3 to 0.9 percent of ammonium chloride, 0.08 to 0.8 percent of aliphatic diamine and the balance of deionized water. The glass fiber yarn efficient impregnating agent provided by the invention has good penetration effect, high moisturizing property and high heat stability, can give high mechanical property to the glass fiber yarn and realizes a good weaving effect.

Owner:ANHUI TONGLI NEW MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com